Coal ash gangue filling activity-stimulating rubber solid material and preparation method thereof

A technology of active excitation and solidification, applied in the field of inorganic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The ratio of cement-solid material: Surabaya clinker 45.0%, superfine slag powder 20.0%, lime 20%, magnesium chloride 2.0%, sodium sulfate 1.5%, anhydrite 11.5%.

[0046] Preparation process: Grind lime, anhydrite and Surabaya clinker according to the above-mentioned raw material ratio, then mix with superfine slag powder, powdered magnesium chloride and sodium sulfate, stir and homogenize to obtain cemented solid material, namely FAC2-1.

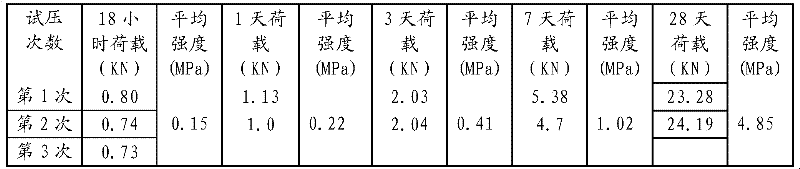

[0047] Slurry ratio: According to the ratio of ash to material (the ratio of cement-solid material to filler, the same below) 1:6.14, the concentration is 67% (the concentration is the ratio of the material to the total material and water. The material includes cement-solid material and crushed stone, Fly ash, etc.), add water and mix the fly ash and cement material in the mixing tank evenly, then inject the 7.07×7.07×7.07cm standard test mold, and put it into the standard concrete curing box for curing. Continue curing after demolding, a...

Embodiment 2

[0051] The ratio of cement-solid material: Surabaya clinker 49.0%, superfine slag powder 23.0%, lime 15.0%, magnesium chloride 3.0%, sodium sulfate 2.0%, anhydrite 8.0%.

[0052] Preparation process: Grind lime, anhydrite, and Surabaya clinker together according to the above-mentioned raw material ratio, then mix with superfine slag powder, powdered magnesium chloride and sodium sulfate, stir and homogenize to obtain a cemented solid material, namely FAC2-2.

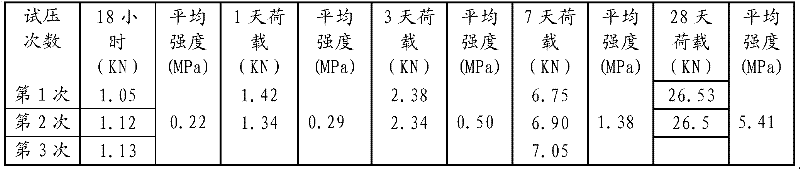

[0053] Slurry ratio: take the ratio of ash to material ratio of 1:5.8, concentration 66%, add water and mix the fly ash and cement material in the mixing tank evenly, and then inject the standard test mold of 7.07×7.07×7.07cm into the standard concrete Conservation box maintenance. Continue curing after demolding, and perform pressure test at the specified time. Among them, the fly ash is grade III coarse-grained fly ash of Shihong Power Plant, with an average particle size of 33.9μm and a specific surface area of 3186.1 (...

Embodiment 3

[0057] Cement-solid ratio: Laiwu Steel's cement clinker 24.0%, Surabaya cement clinker 10.0%, calcium magnesium powder 32.0%, fluorogypsum 12.5%, slag fine powder 20.0%, magnesium chloride 1.5%. The MgO content of the calcium magnesium powder is 30.1%, and the CaO content is 50.4%.

[0058] Preparation process: Calcium magnesium powder, fluorogypsum and clinker are ground together according to the above-mentioned raw material ratio, and then mixed with superfine slag powder and powdered magnesium chloride materials, stirred and homogenized to obtain a cemented material, namely FAC1.

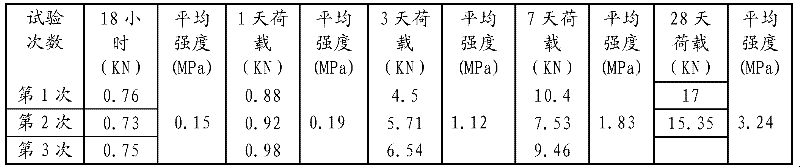

[0059] Slurry ratio: Take the ratio of crushed stone to fly ash at 1:1, ash material ratio at 1:6.7, concentration 60%, add fly ash, broken coal gangue and cementitious material in a mixing tank and stir evenly. The mass ratio of the fly ash to the broken coal gangue is 1:1, and then a standard test model of 7.07×7.07×7.07 cm is injected and put into a standard concrete curing box for curing. Continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com