Flame retarding auxiliary for chemical-fiber sofa plus material

A technology of flame retardant additives and sofas, which is applied in the field of flame retardant additives for chemical fiber sofa fabrics. It can solve the problems that the flame retardant properties of flame retardant fabrics cannot be balanced, achieve excellent shape setting, easy washing and quick drying, and ensure family safety. The effect of high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

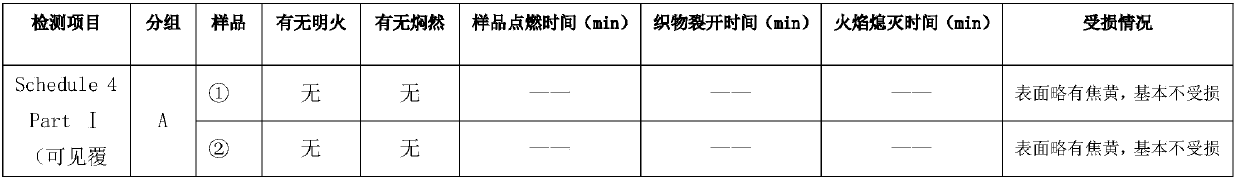

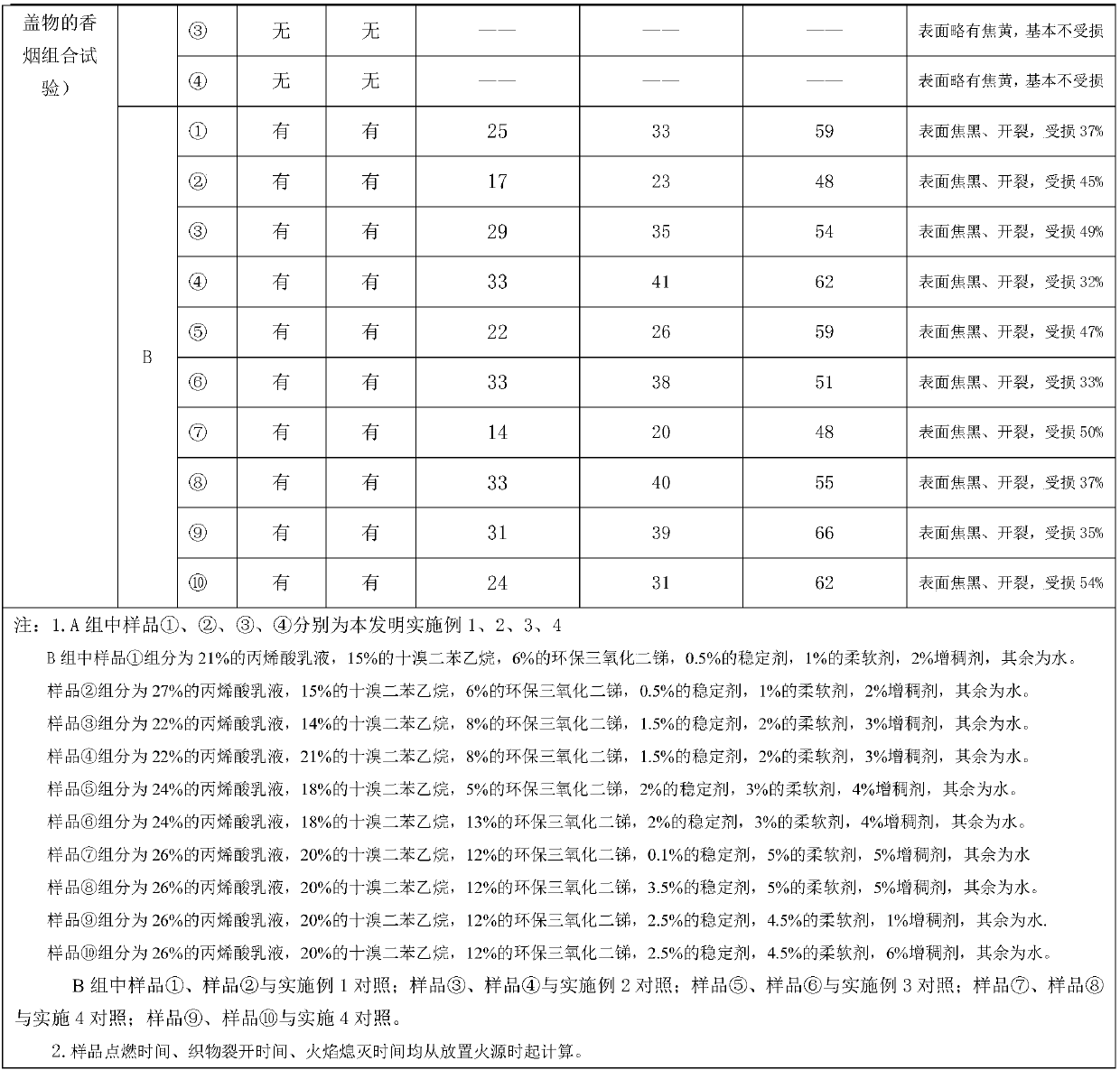

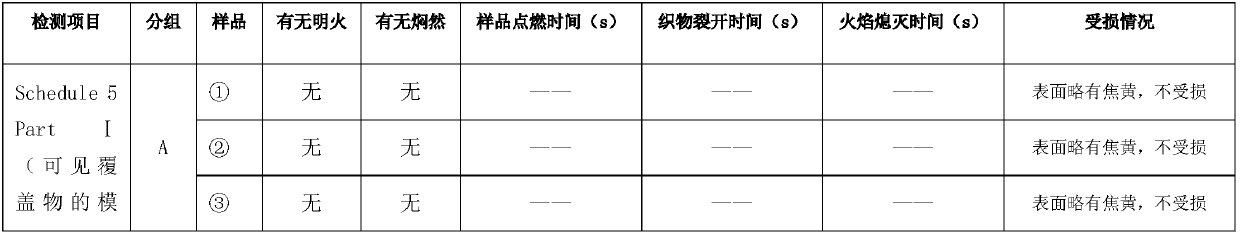

Examples

Embodiment 1

[0017] This embodiment is a flame retardant additive for chemical fiber sofa fabric: 20% acrylic emulsion, 15% decabromodiphenylethane, 6% environmental protection antimony trioxide, 0.5% stabilizer, 1% softener , 2% thickener, the rest is water. In this embodiment,...

Embodiment 2

[0019] In this embodiment, a flame retardant additive for chemical fiber sofa fabrics includes: 22% acrylic emulsion, 16% decabromodiphenylethane, 8% environmental protection antimony trioxide, 1.5% stabilizer, 2% softness Agent, 3% thickener, the rest is water.

Embodiment 3

[0021] In this embodiment, a flame retardant additive for chemical fiber sofa fabric includes: 24% acrylic emulsion, 18% decabromodiphenylethane, 10% environmental protection antimony trioxide, 2% stabilizer, 3% softness Agent, 4% thickener, the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com