Pose measure system of cantilever type heading machine

A cantilever-type roadheader, pose measurement technology, applied in the direction of measuring devices, measuring instruments, line-of-sight measurement, etc., can solve the problems of affecting production efficiency, increasing construction workload, and difficult construction, achieving high accuracy and identification The effect of enhanced ability and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In the following, the measurement principle will be further explained, and the technical means and functions of the present invention will be further described through specific implementation methods in conjunction with the accompanying drawings. However, the accompanying drawings and specific implementation methods are only for reference and description, and are not intended to limit the present invention.

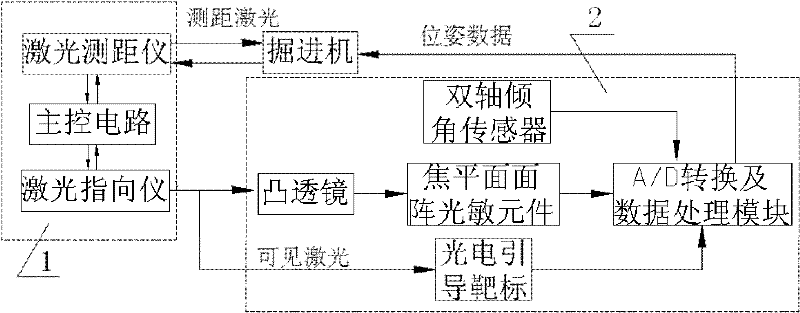

[0050] figure 1 It is a system block diagram of the present invention, describing the compositional relationship and internal relationship among the various components involved in the system.

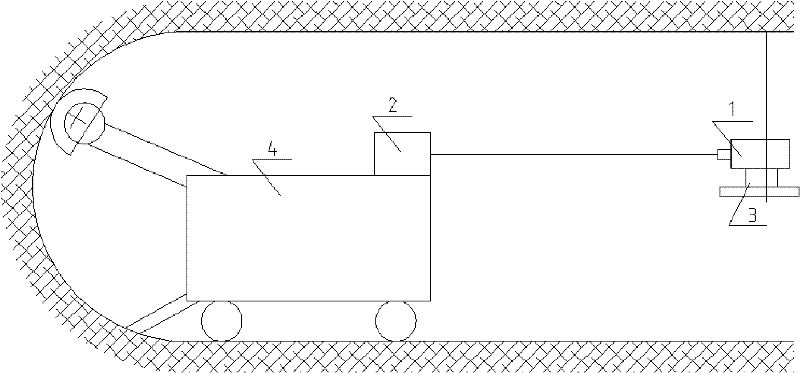

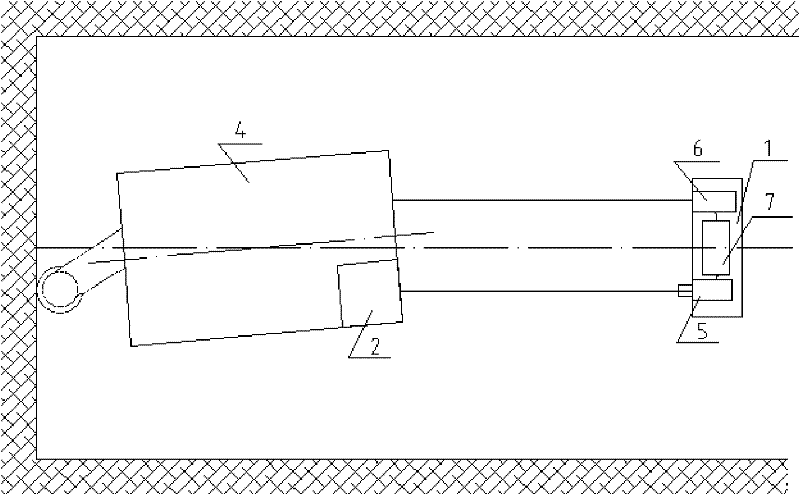

[0051] figure 2 It is a schematic diagram for implementing the method for measuring the position and posture of the cantilever type roadheader of the present invention. It can be seen from the figure that the position and posture measurement system of the cantilever type roadheader in this embodiment includes: a laser set in the roadway for giving the direction of roadway e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com