Reinforced polyamide composition with high liquidity and low warpage and preparation method and application thereof

A technology for polyamide composition and fluidity, which is applied in the field of reinforced polyamide composition and its preparation, can solve the problems of high cost, limited application and the like, and achieves the effects of small warpage, smooth injection molding surface and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

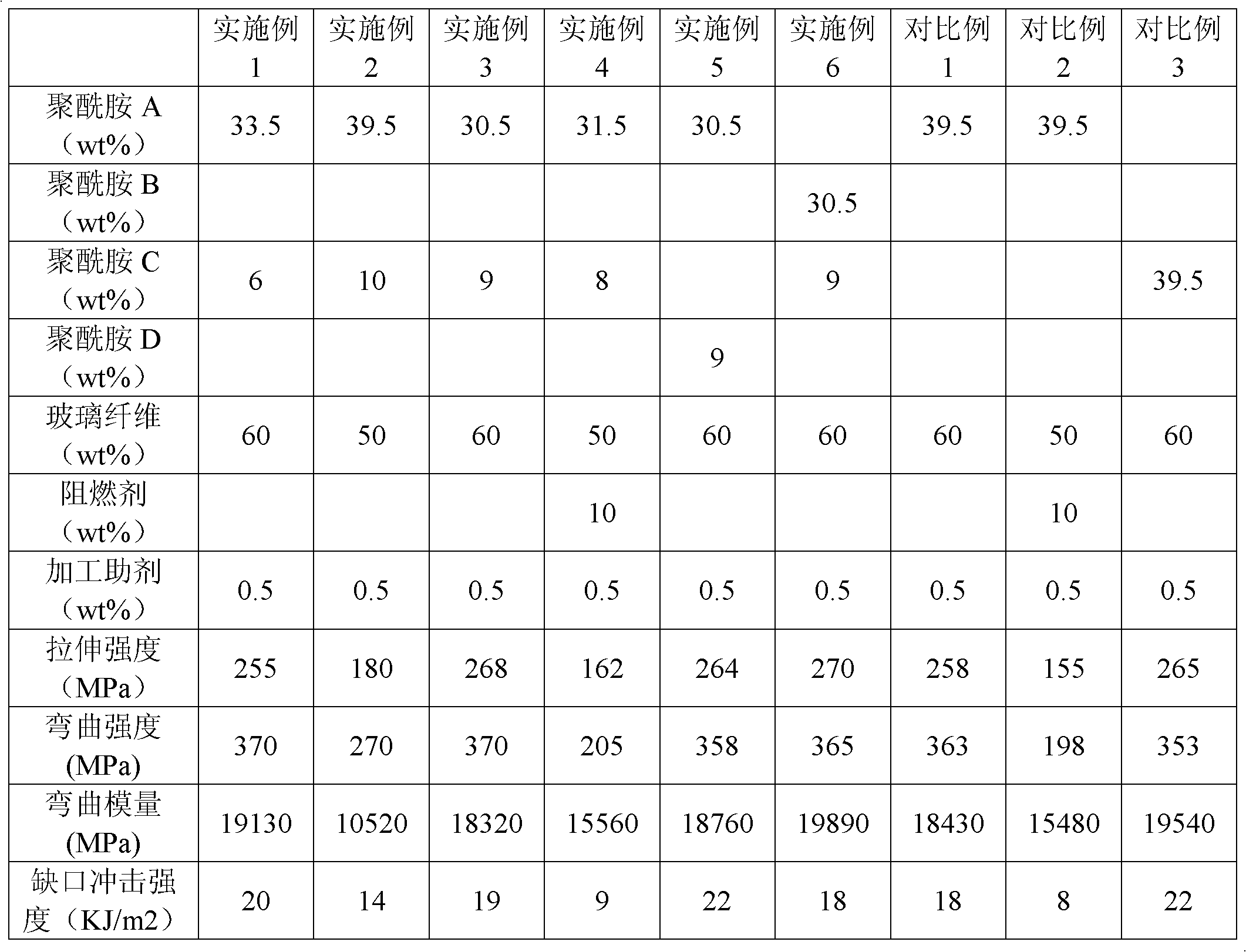

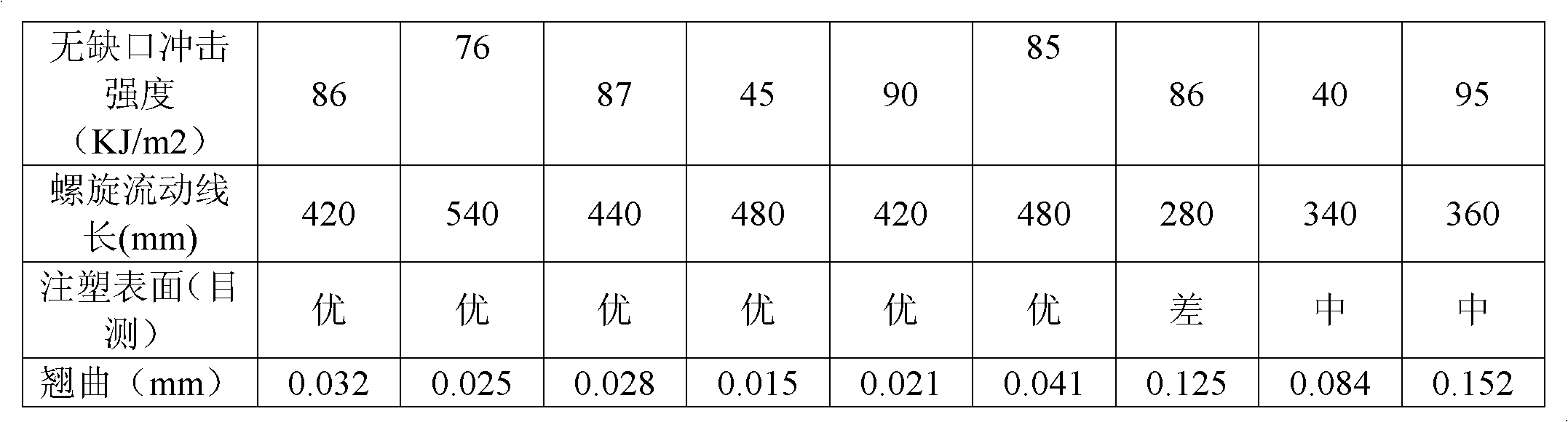

Embodiment 1-6 and comparative example 1-3

[0055] The raw materials of the polyamide compositions of Examples 1-6 and Comparative Examples 1-3 are shown in Table 1, and the preparation methods are the same. All raw materials (excluding glass fiber) are mixed uniformly at 280-320°C, then the mixture and glass fiber are put into a twin-screw extruder for melting and mixing, and the glass fiber is side-fed. The rotation speed of the extruder is 300 rpm, and the temperature of the screw barrel is 320°C. After the molten polymer is extruded from the extruder, it is quenched with water and pelletized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com