Patents

Literature

799results about "Washing/displacing pulp-treating liquors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

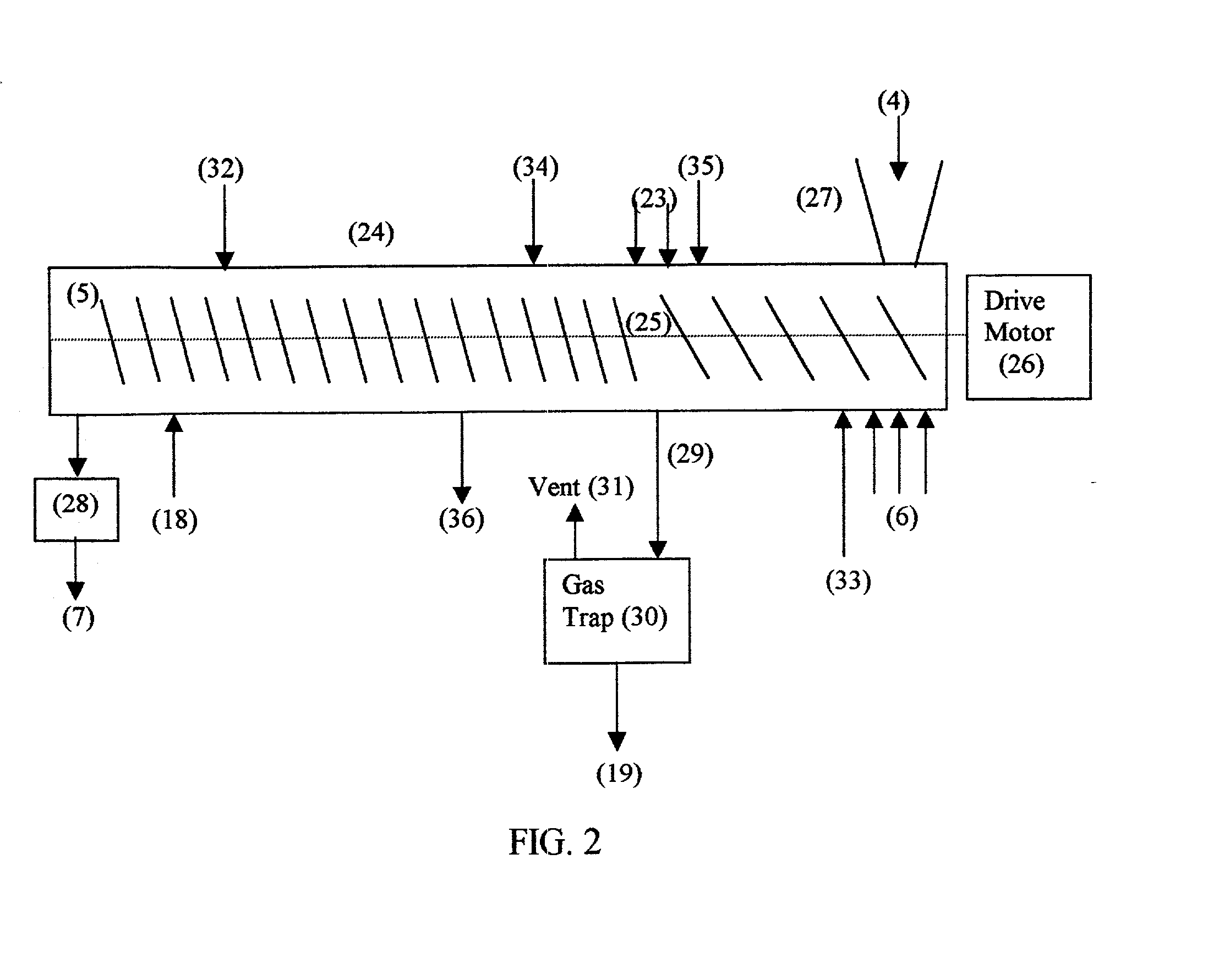

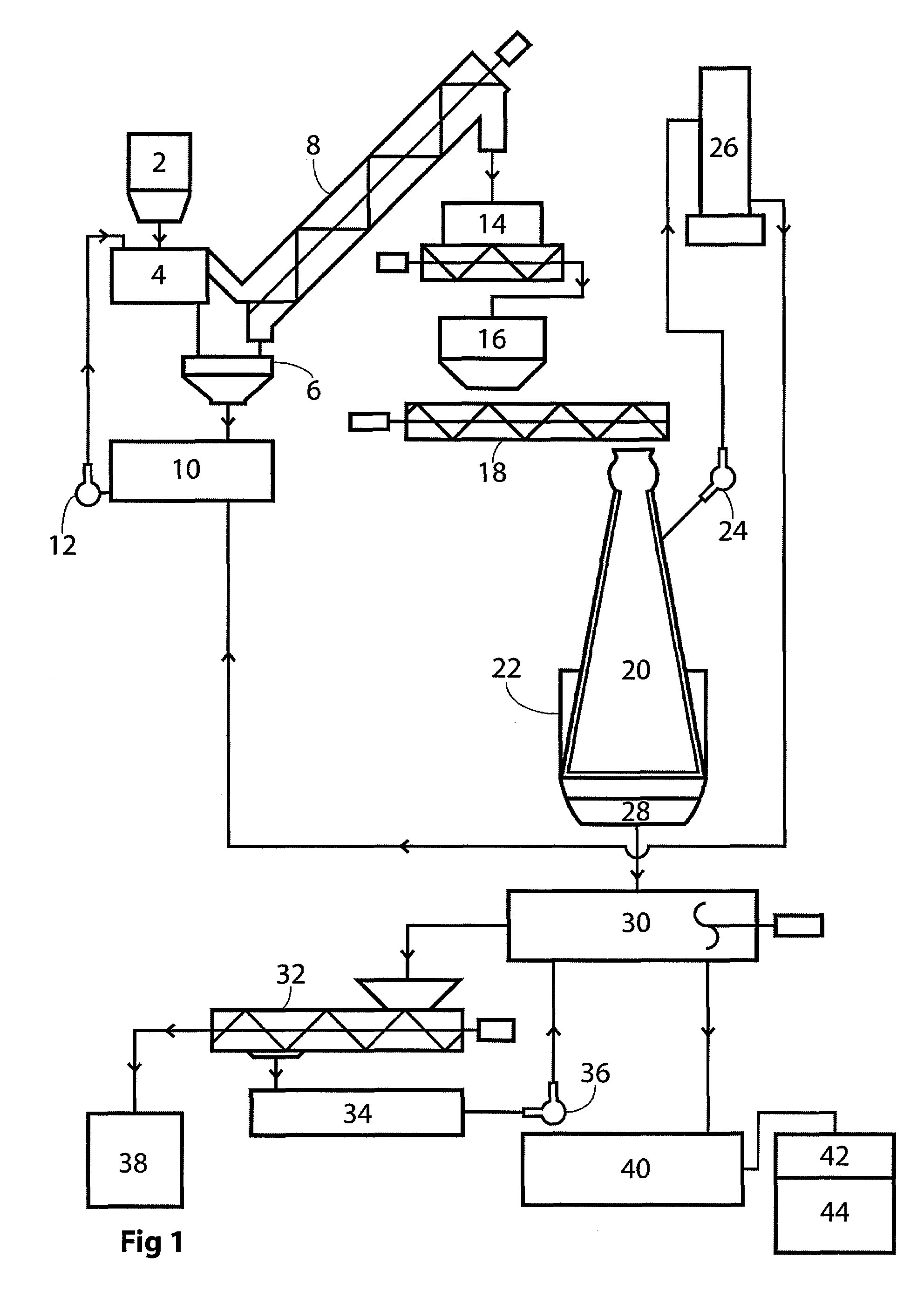

Moving bed biomass fractionation system and method

InactiveUS20080029233A1Improve production yieldIncrease pressureWashing/displacing pulp-treating liquorsDigestersChemical reactionFiltration

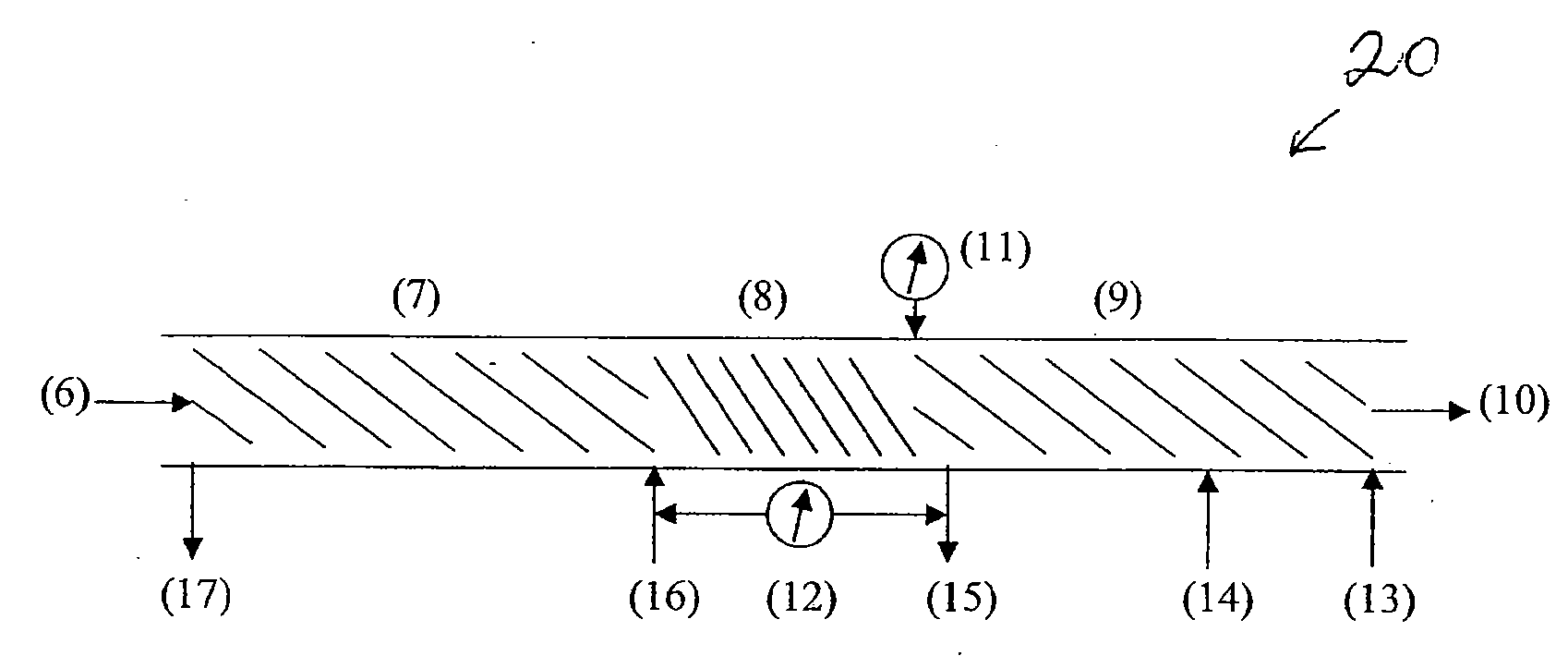

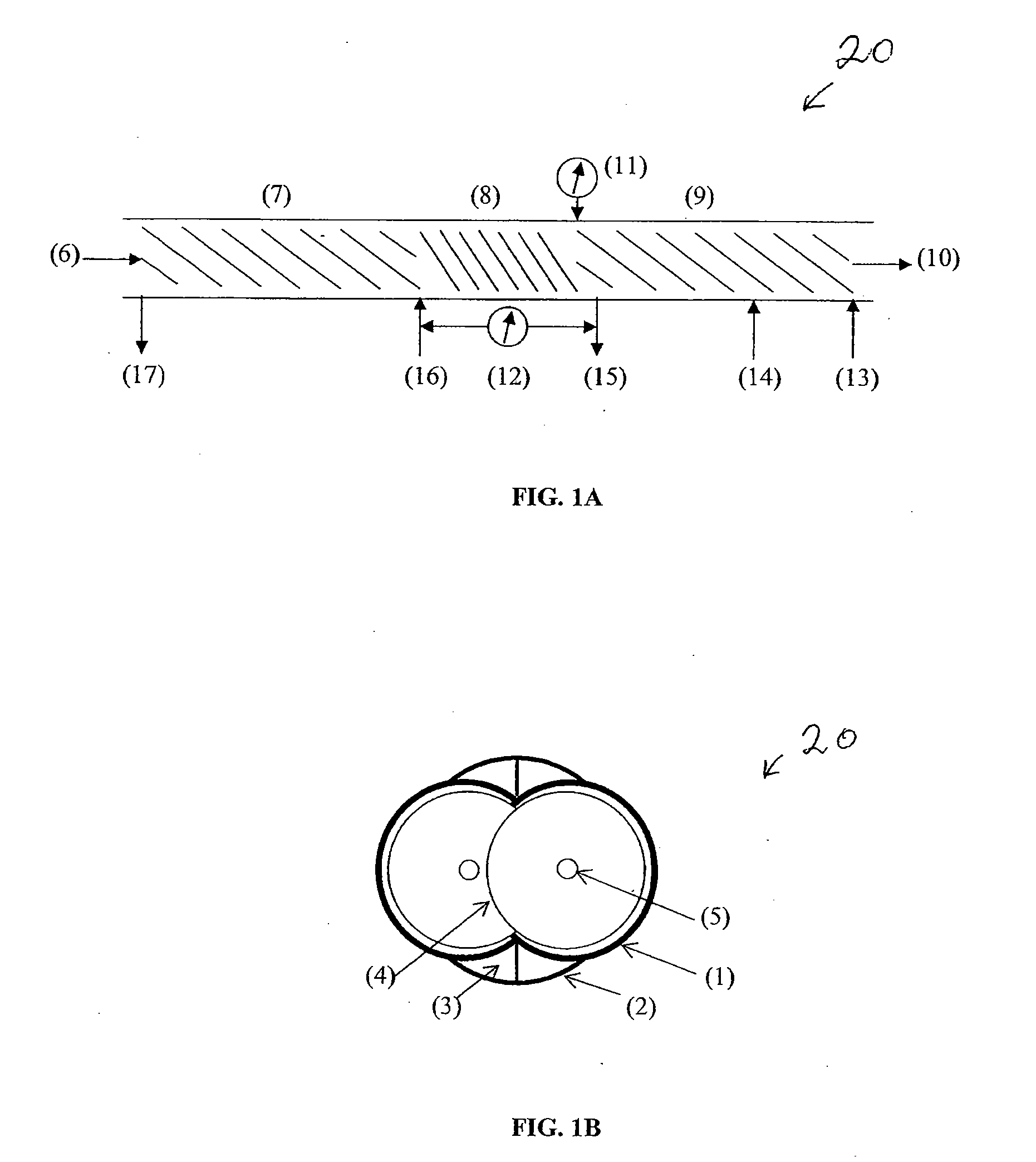

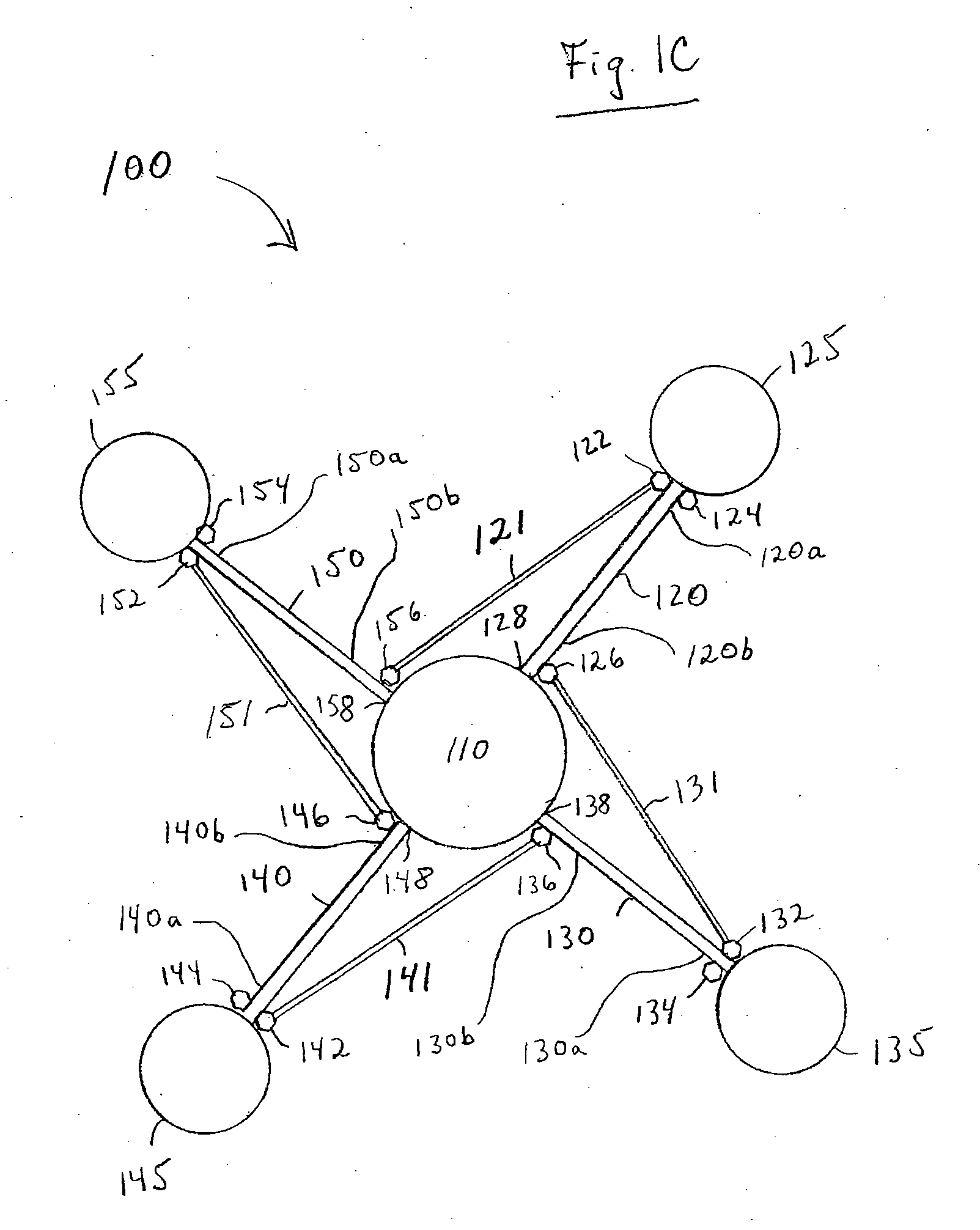

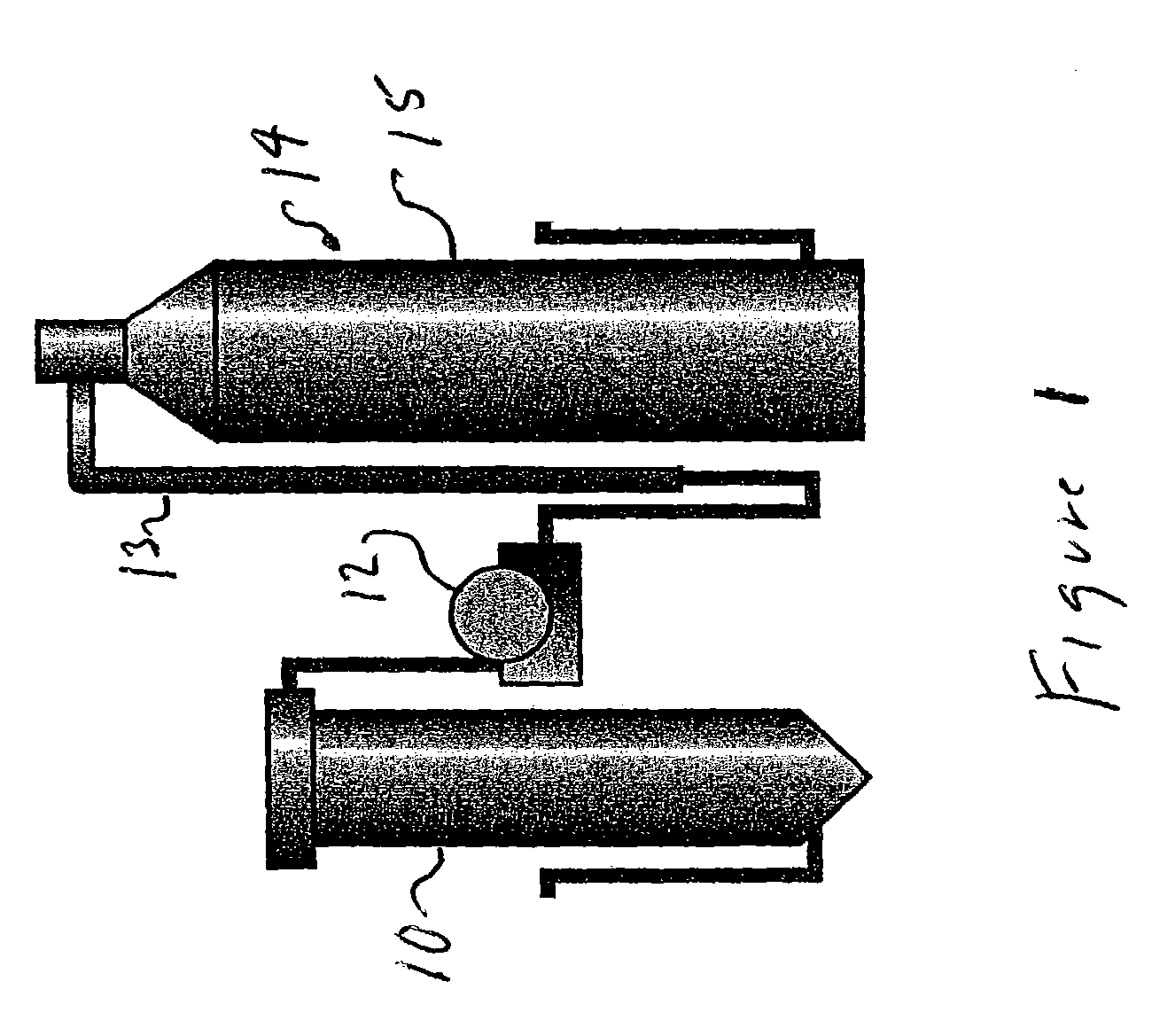

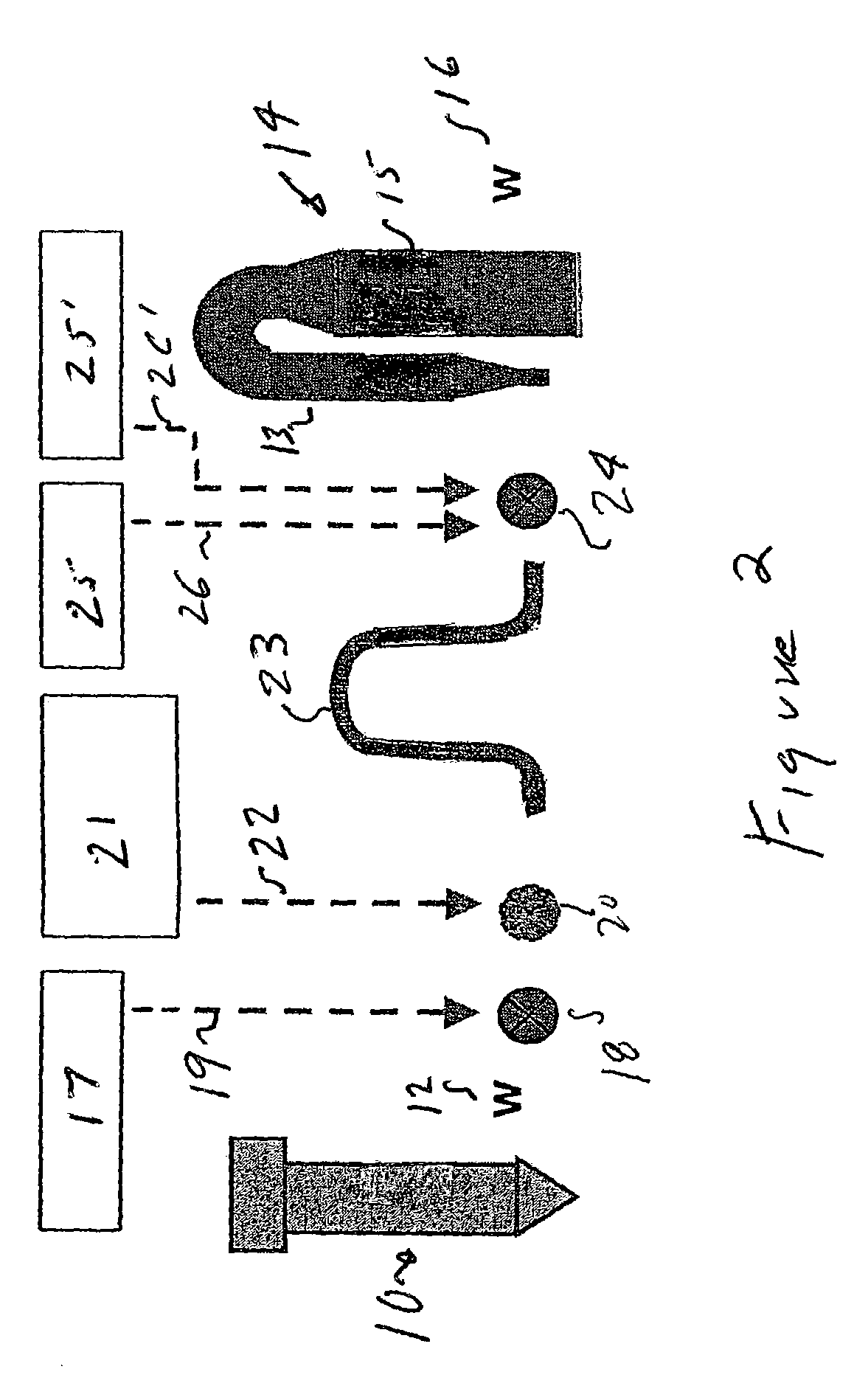

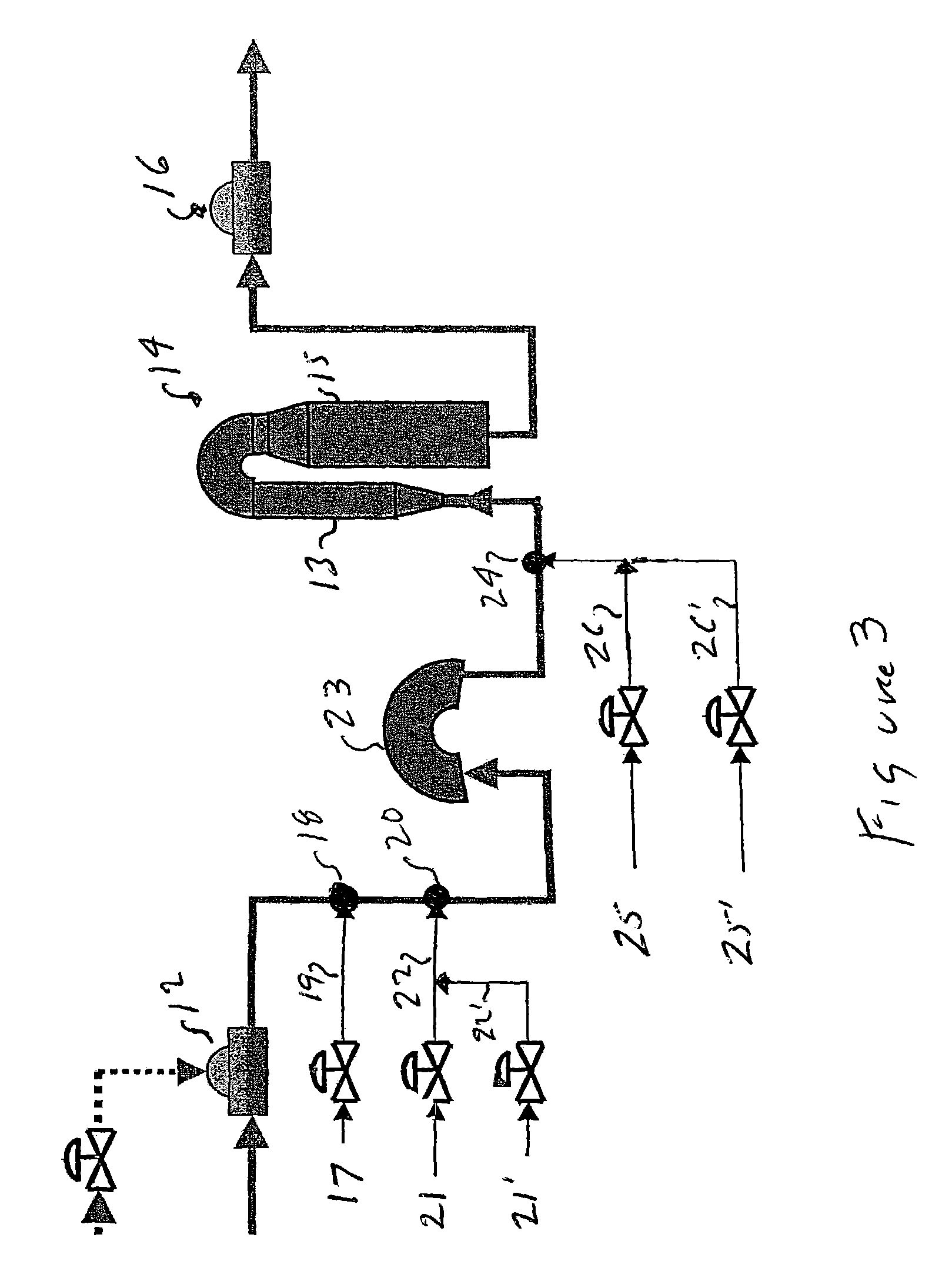

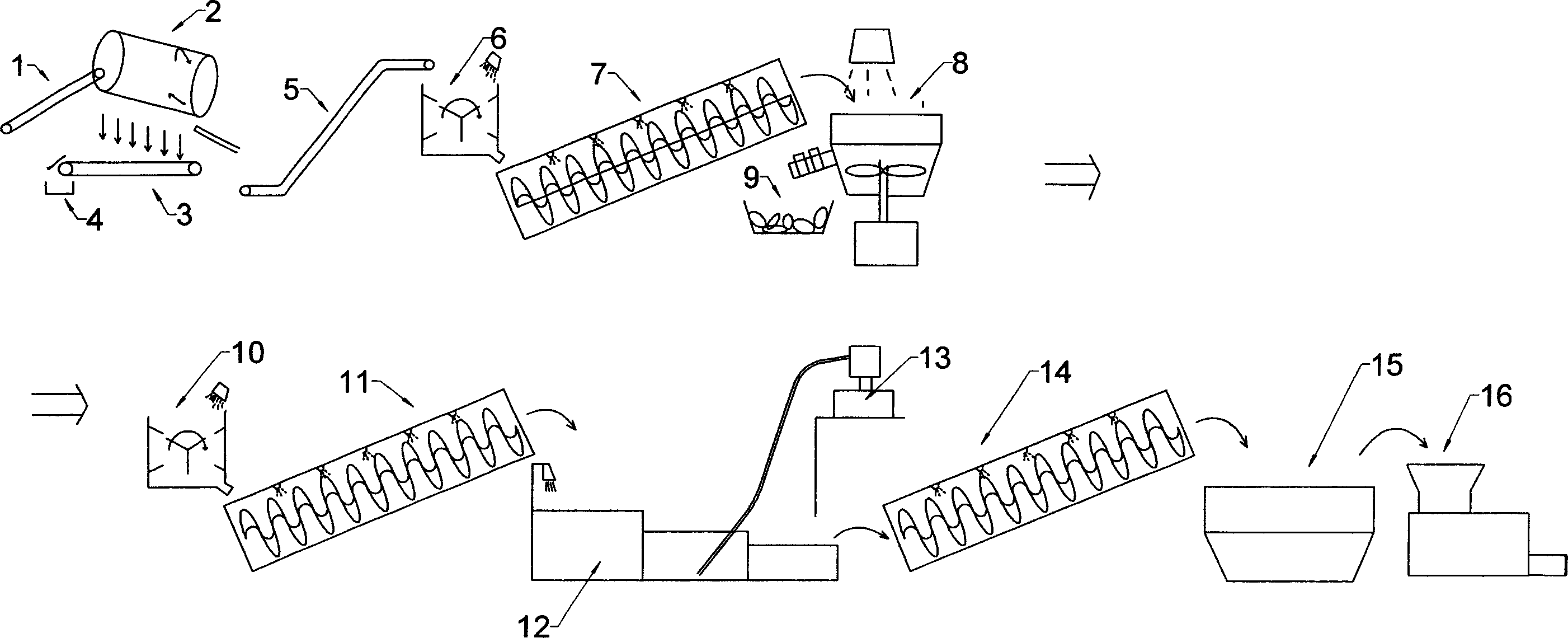

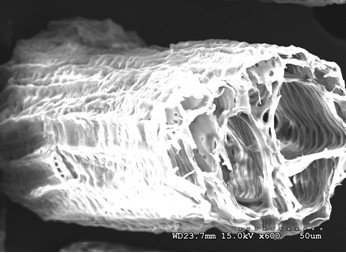

Countercurrent extraction of lignocellulosic biomass such as trees, grasses, shrubs, and agricultural residues or waste involves the separation of cellulose fibers from other constituents, for subsequent use in the manufacture of paper, plastics, ethanol, and other industrial chemicals. Systems and methods involve continuous, multiple processing steps that may include chemical reactions with mixing at elevated temperature and / or pressure, efficient reagent or solvent utilization, filtration at elevated temperature and / or pressure, controlled discharge of liquid and solid products, and energy recuperation.

Owner:PUREVISION TECH

Solvent pulping of biomass

InactiveUS20040060673A1Pretreatment with water/steamWashing/displacing pulp-treating liquorsCellulose fiberChemistry

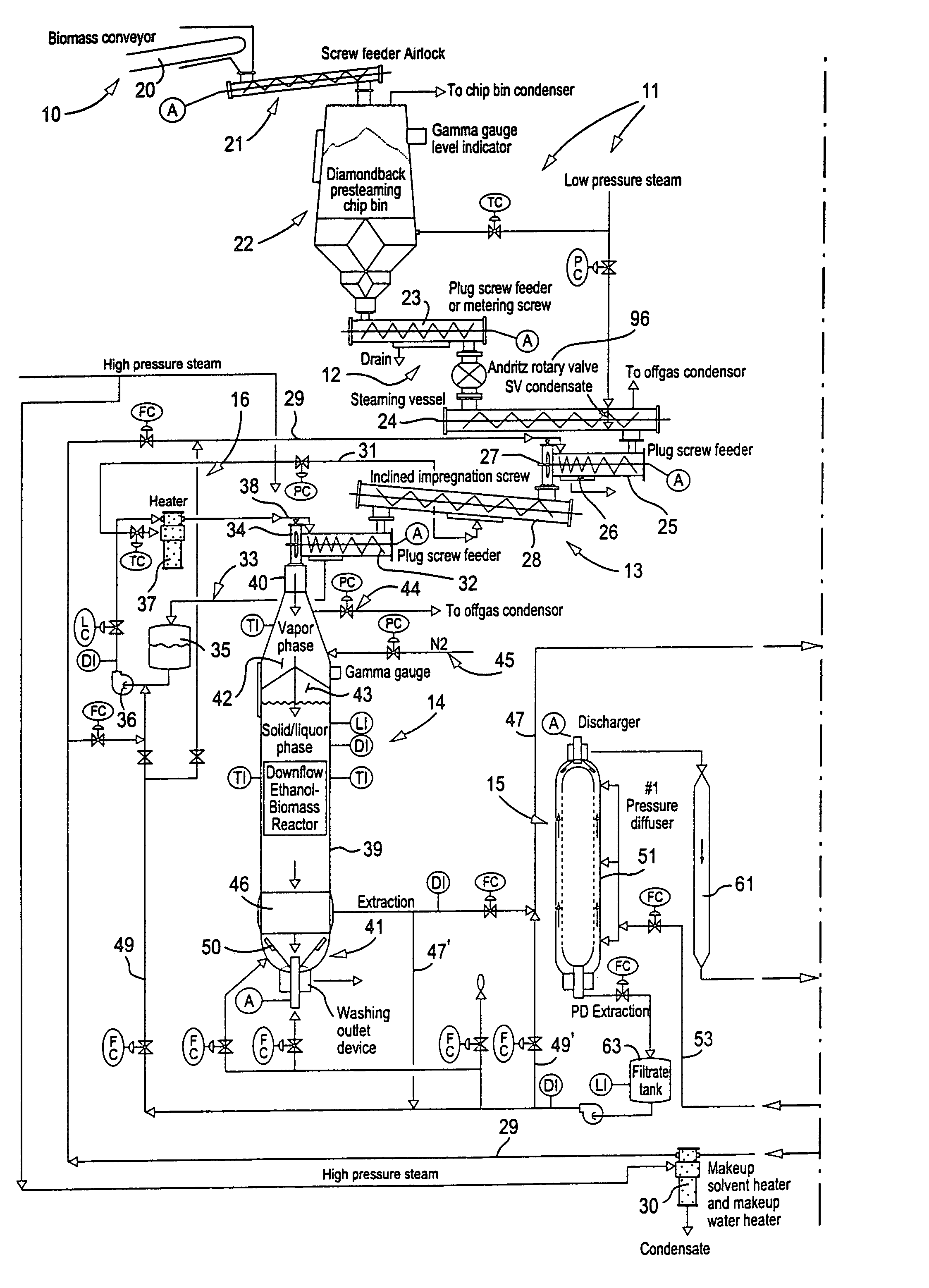

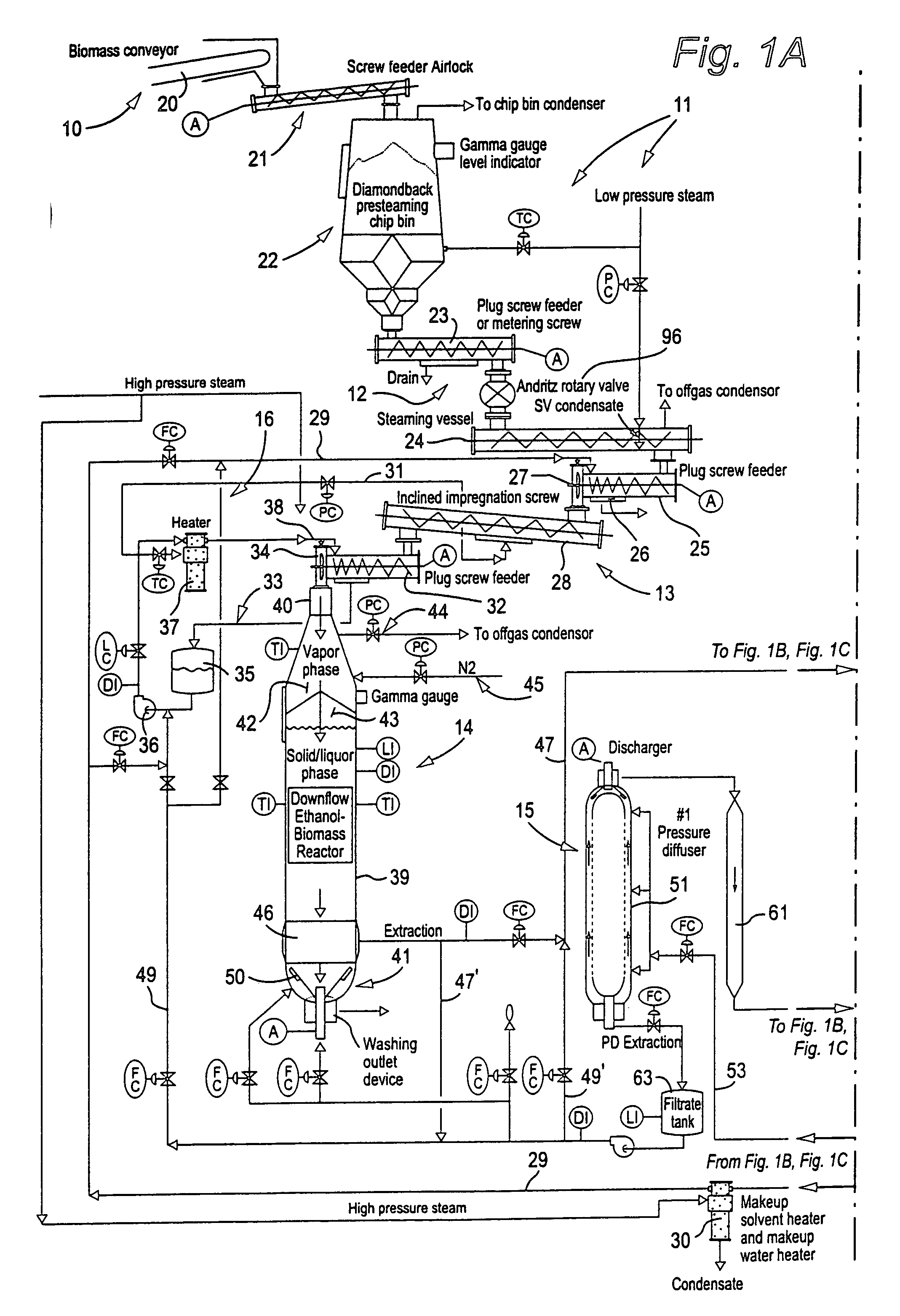

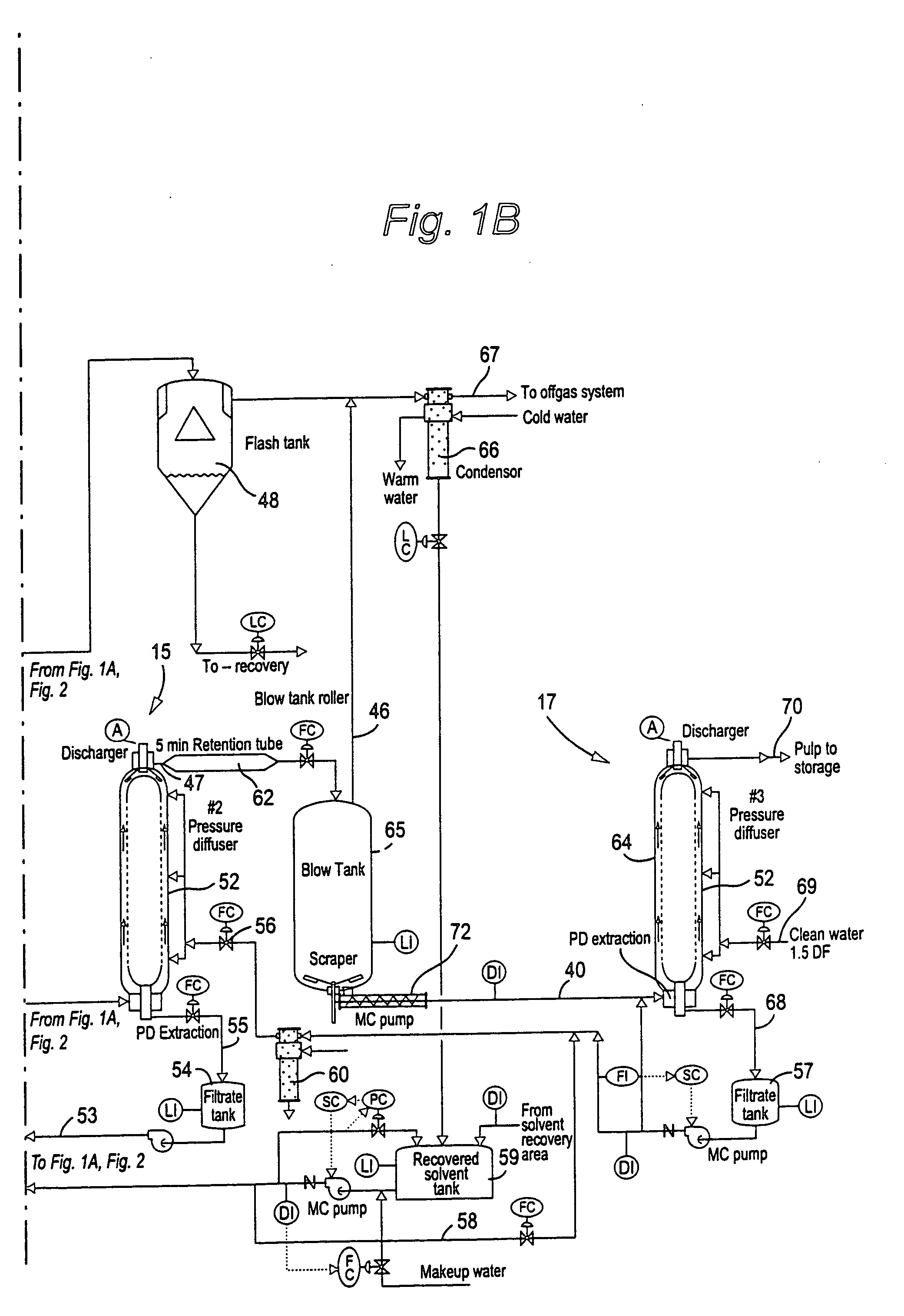

An apparatus and process for solvent pulping of cellulose-containing biomass utilizes at least one steaming vessel, a plug screw feeder or compression screw device, at least one super-atmospheric impregnation vessel, a solvent delignification reactor capable of operating at a pressure of 350 psig or more, and a solvent containing line for introducing solvent-containing liquor at the plug screw feeder outlet or compression screw device outlet. The process and system can also include at least one series connected pressure diffuser and optionally a retention tube downstream of each pressure diffuser to provide sufficient retention time to substantially preclude re-deposition of lignin on the cellulose fibers of the biomass, a blow tank connected to the last of the pressure diffusers and retention tubes, and vessels for multistage alcohol washing. The method steams the biomass and impregnates it with solvent to produce an aqueous slurry of biomass and solvent, delignifies the particulate biomass in the slurry, removes solvent while continuing delignification of the biomass in the slurry and while substantially precluding re-deposition of lignin on the cellulose of the biomass, reduces the pressure of the slurry; and then washes the slurry.

Owner:ANDRITZ INC

Detoxifying and Recylcing of Washing Solution Used In Pretreatment Of Lignocellulose-Containing Materials

ActiveUS20090056889A1Improve hydrolysis efficiencyImprove filtering effectWashing/displacing pulp-treating liquorsBiofuelsPre treatmentOrganic chemistry

The invention relates to a process of detoxifying pretreated lignocellulose-containing material comprising washing the pretreated lignocellulose-containing material in a washing solution and treating the used washing solution to remove an enzyme inhibitor and / or an inhibitor of a fermenting organism before recycling the used washing solution.

Owner:COFCO GROUP

Apparatus for making carboxylated pulp fibers

InactiveUS7001483B2Little additional equipmentDelay transitionNon-fibrous pulp additionSpecial paperFiberBleach

Owner:WEYERHAEUSER CO

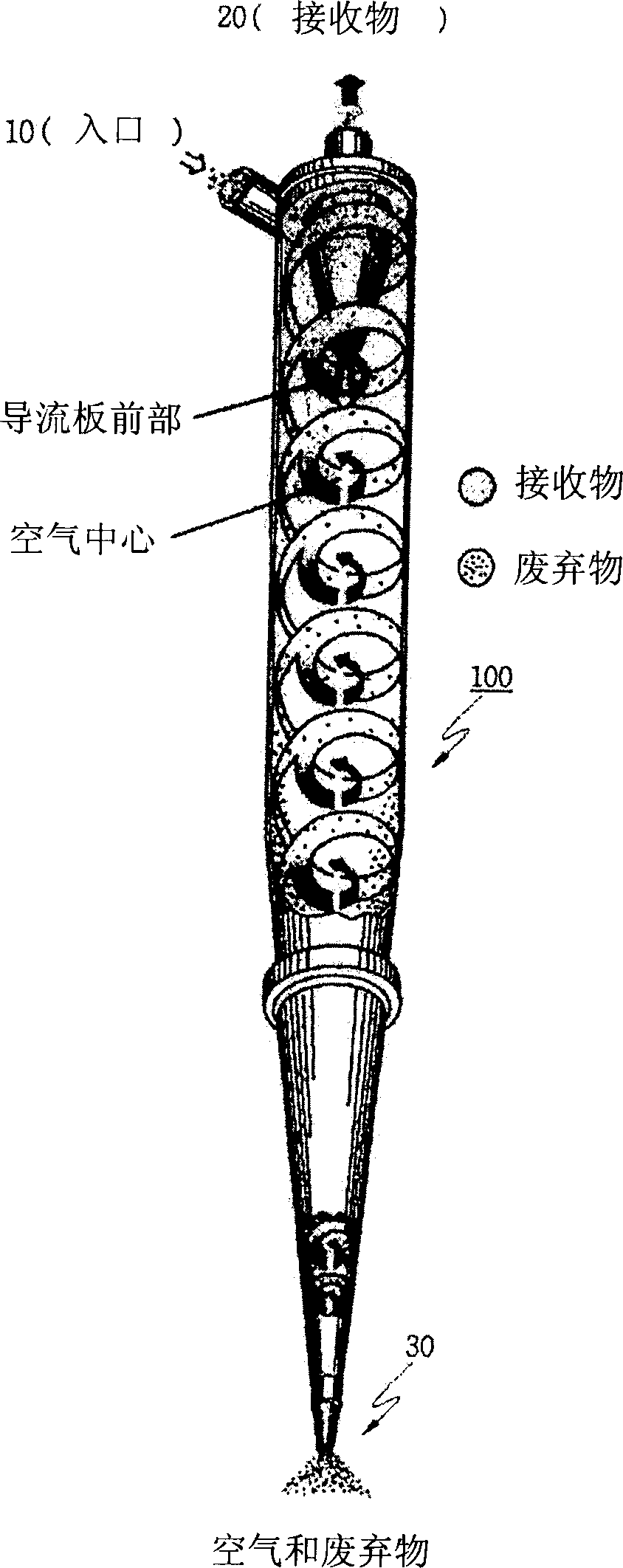

Separating method and system for waste paper and waste plastic mixture

InactiveCN1834340AReduce energy consumptionReduce loadGas current separationWashing/displacing pulp-treating liquorsFiberSingle stage

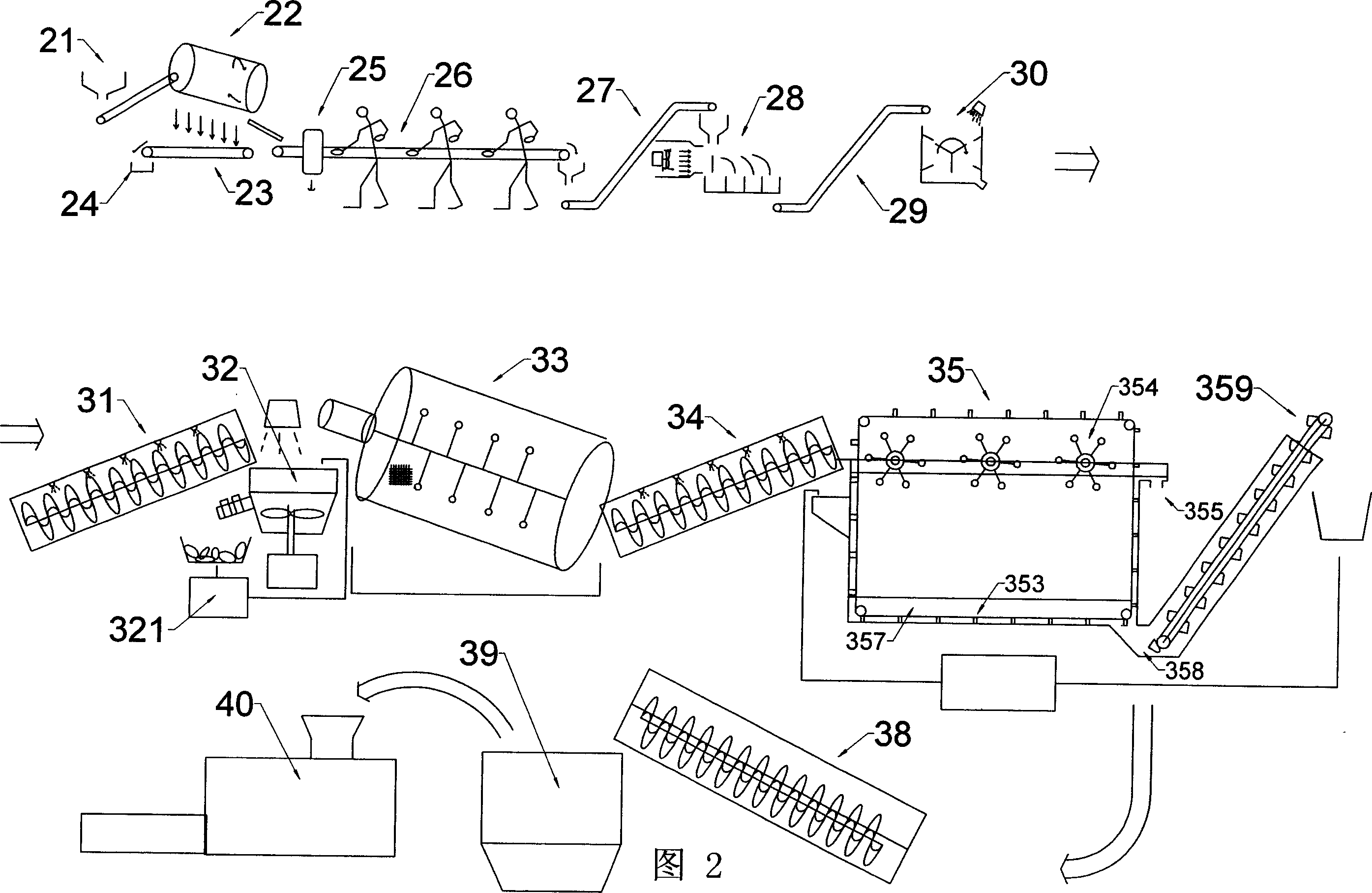

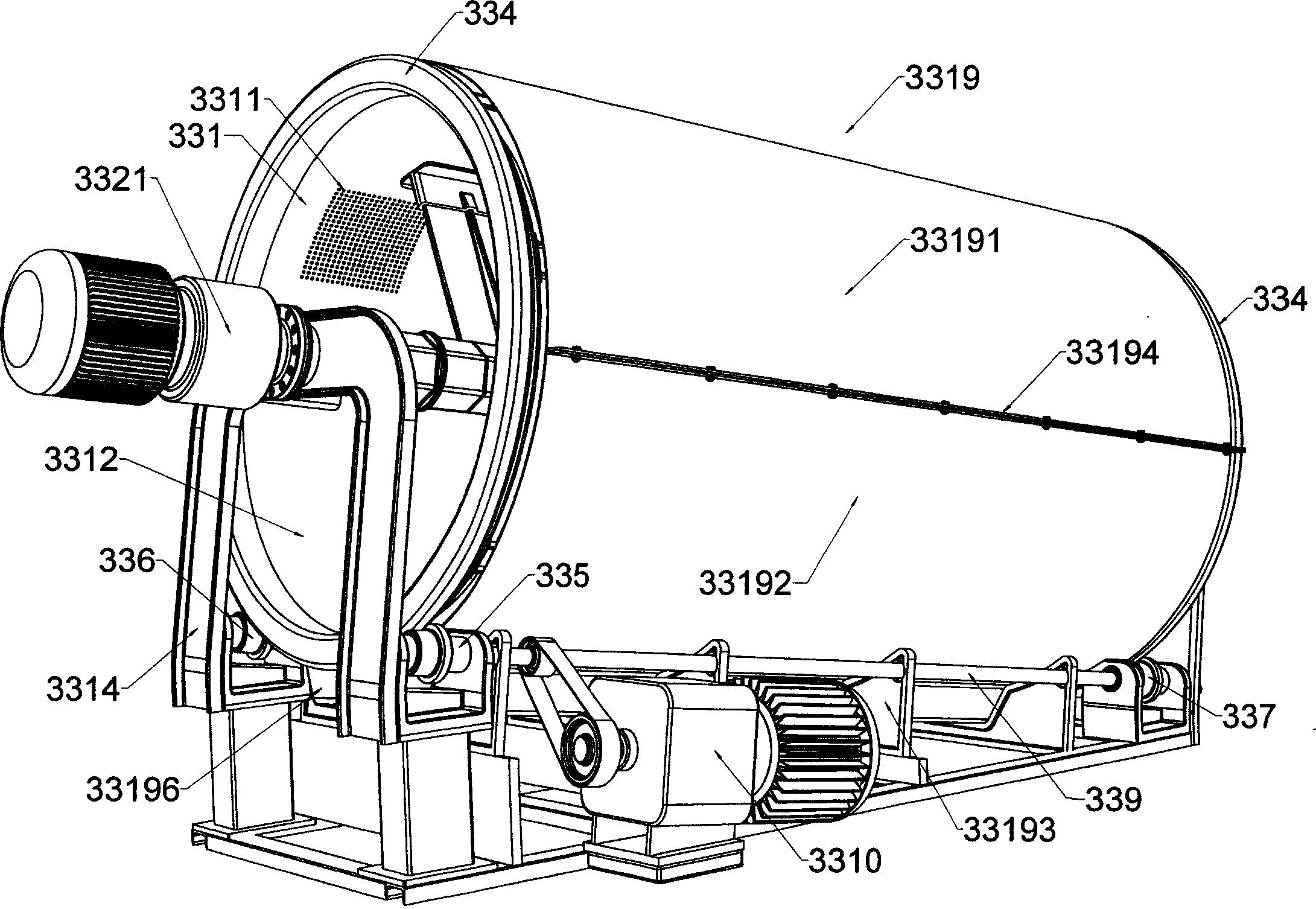

A method for separating out waste paper and waste plastic form their mixture including preliminary selecting, using magnetic separator to select out magnetic impurities, using hand to pick up large impurity block without plastic, using fan to blow impurities with different gravities into different grooves at different distance, using mechanical rubbing machine to separate paper fiber from plastic, using single stage floating tank to beat floating matters for releasing paper fiber off, storing floated out plastic and palletizing them for reutilization.

Owner:曾碚凯

Cellulose production from lignocellulosic biomass

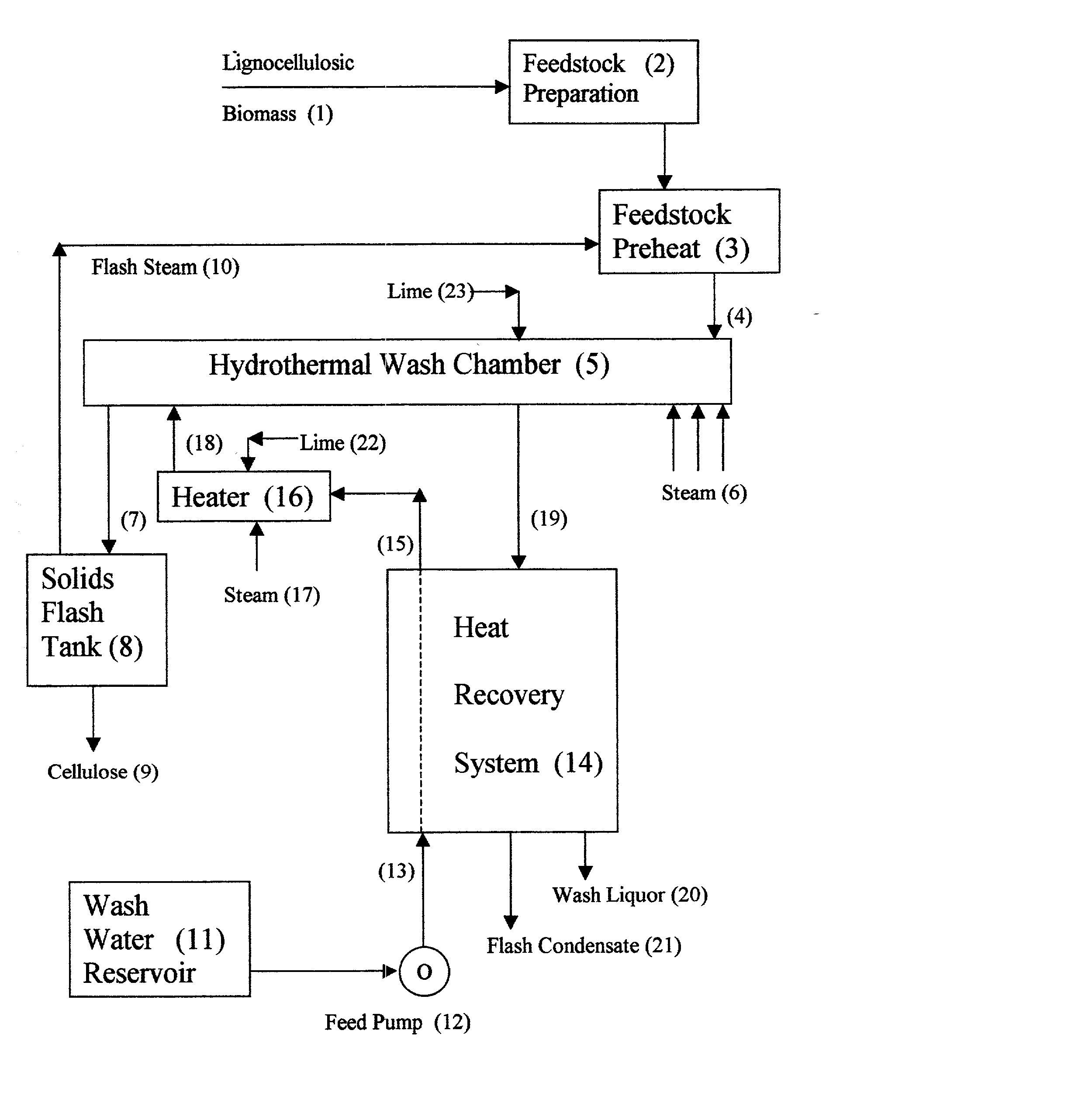

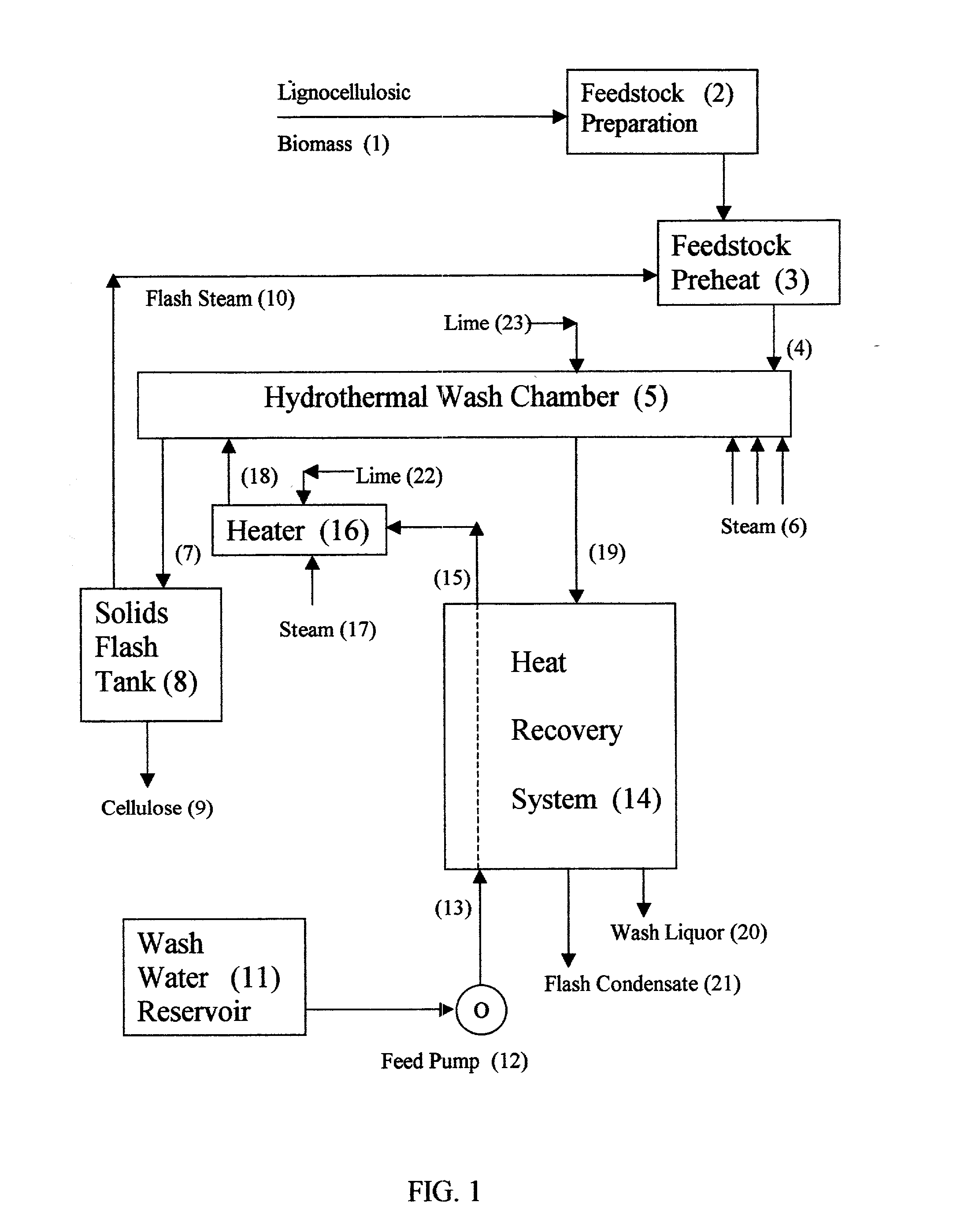

InactiveUS20020148575A1Low costHigh yieldPretreatment with water/steamPulp liquor regenerationEnergy recoveryCellulose fiber

A multi-function process is described for the separation of cellulose fibers from the other constituents of lignocellulosic biomass such as found in trees, grasses, agricultural waste, and waste paper with application in the preparation of feedstocks for use in the manufacture of paper, plastics, ethanol, and other chemicals. This process minimizes waste disposal problems since it uses only steam, water, and oxygen at elevated temperature in the range of 180° C. to 240° C. for 1 to 10 minutes plus a small amount of chemical reagents to maintain pH in the range 8 to 13. An energy recuperation function is important to the economic viability of the process.

Owner:PUREVISION TECH

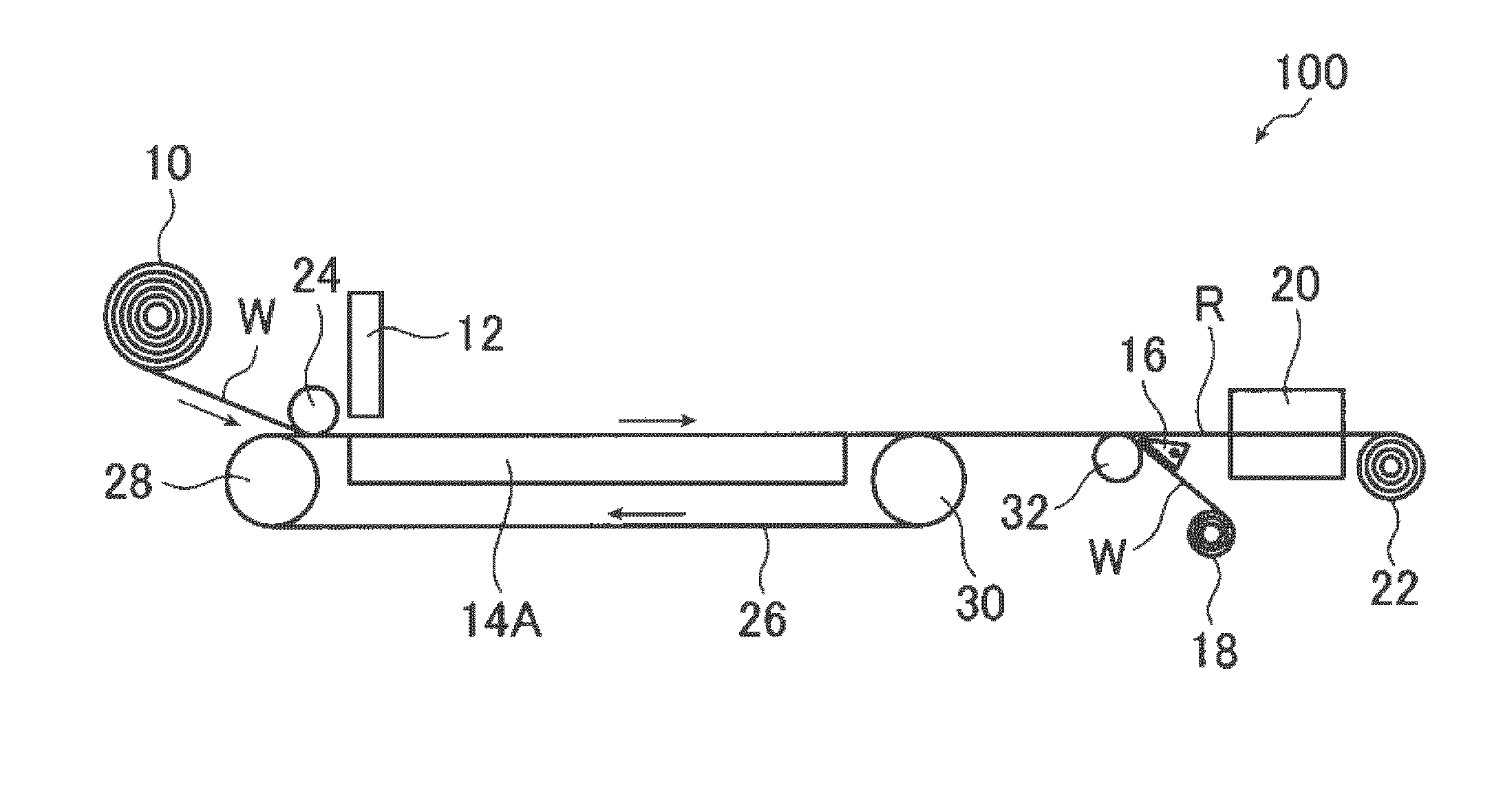

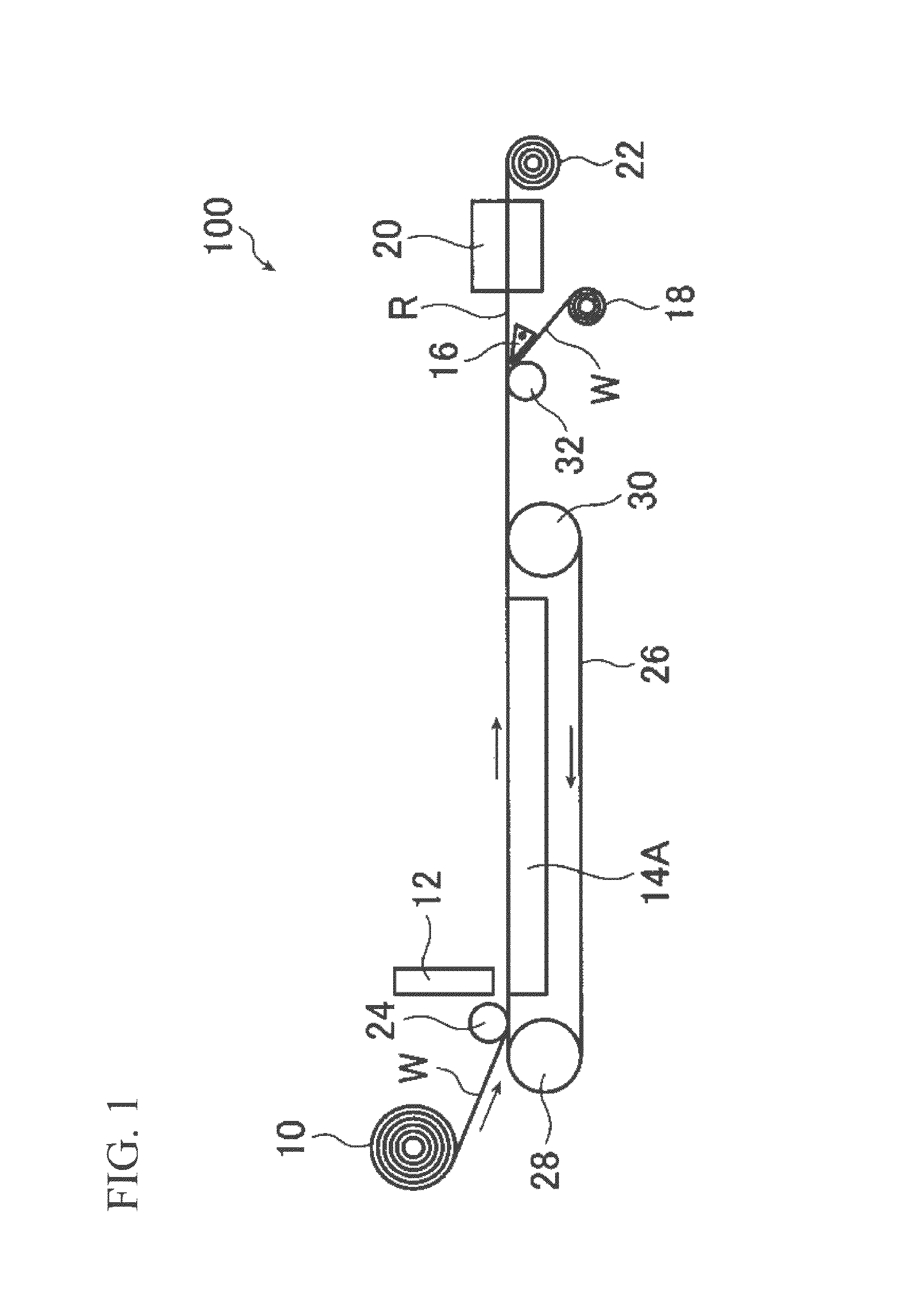

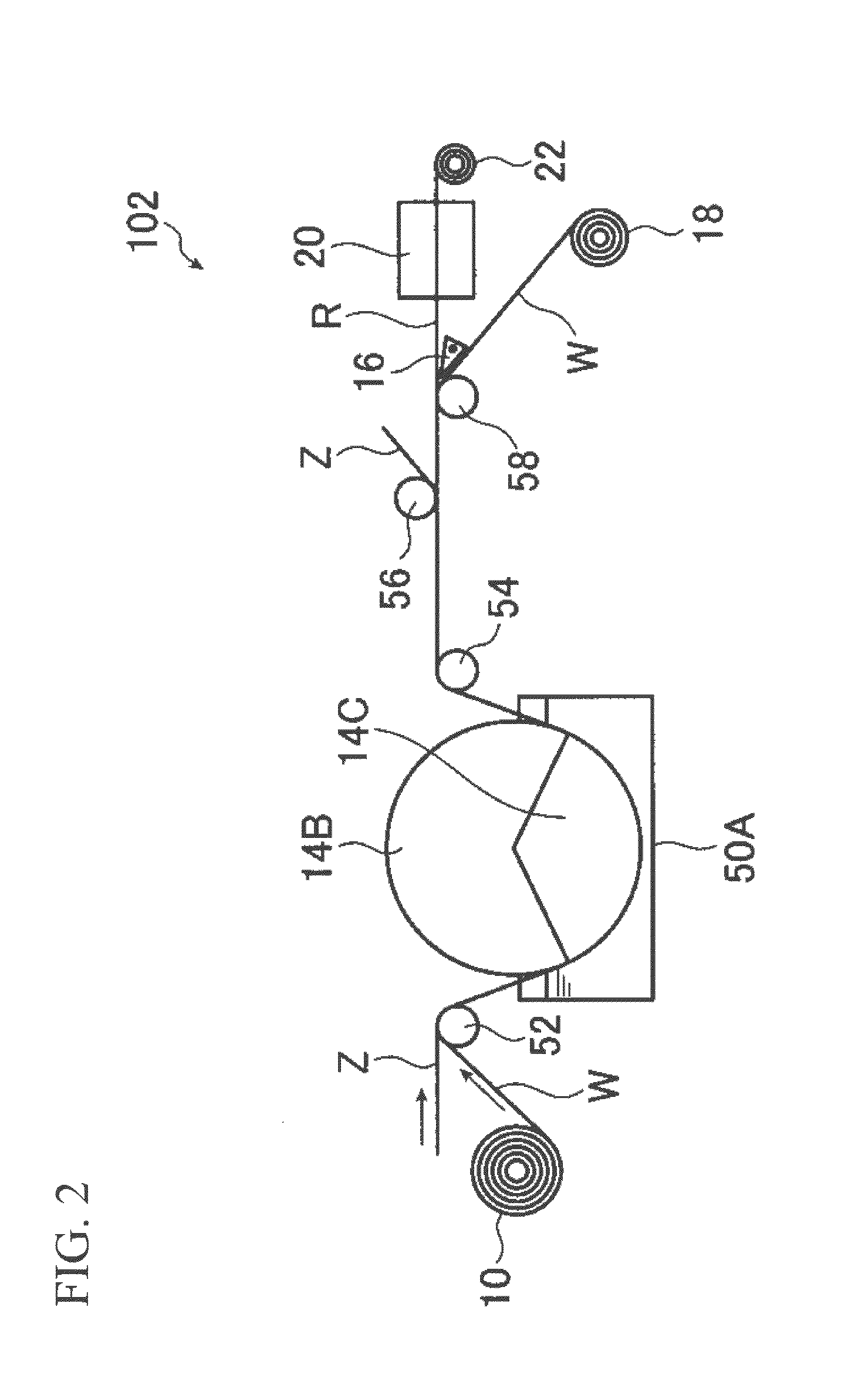

Method for producing cellulose-fiber flat structure

ActiveUS20120298319A1Good surface textureEffective recoveryMembranesSemi-permeable membranesPolymer scienceCellulose fiber

The present invention relates to a method of producing a cellulose-fiber flat structure, the method including obtaining a cellulose-fiber flat structure by filtering a fine cellulose-fiber dispersion containing fine cellulose fibers having an average fiber diameter of 4 to 100 nm, using a filter material having a water permeability of not more than 100 ml / m2·s and an initial tensile modulus of 20 MPa or greater. The present invention is able to produce a cellulose-fiber flat structure by efficiently recovering fine cellulose fibers from a dispersion containing fine cellulose fibers having an average fiber diameter at the nano level. The method of producing a cellulose-fiber flat structure can also be applied to a continuous process.

Owner:OJI HLDG CORP

Process of producing xylose and dissolving pulp

ActiveUS20110192560A1High yieldReduce the amount requiredPretreatment with water/steamWashing/displacing pulp-treating liquorsChromatographic separationXylan

The present invention relates to a process for the production of xylose and dissolving pulp from xylan-containing biomass, such as hardwood. The invention is based on prehydrolysis of the xylan-containing biomass with SO2 in specified conditions, followed by chromatographic fractionation, nanofiltration or precipitation crystallization of the xylose-containing prehydrolyzate to obtain a xylose product having a xylose content of at least 55% on DS. The dissolving pulp obtained from the process can be used for example for the production of viscose.

Owner:DUPONT NUTRITION BIOSCIENCES APS

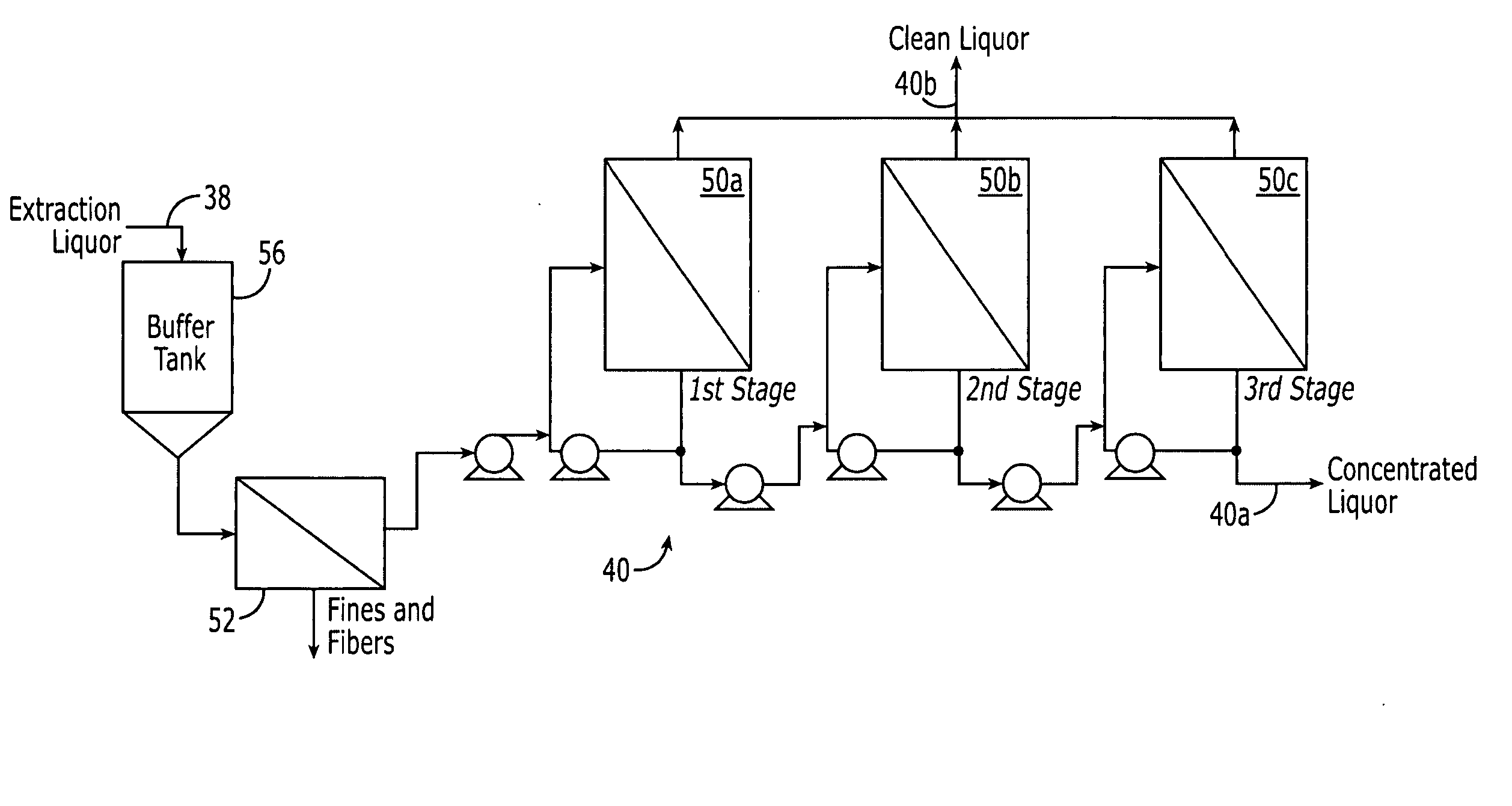

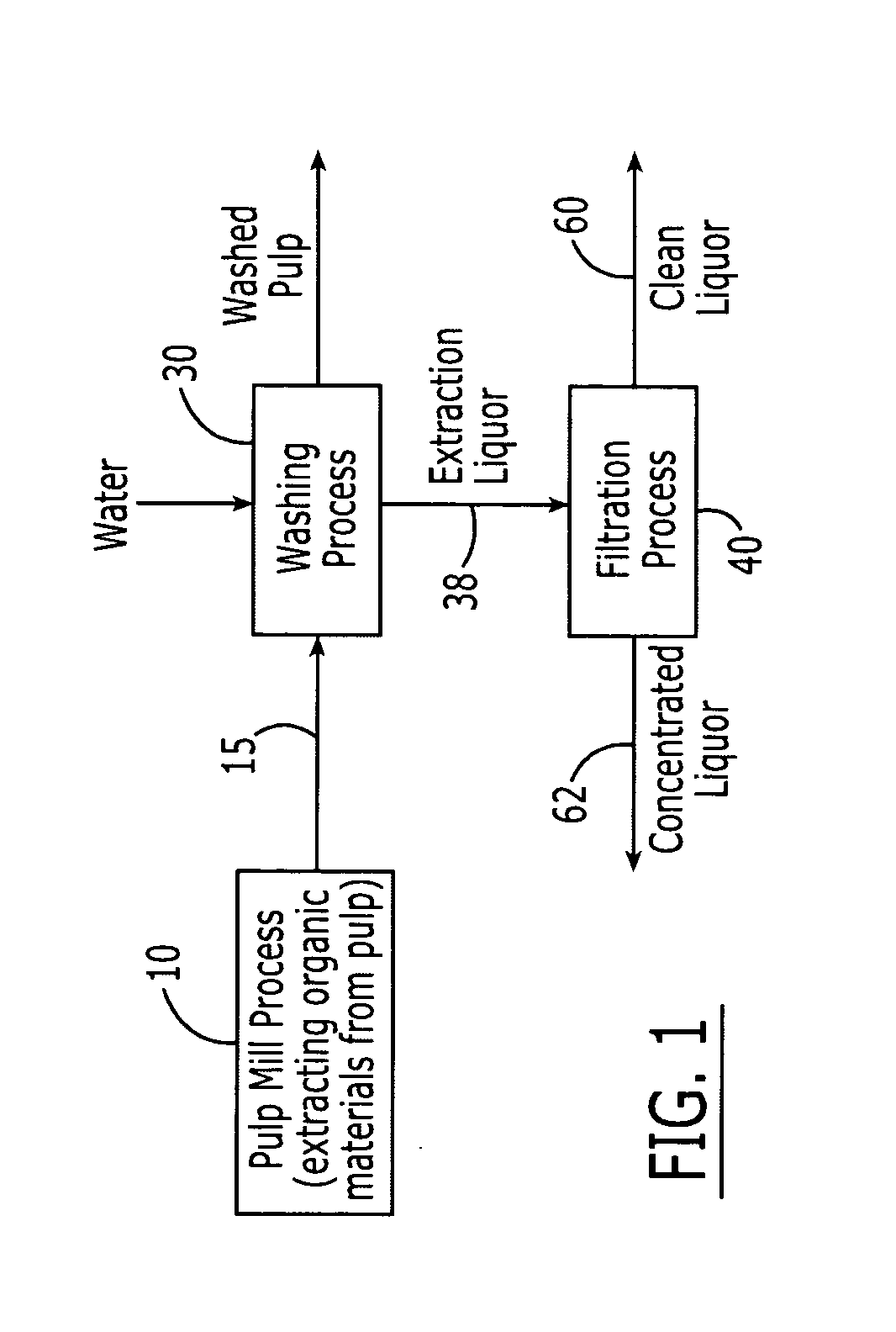

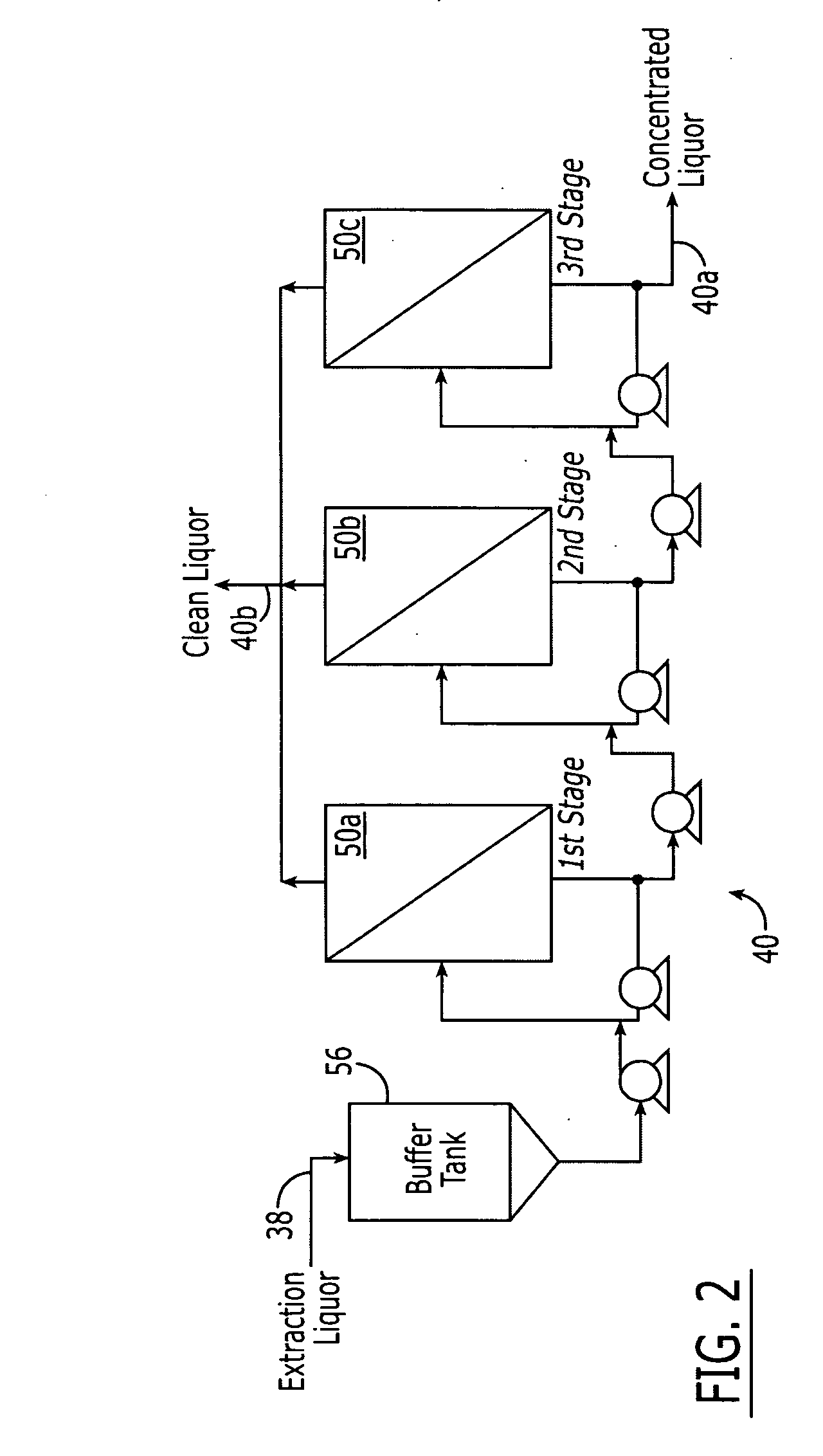

Method of concentrating pulp mill extracts

InactiveUS20060016751A1Reduce loadReduce processMembranesPulp liquors combustionWaste streamPulp mill

A process for separating organic components from a pulp mill waste stream comprising the steps of washing a cellulose pulp to obtain an aqueous extraction liquor containing organic components, and separating at least a portion of said organic components from the extraction liquor by passing the extraction liquor through at least one nanofiltration membrane. The process may be used in conjunction with a variety of pulp mill processes, including kraft cooking processes, hot caustic extraction processes, sulfite cooking processes, and bleaching processes.

Owner:RAYONIER PRODUCTS AND FINANCIAL SERVICES COMPANY

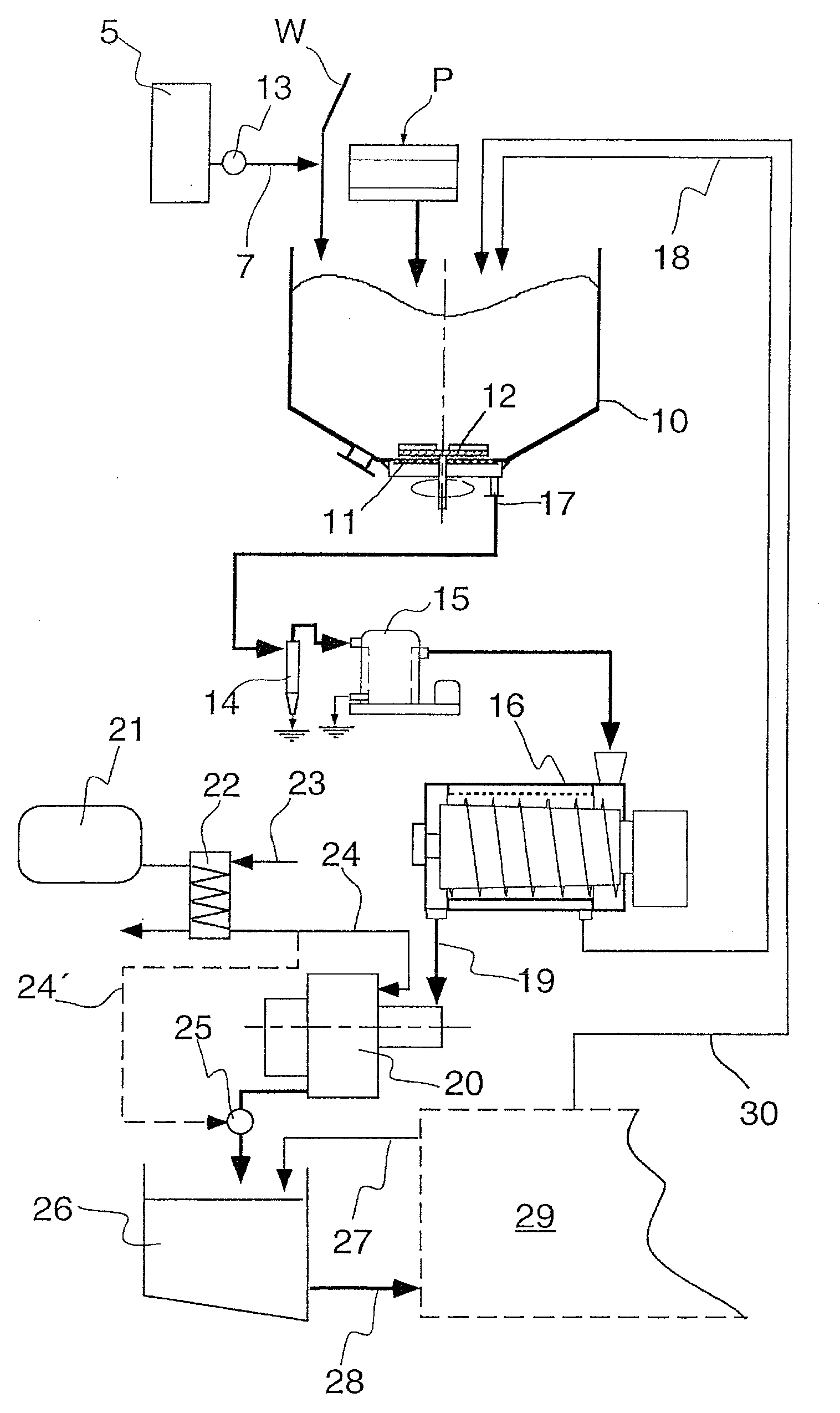

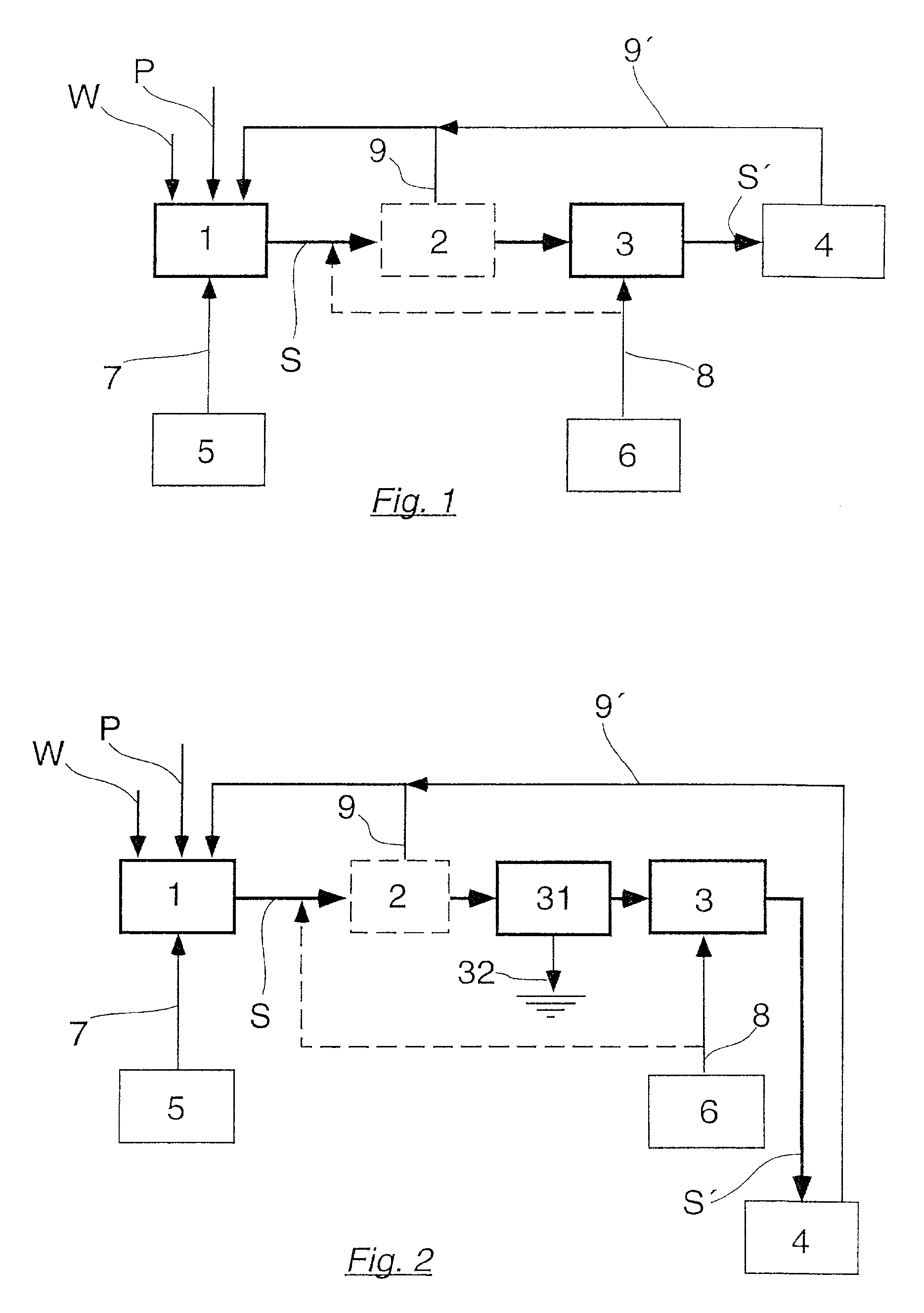

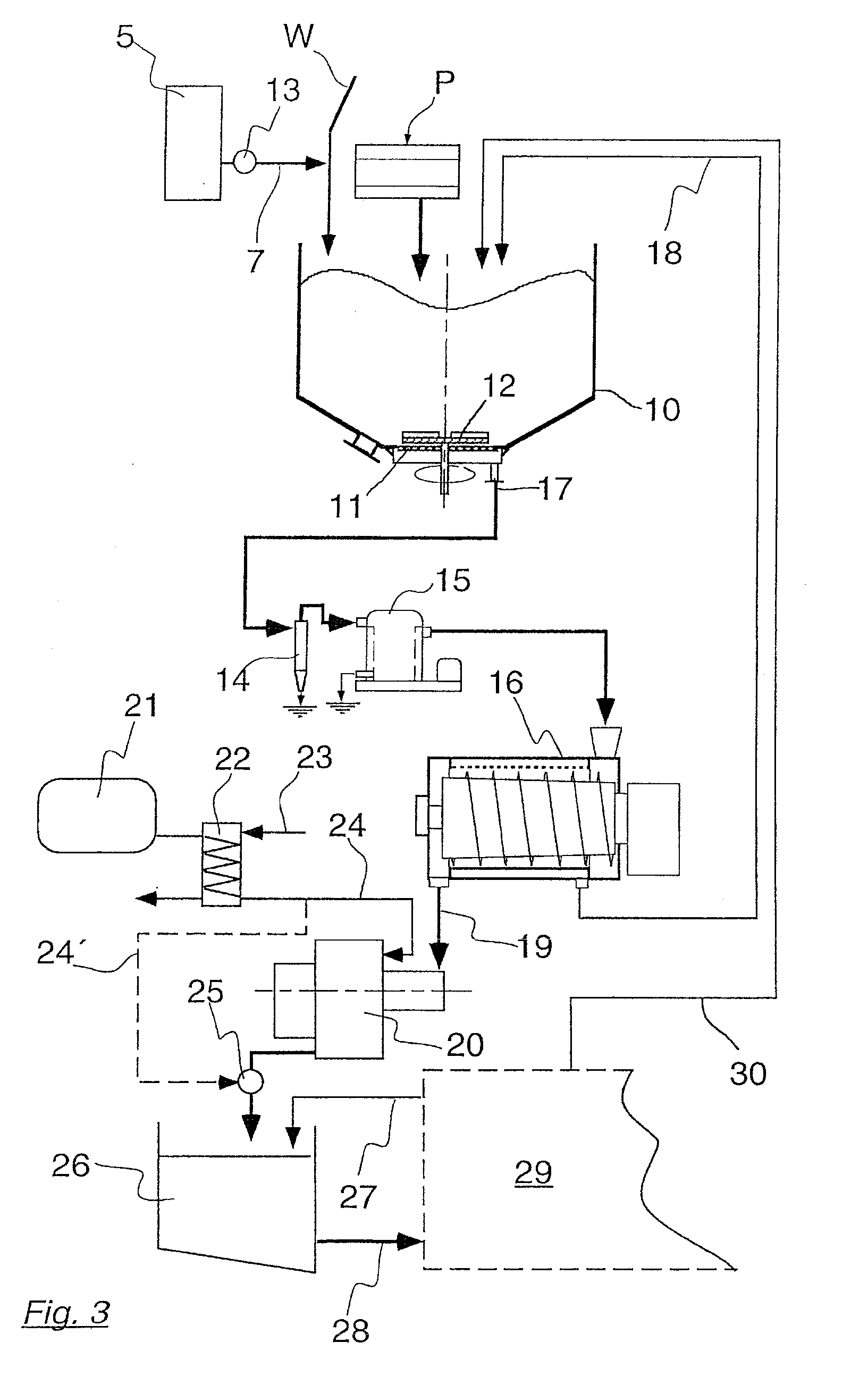

Method for loading fibers contained in a pulp suspension

InactiveUS20080210391A1Easy to usePulp properties modificationWashing/displacing pulp-treating liquorsFiberCalcium hydroxide

The present invention serves for loading a pulp suspension (S) with calcium carbonate. Liquid calcium hydroxide as milk of lime (7) is added during or before the pulp operation (1) carried out to form the pulp. By introducing gaseous carbon dioxide (8) into the pulp suspension thus treated, a chemical reaction is triggered therein, in which the finely divided calcium carbonate is precipitated. The present invention is particularly economic and effective due to the early addition of calcium oxide or calcium hydroxide.

Owner:VOITH PATENT GMBH

Scouring process for grass pulping course

ActiveCN101082188AQuality exceedsWashing/displacing pulp-treating liquorsPulp and paper industryEngineering

The invention provides a washing process in the grass pulping. It contains the following steps: A) send the cooked pulp into the presser for pressing to get the coarse pulp. B) Process the coarse pulp through the jumping screen. C) Send the screened pulp into the pulp washer for washing. The rigidity of the screened pulp is potassium permanganate value 16-28 (equals to karber value 24-50). The washed solvent remains 90-150ppm. Take the high rigidity pulp in this invention as materials to prepare bleaching chemical pulp by pressing and washing. The whiteness of the chemical pulp is 68-82%ISO and the removal rate of the lignin is 84-98%. The quality of the bleaching chemical pulp prepared by the grass is similar, even better than that of the exciting hardwood pulp.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

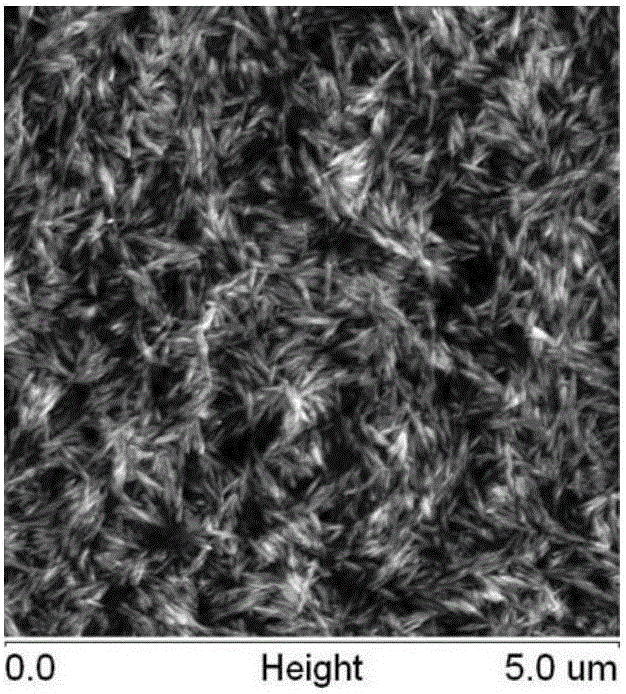

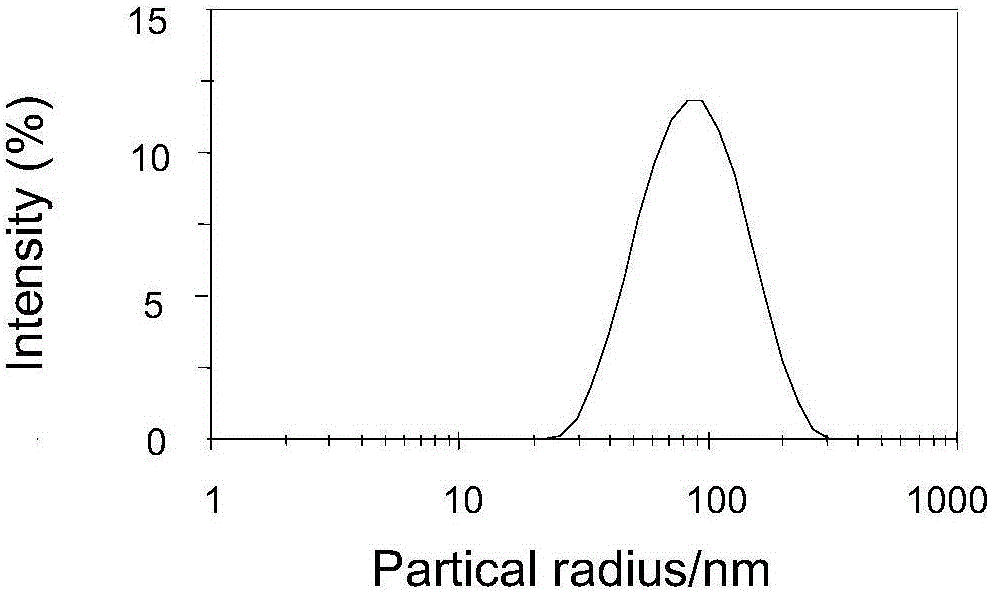

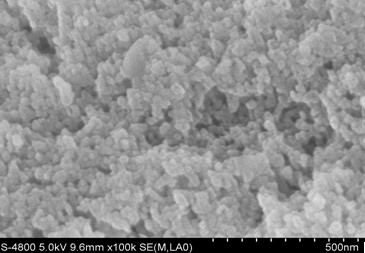

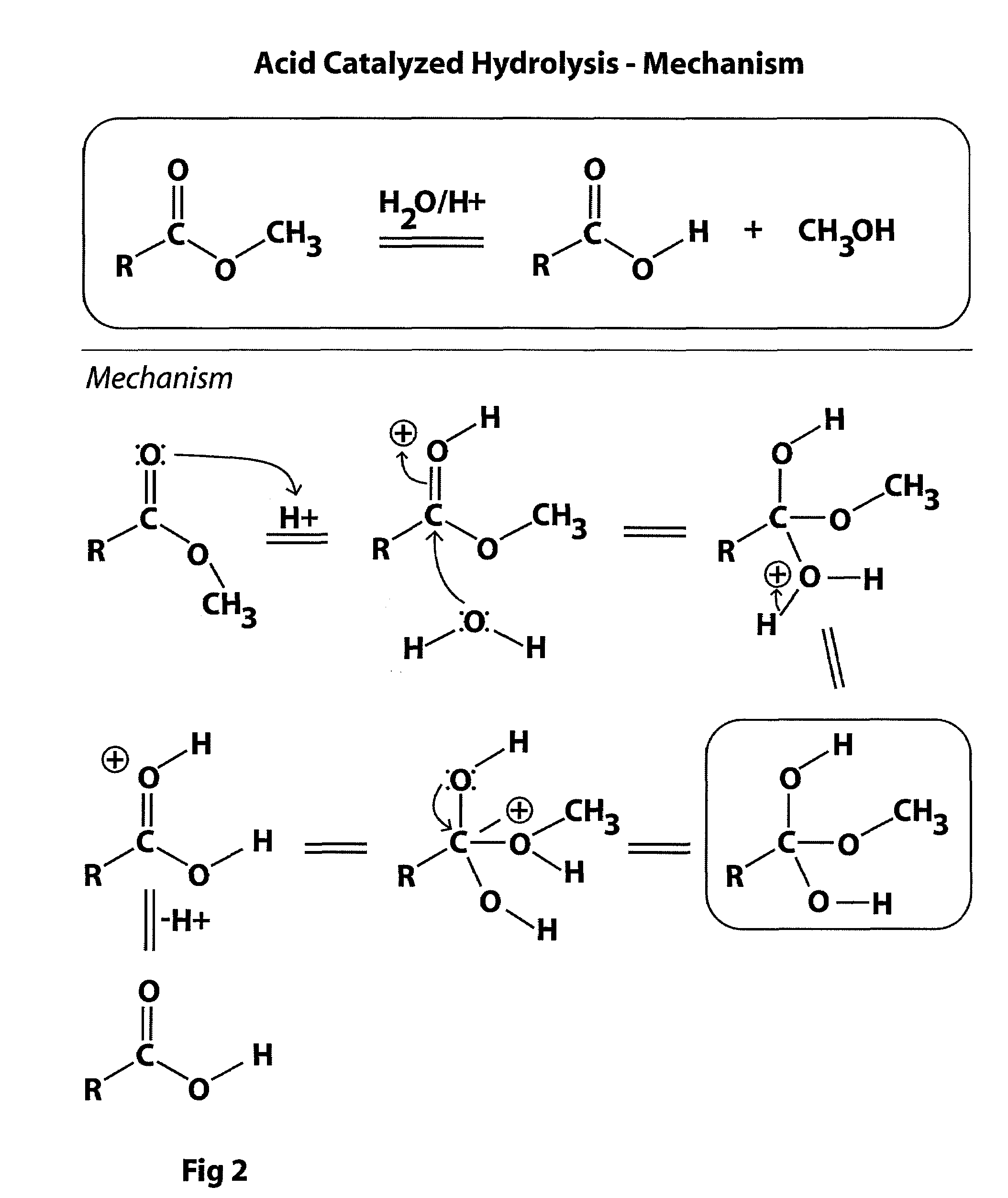

Efficient cellulose nanocrystalline preparing method

ActiveCN105777913AHigh yieldImproved particle size distributionPulp properties modificationWashing/displacing pulp-treating liquorsInorganic saltsCellulose

The invention provides an efficient and quick cellulose nanocrystalline preparing method.According to the method, a cellulose raw material is pretreated with aqueous alkali and then subjected to acidolysis, and inorganic salt containing metal ions is added during acidolysis to serve as a promoter to promote acidolysis reaction.Reaction condition is mild and easy to control, raw materials needed by reaction are simple and easy to obtain, and the method can be widely applied to preparation of cellulose nanocrystalline from various cellulose raw materials.

Owner:QINGDAO UNIV OF SCI & TECH

Efficient and clean puling and bleaching method dissolving alpha-pulp by Chinese alpine rush

InactiveCN101748631AEfficient continuous production technologyLabor intensiveWashing/displacing pulp-treating liquorsPulp de-wateringBlack liquorMagnesium salt

The invention discloses an efficient and clean puling and bleaching method dissolving alpha-pulp by Chinese alpine rush. The method comprises the steps of stock preparation, prehydrolysis, alkaline cooking, black liquor extraction, closed screening, total chlorine free bleaching, bleached pulp treatment and the like, namely, adding stock blank after prehydrolysis into a continuous digester to carry out alkaline cooking; adopting a vacuum pulp washer to extract black liquor from sizing agent, sealing and screening, then washing and concentrating the sizing agent through a vacuum filter, wherein the mass concentration of pulp after concentration is larger than or equal to 10%; adding NaOH solution and magnesium salt protective agent in concentrated pulp, then sequentially passing through a medium concentration pump and a medium concentration mixer to enter an upflow type bleaching tower to carry out total chlorine free bleaching. In the invention, the productive process is continuous, and non chlorine bleaching agent is utilized in the production, waste water can flow reversely for reuse and does not contain toxic and harmful adsorbable organic chloride AOX, thereby realizing energy saving and emission reduction, cleaning and bleaching of alpha-pulp production, improving the additional value of Chinese alpine rush, thus the method can be promoted and utilized industrially.

Owner:SOUTH CHINA UNIV OF TECH

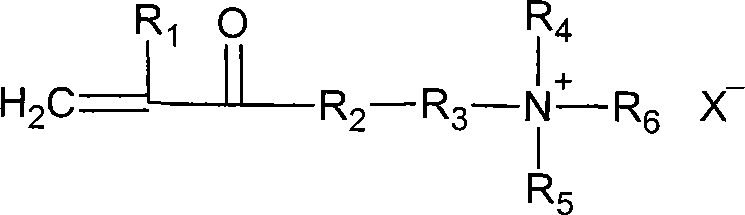

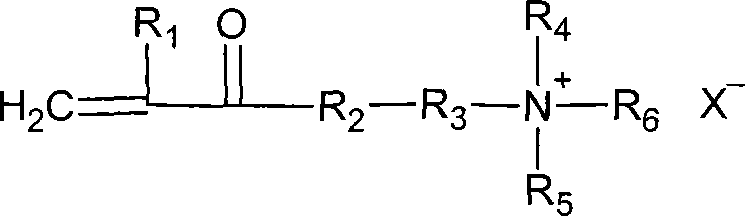

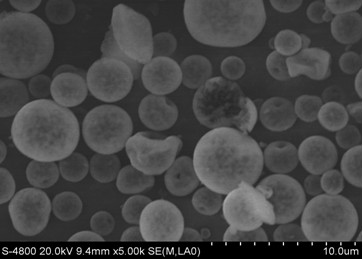

Dispersion polymeric acrylamide emulsion and its application in oil field produced liquid treatment

ActiveCN101161691AEasy to useFast dissolutionWashing/displacing pulp-treating liquorsReinforcing agents additionWater qualityDouble bond

The present invention relates to a waterborne polyacrylamide emulsion, the preparation thereof and the application thereof. The waterborne polyacrylamide emulsion is prepared by the free radical polymerization of the nonionic monomer with the double bond or combined polymerization of the nonionic monomer with the double bond with the cation, using multi inorganic salt solution as the mediums and using polyelectrolyte as the stabilizer. The appearance of the product is cream white, the particle diameter is about 10-100 Mum, the emulsion has high solution rate, and the production process without any organic solvent is innocuous and environmental protection. Compared with the dry powder and the microemulsion of the traditional polyacrylamide, the emulsion of the invention is safe and convenient in use, is capable of being used in the treatment of the oilfield produced liquid combined with the demulsifier to promote the oil-water separation to increase the dehydration of crude oil, wherein the water quality of the dehydrate water. The product can be used as an oil-water separating agent of the oily wastewater in industry and as a water purificant, also be used for sewerage treatment of the oil field and the city as an organic flocculent, and be used in paper making field as a filter aid, a retention aid, a paper strengthening agent, etc.

Owner:HAISO TECH

Paper-making grade softwood pulp plate modifying production technique

ActiveCN101158125AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpTO-18Cooking methods

The invention provides a denaturizing production technique of paper making needle wood pulp plate, which solves the problems of uneven dipping, slow hemicelluloses stripping, difficult accumulation descending, uneven cooking, single cooking method, single bleaching method and violent conditions existing in denaturizing production technique of wood pulp in the prior art. The invention comprises the following steps: wood pulp plate paging, alkali soaking, pressing, untwining and dispersion, cooking, washing, impurity removal, bleaching, a secondary washing and pulping; wherein, the wood pulp plate paging, alkali soaking, pressing, untwining and dispersion are to send papers into a alkali dipping barrel with concentration of 6 percent to 18 percent after the paper making bleaching wood pulp plates are separated by a paging device. When the wood pulp plates are changed into pulp with concentration of 3 percent to 6 percent, the pulp with concentration of 3 percent to 6 percent is sent to a squeezer to be squeezed and to untwine and disperse fiber. By adopting the invention, the quality of the dissolved viscose fiber wood pulp can be better and more stable; furthermore, the invention provides wider selection range of raw material.

Owner:YIBIN GRACE GROUP CO LTD

Natural color bamboo pulp production method and natural color paper for daily use produced through same

InactiveCN105672013AAchieve mass productionImprove efficiencyWashing/displacing pulp-treating liquorsPulping with inorganic basesCelluloseMaterials preparation

The invention discloses a production method of natural-color bamboo pulp and natural-color household paper, comprising the following steps: material selection, material preparation, material washing, cooking, screening, washing, oxidation treatment, pulp washing, pulp making and papermaking. According to the above method, after the cooking section is finished, the whiteness of the obtained pulp is 25-28%, the L value is 70-74, the a value is 4-5, and the b value is 19-23. 32%, L value 71-76, a value 3-4, b value 20-25, finally the whiteness of natural color tissue paper is 30-36%, L value 72-78, a value 3-4, b value 20 -25. The present invention adopts all the natural growth raw materials of bamboo with high cellulose content, such as Ci bamboo, Mian bamboo, Siji bamboo, etc., and utilizes advanced displacement cooking technology and oxidation treatment technology to obtain natural-color bamboo pulp with the characteristics of good brightness and natural soft yellow hue. The natural-color household paper produced has fine touch, soft and natural color, and a light bamboo smell. This method also has the characteristics of low energy consumption, high output, high yield, low cost, and low pollution.

Owner:SICHUAN YONGFENG PAPER MAKING JOINT STOCK

Short fiber food waste residue-based nano cellulose and preparation method thereof

InactiveCN102182089AFine granularityThe compactness of the crystal region is weakPretreatment with water/steamWashing/displacing pulp-treating liquorsFood additiveFiber

The invention relates to the field of processing of agricultural products, in particular to short fiber food waste residue-based nano cellulose and a preparation method thereof. The preparation method comprises three parts of pretreatment of short fiber food waste residues, acid hydrolysis of food residue fibers and homogenization. The nano cellulose prepared by the method has the granularity of 50-300nm, is short bar-shaped or microsphere-shaped and can be widely used for preparing a food additive or medicament excipient, and the like. In the method, acid hydrolysis is combined with high-pressure homogenization, thus the acid consumption and hydrolysis time are reduced, the granularity uniformity of the nano cellulose is improved; and the invention is suitable for mass production.

Owner:SOUTHWEST UNIV

Paper pulp made from bamboo fiber, preparation method thereof, and paper product made from paper pulp

ActiveCN104141255AGood performance parametersReduce usageWashing/displacing pulp-treating liquorsPulping with inorganic basesFiberRaw material

The invention discloses paper pulp made from bamboo fiber, a preparation method of the paper pulp, and a paper product made from the paper pulp and belongs to the field of pulp making and papermaking technology. The whiteness of the paper pulp made from bamboo fiber ranges from 20% to 40% ISO, the tensile index is larger than or equal to 7.9 N*m / g, the folding strength ranges from 15 times to 200 times, the fracture length ranges from 5 km to 10 km, the ash content is smaller than or equal to 1%, the tearing strength ranges from 200 mN to 650 mN, and the beating degree ranges from 10 degree SR to 25 degree SR. The preparation method of the paper pulp made from bamboo fiber includes the steps of raw material breaking, stewing, defibering, defibrination, screening and washing. The paper pulp made from bamboo fiber can be used for making culture paper or paper for daily use. The paper pulp has a good performance parameter, can replace conventional wood pulp and is superior to the conventional wood pulp; the preparation method of the paper pulp has the advantages of being high in yield, easy to operate, convenient to produce, low in cost and environmentally friendly, and the 100% natural features of bamboo fiber are kept.

Owner:SICHUAN HUANLONG NEW MATERIAL

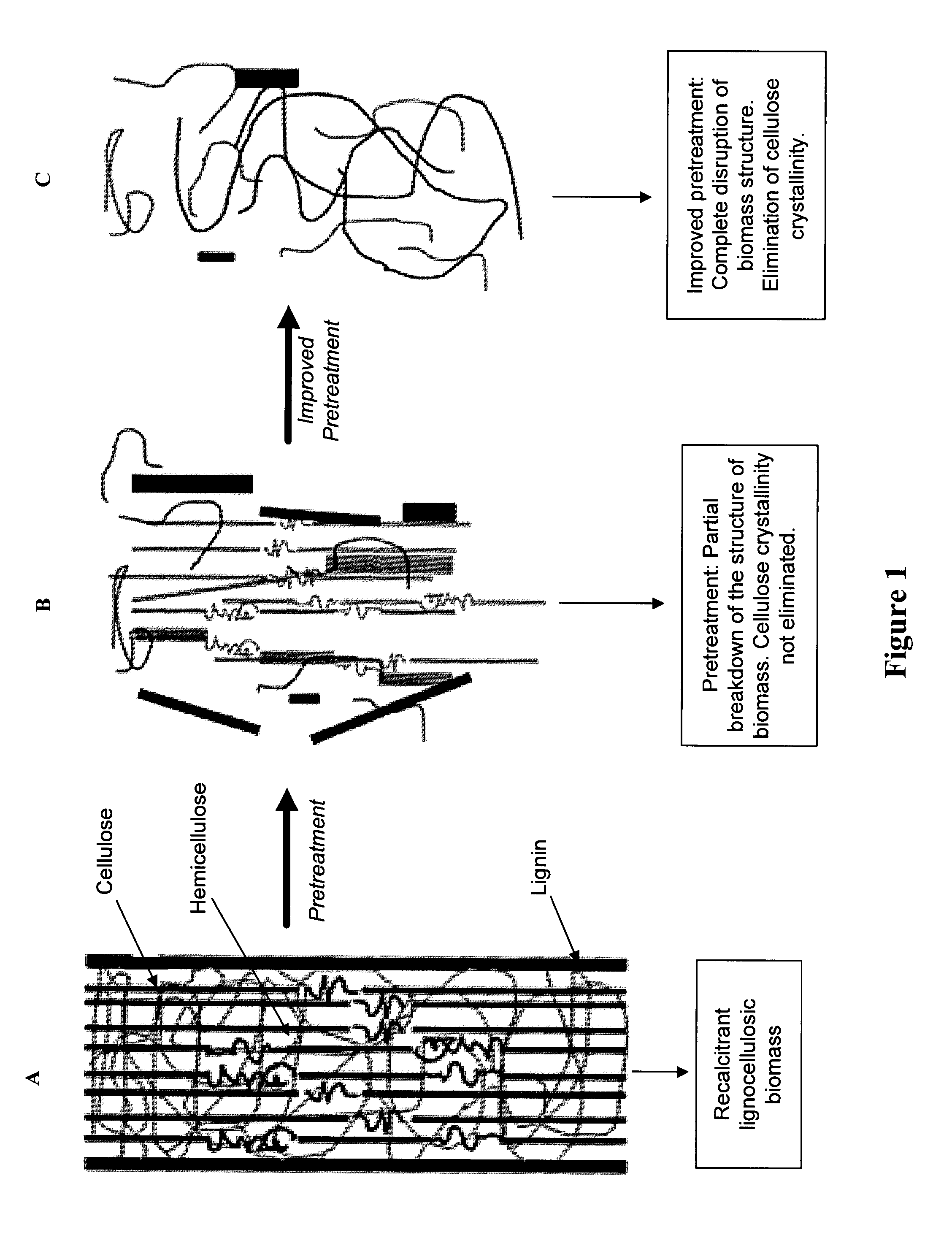

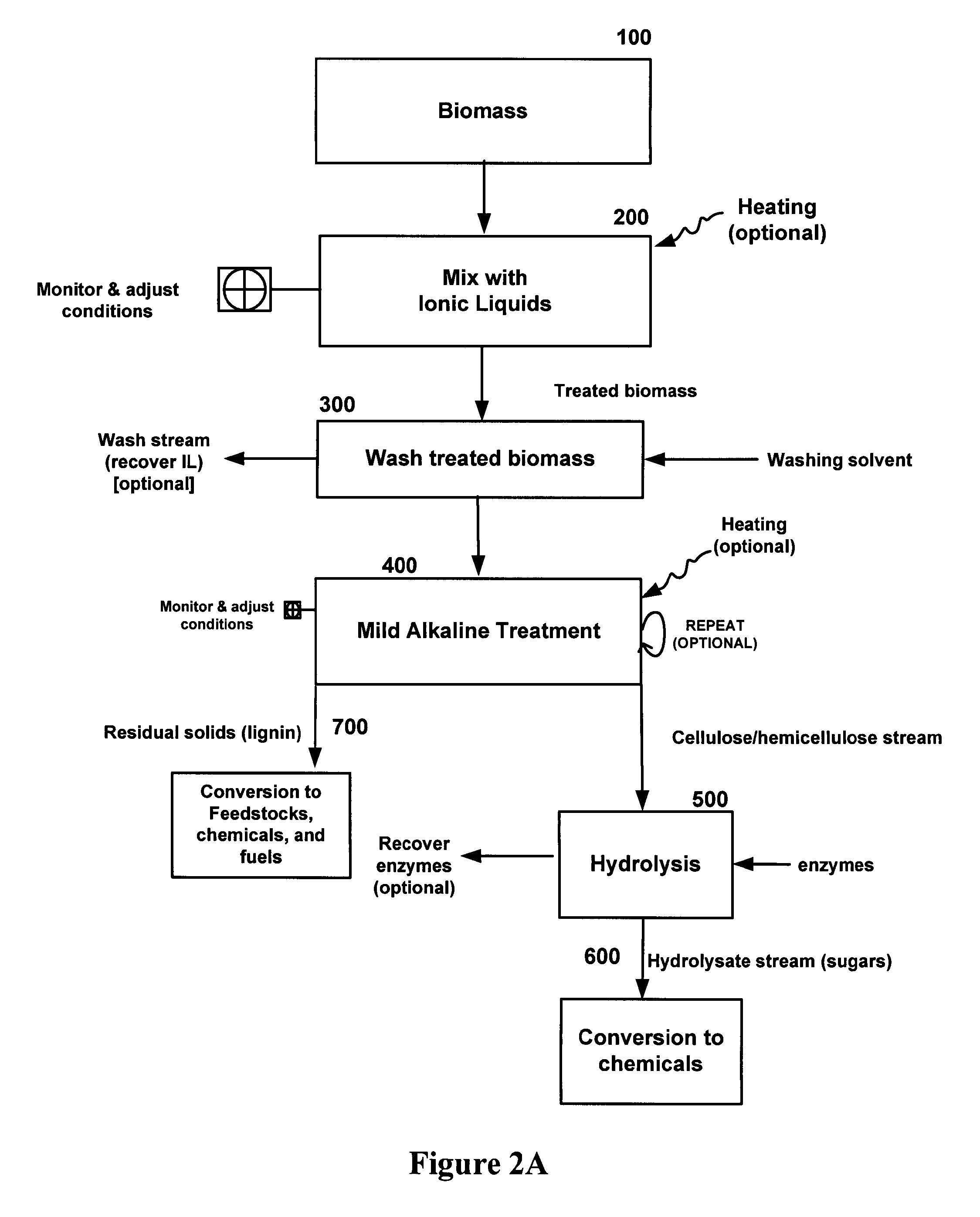

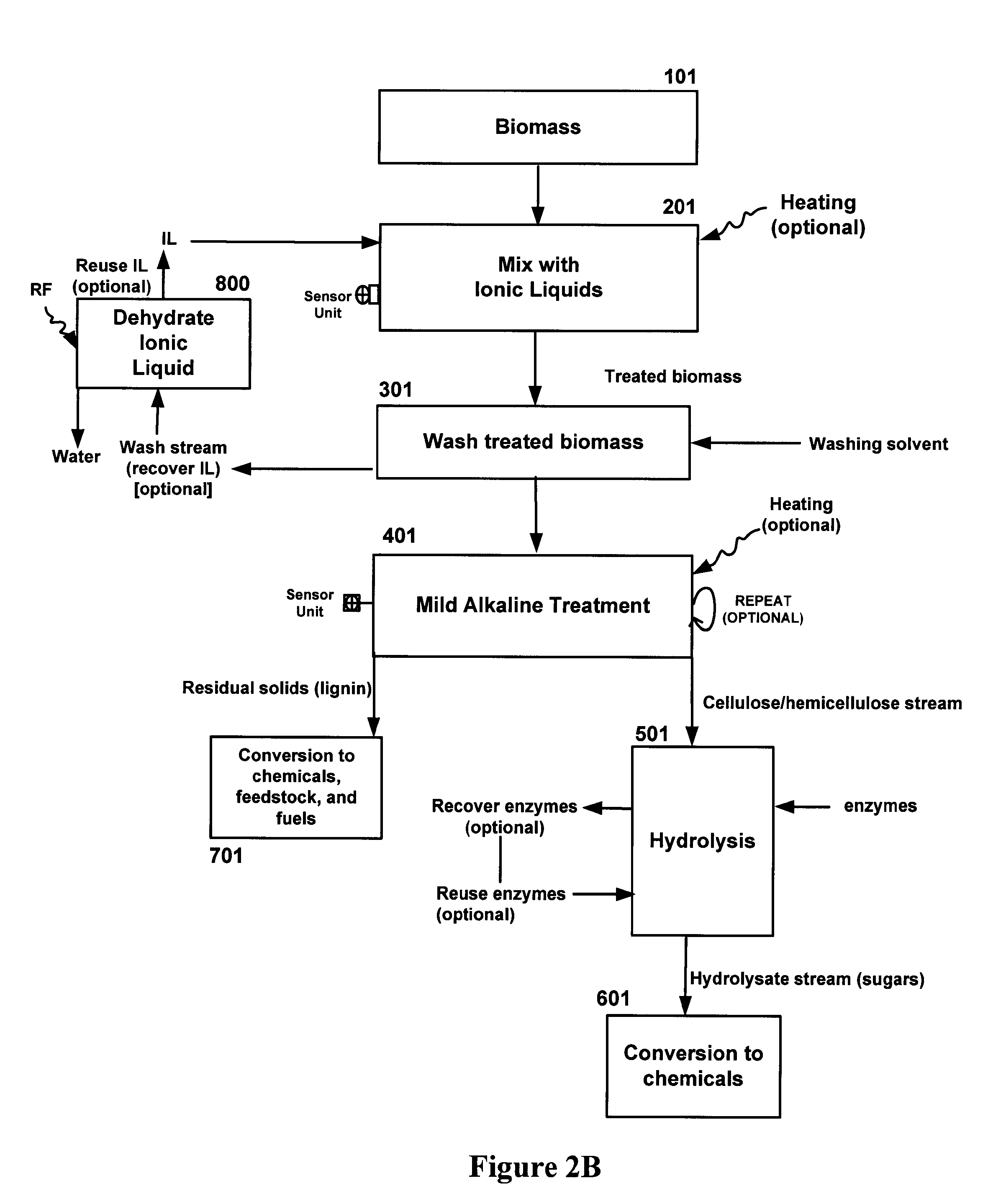

Pretreatment and fractionation of lignocellulosic biomass

InactiveUS20140273104A1Pulp liquor regenerationPretreatment with alkaline reacting compoundsCelluloseFractionation

Method and apparatus for enhanced production of sugars and lignin via fractionation of lignocellulosic biomass through sequential ionic liquid pretreatment and mild alkaline treatment. The resulting biomass is easily fractionated and amenable to efficient and rapid hydrolysis and catalytic conversion to valuable products with high recovery of the enzymes used in the hydrolysis.

Owner:SUGANIT SYSTEMS INC

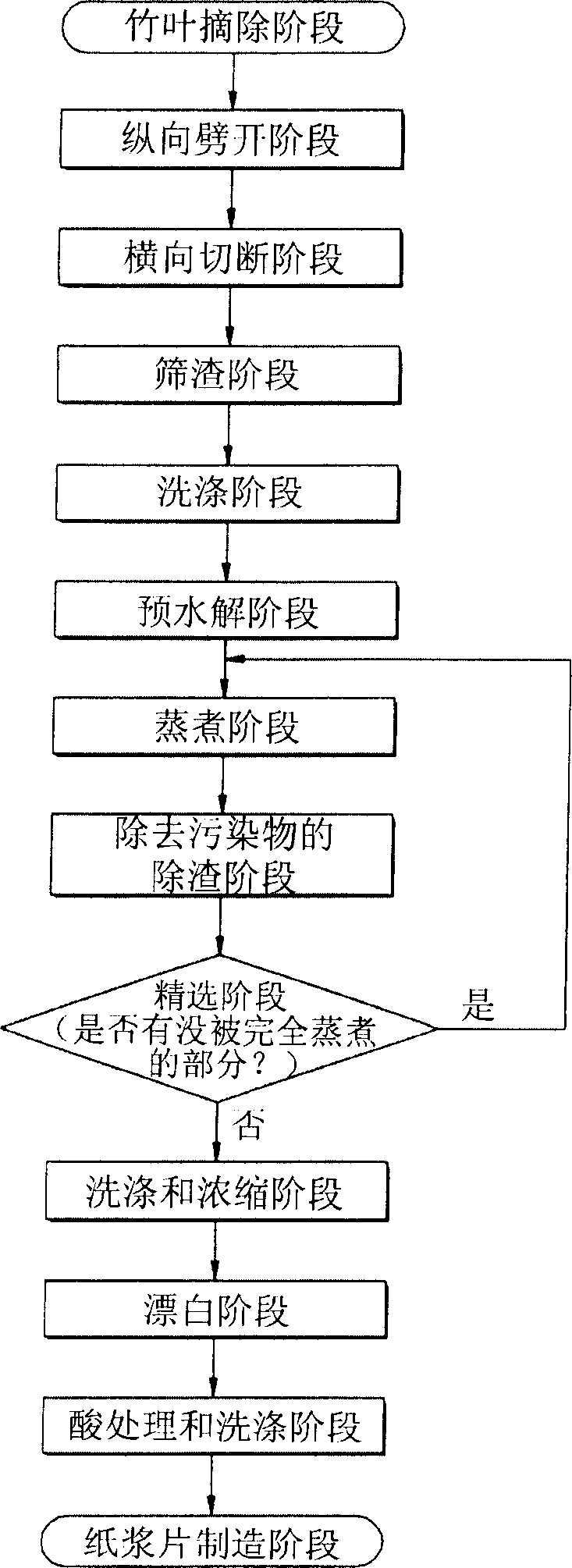

Production method of bamboo chemical dissolving pulp

ActiveCN101457494ASimple switching processHighly corrosiveWashing/displacing pulp-treating liquorsDigestersMaterial consumptionDissolving pulp

Aiming at the current situation of the cotton dissolving pulp and the wood dissolving pulp and the characteristics of the bamboo and the defects in the existing preparation of the dissolving pulp, the invention provides a method for preparing a chemical bamboo dissolving pulp. The chemical dissolving pulp produced can be widely applied in the cellulose derivative industries such as spinning viscose fiber, nitrocellulose and acetate fiber. The method comprises the following steps of: material preparation, cooking, screening, scrubbing, bleaching and paper making. The cooking procedure comprises two grades of cooking steps, wherein the primary cooking procedure is continuous cooking and the secondary cooking procedure is continuous cooking or intermittent cooking; and the bleaching procedure is elemental chlorine free bleaching or totally chlorine free bleaching. The invention solves the problems existed in the cooking and bleaching procedures. The chemical bamboo dissolving pulp can be prepared with high efficiency, low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

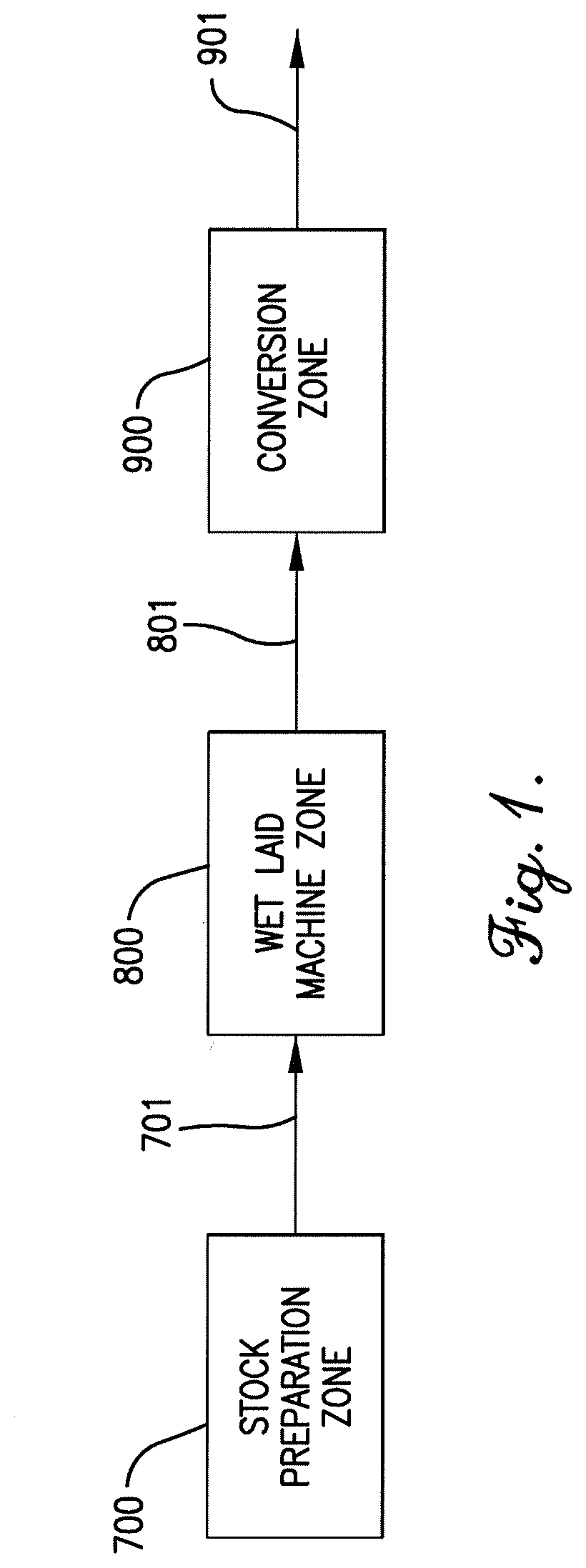

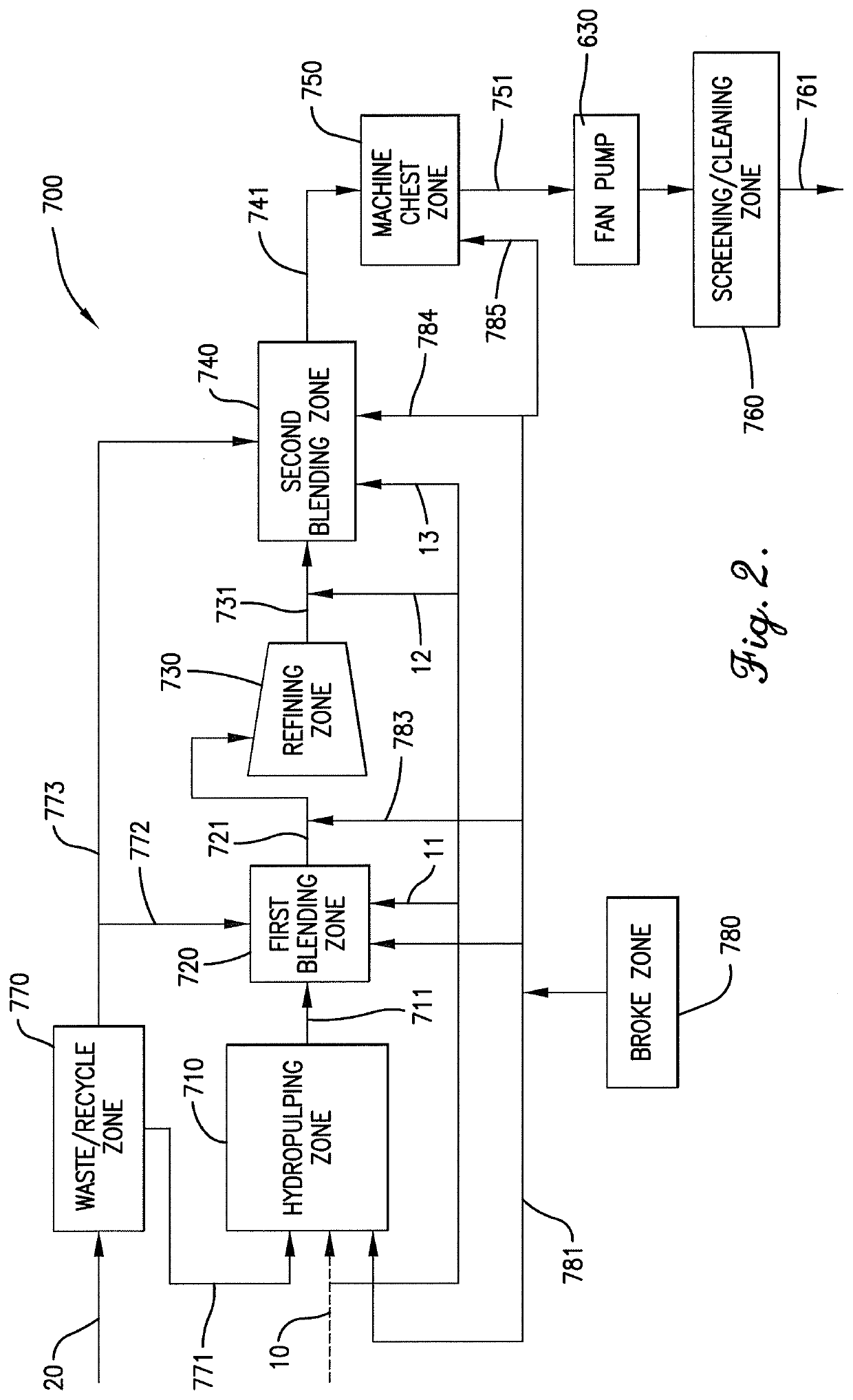

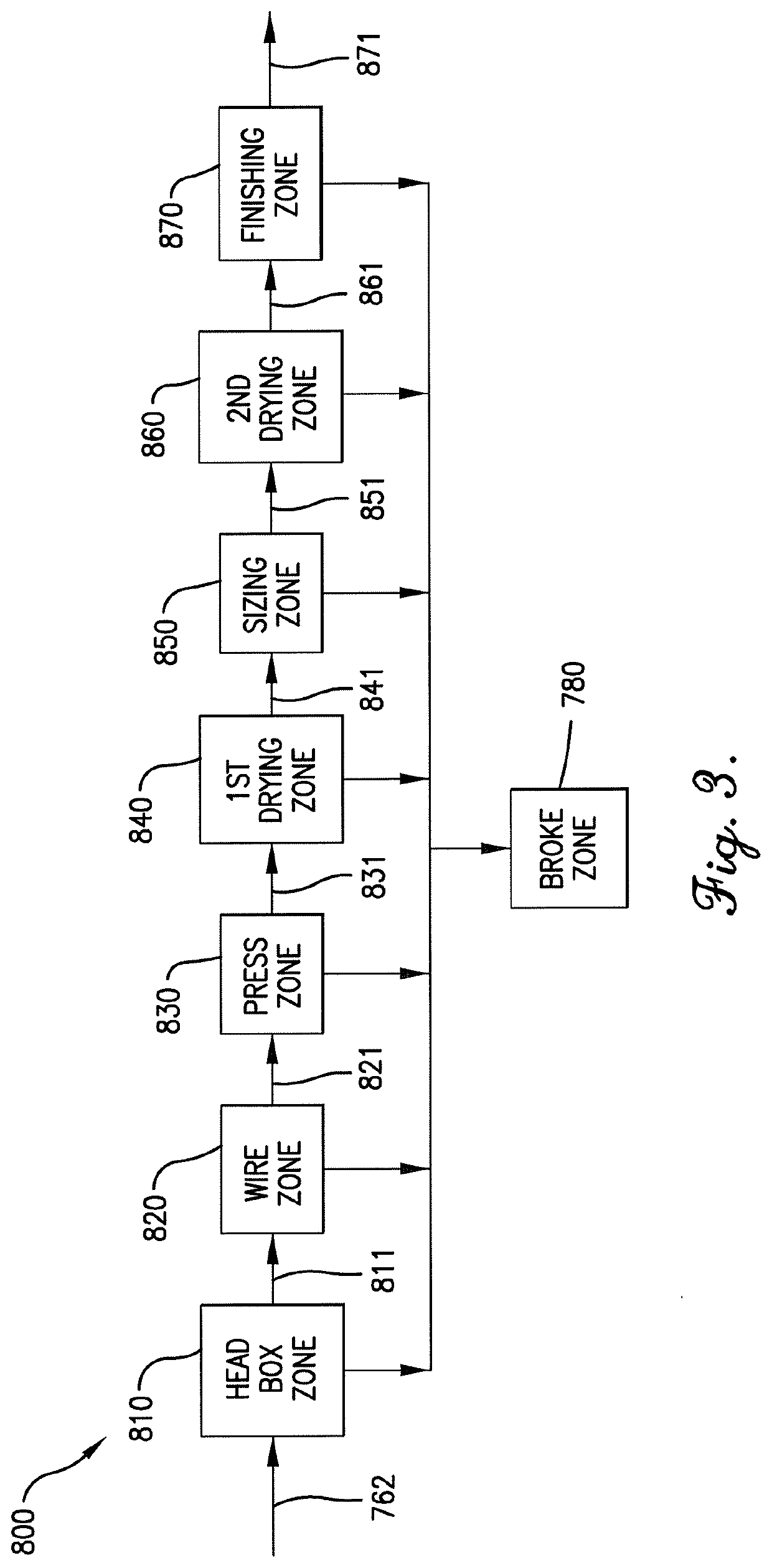

Composition of matter feed to a head box

ActiveUS20200063359A1Reduce consistencyLow variabilityWater-repelling agents additionWashing/displacing pulp-treating liquorsProcess engineeringCellulose fiber

A wet laid process includes a method for making paper in which a composition containing co-refined cellulose fibers and cellulose ester fibers made into a thick stock composition in a machine chest, the thick stock is fed to a cleaning / screening zone through a device that regulates the flow rate of thick stock, the consistency of the thick stock fed to the screening / cleaning zone is reduced to form a thin stock composition; the thin stock composition is subjected to a process for cleaning the thin stock and feeding the cleaned thin stock through screens to form a cleaned and screened thin stock composition, and the cleaned and screened thin stock composition is fed to a headbox.

Owner:EASTMAN CHEM CO

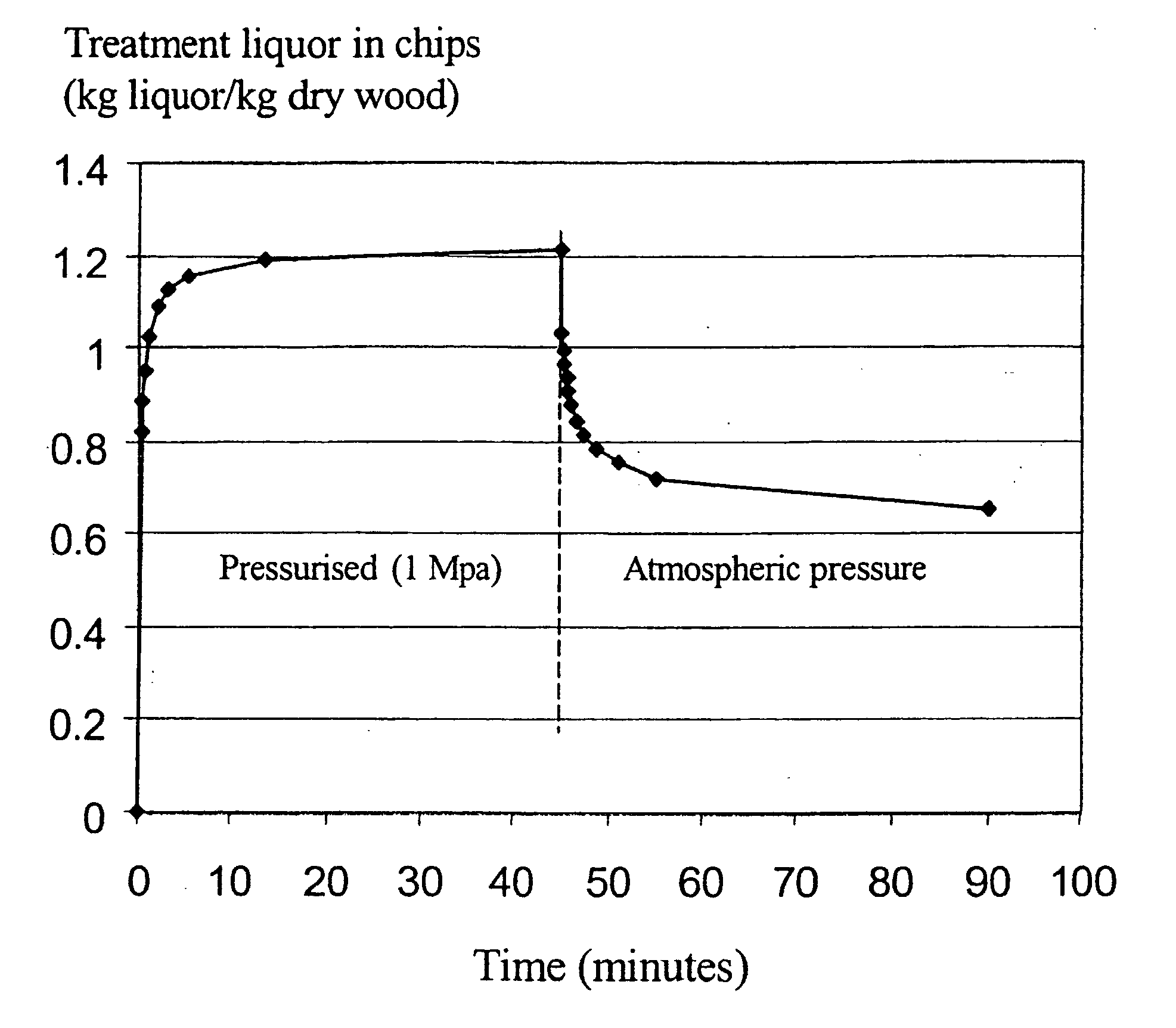

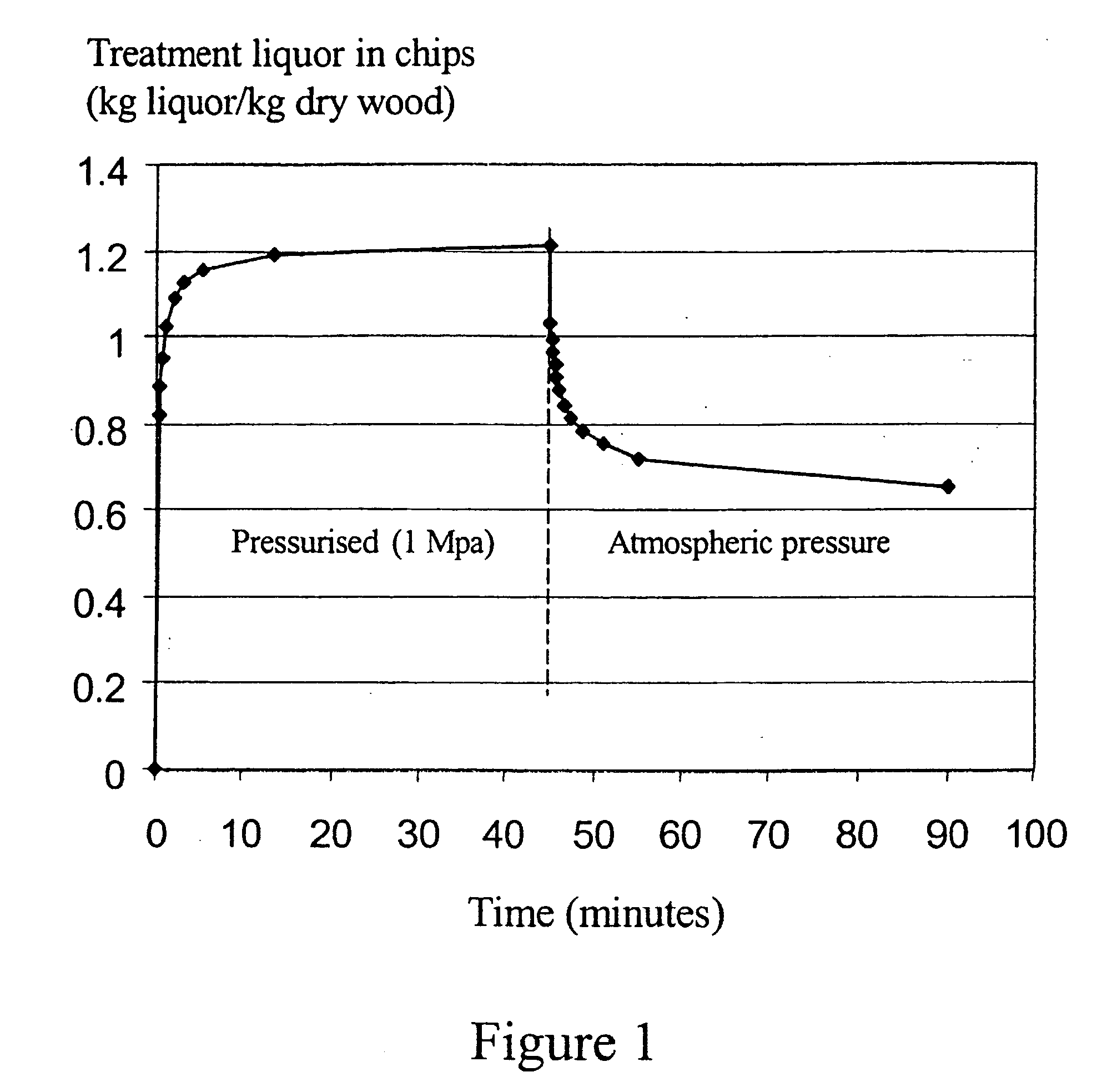

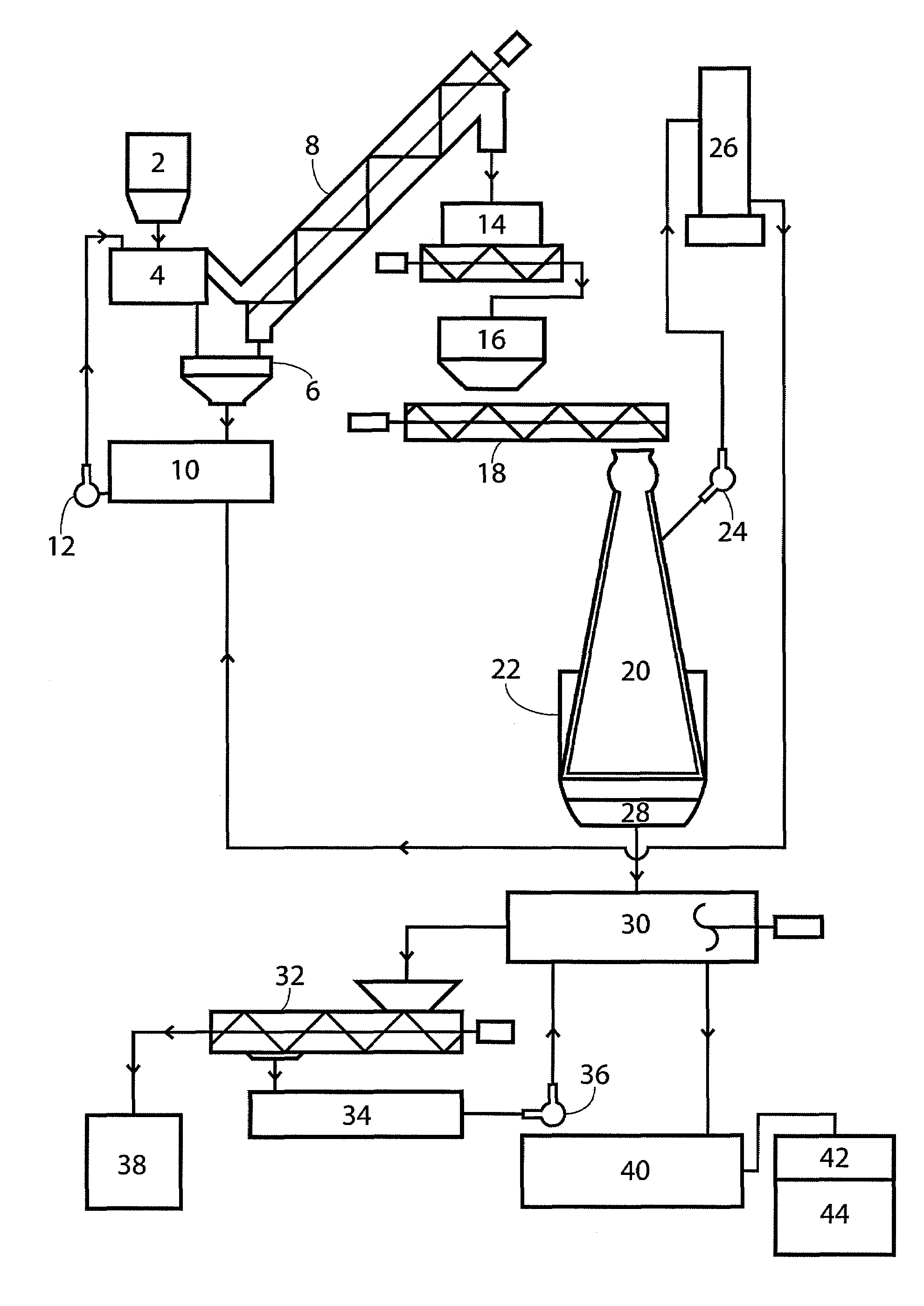

Removal of inorganic elements from wood chips

InactiveUS20050034823A1Less energy consumptionIncrease moisture contentWashing/displacing pulp-treating liquorsPretreatment with acid reacting compoundsProduction linePregnant leach solution

In a process of treating wood chips for reduction of the concentration of undesirable inorganic elements prior to cooking in a production line for chemical pulp, the wood chips, having entrapped air, are treated with an aqueous leaching liquor at elevated temperature and pressure, followed by draining at atmospheric pressure or below atmospheric pressure, the pressures being controlled to yield a moisture content in the wood chips as low as possible for adequate leaching result and behavior of the chips in a subsequent digester. The aqueous leaching liquor is e.g. pulp mill process water with a low content of undesirable inorganic components, such as bleach plant spent liquor or condensate. The aqueous leaching liquor drained from the treated wood chips may be purified and recycled back to the process.

Owner:STFI

Catalytic reactor process for the production of commercial grade pulp, native lignin and unicellular protein

ActiveUS7396434B2Pulp liquor regenerationWashing/displacing pulp-treating liquorsCelluloseChemical solution

A continuous and batch system to produce cellulose, native lignin and unicellular protein from any form of vegetation in a closed process. The biomass is mixed in the impregnate solution of nitric acid and / or ammonium hydroxide and water. After a period of time at room temperature and atmospheric pressure the chemical solution is recycled. The biomass is moved to the reactor and heated. Evaporated impregnate is recovered via absorption tower and recycled back to chemical solution. The biomass is moved to an alkaline solution, then cooled to separate pulp from black liquor. The black liquor is pumped to a separation tank and is treated to precipitate lignin. The solution is filtered to separate sweet liquor and lignin. The lignin is dried and the sweet liquor is fermented to produce unicellular protein.

Owner:PURE LIGNIN ENVIRONMENTAL TECH

Paper-making-stage bamboo wood pulp plate denaturalization producing technique

ActiveCN101148836ADip evenlyFully impregnatedPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscose fiber

The present invention provides denaturating production process of paper-making bamboo pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making bamboo pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

Grass type unbleached paper products and production method thereof

Provided is an unbleached paper product made from grass type pulp, the unbleached paper product has a brightness of 35-60% ISO, the grass type pulp is unbleached. The unbleached paper product includes an unbleached toilet paper, an unbleached hand towel, an unbleached wiping paper, an unbleached duplicating paper, an unbleached meal container, an unbleached food wrapping paper and an unbleached printing paper. The paper products have a high intensity and have no detection of dioxin and absorbable organic halides in the harmful substance detection test.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Whiten method for preparing bamboo chemical dissolving pulp and application thereof

InactiveCN101446053AIncrease contentImprove physical strengthWashing/displacing pulp-treating liquorsPulp bleachingMaterial consumptionDissolving pulp

Aiming at current situations of cotton and wood dissolving pulp, characters of bamboo material and many disadvantages existing in the existing whiten method for preparing dissolving pulp, the invention provides a whiten method for preparing bamboo material chemical dissolving pulp. The chemical dissolving pulp produced by the invention can be widely applied to derivant industry of celluloses, such as spinning viscose fiber, cellulose nitrate, acetate fiber, etc. The whiten method in the invention uses element-free chlorine bleaching or total chlorine free bleaching, thereby solving the problems existing in the whiten method of bamboo material chemical dissolving pulp and preparing bamboo material chemical dissolving pulp high-efficiently with low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

The production method and pulp maked bamboos

InactiveCN1854388AHigh yieldPretreatment with water/steamWashing/displacing pulp-treating liquorsPulp and paper industryCellulose pulp

The present invention relates to a kind of method that utilizes bamboo to make paper pulp, relate to firstly splitting bamboo vertically and transversely and then going through the process of screening and washing to reduce the consumption of medicines in the process of prehydrolysis and pulping and make it easy to react, thereby A method of making pulp from bamboo and its pulp that can produce better-quality, higher-yield dissolving pulp, and that can prevent the generation of dioxins by using the bleaching method of ECF or TCF. Since the anthraquinone caustic soda method using anthraquinone as a catalyst is used in the cooking process, the effects of improving delignification and pulp quality and increasing pulp yield are obtained. Also, the content and degree of polymerization of α-cellulose can be arbitrarily adjusted according to the characteristics of the man-made fibers produced as desired by adjusting the conditions of prehydrolysis, cooking and bleaching. At the same time, by recovering xylose produced in the dissolving pulp manufacturing process, it is used to manufacture xylitol, seasoning, furfural, etc., thereby contributing to the improvement of resource utilization and economic efficiency of waste.

Owner:李权革

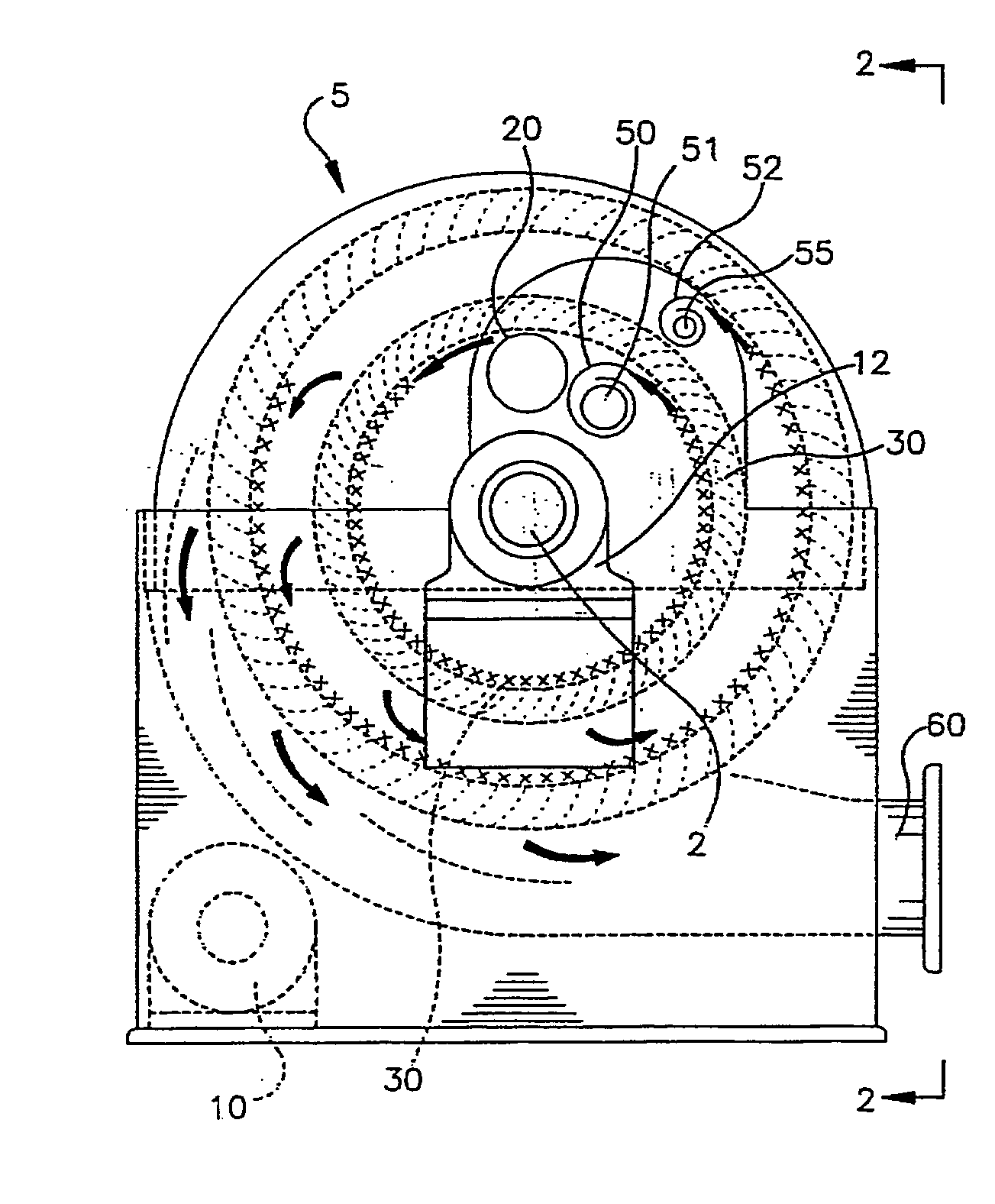

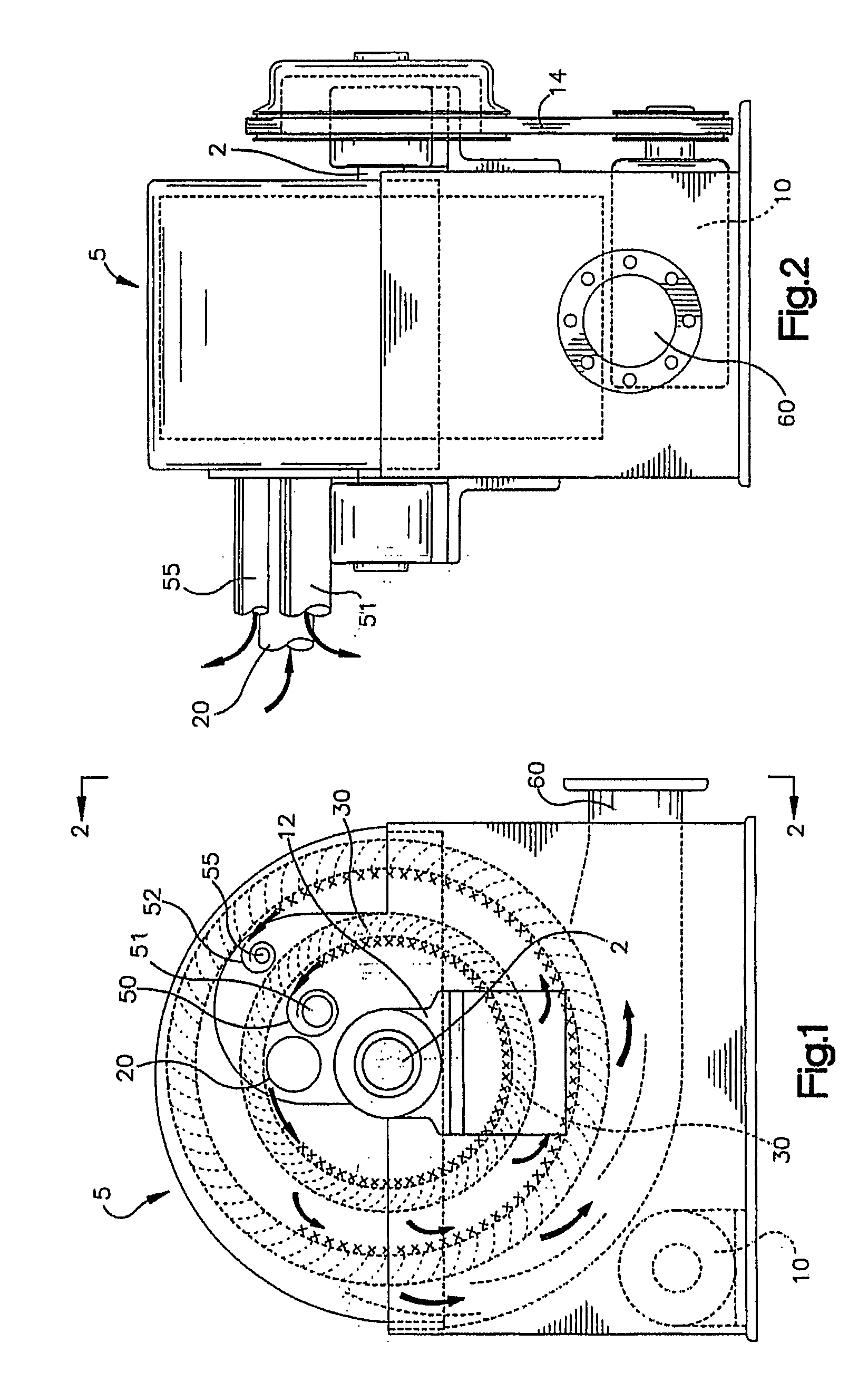

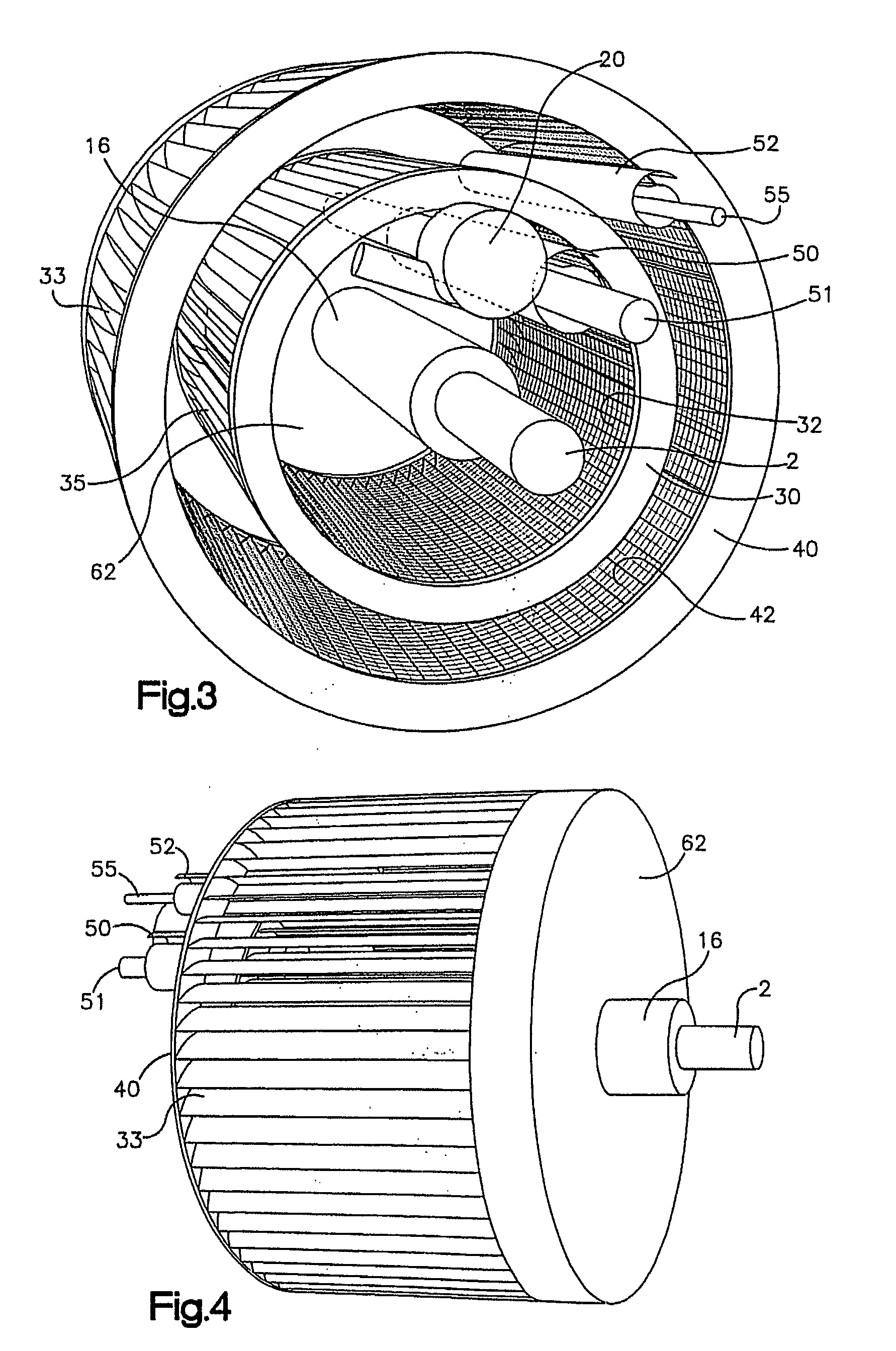

Dual Zone Wireless Pulp Washer

InactiveUS20070210015A1Water/sewage treatment by centrifugal separationWashing/displacing pulp-treating liquorsFiberPulp and paper industry

A wireless dual zone pulp washer with rotating concentric filters for creating centrifugal force against feedstock in order to expel liquid contained in the feedstock before further processing of the stock. A secondary filter surrounds the primary filter to capture viable pulp fibers expelled from the feedstock by the dewatering process.

Owner:THERMO BLACK CLAWSON

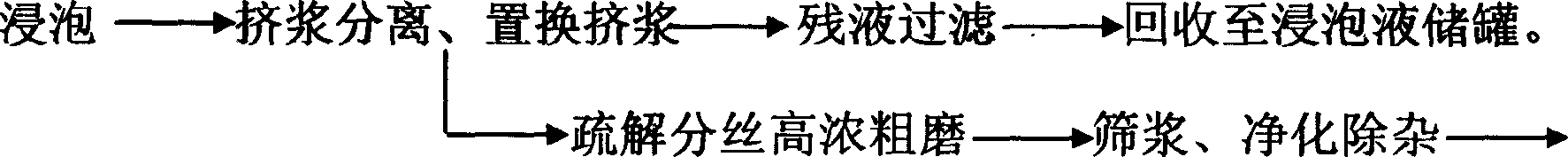

Biocatalytic clean pulping agent and application process thereof

InactiveCN1844572ANo emissionsNo pollutionPulp liquor regenerationWashing/displacing pulp-treating liquorsForeign matterProcess equipment

The invention relates to a biochemical catalysis cleaning slurry agent and relative application. Said invention is formed by: amylase, laccase, hydroxybenztriazole, calcii chloridum SL-1 slurry braise agent, sodium carbonate, and water. And the application comprises: 1, cutting raw material to be kneaded and dedusted; 2, preparing material with wet method; 3, dipping to remove lignin colloid; 4, extruding slurry to replaced and separated, dipping to filter the left liquid to be recycled; 5, rough milling and combing wire; 6, screening slurry to remove foreign matters; 7, washing slurry; 8, finish milling slurry; 9, poaching slurry; 10, washing poached slurry; 11, stepped treating and recycling used water. The invention is characterized in dipping said raw material in normal temperature and pressure. The left liquid is not discharged, but be recycled. And the pulp is poached pulp. The invention can support industrial production.

Owner:石建凯

Method for preparing bleached pulp by using eucalyptus wood chips

InactiveCN103334328AQuality improvementAvoid damagePretreatment with water/steamWashing/displacing pulp-treating liquorsFiberPapermaking

The invention discloses a method for preparing bleached pulp by using eucalyptus wood chips, and belongs to the fields of pulping and papermaking. The method comprises the following steps: orderly washing, dewatering and presteaming a eucalyptus wood material, carrying out double helix extrusion, chemical impregnation and high-consistency refining, eliminating, washing and the like. A double helix extruder with a variable pitch and a variable diameter is adopted in extrusion and concentration treatment of the material before defibrination; the damage of the traditional extrusion tearing machine to a fiber is avoided; the quality of the prepared pulp is similar to that of the pulp prepared by qualified chips; the bulk of the pulp can achieve over 3.4 cm<3> / g; the whiteness can achieve over 76% ISO (international standardization organization); effective utilization of the eucalyptus wood chips in the fields of pulping and papermaking is achieved; alkaline hydrogen peroxide which is friendly to the environment is adopted in the craft process; a fewer of pollutants are generated in the pulping process and are non-toxic; instant bleaching and subsequent bleaching reaction are achieved by effectively utilizing the heat energy generated in the pulping process; and steam consumption is reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Popular searches

Continuous pulping process Sugar extraction from sugar beet Pulping with organic solvents Raw material division Pulp by-products recovery Fractionation/concentration of spent liquors Fermentation Cellulose treatment using microorganisms/enzymes Finely-divided material pretreatment Pulp gases treatment

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com