Patents

Literature

418results about "Paper testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

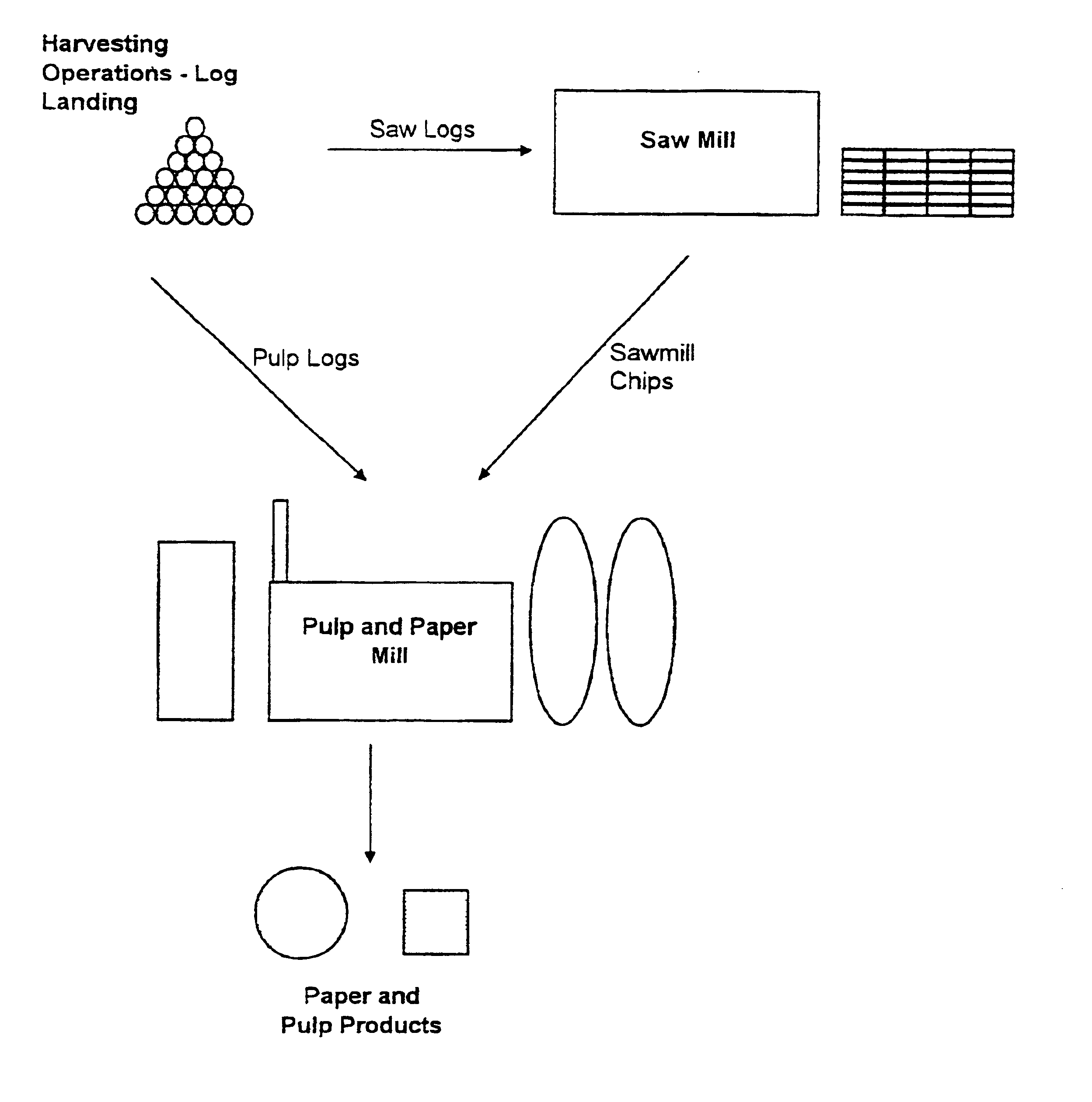

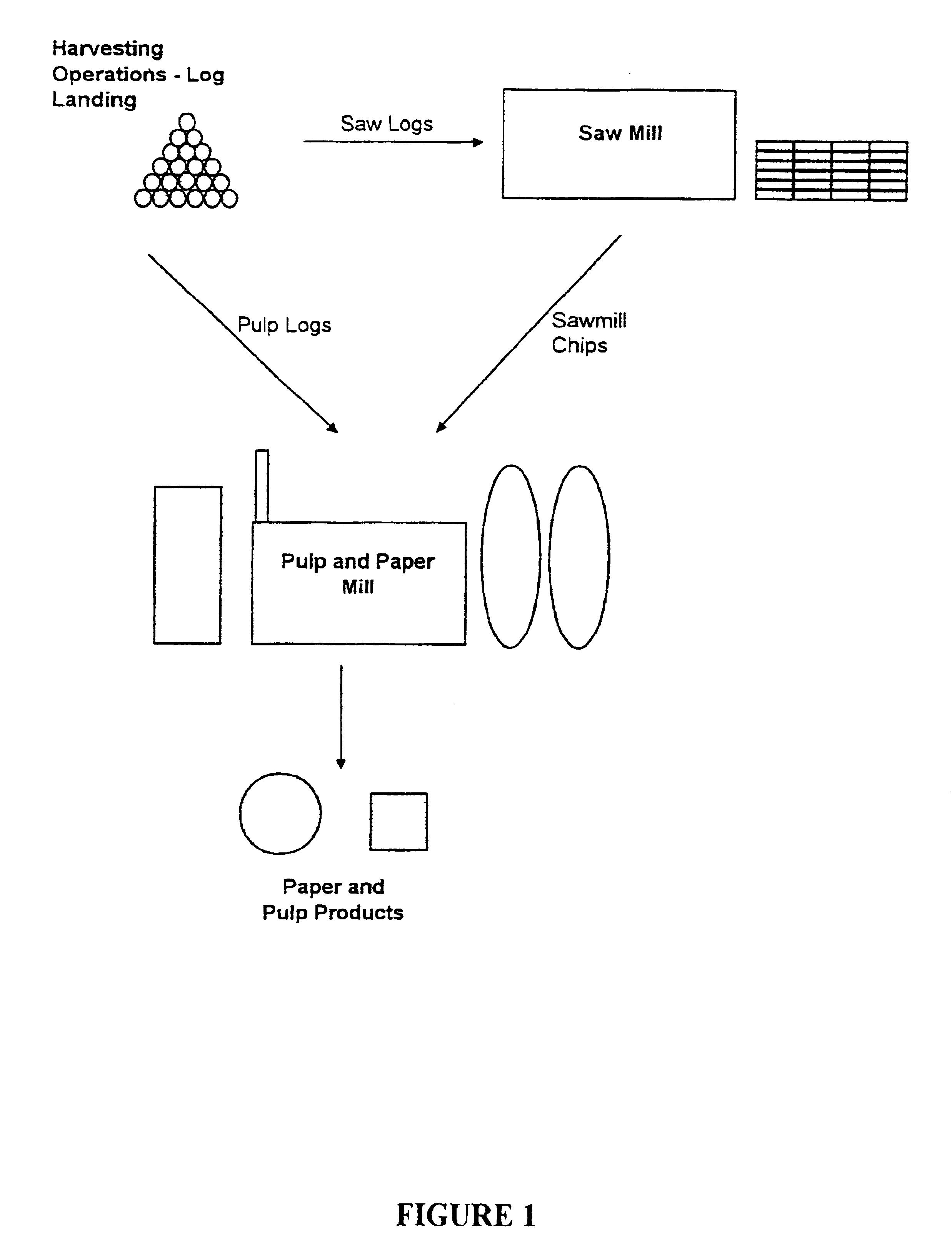

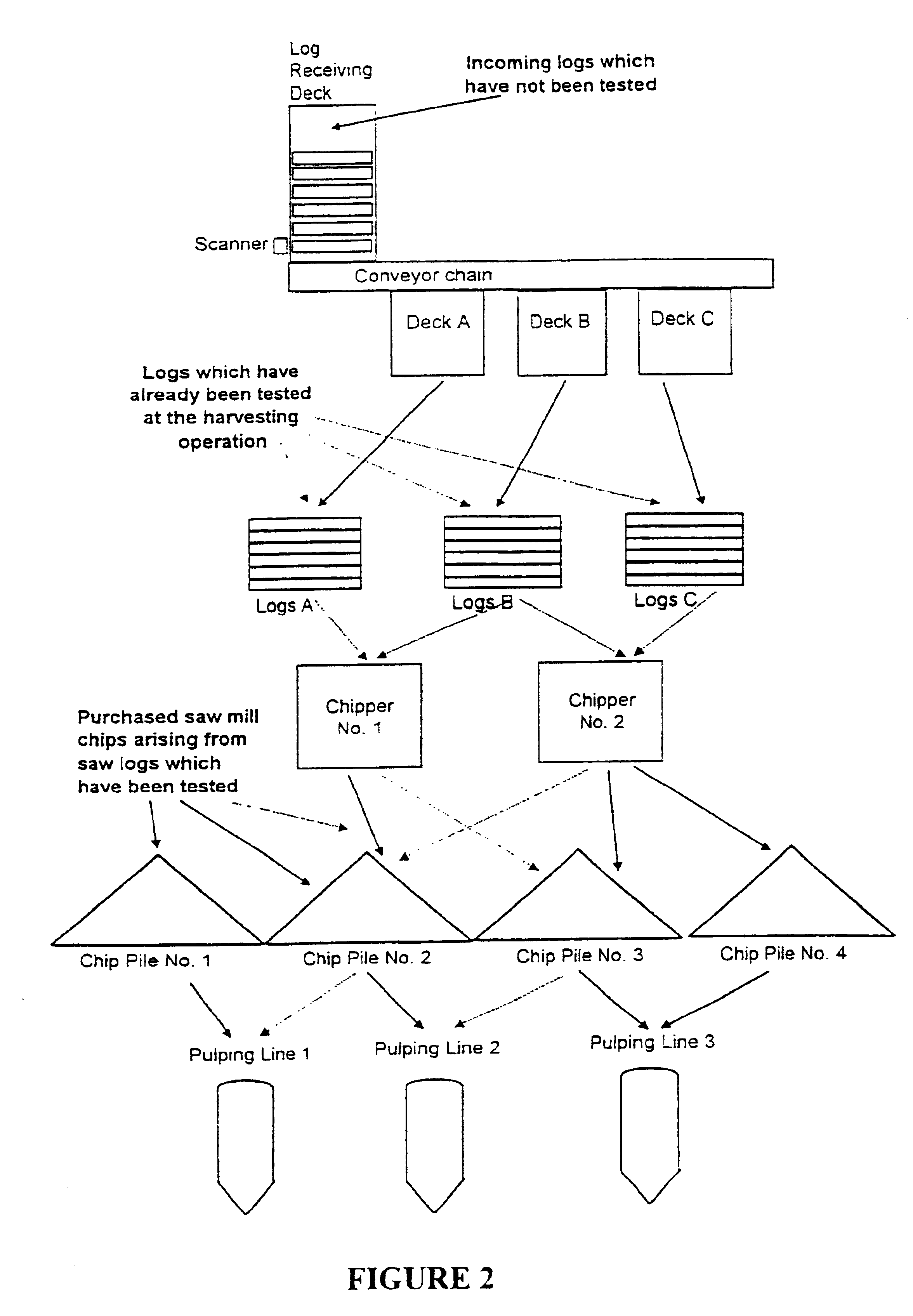

Method of selecting and/or processing wood according to fibre characteristics

InactiveUS6773552B1Analysing solids using sonic/ultrasonic/infrasonic wavesDigestersSolid woodWood fibre

The invention provides a method for predictively assessing one or more characteristics of wood pulp produced from solid wood. The method comprises the steps of determining the velocity of sound through the solid wood, and assessing characteristic(s) of wood fiber or wood pulp produced from the wood by reference to the velocity of sound through the solid wood. The method may also comprise the steps of causing a sound wave to be transmitted through the wood, determining the velocity of the sound wave through the wood, and comparing the result to stored information on fiber characteristic(s) versus sound velocity through the wood-type to determine the fiber characteristic(s) for the wood.

Owner:FIBER GEN INSTR

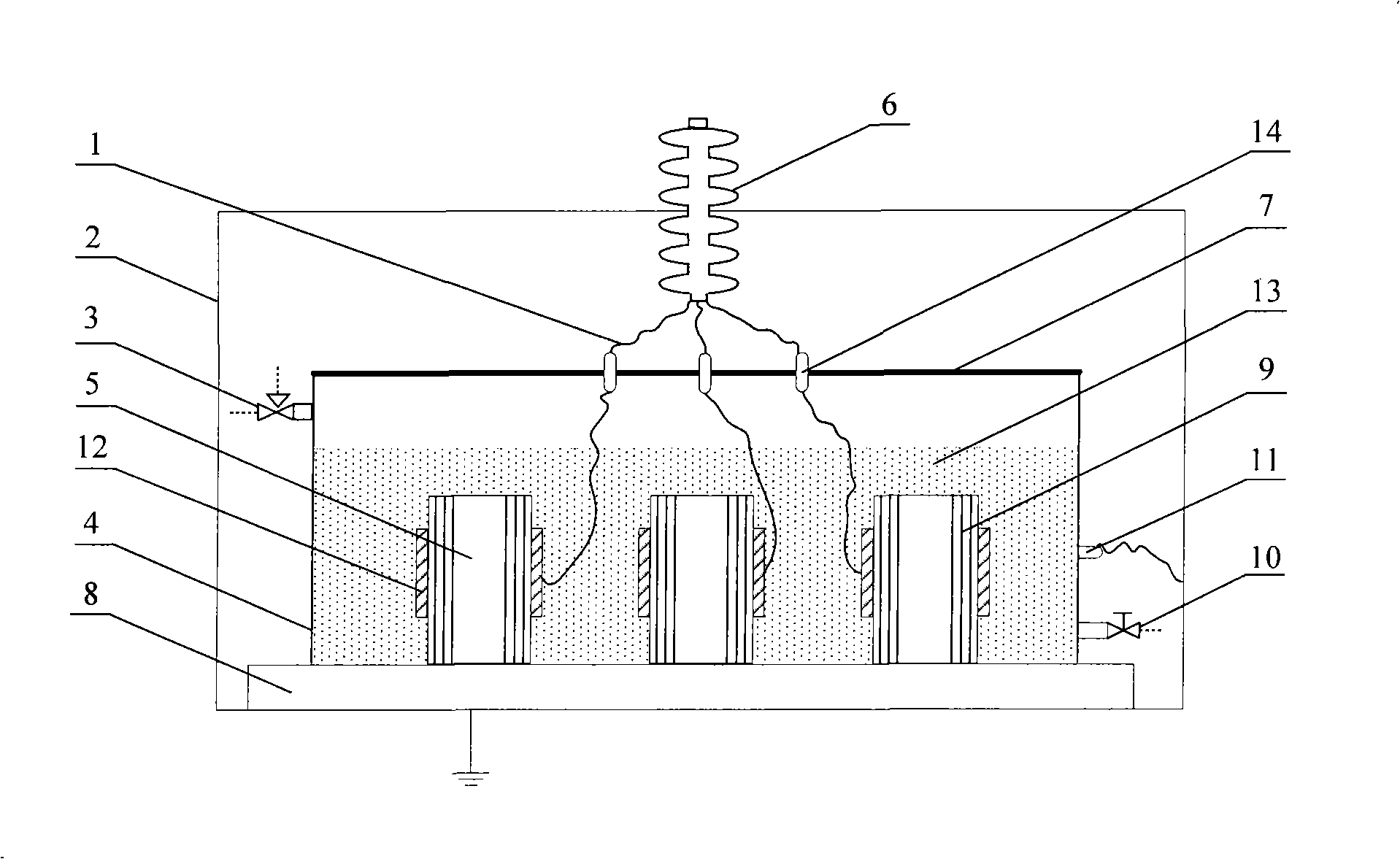

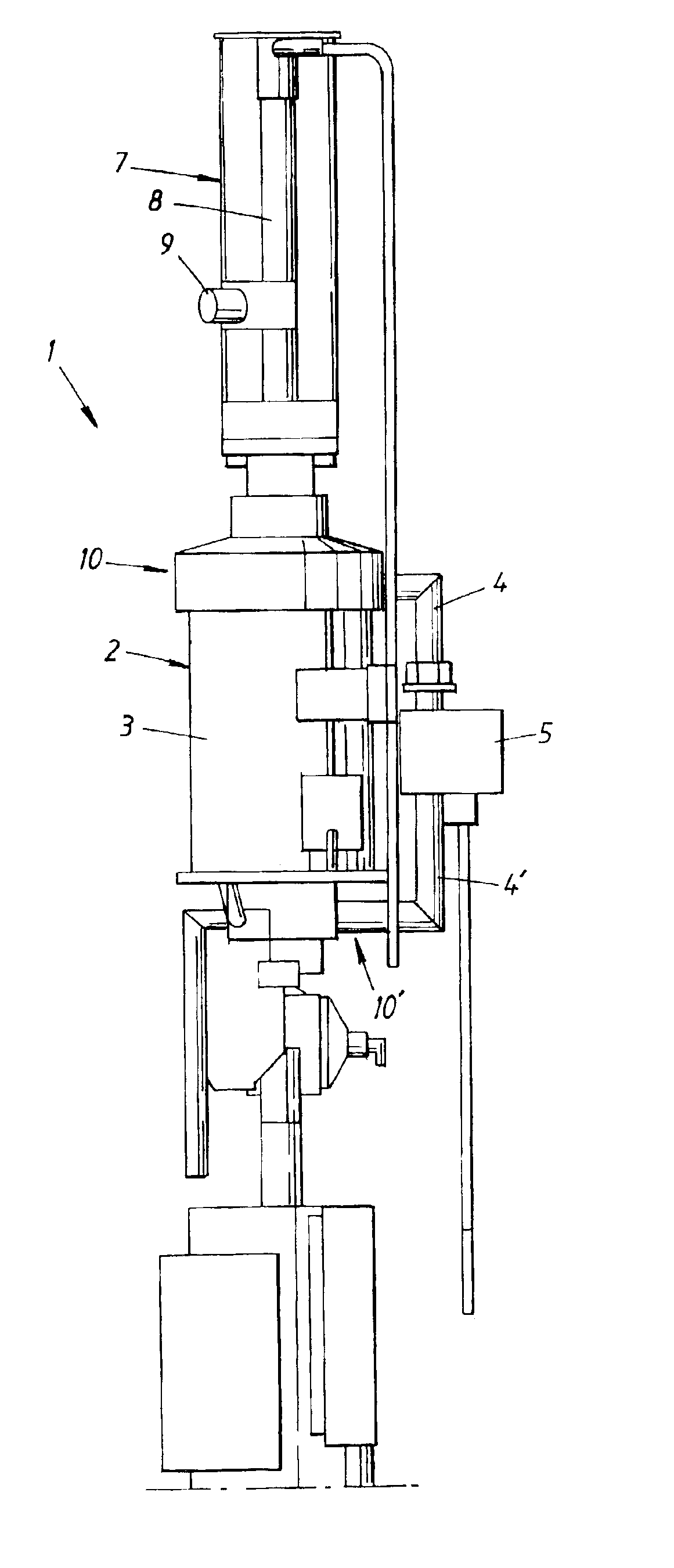

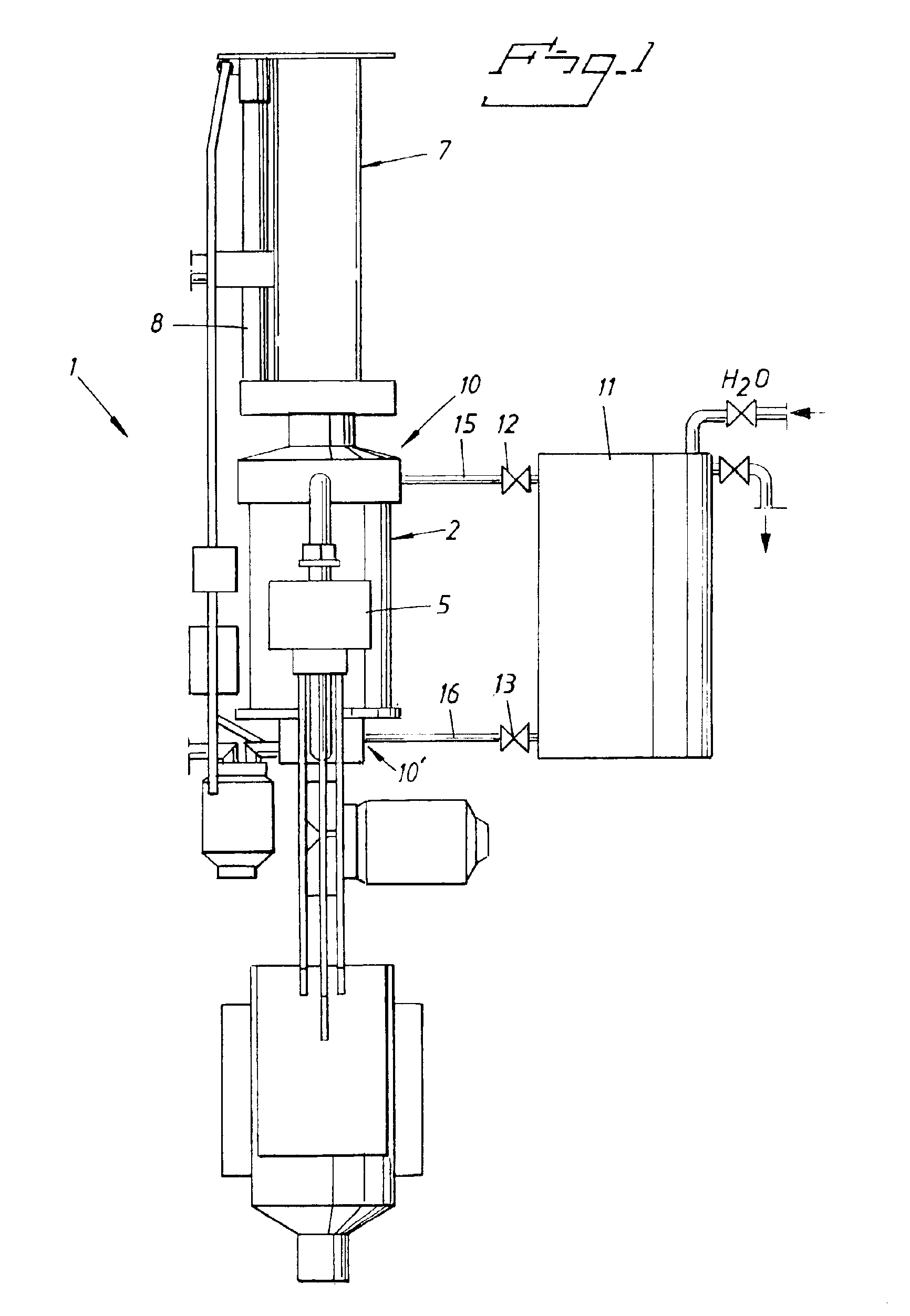

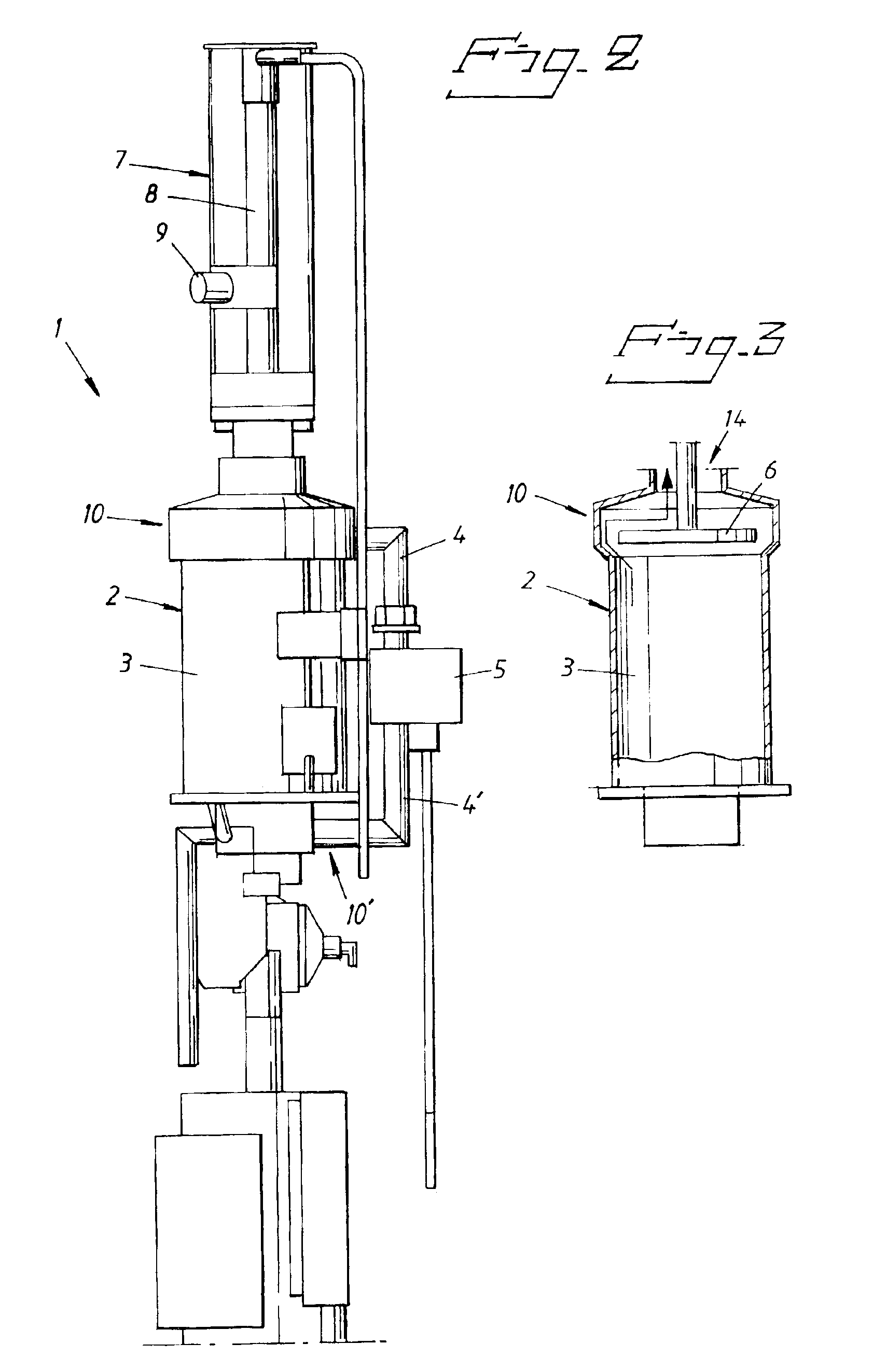

Multiple factors accelerated aging test apparatus and method for oil paper insulation of transformer

InactiveCN101408578AReveal the law of agingImprove reliabilityElectrical testingPaper testingHigh pressureVacuum drying

The invention provides a testing device and a testing method of electricity-heat-mechanical stress three-factor combined ageing for transformer paper oil insulation ageing study; the testing device comprises an electric heating ageing oven, in which a transformer paper oil insulation simulator, a shake unit and a temperature control device used for controlling the temperature of the electric heating ageing oven. The shake unit can drive the simulator to vibrate, the simulator is electrically connected with a high-voltage power supply; the testing method includes vacuum drying and oil impregnation of insulating paper, attaching the paper to the earth electrode in a stainless steel case of the testing device, winding coils as a high voltage electrode outside the insulating paper and the earth electrode and injecting insulating oil to the stainless steel case; connecting a high tension lead with the high-voltage power supply and starting the shake unit; sampling the insulating paper and the insulating oil alternately and measuring insulation ageing parameters.

Owner:CHONGQING UNIV

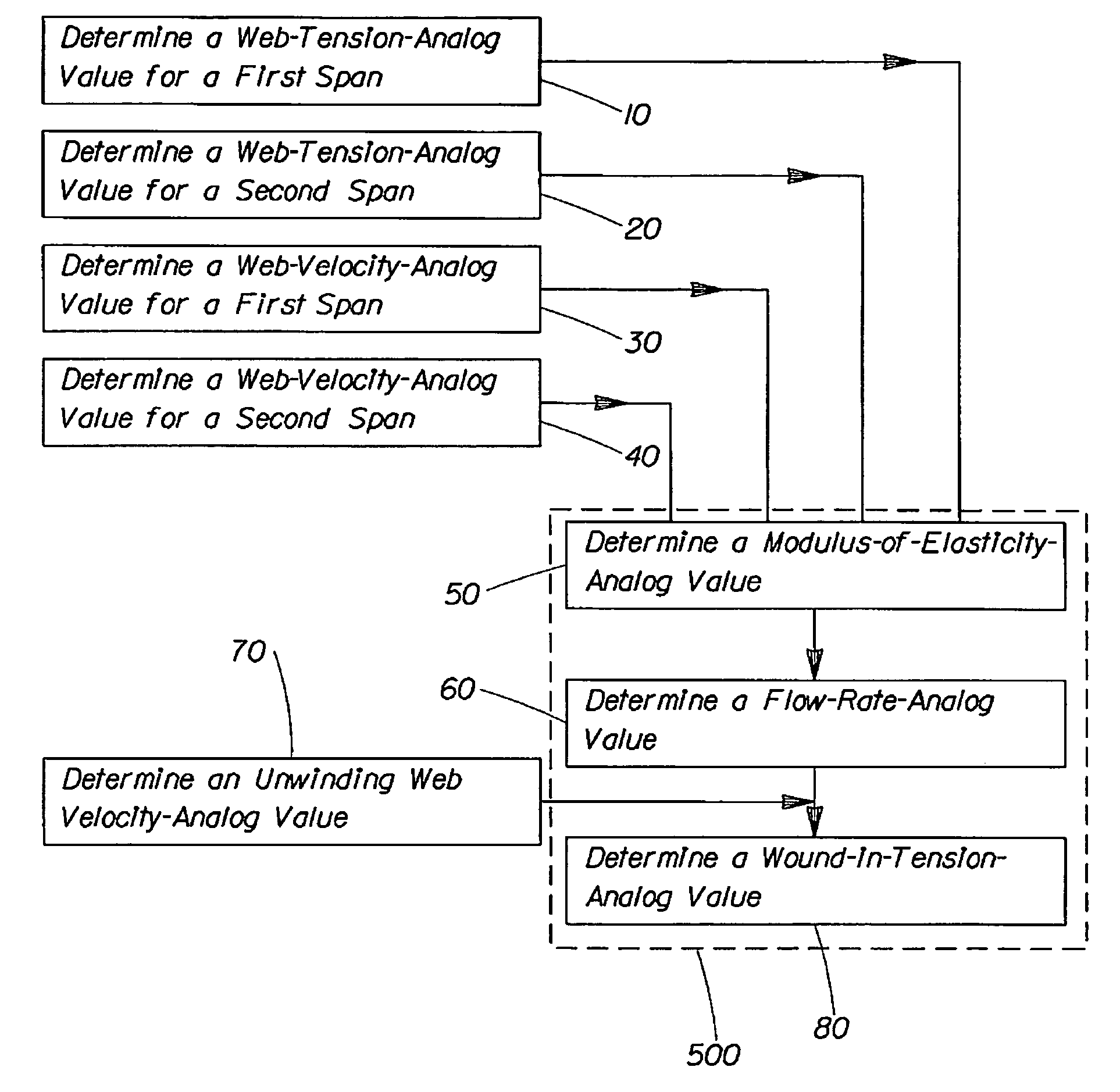

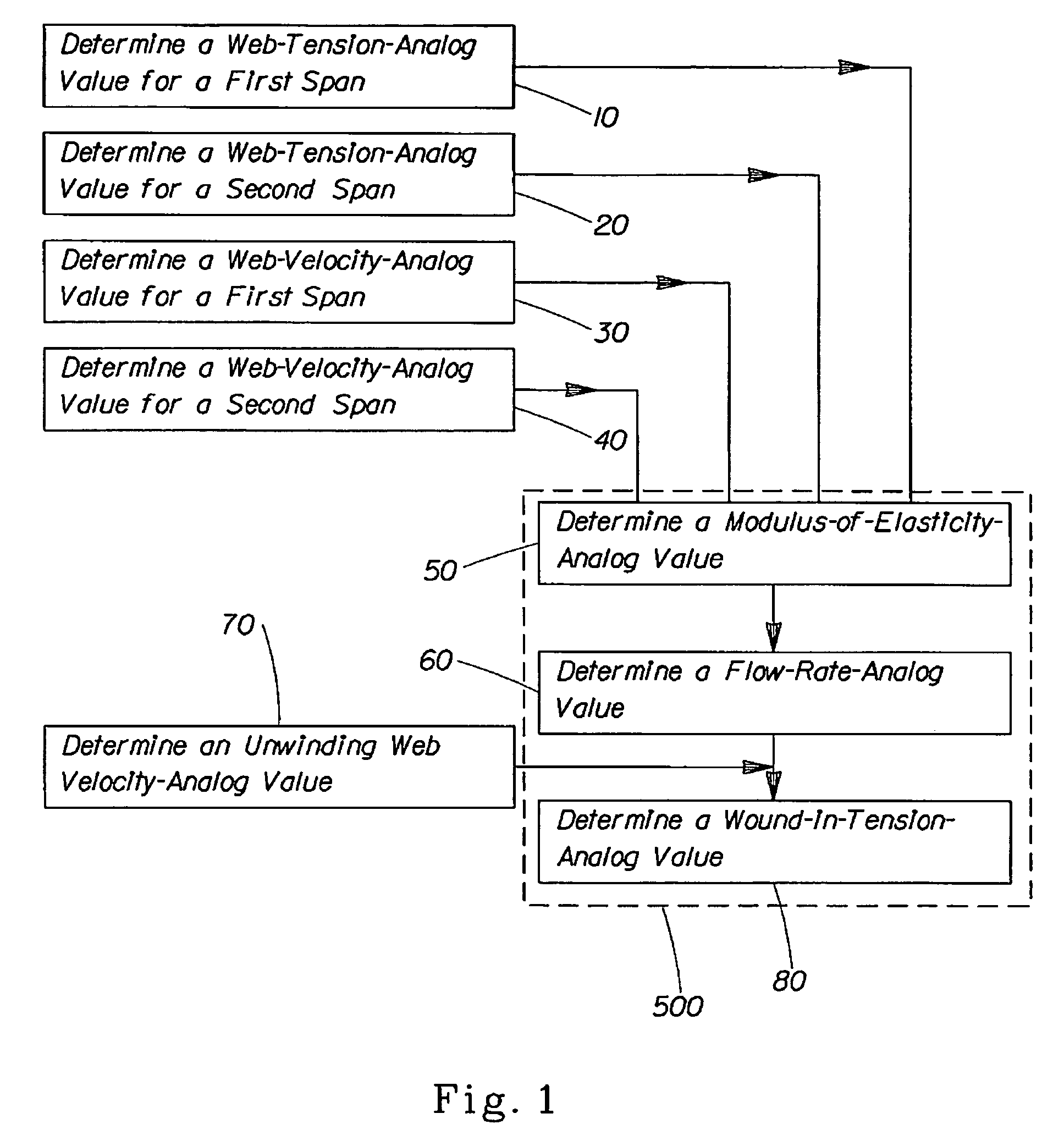

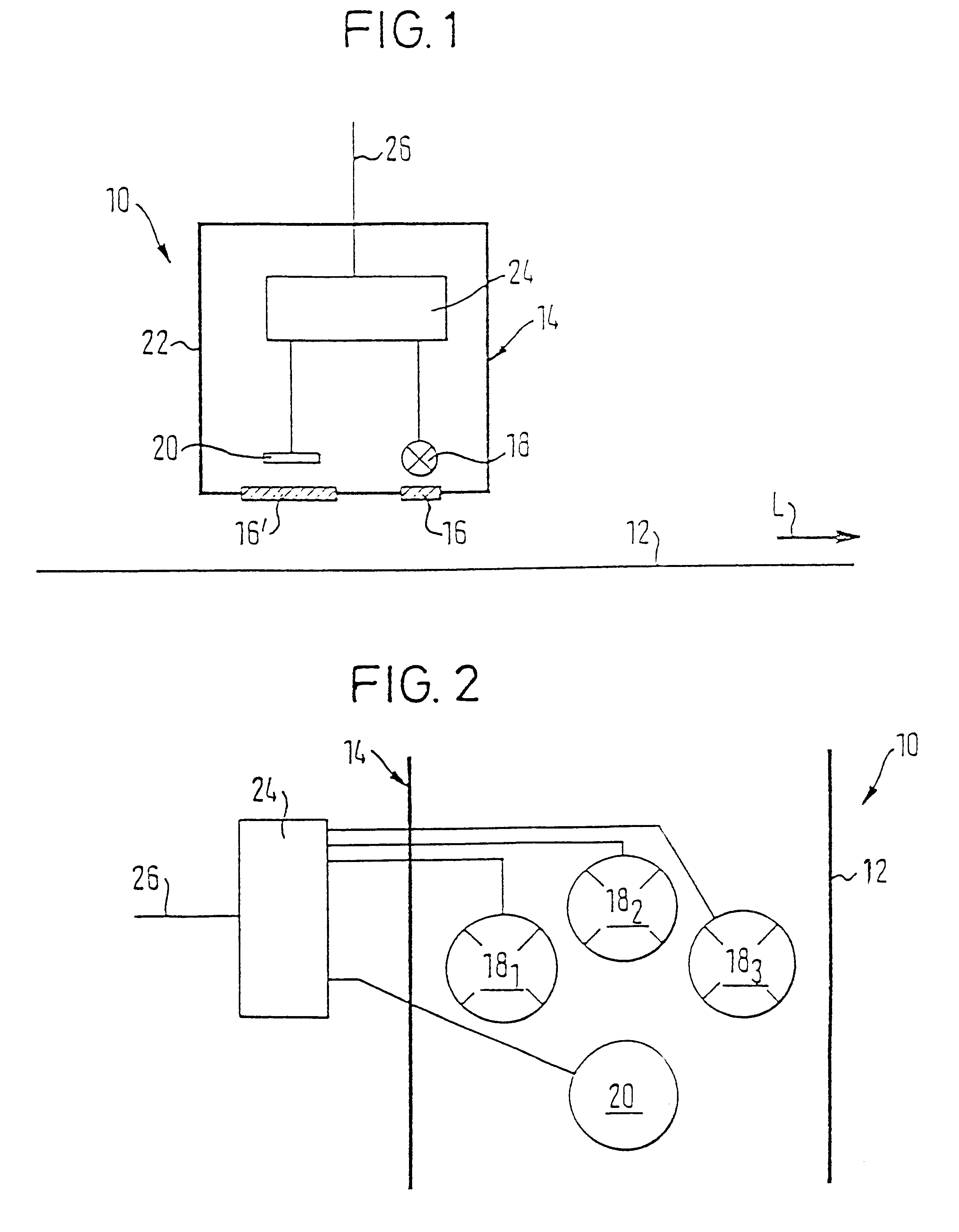

Method of determining a modulus of elasticity of a moving web material

ActiveUS6993964B2Material strength using tensile/compressive forcesPaper testingClassical mechanicsMechanical engineering

Owner:PROCTER & GAMBLE CO

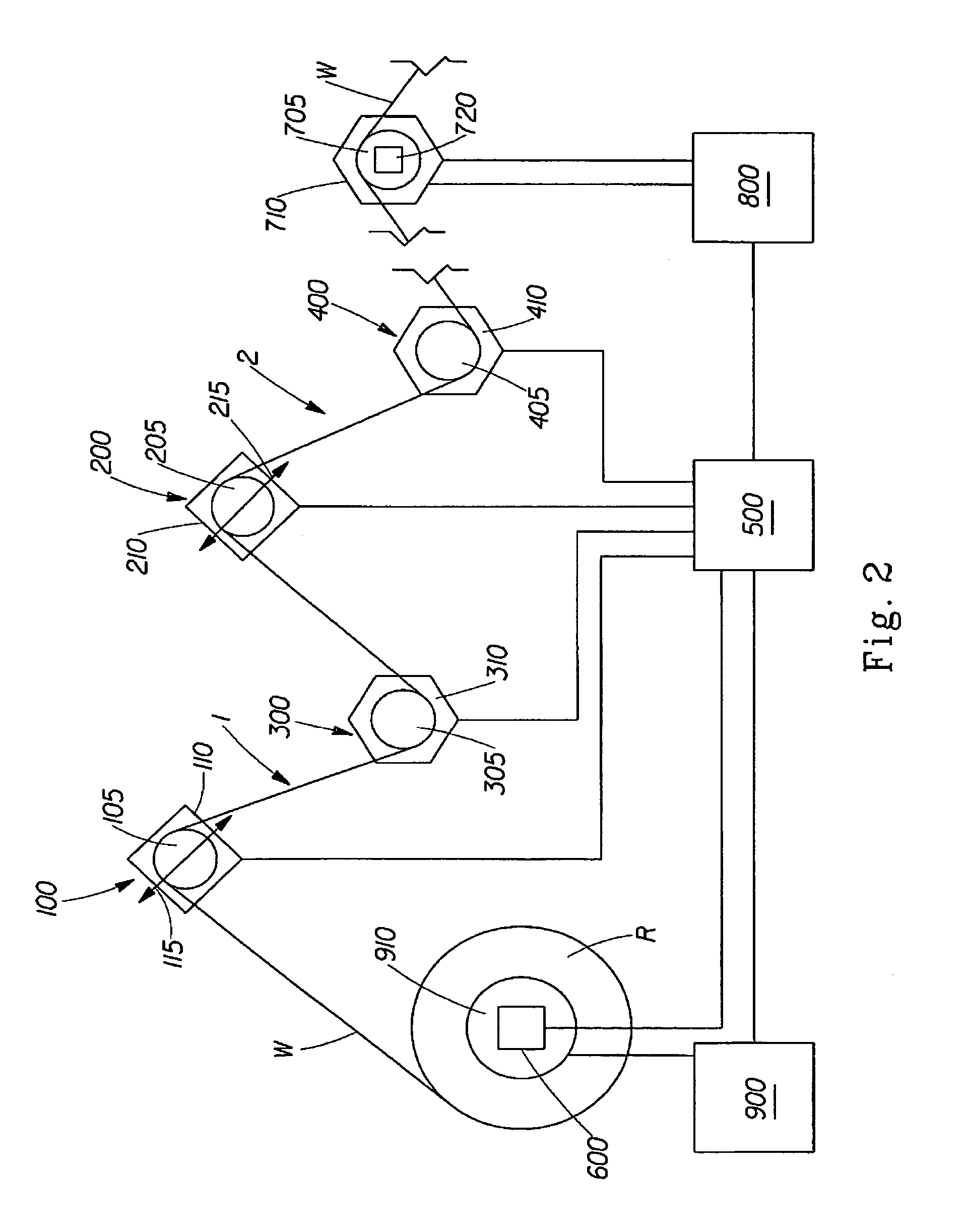

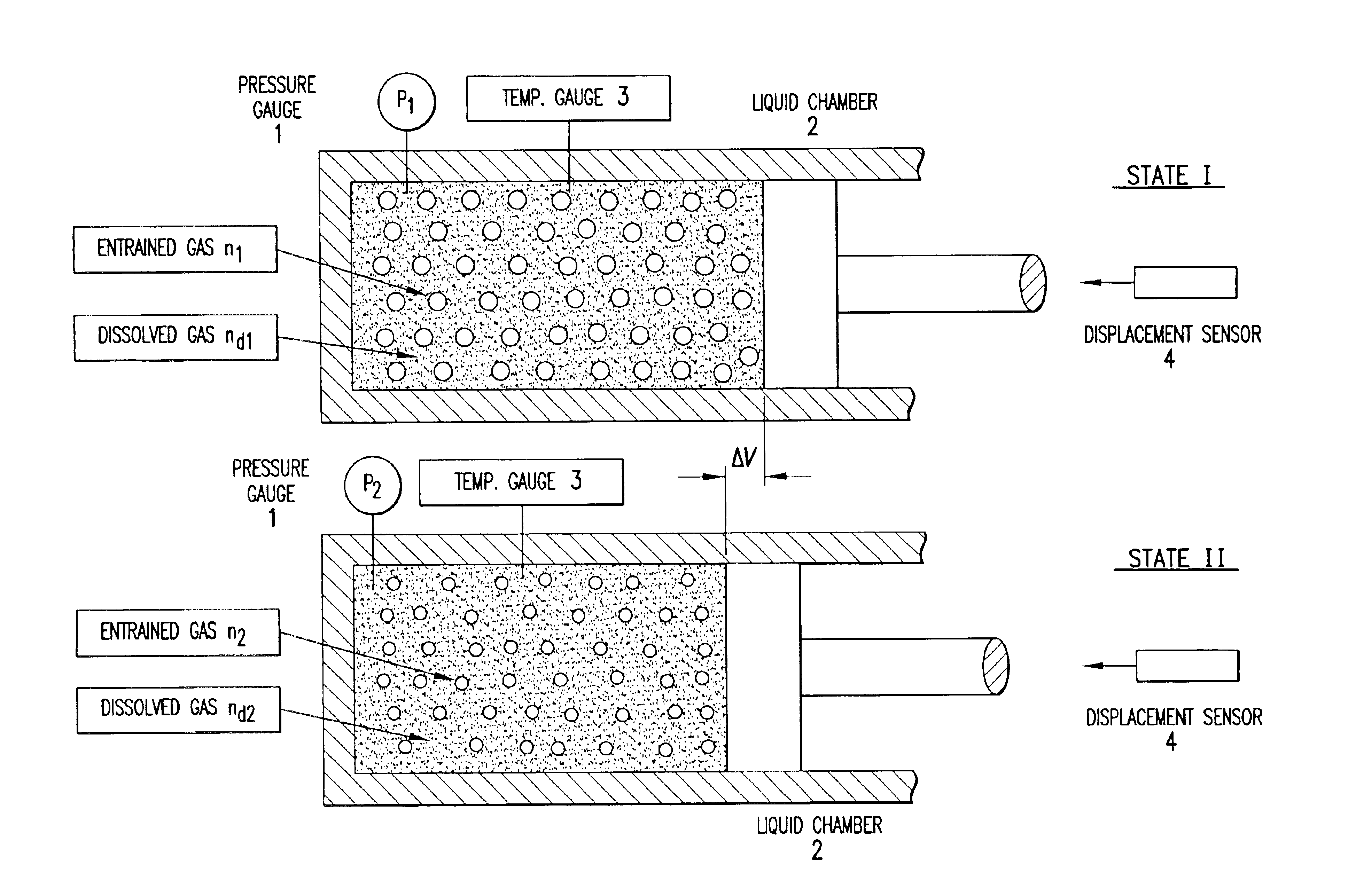

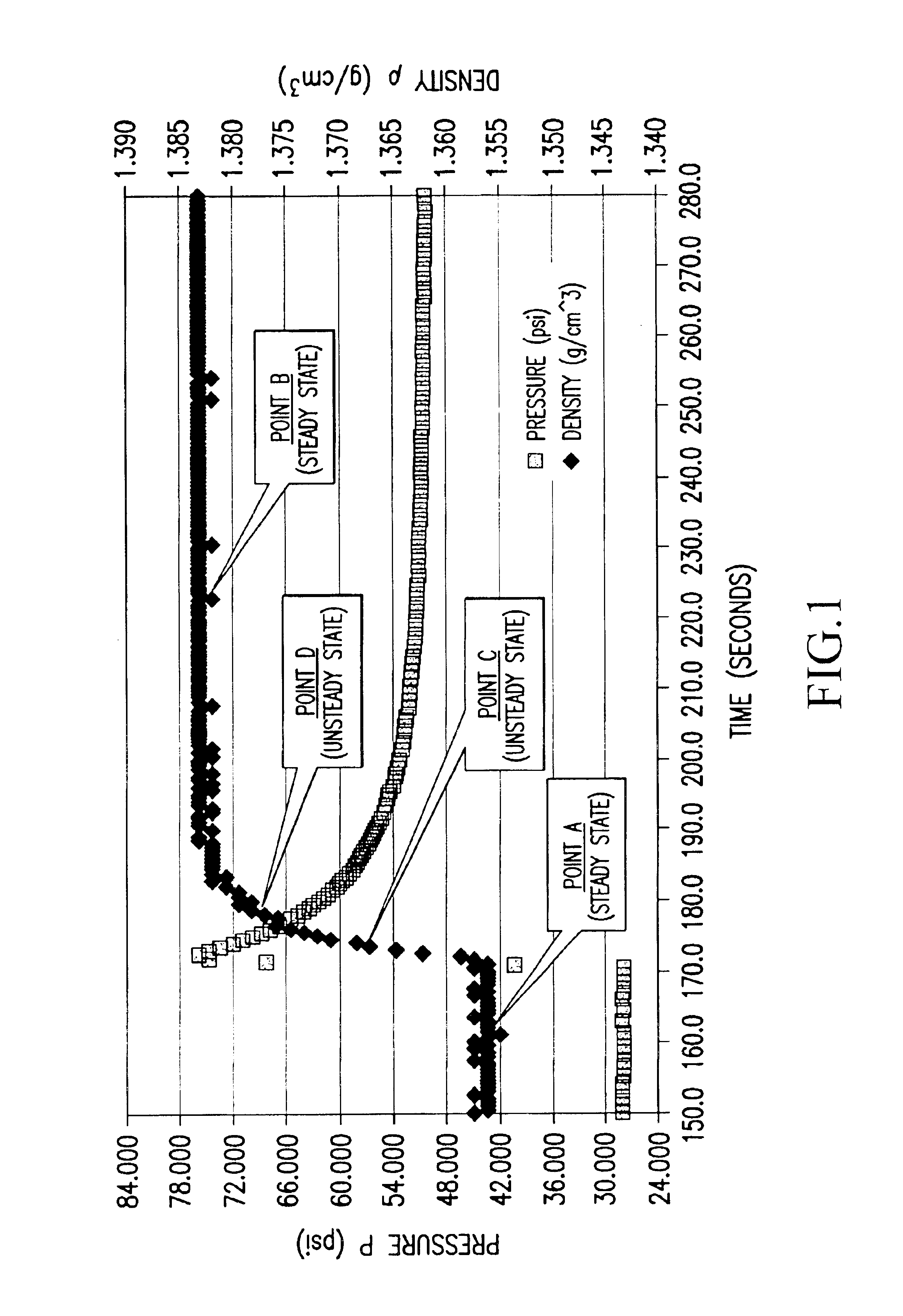

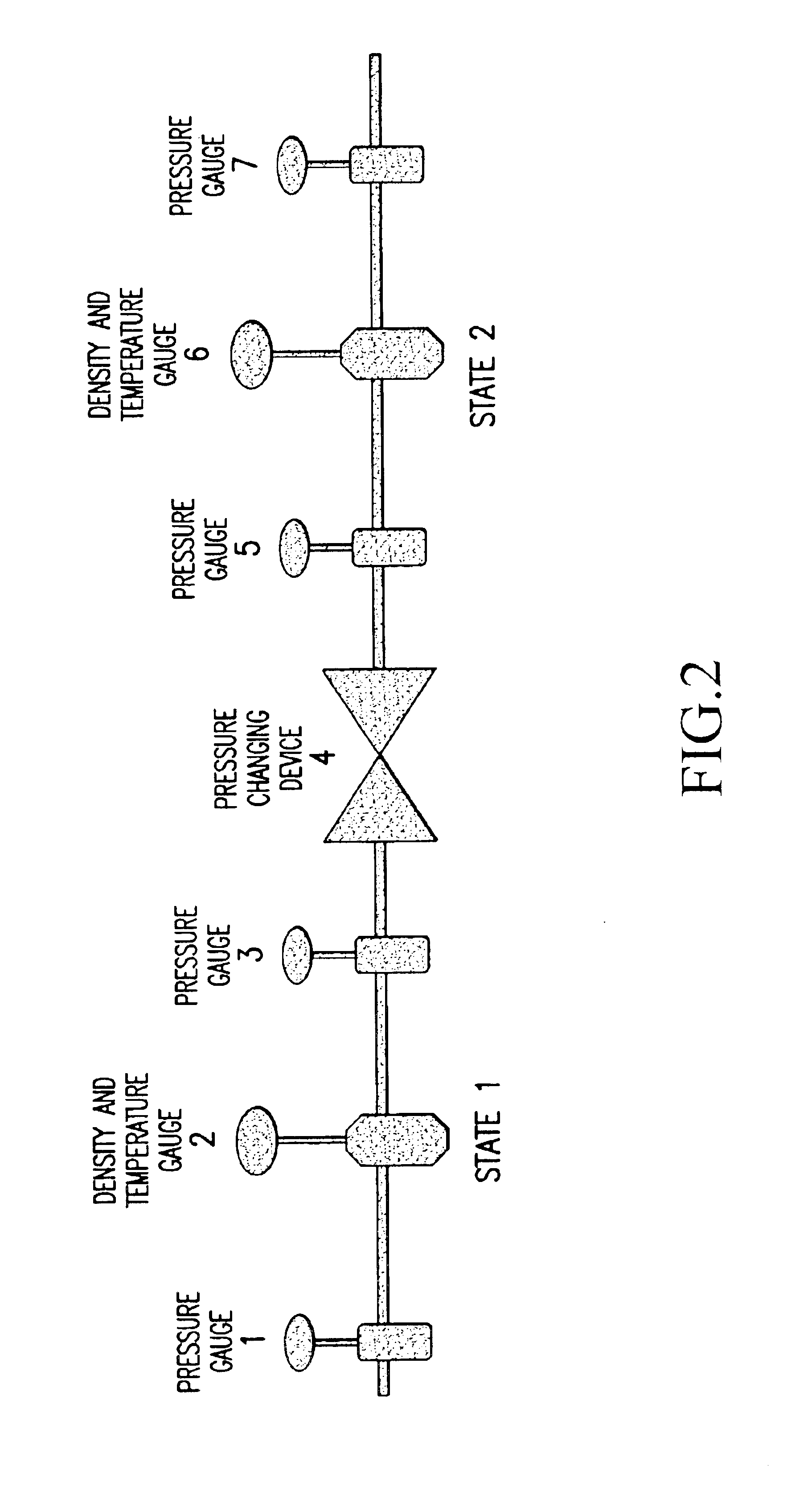

Real time determination of gas solubility and related parameters in manufacturing processes

InactiveUS6847898B1Easy to controlEasy to handleTesting beveragesSpecific gravity by measuring pressure differencesSolubilityApparent density

Methods and apparatuses for determining entrained and / or dissolved gas content of gas-liquid mixtures. Data generated is used to control the True (air-free) or Apparent (air-containing) Density or Entrained Air content of liquids within optimum ranges, e.g. in paper coating processes and in the manufacture of food products, personal care products, pharmaceutical products, paints, petroleum blends, etc. For example, an indirect method of continuously determining the amount of gas entrained in a liquid, by: continuously measuring the temperature, flow rate, and apparent density of the mixture at two different pressure states, and calculating the volume percentage of the gas in the liquid by using equation (28) x%=VsVs+V(28)wherein V is the volume of the gas-free liquid calculated by equation (23) V=1ρ1-[P2P2-P1(1ρ1-1ρ2)-RTP2-P1g(Δ PQa)](23)in which P1 and P2 are two different ambient pressures and ΔP=P2−P1, ρ1 and ρ2 are apparent densities of the liquid sample measured at P1 and P2, respectively, R is the constant of the Ideal Gas Law, T is the liquid temperature, Q is the flow rate, g(ΔP / Qa) is a function for determining the amount of gas being dissolved between P2 and P1, and Vs is determined by equation (27) Vs=TsTP1P2Ps(P2-P1)(1ρ1-1ρ2)-RTsPs(P1P2-P1g(Δ PQa)-g(P1-PsQa)).(27)

Owner:APPVION INC

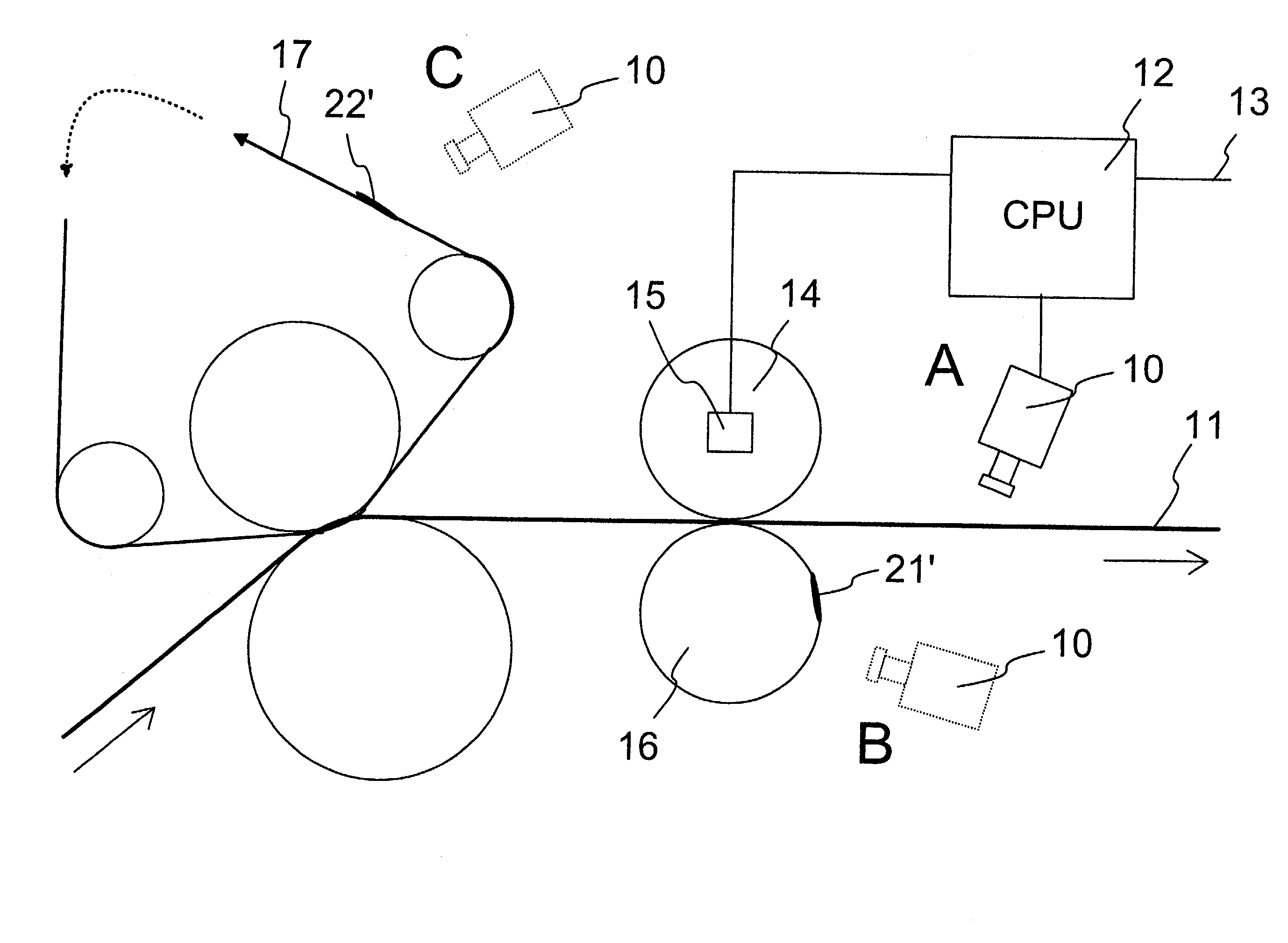

Process and apparatus for determining the properties of a traveling material web

InactiveUS6743337B1Prevents and minimizes productionFew quality fluctuationRadiation pyrometryScattering properties measurementsElectromagnetic radiationRadiation

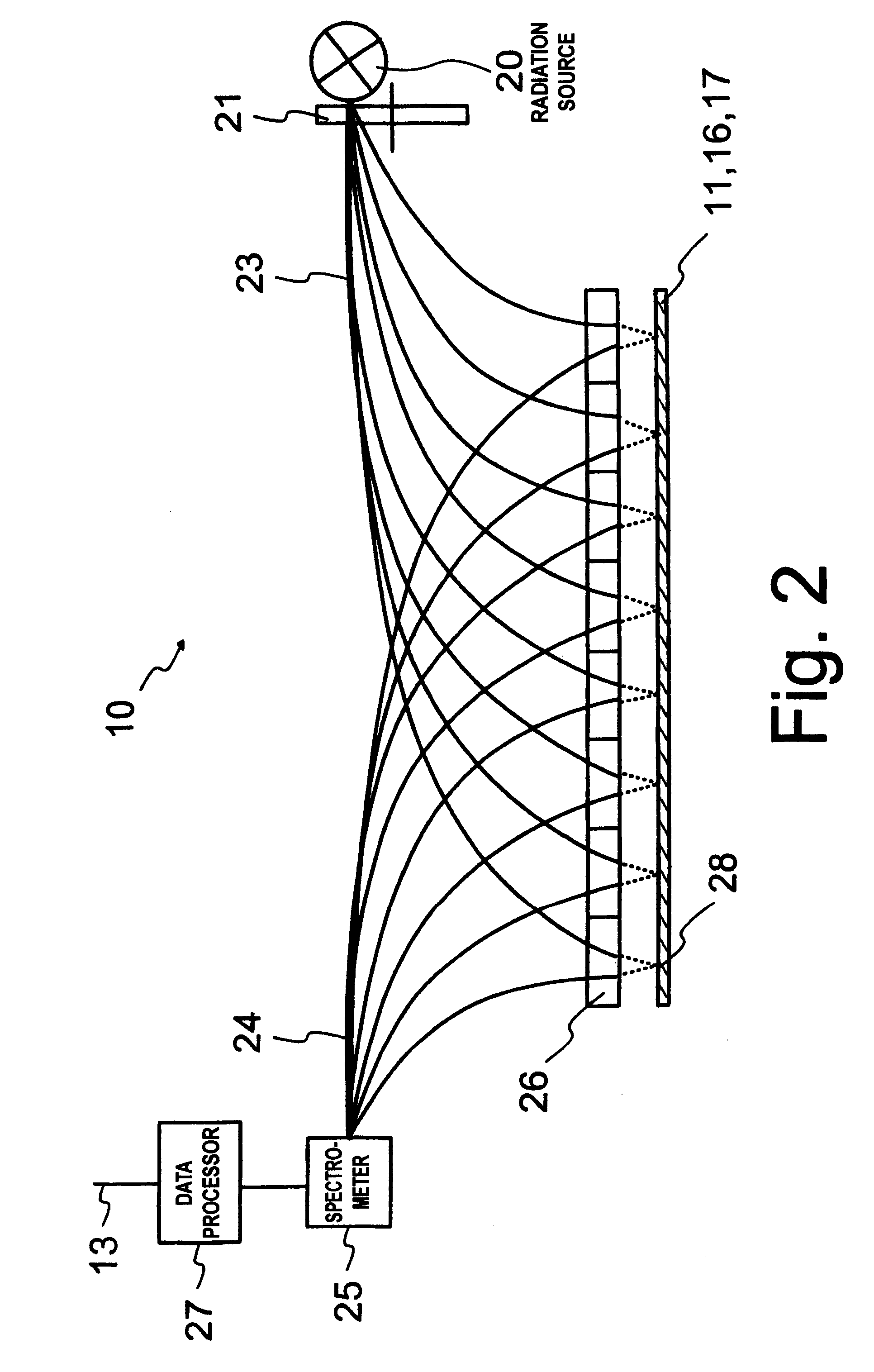

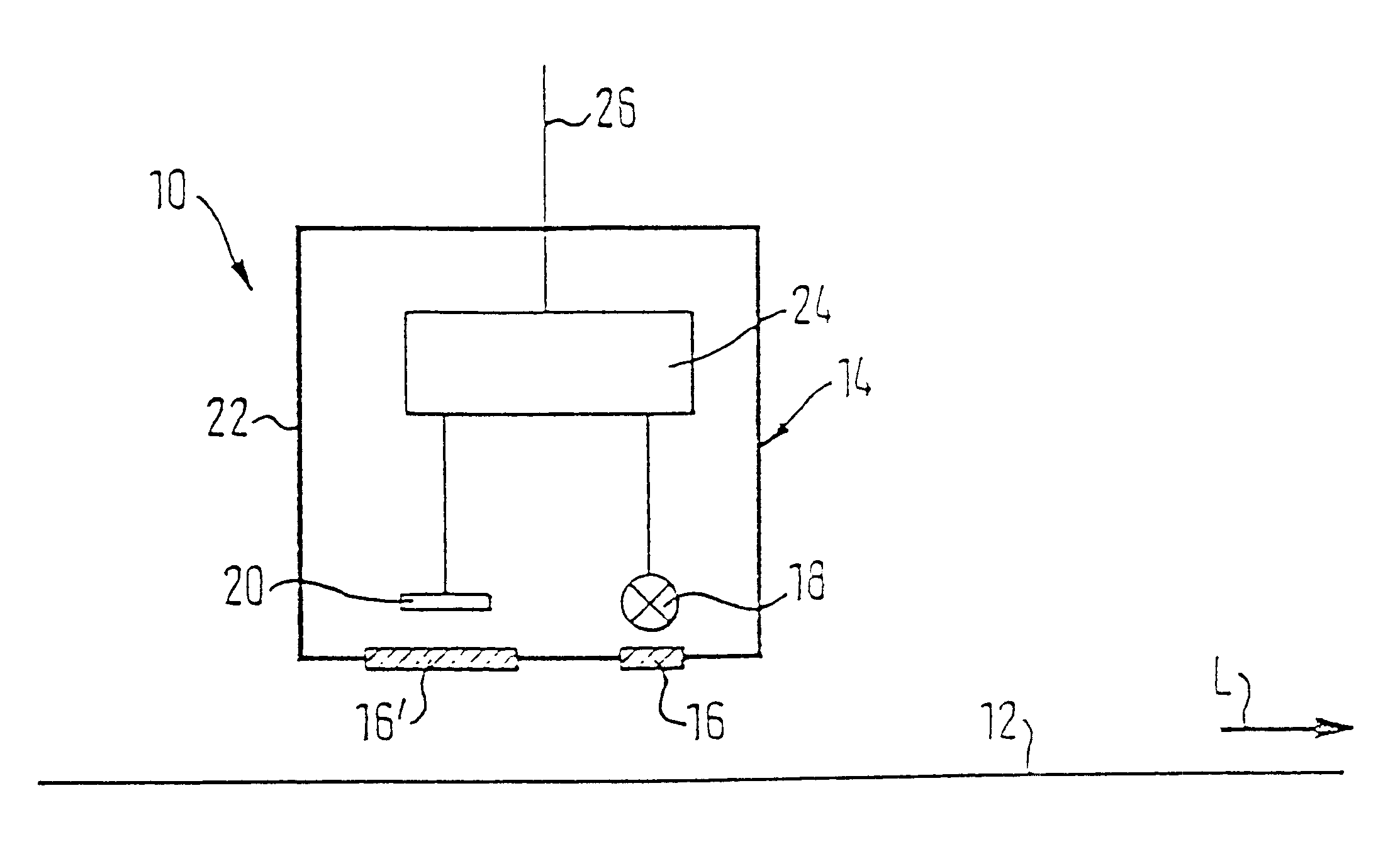

Process and apparatus for determining properties of a traveling material web. The process includes simultaneously illuminating a plurality of measuring points on the material web with electromagnetic radiation, and imaging, through at least one optical device, the plurality of measuring points on one detection surface of at least one detector. The device includes at least one radiation source for illuminating a plurality of measuring points on the material web, at least one detector having a detection surface, and at least one optical device for imaging of the measuring points on the detection surface of the at least one detector.

Owner:VOITH PATENT GMBH

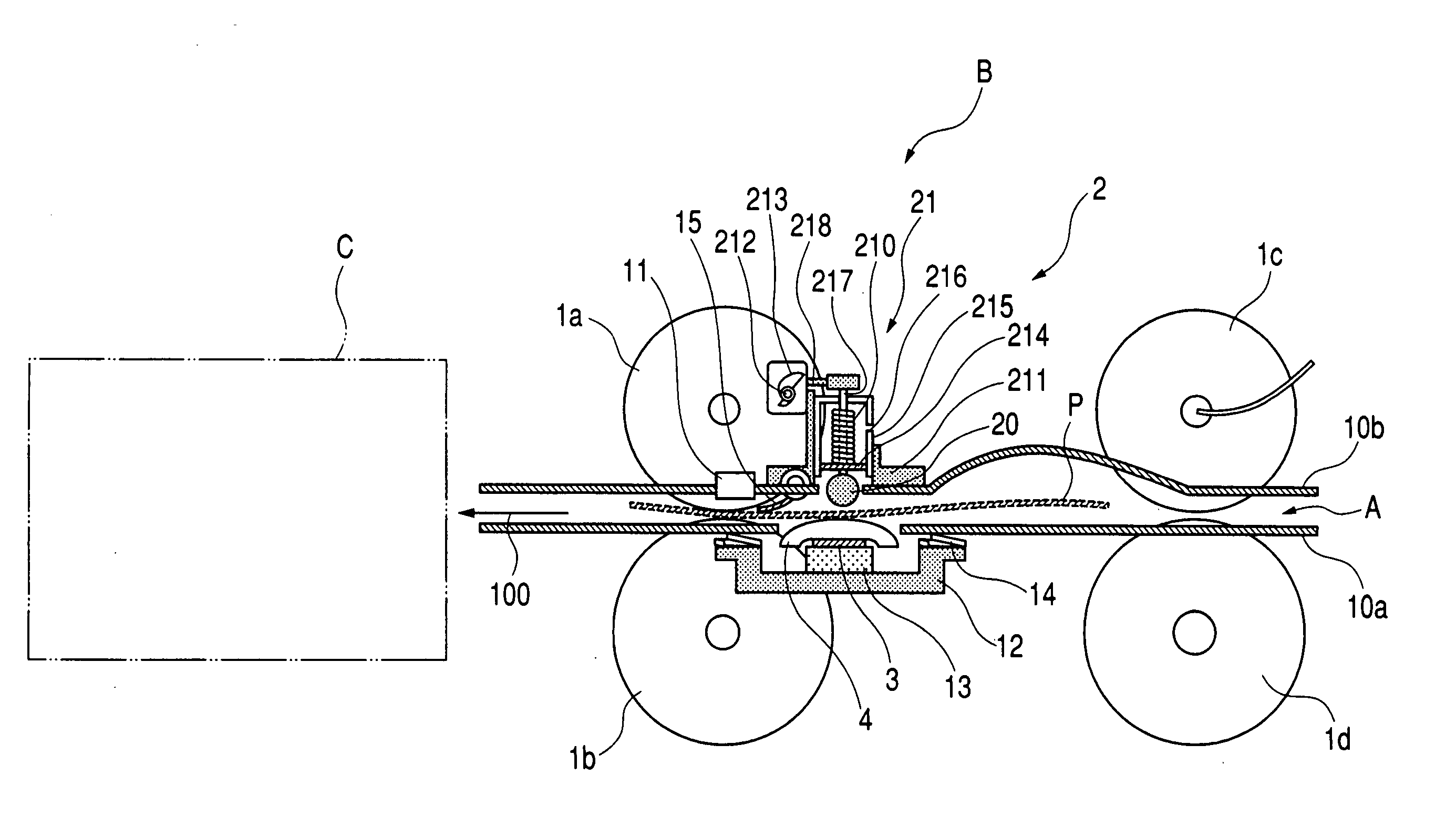

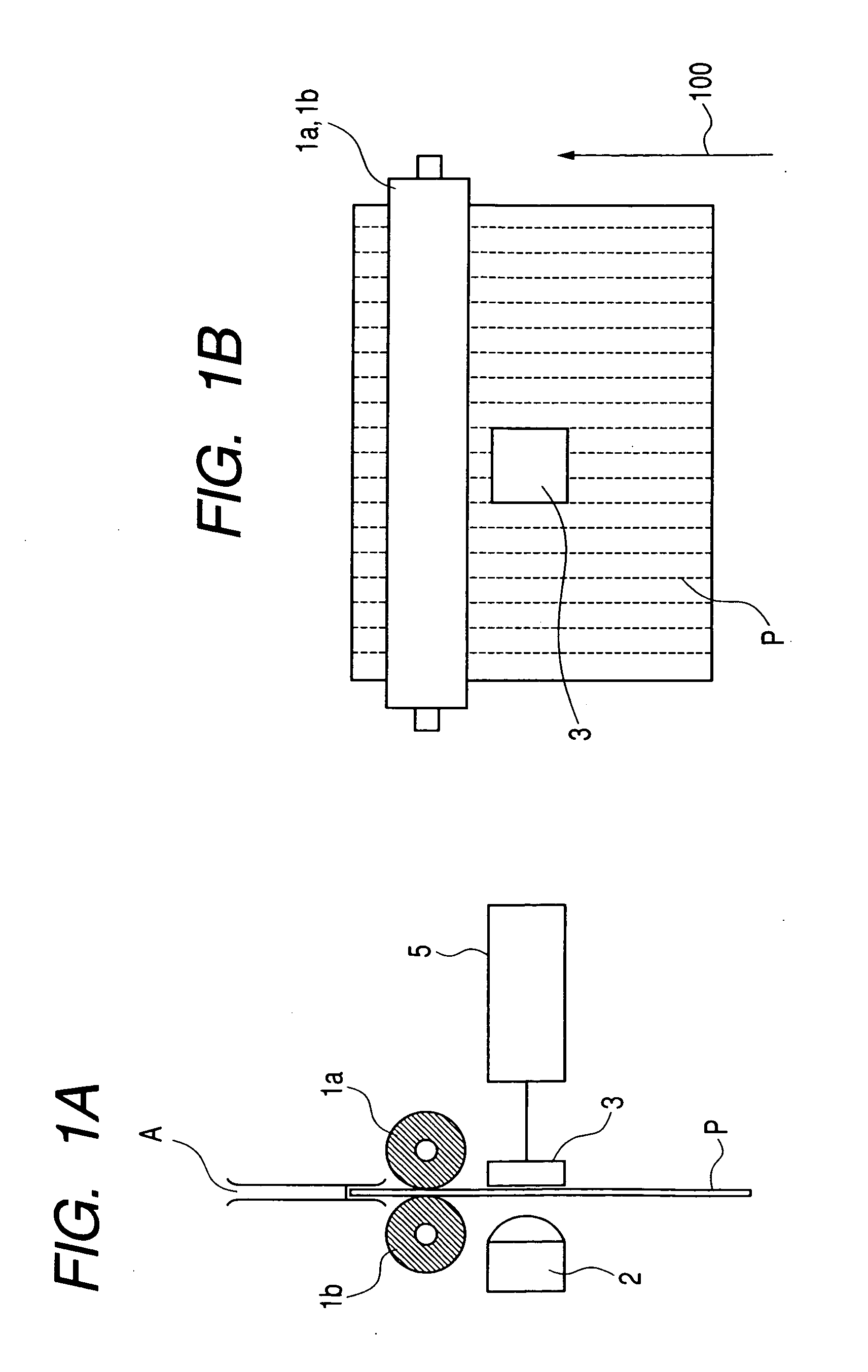

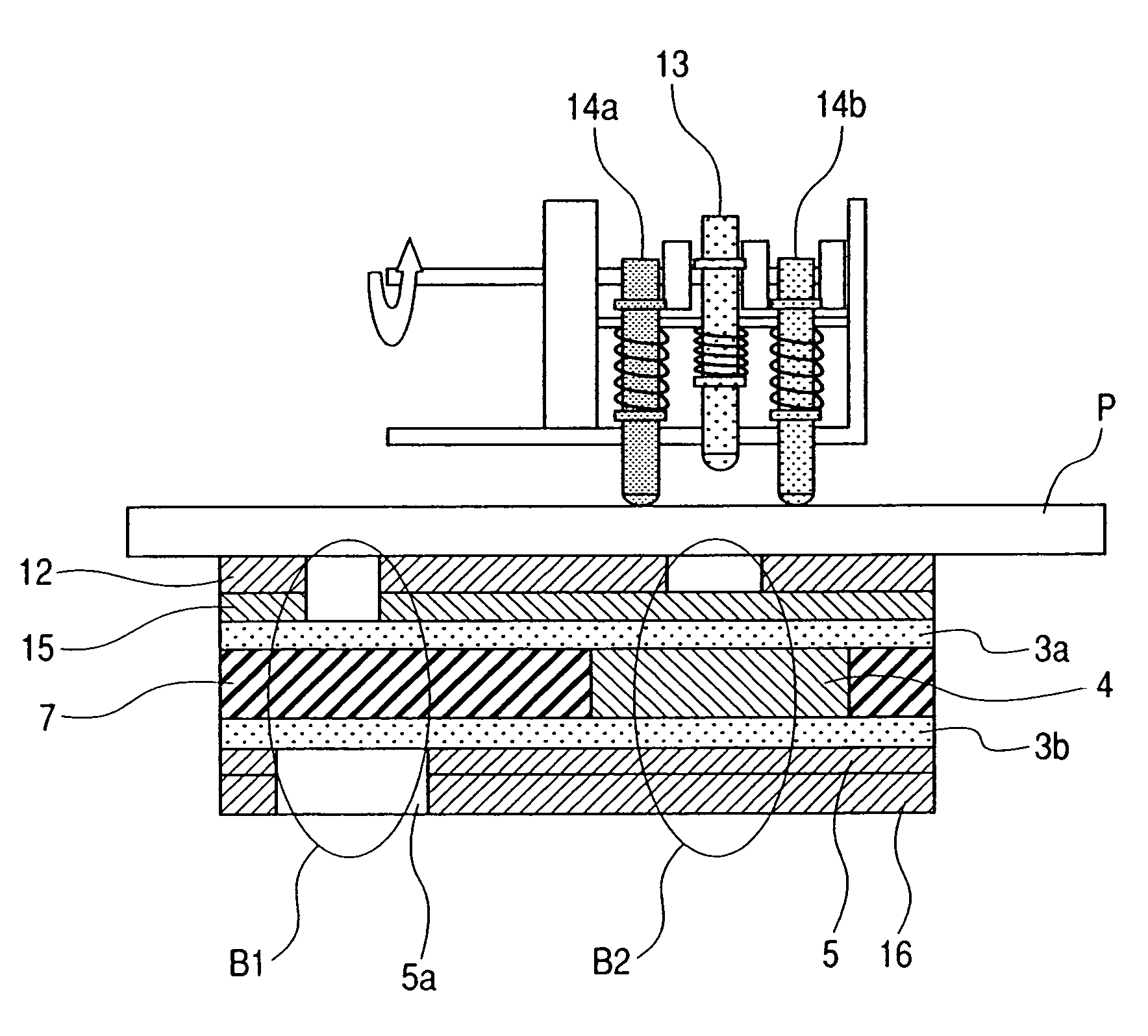

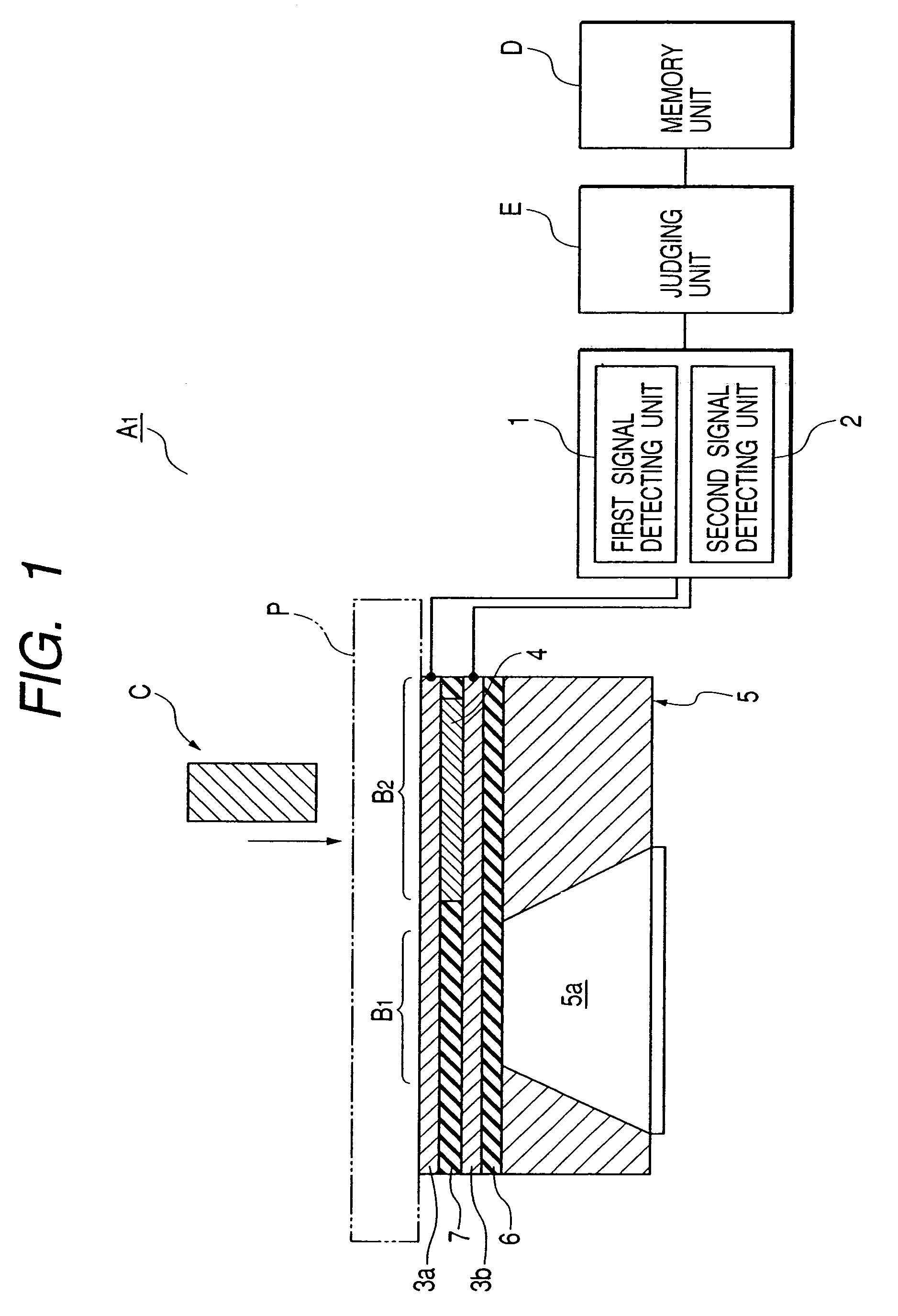

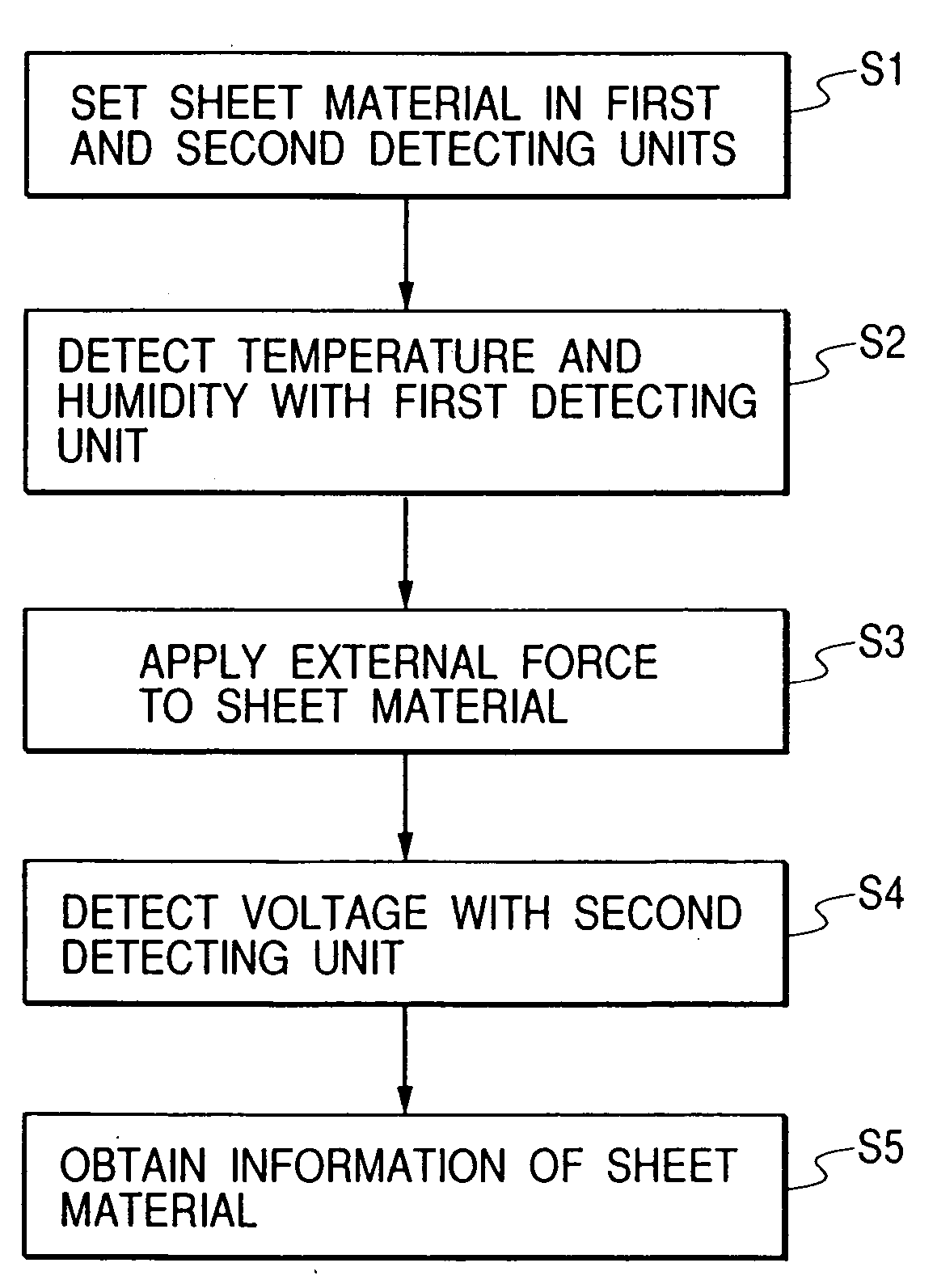

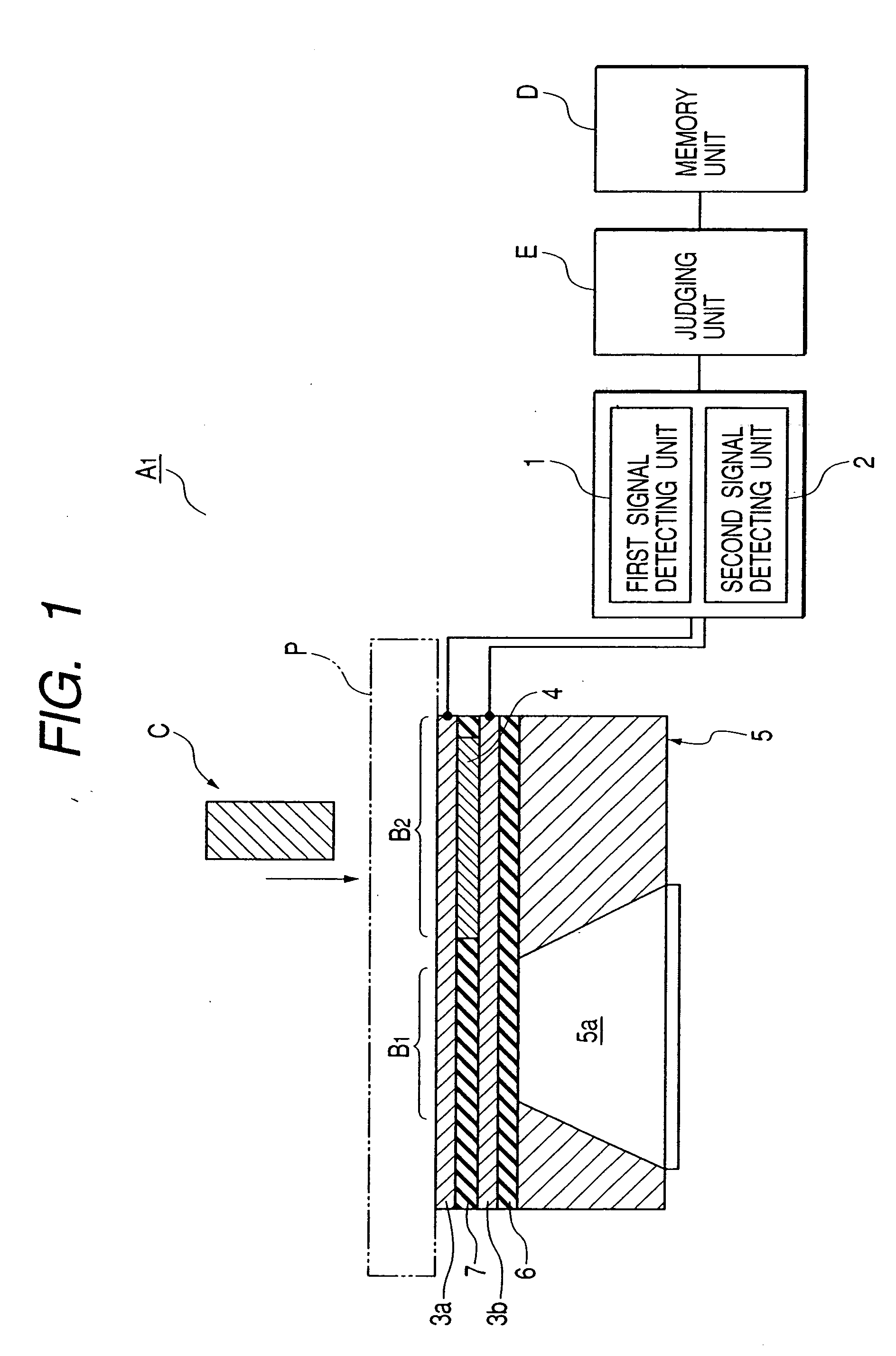

Sheet material information-detecting apparatus

A sheet material information-detecting apparatus is provided which is capable of detecting the type of a sheet material even if the sheet material is anisotropic. When recording paper sheet P is fed, feed rollers 1a and 1b are moved to narrow the nip of the rollers and front edge of recording paper sheet is pushed thereto to correct the oblique feed. Thereafter, external force is applied to recording paper sheet P by external force applying member 2. A signal based on the external force is detected by signal detecting means 3, and sheet material information-acquiring means 5 identify the type of the recording paper sheet. Owing to the oblique feed correction, the type of the sheet material can be identified precisely even if the sheet material is anisotropic.

Owner:CANON KK

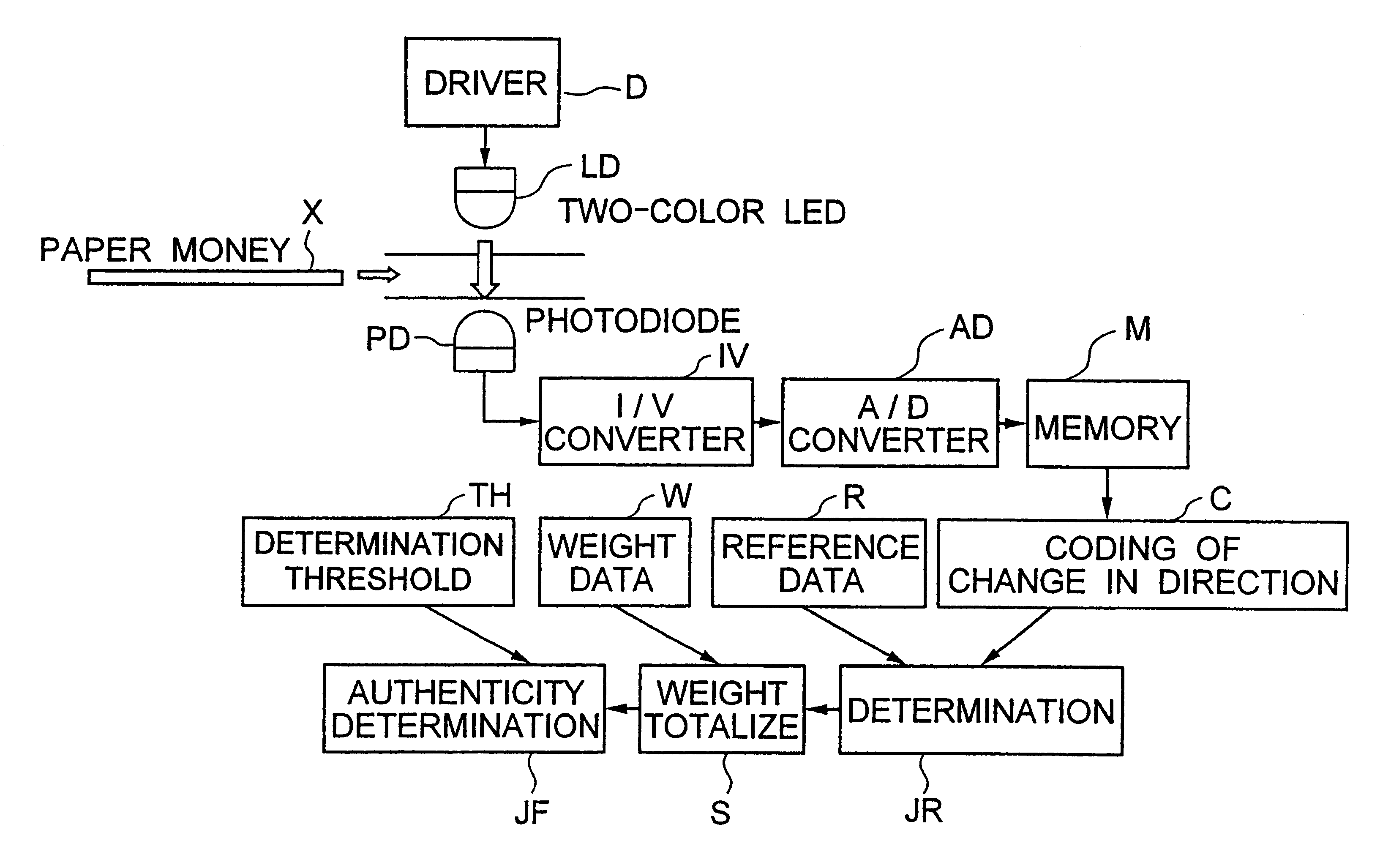

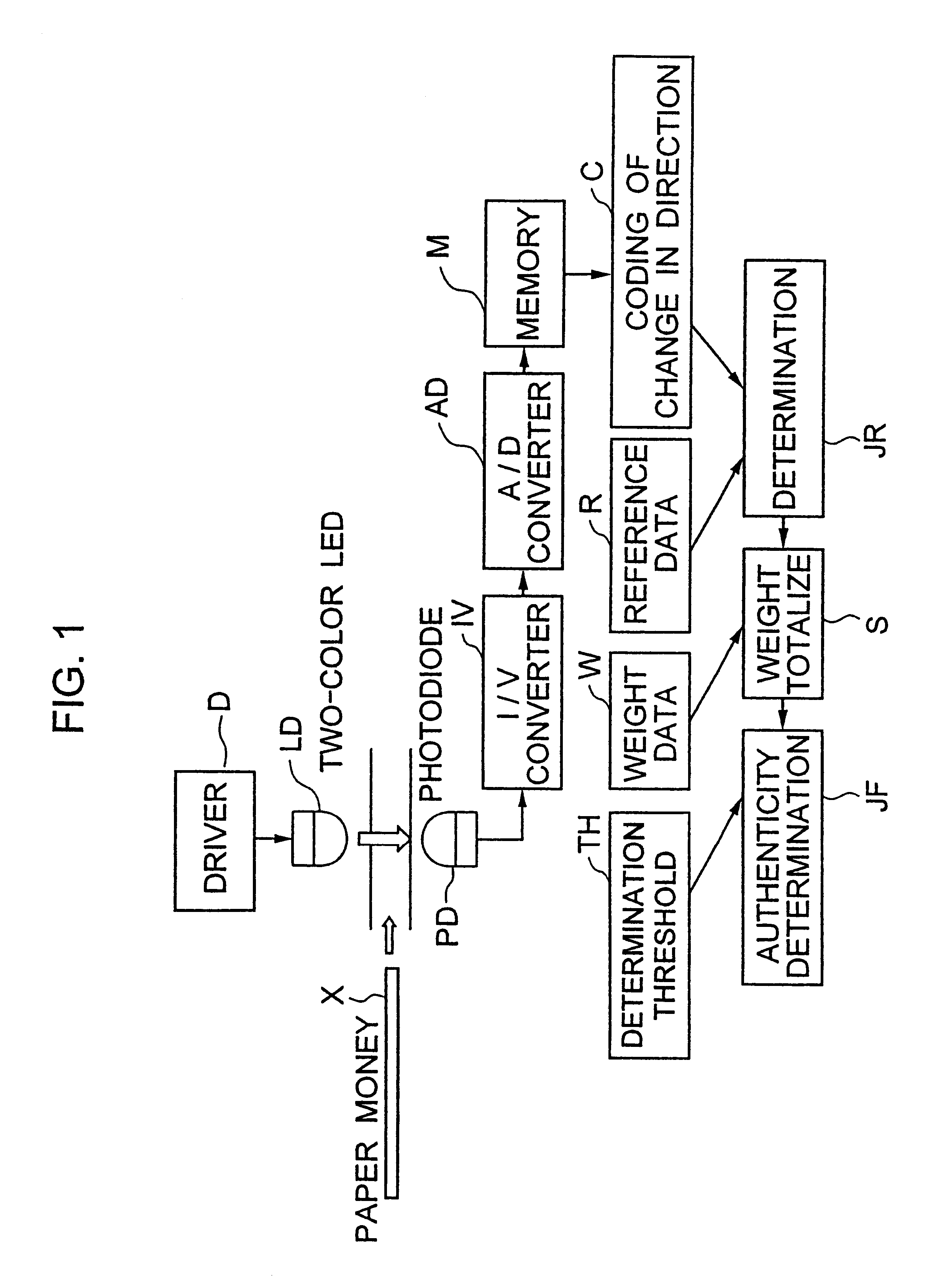

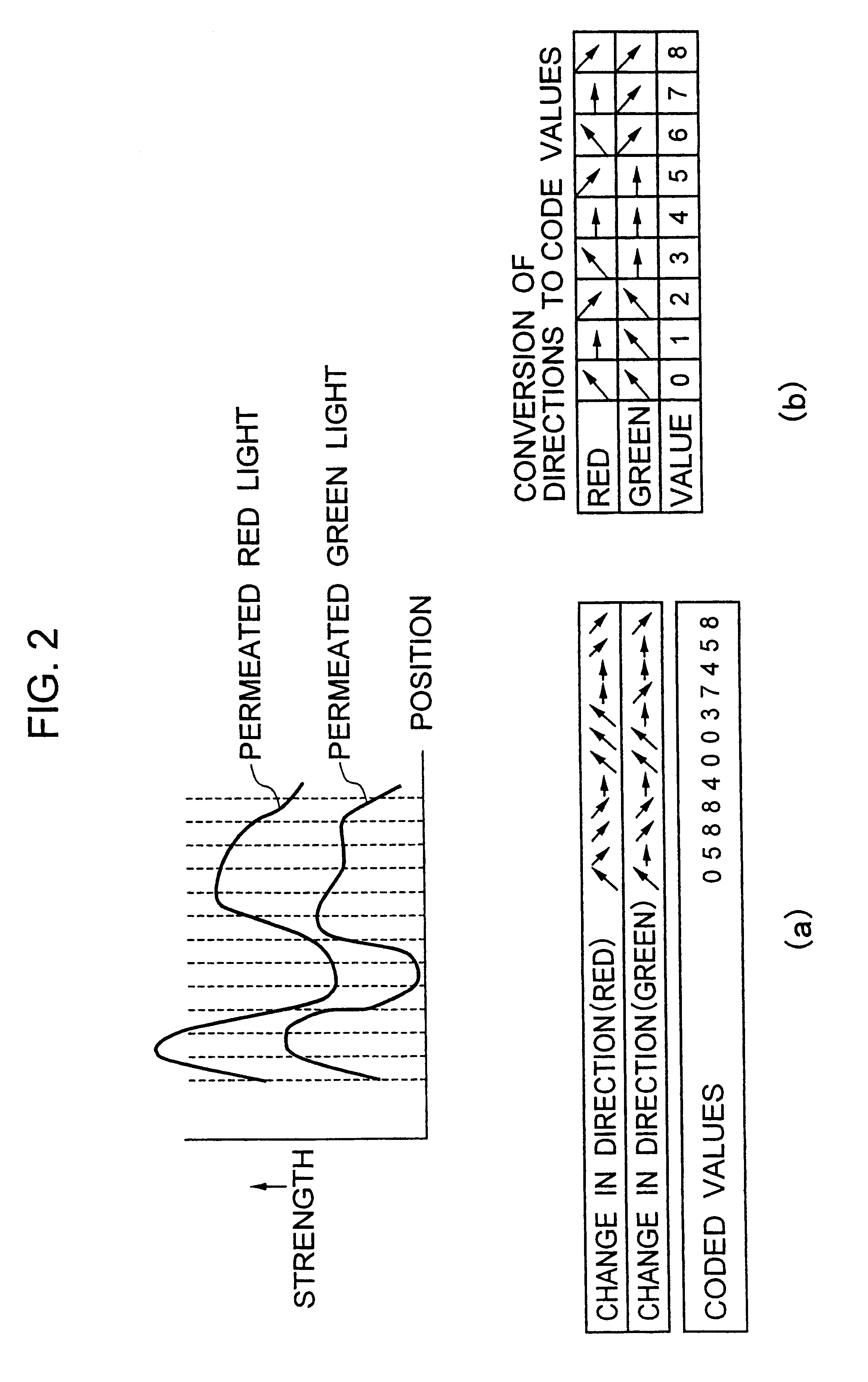

Paper sheet identification method and device

Disclosed are a method and a device capable of high-precision identification of a color-copied paper sheet without increasing the amount of data extracted from the paper sheet. The method and device fox identifying a paper sheet radiate at least two lights having different wavelengths onto the paper sheet, detect light which has permeated therethrough or been reflected therefrom, detect a change in direction of the strength of the detected light, produce coded data, and identify the authenticity of the paper sheet by comparing said coded data with predetermined reference data.

Owner:NIPPON CONLUX

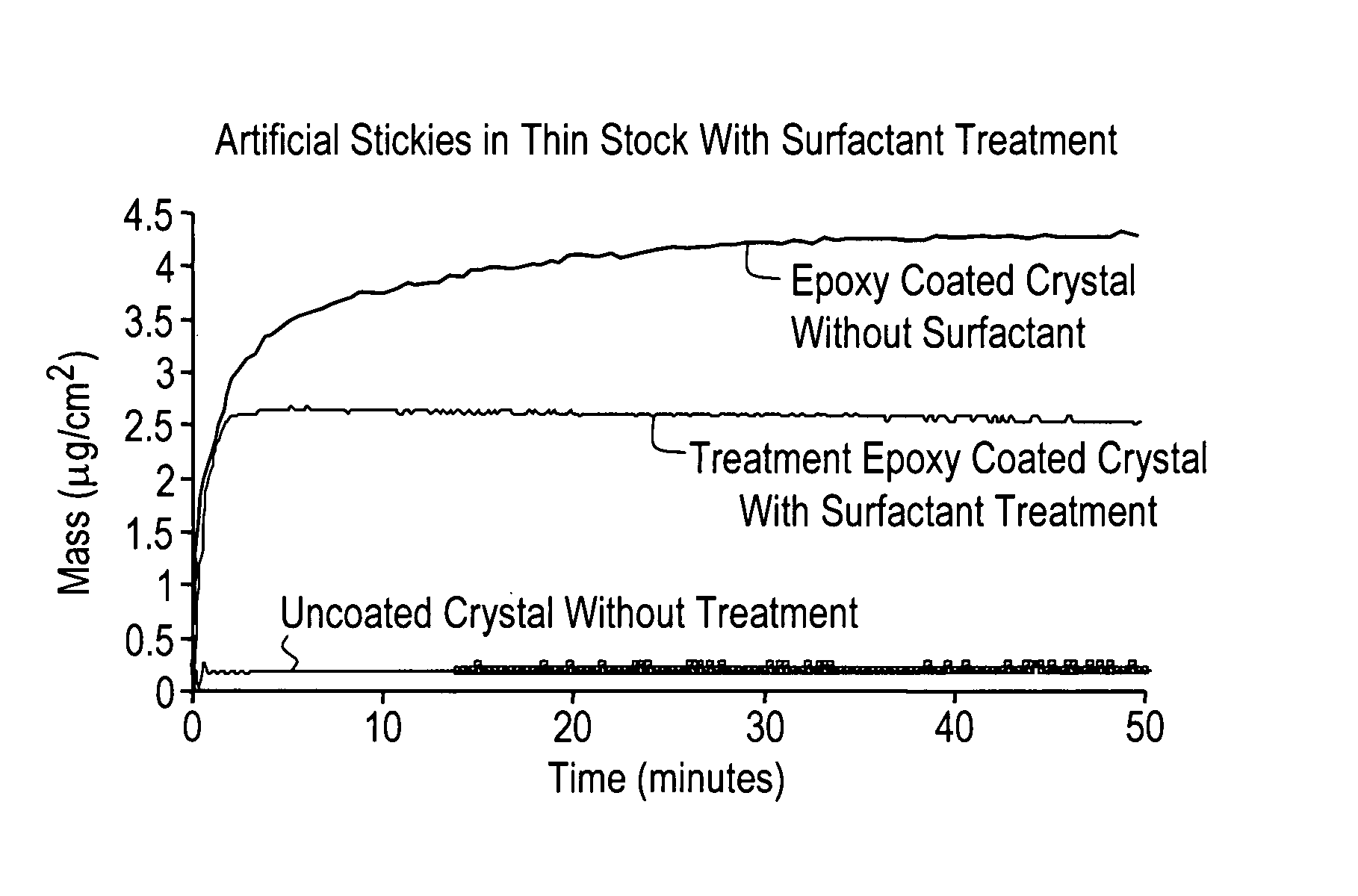

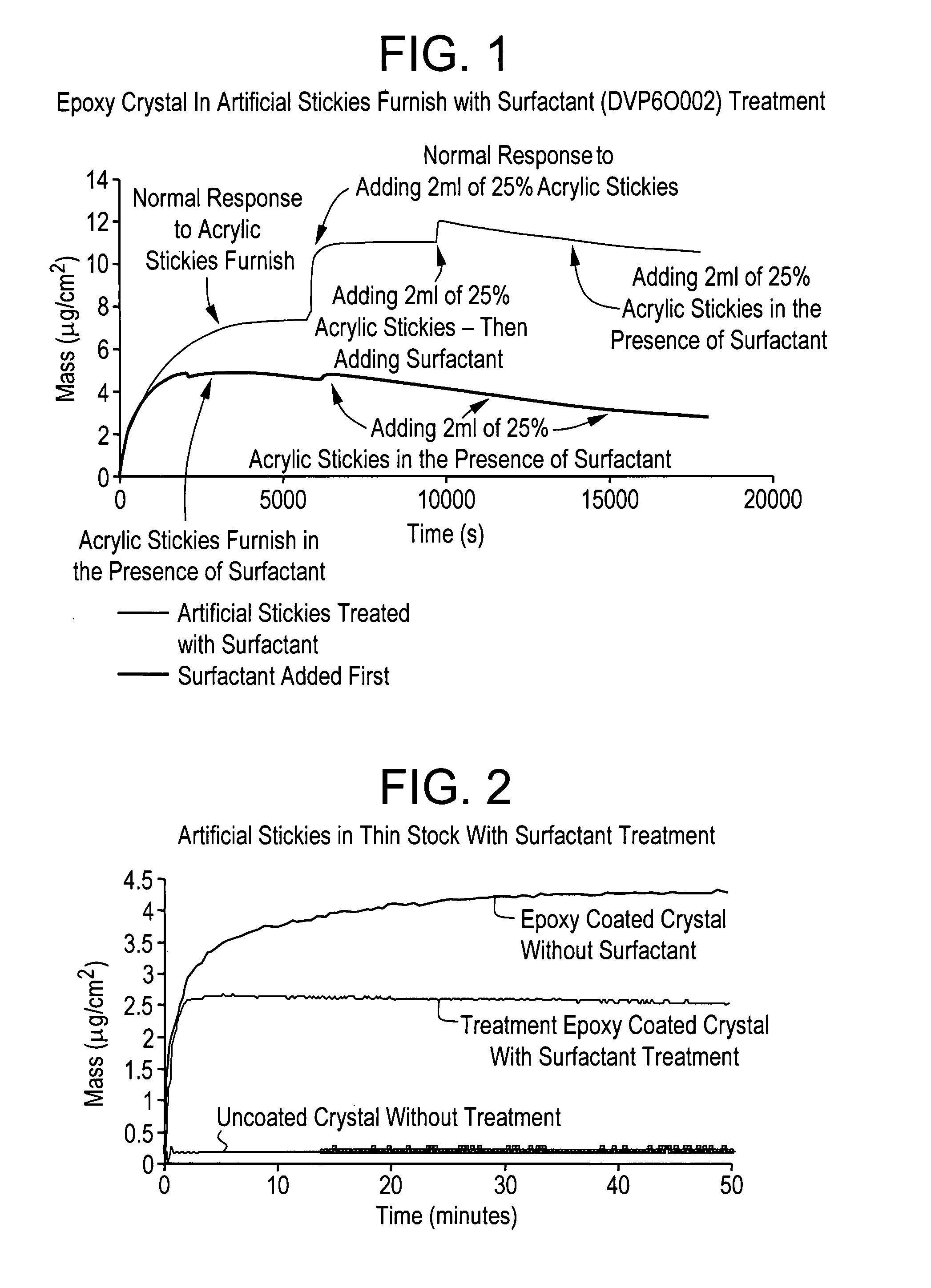

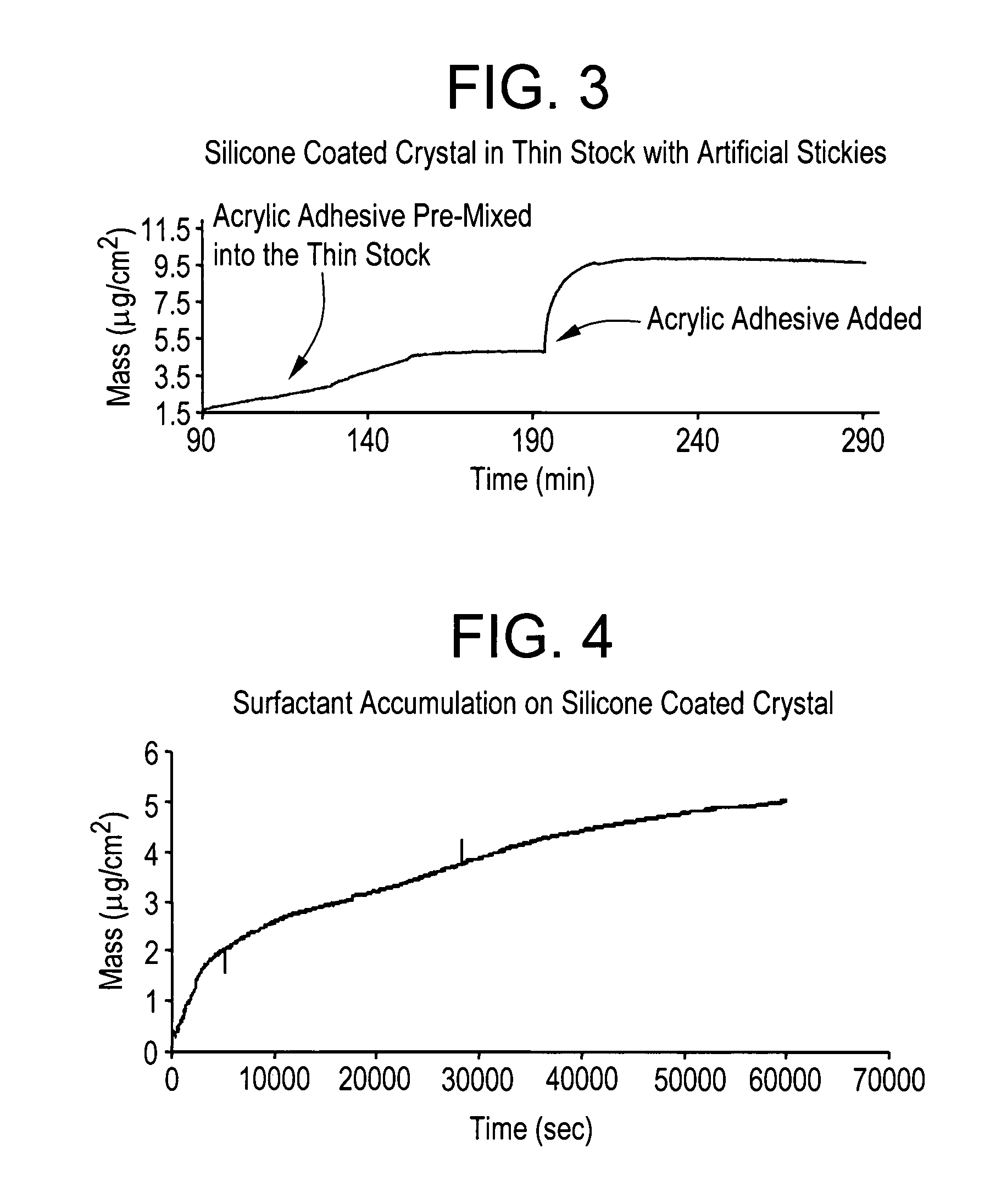

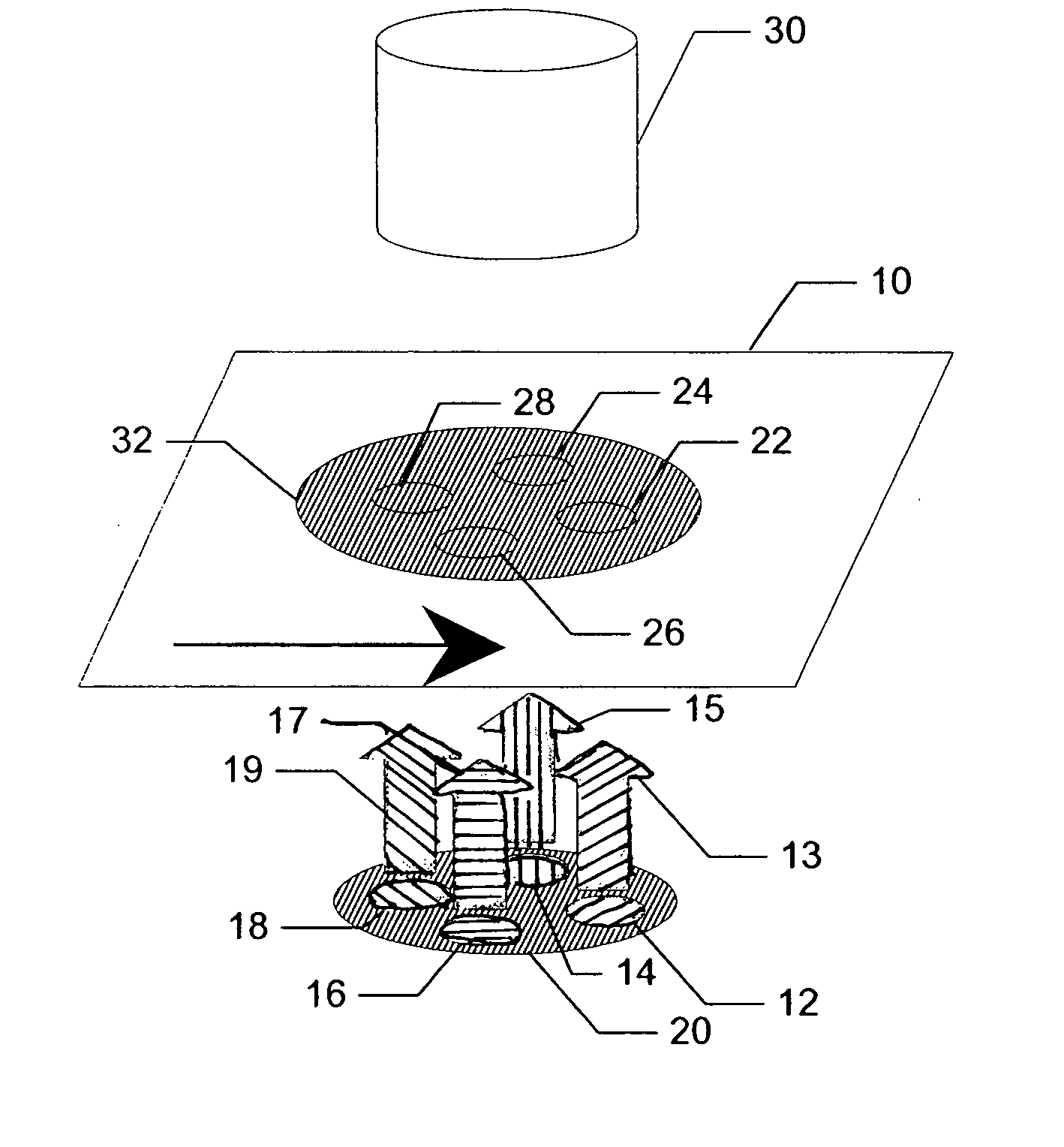

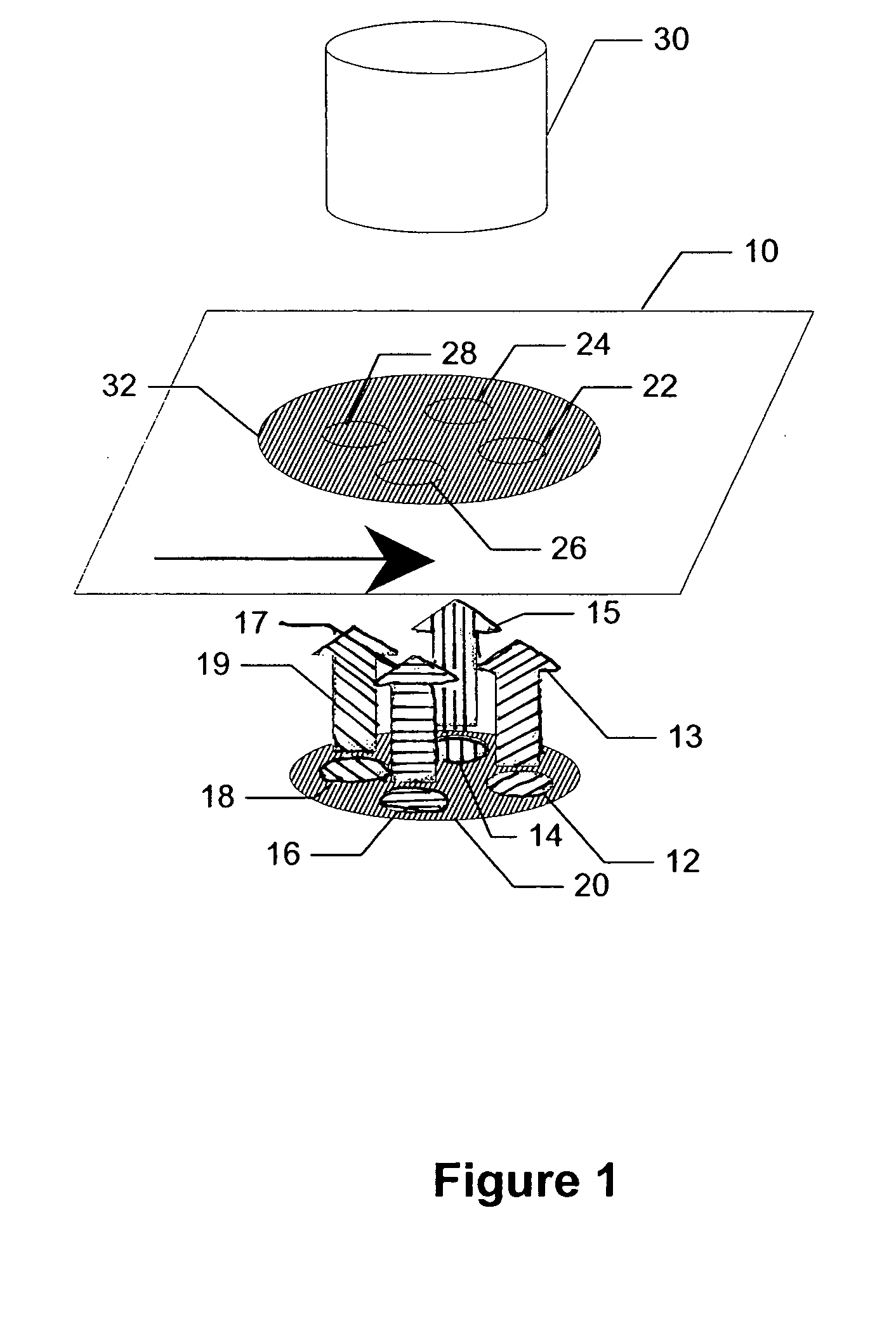

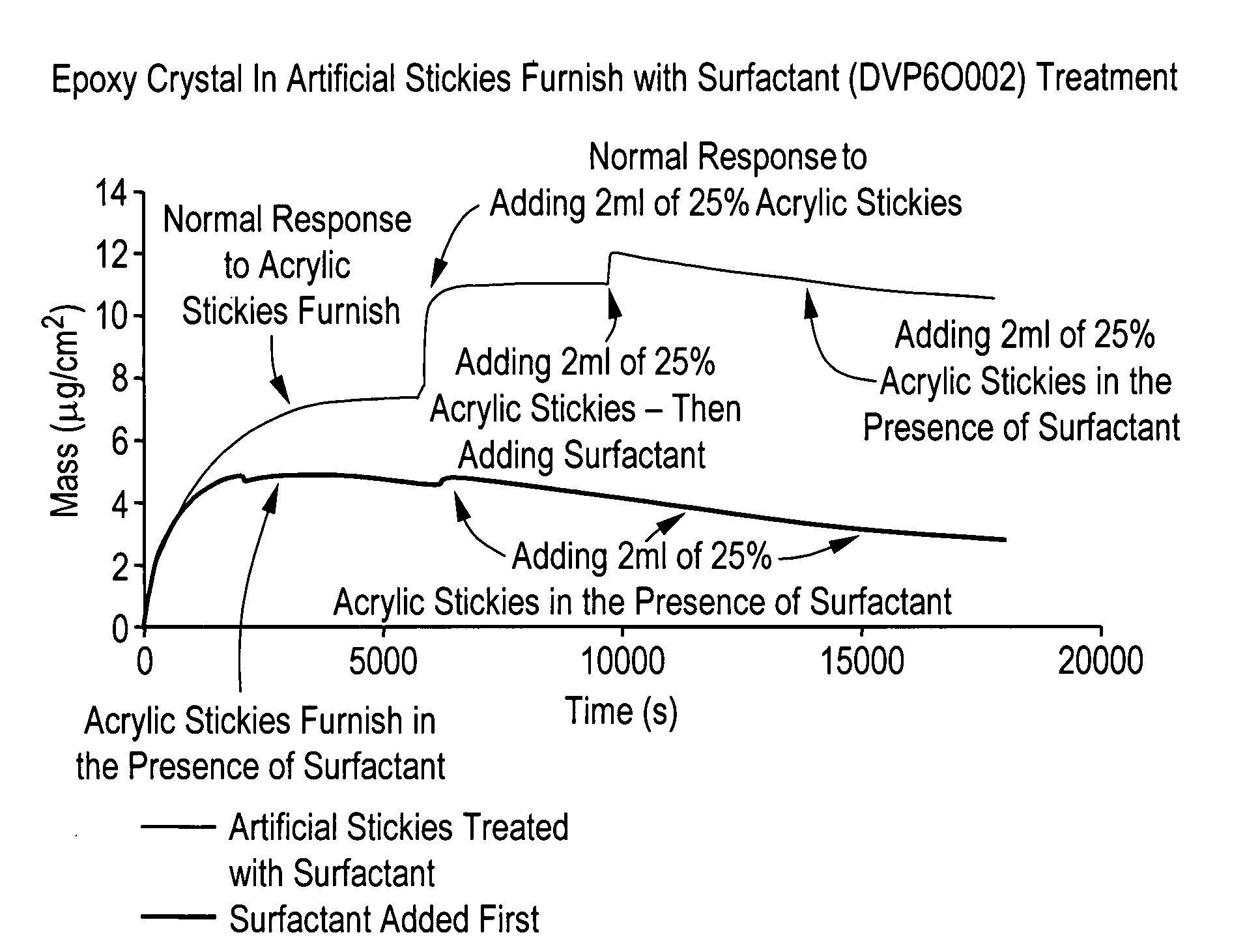

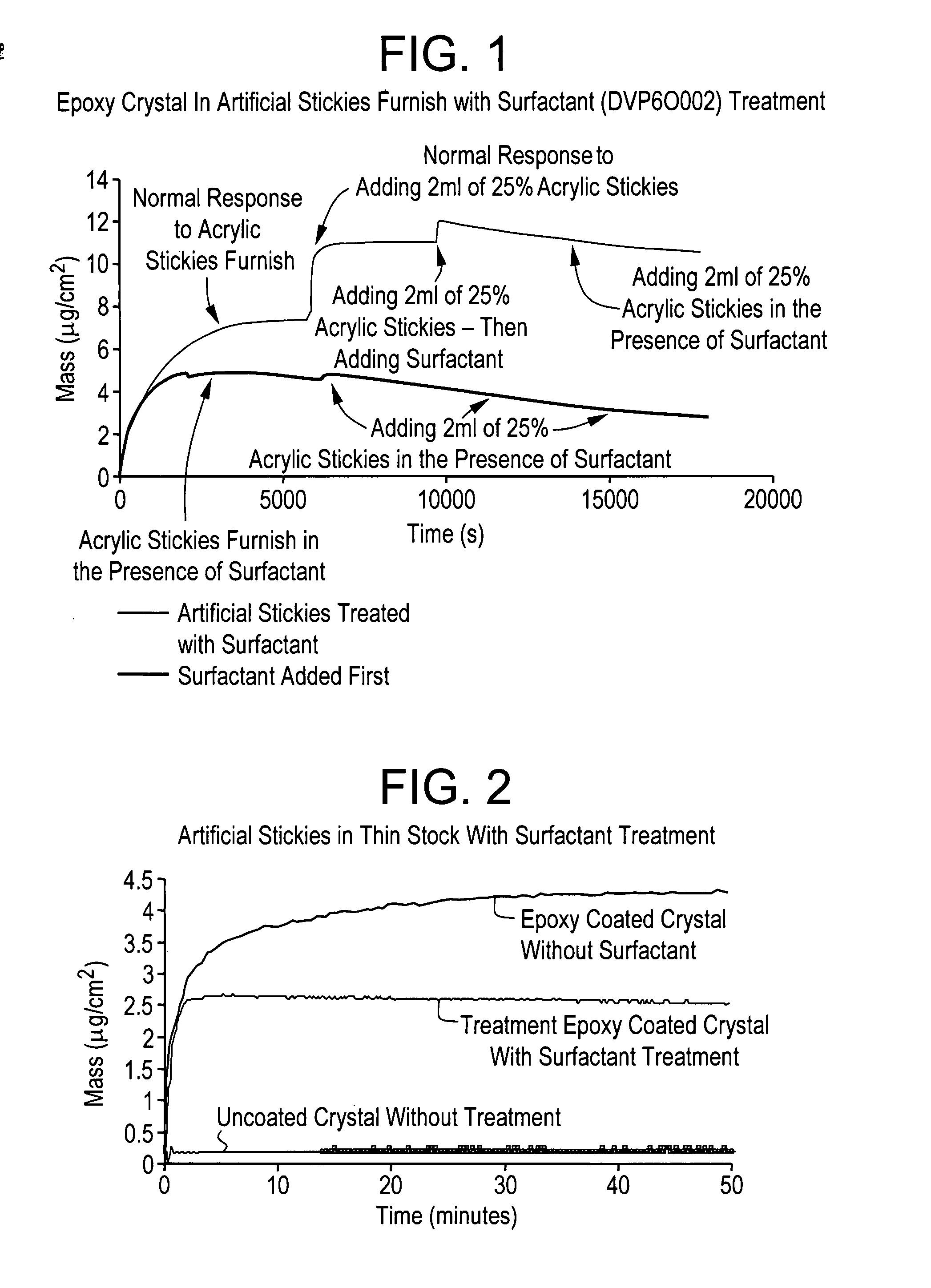

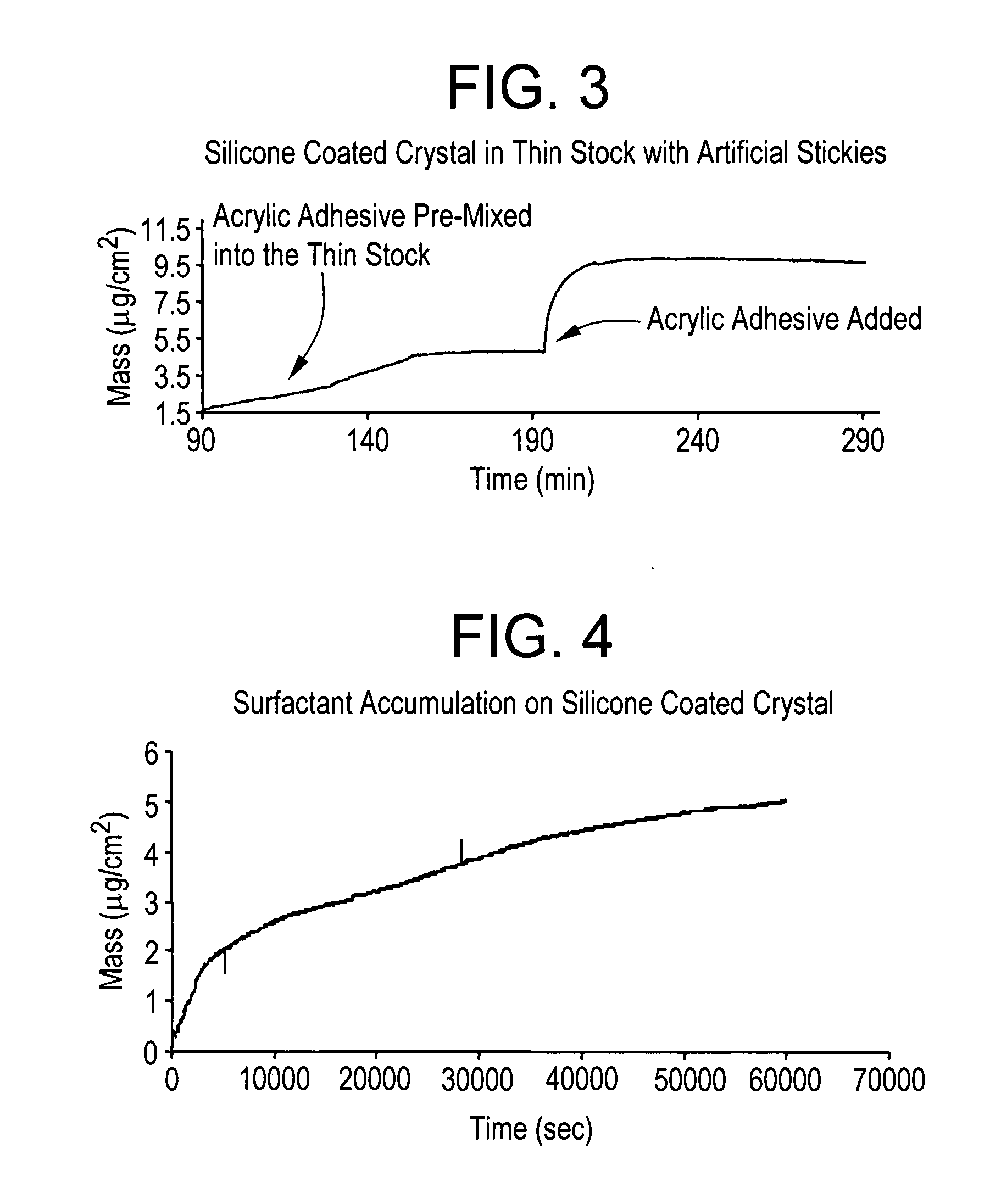

Enhanced method for monitoring the deposition of organic materials in a papermaking process

ActiveUS7842165B2Reduce depositionMaterial analysis using sonic/ultrasonic/infrasonic wavesPaper testingEpoxyQuartz crystal microbalance

A method for monitoring the deposition of one or more organic materials dispersed in an aqueous medium in a papermaking process comprising: measuring the rate of deposition of the organic materials from the aqueous medium on-to a quartz crystal microbalance having a top side contacting with the aqueous medium coated with a layer containing a non-swelling epoxy resin or a silicone containing polymer, and a second, bottom side isolated from the aqueous medium is disclosed. Additionally, a method for measuring the effectiveness of an inhibitor that decreases the deposition of the organic materials in a papermaking process is also disclosed.

Owner:ECOLAB USA INC

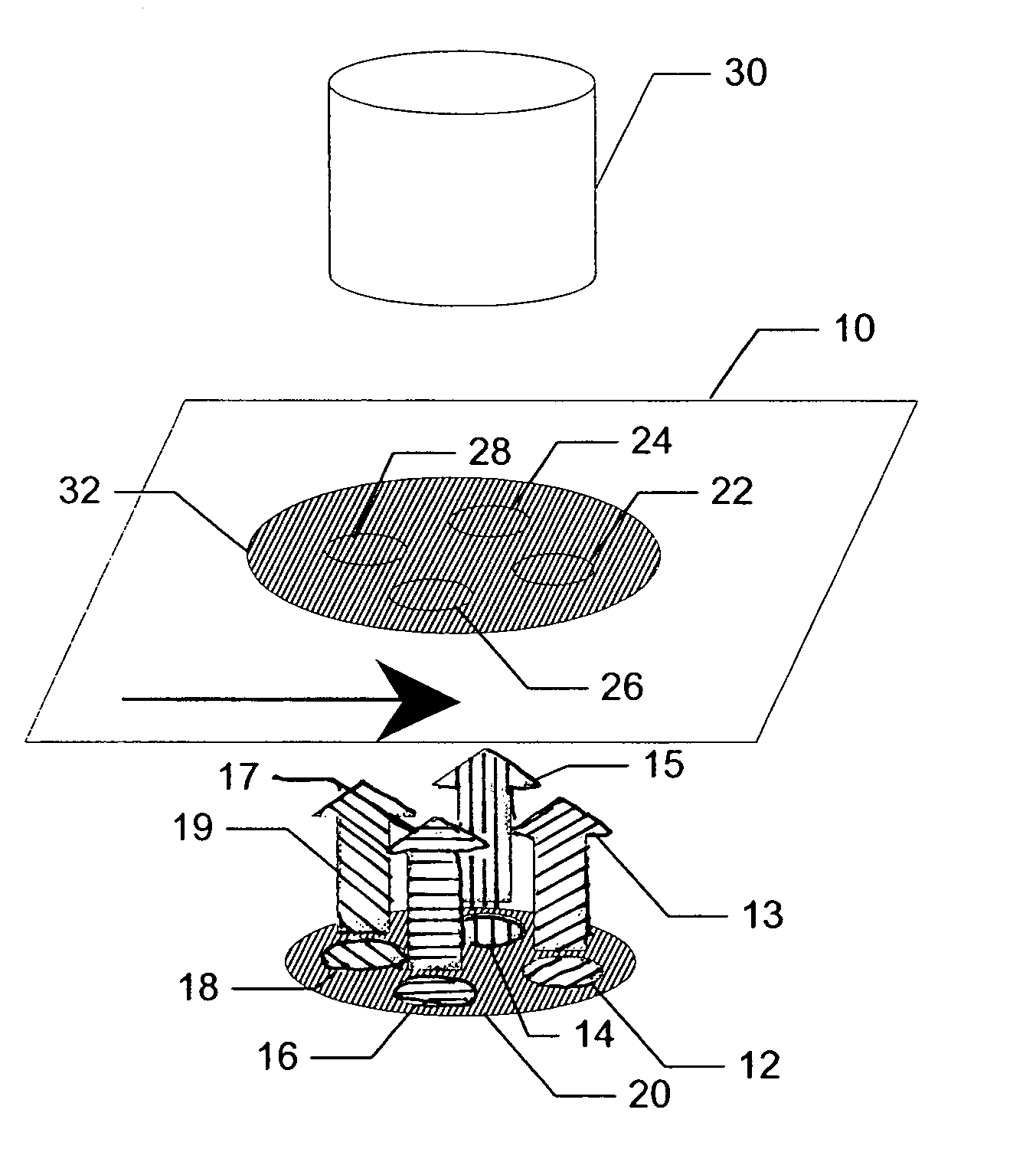

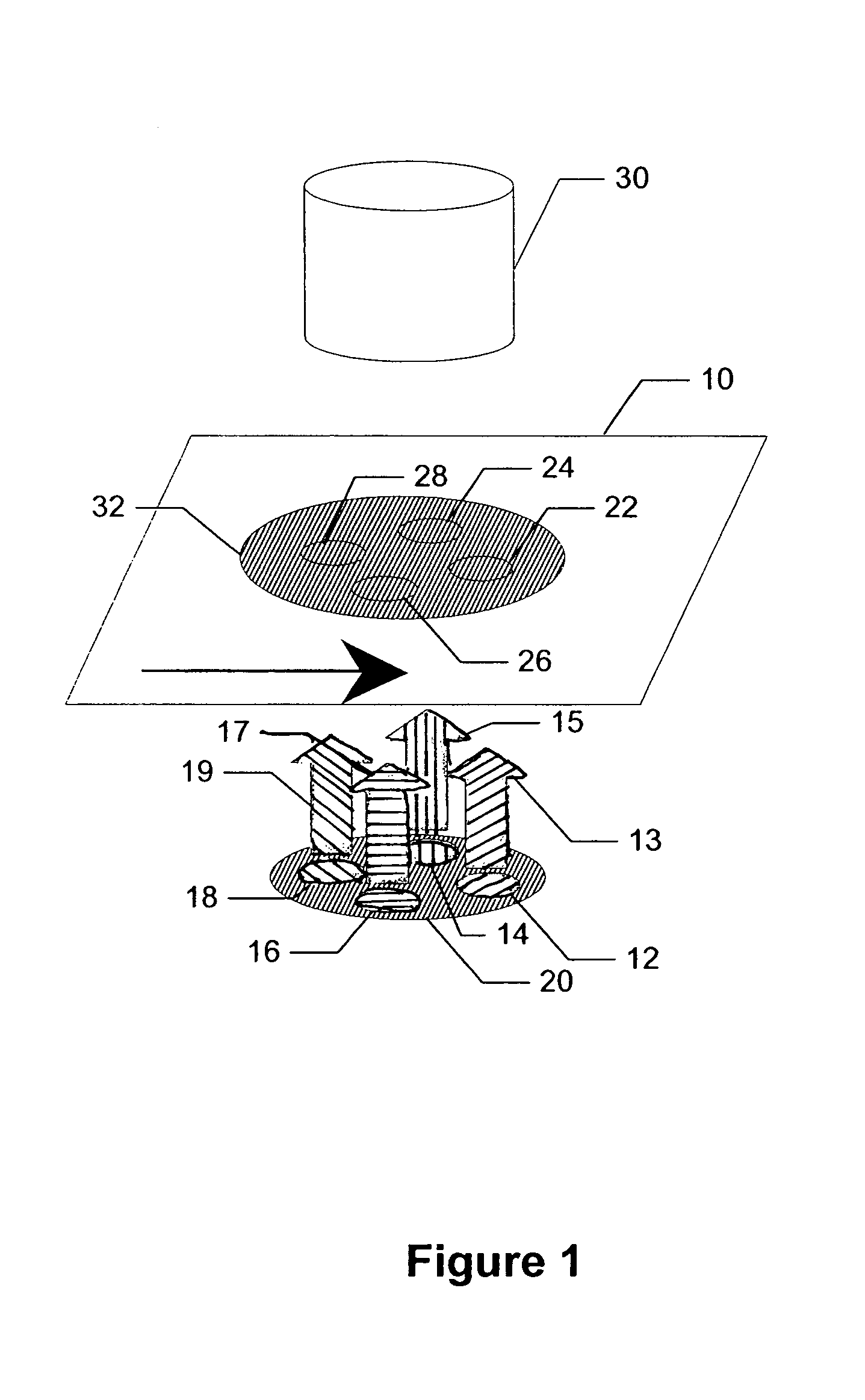

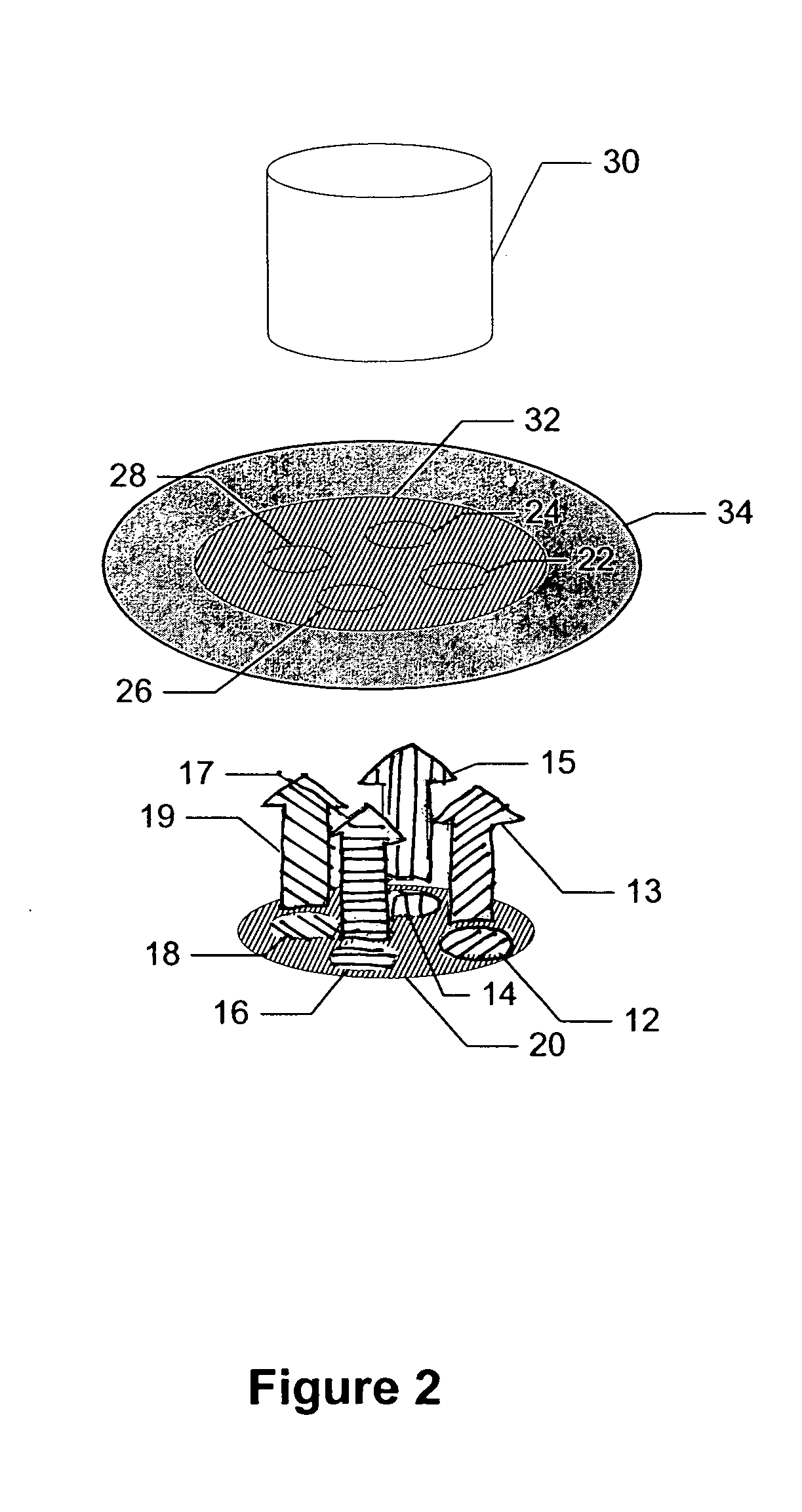

Measuring fiber orientation by detecting dispersion of polarized light

ActiveUS20060255300A1High resolution measurementSimple and strong structureInvestigating moving sheetsPaper testingImage basedOptoelectronics

An image-based technique that measures the orientation of fibers in a moving web of nonwoven material includes the steps of: (a) illuminating essentially simultaneously at least four light spots on one side of the web with at least four plane-polarized incident substantially perpendicular light beams having different polarization characteristics, (b) measuring the dispersion of the excident light spots on the opposite side of the web along at least one linear section which is at a known angle relative to the plane of polarization of the corresponding plane-polarized incident light beam, wherein at least one such linear section lies substantially across the center of the transmitted excident light spot and extends substantially across the width of the transmitted excident light spot, (c) calculating variations in the dispersion of the transmitted excident light spot for the at least four plane-polarized light beams; and (d) estimating the fiber orientation from the variations.

Owner:HONEYWELL INT INC

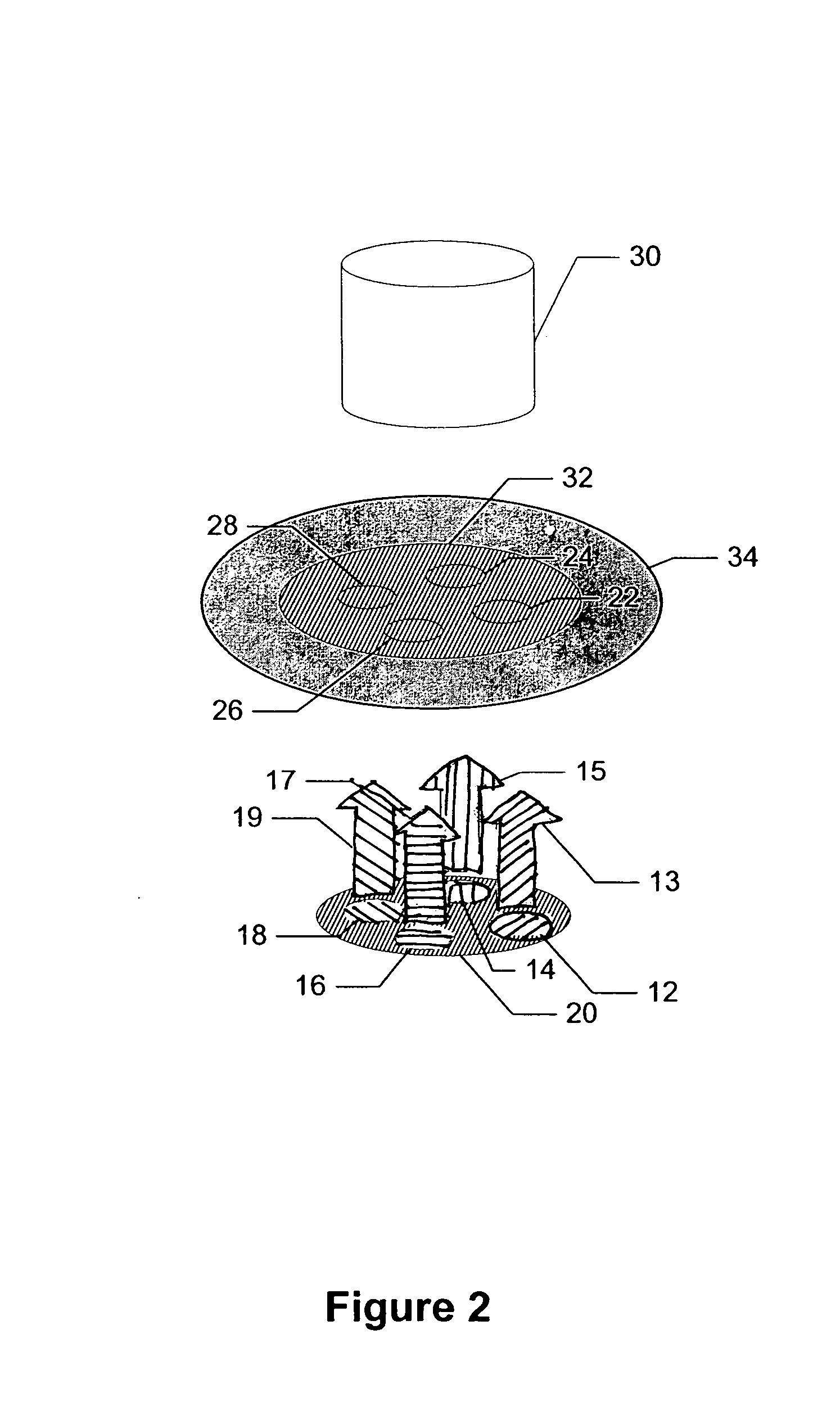

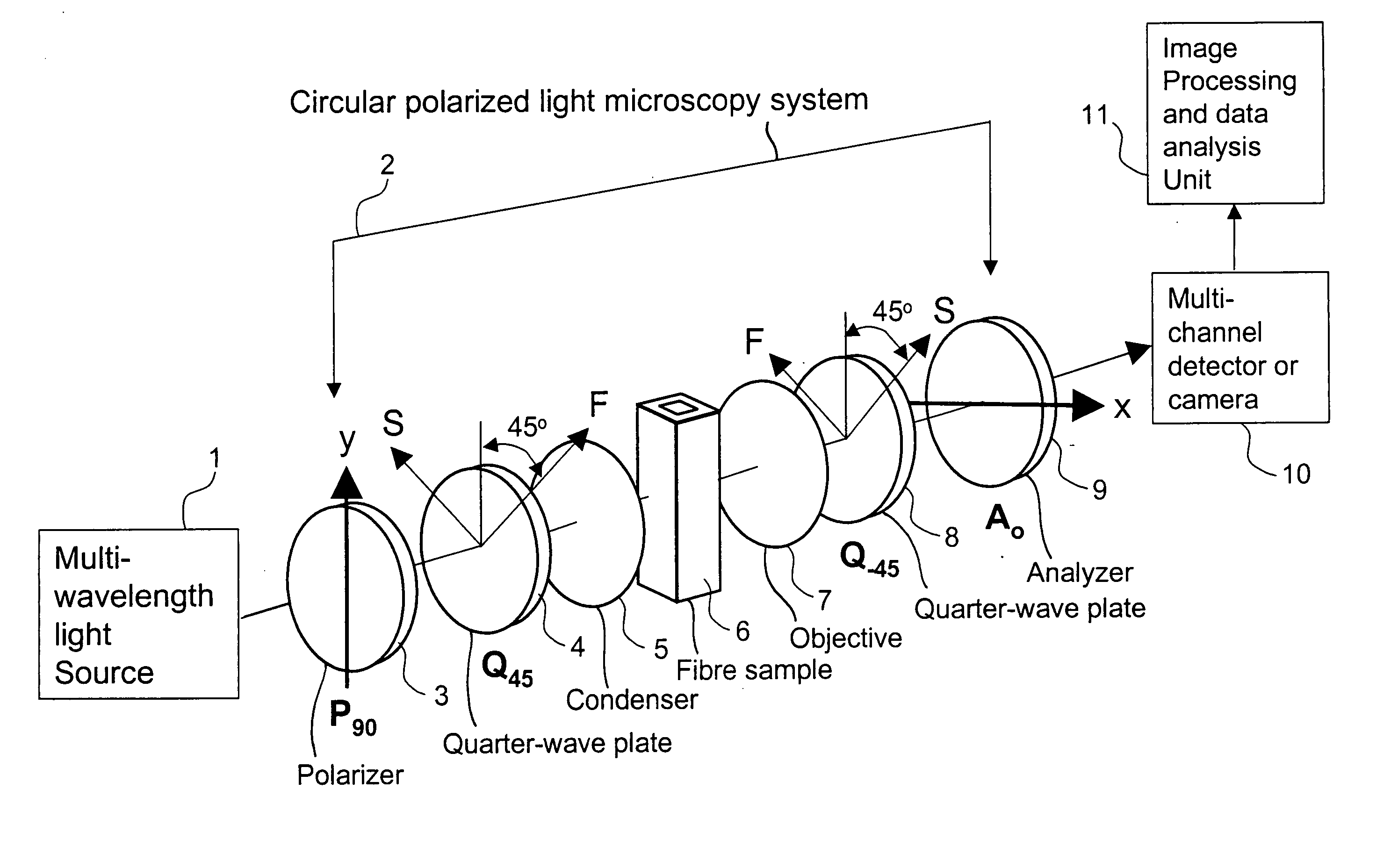

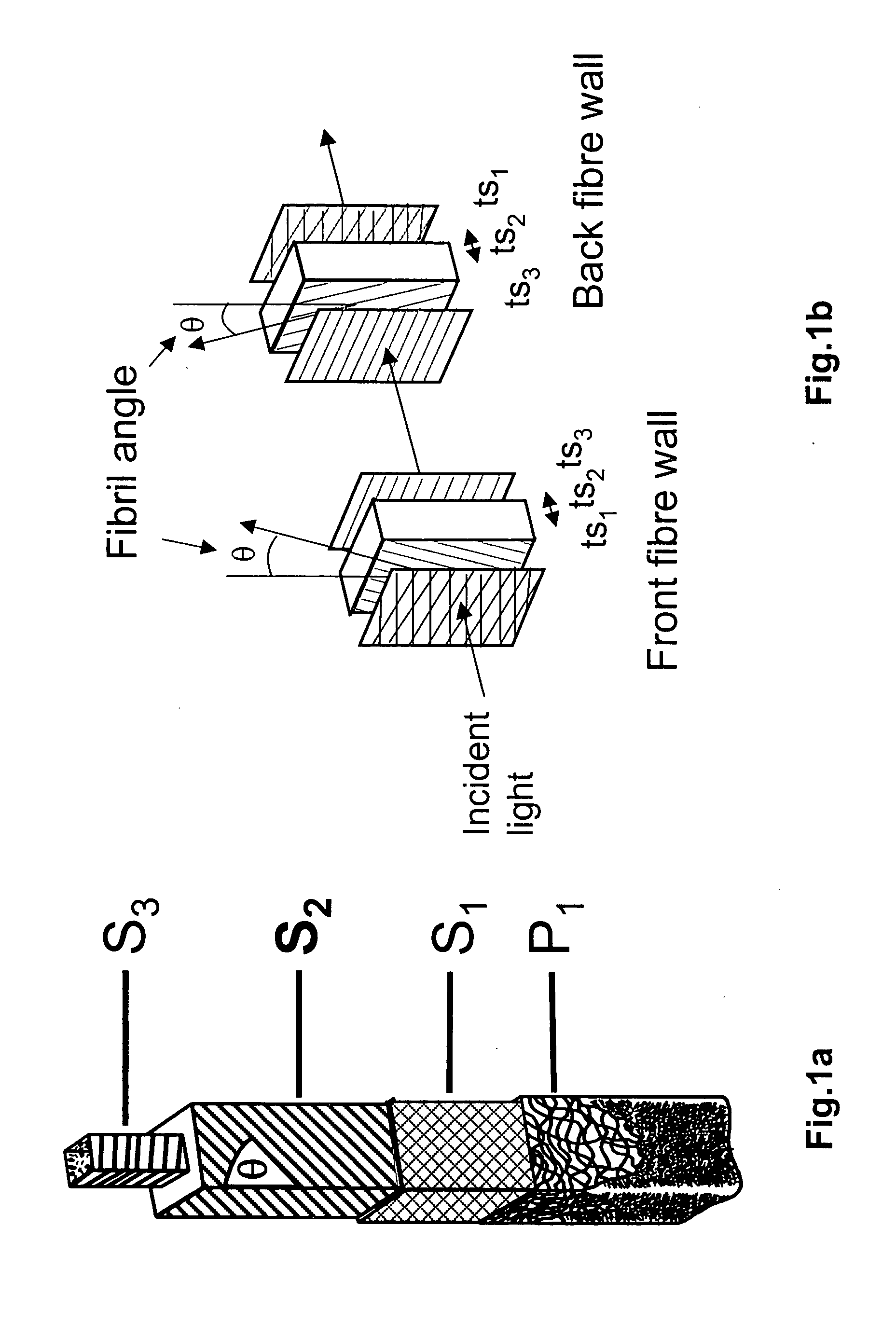

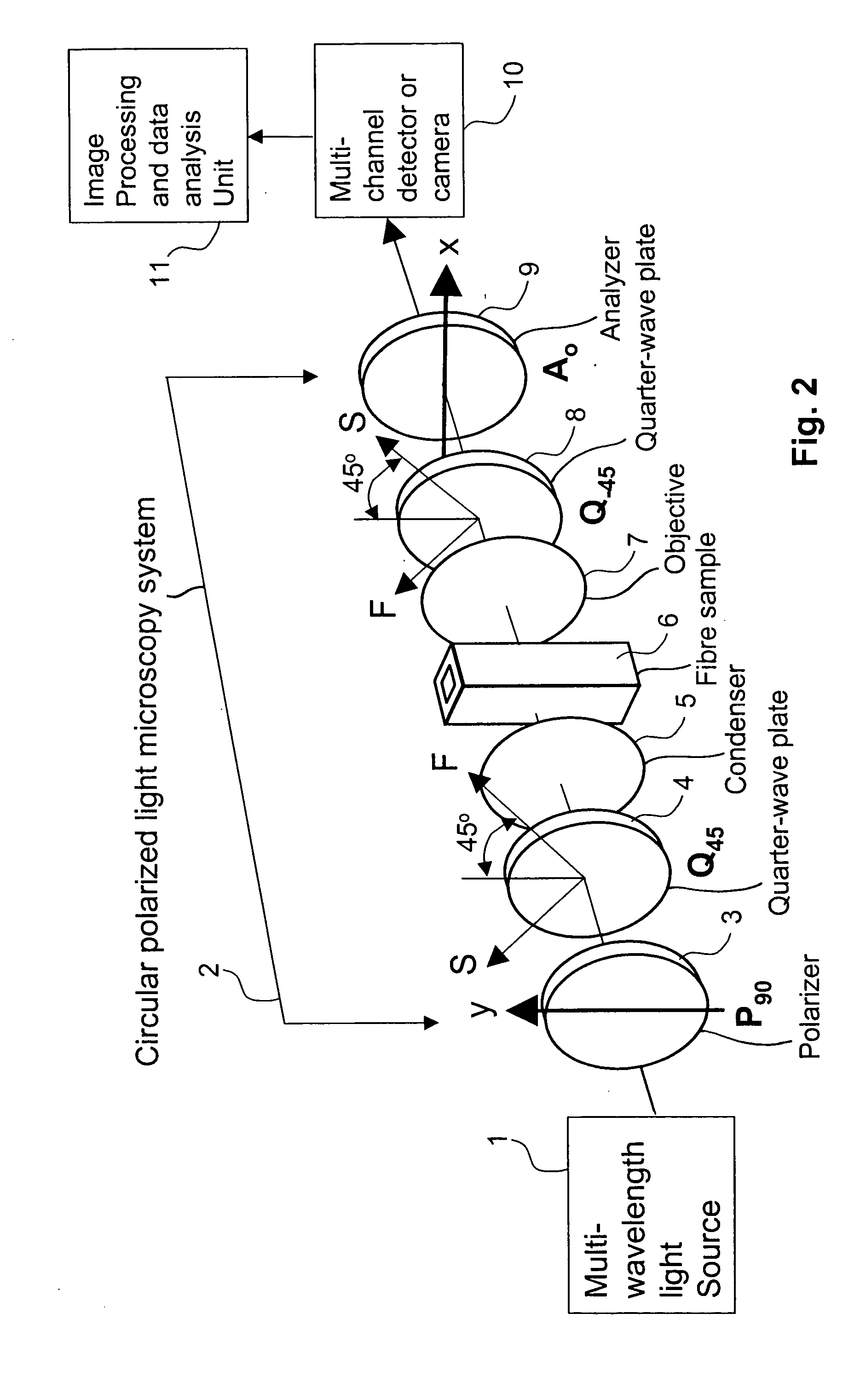

Circular polarized light method and device for determining wall thickness and orientations of fibrils of cellulosic fibres

ActiveUS20050122514A1Polarisation-affecting propertiesPhase-affecting property measurementsFibrilData analysis system

This invention provides a novel, rapid method and device for determining the relative phase retardation of a multi-layered specimen, which is related to the thicknesses of its layers and walls, and the orientations of its optical axes. An intact wood pulp fibre is a typical multi-layered birefringent specimen. This new method is based on the change of polarization of polarized light that passes through a specimen composed of birefringent layers with different optical axis orientations, such as directions of cellulosic microfibrils oriented differently in various layers of wood fibres. In particular, a novel solution is found to relate the emerging light intensity from an intact wood fibre to the incident light intensity, the wavelength of the light, and the relative phase retardations of various layers and orientations of their cellulosic microfibrils, such as fibril angle, in a circular polarized light system. This new method evaluates the transmitted light intensities of multiple predetermined wavelengths simultaneously to determine the optical and physical properties of a multi-layered specimen being measured. A device for determining the relative phase retardation (retardance) of fibre walls and the fibril angle of intact wood fibres in accordance with the presented invention comprises a light source with well defined multi-wavelengths, an achromatic circular polarized light system, appropriate imaging optics, a multi-channel camera such as a digital color camera that has two or more wavelength (color) detection channels, and an image processing and data analysis system. The measurements take advantage of the birefringence of cellulosic microfibrils, and thus require neither sample preparation nor high resolution optics. Specimen alignment is not required as specimens such as wood fibres are evaluated under circular polarized light. Compared with other methods, this invention is more rapid, accurate, and robust. This method can be automated, and implemented in a fibre flow-through system, thus allowing a rapid assessment of wood pulp fibre properties (on-line in real time).

Owner:FPINNOVATIONS INC

Method for controlling quality and condition on the basis of thermal imaging

Owner:METSO AUTOMATION OY

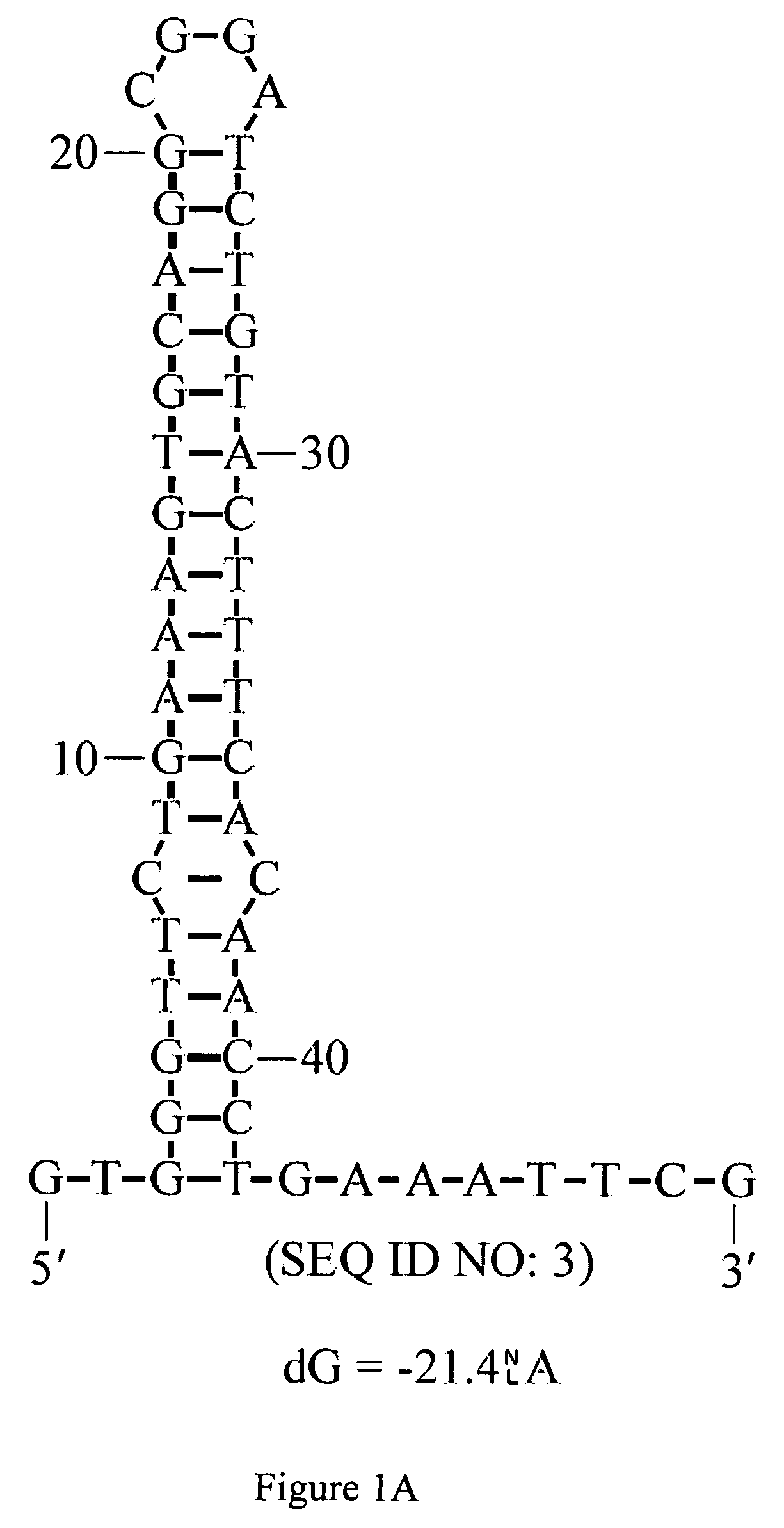

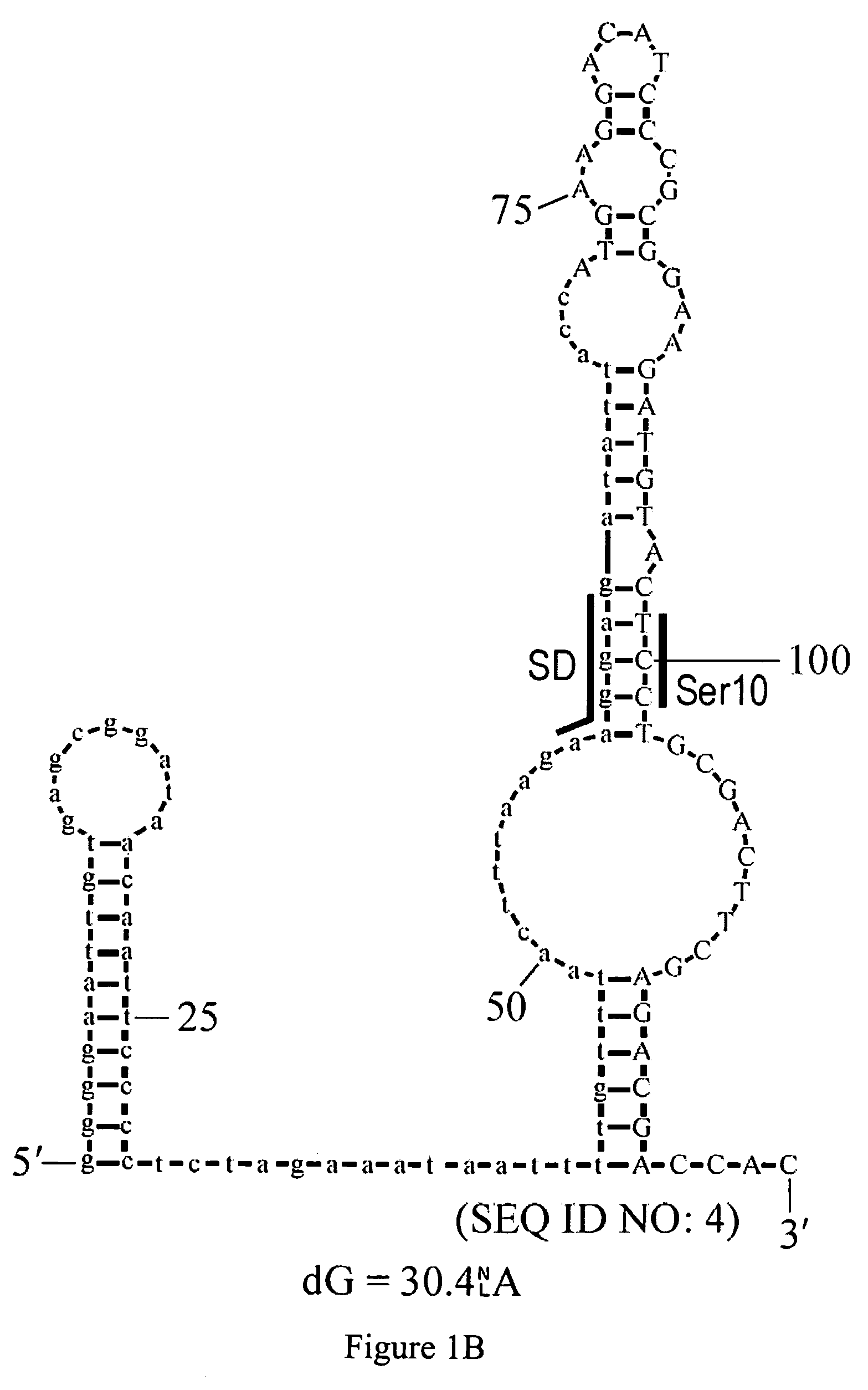

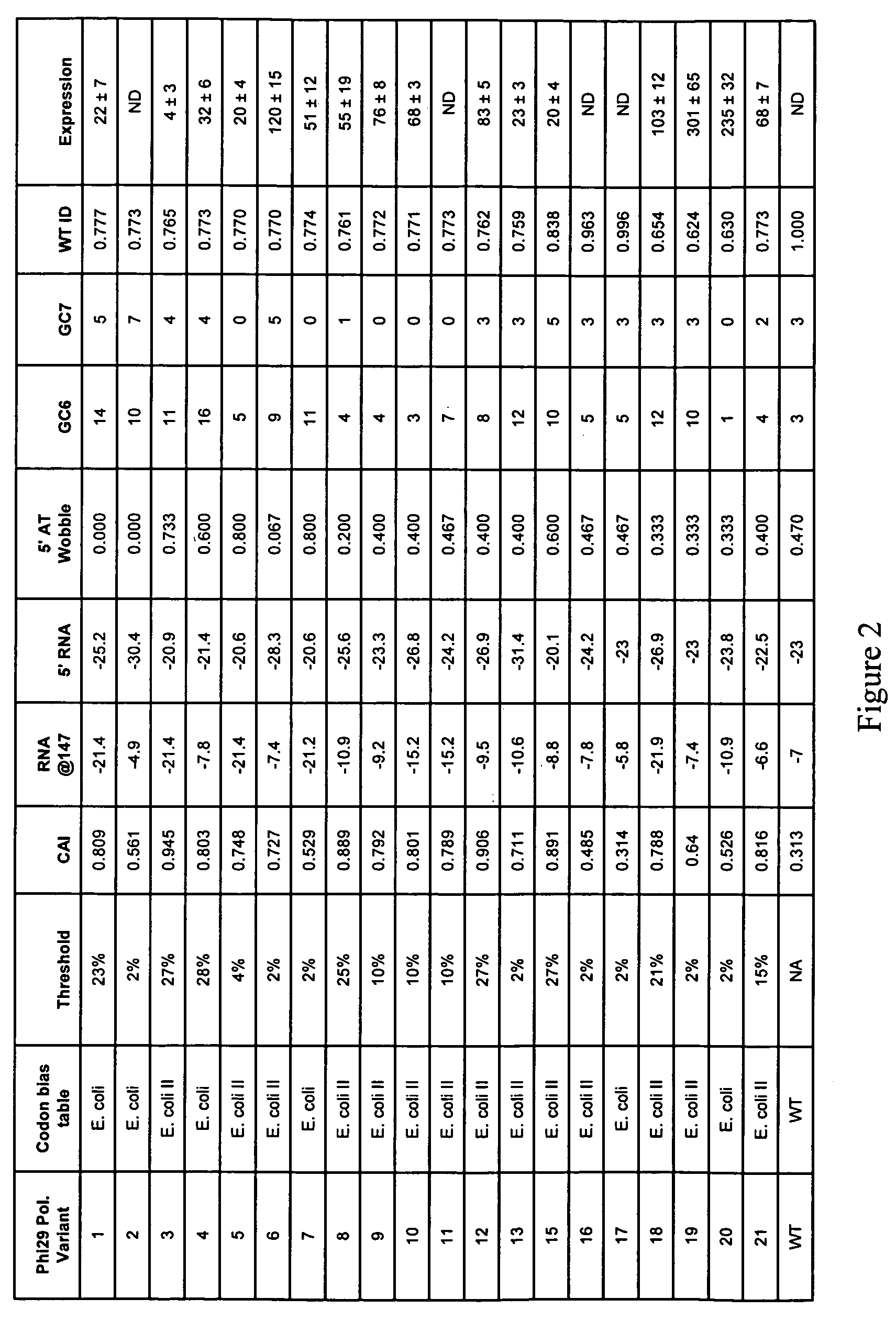

Systems and methods for constructing frequency lookup tables for expression systems

Methods for determining a property that affects expression of polynucleotides are provided. A plurality of polynucleotides each encoding a polypeptide sequence is constructed. A frequency that a sequence element is used in a first polynucleotide is different than in a second polynucleotide. Each polynucleotide is expressed in an expression system to obtain an expression property value thereby constructing a dataset that contains, for each respective polynucleotide, sequence element occurrence in the respective polynucleotide and the measured expression property value of the respective polynucleotide. A model is computed that describes variation in the measured expression property values as a function of a plurality of variables and weights. From the model, a property that affects expression of polynucleotides in the expression system is determined, where the property is an effect that the frequency of occurrence of one or more sequence elements has on the expression property of polynucleotides in the expression system.

Owner:DNA TWOPOINTO

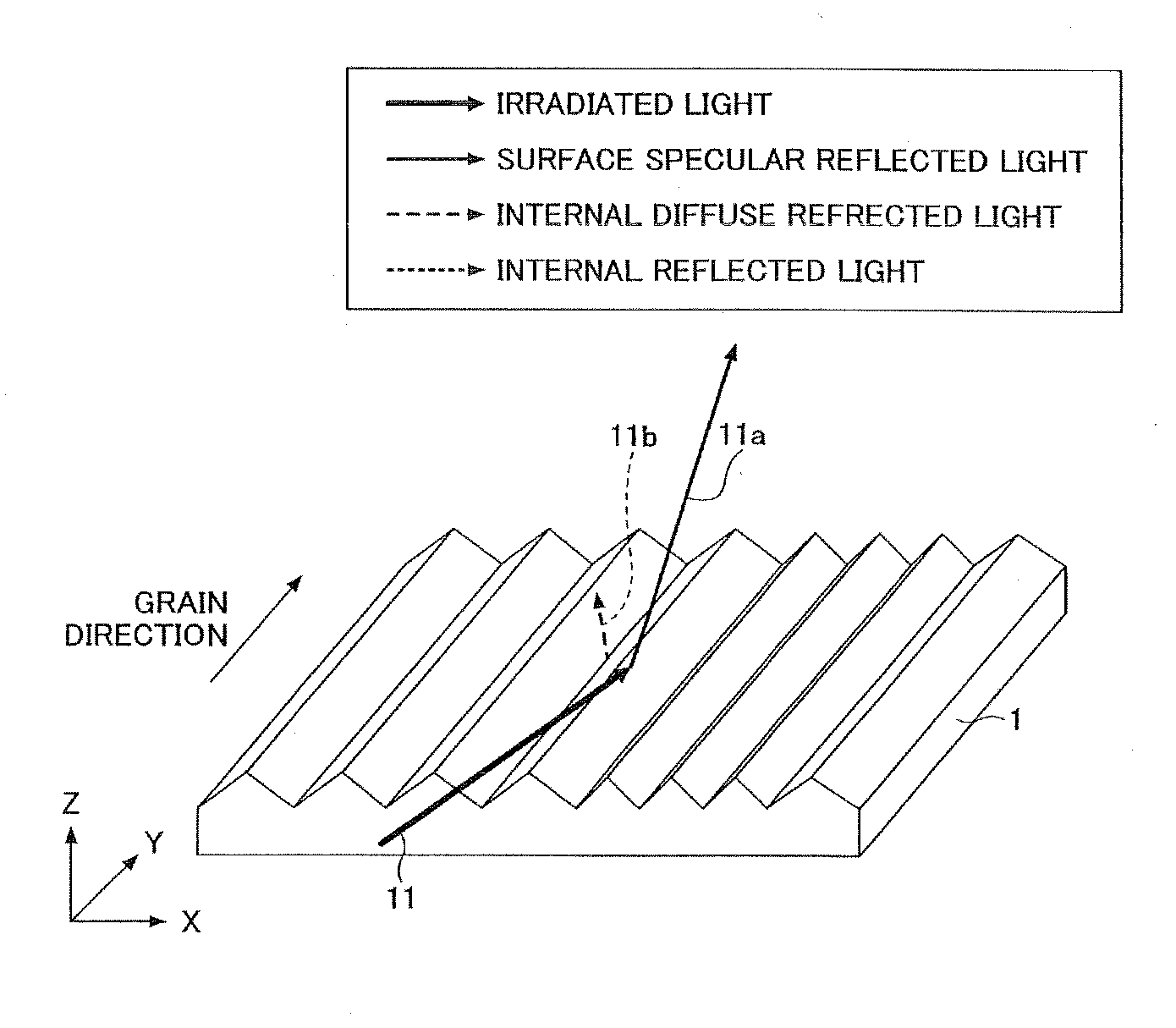

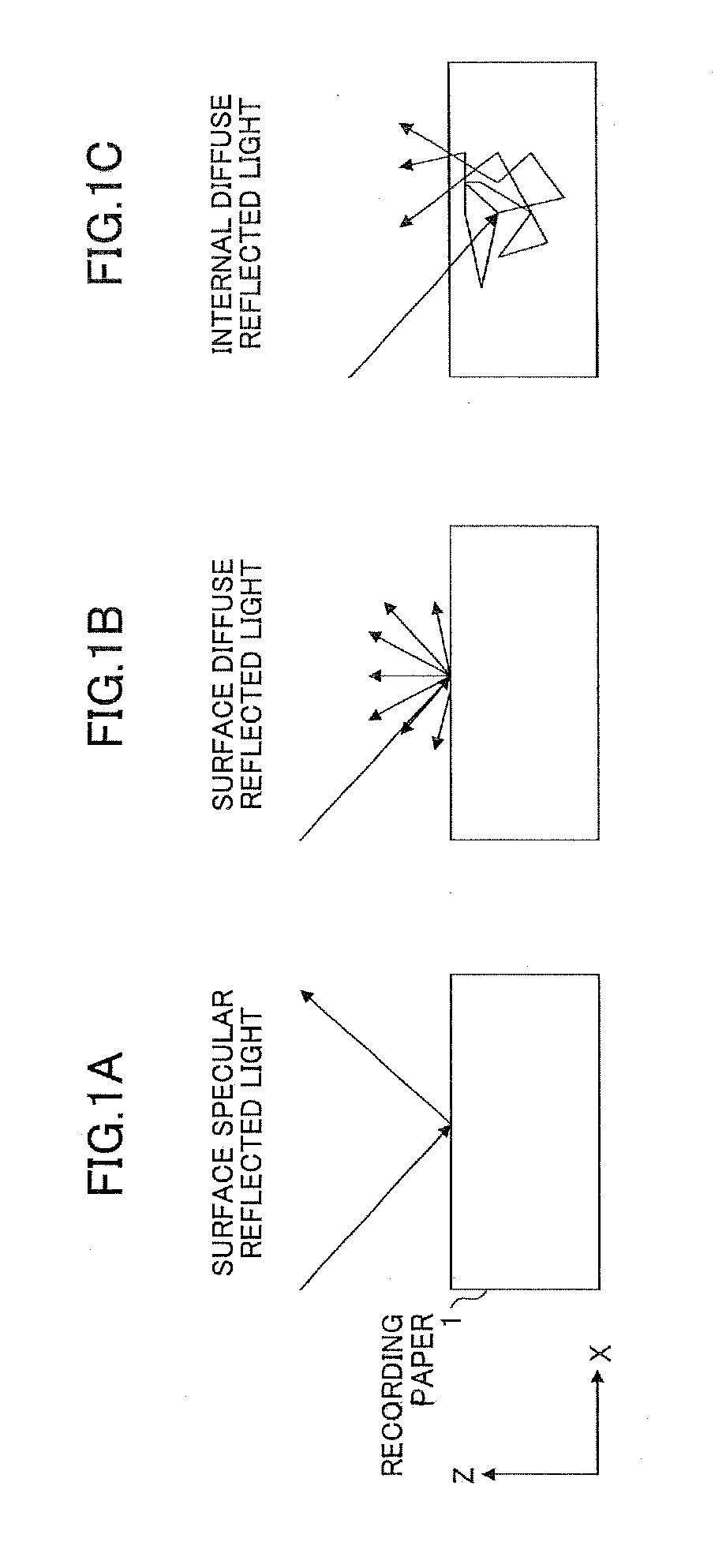

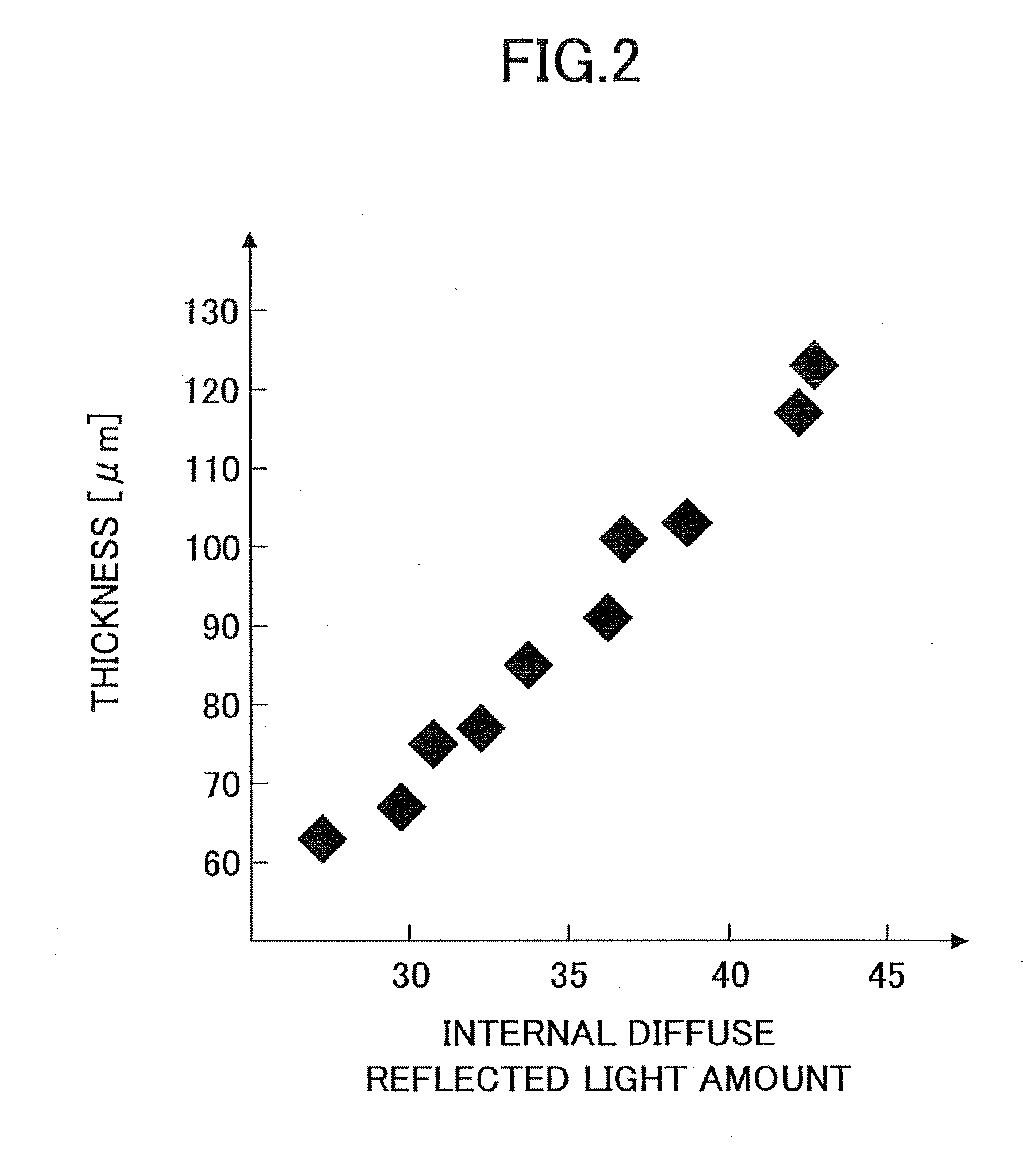

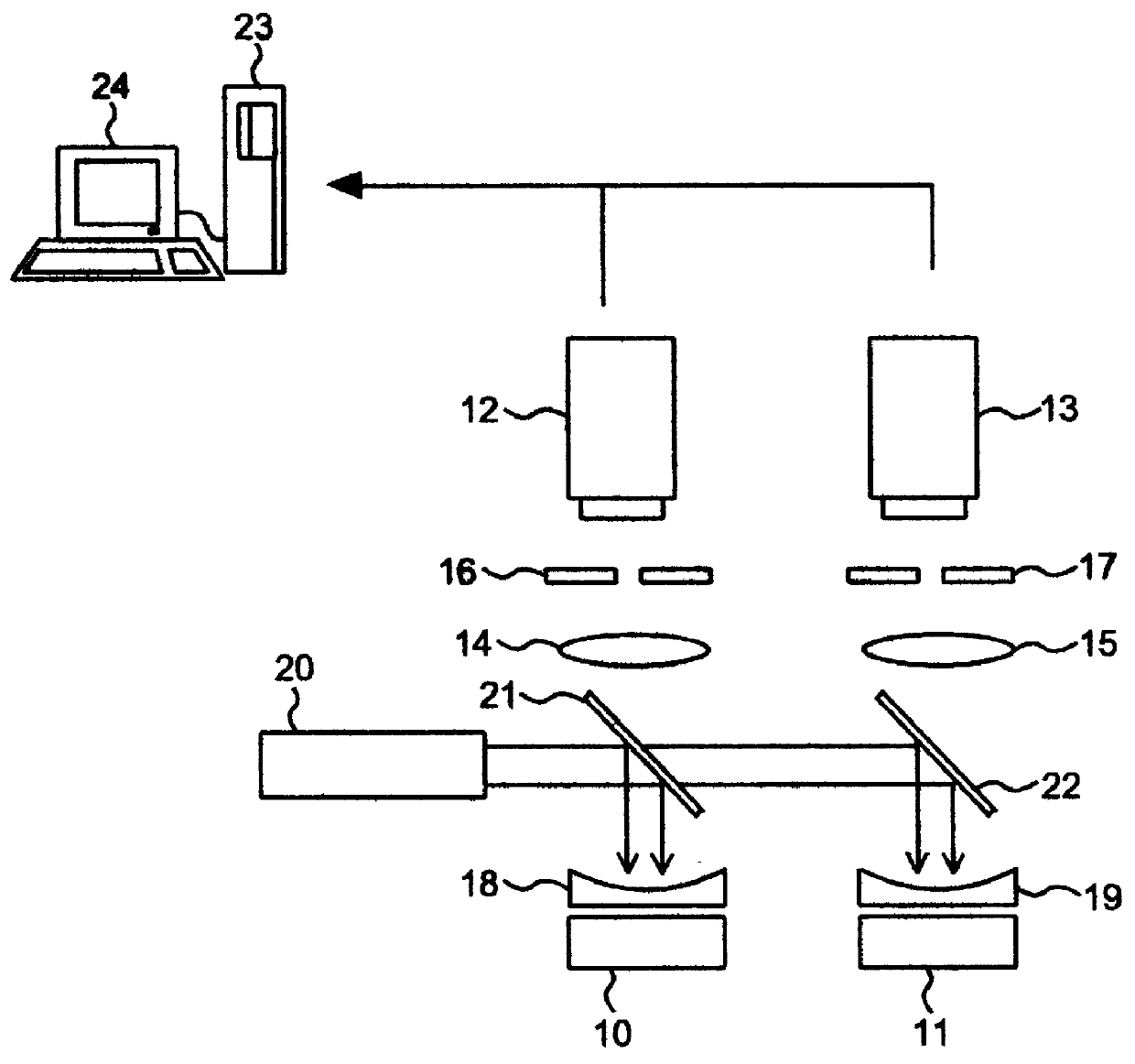

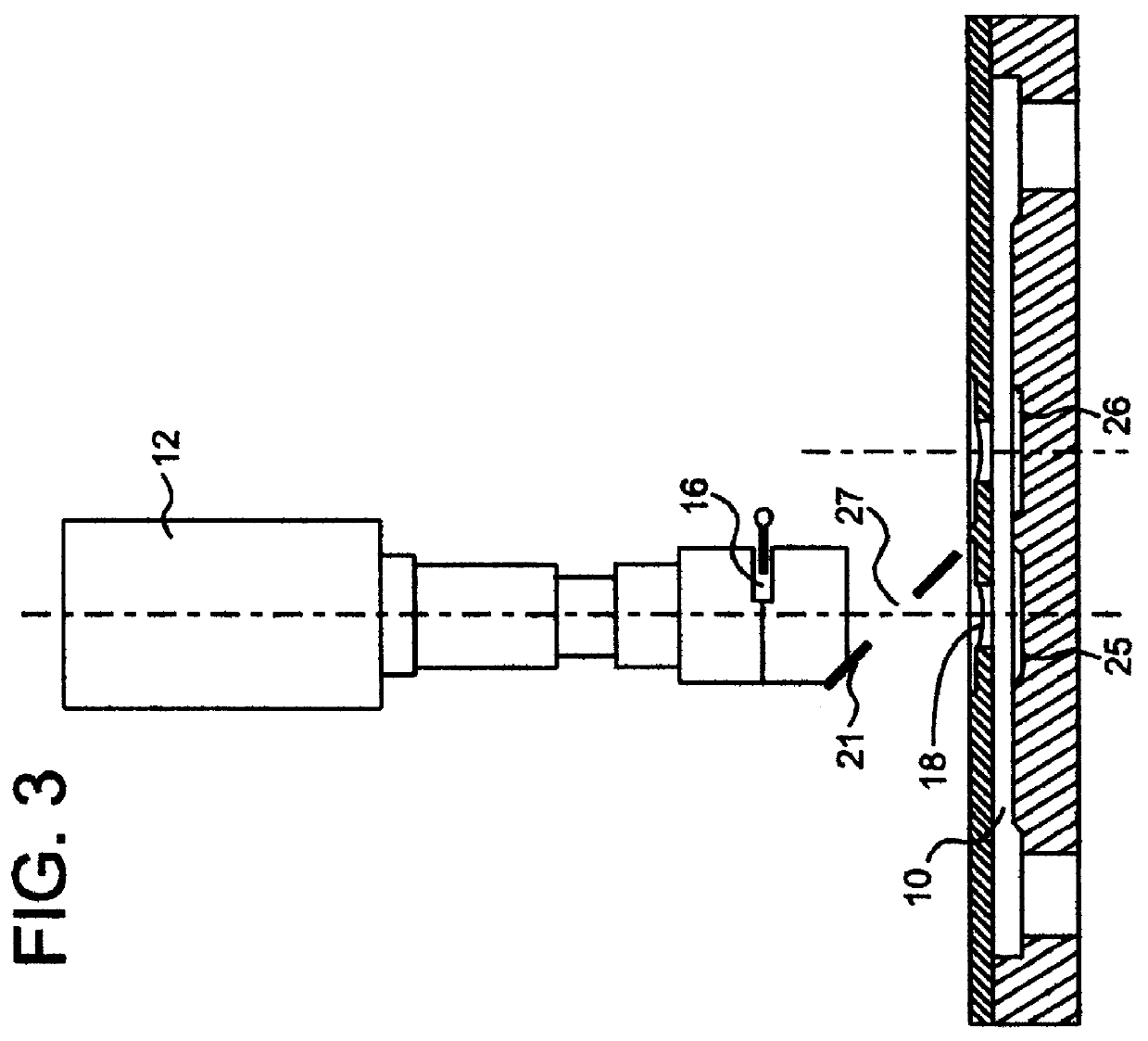

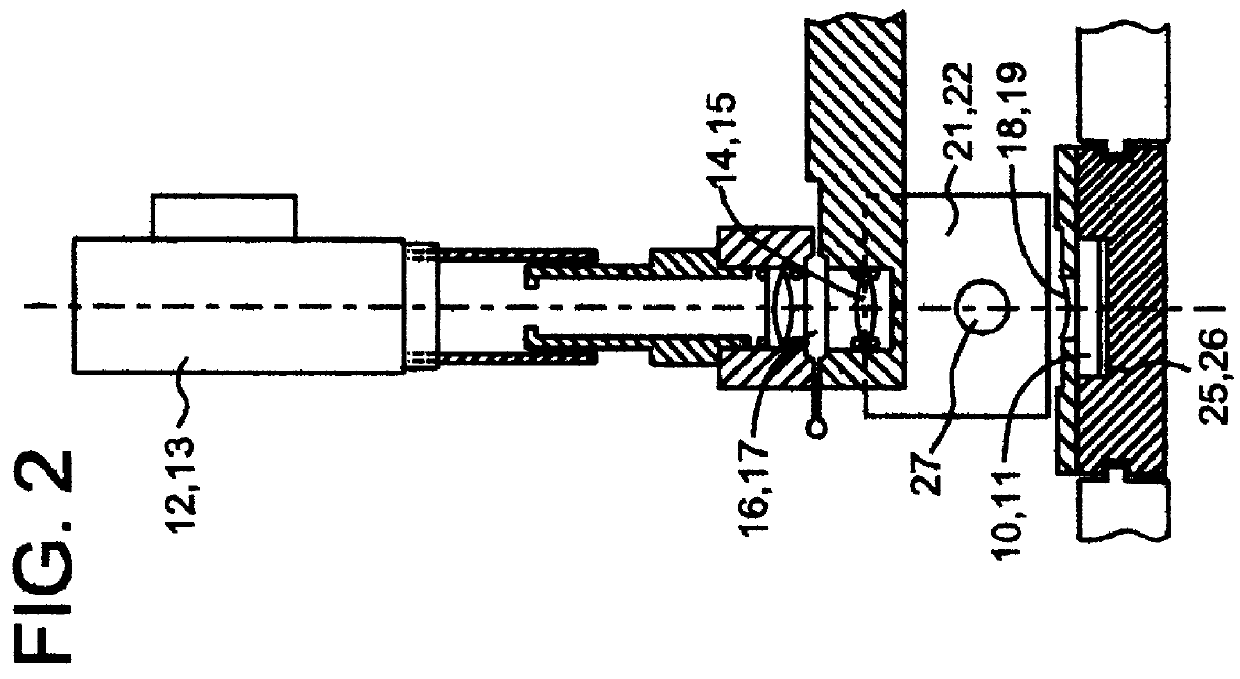

Optical sensor and image forming apparatus

ActiveUS20130194573A1Polarisation-affecting propertiesScattering properties measurementsImage formationSpecular reflection

In an optical sensor, a light emission system emits an irradiated light of a linear polarization in a first polarization direction toward a surface of a target object having a sheet shape from an incident direction which is inclined with respect to a normal direction of the surface. A first light detection system includes a first light detector arranged on a first light path of a specular reflected light, which is emitted from the light emission system and is specularly reflected from the target object. A second light detection system includes a second light detector arranged on a second light path of a diffuse reflected light which is diffusely reflected from an incident plane on the target object. The second light detector receives second light passed by an optical element which passes a linear polarization component of a second polarization direction perpendicular to the first polarization direction.

Owner:RICOH KK

Process for regulating a paper pulp deinking line and device for continuously measuring the quantity of particles contained in a liquid

InactiveUS6010593AParticle size analysisIndividual particle analysisContinuous measurementEngineering

A process and device for continuously measuring the quantity of particles suspended in a liquid, which exist in at least two different physical states, such as detached or attached within the paper pulp. A separation assembly separates the particles into divisions depending on their size, and the separation assembly is continuously fed with liquid via an input pipe. A measuring and processing assembly has two channels or ducts coming from the separation assembly and are provided with translucent windows. A measurement and capture unit illuminates the windows, and at least two cameras located opposite each of the respective windows are synchronized with the illumination unit to capture, at regular intervals, an image of the windows. A system for digitizing the captured images and processing them to determine the quantity of particles for each physical states is forwarded to an output unit in a digital or analog form.

Owner:CENT TECHN IND DIT CENT TECHN

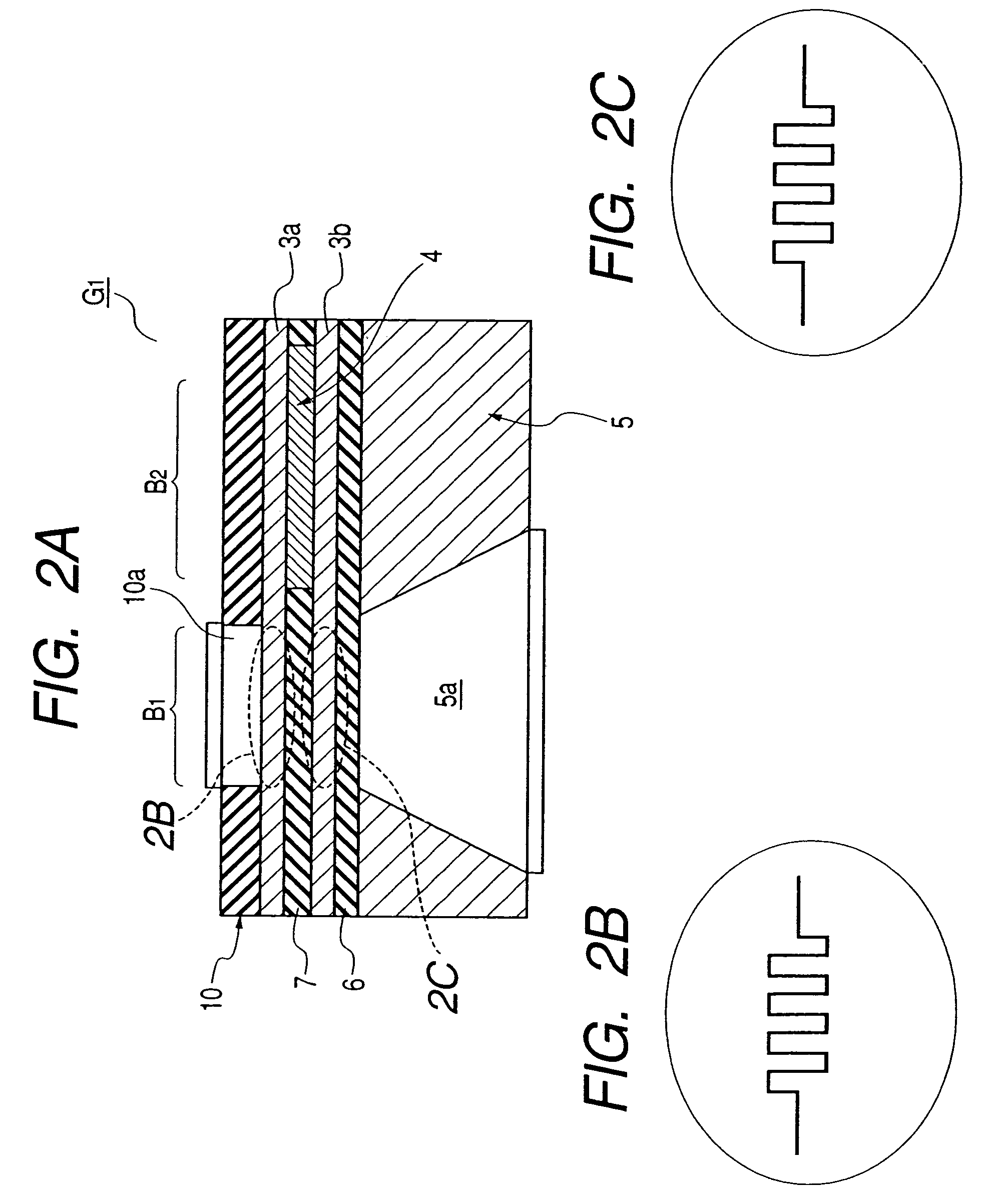

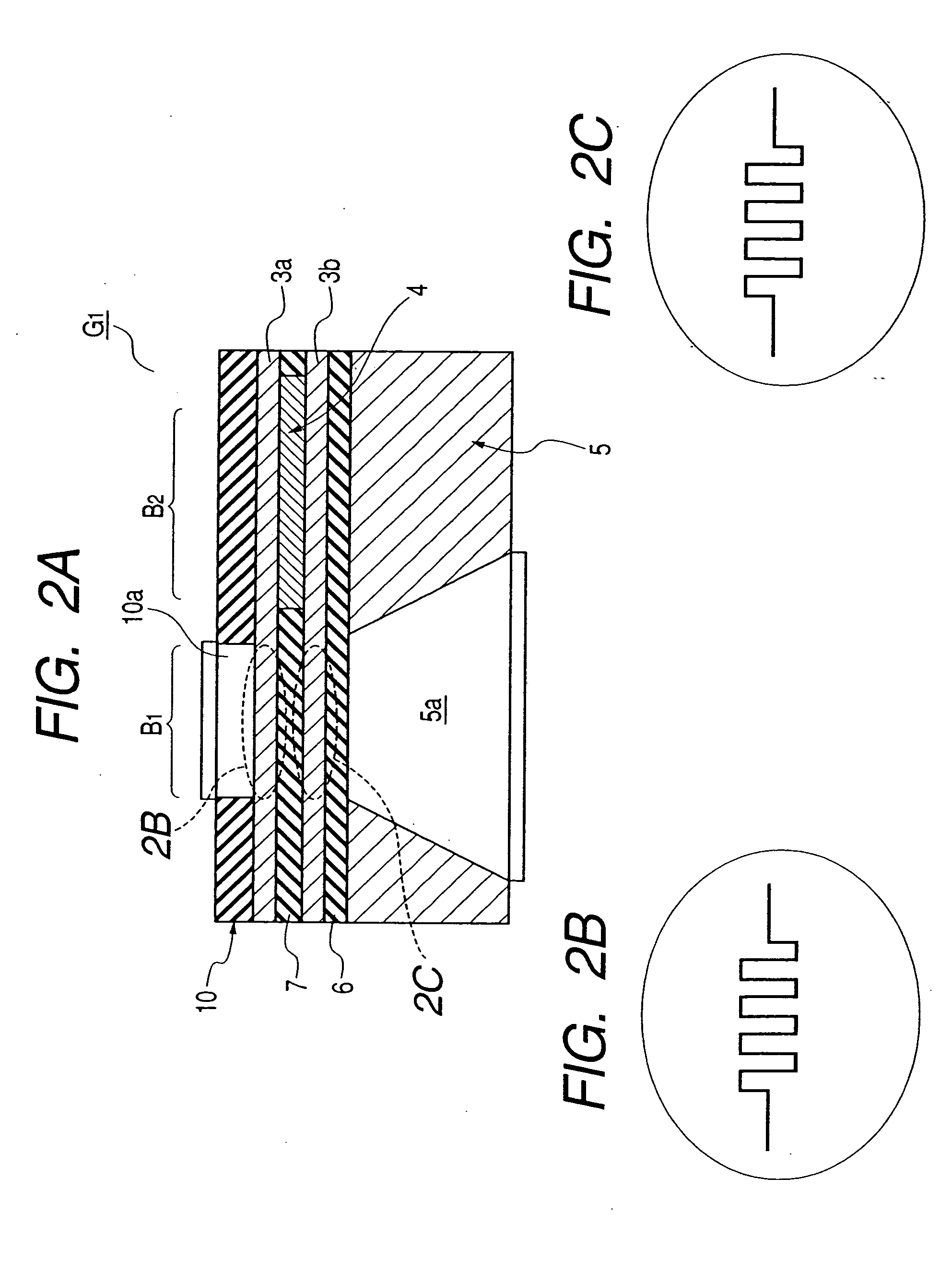

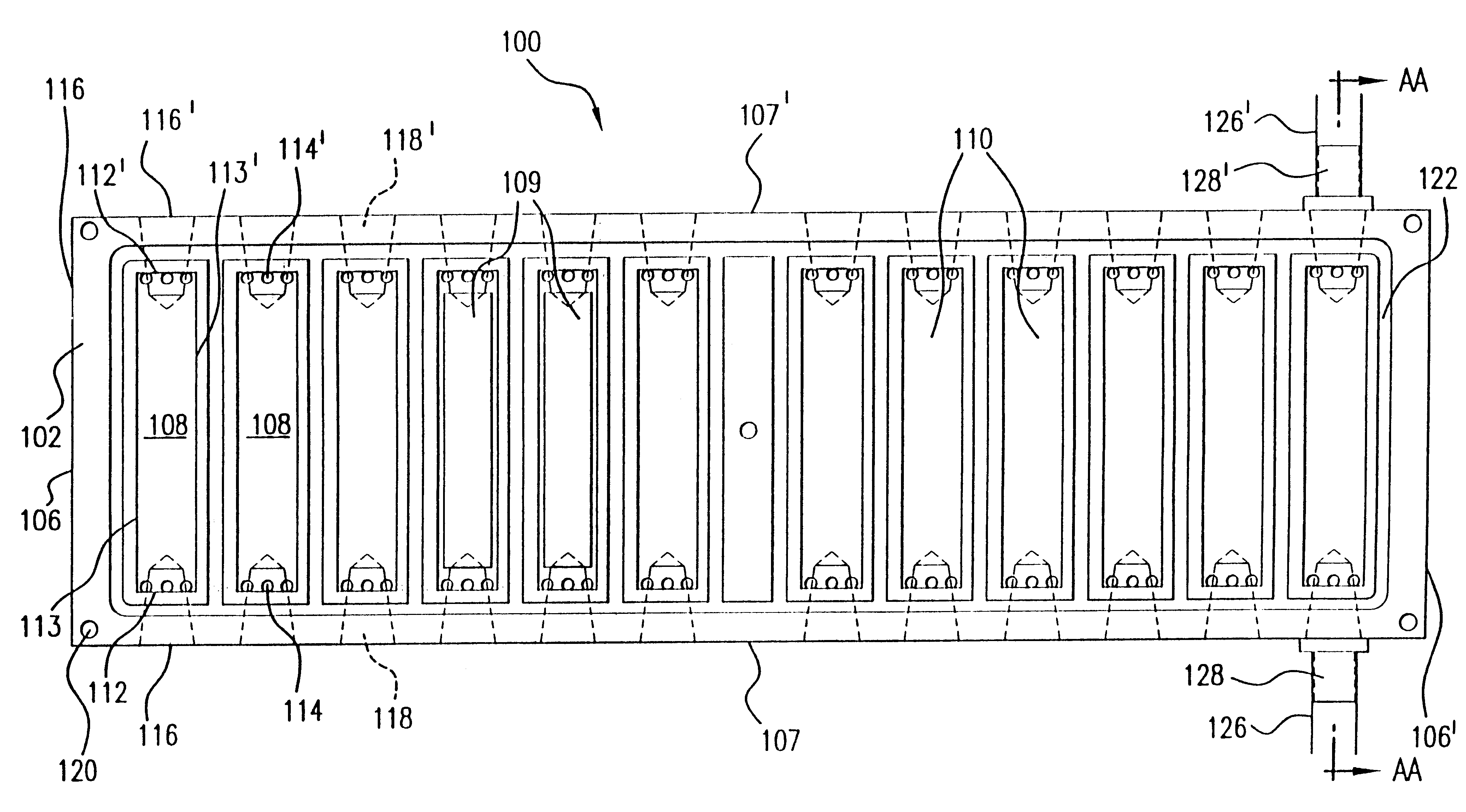

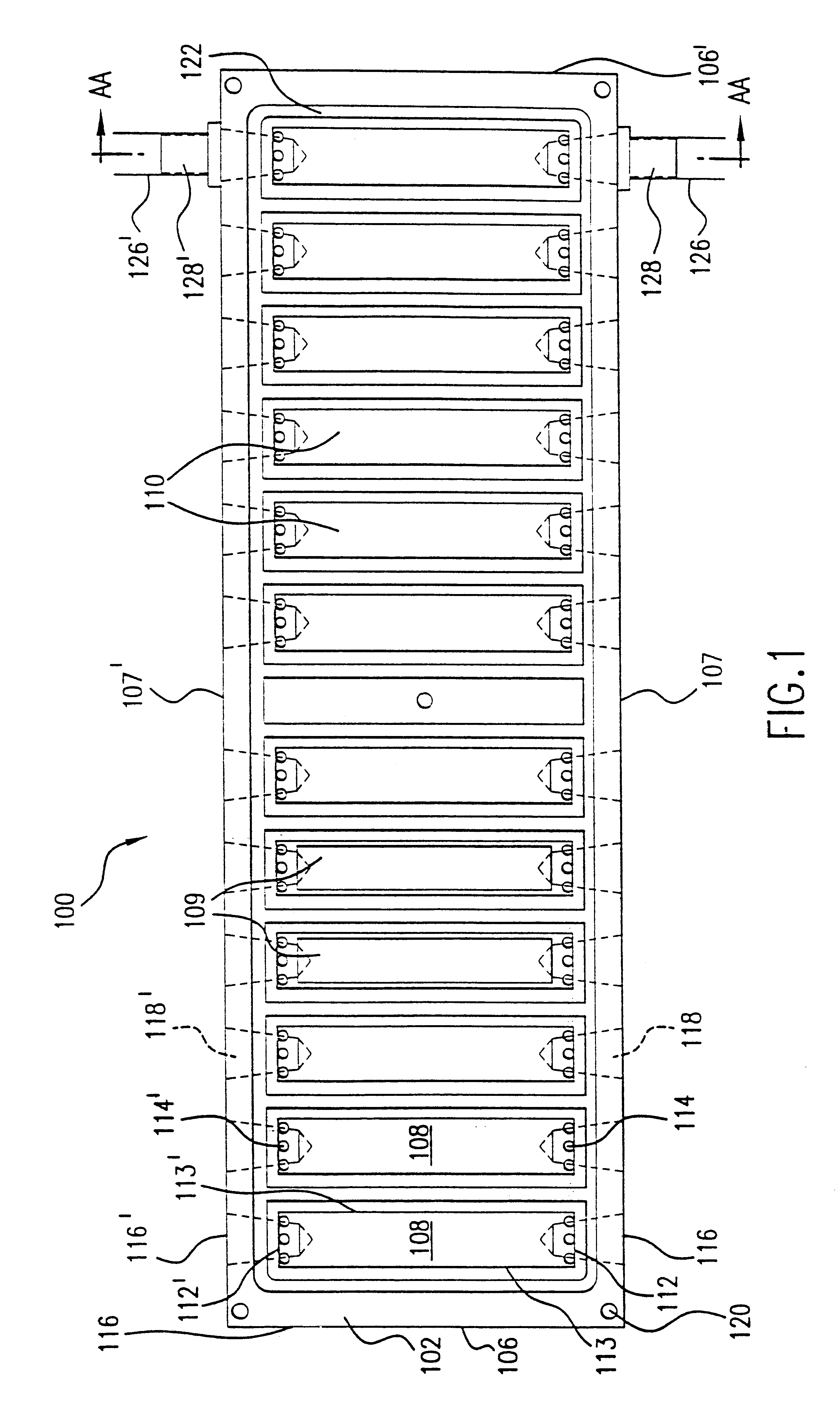

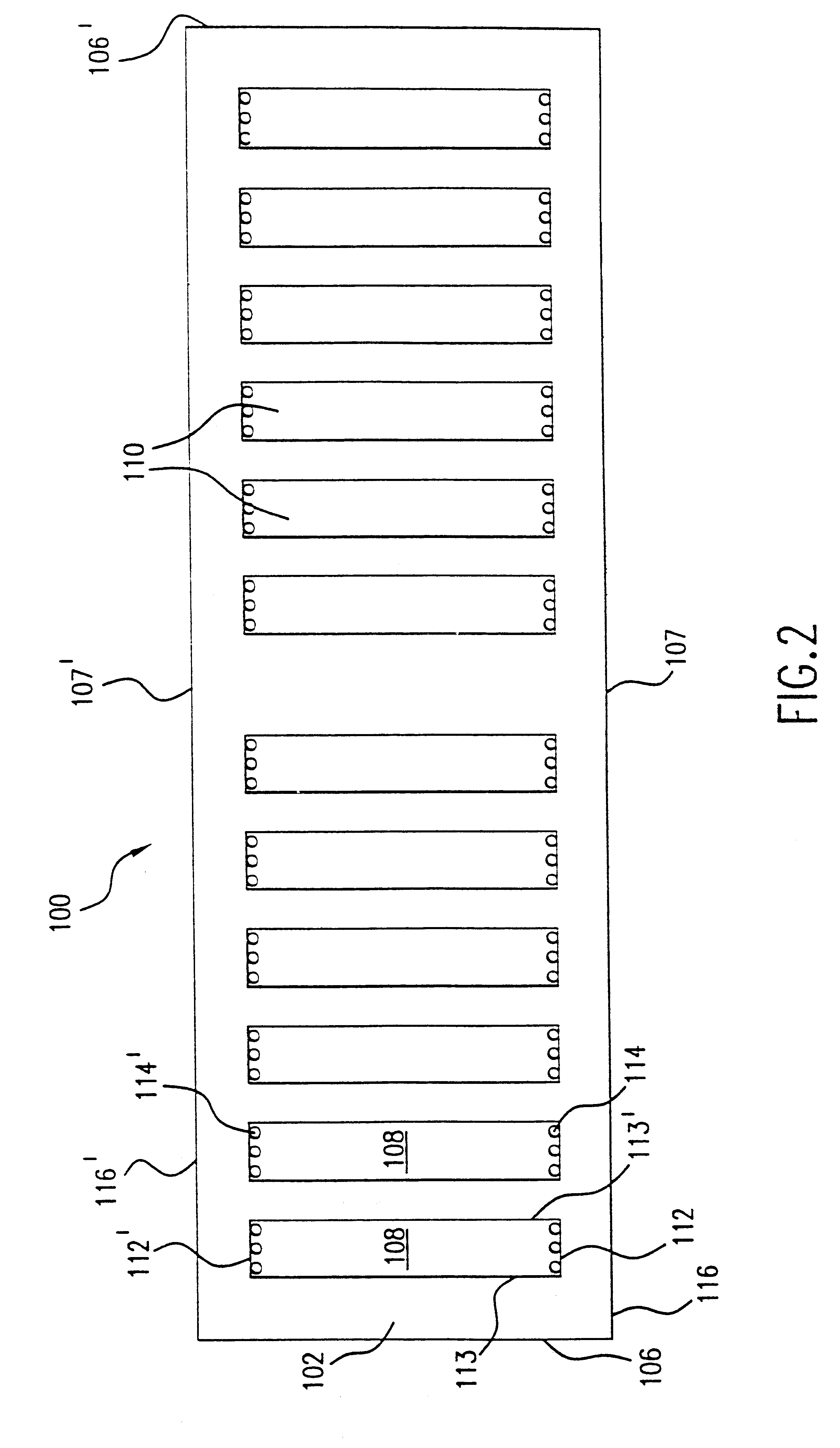

Device for identifying types of sheet materials

InactiveUS7239817B2Accurate detectionRadiation pyrometryMaterial analysis by optical meansMoistureBiomedical engineering

A device for identifying types of sheet materials has a detecting unit for detecting information regarding moisture of a sheet material; external force applicator for applying an external force to the sheet material; information obtaining unit for obtaining information according to a force that is attenuated by the presence of the sheet material when the external force is applied to the sheet material by the external force applicator; and a judging unit for identifying the type of the sheet material based on the information obtained from the detecting unit and the information obtained from the information obtaining unit.

Owner:CANON KK

Device for identifying types of sheet materials

InactiveUS20060016996A1Accurate detectionRadiation pyrometryMaterial analysis by optical meansIdentification deviceMoisture

A device for identifying types of sheet materials comprises: a detecting unit for detecting information regarding moisture of a sheet material; external force applying means for applying an external force to the sheet material; information obtaining means for obtaining information according to a force that is attenuated by the presence of the sheet material when the external force is applied to the sheet material by the external force applying means; and a judging unit for identifying the type of the sheet material based on the information obtained from the detecting unit and the information obtained from the information obtaining means. According to the device, the type of a sheet material can be detected even when the sheet material is not marked in advance with number code or other information, and the water content of the sheet material can be detected as well.

Owner:CANON KK

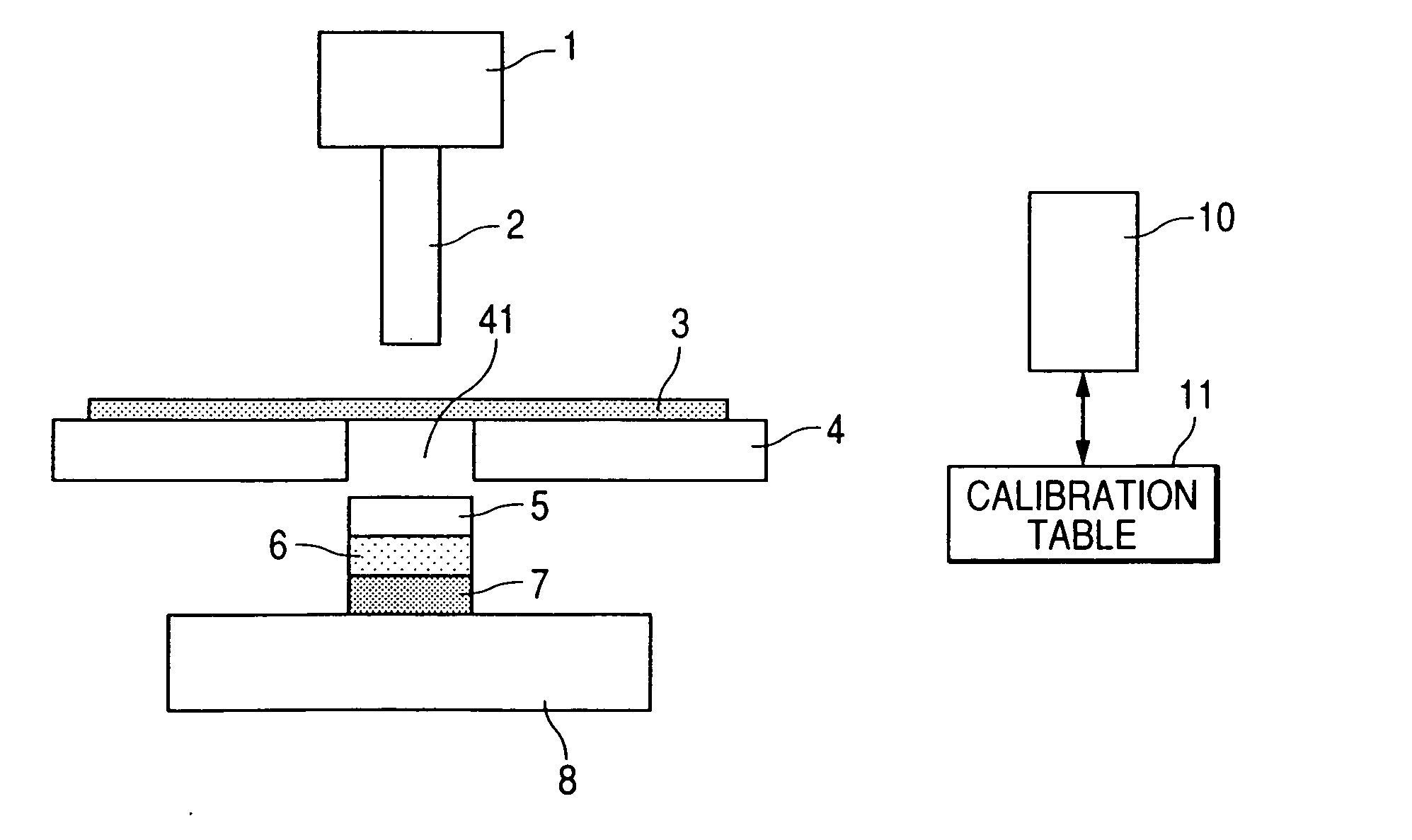

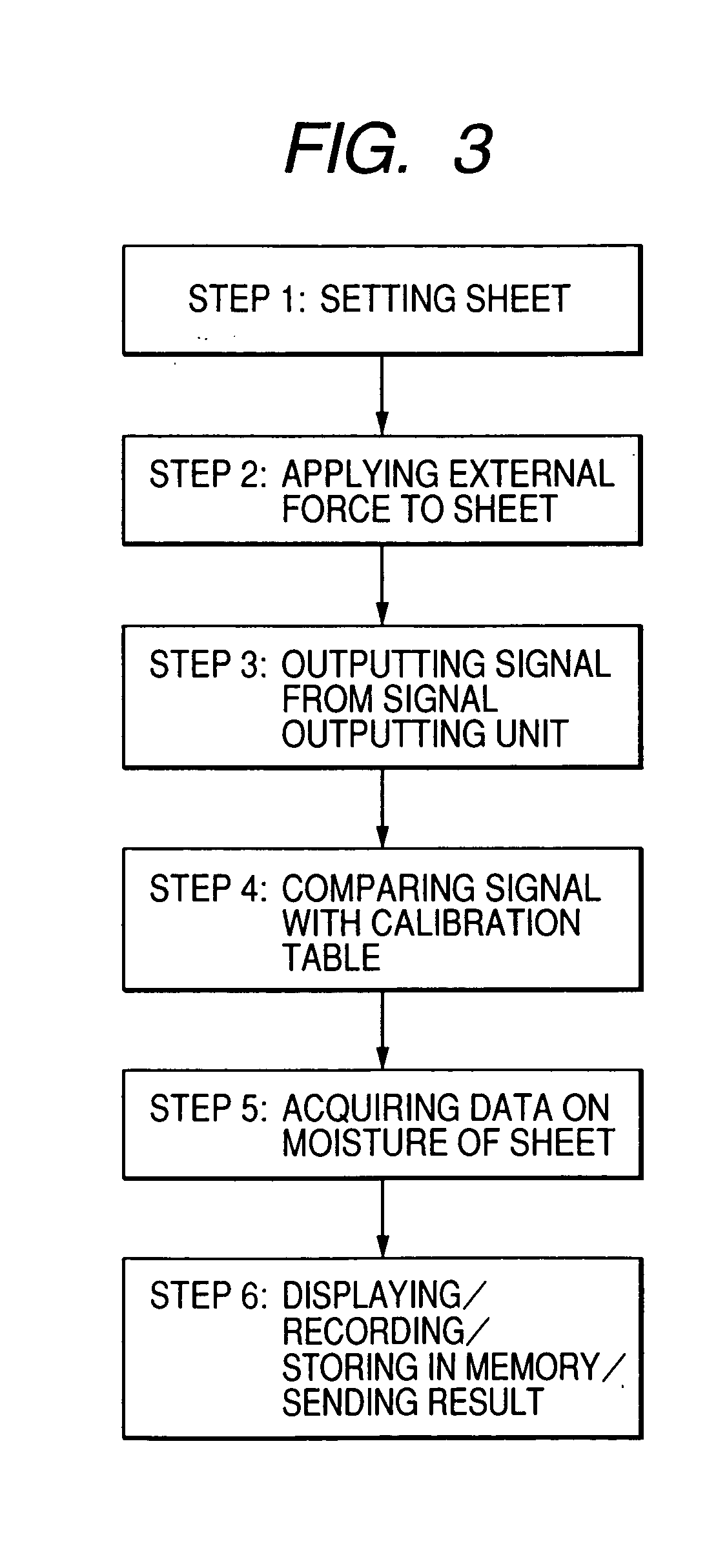

Moisture data-acquiring device and image-forming apparatus

InactiveUS20050271403A1Variation in sensitivityFlow propertiesMachines/enginesEngineeringMechanical property

A moisture data-acquiring device for acquiring data on moisture contained in a sheet comprises a force-applying unit for applying an external force to the sheet, a force-receiving unit for receiving the external force through the sheet, a signal outputting unit for outputting a signal reflecting a mechanical property of the sheet which unit is placed on at least one of the force-applying unit and the force-receiving unit, and a moisture data-acquiring unit for acquiring data on moisture of the sheet based on the signal from the signal outputting unit.

Owner:CANON KK

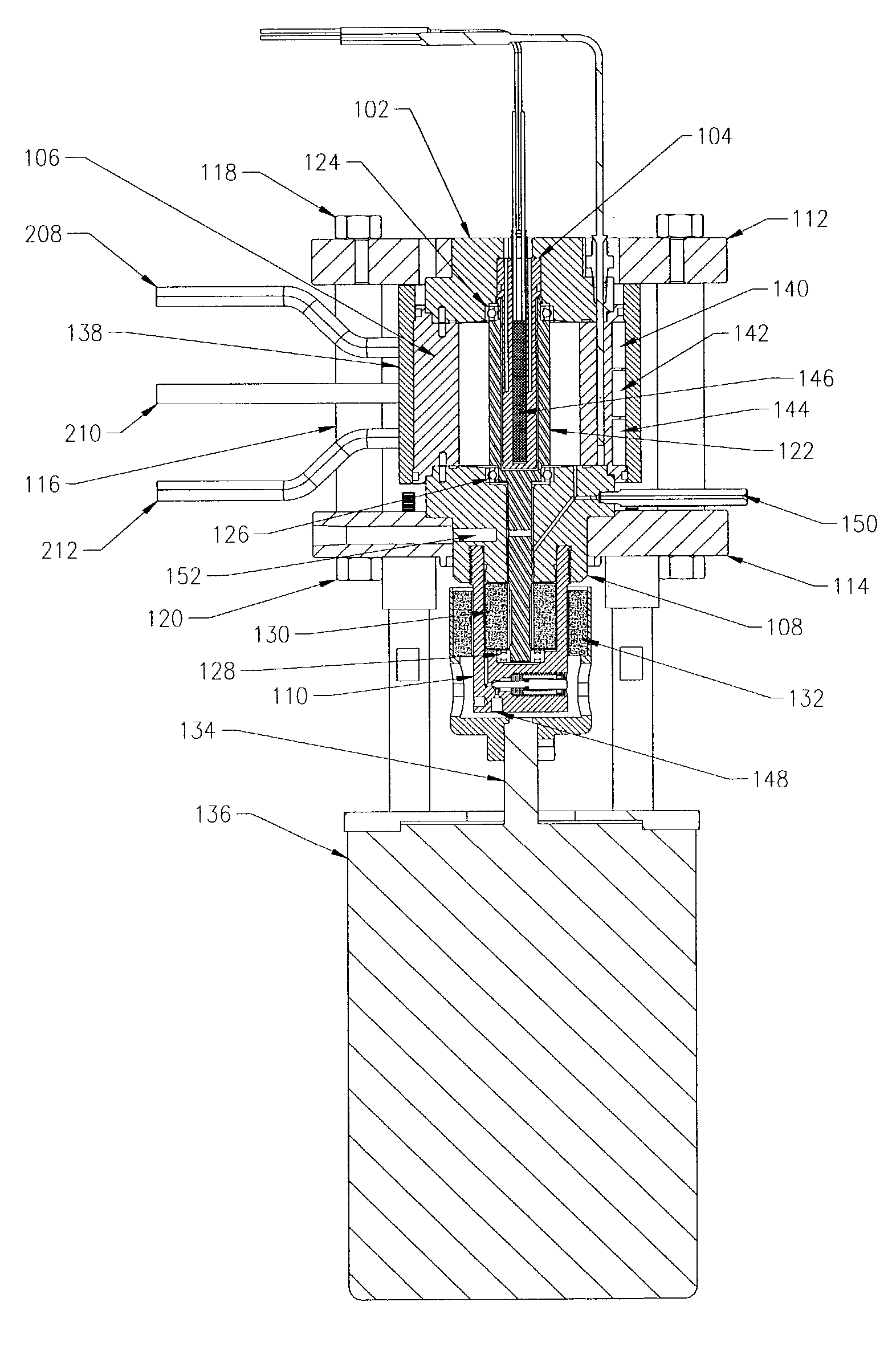

Biofilm growth device

InactiveUS6361963B1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismBiofilm growth

A method and apparatus for determining the effect of various agents on the growth of biological material (biofilm), microbially-influenced corrosion and the deposition of organic and inorganic contaminants is disclosed. The method and apparatus allow for the modeling of the growth of biological contaminants and the deposition of organic and inorganic materials on industrial equipment surfaces, such as those used in the pulp and papermaking industry. The device consists of a tray which includes recessed areas for receiving coupons, as well as fluid inlets and fluid outlets for permitting the flow of liquid samples over the coupons. The design and configuration of the apparatus provides a great deal of versatility in testing various biocidal and other agents under select environmental conditions.

Owner:HERCULES INC

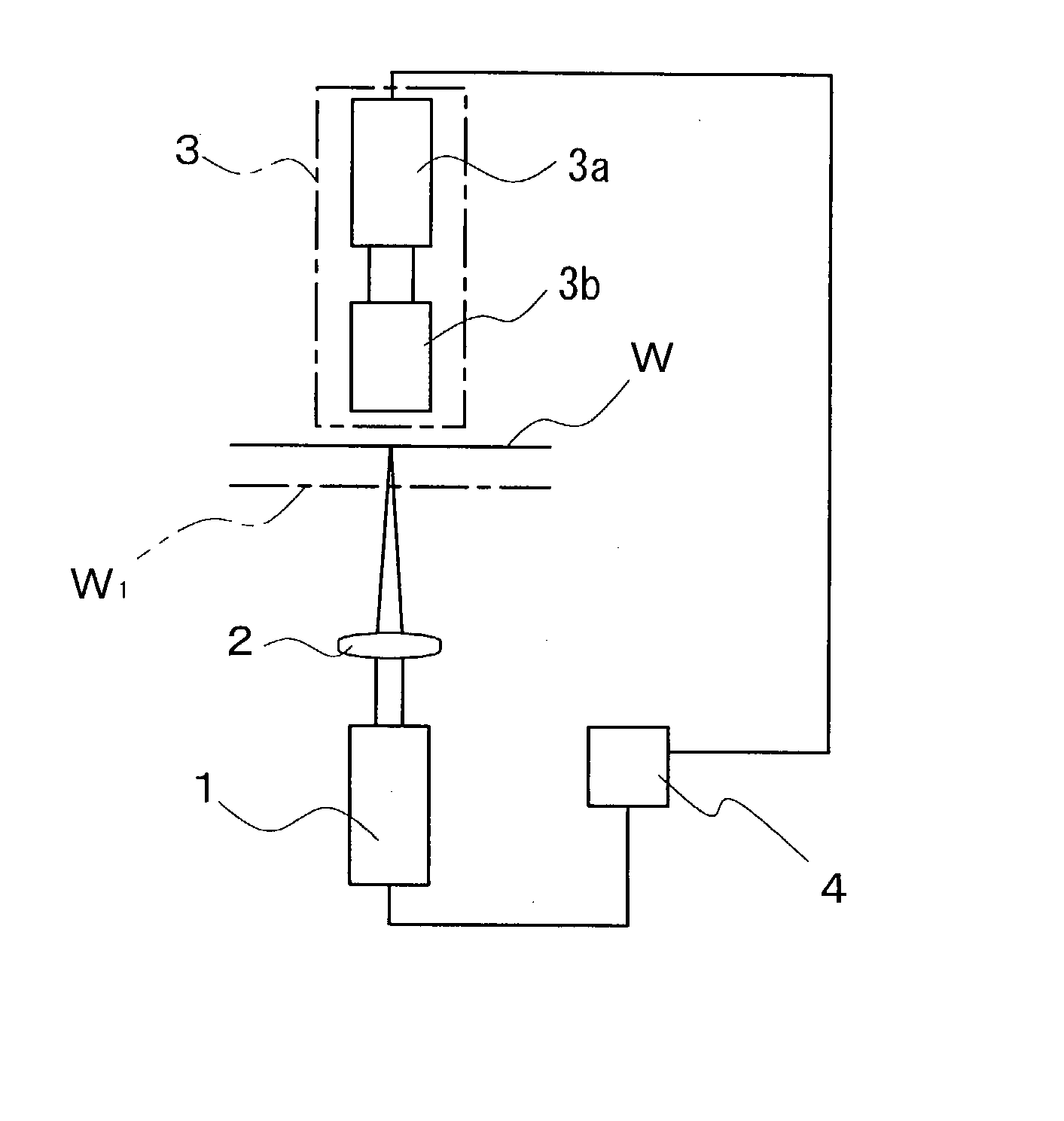

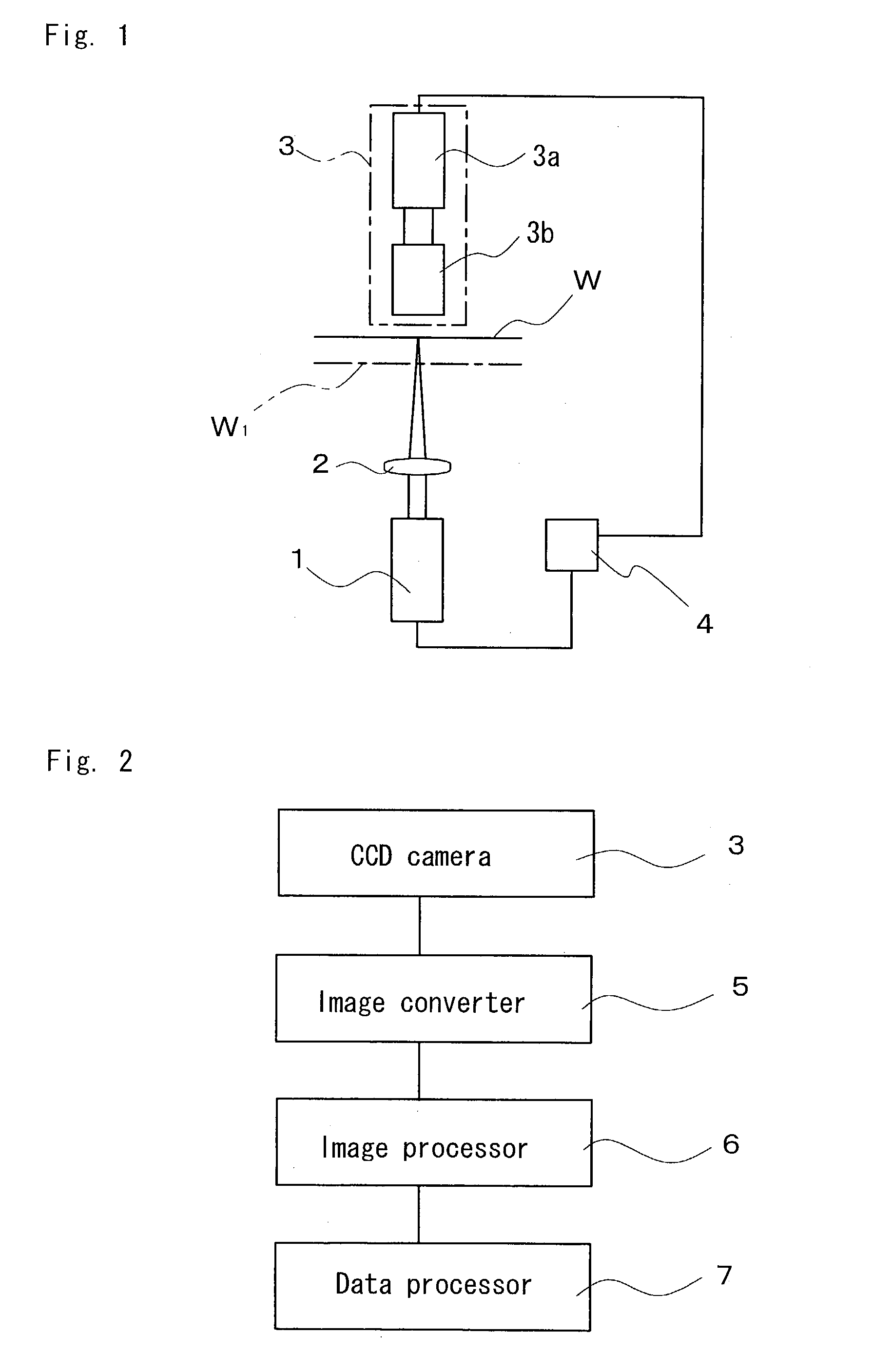

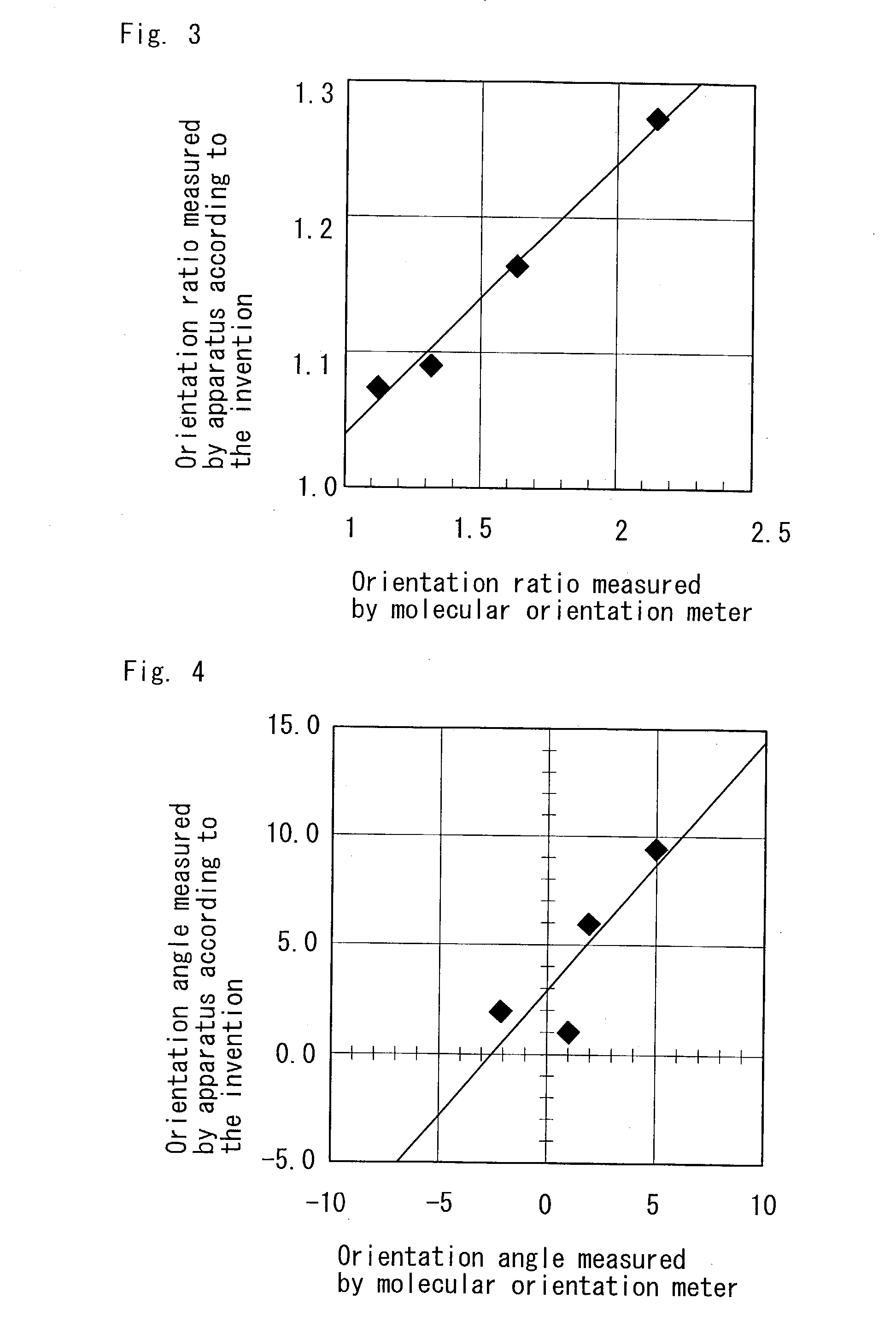

Method for measuring orientation of paper fibers and apparatus for measuring orientation of paper fibers

InactiveUS20030156293A1Big distanceReliable measurementPolarisation-affecting propertiesScattering properties measurementsDepth of fieldEngineering

The present invention aims to provide method and apparatus to measure paper fiber orientation adapted to measure fiber orientation in this paper from an image to be measured formed by light beam transmitted through paper on the paper side opposite to the incident side thereof improved so that the fiber orientation in this paper being running through a paper making machine can be reliably on-line measured. Paper web (W) is irradiated practically at a right angle thereto with light beam emitted from a pulse laser source (1) and unpolarized through a condenser lens (2) and an image to be measured formed on a surface of the paper web (W) opposite to its incident surface is picked up by a CCD camera (3). An image pick-up optical system (3b) of the CCD camera (3) uses an extra depth-of-field lens. The image picked up in this manner is then image processed for elliptic approximation. Then a fiber orientation angle relative to a major axis of the obtained ellipse and a magnitude of fiber orientation based on a difference or a ratio between the major and minor axes of this ellipse are calculated. Pick-up by the CCD camera (3) may be carried out at predetermined periods and with an appropriate pulse width to pick up a target image as if the paper web (W) is in stationary state.

Owner:NIPPON PAPER IND CO LTD

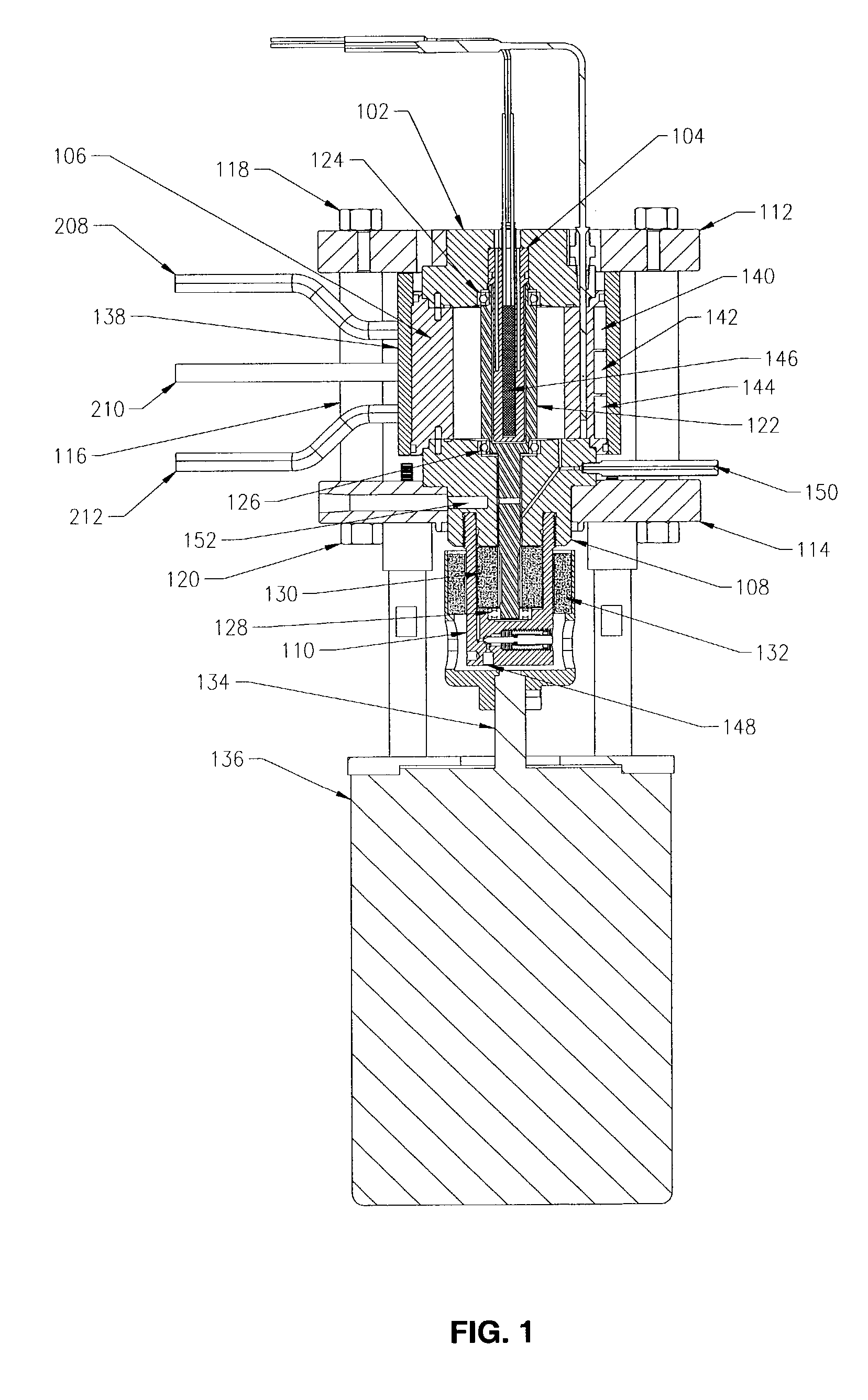

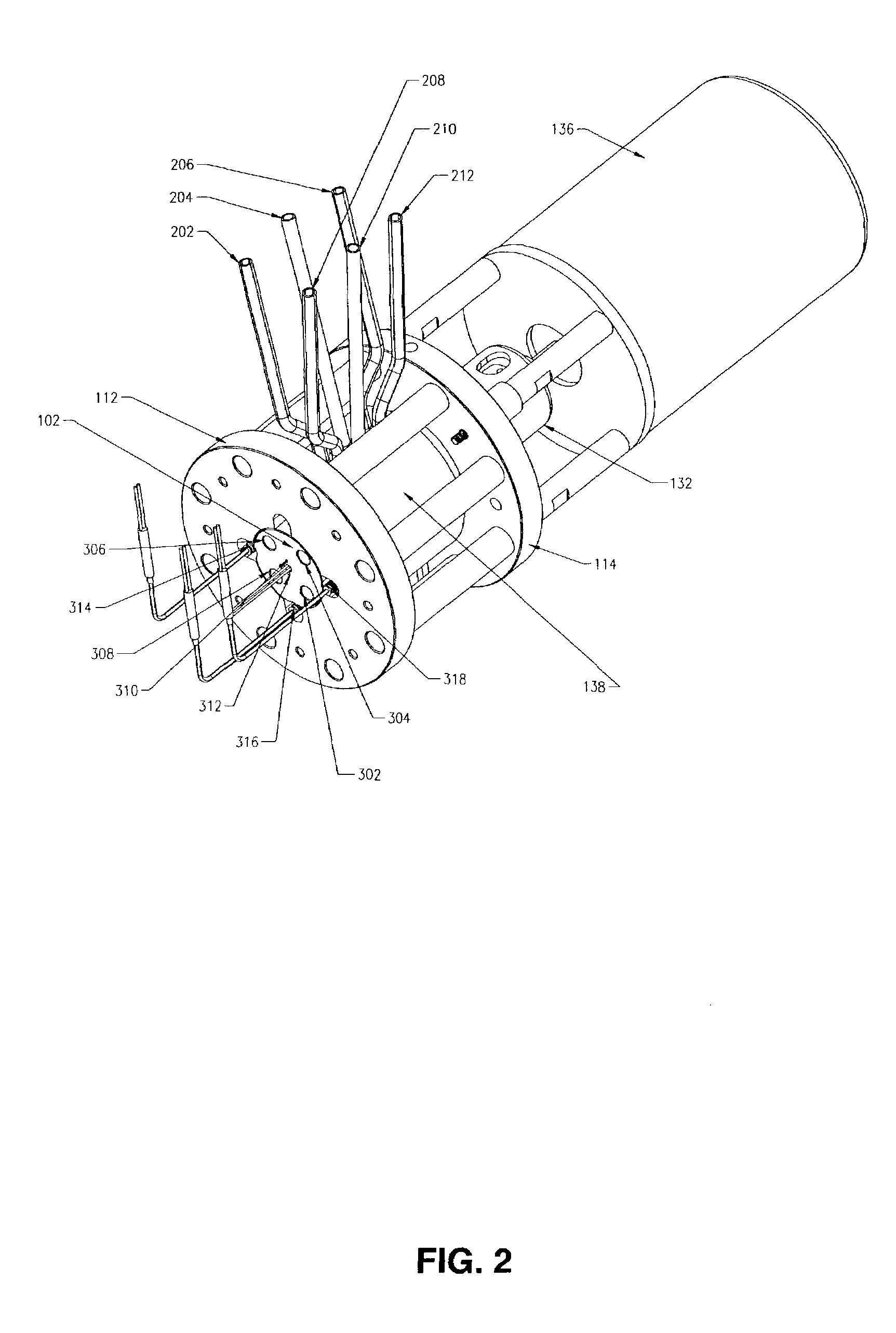

Couette device and method to study solids deposition from flowing fluids

We disclose a method of measuring an emulsion or solids deposition in a fluid sample, comprising charging the sample to a Couette device; subjecting the sample in the Couette device to a pressure, a temperature, and a shear comparable to field conditions; changing at least one of the pressure, temperature, composition, or shear of the sample; and quantifying the type and amount of solids deposited on the interior walls of the Couette device. We also disclose Couette devices which can be used in the method.

Owner:SCHLUMBERGER TECH CORP

Authenticatable bleached chemical paper products

InactiveUS6019872AConvenient verificationEasy to manufactureNon-fibrous pulp additionSpecial paperFiberPapermaking

An authenticable paper product is prepared from a bleached chemical papermaking furnish containing a minor but detectable amount of lignin containing fibers selected from the group consisting of mechanical, thermomechanical, chemi-thermomechanical and bleached-chemi-thermomechanical.

Owner:P H GLATFELTER CO

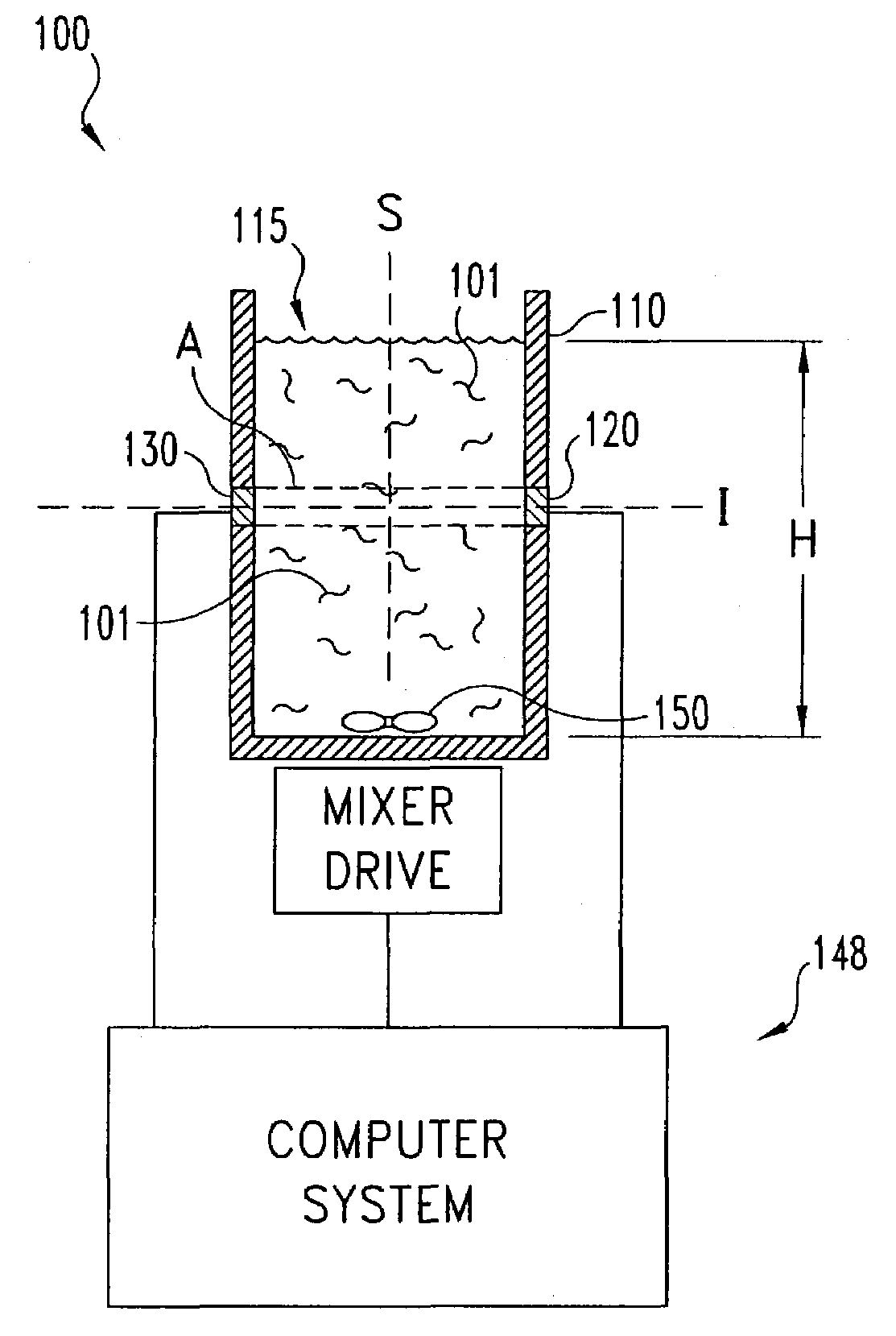

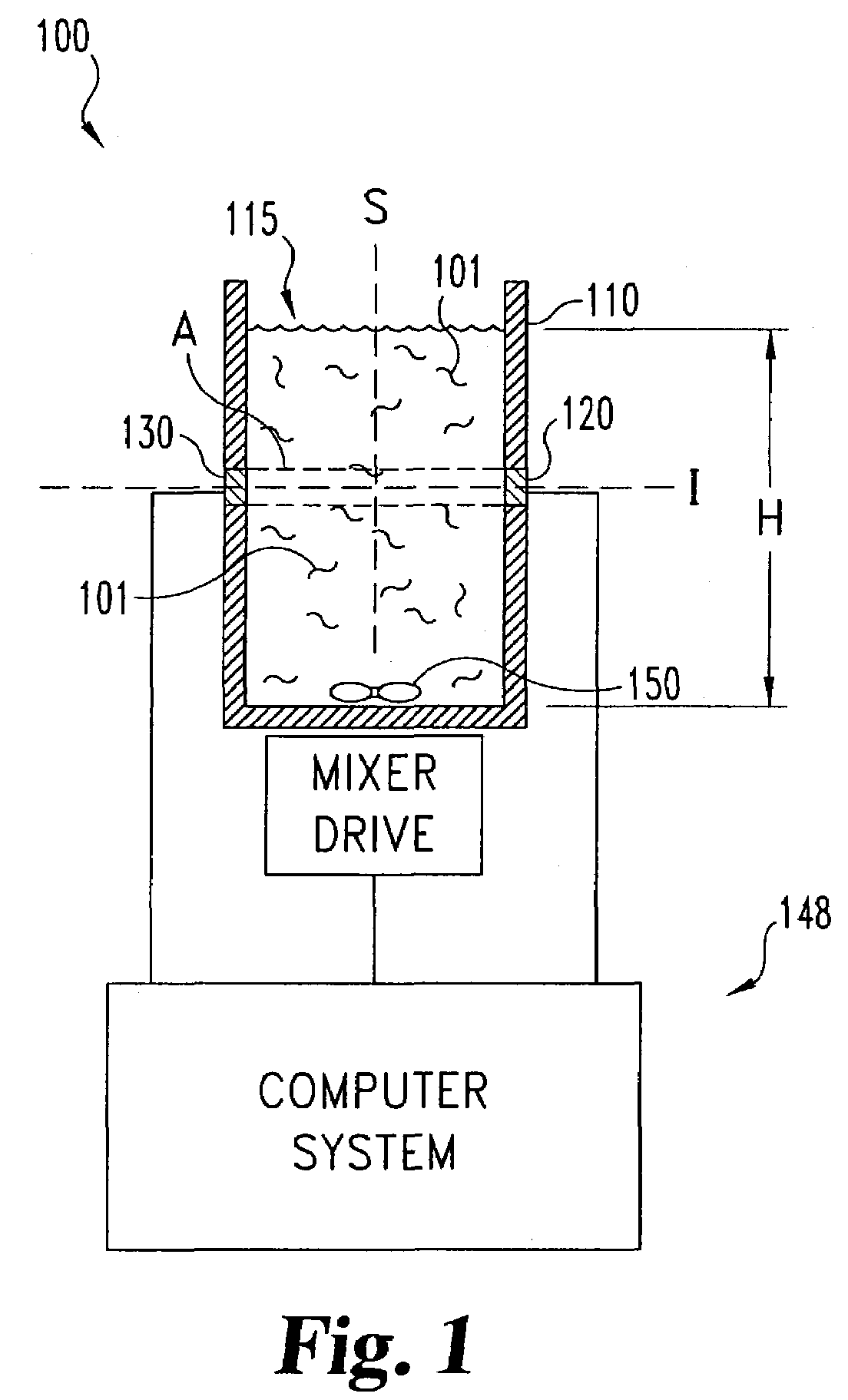

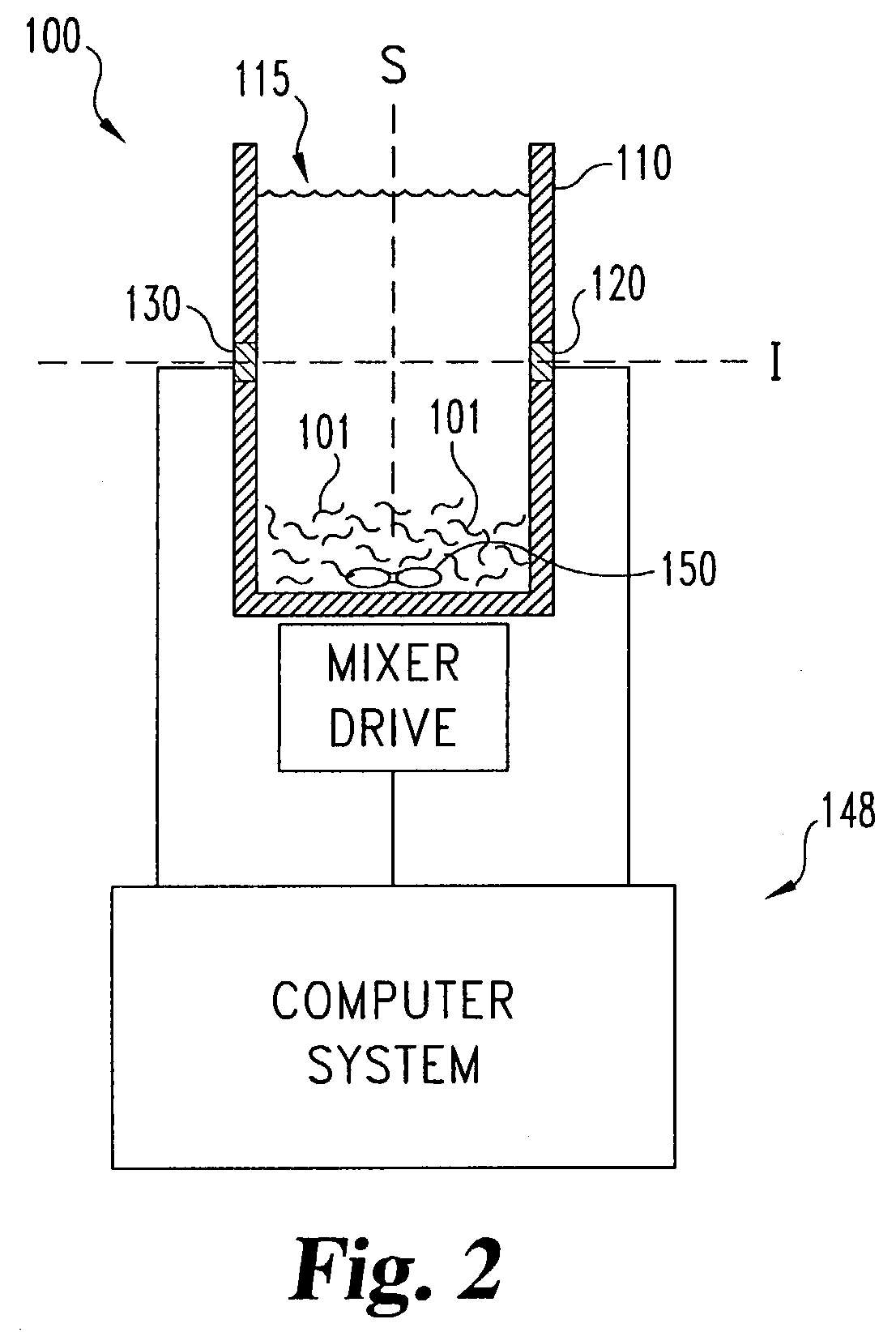

System and technique for ultrasonic characterization of settling suspensions

InactiveUS7140239B2Non-invasively characterizedEfficient and effectiveResponse signal detectionPaper testingUltrasound attenuationSonification

A system for determining properties of settling suspensions includes a settling container, a mixer, and devices for ultrasonic interrogation transverse to the settling direction. A computer system controls operation of the mixer and the interrogation devices and records the response to the interrogating as a function of settling time, which is then used to determine suspension properties. Attenuation versus settling time for dilute suspensions, such as dilute wood pulp suspension, exhibits a peak at different settling times for suspensions having different properties, and the location of this peak is used as one mechanism for characterizing suspensions. Alternatively or in addition, a plurality of ultrasound receivers are arranged at different angles to a common transmitter to receive scattering responses at a variety of angles during particle settling. Angular differences in scattering as a function of settling time are also used to characterize the suspension.

Owner:BATTELLE MEMORIAL INST

Enhanced method for monitoring the deposition of organic materials in a papermaking process

ActiveUS20090056897A1Reduce depositionMaterial analysis using sonic/ultrasonic/infrasonic wavesPaper testingEpoxyQuartz crystal microbalance

A method for monitoring the deposition of one or more organic materials dispersed in an aqueous medium in a papermaking process comprising: measuring the rate of deposition of the organic materials from the aqueous medium on-to a quartz crystal microbalance having a top side contacting with the aqueous medium coated with a layer containing a non-swelling epoxy resin or a silicon containing polymer, and a second, bottom side isolated from the aqueous medium is disclosed. Additionally, a method for measuring the effectiveness of an inhibitor that decreases the deposition of the organic materials in a papermaking process is also disclosed.

Owner:ECOLAB USA INC

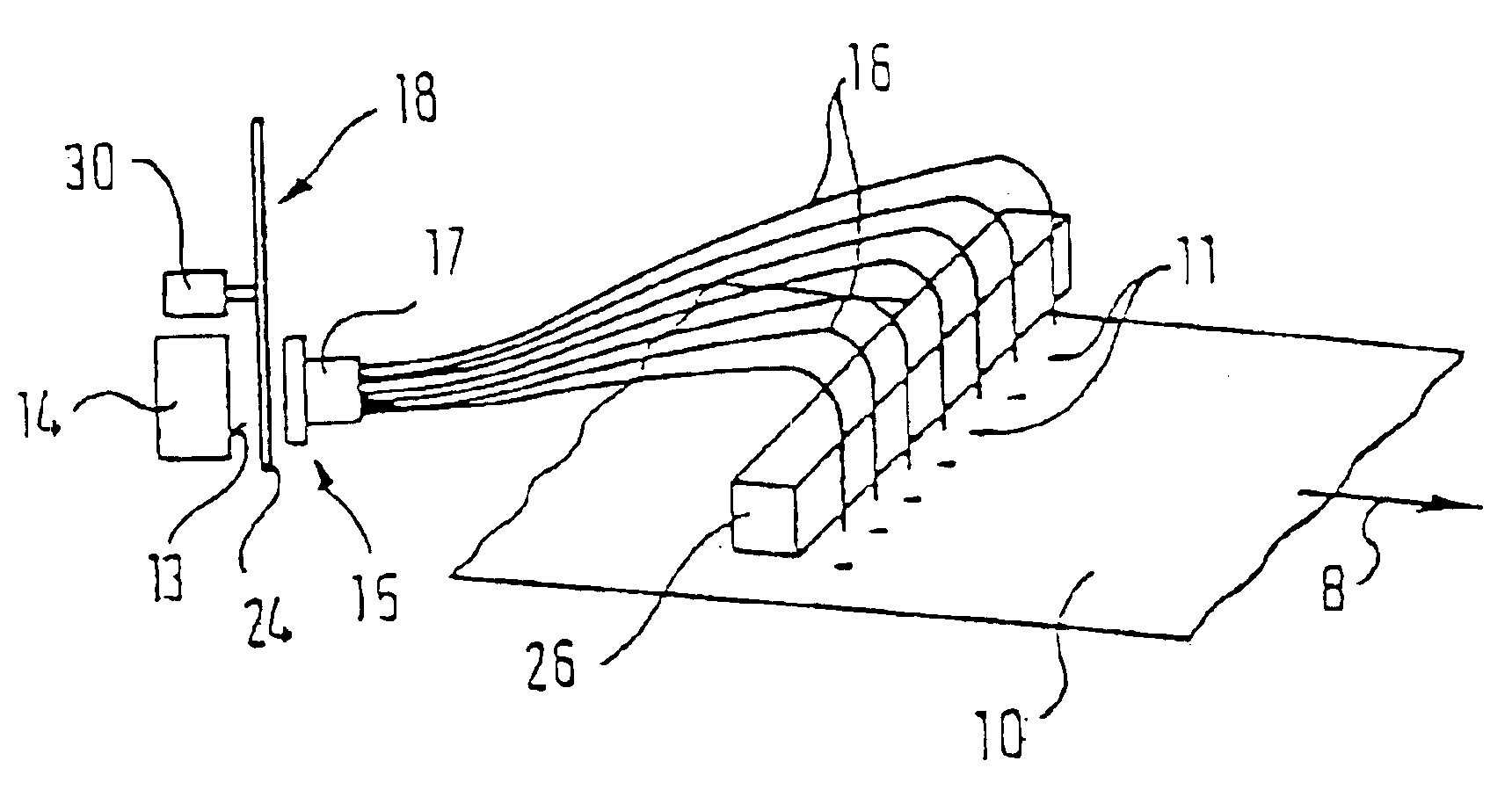

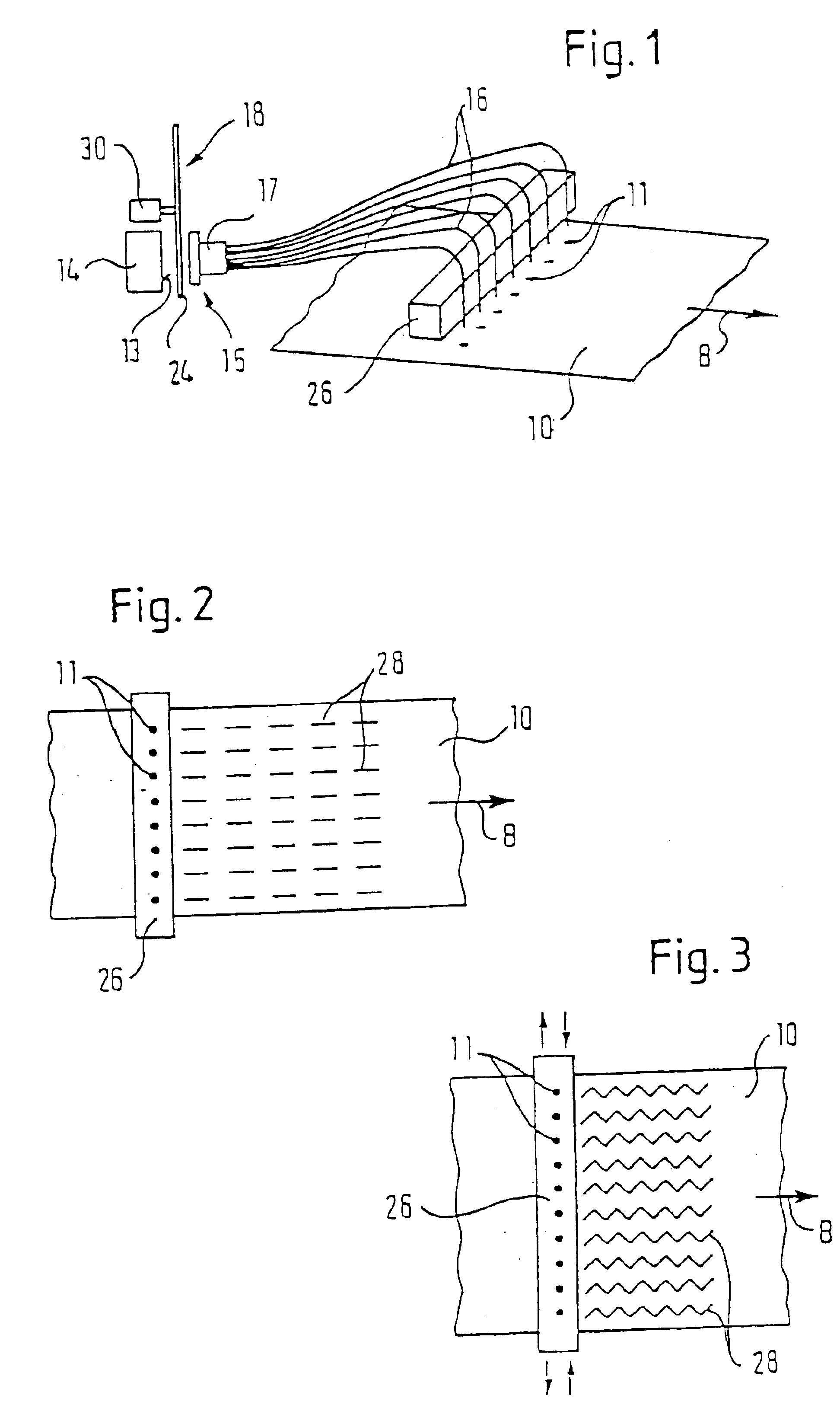

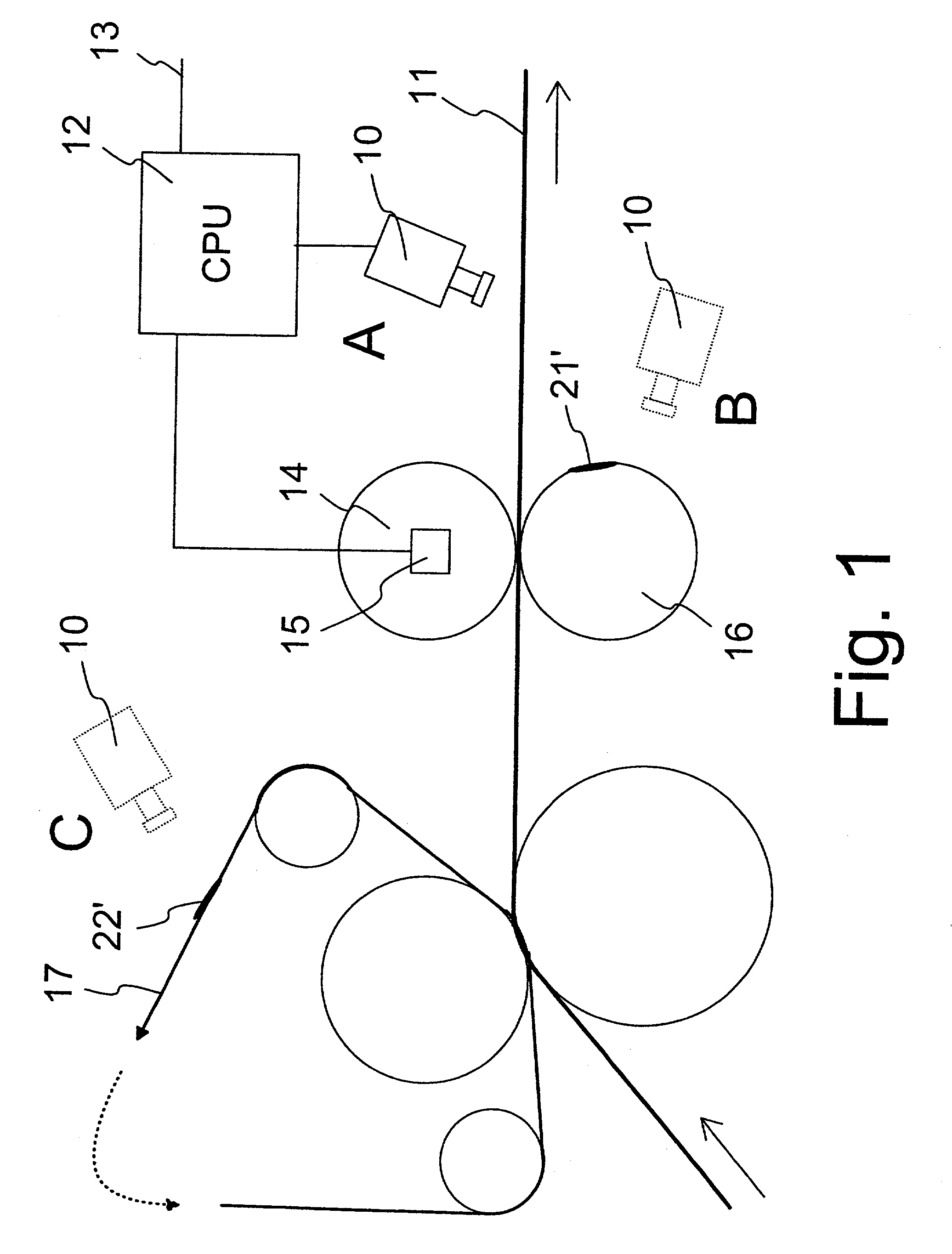

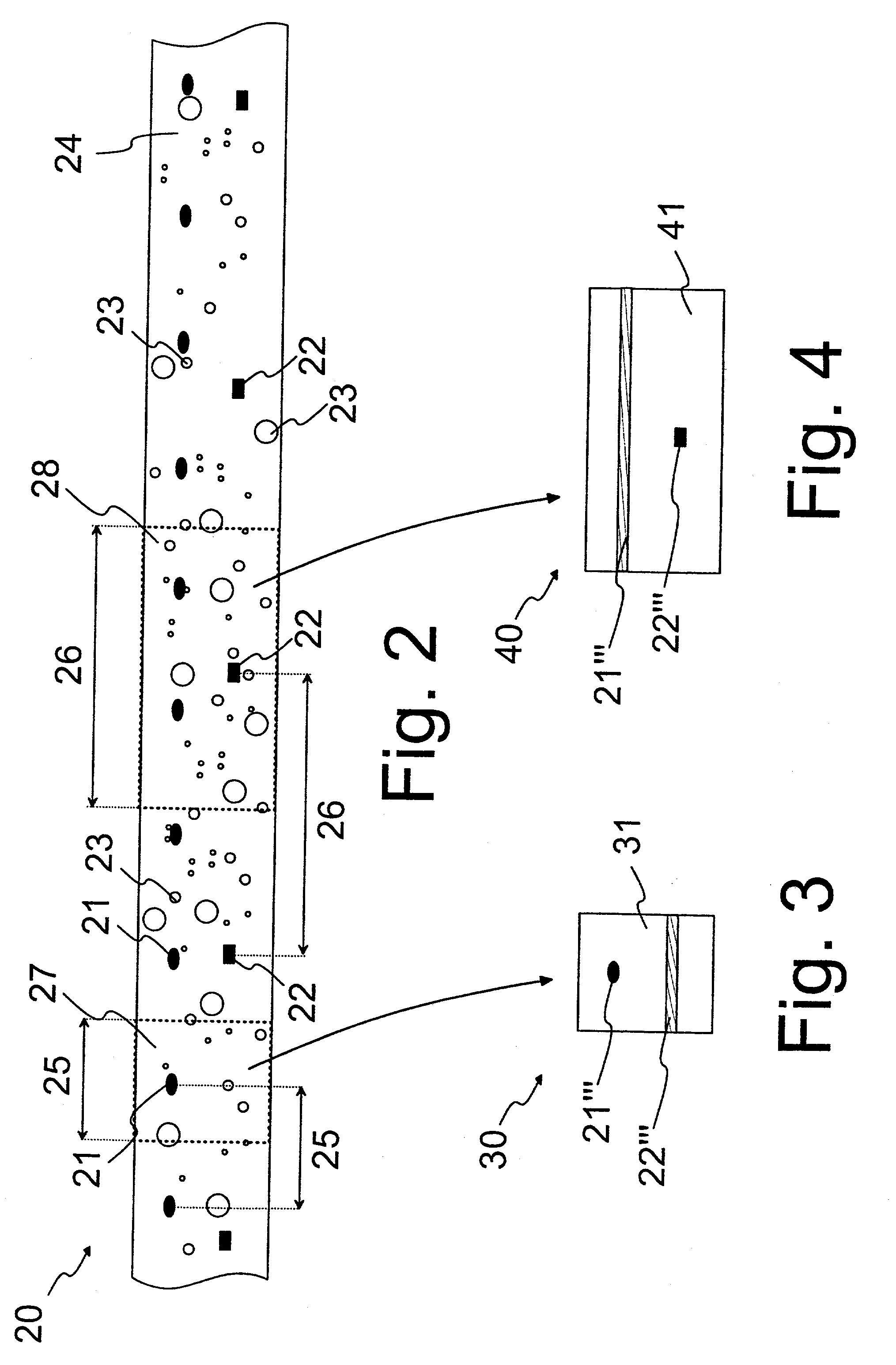

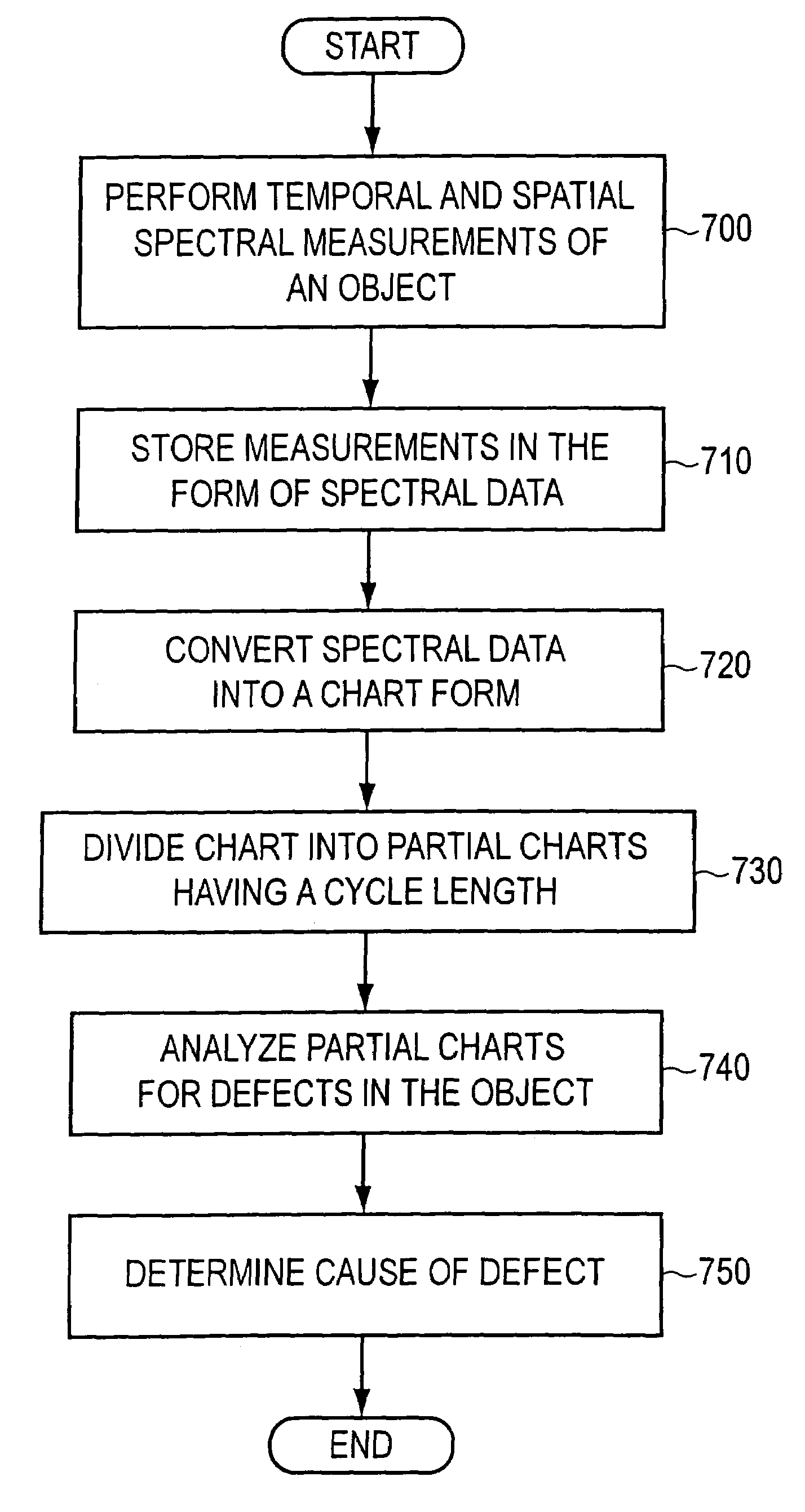

Method for controlling quality and condition on the basis of thermal imaging

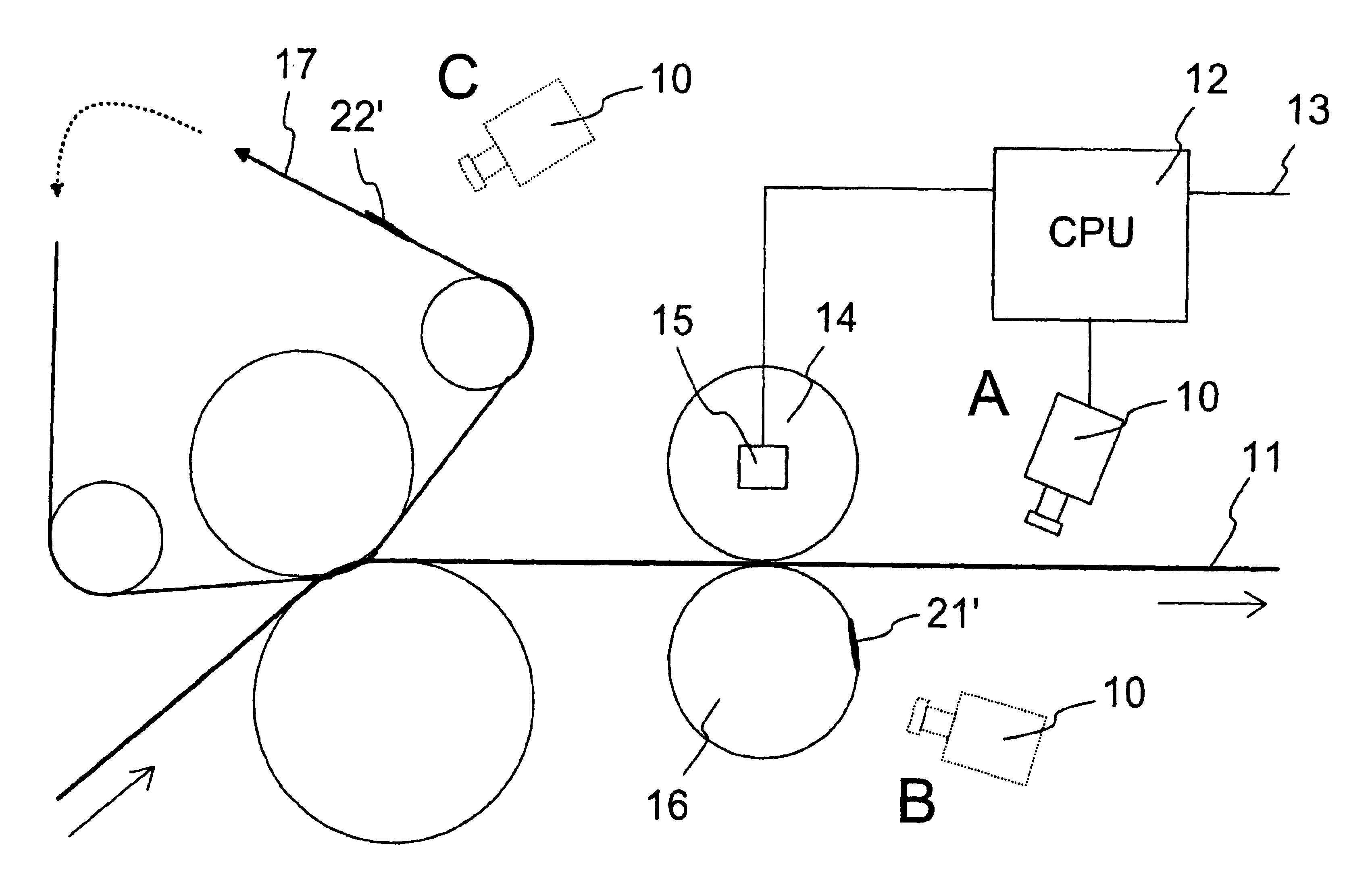

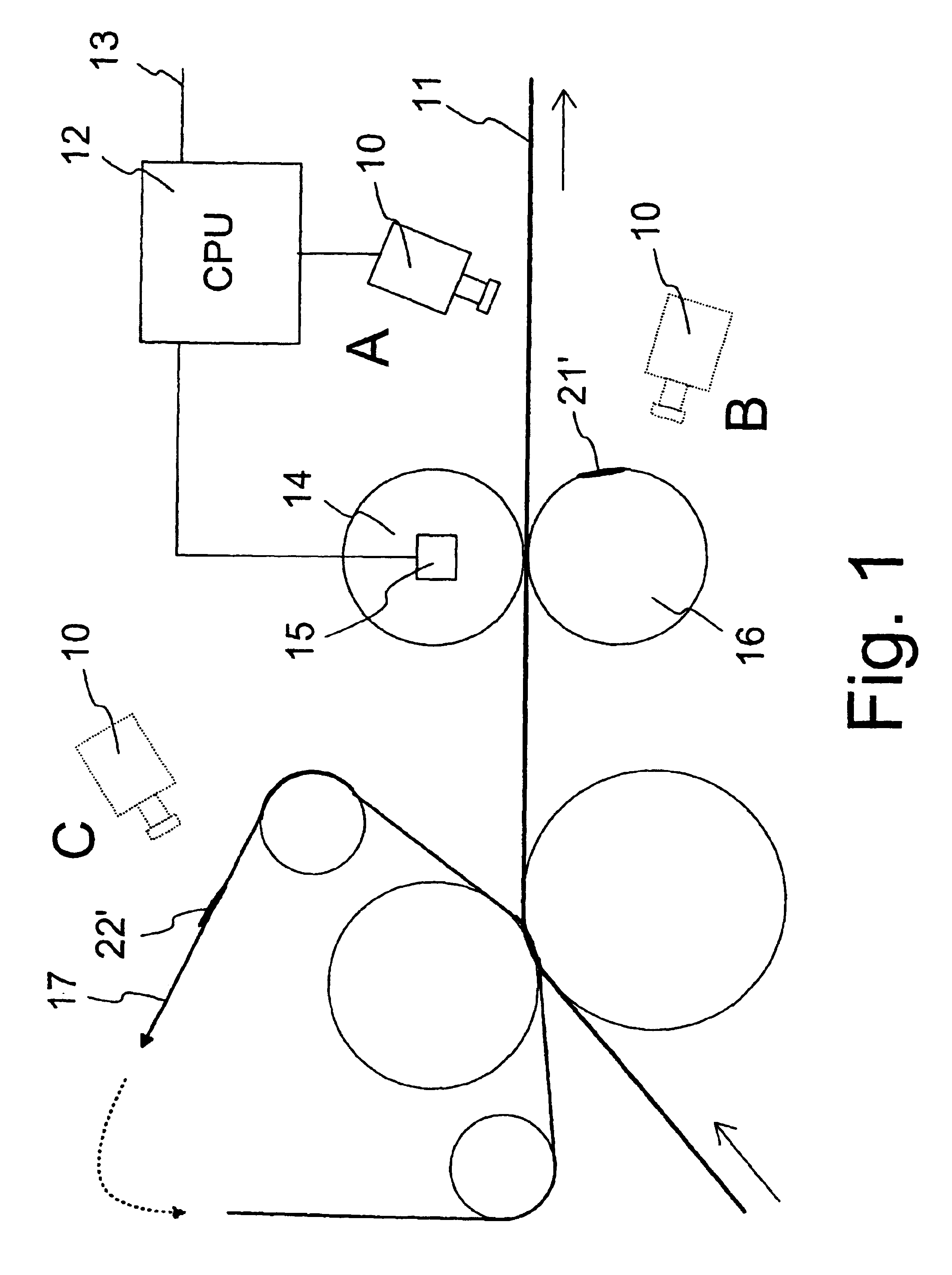

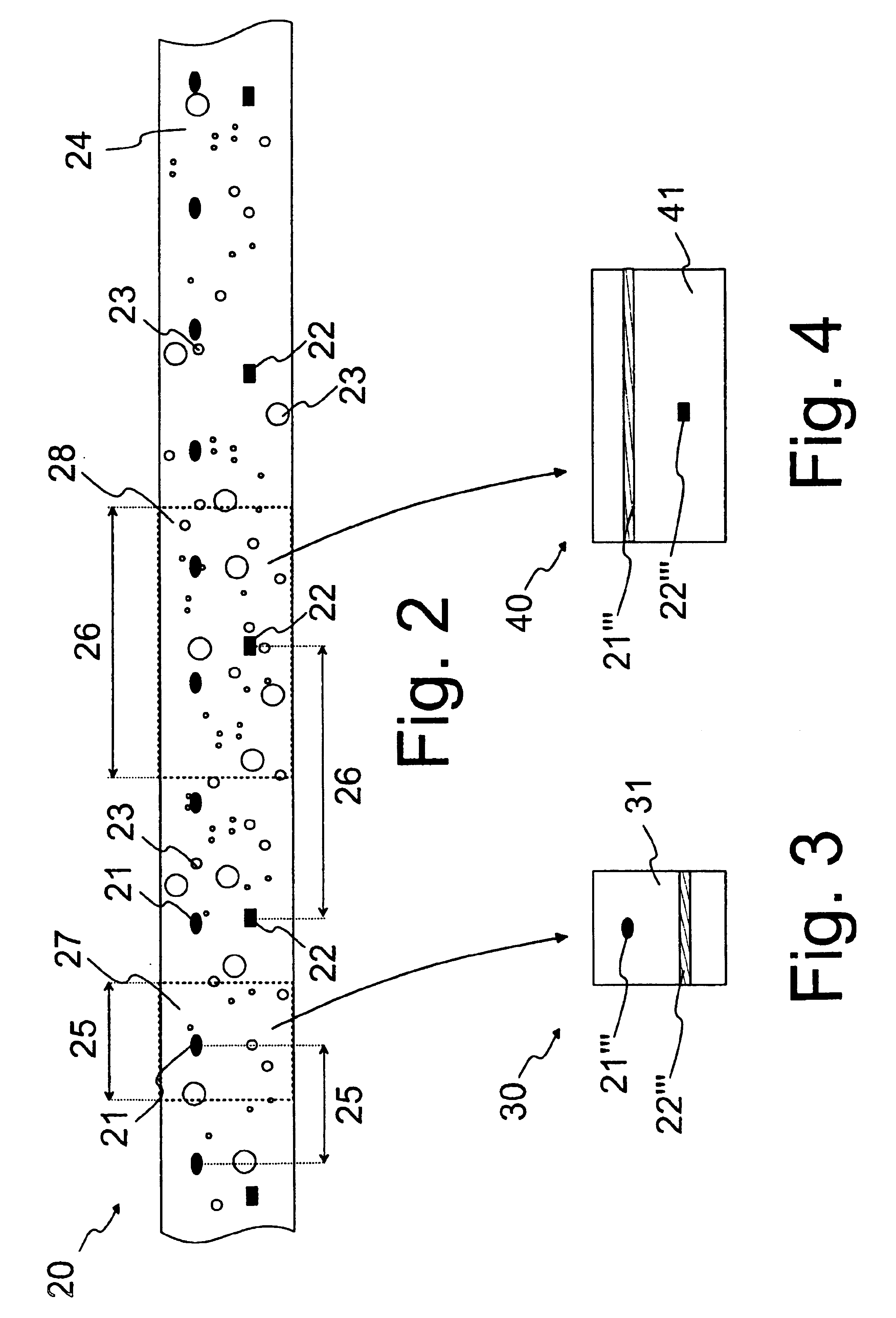

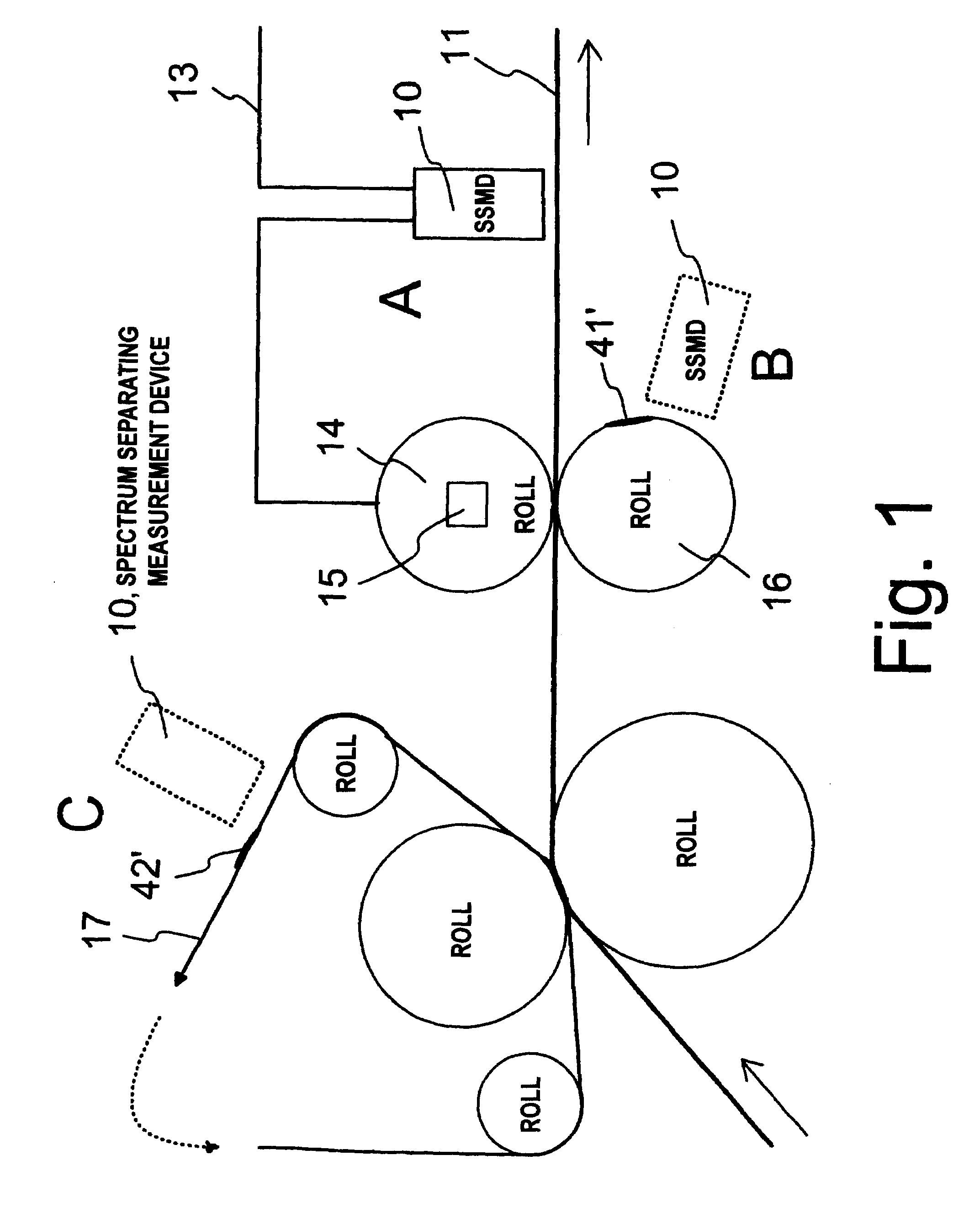

The invention relates to a method in the process of manufacturing and / or finishing a fibre web (11), in which method said continuous and moving web (11), and / or a moving means (16, 17) related to the processing of the web (11), is monitored by one or more thermal cameras (10) of the infrared range or a corresponding detector / detectors for the purpose of controlling the quality or condition. According to the invention, a substantially continuous two-dimensional thermal image or continuous thermal chart (20) of an object (11, 16, 17) being monitored and in a propagating and / or rotating movement is formed by said detector / detectors in a time-resolved manner and in synchronization with the movement of the object (11, 16, 17) in the direction of the movement. To determine the properties of the object (11, 16, 17) and / or to detect defects in the object from the continuous thermal chart (20), local deviations and / or discontinuities (21, 22) in the temperature, particularly in the direction of movement, are detected, and the cause of said deviations and / or discontinuities (21, 22) is identified on the basis of the periodicity of said phenomena in the direction of movement.

Owner:METSO AUTOMATION OY

Measuring fiber orientation by detecting dispersion of polarized light

ActiveUS7164145B2Simple and strong structureReliable measurement resultsPolarisation-affecting propertiesInvestigating moving sheetsLight spotLight beam

An image-based technique that measures the orientation of fibers in a moving web of nonwoven material. At least four light spots on one side of the web are illuminated essentially simultaneously with at least four plane-polarized incident substantially perpendicular light beams having different polarization characteristics. Dispersion of the excident light spots is measured on the opposite side of the web along at least one linear section which is at a known angle relative to the plane of polarization of the corresponding plane-polarized incident light beam, wherein at least one such linear section lies substantially across the center of the transmitted excident light spot and extends substantially across the width of the transmitted excident light spot. Variations in the dispersion of the transmitted excident light spot for the at least four plane-polarized light beams are calculated, and the fiber orientation is estimated from the variations.

Owner:HONEYWELL INT INC

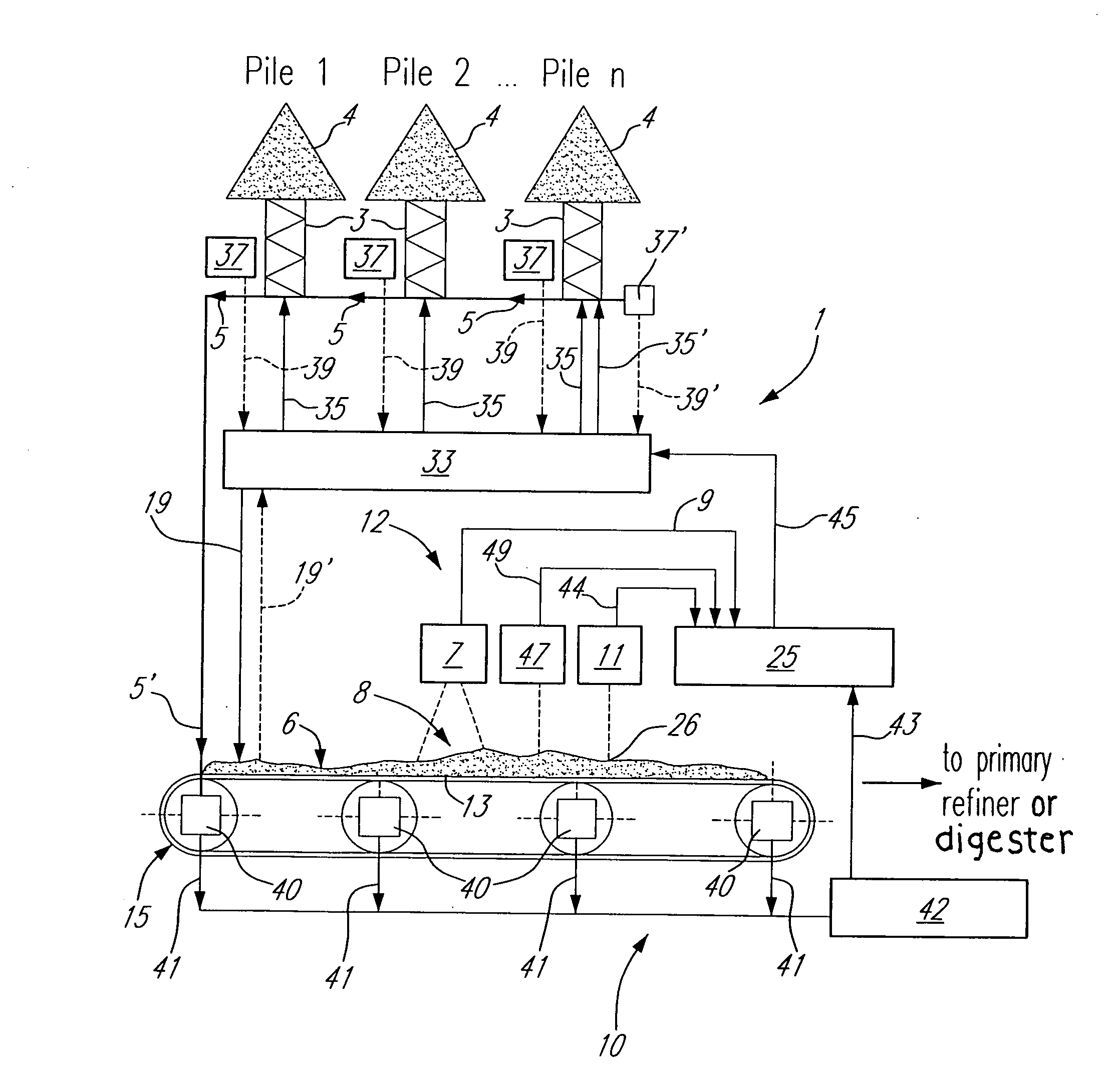

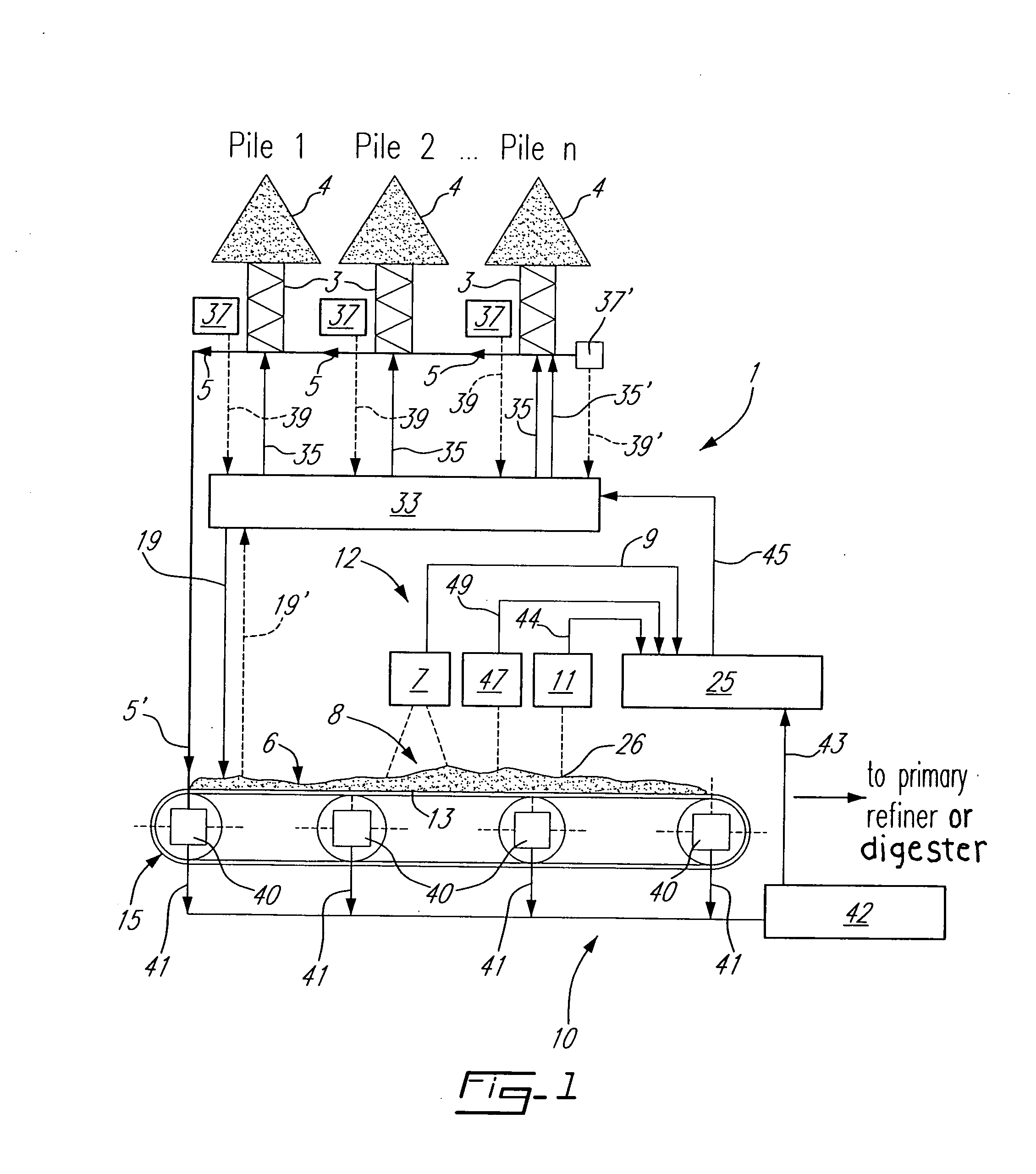

Method and apparatus for estimating relative proportion of wood chips species to be fed to a process for producing pulp

InactiveUS20060278353A1Effective monitoringBeating/refining control devicesDigestersLight reflectionImproved method

Improved methods and apparatus for estimating and controlling relative proportion of wood chips originating from a plurality of sources characterized by various wood species, in a mass of wood chips to be fed to a process for producing pulp, use light reflection-related and density-related properties as input in a model characterizing a relation between such wood chip properties and species information. This principle allows efficient monitoring of the variation in wood species composition characterizing the wood chips to be processed, for the purpose of stabilizing chip feeding control and optimizing process parameters adjustment.

Owner:CENT DE RES & DEV IND DU QUEBEC

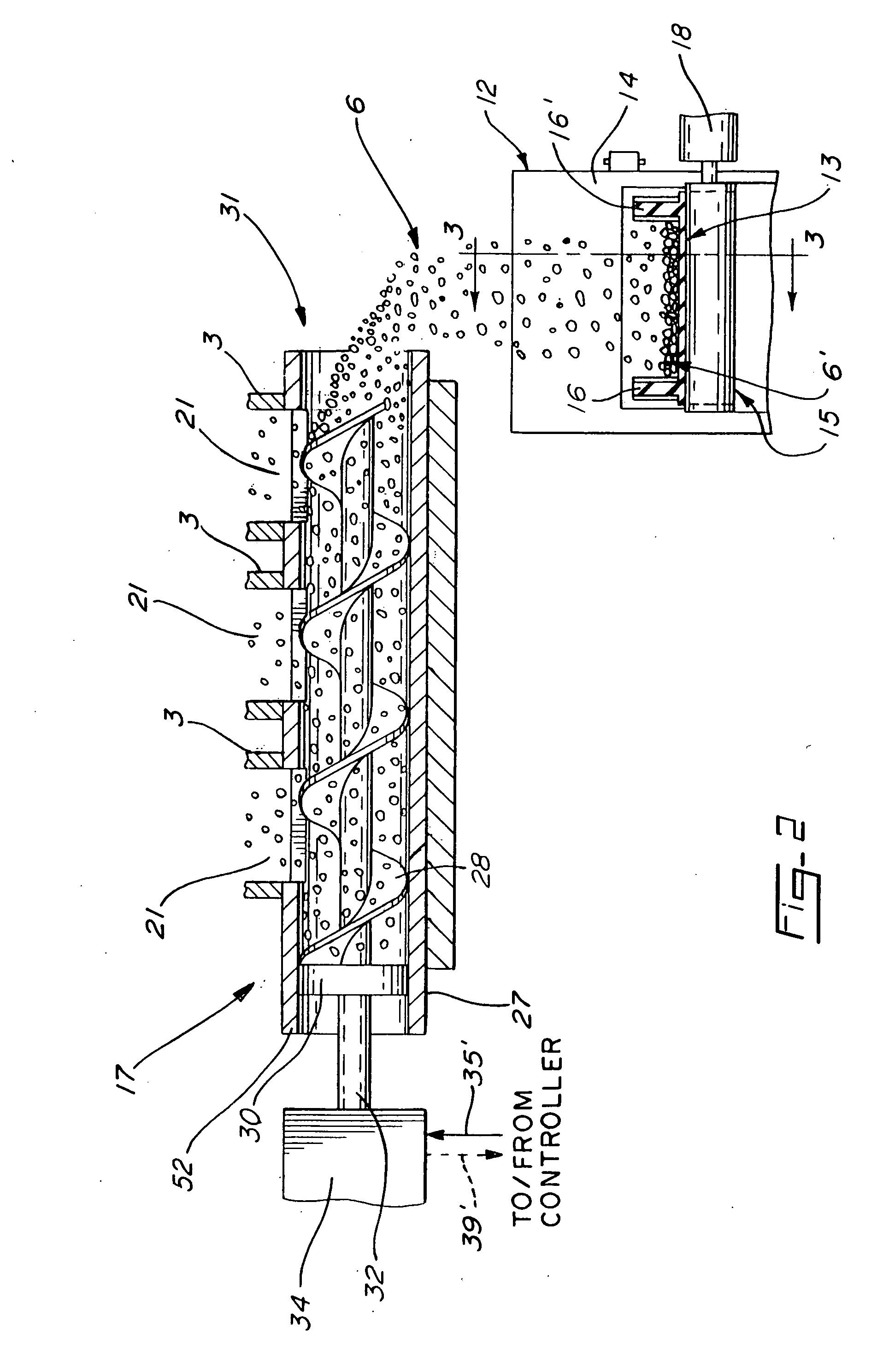

Method and a device for measuring concentrations

InactiveUS6929715B2Guaranteed uptimeImprove efficiencyWithdrawing sample devicesPaper testingFlocculationPiston

A method and a device for measuring concentrations especially in a pulp suspension, from which a sample has been taken. The sample is collected in a measuring vessel, in which a piston is guided upwards and downwards in order to press the sample from each direction through a measuring sensor collected at the side of the measuring vessel via communicating tubes connected in an upper and a lower position to the measurement vessel, whereby the sample is stirred totally to eliminate flocculation in the same. Measurement of the concentration of the sample is made either during the upwards and downwards movement of the piston in the measuring vessel and first occurs when the speed of the sample through the measuring sensor is constant and the sample has been homogenized after at least some movement upwards and downwards of the piston.

Owner:BTG KAELLE INVENTING AKTIEBOLAG

Quality and condition monitoring based on spectrum separating measurement

InactiveUS7155356B2Highly of conditionHighly controlSpectral/fourier analysisInvestigating moving sheetsFiberMeasurement device

A method of controlling the quality and / or condition of a fibre web in a process for manufacturing and / or finishing the fibre web, which includes, monitoring the fibre web with at least one optical spectrum separating measurement device, determining a quality variable of the fibre web, measuring electromagnetic radiation reflected from the fibre web using an optical spectrum separating measurement device synchronously with a movement of the fibre web, and measurements in the form of spectral data, generating a continuous quality variable chart, dividing the continuous quality variable chart into successive matched partial charts having a cycle length, detecting deviations and / or discontinuities of the quality variable from the successive matched partial charts, and detecting malfunctioning of a rotating / moving means using the detected deviations and / or discontinuities of the quality variable.

Owner:METSO AUTOMATION OY

Apparatus and process for a cross-direction profile of a material web

InactiveUS6526369B1Shorten control timeInvestigating moving sheetsDigital computer detailsMeasurement deviceElectronic systems

Measurement system and process for measuring a cross-direction profile of specific properties of at least one of a material web and a coating on the material web. The system includes at least one stationary cross-direction profile measurement device having at least one radiation source adapted to irradiate the at least one of the material web and the coating on the material web in a plurality of defined and different wavelength ranges, and at least one sensor adapted to measure the intensity of radiation affected by the at least one of the material web and the coating on the material web. The system also includes at least one measurement and / or evaluation electronics system. Each sensor detects only one of the defined different wavelength ranges of the radiation at a specific point in time. The process includes irradiating the at least one of the material web and the coating on the material web with a plurality of defined and different wavelength ranges via at least one radiation source, and measuring an intensity of radiation affected by the at least one of the material web and the coating on the material web with at least one sensor. Only one of the defined different wavelength ranges of the radiation is measured by each sensor at a specific point in time.

Owner:VOITH SULZER PAPIERTECHN PATENT

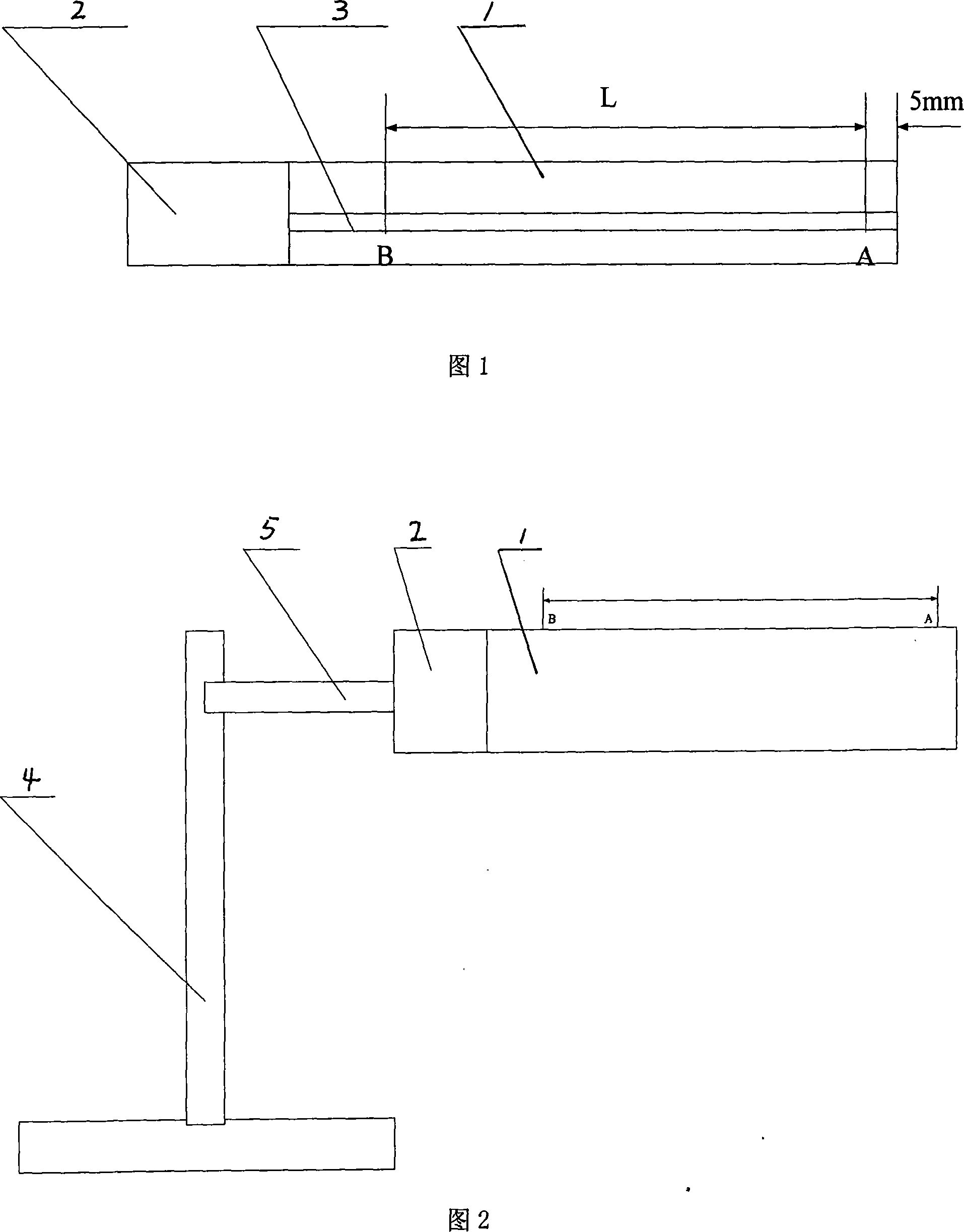

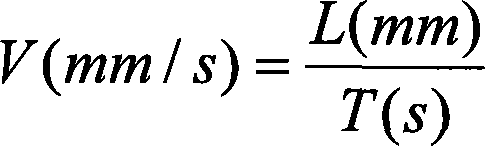

Method for determining cigarette paper smolder speed

InactiveCN101226186AGood repeatabilitySmall discreteChemical analysis using combustionPaper testingPulp and paper industrySingle level

The invention relates to a measuring method of smoldering speed of cigarette paper, which comprises a, preparing a cigarette hollow paper drum sample, b, setting relative marks, c, setting fixing method, d, setting test conditions, e, calculating out the cigarette paper smoldering speed via formula. Compared with prior three test methods, the invention has the advantages that 1, the test result has good repeatability, 2, the test result has good stability, 3, the test result can actually represent product quality, 4, the test result can represent the application character of product, 5, and the method has good operability. The test result indicates that since the cigarette paper has single-layer drum structure, is suspended and horizontally arranged and smoldered, the sample is in one small space, to make smoldering line regular, obtain the test result with good repeatability and reduce dispersion as small variation factor, thereby truly representing the quality and application character of product.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com