Positive pole piece, preparation method thereof and lithium ion battery

A technology of positive pole piece and positive active material, applied in the field of positive pole piece and its preparation, can solve the problems of restricting the use range and further application of ternary materials, affecting the charging and discharging efficiency of lithium ion batteries, poor material irreversibility, etc. The effect of preparation cycle, improved electrochemical performance and safety performance, excellent high temperature performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

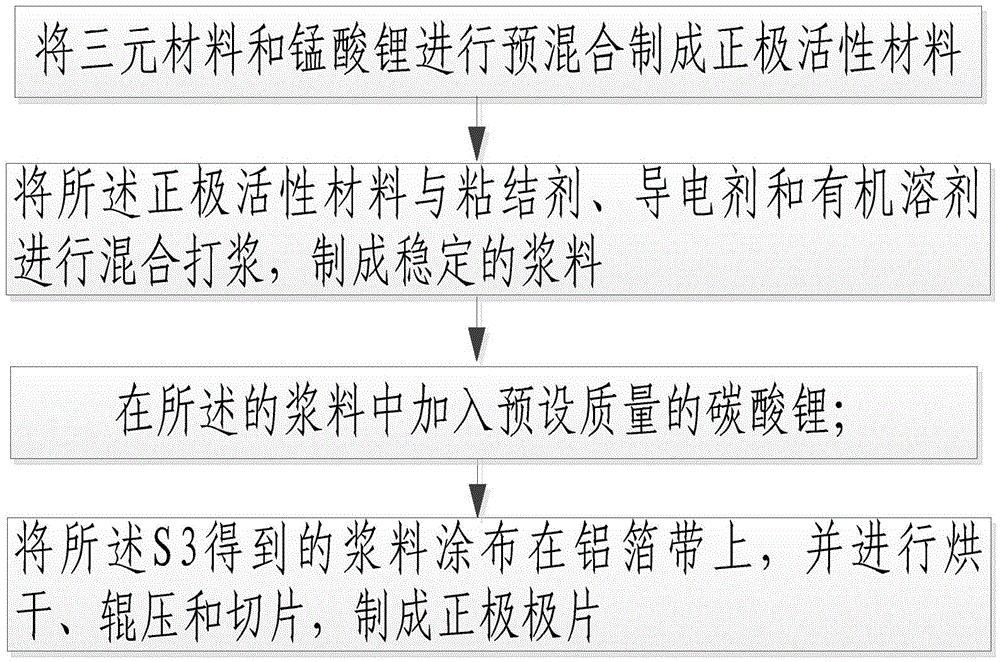

[0027] Such as figure 1 As shown, the present invention provides a method for preparing a positive pole sheet, comprising the following steps: S1: premixing a ternary material and lithium manganate to prepare a positive active material; S2: combining the positive active material with a binder agent, conductive agent and organic solvent to make a stable slurry; S3: add a preset quality of lithium carbonate to the slurry, S4: coat the slurry obtained in S3 on an aluminum foil strip Then, drying, rolling, and slicing are carried out to make positive electrode sheets. Among them, preferably, before step S1, it also includes: drying the ternary material and lithium manganate to make dry powder and then mixing, which can make the mixing more uniform. Wherein, the ternary material and lithium manganate can be mixed by physical methods after being dried under vacuum conditions. Among them, preferably, the drying temperature of the ternary material and lithium manganate is 120°C-200°...

Embodiment 2

[0029] The present invention also provides a positive electrode sheet produced by the preparation method of Example 1. After the slurry is dried, the organic solvent evaporates, so the positive electrode sheet includes: positive electrode active material, binder, conductive agent and carbonic acid Lithium; Wherein, the quality of described positive electrode active material accounts for 75%-85% of the total mass of described positive electrode active material, binder and conductive agent, and the quality of described binder accounts for described positive electrode active material, binder 1%-10% of the total mass of the conductive agent and the conductive agent, and the mass of the conductive agent accounts for 1%-10% of the total mass of the positive electrode active material, binder and conductive agent; the positive electrode active material is three A mixed material of primary material and lithium manganate, the mass ratio of the ternary material and lithium manganate is 2:...

Embodiment 3

[0031] The present invention also provides a lithium-ion battery comprising the positive pole piece of Example 3. The power lithium-ion battery includes: a casing, a positive pole, a negative pole, a diaphragm and an electrolyte, and the positive pole provided in Example 2 can be used for the positive pole. The negative electrode can be artificial graphite or natural graphite, the separator can be polyethylene (PE), and the electrolyte can be a ternary electrolyte. The production process of lithium-ion batteries is generally: positive and negative ingredients - positive and negative pulping - positive Negative electrode coating - positive and negative electrode drying - positive and negative electrode rolling - positive and negative electrode sheeting - positive and negative electrode winding - packaging - baking - grouting - formation - vacuum sealing - capacity separation - product battery.

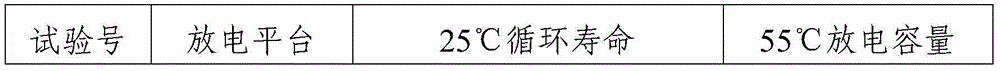

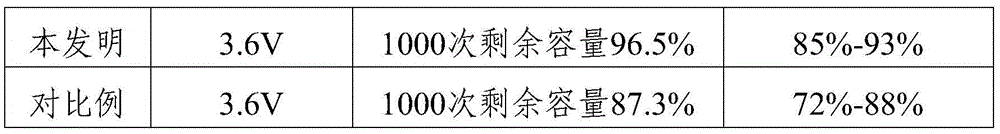

[0032]Adopt the lithium ion battery provided by the present invention to carry out c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com