Patents

Literature

788results about "Raw material pretreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process of cellulose nanofibers from renewable feed stocks

InactiveUS20080146701A1High aspect ratioRaise the potentialMaterial nanotechnologyFats/resins/pitch/waxes removal in pulpCelluloseNatural fiber

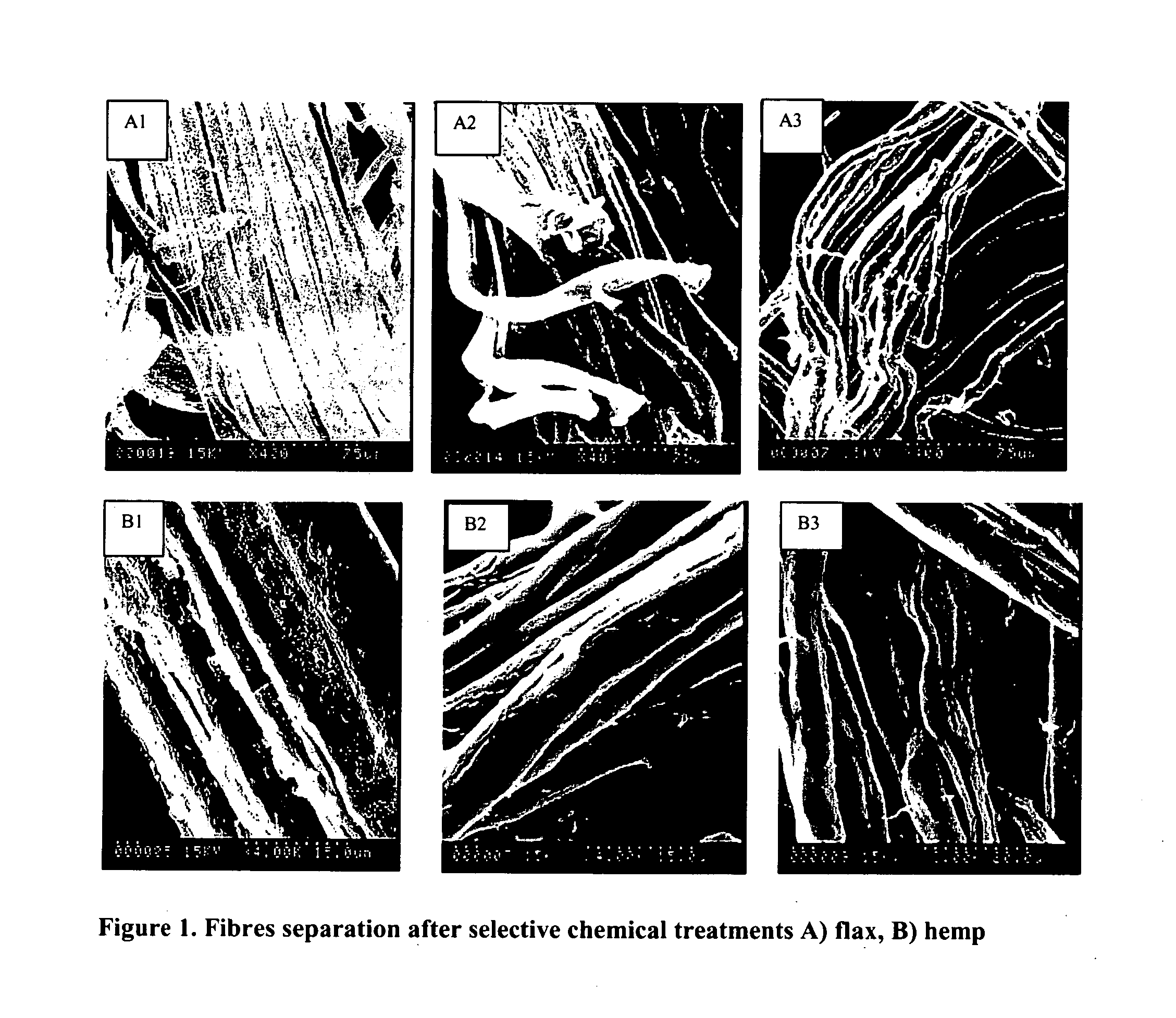

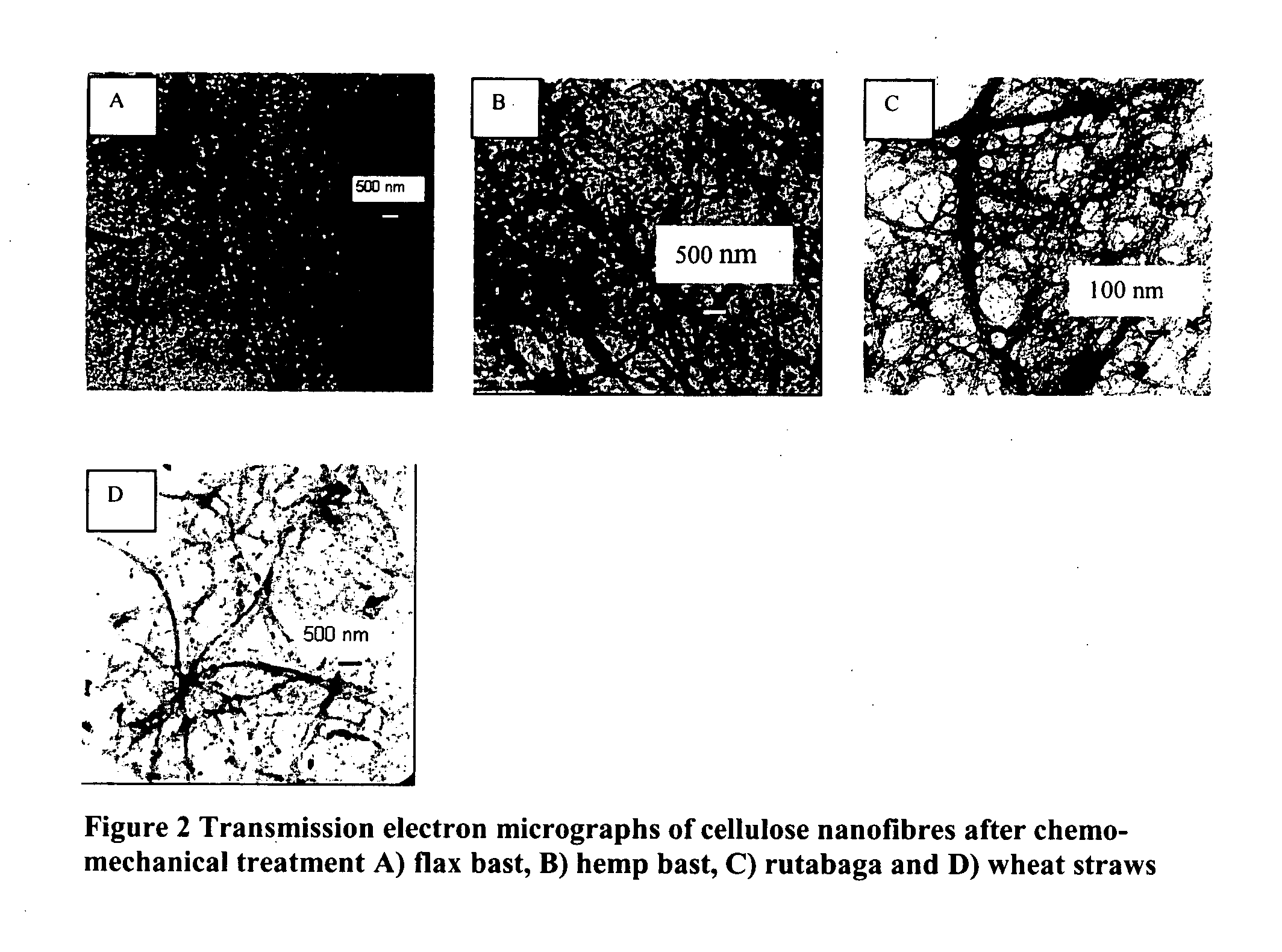

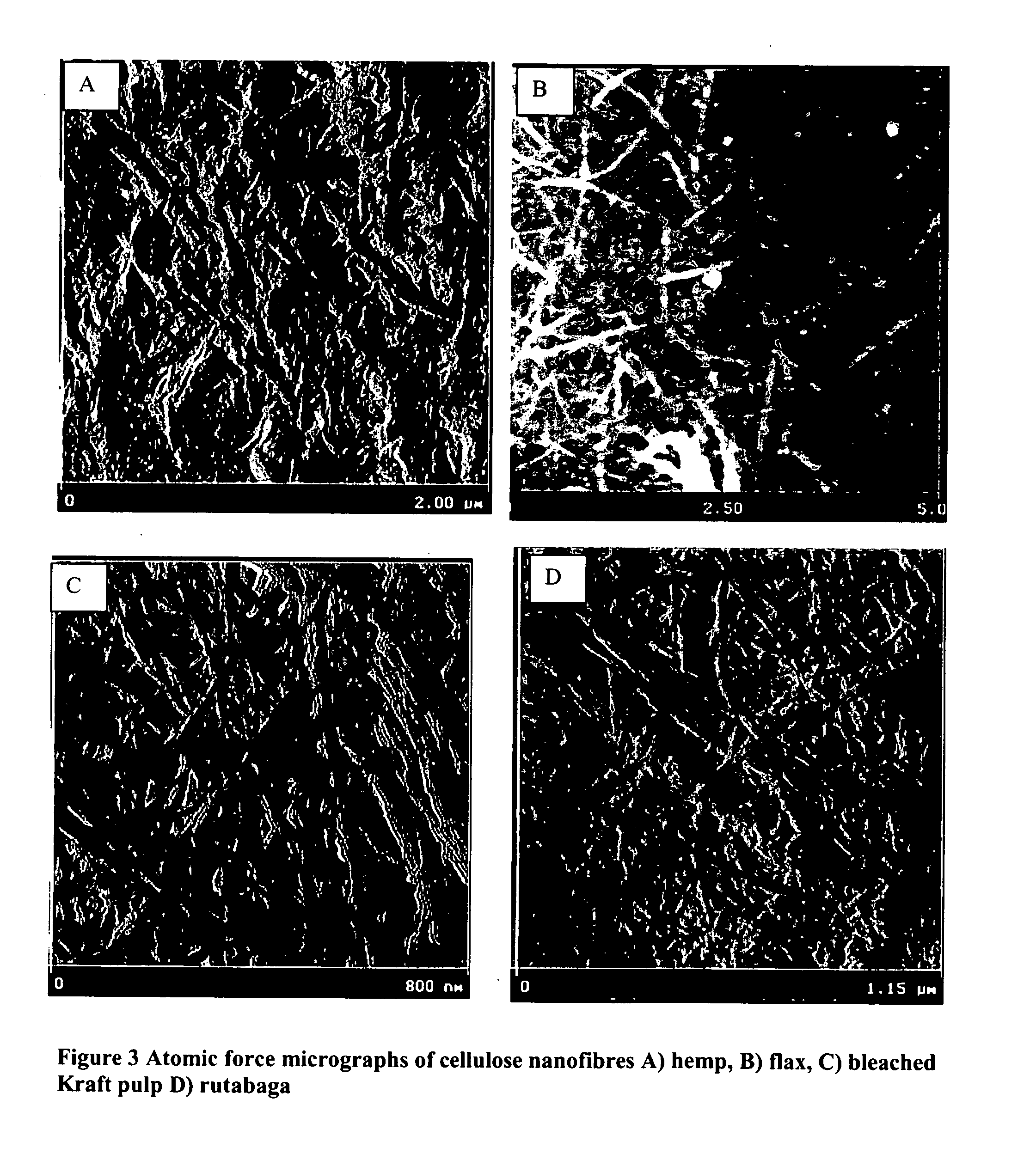

Cellulose nanofibers have been processed from renewable feedstock in particularly from natural fibers, root crops and agro fibers, wherein the pulp was hydrolysed at a moderate temperature of 50 to 90 degree C., one extraction was performed using dilute acid and one extraction using alkali of concentration less than 10%; and residue was cryocrushed using liquid nitrogen, followed by individualization of the cellulose nanofibers using mechanical shear force. The nanofibers manufactured with this technique have diameters in the range of 20-60 nm and much higher aspect ratios than long fibers. Due to its lightweight and high strength its potential applications will be in aerospace industry and due to their biodegradable potential with tremendous stiffness and strength, they find application in the medical field such as blood bags, cardiac devices, valves as a reinforcing biomaterial.

Owner:SAIN MOHINI M +1

Bamboo pulp denatured productive technology

InactiveCN1385287AEmission reductionConducive to the sustainable development of productionPretreatment with alkaline reacting compoundsWood treatment detailsPulp and paper industryViscose fiber

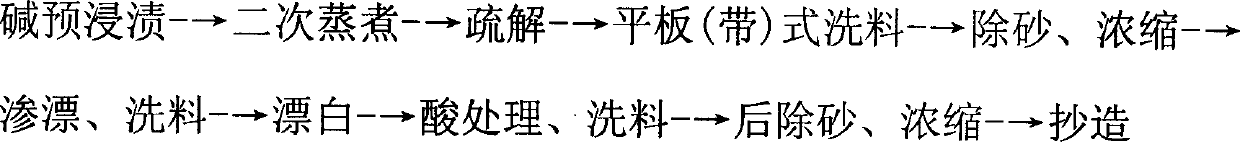

The production process of bamboo fibre viscose pulp includes the following main steps: pre-alkalizing, secondary cooking, plate (belt) type washing and bleaching, and is characterized by mixing insoluble bamboo pulp undergo the process of modification treatment to produce soluble viscose bamboo pulp. As compared with cotton pulp production process it can reduce discharge of waste water by 35%, and is approaching to or superior to cotton pulp in quality.

Owner:上海第五化学纤维厂

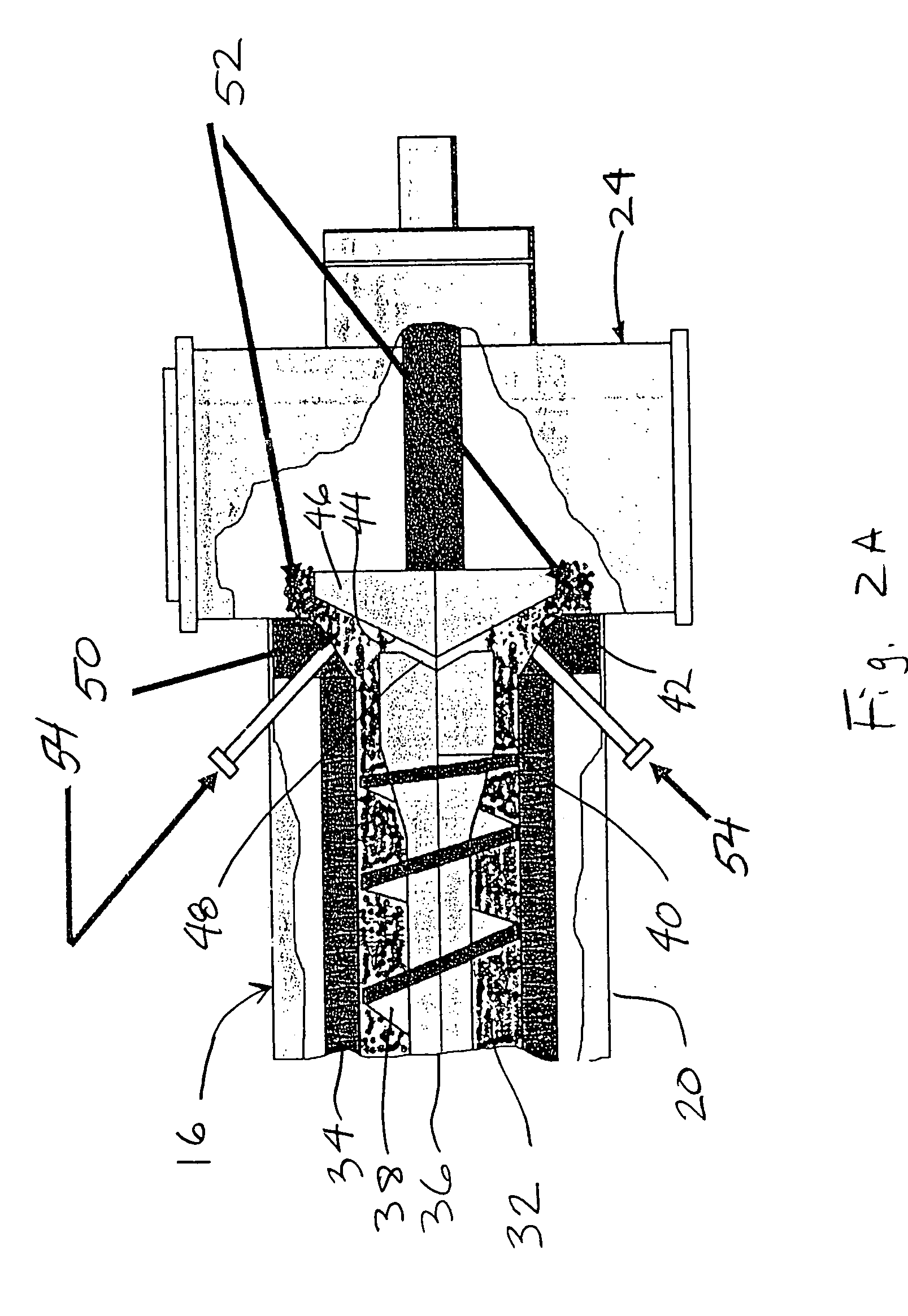

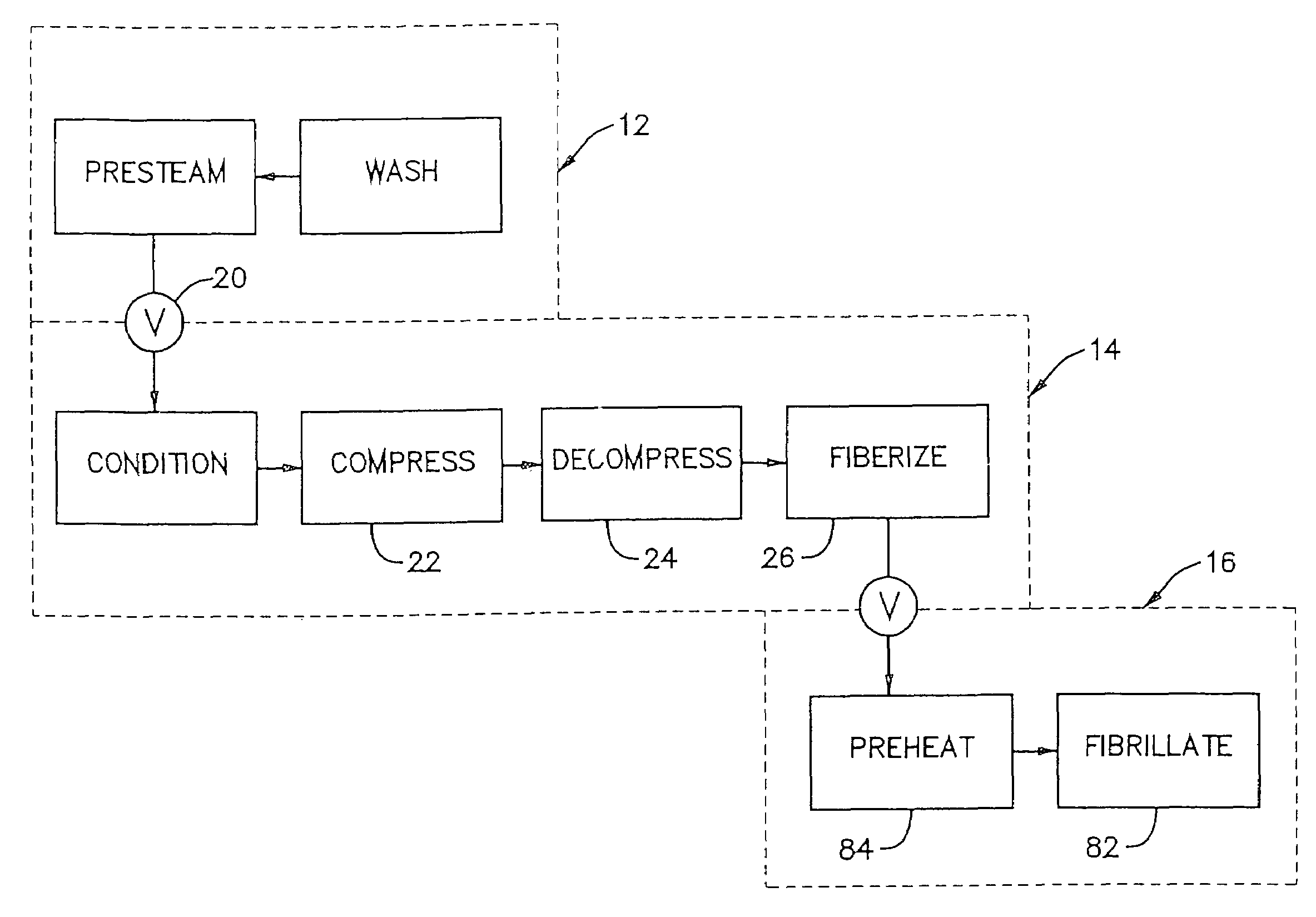

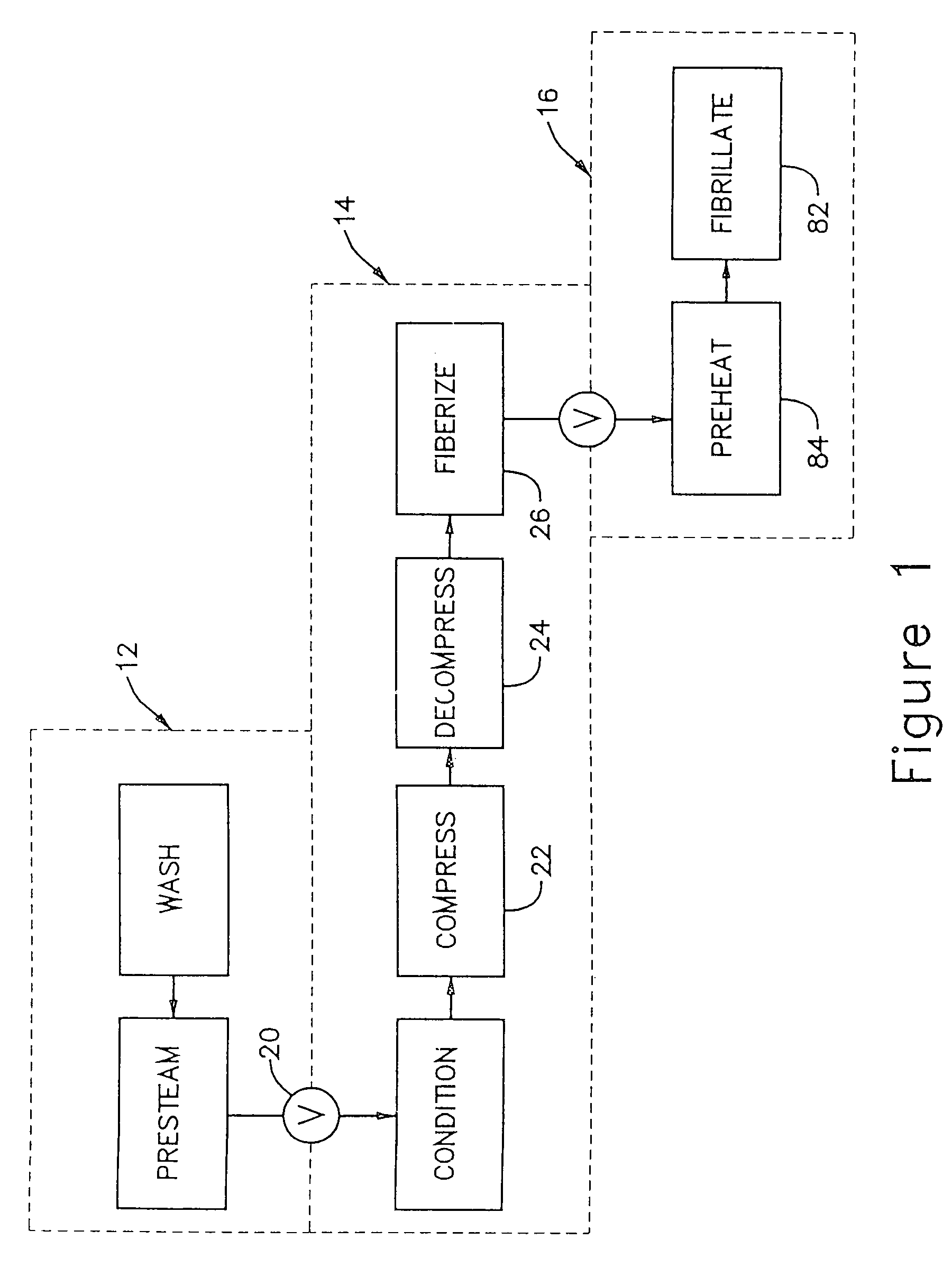

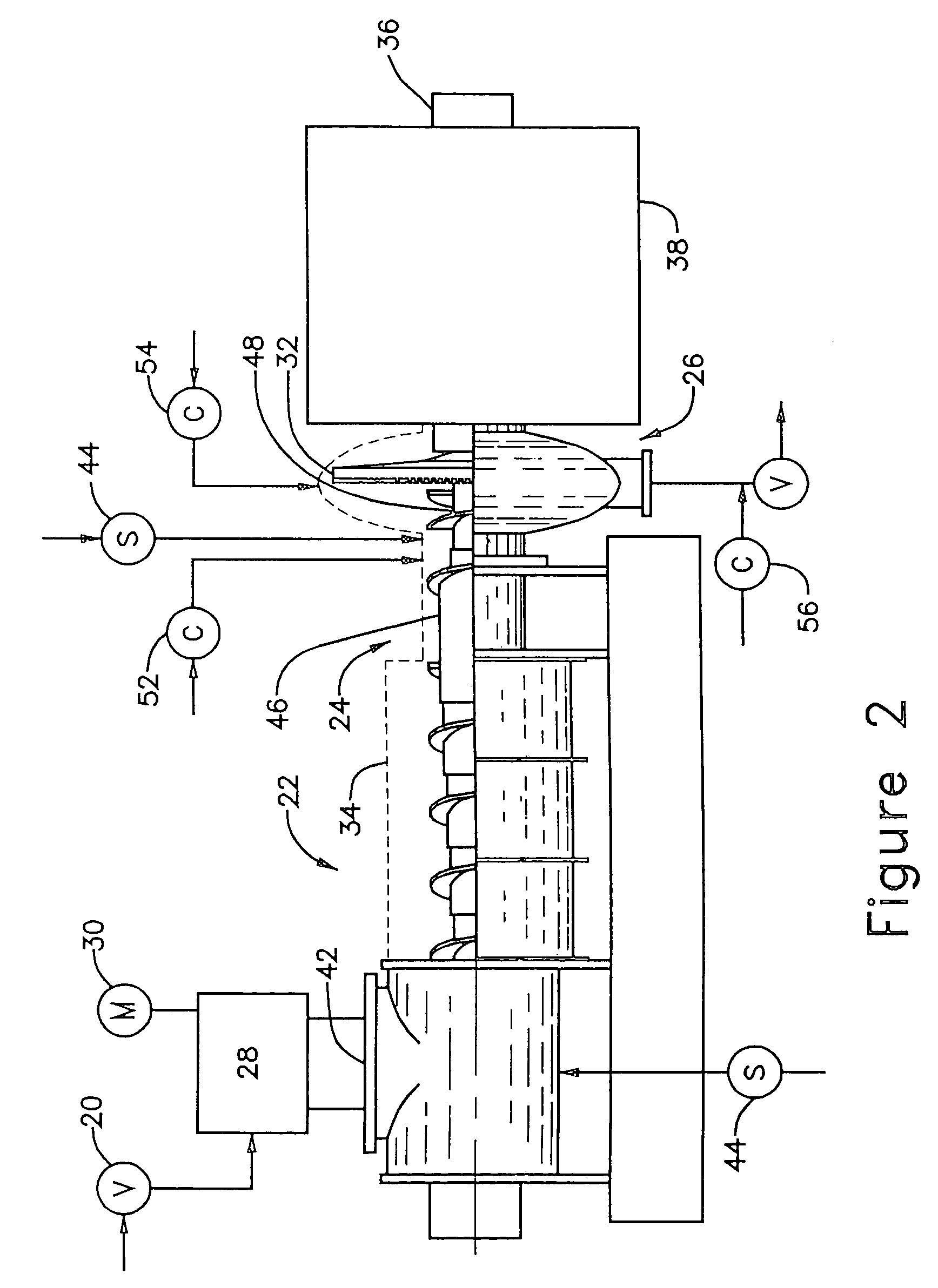

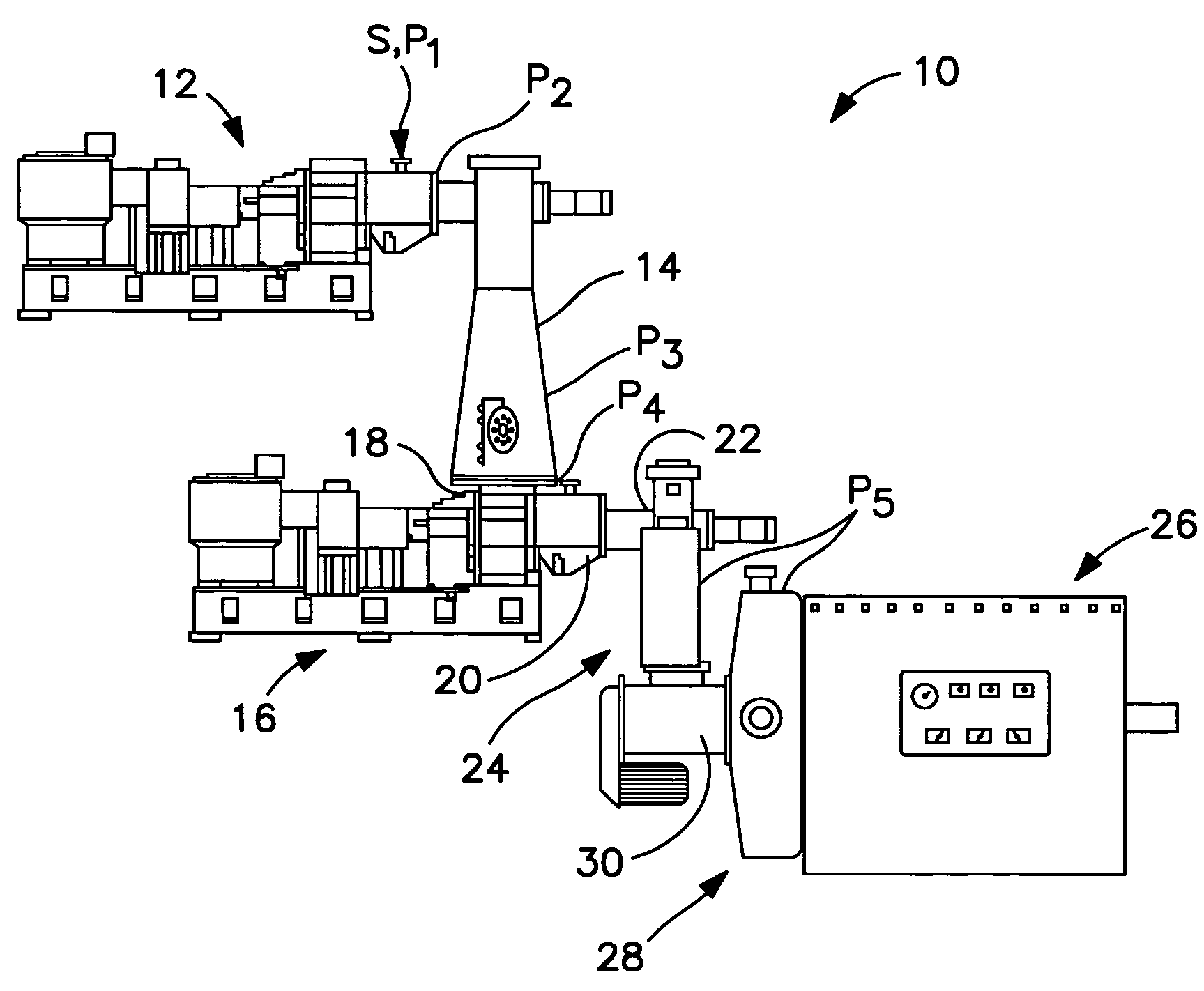

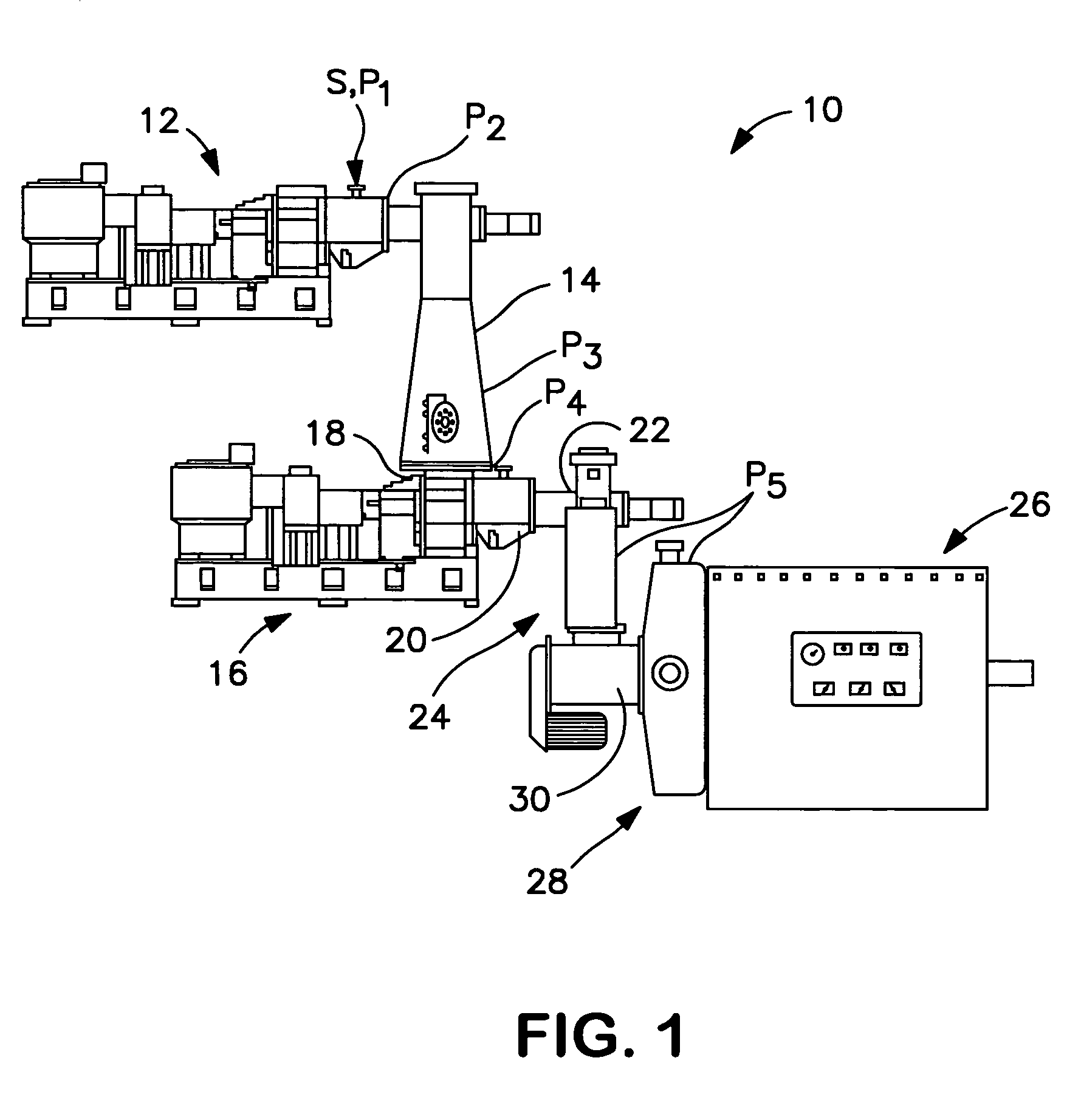

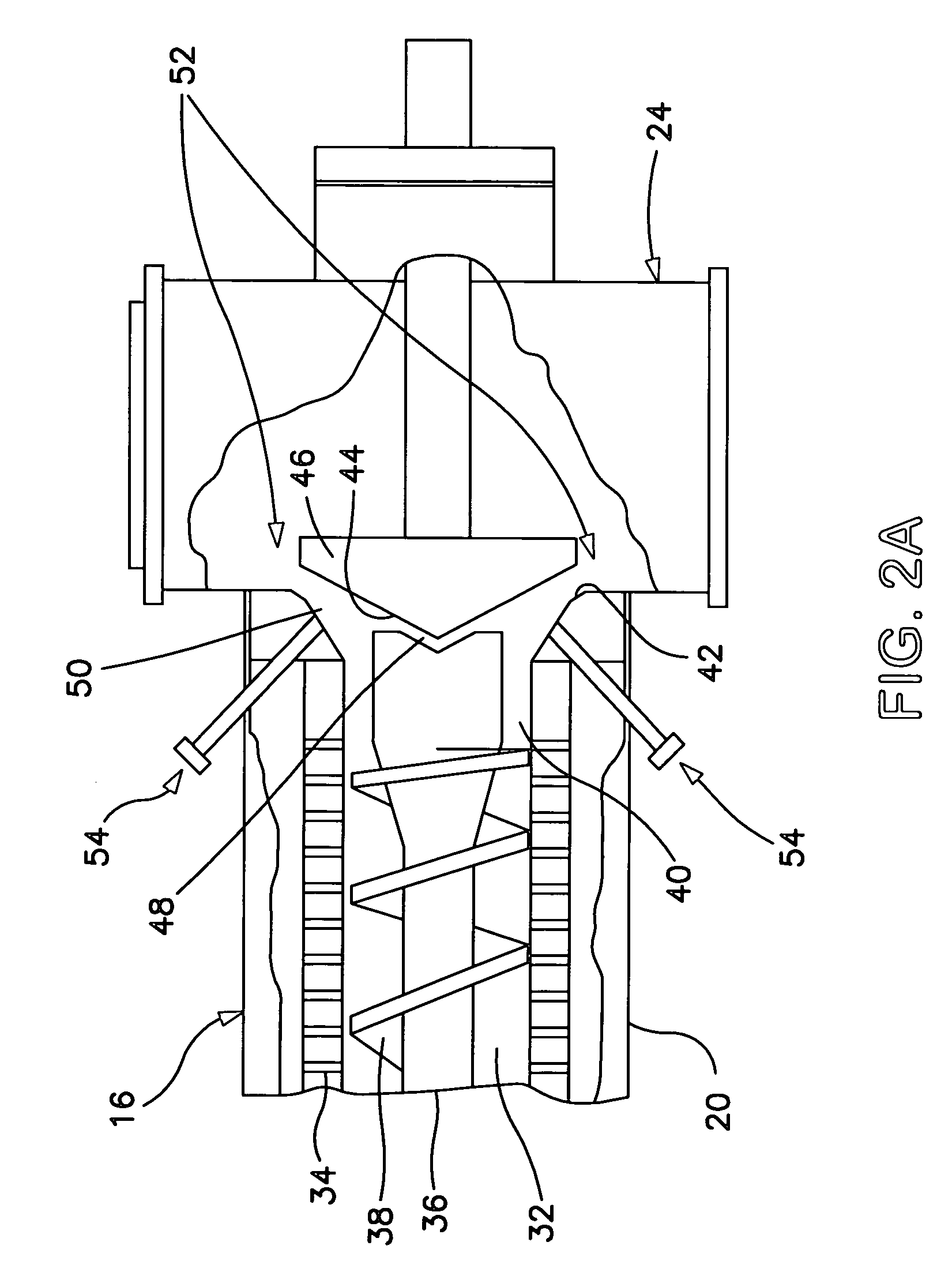

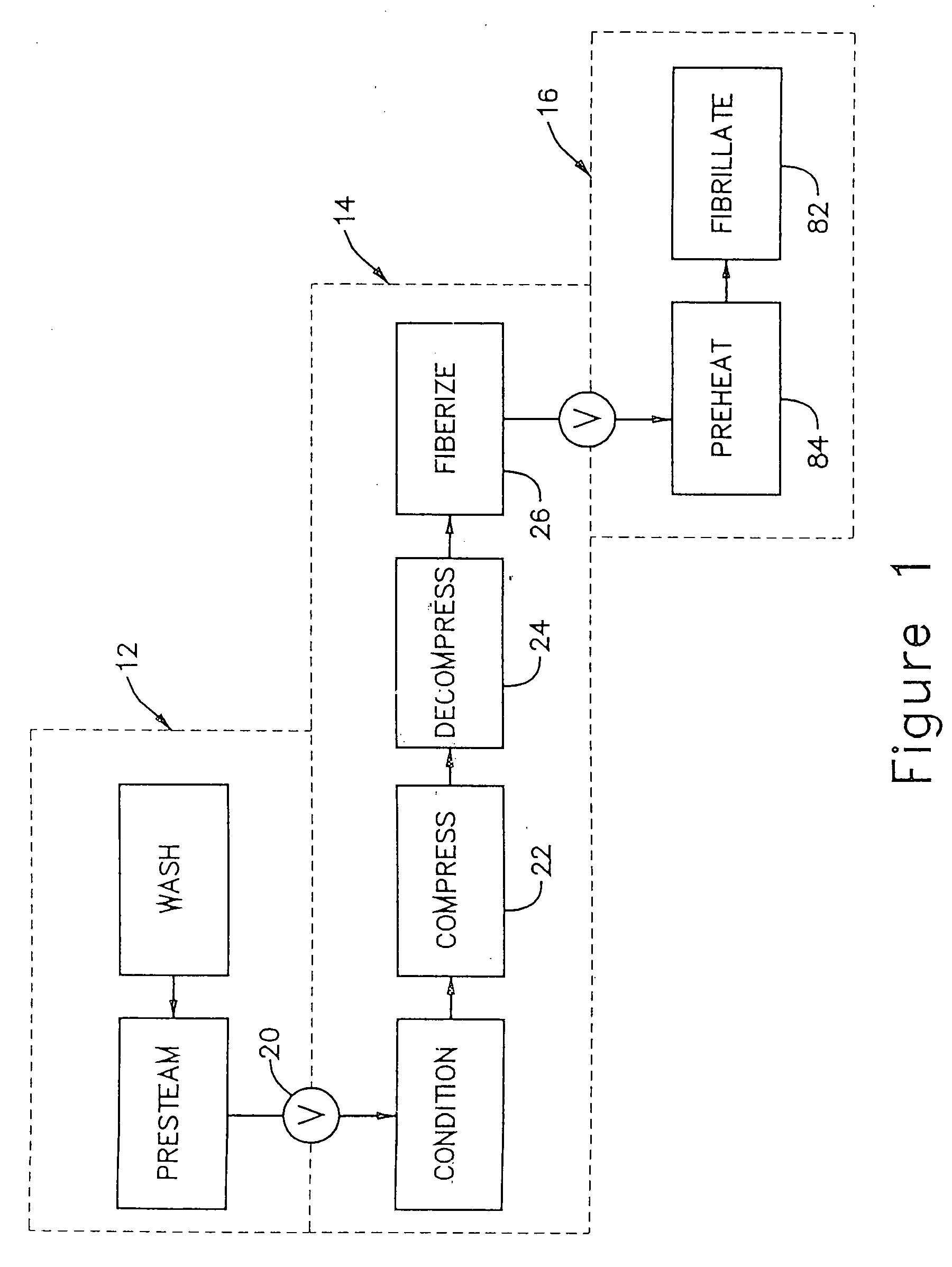

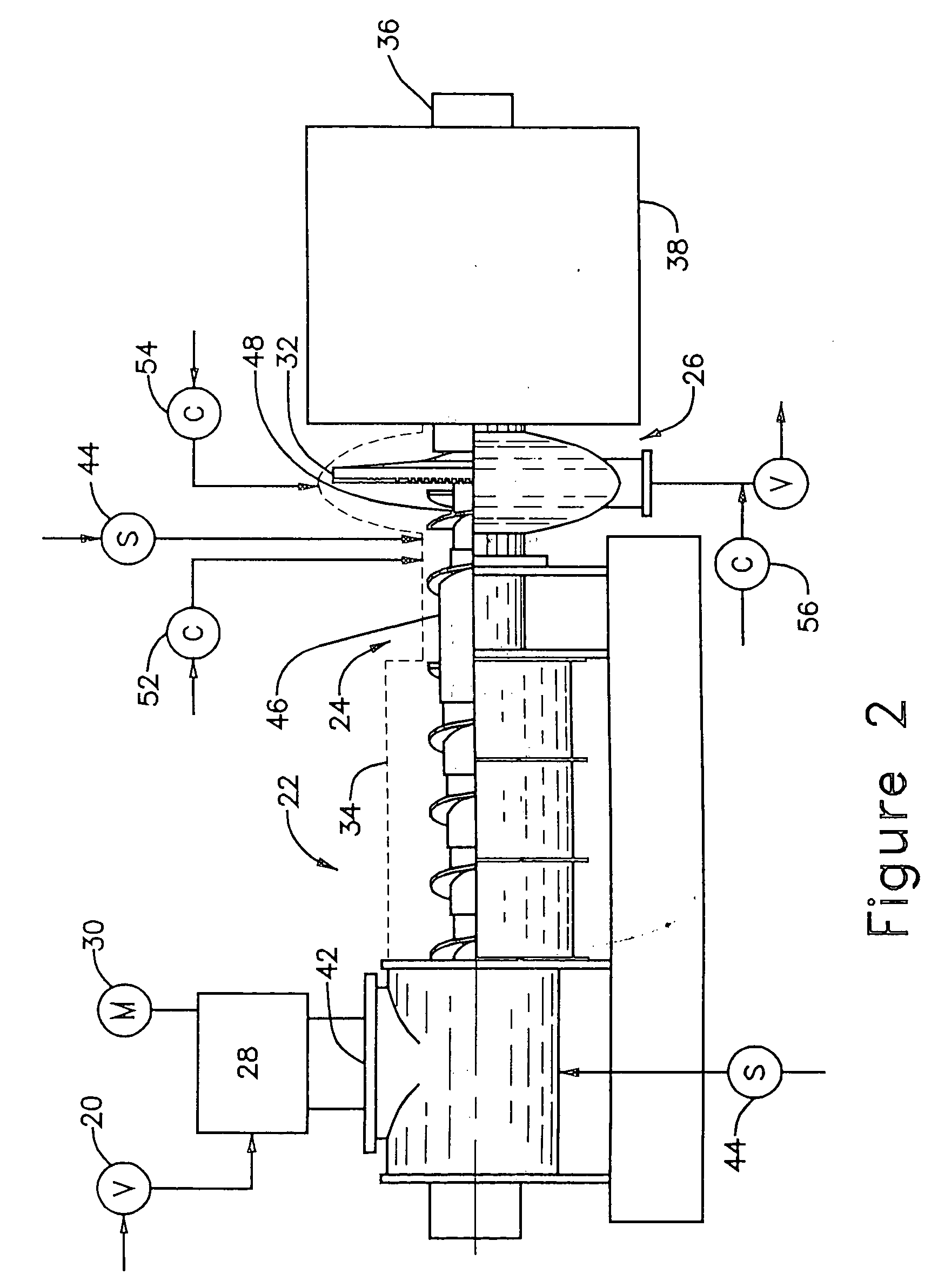

Energy efficient TMP refining of destructured chips

InactiveUS20060006264A1Quality improvementReduce energy consumptionCellulosic pulp after-treatmentPretreatment with water/steamFiberRing pattern

A system and method for thermomechanical refining of wood chips comprises preparing the chips for refining by exposing the chips to an environment of steam to soften the chips, compressively destructuring and dewatering the softened chips to a solids consistency above 55 percent, and diluting the destructured and dewatered chips to a consistency in the range of about 30 to 55 percent. The destructuring partially defibrates the material. This diluted material is fed to a rotating disc primary refiner wherein each of the opposed discs has an inner ring pattern of bars and grooves and an outer ring pattern of bars and grooves. The destructured and partially defibrated chips are substantially completely defibrated in the inner ring and the resulting fibers are fibrillated in the outer ring. The compressive destructuring, dewatering, and dilution can all be implemented in one integrated piece of equipment immediately upstream of the primary refiner, and the fiberizing and fibrillating are both achieved between only one set of relatively rotating discs in the primary refiner.

Owner:ANDRITZ INC

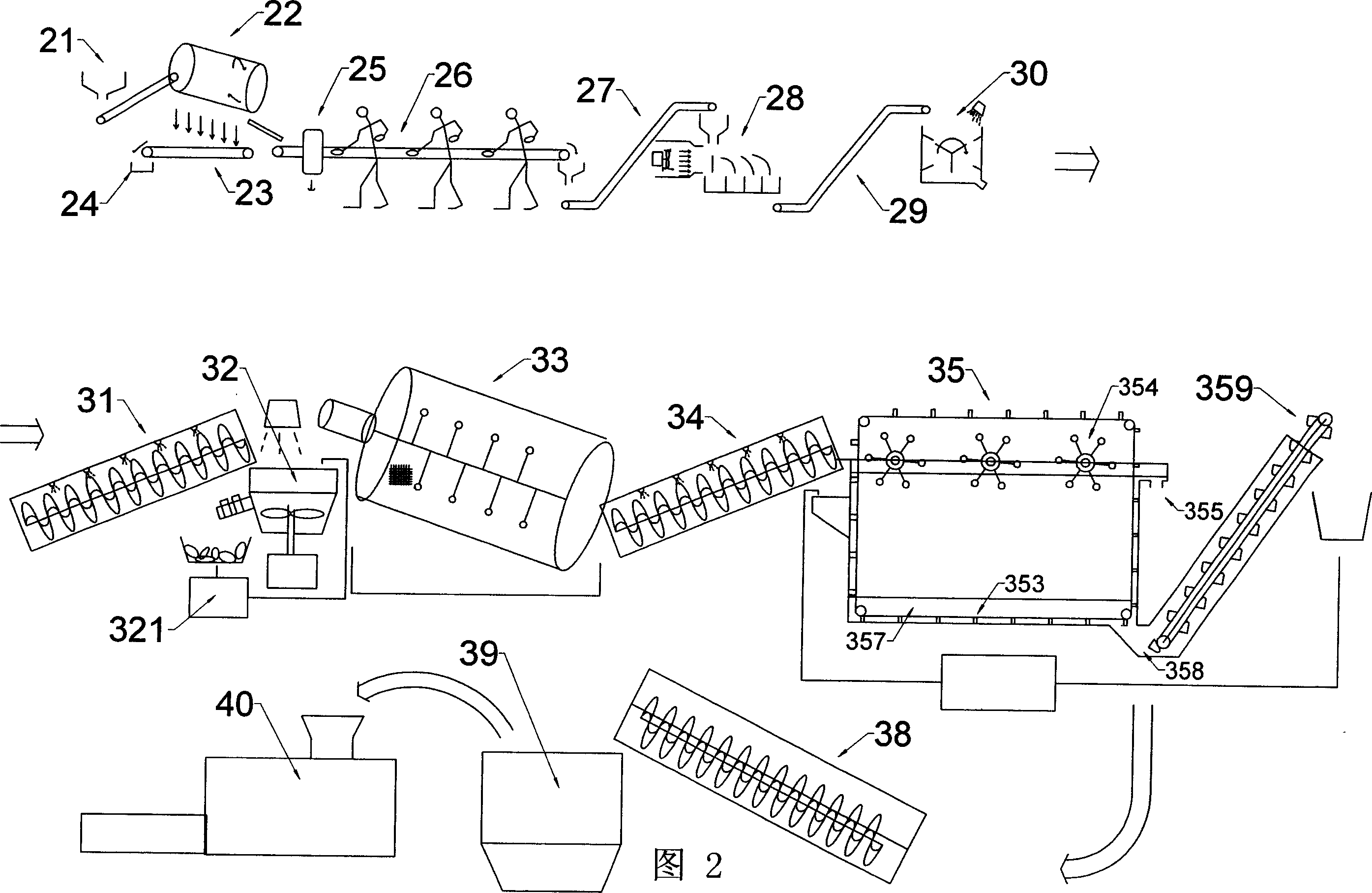

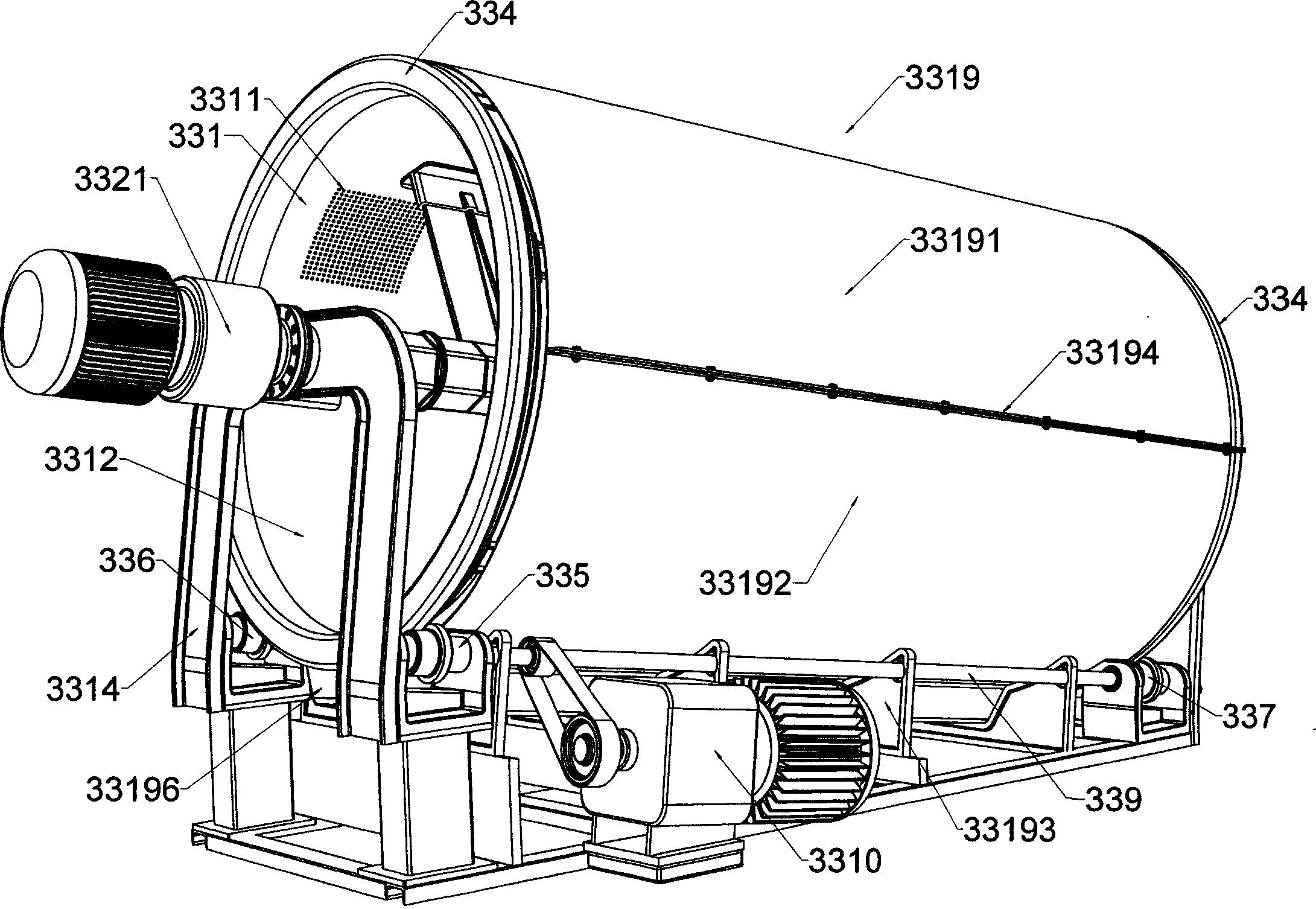

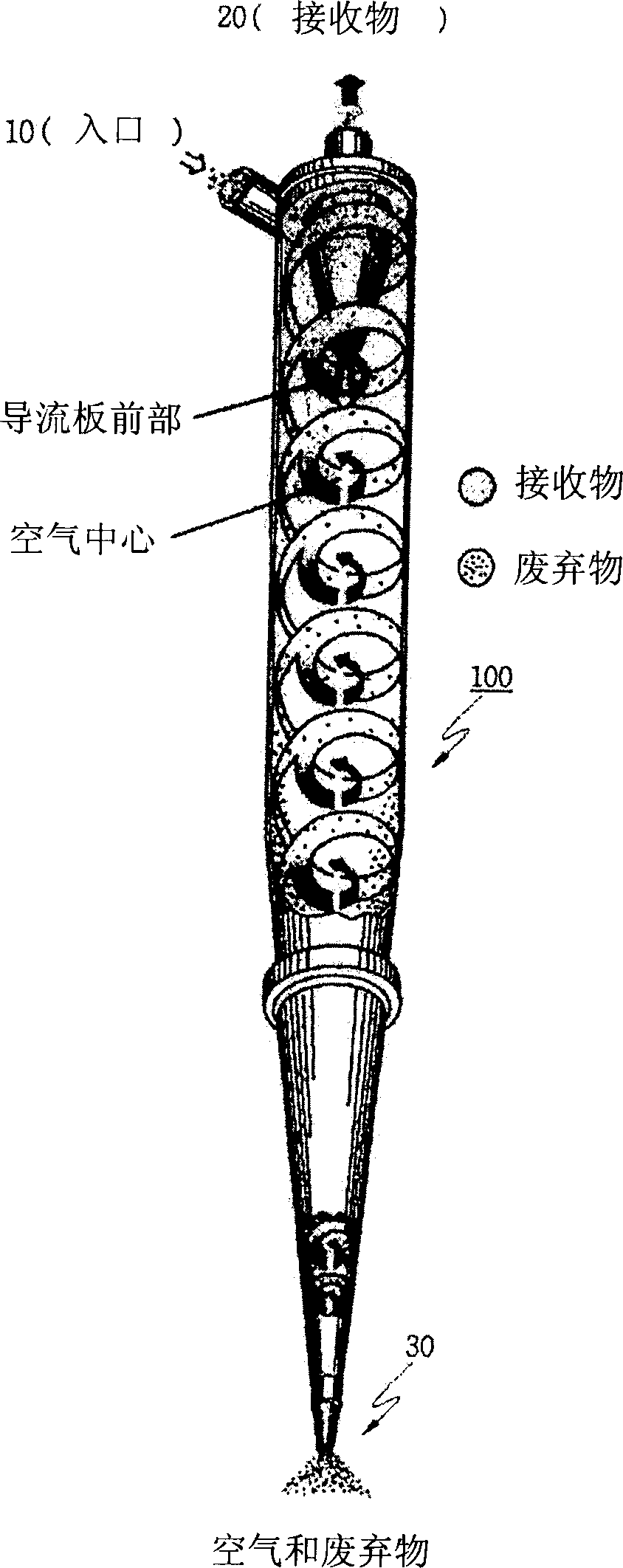

Separating method and system for waste paper and waste plastic mixture

InactiveCN1834340AReduce energy consumptionReduce loadGas current separationWashing/displacing pulp-treating liquorsFiberSingle stage

A method for separating out waste paper and waste plastic form their mixture including preliminary selecting, using magnetic separator to select out magnetic impurities, using hand to pick up large impurity block without plastic, using fan to blow impurities with different gravities into different grooves at different distance, using mechanical rubbing machine to separate paper fiber from plastic, using single stage floating tank to beat floating matters for releasing paper fiber off, storing floated out plastic and palletizing them for reutilization.

Owner:曾碚凯

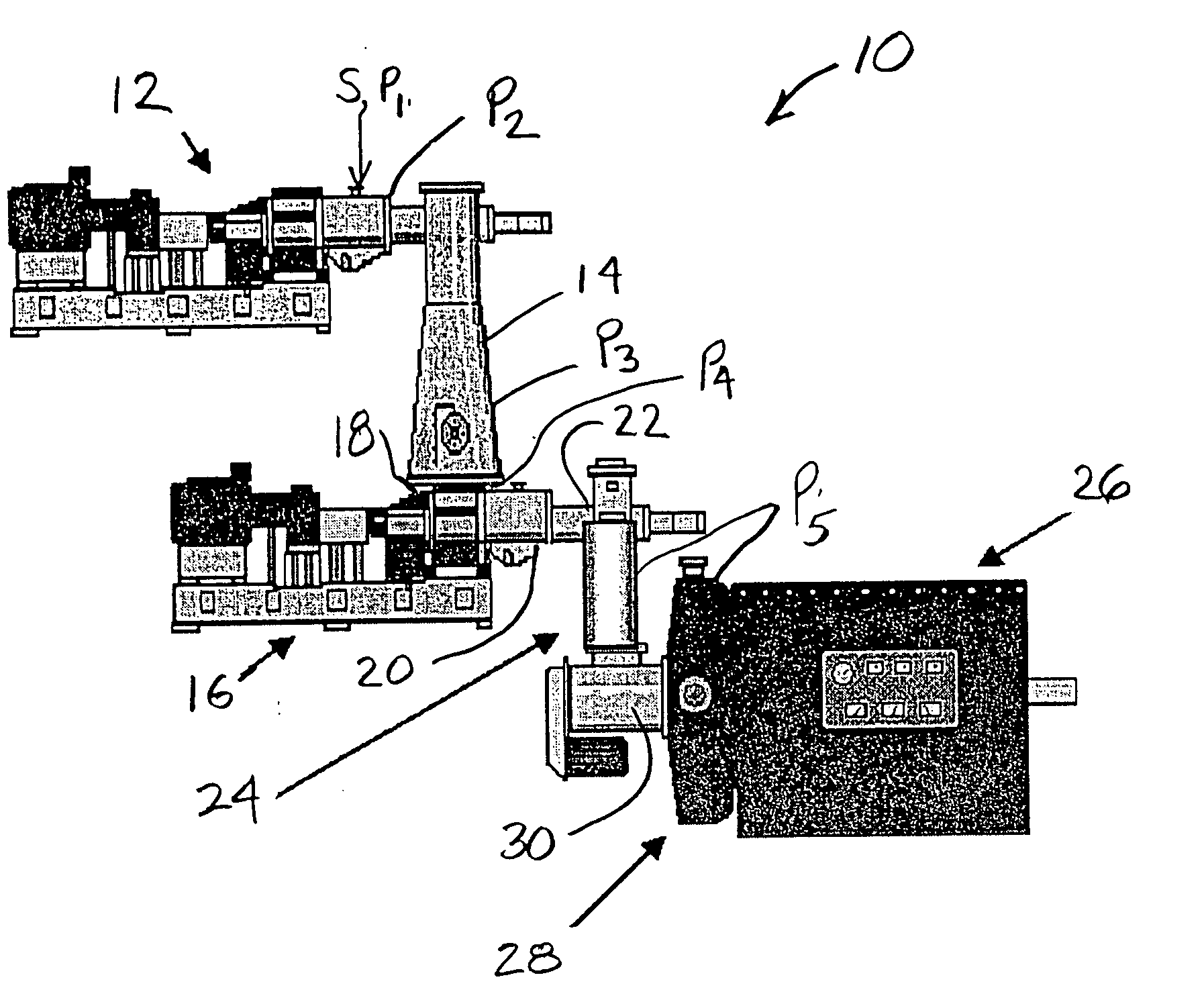

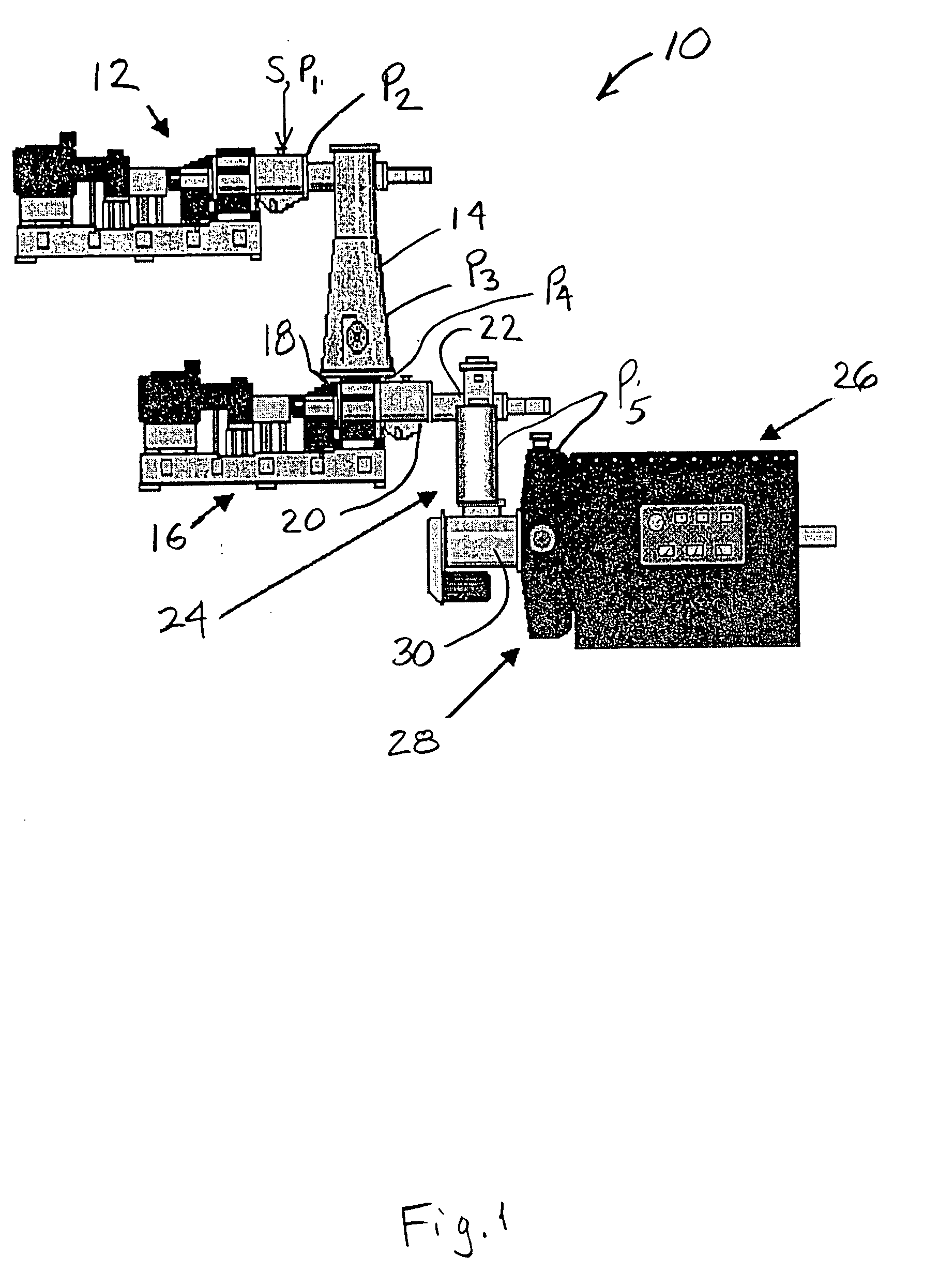

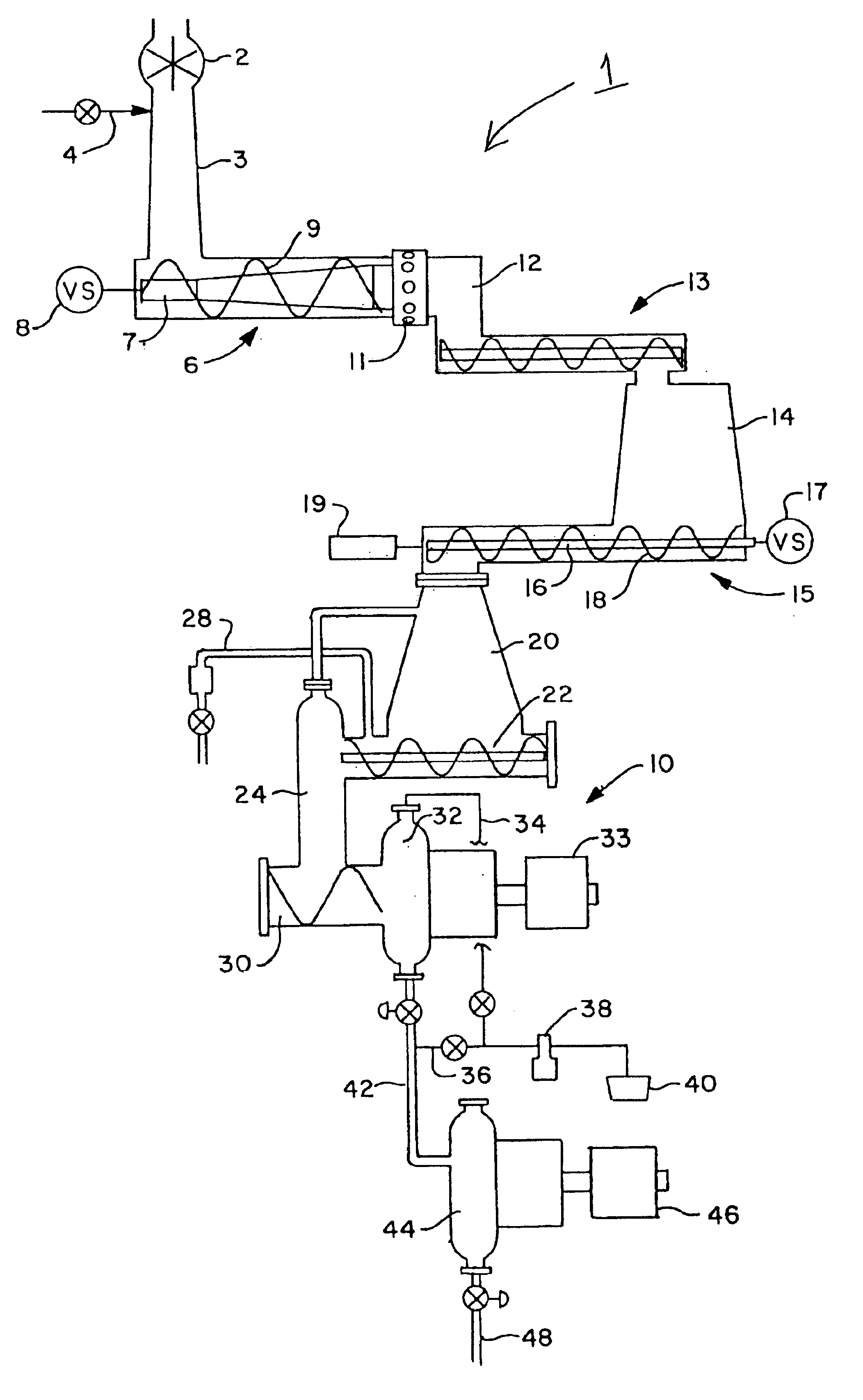

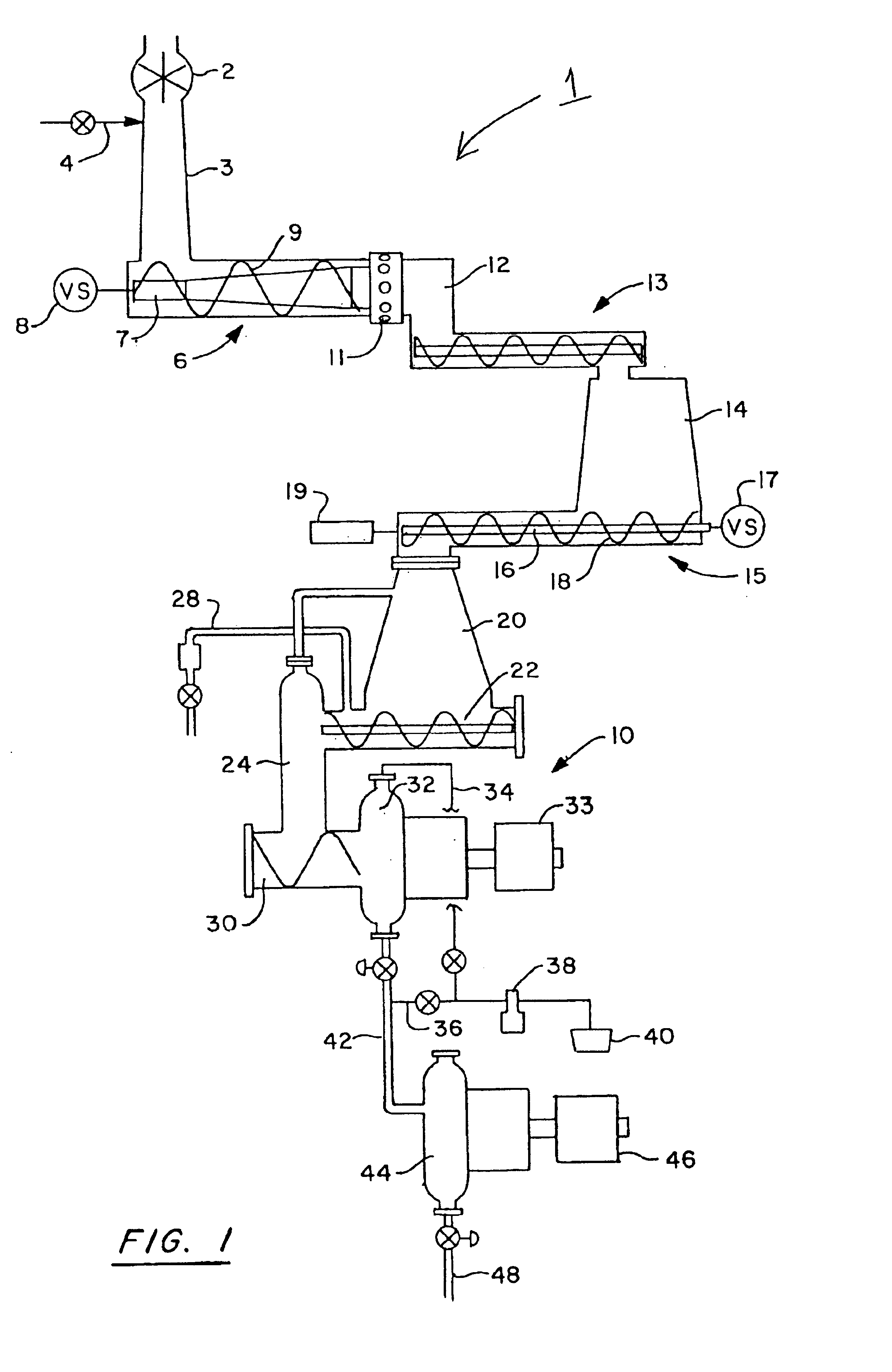

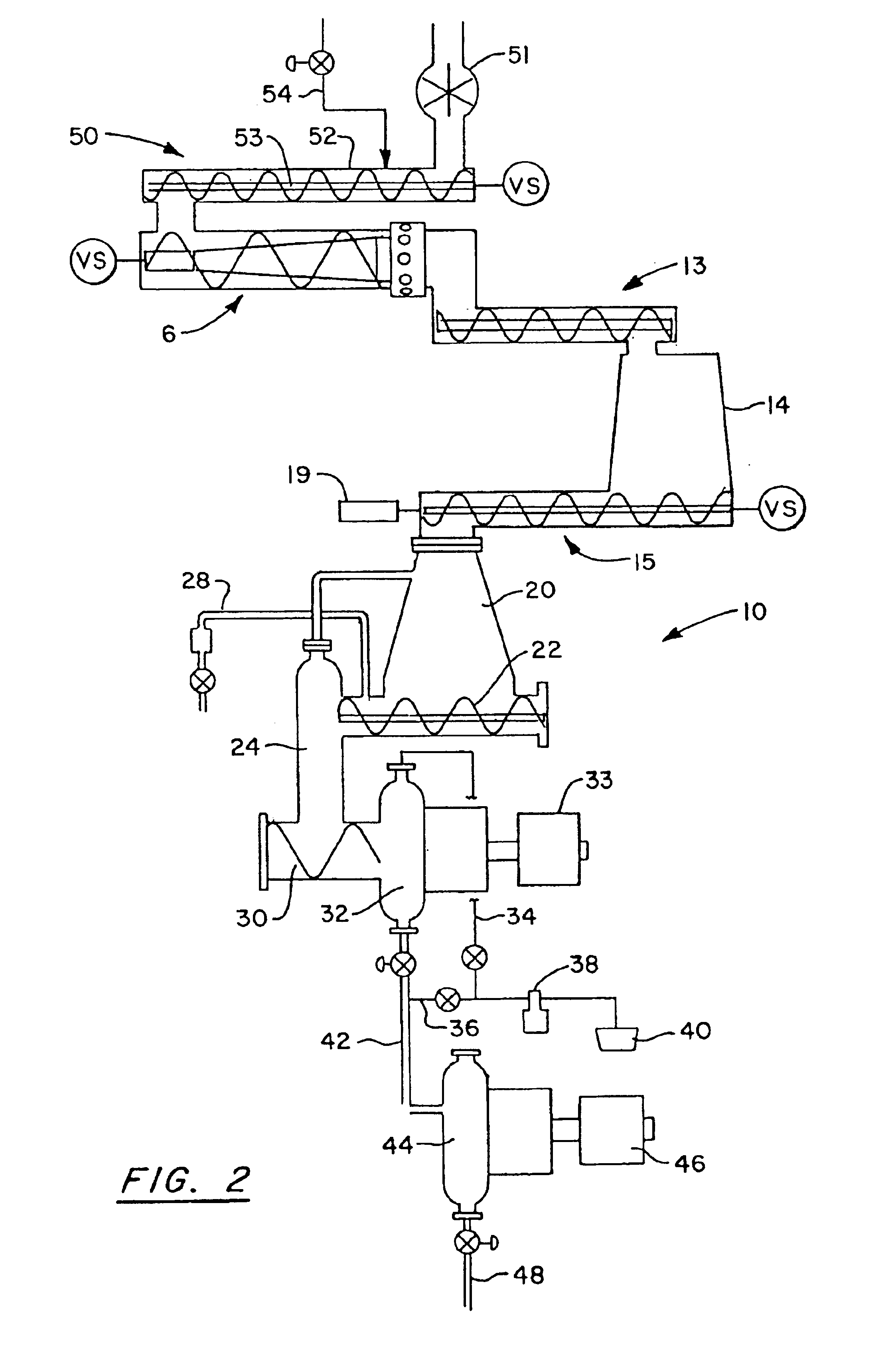

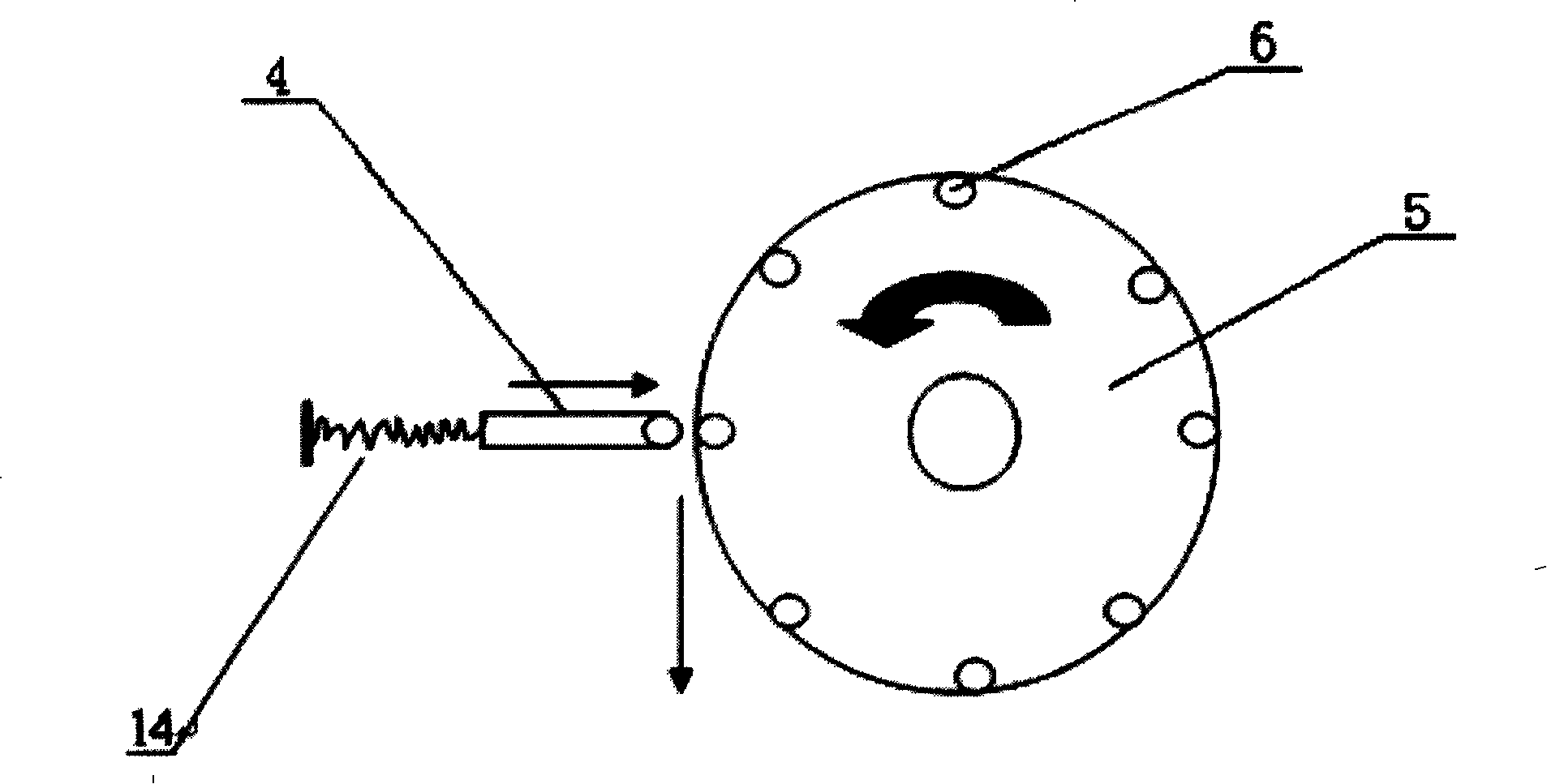

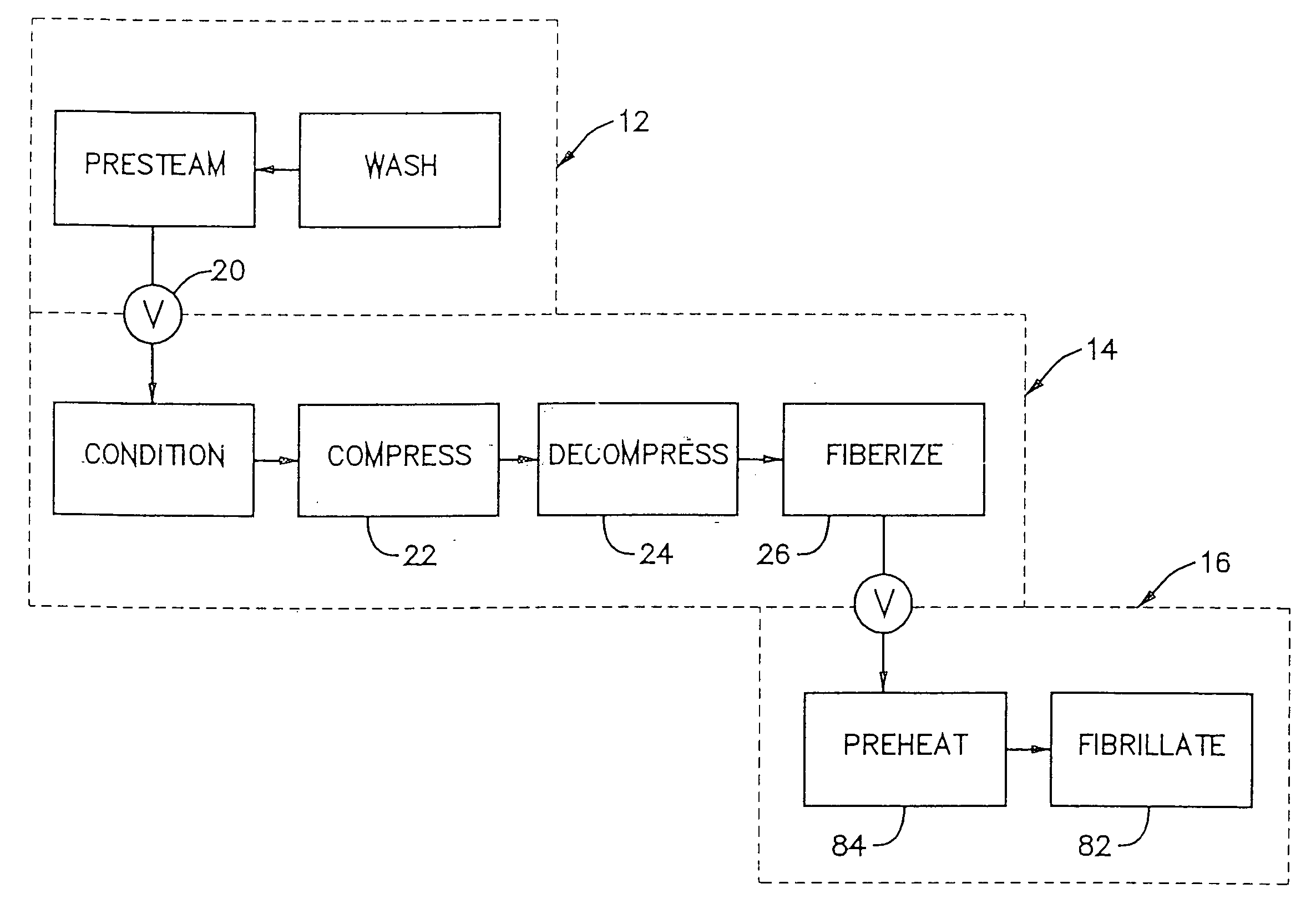

High defiberization chip pretreatment

ActiveUS7300541B2Reduce energy consumptionGood removal effectCellulosic pulp after-treatmentPretreatment with water/steamChemical treatmentFiber bundle

A chip pretreatment process which comprises conveying the feed material through a compression screw device having an atmosphere of saturated steam at a pressure above about 5 psig, decompressing and discharging the compressed material from the screw device into a decompression region, feeding the decompressed material from the decompression region into a fiberizing device, such as a low intensity disc refiner, where at least about 30 percent of the fiber bundles and fibers are axially separated, without substantial fibrillation of the fibers. Preferably, the fibers are axially separated with less than about 5 percent fibrillation, and subsequently the fiberized material is refined in a high intensity disc refiner until at least about 90 percent of the fibers are fibrillated. In another form the invention combines chip fiberizing with chemical treatments, for improving the pulp property versus energy relationships.

Owner:ANDRITZ INC

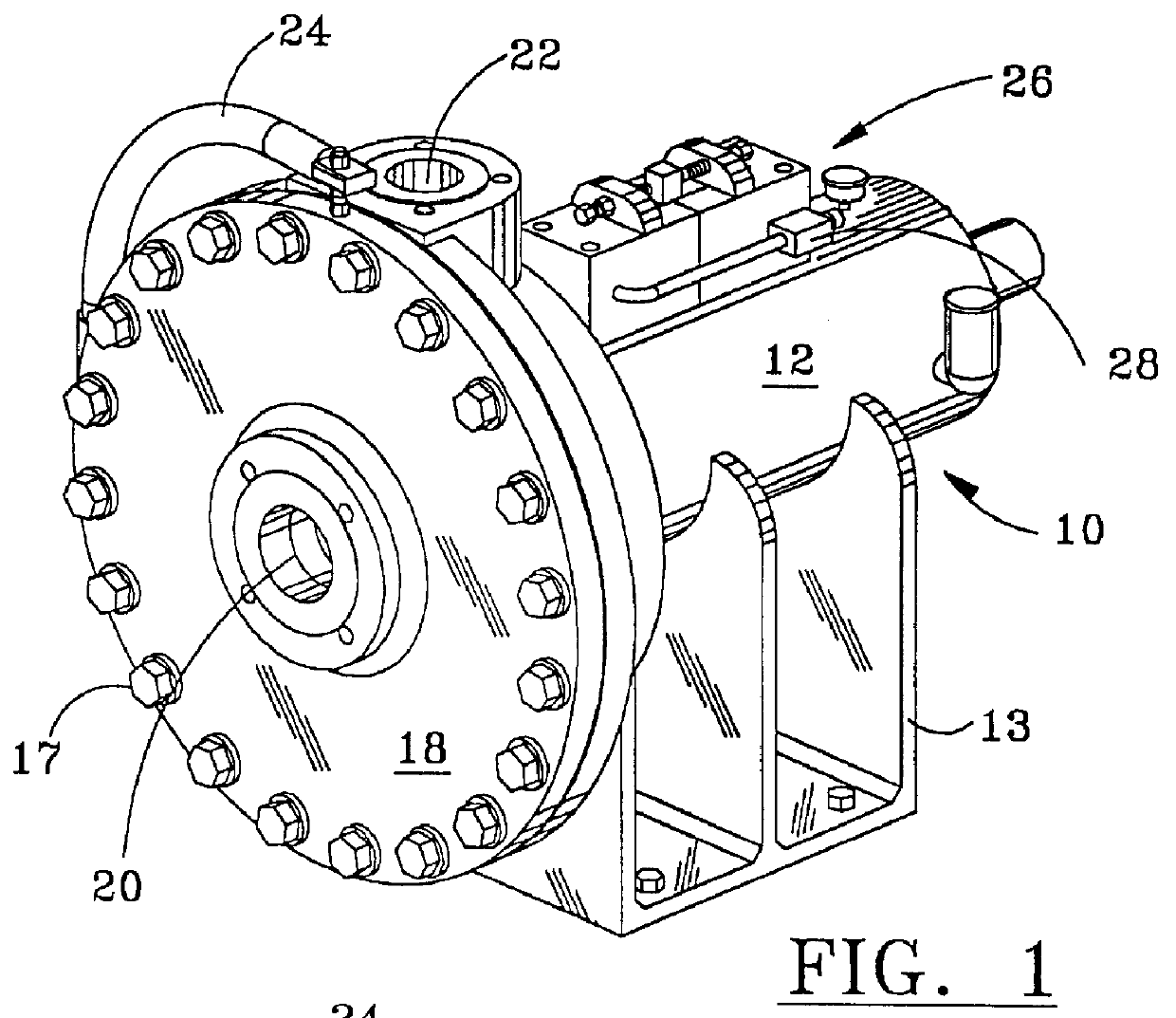

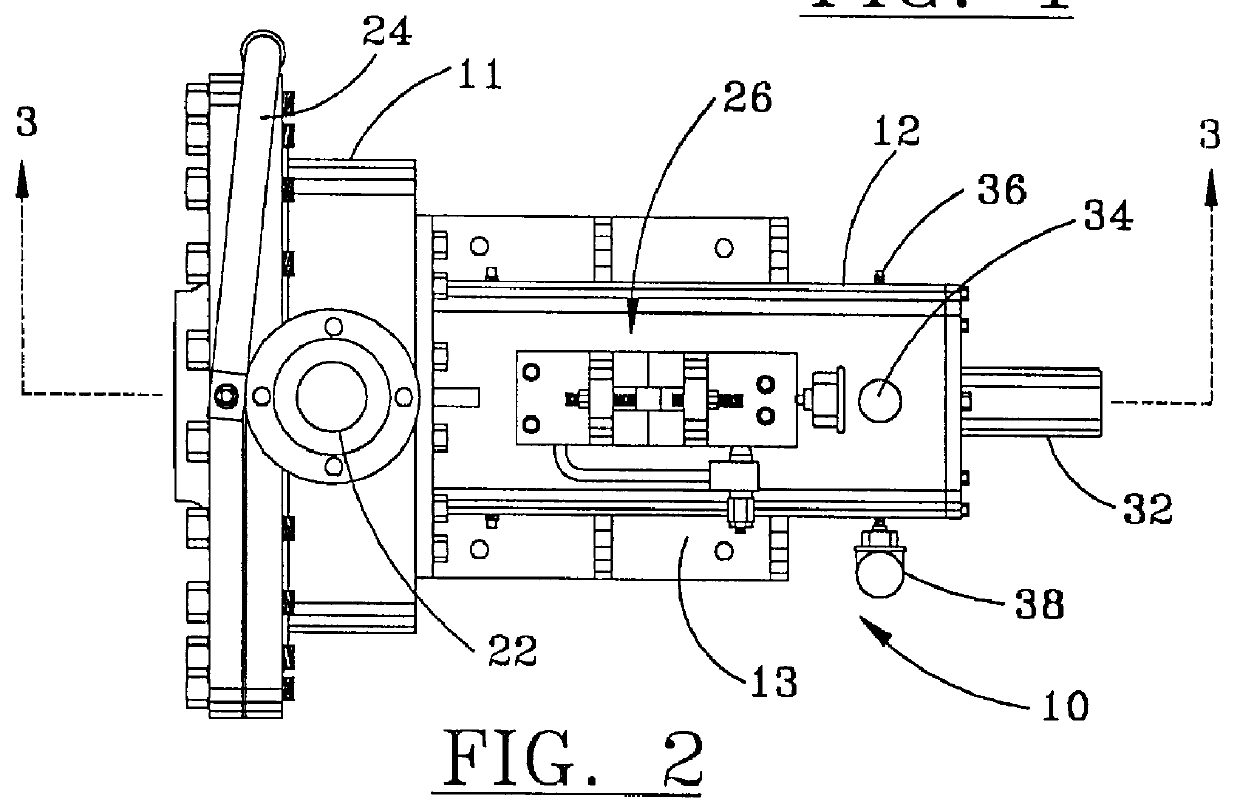

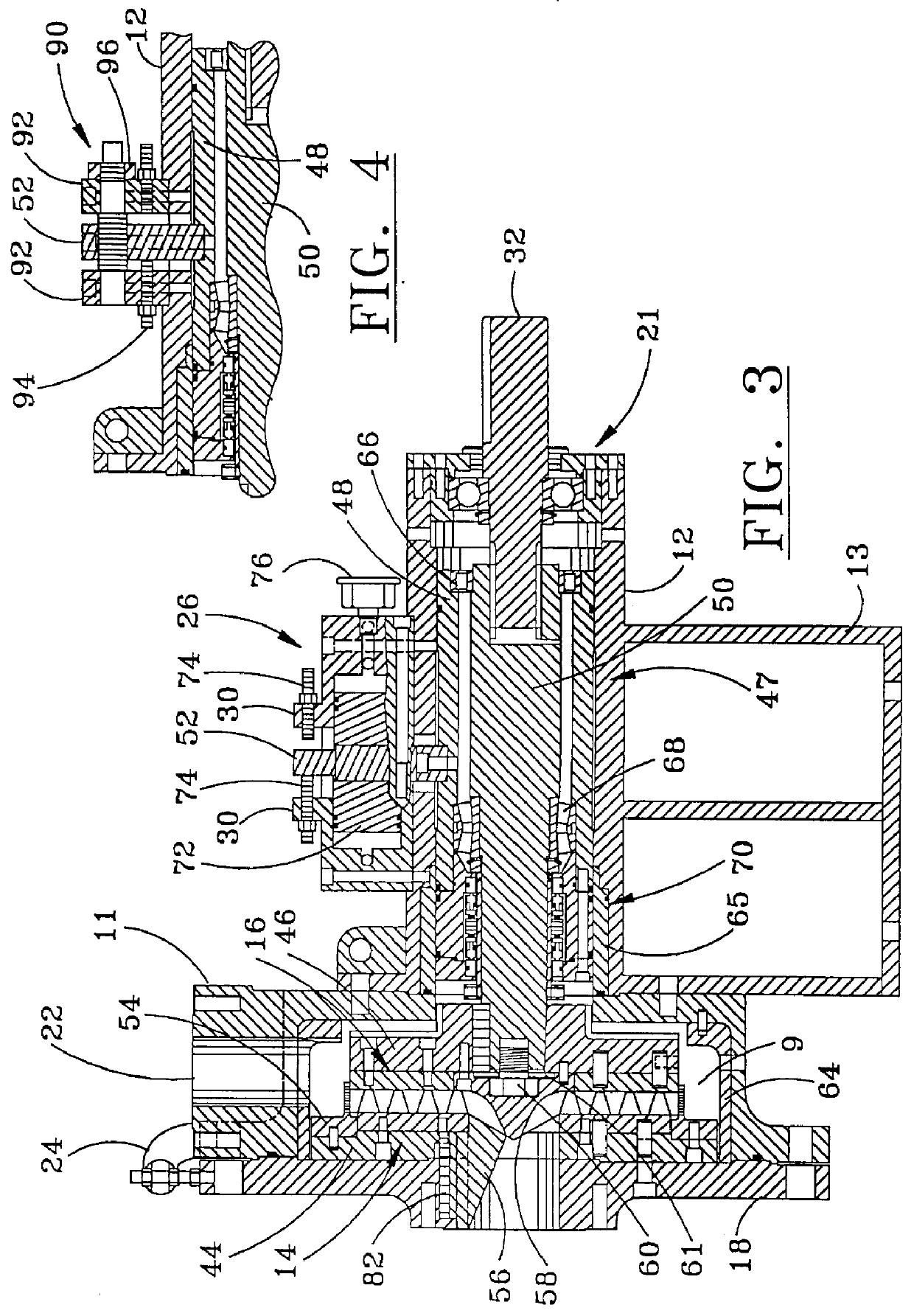

Rotary grinder method and apparatus

InactiveUS6102310AIncrease the number ofImprove permeabilityGas current separationCocoaSlurryEngineering

An in-line grinder has been developed which can be configured to perform in a variety of applications through the use of an adjustable rotor / stator assembly, removable shear bar, and a variety of interchangeable stator-rotor configurations. A unique drive system utilizing a mechanical seal cartridge provides maximum sealing with a minimum of shaft deflection and run-out, thereby improving performance. These improvements collectively allow the grinder to be configured for optimum sizing of solids to a predetermined particle size for a broad range of materials. It has been demonstrated that a class of in-line grinders such as that described herein is applicable for sizing drill cuttings for injection into a subsurface formation by way of an annular space formed in a wellbore. The cuttings are removed from the drilling fluid, conveyed to a shearing and grinding system that converts the cuttings into a viscous slurry with the addition of water and viscosity enhancing polymers. The system in its simplest form comprises a slurry tank, a pump, and the instant in-line grinder. The pump circulates the mixture of cuttings, water including sea water and chemicals between the slurry tank and the in-line grinder. The ground mixture leaving the in-line grinder is then routed to an injection pump for high pressure injection into the formation.

Owner:RICKY & MARCELLE DAVENPORT REVOCABLE TRUST

Method of pretreating lignocellulose fiber-containing material in a pulp refining process

InactiveUS6899791B2Improvement in pulp strength property and shive content of pulpHigh strengthPretreatment with water/steamPulp beating/refining methodsCellulose fiberDigestion

A method and apparatus for pretreating or conditioning lignocellulose fiber containing feed material in preparation for conversion to pulp. Wood chips are pretreated under conditions of elevated temperature, pressure and humidity and subsequently compressed to cause destructuring of the fibers of the feed material. The pretreated wood chips are then converted to pulp using such methods as the ground wood pulping process or chemical digestion process.

Owner:ANDRITZ INC

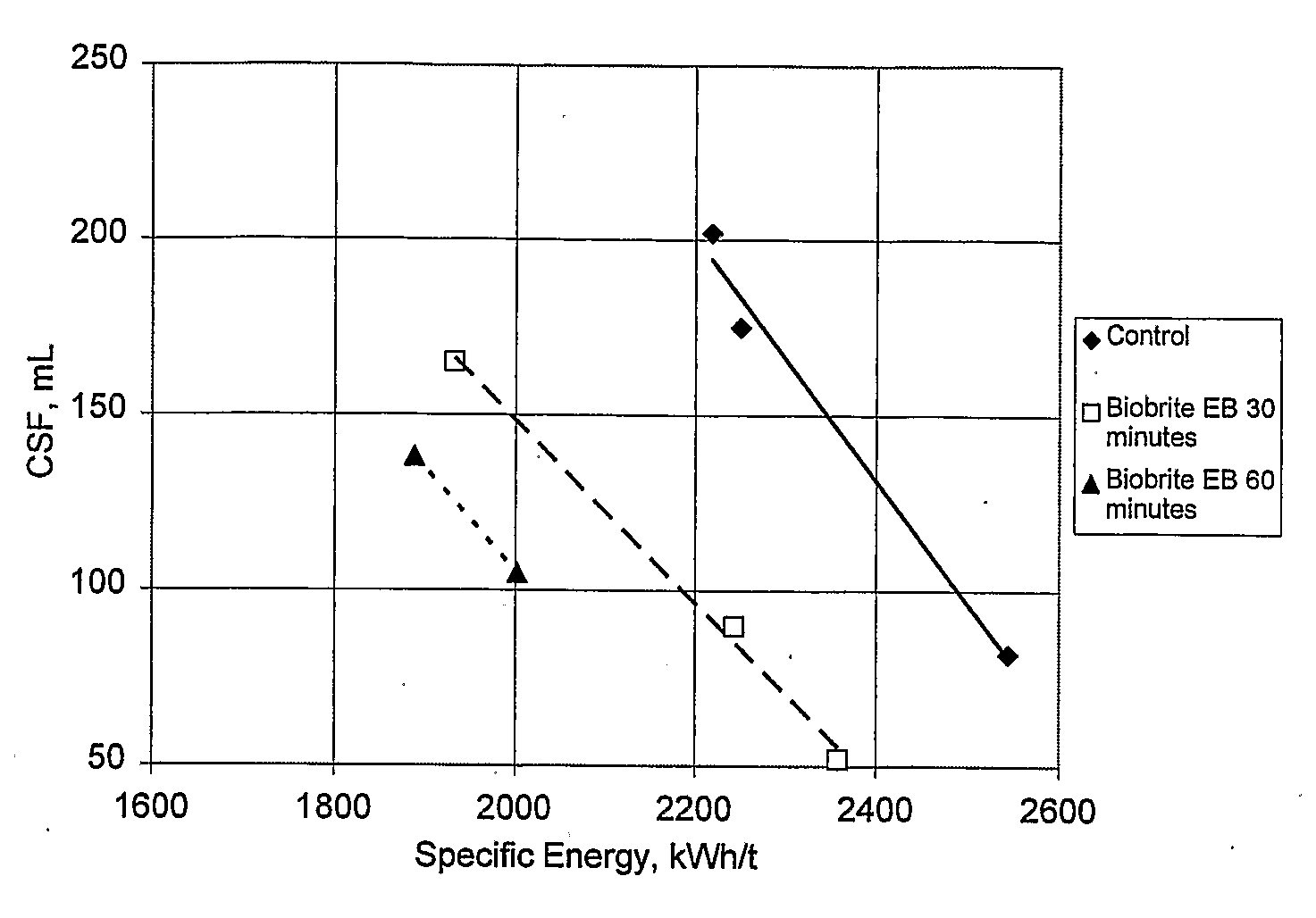

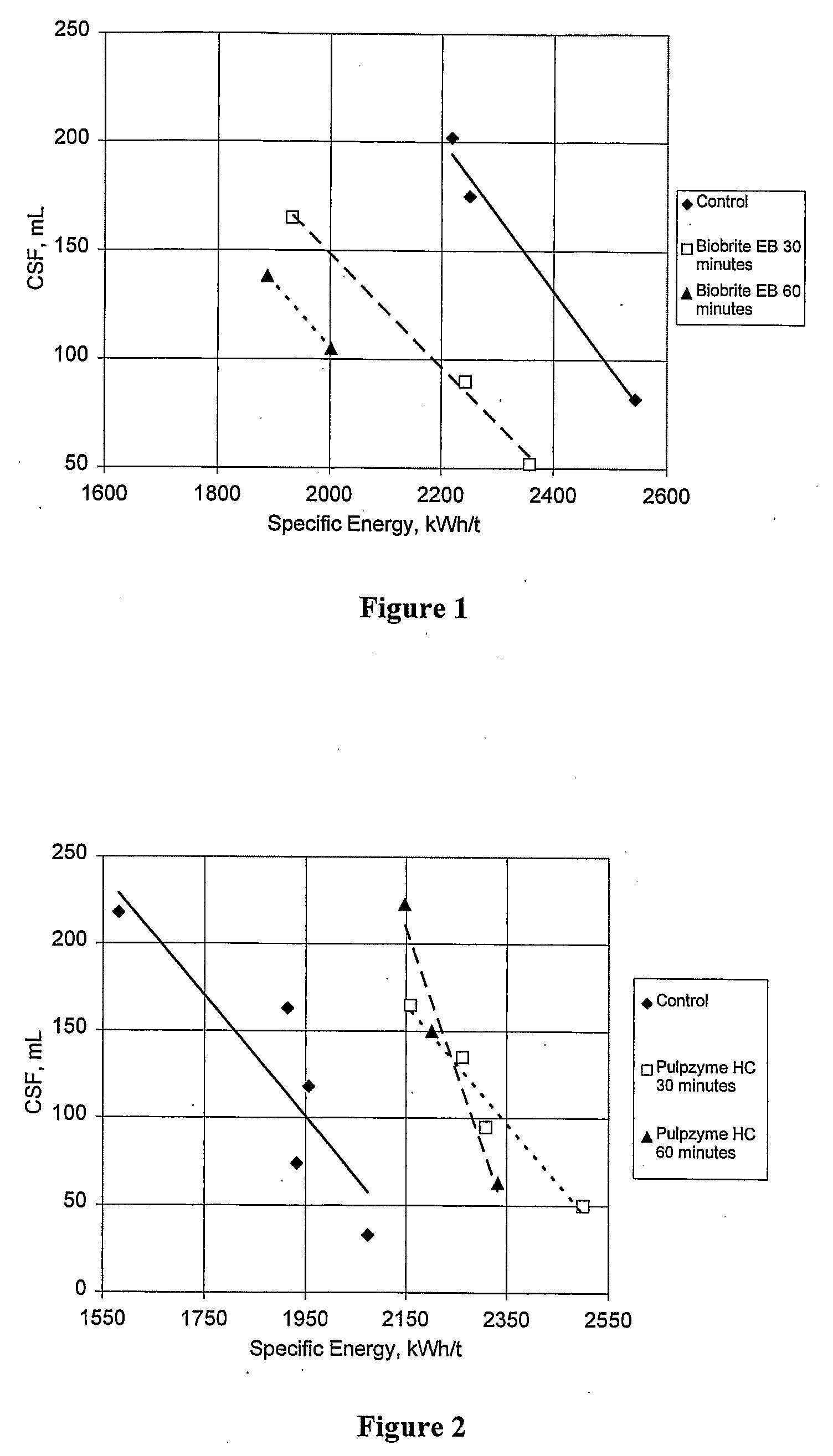

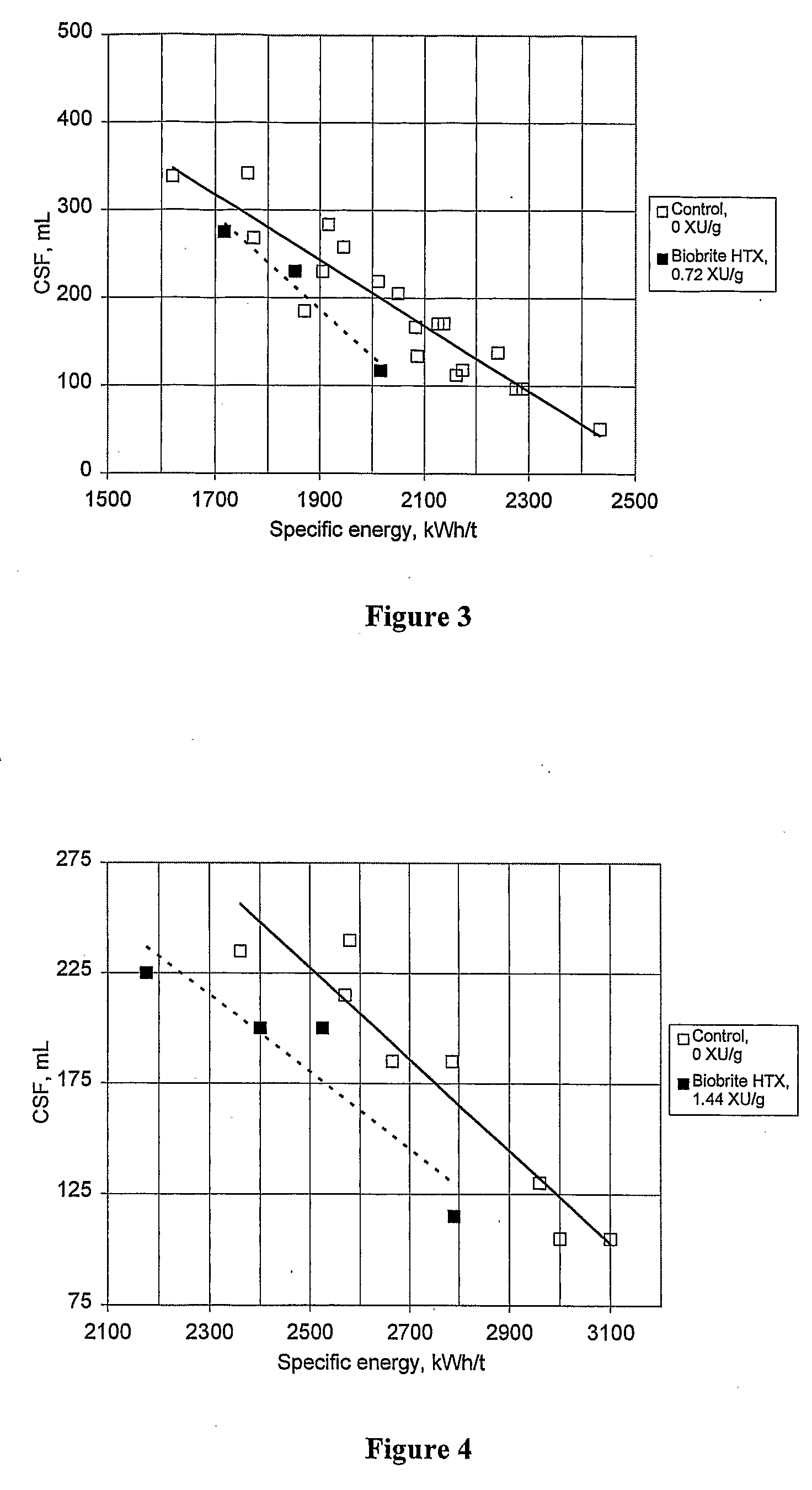

Process for increasing the refiner production rate and/or decreasing the specific energy of pulping wood

InactiveUS20050133643A1Pose health riskIncrease ratingsPaper recyclingReed/straw treatmentProduction rateEngineering

The present invention relates to processes for enhancing a refiner's production rate and / or reducing the specific energy consumption for a freeness target through the use of lubricant(s) or carrier(s) / frictionizer(s), respectively.

Owner:SOLENIS TECH CAYMAN

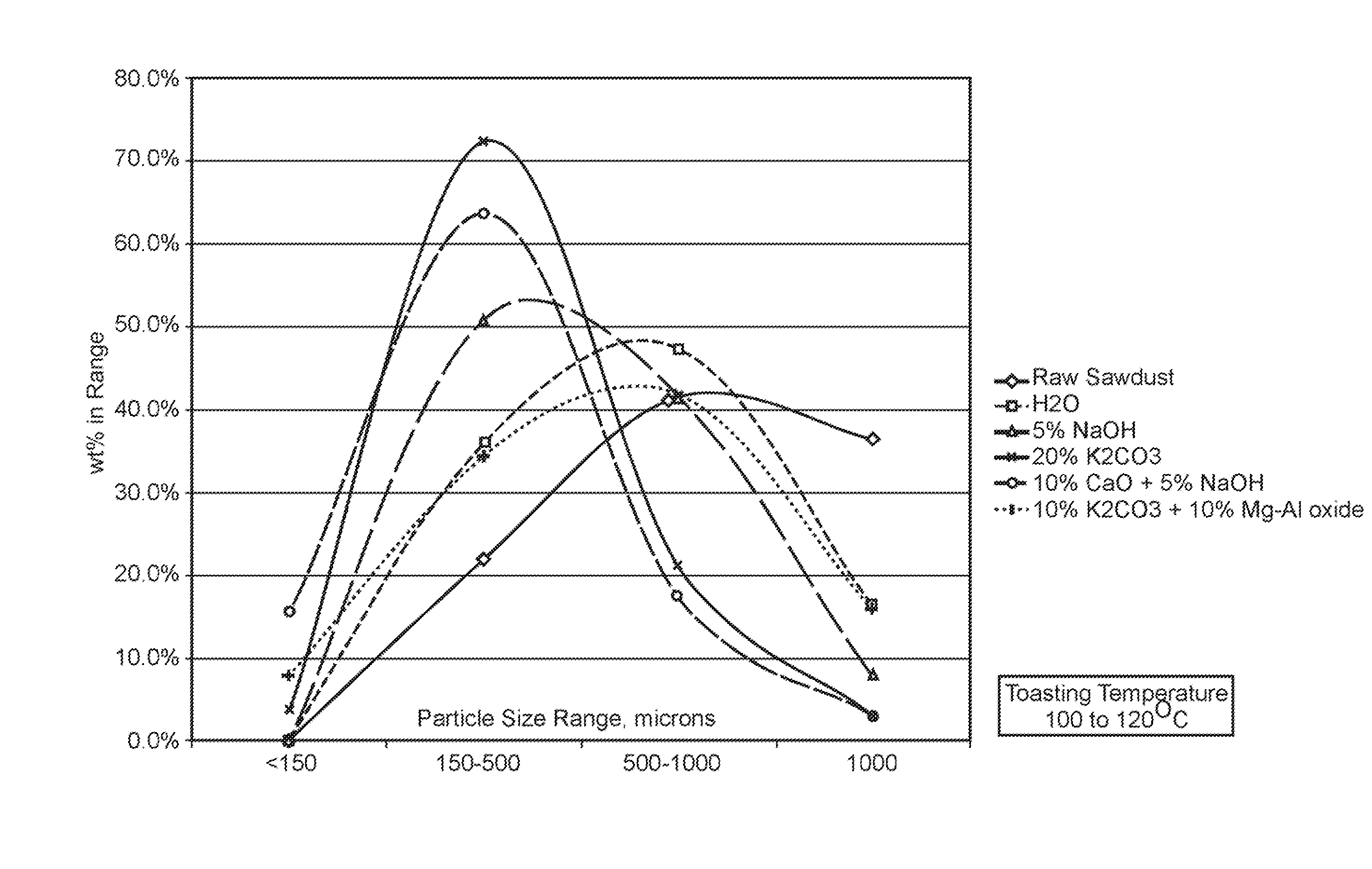

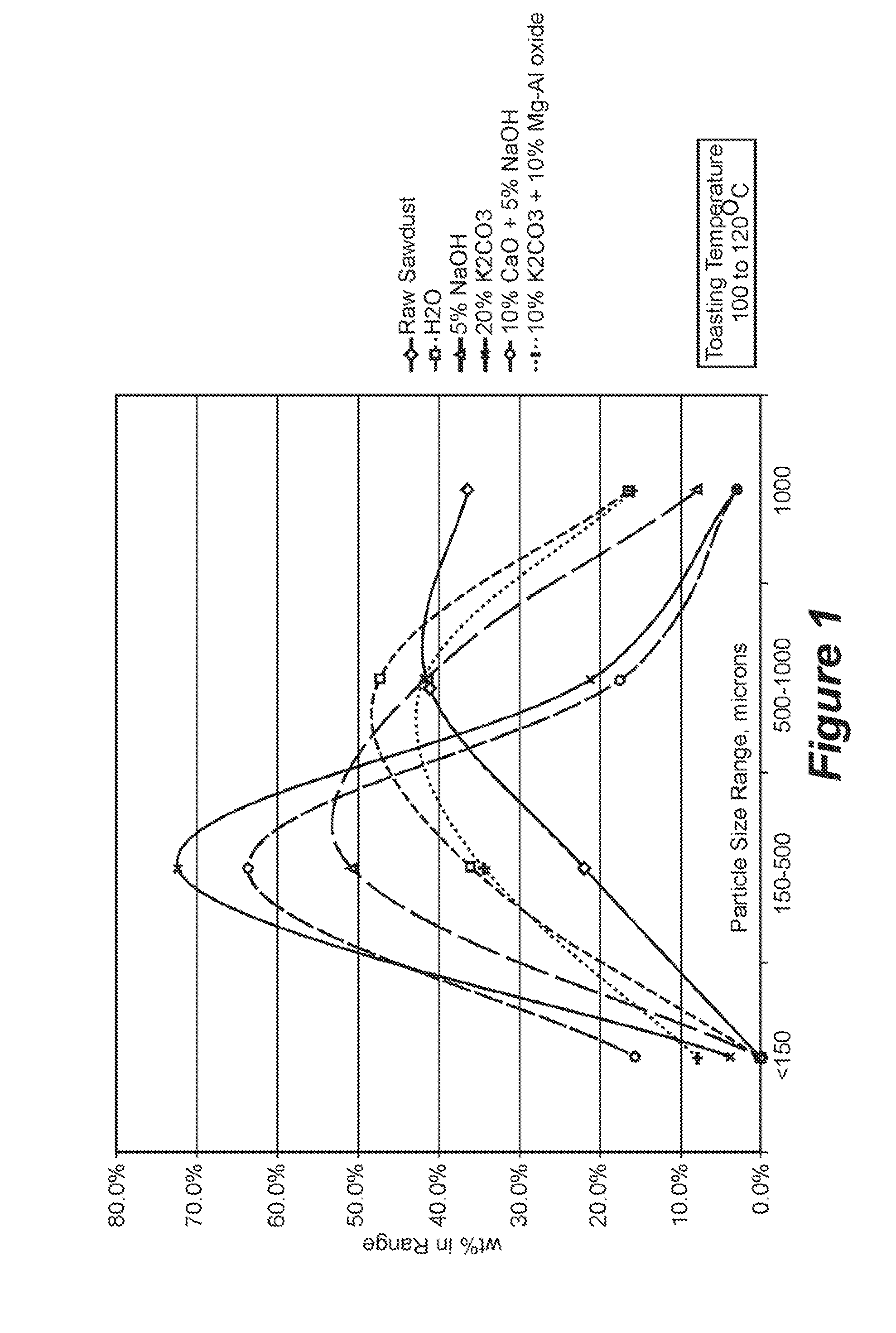

Comminution and densification of biomass particles

A method is disclosed for reducing the mechanical strength of solid biomass material, in particular ligno-cellulosic biomass. The method comprises heating the solid biomass material to a temperature in the range of 105° C. to 200° C. The heat treatment, which is referred to as “toasting”, significantly reduces the mechanical energy required for reducing the particle size of the solid biomass material.The method is particularly suitable as a pretreatment step to a conversion reaction of the solid biomass material.

Owner:MARD INC

Preparation method for bagasse cellulose nanofiber membrane

ActiveCN103422379AConducive to high-value utilizationImprove featuresPulp bleachingPaper-making machinesFiberChemical treatment

The invention discloses a preparation method for a bagasse cellulose nanofiber membrane. The method comprises the main steps of preparing bagasse, preparing bagasse cellulose and preparing the bagasse nano-cellulose membrane. (1) acid-base chemical treatment is carried out; (2) solution is treated through the mechanical methods such as grinding and centrifuging, and uniform biomass cellulose nanofiber is prepared; (3) membrane formation is carried out through vacuum filtration. The preparation method has the advantages that the method is simple, the cost is lower, the popularization is easy, the reclamation and effective recycling of waste are realized, the pollution to the environment is relieved, and the high-value utilization of bagasse is also facilitated.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

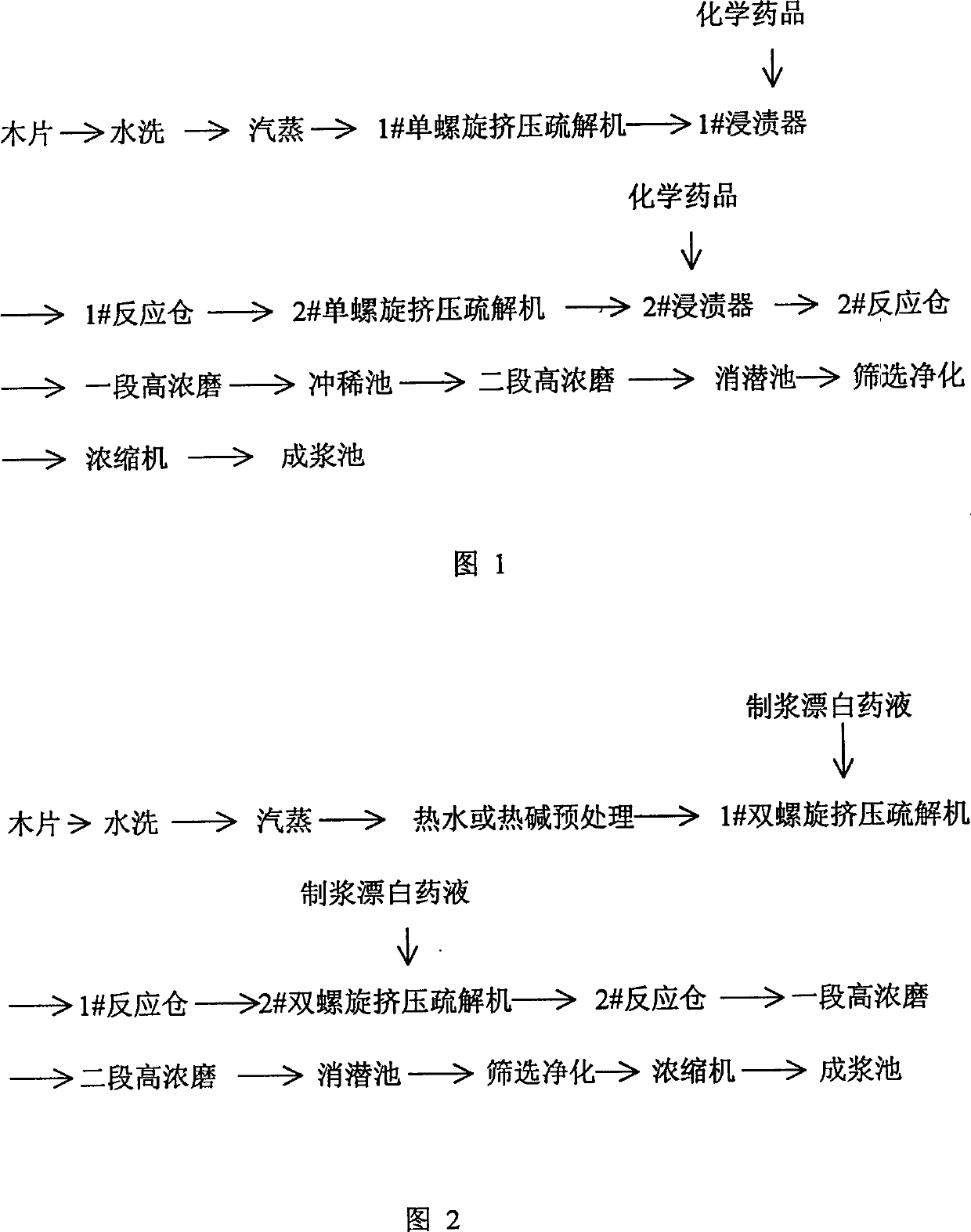

New process for producing alkaline hydrogen peroxide mechanical pulp by double scrwe extruding method

InactiveCN1587502AImprove extrusion tear effectImprove pulping qualityPulp bleachingPulp beating/refining methodsHigh concentrationFiber

The present invention is improved double screw extruding pulp producing process of alkali hydrogen peroxide mechanical pulp (APMP). The technological process includes water washing spill, steam digestion, hot water or hot alkali pre-treatment, treating in the first screw extruding breaker beater, reaction in the first reaction compartment, treating in the second screw extruding breaker beater, reaction in the second reaction compartment, milling in the first high concentration mill, milling in the second high concentration mill, sieving and purification, concentration, pulping pond treatment and other steps. Compared with traditional APMP, the present invention has similar quality and the advantages of simplified technological process, saving in investment and power consumption, less water consumption and lower waste water treating load. The present invention is suitable for producing APMP with different timber material, bagasse, etc.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process of producing high-yield pulp

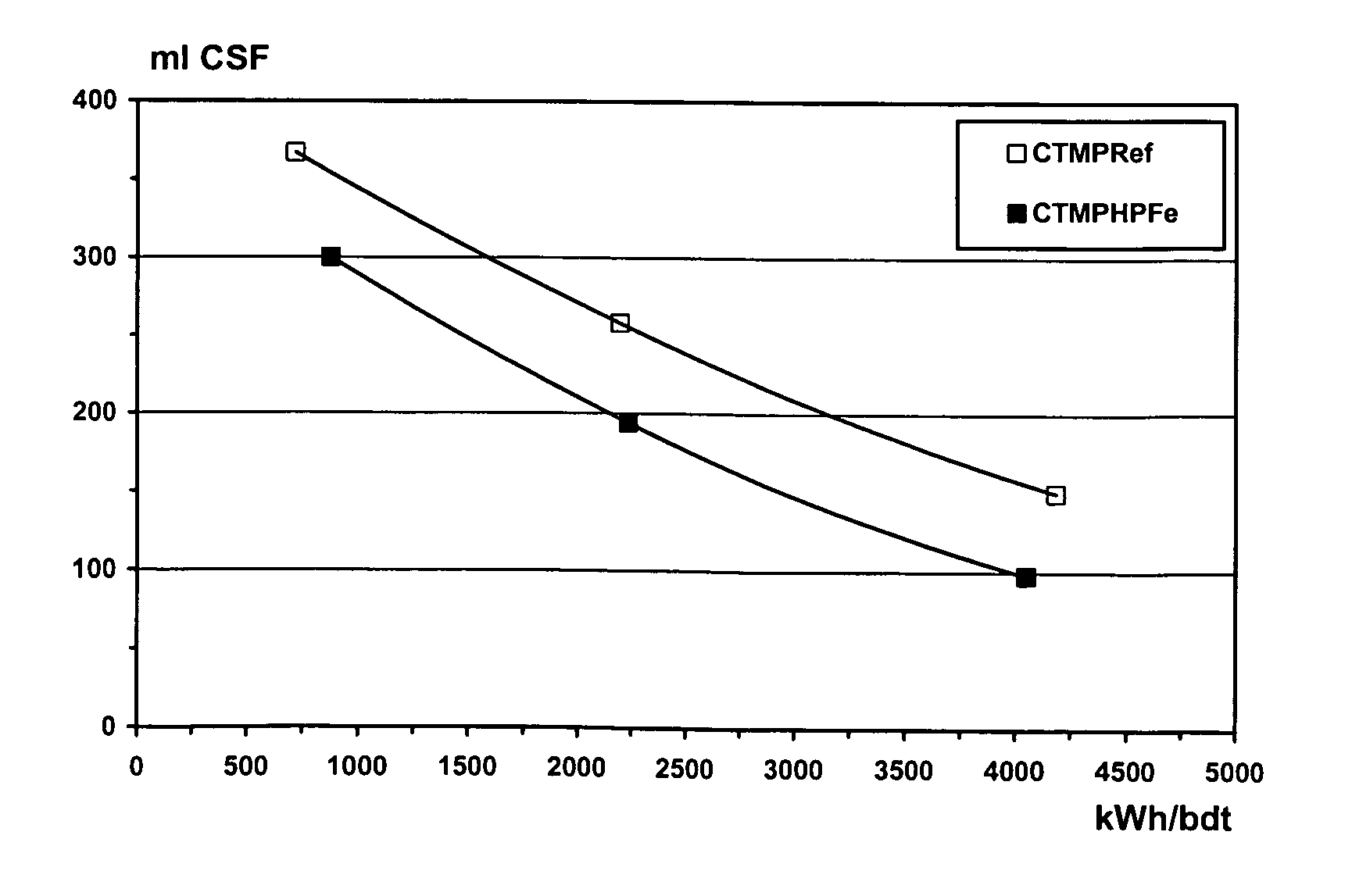

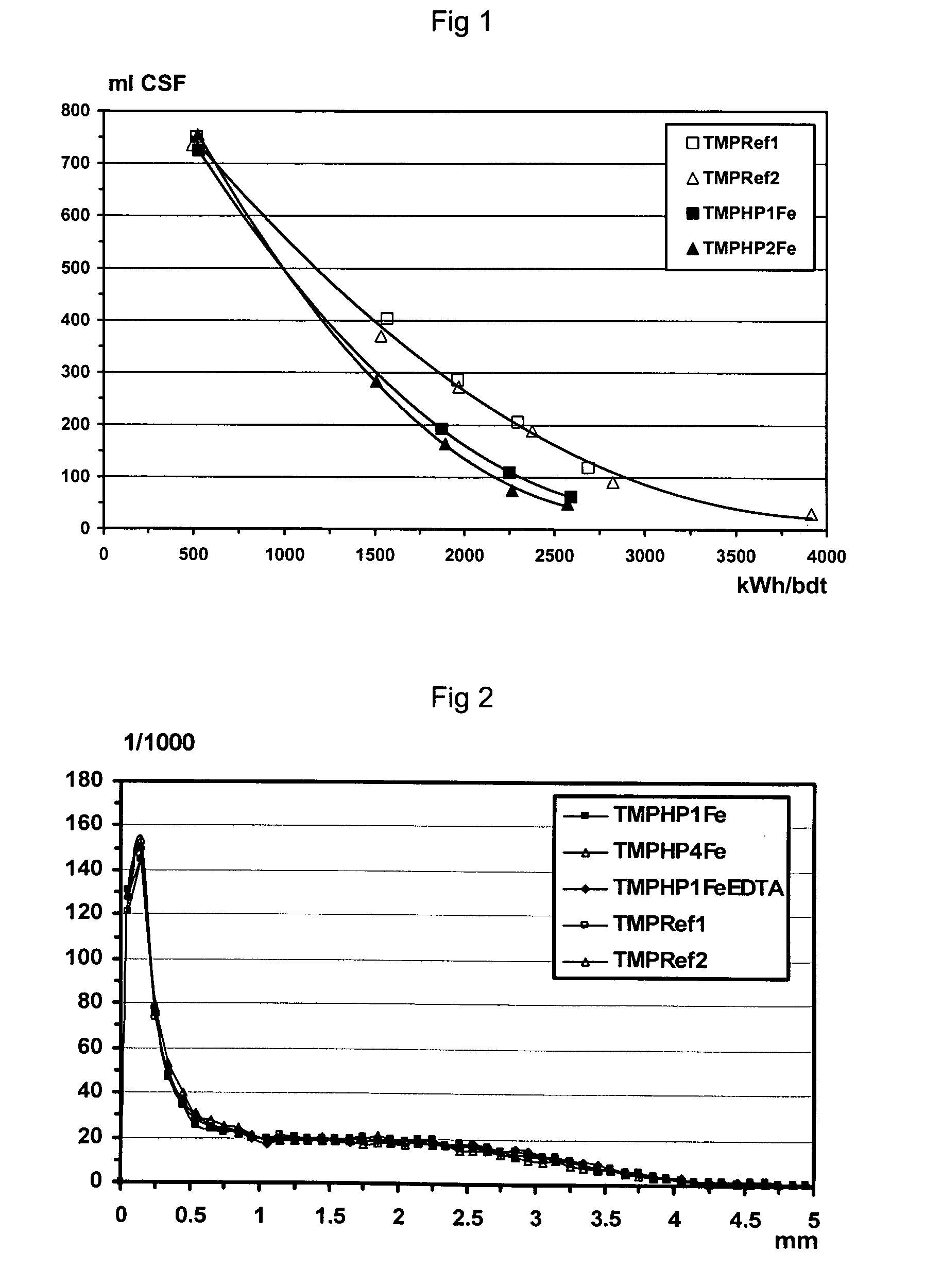

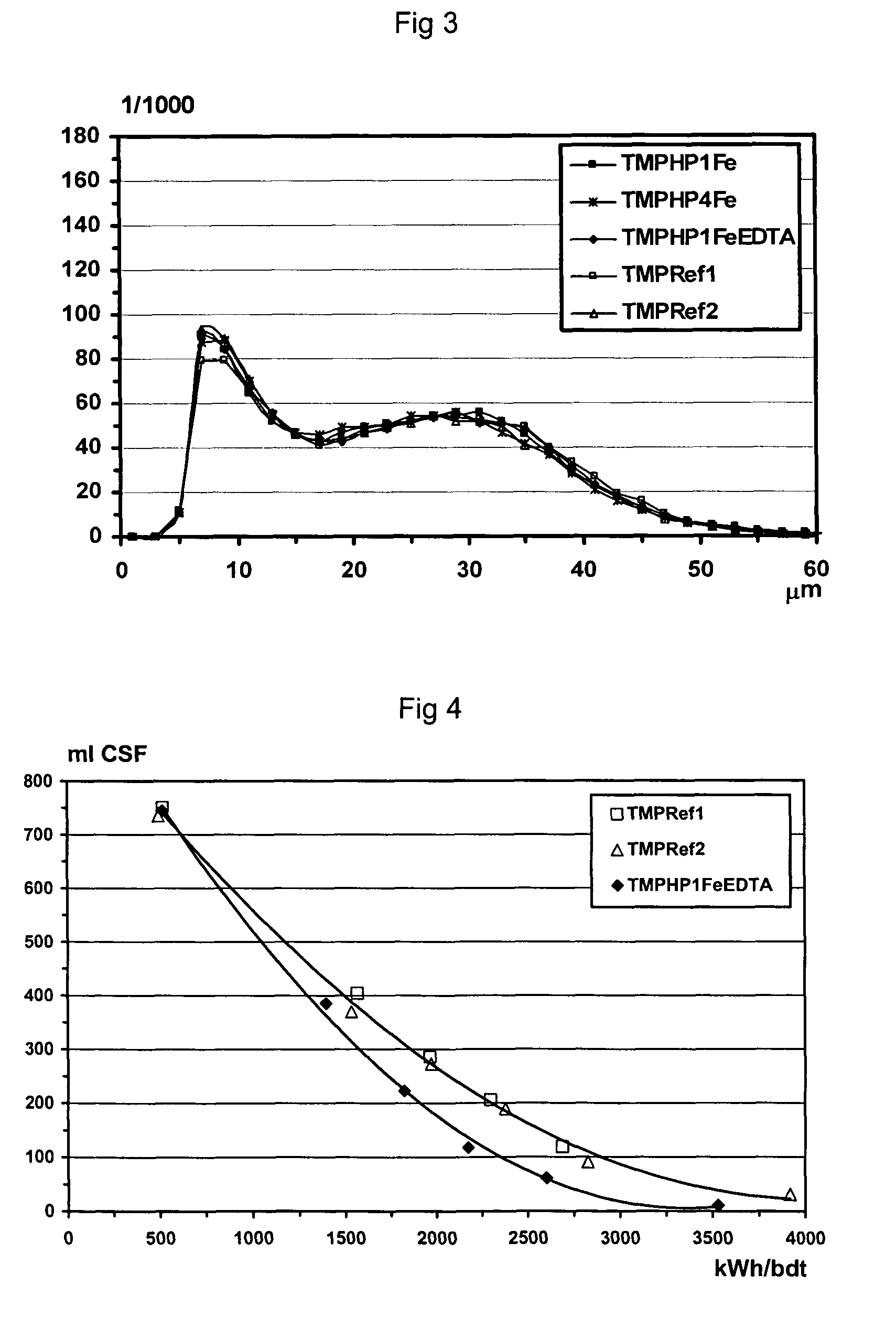

InactiveUS8268122B2Pulp bleachingPretreatment with oxygen-generating compoundsCelluloseChemical treatment

The present invention relates to a process for preparing a high-yield pulp comprisinga) treating a lignocellulose containing material chemically by means of an oxidizing system comprising at least one non-enzymatic oxidant substantially free from ozone and chlorine dioxide and an activator at a pH from about 2 to about 6.5; andb) treating the lignocellulose containing material mechanically for a time sufficient to produce a high-yield pulp, wherein the lignocellulose containing material is chemically treated prior to and / or during any mechanical treatment stage, and wherein the lignocellulose containing material is not chemically treated at a pH from about 11.5 to about 14 between stages a) and b).

Owner:NOURYON CHEM INT BV

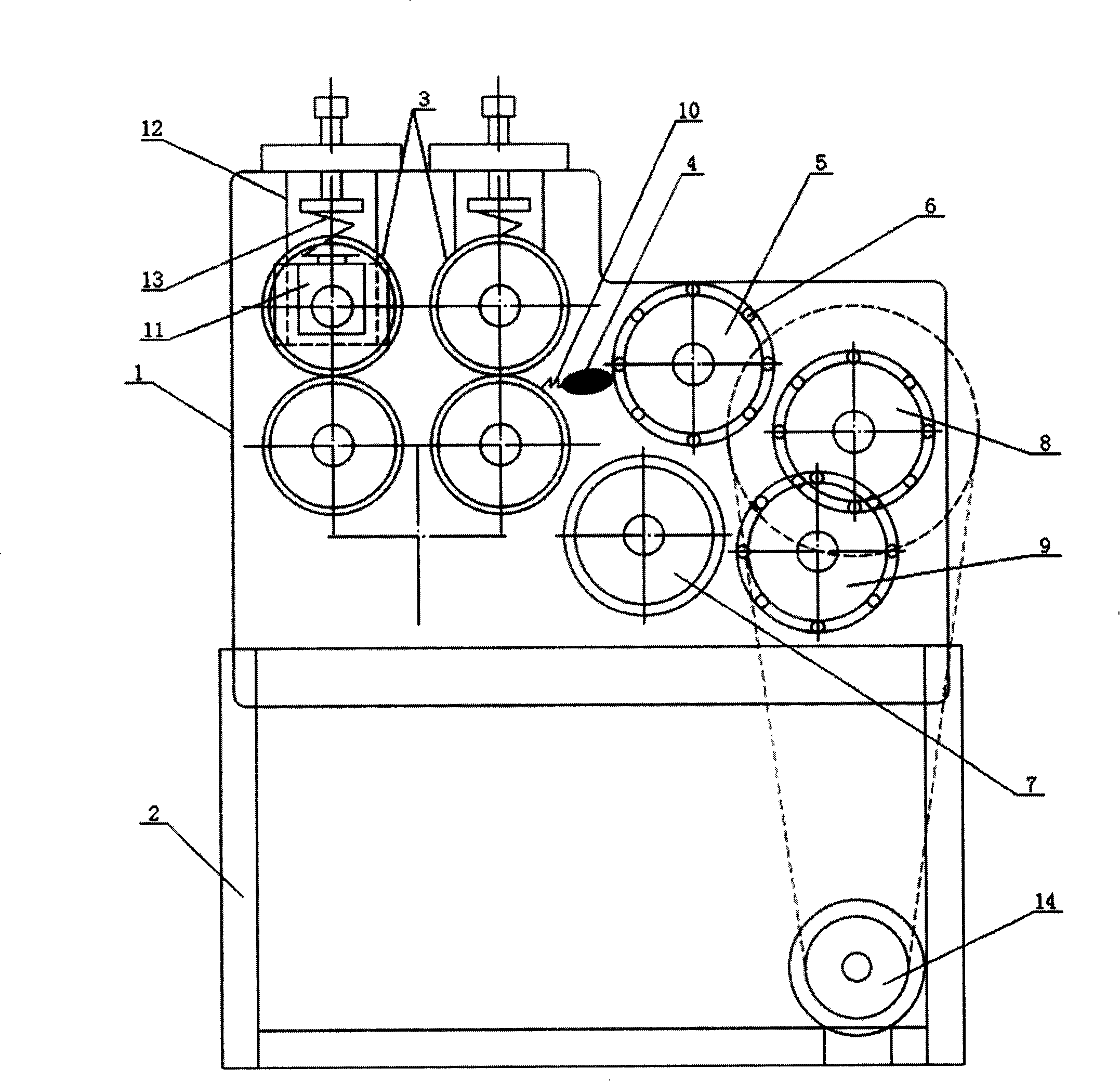

Cotton stalk skin-core mechanical separation method and special equipment

InactiveCN101230491ALow impurity contentAvoid damageMechanical fibre separationRaw material pretreatmentEngineeringSkin core

The invention relates to a processing method of separating a cotton stalk skin from a cotton stalk core mechanically as well as special equipment. Firstly, the cross section of a cotton stalk is squeezed to be of a flatly cracked shape and caused to present a continuous shape along the longitude direction; secondly, the flatly-cracked cotton stalk is struck every a certain length to be bent 85 to 90 degrees rapidly, thus leaving the skin separated from the core preliminarily. A free high-frequency strike is conducted to the strap-shaped cotton stalk skin to remove the broken core residue; and finally, the strap-shaped cotton stalk skin is conducted a cross free strike with a frequency higher than the frequency in the second step to eliminate the remaining attached core residue and obtain an eligible cotton stalk skin. The special equipment consists of a squeezing device, a vertical striking device, a diverted striking and skin separating device together with a wallboard and a stand that are used for fixing the devices and all the devices are arranged in sequence. The mandrel of each device is arranged in parallel, supported and fixed by the wallboard and driven by a drive mechanism. The special equipment can realize a mechanical separation of a cotton stalk skin from a cotton stalk core. The processed cotton stalk skin takes the shape of a continuous strap and can be processed further. The processed cotton stalk core takes the shape of millimeter-level crumbs and is an excellent material for pulping and paper making.

Owner:凌受明 +1

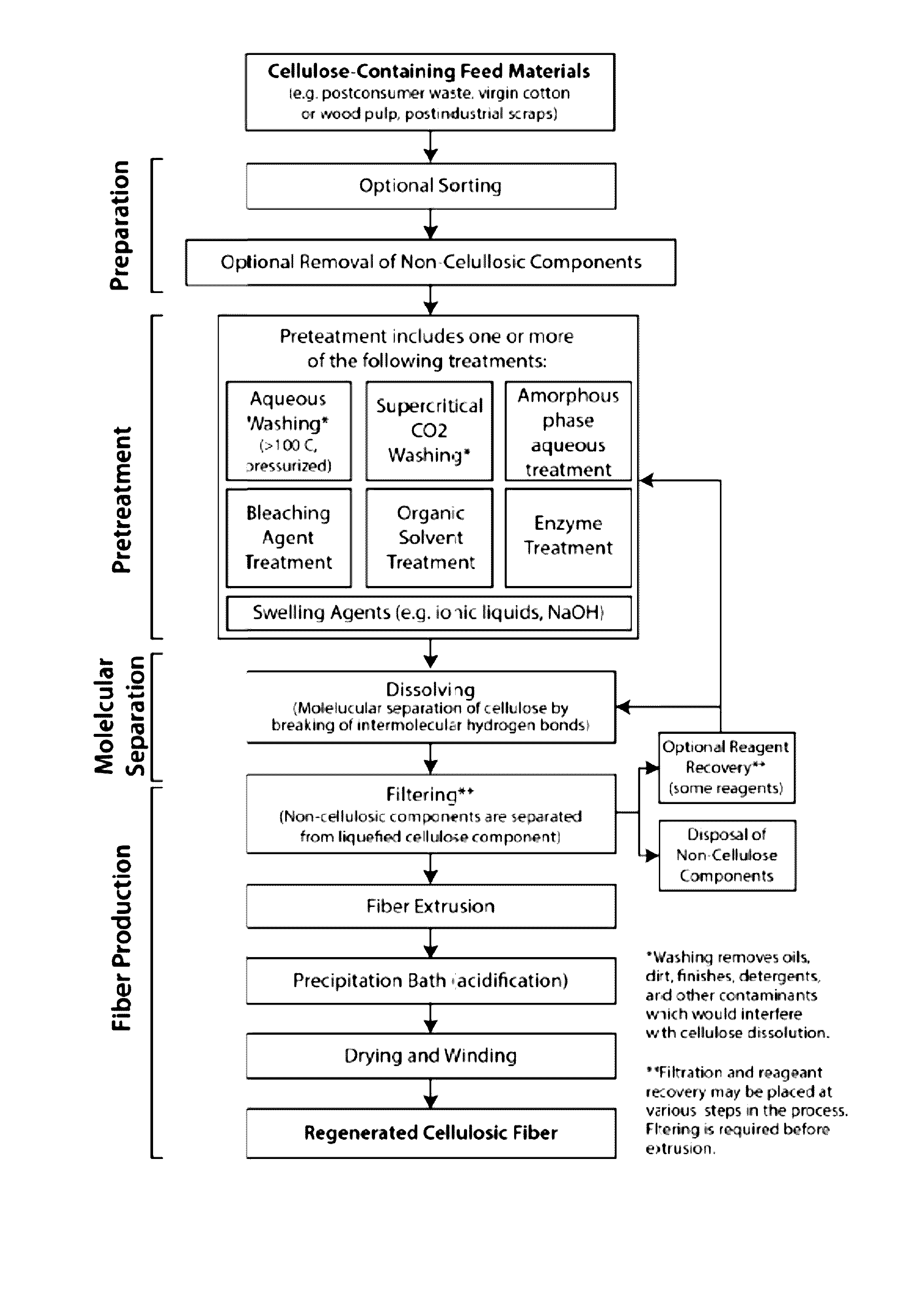

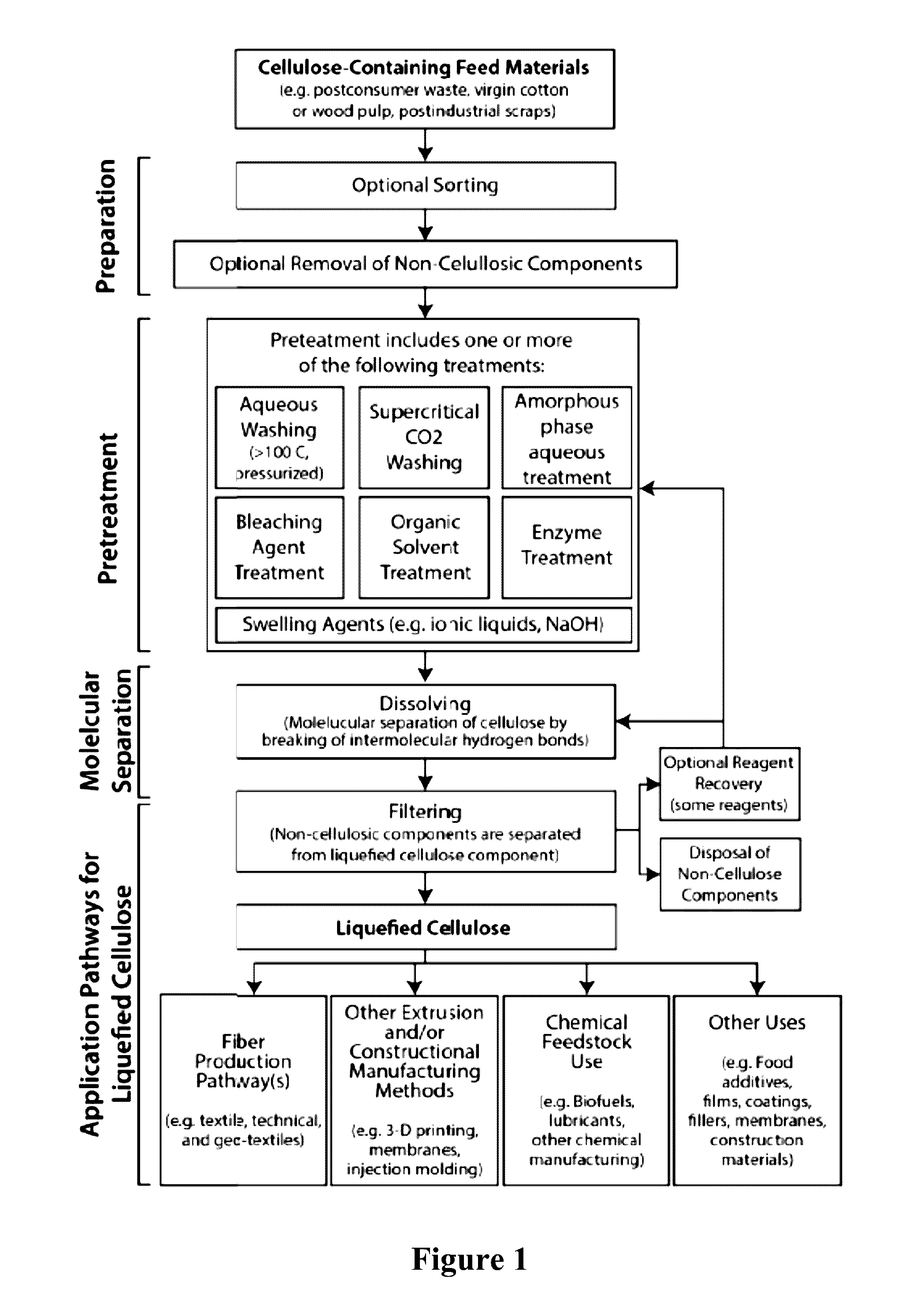

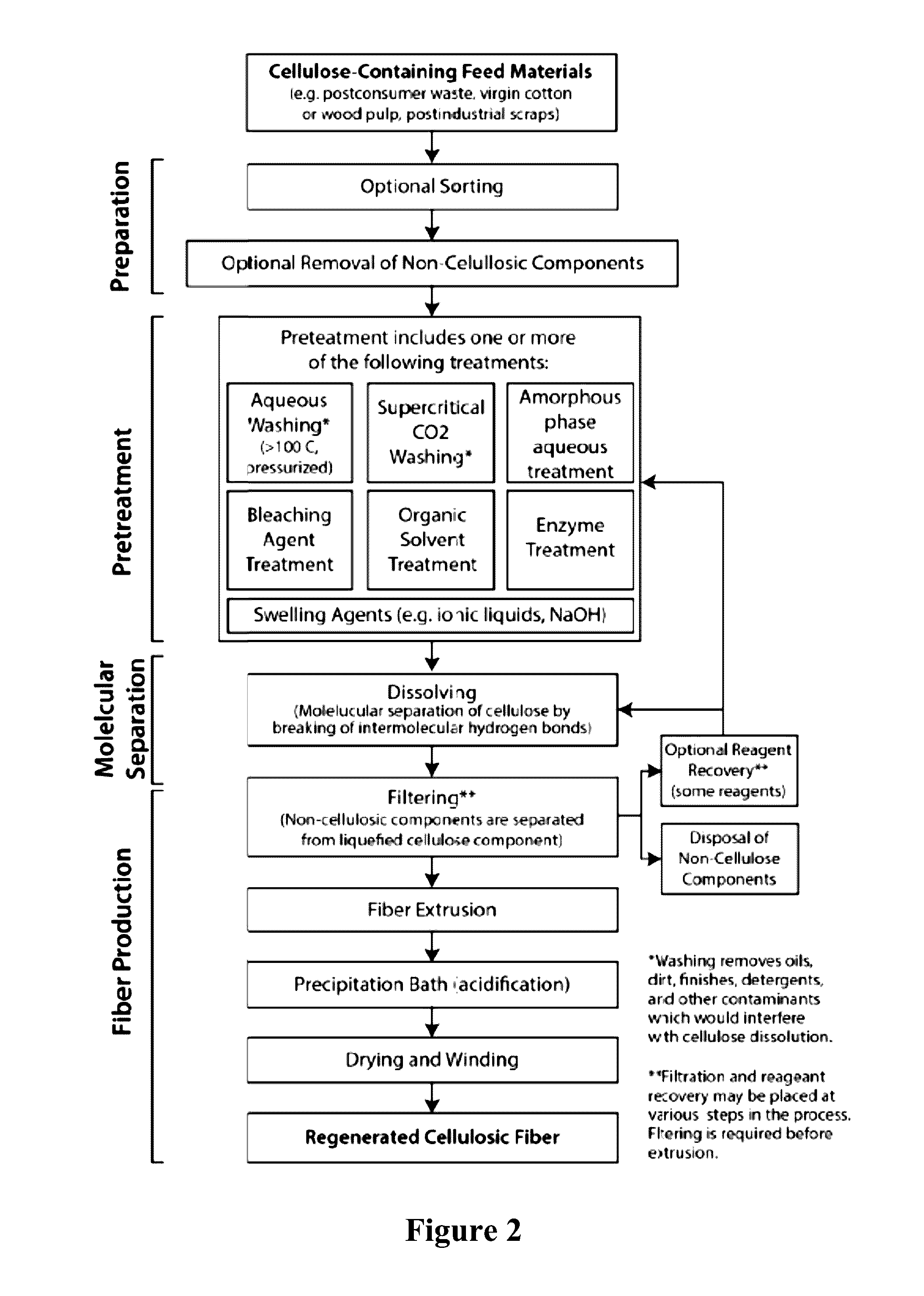

Methods and systems for processing cellulose-containing materials and isolating cellulose molecules; methods for regenerating cellulosic fibers

InactiveUS20160369456A1Reduce environmental impactPretreatment with water/steamPulp properties modificationPost-consumer wastePre treatment

Methods and systems of the present invention use cellulose-containing materials, which may include post-consumer waste garments, scrap fabric and / or various biomass materials as a raw feed material to produce isolated cellulose molecules having desirable properties that can be used in the textile and apparel industries, and in other industries. A multi-stage process is provided, in which cellulose-containing feed material is subjected to one or more pretreatment stages, followed by a pulping treatment, to isolate cellulose molecules. The isolated cellulose molecules may be used in a variety of downstream applications. In one application, isolated cellulose molecules are extruded to provide regenerated cellulose fibers having desirable (and selectable) properties that are usable in various industrial applications, including textile production.

Owner:EVRNU SPC

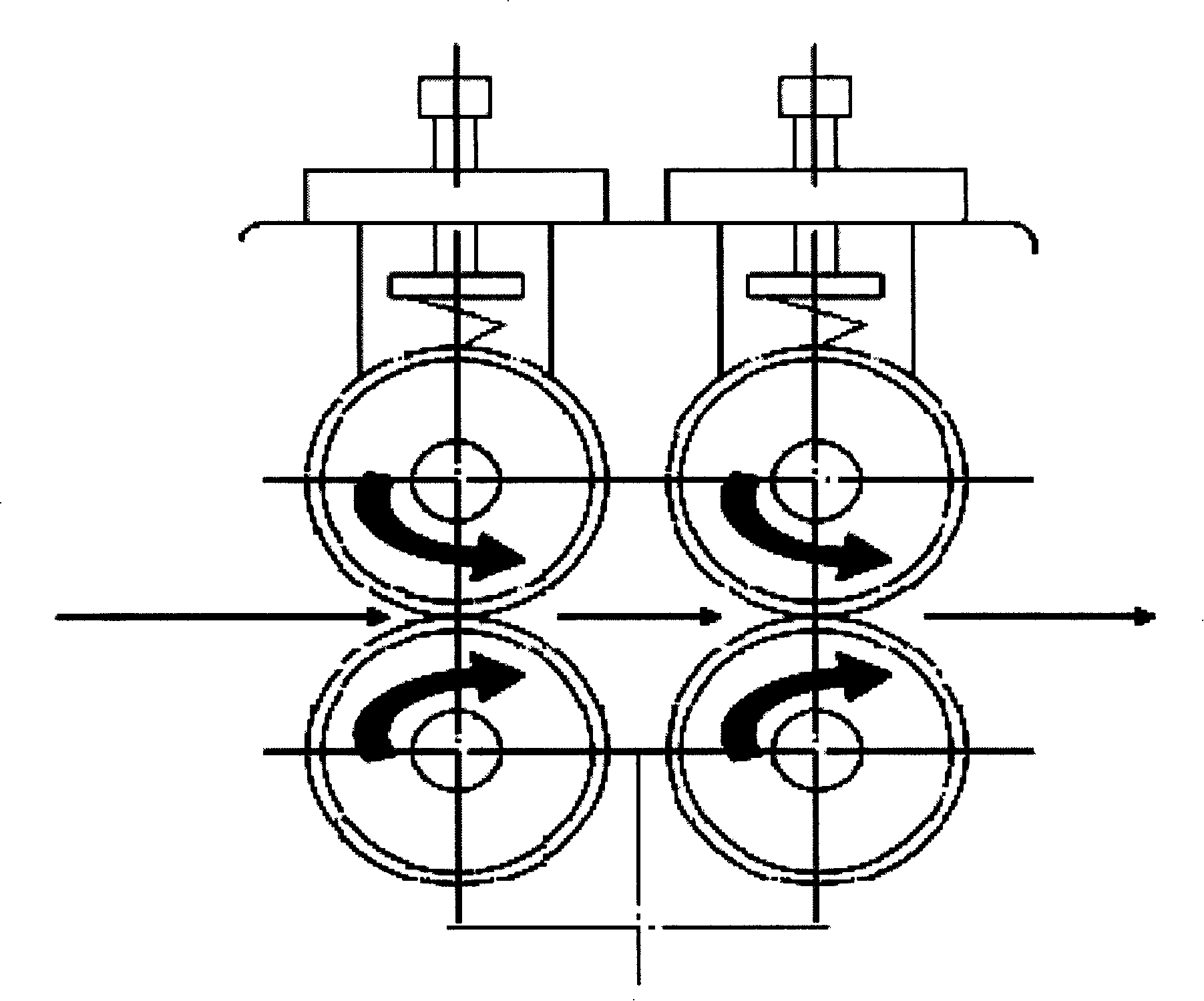

Energy efficient TMP refining of destructured chips

InactiveUS7300540B2Quality improvementReduce energy consumptionCellulosic pulp after-treatmentPretreatment with water/steamFiberRing pattern

A system and method for thermomechanical refining of wood chips comprises preparing the chips for refining by exposing the chips to an environment of steam to soften the chips, compressively destructuring and dewatering the softened chips to a solids consistency above 55 percent, and diluting the destructured and dewatered chips to a consistency in the range of about 30 to 55 percent. The destructuring partially defibrates the material. This diluted material is fed to a rotating disc primary refiner wherein each of the opposed discs has an inner ring pattern of bars and grooves and an outer ring pattern of bars and grooves. The destructured and partially defibrated chips are substantially completely defibrated in the inner ring and the resulting fibers are fibrillated in the outer ring. The compressive destructuring, dewatering, and dilution can all be implemented in one integrated piece of equipment immediately upstream of the primary refiner, and the fiberizing and fibrillating are both achieved between only one set of relatively rotating discs in the primary refiner.

Owner:ANDRITZ INC

Process for increasing the refiner production rate and/or decreasing the specific energy of pulping wood

InactiveUS7726592B2Increase ratingsReduce energy consumptionPaper recyclingReed/straw treatmentProduction rateEngineering

The present invention relates to processes for enhancing a refiner's production rate and / or reducing the specific energy consumption for a freeness target through the use of lubricant(s) or carrier(s) / frictionizer(s), respectively.

Owner:SOLENIS TECH CAYMAN

Strong acid pretreatment assisted cellulose nano-filament preparation method

ActiveCN103061174AReduce energy consumptionHigh crystallinityRaw material pretreatmentFiberCellulose

A strong acid pretreatment assisted cellulose nano-filament preparation method includes: performing hydrolysis pretreatment for bleached paper pulp fibers for 1.0-1.5 hours at the temperature of 40-60 DEG C by the aid of 60-70wt% of concentrated sulfuric acid or hydrochloric acid, swelling up, dissolving and opening partial cellulose amorphous regions, and performing high-speed homogenizing mechanical shearing so that cellulose nano-filaments are obtained rapidly. The cellulose nano-filaments obtained by the method are low in energy consumption during production, high in fiber crystallization degree, large in filament length-diameter ratio and good in heat stability, and can be widely applied to the fields of reinforced composites, dust absorption filtering materials, ecological environment-friendly materials, biomedical materials and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

High defiberization chip pretreatment

ActiveUS20050011622A1Improve the level ofMinimal damageCellulosic pulp after-treatmentPretreatment with water/steamChemical treatmentFiber bundle

A chip pretreatment process which comprises conveying the feed material through a compression screw device having an atmosphere of saturated steam at a pressure above about 5 psig, decompressing and discharging the compressed material from the screw device into a decompression region, feeding the decompressed material from the decompression region into a fiberizing device, such as a low intensity disc refiner, where at least about 30 percent of the fiber bundles and fibers are axially separated, without substantial fibrillation of the fibers. In a more specific form the invention is directed to a process for producing mechanical pulp, including the steps of fiberizing wood chip feed material in a low intensity disc refiner until at least about 30 percent of the fibers are axially separated with less than about 5 percent fibrillation, and subsequently refining the fiberized material in a high intensity disc refiner until at least about 90 percent of the fibers are fibrillated. In another form the invention combines chip fiberizing with chemical treatments, for improving the pulp property versus energy relationships.

Owner:ANDRITZ INC

Method for preparing straw cellulose nano crystal whisker

InactiveCN104805722AReduce crystallinityReduce intensityPretreatment with alkaline reacting compoundsRaw material divisionHazardous substanceWhiskers

The invention provides a method for preparing straw cellulose nano crystal whisker. The method is characterized by comprising the steps: utilizing crop straws as raw materials, performing pretreatment and cellulose purifying treatment, mechanically grinding into straw cellulose powder; performing DMSO (Dimethylsulfoxide) treatment and TEMPO (Tetramethylpiperidine) oxidation treatment and stirring at high speed, thereby obtaining straw cellulose powder suspension liquid; performing centrifugal treatment, decentralized treatment and freezing and drying, thereby obtaining straw cellulose nano crystal whisker. The preparation process is simple and has high yield and low energy consumption; no toxic and harmful matters are discharged during production and the preparation process has a capability of large-scale promotion and application; utilized straws can be wastes of plant crops such as rice straws, wheat straws and oilseed rape straws; the raw material has wide source and cost is low; pollution to the environment is solved and additional value of straws is improved.

Owner:DONGHUA UNIV

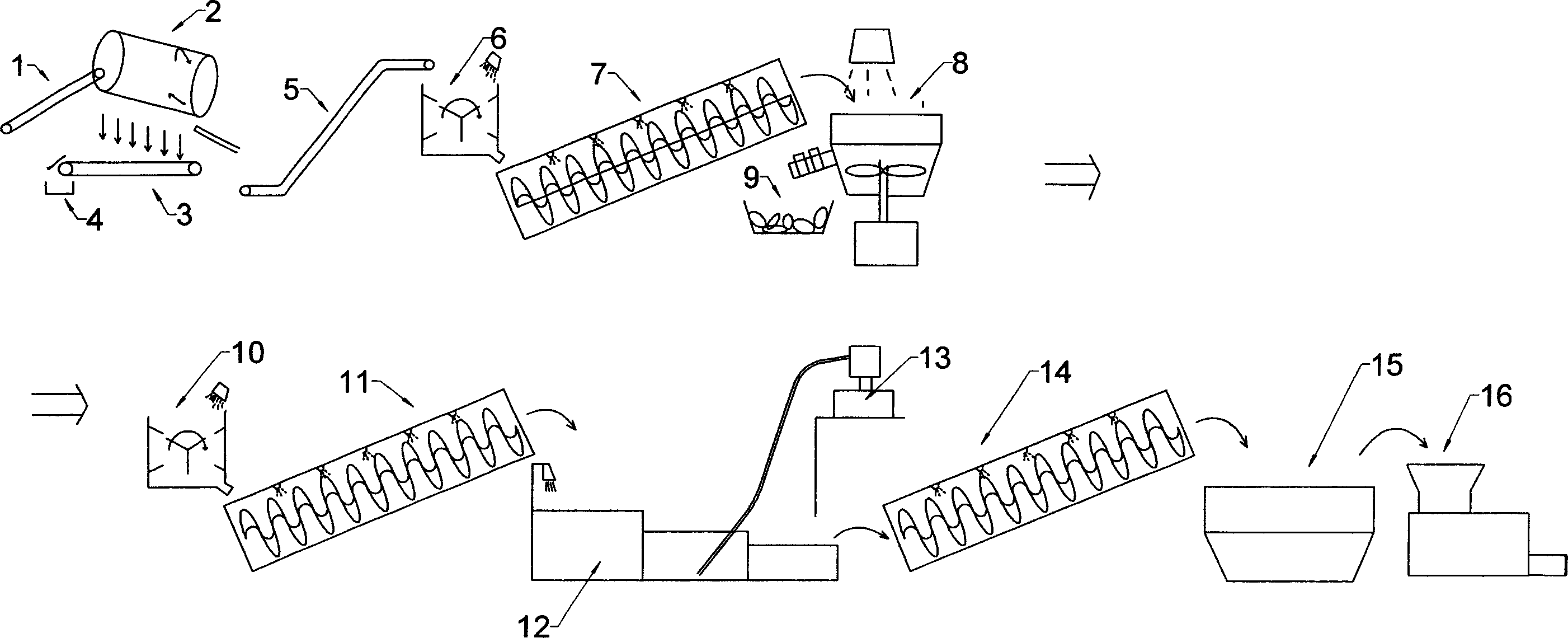

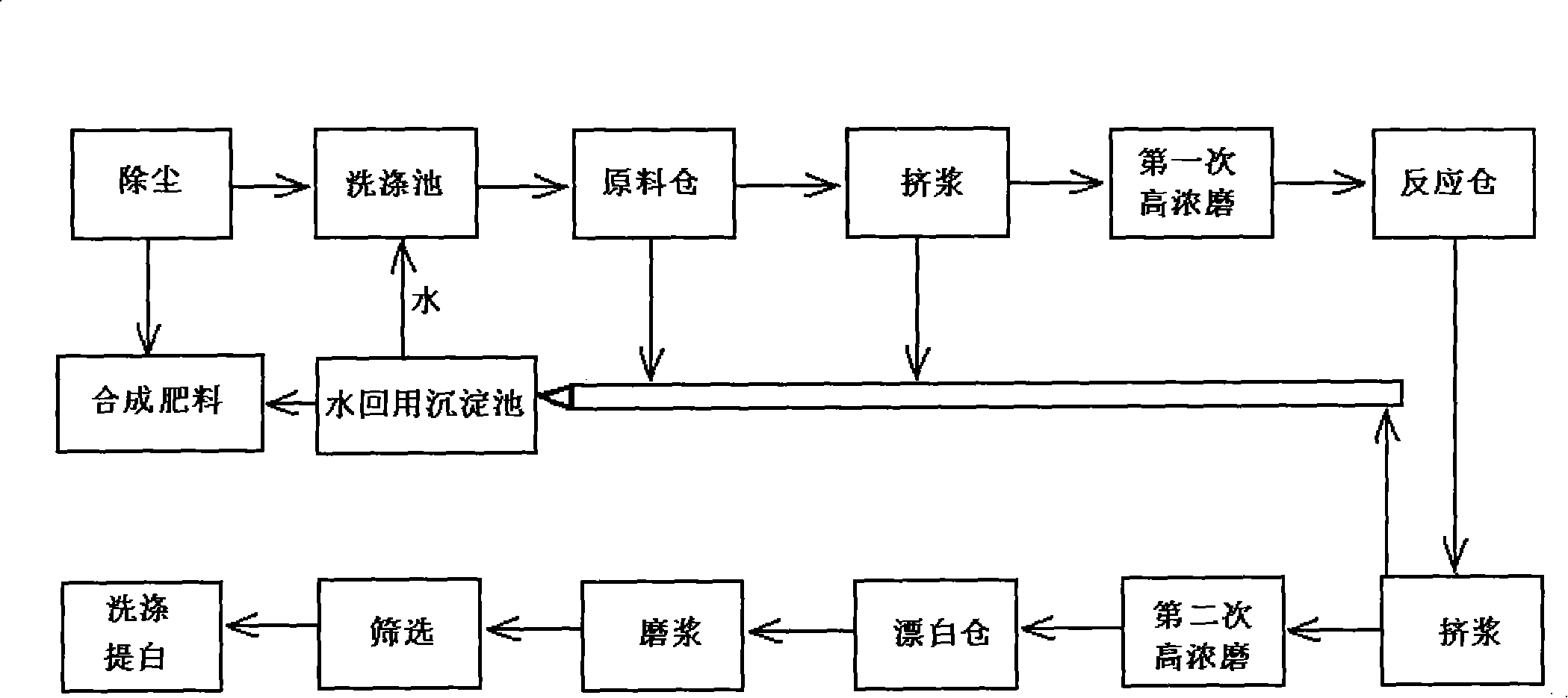

Clean pulping process

InactiveCN101200862ASimple pulping processReduce manufacturing costPulp de-wateringPulp bleachingFiberPulp and paper industry

The present invention relates to a pulping technology, in particular to a clean pulping technique with straw or broad leaves as raw materials. In the technical scheme, the clean pulping technology mainly includes twelve steps: (1) straw cutting or fragmenting and dedusting; (2) a fly cutter material-washing pool; (3) a raw material bin; (4) a press master; (5) the first-stage high-consistency grinding; (6) a reaction bin; (7) a press master; (8) the second-stage high-consistency grinding; (9) a high-consistency bleaching and temperature-keeping bin; (10) pulping; (11) filtering; (12) washing and whiteness enhancement. The technology uses straw or broad leaves as raw materials to realize the pollution-free fiber pulping technique, and applicable to large and medium paper-making enterprises, the whole pulping technique has the advantages of simplicity, low production cost, high yield rate of white pulp, good pulp quality, obvious reduction of energy consumption, etc.

Owner:SHANDONG HUALIN ENVIRONMENTAL PROTECTION TECH +1

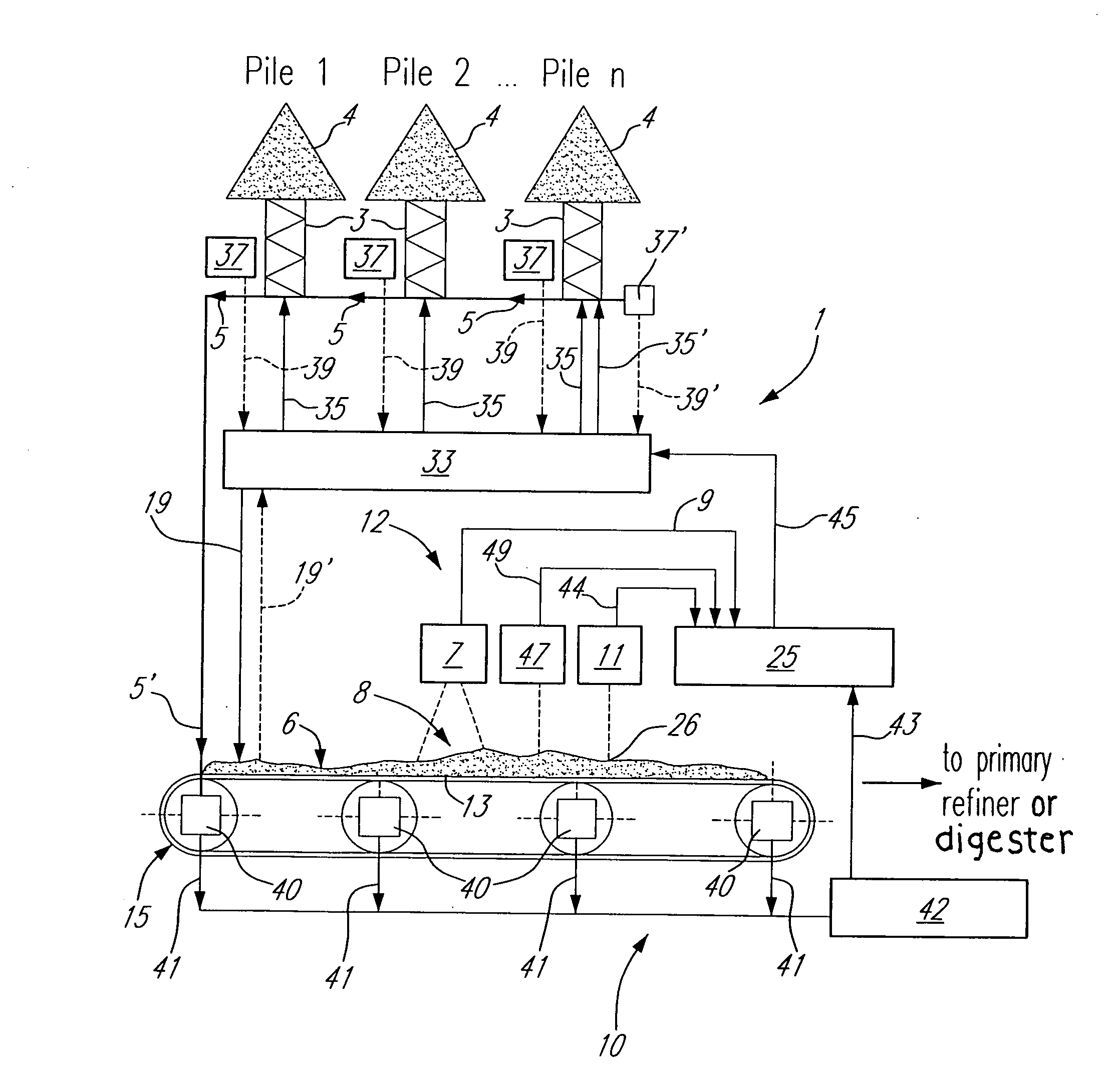

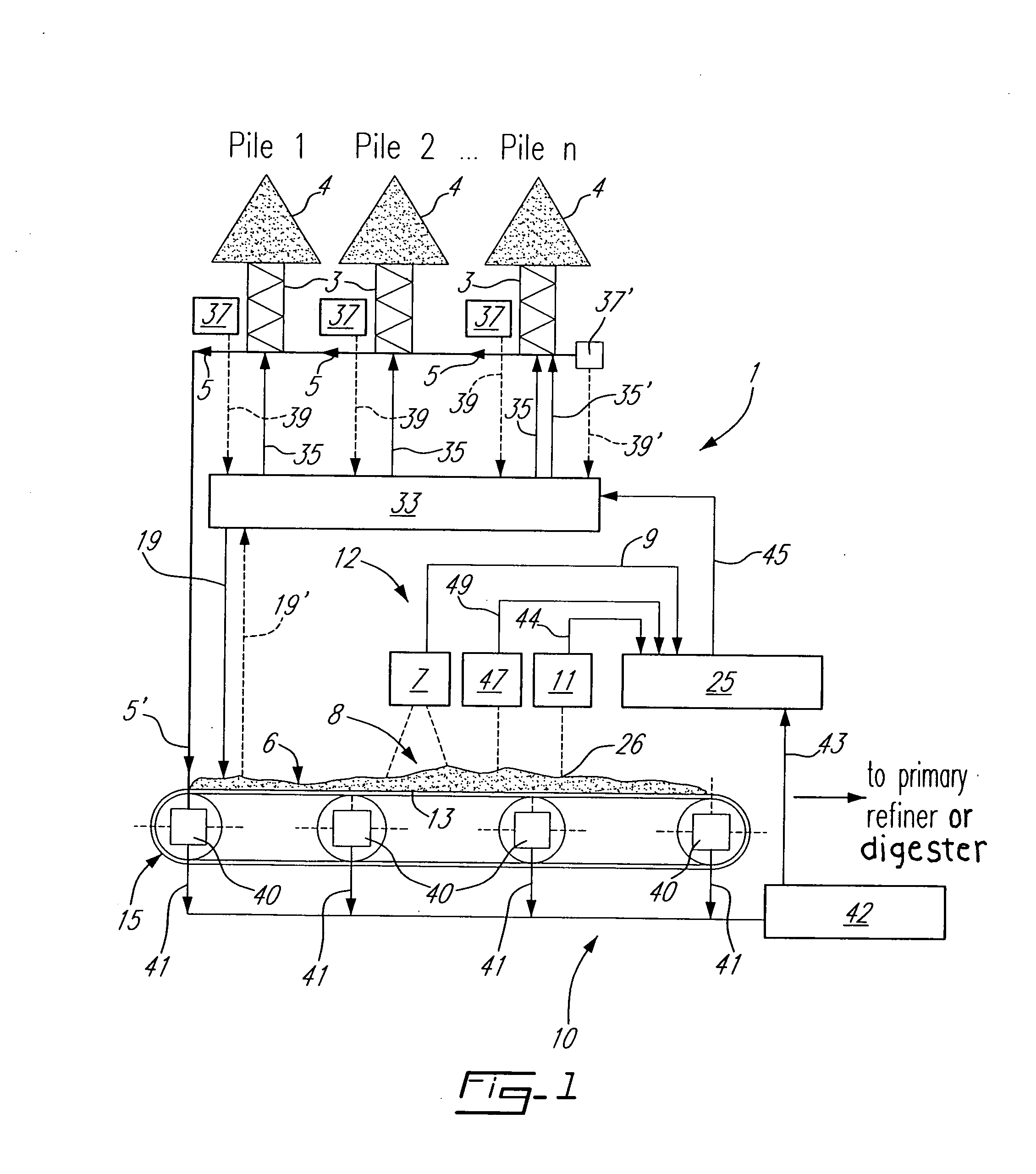

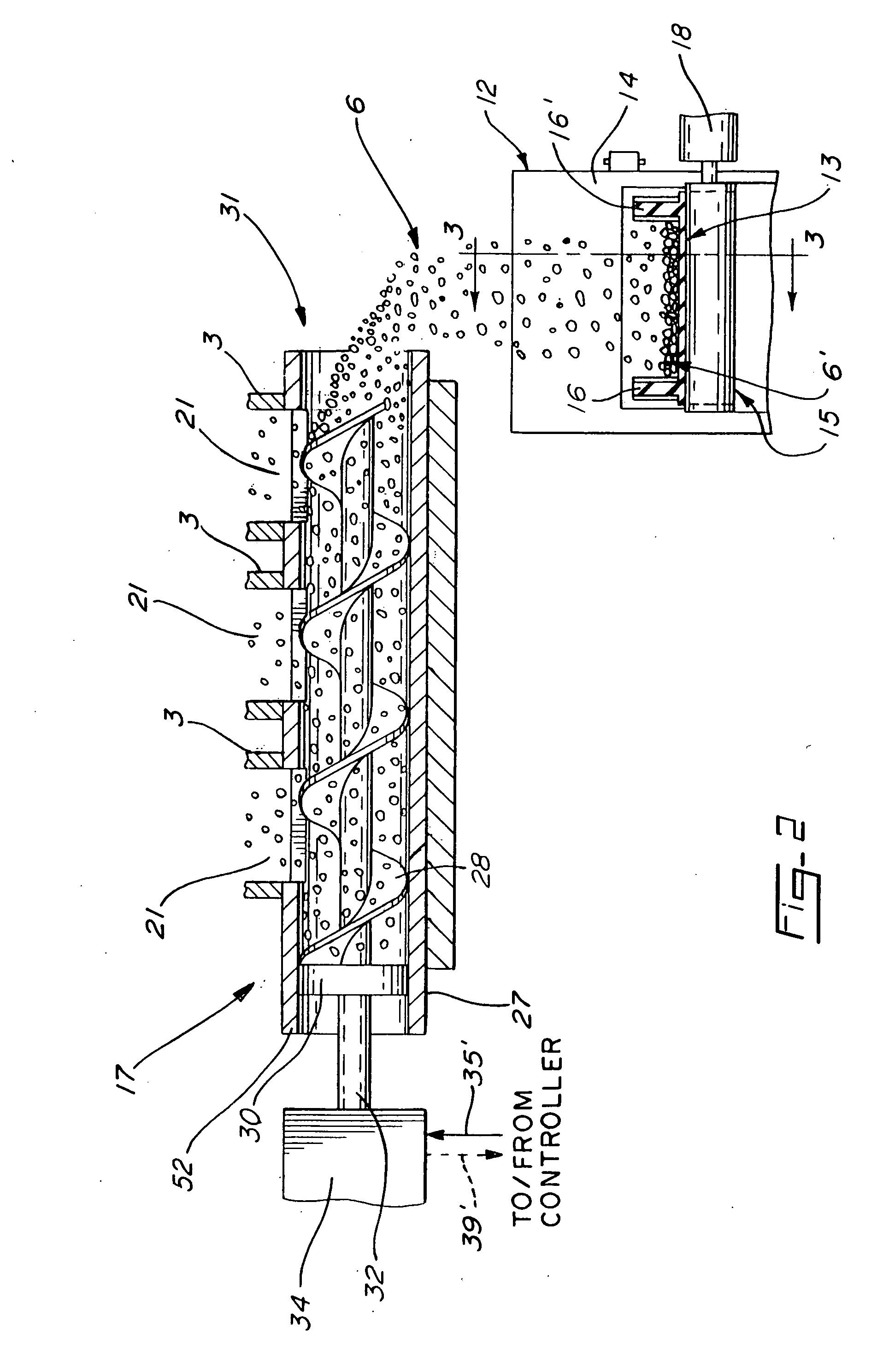

Method and apparatus for estimating relative proportion of wood chips species to be fed to a process for producing pulp

InactiveUS20060278353A1Effective monitoringBeating/refining control devicesDigestersLight reflectionImproved method

Improved methods and apparatus for estimating and controlling relative proportion of wood chips originating from a plurality of sources characterized by various wood species, in a mass of wood chips to be fed to a process for producing pulp, use light reflection-related and density-related properties as input in a model characterizing a relation between such wood chip properties and species information. This principle allows efficient monitoring of the variation in wood species composition characterizing the wood chips to be processed, for the purpose of stabilizing chip feeding control and optimizing process parameters adjustment.

Owner:CENT DE RES & DEV IND DU QUEBEC

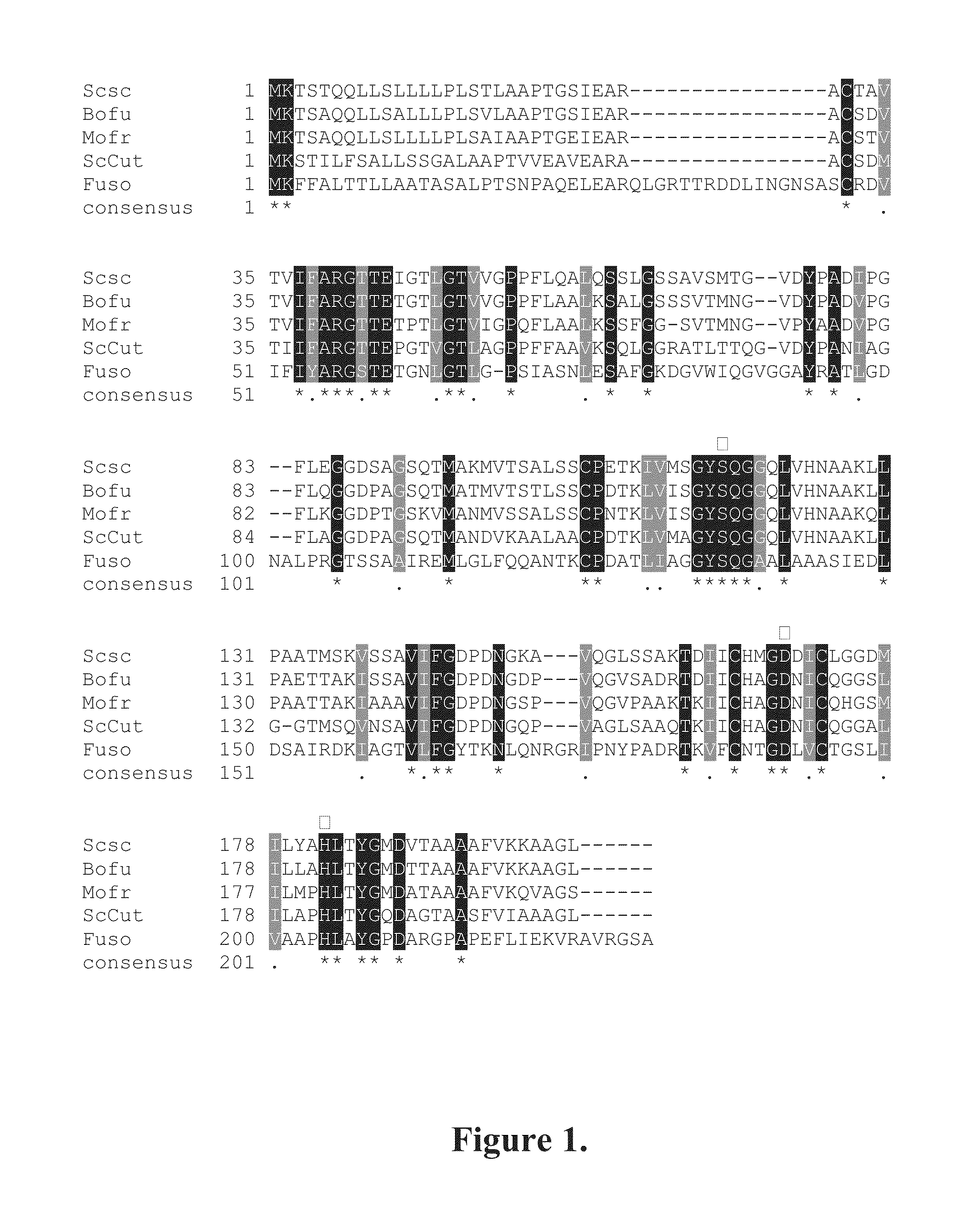

Novel cutinases, their production and uses

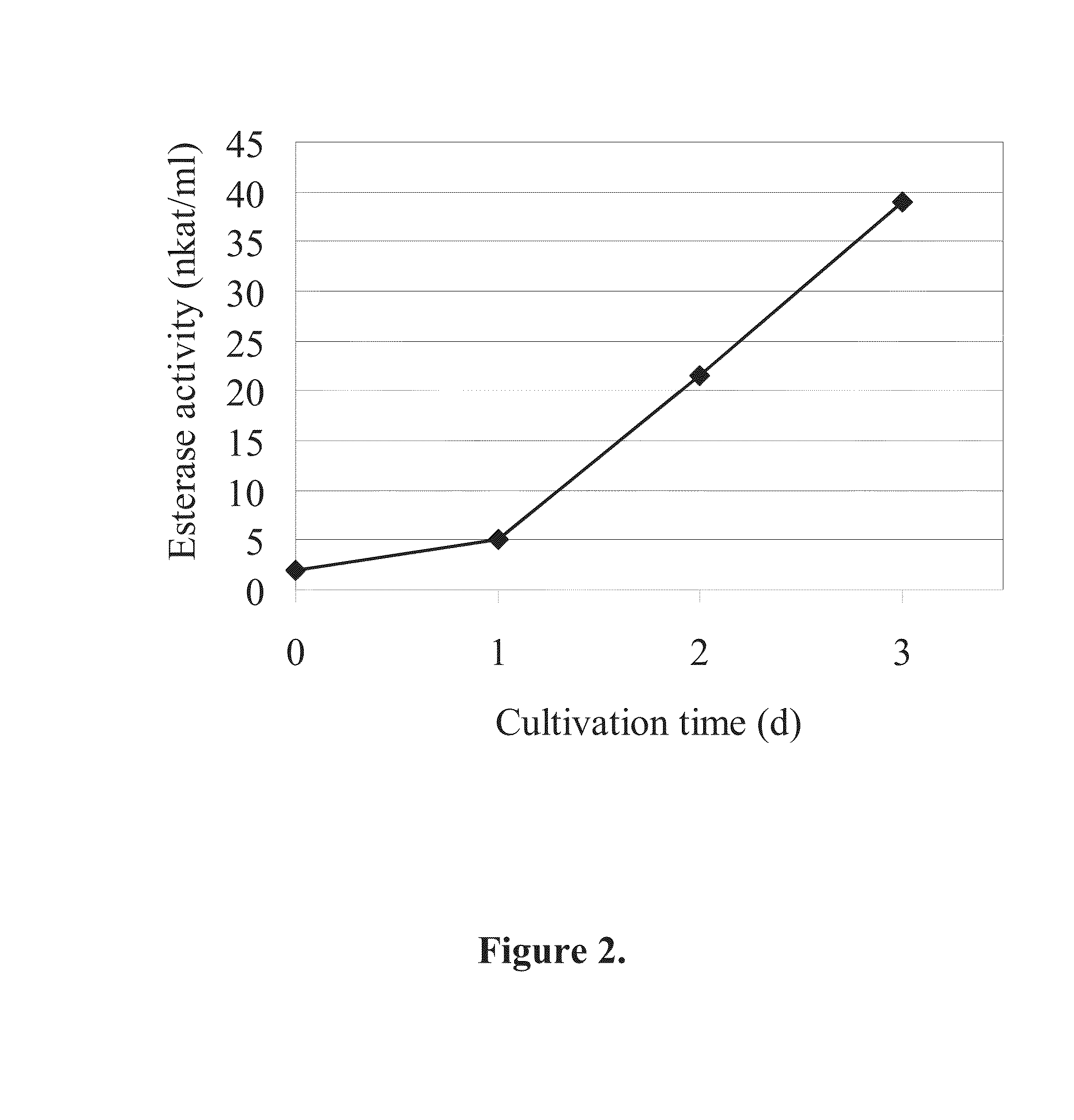

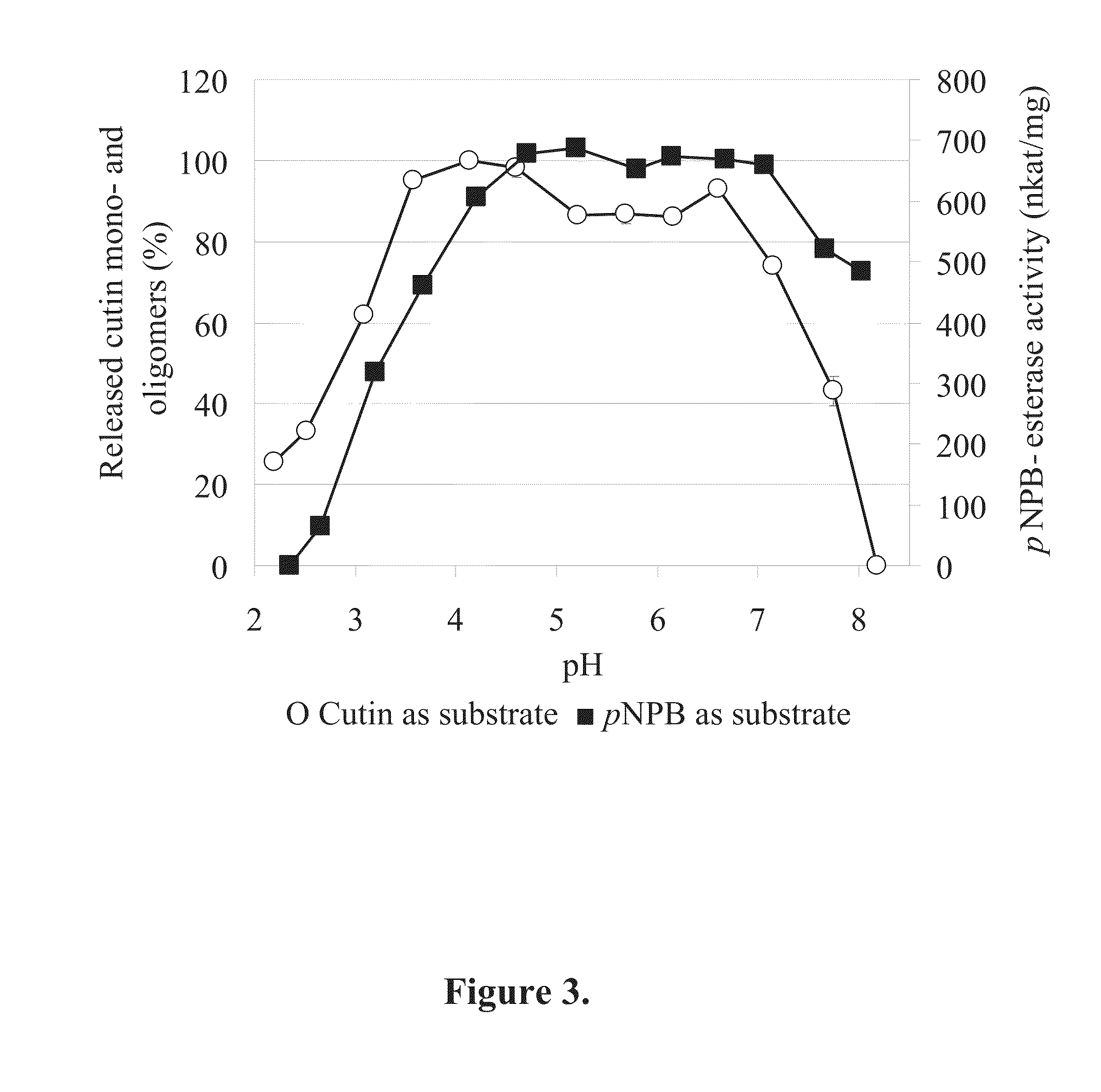

The present invention relates to novel polypeptides, or fragments of polypeptides, genes encoding them and means for producing said polypeptides. In detail the invention relates to polypeptides having esterase, suberinase and / or cutinase activity at low pH. This invention relates also to compositions containing the polypeptides and methods of using the polypeptides.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

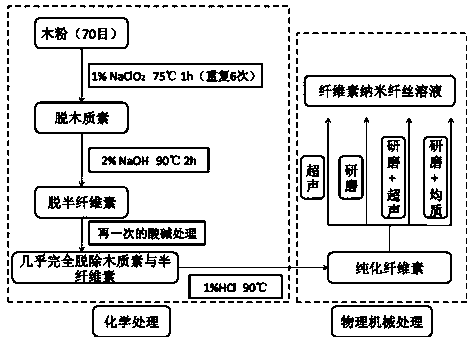

Cellulose nano-fibril/epoxy resin composite film preparation method

InactiveCN103396654AImprove thermal stabilityHigh impact strengthRaw material pretreatmentEpoxyChemical treatment

The present invention relates to a cellulose nano-fibril / epoxy resin composite film preparation method, which comprises the following steps: a) purifying a raw material; 2) carrying out chemical treatments, wherein the chemical treatments comprise three acid treatments and two alkali treatments; 3) carrying out physical treatments, wherein the physical treatments contain three mechanical treatments such as ultrasonic crushing, grinding through a grinding machine, and a high pressure homogenizer; 4) preparing a fiber nano-fibril film; and 5) preparing a cellulose nano-fibril / epoxy resin composite material. According to the present invention, the prepared cellulose nano-fibril has a diameter of 20-80 nm, the nano-cellulose film has a tensile strength of 159.2 MPa and an elastic modulus of 7.3 GPa, transmittance of the nano-cellulose resin film is 86%, the cellulose film has characteristics of high length-diameter ratio, uniform fiber diameter distribution, good thermal stability, and a thermal expansion coefficient of 14 ppm / K, and the film can be widely applied in the fields of high temperature resistance flexible electronic device light transmittance films, optically transparent functional paper, gas barrier packaging materials, tissue engineering materials, filtration membrane materials and the like.

Owner:NANJING FORESTRY UNIV

Method for preparing pulp by gramineous straw and use of obtained pulp

The invention discloses a method for preparing pulp by gramineous straw. The method sequentially comprises the following steps: (1) pre-treating the gramineous straw as a raw material; (2) physically pulping to obtain a straw fiber reinforced polymer (FRP); (3) adding water to the straw FRP obtained in step (2), thread-rolling and grinding until length of the straw FRP is 10-20mm to obtain fiber pulp; (4) decoloring or coloring the fiber pulp; and (5) mixing the fiber pulp treated in step (4) with the conventional chemical pulp or waste pulp based on the dry weight ratio of 1:0.1-10, then adding water for diluting the obtained mixed pulp, and finally obtaining the mixed pulp raw material. The invention further discloses use of the obtained pulp in preparation of the pulp molding product. The pulp obtained by the method takes the waste crop-the gramineous straw as the raw material and has the characteristics of low raw material cost, wide use, good industrial application prospect and the like.

Owner:NANJING BIOFUNCTION CO LTD

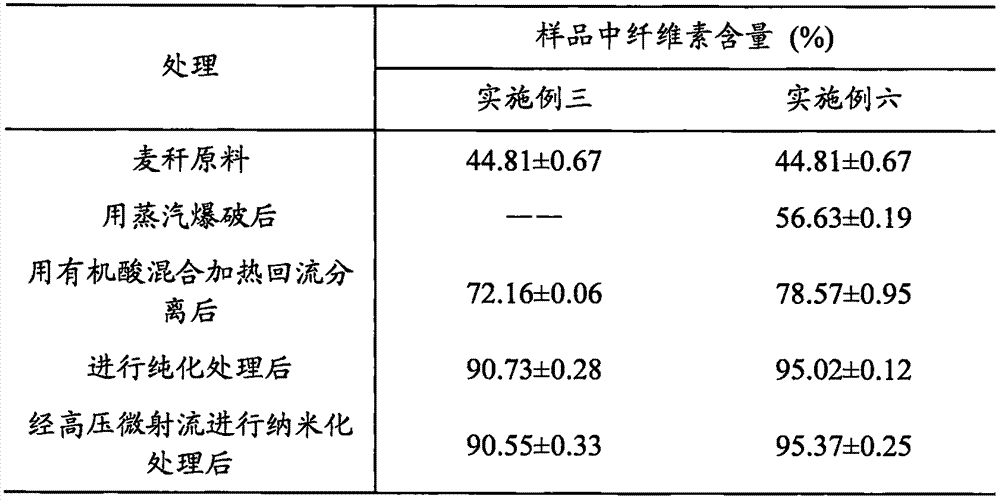

Method for preparing cellulose nano-fibers based on biomass material

The invention discloses a method for preparing cellulose nano-fibers based on a biomass material. The method comprises the following steps: carrying out drying and fining treatment on the biomass material; then, mixing the generated biomass material and an organic acid solvent, heating, reflowing and separating biomass cellulose; then carrying out nano fibration treatment on the separated biomass cellulose by adopting a physical method, so as to obtain the cellulose nano-fibers with high purity and a high length-diameter ratio. By adopting the method disclosed by the invention, the preparation efficiency is effectively improved and the cellulose nano-fibers with the high purity and the high length-diameter ratio can be prepared; the generation of chemical pollution wastes is reduced; meanwhile, a series of environment problems caused by the fact that chlorine is used in a traditional purification method are avoided.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

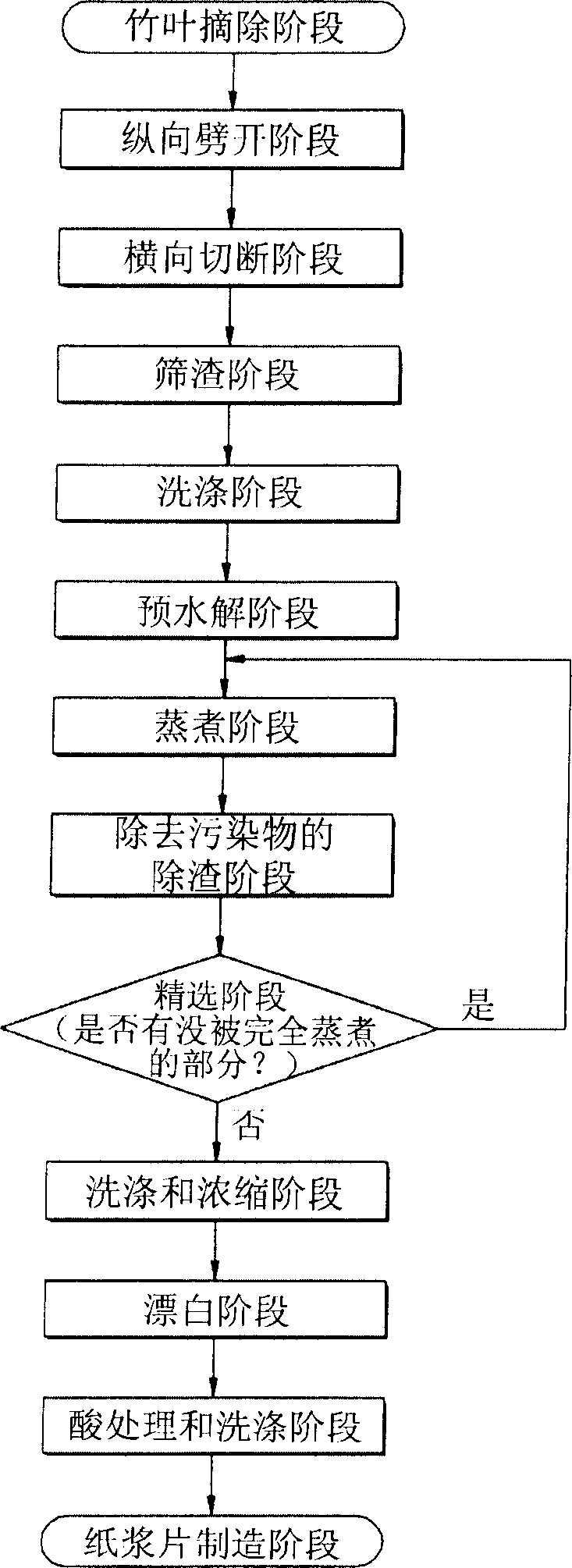

The production method and pulp maked bamboos

InactiveCN1854388AHigh yieldPretreatment with water/steamWashing/displacing pulp-treating liquorsPulp and paper industryCellulose pulp

The present invention relates to a kind of method that utilizes bamboo to make paper pulp, relate to firstly splitting bamboo vertically and transversely and then going through the process of screening and washing to reduce the consumption of medicines in the process of prehydrolysis and pulping and make it easy to react, thereby A method of making pulp from bamboo and its pulp that can produce better-quality, higher-yield dissolving pulp, and that can prevent the generation of dioxins by using the bleaching method of ECF or TCF. Since the anthraquinone caustic soda method using anthraquinone as a catalyst is used in the cooking process, the effects of improving delignification and pulp quality and increasing pulp yield are obtained. Also, the content and degree of polymerization of α-cellulose can be arbitrarily adjusted according to the characteristics of the man-made fibers produced as desired by adjusting the conditions of prehydrolysis, cooking and bleaching. At the same time, by recovering xylose produced in the dissolving pulp manufacturing process, it is used to manufacture xylitol, seasoning, furfural, etc., thereby contributing to the improvement of resource utilization and economic efficiency of waste.

Owner:李权革

Clean high-valued utilization method for straw resources

InactiveCN101787656AHigh yieldEasy to separatePulp liquor regenerationSewage/sludge fertilisersEvaporationPotassium

The invention provides a paper pulp and fertilizer co-production technique, which aims at the present statuses of generally low utilization value of straw resources and serious environmental pollution caused by papermaking black liquor in China. In the technique, KOH and 1,3-propane diamine are used as the main stewing components to prepare pulp from various straws. The 1,3-propane diamine is beneficial to removing lignin and enhancing the product yield. High value-added paper products are obtained, and meanwhile, black liquor contains kalium, nitrogen and humic acid, thereby being a good nutrient source for organic fertilizers. Acid is added to the black liquor to neutralize, thereby obtaining a humic acid liquid fertilizer; and nitrogen, phosphorus, kalium and chelated microelements are added to obtain a liquid compound fertilizer. The pulverized straw scraps leftover materials can be directly used for adsorbing the black liquor, and are subjected to evaporation and granulation to prepare a solid organic fertilizer. The whole paper pulp and fertilizer co-production system does not discharge waste, thus the invention can thoroughly eliminate the pollution caused by the papermaking black liquor and realize the clean high-valued utilization of the straw resources.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

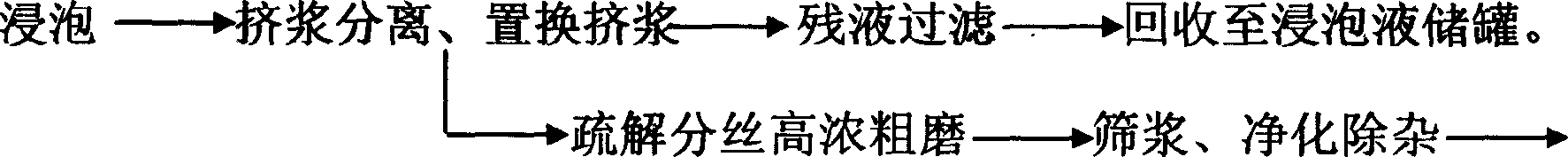

Biocatalytic clean pulping agent and application process thereof

InactiveCN1844572ANo emissionsNo pollutionPulp liquor regenerationWashing/displacing pulp-treating liquorsForeign matterProcess equipment

The invention relates to a biochemical catalysis cleaning slurry agent and relative application. Said invention is formed by: amylase, laccase, hydroxybenztriazole, calcii chloridum SL-1 slurry braise agent, sodium carbonate, and water. And the application comprises: 1, cutting raw material to be kneaded and dedusted; 2, preparing material with wet method; 3, dipping to remove lignin colloid; 4, extruding slurry to replaced and separated, dipping to filter the left liquid to be recycled; 5, rough milling and combing wire; 6, screening slurry to remove foreign matters; 7, washing slurry; 8, finish milling slurry; 9, poaching slurry; 10, washing poached slurry; 11, stepped treating and recycling used water. The invention is characterized in dipping said raw material in normal temperature and pressure. The left liquid is not discharged, but be recycled. And the pulp is poached pulp. The invention can support industrial production.

Owner:石建凯

Method For Mechanical Pulp Production

InactiveUS20090107643A1Reduce refiner energyHigh energyPretreatment with water/steamPretreatment with acid reacting compoundsPulp and paper industryOxidative enzyme

A method of producing hardwood pulp is provided. This method comprises treating hardwood chips with one or more than one Family 11 xylanase enzyme in the absence of adding an oxidizing enzyme for about 5 minutes to about 120 minutes, to produce a treated chip mixture. The treated chip mixture is then mechanically refined to produce the hardwood pulp.

Owner:CENT TECHN IND DIT CENT TECHN

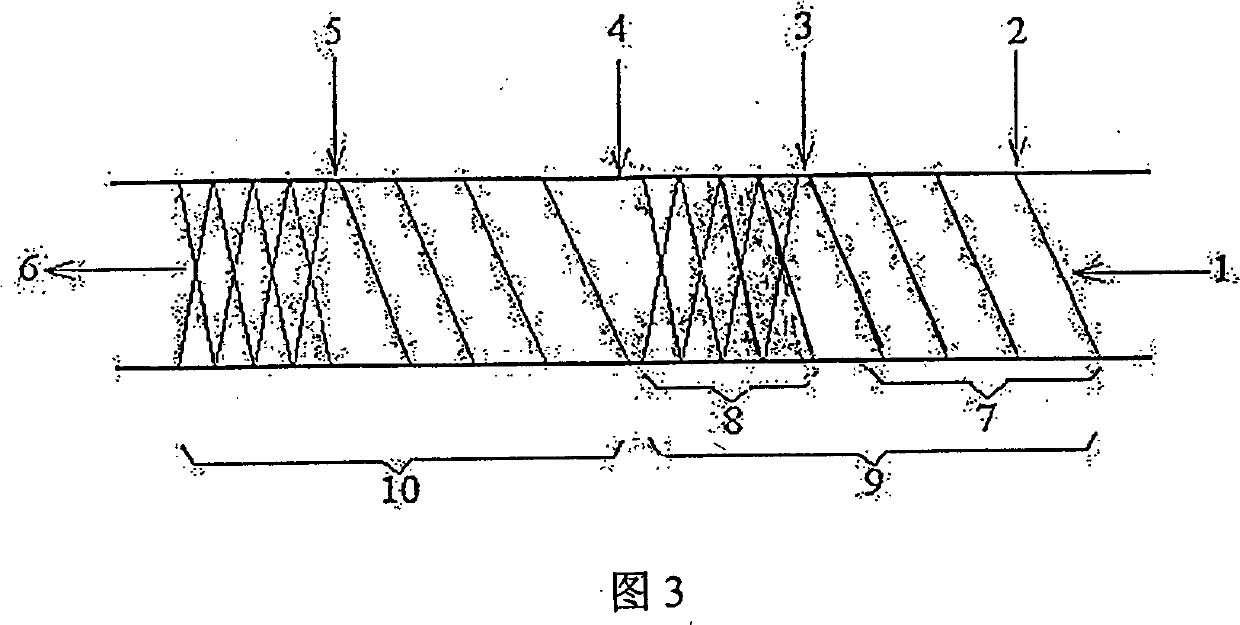

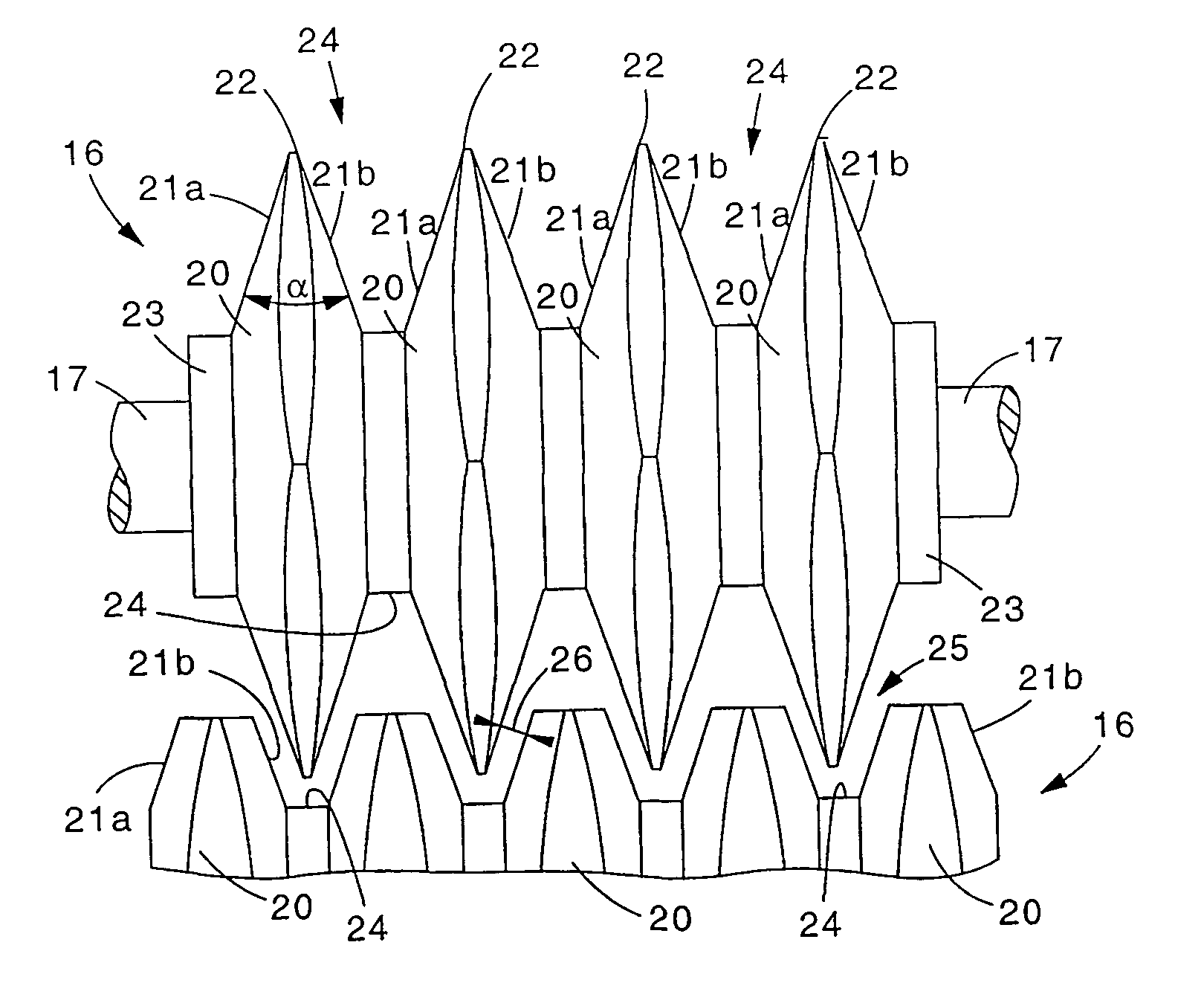

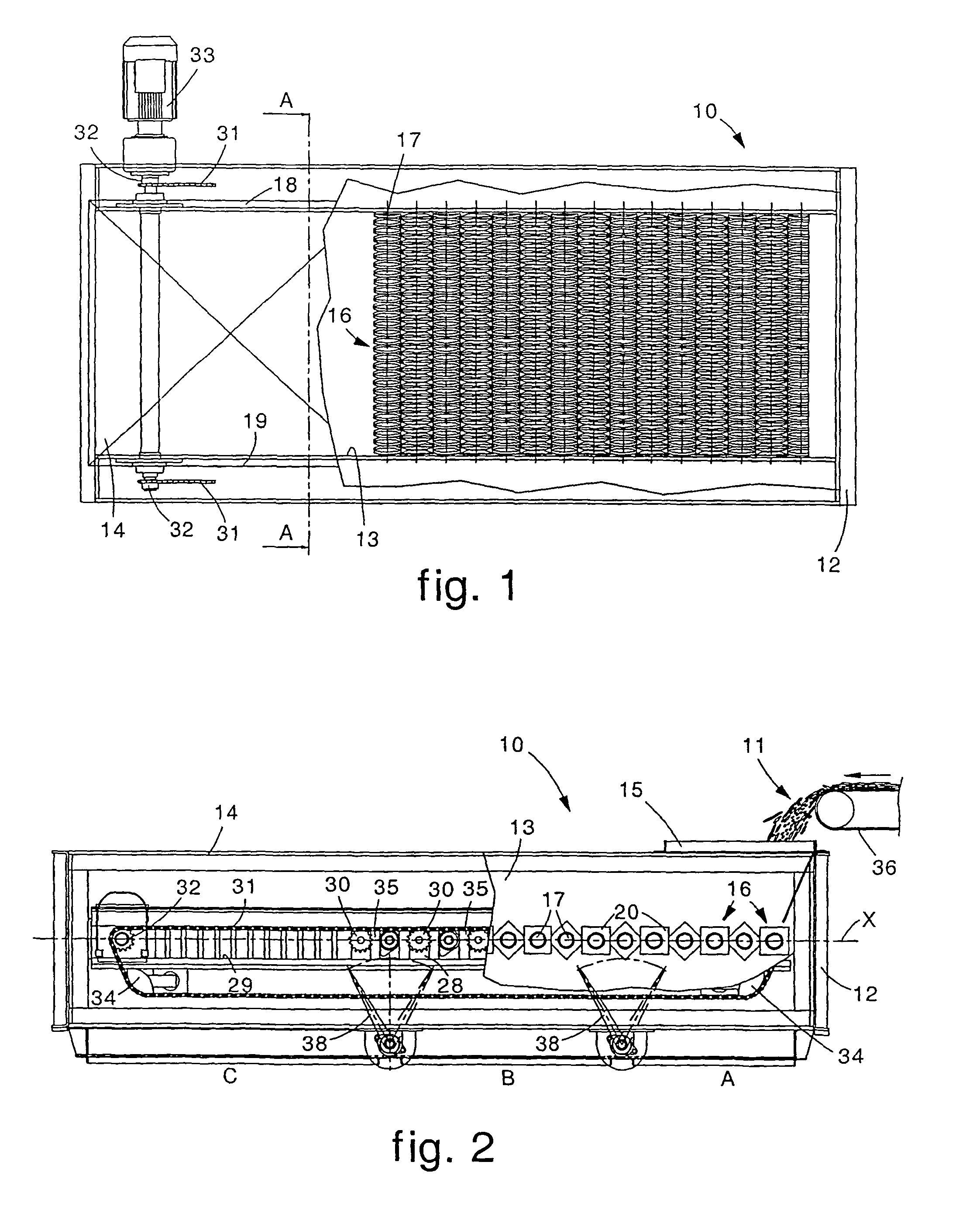

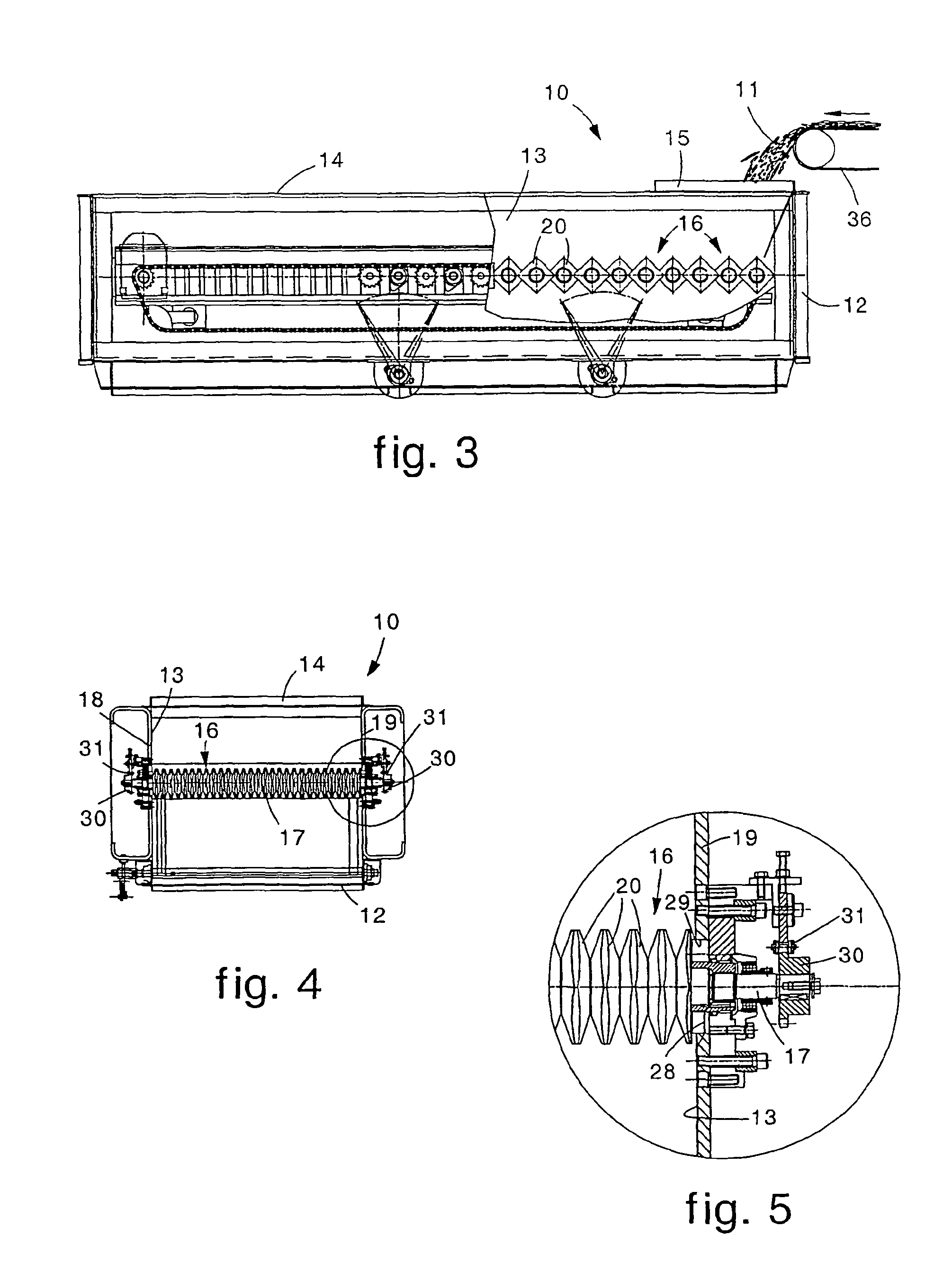

Apparatus and method to separate elements or materials of different sizes

Apparatus (10) and method to separate a loose mass formed by elements or materials (11) of different sizes, such as woody strands or wafers, comprising a separation chamber (13) into which the mass is inserted, a plurality of riddling rolls (16), mounted inside the chamber (13) rotating on axes of rotation parallel to each other and lying sybstantially on a same plane (X). Each of the riddling rolls (16) comprises a plurality of riddling elements (20), each of which is substantially square in shape, so as to form four cusps (22) in correspondence with the four tips of the square. The riddling elements (20) are adjacent to each other so that the cusps (22) form a plurality of grooves (24), and the riddling rolls (16) are axially staggered therebetween so that the cusps (22) of each roll (16) are constantly inserted, more or less deeply into the corresponding grooves (24) of the adjacent riddling roll (16), so as to define discharge apertures (25) with an alternated profile.

Owner:PAL PONTE DI PIAVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com