Patents

Literature

13930 results about "Vacuum drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum drying is the mass transfer operation in which the moisture present in a substance, usually a wet solid, is removed by means of creating a vacuum. In chemical processing industries like food processing, pharmacology, agriculture, and textiles, drying is an essential unit operation to remove moisture. Vacuum drying is generally used for the drying of substances which are hygroscopic and heat sensitive, and is based on the principle of creating a vacuum to decrease the chamber pressure below the vapor pressure of the water, causing it to boil. With the help of vacuum pumps, the pressure is reduced around the substance to be dried. This decreases the boiling point of water inside that product and thereby increases the rate of evaporation significantly. The result is a significantly increased drying rate of the product. The pressure maintained in vacuum drying is generally 0.03–0.06 atm and the boiling point of water is 25-30 °C. The vacuum drying process is a batch operation performed at reduced pressures and lower relative humidity compared to ambient pressure, enabling faster drying.

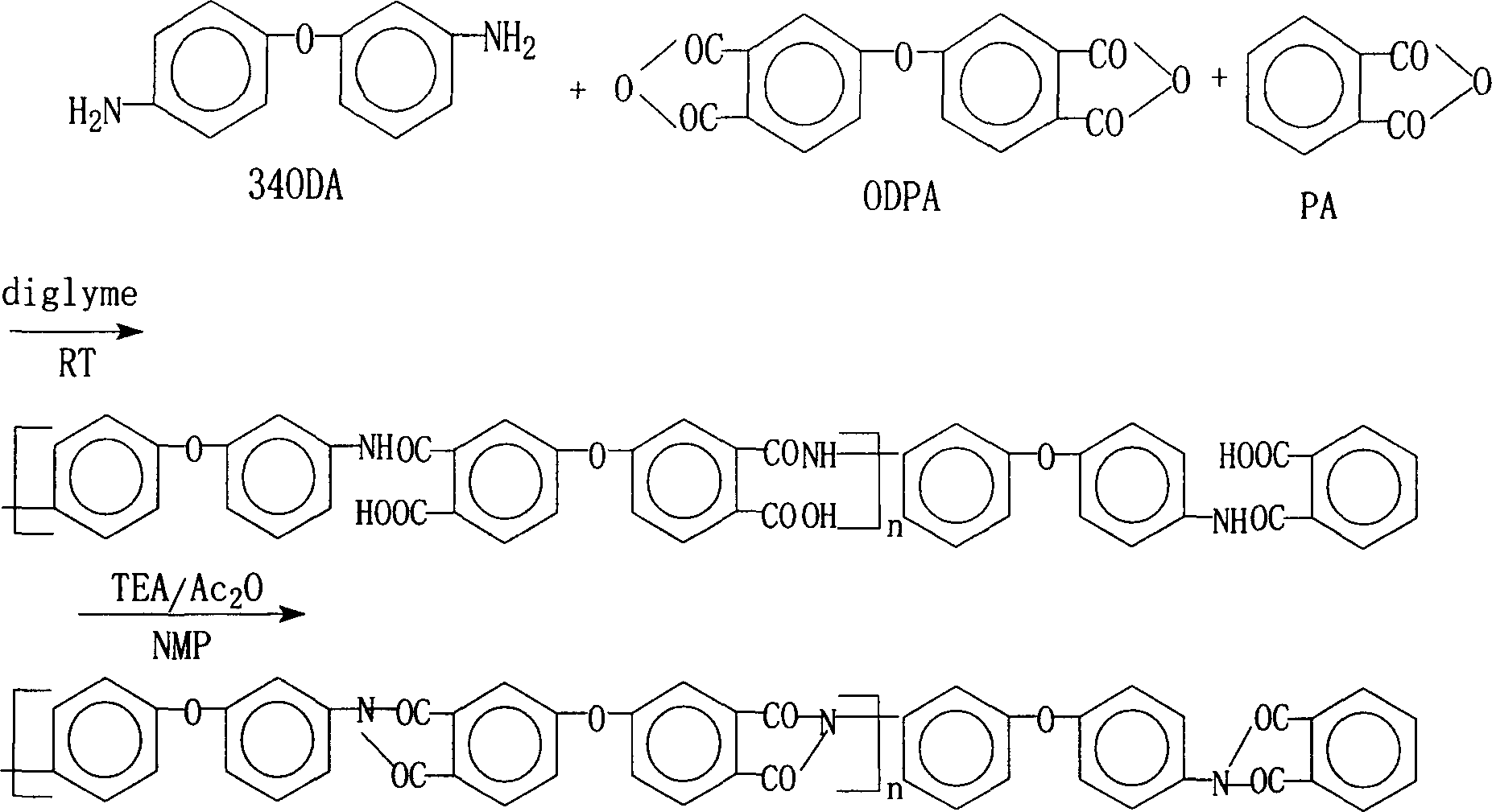

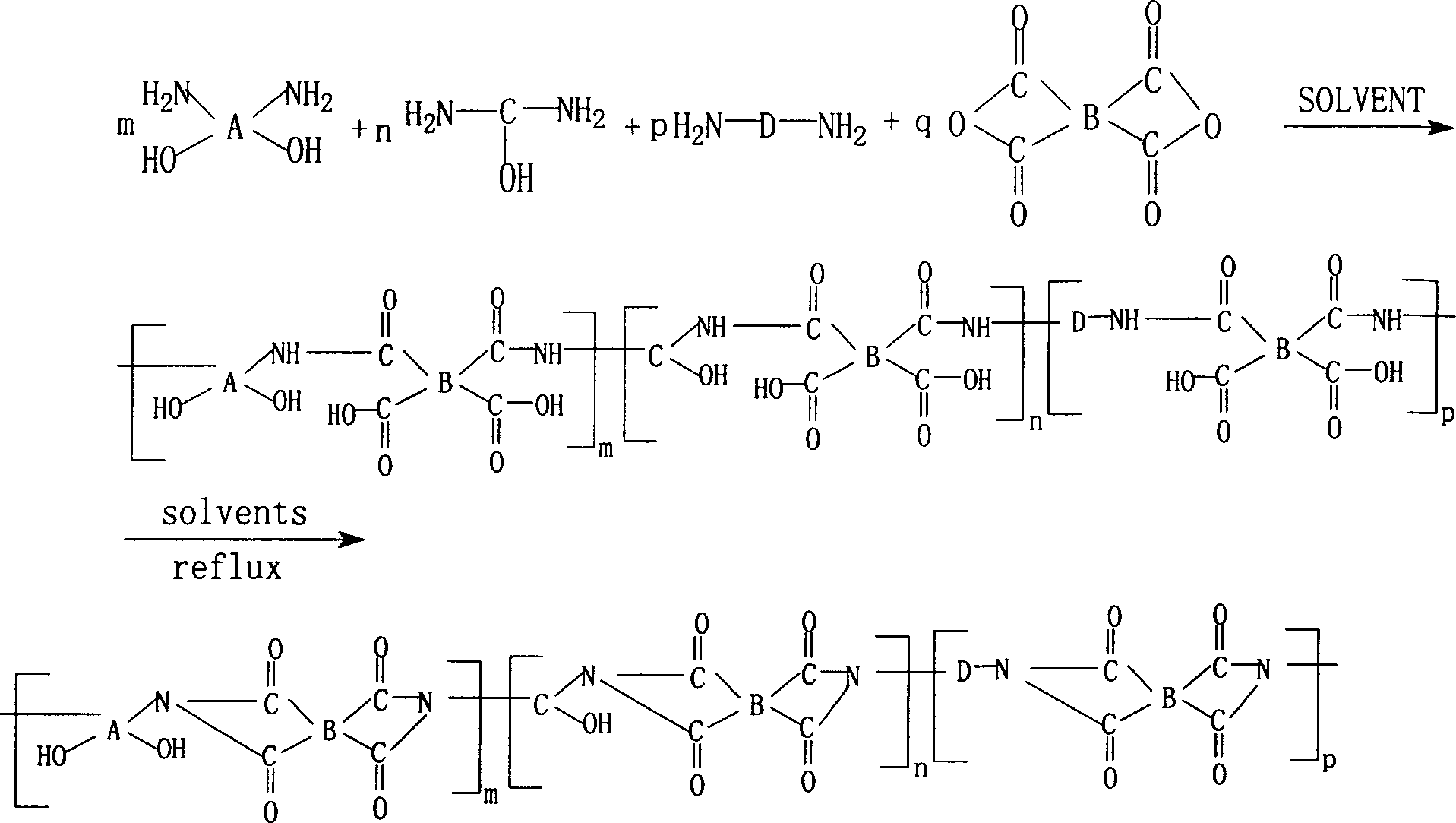

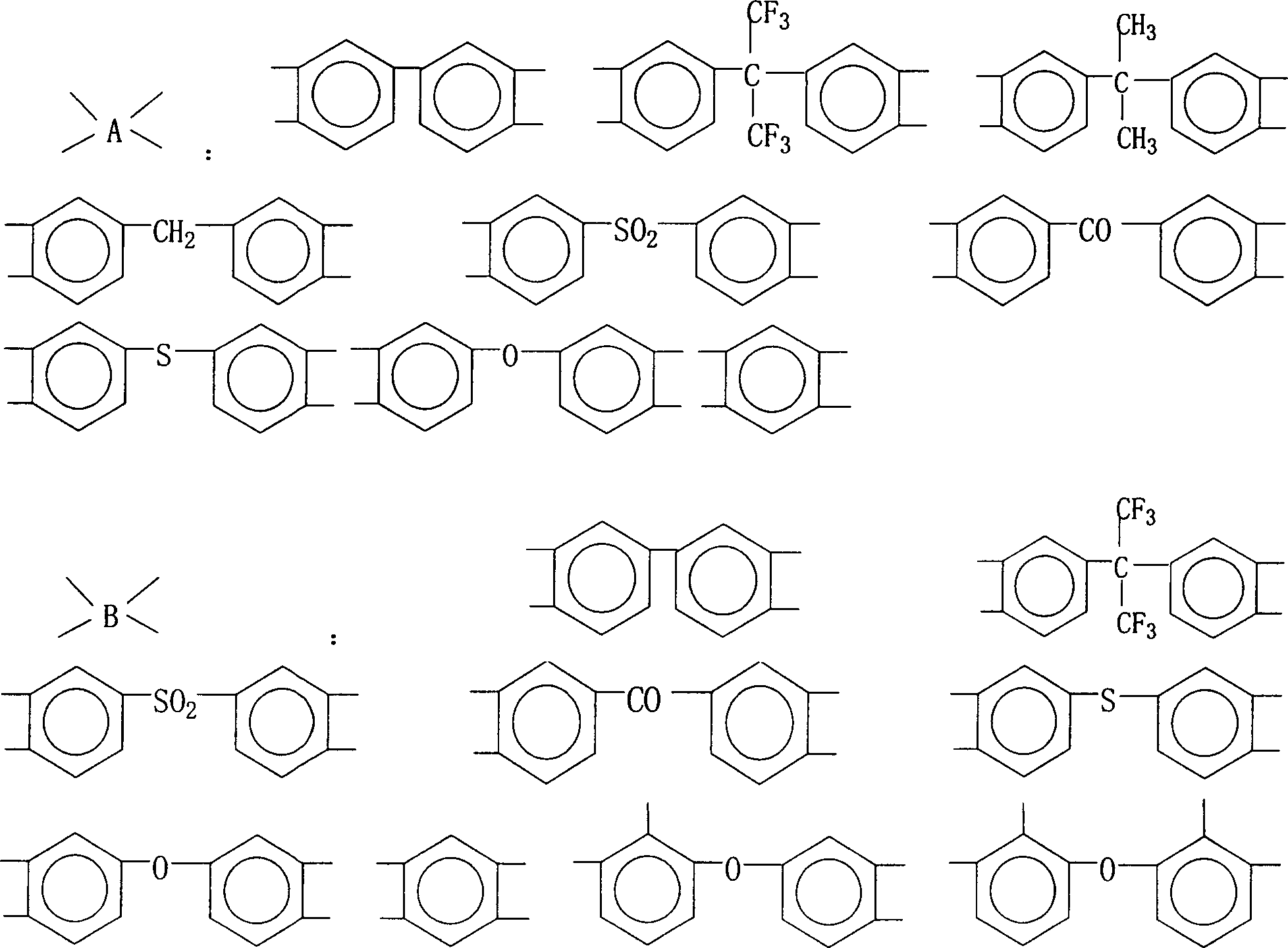

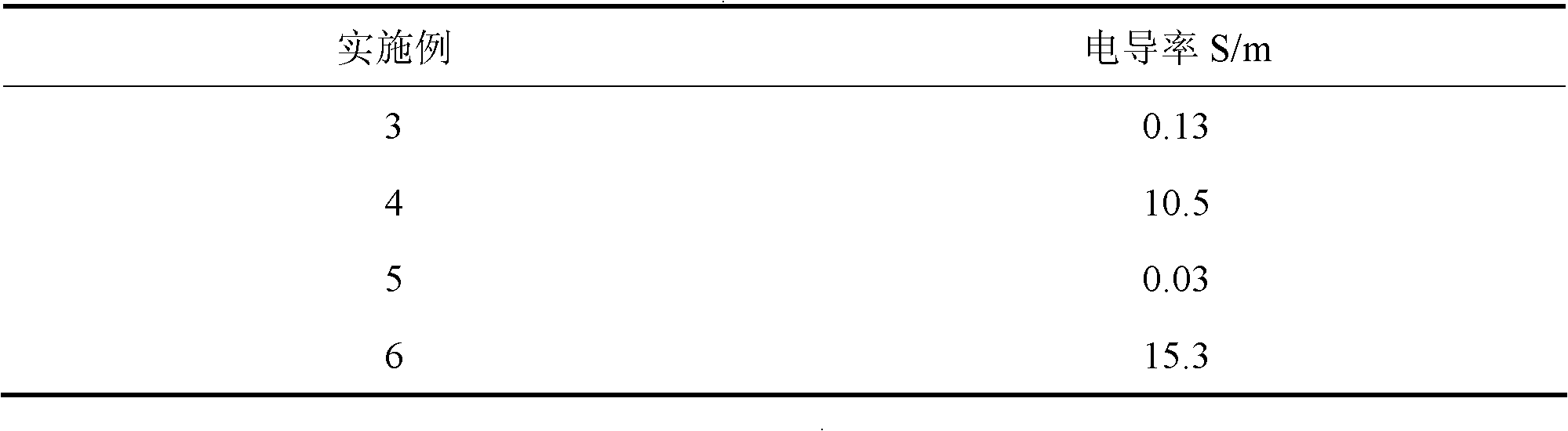

Preparation method of phenolic hydroxyl group containing polyimide powder

The preparation process of phenolic hydroxyl group-containing polyimide powder includes the following steps: 1. reaction of phenolic hydroxyl group-containing aromatic diamine compound or its mixture with other diamine compound and aromatic binary anhydride in the molar ratio of 1 to 1 in strong polar non-protonic organic solvent under protection of nitrogen at 0-30 deg.c for 3-12 hr to obtain transparent ropy polyhydroxy amido acid solution; and 2. adding azeotropic dewatering agent in nitrogen atmosphere and heating to 120-160 deg.c to reflux, azeotropically dewater and imidize for 5-18 hr, cooling to room temperature, washing and vacuum drying to obtain phenolic hydroxyl group-containing polyimide powder. The industrial production process has environment friendship, simple operation, low cost and easy solvent recovery.

Owner:DONGHUA UNIV

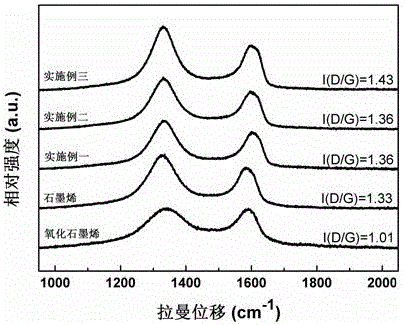

Preparation method of graphene/polymer nano composite material

ActiveCN102161785AEvenly dispersedGood mechanical propertiesOther chemical processesMagnetic/electric field screeningUltrasonic dispersionVacuum drying

The invention discloses a preparation method of a graphene / polymer nano composite material, which is characterized by comprising the following steps: adding 0.1-30 parts by weight of graphite oxide into 10-3000 parts by weight of water, and dispersing and exfoliating by carrying out ultrasonic dispersion (the power is 50-500W, and the frequency is 10-100000Hz) at 10-100 DEG C for 15 minutes-5 hours or mechanical lapping for 15 minutes-5 hours or mechanical stirring for 1-48 hours to obtain a graphene oxide water solution; adding the graphene oxide water solution into 100 parts by weight of polymer emulsion of which the solid content is 10-70%; continuing the ultrasonic or mechanical stirring to carry out uniform mixing; demulsifying by adding 1-100 parts by weight of 5-100% demulsifier toobtain a graphene oxide / polymer granular suspension; adding 0.1-100 parts by weight of reducer into the graphene oxide / polymer granular suspension, reducing at 20-100 DEG C for 1-72 hours, filtering,and drying in a drying oven at 20-100 DEG C for 2-72 hours or drying in a vacuum drying oven at 20-120 DEG C under a vacuum degree of 0.1-0.01 MPa for 2-48 hours, thereby obtaining the graphene / polymer nano composite material.

Owner:SICHUAN UNIV

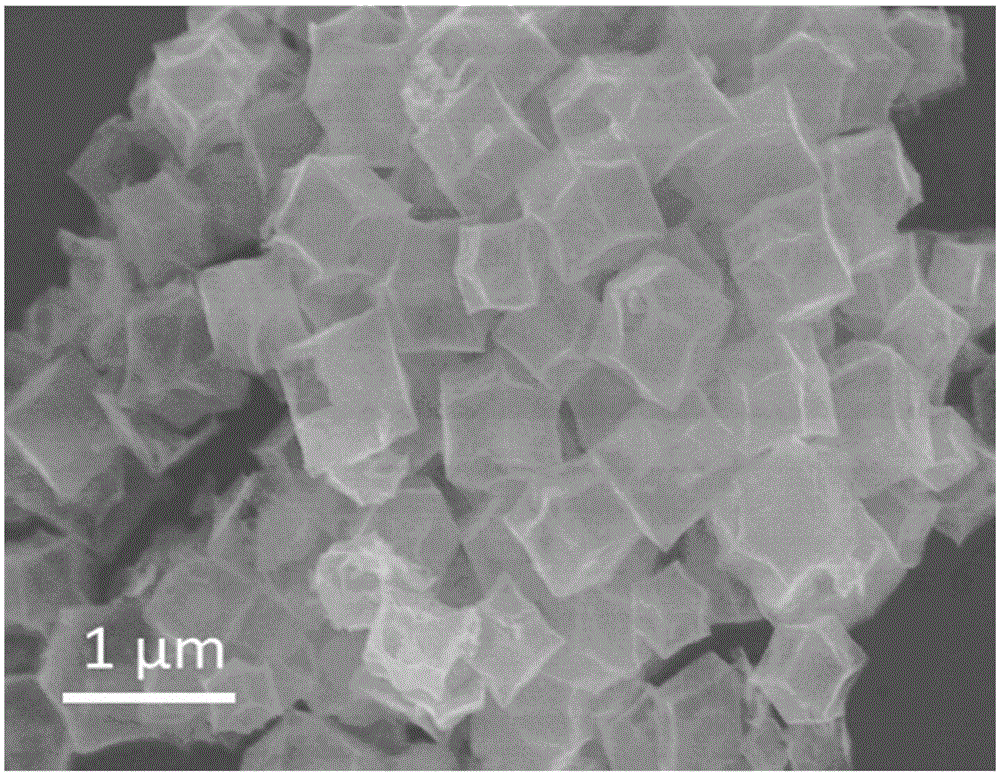

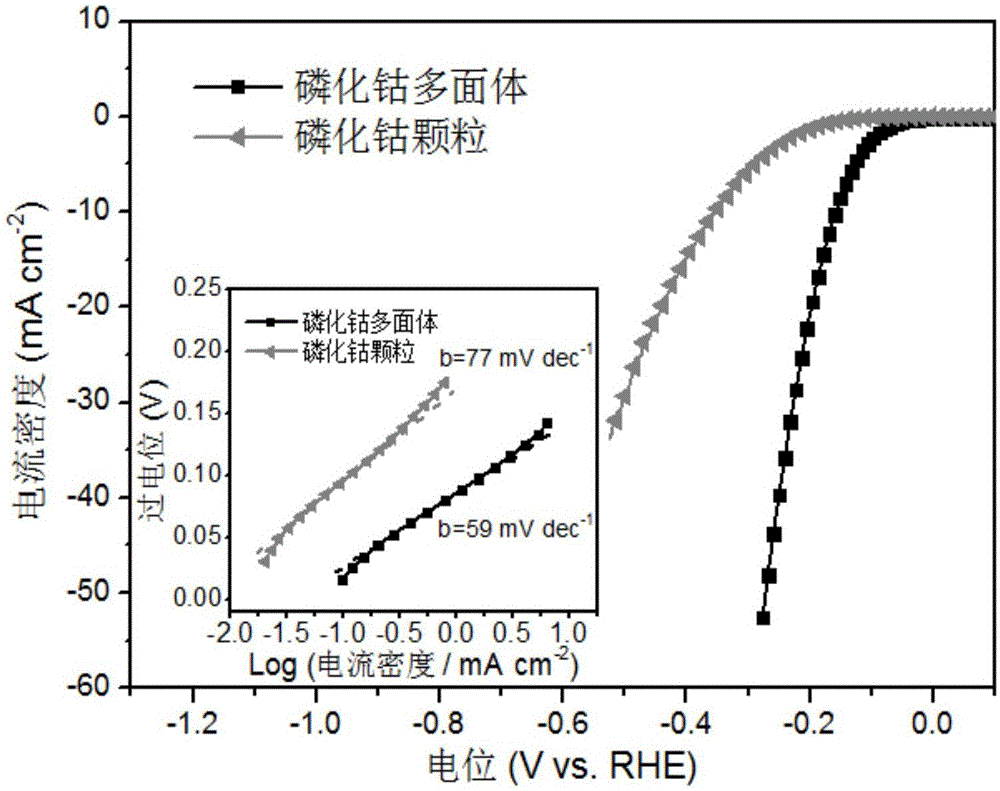

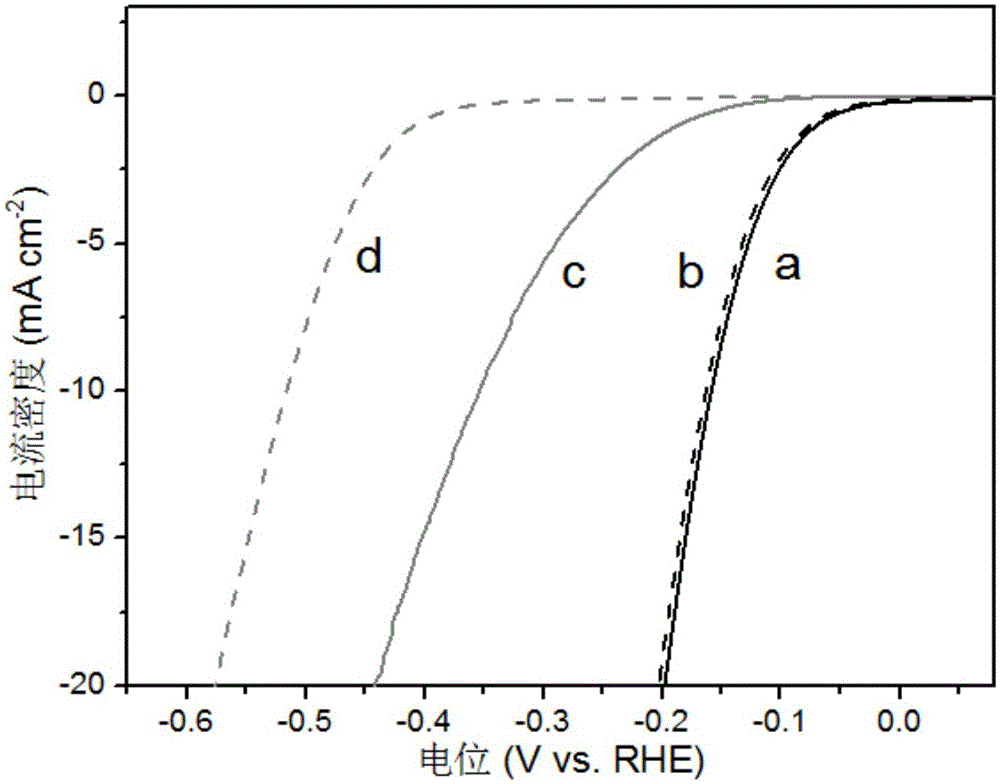

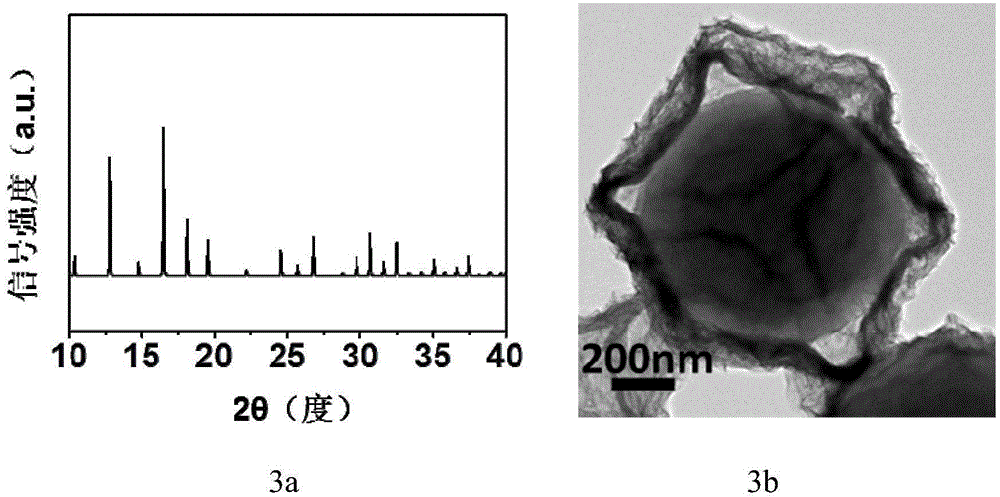

Preparation method of polyhedral cobalt phosphide catalyst for hydrogen production through water electrolysis

ActiveCN105107536AHigh crystallinityIncrease the areaElectrolysis componentsPhysical/chemical process catalystsAir atmosphereElectrolysis

A preparation method of a polyhedral cobalt phosphide catalyst for hydrogen production through water electrolysis comprises steps as follows: Co(NO3)2*6H2O and 2-methylimidazole are dissolved in methanol respectively, a 2-methylimidazole solution is poured into a Co(NO3)2 solution, the mixture is stirred and then aged at the room temperature, a product is centrifugally separated, vacuum drying is performed after washing with methanol, and a polyhedral metal organic frame ZIF-67 is obtained; then the polyhedral metal organic frame ZIF-67 is placed in a tube furnace, cobaltosic oxide is obtained through calcination in the air atmosphere, then the cobaltosic oxide and NaH2PO2*H2O are placed at two ends of a porcelain boat respectively, the NaH2PO2*H2O is located in the windward position of the tube furnace, and the polyhedral cobalt phosphide catalyst for hydrogen production through water electrolysis is obtained through calcination in the inert atmosphere. The crystallinity of the prepared cobalt phosphide catalyst material is high, the polyhedral morphology of a metal organic frame template is kept, the catalyst shows excellent properties in an electrocatalytic hydrogen evolution reaction, and the preparation technology is simple in process.

Owner:TSINGHUA UNIV

Olefinic polymerization catalyst carried by carrier of sphere MgCl-alcohol-organic complexing agent and preparation method

The invention discloses an defin polymerization catalyst loaded on spherical MgCl2-alcohol-organic complexing agent camier and its preparation method. Said method includes the following steps: under the protection of argon gas using TiCl4 and MgCl2-alcohol-organic complexing agent spherical carrier, stirring them at -30 deg.c-0 deg.C in reaction still and making them produce reaction for 10-30 min., heating to 60 deg.C-80 deg.C, adding internal doner residues, and more heating to 90 deg.C-140 deg.C, thermostatically stirring and making reaction for 1-3 hr., then removing liquid phase, adding TiCl4 to make treatment once, and removing liquod phase, washing by using solvent, removing solvent, vacuum drying so as to obtain spherical catalyst. Said spherical catalyst uses spherical MgCl2-alcohol-organic complexing agent as carrier, and the preparation process of said catalyst is retatively simple, and small in environmental pollution. Said invention can effectively regulate grain size of catalyst and its distribution by controlling grain size of spherical MgCl2-alcohol-organic copmlexing agent carrier and its distribution, after the olefin is catalyzed and polymerized, the spherical polyolefin can be obained.

Owner:ZHEJIANG UNIV

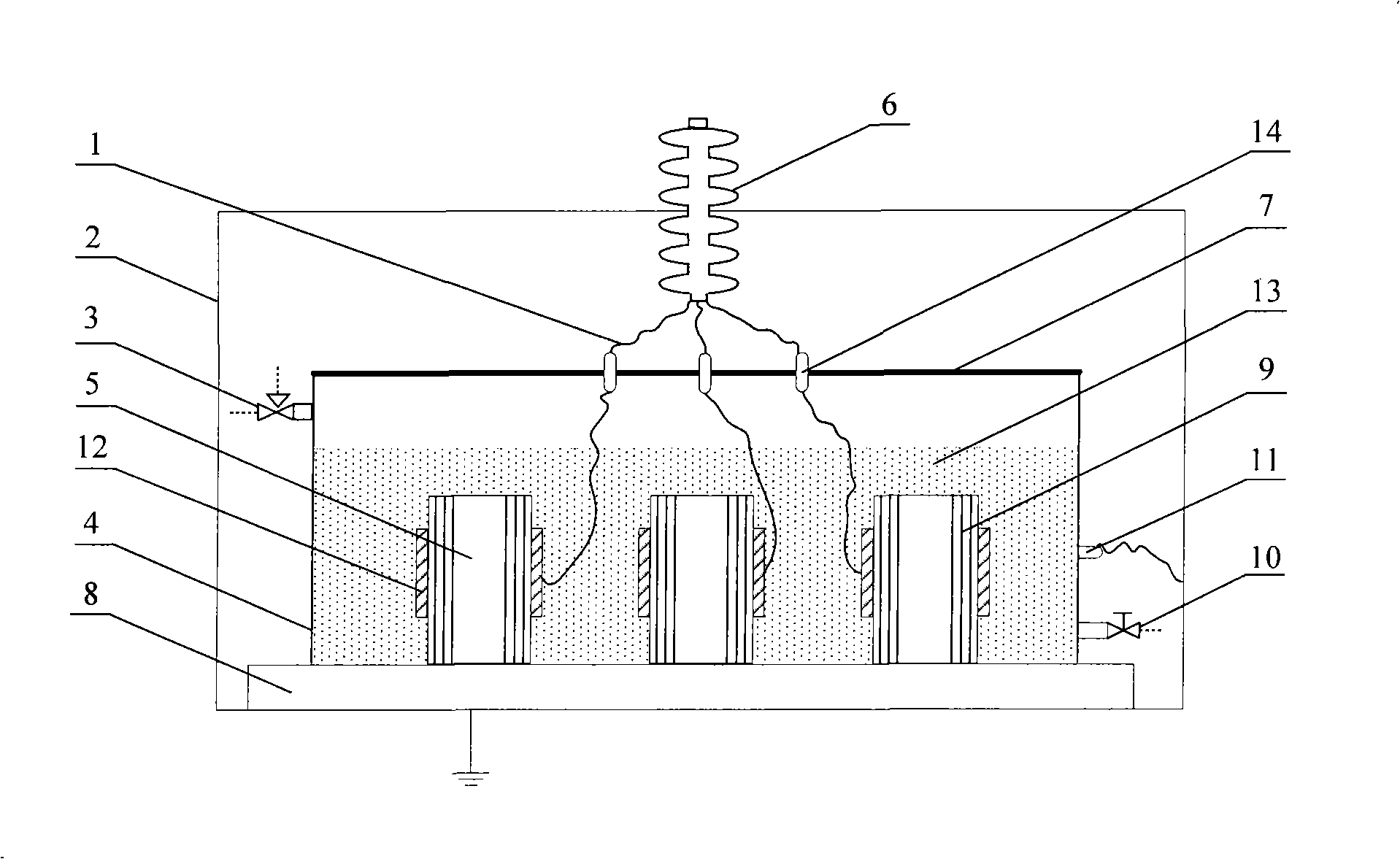

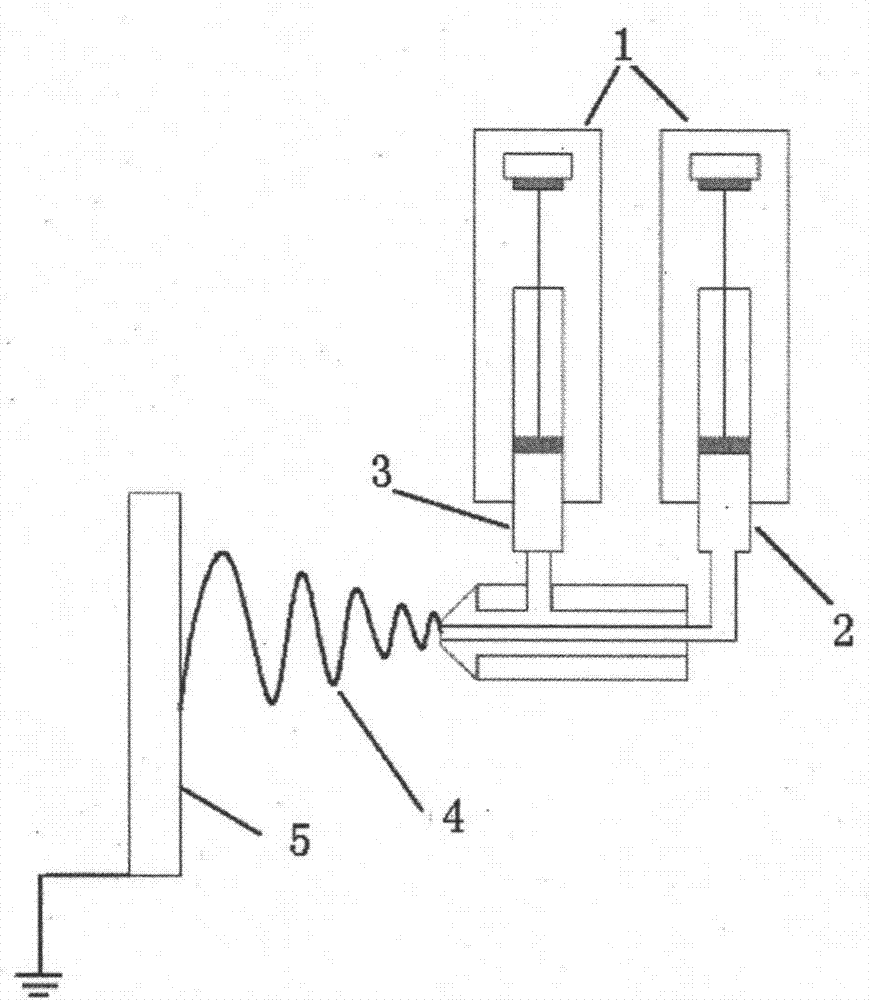

Multiple factors accelerated aging test apparatus and method for oil paper insulation of transformer

InactiveCN101408578AReveal the law of agingImprove reliabilityElectrical testingPaper testingHigh pressureVacuum drying

The invention provides a testing device and a testing method of electricity-heat-mechanical stress three-factor combined ageing for transformer paper oil insulation ageing study; the testing device comprises an electric heating ageing oven, in which a transformer paper oil insulation simulator, a shake unit and a temperature control device used for controlling the temperature of the electric heating ageing oven. The shake unit can drive the simulator to vibrate, the simulator is electrically connected with a high-voltage power supply; the testing method includes vacuum drying and oil impregnation of insulating paper, attaching the paper to the earth electrode in a stainless steel case of the testing device, winding coils as a high voltage electrode outside the insulating paper and the earth electrode and injecting insulating oil to the stainless steel case; connecting a high tension lead with the high-voltage power supply and starting the shake unit; sampling the insulating paper and the insulating oil alternately and measuring insulation ageing parameters.

Owner:CHONGQING UNIV

Olefinic polymerization catalyst carried by carrier of sphere MgCl-alcohol-organic complexing agent and preparation method

The invention discloses an defin polymerization catalyst loaded on spherical MgCl2-alcohol-organic complexing agent camier and its preparation method. Said method includes the following steps: under the protection of argon gas using TiCl4 and MgCl2-alcohol-organic complexing agent spherical carrier, stirring them at -30 deg.c-0 deg.C in reaction still and making them produce reaction for 10-30 min., heating to 60 deg.C-80 deg.C, adding internal doner residues, and more heating to 90 deg.C-140 deg.C, thermostatically stirring and making reaction for 1-3 hr., then removing liquid phase, adding TiCl4 to make treatment once, and removing liquod phase, washing by using solvent, removing solvent, vacuum drying so as to obtain spherical catalyst. Said spherical catalyst uses spherical MgCl2-alcohol-organic complexing agent as carrier, and the preparation process of said catalyst is retatively simple, and small in environmental pollution. Said invention can effectively regulate grain size of catalyst and its distribution by controlling grain size of spherical MgCl2-alcohol-organic copmlexing agent carrier and its distribution, after the olefin is catalyzed and polymerized, the spherical polyolefin can be obained.

Owner:ZHEJIANG UNIV

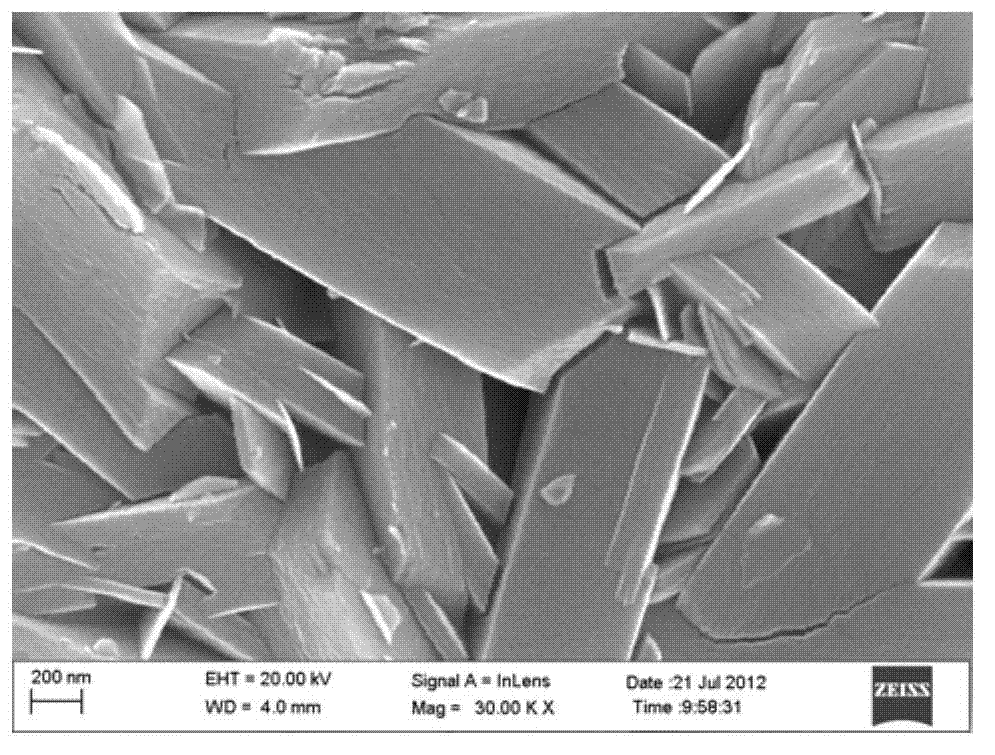

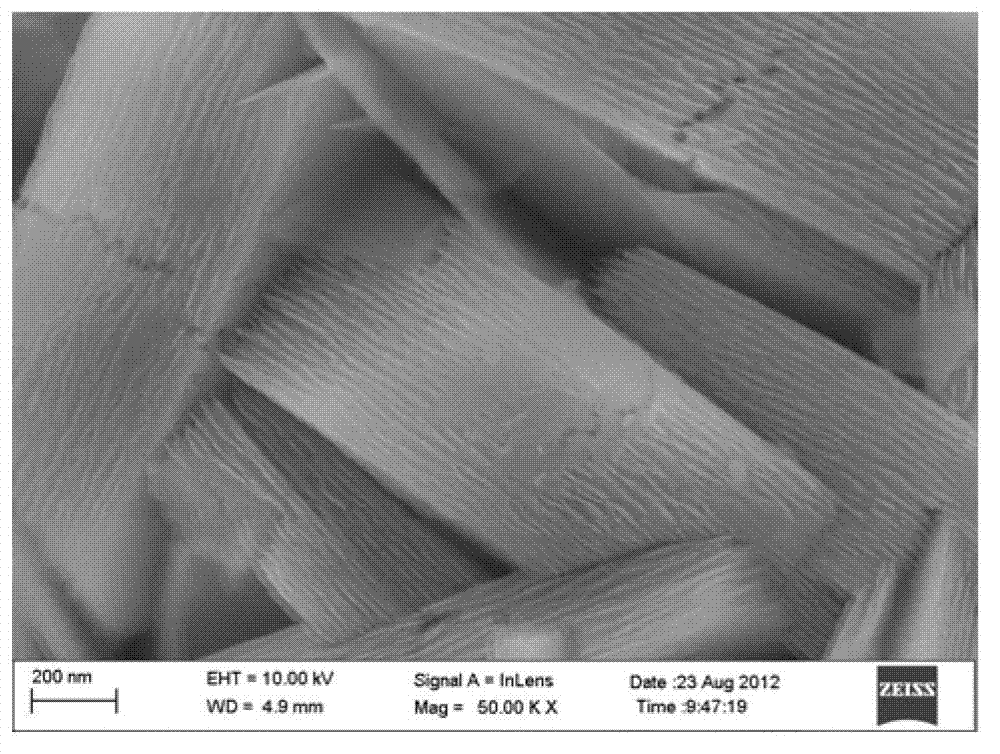

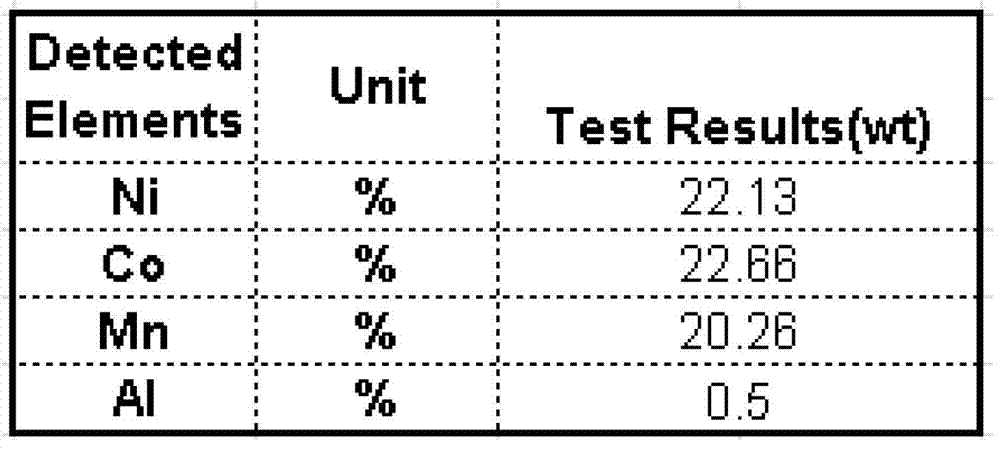

Method for preparing aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material

ActiveCN103178258AAdvantages of preparation methodInhibition of agglomerationCell electrodesManganates/permanganatesLamellar crystalsReaction temperature

The invention discloses a method for preparing an aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material. The method comprises the following steps of: (1) preparation of a precursor: mixing water-soluble metallic nickel salt, cobalt salt and manganese salt into a mixed solution, dripping the mixed solution, a precipitator and a morphological control agent into a reaction container, controlling the pH value and reaction temperature of a system, and performing filtering, washing and vacuum drying after reaction to obtain a (NixCoyMn1-x-y)(OH)2 precursor, wherein x, y and x+y are more than 0 and less than 1; (2) preparation of an aluminum oxide coated precursor: dispersing the (NixCoyMn1-x-y)(OH)2 precursor, water-soluble aluminum salt and a disperser into deionized water, stirring while heating until the disperser is hydrolyzed, filtering to obtain an Al(OH)3-coated (NixCoyMn1-x-y)(OH)2 precursor, roasting the precursor in a sintering furnace to obtain Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder; and (3) uniformly mixing the Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder with lithium salt powder, and calcinating at high temperature to obtain an aluminum oxide coated modified Li(NixCoyMn1-x-y)O2 cathode material with a lamellar crystal structure.

Owner:NINGDE AMPEREX TECH

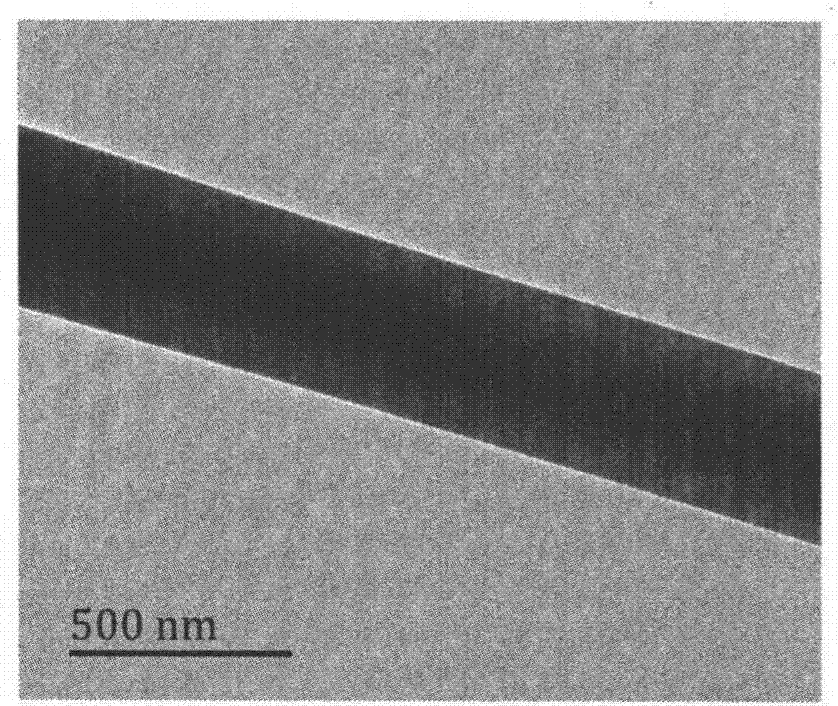

Preparation method of core-shell structure superfine fiber carrier material for medical dressing

ActiveCN103611182AEasy to operateOptimizing Control ParametersFilament/thread formingAbsorbent padsFiberWound healing

The invention provides a preparation method of a core-shell structure superfine fiber carrier material for medical dressing. The preparation method is basically characterized by specifically comprising the following steps: mixing and dissolving macromolecular polymers into a solvent to obtain a shell layer solution; selecting at least one of a functional high polymer and a medicine and dissolving the functional high polymer or the medicine into a solvent under the aseptic condition to obtain a core layer solution; and performing coaxial electrostatic spinning, placing into a vacuum drying box, and vacuum-drying to remove the residual solvent to obtain the core-shell structure superfine fiber carrier material for the medical dressing. The core-shell structure superfine fiber carrier material for the medical dressing has excellent water-absorbing property, moisturizing property and air permeability, can provide a wet microenvironment for wound healing, is uniform in pore size distribution, and achieves a bacterium blocking effect. The core layer high polymer or medicine can achieve zero-order release through corrosion or diffusion mechanism, so the influence of the environment on the medicine effect is reduced and unnecessary damage to a human body by the medicine is reduced.

Owner:上海必趣医疗科技有限公司

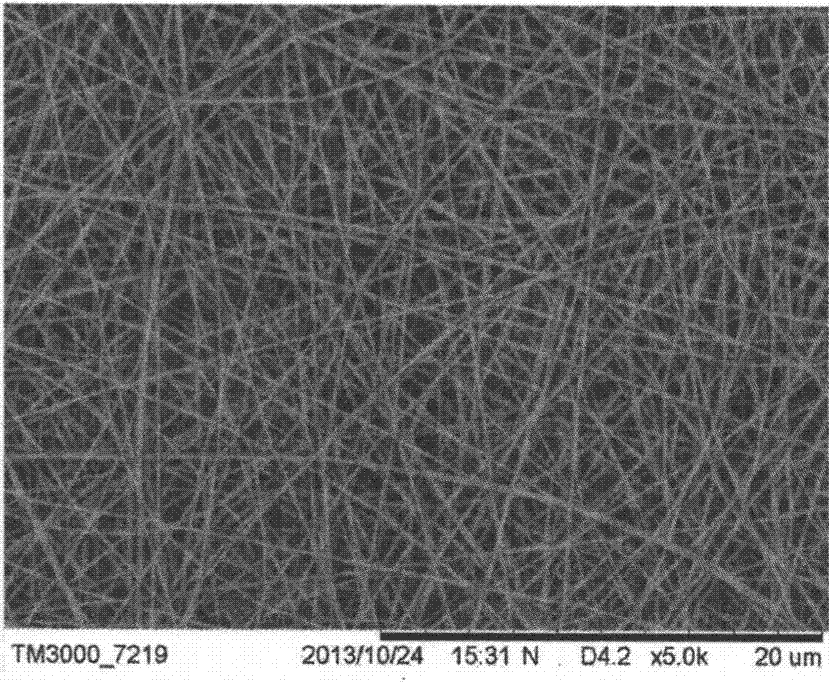

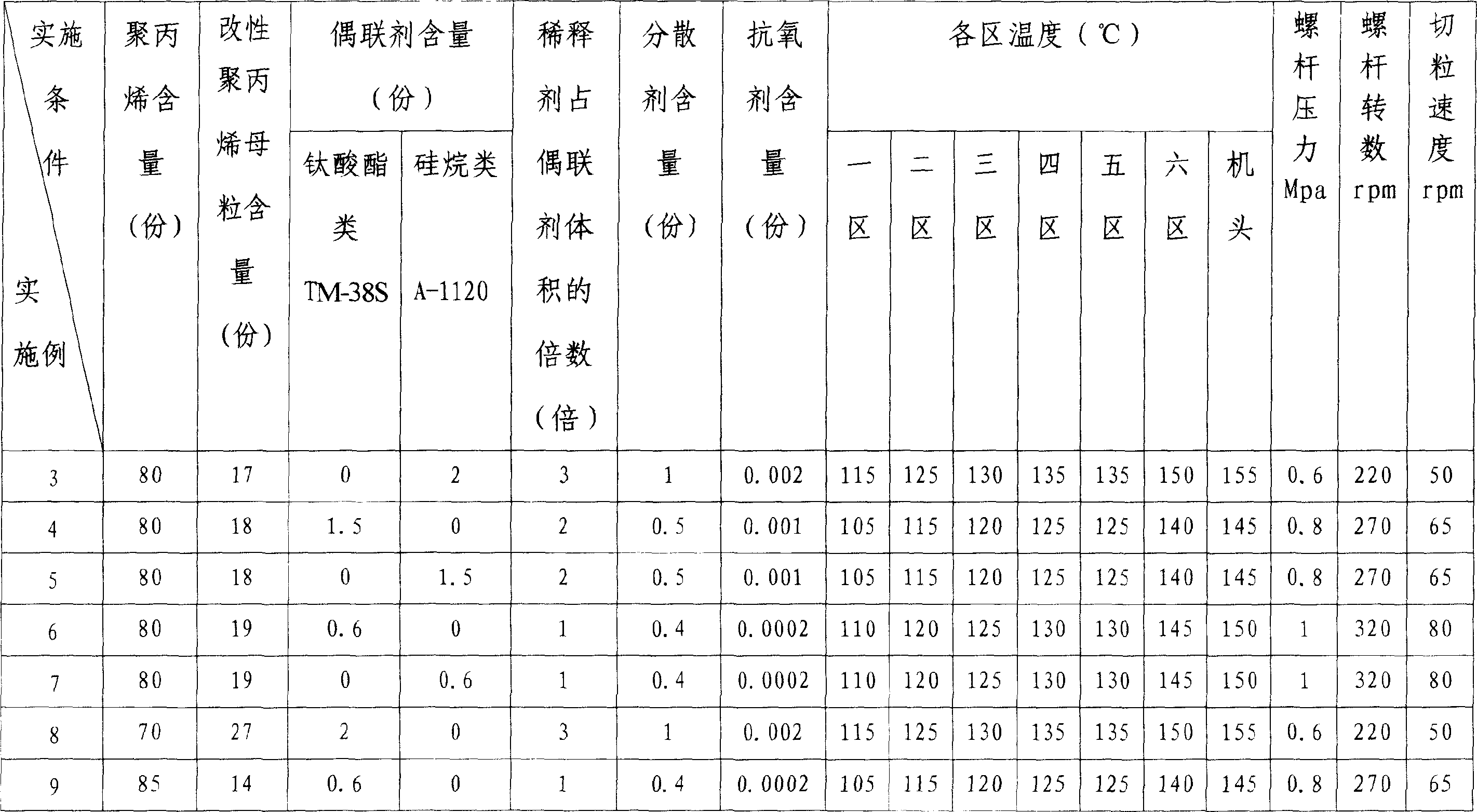

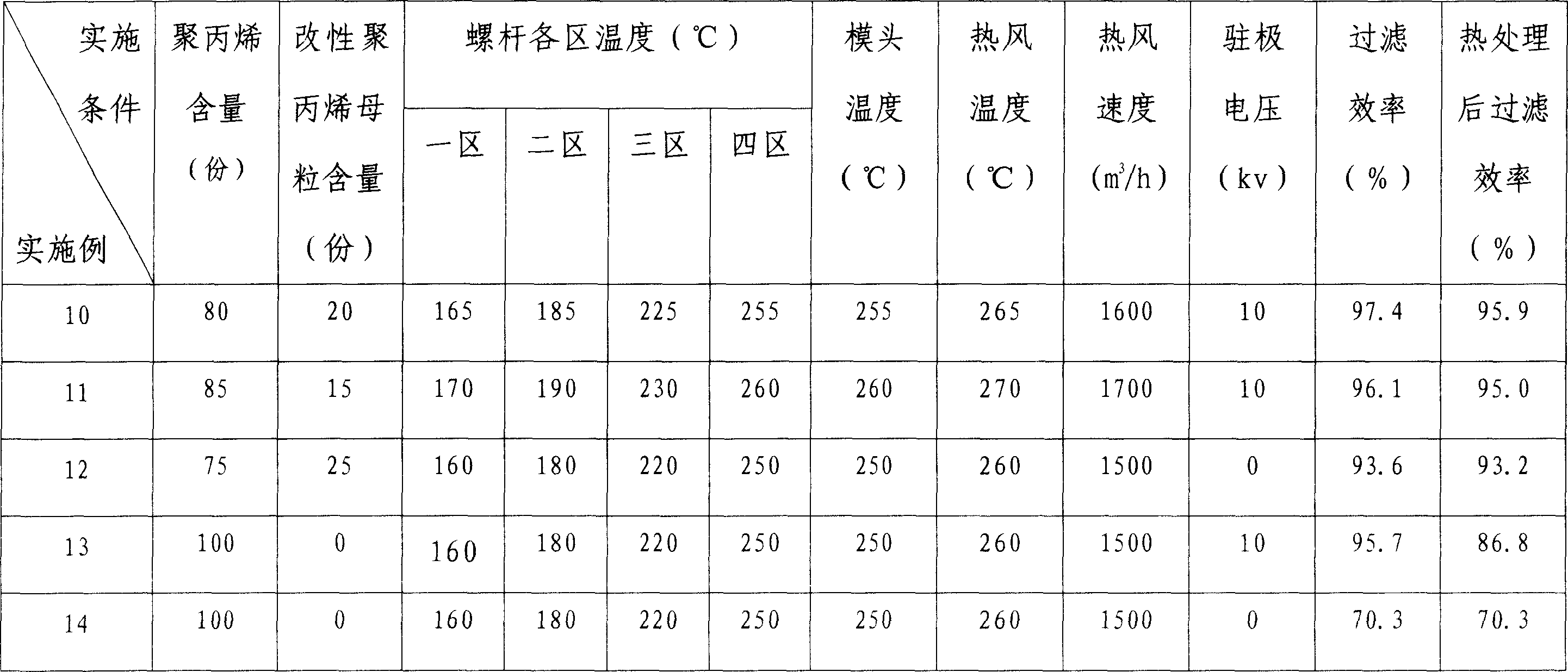

Modified polypropylene mother particle for melt spray, its preparation method and use

The present invention relates to a modified polypropylene mother granule for melt-blowing process, its preparation method and application technique. Its composition contains (by wt %) 70-85% of polypropylene, 14-27% of tourmaline and 1-3% of adjuvant. The described polypropylene is a low molecular weight melt-blowing polypropylene resin, the average grain size of tourmaline is less than 0.5 microns, and the adjuvant includes coupling agent, dispersing agent and antioxidant. Its preparation method includes the steps of surface modification of tourmaline, vacuum drying and meltblending and granulating, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Method for recovering carbon-fiber enhanced epoxy resin composite material

The invention relates to a method for recovering a carbon-fiber enhanced epoxy resin composite material. In the existing method, the requirement for equipment is high and the recovery cost is large. The method comprises the following steps of: cutting materials needing to be decomposed into blocks with the volume being 5cm<3>, putting the blocks in a backflow device containing acid liquor, heating for 5-20 minutes at the temperature of boiling point, cleaning and carrying out vacuum drying; then putting the obtained mixture into a reaction kettle, adding an organic solvent and an oxidizing agent, firstly heating, then cooling to normal temperature, and obtaining a primary product; and after cleaning, putting a solid product in the primary product into industrial acetone solution for dipping, obtaining recovered carbon fiber and carrying out pressure-reduced distillation on a liquid product to obtain phenol and derivatives thereof. In the method, reaction under low temperature and low pressure is realized and has the advantages of moderate reaction condition, easy control of reaction, fewer side products, no pollution basically and no corrosion to equipment and the like, so that the method is a green recovering method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Flexible nanocellulose-graphene composite membrane and preparation method thereof

InactiveCN105860143ANo pollution in the processSimple processHeat-exchange elementsNanofiberCvd graphene

The invention discloses a flexible nano-cellulose-graphene composite film and a preparation method thereof. The mass fraction of the composite film is composed of: graphene 0.1%-90%, nano-cellulose 10%-99.9%, and the preparation steps are as follows: : (1) Prepare a graphene oxide dispersion with a concentration of 0.05-5 mg / ml and a nano-cellulose dispersion with a concentration of 0.05-5 mg / ml, ultrasonically disperse for 1-2 hours, and mix to obtain a concentration of 0.05-5 mg / ml The first dispersion liquid of nanocellulose-graphene oxide; (2) add reducing agent in the first dispersion liquid, heat up, stir, stir evenly, obtain the second dispersion liquid of nanocellulose-graphene; (3) The above-mentioned second dispersion liquid is subjected to centrifugal degassing, and then vacuum-filtered to form a composite film, and the composite film is transferred to an oven, and vacuum-dried to obtain a flexible nanocellulose-graphene composite film. There will be no agglomeration between the graphene sheets in the composite film, and its thermal conductivity in the parallel direction is ≥2W·m ‑1 ·K ‑1 , vertical thermal conductivity ≤0.3W·m ‑1 ·K ‑1 , Thermal conductivity anisotropy ratio ≥ 5.

Owner:SHANGHAI UNIV

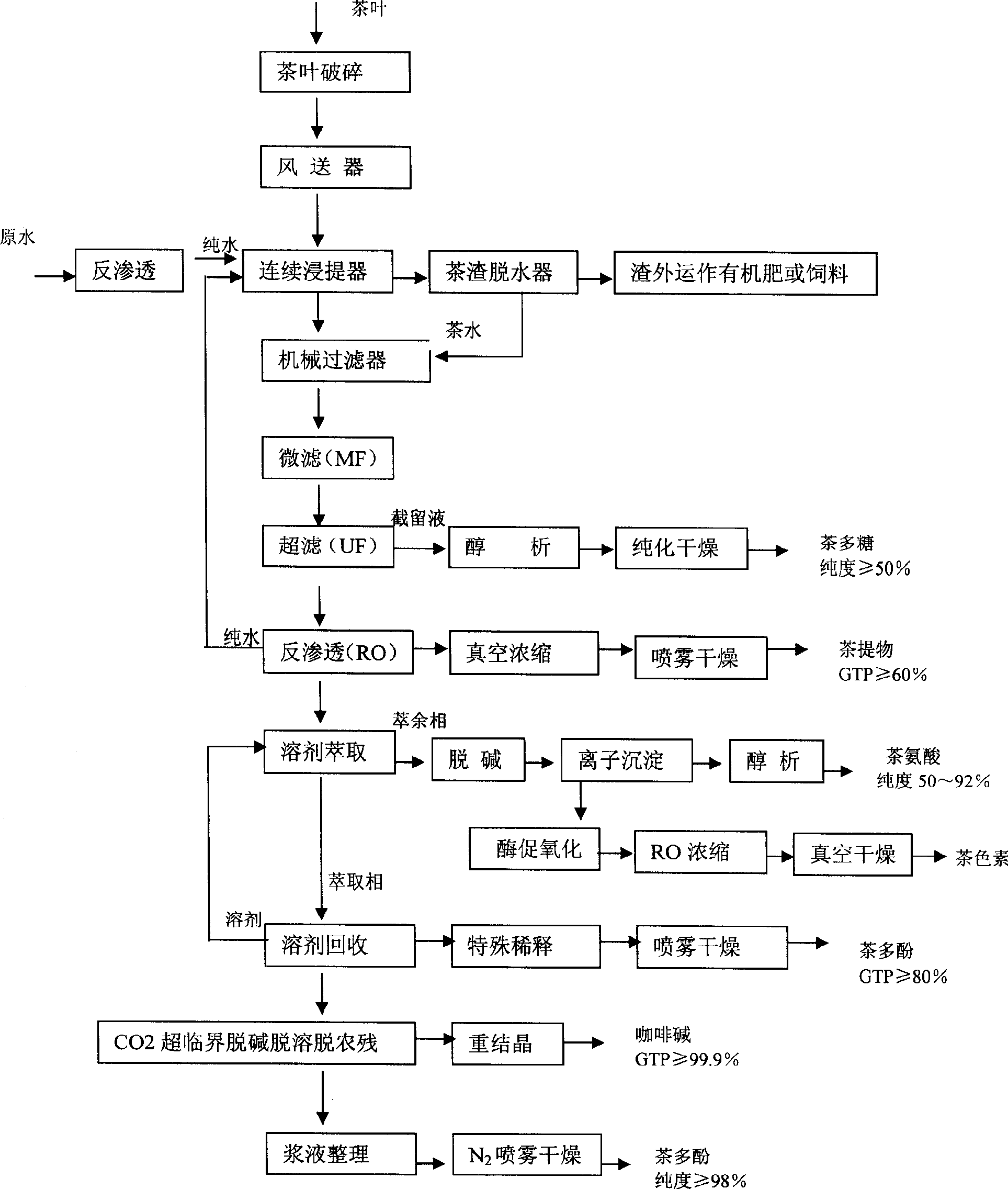

Process for extracting tea polyphenol, theanine, tea polysaccharide and tea pigment from tea

InactiveCN1837201AHigh purityReduce labor intensityCarboxylic acid amide separation/purificationBulk chemical productionForeign matterPhenolic content in tea

The invention discloses an extracting polyphenol, theanine, tea polysaccharide and tea pigment method from tea, which is characterized by the following: using deionized water for lixiviating tea at constant temperature with continuous flow upstream at multi-speed; adopting microstrainer to dislodge the foreign matter of raffinate; using hyperfiltration for putting-off pectin and protein; concentrating by hyperfiltration and dehydration; extracting tea polyphenol by acetic acid ethyl ester and recovering dissolvant; stripping caffeine of extracting extract phase, pesticide residue and dissolvant by CO2 supercritical fluid; getting tea polyphenol by low-temperature nitrogen spray-drying; using alcohol separation and low temperation vacuum drying by hyperfiltration trapped fluid to prepare tea polysaccharide; separating alcohol recrystallization by basic copper carbonate and hydrogen sulfide to get theanine; using enzymatic oxidation and alkaline air to oxygenate remain polyphenols substance of liquid phantom; getting tea pigment by hyperfiltration dehydration compression and vacuum drying; merging caffeine form carbon dioxide above-critical fluid and caffeine from carrene; recovering dissolvent; using deionized water for washing; obtaining caffeine by recrystallization vacuum drying.

Owner:张守政

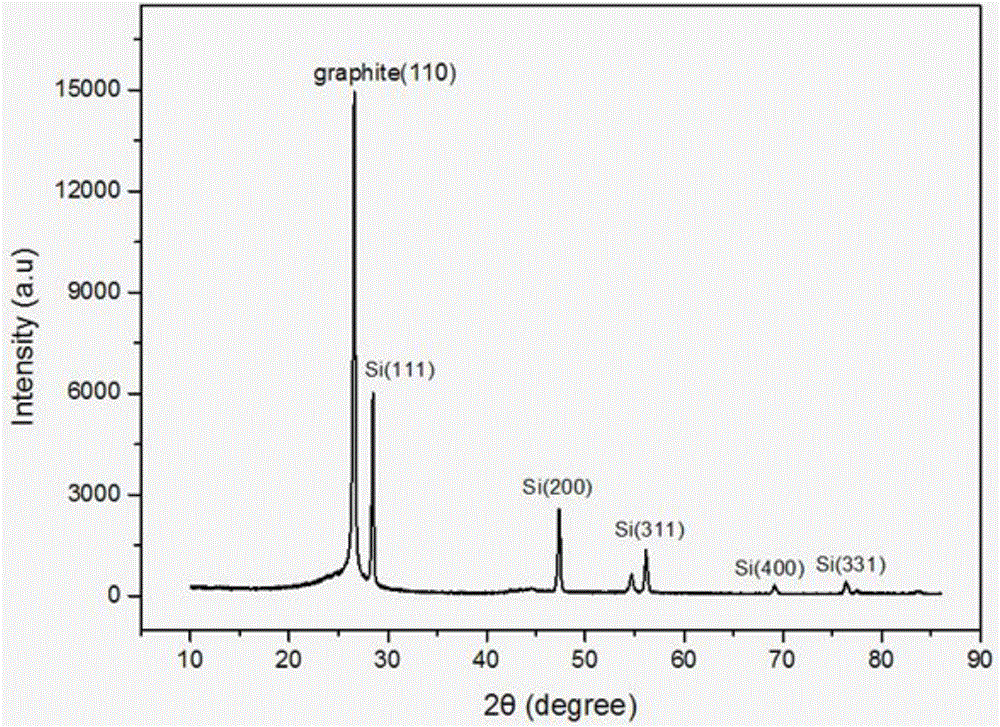

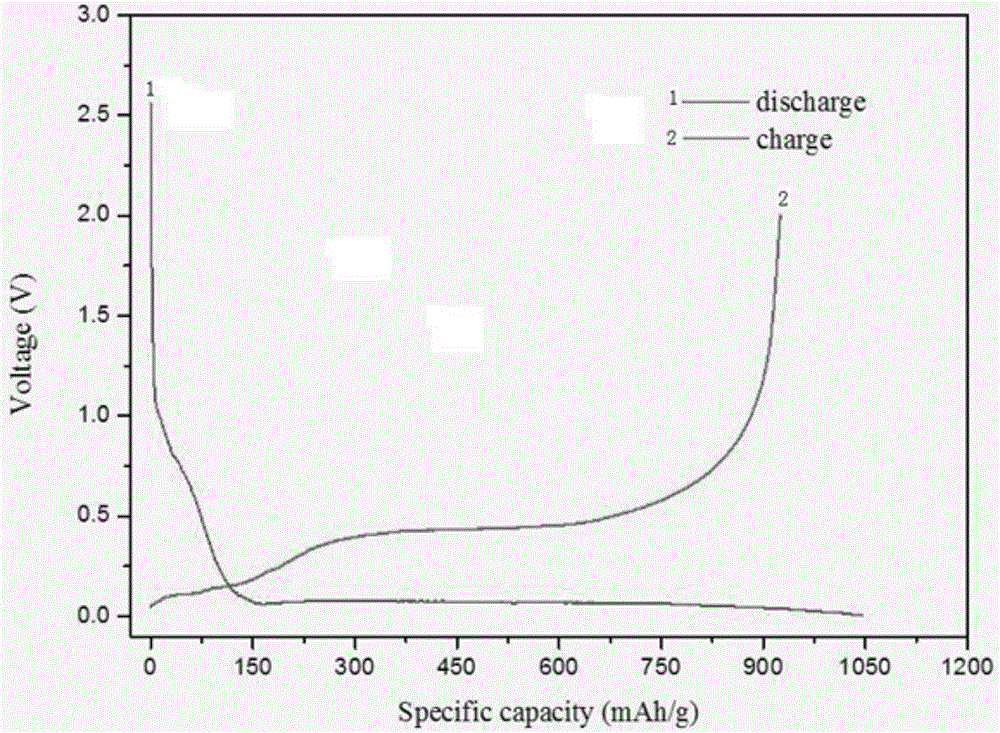

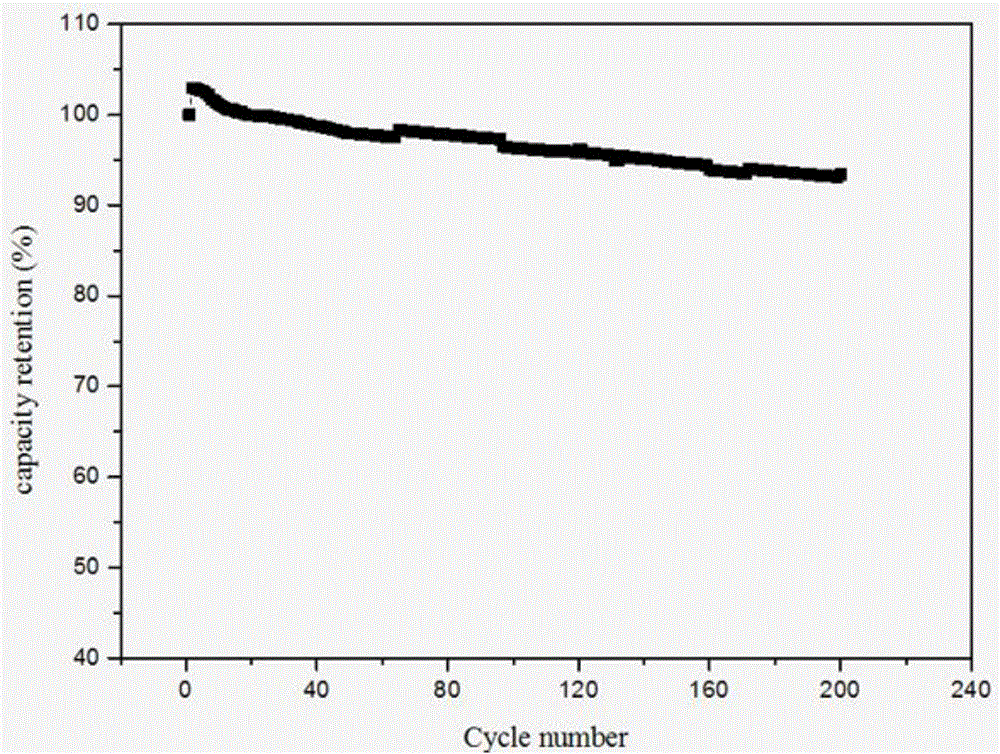

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

Drying method of lithium-ion battery electric core

ActiveCN102735023AGood water contentReduce labor loadFinal product manufactureDrying solid materials without heatVacuum pumpingElectrical battery

The invention relates to the field of battery manufacturing and particularly relates to a drying method of a lithium-ion battery electric core. The method comprises the following steps that: the electric core to be dried is placed in a closed cavity; constant temperature of the cavity is set; multiple times of vacuum pumping and vacuum relieving are cyclingly carried out; and a cycling air flow is formed in the closed cavity and the electric core is dried. When the lithium-ion battery electric core adopts the drying method provided by the invention, cycling of air pumping and air changing is introduced in the process of vacuum drying, and water content in the lithium-ion battery electric core can be reduced in a relatively short period of time, and operation processes are simplified and work load of an operator is reduced.

Owner:DONGGUAN AMPEREX TECH +1

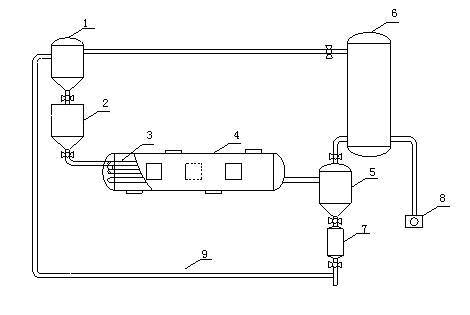

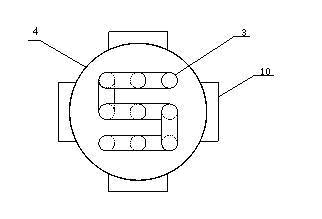

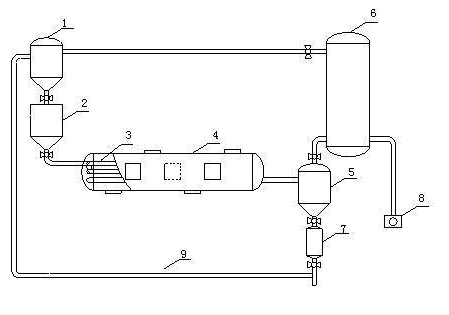

Negative-pressure microwave uniform spraying and drying device and application

ActiveCN102062525ADry evenlyAvoid uneven heatingDrying using combination processesDrying machinesMicrowaveDrying time

The invention discloses a negative-pressure microwave uniform spraying and drying device and application, belonging to the technical field of uniform drying devices. The negative-pressure microwave uniform spraying and drying device comprises a circulating material storage device, a feeder, a negative-pressure spraying pipe, a microwave heating cavity, a cyclone separator, a vacuum storage tank, a discharger, a water ring vacuum pump, a circulating pipe and microwave sources. The circulating material storage device is used for storing materials dried circularly, the feeder is used for feeding dry materials to the negative-pressure spraying pipe which is a channel for drying and circulating the materials, and the microwave sources are uniformly distributed inside the microwave heating cavity, two ends of which are sealed. The cyclone separator is connected with an outlet of the negative-pressure spraying pipe inside the microwave heating cavity and is connected with the vacuum storage tank and the discharger through a channel. The discharger is connected with the circulating material storage device through the circulating pipe. Because the materials can be sprayed under negative pressure, the device can be used for spraying, rotating and circulating the materials under a microwave vacuum drying condition so as to achieve the purpose of drying the materials efficiently and uniformly, meanwhile, is favorable for shortening the drying time by above 40% and reducing the cost of large-scale production.

Owner:JIANGNAN UNIV

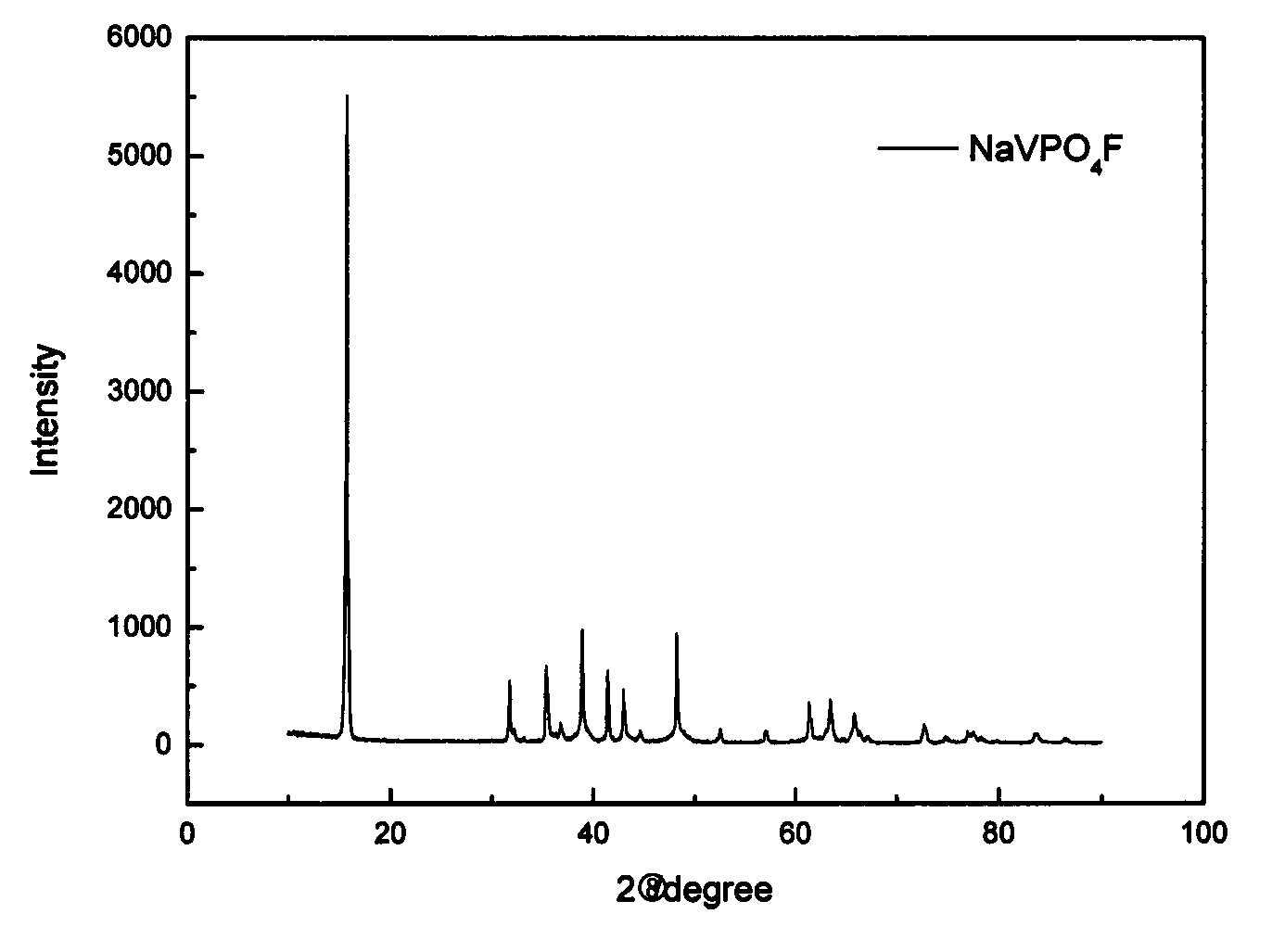

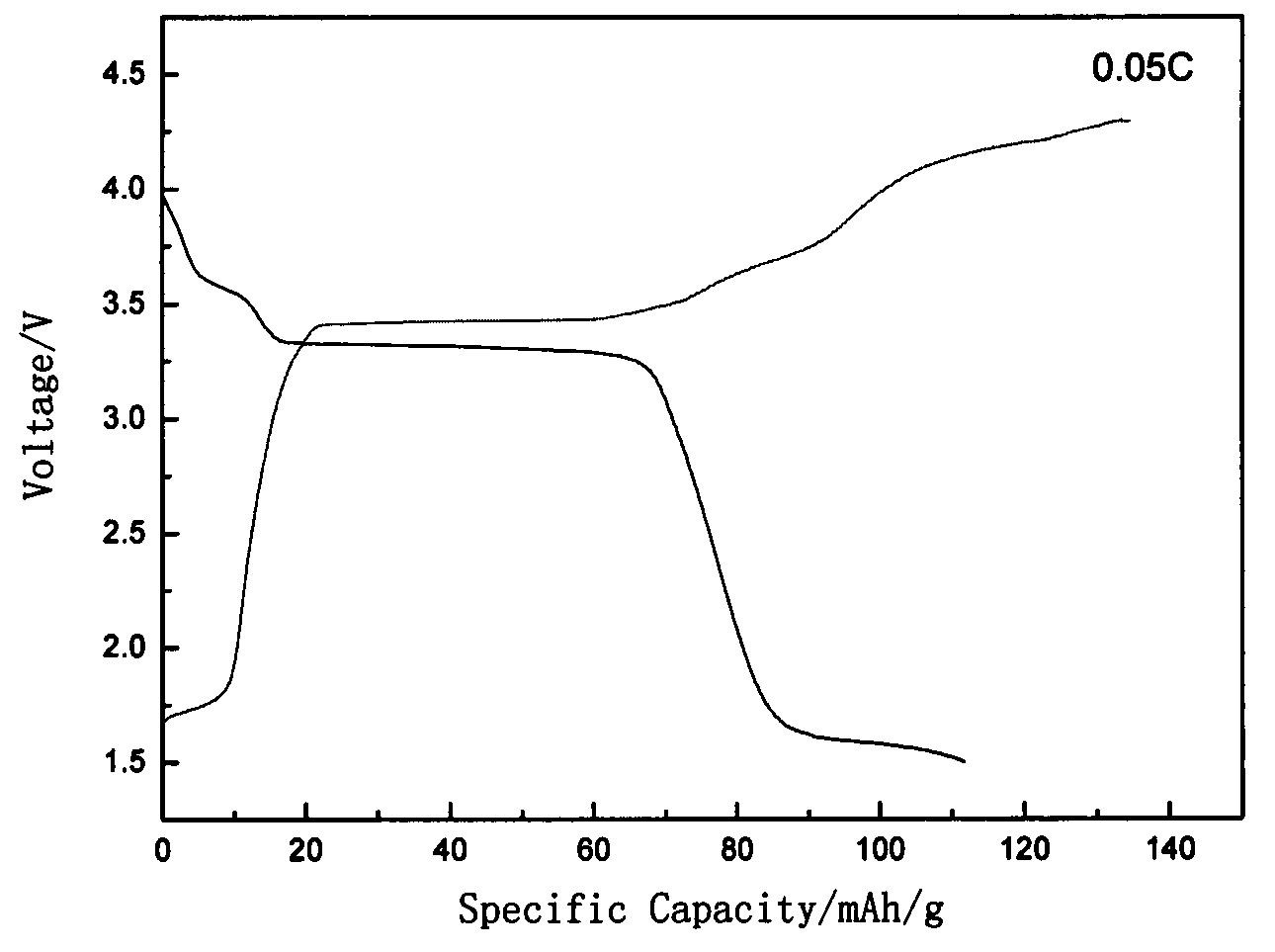

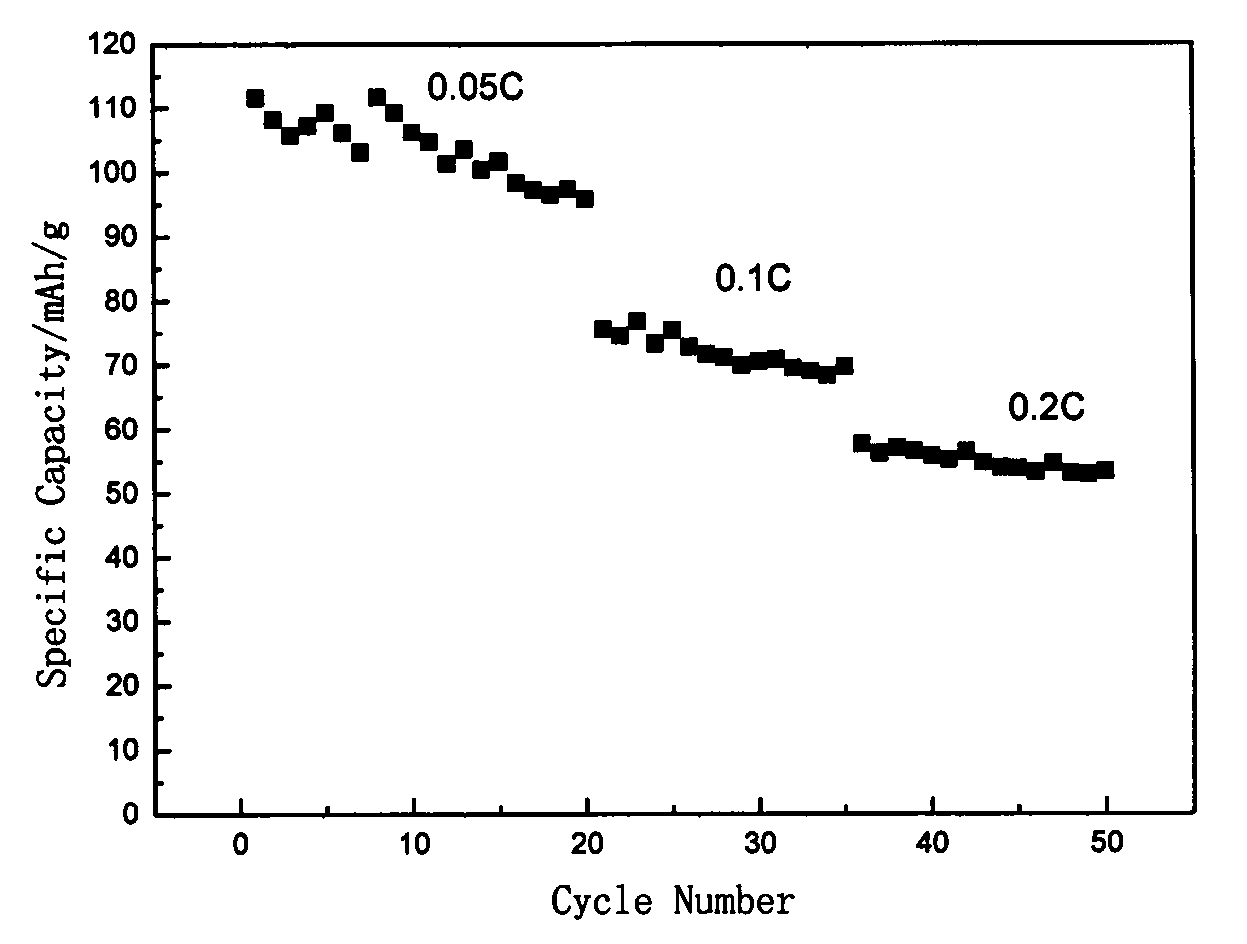

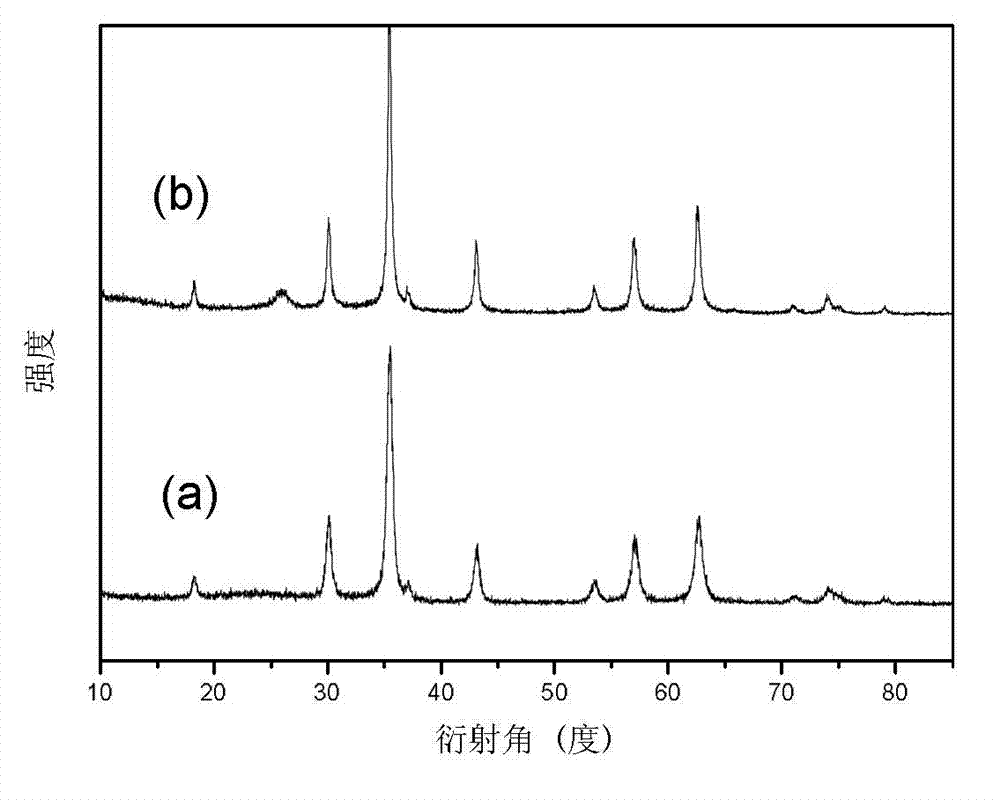

Method for preparing cathode material of sodium-ion battery, namely sodium vanadium fluorophosphates

InactiveCN103594716AImprove electrochemical performanceThe synthesis process is simpleCell electrodesWater bathsSodium-ion battery

The invention discloses a method for preparing a cathode material of a sodium-ion battery, namely sodium vanadium fluorophosphates. The method comprises the following steps: using a vanadium source, a phosphorus source and a carbon source as main synthetic raw materials; dissolving into deionized water according to the molar ratio 1:1:1.2 of vanadium: phosphorus: carbon, heating in water bath, and continuously stirring to obtain light green pulp; after vacuum drying, grinding, then transferring into a tube furnace, preburning in an inert atmosphere at a certain temperature rise rate, cooling and then taking out to obtain black VPO4 / C precursor powder; mixing the VPO4 / C with NaF according to a stoichiometric ratio, ball-milling for 3 hours, sending into the tube furnace, then roasting in the inert atmosphere at the certain temperature rise rate, and cooling along with the furnace to obtain a positive active material NaVPO4F / C. According to the invention, cheap and easily-obtained pentavalent vanadium oxide or trivalent vanadium oxide is used as the main raw materials to prepare the sodium vanadium fluorophosphates cathode material through a sol gel activated auxiliary two-step high-temperature solid phase method, and the sodium vanadium fluorophosphates cathode material has the advantages of good stability, uniform particle size and good electrochemical performance. Meanwhile, the method has the advantages of simple synthesis process, short period and low cost and is convenient for large-scale production.

Owner:TIANJIN POLYTECHNIC UNIV

Fucoidin ester as antiviral immunoregulator and its prepn

InactiveCN1344565AHigh yieldSimple and fast operationPharmaceutical non-active ingredientsImmunological disordersShrimpReverse osmosis

Owner:汤洁 +1

Tissue regeneration membrane with bioactivity and preparation method thereof

InactiveCN101474430APrevent invasionPromote intensiveSurgeryProsthesisElectrospinningIsolation layer

The invention discloses a bioactive tissue regeneration membrane and a preparing method thereof. The membrane is double compound layer. One layer is a tissue isolation layer which comprises silk fibroin, and the other layer is a tissue orientation layer which comprises silk fibroin bundles adhered on the tissue isolation layer or silk fibroin bundles mixed with bioactive factors. One side of the membrane is a smooth dense shape, and the other side is a loose porous structure. In the preparing method of the bioactive tissue regeneration membrane, the silk fibroin solution is swollen, stirred, deaerated and casted into membrane to obtain the tissue isolation layer. One side of the tissue isolation layer is scratched to be coarsened. Then, the silk fibroin solution or the silk fibroin solution mixed with the bioactive factors is coated or sprayed on the scratched layer by an electrostatic spinning method. After freezing and vacuum drying demoulding, the membrane is obtained. The membranehas the advantages of nontoxic and harmless property, perfect biocompatibility, good cell adhering growth property, abundant raw material and low cost and can substitute bio-medical materials of collagen and the like and widely applied to a plurality of clinical subjects.

Owner:WUHAN UNIV

Method of preparing walnut polypeptide powder

InactiveCN101228918ALess impuritiesAnti-fatigueMetabolism disorderProtein composition from vegetable seedsEnzymatic hydrolysisCentrifugation

The invention relates to a preparation method of a walnut peptide powder, which effectively embodies a plurality of biological functional properties of the walnut peptide powder, reserves a plurality of nutritional components of walnuts. The polypeptide content in the walnut peptide powder is 60-80 percent, while the walnut peptide powder is light yellow or yellow-white color and has functions of anti-fatigue and antioxidation, etc. The invention comprises the following operation steps: crushing the walnut cakes before extracting the walnut protein, then carrying out enzymatic hydrolysis and centrifugation to the crude walnut protein to acquire the supernatant, dialyzing the supernatant and removing impurities and macromolecular compounds, and then concentrating the acquired dialysate, and at last vacuum drying to prepare the walnut peptide powder and packing into finished products.

Owner:NORTHWEST A & F UNIV +1

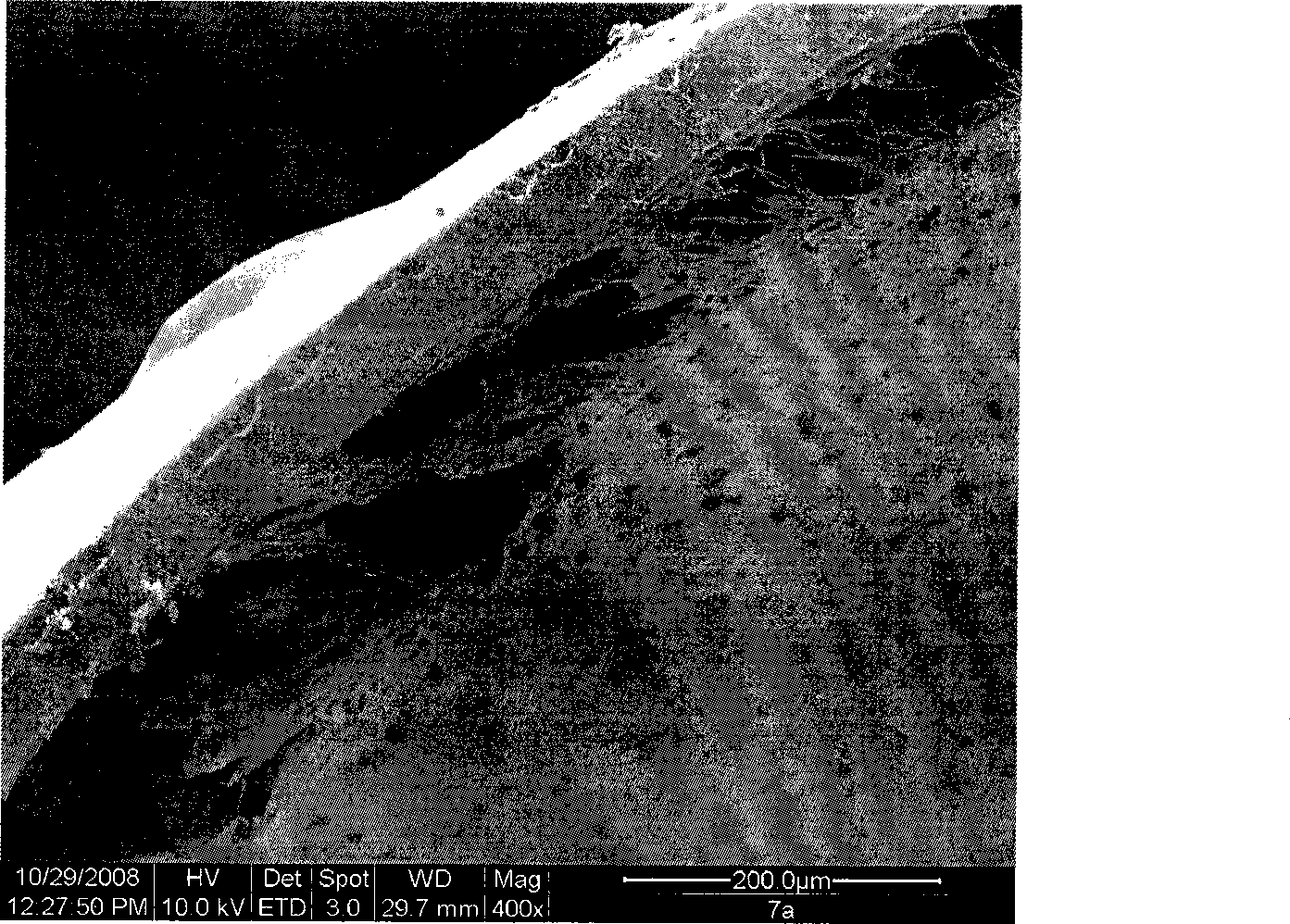

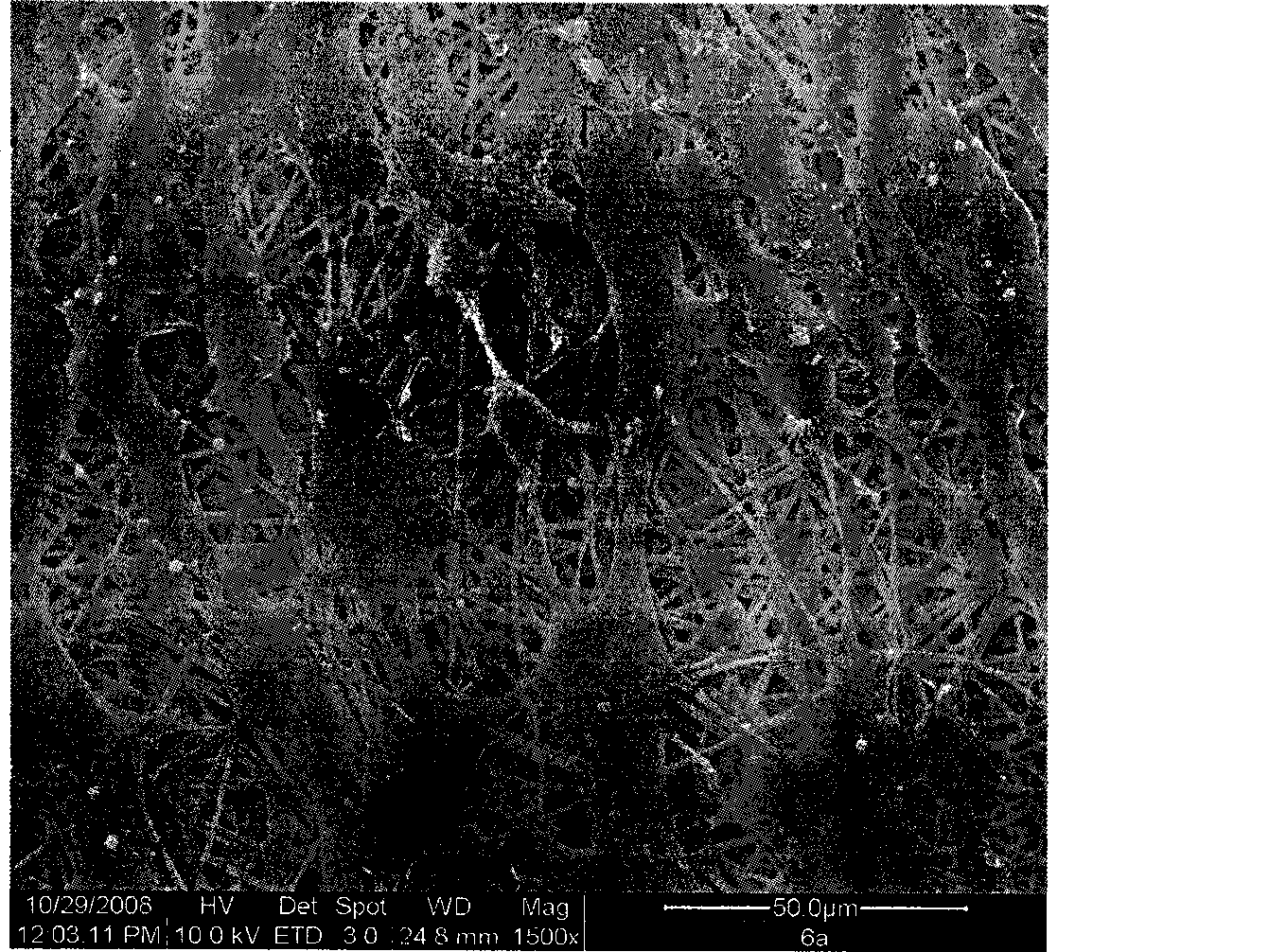

Magnetic carbon nanotube composite material and preparation method and application thereof

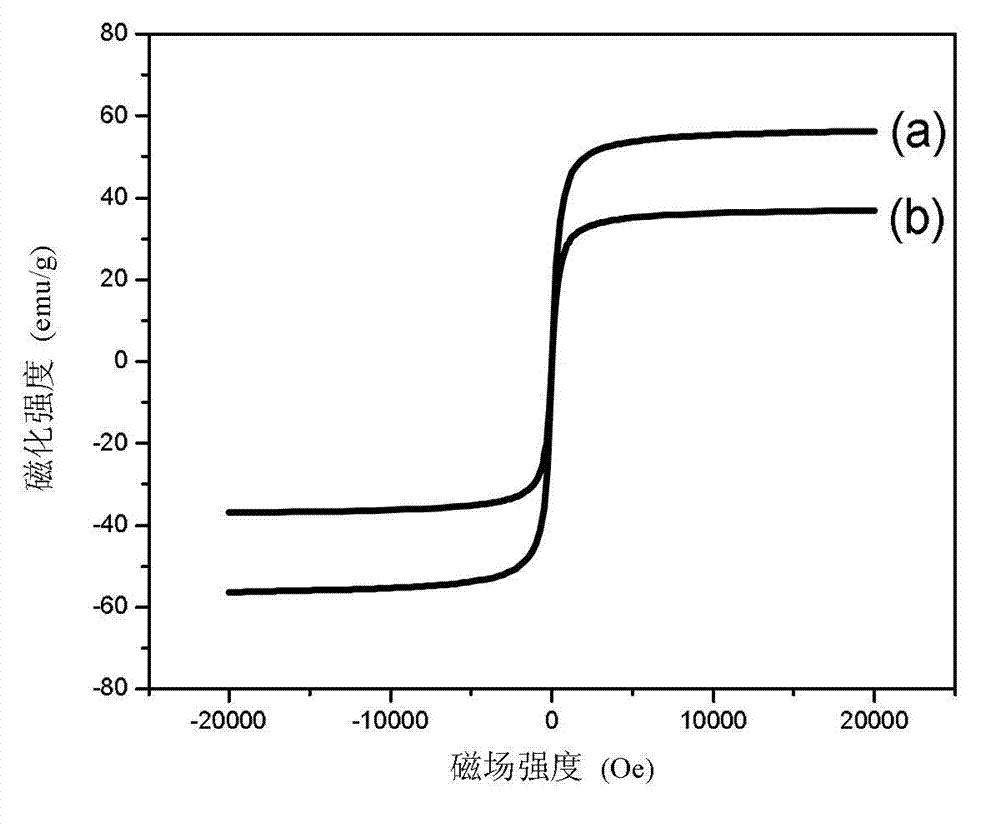

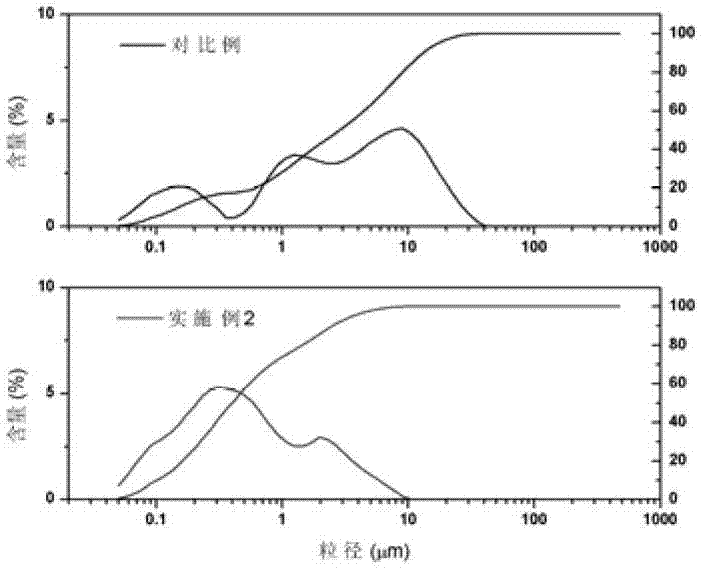

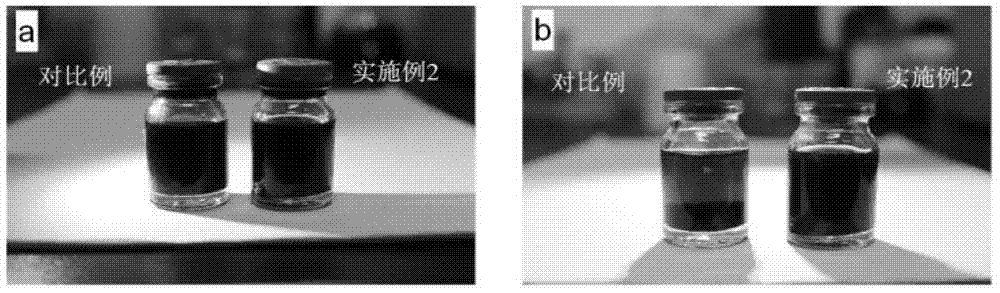

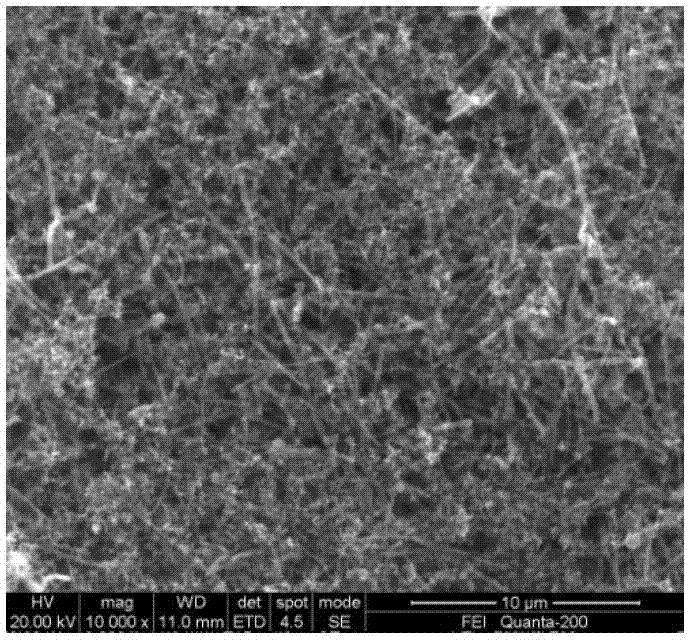

InactiveCN103041773AImprove bindingEasy to separateIon-exchange process apparatusComponent separationSorbentHexamethylenediamine

The invention discloses a magnetic carbon nanotube composite material and a preparation method and an application thereof. The preparation method comprises the following steps: adding FeCl3.6H2O to an ethylene glycol solution; then adding anhydrous sodium acetate and polyethylene glycol; adding a carboxylated multiwalled carbon nanotube; performing ultrasonic dispersion; adding hexamethylenediamine or ethanediamine; heating to 200-300 DEG C for reaction for 8-24h; and washing and performing vacuum drying to prepare the amino-modified magnetic Fe3O4-carbon nanotube composite material. The amino-modified magnetic Fe3O4-carbon nanotube composite material prepared by the invention is of nanoscale and superparamagnetism, can be stably dispersed in solutions, and can be quickly separated and enriched through a simple action of a magnetic field. As an adsorbent, the material is large in superficial area and has various active groups on the surface. The material can adsorb pigments from complex substrates through pi-pi electron interaction and hydrophobic effect of the carbon nanotube and can adsorb compounds such as organic acids and phenols through weak anion exchange effect of amino groups on the surfaces of magnetic nanoparticles.

Owner:TIANJIN UNIV

Current collector carbon coated aluminum foil and its preparation method

InactiveCN102832392AGood adhesionImprove conductivityElectrode manufacturing processesElectrolytic capacitorsInterface impedanceInternal resistance

The invention discloses a current collector carbon coated aluminum foil and its preparation method. A carbon-containing composite layer is arranged on the substrate of the current collector carbon coated aluminum foil, and is combined with the substrate through a binder, wherein the thickness of the carbon-containing composite layer is 1-100mum; the carbon-containing composite layer comprises granular conductive carbon black pre-dispersed by a dispersant, and fibrous conductive carbon; the granular conductive carbon black and the fibrous conductive carbon filled between the layers of the granular conductive carbon black form a netted node form conductive network. The composite layer is tightly combined with the substrate of the aluminum foil, so the conductivity and the corrosion resistance of the aluminum foil are improved, and the aluminum foil is protected from oxidation or chemical corrosion. The preparation method of the aluminum foil comprises the following operations: mixing the conductive carbon black with the dispersant in an organic solvent to pre-disperse, adding the fibrous conductive carbon, uniformly mixing, adding the binder to prepare a slurry, coating on the aluminum foil, and carrying out vacuum drying. The current collector carbon coated aluminum foil enables the interface impedances of the current collector and an active layer to be reduced, the internal resistance of a battery to be reduced, and the cycle life and the ratio performances of the battery to be improved when the aluminum foil is used as a lithium ion battery anode current collector. The aluminum foil has the advantages of simple technology, low cost and wide application prospect.

Owner:HUNAN CMAX NEW ENERGY TECH

Preparation method of nanofluid for improving oil recovery

ActiveCN103937478AIncrease profitGood dispersionFluid removalDrilling compositionActive agentSurface-active agents

The invention discloses a preparation method of a nanofluid for improving oil recovery. The preparation method comprises the following steps: taking 2.0-4.0g of nanopowder, adding 60-80mL of deionized water to the nanopowder and carrying out ultrasonic dispersion at a room temperature for 30-60 minutes; dissolving 2.0g of a silane coupling agent in absolute ethyl alcohol; mixing the nano-base solution with the ethanol solution of the silane coupling agent in a three-neck boiling flask, heating while stirring to the range of 70 to 75 DEG C, reacting for 4-6 hours, filtering, washing by using an anhydrous solvent a plurality of times, and drying in a vacuum drying box at 60-70 DEG C for 12 hours to obtain modified nanoparticles; putting 0.1-0.5g of nanoparticles in the three-neck boiling flask, adding 200-300mL of water, heating to the range of 60-75 DEG C by use of a water bath, mixing a surfactant with PEG (Poly Ethylene Glycol), adding 100mL of mixed solution of the surfactant and the PEG, mechanically stirring for 6-8 hours, washing the stirred dispersion 2-3 times, adjusting the pH value to the range of 8-9, and adding deionized water to 1L, thereby obtaining the water-based nanofluid.

Owner:NORTHEAST GASOLINEEUM UNIV

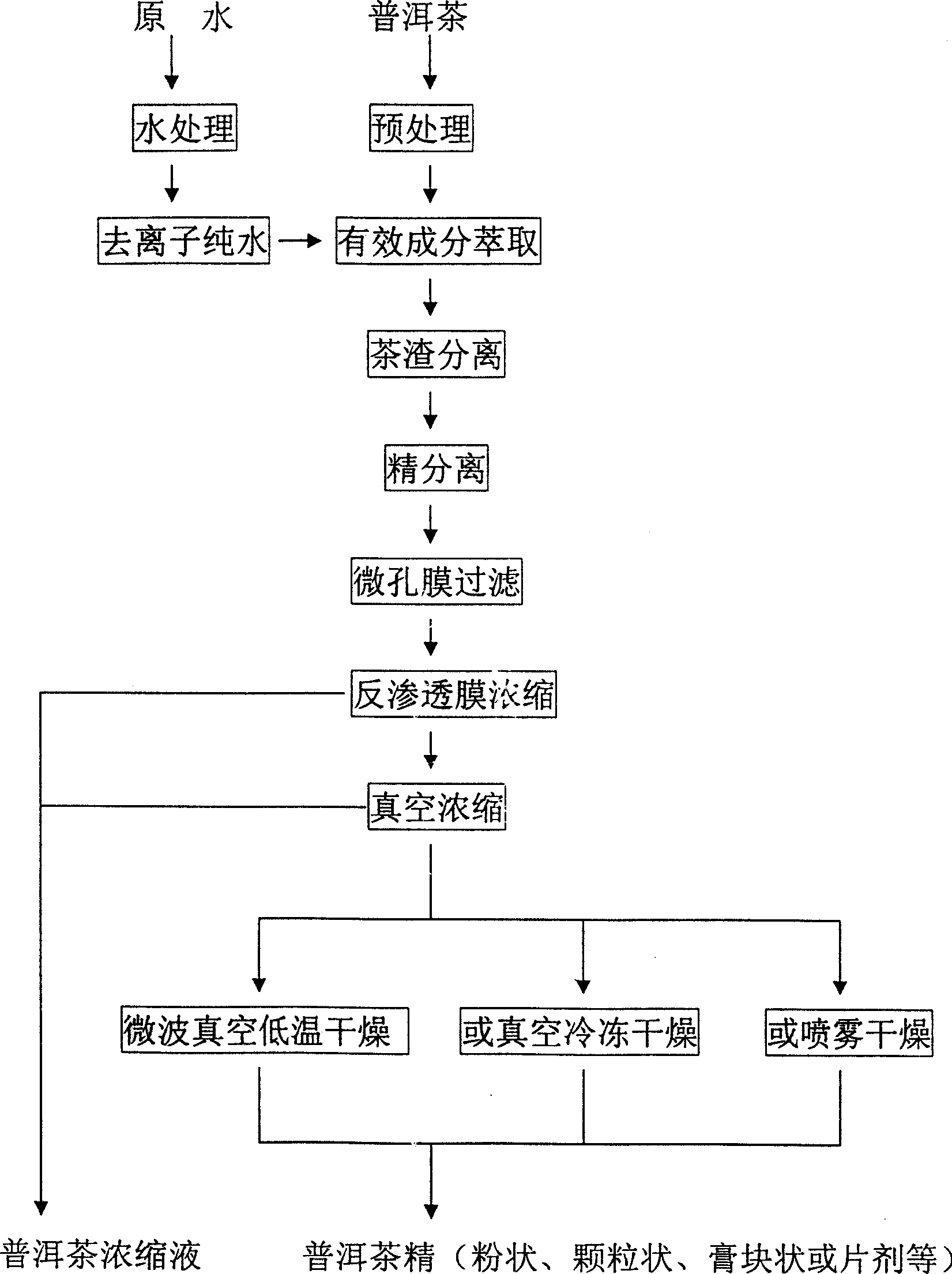

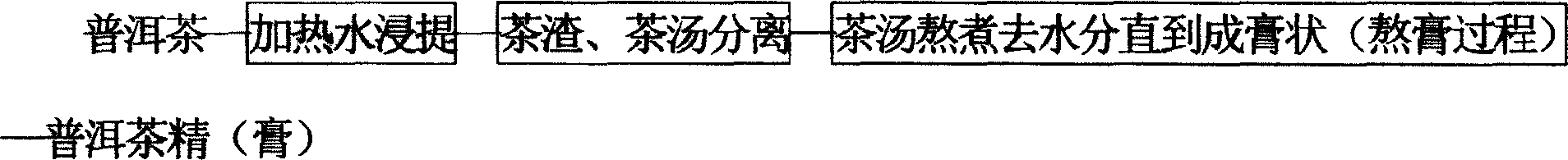

'Puer' caffeine and processing method

An extract of Puí»er tea is prepared from the Puí»er tea through extracting in hot water, separating liquid from dregs, refining and purifying the liquid, vacuum concentrating by reverse osmosis membrane, adding dextrin and sugar, shaping, and low-temp vacuum drying. Its advantage is no loss in color, smell and taste.

Owner:YUNNAN PROV AGRI MACHINERY INST

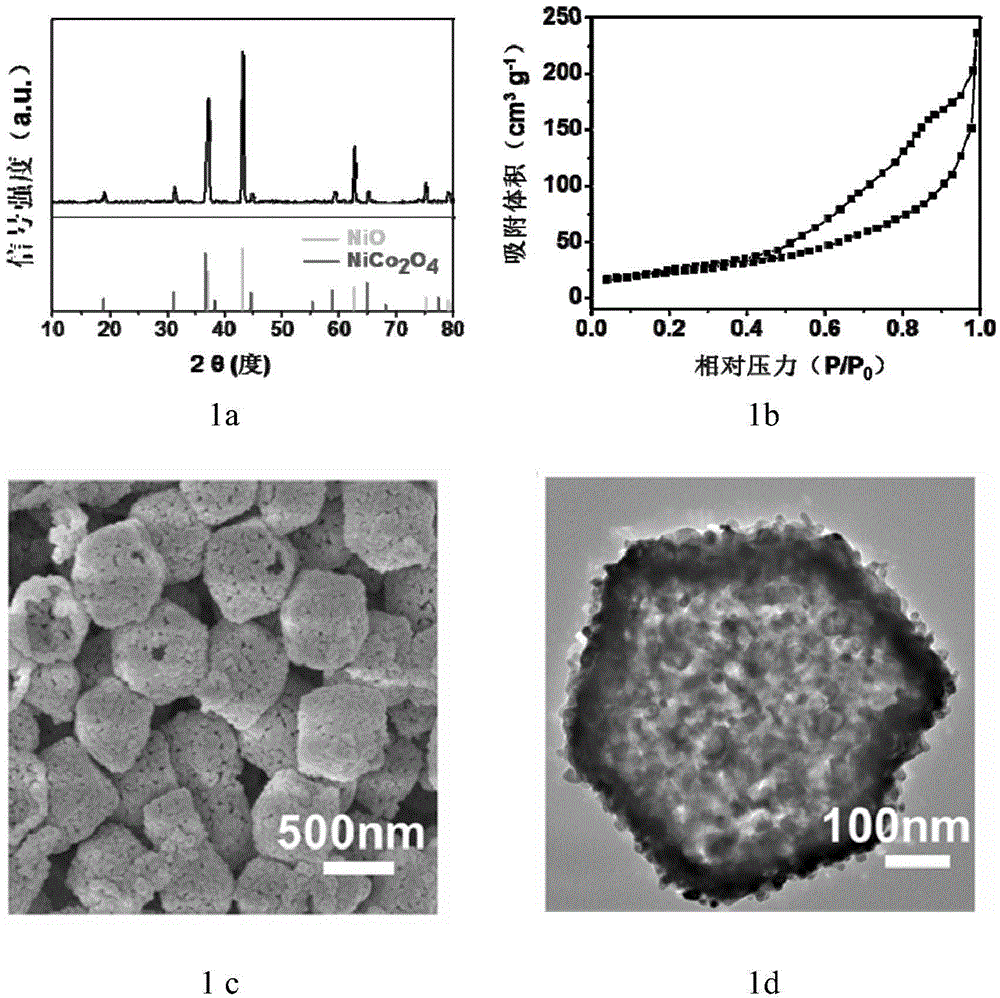

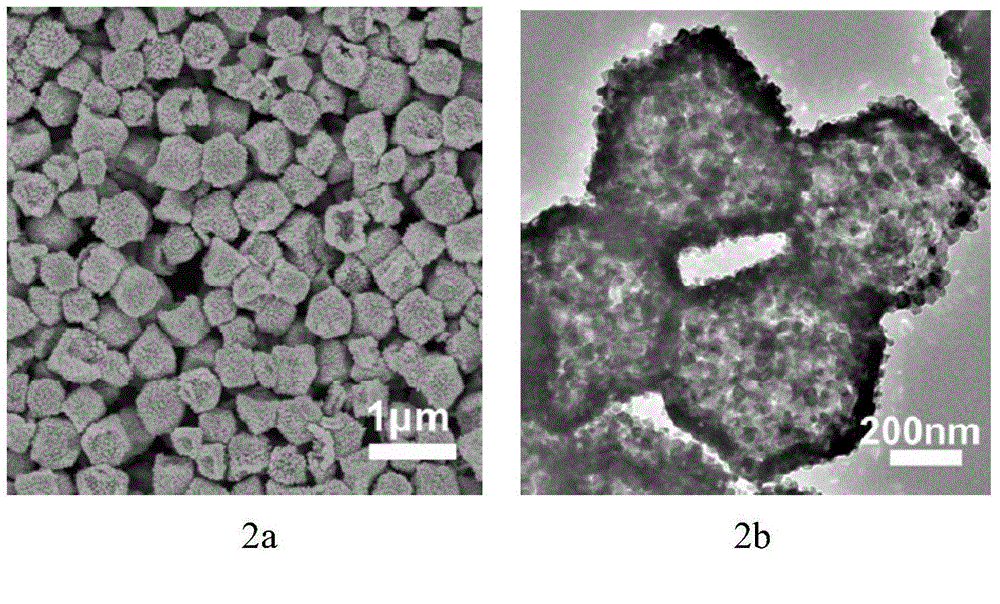

Preparation method of hollow nickel cobaltate nano polyhedron

The invention discloses a preparation method of a hollow nickel cobaltate nano polyhedron. The method comprises the following steps: (1) mixing an organic metal framework complex ZIF-67 and an alcoholic solution of nickel nitrate uniformly, and reacting at the temperature condition of 80-100 DEG C; (2) cooling to room temperature after reaction, collecting precipitate, cleaning by ethyl alcohol or other non-polar solvents, centrifuging, removing the solvents, and carrying out vacuum drying so as to obtain a hollow nickel cobalt hydroxide polyhedron; and (3) annealing the hollow nickel cobalt hydroxide polyhedron in air heating so as to obtain the porous nickel cobaltate nano hollow polyhedron. The method is simple to operate, and is environmentally friendly, and the mold plate removing process is omitted; the hollow obtained nickel cobaltate nano polyhedron has the relatively high specific surface area, relatively low mass transfer resistance and relatively excellent structure stability; as an electrode material of the lithium ion battery, the hollow nickel cobaltate nano polyhedron is superior to an existing transition metal oxide electrode material in cost and performance.

Owner:NANJING UNIV OF TECH

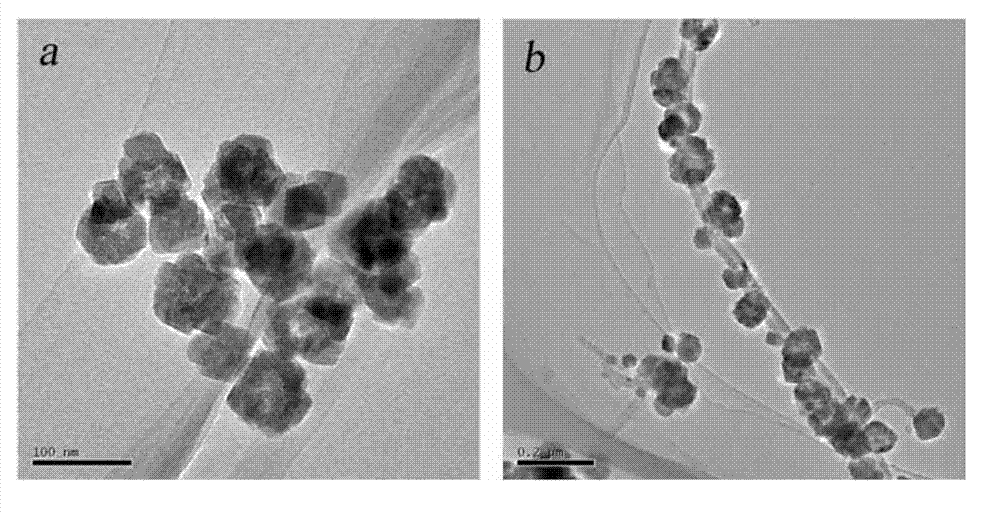

Preparation method of carbon nano-tube loaded nano-cobalt catalyst

ActiveCN103816905ALow costSimple production processMetal/metal-oxides/metal-hydroxide catalystsFiltrationCarbon nanotube

The invention discloses a preparation method of a carbon nano-tube loaded nano-cobalt catalyst. The method comprises the following steps: (1) dissolving a cobalt salt in an organic solvent and then adding a ligand to obtain a mixed liquid; (2) transferring the mixed liquid to a high-pressure kettle, performing a thermostatic heating reaction, naturally cooling to room temperature and then orderly performing filtration, washing and vacuum drying treatment on the generated crystal or powder to obtain a metal organic skeleton product Co-MOF of cobalt; and (3) roasting the metal organic skeleton product Co-MOF for 100-180 minutes at a roasting temperature of 400 DEG C to 1000 DEG C in a calcination atmosphere of argon inside a tubular furnace so as to obtain the carbon nano-tube loaded nano-cobalt catalyst. The preparation method disclosed by the invention has the advantages that the raw materials are low in cost, the production process is also simple, the reaction condition is easy to control, no template agent and surfactant are needed, the prepared product is good in consistency and environment-friendly; and the preparation method is beneficial to batch production and application of carbon nano-tube loaded nano-cobalt.

Owner:NANKAI UNIV

Preparation method of polylactic acid/nano-cellulose composite material

The invention provides a preparation method of a polylactic acid / nano cellulose composite material. The composite material comprises the following components in percentage by weight: 55 to 99.8% of polylactic acid, 0.1 to 15% of nano cellulose, and 0.1 to 30% of polyethylene glycol. The method comprises the following steps of: preparing a 5 to 15% an aqueous solution of microcrystalline cellulose, dripping concentrated sulfuric acid until the concentration of sulfuric acid reaches 40 to 60%, stirring and reacting for 1 to 2hours, carrying out centrifugation, ultrasound treatment and adjusting pH value to be neutral to obtain a nano cellulose suspension; dissolving polyethylene glycol, mixing with the nano cellulose suspension, stirring for 1 to 3hours at the temperature of 90 DEG C and carrying out vacuum drying to obtain a polyethylene glycol / nano cellulose comixture; and carrying out melt blending on the polyethylene glycol / nano cellulose comixture and polylactic acid for 5 to 8minutes at the temperature of 120 to 170 DEG C to obtain the composite material. The method is convenient and simple to operate, short in the time of the preparation process and solves the problem of uniform dispersion of nano-cellulose in the polylactic acid.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

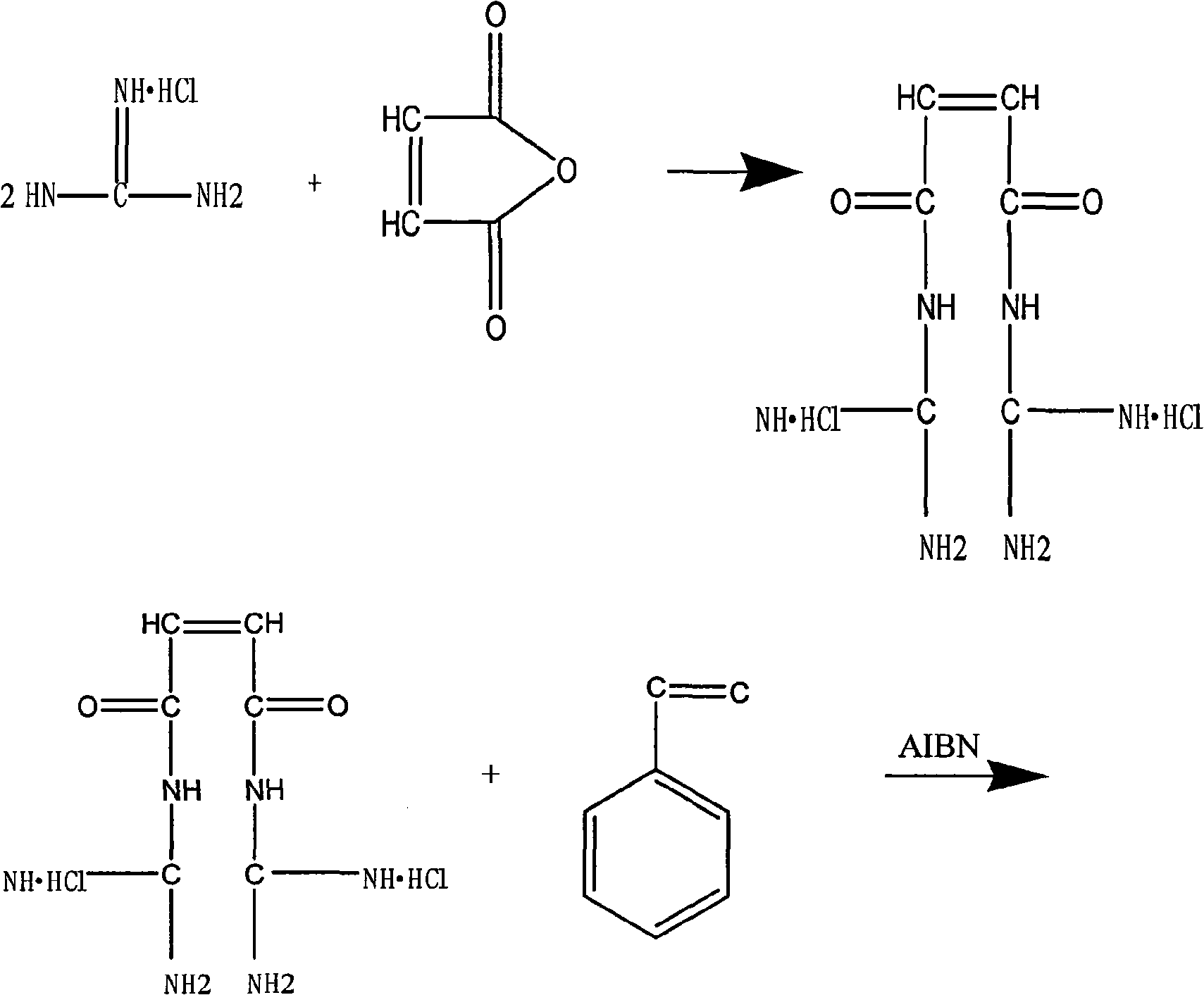

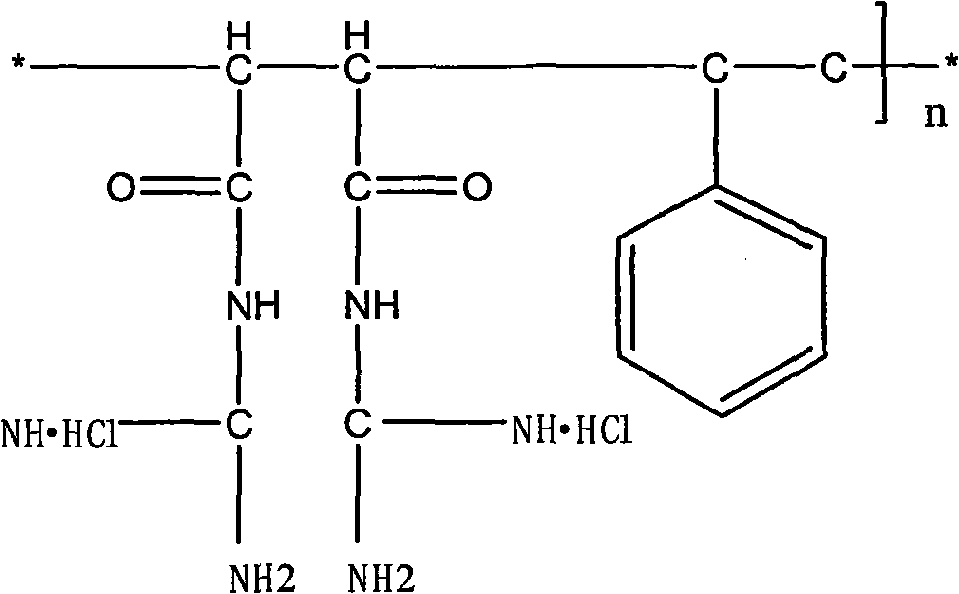

Method for preparing uramine-type macromolecule anti-bacterial agent

ActiveCN101628952ANot easy to migrateImprove antibacterial propertiesBiocideDisinfectantsWater bathsNitrogen gas

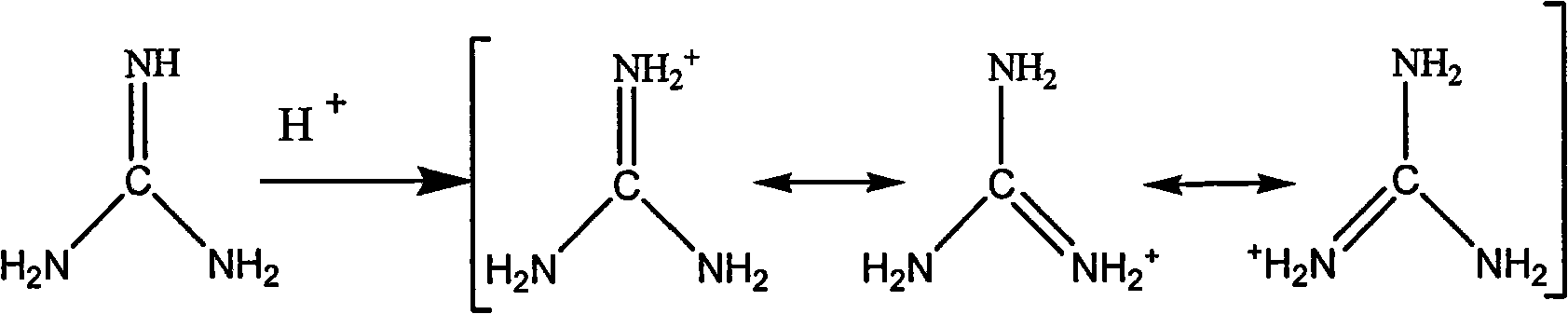

The invention relates to a method for preparing an uramine-type macromolecule anti-bacterial agent, comprising two steps as follows: A, mixing any one solution of guanidine hcl, Polyhexamethyleneguanidine chloride and polyhexamethylene biguanide hydrochloride with maleic anhydride solution; introducing nitrogen for constant-temperature water bath reaction to obtain functional uramine salt; B, mixing functional uramine salt solution with acrylamide and / or styrene for constant-temperature water bath reaction to obtain ivory-white stringy liquid; depositing soft white solid with solvent for vacuum drying to obtain ivory-white bulk uramine-type copolymer, i.e, uramine-type macromolecule anti-bacterial agent. The uramine-type macromolecule anti-bacterial agent has remarkable effect and simple synthesis process, ensures that the anti-bacterial group is hard to move and the processing thermal stability is excellent through copolymerization on macromolecule long chain. The invention can be widely used in fields of plastic, dope, powder dope, rubber, wood plastic, rubber plastic, spinning, water processing, and the like.

Owner:安徽合汇金源科技有限公司

Synthesizing process for obtaining lithium difluoro-oxalato-borate and lithium tetrafluoroborate

InactiveCN101648963AImprove performanceSimple processGroup 3/13 element organic compoundsBoron halogen compoundsOrganic solventPhysical chemistry

The invention discloses a synthesizing process for simultaneously obtaining lithium difluoro-oxalato-borate and lithium tetrafluoroborate with favorable performance, which comprises the following steps: (1) leading a fluorine-contained compound, a boron-contained compound, a lithium-contained compound and an oxalate-contained compound to react in a reaction medium at the reaction pressure of 0.1-1MPa and the temperature of 0-100 DEG C, wherein the molar ratio of lithium element, fluorine element, boron element and oxalate ion is (2-3):(5-6):6:2:1; generating reaction liquid containing the lithium difluoro-oxalato-borate and the lithium tetrafluoroborate; (2) carrying out initial separation on the lithium difluoro-oxalato-borate and the lithium tetrafluoroborate in the reaction liquid and then carrying out further extraction separation by an organic solvent which can extract the lithium difluoro-oxalato-borate or the lithium tetrafluoroborate; and (3) respectively carrying out recrystallization and vacuum drying to obtain the battery-grade lithium difluoro-oxalato-borate and the lithium tetrafluoroborate. The invention is suitable for industrially producing two lithium salts which have favorable performance and are used for a lithium ion battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

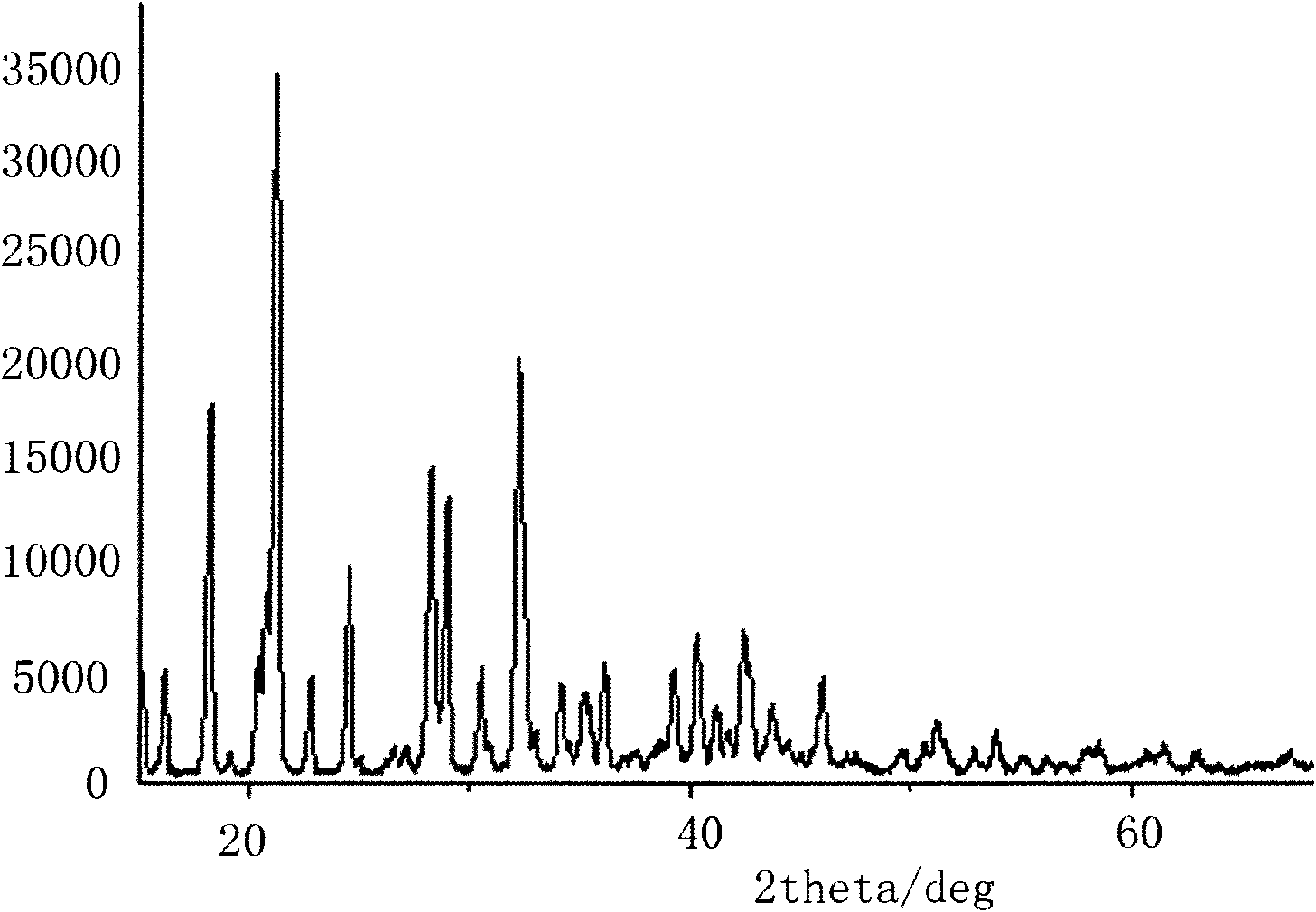

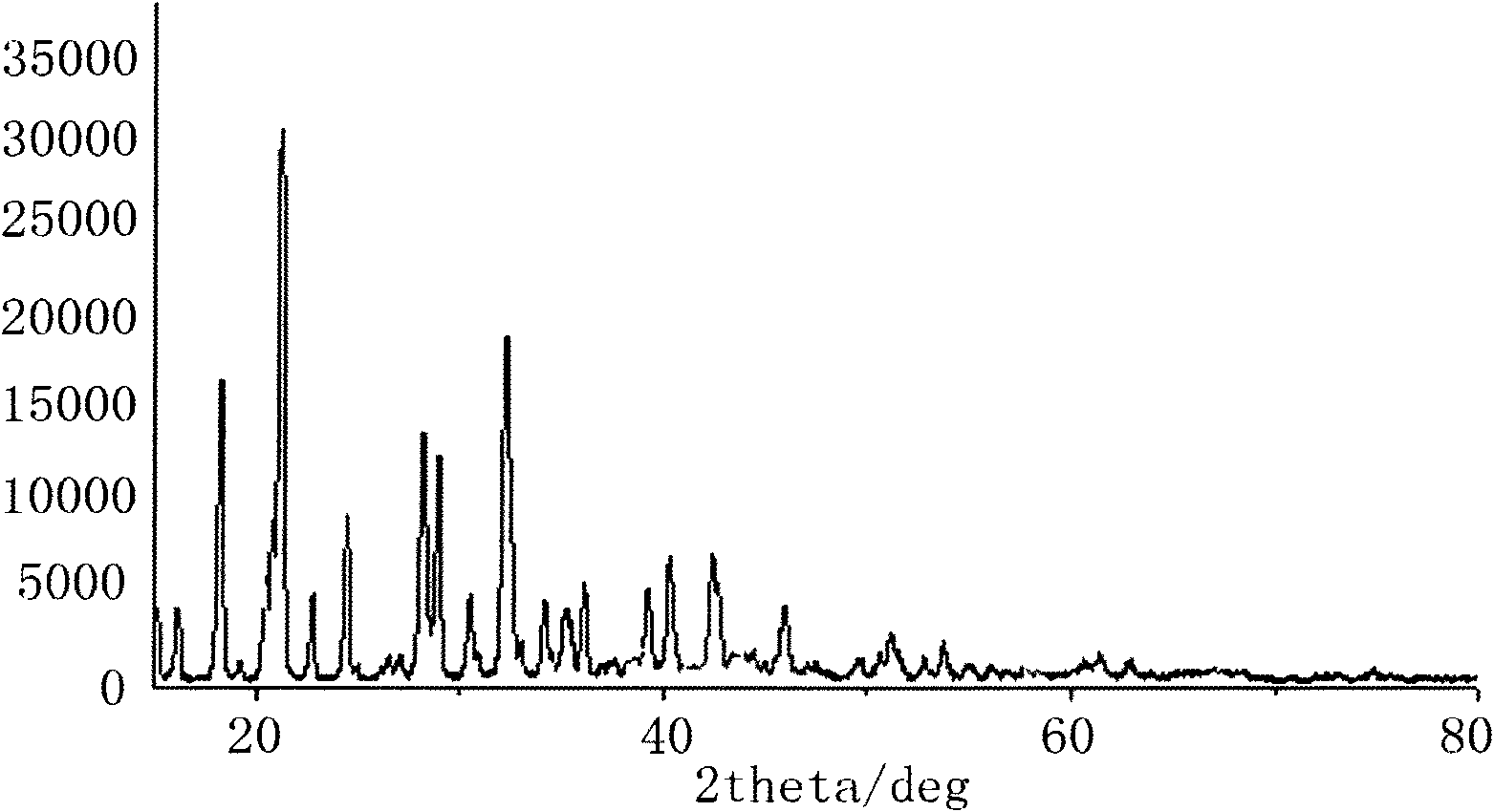

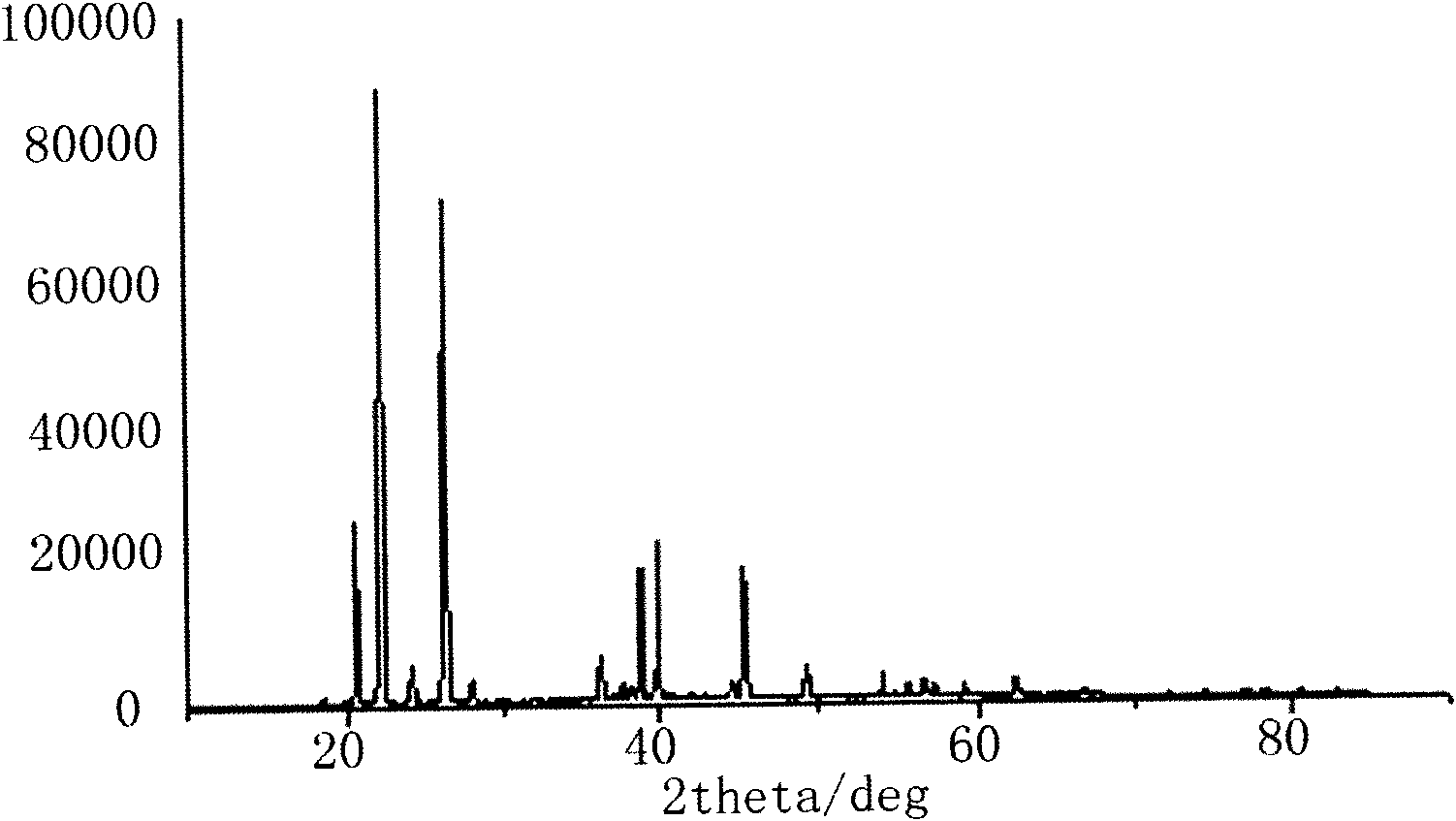

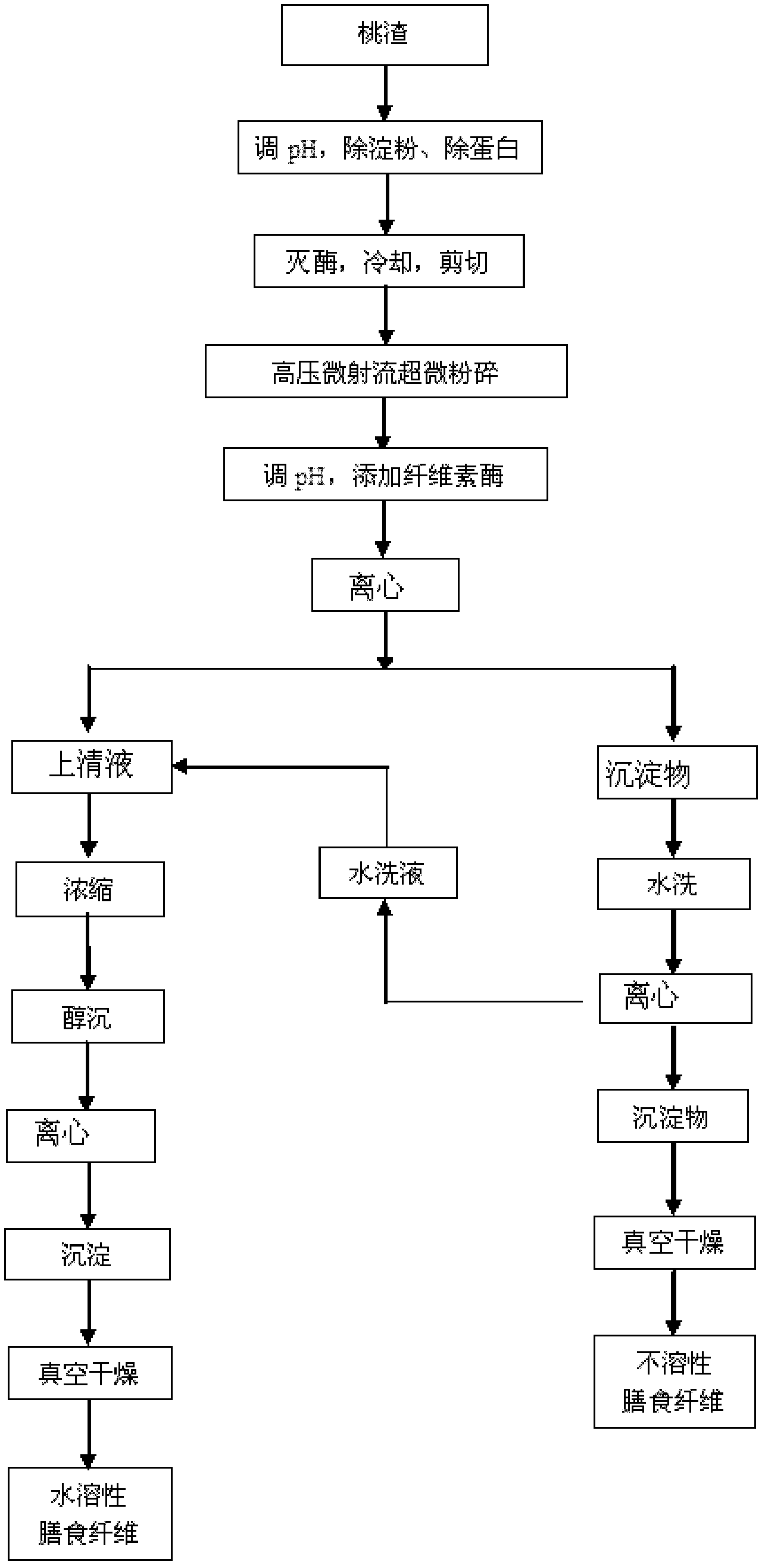

Method for extracting fruit dreg dietary fiber through high-pressure microfluidization ultramicro crushing and enzymolysis coupling

ActiveCN102524803AChange compositionChange structureFood preparationEthanol precipitationAlpha-amylase

The invention discloses a method for extracting fruit dreg dietary fiber through high-pressure microfluidization ultramicro crushing and enzymolysis coupling and belongs to the technical field of agricultural and sideline product waste deep processing. According to the method, water is added into peach dreg for dispersing the peach dreg, the pH is regulated, high-temperature-resistance alpha-amylase and protease are respectively used for enzymolysis for eliminating starch and protein, the peach dreg subjected to the enzymolysis is treated by a high-speed shearing instrument and is subjected to high-pressure microfluidization ultramicro crushing, then, cellulose is added for enzymolysis and centrifugation, filter liquid after enzymolysis and precipitates after enzymolysis are respectively obtained, the filter liquid is subjected to concentration, ethanol precipitation and vacuum drying to obtain high-activity water-soluble dietary fiber, and the precipitates are subjected to water washing and vacuum drying to obtain high-purity insoluble dietary fiber. Waste fruit dreg after the juice squeezing is utilized as raw materials, the fine and deep processing of agricultural and sideline products is realized, and the resource waste is reduced.

Owner:CHINA AGRI UNIV

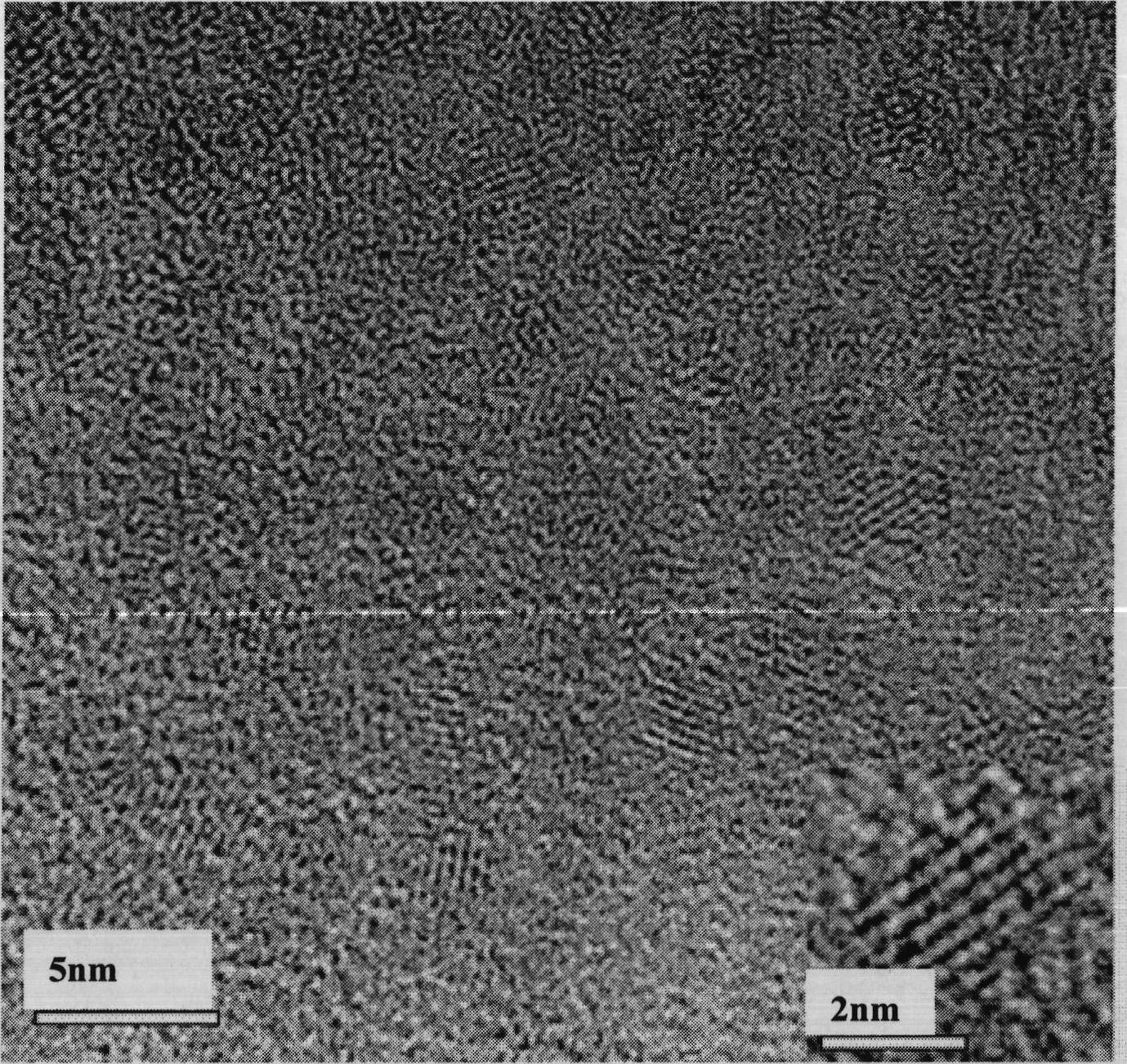

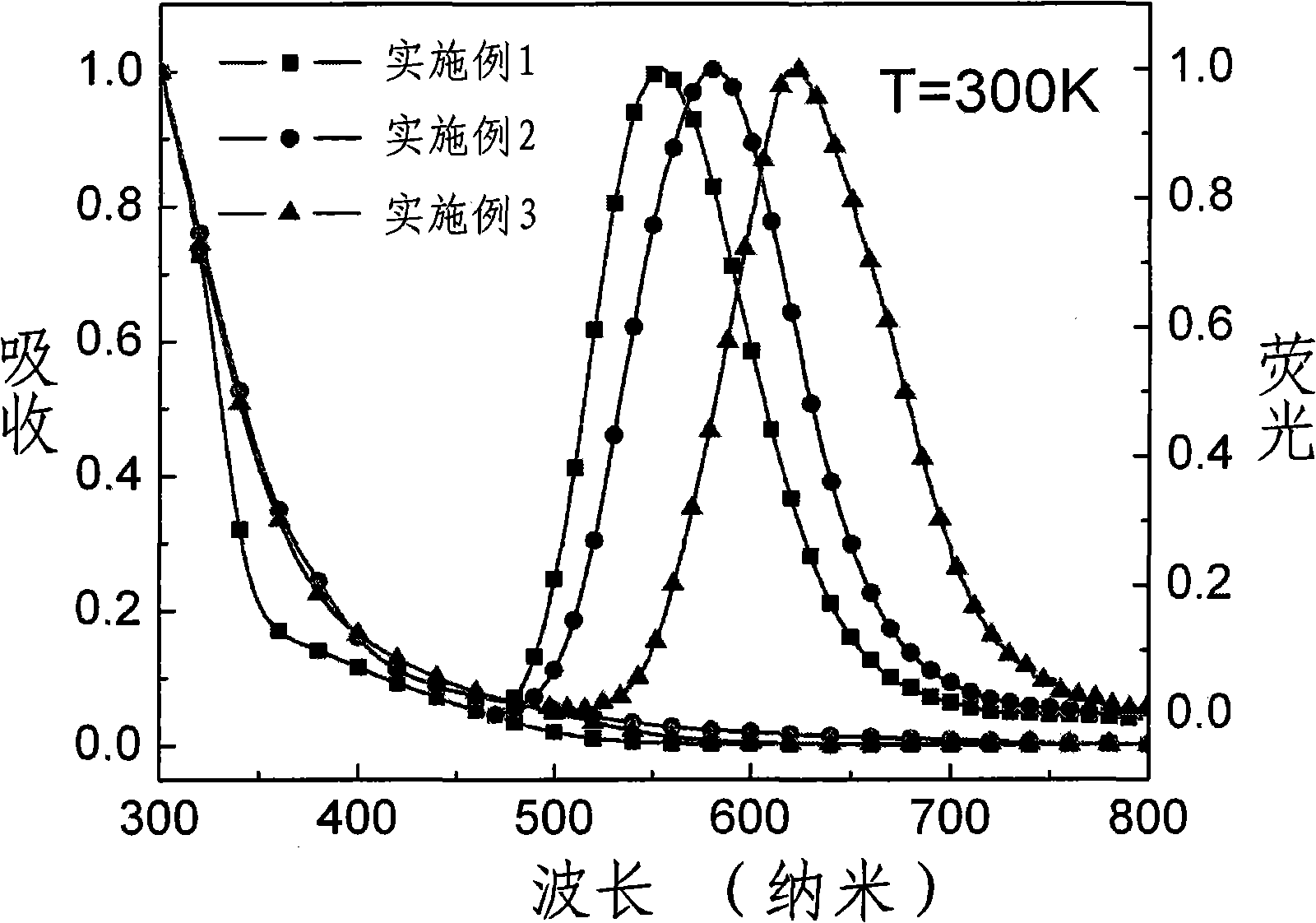

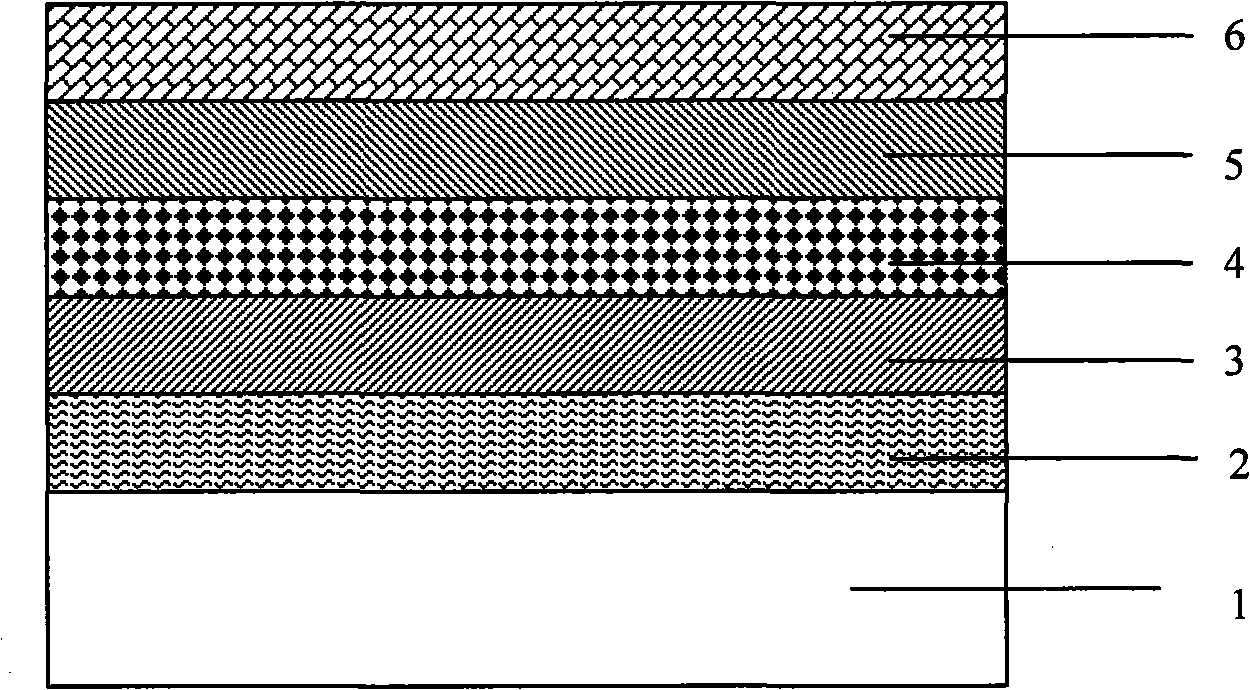

Preparation method and application in luminescent element thereof of CuInS2-ZnS/ZnSe/ZnS semiconductor quantum dots with core-shell structure

The invention discloses a preparation method and application in the luminescent element thereof of CuInS2-ZnS / ZnSe / ZnS semiconductor quantum dots with a core-shell structure, belonging to the technical field of the preparation method of the semiconductor quantum dot. The method comprises the following steps: dissolving the precursors of copper source, zinc source, indium source and sulfur source in nonpolar mixed solvent to perform nucleation and growth under a certain temperature and obtain a CuInS2-ZnS alloy core-ZCIS, then adding zinc source and selenium source alternately in the solution to perform epitaxial growth of ZnSe on the core, then perform epitaxial growth of ZnS to prepare the CuInS2-ZnS / ZnSe / ZnS quantum dots, finally adding polar solvent in the solution, settling, centrifuging, cleaning, and perform vacuum drying to obtain solid quantum dot powder. The prepared quantum dots are 2-8nm and have uniform particle size, controllable emission wavelength and high yield. The quantum dots are used as luminescent material to prepare red, yellow and green quantum dot luminescent elements and the luminescent elements have excellent luminescent property.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com