Patents

Literature

77results about How to "Reduce the chance of formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

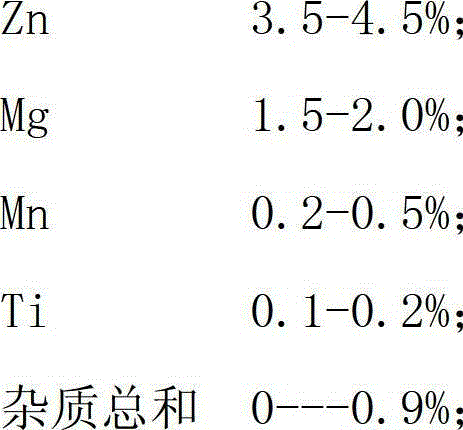

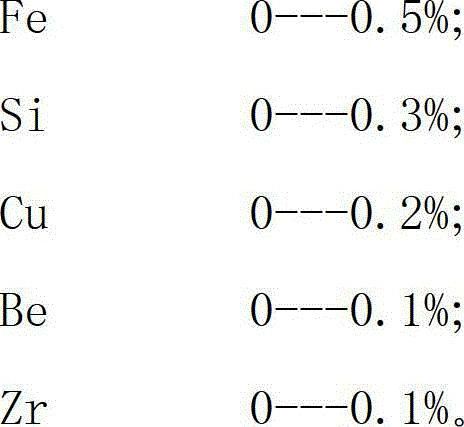

Counter-pressure casting process for ZL424 aluminum alloy castings

ActiveCN102873301AIncrease the speed of solidificationNot easy to precipitateCounter pressureShrinkage porosity

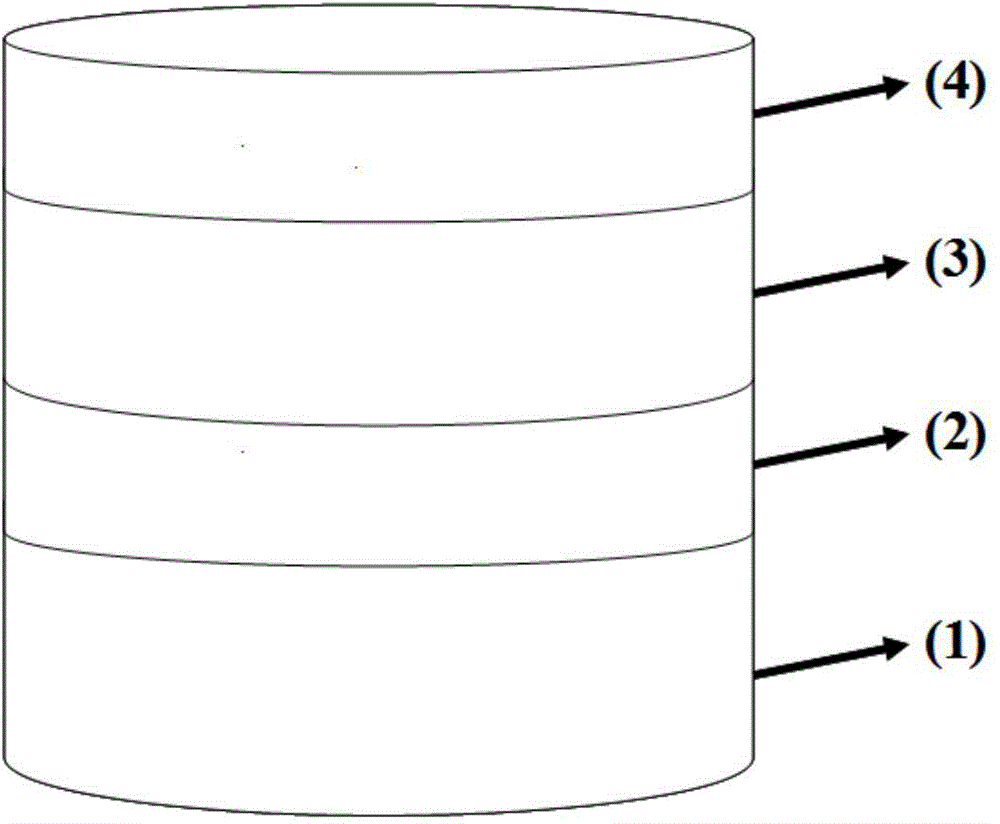

The invention relates to a counter-pressure casting process for ZL424 aluminum alloy castings. The process includes the steps: (1) alloy burdening; (2) using secondary refining and intermediate purifying for smelting alloy; (3) using a counter-pressure casting method for preparing ZL424 aluminum alloy castings; (4) cleaning the ZL424 aluminum alloy blank castings prepared at the step (3) before heat treatment; (5) checking the ZL424 aluminum alloy blank castings subjected to heat treatment. Blank castings prepared by the counter-pressure casting process overcome defects of ZL424 aluminum alloy castings obtained by traditional gravity casting methods, internal pinholes, microscopic shrinkage porosity and microcracks of castings are eliminated, and chemical component acceptability, mechanical performance and compactness of the castings are improved. In addition, the process has the advantages of high efficiency, high casting yield, low manufacturing cost and the like.

Owner:TIANJIN NAVIGATION INSTR RES INST

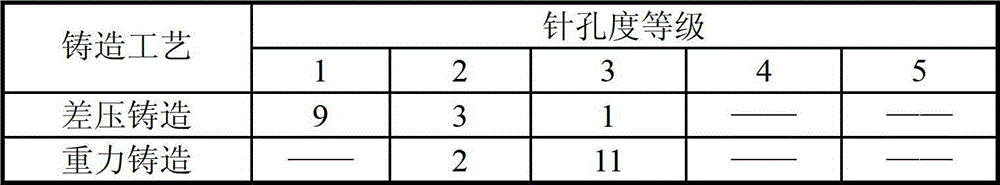

Pulsation axial flow blood pump

An axial-flow pulse blood pump for the patient of acute heart failure and final-phase heart disease is composed of a stator consisting of windings and shell, and a rotor consisting of high-energy magnet and propulsion unit. Said propulsion unit comprises spiral rotor, central axle and three pairs of cylindrical magnets to form a sealed one-way spiral blood channel. The rotation speed of rotor is pulsed by changing the pulse width and frequency of voltage or current in stator.

Owner:张杰民 +1

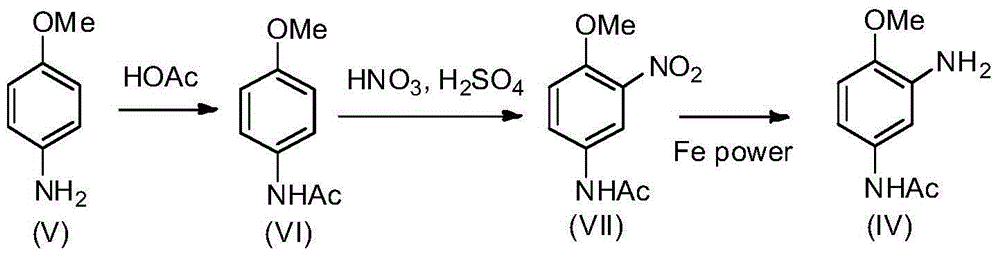

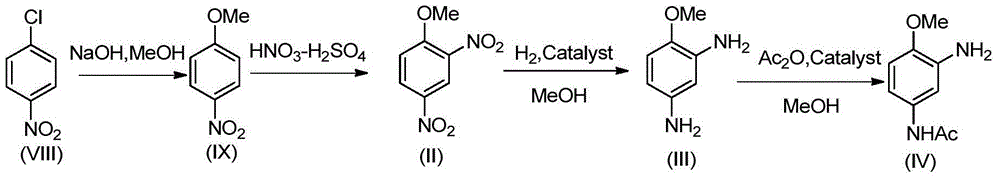

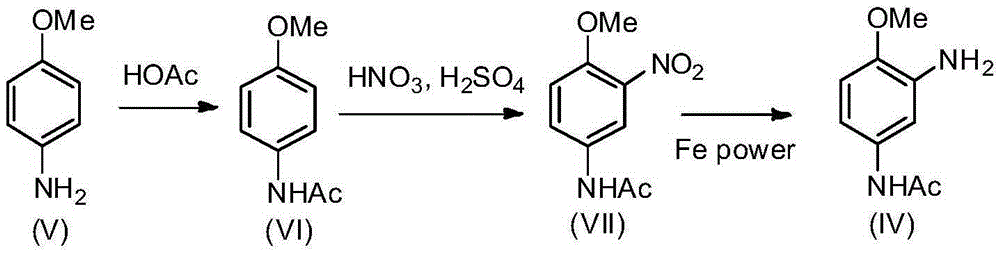

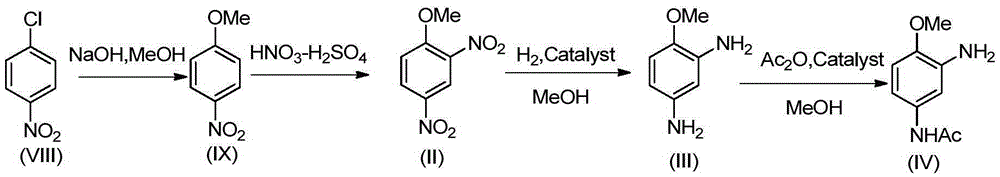

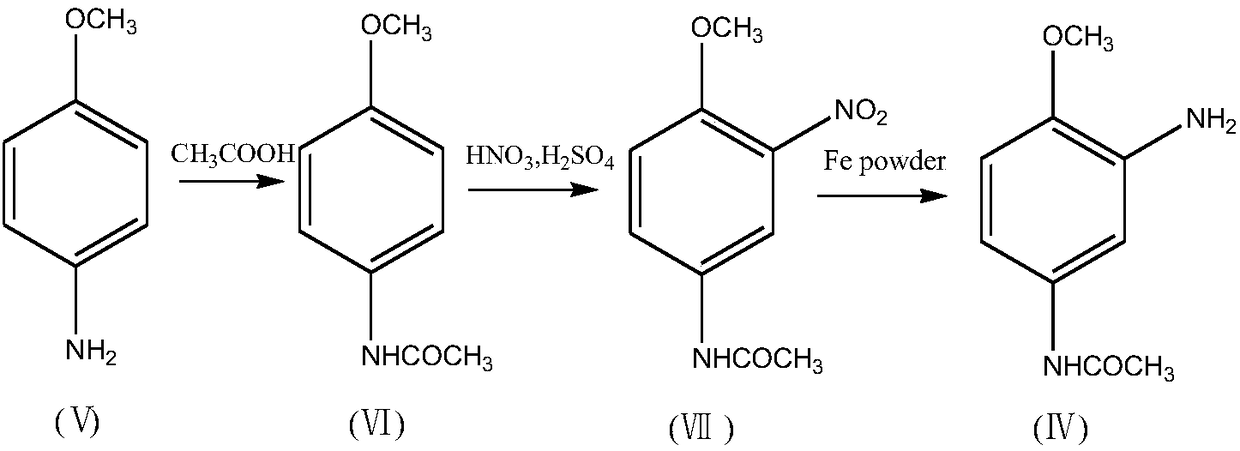

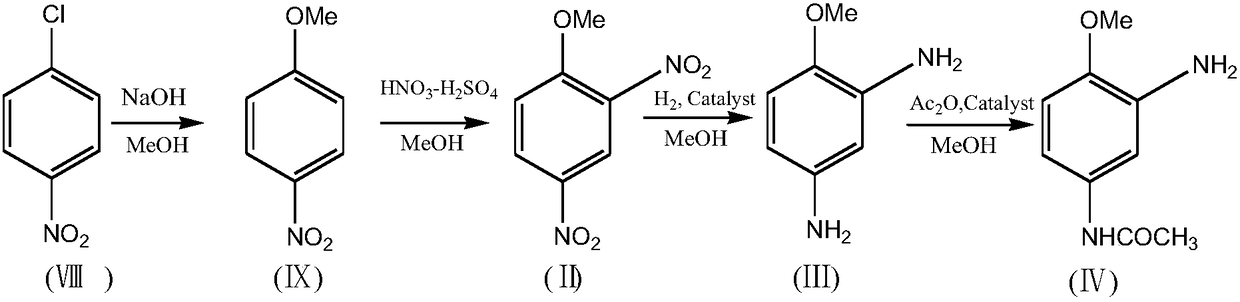

Synthesis process of 2-amino-4-acetamino anisole

InactiveCN104788334AReduce dosageReduce lossOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideEnergy consumption

The invention discloses a synthesis process of 2-amino-4-acetamino anisole. The synthesis process comprises the following steps: in methanol, under the action of an acid-binding agent, 2,4-diaminoanisole (III) and acetic anhydride are subject to acylation reaction shown in the description to obtain 2-amino-4-acetamino anisole (IV), wherein the molar ratio of the acid-binding agent to 2,4-diaminoanisole is (0.3 : 1)-(0.6 : 1). The synthesis process is low in energy consumption and cost, less in waste solids and waste liquid, environment-friendly, simple in operation, mild in reaction condition and high in industrial safety factor, the yield of the target compound is above 86% (counting according to original reaction raw materials), the HPLC purity is above 99.0%, the target compound is high in yield and good in quality, and the synthesis process is more suitable for industrial production.

Owner:SHANGHAI ZONGXING CHEM TECH CO LTD

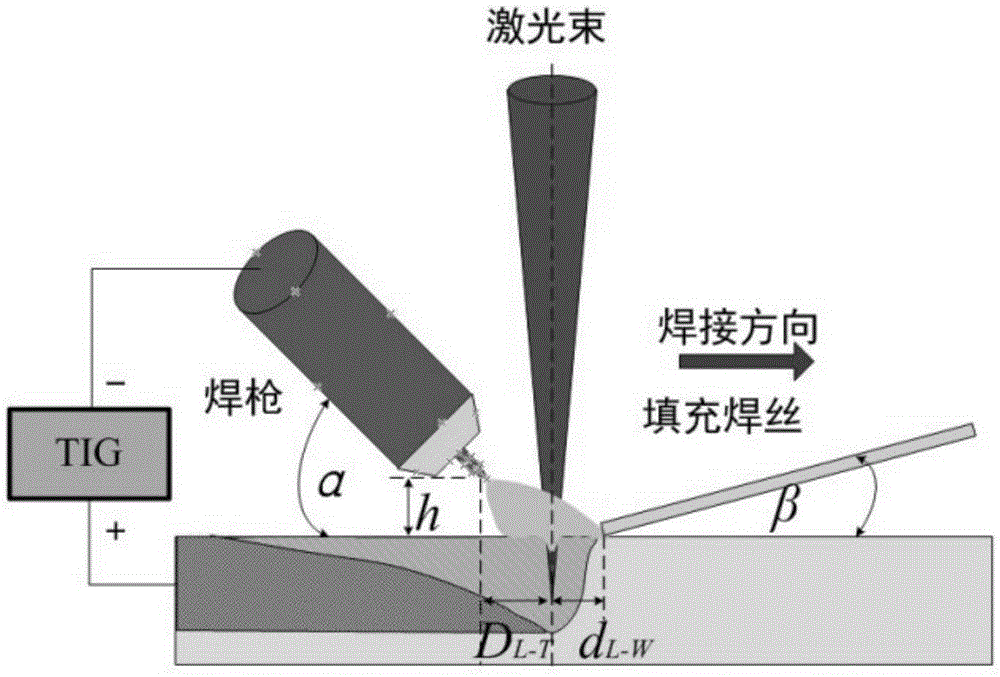

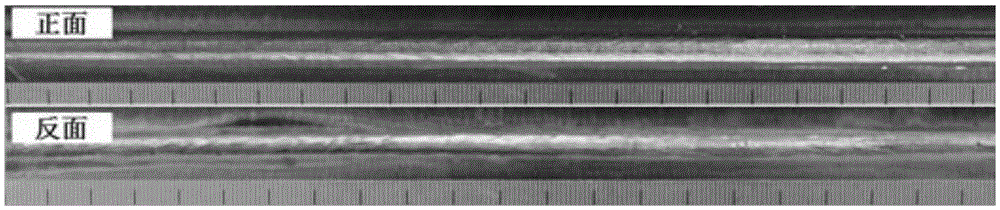

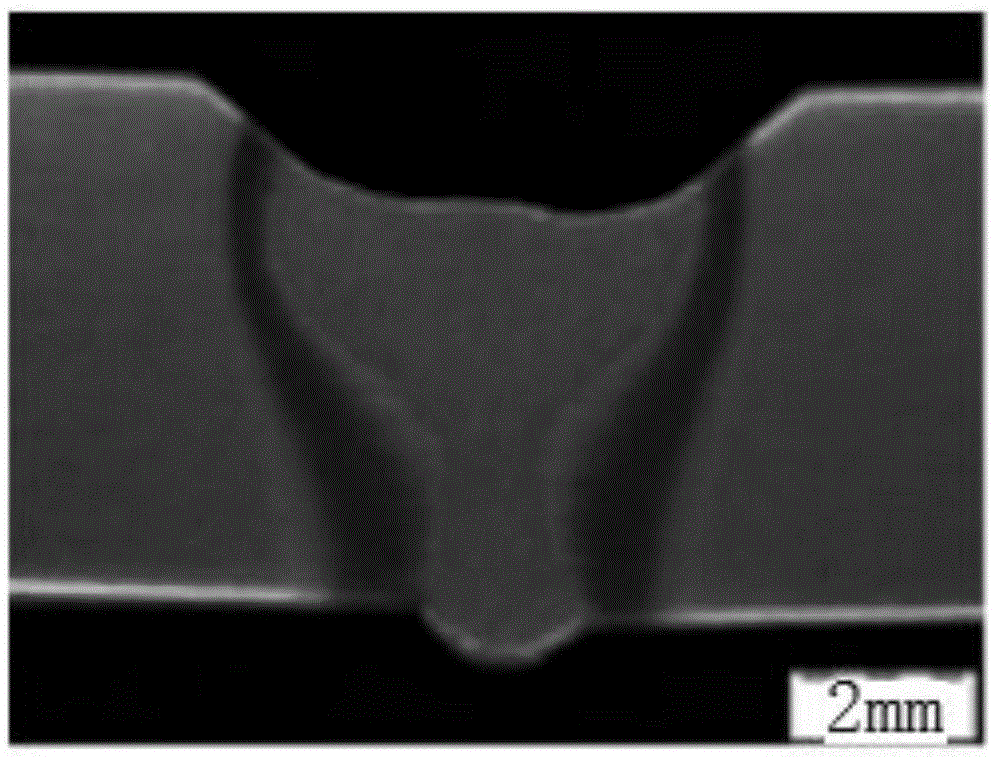

Method for removing laser welding pores of medium-thick D406A ultra-high-strength steel

InactiveCN105328342AReduce couplingReduce cooling rateLaser beam welding apparatusMaterials scienceSoldering process

The invention provides a method for removing laser welding pores of a medium-thick D406A ultra-high-strength steel, and aims at solving the problem of pores of a medium-thick D406A ultra-high-strength steel plate in welding. The method comprises the following steps: grinding and cleaning a part to be welded; assembling; setting backing weld and filling weld process parameters; controlling the welding process parameters through a robot integration system; arcing through TIG (Tungsten Inert Gas Welding) electric arc; stabilizing the electric arc for 1 to 2 seconds; controlling a laser to emit laser; finally controlling a robot to drive a laser working head and a TIG welding gun to work together to finish the welding process. According to the method, different pore inhibiting measures are carried out for backing weld and filling weld.

Owner:HARBIN INST OF TECH

Pearl nucleus active liquid used for saltwater pearl culture and preparation method thereof

InactiveCN101803580AReduce wound infectionPromote rapid formationClimate change adaptationPisciculture and aquariaAcetic acidCultured pearl

The invention discloses a pearl nucleus active liquid used for saltwater pearl culture and a preparation method thereof. In the pearl culture process, by using drug-treated pearl nuclei, immunological rejection on the pearl nuclei after a pearl shell nucleus-implanting operation can be reduced, the migration and the division of small cells are irritated, the formation of pearl sacs is promoted, the wound infection after the operation is reduced, and the goal of comprehensively improving the pearl quality and yield by reducing the nucleus-spitting rate, increasing the thickness of pearl layers and improving the survival rate of cultured pearls is achieved. In the invention, the pearl nucleus active liquid is prepared by utilizing glacial acetic acid, chitosan, tetracycline antibiotics and sterilized filtered seawater. When the pearl nuclei treated by the invention are used for pearl culture, the survival rate of the cultured pearls is increased by 2.59 to 7.33 percent, the pearl-containing rate is increased by 9.8 to 20.07 percent, and the high-quality pearl rate is increased by 5.97 to 12.55 percent.

Owner:广西海洋研究所有限责任公司 +1

2-amino-4-acetamino anisole synthesis process

InactiveCN105348132AReduce process time and energy consumptionReduce dosageOrganic compound preparationCarboxylic acid amides preparationChemistryAcetic anhydride

The invention discloses a 2-amino-4-acetamino anisole synthesis process. The process comprises the following steps that in methyl alcohol, 2,4-diaminobenzene methyl ether (III) and acetic anhydride are subjected to an acylation reaction as follows under the effect of an acid-binding agent to obtain 2-amino-4-acetamino anisole (IV), wherein the mole ratio of the acid-binding agent to the 2,4-diaminobenzene methyl ether is 0.3:1-0.6:1. The synthesis process is low in energy consumption, low in cost, small in amount of solid waste and liquid waste, free of pollution, environmentally friendly, easy to operate, mild in reaction condition and high in industrial safety coefficient, the target compound yield is 86% or above (based on initial reaction raw materials), the HPLC purity is 99.0% or above, and the target compound is high in yield, good in quality, and more applicable to industrial production.

Owner:安徽奥瑞化工有限公司

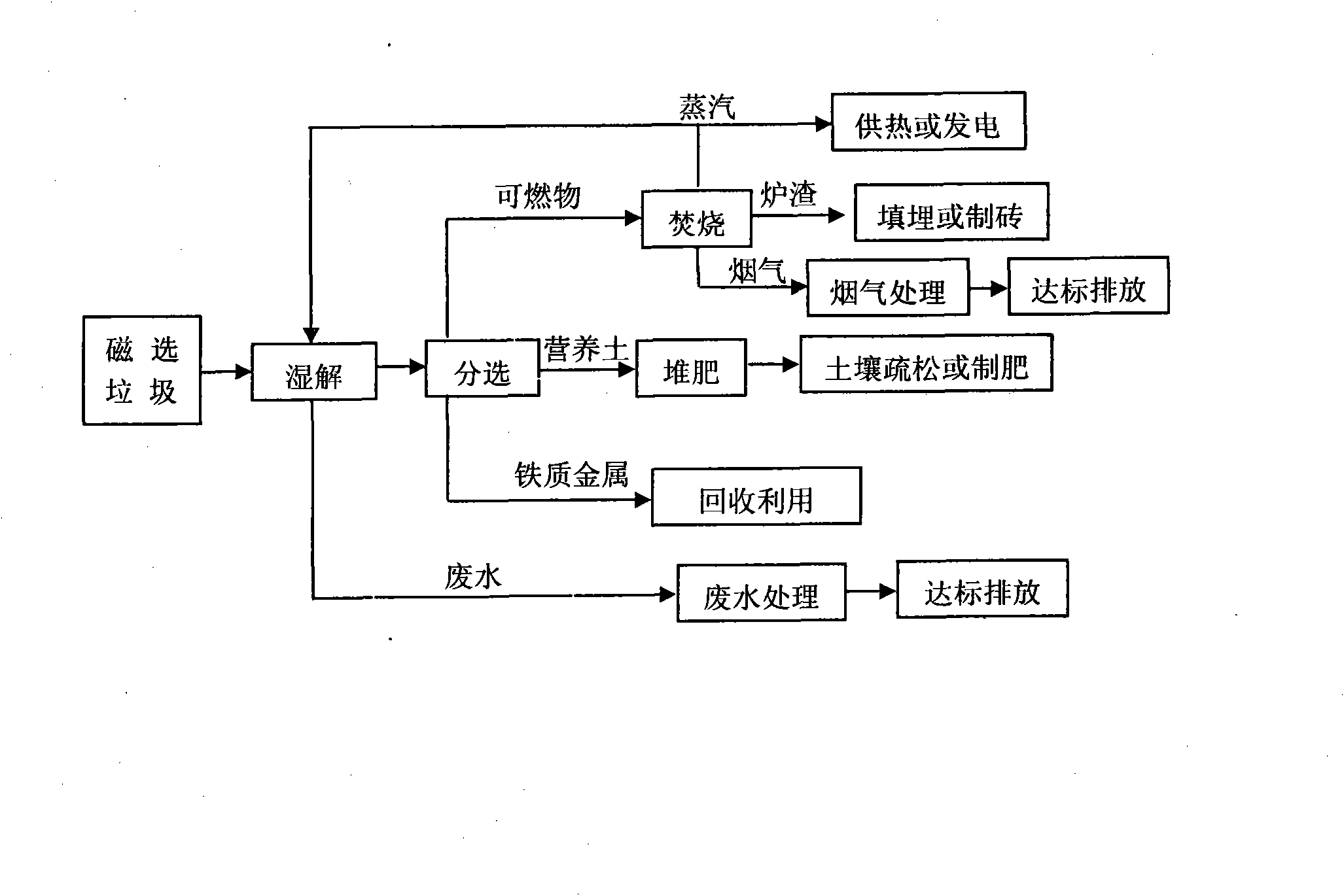

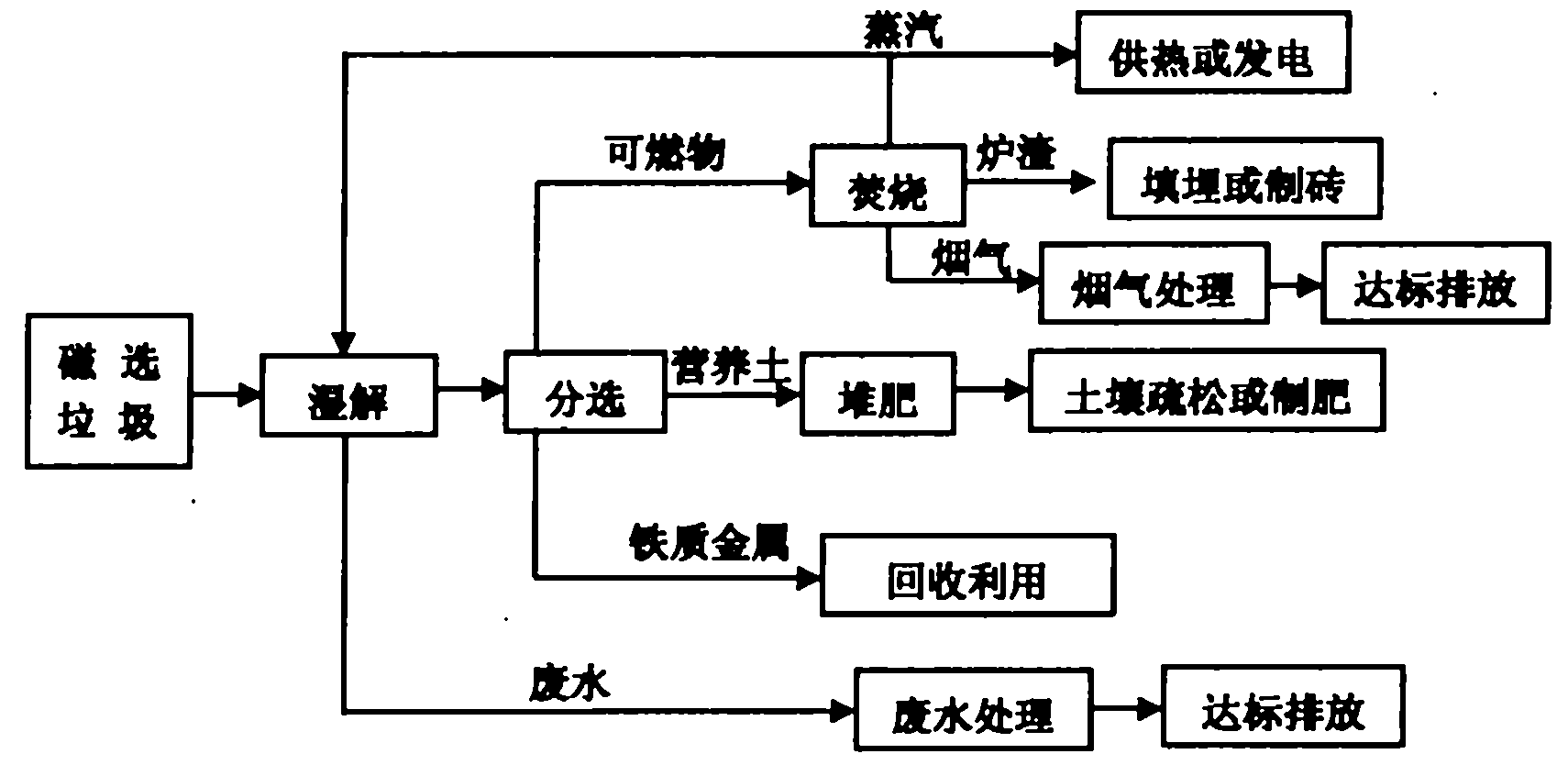

Hydrothermal degradation comprehensive processing technology for domestic garbage

ActiveCN101869904AGuaranteed stabilityReduce the chance of formationSolid waste disposalClimate change adaptationBrickSlag

The invention discloses hydrothermal degradation comprehensive processing technology for domestic garbage. The technology is characterized by comprising the following steps of: rapidly degrading the garbage which is subjected to magnetic separation, feeding the wastewater produced during digestion into a water treatment device and discharging the water until the water reaches the standard; feeding the digested garbage into a separation device and burning the separated undegraded combustible, wherein a part of the combustion product is used as saturated steam during the hydrothermal degradation and the other part is used for providing heat or generating power; treating the smoke produced by the burning by using a smoke treatment system and discharging the smoke after the smoke reaches the standard, wherein the slag produced after the burning is used for paving roads or making bricks or used as covering soil at landfill sites; performing composting on the separated degraded nutritive soil, wherein the degraded nutritive soil is used for loosening soil or to be prepared into various organic compound fertilizers; and recycling the separated ferrous metal. The technology has the advantages of complete degradation, recycling of resources, heat supply, power generation and capability of ensuring the discharging of the smoke, the wastewater and the like after reaching the standards and realizing harmlessness, reduction and reutilization.

Owner:RUNDA REFUSE TREATMENT DEV YANTAI

Method for growing a BaAlBO3F2 crystal by fusing agent

InactiveCN101514481ASmall sizeQuality improvementPolycrystalline material growthFrom melt solutionsRoom temperatureLarge size

The invention relates to a method for growing a BaAlBO3F2 crystal by a fusing agent, which comprises the following steps: evenly mixing BaAlBO3F2, B2O3, LiF and NaF in a molar ratio of 1:0.2-1:1.5-3:0.2-0.6, and obtaining a crystal growing raw material after fusion and cooling; placing the raw material into a growing furnace, and heating and fusing the raw material; introducing a seed crystal 5 to 15 mm below the liquid level at a temperature of between 1 and 5 DEG C higher than a saturation temperature, keeping a constant temperature for 10 to 60 minutes, and reducing the temperature to a saturation point temperature; reducing the temperature at a speed of 0.2 to 5 DEG C / day, and simultaneously rotating the crystal; and after the crystal grows to the required size, extracting the crystal, and reducing the temperature to room temperature to obtain the BaAlBO3F2 crystal. The method uses a B2O3-LiF-NaF fusing agent system, and can reduce crystal growing temperature, high temperature solution viscosity and systemic volatility, solve the problems of bottom crystallization in the crystal growing process, easy cracking of the growing crystal, and the like, and obtain large-size and high-quality BABF crystal stably.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

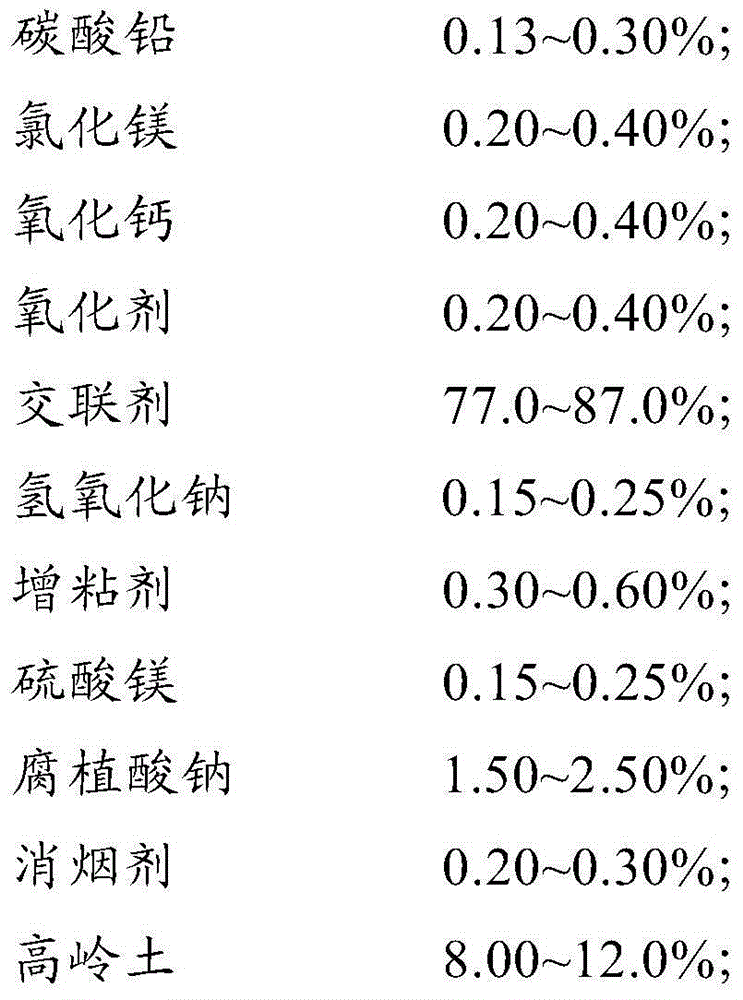

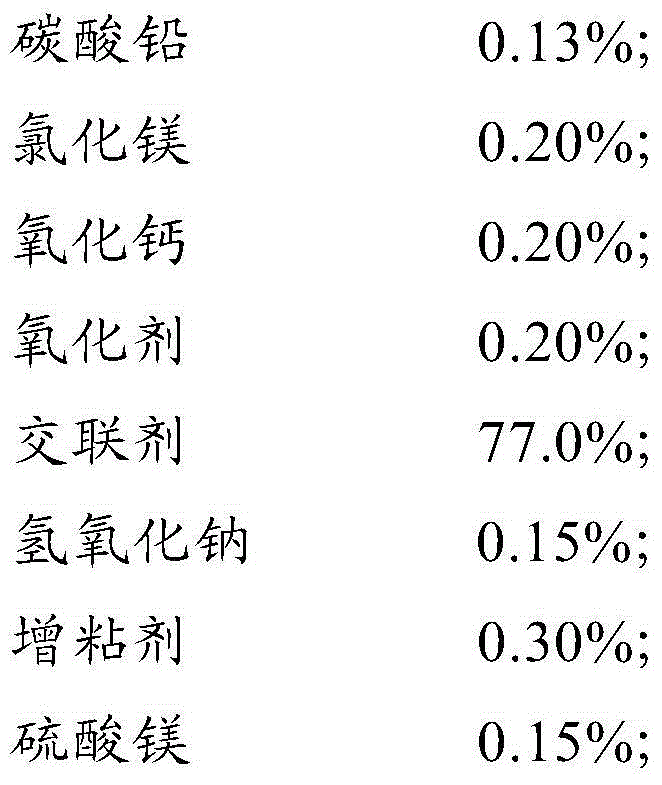

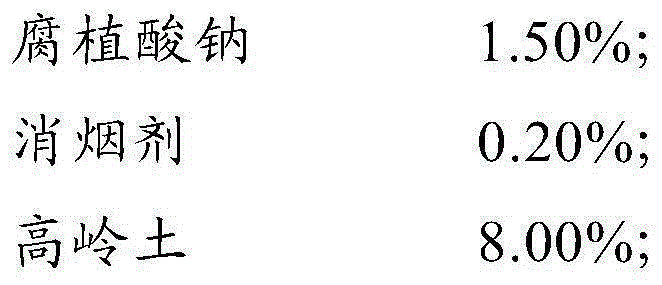

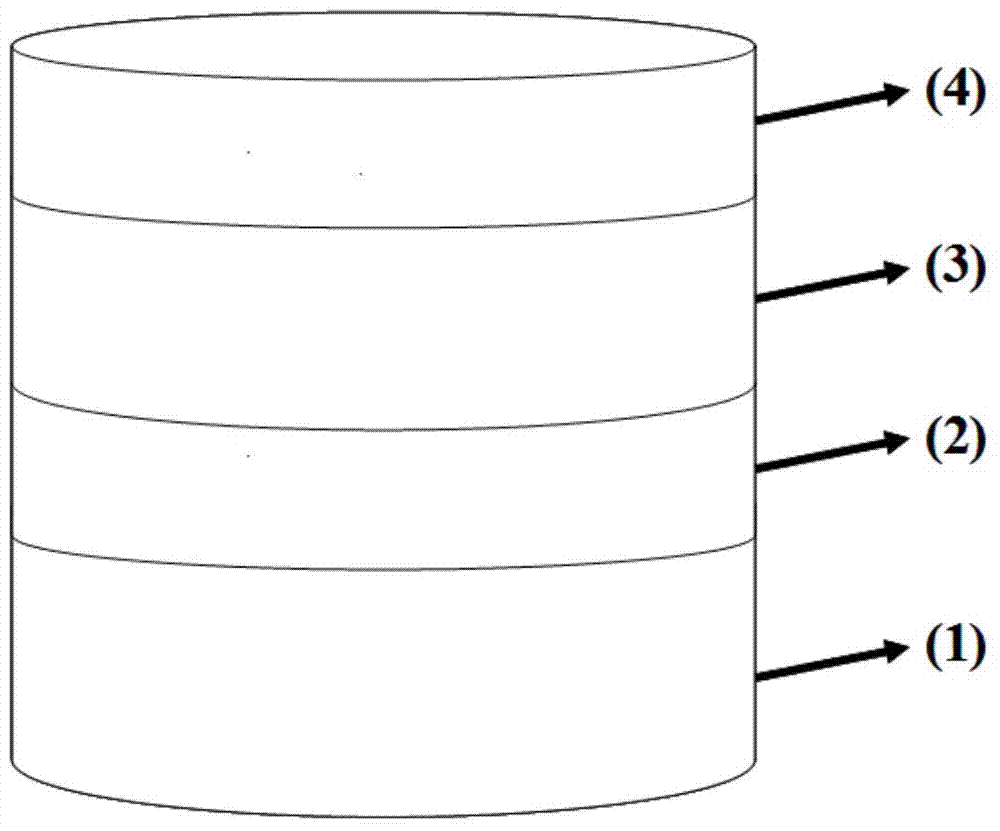

Cleaning briquette coal binder

The invention discloses a cleaning briquette coal binder. The binder comprises the following raw materials: 0.13-0.30% of lead carbonate, 0.20-0.40% of magnesium chloride, 0.20-0.40% of calcium oxide, 0.20-0.40% of an oxidizing agent, 77.0-87.0% of a crosslinking agent, 0.15%-0.25% of sodium hydroxide, 0.30-0.60% of a tackifier, 0.15%-0.25% of magnesium sulfate, 1.50-2.50% of sodium humate, 0.20-0.30% of a smoke suppressant and 8.00-12.0% of kaolin. The briquette coal binder disclosed by the invention has the effects of suppressing smoke, preventing moisture, reducing dust, fixing sulfur, inhibiting nitrogen and the like, and is developed in line with the national situation of energy conservation, emission reduction and haze treatment according to China coal energy actual application and the characteristics of the haze formation cause in recent years; the binder has prominent energy conservation and emission reduction effects and an oxidative combustion-promoting effect; and since the binder is fully burnt, the energy conservation effect is achieved.

Owner:李晓雷

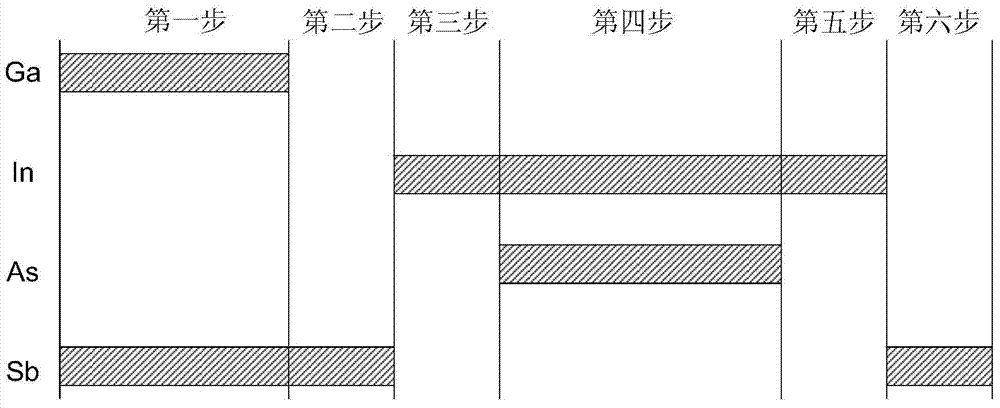

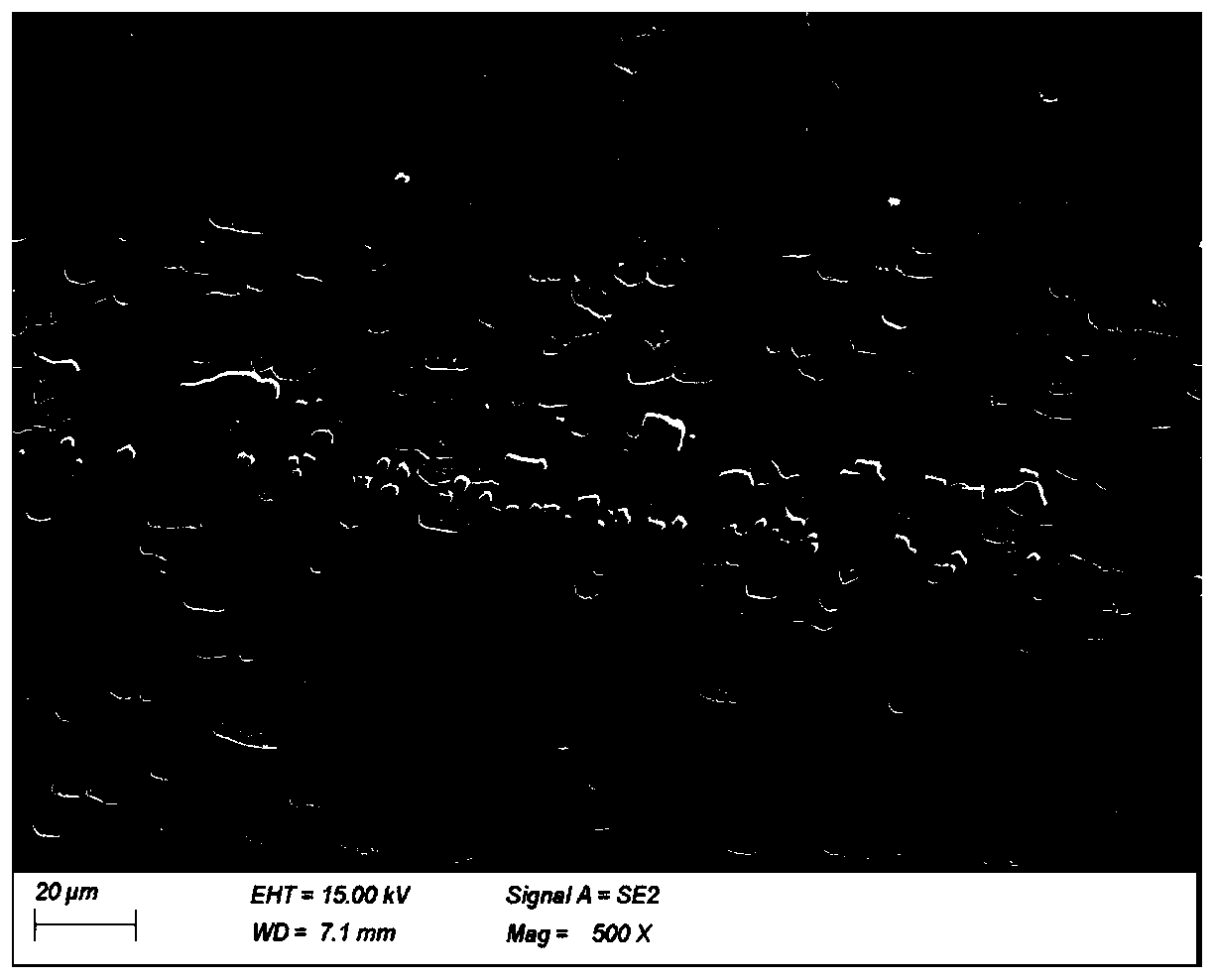

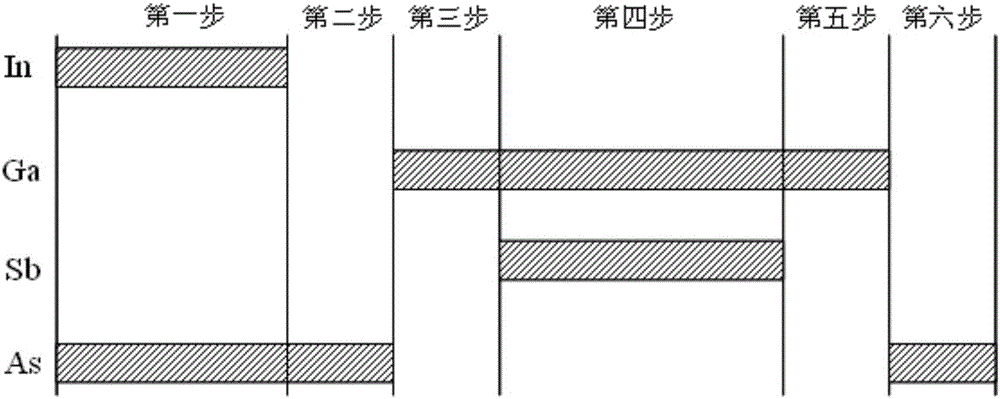

Type-II superlattice structure based on arsenic valve switch and preparation method

ActiveCN103500765AReduce interdiffusionReduce the chance of formationFinal product manufactureNanoopticsInterface layerBinary compound

The invention discloses a type-II superlattice structure based on an arsenic valve switch and a preparation method. Compared with a traditional type-II superlattice structure, the original binary compounds GaSb and InSb are respectively replaced by ternary compounds GaAsSb and InAsSb. The preparation method is characterized in that the As valve is always in an open state in the enter type-II superlattice growth process, the valve position is the same as that during the growth of an InAs layer, and the tertiary compounds GaAsSb and InAsSb are formed because partial As flows out when an GaSb layer and an InSb interface layer grown. The type-II superlattice structure based on the arsenic valve switch and the preparation method have the characteristics that since a common element As exists in all layers, the growth temperature of all layers is enabled to trend to be consistent and the mutual diffusion at the position of interfaces is reduced; under the effect of As atom surfactant, the migration rate of Sb atoms is increased, the forming probability of Sb clusters is reduced, the defects of materials are reduced and the material performance is improved.

Owner:中科爱毕赛思(常州)光电科技有限公司

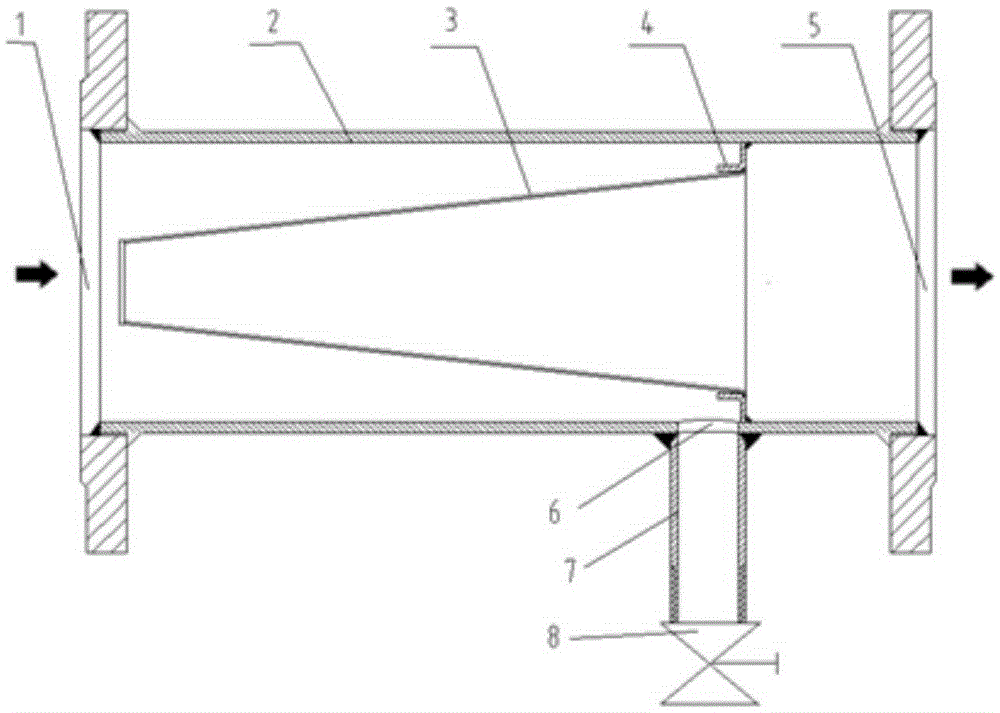

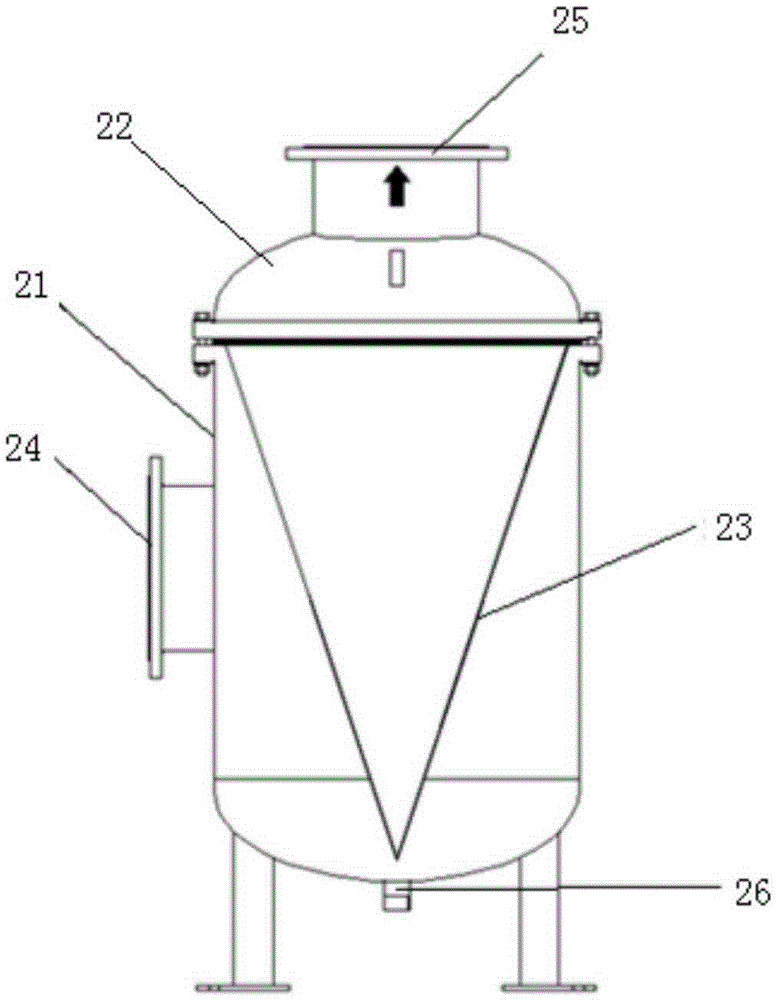

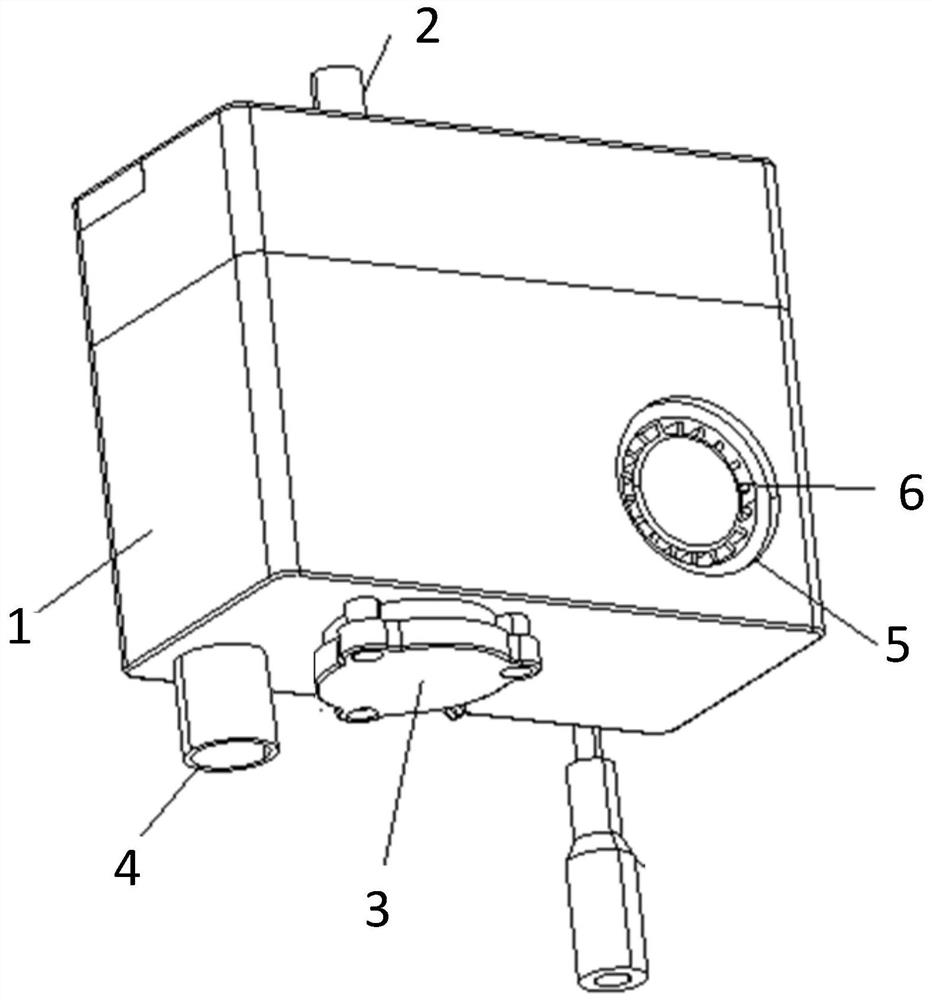

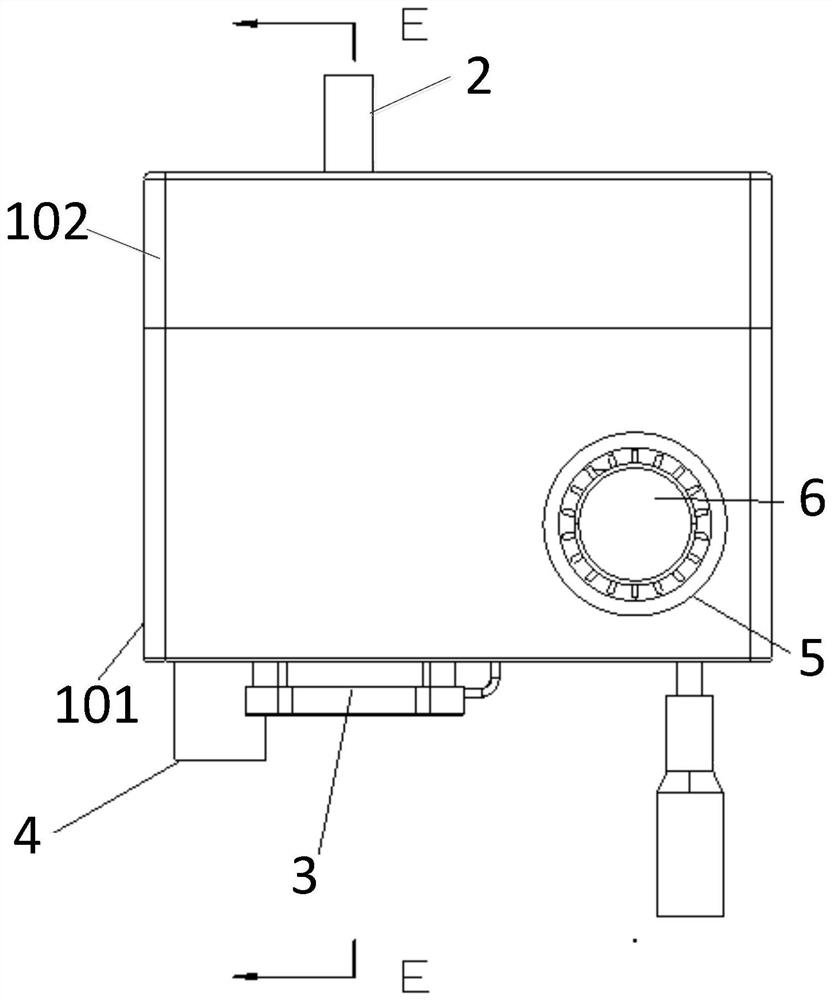

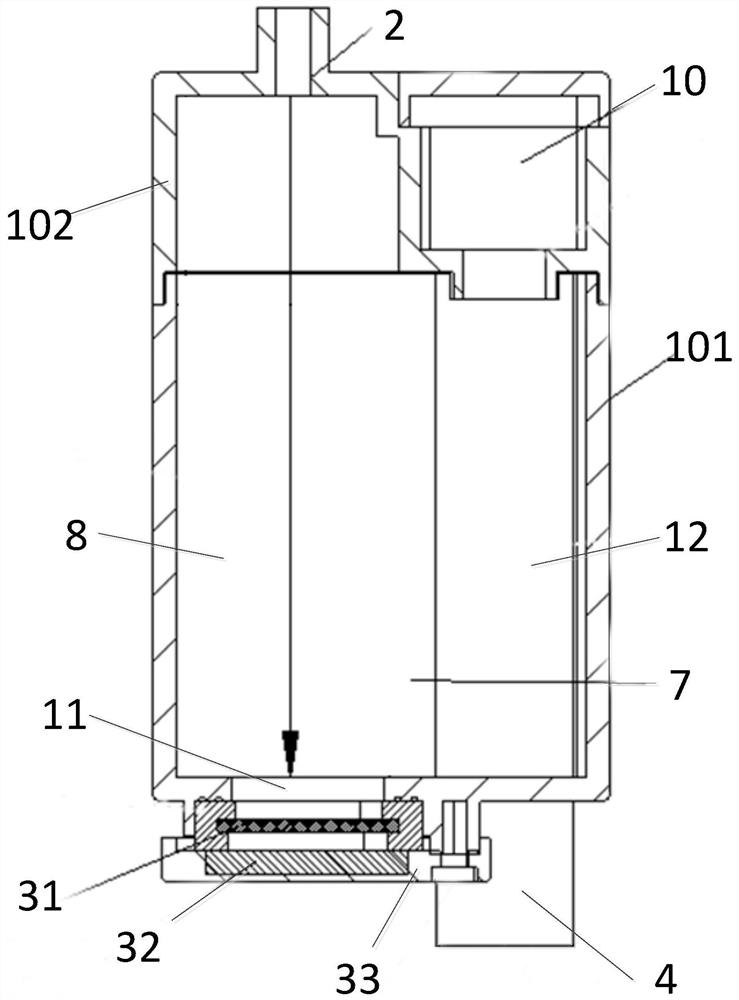

Liquid filtering method and filtering device

InactiveCN105413284AReduce the chance of formationReduce the number of resurrection sewageMembrane filtersStationary filtering element filtersBody positionsImpurity

The invention discloses a liquid filtering method. Liquid to be filtered is filtered from the outer side of a conical filtering screen to the inner side; an openable sewage discharging opening is formed in the outer side of the conical filtering screen; impurities blocked by the conical filtering screen can be discharged from the sewage discharging opening. The invention further discloses a liquid filtering device. The liquid filtering device comprises an equipment body and a filtering body positioned in the equipment body; the filtering body is the conical filtering screen; the open end of the conical filtering screen is hermitically and fixedly connected with the inner wall of the equipment body; the conical outer side of the conical filtering screen is a liquid feeding side, and the conical inner side of the conical filtering screen is a liquid discharging side; a liquid inlet and a sewage discharging opening are formed in the equipment body at the liquid feeding side; the sewage discharging opening is formed in the lowest end of the equipment body at the liquid feeding side; a sewage discharging valve is arranged at the sewage discharging opening; a liquid outlet is formed in the equipment body at the liquid discharging side. According to the liquid filtering method and the liquid filtering device, by the adoption of the conical filtering body for reverse filtering, fluid forms shearing force on the surface of the filtering body, so that the water film forming possibility is reduced, and the loss of filtering resistance is reduced; the liquid filtering device has a self-cleaning resetting function of the filtering body.

Owner:汪传发

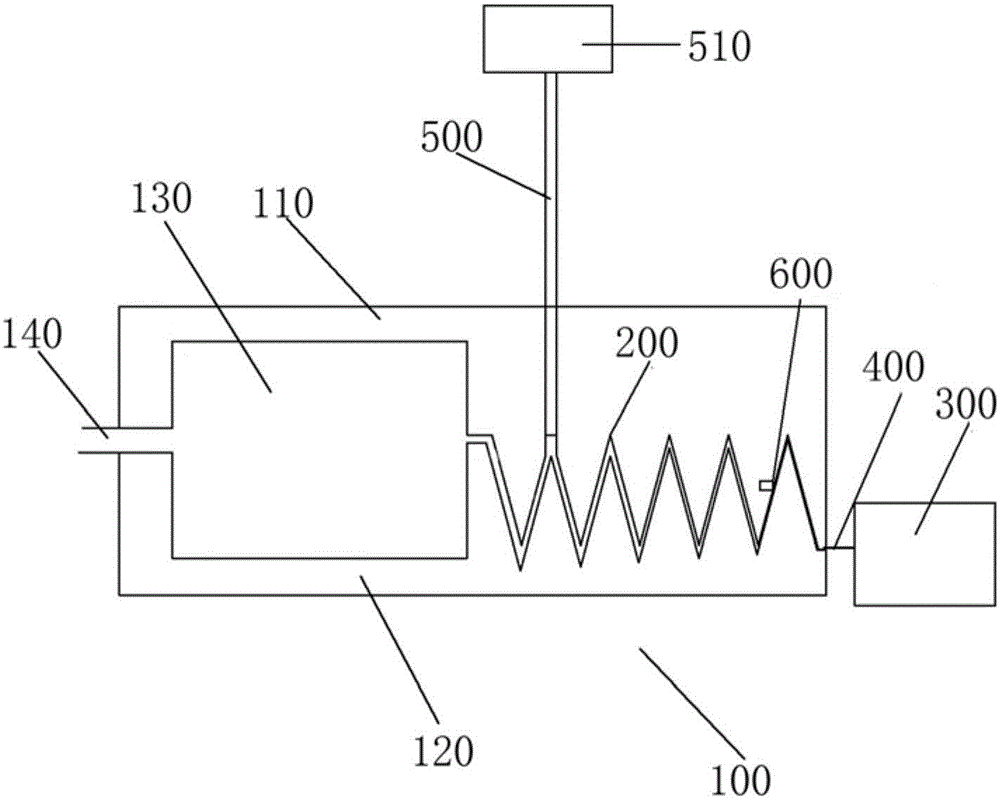

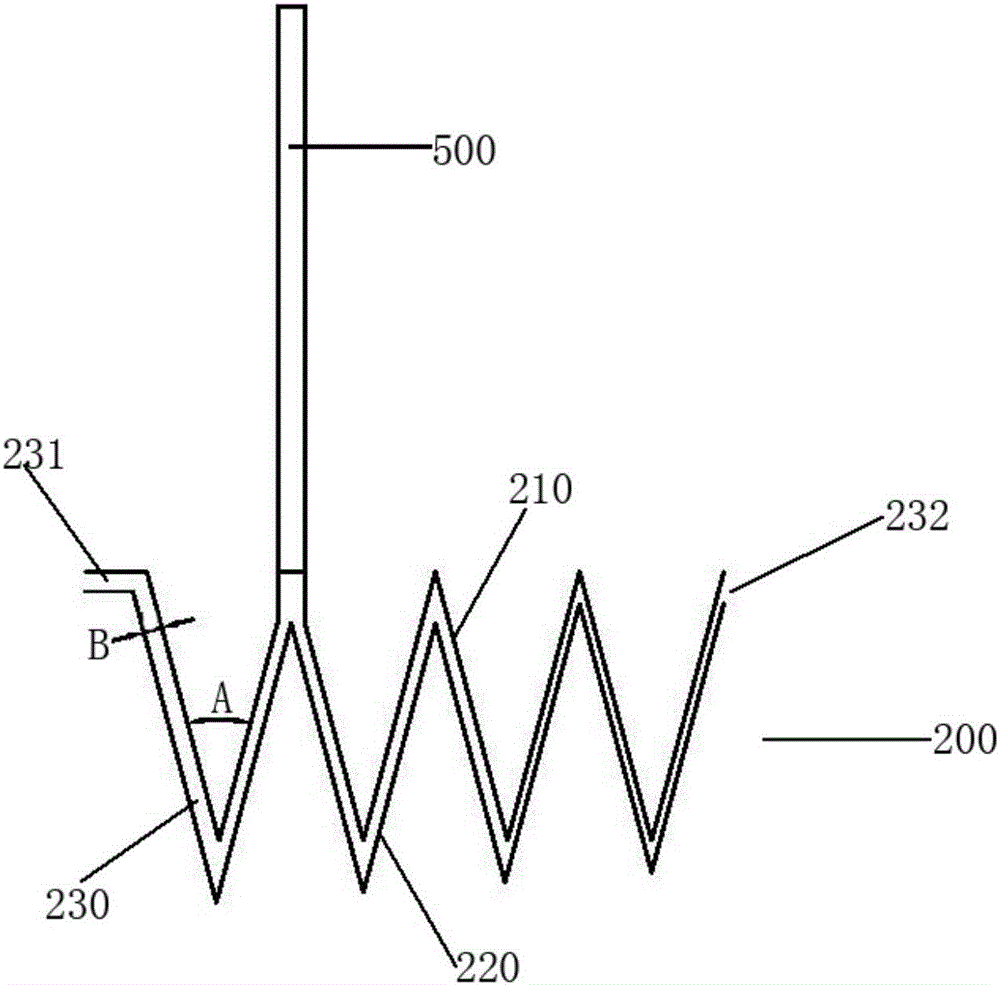

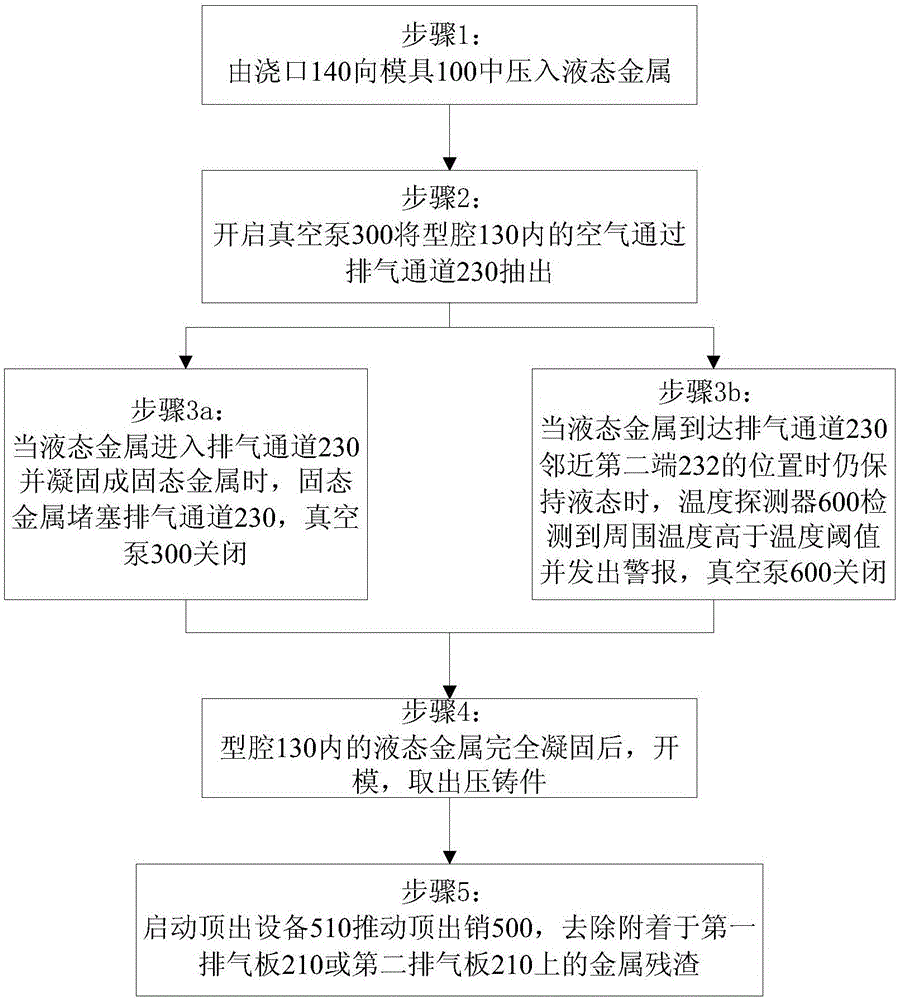

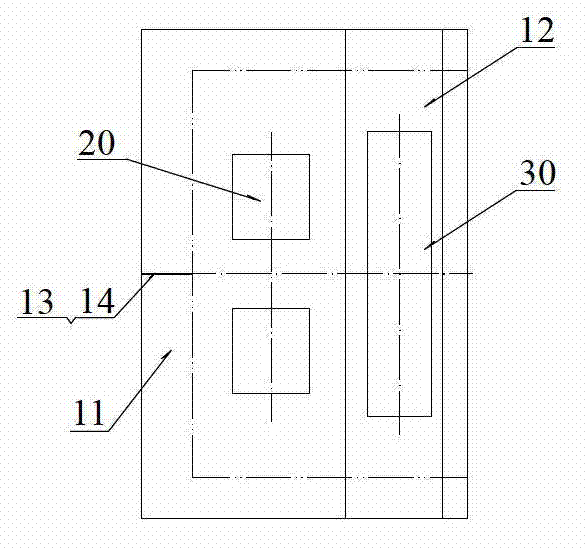

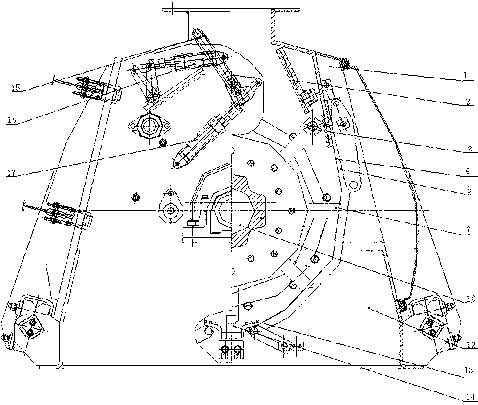

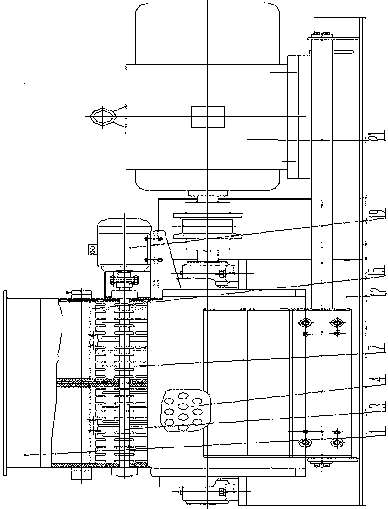

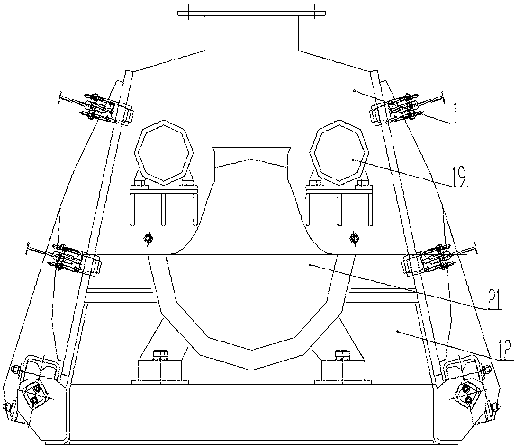

Pressure casting device and method

InactiveCN106694848AReduces the chance of shrinkage and porosity formationFaster filling ratePressure castingPorosity

The invention discloses a pressure casting device which comprises a mould, a gas exhaust structure arranged in the mould and a vacuum pump arranged on the outer part of the mould; the mould comprises a first mould base, a second mould base as well as a mould cavity and a pouring gate defined by the first mould base and the second mould base when the first mould base and the second mould base are closed; through the pouring gate, the mould cavity communicates with the outer part of the mould; the gas exhaust structure comprises a first gas exhaust plate arranged on the first mould base, a second gas exhaust plate arranged on the second mould base and a gas exhaust channel defined by the first gas exhaust plate and the second gas exhaust plate when the first mould base and the second mould base are closed; and a first end of the gas exhaust channel communicates with the mould cavity in the mould, and a second end opposite to the first end is connected with a vacuum pump through a connecting tube. The pressure casting device disclosed by the invention quickly exhausts air in the mould cavity through the gas exhaust structure, not only can reduce porosity of pressure castings, also increases a mould filling rate, and ensures a relatively high yield and relatively high production efficiency. The invention also discloses a pressure casting method.

Owner:TAICANG HAIJIA VEHICLE FITTINGS

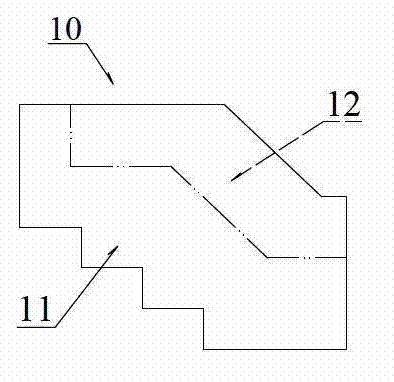

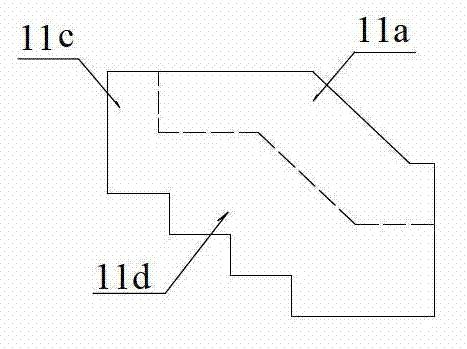

Bridge bulk mass concrete skewback structure

A bridge bulk mass concrete skewback structure has the advantages of being concise in structure, clear in stress, simple and convenient to construct, economical and reasonable, and can not only well meet the longitudinal and transversal stressing requirements of the skewback structure, but also simultaneously lower influence brought by heat of hydration and concrete shrinkage during construction process. The bridge bulk mass concrete skewback structure comprises a skewback (10) which supports and fixedly connecting a border pier (20) and an arch ring (30), and the whole of the skewback (10) is in a transversal uniform-section step shape and composed of a lower-portion plain concrete casting body (11) and an upper-portion reinforced concrete casting body (12). A transversal breaking joint (13) is arranged in the middle of the plain concrete casting body (11), and steel plates (14) are filled in the transversal breaking joint (13). The border pier (20) and the arch ring (30) are cast on the upper-portion reinforced concrete casting body (12).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Fluxing agent growing method of K2Al2B2O7 crystal

InactiveCN101787558AImprove optical qualityLow growth temperaturePolycrystalline material growthFrom frozen solutionsHigh-temperature corrosionMuffle furnace

The invention relates to a fluxing agent growing method of K2Al2B2O7 crystal. The method comprises the following steps: mixing K2Al2B2O7 with fluxing agent in a molar ratio of 1:1.4-2.2, placing the mixture in a 950-1050 DEG C of muffle furnace to melt, cooling at room temperature to obtain growing raw material; then placing in an electric stove wire heating crystal growing furnace to heat and obtain a high temperature solution; introducing seed crystal under 2-10 DEG C above saturation temperature; cooling by using the saturation point temperature as the cooling starting point while rotating the crystal, wherein the vertical temperature gradient of the high temperature solution is 0.05-1 DEG C / cm; lifting the crystal, which grows to the required size, from the level surface to cool to the room temperature and obtain K2Al2B2O7 crystal, wherein the fluxing agent is M'F, M''F or M'F+M''F, M' is Li, Na or K, and M'' is Ca or Ba. The method of the invention has low growing temperature and the growing system has low volatility and viscosity so that solute can be conveniently transported and high optical quality K2Al2B2O7 crystal without inclusion and optical path can be grown.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

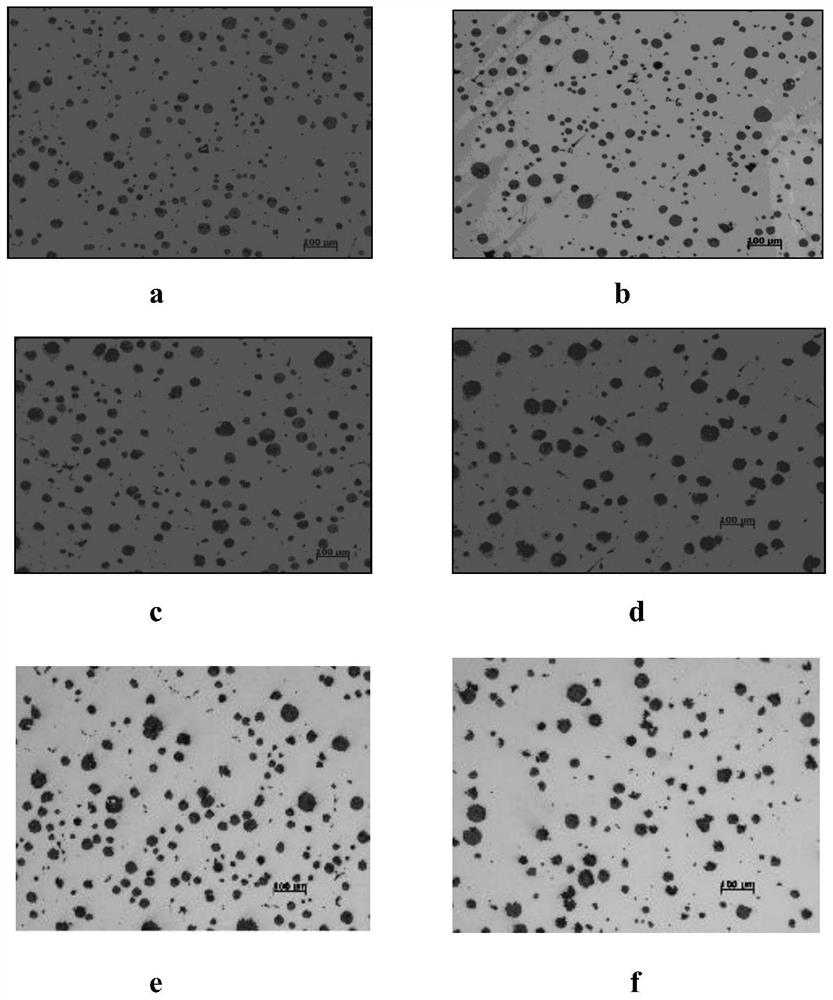

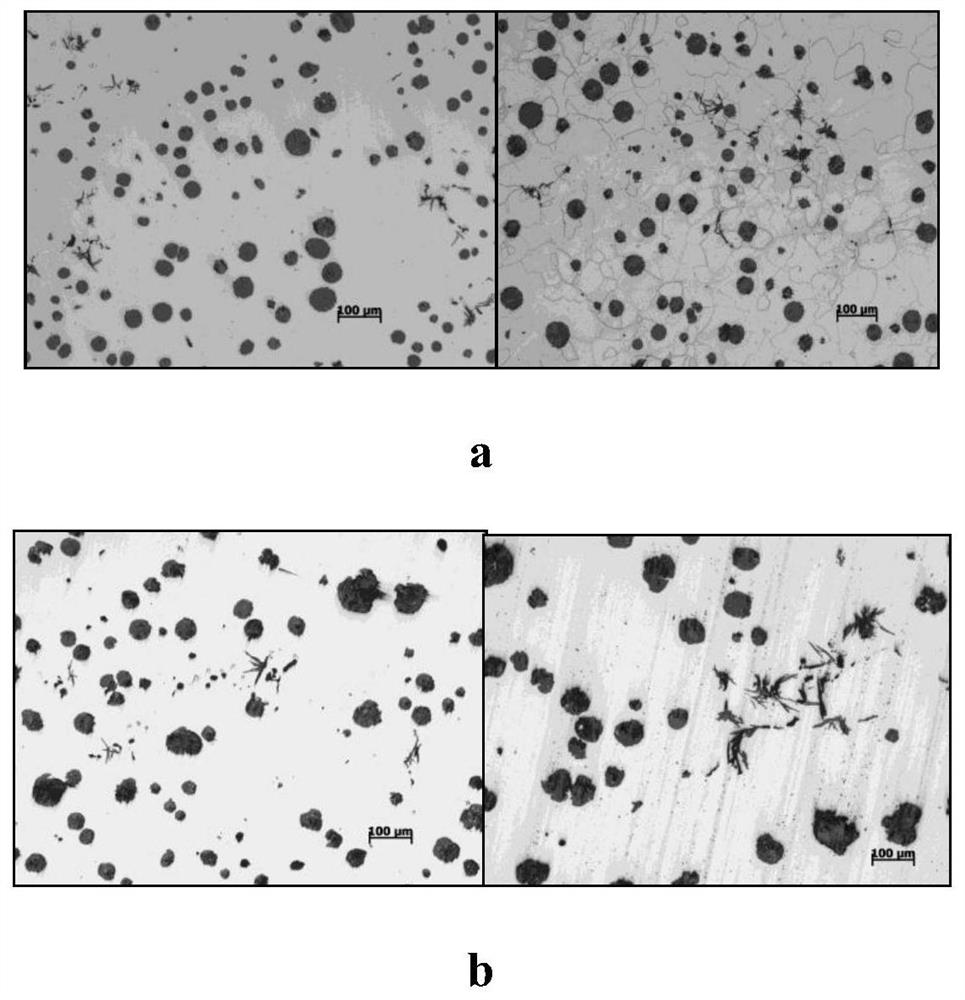

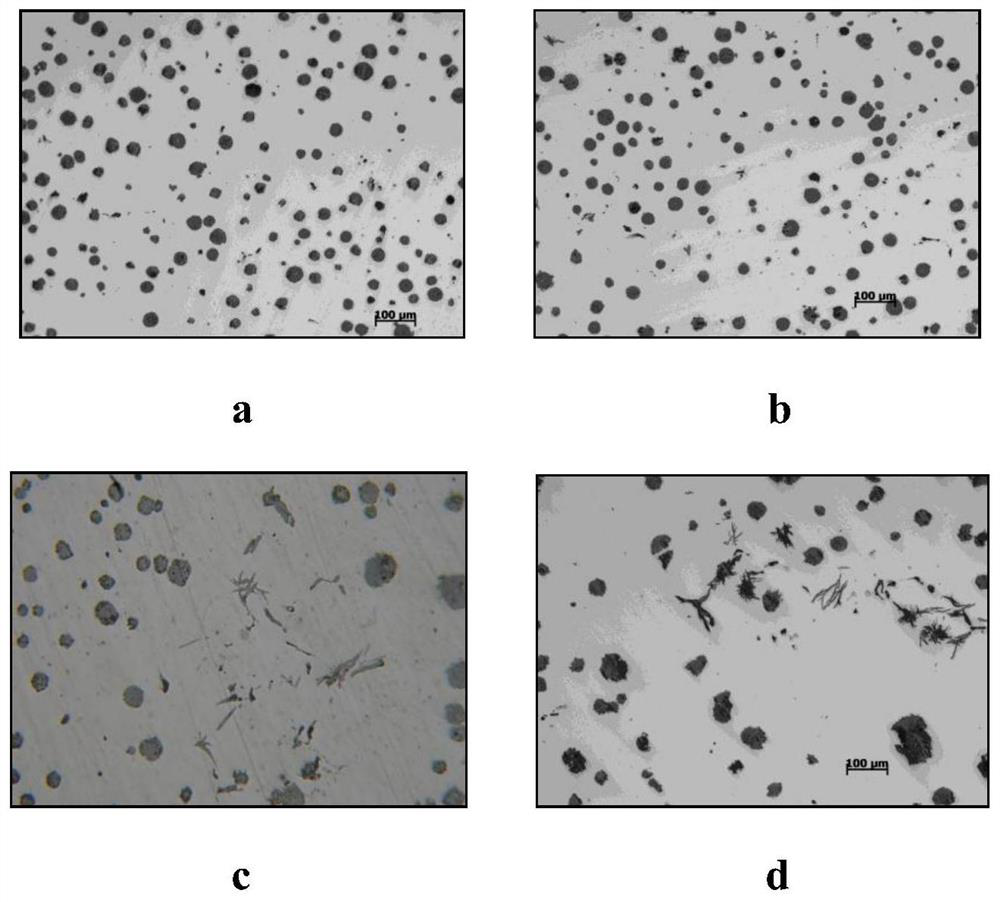

Nail-like-graphite-free nodular cast iron for wind power equipment and preparation method thereof

ActiveCN113106326AReduce segregationReduce the chance of formationFoundry mouldsFoundry coresWind powerDuctile iron

The invention belongs to the field of nodular cast iron casting, and relates to nail-like-graphite-free nodular cast iron for wind power equipment and a preparation method thereof. By optimizing the component content of the nodular cast iron, intake of harmful elements is reduced, the carbon content is strictly controlled in the eutectic period, after a large number of silicon solid solutions are formed, dissolution of carbon in hexagonal lattices is accelerated, and precipitation of a large number of carbon on the grain boundary is prevented. At the moment, anti-nodulizing segregation elements with a high content exist on the grain boundary, and the diffusion and accumulation of carbon to a nucleation substance from different directions are prevented from being blocked, so that graphite is balled, and nail-like graphite is prevented from being formed. In the preparation process of the nodular cast iron, the pouring temperature, the mold filling speed and the heat preservation time are strictly controlled, segregation of anti-nodulizing elements is reduced, the forming probability of the nail-like graphite is reduced again, and the physical performance of the cast iron is guaranteed to a certain degree.

Owner:宁波明凌科技有限公司

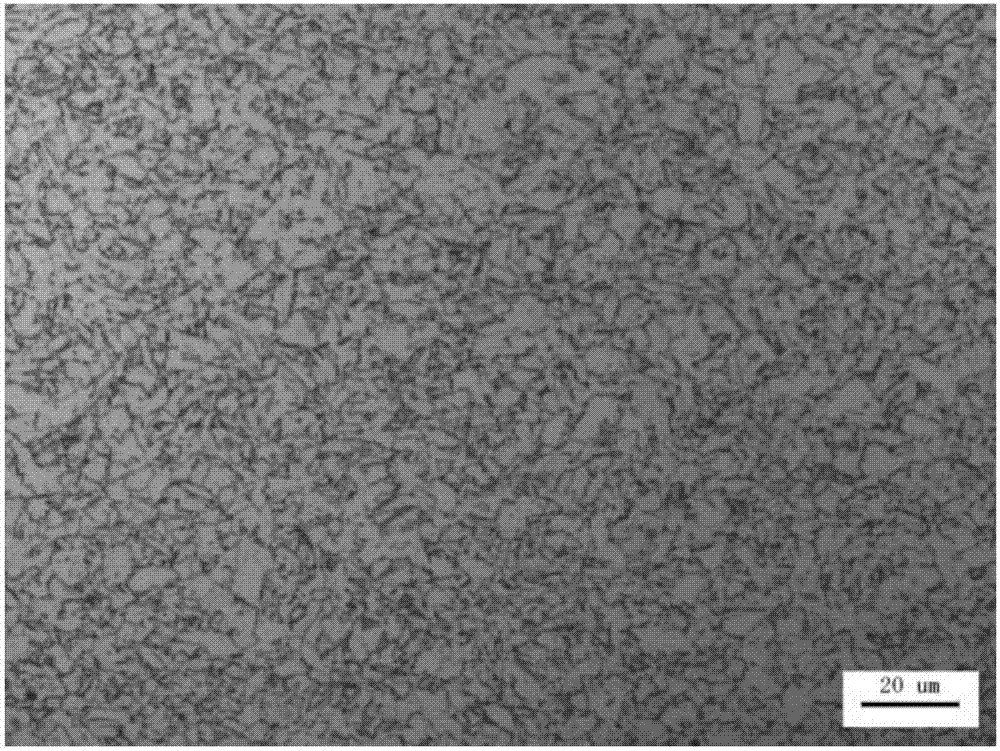

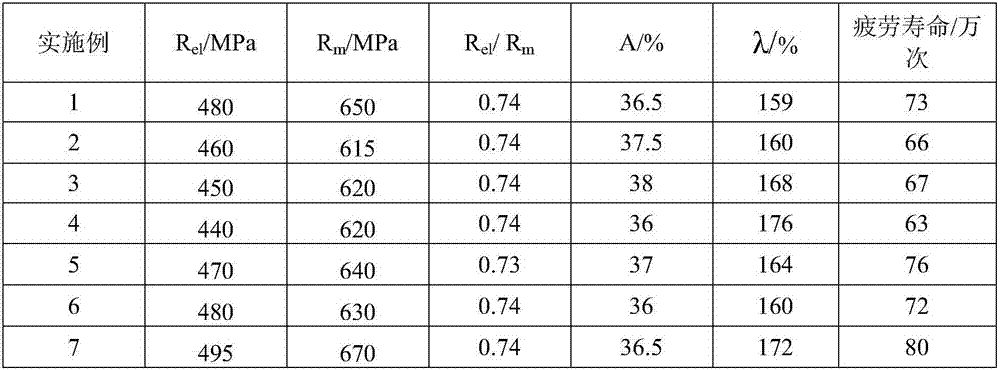

Steel used for high-strength automobile wheel with excellent flange elongation and production method thereof

The invention discloses a high-strength automobile wheel steel with excellent stretch flangeability and a production method thereof. The chemical composition in steel is by weight percentage: C 0.07%~0.1%, Si0.15%~0.25%, Mn 1.2%~1.4%, P<0.02%, S<0.008%, Als0.02%~0.04%, RE / S=1.8-2.2, wherein the rare earth RE is one or a combination of more than two elements in La, Ce and Nd, the content is 0.007%-0.018%, and the balance is Fe and unavoidable impurities. Heat the continuous casting slab to 1200-1300°C and keep it warm for 2-3 hours; the starting temperature of rough rolling is 1100-1250°C, the finishing rolling temperature is >1000°C; the finishing rolling starting temperature is 950-990°C, and the total reduction ratio is >70 %, the final rolling temperature is 780-840°C; the laminar flow cooling process is adopted, the cooling rate is 25-30°C / s, and the final cooling is 450-500°C for coiling.

Owner:ANGANG STEEL CO LTD

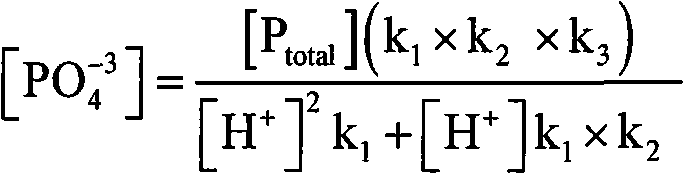

Medicinal health agent for preventing and treating canine urinary calculi

InactiveCN101664439AGuaranteed normal generationInhibition formationHydroxy compound active ingredientsUrinary disorderEpitheliumMagnesium ammonium phosphate

The invention relates to a medicinal health agent for preventing and treating canine urinary calculi, which is characterized in that the agent is obtained by evenly mixing the following effective components in ratio by weight or unit: 10 to 40 mg of organic germanium, 1,000 to 6,000 mg of potassium citrate, 20,000 mg of lysimachia nummularia particles, 5,000 IU of vitamin A and 10 mg of vitamin B6, wherein the vitamin A maintains the integrity of urinary tract epithelium to realize the activity of crystallization inhibitor so as to inhibit crystallization; the organic germanium enhances the process of crystallization inhibition; lysimachia nummularia promotes urination, treats stranguria and plays a significant role in promoting urination and removing stones; meanwhile, the lysimachia nummularia has the function of resisting inflammation and bacteria, reduces urinary tract injury, inhibits urease-producing bacteria, and turns urine to be acidic after the lysimachia nummularia is metabolized in human bodies so as to inhibit the formation of magnesium ammonium phosphate stones; citric acid competes with oxalic acid for calcium in urine; and the vitamin B6 promotes the combination ofthe citric acid with urine calcium so as to reduce the chance of forming calcium oxalate stones. The health agent is reasonable in compatibility, and jointly uses medicaments from different angles toeliminate the inducing factors of magnesium ammonium phosphate and calcium oxalate urinary calculi which are the most common among dogs.

Owner:TIANJIN SHENGJI GRP CO LTD

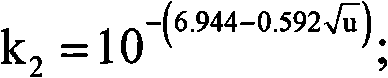

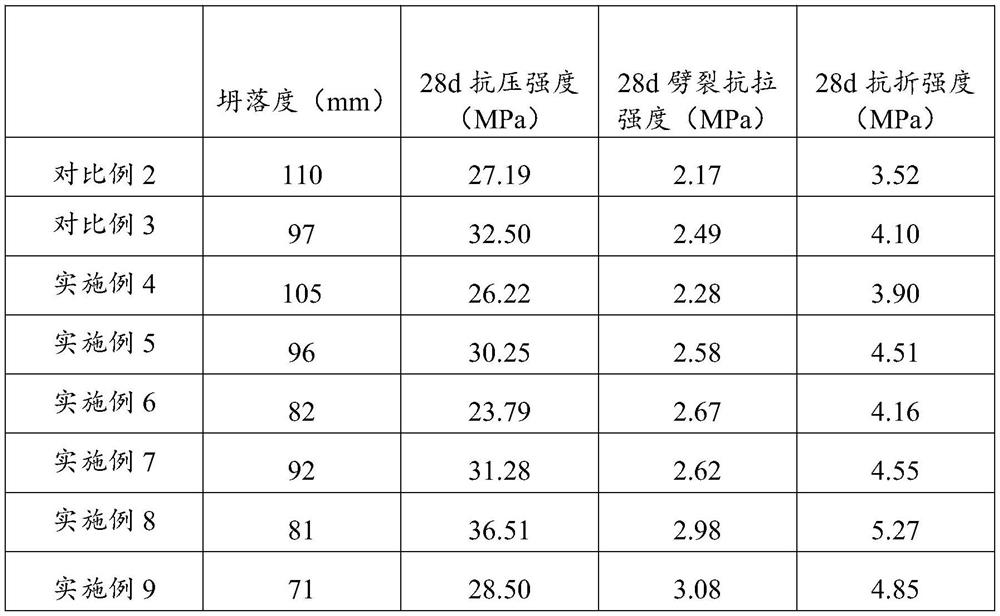

Nano silicon dioxide and basalt fiber synergistically enhanced recycled concrete and preparation method thereof

The invention discloses a nano silicon dioxide and basalt fiber synergistically enhanced recycled concrete and a preparation method thereof.The mass ratio of cement to water to modified recycled coarse aggregate to natural fine aggregate to basalt fiber to polycarboxylic acid high-performance water reducing agent in the recycled concrete is 1: (0.48-0.52): (2.72-2.76): (1.45-1.49): (0.006-0.018): (0.006-0.012), the compressive strength of the recycled concrete reaches 36.51 MPa, the splitting tensile strength reaches 2.98 MPa, and the tensile strength of the recycled concrete reaches 36.51 MPa. And the breaking strength reaches 5.27 Mpa. Besides, nano silicon dioxide which is not completely reacted and exists on the surface of the recycled coarse aggregate can react with a cement hydration product Ca (OH) 2 to generate C-S-H gel, so that mortar attached to the surface of the recycled coarse aggregate is strengthened, and the strength of an interface transition area of the recycled concrete is improved; the distribution of the basalt fibers is facilitated by the rough surfaces of the nano silicon dioxide and the recycled aggregate, so that the toughening and anti-cracking effects of the fibers are fully exerted, and the mechanical property and the durability of the recycled concrete are remarkably improved by the synergistic effect of the nano silicon dioxide and the basalt fibers.

Owner:ZHENGZHOU UNIV +1

Heat treatment method for reducing block-shaped Nb in Inconel783 alloy

ActiveCN110257744AImprove slip resistanceReduce the chance of inclusion formationSolution treatmentGrain boundary

The invention discloses a heat treatment method for reducing block-shaped Nb in Inconel783 alloy and relates to the technical field of alloy heat treatment. The heat treatment method for reducing the block-shaped Nb in the Inconel783 alloy is put forward based on the problem that the block-shaped Nb is precipitated from the inside to affect the material use safety in the use process of the Inconel783 alloy. The heat treatment method comprises the following steps of (1), solid solution treatment; (2), beta aging treatment; and (3), gamma' aging treatment. The heat treatment method for reducing the block-shaped Nb in the Inconel783 alloy has the beneficial effects that the Nb in materials can be refined, the size of the block-shaped Nb is reduced, in subsequent aging, NbC of tiny size is precipitated out, fine and uniform carbide can improve the anti-slip ability of grain boundary significantly, and the probability of formation of harmful inclusions inside the materials is reduced.

Owner:大唐锅炉压力容器检验中心有限公司 +2

Wafer cutting liquid

The invention relates to a wafer cutting liquid which is prepared from 100 of purified water, 3 of glycerin and 0.02 of silicate by weight proportion. By changing the essential component in the existing cutting liquid from soft water to the purified water, the invention reduces the component of hard ions in the cutting liquid so as to reduce the combination probability of soft ions and hard ions,and the formation probability of grains in the cutting liquid is greatly reduced.

Owner:RF360 TECH (WUXI) CO LTD

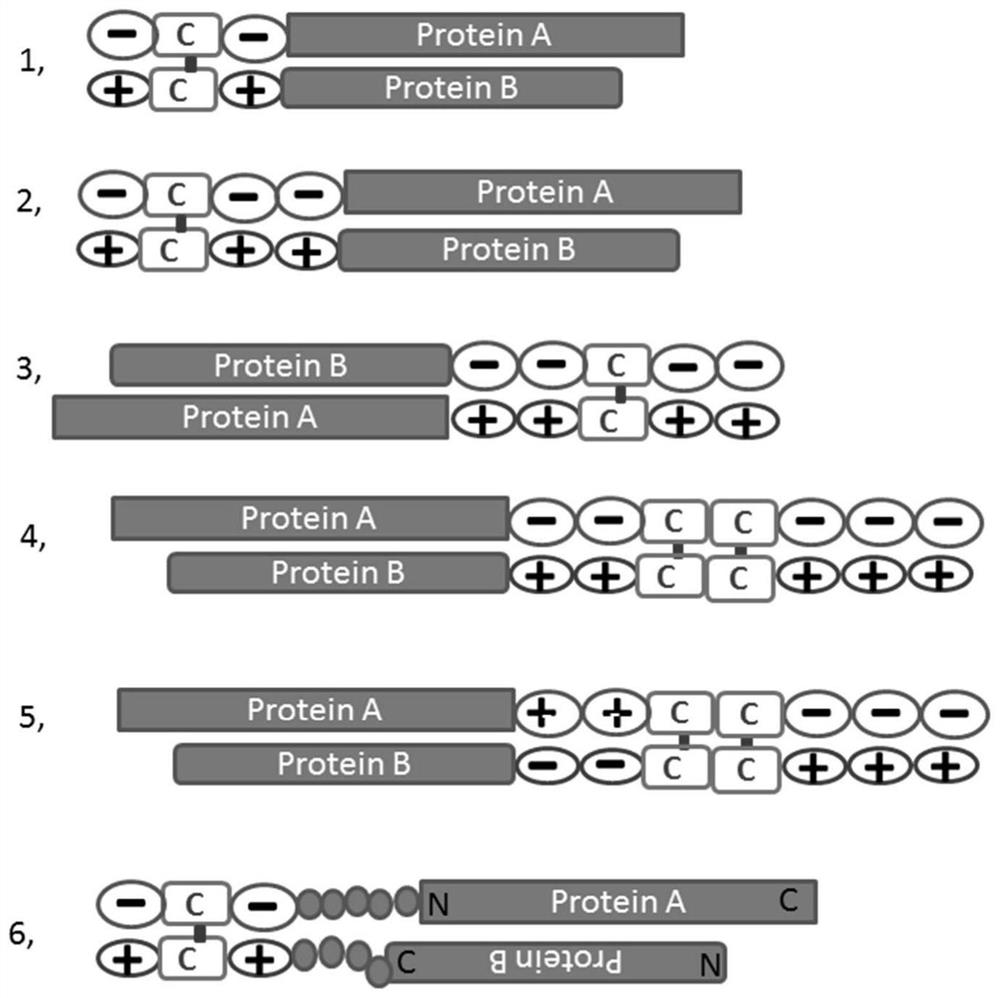

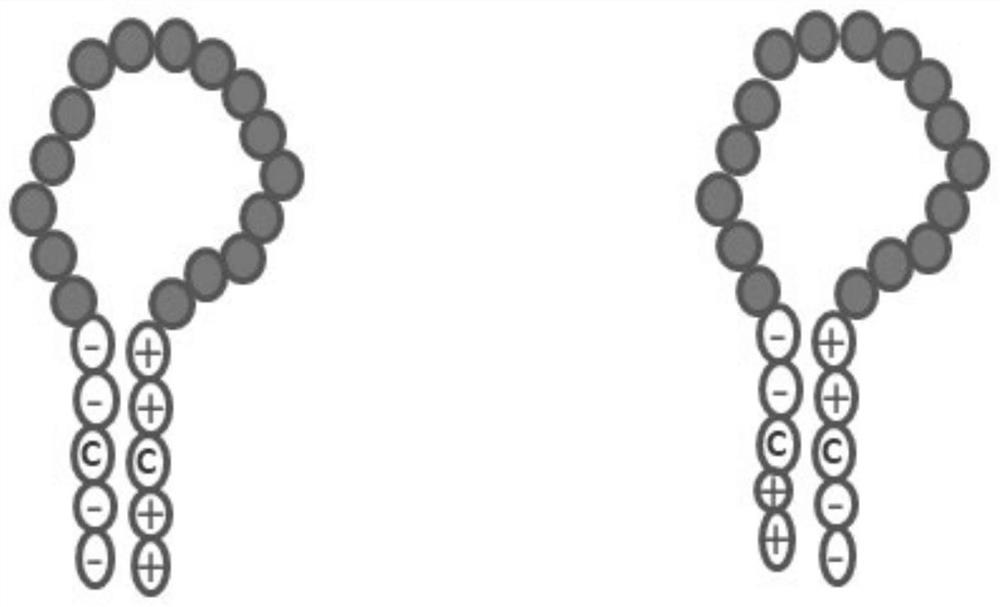

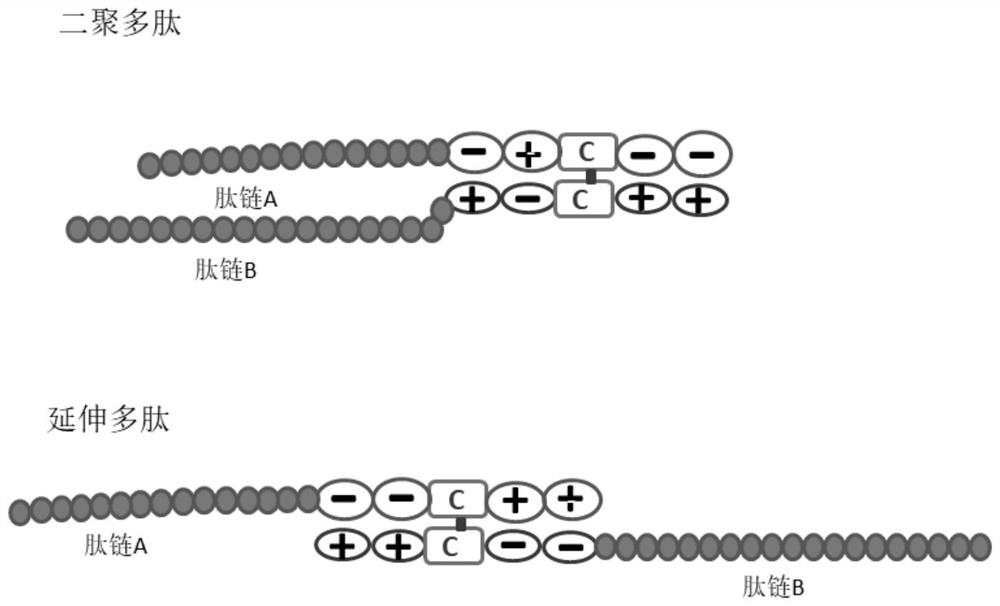

Zipper fastener structure for promoting formation of protein dimers and application thereof

PendingCN111655734AReduce the chance of formationAuxiliary formationAntibody mimetics/scaffoldsDepsipeptidesDimerAntiendomysial antibodies

The invention belongs to the field of gene engineering, and relates to a zipper fastener structure for promoting formation of protein dimers and an application thereof, and the zipper fastener can beused for dimerization of homologous proteins and dimerization of heterologous proteins, and can also be used for polypeptide cyclization, dimerization of polypeptides and extension of polypeptides. Some examples can obtain an ESAT6-CFP10 dimer close to native conformation, wherein the dimer has better solubility and has a better stimulation effect on memory T cells than ESAT6-CFP10 protein expressed by linear fusion. The inventor also finds that the dimer zipper fastener can help to form more stable cyclic polypeptide, and the CCP polypeptide added with the dimer fastener can increase the detection rate of citrullinated antibody in serum of rheumatoid arthritis patients.

Owner:GUANGZHOU LDEBIO TECH CO LTD

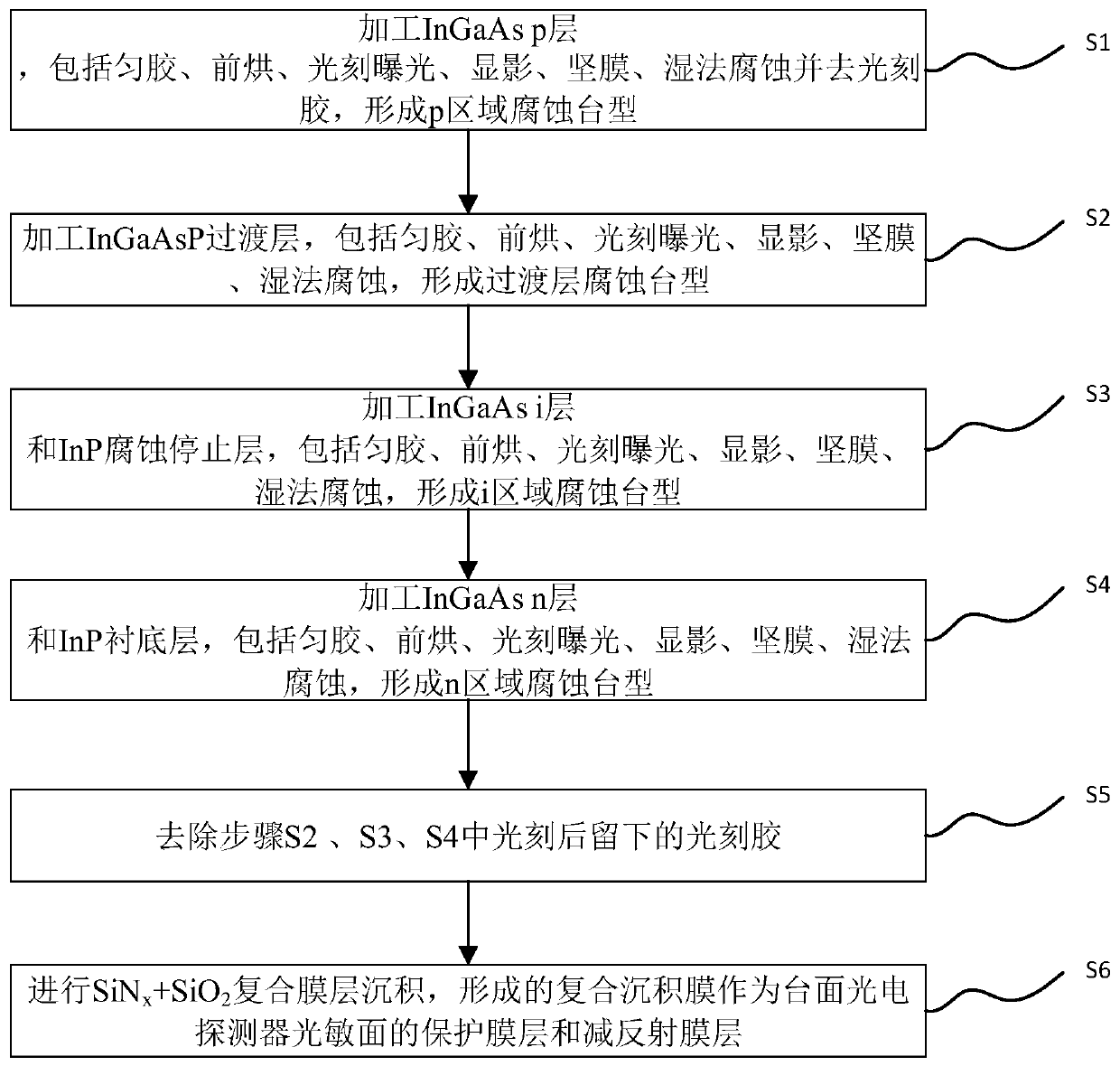

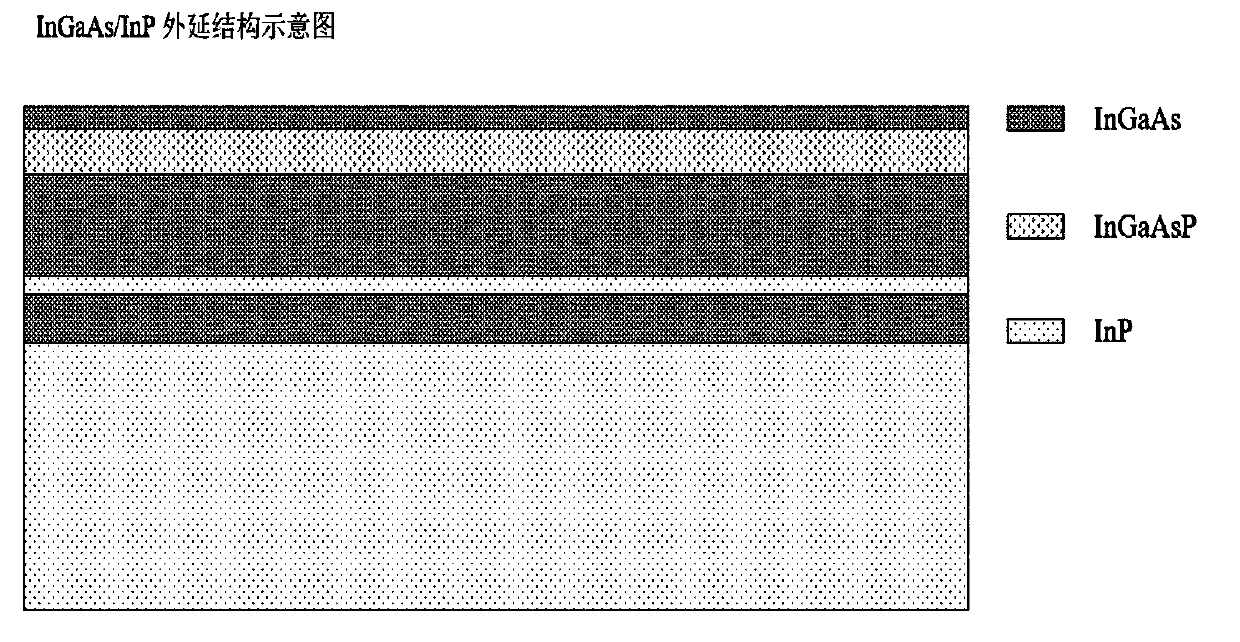

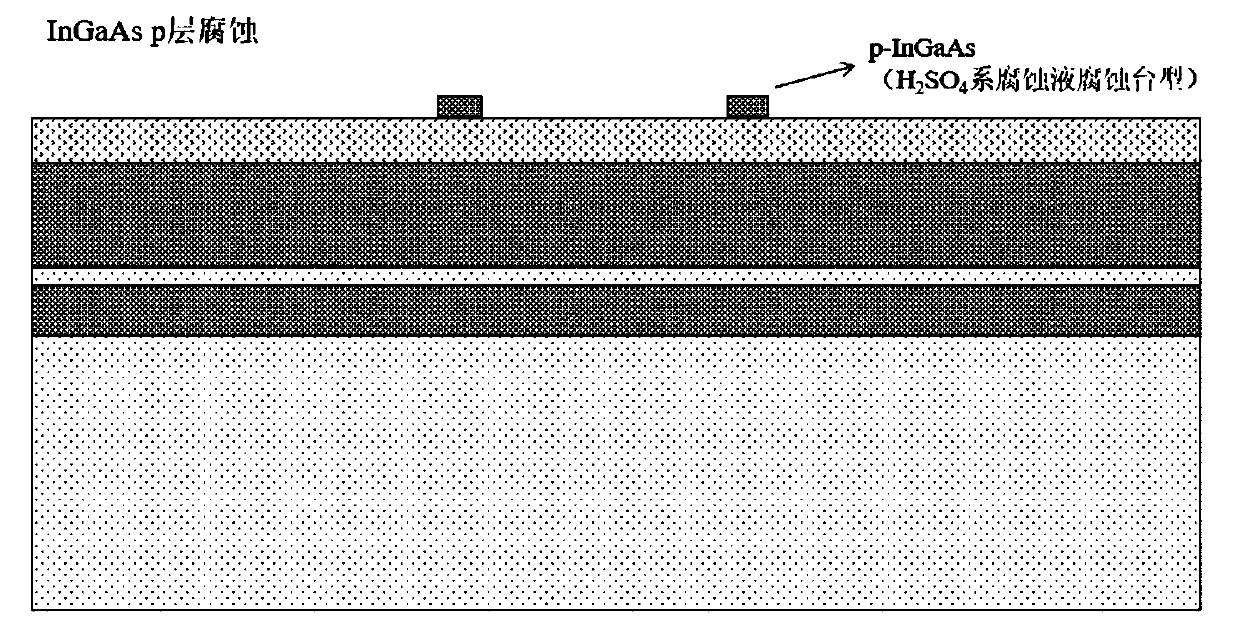

Manufacturing method of mesa type photoelectric detector

ActiveCN110707181AAvoid exposure to oxidationReduce the chance of formationFinal product manufactureSemiconductor devicesPhotovoltaic detectorsEngineering

The invention discloses a manufacturing method of a mesa type photoelectric detector. According to the manufacturing method, in the process of processing the InGaAsP transition layer, the InGaAs i layer, the InP corrosion stopping layer, the InGaAs n layer and the InP substrate layer, photoresist removing treatment is not carried out, and finally photoresist left after photoetching is removed at atime. According to the invention, the gluing layer is used for fully protecting the photosensitive surface structure of the photoelectric detector; the InGaAs / InP PIN mesa photoelectric detector withhigh performance is obtained by removing photoresist, cleaning the InGaAs / InP PIN mesa photoelectric detector, avoiding bringing new impurities and contact oxidation with oxygen in the steps of photoresist removal, cleaning and the like, reducing the formation probability of the surface state of the device, and reducing the dark current of the device.

Owner:武汉敏芯半导体股份有限公司

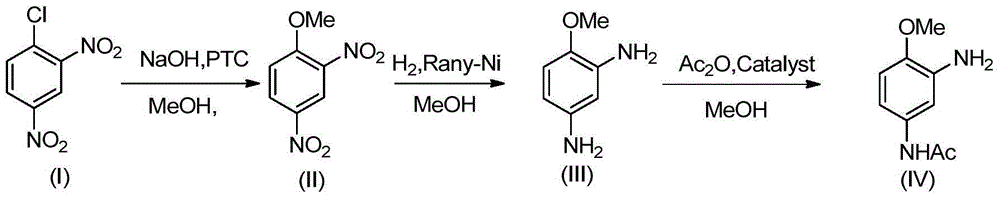

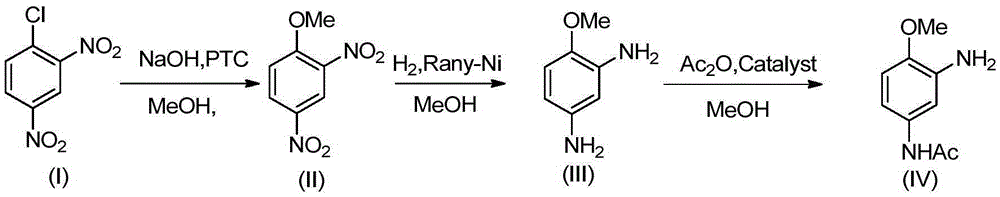

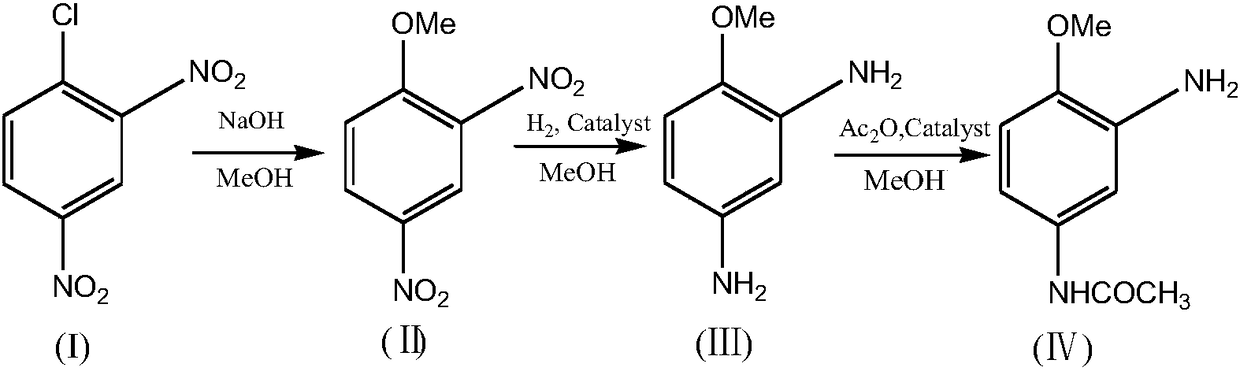

Process for synthesizing 2-amino-4-acetylaminoanisole

InactiveCN108299205AReduce instantaneous moisture contentReduce the amount of alkaliOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideHydrogen

The invention discloses a process for synthesizing 2-amino-4-acetylaminoanisole. The process comprises the steps of preparing 2,4-dinitroanisole from 2,4-dinitrochlorobenzene, which serves as a raw material, in methanol, in the presence of sodium hydroxide or potassium hydroxide, carrying out reduction in the presence of action of Pd / C catalyst by taking hydrazine monoformate as a hydrogen sourceso as to prepare a 2,4-diaminoanisole-methanol solution, and then, subjecting 2,4-diaminoanisole and acetic anhydride to a partial acylation reaction in the presence of an acid binding agent, therebypreparing the 2-amino-4-acetylaminoanisole. According to the process disclosed by the invention, the energy consumption is low, the cost is low, the volume of solid waste and waste liquid is small, the process is environmentally friendly, the operation is simple, the reaction conditions are mild, the industrial safety coefficient is big, the total yield of a target compound is 85% or more (by initial reactants), the HPLC purity is 99.0% or more, and the target compound is high in yield and good in quality, so that the process is more applicable to industrial production.

Owner:张翔

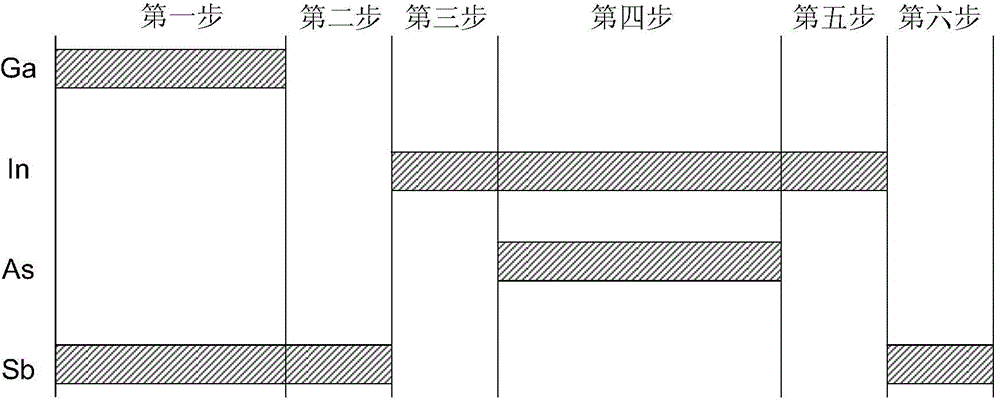

Type-II superlattice structure based on indium arsenide and preparation method

InactiveCN105789355AIncrease growth temperatureIncrease the diffusion lengthFinal product manufactureSemiconductor devicesMaterial defectAluminium arsenide

The invention discloses a type-II superlattice structure based on indium arsenide and a preparation method. The type-II superlattice structure based on indium arsenide comprises an InAs layer, a GaAs layer, a GaAsxSb1-xlayer and a GaAs layer from bottom to top, and is characterized in that: (1) an original GaSb substrate is replaced with an InAs substrate, so that the growth temperature of superlattices is substantially increased, and the increasement of the growth temperature is conductive to increasing a diffusion length of surface atoms, thereby being more conductive to the two-dimensional growth of materials and the reduction of material defect density; (2) an As valve is always in an open state during the whole growth process of type-II superlattices, so that a GaAsSb ternary compound is formed due to the outflow of partial As when growing a GaSb layer, growth temperature of the layers tends to be uniform due to the existence of the common element As in the layers, and the counterdiffusion at interfaces is reduced; (3) variation of thickness of the InAs layer has small influence on mismatching of the InAs-based type-II superlattices, the growth difficulty of long waves materials, particularly extremely-long-wave materials, is extremely reduced, and the performance and quality of the materials can be more easily improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Chromium alloy non-quenched and tempered steel wire rod and production method thereof

InactiveCN112410679AImprove plasticityReduce the chance of formationMetal rolling arrangementsWire rodManganese

The invention is suitable for the technical field of steel wire rod machining, and provides a chromium alloy non-quenched and tempered steel wire rod and a production method thereof. The chromium alloy non-quenched and tempered steel wire rod comprises the following chemical components of, by weight, 0.22-0.31% of C, 1.20-1.55% of Mn, 0.15-0.30% of Si, 0.30-0.40% of Cr, less than or equal to 0.012% of P, less than or equal to 0.008% of S; less than or equal to 0.05% of Ni, less than or equal to 0.05% of Cu, less than or equal to 0.03% of Mo, less than or equal to 0.003% of Al, less than or equal to 0.002% of Ti, less than or equal to 0.002% of O, less than or equal to 0.005% of N, 0.05-0.20% of V, and the balance Fe and inevitable impurities. According to the method, the carbon content isreduced, the manganese content is reduced, the carbon segregation of the wire rod is improved, the plasticity of the wire rod is slightly improved, the forming probability of net carbon is reduced bycombining high-temperature rolling and controlled cooling processes, and the user machining wire breakage rate is reduced, so that the production efficiency of the user is improved; and in the coolingprocess, the process design of proper quick cooling and then slow cooling is adopted, growth of grains is controlled, ferrite-pearlite zonal segregation is reduced, and meanwhile, the situation thatthe cold working performance is deteriorated due to too high strength caused by an abnormal quenching structure is avoided.

Owner:JIANGSU YONGGANG GROUP CO LTD

Type II superlattice structure and preparation method based on arsenic valve switch

ActiveCN103500765BReduce interdiffusionReduce the chance of formationFinal product manufactureNanoopticsInterface layerBinary compound

Owner:中科爱毕赛思(常州)光电科技有限公司

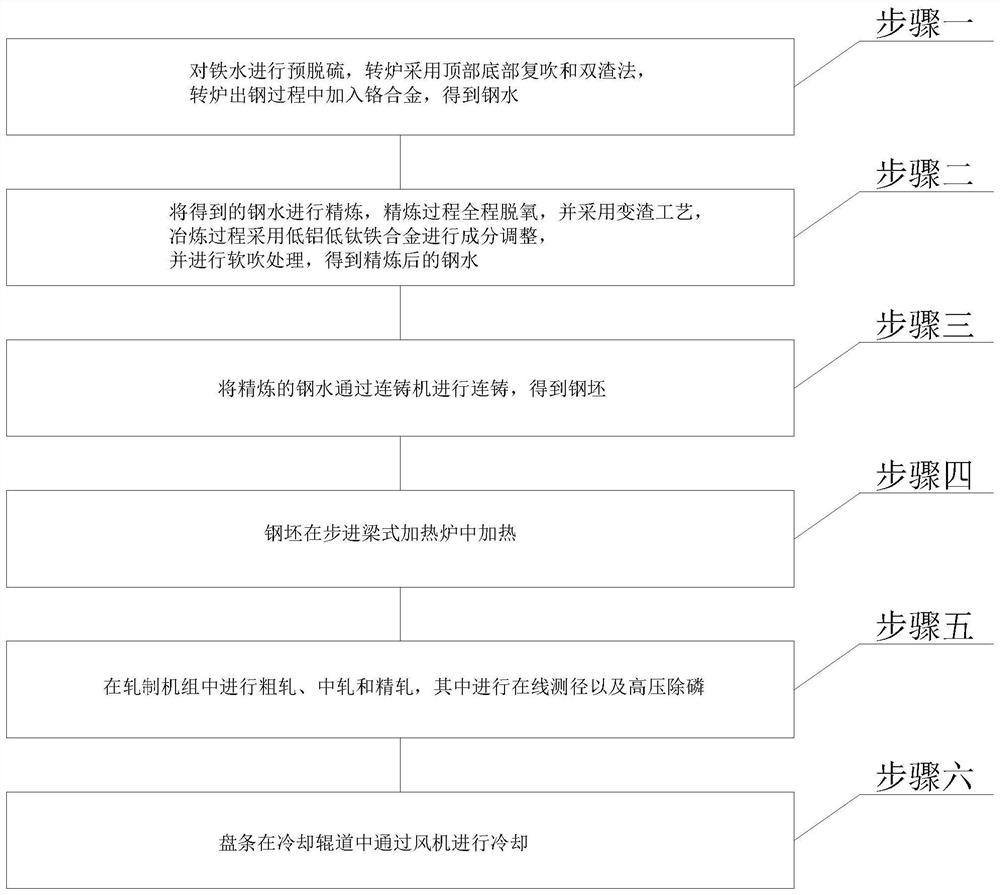

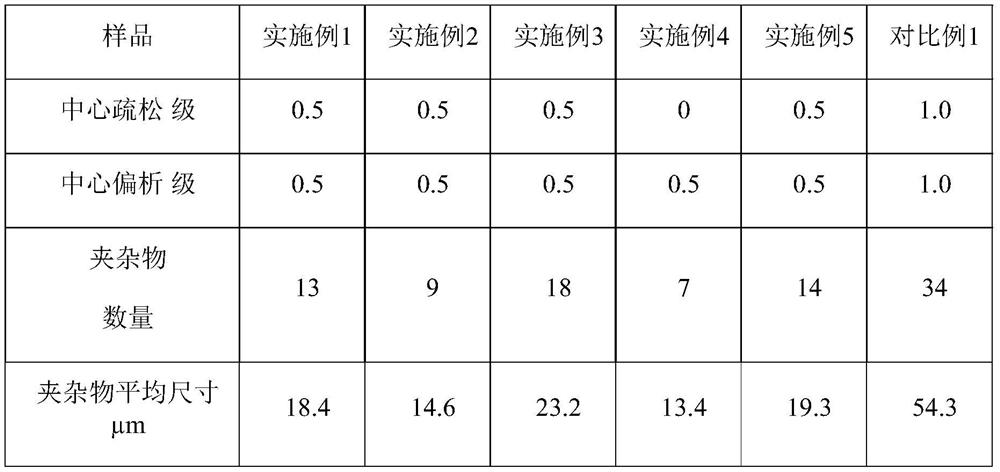

Preparation process of H08A steel

The invention provides a preparation process of H08A steel. The preparation process comprises the following specific steps of first, smelting in a converter, wherein magnesium alloy is added in the tapping process to carry out pre-deoxidation and argon blowing, and the free oxygen content of molten steel is controlled to range from 80 ppm to 100 ppm; second, LF refining, wherein calcium is added in the process to remove oxygen again, and the free oxygen content is controlled to range from 10 ppm to 20 ppm after LF refining heating of the molten steel is finished; and third, continuous casting;wherein according to the feeding manner of adding the magnesium alloy in the first step, powdery magnesium alloy is blown into the bottom of a steel ladle by using carrier gas. According to the preparation process of the H08A steel, the section of a produced casting blank (8 hours of continuous casting) sample produced is free of any obvious bubbles, the central porosity grade is less than or equal to 0.5 grade, the central segregation grade is less than or equal to 0.5 grade, other obvious defects do not exist, and the percent of pass is 99%; and meanwhile, in the cross section of a steel body with the area of 100 * 100 millimeters, the number of inclusions is no larger than 30, and the maximum diameter of the inclusions is no larger than 20 micrometers.

Owner:福建三宝钢铁有限公司

Atomization device for clothes processing equipment, clothes processing equipment, and control method

ActiveCN111663302AEasy maintenanceImprove maintenance work efficiencyOther washing machinesControl devices for washing apparatusProcess engineeringMechanical engineering

The invention belongs to the technical field of clothes processing, and specifically provides an atomization device for clothes processing equipment, the clothes processing equipment, and a control method. The invention aims to solve the problem that an atomization piece of an atomization device in existing clothes processing equipment is easy to form dirt and affects the atomization efficiency. The invention provides the atomization device for the clothes processing equipment, the clothes processing equipment, and the control method. The atomization device comprises a shell and an atomizationmodule; an atomization cavity is arranged inside the shell; and the atomization module comprises an atomization piece that can atomize liquid in the atomization cavity, and a liquid inlet is set toward the atomization piece. The atomization device for the clothes processing equipment provided by the invention improves the atomization efficiency and the atomization amount, and improves the user experience.

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

Choleresis increasing and gall-stone removal tea and preparation method thereof

InactiveCN107375856ASimple treatmentLow costDigestive systemBird material medical ingredientsSide effectRadix bupleuri

The invention relates to choleresis increasing and gall-stone removal tea and a preparation method thereof. The choleresis increasing and gall-stone removal tea is prepared from the following raw materials in parts by weight: 4 to 20 parts of radix bupleuri, 12 to 28 parts of herba lysimachiae, 4 to 20 parts of radix curcumae, 12 to 28 parts of taraxacum, 12 to 28 parts of herba artemisiae capillariae, and 12 to 28 parts of endothelium corneum gigeriae galli. The process is simple, and by adopting the pure traditional Chinese medicine formula, the choleresis increasing and gall-stone removal tea has no toxic and side effect for the human body.

Owner:HENAN QIANFANG PHARMA

Hammer sheet crusher

ActiveCN103212468AIncrease the striking powerEnsure quality stabilityGrain treatmentsElectric machineryCrusher

The invention discloses a hammer sheet crusher. The hammer sheet crusher comprises an upper body, a main motor arranged outside the upper body, a main shaft connected with the main motor, a sieve plate, hammer sheets, a rotating shaft moving cutter and an auxiliary motor, the hammer sheets are arranged on the main shaft, the sieve plate is arranged outside the hammer sheets and is arranged in the upper body around the main shaft, the auxiliary motor is arranged outside the upper body, the rotating shaft moving cutter is arranged in the upper body and parallels to the main shaft, and the rotating shaft moving cutter is connected with the auxiliary motor. How to improve the crushing capability of the crusher and destroy a circulation layer in the crusher is a technique problem to be solved. The hammer sheet crusher which adopts the rotating shaft moving cutter driven by the auxiliary motor increases the cutting force to a material and is in favor of destroying the circulation layer of the material in the crusher, so the crushing efficiency and the crushing quality are effectively improved.

Owner:TSZJANSU CHZHEHNCHAN SIRIEHL OIL EHND FID MASHINERI KO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com