Preparation method of polyhedral cobalt phosphide catalyst for hydrogen production through water electrolysis

A technology for electrolysis of water and catalysts, which is applied in physical/chemical process catalysts, chemical instruments and methods, electrolysis processes, etc., can solve the problems of reduced catalytic activity, agglomeration of catalyst particles, irregular morphology, etc., and achieves simple process flow and product quality. The effect of high purity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of polyhedral cobalt phosphide electrolysis water hydrogen production catalyst, comprising the following steps:

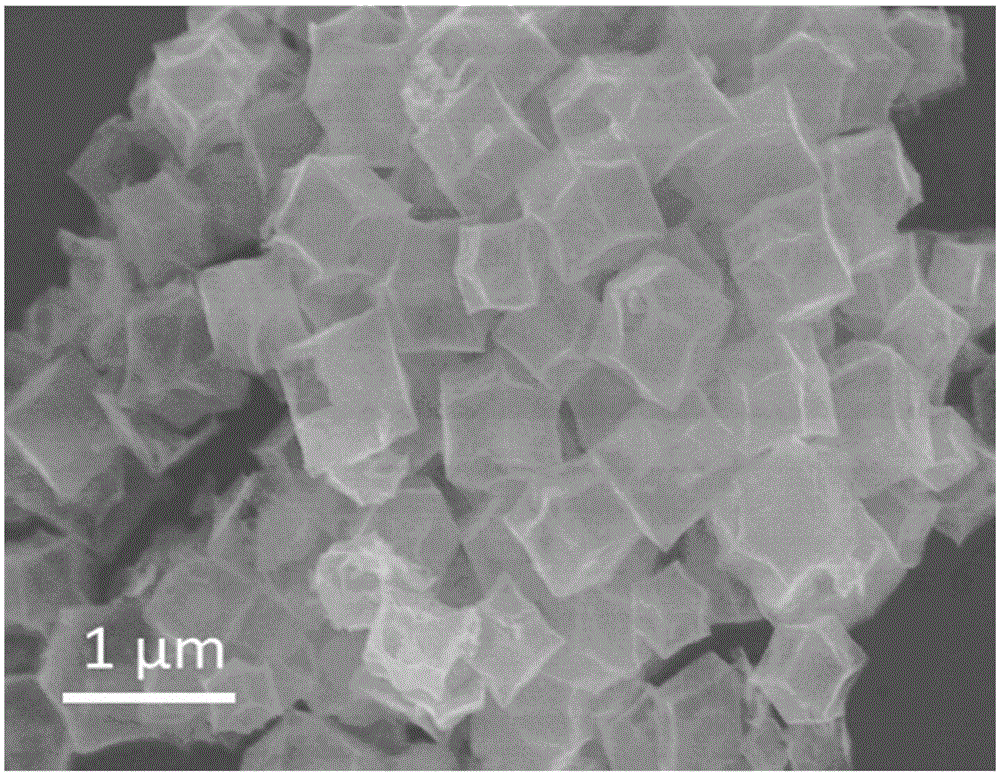

[0019] 1) Preparation of polyhedral metal-organic framework ZIF-67: Weigh 0.996g Co(NO 3 ) 2 ·6H 2 O and 1.312g 2-methylimidazole were dissolved in 100ml methanol respectively, and after stirring and dissolving, the 2-methylimidazole solution was poured into Co(NO 3 ) 2 solution, stirred for 8 minutes, aged at room temperature for 18 hours after the stirring was stopped, the product was centrifuged, washed 3 times with methanol, and finally placed at 60°C for 8 hours in vacuum. Purple, the shape is rhombic dodecahedron, the particle size is 600nm;

[0020] 2) Preparation of polyhedral cobalt phosphide water electrolysis catalyst for hydrogen production: put the polyhedral metal organic framework ZIF-67 prepared in step 1) into a tube furnace, and calcinate at 300°C for 2 hours in an air atmosphere to obtain a black polyhedral Three ...

Embodiment 2

[0027] A preparation method of polyhedral cobalt phosphide electrolysis water hydrogen production catalyst, comprising the following steps:

[0028] 1) Preparation of polyhedral metal-organic framework ZIF-67: Weigh 0.996g Co(NO 3 ) 2 ·6H 2 O and 1.312g 2-methylimidazole were dissolved in 100ml methanol respectively, and after stirring and dissolving, the 2-methylimidazole solution was poured into Co(NO 3 ) 2 solution, stirred for 12 minutes, aged at room temperature for 20 hours after stopping the stirring, centrifuged the product, washed 3 times with methanol, and finally placed it in vacuum at 80°C for 10 hours. Purple, the shape is rhombic dodecahedron, the particle size is 750nm;

[0029] 2) Preparation of polyhedral cobalt phosphide water electrolysis catalyst for hydrogen production: put the polyhedral metal organic framework ZIF-67 prepared in step 1) into a tube furnace, and calcinate at 400°C for 4 hours in an air atmosphere to obtain a black polyhedral Three co...

Embodiment 3

[0034] A preparation method of polyhedral cobalt phosphide electrolysis water hydrogen production catalyst, comprising the following steps:

[0035] 1) Preparation of polyhedral metal-organic framework ZIF-67: Weigh 0.996g Co(NO 3 ) 2 ·6H 2 O and 1.312g 2-methylimidazole were dissolved in 100ml methanol respectively, and after stirring and dissolving, the 2-methylimidazole solution was poured into Co(NO 3 ) 2 solution, stirred for 15 minutes, aged at room temperature for 24 hours after the stirring was stopped, the product was centrifuged, washed 3 times with methanol, and finally placed in 120°C for 12 hours in vacuum, the product obtained was the polyhedral metal organic framework ZIF-67, and the product was blue Purple, the shape is rhombic dodecahedron, the particle size is 900nm;

[0036] 2) Preparation of polyhedral cobalt phosphide water electrolysis catalyst for hydrogen production: put the polyhedral metal organic framework ZIF-67 prepared in step 1) into a tube f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com