Patents

Literature

463results about How to "Good liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

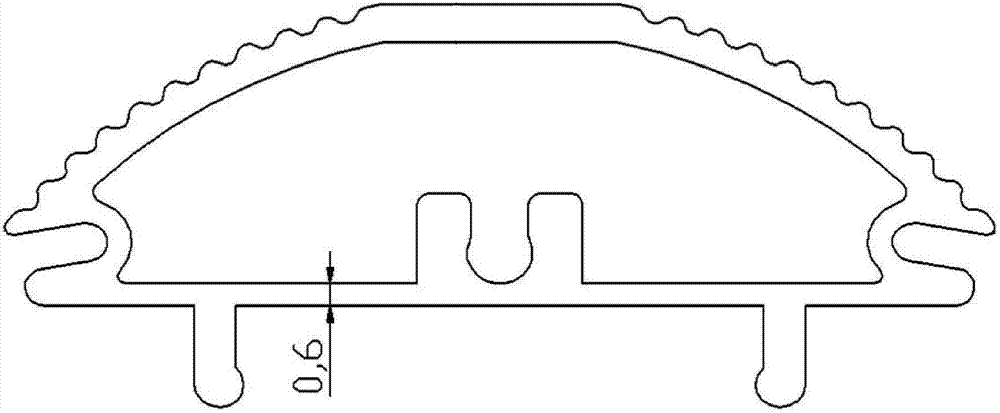

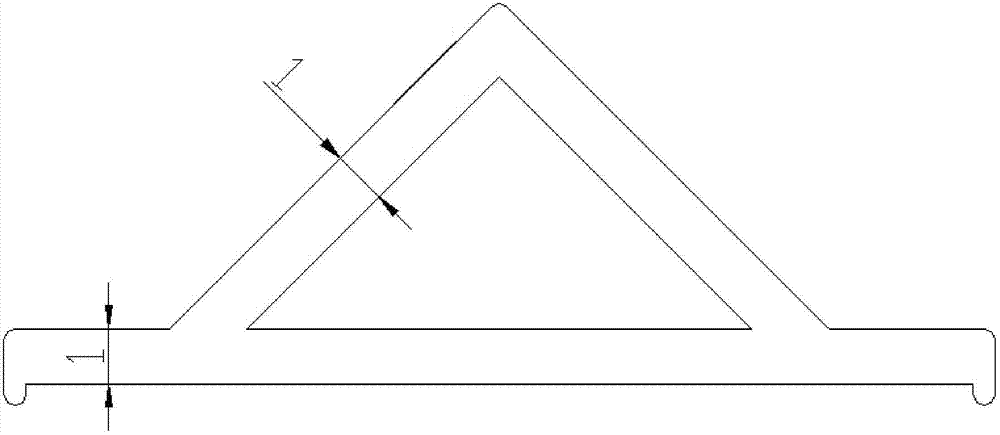

Magnetorheological fluid speed bump

InactiveCN103061287AGood liquidityGuaranteed smoothnessTraffic signalsRoad signsSpeed bumpPiston cylinder

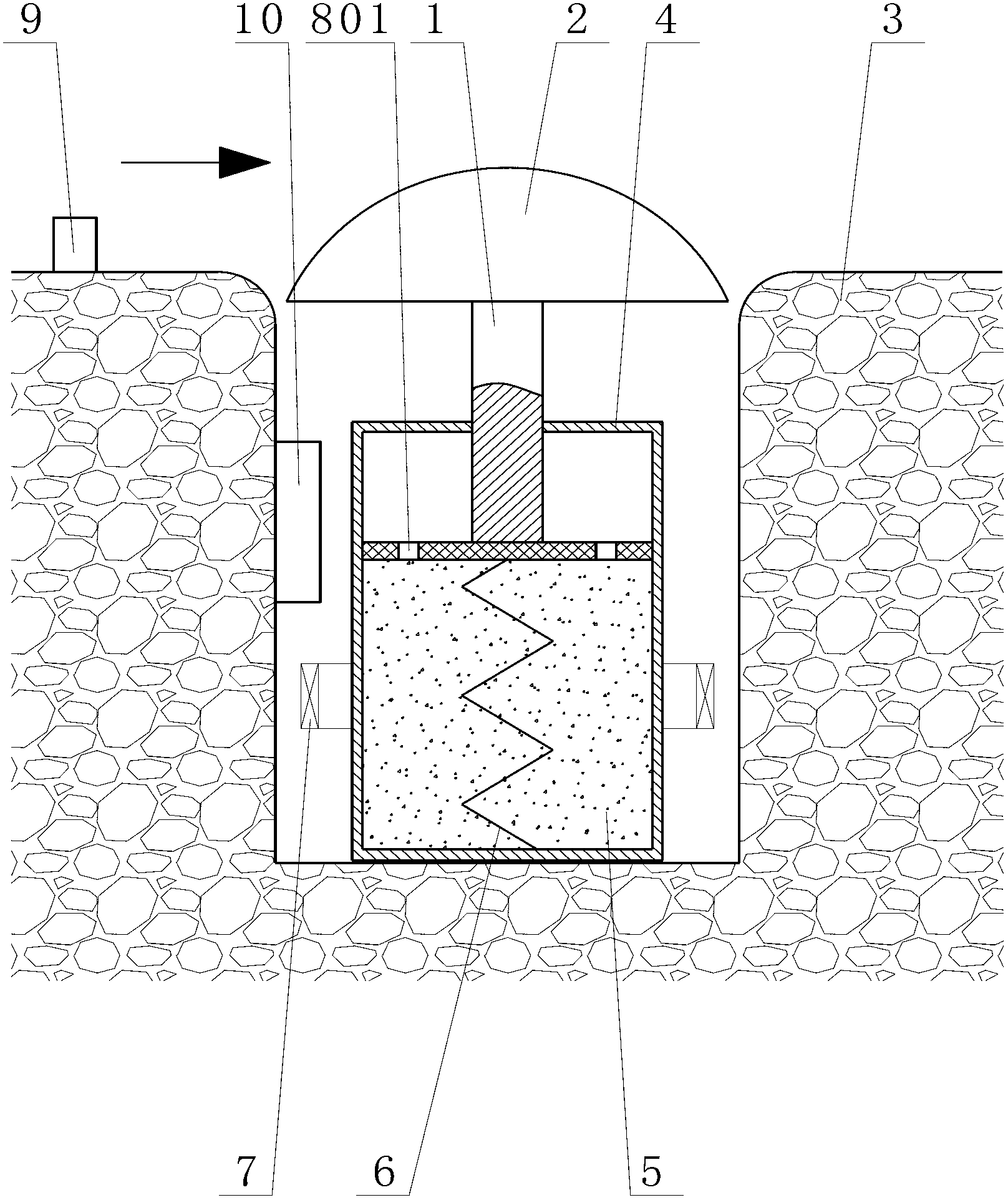

Disclosed is a magnetorheological fluid speed bump. At least one rectangular channel is arranged in a direction perpendicular to the lane length direction on the entry side of a lane speed zone. A piston cylinder is disposed in each channel; a piston in the piston cylinder is provided with through holes; a spring is elastically compressed between the bottom wall of a cylinder block and the piston; the cylinder block is full of magnetorheological fluid below the piston; a solenoid coil is disposed around the magnetorheological fluid in a cavity of the channel; a piston rod at the top of the piston upwardly penetrates through the top of the cylinder block of the piston cylinder, and a speed bump is fixed at the top of the penetrating end; the speed bump covers an opening of the channel; the speed bump can horizontally move up and down in the channel. A speedometer is installed on the lane on the entry side of the speed bump and is in signal connection with an electric control unit. The rigidity of the speed bump is flexibly variable, rigid contact and stress between the speed bump and vehicles can be reduced within an allowable speed range, the vehicles and the speed bump are protected effectively, driving comfort is improved, and the speed of the vehicle exceeding the allowable speed range can be limited effectively.

Owner:SHANGHAI UNIV OF ENG SCI

Method for preparing spherical aluminum-doped nickel lithium carbonate for lithium ion battery positive electrode material

ActiveCN102074679AMorphology and particle size distribution controllableGood liquidityCell electrodesLoop stabilityLithium electrode

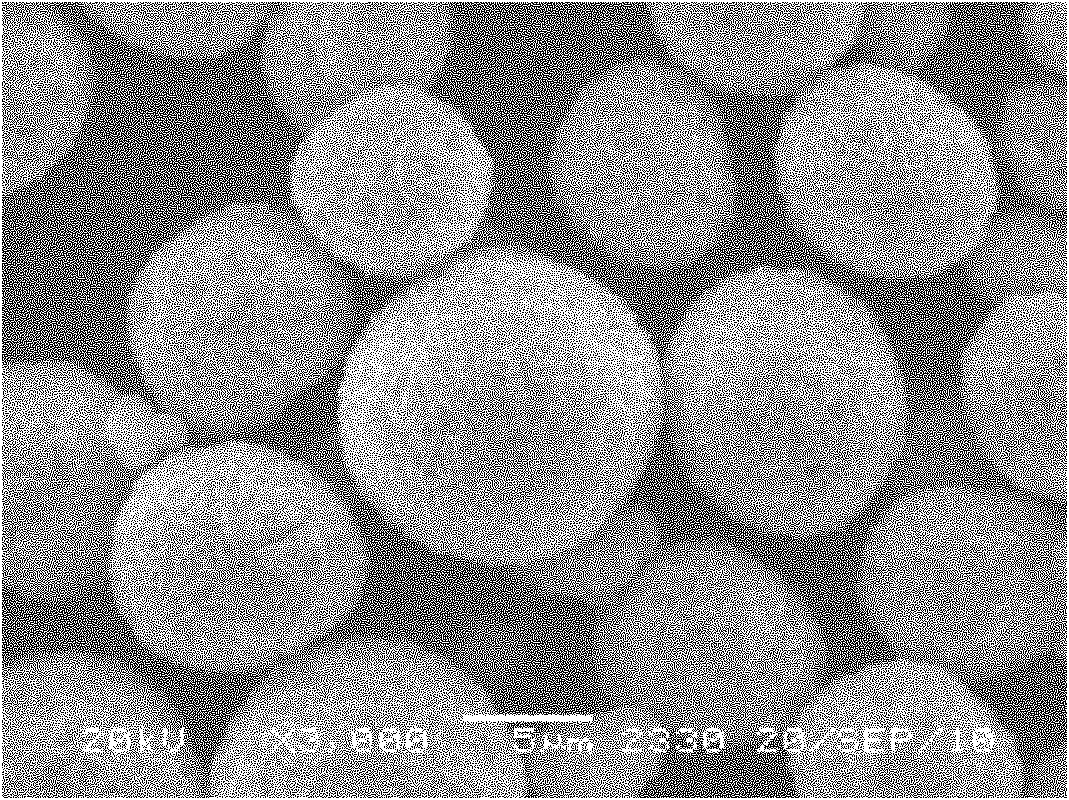

The invention relates to a method for preparing spherical aluminum-doped nickel lithium carbonate for a lithium ion battery positive electrode material by combining liquid phase oxidation and crystallization controlling. Through controlling of the preparation technique, firstly synthesizing a spherical hydroxyl oxygenized nickel cobalt aluminum precursor with high density, and then calcining at the temperature of 500-800 DEG C for 10-24 hours in a flow oxygen gas atmosphere after mixing the precursor with a lithium source, thus acquire the spherical aluminum-doped nickel lithium carbonate with high density. The synthesized aluminum-doped nickel lithium carbonate is in a single spherical shape, has good stacking density, and can be used for improving the volume ratio capacity of a battery.The aluminum-doped nickel lithium carbonate prepared by the method in the invention has the advantages of high specific capacity and good loop stability. The method provided by the invention has the advantages of simple technique, low cost, less pollution, good product performance and suitability for industrialized production.

Owner:深圳市费特森新能源有限责任公司

Sugar-free bread and method for producing the same

The invention relates to a sugar-free bread, characterized by comprising the materials with the following components: high-gluten flour 150-900 parts, low-gluten flour 200-800 200-800 parts, water-free ghee 50-200 parts, sugar-free modifier 50-200 parts, sugar-free milk 10-150 parts, egg 50-10 parts, bread modifier 1-20 parts, yeast 10-20 parts, ghee 200-800 parts. The inventive technology avoids coldness or heat in fed materials contacted with yeast, causing the yeast to exert optimal fermentation ability. The prepared sugar-free nutritious bread is deeply favored by wide consumers.

Owner:天津金世制药有限公司

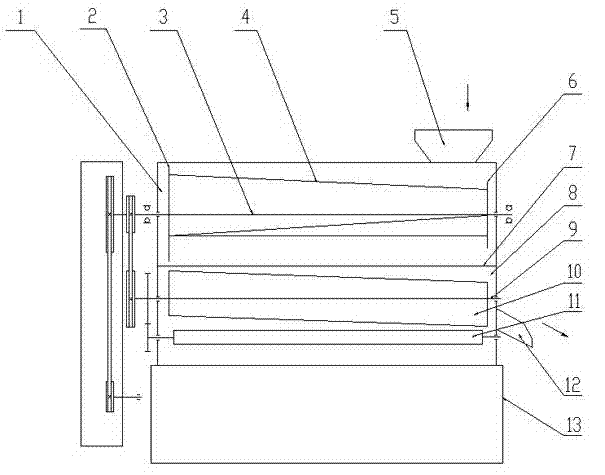

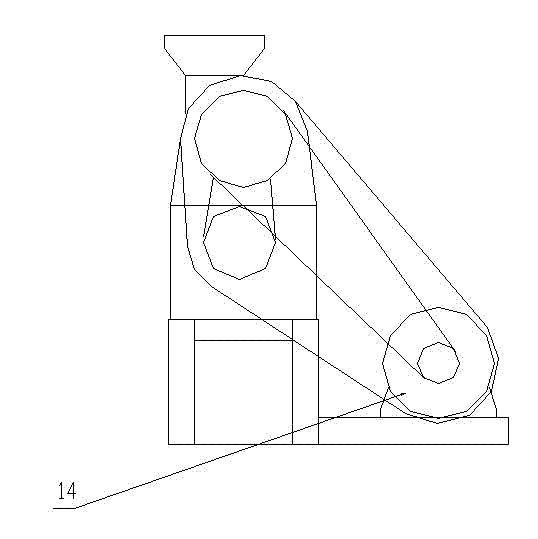

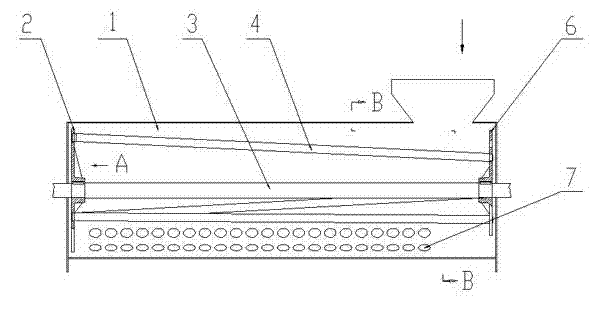

Oil tea fruit unshelling separator

InactiveCN102948912AReduce broken rateGood liquidityFatty-oils/fats productionHuskingMechanical engineeringCamellia oleifera

An oil tea fruit unshelling separator relates to an oil tea fruit unshelling and shell and tea seed seperation combination device. The oil tea fruit unshelling separator comprises a feed hopper, a unshelling rotary drum part, a shell and tea seed separating part, a power transmission part and a machine frame and is characterized in that the unshelling rotary drum part is positioned above the shell and tea seed separating part, the unshelling rotary drum part and the shell and tea seed separating part are arranged on the machine frame, the feed hopper is arranged above the unshelling rotary drum part, and the power transmission part is sequentially connected with the unshelling rotary drum part and the shell and tea seed separating part through a belt. The oil tea fruit unshelling separator has the beneficial effects of being capable of unshelling oil tea fruit, simultaneously also being capable of separating shells and tee seeds and unshelling fresh-picked wet tea fruits, retting piled micro-cracked fruit and cracked dried tea fruit and the characteristics of high unshelling efficiency, high seperation efficiency, little tee seed loss, low power dissipation, light and ingenious structure, is convenient to use and maintain and the like.

Owner:JIANGXI AGRI MACHINERY RES INST

Preparation method of non-ionic hyperbranched macromolecular dispersant for organic pigment

The invention relates to a preparation method of non-ionic hyperbranched macromolecular dispersing agent for organic pigment belonging to the fine chemical field. The invention mainly adopts hydrophobic hyperbranched polymer, coupling agent and hydrophilic chain which are respectively dissolved in solvent to be made into solution through complete dissolving and even mixing; coupling agent solvent solution is added in a reaction vessel and warms up through stirring; hydrophilic chain solvent solution is also added in the reaction vessel for stirring and heat preservation reaction; and then, hydrophobic hyperbranched polymer solvent solution is added to complete warming-up and heat preservation reaction through stirring; finally, the non-ionic hyperbranched macromolecular dispersing agent is obtained after cooling, filtration, washing and vacuum drying. The invention can make nanometer organic dye with high solid content, ideal liquidity, high stability and fresh color; meanwhile, the invention has the advantages of simple technical process, reaction being completed at lower temperature, convenient purification of products and non-occurrence of gel and automatic acceleration phenomena.

Owner:SUZHOU SUNMUN TECH CO LTD

Clean fracturing fluid and use thereof

InactiveCN101481608AGood liquidityIncrease concentrationDrilling compositionChemistryAqueous solution

The invention relates to a clean fracturing fluid and the application thereof, and the fracturing fluid comprises the components based on the parts by mass: 50-80 parts of thickening agent, 10-35 parts of salicylate and 2-5 parts of gel breaker. The clean fracturing fluid is used for fracturing oil field; in the application site, the components are mixed according to the parts by mass to prepare aqueous solution with the mass percent of 2-6% and evenly stirred, and then is thrown into an oil well together fracturing propping agent. The fracturing propping agent of the clean fracturing fluid is even in dispersion and thorough in gelout.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

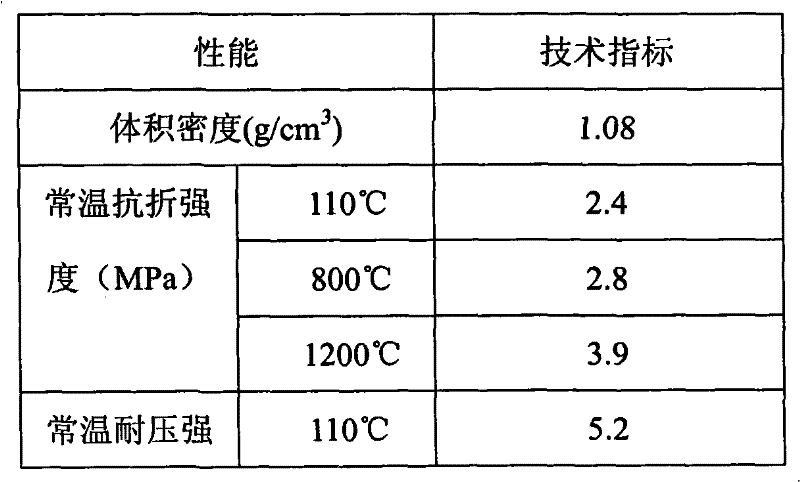

Lightweight energy-saving paint and its preparation method

The invention discloses a lightweight energy-saving paint and its preparation method. The paint provided by the invention comprises the following components of: by weight, 45-55 parts of corundum hollow spheres, 20-30 parts of a lightweight filling material, 5-10 parts of fiber, 15-20 parts of a binder and 0-5 parts of an additive. The lightweight energy-saving paint prepared in the invention has characteristics of good fluidity, high strength, low thermal conductivity, strong adhesive force, high refractoriness, good chemical stability, strong corrosion resistance and the like, can be used for the surface coating of high temperature pipelines, thermal equipment and hearth inside and outside parts to effectively inhibit heat radiation and calorific loss, and can be used for spraying and coating the internal and external surfaces of various concrete structures and steel structure buildings so as to save energy, insulate sound and prevent fire.

Owner:王立旺

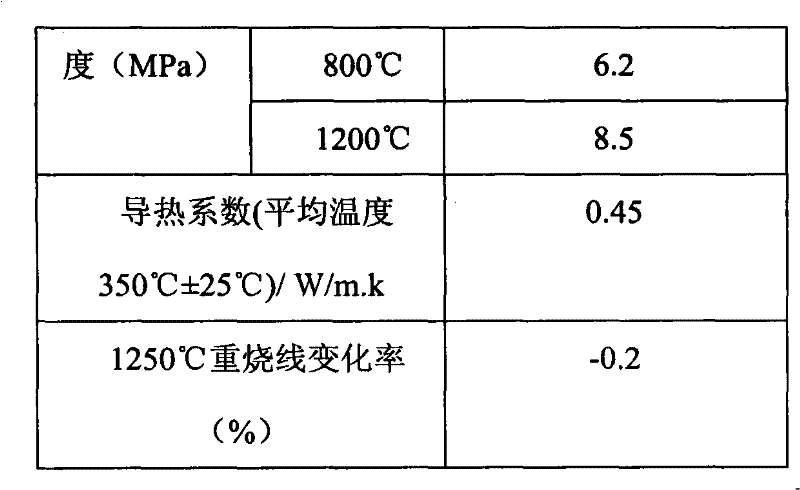

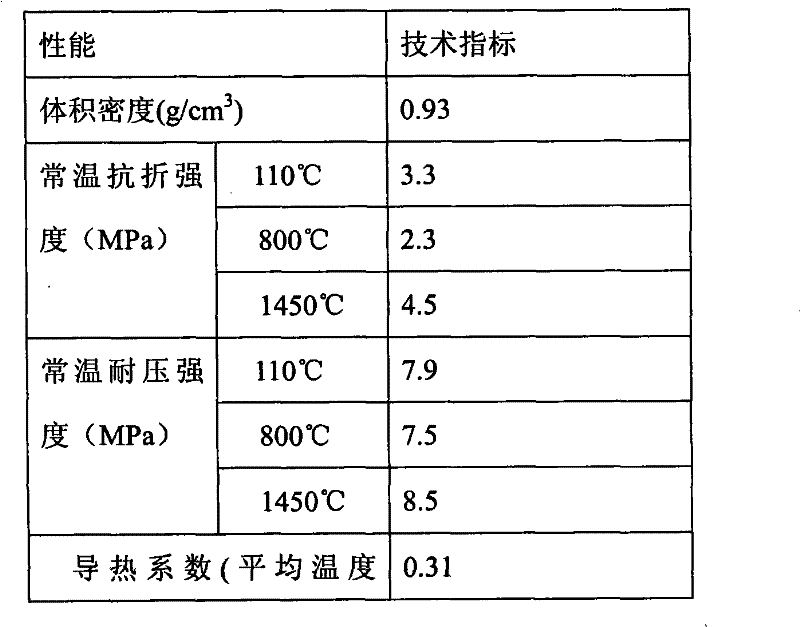

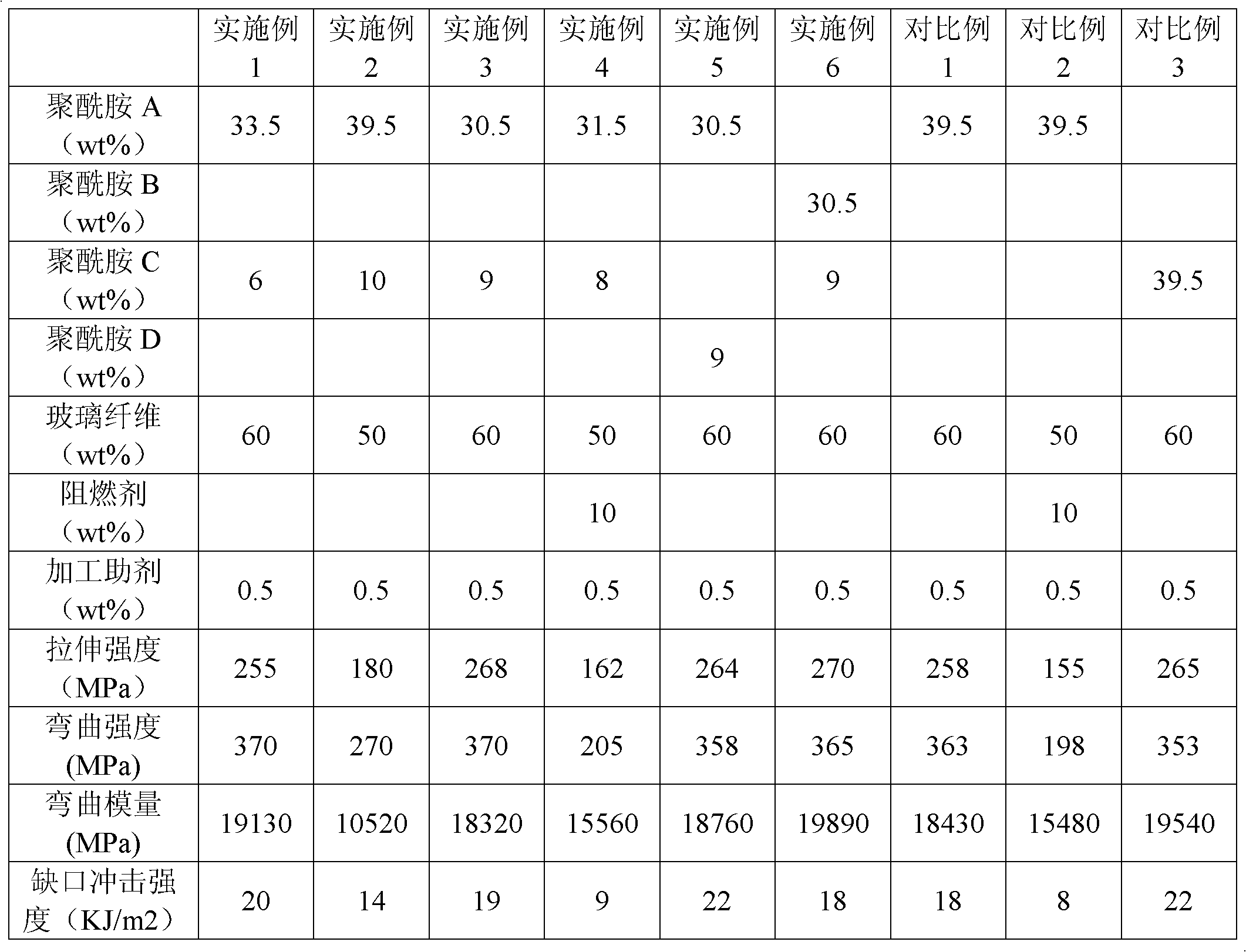

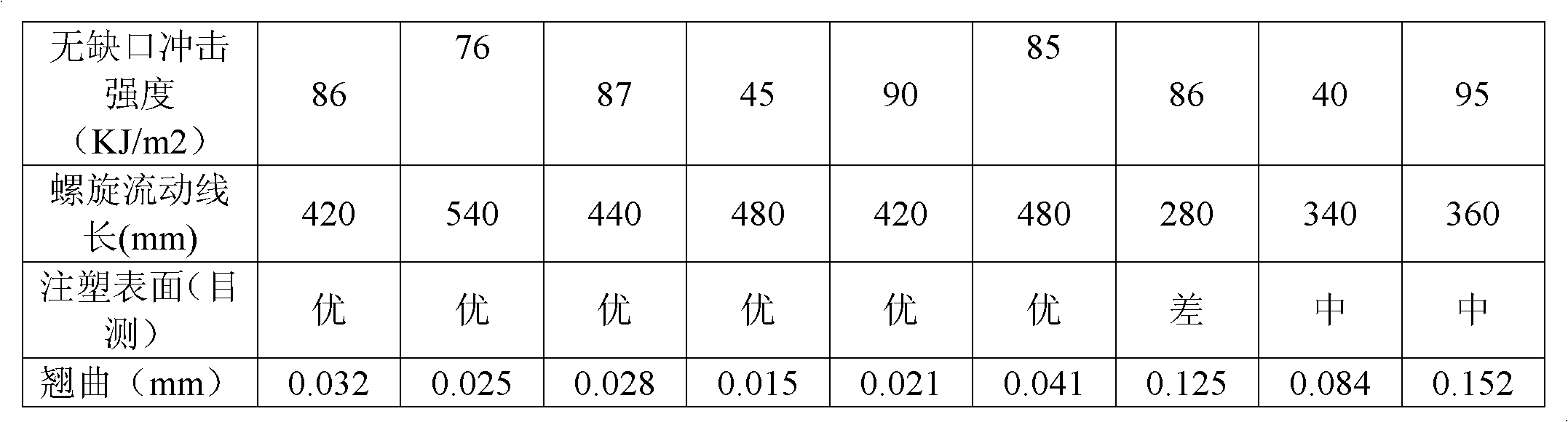

Reinforced polyamide composition with high liquidity and low warpage and preparation method and application thereof

The invention discloses a reinforced polyamide composition with high liquidity and low warpage and a preparation method and application thereof. The reinforced polyamide composition is prepared from the following components in percentage by mass: 30 to 60 percent of polyamide, 40 to 70 percent of inorganic reinforcing filler and 0 to 20 percent of flame retardant, wherein the polyamide consists of semi-aromatic polyamide and fatty polyamide in a mass ratio of 10:(1-3). The reinforced polyamide composition with high liquidity and low warpage has high mechanical property, liquidity and dimensional stability, can replace metal and is suitable for a shell material of electronic consumer equipment and automobile parts, and an injection-molded surface is smooth and low in warpage.

Owner:KINGFA SCI & TECH CO LTD +1

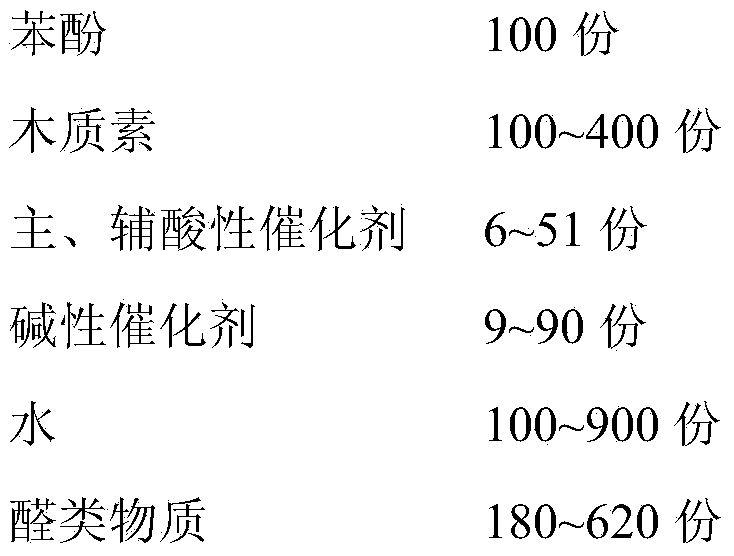

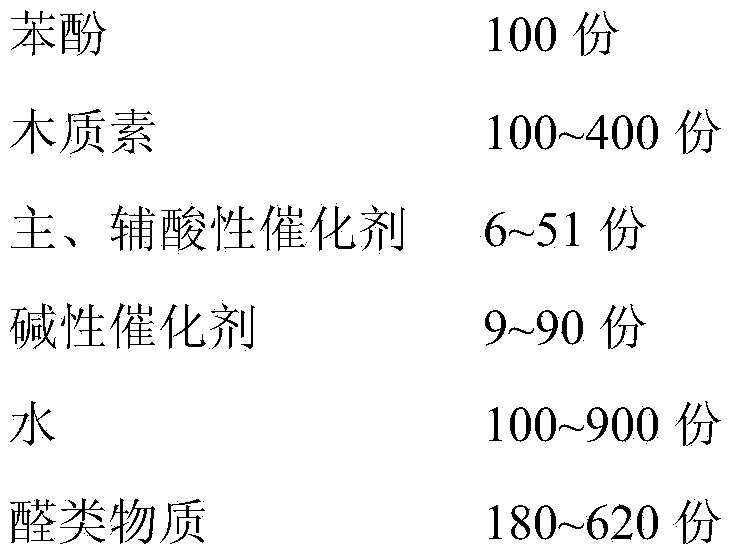

Phenolate lignin tackiness agent and preparing method of phenolate lignin tackiness agent

InactiveCN104004479AGood storage stabilityGood liquidityAldehyde/ketone condensation polymer adhesivesEnvironmentally friendlyPhenols

The invention discloses a phenolate lignin tackiness agent and a preparing method of the phenolate lignin tackiness agent. Under the normal pressure, phenol serves as a phenolate reagent, lignin and master and slave acid catalysts are added at a certain temperature at four to five times in sequence, the temperature is rose to 100 DEG C-130 DEG C, heat preservation reaction is carried out, cooling is carried out, basic catalysts are added, after the heat preservation reaction is carried out for a certain time, aldehydes materials are added at four times, heat preservation reaction is carried out at 80 DEG C-95 DEG C until the viscosity meets the requirement, water is added to adjust the solid content, and meanwhile rapid cooling is carried to enable the temperature to be lower than 50 DEG C, discharging is carried out, and then the phenolate lignin tackiness agent is obtained. Compared with a traditional phenolate lignin tackiness agent, the prepared phenolate lignin tackiness agent has the advantages that the replacement amount of the lignin to the phenol is as high as 50%-80%, and the cost can be reduced by about 40%. The phenolate lignin tackiness agent prepared with the method is safe, environmentally friendly, good in mobility and good in storage stability. Bamboo / wood plywood manufactured with the phenolate lignin tackiness agent has the good mechanics performance and the good hydrolytic resistance.

Owner:方红霞 +1

Coating and suspending chocolate with sweet potato powder added

The invention relates to a coating chocolate, wherein, every 1000 weight portions of chocolate comprises raw materials of 220 to 250 weight portions of sugar, 30 to 80 weight portions of sweet potato powder, 180 to 280 weight portions of milk solid, 340 to 430 weight portions of oil, 70 to 110 weight portions of cocoa powder and 0.5 to 1 weight portion of emulsifier. The sweet potato powder is cheap, full of nutriments, rich in cellulose, pectin and protein and relatively expensive raw materials such as milk powder, whey powder, etc., are replaced in the current coating chocolate, thus guaranteeing the quality of the coating chocolate and greatly saving cost. The coating chocolate provided by the invention can be applied to producing ice cream with surface coated with particles, can improve the adhesive capacity of particles by 5 to 10 percent, thereby not only improving the flavor and taste of ice cream, but also reducing the waste of particles.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

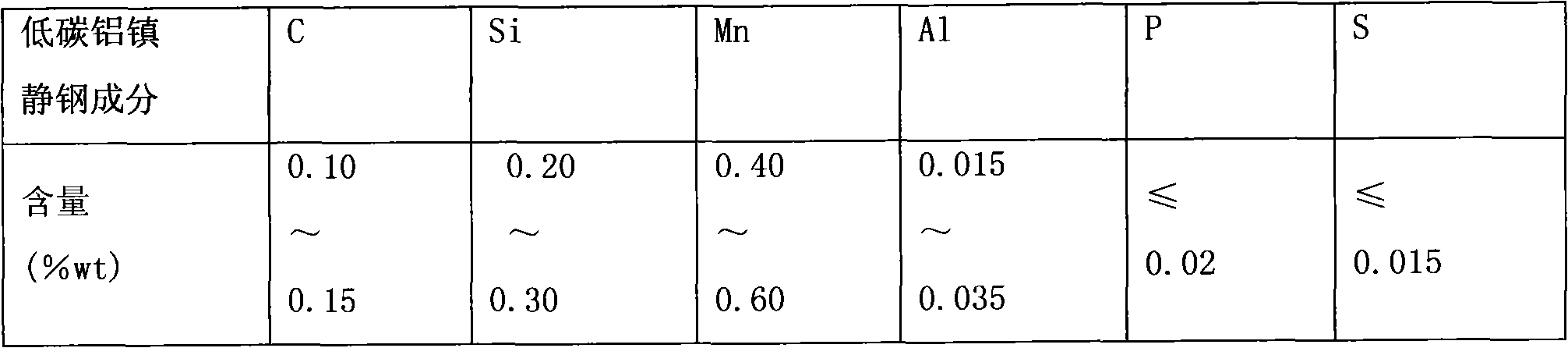

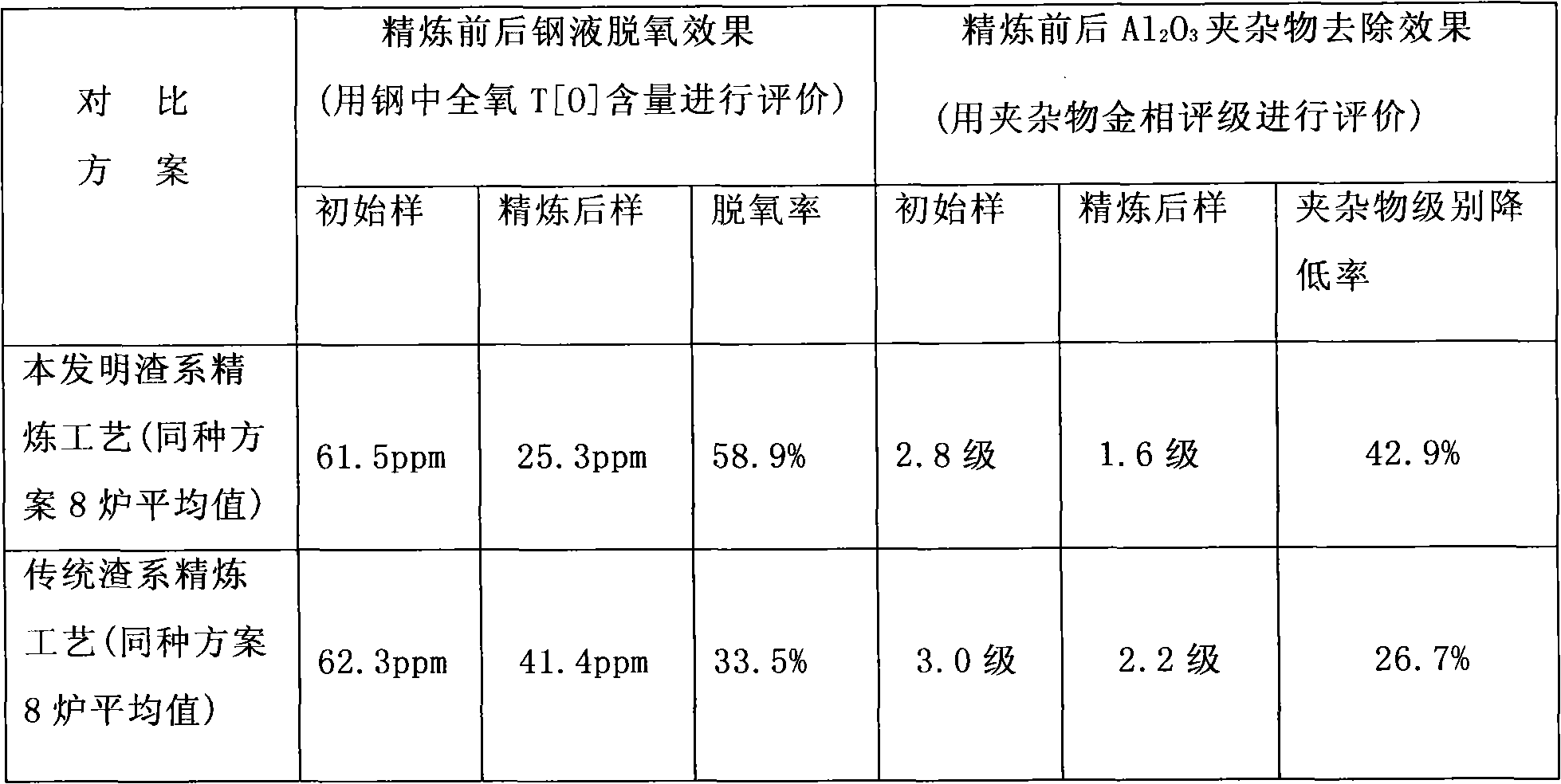

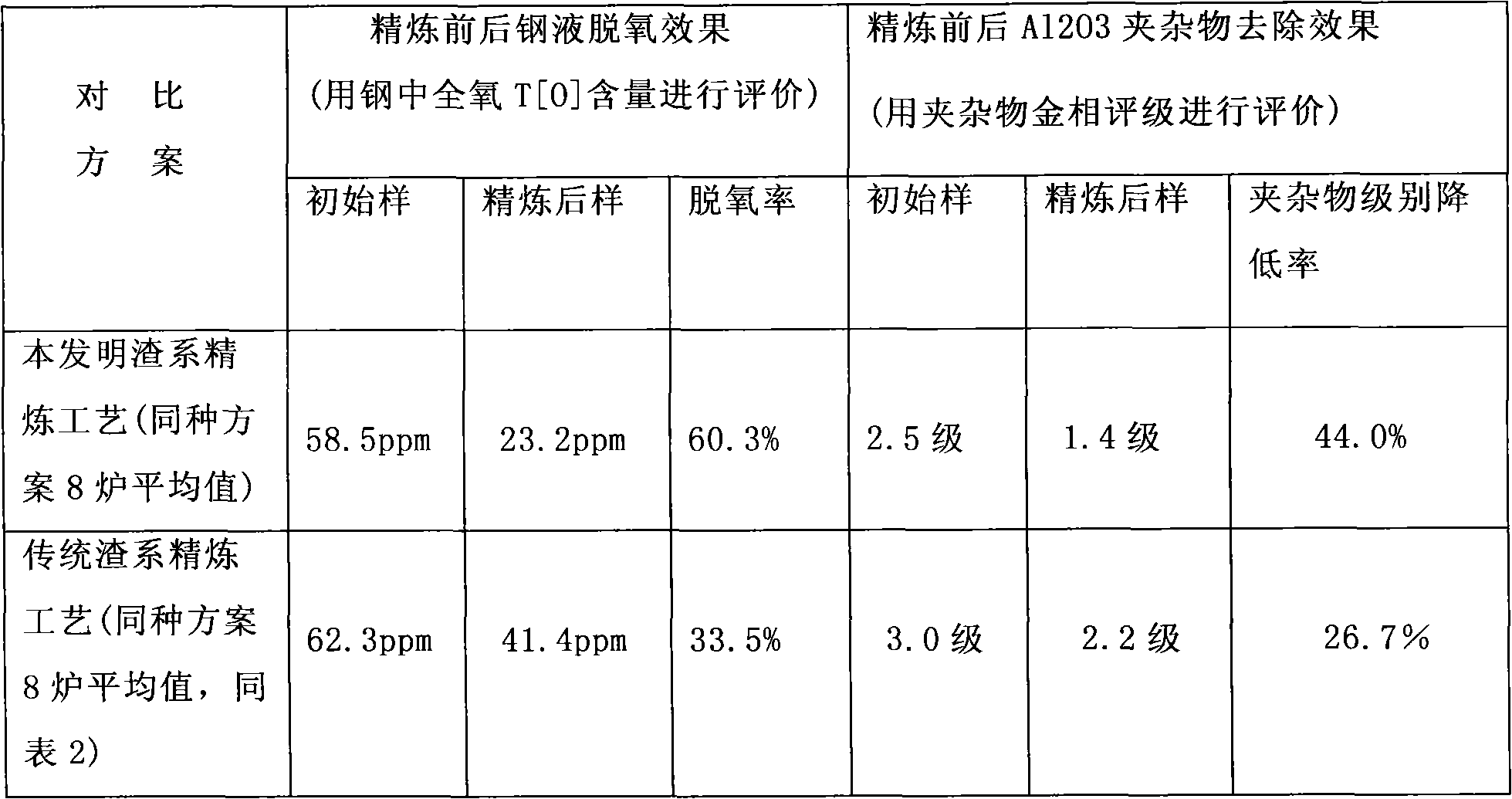

Rare earth oxide-containing steelmaking refining slag, and preparation method and using method thereof

ActiveCN102002556ALower melting temperatureGood liquidityProcess efficiency improvementReduction rateMagnesium

The invention belongs to the technical field of steelmaking refining and relates to rare earth oxide-containing steelmaking refining slag, and a preparation method and a using method thereof. The invention is characterized in that: a refining slag system comprises the following chemical components in percentage by mass: 40 to 55 percent of calcium oxide (CaO), 6 to 25 percent of aluminum oxide (Al2O3), 3 to 16 percent of cerium trioxide (Ce2O3), 3 to 10 percent of magnesium oxide (MgO), 3 to 15 percent of silicon oxide (SiO) and 1 to 6 percent of calcium fluoride. The refining slag system hashigh melting property, melting temperature of between 1,300 and 1,370 DEG C, low viscosity value of 0.1 to 0.3 Pa.s at the steelmaking temperature of between 1,550 and 1,600 DEG C and high flowability. Molten steel refining tests in a 200-kg induction furnace, a 100-t combined blown converter and a 60-t arc furnace show that compared with the traditional refining slag system, the refining slag system provided by the invention has deoxidizing rate and impurity level reduction rate of over 15 percent and effectively improving refining efficiency.

Owner:ZHONGXING ENERGY EQUIP

Nonaqueous non-abrasive polishing solution for soft, crisp and deliquescent crystal

The invention discloses a nonwater-based grinding-medium-free chemical mechanical polishing solution adapted to polishing crispy and easily deliquescent crystal. The components of the polishing solution are as below in terms of weight percentage: 40-65% of oil phase, 10-22% of deionized water, and the balance of surface active agent. The oil phase is alcohol or ester, and the surface active agent can adopt high-carbon fatty alcohol polyethenoxy ether, polyoxyethylene nonyl phenyl ether, polyoxyethylene octyl phenyl ether or polyoxyethylate amide of a non-ionic surface active agent. The invention has the advantages of simple polishing solution preparing method, good fluidity, no toxicity, no pollution, no corrosion, good stability, no easy volatilization and long service life. The surface of a polished sample has a roughness concentration which can be up to 1.7 nm, is free from such defects as scratch, damage, and the like, and can be permanently stored at the room temperature in the airtight condition.

Owner:DALIAN UNIV OF TECH

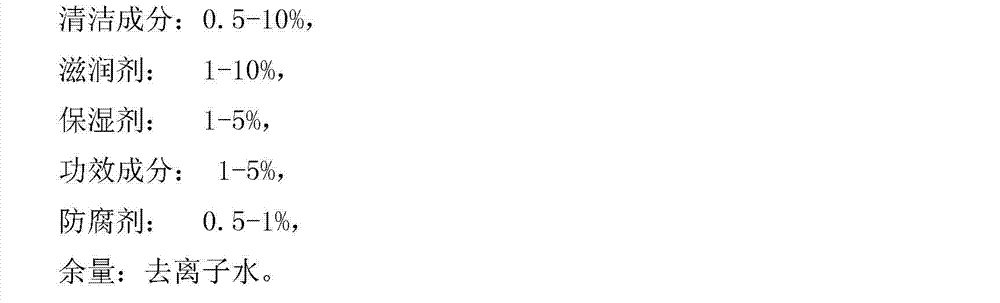

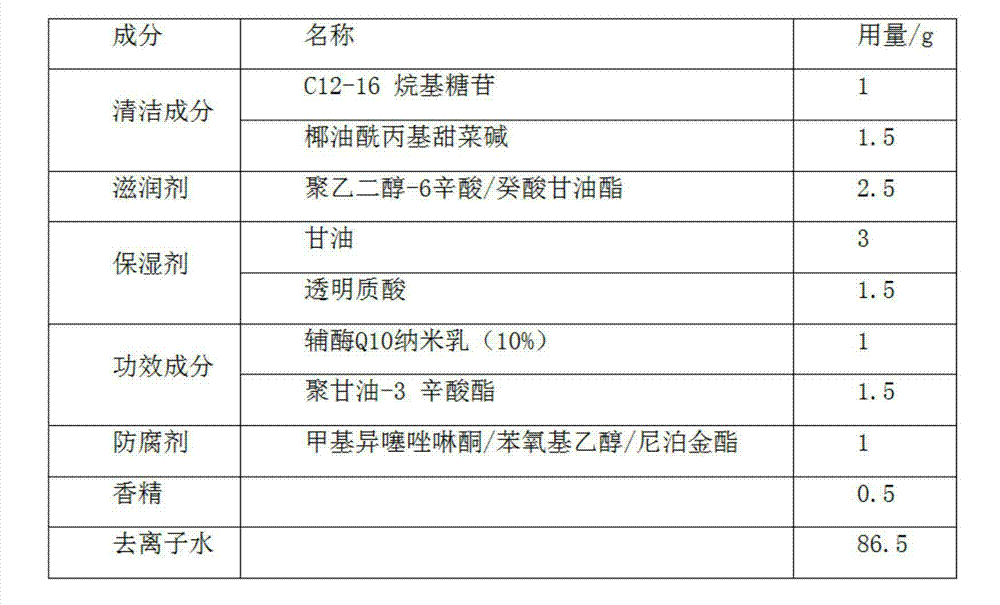

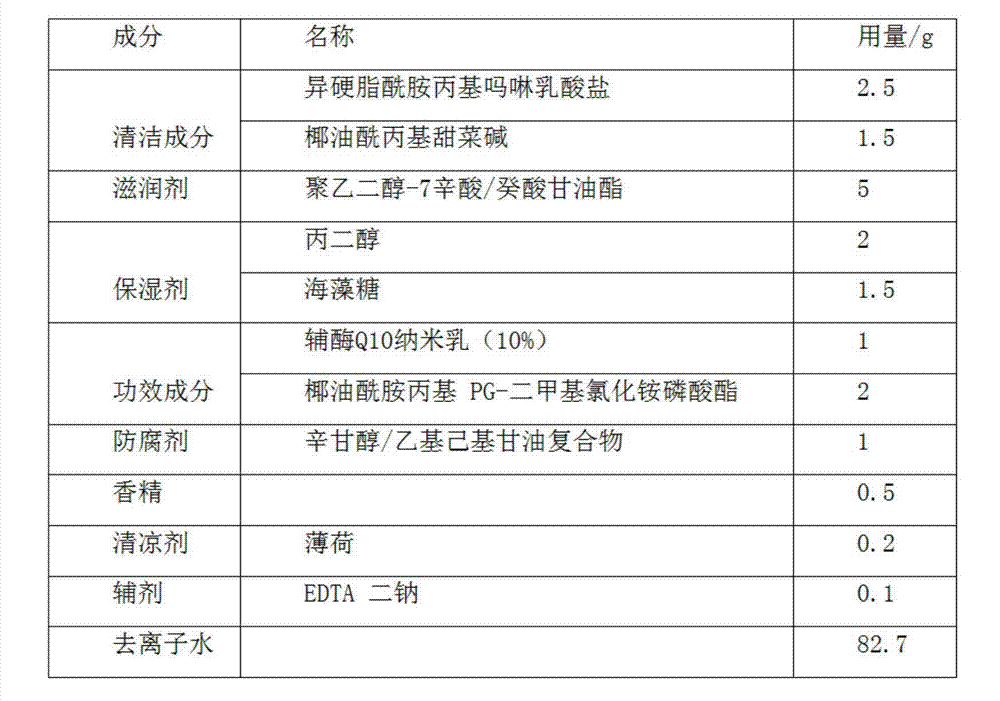

Washing-free skin cleaning care product and preparation method thereof

InactiveCN102805715AGood liquidityStable in natureCosmetic preparationsToilet preparationsPatient careAerospace

The invention discloses a washing-free skin cleaning care product and a preparation method thereof, and belongs to the technical field of skin cleaning products. The washing-free skin cleaning care product comprises the following components in percentage by weight: 0.5 to 10 percent of cleaning component, 1 to 10 percent of moistening agent, 1 to 5 percent of wetting agent, 1 to 5 percent of functional component, 0.5 to 1 percent of preservative and the balance of water. The washing-free skin cleaning care product has the advantages that the product is convenient to use and safe, is not irritating, has the characteristics of moisturizing and protecting skin simultaneously, has the peculiar smell-resisting and antibacterial biological activity on the skin and can be widely applied to the patient care, aerospace, field trip, and scientific research fields where personal hygiene is needed to be kept under various water-limited environments; and skin is refreshing after the skin cleaning care product is used, and the skin cleaning care product is not needed to be washed with water.

Owner:SHENZHOUSPACEBIOTECHGRP

Ultraviolet curable resin composition and application thereof

ActiveCN102766428AGood liquidityNot crushableLayered productsPolyureas/polyurethane adhesivesPrepolymerPhotoinitiator

The invention discloses an ultraviolet curable resin composition, which comprises the following components by weight: 50-90 parts of ultraviolent sensitive prepolymer resin, 10-50 parts of active diluent monomer, 5-20 part of olefin modified resin, 1-20 parts of ultraviolent free radical photoinitiator and 1-2 parts of functional auxiliary agent. The ultraviolet curable resin composition prepared by the invention is better in mobility, more excellent in optical performance and bonding strength, lower in Shore hardness, and small in impedance corrosion for ITO (indium tin oxide), can be widely applied to plane or curved surface bonding of the transparent materials in the optical field, such as a touch screen, and is capable of effectively inhibiting unevenness display of laminated bodies caused by an internal stress and an external stress and stripping of cured resin; and furthermore, the operating process is simpler, reworking is easier and the product yield is high.

Owner:PANYU NANSHA YAN TIN CHEM

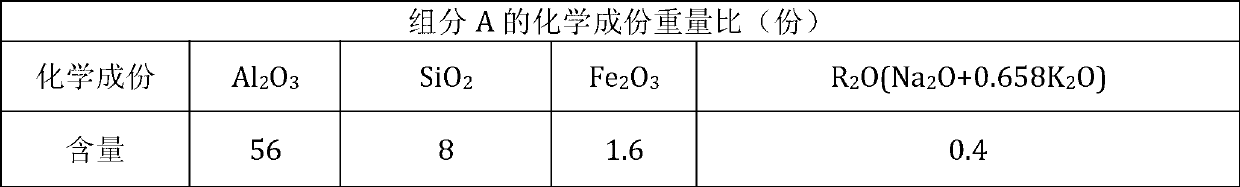

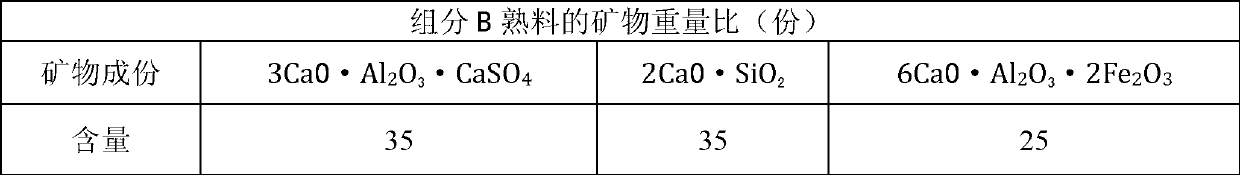

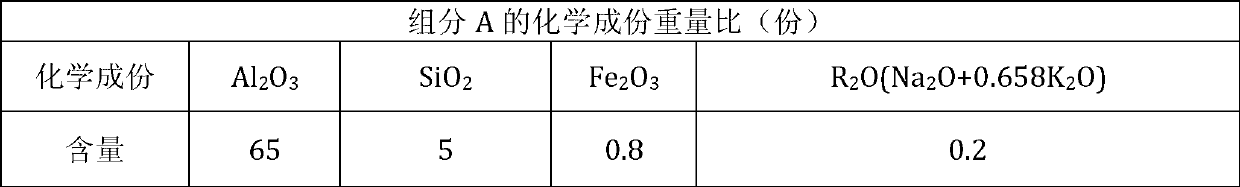

High-temperature-resistant non-silicate cement paste system for cementing thermal production well of thickened oil

ActiveCN102994058AAdjustable density and thickening timeGood liquidityDrilling compositionSilicate CementHeat regulation

The invention relates to a high-temperature-resistant non-silicate cement paste system for cementing a thermal production well for thickened oil. The high-temperature-resistant non-silicate cement paste system is composed of the following components in parts by weight: 100 parts of high-temperature-resistant cement, 1.0-4.0 part(s) of fluid loss agent, 1.0-4.0 part(s) of dispersant, 0.5-3.0 part(s) of thickening time control agent, 60-120 parts of water and 15-80 parts of heat regulators, wherein the high-temperature-resistant cement is formed by mixing components A and B, the component A comprises 50-77 parts of Al2O3, 0.5-8.0 part(s) of SiO2, 0.5-2.5 part(s) of Fe2O3 and 0-0.4 part of R2O(Na2O+0.658K2O), and the component B comprises 33-63 parts of 3CaO.Al2O3.CaSO4, 14-37 parts of 2CaO.SiO2 and 15-35 parts of 6CaO.Al2O3.2Fe2O3. The high-temperature-resistant non-silicate cement paste system disclosed by the invention has great significance to enhancement of safe and efficient development of the thickened oil and has broad market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

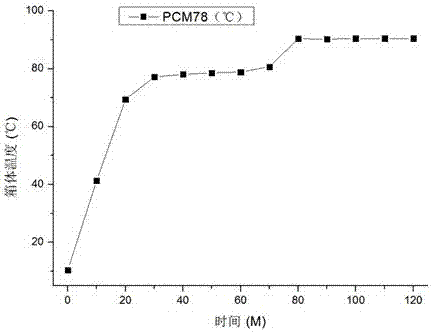

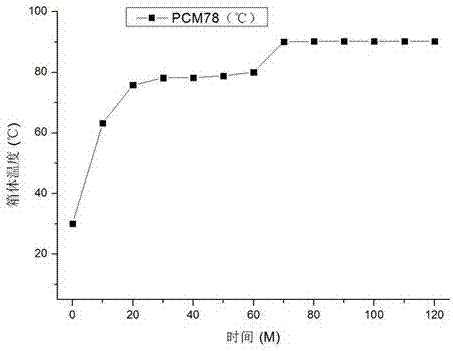

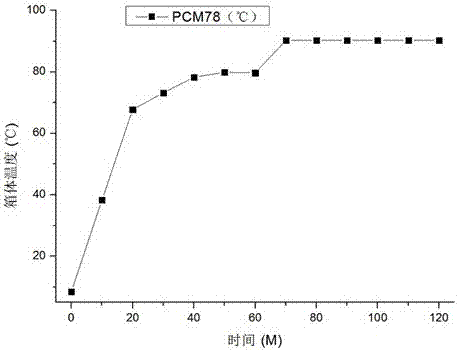

Inorganic phase-changing energy storage material

InactiveCN107011867AStrong cycle stabilityGood liquidityHeat-exchange elementsCyclic stabilityStorage material

The invention relates to the technical field of energy storage materials, in particular to an inorganic phase-changing energy storage material. The inorganic phase-changing energy storage material is prepared from the following components in percentage by mass: 86 to 98.5 percent of inorganic materials, 0.5 to 3 percent of nucleating agents, 1 to 10 percent of thickening agents, and 0 to 1 percent of water. The obtained phase-changing energy storage material is low in price, good in recycling stability, capable of effectively solving the phase separation problem of the materials, and constant in potential heat value after being recycled for thousand times.

Owner:北京华厚能源科技有限公司

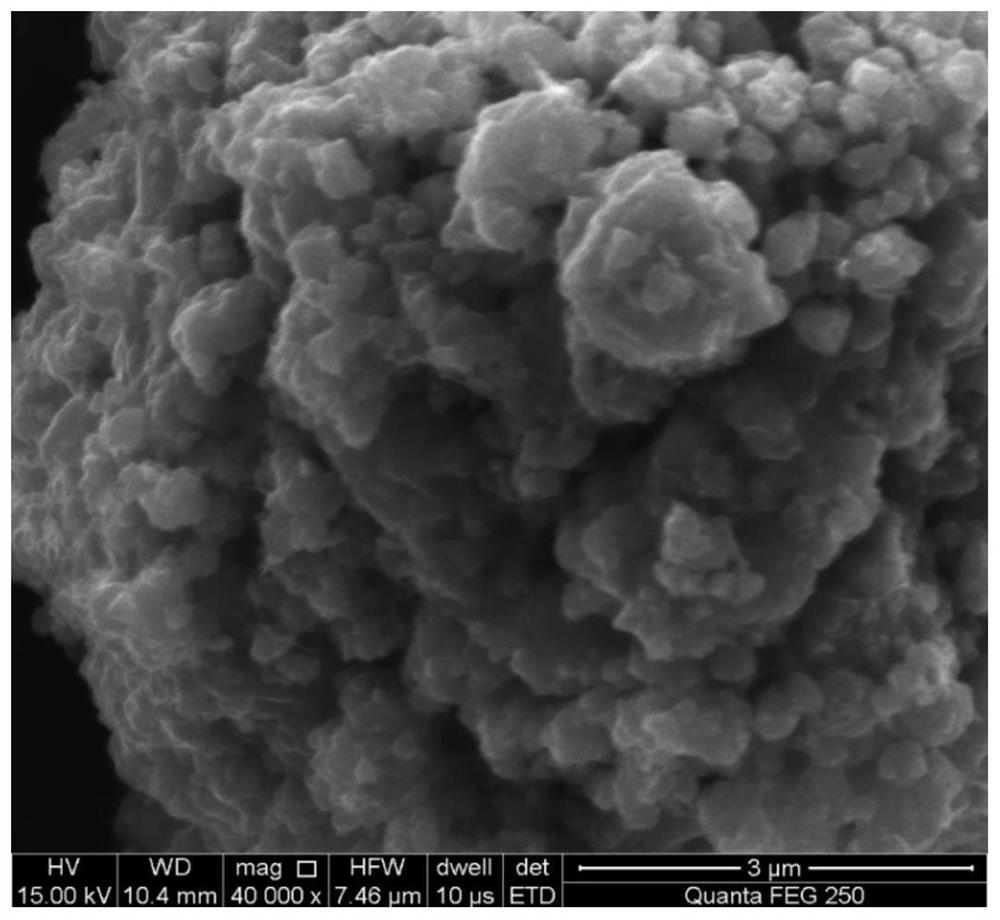

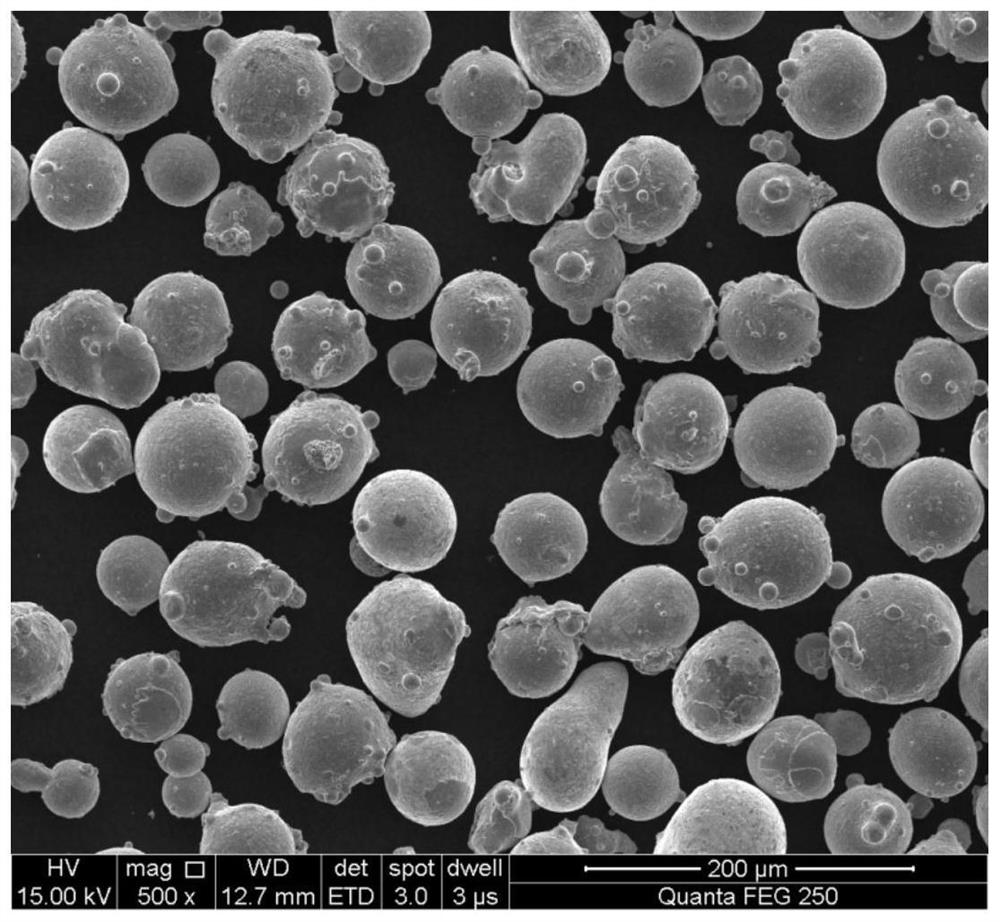

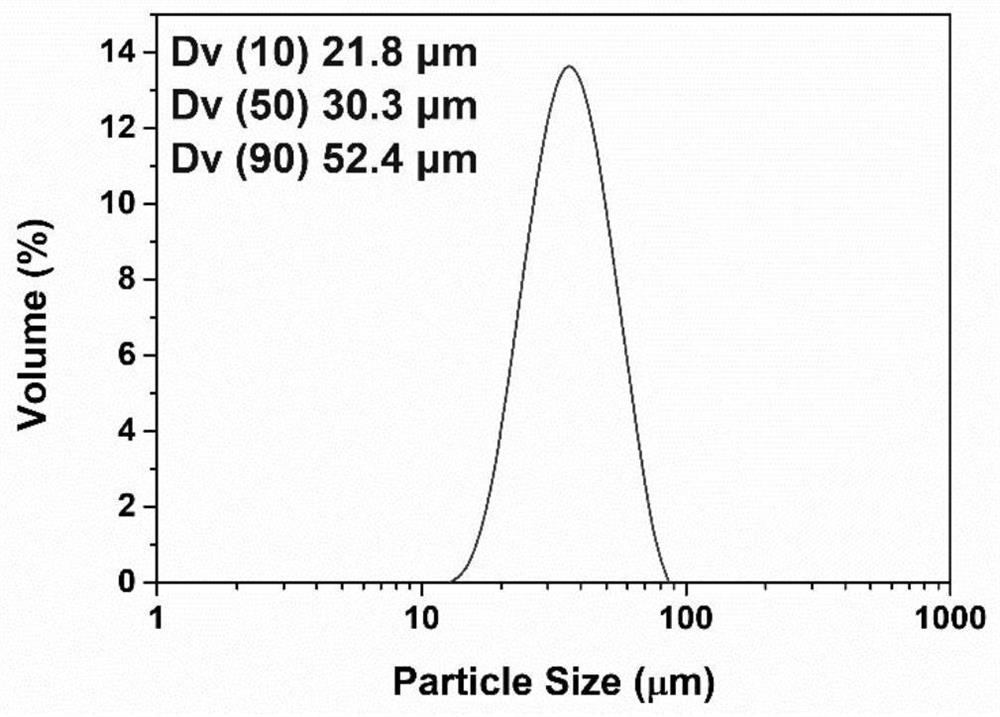

Nano ceramic metal composite powder for 3D printing and application

ActiveCN111940723AHigh sphericityGood liquidityAdditive manufacturing apparatusTransportation and packagingCeramic particleCeramic metal

The invention provides nano ceramic metal composite powder for 3D printing and application. A metal material is used as a matrix, and ceramic particles are used as a reinforcing phase. One or more ceramic particles of micron-sized TiC, TiB2, WC, SiC, CrC, Al2O3, Y2O3 and TiO2 are used as raw materials, the mass percent of the added ceramic particles is 0.5-10.0%, through a specific ball milling process, plasma spheroidization, airflow classification and screening, the metal composite powder with high sphericity, good fluidity, narrow particle size range and uniformly distributed nano-ceramicsis obtained, and the high requirement of a 3D printing technology for powder is met; and a nano-ceramic reinforced metal composite material is prepared through the 3D printing technology. According tothe prepared metal composite material, nano ceramic phases are uniformly distributed, and the metal composite material has excellent mechanical properties. Micron-sized ceramic particles are adopted,uniform dispersion is achieved through nanocrystallization, and the cost is low; and parts in any complex shape can be integrally formed and prepared, and the material utilization rate is increased.

Owner:CENT SOUTH UNIV

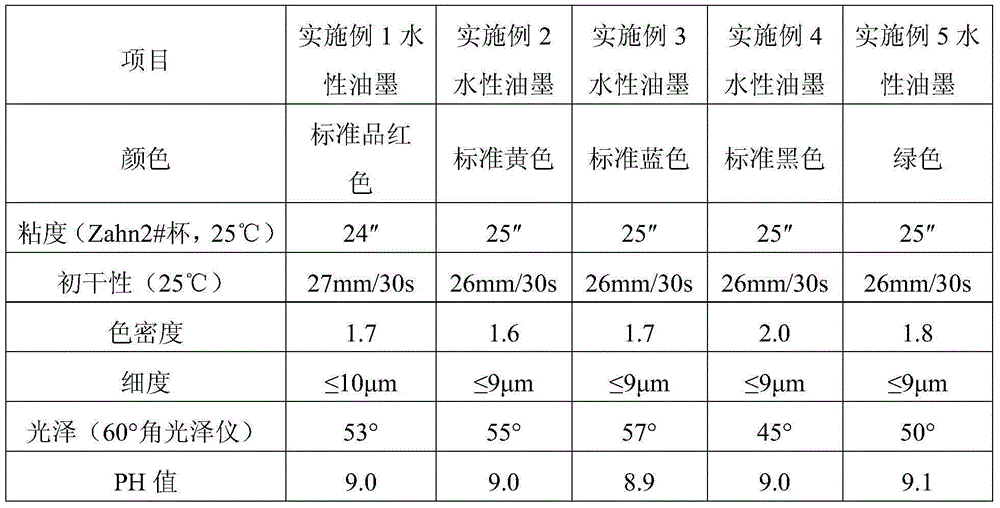

Flexographic plate water-based ink for high-speed printing and preparation method thereof

The present invention provides a flexographic plate water-based ink for high-speed printing and a preparation method thereof. The flexographic plate water-based ink comprises the following components by weight: 30-40 parts of a non-film forming acrylic emulsion, 5-10 parts of an acrylic film-forming emulsion, 15-0 parts of an acrylic resin solution, 30-40 parts of an aqueous paste, 1-3 parts of polyethylene wax, 1-2 parts of a film-forming aid, 0.3-1 part of a leveling agent, 0.1-0.5 part of a defoamer, 3-7 parts of deionized water and a pH modifier. The non-film forming acrylic emulsion is an acrylic emulsion with Tg value no less than 90 DEG C, the acrylic film-forming emulsion is an acrylic emulsion with Tg value less than 30 DEG C, the content of the pigment in the aqueous paste is 40-45%, and the pH modifier reaches pH value of the flexographic plate water-based ink of 8-9.5. The water-based ink can well adapt to printing of high-speed satellite-type press, and has good re-solubility and excellent leveling and trapping effect; and the printed product has high color saturation, bright color and good gloss; therefore, the water-based ink has wide range of applications.

Owner:山东布瑞特油墨有限公司

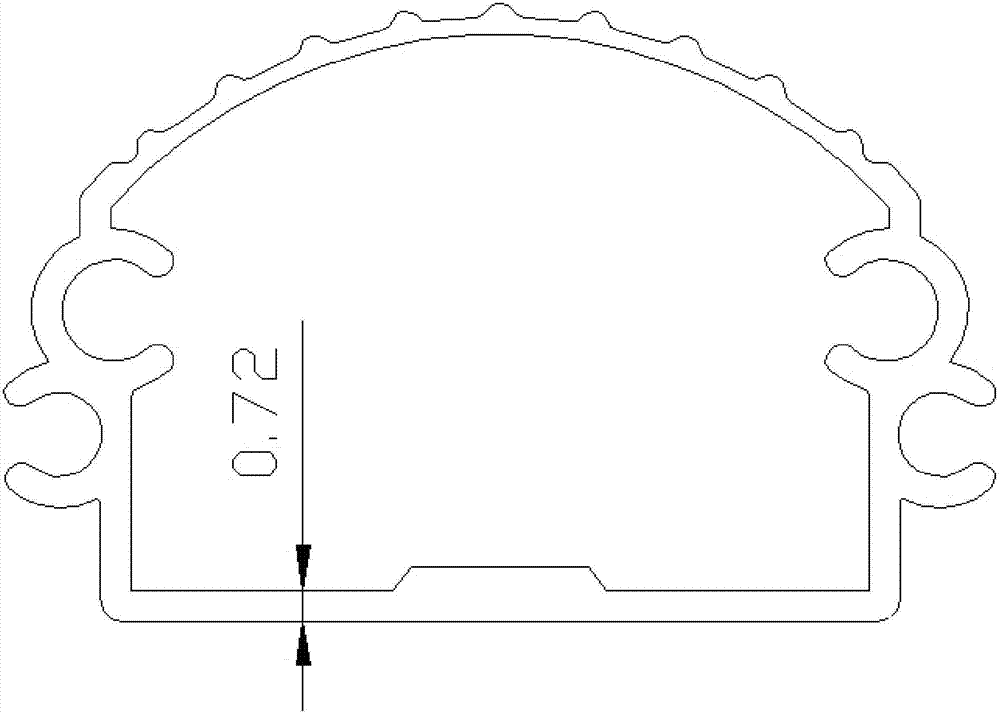

Magnesium alloy LED (Light Emitting Diode) tube profile and extrusion molding process thereof

The invention discloses a magnesium alloy LED (Light Emitting Diode) tube profile and an extrusion molding process thereof. The extrusion molding process comprises the following steps of: (1). according to the component proportioning requirements, smelting a magnesium alloy raw material; (2). preparing a magnesium alloy casting rod with the obtained magnesium alloy raw material; (3). heating the magnesium alloy casting rod to 400 DEG C to carry out heat preservation for 6 hours, and slowly cooling to room temperature along with a furnace after homogenization treatment; (4). heating the magnesium alloy casting rod subjected to homogenization treatment to 350 DEG C to carry out heat preservation for 2 hours, then slowly heating to 410 DEG C to carry out heat preservation for 2 hours, afterwards cooling to 380 DEG C to carry out heat preservation for 1 hour, and simultaneously heating an extrusion mould to 400 DEG C to carry out heat preservation; and (5). finally taking out the extrusion mould, assembling the extrusion mould on an extrusion machine, filling the magnesium alloy casting rod into the extrusion container of the extrusion mould for extrusion molding, so as to obtain the magnesium alloy LED tube profile by extrusion molding. The magnesium alloy LED tube profile and the extrusion molding process thereof have the advantages that the production efficiency and yield are improved and the machining cost is reduced on the premise that the size precision is ensured to meet the design requirements.

Owner:WUXI FUMEI LIGHT ALLOY TECH

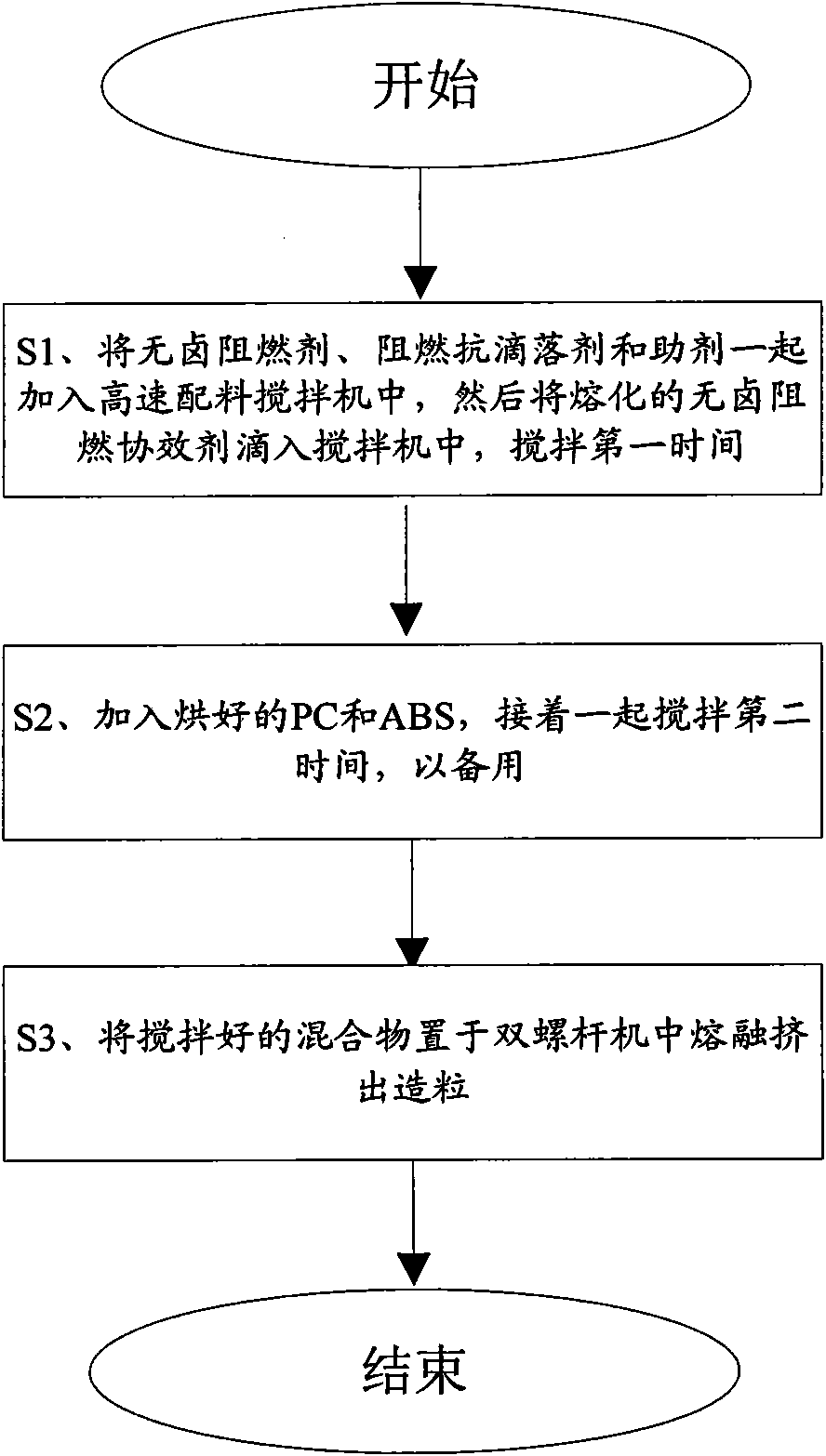

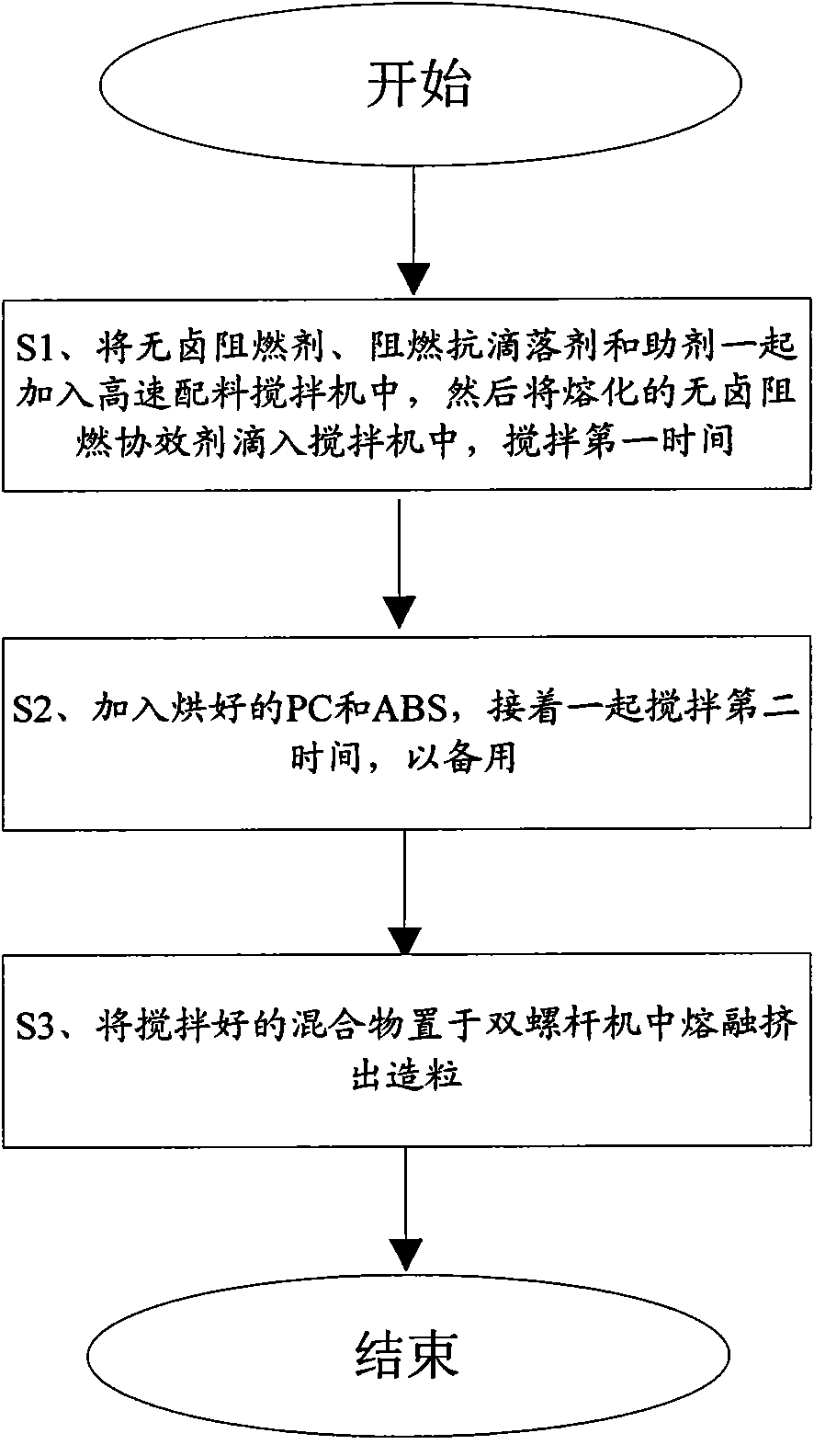

PC/ABS alloy and preparation method thereof

The invention relates to a PC / ABS alloy and a preparation method thereof.The method comprises the following steps: S1. adding non-halogen flame-retardant agent, inflaming retarding and anti-drippage agent into a high-speed burdening agitator, then dropwise adding melted non-halogen flame-retardant synergist into the agitator and agitating for a first time; S2. adding dried PC and ABS and agitating for a second time for standby use; S3. placing the agitated mixture in a double-screw machine for melt extrusion for pelleting.The prepared PC / ABS alloy comprises the following raw materials according to parts by weight: 60-68 parts of PC, 12-18 parts of ABS, 7-12 parts of non-halogen flame-retardant agent, 1-3 parts of non-halogen flame-retardant synergist, 0.1-1 part of inflaming retarding and anti-drippage agent and 6-20 parts of auxiliary.The PC / ABS alloy features good inflaming retarding effect and good comprehensive property and is halogen-free and environment-friendly; in addition, the alloy features fine suboptical effect and can be applied to components such as automobile upholsteries in need of suboptical effect and the like.

Owner:徐东

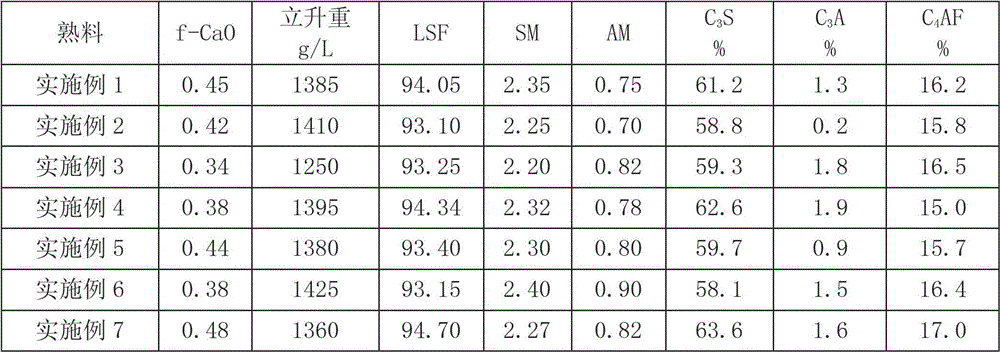

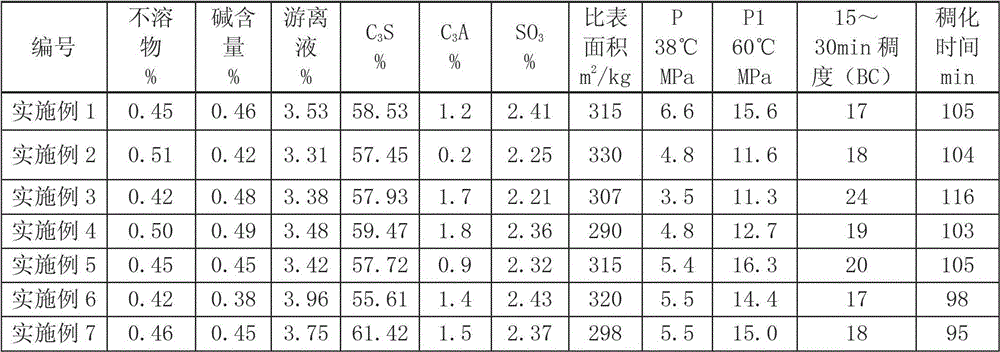

Oil well cement and production method thereof

ActiveCN102942314AGood liquidityStrengthen cement strength and durabilityCement productionAluminiumFilter cake

The invention discloses oil well cement and a production method thereof and belongs to the technical field of building materials. The cement contains oil well cement clinker and gypsum, wherein the weight ratio of the oil well cement clinker to the gypsum is (94:6):(96-4); and the oil well cement clinker is made by preparing raw batch from the following raw materials in percent by weight: 75-85% of limestone, 8-18% of sandstone and 5-12% of converter slag, grinding the raw batch, dehydrating slurry, drying and crushing filter cake and sintering to obtain the clinker. The oil well cement disclosed by the invention adopts a scientific clinker formula with high saturation ratio, high iron content and low aluminium ratio, the obtained cement has high strength, appropriate thickness and good mobility, can be used for effectively controlling the thickening time and free liquid and is applicable to oil well construction.

Owner:GUANGXI YUFENG CEMENT

Preparation method of low-viscosity casting powder for preparing steelmaking cast ingots

The invention discloses a preparation method of a low-viscosity casting powder for preparing steelmaking cast ingots, which comprises the following steps: using fly ash and blast-furnace granulated slag as basic slag materials, successively placing the ignited fly ash in 20-25% of hydrochloric acid and 15-20% of sodium hydroxide solution to be stirred for 20-24h, then washing the fly ash filtered from acid-alkali immersion liquid to be neutral with de-ionized water, testing with pH test paper for determination, and finally filtering and drying, wherein the addition amount of fly ash is 45-65 parts by weight. The preparation method provided by the invention has the advantages of reducing the unit weight of raw materials, improving the melting property, the spreading property and the thermal insulation property, and effectively reducing the usage amount of ingot carbon.

Owner:马鞍山科润冶金材料有限公司

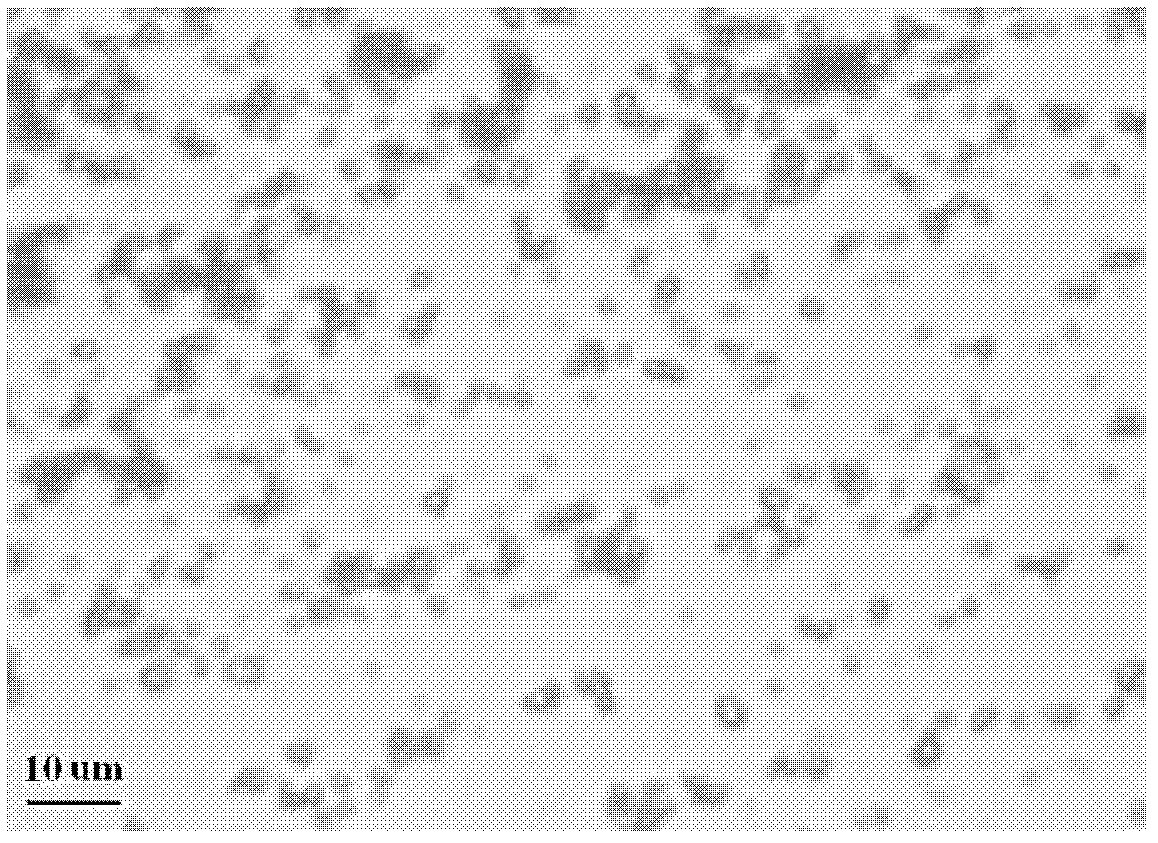

Tecovirimat dry suspension and preparation method thereof

ActiveCN102406617AGood liquidityLess foamOrganic active ingredientsPowder deliveryChemistryHalf-life

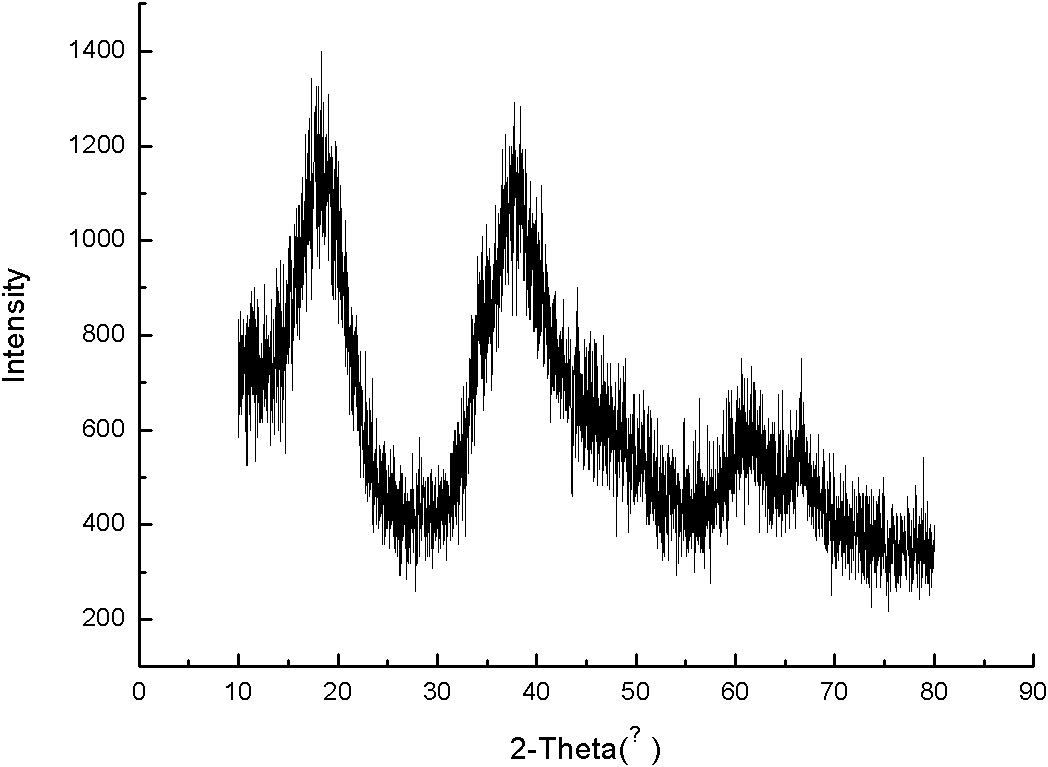

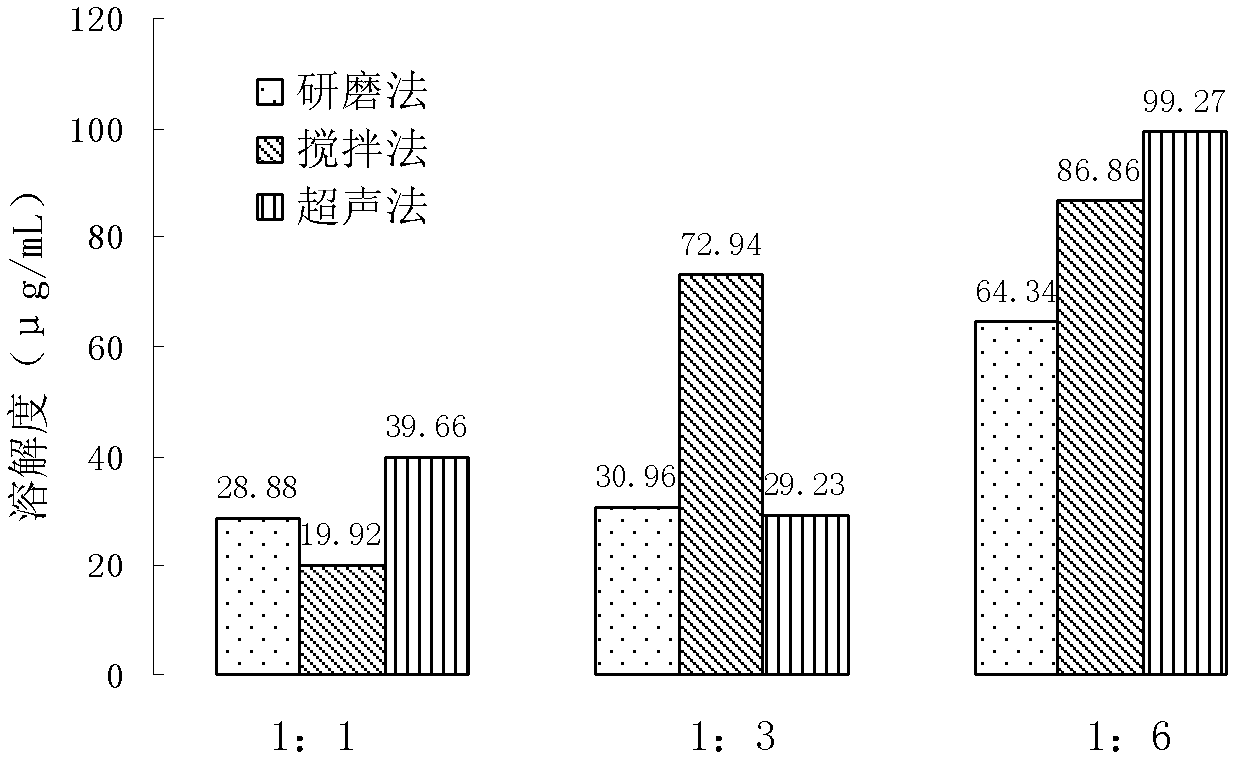

The invention discloses a tecovirimat dry suspension and a preparation method thereof. The tecovirimat dry suspension provided by the invention comprises the following components in parts by mass: 20 to 30 parts of monoclinic crystal micro-powder of tecovirimat monohydrate, 40 to 80 parts of filler, 5 to 10 parts of suspending aid, and 1 to 5 parts of wetting agent, wherein, in the monoclinic crystal micro-powder of tecovirimat monohydrate, the space group of a monoclinic system is C2 / c, cell parameters are as follows: a is 28.724 (2), b is 10.533 (1), c is 12.902 (1) tenthmeter and beta is 112.18 (1) degrees, the cell volume V is 3614.7 (6) cubic tenthmeter, and the number Z of molecules in unit cell is 8. The dry suspension solid powder has good liquidity, can be quickly transformed into a uniform and stable suspension after being mixed with water, has less foam, low deposition speed and excellent redispersibility, and is convenient for administration of patients. Animal experimentsprove that: the preparation has long half-life period, high blood concentration and strong mousepox virus resisting activity.

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

Special cutting fluid for diamond wire

InactiveCN102352278AGuaranteed surface qualityGood liquidityLubricant compositionDefoamerTotal thickness

The invention discloses special cutting fluid for a diamond wire. The special cutting fluid comprises the following components in weight percent: 19-59% of polyethylene glycol, 40.5-80.5% of pure water, 0.05-0.2% of anti-rusting agent, 0.05-0.2% of emulsifier and 0.3-0.5% of defoamer. The density and the viscosity of the cutting fluid are smaller than those of the traditional cutting fluid, the cutting fluid has not only good flowability but also easiness in cleaning, the cleaning can be performed according to the normal cleaning process of a silicon wafer after cutting, and the abnormal phenomena can be avoided; the thickness of the silicon wafer, the TTV (total thickness variation) and the WARP for cutting the diamond wire are meet the requirements respectively, and a cell sheet has no abnormities after texturing; and the cutting fluid is low in preparation cost, the cost of the cutting fluid does not exceed 60% of that of the traditional cutting fluid, and the cutting fluid is conductive to replacing the imported cutting fluid.

Owner:江西金葵能源科技有限公司

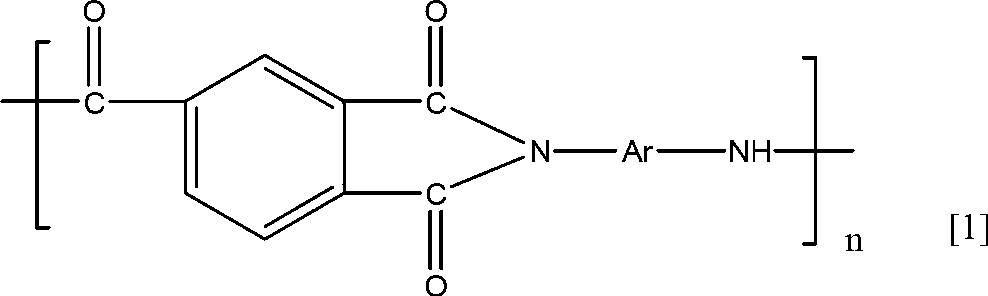

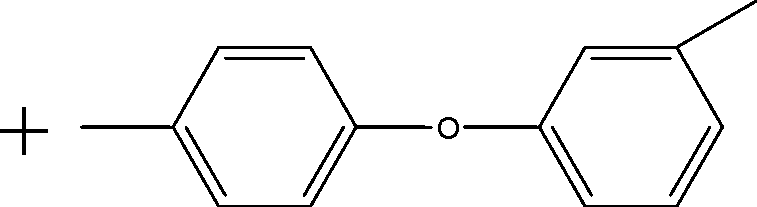

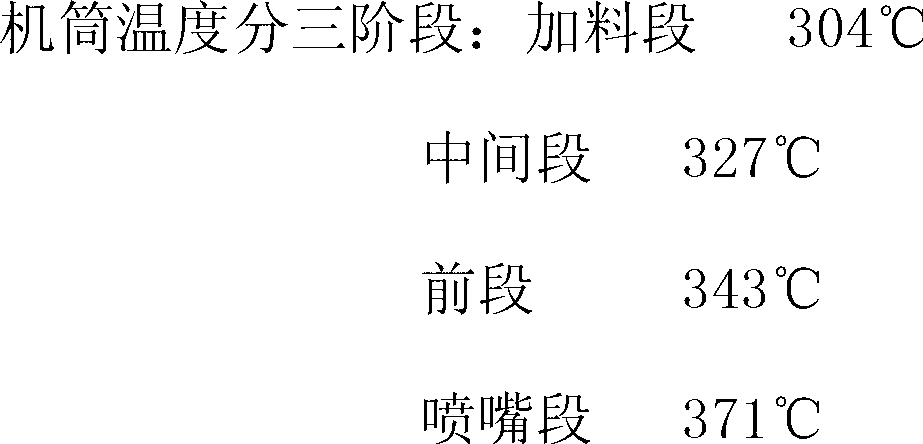

Preparation method of polyamide-imide copolymer

The invention relates to a preparation method of a polyamide-imide copolymer, reacting trimellitic anhydride acyl chloride, 4,4'-diaminodiphenyl ether, 3,4'-diaminodiphenyl ether and m-phenylenediamine according to equal anhydride / amine mol ratio at 5-25 DEG C for 3 hours to prepare polyamide imide acid; and adding 0.5-3 wt% of blocking agent to react for 1-2 hours, precipitating in water, filtering, and drying at 220-250 DEG C for imidization for 3 hours to prepare the polyamide-imide copolymer. The polyamide-imide copolymer has the characteristics of high temperature resistance, low disproportionation degree, favorable flowability in machining, favorable alkali resistance and the like; the inherent viscosity is 0.5-1.0dl / g, and the Tg is 265-285 DEG C; and the properties of the injected sample piece are as follows: the tensile strength is 152 MPa, the bending strength is 241 MPa, the notched Izod impact strength is 140 J / m, the surface resistivity is 5.0*10<18> Omega, the volume resistivity is 2.0*10<17> Omega.cm, the dielectric constant (60Hz) is 4.20, the dielectric loss tangent (60Hz) is 0.026, and the heat-deformation temperature (1.8 MPa) is 278 DEG C.

Owner:SHANGHAI PLASTICS RES INST CO LTD

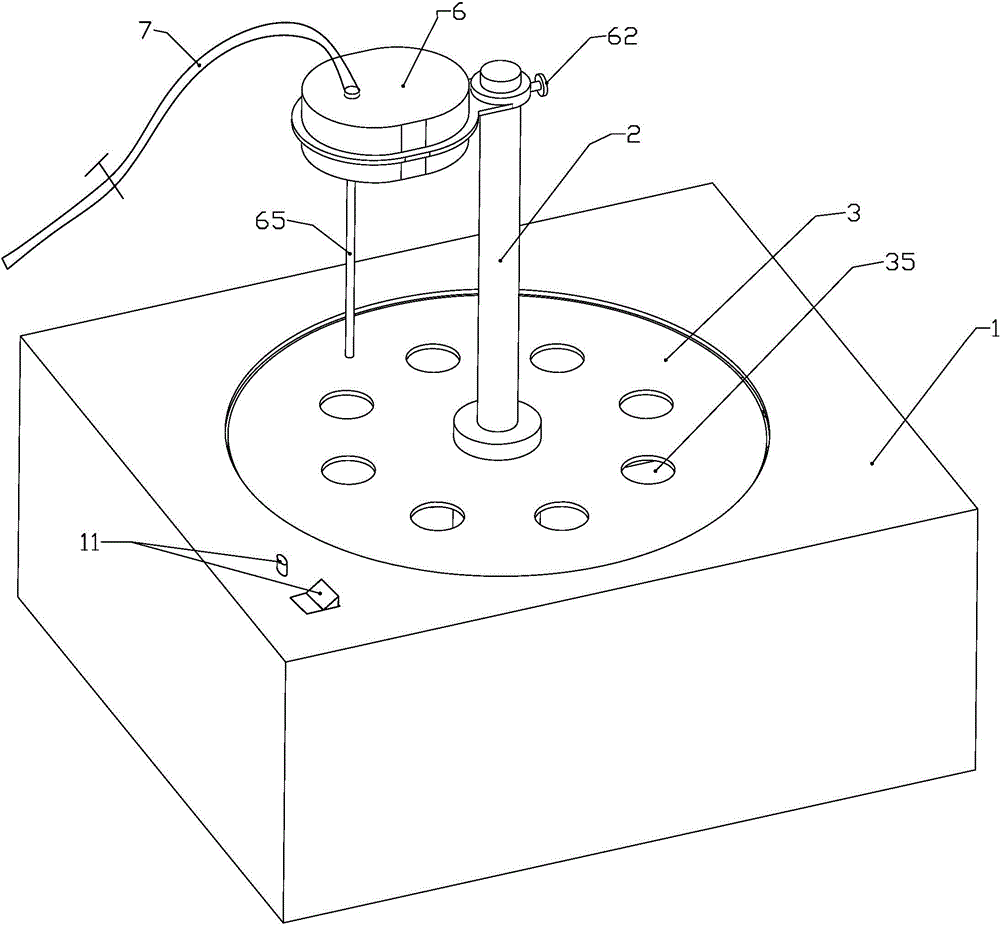

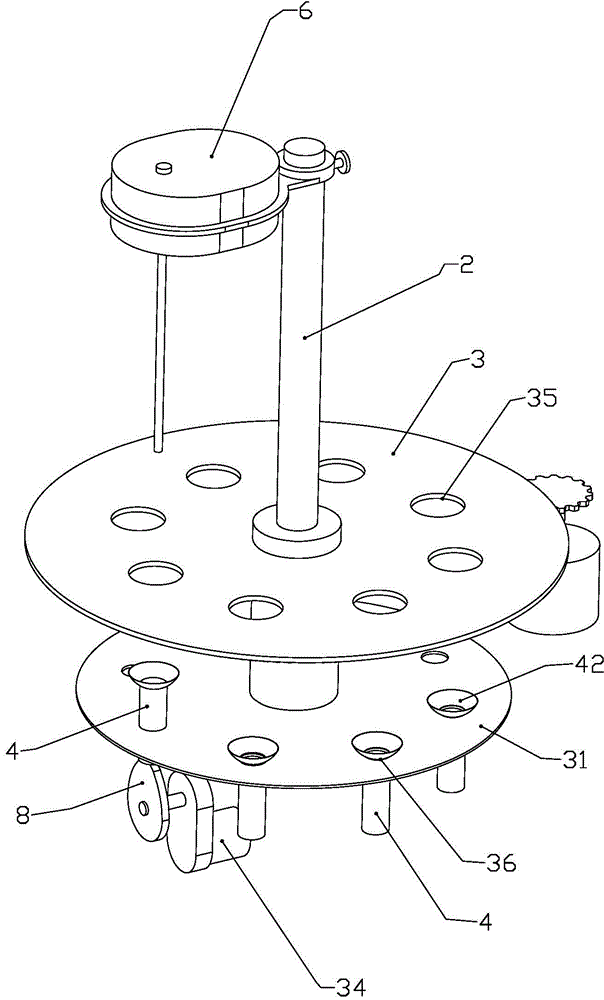

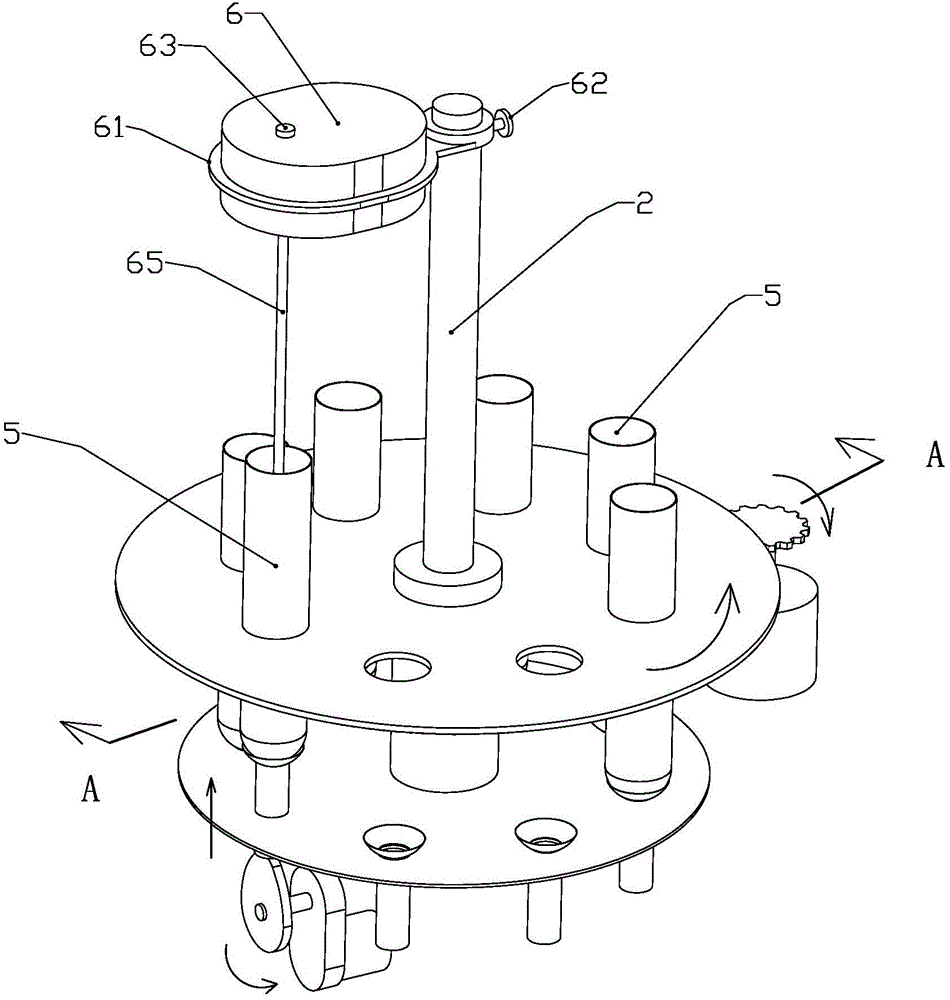

Culture medium split charging device for test tubes

InactiveCN104140066AImprove filling efficiencyGood liquidityFilling without pressureEngineeringCulture mediums

A culture medium split charging device for test tubes comprises a stand column for fixing a sealing container. An air inlet and a liquid outlet are formed in an upper cover and a bottom plate of the container respectively. The stand column is fixed at the center of a base. An annular first groove is formed in the base on the periphery of the stand column. A rotating disc which is driven by a first motor and can carry out quantitative rotating is arranged on the stand column through a sleeve and is placed in the first groove. A coaxialy-arranged tray is arranged on the lower side of the rotating disc. First through holes which are formed in the periphery direction and are used for the test tubes to penetrate through and second through holes which are used for locating the bottoms of the test tubes are formed in the rotating disc and the tray respectively. A pushing rod which can slide vertically is inserted into each second through hole. An eccentric wheel and a second motor for driving are arranged at the lower end of one pushing rod. The culture medium split charging device is a semi-automatic device, split charging efficiency can be effectively improved, split charging accuracy can be improved, and split charging errors are avoided.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

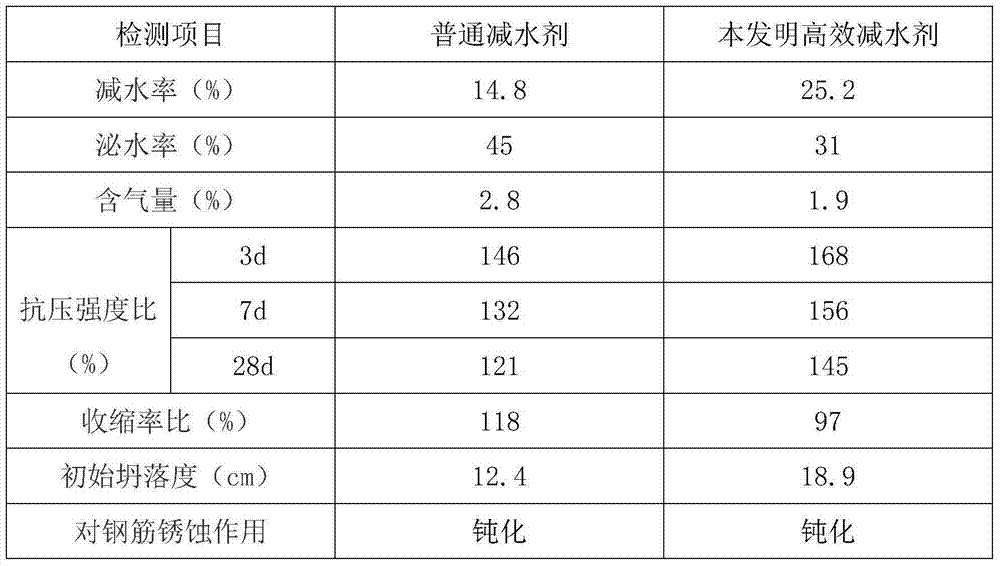

High-efficiency water-reducing agent

The invention discloses a high-efficiency water-reducing agent, which is prepared by the following raw materials in parts by weight: 50-60 parts of beta-naphthalene sulfonate formaldehyde condensate, 20-30 parts of poly(ethylene glycol) monomethyl ether methacrylate, 15-25 parts of calcium lignosulphonate, 10-15 parts of ethylene oxide-propylene oxide copolymer, 2-4 parts of trehalose, 1.5-2.5 parts of silicone powder, 4-8 parts of shale ashes, 2.5-4.5 parts of sodium hydrogen sulfite, 5-10 parts of polyethylene oxide, 8-14 parts of aluminum tripolyphosphate, 2-3 parts of cocoanut oil diethanolamide, 1-2 parts of barium dinonyl naphthalenesulfonate, 2-3 parts of urotropine, and 3-5 parts of auxiliaries. The water-reducing agent is high in water-reducing rate, good in flowability, capable of obviously improving the flowability and working degree of the concrete, obvious in early-strength effect after being finally set, capable of greatly improving the strength of the concrete in all ages, and applicable to various concretes.

Owner:唐山砼科建筑科技有限公司

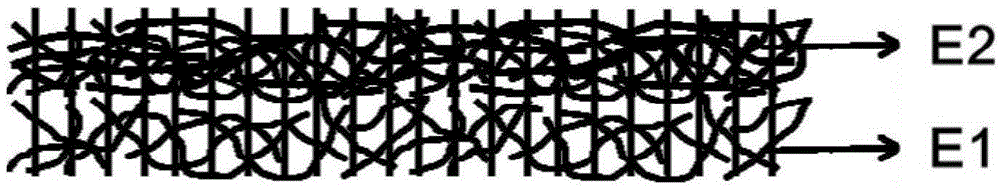

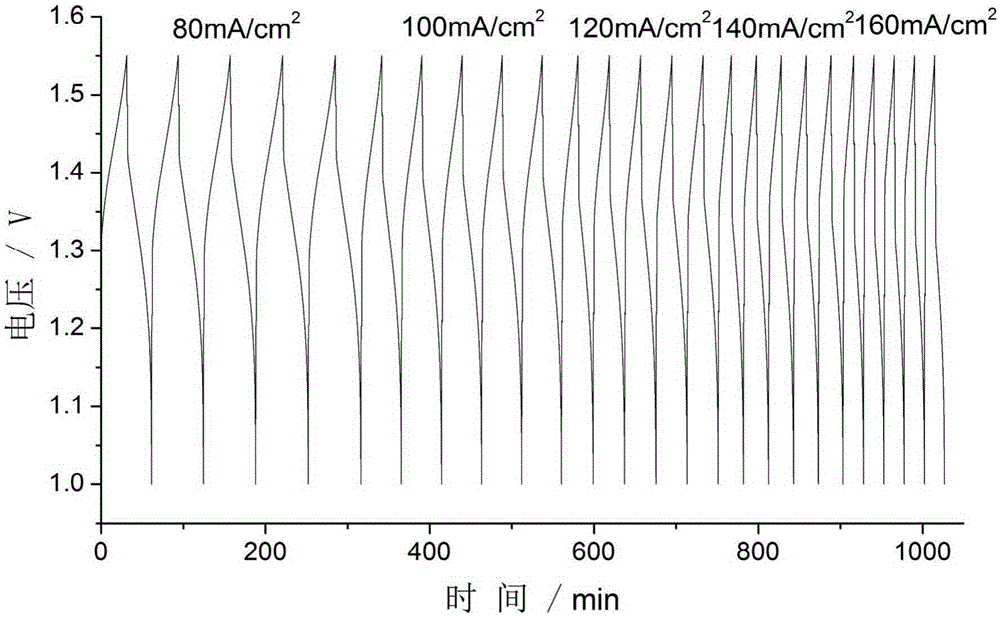

Gradient electrode for flow batteries and application thereof

The invention relates to a gradient electrode for flow batteries. The gradient electrode is formed by: stacking at least two layers of graphite fiber or carbon fiber felt with different bulk densities in an order from low bulk density to high bulk density, and making the materials into a whole by longitudinal needling perpendicular to an electrode surface. The electrode can effectively reduce the resistance of the electrode body, and lower the flow resistance of an electrolyte solution and provide more reaction sites, thus finally reducing ohmic polarization, electrochemical polarization and concentration polarization of flow batteries. The gradient electrode provided by the invention improves the energy efficiency and voltage efficiency of flow batteries so as to improve the working current density, thus greatly reducing the weight, volume and cost of batteries with similar output power.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

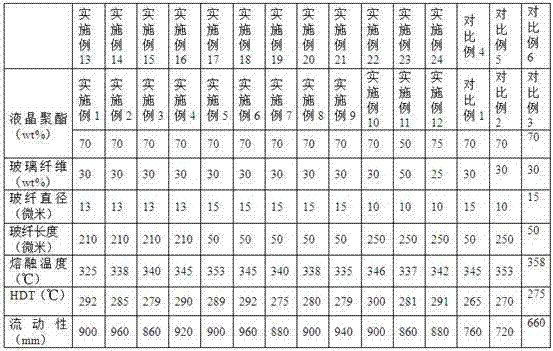

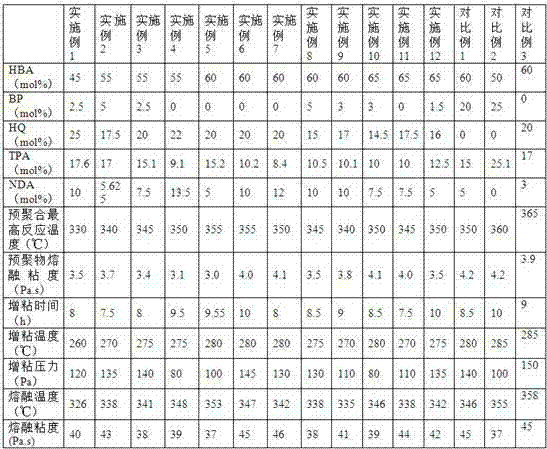

Liquid crystal polyester, liquid crystal polyester composition composed of liquid crystal polyester, and applications of liquid crystal polyester composition

The invention discloses a liquid crystal polyester comprising repeated units of (I), (II), (III), (IV), and (V) corresponding to monomers of (A), (B), (C), (D), and (E) respectively. Based on the total amount of the repeated units, molar ratio of (I) ranges from 45 to 65%; the total molar ratio of (II) and (III) ranges from 17.5 to 27.5%, wherein the amount of (II) accounts for 0 to 25% of the total amount of (II) and (III); and molar ratio of (IV) and (V) ranges from 17.5 to 27.5%, wherein the amount of (IV) accounts for 25 to 60% of the total amount of (IV) and (V). The invention also discloses a liquid crystal polyester composition containing the liquid crystal polyester. The liquid crystal polyester composition comprises 50 to 75wt% of the liquid crystal polyester, and 25 to 50wt% of an inorganic filling material. Melting temperature of the liquid crystal polyester composition is lower than 355 DEG C; HDT>=275 DEG C; liquidity is excellent; and the liquid crystal polyester composition can be used for preparation of electric product couplers.

Owner:ZHUHAI WANTONG SPECIAL ENG PLASTICS CO LTD

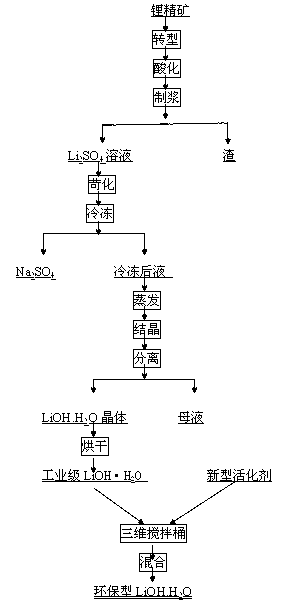

Method for directly producing environment-friendly lithium hydroxide monohydrate from spodumene

ActiveCN102838140AGood liquidityLarge crystalLithium oxides/hydroxidesCycloalkaneLithium hydroxide monohydrate

Owner:SICHUAN GUORUN NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com