Method for preparation of sulfur-nitrogen codoped carbon coated nano flower-like lithium titanate composite negative electrode material

A technology of lithium titanate and negative electrode materials, which is applied in the field of preparation of sulfur-nitrogen co-doped carbon-coated nano flower-shaped lithium titanate composite negative electrode materials, can solve the problems of poor electronic conductivity and achieve the effect of rapid hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

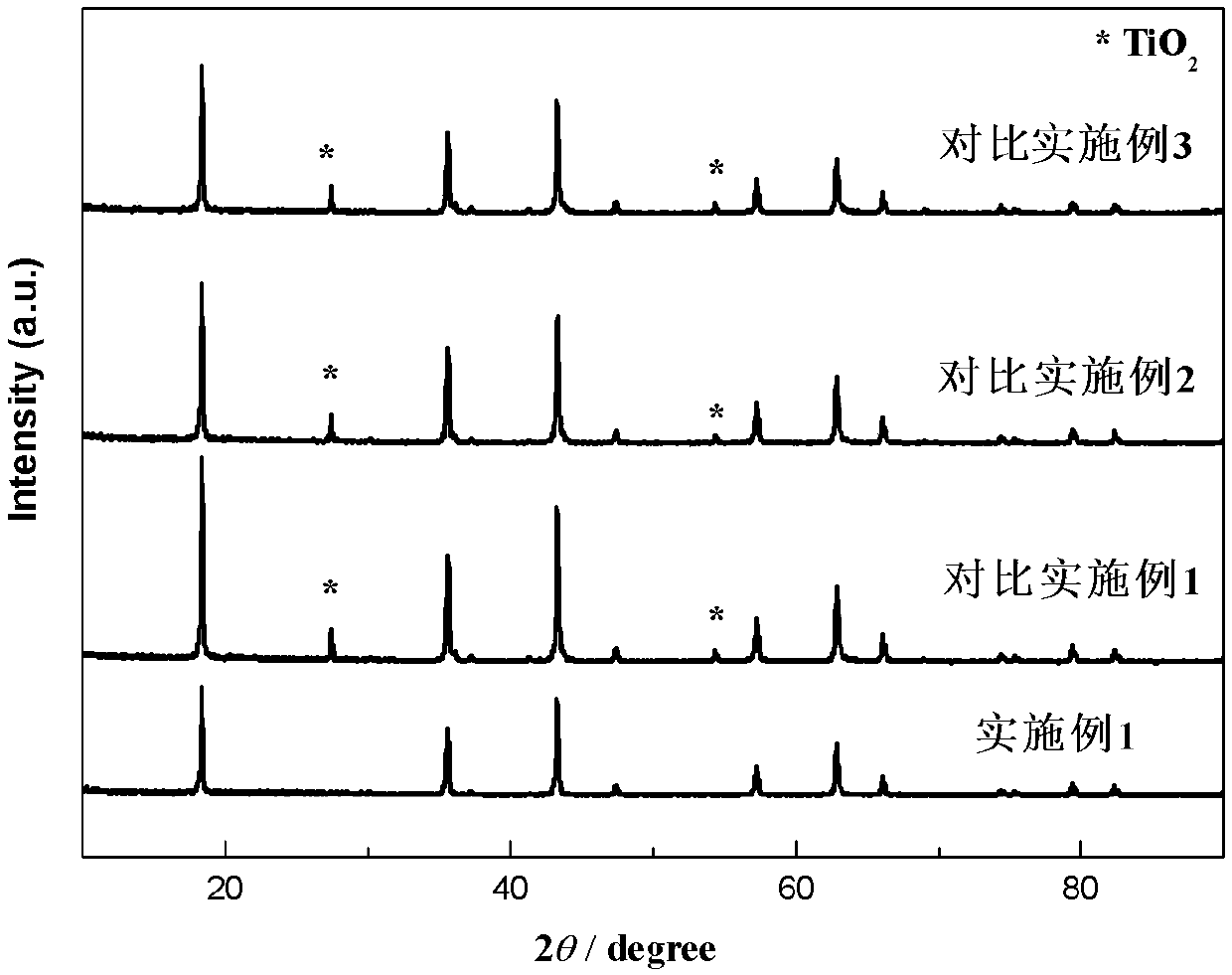

Embodiment 1

[0022] Fully disperse 0.3g of polyvinylpyrrolidone, 0.015mol of n-butyl titanate and 0.01275mol of lithium hydroxide monohydrate in a mixed solvent of 200mL of anhydrous methanol and anhydrous DMF (the volume ratio of anhydrous methanol and anhydrous DMF is 4 : 1), and then transferred to a 250mL lined PPL reactor, the reactor was placed in a constant temperature infrared oven, and reacted for 8 hours at 180°C; the reacted suspension was filtered with a sand core filter, and the filter cake was filtered with Fully wash with water and methanol, dry at 80°C to obtain a lithium titanate precursor, and then plasma treat the precursor at 600°C for 30 minutes to obtain nano flower-shaped lithium titanate.

Embodiment 2

[0031] Fully disperse 0.2g of thiourea, 0.4g of polyacrylamide and the nano-flower-shaped lithium titanate obtained in Example 1 in distilled water, evaporate the solvent to dryness at 100°C, and fully vacuum-dry at 100°C to obtain sulfur-nitrogen Co-doped carbon-coated lithium titanate precursor; then plasma-treated the sulfur-nitrogen co-doped carbon-coated lithium titanate precursor at 600°C for 10 minutes to obtain sulfur-nitrogen co-doped carbon-coated nanoflowers Lithium titanate composite negative electrode material, the specific morphology is as attached figure 2 shown.

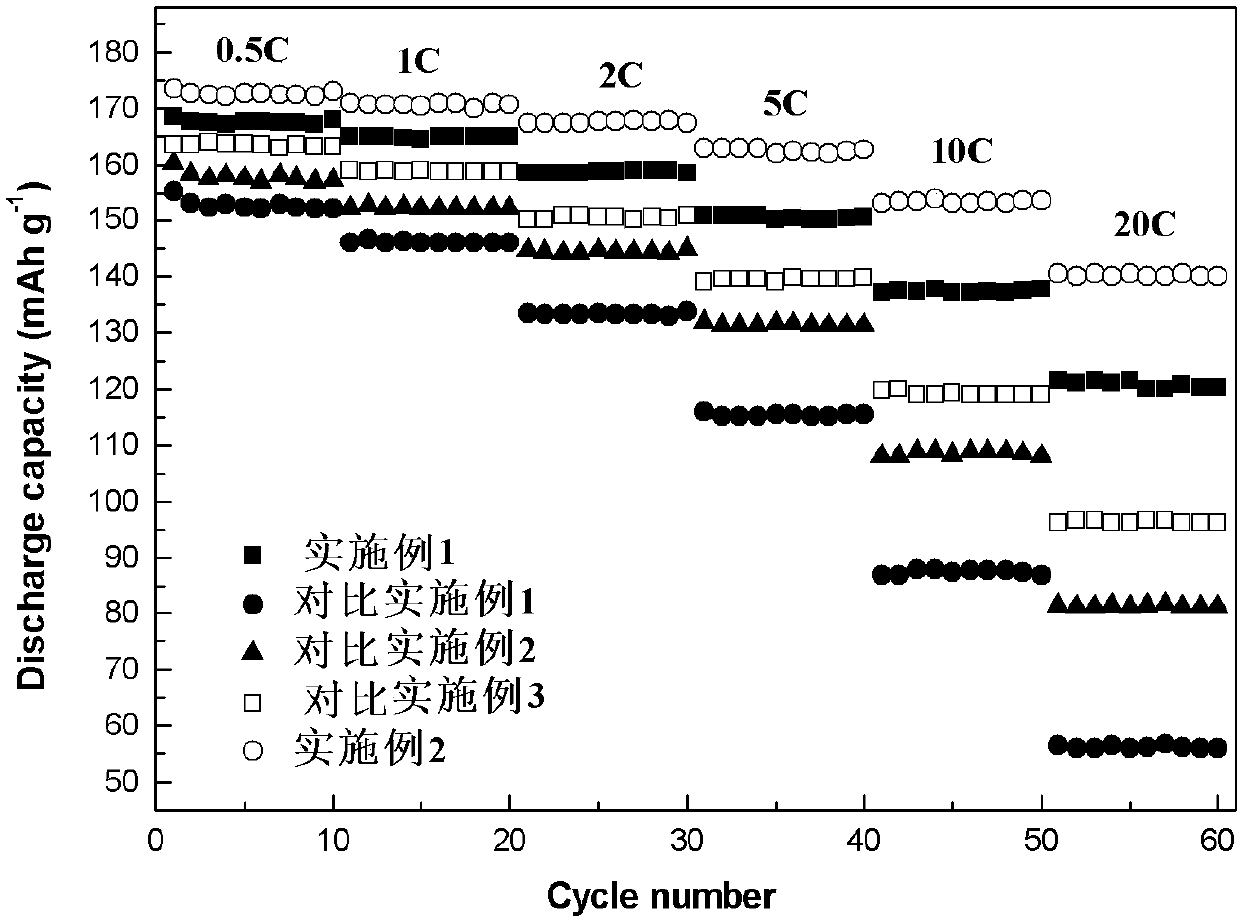

[0032] Electrochemical performance test

[0033] Using the products prepared in Example 1 of this patent, Comparative Example 1, Comparative Example 2, Comparative Example 3 and the negative electrode material prepared in Example 2 as active components respectively, the negative electrode for lithium ion batteries was prepared by the slurry method, specifically The operation is: mix the active ingr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com