Method and apparatus for estimating relative proportion of wood chips species to be fed to a process for producing pulp

a technology of relative proportion and pulp, applied in the field of pulp and paper process automation, can solve the problems of instability of the control of this variable, the inability to adjust the process parameters, etc., to achieve the effect of optimizing process parameter adjustment, optimizing process parameters, and stabilizing chip feeding control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

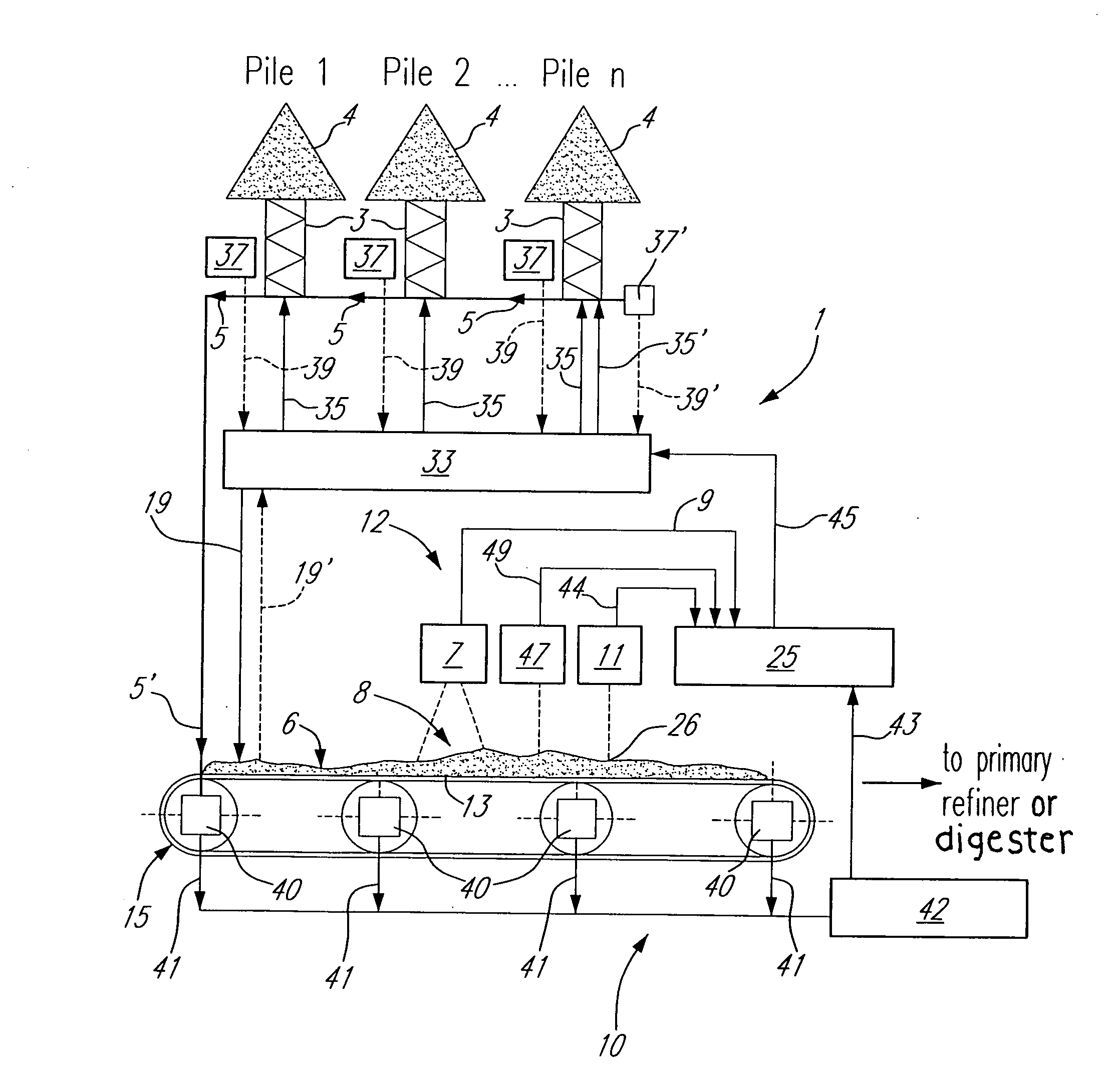

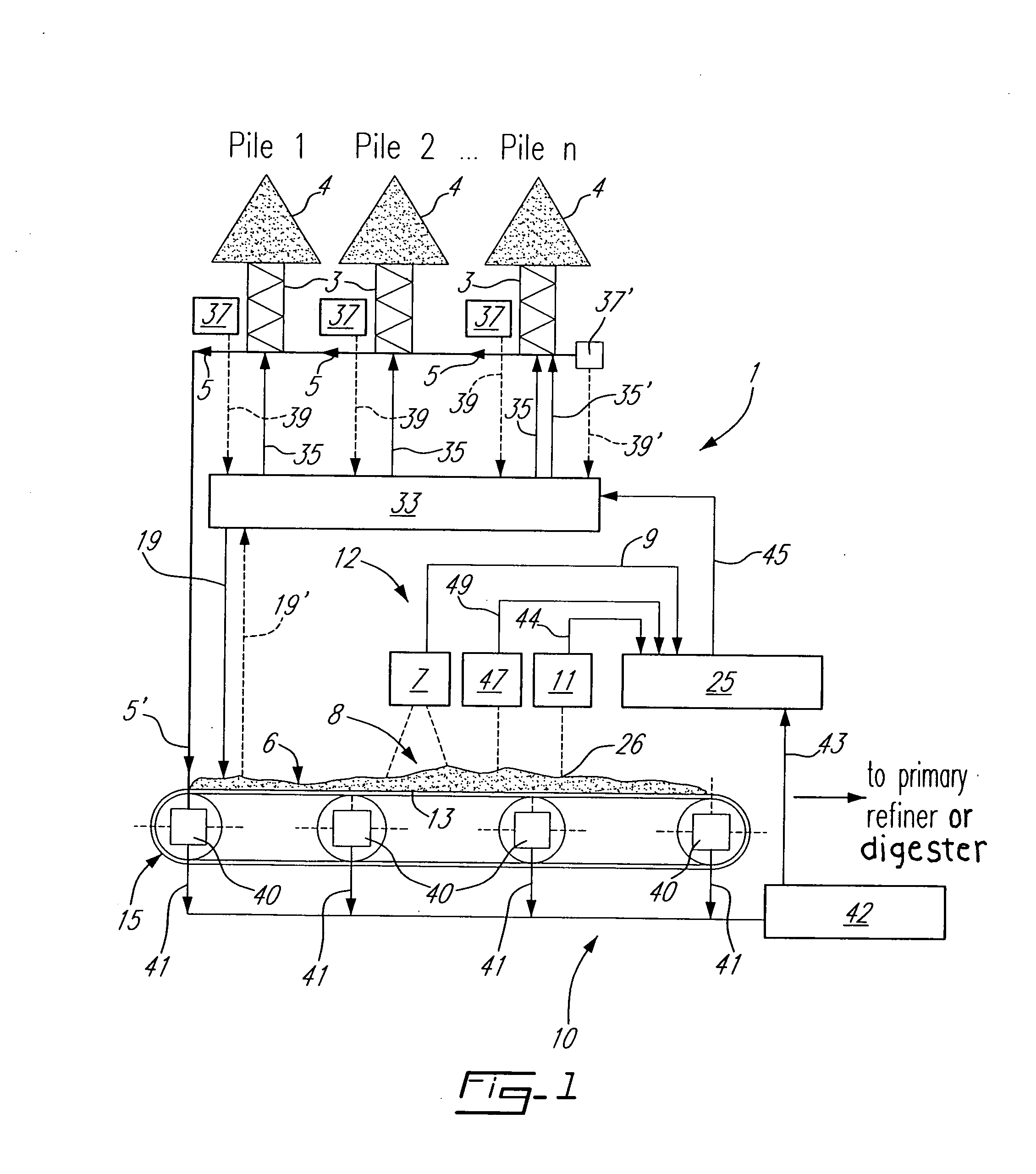

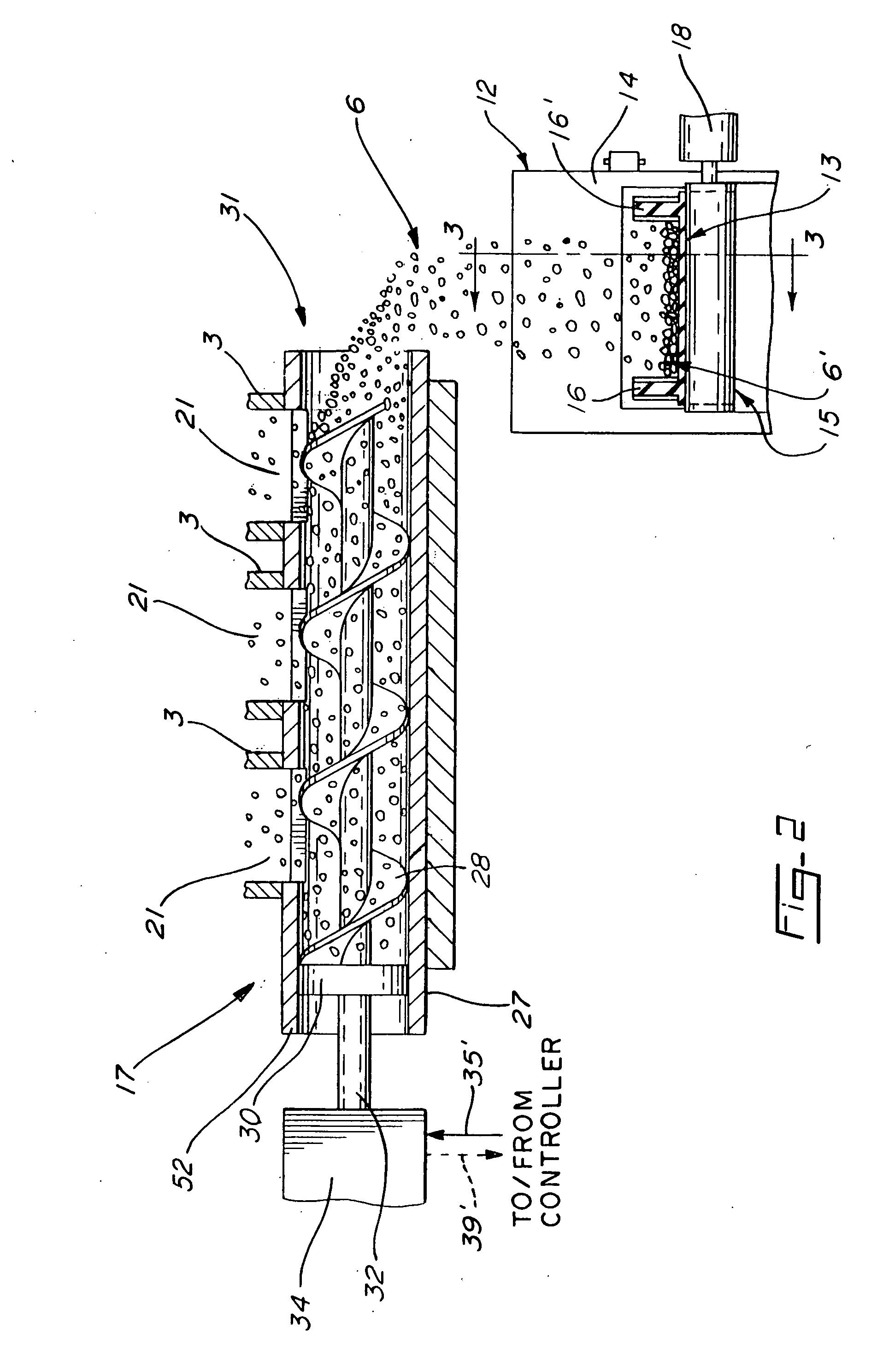

[0037] After further weighing the importance of many chip physical characteristics, it has been found that while chip density is an important parameter closely associated with species, that variable was lacking in prior art modeling for the purpose of wood species monitoring. Basically, according to the present invention, It has been discovered that a relation between density data along with one or more light reflection-related properties in one hand, and wood species characterizing the wood chips coming from a plurality of sources in the other hand, may be implemented in a model, which can then be used to estimate relative proportion of wood chip species in a mass of wood chips obtained from said sources. It has been found that such estimation may be advantageously used for monitoring variation of wood species composition, so as to allow selective discharge adjustment of the chip sources in order to stabilize wood species composition to be fed to a TMP or chemical pulping process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com