Preparation method for composite material based on porous aluminum or aluminum alloy

A technology of aluminum alloy matrix and composite materials, applied in the field of porous metal materials, can solve the problems of easy oxidation, difficulty in obtaining porous aluminum or aluminum alloy matrix composite materials, etc., and achieve the effect of ensuring metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

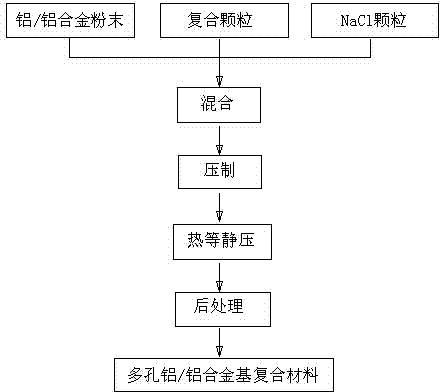

Image

Examples

Embodiment 1

[0032] (1) Preparation of mixed powder blank: 1060 industrial pure aluminum powder with a particle size of 10-25 μm, diamond particles with a particle size of 0.1-1.5 μm and NaCl particles with a particle size of 178-297 μm are used as raw materials for batching, among which NaCl particles, The volume percentages of diamond particles and 1060 industrial pure aluminum powder in the mixed powder were 30%, 7% and 63% respectively, and 1060 industrial pure aluminum powder, diamond composite particles and NaCl particles were mixed in the mixer for 3 hours to obtain a uniform Mixed powder, this mixed powder is pressed under the pressure of 500MPa to obtain mixed powder base;

[0033] (2) Hot isostatic pressing of the mixed powder compact: heat the mixed powder compact prepared in step (1) to 620°C for hot isostatic pressing (hot isostatic pressing pressure 100 MPa, hot isostatic pressing time 2 hours), hot After isostatic pressing, it is cooled with the furnace to obtain a hot isost...

Embodiment 2

[0036] (1) Preparation of mixed powder base: 3004 aluminum alloy powder with a particle size of 25-37 μm, TiB2 particles with a particle size of 0.1-3.4 μm and NaCl particles with a particle size of 250-350 μm are used as raw materials for batching. Among them, NaCl particles, TiB2 The volume percentages of particles and 3004 aluminum alloy powder in the mixed powder are 50%, 10% and 40% respectively, 3004 aluminum alloy powder, TiB 2 Composite particles and NaCl particles were mixed in a mixer for 2 hours to obtain a uniform mixed powder, and the mixed powder was pressed under a pressure of 400MPa to obtain a mixed powder compact;

[0037] (2) Hot isostatic pressing of the mixed powder compact: heat the mixed powder compact prepared in step (1) to 560°C for hot isostatic pressing (hot isostatic pressing pressure 150 MPa, hot isostatic pressing time 1 hour), hot After isostatic pressing, it is cooled with the furnace to obtain a hot isostatic compact;

[0038] (3) Post-treatm...

Embodiment 3

[0040](1) Preparation of mixed powder blank: ZL111 aluminum alloy powder with a particle size of 37-53 μm, SiC particles with a particle size of 0.1-5 μm and NaCl particles with a particle size of 420-590 μm are used as raw materials, among which NaCl particles, SiC particles, ZL101 The volume percentages of aluminum alloy powder in the mixed powder are 70%, 9% and 21% respectively. The ZL111 aluminum alloy powder, SiC composite particles and NaCl particles are mixed in the mixer for 1 hour to obtain a uniform mixed powder. The powder is compressed under a pressure of 100MPa to obtain a mixed powder compact;

[0041] (2) Hot isostatic pressing of the mixed powder compact: heat the mixed powder compact prepared in step (1) to 550°C for hot isostatic pressing (hot isostatic pressing pressure 180MPa, hot isostatic pressing time 0.5 hours), After hot isostatic pressing, the hot isostatic compact is obtained by cooling with the furnace;

[0042] (3) Post-treatment of the hot isost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com