Multiple factors accelerated aging test apparatus and method for oil paper insulation of transformer

A transformer oil, accelerated aging technology, used in paper testing, measuring devices, instruments, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

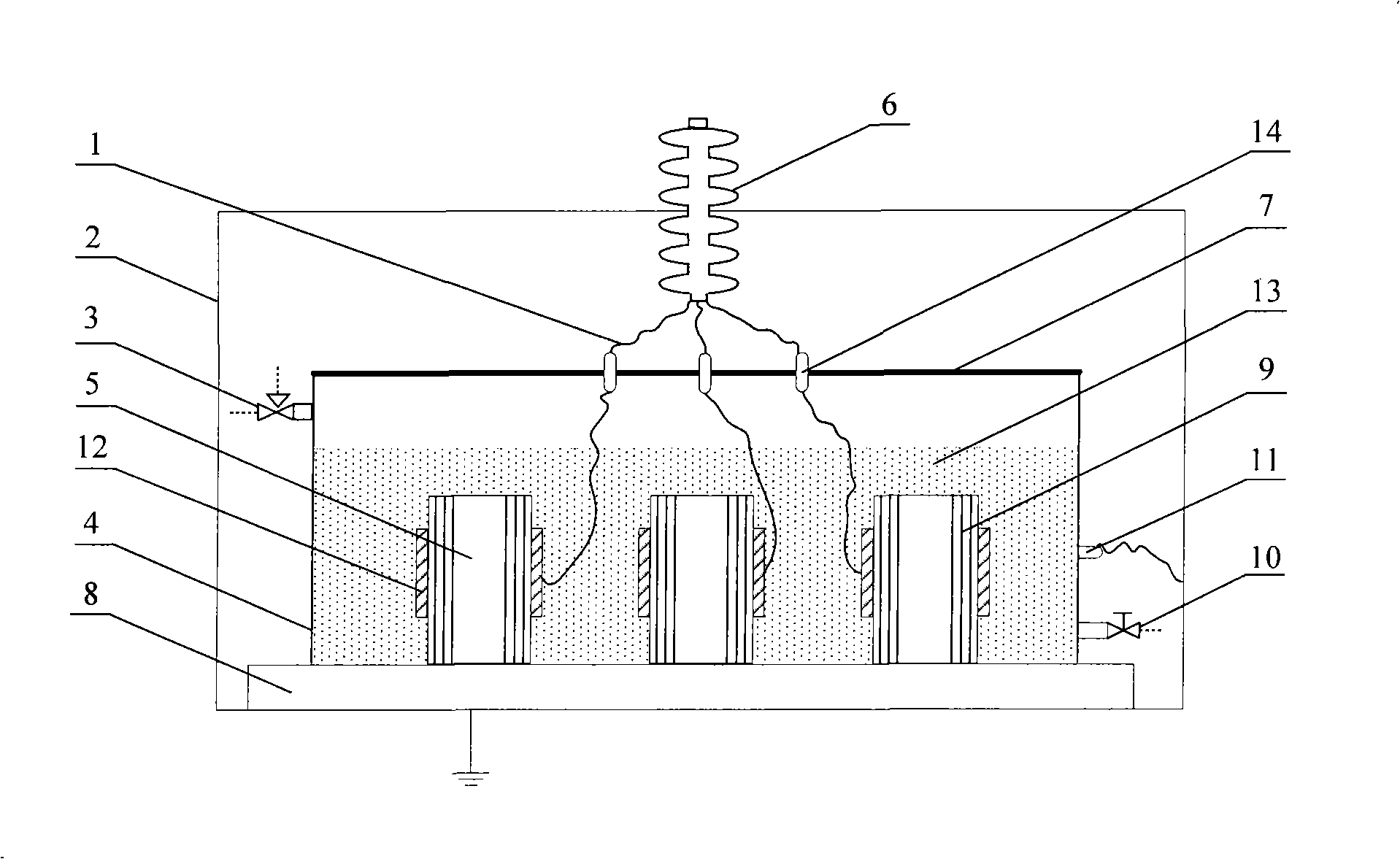

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0024] Referring to Fig. 1, the transformer oil-paper insulation multi-factor accelerated aging test device of this preferred embodiment includes an electrothermal aging box 2, and the bottom of the inner cavity of the electrothermal aging box 2 is provided with a vibrating device 8, and the stainless steel box body 4 is arranged on the vibrating device 8 , can vibrate with the vibrating device, the upper cover of the stainless steel box 4 is an insulating sealing plate 7, and three silicon steel plates 5 are arranged at intervals in the stainless steel box 4 as ground electrodes. When the device is in use, the insulating paper 9 is pasted on the silicon steel On the plate 5, three coils are respectively wound and fixed on the outside of the insulating paper 9 as the high-voltage electrode 12, and insulating oil 13 is injected into the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com