Patents

Literature

322 results about "Lithium hydroxide monohydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium hydroxide monohydrate is used in preparation of other lithium salts where use of carbonate is not practical; as a catalyst in the production of alkyd resins, in esterifications. Lithium hydroxide monohydrate is also used in the production of lithium soaps, greases and sulfonates.

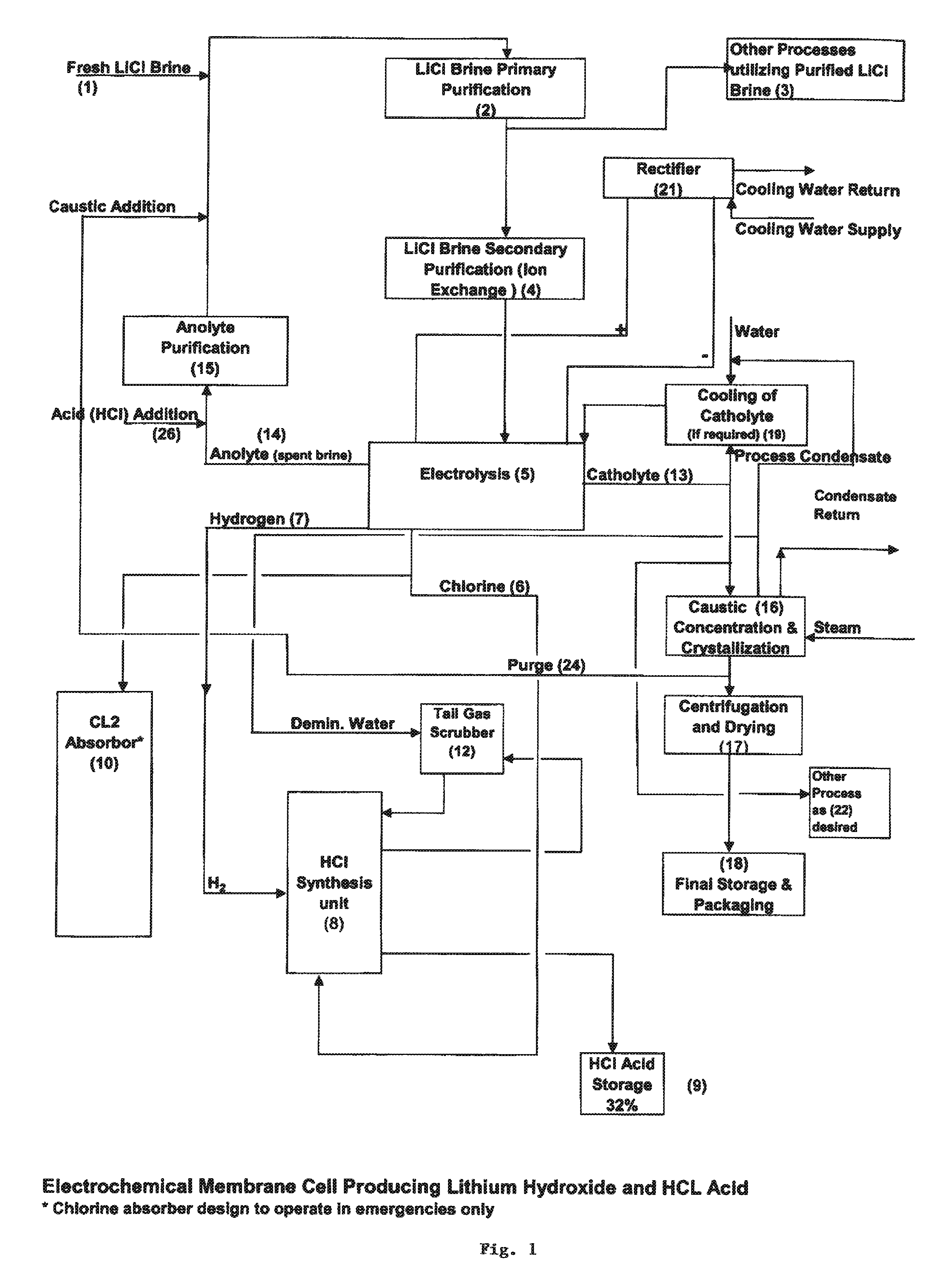

Method of making high purity lithium hydroxide and hydrochloric acid

InactiveUS20110044882A1Simple and economical processEasy to convertElectrolysis componentsEnergy inputElectrolysisIon exchange

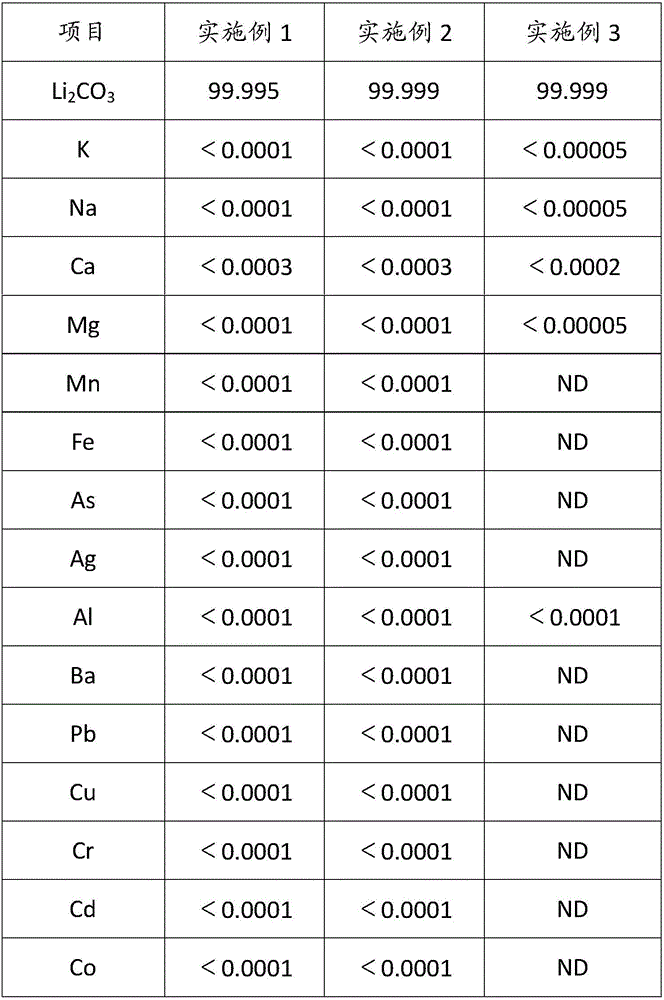

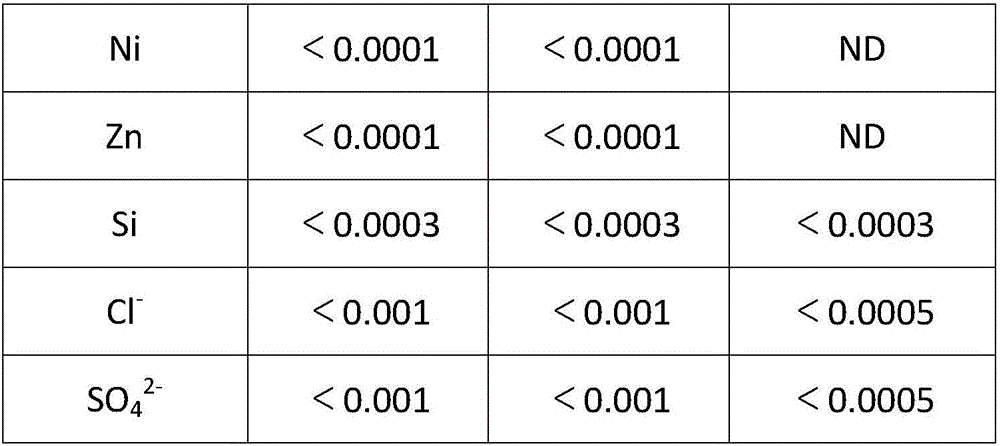

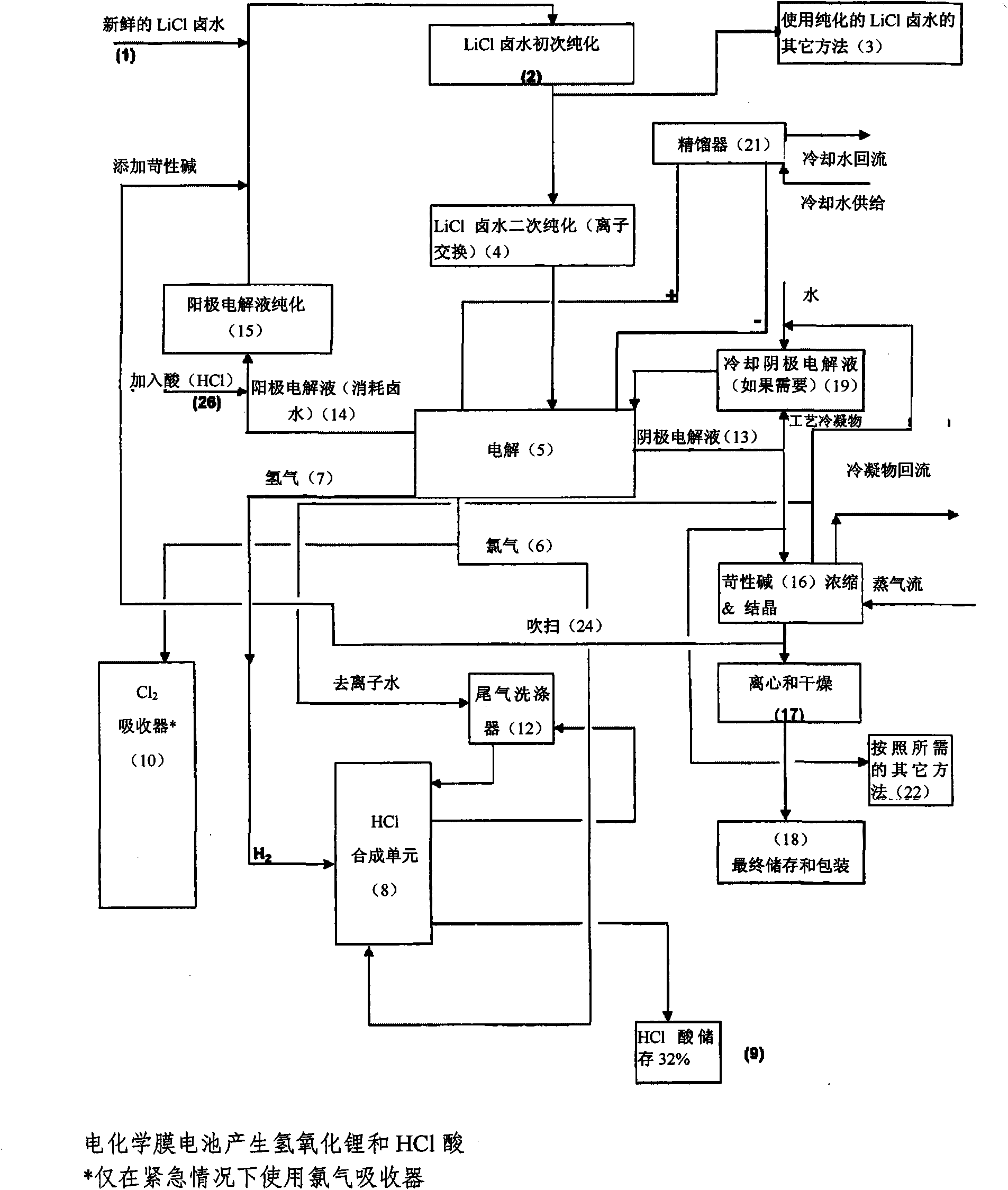

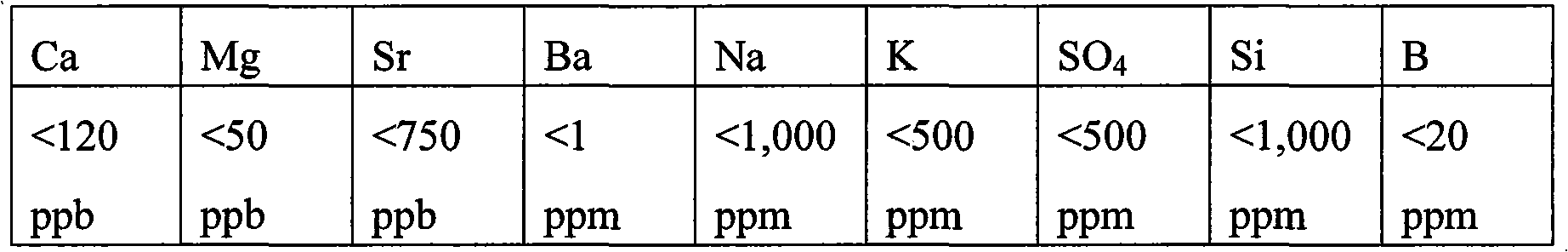

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

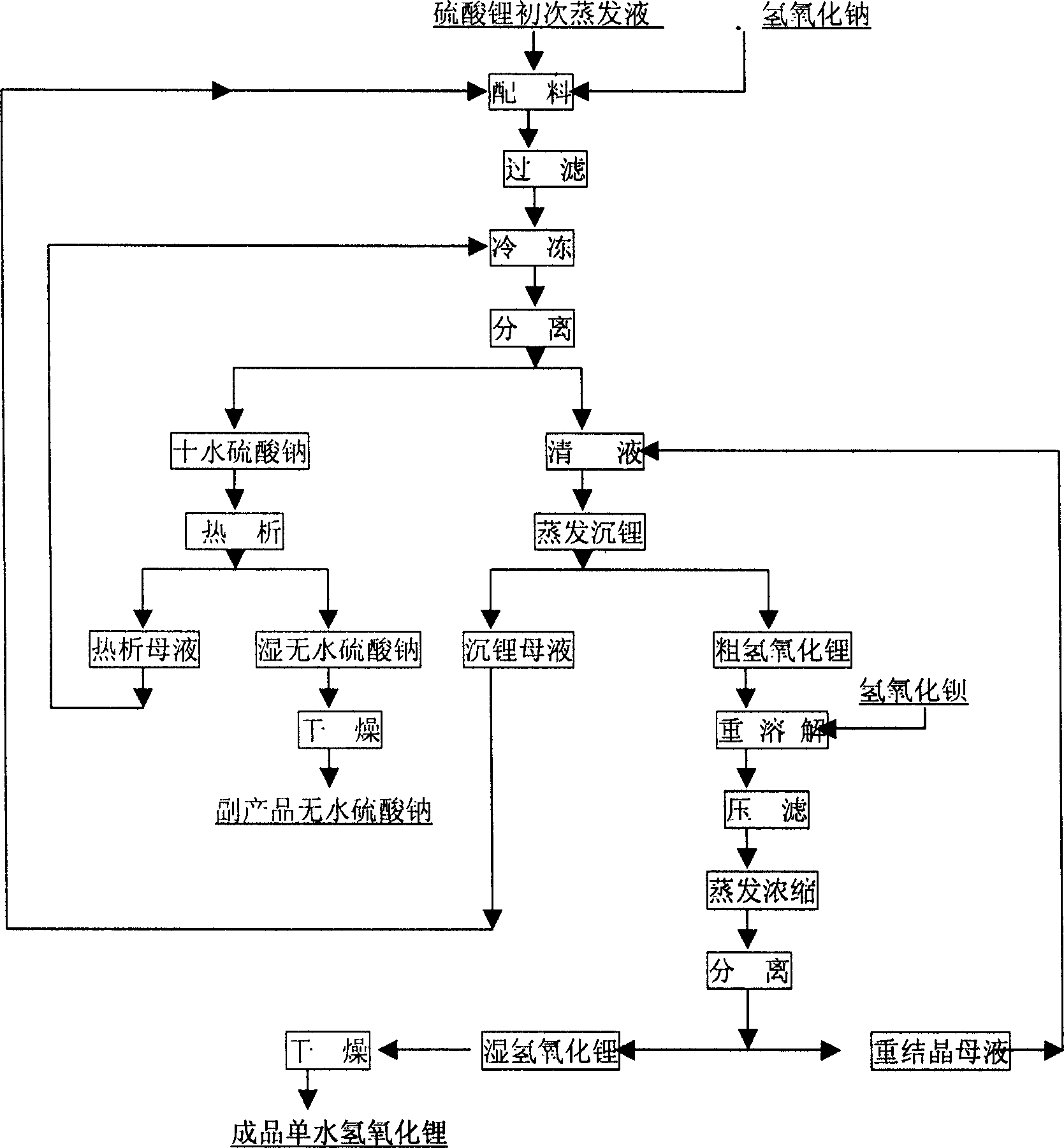

Production process of lithium hydroxide monohydrate

InactiveCN1486931AShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

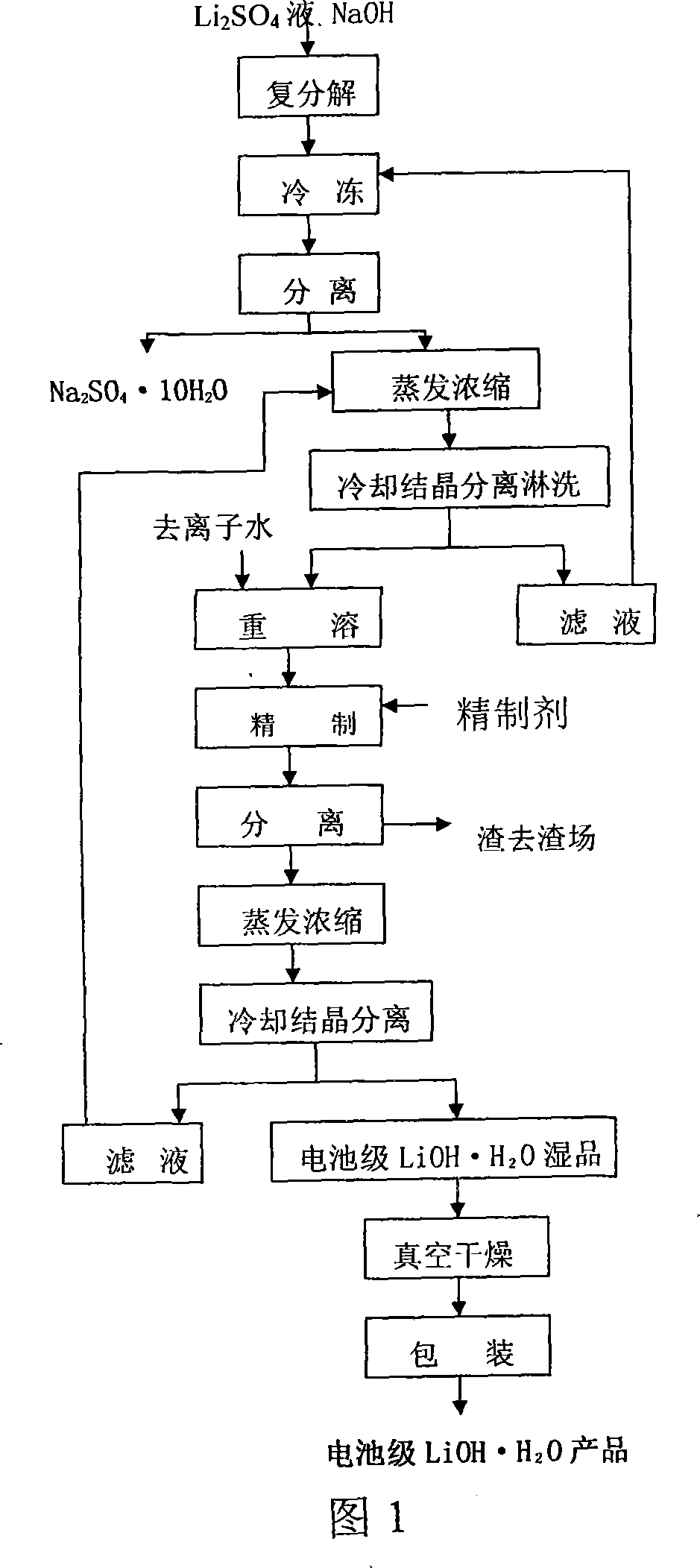

Method for preparing battery-stage monohydrate lithium hydroxide

ActiveCN101214978AHigh recovery rateSuit one's needsCell electrodesLithium oxides/hydroxidesLithium sulphateSodium hydroxide

The invention provides a process for preparing battery grade lithium hydroxide monohydrate, comprising: (1) adding sodium hydroxide in lithium sulfate purification fluid and obtaining solid of Na2SO4, 10H2O and liquid of LiOH after completely dissolving and cooling, (2) obtaining liquid of LiOH after filtering and separating, (3) evaporating and concentrating the liquid of LiOH and filtering, separating and leaching the liquid of LiOH after cooling and crystallizing to obtain one-time crude product of LiOH, H2O, (4) adding deionized water in the one-time crude product of LiOH, H2O and obtaining re-dissolving solution of the one-time crude product of LiOH, H2O, (5) adding refining agent in the re-dissolving solution of the one-time crude product of LiOH, H2O and obtaining filtrate of LiOH refined liquor after filtering and separating, (6) filtering and separating the LiOH refined liquor after evaporating, concentrating, cooling and crystallizing to obtain solid of battery grade wet product of LiOH, H2O and (7) taking out the battery grade wet product of LiOH, H2O after drying to obtain battery product of LiOH, H2O. The invention is simple in production process, easy operation and perfect product quality.

Owner:TIANQI LITHIUM CORP

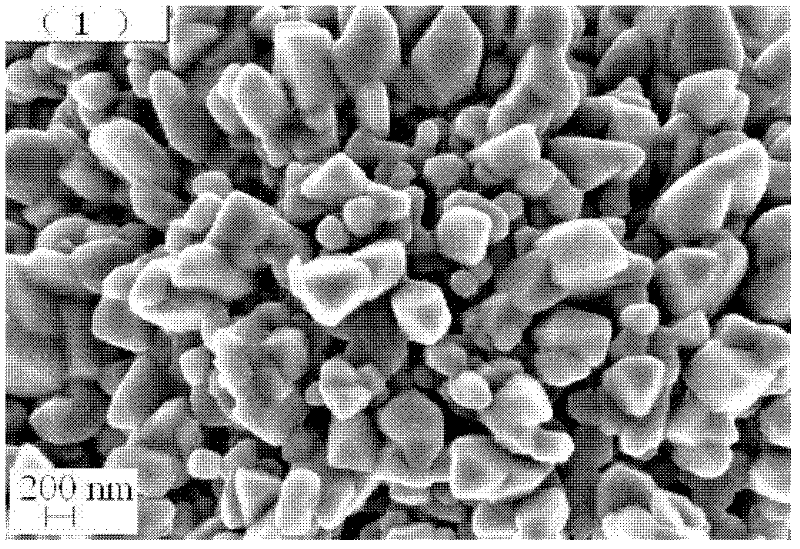

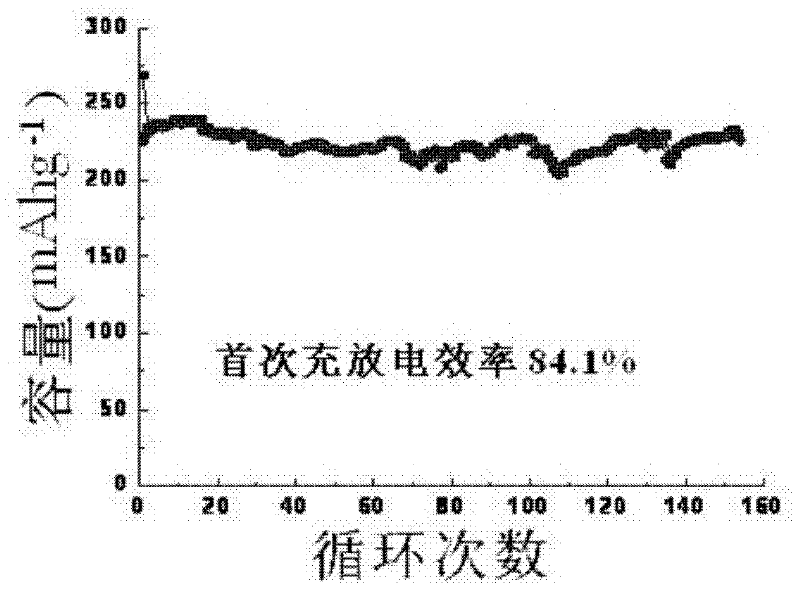

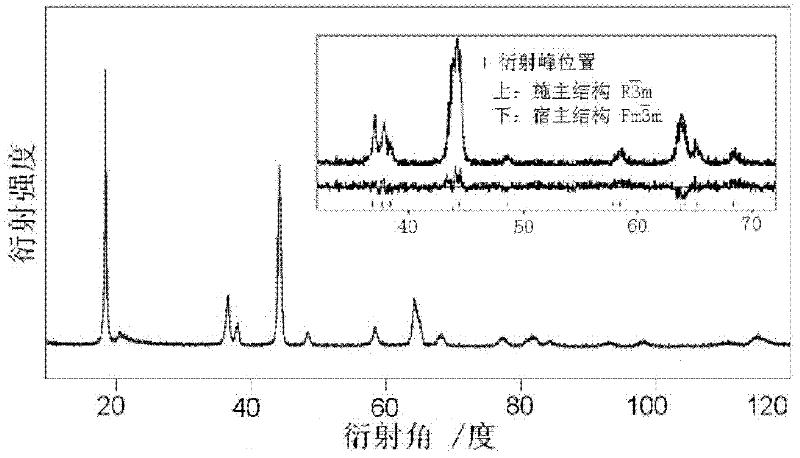

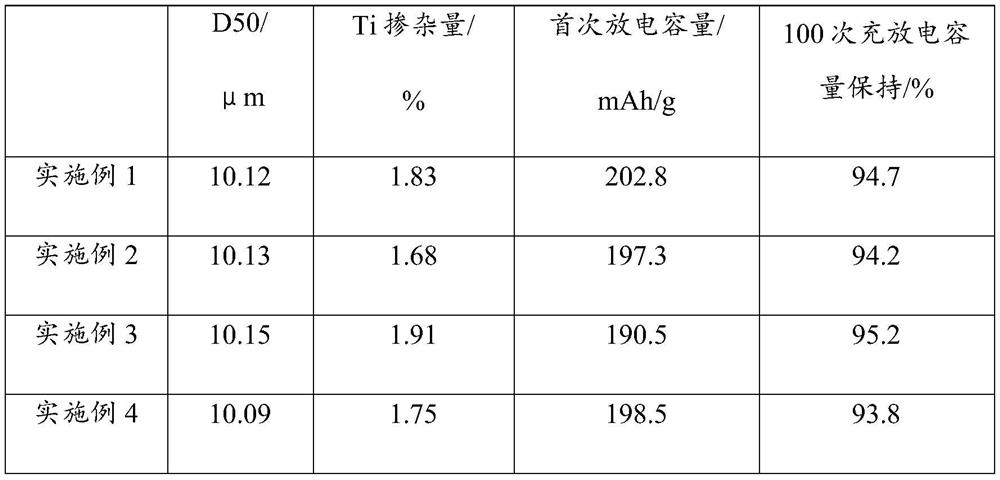

Preparation method of layered manganese-based cathode material for raising initial charge/discharge efficiency

InactiveCN102447103APrecise Control of Chemical CompositionReduced electrochemical performanceCell electrodesDischarge efficiencyManganese

A preparation method of a layered manganese-based cathode material for raising initial charge / discharge efficiency comprises the following steps of: using ammonium bicarbonate as a precipitating agent, simultaneously adding ammoniacal liquor in a dropwise manner so as to control coprecipitation reaction pH value to 8-9, continuing for 8-12 hours, precipitating a coprecipitation product, adding deionized water to prepare a slurry with the concentration of 150-200g / l, carrying out spray drying on the slurry at the temperature of 100-120 DEG C to prepare a Ni-Mn carbonate powder, insulating at the temperature of 300-350 DEG C for 4-6 hours, heating up to 450-500 DEG C and insulating for 2-4 hours to obtain a precursor powder, weighing lithium hydroxide monohydrate with its mole number being K[1+x / (2+x)], grinding the prepared xLi2MnO3.(1-x)LiNi1 / 2Mn1 / 2O2 powder, roasting at the temperature of 600-650 DEG C for 1-6 hours, and annealing. According to the invention, the initial charge / discharge efficiency of the layered manganese-based cathode material is substantially raised, and the cycle stability is obviously improved.

Owner:UNIV OF SCI & TECH BEIJING

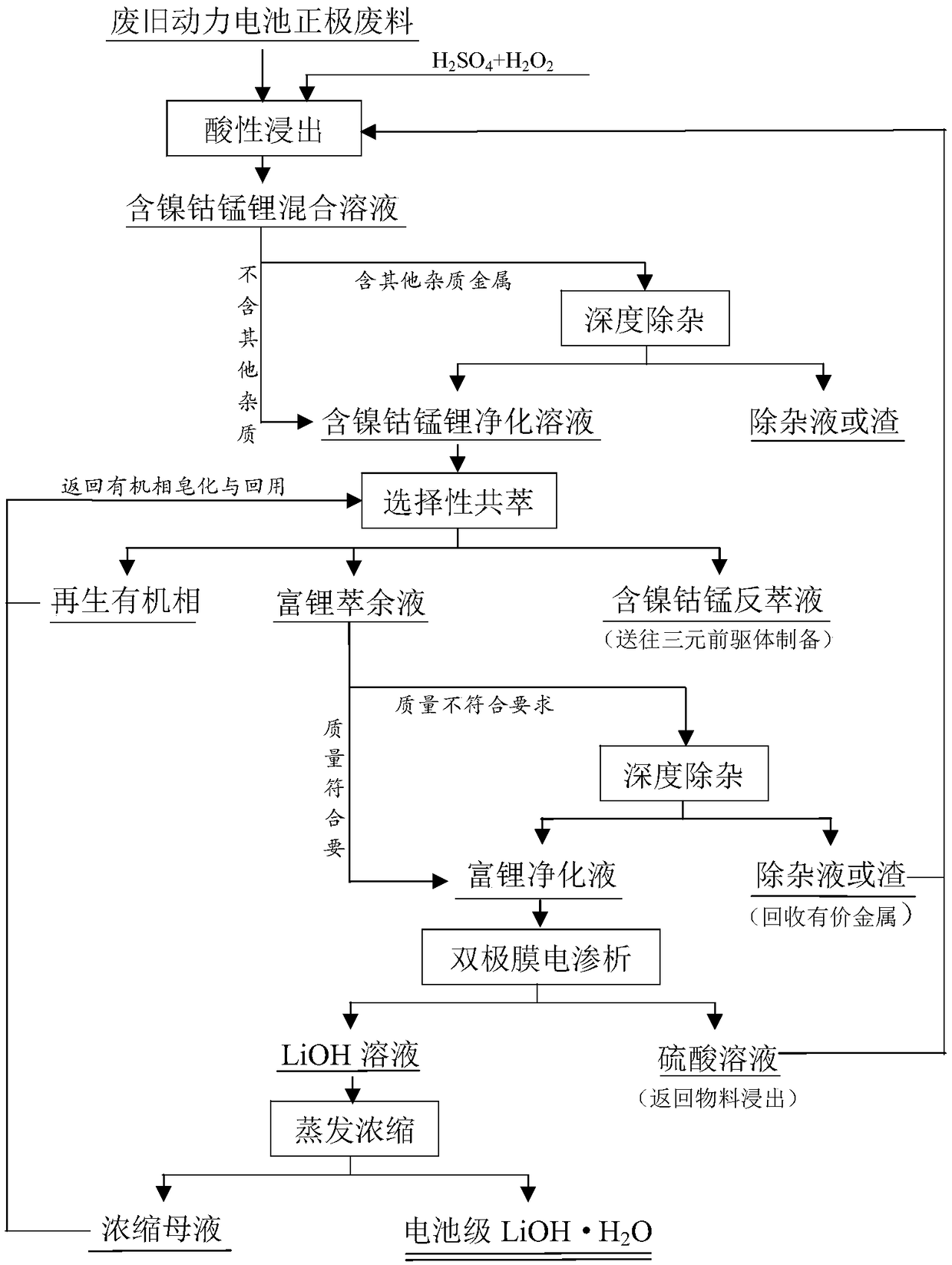

Method for recovering valuable metal from waste power battery cathode waste material

ActiveCN108517409AAvoid high alkali consumptionAvoid conversionWaste accumulators reclaimingProcess efficiency improvementManganeseRaffinate

The invention discloses a method for recovering valuable metal from a waste power battery cathode waste material. The method comprises the following steps that (1) the waste power battery cathode waste material is subjected to acid dipping treatment, and a nickel cobalt manganese and lithium containing mixed solution is obtained; (2) the nickel cobalt manganese and lithium containing mixed solution is subjected to impurity removal, nickel cobalt manganese and lithium containing purified liquid and impurity removed liquid or impurity removed residue are obtained; (3) nickel cobalt and manganeseare separated from the nickel cobalt manganese and lithium containing purified liquid through a selective co-extraction method, and nickel cobalt and manganese containing strip liquid and lithium-rich extraction raffinate are obtained; (4) lithium-rich extraction raffinate is subjected to deep impurity removal treatment, and lithium-rich purified liquid and impurity removal liquid or impurity removal residue are obtained; (5) the lithium-rich purified liquid is treated by adopting a bipolar membrane electrodialysis method after being subjected to deep degreasing treatment, and a lithium hydroxide solution and a sulfuric acid solution are generated; and (6) the lithium hydroxide solution is evaporated and concentrated, and a battery-level lithium hydroxide monohydrate and concentrated mother liquid are obtained. The recovery rate of nickel cobalt manganese and lithium is higher than 98%, and appreciation of metal products is achieved while the valuable metal is efficiently recovered.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

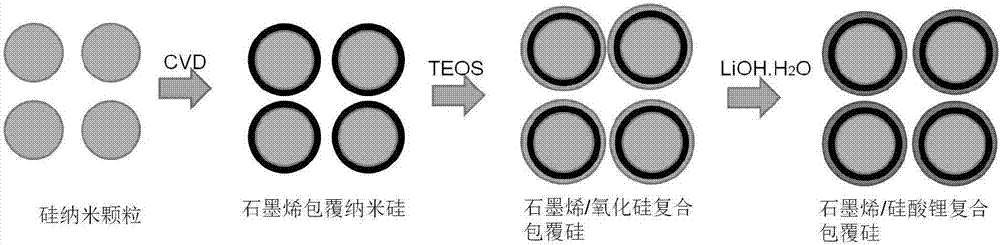

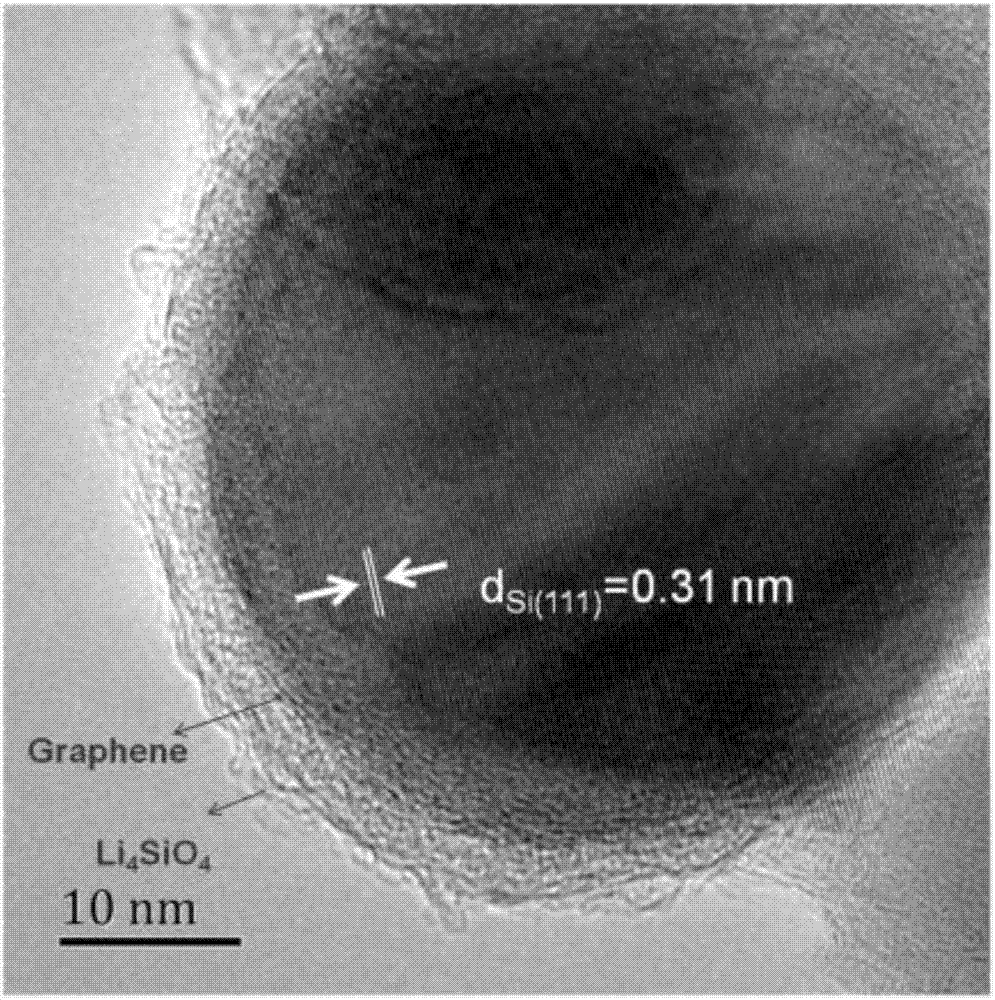

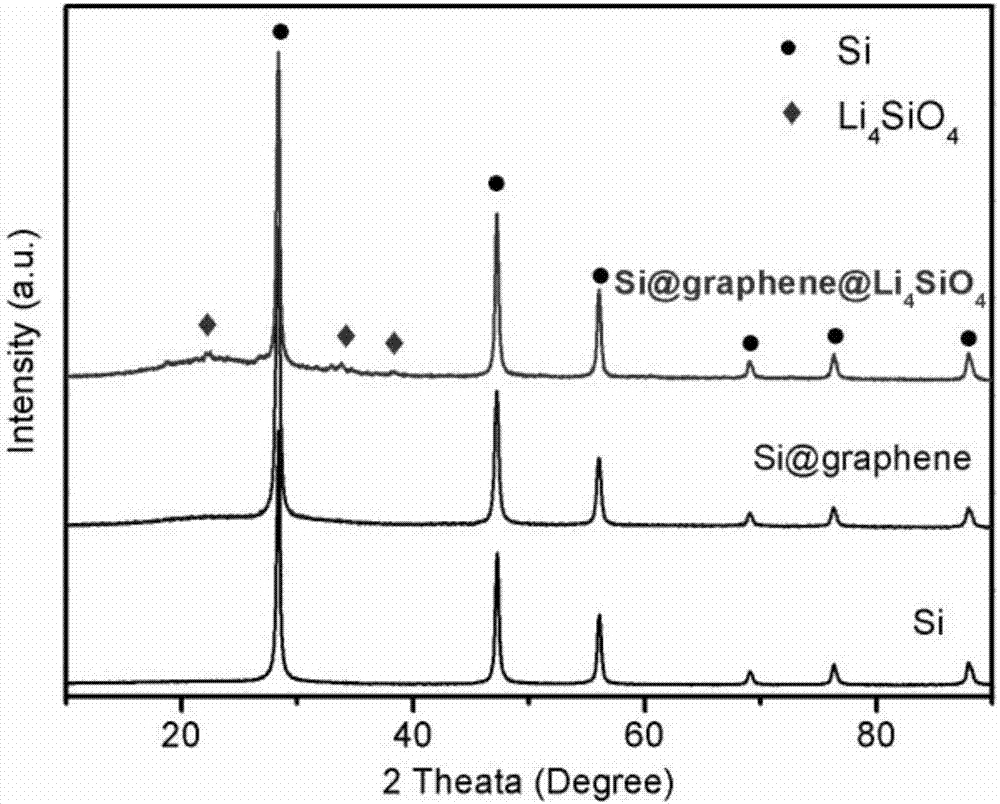

Graphene/solid-state electrolyte composite coated silicon composite negative electrode and preparation method thereof

ActiveCN107579239ASimple processCoated evenlyCell electrodesSecondary cellsElectrochemical responseSolid state electrolyte

The invention discloses a graphene / solid-state electrolyte coated silicon composite material and a preparation method thereof. The preparation method comprises the following steps: coating a silicon-based material with a layer of graphene through a chemical vapor deposition method, and accumulating concentrated ammonia water into an oxide through a precursor ester of an oxide for coating to obtainan oxide and graphene co-coated silicon negative electrode material; performing lithiation on the composite material with lithium hydroxide monohydrate to finally obtain the graphene / solid-state electrolyte coated silicon composite material. In the composite material, graphene directly grows on the surfaces of silicon particles, and the surface of graphene is coated with solid-state electrolyte,thereby forming double-layer coating. The graphene inside can increase the electronic conductivity of the silicon-based material, and relieve volume expansion of silicon. The coating solid-state electrolyte outside can improve the Coulomb efficiency and the magnification performance of the silicon-based negative electrode material, reduce the electrochemical reaction between the negative electrodematerial and electrolyte, increase the Coulomb efficiency of the silicon-based negative electrode and improve the high current charging and discharging performance of the material.

Owner:深圳索理德新材料科技有限公司

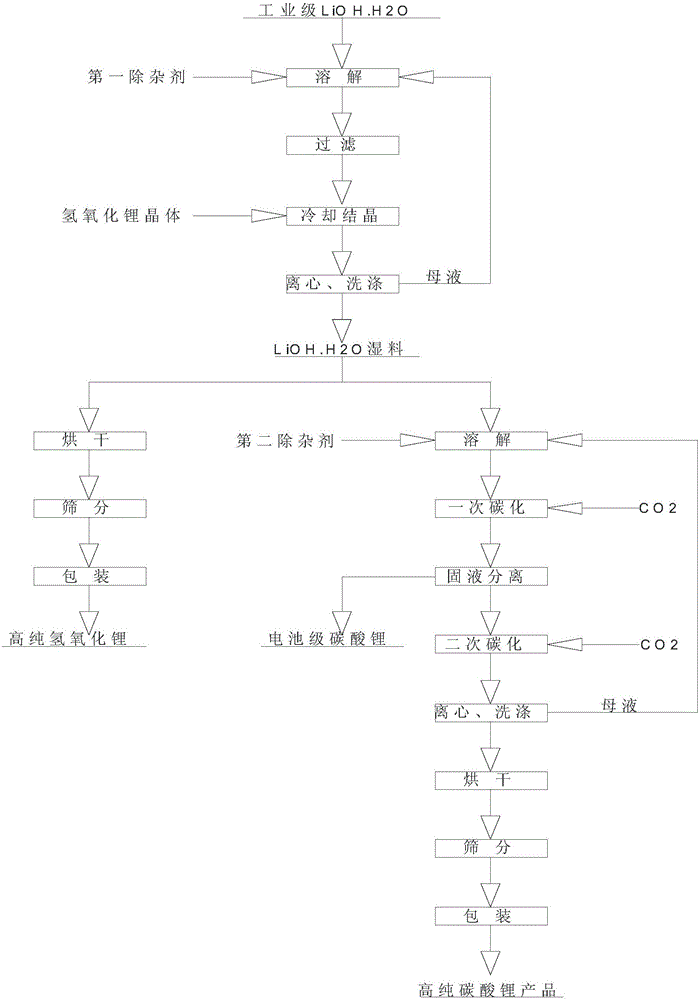

Method for composite production of high-purity lithium hydroxide monohydrate, high-purity lithium carbonate and battery grade lithium carbonate

ActiveCN106315625AHigh recovery rateAdjust outputAlkali metal oxides/hydroxidesCarbonate preparationLithium carbonatePhysical chemistry

The invention discloses a method for composite production of high-purity lithium hydroxide monohydrate, high-purity lithium carbonate and battery grade lithium carbonate. Industrial grade lithium hydroxide is dissolved into pure water or crystallization mother liquor, and a first solution is prepared; a first impurity removal agent is added into the first solution, then filtering is performed, a lithium hydroxide crystal is added into a filtrate, cooling crystallization is performed, solid-liquid separation is performed to obtain a high-purity lithium hydroxide monohydrate wet material and crystallization mother liquor; the high-purity lithium hydroxide monohydrate wet material is dissolved into pure water or carbonization mother liquor, and a second solution is prepared; carbon dioxide is introduced into the second solution to perform primary carbonization, and solid-liquid separation is performed to obtain a lithium carbonate wet material and a filtrate; a second impurity removal agent is added into the filtrate, after a heat preservation reaction is performed, carbon dioxide is introduced to perform secondary carbonization, then, introduction of the carbon dioxide is stopped, the reaction continues to be performed, then, solid-liquid separation is performed, obtained solids are washed, a high-purity lithium carbonate wet material and carbonization mother liquor are obtained, and after the high-purity lithium carbonate wet material is post-processed, a high-purity lithium carbonate product is obtained.

Owner:CHENGDU CHEMPHYS CHEM IND

Method of making high purity lithium hydroxide and hydrochloric acid

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

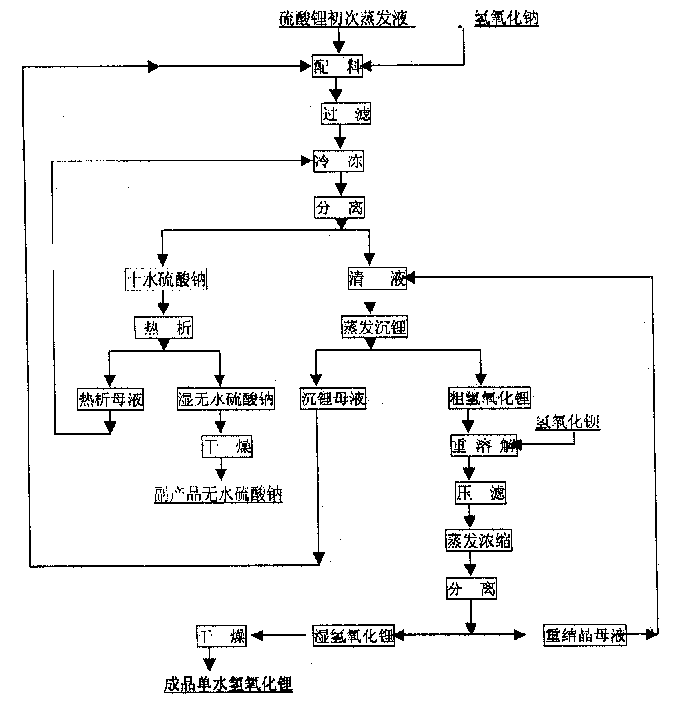

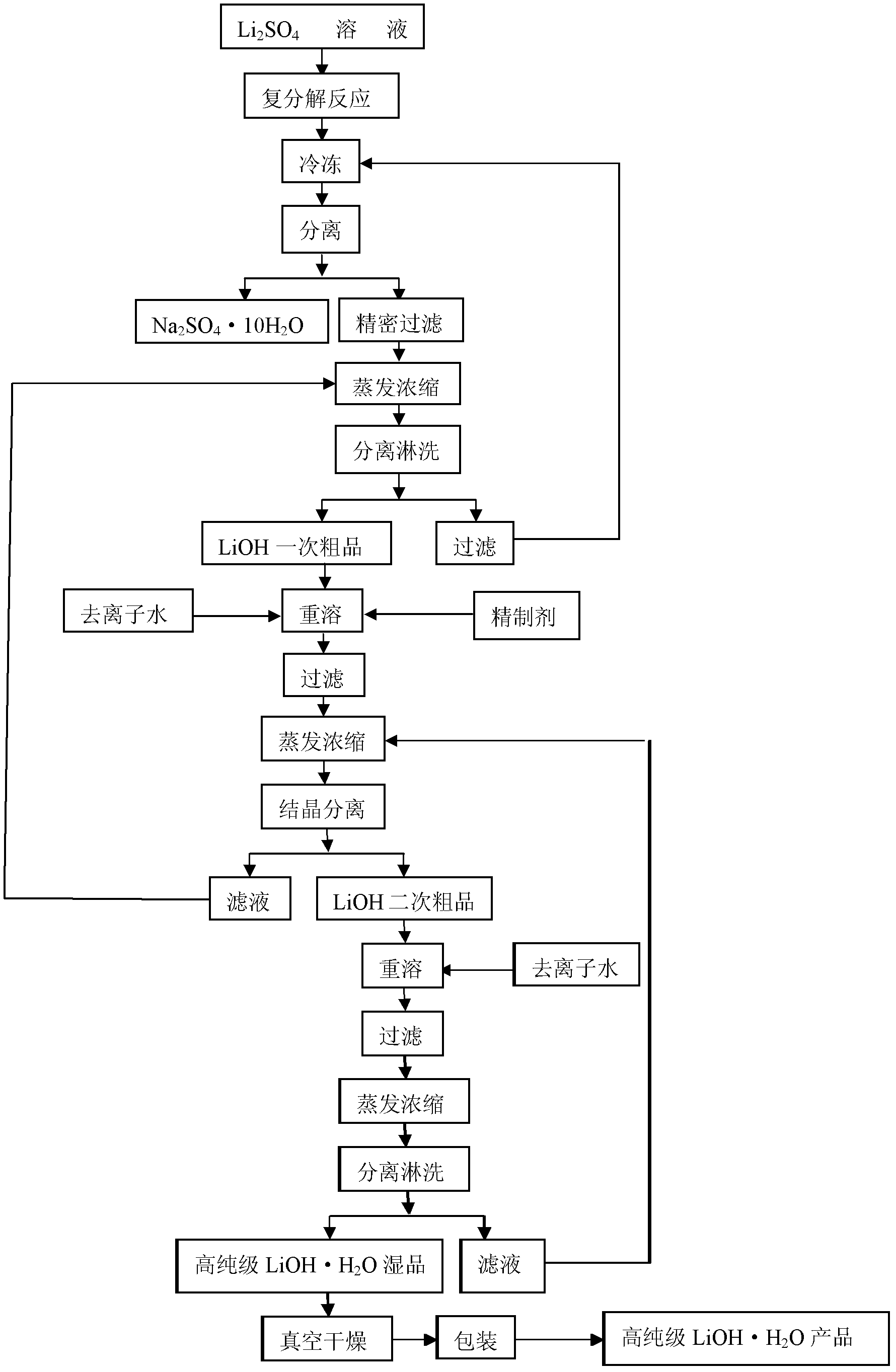

Method for preparing battery grade lithium hydroxide monohydrate

ActiveCN104944447AHigh yieldGuaranteed qualityLithium oxides/hydroxidesLithium sulphateCost effectiveness

The invention discloses a method for preparing battery grade lithium hydroxide monohydrate, which comprises steps: edulcoration and purification of lithium sulfate solution, freezing separation, preparation of lithium hydroxide monohydrate crude products, dissolution and purification of the lithium hydroxide monohydrate crude products and recrystallization. The method for preparing the battery grade lithium hydroxide monohydrate can obtain lithium hydroxide monohydrate finished products just through twice crystallization, and improves leaching efficiency of lithium. Sodium sulfafe decahydrate which is frozen and separated is washed through low temperature water, the lithium in the sodium sulfafe decahydrate is effectively recycled, the technological process is reduced, the yield of the lithium is further greatly improved, the investment of evaporator equipment is reduced, and the cost effectiveness is obvious.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

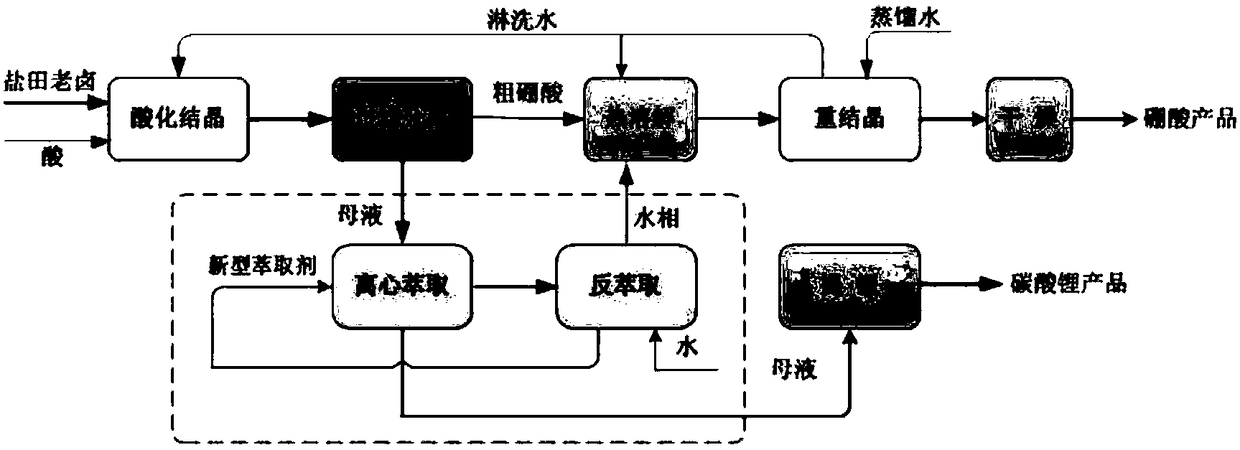

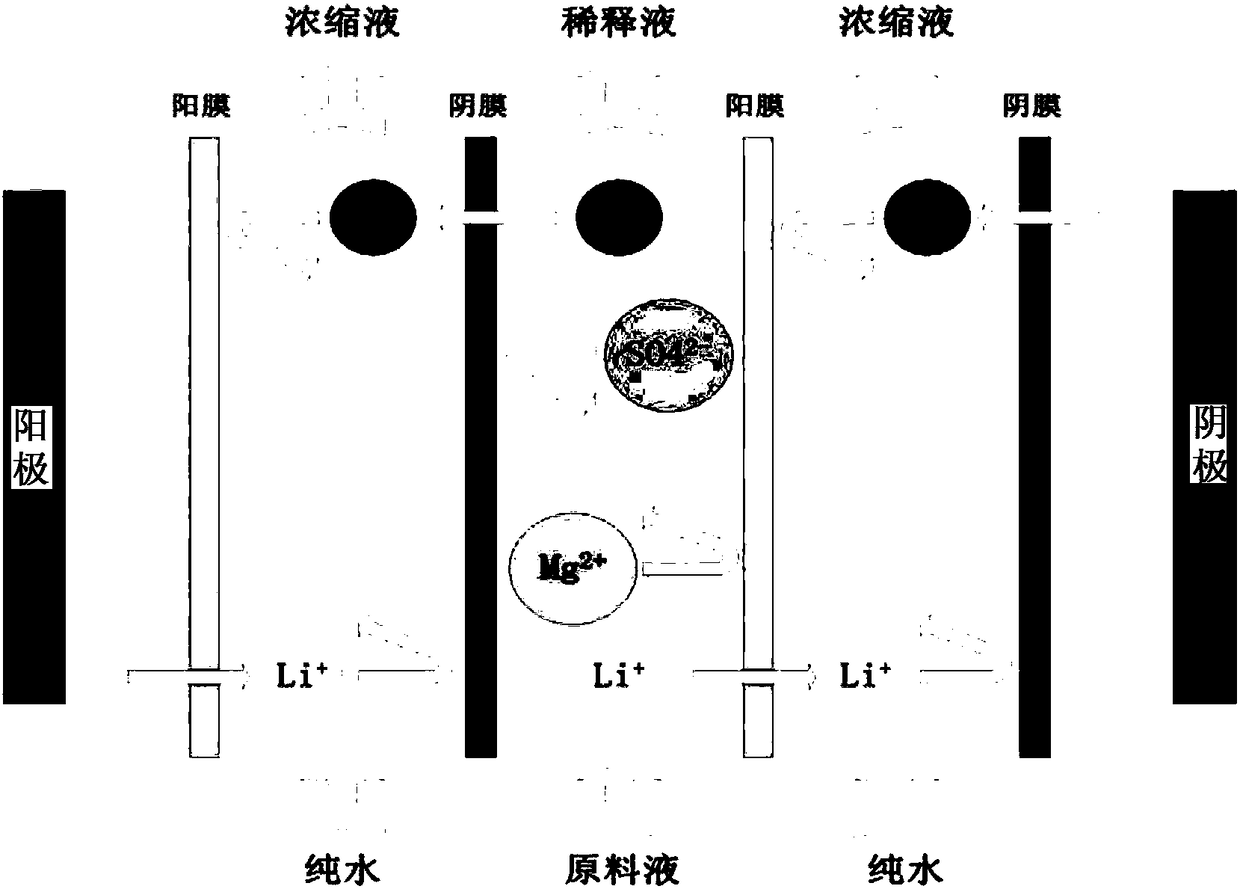

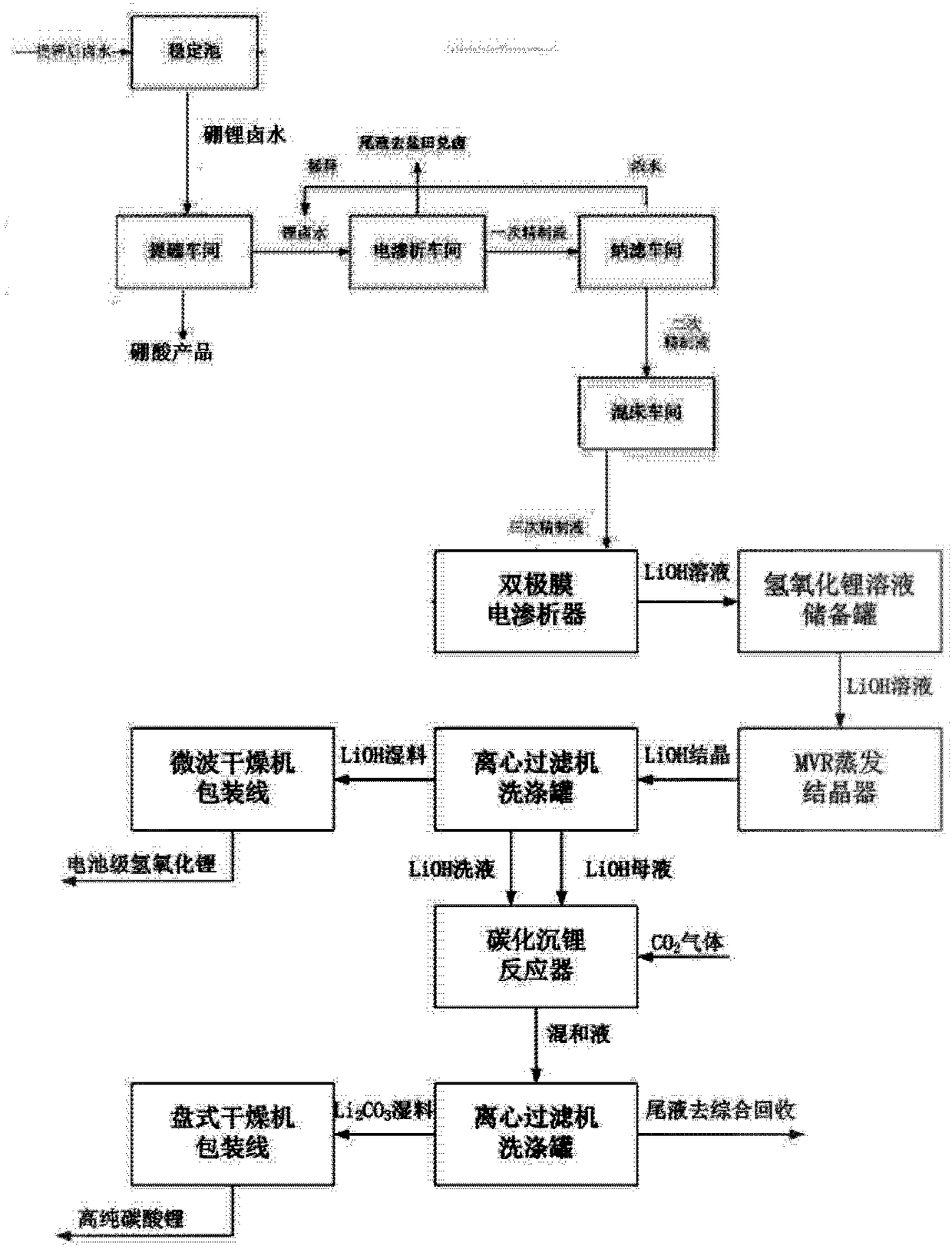

Method for directly preparing lithium hydroxide and lithium carbonate from salt lake brine with high magnesium-to-lithium ratio

ActiveCN108341420AEasy to operateEfficient extractionBoron oxyacidsLithium oxides/hydroxidesPotassiumEvaporation

The invention discloses a method for directly preparing lithium hydroxide and lithium carbonate from salt lake brine with a high magnesium-to-lithium ratio. The method comprises the following steps: 1, further stabilizing brine obtained after potassium extraction of a salt pan in a stabilization pond to form boron and lithium brine with low potassium and sodium content; 2, carrying out boron extraction treatment on the boron and lithium brine to form a boric acid product and lithium brine; 3, 4 and 5, allowing the lithium brine to go through three times of refining to obtain a thirdly refinedsolution; 6, allowing the thirdly refined solution to go through a bipolar membrane electrodialyzer to form a lithium hydroxide solution; 7, allowing the lithium hydroxide solution to go through an evaporation crystallizer to obtain a lithium hydroxide monohydrate solid and evaporation mother liquor; 8, washing the lithium hydroxide monohydrate solid for recrystallization to form battery grade lithium hydroxide and a washing solution; and 9, allowing the evaporation mother liquor and the washing solution to go through a gas-liquid reactor to react with carbon dioxide gas to form the lithium carbonate. The method has the advantages of good maneuverability, and great increase of the recovery rate of lithium ions.

Owner:马培华

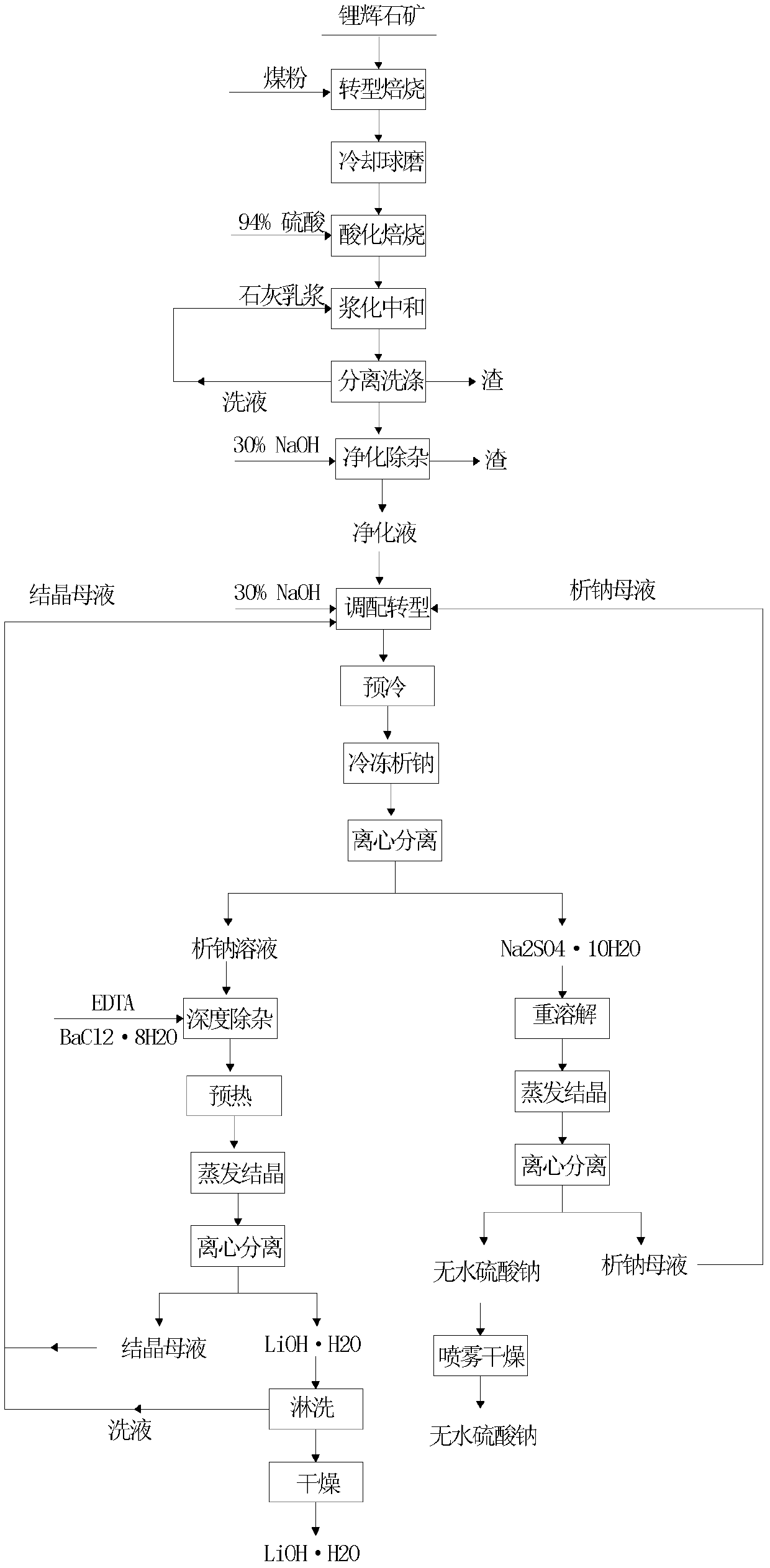

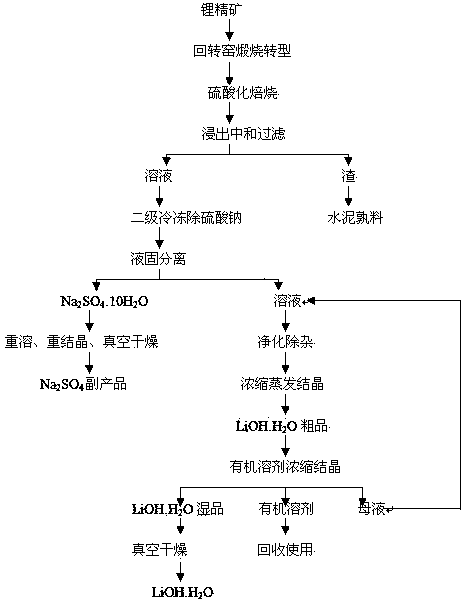

Method for preparing lithium hydroxide monohydrate by extracting lithium from spodumene

ActiveCN102701239AAchieve coolingAchieve evaporative crystallizationLithium oxides/hydroxidesResource utilizationPhysical chemistry

The invention discloses a method for preparing lithium hydroxide monohydrate by extracting lithium from spodumene. The method includes steps of transformation roasting, cooling, ball milling, acidification roasting, pulping, neutralizing, separation washing, purifying, blending for transformation, freezing for sodium precipitation, deep decontaminating, evaporative crystallization, centrifugal separation, drip washing and drying. By means of a DTB (draft tube baffle) type crystallizer, an FC (forced circulation) crystallizer or an OSLO crystallizer, continuous cooling crystallization and evaporative crystallization are realized, equipment yield is increased by more than 50%, and equipment utilization rate is increased. Therefore, the method is simple and practical in process, high in equipment yield, low in production cost, high in resource utilization rate, low in energy loss and low in three wastes (waste gas, waste water and waste residues).

Owner:GANFENG LITHIUM CO LTD

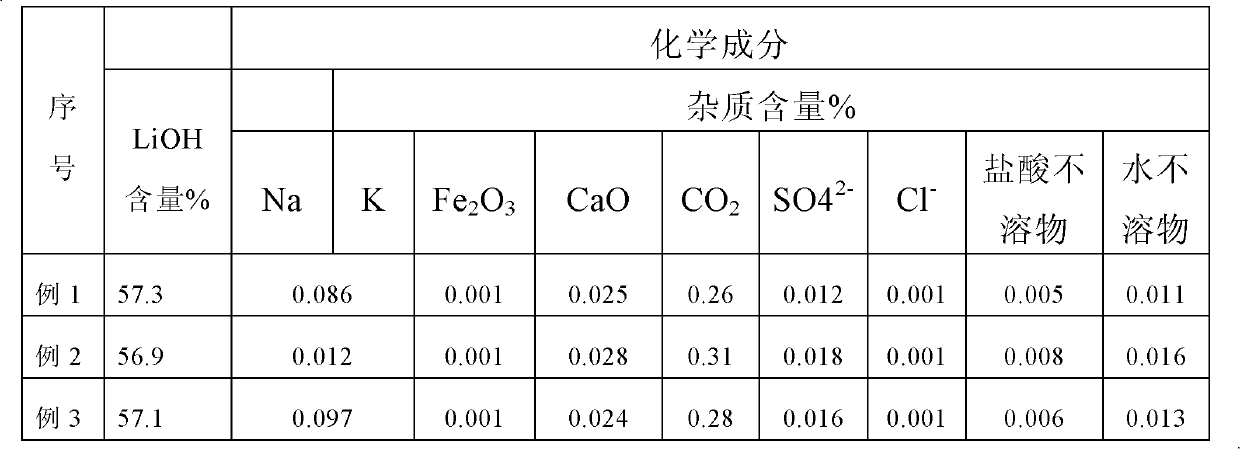

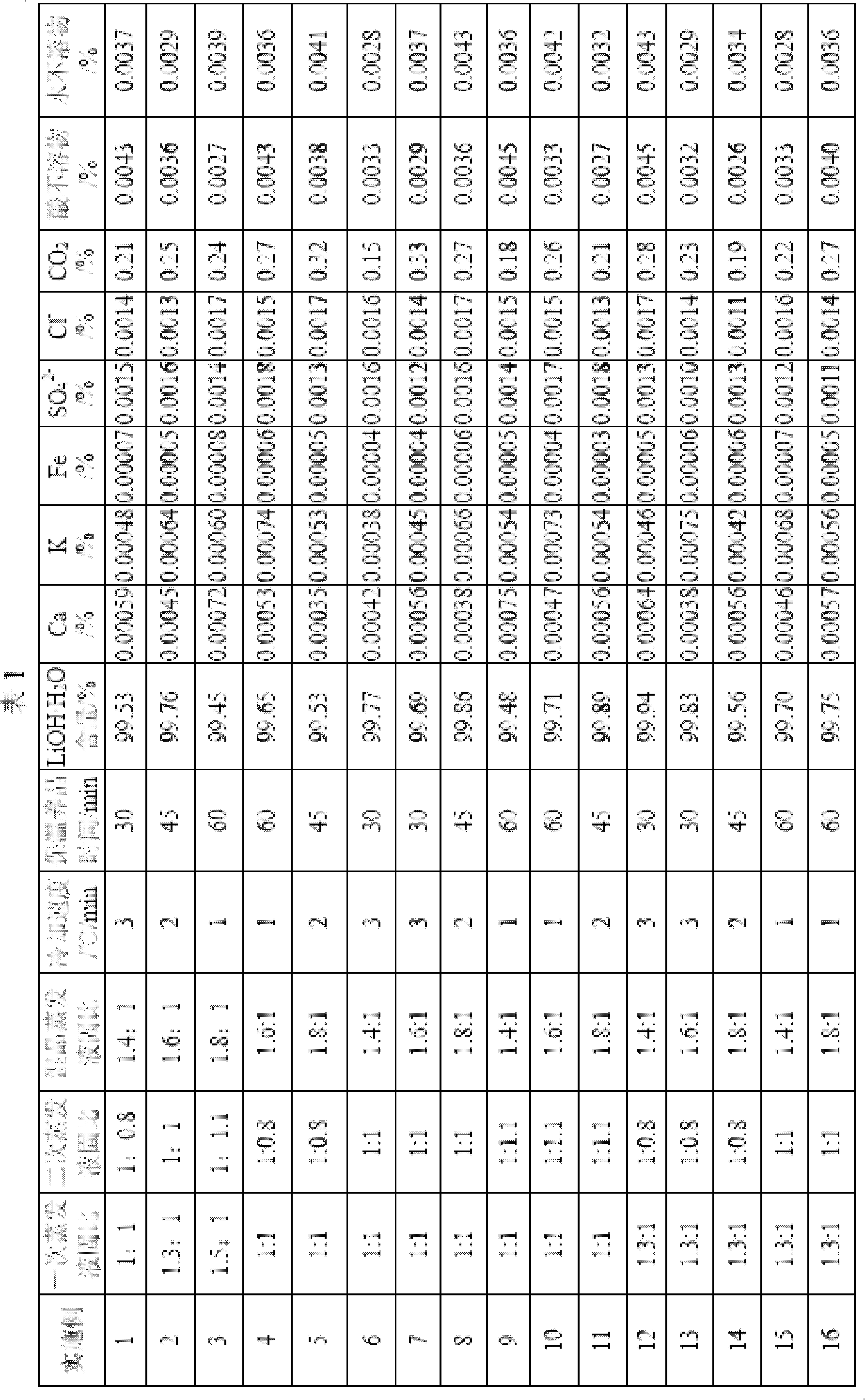

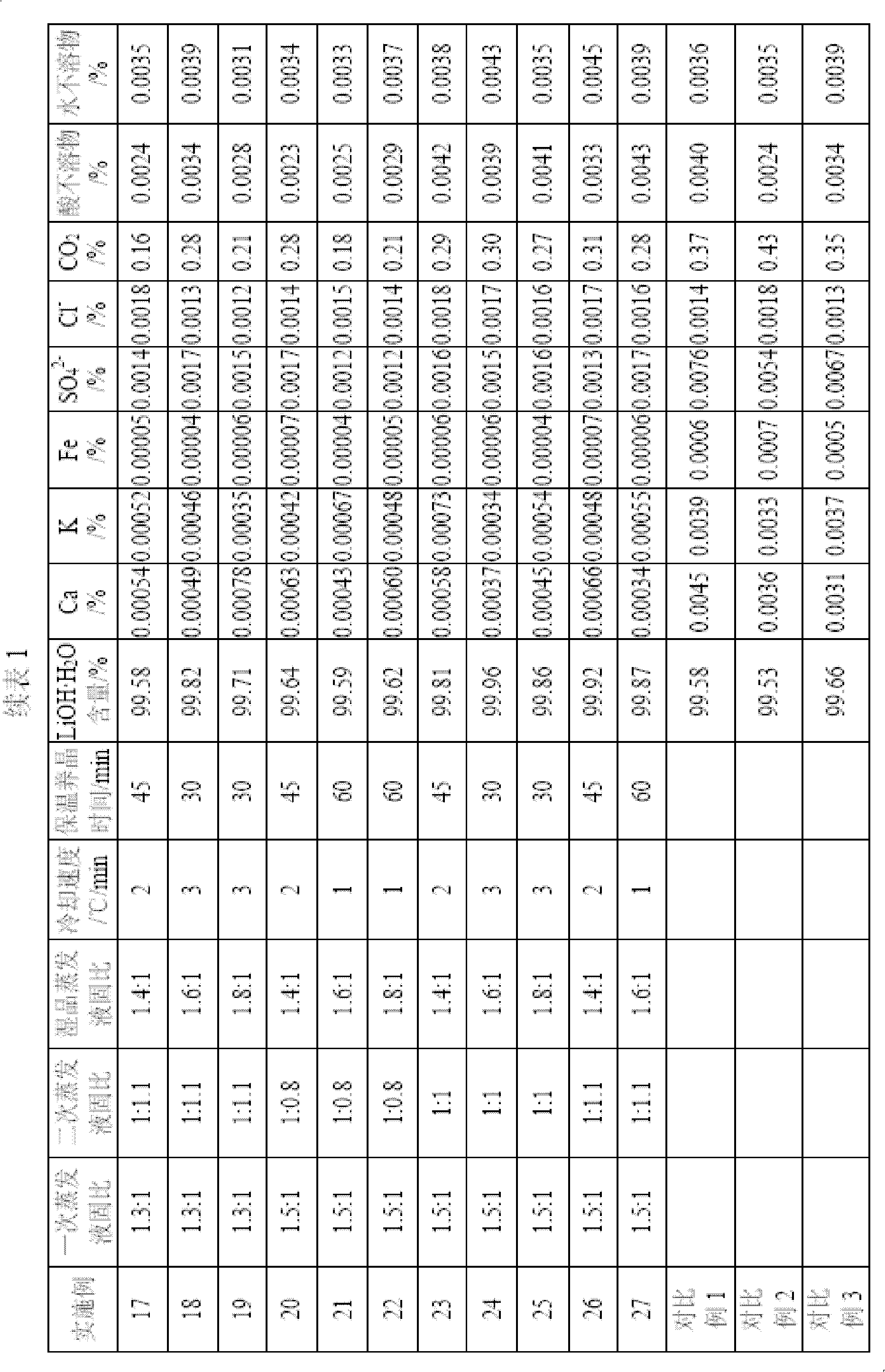

Method for preparing high purity level lithium hydroxide monohydrate

ActiveCN102659144AHigh recovery rate of lithiumSimple processLithium oxides/hydroxidesCalcium hydroxideHydrogen

The invention relates to a method for preparing a high purity level lithium hydroxide monohydrate and belongs to the technical field of lithium hydroxide preparations. The method includes the following steps of adding calcium hydroxide into a lithium sulfate leaching liquid to adjust the potential of hydrogen (pH) value, filtering to obtain a lithium sulfate primary cleaning liquid, adding sodium hydroxide, then filtering and removing impurities, crystallizing to obtain a sodium sulfate decahydrate solid and a lithium hydroxide refrigerating fluid, finely filtering the lithium hydroxide refrigerating fluid, then performing an evaporating separation to obtain a Lithium hydroxide monohydrate primary crude product, dissolving the crude product by adding water, adding a refining agent to remove sodium, then performing an evaporation concentration, separating and leaching to obtain a Lithium hydroxide monohydrate secondary crude product, adding water into the secondary crude product, performing the evaporation concentration, cooling to crystallize, and drying to obtain the high purity level lithium hydroxide monohydrate. By means of the method, the evaporation liquid-solid ratio is reasonably controlled, and processes of crystallizing and crystal growing are modified, so that the high purity level lithium hydroxide monohydrate product is obtained, the process is simple, the operation is easy, the equipment investment is few, the product cost is low, the lithium recovery rate is high, product qualities are stable, and the method is suitable for the industrialized production of the high purity level lithium hydroxide monohydrate.

Owner:TIANQI LITHIUM CORP

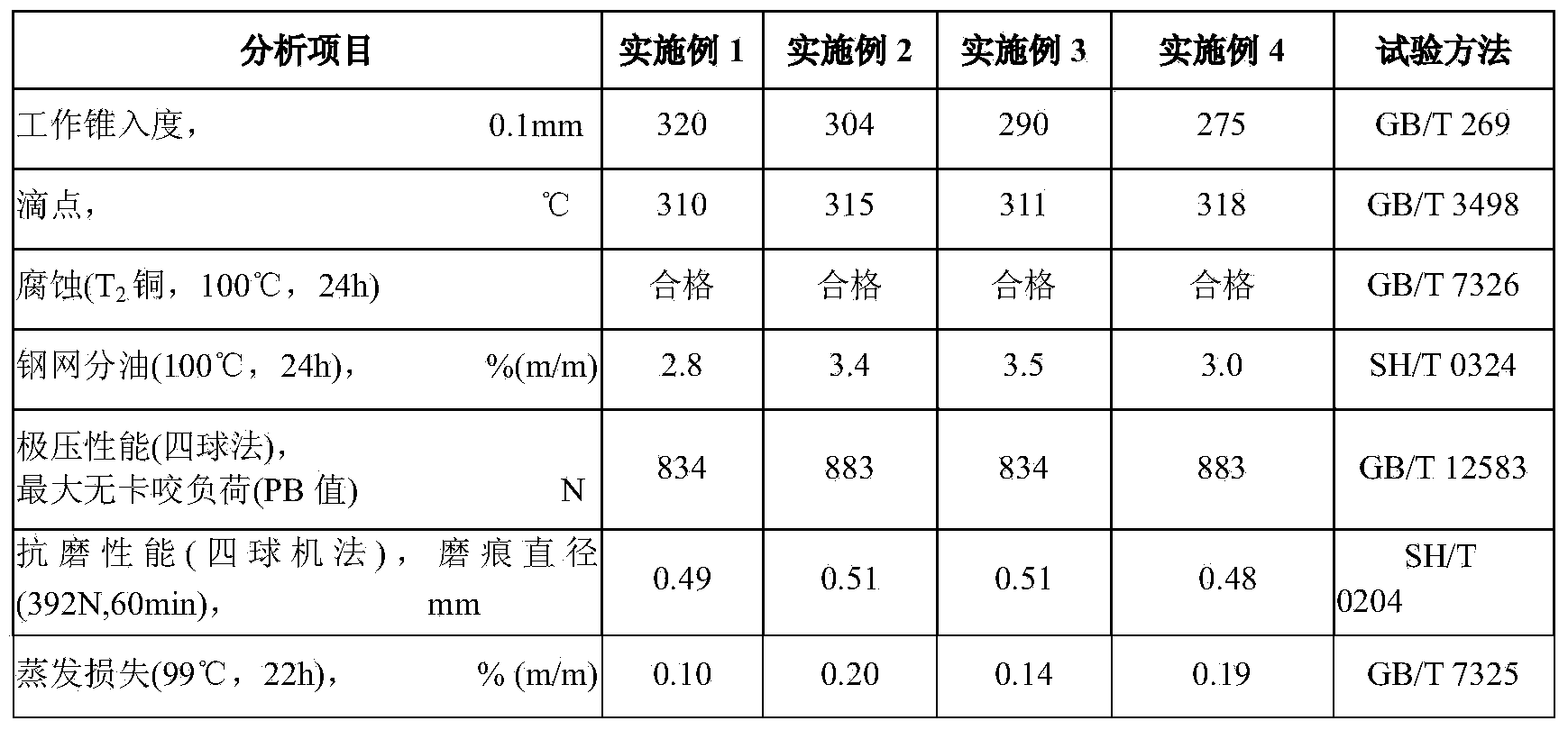

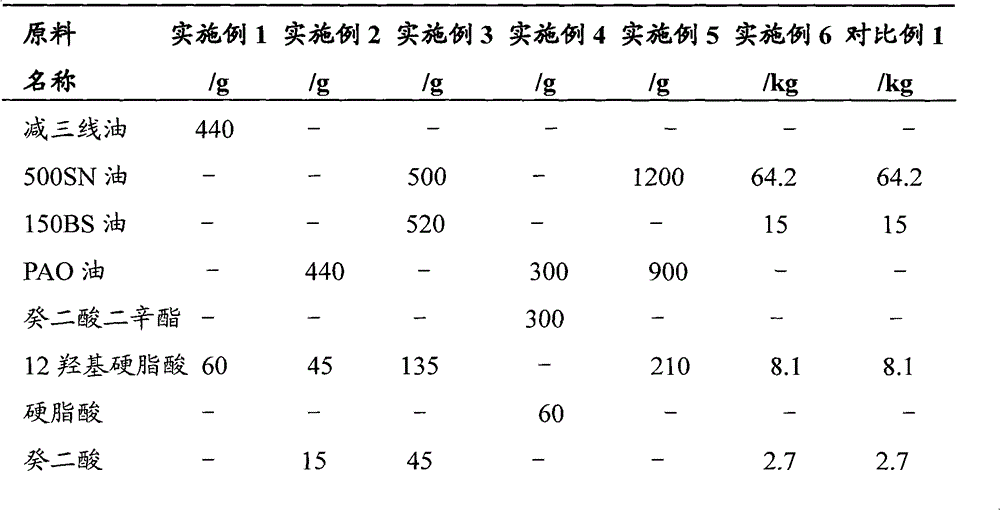

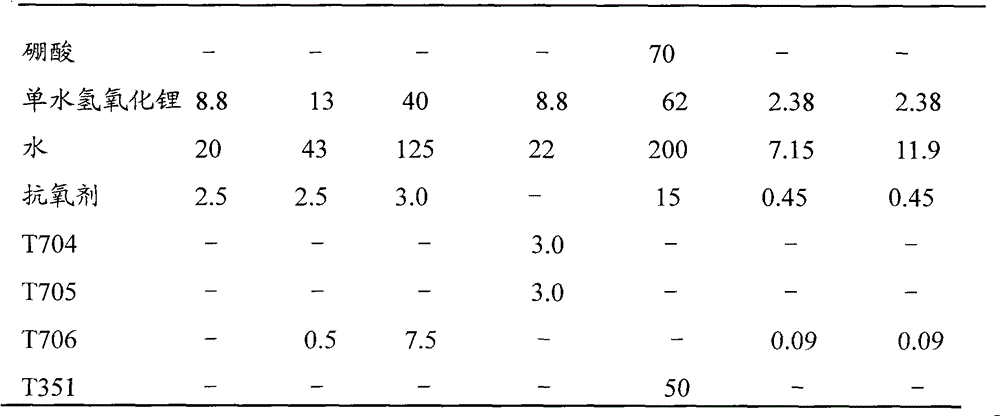

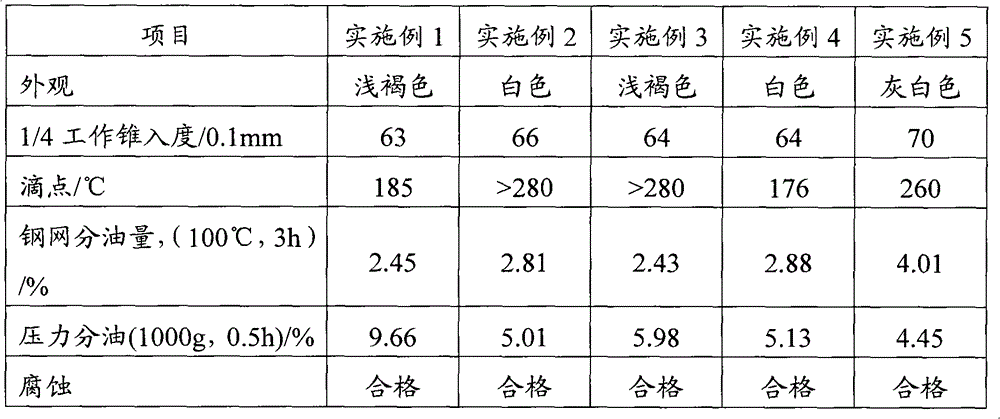

Special lubricating grease composition for sintering machine elastic slideways and preparation method thereof

InactiveCN104164278AWide variety of sourcesLow costLubricant compositionChemistryLithium hydroxide monohydrate

The invention relates to a special lubricating grease composition for sintering machine elastic slideways, which comprises 7-12% of thickener, 83-87% of base oil and 4-6% of additive. The additive comprises antioxidant, filler, tackifier and the like. The thickener is complex lithium lubricating grease prepared by reacting C12-C18 long-chain fatty monobasic acid, C6-C10 organic dibasic acid and micromolecule acid with lithium hydroxide monohydrate, wherein the mole ratio of the C12-C18 long-chain fatty monobasic acid to the C6-C10 organic dibasic acid to the micromolecule acid is (10-12):(2-5):(2-4). The mole overrate of the lithium hydroxide monohydrate is 2-20%. The special lubricating grease composition for sintering machine elastic slideways has the advantages of wide raw material sources, lower cost and excellent product performance, can completely satisfy the lubricating requirements of the sintering machine elastic slideway, and thus, has wide application prospects in steel industry as a special lubricating grease for sintering machine elastic slideways.

Owner:CHINA PETROLEUM & CHEM CORP

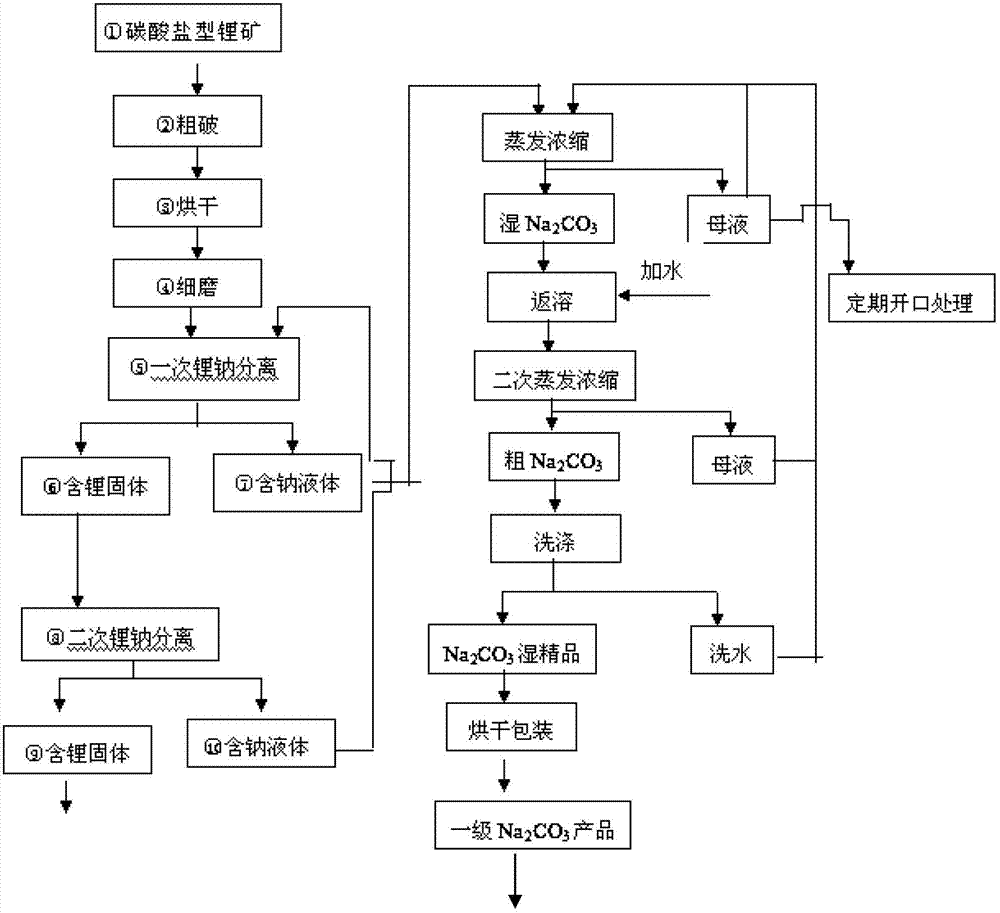

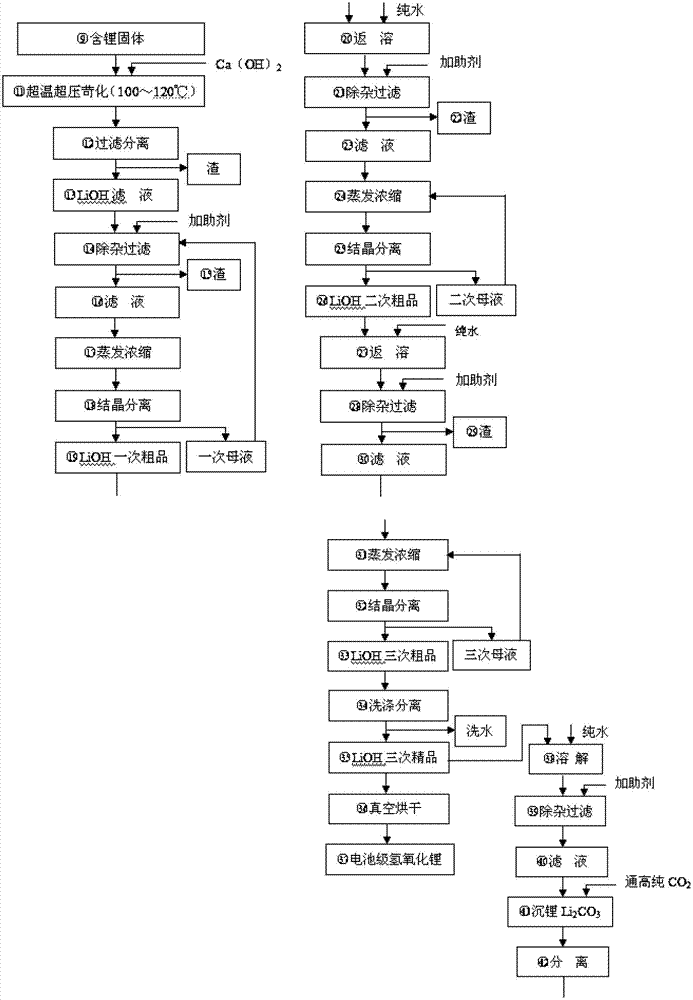

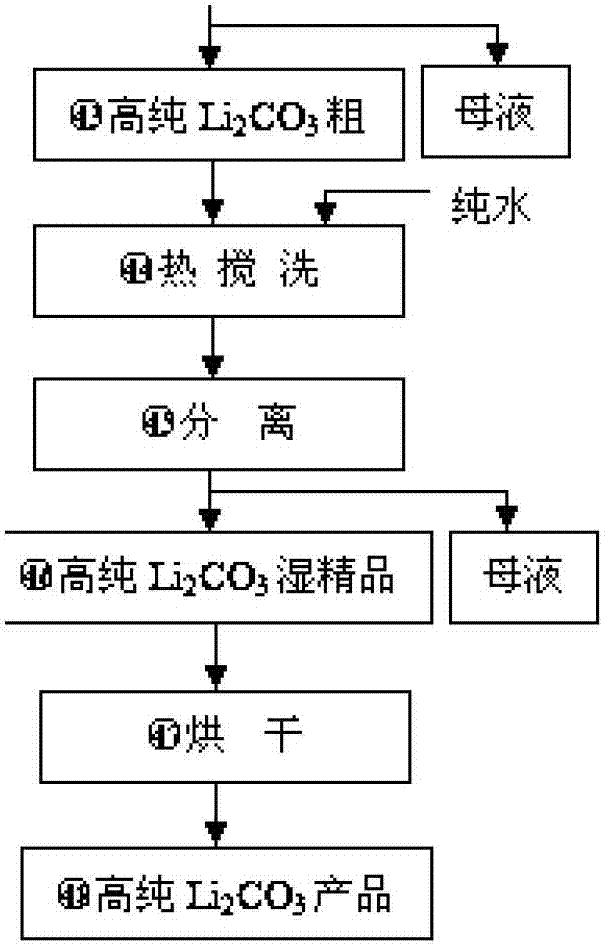

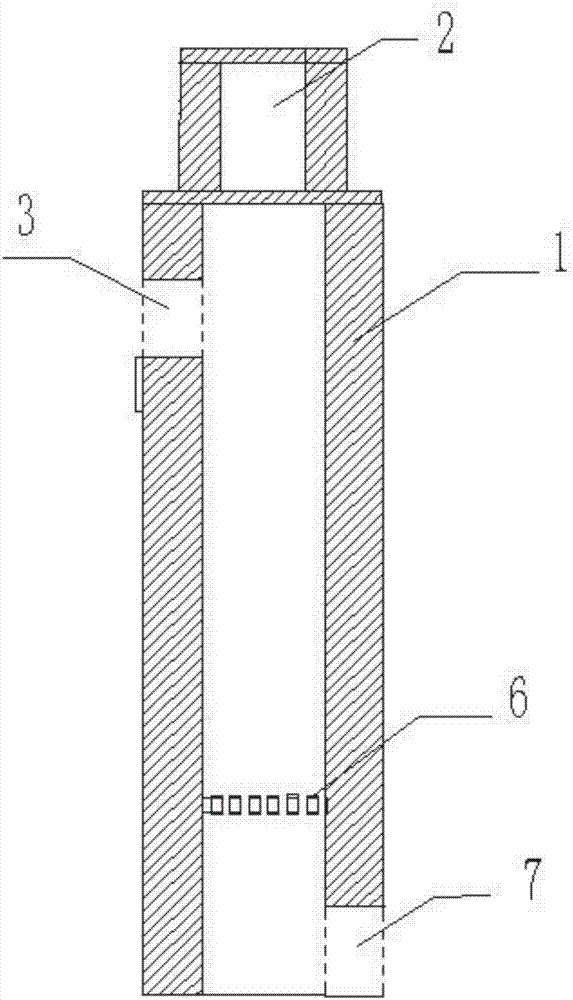

Method for industrially producing industrial, cell-grade or high-purity lithium hydroxide monohydrate

InactiveCN102826576AReduce consumptionReduce pollutionLithium oxides/hydroxidesLithium carbonateWater resources

The invention provides a method for industrially producing an industrial, cell-grade or high-purity lithium hydroxide monohydrate, which comprises the following steps of: (1) grinding; (2) removing impurities by a thermal precipitation method; (3) causticizing; and (4) removing impurities, crystallizing, washing, separating and drying. The invention also provides a method for preparing high-purity lithium carbonate. After causticizing reaction equipment and a reaction method which are provided by the invention are utilized, the feeding amount of the single causticizing production can be greatly improved and the large-scale industrial continuous production of the industrial and cell-grade lithium hydroxide monohydrate and the high-purity lithium carbonate is implemented; the consumption of water resources and energy can be effectively reduced and in the reaction, only a cheap precipitating agent or a cheap complexing agent needs to be used, so that the production cost is reduced; and the reaction is simple and convenient to operate and, the environment pollution is small, the obtained product has high quality and yield, the quality of the obtained product is stable and the product has wide industrial application prospect.

Owner:四川长和华锂科技有限公司

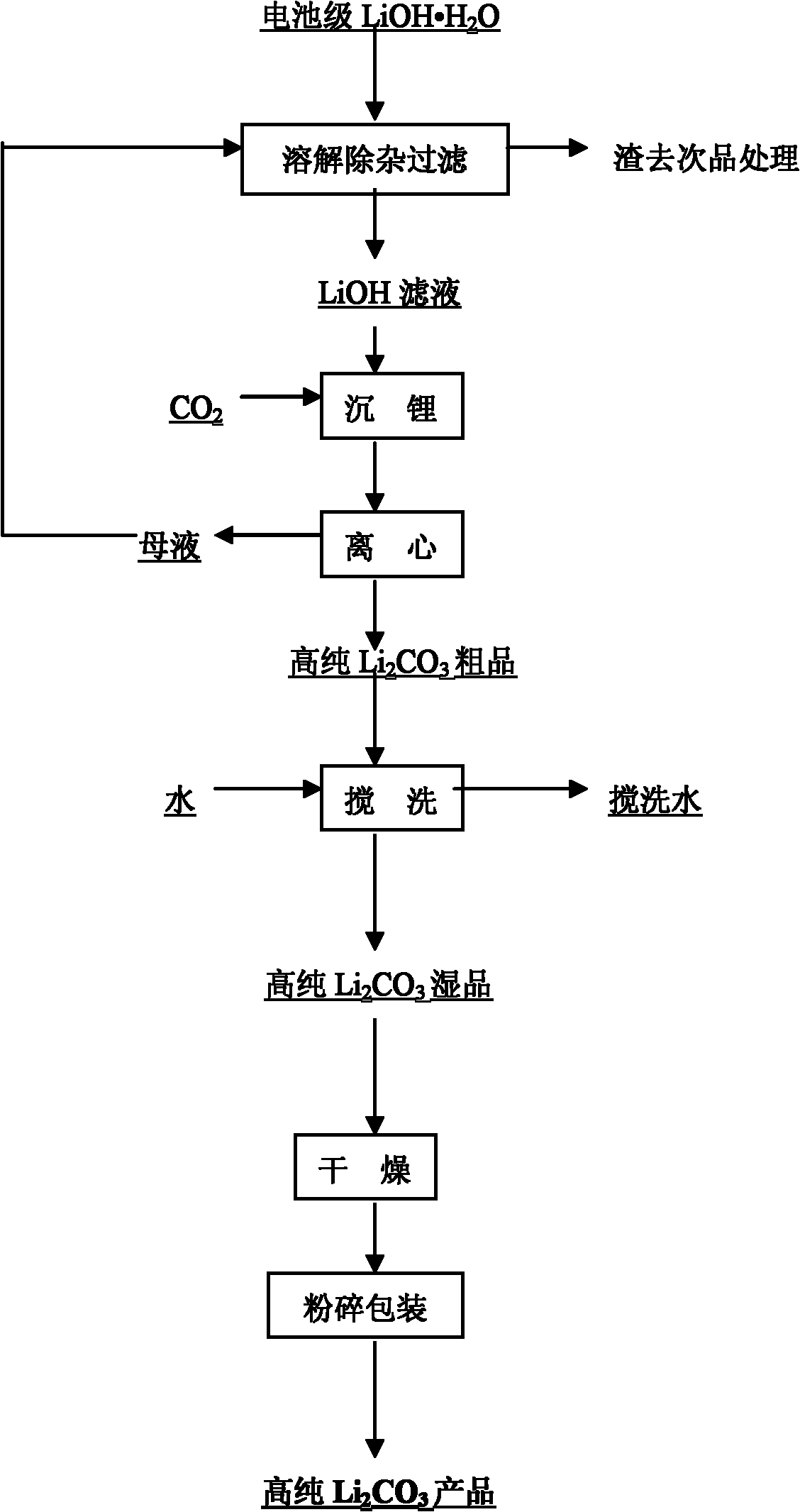

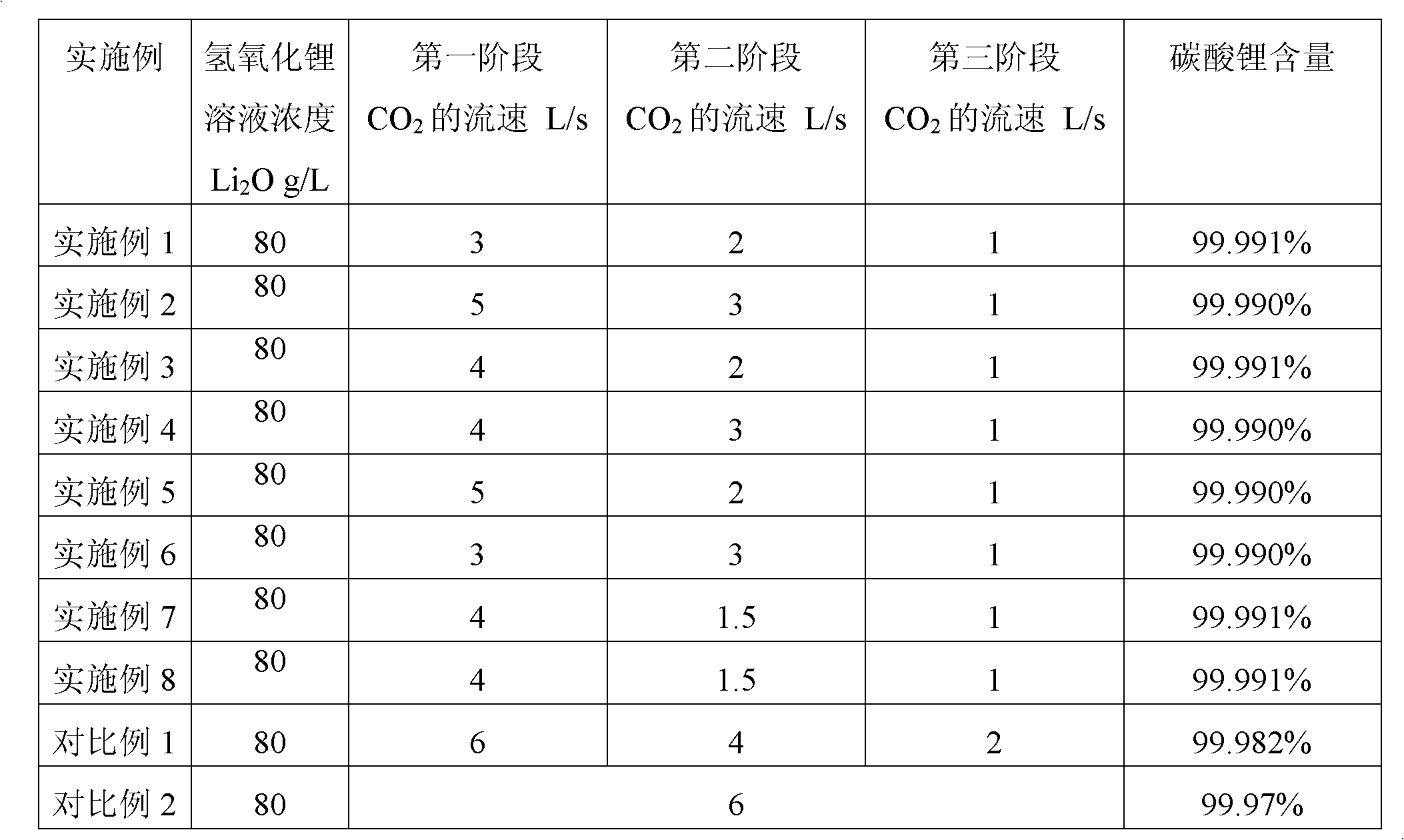

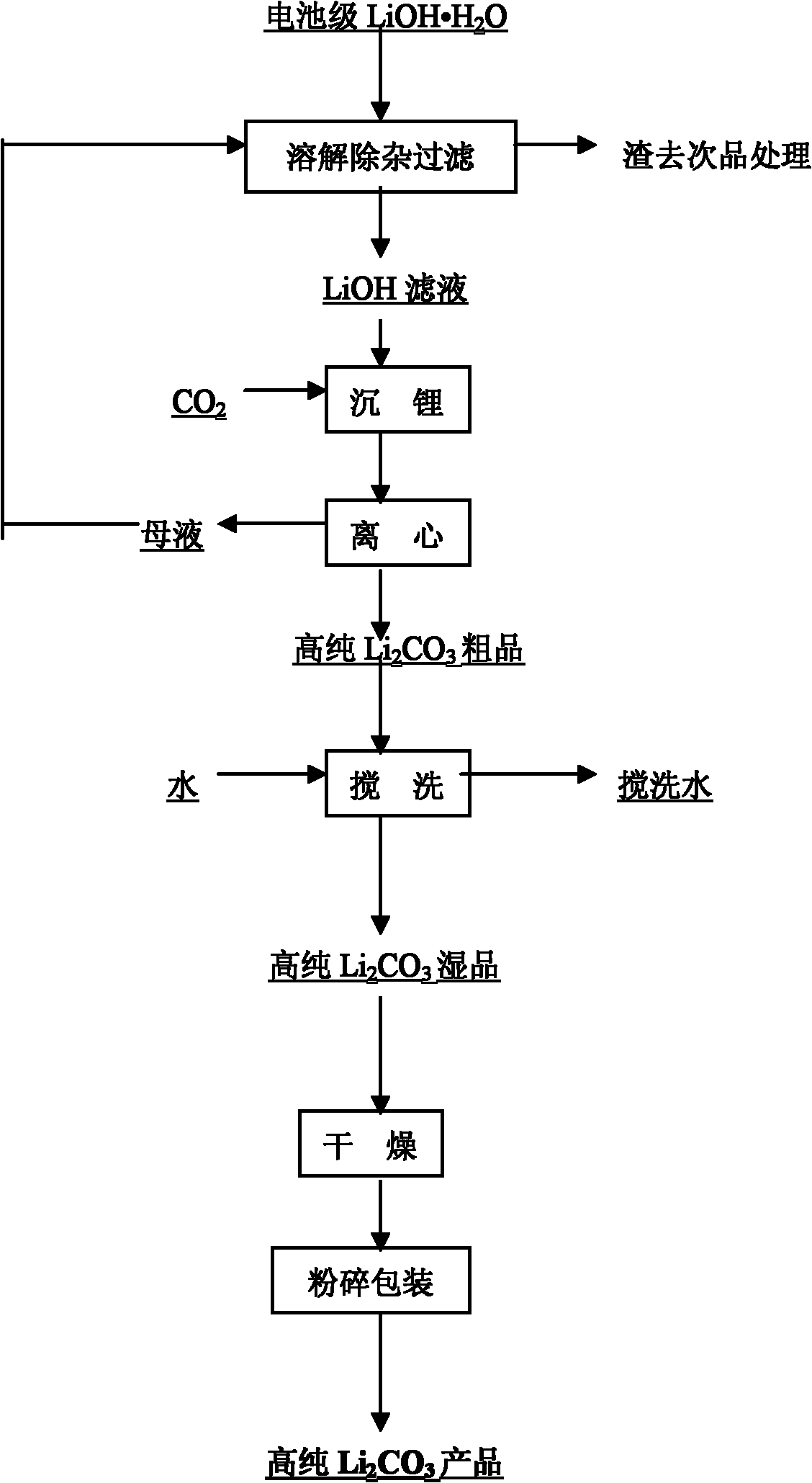

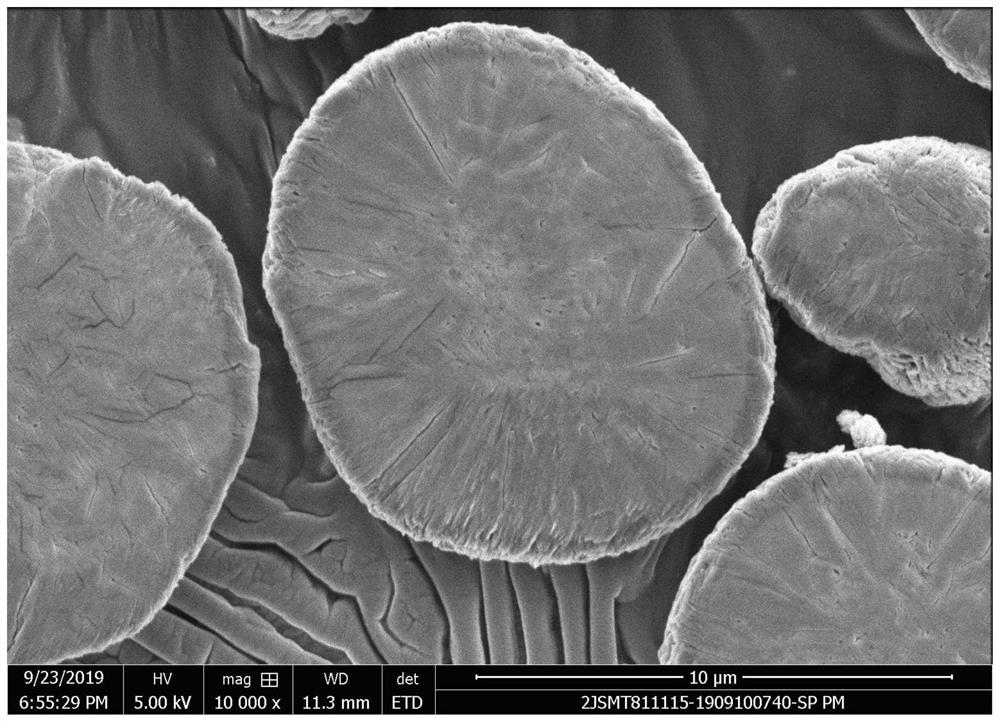

Preparation method of high-purity lithium carbonate

The invention relates to a preparation method of high-purity lithium carbonate, which belongs to the technical field of preparation of high-purity lithium carbonate. The invention aims at providing the method for directly preparing 99.99% lithium hydroxide by adopting lithium hydroxide, which is simple in production process. The technical scheme of the invention is as follows: preparing battery level lithium hydroxide monohydrate into solution of Li2O with concentration of 50-90g / L; introducing CO2 gas at the flow rate of 3-5L / s into the lithium hydroxide solution, wherein the flow rate of CO2 is decreased to 2-3L / s when the concentration of Li2O in the solution is decreased to 40g / L; decreasing the flow rate of CO2 to 0.8-1.2L / s when the concentration of Li2O in the solution is decreased to 20g / L; stop introducing the gas when a large number of liquids appear in the solution, and preparing lithium carbonate slurry; and separating the lithium carbonate slurry, washing the solids, drying until moisture is less than 0.1%, finally preparing the lithium carbonate. The battery level lithium hydroxide monohydrate is adopted as raw material, the high-purity lithium carbonate with the purity of 99.99% can be simply and conveniently prepared by adopting the method, and further purification is not required.

Owner:天齐锂业(江苏)有限公司 +2

Gradient-doped high-nickel ternary positive electrode material and preparation method thereof

InactiveCN111628149AImprove cycle performanceOptimal Capacity PerformanceSecondary cellsPositive electrodesManganeseCobalt

A physical structure of a gradient-doped high-nickel ternary positive electrode material comprises an inner core and a shell coating the outer surface of the inner core. A preparation method of the gradient-doped high-nickel ternary positive electrode material comprises the following steps: preparing a salt solution of nickel, cobalt and manganese, the salt solution being one of a sulfate solution, a nitrate solution and a chloride solution; adding the salt solution and a sodium hydroxide solution into a reaction kettle, pumping an ammonia water solution into the reaction kettle, and after theobtained particles of which the inner cores are the nickel-cobalt-manganese ternary precursors grow to 85%-95% of the target particle size, adding a doping solution into the reaction kettle in a gradient manner; sequentially carrying out centrifugal washing, drying, screening and iron removal on the obtained ternary precursor particles with the target particle size to obtain a ternary precursor;and mixing the ternary precursor with lithium hydroxide monohydrate, and carrying out sintering, dissociating and screening to obtain the nickel-cobalt-manganese ternary positive electrode material doped with the concentration gradient. The purpose of gradient doping is achieved in a doping element gradient feeding mode, and the cycle performance of the material is optimized under the condition that the doping amount is as small as possible.

Owner:GEM CO LTD +1

Method for preparing lithium lubricating grease

ActiveCN102796603AWith energy saving and emission reductionReduce energy consumptionLubricant compositionBase oilAqueous solution

The invention provides a method for preparing lithium lubricating grease. The method comprises the following steps of: 1) adding one third to one second of the weight of the entire base oil into a grease kettle, adding a calculated amount of monobasic acid or monobasic acid and at least one kind of dibasic acid or polybasic acid, raising the temperature, and stirring to ensure that the acid and the base oil are fully mixed; 2) raising the temperature to 40 to 80 DEG C, adding one third to one second of a calculated amount of lithium hydroxide monohydrate crystals under stirring, and fully mixing; 3) raising the temperature to 82 to 120 DEG C, and adding an aqueous solution of residual lithium hydroxide monohydrate for saponification reaction; and 4) after full saponification reaction, raising the temperature and dehydrating, continuing to raise the temperature to 200 to 220 DEG C, adding the residual base oil serving as quenching oil, reducing the temperature and cooling, adding necessary additives, homogenizing, grinding, and degassing to obtain finished lubricating grease. The method for preparing the lithium lubricating grease has the advantages of energy conservation, emission reduction and energy consumption reduction, can be used for lithium or complex lithium lubricating grease, and is particularly suitable for a process for preparing the lithium or complex lithium lubricating grease in an atmospheric kettle.

Owner:CHINA PETROLEUM & CHEM CORP +1

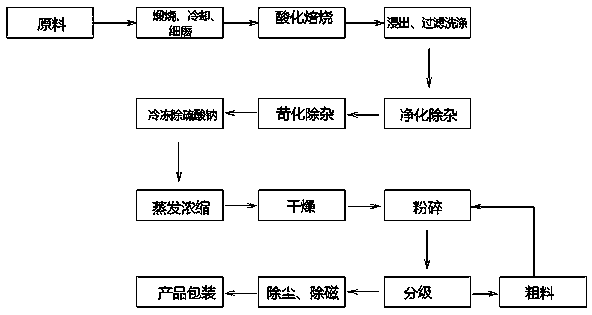

Production process of micro-powder-grade lithium hydroxide monohydrate

PendingCN111439760AMeet production needsAdequate responseSulfate/bisulfate preparationLithium oxides/hydroxidesPhysical chemistryProcess engineering

The invention discloses a production process of micro-powder-grade lithium hydroxide monohydrate. The production process comprises the following steps: (1) sequentially calcining spodumene, cooling the calcining product, finely grinding the calcining product, adding acid for reaction, and then mixing the obtained powder and the acid into slurry; (2) adding calcium salt into the slurry, and carrying out stirring and leaching; (3) filtering the filtered clear liquid again, and purifying the filtered clear liquid by using an alkaline solution; (4) filtering the causticized solution; (5) freezingthe filtered causticized liquid in a freezing workshop to separate out sodium sulfate decahydrate and a lithium hydroxide solution; (6) evaporating, concentrating and purifying the sodium sulfate decahydrate; (7) screening and weighing the sodium sulfate decahydrate; (8) carrying out shunting; (9) carrying out crushing; (10) carrying out grading; and (11) carrying out packaging.

Owner:广西雅保锂业有限公司

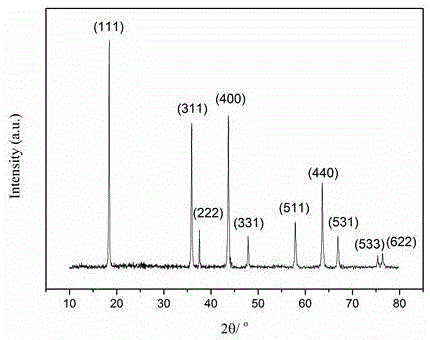

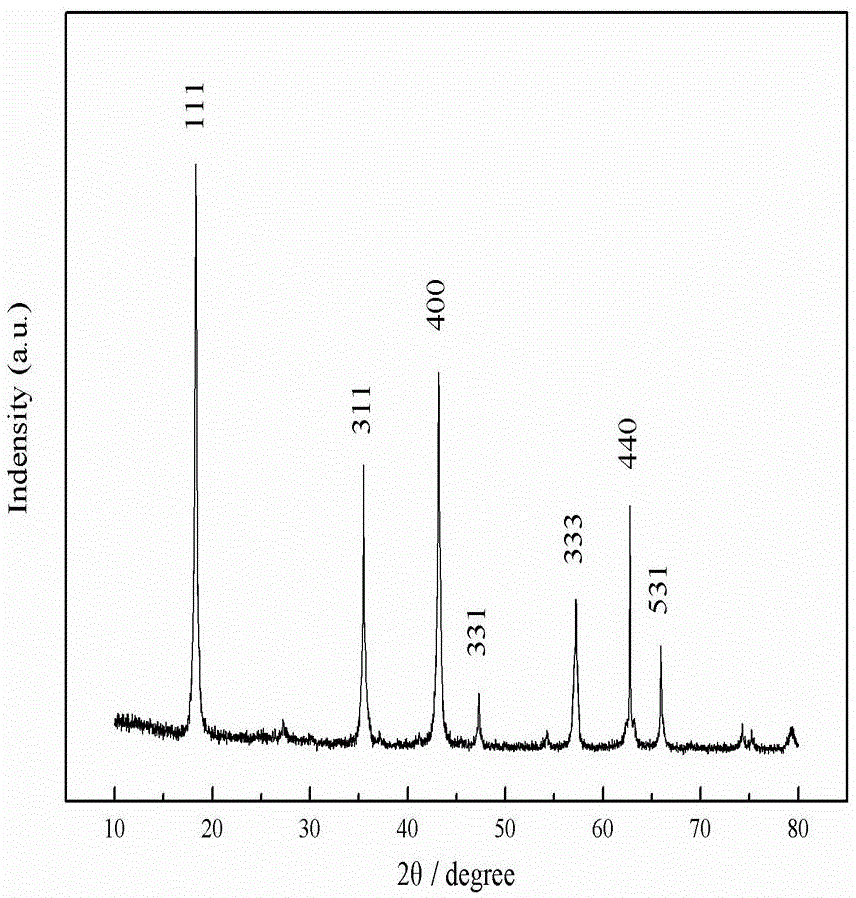

Preparation method of LiAlO2-coated lithium manganese oxide spinel cathode material

InactiveCN102903904AIncrease capacityImprove cycle performanceCell electrodesMixed materialsAluminium isopropoxide

The invention relates to a preparation method of a LiAlO2-coated lithium manganese oxide spinel cathode material. The preparation method comprises the steps of: (a) blending electrolytic manganese dioxide, lithium carbonate and chromium oxide at a molar ratio of Li to Mn of 0.51, and a molar ratio of Cr to Mn of 0.026, crushing and mixing; (b) sintering the material mixture in an air sintering furnace, grinding, sieving, and mixing for the second time; (c) placing the mixed material in the air sintering furnace, and keeping temperature for 10 to 20 hours; (d) blending the product sintered for the second time with lithium fluoride, crushing, and mixing; (e) placing the mixture obtained in the step (d) in the air sintering furnace to obtain LiMn1.95Cr0.05O3.95F0.05; and (f) preparing a 0.2mol / L mixed solution containing lithium hydroxide monohydrate and aluminium isopropoxide, and coating to obtain the final product, namely LiAlO2-coated LiMn1.95Cr0.05O3.95F0.05. The capacity and the cycle performance of the cathode material can be improved effectively by modifying the lithium manganese oxide spinel cathode material by coating.

Owner:JIANGSU KING LITHIUM CELL

Cobaltosic oxide coated and modified nickel-doped lithium manganate and preparation method thereof

InactiveCN106356509AInhibition of dissolutionIncrease contentCell electrodesSecondary cellsMANGANESE ACETATE TETRAHYDRATENickel acetate tetrahydrate

The embodiment of the invention discloses modified lithium manganate coated based on a sol-gel method, and a preparation method thereof. The preparation method comprises the steps of preparing a nickel-doped lithium manganate material with the sol-gel method by firstly, weighing lithium hydroxide monohydrate, nickel acetate tetrahydrate, manganese acetate tetrahydrate and citric acid according to a certain stoichiometric ratio, adding deionized water, and uniformly mixing, wherein the citric acid is used as a chelating agent; mixing the prepared nickel-doped lithium manganate with cobalt acetate tetrahydrate; grinding, and calcining in a tube furnace to obtain a cobaltosic oxide coated and modified nickel-doped lithium manganate composite material. The composite material prepared by using the technical scheme has excellent cycling stability, rate capability and high-temperature performance.

Owner:EAST CHINA UNIV OF SCI & TECH

Mining grease composition and preparation method thereof

ActiveCN102899135AGood high load performanceImprove water resistanceThickenersAdditivesHydroxystearic AcidSebacic acid

The invention provides a mining grease composition and a preparation method thereof. A thickening agent consists of products of reaction of 12-hydroxystearic acid, boric acid and sebacic acid with aqueous solutions of lithium hydroxide and calcium hydroxide; and an additive comprises an ethylene-propylene copolymer, an extreme pressure agent, an antirust agent and an antiwear agent. The preparation method comprises the following steps of: adding 12-hydroxystearic acid, sebacic acid and ethylene-propylene copolymer into base oil, mixing, heating to 60 to 90 DEG C, adding lithium hydroxide monohydrate containing boric acid and calcium hydroxide to carry out saponification and compounding for 1.5 to 2 hours; heating to 185 to 190 DEG C in a period of 2 hours, and keeping the temperature for 1.5 hours; and continuing to heat to 220 to 240 DEG C, naturally cooling to below 120 DEG C, adding the extreme pressure agent, the antirust agent and the antiwear agent and carrying out posttreatment to obtain the product needed. The grease has high high-load performance, so the wear is low under a high load (PD is more than 315kg).The grease also has highly improved water resistance and adhesive strength.

Owner:CHINA PETROLEUM & CHEM CORP

Production process of lithium hydroxide

ActiveCN104724729AHigh purityImprove qualityAlkali metal sulfite/sulfate purificationAlkali metal oxides/hydroxidesHigh concentrationSeparation technology

The invention discloses a production process of lithium hydroxide. According to the production process of lithium hydroxide, the crystallization mother liquor with high-concentration sodium sulfate and lithium hydroxide is used as the raw material, wherein the crystallization mother liquor with high-concentration sodium sulfate and lithium hydroxide is obtained after crystallization precipitation of sodium sulfate decahydrate in the production process of lithium hydroxide by the lithium sulfate method. Lithium hydroxide is prepared by the following steps: step A, introducing the crystallization mother liquor into a membrane separation system, wherein concentrated sodium sulfate solution is the intercept liquid and lithium hydroxide solution is the permeate liquid; step B, cooling (or cooling after further concentration) the sodium sulfate solution obtained in the step A, separating the sodium sulfate solution by centrifugation and drying the centrifuged sodium sulfate solution, so that crystal of sodium sulfate decahydrate is obtained; step C, concentrating the lithium hydroxide solution obtained in the step A by a steamer and further concentrating the concentrated lithium hydroxide solution in a crystallizing tank, then cooling, crystallizing and separating the concentrated lithium hydroxide solution by centrifugation and drying the centrifuged lithium hydroxide solution to obtain crystal of lithium hydroxide monohydrate. According to the production process, sodium sulfate and lithium hydroxide are effectively separated by the membrane separation technology, so that the purity of the lithium hydroxide solution is improved; thus, the quality of the lithium hydroxide product is effectively improved and production efficiency of the lithium hydroxide product is raised while the production cost is reduced.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

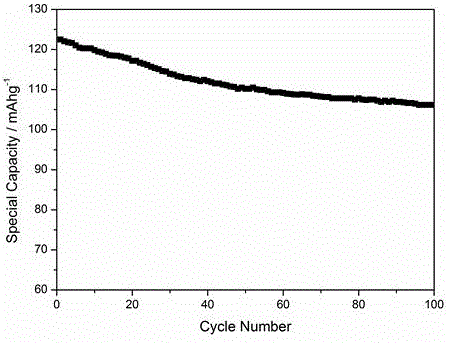

Improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction

ActiveCN102219262APromote growthSimple processCell electrodesManganese oxides/hydroxidesMANGANESE ACETATEOXALIC ACID DIHYDRATE

The invention provides an improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction. The method comprises the following steps: weighing lithium hydroxide monohydrate, nickel acetate and manganese acetate, and oxalic acid dihydrate according to the stoichiometry as follows: Li1+xMnyNi1-x-yO2, x being more than 0 and less than or equal to 1 / 3, y being more than 0 and less than 1, and x+y being more than 0 and less than 1 (wherein the mole ratio of LiOH.H2O to C2H2O4.2H2O is 1:1-1.2), and adding into a ball milling tank together for balling milling for 0.5-2h; obtaining slurry, adding deionized water in the slurry to adjust concentration, spraying and drying the slurry, and roasting the dried powder to obtain the final product -Li1+xMnyNil-x-yO2. The improved method has the following advantages: the process flow is short, the component of the material can be accurately controlled, the problems of material loss and inaccurate stoichiometry caused by repeatedly washing the product in a liquid phase method are overcome, the generation of a large quantity of waste water is avoided; simultaneously, the shape and particle size of a synthesized material can be controlled, the engineering index requirement can be achieved, the impurity pollution caused by dependence of a synthetic material by a solid phase method on crushing process can be overcome, the enriched lithium-manganese-nickel oxide has typical layered structure property, the particle size is 3-12mum, the specific capacity is high, and the cyclic performance is stable.

Owner:湖南金富力新能源股份有限公司

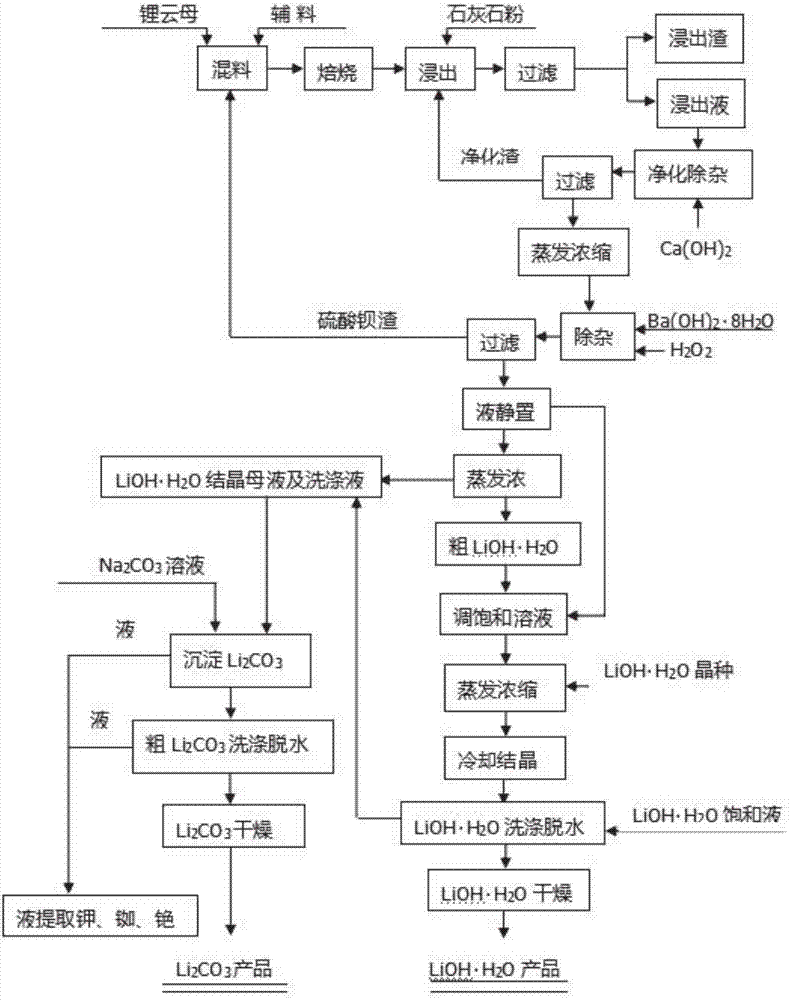

Method for extracting lithium from lepidolite concentrate

ActiveCN107032372ASolve dust returnSolve technical problems such as melting in the roasting processLithium oxides/hydroxidesLithium carbonates/bicarbonatesSlagLepidolite

The invention discloses a technology for extracting lithium hydroxide monohydrate and lithium carbonate by activating, roasting and leaching lepidolite concentrate with sulfuric acid. The technology comprises the following steps: adding water into lepidolite concentrate and calcium sulfate, barite powder or barium sulfate slag and carbon fuel, pressing and acquiring a green ball; roasting in a shaft kiln under an appropriate temperature and at appropriate time; milling the roasted ball; leaching with sulfuric acid; primarily purifying the leachate, concentrating and secondarily purifying, thereby acquiring a finished LiOH solution; secondarily crystalizing and firstly washing the finished solution with saturated solution, thereby acquiring a lithium hydroxide monohydrate product; adding sodium carbonate into lithium hydroxide monohydrate crystallization mother liquor and scrubbing solution and precipitating, thereby acquiring the lithium carbonate product. According to the technology, the lithium can be effectively separated from the lepidolite concentrate and the qualified lithium hydroxide monohydrate and lithium carbonate products can be produced. The technology has the advantages of less energy consumption, few flowing materials, low production cost, less discharge capacity, environmental protection, capability of efficiently realizing the recycling comprehensive utilization and suitability for industrial production.

Owner:谭春波

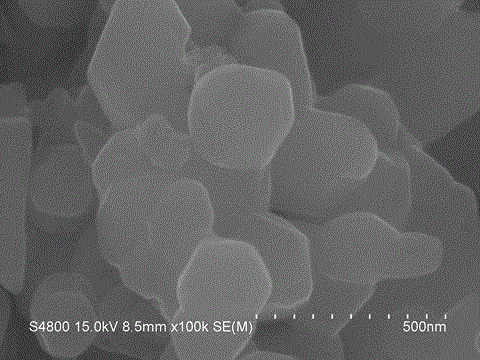

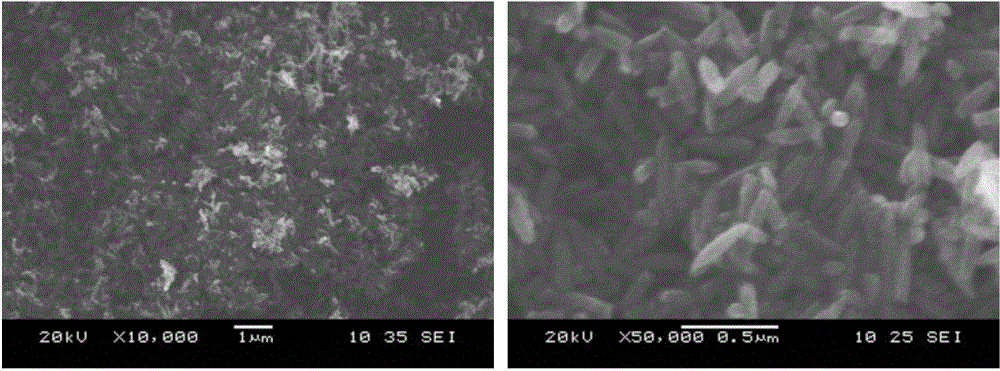

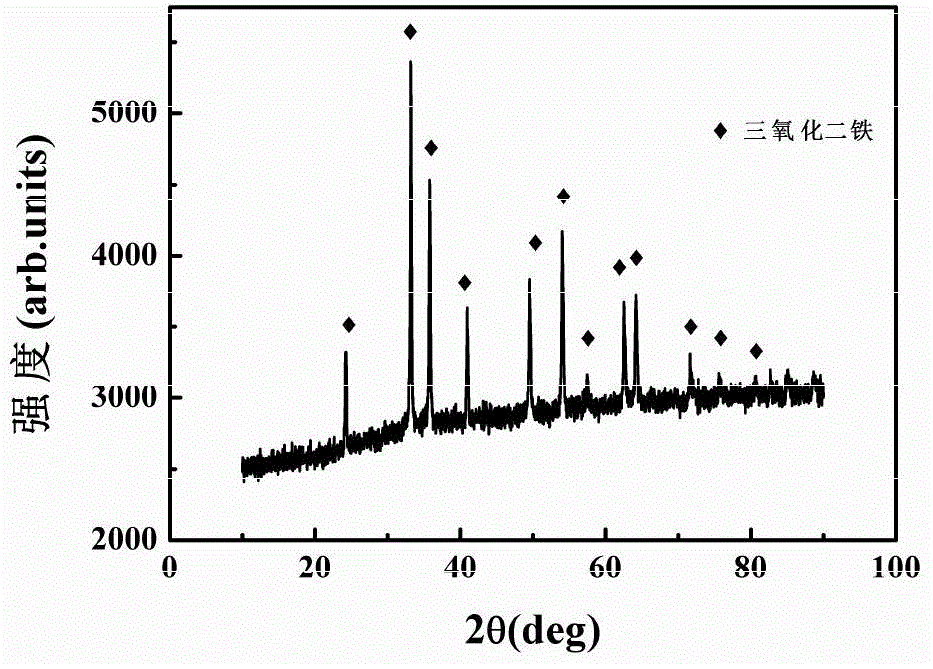

Nanometer iron-lithium oxide composite negative electrode material and preparation method thereof

ActiveCN103560237ARaw materials are easy to getSimple preparation processMaterial nanotechnologyCell electrodesLithium oxideLithium-ion battery

The invention belongs to the technical field of preparation of electrode materials for lithium ion batteries, and particularly relates to a nanometer iron-lithium oxide composite negative electrode material and a preparation method thereof. The material is a mixture or one of Li0.5F2.5O4 and LiFeO2, is a nanometer material and is uniform in size. The particle diameter of the prepared iron-lithium oxide material is about 250-300 nanometer. The preparation method of the material comprises the following steps: firstly preparing a ferric oxide (Fe2O3) nanorod through the hydrothermal reaction of ferric chloride hexahydrate (FeC13.6H2O) and ammonium dihydrogen phosphate (NH4H2PO4), then mixing the prepared ferric oxide (Fe2O3) nanorod with lithium hydroxide monohydrate (LiOH.H2O), and carrying out high-temperature calcination so as to prepare the nanometer iron-lithium oxide composite negative electrode material. The nanometer iron-lithium oxide composite negative electrode material has regular morphology, high purity and good electrochemical performance and is relatively uniform in size; the preparation method of the nanometer iron-lithium oxide composite negative electrode material is simple in process and is easy for large-scale industrial production.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

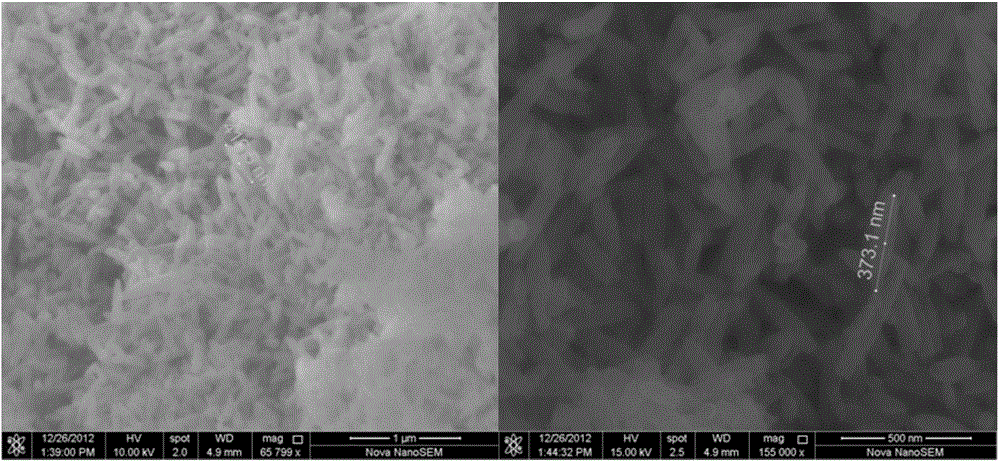

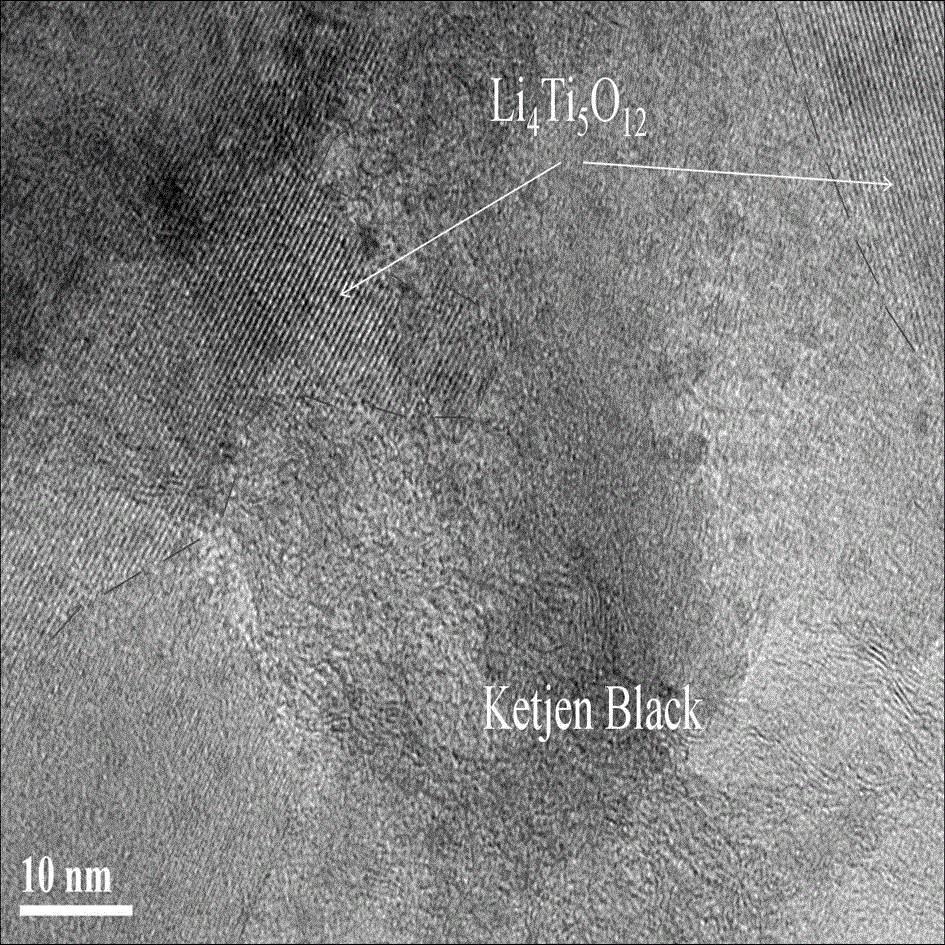

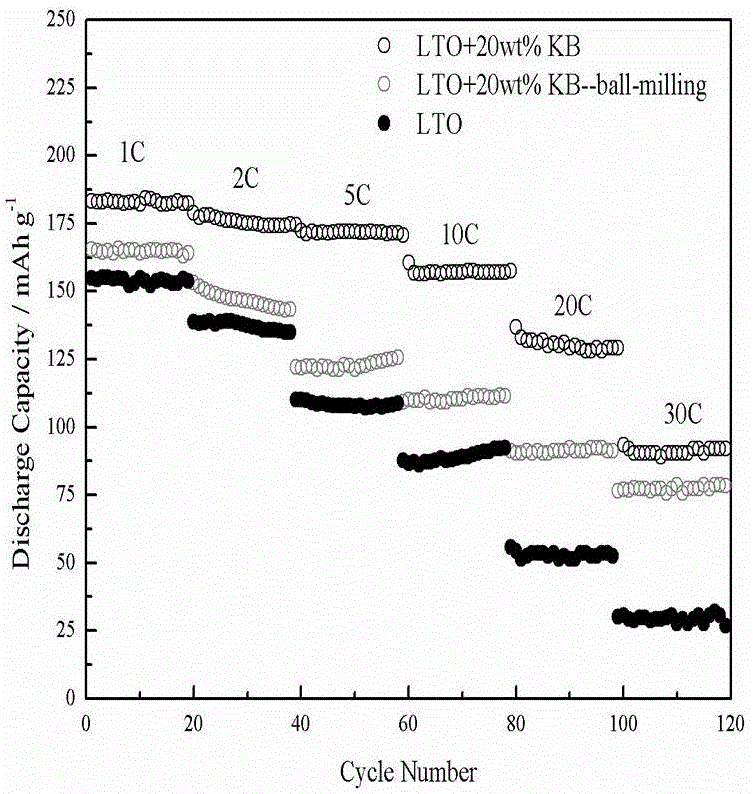

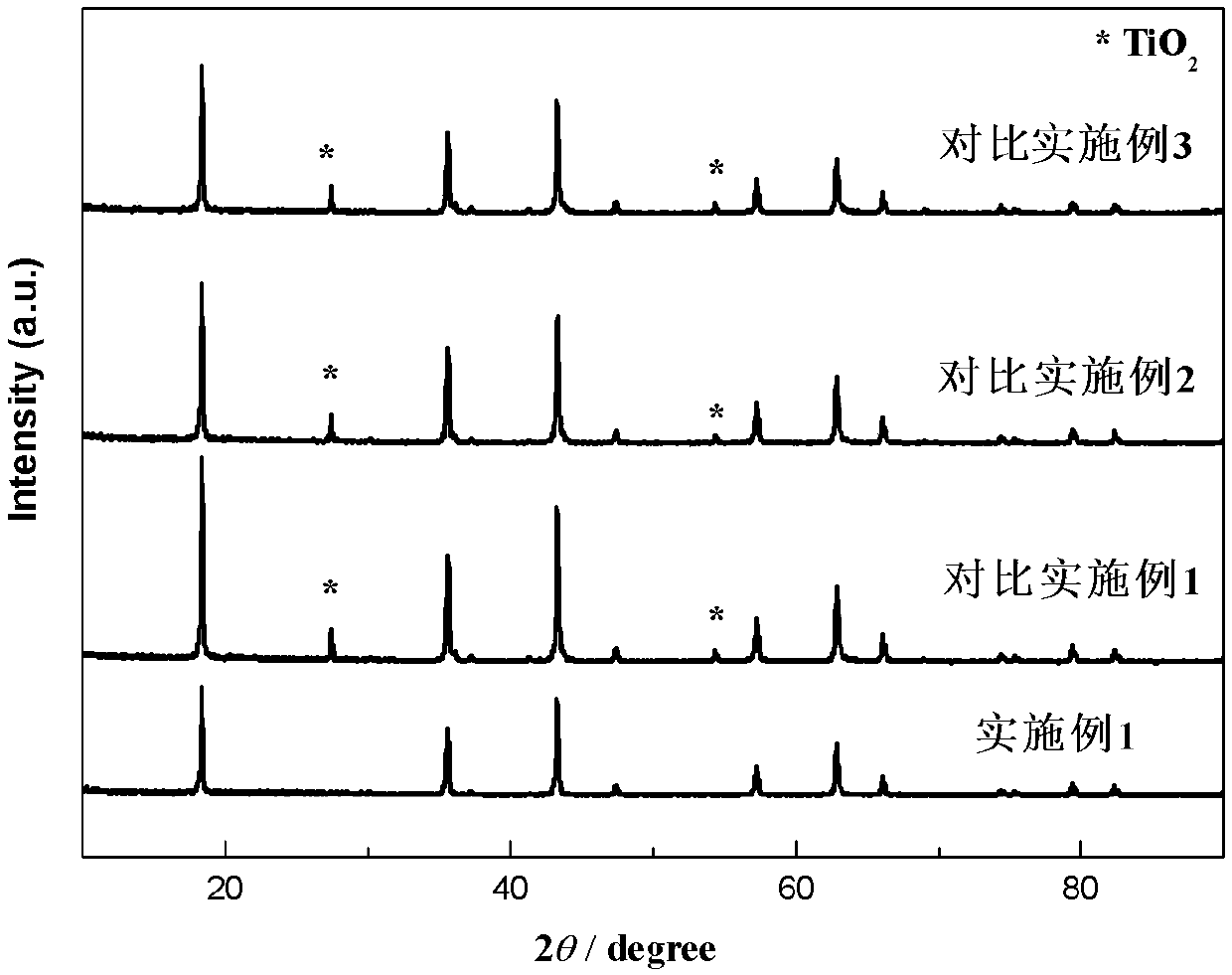

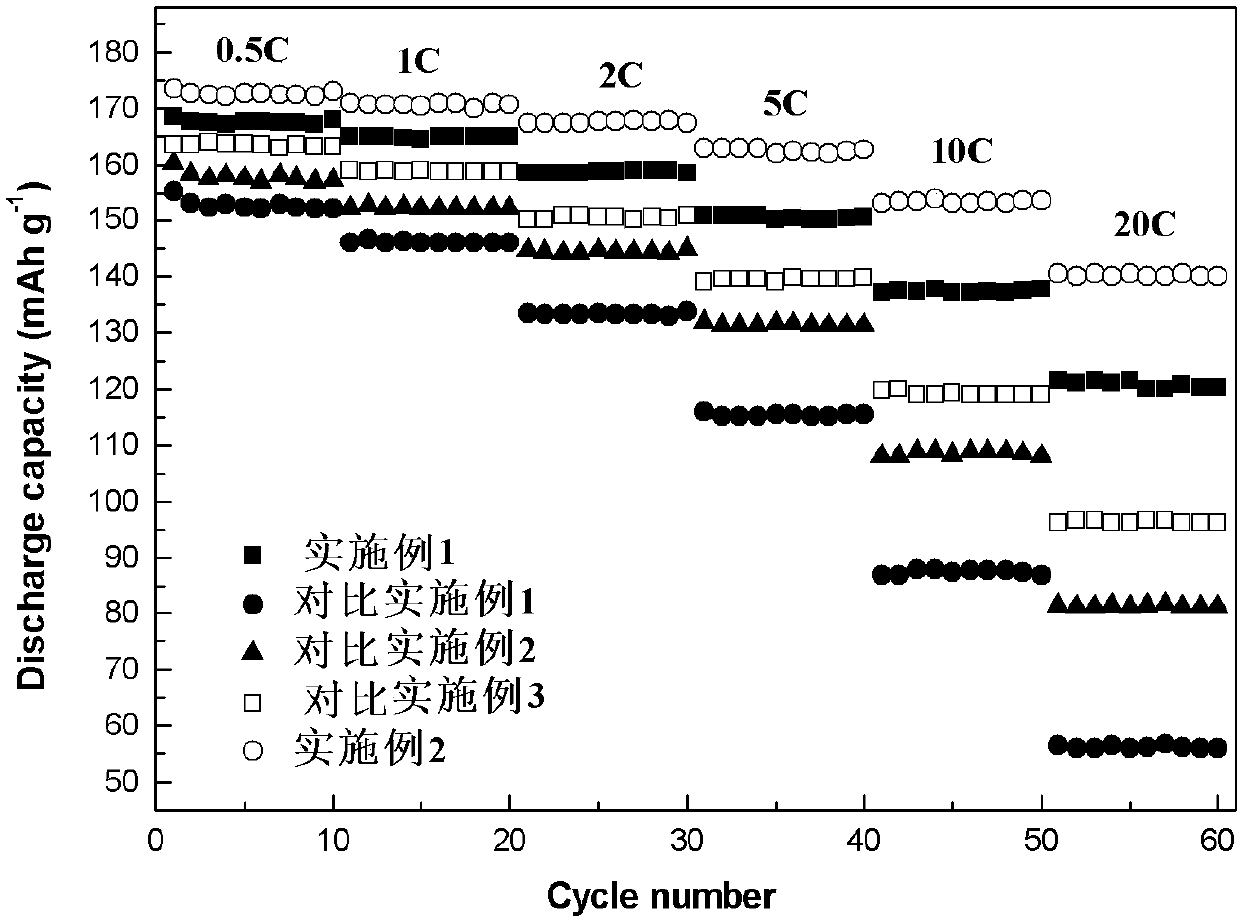

Lithium titanate/porous carbon composite material and preparation method of lithium titanate/porous carbon composite material

InactiveCN105789582AImprove electronic conductivityIncrease the diffusion coefficientCell electrodesSecondary cellsCarbon compositesHydration reaction

The invention discloses a lithium titanate / porous carbon composite material. The invention further discloses a preparation method of the lithium titanate / porous carbon composite material. The prepapration method comprises the following steps: weighing lithium hydroxide monohydrate, tetrabutyl titanate and porous carbon according to a certain stoichiometric ratio; adding ethanol and de-ionized water and uniformly mixing; transferring a stirred suspension solution into a hydrothermal reaction kettle and reacting at 180 DEG C for 24h to 48h to obtain precursor slurry; drying and crushing the precursor slurry to obtain precursor powder; treating the precursor powder in an inert atmosphere at the temperature of 500 DEG C to 700 DEG C for 5 to 10 hours to obtain the lithium titanate / porous carbon composite material. The composite material prepared by the technical scheme provided by the invention has excellent rate performance and low-temperature property.

Owner:EAST CHINA UNIV OF SCI & TECH

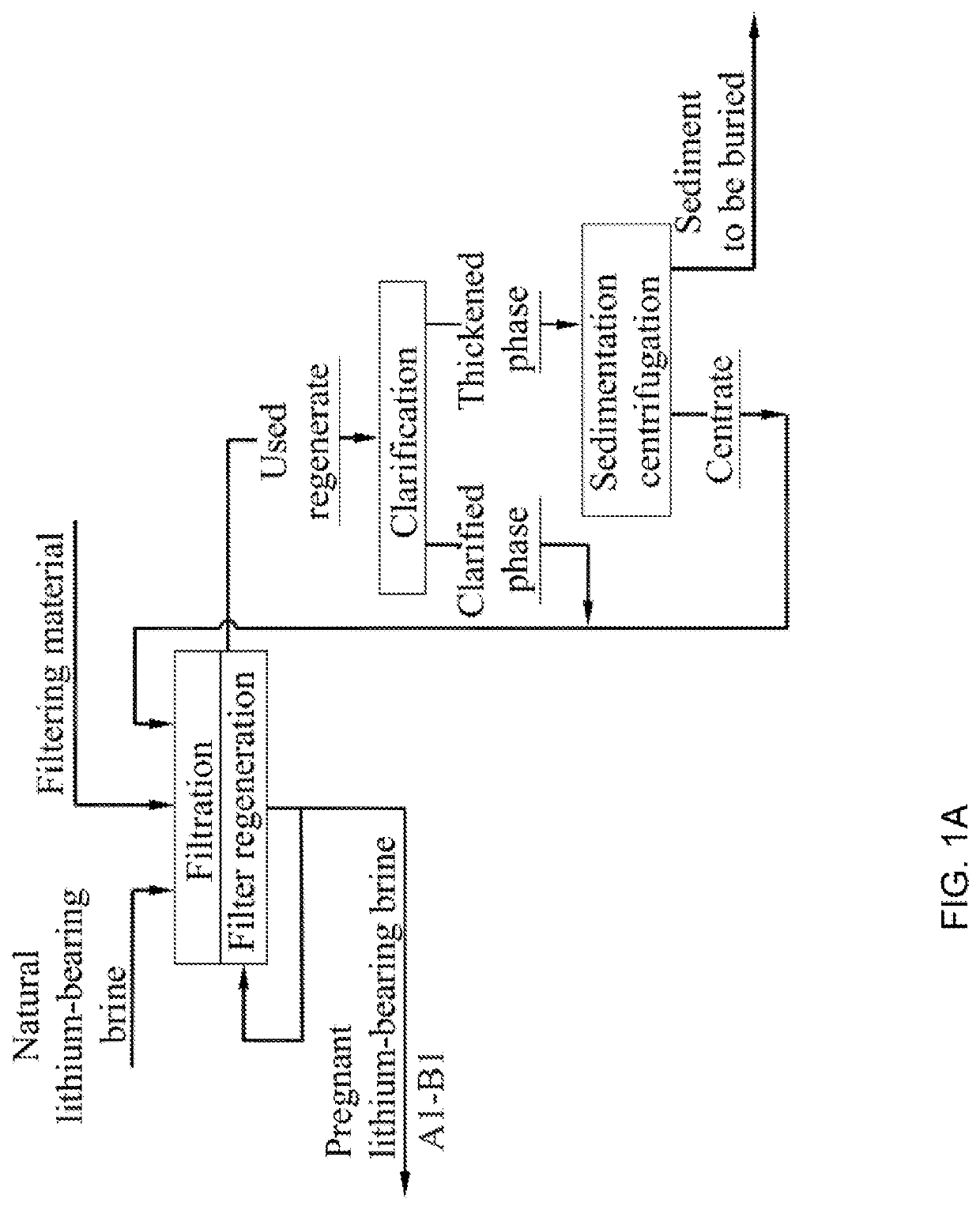

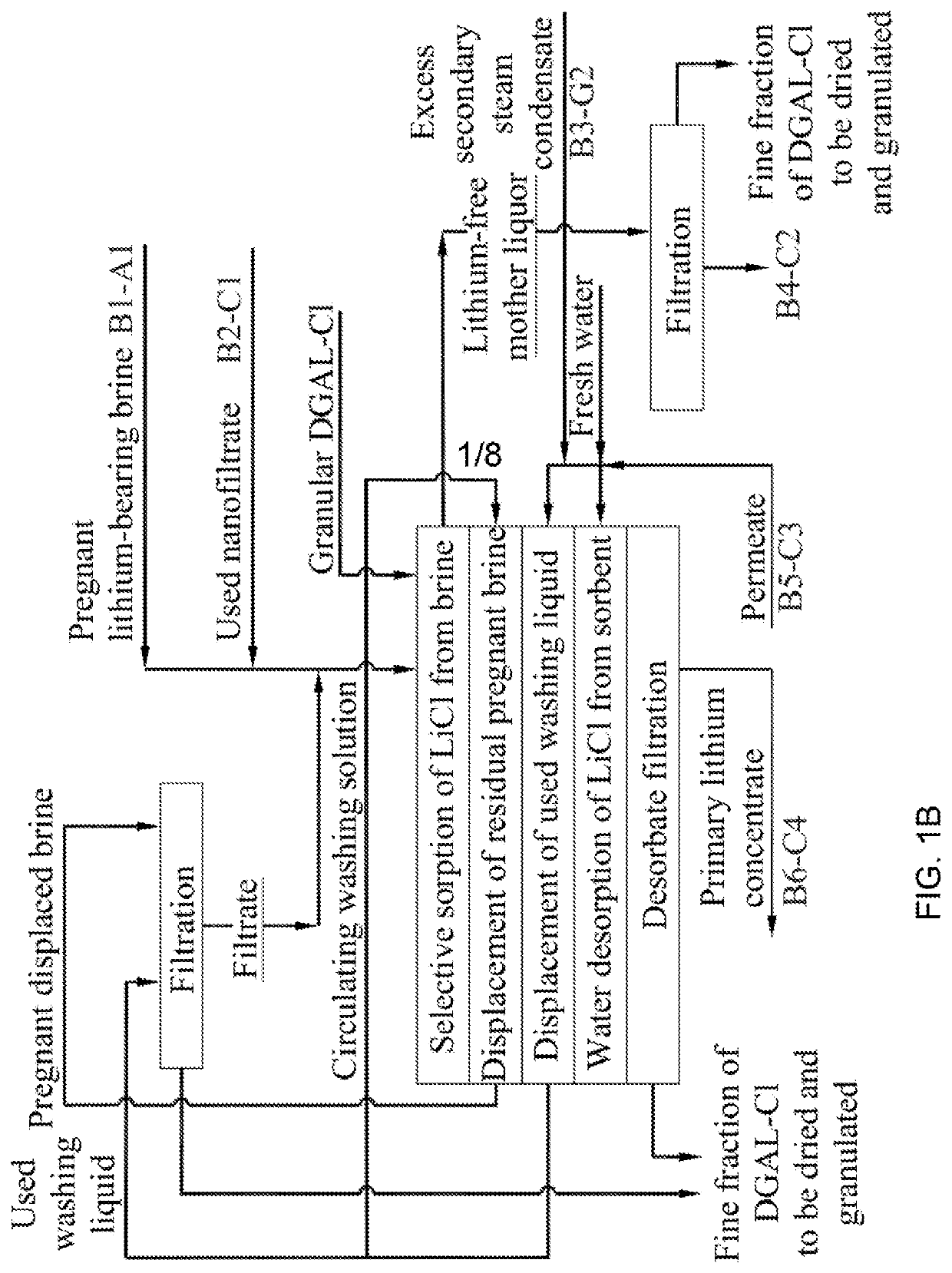

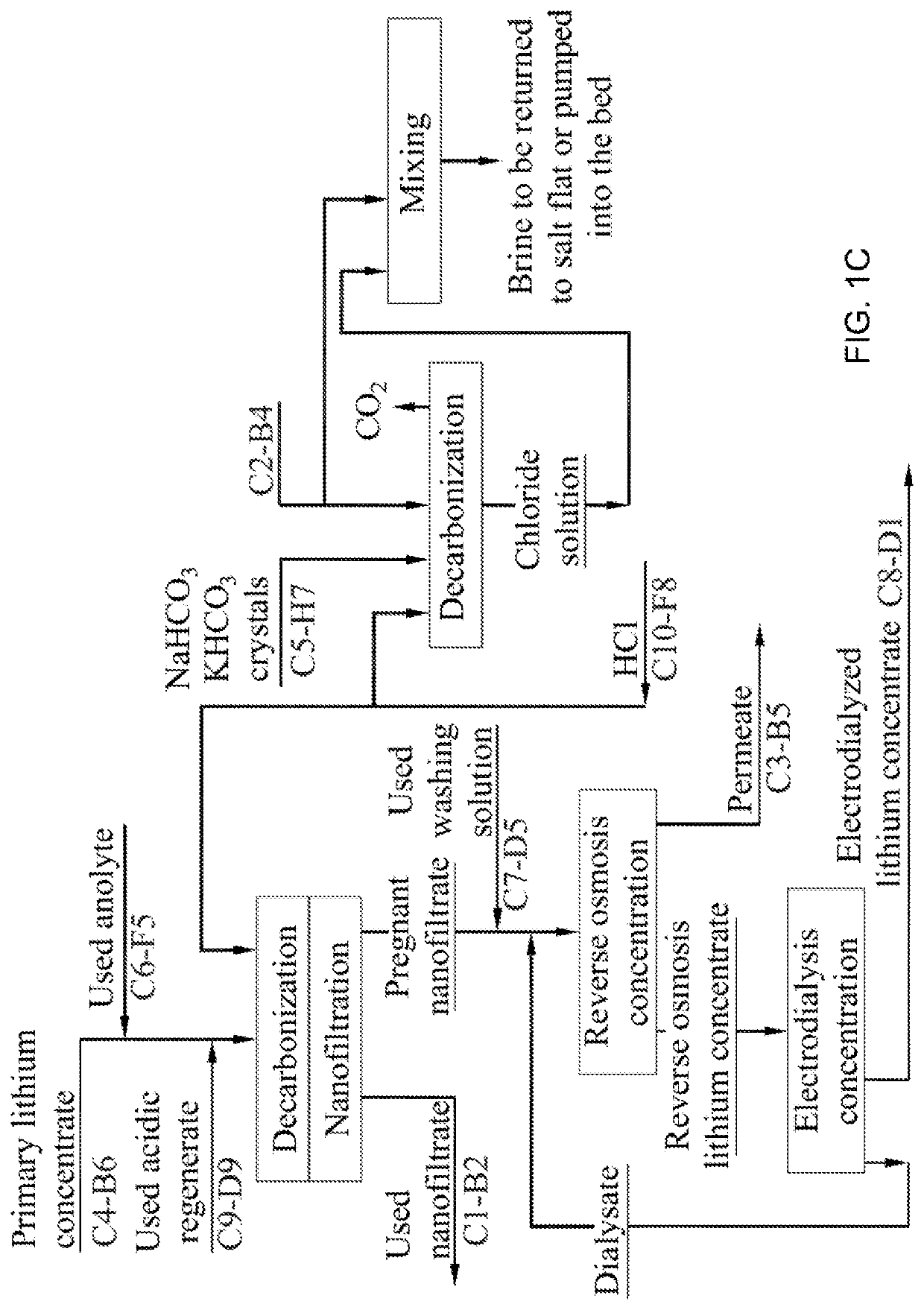

Method for producing lithium hydroxide monohydrate from brines

ActiveUS20210087697A1Reduce consumptionEliminate riskSeawater treatmentWater/sewage treatment apparatusSuspended particlesLithium chloride

A method for LiOHH2O production from lithium-bearing multicomponent hydromineral raw materials includes filtering lithium-bearing brine contaminated with suspended particles with regeneration of filters and processing of used regenerate, and obtaining pregnant lithium-bearing brine, isolation of lithium chloride from the brine in the form of a primary concentrate in sorption-desorption modules, and nanofiltration of the primary lithium concentrate from magnesium, calcium and sulfate ions. By means of reverse osmosis, electrodialysis concentration and ion-exchange purification from impurities followed by thermal concentration, the primary lithium concentrate is converted into a pregnant lithium chloride concentrate which is converted into a LiOH solution by membrane electrolysis. The LiOH solution is boiled down, resulting in LiOH.H2O crystallization.

Owner:ECOSTAR NAUTECH CO LTD

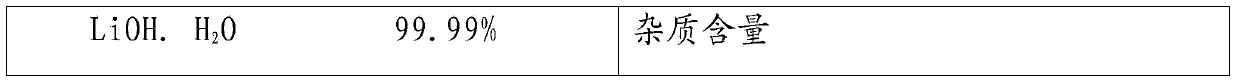

Method for preparing sheet high-purity lithium hydroxide by using spodumene concentrate

ActiveCN104003427AImprove labor efficiencyLow reaction temperatureLithium oxides/hydroxidesHydration reactionPrill

The invention relates to the preparation of high-purity compounds in the technical field of chemical engineering, and particularly relates to a method for preparing sheet high-purity lithium hydroxide by using spodumene concentrate. The method comprises the steps of dissolving the obtained crude product of the lithium hydroxide monohydrate to ensure that the mass concentration of Li2O is 65-70g / L, carrying out concentration and crystallization by using an organic solvent and finally carrying out solid-liquid separation and drying to obtain the sheet high-purity lithium hydroxide. The method can be used for treating different types of minerals; the hydration reaction of the organic solvent plays a role in concentration to ensure that the lithium hydroxide is separated out more easily and more quickly and the impurities are not crystallized along with the lithium hydroxide, so that the purity of the lithium hydroxide is improved, the purity is above 99.8% and the light transmittance is up to 99%. The crystallized particles are narrow in distribution and easy to control; the product quality is stable and exceeds the international electronic-grade standard; and the crystal is sheet; the organic solvent is convenient for repeated application; the operation is carried out at normal temperature so that the energy consumption is reduced.

Owner:SICHUAN GUORUN NEW MATERIAL

Method for preparation of sulfur-nitrogen codoped carbon coated nano flower-like lithium titanate composite negative electrode material

ActiveCN107732205ARapid hydrolysisHigh specific capacityCell electrodesHigh rateManufacturing technology

The invention relates to the technical field of lithium-ion-battery manufacture, in particular to a method for preparation of a sulfur-nitrogen codoped carbon coated nano flower-like lithium titanatecomposite negative electrode material. According to the method, polyvinylpyrrolidone, tetrabutyl titanate and lithium hydroxide monohydrate are dispersed in an organic solvent, after hydrolysis and calcination, thiourea and polyacrylamide are added, then high-temperature plasma treatment is conducted, and the sulfur-nitrogen codoped carbon coated nano flower-like lithium titanate composite negative electrode material is obtained. The seep of preparation of the electrode material and the specific capacity under the high rate condition are improved.

Owner:CHANGZHOU UNIV

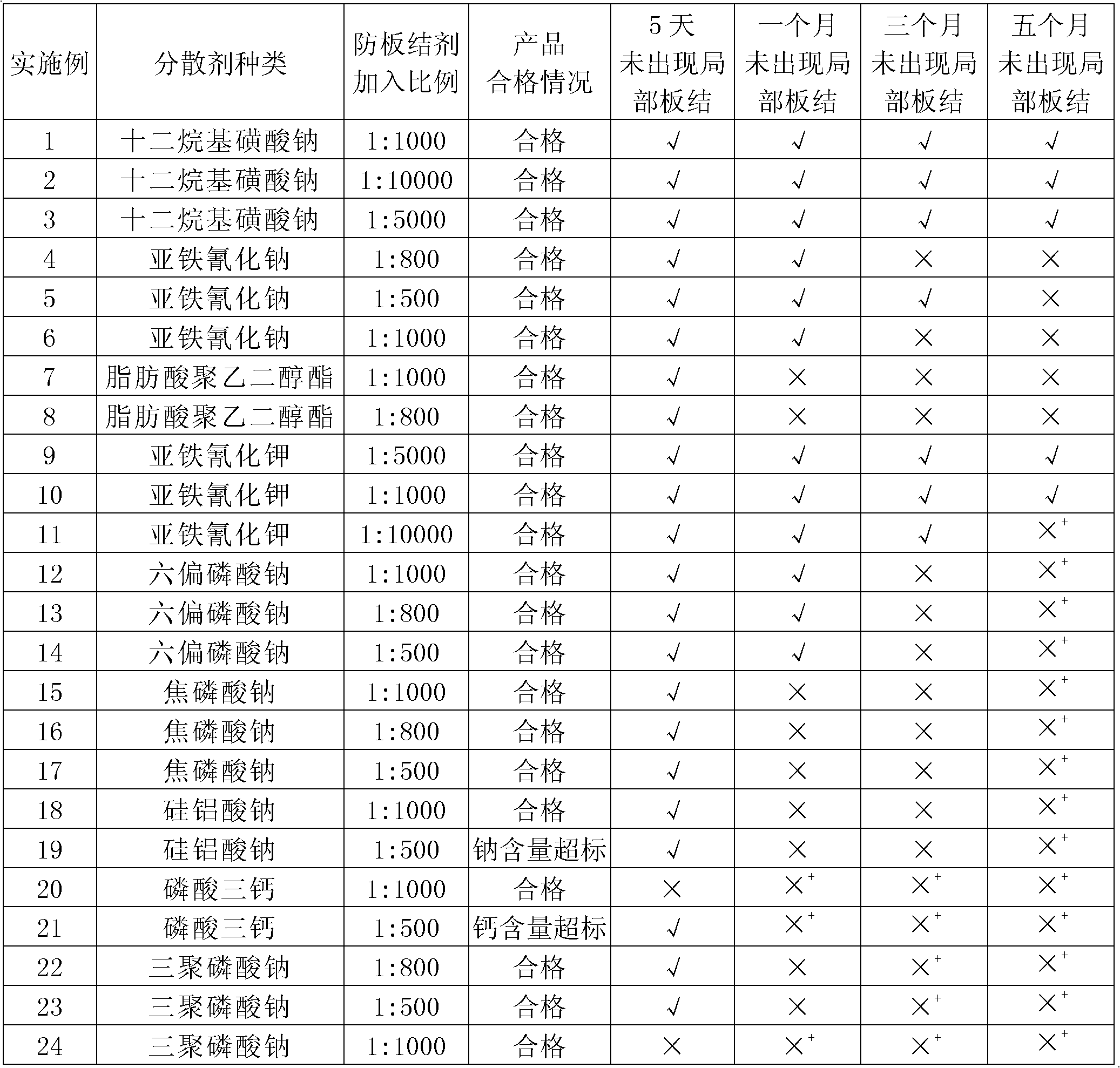

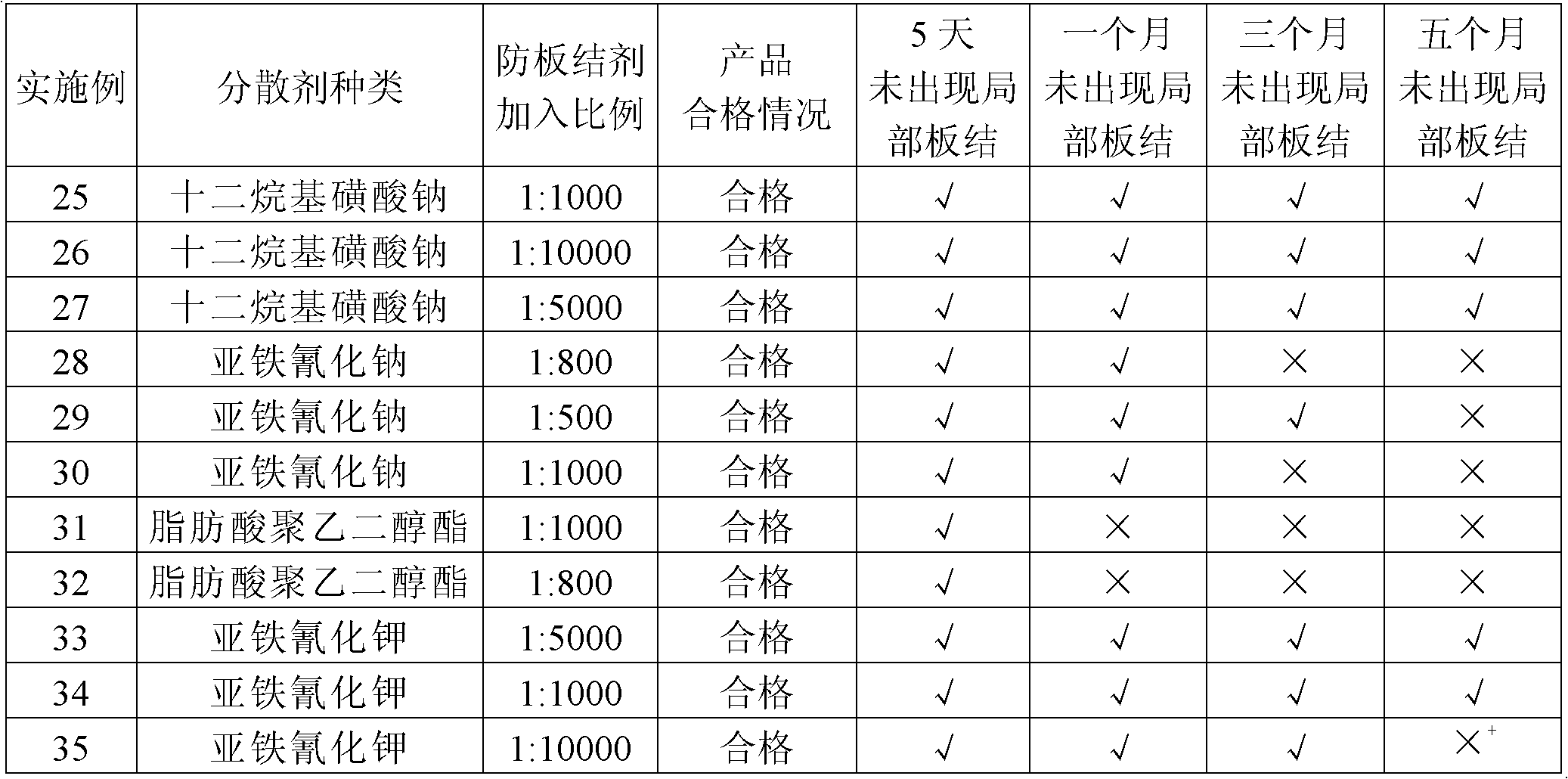

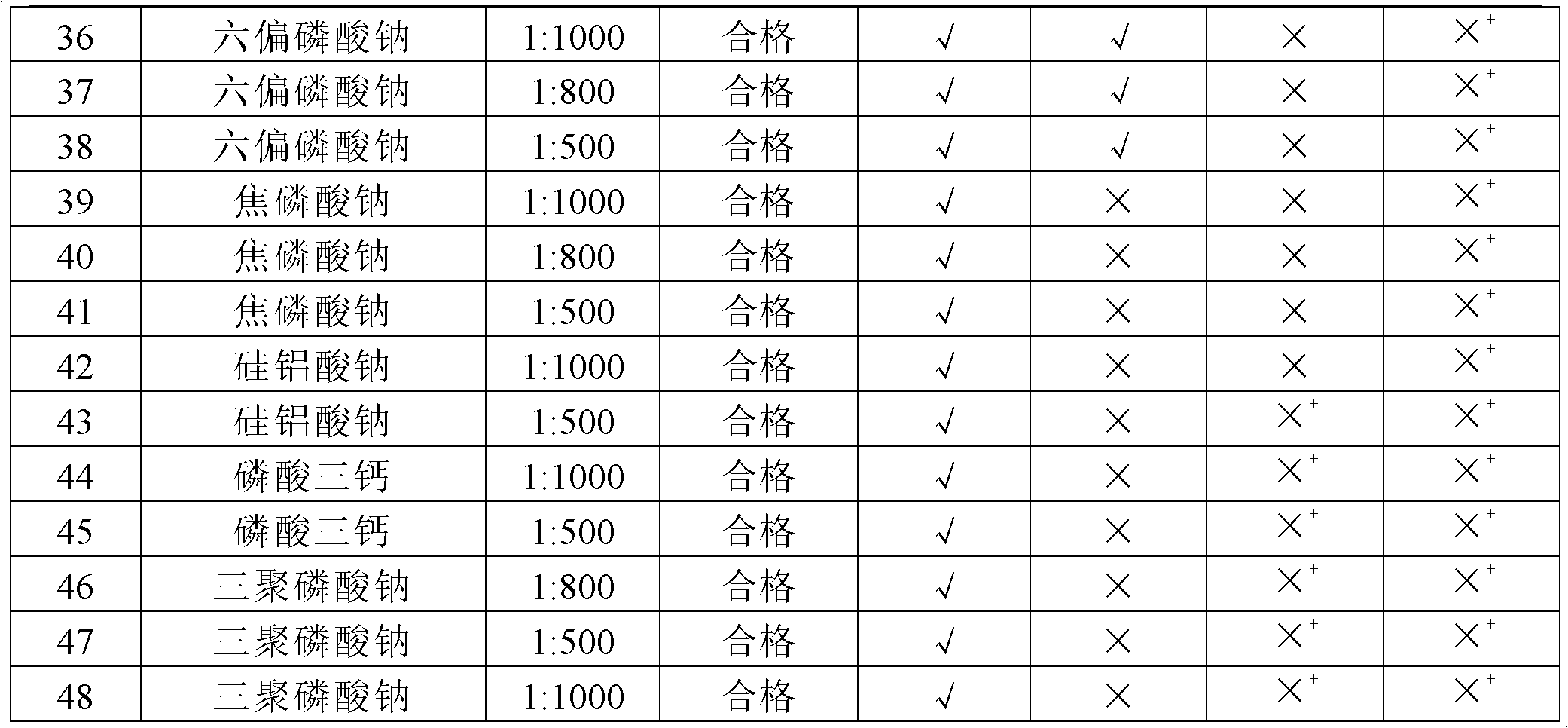

Lithium hydroxide monohydrate and preparation method thereof

ActiveCN102020294ANo flyingMeet the qualityTransportation and packagingLithium oxides/hydroxidesCalcium hydroxideDust explosion

The invention refers to a dust-free lithium hydroxide monohydrate and a preparation method thereof, belonging to the technical field of lithium hydroxide. The technical problems to be solved by the invention are that wet LiOH.H2O has a problem of hardening and dry LiOH.H2O has a problem of dust explosion in the prior art. The invention provides a novel LiOH.H2O, that is, dust-free lithium hydroxide monohydrate without hardening. The lithium hydroxide monohydrate is a loosened granular wet product, wherein the content of water is less than or equal to 3.5%, and the surface of the lithium hydroxide monohydrate is coated with a little anti-hardening agent. The dust-free lithium hydroxide monohydrate is prepared by the following methods: (1) preparing a LiOH solution having a Li2O concentration of 70+-5g / l, and the concentration of SO42- is less than or equal to 15g / l; (2) evaporating the LiOH solution obtained in the step (1) until the ratio of liquid to solid is 1: (0.8-1.5); adding a little anti-hardening agent; uniformly stirring; separating and washing the mixture to obtain dust-free wet LiOH.H2O; and carrying out vacuum seal and packing the wet product, wherein the obtained product is not hardened within 3-5 months.

Owner:TIANQI LITHIUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com