Patents

Literature

58results about How to "High equipment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

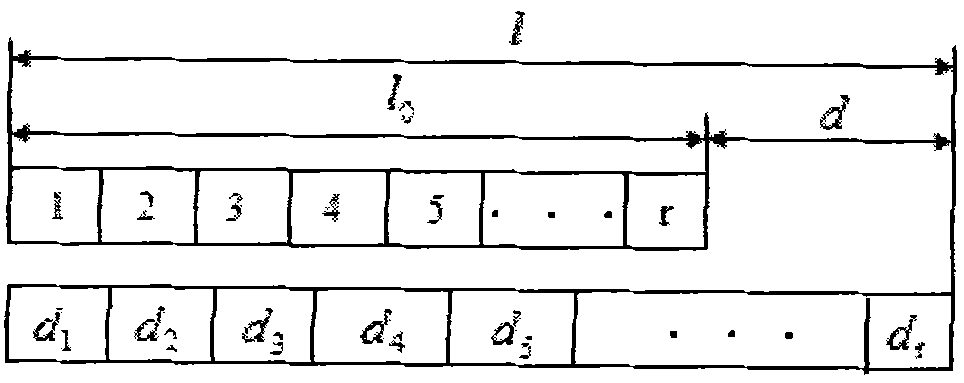

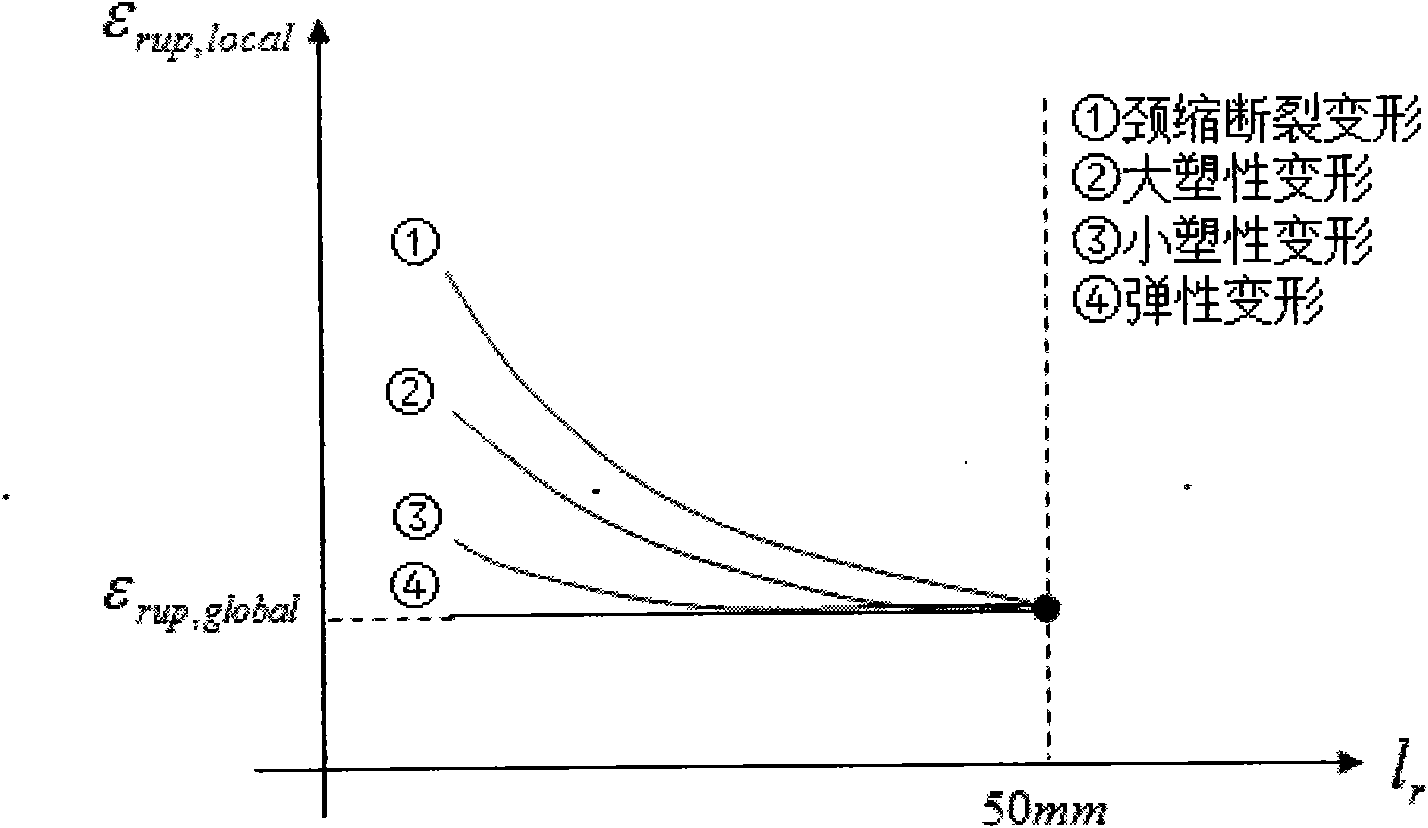

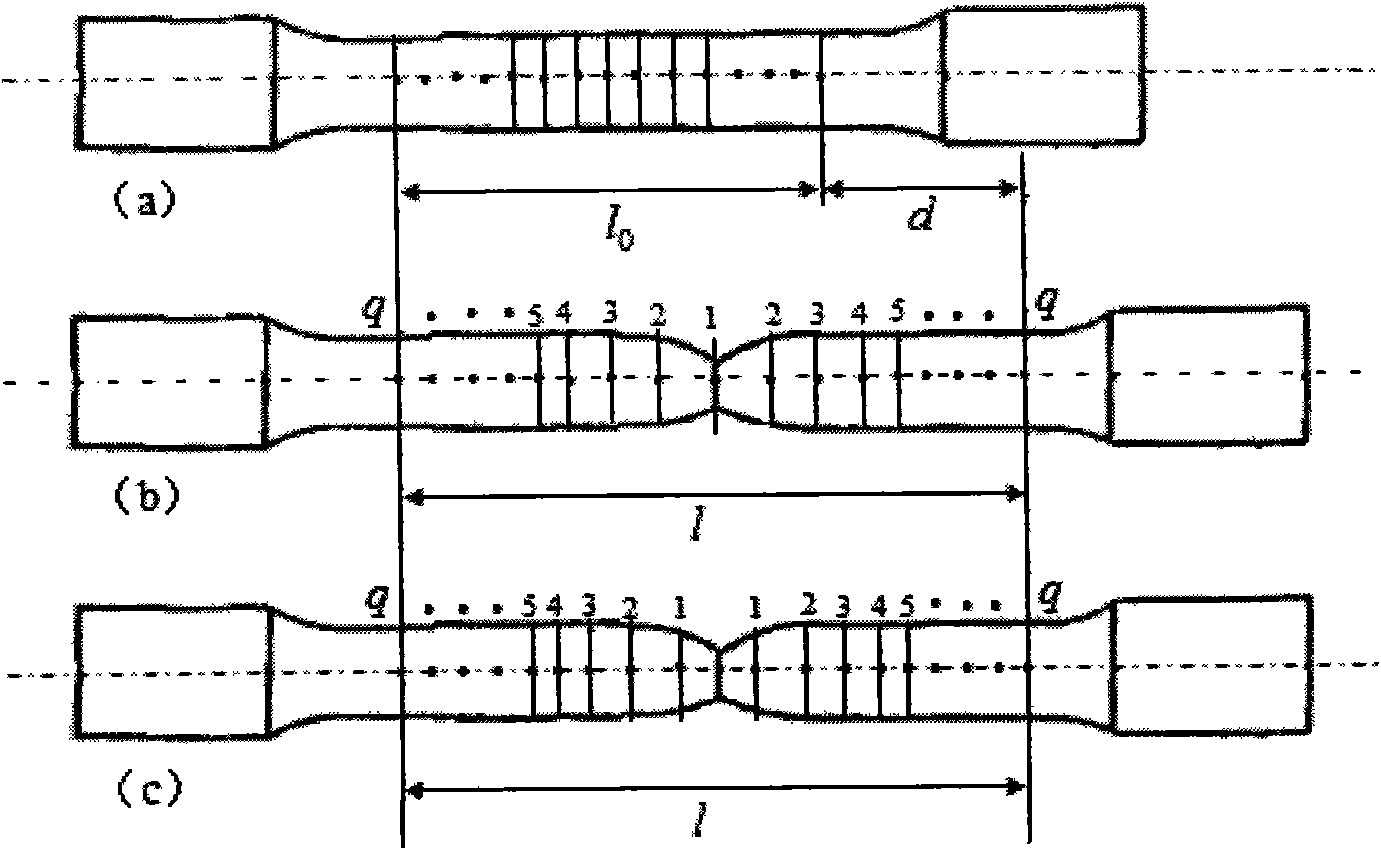

Data measuring and calculating method for uniaxial tensile test

InactiveCN101975693AReduce calculation precisionDiscovery of the intensity effectMaterial strength using tensile/compressive forcesLength effectEnergy absorption

The invention discloses a data measuring and calculating method for a uniaxial tensile test, which comprises the following steps of: marking a measuring point; measuring test data; calculating real breaking strain stress; and drawing an engineering and real stress strain curve. The method of the invention can obtain engineering and real stress strain curves in different reference lengths in the same uniaxial tensile test, establishes a corresponding relationship between the reference length effect and the mesh size effect and provides a thorough solution for the mesh size effect problem in a finite element method, i.e. a real stress strain curve in the equal reference lengths is defined for the same material with different mesh sizes. Meanwhile, theoretical explanation is provided for the practical problems, such as mesh size effect, energy absorption, material strain invalidation, and the like according to a uniaxial tensile basic theory provided by the invention, therefore, the invention has important theory and engineering practical significance.

Owner:肖锋

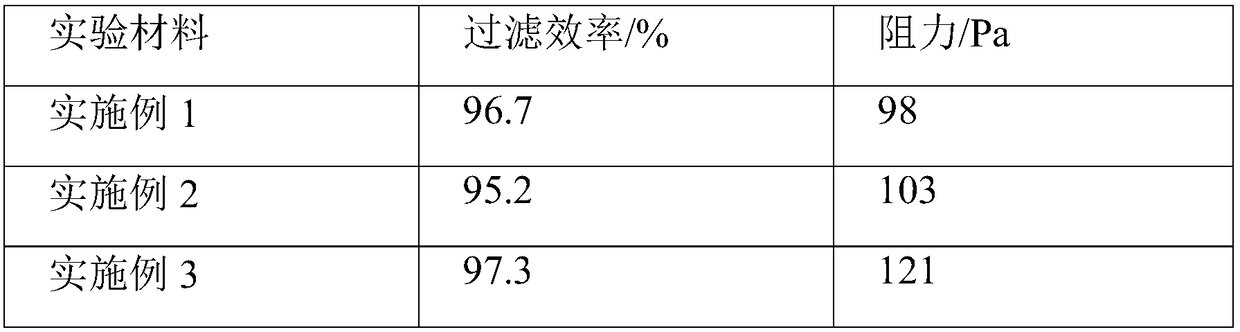

Polypropylene electret master batch material, method for preparing same and application of polypropylene electret master batch material

The invention belongs to the technical field of high-polymer materials, and particularly relates to a polypropylene (PP) electret master batch material, a method for preparing the same and applicationof the polypropylene electret master batch material. The PP electret master batch material is mainly prepared from components including, by weight, 50-100 parts of polypropylene, 8-50 parts of electret agents, 0-3 parts of compatibilizers, 0.05-0.35 part of antioxidants and 0-3 parts of anti-aging agents. The components are molten and granulated to obtain the polypropylene electret master batch material. The polypropylene electret master batch material, the method and the application have the advantages that resin and auxiliaries are uniformly mixed with one another in melt blending modes, accordingly, obvious electret effects can be realized by melt-blow non-woven materials produced from the polypropylene electret master batch material prepared by the aid of the method, the melt-blow non-woven materials are high in filter efficiency and low in filter resistance, and the like.

Owner:联泓(江苏)新材料研究院有限公司

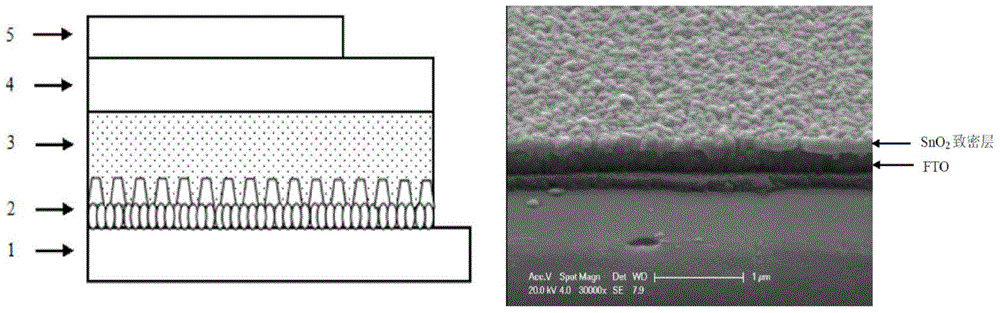

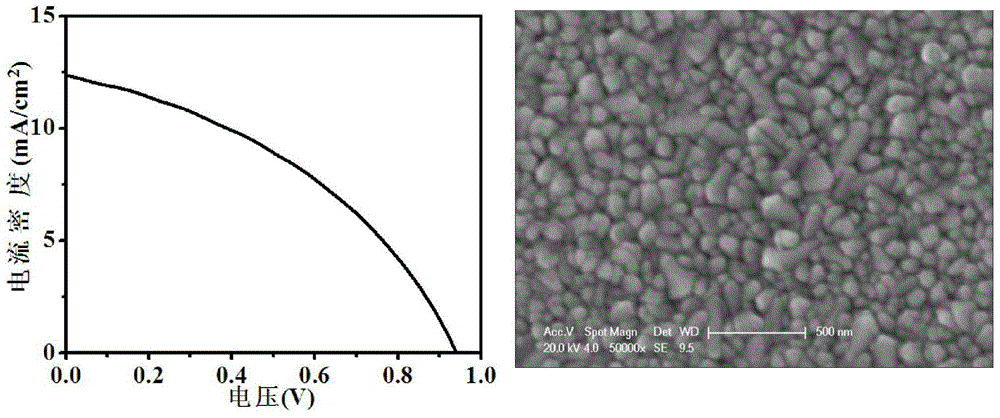

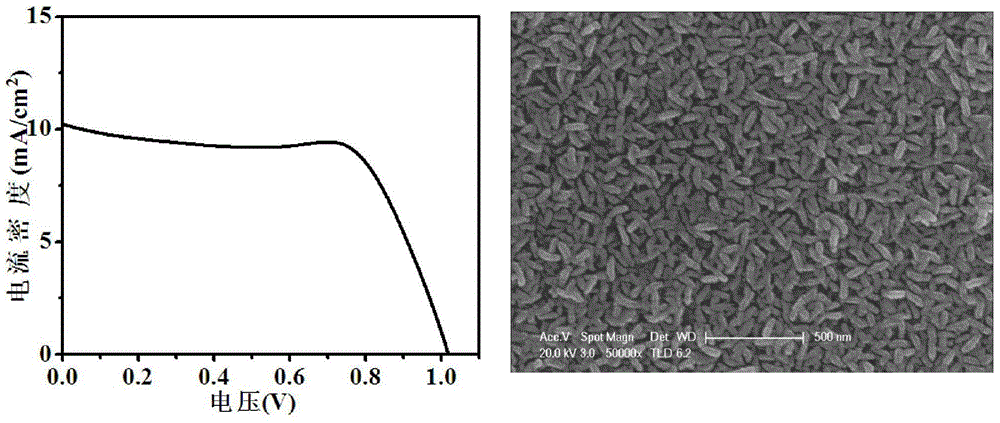

Mesoscopic perovskite photovoltaic cell with tin-oxide electron-transporting layer and preparation method thereof

InactiveCN104576932AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectrical batteryPerovskite (structure)

The invention relates to a perovskite photovoltaic cell with bilayer nanometer mesoporous electron-transporting layer and preparation method thereof. The cell comprises a conducting substrate, an electron-transporting layer with double-layer structure, a perovskite light absorption layer, a hole-transporting layer and metal electrodes. The perovskite photovoltaic cell with bilayer nanometer mesoporous electron-transporting layer has the advantages that the SnO2 with one step method low-temperature growth, is used as the electron-transporting layer in the photovoltaic cell, replaces the TiO2 electron-transporting layer with two steps method high temperature sintering, and the preparation process is simplified. The mesoporous perovskite photovoltaic cell prepared with one step low-temperature growth method obtains 13.82% of highlight electricity transfer efficiency, and reduces the manufacturing cost effectively at the same time. Compared with a planer construction, the mesoporous structure used in the perovskite photovoltaic cell is liable for the adherence of the perovskite light absorption material. SnO2 conducts a smaller dissimilation on the perovskite light absorption layer than the TiO2 does, the performance and stability of the cell are improved in this way. The perovskite photovoltaic cell with bilayer nanometer mesoporous electron-transporting layer and preparation method thereof plays a great promoting role in the development and popularization on the flexible solar cell, and further promotes the industrialized application on the perovskite solar cell.

Owner:WUHAN UNIV

Aluminum alloy precast-forging forming technique and mold thereof

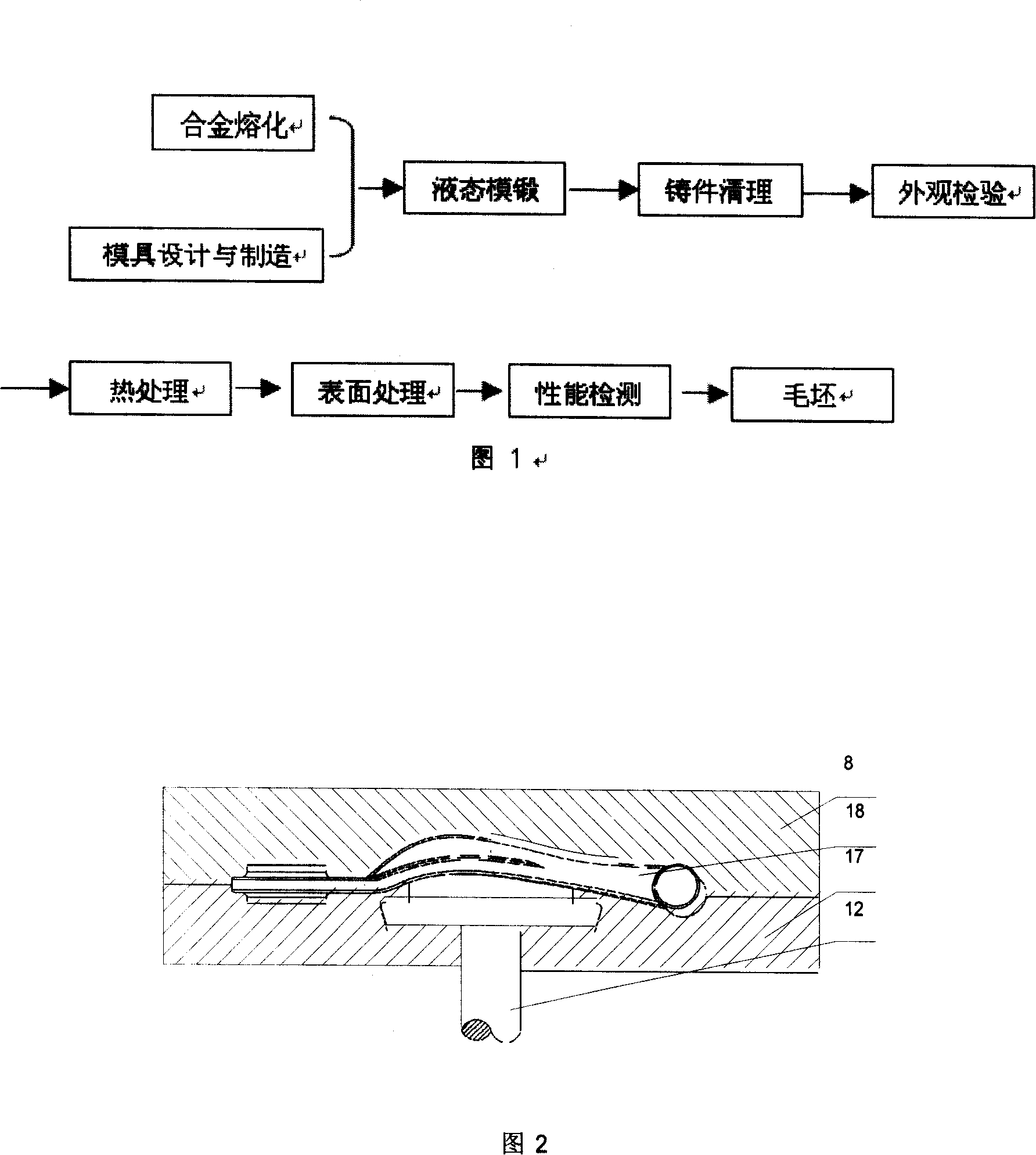

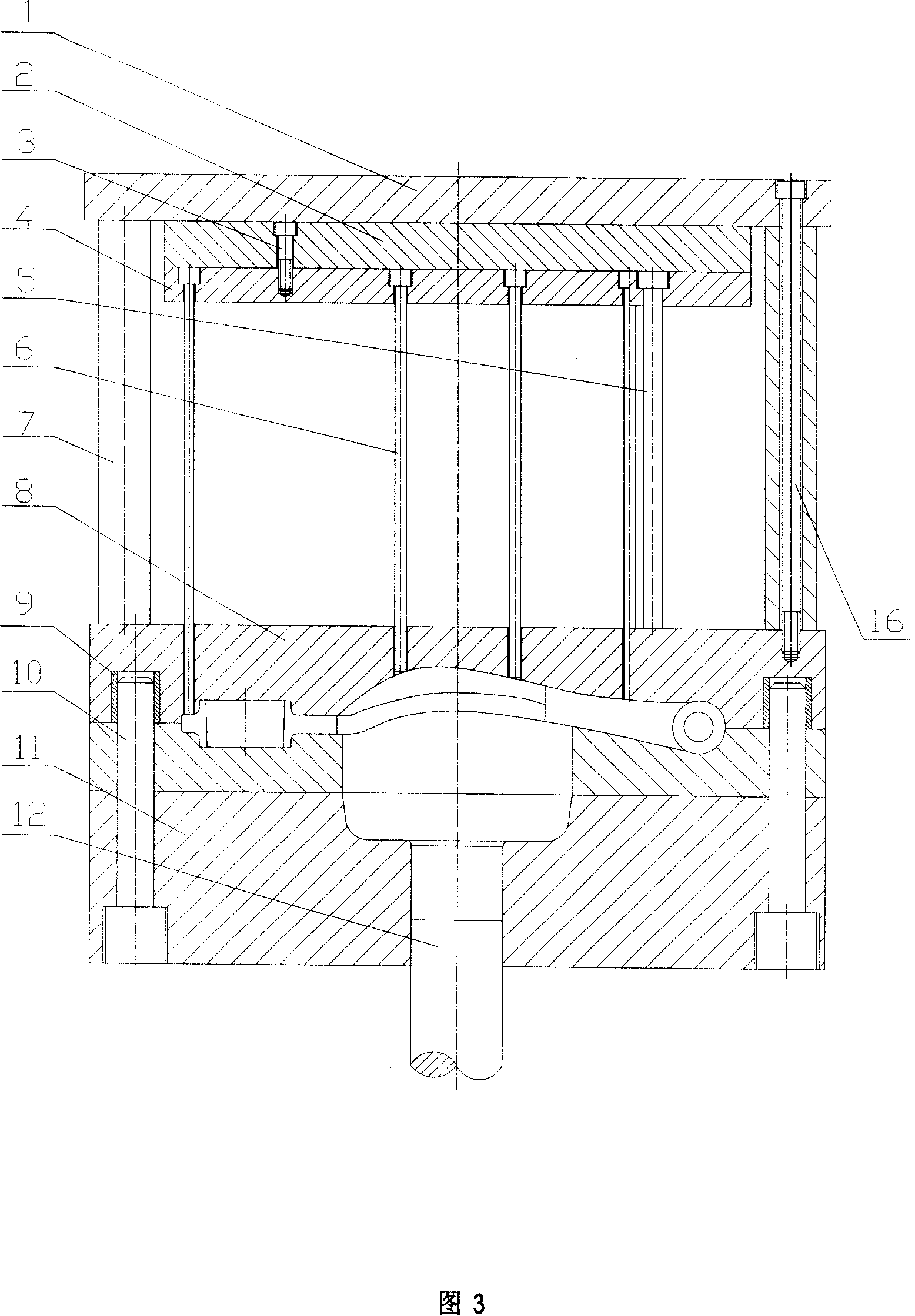

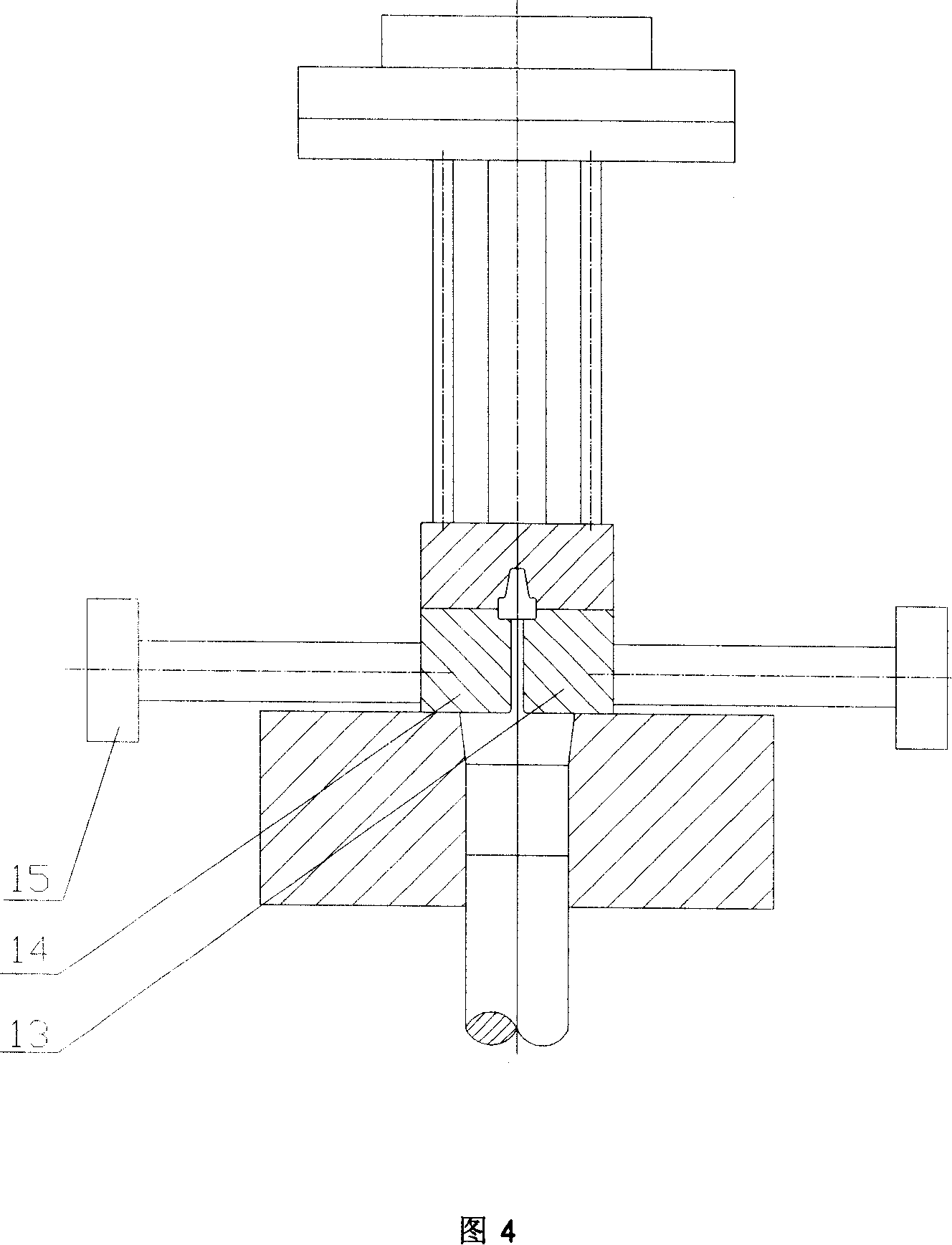

The invention relates to a forging technology and a device, in particular to aluminum alloy liquid forging molding technology and a module. In light of the technical problems that the prior art adopts complex module and process not suitable for aluminum alloy liquid forging, etc., the invention provides the forging module with simple structure and easy operation as well as the aluminum alloy liquid forging molding technology with reasonable process. The main technical proposal of the invention is as follows: a lower left module and a lower right module are arranged and fixed on a lower template in parallel, and a cylinder bottom punch gets through the lower template and is arranged between the lower left module and the lower right module; liquid aluminum alloy is injected into a cavity through a pouring port between the lower left module and the lower right module; an upper module is arranged on the lower left module and the lower right module and a pillar is also arranged and fixed; when in forging, the cylinder bottom punch conducts upward squeezing movement on liquid aluminum alloy; after meeting forging requirement, pressure can be maintained for 30 to 50 minutes.

Owner:宁波拓普隔音系统有限公司

Fresh kiwi fruit slices and preparation method thereof

InactiveCN105962190ADelayed ripeningGuaranteed fresh qualityFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by coatingActinidiaKiwi fruit

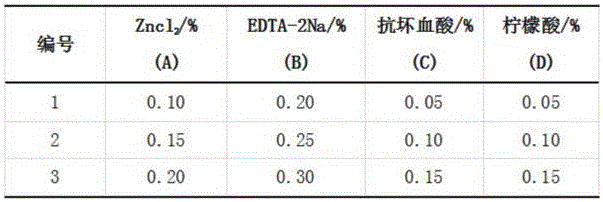

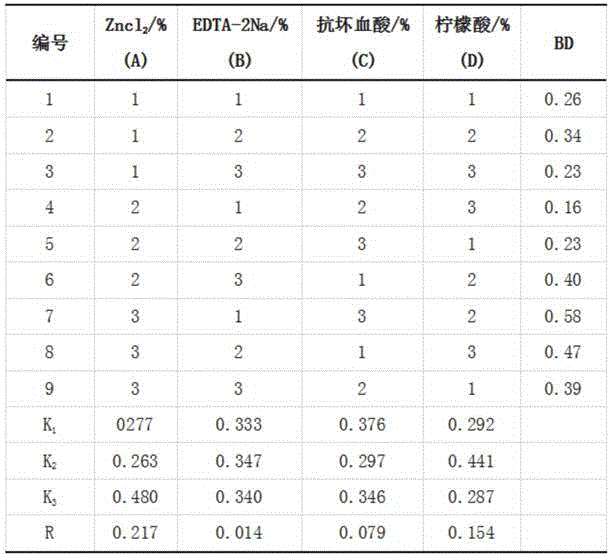

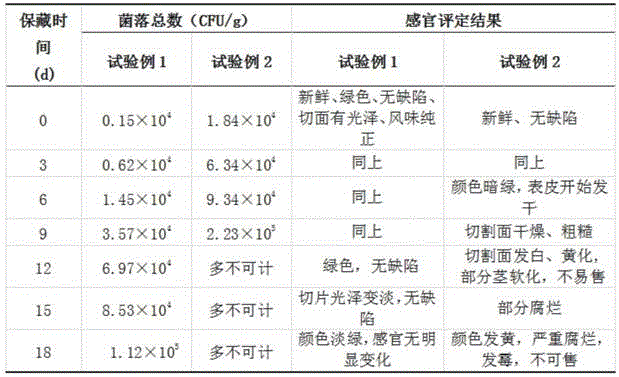

The invention discloses a preparation method of fresh kiwi fruit slices. The preparation method comprises the following steps: taking fresh high-quality kiwi fruits of which the hardness is between 9.0 kg / cm<2> and 11.0 kg / cm<2> as standard raw materials, putting slices into distilled water after washing, peeling and cutting the kiwi fruits, pumping ozone until the concentration is 0.8 to 1.0 mg / L, and carrying out ultrasonic assisted sterilization for 5 to 8 minutes; then, adding the slices into a kiwi fruit mixed color protecting solution which is prepared from 0.2 percent of ZnCl2, 0.25 percent of EDTA (Ethylene Diamine Tetraacetic Acid)-2Na, 0.10 percent of ascorbic acid and 0.1 percent of citric acid for carrying out color protection, and infiltrating by using 0.5 to 2.0 percent of PEG (Polyethylene Glycol)-chitosan edible coating film after dewatering; finally, packaging by using a PP (Propene Polymer) pallet and a PE (Poly Ethylene) film, and storing at low temperature. The fresh kiwi fruit slices prepared through the preparation method have the characteristics that the appearance color is well kept, browning is not easy to cause, the bacteria inhibiting and fresh keeping effects are good, the storage period is long, and the quality is stable.

Owner:SICHUAN UNIV

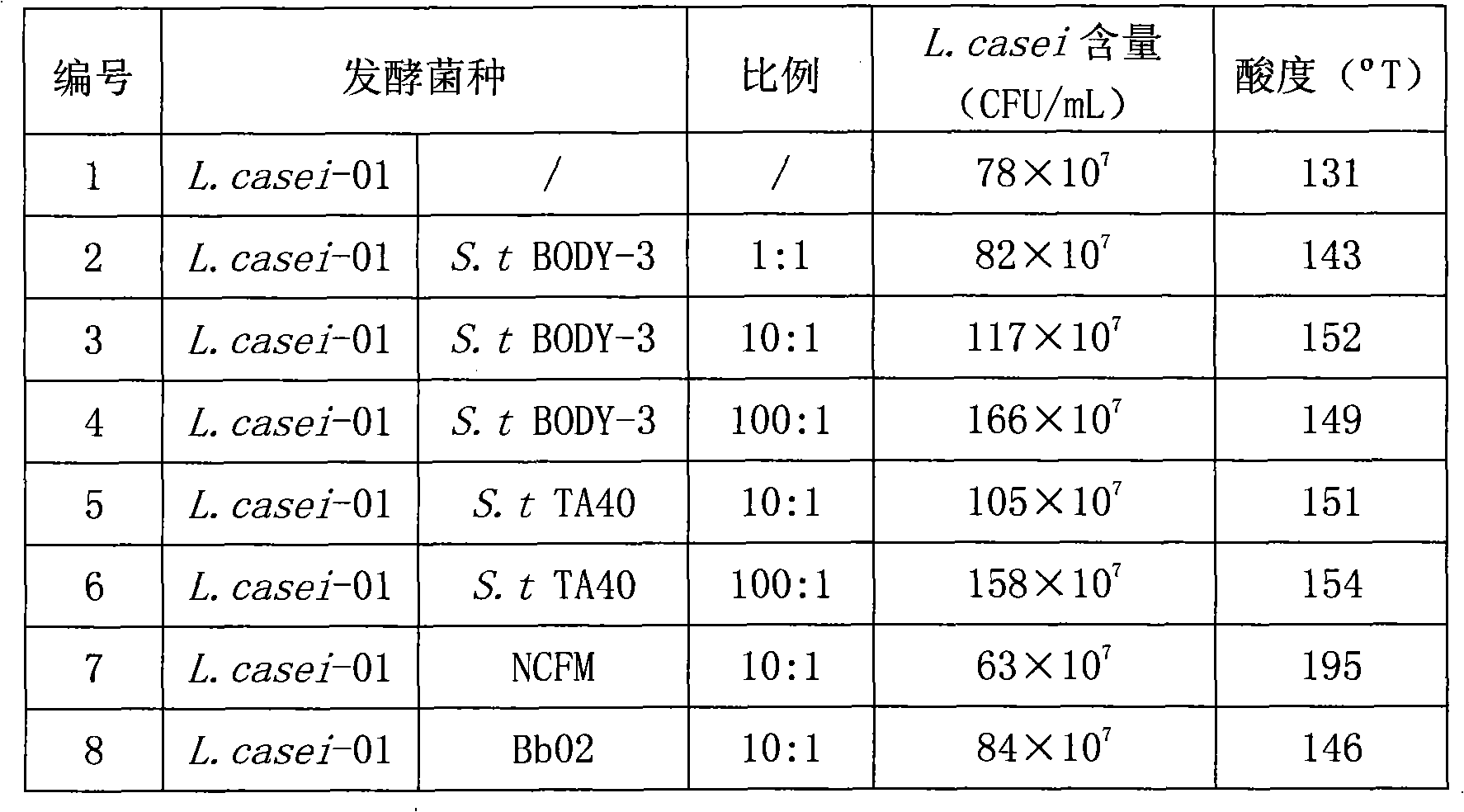

Active lactobacillus casei beverage and preparation method thereof

ActiveCN101911973AShorten fermentation timeBacteria content increasedMilk preparationMicroorganismSugar

The invention discloses an active lactobacillus casei beverage and a preparation method thereof and relates to an active probiotics beverage in the technical field of microorganism fermentation. The beverage comprises the following components in percentage by mass: 25 to 40 percent of fermented milk, 8 to 12 percent of white granulated sugar, 0.3 to 0.5 percent of stabilizing agent, 0.03 to 0.05 percent of food flavor and 50 to 70 percent of purified water. The preparation method comprises the following steps of: 1, preparing base materials; 2, fermenting the base materials; (3) preparing and disinfecting sugar liquor; and (4) preparing the beverage. Compared with the prior art, the method has the advantages of remarkably shortened product fermentation time, remarkably increased bacteria content of lactobacillus casei, lowered product cost and fermentation pollution risk, lowered equipment investment and suitability for producing the lactobacillus casei probiotics beverage under the conventional equipment condition by national dairy enterprises.

Owner:武汉光明乳品有限公司

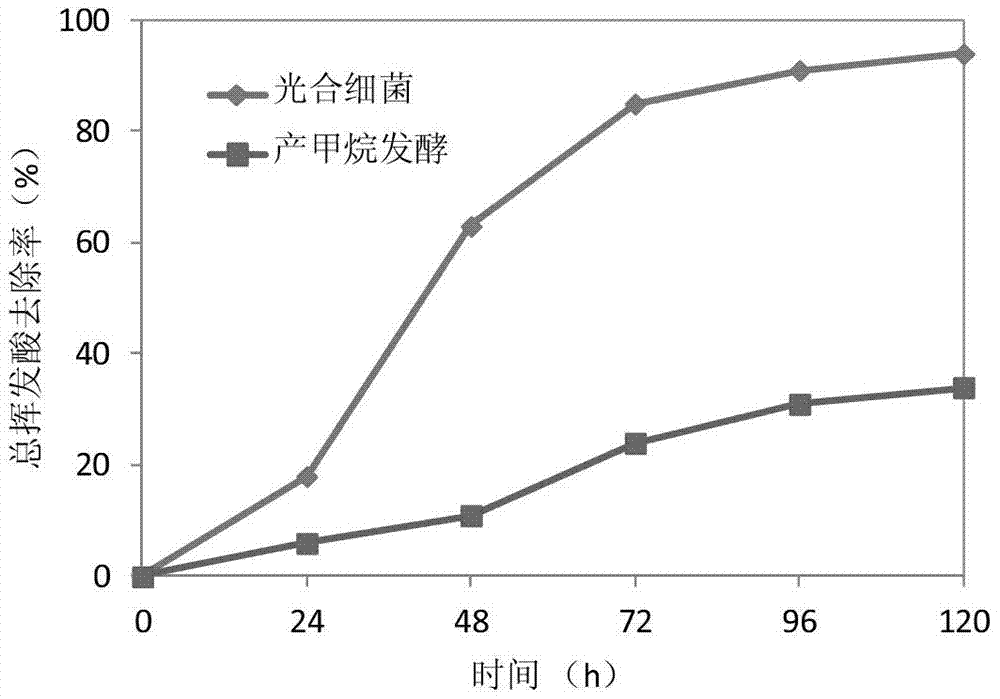

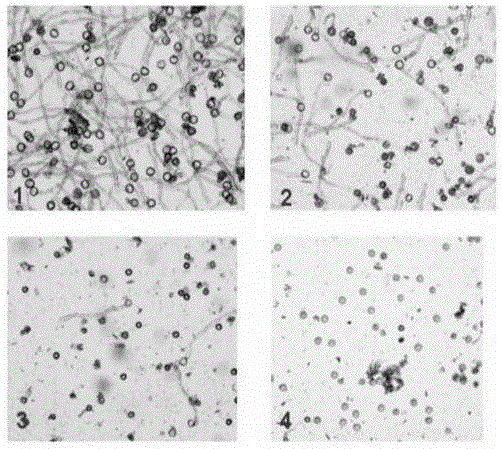

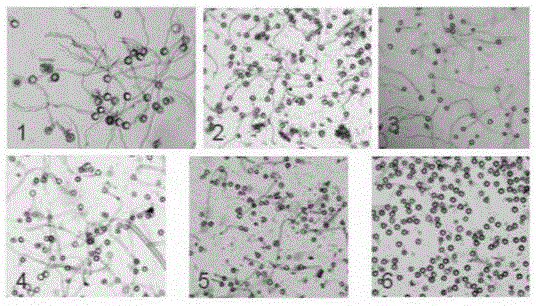

Treatment and recycling of kitchen wastes

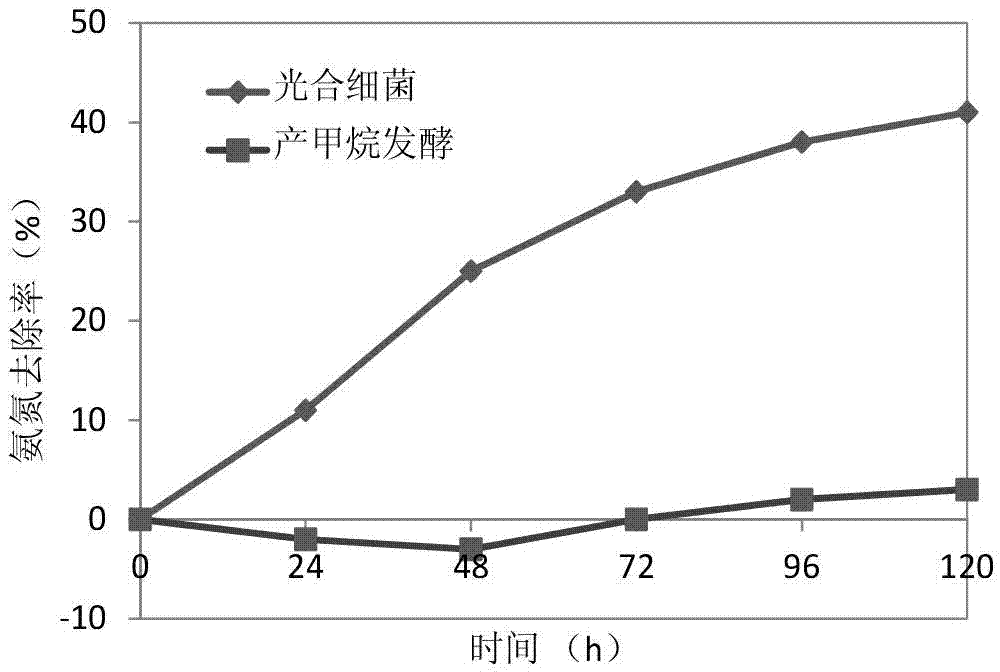

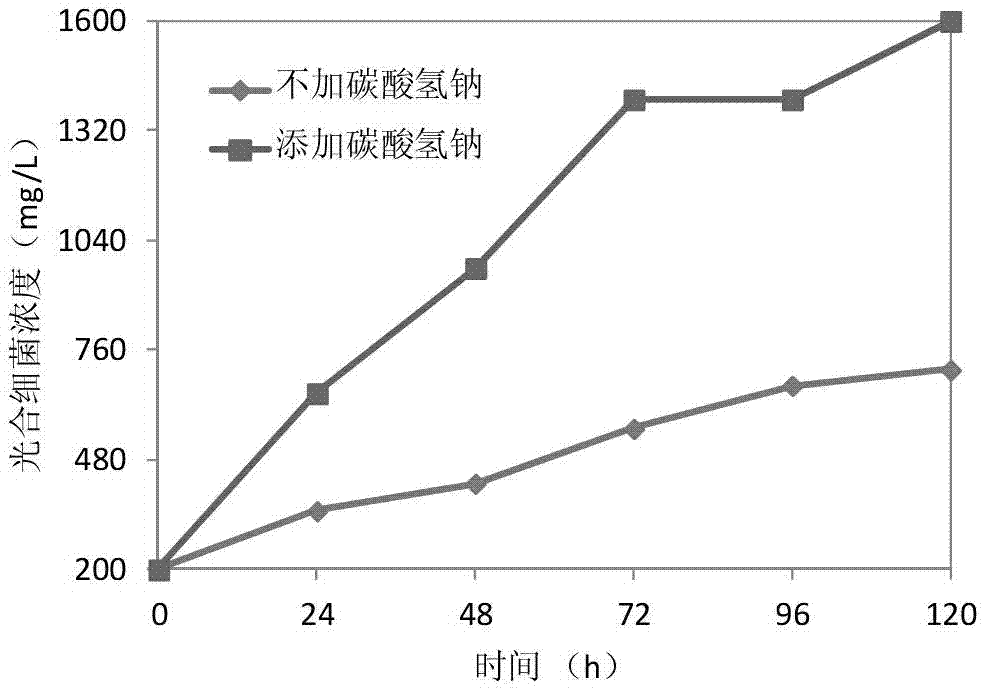

InactiveCN103084377AImprove processing efficiencyRealize resourcesBacteriaSolid waste disposalPretreatment methodVolatile fatty acids

The invention relates to a method for treating kitchen wastes by utilizing photosynthetic bacteria and recycling the kitchen wastes. The method particularly comprises a kitchen waste pretreating method which includes carrying out hydrolysis acidification treatment on the kitchen wastes until the concentration of volatile fatty acid is up to be 5000-15000mg / L to obtain hydrolysis acidification liquid, performing solid and liquid separation on the hydrolysis acidification liquid, adjusting the pH value of the liquid to be 6.5-7.5 to obtain a pretreated material, and a method for culturing the photosynthetic bacteria by using the pretreated material, which comprises the following steps of: inoculating 100-1000mg / L of a photosynthetic bacteria flora in the pretreated material and culturing the photosynthetic bacteria flora for 3-5 days under conditions that the illuminance is 1500-5000lux, the temperature is 25-35 DEG C and the dissolved oxygen concentration is 0-0.8mg / L. A product obtained by using the method can be used for preparing feed additives, water purification agents, ecological organic fertilizers or aquaculture baits. The method is strong in poison resistance capability for treating the kitchen wastes, good in denitrification and high in organic matter removal capability.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

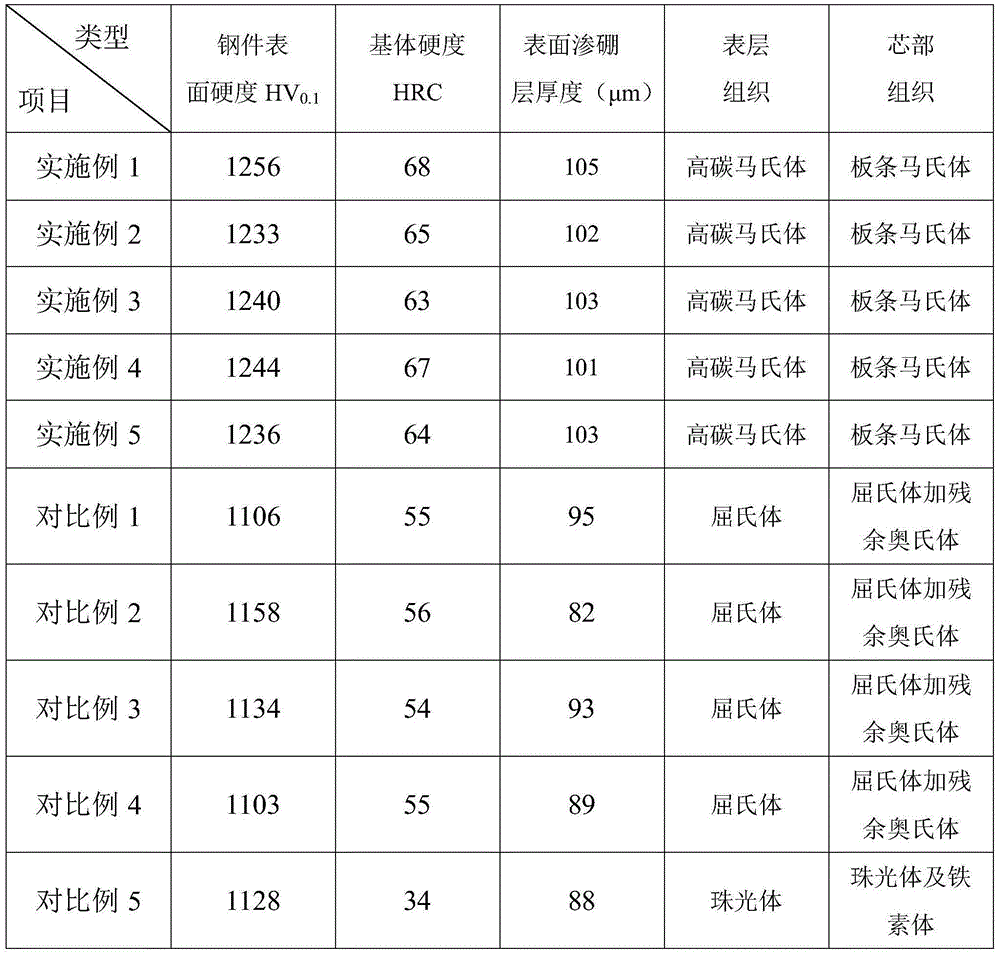

Surface treatment method for solid carbon-boron complex penetration of low-carbon alloy steel part

InactiveCN105088132AImprove bindingNot easy to fall offSolid state diffusion coatingQuenching agentsSolid carbonRoom temperature

The invention discloses a surface treatment method for solid carbon-boron complex penetration of a low-carbon alloy steel part. The method at least comprises the steps of: (a) carburizing pretreatment and steel part cleaning; (b) carburizing treatment; (c) taking out of a penetration box for carburizing from a resistance furnace, natural cooling to a room temperature, and taking out of a low-carbon alloy steel part after the carburizing treatment; (d) boriding pretreatment and steel part cleaning; (e) boriding treatment; (f) taking out of a penetration box for boriding from the resistance furnace after the boriding treatment in the step (e), natural cooling to the room temperature, and taking out of a low-carbon alloy steel part after the boriding treatment; (g) quenching treatment; and (h) tempering treatment. The method has the following beneficial effects: the carburizing and the boriding are performed in sequence to form a transition layer on the surface of the low-carbon alloy steel, so that a boriding layer and a steel basal body are better in combination and not easy to drop.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

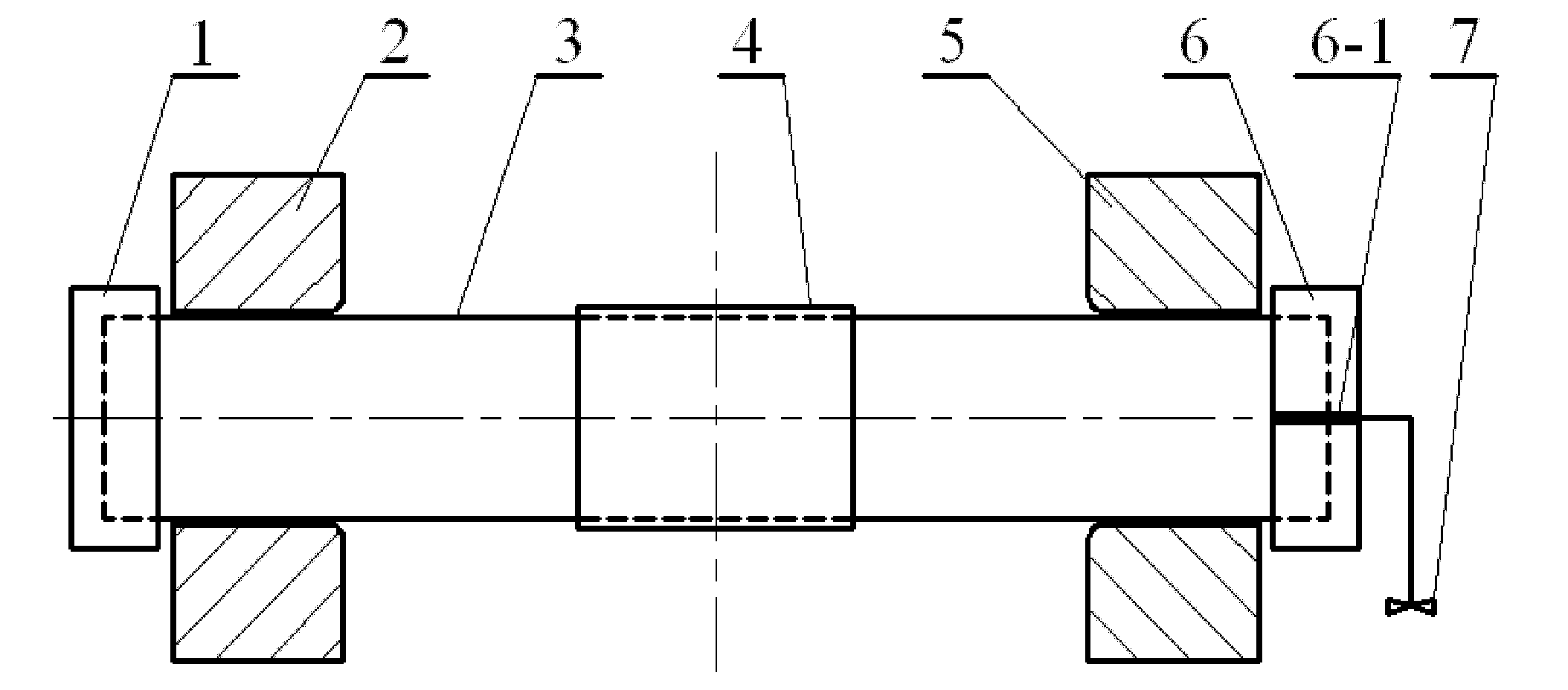

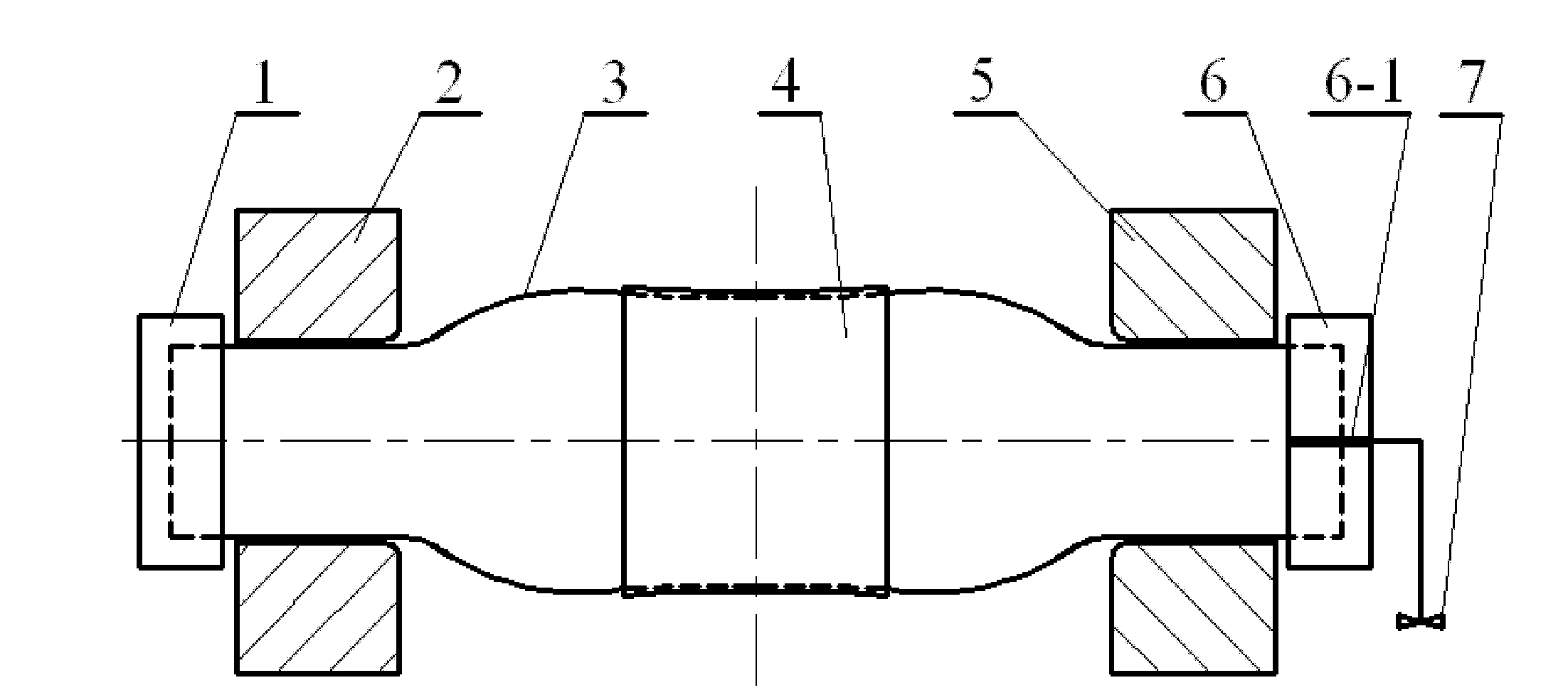

Device for improving pipe internal-pressure forming limit and method for improving pipe internal-pressure forming limit by utilizing same

The invention provides a device for improving pipe internal-pressure forming limit and a method for improving pipe internal-pressure forming limit by utilizing the same, which relate to a device and method for improving pipe internal-pressure forming limit and solve the problems of poor deformation uniformity, cracking due to the excessive thinning of a local part and low room-temperature forminglimit in the traditional pipe internal-pressure forming process. In the device provided by the invention, a constraint sleeve is arranged at the middle part of the outer side wall of a pipe or a die is arranged outside the pipe; in the method provided by the invention, the constraint sleeve is arranged at the middle part of the outer side wall of the pipe or the die is arranged outside the pipe, a filler is added into the gap between the die and the pipe, the pipe is fixed on a die frame with the two ends sealed, an internal pressure is introduced into the inner cavity of the pipe, and forming is finally carried out. In the invention, a back pressure is applied to the outer side of the pipe, so that the stress state of the pipe at a sectional part subjected to the maximum deformation is changed into a two-pulling and one-pressing mode from a two-pulling mode, thereby avoiding the possibility that a cracking defect is caused as the wall thickness of the part is excessively thinned, improving the room-temperature forming limit, and increasing the expansion ratio to 30-45%.

Owner:HARBIN INST OF TECH

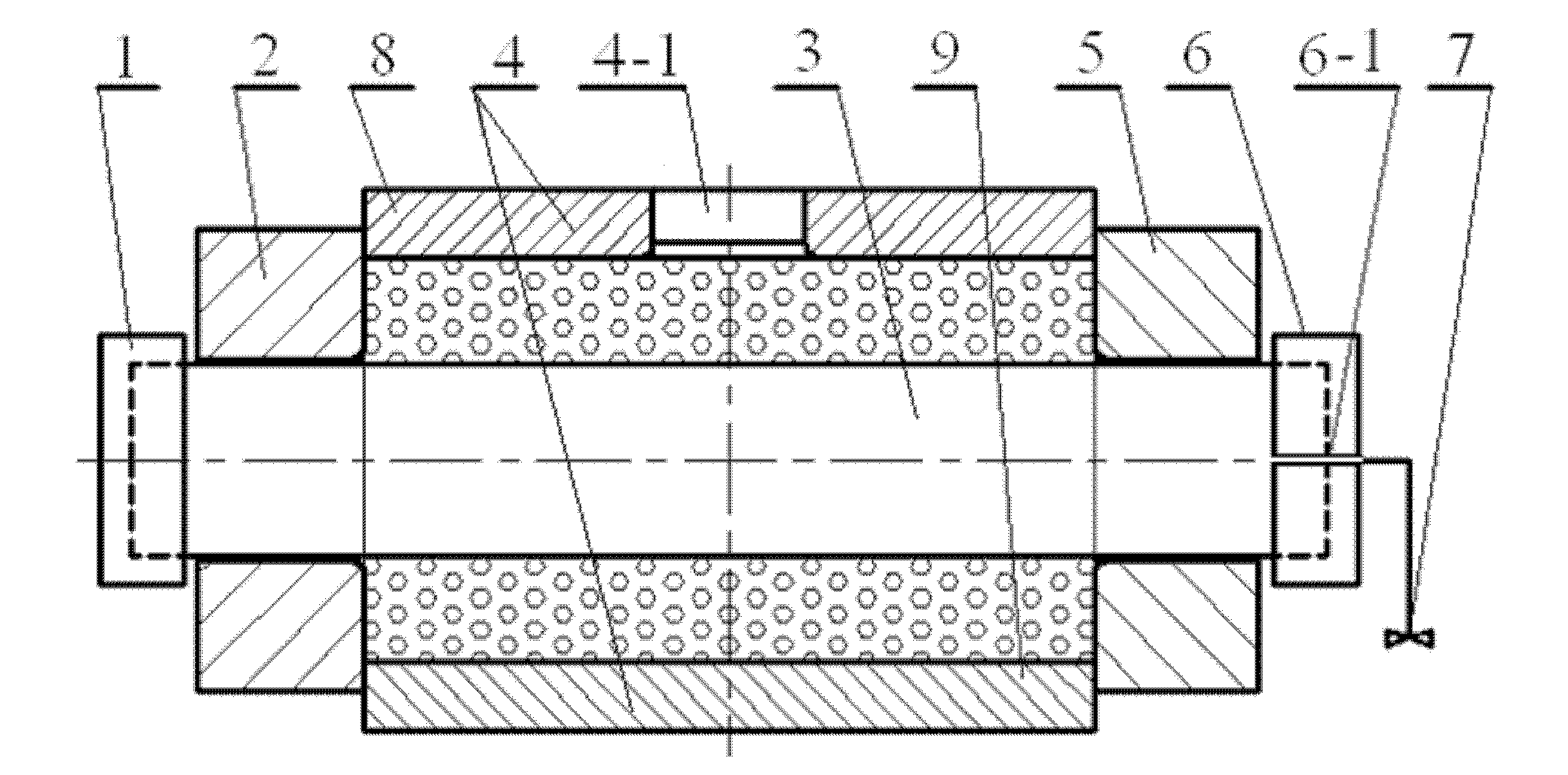

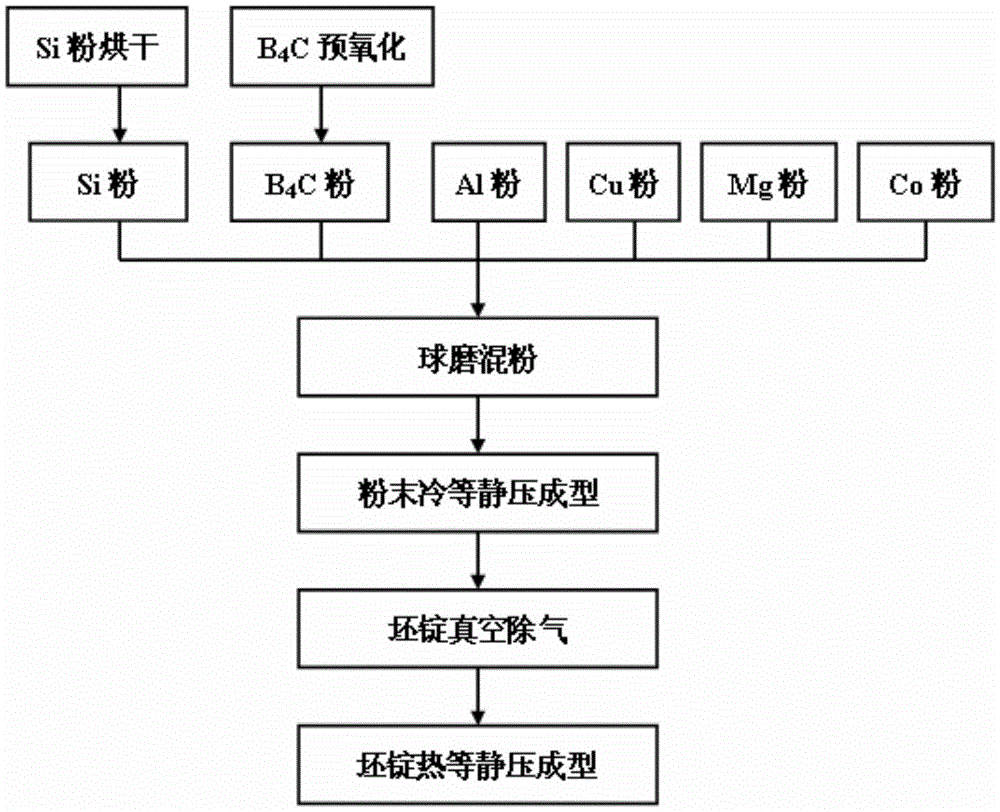

High-volume fraction B4C and Si particle mixing enhancement aluminum-based composite material and preparation process thereof

The invention discloses a high-volume fraction B4C and Si particle mixing enhancement aluminum-based composite material and a preparation process thereof. The aluminum-based composite material is composed of an Al-Cu-Mg-Co alloy base body and a mixing enhancement phase of B4C and Si. By volume percent, the content of the Al-Cu-Mg-Co alloy base body is 30%-45%, the content of the B4C is 55%-60%, the content of the Si is a, and a is larger than zero and smaller than or equal to 10%. The aluminum-based composite material is prepared through a powder metallurgy method. The preparation process mainly comprises the steps of pretreatment of the B4C and Si particles, ball mill mixing of the enhancement phase and Al alloy base body powder, powder cold isostatic pressing, vacuum degassing, hot isostatic pressing and the like. The density of the aluminum-based composite material is 2.55-2.60 g / cm<3>, the bending strength is 450-530 MPa, the elastic modulus is 180-220 GPa, the thermal expansion coefficient is 7.6-9.5*10<-6>K<-1>, and the thermal conductivity is 70-100 W / m.K. The excellent performance of the aluminum-based composite material can well meet the using requirements of spaceflight light high-strength structure function part materials.

Owner:有研金属复材技术有限公司

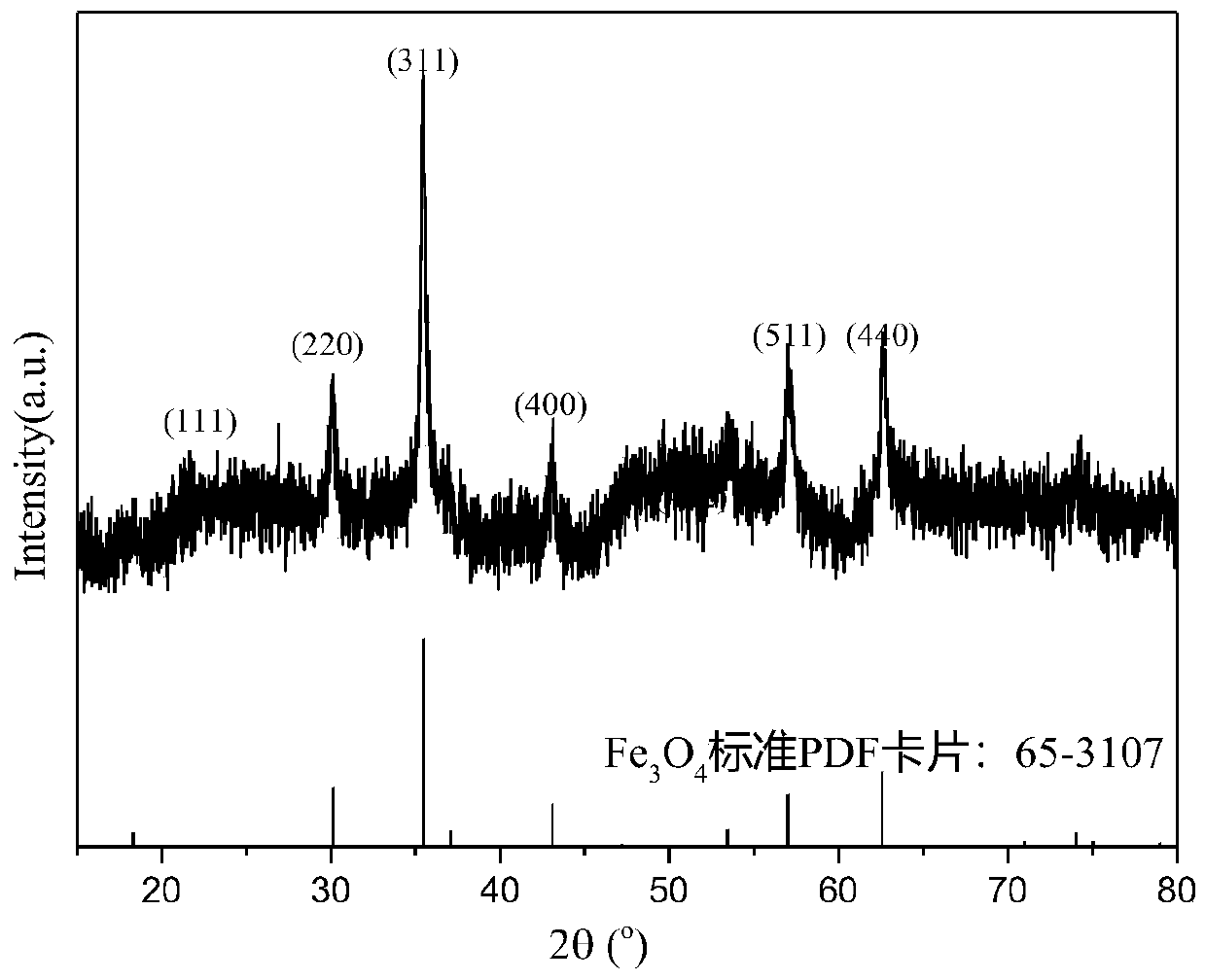

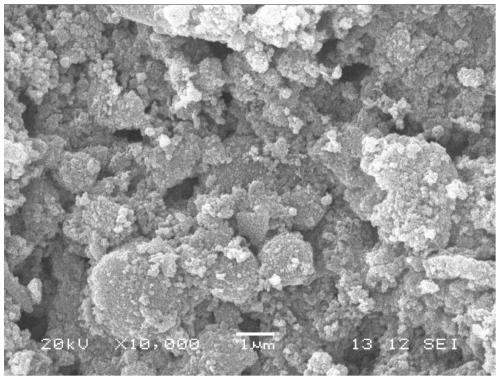

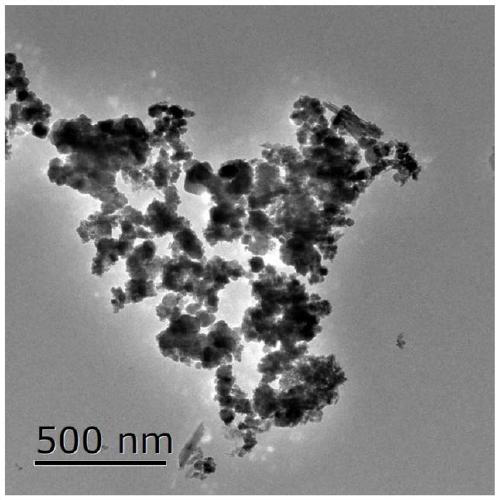

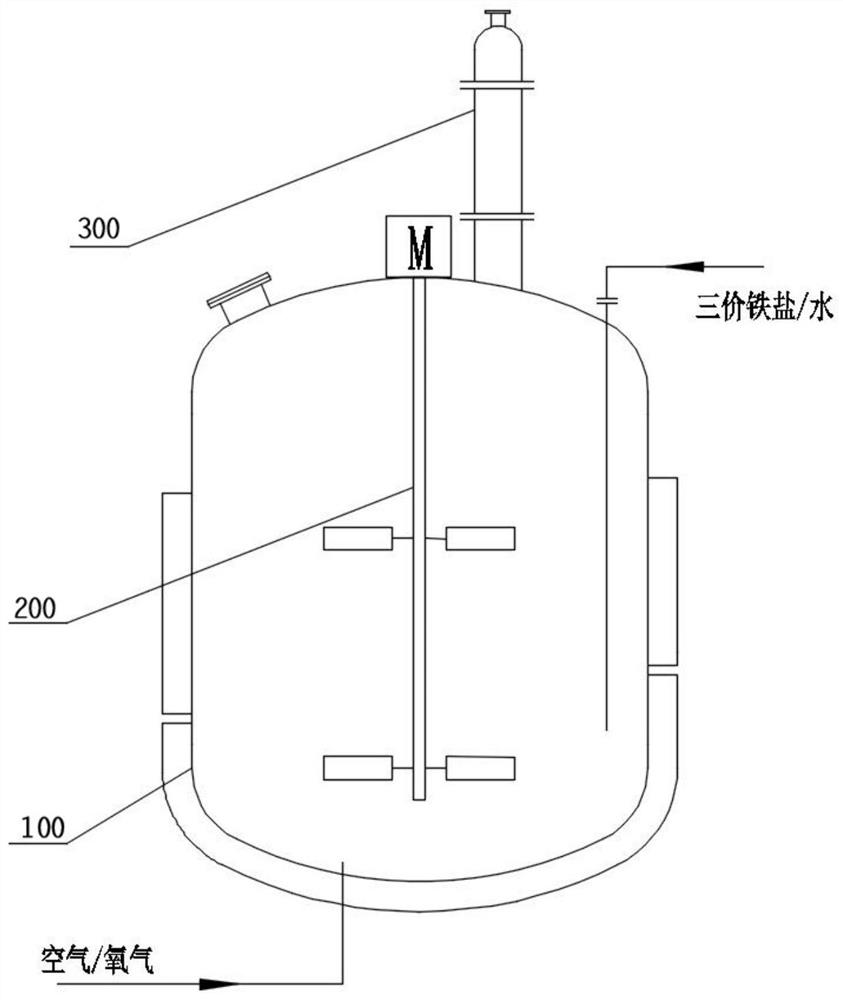

Titanium modified Fe3O4 magnetic nano-particle, preparation method and application thereof

InactiveCN110075846ARapid hydrolysisGreen environmental protection equipment requirementsWater treatment compoundsWater contaminantsMagnetite NanoparticlesSolvent

The invention provides a titanium modified Fe3O4 magnetic nano-particle, a preparation method and the application thereof. The preparation method specifically comprises the following steps: in a eutecticevaporate solvent of choline chloride and urea, taking ferrite as an iron source, tetrabutyl titanate as a titanium source and air as an oxidizing agent, and using a precipitation oxidization process to synthesize the titanium modified Fe3O4 magnetic nano-particle in one step. According to the preparation method provided by the invention, the obtained material has excellent catalytic degradation capacity (for example, under the conditions of room temperature and neutral pH, the color removal rate for a 0.01 mmol / L methylene blue solution within 2h reaching 93.8%, and the removal rate for a20 mg / L Ciprofloxacin solution reaching 96.5%) for organic waste water, is easy for magnetic separation recycle and stable in reuse performance, and is a novel magnetic environmentally-friendly material with low cost, quick and convenient operation, obvious effect and wide application prospect.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Waste electrolyte treatment method for lithium-ion battery

InactiveCN108923092AReaction is easy to controlReduce security risksWaste accumulators reclaimingBattery recyclingReaction temperatureLithium-ion battery

The invention discloses a waste electrolyte treatment method for lithium-ion battery which comprises the following steps: S1, adding the waste electrolyte into a basic solution for reaction, and forming a three-phase system comprising a solid phase, an organic phase and a water phase, wherein the addition speed is 0.5 to 30 kg / h, the stirring speed during the reaction is 20 to 300 r / min, the reaction temperature is 20 to 80 DEG C and the reaction time is 2 to 8 h; S2, performing solid-liquid separation on the three-phase system in S1 to obtain a solid phase and a liquid phase, standing and layering the liquid phase to separate the organic phase and the water phase; S3, putting the solid phase in S2 into water, heating and dissolving, cooling and performing recrystallization to obtain the crystal and recrystallized mother liquor. The waste electrolyte treatment method for lithium-ion battery provided by the invention has advantages of safe operation, high effective utilization rate of sources and environmental protection and the like.

Owner:HUIZHOU CAPCHEM CHEM CO LTD

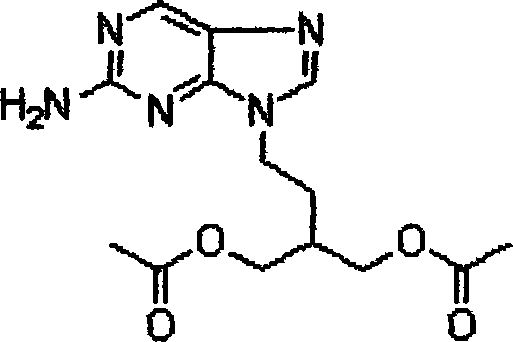

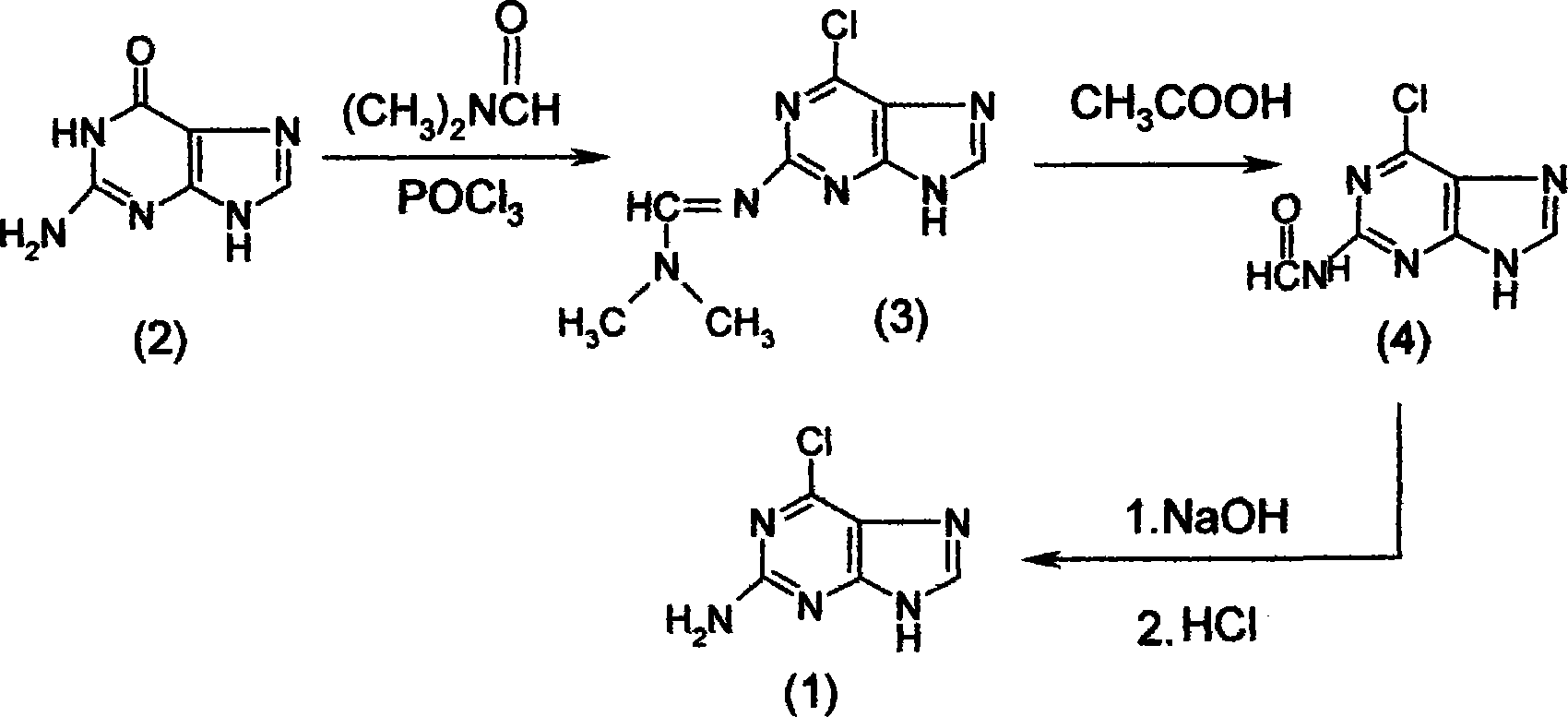

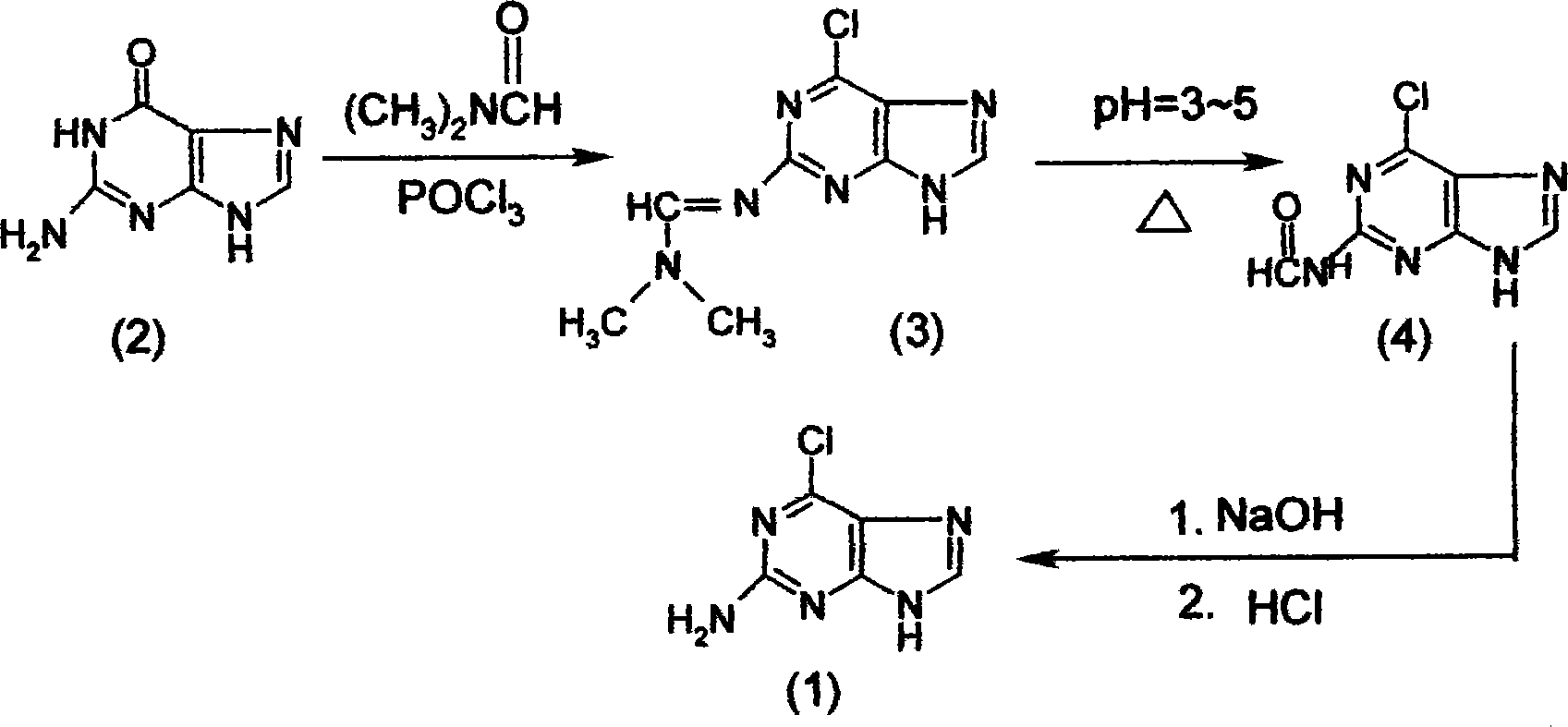

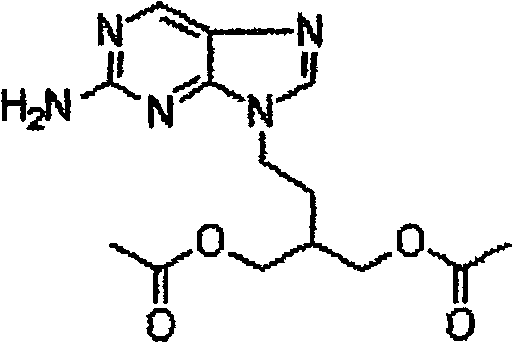

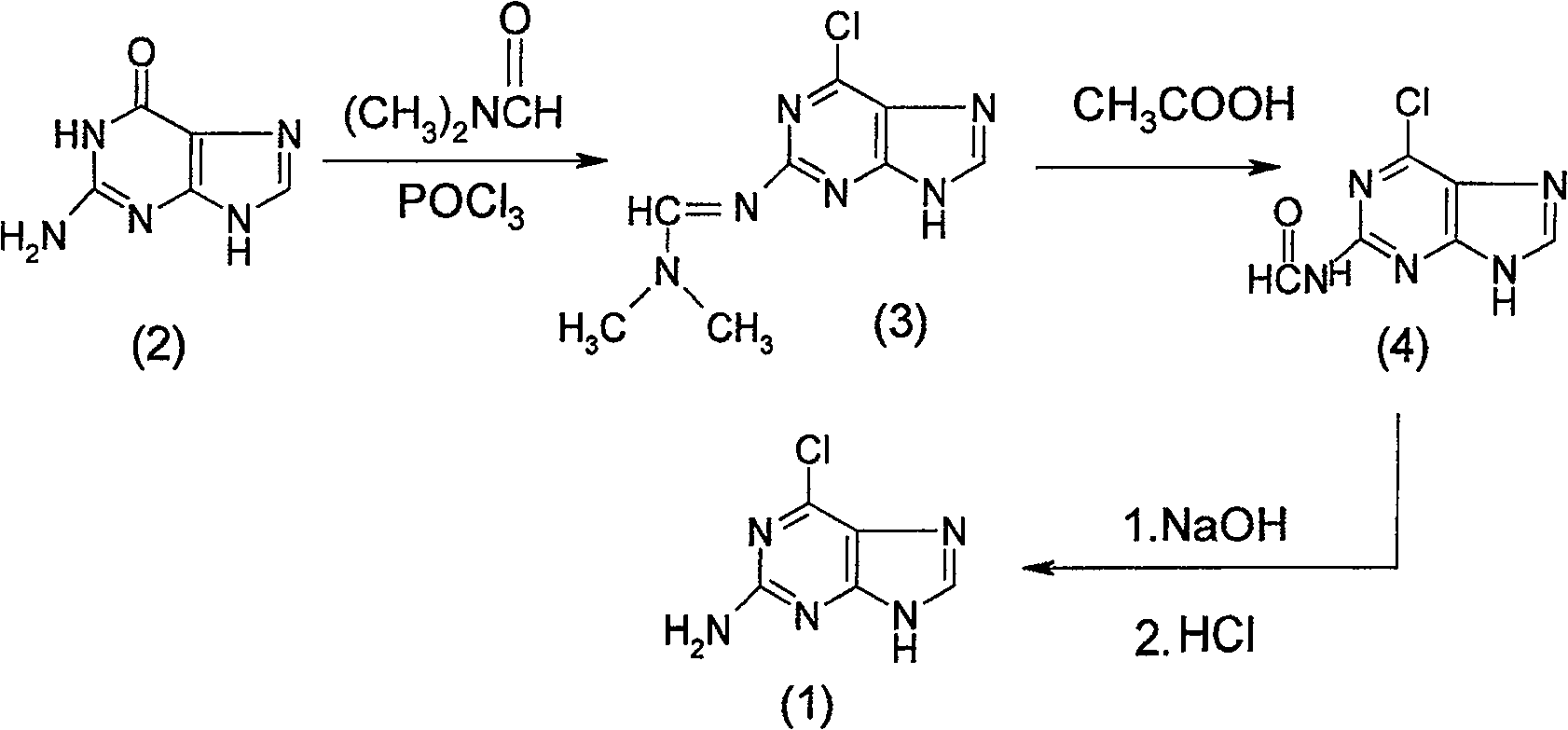

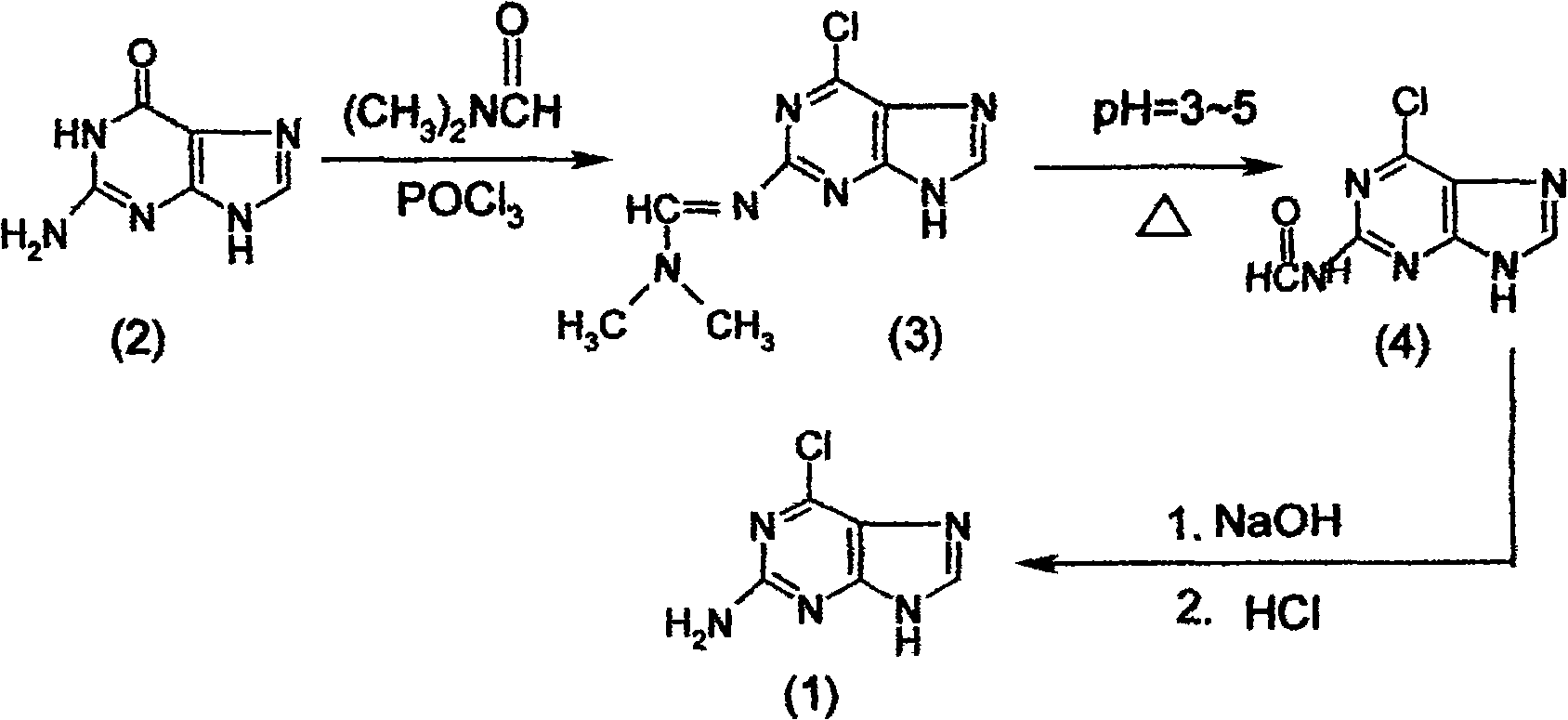

Method for synthesizing 2-amido-6-chloropurine

InactiveCN101139348AAvoid the disadvantage of being prone to side reactions with guanineHigh yieldOrganic chemistryN dimethylformamideSynthesis methods

The present invention relates to a synthesis method of the 2-amino-6-chlorine purine (1), orderly comprising the following steps: the N, N-dimethylformamide is first added in the phosphorus oxychloride at a low temperature to prepare the mixture solution; then the 1, 2-dichloromethane of the guanine (2) is dropped to react to get the 2-dimethylamino-ene imino-6-chlorine purine (3); the product (3) is dropped into the water; the organic phase is separated and recycled for reuse; the alkali metal hydroxide solution is used for adjusting the pH value of the water phase to be between 3 and 5; the 2- formamide-6-chlorine purine (4) wet material is produced after heating; the product (4) wet material is done with the hydrolysis reaction in the alkali metal hydroxide solution; then the hydrochloric acid is used for adjusting the pH value to get the crude material of the 2-amino-6-chlorine purine (1); finally the fine target product (1) can be got through purification.

Owner:LIANYUNGANG CCA CHEM CO LTD

Vacuum storage method and application of soybean pollen

ActiveCN104145947AHigh equipment requirementsHigh storage costDead plant preservationPlant genotype modificationHybrid seedPollen

The invention discloses a vacuum storage method and application of soybean pollen. The method comprises the following specific operation steps of putting a flower bud in a vacuum bag, completely pumping the air in the bag, sealing the vacuum bag and storing the vacuum bag at 4 DEG C. Experiments prove that when the soybean pollen is stored by using the vacuum storage method, the vigor preservation time of the pollen is prolonged from 2-4 hours to 48 hours, so that the effective pollination time is prolonged, the degree of freedom of the pollination time is increased, the environment unfavorable to the development of fertilized eggs is avoided, the labor intensity is reduced, the work efficiency is improved and a foundation is laid for the hybrid seed production and the genetic research.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

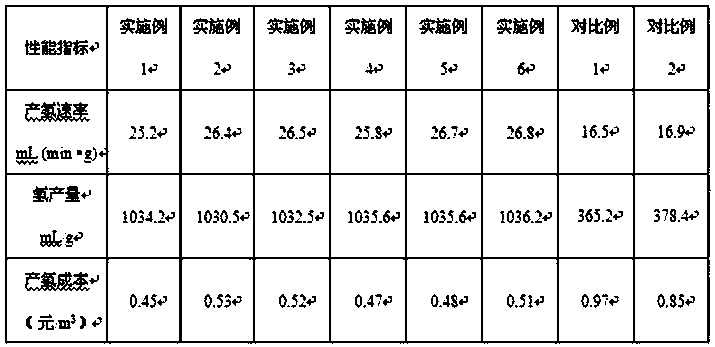

Method of producing hydrogen energy through physical ball milling of metal powder

InactiveCN108751128AIncrease manufacturing costHigh cost of preparationHydrogen productionMetal chlorideReaction rate

The invention provides a method of producing hydrogen energy through physical ball milling of metal powder. The method comprises: putting metal powder into a vacuum ball mill, adding a small amount ofa metal chloride aqueous solution and an aid into the powder and carrying out wet ball milling in a hydrogen protective atmosphere so that the oxide layers or hydroxide formed by the reaction is peeled from the metal powder under the action of ball milling. Through use of the aid in the metal powder-based hydrogen production and physical ball milling, the oxide / hydroxide film formed in the hydrolysis hydrogen production reaction is peeled from the metal powder so that the hydrogen production yield and the reaction rate are effectively ensured. The whole process is simple, the reaction processis neutral, the equipment requirements are low and the production cost is low.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

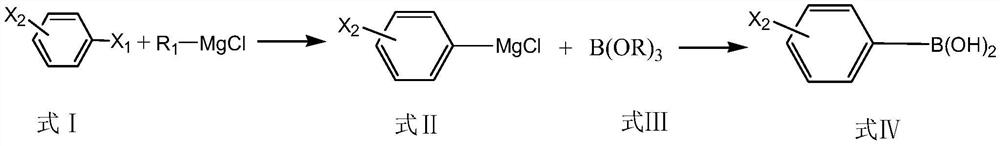

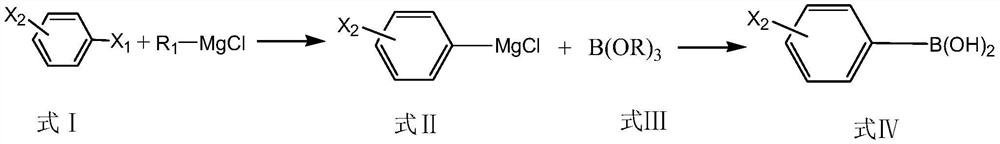

Preparation method of monohalogenated phenylboronic acid

ActiveCN111647011ARealize industrial productionAvoid it happening againGroup 3/13 element organic compoundsBulk chemical productionChemical synthesisPtru catalyst

The invention relates to the technical field of chemical synthesis, and particularly discloses a preparation method of monohalogenated phenylboronic acid. The preparation method comprises the following steps of: by taking dihalogenated benzene as a raw material and a mixture of lithium salt and alkaline ionic liquid as a catalyst, carrying out Grignard exchange with R1MgCl to generate monohalogenated phenyl magnesium chloride, reacting with B (OR) 3 to generate monohalogenated phenyl borate, and hydrolyzing under acidic conditions to obtain monohalogenated phenylboronic acid. The HPLC (High Performance Liquid Chromatography) content of the monohalogenated phenylboronic acid prepared by the method is greater than 99.5%; the total yield of the product is greater than 80%, the contents of monohalogenated phenylboronic acid and phenyldiboronic acid impurities of another halogen are both less than 0.003%, the requirements of modern fine chemical synthesis are completely met, the raw materials are easily available, the operation is simple, the safety is high, and the industrial production of monohalogenated phenylboronic acid is realized.

Owner:宁夏中星显示材料有限公司

Solid state fermentation production method for prodigiosin

ActiveCN103627747AIncrease productionRealize industrial productionMicroorganism based processesFermentationMass ratioSerratia species

The invention provides a solid state fermentation production method for prodigiosin by using an inert carrier. The method is characterized by comprising the following steps: preparing a seed liquid of Serratia marcescens; and inoculating the seed liquid into a solid state fermentation medium according to a volume mass ratio of 4-15 ml / 100 g and carrying out culture for 24 to 48 h under the conditions of a temperature of 24 to 30 DEG C and relative humidity of 70 to 90% so as to obtain a solid state fermentation prodigiosin product; wherein the solid state fermentation medium is composed of the inert carrier, a carbon source, a nitrogen source, salt and water according to a mass ratio of 1: 0.5-3: 0.2-2: 0.01-0.05: 5-18.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

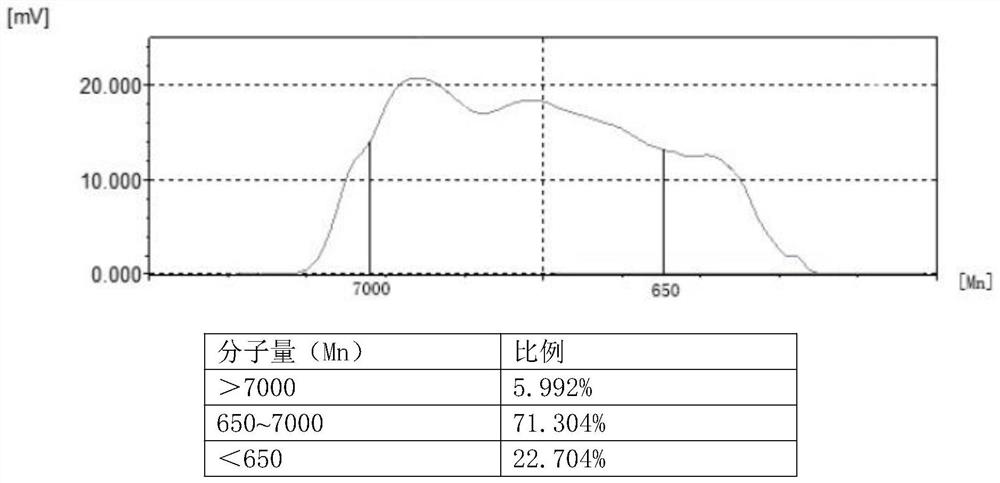

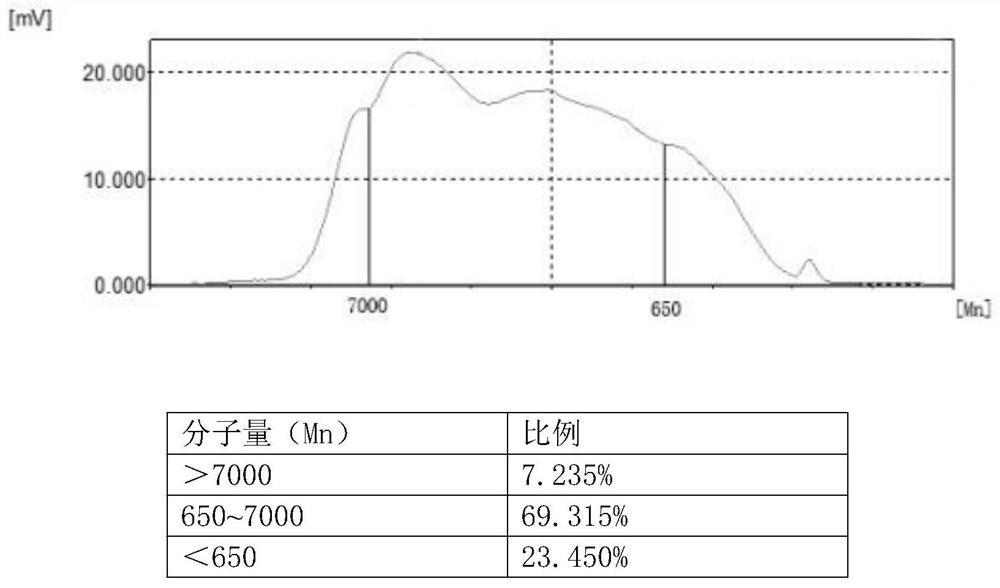

Preparation method of polycarbosilane ceramic precursor material

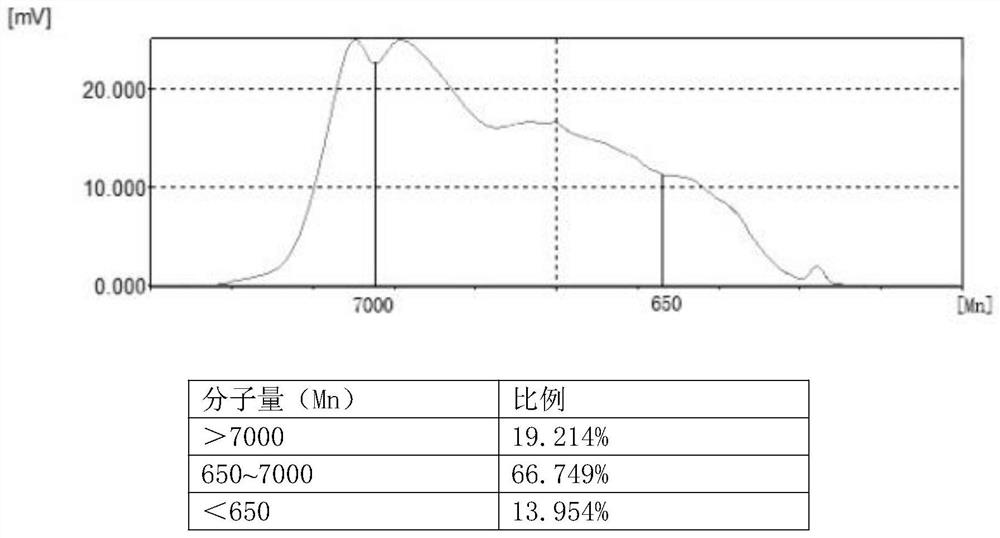

ActiveCN112062967ALow equipment and process requirementsThe qualification rate of the process is highAdditive manufacturing apparatusFibre chemical featuresComposite materialPropanol

The invention discloses a preparation method of a polycarbosilane ceramic precursor material. The method comprises the following steps: putting polydimethylsilane into a high-pressure synthesis kettle, repeatedly vacuumizing, replacing gas in the kettle with high-purity nitrogen, introducing nitrogen, controlling the temperature, cracking polycarbosilane under normal pressure, adding nitrogen to maintain the pressure, continuing heating to react, controlling a certain pressure, and cooling to obtain a polycarbosilane crude product; grinding and screening the polycarbosilane crude product to form polycarbosilane powder; soaking the screened polycarbosilane powder with absolute ethyl alcohol, fully stirring and filtering to collect polycarbosilane insoluble in the absolute ethyl alcohol; dissolving polycarbosilane which is insoluble in n-propanol by using xylene, introducing nitrogen during reaction, and fully stirring to obtain a mixed solution; heating the mixed solution under the protection of nitrogen, and cooling to obtain a polycarbosilane finished product of which the softening point is 200-210 DEG C, the high molecular weight part is 8-12% and the medium molecular weight partis more than 70%.

Owner:福建立亚化学有限公司

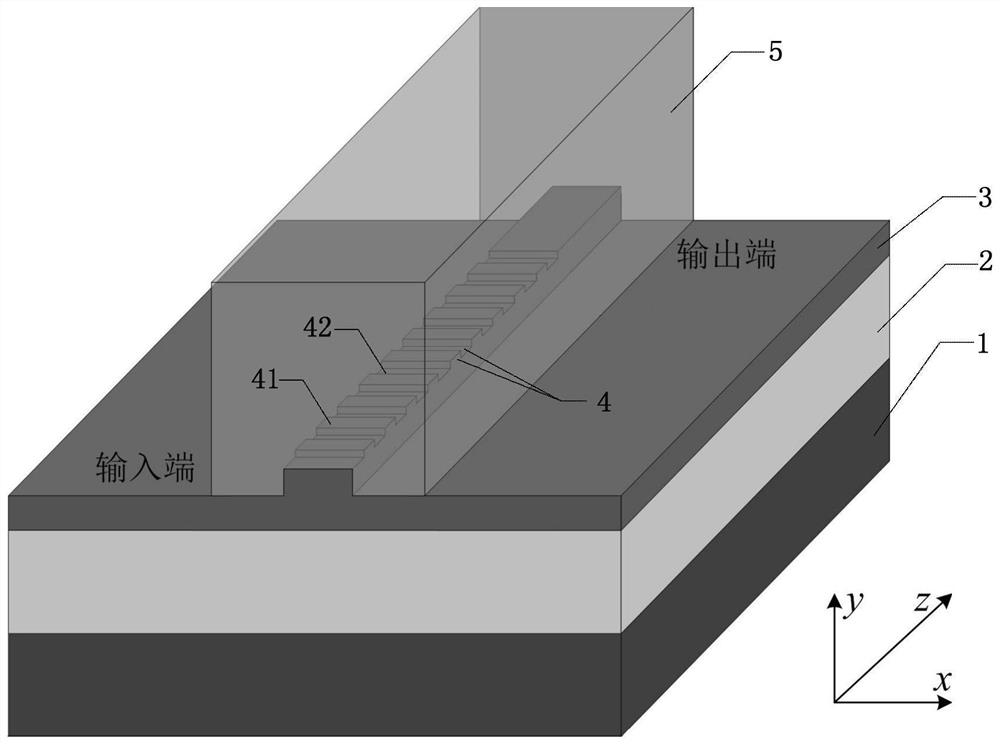

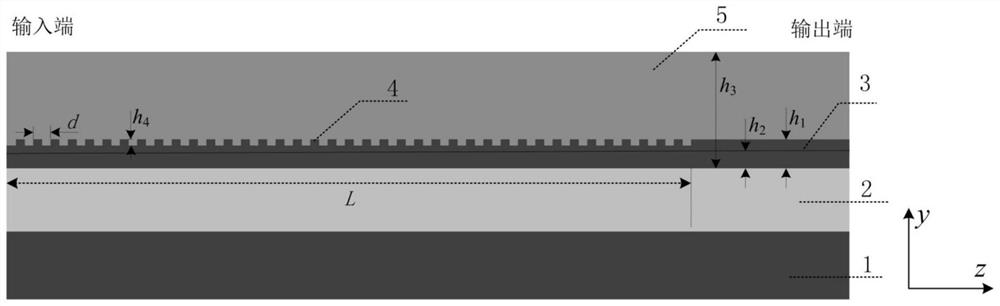

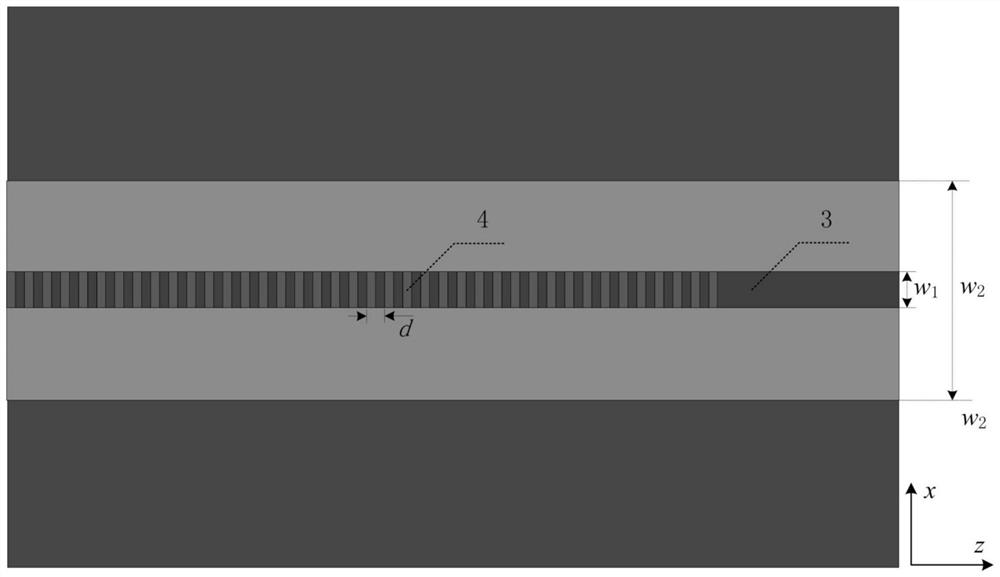

Spot size converter based on long-period grating

ActiveCN113376743AImprove optical coupling efficiencyImprove robustnessOptical waveguide light guideLight waveEngineering

The invention discloses a spot size converter based on a long-period grating. The spot size converter is applied to the field of optical communication and optical waveguide devices, realizes the conversion of the spot size of an optical wave mode, and comprises a substrate, a buffer layer, a high-refractive-index waveguide core, the long-period grating and a low-refractive-index upper cladding strip waveguide, wherein one surface of the buffer layer is fixedly connected with the substrate, and the other opposite surface of the buffer layer is fixedly connected with one surface of the high-refractive-index waveguide core; the other opposite surface of the high-refractive-index waveguide core is used for etching to obtain the long-period grating; and the other opposite surface of the high-refractive-index waveguide core and the long-period grating are fixedly connected with the low-refractive-index upper cladding strip waveguide. According to the invention, the problems of complex structure, high manufacturing difficulty, high technical cost and poor long-term stability of a traditional nanometer photonic waveguide end face coupling spot size converter are solved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

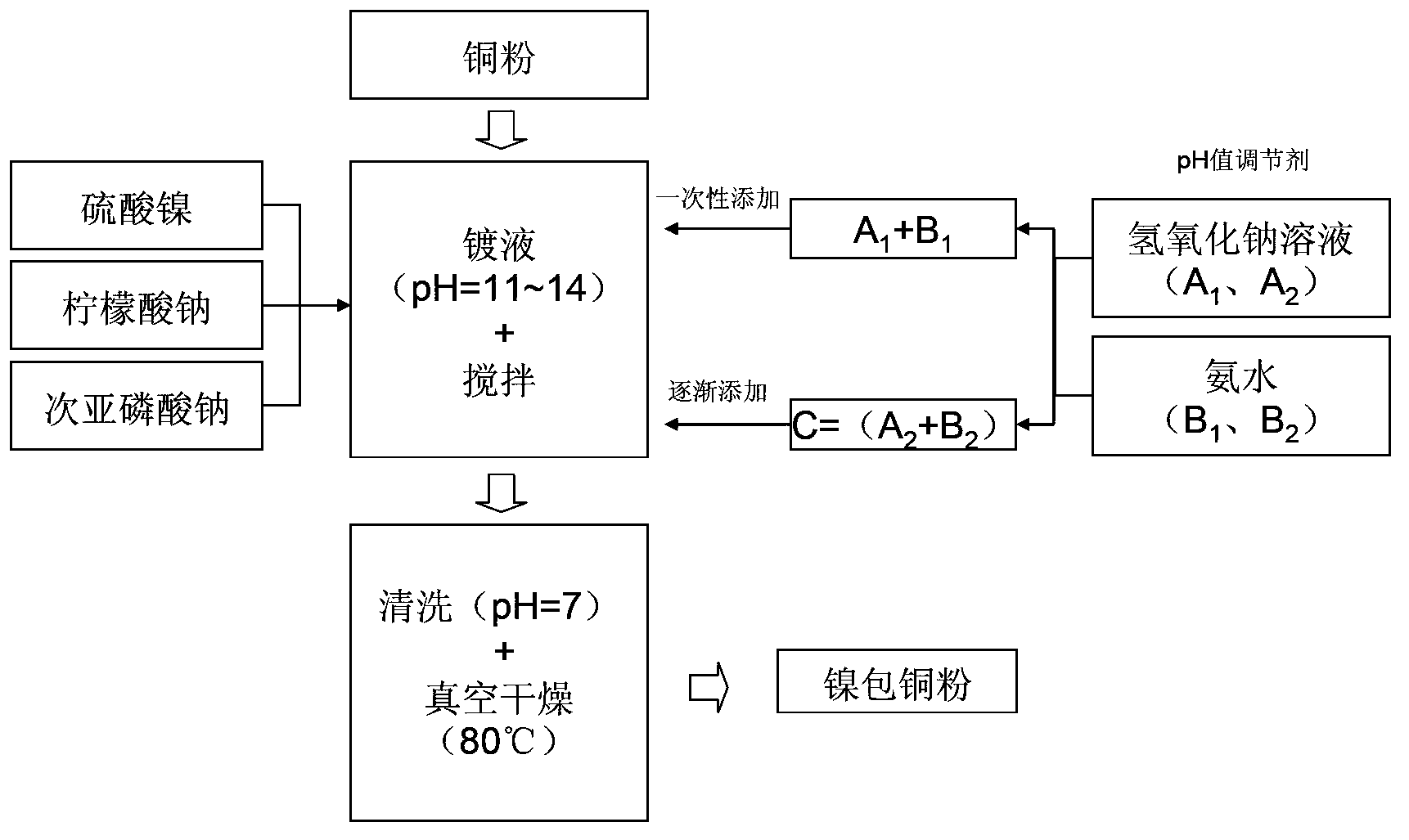

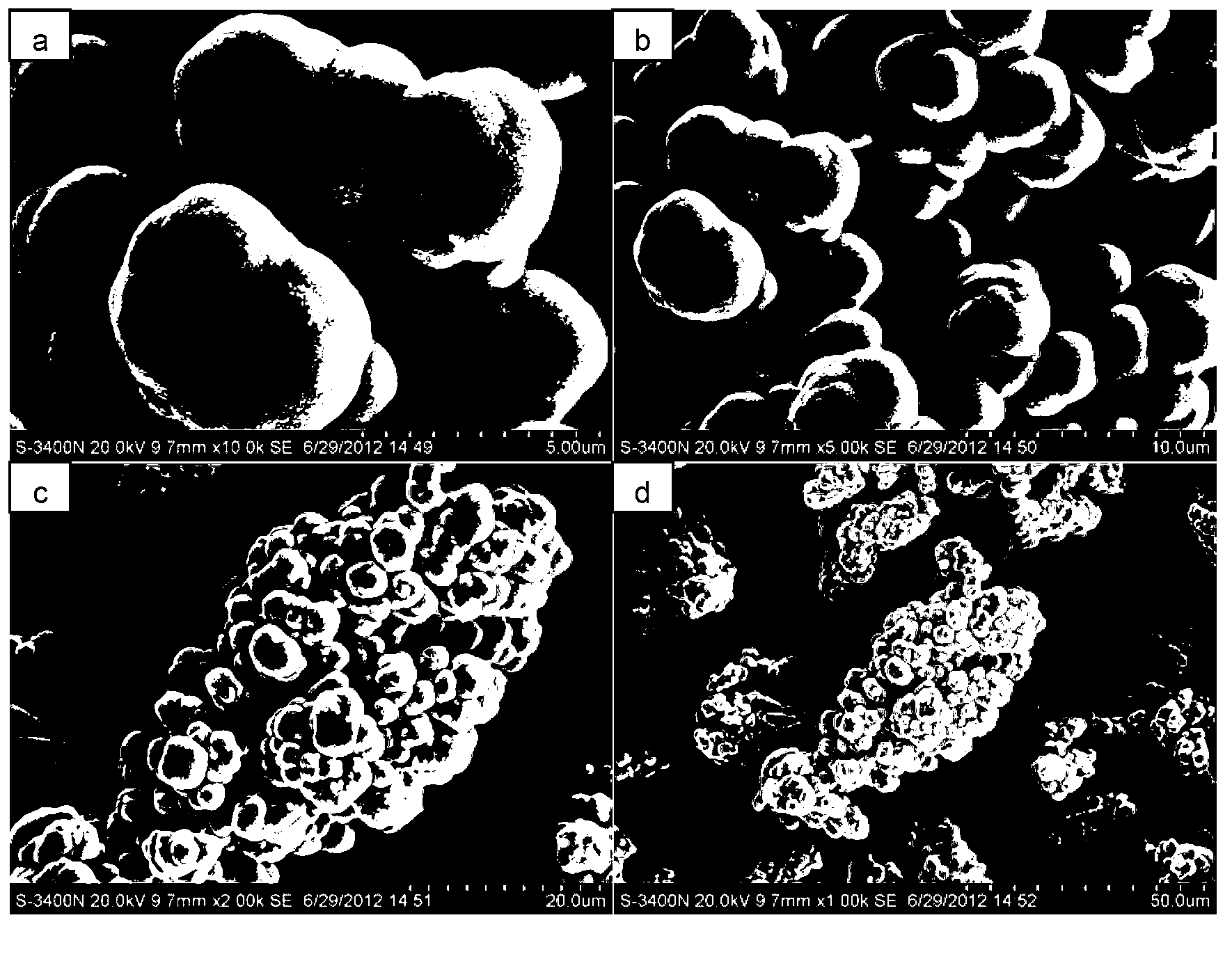

Preparation method of nickel-coated copper powder for conductive rubber

ActiveCN103060780AUniform coatingStrong combinationLiquid/solution decomposition chemical coatingMetallic NickelConductive rubber

The invention provides a preparation method of a nickel-coated copper powder for a conductive rubber, and belongs to the technical field of surface treatment of powder bodies. According to the preparation method, a chemical reduction method is carried out, a plating solution and a pH (Potential Of Hydrogen) regulator are reasonably prepared at a room-temperature condition, therefore the surface of copper powder is subjected to basic deoxidation in order to realize the purpose of optimizing a plating-coating process; the method of continuously dropping the mixed solution of ammonia water and sodium hydroxide is carried out, thereby the stability of the plating solution is maintained, and the pH value of the plating solution is maintained to between 11 to 14; and the prescriptions under different concentrations are prepared, therefore the nickel-coated copper powder containing different nickel contents can be obtained. The nickel-coated copper powder prepared by the preparation method provided by the invention is complete, continuous and dense; the plating solution is clear; the nickel ions are completely transformed; the plating layer has the thickness up to more than 1 micron; the magnetizing strength of the power bodies is more than 10emu / g; the nickel-coated copper powder contains 30wt.% of nickel; and the shielding effectiveness of the conductive rubber at middle-high frequency can be more than 50 by testing through a coaxial method when the mass is filled to 220 parts.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

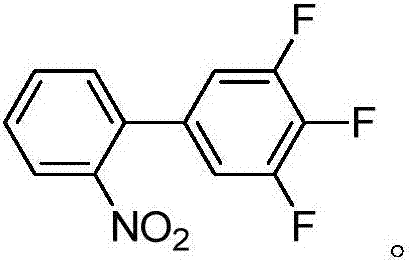

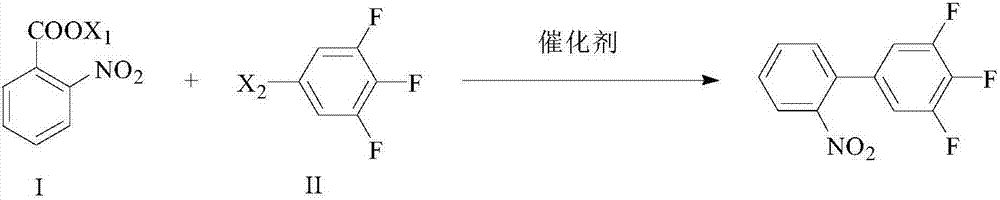

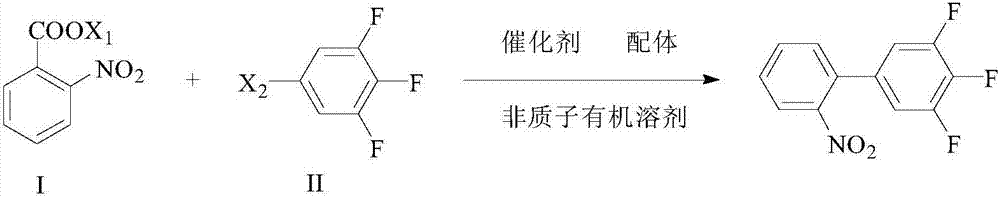

Preparation method of 3,4,5-trifluoro-2'-nitro-1,1'-biphenyl

InactiveCN107344913ALow costShort stepsOrganic chemistryOrganic compound preparationInorganic chemistryBiphenyl

The invention provides a preparation method of 3,4,5-trifluoro-2'-nitro-1,1'-biphenyl. The method comprises the following step: performing a decarboxylation coupling reaction on o-nitrobenzoate shown as a formula I and halogeno benzene shown as a formula II in the presence of a catalyst to obtain the 3,4,5-trifluoro-2'-nitro-1,1'-biphenyl, wherein X1 is a metal cation; X2 is any one of Cl, Br or I. The preparation method has the advantages of use of cheap and readily-available raw materials, avoidance of preparation of an arylboronic acid compound, short synthesis step, higher yield, high product purity, low production cost, no harsh reaction conditions, low equipment requirement, little emission of three wastes, only emission of carbon dioxide and inorganic salts, safety and environmental friendliness, and is suitable for industrial production.

Owner:SHANGHAI TAIHE INT TRADE CO LTD

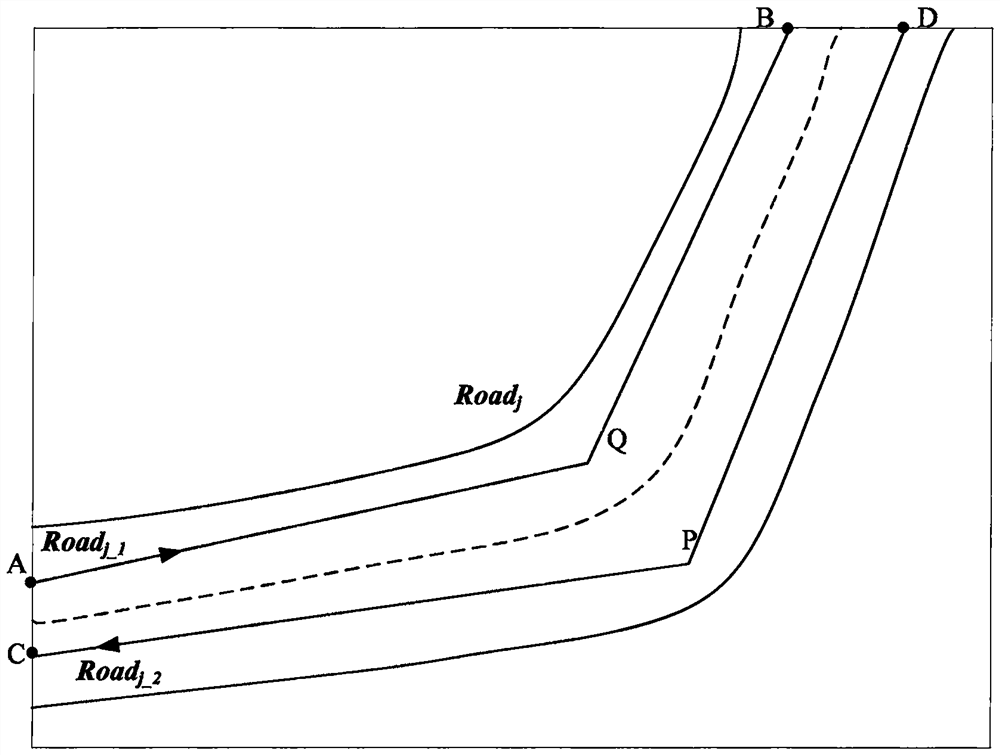

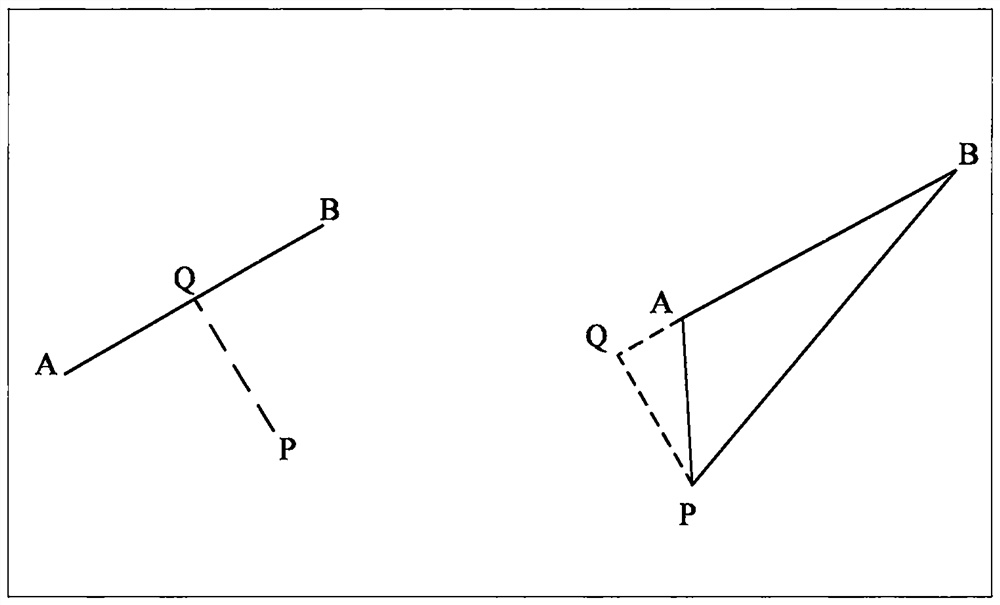

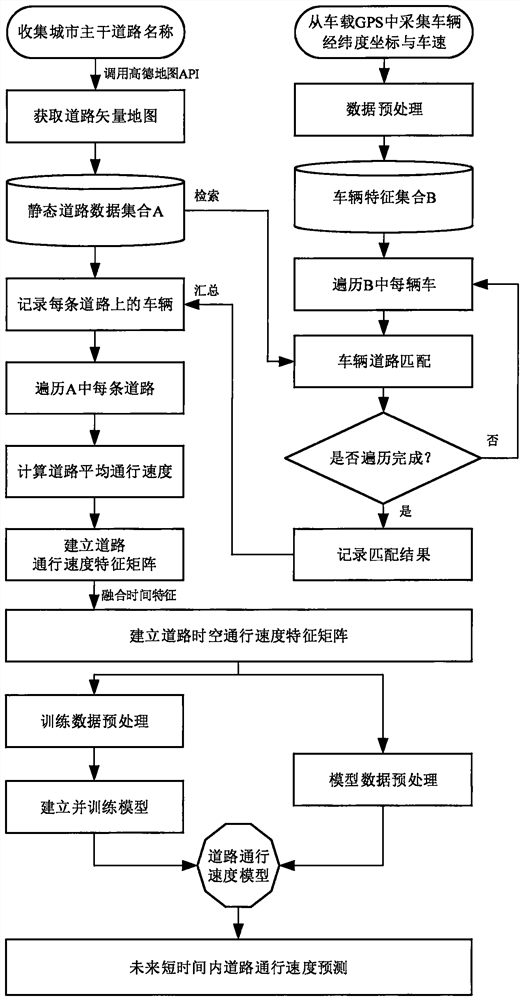

Urban main road speed prediction method based on big data and deep learning

PendingCN112950926ALow cost of speedHigh Traffic Speed Data CostsDetection of traffic movementForecastingUrban main roadIn vehicle

The invention discloses an urban main road speed prediction method based on big data and deep learning. The method comprises the following steps: calling an Amap API (Application Program Interface) to collect urban main road map data; collecting vehicle latitude and longitude coordinates and vehicle speed data in a vehicle-mounted GPS device (a new energy vehicle slave TBOX device), and performing road matching on each vehicle; calculating road average passing speed according to a road matching result, and establishing a road passing speed characteristic matrix by taking the road average passing speed as a characteristic; expanding a time dimension to create a road space-time passing speed characteristic matrix; utilizing a convolutional neural network model to extract road space-time passing speed features, and training the model to achieve main road passing speed prediction in a short time in the future. According to the road speed prediction method, few vehicle data features are needed, road matching is achieved through latitude and longitude coordinates, and vector operation is reduced; the road passing speed is calculated by using the vehicle speed, and the prediction model considers the relevance between time and space, so that the prediction accuracy and reliability are improved.

Owner:宁波中科信息技术应用研究院(宁波人工智能产业研究院) +1

Preparation method of Chinese toon tea

InactiveCN107691716ARetain natural fragranceRetain natural fragrance, no miscellaneous tasteTea substituesFlavorFermentation

The invention discloses a preparation method of Chinese toon tea. The preparation method comprises the following steps: 1, material selection; 2, picking of raw materials; 3, cleaning and management of fresh Chinese toon leaves; 4, withering; 5, rolling; 6, fermentation; 7, shaping; and 8, drying. The Chinese toon tea prepared by the preparation method disclosed by the invention has the appearanceof traditional tea and reserves the natural fragrance of the Chinese toon without off-flavor; the Chinese toon tea prepared by the preparation method has fragrant aroma, strong taste, bright yellow color of liquor and high product quality; and the preparation method disclosed by the invention is simple, low in facility request and favorable for production and has higher economic value.

Owner:四川鑫地源生物科技有限公司

Method for synthesizing 2-amido-6-chloropurine

InactiveCN100549013CAvoid the disadvantage of being prone to side reactions with guanineHigh yieldOrganic chemistrySynthesis methodsEthane Dichloride

The present invention relates to a kind of synthesis method of 2-amino-6-chloropurine (1), comprising the following steps in turn: first drop phosphorus oxychloride into N,N-dimethylformamide at low temperature to form a mixed solution, Then drop into the 1,2-dichloroethane of guanine (2) and react to obtain 2-dimethylaminomethenimino-6-chloropurine (3); the reaction product (3) is dropped into water, and The organic phase is recovered and used mechanically, the pH of the aqueous phase is adjusted to 3 to 5 with an alkali metal hydroxide solution, and the reaction is heated to obtain a wet product of 2-formylamino-6-chloropurine (4); the wet product of the above reaction product (4) is then The hydrolysis reaction is carried out in an alkali metal hydroxide solution, and then the pH value is adjusted with hydrochloric acid to obtain the crude product of 2-amino-6-chloropurine (1), and finally purified to obtain the fine product of the target product (1).

Owner:LIANYUNGANG CCA CHEM CO LTD

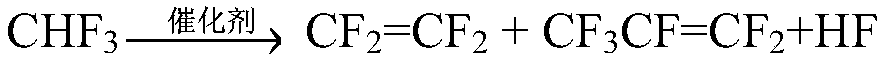

Method for preparing tetrafluoroethylene and producing hexafluoropropylene by catalytic cracking of trifluoromethane

ActiveCN109180422AEasy to prepareMild reaction conditionsCatalyst activation/preparationHalogenated hydrocarbon preparationChemistryFluid catalytic cracking

The invention relates to a method for preparing tetrafluoroethylene and producing hexafluoropropylene by catalytic cracking of trifluoromethane. The method comprises the steps of: under the catalysisof a supported catalyst, catalytic cracking of trifluoromethane is carried out to obtain a reactant; the reactant is washed with cooling alkali to remove acid, dried, rectified and extracted, and separated into tetrafluoroethylene, hexafluoropropylene and incompletely reacted trifluoromethane; the obtained trifluoromethane is introduced into a reaction system to carry out a cracking reaction; thesupported catalyst comprises a carrier and an active component, and the carrier is AlF3 or Al2O3, the active component is one or a combination of two or more of CsF, LaF3, SmF3, PdF2 or PtF4, and themass of the active component is 0.2 to 12% of that of the supported catalyst. The method of the invention is simple and the reaction conditions are mild; the catalyst used overcomes the problem of easy carbon deposition, and the high conversion of trifluoromethane and the high selectivity of tetrafluoroethylene and hexafluoropropylene can be achieved at lower temperature.

Owner:SHANDONG DONGYUE CHEM

Resin spacer for chip stack packaging and preparation method thereof

ActiveCN109135191BGood flexibilityAvoid breakingSemiconductor/solid-state device detailsSynthetic resin layered productsFiberPolymer science

The invention relates to a resin pad for chip stack packaging, which uses fiberglass cloth as the base material, and the weight ratio of the fiberglass cloth is 10-60wt%, and the following components are attached to it to account for the resin pad Percentage of total sheet weight: epoxy resin 8-40wt%, quartz powder 10-30wt%, aluminum oxide 2-10wt%, calcium oxide 1-8wt%, curing agent 1-8wt%, and the resin gasket is passed It is made of resin blending, dipping, semi-curing, stacking and pressing. The resin spacer used for chip stack packaging of the present invention has good flexibility and is not easy to break, can realize more layers of chips stacked on the substrate, and effectively avoids reducing the warping of the packaging structure and the risk of internal chip fragmentation. In addition, , the resin spacer of the present invention has excellent electrical insulation and good hydrophilic effect, and can replace silicon-based spacers widely used in chip stack packaging at present.

Owner:SU ZHOU DREAM TECH CO LTD

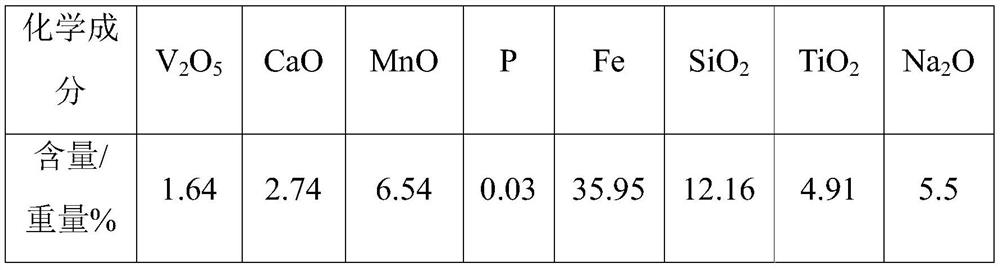

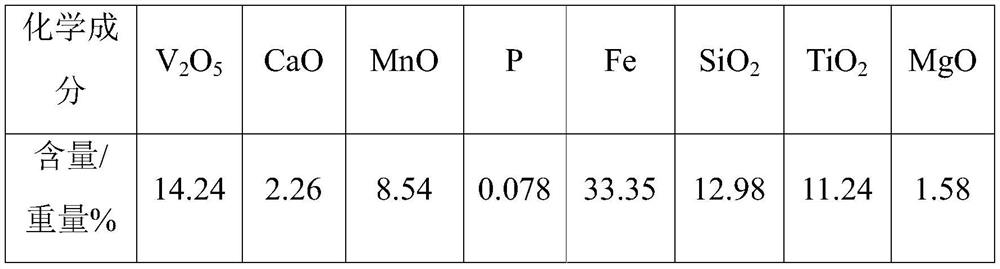

Method for extracting vanadium by utilizing sodium-modified vanadium extraction tailings and converter vanadium slag

ActiveCN112301234APromote oxidationImprove conversion rateProcess efficiency improvementPhysical chemistryVanadium atom

The invention relates to the technical field of chemical engineering, and discloses a method for extracting vanadium by utilizing sodium-modified vanadium extraction tailings and converter vanadium slag. The method comprises the following steps: (1) drying the sodium-modified vanadium extraction tailings with the water content of 3-20wt% until the water content is less than 1wt%, and then grindingthe dried sodium-modified vanadium extraction tailings until the particle size is less than 0.125mm; (2) adding converter vanadium slag fine powder and an activating agent into the ground sodium-modified vanadium extraction tailings obtained in the step (1), and carrying out mechanical activation to obtain a mixture; and (3) roasting the mixture obtained in the step (2) to obtain clinker, crushing the clinker, and then leaching to obtain an acidic vanadium solution, wherein in the step (1), the drying temperature is 100-500 DEG C, and the drying time is 40-180min. According to the method, thesodium-modified vanadium extraction tailings are pretreated, so that vanadium can be efficiently extracted, the process is simple and easy to use, the application range is wide, the cost is low, andgood social and economic benefits are achieved.

Owner:攀枝花市锦利钒钛有限公司 +2

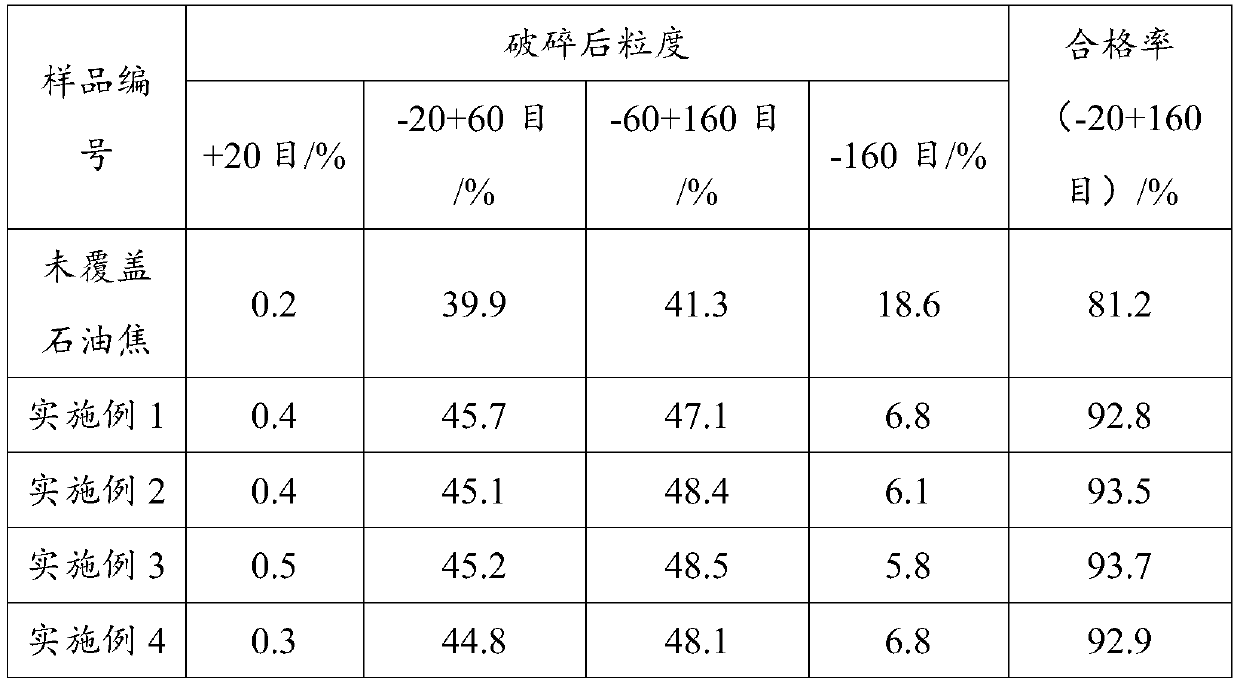

Method for preparing TiO2 raw material for chlorination process from titanium-rich fine powder

The invention provides a method for preparing a TiO2 raw material for a chlorination process from titanium-rich fine powder. The method comprises the following steps: S1, weighing the titanium-rich fine powder, and uniformly mixing the titanium-rich fine powder with a solid organic binder and petroleum coke at room temperature; S2, uniformly covering the surface of a mixed material obtained in thestep S1 with petroleum coke, and then performing low-temperature coking at 380-420 DEG C for 2.5-4 hours; and S3, crushing the material having undergone low-temperature coking in the step S2 into particles for the first time, then carrying out high-temperature coking at 900-1200 DEG C for 20-60 minutes, and crushing a coked material into particles again so as to obtain the TiO2 raw material for the chlorination process. The method can prepare the TiO2 raw material with high yield (higher than 92%) and qualified granularity for the chlorination process and realizes the cyclic utilization of the titanium-rich fine powder; and the batching procedure of a later chlorination reaction is reduced by adding the petroleum coke in advance.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

Forming method of high performance wide aluminum alloy panel plate cut

InactiveCN111519053AEnhanced Mechanical FeaturesReduce weightShaping toolsTransportation and packagingThermal treatmentUltimate tensile strength

The invention discloses a forming method of high performance wide aluminum alloy panel plate cut. The forming method is characterized by comprising the following steps of S1, high-temperature smelting; S2, continuous casting and continuous rolling to prepare an aluminum alloy slab; S3, punch forming; S4, pressurized thermal treatment; and S5, processing and polishing. The forming method of high performance wide aluminum alloy panel plate cut is short in process flow and low in cost, simplifies the process operating steps and enhances the tensile strength and toughness index of a wide aluminumalloy panel greatly. The prepared panel is excellent in comprehensive performance, high in dimensional precision, excellent in performance stability, good in corrosion resistance and long in service life.

Owner:汪晓难

Method for leaching and extracting valuable metal and sulfur element from low nickel matte

InactiveCN113774221AAvoid leachingAvoid wastingSulfur preparation/purificationCopper sulfidesFerric hydroxideCobalt metal

The invention discloses a method for leaching and extracting valuable metals and sulfur elements from low nickel matte. The method comprises the following steps that a trivalent iron salt solution and an organic solvent are added into a low nickel matte crushed material, oxidizing gas is introduced in a stirring state to react, and a solid slag layer, an organic layer and a water layer are separated after the reaction is finished. According to the method for leaching and extracting the valuable metals and sulfur elements from the low nickel matte, the low nickel matte is subjected to oxidation leaching through the oxidability of ferric ions, in the whole reaction process, iron in the low nickel matte is oxidized after being leached to form ferric hydroxide, only water and oxygen are consumed, ferric iron is consumed only when nickel, copper and cobalt metal ions are leached, elemental sulfur generated through the reaction is dissolved through an organic solvent. A passivation layer is prevented from being formed to hinder the reaction; the process flow is short, reaction can be carried out under normal pressure, the requirement for equipment is low, the production cost is low, the blowing process of intermediate product high nickel matte is omitted, waste of valuable metal is avoided, auxiliary materials are saved, meanwhile, the investment cost is reduced, and the method for leaching and extracting the valuable metals and sulfur elements from the low nickel matte is suitable for industrial popularization.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com