Separating method and system for waste paper and waste plastic mixture

A separation system and separation method technology, applied in raw material separation, solid separation, magnetic separation and other directions, can solve the problems of flotation blockage, large water consumption, waste water recontamination, etc., to strengthen rubbing treatment, reduce maintenance costs, reduce The effect of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

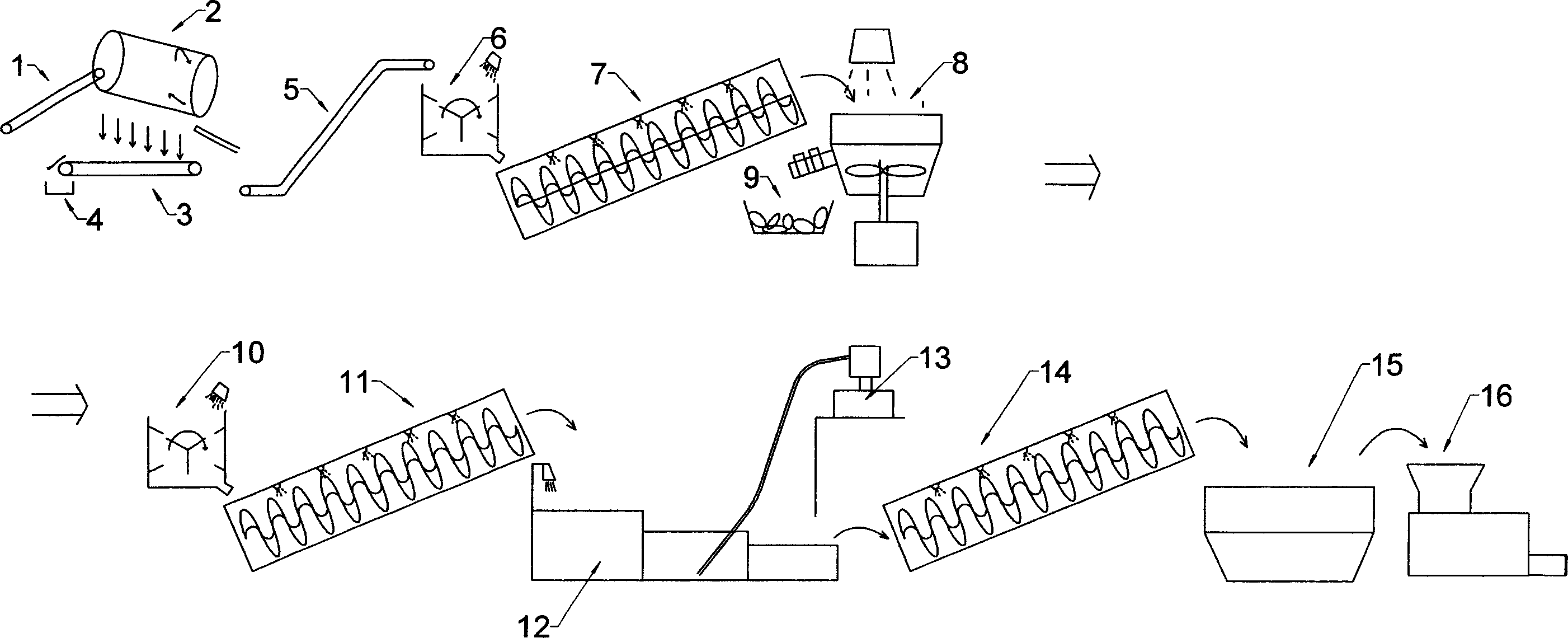

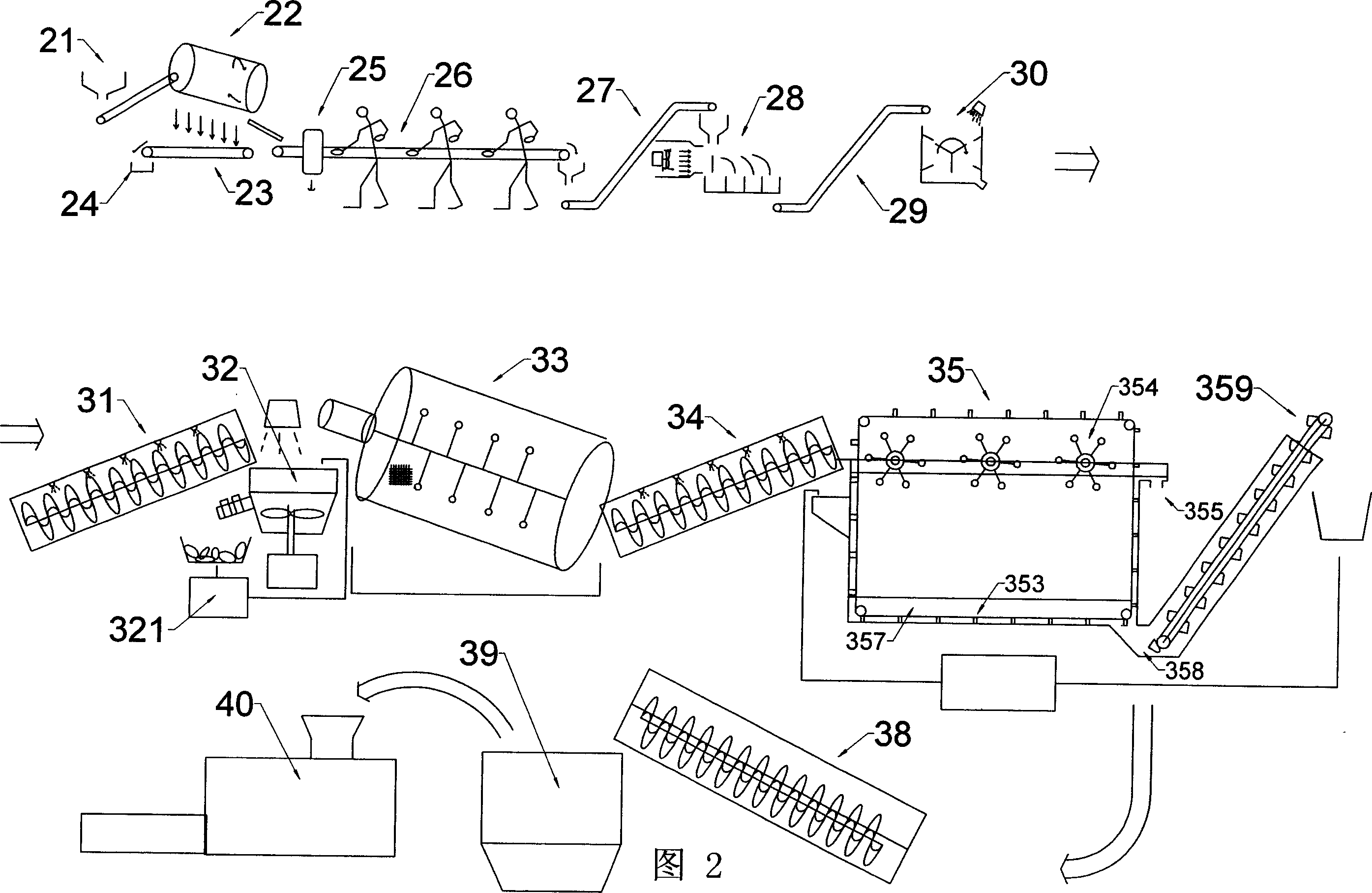

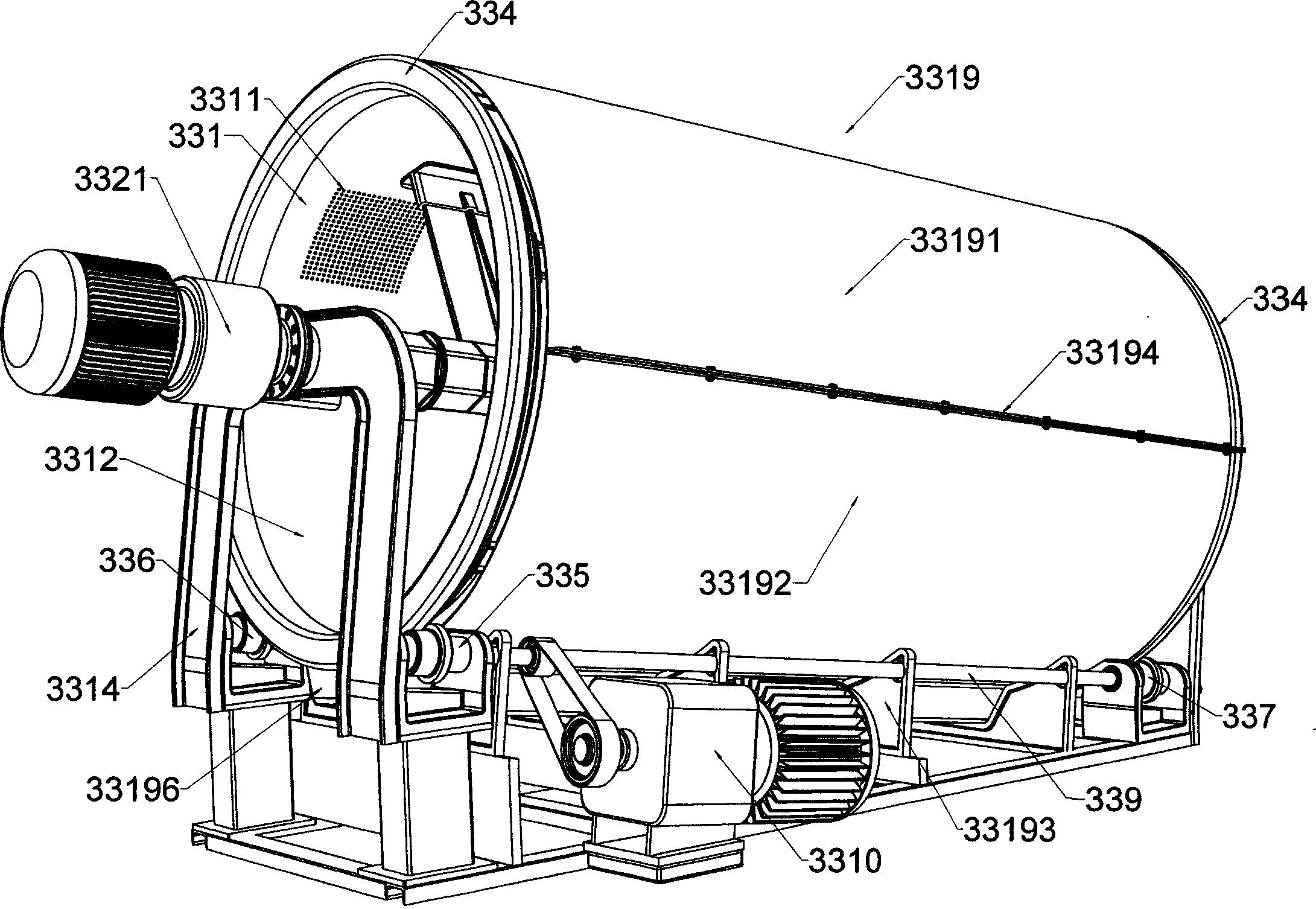

[0046] As shown in Figure 2, the system equipment of the present invention is made up of 14 parts altogether, and they are: quantitative feeding machine 21, trommel B 22, magnetic separation separator 25, manual screening platform 26, winnowing separator 28, pulverizer C30, open separator C31, loose pulp machine B32, rubbing and rolling screen 33, open separator D34, single-stage horizontal flotation cell 35, open separator E38, plastic storage bin 39, granulator 40, among others The connection structure is as follows: the quantitative feeding machine 21 is set at the inlet end of the trommel screen B22, and the magnetic separation separator 25 is arranged at the exit end of the trommel screen B22, and after passing through the manual screening platform 26 and the belt conveyor B27, it reaches the winnowing separator 28, and the pulverizer C30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com