Patents

Literature

40results about How to "Make up for loss of strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium alloy profile for building template, and preparation method thereof

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

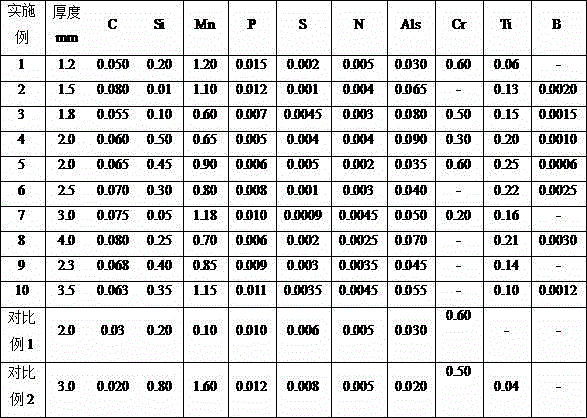

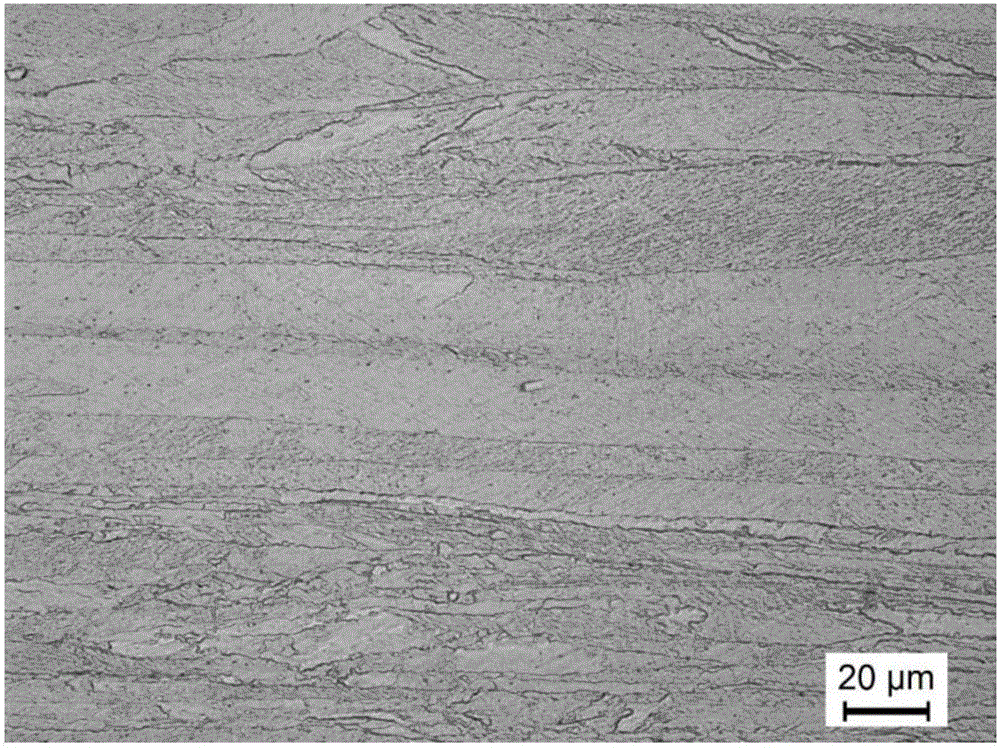

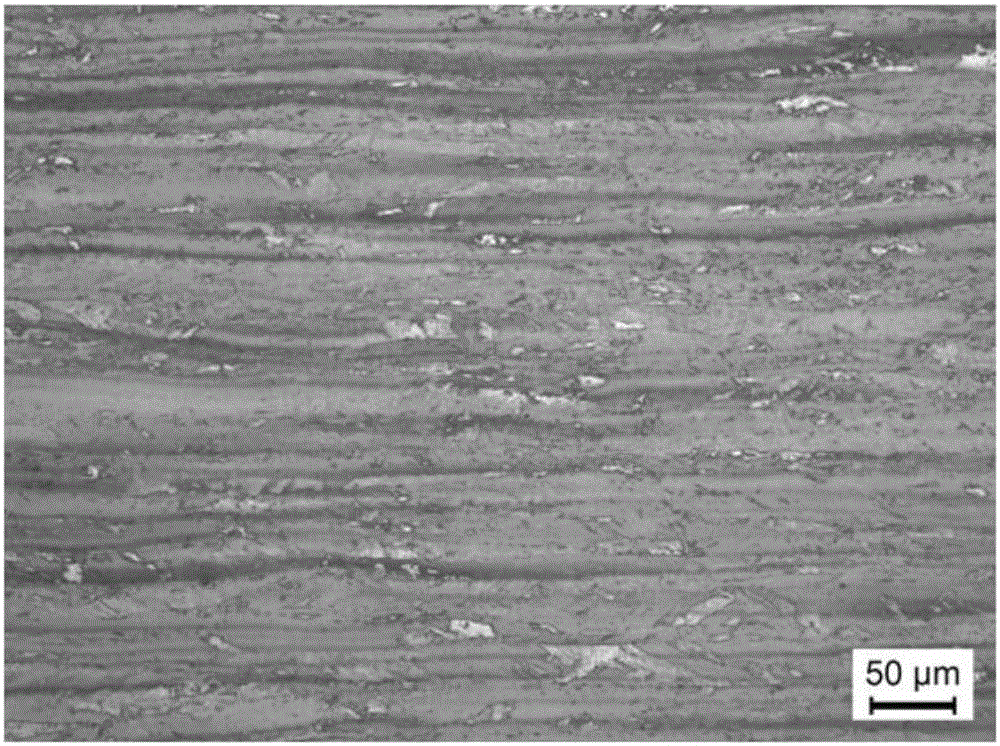

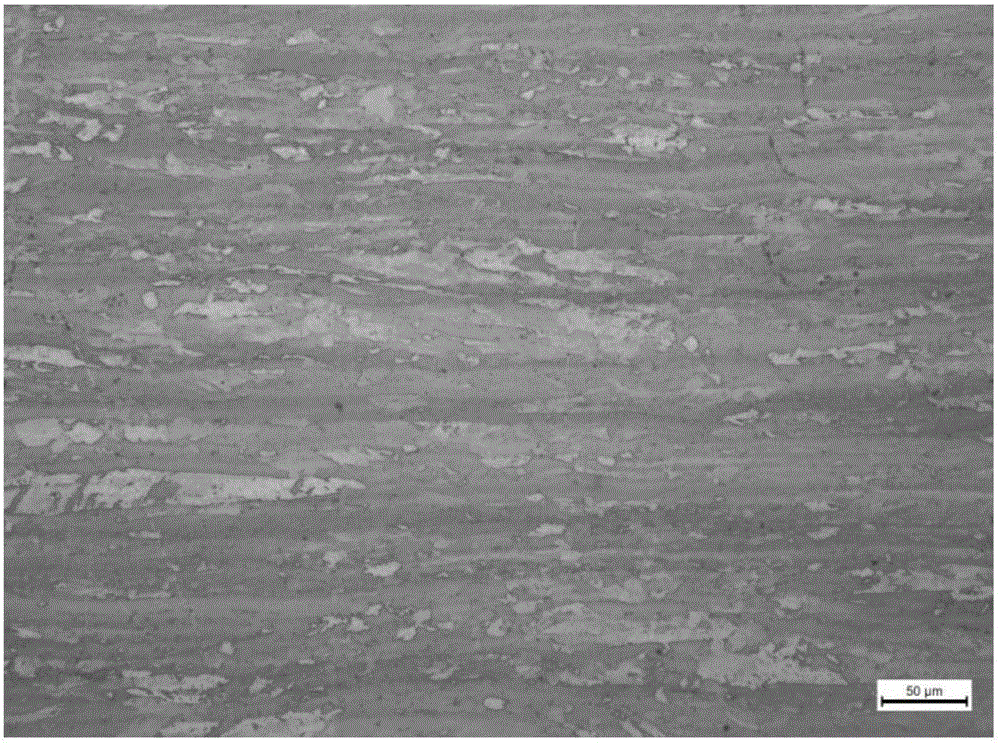

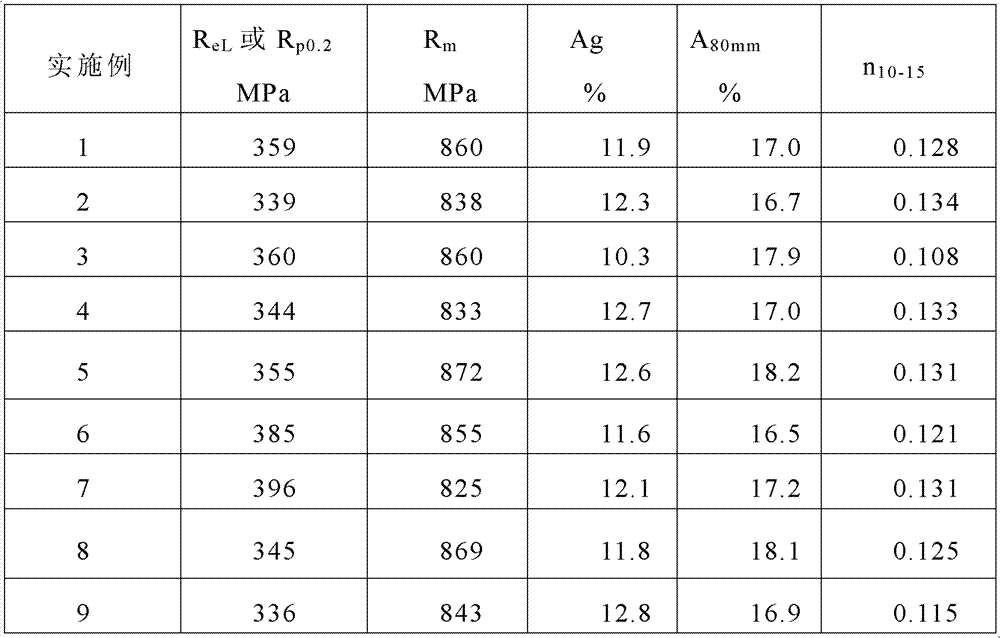

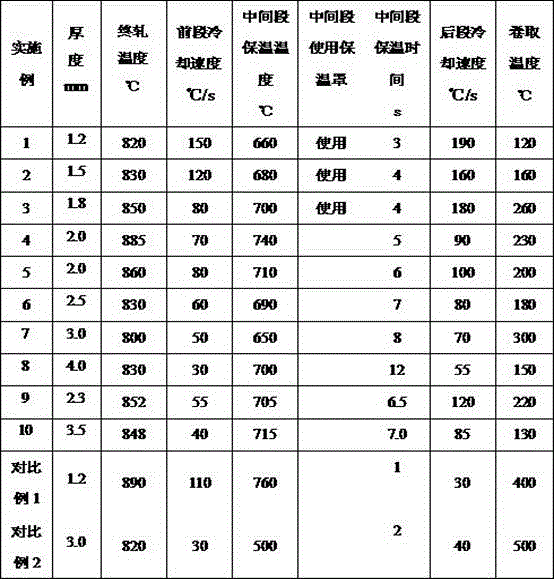

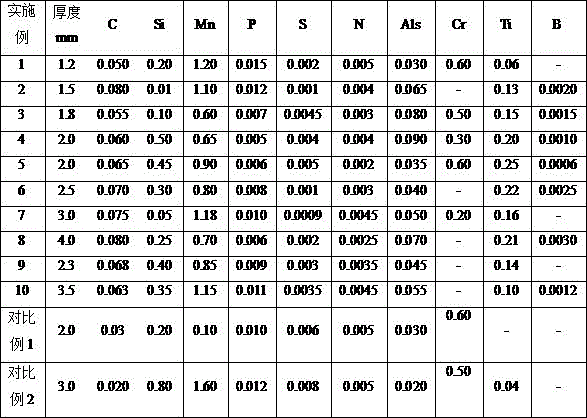

Tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel and production method thereof

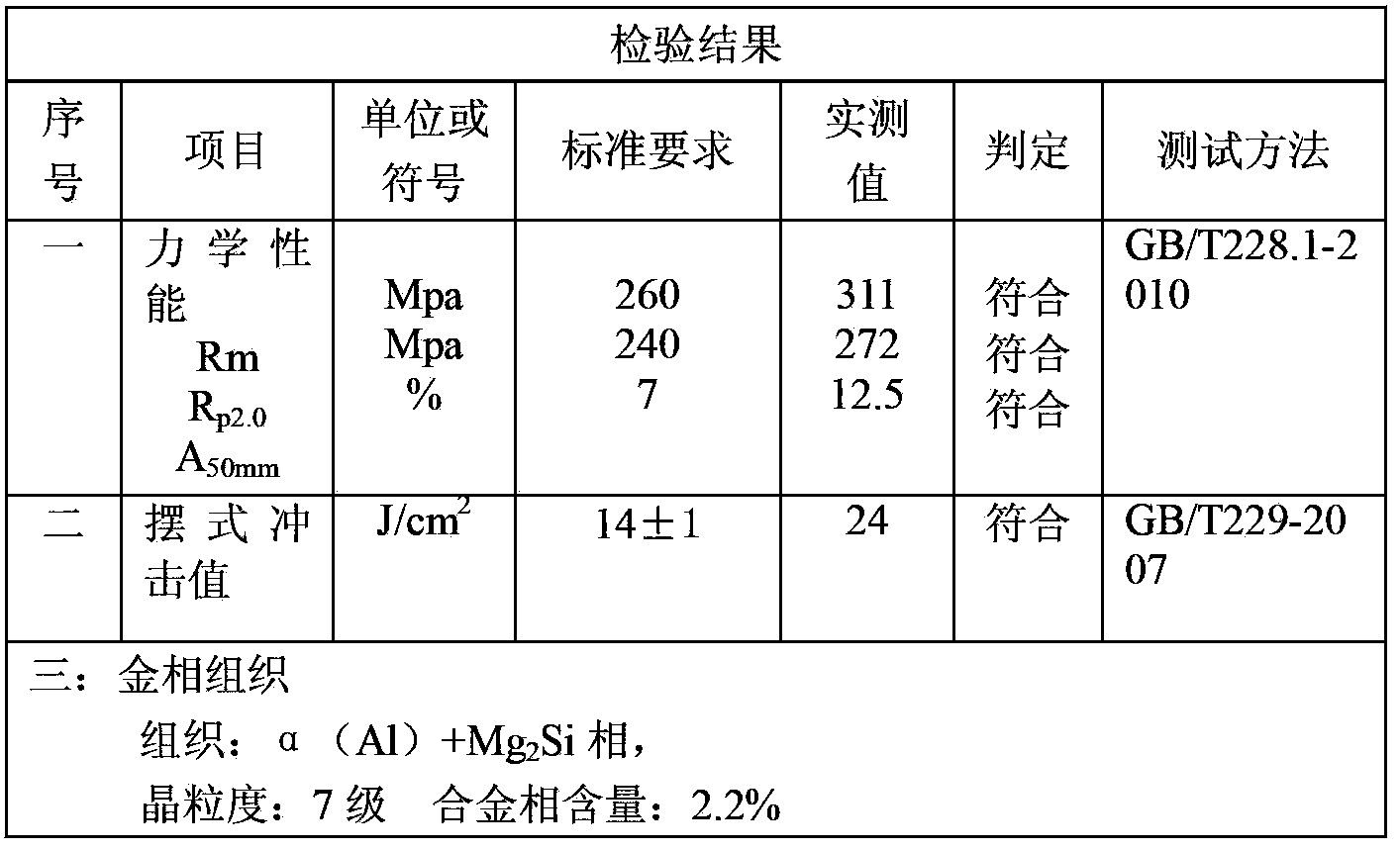

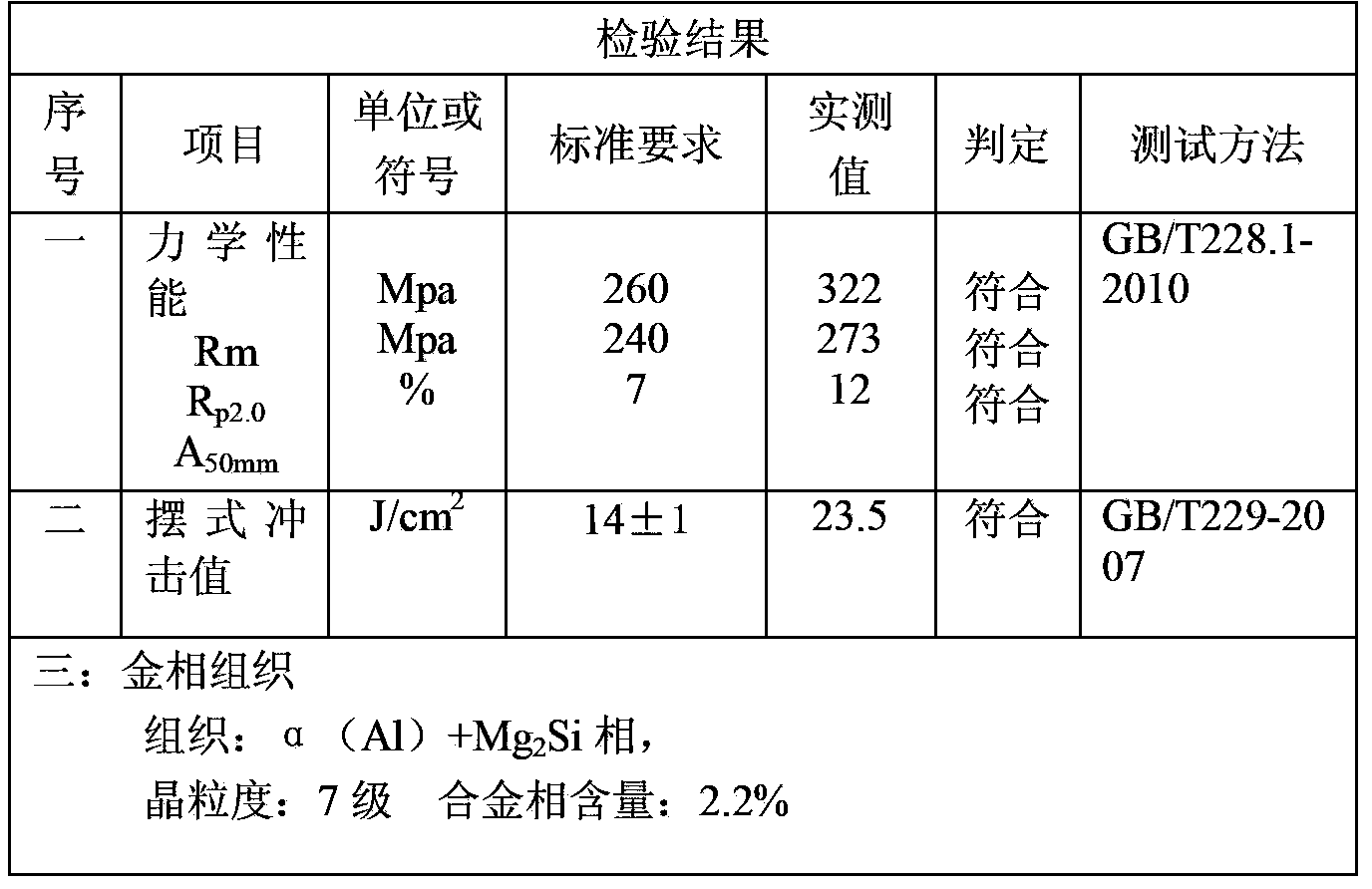

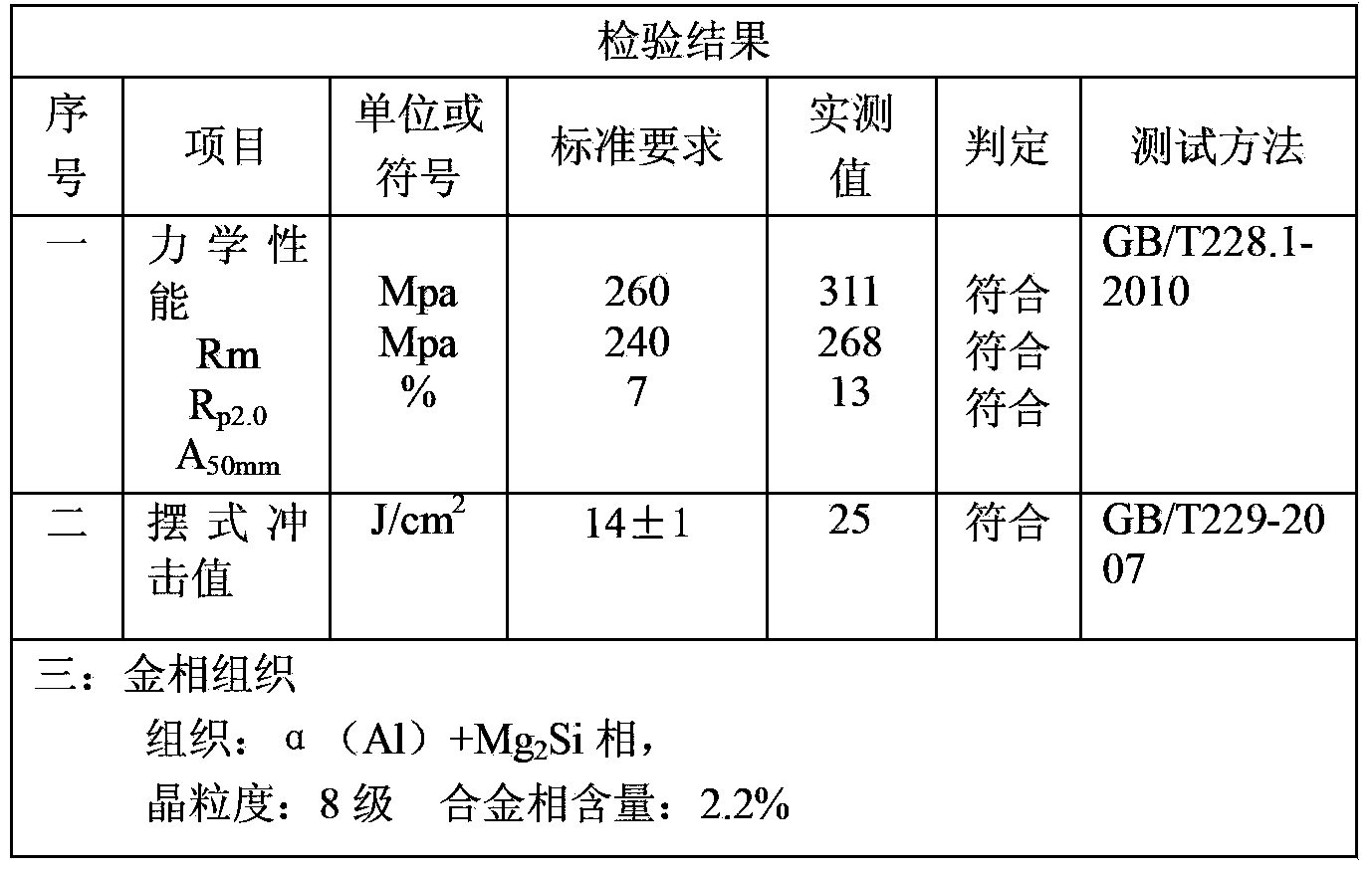

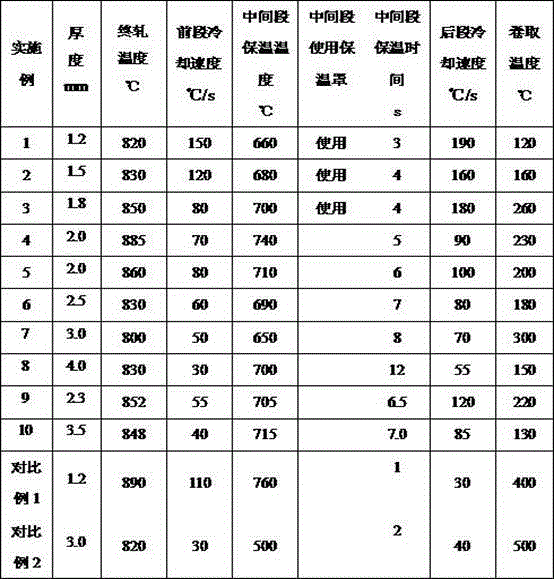

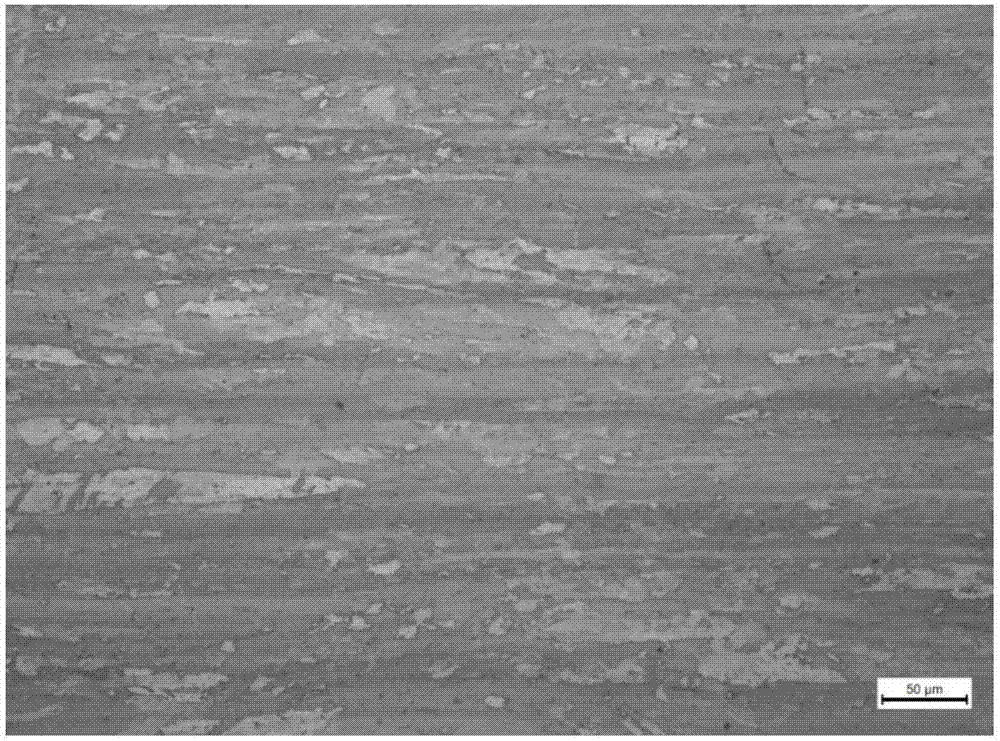

The invention provides tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel. The dual-phase steel comprises the following components in percentage by weight: 0.05-0.08 percent of C, not more than 0.5 percent of S, 0.6-1.2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.006 percent of N, 0.01-0.1 percent of Als, 0.05-0.25 percent of Ti, less than or equal to 0.6 percent of Cr or less than or equal to 0.003 percent of B or mixture of Cr and B. The production method by using CSP comprises the following steps: melting and continuously casting to form a slab; heating the continuous cast slab; rolling; carrying out laminar cooling; reeling; and naturally cooling to room temperature. The hot-rolled dual phase steel has the tensile strength of more than or equal to 780MPa, elongation of more than or equal to 15 percent and yield ratio of less than or equal to 0.70. An insulation cover additionally covers the intermediate insulation section, and the band steel cooling speed is reduced, so that generation of pearlite phase change can be effectively prevented. Production of hot-rolled dual phase steel with thickness of 1.2-4.0mm can be realized, the product has the advantages of uniform structure, small molding resilience and no cracking, existing equipment is utilized without adopting ultra fast cooling and other equipment, the production efficiency is high, and the investment is small.

Owner:武汉钢铁有限公司

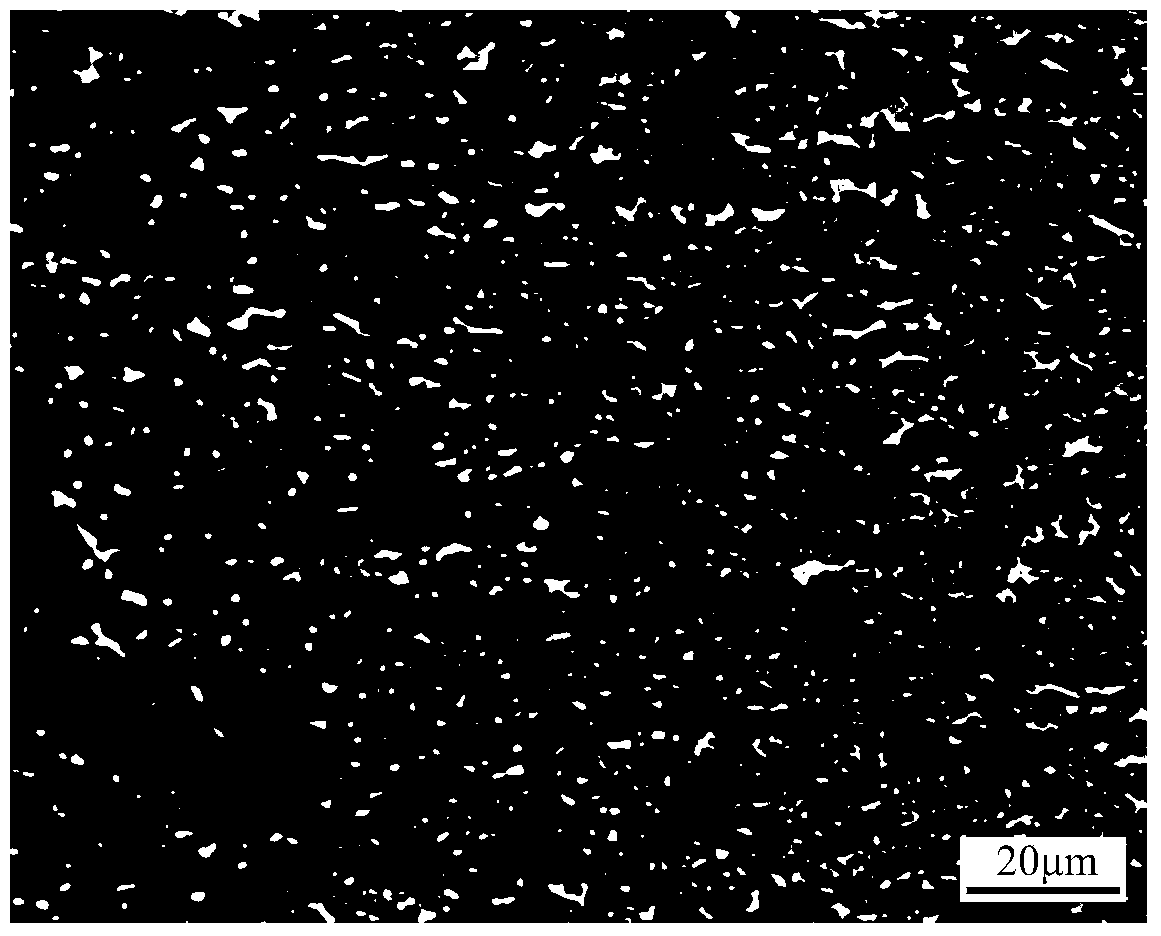

Cu-containing nanophase strengthened easy-to-weld steel and preparation method

The invention provides Cu-containing nanophase strengthened easy-to-weld steel and a preparation method. The Cu-containing nanophase strengthened easy-to-weld steel comprises the following components by weight percent: less than 0.05% of C, 0.1-0.3% of Si, 0.5-1.5% of Mn, less than 0.002% of S, less than 0.004% of P, 1.5-2.5% of Cu, 4-8% of Ni, 0.3-0.8% of Al, 0.2-1% of Mo, less than 1% of Cr, 001-0.04% of Nb, 0.01-0.05% of Ti, 0.01-0.08% of V, and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps: performing induction smelting and casting under argon protection; heating cast ingots at 1,100-1,200 DEG C for 1-3 h, directly performing hot rolling at the initial temperature of 1,050-1,150 DEG C and the final temperature of 950 DEG C, and performing super-speed high-pressure water cooling after final rolling, wherein the hot rolling deformation is 50-90%; and selectively conducting solution and aging heat treatment on a rolled steel plate to obtain high-strength high-toughness easy-to-weld steel. The alloy steel is high in strength, good in plasticity, excellent in low-temperature impact toughness and easy to weld. Besides, the machining process is high in controllability, the cost is low and the operation is simple.

Owner:HARBIN ENG UNIV

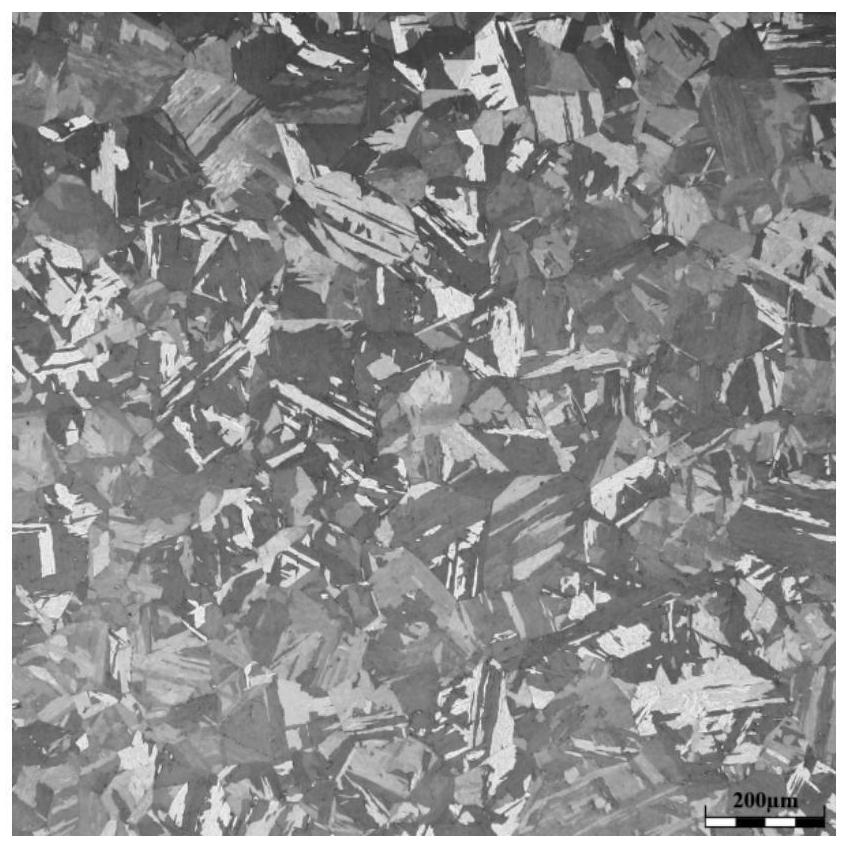

Al-Mg-Si-Cu alloy and preparation method thereof

The invention discloses Al-Mg-Si-Cu alloy and a preparation method thereof. The alloy consists of the following components in percentage by mass: 0.4 to 0.6 percent of Mg, 0.45 to 0.6 percent of Si, 0.3 to 0.8 percent of Cu, 0.1 to 0.2 percent of Mn, 0.1 to 0.7 percent of Zn, 0 to 0.1 percent of Cr, 0.01 to 0.02 percent of Ti, not more than 0.3 percent of Fe, not more than 0.1 percent of other impurities (total content), and the balance of Al. The alloy has the characteristics of the reduction of deformation resistance, improves extrusion speed and production efficiency, and can improve the yield under the condition of constant productivity. In addition, the alloy does not need an extra water quenching process, and can reduce investment cost of equipment by on-line air quenching after hot extrusion.

Owner:CENT SOUTH UNIV

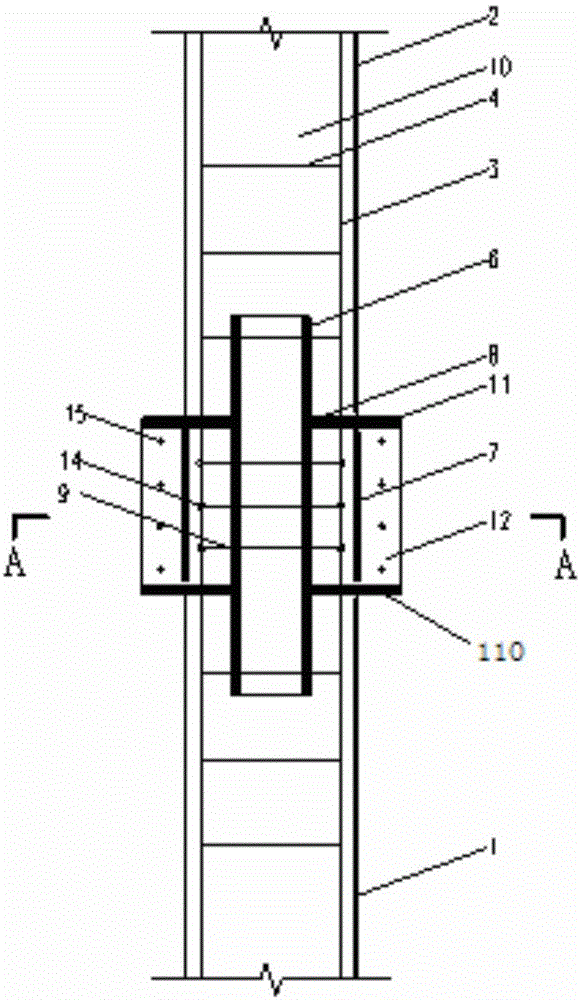

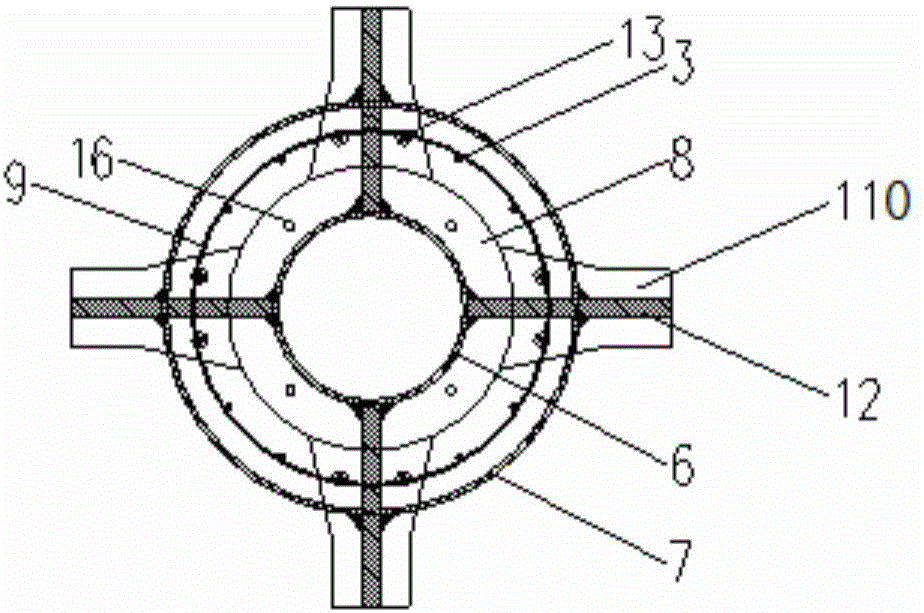

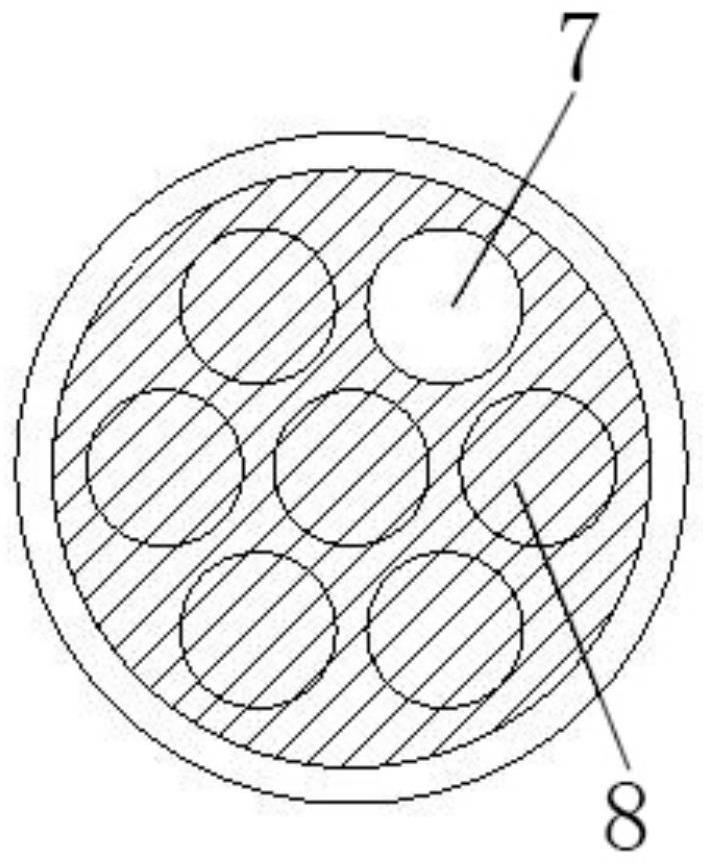

Circular steel tube constraining reinforced concrete-steel beam framework node for nodal-region composite steel tube

InactiveCN105672491AImprove bearing capacityImprove ductilityBuilding constructionsReinforced concrete columnShear capacity

The invention provides a circular steel tube constraining reinforced concrete-steel beam framework node for a nodal-region composite steel tube. The node comprises a first columnar circular steel tube, a second columnar circular steel tube, columnar longitudinal bars, columnar stirrups, a steel beam, a nodal-region inner-layer circular steel tube, a nodal-region outer-layer circular steel tube, outer reinforcing rings, nodal-region stirrups and concrete. The second columnar circular steel tube and the first columnar circular steel tube are located on the upper side and the lower side of the steel beam respectively. The steel beam directly transmits the shear force and the bending moment to the nodal-region inner-layer circular steel tube and then transmits the shear force and the bending moment to the core-region concrete, the condition that the nodal-region outer-layer steel tube directly bears the shear force is avoided to prevent the steel tube from being bent, and therefore the steel tube can fully play an annular constraining role to ensure the bearing capacity and the ductility of the node; the two ends of the nodal-region inner-layer circular steel tube stretch into an upper steel tube constraining reinforced concrete column and a lower steel tube constraining reinforced concrete column by a certain distance respectively, the integrity of the node is guaranteed, and the shear capacity and anti-seismic performance of the node are improved. The node is safe, reliable, good in integrity, clear in force transmission and convenient to construct and has the advantage on force bearing and the economic performance.

Owner:CHONGQING UNIV

Vanadium-microalloyed hot-rolled transformation induced plasticity steel and preparation method

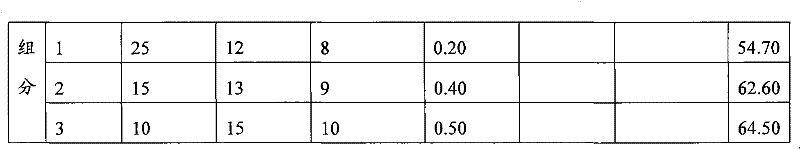

The invention discloses vanadium-microalloyed hot-rolled transformation induced plasticity steel with a grade above 1000MPa and a preparation method. The hot-rolled transformation induced plasticity steel comprises the following components by mass percent: 0.18-0.23% of C, not more than 0.50% of Si, 1.0-1.5% of Mn, 0.16-0.20% of V, 0.01-0.03% of N, not more than 0.06% of P, not more than 0.005% of S and the balance of Fe and other inevitable impurities. Through reasonable component design and process control, the tensile strength is not less than 1000MPa, the elongation at break is not less than 22.0%, the yield ratio is not more than 0.69, the work hardening index is not less than 0.22, the hole expansion rate is not less than 90%, the volume fraction of residual austenite in microscopic structures is not less than 12.0%, and fine V (C, N) precipitated particles with diameters of 2-5nm are diffusely distributed in a matrix.

Owner:LAIWU IRON & STEEL GRP

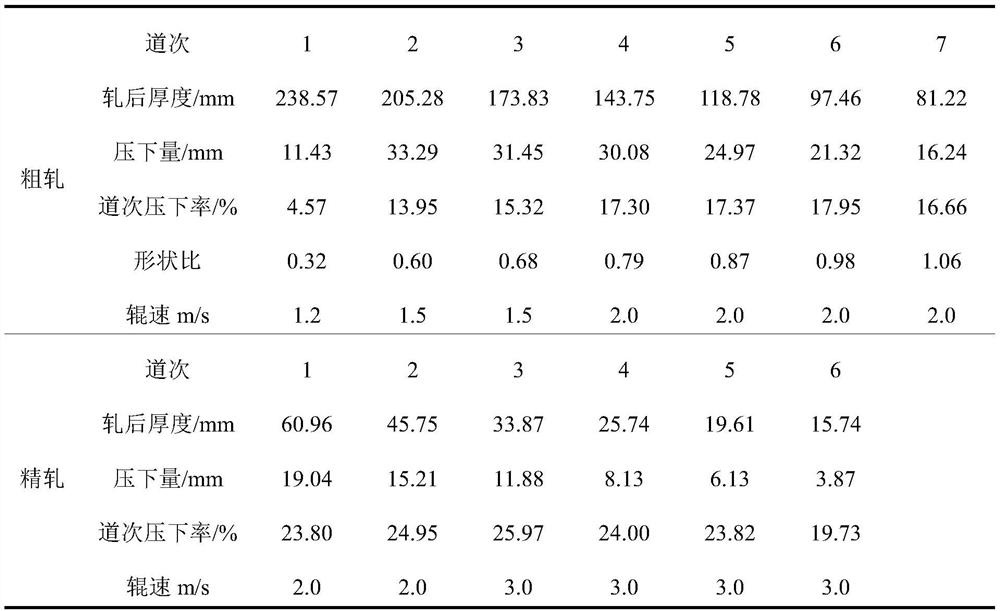

Hot continuous rolled steel plate and production method thereof

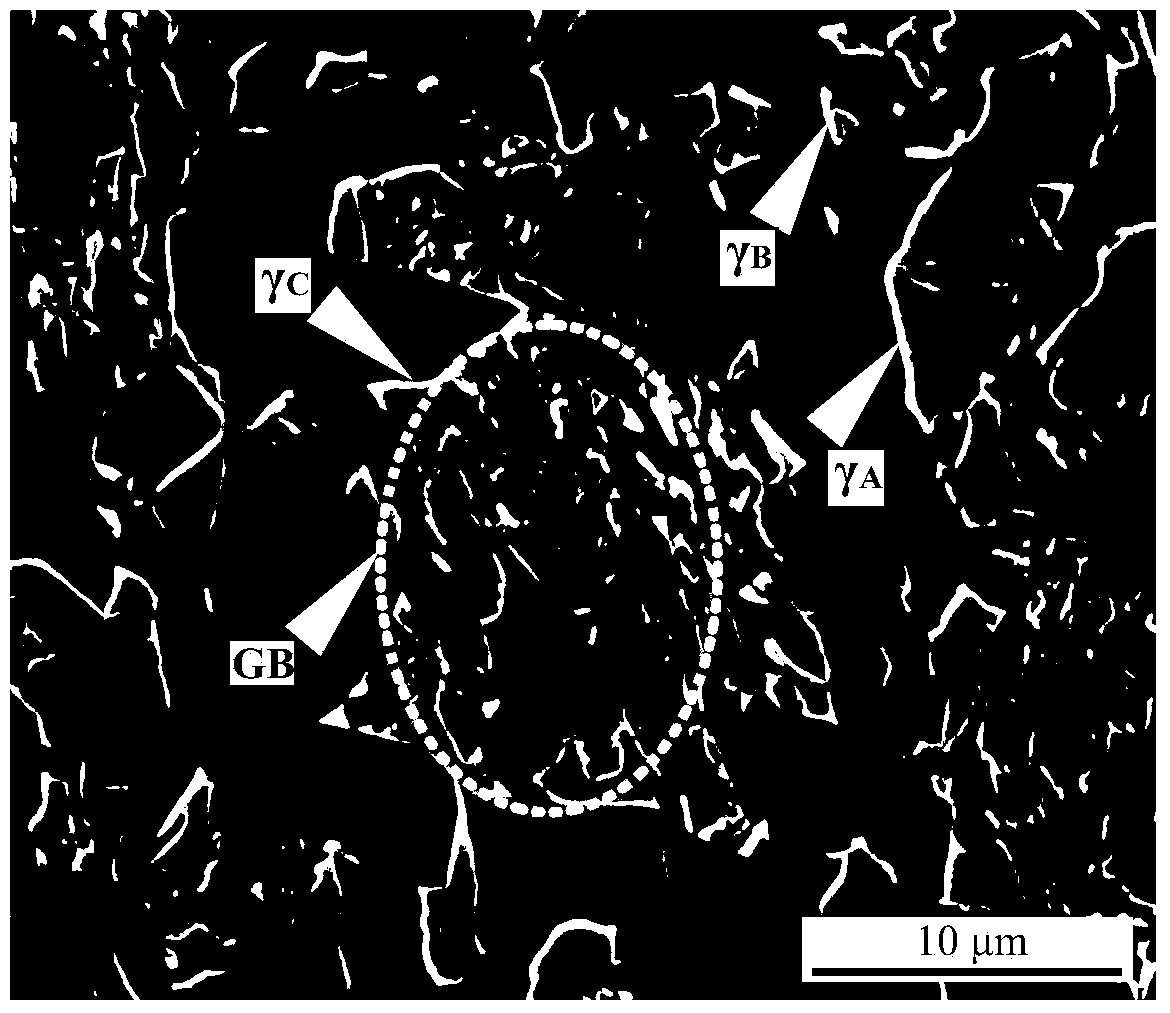

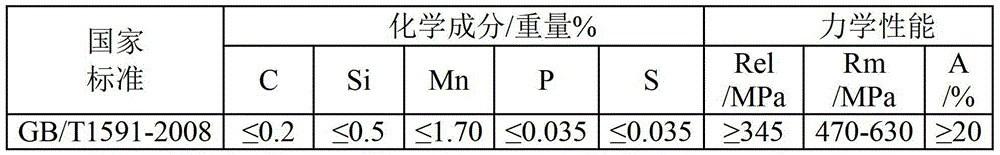

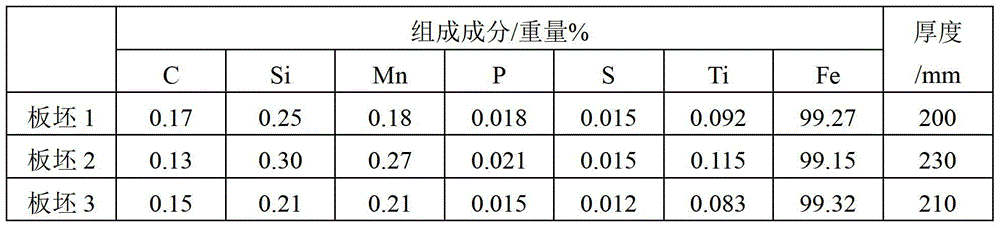

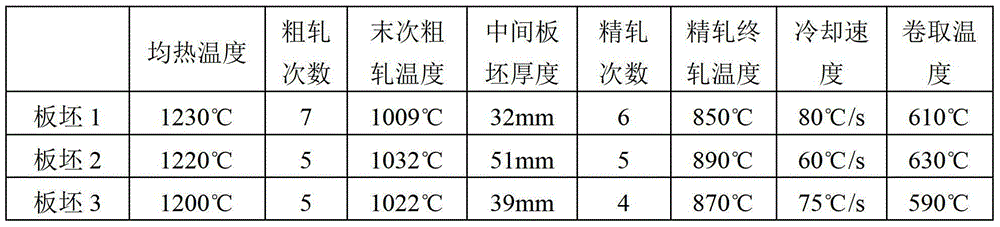

InactiveCN104060161AReduce Mn contentMake up for loss of strengthRoll mill control devicesMetal rolling arrangementsSheet steelREL

The invention discloses a production method of a hot continuous rolled steel plate, the method includes sequential rough rolling, finish rolling, cooling and coiling of a plate blank, and the plate blank comprises the following components by weight: 0.1-0.2 wt% of C, less than or equal to 0.45 wt% of Si, 0.15-0.5 wt% of Mn, less than or equal to 0.025 wt% of P, less than or equal to 0.025 wt% of S, 0.08-0.2 wt% of Ti, and 98.6-99.7 wt% of Fe; and the cooling speed is 50 to 100 DEG C / s. The invention also discloses the hot continuous rolled steel plate prepared by the method. The yield strength ReL of the hot continuous rolled steel plate is greater than or equal to 345MPa, the tensile strength Rm is 470-630MPa, and the elongation rate A is greater than or equal to 21.0%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Toughened abrasion-resistant epoxy resin cement gum and preparation method thereof

ActiveCN111607312AImprove fracture toughnessMake up for loss of strengthEpoxy resin coatingsBridge engineeringPolymer science

The invention provides toughened abrasion-resistant epoxy resin cement gum which is composed of a component A and a component B. The component A comprises epoxy resin, a diluent, an active diluent AGE, a silane coupling agent, fumed silica and brominated nano light calcium carbonate. The component B is prepared from a curing agent, a DMP-30 accelerant, brominated nano light calcium carbonate and graphene oxide nanosheets. The epoxy resin is composed of a bonding body and a modifying body, wherein the bonding body is bisphenol A type epoxy resin or bisphenol F type epoxy resin, and the modifying body is epoxy-terminated polysiloxane with epoxy equivalent weight of 400-900g / mol. The epoxy cement gum prepared by the preparation method has relatively high strength, toughness, impact resistanceand abrasion resistance, is good in comprehensive performance, and can be applied to hydroelectric and hydraulic engineering, bridge engineering, high-speed rail traffic engineering, constructional engineering and the like.

Owner:杭州每步材料科技有限公司

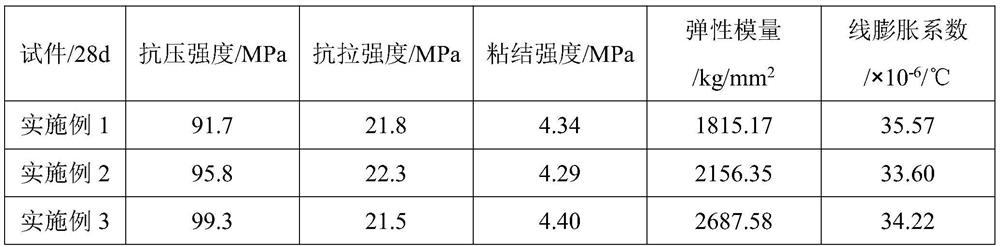

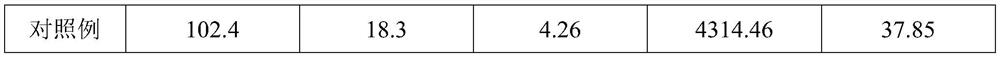

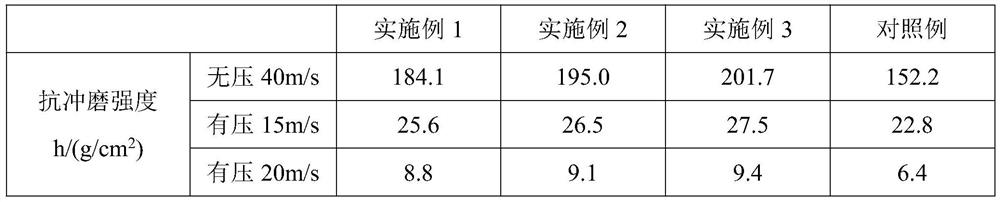

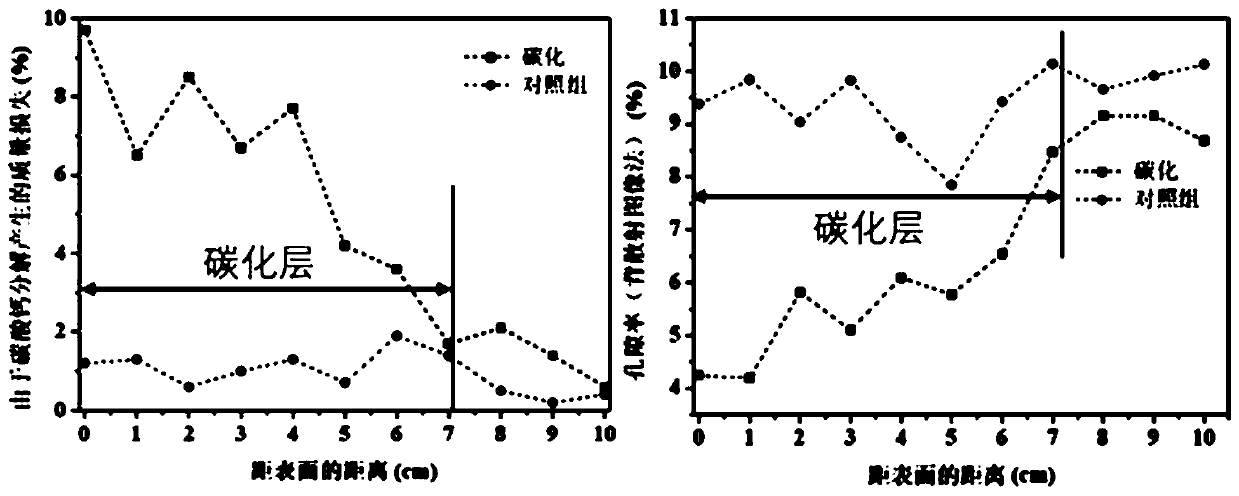

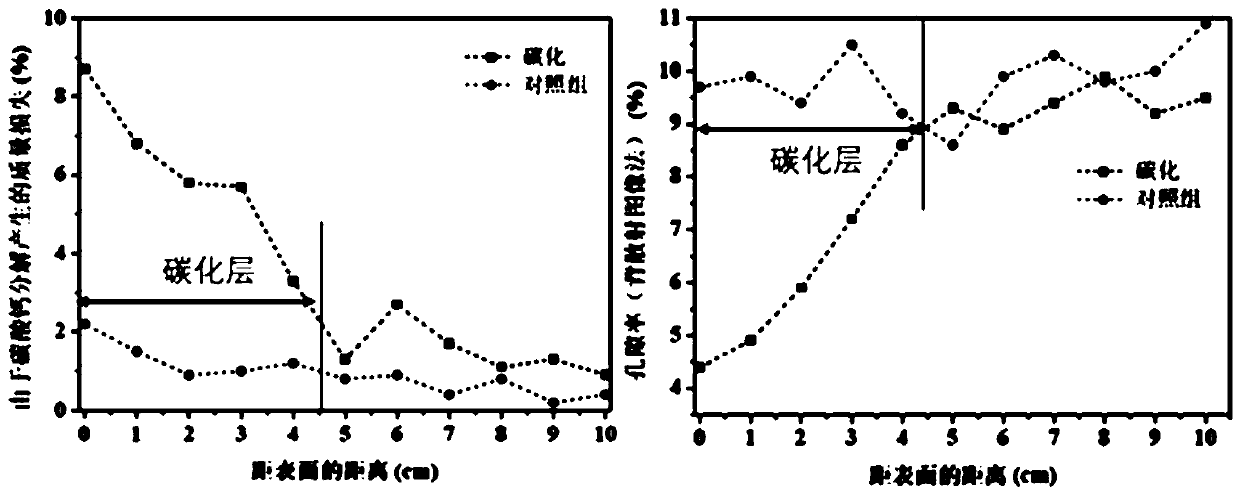

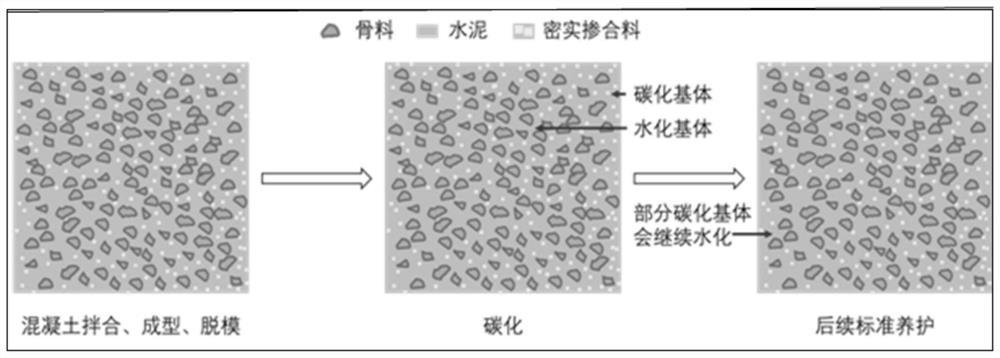

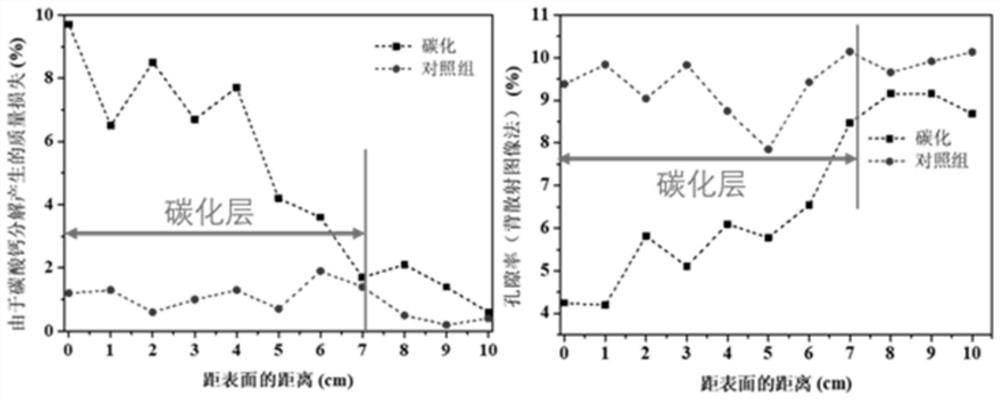

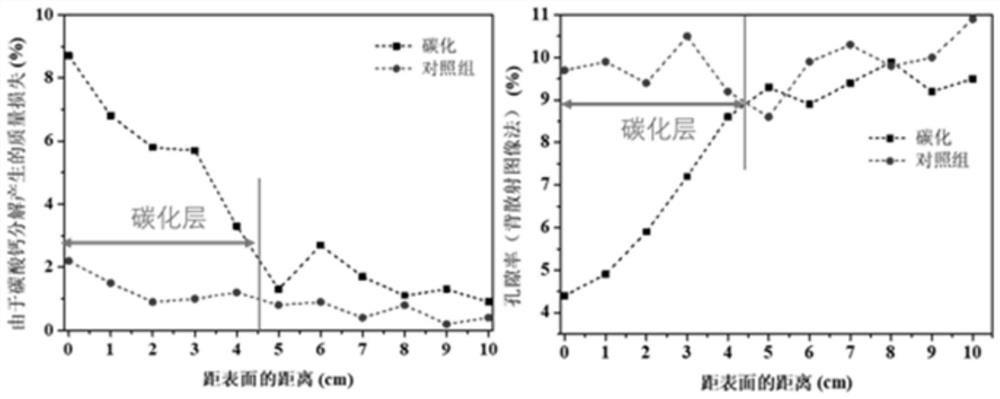

High-durability concrete product with gradient structure, and preparation method thereof

ActiveCN109694224AImprove ion erosion resistanceReduce ubiquitinationCarbonizationUltimate tensile strength

The invention relates to a high-durability concrete product with a gradient structure, and a preparation method thereof. The preparation method comprises the following steps: 1) mixing for obtaining concrete: mixing a dense admixture for substituting a part of a cementing material to obtain the concrete; 2) pouring the concrete into a mold, molding the concrete, and curing and demolding the moldedconcrete to obtain a concrete test piece; and 3) drying the surface of the concrete test piece, carrying out carbonization curing on the dried concrete test piece in an autoclave in a carbon dioxideatmosphere, and then carrying out standard curing to obtain the high-durability concrete product with the gradient structure. The gradient structure which gradually densifies from the inside to the outside is formed on the surface of the concrete test piece through the carbonization curing treatment, and the surface carbonized dense layer can improve the corrosion resistance of the concrete material and prolong the service life; and the outer layer has a high strength, so the confinement effect is formed, thereby the deformation resistance of the test piece is improved, and the hardening of the concrete test piece is accelerated.

Owner:WUHAN UNIV OF TECH

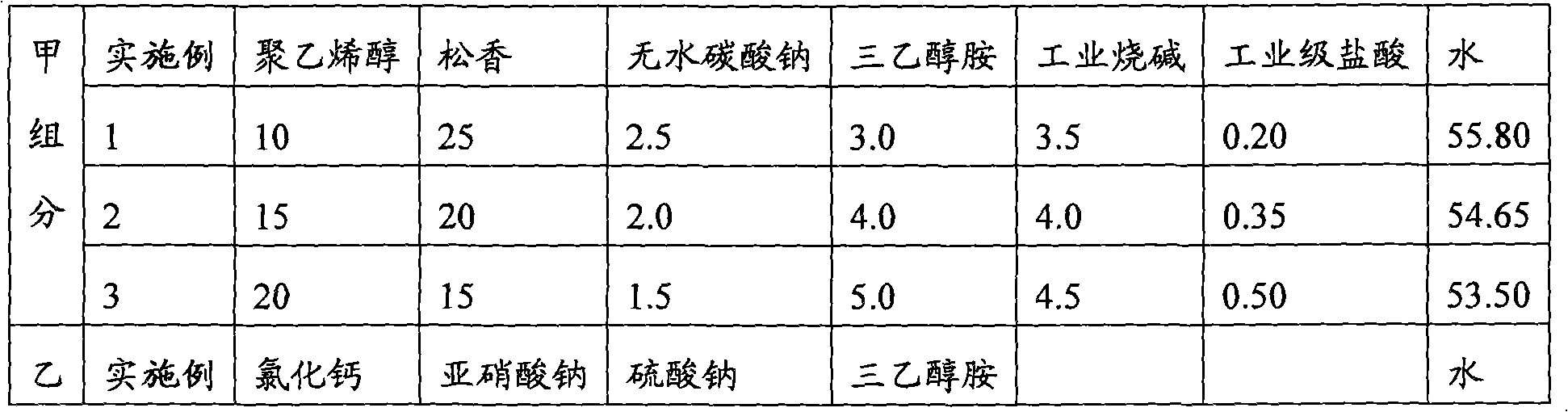

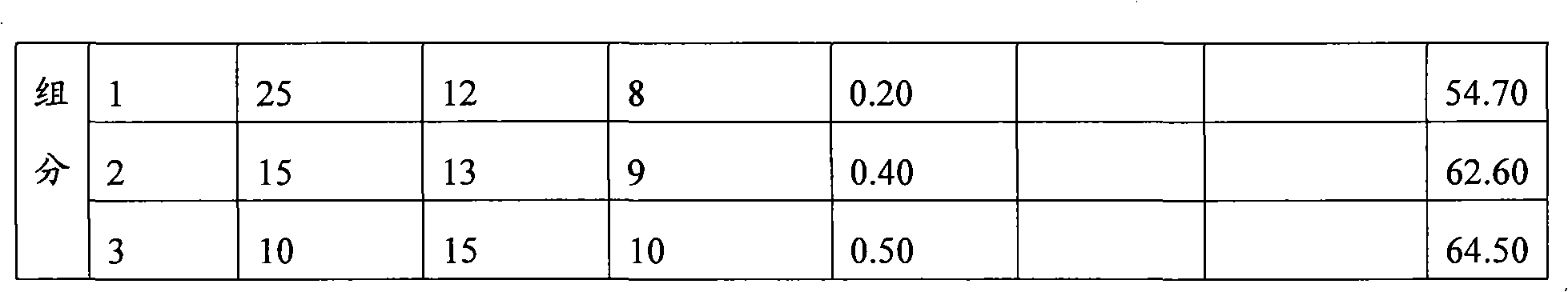

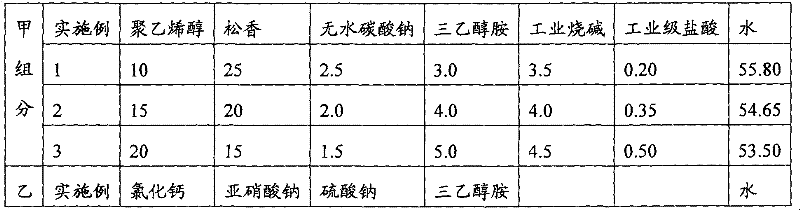

Compound type concrete foaming agent, preparation method and application thereof

The invention provides a compound type concrete foaming agent, a preparation method and an application thereof. The compound type concrete foaming agent is prepared by compounding a component A and acomponent B, wherein the component A comprises 10-20 parts of polyvinyl alcohol, 15-25 parts of colophony, 1.5-2.5 parts of anhydrous sodium carbonate, 3.5-4.5 parts of industrial sodium hydroxide, 3-5 parts of triethanolamine, 0.2-0.5 parts of industrial grade hydrochloric acid and 53.5-55.8 parts of water; and the component B comprises 0.2-0.5 parts of triethanolamine, 8-10 parts of sodium sulfate, 12-15 parts of sodium nitrite, 10-25 parts of calcium chloride and 54.7-64.5 parts of water. The compound type concrete foaming agent not only can increase the doped quantity of the foaming agentbut also can compensate the concrete strength and the solidification time; the compound type concrete foaming agent can be used for manufacturing foam concrete with super-low capacity, also utilize alarge amount of waste residues, such as industrial and architectural rubbish and the like, to produce light foamed concrete.

Owner:刘兴山

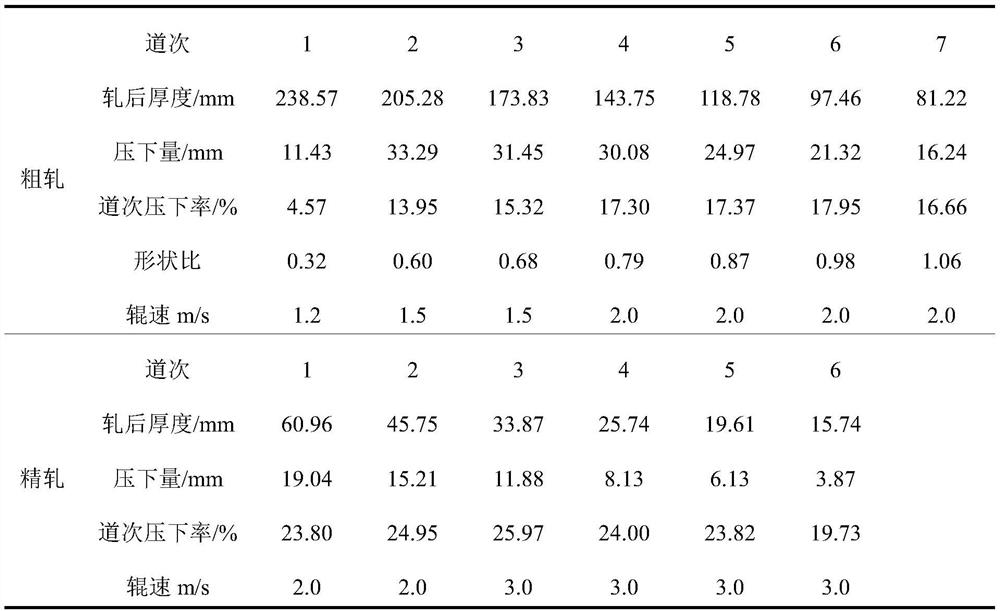

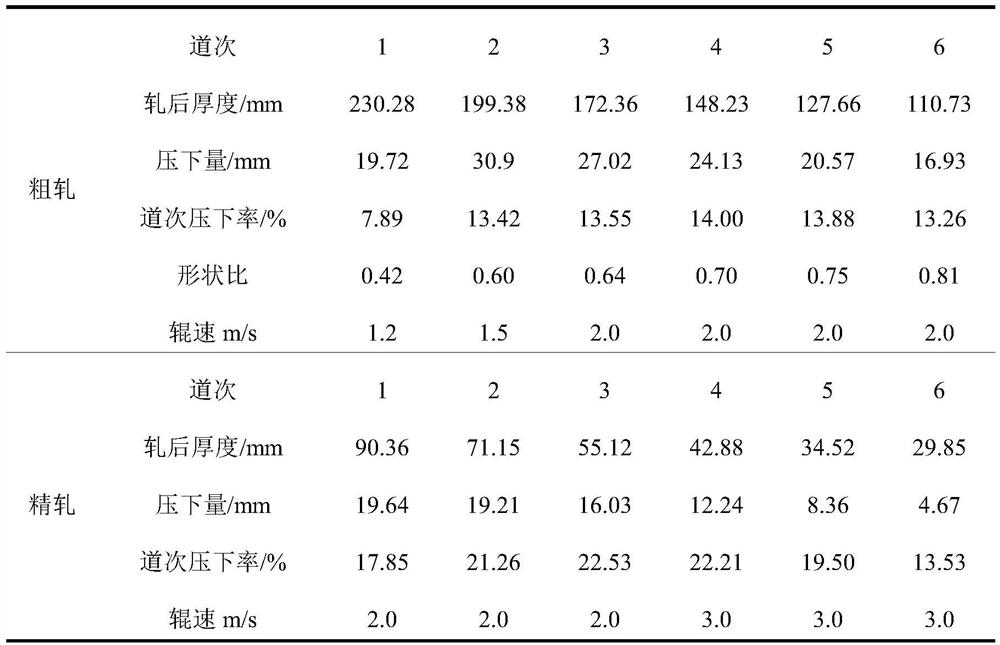

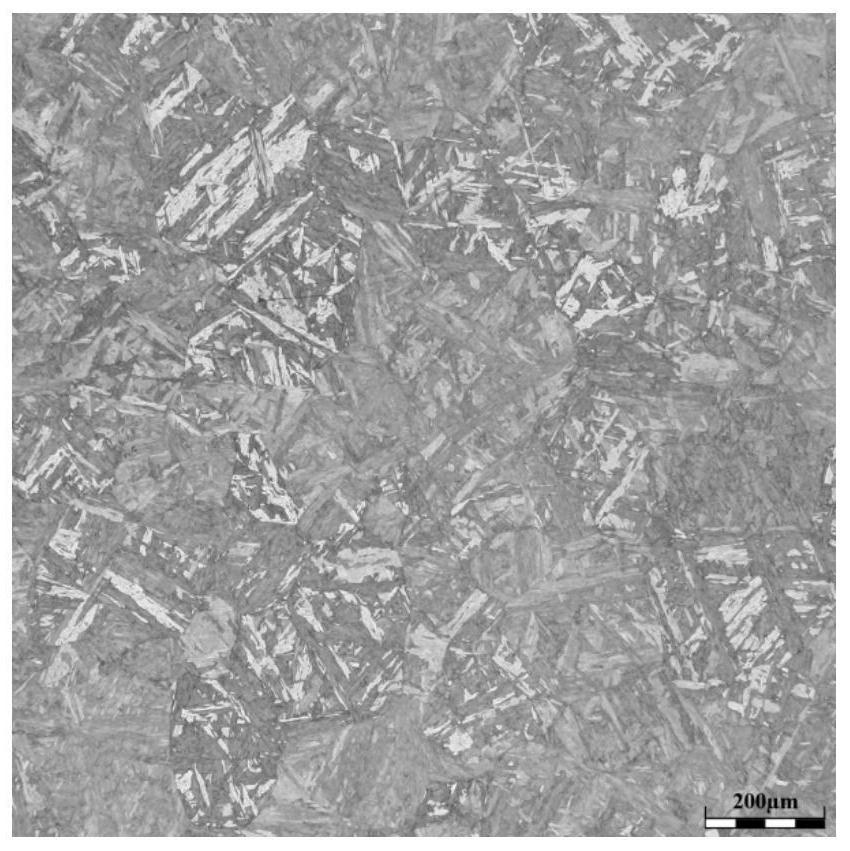

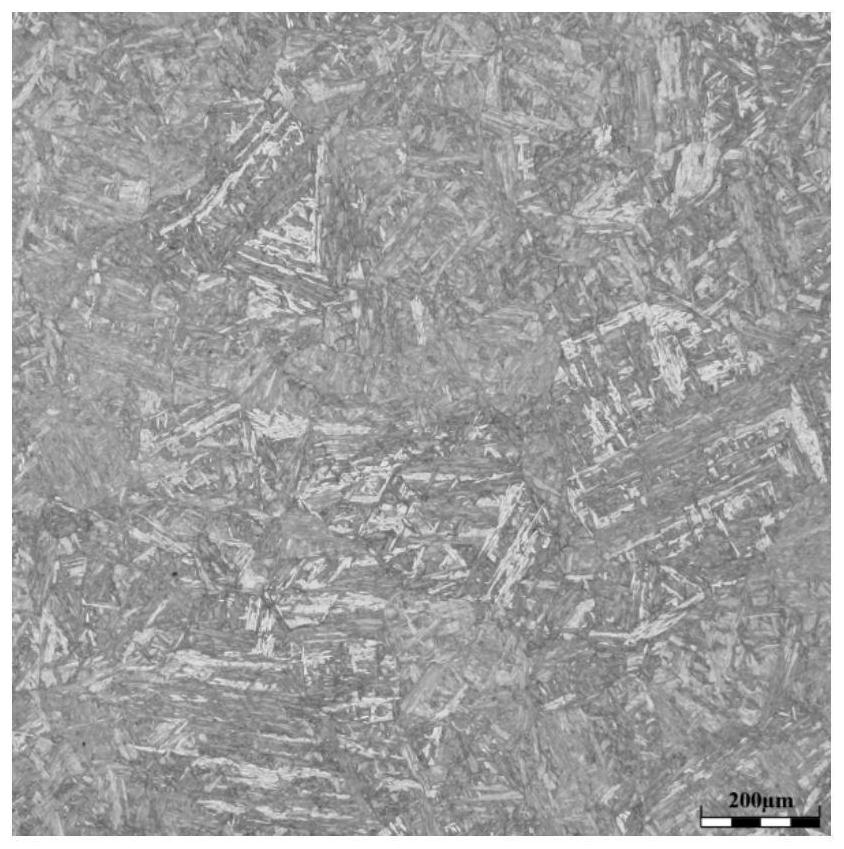

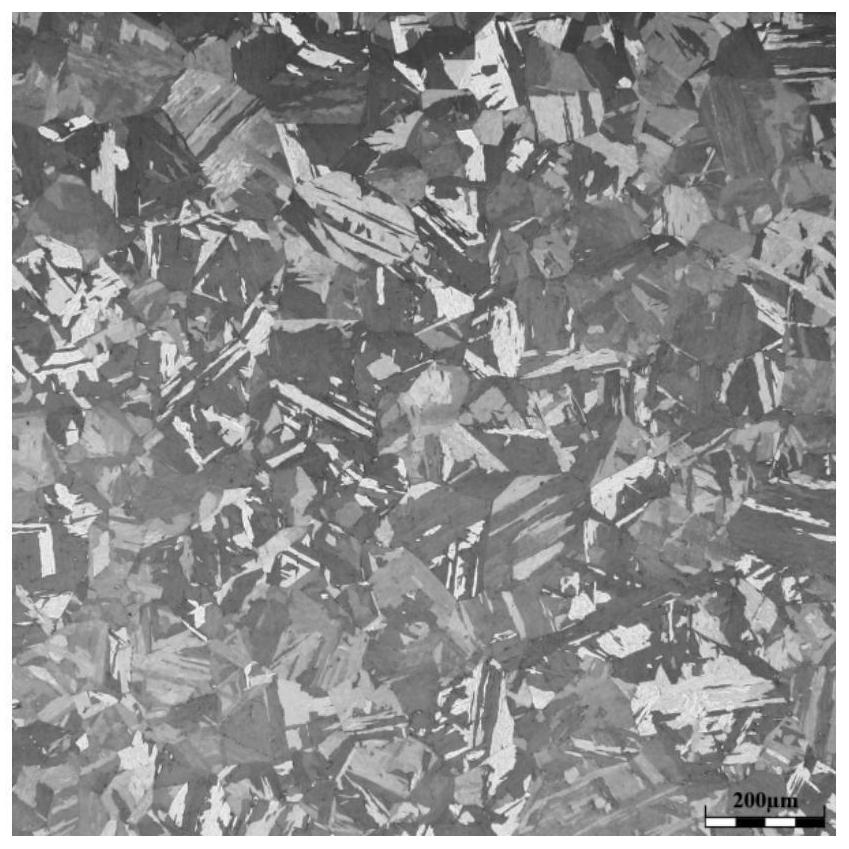

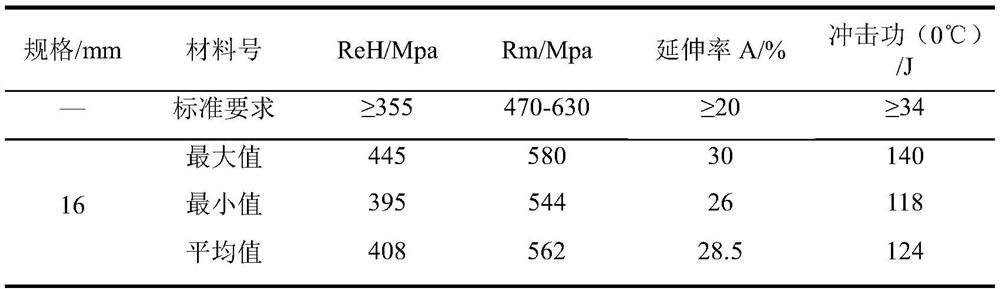

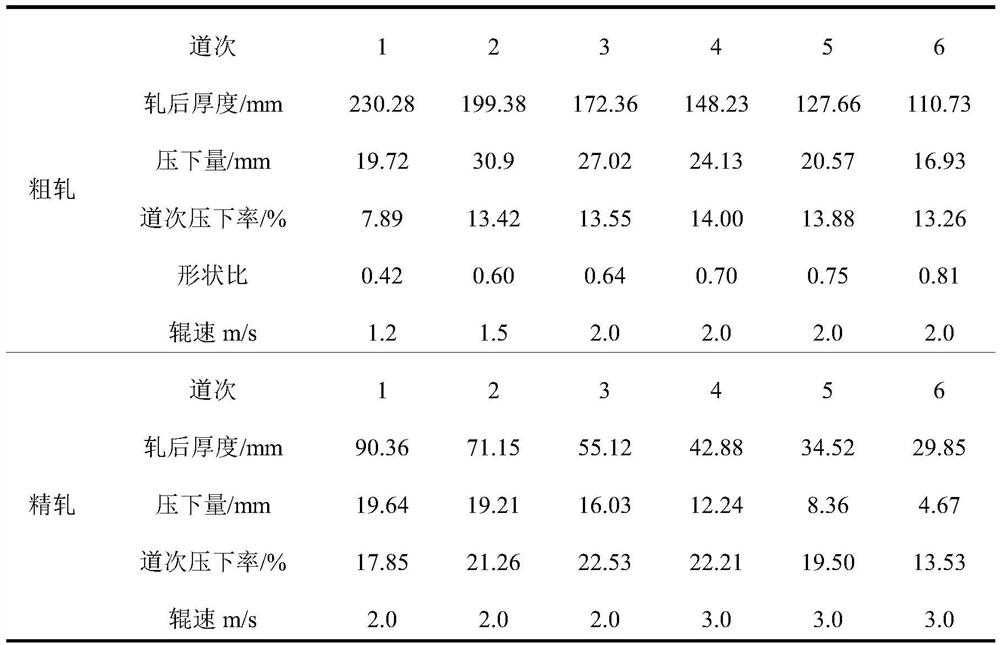

Low-cost production process for Q355C steel plate

The invention relates to low-cost production process for a Q355C steel plate. The Q355C steel plate comprises the following chemical components in percentage by mass: 0.11%-0.20% of C, not greater than 0.20%-0.45% of Si, 1.1%-1.6% of Mn, 0.015%-0.045% of Alt, not greater than 0.025% of P, not greater than 0.015% of S and the balance Fe; the internal quality of the steel plate is improved via converter smelting, reasonable end-point carbon content control, complete deoxygenation, white slag refining and soft blowing, calcium treatment, and continuous casting; and the internal quality of the steel plate is further improved through rough rolling and finish rolling two-phase controlled rolling, and reasonable allocation for rolling temperatures, speeds and passes. According to the low-cost production process for the Q355C steel plate, the impact toughness at 0 DEG C is improved by reducing a C content; expensive Nb and V are replaced by cheap micro-alloy element Al, so that the profit maximization is realized, and the impact toughness is further improved; and the Q355C steel plate is produced through a rolling process which is matched with the components, and the cost of a ton of steelcan be reduced by 50 yuan.

Owner:TIANJIN IRON & STEEL GRP

800 MPa grade cold-rolling dual-phase steel and manufacturing method thereof

InactiveCN102174685BHigh strengthImprove hardenabilityRoll mill control devicesMetal rolling arrangementsChemical compositionUltimate tensile strength

The invention discloses 800 MPa grade cold-rolling dual-phase steel and a manufacturing method thereof. The steel contains the following chemical compositions in percentage by weight: 0.10-0.18% of C, 0.03-0.19% of Si, 2.6-3.0% of Mn, 0.01-0.04% of Als, 0.15-0.9% of Cr, and the balance of Fe and other inevitable impurities. The manufacturing method for the steel comprises the following steps sequentially: heating billet steel to 1150-1250 DEG C along with a furnace and preserving the temperature for 1.5-3 hours under heat insulation condition, then performing hot rolling, wherein the rough rolling start rolling temperature is controlled within the range from 1050 DEG C to 1110 DEG C, the precision rolling finish rolling temperature is controlled within the range from 860 DEG C to 900 DEG C, and the simulation curling temperature is controlled within the range from 560 to 600 DEG C; washing a hot rolled plate with acid and then carrying out cold rolling; wherein the cold rolling pressing rate is controlled to be 45-75%, then performing the annealing treatment, wherein the annealing temperature is controlled within the range from 760 DEG C to 860 DEG C; and slowly cooling the hot rolled plate to 630-680 DEG C after keeping for 1-5 minutes under heat preservation condition and then rapidly cooling to be below 350 DEG C at a speed more than 25 DEG C / s for ageing treatment lasting for 5-10 minutes. The practice proves that the steel has the advantages of low yield strength, low yield ratio, high coefficient of elongation, and excellent forming property, and the manufacturing method has simple process and low cost.

Owner:武汉钢铁有限公司

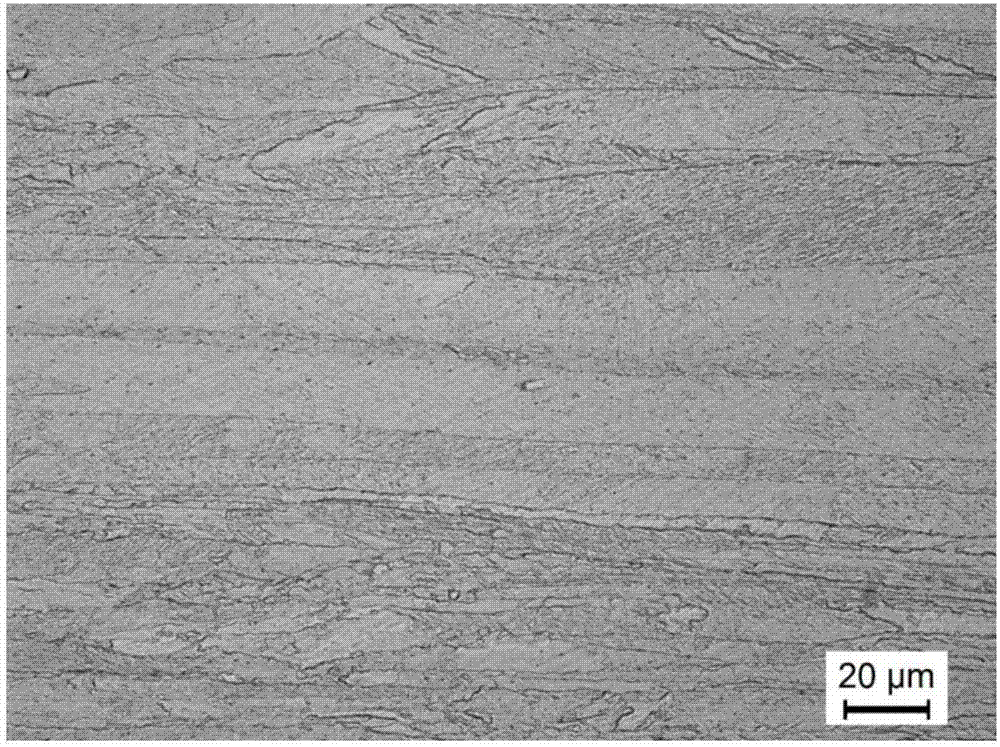

Microwave-dipping modifying treatment process for wood of solid wood ground heating floor

ActiveCN107160510ARaise RadialImprove permeabilityRadiation/waves wood treatmentWood treatment detailsSolid woodMicrowave

The invention discloses a microwave-dipping modifying treatment process for wood of a solid wood ground heating floor. The treatment process comprises a, microwave treatment: placing the wood in a microwave treatment device for performing microwave treatment, wherein the microwave treatment process is divided into 3 times, and the treatment every time has a time interval of 1-3min; adjusting radiation power to 2-5KW for the first time, wherein the radiation time is 30-60s; adjusting the radiation power to 1-4KW for the second time, wherein the radiation time is 20-40s; adjusting the radiation power to 0.2-0.8KW for the third time, wherein the radiation time is 8-15s; b, cooling; performing cooling and temperature reduction, taking the wood out of a tank after the temperature is reduced to 25-40 DEG C; c dipping for the first time: dipping the wood in an analysis pure water solution with a mass percent of 20-30%, wherein a dipping temperature is 50-70 DEG C; taking out for drying after dipping for 25-35h, and drying till a water content is 8%; d, dipping for the second time: placing the well-dried wood in a vacuum dipping tank, adjusting a vacuum degree to -0.20 to (-0.10)MPa, keeping for 10-20min, using negative pressure to inject resin into the tank body so as to dip the wood in the resin, and controlling a pressure to be 1-3MPa and keeping for 1-4h; and e: obtaining a finished product: drying to obtain the final material.

Owner:JIUSHENG WOOD

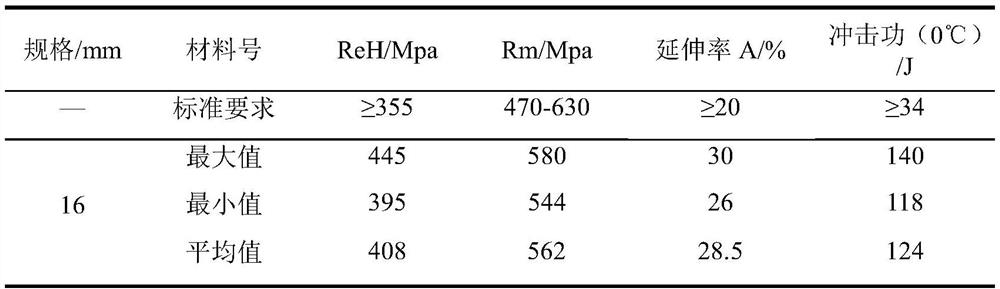

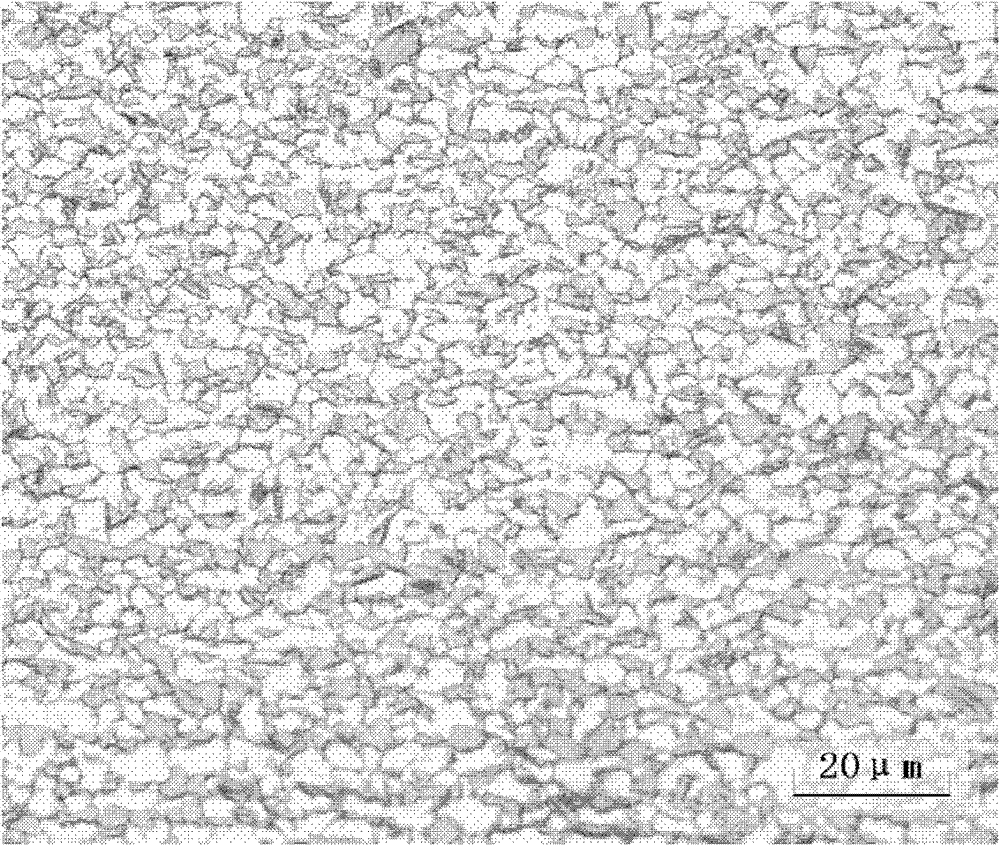

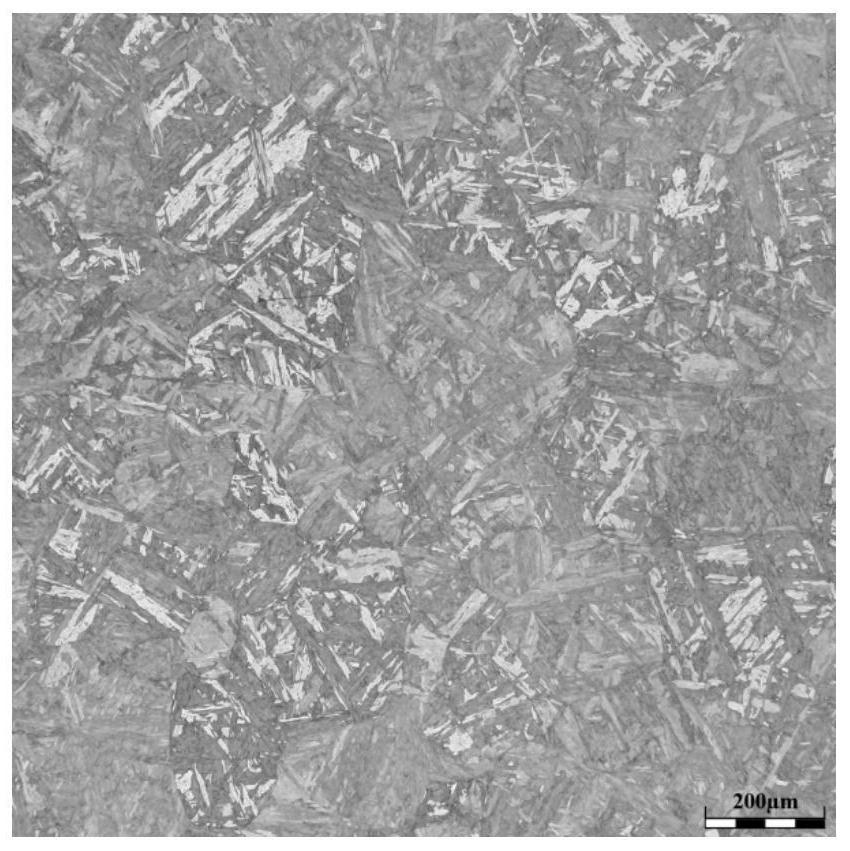

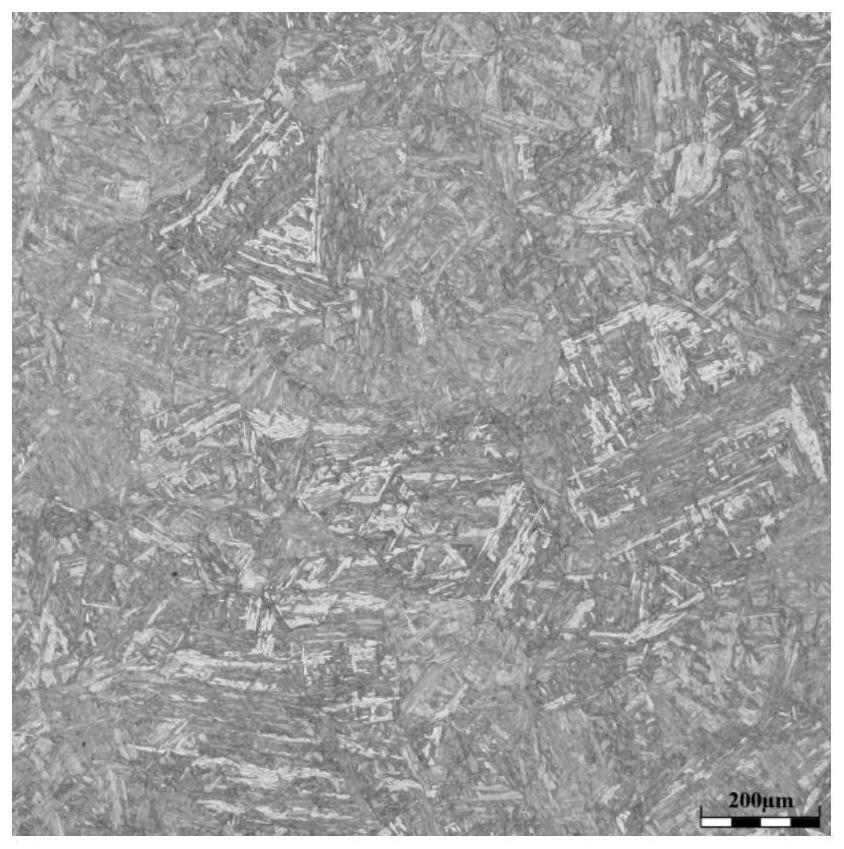

Q345D steel with thickness of 16 mm and production method thereof

InactiveCN108914013AReduce manufacturing costGrain refinementProcess efficiency improvementHeating timeHigh intensity

The invention provides a Q345D steel with a thickness of 16 mm and a production method thereof. The Q345D steel comprises the following elements by mass: 0.14 to 0.18% of C, 0.90 to 1.03% of Mn and 0.012 to 0. 020% of Nb. In the process of production, the surface temperature of a casting blank at the ending moment of heating is controlled within the range of 1100-1150 DEG C, heating time is no less than 8 min / cm; an initial rolling temperature is 1080-1100 DEG C, a first-stage finish rolling temperature is more than 1000 DEG C, and a second-stage finish rolling temperature is no more than 890DEG C; in the second stage, the temperature-waiting thickness of the casting blank 2.5 times or more the thickness of a finished steel sheet, and the finish rolling temperature is controlled within the range of 810 to 850 DEG C; an initial cooling temperature is no less than 740 DEG C, and a finish cooling temperature is 650+ / - 20 DEG C. The production method of the invention successfully producesthe Q345D low-alloy high-strength steel under the premise of ensuring low production cost, and the mechanical properties and internal quality of the produced steel plate meet requirements prescribedin GB / T1591.

Owner:HANDAN IRON & STEEL GROUP +1

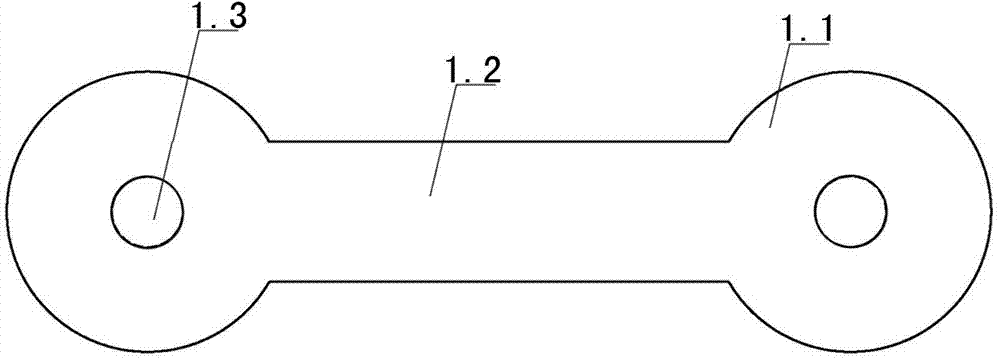

Glass fiber net reinforcement part, exterior wall heat-preservation anti-cracking structure and construction method thereof

ActiveCN104499651AOvercome strengthOvercoming easy crackingHeat proofingBuilding reinforcementsGlass fiberSurface layer

The invention relates to a glass fiber net reinforcement part, an exterior wall heat-preservation anti-cracking structure and a construction method of the exterior wall heat-preservation anti-cracking structure. The glass fiber net reinforcement part is of an integral sheet structure formed by two fixing sheets with the same shape and a connecting bridge connected between the two fixing sheets, and a threaded hole penetrating through a screw is formed at the center position of the fixing sheet. In addition, the glass fiber net reinforcement part is designed to be used for reinforcing the connecting strength of an anti-cracking mortar layer and a heat preservation layer, the glass fiber net reinforcement part has a simple structure, has low cost, can be constructed conveniently, and has a good fixing effect, can compensate the strength loss when the binding power between the anti-cracking mortar layer and the heat preservation layer is low, and can ensure the bonding quality and the construction reliability of the follow-up surface layer, the construction operation is simple, the construction difficulty is not increased, the original construction quality and the construction efficiency are not influenced, the using amount of the anti-cracking mortar can be used to a certain extent, the cost is reduced and the glass fiber net reinforcement part can be widely applied to exterior wall construction.

Owner:BUCG THE EIGHTH CONSTR DEV

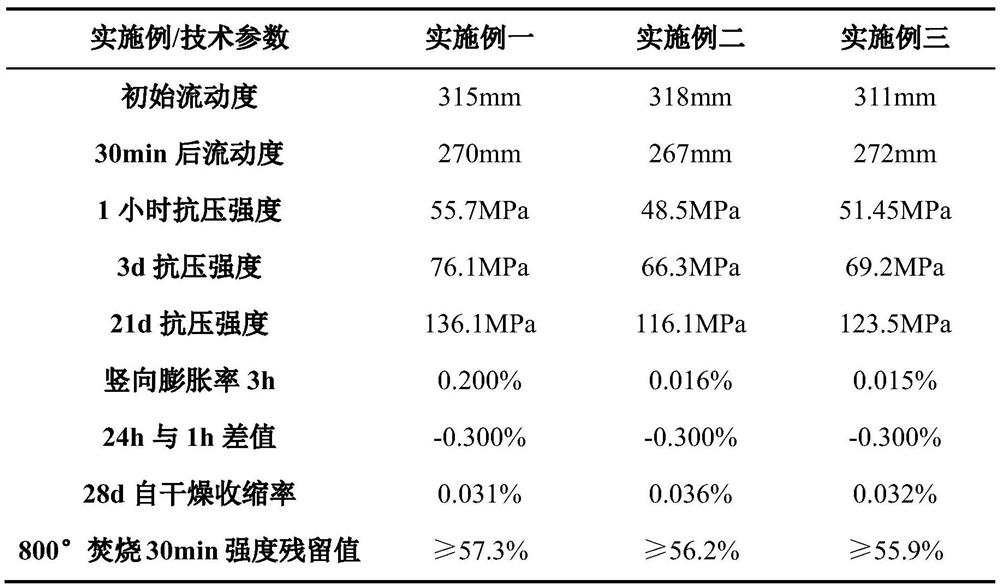

High-temperature-resistant sleeve grouting material for steel bar connection and preparation method thereof

The invention particularly relates to a high-temperature-resistant sleeve grouting material for steel bar connection, which comprises a component A and a component B. The component A comprises 20-30%of Portland cement, 3-5% of high-alumina cement, 2-3% of S95 mineral powder, 1-2% of silica fume, 5-10% of fly ash, 5-10% of quartz sand fine powder, 0.5-1% of expanding agent, 1-2% of copolyoxymethylene fiber, 20-30% of magnesite fine aggregate with a fineness modulus of 2.7, and 10-20% of blast furnace steel slag fine aggregate subjected to high-temperature autoclaving treatment, and the like. The component B comprises the following components in percentage by weight: 4-10% of water, 0.01-0.02% of graphene oxide, 2-3% of polycarboxylic acid water reducing agent mother liquor, 1-2% of polycarboxylic acid slump retaining mother liquor, 0.03-0.1% of air entraining agent and 0.03-0.1% of defoaming agent. The sleeve grouting material forms a steam dissipation channel in the grouting sleeve and maintains high mechanical properties, so that structural burst of a steel bar connecting joint is avoided, and secondary disasters can be avoided.

Owner:福建鸿生高科环保科技有限公司 +1

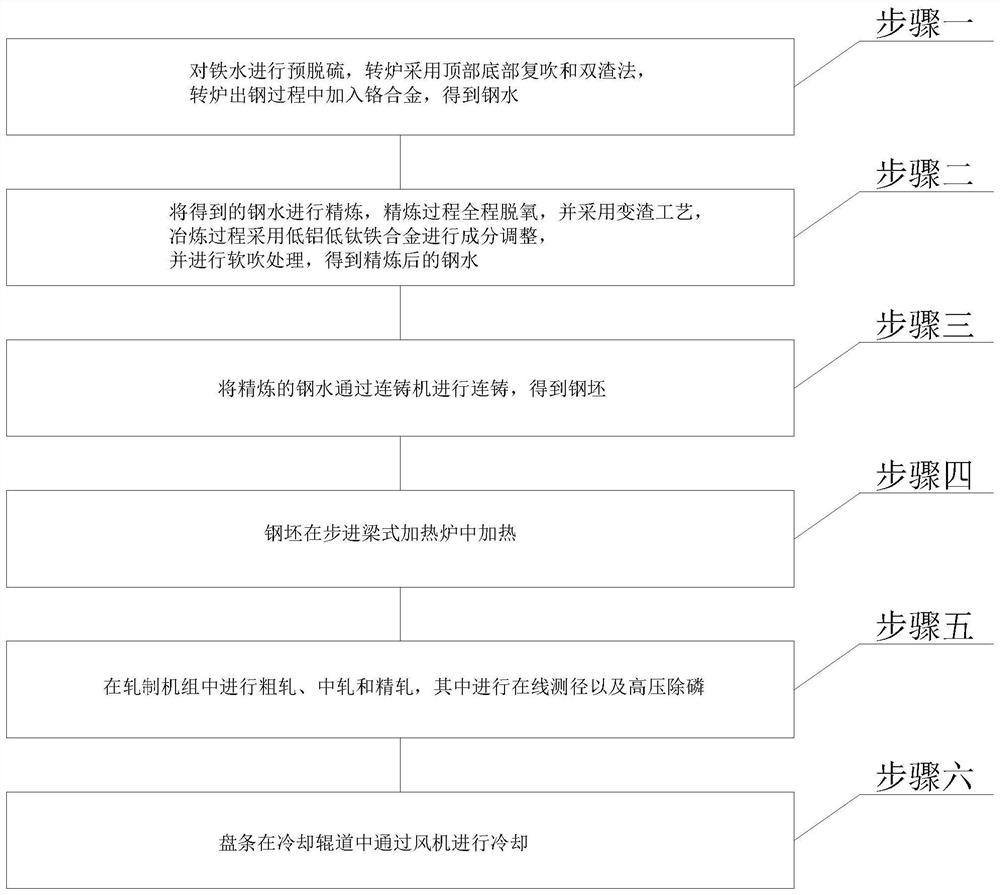

Chromium alloy non-quenched and tempered steel wire rod and production method thereof

InactiveCN112410679AImprove plasticityReduce the chance of formationMetal rolling arrangementsWire rodManganese

The invention is suitable for the technical field of steel wire rod machining, and provides a chromium alloy non-quenched and tempered steel wire rod and a production method thereof. The chromium alloy non-quenched and tempered steel wire rod comprises the following chemical components of, by weight, 0.22-0.31% of C, 1.20-1.55% of Mn, 0.15-0.30% of Si, 0.30-0.40% of Cr, less than or equal to 0.012% of P, less than or equal to 0.008% of S; less than or equal to 0.05% of Ni, less than or equal to 0.05% of Cu, less than or equal to 0.03% of Mo, less than or equal to 0.003% of Al, less than or equal to 0.002% of Ti, less than or equal to 0.002% of O, less than or equal to 0.005% of N, 0.05-0.20% of V, and the balance Fe and inevitable impurities. According to the method, the carbon content isreduced, the manganese content is reduced, the carbon segregation of the wire rod is improved, the plasticity of the wire rod is slightly improved, the forming probability of net carbon is reduced bycombining high-temperature rolling and controlled cooling processes, and the user machining wire breakage rate is reduced, so that the production efficiency of the user is improved; and in the coolingprocess, the process design of proper quick cooling and then slow cooling is adopted, growth of grains is controlled, ferrite-pearlite zonal segregation is reduced, and meanwhile, the situation thatthe cold working performance is deteriorated due to too high strength caused by an abnormal quenching structure is avoided.

Owner:JIANGSU YONGGANG GROUP CO LTD

A kind of composite concrete foaming agent and its preparation method and application

The invention provides a compound concrete foaming agent and its preparation method and application. 1.5-2.5 parts of anhydrous sodium carbonate, 3.5-4.5 parts of industrial caustic soda, 3-5 parts of triethanolamine, 0.2-0.5 parts of industrial grade hydrochloric acid, 53.5-55.8 parts of water; the B component is: triethanolamine 0.2- 0.5 parts, 8-10 parts of sodium sulfate, 12-15 parts of sodium nitrite, 10-25 parts of calcium chloride, 54.7-64.5 parts of water. The composite concrete foaming agent of the present invention can not only increase the amount of foaming agent, but also compensate the concrete strength and solidification time; it can not only produce ultra-low-capacity foamed concrete, but also use a large amount of waste residues such as industrial and construction waste , to produce lightweight foamed concrete.

Owner:刘兴山

A kind of cu-containing nano-phase strengthened easy-weld steel and its preparation method

Owner:HARBIN ENG UNIV

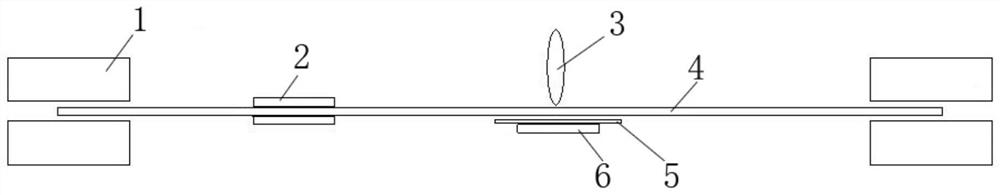

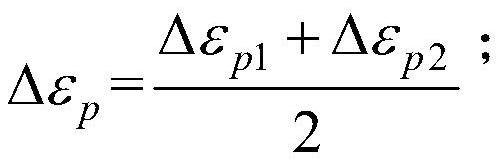

Method for testing value of bonded prestress released after pre-reinforcement of existing structure

The invention relates to a method for testing the value of bonded prestress released after pre-reinforcement of an existing structure, and belongs to the technical field of prestress measurement in civil engineering, the device comprises a concrete structure body, bonded prestressed tendons, a first strain gauge, a second strain gauge, a third strain gauge and a fourth strain gauge, at least one first strain gauge is bonded on the bonded prestressed tendon and is bonded along the prestressed direction; the carbon fiber sheet is adhered to the surface of the bonded prestressed tendon, and the carbon fiber sheet is adhered to one side opposite to the cutting device; the bonded prestressed tendons are pre-reinforced by the carbon fiber sheets; and the second strain gauge is bonded on the carbon fiber sheet and is bonded along the pre-stress direction. The method has the advantages that the prestress value can be accurately measured, and the strength of the prestressed tendon cannot be greatly weakened.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Chemical activator for improving activity of coal gangue

The invention relates to the technical field of new material processing, and discloses a chemical activator for improving the activity of coal gangue, which is used for activating the activity of a prepared chemical activator when the coal gangue is used for processing a building thermal insulation material, so that the strength loss caused in later processing can be compensated, and the comprehensive material achieves excellent performance. The utilization rate of coal gangue is increased, the cost of building materials is reduced, the burden on the environment is reduced, and the applicationvalue of waste solid materials is increased.

Owner:安徽滨江新型墙材有限公司

Ultralow-carbon high-strength high-plasticity martensitic steel and preparation method thereof

ActiveCN113186464AHigh strengthGood welding performanceFurnace typesHeat treatment furnacesCryogenic treatmentHeat treating

The invention relates to ultralow-carbon high-strength high-plasticity martensitic steel and a preparation method thereof, and belongs to the field of steel preparation. The martensitic steel comprises the following chemical components in percentage by mass: 0.01-0.05% of C, 0.2-0.5% of Si, 0.5-0.8% of Mn, 0.8-1.2% of Cr, 2.0-4.0% of Cu, 10.0-11.0% of Ni, 0.05-0.15% of V, 0.5-0.9% of Mo, 0.2-0.5% of Al, less than or equal to 0.02% of P, less than or equal to 0.02% of S and the balance of Fe. The elements of Cu, Ni, Al and Mn are added into the alloy, and Cu and Ni3Al (Mn)-rich phases can be separated out in the aging heat treatment process, so that the high strength of the alloy is achieved, and meanwhile the welding performance is excellent. The martensitic steel does not need rolling, subzero treatment and the heat treatment process are simple, the production efficiency is high, and implementation is easy.

Owner:NORTHEASTERN UNIV

A low-cost q355c steel plate production process

The invention relates to a low-cost Q355C steel plate production process. The chemical composition according to mass percentage is as follows: C: 0.11%-0.20%, Si: ≤0.20-0.45%, Mn: 1.1%-1.6%, Alt: 0.015%-0.045% , P: ≤0.025%, S: ≤0.015%, the rest is Fe; through converter smelting, reasonable end-point carbon content control, complete deoxidation, white slag refining and soft blowing, calcium treatment at the same time, and continuous casting to improve the internal quality of the steel plate ;Through the two-stage controlled rolling of rough and finish rolling, the rolling temperature, speed and pass are reasonably distributed to further improve the internal quality of the steel plate. The invention reduces the C content, improves the impact toughness at 0°C, and replaces expensive Nb and V with cheap micro-alloying elements Al to maximize profits, and further improves the impact toughness at the same time, and produces Q355C steel plates through a rolling process that matches the composition. Ton of steel can be reduced by 50 yuan.

Owner:TIANJIN IRON & STEEL GRP

A kind of ultra-low-carbon high-strength high-plasticity martensitic steel and preparation method thereof

ActiveCN113186464BHigh strengthGood welding performanceFurnace typesHeat treatment furnacesCryogenic treatmentMartensite

An ultra-low-carbon, high-strength, high-plasticity martensitic steel and a preparation method thereof, belonging to the field of steel preparation, the mass percentage of the chemical composition of the martensitic steel is: C: 0.01-0.05%, Si: 0.2-0.5%, Mn: 0.5~0.8%, Cr: 0.8~1.2%, Cu: 2.0~4.0%, Ni: 10.0~11.0%, V: 0.05~0.15%, Mo: 0.5~0.9%, Al: 0.2~0.5%, P: ≤ 0.02%, S: ≤0.02%, the balance is Fe. Adding Cu, Ni, Al and Mn elements to the alloy of the present invention can precipitate rich Cu and Ni during the aging heat treatment process. 3 Al(Mn) phase, so as to realize the high strength of the alloy and excellent welding performance; the martensitic steel of the present invention does not need rolling, cryogenic treatment, simple heat treatment process, high production efficiency, and easy realization.

Owner:NORTHEASTERN UNIV LIAONING

High-durability concrete product with gradient structure and preparation method thereof

Owner:WUHAN UNIV OF TECH

Wood microwave-impregnation modification process for solid wood floor heating

ActiveCN107160510BImprove permeabilityImmediateRadiation/waves wood treatmentWood treatment detailsSolid woodMicrowave

Disclosed is a microwave-impregnating modified treatment process for wood for ground heating solid-wood flooring. The process comprises a. microwave treatment: putting wood in a microwave treatment device to undergo microwave treatment, wherein a microwave treatment process is carried out three times, and a treatment time interval is 1-3 min; regulating the radiation power to 2-5 KW the first time, the radiation time being 30-60 s; regulating the radiation power to 1-4 KW the second time, the radiation time being 20-40 s; and regulating the radiation power to 0.2-0.8 KW the third time, the radiation time being 8-15 s; b. cooling: carrying out cooling to reduce the temperature, and removing the wood from a tank when the temperature is reduced to 25-40°C; c. primary impregnation: impregnating the wood in an analytically pure water solution in a mass fraction of 20-30 % at an impregnation temperature of 50-70°C, taking out the wood and drying same after impregnating the wood for 25-35 h, wherein drying the wood is carried out until the water content reaches 8 %; d. secondary impregnation: putting the dried wood in a vacuum impregnating tank, regulating a vacuum degree to -0.20-(-0.10) MPa, maintaining the vacuum degree for 10-20 min, using a negative pressure to inject resin into a tank body at the same time, so that the wood is impregnated in the resin, and controlling the pressure to be 1-3 MPa and maintaining the pressure for 1-4 h; and e. obtaining the finished product: drying the wood and obtaining a final material.

Owner:JIUSHENG WOOD

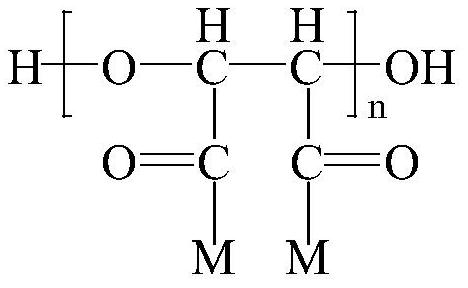

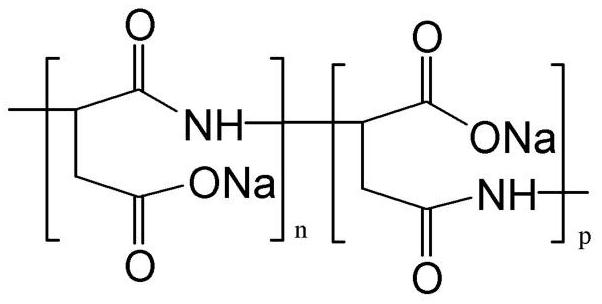

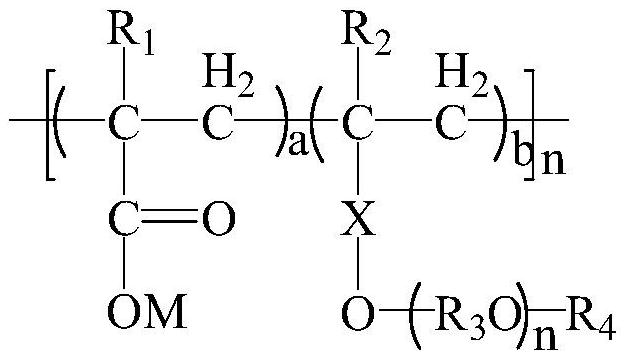

Macromolecular gypsum retarder and preparation method and application thereof

ActiveCN112573858AMake up for loss of strengthReduce water consumptionPolyaspartic acidSuperplasticizer

The invention provides a macromolecular gypsum retarder and a preparation method and application thereof, and the macromolecular gypsum retarder comprises the following raw materials: polyepoxysuccinic acid, polyaspartic acid and a polycarboxylate superplasticizer. The invention also provides a preparation method of the polymer gypsum retarder and application of the polymer gypsum retarder. The polymer gypsum retarder provided by the invention can realize efficient retarding in the gypsum slurry hardening process, reduces the water consumption, improves the strength, and effectively solves theproblem of gypsum strength reduction caused by retarding.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

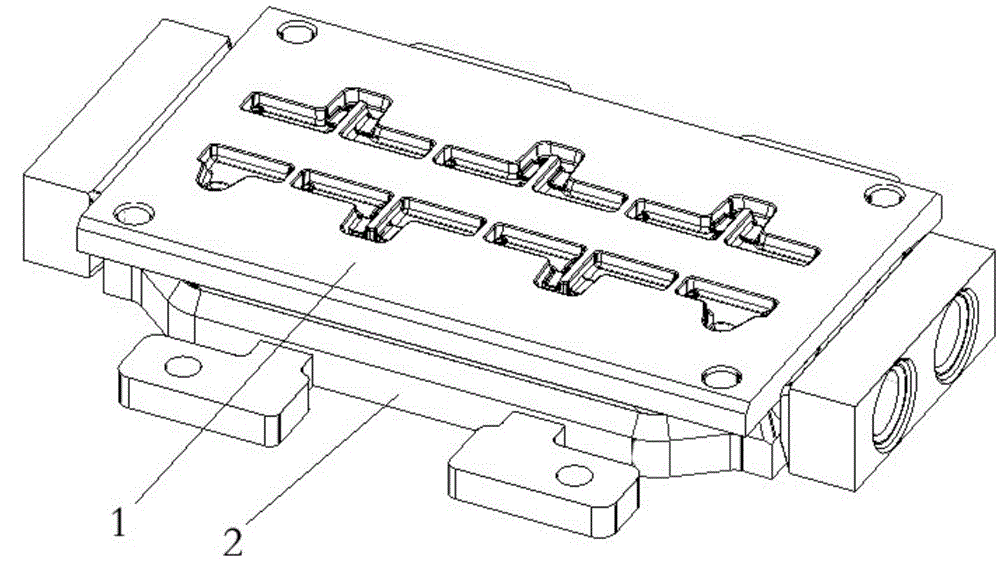

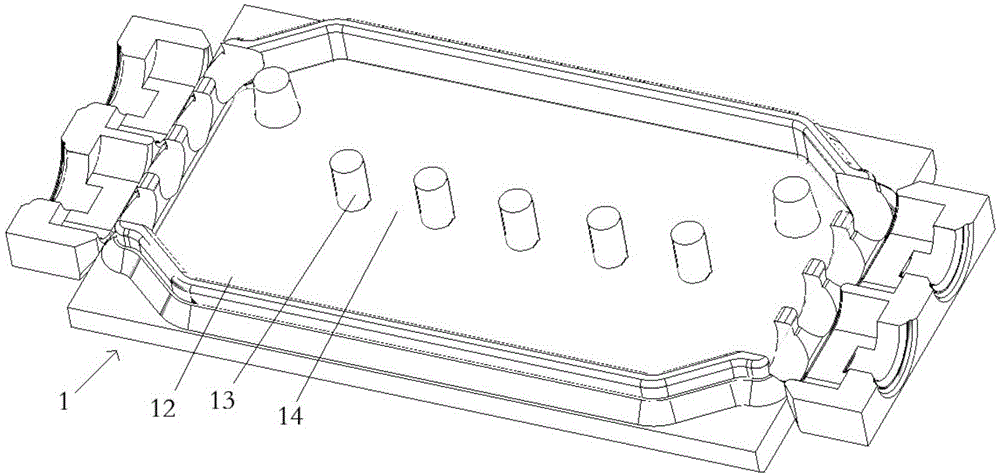

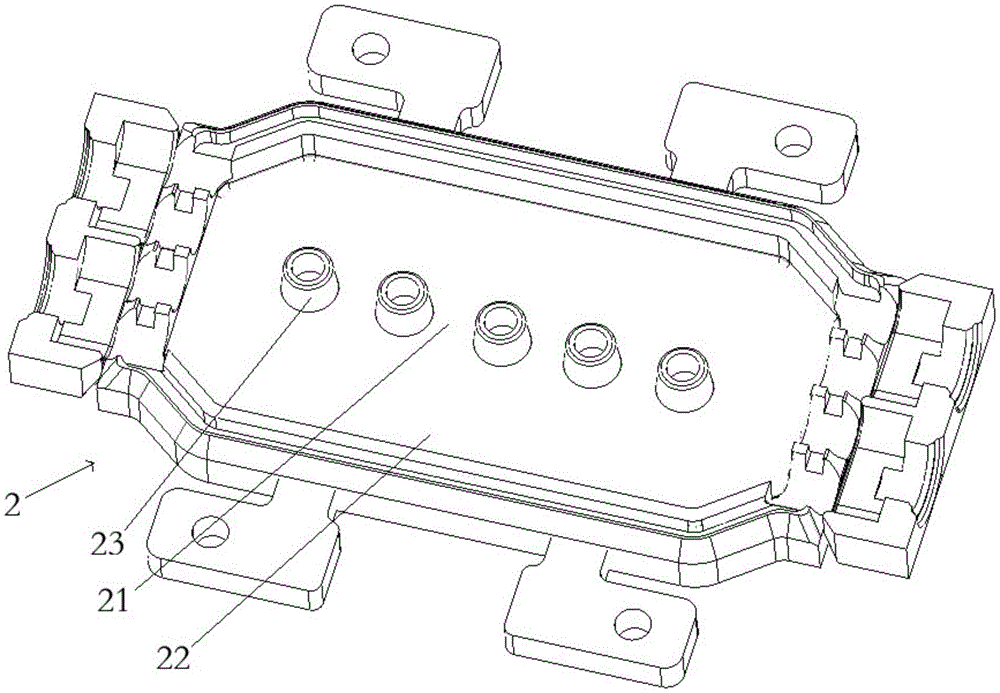

A battery casting and welding mold

The invention discloses a cast welding die for a storage battery, which belongs to the field of storage batteries. According to the cast welding die, the problem that a die is easy to break off is solved. The cast welding die comprises an upper plate and a lower plate, wherein the upper plate can be buckled with the lower plate; after the upper plate is mutually buckled with the lower plate, an inner cavity is formed by the lower surface of the upper plate and the upper surface of the lower plate; two upper reinforcing parts are respectively arranged on two sides of the upper plate; the upper reinforcing parts and the upper plate form an integrated structure; the lower surface of the upper plate is a polished surface; two lower reinforcing parts are respectively arranged on two sides of the lower plate; the lower reinforcing parts and the lower plate form an integrated structure; the upper surface of the lower plate is a polished surface; a plurality of mounting columns are arranged on the lower surface of the upper plate; a plurality of mounting seats are arranged at the positions corresponding to the mounting columns, of the upper surface of the lower plate. The lower surface of the upper plate and the upper surface of the lower plate are kept as the polished surfaces, so that the step of processing reinforcing ribs is eliminated and cutting scars caused by cutting of the reinforcing ribs are avoided while the cost is reduced; the reinforcing parts are respectively and additionally arranged on two sides of each of the upper plate and the lower plate so as to make up the strength loss caused by the reinforcing ribs.

Owner:长兴杰盛机械制造厂

A kind of hot-rolled dual-phase steel with tensile strength ≥ 780mpa and its production method

Owner:武汉钢铁有限公司

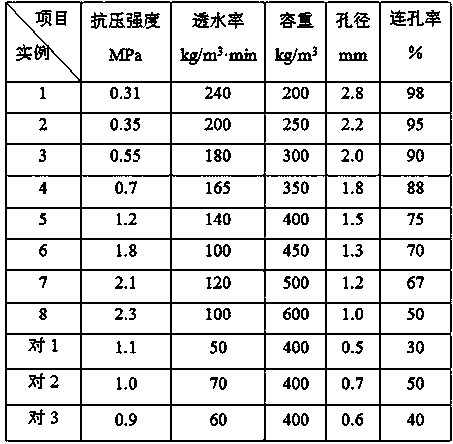

A kind of permeable foam concrete

Owner:河南华泰新材科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com