Patents

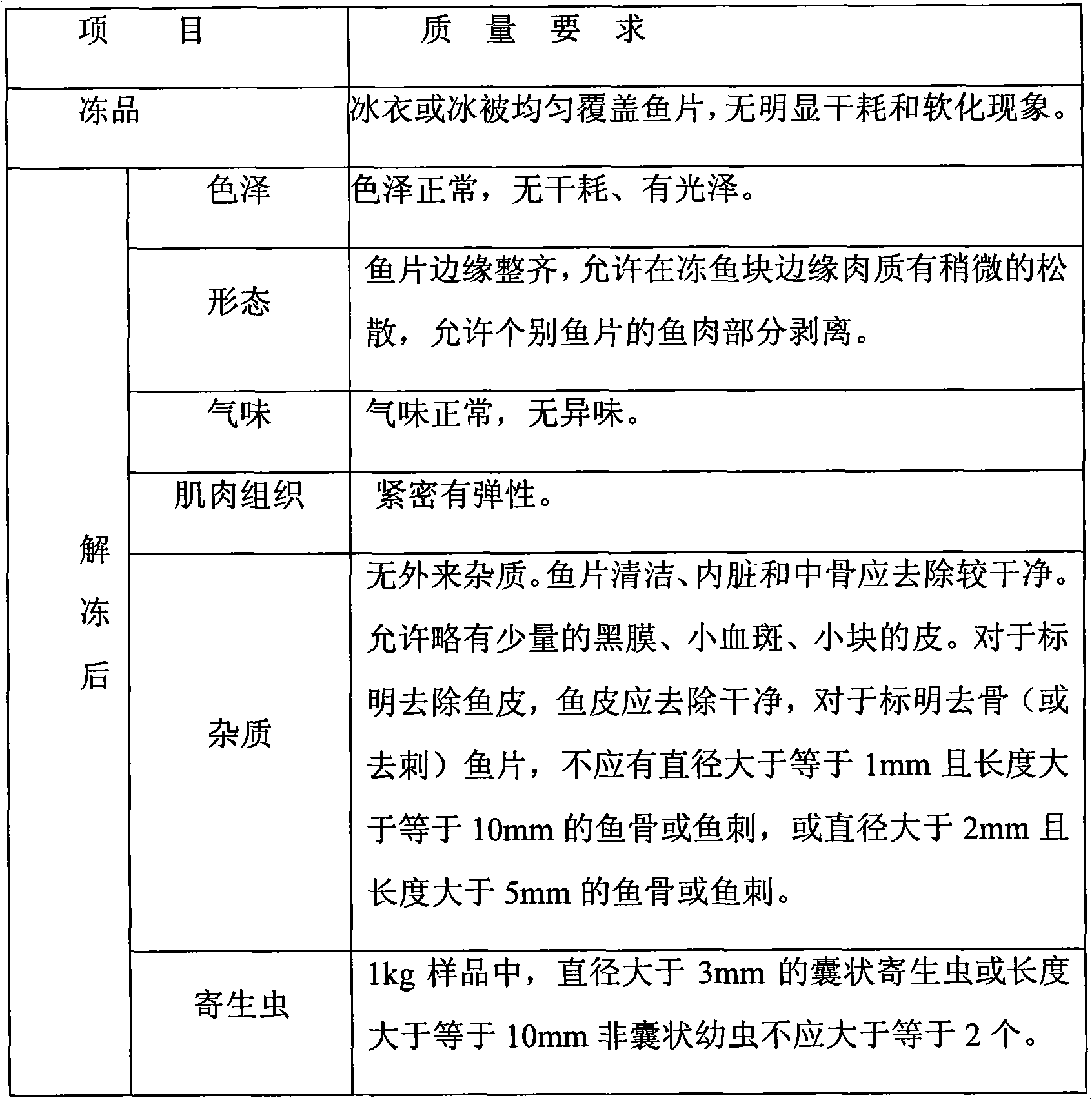

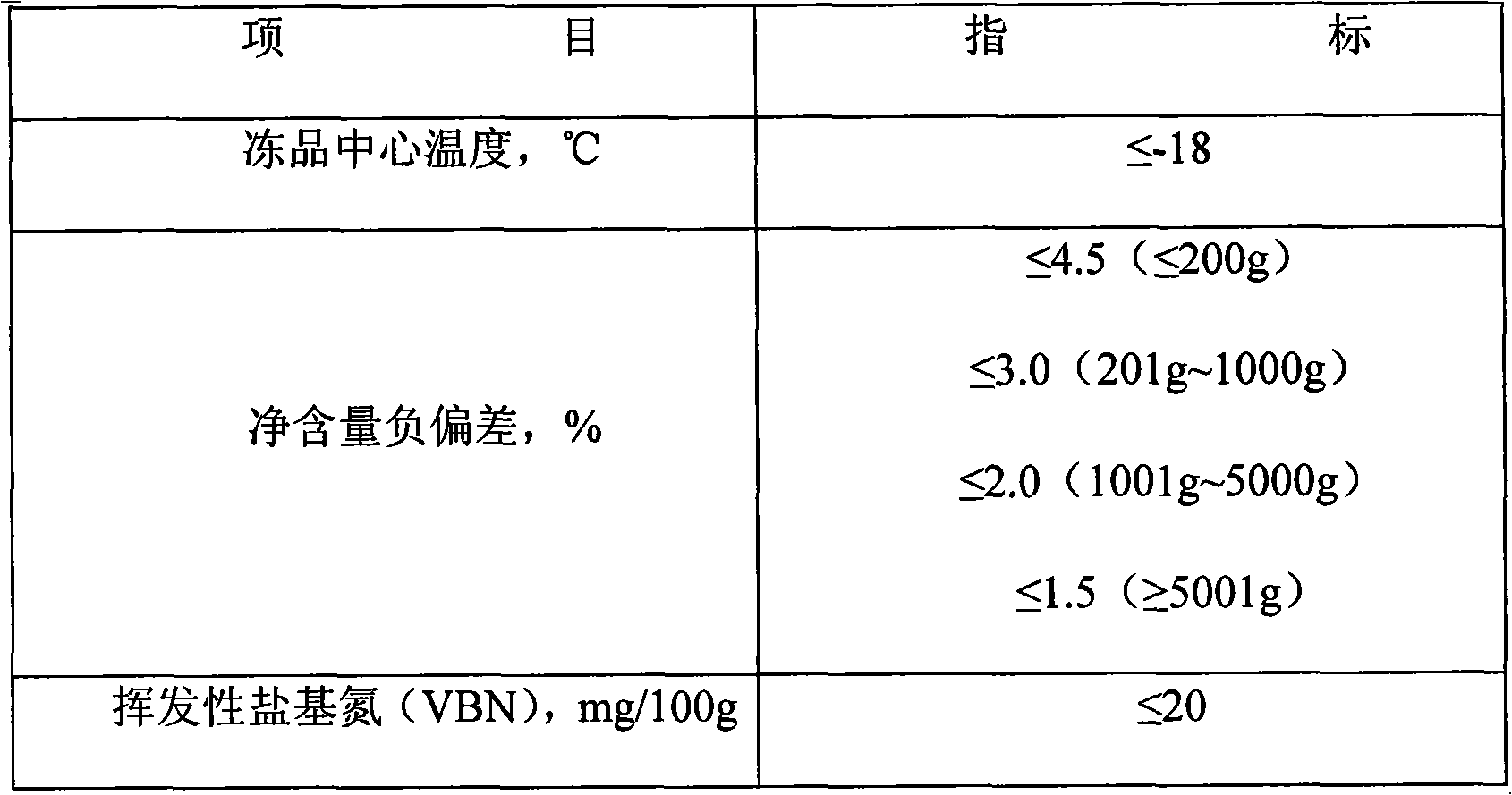

Literature

1162results about How to "Freeze fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

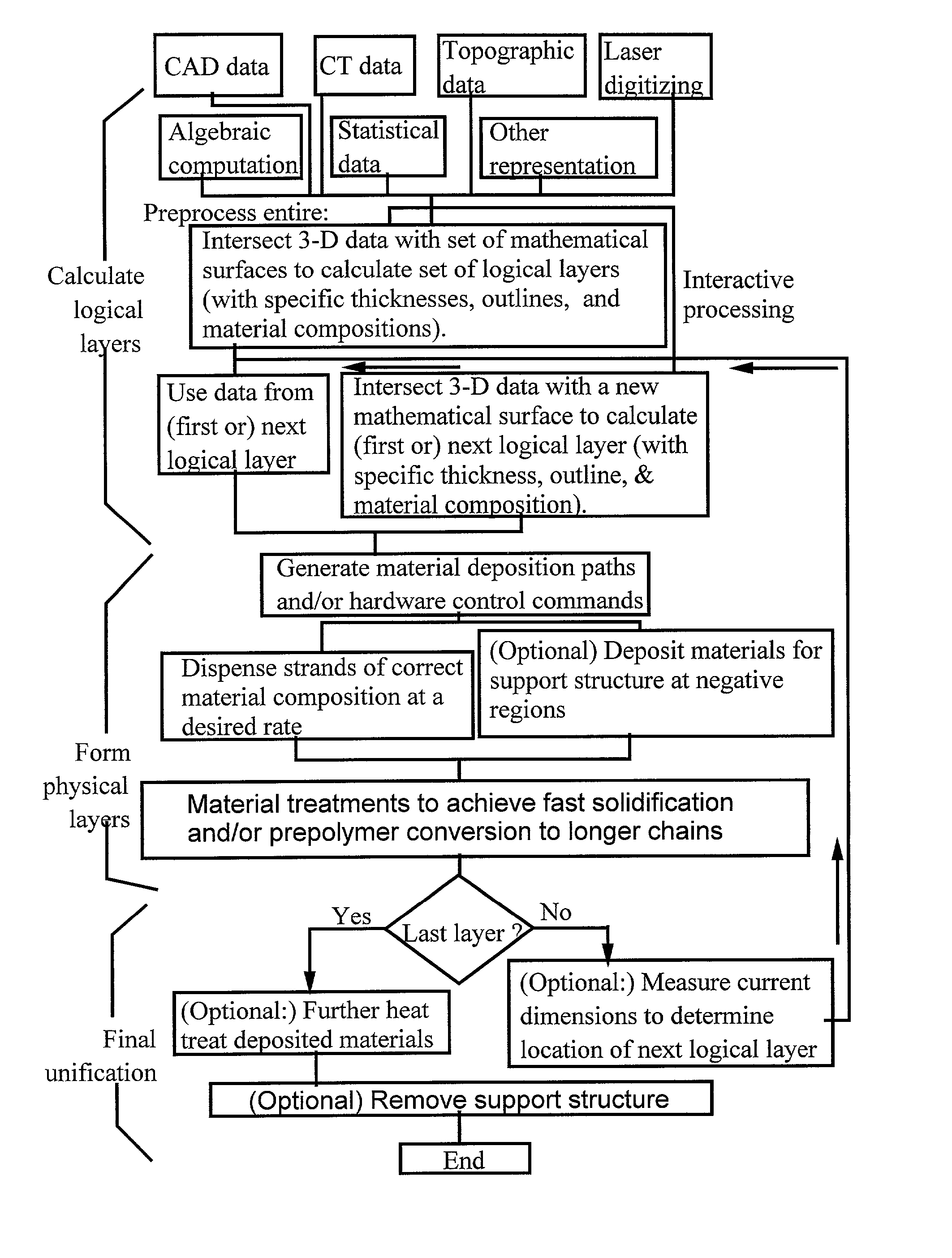

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

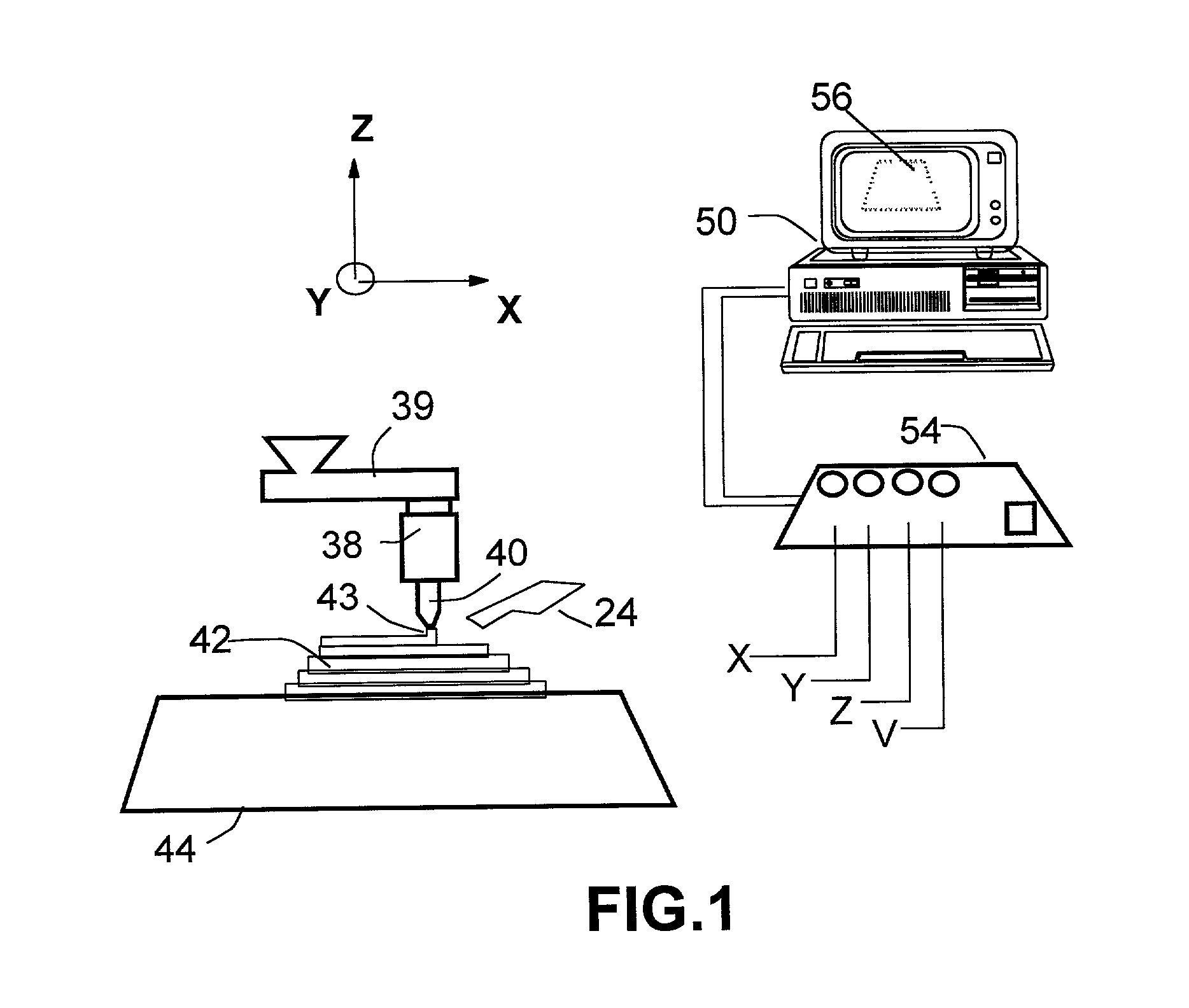

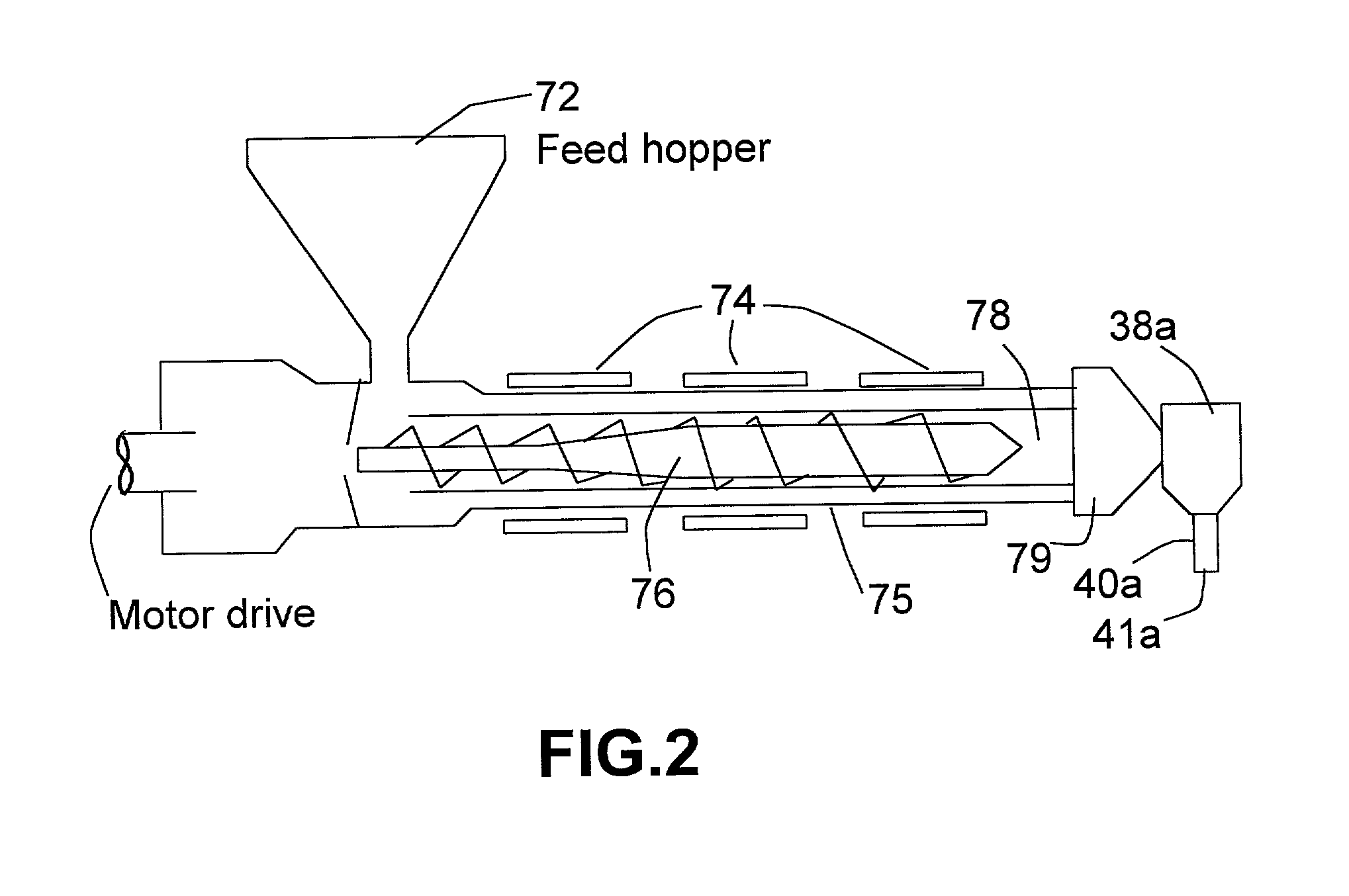

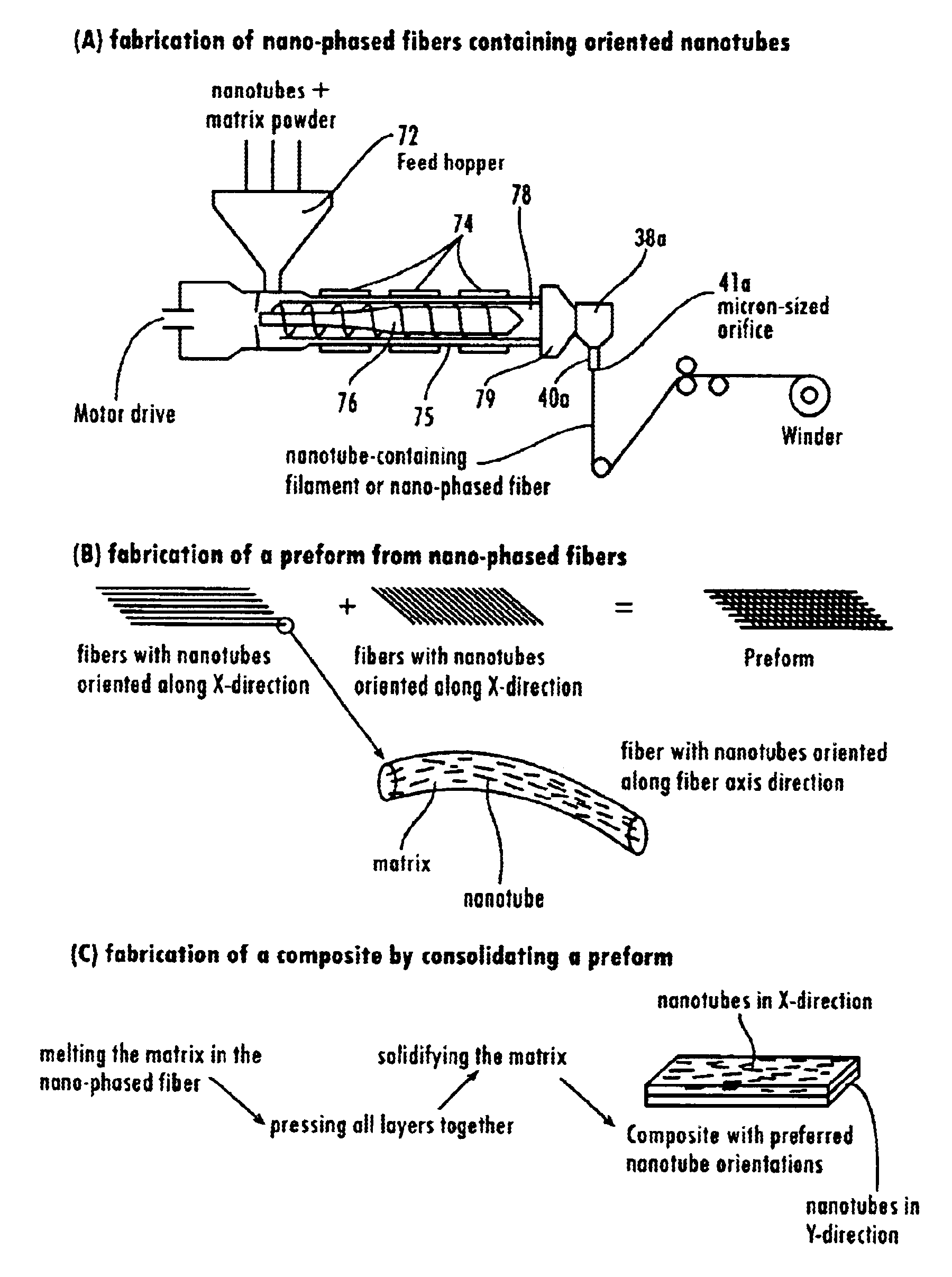

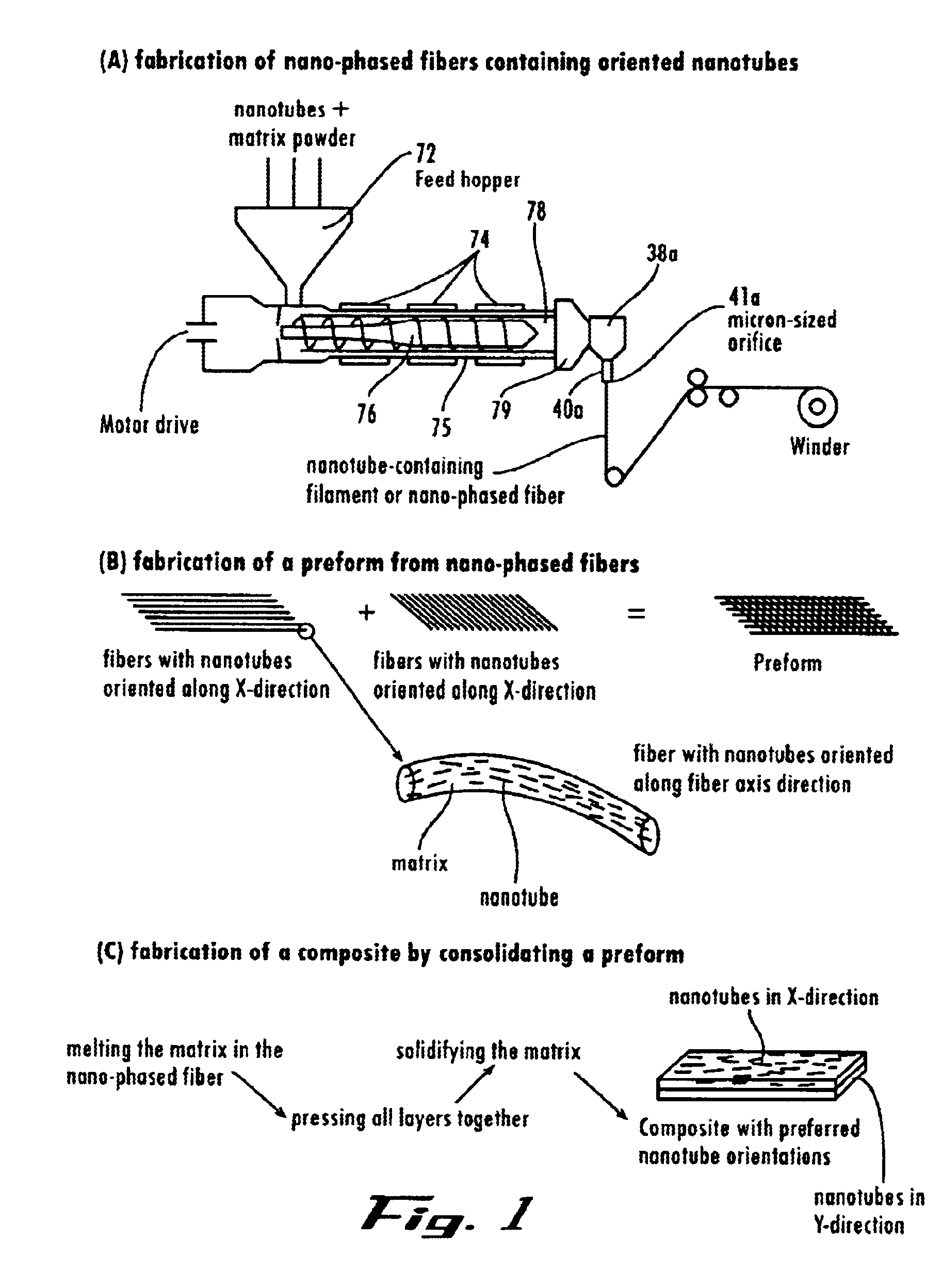

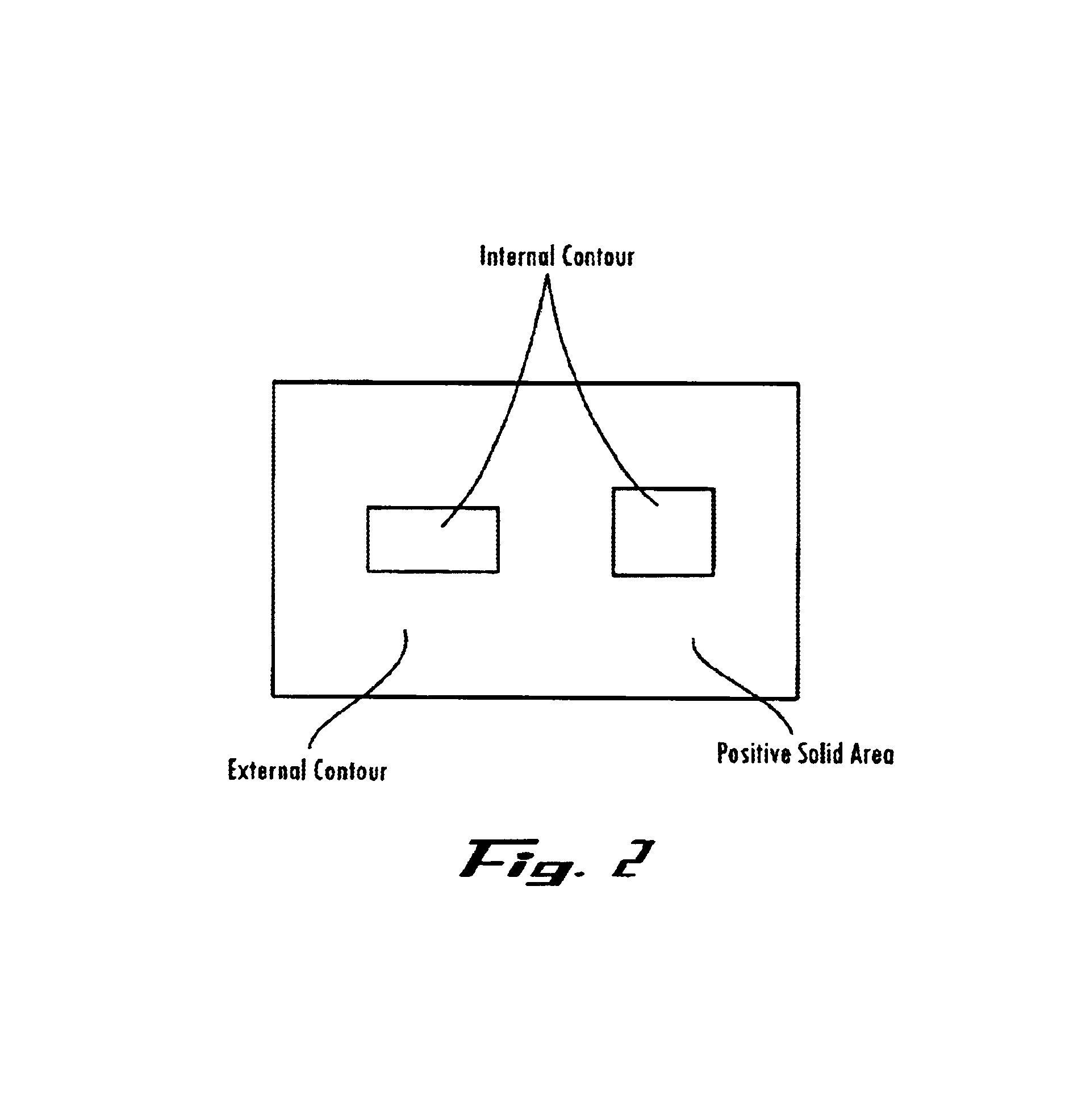

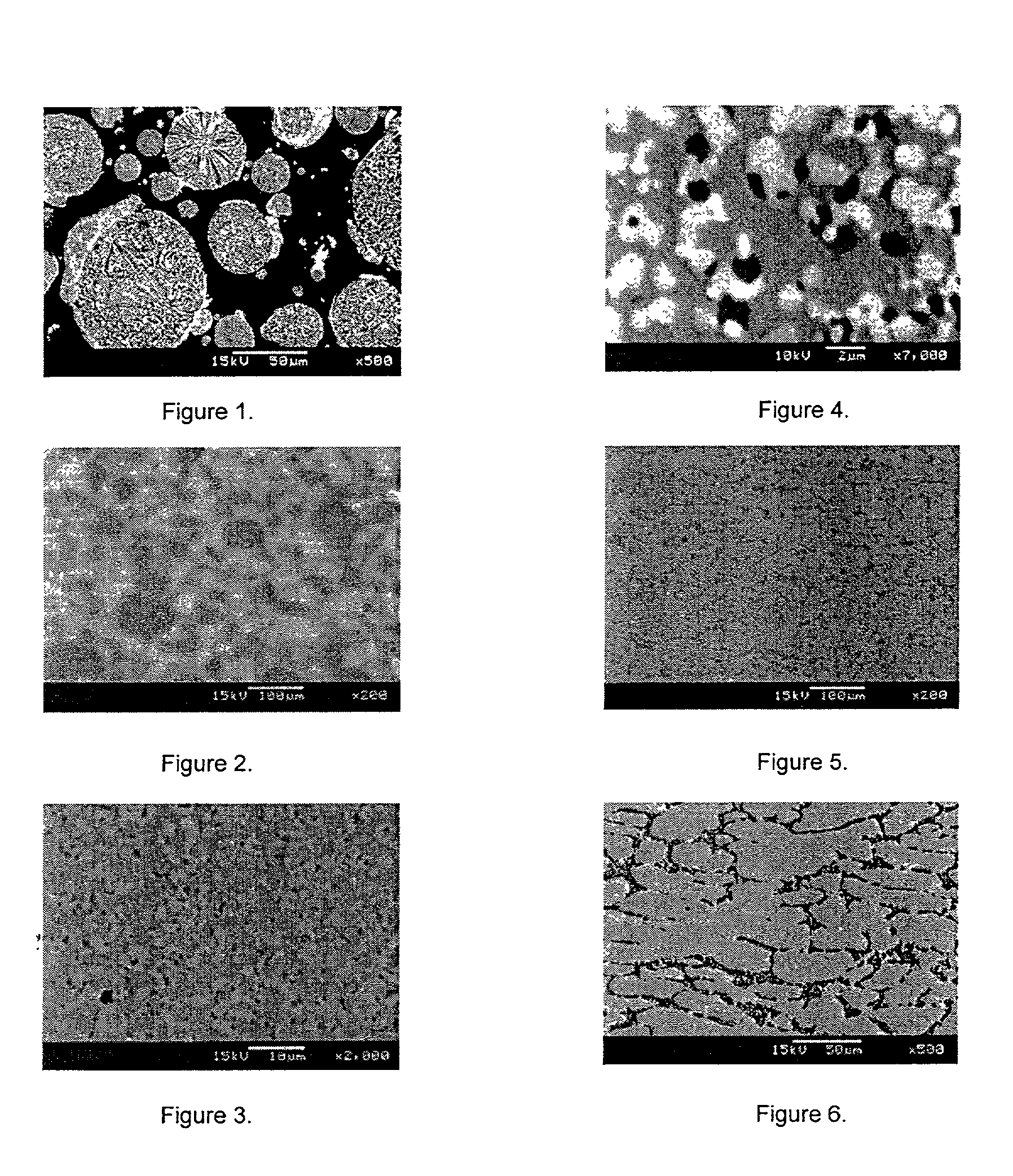

Nanotube fiber reinforced composite materials and method of producing fiber reinforced composites

InactiveUS6934600B2Requires minimizationGenerate efficientlyMaterial nanotechnologyAdditive manufacturing apparatusFiber-reinforced compositeMotion controller

Owner:AUBURN UNIV

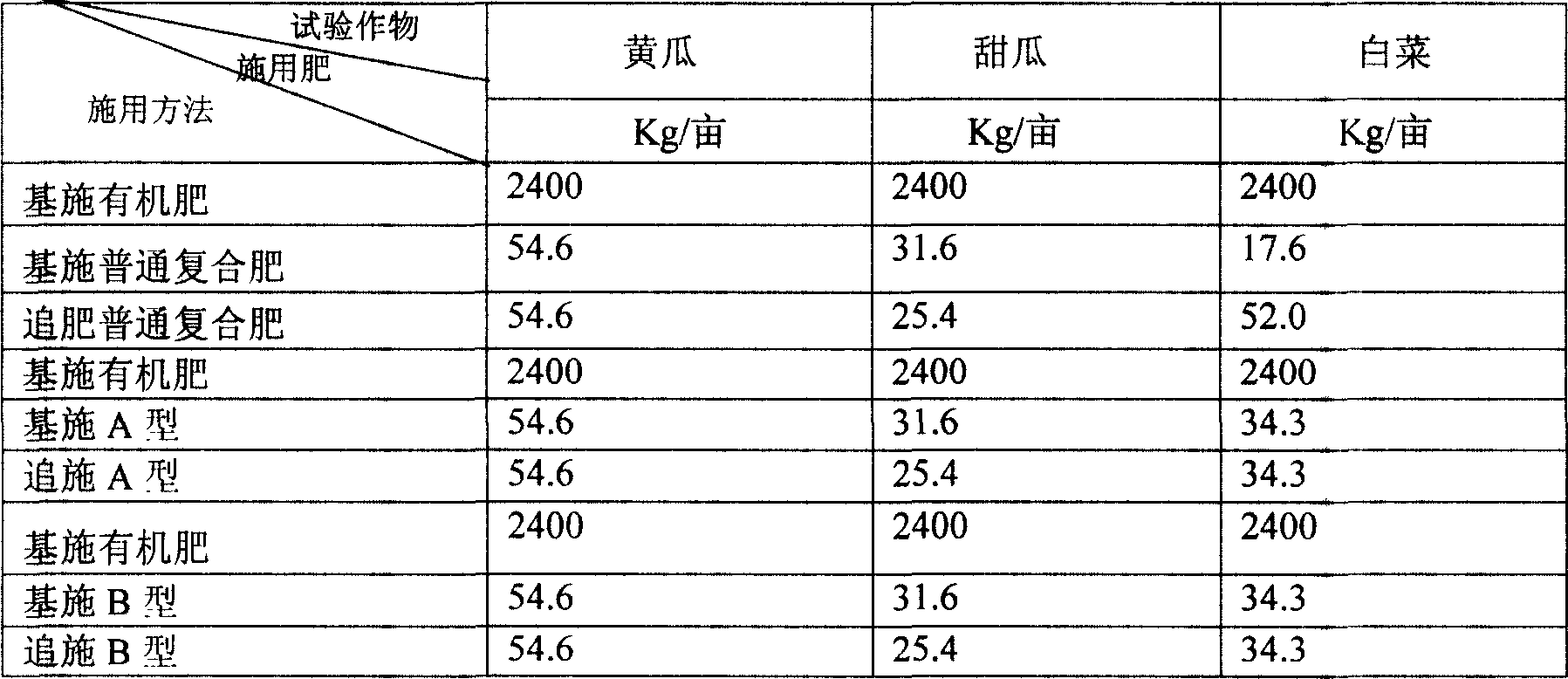

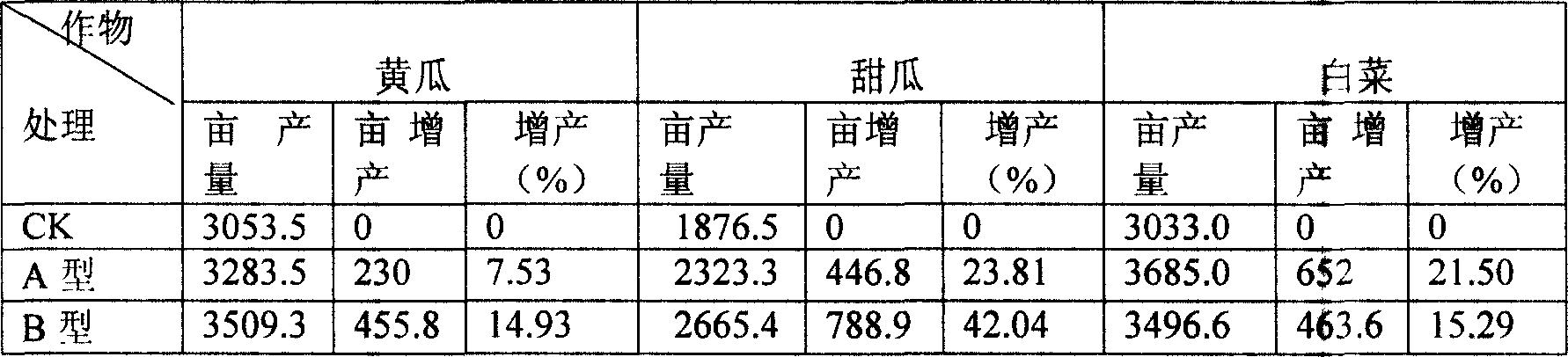

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

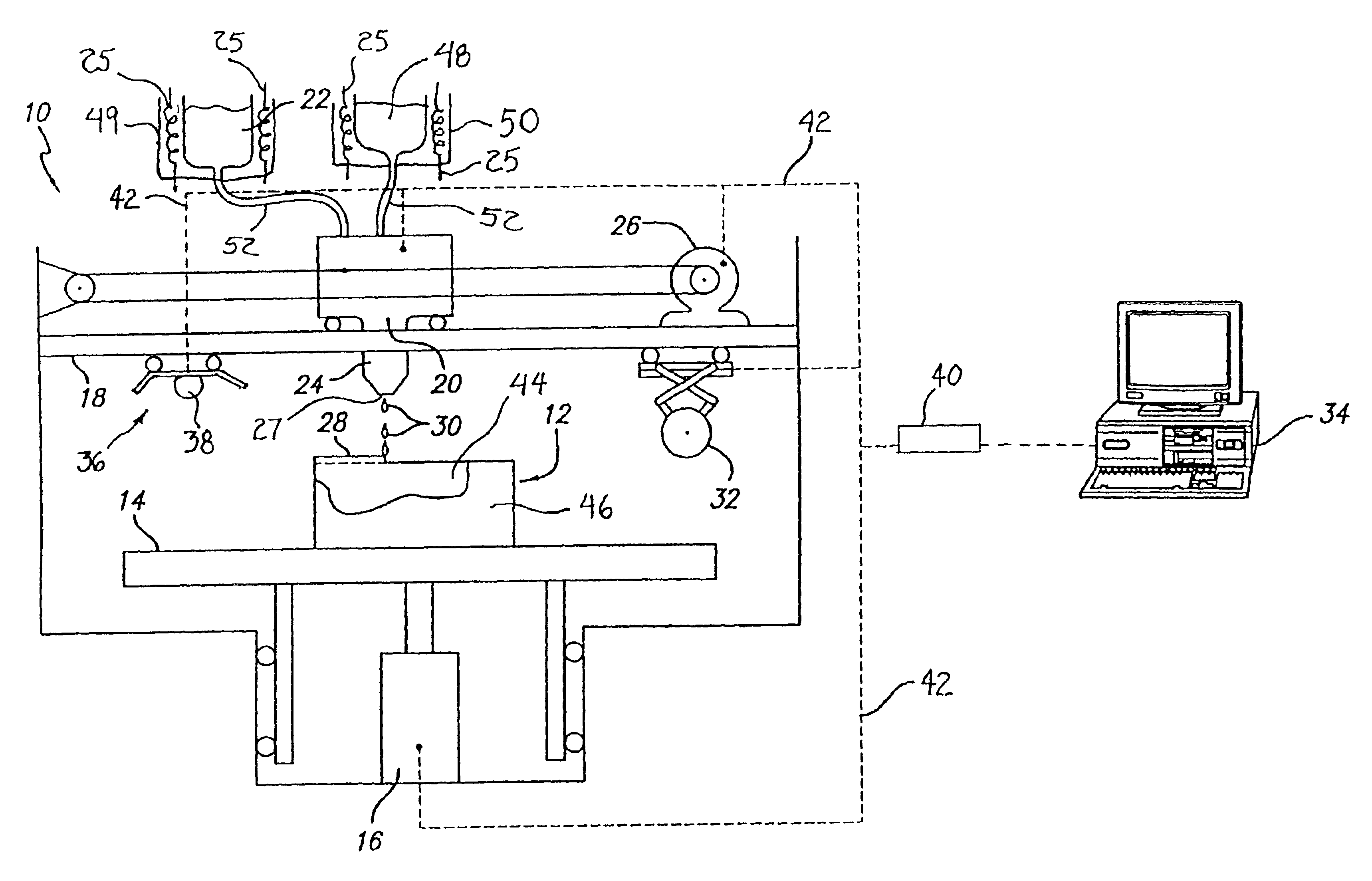

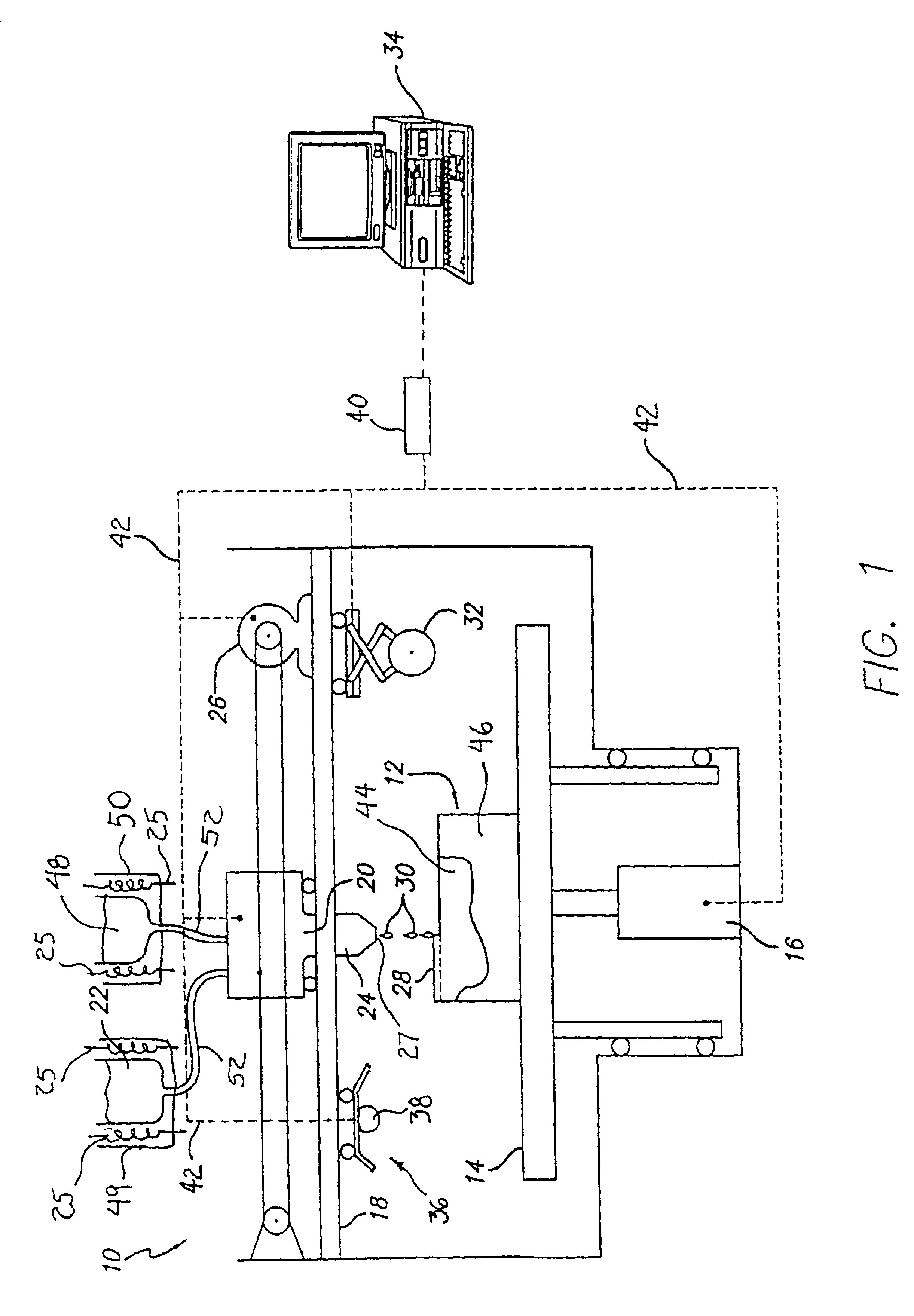

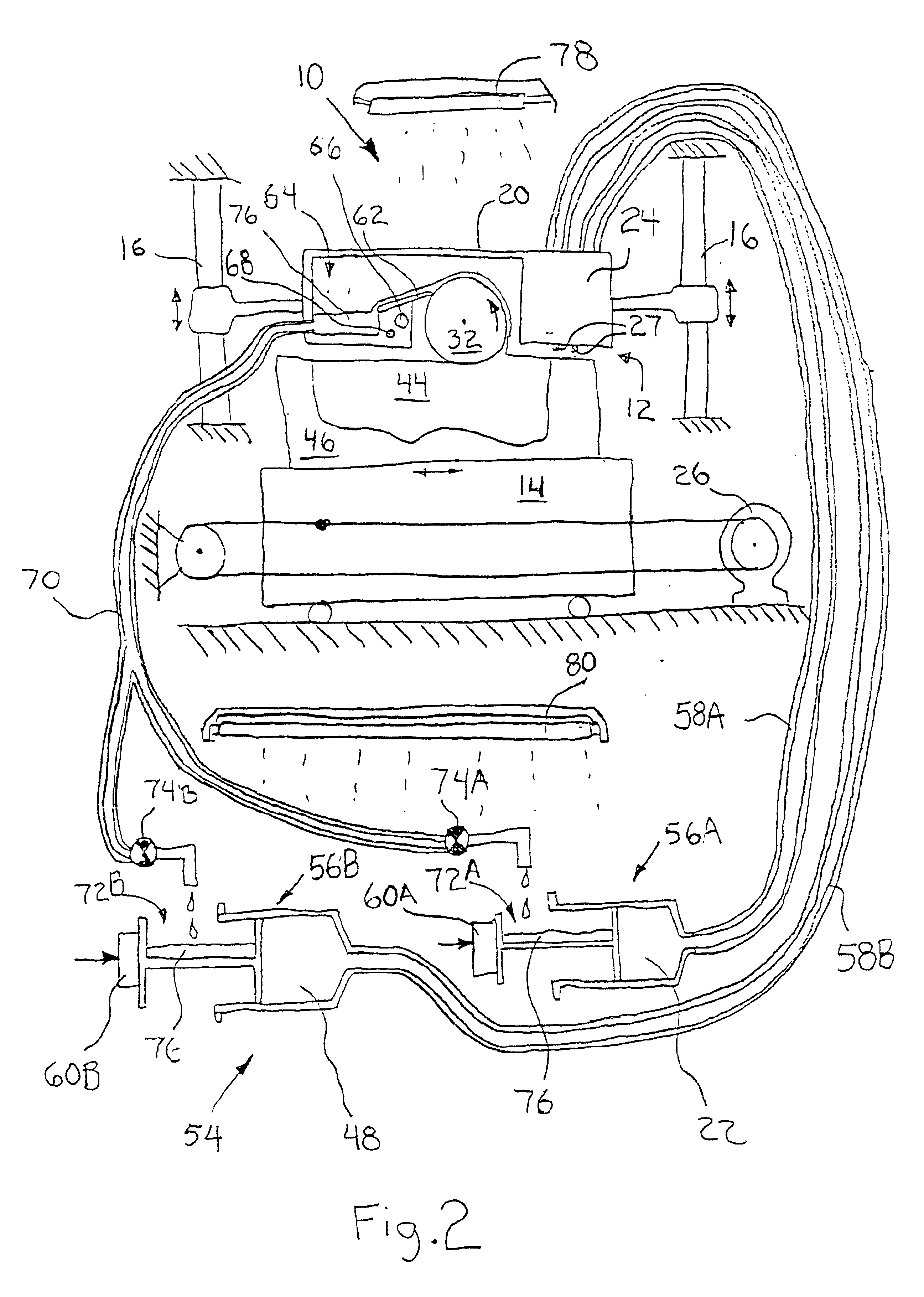

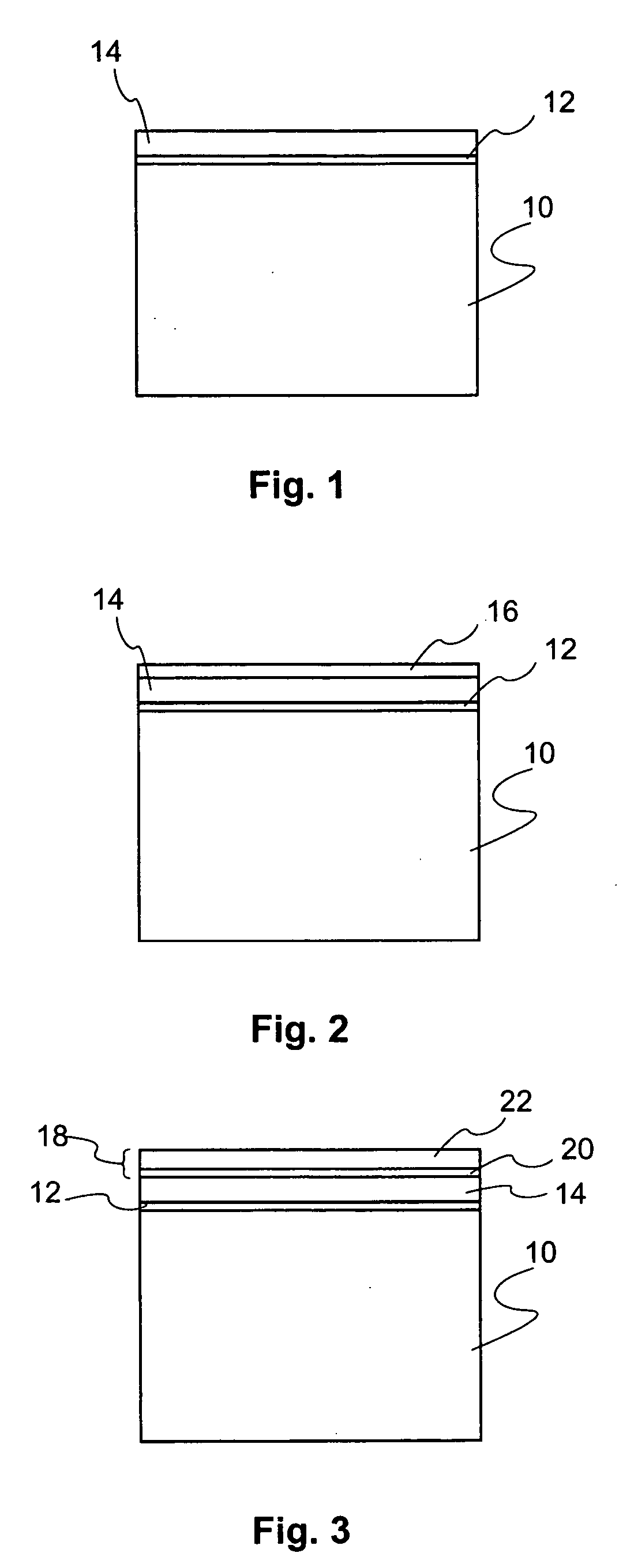

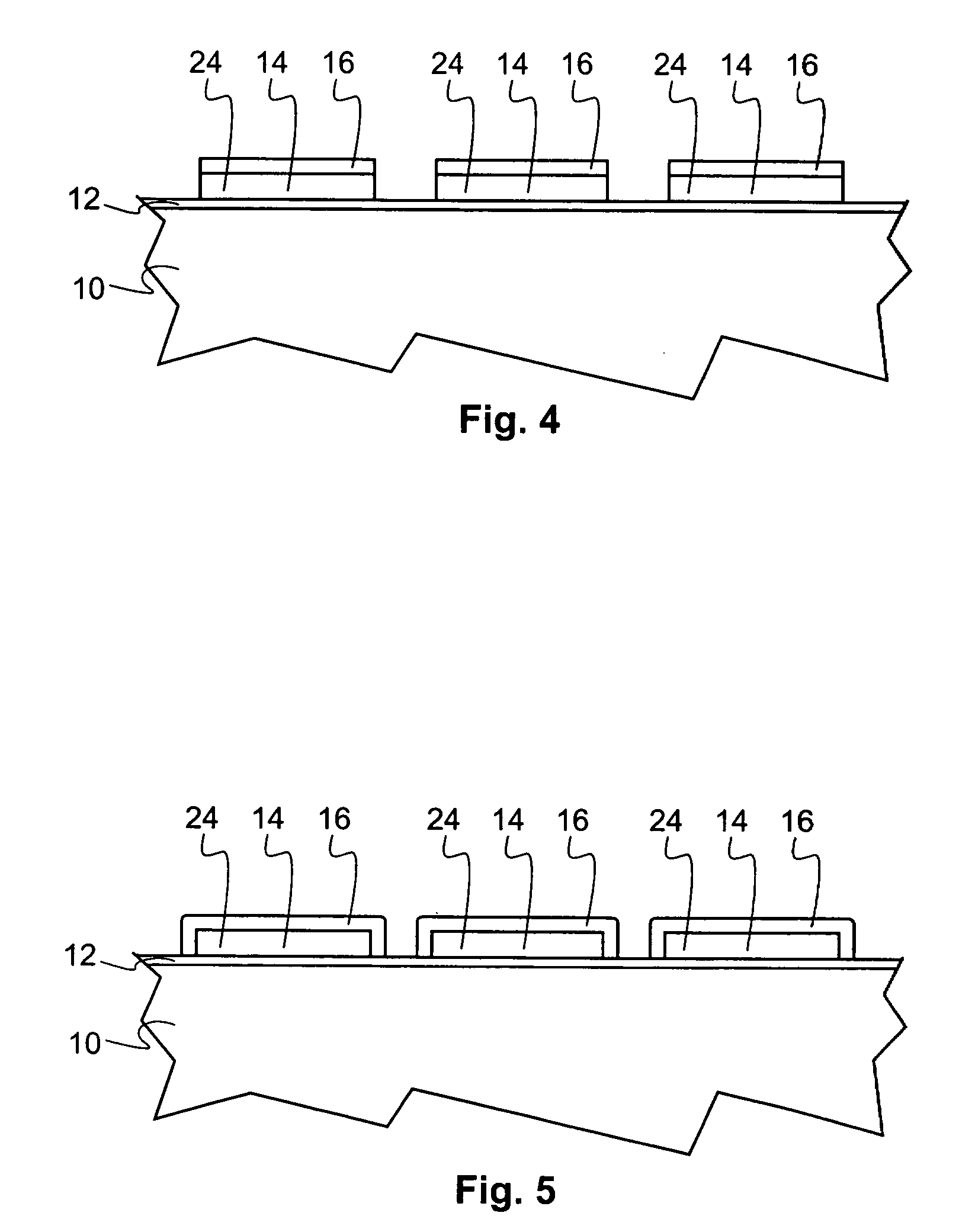

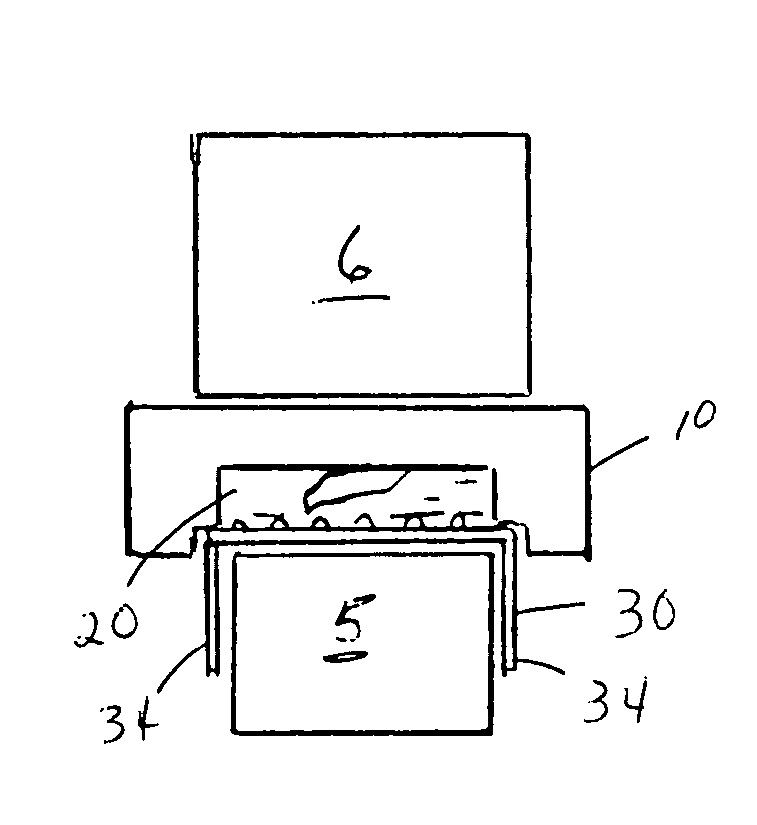

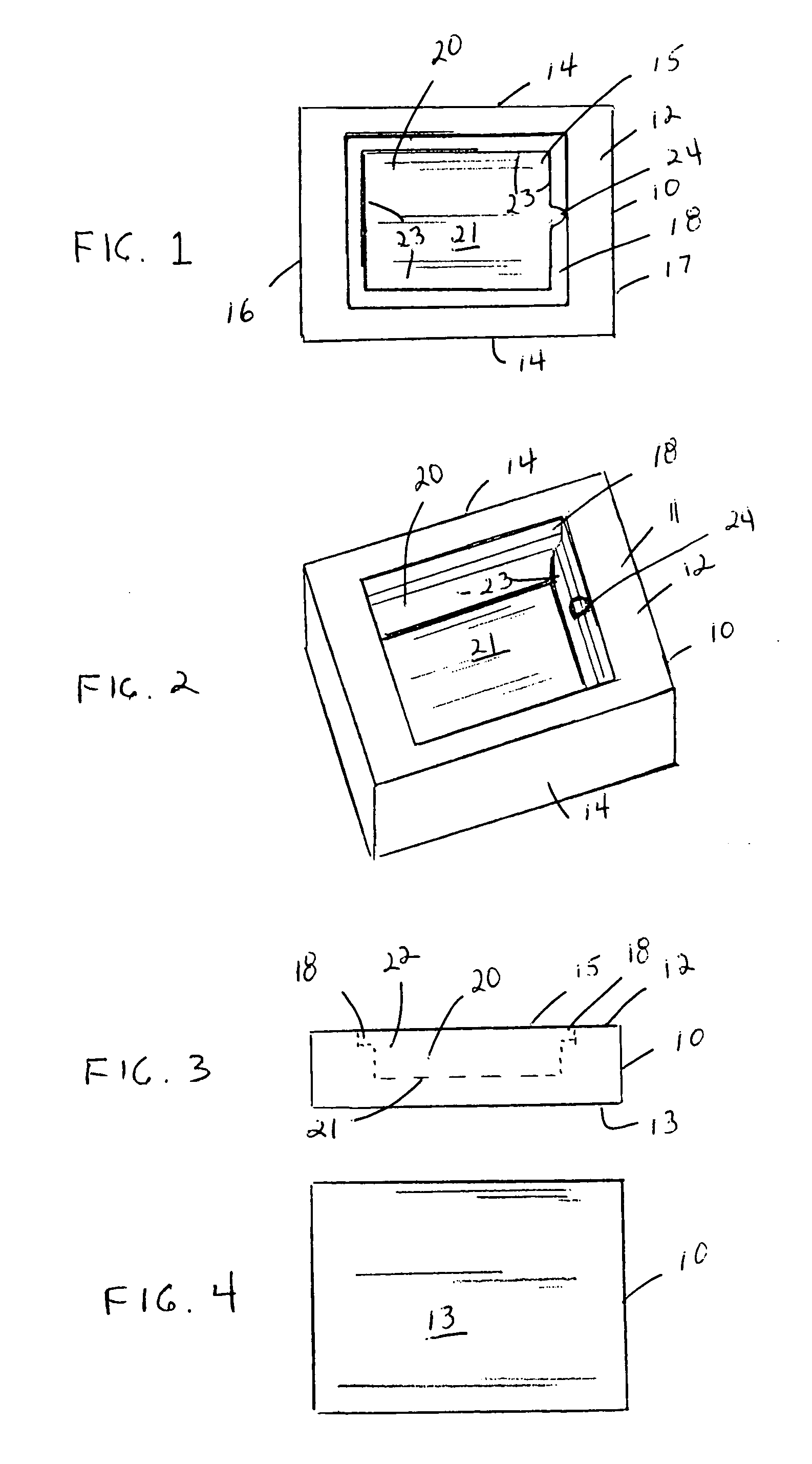

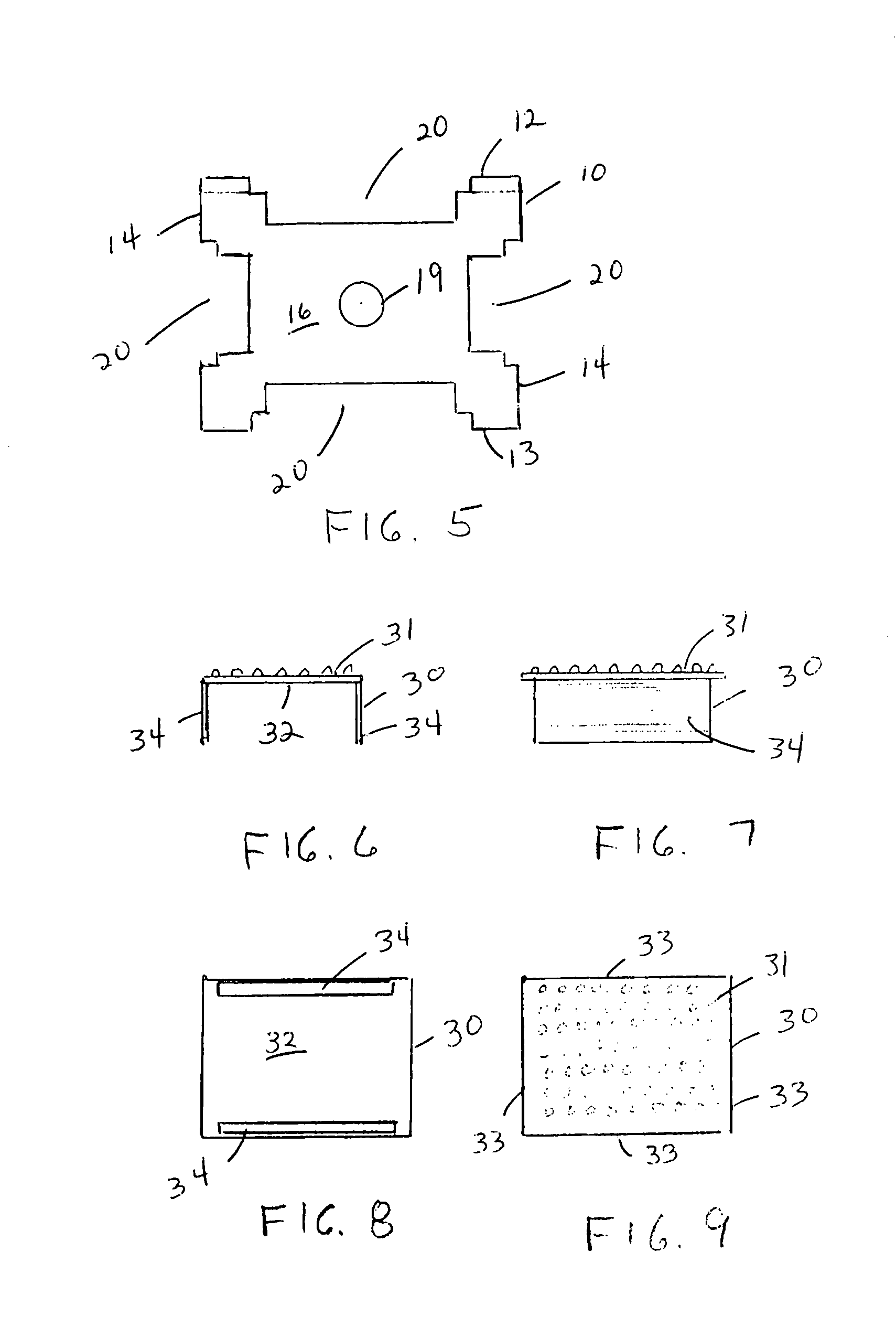

Selective deposition modeling with curable phase change materials

InactiveUS6841116B2Improve mechanical propertiesEasy to disassembleConfectionerySweetmeatsSelective depositionPhase change

A selective deposition modeling method and apparatus for dispensing a curable phase change material. The dispensing temperature of the material is set at or less than a thermally stable temperature value for the material in which the reactive component of the material remains substantially uncured when held at the temperature for a desired time period. The dispensed material is provided with an environment that enables the material to solidify to form layers of the object. The solidified material is normalized to a desired layer thickness and is then cured by exposure to actinic radiation. In a preferred embodiment a UV curable phase change material is dispensed at about 80° C. and has a viscosity of about 13 to about 14 centipoise at this temperature. The cured material provides substantially increased physical properties over thermoplastic phase change materials previously used in selective deposition modeling.

Owner:3D SYST INC

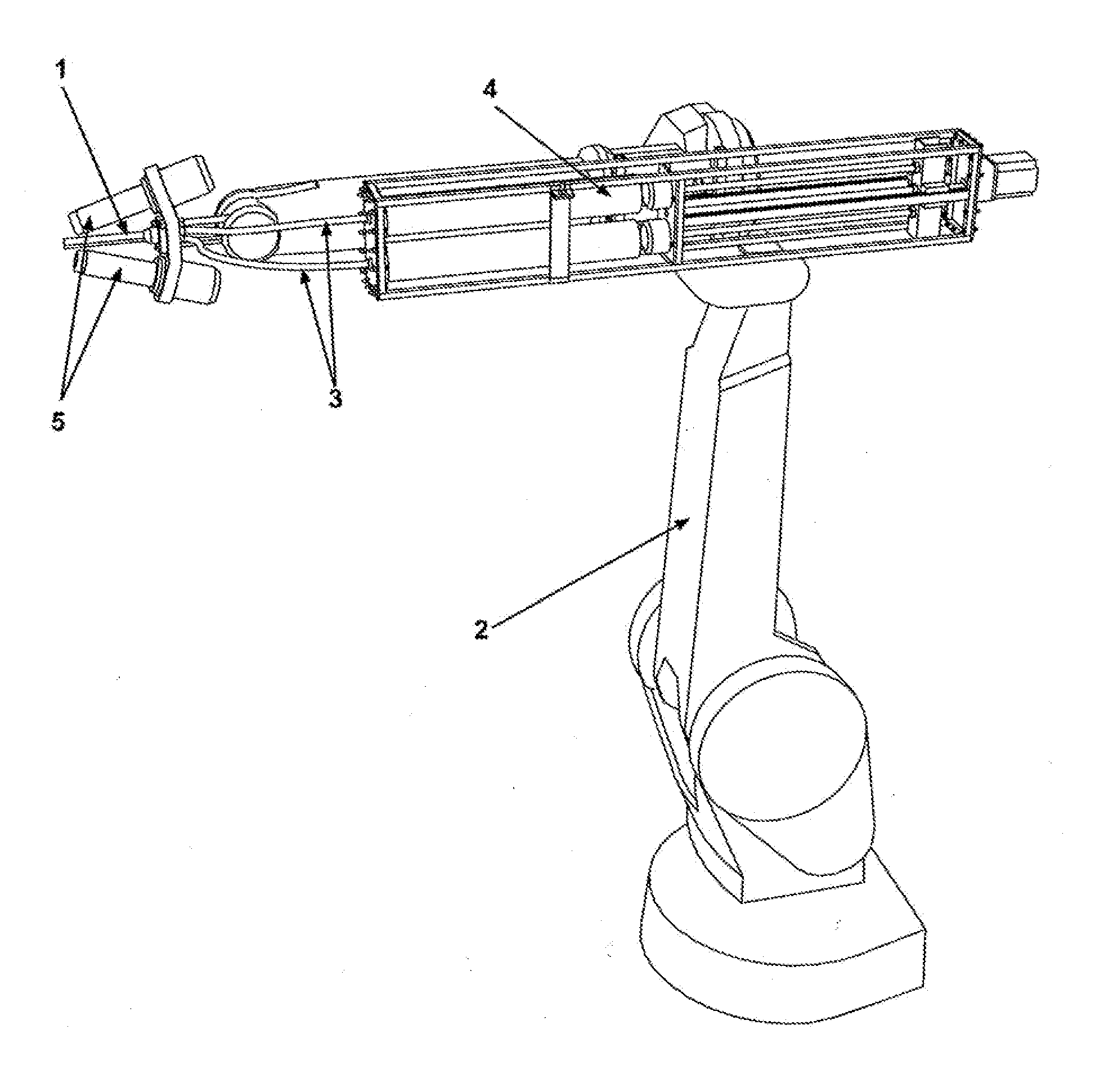

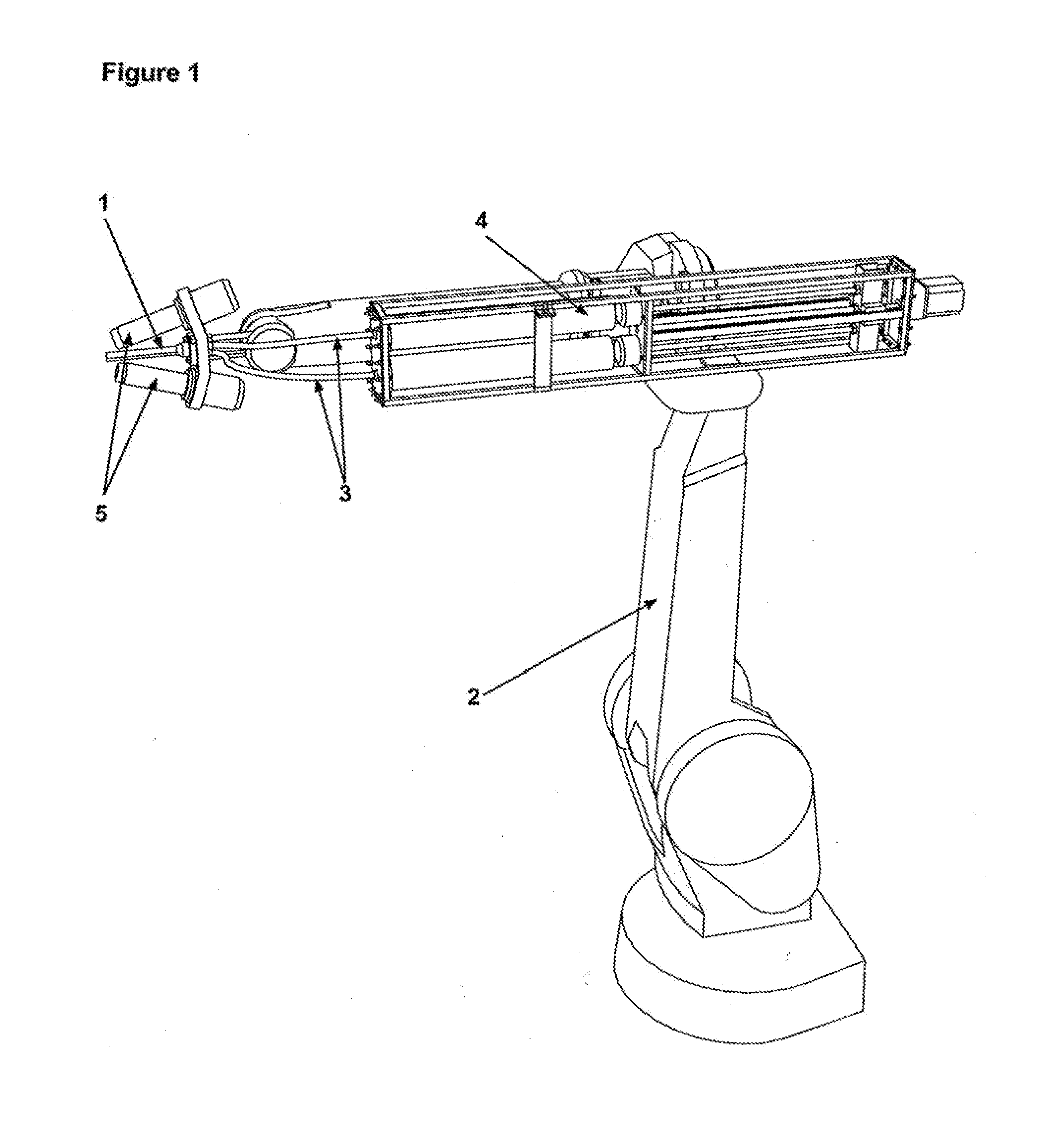

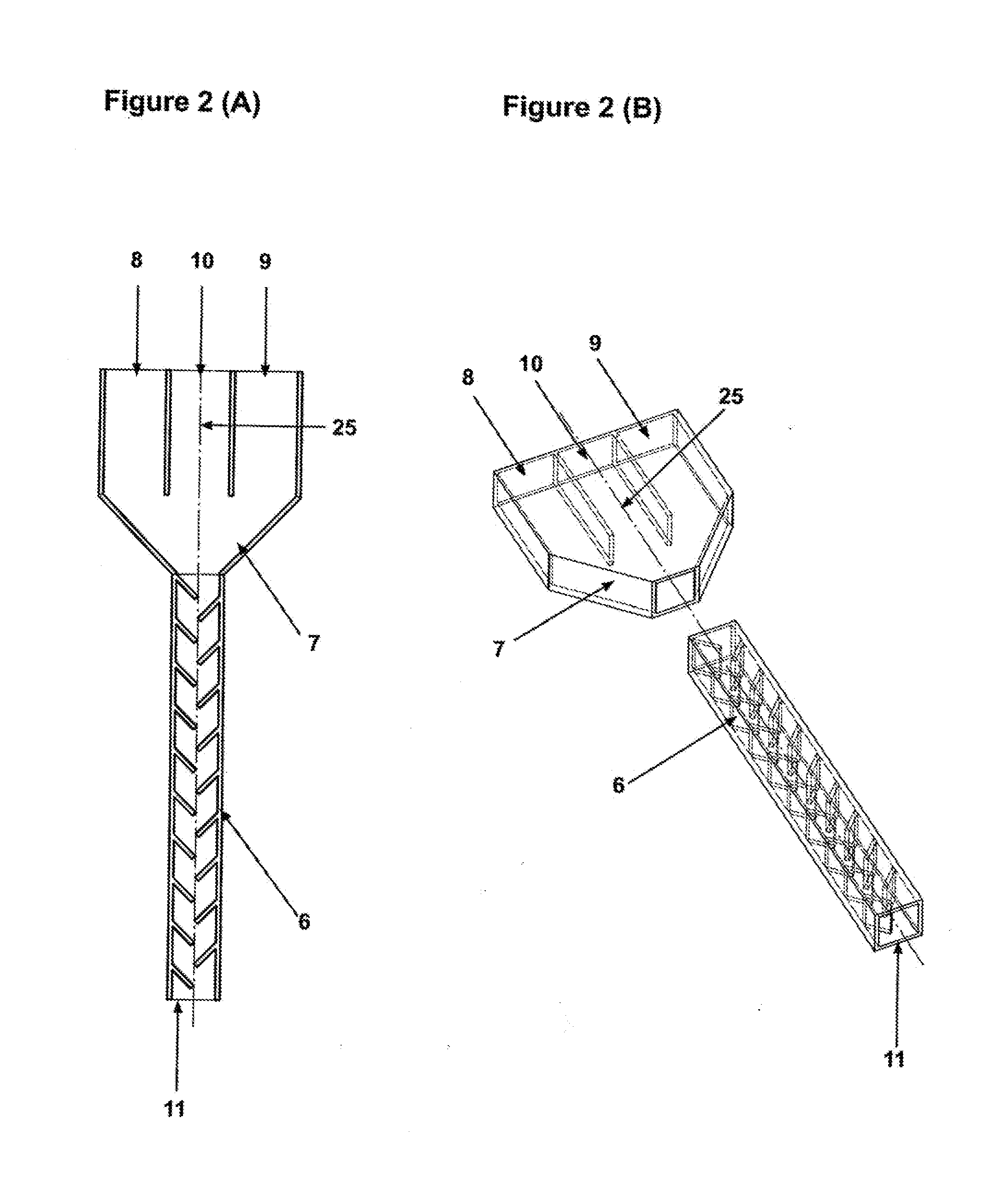

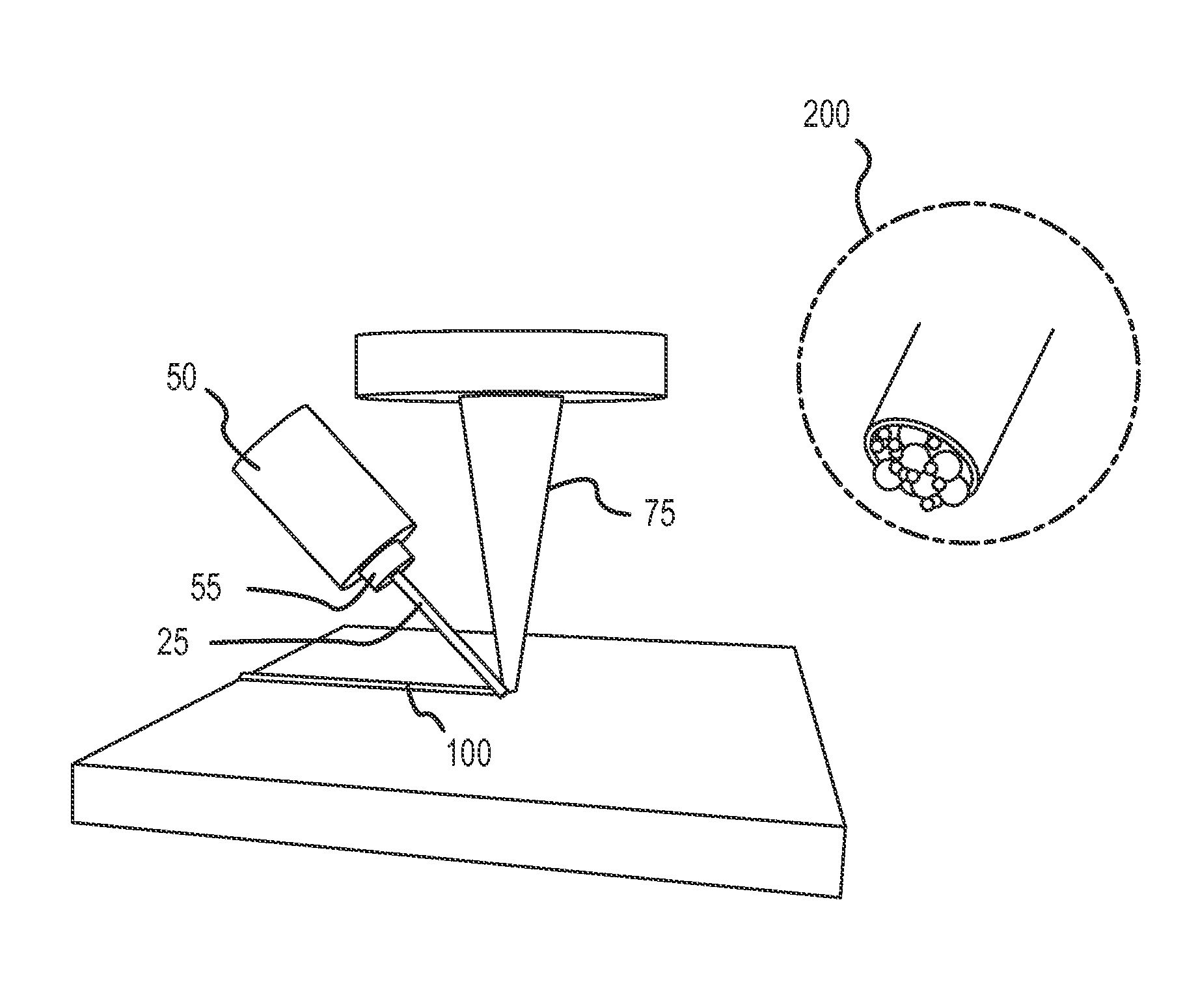

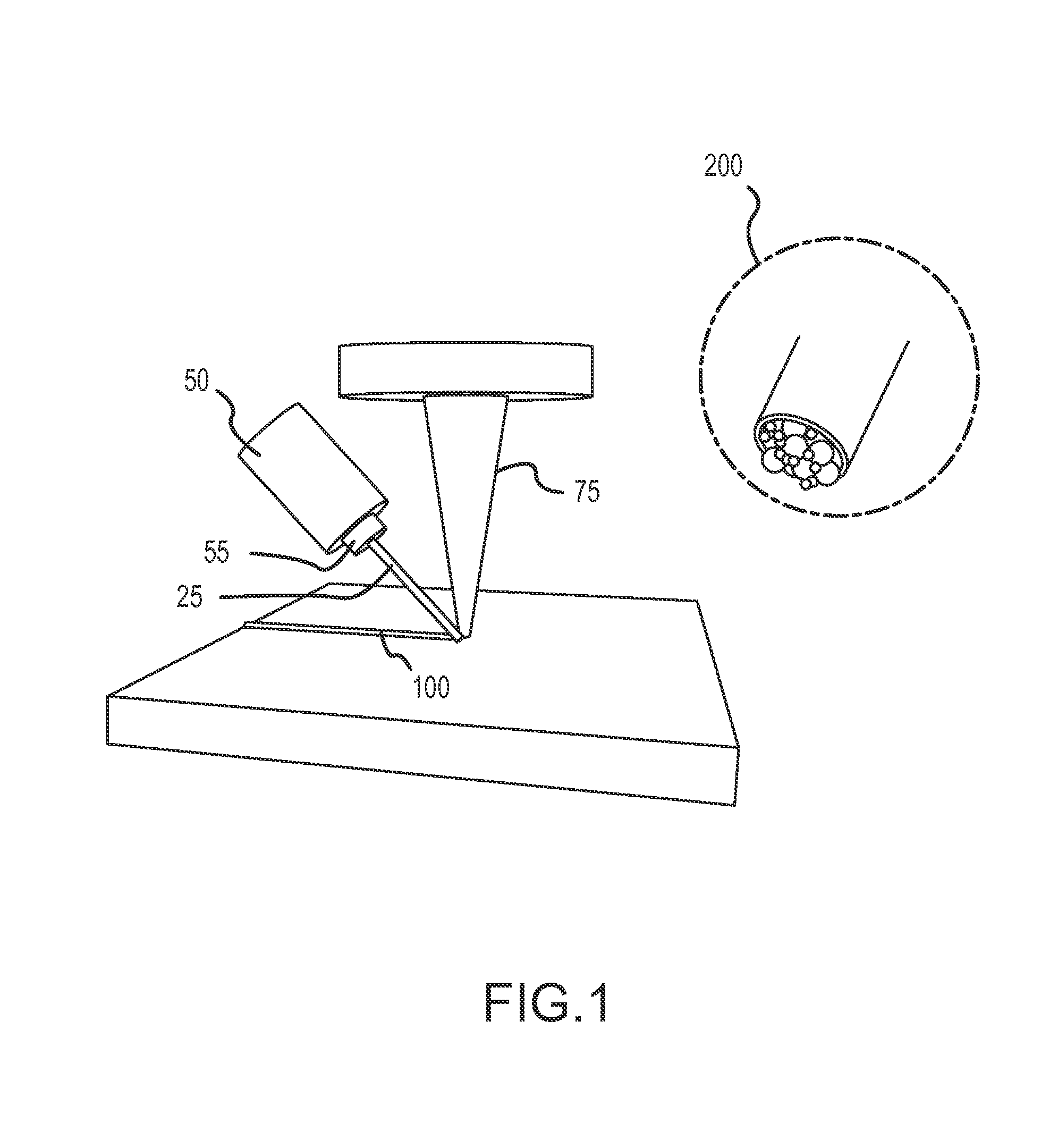

System and Method for Manufacturing a Three-Dimensional Object from Freely Formed Three-Dimensional Curves

InactiveUS20140284832A1Increase or decrease the speed of the extrusion of the source componentsIncrease or decrease thicknessAuxillary shaping apparatusAdditive manufacturing with liquidsEngineeringSurface geometry

A three-dimensional object is manufactured by forming a series of three-dimensional formed curves of extruded material that together comprise the geometry of the surface of the object. The material is extruded from a nozzle that is positioned by a robotic arm under the control of a robotic controller. A computer that has a definition of the geometric surface generates commands to the robotic controller to cause it to sequentially form the series of formed curves that the computer calculates comprise the surface geometry.

Owner:NOVIKOV PETR +1

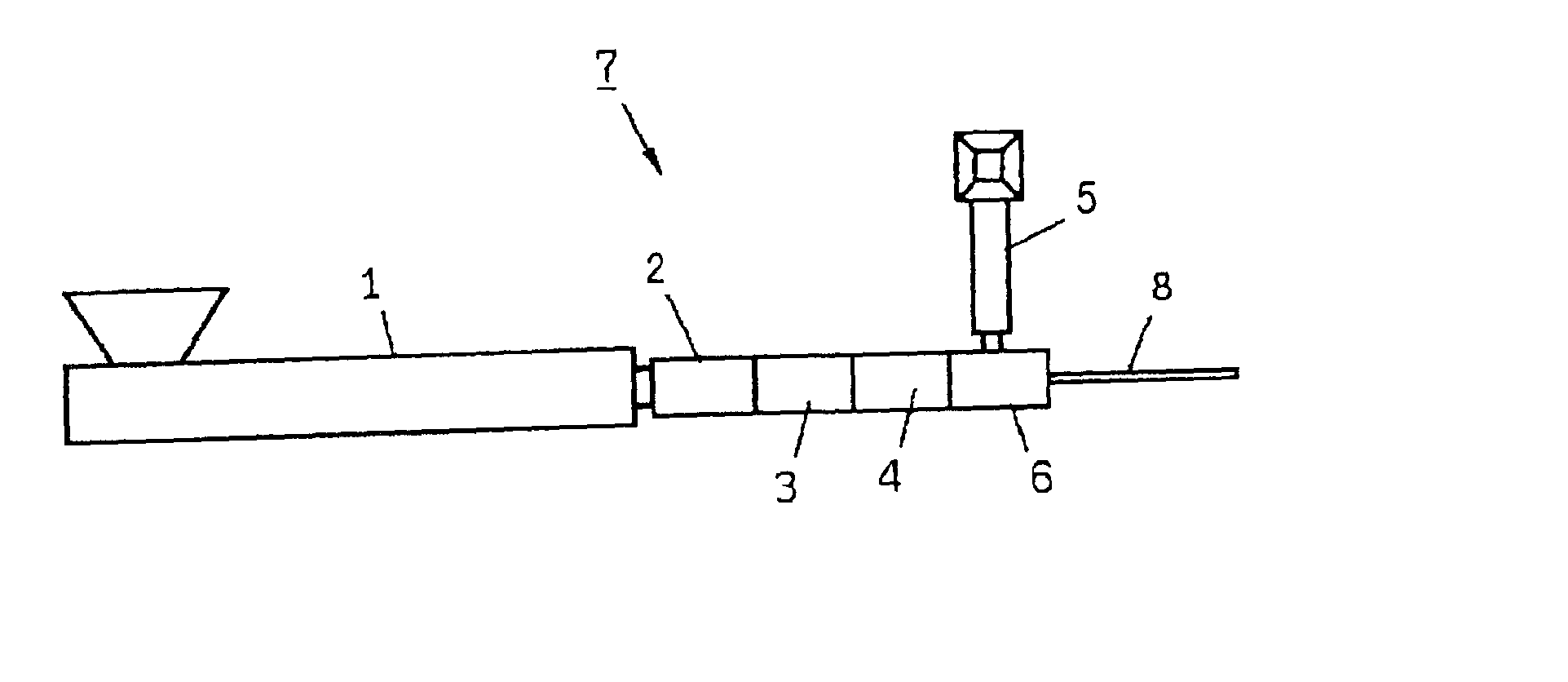

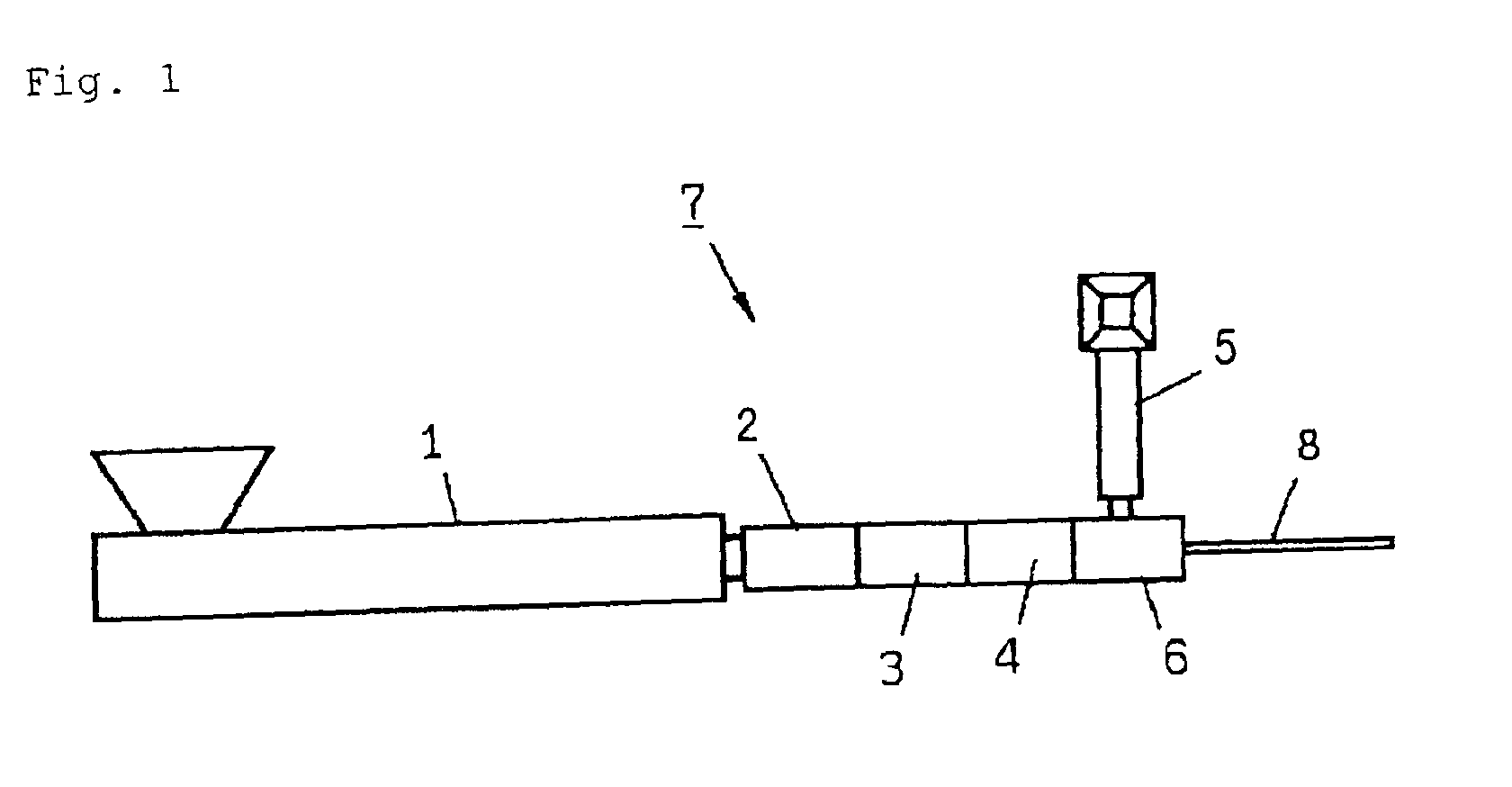

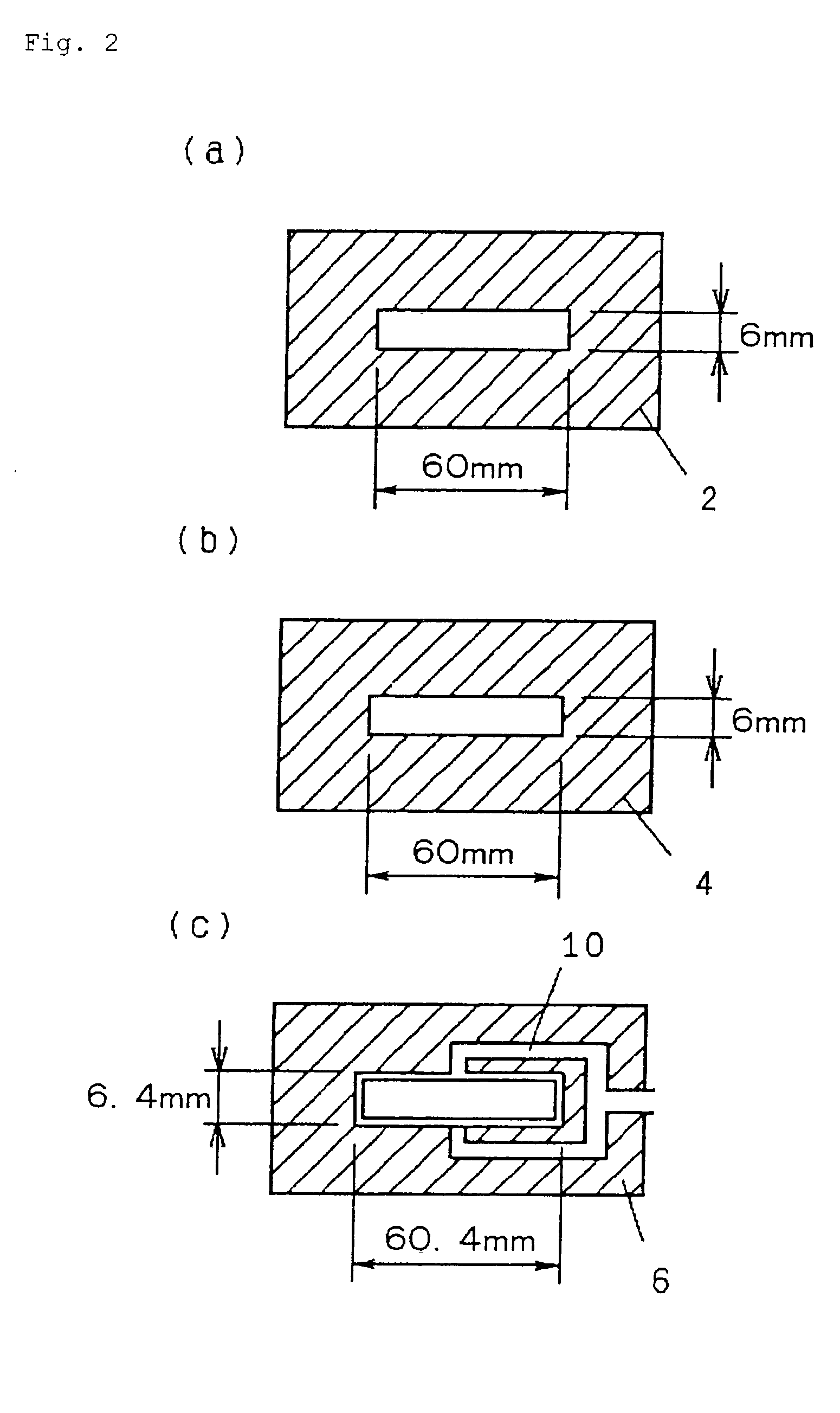

Molded article from thermoplastic composite material and method for producing the same

InactiveUS20020192401A1Uniform temperature distributionSuitable temperatureHair accessoriesWood working apparatusShell moldingThermoplastic composites

The present invention has for its object to provide a molded article of a thermoplastic composite material which is not only durable with little discoloration or fading even on prolonged outdoor exposure and is very satisfactory in physical properties and appearance qualities inclusive of wood-like texture but also has high productivity and good economics. The present invention is a method of producing a molded article of a thermoplastic composite material comprising extruding the thermoplastic composite material containing a thermoplastic resin and a vegetable filler, said vegetable filler content being 50 to 90 weight % of the total weight of said thermoplastic resin and said vegetable filler, wherein extrusion is carried out by means of an extrusion apparatus comprising at least an extruder, a hot shaping die, and a cooling die, said hot shaping die and cooling die being directly coupled.

Owner:SEKISUI CHEM CO LTD

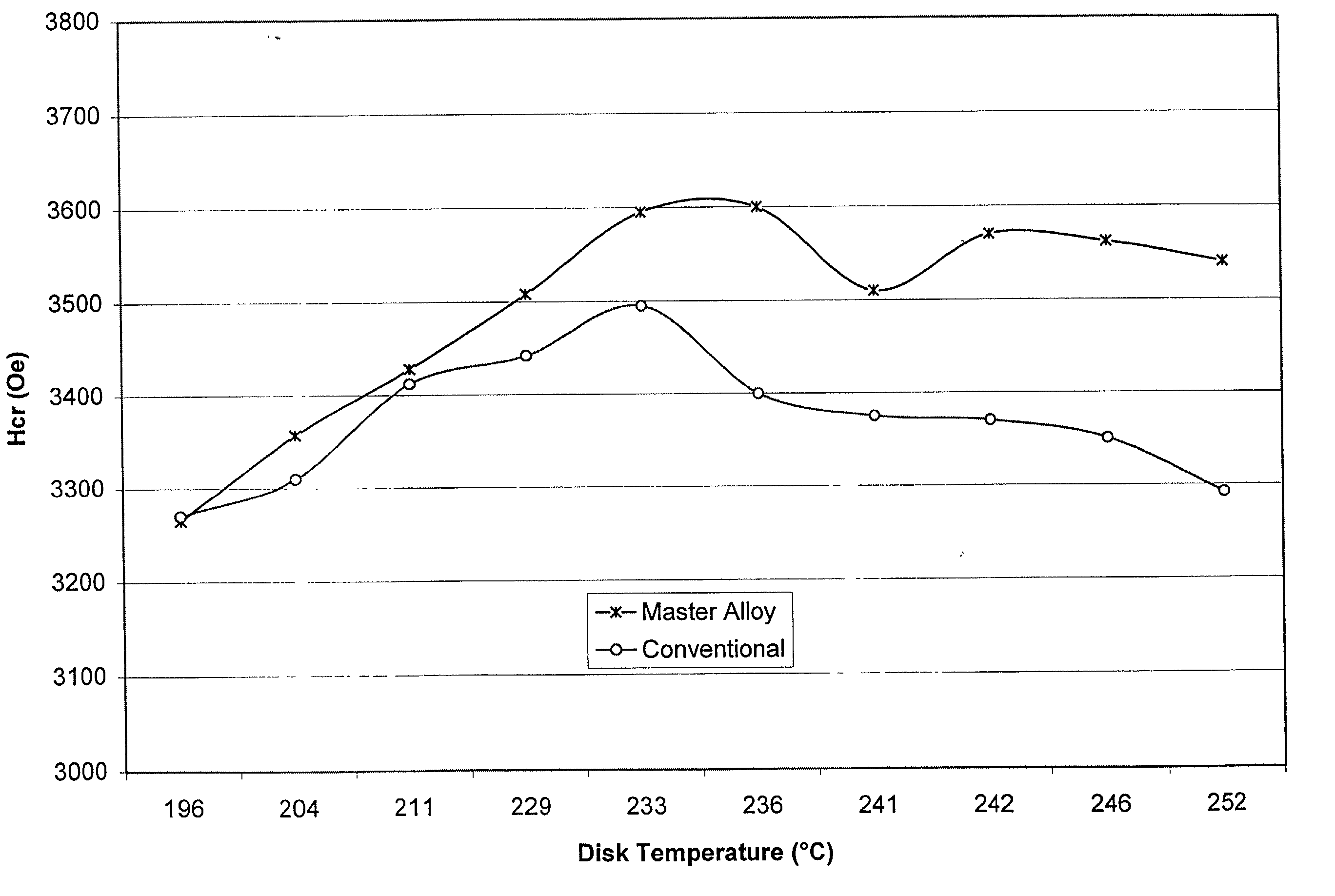

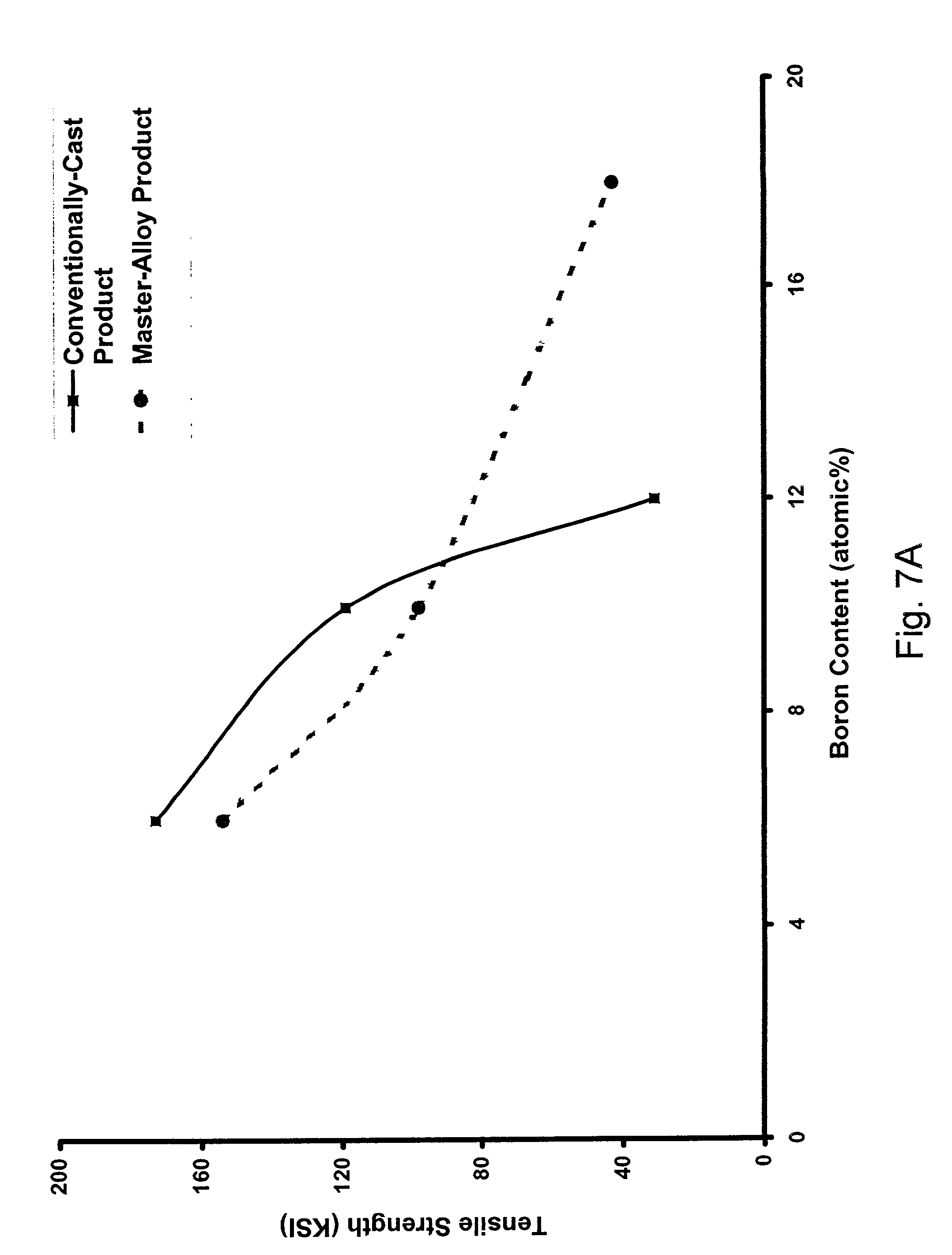

Mechanically alloyed precious metal magnetic sputtering targets fabricated using rapidly solidified alloy powders and elemental Pt metal

InactiveUS20020170821A1Improve featuresImprove manufacturabilityCellsVacuum evaporation coatingPlatinumAlloy

A cobalt-chromium-boron-platinum sputtering target alloy having multiple phases. The alloy can include Cr, B, Ta, Nb, C, Mo, Ti, V, W, Zr, Zn, Cu, Hf, O, Si or N. The alloy is prepared by mixing Pt powder with a cobalt-chromium-boron master alloy, ball milling the powders and HIP'ing to densify the powder into the alloy.

Owner:HERAEUS INC

Hot melt conductor paste composition

InactiveUS6814795B2Freeze fastHigh densitySemiconductor/solid-state device detailsConductive materialScreen printingWire gauze

The present invention provides a hot melt conductor paste composition that includes conductive particles and glass particles dispersed in a thermoplastic polymer system. The hot melt conductor paste composition according to the invention is a solid at room temperature, but melts at a temperature of from about 35.degree. C. to about 90.degree. C. to form a flowable liquid that can be applied to a silicon substrate by screen printing. The hot melt conductor paste composition is particularly suitable for use in the fabrication of photovoltaic cells.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

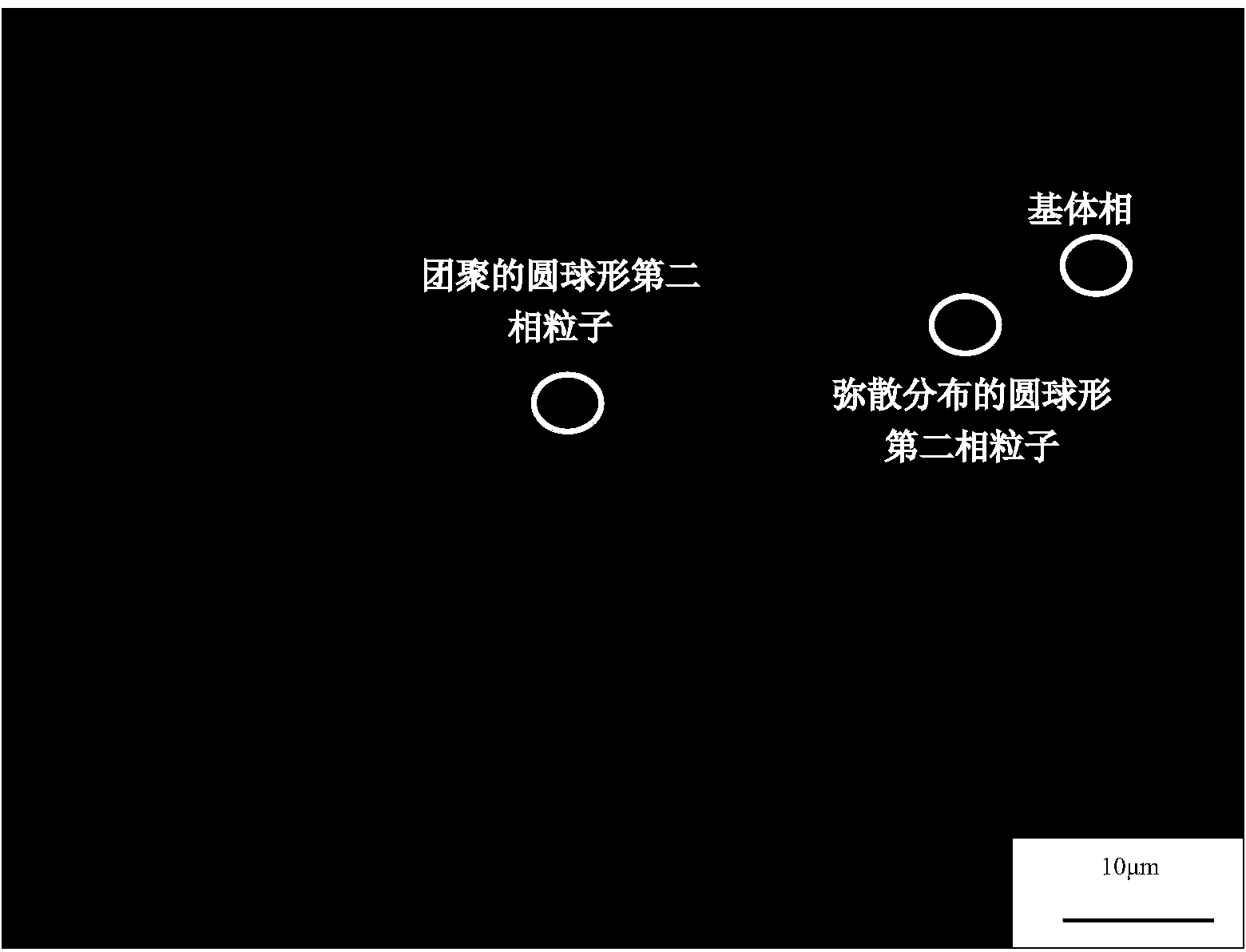

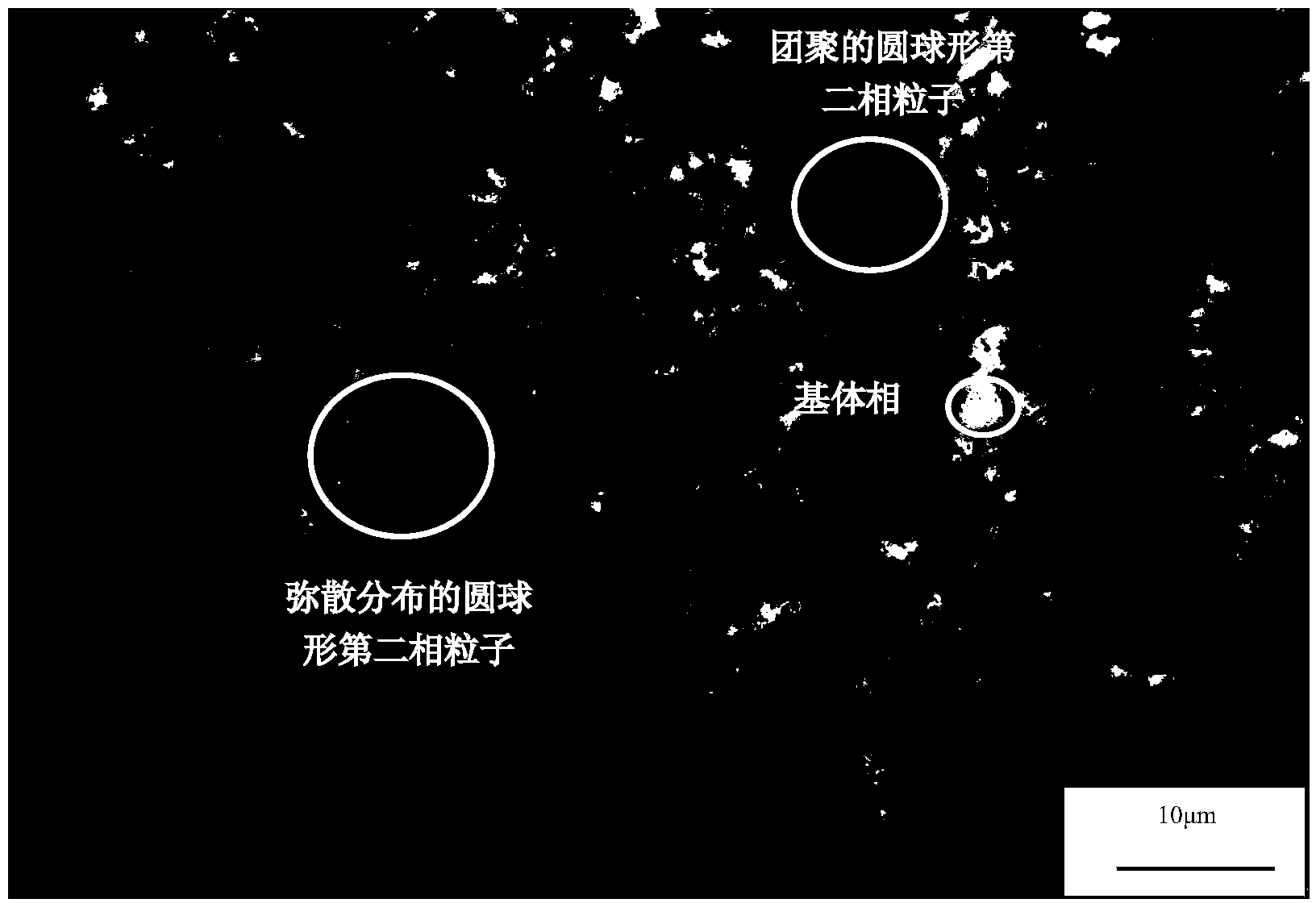

Preparation method of high-performance magnesium alloy plate with double-phase structure

The invention belongs to the technical field of non-ferrous metal magnesium alloy preparation and processing, and particularly relates to a preparation method of a high-performance magnesium alloy plate with a double-phase structure. In the method provided by the invention, a virgin alloy blank of a double-phase microstructure magnesium alloy is prepared by a spray deposition or quick-flow powder preparation or powder metallurgy process; the virgin alloy blank of the double-phase microstructure magnesium alloy is subjected to extrusion, forging, rolling and stamping 'pre-deformation' to form a pre-deformed blank with a 'double-phase texture'; and the pre-deformed blank is subjected to hot rolling or cold rolling to obtain the finished product. The magnesium alloy provided by the invention has the characteristics of 'double-phase structure' (consisting of fine alpha-Mg matrix phase and stable fine second-phase particles) and 'double-phase texture', and a magnesium alloy plate with good comprehensive performance can be obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Shelf life of polyol blends containing halogenated olefins by encapsulation of active components

ActiveUS20140371338A1Less reactivityProlong shelf-life stabilityActive componentThermoplastic polymer

The shelf life of polyurethane polyol pre-blends containing halogenated olefins is extended by encapsulation of active components such as catalysts and / or surfactants. The active component is encapsulated in a crystallizable or thermoplastic polymer. The encapsulated particles have a size of 2,800 microns or less and the active components are not significantly leaked out, particularly in the presence of halogenated olefins.

Owner:ARKEMA INC

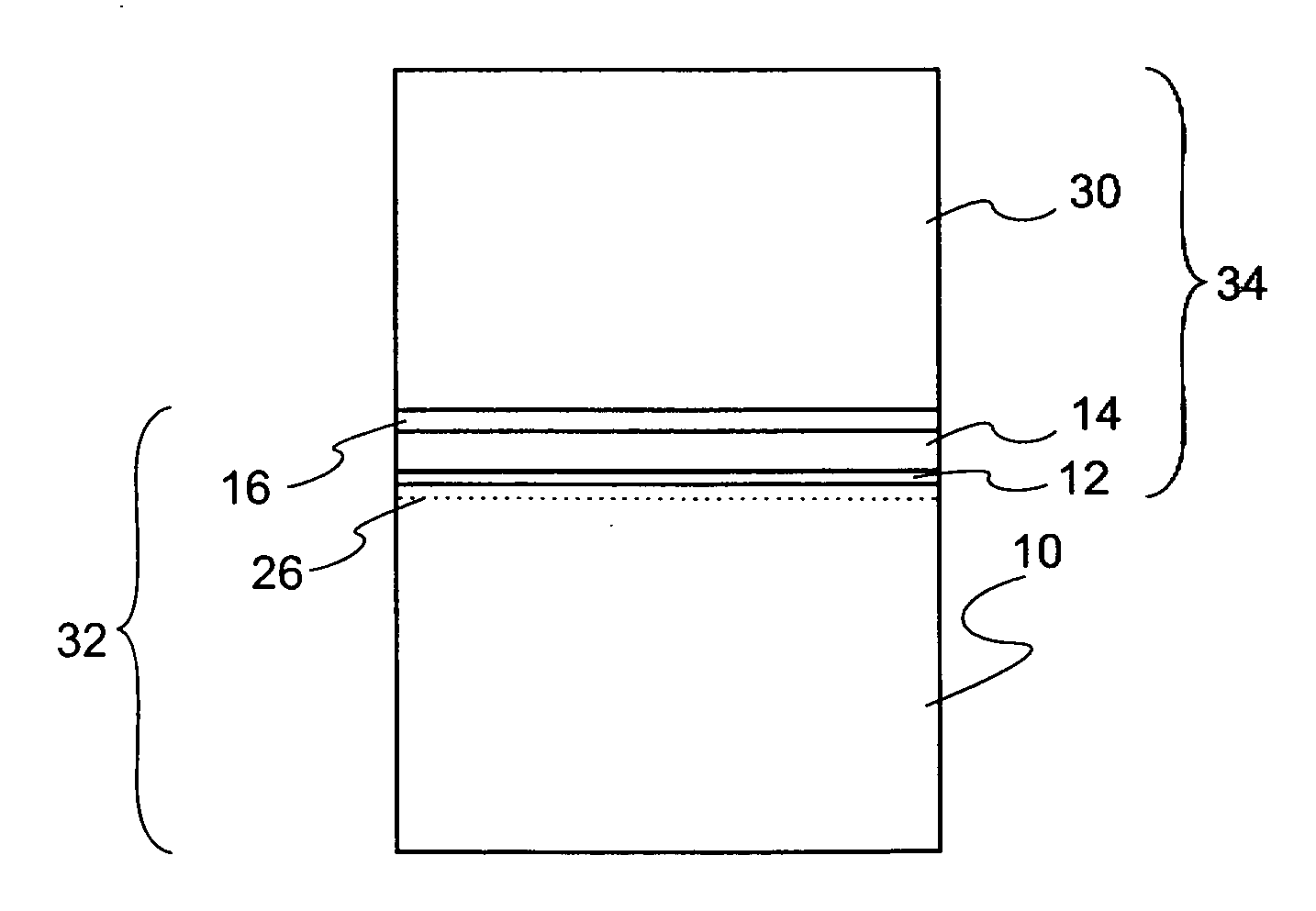

Relaxation of a strained layer using a molten layer

ActiveUS20060175608A1Freeze fastLarge diffusionSemiconductor/solid-state device manufacturingSemiconductor devicesInterface layerComputer science

A method for making a crystalline wafer, in which an interface layer is associated with a support substrate. A first layer is associated with the interface layer in a strained state. The interface layer is melted sufficiently to substantially uncouple the first layer from the support substrate to relax the first layer from the strained to state to a relaxed state. The interface material is solidified with the first layer in the relaxed state to obtain a first wafer.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

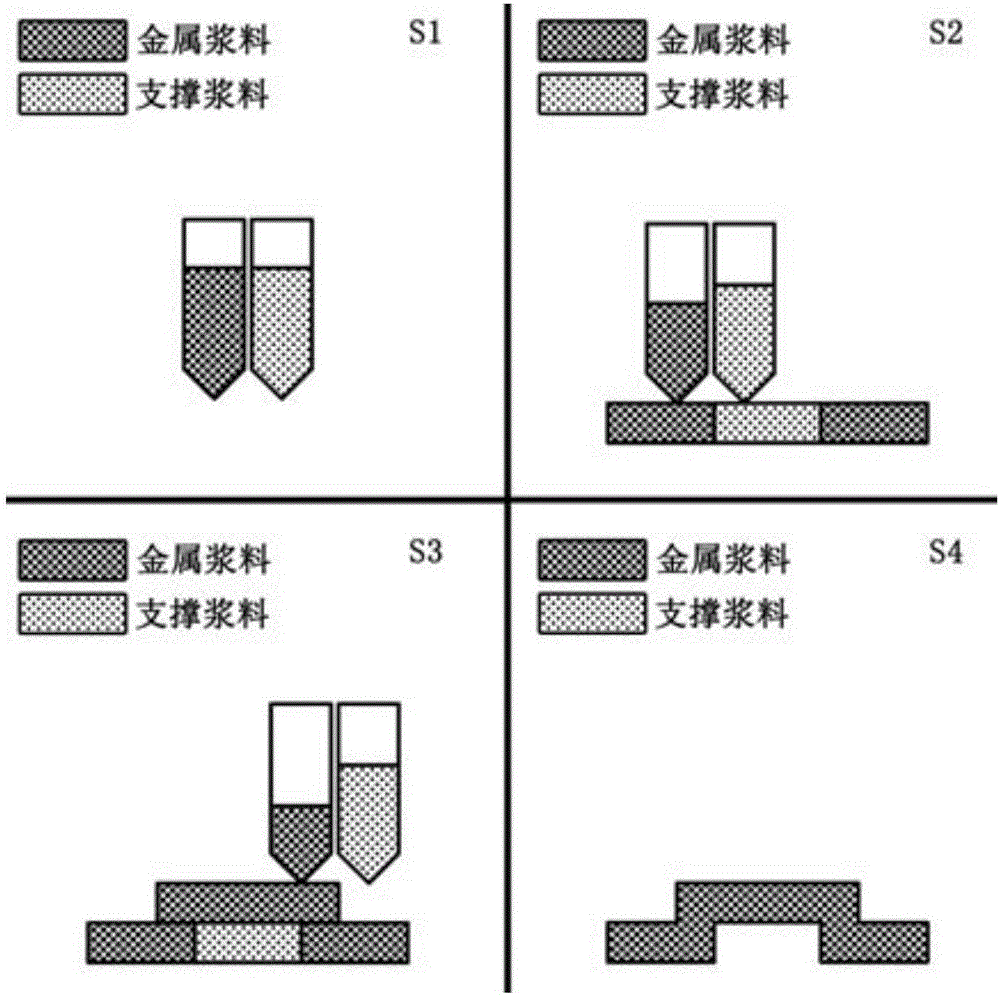

3D printing metal-complex-structure supporting slurry, metal slurry and printing method

InactiveCN106270512AFreeze fastGood removal effectAdditive manufacturing apparatusIncreasing energy efficiencySlurryEngineering

The invention discloses 3D printing metal-complex-structure supporting slurry, metal slurry and a printing method. The metal slurry and the supporting slurry are respectively charged into a storing device or a feeding device of a multi-nozzle 3D printer; in accordance with a mechanical control instruction, the metal slurry and the supporting slurry are respectively extruded at corresponding positions of a printing plate; a printing head raises or the printing plate descends a certain distance, and the metal slurry and the supporting slurry are respectively extruded again at corresponding positions in accordance with the mechanical control instruction, thereby overlapping the extruded metal slurry and supporting slurry on a previous layer of the metal slurry and supporting slurry. Hence, in accordance with the mechanical control instruction, the metal slurry and the supporting slurry are overlapped layer by layer until completion of printing of a model; by a series of post-processing procedures, the supporting slurry is removed and the metal slurry is sintered into dense metal parts, thereby completing manufacture of the metal parts with a complex structure. In the invention, the supporting slurry is easily removed from the metal parts, so as to realize more advantages in modeling of complex-metal-structure 3D printing.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

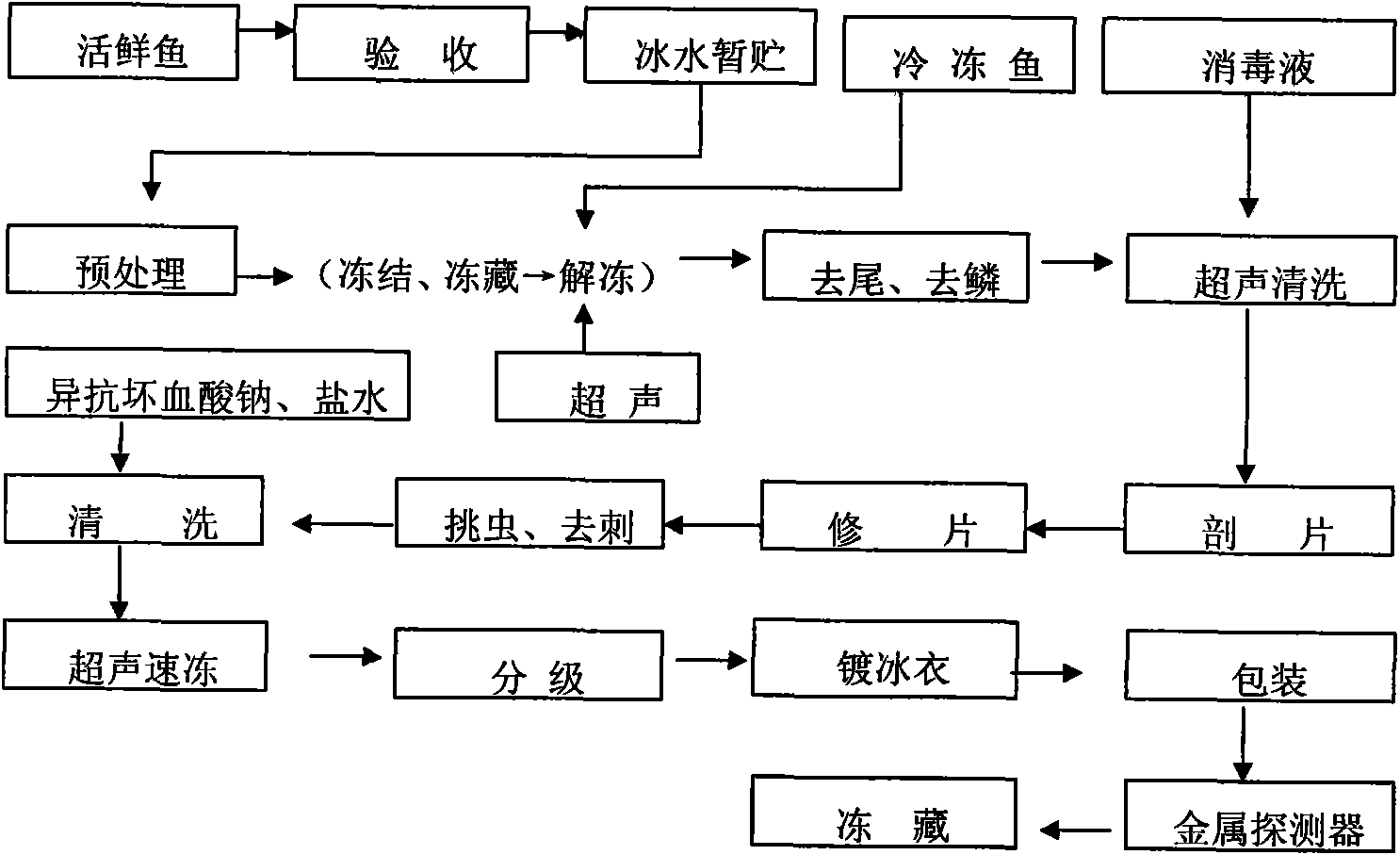

Processing method of sushi sashimi

InactiveCN101919539AExtended shelf lifeAvoid "cooking"Fish washing/descalingMeat/fish preservation by freezing/coolingIce waterAquatic product

The invention provides a processing method of sushi sashimi, which belongs to the field of processing of aquatic products. The processing method comprises the steps of taking a live fresh scaly fish as a raw material, carrying out acceptance, temporary storage in ice water and pretreatment, or taking a frozen scaly fish as the raw material, firstly carrying out ultrasonic thawing, further removing a tail, removing scales, carrying out ultrasonic cleaning, cutting into slices, trimming, picking out insects, removing bones, cleaning, carrying out ultrasonic quick freezing, classifying, glazing, packaging, carrying out metal detection, freezing, and carrying out other process steps for processing the sushi sashimi. The sushi sashimi processed by adopting the method has good quality, and the sensory, the physical and the chemical properties, as well as the safety sanitation quality are in line with requirements; furthermore, the processing method has short thawing time, short freezing time and high processing efficiency, and can be popularized in the processing of the aquatic products.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Spore-like cells and uses thereof

InactiveUS7575921B2Promote growthFreeze fastBiocideGenetic material ingredientsDiseaseSpore-like cells

Highly undifferentiated spore-like cells can be isolated from many different tissues and bodily fluids and used to treat a wide variety of disorders.

Owner:VCELL THERAPEUTICS

Aluminum alloys having iron, silicon, vanadium and copper

InactiveUS20160138400A1Facilitates selective heatingFreeze fastTurbinesAdditive manufacturing apparatusCopperSilicon

New aluminum alloys having iron, vanadium, silicon and copper are disclosed. The new alloys may include from 3 to 12 wt. % Fe, from 0.1 to 3 wt. % V, from 0.1 to 3 wt. % Si, and from 1.0 to 6 wt. % Cu, the balance being aluminum and impurities. The new aluminum alloys may be produced via additive manufacturing techniques, which may facilitate rapid solidification of a molten pool of the aluminum alloy.

Owner:ARCONIC INC

Preparation method of particle-reinforced magnesium-based composite material

The invention relates to a preparation method of a particle-reinforced magnesium-based composite material and aims at solving the problem that the particle-reinforced magnesium-based composite material prepared by an existing method is low in strength and poor in plasticity, particles are unevenly dispersed in magnesium alloy and the preparation time is long. The preparation method comprises the following steps of 1 preparing a magnesium alloy semi-solid melt; 2 preparing a particle-magnesium alloy melt; 3 enabling the particle-magnesium alloy melt to be solidified and formed. The preparation method has the advantages that the tensile strength and yield strength of the obtained particle-reinforced magnesium-based composite material are improved by 50%-150%, the highest elongation rate reaches to 8%; the particles are evenly dispersed in the magnesium alloy, the pore defect in the magnesium-based composite material is overcome; the process is simple, the preparation time is shortened by 15%-30%. The particle-reinforced magnesium-based composite material can be obtained by using the preparation method.

Owner:严格集团股份有限公司

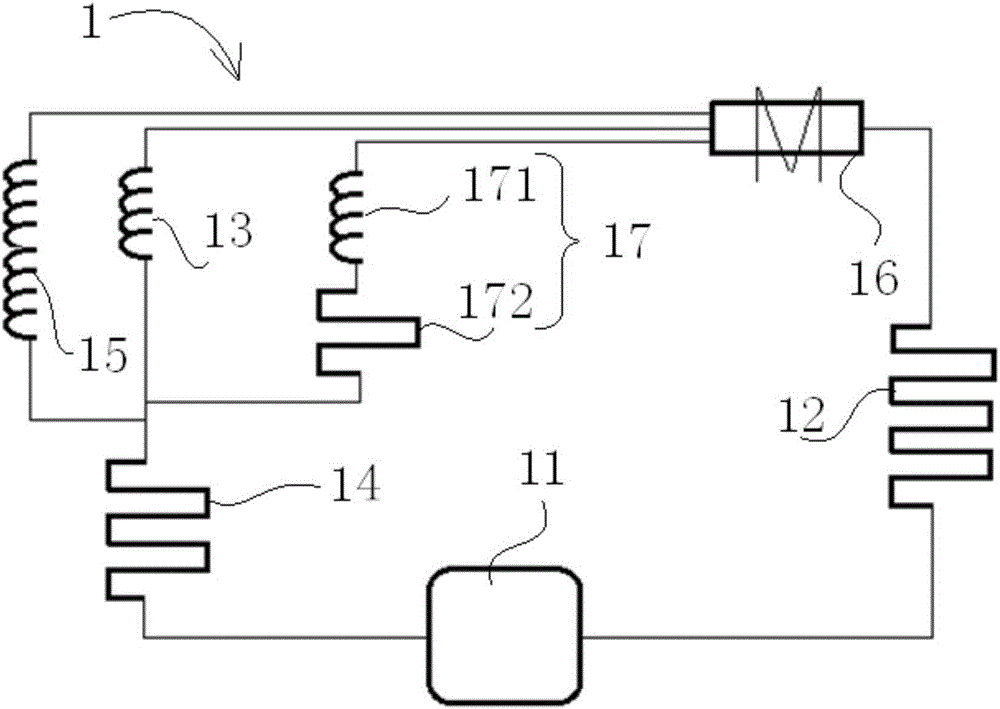

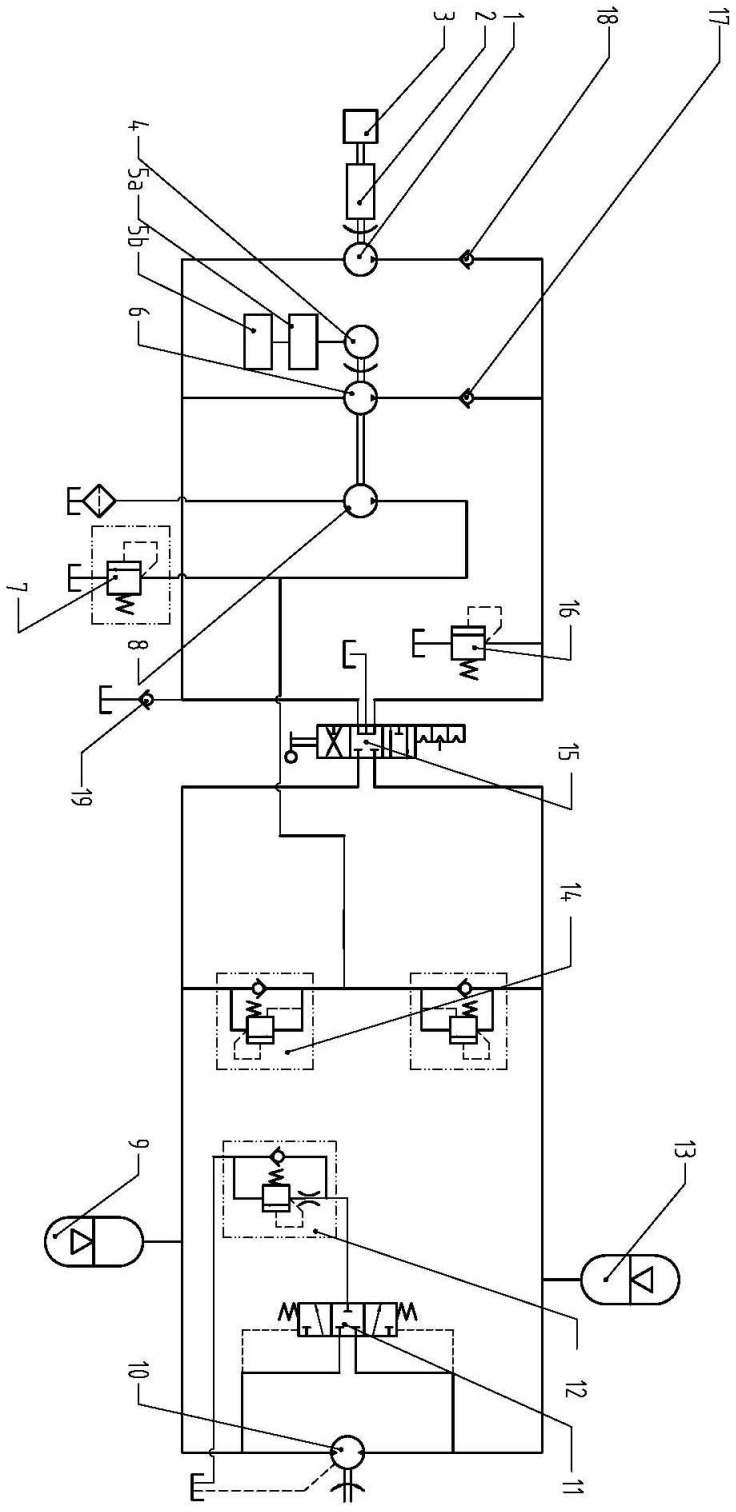

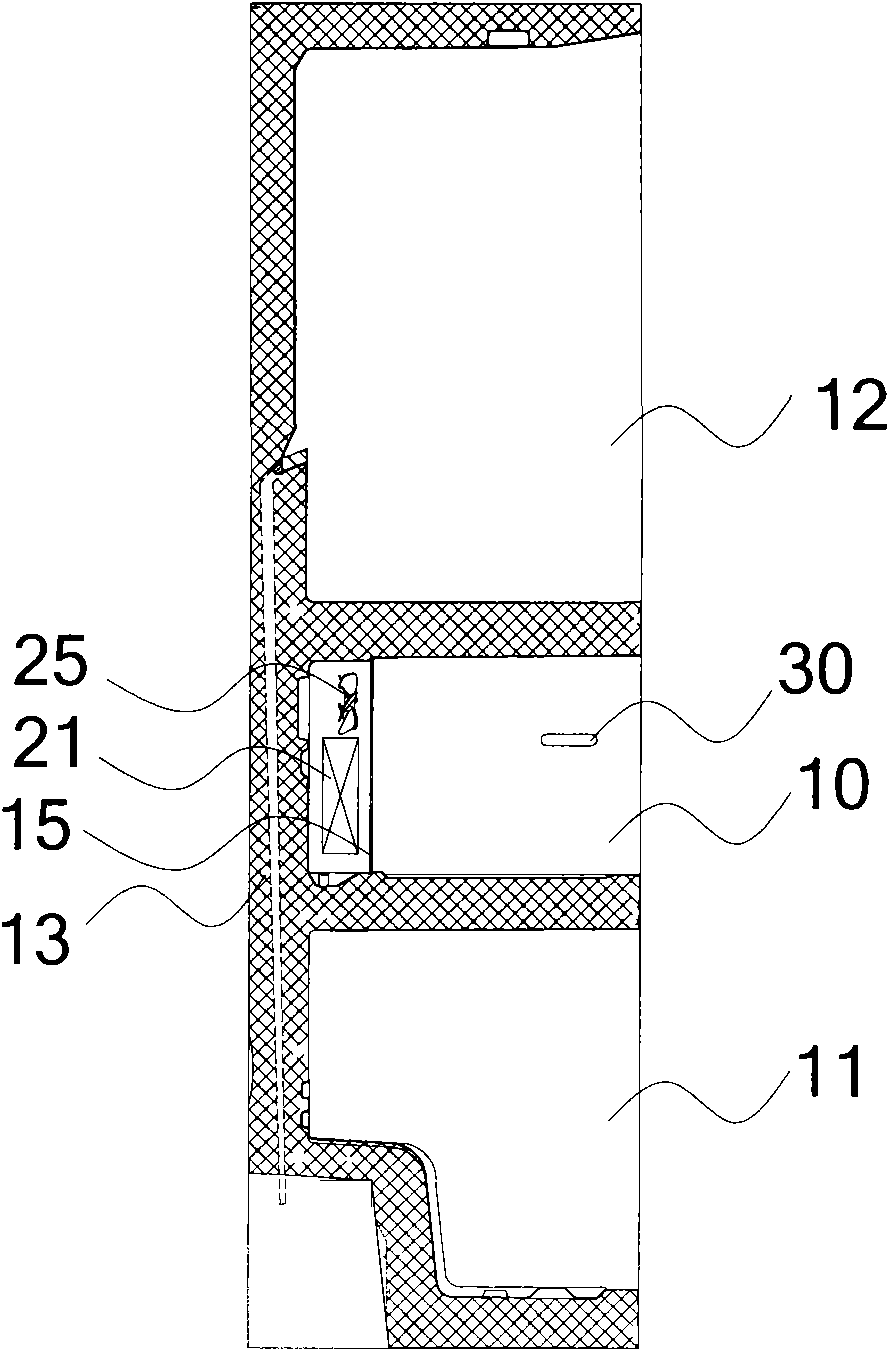

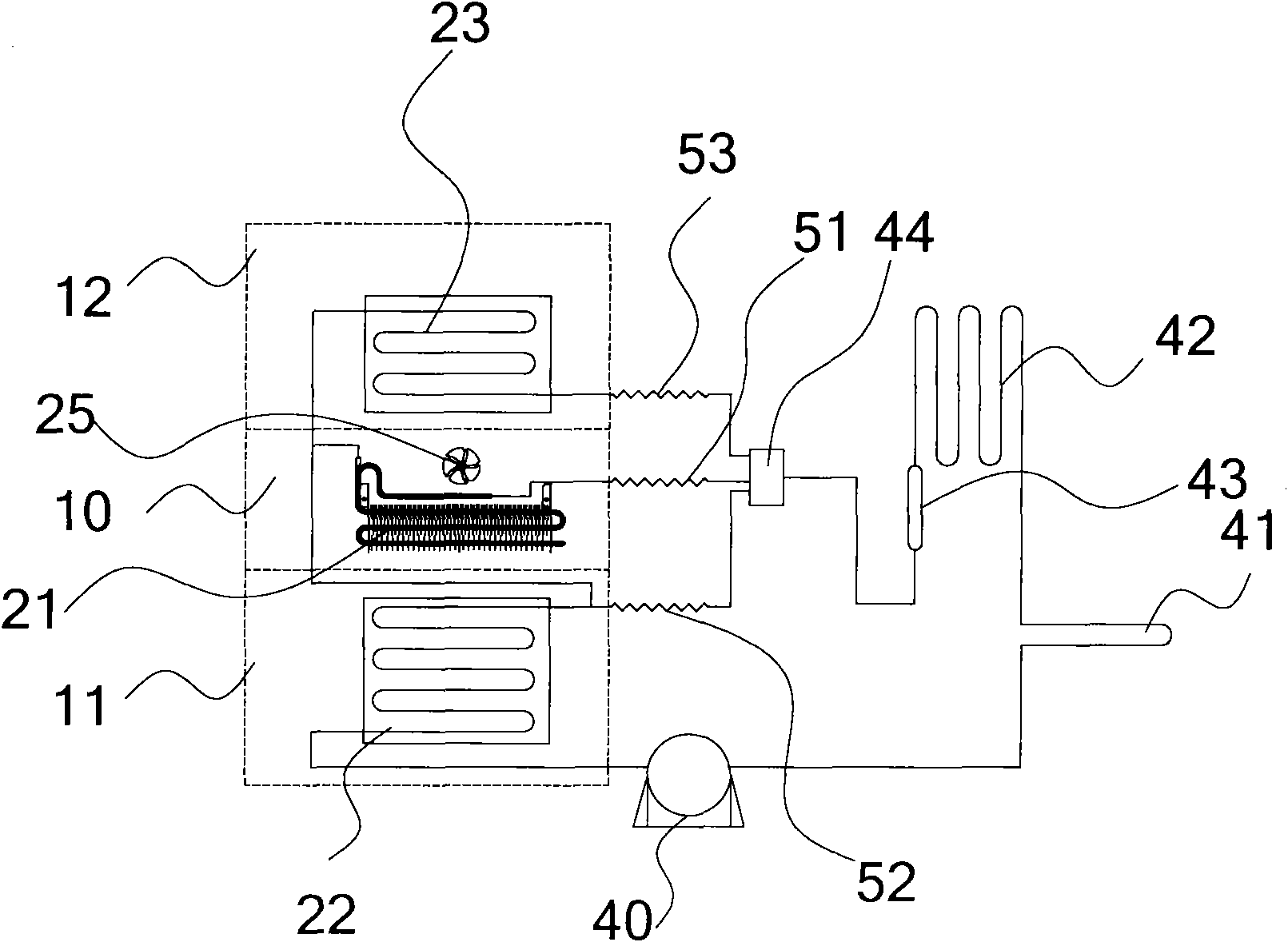

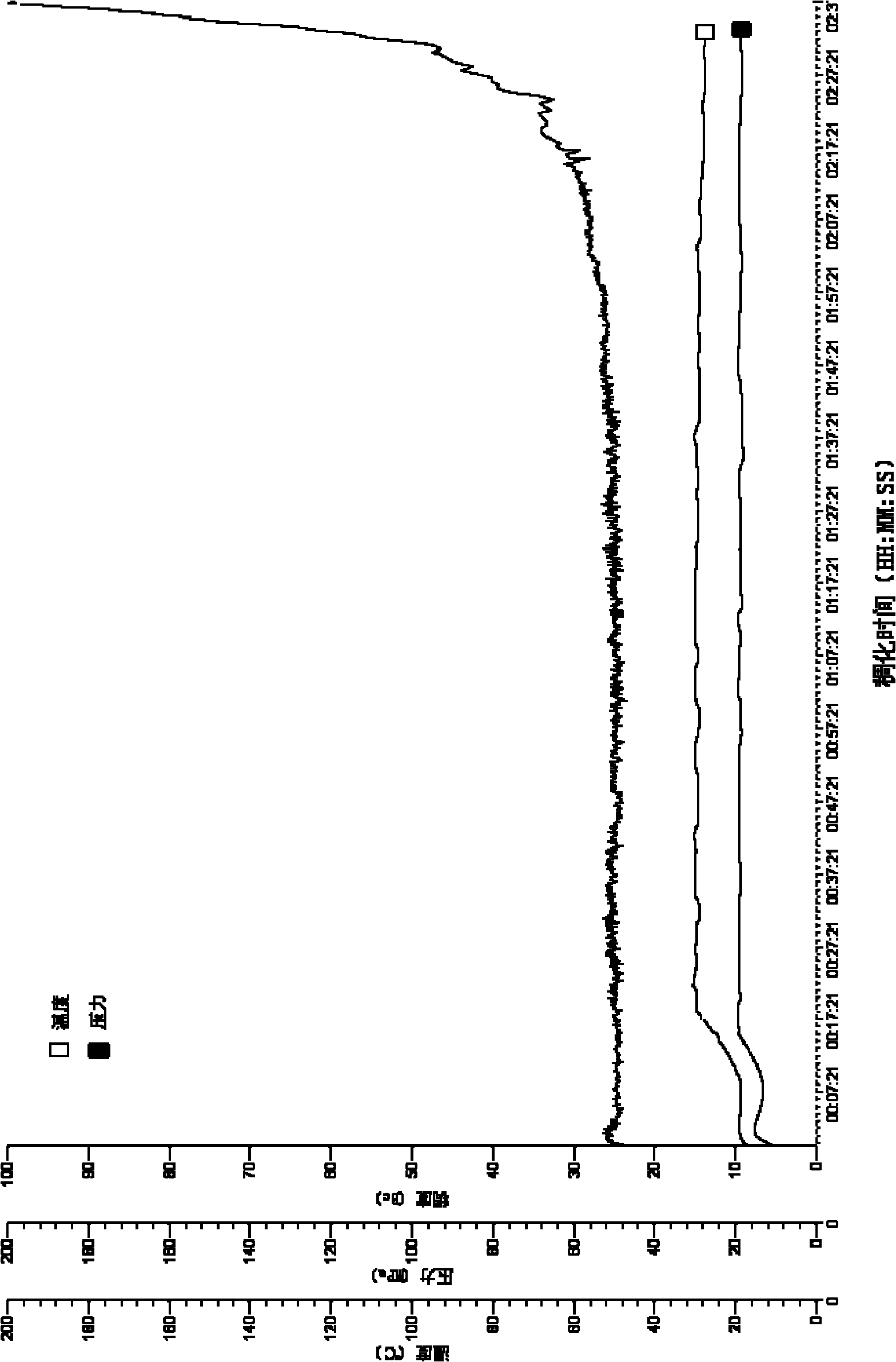

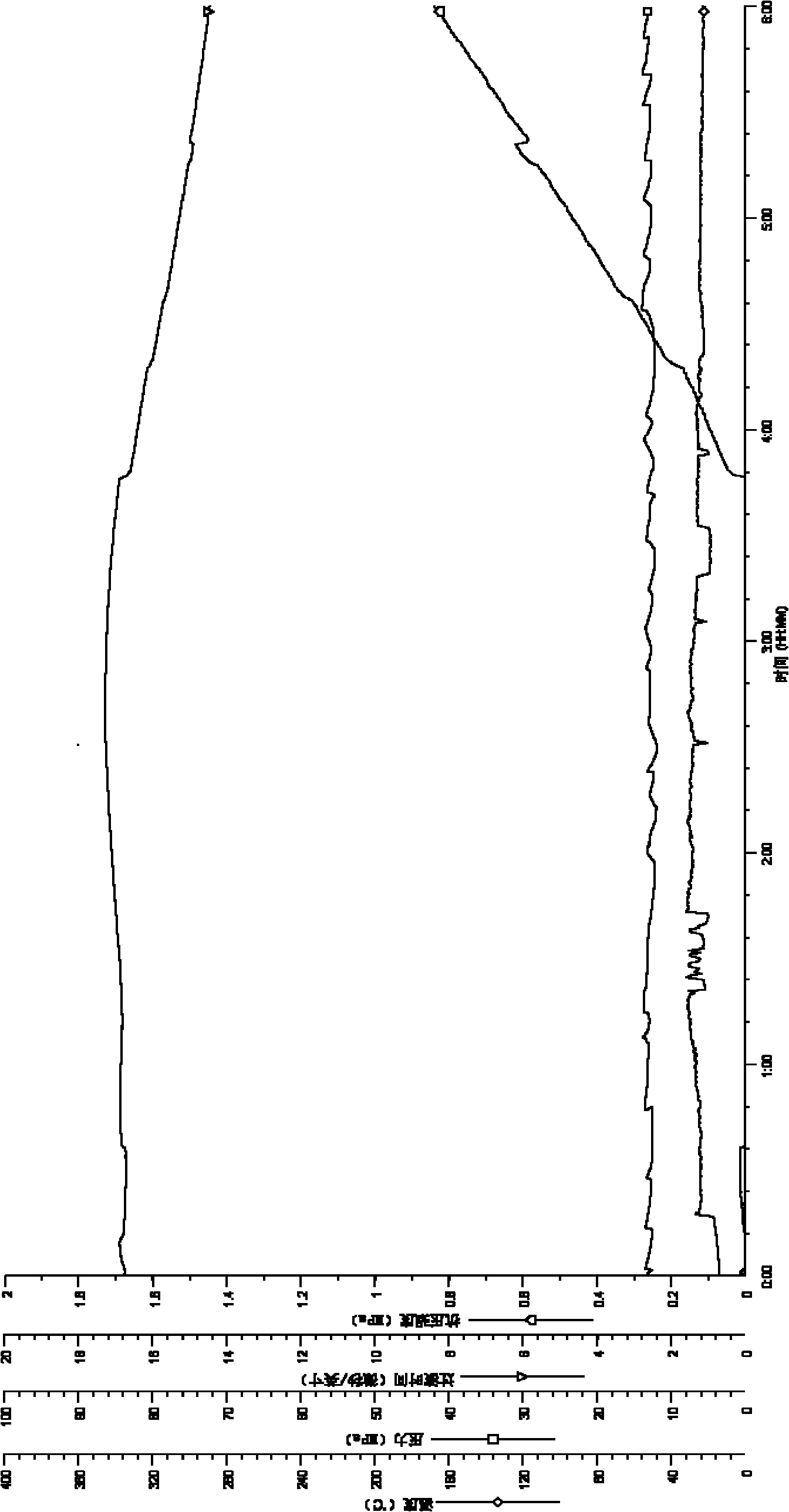

Refrigeration system of refrigerator with quick-freezing function, refrigerator and quick-freezing control method

InactiveCN106091538AReduce trafficLower evaporation temperatureLighting and heating apparatusDomestic refrigeratorsQuick FreezeControl system

The embodiment of the invention provides a refrigeration system of a refrigerator with a quick-freezing function, the refrigerator and a quick-freezing control method, and relates to the technical field of refrigeration equipment. The refrigeration system of the refrigerator with the quick-freezing function, the refrigerator and the quick-freezing control method are invented for solving the problem that a quick-freezing chamber of an existing refrigerator is poor in quick-freezing effect. A control system of the refrigerator with the quick-freezing function comprises a compressor, a condenser, a freezing capillary tube and a freezing evaporator which are in serial connection in sequence to form a loop; quick-freezing capillary tubes are in parallel connection with the two ends of the freezing capillary tube, and the length of the quick-freezing capillary tubes is larger than that of the freezing capillary tube; and an electromagnetic valve is further included, and a refrigerant is controlled by the electromagnetic valve to flow to the freezing capillary tube or quick-freezing capillary tubes. The refrigerating system of the refrigerator with the quick-freezing function, the refrigerator and the quick-freezing control method are used for low-temperature storage of food.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Lead-free solder alloys

InactiveUS6503338B1High bonding strengthAvoid heat damageWelding/cutting media/materialsSoldering mediaMelting temperatureLiquidus

A lead-free solder alloy which has a relatively low melting temperature and which is suitable for soldering electronic devices consists essentially of from 5 to 9 mass % of Zn, from 2 to 15 mass % of Bi, optionally from 0.001 to 1 mass % of P or from 0.001 to 0.1 mass % of Ge, and a balance of Sn. The solder alloy has a liquidus temperature of at most 220° C.

Owner:SENJU METAL IND CO LTD

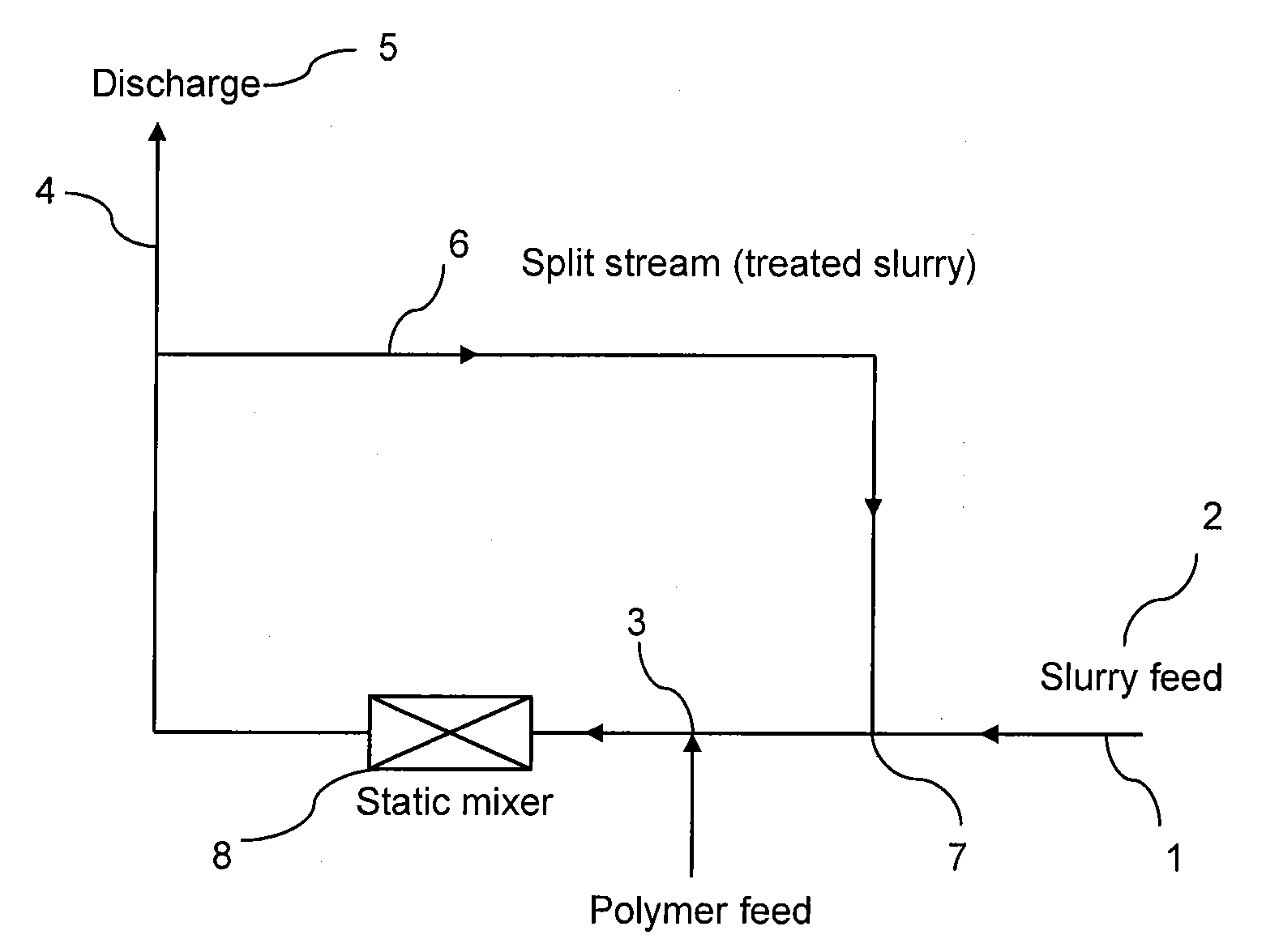

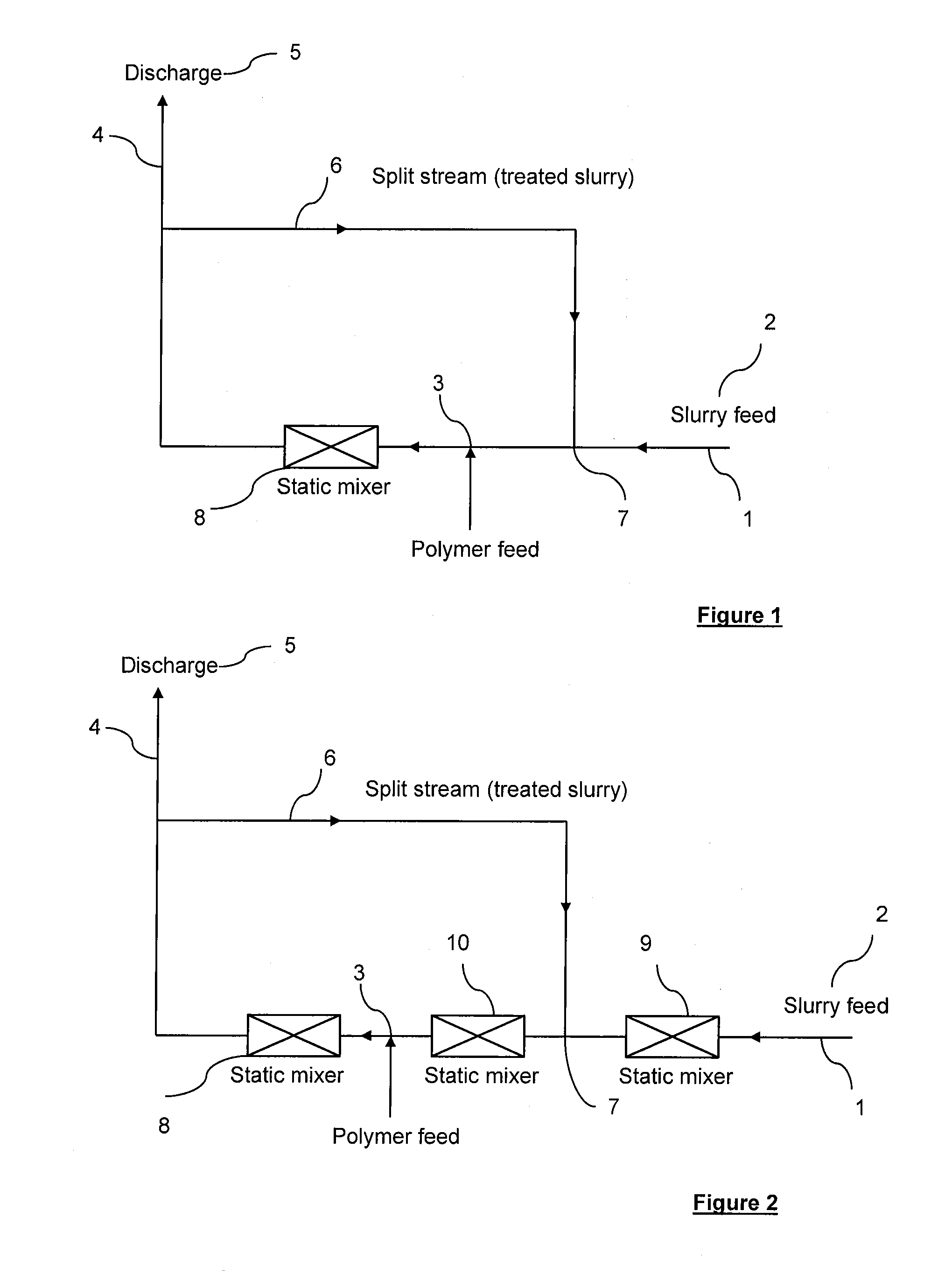

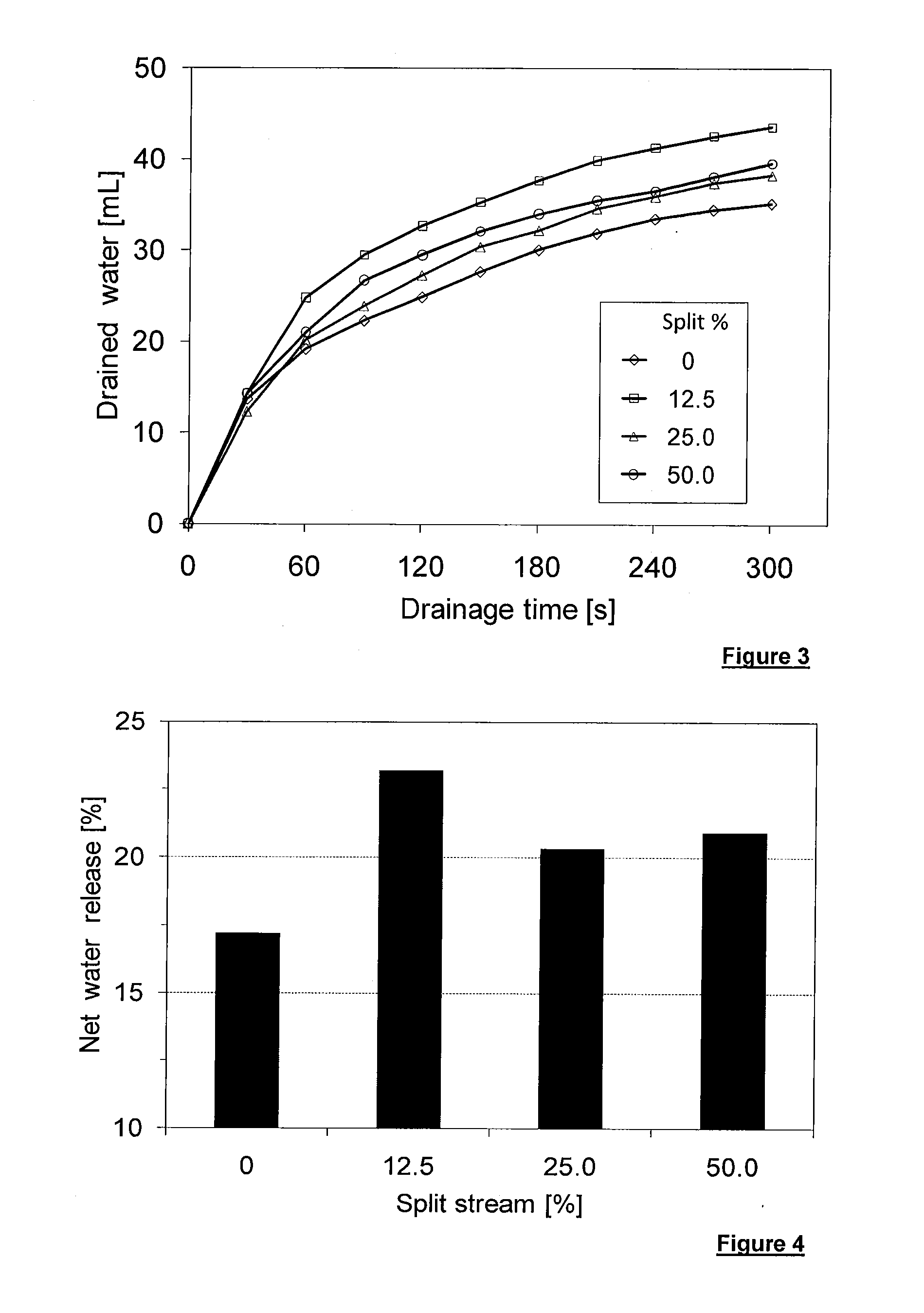

Process for improving inline tailings treatment

InactiveUS20120138542A1Improve processing efficiencyEasily improve performanceTransportation and packagingSolid waste disposalFlocculationPolymer science

A process for improving inline mineral slurries treatment comprises successively: providing an in-line flow of slurries in a main stream; introducing at least one polymer into the main stream through at least one polymer injection point to cause dispersion of the polymer and to start the coagulation and / or the flocculation of slurries to produce treated slurries; and splitting the main stream containing treated slurries into two streams respectively: a discharge stream which directly transfers a part of treated slurries to the deposit area, and a split stream which reintroduces the other part of treated slurries into the main stream through at least a reinjection point in a location prior to the at least one polymer injection point.

Owner:S P C M SA

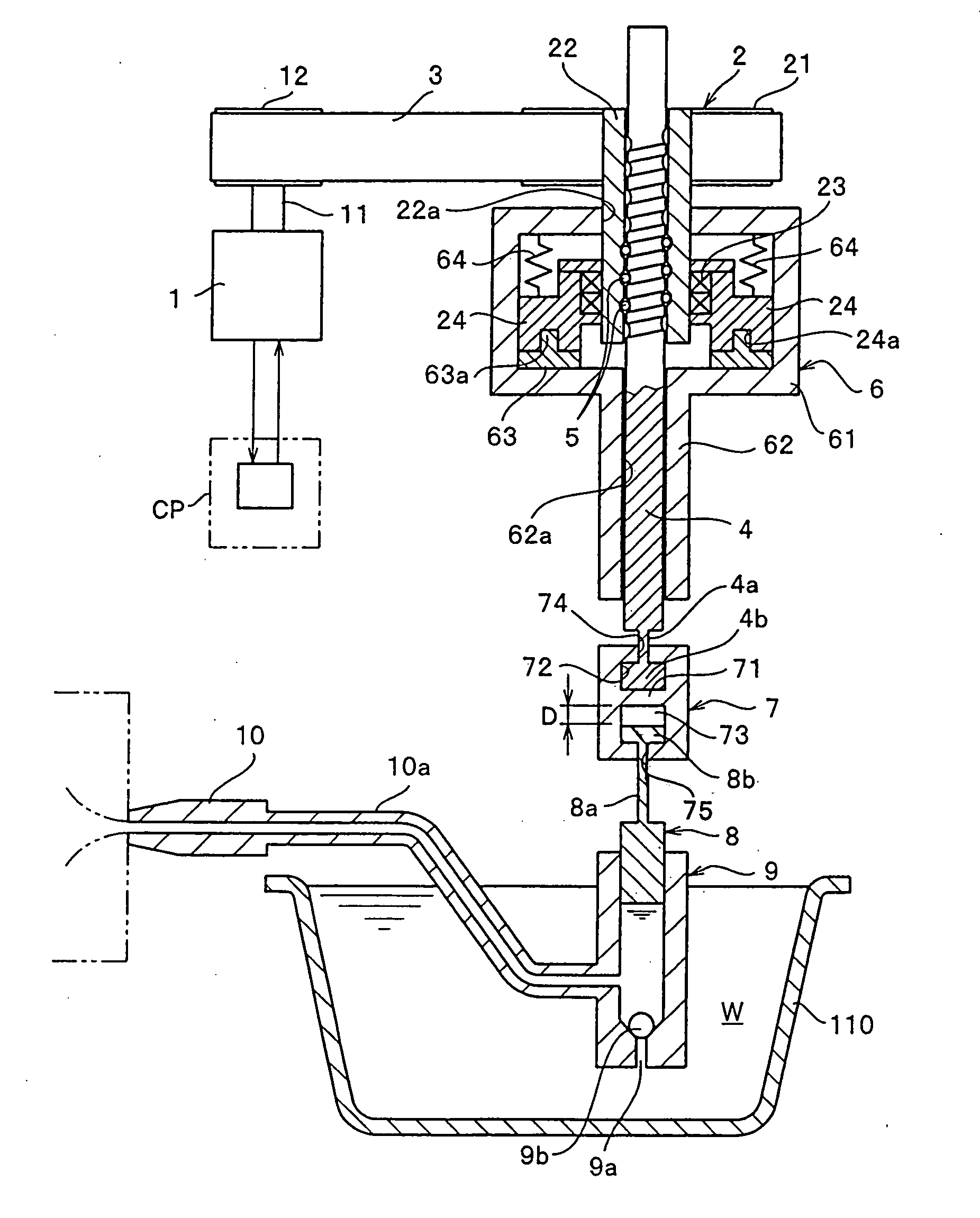

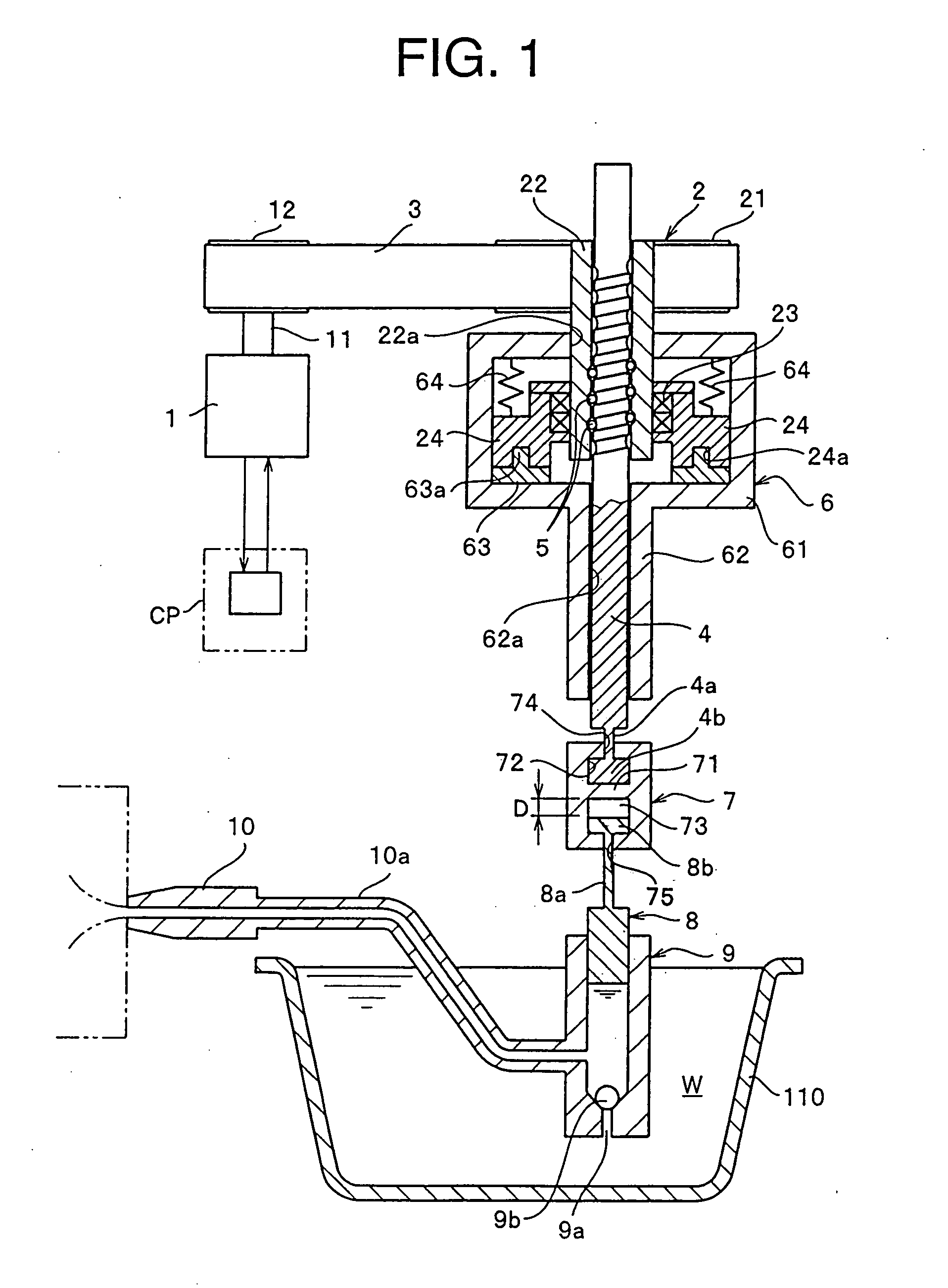

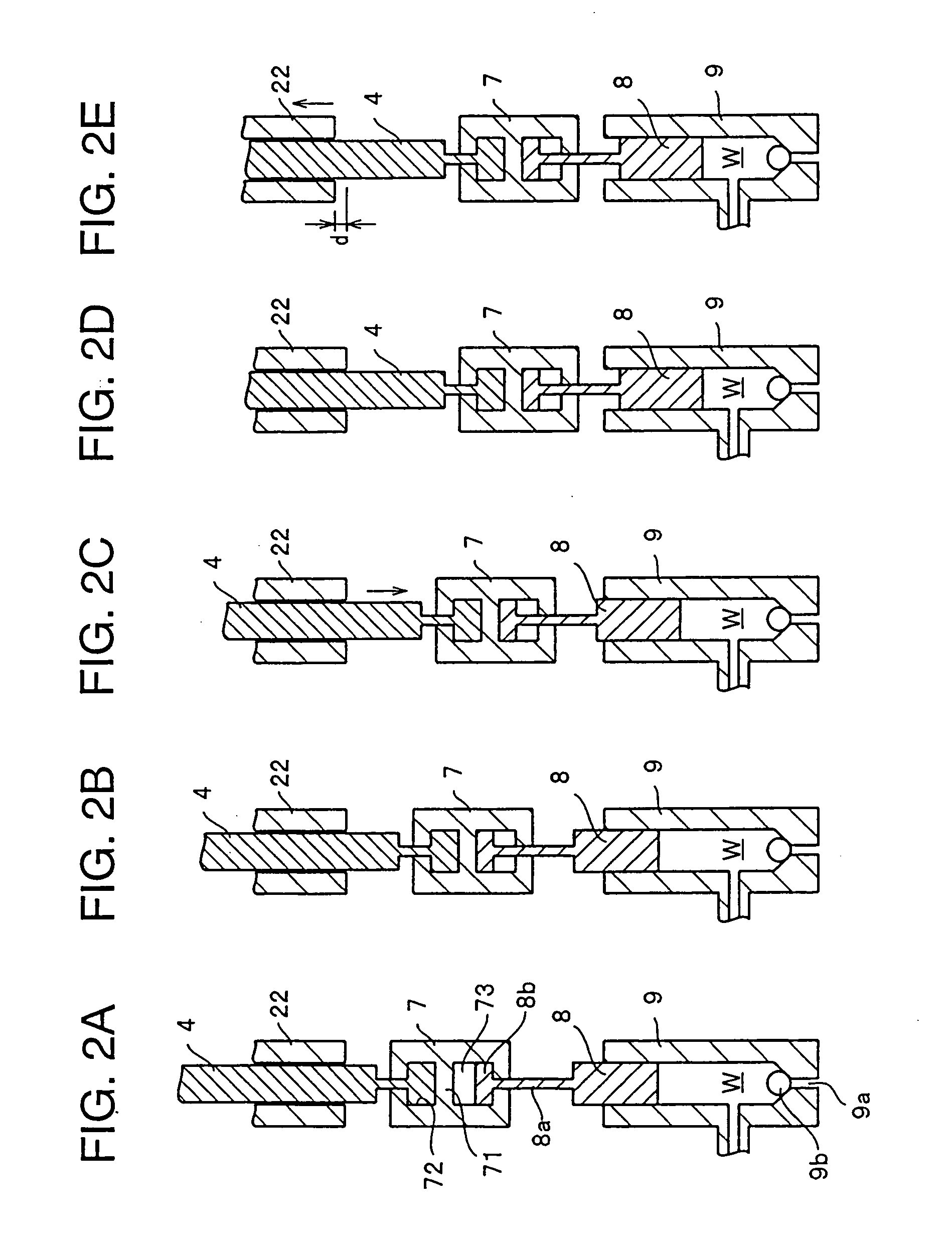

Motor drive injection unit, die cast machine having the unit, and motor drive injection method

InactiveUS20060124269A1Freeze fastEfficient implementationMolten metal supplying equipmentsEngineeringRotation control

In a motor drive injection unit and a motor drive injection method, which can obtain an injection speed suitable for a molding material having fast solidifying speed as well as can securely carry out pressure keeping for a predetermined period of time while making a position of an injection piston unmovable after injection and filling are completed, a molding material in a cylinder is injected into a metal mold by converting a rotational motion of an electric servo motor into a reciprocating motion of an injection piston in the cylinder through a plunger with a ball screw, a surge pressure control means is provided for placing the injection piston in the cylinder in an unmovable state when at least a predetermined amount of a load is applied to the injection piston by the molding material in the cylinder, the surge pressure control means includes a combination of rotation control means of the electric servo motor and an upward movement suppression mechanism of the injection piston, and further, an injection speed of the injection piston is increased by providing a time difference between initial motions of the plunger and the injection piston.

Owner:YKK CORP

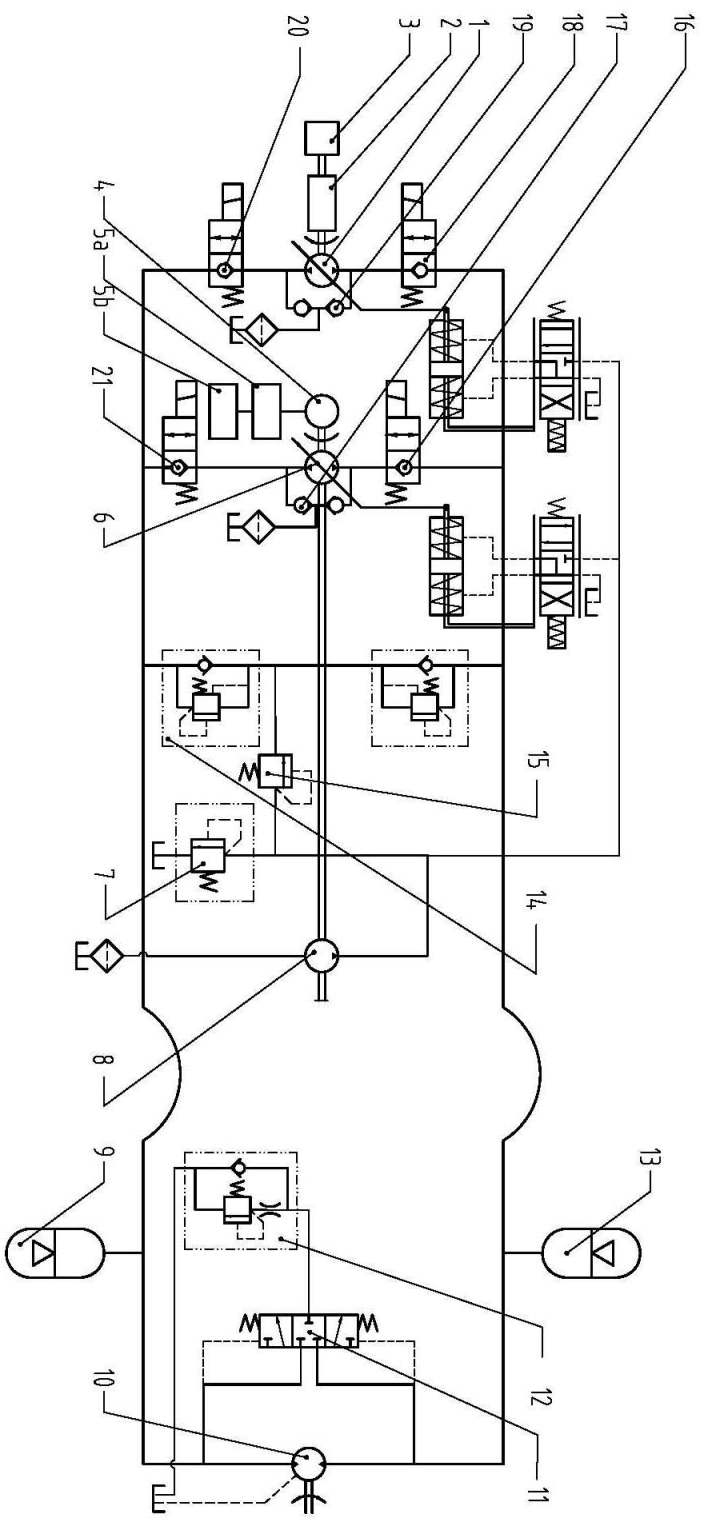

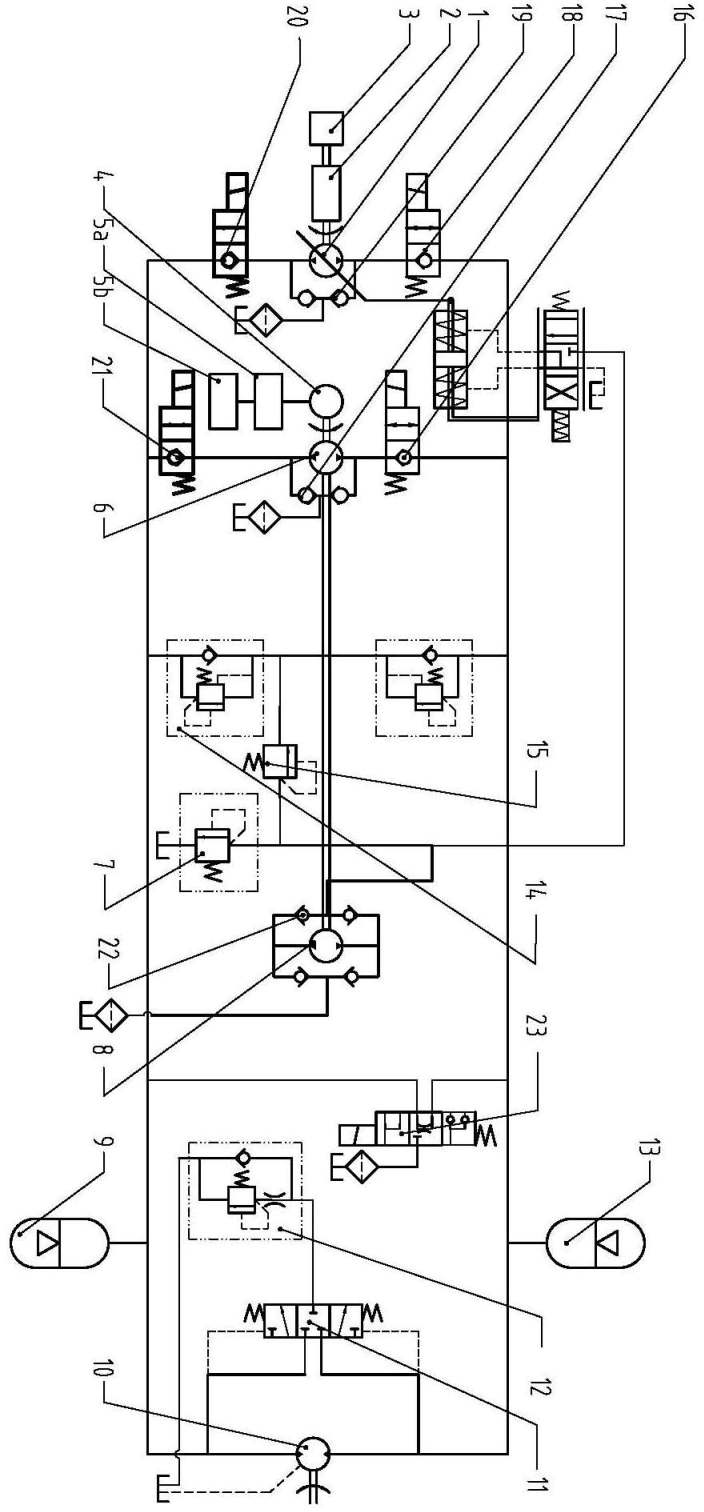

A new type of rotating drive system for mixing drum of concrete mixer truck

InactiveCN102275223AReduced power ratingImprove work efficiencyCement mixing apparatusPrime moverHydraulic motor

The invention relates to a novel rotation driving system for a mixing drum of a concrete mixing transport vehicle. In the system, two prime movers, two hydraulic main pumps, an oil supply pump and a hydraulic motor form a hydraulic closed loop together with a hydraulic valve block with the functions of relatively completing oil supply, cooling and safe buffering; the delivery volumes of the two hydraulic main pumps are different; and the low-delivery volume hydraulic main pump is used for separately realizing slow and constant mixing action of the mixing drum, and the high-delivery volume hydraulic main pump is used for rotating the mixing drum along positive and negative directions at a high speed during feeding and discharging when separately operated or combined with the low-delivery volume hydraulic main pump. The system aims to solve the problems of the influence on the concrete uniformity and the influence on the driving dynamic performance and driving safety performance which are caused by driving a roller to rotate by separately using a chassis engine under different working conditions and different road conditions in the mixing drum, fuel waste caused by the long-term operation of the high-power chassis engine at low-efficiency points and the hydraulic shock generated during the switching of the mixing drum under different working conditions.

Owner:SICHUAN UNIV

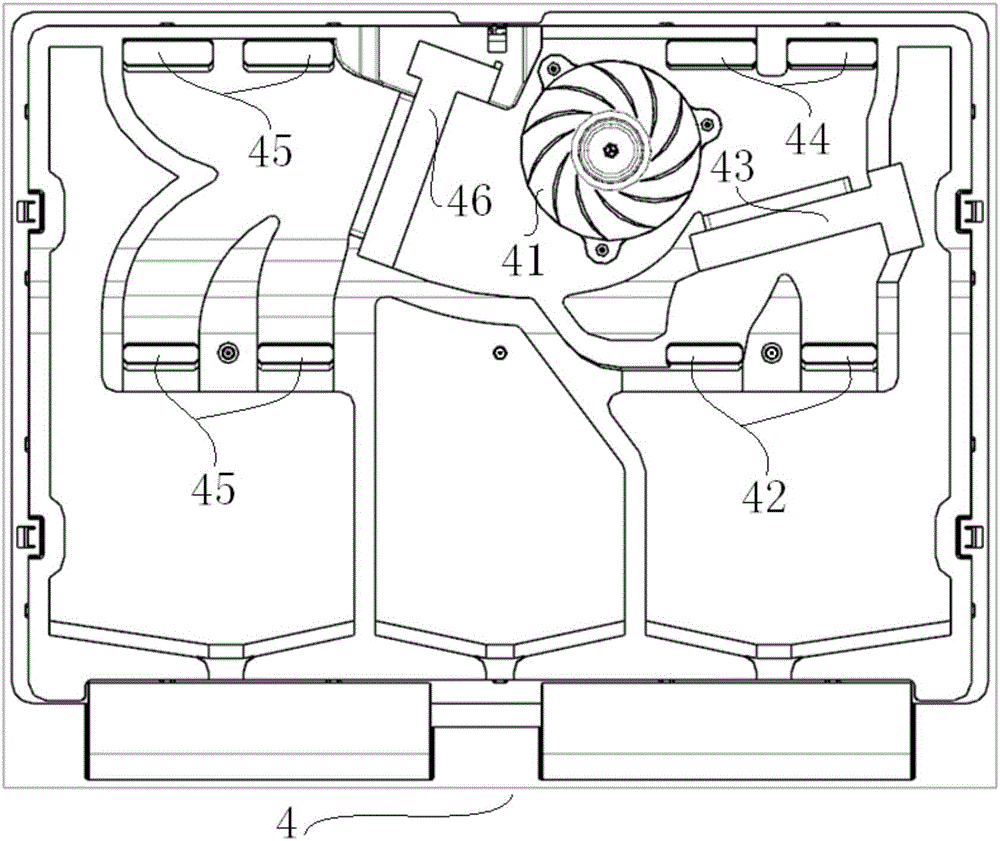

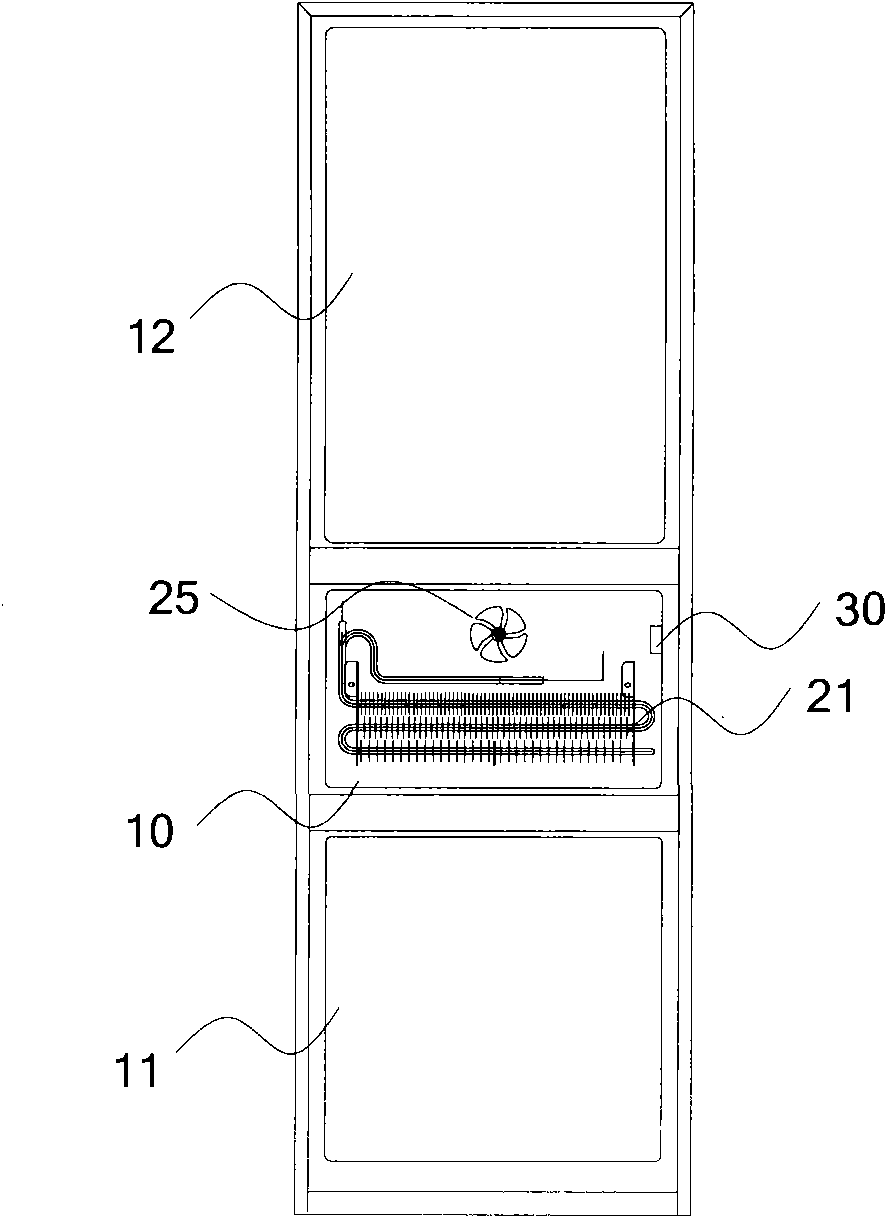

Refrigerator

InactiveCN101871715AImprove cooling effectFreeze fastDomestic refrigeratorsCompression machines with several evaporatorsCold airQuick Freeze

The invention discloses a refrigerator which comprises a freezing chamber and at least one temperature-changing chamber and is internally provided with a finned evaporator, a fan and temperature sensors, wherein the finned evaporator is arranged on the rear wall of the temperature-changing chamber or / and the freezing chamber; the fan is arranged beside the evaporator and used for providing the cold air of the evaporator for an indoor room; and the temperature sensors are arranged in the temperature-changing chamber and the freezing chamber. The temperature-changing chamber or / and the freezing chamber of the refrigerator of the invention has / have strong refrigerating effect and can enable foods to be rapidly frozen through an ice crystal area at the temperature of -1 to -5 DEG C, thereby the original freshness and the nutrient components of the foods are kept to be not lost; the foods are kept to be stored at the low temperature of -30 DEG C, thereby the storage time of the foods is prolonged.

Owner:HAIER GRP CORP +1

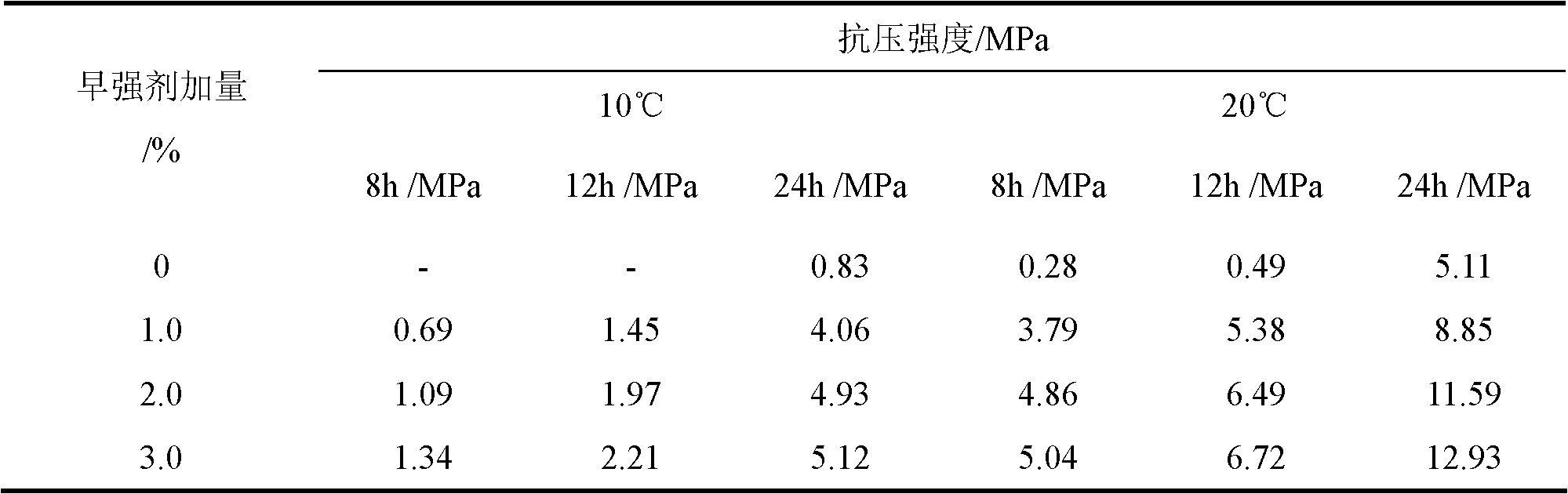

Deepwater cementing low-temperature early strength agent

InactiveCN101864285APromotes hydration processImprove compactnessDrilling compositionTriisopropanolamineCement paste

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Cold mold

InactiveUS7234308B1Freeze fastIncrease production capacityMould separation apparatusLaboratory glasswaresTissue specimenThermal water

A metallic, reusable mold with one or more wells. The mold is kept within a cryostat at low temperature. The mold is removed from the cryostat and a tissue specimen is placed into a well within the mold. An embedding medium is added to the well around the tissue specimen. A pre-chilled chuck is then placed against the well opening. The mold with tissue specimen, embedding medium and chuck are returned to the cryostat and the specimen is frozen into a block. The mold and contents are removed and hot water poured against the mold releasing the block with attached chuck from the well. The chuck with attached block is then available for sectioning or other processing.

Owner:CRITZ CARL H

Method for preparing air inlet edge surface wear-resistant anti-corrosion alloy coating of tail stage blade of steam turbine

InactiveCN102453896AMelting fastFreeze fastMetallic material coating processesNumerical controlEdge surface

The invention relates to a method for preparing an air inlet edge surface wear-resistant anti-corrosion alloy coating of a tail stage blade of a steam turbine. The method is characterized by comprising the following steps that: 1) the air inlet edge surface of the tail stage blade of the steam turbine is pre-treated; 2) alloy powder is selected, and an automatic powder conveyor is regulated; 3) light beams are regulated; 4) the wear-resistant anti-corrosion coating laser cladding is carried out, a DL-HL-T5000 type CO2 laser is adopted, a work table is a SIMENS numerical control laser processing machine, a synchronous powder conveyor is adopted for conveying the alloy powder into a laser molten pool, high-power focus laser beams and an automatic powder conveying head are fed in the specified direction of the air inlet edge surface of the blade, and uniform and compact laser cladding layers are formed on the blade surface through processing; and 5) flaw detection is carried out after the cladding. According to the method, the laser cladding is adopted for uniformly cladding the alloy powder with the wear-resistant anti-corrosion performance onto the blade of the steam turbine, the uniform and compact metallurgical combining coatings are formed, the anti-corrosion performance reaches the stainless steel level, the cladding layer and a substrate form firm metallurgical combination, and the peeling is not easy to occur.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

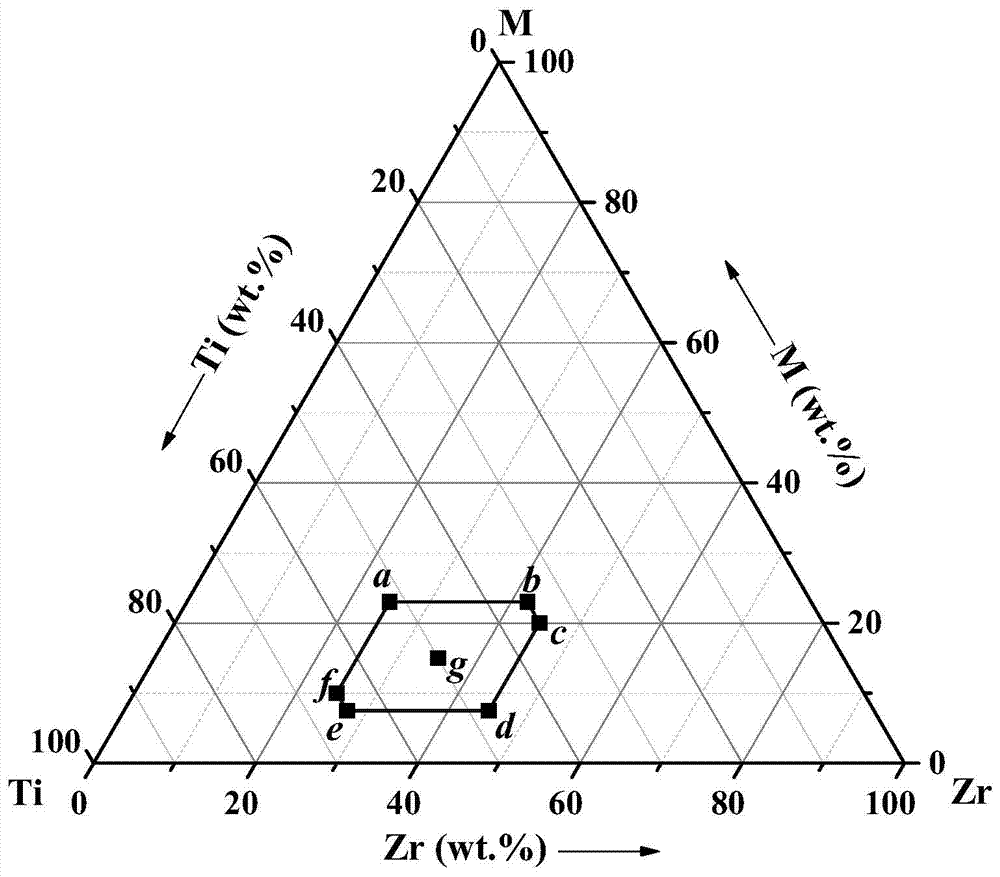

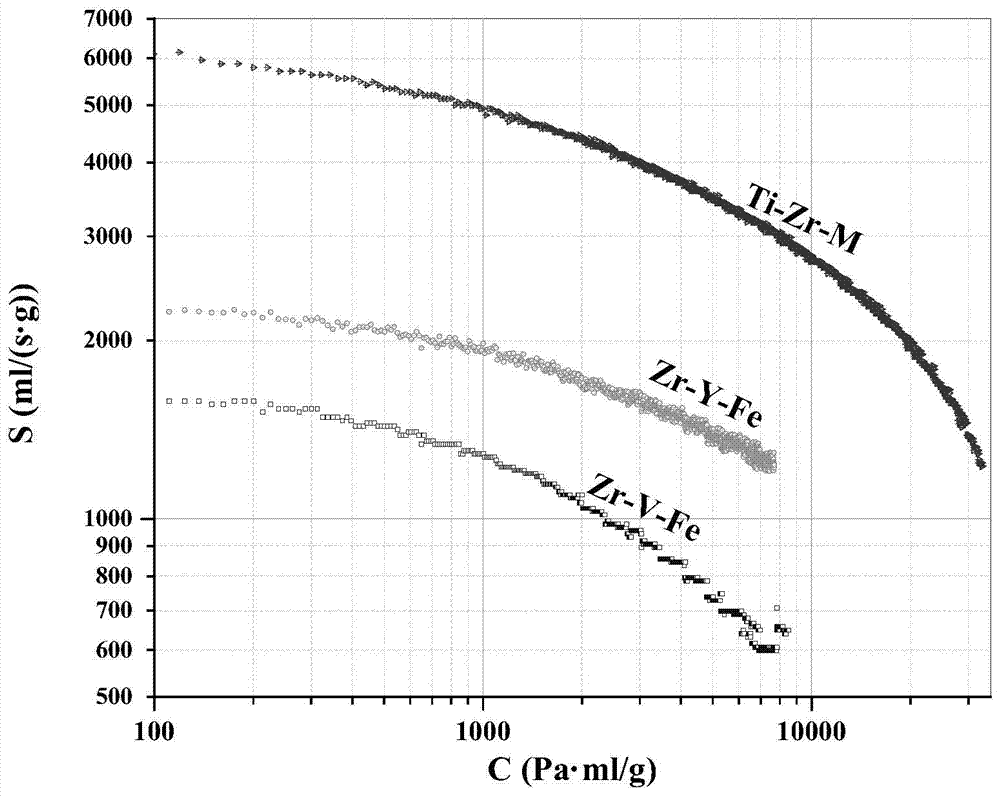

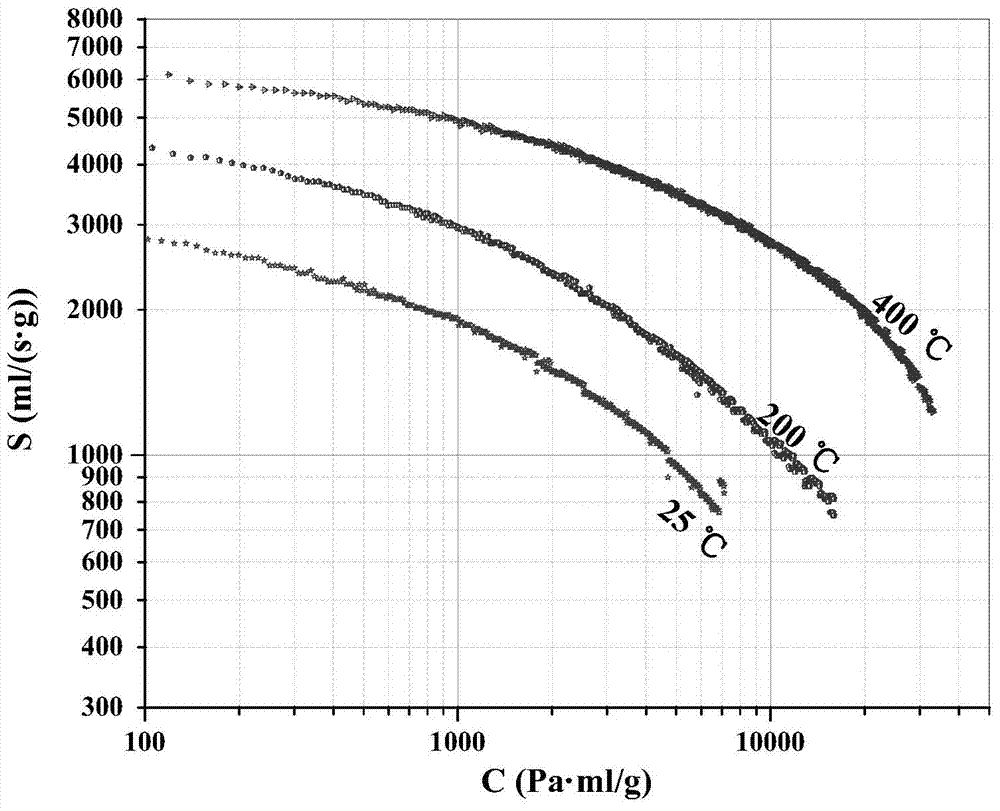

Ti-Zr based light-weight high-capacity hydrogen absorption material, and preparation method and application method thereof

The invention relates to a Ti-Zr based light-weight high-capacity hydrogen absorption material, and a preparation method and an application method thereof. The Ti-Zr based light-weight high-capacity hydrogen absorption material comprises, by weight, 35.0 to 65.0 parts of titanium, 25.0 to 45.0 parts of zirconium, 5.0 to 19.0 parts of a transition metal, and 2.5 to 5.0 parts of a rare earth metal; wherein the transition metal is one or more than two selected from V, Cr, Mn, Fe, Co, Ni, Cu, and Mo, and the rare earth metal is one or more than two selected from La, Ce, and Pr. According to the application method, the Ti-Zr based light-weight high-capacity hydrogen absorption material is heated to 300 to 400 DEG C at vacuum conditions, is subjected to activation for 30 to 60min, and is cooled to an operating temperature for hydrogen absorption, wherein the operating temperature ranges from room temperature to 400 DEG C. The Ti-Zr based light-weight high-capacity hydrogen absorption material possesses following advantages: manufacturing technology is simple; activation temperature is low; hydrogen absorption balance pressure is low; hydrogen absorption capacity is high; and hydrogen absorption speed is high.

Owner:GRIMAT ENG INST CO LTD

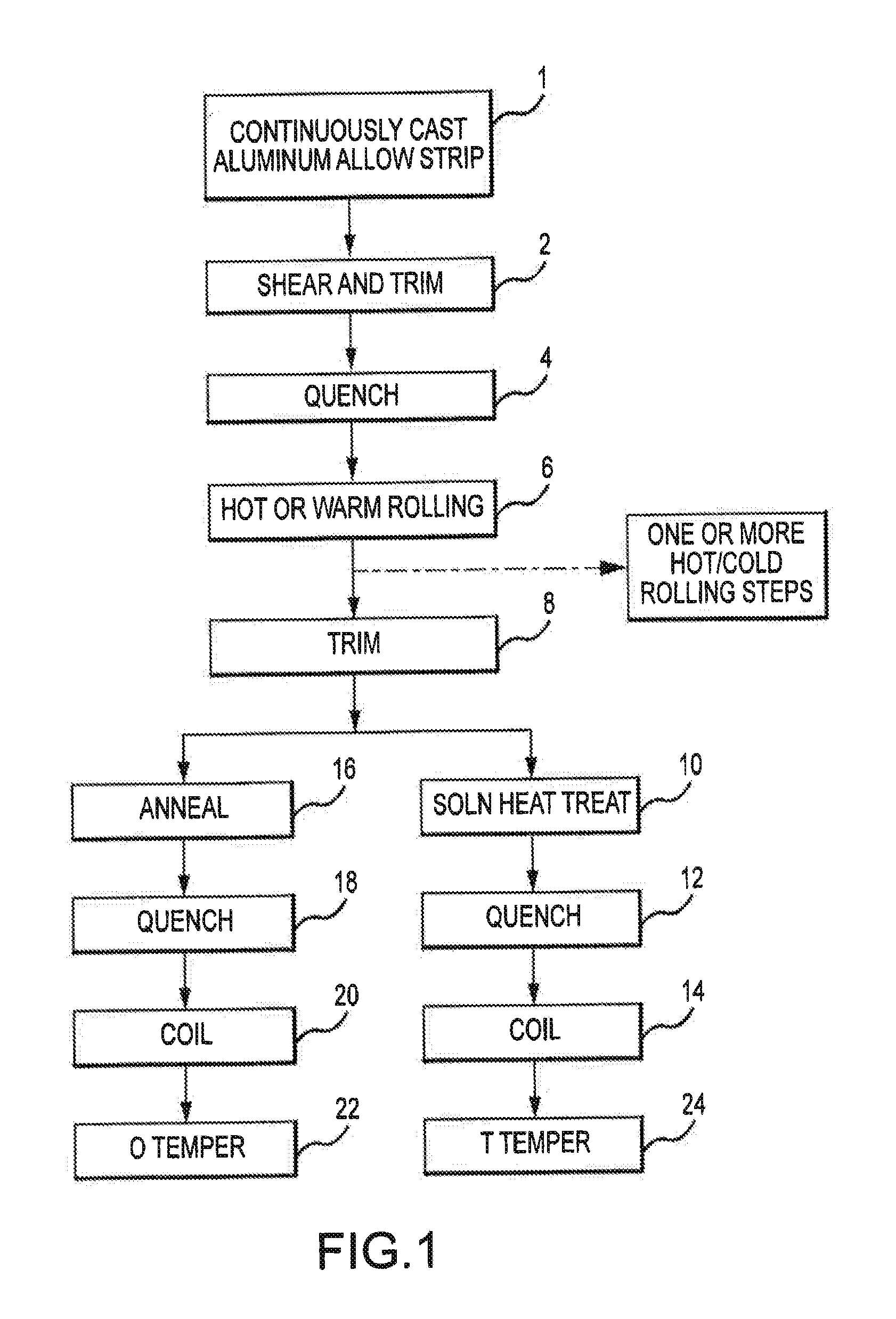

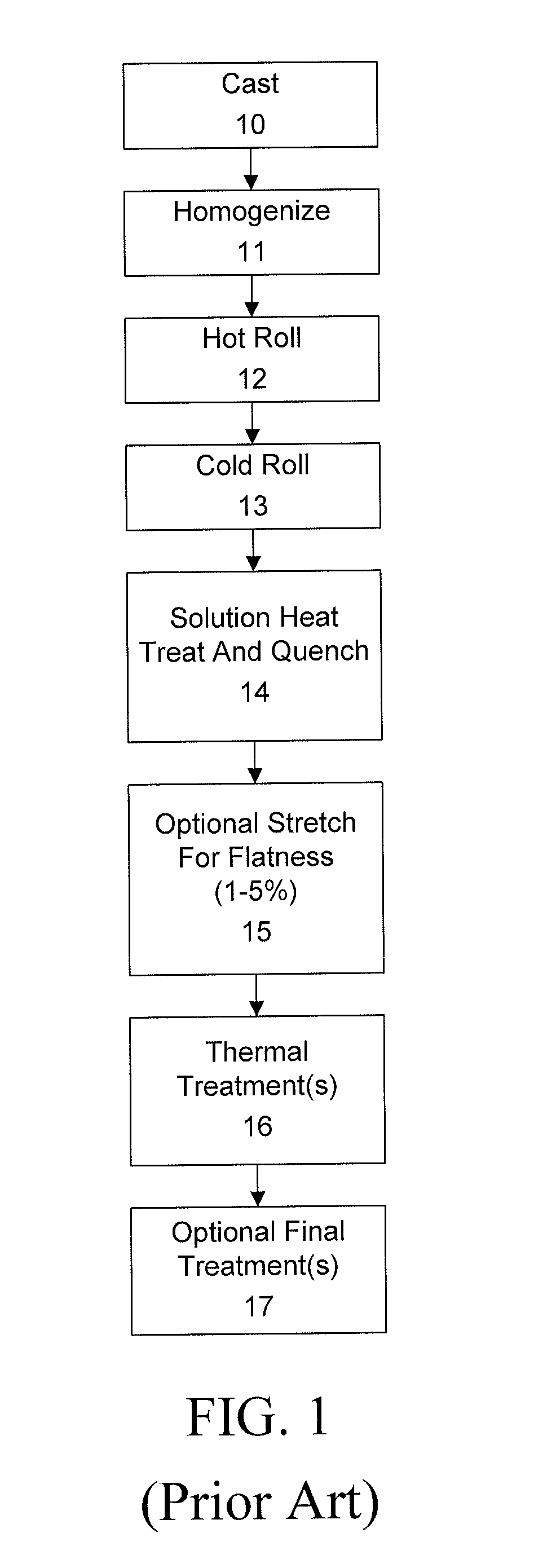

Aluminum alloys and methods for producing the same

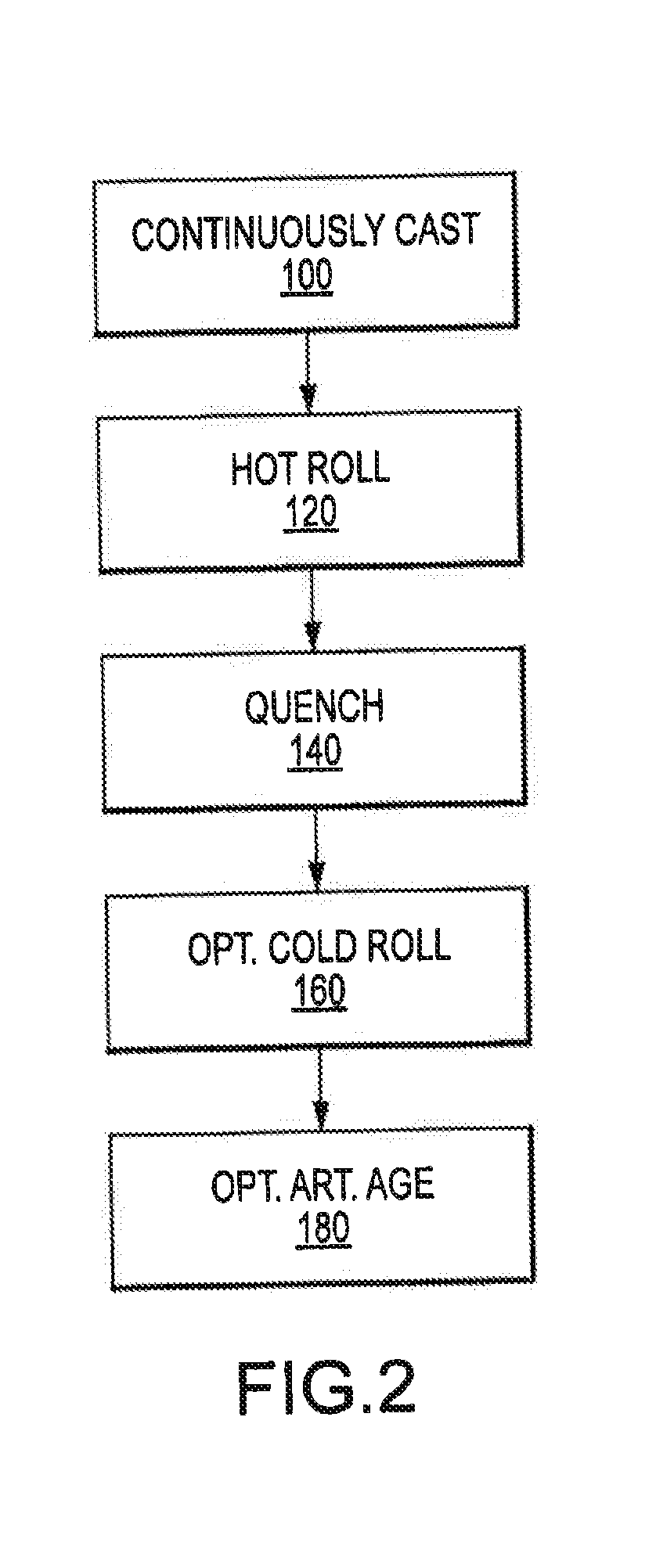

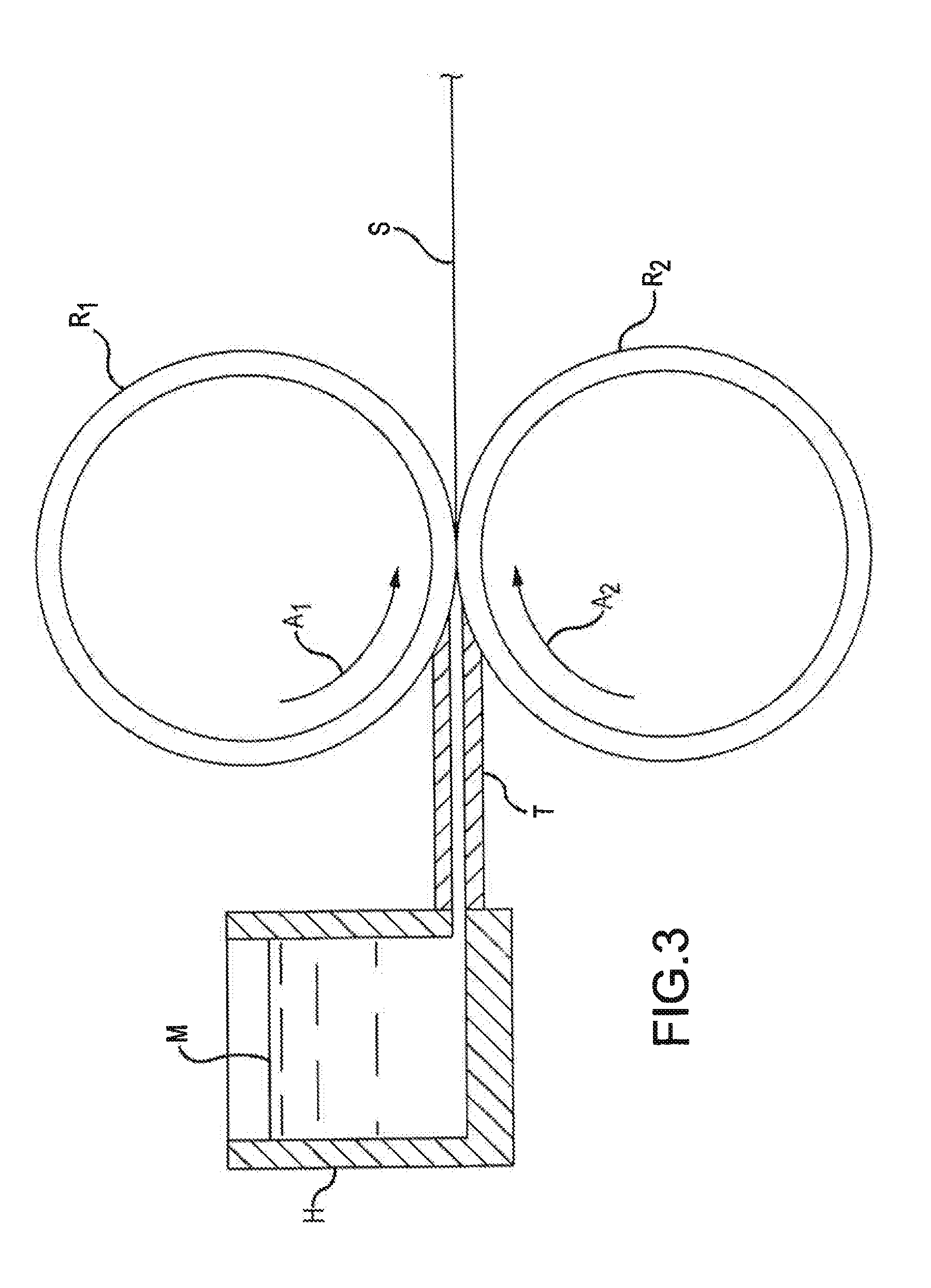

ActiveUS20130334091A1Minimize changesAvoid unevennessPackaging corrosive chemicalsHeat treatedContinuous casting

Heat treatable aluminum alloy strips and methods for making the same are disclosed. The heat treatable aluminum alloy strips are continuously cast and quenched, with optional rolling occurring before and / or after quenching. After quenching, the heat treatable aluminum alloy strip is neither annealed nor solution heat treated.

Owner:ARCONIC TECH LLC

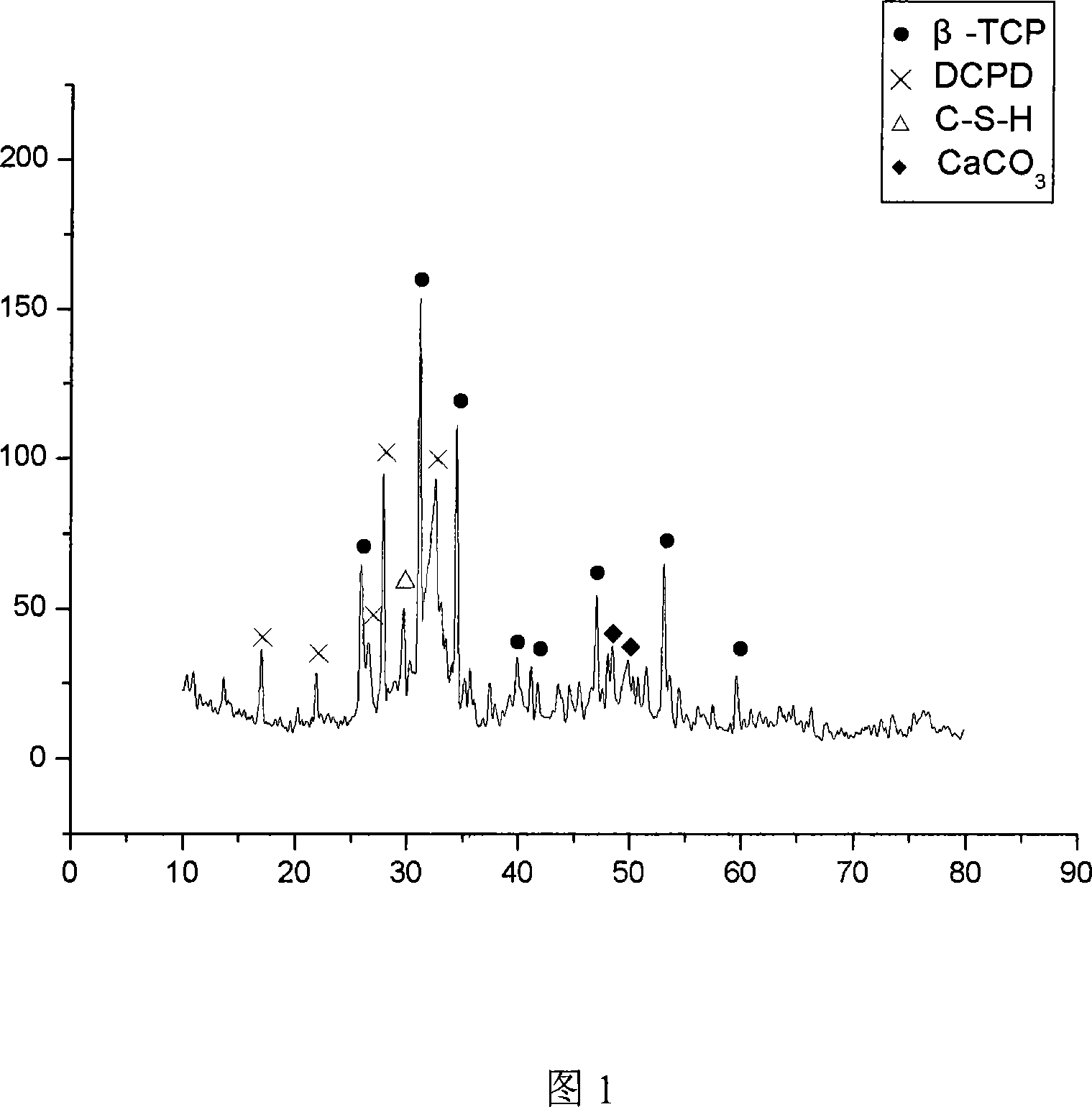

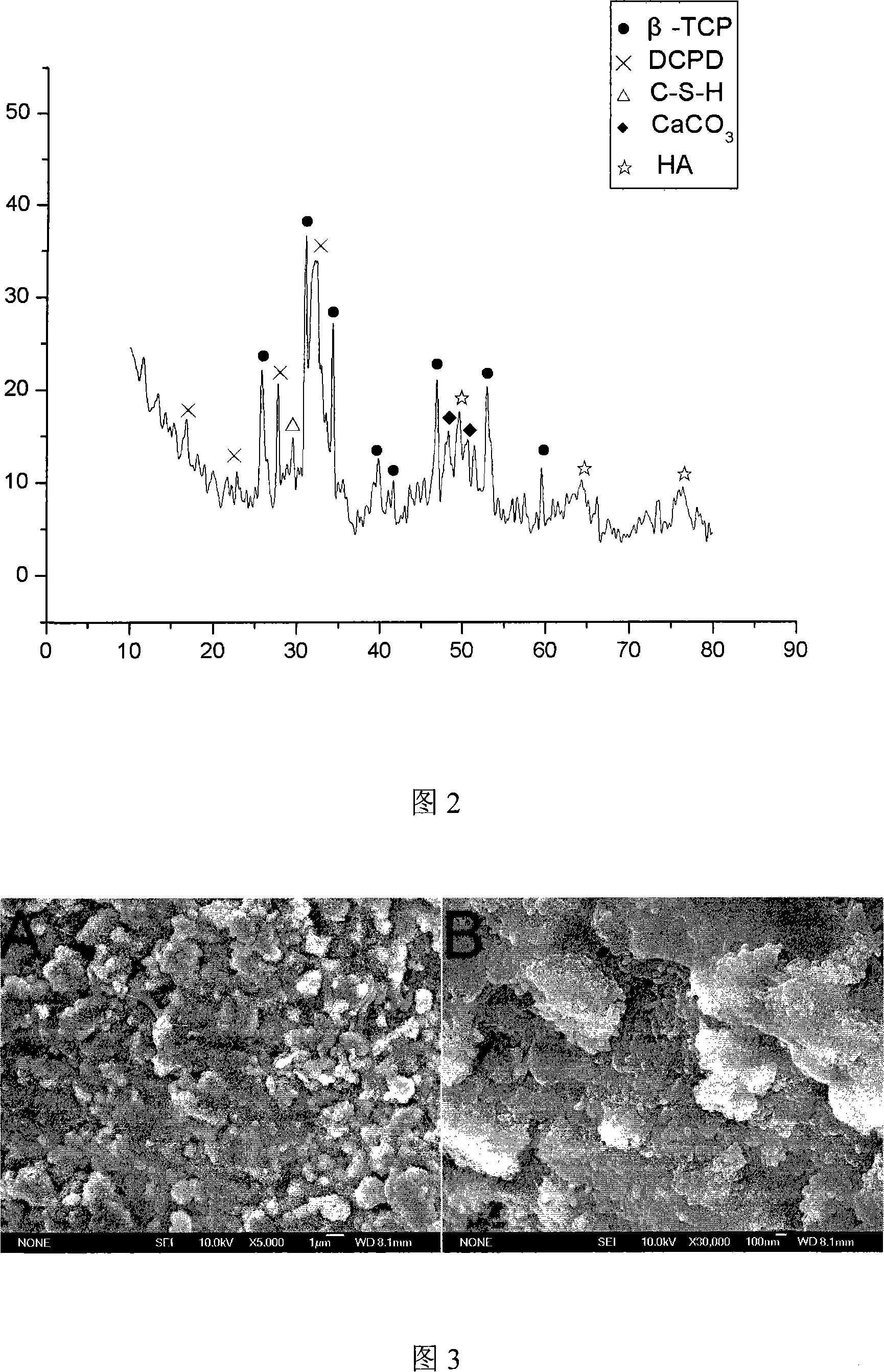

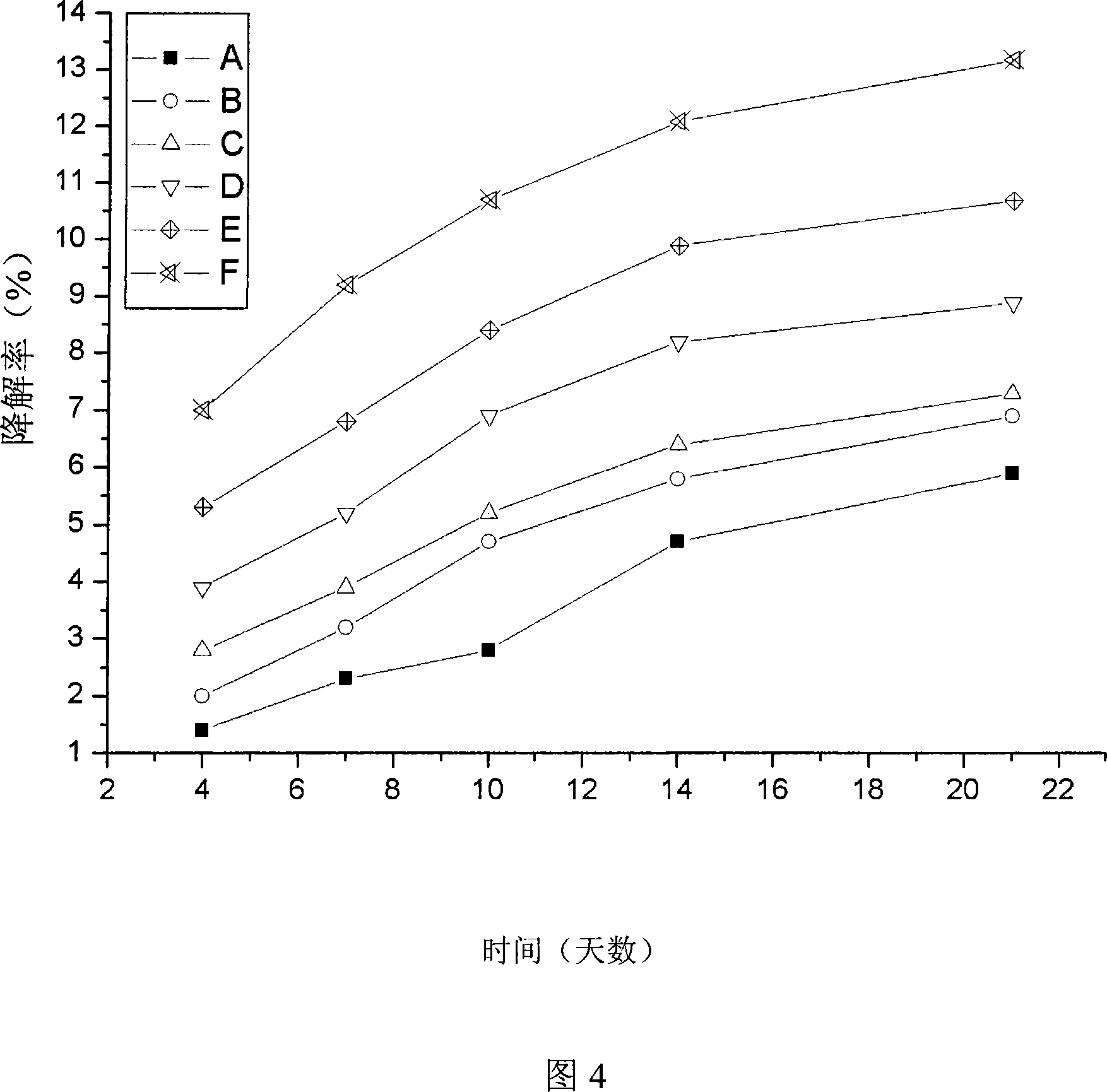

Complex self-curing material, method and application of bioactivity calcium phosphate/tricalcium silicate

InactiveCN101157045AImprove biological activityGood biocompatibilityPhysical/chemical process catalystsCalcium silicateCalcium biphosphate

The invention relates to human bone defect filling original position self-solidified bioactive material and the preparation method thereof. The material is bone / tooth defect repair material which is developed with bioactive calcium phosphate / tricalcium silicate composite powder and mixing liquid having the biological activity as raw materials. Compared with the prior material, the material of the invention has the advantages that the biological activity is excellent, the shaping is arbitrary, the material is self-solidified, no cytotoxicity exists, and the degradation is gradual, the degradation rate can be adjusted, and the effect of inducing bone-like apatite formation can be achieved; the biological activity is more excellent than that of the calcium phosphate calcium phosphate bone-like cement, and the preparation method is simple.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

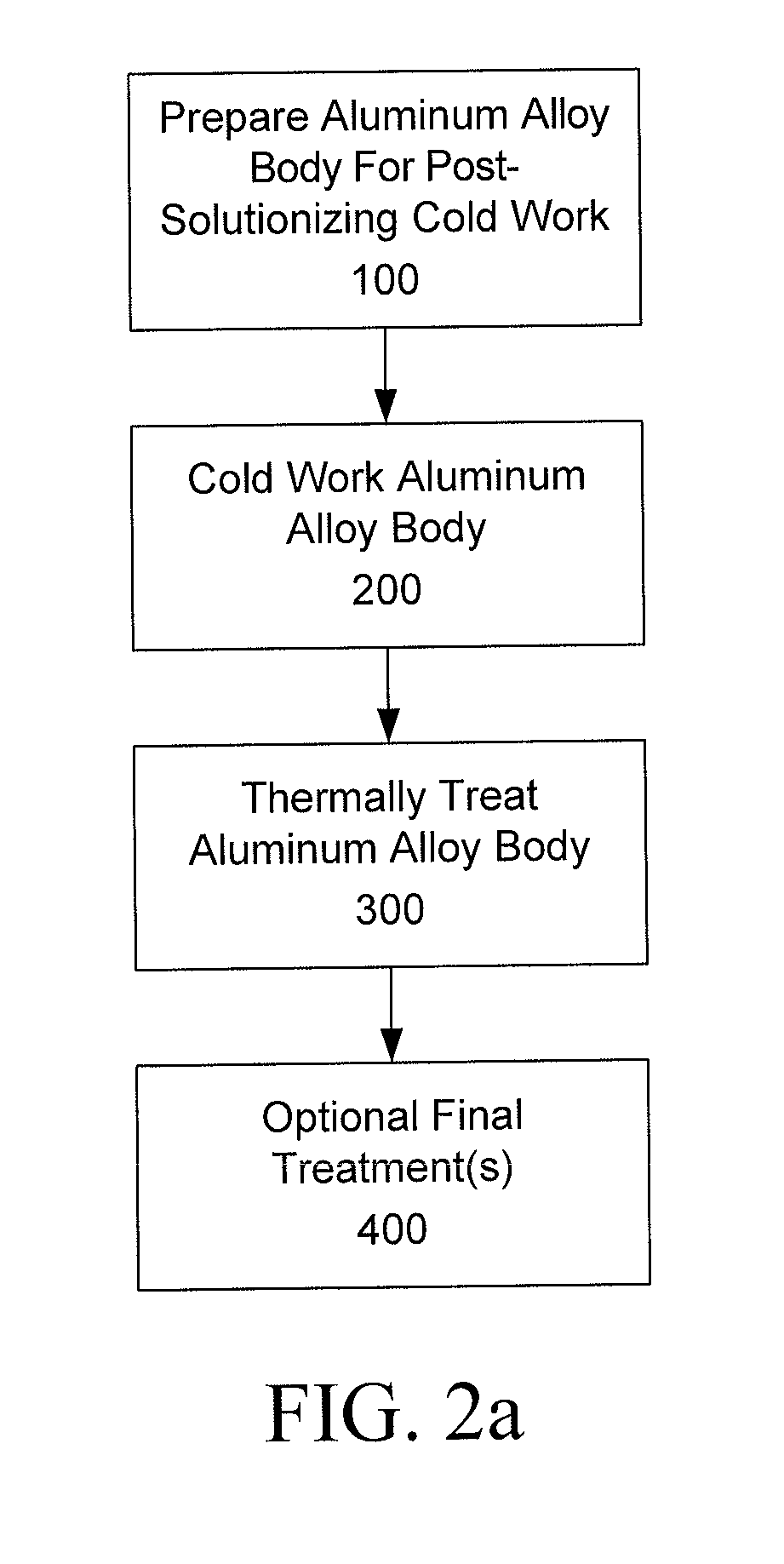

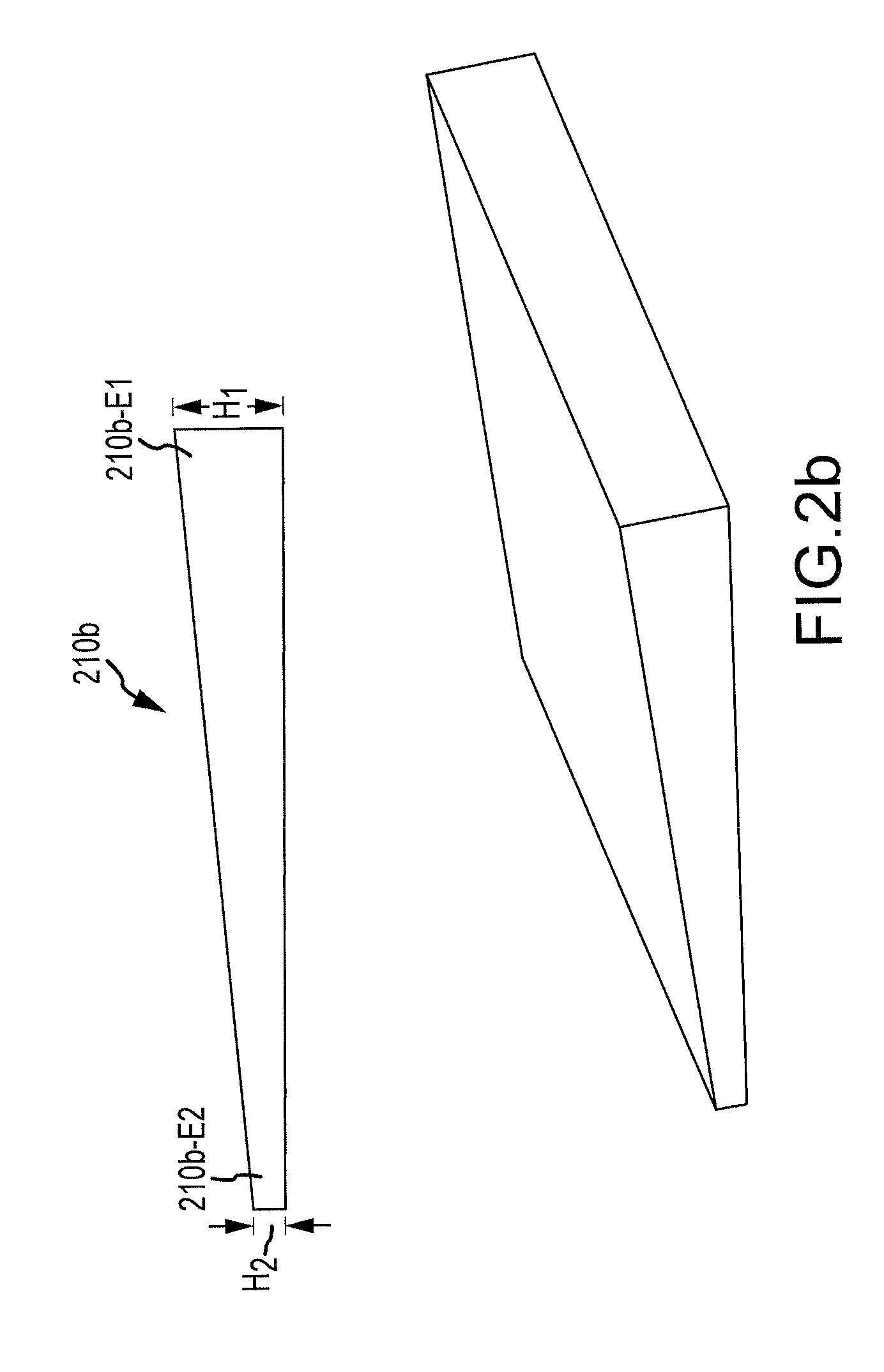

Heat treatable aluminum alloys having magnesium and zinc and methods for producing the same

New magnesium-zinc aluminum alloy bodies and methods of producing the same are disclosed. The new magnesium-zinc aluminum alloy bodies generally include 3.0-6.0 wt. % magnesium and 2.5-5.0 wt. % zinc, where at least one of the magnesium and the zinc is the predominate alloying element of the aluminum alloy bodies other than aluminum, and wherein (wt. % Mg) / (wt. % Zn) is from 0.6 to 2.40, and may be produced by preparing the aluminum alloy body for post-solutionizing cold work, cold working by at least 25%, and then thermally treating. The new magnesium-zinc aluminum alloy bodies may realize improved strength and other properties.

Owner:ARCONIC INC

Method for preparing nickel-based superalloy Rene80 directionally-grown column crystal/single crystal alloy and manufacturing parts

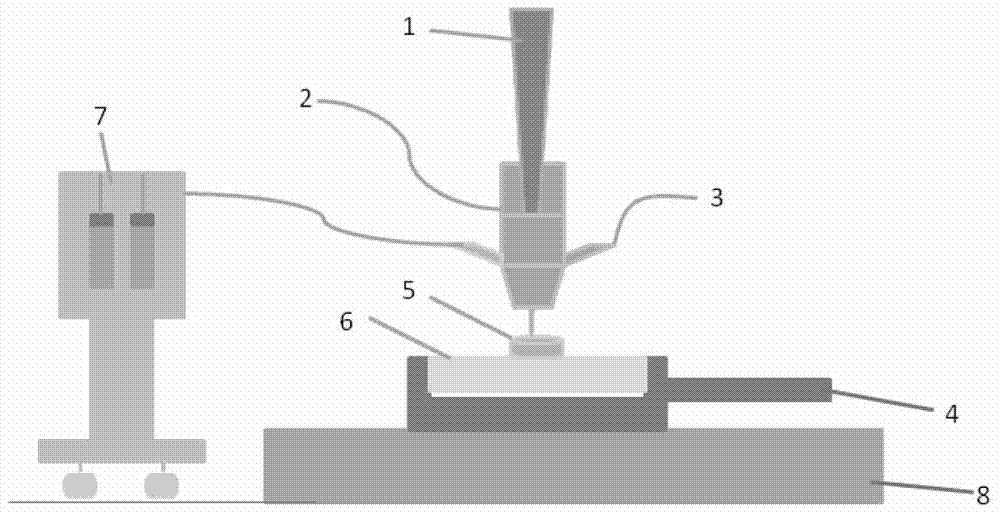

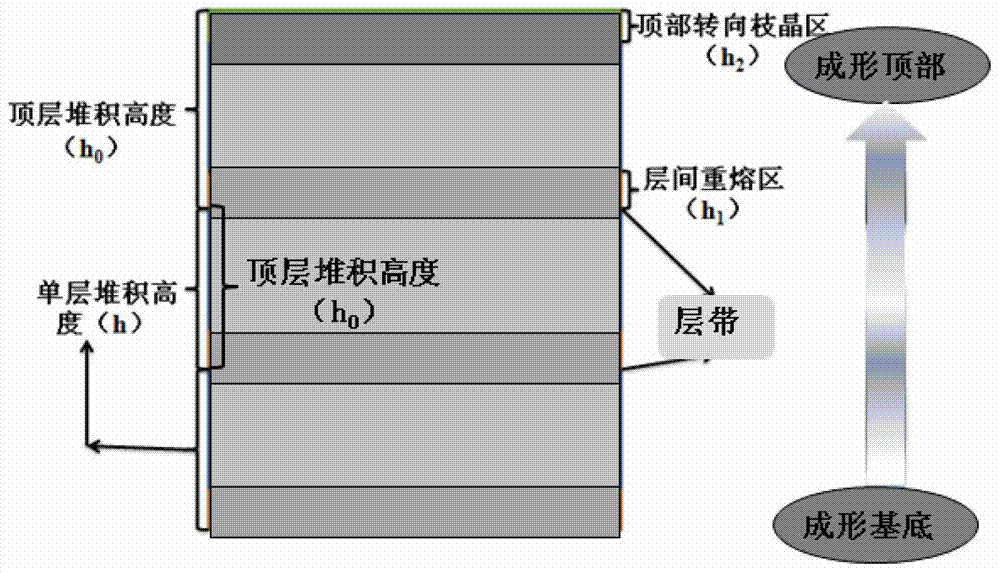

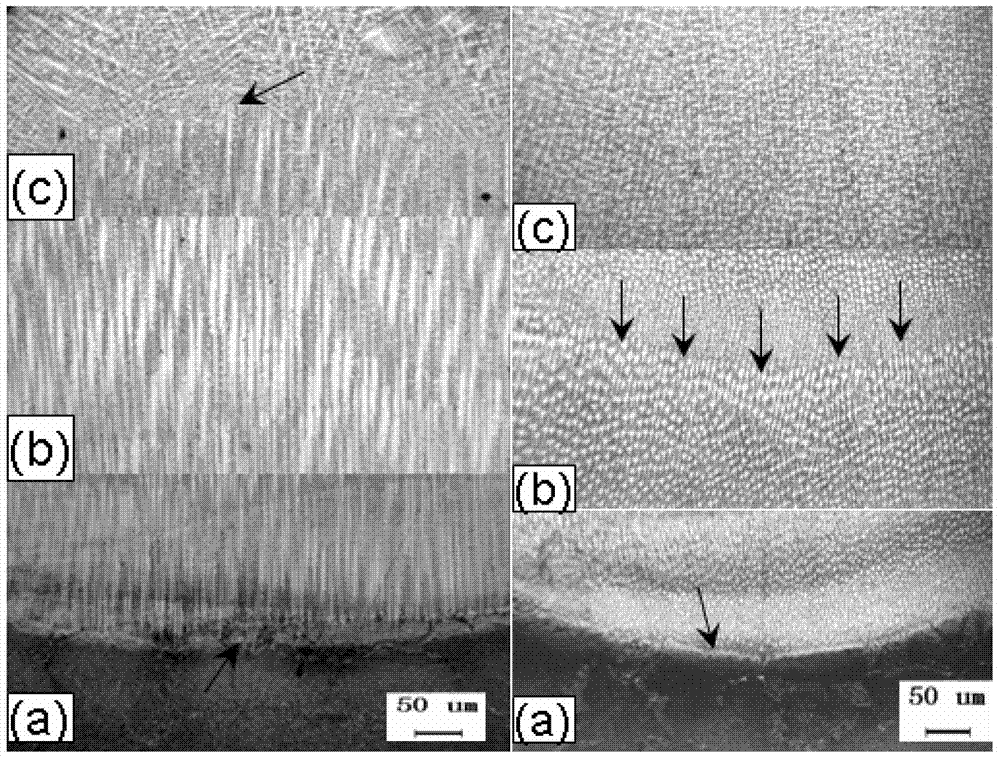

InactiveCN103668461AShorten the manufacturing cycleReduce manufacturing costsPolycrystalline material growthEutectic material solidificationAlloy substrateDirectional solidification

The invention relates to a method for preparing a nickel-based superalloy Rene80 directionally-grown column crystal / single crystal alloy and manufacturing parts, and belongs to the processing field of the laser materials. The method is carried out in atmosphere; a high-energy beam is taken as the heat source; the movement of the high-energy beam is achieved under the control of a numerical control system; the Rene80 powder flow conveyed by a carrier gas is smelted and deposited on a directionally-solidified nickel-based alloy substrate layer by layer; in this way, the nickel-based superalloy and parts having directionally-grown straight column crystal structure / single crystals and different cross-section shapes can be directly manufactured. The nickel-based alloy Rene80 directionally-grown column crystal / single crystal alloy parts manufactured by the method can be applied to manufacturing the hot end parts of naval ships, gas turbines and aero-engines.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com