Overlay welding and shape rolling device and re-manufacturing method

A remanufacturing and rolling technology, which is applied in the field of surfacing welding rolling device and remanufacturing, can solve the problems of low manual grinding precision, difficulty in disassembling parts, economic loss, etc., and achieve short repair work time, high repair efficiency, and easy maintenance. Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

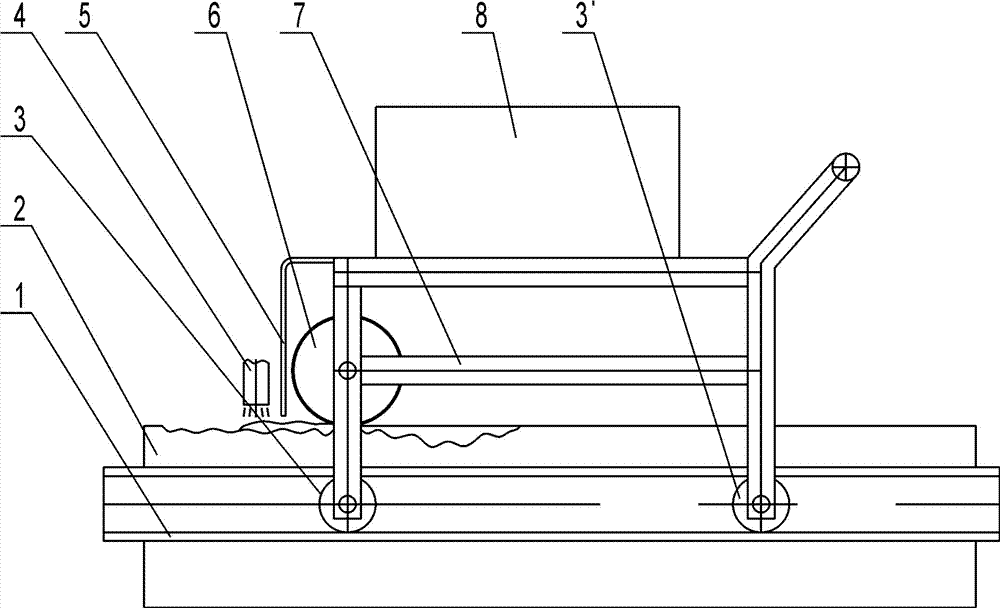

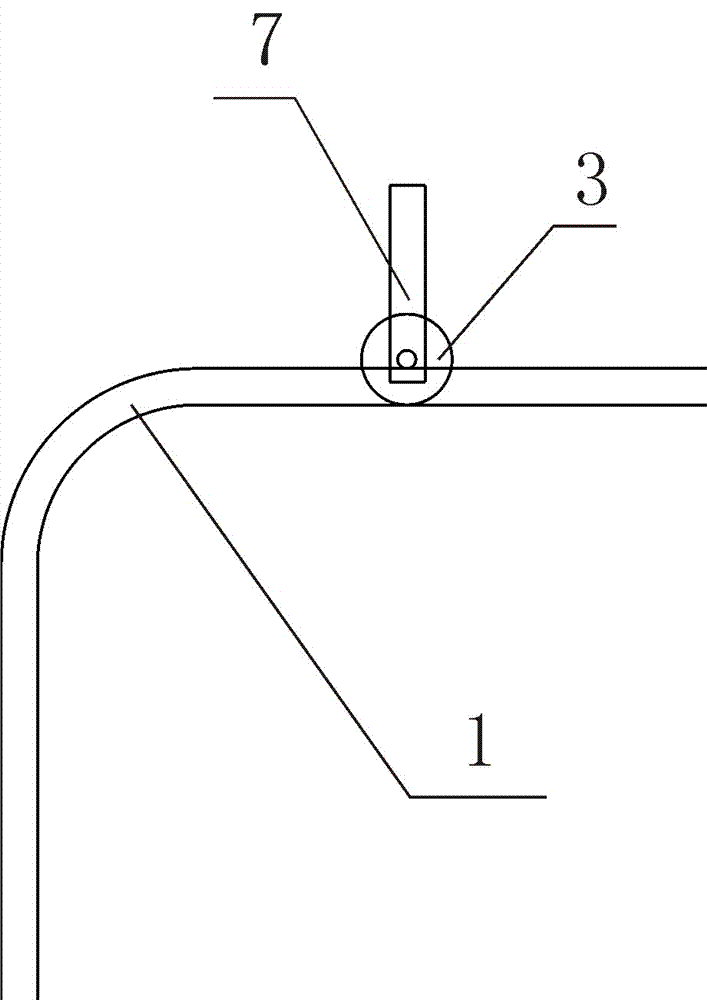

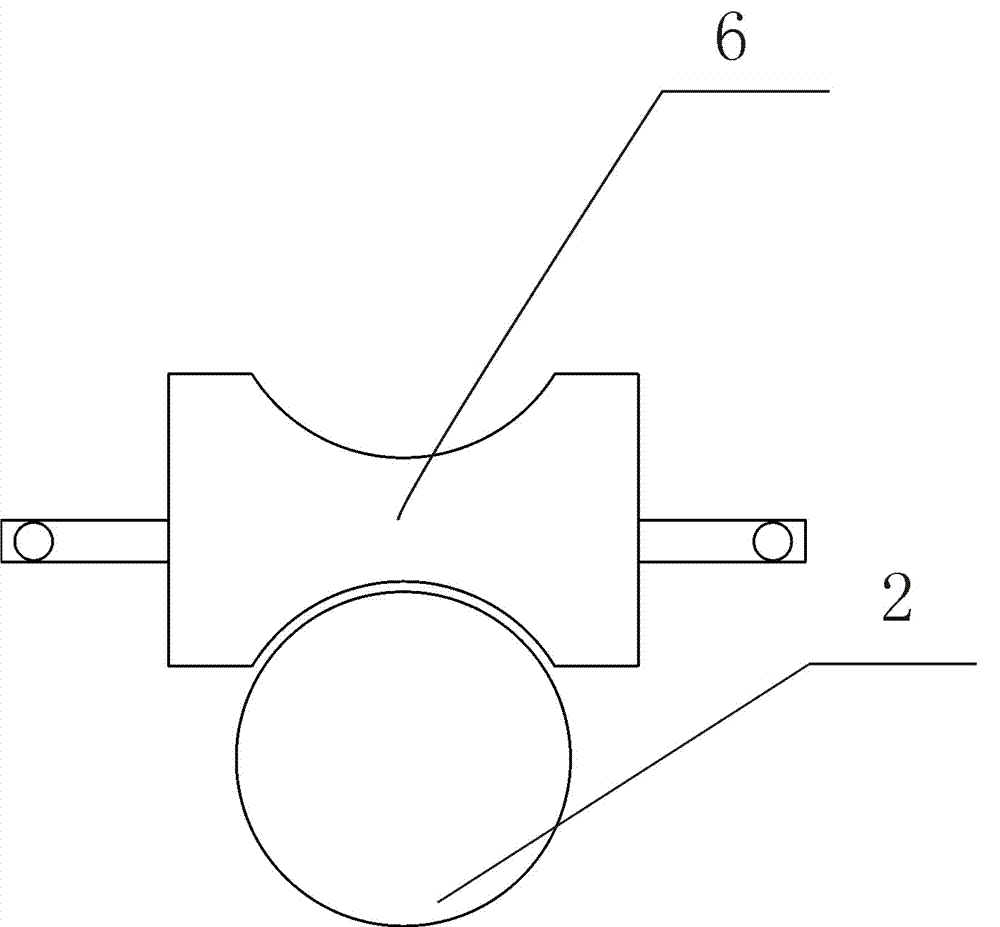

[0033] A kind of surfacing welding rolling device, comprising surfacing welding equipment 8, nozzle 4 and guide rail 1, guide wheels 3, 3' are installed on the walking support 7, guide wheels 3, 3' run along the guide rail 1, and the forming roller 6 is installed on On the walking support 7.

[0034] The walking support 7 is connected with a baffle 5 , and the baffle 5 is located between the nozzle 4 and the profile roller 6 .

[0035] The guide rail 1 is straight or curved.

[0036] The outer contour of the profiled roller 6 is a straight line or a curve.

[0037] The intersection line between the surface of the profiled roller 6 and the original surface of the repaired part 2 is the generatrix of the repaired surface, and the direction line of the guide rail 1 is the wire.

[0038] A method for remanufacturing a surfacing roller using a surfacing roller device, comprising the following steps:

[0039] 1), the step of making the molded roller: make the molded roller 6 acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com