Titanium modified Fe3O4 magnetic nano-particle, preparation method and application thereof

A magnetic nanoparticle modification technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc. Waste and other problems, to achieve the effect of low equipment requirements, low consumption, and serious waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of titanium modified Fe 3 o 4 A method for preparing magnetic nanoparticles, comprising the following steps:

[0034] 1) Weigh 5.586g (0.04mol) of choline chloride and 4.804g of urea (0.08mol) into a 60mL reaction kettle, stir at 50°C until the solid mixture turns into a liquid, and obtain the choline chloride-urea eutectic solvent.

[0035] 2) Add 1.668g (0.0060mol) FeSO to the choline chloride-urea deep eutectic solvent prepared in step 1) 4 ·7H 2 O and 0.584g (0.0104mol) KOH and stirred for 30min, then added 0.408g (0.0012mol) n-butyl titanate and stirred for 5min, finally added 0.420g (0.0075mol) KOH, stirred at 80°C for 30min, then put the reaction kettle Put it in an oven at 110°C for 4 hours to obtain solid particles, centrifuge, wash with distilled water (3×20mL) and ethanol (1×20mL), and dry in air to obtain the product titanium-modified Fe 3 o 4 magnetic nanoparticles.

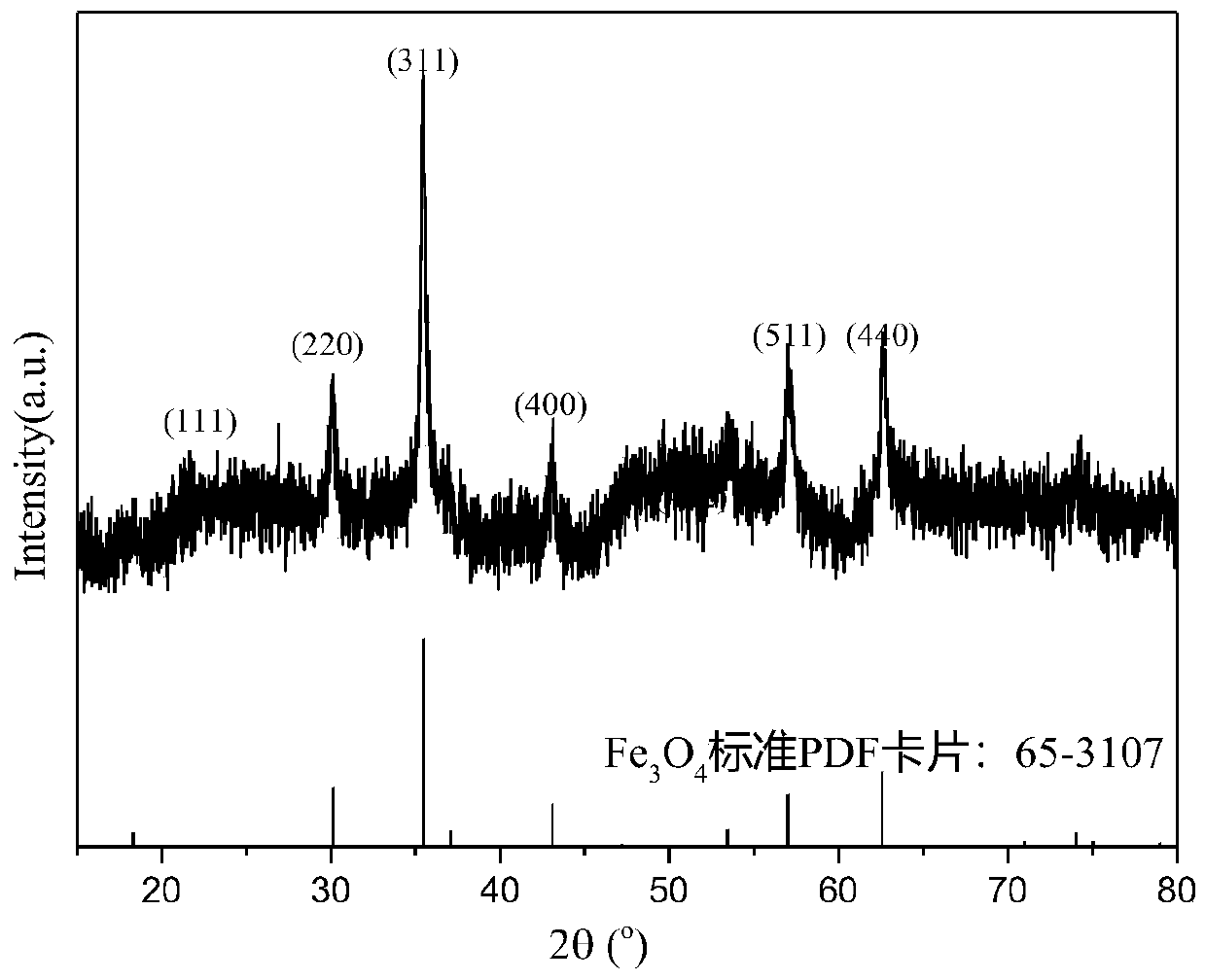

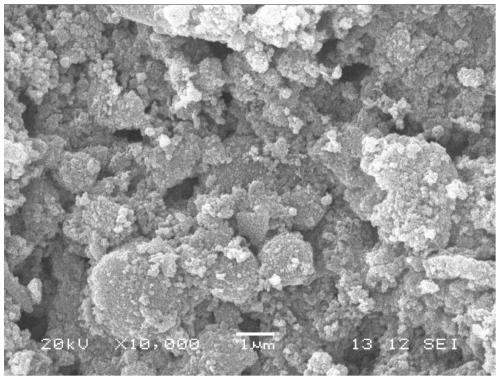

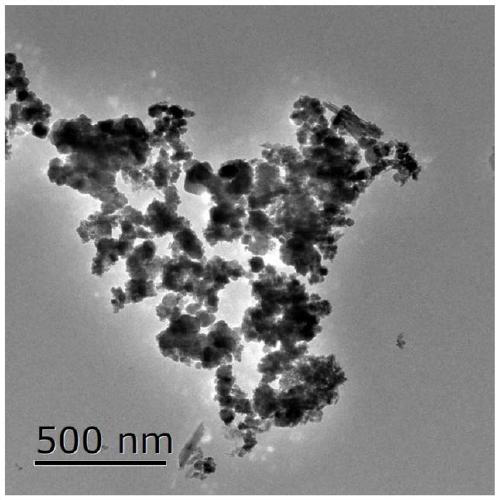

[0036] The product obtained in this embodiment titanium modified Fe 3 o 4 ...

Embodiment 2

[0042] A kind of titanium modified Fe 3 o 4 A method for preparing magnetic nanoparticles, comprising the following steps:

[0043] 1) Weigh 5.586g (0.04mol) of choline chloride and 4.804g (0.08mol) of urea into a 60mL reaction kettle, stir at 50°C until the solid mixture turns into a liquid, and obtain the choline chloride-urea eutectic solvent.

[0044] 2) Add 1.668g (0.0060mol) FeSO to the choline chloride-urea deep eutectic solvent prepared in step 1) 4 ·7H 2 O and 0.584g (0.0104mol) KOH and stirred for 30min, then added 0.050g (0.00015mol) n-butyl titanate and stirred for 5min, finally added 0.420g (0.0075mol) KOH, stirred at 80°C for 30min, then put the reaction kettle Put it in an oven at 110°C for 4 hours to obtain solid particles, which were centrifuged, washed with distilled water (3×20 mL) and ethanol (1×20 mL), and dried in air to obtain the product.

Embodiment 3

[0046] A kind of titanium modified Fe 3 o 4 A method for preparing magnetic nanoparticles, comprising the following steps:

[0047] 1) Weigh 5.586g (0.04mol) of choline chloride and 4.804g (0.08mol) of urea in a 60mL reactor, and stir at 50°C until the solid mixture turns into a liquid to obtain the choline chloride-urea eutectic solvent.

[0048] 2) Add 1.668g (0.0060mol) FeSO to the choline chloride-urea deep eutectic solvent prepared in step 1) successively 4 ·7H 2 O and 0.584g (0.0104mol) KOH and stirred for 30min, then added 4.080g (0.012mol) of n-butyl titanate and stirred for 5min, finally added 0.420g (0.0075mol) KOH, stirred at 80°C for 30min, then put the reaction kettle Put it in an oven at 110°C for 4 hours to obtain solid particles, which were centrifuged, washed with distilled water (3×20 mL) and ethanol (1×20 mL), and dried in air to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com