Patents

Literature

131results about How to "Affect flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

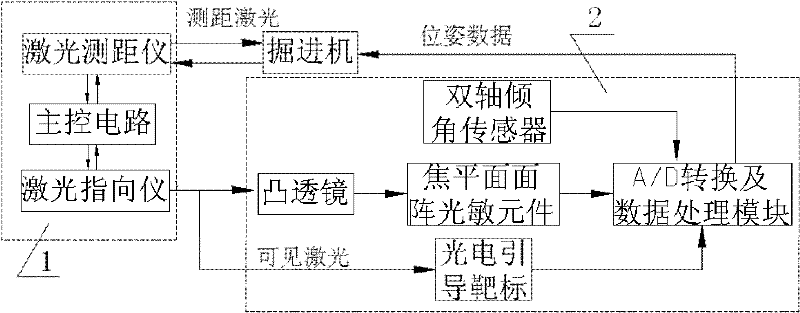

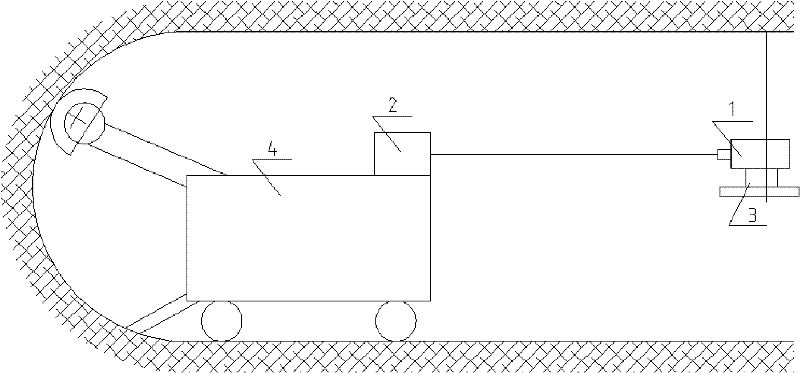

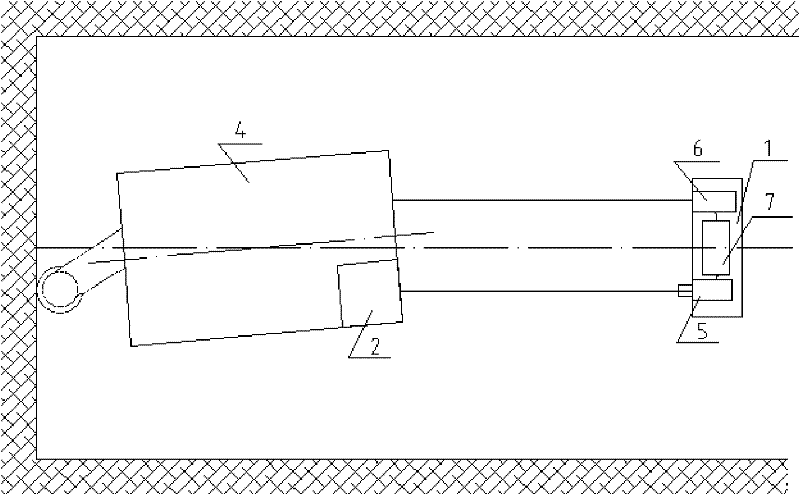

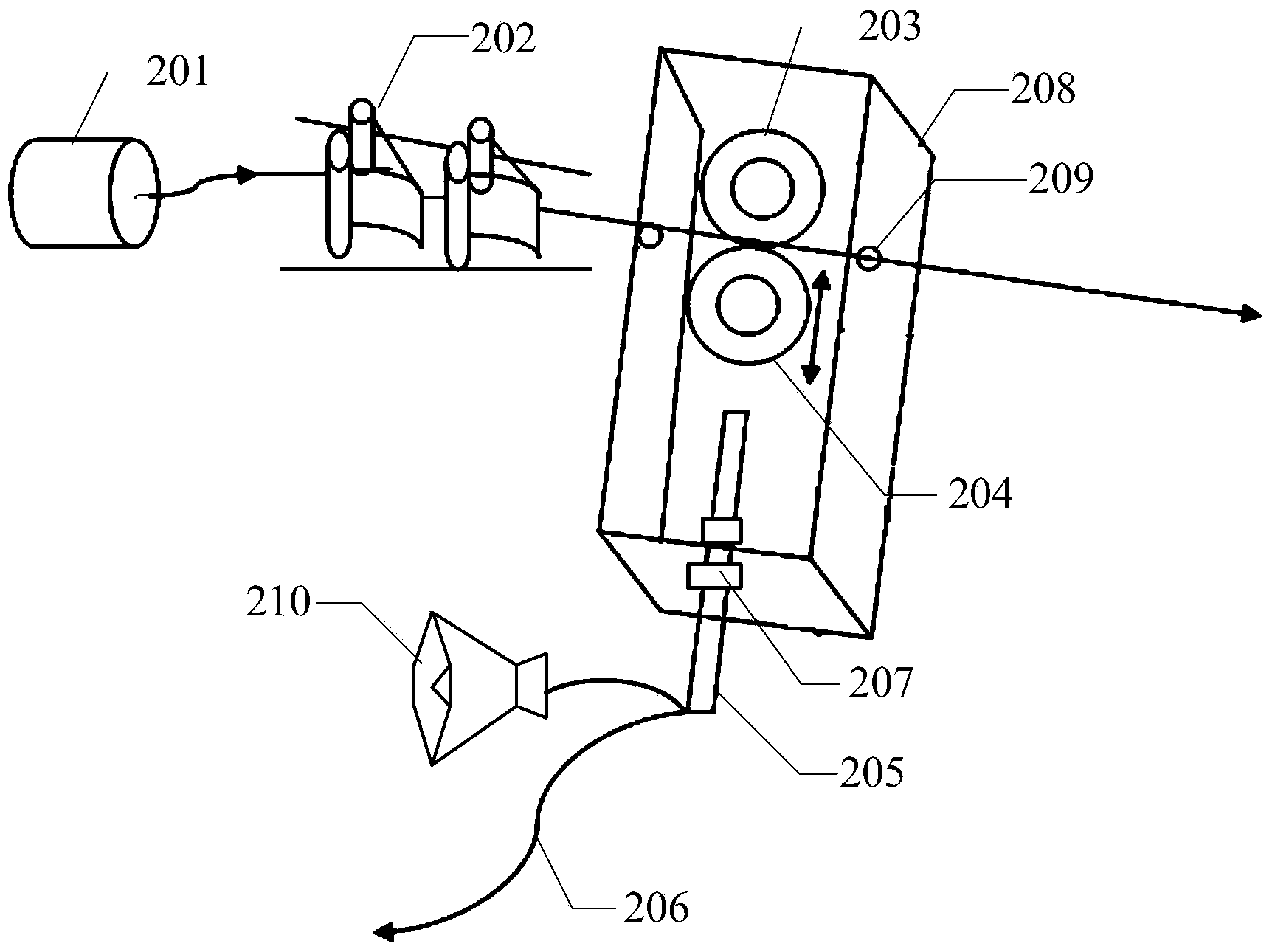

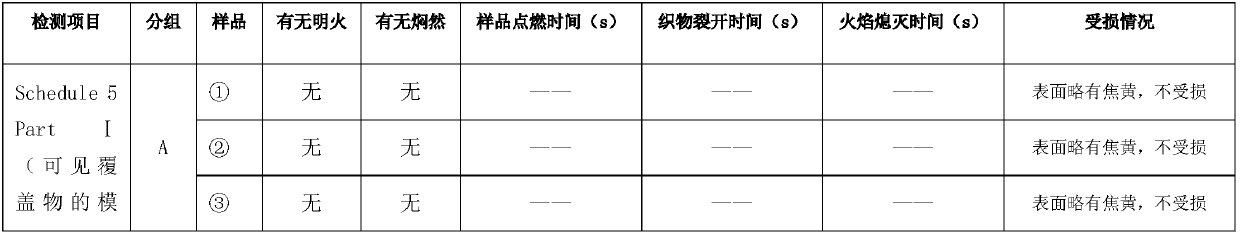

Pose measure system of cantilever type heading machine

InactiveCN102207382AReduced precision requirementsImprove anti-interference abilityAngle measurementOptical rangefindersGoniometerOptical axis

The invention relates to a pose measure system of a cantilever type heading machine. The pose measure system comprises a laser pointing rangefinder and an optical goniometer. The pose measure system is characterized in that: the laser pointing rangefinder respectively emits a visible laser and an infrared ranging laser; the visible laser forms an image on a focal plane of a convex lens of the optical goniometer through the convex lens; a direction angle alpha<,> and a pitch angle beta<,> of a optical axis of the optical goniometer relative to a laser beam are obtained through image point coordinates. Because a preset optical axis of the optical goniometer is parallel to a fuselage axis of the heading machine, the alpha<,> and the beta<,> are the direction angle and the pitch angle of the fuselage axis relative to the laser beam. A spinning angle gamma of the fuselage relative to a horizontal plane can be obtained through a tilt angle sensor installed parallel to a datum plane of the heading machine. Therefore, influence on measurements of the direction angle alpha<,> and the pitch angle beta<,> due to the spinning angle gamma is corrected so as to complete the measurements of the direction angle alpha<,> and the pitch angle beta of the heading machine relative to the laser beam, and the spinning angle gamma of the heading machine relative to the horizontal plane. With the present invention, a range between the fuselage of the heading machine and the laser pointing rangefinder can be obtained through the infrared ranging laser; a position coordinate of the heading machine can be obtained through combining the position coordinate of the laser pointing rangefinder and parameters of emission angle of the laser beam; tunnelling workload and other information can be obtained through system output data.

Owner:TIANDI CHANGZHOU AUTOMATION +1

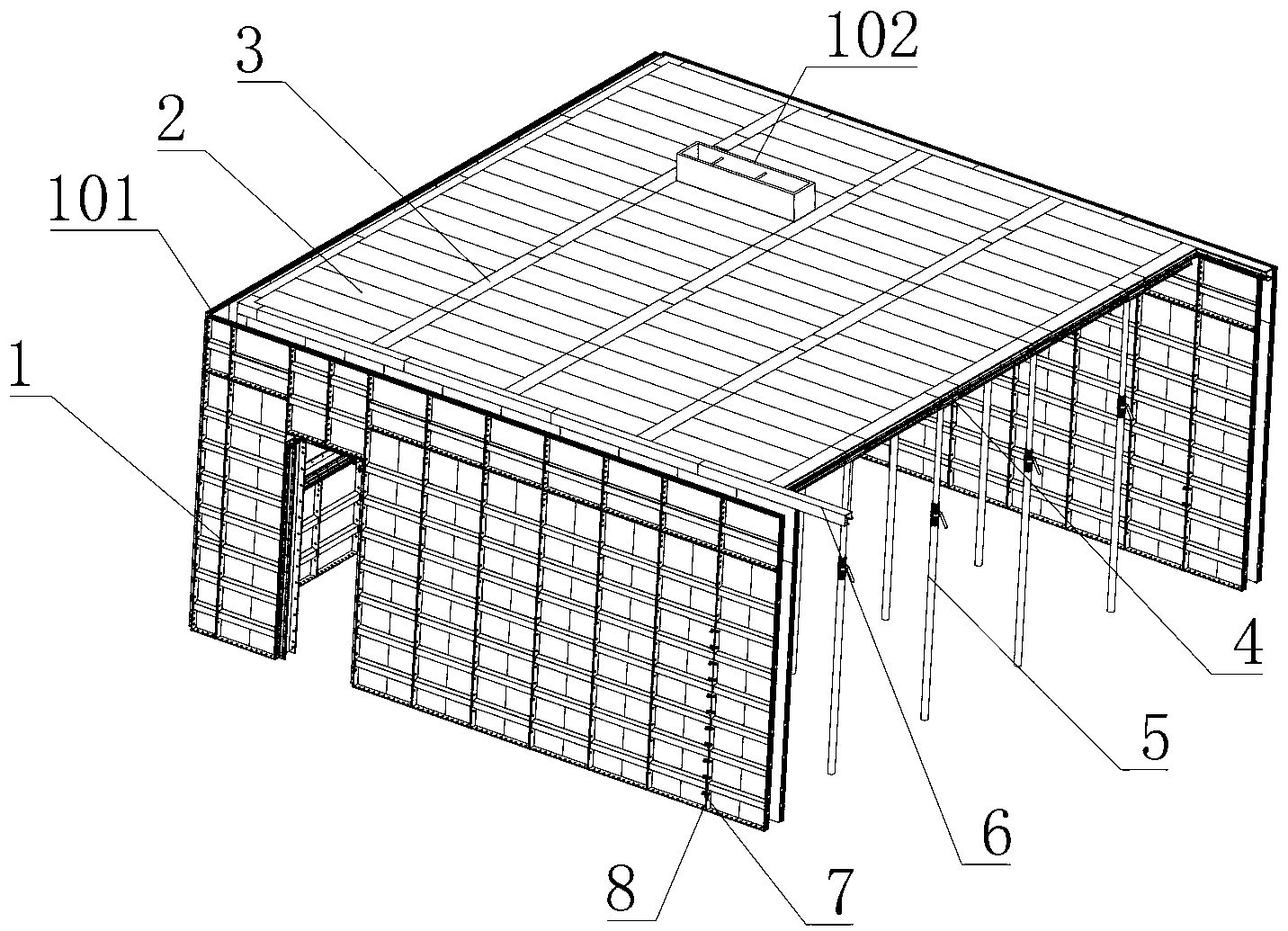

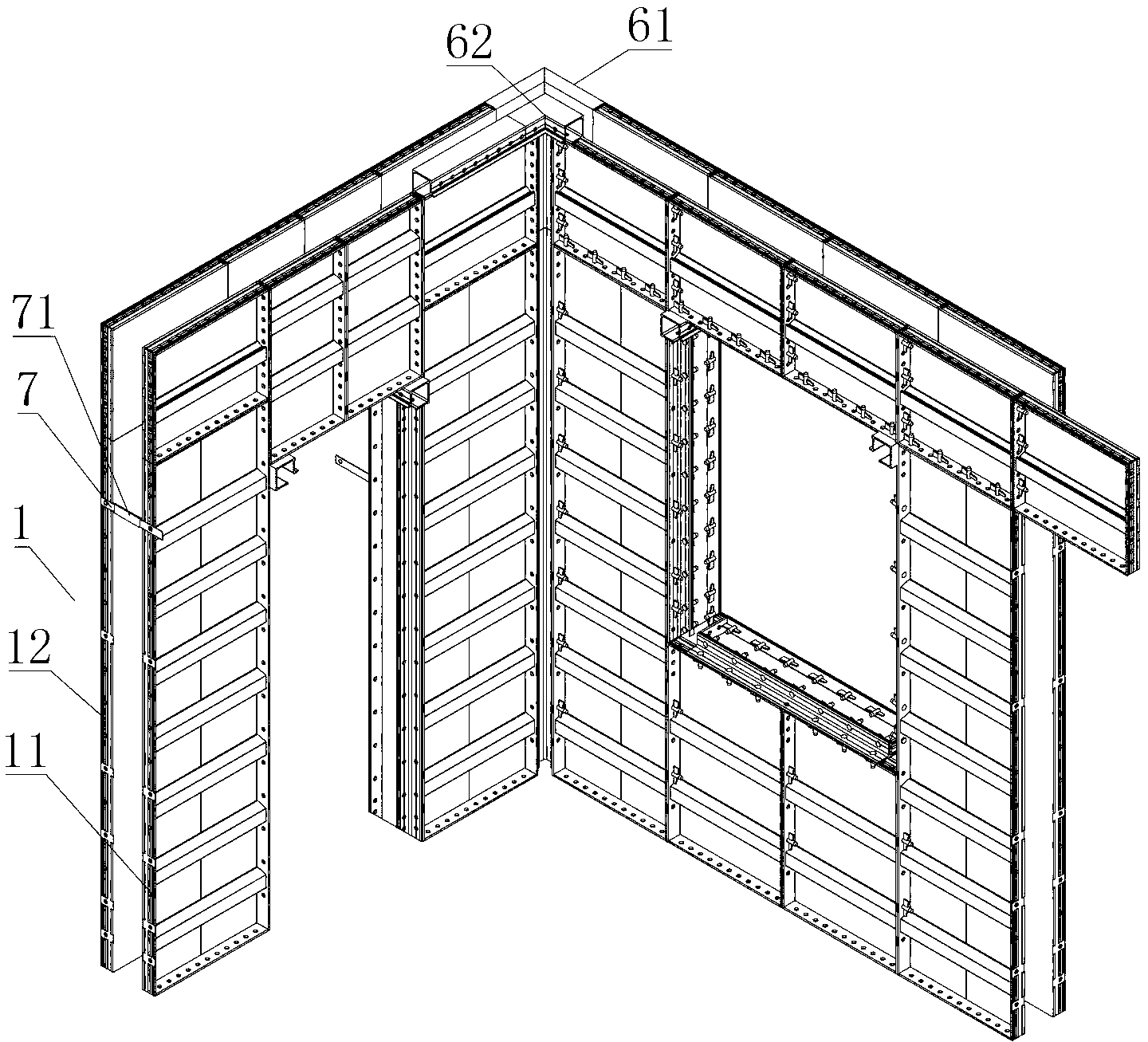

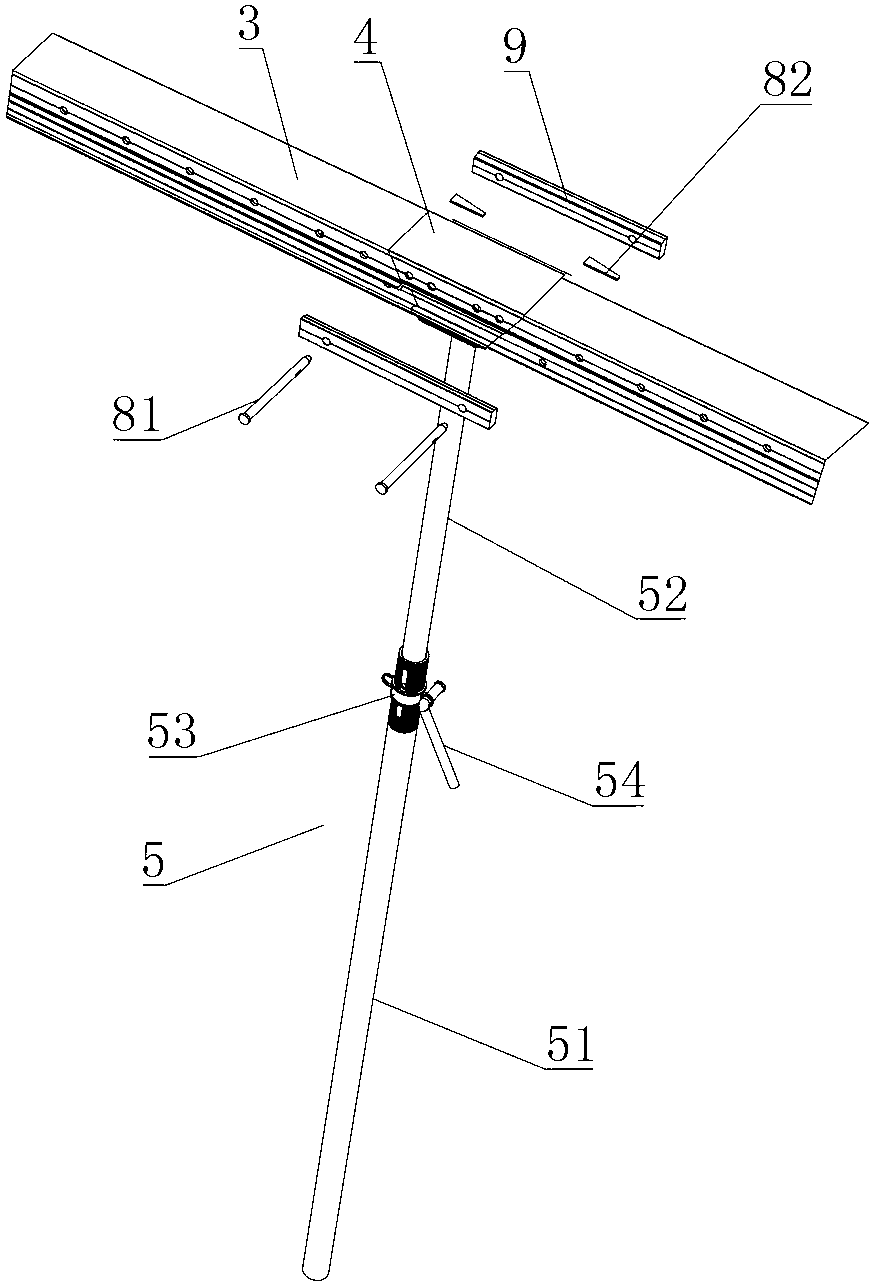

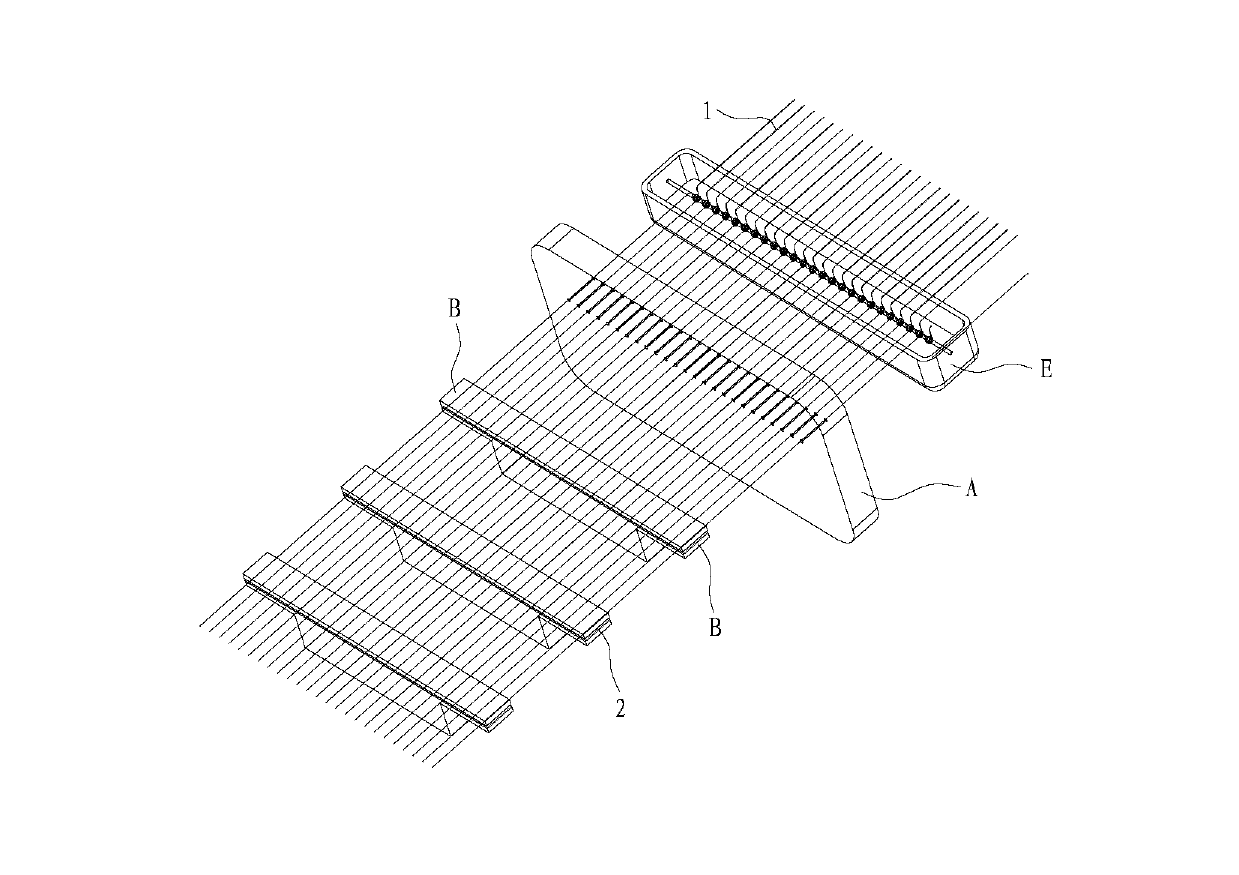

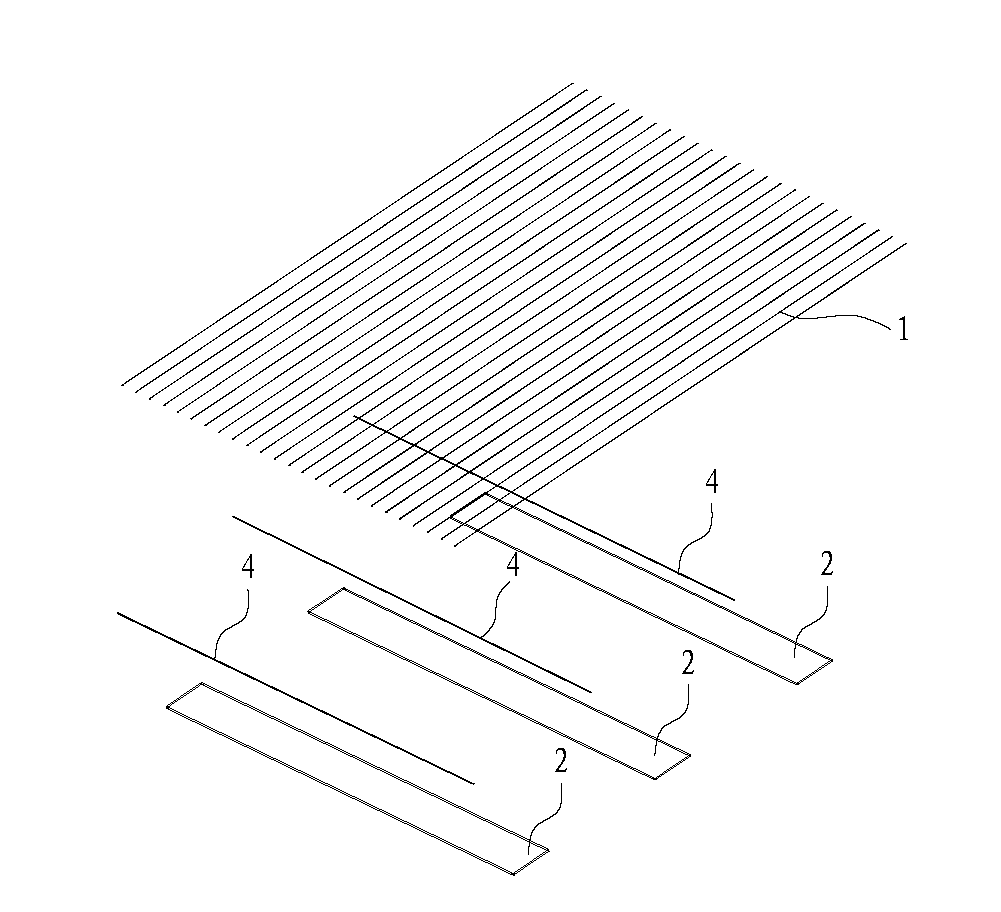

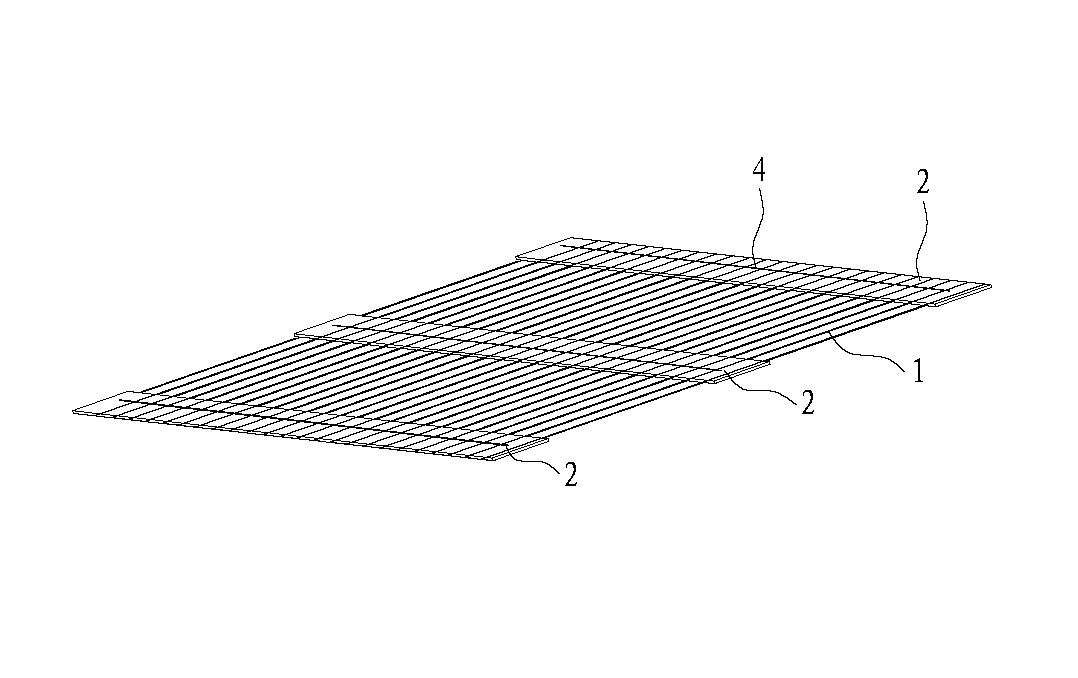

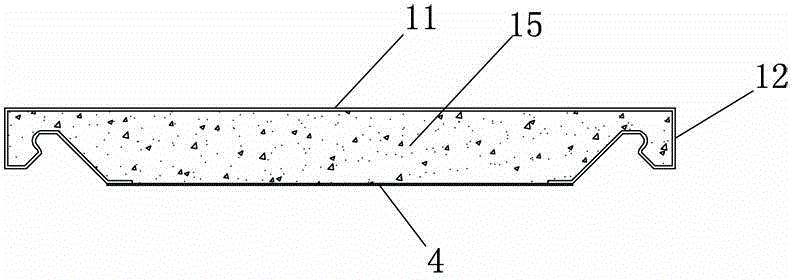

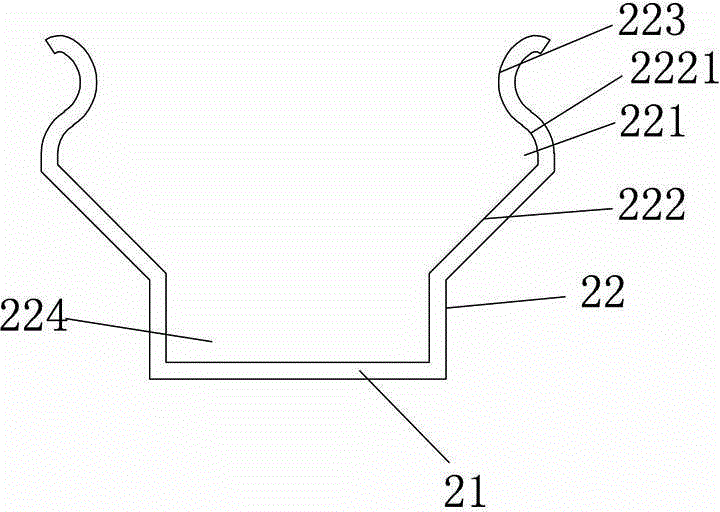

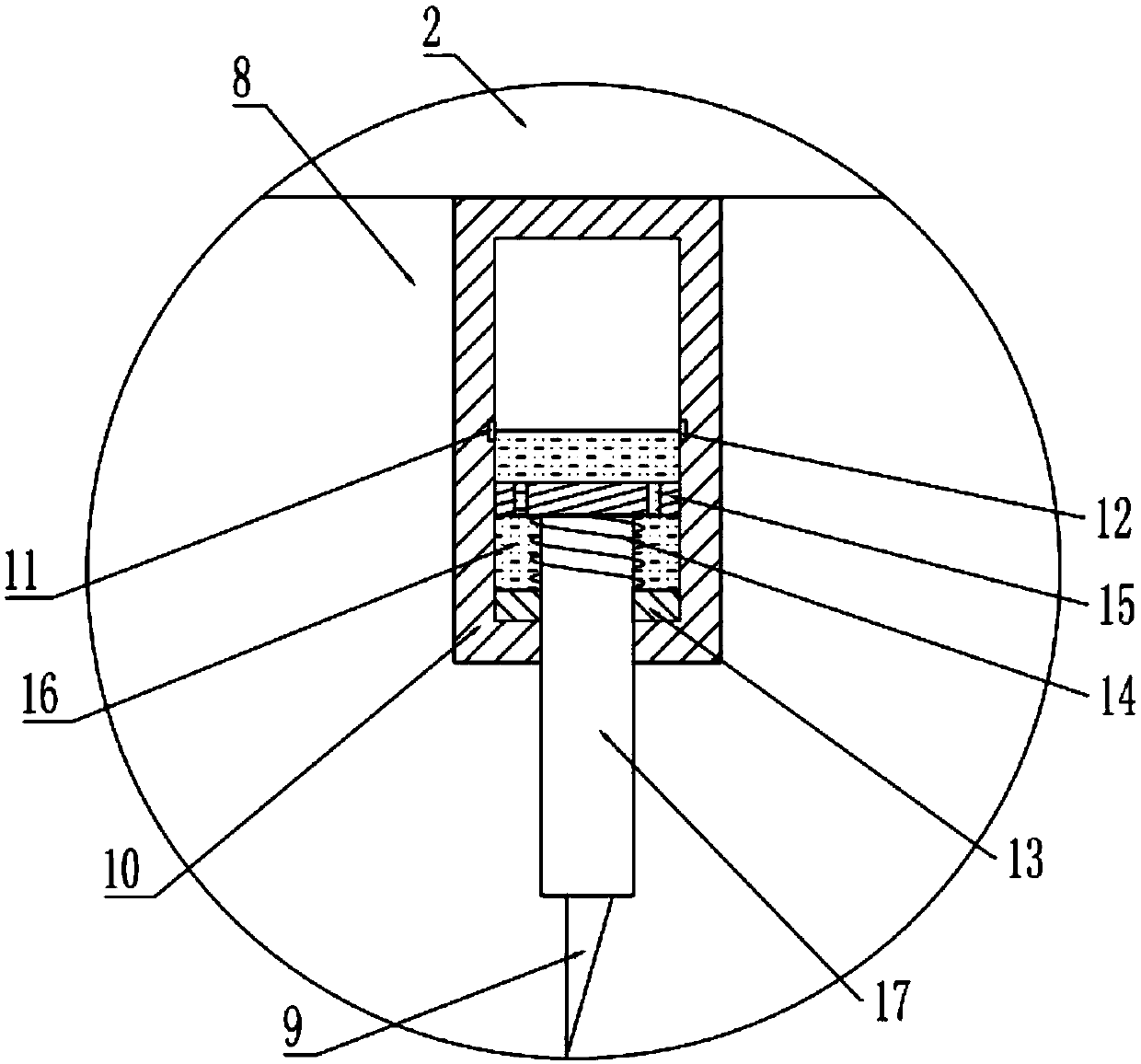

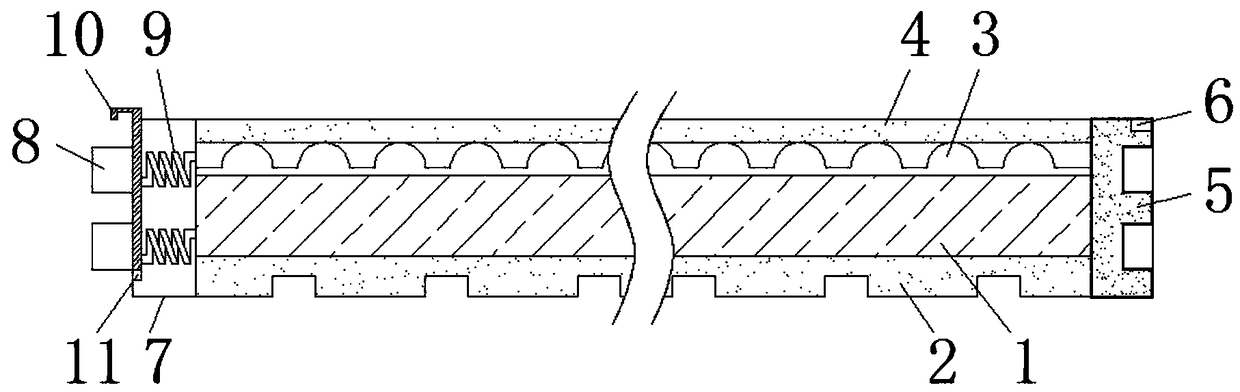

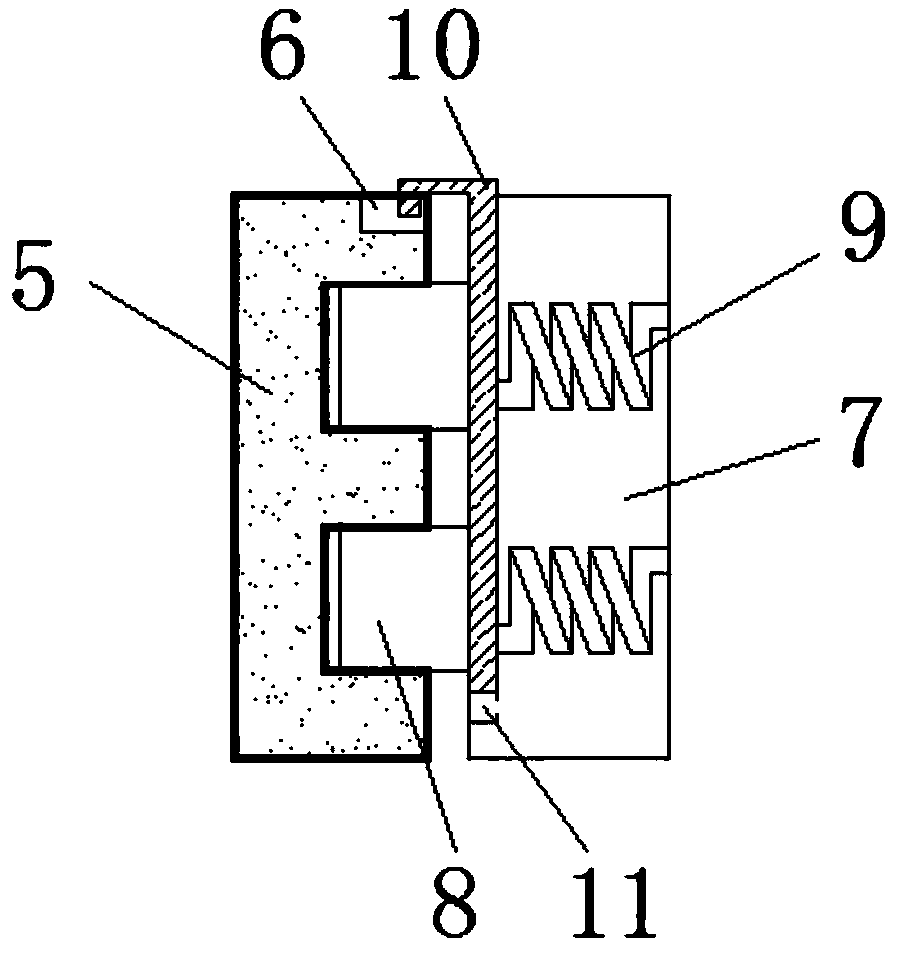

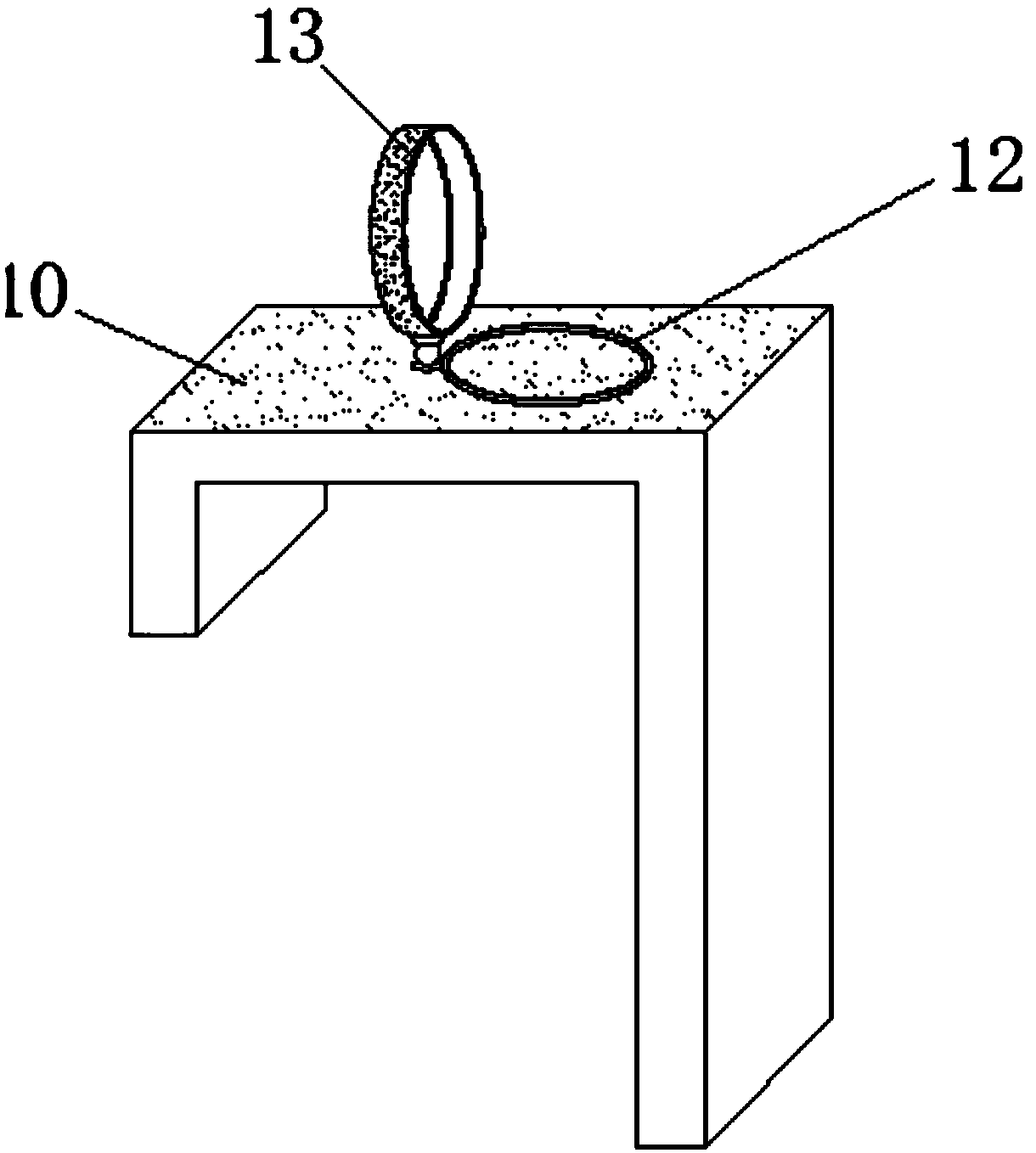

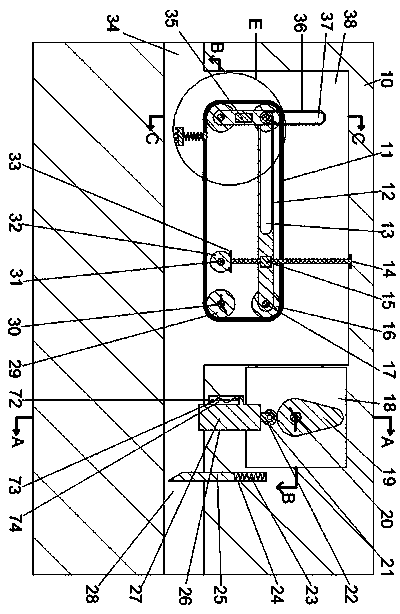

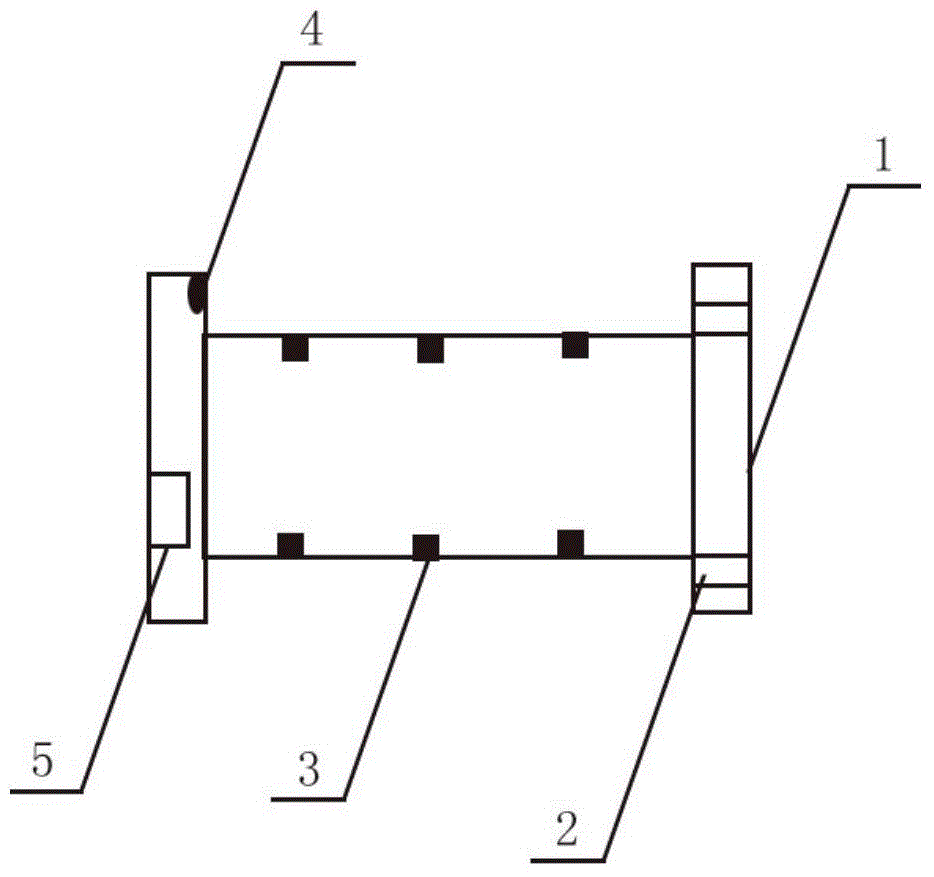

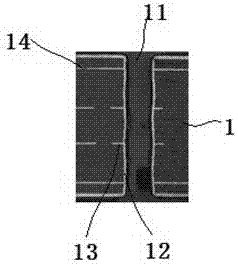

Aluminum template system for building

InactiveCN103276891AImprove turnover rateReduce construction costsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksUtilization rateBuilding construction

The invention belongs to the technical field of building construction and particularly discloses an aluminum template system for building. The system comprises wall boards, floor boards and supporting structures used for supporting the floor boards. The wall boards comprise inner wall boards and outer wall boards. The supporting structures comprise support columns, end beams and top head sleeves rotating at the top ends of the support columns and connected with the end beams. Quick locking and connection of adjacent templates are achieved through a bolt locking structure. Corner templates are arranged at the corner positions among the boards. Matching splicing of standard templates and non-standard templates is adopted in the system to form a building floor, then concrete is poured conveniently and quickly, the supporting structures adopt the mode that the end beams are separated from the support columns, the wall boards can be disassembled 12 hours after the concrete is poured, the floor boards and the end beams can be disassembled after 35 hours, template utilization rate is improved, the standard degree is high, construction cost is reduced, construction efficiency is improved, and the requirement for modern construction can be met.

Owner:GUANGDONG TAIAO SPECIAL ALUMINUM

Rigidity enhanced, modified dedicated material of plastic pipe material

This invention relates to a specific modification material for increasing the rigidity of plastic pipes. The specific modification material is composed of: ultra-fine talcum powder 20-30 parts, toughening agent 10-15 parts, coupling agent 1-2 parts, plasticizer 5-8 parts, dispersant 3-5 parts, and high density polyethylene (HDPE) 50-55 parts. Plastic pipes modified with the specific modification material have rigidity 5-6% higher than that of neat HDPE pipes, thus can solve the problems of easy deformation, large influence to ground smoothness and easy breakage of HDPE pipes. Besides, plastic pipes modified with the specific modification material have improved impact strength and physical properties. Talcum powder can partly replace synthetic resin to reduce the cost.

Owner:辽宁艾海滑石有限公司

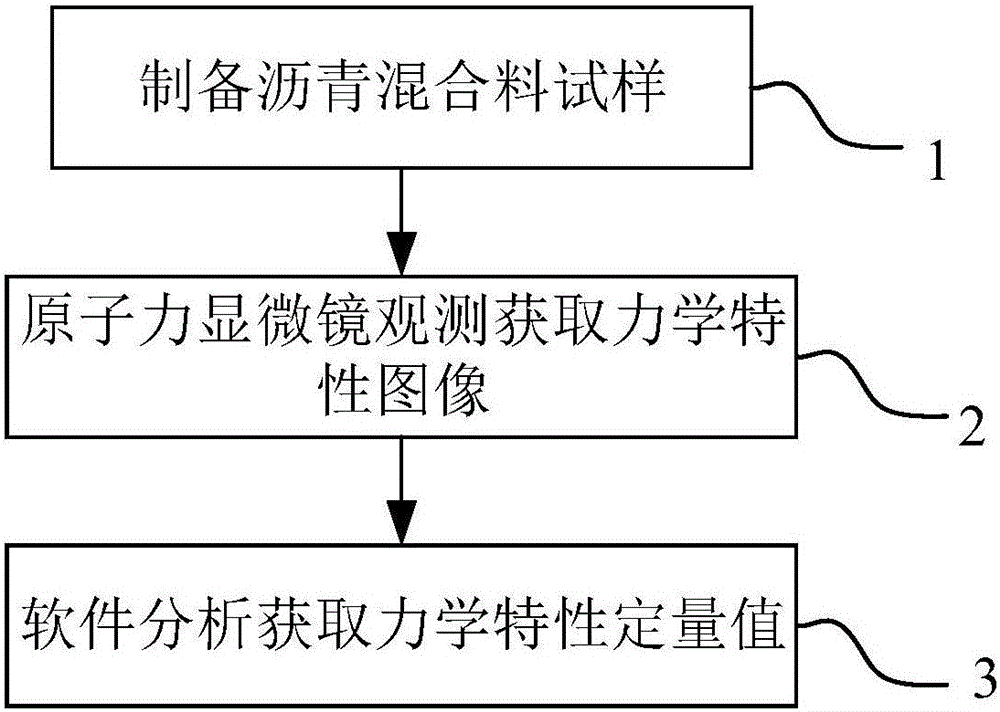

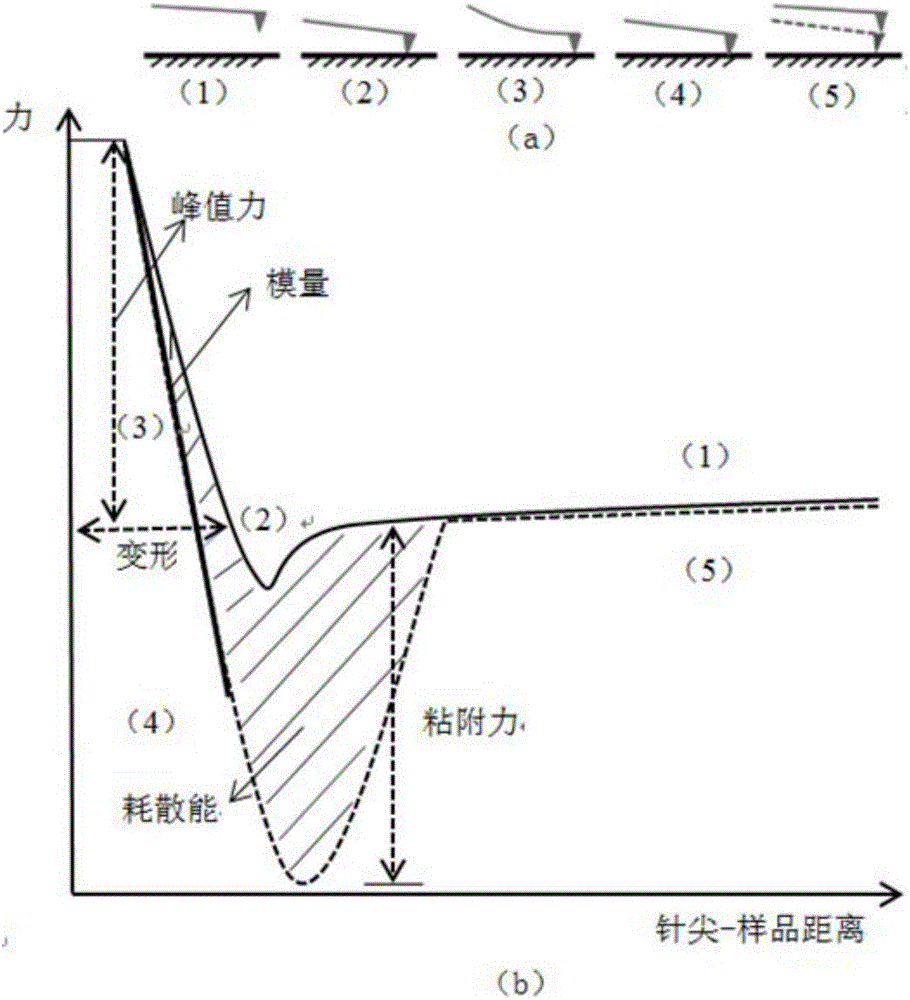

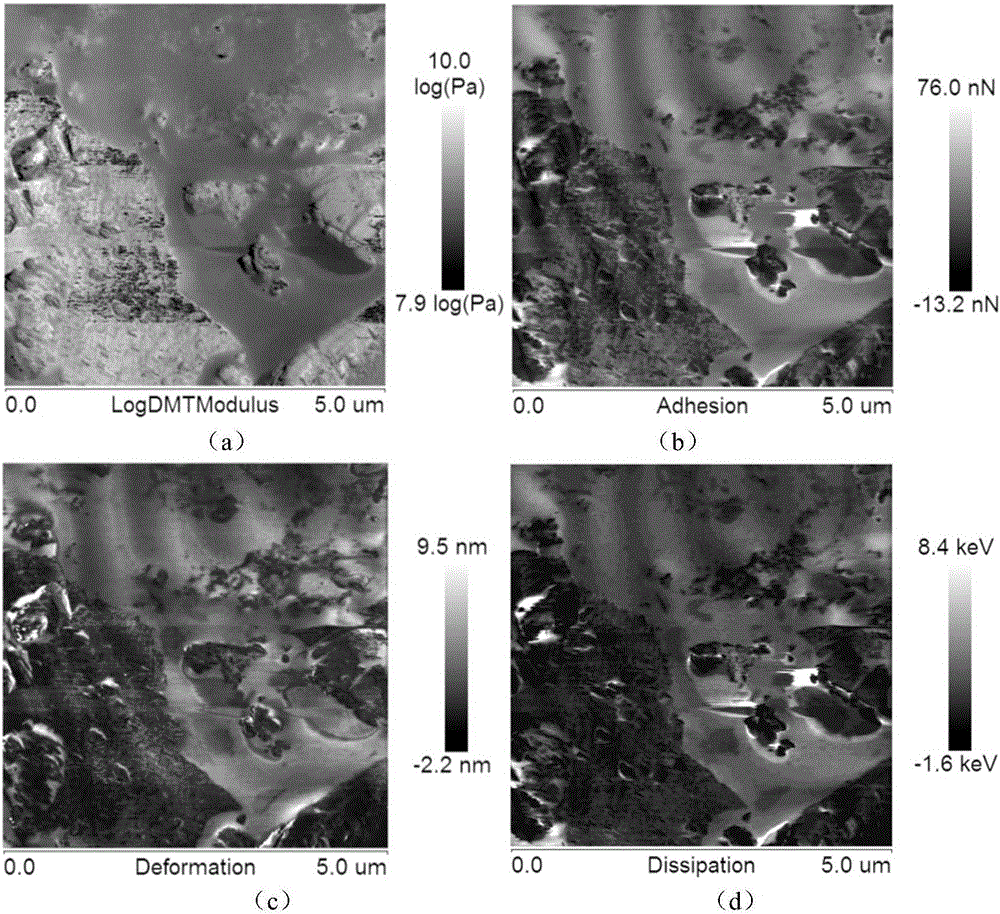

Mechanical characteristic researching method of asphalt mixture based on atomic force microscopic technology

ActiveCN106248998ASample quality is goodImage of good mechanical propertiesScanning probe microscopyMicro nanoMechanical property

The invention relates to a mechanical characteristic researching method of an asphalt mixture based on an atomic force microscopic technology. The method comprises the following steps that (1) a freezing low-temperature cutting method is used to prepare an asphalt mixture sample; (2) an AFM-QNM nano-scale mechanical property quantification module of an atomic force microscope is used to observe the asphalt mixture sample, mechanical characteristic images, including a modulus characteristic image, an anchoring strength characteristic image, a dissipation energy characteristic image and a deflection characteristic image, of the asphalt mixture sample are obtained; and (3) Nanoscope Analysis software is used analyze the mechanical characteristic images quantitatively, and the modulus value, anchoring strength value, dissipation energy value and deflection value of a component to be researched are obtained. The method provided by the invention is simple and easy to operate, and on the premise that different components of the mixture are not separated, the mechanical characteristic of the micro nano-scale of certain component can be measured directly, and basis is provided for in-situ discrimination of asphalt performance.

Owner:TONGJI UNIV

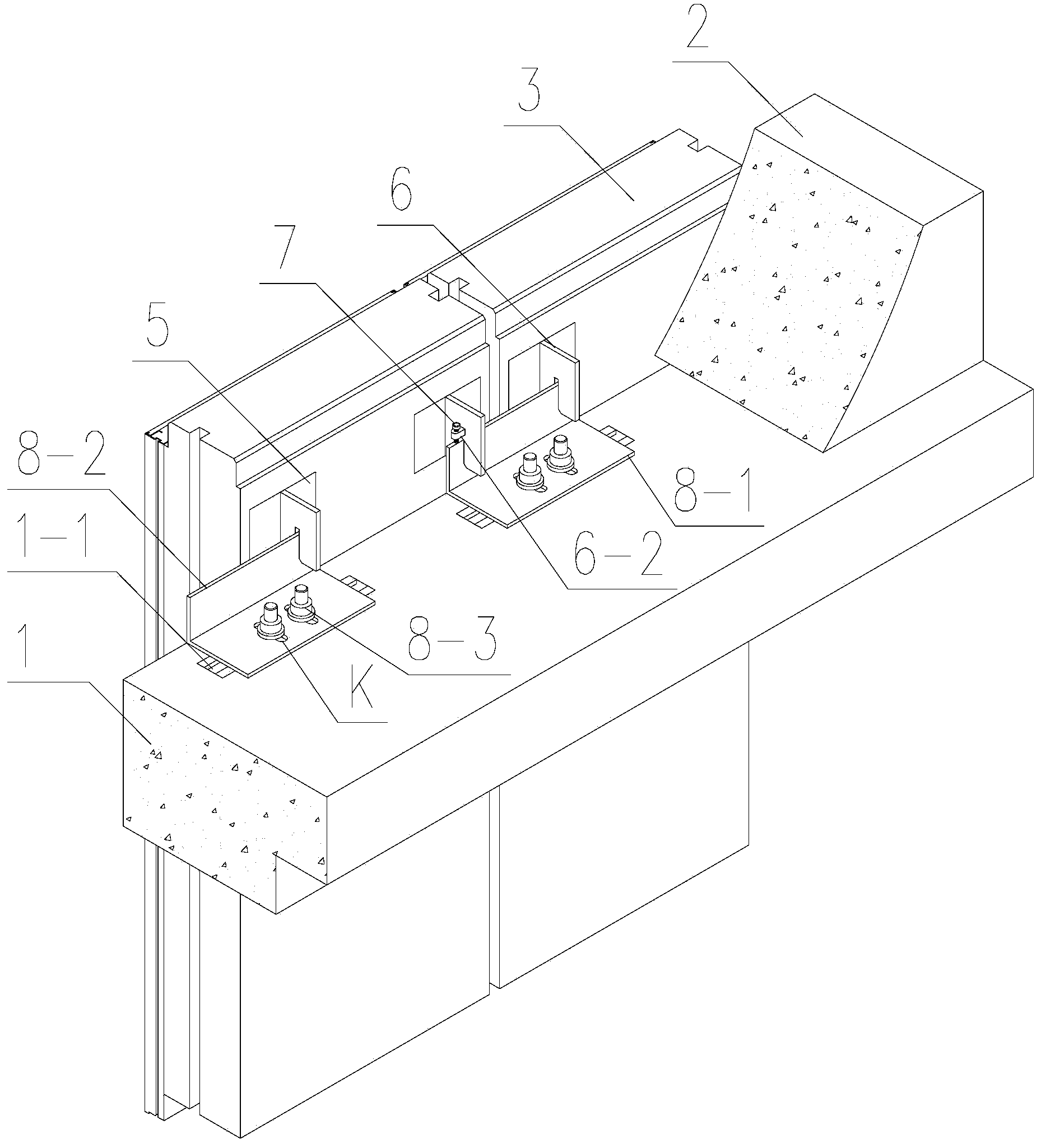

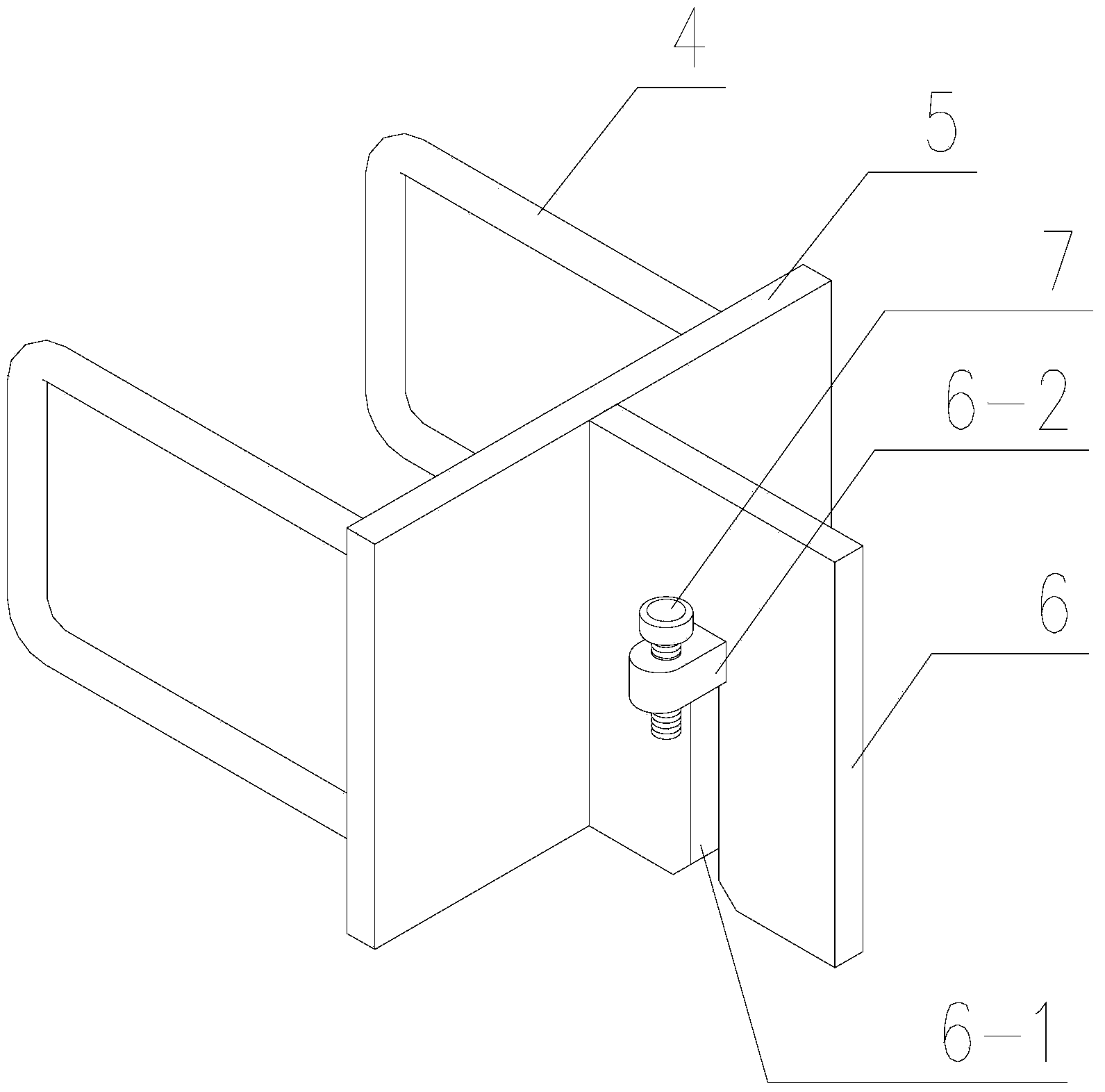

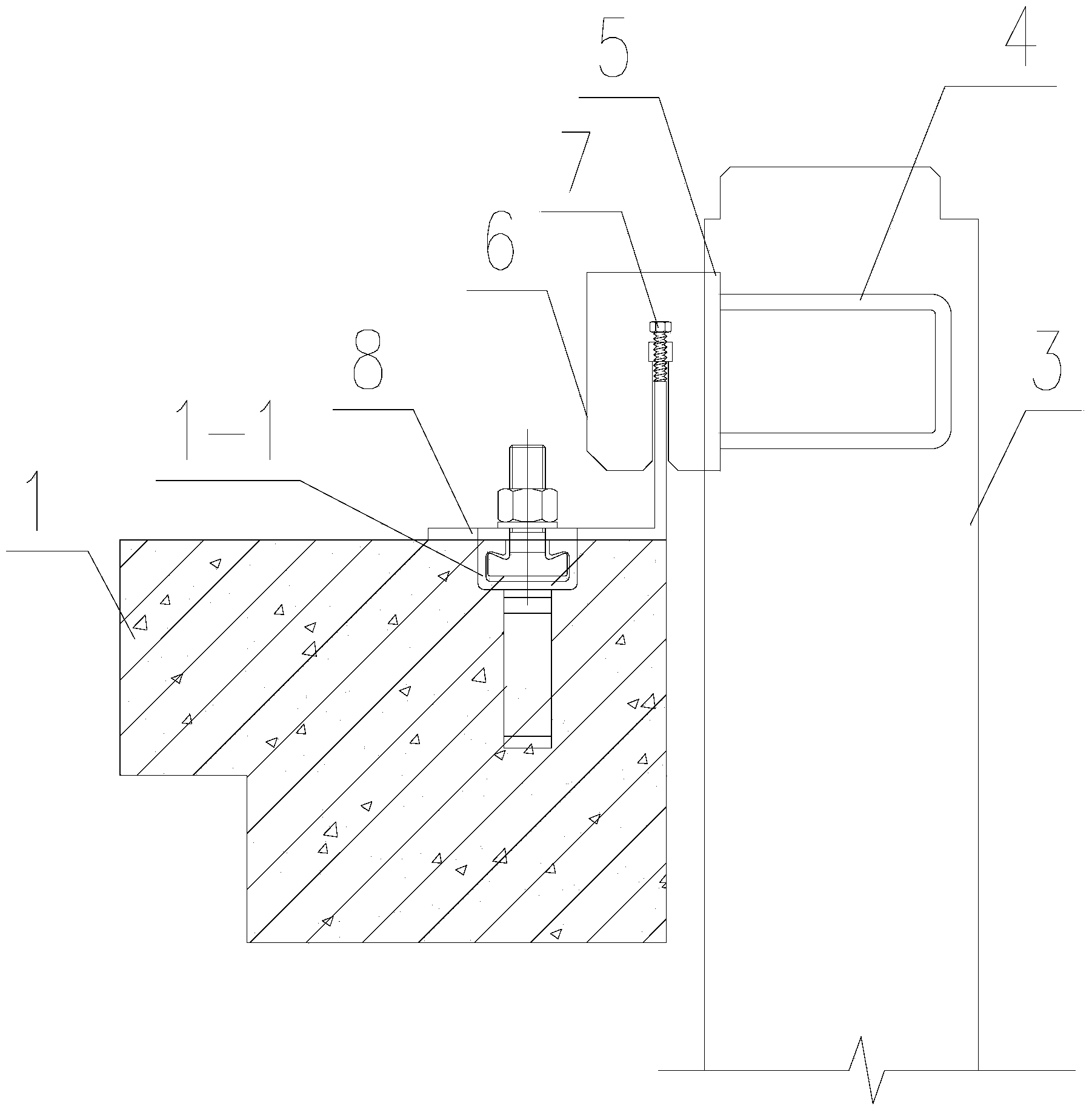

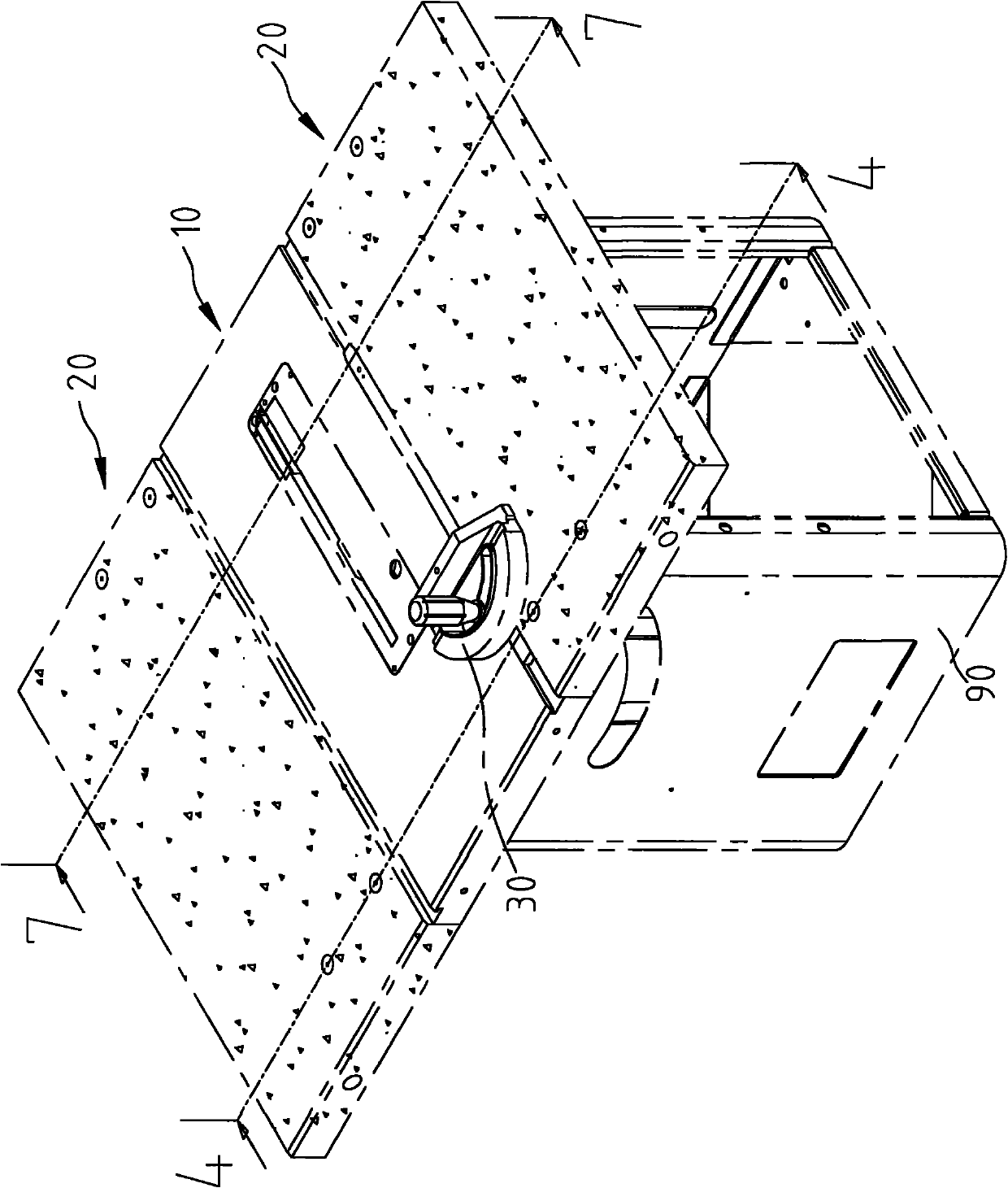

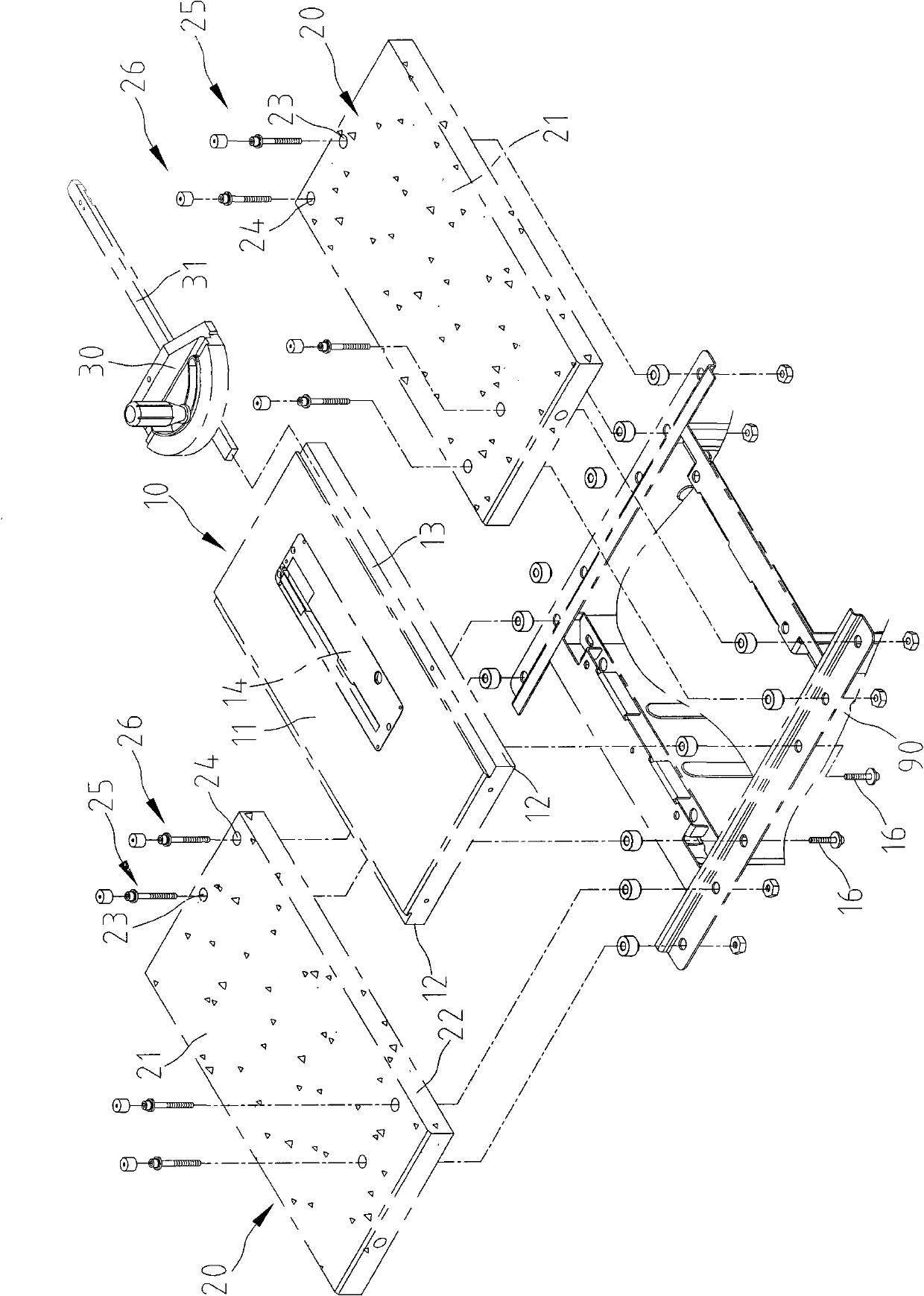

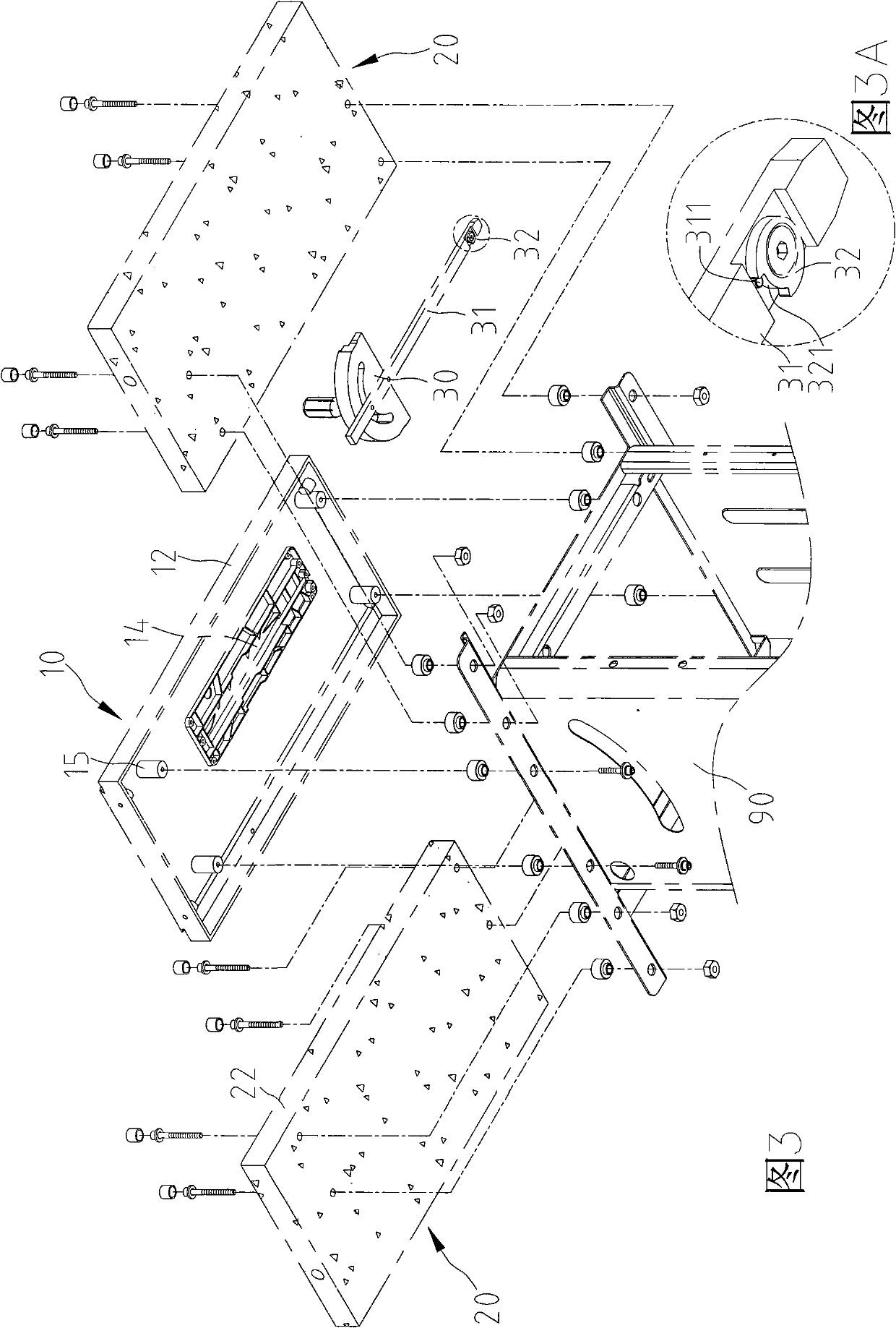

Three-dimensional adjustable mounting connecting structure of assembled wallboard and laminated beam

InactiveCN103953119APrecise flatness controlReduce the amount of aerial workBuilding constructionsBeam switchingWall plate

The invention discloses a three-dimensional adjustable mounting connecting structure of an assembled wallboard and laminated beam, and belongs to the field of assembled building connection structures. The mounting connecting structure comprises the laminated beam, the wallboard, a wallboard embedded connecting component and a wall beam switching member, wherein the beam switching member is provided with horizontal connecting surfaces of long-strip elliptical holes, and is correspondingly connected with embedded C-shaped steel chutes of a lower precast beam below the laminated beam through bolts; the wall beam switching member is moved, adjusted and fastened in the directions of a longitudinal beam and a beam relative to the lower precast beam; a vertical suspension socket of a connecting plate of the wallboard embedded connecting component is correspondingly spliced with a vertical connecting surface of the wall beam switching member, advancing and retracting of an adjusting bolt at the upper end of the vertical suspension socket of the connecting plate is screwed, and the wallboard is adjusted to be moved and fastened in the vertical direction relative to the lower precast beam, therefore, three-dimensional adjustable fastening and mounting of the assembled wallboard and laminated beam are realized. The overall mounting structure of the invention is simple in structure and accurate in controlling the wallboard flatness, and obviously improves the mounting and construction efficiency and the construction quality.

Owner:HUBEI HONGYI STEEL CONSTR ENG

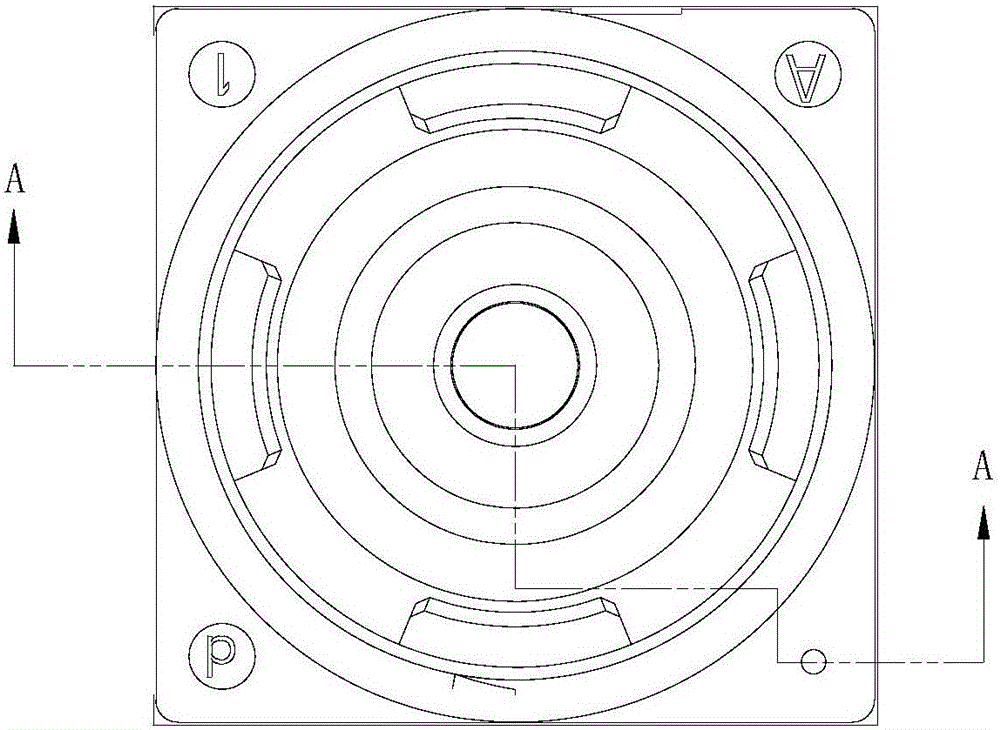

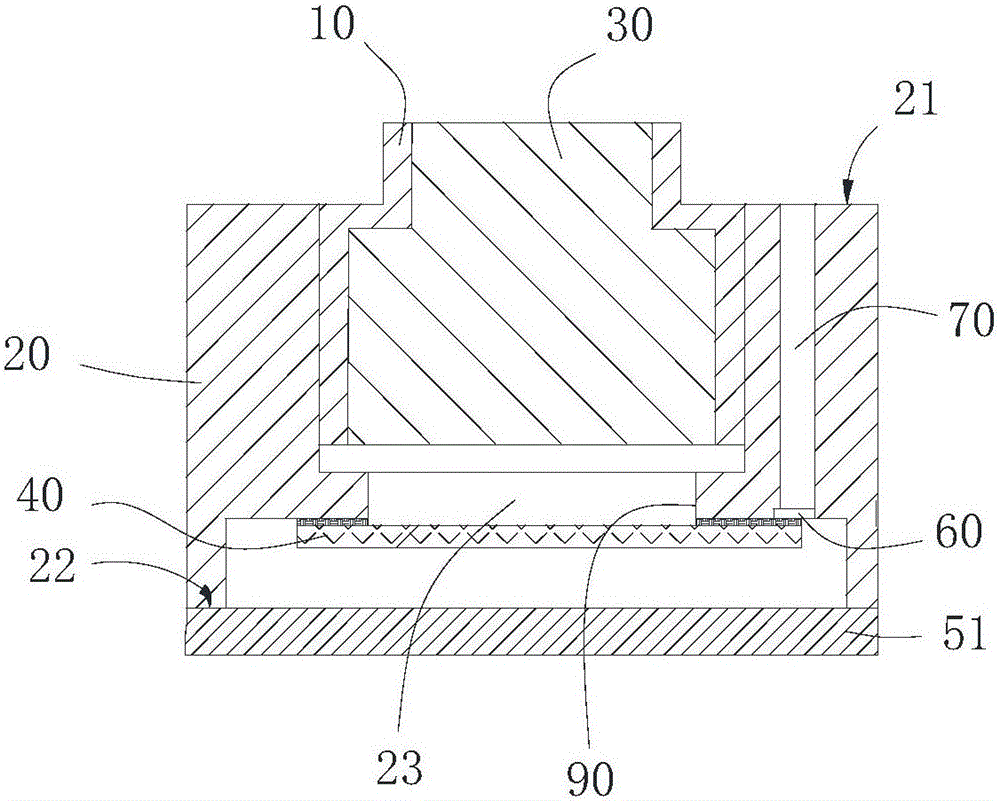

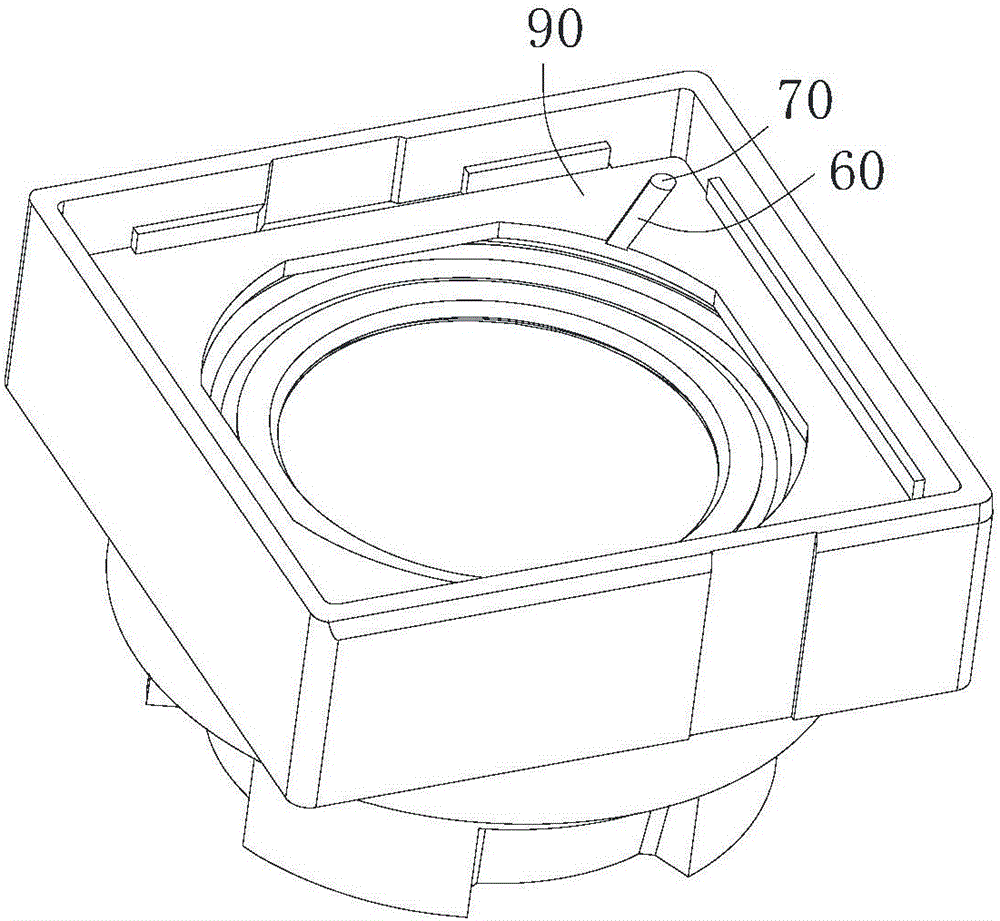

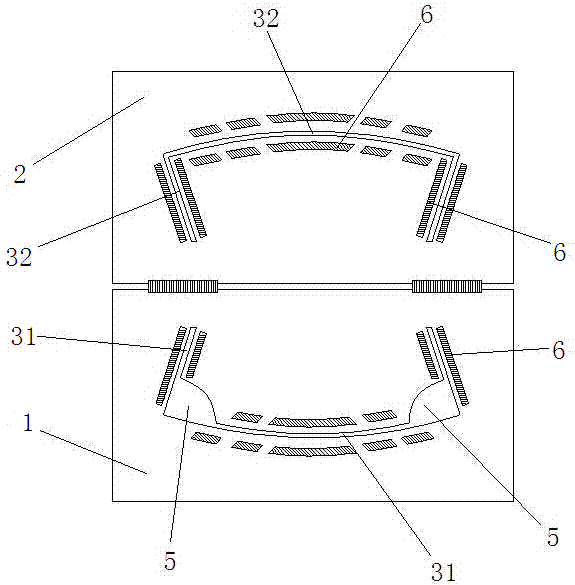

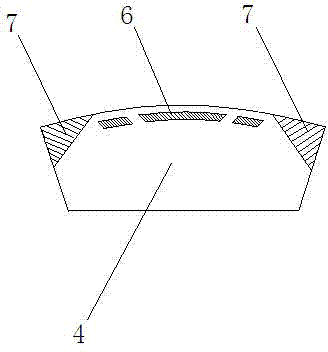

Camera module group

Disclosed in the invention is a camera module group comprising a lens barrel, a lens seat, a lens piece group, and a light filter. The lens seat has an upper surface, a lower surface, and an inner cavity penetrating the upper surface and the lower surface. One part of or the whole lens barrel is accommodated into the lens seat; and the lens barrel and the lens seat form an integrated structure. The lens piece group is accommodated into the lens barrel. The lens seat includes a boss that is arranged at the inner wall of the lens seat in a protruding mode and is located between the lens barrel and the lower surface. The light filter is fixed at the bottom of the boss; and an air discharge duct is formed in the bottom of the boss. An exhaust vent is formed in the lens seat and extends to the upper surface of the lens seat from the bottom of the boss. The air discharge duct and the exhaust vent are communicated with each other; and with the air discharge duct and the exhaust vent, the inner cavity and the external space of the lens seat are communicated. Therefore, gas caused by heating solidification glue can be exhausted outside of the camera module group timely, thereby avoiding the influence on the smoothness among all electronic elements of the camera module group. Besides, the lens barrel and the lens are in an integrated mode, so that a phenomenon that the imaging quality is affected due to chippings generated during the assembling process can be prevented.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

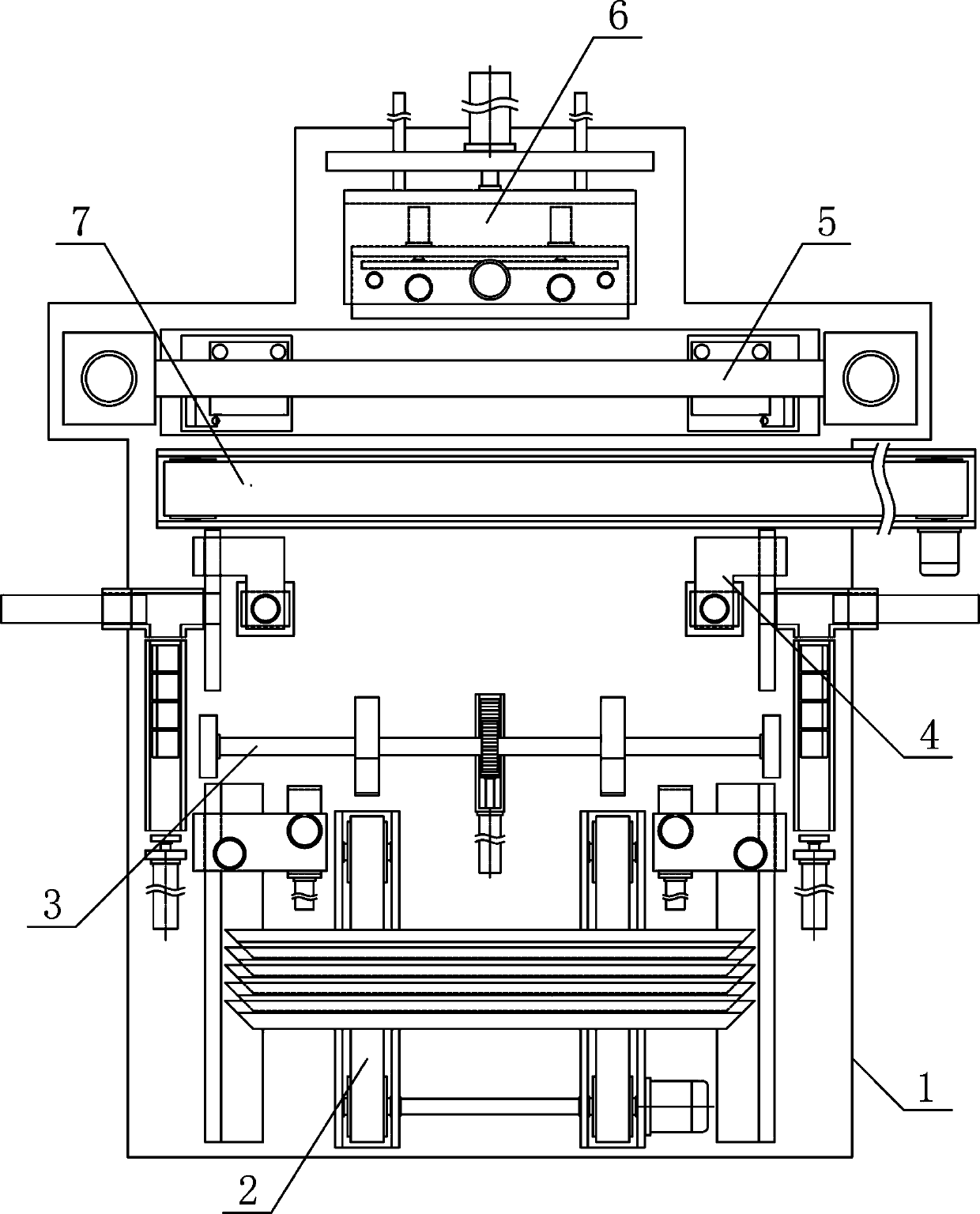

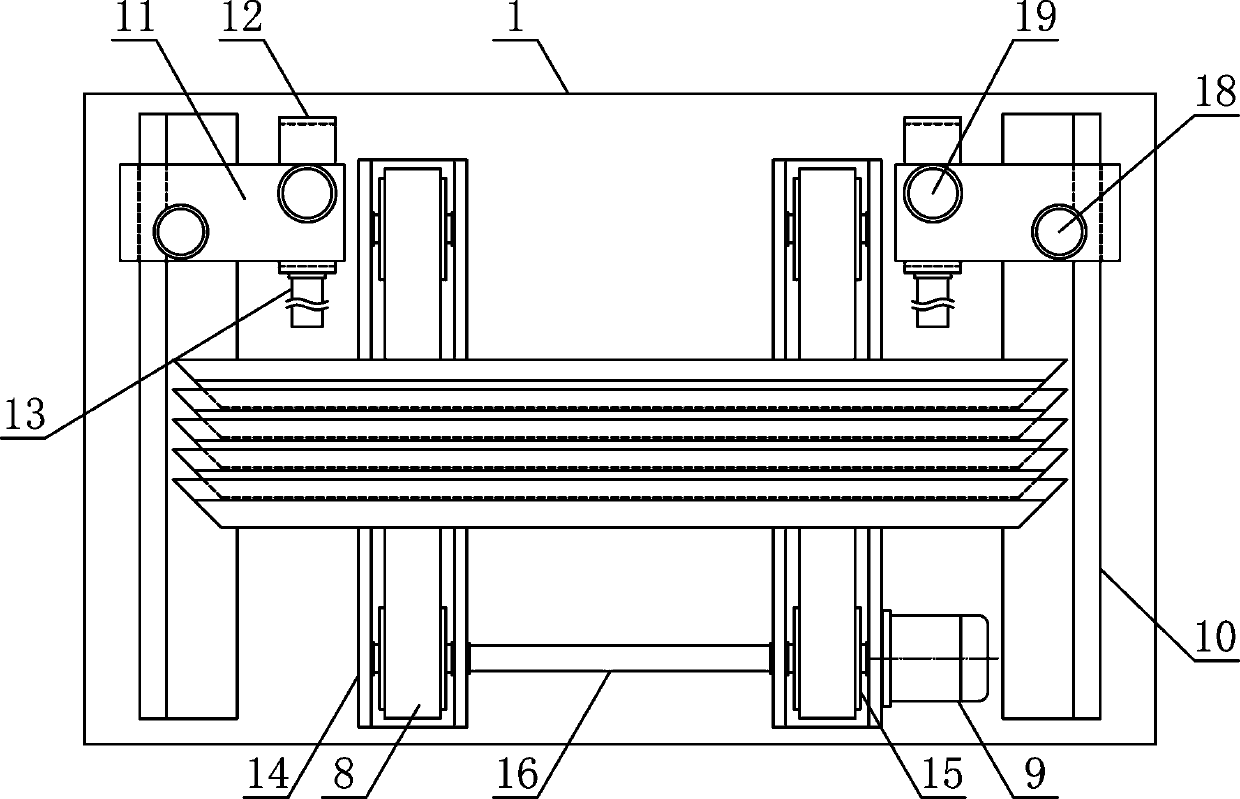

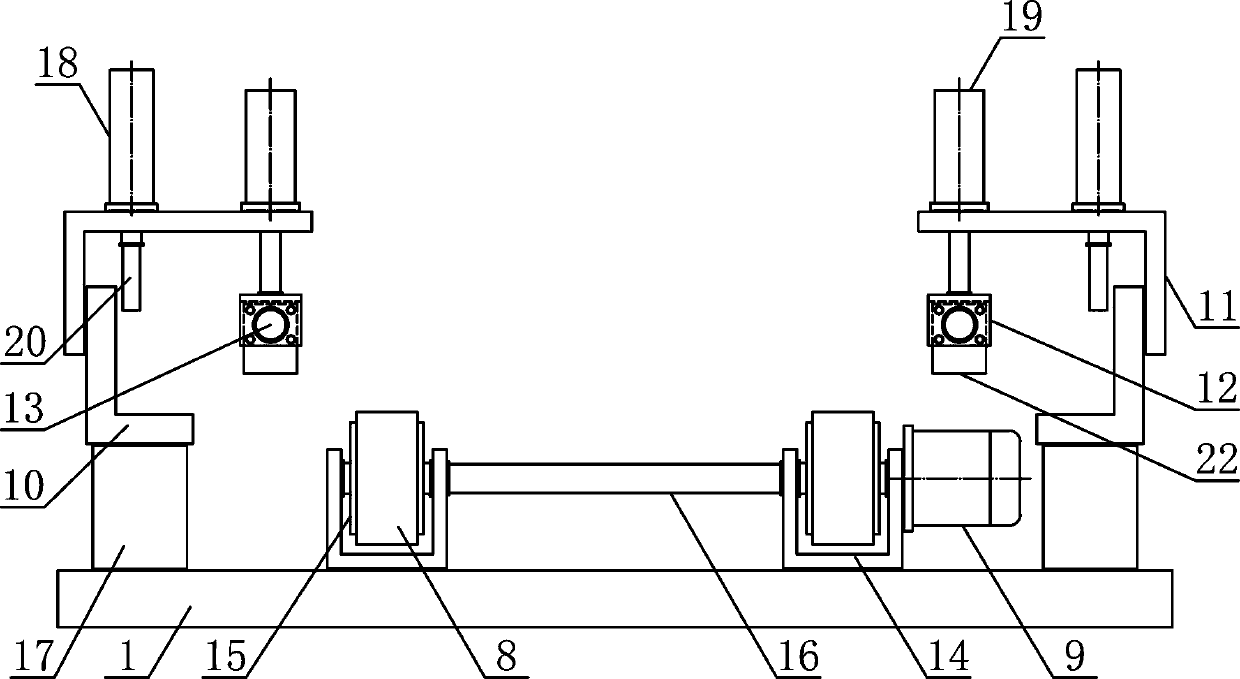

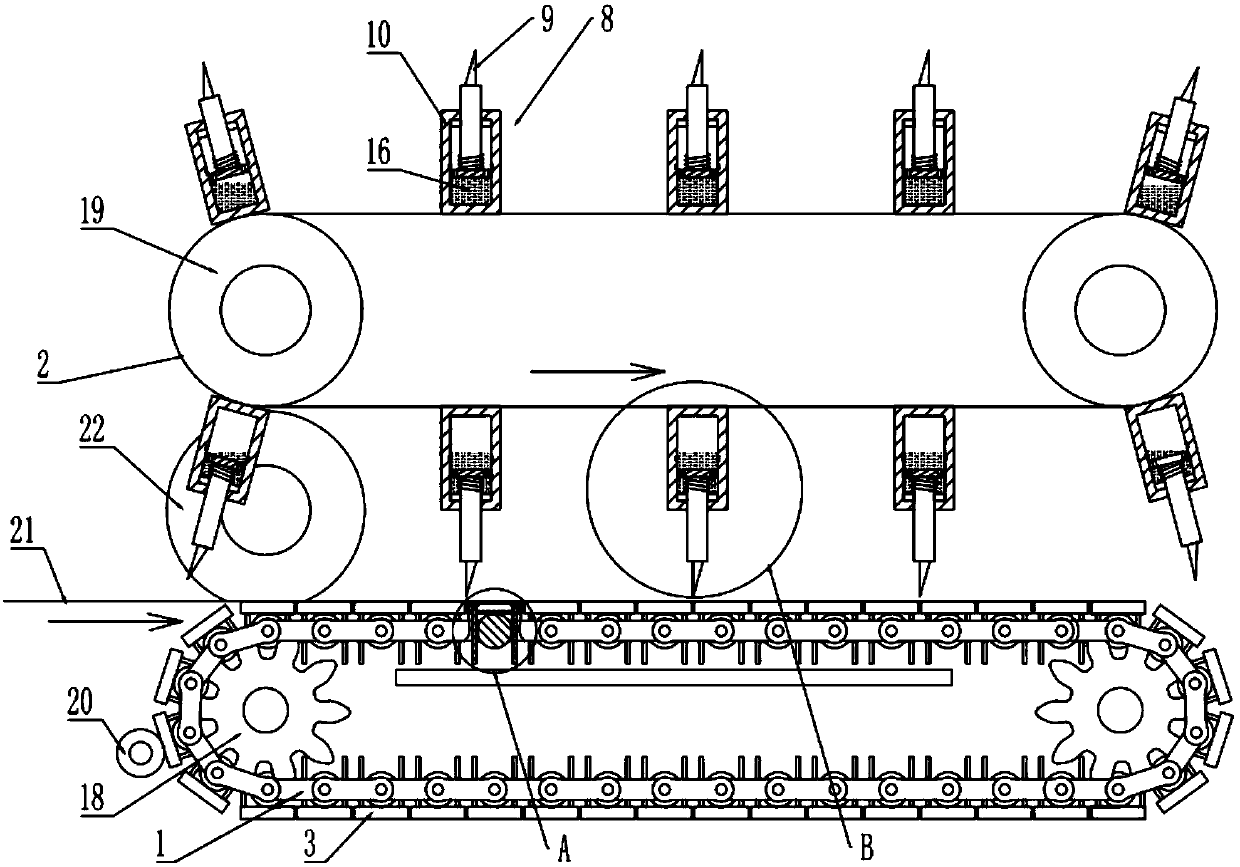

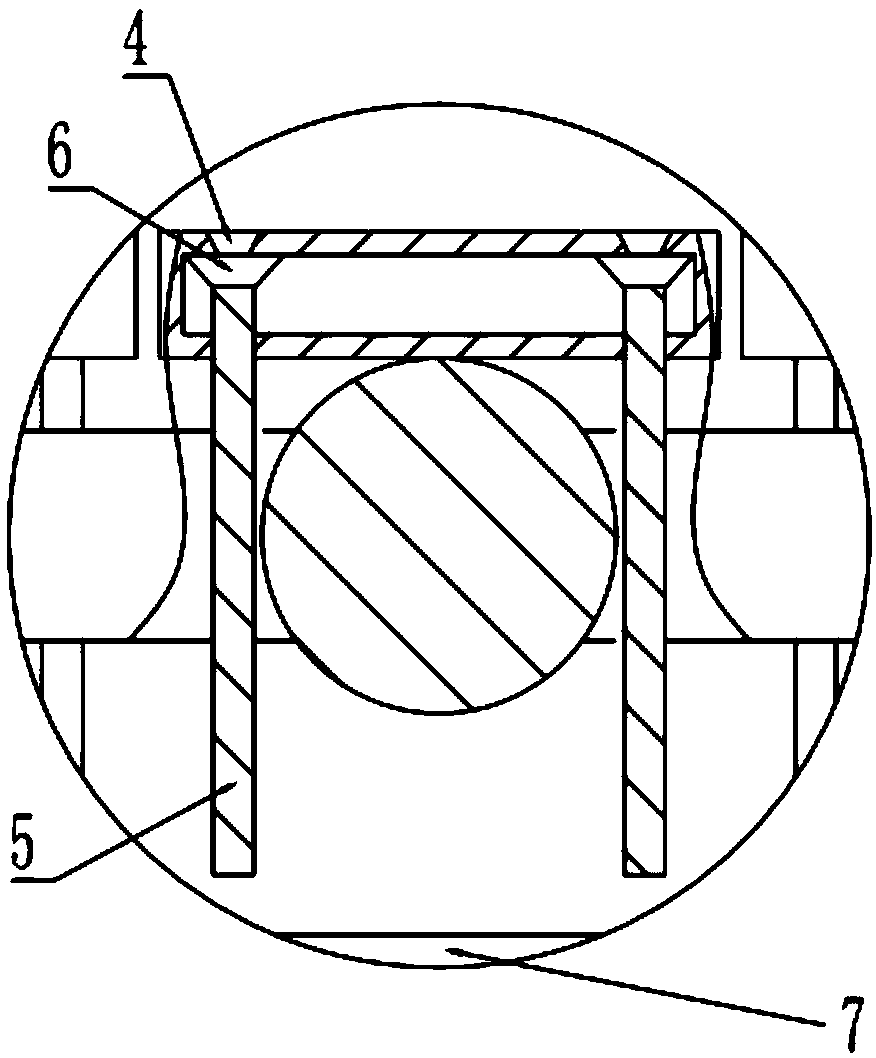

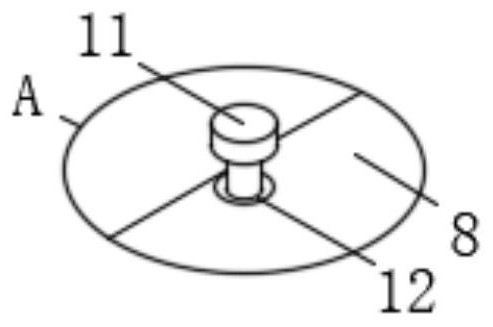

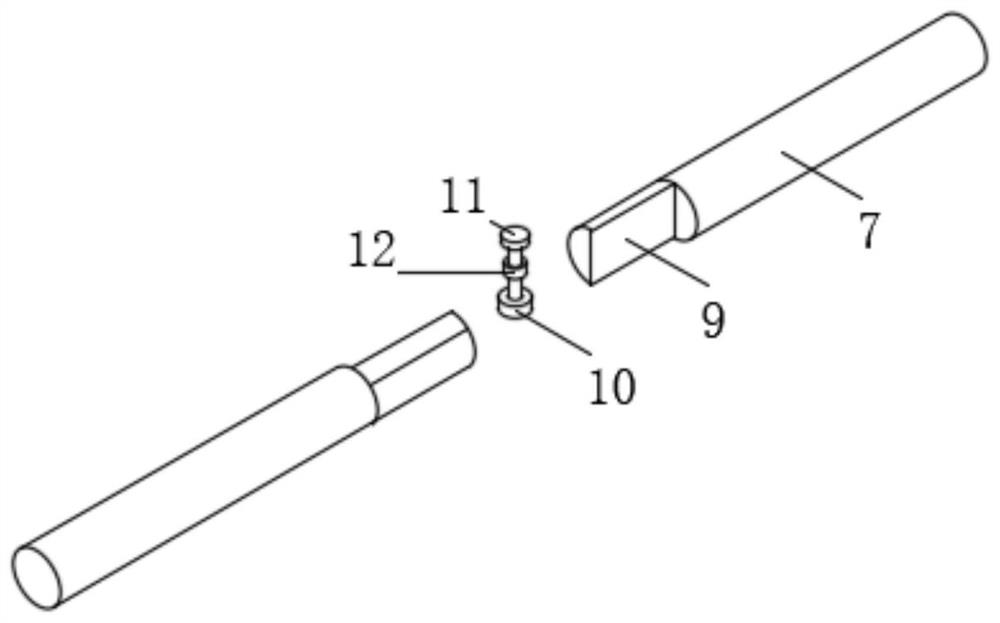

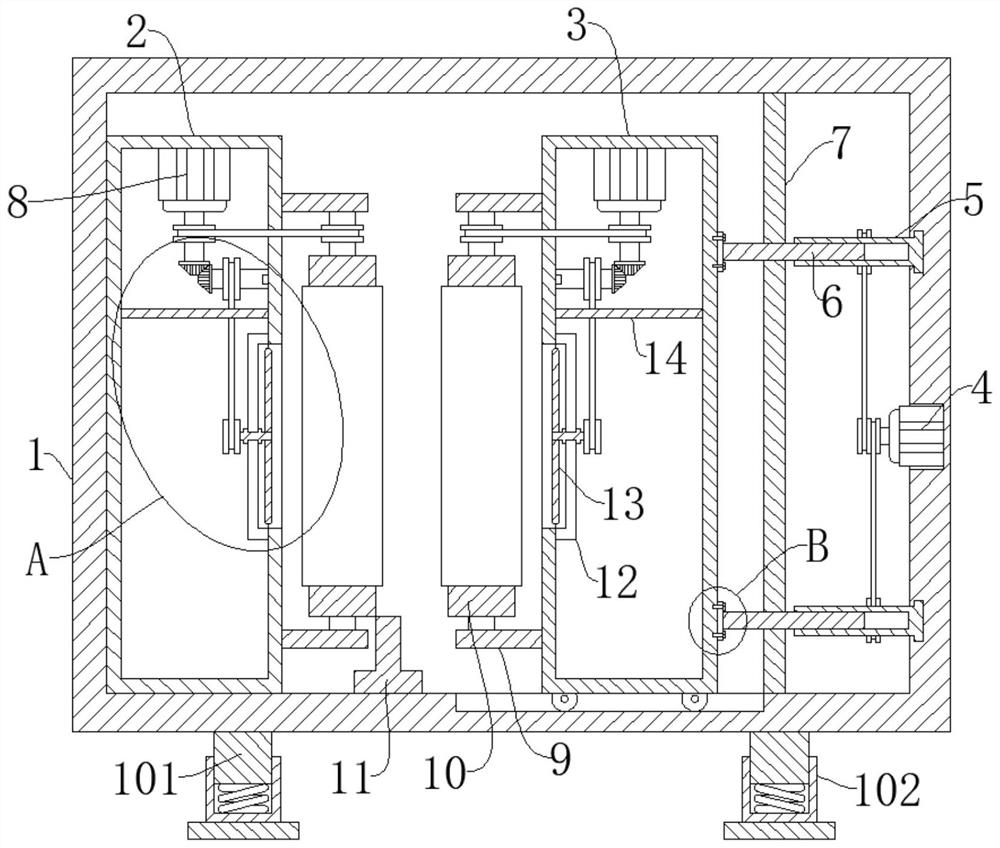

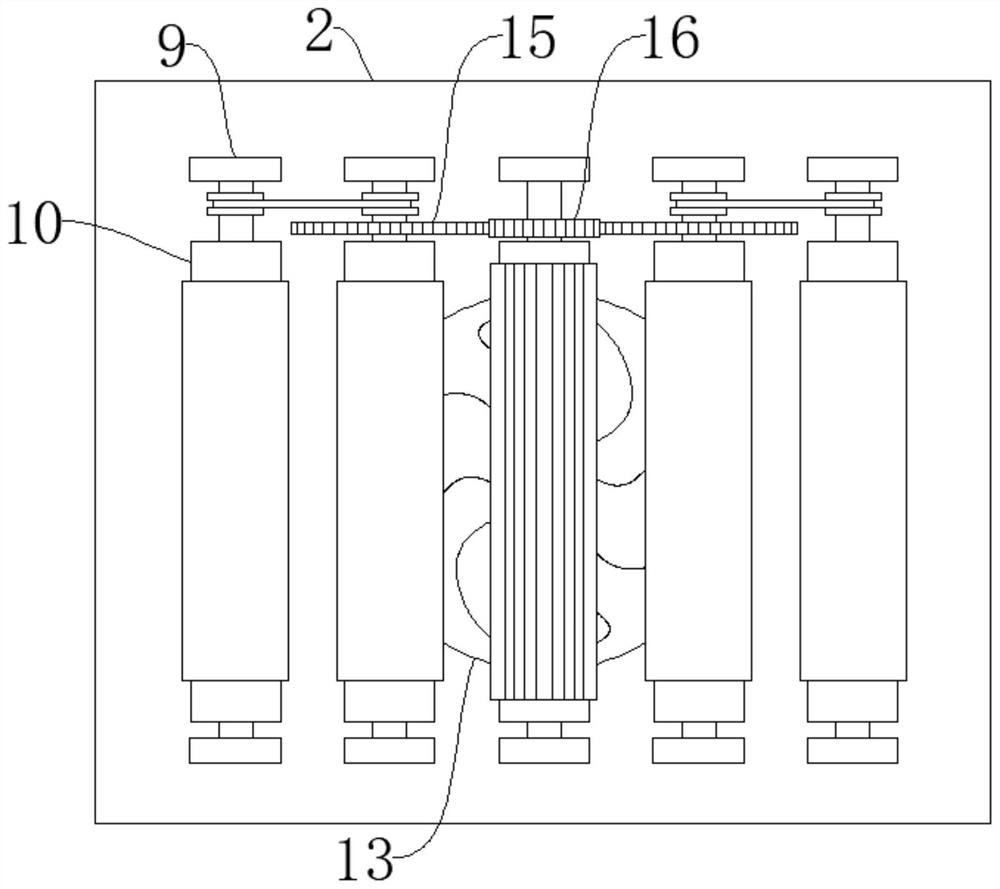

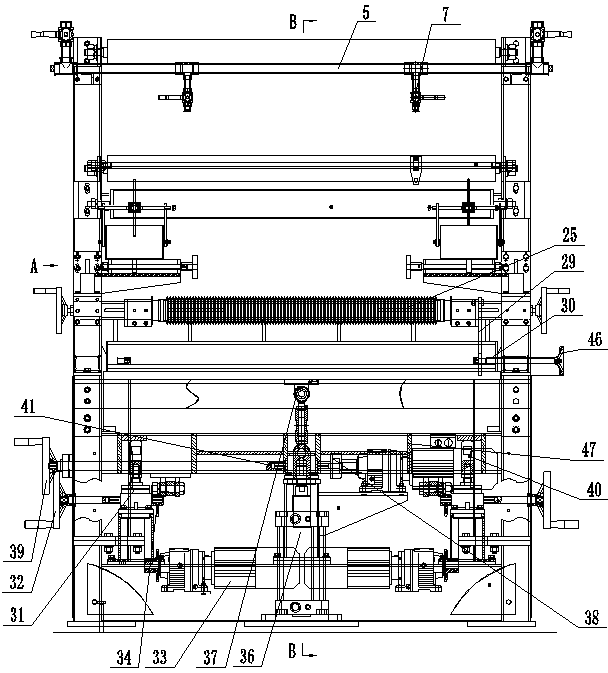

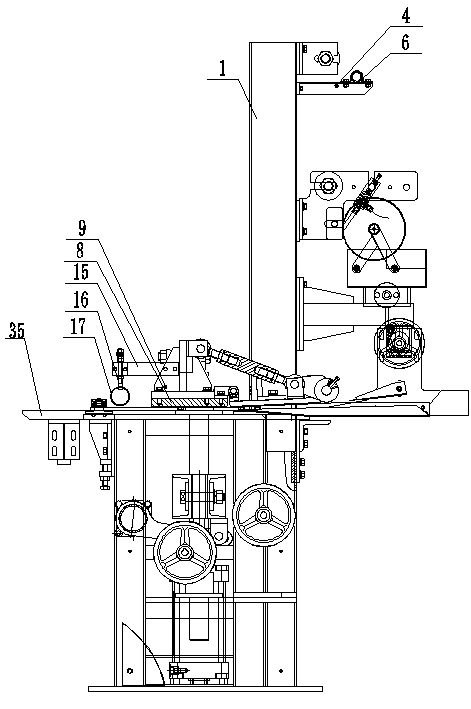

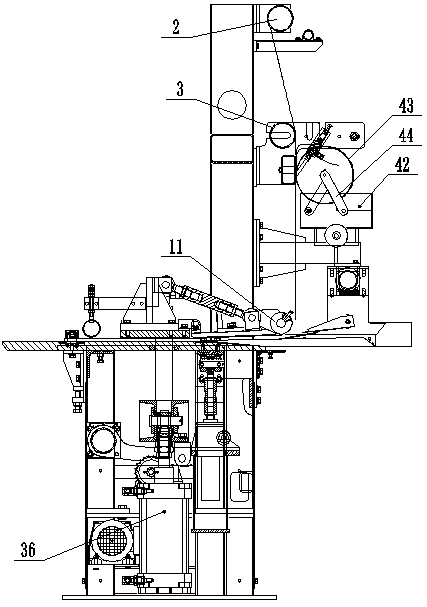

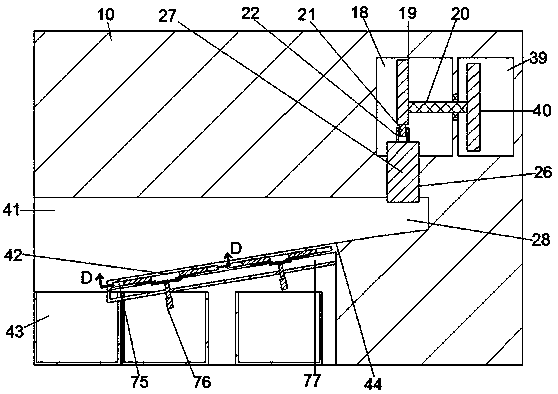

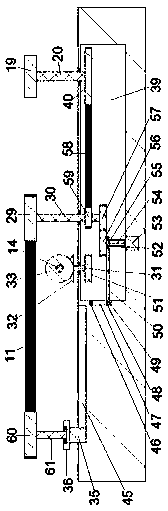

Machining device for solar module frame

ActiveCN111283095ASmooth and precise transmissionGuaranteed normal transmissionMetal-working feeding devicesPhotovoltaicsPunchingEngineering

The invention discloses a machining device for a solar module frame, and belongs to the field of aluminum profile machining mechanical equipment. According to the machining device, a feeding conveyingbelt is horizontally arranged on the upper side of a feeding conveying belt support, and frame bearing supports are horizontally arranged on the two sides of the upper portion of a machining main support correspondingly. Bearing turnover round plates are vertically and fixedly arranged on the two sides of a frame turnover rotary shaft, and the output end of a punching and riveting machining air cylinder is fixedly connected with the upper side of a lifting punching and riveting plate. Multiple punching and riveting pressing nails of conical structures are evenly arranged on the lower side ofa punching and riveting compressing plate. The output end of a frame translation air cylinder is fixedly connected with a frame translation support, and the output end of a lifting adjusting air cylinder is fixedly connected with the middle of the upper side of a frame containing and bearing support. The machining device is reasonable in structural design, corner pressing can be synchronously carried out on the ends of the two sides of the solar module frame fast, accurately, efficiently and stably, continuous and automatic producing and machining of the solar module frame are achieved, and the needs of production use are met.

Owner:ZHEJIANG ZHUOYI ALUMINUM

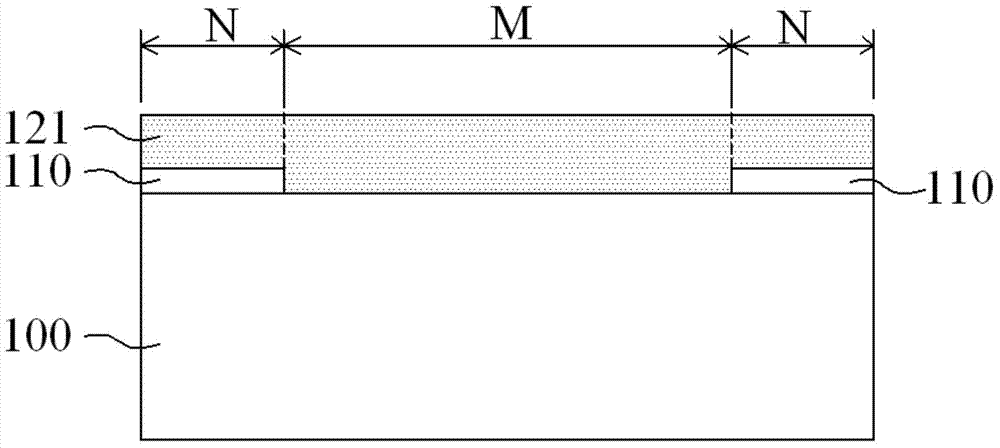

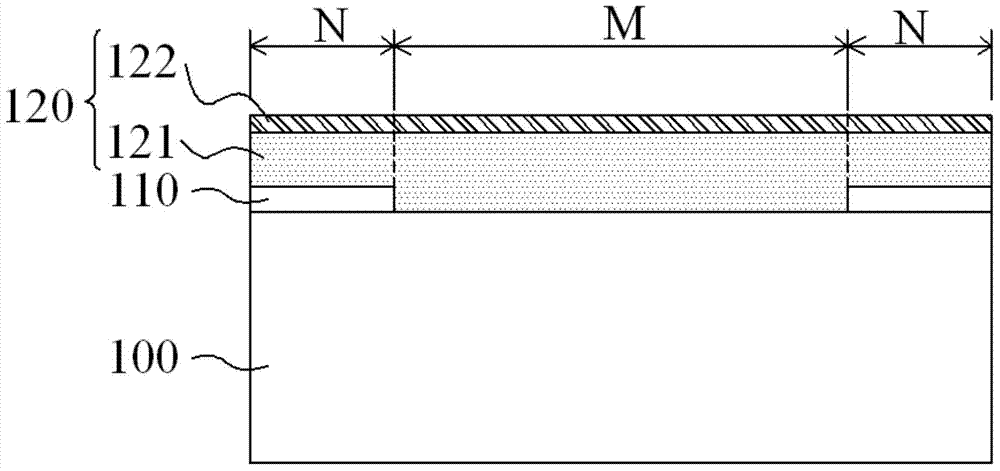

Touch panel

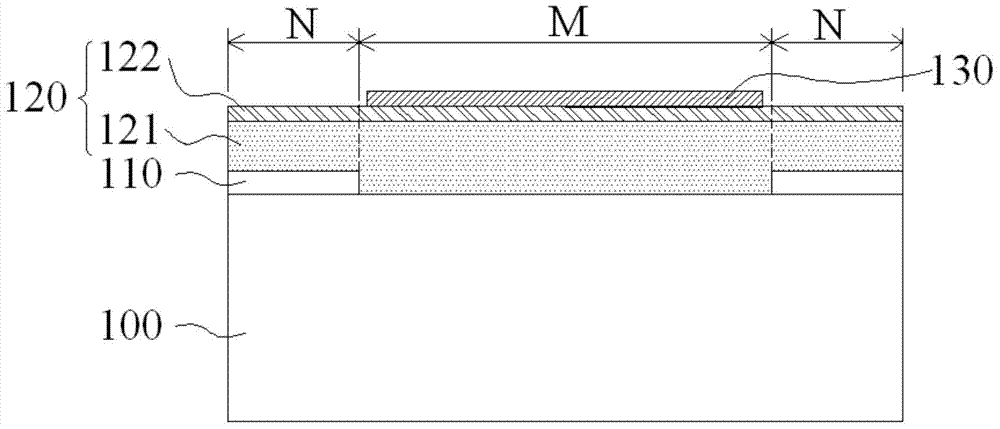

ActiveCN104516577AReduce manufacturing costAffect flatnessLamination ancillary operationsLayered product treatmentEngineeringTouch panel

A touch panel is formed by firstly forming a film layer on a first plate, and next, sequentially forming a buffer layer on the film layer, forming a sensing layer on the buffer layer, forming a second plate on the sensing layer. After the foregoing formation procedures, the first plate is removed from the film layer. Next, a cover is attached to the film layer. In this way, the film layer is located between the cover and the buffer layer. Finally, the second plate is removed from the sensing layer, so as to form a touch panel with the features of light weight, thin thickness and low costs.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Manufacturing method of inflating product pulling piece

The invention discloses a manufacturing method of an inflating product pulling piece. The manufacturing method comprises the following steps of: providing a plurality of wire bodies through a yarn-placing frame, and continuously delivering a flat surface in an interval uniform parallel configuration shape state through a clamping wire fixture; providing a glue groove on the front or rear of the clamping wire fixture, and causing a plurality of wire bodies to pass the glue groove so as to be adhered with a glue; and taking plastic film strips the length of which are matched with the configuration width of the plurality of wire bodies so as to be placed on a stitching mould of fixed equipment, closing the stitching mould of the fixed equipment so as to fixedly connect the plastic film strips and the plurality of wire bodies, wherein the plastic film strips parallelly arranged at intervals in the length direction of the wire bodies and the plurality of wire bodies are fixed together to form a pulling piece material. A glue layer is formed on the outer surface of the wire bodies in the formed pulling piece soft material, and the intensity of the wire bodies is increased so as to have a sizing action; and the soft wire bodies are prevented from being wound and further influencing the flatness of the pulling piece in the next production, the intensity of the pulling piece is further improved, the service life of the pulling piece is prolonged, and the manufacture of the pulling piece is simultaneously more convenient.

Owner:INTEX IND (XIAMEN) CO LTD

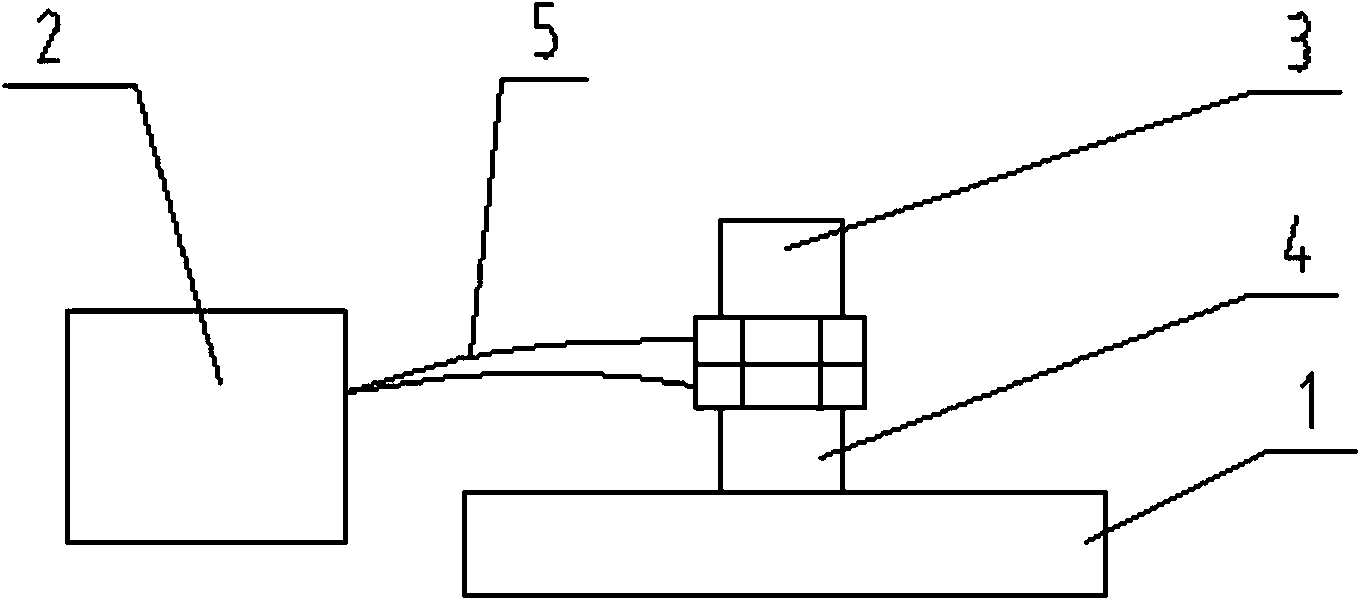

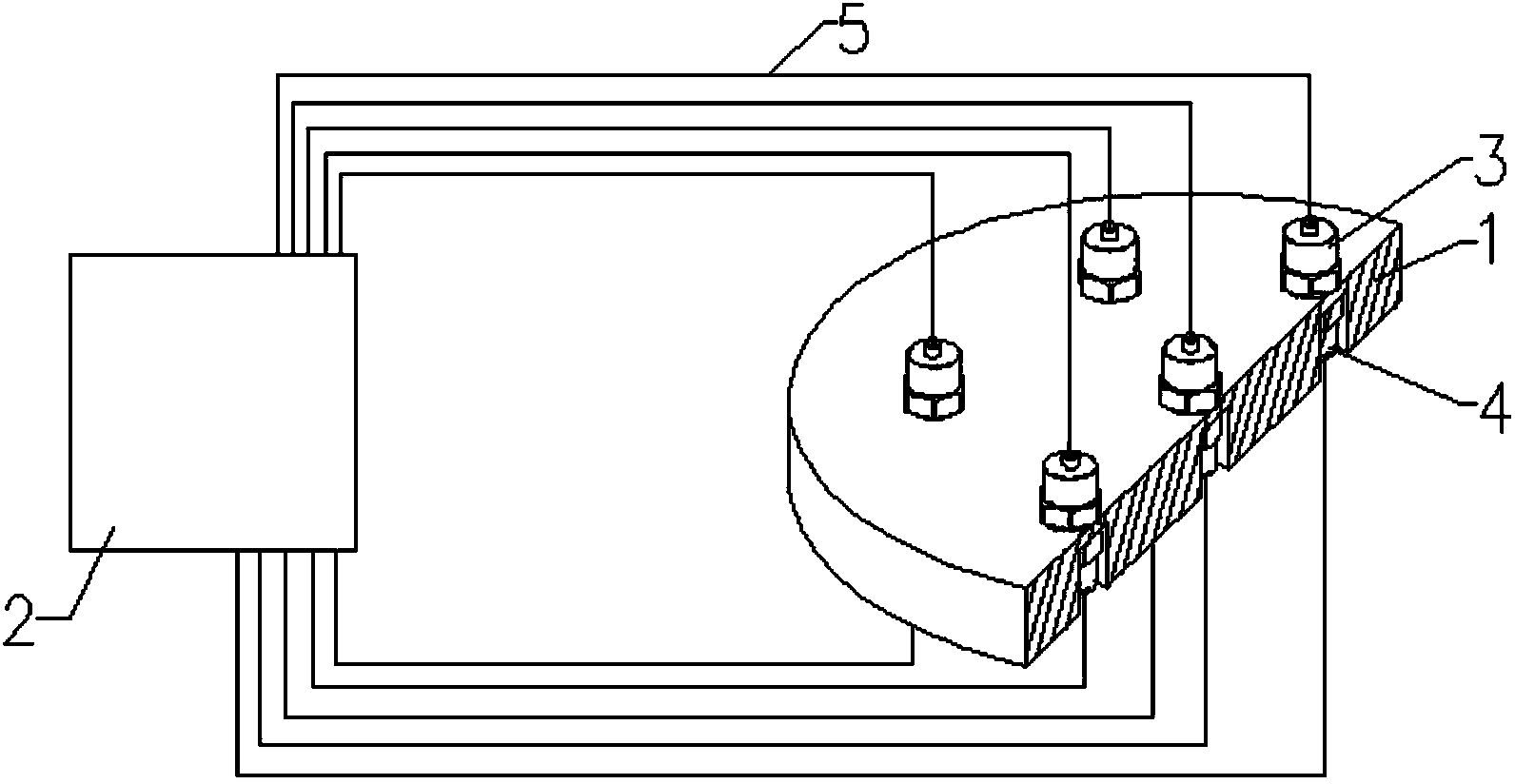

Method for calibrating sensitivity of multiple sensors

InactiveCN104316728ANo errorsAffect flatnessTesting/calibration of speed/acceleration/shock measurement devicesMultiple sensorClassical mechanics

The invention discloses a method for calibrating the sensitivity of multiple sensors. The method comprises the following steps that a plurality of acceleration sensors to be calibrated and a plurality of standard acceleration sensors are fixed above the work surface of a vibrating table and below the work surface of the vibrating table respectively in a back-to-back mode, and the multiple sets of acceleration sensors to be calibrated and the standard acceleration sensors are electrically connected with detection equipment. According to the calibrating method, the acceleration sensors to be calibrated and the standard acceleration sensors are fixed above the work surface and below the work surface respectively in back-to-back and one-to-one correspondence modes, so that when the acceleration sensors to be calibrated are calibrated, the influence of the flatness and the evenness of the work surface is avoided, and the errors of the calibration results of all the acceleration sensors to be calibrated can not happen in the batch calibration process. Accordingly, the calibrating method saves time and labor, and improves working efficiency.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

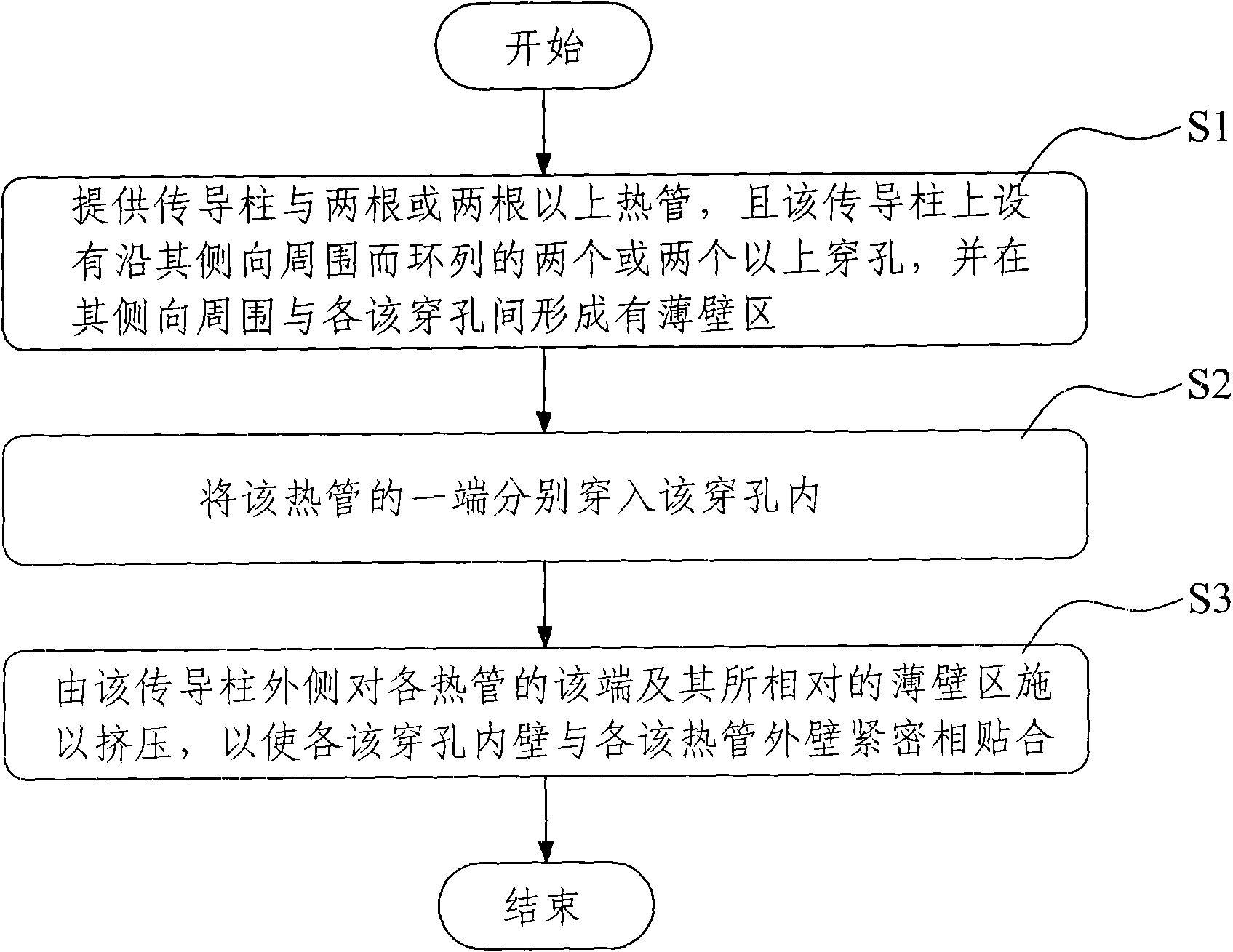

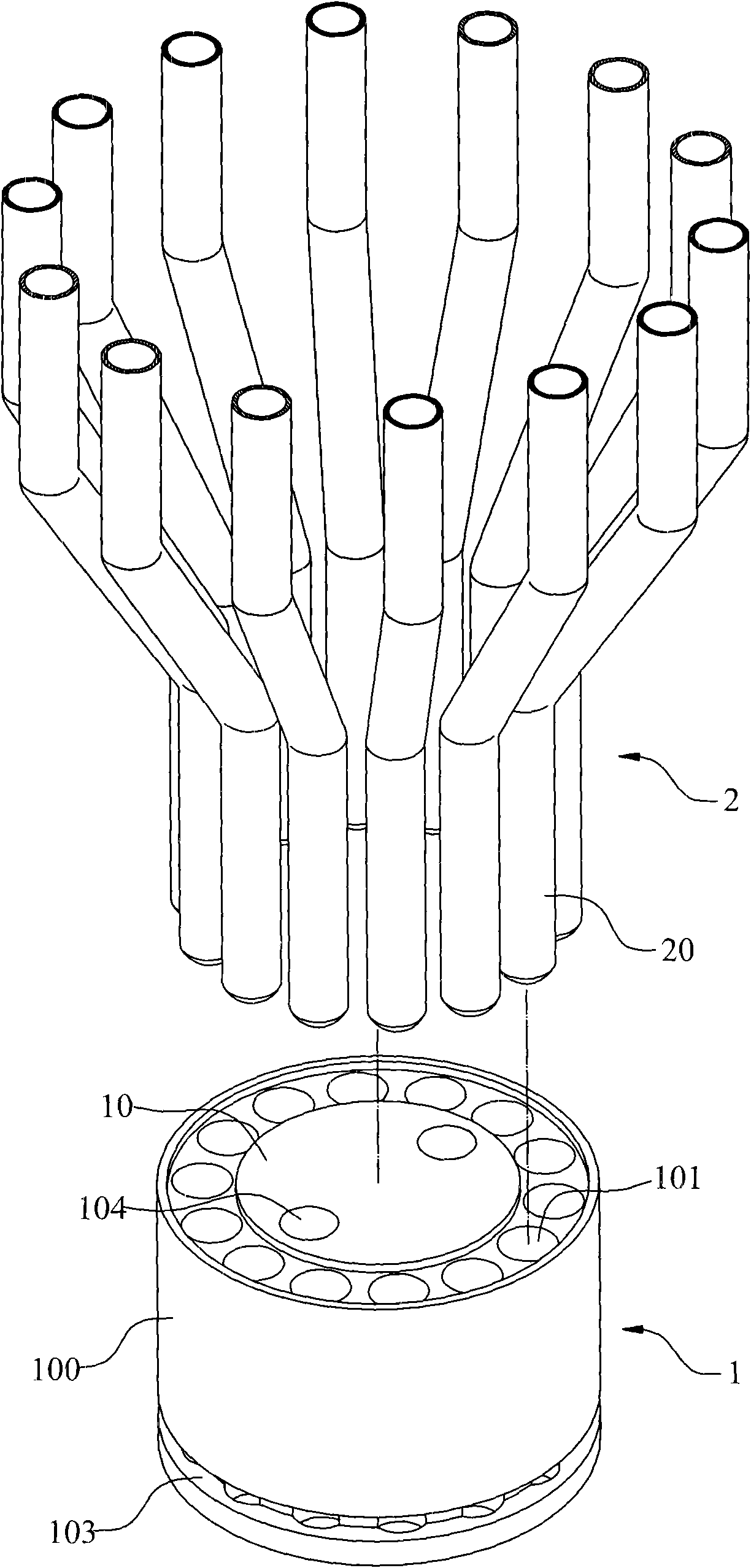

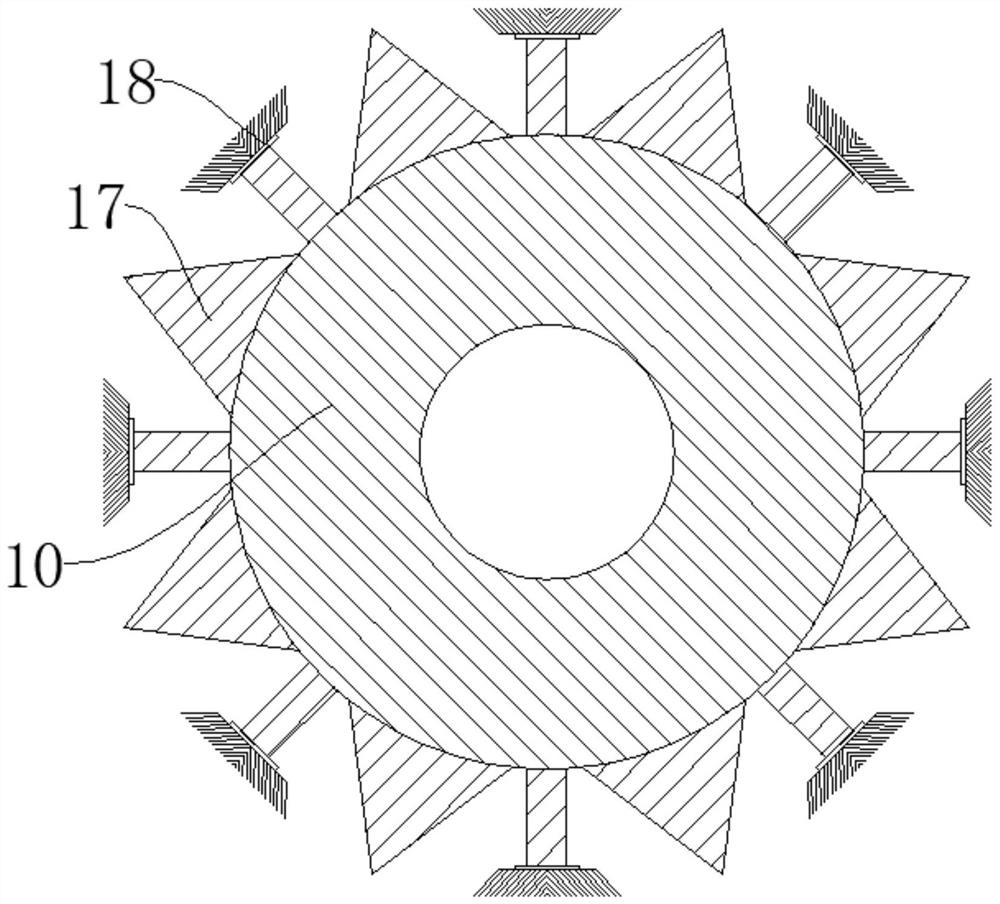

Multi-heat pipe cooling module and manufacturing method thereof

InactiveCN101639207AStrong penetrating powerClose contactPoint-like light sourceSemiconductor/solid-state device detailsComputer moduleEngineering

The invention provides a multi-heat pipe cooling module and a manufacturing method thereof. The method comprises the following steps: firstly, providing a conductive column and two or more heat pipes,wherein the conductive column is provided with two or more perforations in circular arrangement along the lateral periphery; forming a thin-wall area between the lateral periphery and each of the perforations; and then, penetrating one end of each of the heat pipes into the perforations respectively to extrude the end of each of the heat pipes and the corresponding thin-wall area from the outsideof the conductive column so as to make the inner wall of each of the perforations tightly fit with the outer wall of each of the heat pipes, and the aim of making the heat pipes tightly contact the inner walls of the perforations is achieved.

Owner:白豪

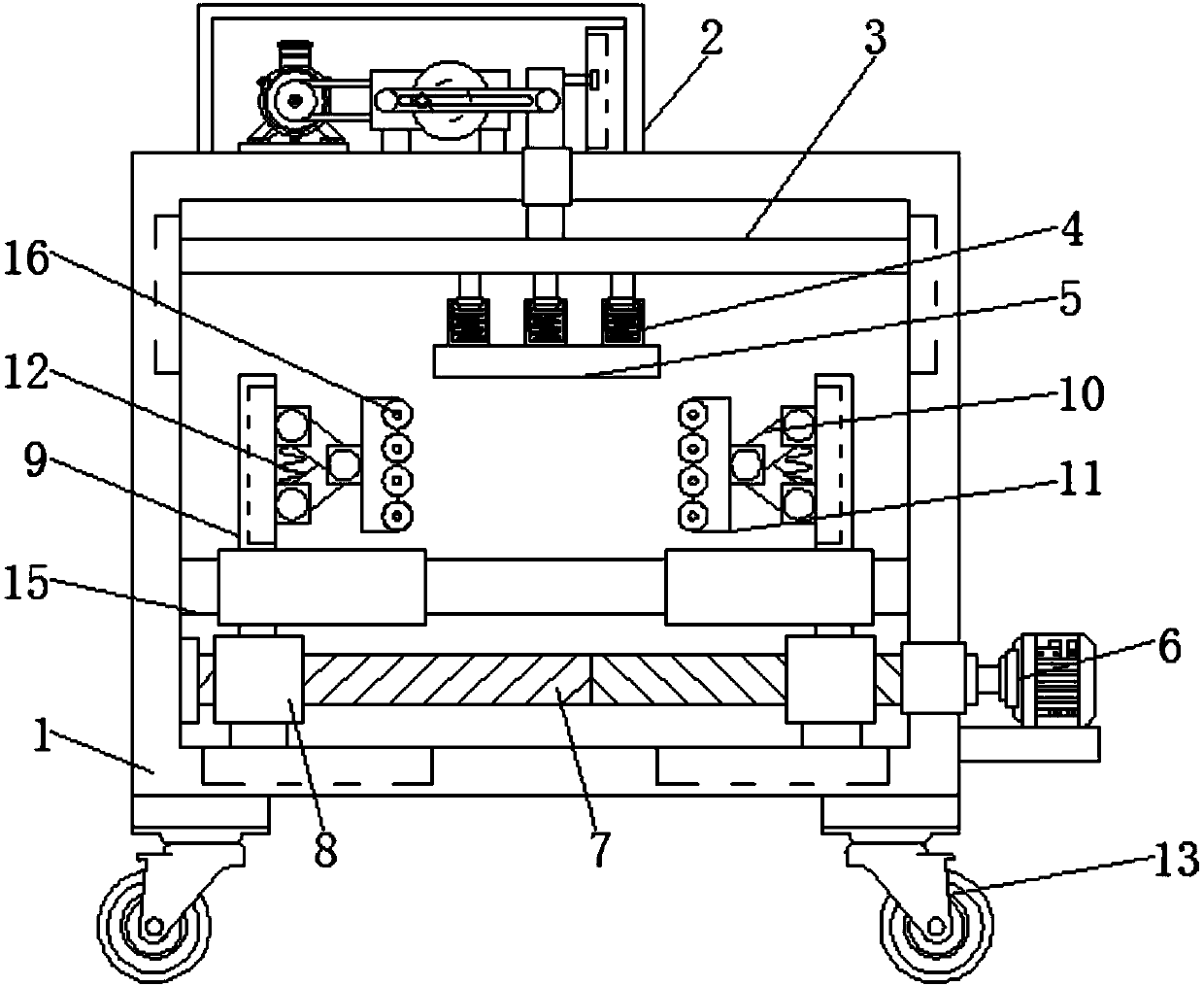

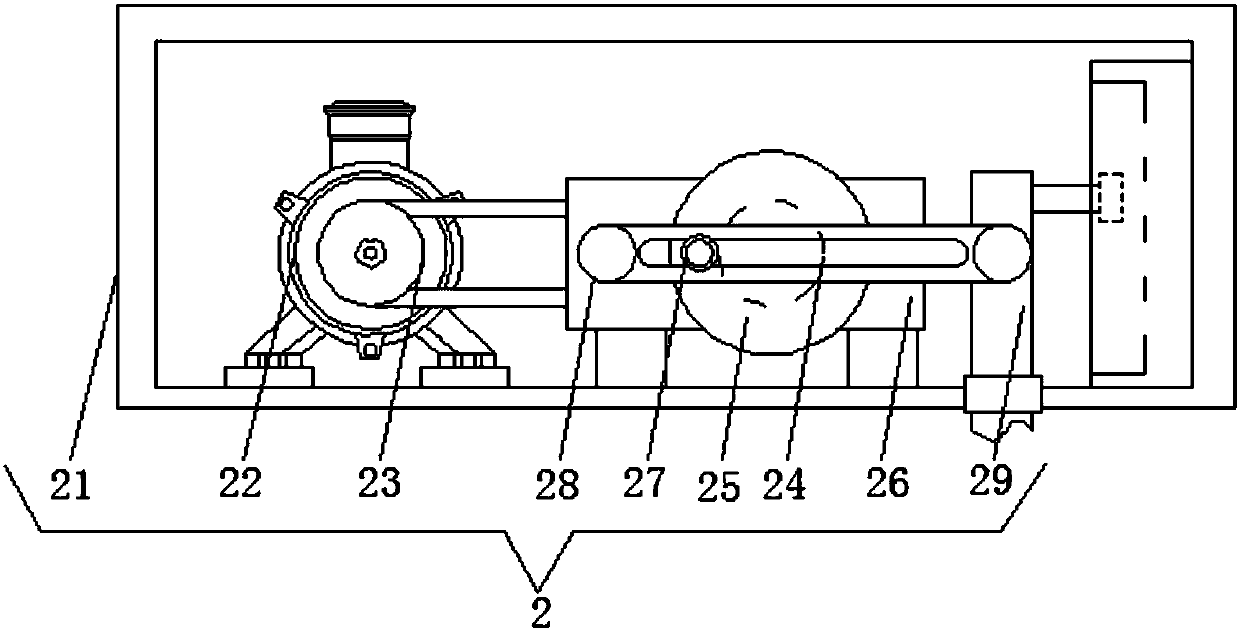

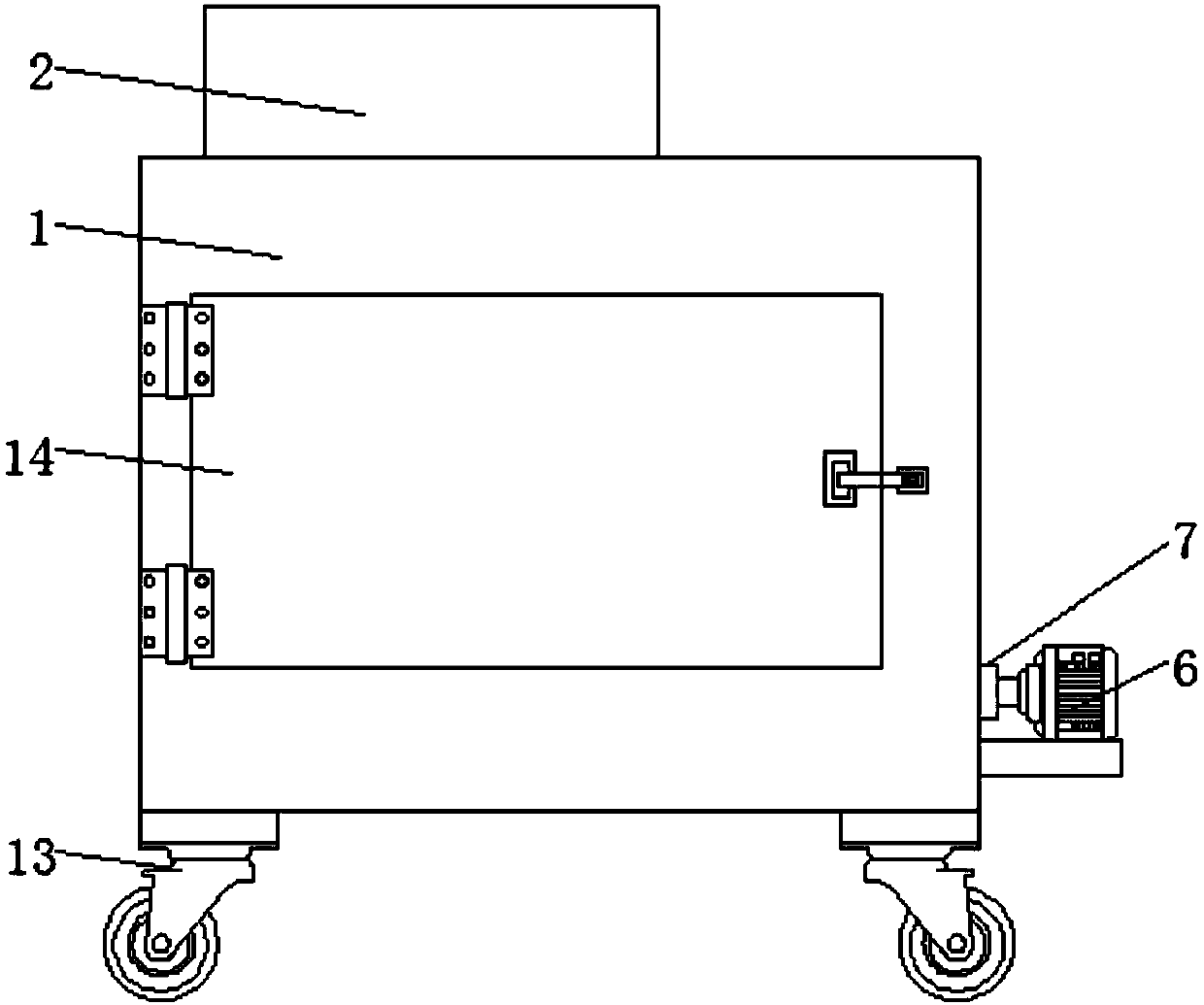

Press for heating ceramic tile machining

The invention discloses a press for heating ceramic tile machining. The press comprises a box; the left side of the top of the box is fixedly connected with an extrusion device; a slide plate is slidingly connected between the tops of two sides of the inner wall of the box; the bottom of the slide plate is fixedly connected with an extrusion plate through a buffer device; the bottom of the right side of the box is fixedly connected with a first motor through a motor base; an output shaft of the first motor is fixedly connected with a lead screw; and the press for heating ceramic tile machiningrelates to the technical field of equipment for heating ceramic tile machining. The press for heating ceramic tile machining can preferably fix heating ceramic tiles during extruding to prevent influence on overall flatness by movement of the heating ceramic tiles in the extruding process, and can provide a certain buffer protection to the heating ceramic tiles in the extruding process to preventdamage of the heating ceramic tiles; and the mass of the heating ceramic tiles is reduced, so that workers are convenient to shift the device to an appointed position for use, and the practicabilityof the device is improved.

Owner:WUXI HUIOU CERAMIC CO LTD

Worktable for circular sawing machine

InactiveCN102019647AEasy to processImprove flatnessStone-like material working toolsEngineeringWorkbench

The invention provides a worktable for a circular sawing machine. The worktable comprises a platform and two extending tables, wherein the platform is made of metal and is arranged on a machine base; the platform is provided with a top surface and two side faces; the two extending tables are made of granite; each of the extending tables is provided with a top surface and a side face; the side faces of the two extending tables are respectively arranged on the two side faces of the platform; and the area of the top surface of the extending table is larger than that of the top surface of the platform.

Owner:SHINMAX IND

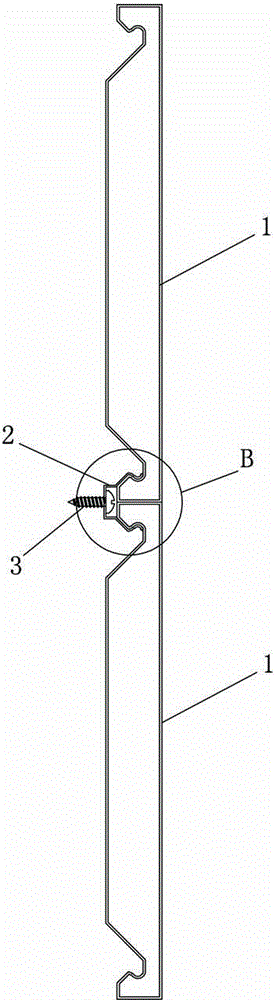

Integrated wall surface installation structure

The invention relates to an integrated wall surface installation structure. An existing integrated wall surface installation structure has the following disadvantages: 1) when one piece of wall surface module is damaged, the damaged wall surface module can be replaced by detaching the wall surface modules behind in sequence; and 2) after the wall surface modules are detached, the wall surface modules cannot be used again. The invention provides the integrated wall surface installation structure which comprises the wall surface modules. The integrated wall surface installation structure is characterized in that the integrated wall surface installation structure also comprises clamp strips; each wall surface module is of a square structure and has a decoration surface and side surfaces, wherein one end of each side surface is connected with the decoration surface, and the other end extends to the inner side of the wall surface module and forms a bending edge; each bending edge is provided with a buckling portion; and the buckling portion is in a protrusion shape with respect to the corresponding side surface. Each clamp strip comprises a bottom edge and two clamp edges symmetrically arranged on the bottom edge, wherein each clamp edge has a buckling groove matched with the buckling portion, and a reserved cavity is formed between the bottom edge and the clamp edges. The integrated wall surface installation structure is simple in structure, reasonable in design, convenient to use and mount and dismount, reliable in structure, and convenient to replace the wall surface module.

Owner:FSILON BUILDING MATERIAL TECH CO LTD

Slitting machine for machining aluminum foil packaging bag

ActiveCN109625468AGuaranteed continuityAvoid Cutting Bad SituationsPackagingAnnular cutterEngineering

The invention relates to the technical field of packaging, and particularly discloses a slitting machine for machining an aluminum foil packaging bag. The slitting machine for machining the aluminum foil packaging bag comprises a packaging bag conveying line and a plurality of cutting knives, wherein the packaging bag conveying line is an iron plate conveying line, the iron plate conveying line isa chain-driven iron plate conveying line, an annular cutter moving line is further included, the cutting knives are uniformly distributed on the annular cutter moving line, and the spacing between every two adjacent cutting knives is the same as the width of the packaging bag. The cutting knives can move downwards, the annular cutter moving line and the iron plate conveying line have the same linear speed in size and direction, and a plurality of air suction holes are formed in an iron plate on the iron plate conveying line. The scheme of the slitting machine for machining the aluminum foil packaging bag is used for solving the problem of low efficiency in slitting the packaging bag in the prior art.

Owner:DINGSHENG CORP

Bamboo flooring with anti-wrinkle and anti-cracking function

The invention discloses bamboo flooring with anti-wrinkle and anti-cracking functions. The bamboo flooring with the anti-wrinkle and anti-cracking functions is characterized in that the bamboo flooring comprises a bamboo flooring main board, a wear resistant layer, a spring and a pull ring; a moisture-proof layer is arranged on the lower end of the bamboo flooring main body, while a compression resistance layer is arranged on the upper end of the bamboo flooring main body; the wear resistance layer is located on the upper side of the compression resistance layer, while a fixed block is disposed on the left side of the compression resistance layer; the spring is positioned on the inner side of the fixed block; the left side of the fixed block is connected with a buckle whose left end is connected with a second fixture block and lower end provided with a second groove; a first fixture block with the upper end provided with a first groove is disposed on the right side of the bamboo flooring main board; the pull ring is located on the upper end of the buckle; a pull ring groove is disposed on the surface of the upper end of the buckle. The bamboo flooring with the anti-wrinkle and anti-cracking functions has the advantages of improving the strength of the bamboo flooring, facilitating bottom ventilation, avoiding moisture and cracking, facilitating connection between bamboo flooring to be stable, and avoiding getting loose and affecting usage.

Owner:ANHUI ZHI CHANG BAMBOO TECH CO LTD

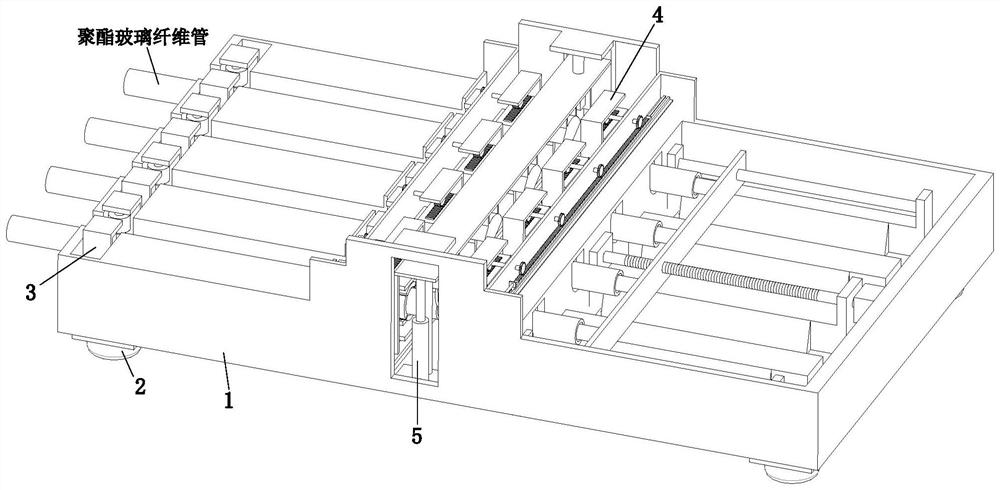

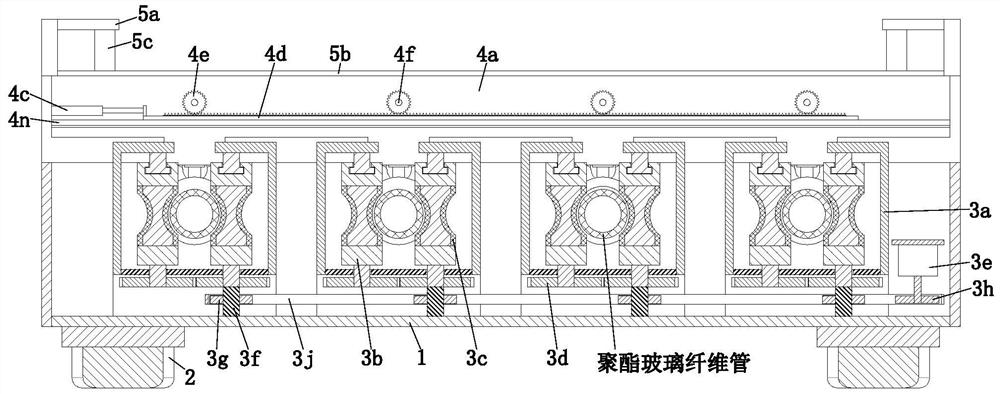

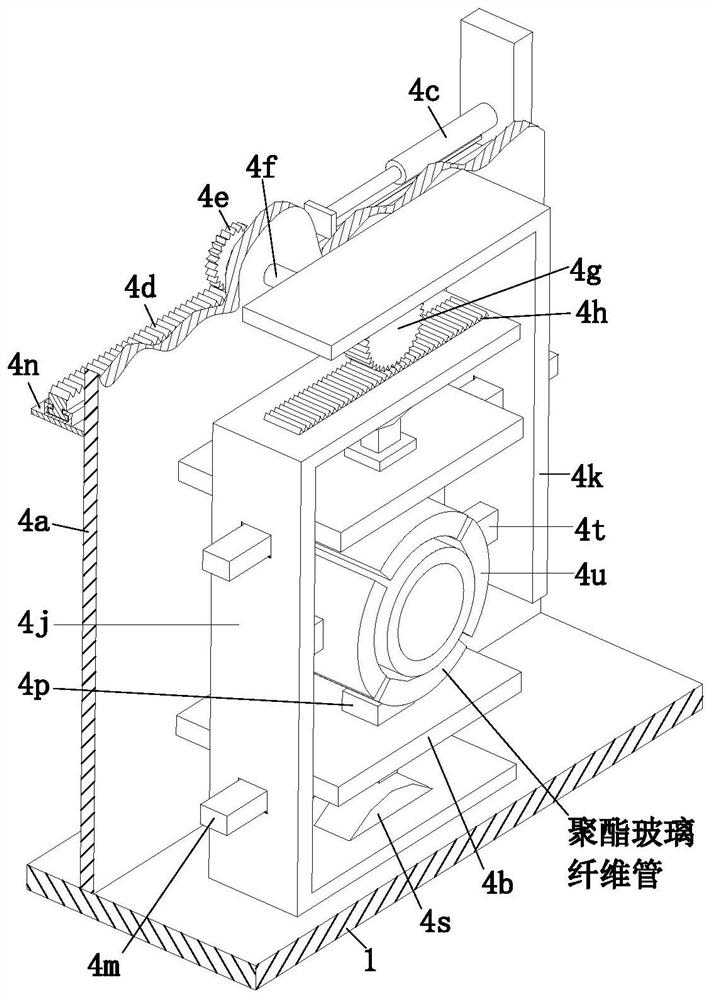

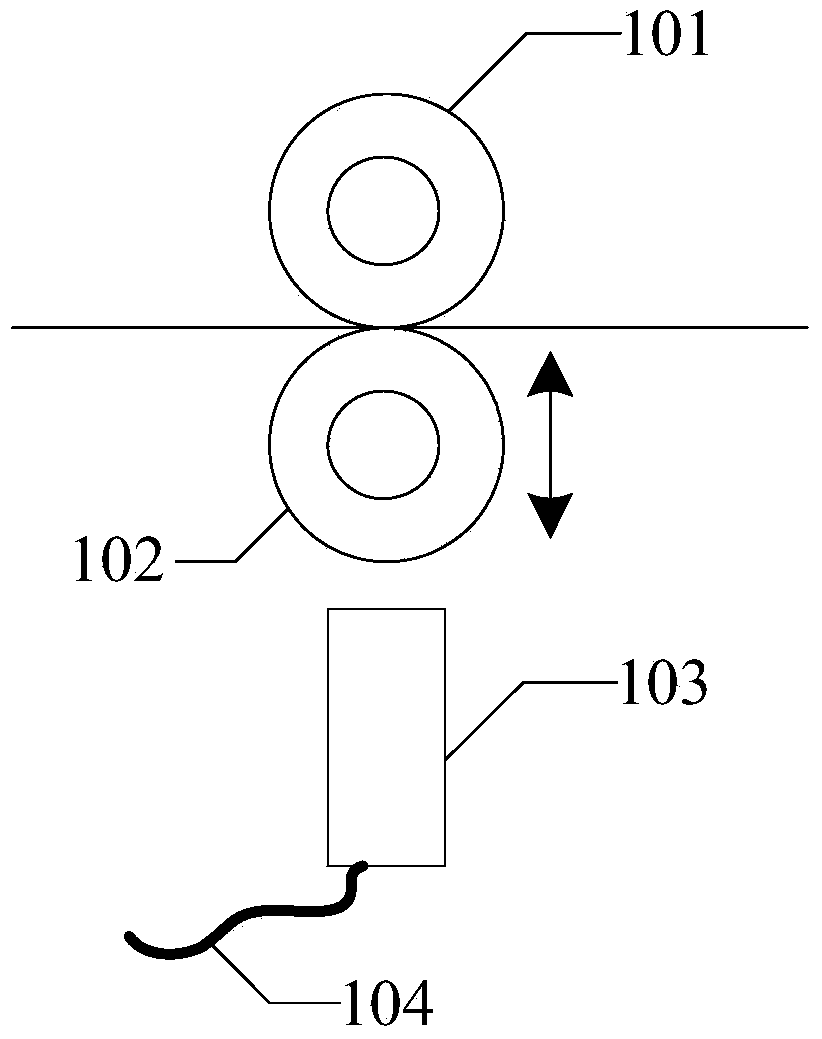

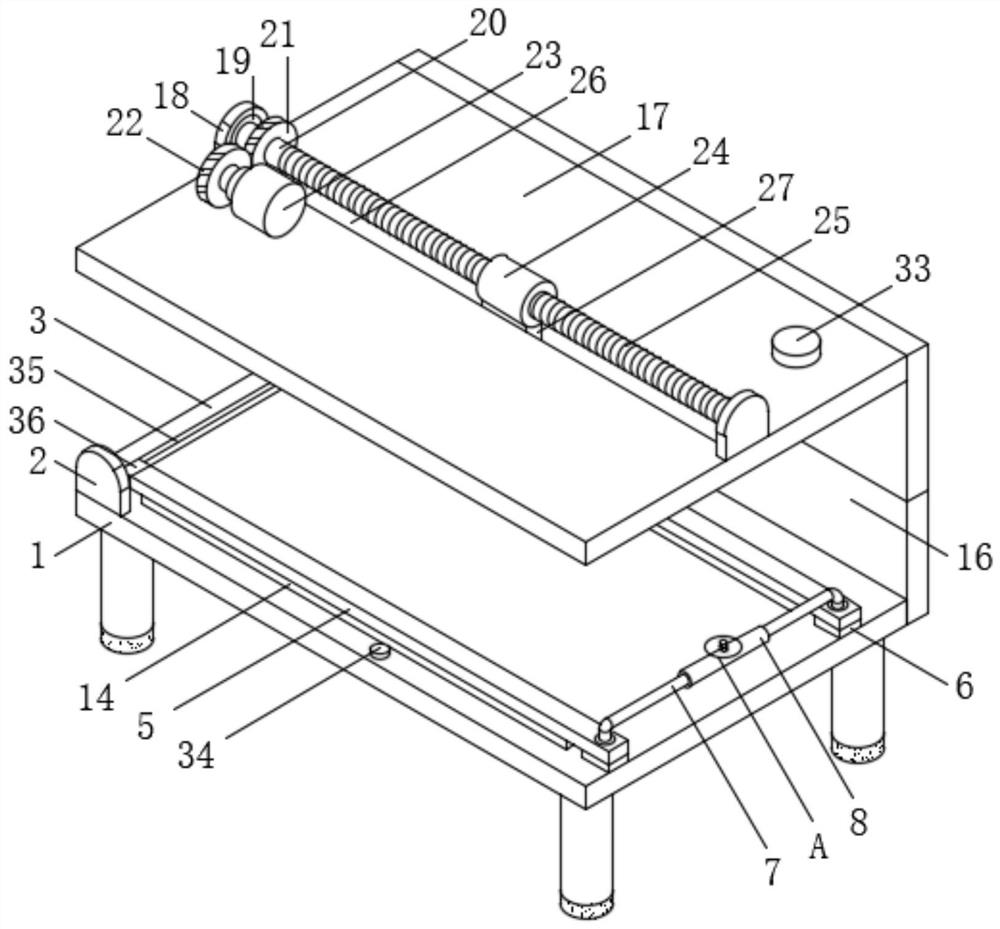

Fixed-length cutting equipment and fixed-length cutting process for polyester glass fiber tube

InactiveCN111958657AImprove the delivery effectEffective adhesionMetal working apparatusPolyesterGlass fiber

The invention discloses fixed-length cutting equipment and a fixed-length cutting process for a polyester glass fiber tube. The fixed-length cutting equipment comprises a mounting base, stand columns,a conveying mechanism, clamping mechanisms and a cutting mechanism, wherein the stand columns are evenly mounted at the corners of the periphery of the lower end of the mounting base, the conveying mechanism is mounted at the upper end of the mounting base, the clamping mechanisms are symmetrically mounted on the mounting base, and the cutting mechanism is mounted on the mounting base in a sliding fit mode and located between the clamping mechanisms. According to the fixed-length cutting equipment for the polyester glass fiber tube, the conveying mechanism can stably convey the polyester glass fiber tube, the clamping mechanisms can prevent the situation that the polyester glass fiber tube freely rotates when the cutting mechanism works to cause unevenness of a cut surface, so that the stability of cutting operation is improved, the cutting mechanism is provided with multiple cutting stations, the number of single-time cutting can be increased, and the working efficiency is improved.

Owner:广州立芯智能科技有限公司

Instant cloth cover quality detection system

The invention provides an instant cloth cover quality detection system which comprises a first bearing, a second bearing, a proximity switch and a proximity switch wire. The first rolling can be in contact with the roll face of the second bearing and is used for guiding weft yarns and fixing the longitudinal positions of the weft yarns. The first bearing is a fixed rotating bearing, and the second bearing can slide in the direction perpendicular to the weft yarn advancing direction. When the second bearing slides towards the direction away from the first bearing, the second bearing makes contact with a sensing end of the proximity switch to trigger the proximity switch, and when the proximity switch is triggered, the proximity switch controls a starting / closing switch of a loom to be switched off through the proximity switch wire. By means of the instant cloth cover quality detection system, weft yarn knot detection or weft yarn ring detection can be rapidly and sensitively conducted on the weft yarns about to entering the cloth cover in the weaving process, so that the weft yarn knots or the weft yarn rings can be eliminated or the loom stops working automatically, and thus influences, brought out by defect points generated on the cloth cover, on the coated surface smoothness in the next process are avoided.

Owner:重庆亿煊新材料科技有限公司

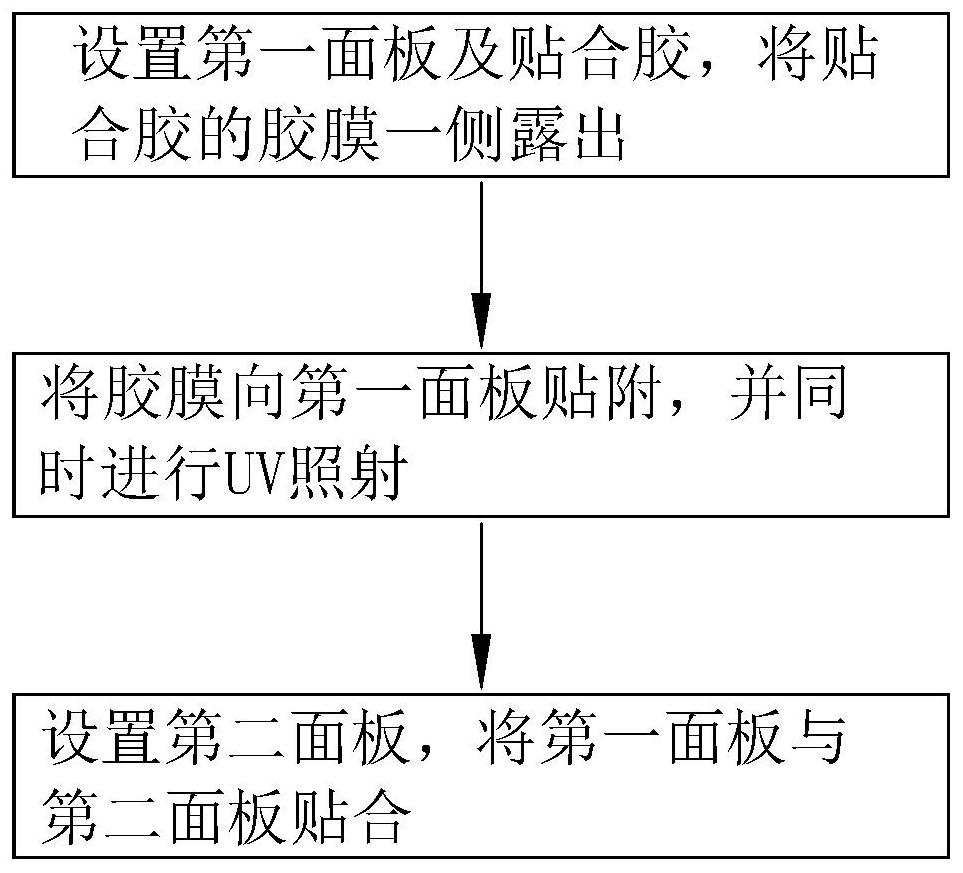

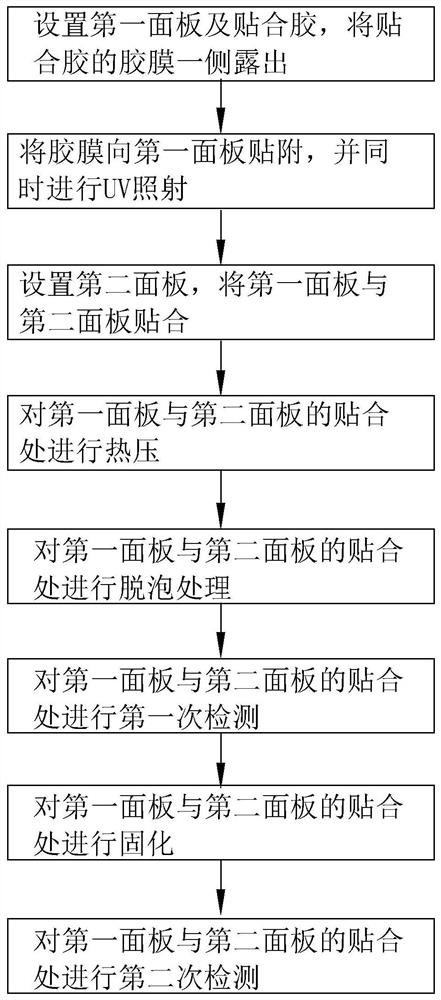

Display screen laminating process and display screen

ActiveCN111806052ASelf-adhesivePrevent overflowLaminationLamination apparatusMembrane surfaceEngineering

The invention discloses a display screen laminating process and a display screen. The display screen laminating process comprises the steps that: arranging a first panel and an attaching glue, whereinthe attaching glue comprises a release film with a glue film attached to the surface of the glue film, the release film on one side of the attaching glue is torn off to expose the glue film, the gluefilm is attached to the first panel, UV irradiation is conducted on the glue film at the same time; arranging a second panel, and attaching the first panel and the second panel together; preparing the display screen by using the above process. According to the display screen laminating process, the glue film can be excited in advance, the adhesive force and the bonding degree between the glue film and the first panel are improved, and the glue film is prevented from being taken away from the first panel in the release film tearing process; besides, in the hot pressing process of the glue film, after a hot pressing plate is lifted up, the edge of the glue film is prone to rebounding to cause excessive glue on the edge of the panel, UV irradiation is conducted on the glue film in advance, on one hand, certain adhesive force exists between the glue film and the panel, rebounding of the glue film is avoided, on the other hand, overflowing of the glue film can be avoided, and the attachingquality of the display screen is improved.

Owner:深圳全息界科技有限公司

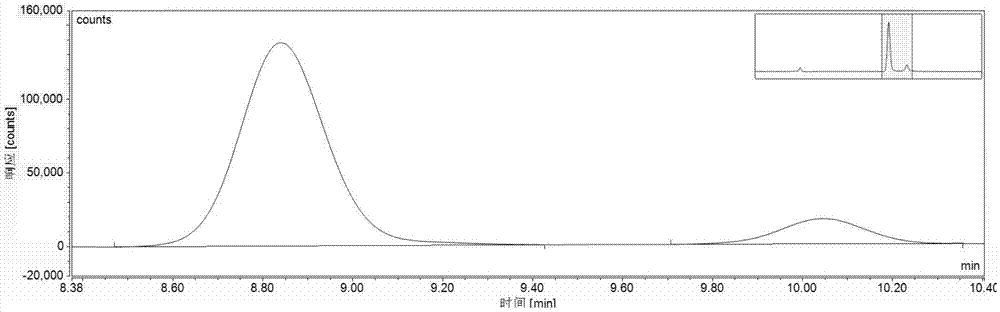

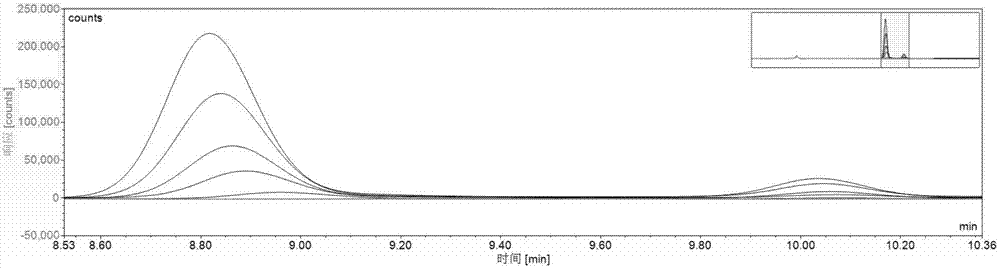

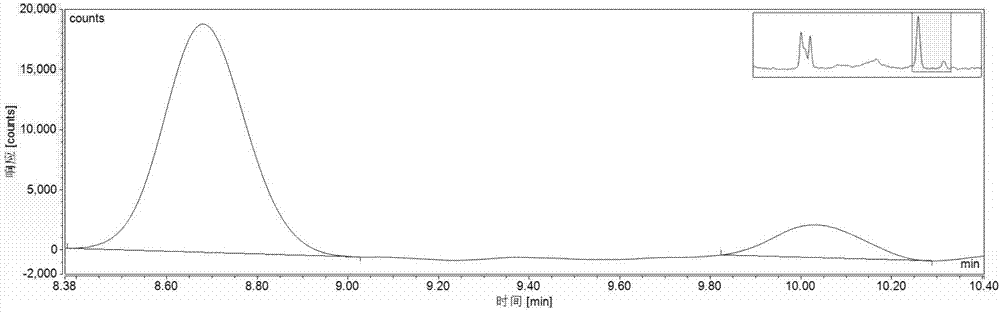

Method for simultaneously detecting ochratoxin A and zearalenone

InactiveCN107462641AImprove accuracyHigh sensitivityComponent separationBiological testingAlcoholOchratoxin A

The invention provides a method for simultaneously detecting ochratoxin A and zearalenone. The method comprises the steps of performing extraction on cereals and / or cereal products by using acetonitrile-water mixed solvent, collecting extracting solution, filtering, diluting filtrate and then transferring to an immunoaffinity column, eluting with methyl alcohol for at least two times, combining eluent and drying by blowing, dissolving and filtering residue to acquire test liquid; and detecting the test liquid by high performance liquid chromatography. The detection method provided by the invention has detection limits of 0.7ng / ml and 4ng / ml for the ochratoxin A and the zearalenone, separately achieves ochratoxin A recovery rates of 98.4%, 99.6% and 99.3% when standard addition levels are 2.5, 5 and 10 microgram / kg, and separately achieves zearalenone recovery rates of 95.17%, 95.23% and 98.62% when standard addition levels are 30, 60 and 120 microgram / kg, which are far higher than the prior art. Therefore, the method provided by the invention is high in sensitivity and accuracy, and can simultaneously detect the ochratoxin A and the zearalenone.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Sewing clamp plate for shirt collar

InactiveCN104264380AConvenience guaranteedEnsure accurateWork-feeding meansEngineeringRejection rate

The invention discloses a sewing clamp plate for a shirt collar. The sewing clamp plate comprises an upper-layer pressing plate and a lower-layer pressing plate, wherein the upper-layer pressing plate is provided with an upper-layer needle running strip, the lower-layer pressing plate is provided with a lower-layer needle running strip, relative positions of the upper-layer needle running strip and the lower-layer needle running strip are mutually aligned with each other and communicate with each other after the upper-layer pressing plate and the lower-layer pressing plate are folded, a partition plate is arranged between the upper-layer pressing plate and the lower-layer pressing plate, and the outline of the partition plate is arranged along the line shapes of the upper-layer needle running strip and the lower-layer needle running strip. Compared with the prior art, the sewing clamp plate for the shirt collar adopts the upper-layer pressing plate, the lower-layer pressing plate and the partition plate to clamping and fixing cloth for many times, so that a double-layer collar can be conveniently sewed in the upper-layer needle running strip and the lower-layer needle running strip by a sewing machine, the previous steps of scribing by a chalk and ironing for shaping before sewing can be omitted, operation is more convenient and rapid and rejection rate is reduced.

Owner:JIANGSU HUAJIA SILK

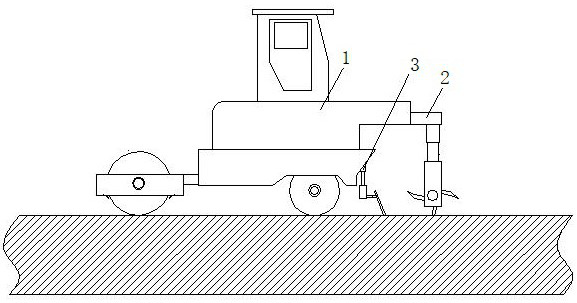

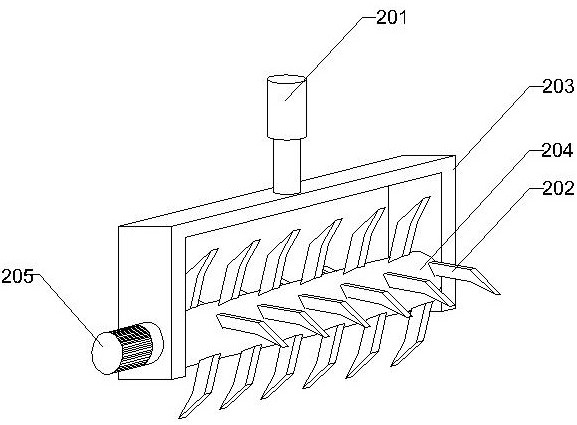

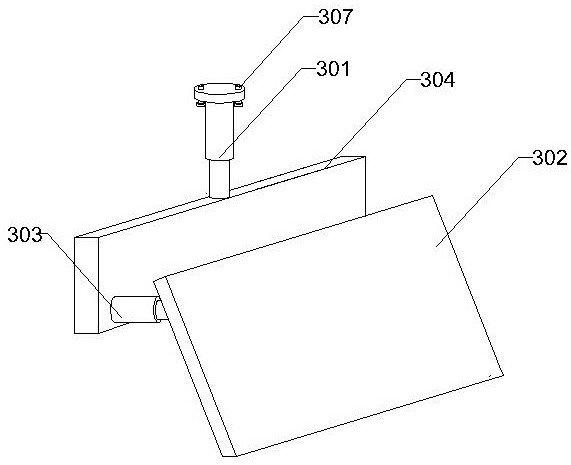

Pavement construction compactor

ActiveCN112854178AEvenly distributedAffect flatnessMechanical machines/dredgersSoil preservationArchitectural engineeringStructural engineering

Owner:ZHEJIANG JINZHU TRANSPORTATION CONSTR

Cold light source cutting device for processing light-resistant screen

PendingCN112372149APlay a pulling effectStable and stableLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a cold light source cutting device for processing a light-resistant screen, and belongs to the technical field of light-resistant screens. The cold light source cutting devicecomprises a base, wherein a first side plate base is fixedly connected to the top of the base, a first bearing is clamped on the side surface of the first side plate base, and an adapter shaft is sleeved with the first bearing. According to the cold light source cutting device for processing the light-resistant screen, under the mutual cooperation of the designed structures such as a first hot ironing roller, a second hot ironing roller, a cold ironing roller, a pressing plate, a supporting spring, a lifting base, a connecting sleeve, toothed plates, a gear and a connecting frame, a certain pulling effect can be achieved on a to-be-cut light-resistant screen flatly laid on the base, it can be avoided that a cut part deforms under heat and affects the flatness of a non-cut part, it can be avoided that the to-be-cut light-resistant screen deforms under instantaneous overhigh heat when the to-be-cut light-resistant screen is subjected to the action of a cold light source laser cutter, theflatness of the cut part of the cut light-resistant screen can be ensured, and the stability of the light-resistant screen is rapidly stabilized by utilizing cold ironing.

Owner:SHENZHEN POLYTECHNIC +1

Double-sided planer for vertical planing

InactiveCN112497351AImprove practicalityPrevent fallingWood feeding arangementsBark-zones/chip/dust/waste removalEngineeringStructural engineering

The invention discloses a double-sided planer for vertical planing, and belongs to the technical field of double-sided planers. The double-sided planer for vertical planing comprises a fixed frame, afixed box and a movable box, wherein the upper ends and the lower ends of the inner sides of the fixed box and the movable box are fixedly connected with a plurality of groups of matched supporting blocks, a conveying roller is rotationally connected between every two supporting blocks, a plurality of planing tools are fixedly connected to the surface of the middle conveying roller, and a cleaningbrush is fixedly connected between every two planing tools. According to the double-sided planer, a collecting mechanism is arranged, so that impurities such as wood chips can be prevented from drifting around and falling into a planer body, the cleaning difficulty of workers is increased, and meanwhile, the body health of the workers can be prevented from being influenced by chippings; and the cleaning brushes are arranged, so that the surface of a planed plate can be cleaned, the problem that the wood chips are conveyed backwards along with the plate, the wood chips are extruded by the conveying rollers, so that indentations are generated on the surface of the plate, and the flatness of the plate surface is influenced can be solved, and the practicability of the planer during use is effectively improved.

Owner:肖轩杰

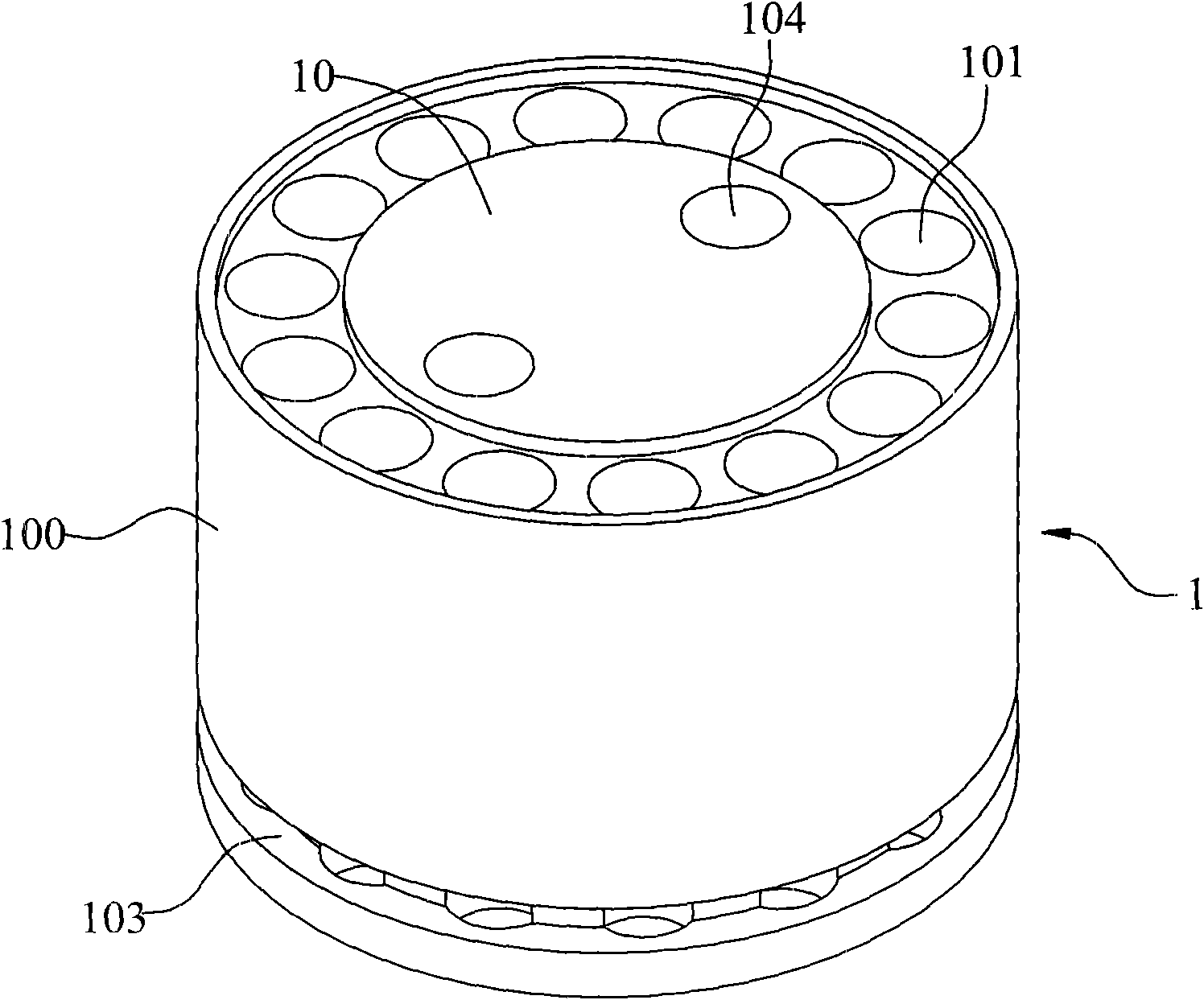

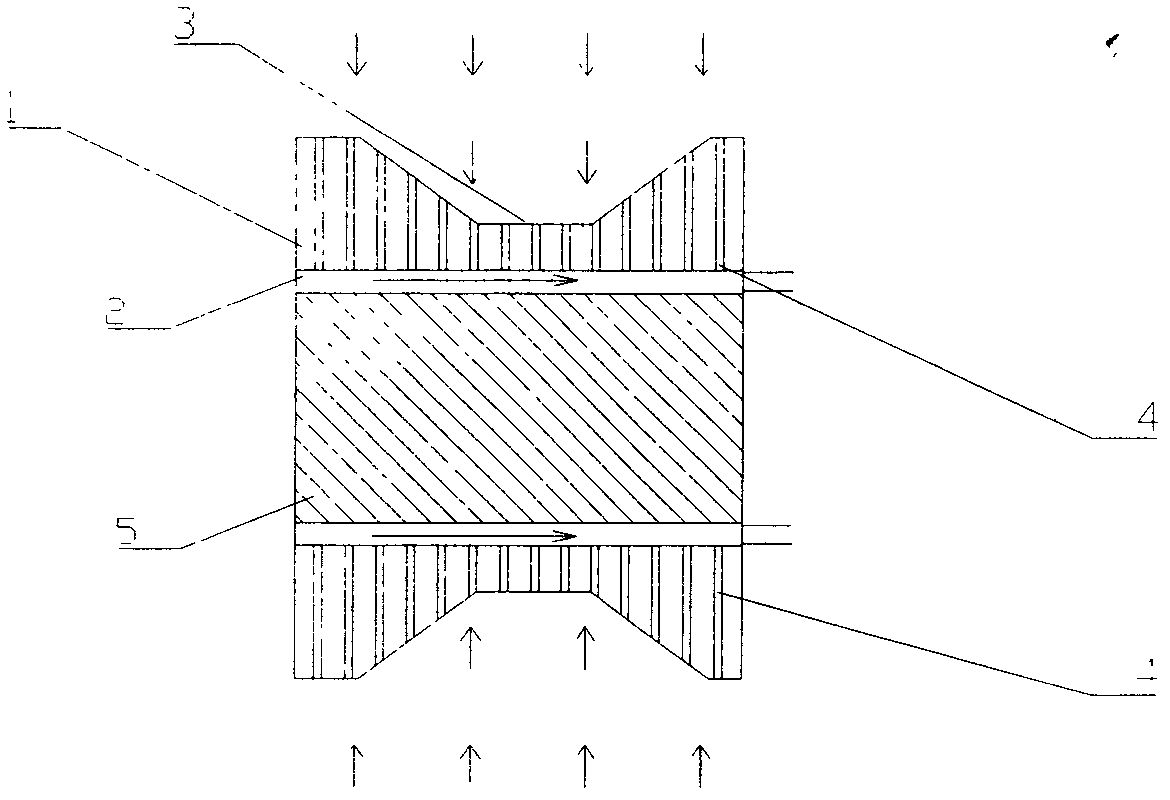

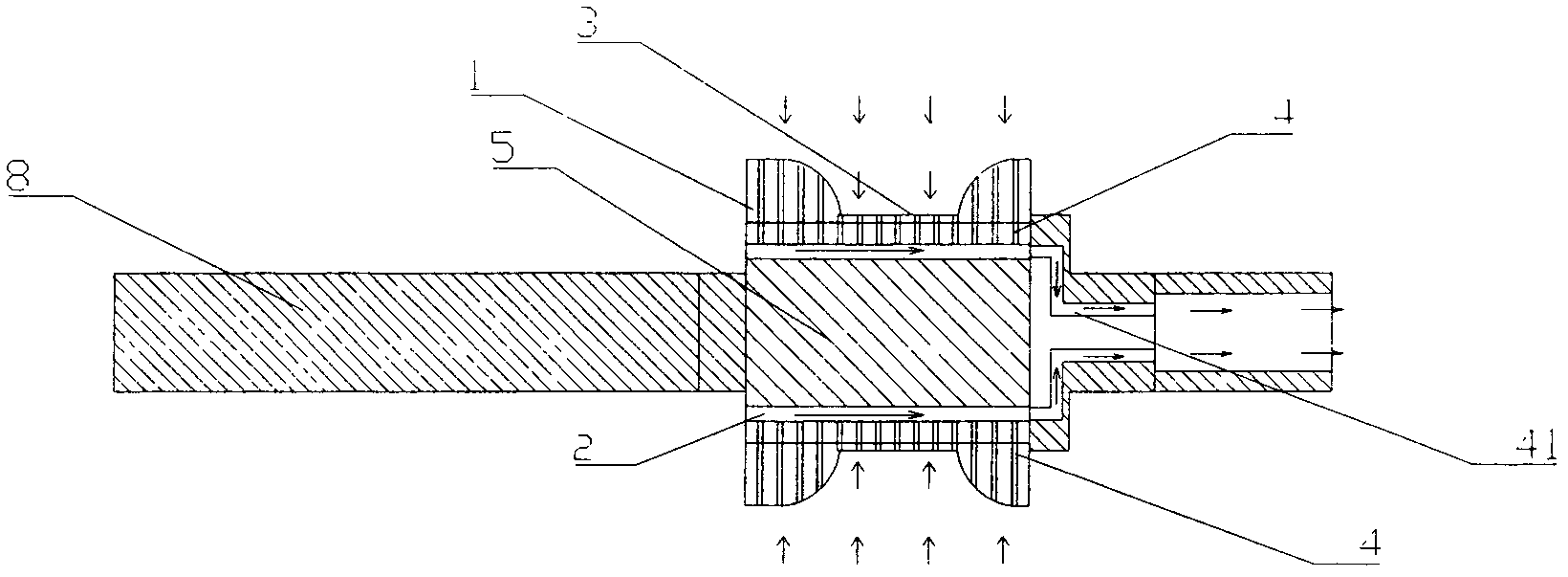

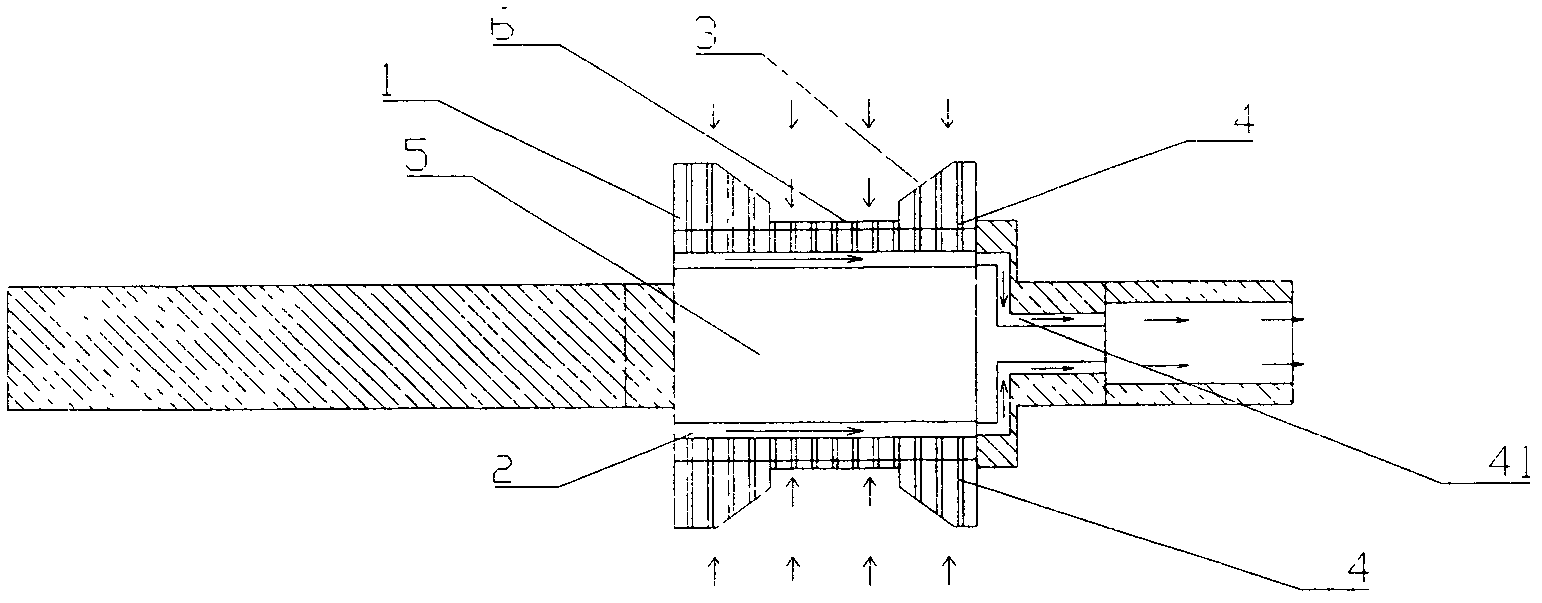

Ferro-magnetic quenching metal strip coiling device

The invention provides a quenching metal strip coiling device which comprises a shell, wherein the shell can continuously rotate along the axial direction, and an air exhaust channel is formed on the shell so as to form a negative pressure environment on the shell. The quenching metal strip coiling device is characterized in that a first groove is arranged on the shell along the circumferential direction of the shell; the width of the bottom of the first groove is greater than or equal to that of a quenching metal strip; the width of the first groove is gradually increased from the bottom of the first groove to the open end of the first groove; and a cavity containing a magnetic inner core is arranged in the shell. The quenching metal strip coiling device provided by the invention can effectively avoid the strip distortion, and has a relatively high capturing success rate at the same time.

Owner:滨州益谦非晶金属材料科技有限公司

Forming machine for gypsum board production line

PendingCN109318362ALow costSave human effortCeramic shaping plantsSurface layering apparatusGypsumBall valve

The invention discloses a forming machine for a gypsum board production line and belongs to gypsum board production equipment. The forming machine for the gypsum board production line solves the technical problem of how to meet the production demands of formed gypsum boards of different specifications. The forming machine is energy-saving and environment-friendly and lowers the cost. The technicalscheme is as follows: the forming machine structurally comprises a rack. A gluing device, an upper forming device and a lower forming device are successively arranged from top to bottom on the rack;an upper paper guide roller and a middle paper guide roller are separately arranged above and below the gluing device; the gluing device comprises a pipe bracket, the pipe bracket is fixedly mounted on the rack, a gluing hose is arranged on the pipe bracket, the gluing hose is fixed to the pipe bracket through a pipe clamp, and a ball valve is arranged on the gluing hose for controlling the flow rate of glue; the upper forming device comprises an upper forming plate, an upper forming plate bracket, a pull rod and a lower paper guide roller, the upper forming plate is arranged at the lower endof the upper forming plate bracket, and a connecting rod base is arranged at the upper end of the upper forming plate bracket.

Owner:山东腾飞机电科技有限公司

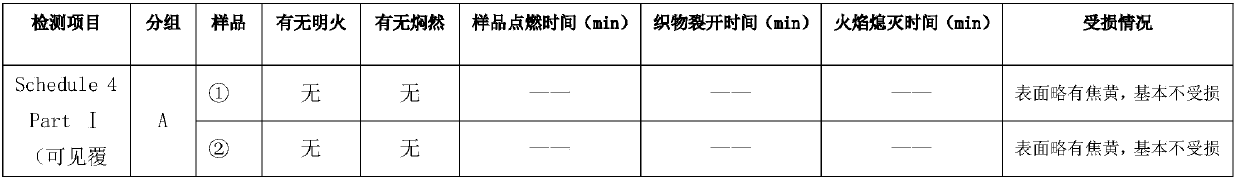

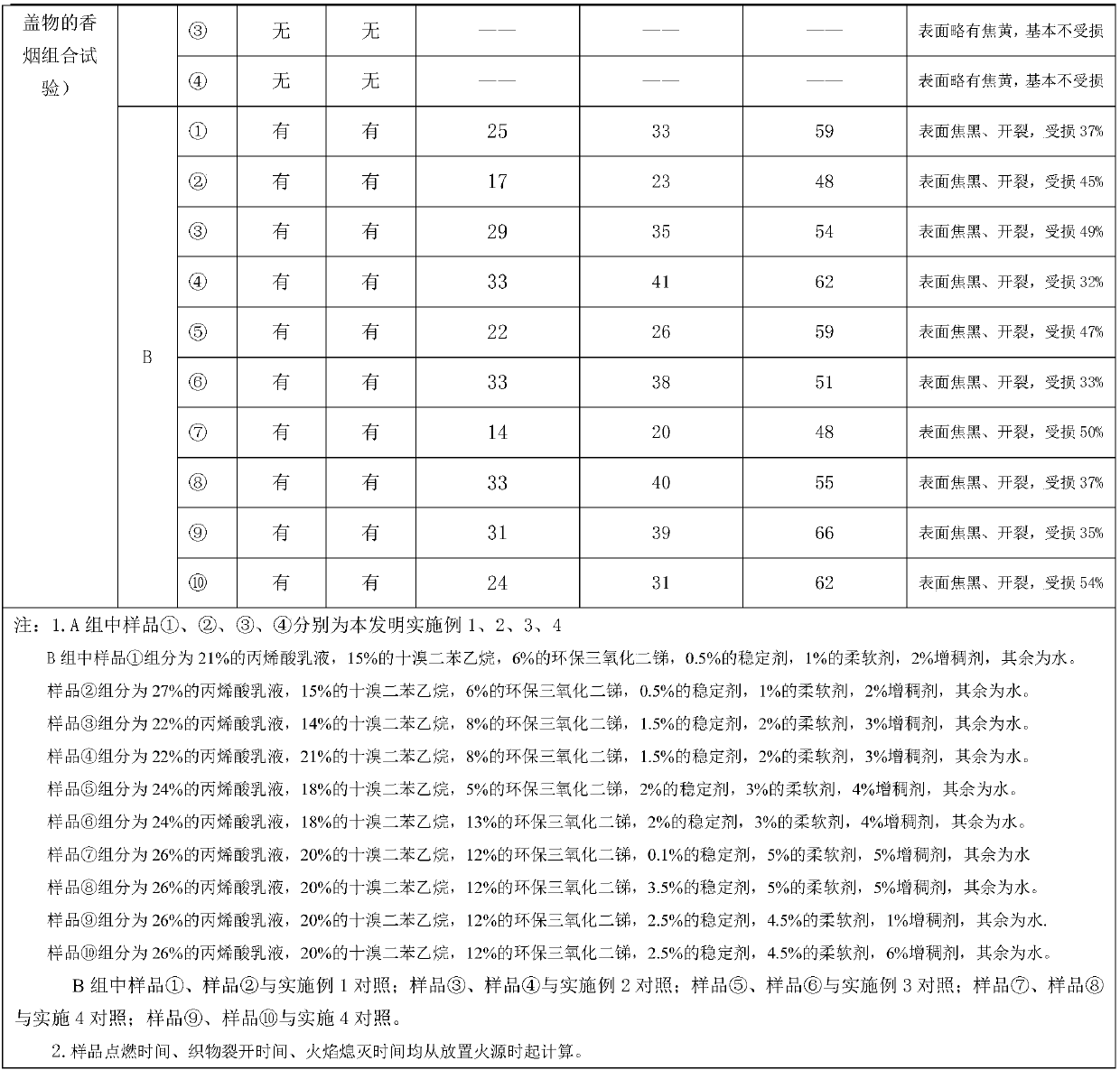

Flame retarding auxiliary for chemical-fiber sofa plus material

InactiveCN107556840AEasy to shapeExcellent washable and quick dryingFireproof paintsFlame-proof filament manufactureFiberPolyester

The invention discloses a flame retarding auxiliary for a chemical-fiber sofa plus material. The flame retarding auxiliary is prepared from 20 to 26 percent of acrylic emulsion, 15 to 20 percent of decabromodiphenyl ethane, 6 to 12 percent of environment-friendly antimonous oxide, 0.5 to 3 percent of stabilizer, 1 to 5 percent of softener, 2 to 5 percent of thickener and the balance of water. Theflame retarding auxiliary provided by the invention is developed aiming at the purpose of a sofa for which a chemical-fiber material is adopted; the decabromodiphenyl ethane and the environment-friendly antimonous oxide can be combined with the material characteristic of a chemical fiber (a polyester fiber, polyester cotton and the like) to realize better flame retarding performance; meanwhile, own excellent performance, of setting, easy cleaning, quick drying and the like of a chemical-fiber plus material is maintained; the composition is simple; the cost is low; the durability is high; the occurrences of fire disasters in a home and a public place can be reduced and the safety of the home is ensured.

Owner:SHAOXING SIAN FLAME RETARDANT TECH CO LTD

Steel bar shearing device capable of adjusting shearing length

The invention discloses a steel bar shearing device capable of adjusting a shearing length. The steel bar shearing device capable of adjusting the shearing length comprises a main body. The main bodyis provided with a feeding cavity. The left side of the feeding cavity is connected with a feeding port communicating with the outside. A feeding assembly is arranged in the feeding cavity. The feeding assembly comprises a drive sprocket shaft. The drive sprocket shaft is rotatably installed on the front wall of the feeding cavity and extends forward to the driving cavity. A drive sprocket is disposed in the feeding cavity. The drive sprocket is fixedly connected to the drive sprocket shaft. A bevel gear shaft is rotatably mounted on the front end wall of the feeding cavity. The bevel gear shaft is located at the left side of the drive sprocket shaft and extends forward to the driving cavity. The feeding length of the feeding assembly can be adjusted according to the shearing length of a steel pipe. When shearing the steel pipe, a part to be sheared is pressed by a pressure block to prevent the steel pipe from moving and affect the flatness of the shearing surface. Meanwhile, the steelpipe is prevented from splashing. After a shearing is completed, the width of the blanking opening can be adjusted by turning the handle, so that steel pipes of different thicknesses can be classified and placed and time and manpower are saved.

Owner:江苏顺隆鸿泰电力设备有限公司

Paper operation monitoring component of laminating machine

InactiveCN104827766AAffect flatnessAvoid it happening againPrinting press partsPulp and paper industry

The invention relates to a paper operation monitoring component of a laminating machine. The paper operation monitoring component of the laminating machine comprises a laminating machine body (1), a reminding device (4), mark marking devices (2) and induction monitoring devices (3), wherein the mark marking devices (2) are arranged at the two sides of a paper feeding device of the machine body (1), when paper entering the front end portion of the machine body in a sucked mode, corresponding small marks are marked on the four corners of the paper, and the induction monitoring devices (3) are arranged on the translation portion of the machine body to monitor the flatness and the operating state of the paper; the reminding device (4) is arranged, when the problems of deviation, wrinkling and breakage of the paper position occur, an operator is reminded to adjust an operating mode in time; the mark marking devices (2) adopt novel materials to print points, the integrality of the paper is not influenced, and the abandoned portions of the edges of the paper are marked; the induction monitoring devices (3) are distributed at intervals correspondingly, and the induction monitoring devices (3) monitor the problem that whether the wrinkling occurs or not; real-time monitoring is implemented, the fact that the flatness of laminating is influenced by the paper wrinkling and breakage occurring in the laminating process is effectively prevented, meanwhile, the generation of laminating bubbles is avoided, the product quality is improved, the scrappage rate of paper resources is reduced, and the production effectiveness is high.

Owner:ANQING DECHUANG ELECTROMECHANICAL PROD DESIGN

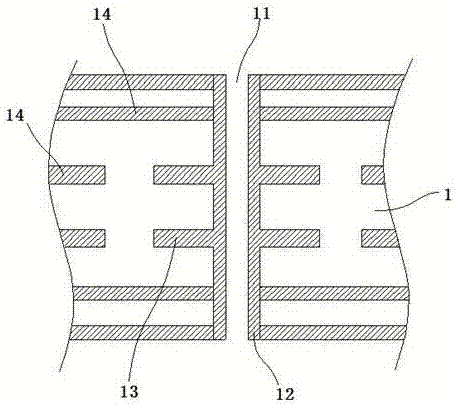

PCB of preventing separating of hole walls, and processing technology thereof

PendingCN108012417AImprove bindingAvoid separationElectrical connection printed elementsPrinted element electric connection formationEngineeringCopper

The invention relates to a PCB of preventing separating of hole walls. The PCB of preventing separating of hole walls is characterized in that the PCB of preventing separating of hole walls includes aPCB body; a plurality of mutually parallel conductive copper layers and PTH holes are formed in the PCB body 1; the PTH holes are perpendicular to the conductive copper layers; copper plates are arranged on the hole walls of the PTH holes; a plurality of hole rings are fixedly at the outer side of each copper plate, and the hole rings encircle the copper plate; and the hole rings are embedded into the PCB body. The PCB of preventing separating of hole walls can effectively avoid the copper plates separating from hole walls of the PTH holes by increasing the hole rings.

Owner:广州广合科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com