Parallelism detector for optical axis of multi-optical system

An optical system and parallelism technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of lack of versatility and flexibility, and achieve the effects of convenient detection and calibration, low cost, and simple processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

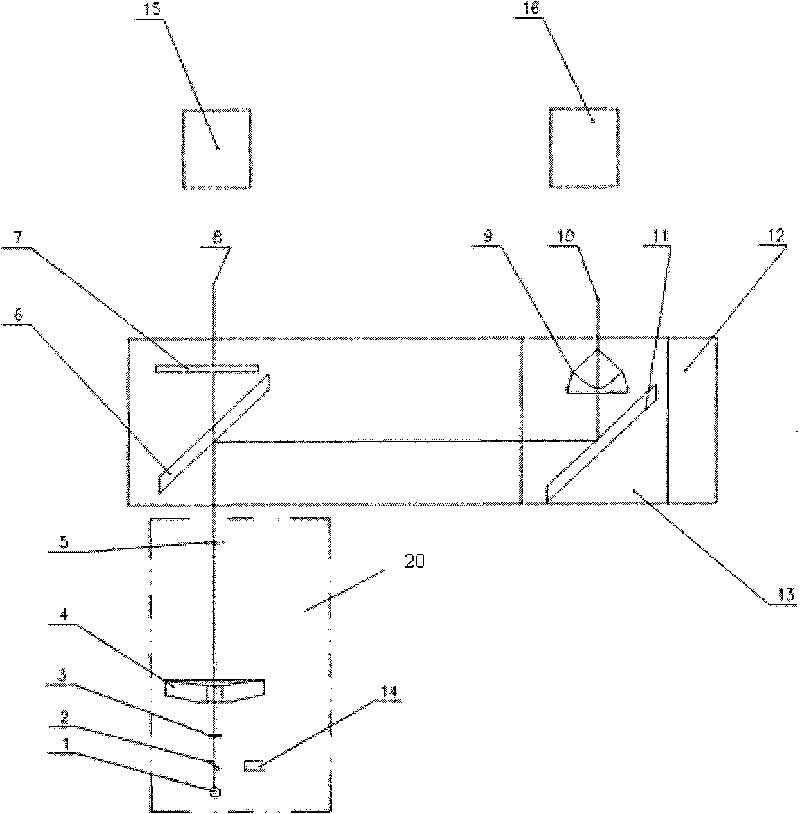

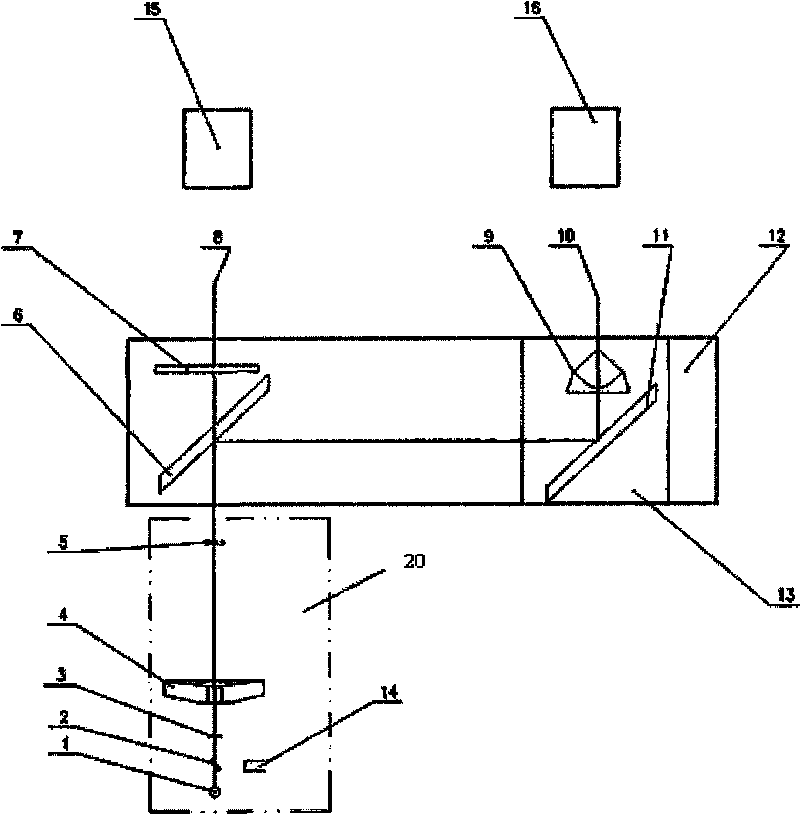

[0014] Such as figure 1 As shown, the multi-optical system optical axis parallelism detector of the present invention comprises a first half mirror 6, a folding mirror 11, a collimation system 20, a light source 1, a reticle 3, a guide rail 12, and a guide rail slide Block 13, calibration reflector 7, cone prism 9, second half mirror 2, microscope 14; first half mirror 6 is fixed on the guide rail 12, calibration mirror 7 is fixed on the known two-dimensional adjustment In terms of mechanism, the two-dimensional adjustment mechanism is fixedly connected with the guide rail 12; the folding mirror 11 is fixed on the known two-dimensional adjustment mechanism, and the two-dimensional adjustment mechanism is fixedly connected with the guide rail slider 13, and the guide rail slider 13 can move along the guide rail 12; The collimation system 20 may adopt a collimator composed of a parabolic mirror 4 and a hyperboloid mirror 5, the reticle 3 is located on the focal plane of the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com