Production method of composite bimetal pipe

A composite bimetallic and production method technology, applied in the production field of composite bimetallic pipes, can solve problems such as expensive production equipment and complex production process, and achieve the effects of wide application, simple production process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

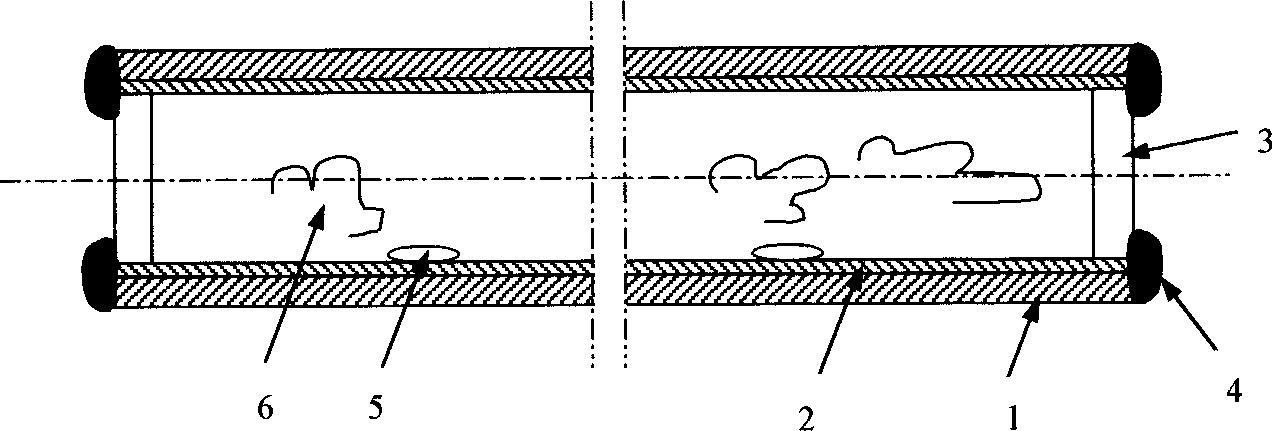

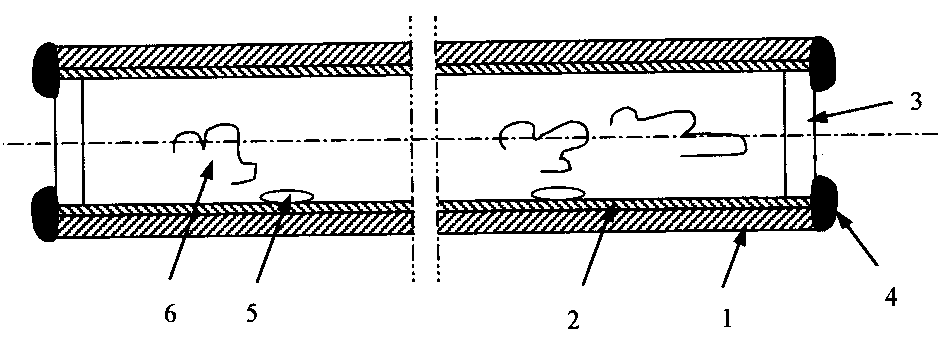

[0017] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings.

[0018] According to the mechanical performance requirements of the composite bimetallic pipe, carbon structural steel pipes with different carbon contents are selected as the outer pipe 1 . The outer tube of this embodiment is a 10 steel round tube with an outer diameter of 25 mm and a wall thickness of 2.5 mm. According to the requirements of corrosion resistance, different corrosion-resistant metal pipes are selected as the inner pipe 2 . The inner tube of this embodiment is a T2 round copper tube with an outer diameter of 19 mm and a wall thickness of 0.5 mm. The inner diameter of the carbon steel round pipe is slightly larger than the outer diameter of the copper pipe, which makes it easy to insert the copper pipe into the steel pipe.

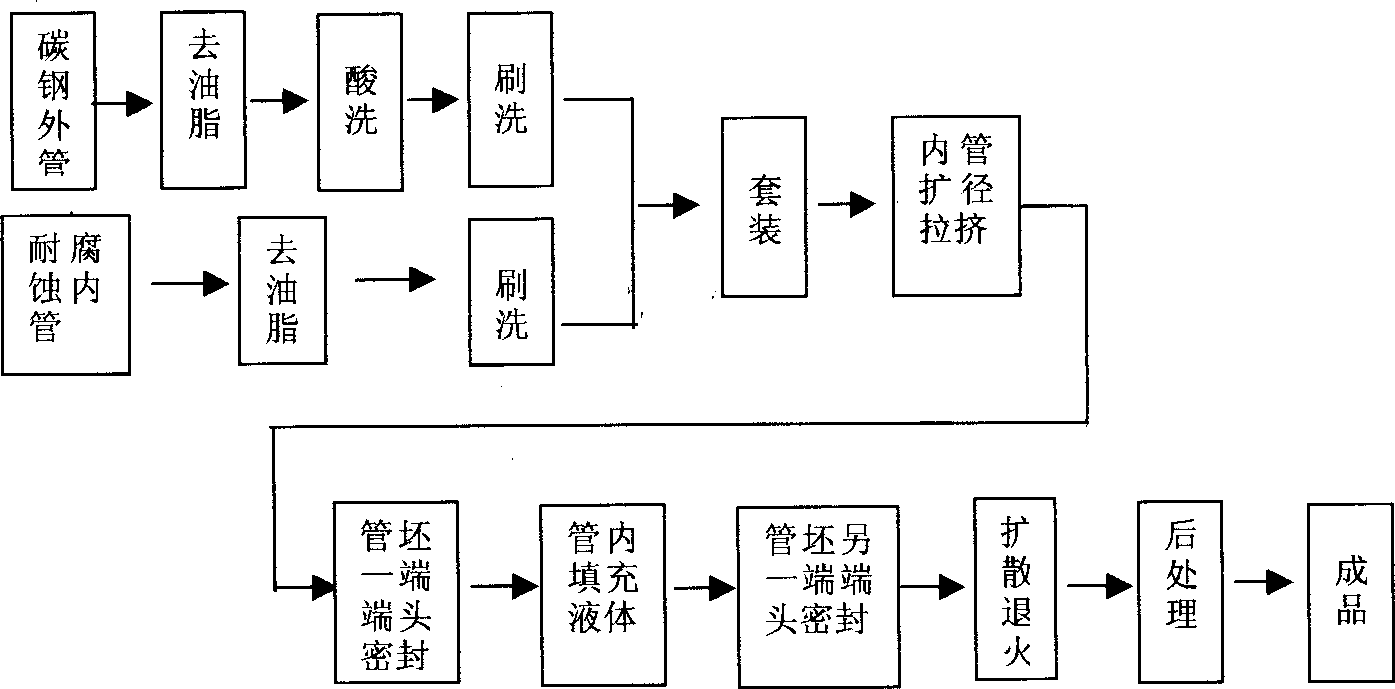

[0019] The production technology of the embodiment of the present invention is as figure 1 , 2 Sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com