Patents

Literature

3559results about How to "Guaranteed mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

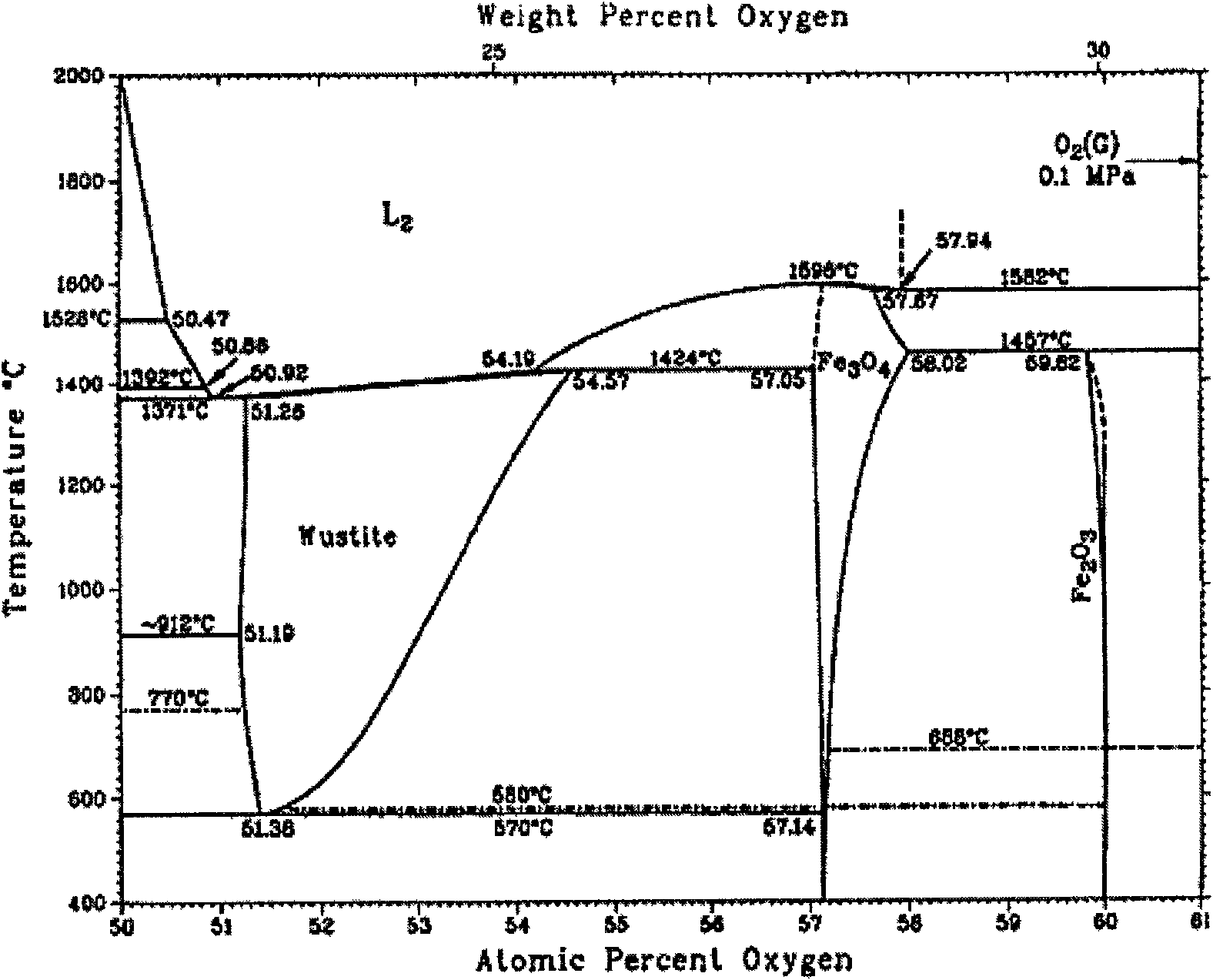

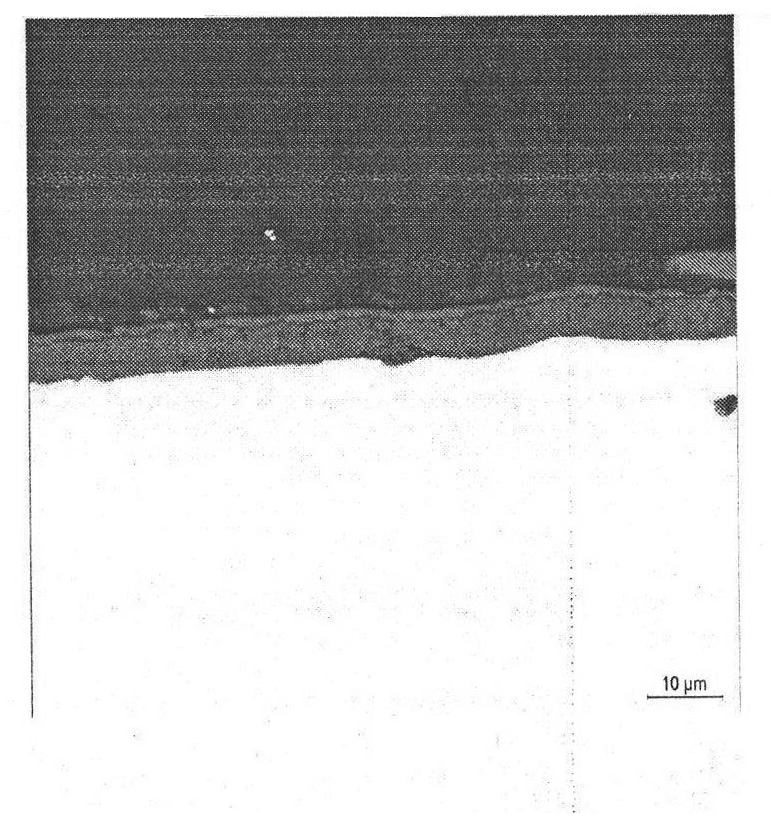

Control method of softness of oxide scales on surface of hot-rolling strip steel

ActiveCN101856669AImprove adhesionReduce FeO fragmentationTemperature control deviceWork treatment devicesOxideRolling speed

The invention provides a control method of softness of oxide scales on the surface of hot-rolling strip steel, belonging to the technical field of metallurgy. The method comprises the following steps: smelting liquid steel and continuously casting into plate blanks, heating and conducting thermal insulation on the plate blanks, then descaling, and rough rolling; and descaling again, and then finish rolling, wherein the initial rolling temperature is 1020-1070 DEG C, the finish rolling temperature is 870-920 DEG C, the rolling reduction is 75-95%, and the rolling speed is 3.5-12 m / s; cooling to 500-650 DEG C at the speed of 8-25 DEG C / s; and coiling. Aiming to different oxide scales structures, a hot-rolling process regulation scheme is provided in the method. In the hot-rolling process regulation scheme, by controlling the cooling speed and coiling temperature and the degree of a eutectoid reaction of FeO, reasonable control of the structure of the oxide scales is achieved, and loss of mechanical properties of products, which is caused by high temperature rolling, is compensated. The production efficiency is improved by using the existing devices and process conditions in a steel plant, surface quality is improved on the premise of ensuring mechanical properties of the steel plate and flexible production of oxide scale control.

Owner:NORTHEASTERN UNIV

Permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation

The invention discloses permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation. The permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste is characterized in that recycled coarse aggregates and ceramsites are taken as coarse aggregates of concrete, an appropriate amount of pretreated industrial and agricultural solid waste such as industrial waste, agricultural waste, household garbage and the like is taken as an admixture, a cementing agent is prepared from cement, water, a superplasticizer and a reinforcement material, and the materials are mixed with a preset stirring process and preparation method, so that ecological concrete with good mechanical property, permeable property and durability is produced. According to the concrete, the waste utilization rate is up to about 80%, the concrete is environment-friendly, locally available materials can be used, the economic benefit is remarkable, ceramist pore is smaller, and sewage can be continuously and stably treated, so that the concrete is commonly used in water environment comprehensive improvement engineering; and besides, the concrete has light weight, high strength and good water permeability and can be also used in permeable pavement engineering such as a sidewalk, a parking lot and the like as well as plant engineering such as ecological riverway slope protection, roof landscape planting and the like.

Owner:YANGZHOU UNIV

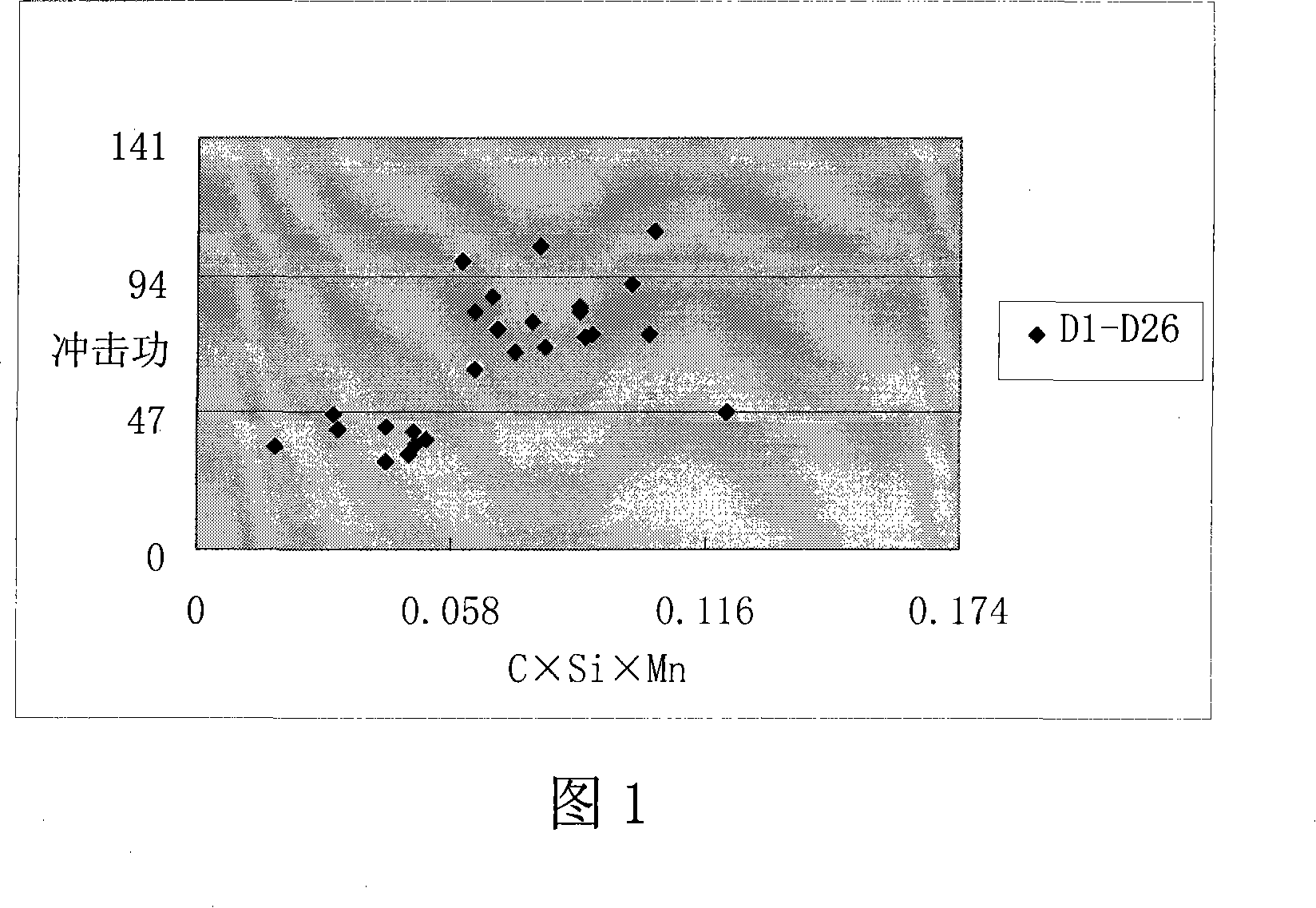

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

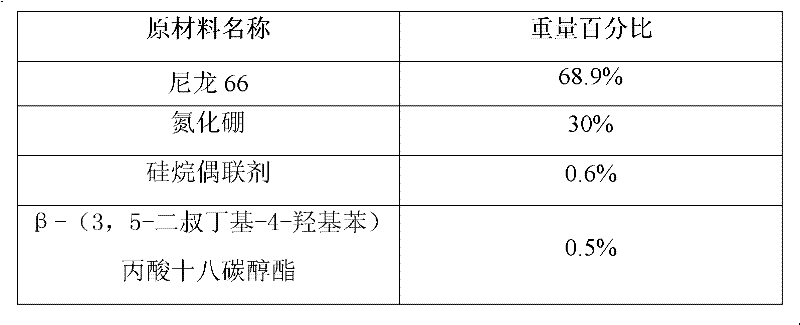

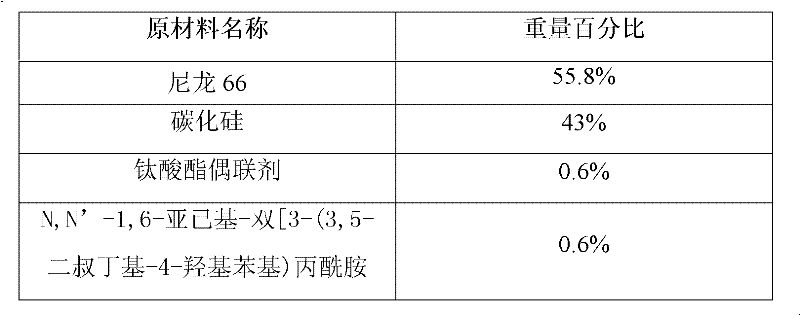

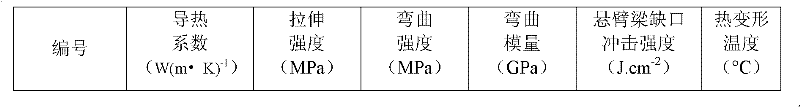

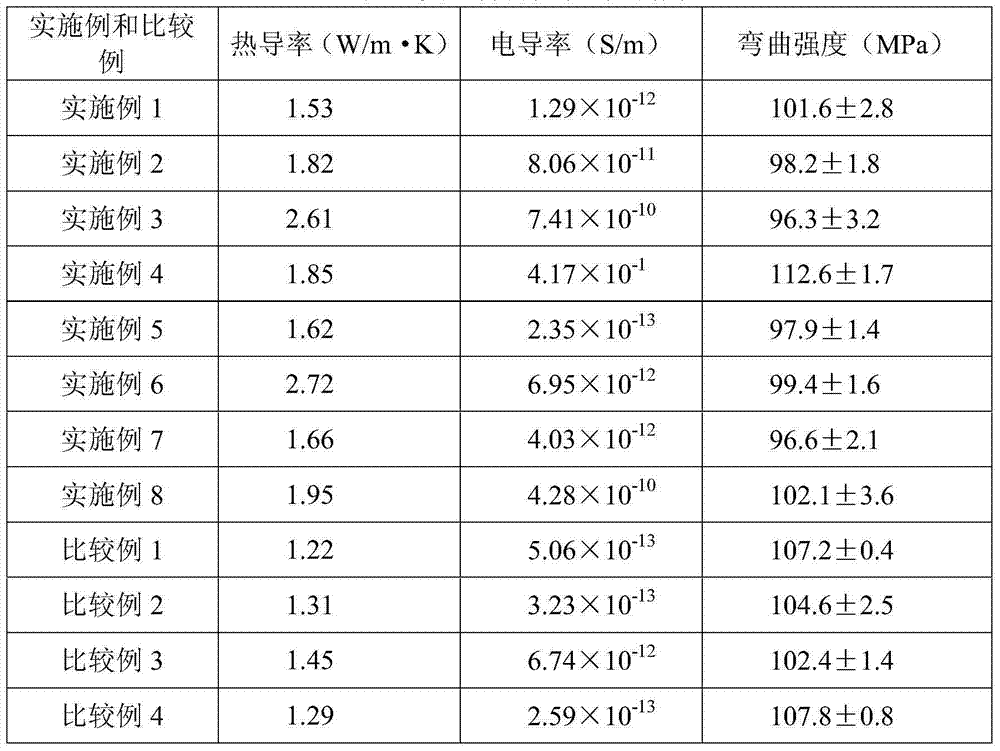

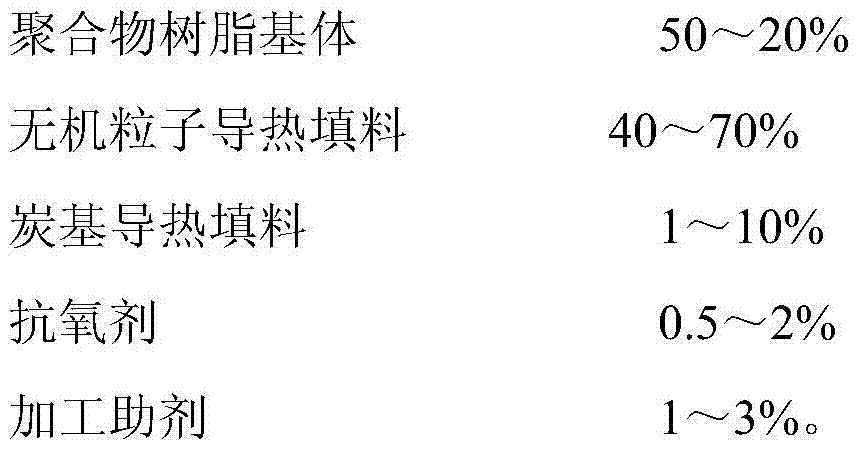

Nylon 66 composite material with high heat conductivity and preparation method thereof

ActiveCN102408710AGood dispersionEvenly dispersedHeat-exchange elementsStrength of materialsNylon 66

The invention discloses a nylon 66 composite material with high heat conductivity, comprising the following substances based on weight percentages: 70-42% of nylon 66, 27-55% of heat conduction filler, 0.5-1.5% of coupling agent and 0.5-1.5% of anti-oxidant. In addition, the invention also discloses a preparation method for the nylon 66 composite material with high heat conductivity, wherein the method adds a processing step on the heat conduction filler based on the conventional method. The nylon 66 composite materials with high heat conductivity prepared by the invention can better keep themechanical property of the nylon 66 composite material and largely raise the heat conductivity at the same time. In comparison with the heat conductivity of the nylon 66 composite material prepared from the heat conduction filler without processing, the heat conductivity of the nylon 66 composite material prepared from the processed heat conduction filler is raised by about 30-50%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Current conducting silicon rubber with capability of electromagnetic shielding, and fabricating method

ActiveCN101050307AMeet electromagnetic shielding requirementsImprove shielding effectMagnetic/electric field screeningNon-conductive material with dispersed conductive materialElectromagnetic shieldingSilicon rubber

This invention relates to an electrically conductive silicon rubber with electromagnetic shielding performance. The electrically conductive silicon rubber is prepared by: filling organosilicon rubber matrix with electrically and magnetically conductive media. The electrically and magnetically conductive media comprise: Ag powder 30-70 wt. %, Ni powder 0-40 wt. %, and magnetic powder 0-40 wt. %. The electrically conductive silicon rubber has such advantages as high weathering resistance, good mechanical properties, and high electromagnetic shielding performance.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

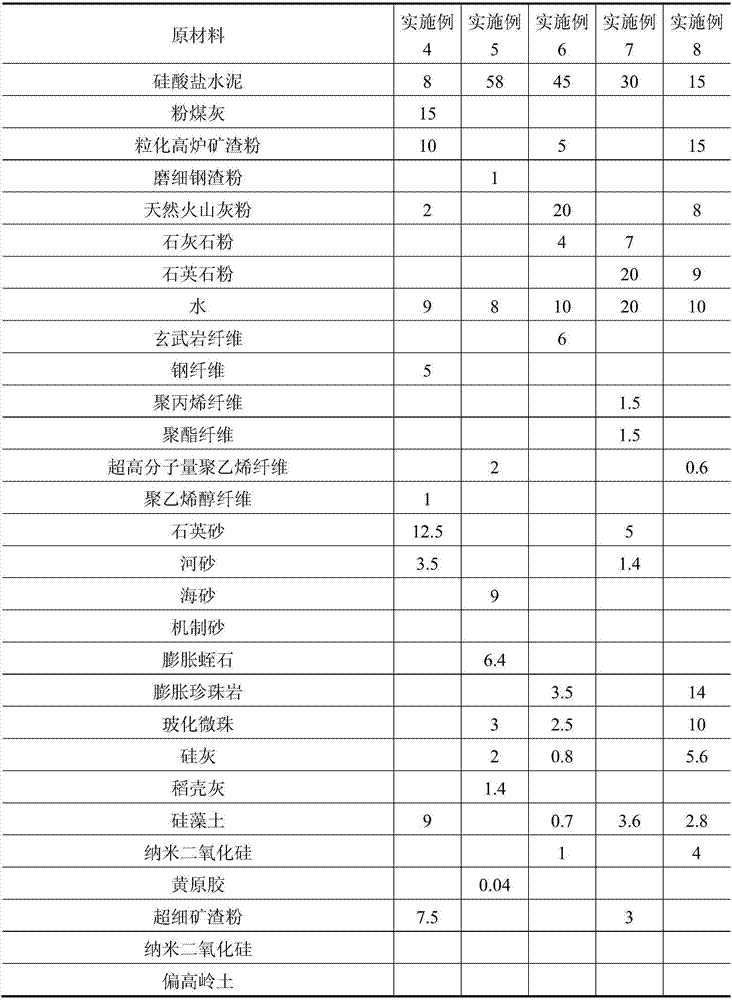

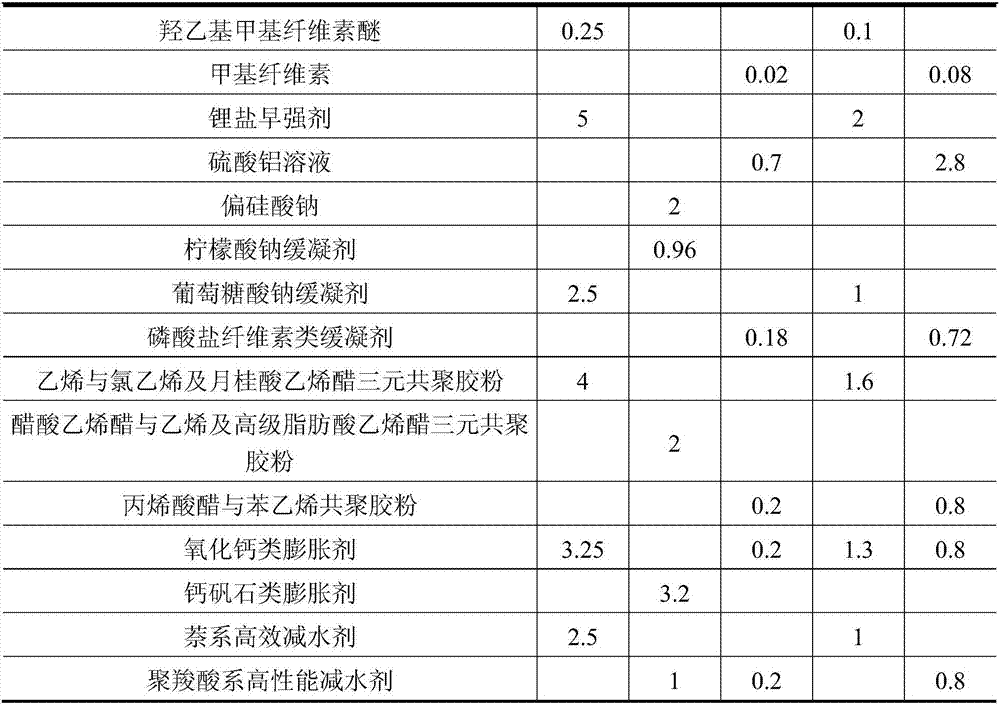

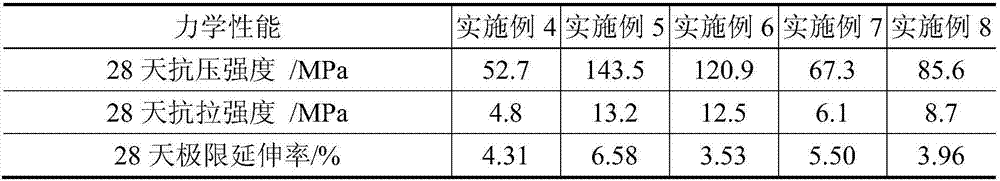

High-ductility fiber-enhanced cement based composite material used for 3D printing and preparation method of composite material

ActiveCN107500687AImprove performanceHigh compressive strengthAdditive manufacturing apparatusRebarWater reducer

The invention provides an additive composition used for a high-ductility fiber-enhanced cement based composite material. The additive composition comprises, by weight percentage, 20-85% of a rheological adjusting component, 2-30% of a setting and hardening adjusting component, 1-20% of an interlayer bonding strength adjusting component, 4-40% of a volume stabilizer, and 1-10% of a water reducer. The invention further provides a high-ductility fiber-enhanced cement based composite material based on the additive composition. Through optimal design of the additive composition and aggregate, the workability and the setting and hardening speed of a material is adjusted, and the printability, constructability, and the interlayer bonding strength of the high-ductility fiber-enhanced cement based composite material in 3D printing are improved. Compared with a 3D printing building material in the prior art, the composite material shows excellent whole performance. A component made from the composite material can meet the ductility of structural requirements without steel bars, thereby solving the problem that a component made from a 3D printing building material in the prior art is finally broken in a brittle failure manner.

Owner:万玉君

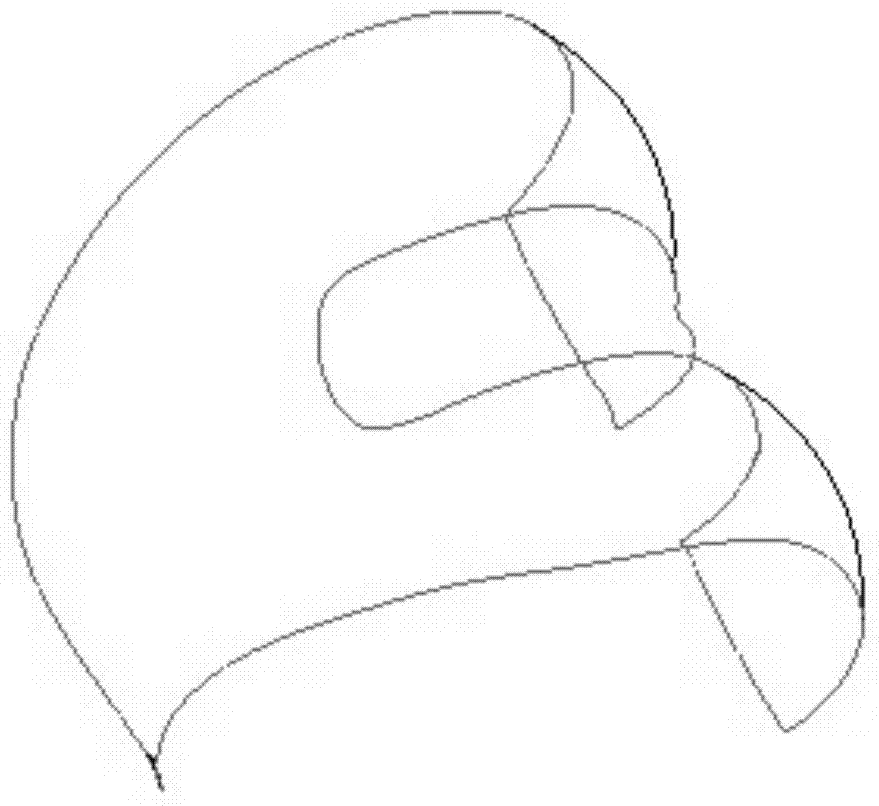

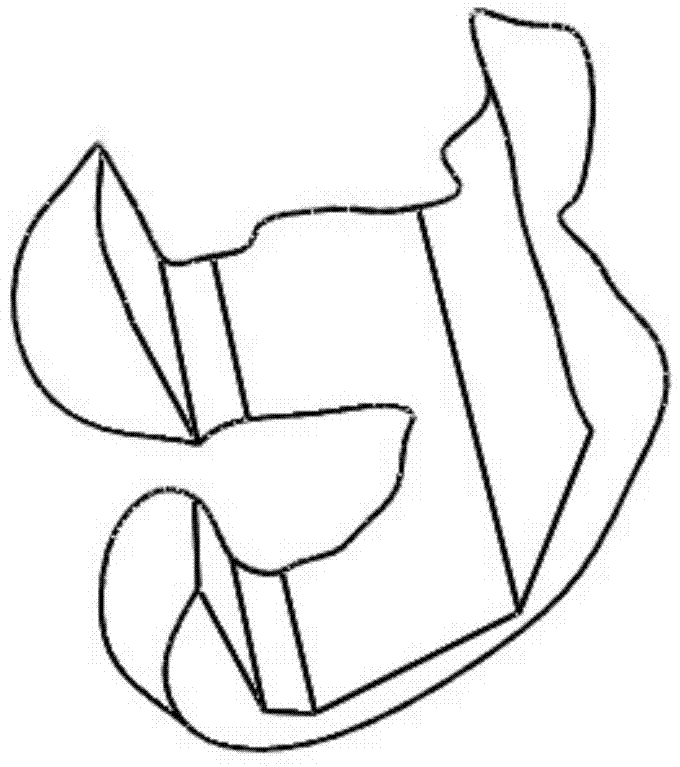

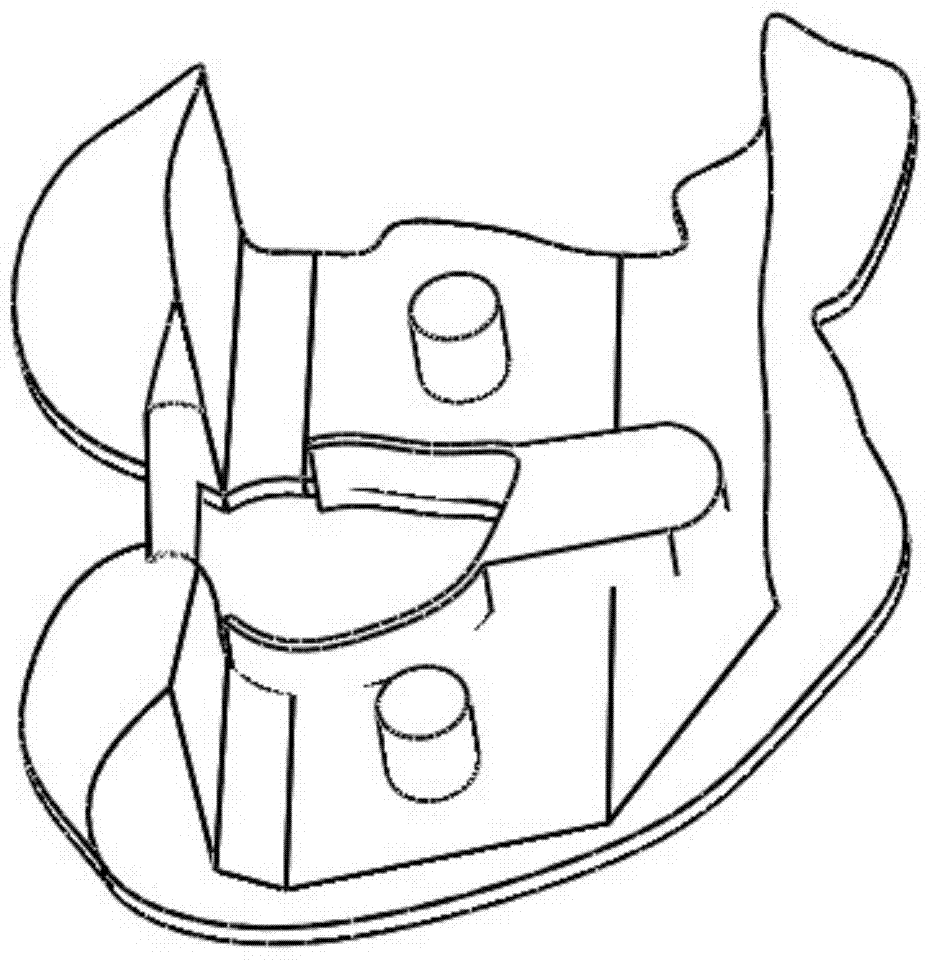

Bionic gradient knee femoral prosthesis structure and a production method thereof

ActiveCN103584931AImprove adaptabilityAdapt to exerciseAdditive manufacturing apparatusJoint implantsKnee JointFemoral prosthesis

The invention discloses a bionic gradient knee femoral prosthesis structure and a production method thereof. The prosthesis structure comprises a smooth curved-surface shell, a post-osteotomy completely-covering joint face, a gradient porous structure and a fixing device. The curved-surface shell is based on the shape of the distal end of a connate femur. The post-osteotomy completely-covering joint face reversely spreads to the distal-end curved surface of the connate femur. A solid more than 5mm distant from the curved surface is replaced by the gradient porous structure, and the fixing device is formed on the distal-end plane on the inner side of a femoral prosthesis. Compared with conventional standard prostheses, the prosthesis structure has the advantages that matching degree is high, and the prosthesis highly fits the bone shape of a connate knee and is adaptable to motions of a patient. The bionic gradient knee femoral prosthesis structure is easy to produce, and conventional production methods for conventional bionic gradient prostheses are complex; by the 3D (three-dimensional)-printing production method, prostheses can be customized according to individual differences of patients, production period is short, cost is low, and a possibility for application and development of individualized therapy is provided.

Owner:BEIJING NATON TECH GRP CO LTD +1

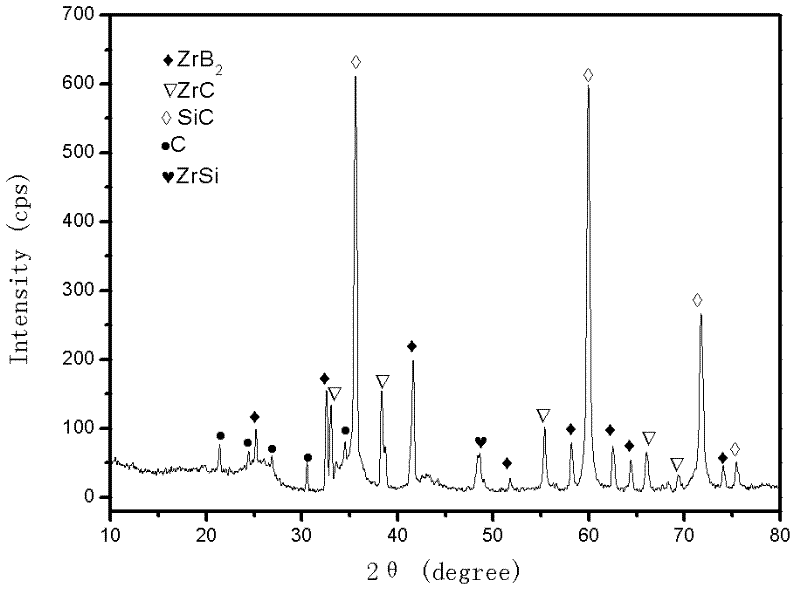

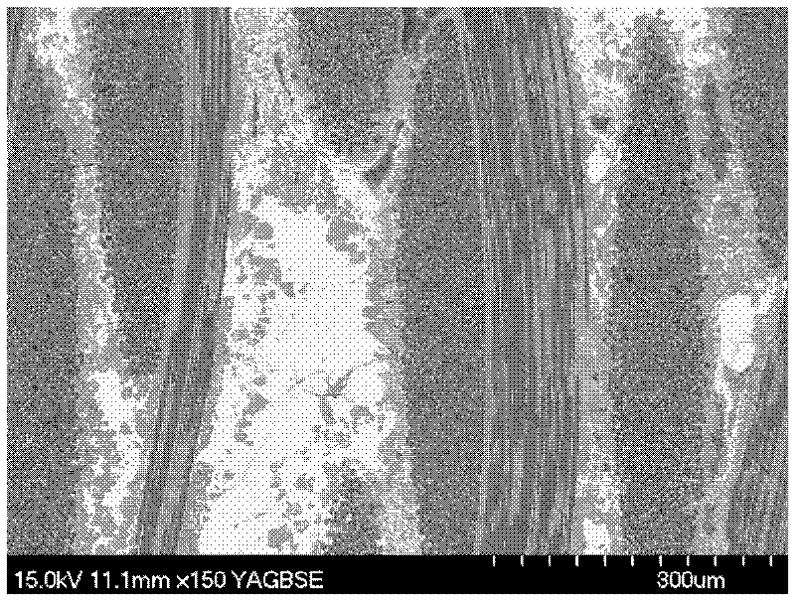

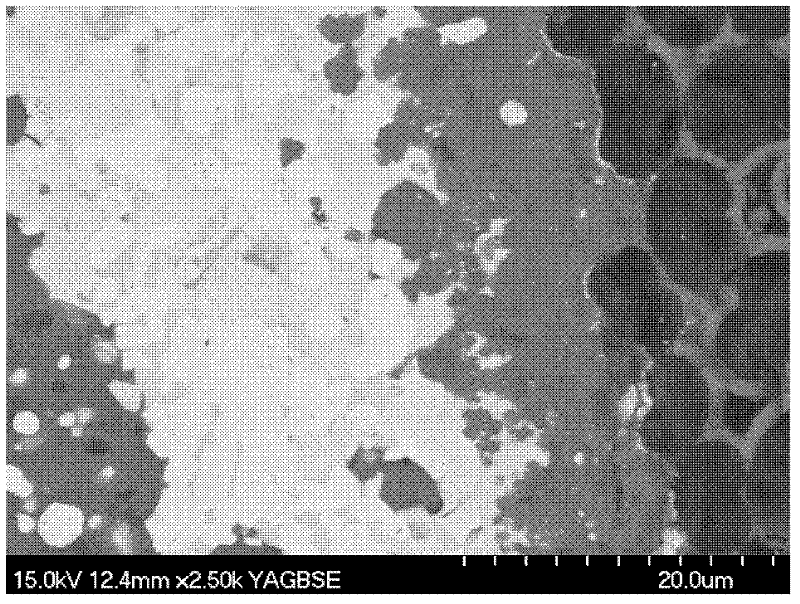

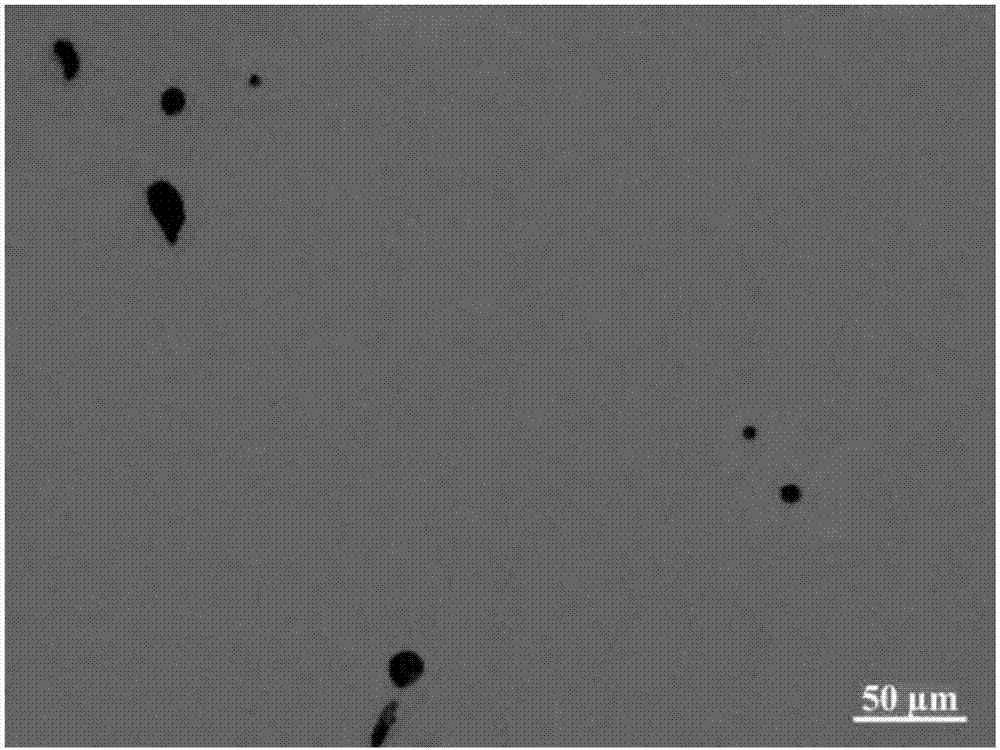

Preparation method of C/SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material

ActiveCN102515870AGuaranteed mechanical propertiesHigh volume contentVacuum pressureUltrahigh temperature ceramics

The invention relates to a preparation method of a C / SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material. According to the invention, B4C and a C organic precursor are introduced into a C / SiC composite material with a vacuum pressure impregnation method; the obtained material is cured and is subject to a heat treatment, such that the C organic precursor is cracked, and pores sealed by the C organic precursor are opened; with a reactive melt infiltration method, under a condition that a temperature is higher than that of silicozirconium alloy, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized, and the C / SiC-ZrB2-ZrC composite material is prepared. According to the invention, with the vacuum pressure impregnation method, B4C and the C organic precursor are introduced into the C / SiC composite material; with the reactive melt infiltration method, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized. The produced ZrB2 and ZrC are advantaged in fine grains and high volume content. The ablation resistance and mechanical properties of the composite material are effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

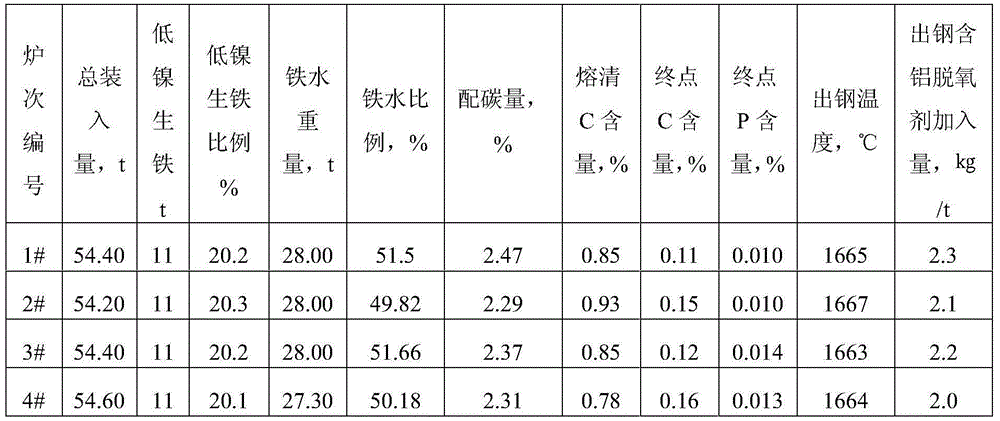

Medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and production technological method thereof

ActiveCN107287504AExcellent machinabilityReduce precipitationProcess efficiency improvementSulfurImpurity

The invention discloses medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and a production technological method thereof. The non-quenched-and-tempered steel mainly comprises 0.35%-0.50% of C, 0.10%-0.80% of Si, 0.75%-1.60% of Mn, 0-0.03% of P, 0.02%-0.08% of S, 0-0.08% of Mo, 0-0.025% of Nb, 0.02%-0.12% of V, 0.012%-0.016% of N, 0.02%-0.08% of Te, 0.001%-0.003% of Ca, and the balance Fe and inevitable impurities. The ratio of the tellurium to the sulfur is 0.25-2.5. According to the free-cutting non-quenched-and-tempered steel disclosed by the invention, occluded foreign substances in the steel can be subjected to modifying treatment by adding the tellurium, the cutting properties, fatigue resistance and the like of the non-quenched-and-tempered steel can be improved obviously, and pollution to the environment can be avoided.

Owner:SHANGHAI UNIV

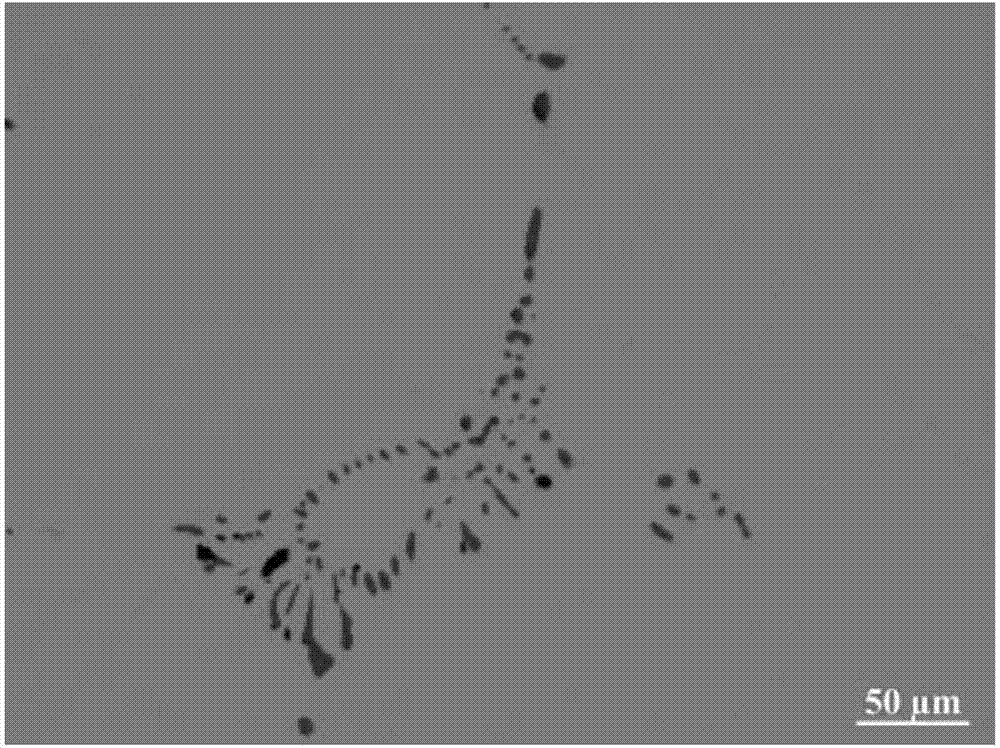

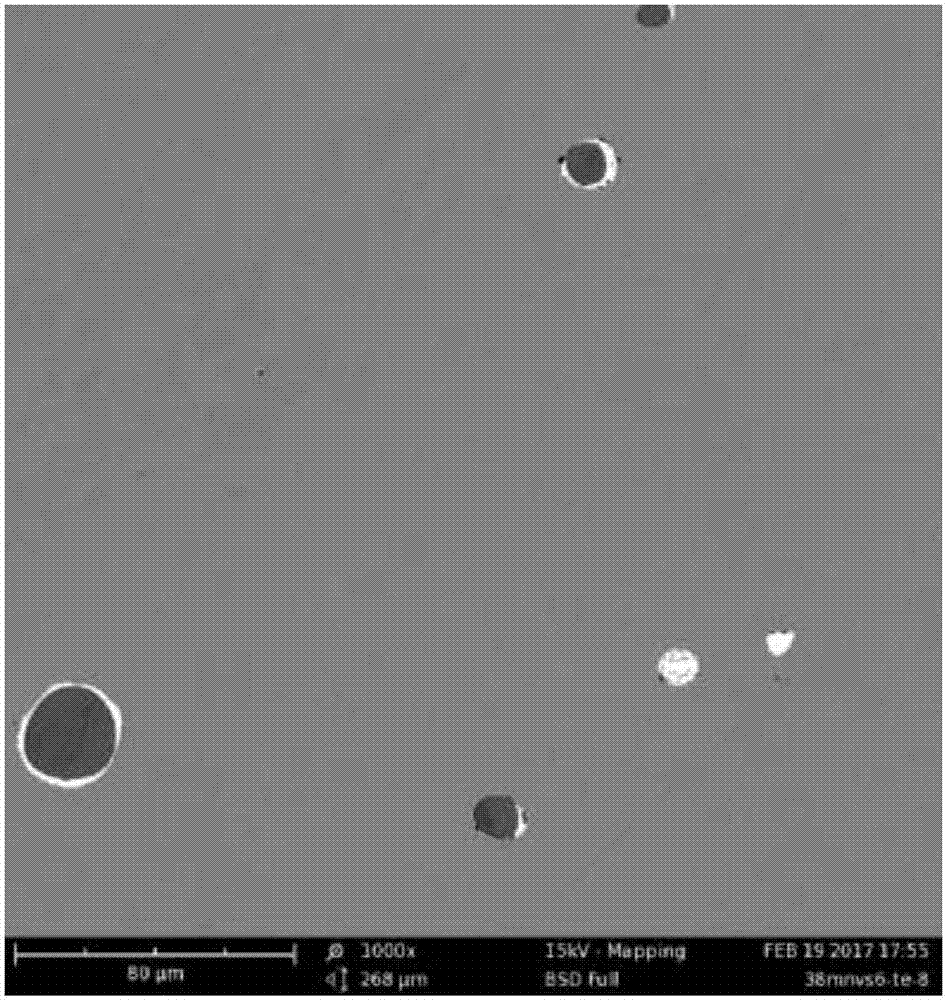

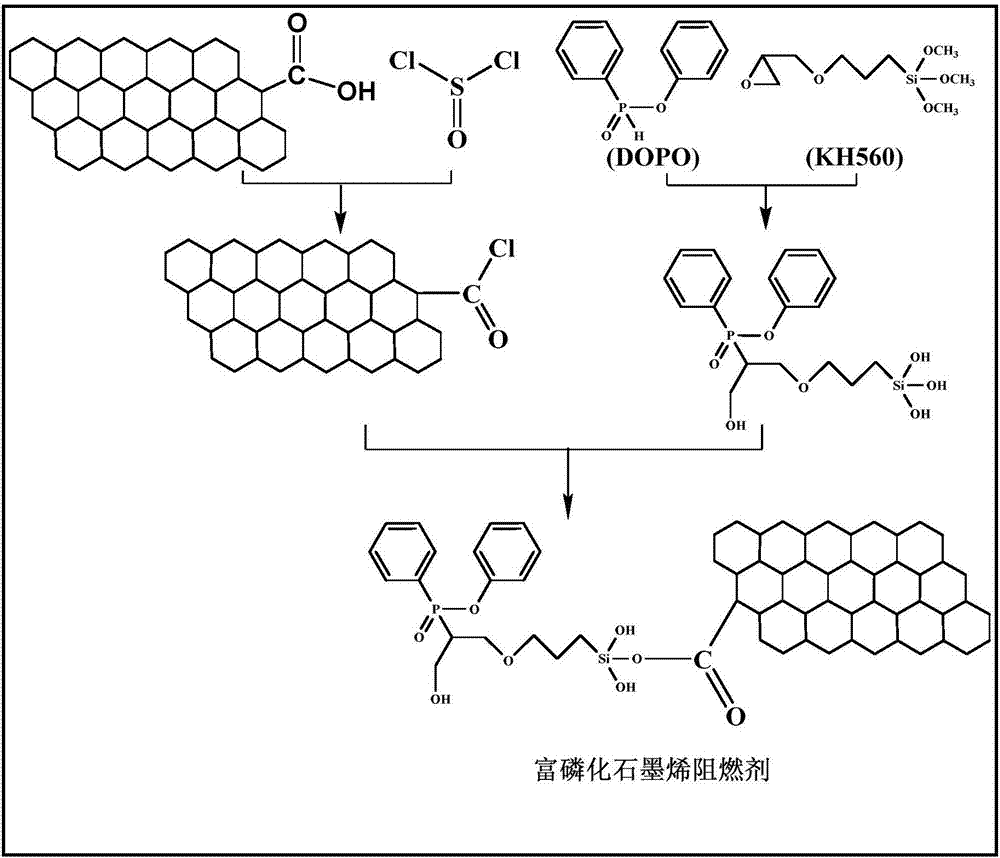

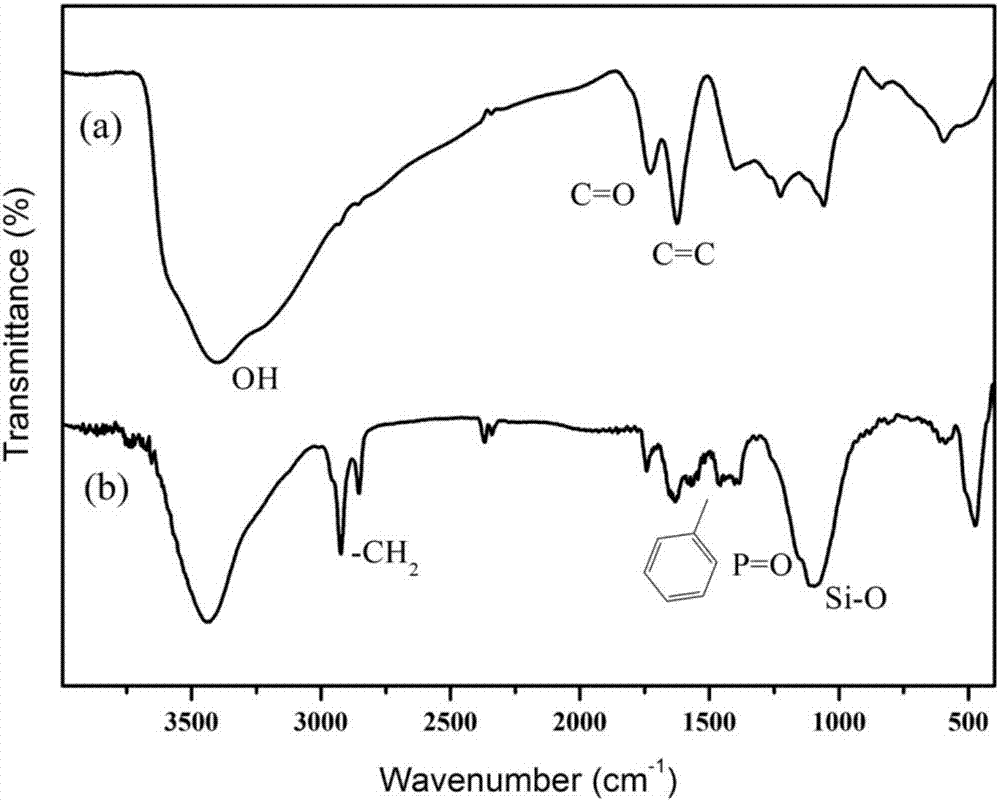

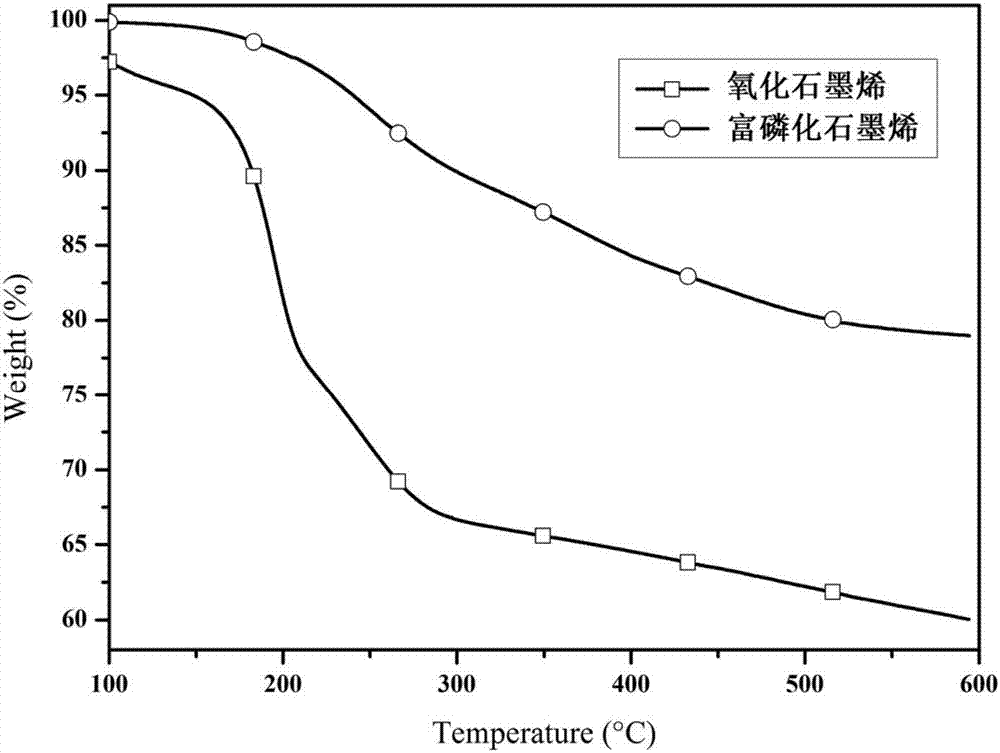

Phosphor-rich graphene flame-retardant agent and preparation method thereof

ActiveCN106883450AHigh flame retardant efficiencyConducive to synergistic flame retardantFireproof paintsPolyurea/polyurethane coatingsCarbon layerSilanes

The invention provides a phosphor-rich graphene flame-retardant agent with a structural formula shown in the description. The invention also provides a preparation method of the phosphor-rich graphene flame-retardant agent. The preparation method is characterized in that graphene oxide is used as a basic raw material, reactive groups at both ends of a silane coupler containing a silicon carbon layer improving agent are fully utilized, one end of the silane coupler is connected with acid source components, such as CEPPA (carboxyethyl phenyl phosphinic acid), DOPO or derivatives, and the other end of the silane coupler is connected with the graphene oxide, so as to obtain a macromolecular flame retardant integrating a physical carbon layer, an acid source and the carbon layer improving agent. The phosphor-rich graphene flame-retardant agent has the advantages that the flame-retardant efficiency is high, the polarity is low, the moisture absorbing property is little, and the mechanical property of the material can be well maintained; by not containing halogen, the flame-retardant agent is friendly to the human body and environment, and meets the green development direction of future flame-retardant agents.

Owner:宿迁聚萃功能复合材料研究所有限公司 +1

900MPa high-strength steel preheating-free combined welding method

The invention discloses a 900MPa high-strength steel preheating-free combined welding method. 700-800 MPa low-hydrogen type high-tenacity shielded metal arc welding is adopted for backing welding, then a 900MPa high-tenacity solid wire is matched with Ar+CO2 mixed gas shielded welding for implementing filling welding, and a 800MPa flux-cored wire is matched with CO2 gas shielded welding for cosmetic welding. A crack-free welding joint can be obtained by welding 900MPa high-strength steel through adopting a preheating-free and postweld heat treatment free combined welding process, and a joint region is smooth and clean, and can meet operating requirements on a high-strength steel welding structure for higher bearing capacity because the room temperature tensile strength of weld metal is more than 860MPa and the damping power of a V-shaped notch of the weld metal with the test temperature of 0 DEG C is more than 90J; and meanwhile, the method has welding cost reduced by about 25 percent, simple and convenient operation and easy popularization.

Owner:SHANDONG UNIV

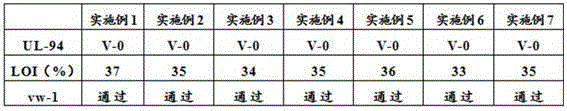

Halogen-free flame retardant polyether thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN104693782AImprove flame retardant performanceGuaranteed mechanical propertiesPolymer scienceMelamine phosphate

The invention relates to a halogen-free flame retardant polyether thermoplastic polyurethane elastomer which is prepared by the following components in parts by weight: 100 parts of polyether thermoplastic polyurethane elastomer resin, 30-50 parts of phosphor-nitrogen flame retardant system and 1-5 parts of flame retardant synergist, wherein the phosphor-nitrogen flame retardant system is prepared by mixing a flame retardant and a char-forming agent with weight ratio of 1-4: 1; and the flame retardant is one or a mixture of phenoxy cycloposphazene, melamine phosphate compound, melamine cyanurate and hypophosphite. The flame retardant performance of the polyether TPU (thermoplastic polyurethane) is modified by selecting the special phosphor-nitrogen flame retardant system; and the obtained flame retardant polyether TPU material is halogen-free, environment-friendly and safe, has a limit oxygen index (LOI) of up to 37% and has excellent flame retardant performance.

Owner:苏州安鸿泰新材料有限公司

Method for preparing conductive composite material by utilizing synergistic reaction of conductive filling material

InactiveCN101240091AImprove efficiencyImprove electrical performanceNon-conductive material with dispersed conductive materialFiberCarbon fibers

A preparation of electric conductive composite by synergism of conductive filler, particularly relates to a preparation of electric conductive composite by synergism between carbon nano-tube and conductive carbon filler. The preparation is characterized by using processing apparatus for high-molecular material to melt mix and granulate after mixing polymer, carbon nano-tube, carbon black, black lead, carbon fiber according to a definite ratio. The preparation is simple to operate, easy for application in industry, can further produce electric conductive composite with great electric conductivity and combination property, which can be widely used in automobile, electric and electronic apparatus, office equipment, industrial mechanism, and can satisfy and expand need of high-molecular materials in various application fields.

Owner:TSINGHUA UNIV

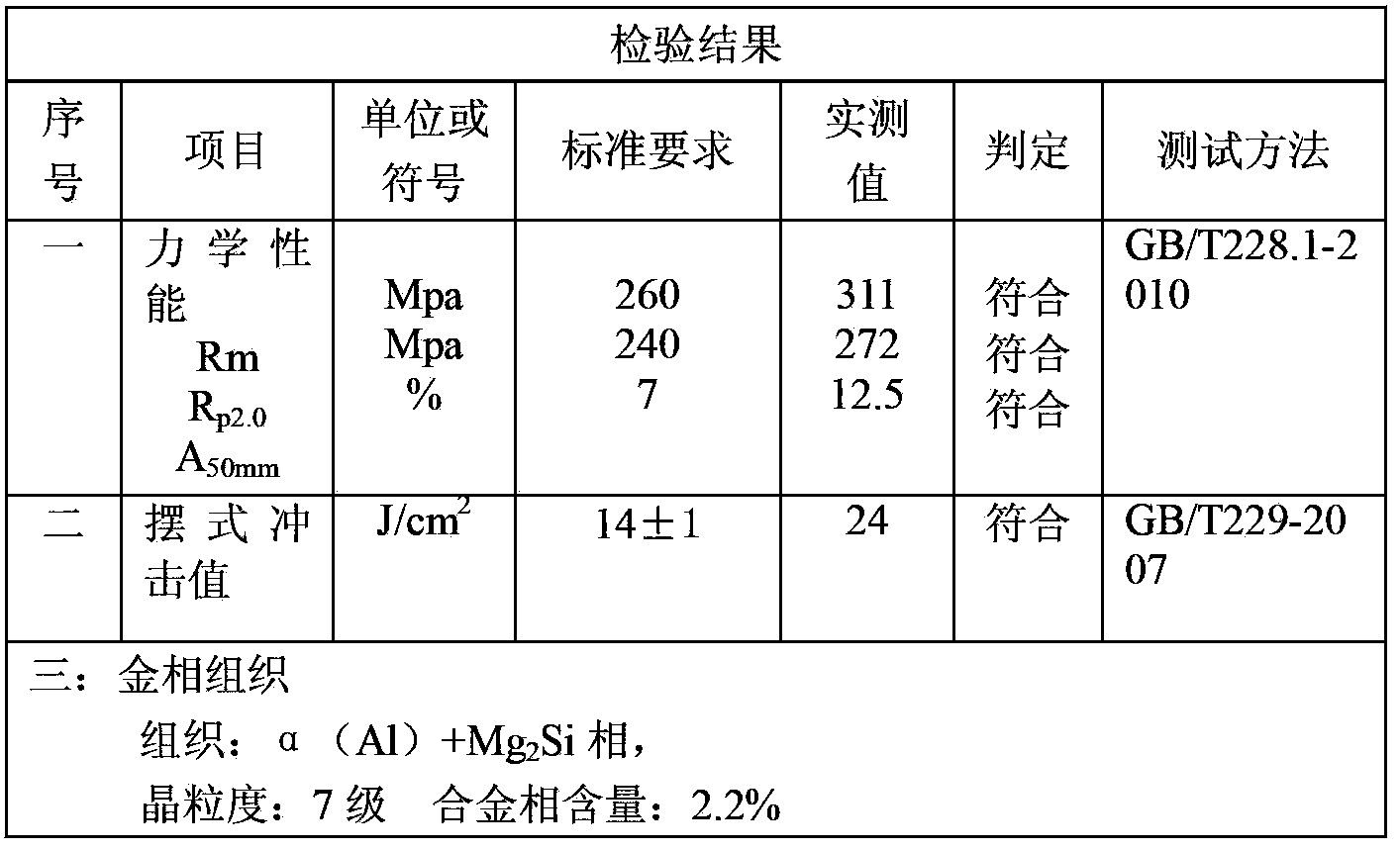

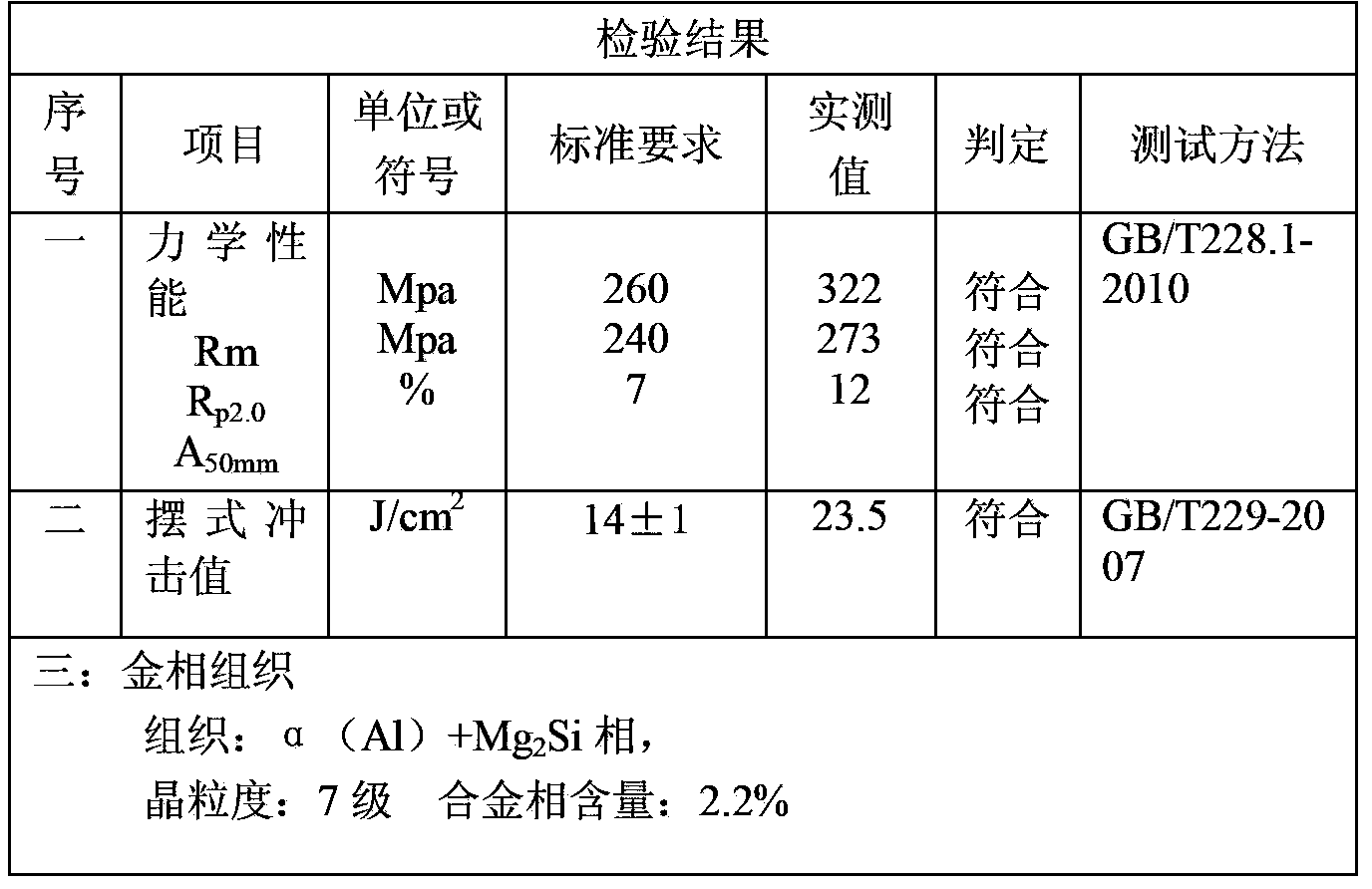

Aluminium alloy profile for building template, and preparation method thereof

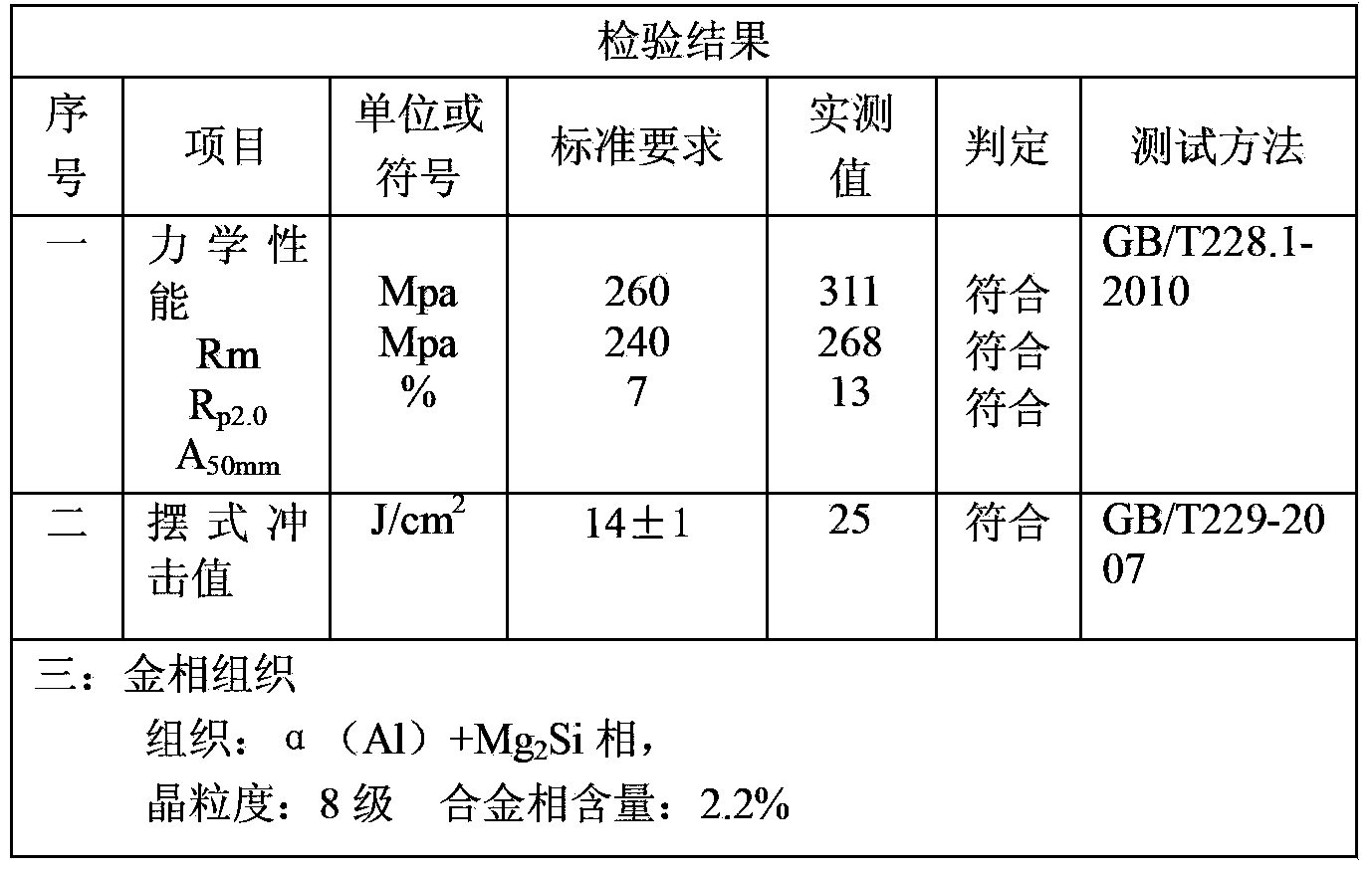

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

Two-component epoxy glue and preparation method thereof

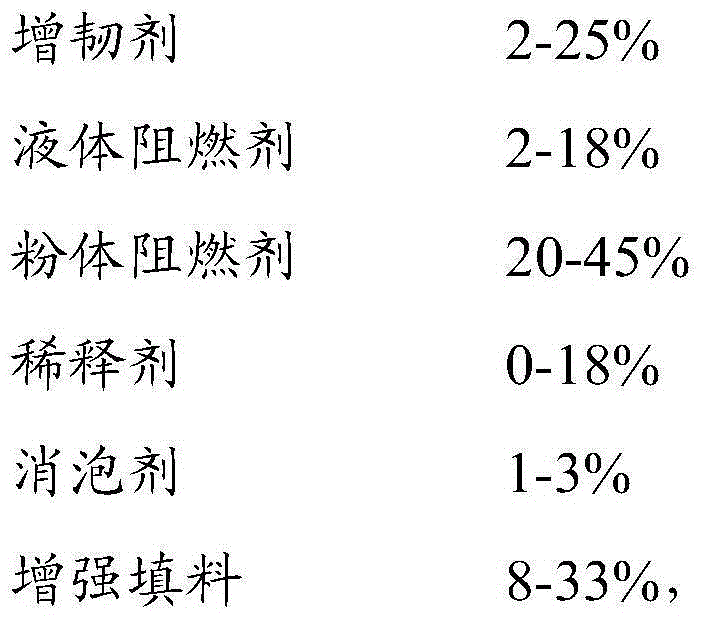

ActiveCN105062395AReduced cured crosslink densityRelatively consistent viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAliphatic amine

The invention relates to two-component epoxy glue and a preparation method thereof. The two-component epoxy glue comprises a component A and a component B, and the component A comprises epoxy resin, a toughening agent, a liquid flame retardant, a powder flame retardant, a diluent, an antifoaming agent and reinforcing fillers; the component B comprises an aliphatic amine curing agent, polyether amine, polyamide 650 and a curing accelerator. According to the two-component epoxy glue and the preparation method thereof, screening is conducted on the components of the epoxy glue, performance complementation of the components is achieved, a two-component epoxy glue with excellent comprehensive performance is formed through synergetic cooperation, the toughness, the anti-stripping strength and the anti-impact performance of the epoxy glue are significantly improved, the flame-retardant performance can reach the grade UL94-V0, the operable time is more appropriate, the curing time is short, and the continuous production can be achieved.

Owner:GUANGZHOU BAIYUN CHEM IND

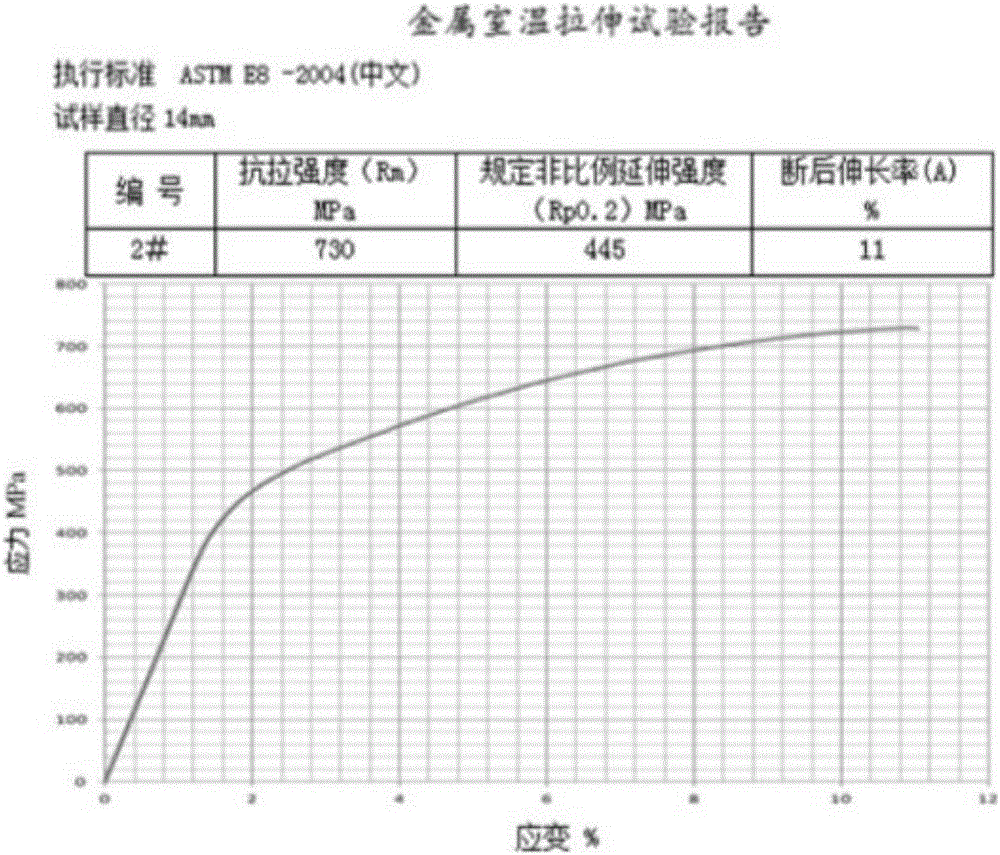

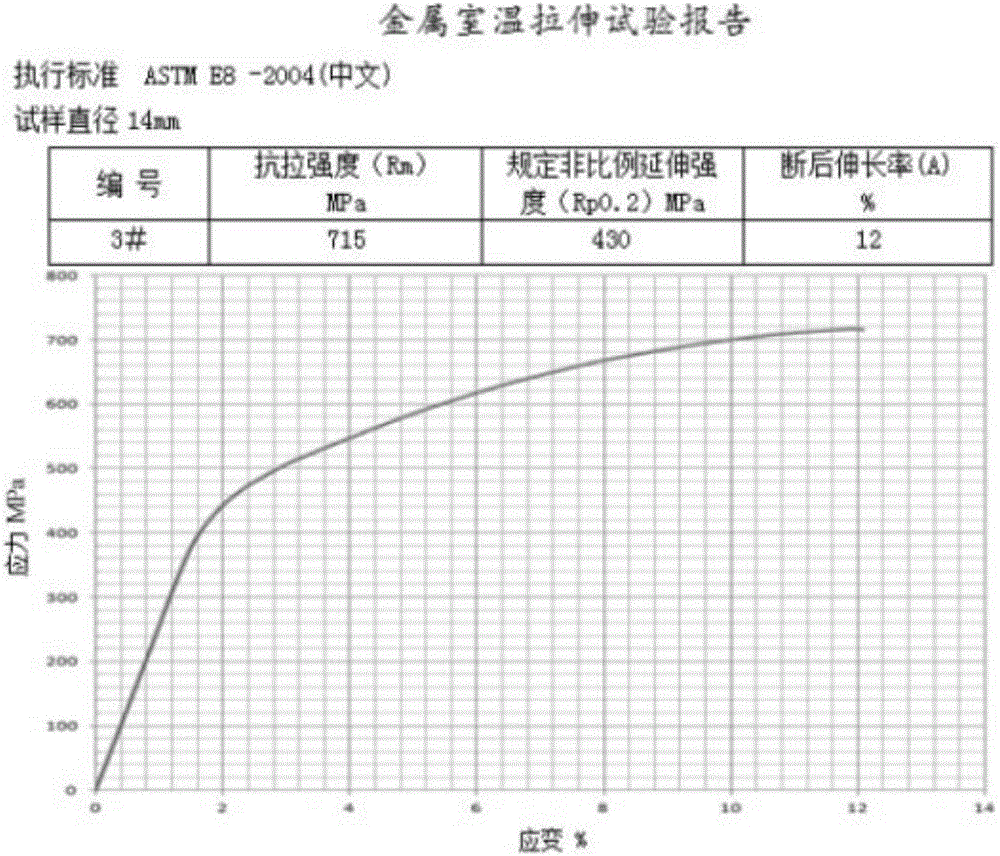

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

Heat and flame resistant nylon composite

InactiveCN101735601AImprove flame retardant performanceImprove mechanical propertiesNylon materialNitrogen

The invention relates to heat and flame resistant nylon composite belonging to the filed of the electrical and electronic material. The heat and flame resistant nylon composite is characterized by comprising phosphorus flame retardant, nitrogen flame retardant, inorganic synergist, filler and auxiliary agent facilitating the processing and stabilizing. Due to the synergistic effect of the phosphorus flame retardant, the nitrogen flame retardant and the inorganic synergist, the nylon has the flame resistance, mains the mechanical performance, the thermal performance and the electrical insulating performance and can pass the test of the glow wire at 850 DEG C, and the problems that the defect of the nylon product is increased and the mechanical performance and the electrical insulating performance of the nylon produce are decreased due to the large consumption of the phosphorus flame retardant are solved. The heat and flame resistant nylon composite has good flame resistance, mechanical performance, thermal performance and electrical insulating performance and is mainly applied to the electrical and electronic industry.

Owner:SINOPLAST NEW MATERIAL

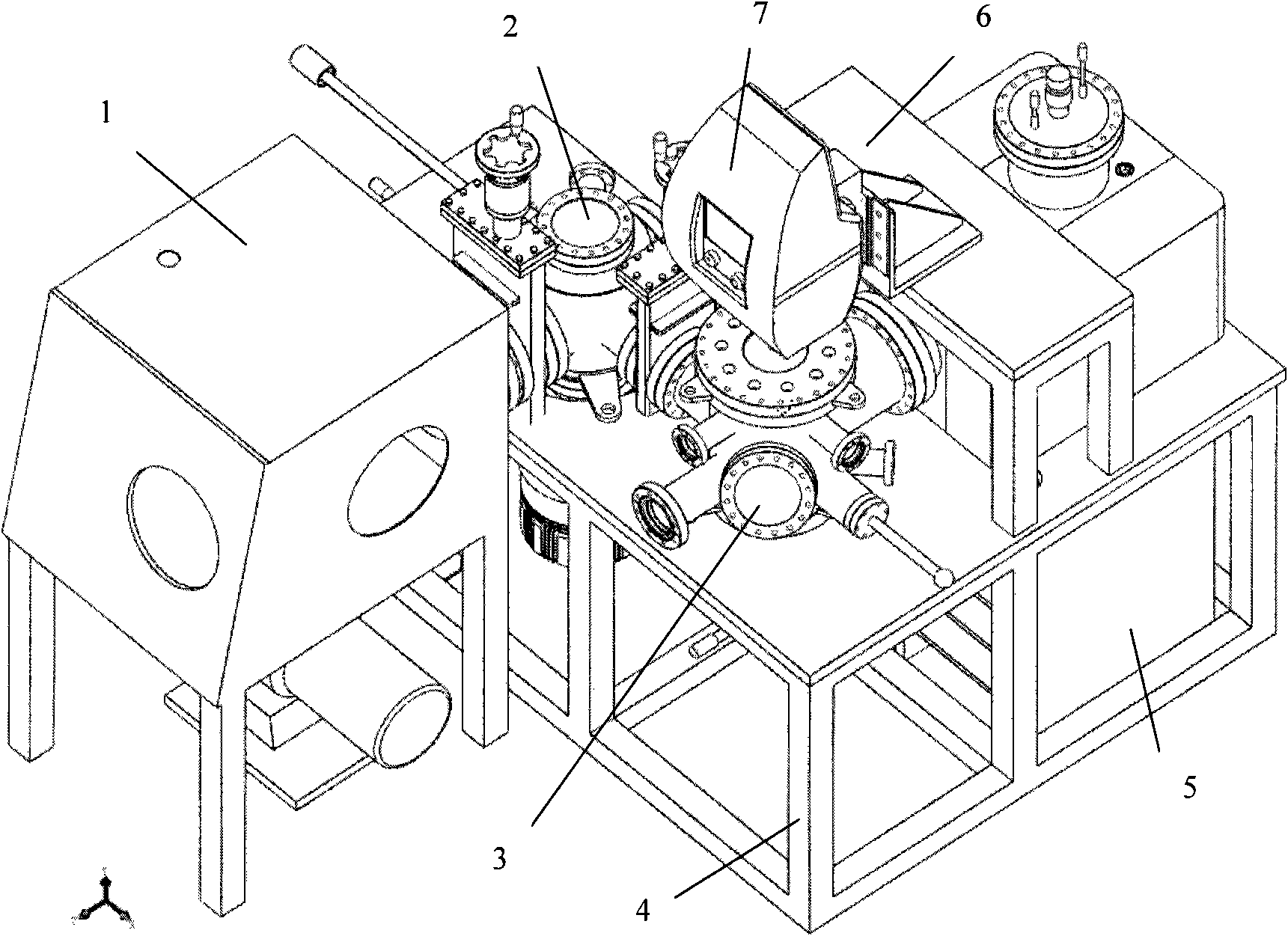

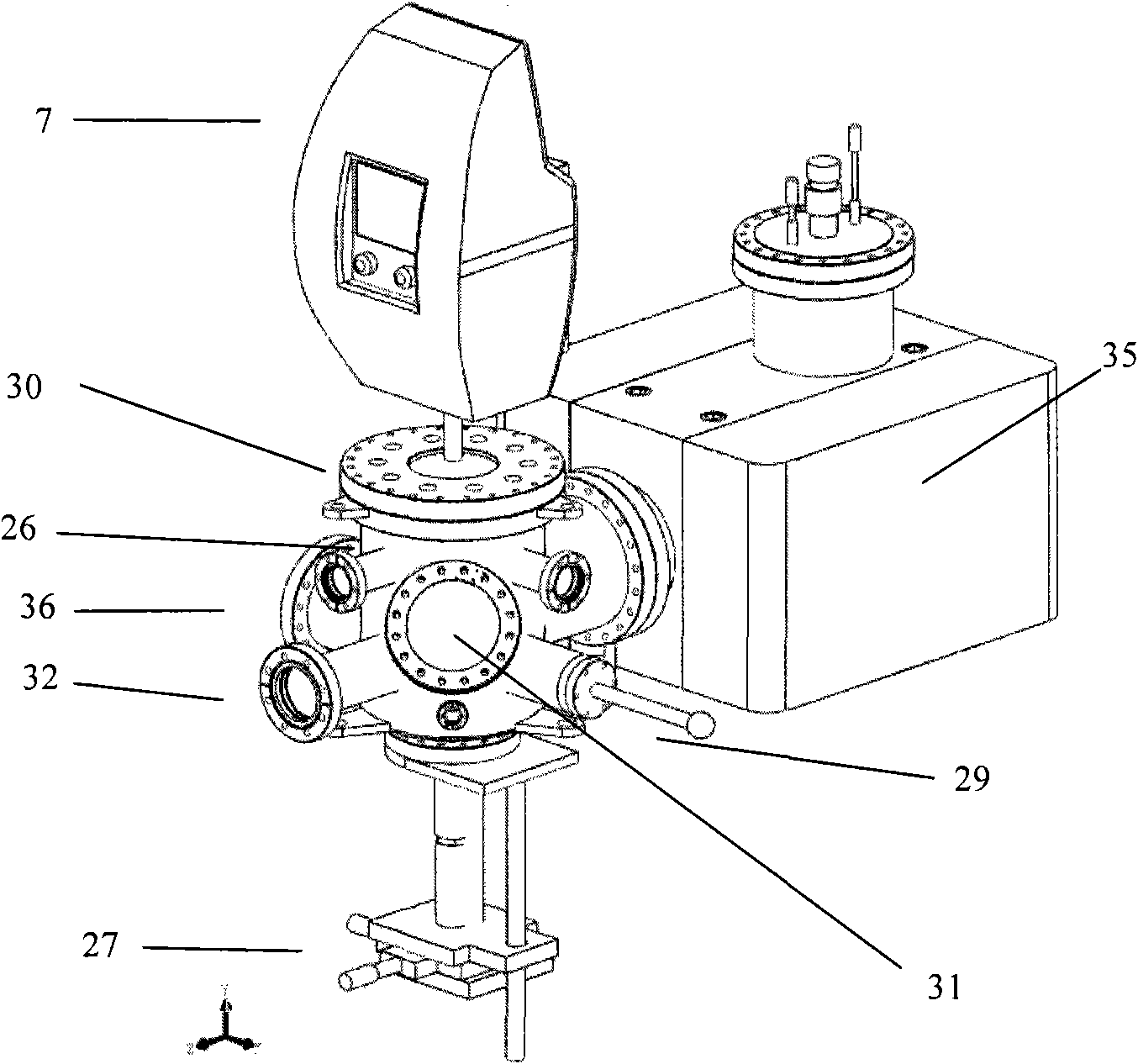

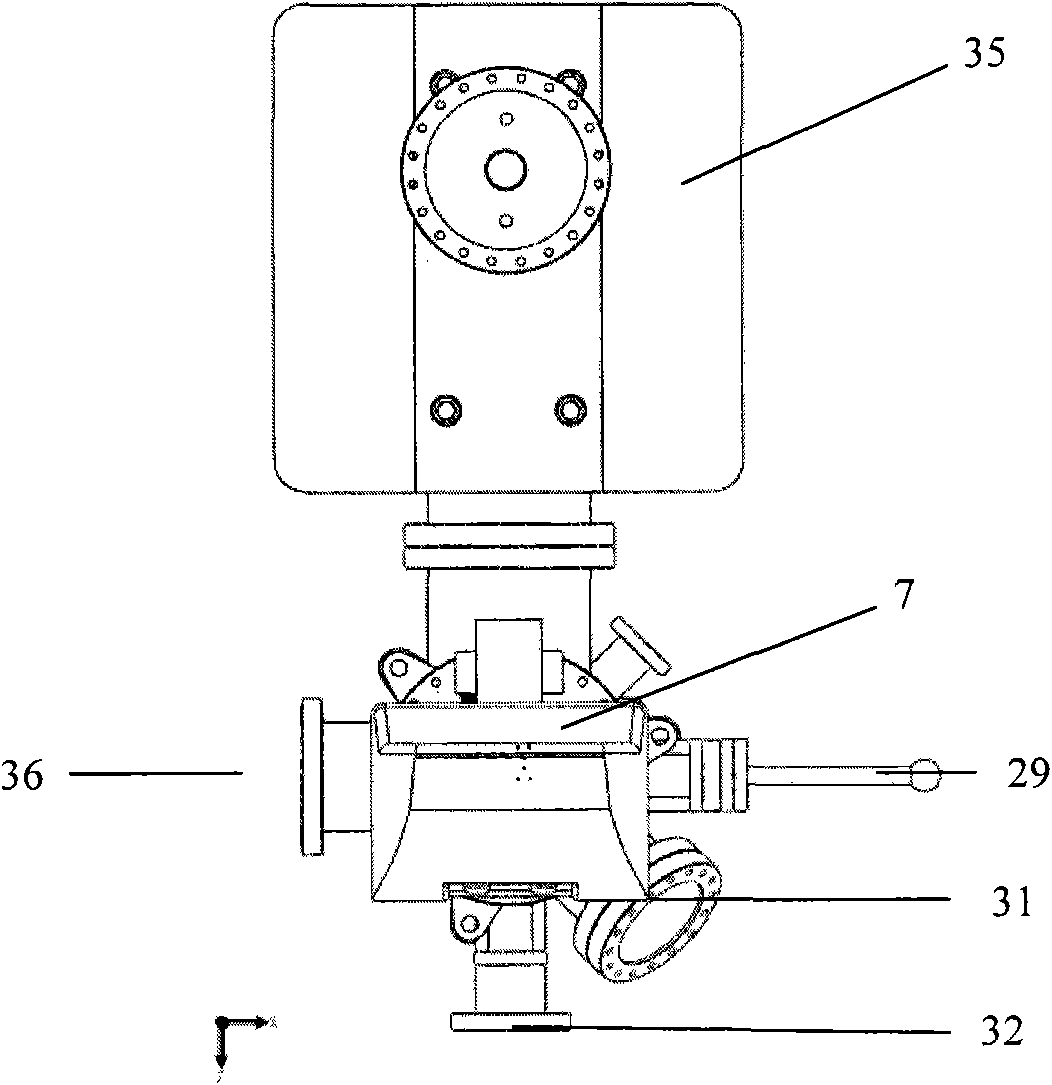

Ultra-high vacuum multifunctional integrated test system

ActiveCN101846635AAvoid serious deviationsGuaranteed mechanical propertiesMaterial analysis by optical meansElectrical testingMicro nanoUltra-high vacuum

The invention discloses an ultra-high vacuum multifunctional integrated test system which is used for surface treatment, surface modification and in-situ characterization of micro-nano devices. The invention comprises a first ultra-high vacuum chamber, a second ultra-high vacuum chamber, a constant pressure chamber and a system frame, wherein the first ultra-high vacuum chamber and the second ultra-high vacuum chamber are connected in a sealing way, the constant pressure chamber is connected with the second ultra-high vacuum chamber in a sealing way, the system frame is of a rectangular frame, and the first ultra-high vacuum chamber, the second ultra-high vacuum chamber and the constant pressure chamber are fixed on the system frame to form the ultra-high vacuum test system. The invention realizes the integration of functions of surface treatment, surface modification and in-situ mechanical characterization, electrical performance test and the like of the micro-nano devices, avoids the serious deviation of test results, which is caused because the surface of a processed stamp is re-polluted during the process of the delivering and testing, and provides the guarantee for clearly and accurately studying the influence of surface damage on the mechanical and electrical properties of the devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

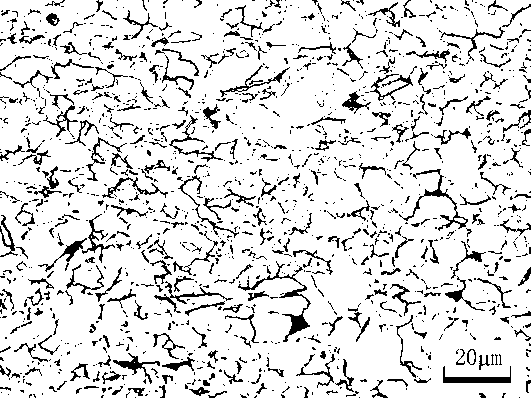

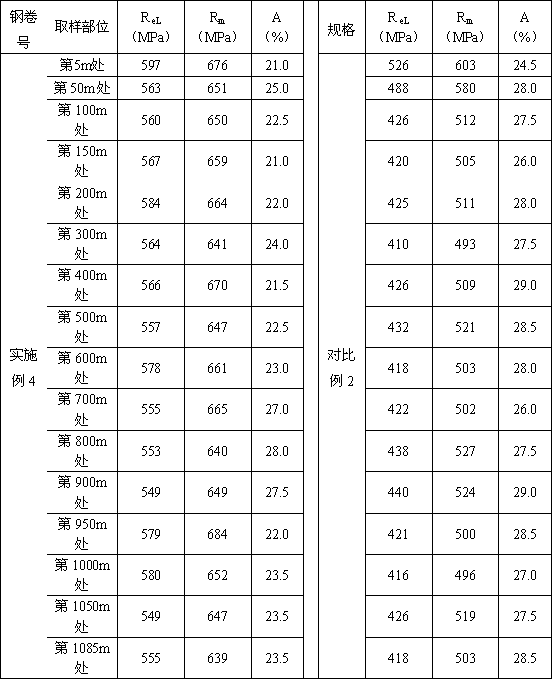

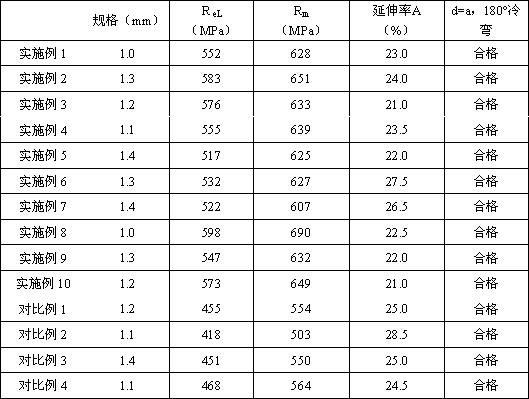

Ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level and manufacturing method thereof

ActiveCN102839321AIncrease the effective Ti contentImprove precipitation strengthening effectCold formedLaminar cooling

An ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level comprises the chemical components by weight: 0.02-007%of C, less than or equal to 0.50% of Si, 0.50-1.40% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.11% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O, or 0.17-0.20% of C, less than or equal to 0.50% of Si, 0.50-0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.08% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O. The process comprises melted iron desulfuration, converter blowing, argon blowing, LF furnace refining, continuous casting, rotary descaling, soaking pit soaking, descaling, seven-frame finish rolling, stream cooling and coiling. The ultrathin hot-rolled sheet strip has the advantages that the addition of the alloying element is low, the mechanical property is as follows: the yield strength is more than or equal to 500MPa, the product thickness is less than or equal to 1.4mm, the sheet shape is good, the production flow is short, and excellent cold forming and welding performances are achieved.

Owner:武汉钢铁有限公司

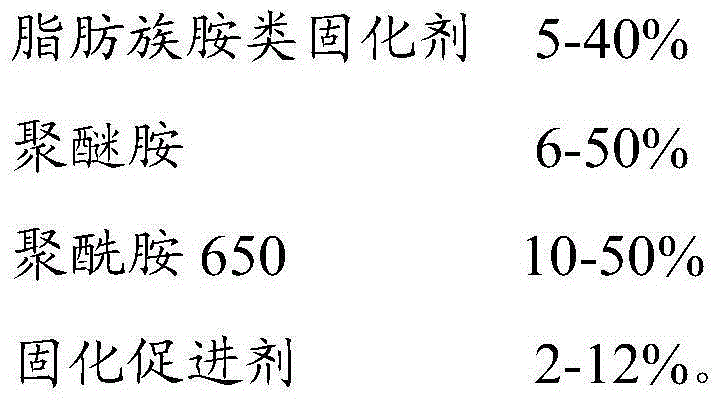

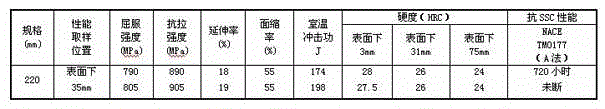

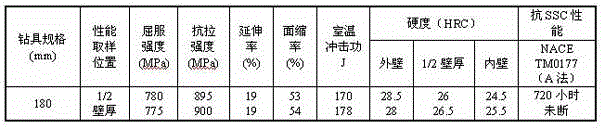

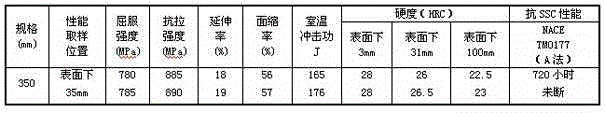

Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

The invention discloses a round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for a drilling tool and a manufacturing method of the round steel. The round steel comprises the following chemical components in percentage by mass: 0.20-0.30% of C, 0.15-0.40% of Si, 0.20-0.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.70-1.30% of Cr, 0.40-0.95% of Mo, less than or equal to 0.25% of Ni, 0.05-0.10% of Cu, 0.05-0.10% of Alt, less than or equal to 0.1% of V, less than or equal to 0.06% of Nb, less than or equal to 0.010% of Ti, less than or equal to 0.009% of N, 0.001-0.003% of B and the balance of Fe and inevitable impurities. By adopting the preparation method, the round steel with the maximum specification of 350mm can be manufactured, and the round steel is particularly suitable for being processed to be stress complex drilling tools with large specifications and high strength and toughness requirements such as hydrogen sulfide corrosion resistant drill rods, drill collars, and drill rod joints applied to acidic oil wells.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

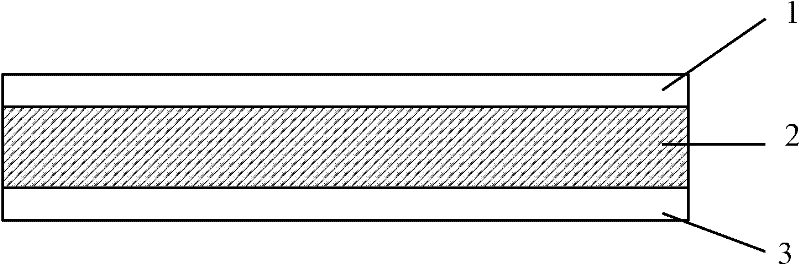

High-barrier polyester film and its preparation method

ActiveCN102225648AImprove barrier propertiesGood physical and mechanical propertiesSynthetic resin layered productsComposite constructionPolyester

The invention discloses a high-barrier polyester film, which has a three-layer composite construction, comprising a core layer, an upper cortex and a lower cortex. The core layer comprises the following components of: 60-100 wt% of PET polyester slices, 0-40 wt% of PEN polyester slices; the cortexes comprise the following components of: 92-98 wt% of PEN polyester slices, 0.2-2 wt% of a nucleating agent and 1-6 wt% of a nucleating modifier. The invention also discloses a coextruding-drawing preparation method of the above high-barrier polyester film. The invention has a simple preparation technology; in addition to excellent physical properties, the produced polyester film has better gas barrier property, heat resistance and radiation resistance performance, and can be applied in the fields of solar energy cell back-piece and the like.

Owner:JIANGSU YUXING FILM TECH

Hub manufacturing technology

The present invention discloses a production technique of a hub, which includes the following steps: (1) a rotary table is fabricated by the casting technique; (2) the cut plank stuff for a wheel felloe is rolled into a cylinder, the gap of which is welded and the burr of which is cleared out; (3) on a vertical press, the cylinder is pressed and flared; (4) on a spinning machine, the flared cylinder is formed into the wheel felloe by spinning; (5) on a positioning tooling workbench, the rotary table formed in the step (1) and the wheel felloe formed in the step (4) are welded by friction stir welding. The technique only applies the horizontally parted upper-lower mold type structure, thus leaving out the side form structure necessary for the traditional hubs, greatly simplifying the structure and the cost of foundry molds and avoiding the production of casting thermal centre in the process of casting. Because the wheel felloe and the rotary table are jointed by friction stir welding, which is a mature welding technique, the mechanical properties of the jointed part are ensured, and the problem of that the 90-degree impact experiment fails is resolved.

Owner:张新颖

High heat conducting nylon composite material and preparation method thereof

The invention discloses a high heat conducting nylon composite material and a preparation method thereof. The high heat conducting nylon composite material belongs to one of functional high molecules. The composite material is prepared from a thermoplastic nylon resin base body, heat conducting filler and other processing agents. The heat conducting coefficient is greater than 2.7W / m.K. The resin base body can be nylon 6 or a compound of nylon 6, nylon 9, nylon 66, nylon 610 and nylon 1010. The heat conducting filler can be one or more of magnesium oxide, aluminum oxide, aluminum nitride, boron nitride, silicon nitride, a multiwalled carbon nanotube and a graphite flake layer. The processing agents can be octadecanamide, polyethylene wax, liquid paraffin and the like. The method disclosed by the invention is simple to operate and low in cost, and can prepare the heat conducting composite material with excellent comprehensive performance by one step. The method is easy to realize industrialized production and can be widely applied to the fields of automobiles, household appliances, meter cases, circuit elements and the like.

Owner:BEIJING UNIV OF CHEM TECH

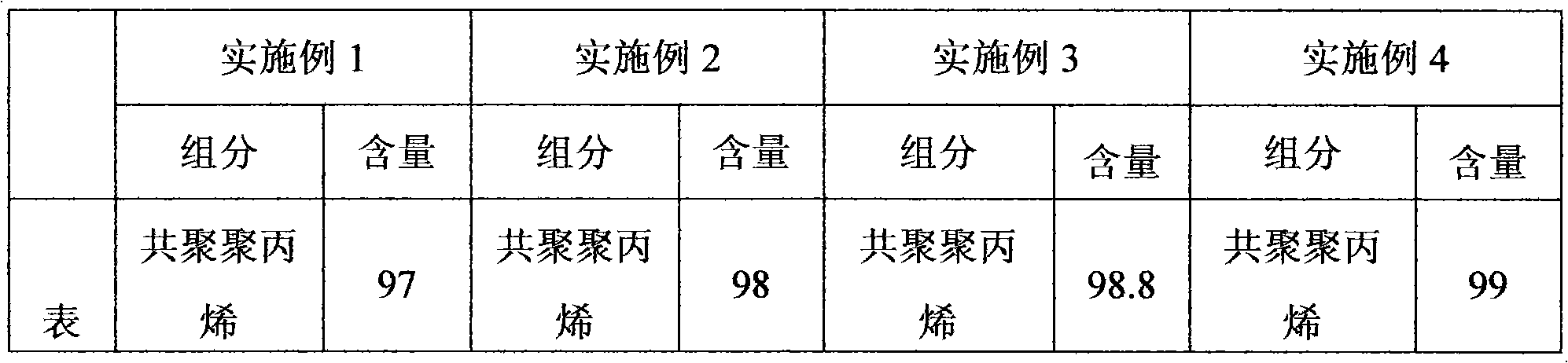

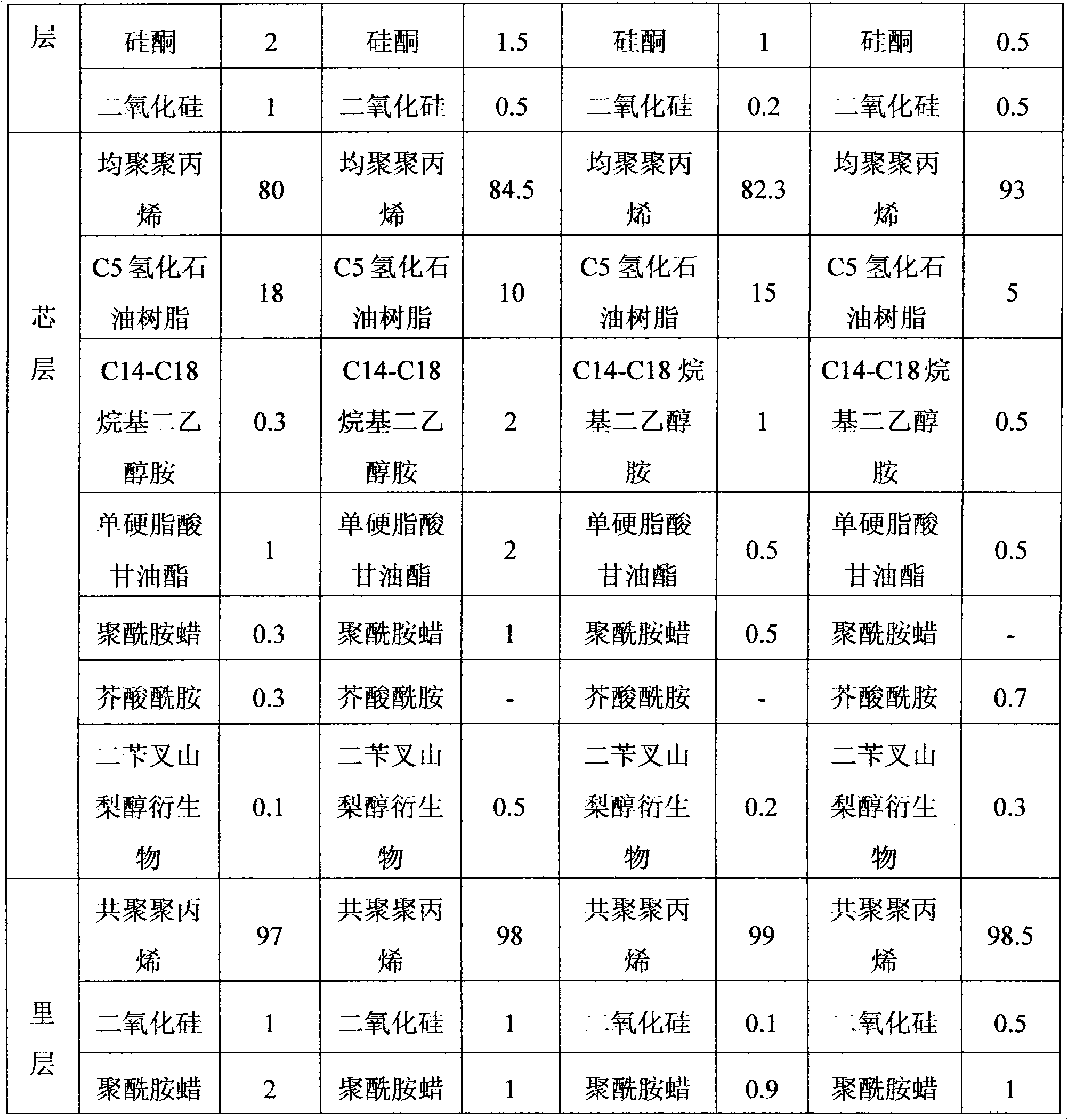

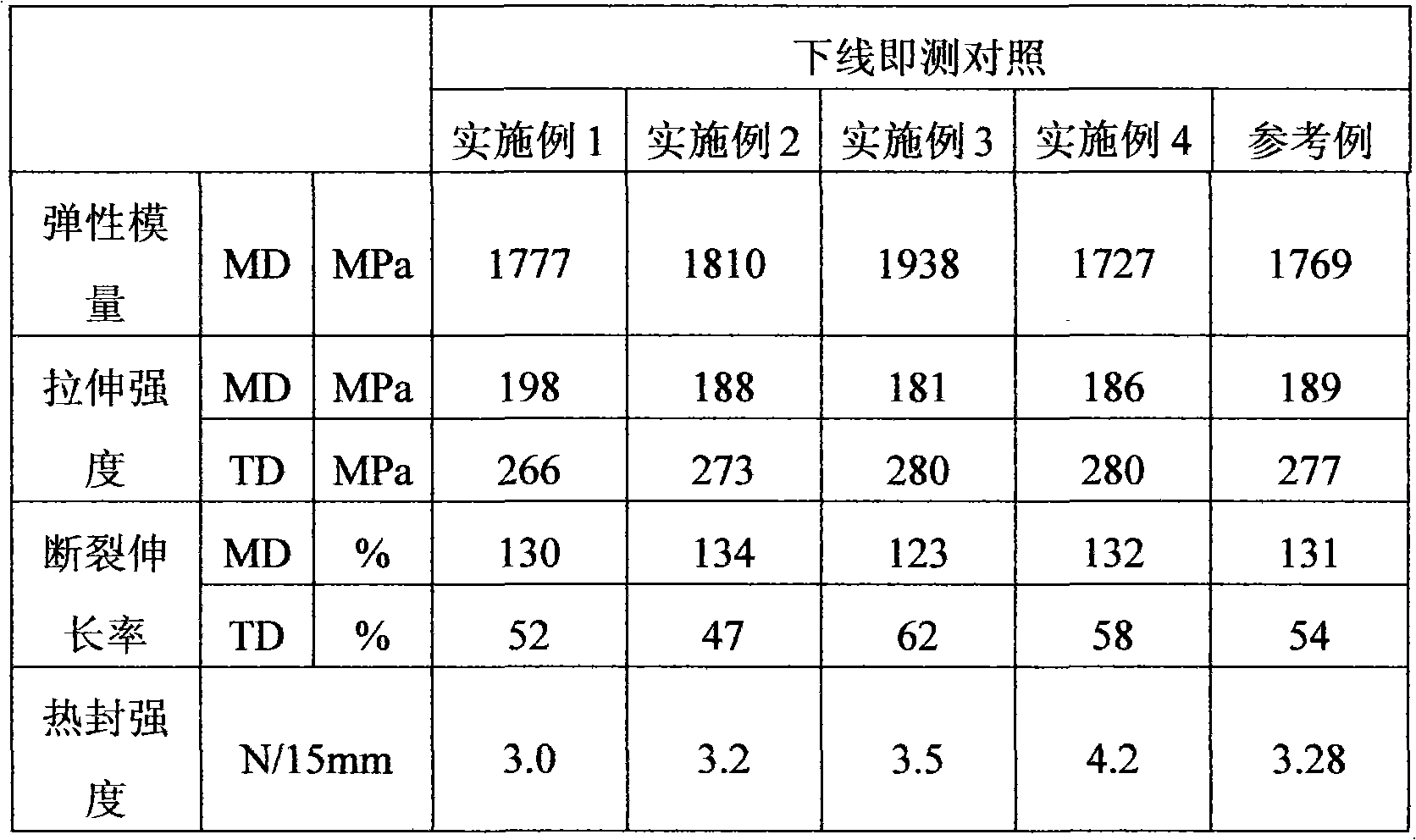

Thermal shrinkage biaxially oriented film

InactiveCN102059836ACrystallization perfectHigh heat shrinkageSynthetic resin layered productsTime changesAcrylic resin

The invention discloses a thermal shrinkage biaxially oriented film which is composed of a surface layer, a sandwich layer and an inner layer, wherein the thickness of the surface layer is 0.5-1.5 micrometers, the thickness of the sandwich layer is 19-22 micrometers, the thickness of the inner layer is 0.5-1.5 micrometers, and the total thickness of the three layers is 20-23 micrometers. The surface layer comprises the following components in percentage by weight: 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The sandwich layer comprises 80-93% of acrylic resin homopolymer, 0.3-3% of anti-static agent, 0.1-0.5% of crystal regulator, 1-2% of surfactant, 5-18% of stiffening agent and 0.5-1% of lubricant. The inner layer comprises 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The film has a stable thermal shrinkage factor which slightly changes as the storage time changes.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

CrNiMo high-strength pinion steel and preparation method thereof

ActiveCN104372258AImprove heat treatment effectGuaranteed mechanical propertiesProcess efficiency improvementPinionUltimate tensile strength

The invention relates to a CrNiMo high-strength pinion steel and a preparation method thereof. The pinion steel comprises the following chemical components in percentage by mass: 0.19%-0.25% of C, 0.17%-0.37% of Si, 0.70%-1.00% of Mn, at most 0.030% of P, at most 0.030% of S, 0.85%-1.25% of Cr, 0.40%-0.70% of Ni, 0.30%-0.40% of Mo, 0.015%-0.050% of Al, at most 2.5*10<-4>% of H, 30*10<-4>%-80*10<-4>% of N, at most 15*10<-4>% of T.O, and the balance of Fe and inevitable impurities. The invention also provides a preparation method of the pinion steel. The nickel molybdenum alloy is added to improve the heat treatability of the material, thereby ensuring the mechanical properties of the material. The hardenability of the material is enhanced, and the material satisfies the performance requirements for large module pinions.

Owner:SHANDONG IRON & STEEL CO LTD

Inorganic material surface biological method

InactiveCN101214395AExcellent anticoagulant propertiesGuaranteed mechanical propertiesSurgeryPharmaceutical containersBio moleculesEngineering

A method of biolization to the surface of inorganic material includes the following steps: the surface is spattered to form a tantalum oxide or a titanium oxide thin film; and then the inorganic material is put in a plasma immersion ion implantation device; after vacuumization, hydrogen, water vapour or ammonia is fed in, with gas pressure 0.05 to 50 Pa; the radio frequency discharge power is 200 to 1200W; the range value of the loaded pulse high-voltage power is 1KV to 100KV, the frequency is 50 to 40000HZ, and the duty ratio is 3 percent to 80 percent; the heating temperature is 20 to 500 DEG C; the treatment time is 0.1 to 5 hours; finally, the inorganic material is put into 10 to 100mg / mL albumin or heparin solution to be soaked for 2 to 48 hours under 20 to 40 DEG C soaking temperature. The method does not damage the activity of the biomolecule and the protein; the prepared inorganic material with biolized surface has good anti-coagulability, is used for medical blood vessel scaffolds and artificial heart valves, and can greatly improve the product performance.

Owner:SOUTHWEST JIAOTONG UNIV

Graphene foam film enhanced heat-conducting gasket and preparation method thereof

PendingCN113290958ALarge poresHigh porosityLamination ancillary operationsLaminationAdhesive cementPolymer science

The invention discloses a graphene foam film enhanced heat-conducting gasket and a preparation method thereof. The graphene foam film enhanced heat-conducting gasket comprises a plurality of layers of graphene foam films and adhesives filled in the graphene foam films and among the layers, and the graphene foam films account for 60-95 wt% of the total weight of the heat-conducting gasket. The graphene is arranged in the heat-conducting gasket in the thickness direction, and the gasket has good heat-conducting performance in the thickness direction; besides, the combination of the graphene foam film and the adhesive has good compressibility and compression resilience, and the application thermal resistance is small.

Owner:CHANGZHOU FUXI TECH CO LTD

Low glue consumption method for making medium density fiberboard

InactiveCN102514071AGuaranteed mechanical propertiesReduce the amount of sizingWood working apparatusFlat articlesFiberFiberboard

The invention relates to a low glue consumption method for making a medium density fiberboard, which comprises the following steps of: material preparation, i.e. processing the raw materials of small dimension wood, brush wood and the like into wood chips by adopting a drum chipper; fiber preparation, i.e. sending qualified wood chips to a wood chip cooking pot through a belt conveyor, introducing papermaking waste liquid into a boiler to carry out cooking softening treatment after filtering the papermaking waste liquid, sending the wood chips which are cooked and preheated into a thermofiner to carry out mechanical separation through a feeding screw, and filling molten wax before the wood chips enter a grinding chamber body of the thermofiner, so that after the wood chips are separated into the fibers, the wax is uniformly distributed on the surfaces of the fibers; sizing and drying of the fibers, wherein a production process of firstly sizing and then drying is adopted; pavement and formation of a board blank; hot-press forming, i.e. sending the single board blank into a hot press to carry out hot pressing through a loader, so that under the combined action of heat and pressure, moisture in the board blank is gasified and evaporated, the density of the board blank is improved, glue is cured and a waterproof agent is redistributed; and post-processing, i.e. finally, sending the obtained product into a sanding machine to carry out surface processing. The low glue consumption method for making the medium density fiberboard is simple and convenient.

Owner:广西新凯骅实业集团股份有限公司

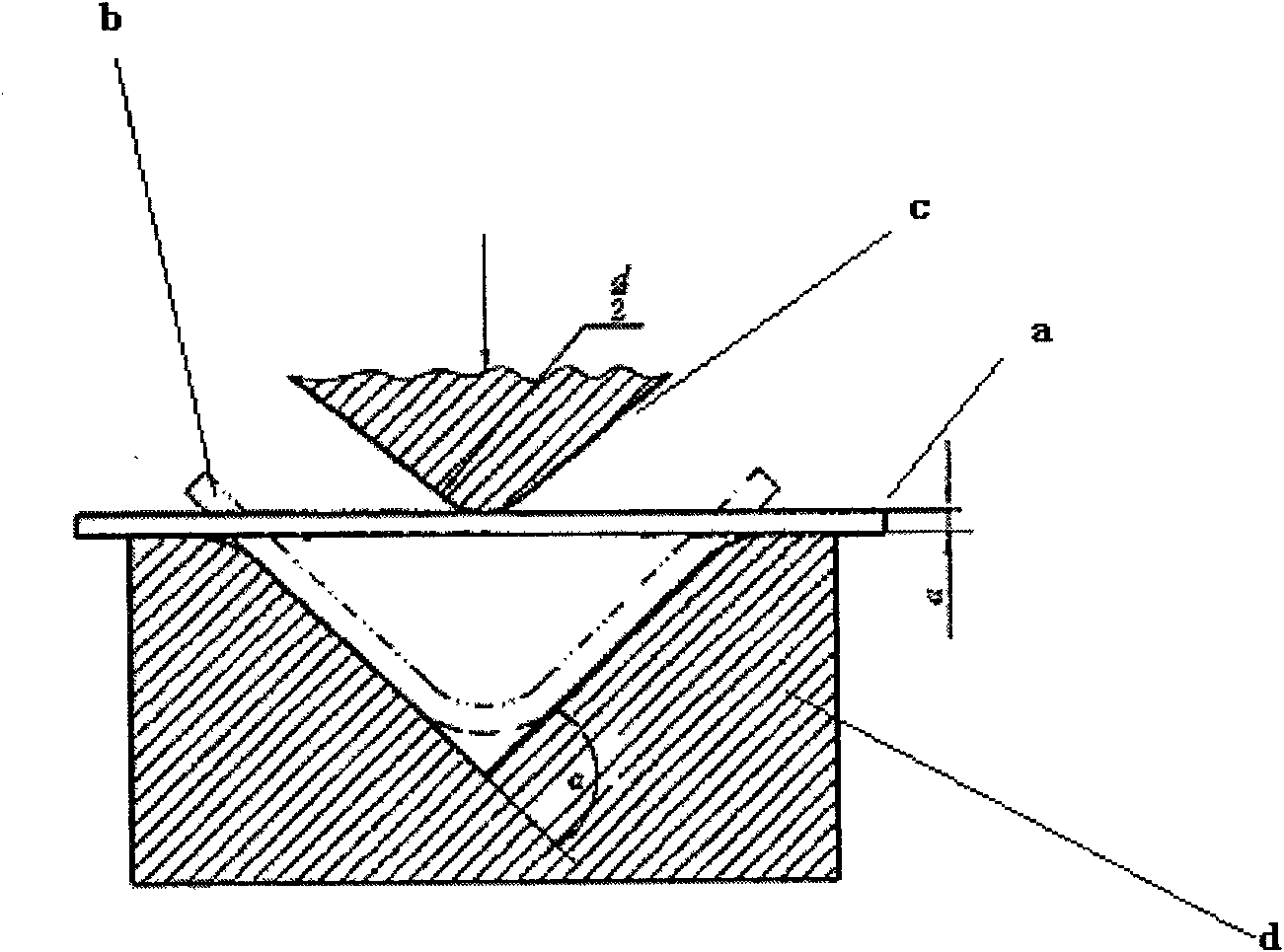

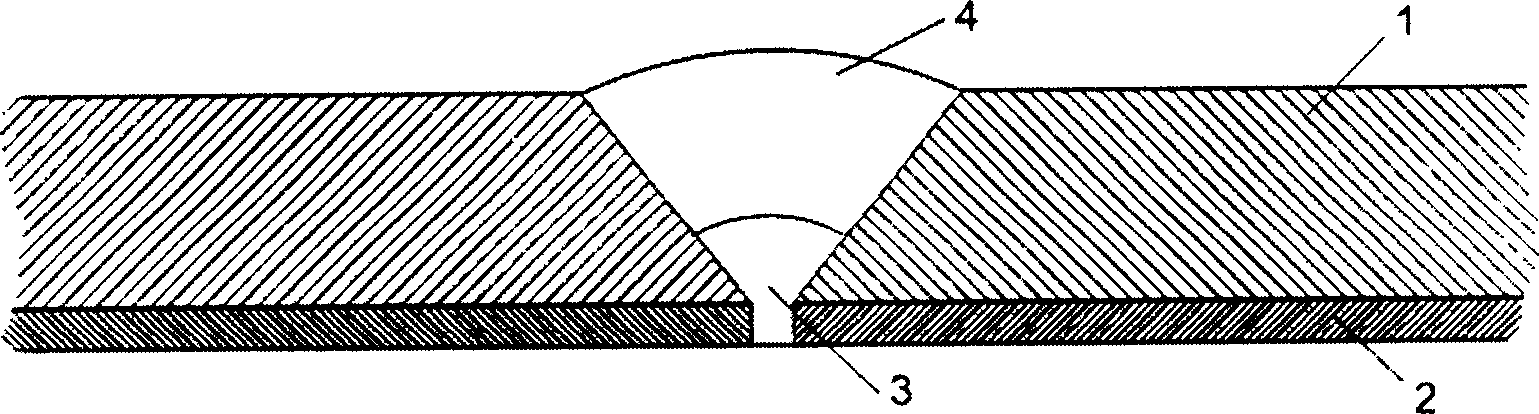

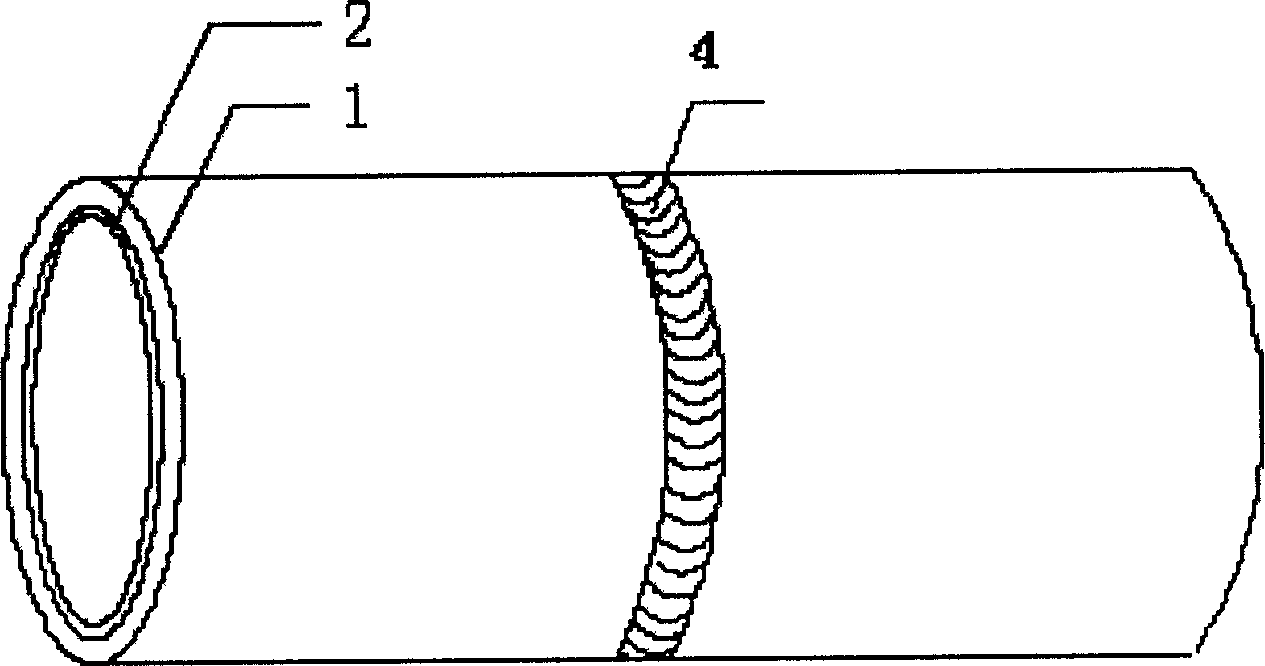

Welding method for ultra-thin composite layer low-carbon steel - austenitic stainless steel multiple tube adaptor

ActiveCN1546267AHigh carbon contentGuaranteed mechanical propertiesArc welding apparatusWelding/cutting media/materialsCarbon steelWeld seam

The invention discloses a welding method for low carbon steel-austenite stainless steel compound pipe of ultra-thin stainless composite bed. The character is: the welding is completed with transition layer welding seam and base layer welding, it hasn't single stainless steel composite bed seam; the welding rod for low carbon steel base layer seam is the same to the one for mother metal; the first welding for stainless steel composite layer and the transition layer between the stainless composite layer and the low carbon steel base layer use argon tungsten-arc welding with back argon filling protection, or uses manual arc welding; the welding wire or welding rod use stainless steel in order to form the transition welding seam; after the transition welding seam is completed, the second time uses manual arc welding to weld the low carbon steel base layer, the welding rod uses low carbon steel in order to form base layer welding seam.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com