Method for preparing monodisperse emulsion

A monodisperse and emulsion technology, applied in the field of emulsion, can solve the problems of small flow rate of dispersed phase and continuous phase, inability to achieve high flux, etc., and achieve the effects of good dispersibility, shortened preparation period and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

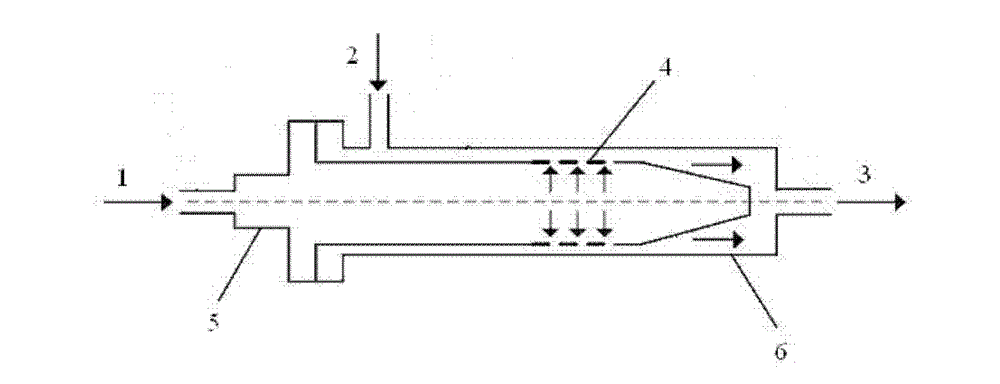

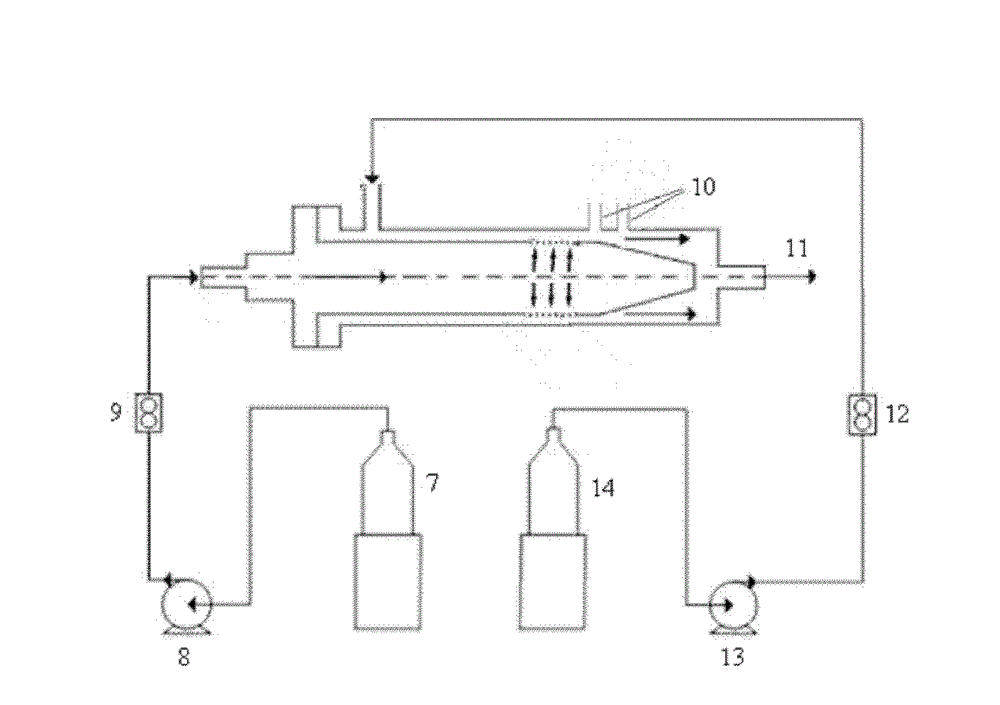

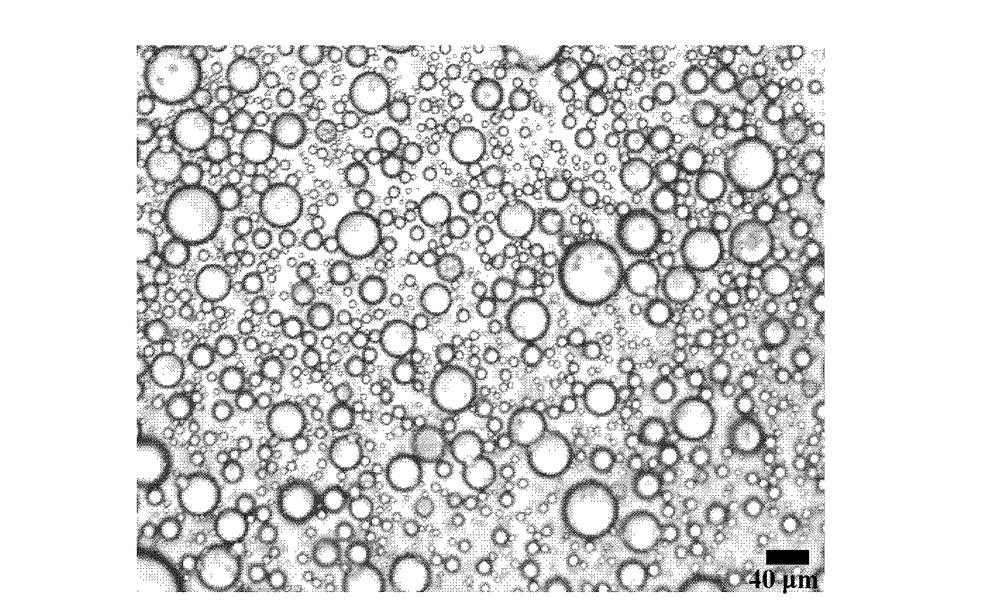

[0033] The structure of the sleeve-type microreactor used is as follows: figure 1 As shown, the radial spacing of the annular microchannel is 500 μm, and the diameter of the micropore is 10 μm. At normal temperature, put 1L of refined soybean oil into the liquid storage tank 7, pass through the peristaltic pump 8 and the liquid flow meter 9, and enter the inner tube 5 from the inlet 1 at one end of the casing microreactor horizontally; the 5L mass fraction is 1% The sodium lauryl sulfate aqueous solution is put into liquid storage tank 14, and through peristaltic pump 13, liquid flowmeter 12, injects the outer pipe 6 of casing type microreactor from the liquid inlet 2 of reactor side. The two solutions come into cross-flow contact in the micropore part of the microreactor to form an emulsion. The feed flow rates of the two solutions can be controlled by adjusting the rotating speeds of the peristaltic pumps 8 and 13 according to the display values of the liquid flow meters ...

Embodiment 2

[0035] The structure of the sleeve-type microreactor used is as follows: figure 1 As shown, the radial spacing of the annular microchannel is 750 μm, and the diameter of the micropore is 10 μm. At normal temperature, put 1L paraffin oil into the liquid storage tank 7, pass through the peristaltic pump 8 and the liquid flow meter 9, and enter the inner tube 5 from the inlet 1 at one end of the casing microreactor in the horizontal direction; the 2.5L mass fraction is 1% The polysorbate-80 aqueous solution is put into liquid storage tank 14, through peristaltic pump 13, liquid flowmeter 12, injects the outer pipe 6 of sleeve type microreactor from the liquid inlet 2 of reactor side. The two solutions come into cross-flow contact in the micropore part of the microreactor to form an emulsion. The feed flow rates of the two solutions can be controlled by adjusting the rotating speeds of the peristaltic pumps 8 and 13 according to the display values of the liquid flow meters 9 an...

Embodiment 3

[0037] The structure of the sleeve-type microreactor used is as follows: figure 1 As shown, the radial spacing of the annular microchannel is 500 μm, and the diameter of the micropore is 10 μm. At normal temperature, put 1L soybean oil into the liquid storage tank 7, through the peristaltic pump 8 and the liquid flow meter 9, enter the inner tube 5 from the inlet 1 at one end of the casing microreactor horizontally; The polysorbate-80 aqueous solution is put into the liquid storage tank 14, through the peristaltic pump 13, the liquid flow meter 12, and injects the outer tube 6 of the casing microreactor from the liquid inlet 2 on the side of the reactor. The two solutions come into cross-flow contact in the micropore part of the microreactor to form an emulsion. The feed flow rates of the two solutions can be controlled by adjusting the rotating speeds of the peristaltic pumps 8 and 13 according to the display values of the liquid flow meters 9 and 12 respectively, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com