Novel micro-nanometer grade fish oil/algae oil microcapsule and preparation process thereof

A microcapsule, micro-nano technology, applied in the field of food processing, can solve the problems of large, from tens of microns or even hundreds of microns, high production cost, uneven particle size, etc., to improve the acceptability and production cost. Low, good coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

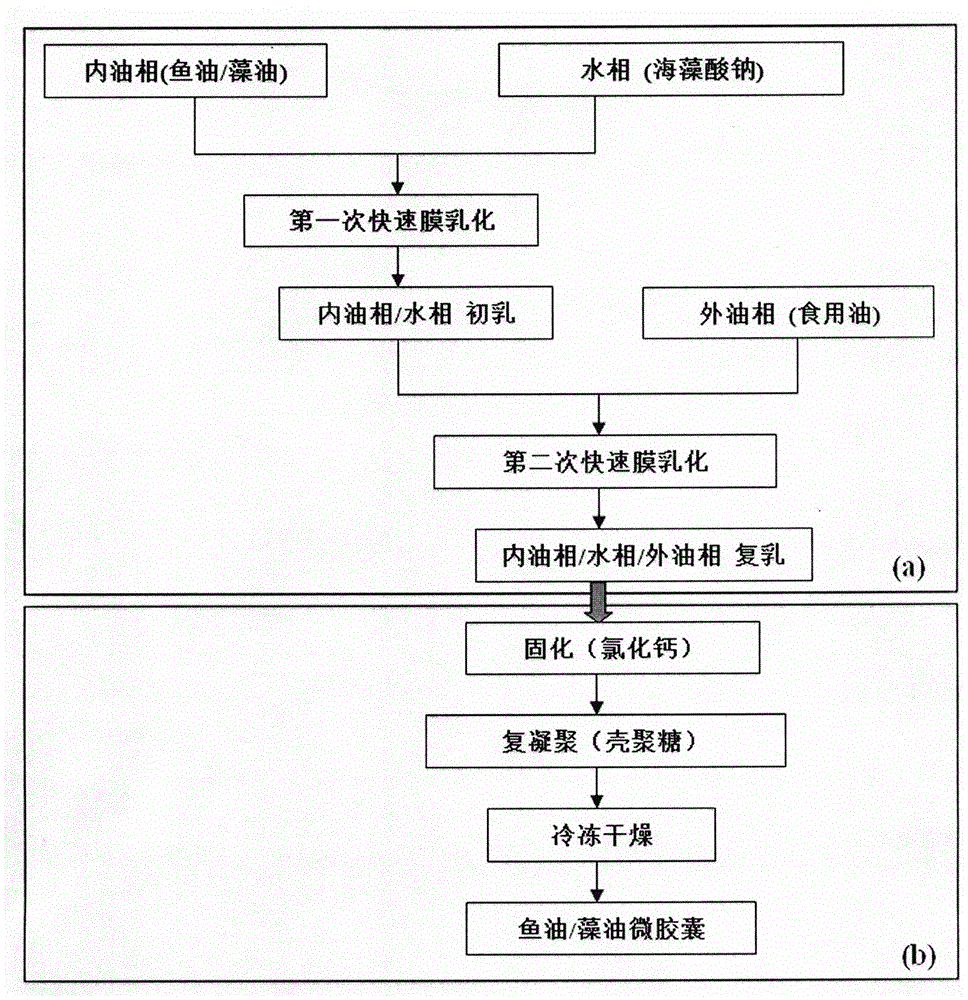

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of internal oil phase: Weigh 0.5g vitamin E, add it to 100mL deep-sea fish oil / algae oil, and stir magnetically for 1 hour;

[0035] (2) Water phase preparation: Weigh 0.2g of sucrose fatty acid ester (SE-15), add it to 100mL of 1.5% sodium alginate aqueous solution, and stir magnetically for 2h;

[0036] (3) Preparation of external oil phase: Weigh an appropriate amount of 1g polyglycerol fatty acid ester (PO-5S), add it to 100mL sunflower oil, and stir for 1 hour;

[0037] (4) Preparation of calcium chloride curing agent: Add 5mL of calcium chloride aqueous solution with a mass ratio of 5% to 15mL of the outer oil phase in step (3), and ultrasonic emulsify for 2min under the condition of setting power at 30%;

[0038] (5) Preparation of chitosan solution: Add 1.5g of chitosan to 100mL of acetic acid solution at pH 4.0, magnetically stir for 2 hours, and centrifuge to take the supernatant for later use;

[0039] (6) The first rapid membrane emulsificat...

Embodiment 2

[0046] (1) Preparation of internal oil phase: Weigh 0.1g of fat-soluble ascorbic acid, add it to 100mL of deep-sea fish oil / algae oil, and stir for 1 hour with magnetic force;

[0047] (2) Water phase preparation: Weigh 0.1g Tween-20, add it to 100mL 1.0% sodium alginate aqueous solution, and stir magnetically for 2h;

[0048] (3) Preparation of external oil phase: Weigh an appropriate amount of 2g of Span-80, add it to 100mL of sunflower oil, and stir for 1 hour with magnetic force;

[0049] (4) Preparation of calcium chloride curing agent: add 5ml of calcium chloride aqueous solution with a mass ratio of 6% to 40mL of the outer oil phase in step (3), and ultrasonically emulsify for 2min under the condition of setting the power at 30%;

[0050] (5) Preparation of chitosan solution: Add 1.0 g of chitosan to 100 mL of acetic acid solution at pH 4.0, stir magnetically for 2 hours, and then centrifuge to take the supernatant for later use;

[0051] (6) The first rapid membrane e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface charge | aaaaa | aaaaa |

| Surface charge | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com