Patents

Literature

277results about How to "Increase the speed of solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

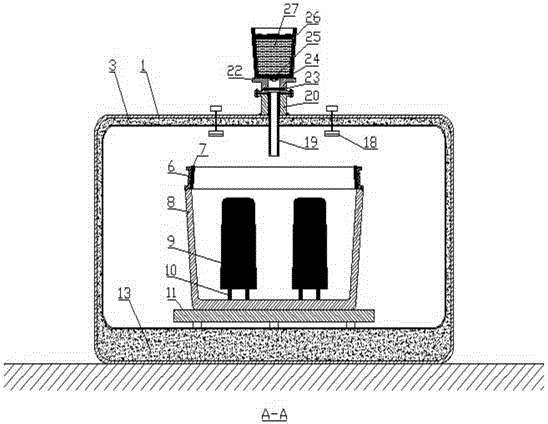

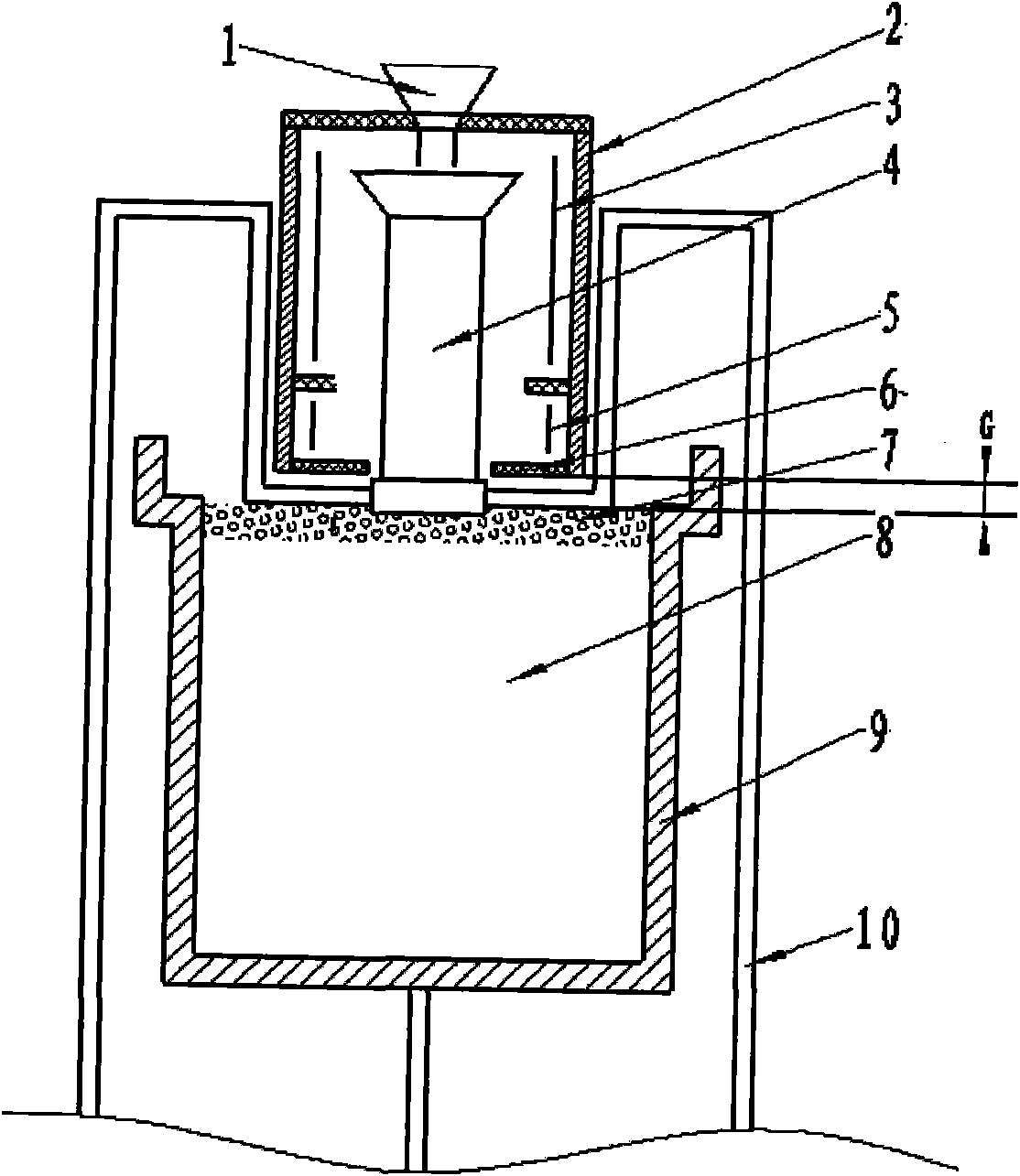

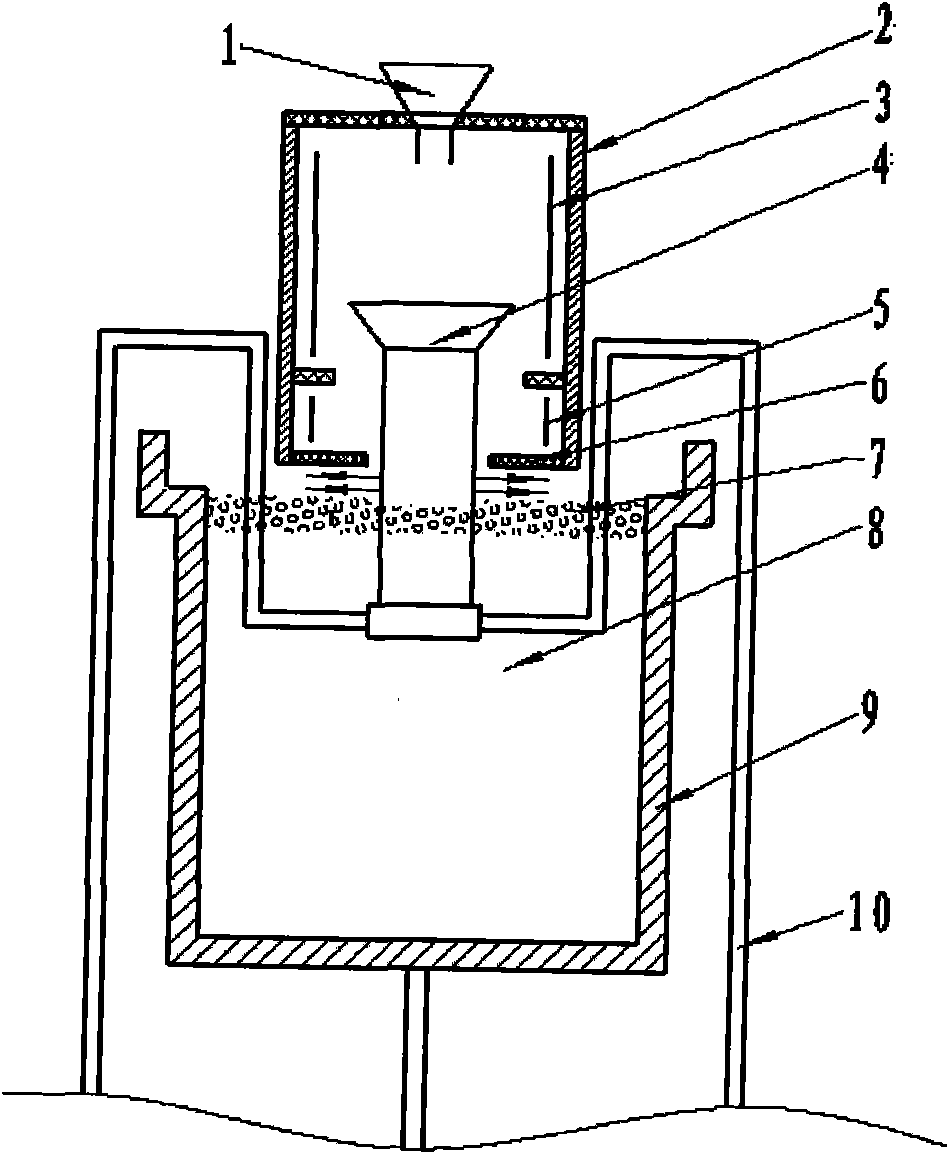

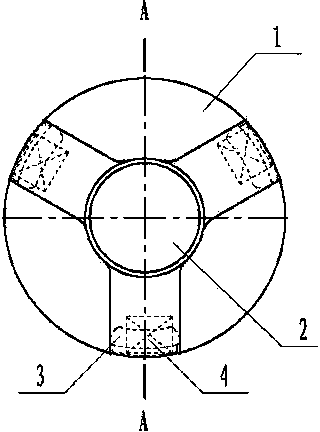

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

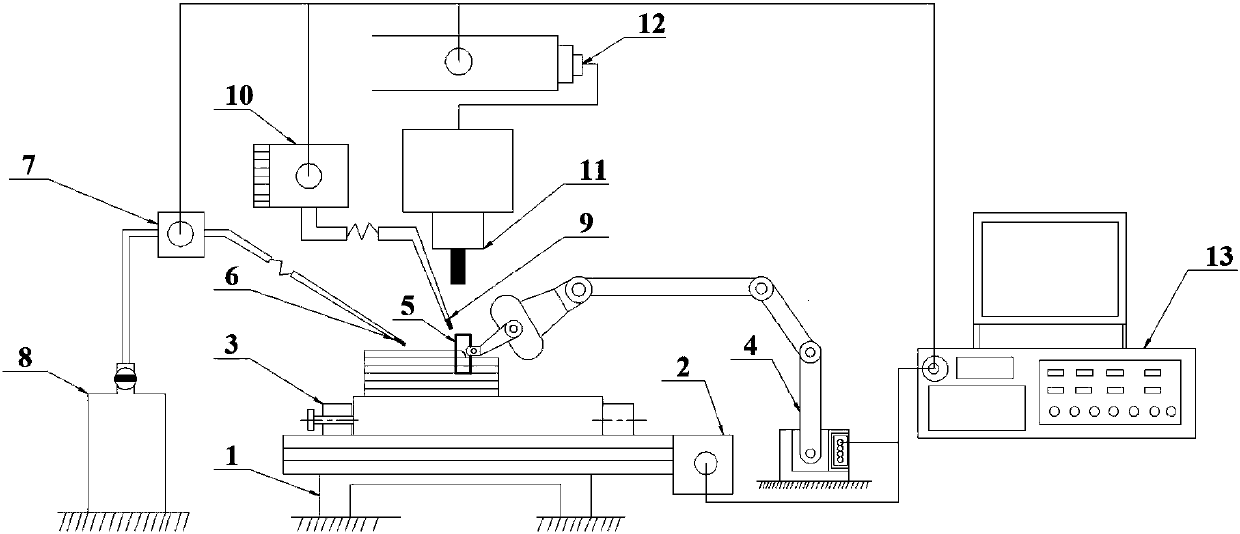

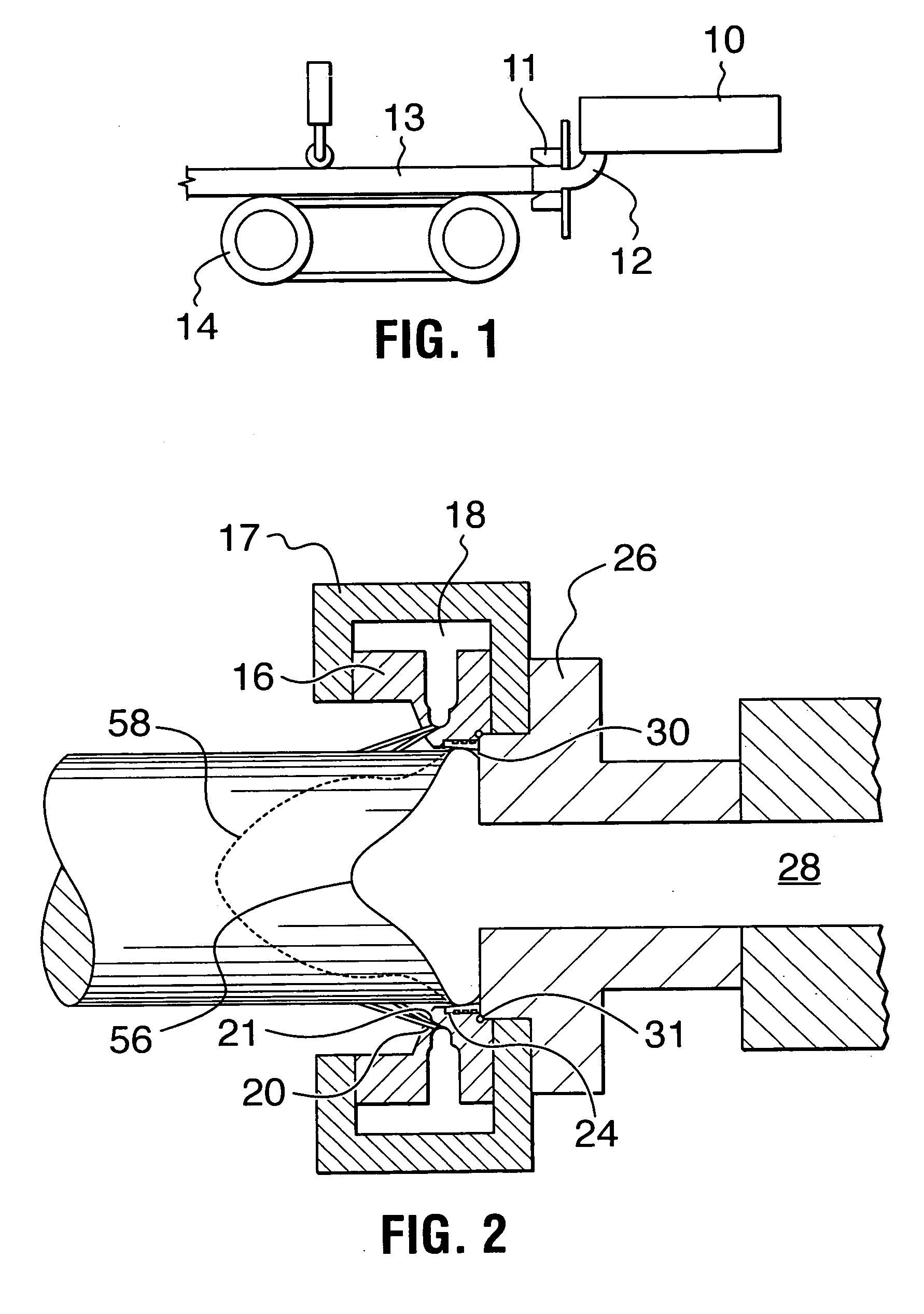

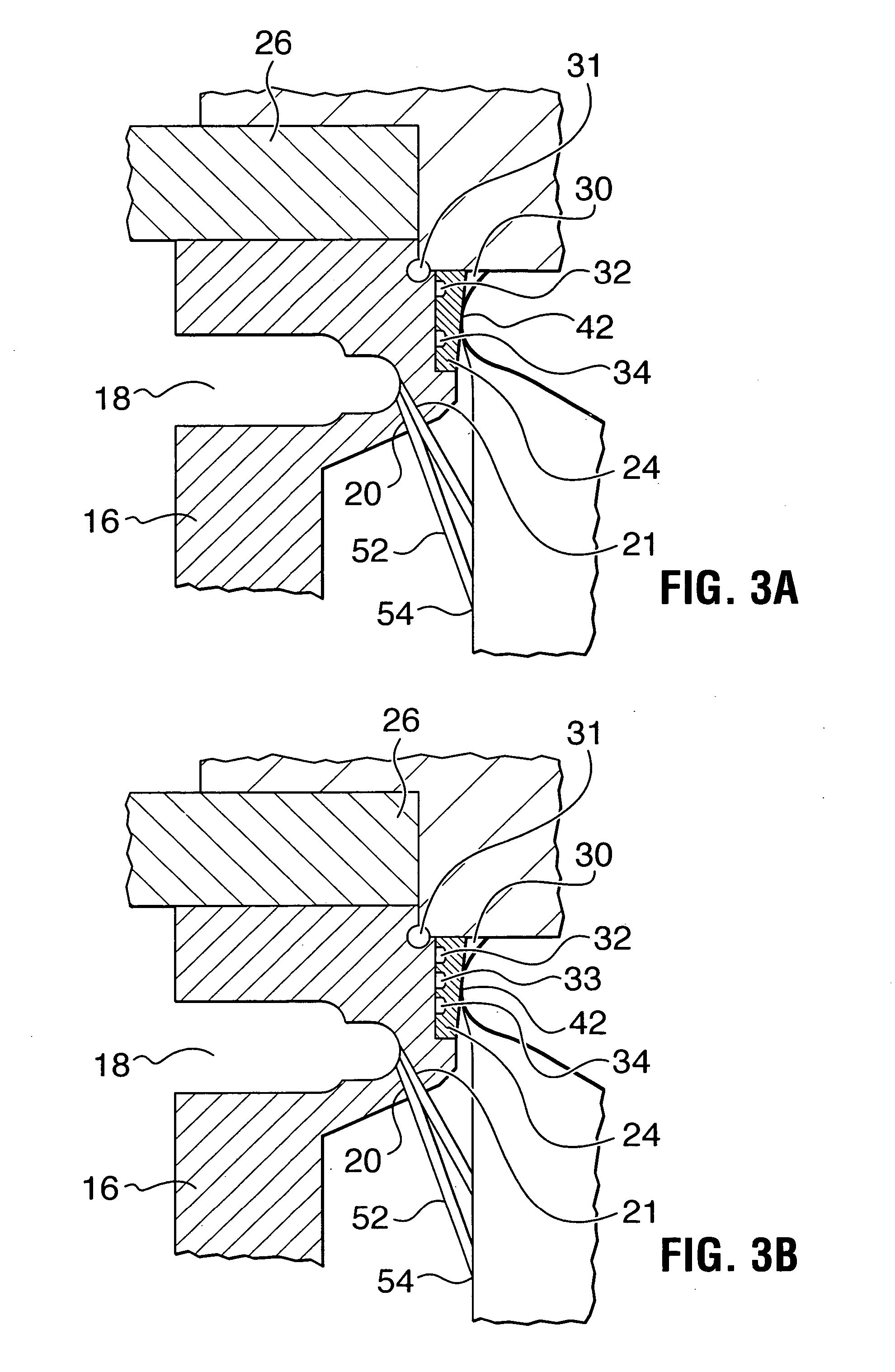

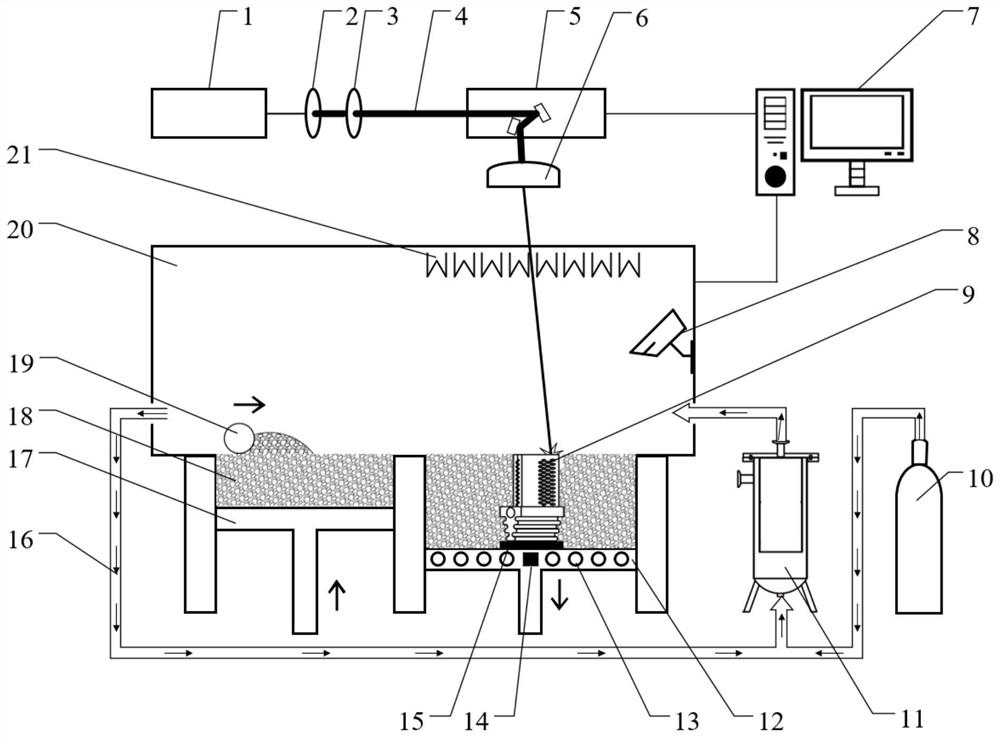

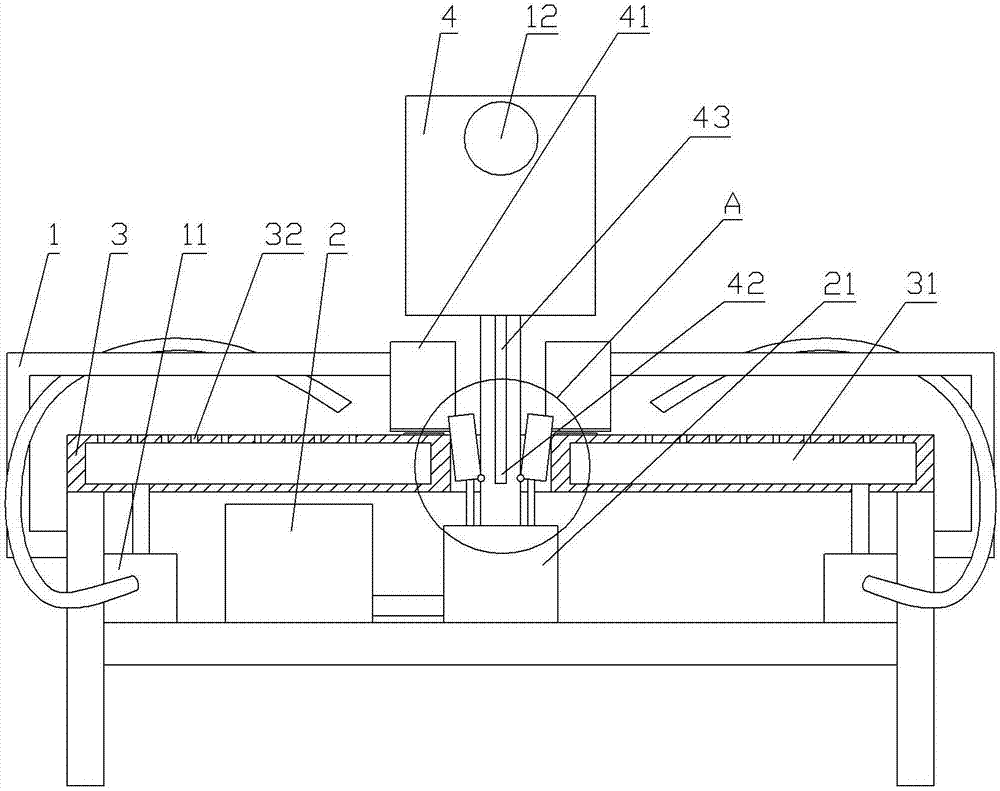

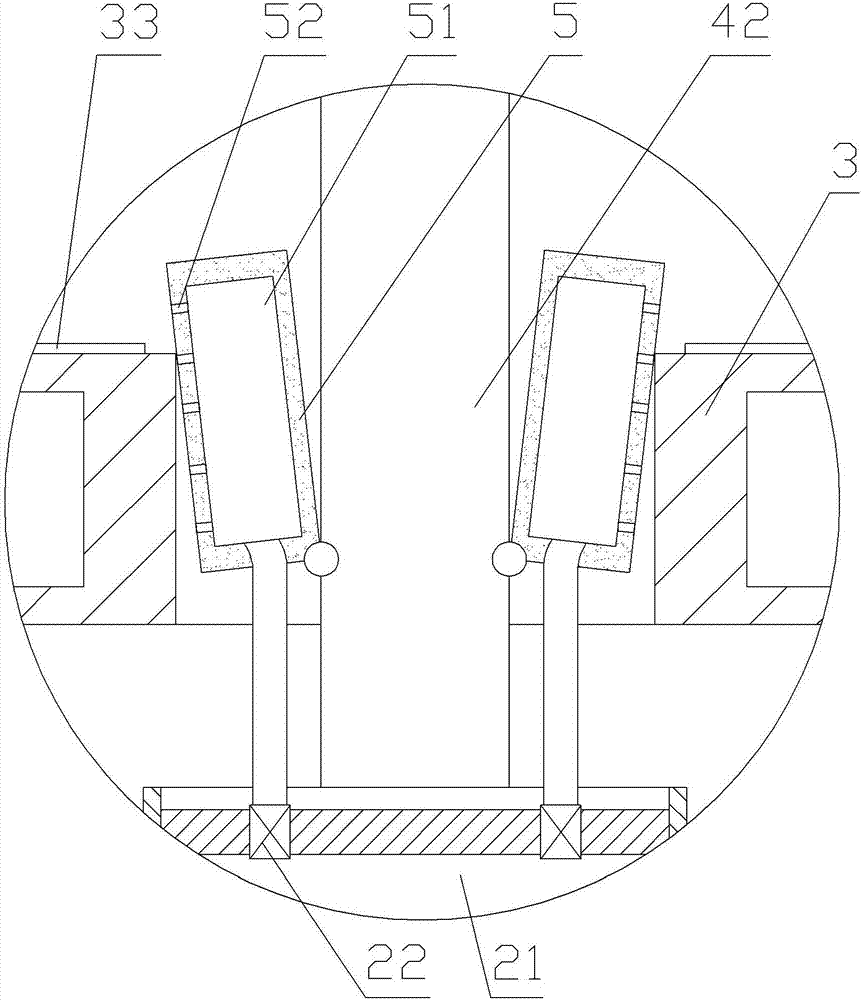

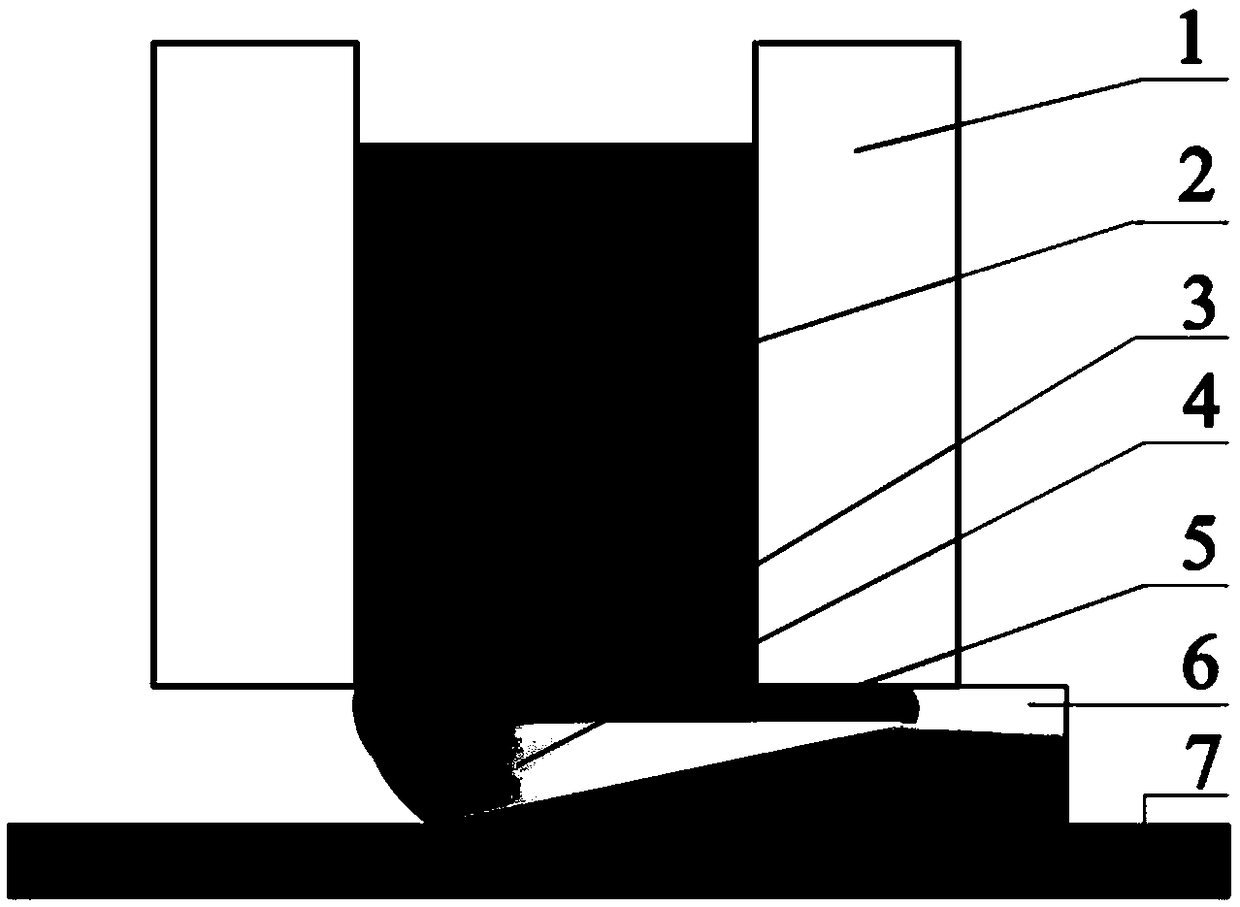

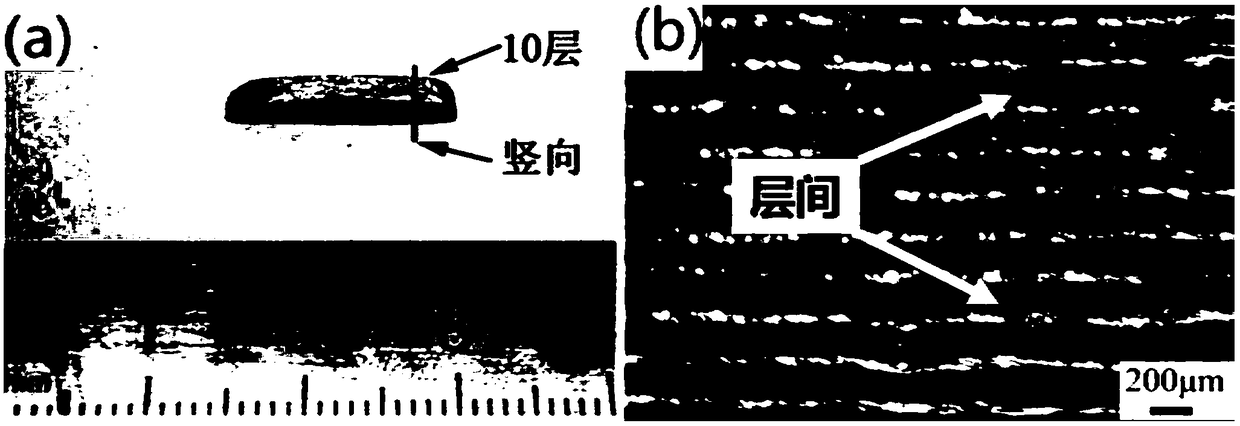

Method and device for improving forming quality of laser additive manufacturing thin-wall parts

ActiveCN107685149AStable jobOvercoming flow problemsAdditive manufacturing apparatusIncreasing energy efficiencyForming processesMetal

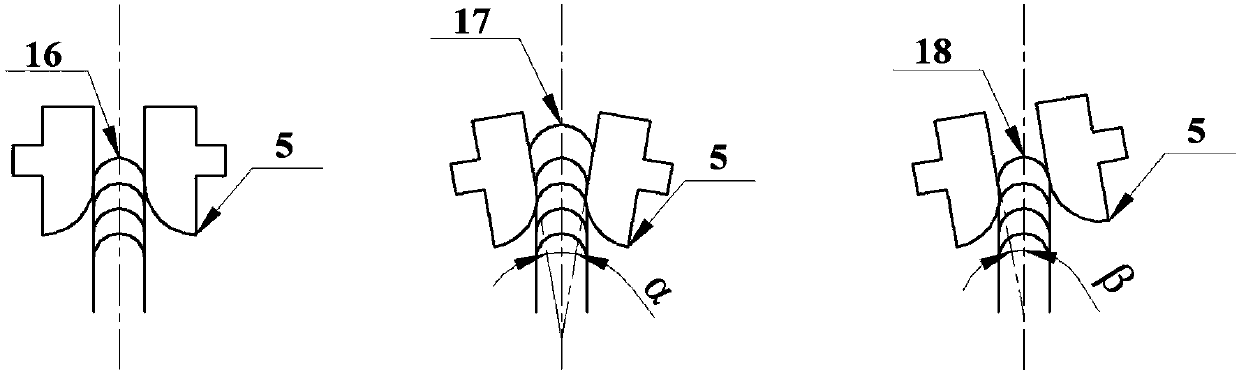

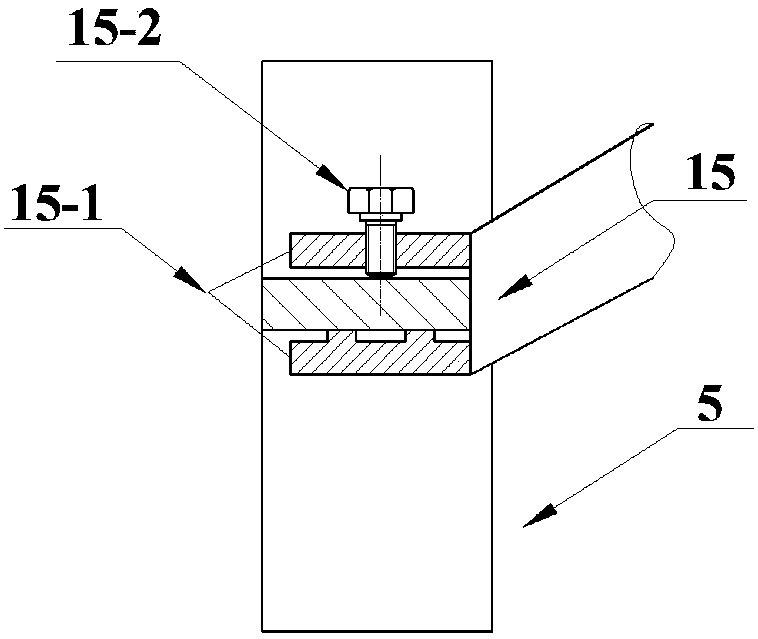

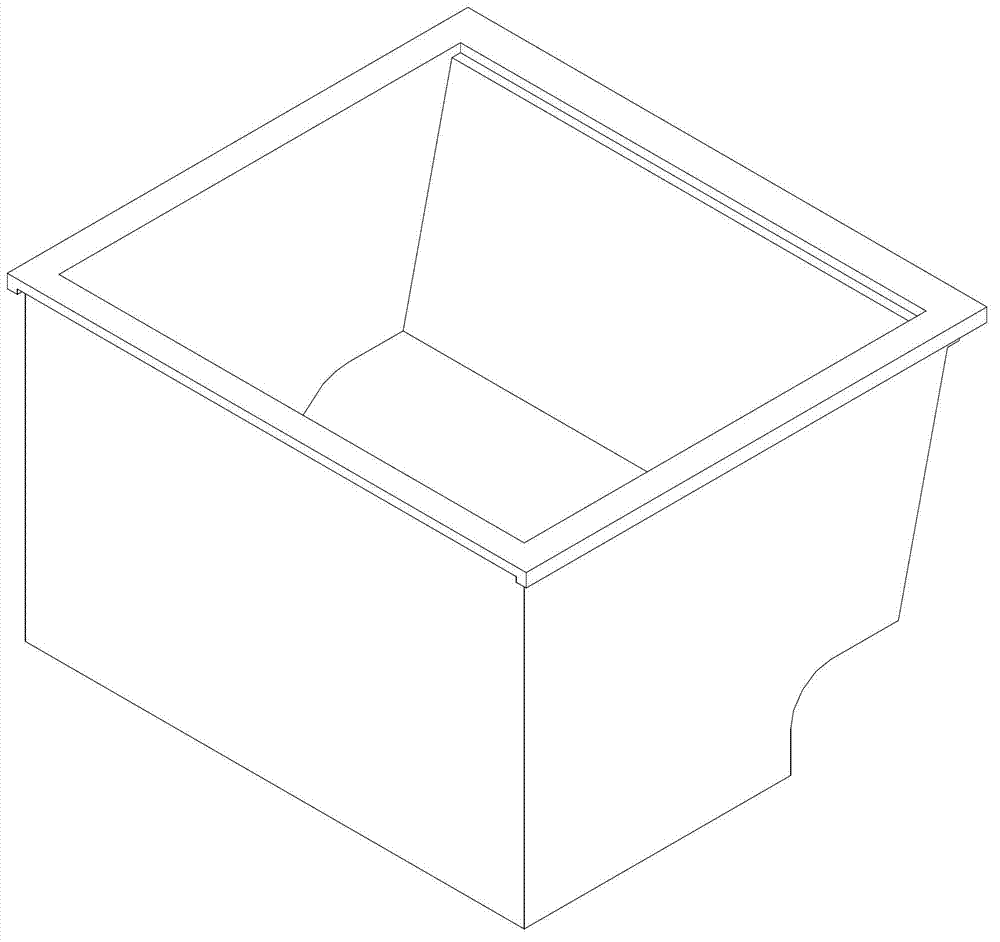

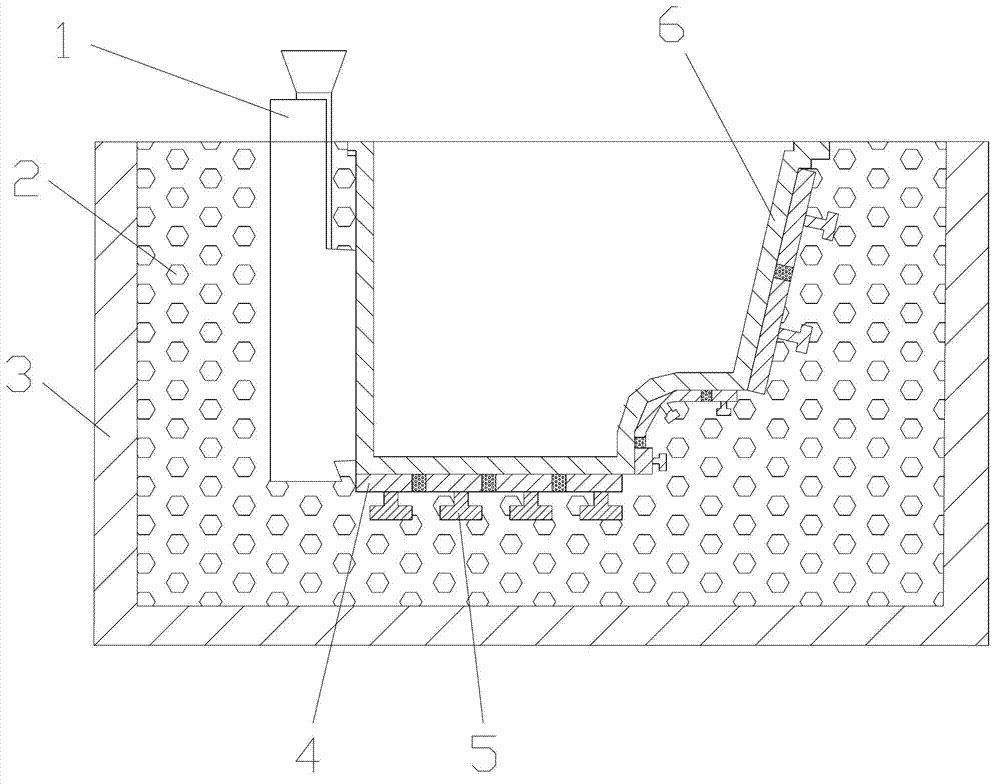

The invention provides a method and device for improving the forming quality of laser additive manufacturing thin-wall parts. The device comprises a movable platform system, a laser metal deposition system, an auxiliary forming system, an active cooling system and a central control system. According to the forming method, when the laser metal deposition system conducts cladding forming on the thin-wall parts, the auxiliary forming system controls the thin-wall thicknesses and the forming directions in real time; when the multiple layers of the thin-wall parts are deposited, the problem of molten pool flowing caused by interlayer stacking can be solved, and the problem that the surface roughness in the thin-wall forming process is excessively large due to interlayer stacking is solved, andthe thickness-changeable thin wall, the flat thin wall and the curved thin wall are machined; and meanwhile, the active cooling system cools deposited layers in real time. The problems that the quality of the laser cladding formed surfaces is low; during continuous multiplayer depositing, the temperature is increased, therefore, thermal stress of the deposited layers is accumulated, consequently the deposited layers are cracked, and microstructures of the deposited layers are coarse; and the forming efficiency is low due to slow cooling are solved, and high-quality and efficient forming of thecomplex thin-wall parts is achieved.

Owner:JIANGSU UNIV

Method for manufacturing casting blank of die for inner containers of household appliances on basis of metal cavity with cold iron structure

InactiveCN102773409AQuality improvementImprove pass rateFoundry mouldsFoundry coresSurface finishFree cooling

The invention discloses a method for manufacturing a casting blank of a die for inner containers of household appliances on the basis of a metal cavity with a cold iron structure, and relates to the technical field of aluminum alloy casting. The method includes particular steps of constructing an outer cavity by cold iron blocks on the periphery of a manufactured wood mold in a form following manner; filling gaps among the cold iron blocks by clay sand, tightly filling the corresponding cold iron blocks by clay sand after each local structure is completed, and compacting a sand mould to prevent the cold iron blocks from moving; constructing a sand core of an inner cavity by the same method after the outer cavity is constructed; opening a case to take out the wood mould after the sand core of the inner cavity is manufactured so that a cavity of a casting is formed; drying the cavity of the casting and the sand core consisting of clay sand; preheating the cavity of the casting at the preheating temperature of 200 DEG C before pouring of the cavity of the casting; casting melted aluminum alloy into the cavity of the casting; and opening the case to take out the casting after the cavity of the casting is cooled naturally. The method is mainly used for casting the die for the inner containers of the household appliances, the surface of a casting product produced by the process is high in smoothness and does not have sand holes or pin holes after the surface of the casting product is treated in a follow-up machining process, and accordingly yield of molded inner container products is greatly increased.

Owner:CHUZHOU JINNUO INDAL

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

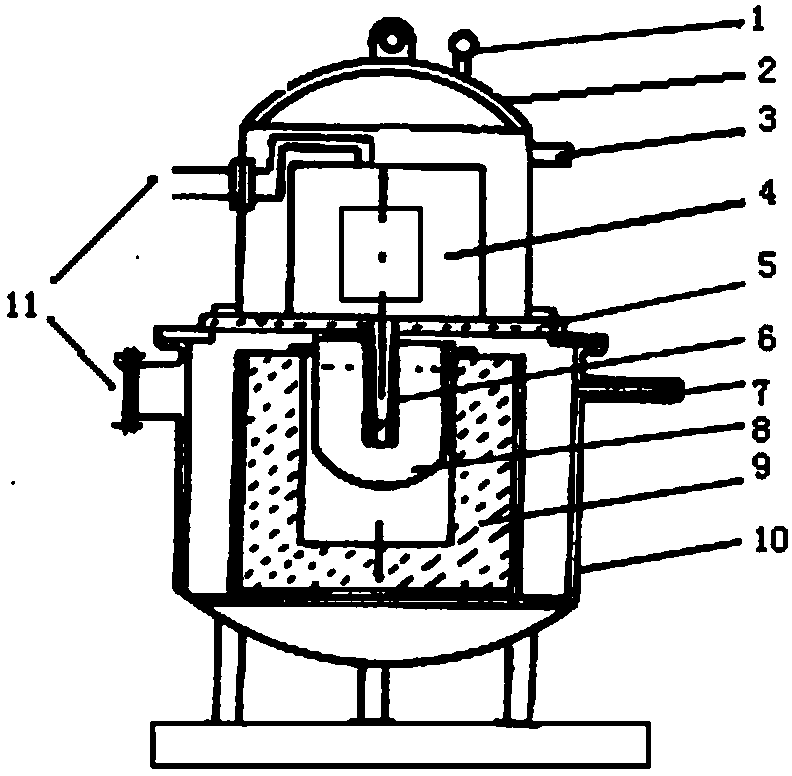

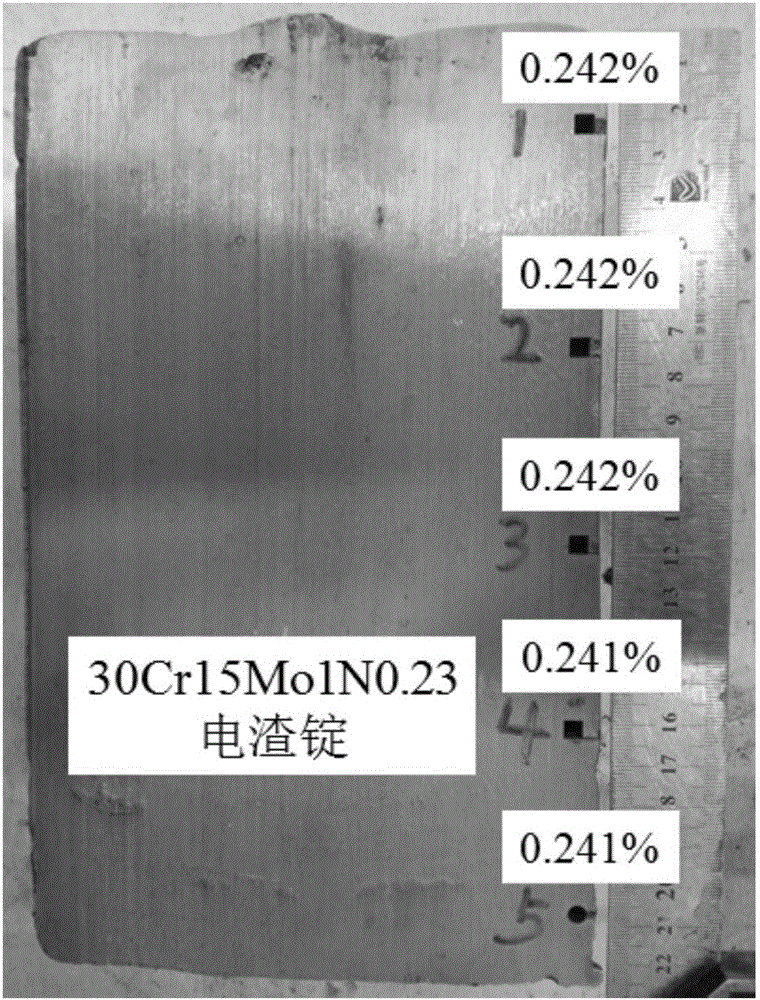

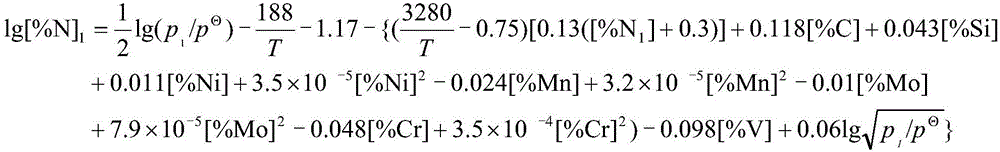

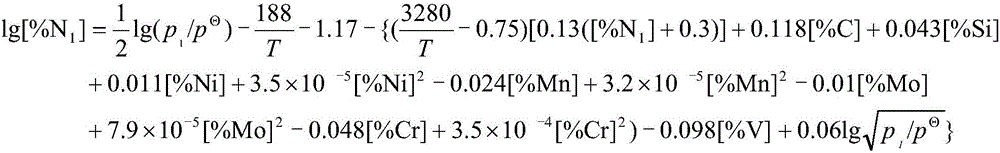

Method for preparing high-nitrogen steel through combination of pressurized induction and protective-atmosphere electro-slag remelting

ActiveCN106756485APrevent escapeReduce manufacturing costIncreasing energy efficiencySolubilityElectro-slag remelting

The invention provides a method for preparing high-nitrogen steel through a combination of pressurized induction and protective-atmosphere electro-slag remelting. High-nitrogen martensitic steel or high-nitrogen austenitic steel serves as the high-nitrogen steel. The method comprises the following steps such as raw material preparation, determination of the melting pressure and the pouring pressure, pressurized induction melting, deoxidization, pouring, and electro-slag remelting. The method provided by the invention has the advantages that the solidification velocity of the electro-slag remelting process is relatively high, so that the escape of nitrogen can be inhibited, a high-nitrogen steel remelting ingot of which the nitrogen content is slightly higher than the normal-pressure solubility is obtained, and the prepared high-nitrogen steel is excellent in corrosion-resistant property and mechanical property; and in order to reduce the production cost of the high-nitrogen steel, a new way for preparing the high-nitrogen steel of which the nitrogen content is slightly higher than the normal-pressure solubility by adopting the protective-atmosphere electro-slag remelting process is provided.

Owner:NORTHEASTERN UNIV

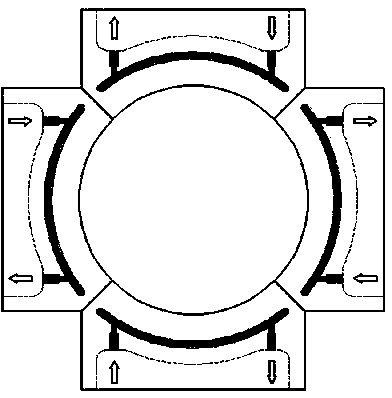

Air-cooled semi-continuous casting system and method of high-activity alloy

The invention relates to an air-cooled semi-continuous casting system and method of a high-activity alloy. The system comprises water-cooled crystallizers, air injection devices, an air-cooling device, an air tank, and a casting device, wherein the water-cooled crystallizers are located above the air injection devices; each air injection device is composed of an air injection ring, an air nozzle, and an air guide plate; the air injection devices are connected with the air cooling device and the air tank in order. The method comprises the following process steps: (1) checking leakproofness and unobstruction of the system, and adjusting angles of the air nozzles; (2) enabling dummy ingots to extend into the water-cooled crystallizers; directing an alloy melt to flow into a cavity, turning on a casting machine, adjusting a casting speed, and controlling a temperature of cooling air and adjusting a flow velocity of the air; and (3) when a length of an ingot blank meets a requirement, stopping melt supply firstly, closing a flow control valve after the melt in the water-cooled crystallizers is gradually cooled and solidified, and after an upper surface of the ingot blank is lowered down to a position below secondary cooling air injection devices, removing the water-cooled crystallizers and the secondary cooling air injection devices, lifting out the metal ingot blank, and then finishing casting.

Owner:NORTHEASTERN UNIV

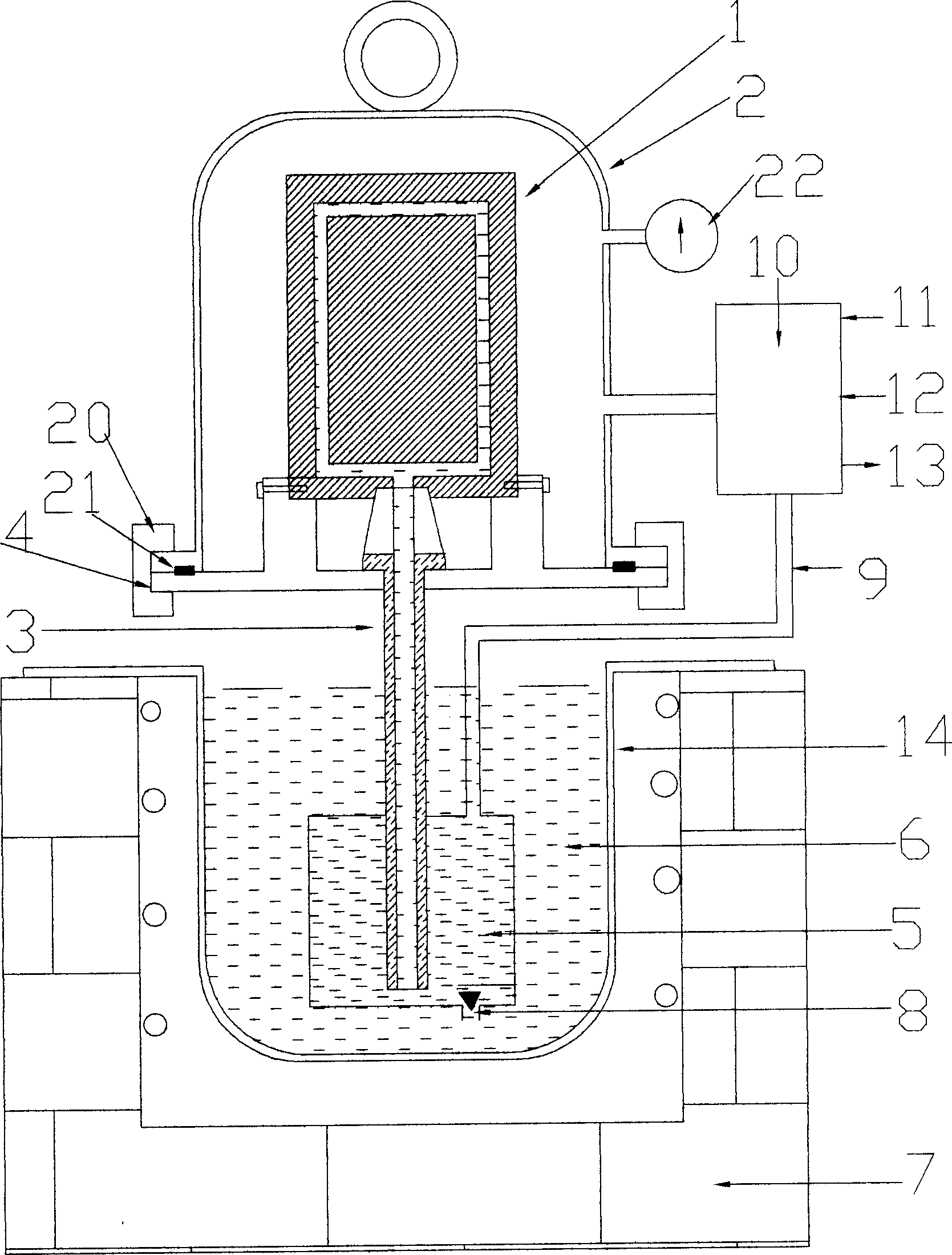

Vacuum pressure casting machine for magnesium alloy

The invention belongs to metal casting device. The magnesium alloy cast is complex, and the performance is bad. The invention is a magnesium alloy casting device which fills shape in vacuum state and solidifies them in various pressure state. It can realize the optimized casting process condition, it can be applied to produce each kind of large, complex, thin magnesium alloy casting piece with precise size and high thickness.

Owner:李书伟 +2

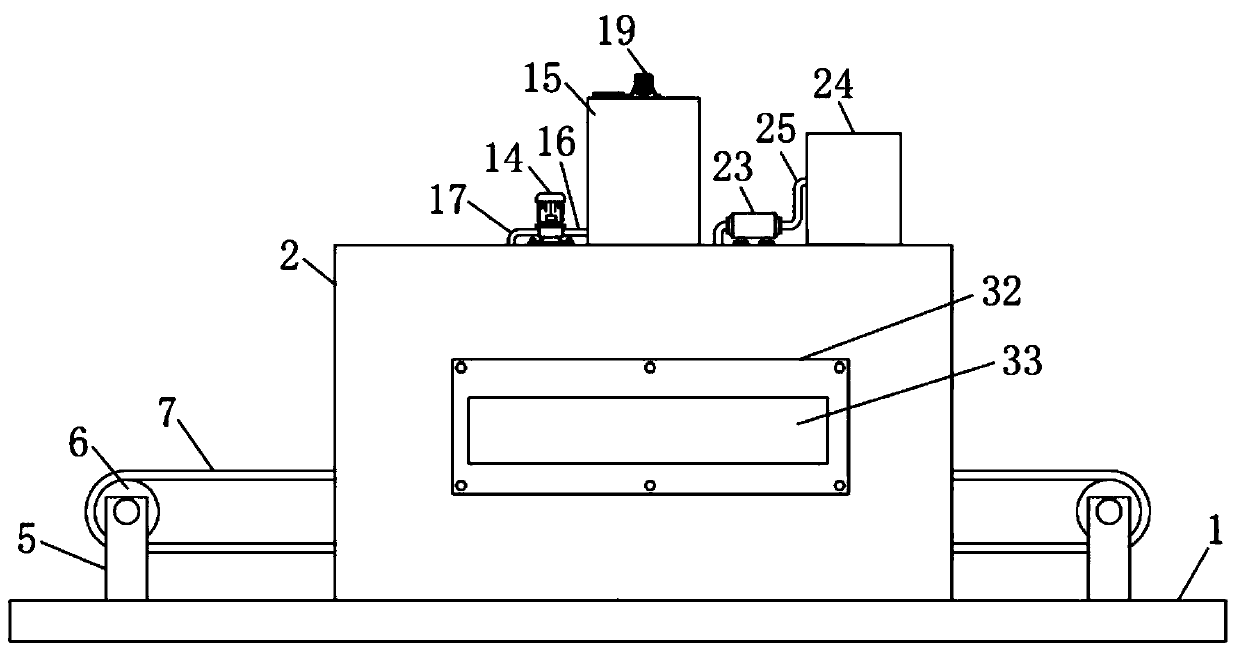

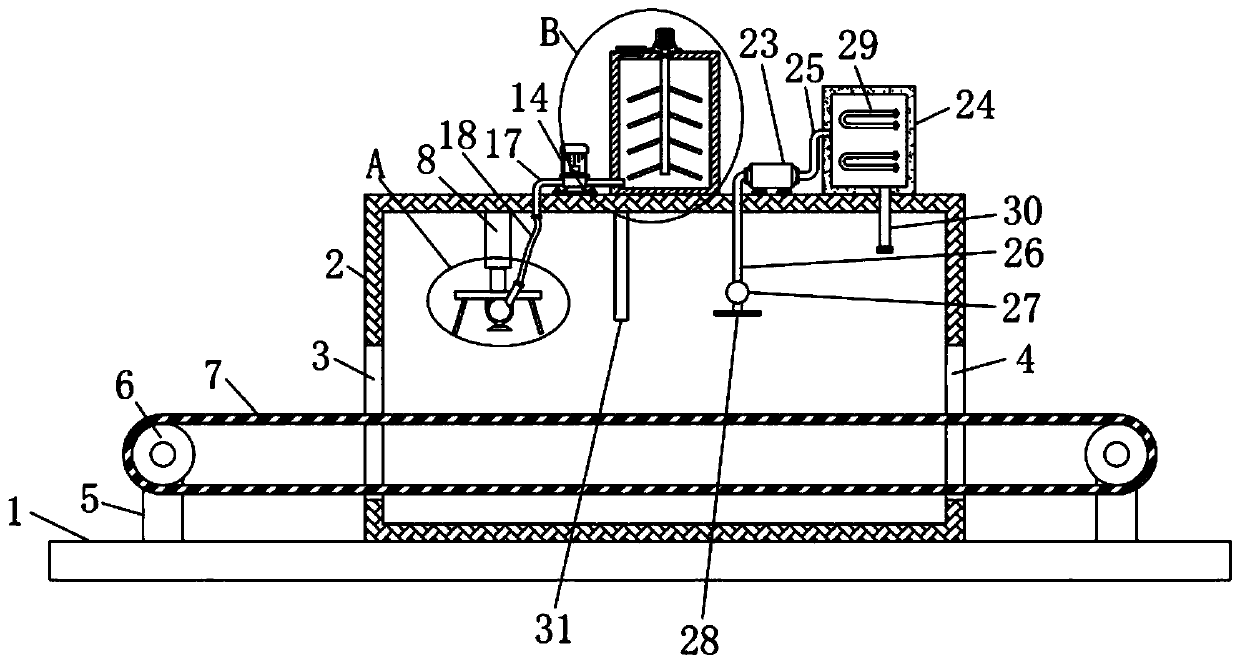

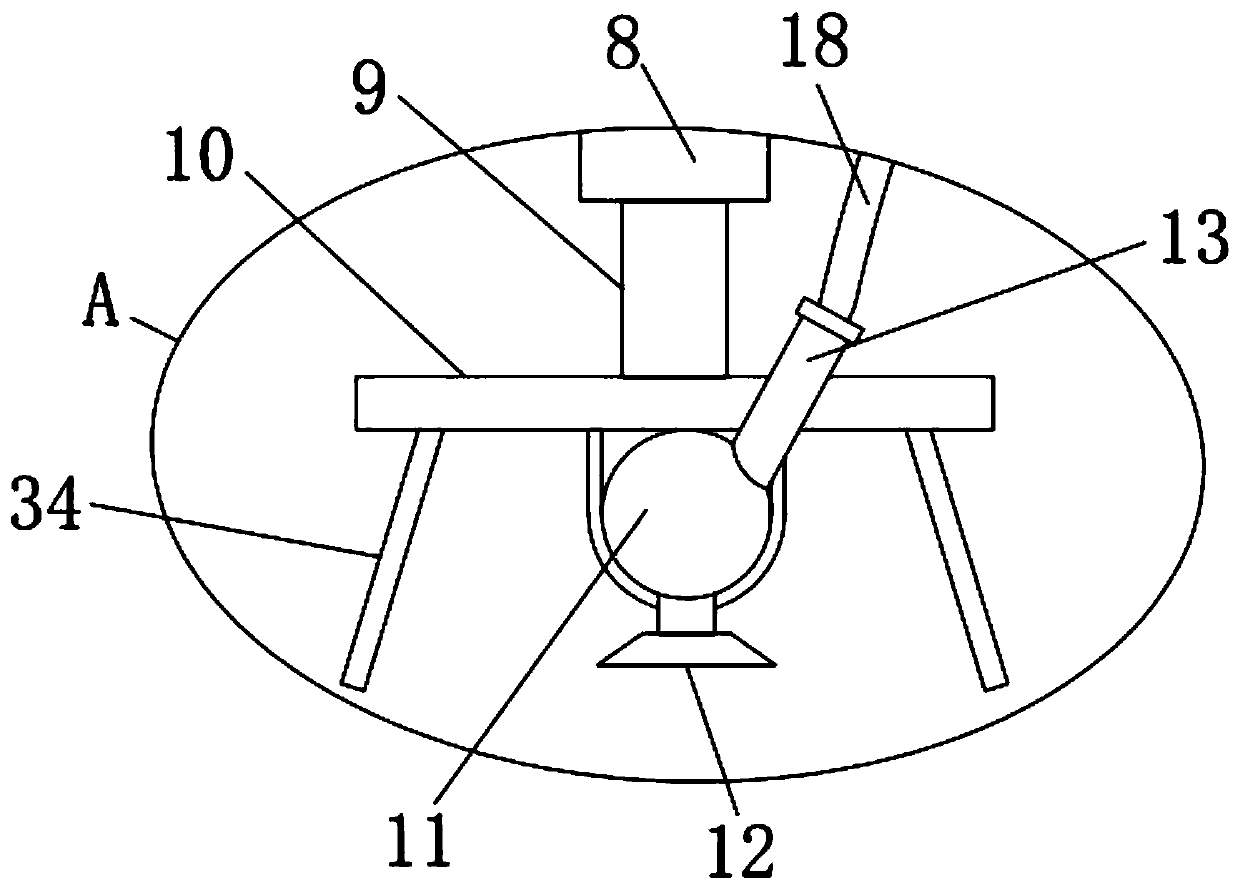

Automobile part paint spraying device capable of uniformly spraying

InactiveCN111495661AAvoid settling and stratificationSpeed up the solidificationPretreated surfacesCoatingsAutomotive engineeringManufacturing engineering

Owner:高敏

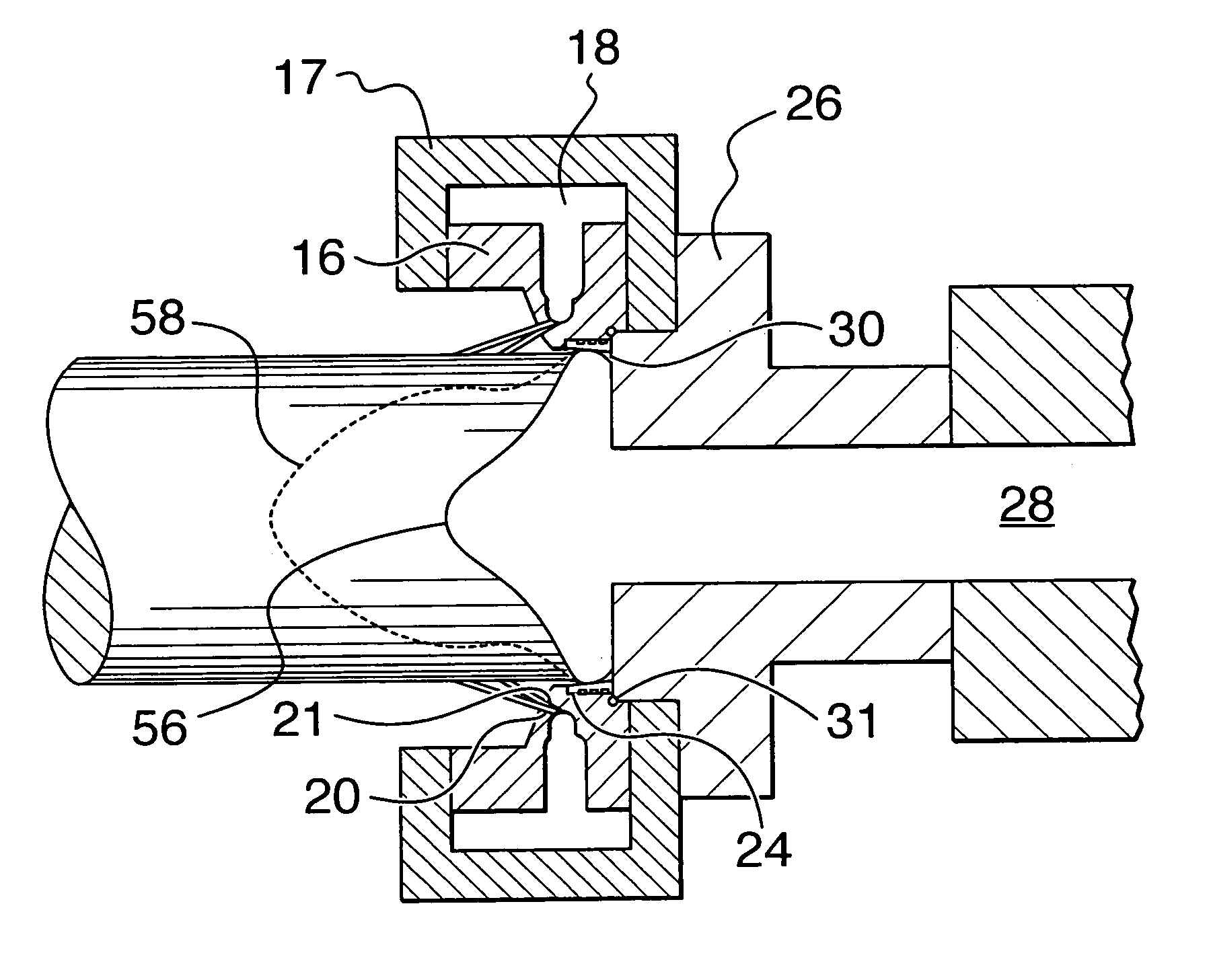

Horizontal continuous casting of metals

A mould for horizontal casting of molten metal comprising a mould body forming an open-ended mould cavity having an inlet end and an outlet end. An annular permeable wall member is mounted in the mould body adjacent the inlet end of the mould cavity with an inner face thereof forming an interior face of the mould. A refractory transition plate is mounted at the inlet end of the mould cavity, this transition plate providing a mould inlet opening having a cross-section less than that of the mould cavity. This provides an annular shoulder at the inlet end of the cavity. Means are provided for feeding molten aluminum through the inlet opening. Separate conduits are also provided for feeding a gas into the shoulder and via the permeable wall means for providing a layer of gas between the metal and the inner face of the mould. A gas that is more reactive with molten aluminum is fed into the shoulder and a less reactive gas is fed via the permeable wall. The reactions with the molten aluminum create a skin or shell on the aluminum which provides smooth passage through the mould and allows for more rapid secondary cooling of the emerging ingot.

Owner:NOVELIS INC

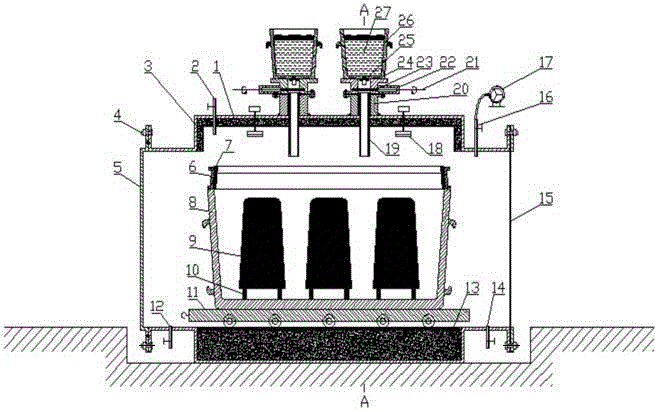

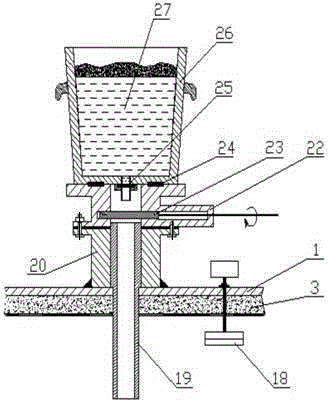

Multi-core reducing multi-ladle co-casting method and device for casting large composite steel ingots

The invention discloses a multi-core reducing multi-ladle co-casting method and device for composite casting large composite steel ingots. The multi-core reducing multi-ladle co-casting method comprises the steps of selecting core blanks, regulating the temperatures of the core blanks, re-removing scales on the surfaces of the core blanks, assembling the core blanks and ingot molds, reducing oxide scales on the surfaces of the core blanks, casting and compositing and cooling composite ingots. The device adopted by the method comprises a tank body, a reducing gas inlet, a heat preservation layer, bolts, a bin door, risers, heat insulation plates, the steel ingot molds, the core blanks, shims, a trolley, an inert gas inlet, a bottom heat insulation layer, an exhaust port, an explosion-proof end cap, a vacuum exhaust valve, a vacuum pump, circulating fans, riser bricks, casting channels, sealing valve rods, sealing valve bodies, sealing valve plates, sealing asbestos, sliding nozzles and steel ladles. Large and ultra-large molded steel ingots which cannot be produced by means of an orthodox casting method can be manufactured. The steel ingots manufactured by means of the multi-core reducing multi-ladle co-casting method and device has the advantages of being low in production cost, high in solidification speed, small in internal segregation, even in components and high in finished product rate.

Owner:佛山市金禾精密模具有限公司

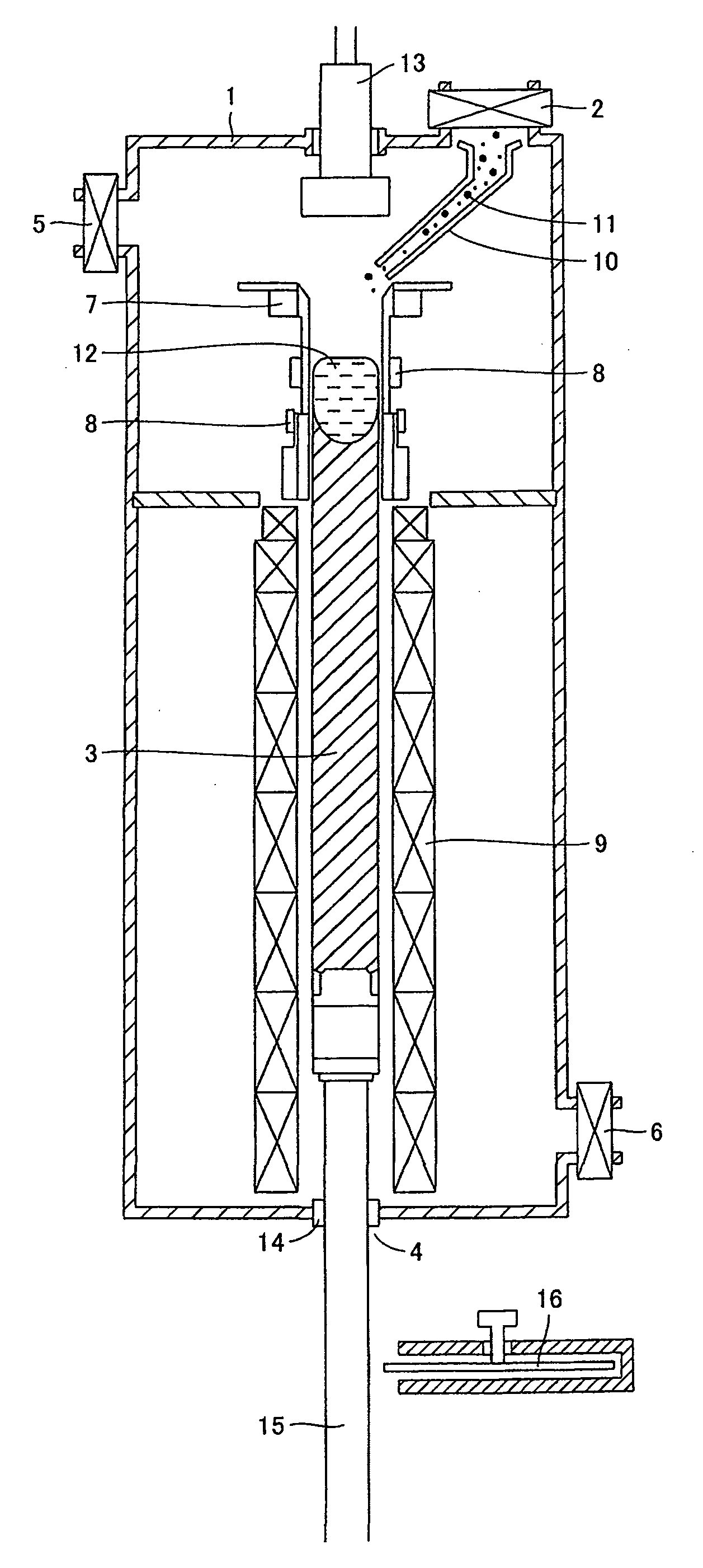

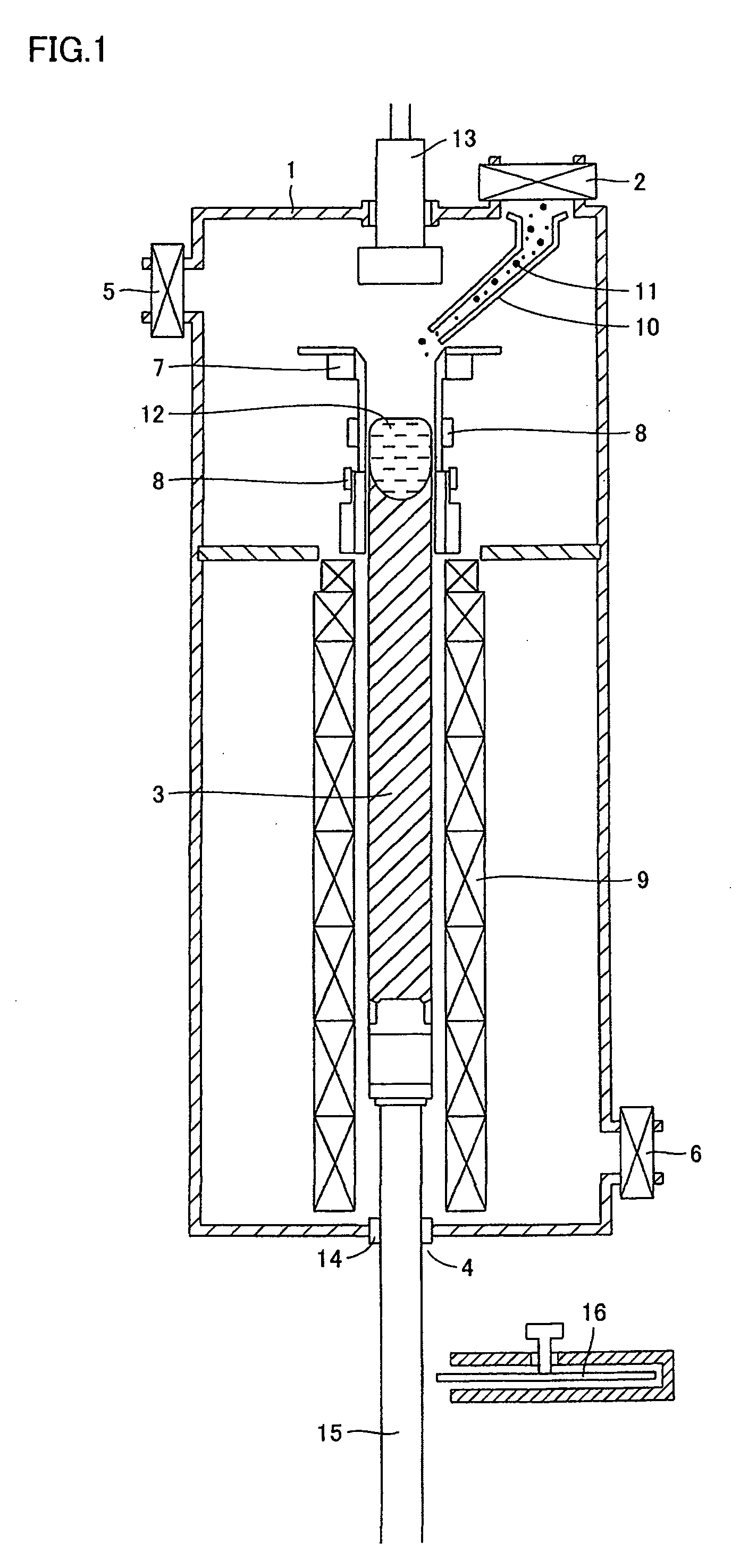

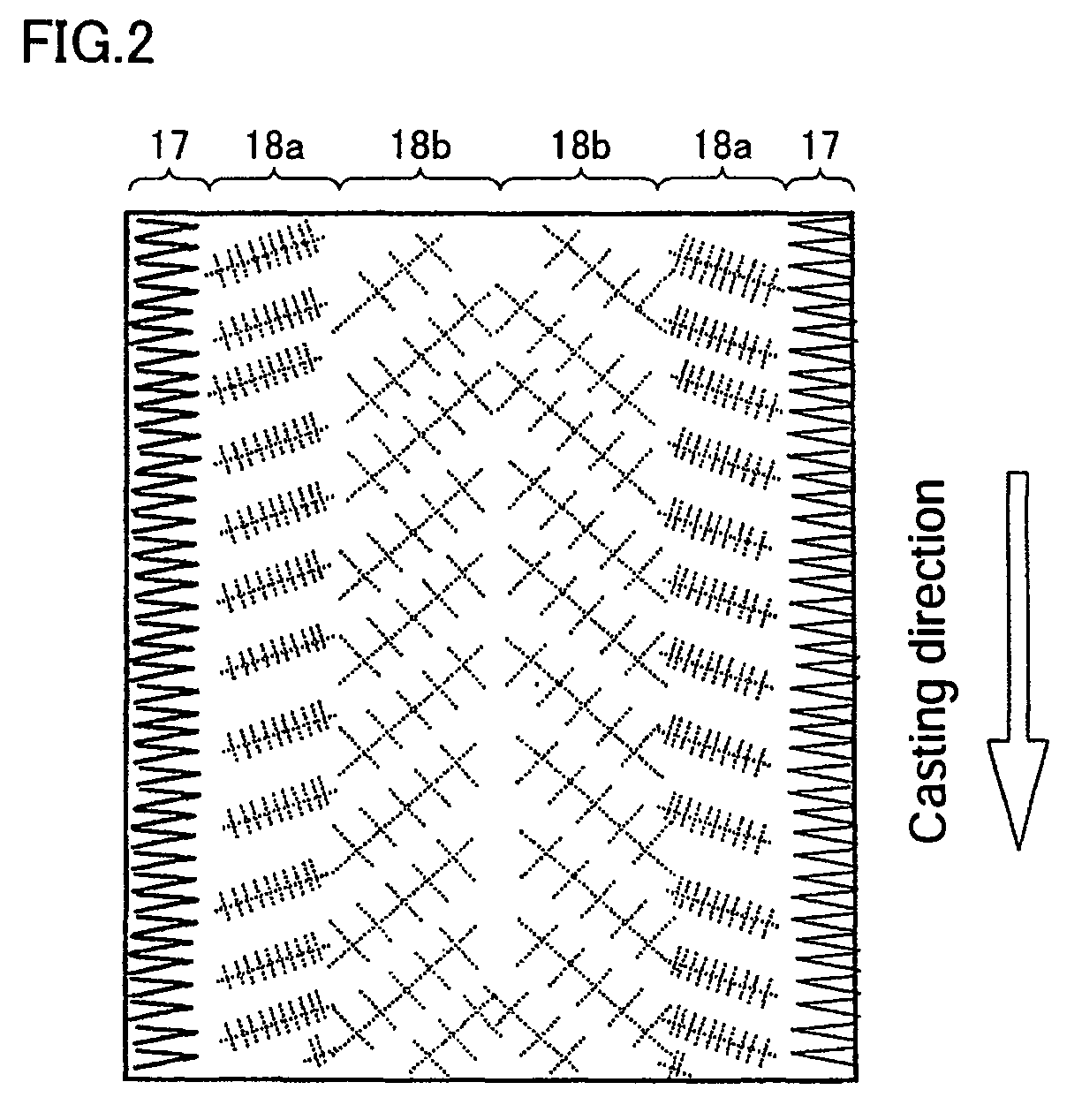

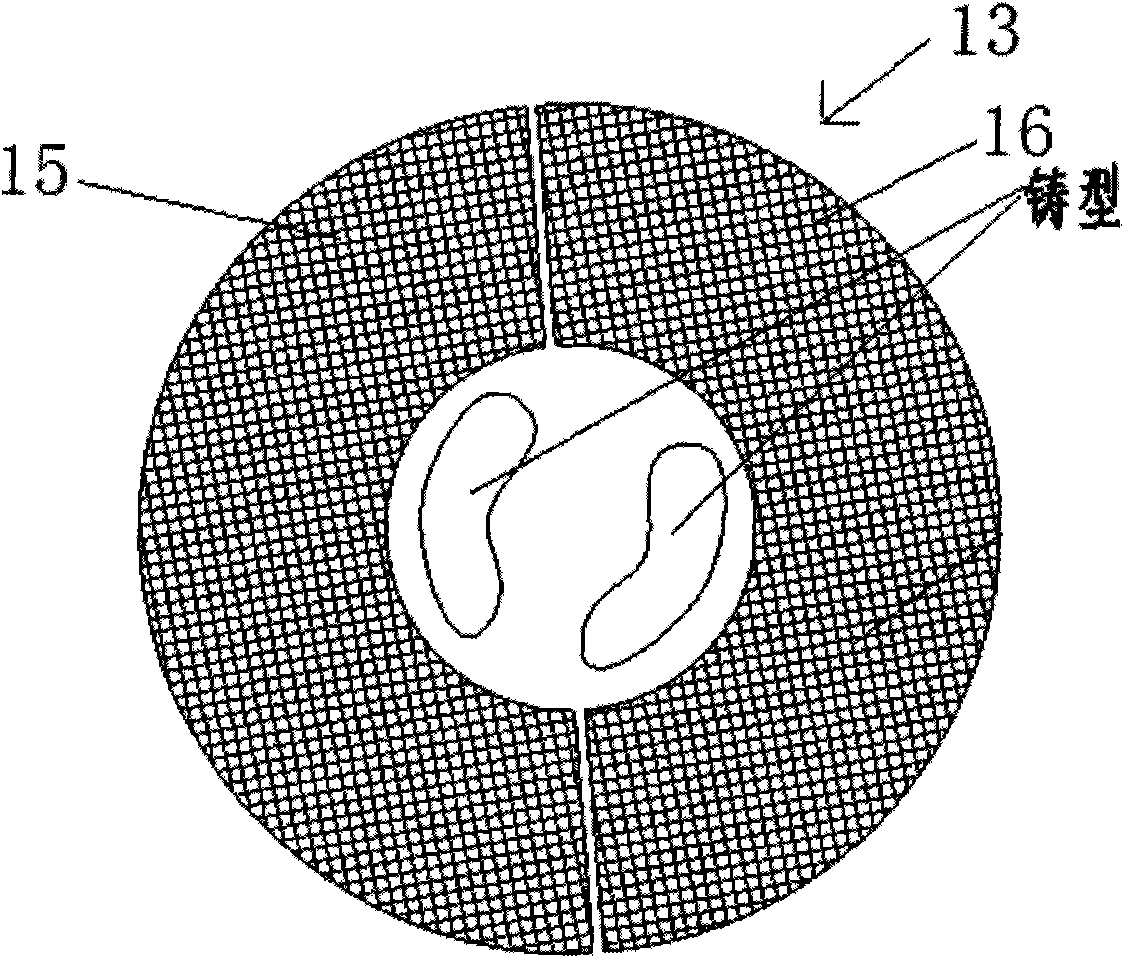

Casting method for polycrystalline silicon

InactiveUS20080210156A1Improve conversion efficiencyMaintain good propertiesPolycrystalline material growthFrom melt solutionsIngotSolar cell

In a casting method for polycrystalline silicon in which a bottomless cooling crucible with a part of a certain length in an axial direction being circumferentially and plurally sectioned is provided inside an induction coil, producing a silicon melt within the cooling crucible by means of electromagnetically induced heating by the induction coil, and withdrawing the silicon melt in a downward direction while being solidified, an alternating current with a frequency of 25-35 kHz is applied on the induction coil. According to the casting method for polycrystalline silicon of the present invention, in addition to preventing rapid cooling of the ingot surface at the time of solidifying the molten silicon and producing the ingot, the stirring of the molten silicon inside the crucible is suppressed to thereby promote the growth of large diameter crystals, with the result that the conversion efficiency of the cast polycrystalline silicon used as solar cells is increased.

Owner:SUMCO CORP

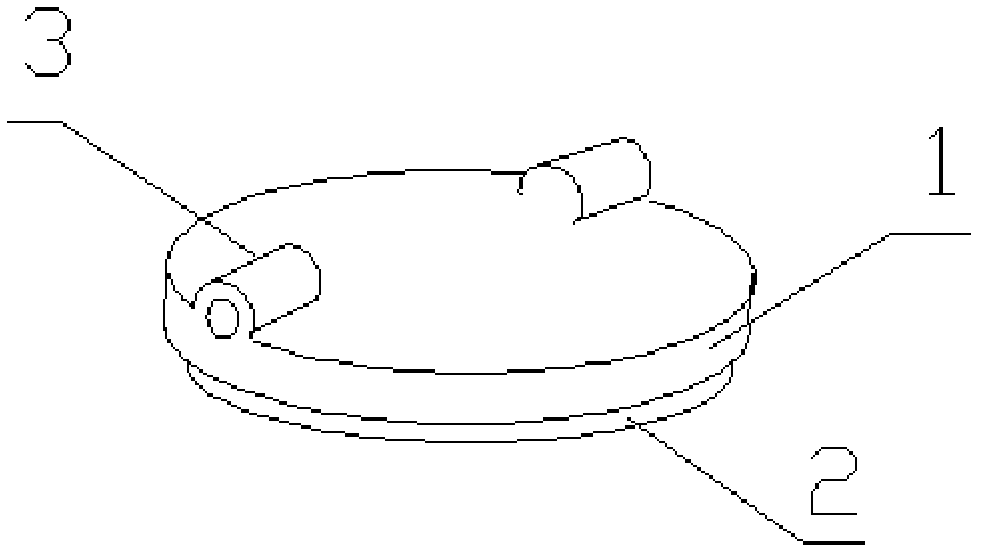

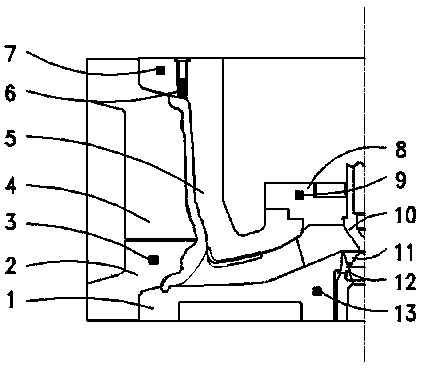

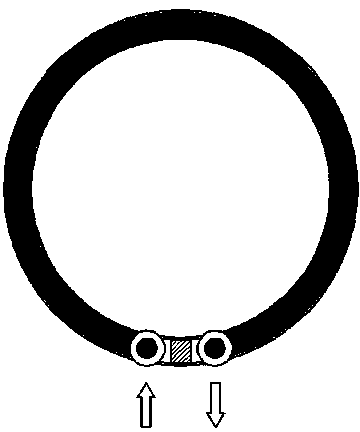

Thermal-insulation baffle plate for liquid metal cooling and oriented solidification casting equipment

The invention discloses a thermal-insulation baffle plate for liquid metal cooling and oriented solidification casting equipment, which is characterized by being an annular thermal-insulation baffle plate formed by jointing two semi-annular baffle plates and moving left and right in a small plane. The semi-annular baffle plates are made of zirconium oxide or formed by pressing graphite sheets and aluminum silicate fibrofelt between the graphite sheets and is 10 to 50 millimeters thick. When used, the thermal-insulation baffle plate forms a closed space together with a fixed thermal-insulation baffle plate, a floating thermal-insulation baffle plate and a heating and heat-preservation furnace. The thermal-insulation baffle plate provides a good generation condition for the generation of oriented column crystal and monocrystal structure castings, and improves the temperature gradient and solidification speed on the front edge of a solid-liquid interface.

Owner:SHENYANG RES INST OF FOUNDRY

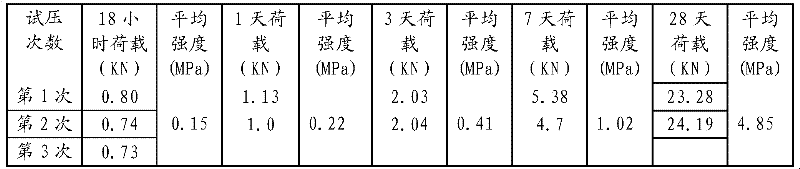

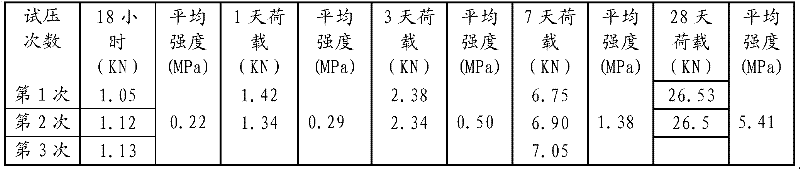

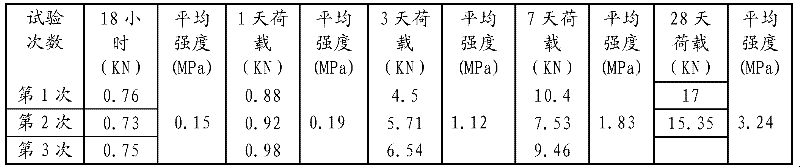

Foam concrete capable of pumping and chemically foaming and production method of foam concrete

The invention discloses foam concrete capable of pumping and chemically foaming and an on-site construction production method. The foam concrete comprises the following materials in parts by weight: 75-500 parts of concrete, 20-120 parts of an active mixing material, 40-300 parts of water, 15-50 parts of an adjusting agent, 30-90 parts of a foaming agent and 2-10 parts of a micro foam agent. The volume weight of the prepared foam concrete is 100-600kg / M<3>; the heat conductivity coefficient of the foam concrete is as low as 0.020W / M.DEG C; the strength of the foam concrete can reach 5Mpa. By virtue of the production method, the advantages of cast-in-situ physical foaming and chemical foaming make an organic combination to form a novel construction method; the production method is relatively high in production efficiency, flexible to operate and relatively wide in application; the foam concrete can be made into high-strength product materials with different shapes; the heat-insulating construction of buildings can be effectively completed with high efficiency and low cost.

Owner:河南华泰新材科技股份有限公司

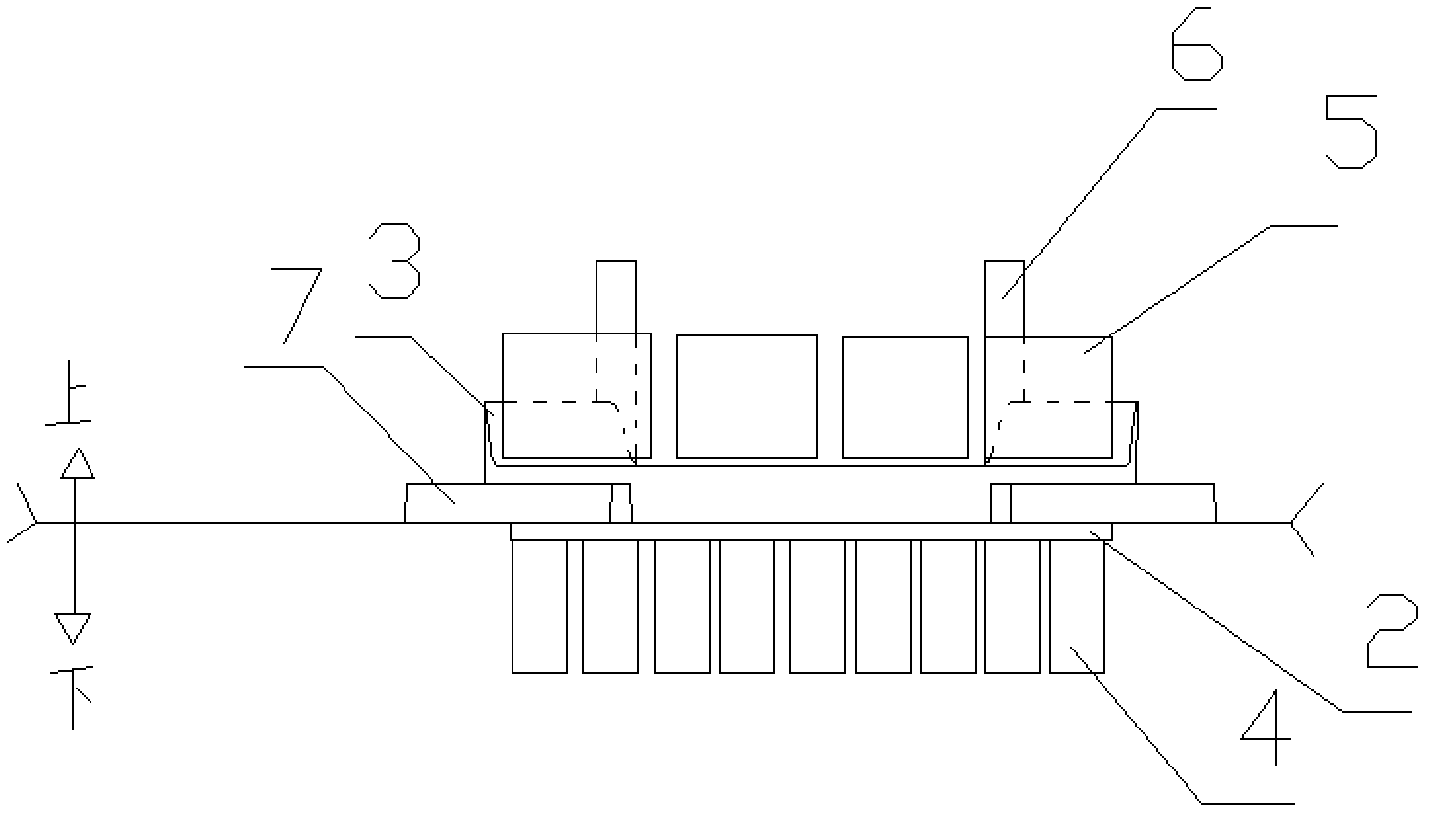

Aluminum wheel water cooling low-pressure casting die and technology

InactiveCN104353813AIncrease the speed of solidificationImprove mechanical propertiesPressure castingMold filling

The invention discloses an aluminum wheel low-pressure casting water cooling die. A center die insert 8 is provided with a water cooling channel 9 for cooling the wheel center; a water cooling channel 7 for cooling the inner rim is arranged at the upper part of a head die 5; a lower edge die 2 is provided with a water cooling passage 3 for cooling a wheel hot spot. The casting technology mainly includes a slow-to-quick mold filling technology and a water-to-air cooling technology. According to the invention, the performance quality of the aluminum alloy wheel casting is improved, and the performance quality of the casting is greatly improved in stability and consistency due to the adoption of the slow-to-quick mold filling technology and the water-to-air cooling technology; the high water cooling intensity increases the freezing rate of the casting, thereby increasing the casting production efficiency; cooling water flows in the water cooling channels relatively sealed, so that noise pollution caused by compressed air in the air cooling technology is eliminated, and the casting working condition is improved.

Owner:CITIC DICASTAL

Cement calcine-free quick coagulator and its production process

The invention discloses a cement baking-free quick-setting agent and the process for preparation, wherein the quick-setting agent is prepared from the raw materials (by weight ratio) of alkaline metal hydroxide 1-10%, soluble carbonates 10-30%, aluminates 15-40%, lemon acid 2-7%, fly ash 20-35% and bone coal 20-35% through steps of mixing raw materials, disintegrating, grinding and sieving.

Owner:张洪伟

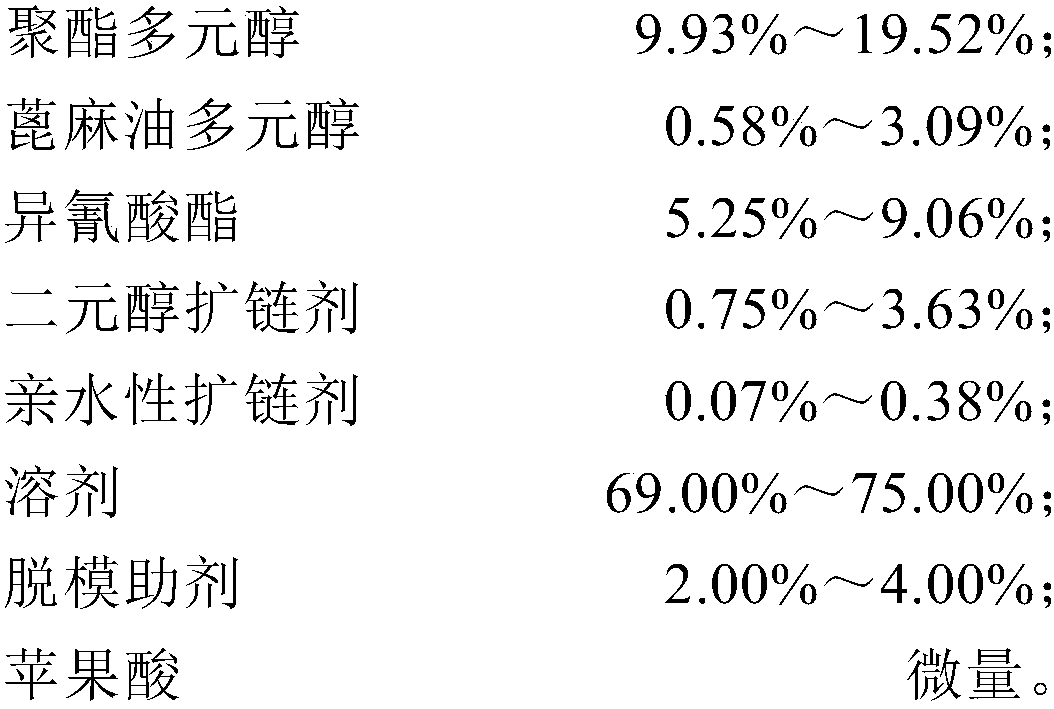

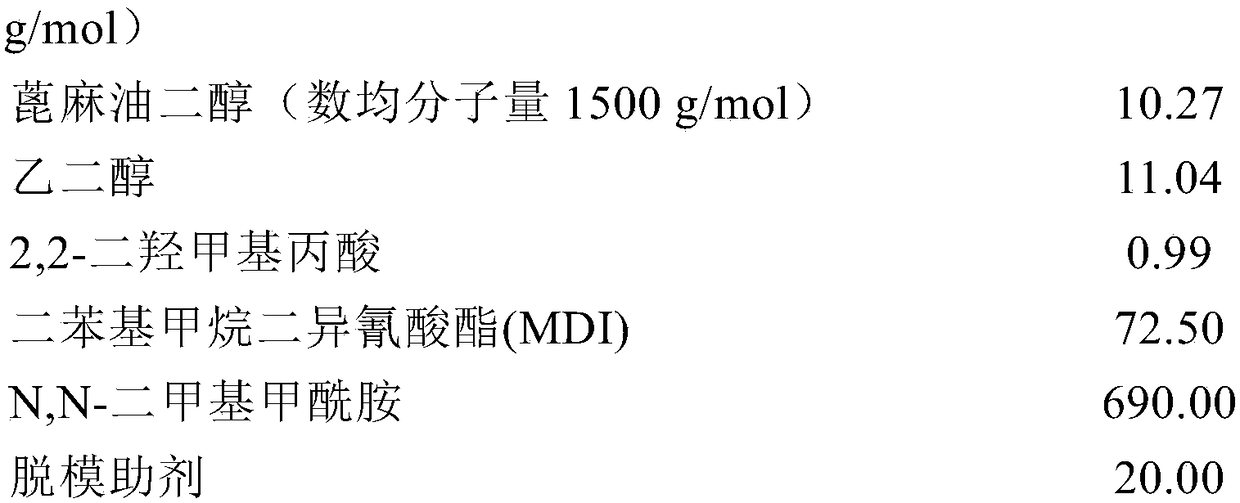

Excellent-demoulding-performance high-wear-resistant wet-method polyurethane resin used for labour protection gloves, and preparation method thereof

The invention discloses an excellent-demoulding-performance high-wear-resistant wet-method polyurethane resin used for labour protection gloves, and a preparation method thereof. The excellent-demoulding-performance high-wear-resistant wet-method polyurethane resin used for labour protection gloves is prepared from a polyester polyol, a castor oil polyol, an isocyanate, a dihydric alcohol chain extender, a hydrophilic chain extender, a solvent, a demoulding auxiliary agent, and malic acid. The Martindale friction times of the excellent-demoulding-performance high-wear-resistant wet-method polyurethane resin is larger than that of PFT-3046L.

Owner:SHANGHAI HUIDE TECH CO LTD

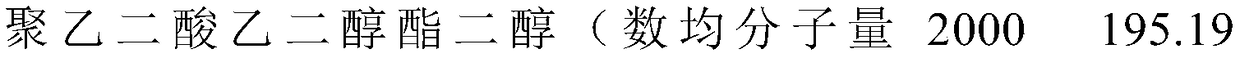

Method for preparing aluminum alloy cast coating

ActiveCN104707934AHigh viscosityGood high temperature crack resistanceFoundry mouldsFoundry coresCrazingBoron nitride

The invention belongs to the field of functional coatings, and in particular relates to a method for preparing an aluminum alloy cast coating. The method specifically comprises the following steps: 1) dispersing attapulgite and silicon oil into an ethanol solvent in a mass ratio of 1:3, backflowing and stirring for 2-4 hours at the water bath temperature of 40-60 DEG C, steaming to dry at the water bath temperature of 90 DEG C, and finally transferring the mixture to a muffle furnace for calcinations, thereby preparing a silanization attapulgite powder material; 2) putting the silanization attapulgite powder material prepared in the step 1), silicon powder, ethylene-vinyl acetate, abietate, carboxymethyl cellulose and ethanol into a wet type ball-milling machine for ball-milling for 2-4 hours, thereby preparing the aluminum alloy cast coating. The method has the advantages that firstly, the coating is relatively good in viscosity, good in high-temperature anti-cracking property and good in high-temperature strength, and secondly, due to the adoption of the nano boron nitride powder, the heat conductivity of the coating is improved, the curing speed of a cast piece is increased, and thus the tendency of pores and micro cracks of an aluminum alloy cast piece is reduced.

Owner:SUZHOU YUXI NEW MATERIAL TECH

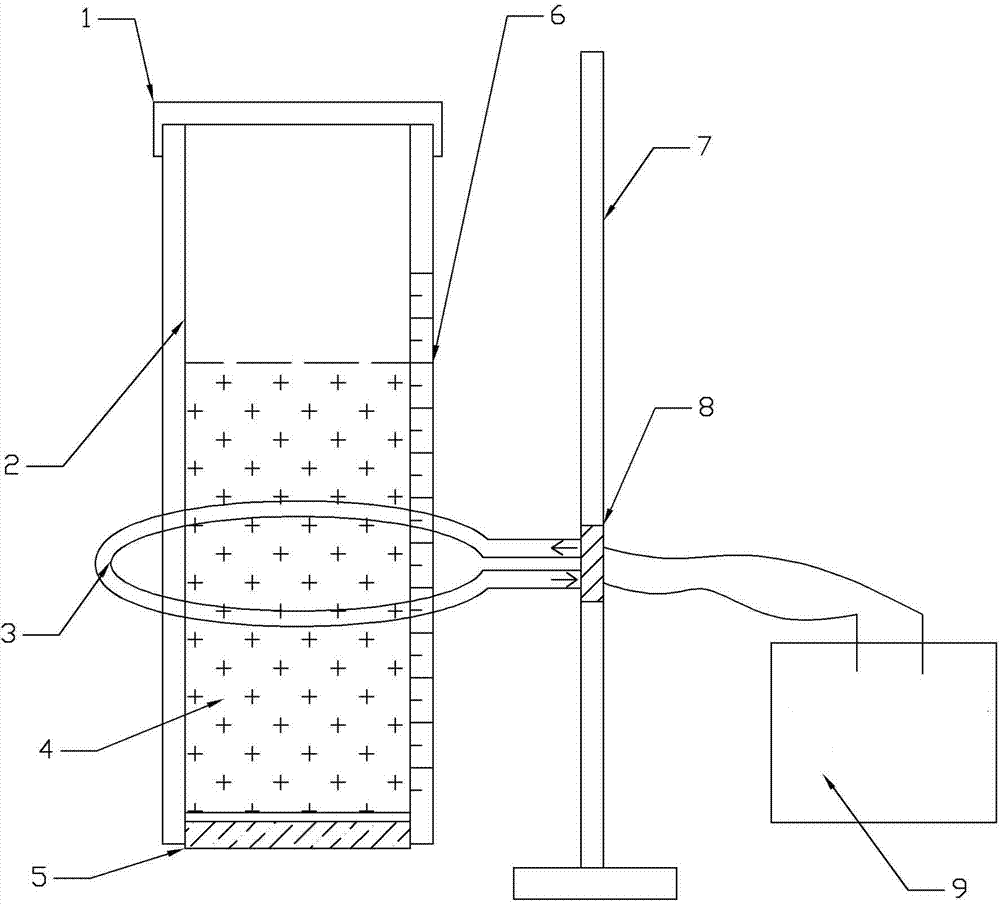

Method and apparatus for preparing high-purity gallium

ActiveCN104711438AEffective migrationStabilize the solid-liquid interface regionLiquid stateLiquid metal

The present invention discloses a method and an apparatus for preparing high-purity gallium. According to the method, liquid-state high-purity gallium is placed on the bottom portion of a container and is cooled as a seed crystal, the liquid-state metal gallium is poured into the cooling container to cool and crystallize, a thermal source coil is opened after complete crystallization, the temperature and the movement speed of the thermal source coil are controlled, the thermal source coil moves from bottom to top, the stable solid-liquid interface during the solidification process is ensured, the solidification interception ratio is 70-90%, and the metal gallium can be purified to achieve more than or equal to 6N. The apparatus comprises the cooling container, a constant temperature cold source, the thermal source coil and a control device, wherein the bottom portion of the cooling container is provided with the constant temperature cold source, the upper portion of the cooling container is provided with a dust preventing cover, the thermal source coil sleeves on the outer side of the cooling container, and the thermal source coil is connected with the control device through a conducting wire so as to make the temperature and the movement speed of the thermal source coil be controlled by the control device. According to the present invention, characteristics of simple apparatus mechanism, easy method operation, convenient specification quantifying, good product stability and the like are provided.

Owner:NORTHEASTERN UNIV

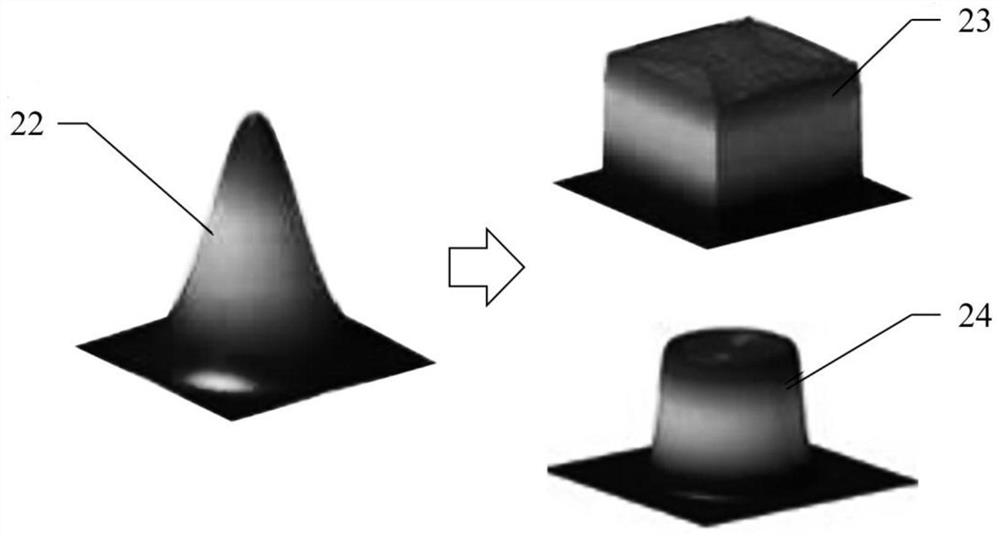

3D printing device and method for oriented crystal or single crystal high-temperature alloy and product

InactiveCN112893874AReduce energy variabilityReduce disruptionTurbinesPolycrystalline material growthSingle crystal superalloySingle crystal

The invention belongs to the related technical field of additive manufacturing, and discloses a 3D printing device and method for an oriented crystal or single crystal high-temperature alloy and a product. The device comprises a forming unit, a shape righting light path unit and a forced temperature difference unit; a DOE diffraction optical element is arranged in the shape righting light path unit, and the shape righting light path unit is used for converting laser spot energy generated by a laser emitting element into uniform distribution from Gaussian distribution; the forced temperature difference unit is arranged in the forming cavity and comprises an infrared heating pipe and a cooling pipeline, heating is conducted above a cooling substrate through the infrared heating pipe, cooling is conducted in the cooling substrate through the cooling pipeline, thus an environment temperature field with the temperature strictly and gradually reduced is formed above the cooling substrate, and then crystals grow in the opposite direction of gradually-reduced temperature when a molten pool is solidified. By means of the device and the method, the temperature gradient in the molten pool can be controlled from top to bottom strictly, mixed crystals such as isometric crystals and the like are reduced or even eliminated, and layer-by-layer stable epitaxial growth of oriented crystals or single crystals along [001] is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Paint for improving inner runner flaky graphite layer of austenitic nodular iron casting and method

ActiveCN105312489AImprove suspension stabilityImprove stabilityFoundry mouldsFoundry coresSodium BentonitePreservative

The invention discloses paint for improving an inner runner flaky graphite layer of an austenitic nodular iron casting. The paint comprises the following components in percentage by weight: 50-60% of zircon powder, 3-5% of sodium bentonite, 2-3% of preservative, 1-2% of defoaming agent, 0.5-2% of sodium alginate, 1-2% of alpha-starch, 1-2% of water glass binder, and 30-40% of water. The invention further provides a method for improving the inner runner flaky graphite layer of the austenitic nodular iron casting; and a sand core is dipped in the paint, and is taken out for drying and pouring. The paint and the method can prevent reducing gas in the volatilizing place in a resin from oxidizing nodular elements in molten iron, guarantee the molten iron to be effectively nodulized, and have a shielding, absorbing or replacing effect on sulfur, so that the sulfur cannot be dispersed to enter the molten iron, flaky graphite is prevented on the surface of the casting, and the surface quality of the austenitic nodular iron casting is greatly improved.

Owner:西峡飞龙特种铸造有限公司

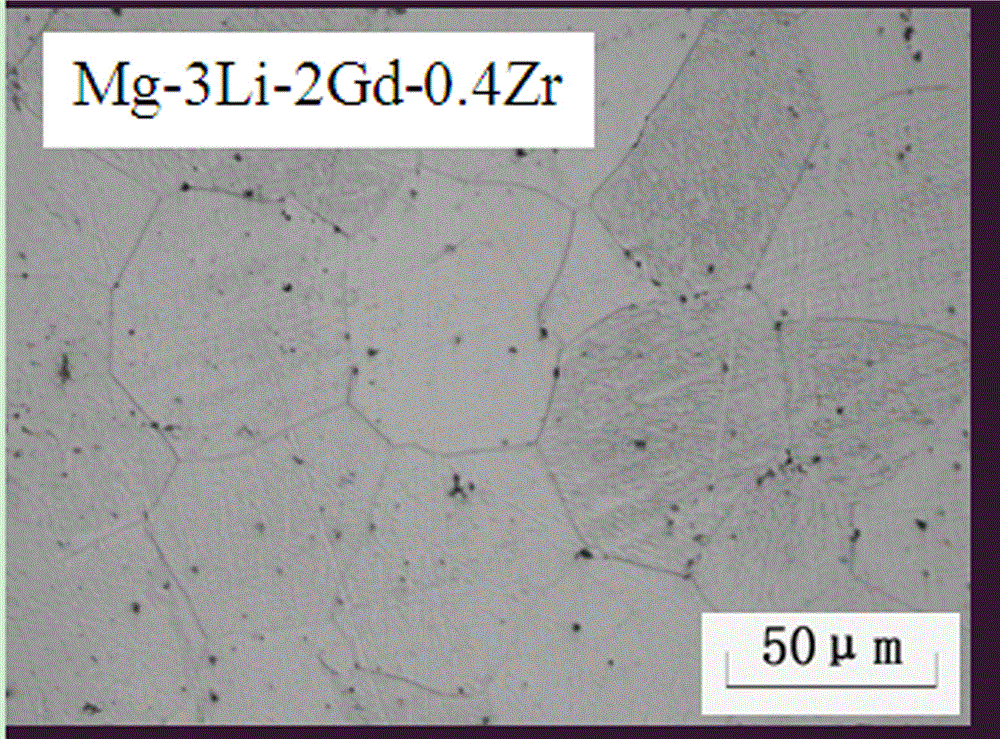

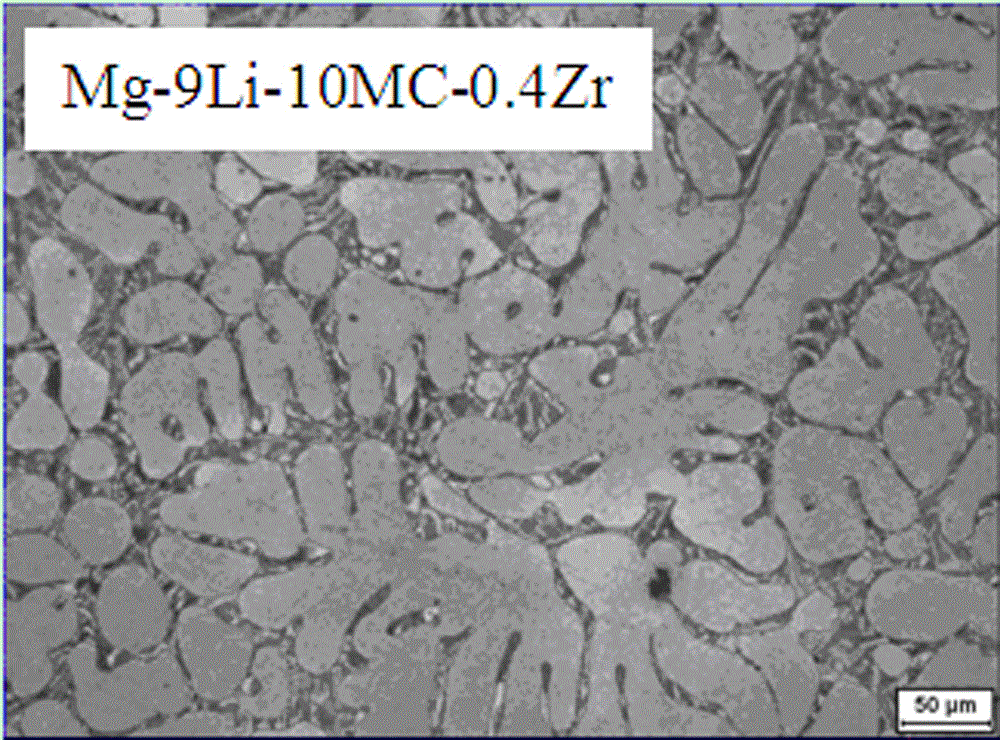

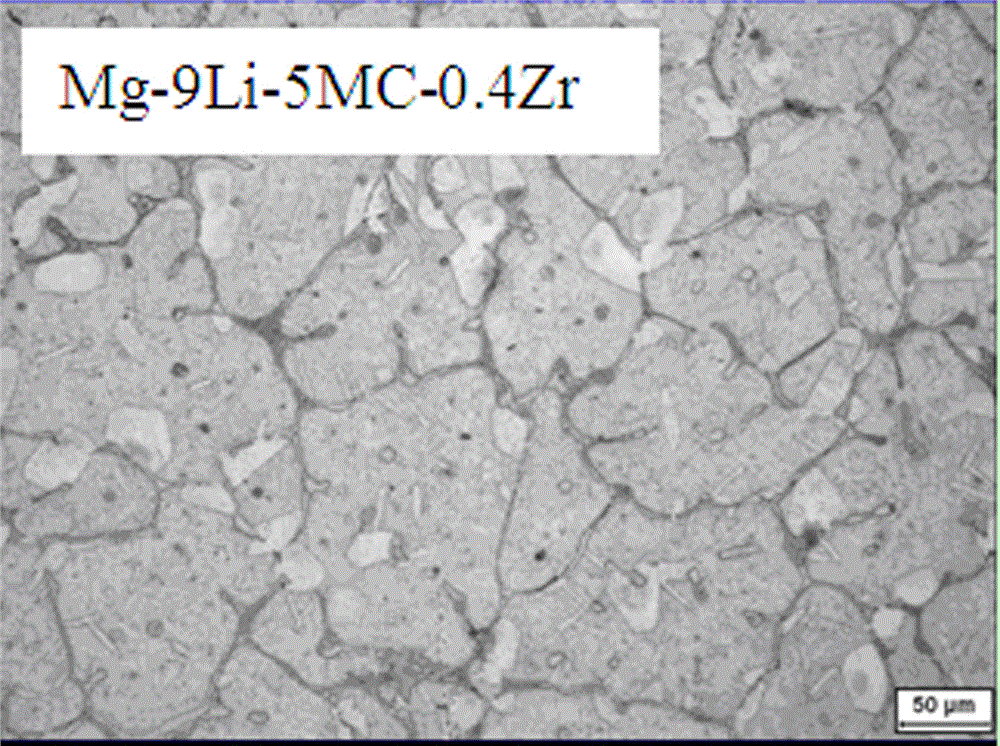

Preparation method for refined magnesium alloy solidification tissue

ActiveCN102071344AIncrease the speed of solidificationShorten the timeCommunications-electronicsMetal

The invention relates to a preparation method for a refined magnesium alloy solidification tissue, which is suitable for preparing thin wall magnesium alloy structural components of high requirements and complicated performance in the industrial fields of automobiles, communication electronics, aerospace and the like. The preparation method comprises the following steps of: adding magnesium alloy raw materials cleaned by using acetone into a crucible resistance furnace; adding a refining agent for refining after smelting under the protection of mixed gas of tetrafluoroethane (CH2F4) and CO2 and maintaining the temperature for 20min; uniformly stirring and mixing; maintaining the temperature for 20min when the melt temperature reaches the smelting temperature again; pouring the smelted magnesium alloy melt into a high-speed rotating metal casting mold in a vertical centrifugal field; stopping the centrifugal rotation after the pouring is completed for 20min; and taking out when a magnesium alloy casting is cooled to the room temperature to prepare the magnesium alloy casting. The preparation method refines the solidification tissue of a magnesium alloy, enhances the performance of the casting and enlarges the application field of the magnesium alloy casting.

Owner:CHINA UNIV OF MINING & TECH

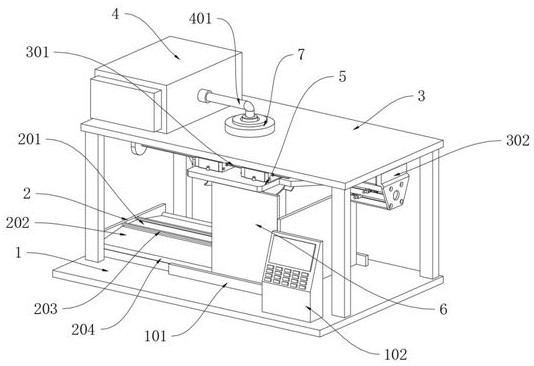

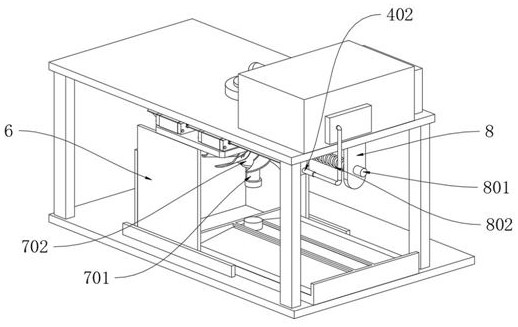

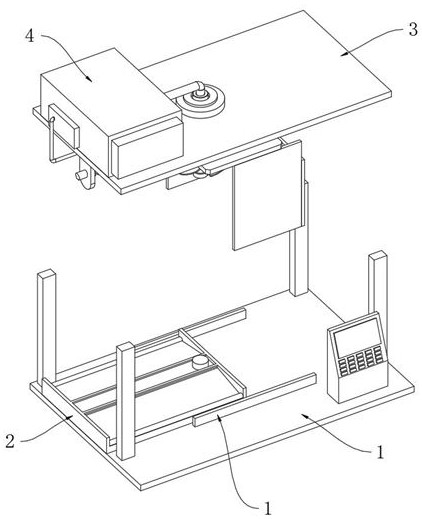

Cloth cutting device

ActiveCN108004758AReduce wasteAvoid constant proliferationTextile selvedgesSevering textilesHydraulic cylinderPulp and paper industry

The invention relates to the field of textile and particularly discloses a cloth cutting device. The cloth cutting device comprises a frame, a hydraulic cylinder, a cutter, a worktable and a glue applying mechanism, wherein the frame is fixedly provided with a guide bar and a spring; the piston rod of the hydraulic cylinder is fixedly provided with a sliding bar; the cutter is fixed onto the sliding bar; the worktable is provided with a sliding groove; a rotating block is hinged to the sliding bar, and the hinge point of the rotating block and the sliding bar is arranged at the bottom of the rotating block; the hydraulic cylinder is provided with an L-shaped separating blade; the glue applying mechanism comprises a glue storage tank and an air cylinder, the glue storage tank is provided with a glue inlet, the air cylinder is provided with a glue inlet check valve, and the glue storage tank is communicated with the glue inlet check valve; the piston of the air cylinder is fixedly provided with a glue outlet check valve, the inside of the air cylinder is provided with a pressure spring, the inside of the rotating block is provided with a cavity, and the side wall of the cavity is provided with a through hole. The cloth cutting device can avoid yarn slippage after cloth is cut.

Owner:NINGBO WENZE TEXTILE CO LTD

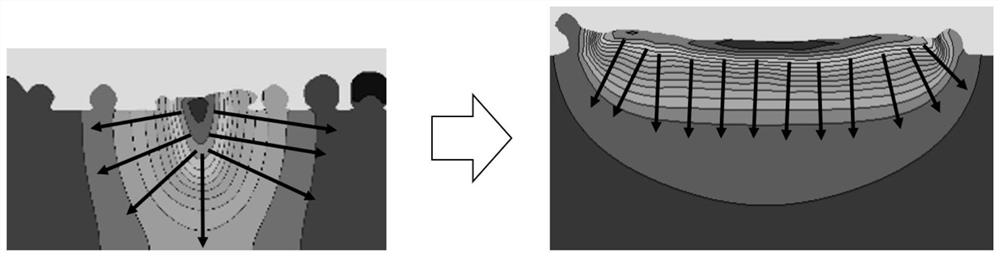

Method and device for manufacturing and forming metal material additives

InactiveCN109261940AAchieve performanceQuality improvementAdditive manufacturing apparatusLiquid stateFront edge

The invention discloses a method for manufacturing and forming metal material additives. The method includes acquiring flowing liquid-state materials from a smelting furnace and leading the flowing liquid-state materials into a middle flow channel; controlling the temperatures and the flow velocities of the liquid-state materials to gradually transform the liquid-state materials in the middle flowchannel into liquid-solid two-phase coexistence fluid; pushing fluid materials into open forming intervals and restraining the fluid materials in the spaces by the aid of surface tension; directionally solidifying the fluid, which is in contact with a substrate / crystallizer, towards inflow directions, simultaneously allowing the substrate / crystallizer to move at certain speeds in certain movementtracks in parallel to discharge outlets, bringing out solidification structures, inhibiting growth of metal dendrites at the front edges of crystals by the aid of frictional force between the solidification structures and melt, repeatedly carrying out the procedures, and gradually forming tangential single-layer structures in specific directions for integral metal wall plates until material components provided with excellent structures with specified thicknesses in specified shapes. A device for manufacturing and forming the metal material additives comprises the smelting furnace, the middleflow channel, the substrate / crystallizer and a protective atmosphere device.

Owner:PINGDINGSHAN UNIVERSITY

Steel moulding sand and manufacturing technology thereof

InactiveCN103567353AImprove thermal conductivityLow costFoundry mouldsFoundry coresMolten stateManufacturing technology

The invention discloses a steel moulding sand and a manufacturing technology thereof. The steel moulding sand is composed of steel beads, phenolic resin, a curing agent, and a lubricant, wherein the phenolic resin, the curing agent and the lubricant are coated on the surfaces of the steel beads. The manufacturing technology of the steel moulding sand comprises the following operation steps: (1) slowly and evenly pouring molten steel liquid onto a roller through a ladle, wherein the lower edge of the roller is soaked in water in a water pool, when the steel liquid falls onto the roller surface with water, numerous micro steel beads are formed and fall into the water pool; (2) fishing out the steel beads, drying the steel beads by baking, and then screening out steel beads with a diameter of 0.20 to 0.85 mm; (3) putting 100 kilograms of steel beads with the same size into a heater, heating the steel beads until the temperature reaches a temperature of 95 to 105 DEG C, at the same time starting a film-coating and sand-mixing machine, orderly adding phenolic resin, a curing agent, and a lubricant into the film-coating and sand-mixing machine, when the temperature of the coated steel beads reaches 70 DEG C or less, discharging the steel beads from the machine. The heat conductive coefficient of the steel moulding sand is high, so the steel moulding sand can accelerate the solidifying speed of iron water to make the iron water around the steel moulding sand solidify firstly, and plays the role as a chilling block. Moreover, the cost of the steel moulding sand is lower, the manufacturing technology of the steel moulding sand is simple, and thus the manufacturing cost is low.

Owner:DALIAN YUANJING FOUNDRY

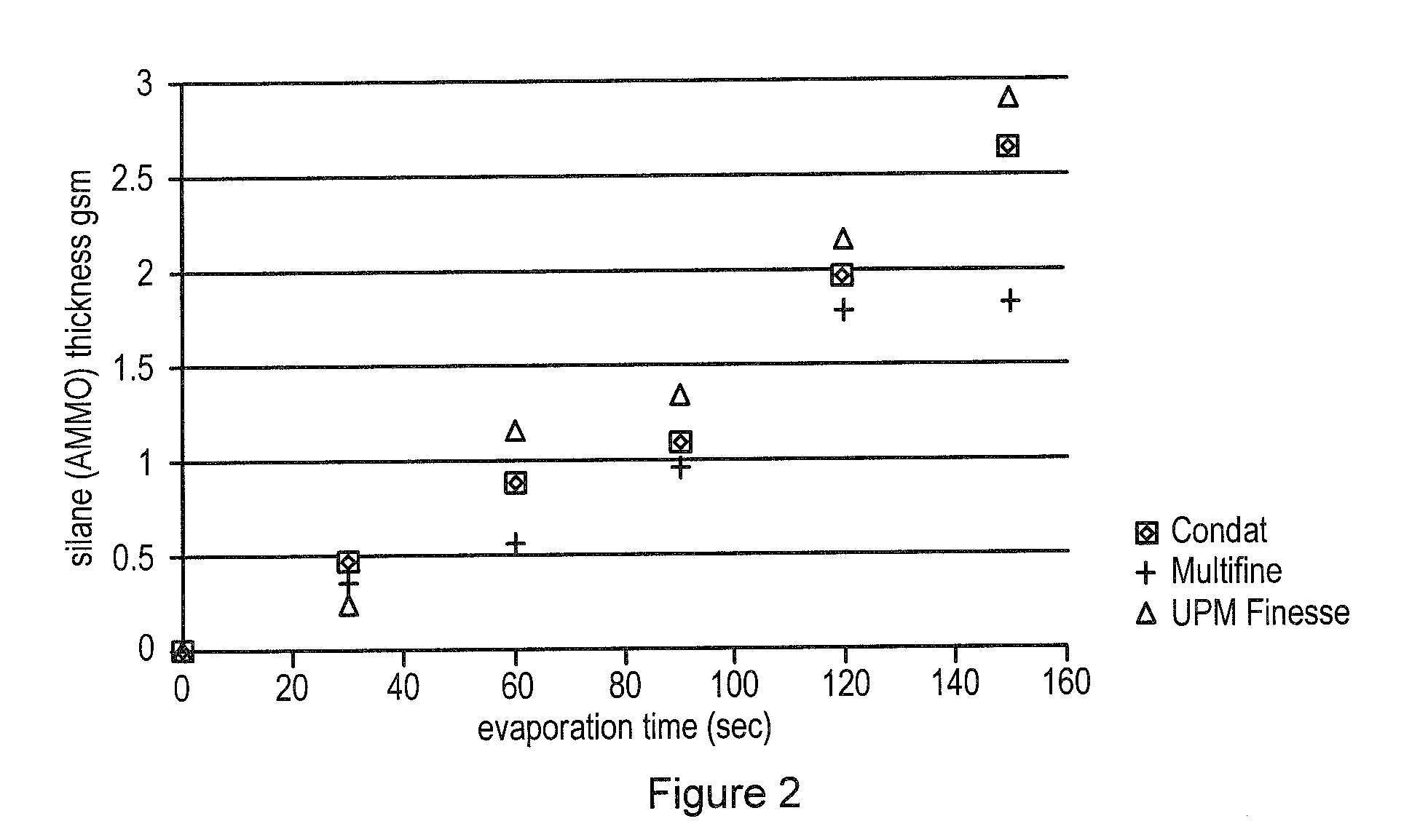

Method for improving the durability of an ink printed on a substrate and substrate formed from such a method

InactiveUS20120231237A1Increased durabilityReduce the smellLayered productsVacuum evaporation coatingNitrogenCoating

Owner:HEWLETT PACKARD INDIGO BV

Automatic paint spraying device for hardware processing

ActiveCN111701778AImprove cleanlinessEasy accessPretreated surfacesCleaning using gasesEngineeringDust particles

The invention provides an automatic paint spraying device for hardware processing, relates to the technical field of automatic mechanical processing, so as to solve the problems that because a workpiece has small volume and high requirement for smoothness of the paint surface, during paint spraying, once dust particles carried in the air fall on the hardware workpiece, convex particles are prone to producing, the quality of a paint film is affected, moreover, the splashed paint liquid is prone to flying to surrounding operators, and the operators are adversely affected. The automatic paint spraying device comprises a base; and a paint spraying table is horizontally and fixedly installed at the part, close to the left, of the middle of the top plane of the base. According to the automatic paint spraying device, since horizontal clamping plates are correspondingly and fixedly installed at the front end edge and the rear end edge of the paint spraying table on the top plane of the base, arack is fixedly installed on a sliding table seat at the rear side of a travel hole, a protective cover can be driven to move through the movement of the sliding table seat, thus during paint spraying, the protective cover can cover the workpiece, when paint spraying is finished, the protective cover can move to the right end with the sliding table seat, and the workpiece is conveniently taken.

Owner:浙江华鑫拉链有限公司

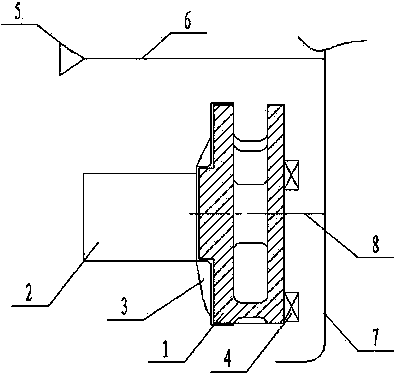

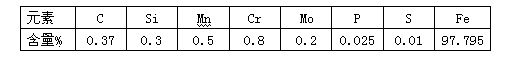

Casting process of two-stage planet carrier of climbing machine for ocean platform

ActiveCN104174820AGood liquidityGood strength and ductilityFoundry mouldsFurnace typesPass ratePlanet

The invention discloses a casting process of a two-stage planet carrier of a climbing machine for an ocean platform. A two-stage planet carrier casting of the climbing machine for the ocean platform is made from a ZG35Gr1Mo material by adopting a whole cast molding process in a heat treatment manner. The casting process comprises the following processing steps: (a) smelting molten steel; (b) casting; (c) carrying put normalizing and tempering pretreatment; and (d) carrying out quenched-tempered heat treatment. In the manner, according to the casting process, the passing rate of two-stage planet carrier casting finished products of the climbing machine for the ocean platform can be greatly increased, and the castings are high in surface accuracy, can meet the requirements of mechanical property, and can achieve the ABS acceptance standard.

Owner:常熟市虹桥铸钢有限公司

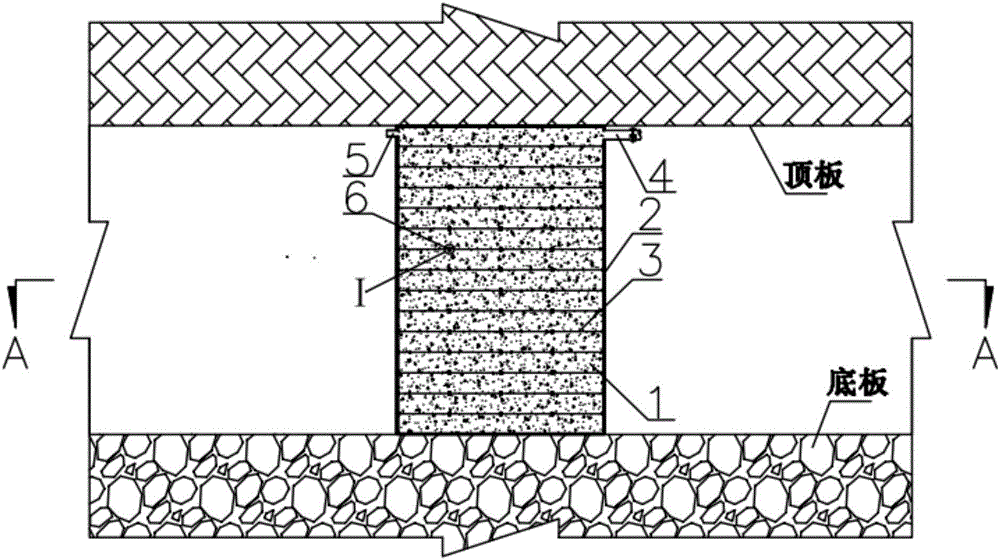

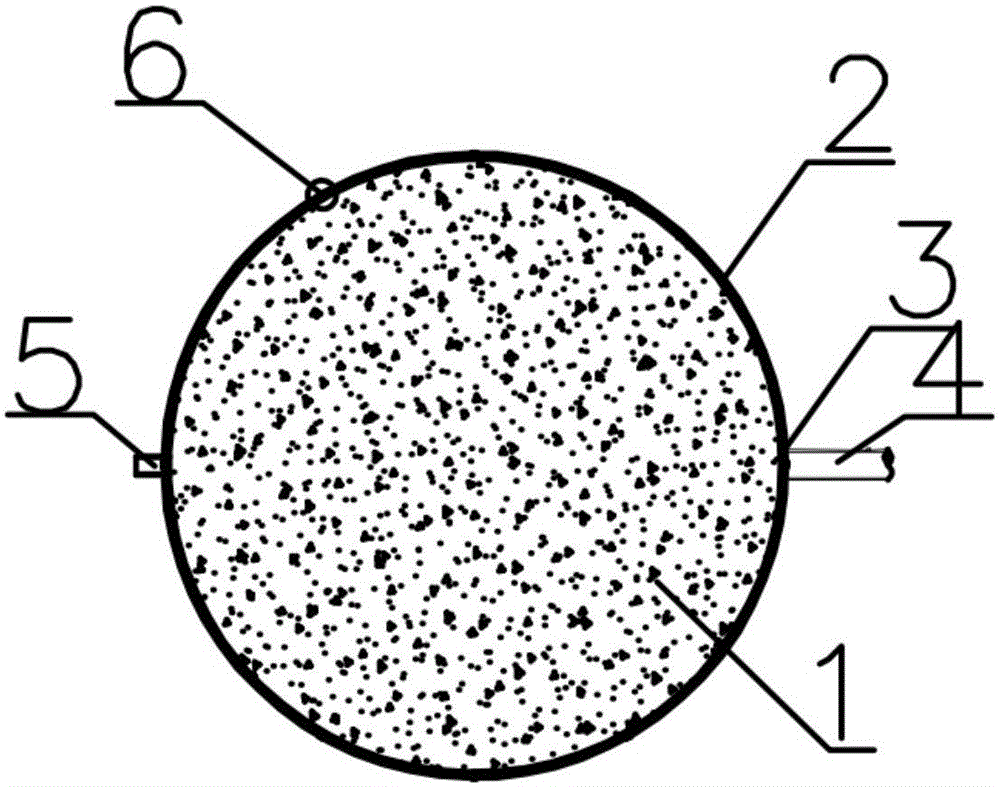

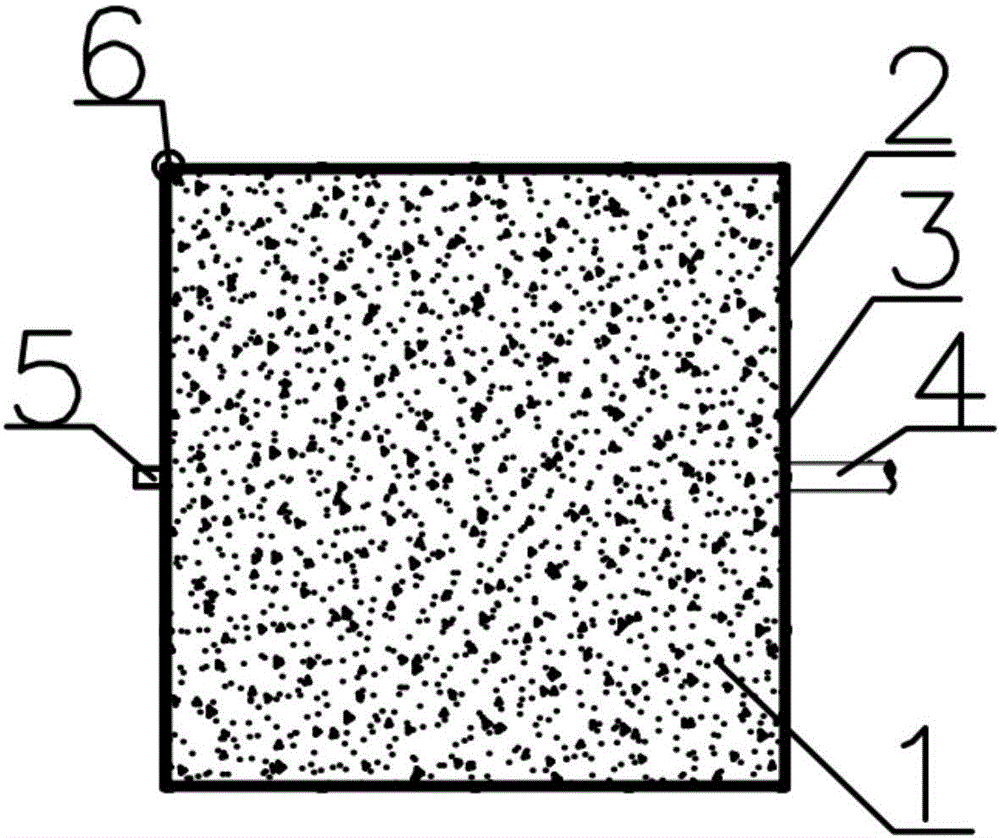

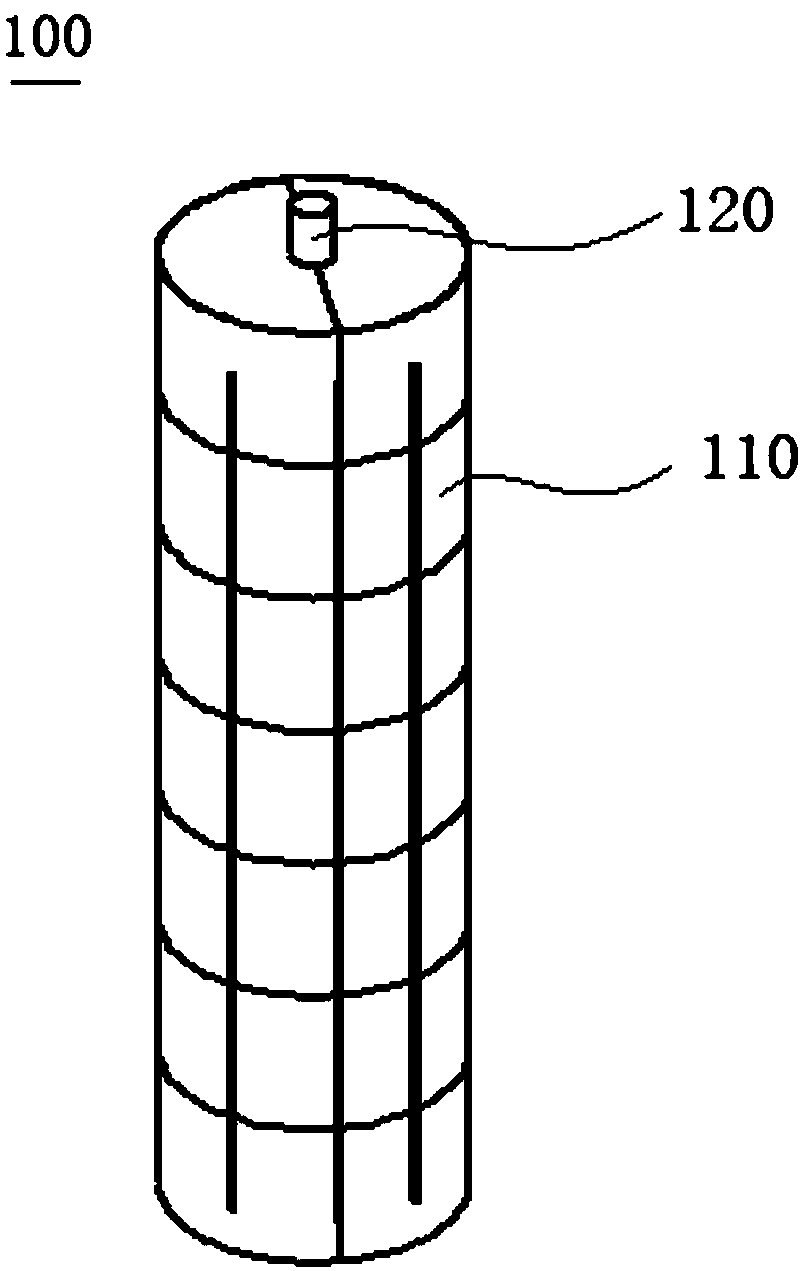

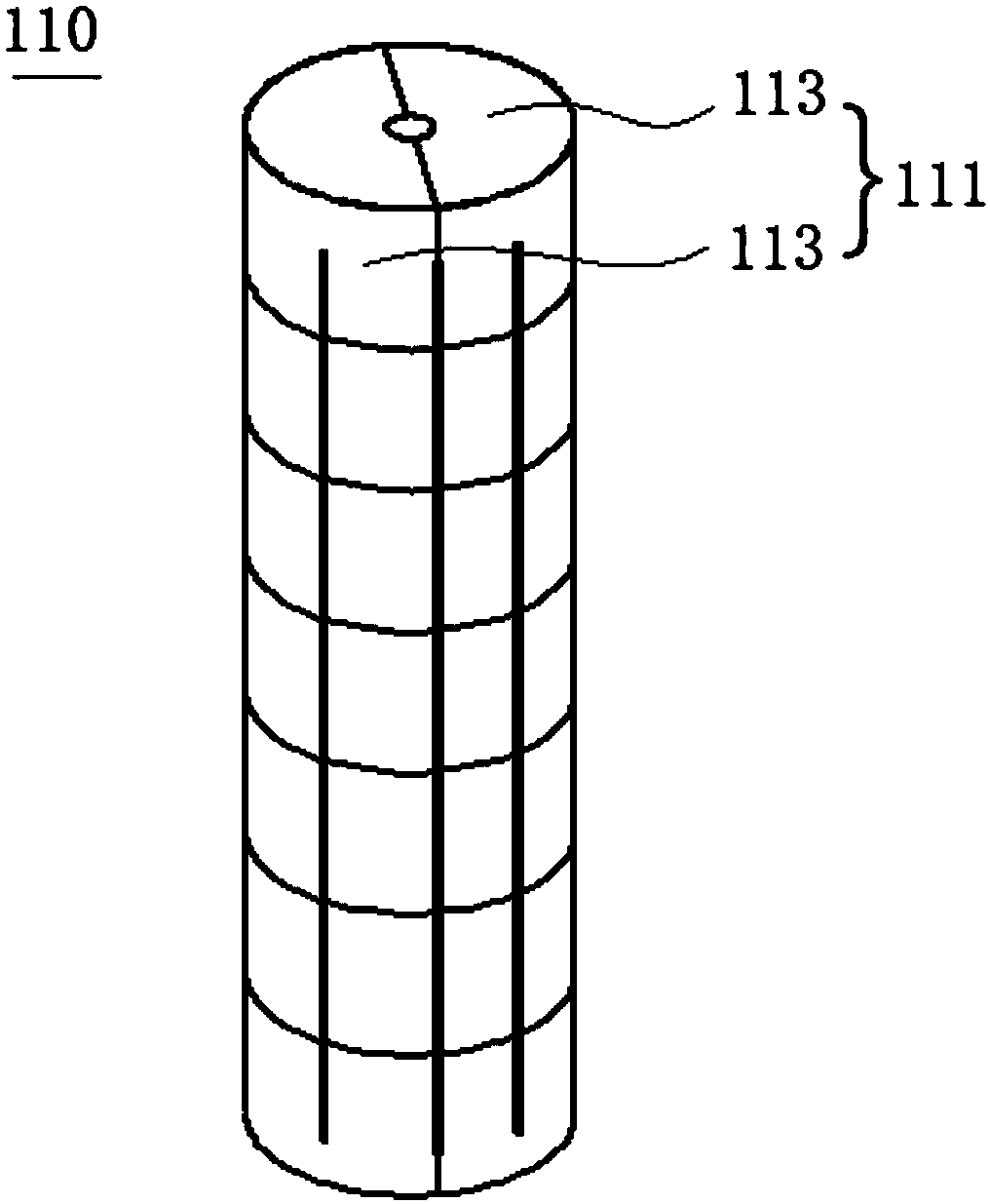

Civil engineering mold bag and method for quickly constructing artificial pillar

ActiveCN107524470ASmall vertical forceImprove the ability to bear the force in the horizontal directionMaterial fill-upEngineeringBuilding construction

The invention relates to a civil engineering mold bag which comprises a mold bag body (2). At least one opening is formed in the mold bag body (2), and a feeding pipe (4) is arranged at the other end of the mold bag body (2); and the exterior of the mold bag body (2) is sleeved with supporting rings (3) matched with the mold bag body (2) every 50-250 mm, and the supporting rings (3) are fixed to the corresponding positions of the mold bag body (2) through at least one bag loop (6). According to the civil engineering mold bag, the civil engineering mold bag sleeved with the reinforcing supporting rings is used as a soft mold to construct a down hole artificial pillar, a pillar body is formed by grouting at a time, construction is easy and convenient, and the speed is high; the constructed artificial pillar is high in integrality and good in stability; and according to a method for quickly constructing the artificial pillar, the down hole mold erecting working procedure is simplified, the constructing efficiency is improved, transporting is convenient, construction is easy and rapid, and the method is particularly suitable for construction of projects such as mine pillar body underground mining.

Owner:CINF ENG CO LTD

Consumable electrode and preparation method thereof and application thereof in melting and molding of titanium alloy ingot casting

ActiveCN107746982AResolve elemental segregationIncrease heat radiation speedCondensation processMelting tank

The invention provides a consumable electrode, a preparation method thereof and an application thereof in the melting and molding of a titanium alloy ingot casting. The consumable electrode comprisesa consumable electrode main body and an inverse segregation core rod, wherein a through hole is formed in the consumable electrode main body along an axial direction; the inverse segregation core rodis inserted in the through hole; the types of elements in the inverse segregation core rod are the same as the types of elements in the consumable electrode main body; and when the consumable electrode main body contains positive segregation elements and / or negative segregation elements, the content by weight of the same type of positive segregation elements in the inverse segregation core rod islower than the content by weight of the same type of positive segregation elements in the consumable electrode main body, and the content by weight of the same type of negative segregation elements inthe inverse segregation core rod is higher than the content by weight of the same type of negative segregation elements in the consumable electrode main body. The consumable electrode corresponds with the segregation rule of the segregation elements in a solidification process, and creatively solves the element segregation problem of the consumable electrode generated in a molten pool condensation process, thereby improving the quality stability of the alloy ingot casting.

Owner:湖南湘投金天钛业科技股份有限公司

Coal ash gangue filling activity-stimulating rubber solid material and preparation method thereof

The invention discloses a coal ash gangue filling activity-stimulating rubber solid material which comprises the following components in parts by weight: 34-60 parts of base material, 15-45 parts of calcium source compound, 7-21 parts of gypsum, 10-42 parts of slag fine powder and 1.5-10 parts of stimulating material, wherein the base material is cement clinker or cement; the calcium source compound is calcined lime and / or calcium magnesium powder; and the stimulating material is chloride and / or sulfate. As Ca(OH)2 is key material for generating hydrated silicate and hydrated aluminum silicate, the coal ash gangue filling activity-stimulating rubber solid material takes the chloride and / or the sulfate as the stimulating material, so that the dissolution of Ca(OH)2 generated by the base material, the calcined lime or the calcium magnesium powder can be promoted, the alkalinity of solution can be improved, the covalent bond of SiO4<4-> in the coal ash can be opened, so that the depolymerization of silica tetrahedron can be promoted, the activity stimulation of the coal ash and the gangue powder can be accelerated, early solidifying and early strengthening when the coarse coal ash and the gangue powder are filled with each other in a mixing way can be realized, and the later strengthening intensity can be improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com