Ti-Zr based light-weight high-capacity hydrogen absorption material, and preparation method and application method thereof

A technology of hydrogen absorption material and high capacity, which is applied in the fields of Ti-Zr-based light-weight and high-capacity hydrogen absorption material and its preparation and use, can solve the problems of low hydrogen absorption rate and capacity of alloys, difficult to satisfy, etc., and achieve the hydrogen absorption rate Fast, simple manufacturing process, low effect of hydrogen absorption equilibrium pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

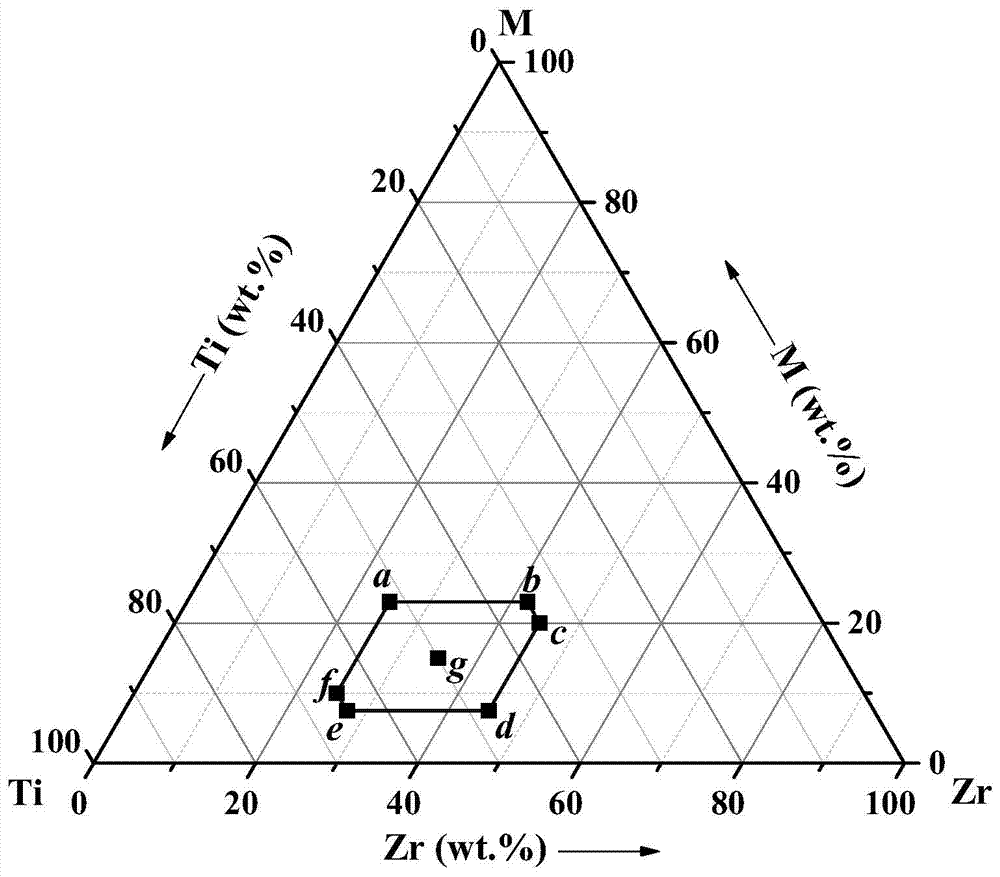

[0040] The raw materials are sponge Ti (purity ≥99.6%), sponge Zr (purity ≥99.4%), Cr (purity ≥99.4%), Fe (purity ≥99.4%), V (purity greater than 99.5%), Ce (purity ≥99.0%) ). The chemical composition of the alloy is figure 1The formulation of the middle g point, that is, according to Example 1 in Table 1: Ti, 50wt.%, Zr, 35wt.%, Cr, 3wt.%, Fe, 2wt.%, V, 7wt.%, Ce, 3wt.% .

[0041] The alloy is prepared by vacuum electric arc furnace / vacuum intermediate frequency induction melting method. When the melting temperature reaches 2000~2200℃, the alloy starts to melt. Mold casting, rapid solidification to obtain ingots, the pouring temperature is 1950-2120 °C; the ingots are crushed and ground to make powder, or hydrogenated dehydrogenated to make particles with a sieve size of less than 80 mesh.

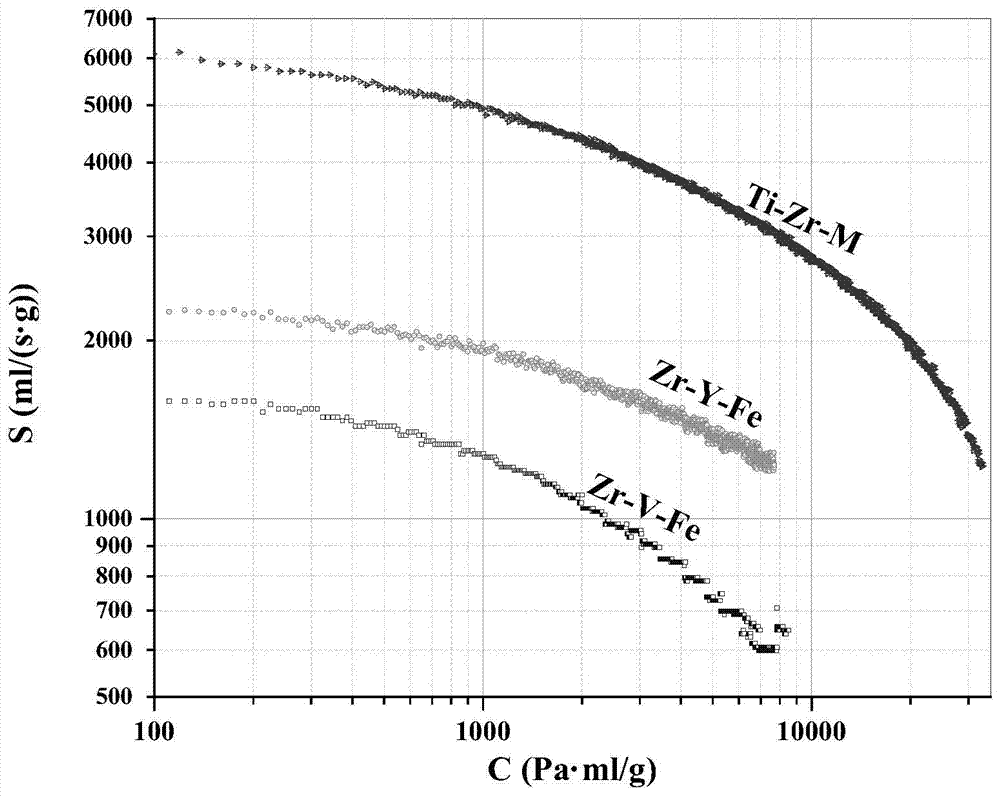

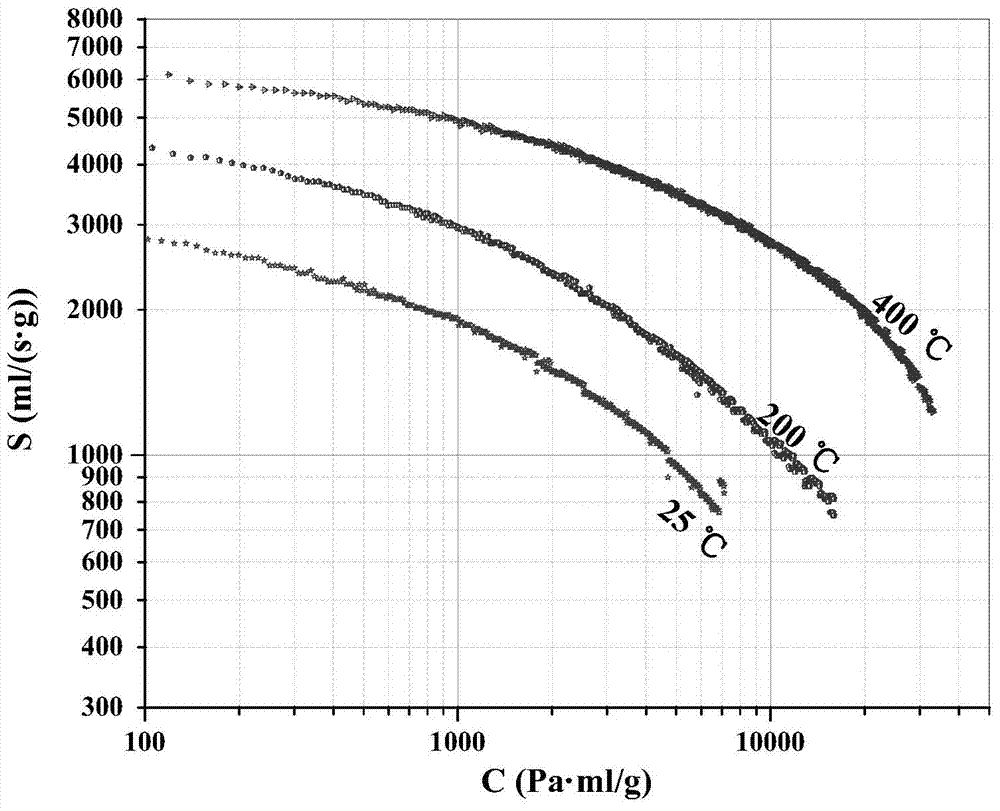

[0042] Take about 1 gram of sample and press it into small pieces of Φ10×3mm. According to the GB / T25497-2010 standard, test the relationship between the hydrogen absorption rate of th...

Embodiment 2

[0044] The raw materials are sponge Ti (purity ≥99.6%), sponge Zr (purity ≥99.4%), Cr (purity ≥99.2%), V (purity greater than 99.5%), and Ce (purity ≥99.0%). The chemical composition of the alloy is figure 1 The formulation of point a is according to Example 2 in Table 1: Ti, 52wt.%, Zr, 25wt.%, Cr, 4wt.%, V: 14wt.%, Ce: 5wt.%. Alloy smelting and sample preparation methods are the same as in Example 1, and the hydrogen absorption kinetics test results are as follows: Figure 4 shown.

Embodiment 3

[0046] The raw materials are sponge Ti (purity ≥99.6%), sponge Zr (purity ≥99.4%), Co (purity ≥99.2%), Mo (purity ≥99.9%), V (purity greater than 99.5%), Ce (purity ≥99.0%) ). The chemical composition of the alloy is figure 1 The composition of point b is formulated according to Example 3 in Table 1: Ti, 35wt.%, Zr, 42wt.%, Co, 4wt.%, Mo, 4.2wt.%, V: 12wt.%, Ce: 2.8wt. .%. Alloy smelting and sample preparation methods are the same as in Example 1, and the hydrogen absorption kinetics test results are as follows: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com