Patents

Literature

299results about How to "Overcoming technical bias" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

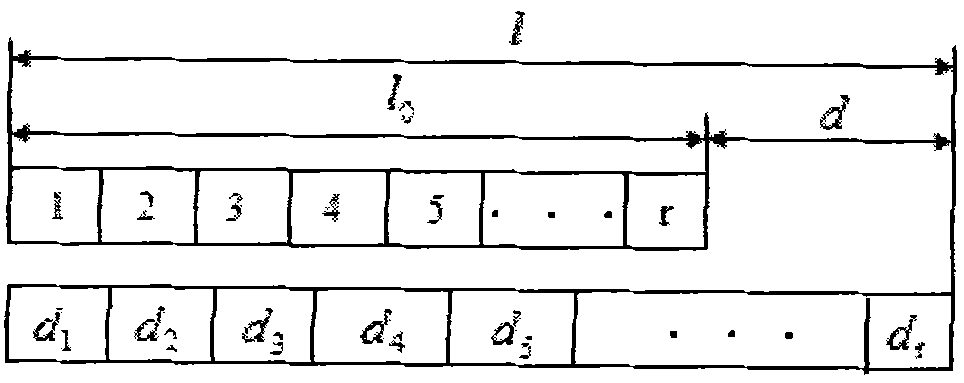

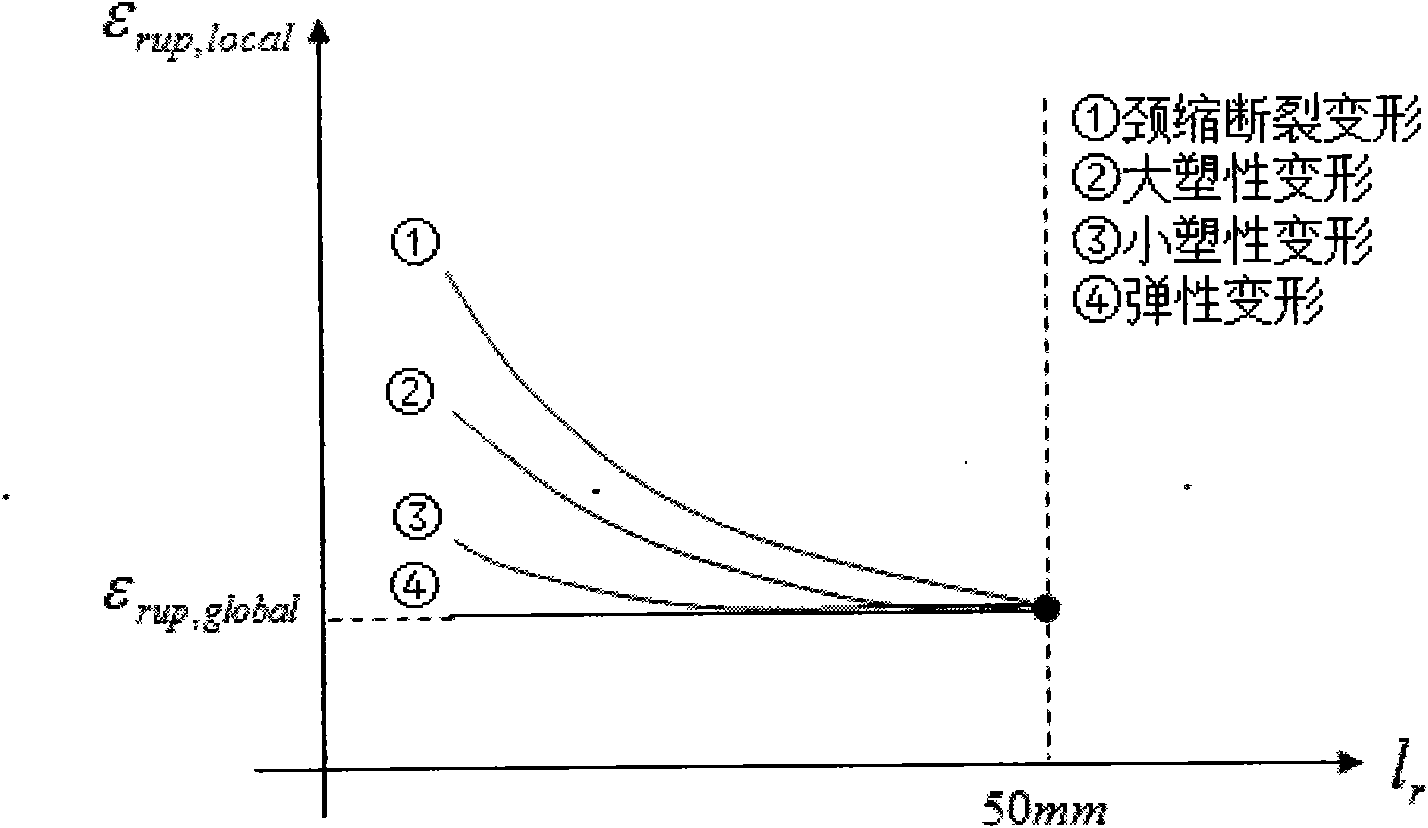

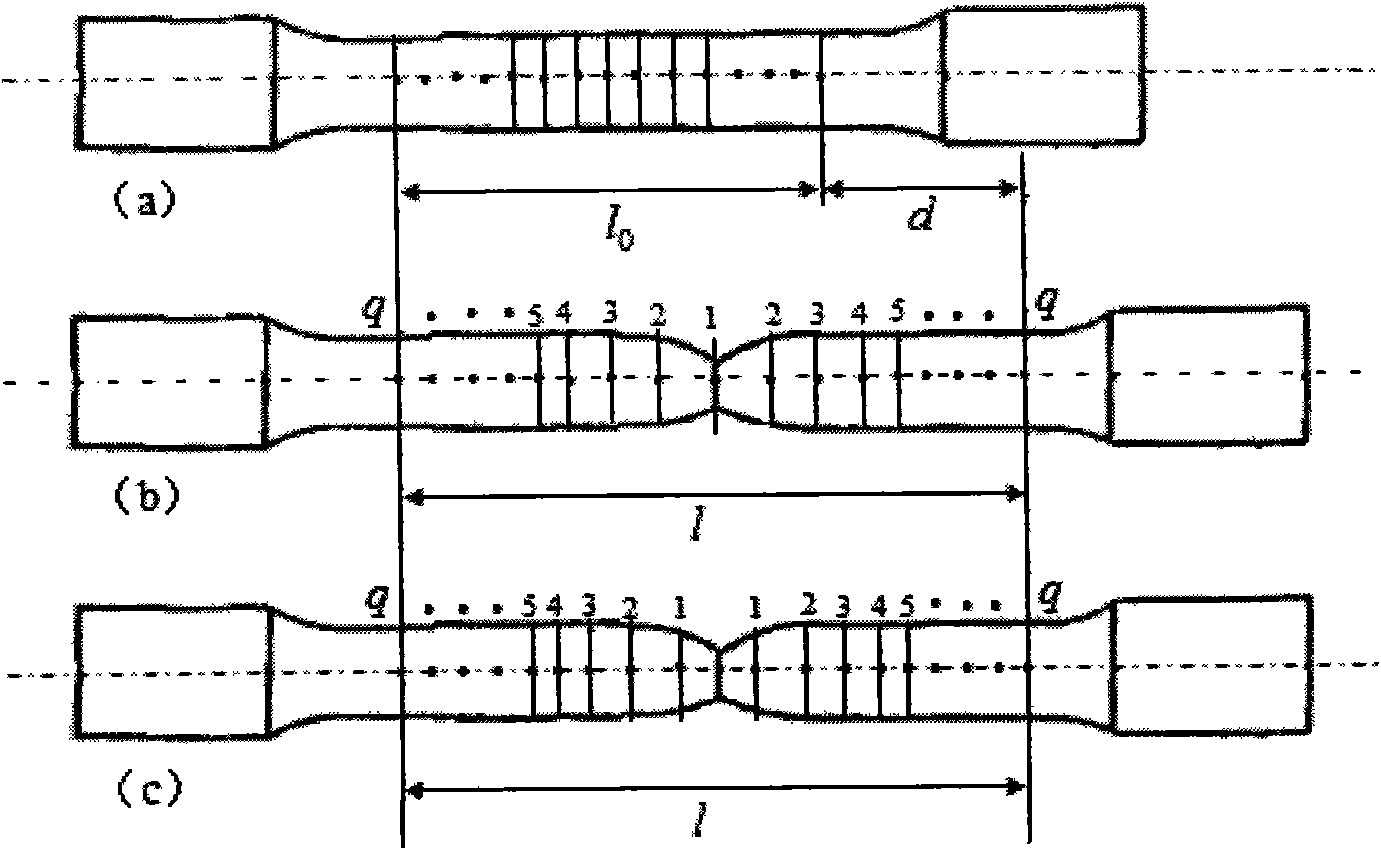

Data measuring and calculating method for uniaxial tensile test

InactiveCN101975693AReduce calculation precisionDiscovery of the intensity effectMaterial strength using tensile/compressive forcesLength effectEnergy absorption

The invention discloses a data measuring and calculating method for a uniaxial tensile test, which comprises the following steps of: marking a measuring point; measuring test data; calculating real breaking strain stress; and drawing an engineering and real stress strain curve. The method of the invention can obtain engineering and real stress strain curves in different reference lengths in the same uniaxial tensile test, establishes a corresponding relationship between the reference length effect and the mesh size effect and provides a thorough solution for the mesh size effect problem in a finite element method, i.e. a real stress strain curve in the equal reference lengths is defined for the same material with different mesh sizes. Meanwhile, theoretical explanation is provided for the practical problems, such as mesh size effect, energy absorption, material strain invalidation, and the like according to a uniaxial tensile basic theory provided by the invention, therefore, the invention has important theory and engineering practical significance.

Owner:肖锋

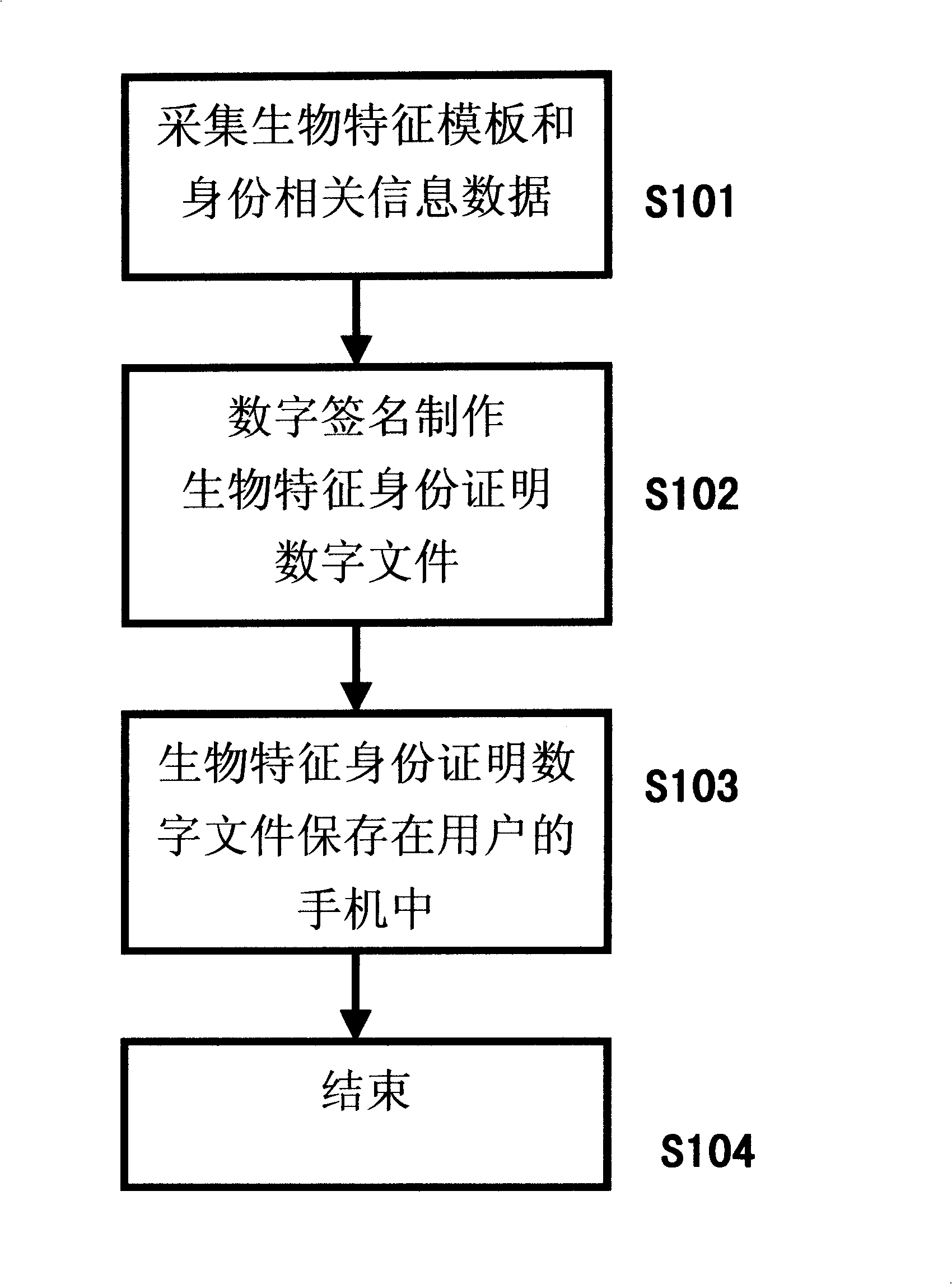

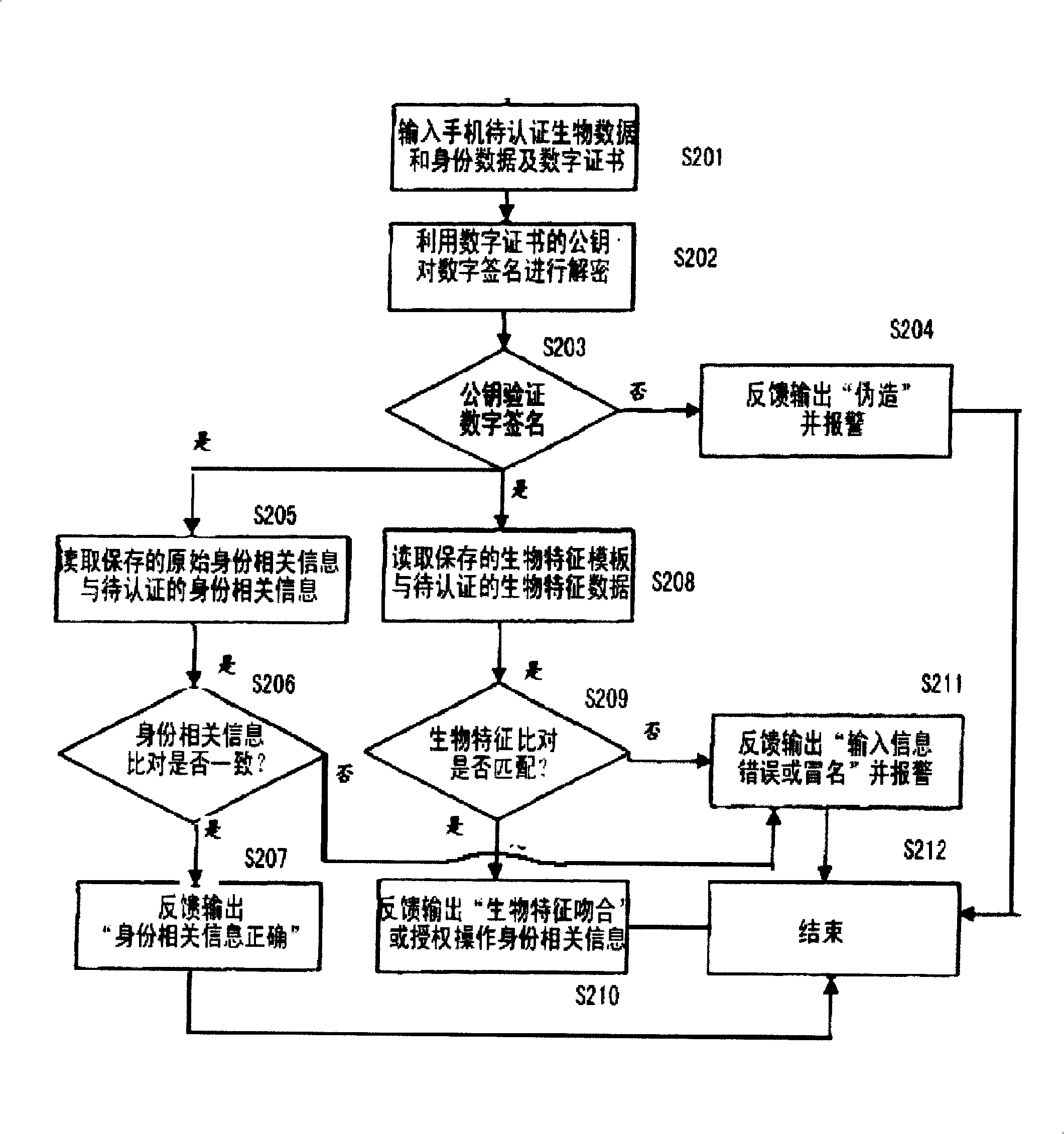

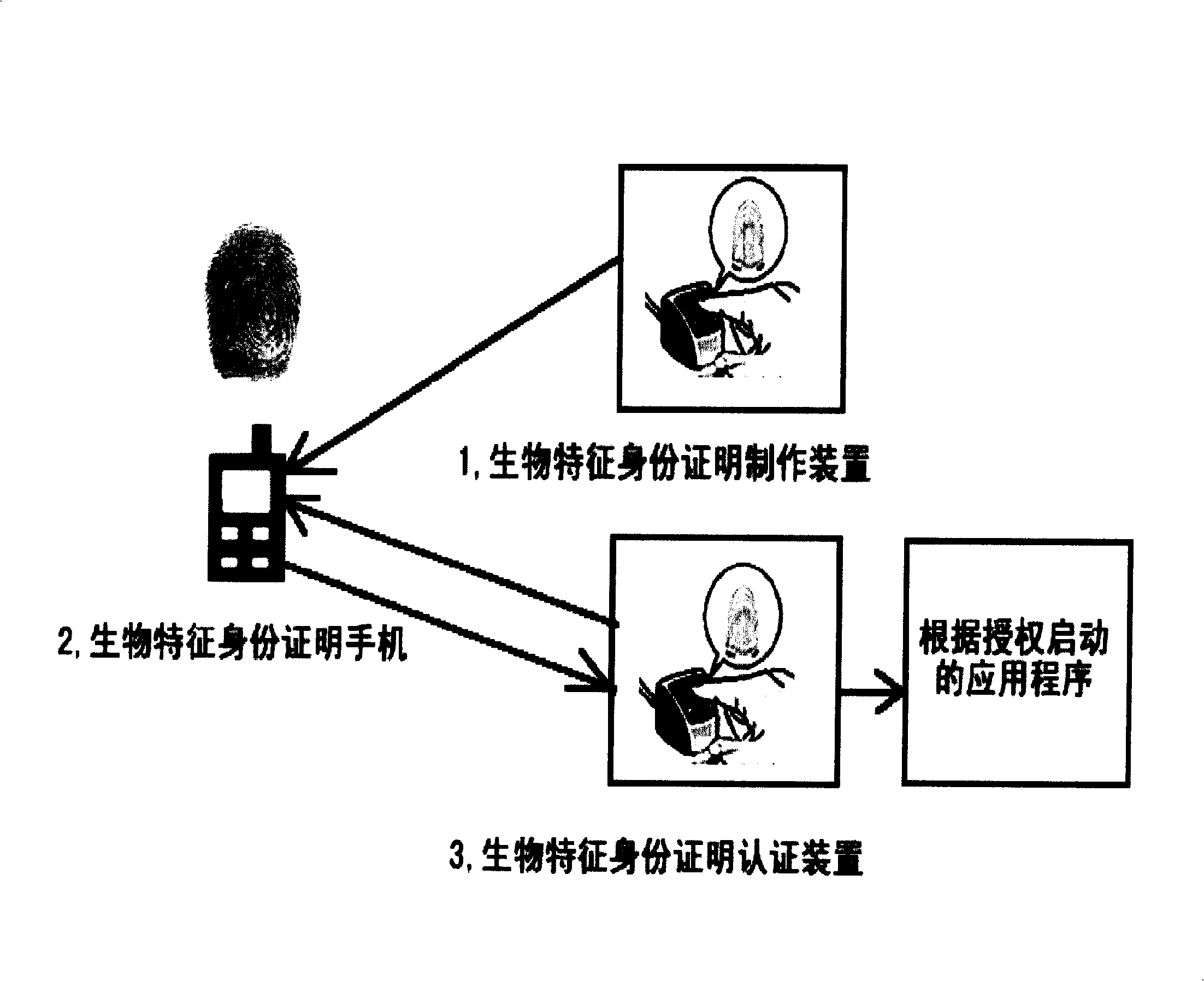

Mobile phone biological identity certification production and authentication method, and its authentication system

InactiveCN101321069AOvercoming technical biasPrivacy protectionUser identity/authority verificationRadio/inductive link selection arrangementsBiometric dataDigital signature

A biologic character template of a user and the related information of the user's identity constitute a whole data block, comprising: selecting an asymmetric key algorithm, using the private key to perform the digital signature or the digital seal, manufacturing the biologic character ID digital file of the digital signature, which is stored in the mobile phone of the user. The biologic character data of the user to be validated is collected on the site, and the digital certiuficate including the public key is sent to the user; mobile phone for storing the biologic character ID digital file in advance for verification; the mobile phone of the user uses the public key in the digital certificate to validate the digital signature of the biologic character ID digital file; the biologic character data to be certificated are inputted, to compare with the corresponding biologic character template in the biologic character ID digital file; the mobile phone of the user outputs the result data of the comparing and the validate, to display the result or output the authorization data of the further operation.

Owner:刘洪利

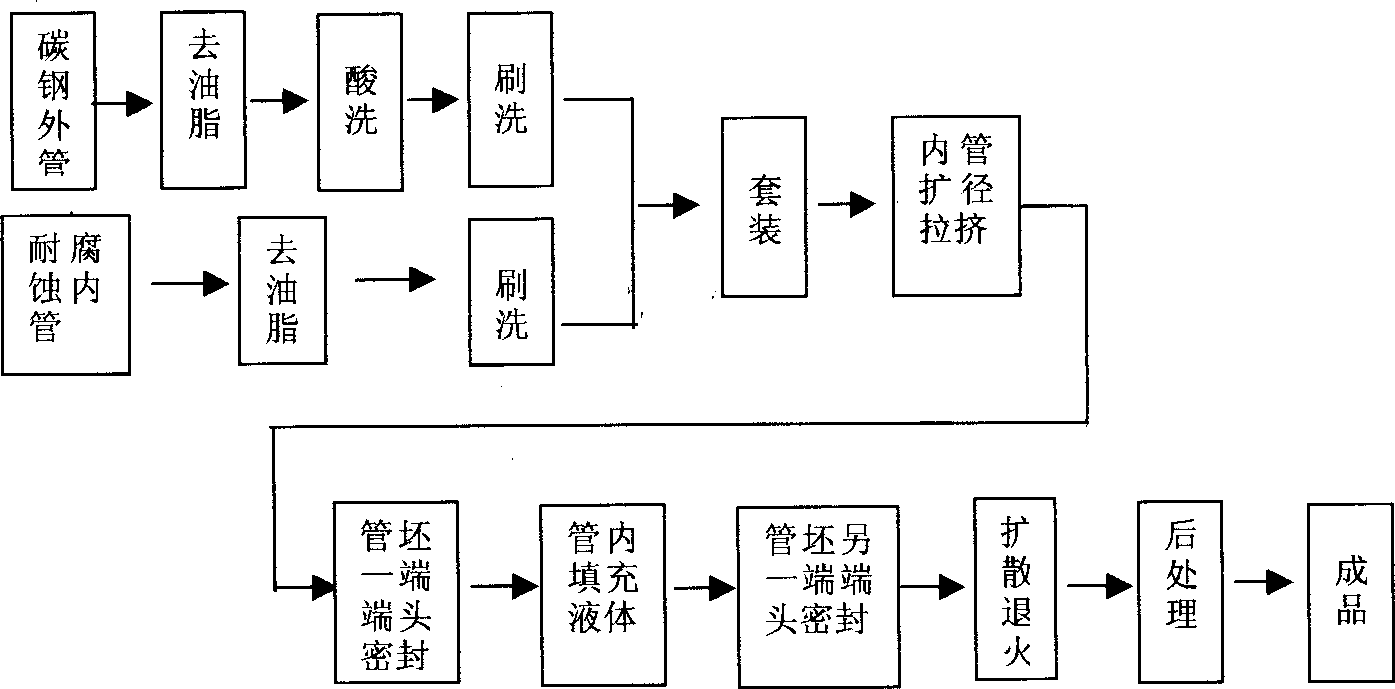

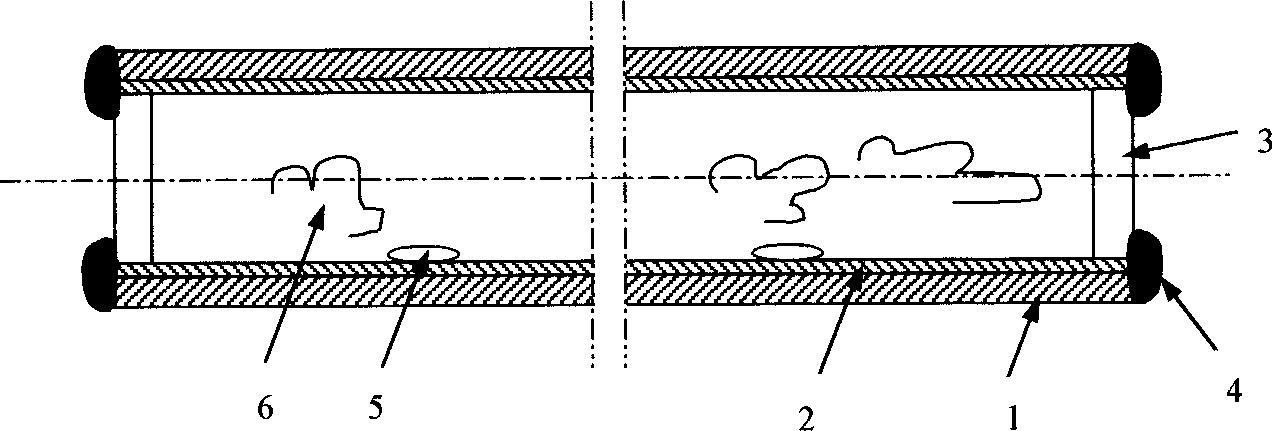

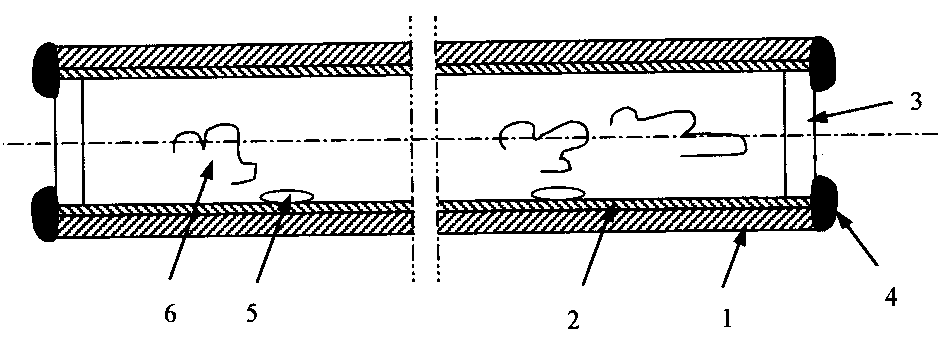

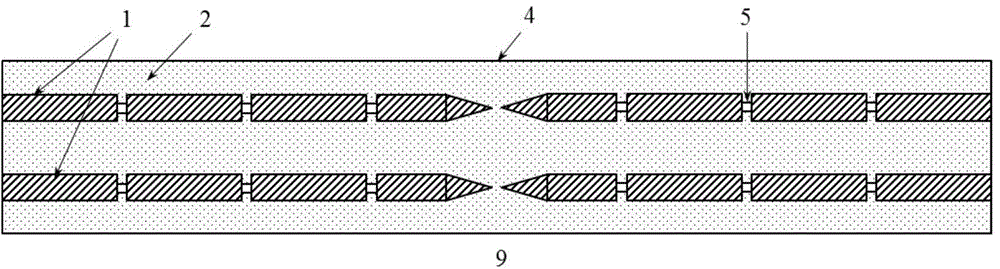

Production method of composite bimetal pipe

A production method of composite bimetal pipe includes the following steps: making surface treatment of internal pipe and external pipe: inserting internal pipe into external pipe, tight fitting to form composite pipe blank; seating the two ends of the said pipe blank with air and liquid in the internal pipe, and sealing the gap between the internal pipe and the external pipe, heating and diffusion annealing so as to obtain the invented product. Its production process is simple, and is applicable to various anticorrosion pipes.

Owner:大连合生科技开发有限公司

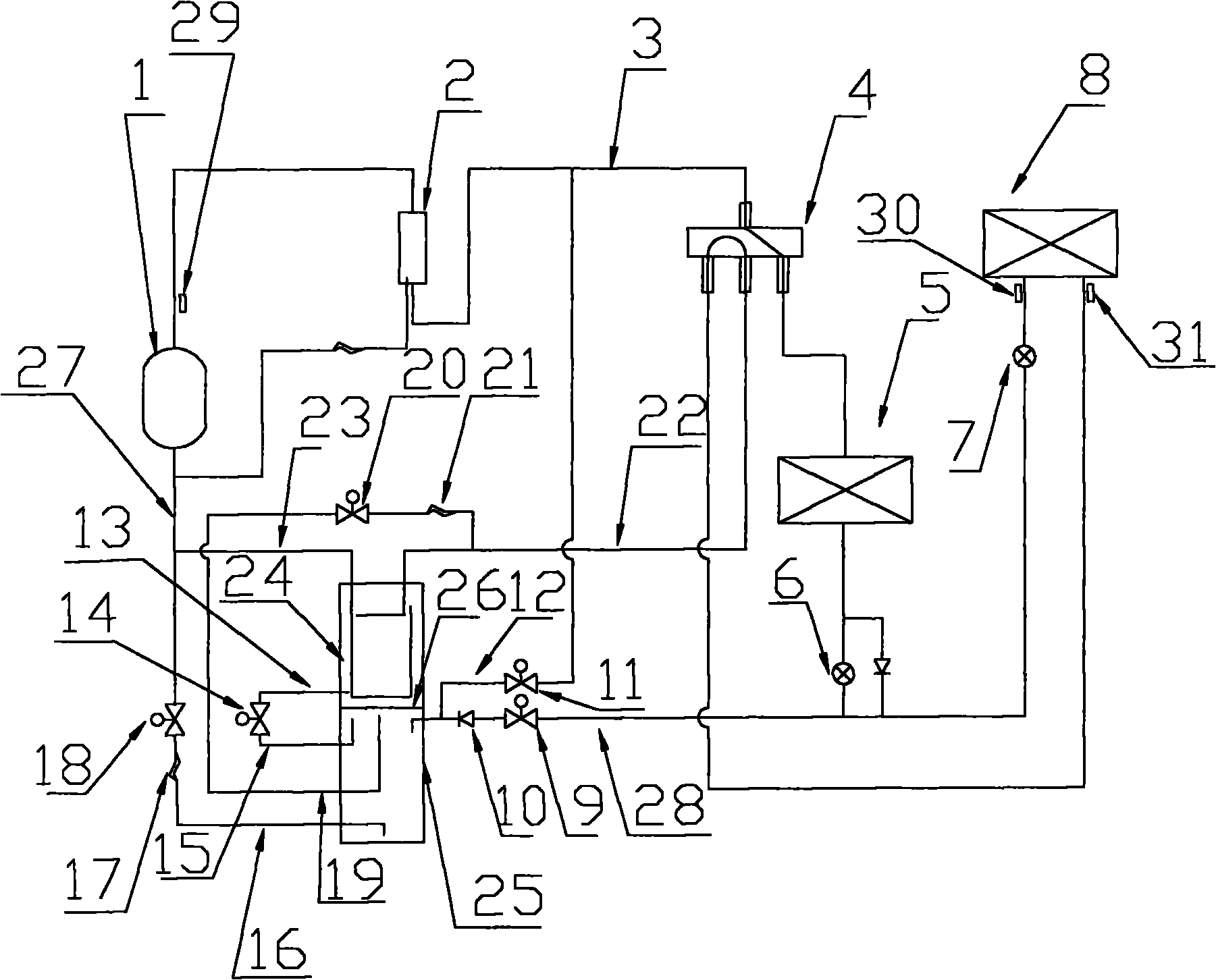

Refrigerant control unit, air conditioner refrigeration system and refrigerant cycle control methods

ActiveCN102042724AChange structureOvercoming traditional thinkingFluid circulation arrangementCompression machines with reversible cycleCycle controlEngineering

The invention provides a refrigerant control unit which comprises a system liquid inlet pipe, an upper volume tank, a lower volume tank, a middle interlayer and a control valve, wherein the system liquid inlet pipe is educed from the lower volume tank; the upper volume tank and the lower volume tank are connected together through the middle interlayer; the upper volume tank is provided with an upper volume tank pipeline which is communicated with an inner cavity of the upper volume tank; the lower volume tank is provided with a lower volume tank pipeline which is communicated with an inner cavity of the lower volume tank; and the control valve comprises a refrigerant storage control valve and a refrigerant release control valve. The invention also provides an air conditioner refrigeration system which comprises the refrigerant control unit. The invention also provides two refrigerant cycle control methods. By using the refrigerant control unit, the air conditioner refrigeration system and the refrigerant cycle control methods provided by the invention, the problems that the system refrigerant cycle amount of the traditional air conditioner is difficult to control and the like can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

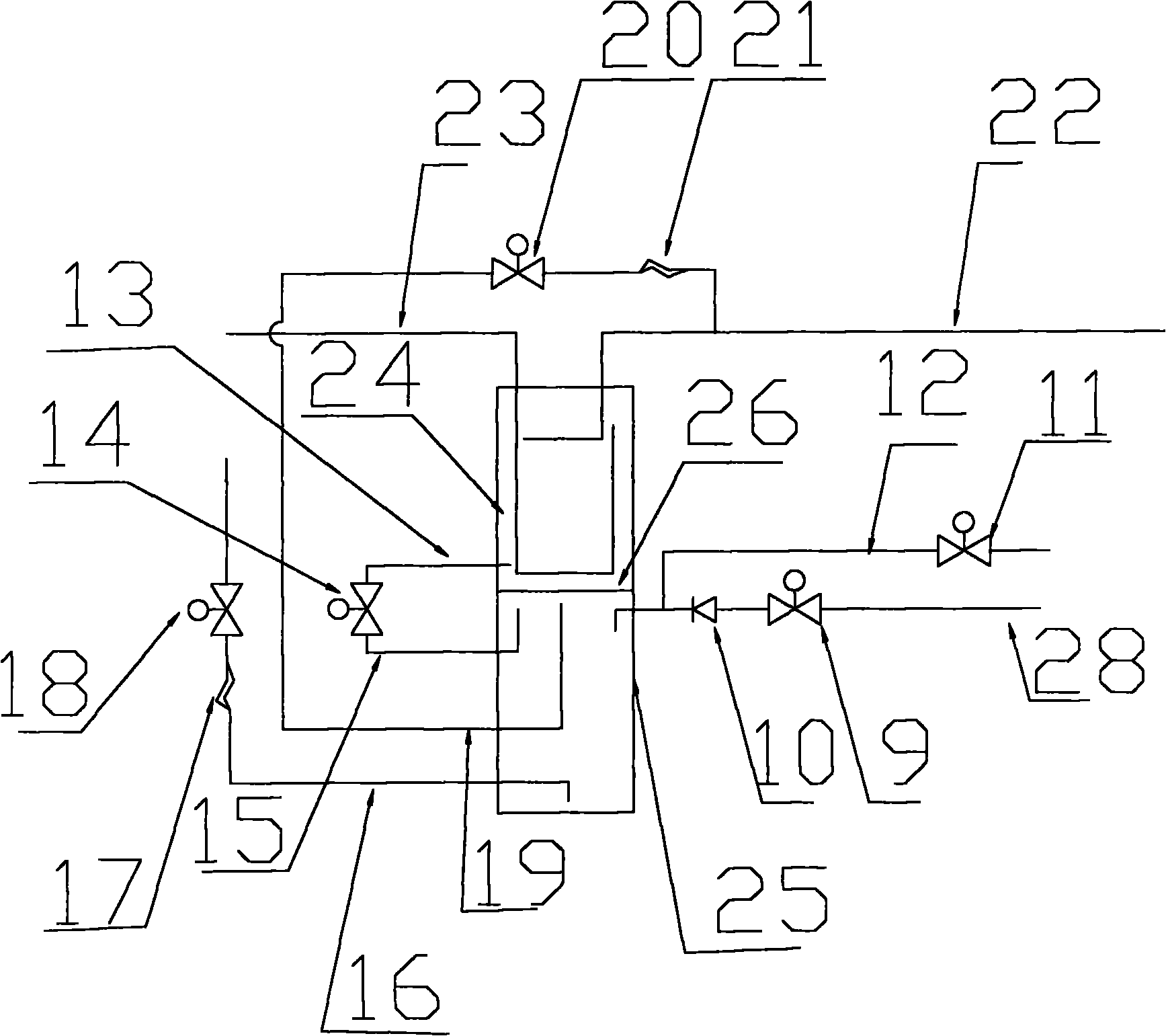

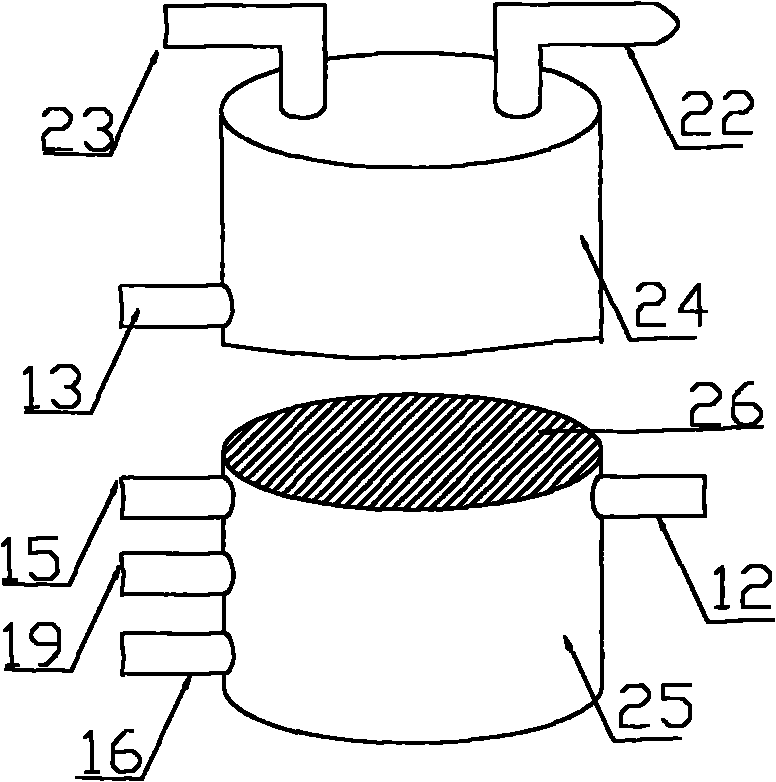

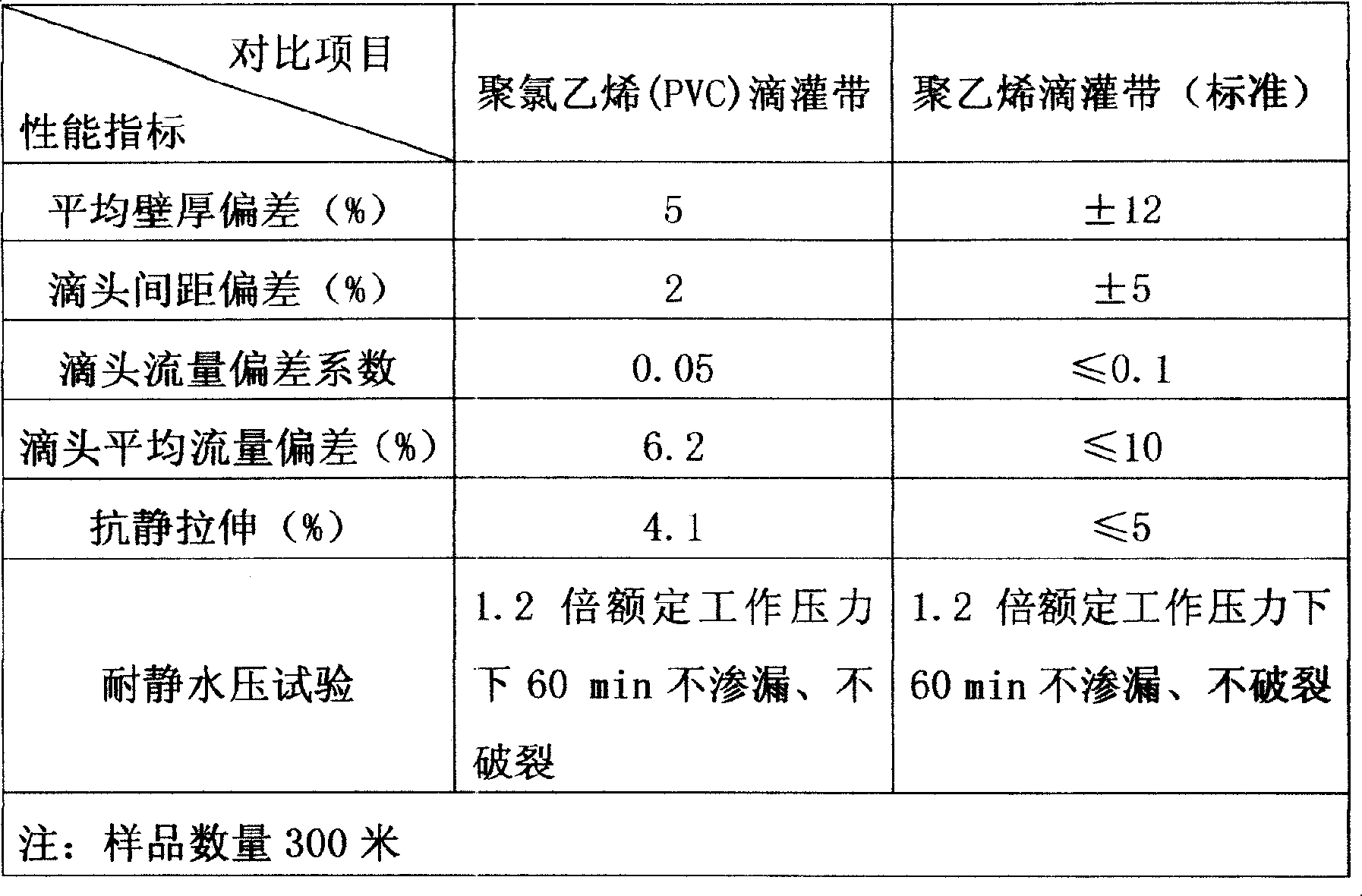

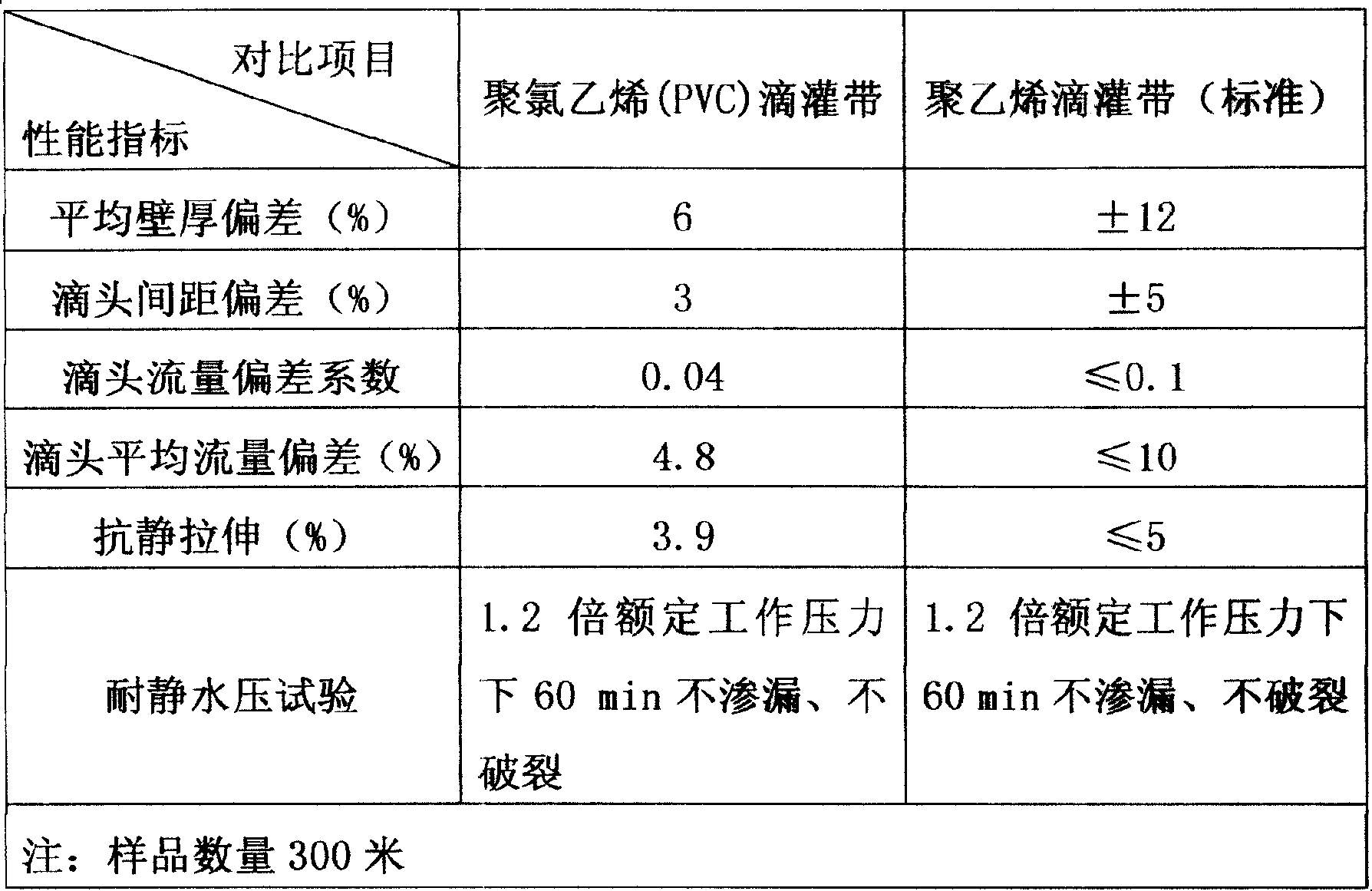

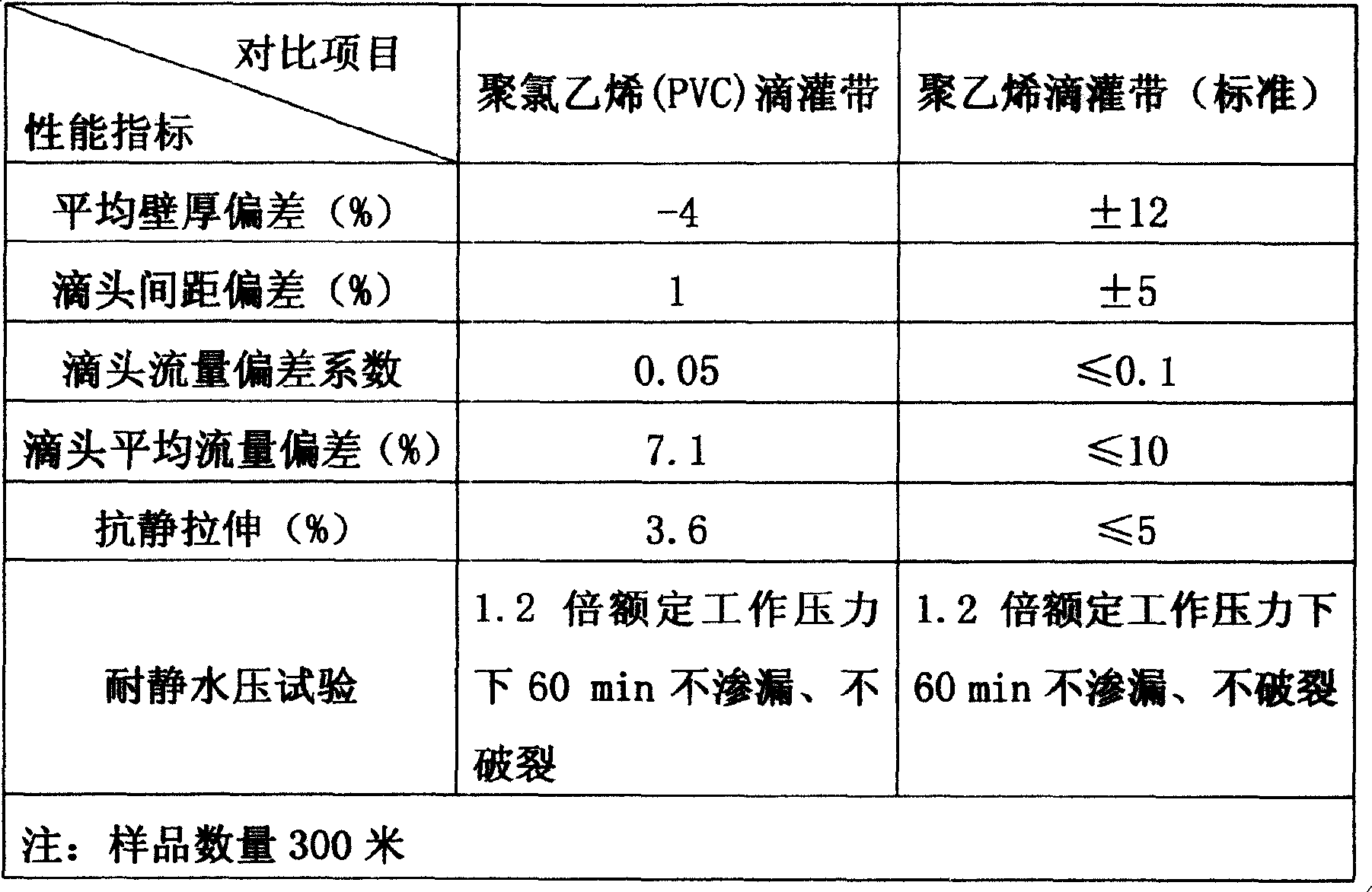

Polyvinyl chloride (PVC) drip irrigation belt

InactiveCN101104718AOvercoming technical biasReduce manufacturing costClimate change adaptationWatering devicesPlasticizerPolyvinyl chloride

Disclosed is a polyvinyl chloride (PVC) drip irrigation belt, which comprises the following components: PVC resin 100 parts by weight, plasticizer 20 to 40 parts by weight, lubricant 0.5 to 2 parts by weight, impact modifier 2 to 6 parts by weight, processing aid 0.5 to 3 parts by weight, heat stabilizer 1 to 2.5 parts by weight, coupling agent 0.1 to 0.8 parts by weight and calcium carbonate 5 to 20 parts by weight. The invention is mainly used as various irrigators used indoor and outdoor, in particularly suitable for water-saving irrigation in field agriculture.

Owner:XINJIANG TIANYE GRP

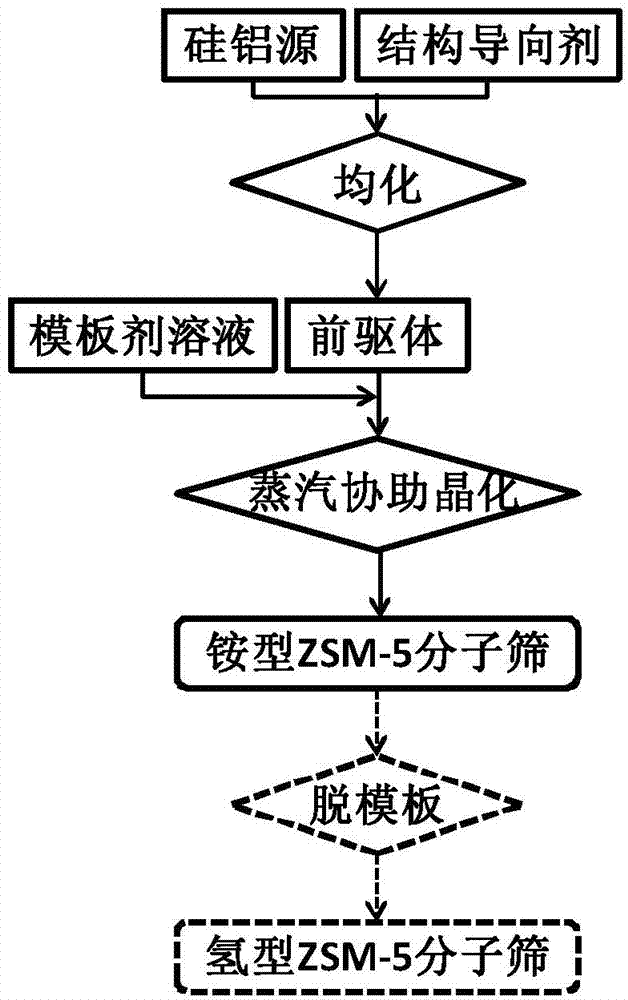

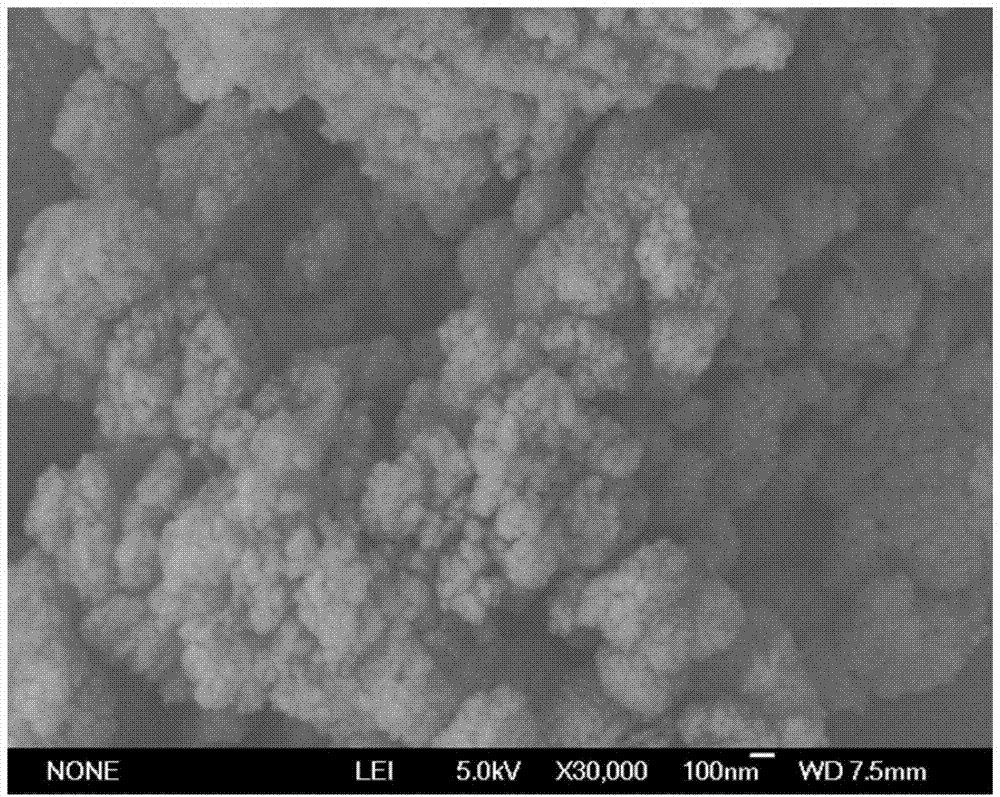

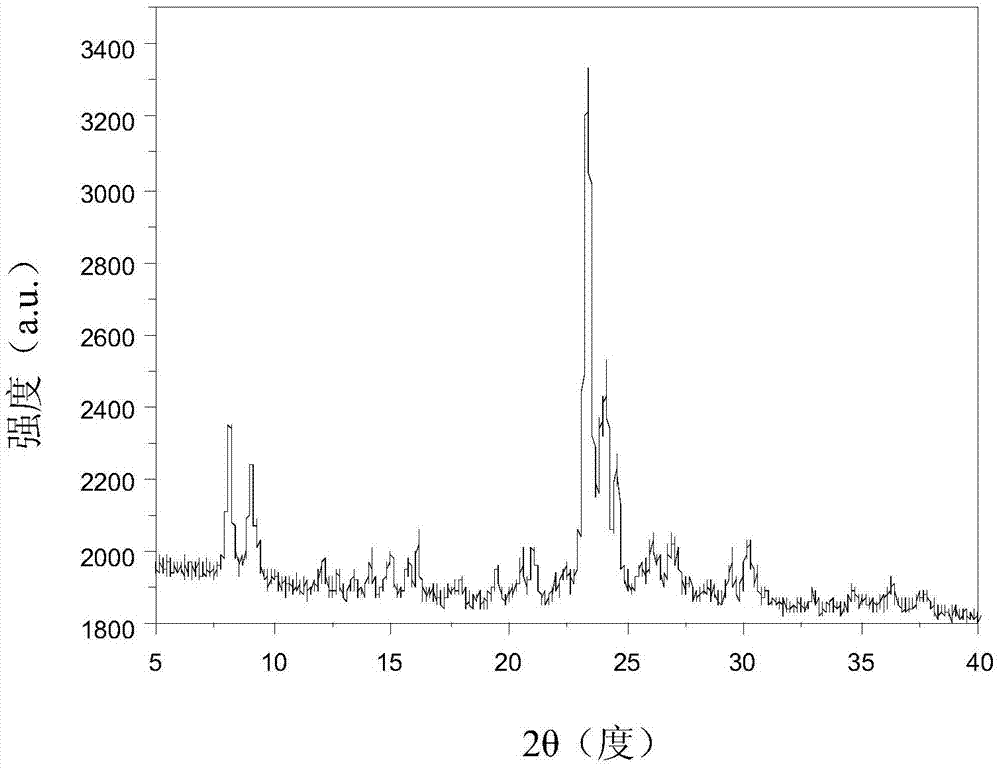

ZSM-5 molecular sieve and preparation method thereof

ActiveCN104843740ASynthesis fastEfficient synthesisMaterial nanotechnologyPentasil aluminosilicate zeoliteAlkaline earth metalHydrogen

The invention relates to a preparation method of a ZSM-5 molecular sieve. The method comprises performing assistant crystallization of a ZSM-5 molecular sieve precursor by utilizing steam of a template agent solution to obtain an ammonium-type ZSM-5 molecular sieve; and optionally, removing the template agent from the ammonium-type ZSM-5 molecular sieve to obtain a hydrogen-type ZSM-5 molecular sieve. According to the invention, the preparation method of the ZSM-5 molecular sieve abandons a conventional continuous medium in a crystallization process, and alkali metals or hydroxides of alkali metals, overcomes the technical prejudice in the prior art, and provides a novel synthesis idea for the field.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

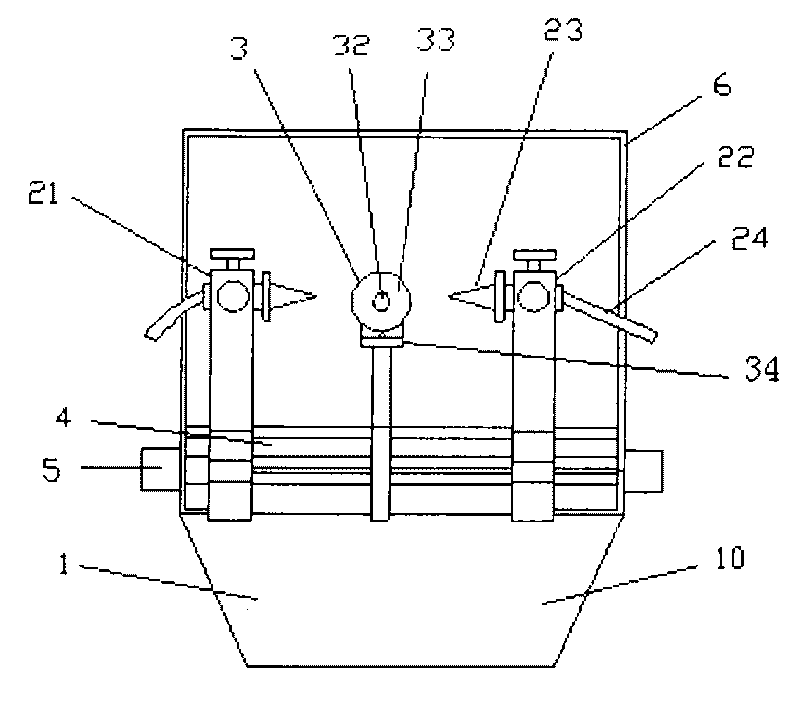

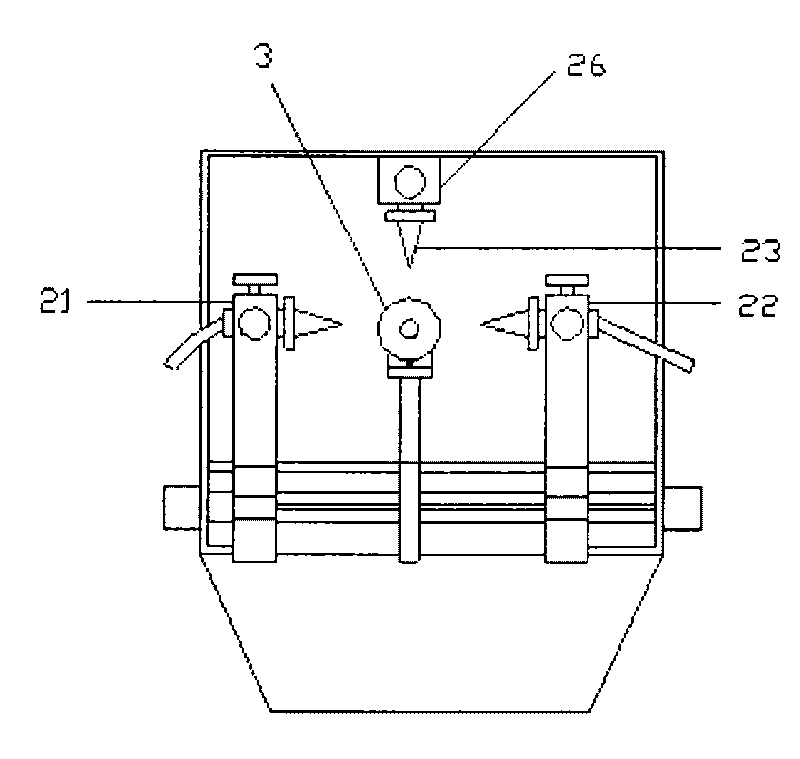

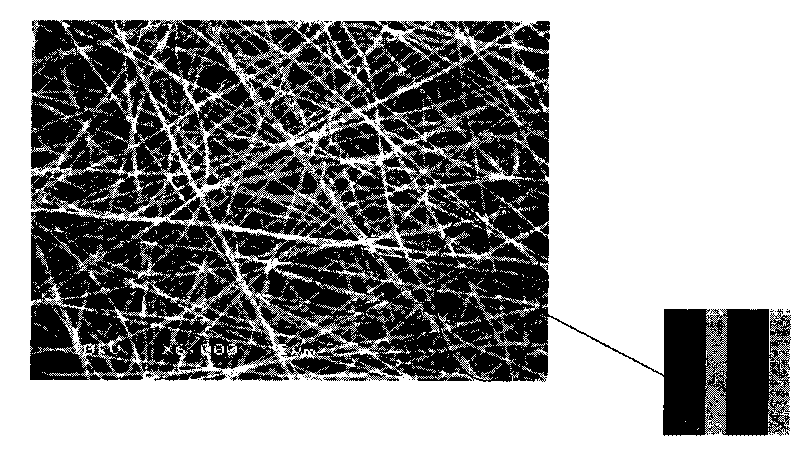

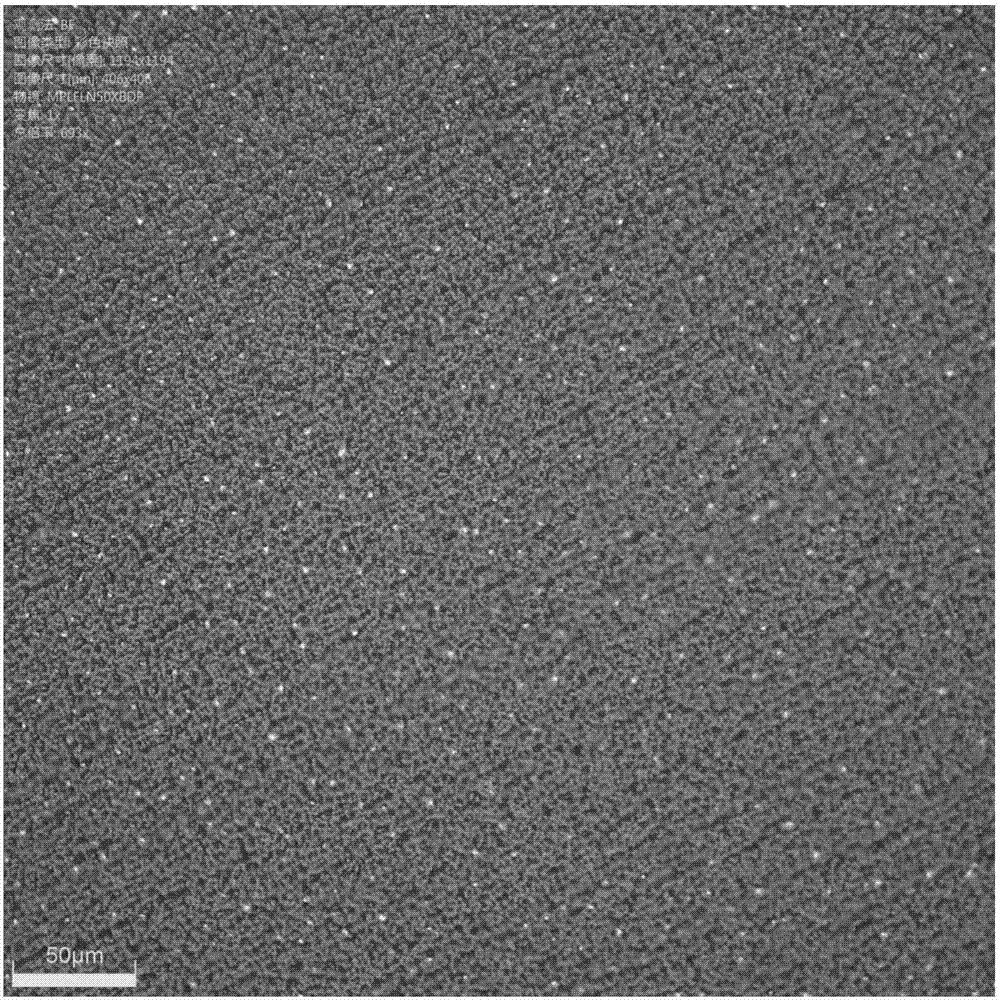

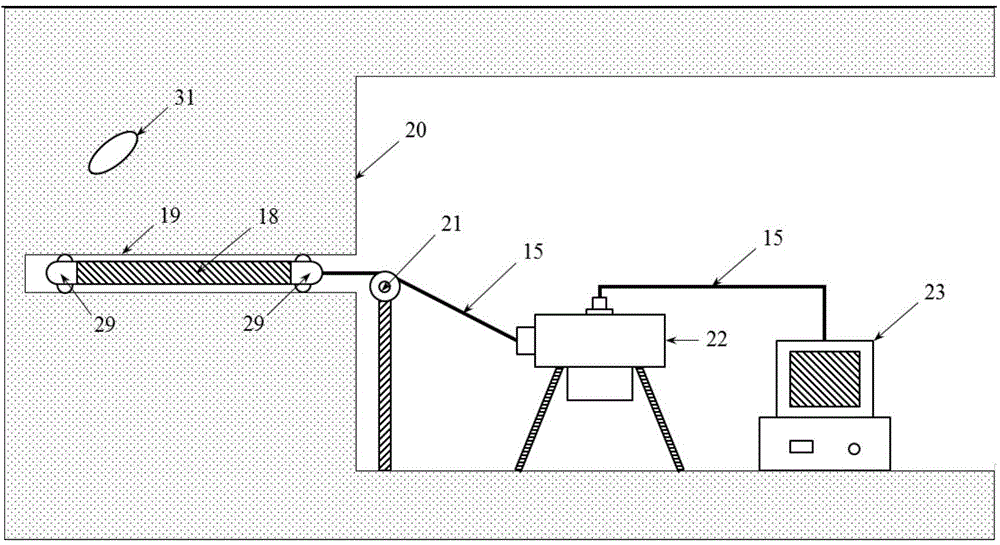

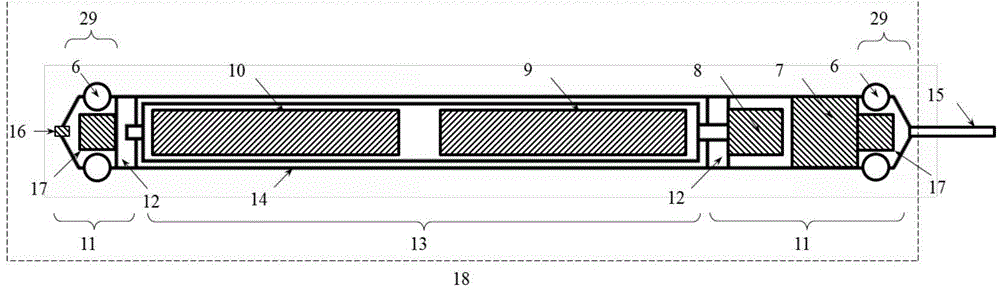

Electrostatic spinning method for preparing interlayer nano-fabric and device thereof

InactiveCN101724979AEasy accessChange limitationsLayered productsFilament/thread formingReciprocating motionElectrospinning

The invention provides a spinning device used for molding interlayer nano-fabric for once, and a method for preparing the interlayer nano-fabric by applying the spinning device. The device comprises a machine body, a liquid supply device, a collecting device and at least two groups of spinning devices, wherein the two groups of spinning devices are respectively positioned at the left and the right sides of the machine body and respectively comprise at least one spinneret; the spinnerets of the two groups of spinning devices are arranged in an opposite way and are respectively connected with high voltage with opposite polarity; the collecting device is a roller device connected with a motor, can rotate around a shaft and is positioned between the two groups of spinnerets; the axial direction of the roller device is vertical to the spinning direction of the spinnerets; and the roller device can make axial reciprocating motion parallel to the roller device under the control of the motor. When different polymer solutions are provided by the two groups of spinning devices, the continuous interlayer nano-fabric can be formed on the surface of the roller device due to the action of electric field force as well as rotation and reciprocating motion of the roller device.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Novel method for controlling casting blank pull rate of round continuous casting machine

ActiveCN103537642ALess attention should be paid to the straightening temperature of the slabOvercoming technical biasMechanical engineeringContinuous caster

The invention belongs to the technical field of alloy steel continuous casting and particularly relates to a novel method for controlling casting blank pull rate of a round continuous casting machine. The method for controlling the casting blank pull rate includes two stages. Stage one, before a continuous casting blank is released from a dummy bar head (about 10-30 minutes), the pull rate of the casting blank is set according to a traditional method that the pull rate is set according to actual degree of superheat of middle bag molten steel. Stage two, after the casting blank is released from the dummy bar head, the actual pull rate of the casting blank is determined according to the actual temperature of the casting blank surface of the casting blank in a straightening section, namely actual pull rate data of the casting blank is adjusted according to surface actual data of the casting blank at the straightening section position, the casting blank is released from a dangerous temperature range of 723-912 DEG C of a theoretical brittleness temperature range as soon as possible, possibility of cracks on the casting blank surface due to casting blank self texture phase change is greatly reduced, and the middle bag molten steel temperature is also considered. By means of the method, the phenomenon that cracks are prone to occur on a billet surface of an arc large round continuous casting machine is effectively reduced or basically avoided, under the premise that the casting blank quality is guaranteed, the whole production efficiency of the continuous casting machine is greatly improved, casting blank yield is further improved, and large round continuous casting blank surface quality is well improved.

Owner:SHANDONG XIWANG SPECIAL STEEL

PERC cell back surface passive film layer and PERC cell preparation method based on ALD process

ActiveCN106972066AImprove conversion efficiencyGood lookingFinal product manufactureSemiconductor devicesScreen printingEtching

The invention discloses a PERC cell back surface passive film layer and further discloses a PERC cell preparation method based on the ALD process. The PERC cell back surface passive film layer comprises a back surface alumina layer, a back surface SiONx layer and a back surface SiNx layer which are sequentially deposited on a PERC cell silicon substrate surface outwardly. The PERC cell preparation method comprises steps of texturing; expansion; back surface polishing, etching and dephosphorization glass; back surface ALD alumina preparation; front surface PECVD deposition of a SiNx anti-reflection film; back surface PECVD deposition of a back surface passive film layer; local back surface laser opening; screen printing; sintering. In a back surface PECVD deposition process of the back surface passive film layer, after a silicon chip enters a furnace tube, furnace tube temperature rises to 400-600 DEG C, the SiONx film is firstly deposited, and the SiNx is then deposited. The PERC cell back surface passive film layer and the PERC cell preparation method are advantaged in that cell conversion efficiency is high, an independent annealing process after ALD alumina preparation is omitted, cost is reduced, and cell conversion efficiency is improved; when front surface plating is carried out after back surface plating, a surface color of the monocrystalline silicon chip is uniform, and cell appearance is effectively improved.

Owner:江苏顺风新能源科技有限公司

Single-hole directional detecting radar antenna for advance geology forecast of tunnel

ActiveCN104698501ASolve the technical problems of directional launchOvercoming technical biasElectric/magnetic detection for well-loggingWave based measurement systemsRadarImage resolution

The invention discloses a single-hole directional detecting radar antenna for advance geology forecast of a tunnel. The single-hole directional detecting radar antenna mainly comprises a drilled directional radar antenna, an in-hole automatic travelling device and a cable receiving and sending device. The single-hole directional detecting radar antenna further comprises a rotor, a stator and a housing; a directional emission antenna in the rotor continuously rotates to change the emission direction of electromagnetic wave, the reflected wave can be received by a directional receiving antenna in the rotor, and the directional angle of a geological anomalous body can be obtained by the strongest reflection wave angle extracting algorithm; the in-hole automatic travelling device and the cable conveying and recovering machine can be controlled by a radar host to automatically send and recover a radar antenna and a communication cable. With the adoption of the single-hole directional detecting radar antenna, the geological anomalous body within a certain range around a drilled hole can be accurately examined, and the directional angle can be accurately positioned; the detecting directionality can be obviously improved; the resolution of the directional angle of the geological anomalous body can be obviously increased; the detection is fully automatically carried out, and therefore, the detecting efficiency and accuracy can be greatly increased.

Owner:山东百廿慧通工程科技有限公司

High-strength nanoporous ceramizable ablation heatproof composite material and preparation method thereof

ActiveCN110951210AImprove tensile propertiesImprove bending resistancePolymer scienceUltimate tensile strength

The invention relates to a high-strength nanoporous ceramizable ablation heatproof composite material and a preparation method thereof. The composite material comprises 20-60 wt% of hybrid resin and 40-80 wt% of a fiber reinforcement, the hybrid resin comprises silicone hybrid phenolic resin, the thickness of the composite material is 2-50 mm, the density of the composite material is 700-1400 kg / m<3>, and the nanopore diameter is 50-1000 nm. The preparation method comprises the following steps: (1) preparing a hybrid resin sol; (2) impregnating the sol; (3) carrying out a sol-gel reaction; and(4) drying the composite material to obtain the composite material. Compared with like materials in the prior art, the composite material of the invention has the advantages of large binding force ofthe resin and fiber interface, high compression modulus, high bending strength, high tensile strength, ceramization at a high temperature, low thermal conductivity and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

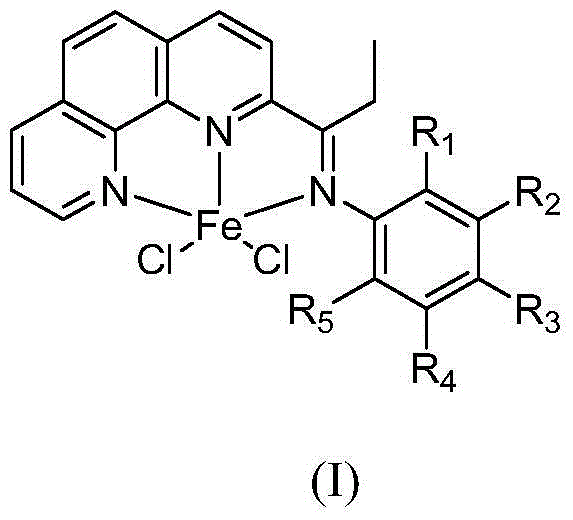

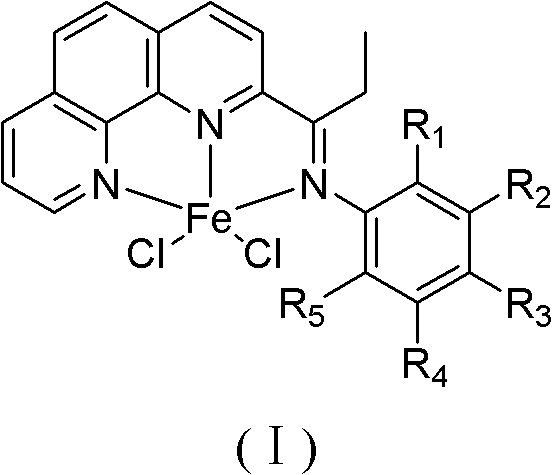

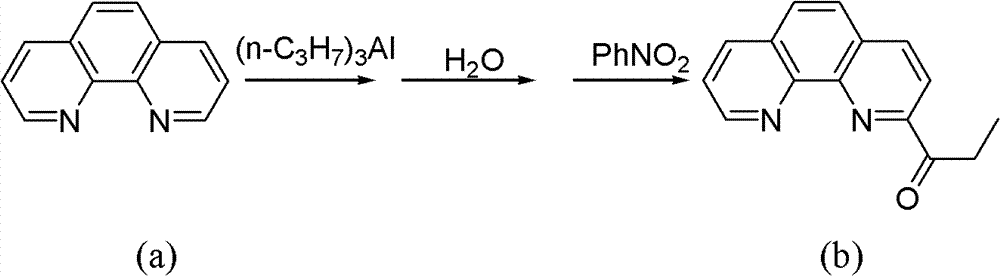

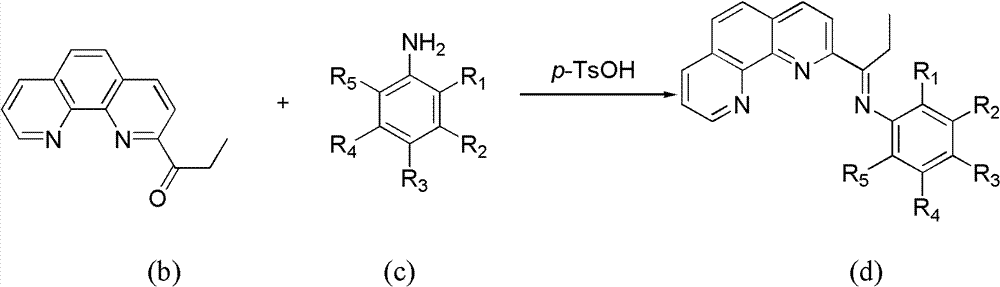

Ethylene oligomerization method

ActiveCN104447161AHigh selectivityHigh oligomerization reactivityHydrocarbonsBulk chemical productionHydrogenHalogen

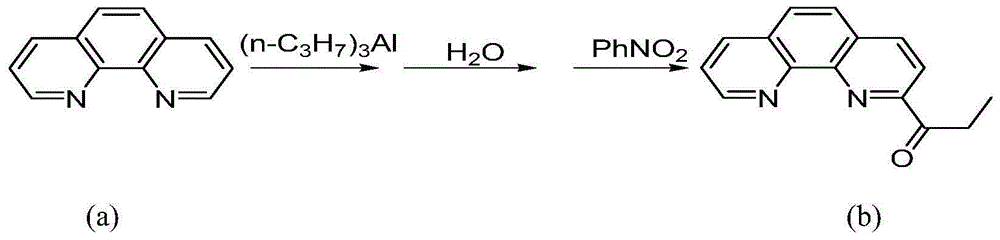

The present invention discloses an ethylene oligomerization method, wherein ethylene is subjected to an oligomerization reaction in a reaction system containing an isobutyryl substituted 1,10-phenanthroline aminal iron (II) complex coordination compound main catalyst represented by a formula (I), an aluminum-containing assisted catalyst, water and a solvent, and the solvent is alpha-olefin of Cn (n is more than 4 and is less than or equal to 10), wherein in the formula (I), R1-R5 are respectively and independently selected from hydrogen, C1-C6 alkyl, halogen, C1-C6 alkoxy and nitro. According to the present invention, the technical prejudice is overcome, the oligomerization process is optimized, the oligomerization activity is high, and advantages of rapid ethylene oligomerization reaction process initiation, stable operation, low toxicity, environmental protection, good catalytic effect and cost balancing, and strong practicality; and the ethylene oligomerization reaction cost is substantially reduced, the catalysis effect and the production cost are comprehensively considered, and the industrialization prospects are broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

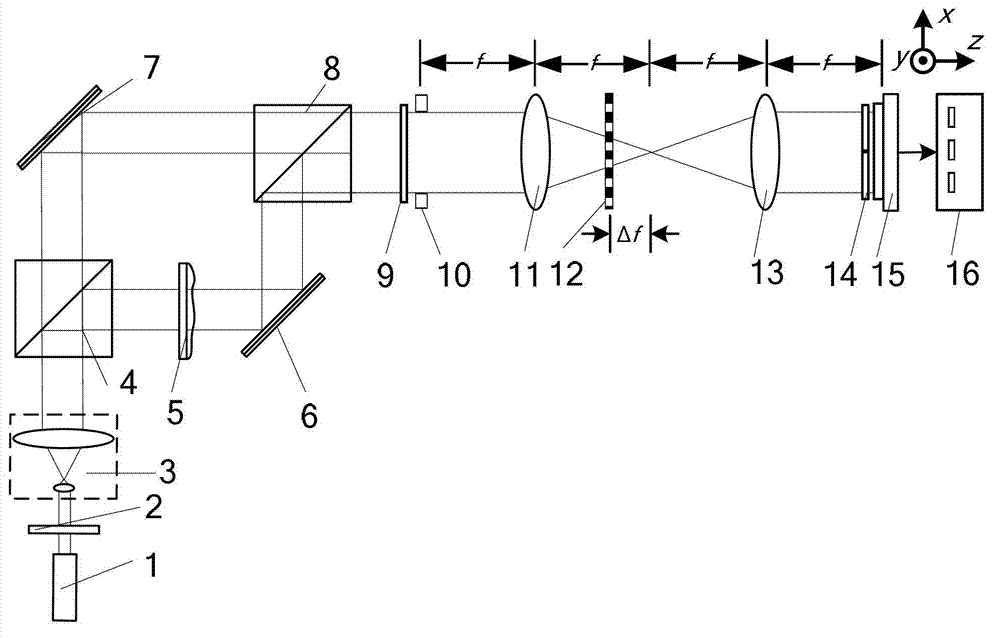

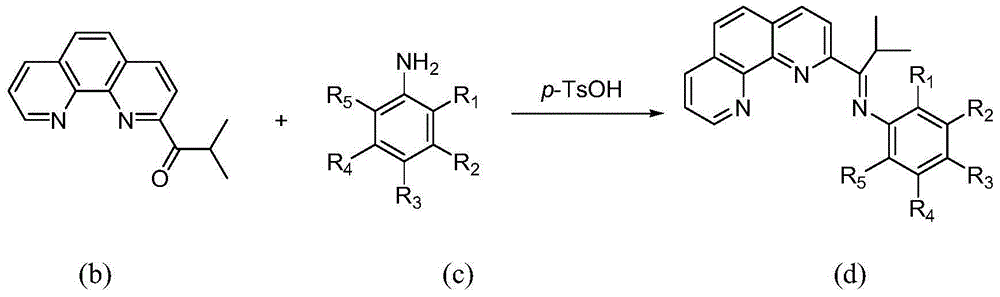

Microscopic interference detecting device based on synchronous carrier phase shift and detecting method of microscopic interference detecting device

InactiveCN102954757ATo achieve the purpose of phase recoveryTake full advantage of horizontal resolutionUsing optical meansGratingPrism

The invention relates to a microscopic interference detecting device based on synchronous carrier phase shift and a detecting method of the microscopic interference detecting device, which belong to the field of optical interference detection and solve the problems that the existing synchronous carrier phase shift interference microscope method is low in light utilization rate and complex in data process. The microscopic interference detecting device comprises an optical source, a linear polarizing film, a first polarization splitting prism, a first collimation and beam expansion system, an object to be detected, a microobjective, a correcting objective, a first mirror, a second mirror, a second collimation and beam expansion system, a second polarization splitting prism, a lambda / 4 wave plate, a rectangular window, a first flourier lens, a one-dimensional period optical grating, a second flourier lens, a polarizing film set, an image sensor and a computer. The detecting method comprises the steps that two phase shift interference images are obtained through once exposure collection after a defocused grating splitting technique and a polarization modulating technique are combined, and phase retrieval of an object is achieved by eliminating a zero frequency component in a differential phase reduction method. The microscopic interference detecting device based on the synchronous carrier phase shift and the detecting method of the microscopic interference detecting device, disclosed by the invention, are suitable for shape measurement of small objects.

Owner:HARBIN ENG UNIV

Ethylene oligomerization catalyst composition containing 1, 10-phenanthroline amino-iron (II) complex substituted by propionyl

InactiveCN103008010AReduce dosageHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsPhenanthrolineEthyl group

The invention provides an ethylene oligomerization catalyst composition. The ethylene oligomerization catalyst composition comprises a main catalyst of a 1, 10-phenanthroline amino-iron (II) complex which is substituted by propionyl in a formula (I) and a catalyst promoter of triethyl aluminum, wherein the molar ratio of the metallic aluminium of the catalyst promoter to the central metallic aluminium of the main catalyst is between 30 and 900. According to the ethylene oligomerization catalyst composition, the triethyl aluminum which is used as the catalyst promoter is low in price and only accounts for a small percentage of the price of methylaluminoxane, and the usage of the catalyst promoter is greatly reduced, the catalyst has good catalytic activity of catalyzing ethylene oligomerization, so that the ethylene oligomerization reaction cost is greatly lowered; the selectivity of linear alpha-olefin in an oligomerization product is high; the oligomerization product is distributed reasonably; polyvinyl cannot be generated; and thus, the ethylene oligomerization catalyst composition has a wide industrial prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

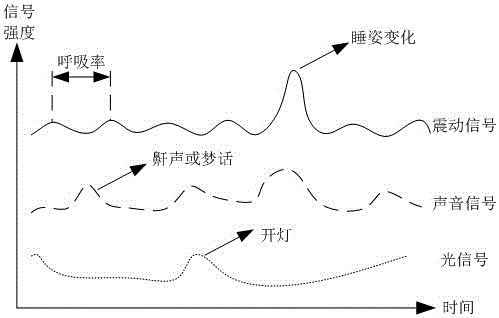

Sleep monitoring watch and implementation method thereof

ActiveCN106037661ARealize idle timeOvercoming conventional optionsRespiratory organ evaluationTime-pieces with integrated devicesHuman bodyEnvironmental noise

The invention discloses a sleep monitoring watch and an implementation method of the sleep monitoring watch, for solving the problems that the existing intelligent wristwatch is in idle and can not be effectively utilized when a user sleeps. The sleep monitoring watch comprises a watch body, and is characterized by further comprising an acceleration sensor, a photosensitive sensor, a sound sensor and a processor, wherein the acceleration sensor is used for monitoring the sleeping posture change of the human body and vibration signals generated by breathing when the user sleeps; the photosensitive sensor is used for monitoring the ambient light change when the user sleeps; the sound sensor is used for monitoring the sounds made by the human body and the environmental noise when the user sleeps; and the processor is used for receiving and processing the signals detected by the sensors. On one hand, the idle time of the intelligent wristwatch when the user sleeps is effectively utilized, on the other hand, the technical biases in the field and the conventional choice of the technical staff are overcome.

Owner:CHENGDUSCEON ELECTRONICS

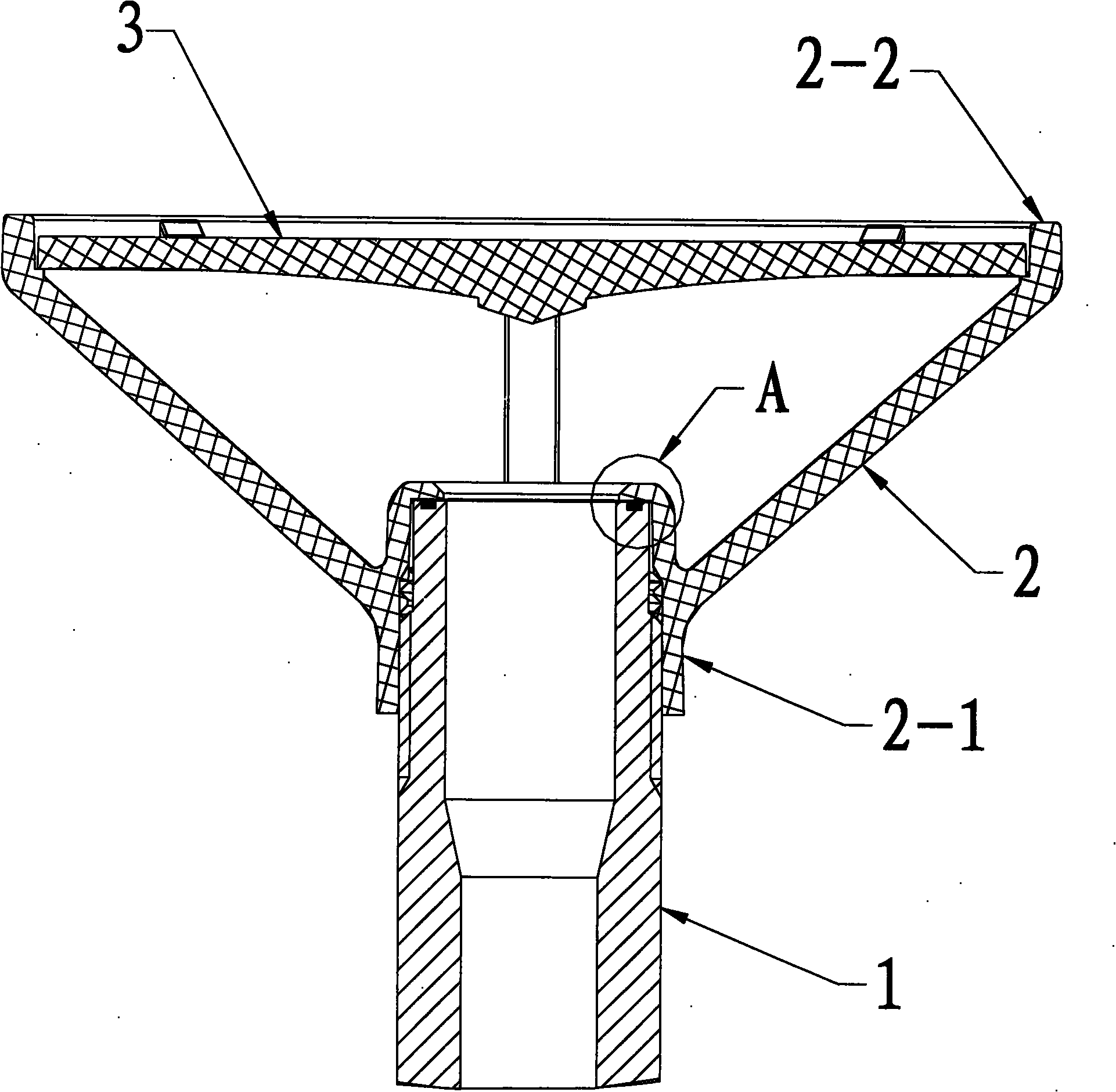

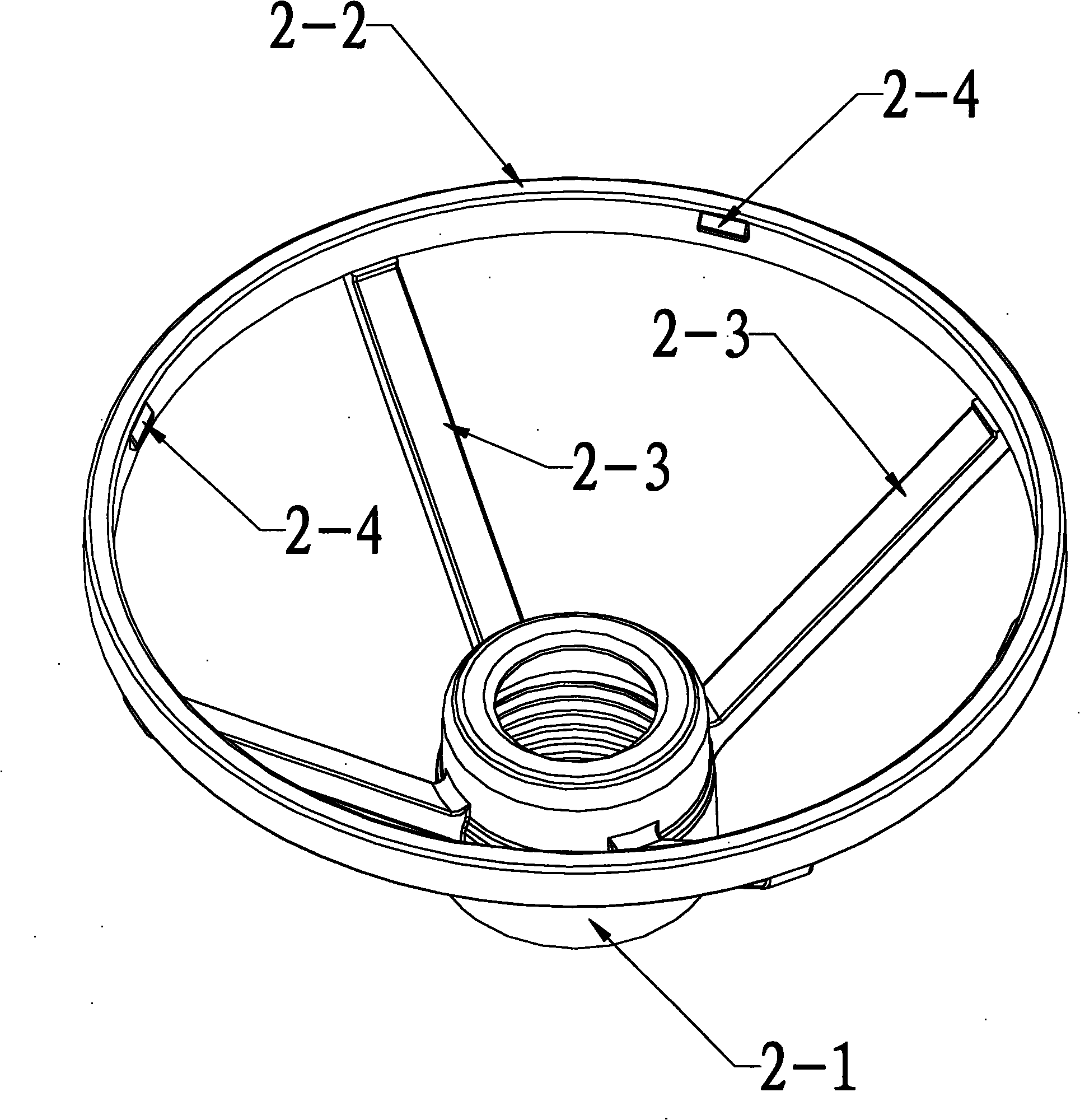

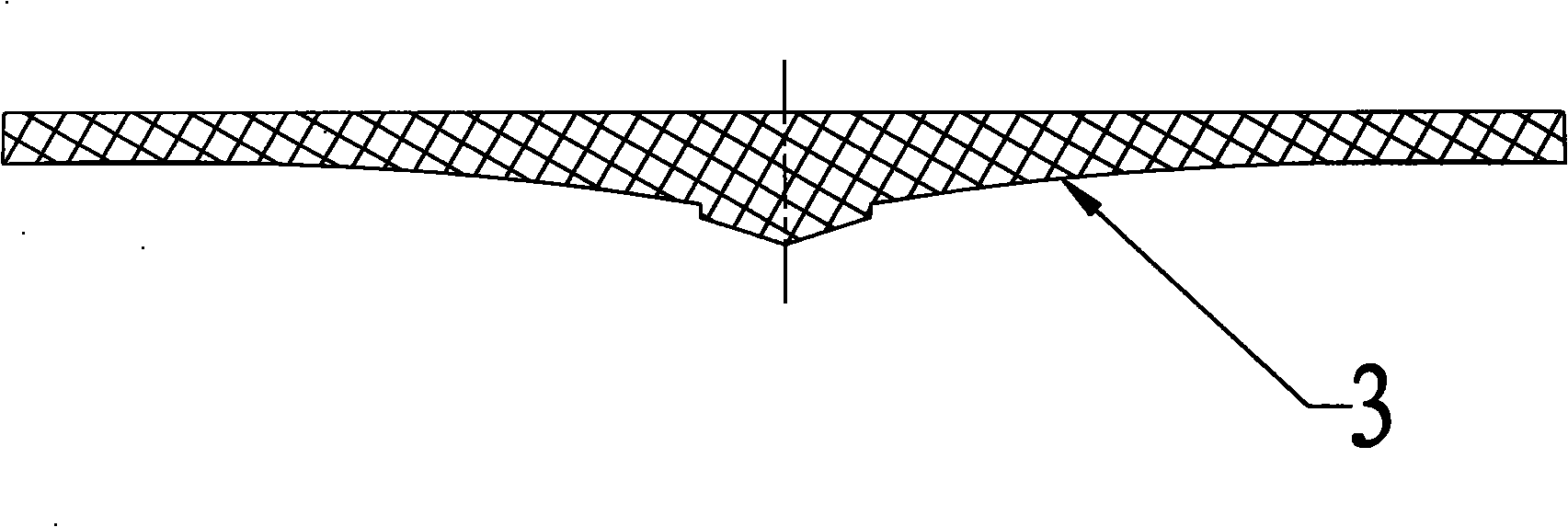

Feed source for microwave antenna and microwave antenna

InactiveCN101841082ABest Antenna Electrical PerformanceLimit shading areaAntenna supports/mountingsMicrowaveHigh volume manufacturing

The invention discloses a feed source for a microwave antenna and the microwave antenna using the same, which comprises a feed horn, a supporting bracket and an auxiliary reflecting surface. The feed horn and the auxiliary reflecting surface are fixed to the same central axis by the supporting bracket; the supporting bracket comprises a first connecting part which is connected with the feed horn and a second part which is connected with the auxiliary reflecting surface; and the first connecting part and the second connecting part are fixedly connected with each other through at least one supporting post. An antenna radiation directional diagram which adopts the feed source meets the enveloping requirement of ETSI Class3 standard; the structure and the processing technique of the microwave antenna can ensure consistent performance well; and the microwave antenna has very low cost and is convenient for mass production.

Owner:TONGYU COMM INC

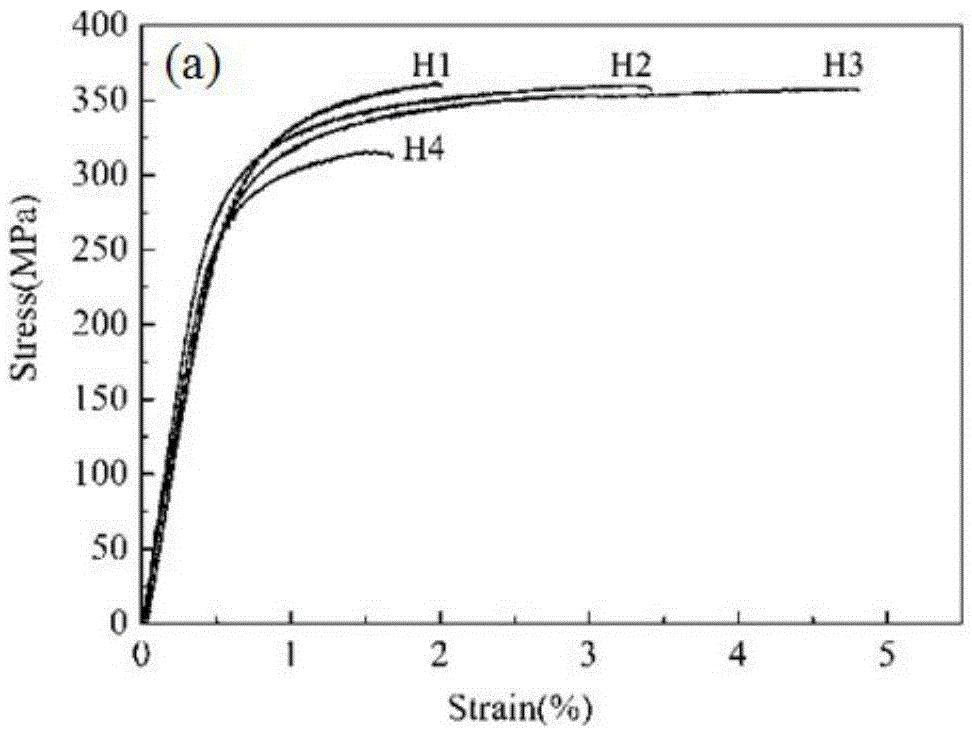

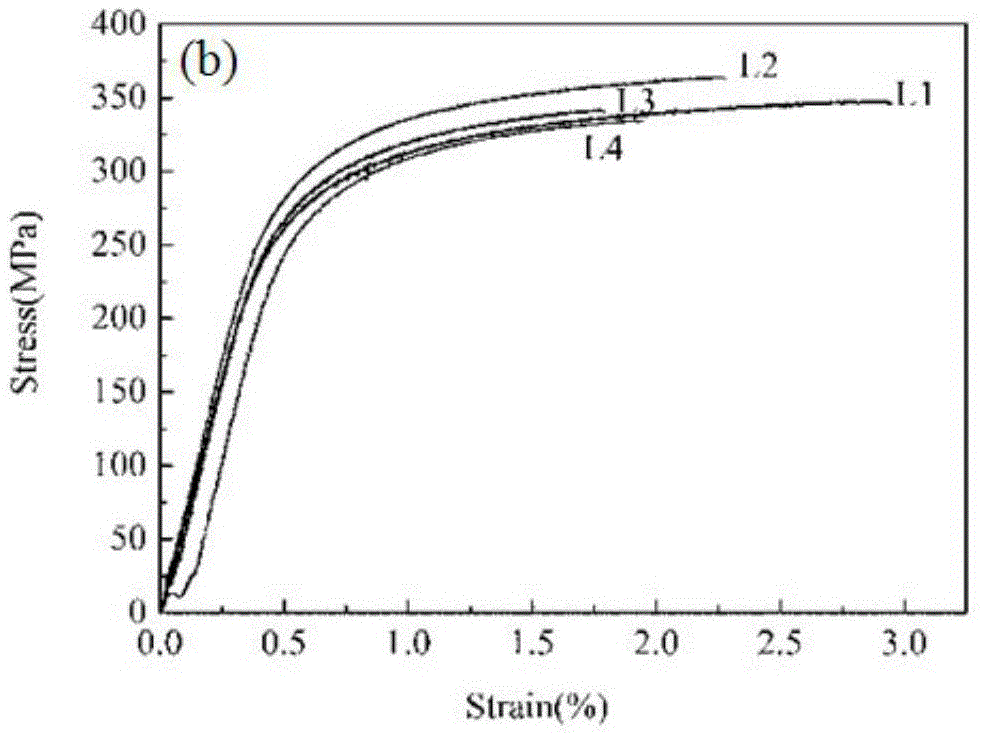

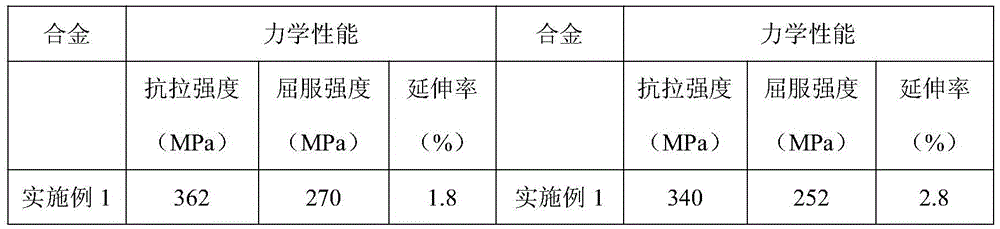

Heat treatment method for Al-Si-Cu-Mg casting alloy

The invention relates to Al-Si-Cu-Mg casting alloy. The Al-Si-Cu-Mg casting alloy is formed by smelting electrolytic aluminum, silicon metal, pure magnesium and Al-Cu intermediate alloy and comprises, by weight, 5.5%-6.5% of Si, 1.8%-2.2% of Cu, 0.45%-0.55% of Mg and the balance Al, and the ratio of the Cu to the Mg is 4:1. The Al-Si-Cu-Mg casting alloy is subjected to two-stage solid solution treatment and two-stage aging treatment, it can be ensured that precipitated phases of the Al-Si-Cu-Mg casting alloy are all dissolved in a matrix through suitable solid solution temperature and time, and overburning of crystal boundaries cannot be caused; and then the characteristics and mechanical properties precipitated by the alloy phases are controlled through two-stage aging treatment, so that the tensile property of the Al-Si-Cu-Mg casting alloy obtained through the method is obviously improved in index compared with the tensile property of Al-Si-Cu-Mg casting alloy subjected to T6 treatment.

Owner:BEIHANG UNIV +1

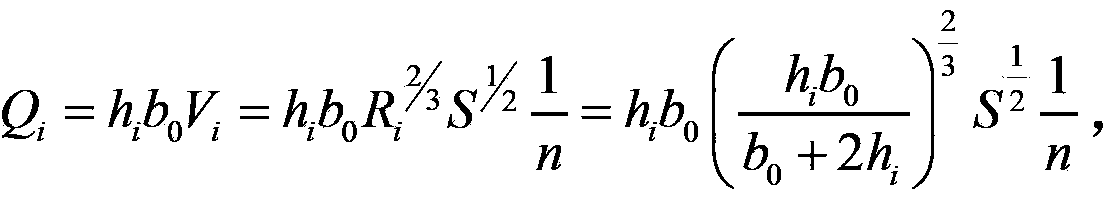

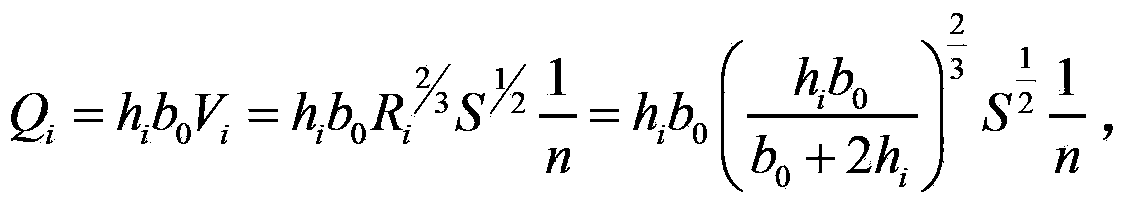

Method for judging groove debris flow occurring possibility at present and groove debris flow occurring possibility in future

The invention discloses a method for judging the groove debris flow occurring possibility at present and the groove debris flow occurring possibility in future. The method for judging the groove debris flow occurring possibility at present includes the steps of S1, selecting a groove, and using the formula (please refer to the specifications for the detailed formula) to calculate the hs, S2, using the formula to calculate the h0, and S3, comparing to judge whether the h0 is larger than or equal to the hs or not, issuing a debris flow alarm starting information if the h0 is larger than or equal to the hs, and being free of issuing the debris flow alarm starting information if the h0 is smaller than the hs. The method for judging the groove debris flow occurring possibility in future includes the steps of S1, selecting the groove, and using the formula to calculate the Q0', S2, using the formula to calculate the Q0, S3, using the formula to calculate the Cq, and using the formula to calculate the n, S4, using the forecast precipitation information issued by the meteorological department, and respectively obtaining P1, P2, P3...Pi, S5, using the formula to calculate the Qi, S6, solving S7, comparing to judge whether the Pi is larger than or equal to the P0 or not, and using the iteration method to determine the hi, and S8, comparing to judge whether the hi is larger than or equal to the hs or not, issuing the debris flow forecast starting information if the hi is larger than or equal to the hs, and being free of issuing the debris flow forecast starting information if the hi is smaller than the hs. The method is concise in technological process and accurate in judged conclusion.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Cinacalcet hydrochloride preparation method

InactiveCN103467304AOvercoming technical biases usedOvercoming technical biasAmino compound purification/separationPreparation by reductive alkylationSolventPollution

The present invention discloses a cinacalcet hydrochloride preparation method, which comprises: 1, adopting 3-(trifluoromethyl) phenyl propionaldehyde and R-1-(1-naphthyl)ethylamine as raw materials, and carrying out a condensation reduction reaction in a mixing reaction solvent in the presence of sodium triacetoxyborohydride, 2, extracting the reaction product with water, a salt or an alkali aqueous solution to obtain a cinacalcet base organic phase solution, and 3, carrying out acidification salification on the obtained cinacalcet base organic phase solution with hydrochloric acid to obtain the cinacalcet hydrochloride, wherein one of components in the mixing reaction solvent is water. According to the present invention, the water-containing mixing solvent is adopted as the reaction medium, such that technical defects of solvent use during the sodium triacetoxyborohydride use process are overcome, the harsh condition that the reaction solvent requires a water-free treatment is avoided while reaction selectivity is increased, types of produced impurities and impurity content are substantially reduced, cost is reduced, and environment pollution is reduced.

Owner:NANJING LIFENERGY R & D

Pea and tobacco intercropping method

InactiveCN103081706ALow costIncrease the multiple land cropping indexHorticultureBiotechnologyMonocropping

The invention discloses a pea and tobacco intercropping method. According to the method, based on the technical background of tobacco monoculture in the southwestern tobacco-growing area, pea seeds are sown on two sides of a tobacco ridge after laminas on the lower middle portion of tobacco are harvested or after harvest is completed, and a plastic net is hung on a tobacco stem as the climbing support of a pea, and then pea and tobacco intercropping is achieved. The pea and tobacco intercropping method has the advantages that the multiple crop index of land is improved; fertilization is not needed for pea planting, a large quantity of nitrogenous fertilizer and potash fertilizer left in tobacco land can be utilized, and the economical benefit of tobacco farmers is increased by 1000-1200 yuan / mu; the tobacco stem is used as the climbing carrier of the pea, and cost of 200-400 yuan / mu for building a support for the pea is saved; and due to the fact that the height of the tobacco stem can not meet climbing requirements of the pea, the plastic net is laid on the top of the tobacco stem by the applier to enable the pea to continue to climb after reaching to the top of the tobacco stem, and technical prejudice of technicians in the field is overcome.

Owner:GUIZHOU TOBACCO SCI RES INST

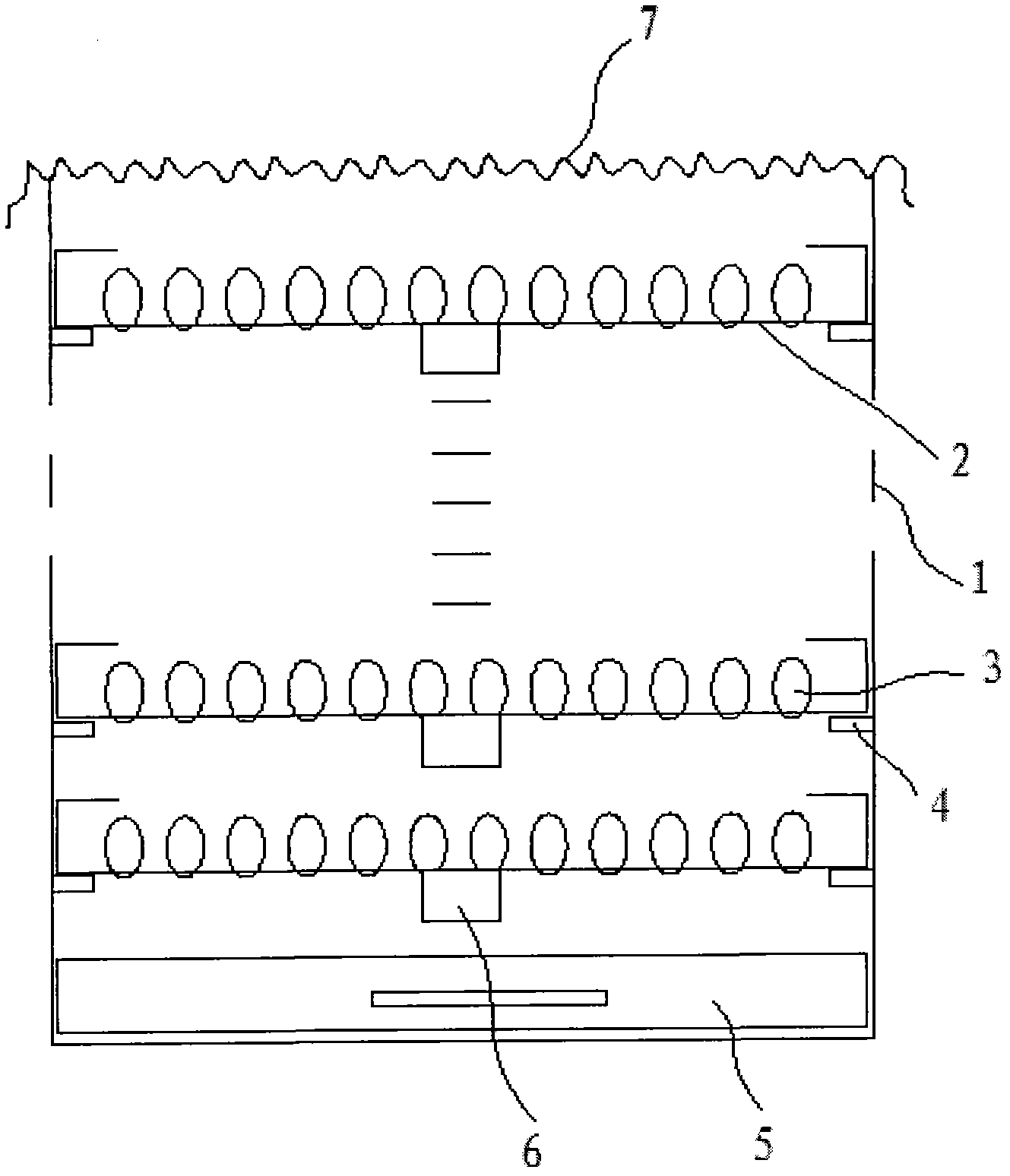

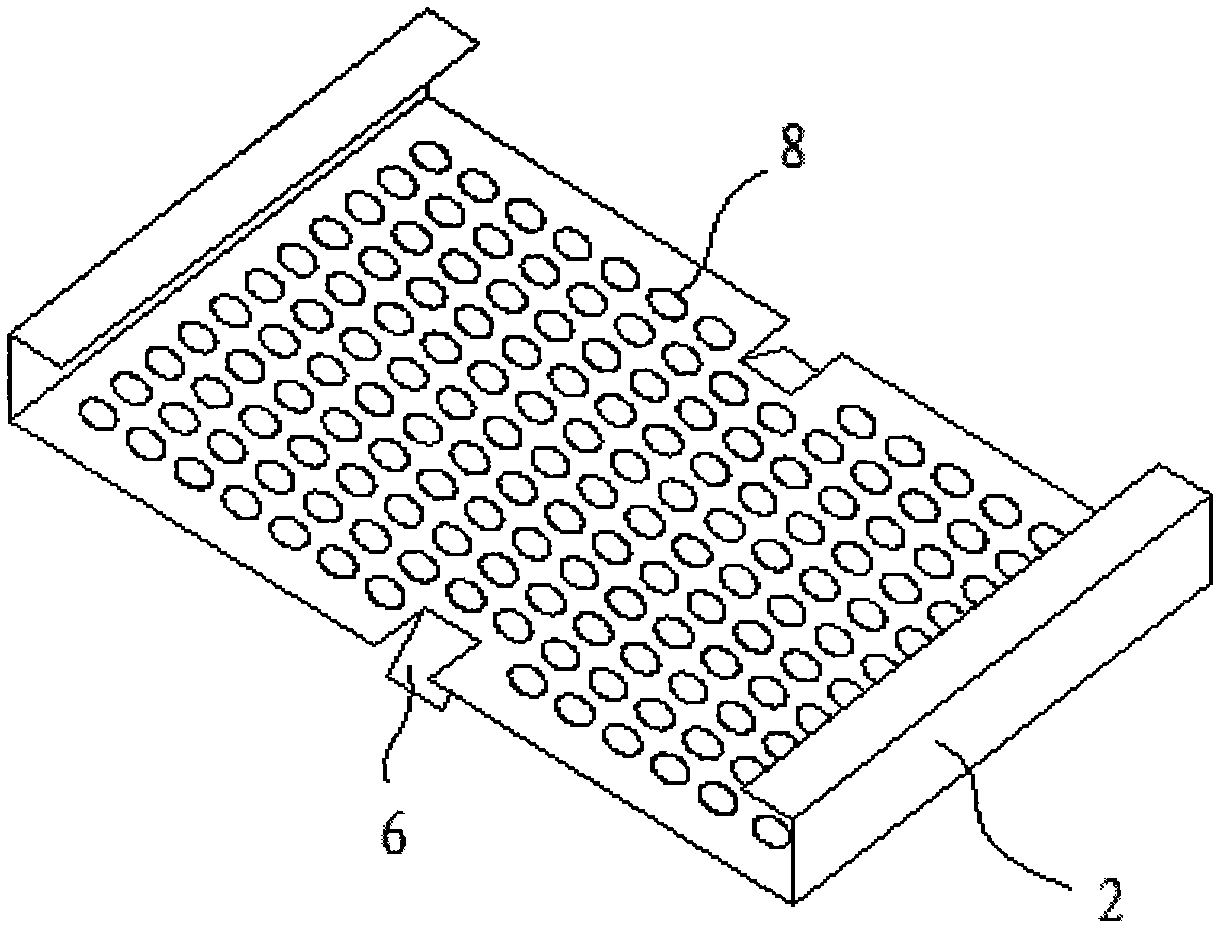

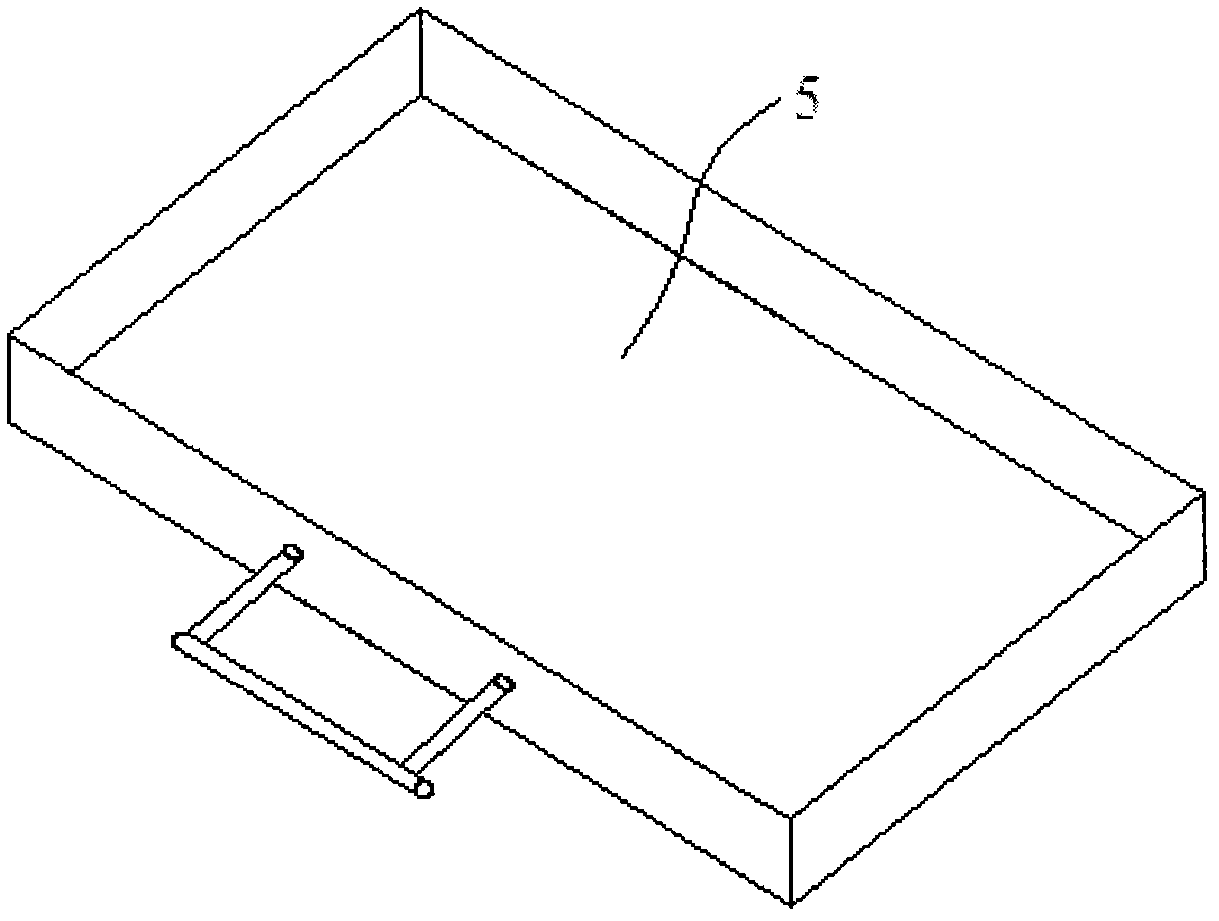

Turtle medium-free hatching method and device

ActiveCN102487884AGood ventilationImprove hatching efficiencyAnimal husbandryEnvironmentally friendlyRelative humidity

The invention relates to a turtle medium-free hatching system and particularly relates to a medium-free hatching method and a device. The turtle medium-free hatching method is as follows: naturally hatching turtle at the temperature of 24-33DEG C under the condition that the relative humidity is 80-90%. The turtle medium-free hatching method and the device, provided by the invention, can be used for overcoming the technical bias of a traditional hatching project, and medium-free hatching method is created and is good in vent ability, constant in temperature and humidity and high in hatching efficiency which approaches 100%; the space is fully utilized, and 10,700 turtle eggs can be contained in per cubic meter; and simultaneously, redundant medium material cost is not needed, and the method is energy-saving, labor-saving, natural, environmentally-friendly and safe and is simple and convenient to operate. The method and the device, provided by the invention, have a remarkable groundbreaking significance, simultaneously provide inspiration for the medium-free hatching technologies of other animals, and have a historical significance.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI +1

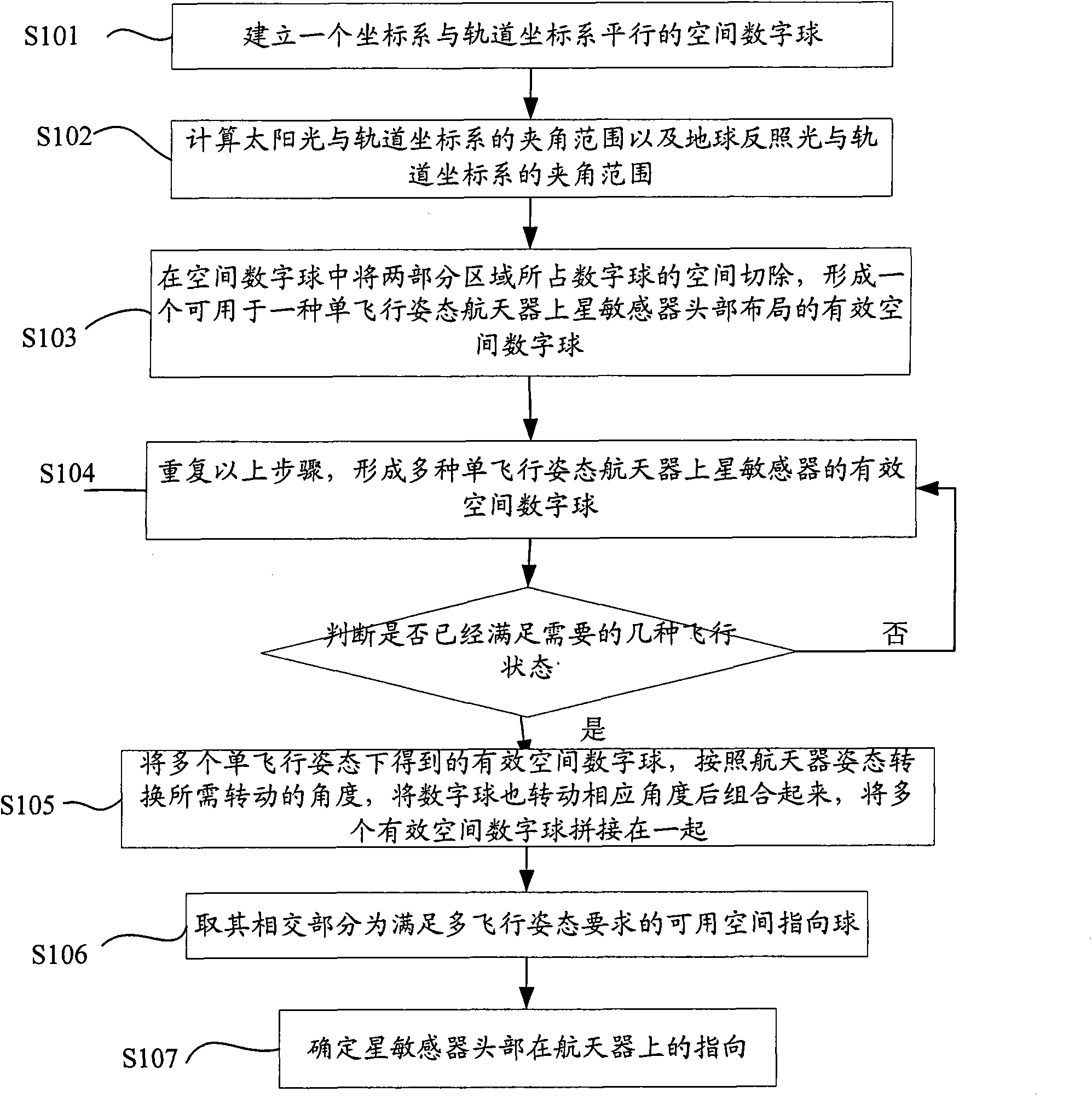

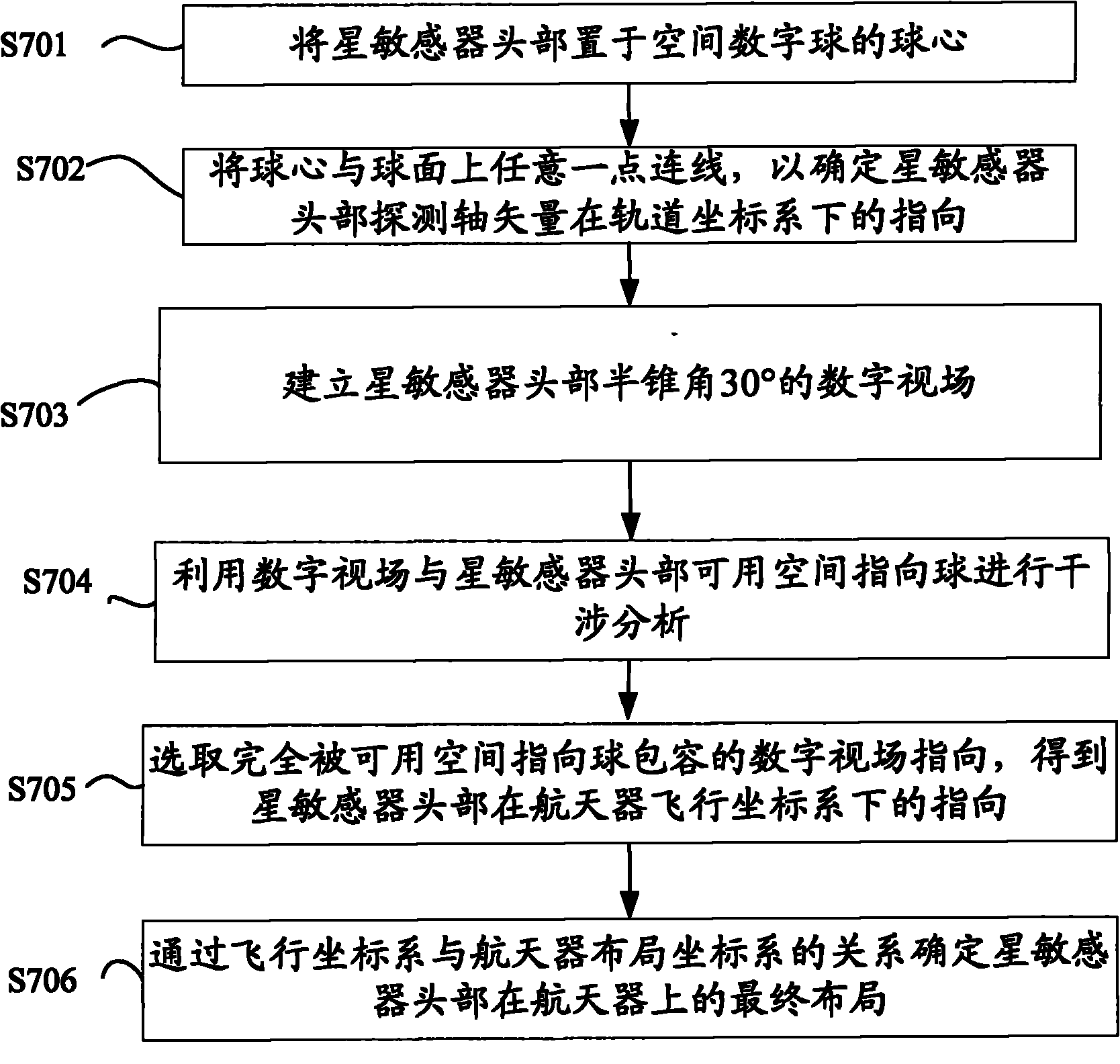

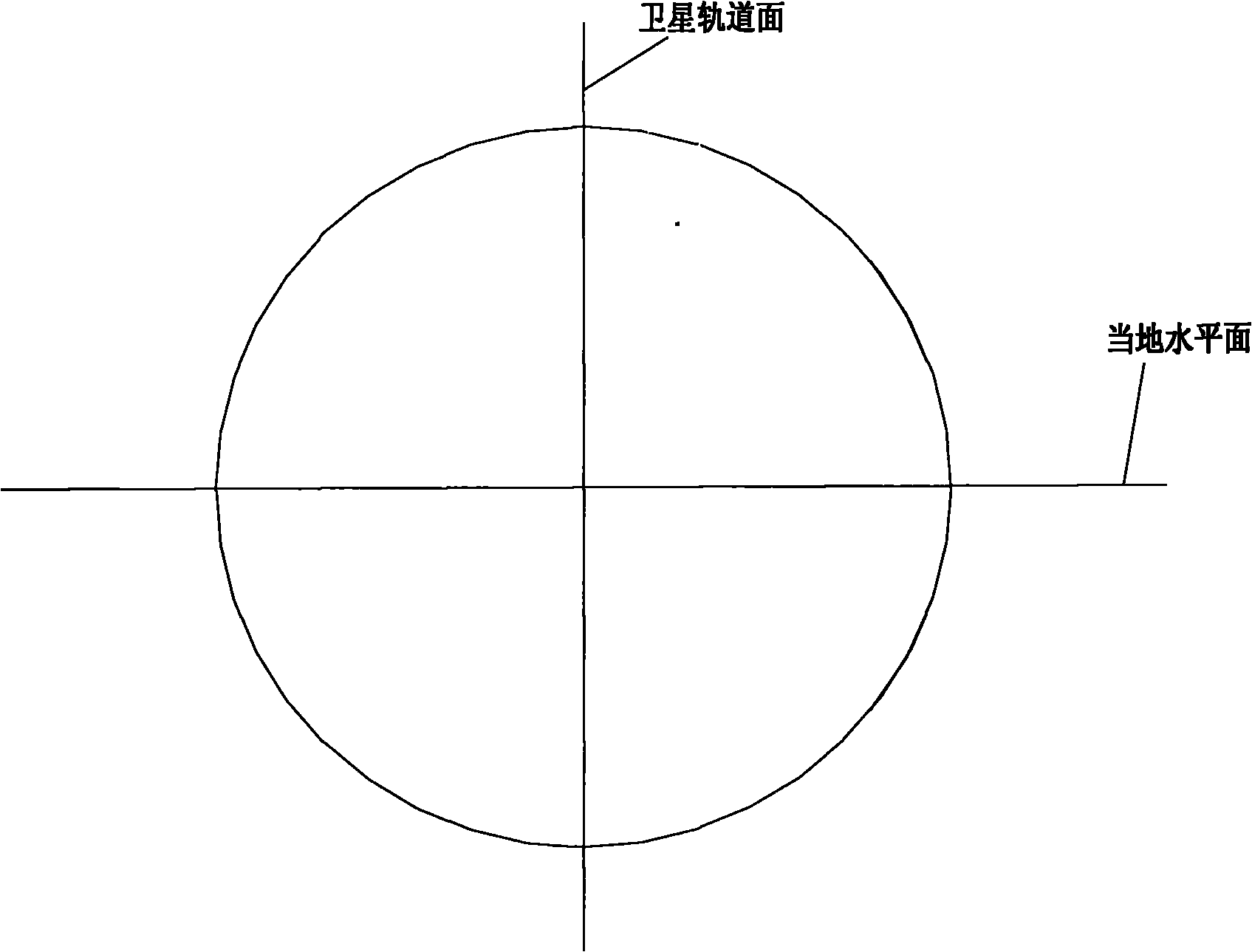

Method for configuration of star sensor head

ActiveCN102372093AFix layout issuesOvercoming technical biasInstruments for comonautical navigationSpacecraft guiding apparatusAngular degreesComputer science

A method for the configuration of a star sensor head comprises the following steps of: establishing a space digital ball by which a coordinate system is parallel to an orbital coordinate system; calculating the scope of an included angle between sunlight and the orbital coordinate system and the scope of an included angle between earthshine light and the orbital coordinate system; cutting the spaces of digital balls occupied by two partial areas in the space digital ball to form an effective space digital ball for the configuration of the star sensor head on a single flight attitude spacecraft; repeating the above steps; converting effective space digital balls obtained under a plurality of single flight attitudes into required rotating angles according to a spacecraft attitude, combining the digital balls rotated for corresponding angles; splicing the effective space digital balls together; taking a crossing part of the effective space digital balls; and determining the direction of the star sensor head on the spacecraft. With the adoption of the method, the requirements of a plurality of flight attitudes can be simultaneously satisfied, and the technical problem that the direction of the star sensor head cannot flexibly rotate along with the spacecraft can be solved.

Owner:SHANGHAI SATELLITE ENG INST

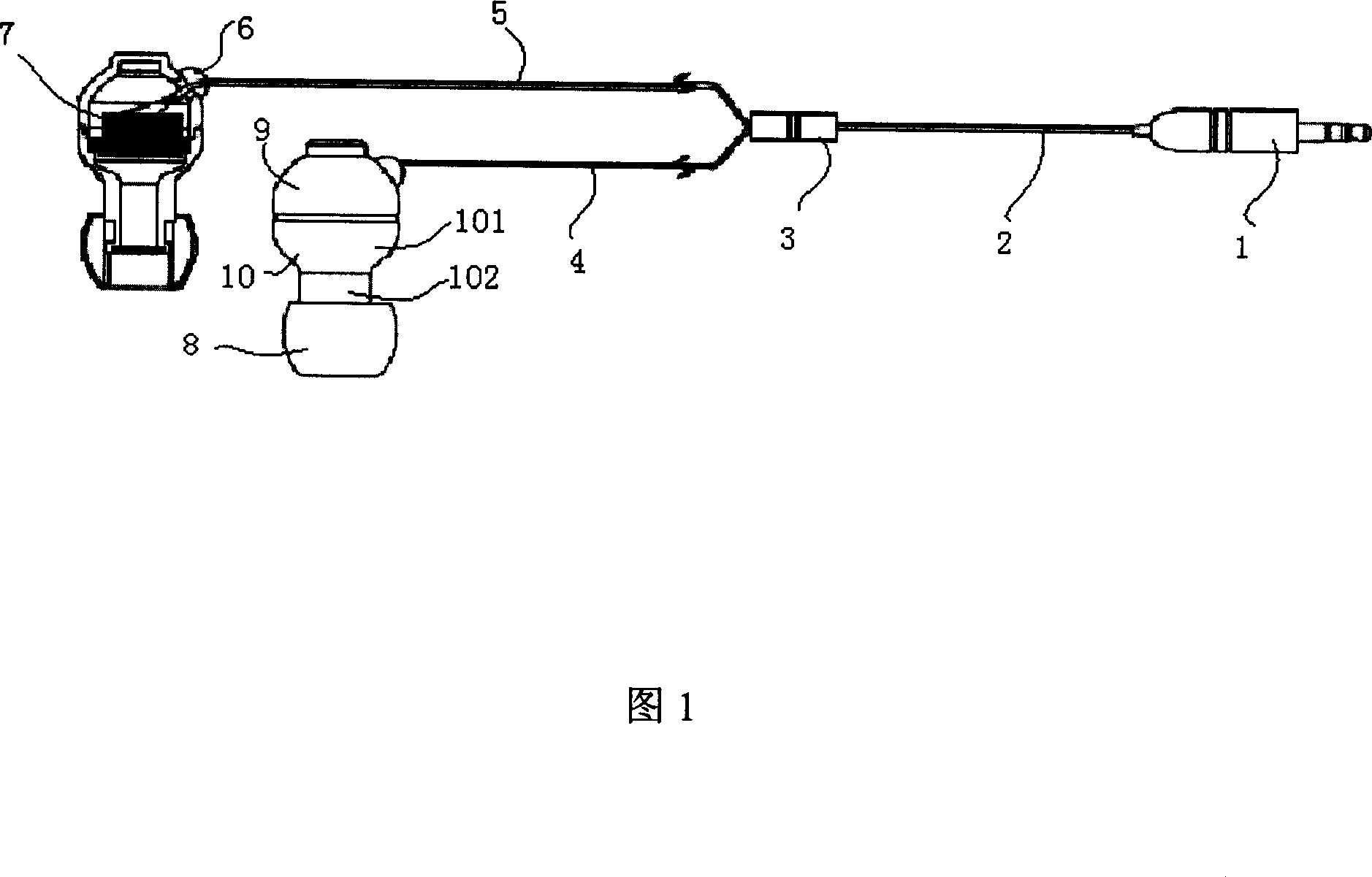

Built-in earphone

InactiveCN1929692AOvercoming technical biasUniform textureEarpiece/earphone attachmentsEngineeringSound quality

This invention discloses one ear small phone to process ear phone front and back shells, wherein, the materials is of good resistance property to absorb redundant vibration besides trumpet to make the sound quality more pure, clear; the materials quality is of good spring and tightness to absorb trumpet.

Owner:张耀国

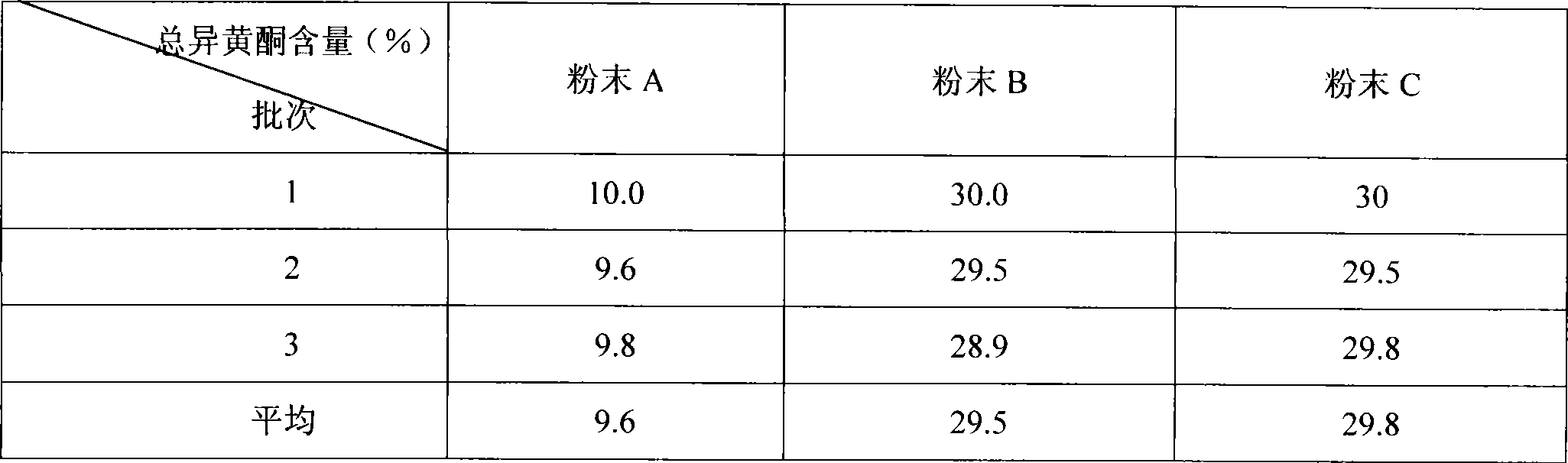

Red clover extract and preparation method thereof

ActiveCN101396422AOvercoming technical biasHigh yieldSexual disorderPlant ingredientsReflux extractionCentrifugation

The invention discloses a red clover extract and a preparation method thereof, red clover is taken, ethanol containing water is used for reflux extraction, filtrate is concentrated to obtain a liquid extract; water precipitation, placement and centrifugation are carried out on the liquid extract to obtain sediments; the ethanol containing the water is sequentially added in the sediments for gradient ethanol precipitation, the centrifugation is carried out, supernatant liquid with the corresponding ethanol concentration is taken, and the extract powder is obtained by concentrating and drying. The content of total isoflavones of the method is not less than 20 percent, the operation is simple and the cost is low, thereby being applicable to industrial production.

Owner:TIANJIN TASLY MORDEN TCM RESOURCES

Method for making edible fungus stick

InactiveCN105557311AReduce the process of manual inoculationPromote growthCultivating equipmentsMushroom cultivationBiotechnologyHigh pressure

The invention relates to a method for making an edible fungus stick. The method comprises the technological processes of culture material stirring, sterilization, cooling, inoculation, fungus culture and bagging. The method specifically comprises the steps of preparing culture materials according to a formula required for edible fungus culture; fully mixing and stirring the culture materials; feeding the culture materials into a sterilization pot for high-pressure sterilization; and finishing fungous material cooling, seed dressing and bagging under the aseptic condition to obtain the edible fungus stick. According to the method, a production process for performing bagging at first and then performing sterilization and inoculation in an original fungus stick making process is changed to a production process for performing sterilization at first and then performing inoculation and bagging under the aseptic condition, so that a process link of artificial inoculation required after the completion of the fungus stick is removed and the technical bias of a conventional fungus stick is overcome; the sterilization time is shortened, the working efficiency is improved exponentially, the energy consumption is reduced, and the labor force is saved; and meanwhile, the fungus seeds are mixed and stirred before bagging, so that a culture medium and the fungus seeds in the fungus stick can be uniformly mixed and stirred and the growth of the fungus seeds in the culture medium can be greatly accelerated.

Owner:LISHUI AGRI SCI

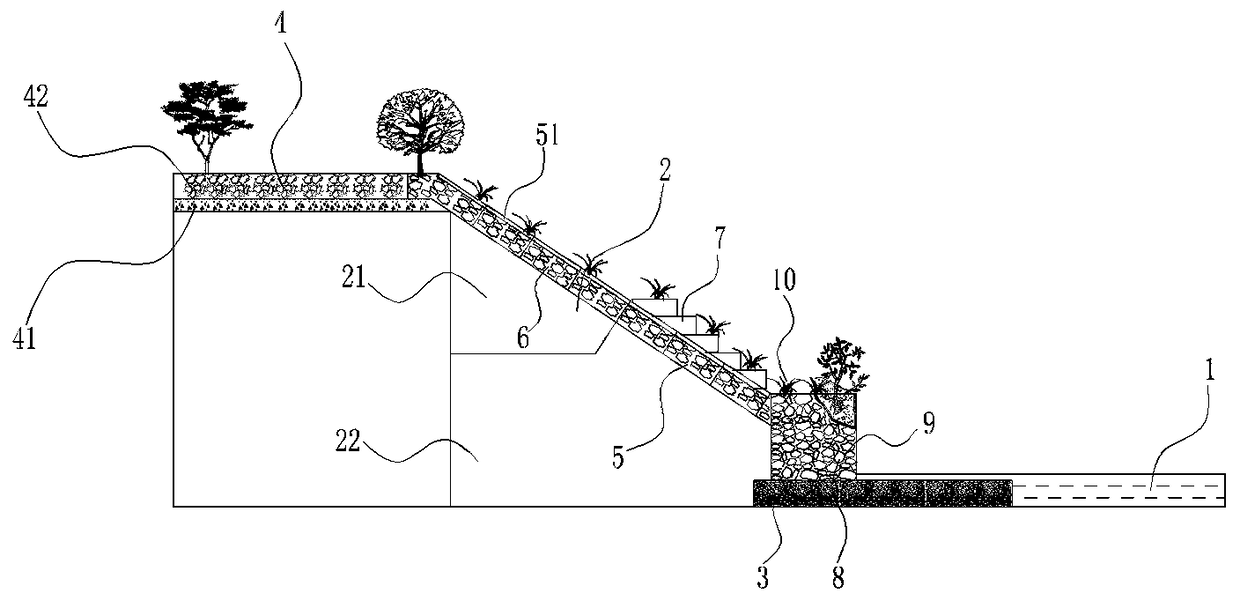

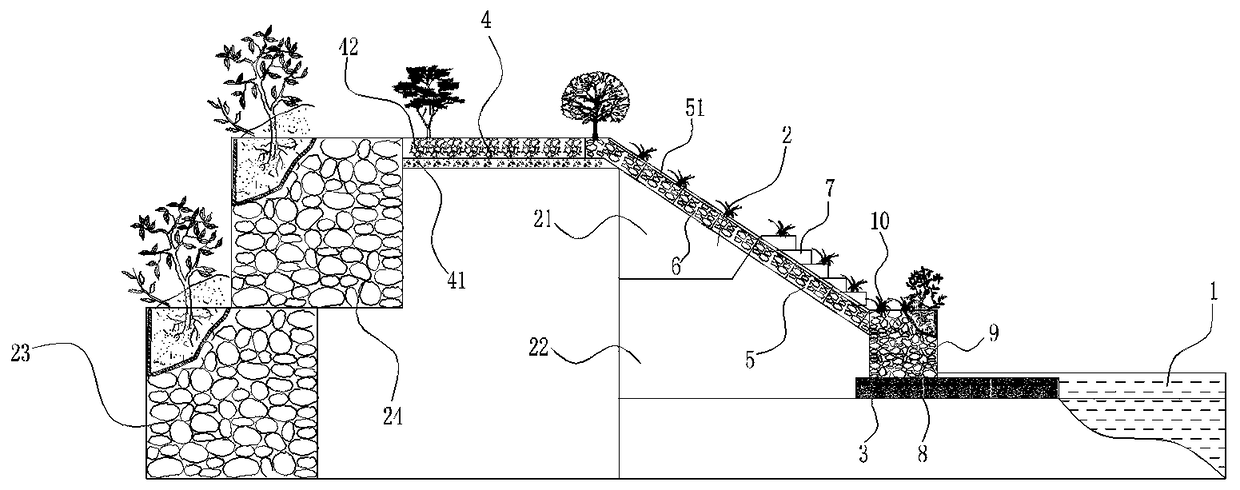

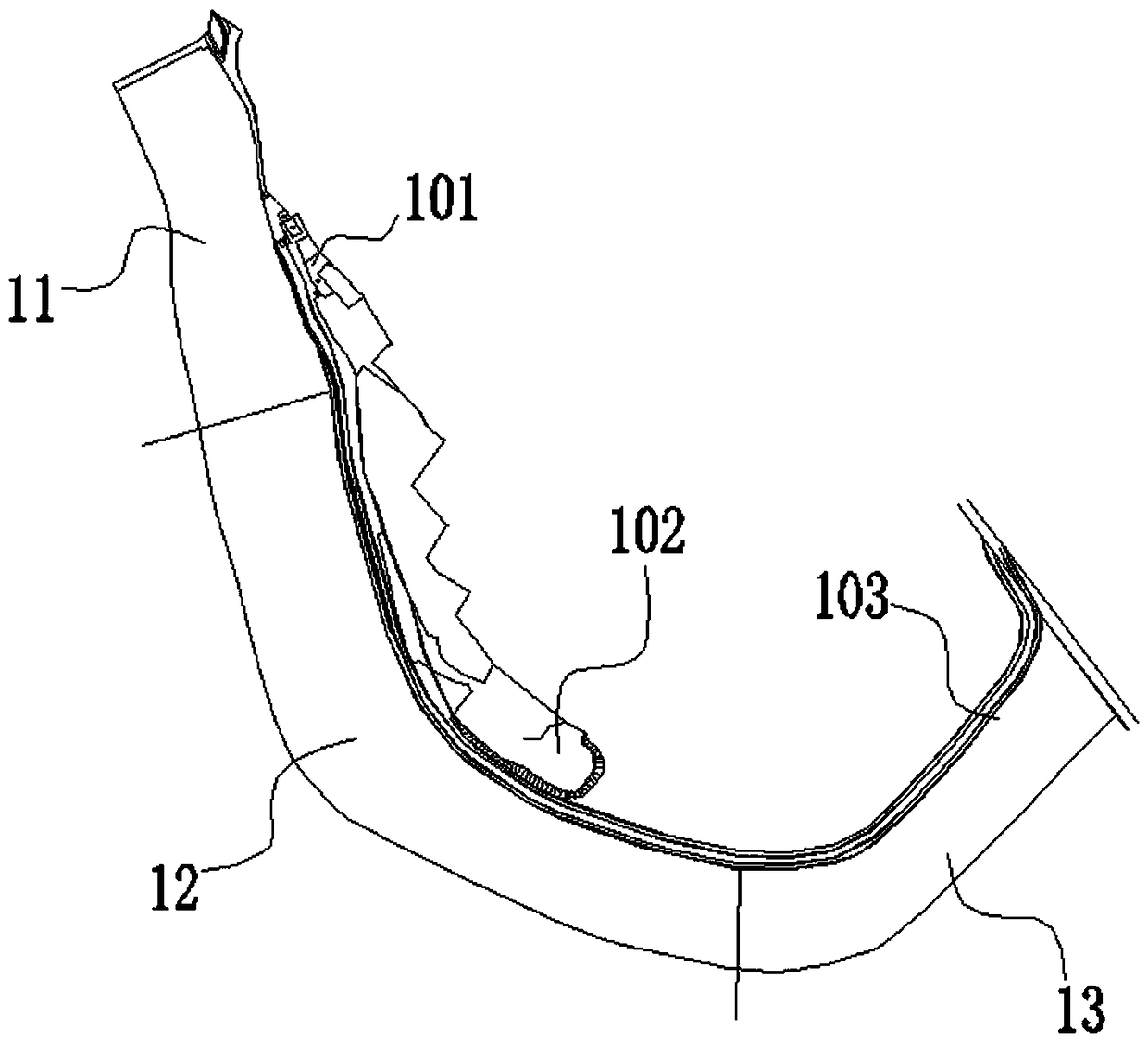

Ecological river technology for mountainous area

PendingCN108316243AGuaranteed structural strengthOvercoming technical biasFlowers cultivationCoastlines protectionRiver routingEngineering

The invention provides an ecological river technology for a mountainous area, and relates to the technical field of water and soil loss prevention of mountainous areas. The ecological river technologyfor the mountainous area is characterized in that a plurality of gauze pads are paved on the surface of a protection slope of a bank revetment; covering soil layers cover the first net cushion and the second net cushion; ecological bags are arranged on the covering soil layer of the first net cushion in a covering manner; the ecological bags are paved from an underwater protection slope in a manner of ladder-shaped laminating and staggering manner; first seams are formed among the ecological bags at the same layer; and second seams are formed between two layers of ecological bags; planting cavities are formed in parts where the first steams are connected with the second seams. According to the technology, the ecological bags are connected as a whole in the early stage, so that the problemof easy deformation of the ecological bags can be solved.

Owner:安吉绿源生态科技有限公司

Method for preparing sodium rabeprazole

The invention relates to a method for preparing sodium rabeprazole. The method is not subjected to concentration, extraction or lyophilization and comprises the steps of reacting rabeprazole with alkaline substances containing sodium ions at 50-55 DEG C and then adding an alkane solvent, thus dissolving out solid sodium rabeprazole.

Owner:JIANGSU HANSOH PHARMA CO LTD

Method for extracting and purifying benzo[a] pyrene in cigarette smoke

InactiveCN102759590AOvercoming technical biasOvercoming stereotypesComponent separationPhysical chemistryPyrene

The invention discloses a method for extracting and purifying benzo[a] pyrene in cigarette smoke, belonging to the technical field of chemical detection. The method comprises the steps of: collecting a filter sheet of smoke particles in an extraction pool filled with a purifying agent in the bottom, adding an internal standard substance, and mixing extraction solutions after extracting, wherein the extraction parameters are as follows: a solvent is cyclohexane, the pressure is 10.3MPa, the temperature is 40-200 DEG C, the heating time is 5-9min, the static extraction time is 01-0min, the static extraction is circulated for 1-5 times, the purging volume is 40-150 percent, the purging time is 60-120s, and the extraction is continuously extracted for 2-5 min. The method is combined with a GC / MS detection condition specified in the national standard without largely modifying the GC / MS detection condition and equipment, can be implemented more accurately and reliably, conveniently and rapidly through slight modification on the basis of the traditional condition in a time and labor saving manner, and has an important industrial application and popularization value.

Owner:CHINA TOBACCO GUANGDONG IND

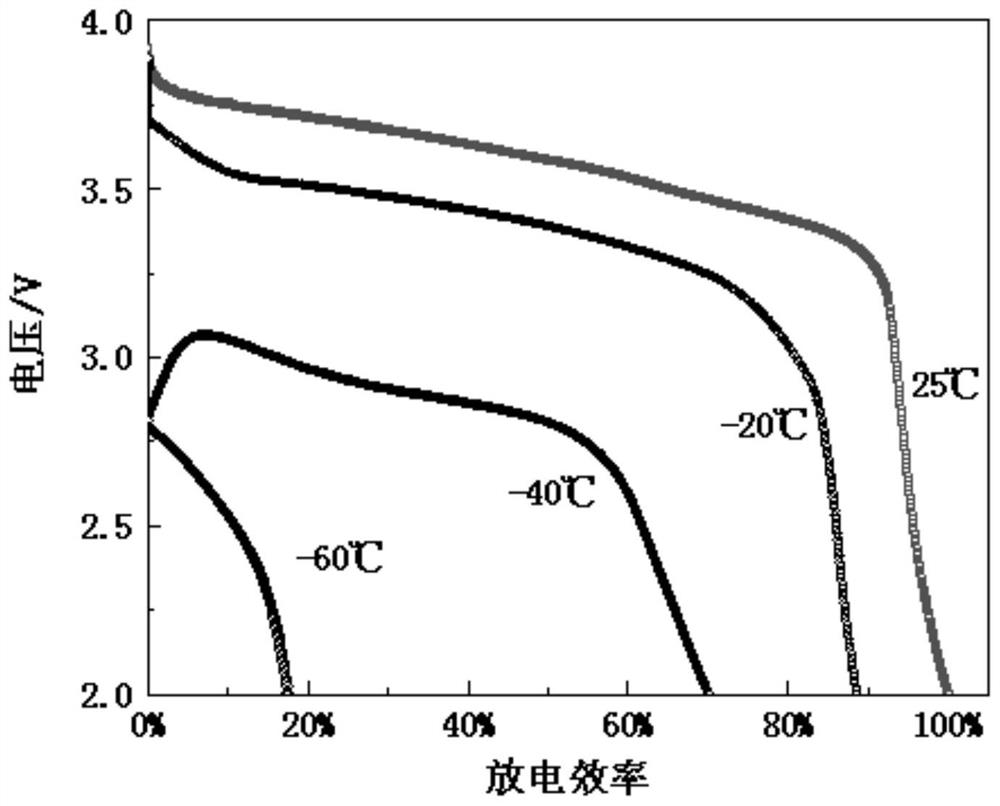

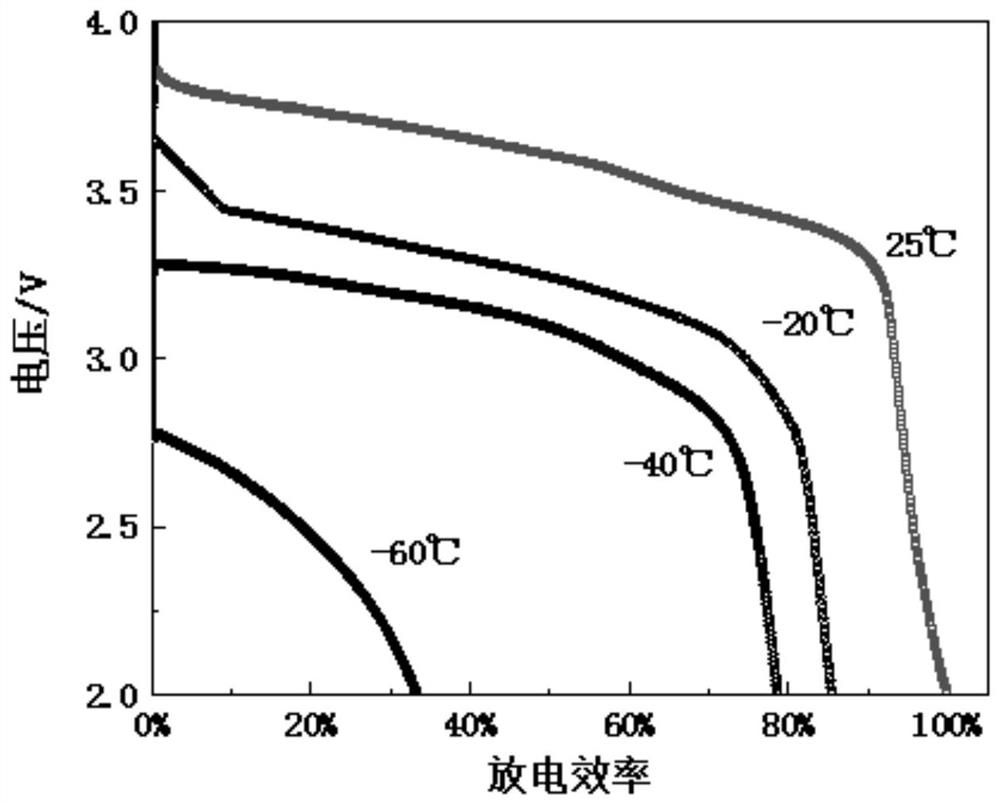

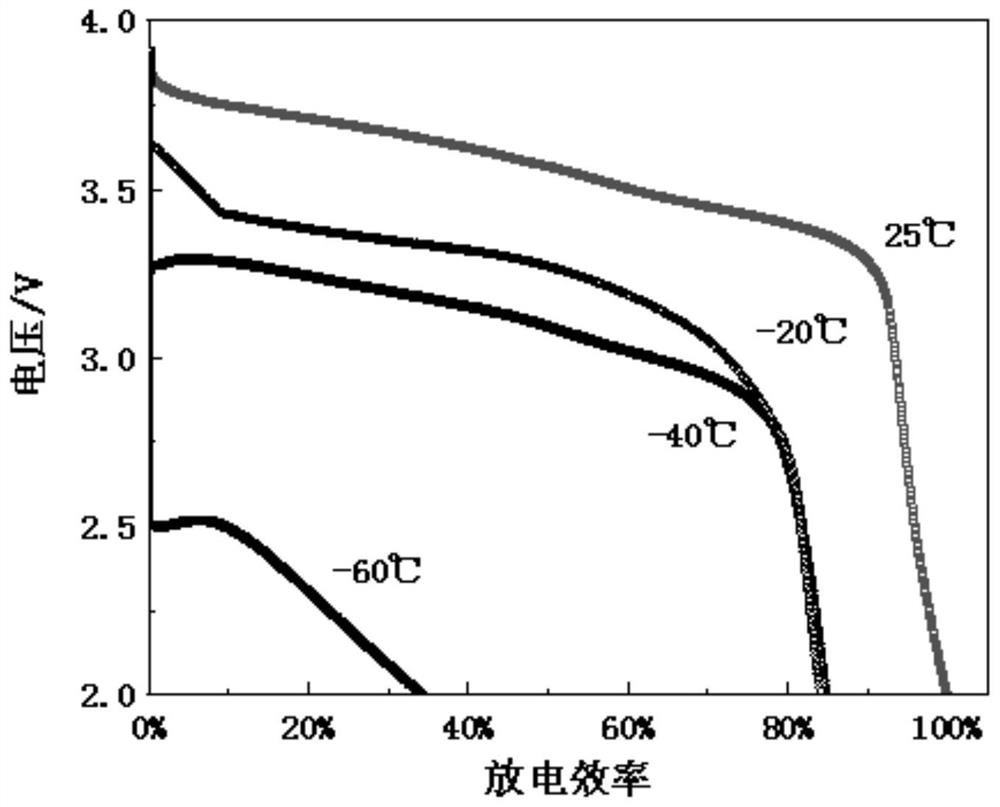

Lithium battery electrolyte, lithium battery and preparation method of lithium battery

InactiveCN112290086ALow viscosityAvoid corrosionSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentOrganic solvent

The invention belongs to the field of lithium ion batteries, and particularly relates to a lithium battery electrolyte, a lithium battery and a preparation method of the lithium battery. The electrolyte comprises an electrolyte lithium salt, an organic solvent and an additive, wherein the organic solvent is a phosphate organic solvent, a carboxylic ester organic solvent and / or a fluorocarboxylic ester organic solvent; and the concentration of the electrolyte lithium salt in the electrolyte is greater than or equal to 1 mol / L. A positive electrode material in the lithium battery is Prussian blue, and the electrolyte is adopted in the lithium battery. The high-concentration electrolyte provided by the invention can effectively inhibit the corrosion of electrolyte lithium salt to a current collector, still has relatively high ionic conductivity at -60 DEG C, and can meet the working requirements of an ultralow-temperature lithium ion battery. The lithium ion battery provided by the invention still has excellent discharge capacity and relatively high capacity retention ratio at ultralow temperature.

Owner:HUAZHONG UNIV OF SCI & TECH

Interference detecting device based on synchronous carrier phase shift and detecting method of interference detecting device

InactiveCN102954758ATo achieve the purpose of phase recoveryTake full advantage of horizontal resolutionUsing optical meansGratingPrism

The invention relates to an interference detecting device based on synchronous carrier phase shift and a detecting method of the interference detecting device, which belong to the field of optical interference detection and solve the problems that the existing synchronous carrier phase shift interference detecting device is complex in structure and the existing detecting method is complex in data process. The interference detecting device comprises an optical source, a polarizing film, a collimation and beam expansion system, a first polarization splitting prism, an object to be detected, a first mirror, a second mirror, a second polarization splitting prism, a lambda / 4 wave plate, a rectangular window, a first flourier lens, a one-dimensional period optical grating, a second flourier lens, a polarizing film set, an image sensor and a computer. The detecting method comprises the steps that light beams emitted by the light source are split into object light beams and reference light beams after passing through the first polarization splitting lens, two phase shift interference images are obtained through once exposure collection after a defocused grating splitting technique and a polarization modulating technique are combined, and phase retrieval of an object is achieved by eliminating a zero frequency component in a differential phase reduction method. The interference detecting device based on the synchronous carrier phase shift and the detecting method of the interference detecting device, disclosed by the invention, are suitable for shape measurement of small objects.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for extracting and purifying benzo[a] pyrene in cigarette smoke Method for extracting and purifying benzo[a] pyrene in cigarette smoke](https://images-eureka.patsnap.com/patent_img/0e9eae20-5246-418d-bdf5-f2334525ab1c/120521113952.PNG)

![Method for extracting and purifying benzo[a] pyrene in cigarette smoke Method for extracting and purifying benzo[a] pyrene in cigarette smoke](https://images-eureka.patsnap.com/patent_img/0e9eae20-5246-418d-bdf5-f2334525ab1c/120521113956.PNG)

![Method for extracting and purifying benzo[a] pyrene in cigarette smoke Method for extracting and purifying benzo[a] pyrene in cigarette smoke](https://images-eureka.patsnap.com/patent_img/0e9eae20-5246-418d-bdf5-f2334525ab1c/120521114000.PNG)