Patents

Literature

181results about How to "Achieve metallurgical bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

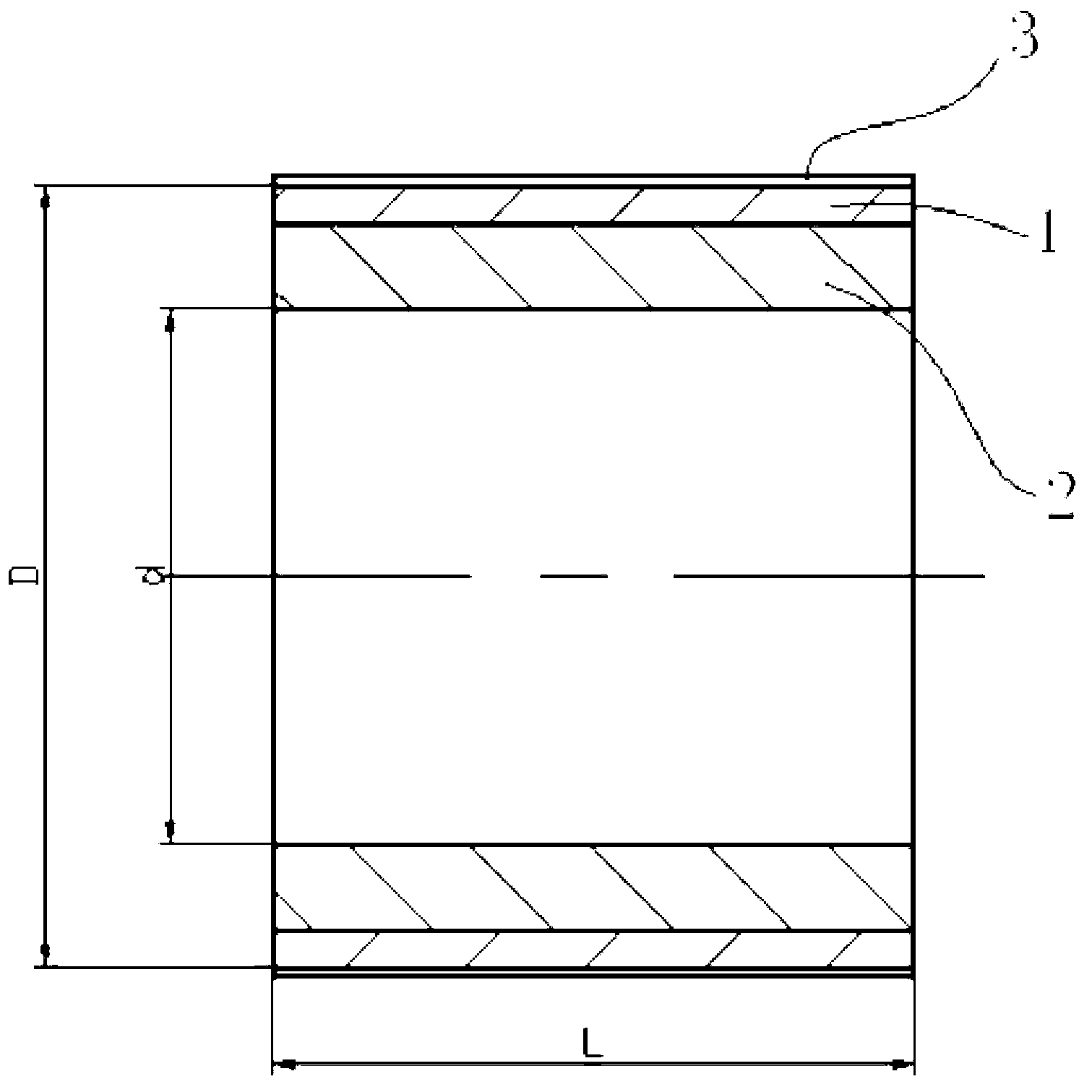

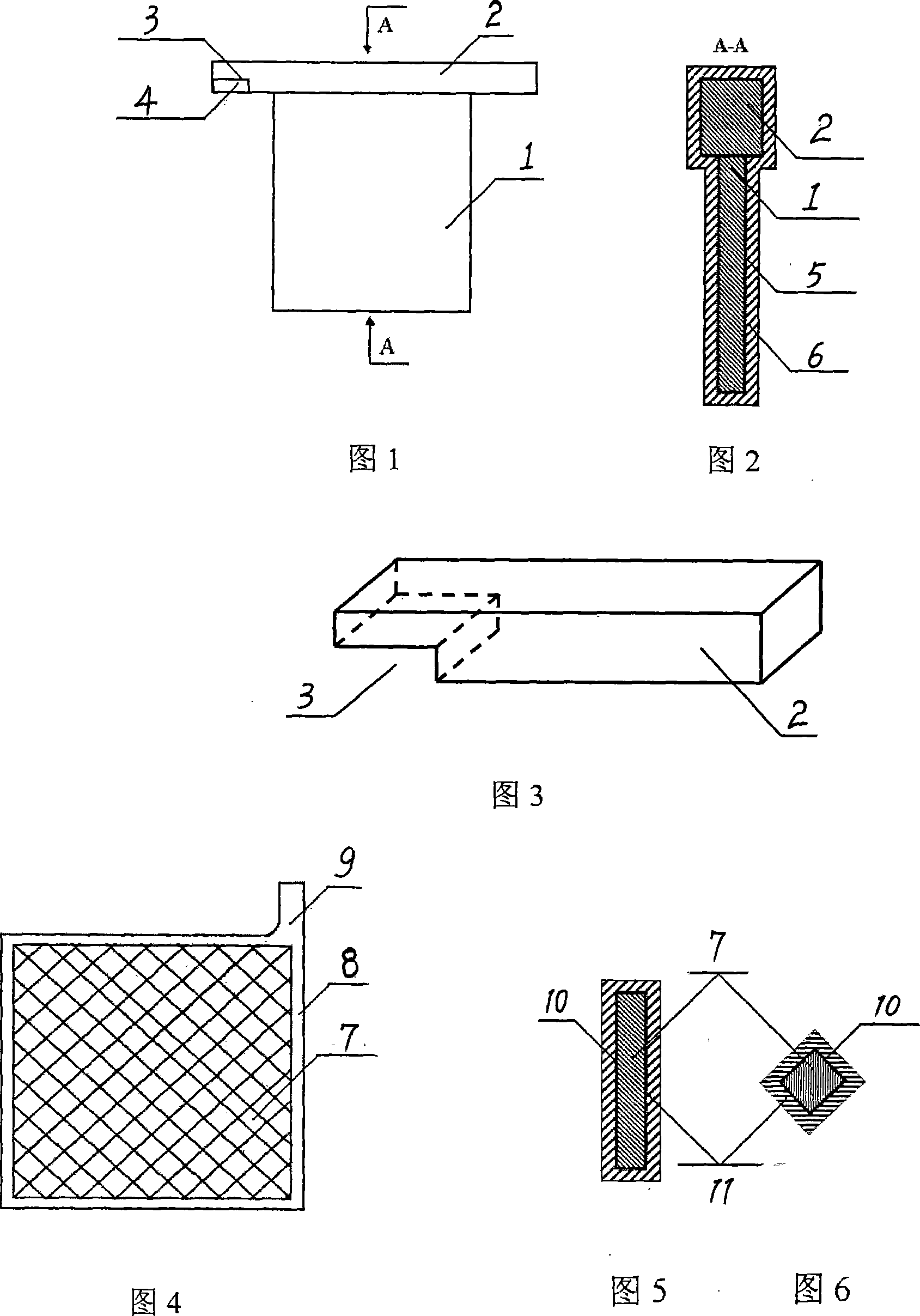

Roll sleeve of ultra-strong wear-resistant high alloy steel roll squeezer and manufacturing method roll sleeve

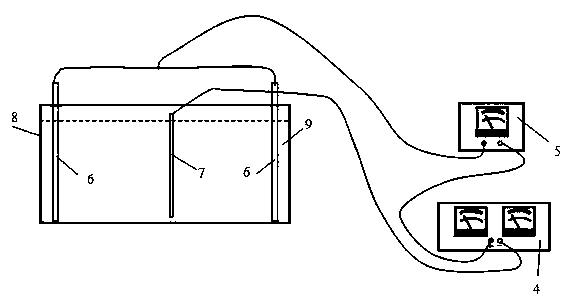

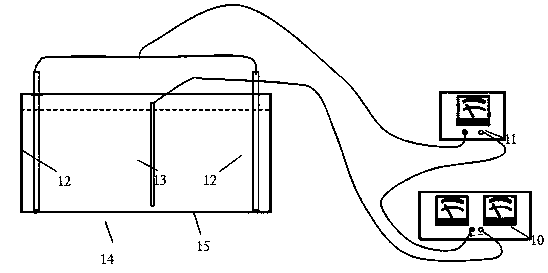

The invention relates to a roll sleeve of an ultra-strong wear-resistant high alloy steel roll squeezer and a manufacturing method of the roll sleeve, belonging to the technical field of casting in building material industry. The technical scheme is as follows: an outer layer adopts ultra-strong wear-resistant high alloy steel, an inner layer is formed by compounding low-carbon medium alloy steel, and the roll sleeve is manufactured through the process steps of melting the outer-layer ultra-strong wear-resistant high alloy steel, melting the inner-layer low-carbon medium alloy steel, centrifugally casting the compound roll sleeve and performing heat treatment on the compound roll sleeve. The roll sleeve and the manufacturing method thereof, disclosed by the invention, have the positive effects that: the preferential mixture ratio of the inner-layer material to the outer-layer material of the roll sleeve is adopted and a reasonable centrifugal compound casting process is adopted, thereby the inner layer and the outer layer are subjected to metallurgical bonding and a good bonding state is achieved. According to the characteristics of high alloy of the roll sleeve, the fracture toughness of the roll sleeve is enhanced by raising tempering temperature and performing multiple tempering processes. The outer layer of the roll sleeve disclosed by the invention has the hardness of 60-64HRC and the impact toughness of 12J / cm<2>, the inner layer has the hardness of 26-30HRC, the tensile strength of 800-900MPa and the yield strength of 730MPa, and the service life of the roll sleeve is prolonged by above 2 times in comparison with the traditional roll sleeve formed by forging and overlaying welding.

Owner:河北津西钢铁集团重工科技有限公司

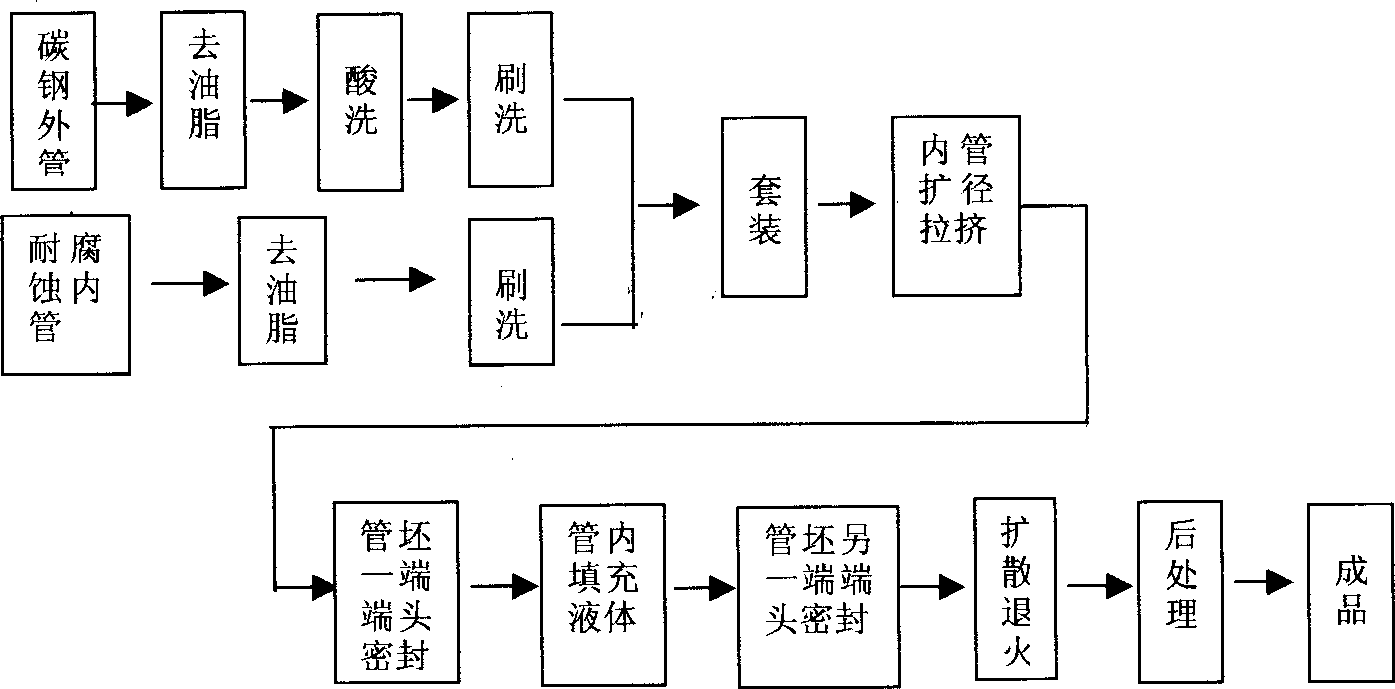

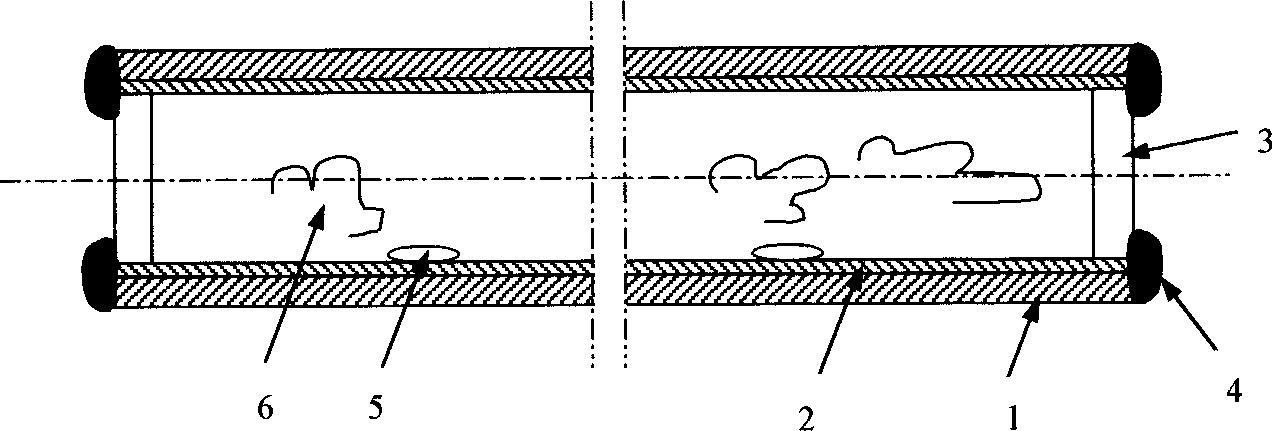

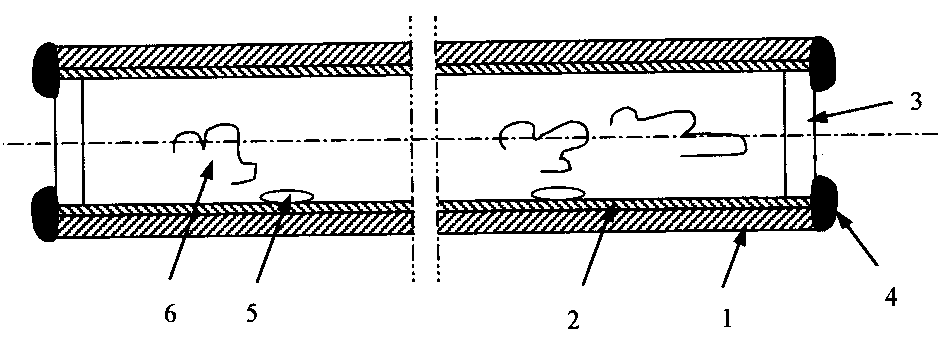

Production method of composite bimetal pipe

A production method of composite bimetal pipe includes the following steps: making surface treatment of internal pipe and external pipe: inserting internal pipe into external pipe, tight fitting to form composite pipe blank; seating the two ends of the said pipe blank with air and liquid in the internal pipe, and sealing the gap between the internal pipe and the external pipe, heating and diffusion annealing so as to obtain the invented product. Its production process is simple, and is applicable to various anticorrosion pipes.

Owner:大连合生科技开发有限公司

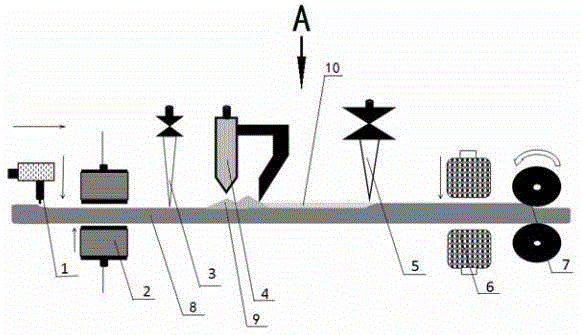

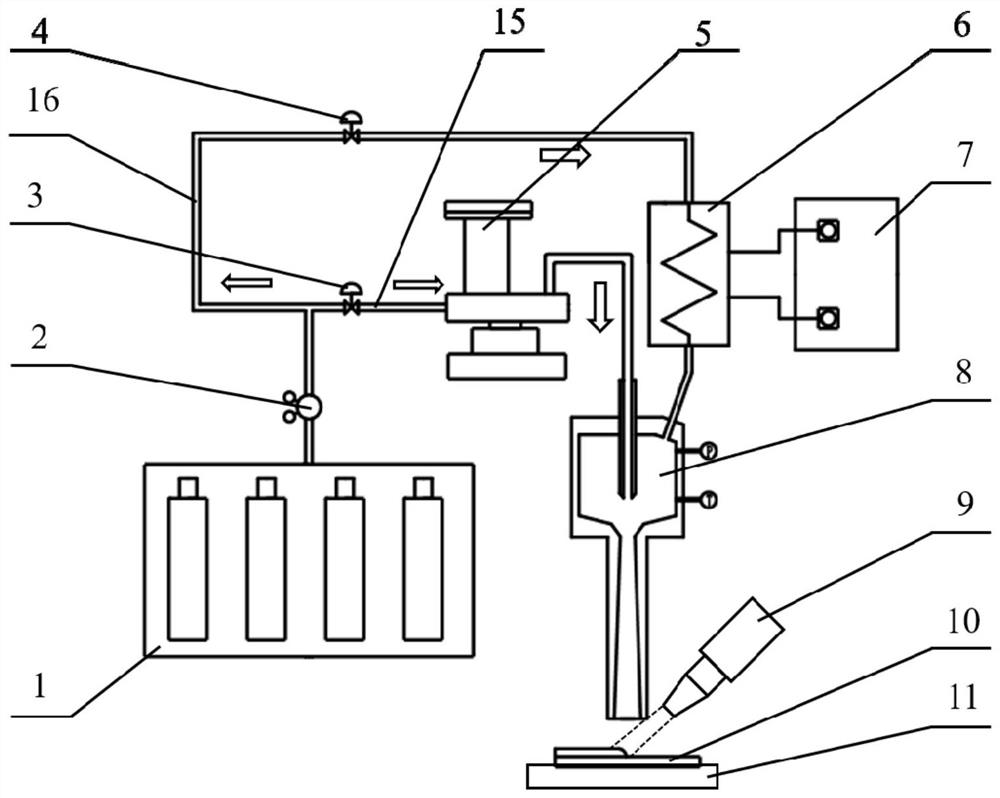

Direct forming manufacturing method of metal-based multilayer/gradient composite board and process unit of direct forming manufacturing method

ActiveCN105643215AHigh bonding strengthEliminate surface stressRoll force/gap control deviceMetal rolling arrangementsHigh energyBound property

The invention discloses a direct forming manufacturing method of a metal-based multilayer / gradient composite board and a process unit of the direct forming manufacturing method. Scale, corrosion materials and other impurities on the joint surface of a base board are removed through chemical cleaning, the cleaned surface is subjected to gradient power electromagnetic induction heating or laser bombardment surface treatment, all phases near the joint surface are fully dissolved, a solid solution is enhanced, toughness and corrosion resistance are improved, the surface stress of the board is eliminated, and surface laser treatment is conducted to improve the binding property of a composite layer; raw materials of the composite layer are added and injected through powder laying, a high-energy heat source is adopted for irradiation or induction heating to melt powder, metallurgical bonding is formed between the composite layer and a base, and control over the final shape of a cold / hot-rolled board is conducted. The obtained multilayer / gradient composite board is compact in surface structure, bonding between the composite layer and the base and between layers is good, and the interlayer bonding performance of the composite board is remarkably improved. The process is high in flexibility, and the production period of the metal-based composite board can be greatly shortened after the process is combined with an existing continuous casting technology.

Owner:SHANGHAI UNIV

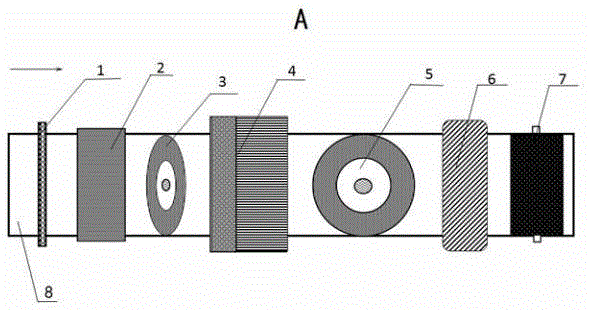

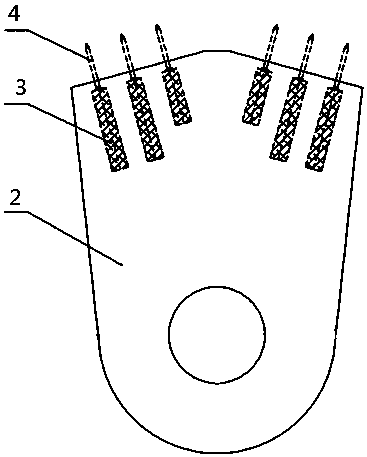

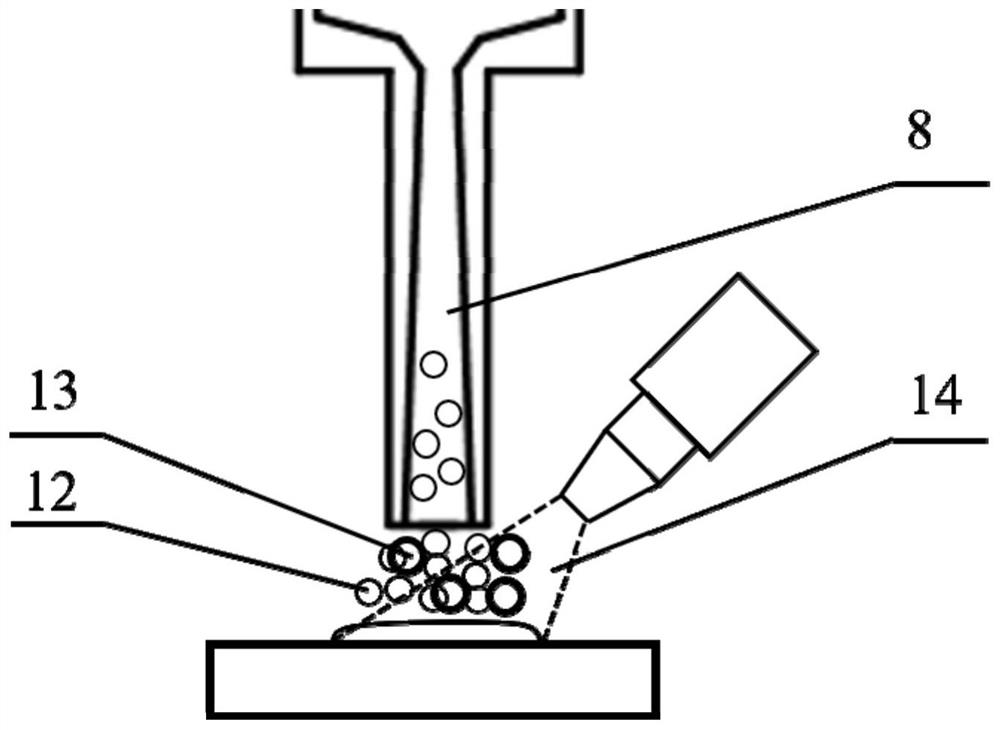

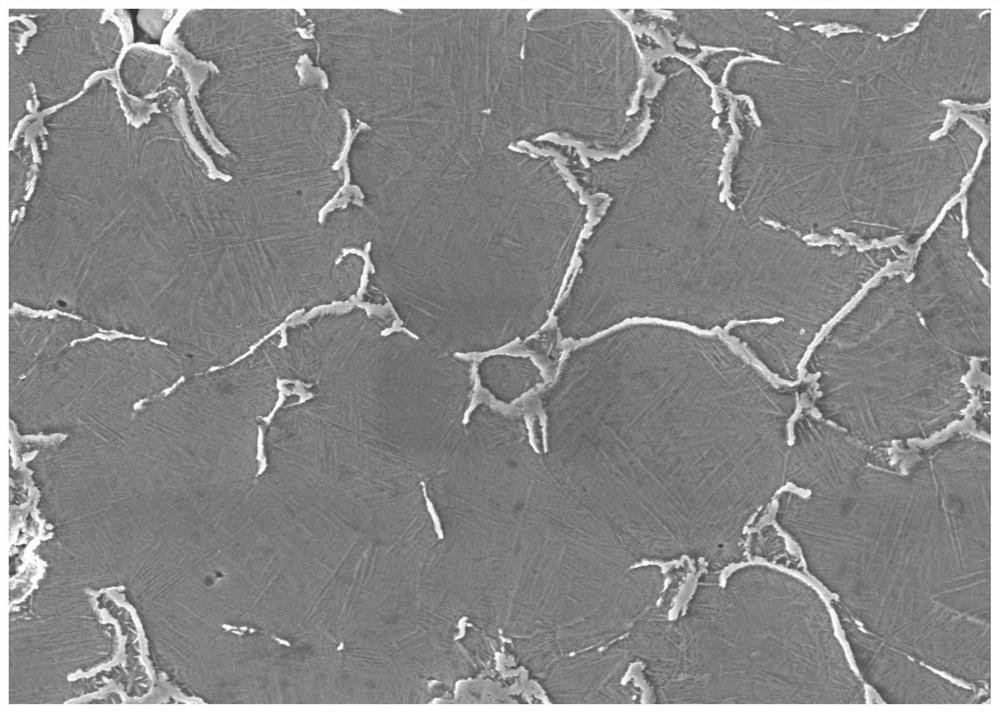

Surfacing-free centrifugal combined ultra-high anti-abrasion roll squeezer roller sleeve and manufacturing method thereof

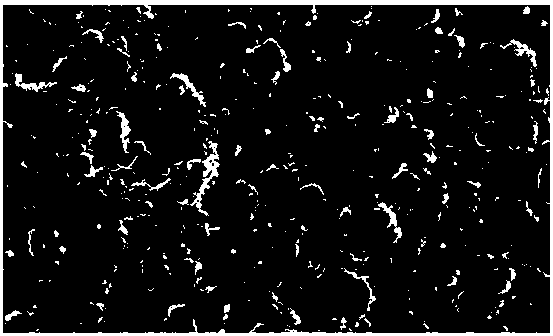

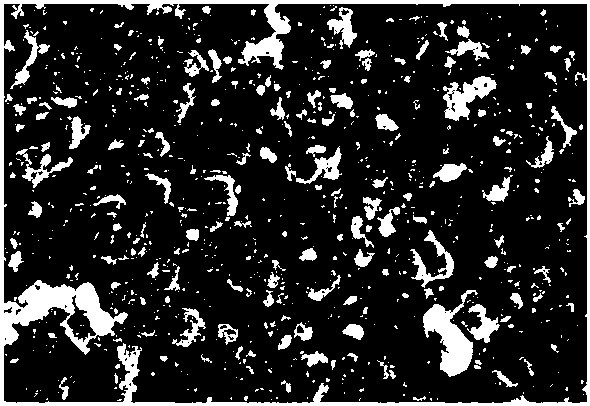

ActiveCN103008050AImprove toughnessWith super high wear-resistant outer layerGrain treatmentsTransitional RegionPulp and paper industry

The invention discloses a surfacing-free centrifugal combined ultra-high anti-abrasion roll squeezer roller sleeve and a manufacturing method thereof. The roller sleeve comprises a roller sleeve body, wherein the roller sleeve body has a double-layer structure with an inner high-flexibility layer and an outer high abrasion resistance layer; and cast textures are arranged on the surface of the high abrasion resistance layer of the roller sleeve body. The roller sleeve has the characteristics that under the action of centrifugal force, the compactness of the roller sleeve is high, and metallurgical bonding of the inner layer and the outer layer is fully realized; a transitional region is smooth; by control over a cast organization subjected to 'less oxidization' thermal treatment, when the ultra-high abrasion resistance of the outer layer and the high flexibility of the core part are guaranteed, the impact resistance of the outer layer is improved; the centrifugally cast textures are basically the same as that of the outer layer; under the action of the centrifugal force, heavy points in steel liquid are subjected to offshoring segregation, so that the abrasion resistance of the textures is slightly higher than that of the outer layer; due to full metallurgical bonding under the action of the centrifugal force, casting defects such as cracks, impurities and air holes areavoided; ineffective forms such as falling and stripping which are caused by welding micro cracks are completely eliminated; the roller sleeve is maintenance free all the time; the production period is short; and large-scale production is realized.

Owner:河北奥木森陶瓷辊套有限公司

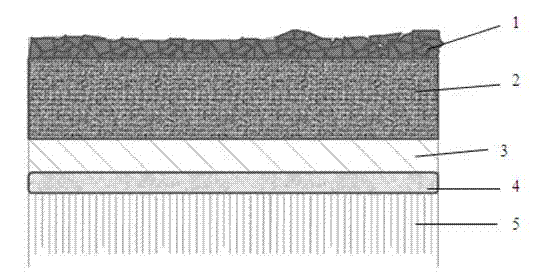

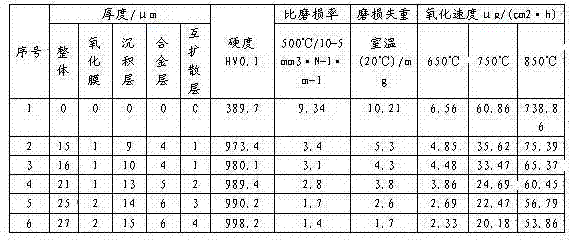

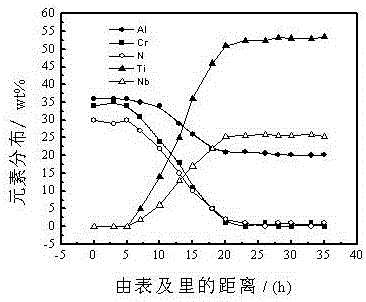

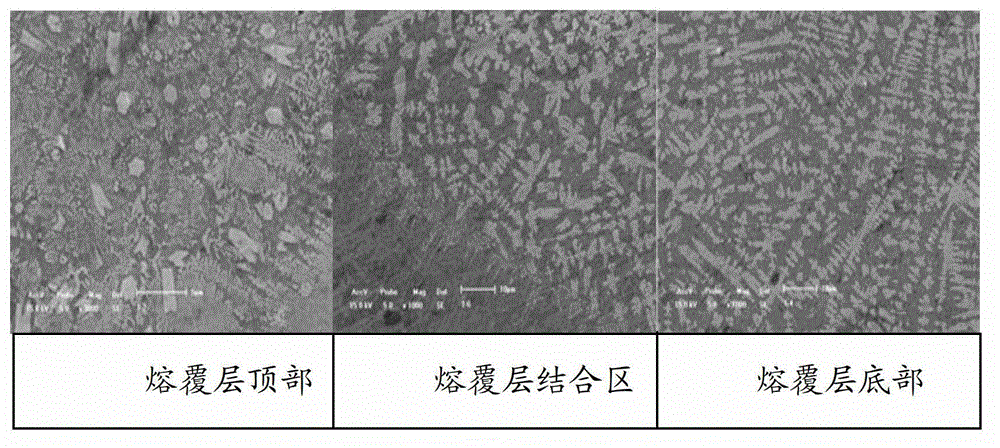

Composite coating with high-temperature oxidation resistance and abrasion resistance on surface of titanium alloy and preparation method of composite coating

ActiveCN103305844AImprove wear resistanceLimited thicknessSuperimposed coating processCoated surfaceSurface layer

The invention relates to a composite coating with high-temperature oxidation resistance and abrasion resistance prepared on the surface of a titanium alloy. The surface layer of the composite coating is a continuous compact Al2O3 oxidation film layer with the thickness of 1-3 microns; an Al settled layer with the thickness of 10-15 microns and a Ni-Co-Cr-Al-Y alloy layer with the thickness of 4-6 microns are arranged in the middle of the composite coating; the metallurgical bonding between the composite coating and a matrix is realized through a NiCoCrAlTi diffusion alloy layer; a uniform continuous compact Al2O3 oxidized film layer is arranged on the surface of the composite coating, and the surface of the composite coating does not have defects of holes, cracks and the like, so that the wear resistance and high-temperature oxidation resistance of the composite coating are greatly improved; the element Al is in graded distribution along the thickness direction in a NiCoCrAlY alloy layer and a NiCoCrAlY diffusion layer to facilitate the combination of coatings, and the storage content of Al phase is high, so that the high-temperature oxidation resistance of the composite coating can be further improved; the juncture part between the composite coating and the matrix is flat and straight and is provided with a bright white mutual diffusion layer which is in metallurgical bonding with the matrix with a firm bonding force. An alloy infiltrated layer is prepared from gamma'-Ni3Al which is a hard phase, is tiny and in dispersed distribution, and can strengthen the matrix and improve the hardness and wear resistance of the matrix.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

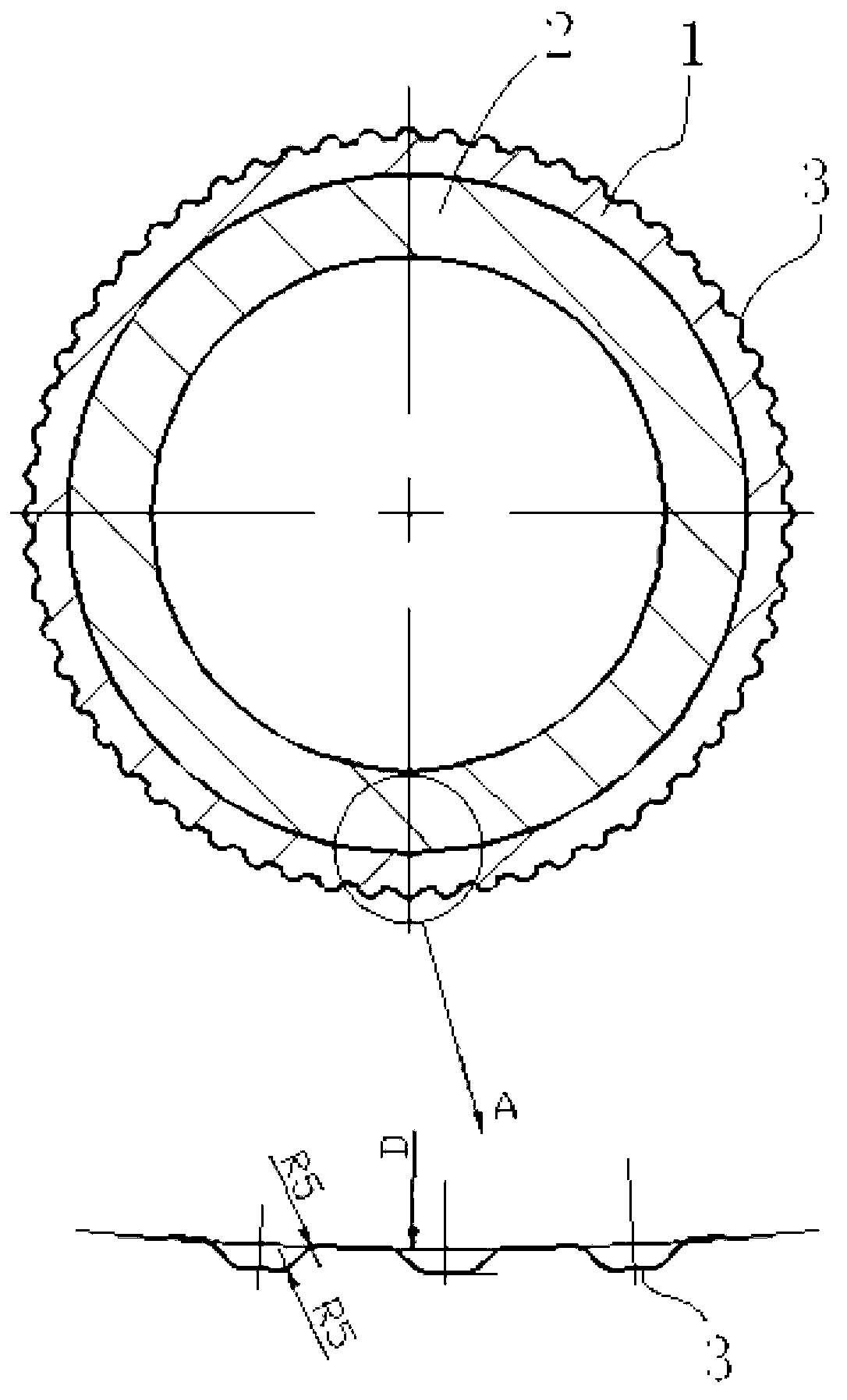

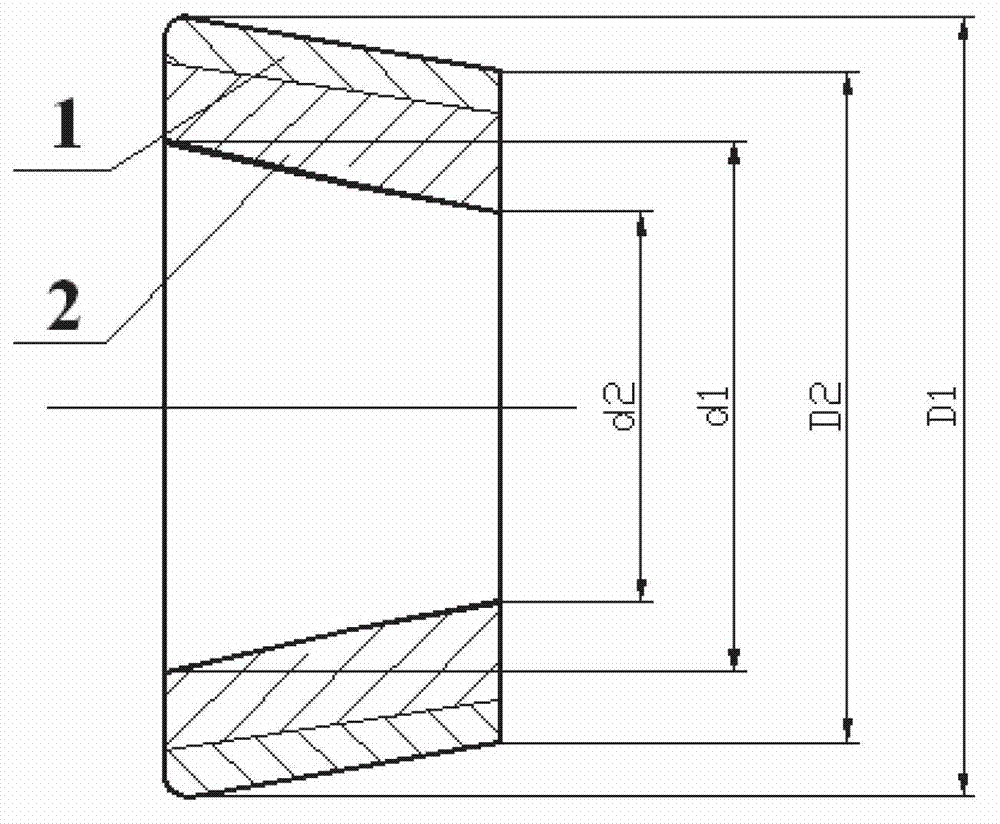

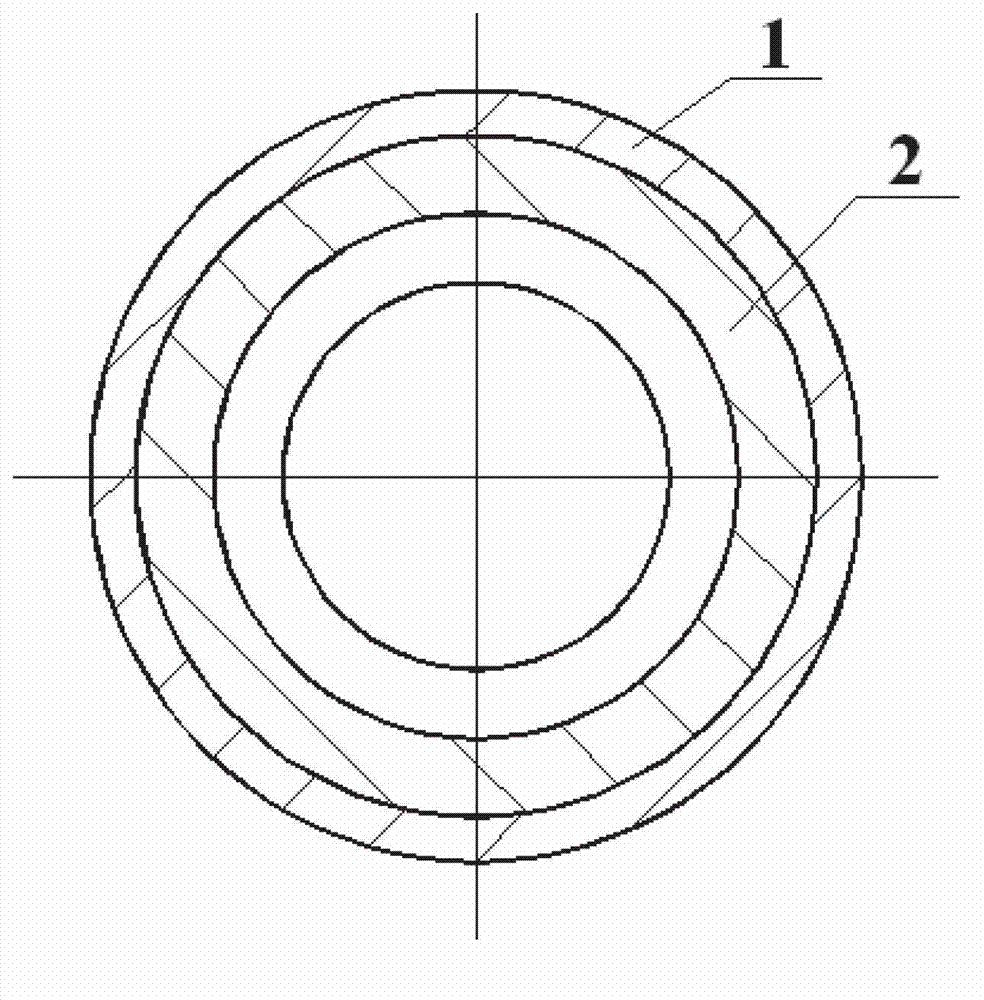

Centrifugal composite high-wear-resistance cone-type vertical mill roller sleeve and manufacture method of vertical mill roller sleeve

ActiveCN103028719AReduce manufacturing costImprove wear resistanceAgricultural engineeringHigh wear resistance

The invention discloses a centrifugal composite high-wear-resistance cone-type vertical mill roller sleeve and a preparation method of the vertical mill roller sleeve. The vertical mill roller sleeve comprises a roller sleeve body, wherein the inner surface and the outer surface of the roller sleeve body are respectively in a cone shape, and the roller sleeve body is in a double-layer structure with a high-toughness layer as the inner layer and a high-wear-resistance layer as the outer layer. The invention discloses the centrifugal composite high-wear-resistance cone-type vertical mill roller sleeve, and the service life of the vertical mill roller sleeve is prolonged by more than 2.5 times than that of a surfacing welding roller sleeve when the vertical mill roller sleeve is applied and used in industries of mine, cement, metallurgy, coal chemical industry, glass and the like. The centrifugal composite high-wear-resistance cone-type vertical mill roller sleeve has the advantages that the effects of strong outside and tough inside are realized, and the accident resistance capability of the roller sleeve is obviously improved. The full metallurgical bonding is realized under the centrifugal force effect, and the generation of casting defects such as cracks, mixed impurities and air holes is avoided. The failure forms such as block falling and peeling caused by microcracks of surfacing welding at the outer layer are thoroughly eliminated, and the lifelong free maintenance can be realized; and a composite casting method has the advantages that the manufacture cost of the roller sleeve is reduced, the production period is shortened, and in addition, the problems of block falling, peeling, breakage and the like in the use process of the surfacing welding roller sleeve are solved.

Owner:河北奥木森陶瓷辊套有限公司

Preparation method of polycrystalline cubic boron nitride (PcBN) composite material

The invention relates to a preparation method of a polycrystalline cubic boron nitride (PcBN) composite material, which comprises the following steps: by using nonstoichiometric titanium nitride (TiNX, 0.3<=x<=0.6) as the basic component of a binder in the PcBN composite material, constituting a binder with one or both of aluminum nitride (AlN) and titanium carbide (TiC), and sintering with monocrystalline cubic boron nitride (cBN) under the conditions of high temperature and high pressure to prepare the PcBN composite material, wherein the pressure is 4-6.5GPa, the temperature is 1400-1650 DEG C, and such pressure and temperature are kept for 1-25 minutes. Since the PcBN composite material is prepared from the cBN and the binder mainly composed of the nonstoichiometric titanium nitride (TiNX, 0.3<=x<=0.6), the polycrystal does not contain any simple substance element or alloy phase, thereby avoiding the existence of soft spot. The hardness of the obtained PcBN composite material is up to 38-55GPa, and the fracture toughness is up to 3.31-4.12MPa.m1 / 2.

Owner:YANSHAN UNIV

4D printing method of in-situ regulation of functional characteristics of nickel-titanium alloy and application

ActiveCN110465662ANickel content controlUniform compositionAdditive manufacturing apparatusTransportation and packagingManufacturing technology4d printing

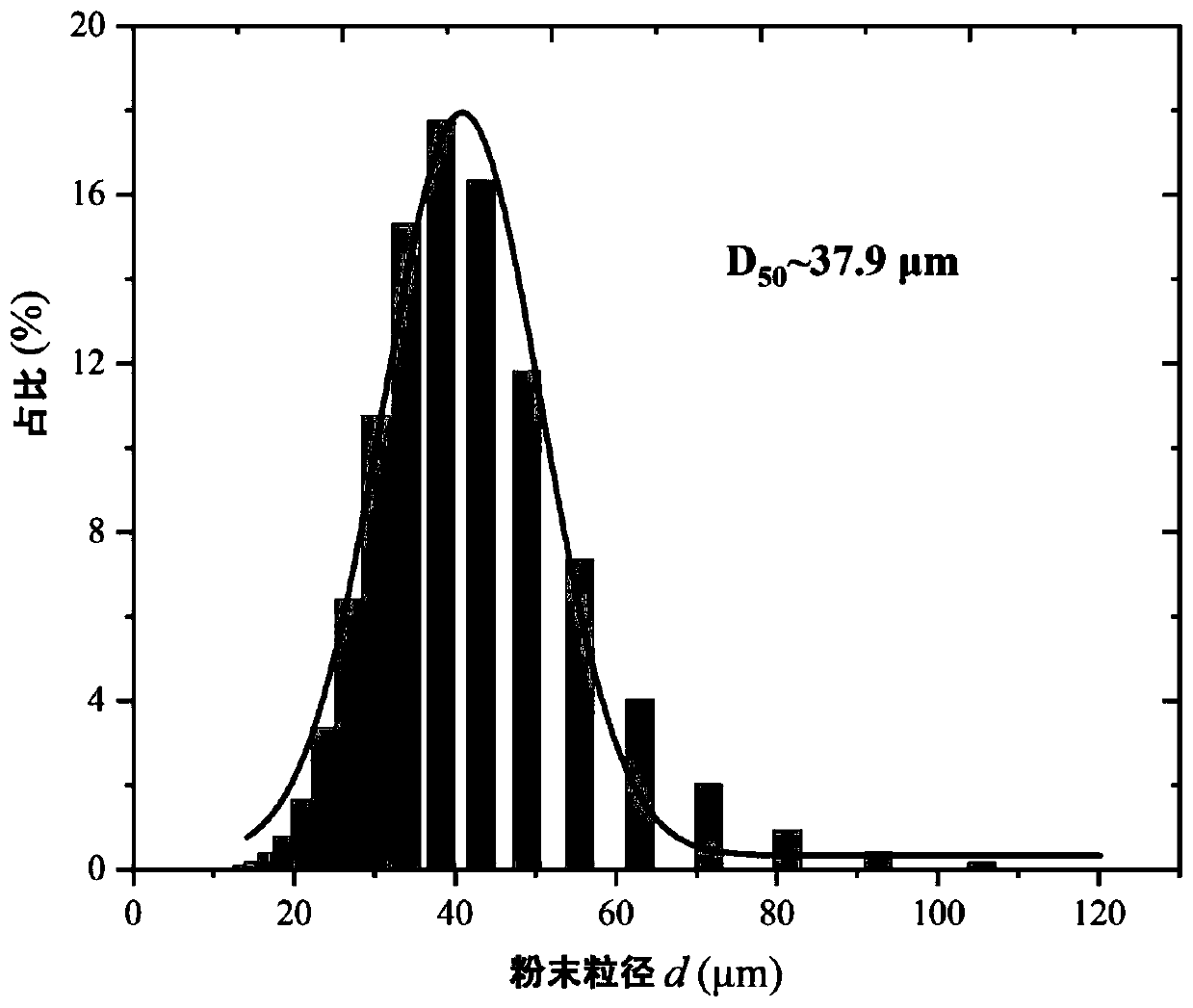

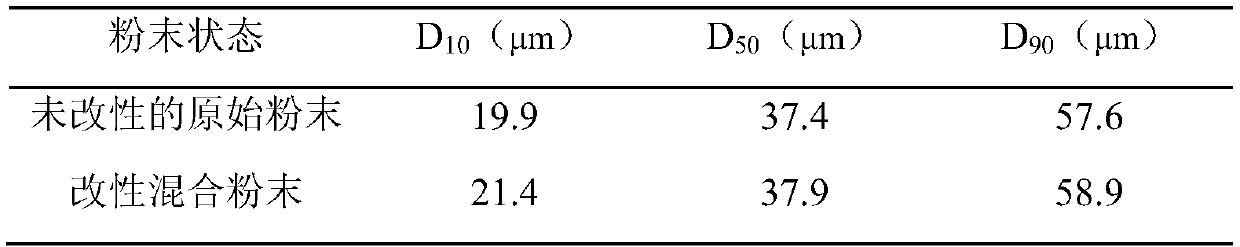

The invention belongs to the technical field of additive manufacturing, and discloses a 4D printing method of in-situ regulation of the functional characteristics of a nickel-titanium alloy and application. A nickel-titanium alloy rod material is powdered by atomization to obtain nickel-titanium alloy powder with a particle size of 15-53 [mu]m, then the nickel-titanium alloy powder is placed in adischarge plasma-assisted ball mill for discharge treatment to promote the activity activation of the powder, and then nano-scale nickel powder with the particle size being 100-800nm is added to obtain mixed powder; the discharge treatment is continued to realize metallurgical bonding between the nickel-titanium alloy powder and the nano-nickel powder to obtain modified powder; and finally the modified powder is prepared and formed by an additive manufacturing technology to obtain the functionalized nickel-titanium alloy. The metallurgical bonding is realized by adding the nano-scale nickel powder and the large-sized spherical nickel-titanium alloy powder during the discharge treatment process, so that a bulk alloy and parts thereof with uniform composition, microstructure and performanceare prepared.

Owner:SOUTH CHINA UNIV OF TECH

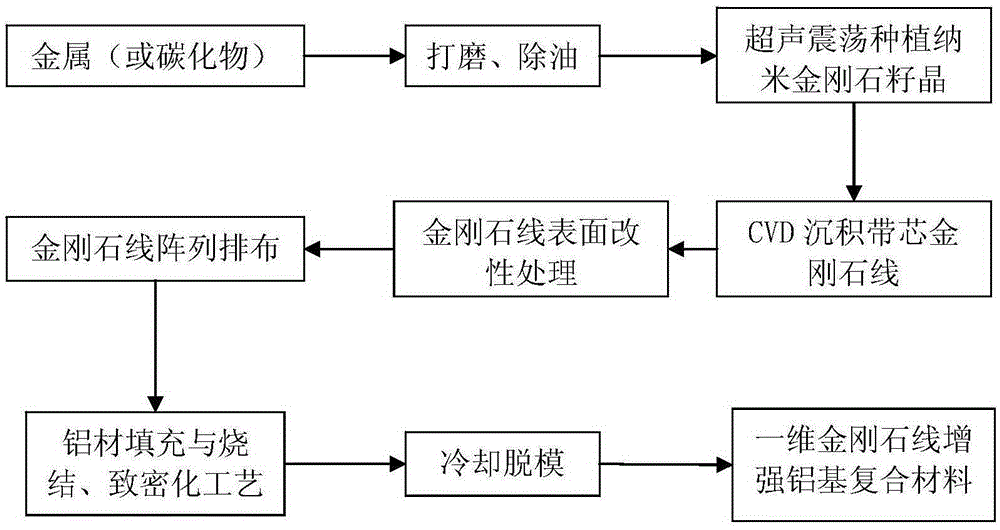

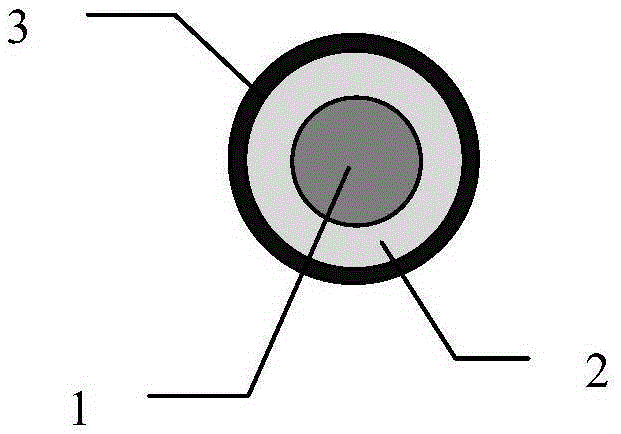

One-dimensional diamond reinforced aluminum matrix composite material and preparing method thereof

ActiveCN105239026AHigh Performance Directional Thermal ConductionGood directional thermal conductivityAluminum matrix compositesWire array

The invention discloses a one-dimensional-diamond-reinforced aluminum matrix composite material and a preparing method. The composite material is characterized in that a diamond array composed of a plurality of one-dimensional diamond wires is distributed in an aluminum matrix, and the one-dimensional diamond wires are surface-modified diamond wires and are combined with the aluminum matrix in a metallurgical manner. The preparing method of the composite material includes the steps that after the surface-modified diamond wires are distributed in an array manner, the aluminum matrix or the aluminum matrix containing surface-modified diamond particles is compounded with the diamond wire array through one of a casting technology, an infiltration technology, a cold pressing sintering technology, a hot pressing sintering technology and a plasma sintering technology, and the one-dimensional-diamond-reinforced aluminum matrix composite material in which the one-dimensional diamond wires are combined with the aluminum matrix in the metallurgical manner is obtained. According to the one-dimensional-diamond-reinforced aluminum matrix composite material and the preparing method, the one-dimensional diamond wires are distributed in the aluminum matrix in the array manner, a series-parallel connection composite heat conduction structure is formed by adding the diamond particles, the heat conducting efficiency is further improved, the composite material can be used as an electronic packaging material, a heat sink material and the like, and packaging of high-temperature, high-frequency and high-power electronic devices is achieved.

Owner:CENT SOUTH UNIV

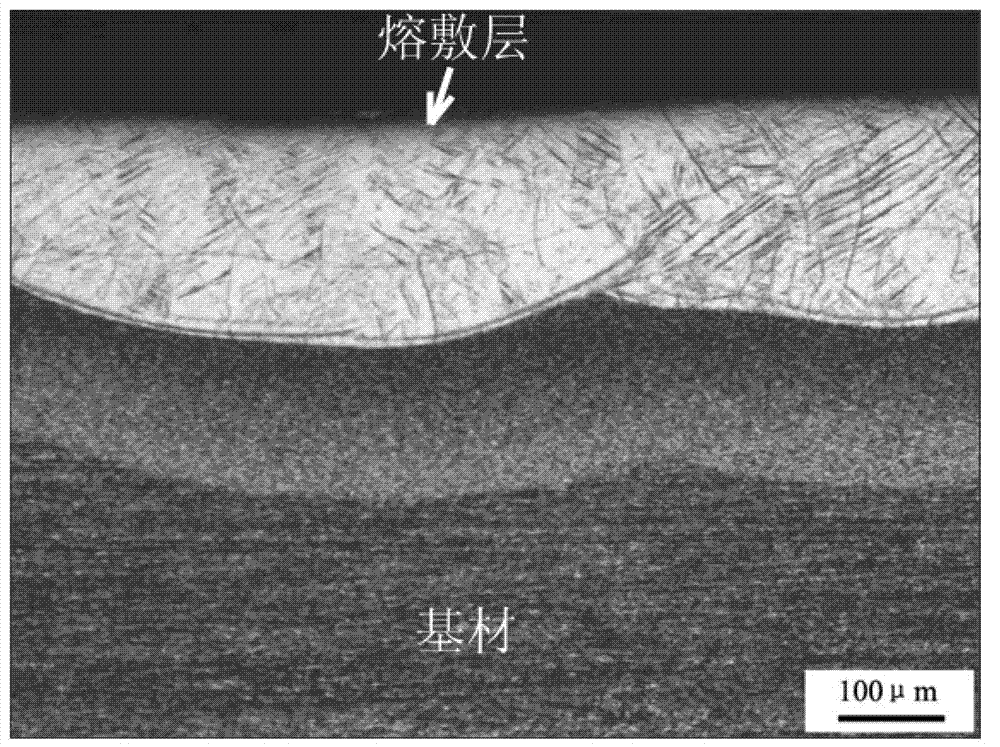

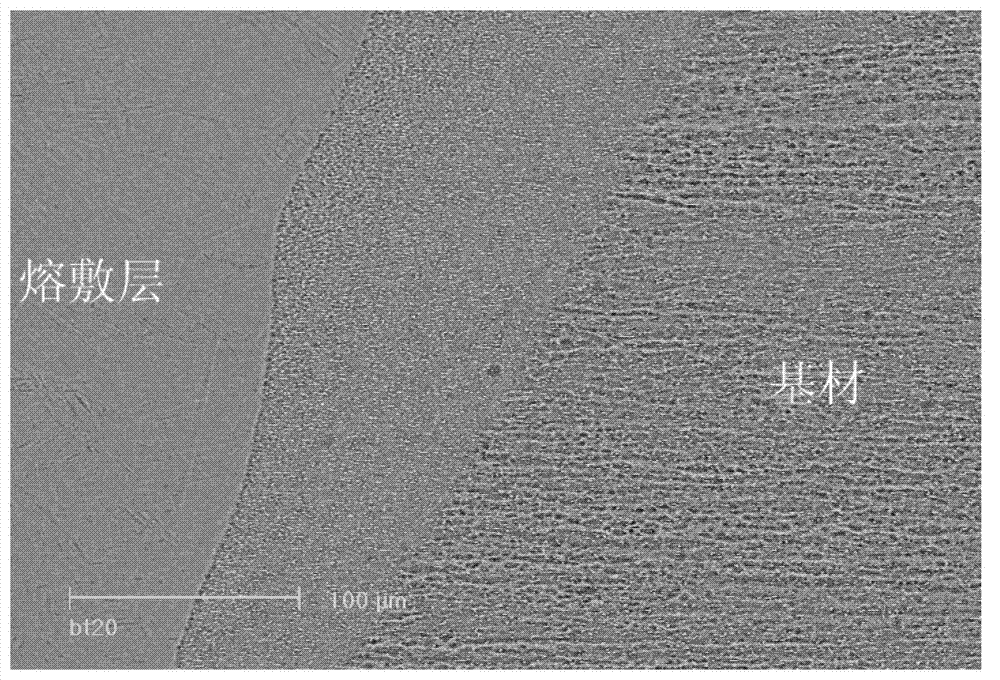

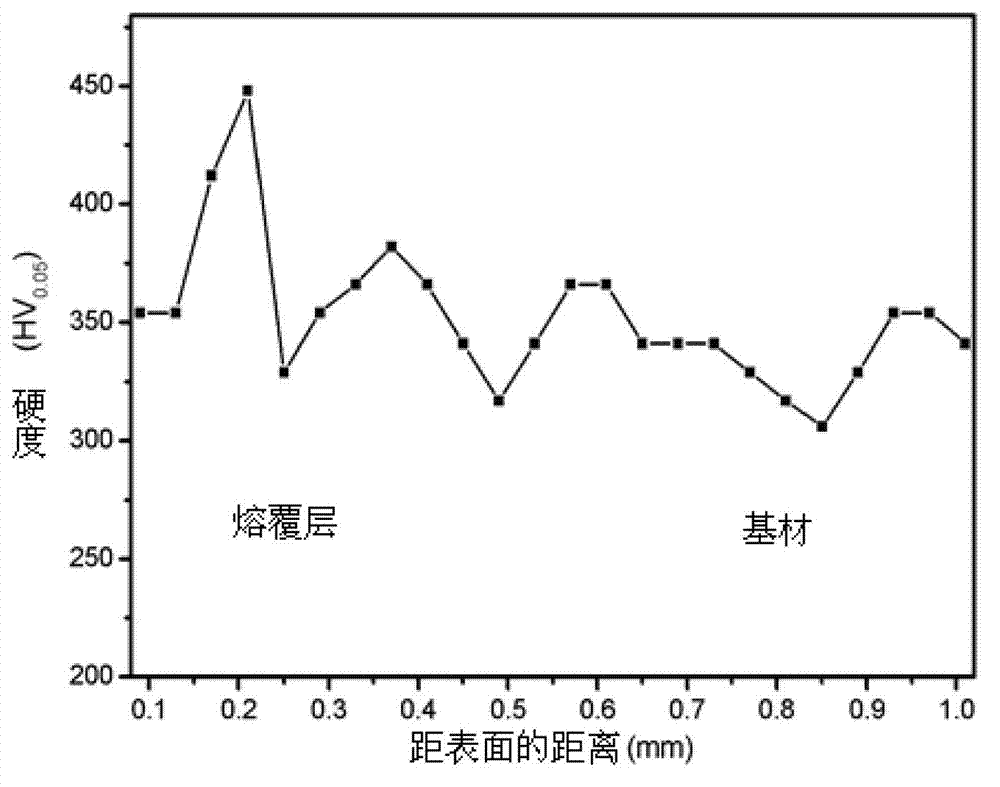

Method for repairing wear of inner wall of intermediate casing of engine

InactiveCN102953058AAchieve metallurgical bondingSatisfy the use effectMetallic material coating processesTitaniumTitanium alloy

The invention aims to provide a method for repairing the wear of the inner wall of an intermediate casing of an engine, and the method is characterized in that a laser cladding method is adopted to repair the worn part on the inner wall of the intermediate casing of the engine; the repair process is as follows: a cladding material is a BT20 titanium alloy; the weight percentage of the components of the titanium alloy is as follows: 5.5 percent to 7.5 percent of aluminum (Al), 1.5 percent to 2.5 percent of zirconium (Zr), 0.5 percent to 2.0 percent of molybdenum (Mo), 0.8 percent to 1.8 percent of vanadium (V), and the rest titanium (Ti); the single-pulse energy is 50J, the frequency is 4Hz, the pulse width is 5ms, the focus is 150mm, the diameter of light spots is 1.2mm, the scanning speed is 1.2mm / s and argon is adopted for protection. Due to the adoption of the method, the service life of the intermediate casing in the aero-engine can be prolonged, so that the intermediate casing can work in a complete technical state, and the use performance is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

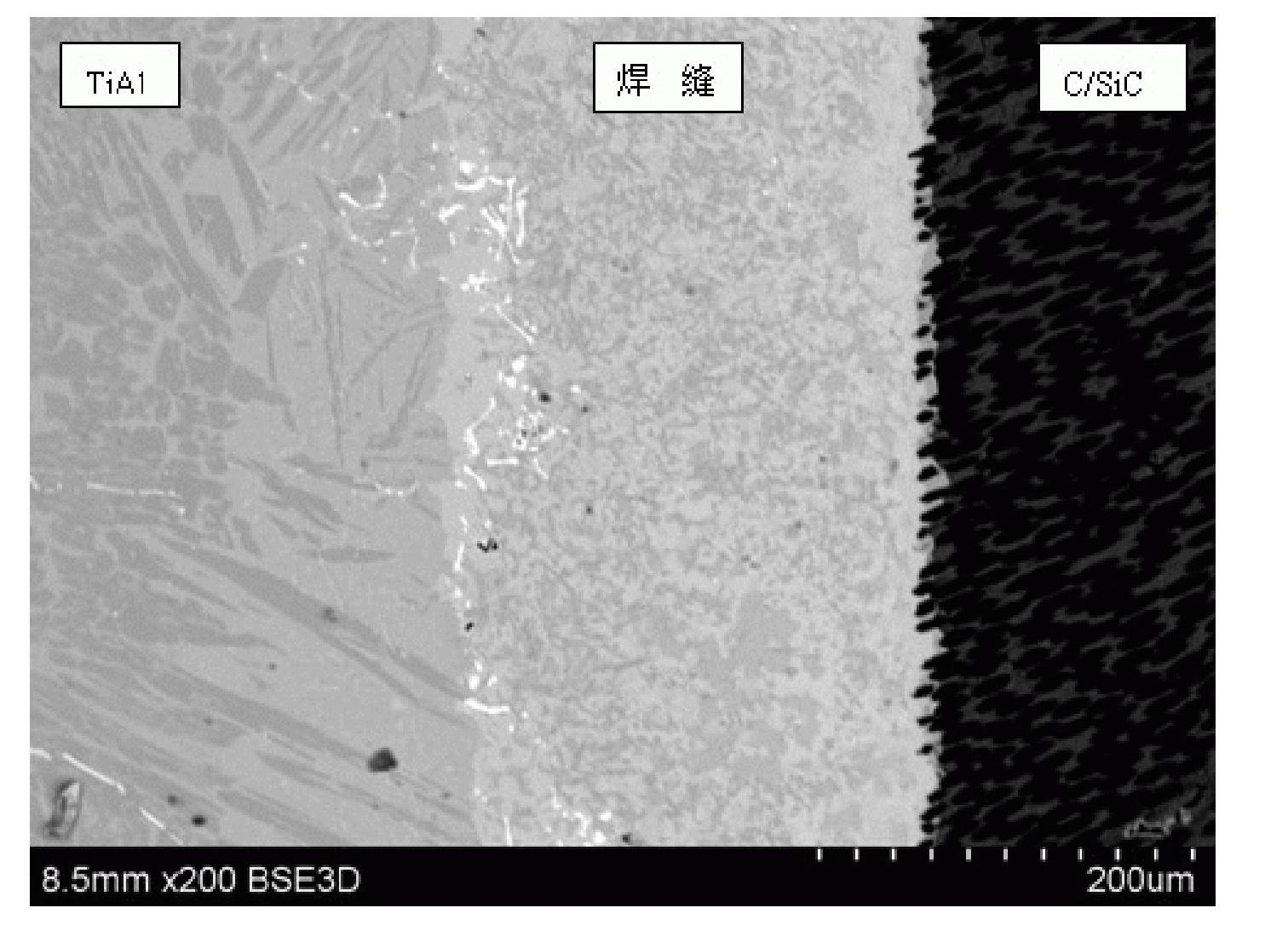

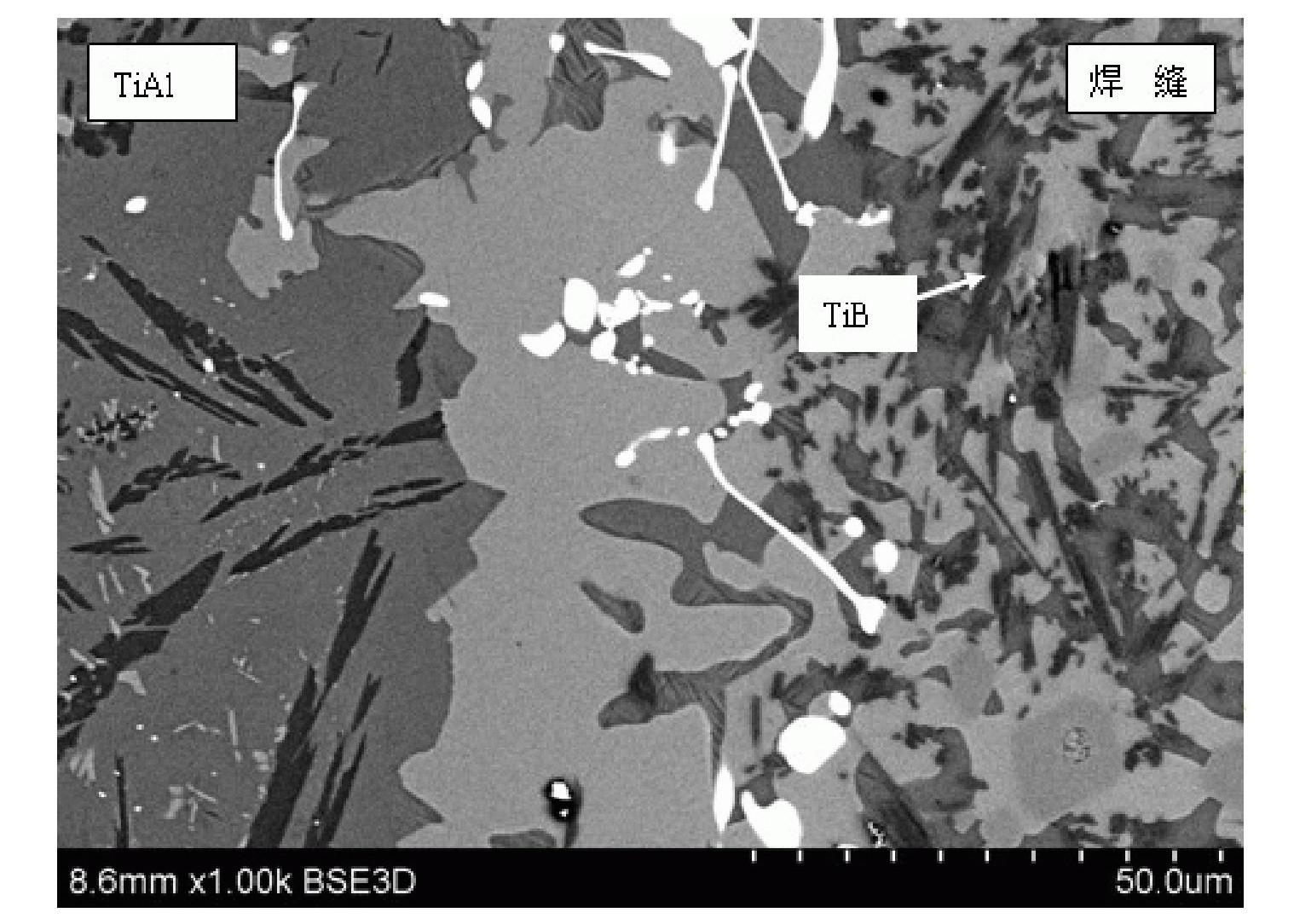

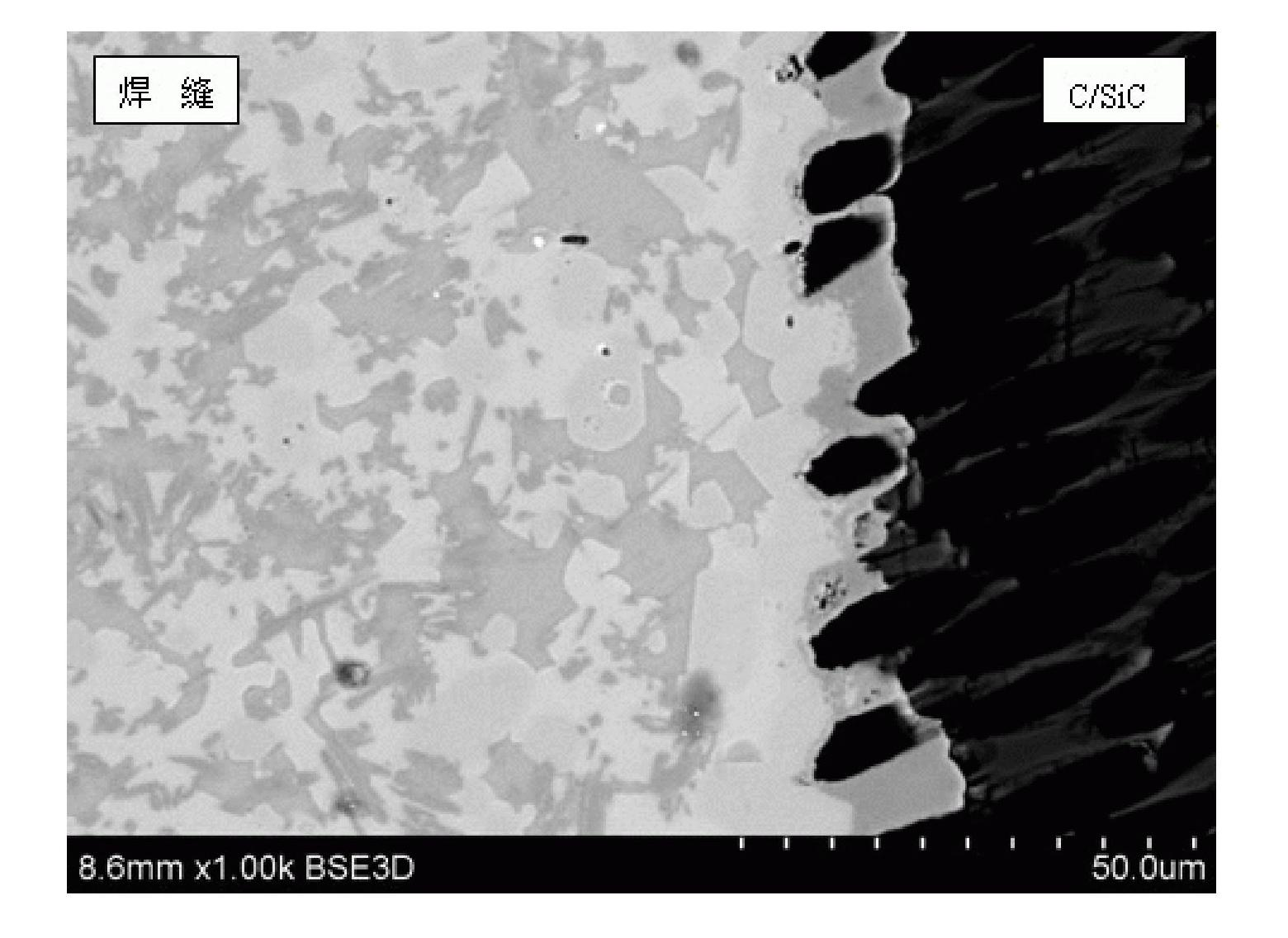

Solder for welding carbon/silicon carbide ceramic matrix composite material and titanium-aluminum-based alloy and soldering method

The invention discloses a solder for welding a carbon / silicon carbide ceramic matrix composite material and a titanium-aluminum-based alloy and a soldering method, relating to solders and soldering methods thereof. By the invention, the problems that the using temperature of the welding joint of the conventional silver-based solder for welding composite materials and titanium alloys is low and the process of a traditional method for indirectly soldering the carbon / silicon carbide ceramic matrix composite materials and metals is complex. The solder comprises titanium material powder, nickel powder and boron powder. The method comprises the following steps of: performing ball milling on the solder, preparing the solder into paste, coating the paste on a joint face to be welded of the carbon / silicon carbide ceramic matrix composite material and the titanium-aluminum-based alloy, putting a piece to be welded into a vacuum heating furnace, heating and preserving heat to complete the welding. The joint welded by the invention has a shearing strength of 40-105MPa at the room temperature, a shearing strength of 30-70MPa at 600 DEG C and the using temperature of not less than 600 DEG C, the soldering process is simple, and the welding efficiency is high. The solder can be used for the welding the carbon / silicon carbide ceramic matrix composite material and the titanium-aluminum-based alloy or a titanium-aluminum-based alloy piece.

Owner:HARBIN INST OF TECH

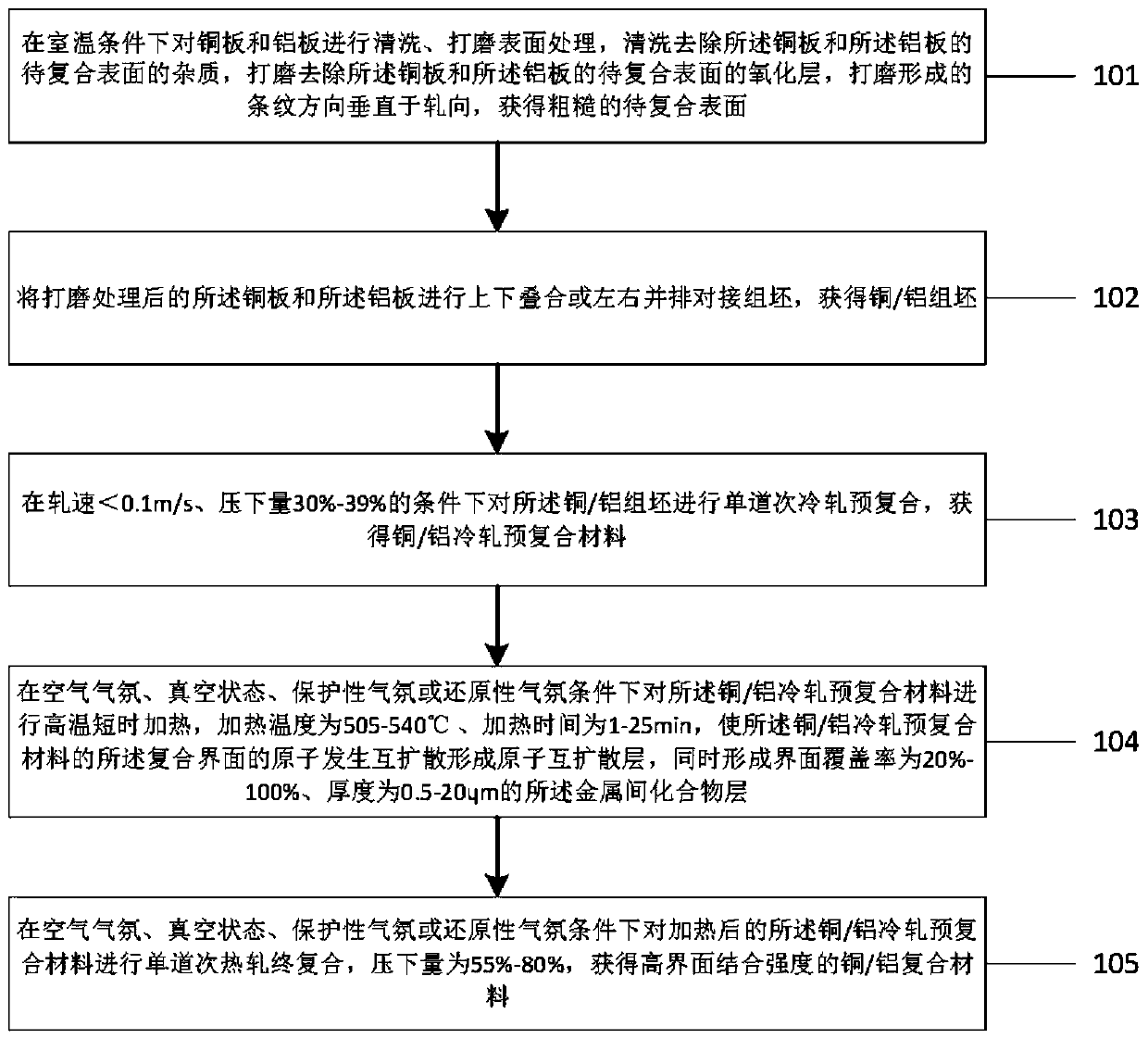

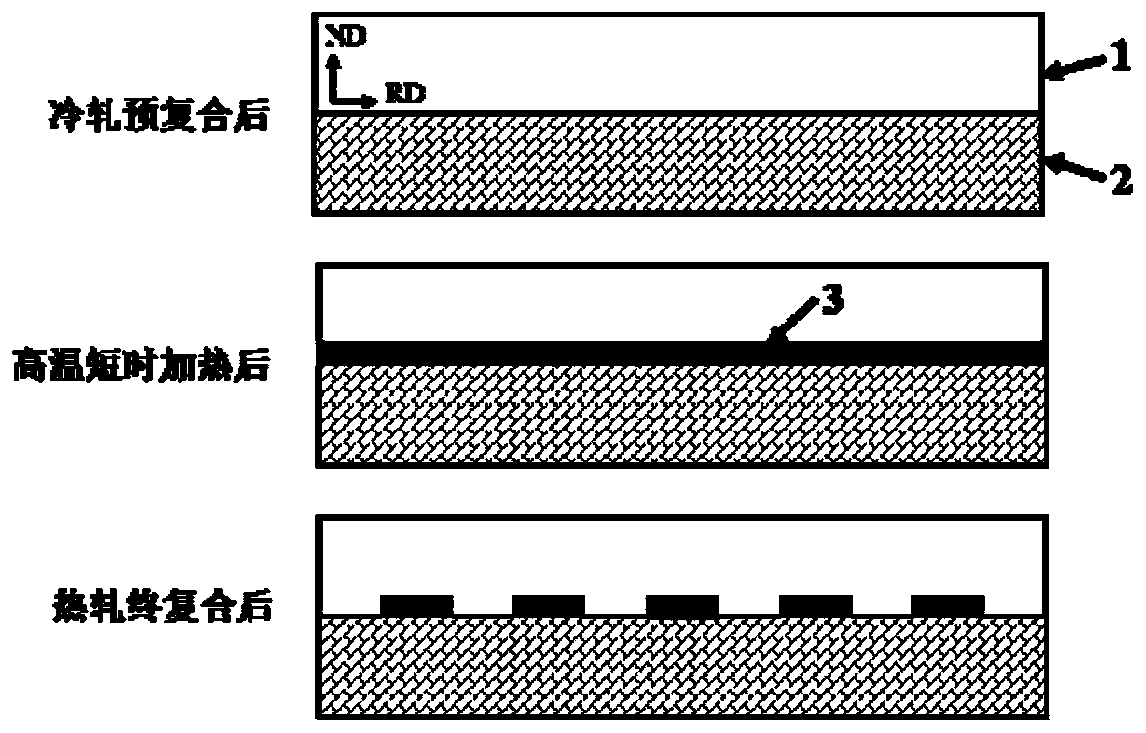

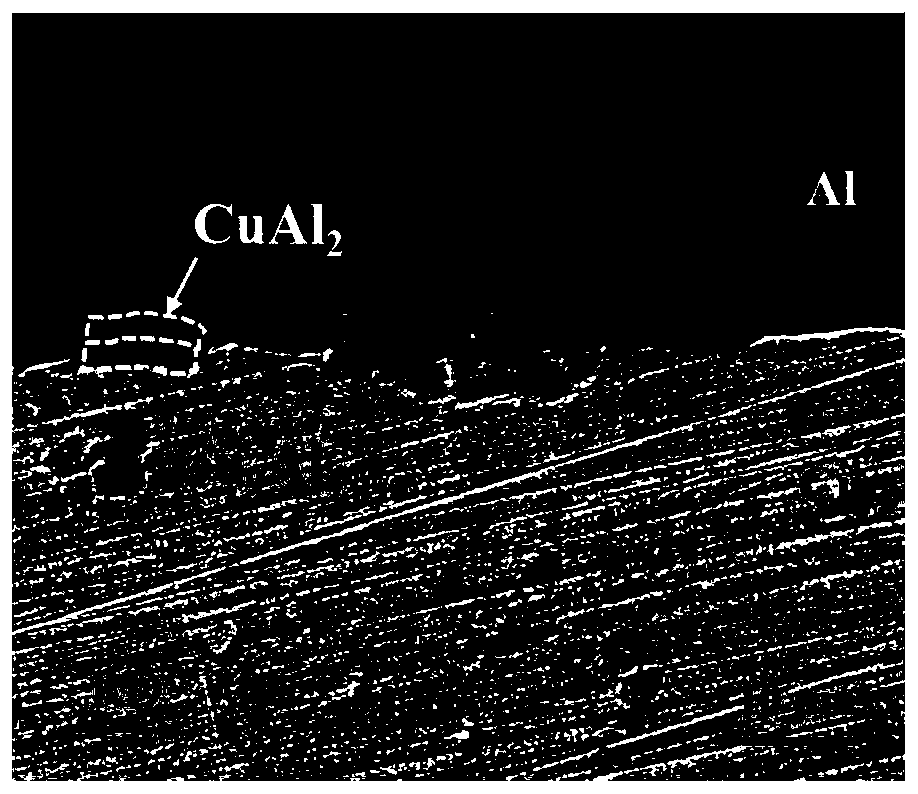

Forming method for high-interface-bonding-strength copper/aluminum composite material

ActiveCN110681694AImprove the bonding strength of the interfaceHigh interface frictionAuxillary arrangementsMetal rolling arrangementsAluminum compositesUltimate tensile strength

The invention discloses a forming method for a high-interface-bonding-strength copper / aluminum composite material, and belongs to the technical field of metal laminar composite material preparing. According to the forming method, to-be-combined surfaces of a copper plate and an aluminum plate are machined, macroscopic rugged to-be-combined surfaces are obtained, a louvre blade is adopted for conducting grinding treatment on the to-be-combined surfaces, the direction of stripes formed through grinding is perpendicular to the rolling direction, then, the copper plate and the aluminum plate are overlapped up and down or arranged left and right side by side to be in butt joint, and a copper / aluminum assembly is obtained; then, single-pass low-rolling-reduction cold rolling pre-composition is conducted, high-temperature short-time heating is conducted, finally, single-pass hot rolling final composition is conducted, and the high-interface-bonding-strength copper / aluminum composite materialis obtained. The forming method has the advantages that the capability requirement for a rolling machine needed for producing the copper / aluminum composite material is low, the technology is simple, the production cost is low, a macroscopic composite interface of a non-flat artificial structure and a microcosmic composite interface of a particle pinning structure can be obtained, the interface bonding strength is larger than or equal to 90 MPa, the applicable copper / aluminum composite material range is wide, and industrial popularization is easy.

Owner:UNIV OF SCI & TECH BEIJING

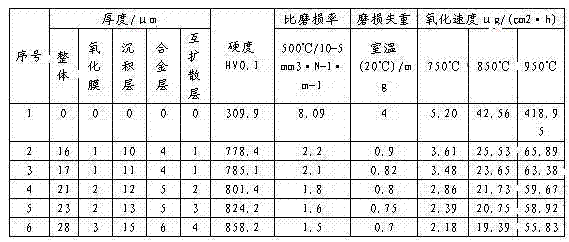

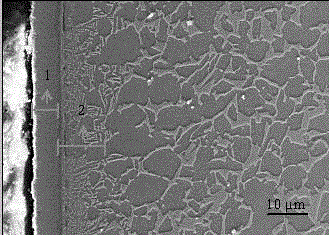

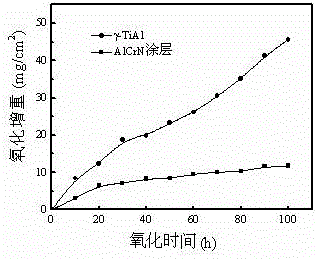

High-temperature-oxidation-resistant and abrasion-resistant AlCrN coating on surface of titanium-aluminum alloy and preparation method thereof

InactiveCN105839049AImprove wear resistanceThe surface of the coating is smooth and denseVacuum evaporation coatingSputtering coatingOxidation resistantGlow plasma

The invention discloses a high-temperature-oxidation-resistant and abrasion-resistant AlCrN coating on the surface of a titanium-aluminum alloy and a preparation method thereof. The coating is deposited on the surface of a titanium-aluminum alloy workpiece through the double glow plasma surface technology, an AlCrN deposited layer is located on the surface of the coating and is 5-10 micrometers thick, and a compact oxidized layer rich in Al2O3 and Cr oxide is formed by the AlCrN deposited layer at a high temperature; an AlCrN diffused layer is arranged in the coating and is 12-15 micrometers thick; the hardness of the obtained coating is 30-37 GPa, the room temperature friction coefficient of the coating is 0.3-0.33, and the high-temperature friction coefficient of the coating is 0.47-0.49. The preparation method includes the steps of charging, vacuumizing, workpiece surface activation, plasma permeation of the AlCrN coating, cooling and discharging. The obtained AlCrN coating solves the problem that the titanium-aluminum alloy is poor in high-temperature-oxidation resistance; meanwhile, the gradient structure of the diffused layer achieves metallurgical bonding of the coating and a substrate, and good high-temperature-oxidation resistance and good abrasion resistance are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

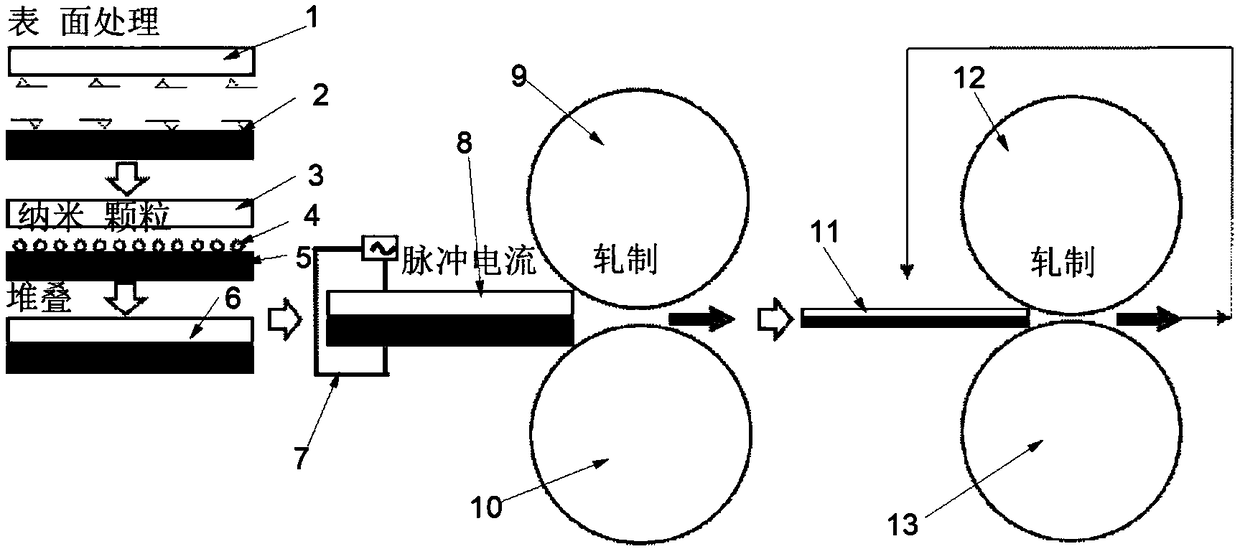

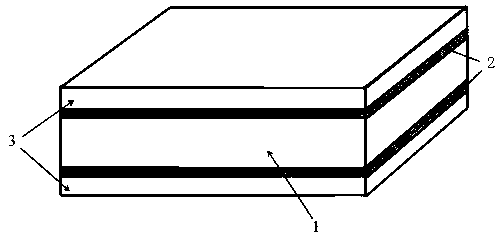

Rolling preparation method for improving interface bonding strength of lamellar aluminum-titanium composite through nano-metal powder

ActiveCN108296288AAchieve meltingAchieve metallurgical bondingMetal rolling arrangementsNoise reductionTitanium alloy

The invention provides a rolling preparation method for improving the interface bonding strength of a lamellar aluminum-titanium composite through nano-metal powder. According to the rolling preparation method, a titanium alloy strip material and an aluminum alloy strip material are machined to be at the same dimension, surface treatment is conducted so as to remove surface oxides, nanometer particles are arranged on the treated surfaces, stacking is conducted, so that a titanium / aluminum composite strip material is obtained, vacuum edge welding is conducted on the titanium / aluminum compositestrip material, a pulse current is exerted to the welded titanium / aluminum composite strip material so as to enable the nanometer particles and a local area of the surface of the composite strip material to conduct electric discharge, and surface metal is molten; then, rolling is conducted on the titanium / aluminum composite strip material, and material interface welding bonding is achieved; and finally, rolling continues until the total reduction rate of the strip material reaches 80%-95%. By the adoption of the rolling preparation method, the high-performance titanium / aluminum composite stripmaterial can be prepared. The plate material has the potential to be applied to the bulletproof protection field, the aerospace field, the sound insulation and noise reduction field, the automobile weight reduction field and the like. The rolling preparation method may be used for preparing composite strip materials composed of other nonferrous metal materials such as copper and magnesium in thefuture.

Owner:CENT SOUTH UNIV

Method for preparing cubic boron nitride glomerocryst composite combined with high-entropy alloy

Provided is a method for preparing a cubic boron nitride glomerocryst composite combined with high-entropy alloy. The method mainly comprises the steps that 40% to 95% of cubic boron nitride single crystals and 5% to 60% of high-entropy alloy binding agent by mass are evenly mixed and contained in a mold, the mixture is subjected to cold pressing on a hydraulic machine to be prepared into compact, and the pressure ranges from 30 MPa to 50 MPa and is kept for 2 min; the obtained compact is contained in a carbon tube furnace and assembled with a pressure transmitting medium, an assembled block is formed and placed between top anvils of a high-pressure press, the pressure ranges from 4 GPa to 6 GPa, the assembled block is heated to 1,200 DEG C to 1,650 DEG C, and the temperature is kept for 2 min to 25 min; then the pressure is removed, the assembled block is cooled to 60 DEG C or below, and the assembled block is taken out to obtain cubic boron nitride glomerocryst. No elementary element exists in the glomerocryst, a soft spot is avoided, and the hardness is relatively high and uniform; the sintering temperature and the expansion coefficient are controllable, the sintering temperature is reduced, sintering is easy, the toughness of the glomerocryst is improved, and heat stability is improved.

Owner:YANSHAN UNIV

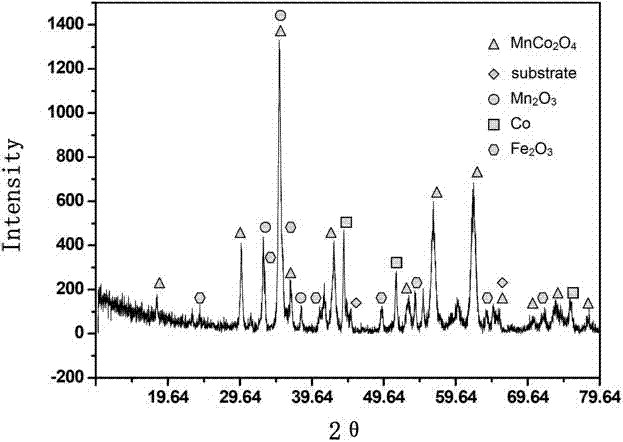

Preparation method of CoMn spinel coating on SOFC (Solid Oxide Fuel Cell) metal connector surface

ActiveCN103194713AMeet surface protection requirementsImprove production efficiencyMolten spray coatingFuel cells groupingHigh energyManganese

The invention belongs to the technology of metal surface modification and in particular relates to a preparation method of a CoMn spinel coating on an SOFC (Solid Oxide Fuel Cell) metal connector surface. The preparation method comprises the following steps of: (1), pretreating the metal surface; (2), pretreating a deposition electrode; (3), preparing a microcrystalline coating; and (4), preoxidizing a coasting to form the CoMn spinel coating on the alloy coasting surface. The preparation method of the CoMn spinel coating on the SOFC metal connector surface is free of a process for pre-synthesizing cobalt-manganese spinel, simple in process method, low in cost, capable of improving the preparation efficiency of the cobalt-manganese spinel and capable of obtaining CoMn alloy layers of different thickness and different atomic ratios by changing process parameters. The alloy coatings are combined with the base body in a metallurgical manner, so that the binding force is strong and the coating is compact; moreover, the prepared coating can be used for effectively blocking the volatilization of the Cr; and besides, the strict working conditions of the SOFC metal connector surface can be satisfied as the CoMn coating applied by high-energy micro-arc spark deposition has a thermal expansion coefficient close to the ferrite stainless steel and has good conductive performances.

Owner:兴化市青松农药化工有限公司

Preparation process of molybdenum/palladium/silver laminar metal matrix composite

InactiveCN103668368AImproves solderability and conductivityGood solderabilityPhotovoltaic energy generationSemiconductor devicesMetal foilWeld strength

The invention relates to a preparation process of a molybdenum / palladium / silver laminar metal matrix composite. The preparation process comprises the steps of pretreating a molybdenum metal foil, electroplating the surface of the molybdenum metal with palladium, annealing a molybdenum / palladium electroplating sample, carrying out dehydrogenation treatment, electroplating the surface of a molybdenum / palladium laminar annealed and dehydrogenized sample with silver, annealing a molybdenum / palladium / silver electroplating sample under pressure, and carrying out scanning electron microscope observation on the section morphology of the molybdenum / palladium / silver laminar metal matrix composite and resistance spot welding tensile strength testing. The preparation process has the beneficial effects that metallurgical bonding is achieved on the molybdenum / palladium and palladium / silver interfaces by diffusing the molybdenum / palladium and palladium / silver interfaces, so that the molybdenum / palladium / silver laminar metal matrix composite with good weldability and high interface bonding strength is obtained; the welding tensile strength of the composite during single resistance spot welding of the composite and solar cells is 416gf and exceeds the welding strength index stipulated in the national military standard GJB2602-1996.

Owner:TIANJIN UNIV

Method for preparing aluminum or aluminum-tin alloy plated layer on surface of sintered neodymium-iron-boron permanent magnet

InactiveCN107653440ALow melting pointLow coercivityVacuum evaporation coatingSputtering coatingSurface oxidationAlloy

The invention discloses a method for preparing an aluminum or aluminum-tin alloy plated layer on the surface of a sintered neodymium-iron-boron permanent magnet. The method is characterized in that magnetron-sputtering ion plating equipment is adopted, a sintered neodymium-iron-boron base body is cleaned, dried and then placed in a vacuum chamber, and the distance between the base body and a target material is adjusted; high vacuum is pumped, argon is led into the vacuum chamber for ion bombarding cleaning, and the aluminum-tin alloy plated layer is prepared through multi-arc ion plating; thetemperature in the vacuum chamber is decreased to be the indoor temperature, and then a neodymium-iron-boron magnet is taken out; and the plated neodymium-iron-boron magnet is placed into a heat treatment furnace and heated to a certain temperature to be subjected to plated layer diffusion and surface oxidation treatment, and thus the surface plated layer with the good surface form and corrosion performance is obtained. According to the method for preparing the aluminum or aluminum-tin alloy plated layer on the surface of the sintered neodymium-iron-boron permanent magnet, the preparation process is environmentally friendly, pollution is voided, the technique is stable, the magnetic performance of the magnet is not lowered, the obtained neodymium-iron-boron magnet surface plated layer canachieve metallurgical combination, the combining force of the base body and the plated layer is good, and the corrosion resistance of the sintered neodymium-iron-boron permanent magnet can be obviously improved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

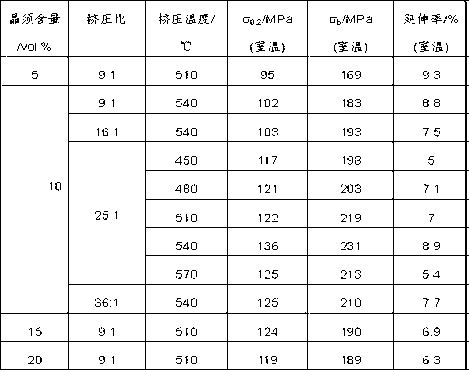

Preparation method of reinforced 6061aluminum matrix composite material

InactiveCN103276324AAchieve metallurgical bondingReduce production processAluminum matrix compositesSmooth surface

A preparation method of a reinforced 6061aluminum matrix composite material comprises steps as follows: a magnesium borate whisker and 6061 aluminum alloy powder are mixed to from a mixture of the magnesium borate whisker and the 6061 aluminum alloy powder with the volume fraction accounting for 5%-20% of the total volume, and sequentially placed into a ball mill for ball milling, wherein the ball-milling parameters are set as follows: the ratio of balls to materials is 10:1, the revolving speed of the ball mill is 150 r / min, the ball-milling time is 10 hours, the ball mill works in the manner that the ball mill forwards rotates for 600s, stops working for 60s, reversely rotates for 600s and stops working for 60s, and such circulation is repeated; ball-milling powder is placed in a mold cavity and pressed into a prepressing blank at the temperature of 100 DEG C; the prepressing blank is heated slowly to 510 DEG C and kept warm for 30 minutes, finally, the prepressing blank is uniformly extruded at an extrusion ratio of 9:1 and at the speed of 10min / s, and a composite extrusion rod with a smooth surface is prepared; and a workpiece is subjected to solid solution and ageing treatment, the solid solution treatment temperature is 520 DEG C, heat preservation is performed for 50min, water quenching is performed at the indoor temperature, and ageing treatment is performed at the temperature of 170 DEG C for 10 hours.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

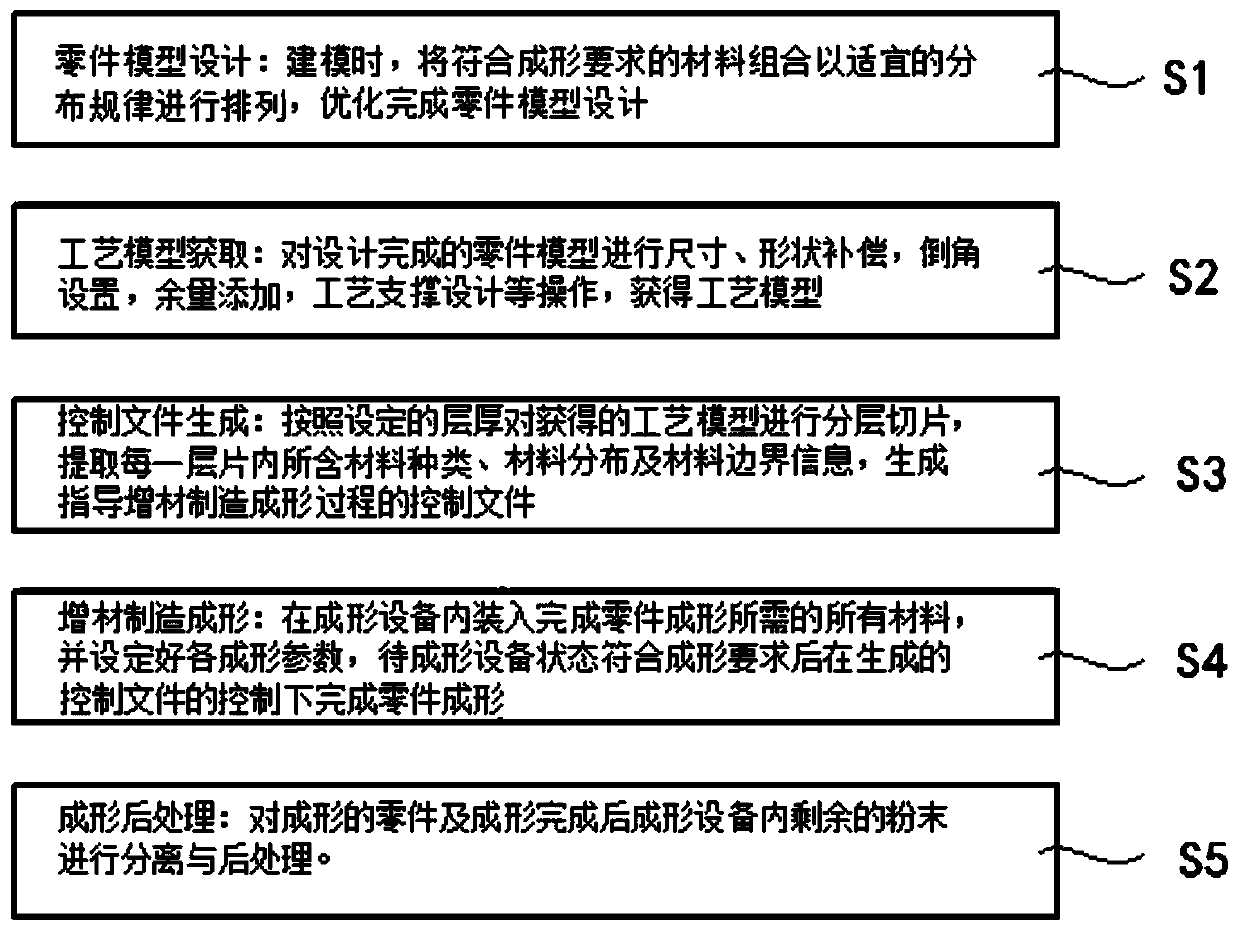

Selective laser melting forming method of multi-material part

InactiveCN111036901ASolve the problem of low bonding strengthQuality improvementAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingProcess engineering

The invention relates to the field of a part forming process, and discloses a selective laser melting forming method of a multi-material part. The method comprises the following steps of S1, part model design, wherein during modeling, materials meeting forming needs are combined to be arranged according to the proper distribution rule, and part model design is finished in an optimized manner; S2,process model obtaining, wherein a designed part model is subjected to size and shape compensation, chamfering, remaining adding, process support design and the like, and a process model is obtained;S3, control file generation, wherein the obtained process model is subjected to layered slicing, the material kind, material distribution and material boundary information contained in each layer areextracted, and a control file guiding an additive manufacturing forming process is generated; S4, additive manufacturing forming; and S5, forming aftertreatment. According to the method, through the selective laser melting forming technology, the high-precision high-quality multi-material part can be formed.

Owner:XIAN SPACE ENGINE CO LTD

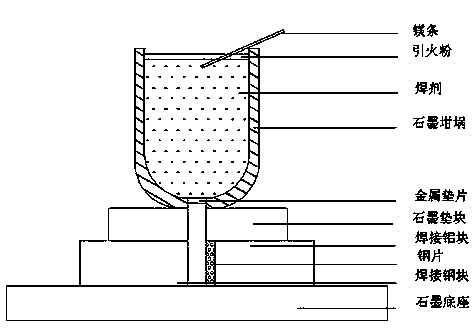

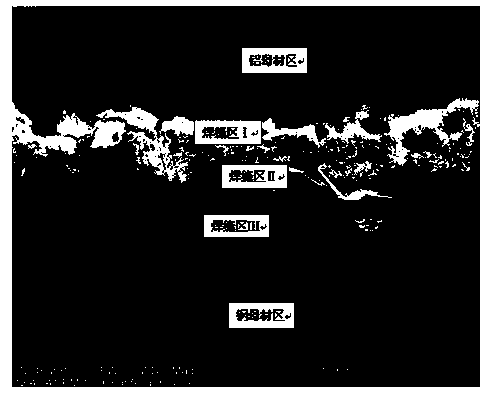

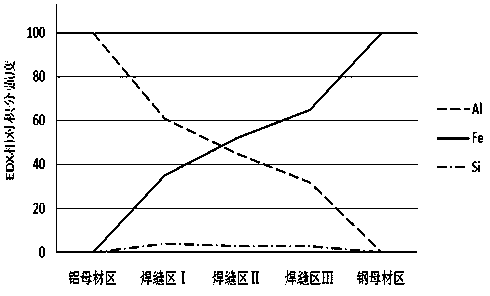

Aluminum-steel heat release welding method

InactiveCN103639589AReduce embrittlementIt conforms to the thermodynamic law that the temperature of the flow down gradually decreasesWelding/cutting media/materialsWelding/soldering/cutting articlesExothermic weldingAl powder

The invention discloses an aluminum-steel heat release welding method. The method comprises the steps that to-be-welded sections of an aluminum block and a steel block are polished cleanly; a pre-polished steel sheet is placed to cling to the aluminum block between a gap of the to-be-welded sections of the aluminum block and the steel block; a bottom through hole of a graphite crucible is aligned to the center of the gap; a self-propagating welding flux is put into the graphite crucible; pyrophoric powder on the surface of the self-propagating welding flux is ignited; molten liquid generated by self-propagating welding flux reaction flows into the gap between the aluminum block and the steel block from the bottom small hole of the graphite crucible; the steel sheet is heated, molten, and cooled to a room temperature; and then aluminum-steel welding is accomplished. The adopted self-propagating welding flux comprises the following raw materials by mass percent: 22-28% of Al powder, 62-68% of Fe2O3 powder, 4-7% of Si powder and 3-6% of slag forming constituent. The method is simple to operate, simple in equipment, stable, safe and reliable in reaction, extensive in raw material, low in cost and less in joint slag inclusion, and has a great industrial popularization value; aluminum steel bonding adopts metallurgical bonding; and the quality is good.

Owner:WUHAN UNIV

Method for preparing WC/graphite composite coating on surface of titanium alloy

ActiveCN105386040AImprove wear resistanceReduce coefficient of frictionMetallic material coating processesLaser technologyPolyvinyl alcohol

The invention discloses a method for preparing a WC / graphite composite coating on the surface of titanium alloy. The method includes the steps that firstly, the surface of a titanium alloy base material is pretreated so that an oxidation film on the surface is removed; secondly, WC powder and diamond powder are evenly mixed to obtain mixed powder, a polyvinyl alcohol aqueous solution is added into the mixed powder and stirred evenly, and a cladding material is obtained; thirdly, the cladding material is arranged on the surface of the titanium alloy base material in advance, and a precoated layer is obtained after drying; and fourthly, laser cladding treatment is carried out on the surface of the titanium alloy base material with the precoated layer, and the WC / graphite composite coating is obtained through preparation. Polymorphism occurs to the diamond in the precoated layer on the surface of the titanium alloy base material through the heat generated in the laser cladding treatment, and graphite is generated after conversion. The defect that a graphite coating can not be prepared through the laser technology in the prior art is overcome, the WC / graphite composite coating is prepared on the surface of the titanium alloy, the abrasion resistance of the surface of the titanium alloy is improved, and the friction coefficient of the titanium alloy is lowered.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

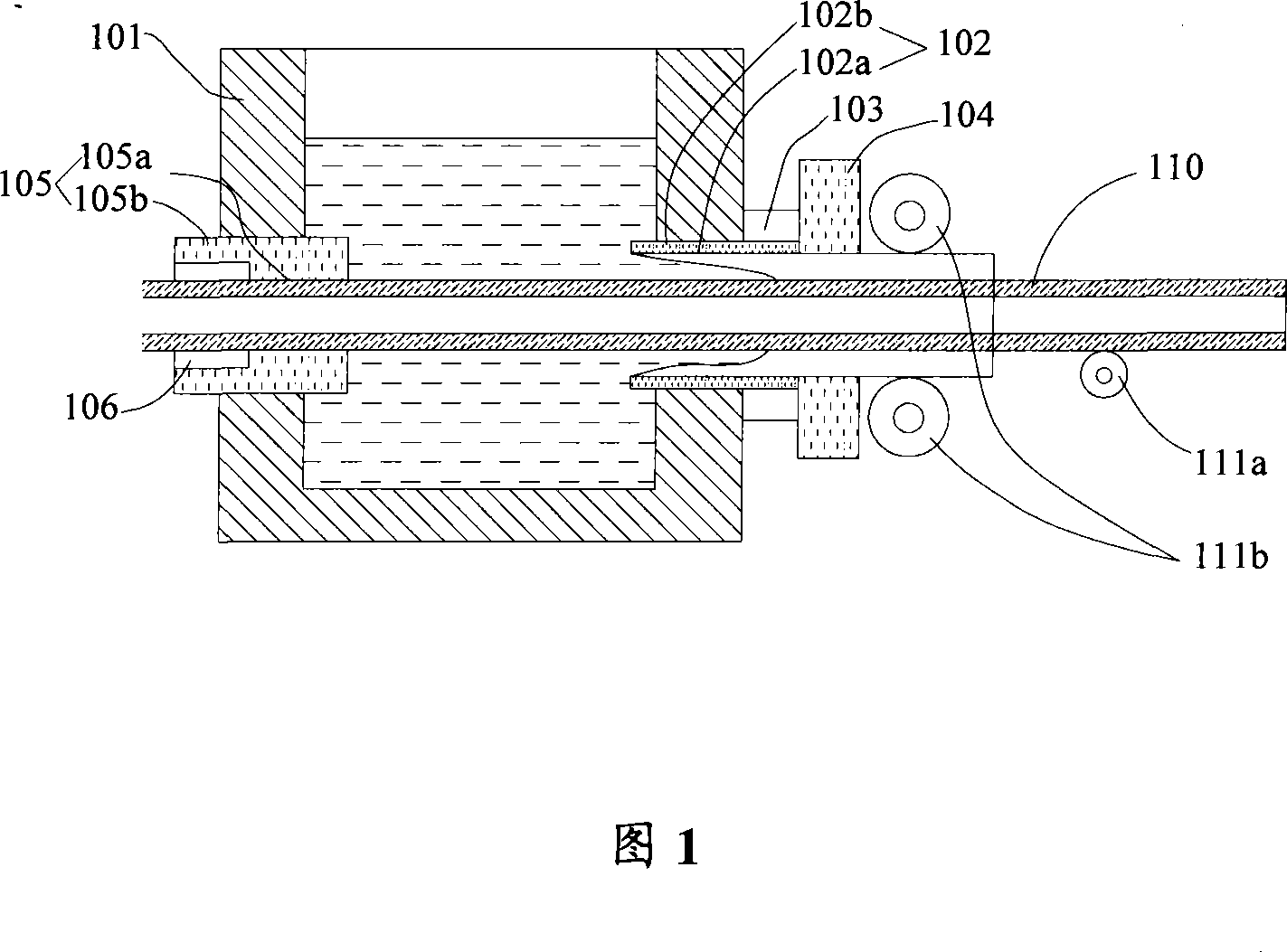

Method for manufacturing metal composite pipe blank and device for manufacturing metal composite pipe blank

The invention discloses a manufacturing method and a manufacturing device used for manufacturing a metal compound tube blank. The manufacturing method of the metal compound tube blank is that a metal tube blank made from a first metal is used as a guiding tube, a continuous casting method is adopted to manufacture the metal compound tube blank which adopts the metal tube blank made from the first metal as an inner tube and adopts a second metal whose melting point is less than that of the first metal as an outer tube. The invention also provides a device used for manufacturing the compound tube blank. The method disclosed by the invention realizes the compound of the first metal and the second metal and can manufacture metal compound tube blank with better interface capability. The device of the invention used for manufacturing the compound tube blank is suitable for manufacturing the metal compound tube blank.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

Method for manufacturing pre-deformation line diamond line saw through powder metallurgy

InactiveCN102218537AImprove gripExtended service lifeMetal sawing toolsStone-like material working toolsBLENDER/MIXERPre deformation

The invention provides a method for manufacturing a pre-deformation line diamond line saw through powder metallurgy, comprising the following steps: basic line manufacturing: selecting metal wires, stranding at least two metal wires into a line, and deforming the stranded line by a deformer to obtain a pre-deformation base line; powder preparation: weighing metal powder, a binder and diamond by mass percent, and adding the mixture into a blender mixer to evenly mixing; line blank manufacturing: putting the base line and powder into a mould, and taking the pre-deformation base line as a center to prepare a line blank by using a forming technology; and line saw manufacturing: putting the line blank to a sintering furnace for sintering, and cooling with the furnace to obtain the line saw. The manufacturing method provided by the invention has the advantages of simple process, low cost and high production efficiency. The produced line saw has excellent performance, high strength, good flexibility, high hold to diamonds, stable cutting performance, good chip discharging performance and long service life, and is not easy to crack.

Owner:长沙和谦新材料科技有限公司

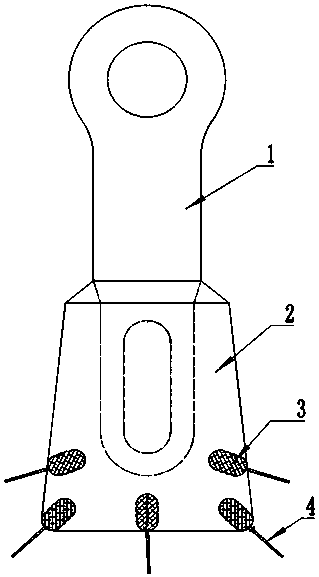

Method used for manufacturing composite wear-resistant hammerhead from hard alloy through high temperature casting

ActiveCN108456826AAchieve metallurgical bondingSimple processFoundry mouldsFoundry coresWear resistantCasting mold

The invention discloses a method used for manufacturing a composite wear-resistant hammerhead from a hard alloy through high temperature casting. The composite wear-resistant hammerhead comprises a hammer handle, a hammerhead base body, and the hard alloy embedded in the hammerhead base body. The method comprises following steps: the hard alloy is fixedly arranged in a casting mold, the casting mold is heated to 1100 to 1250 DEG C, casting of molten metal of the hammerhead base body is carried out so as to form metallurgical bonding between the hammerhead base body and the hard alloy, after cooling, a mold shell is removed so as to obtain the composite wear-resistance hammerhead. According to the method, high temperature casting is capable of removing defects, such as casting alloy block shedding caused by cold shut, generation of holes caused by blocking of molten steel by cold iron and fill shrink, pores caused by obstruction on gas elimination, and cracks caused in cooling shrinkage,caused by cold iron casting; high temperature casting is capable of realizing metallurgical bonding between the hammerhead base body and the hard alloy in the hammerhead base body, and obtaining compact castings.

Owner:嘉禾县飞恒合金铸造有限公司

Method for repairing high-speed steel cutter by means of laser cladding

InactiveCN102912341ARealize repair and remanufacturingAchieve metallurgical bondingMetallic material coating processesHardnessHigh intensity

Disclosed is a method for repairing a high-speed steel cutter by means of laser cladding. The method is designed to solve technical problems that when an existing high-speed steel cutter is repaired in a high-frequency brazing method, a heat affected zone, which is caused by the high-frequency brazing method, of the cutter is over large, and the hardness of the cutter is reduced; and when the existing high-speed steel cutter is repaired in a mechanical connection method, threads are machined on high-speed steel difficultly, and the like. The method includes hard alloy powder covers abraded portions of a matrix of the high-speed steel cutter in a vacuum environment by means of laser cladding, so that the cutter is repaired and remanufactured. The method has the advantages that high-speed steel and hard alloy are metallurgically bonded, on the one hand, problems that oxygen exists on a cladding layer and generates air holes and accordingly the cladding quality is affected are prevented, and on the other hand, the hardness of the cladding layer is higher than that of the matrix. Accordingly, by the method, high-strength connection between the high-speed steel and the hard alloy is realized, and the damaged cutter is repaired and remanufactured.

Owner:SHENYANG AEROSPACE UNIVERSITY

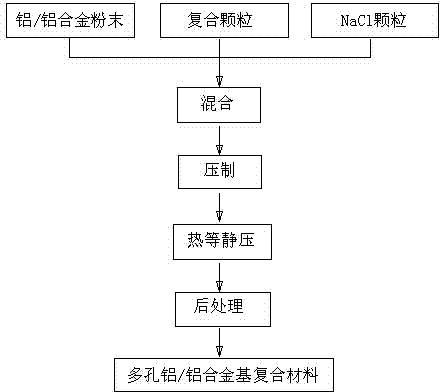

Preparation method for composite material based on porous aluminum or aluminum alloy

InactiveCN104117675AGuaranteed Metallurgical BondingImprove controllabilityHot isostatic pressingRaw material

The invention relates to a preparation method for a composite material based on porous aluminum or aluminum alloy, and belongs to the field of porous metal materials. Aluminum or aluminum alloy powder, composite particles and pore-forming agent NaCl particles are adopted as raw materials, the powder is mixed and then pressed to form a blank, the blank is pressed and heated to the aluminum melting point or the temperature 20-50 DEG C below the temperature of the aluminum alloy solidus curve for hot isostatic pressing, metallurgical bonding between aluminum or aluminum alloy powder is achieved, after the hot isostatic pressing blank is cooled, NaCl particles in the hot isostatic pressing blank are dissolved and removed with water, and the composite material based on the porous aluminum or aluminum alloy is obtained.

Owner:KUNMING UNIV OF SCI & TECH

Method for manufacturing titanium alloy additive with laser-induced interface in-situ reaction enhancement

PendingCN111992715AImprove product qualityReduce manufacturing costAdditive manufacturing apparatusIncreasing energy efficiencyIn situ reactionTitanium

The invention discloses a method for manufacturing a titanium alloy additive with laser-induced interface in-situ reaction enhancement. Firstly, atomized titanium alloy powder is poured into a powderfeeder, high-pressure nitrogen passes through the powder feeder and a cold spray gun, and the titanium alloy powder and the high-pressure nitrogen are sprayed to the surface of a titanium alloy matrixthrough the cold spray gun; and during spraying, a laser generator is synchronously started, laser is irradiated on particles of the titanium alloy powder sprayed on the surface of the titanium alloymatrix, the particles of the titanium alloy powder are subjected to micro-melting under the action of laser heating and react with the surrounding high-pressure nitrogen flow, an in-situ reaction occurs, the particles of the titanium alloy powder are mechanically and metallurgically bonded to form a titanium alloy coating on the titanium alloy matrix, thereby producing a highly dense titanium alloy part. According to the method, by means of laser induction, the plastic deformation capability of the powder is improved, so that bonding pores are reduced, a titanium alloy component is strengthened through metallurgical bonding of the in-situ nitridation reaction, and the product quality is improved.

Owner:ZHEJIANG UNIV OF TECH

Aluminium and lead laminar composite material

InactiveCN101092708ALower internal resistanceReduce consumptionMetal layered productsElectrodesInternal resistanceComposite laminates

This invention provides an aluminum-tin composite laminate, which comprises aluminum as the core, tin or tin alloy as the outer layer, and transition element as the middle layer. The aluminum-tin composite laminate has such advantages as low internal resistance, high strength, light weight, high corrosion resistance, and high electrochemical performance.

Owner:KUNMING UNIV OF SCI & TECH

Process for repairing continuous casting crystal roller

ActiveCN101333637ASmall heat affected zoneImprove bindingMolten spray coatingMolten stateHigh pressure

The invention discloses a repairing method of a continuous casting crystallization roller, which relates to a repairing technique of the continuous casting crystallization roller, in particular to a technique utilizing a metal atomization spray and deposition process to repair the crystallization roller. The method is mainly characterized in that: the surface of the crystallization roller is cleaned, then the roller is positioned into a spraying atomization and deposition chamber and heated, then high pressure inert gases are input thereto for atomizing a metal repairing material in a molten state and making the material deposit on parts needing to be repaired of the crystallization roller, finally the redundant parts are removed through machining, thereby the repairing to the damaged parts or the whole surface of the crystallization roller is completed. The method can avoid the defects existing in the current crystallization roller repairing technique, and can improve the repairing efficiency and quality of the crystallization roller and extend the service life of the crystallization roller.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com