Patents

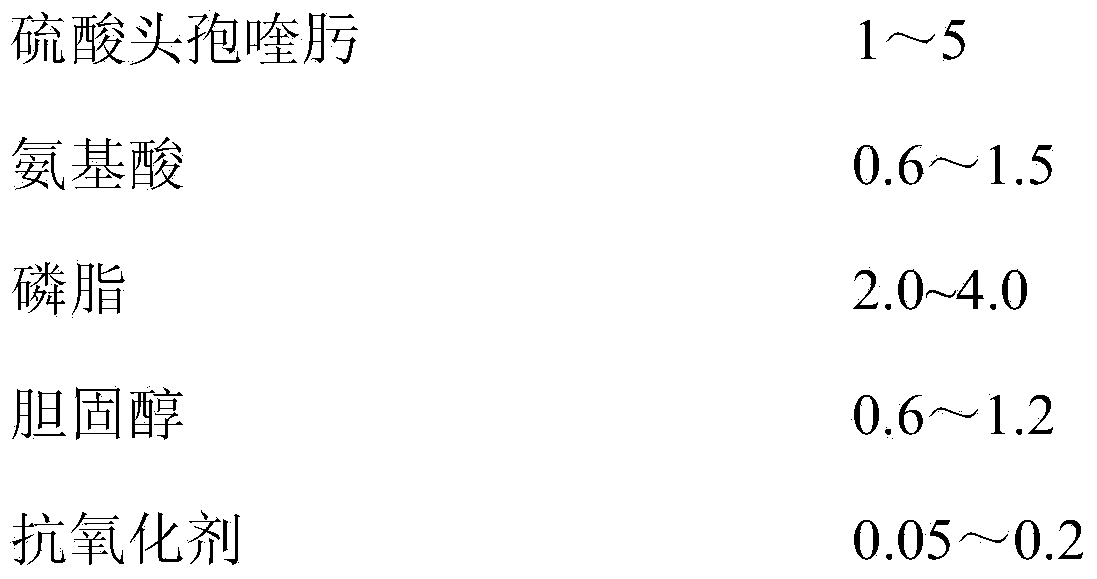

Literature

103 results about "Membrane emulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

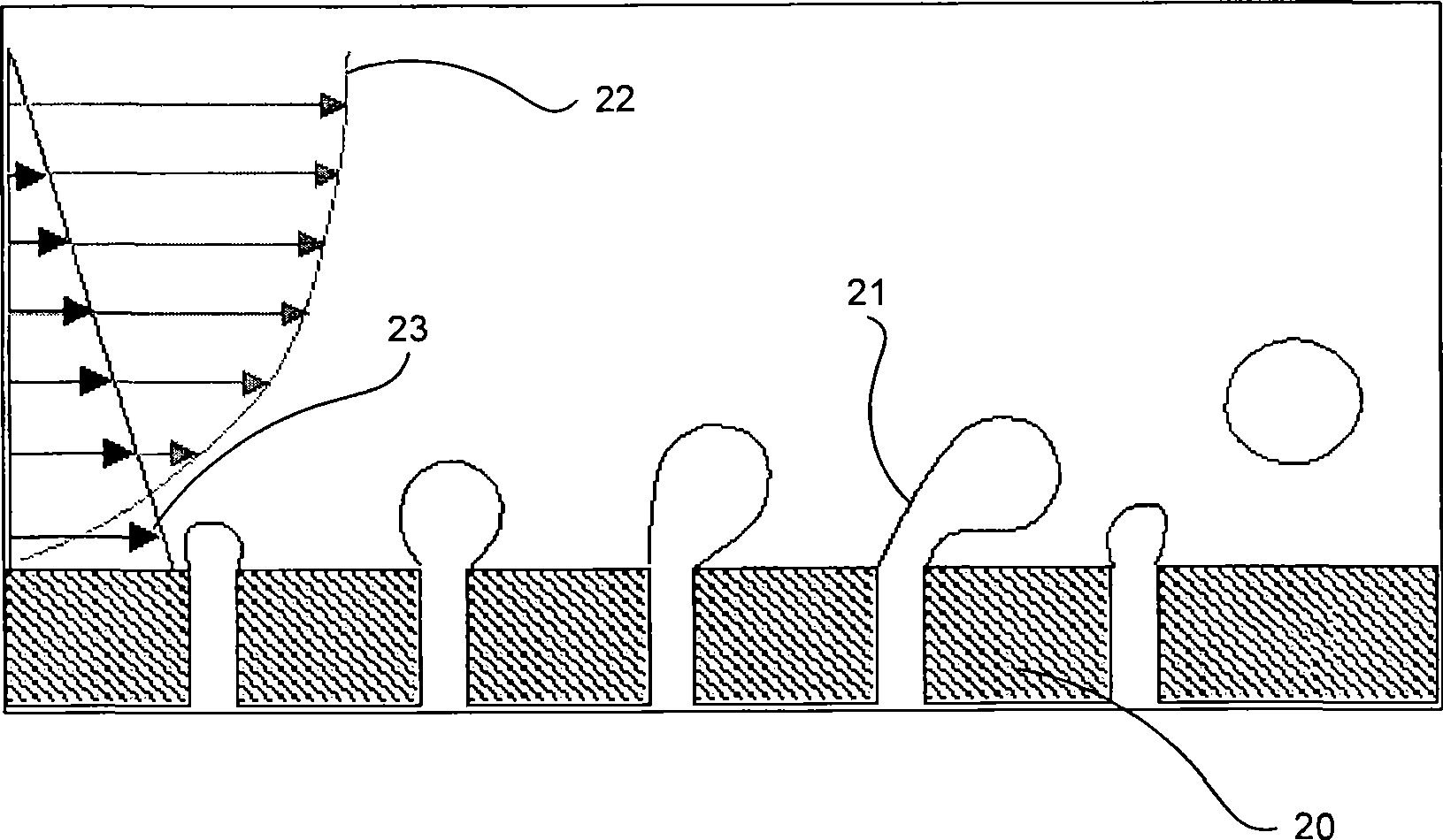

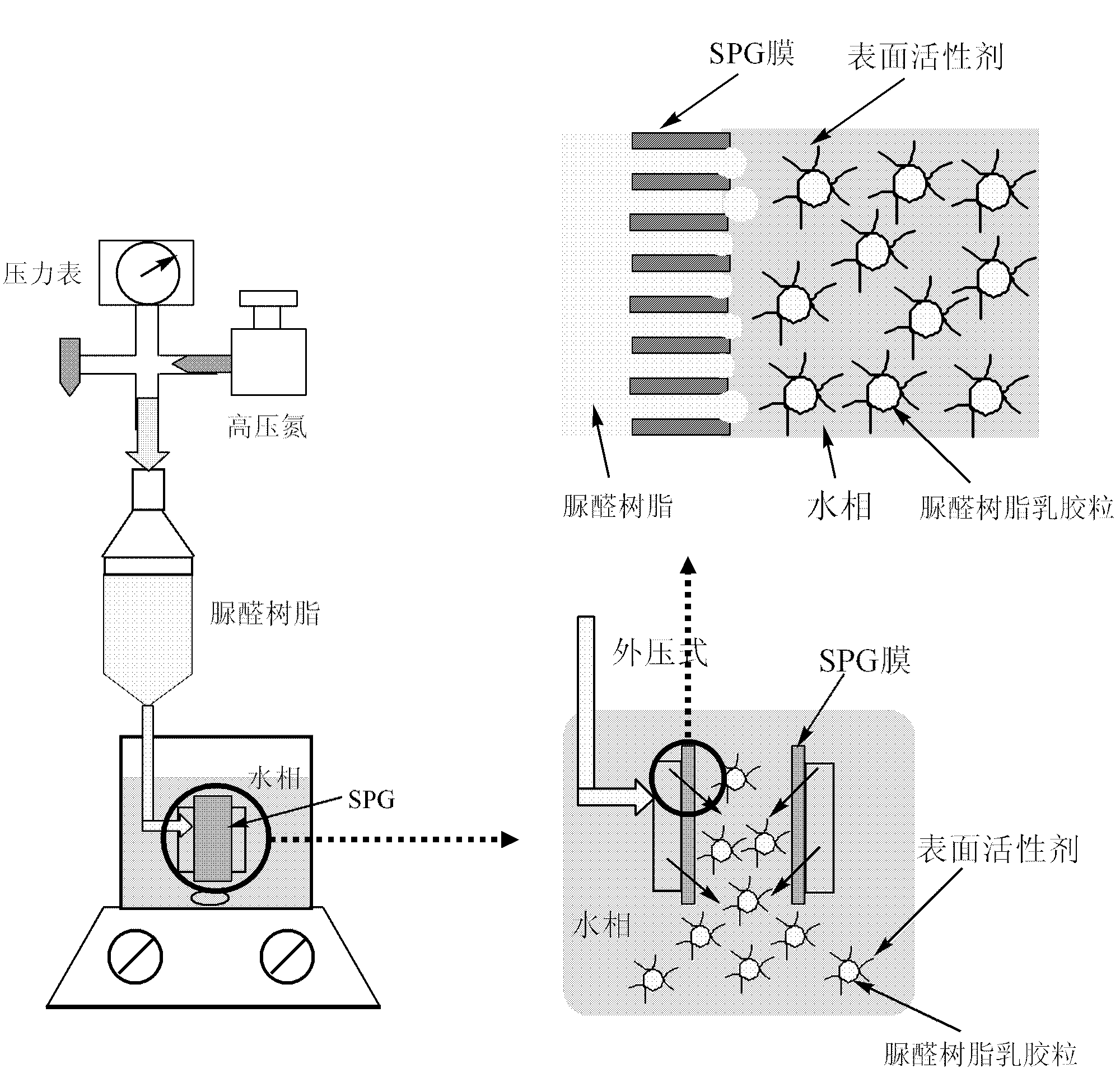

Membrane emulsification (ME) is a relatively novel technique for producing all types of single and multiple emulsions for DDS (drug delivery systems), solid micro carriers for encapsulation of drug or nutrient, solder particles for surface-mount technology, mono dispersed polymer microspheres (for analytical column packing, enzyme carriers, liquid crystal display spacers, toner core particles). Membrane emulsification was introduced by Nakashima and Shimizu in the late 1980s in Japan.

Pickering emulsion with uniform particle size, and preparation method and application thereof

ActiveCN104001437AUniform particle sizeParticle size can be controlled and adjustedMixing methodsTransportation and packagingMembrane emulsificationWastewater

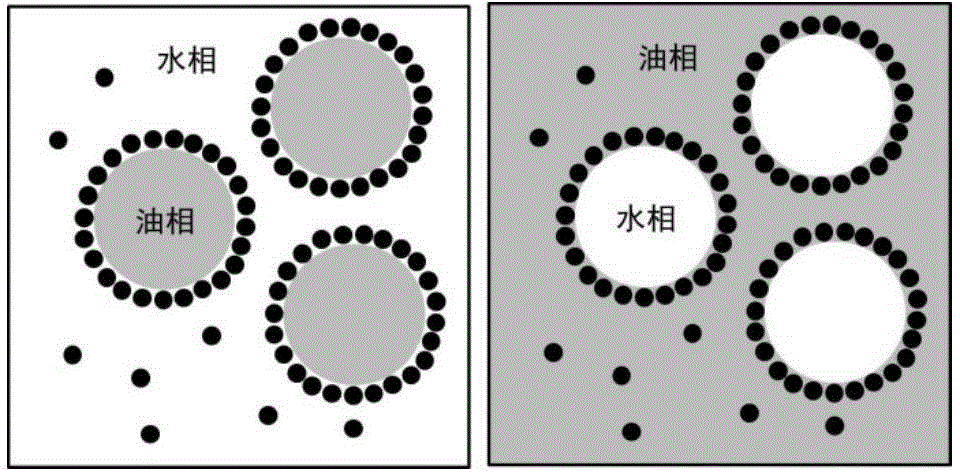

The invention discloses a Pickering emulsion with uniform particle size and a preparation method and application thereof. The uniform and stable Pickering emulsion is formed by using a solid particle as a stabilizing agent, dispersing the solid particle in a water (or oil) phase, then subjecting the dispersed solid particle and an oil (or water) phase to emulsification and then allowing a formed pre-emulsion to pass through a membrane emulsification apparatus. Or the uniform and stable Pickering emulsion is formed by allowing a dispersed phase (water phase or oil phase) to pass through membrane holes under pressing and then to enter a continuous phase (oil phase or water phase) with the dispersed solid particle and then enabling an emulsion to fall off from the membrane holes under the action of external force. The preparation method is simple; through adjusting of the proportion of water and oil phases, particle concentration, the size of the particle and a microporous membrane, the properties of the emulsion are regulated and controlled, the prepared emulsion is stable and has a uniform and controllable particle size and enhanced stability, usage of a traditional emulsifier is avoided, and toxicity to human bodies and environmental pollution can be reduced; and the emulsion can be extensively used in fields like biological medicine, cosmetics, food, petroleum and waste water treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Dual-hole polysaccharide microspheres, preparation method and purpose thereof

ActiveCN103341172ASimple processAvoid removal stepsCosmetic preparationsToilet preparationsMembrane emulsificationMicrosphere

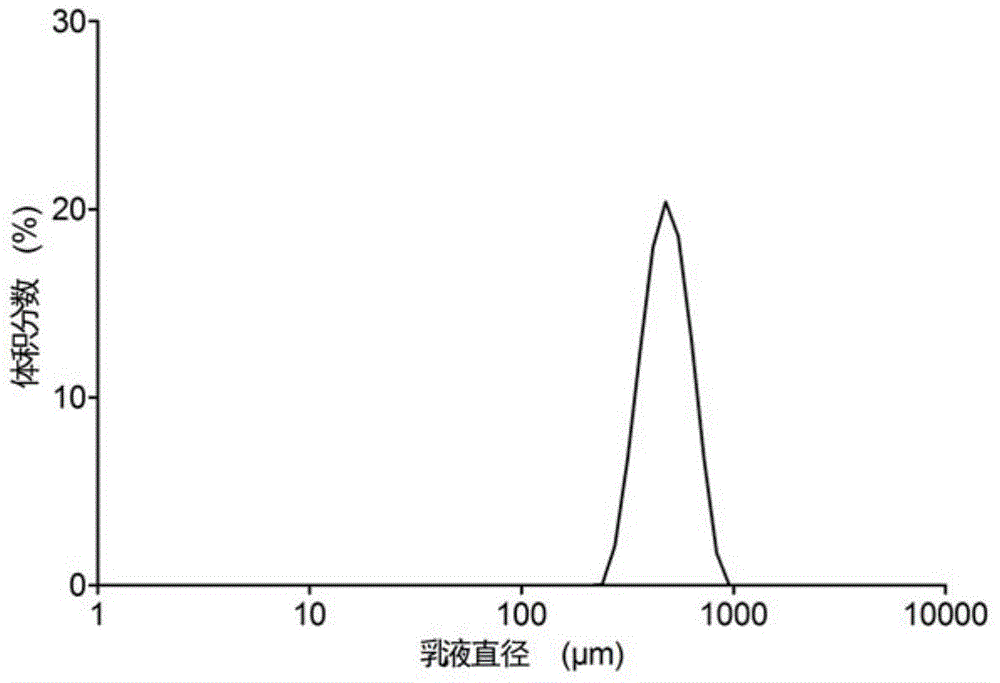

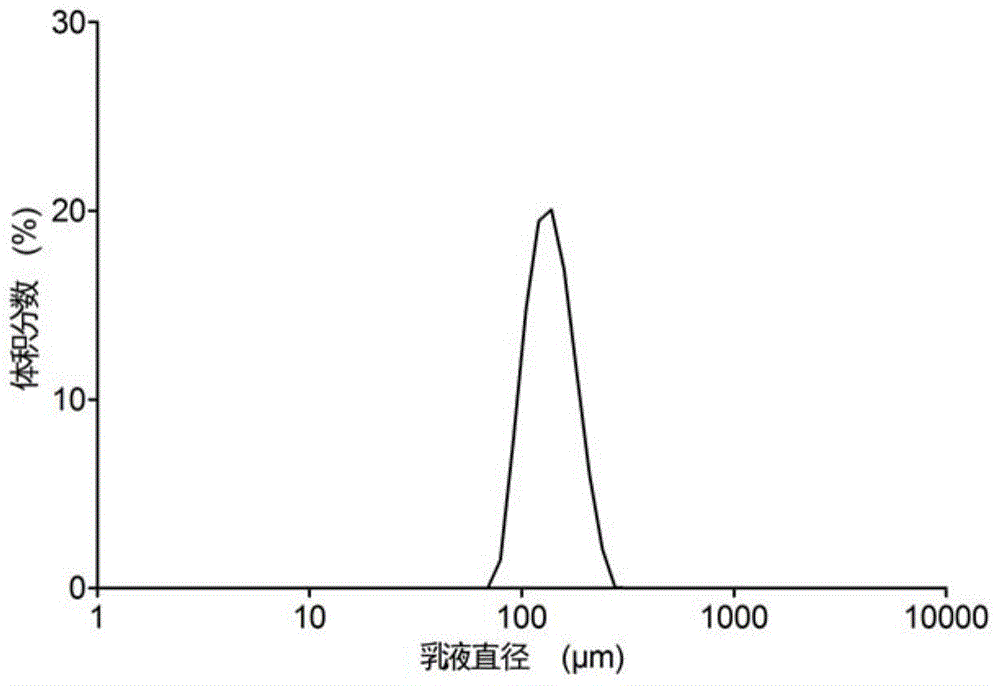

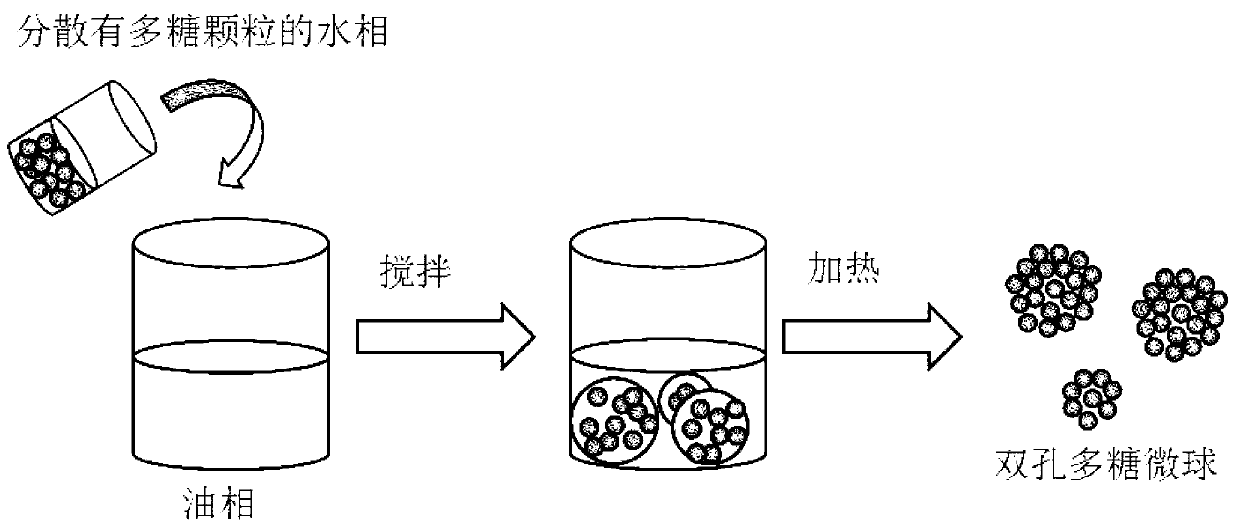

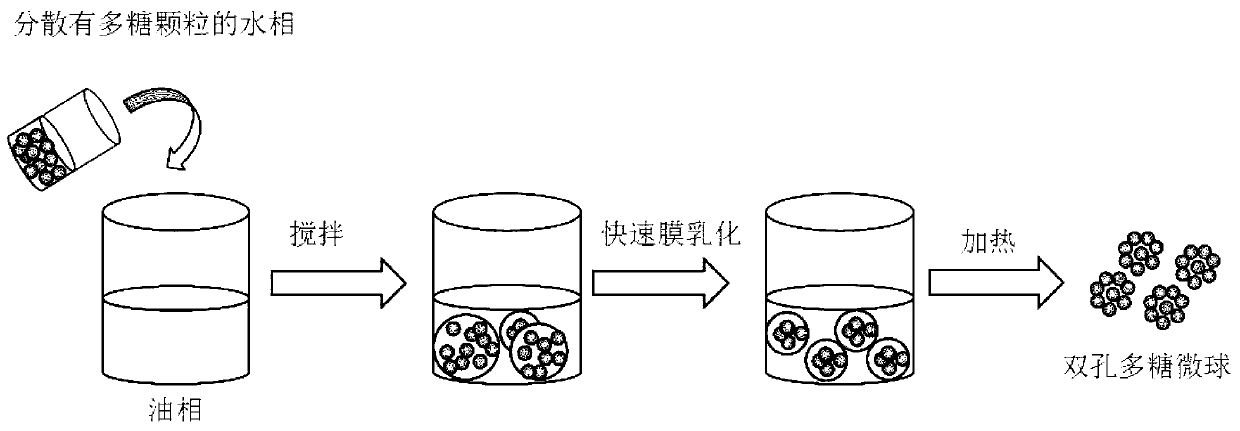

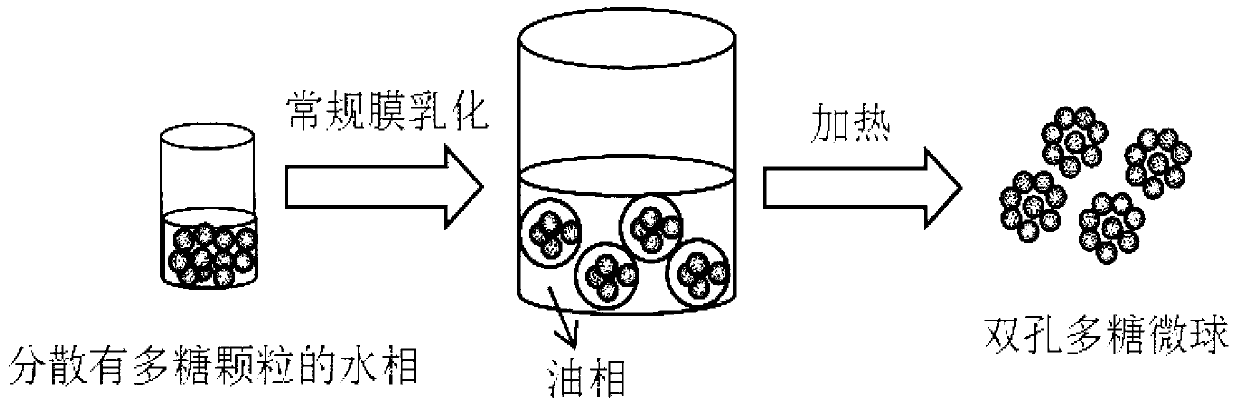

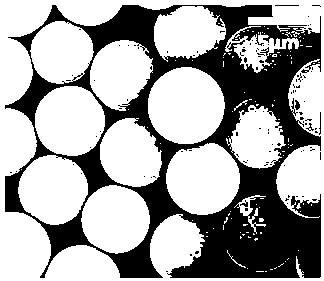

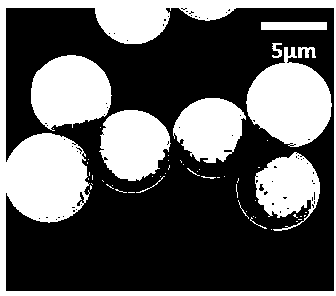

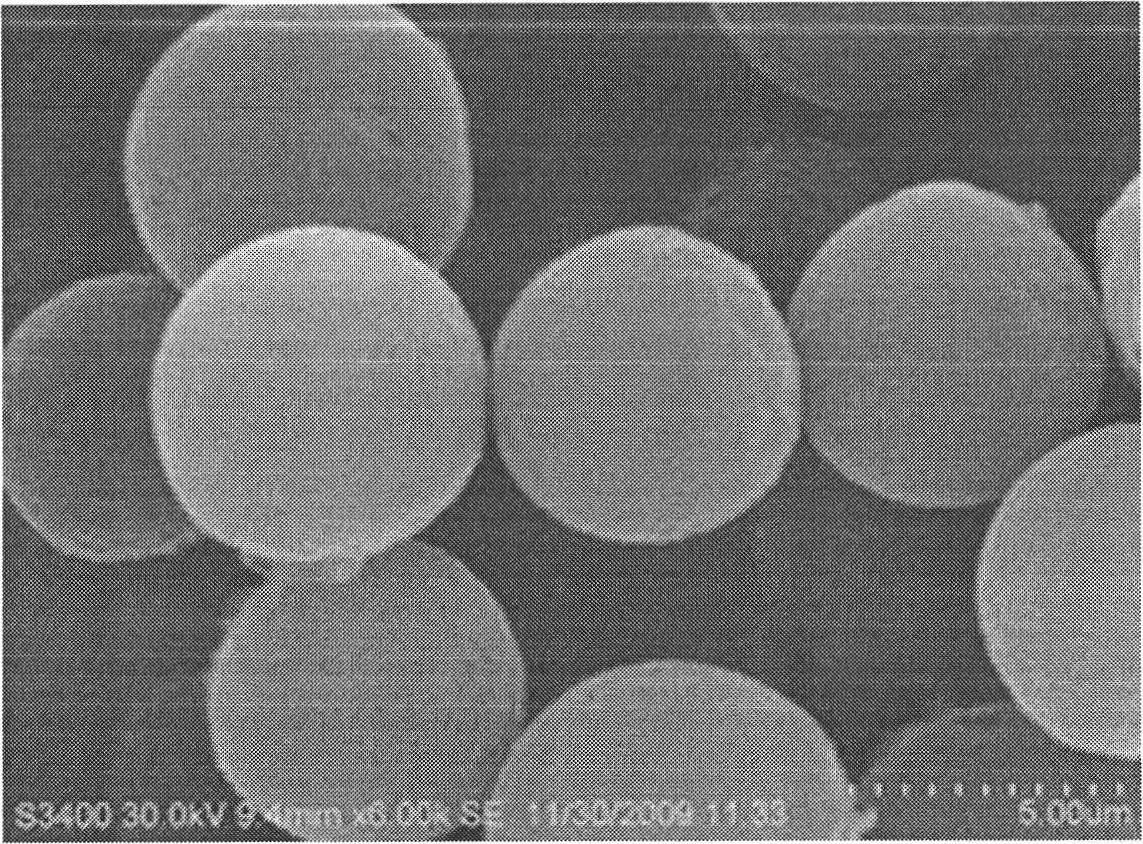

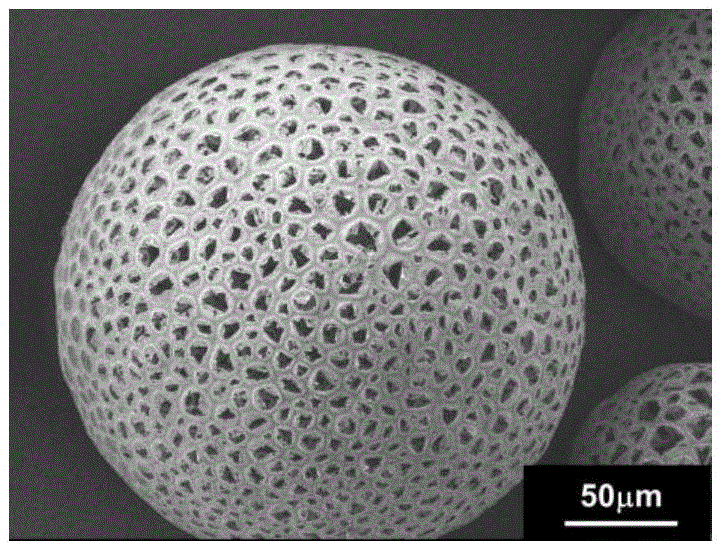

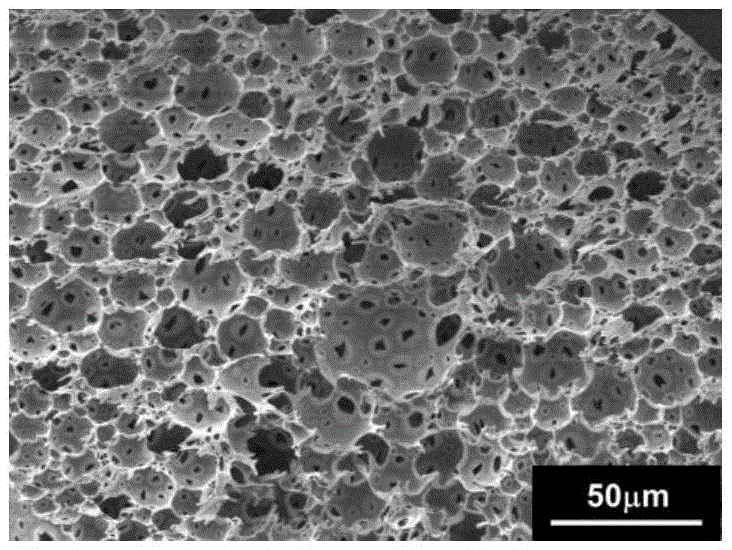

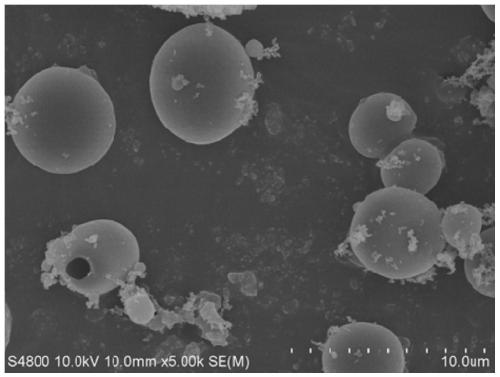

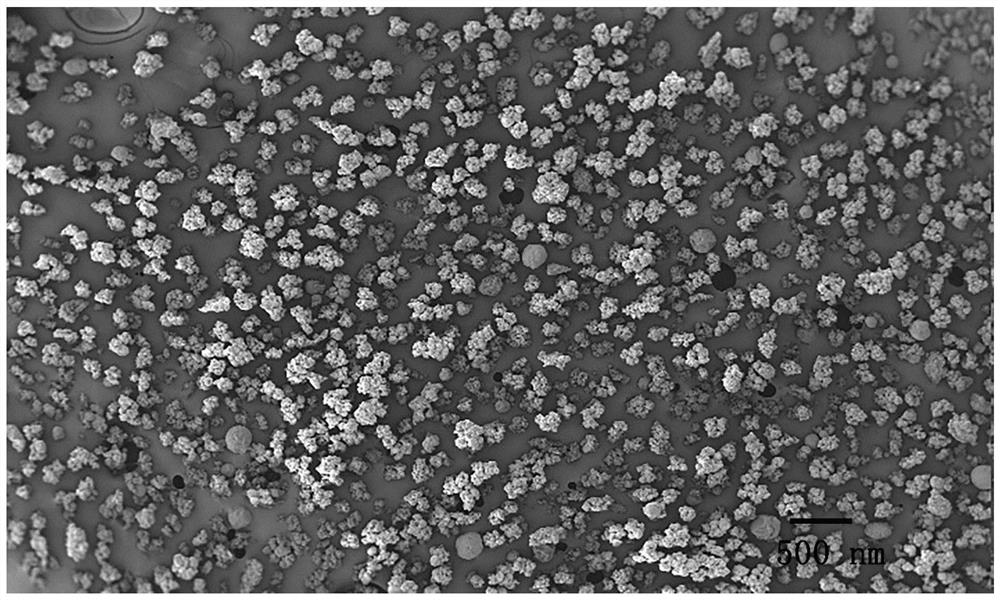

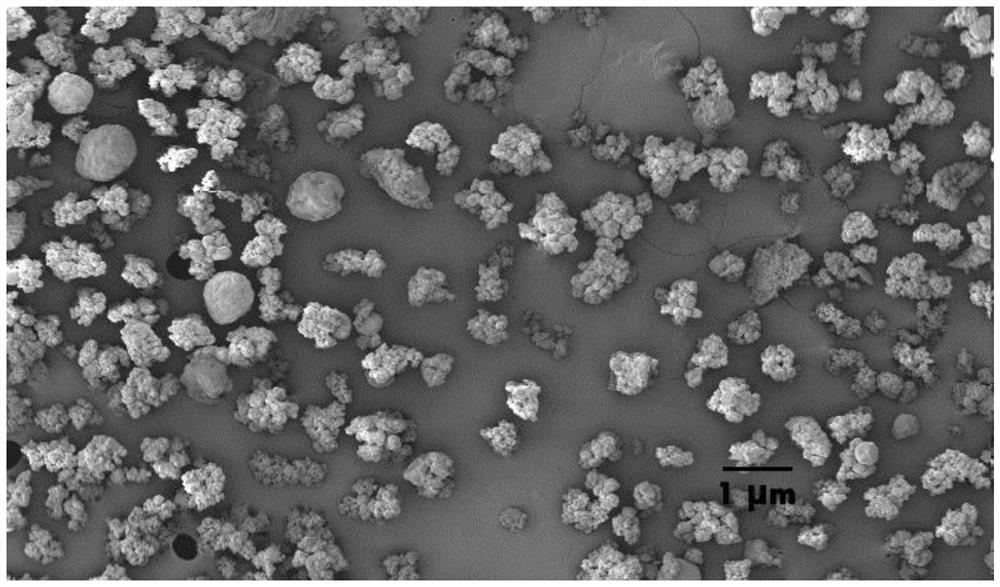

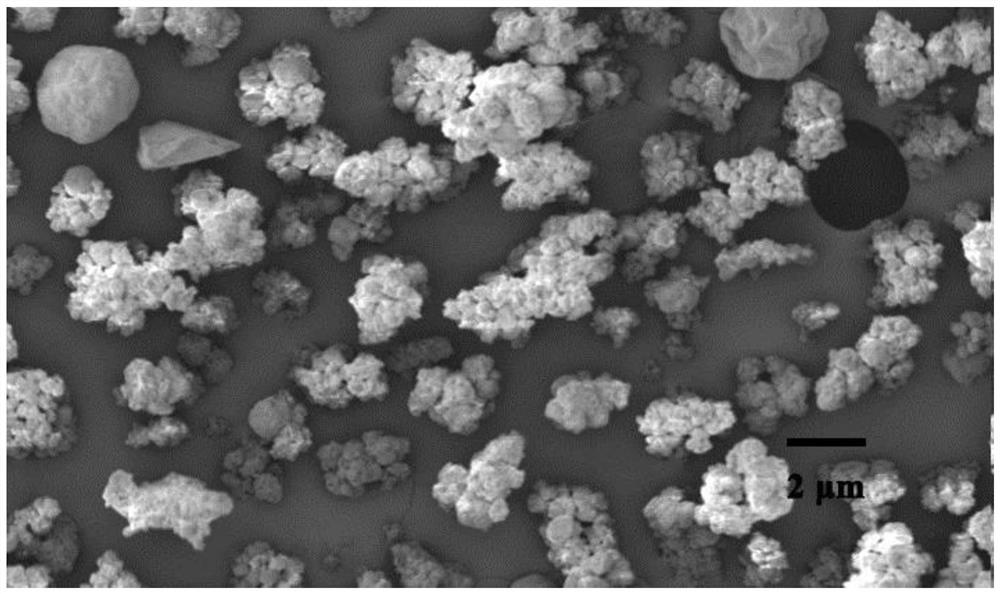

The invention relates to dual-hole polysaccharide microspheres, a preparation method and a purpose thereof. The microspheres are formed by a plurality of stacked polysaccharide particles with small particle sizes, with an average particle size of the microspheres being 500 nm to 500 [mu]m; and comprises gel pores containing the polysaccharide as well as macroporous dual-hole structure formed by gaps among the polysaccharide particles. The preparation method of the microspheres comprises dispersing the polysaccharide particles in a water phase and then in an oil phase to form water in oil emulsion, heating the emulsion, and stirring to obtain the dual-hole polysaccharide microspheres. Furthermore, according to the preparation method, together with a membrane emulsification technology, the dual-hole polysaccharide microspheres with uniform particle size distribution can be prepared, with an average particle size range being 500 nm to 100 [mu]m and a particle size distribution coefficient being less than 20 %. The dual-hole polysaccharide microspheres provided by the invention are suitable for being used as separation mediums for separating biomacromolecules, biologically active material carriers, etc.

Owner:SENHUI MICROSPHERE TECH SUZHOU CO LTD

Functional nanometer particle composite non-crosslinking microspheres and preparation method and application thereof

InactiveCN102908961AIncrease productionUniform and controllable particle sizeFluorescence/phosphorescenceMacromolecular non-active ingredientsMembrane emulsificationMicrosphere

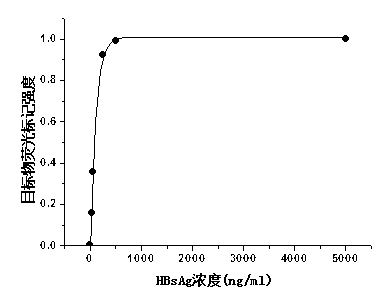

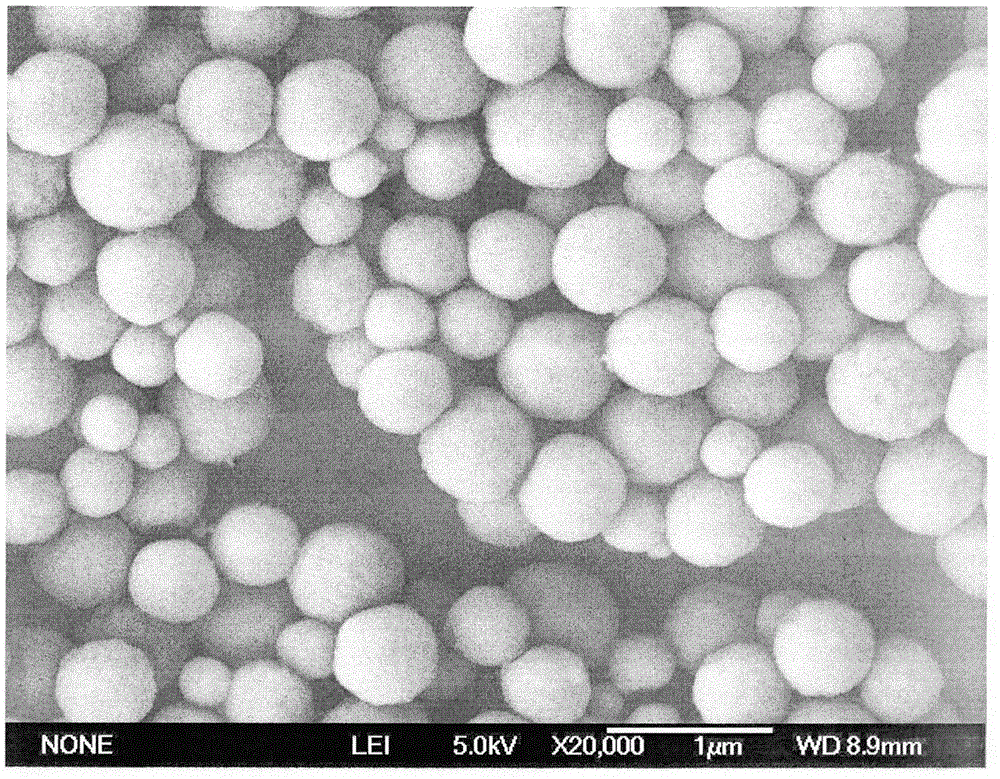

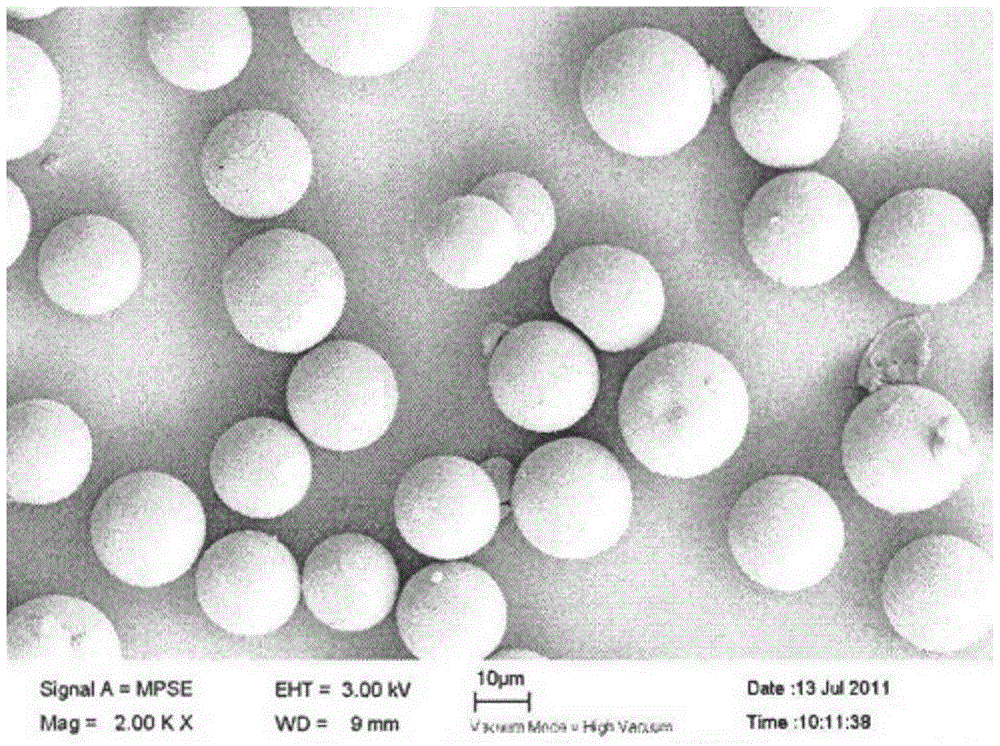

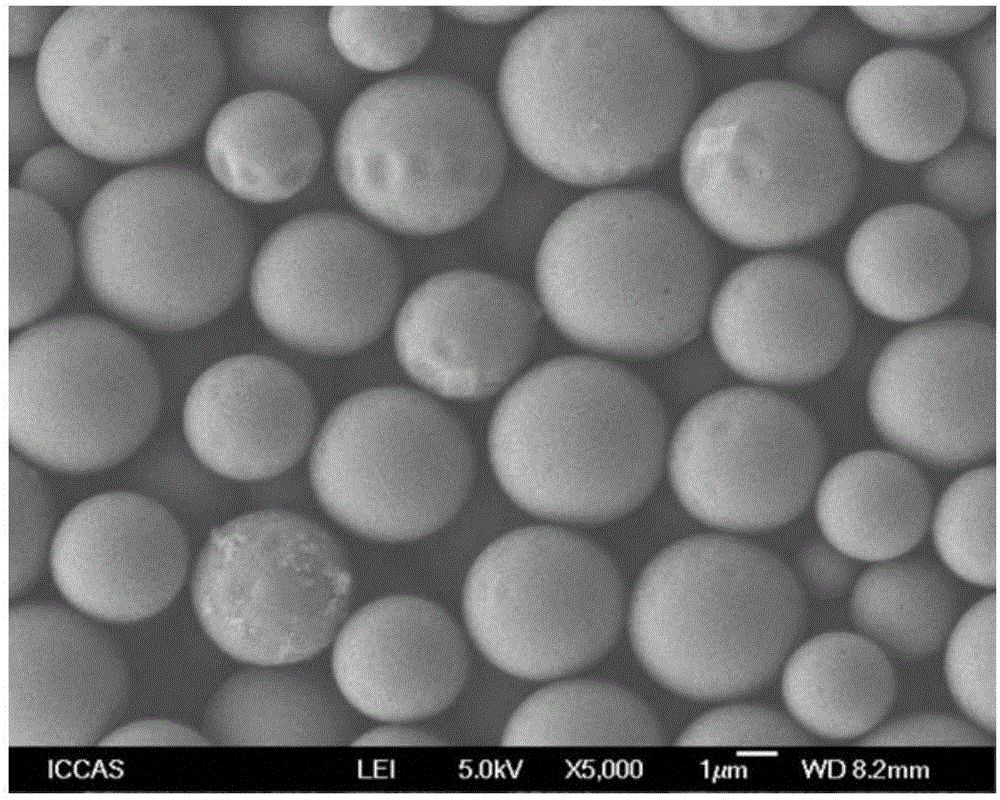

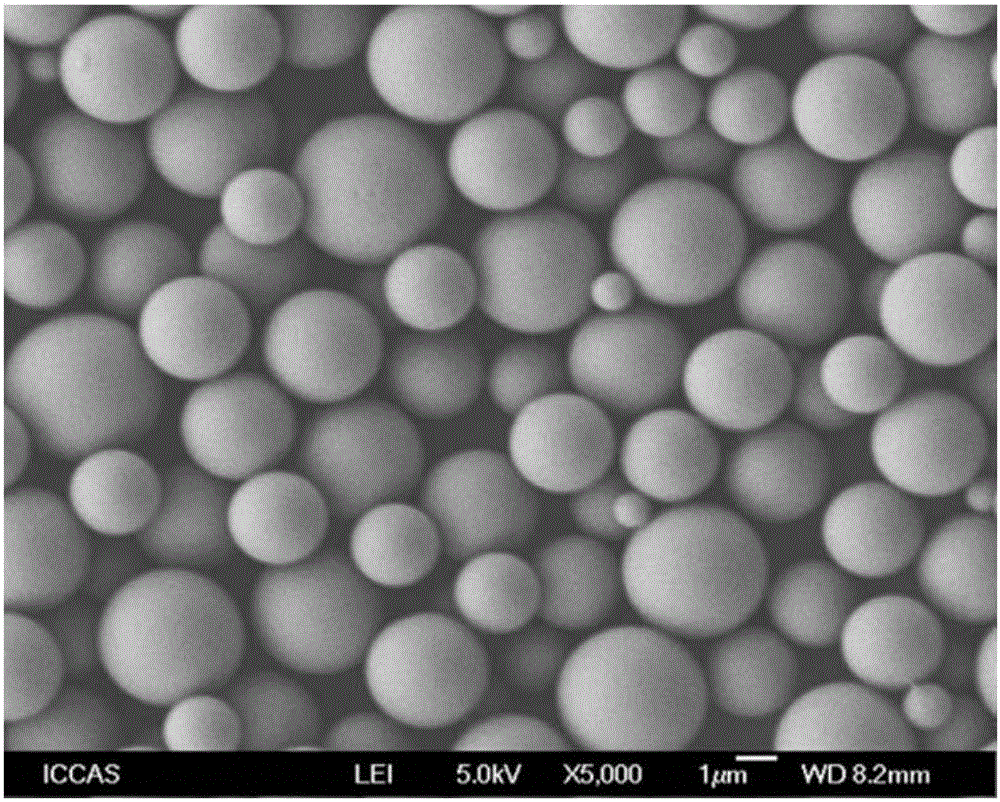

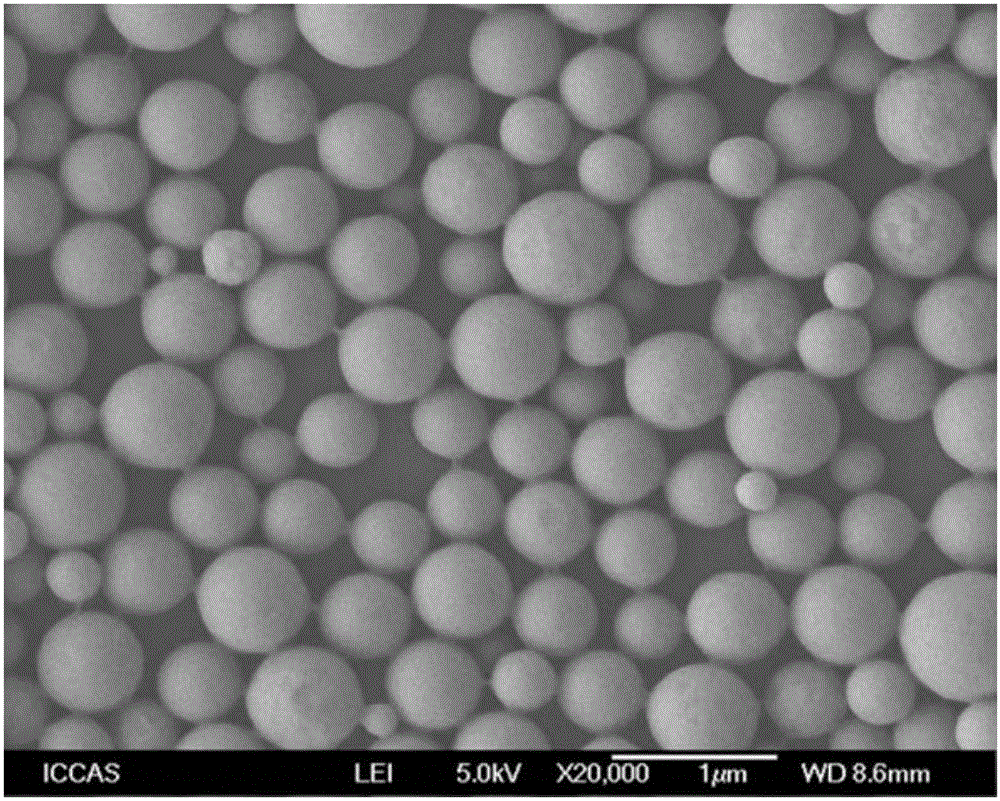

The invention relates to functional nanometer particle composite non-crosslinking microsphere powder, and a preparation method and application of the functional nanometer particle composite non-crosslinking microsphere powder. The functional nanometer particle composite non-crosslinking microsphere powder contains functional nanometer particle composite non-crosslinking microspheres; the functional nanometer particle composite non-crosslinking microspheres contain functional nanometer particles and polymers, average particle size is 0.1micron to 20micron, and particle size distribution variable coefficient is less than or equal to 9.1%. The preparation method is a combination of a membrane emulsification technique and a solvent volatilization method. The invention also relates to a biometric probe and application of the biometric probe based on the above composite non-crosslinking microsphere powder. The preparation method has the advantages that the functional nanometer composite non-crosslinking microsphere powder which is uniform in particle size can be prepared; the prepared functional nanometer composite non-crosslinking microspheres belong to micron order, the particle size variable coefficient is small, monodispersity is good, and performance is excellent; and the prepared functional nanometer composite non-crosslinking microspheres have broad application prospect in biometric and biomedical fields and the like.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

High-specific surface polymer microsphere resin with even particle size and preparation method thereof

InactiveCN101773812AReduce pollutionSimple stepsOther chemical processesAlkali metal oxides/hydroxidesResin microspherePolymer science

The invention discloses a high-specific surface polymer microsphere resin with even particle size and a preparation method thereof. In the method, a high-specific surface resin microsphere is prepared by the following steps of: dispersing vinylbenzylchloride and the like as monomers by a membrane emulsification method and polymerizing at a certain temperature and condition. The monodisperse polymer microsphere resin within the range of 1-60 Mum can be synthetized by the method, wherein the specific surface is 800-1200m2 / g. The invention has simple steps and environmental pollution reduction, easy control of process flow, strong repeatability, thereby being beneficial to scale production. The resin microsphere prepared by the method has very high specific surface, thereby being beneficial to carrying out enrichment separation and analysis on water-soluble organic pollutants in a water body and having wide application prospect.

Owner:NANJING UNIV

Microbeads and preparing method and application thereof

ActiveCN105418944ALarge specific surface areaSoft textureCosmetic preparationsToilet preparationsMembrane emulsificationBiodegradable polymer

The invention provides microbeads. The microbeads are prepared from raw materials comprising biodegradable polymers and are spherical microbeads. The invention provides a preparing method of the microbeads in the technical scheme. The preparing method includes the step that the raw materials comprising the biodegradable polymers are prepared into the spherical microbeads with an emulsion-solvent evaporation method or a membrane emulsification method or a spray drying method or a polymerization method. Compared with the prior art, the microbeads are the degradable spherical microbeads, and are large in specific surface area, soft in texture, small in skin irritation and high in skin comfort. By means of the preparing method of the microbeads, the size, the size distribution, the microstructure and the feature of the microbeads can be controlled, functional substances can be led into the interiors or the surfaces of the microbeads in the microbead preparing process, and the prepared microbeads meet different application requirements accordingly. The invention further provides an application of the microbeads to preparing of cleaning care products and cosmetics.

Owner:CHANGCHUN SINOBIOMATERIALS

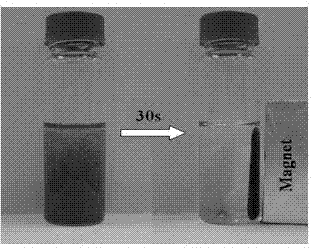

Magnetic microsphere resin with high specific surface area and preparation method and application thereof

ActiveCN102516679AEvenly distributedEasy to separateIon-exchange process apparatusWater/sewage treatment by ion-exchangePolymer scienceMicrosphere

The invention discloses a magnetic powdered resin with high specific surface area and a preparation method and application thereof, and belongs to the field of resin materials. The average particle size of the magnetic powdered resin is 1 to 60mum, the specific saturation magnetization degree is 0.1 to 20emu / g, and the specific surface area is 800 to 1,600m<2> / g. The resin is prepared by adopting a membrane emulsification-suspension polymerization method, divinyl benzene is used as a reaction monomer, magnetic particles are modified by oleic acid and then subjected to membrane filtering emulsification together with the oil phase, emulsion is suspended and polymerized to form the magnetic microsphere resin, and the specific surface area of microspheres is further enlarged by post cross-linking reaction. Magnetic nano particles in the magnetic microsphere resin prepared by the method are distributed uniformly and have excellent separation performance; the particle size of the resin is small and uniform, so the resin has good adsorption dynamics performance and can realize quick enrichment; and due to the high specific surface area and a rich pore structure, the resin has large adsorption capacity for various polar and non-polar organic substances.

Owner:NANJING UNIV +1

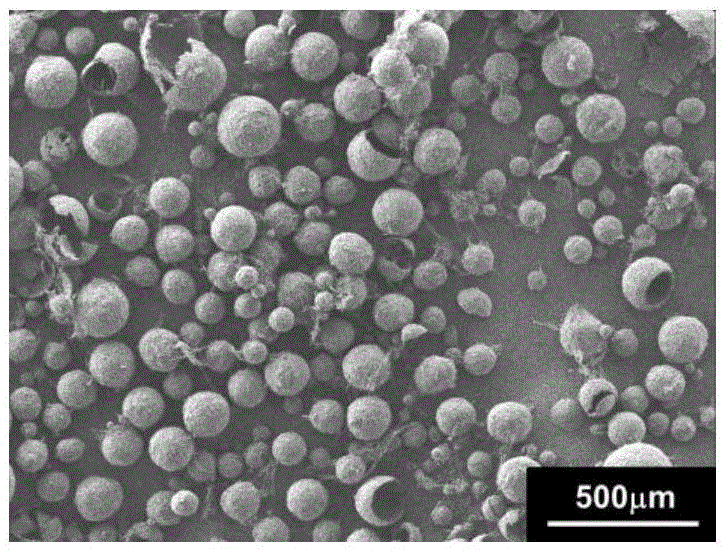

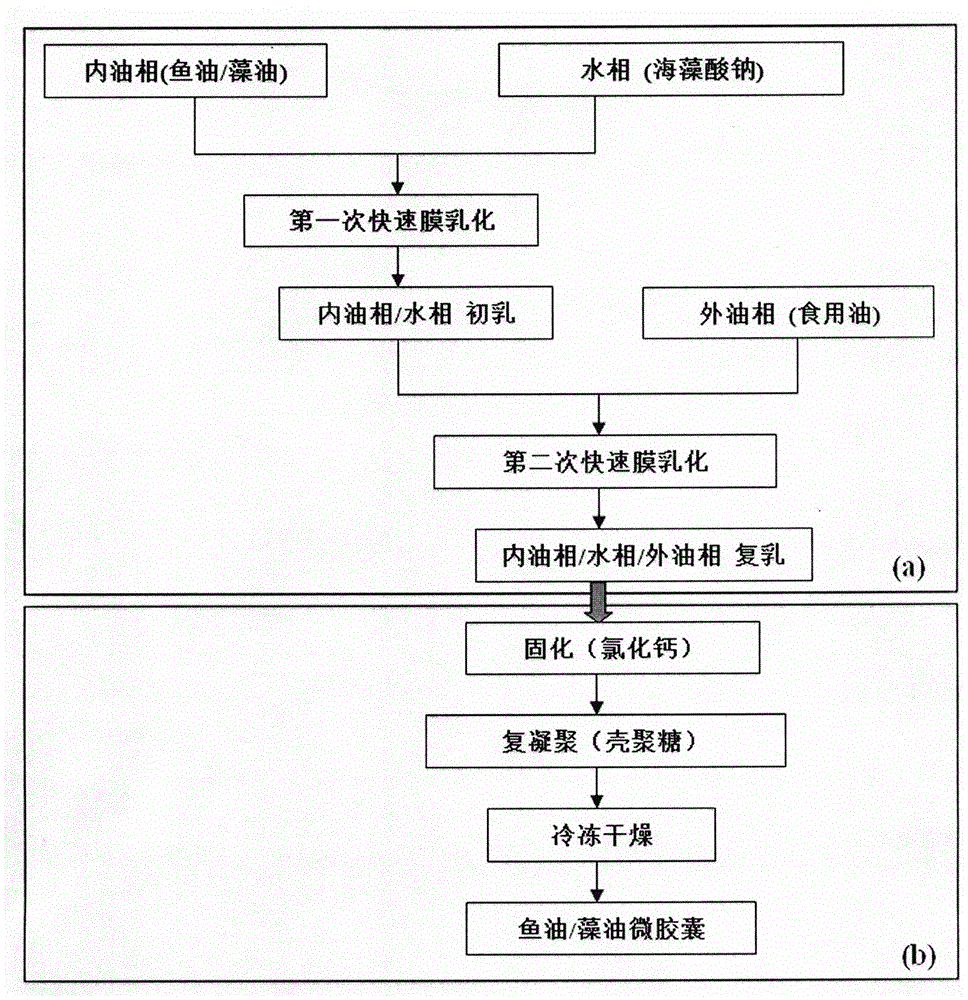

Novel micro-nanometer grade fish oil/algae oil microcapsule and preparation process thereof

ActiveCN105533691AUniform particle sizeEnhance safety and reliabilityFood shapingHigh absorptionMembrane emulsification

The present invention relates to a fish oil / algal oil microencapsulated product rich in polyunsaturated fatty acids (PUFA) essential to the human body and a production process thereof. The microcapsule is prepared by means of a premix membrane emulsification process and a complex coacervation method using sodium alginate and chitosan which are biodegradable, have health-care functions and are cheap and readily available as wall materials. The prepared fish oil / algal oil microcapsule is uniform in particle size, and the particle size can be controlled at hundreds of nanometers-tens of microns. The prepared fish oil / algal oil microcapsule has the advantages of good sustained release and enteric digestion effects, high absorption efficiency, low production cost, etc., and can be widely applied to food nutrition enhancement and health-care food.

Owner:NAT INST FOR NUTRITION & HEALTH CHINESE CENT FOR DISEASE CONTROL & PREVENTION +1

Method for controlling droplet size of an emulsion when mixing two immiscible fluids

InactiveUS20060128815A1Shaking/oscillating/vibrating mixersFlow mixersMembrane emulsificationPolymer chemistry

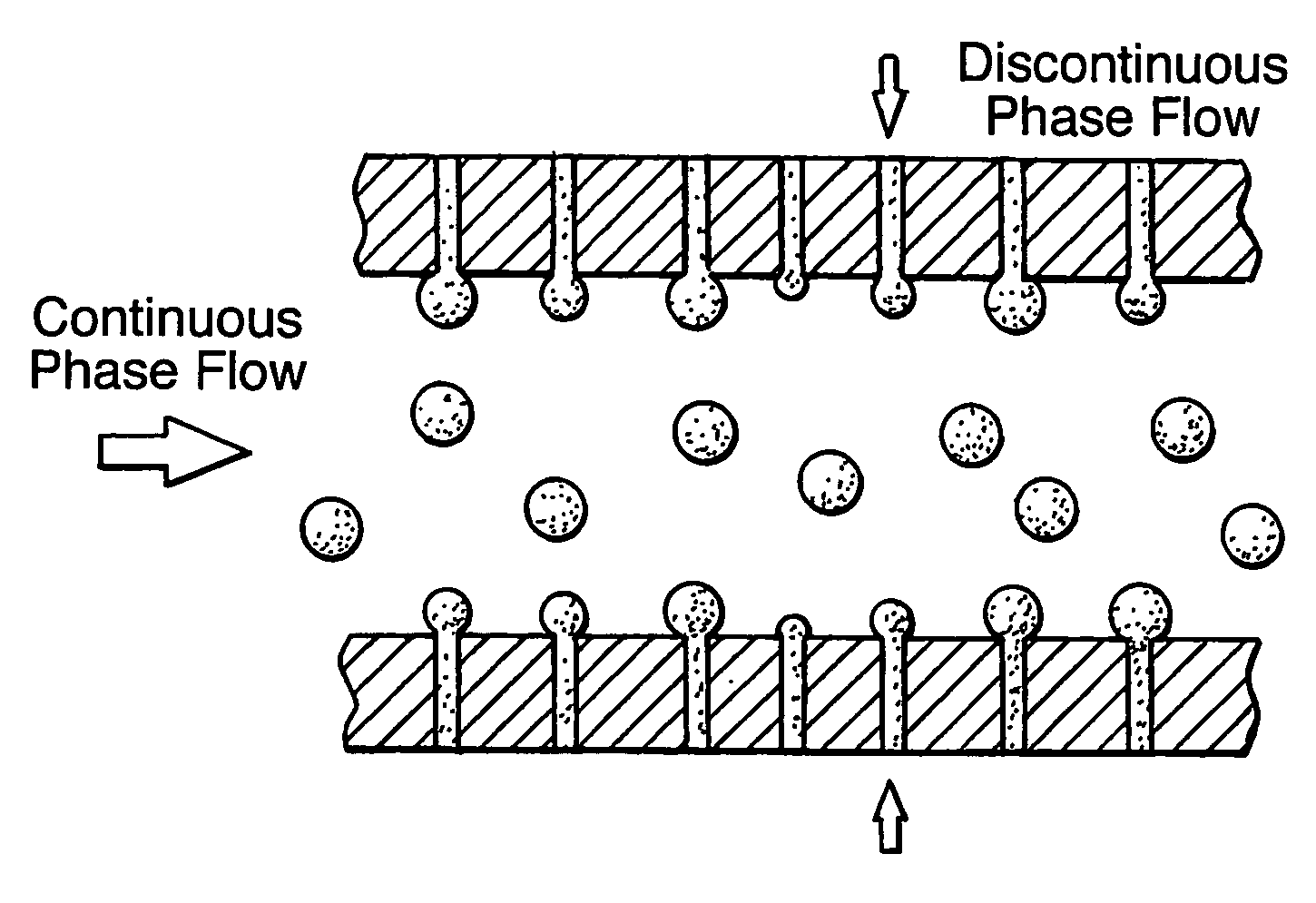

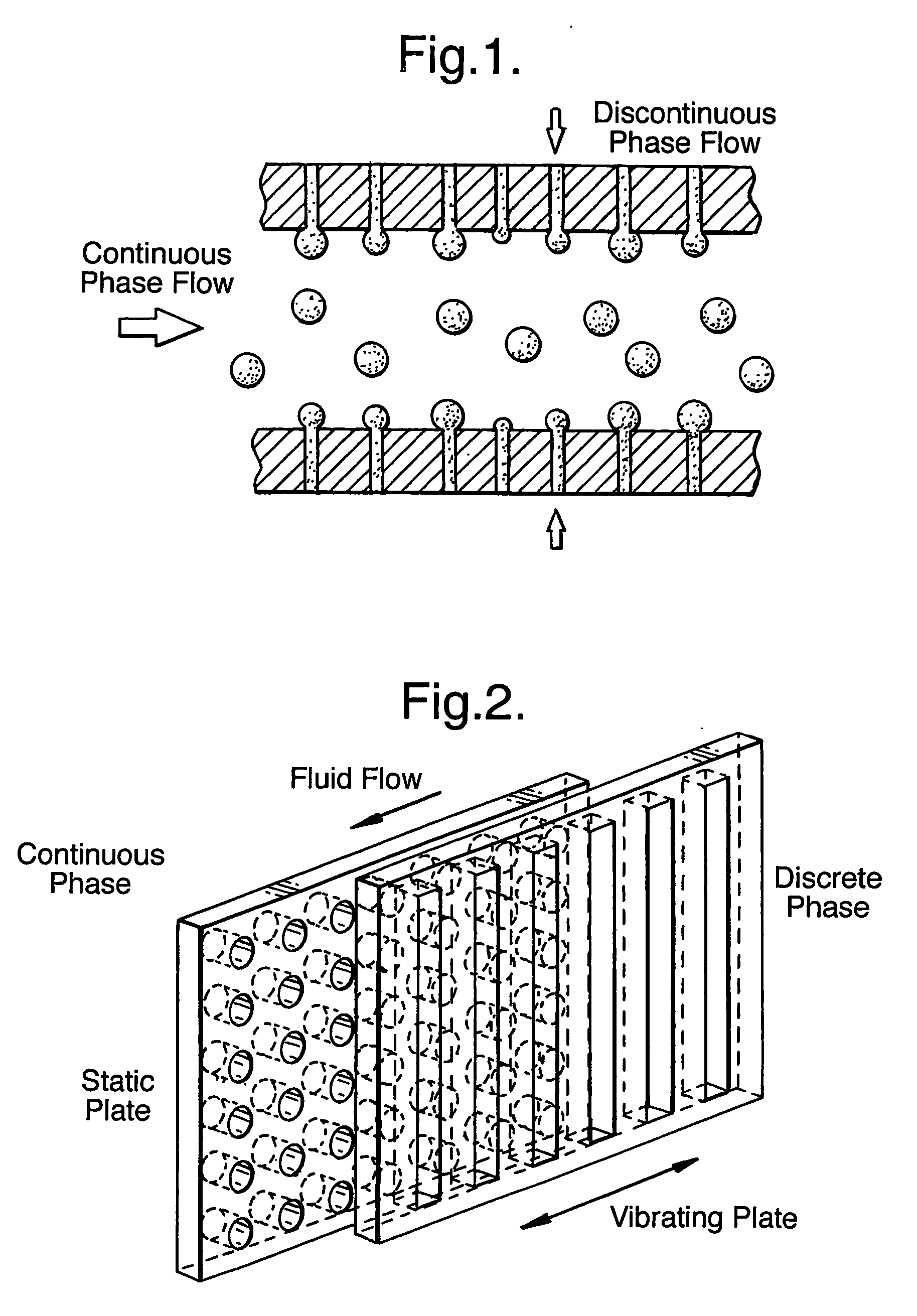

The invention relates to a method for preparing an emulsion by membrane emulsification enabling control of the dispersed phase size and size distribution by interrupting extrusion of the dispersed phase.

Owner:CLARE HUGH JOHN +2

Functional nano-particle compound cross-linking microsphere powder as well as preparation method and application thereof

InactiveCN102908960AUniform and controllable particle sizeSmall coefficient of variationFluorescence/phosphorescenceMicroballoon preparationMembrane emulsificationMicrosphere

The invention relates to functional nano-particle compound cross-linking microsphere powder as well as a preparation method and application of the functional nano-particle compound cross-linking microsphere powder. The functional nano-particle compound cross-linking microsphere powder contains functional nano-particle compound cross-linking microspheres, wherein each functional nano-particle compound cross-linking microsphere comprises a functional nano-particle, a monomer, a crosslinking agent and an initiator, the average particle size of the functional nano-particle compound cross-linking microspheres is 0.1-20 microns, and the particle size distribution variable coefficient is no larger than 9.6 percent. The preparation method is combination of a membrane emulsification technology and an emulsion polymerization method. The invention also relates to a biological detection probe based on the compound cross-linking microsphere powder and application of the probe. The functional nano-particle compound cross-linking microsphere powder as well as the preparation method and the application of the functional nano-particle compound cross-linking microsphere powder have the advantages that the functional nano-particle compound cross-linking microspheres with uniform particle size can be prepared, is in a micron order, has small particle size variable coefficient, is good in monodispersity and performances and has wide application prospect in the field of biological detection, biological medicine and the like.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Spice nano-microcapsule and preparation method thereof

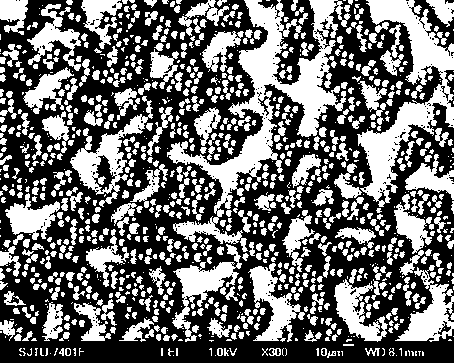

InactiveCN105733808AImprove uniformityHigh embedding rateEssential-oils/perfumesPolymer scienceSucrose

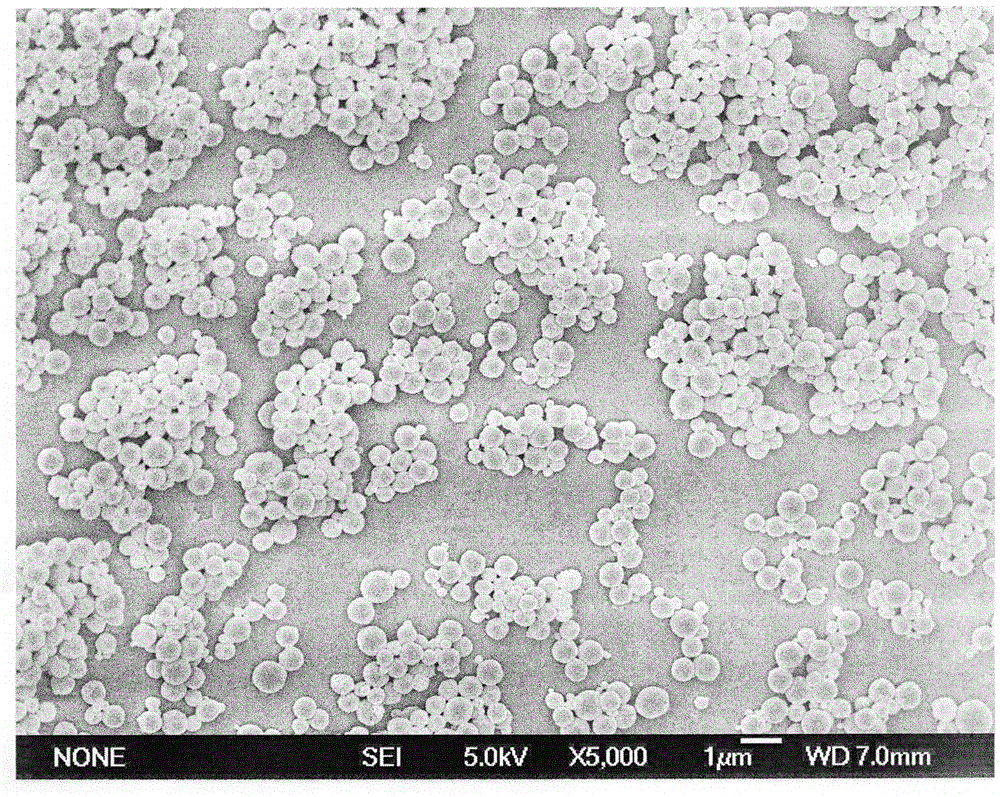

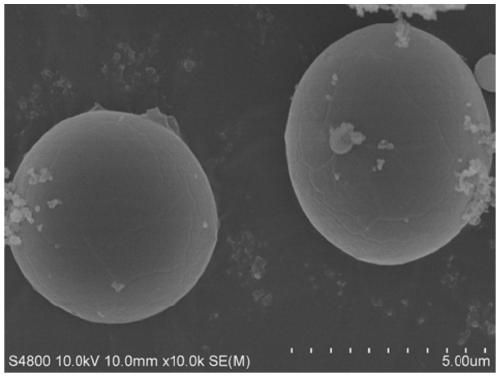

The invention discloses a spice nano-microcapsule and a preparation method thereof. Raw materials of the spice nano-microcapsule comprise spices and a wall material, wherein the wall material is a mixture of Arabic gum, sodium caseinate, maltodextrin, beta-cyclodextrin, modified starch and glucose in a mass percentage of (5%-15%):(5%-20%):(20%-40%):(5%-15%):(20%-40):(5%-15%). According to the spice nano-microcapsule and the preparation method thereof, Arabic gum, sodium caseinate, maltodextrin, beta-cyclodextrin, modified starch and glucose are mixed and used, and are limited in ratio, an emulsifier, namely sucrose ester, and the wall material in a mass ratio of (1:8)-(1:20) are also added, and a membrane emulsifying device is used at the same time, so that the evenness, the encapsulation rate and the dispersity of the microcapsule are improved; moreover, by means of SEM (scanning electron microscope) representation, the surface topography of the microcapsule is in a smooth spherical shape, the uniformity and the dispersity are good, the encapsulation rate of the microcapsule is high, and reaches up to 50% or more, and the loading capacity reaches 25% or more; the spice nano-microcapsule is quite suitable for spices with high volatility.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Method for preparing starch micro-capsules and microballons on basis of fast membrane emulsification method

ActiveCN104138735AAdjust and control particle sizeImproved particle size distributionPharmaceutical non-active ingredientsGranular deliveryMembrane emulsificationPhosphate

The invention discloses a method for preparing starch micro-capsules and microballons on the basis of a fast membrane emulsification method. The fast membrane emulsification method is combined with an oil / water and water / oil / water solution volatilization technology, the size of the prepared starch micro-capsules and microballons can be adjusted and controlled between 0.3 micrometer and 7 micrometers by adjusting the membrane emulsification process parameters, and the particle size distribution is uniform. The prepared starch micro-capsules and microballons can be used as drug carriers to contain water-soluble or oil-soluble drugs, can be embedded with inorganic particles such as magnetic particles, hydroxyapatite and tricalcium phosphate, can be used for adsorbing heavy metal ions such as Cu2+, Pd2+, Cd2+ and Hg2+, and can also be loaded with the enzymic catalytic reaction, and the application prospect is wide.

Owner:厦门富源堂投资管理有限公司

Polymer porous membrane as well as preparation method and application thereof

ActiveCN103833957AGood chemical stabilityUniform pore sizeMixing methodsPolymer scienceMembrane emulsification

The invention provides a hydrophobic polymer porous membrane and a preparation method specific to the current situation of lack of a hydrophobic polymer membrane suitable for a membrane emulsification technology. The preparation method is characterized in that the polymer porous membrane with certain mechanical strength, different pore diameters and a bicontinuous structure is obtained by using a hydrophobic monomer comprising a frequently-used monomer as a reaction monomer and a polyfunctional group reactant as a catalyst through a reaction-induced phase separation method, wherein the frequently-used monomer and the polyfunctional group reactant are both suitable for stepwise polymerization and free radical polymerization. The hydrophobic polymer porous membrane is narrow in pore diameter distribution, and the size of the pore diameter of the membrane can be adjusted at random in the range of 1-60 micrometers. The membrane is applied to membrane emulsification for preparing W / O, W / O / W system emulsion, and the obtained emulsion is good in uniformity. Compared with a hydrophobic modified SPG membrane, the hydrophobic polymer porous membrane has the advantages that the stability is obviously improved under an alkaline using condition.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

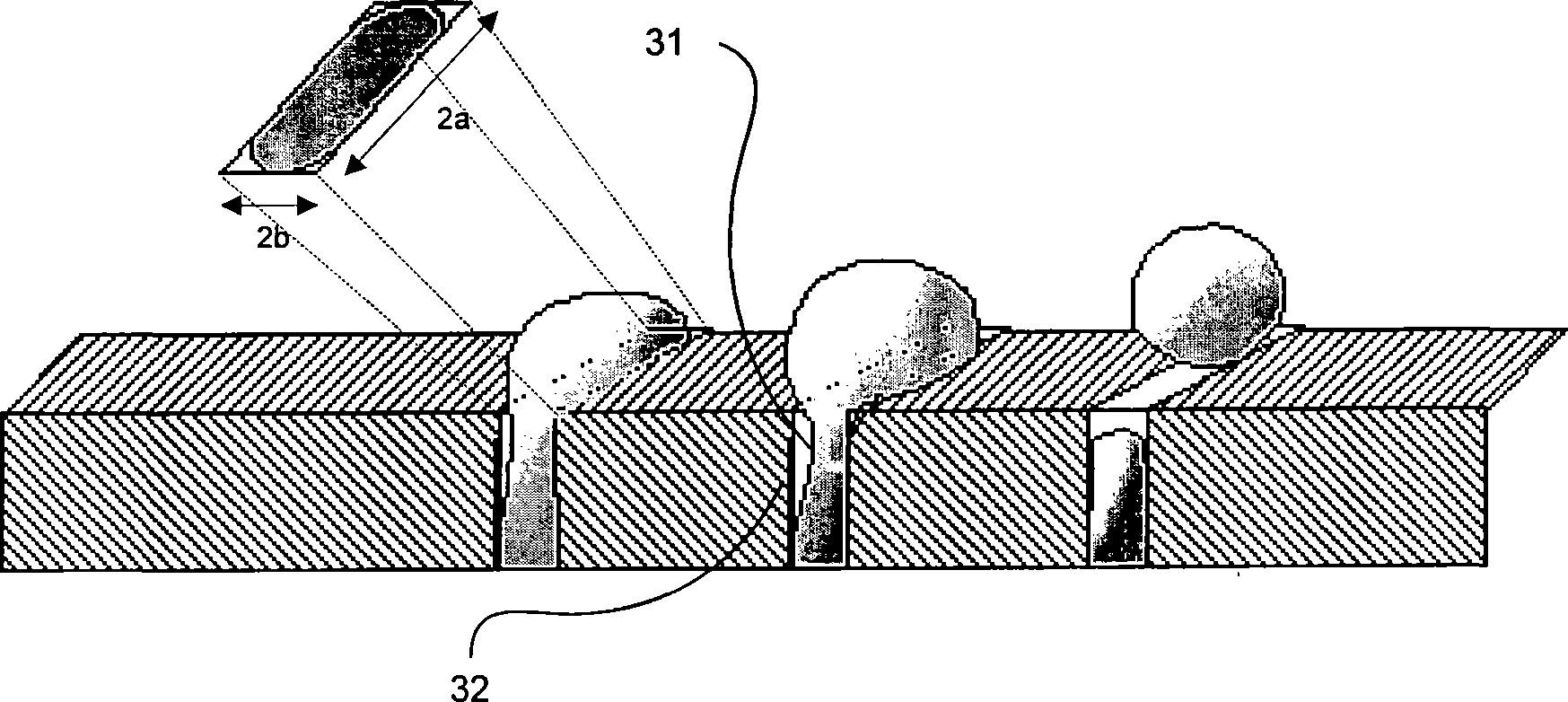

Manufacturing method of a membrane and a membrane thereof, for emulsification

The present invention provides a manufacturing method of a membrane, a membrane obtained therefrom, and a use of said membrane for membrane emulsification. A desired shape of the membrane pores for spontaneous interfacial tension driven droplet formation is achieved by stretching the membrane material containing pores with a first shape, such that a second shape, i.e. the pores having an aspect ratio greater or equal to 3, is obtained.

Owner:玛里琳·雷纳

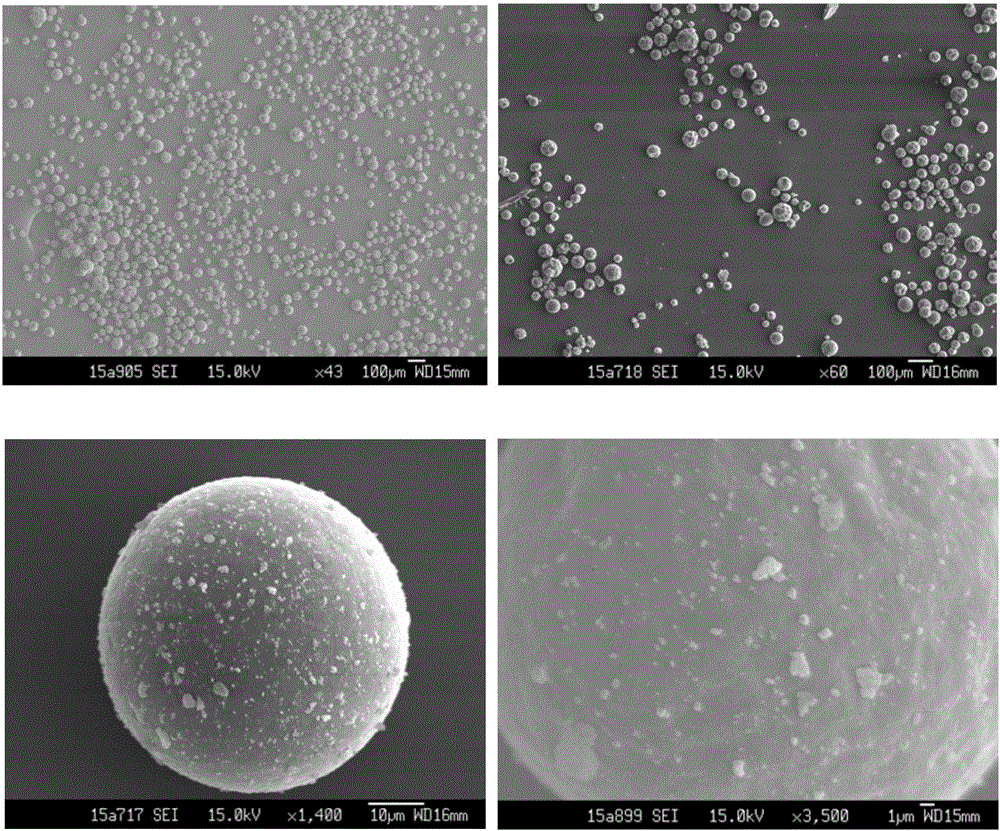

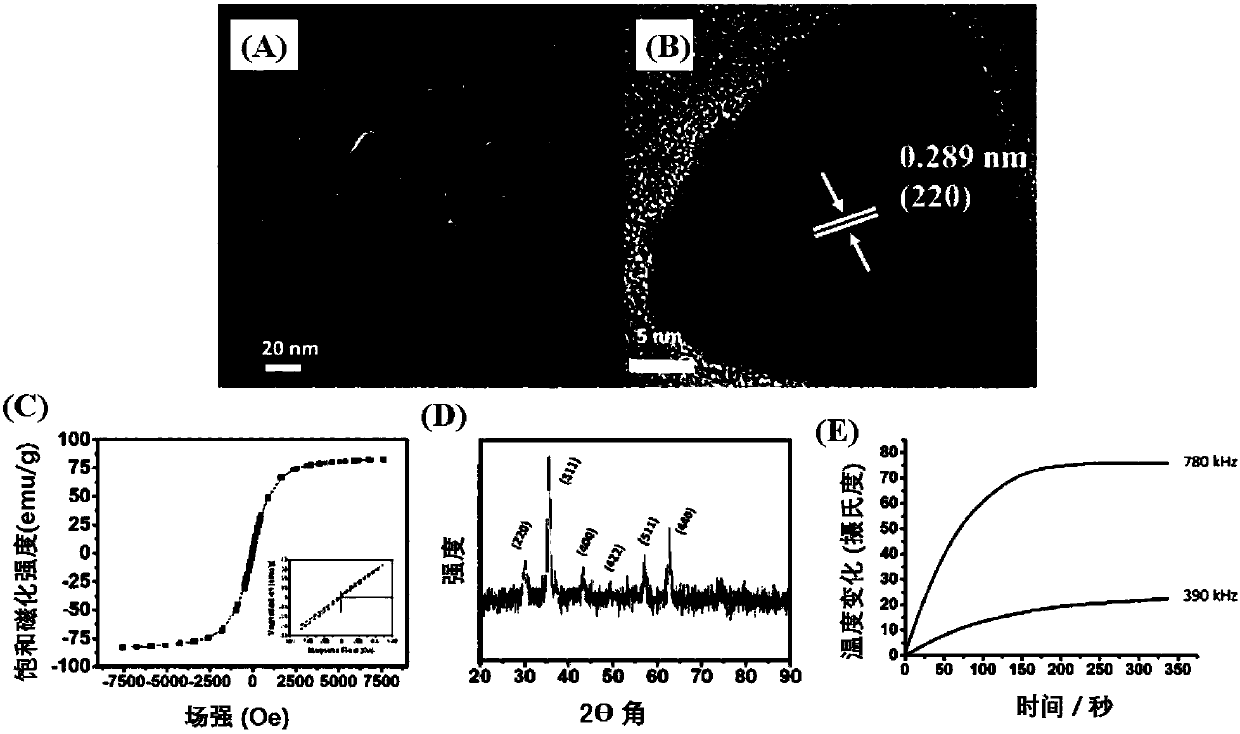

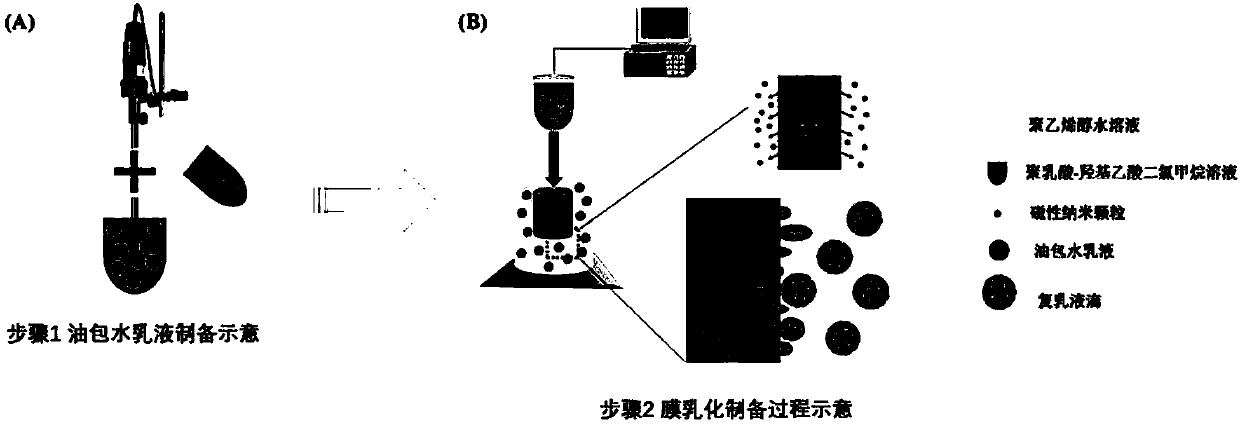

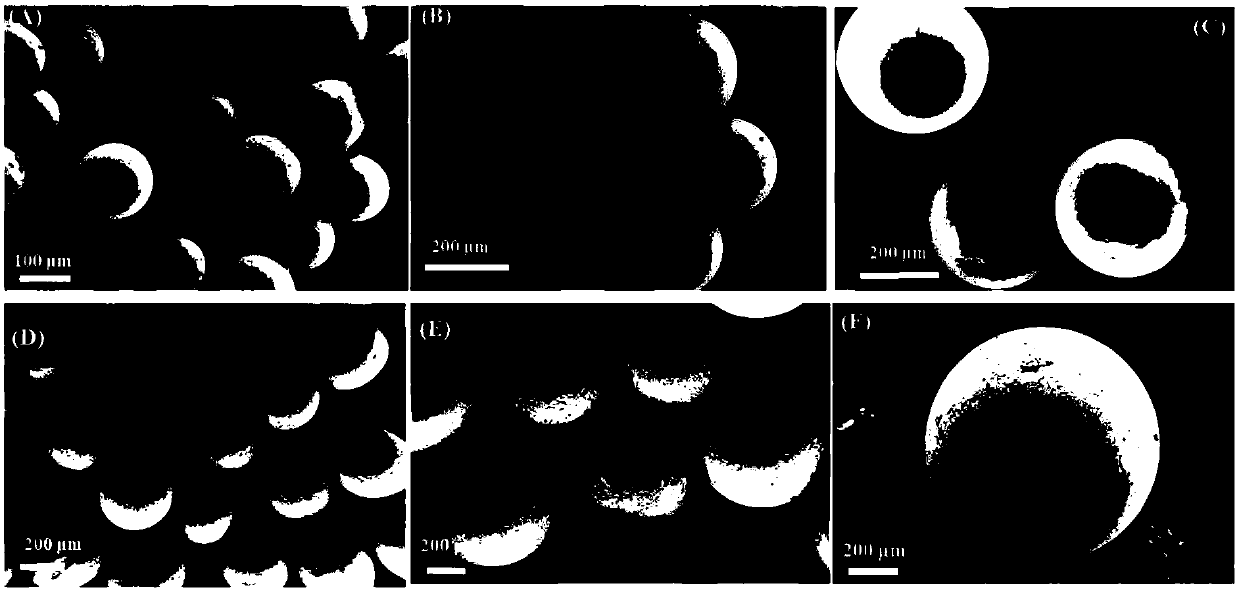

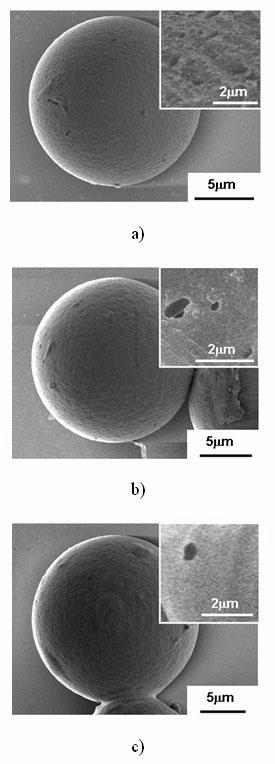

Preparation method of magnetic induction hyperthermia embolism microspheres

ActiveCN107661499ABlocking supportWon't leakEnergy modified materialsPharmaceutical non-active ingredientsPolyvinyl alcoholMicrosphere

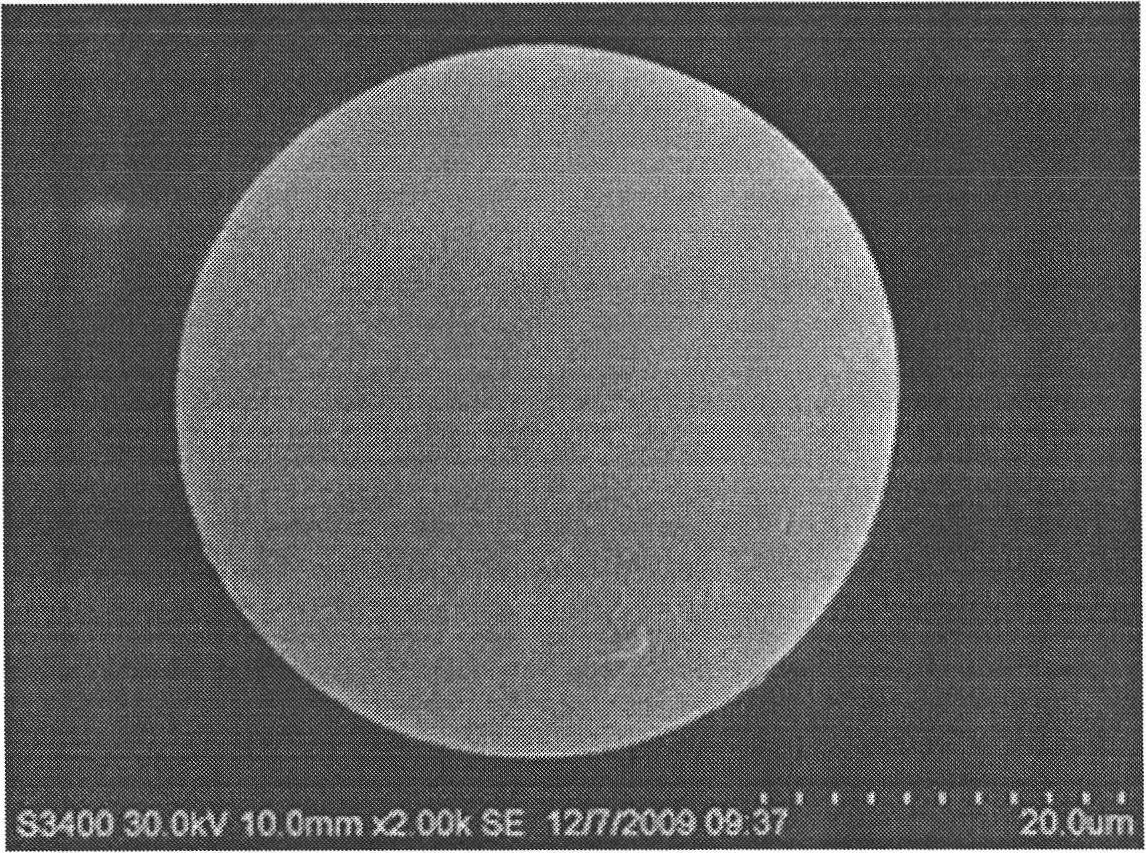

The invention discloses a preparation method of magnetic induction hyperthermia embolism microspheres. The preparation method comprises the following steps of by taking a dissolved matter obtained bydissolving biodegradable high molecular polymers with low transition temperature and super paramagnetic Fe3O4 nano-particles into dichloromethane as an oil phase, Span 80 as a surfactant and an aqueous solution dissolved with polyvinyl alcohol (PVA) as an internal water phase, dropwise adding a water phase in the oil phase under the conditions with low temperature and high shearing to form primaryemulsion; placing the primary emulsion in a membrane emulsification instrument for membrane emulsification under the low temperature condition; forming multiple emulsion in a continuous phase of an external water phase PVA after the primary emulsion permeates a membrane, and performing low-temperature solidification to obtain the magnetic induction hyperthermia embolism microspheres which meet the demand for clinic size. The obtained microspheres are arbitrarily adjustable in size in a range from 100 microns to 1000 microns, can realize rabbit orthotopic liver cancer model embolism hyperthermia under guidance of iconography and have potential application in the interventional hyperthermia field of orthotopic tumors.

Owner:SOUTHEAST UNIV

Method of regulating microsphere drug-load rate by treating calcium alginate microspheres with sodium chloride solution

InactiveCN102631680AWide variety of sourcesSimple processPharmaceutical non-active ingredientsGranular deliveryMicrosphereMembrane emulsification

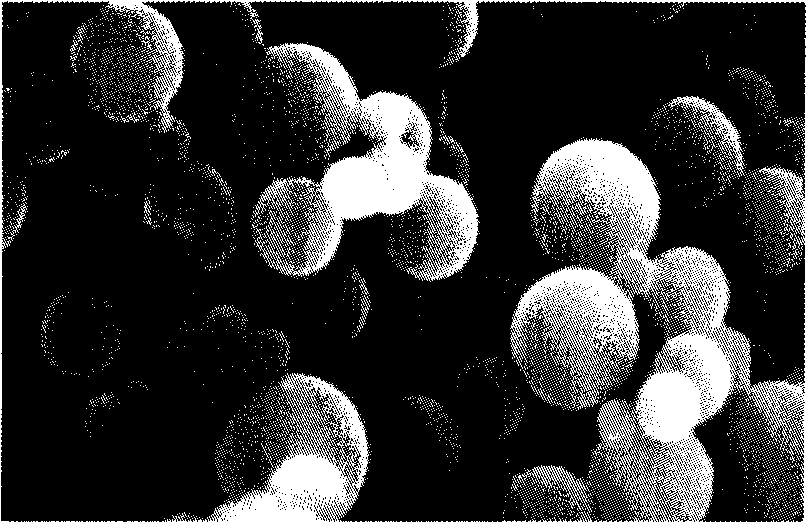

The invention discloses a method of regulating microsphere drug-load rate by treating calcium alginate microspheres with sodium chloride solution. The method comprises the following steps: preparing calcium alginate microspheres with uniform grain diameter by adopting a membrane emulsification-gelatinization method; soaking the microspheres with sodium chloride solutions with different concentrations to substitute sodium ions for part of calcium ions in the calcium alginate microspheres, and then cleaning with ultrapure water; and soaking the treated microspheres into medicinal solution with positive charges, and loading drugs by virtue of static effect to obtain the calcium alginate microspheres with different drug-load rates finally. The preparation method is easy and controllable, the material sources are wide, the drug-load rate of microspheres can be conveniently adjusted, and the method has the advantage of excellent application prospect.

Owner:ZHEJIANG UNIV

Micro-capsule ultrasonic contrast agent and preparation method thereof

ActiveCN103432602AChange the ultrasonic propertiesIncrease contrastEchographic/ultrasound-imaging preparationsMicrocapsulesOrganic solventMembrane emulsification

The invention discloses a micro-capsule ultrasonic contrast agent and a preparation method thereof. The preparation method comprises the following steps of (1) dissolving biodegradable high polymer materials into an organic solvent to obtain a solution marked as a solution A, and dissolving a stabilizer into water to obtain a solution marked as a solution B; (2) mixing the solution A with water, and carrying out ultrasonic treatment to obtain a water-in-oil primary emulsion; (3) adding the primary emulsion into the solution B, and stirring to obtain an oil-in-water-in-water pre-composite emulsion; (4) adding the pre-composite emulsion into a membrane emulsification device for passing through the membrane to obtain an oil-in-water-in-water composite emulsion; (5) stirring and centrifuging the oil-in-water-in-water composite emulsion, and collecting the precipitate to obtain the micro-capsule ultrasonic contrast agent. The ultrasonic contrast agent is sent into the part of the human body to be detected through injection and intravenous perfusion, vibrates under the action of the ultrasonic so as to change the ultrasound characters of the tissue, and increases the contrast ratio between the lesion tissue and the normal tissue as well as between the motion part and the static part, thereby playing an ultrasonic developing effect.

Owner:厦门富源堂投资管理有限公司

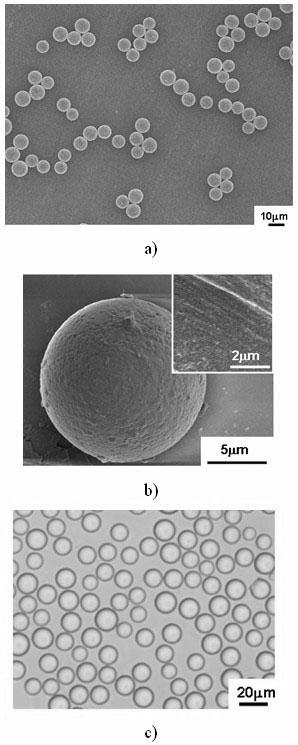

Preparation method of monodisperse large size carbon ball

The invention belongs to the field of chemical industry and specifically relates to a preparation method of monodisperse large size carbon ball. The invention takes liquid urea resin as precursor material, prepares stable micron urea resin emulsion with uniform size by glass membrane emulsification method, conducting emulsification at room temperature, pressure of disperse phase being 0.2-0.5 MPa, concentration of emulsifier in aqueous phase being 0.1-1.0wt%, concentration of ammonium chloride being 0.05-0.5mol / L, and concentration of PVA being 0.1-0.5wt%; after emulsification, stirring 2 hours, curing urea resin under catalysis of ammonium chloride completely, precipitating cured urea resin from aqueous phase; separating settled resin particles, drying and carbonizing at high temperaturein argon gas. The sizes of the carbon balls prepared by the invention are uniform, and the grain diameter of the carbon ball is adjustable within 10-80mm by changing aperture of SPG membrane or pressure of disperse phase during the emulsification. The invention has simple technique and low cost.

Owner:HUNAN UNIV OF SCI & TECH

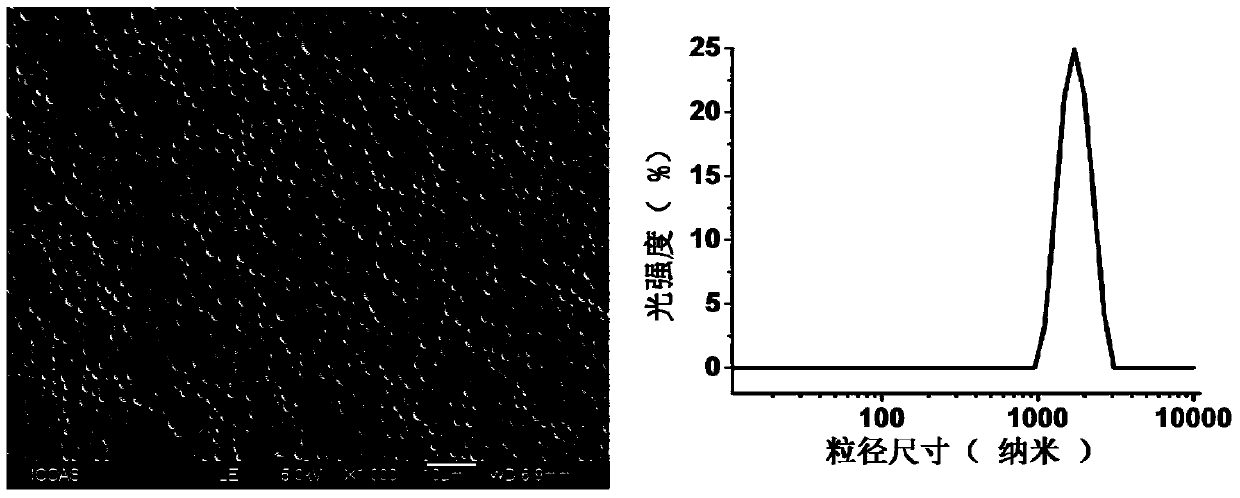

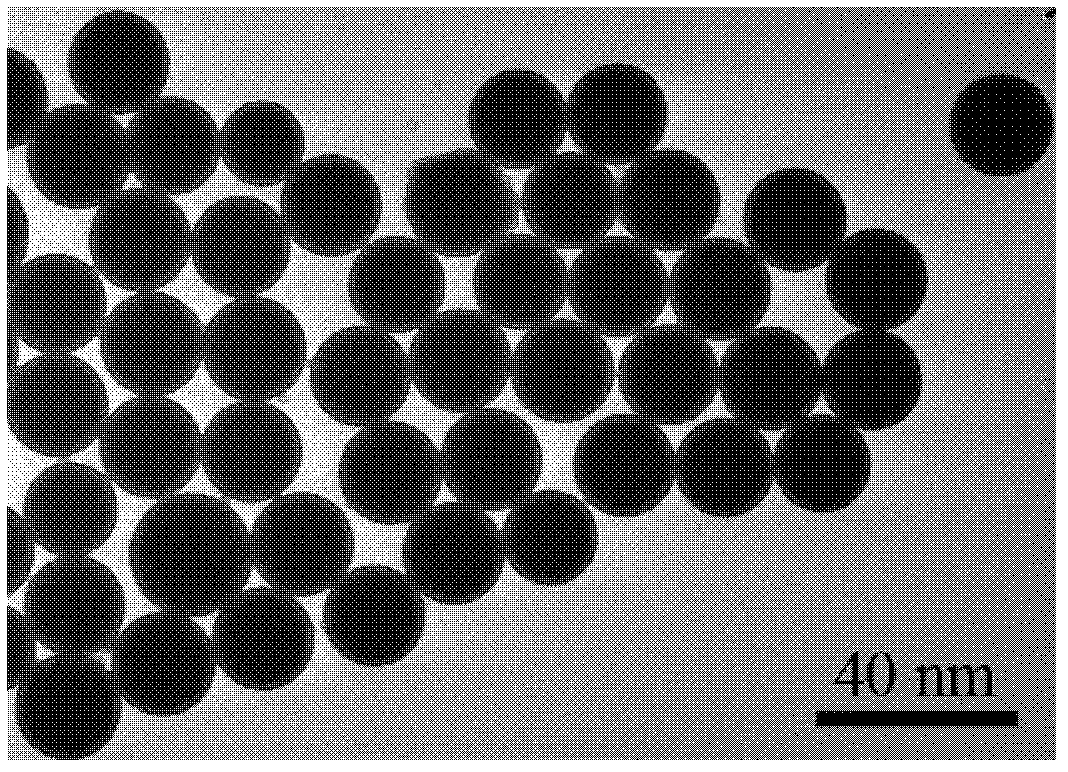

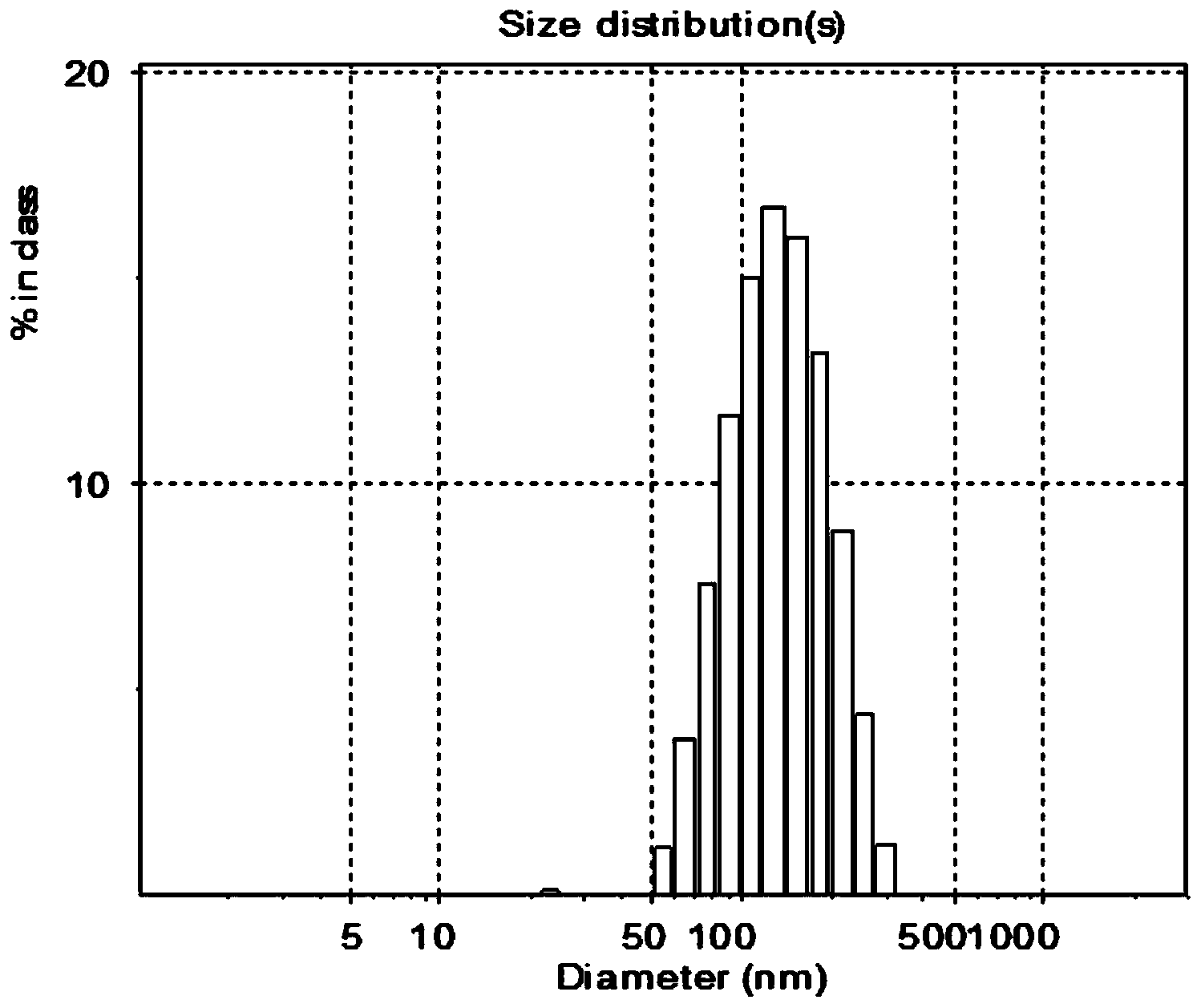

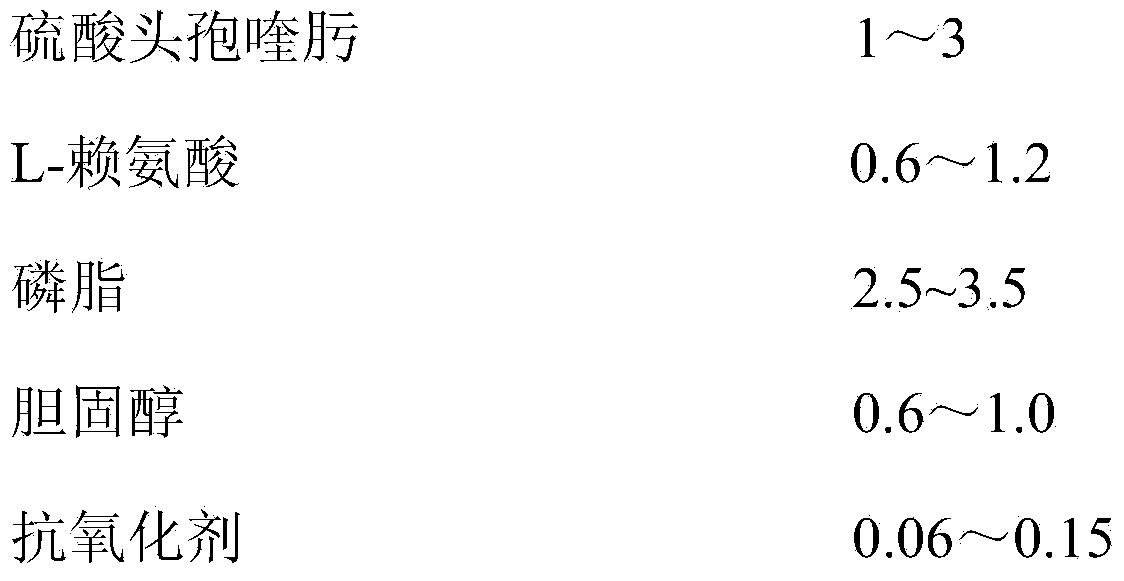

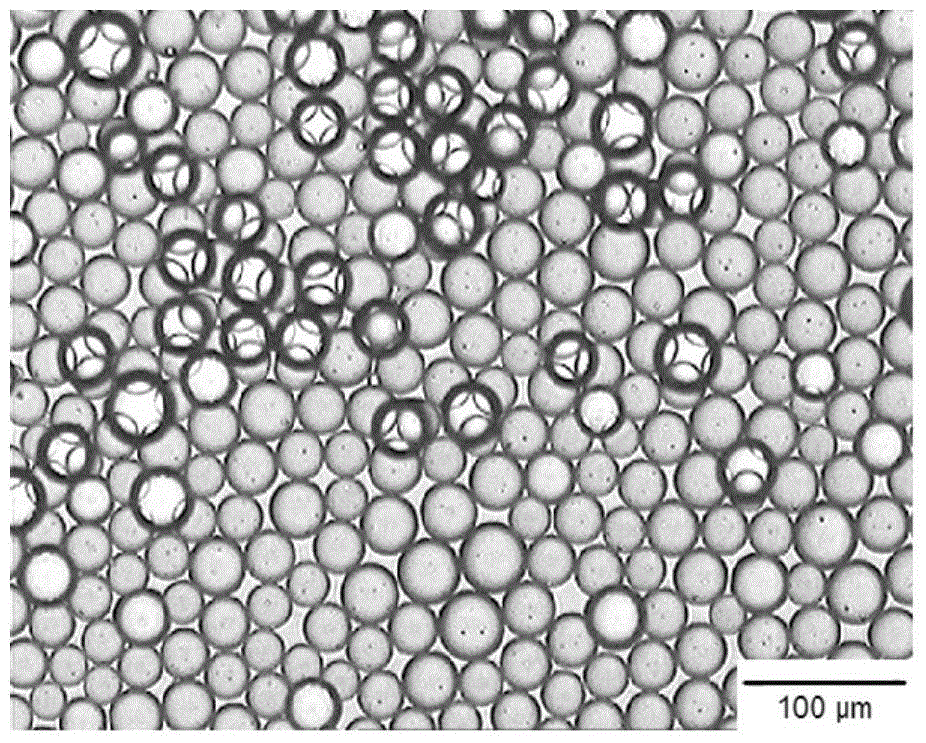

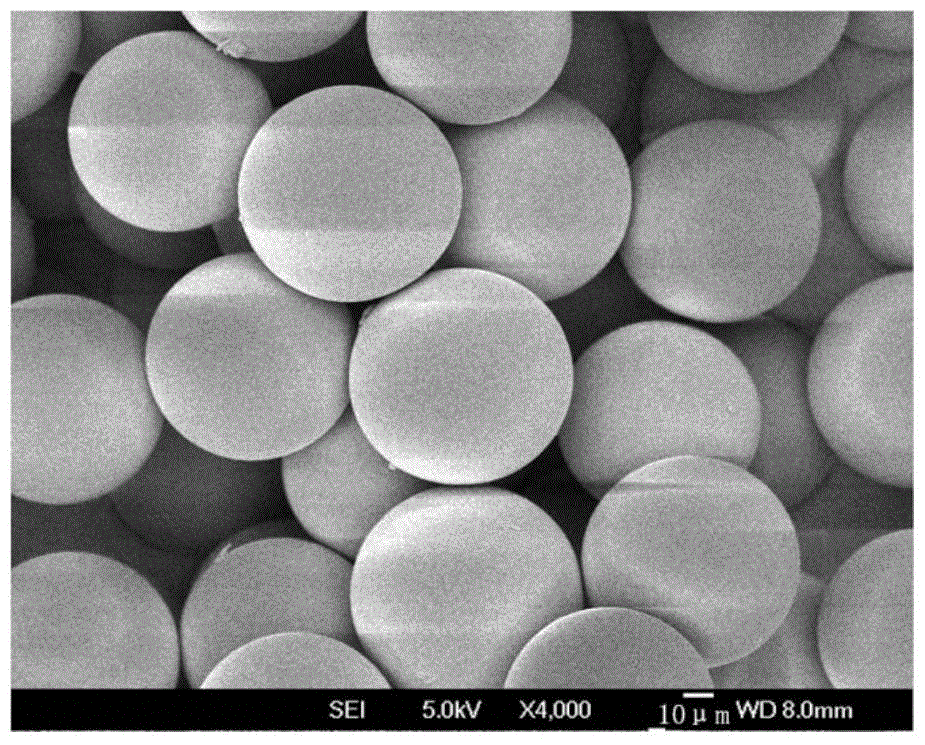

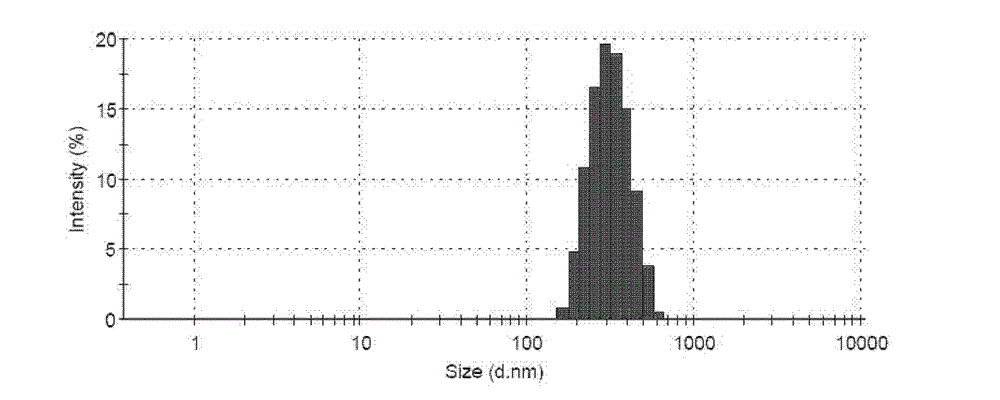

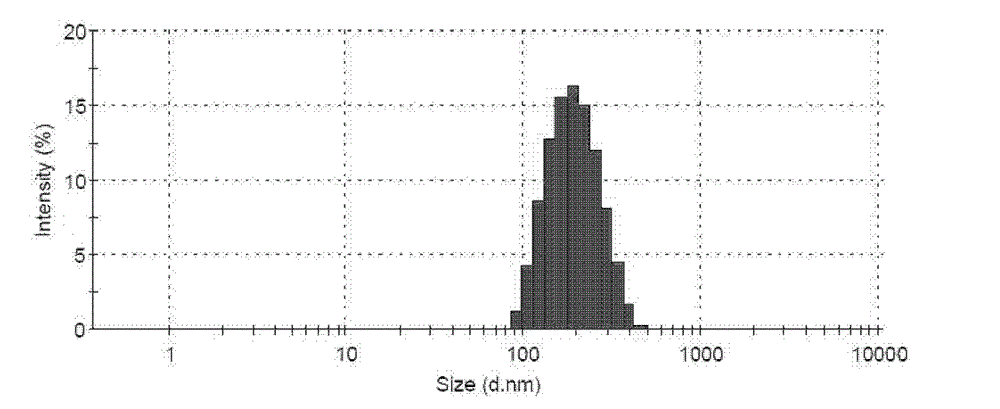

Monodisperse nano cefquinome sulfate liposome preparation and preparation method thereof

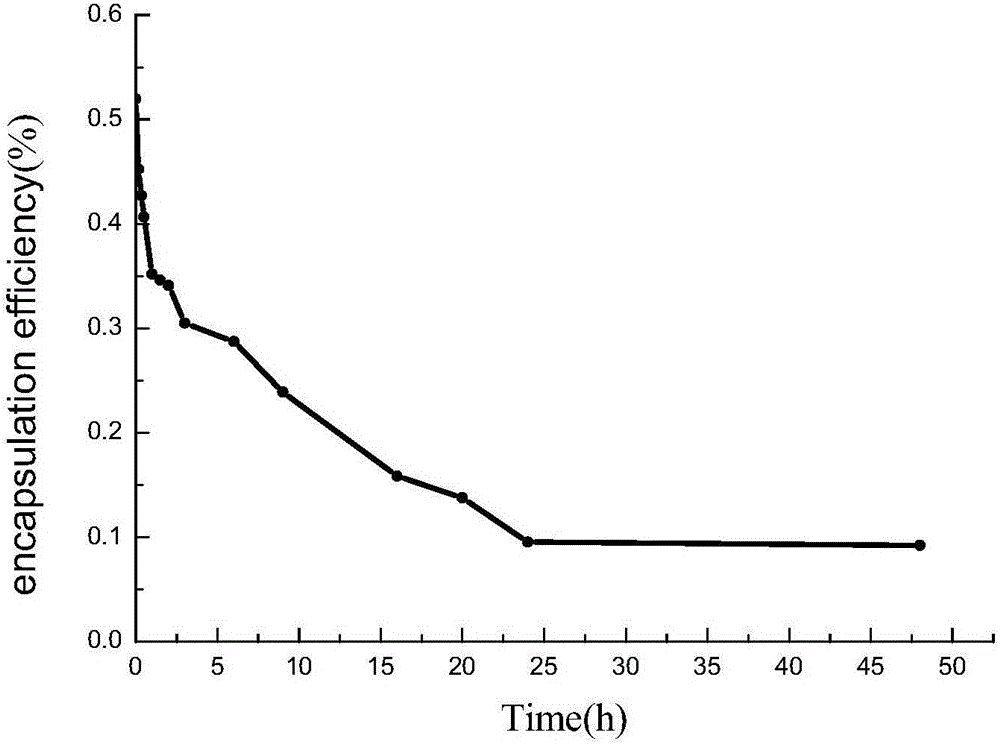

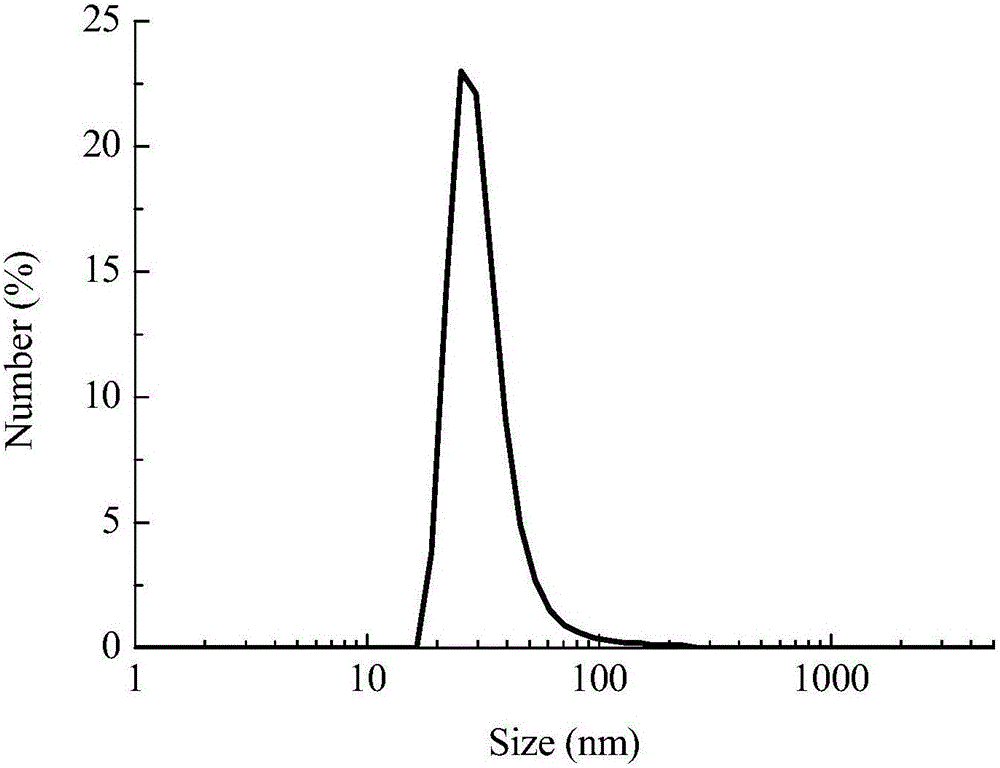

InactiveCN103637993AUniform sizeHigh encapsulation efficiencyAntibacterial agentsOrganic active ingredientsMembrane emulsificationCholesterol

The invention relates to a monodisperse nano cefquinome sulfate liposome preparation and a preparation method thereof. The monodisperse nano cefquinome sulfate liposome preparation is prepared by adopting a membrane emulsification technique. The preparation method comprises the following steps: directly suspending sterile cefquinome sulfate into injection water, adding sterile L-lysine to adjust the PH value, and completely dissolving the sterile cefquinome sulfate to obtain the aqueous solution of cefquinome sulfate / L-lysine, wherein the the aqueous solution of cefquinome sulfate / L-lysine is a continuous phase; dissolving an anti-oxidant-containing injection phospholipid and cholesterol in ethyl alcohol, wherein the obtained solution is a dispersed phase; dispersing the dispersed phase in the continuous phase through a porous membrane under the action of a pressure; removing the ethyl alcohol under reduced pressure; sterilizing, packaging, and freeze-drying to finally obtain the monodisperse nano cefquinome sulfate liposome preparation for injection. The preparation method provided by the invention is simple; the prepared particles are uniform in size, high in encapsulation rate and high in stability; in an emulsification process, the energy consumption is low, the conditions are mild, and the reproducibility is high; the stability of a cefquinome sulfate medicament is stable, toxic or side effects are reduced, and the medicament utilization degree is improved; moreover, the preparation process is simple and is suitable for industrial production.

Owner:湖北领盛制药有限公司

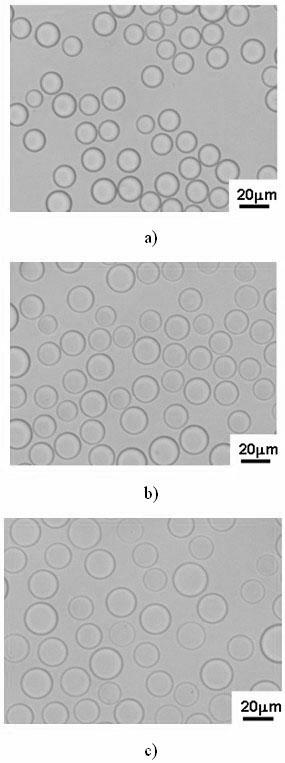

Chitosan microspheres prepared from chitosan solution with pH value of 6-8 and preparation method of chitosan microspheres

ActiveCN111748109AReduce degradationImprove stabilityCarbon preparation/purificationMicroballoon preparationMicrosphereMembrane emulsification

The invention discloses a microsphere material prepared from a chitosan solution with the pH value of 6-8 and a preparation method of the microsphere material. The preparation method comprises the following steps: (1) preparing a dispersion liquid; (2) adding chitosan into the dispersion liquid, controlling the temperature to range from a freezing point to 35 DEG C, introducing carbon dioxide intothe solution, stirring to dissolve the chitosan, stopping introduction of the carbon dioxide after the chitosan is completely dissolved, and defoaming to obtain a transparent chitosan solution with the pH value of 6-8; and (3) enabling the chitosan aqueous solution and an oil phase to form chitosan emulsion drops through a membrane emulsifier or microfluidic equipment or a conventional stirring device, and curing the emulsion drops through a coagulator or a chemical cross-linking agent to form the chitosan microspheres. The microsphere material and the method have the beneficial effects that:the method for preparing the chitosan microspheres is carried out in an environment with the pH value of 6-8, and degradation of a chitosan molecular chain can be effectively weakened; and the process of preparing the chitosan microspheres is environment-friendly, so that the production efficiency is improved, and the production cost is reduced.

Owner:WUHAN UNIV

Monodisperse copolymer microsphere and preparation method thereof

ActiveCN105037603ANarrow particle size distributionParticle size controllableOther chemical processesMicrosphereMembrane emulsification

The invention provides a preparation method of a monodisperse copolymer microsphere with uniform particle size and controllable dimension. The method comprises the steps that a membrane emulsification method is used, oil phase and water phase are prepared into stable emulsion, a liquid drop is taken as a nucleus to conduct a polymerization reaction, and the monodisperse copolymer microsphere is prepared; the particle size of the finally obtained microsphere can be controlled by adjusting the pore diameter of a membrane and applied pressure, so that the form and the performance of the product are easy to control, meanwhile, uniformity of particle size distribution and the yield of the product are increased, the operation is easy, and the energy consumption is low. The invention provides the monodisperse copolymer microsphere, the particle size is uniform, the dimension is controllable, the adsorption capacity and the sample capacity are high, pH range of suitable samples is wide, and the monodisperse copolymer microsphere which serves as solid phase extraction packing has the wide application prospect in the aspects of extraction, enrichment and purification of compounds.

Owner:天津博纳艾杰尔科技有限公司

Polymer microsphere with controllable particle size and method for preparing same

The invention provides a polymer microsphere with a controllable particle size and a method for preparing the polymer microsphere. The method comprises the following steps of: (1) preparing a water phase containing an emulsifier, wherein 0.01-0.15 part by weight of emulsifier is added to every 100 parts by weight of water, and preparing an oil phase containing a monomer and an initiator, wherein 0.5-5 parts by weigh of initiator and 20.0-50.0 parts by weight of monomer are added to every 100 parts by weight of oil; (2) increasing pressure on one side of a membrane by adopting the membrane emulsification method, pressing the mixture of the water phase and the oil phase into the membrane to obtain an uniform emulsion, wherein the volume ratio of the water phase to the oil phase is (1:3) to (1:5); and (3) enabling the emulsion obtained in the step (2) to be subjected to polymerization reaction for 10-24 hours to obtain the polymer microsphere. The technical scheme solves the problems that the original mixing method is complex in process flow, has a high requirement for raw materials, equipment and process conditions and consumes a large amount of energy. According to the technical scheme, the method comprises the steps of: dissolving a dye into the oil phase, mixing the oil phase with the water phase, emulsifying under a certain pressure by using a membrane emulsification device, and enabling the emulsion to be subjected to polymerization reaction to obtain the colored microsphere.

Owner:SPECIAL CHEM CO LTD DALIAN FIRSTAR

Method for continuously preparing chitin/chitosan microsphere materials with different deacetylation degrees

ActiveCN111514829AControllableUniform sizeMicroballoon preparationMicrocapsule preparationAlkaline waterMicrosphere

The invention discloses a method for continuously preparing chitin / chitosan microsphere materials with different deacetylation degrees. The preparation method comprises the following steps: firstly mixing chitin with a potassium hydroxide solution, heating to carry out deacetylation reaction, then adding water into the mixture of chitosan and the potassium hydroxide solution to dilute to a certainconcentration, cooling, adding a stabilizer, and continuously stirring at a temperature above the freezing point to quickly dissolve the chitosan and the potassium hydroxide solution; and preparing an emulsion from an alkaline aqueous solution in which chitin / chitosan is dissolved and an oil phase through a membrane emulsifier, microfluidic equipment and a conventional stirring device, convertingchitin / chitosan emulsion droplets into chitin / chitosan microspheres by using a coagulator, and washing and drying the microspheres to obtain a microsphere finished product. Functional components areintroduced in the microsphere preparation process, and the functional microsphere material is obtained. The prepared microspheres are carbonized to obtain the nitrogen element doped carbon aerogel microspheres. Discontinuity caused by separation and purification steps in the process of preparing chitin / chitosan microsphere materials with different deacetylation degrees is avoided.

Owner:WUHAN UNIV

Preparation method of thermally expandable microspheres with controllable particle size

InactiveCN110551248AParticle size controllableNarrow particle size distributionFiltrationIn situ polymerization

The invention discloses a preparation method of thermally expandable microspheres with controllable particle size. The preparation method comprises the steps of aqueous phase preparation, oil phase preparation, membrane emulsification and in-situ polymerization reaction. After the in-situ polymerization reaction is finished, a reaction solution is subjected to vacuum suction filtration, the product is washed with a solvent, the washed wet material is dried in a vacuum drying oven, and the dried material is crushed. According to the method, through selection of membrane materials and membrane pore diameters and control of membrane particle size distribution, the emulsified microspheres with controllable particle size and narrow particle size distribution are obtained, and then the thermallyexpandable microspheres with controllable particle size are obtained through in-situ polymerization reaction. The membrane emulsification mode is low in energy consumption, low in investment cost andbeneficial to industrialized production, the obtained thermally expandable microspheres are controllable in particle size and narrow in particle size distribution, the particle size distribution range is controlled within 15 [mu]m, and the quantitative requirements of different customers can be met.

Owner:NANJING RENTIAN EP SCI TECH CO LTD

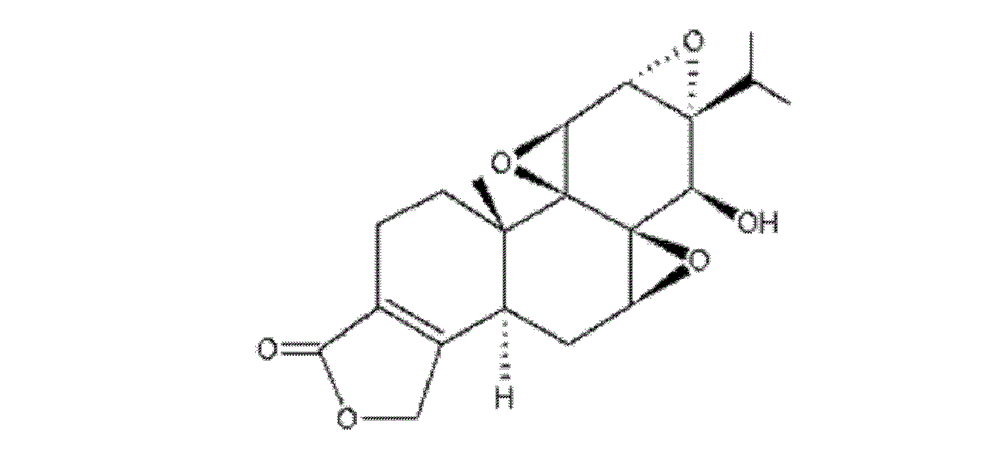

Triptolide solid lipid nanoparticle as well as preparation method and application thereof

InactiveCN102793674ASimple manufacturing methodMild conditionsOrganic active ingredientsAntipyreticLipid particleOrganic solvent

The invention discloses a method for preparing triptolide solid lipid nanoparticles by quick membrane emulsification. The method comprises the following steps of: dissolving triptolide and mixed lipid into an organic solvent to serve as an oil phase, and dispersing into deionized water with an emulsifying agent; performing high-speed shearing emulsification at temperature higher than a melting point of the mixed lipid to obtain O / W type pre-emulsion; circulating the pre-emulsion under nitrogen pressure by adopting quick membrane emulsification equipment, and obtaining O / W type emulsion; and removing the organic solvent, and solidifying the lipid particles to obtain a solid lipid nanoparticle dispersion solution, or centrifugally separating the dispersion solution to collect the nanoparticles, or performing spraying drying or freezing drying to obtain the triptolide solid lipid nanoparticles. The triptolide solid lipid nanoparticles are high in monodispersity, high in entrapment efficiency and stable in process.

Owner:MACAU UNIV OF SCI & TECH

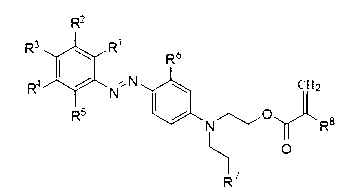

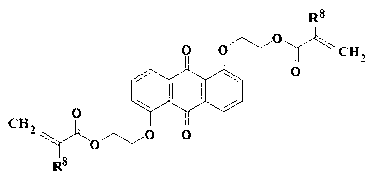

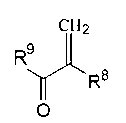

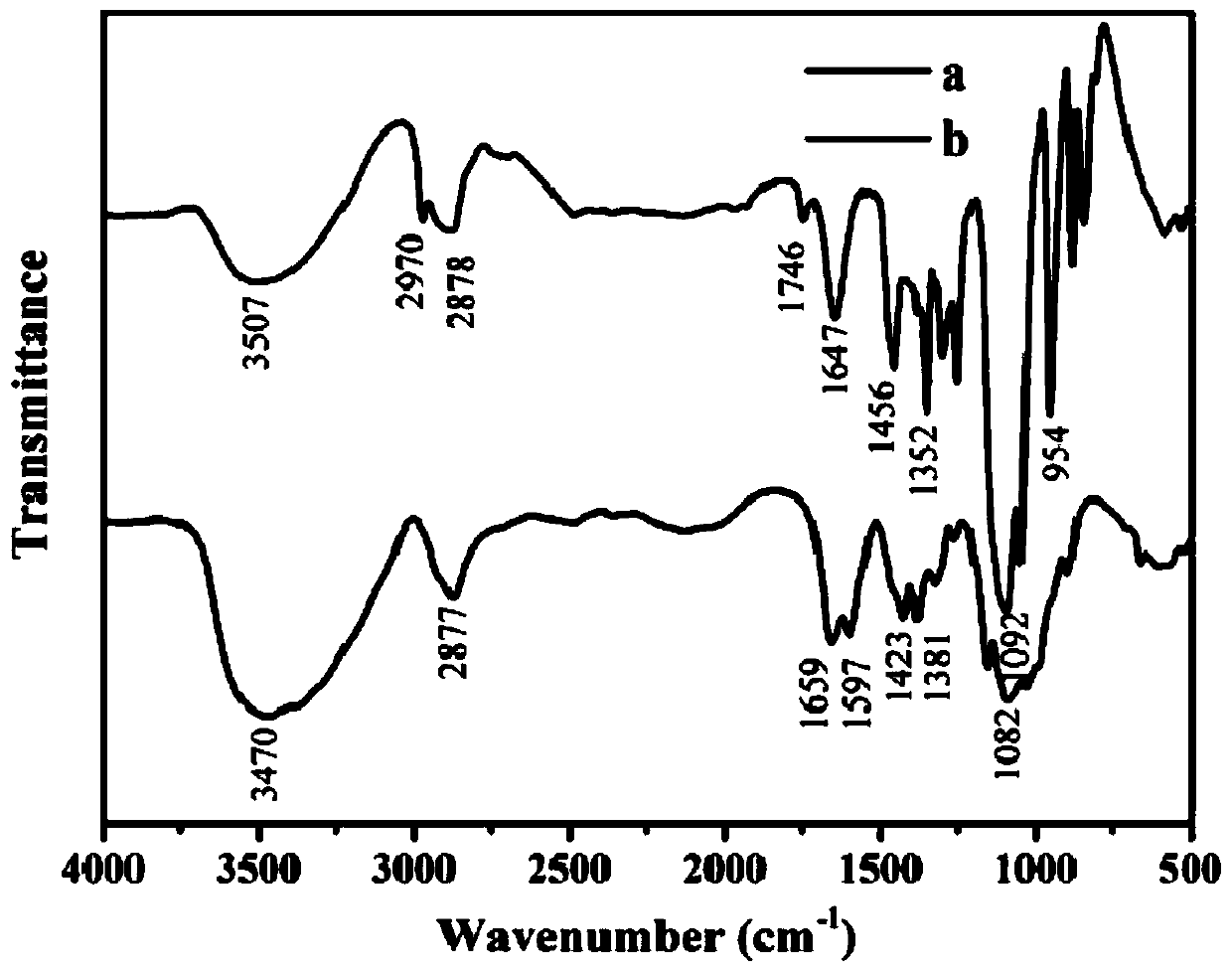

Dyestuff with polymerizable group and preparation of microspheres containing dyestuff

ActiveCN103319909AOvercoming incompatibilitiesEliminate colorless particlesMethine/polymethine dyesHydroxy-anthraquinone dyesPolymer scienceMembrane emulsification

The invention discloses dyestuff with a polymerizable group and the preparation of microspheres containing dyestuff. Dyestuff molecule covalence is bound into resin, and is compatible with other dewatering systems of resin, paraffin and the like, and the problem that pigment particles are can not be compatible in a scattering system easily is overcome; dyestuff exists in colourment in a molecule state, colorless particles can be completely eliminated, and the product quality can be improved. According to the dyestuff, emulsion is formed by a membrane emulsion method, and is polymerized again so as to obtain polymeric microspheres which are good in size, shape and uniformity, and have narrow particle diameter distribution, and the microsphere particles are regular in shape, are fresh in color, and have glossiness.

Owner:SPECIAL CHEM CO LTD DALIAN FIRSTAR

Making method of colored toner

InactiveCN106873321AProcess stabilitySimple processDevelopersMembrane emulsificationEmulsion polymerization

The invention discloses a making method of colored toner. The method comprises the steps of dissolving dye into an oil phase, then mixing the oil phase with a water phase, emulsifying by using a membrane emulsification apparatus under certain pressure, and adopting an emulsion polymerization method to obtain colored microspheres. The method solves the problems that the original 'mixed melting method' is complicated in process technology, high in requirements for raw materials, equipment and process conditions, high in energy consumption, and the like. The method also solves the problem that the common chemical method for preparing the toner is poor in process amplification stability. The colored microspheres prepared by the method are good in particle size uniformity, high in degree of sphericity, bright in color, glossy, high in resolution ratio, low in powder rejection rate, simple in technology and low in energy consumption, and do not need to be classified; after the colored microspheres are used, the colored toner with the needed particle size can be obtained at one time, and a series of performance tests such as particle size, sphericity, amount of charge and fixing temperature distribution can be carried out on the colored toner.

Owner:SPECIAL CHEM CO LTD DALIAN FIRSTAR

Photo-thermal dual-responsiveness chitosan derivative as well as preparation method and application thereof

ActiveCN111533848AIncreased sensitivityImprove functionalityDrug photocleavagePharmaceutical delivery mechanismPolymer scienceMembrane emulsification

The invention relates to the technical field of polymer materials, in particular to a photo-thermal dual-responsiveness chitosan derivative of which the structural formula is shown as a formula (I) shown in the specification. In the formula, x, y, z and n are natural numbers greater than or equal to 1, and m is a natural number greater than or equal to 0. The invention also provides nano-microcapsules, which take the photo-thermal dual-responsiveness chitosan derivative shown in the formula (I) as a wall material, take a bioactive drug or plant essential oil as a core material, and adopt a method of a rapid membrane emulsification instrument to embed the core material in the wall material through intermolecular force and electrostatic attraction of the wall material, so as to form a core-shell structure. According to the photo-thermal dual-responsiveness chitosan derivative disclosed by the invention, a tung oil-based derivative that is eleocharic anhydride is used as a connecting arm,which has characteristics of being renewable and green; meanwhile, tung maleic anhydride contains unsaturated double bonds, the double bonds are sensitive to an external environment light source andcan be subjected to a photochemical reaction, and tung maleic anhydride itself can be used as a photoresponse group so as to increase the sensitivity of a carrier material to the external environmentlight source.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Medicine-carrying polylactic acid microcapsular ultrasound contrast agent and preparation method thereof

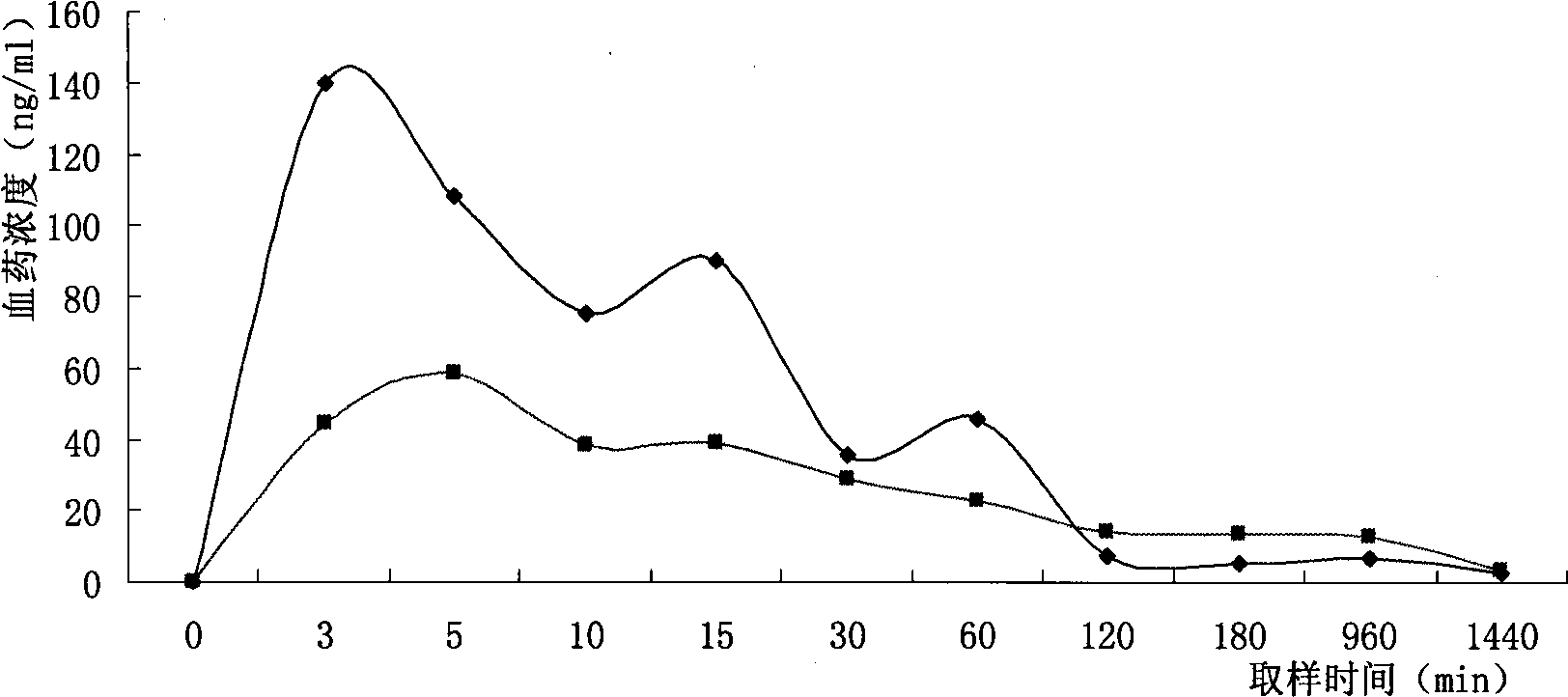

InactiveCN101502660AIncrease blood concentrationUniform and controllable particle sizeOrganic active ingredientsEchographic/ultrasound-imaging preparationsMicrovesicleMethylene Dichloride

The invention provides a drug-loading polylactic acid microvesicle ultrasound contrast agent and a preparation method thereof, relating to a new preparation of antineoplastic drug. Specifically, the invention provides a drug-loading polylactic acid microvesicle ultrasound contrast agent with noticeable antineoplastic effect and a preparation method thereof. The drug-loading polylactic acid microvesicle ultrasound contrast agent comprises an adventitia material, a main drug and charge gas; wherein, the adventitia material is polylactic acid, the main drug is 10-hydroxycamptothecine and the charge gas is perfluoropropane; wherein, concentration of bulk main drug is 3-5mg / mL; the concentration of the adventitia material is 0.025-0.030g / mL. Under ultra audible sound, internal water phase containing hydroxycamptothecine is added to methylene dichloride containing polylactic acid to prepare initial emulsion; the initial emulsion is dispersed to external water phase containing polyvinyl alcohol by a membrane emulsifier to form diphase emulsion; low velocity stirring by magnetic force at constant temperature is carried out overnight to facilitate oil phase to volatize; the polylactic acid is solidified into envelope; microvesicle precipitation is collected and then is washed, cooled and dried; perfluoropropane is used to charge drug-loading microvesicle samples, thus obtaining the drug-loading microvesicle ultrasound contrast agent.

Owner:XIAMEN UNIV

Solid-state avermectin particle preparation and preparation method and application thereof

ActiveCN105851022ASolve the problem of unstable storage processEasy to prepareBiocideAnimal repellantsMicrosphereMembrane emulsification

The invention discloses a solid-state avermectin particle preparation and a preparation method and application thereof. Particles comprise microspheres and microcapsules. A preparation method of the microspheres includes following steps: 1), dissolving avermectin in an organic solvent to obtain an organic solution of avermectin as an oil phase; 2), dissolving a stabilizer in water to obtain a stabilizer water solution as an outer water phase; 3), mixing the oil phase with the outer water phase for mechanical stirring to obtain an oil-in-water primary emulsion; 4), utilizing a membrane emulsification device to perform membrane filtering on the oil-in-water primary emulsion under action of nitrogen to obtain an oil-in-water emulsion; 5), sequentially stirring and centrifuging the oil-in-water emulsion to collect precipitate, washing with water, and drying to obtain the solid-state avermectin microspheres. A membrane emulsification method is combined with an emulsion solvent evaporation method to obtain the solid-state avermectin microspheres and microcapsule preparation which has the advantages of stability in storage, safety and convenience in transport and use and low cost.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Chitosan microsphere and preparation method thereof

ActiveCN113637188ASimple processMild conditionsMicroballoon preparationMicrocapsule preparationMembrane emulsificationFreeze-drying

The invention provides a chitosan microsphere and a preparation method thereof. The preparation method comprises the following steps: a) dissolving modified chitosan in an organic solvent, and then adding a cross-linking agent to obtain a modified chitosan oil solution; adding the modified chitosan oil solution into an emulsifier aqueous solution for pre-emulsification to obtain an oil-in-water pre-emulsion; b) carrying out rapid membrane emulsification on the oil-in-water pre-emulsion obtained in the step a), stirring the obtained emulsion, centrifuging, and collecting the precipitate; and finally, sequentially washing and freeze-drying the obtained precipitate to obtain the chitosan microsphere. The membrane adopted in the rapid membrane emulsification is an SPG membrane, and the aperture of the membrane is 1-9 microns. Compared with the prior art, the preparation method adopts a rapid membrane emulsification method, and the chitosan microspheres with uniform particle size distribution can be finally obtained by adjusting membrane emulsification process parameters, controlling the size of the microspheres and optimizing the particle size distribution of the microspheres.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com