Patents

Literature

261 results about "Pulp treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pediatric pulp therapy is known by several other names, including: root canal, pulpotomy, pulpectomy, and nerve treatment. The primary goal of pulp therapy is to treat, restore, and save the affected tooth.

Efficient and clean puling and bleaching method dissolving alpha-pulp by Chinese alpine rush

InactiveCN101748631AEfficient continuous production technologyLabor intensiveWashing/displacing pulp-treating liquorsPulp de-wateringBlack liquorMagnesium salt

The invention discloses an efficient and clean puling and bleaching method dissolving alpha-pulp by Chinese alpine rush. The method comprises the steps of stock preparation, prehydrolysis, alkaline cooking, black liquor extraction, closed screening, total chlorine free bleaching, bleached pulp treatment and the like, namely, adding stock blank after prehydrolysis into a continuous digester to carry out alkaline cooking; adopting a vacuum pulp washer to extract black liquor from sizing agent, sealing and screening, then washing and concentrating the sizing agent through a vacuum filter, wherein the mass concentration of pulp after concentration is larger than or equal to 10%; adding NaOH solution and magnesium salt protective agent in concentrated pulp, then sequentially passing through a medium concentration pump and a medium concentration mixer to enter an upflow type bleaching tower to carry out total chlorine free bleaching. In the invention, the productive process is continuous, and non chlorine bleaching agent is utilized in the production, waste water can flow reversely for reuse and does not contain toxic and harmful adsorbable organic chloride AOX, thereby realizing energy saving and emission reduction, cleaning and bleaching of alpha-pulp production, improving the additional value of Chinese alpine rush, thus the method can be promoted and utilized industrially.

Owner:SOUTH CHINA UNIV OF TECH

Pulp treatment and process

InactiveUS7267744B2Reduce stepsReduce in quantityElectrolysis componentsWood treatment detailsPulp treatmentCompound (substance)

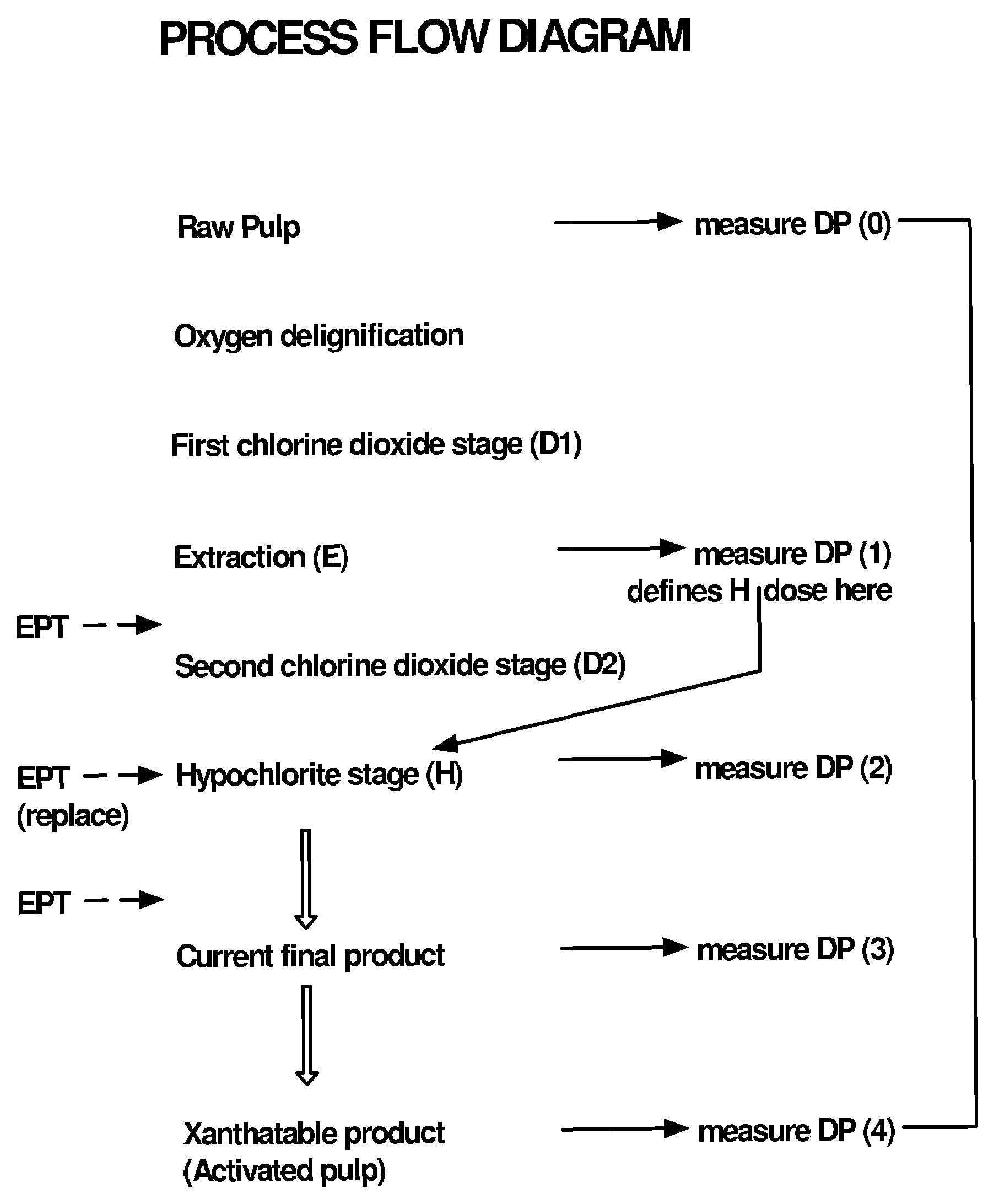

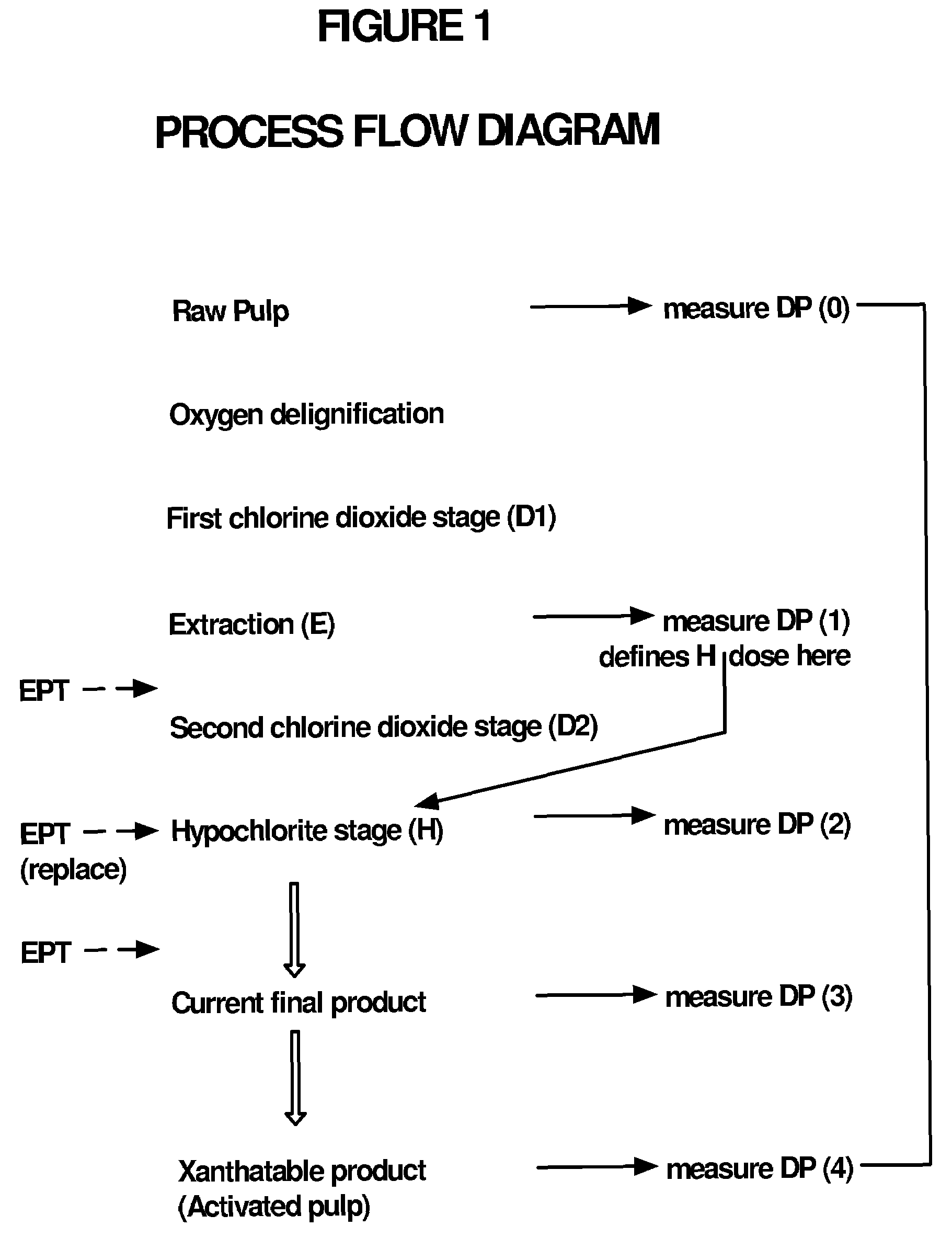

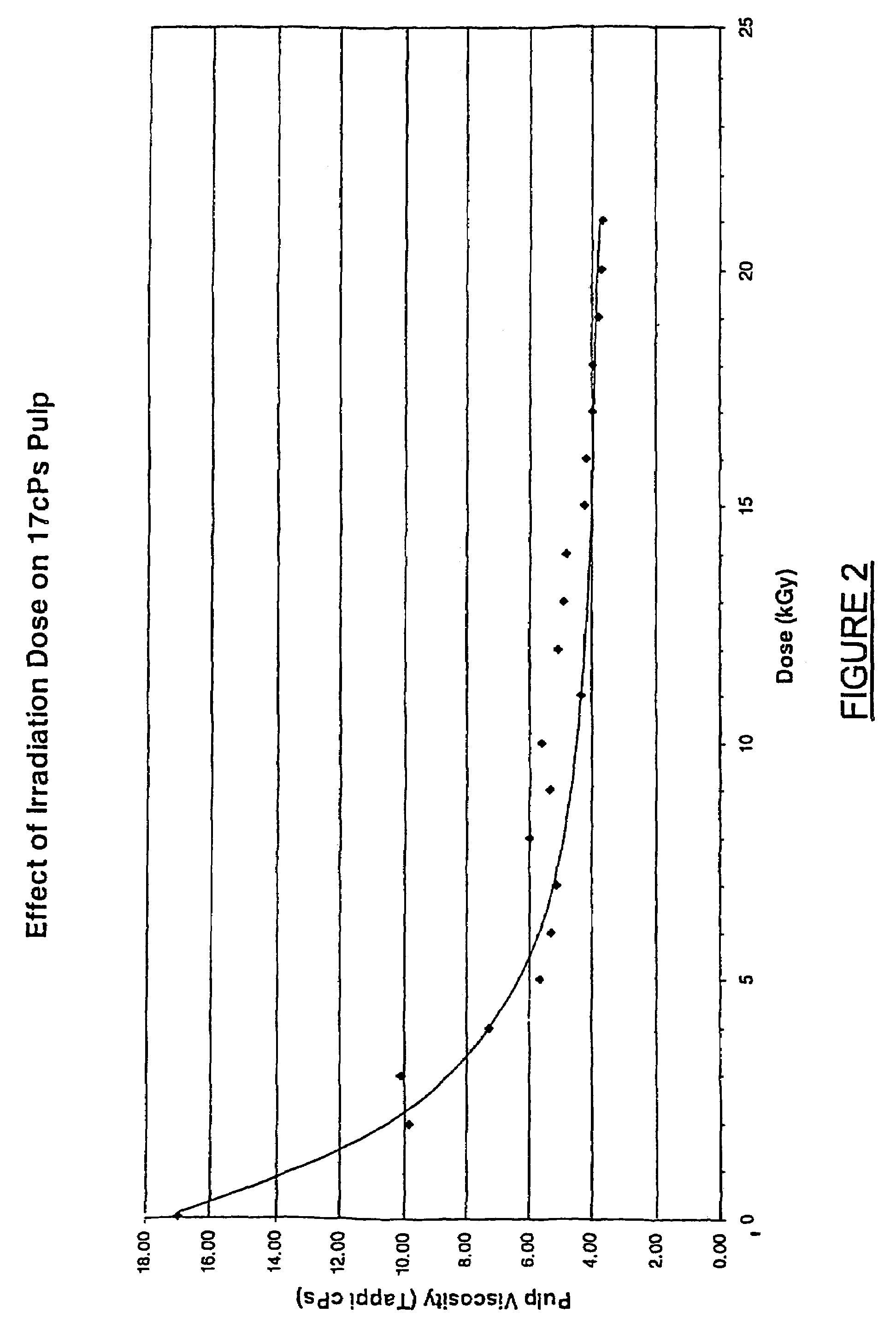

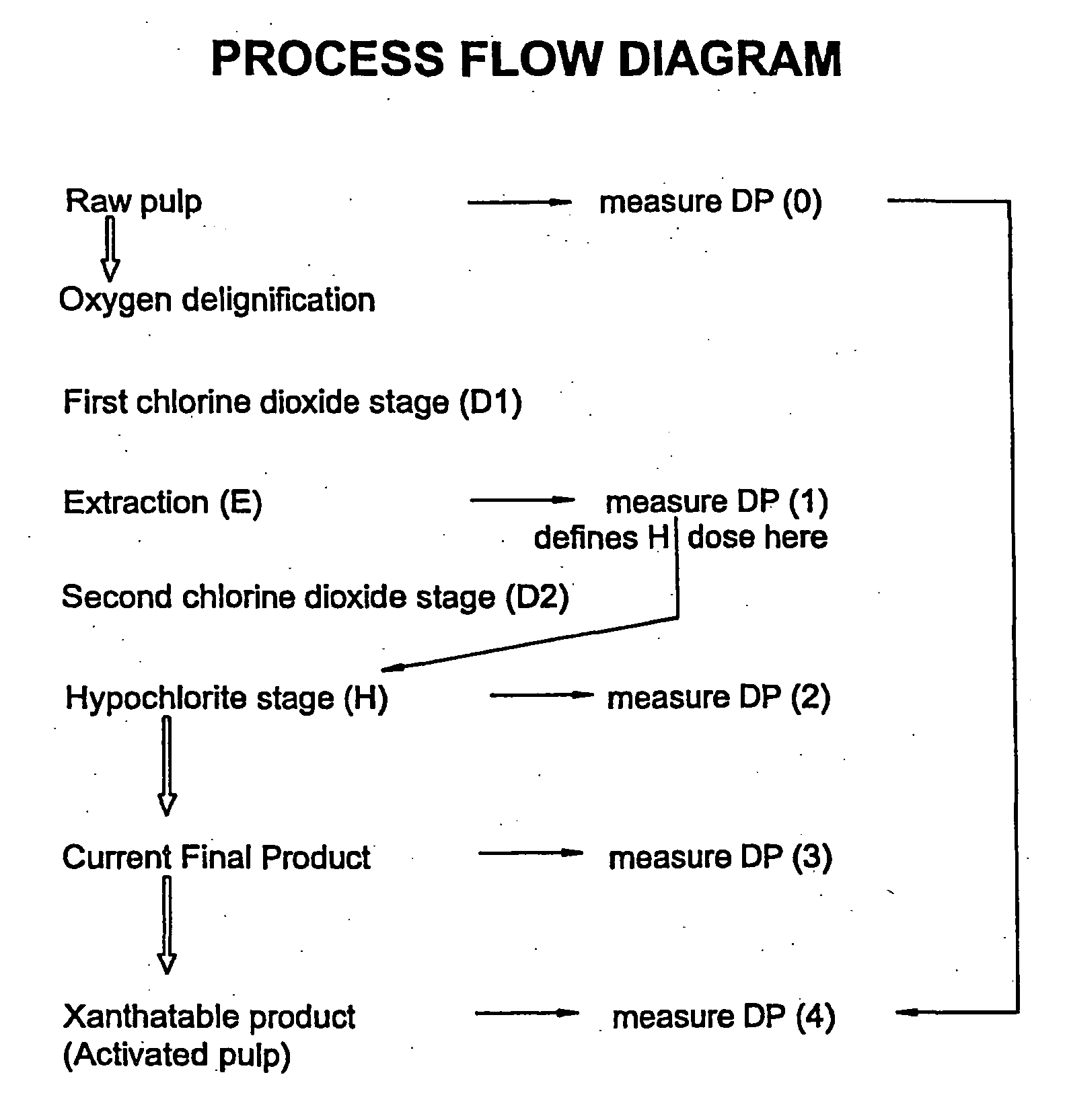

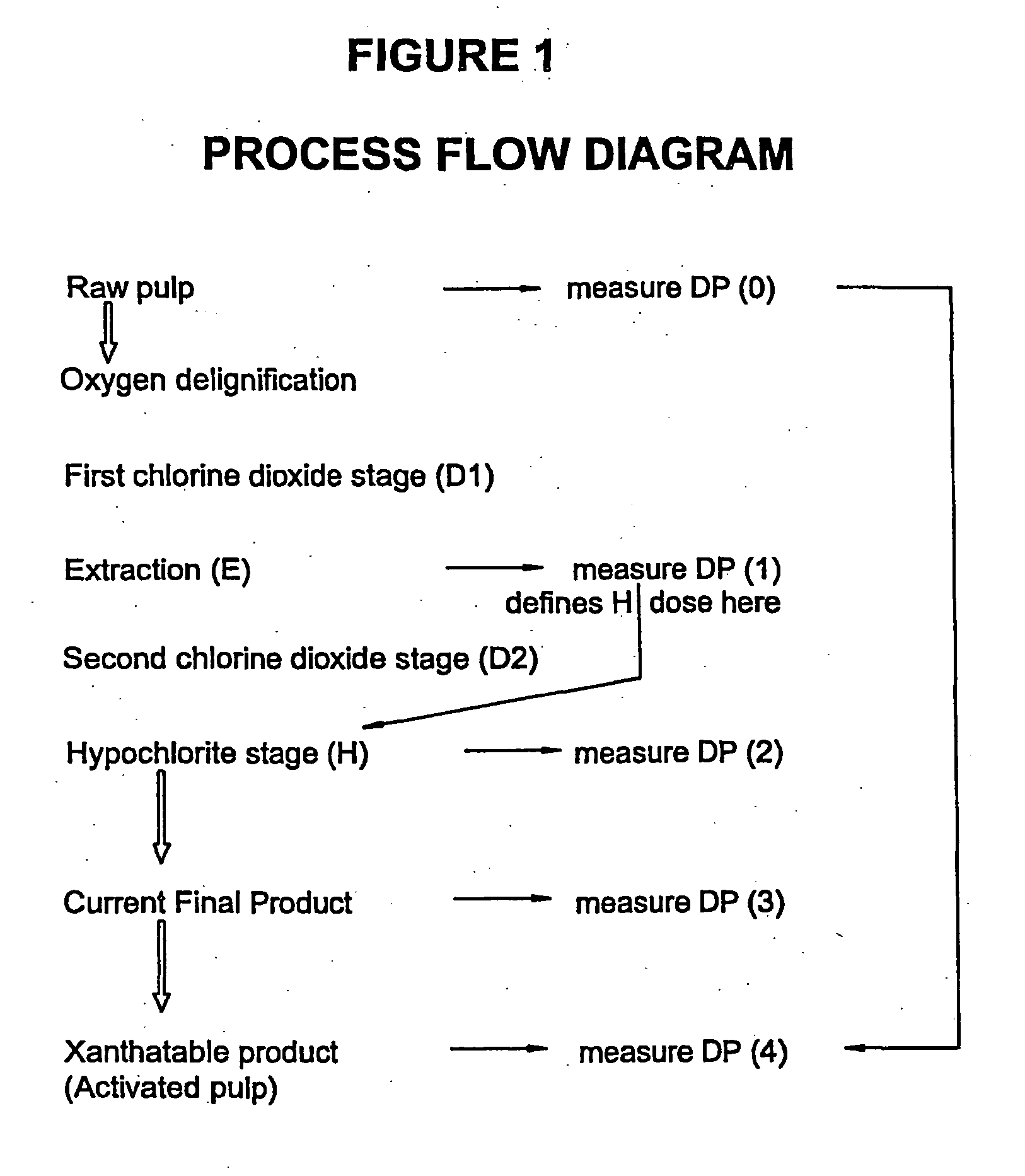

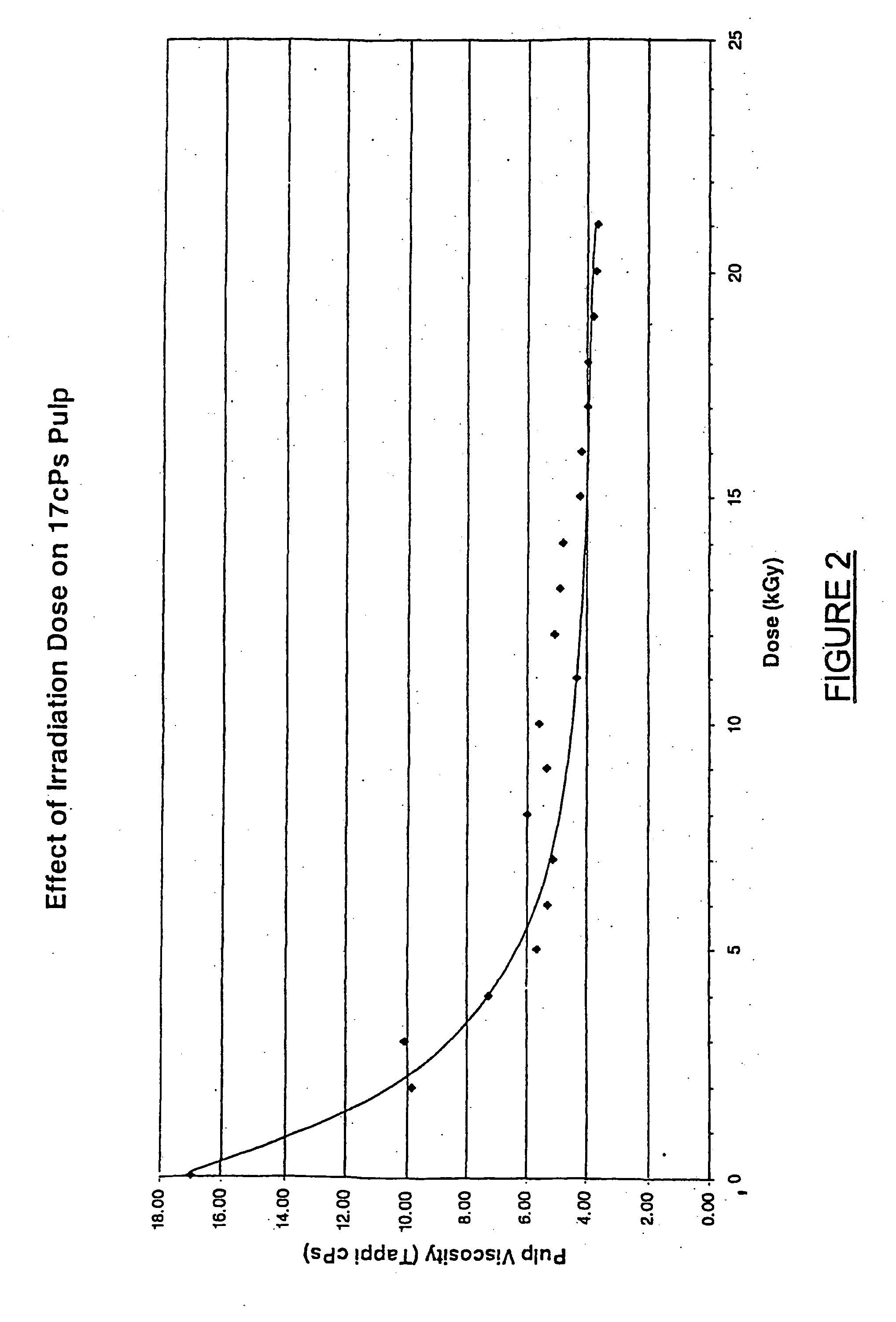

This invention provides a process for treating chemical woodpulp, or chemical cellulose including cotton linter, including the step of applying an electron processing technology (EPT) step to chemical woodpulp, or chemical cellulose, as the case may be, on an in-line basis to provide control of pulp viscosity or degree of polymerization (DP). The invention also provides a method of process control in treating the aforementioned woodpulp or cellulose, including the step of using radiation dose-viscosity relationship curve for applying an EPT step on an in-line basis. The in-line EPT step may, in one form of the invention, replace and hence eliminate a chemical DP reduction step.

Owner:SAPPI LTD

Pulp treatment and process

InactiveUS20040129394A1Reduce environmental problemsSmall DP rangeElectrolysis componentsWood treatment detailsPulp treatmentCompound (substance)

This invention provides a process for treating chemical woodpulp, or chemical cellulose including cotton linter, including the step of applying an electron processing technology (EPT) step to chemical woodpulp, or chemical cellulose, as the case may be, on an in-line basis to provide control of pulp viscosity or degree of polymerisation (DP). The invention also provides a method of process control in treating the aforementioned woodpulp or cellulose, including the step of using radiation dose-viscosity relationship curve for applying an EPT step on an in-line basis. The in-line EPT step may, in one form of the invention, replace and hence eliminate a chemical DP reduction step.

Owner:SAPPI LTD

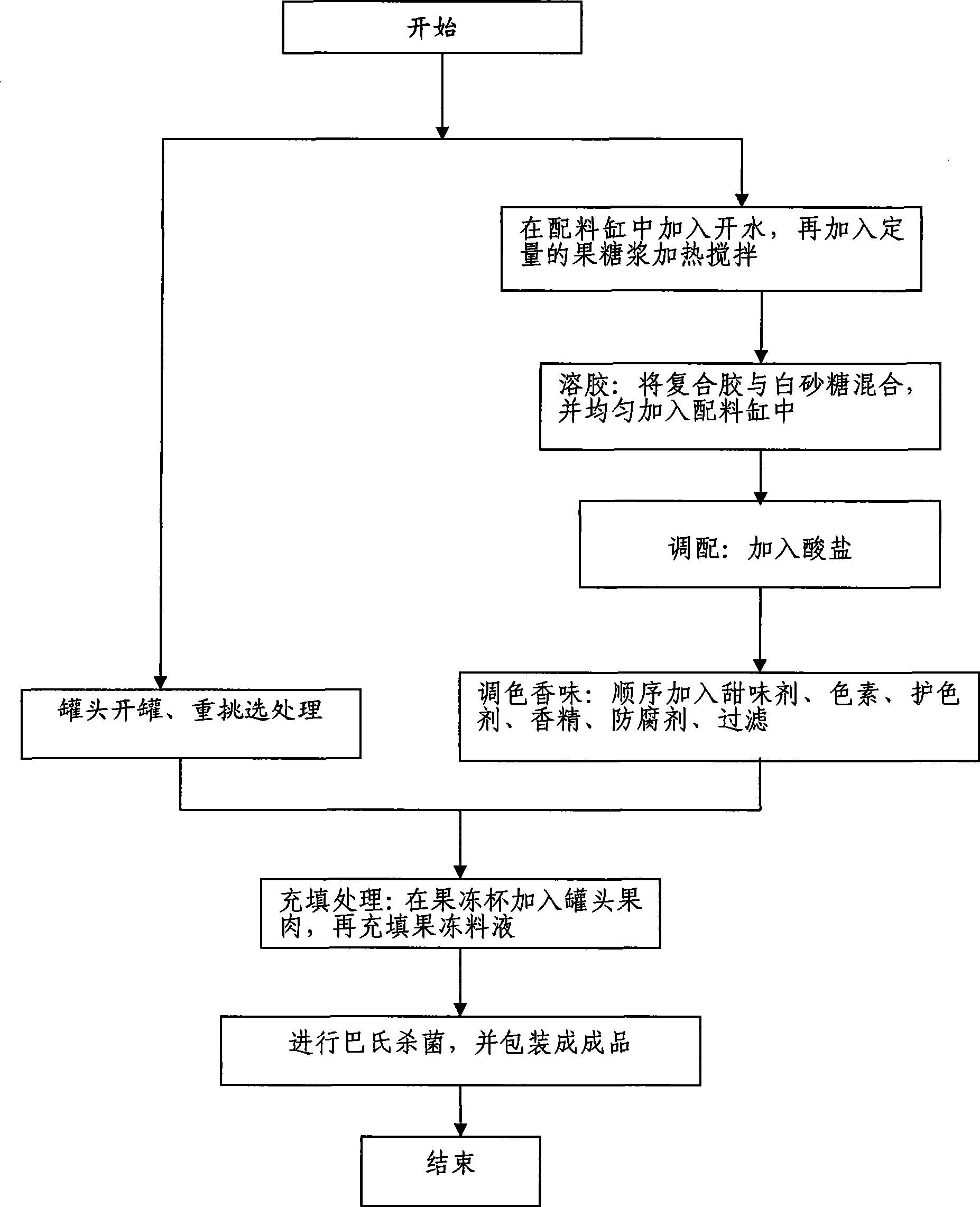

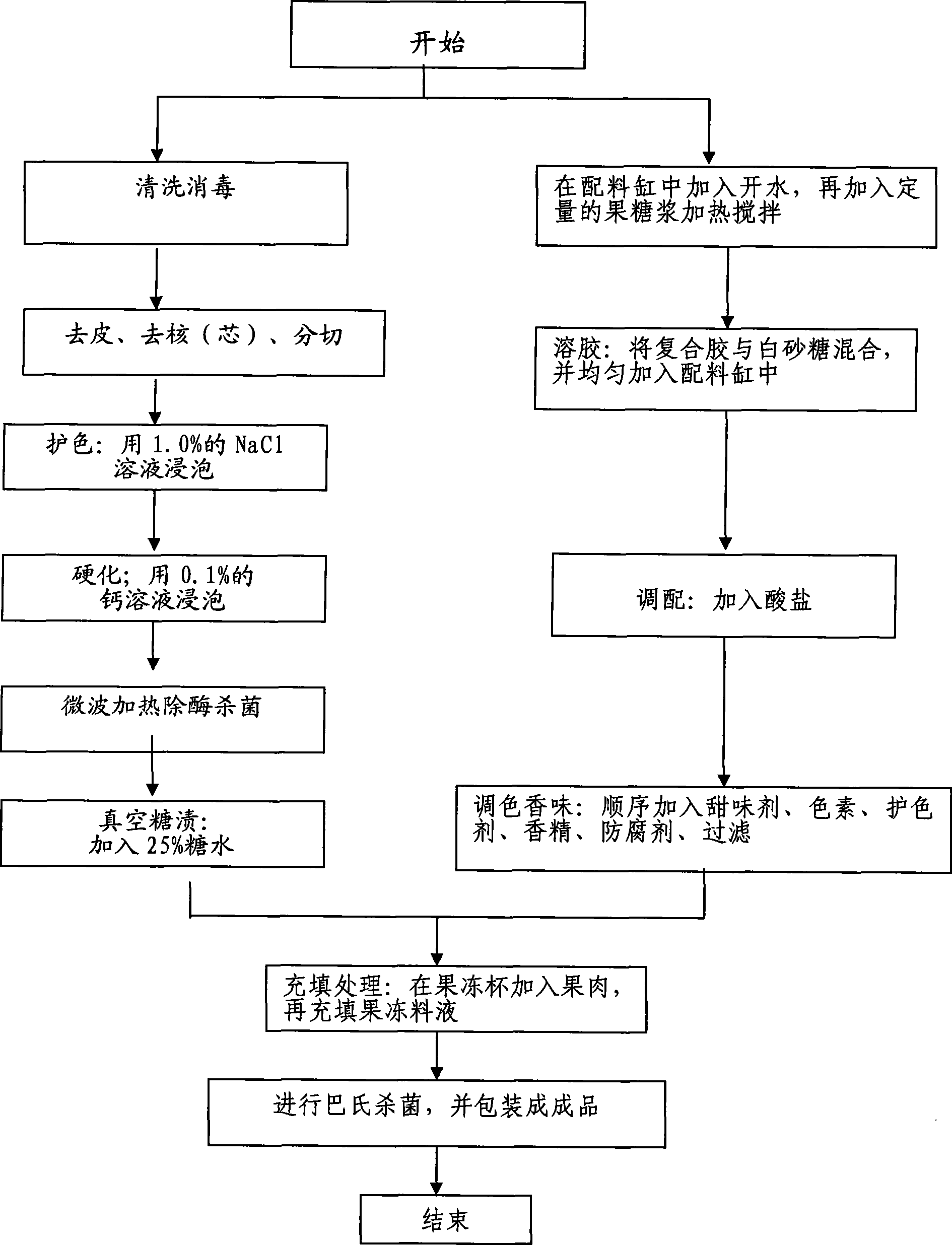

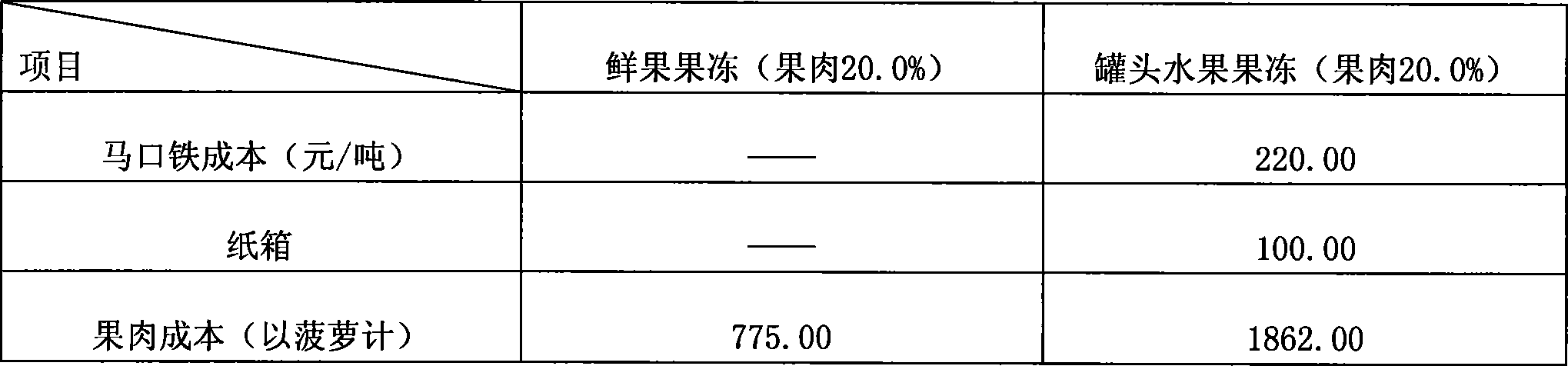

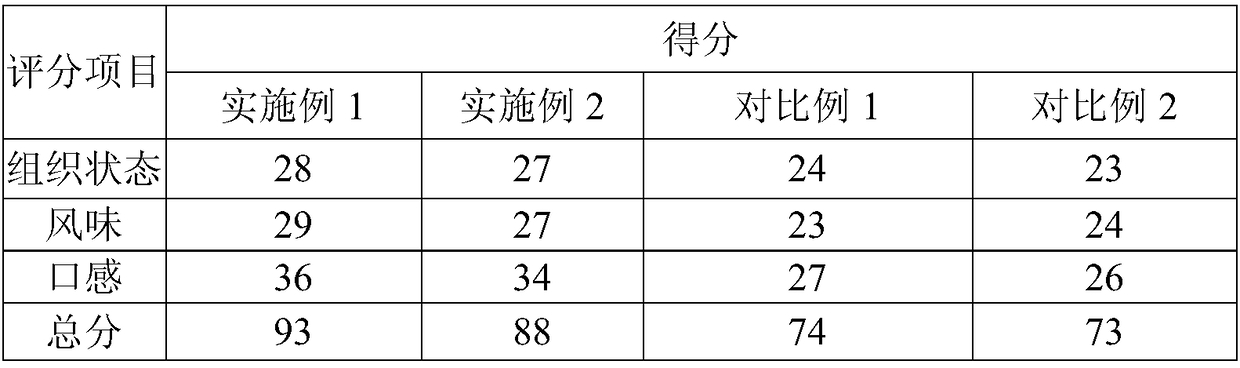

Fresh fruit pure jelly and method for producing the same

The invention discloses a fresh fruit jelly and preparation method thereof. The raw materials of the fresh fruit jelly comprises: water, fresh pulp, golden syrup, white granulated sugar, composite glue, citric acid, sodium citrate, sweetening agent, essence, color protecting agent, anticorrisive agent and pigment; the preparation method of the fresh fruit jelly comprises the following steps: A, treating fresh fruits; B, making jelly material liquid; C, fusing the fresh fruit pieces into the jelly material liquid and obtaining the fresh fruit jelly. In the invention, the pulp treatment includes microwave heat treatment, dezymotizing and sterilization, the treatment time is 1 / 10 of the can heat treatment time, which maintains the fresh taste and flavor of the fruit and reduces the loss of nutrition components such as vitamins; and vacuum stain is used, which shortens time and the whole flow.

Owner:NANJING LAIYIKOU FOOD CO LTD

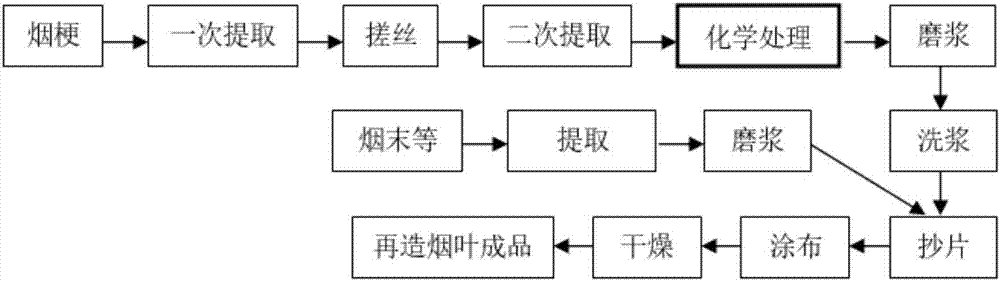

Tobacco stem treatment method for improving papermaking method remanufactured tobacco leaf quality

The invention discloses a method for treating tobacco stems for improving the quality of reconstituted tobacco leaves by a papermaking method, which comprises the following steps: adding the pretreated tobacco stems together with water into a stirring extraction tank, extracting at high temperature, and squeezing dry to obtain tobacco stems A; Tobacco stem A is sent to the thread rolling machine for thread rolling to obtain tobacco stem B; Tobacco stem B and water are added to the stirring extraction tank, after high temperature extraction, squeezed dry to obtain Tobacco stem C; The composite solvent is added to Tobacco stem C is stirred and soaked at high temperature to obtain a mixed solution D; the mixed solution D is added to a refiner, and the slurry E is obtained through refining treatment; the slurry E is processed by sheeting and coating, and then dried, Cut and serve. Compared with the traditional method, the extraction rate of the active components of the tobacco stems of the present invention is high, the beating degree of the tobacco stem pulp is improved, the energy consumption of the subsequent beating is reduced, the fiber quality of the tobacco stem pulp is improved, and the quality of the reconstituted tobacco leaves by the papermaking method is improved. .

Owner:山东烟草研究院有限公司

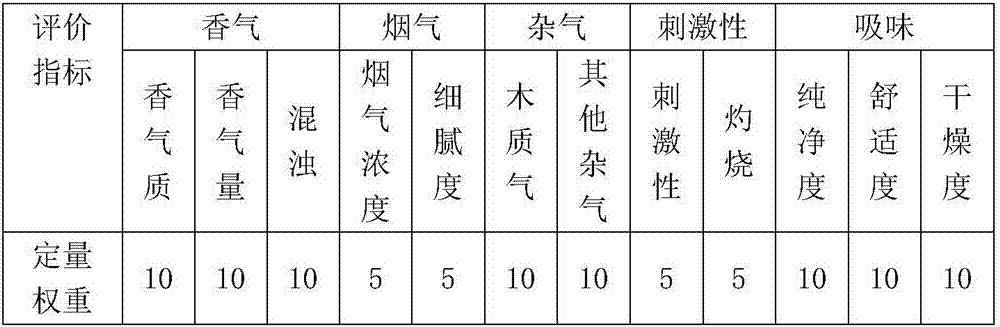

Method for improving ash content of paper-making process reconstituted tobaccos

InactiveCN103653233AHigh strengthIncrease ash contentTobacco preparationCell cavityPaper manufacturing

The invention discloses a method for improving the ash content of paper-making process reconstituted tobaccos. The method includes the steps that after tobacco raw materials are extracted, solid-liquid separation is carried out, tobacco liquid is partially refined, concentrated and charged and then is manufactured into coating liquid, pulping treatment is partially conducted on the tobacco solid part, so that tobacco slurry fibers are obtained, CaCO3 is added into the tobacco slurry fibers, and the CaCO3 is filled into cell cavities of the tobacco slurry fibers through pits of the tobacco slurry fibers; afterwards, the tobacco slurry fibers and additional fiber slurry are mixed according to the weight ratio of 4 to 1, and then paper manufacturing with pulp is carried out to manufacture reconstituted tobacco sheets; the coating liquid is made to coat the reconstituted tobacco sheets, so that the paper-making process reconstituted tobaccos are manufactured. According to the method, the technology that the CaCO3 is filled into the cell cavities of the tobacco slurry fibers is applied to the preparation technology of the paper-making process reconstituted tobaccos, any chemical agent such as a high-molecular polymer is not added, and the purposes that the ash content is improved and meanwhile the strength performance of the paper-making process reconstituted tobacco sheets is improved can be achieved.

Owner:HUBEI XINYE TOBACCO SLICE DEV

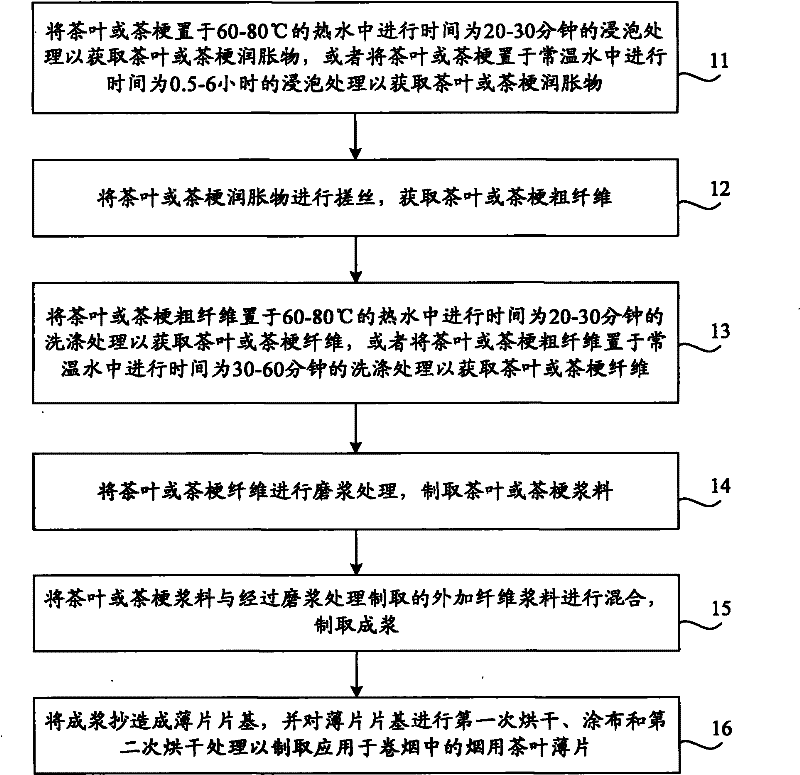

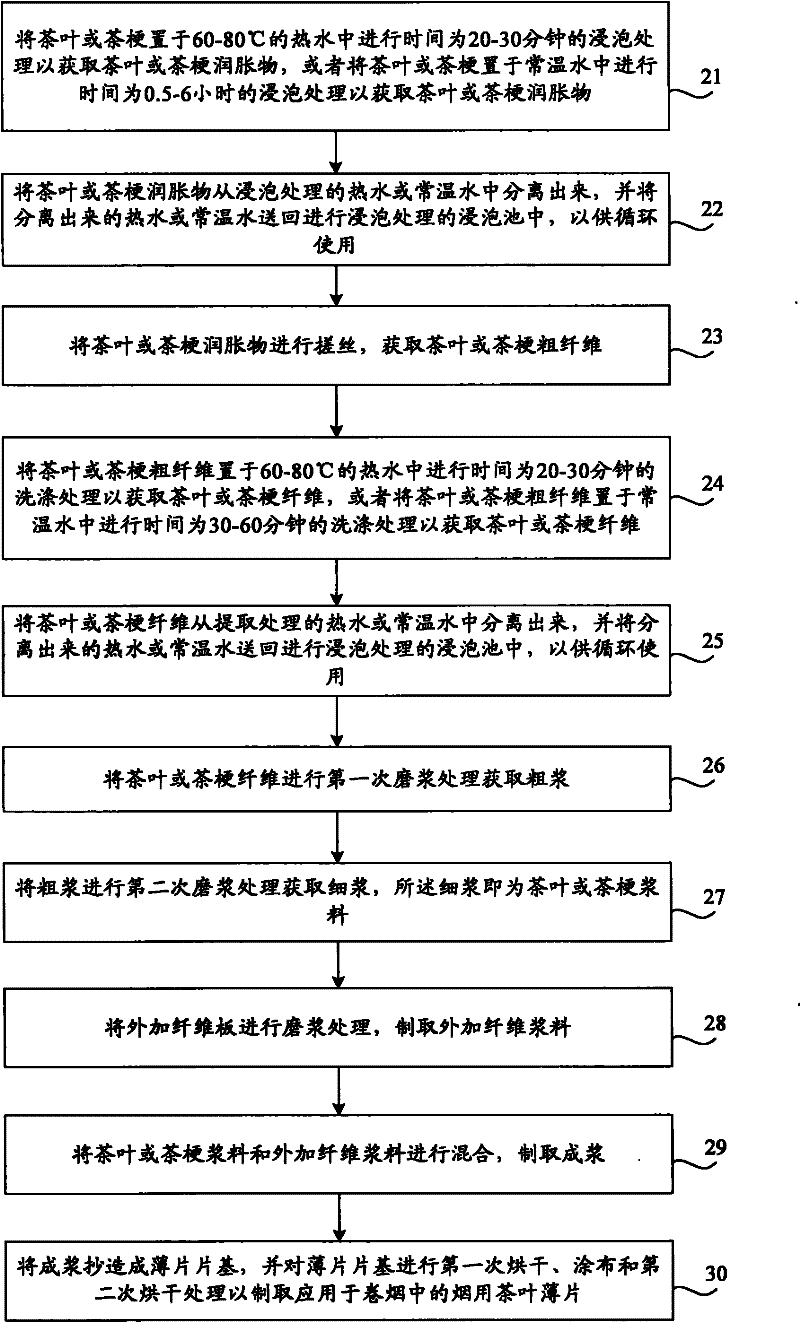

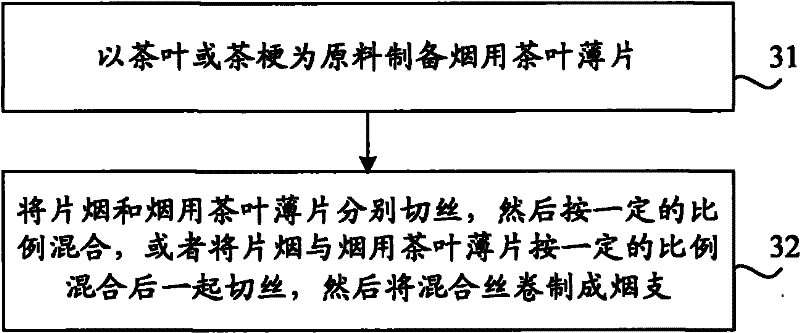

Tea leaf thin sheet for cigarette, preparation method thereof and cigarette

InactiveCN102217782ABurn fasterReduce releaseTobacco preparationTobacco treatmentFiberPulp treatment

The invention provides a tea leaf thin sheet for a cigarette, a preparation method thereof and the cigarette, wherein the tea leaf thin sheet for the cigarette takes tea leaves or tea stalks as raw material, and the preparation method comprises the following steps: placing the tea leaves or the tea stalks in hot water or normal temperature water for performing soaking treatment so as to get a swollen matter of the tea leaves or the tea stalks; performing thread rolling on the swollen matter of the tea leaves or the tea stalks to get crude fiber of the tea leaves or the tea stalks; placing the crude fiber of the tea leaves or the tea stalks into the hot water or the normal temperature water for performing washing treatment so as to get fiber of the tea leaves or the tea stalks; performing pulping treatment on the fiber of the tea leaves or the tea stalks to prepare pulp of the tea leaves or the tea stalks; and preparing the pulp of the tea leaves or the tea stalks and the additional fiber pulp prepared by the pulping treatment into finished pulp, further manufacturing paper with the pulp for making a thin sheet base, and performing primary drying, coating and secondary drying on the thin sheet base for getting the tea leaf thin sheet for the cigarette. The tea leaf thin sheet for the cigarette, which is prepared according to the preparation method, is applied in the cigarette, can solve the problems of limited harm-reducing effect and instability in the prior art and realizes the purpose of reducing harm.

Owner:北京中海钓台食品供应中心有限公司

Aroma type green plum stuffing as well as production method thereof and food with green plum stuffing

The invention discloses aromatic greengage filling, a production method thereof, and a greengage filling food. The method comprises the following steps: greengage is cleaned, denucleated and subjected to pulping treatment, biological enzyme treatment by flavoring enzymes, finish grinding and superhigh pressure homogenization treatment; the conditions of the biological enzyme treatment are that the temperature is between 30 and 60 DEG C, PH value is 4 to 6, and the time is 1 to 6 hours; the flavoring enzymes take two to three of Aspergillus niger, Aspergillus oryzae, Aspergillus ficcum, Aspergillus fumigatus, Aspergillus japonicus Saito, Aspergillus awamori, Aspergillus carbonarius, Aspergillus terreus, Aspergillus tubingensis, Aspergillus usammi and Aspergillus sojae as zymogens; and the greengage is subjected to mixed fermentation in a culture medium for 2 to 5 days at a temperature of between 20 and 40 DEG C and under the condition of 200 to 600r / min, and leached, filtrate is leached and centrifuged, and the supernatant is taken as flavoring enzyme liquid. By the production method, high-quality aromatic greengage filling food can be manufactured, and has unique flavor, aromatic and rich fragrance of the greengage, high quality and wide development prospect.

Owner:SOUTH CHINA UNIV OF TECH +1

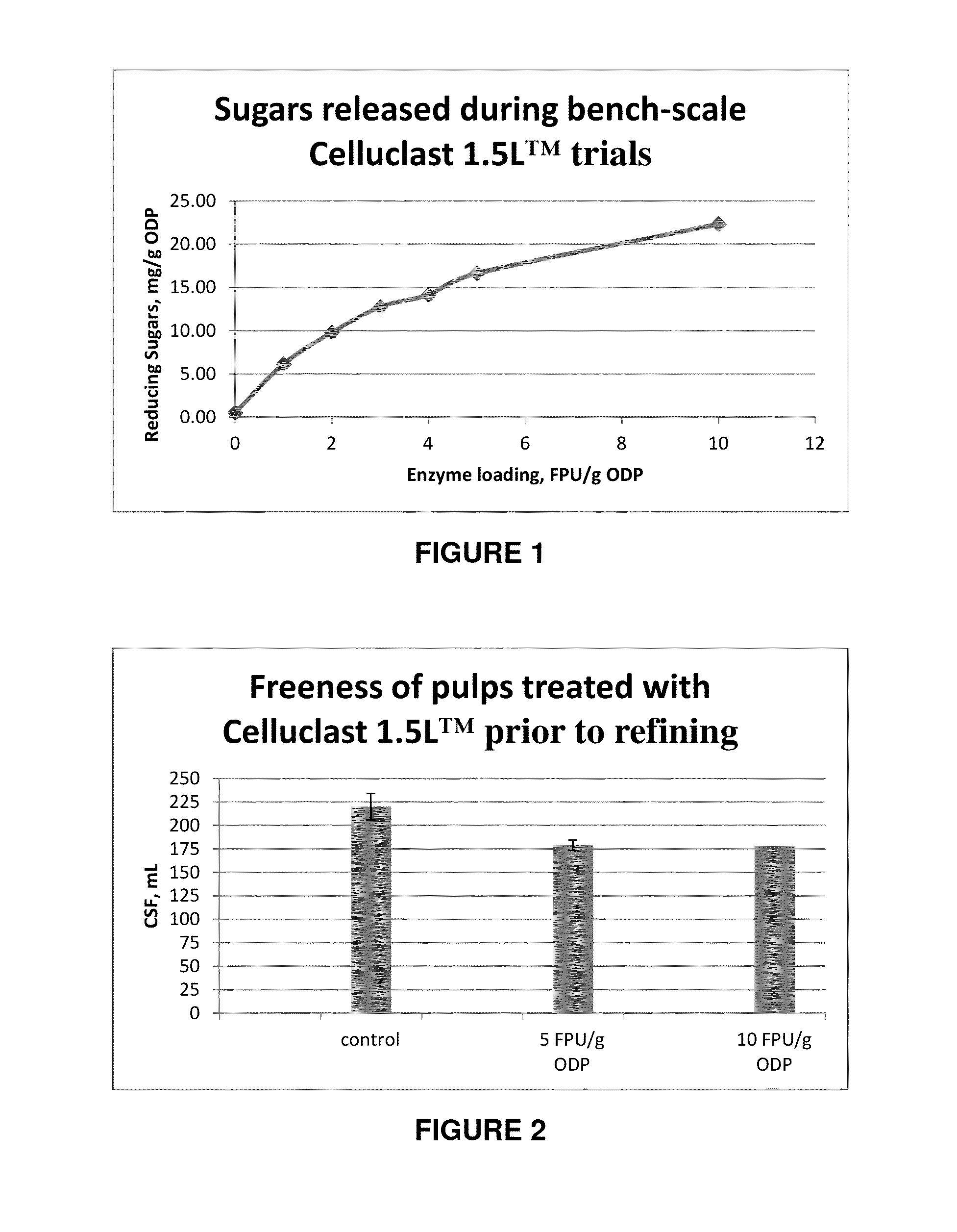

Wood pulp treatment

InactiveUS20140209259A1Lower energy requirementsMaintain tensile strengthPulp properties modificationFibrous raw materialsGlycanMannanase activity

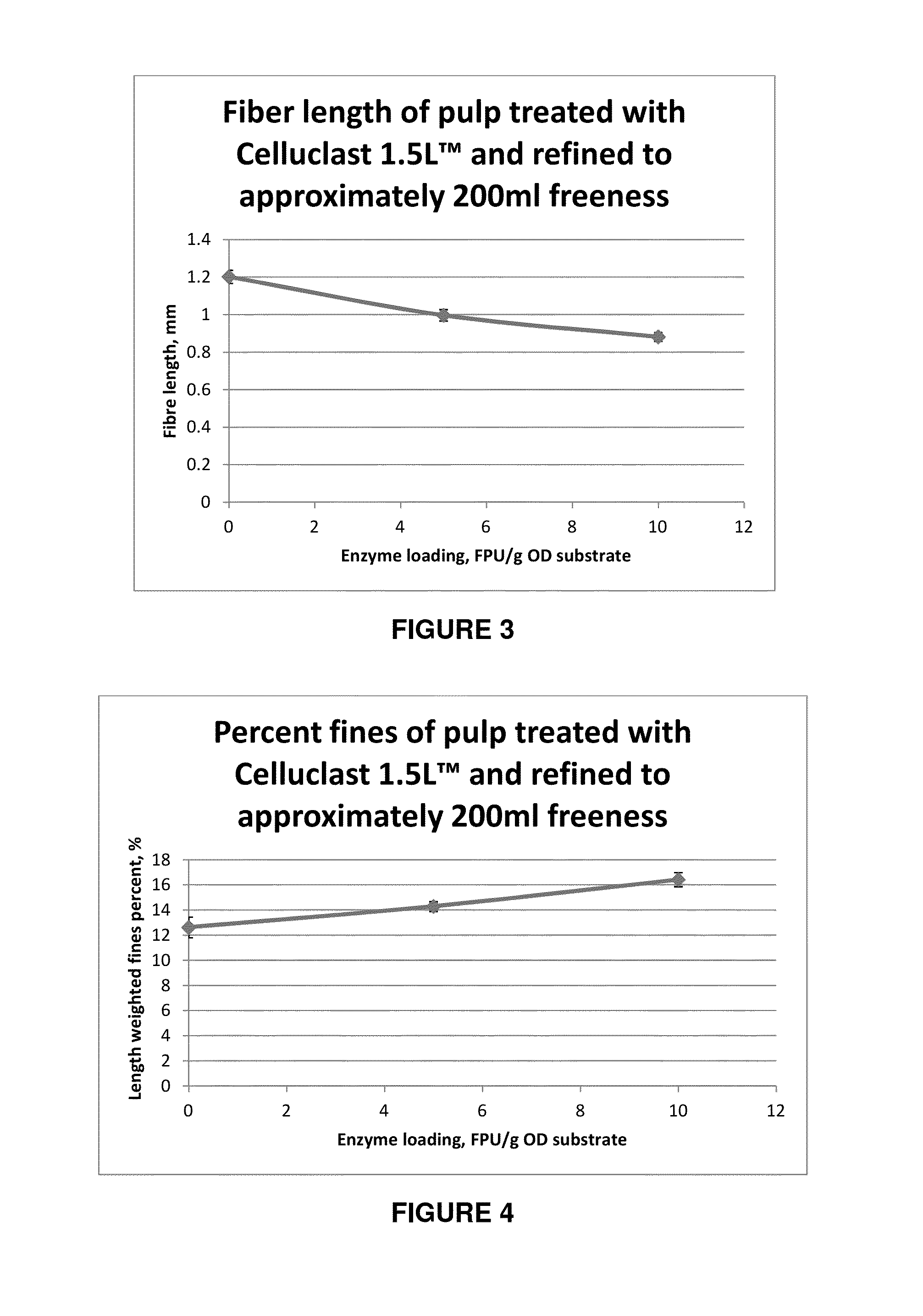

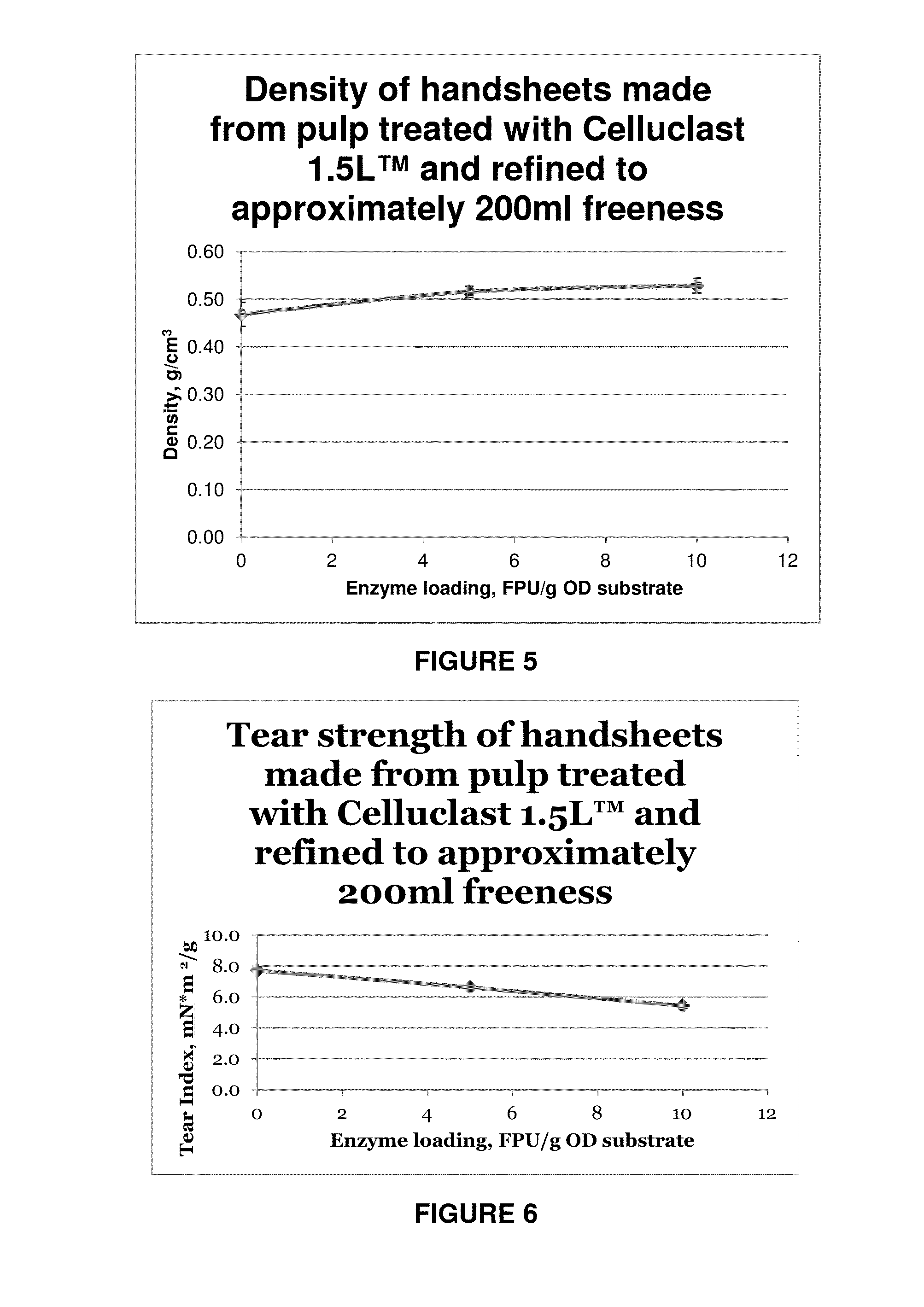

A process using a multicomponent enzyme preparation to treat screened once refined pulps and reduces the specific energy consumption and / or increasing production while maintaining or increasing handsheet physical properties. The enzyme preparation has a major endoglucanase activity, a significant mannanase activity and a relatively small cellobiohydrolase activity. This enzyme mixture is prepared from a genetically modified strain of Trichoderma reseii.

Owner:UNIVERSITY OF NEW BRUNSWICK

Treatment of pulp

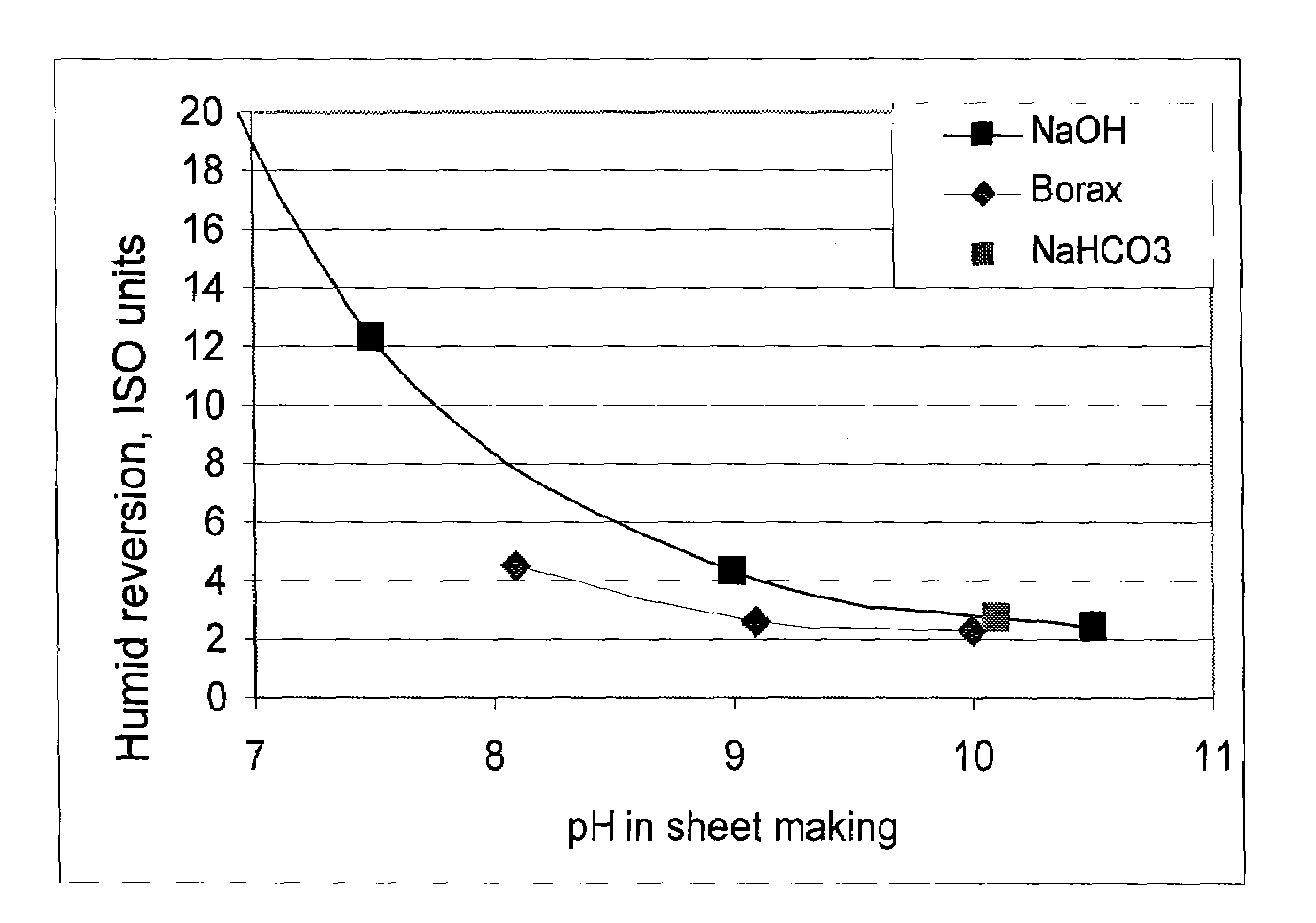

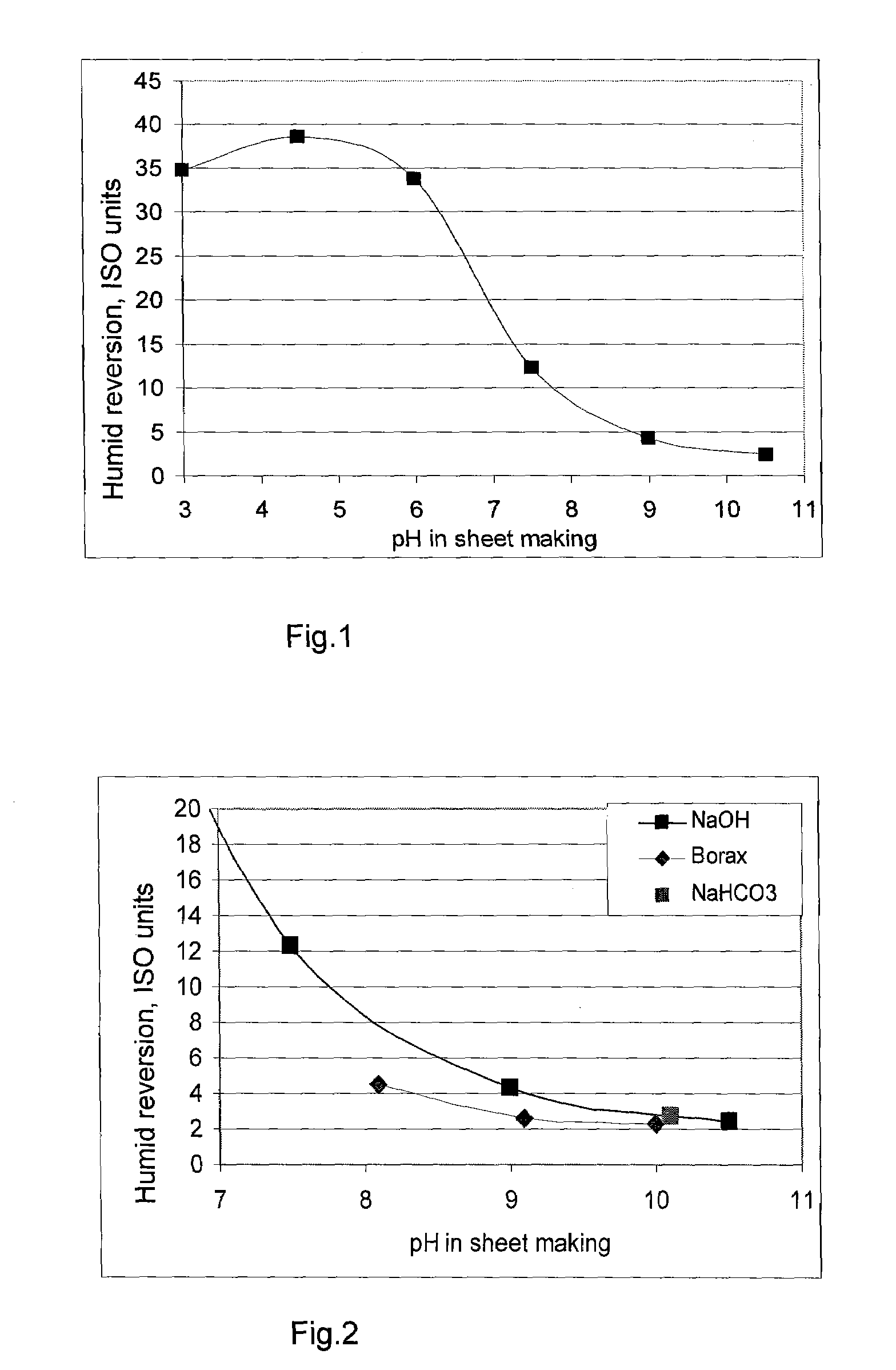

InactiveUS20080073043A1Improve brightness stabilityPulp de-wateringPulping with inorganic basesChemistryAqueous suspension

The present invention relates to a method of treating an aqueous suspension of bleached pulp derived from an alkaline pulping process comprising dewatering and drying said suspension, wherein the pH of the suspension to be treated ranges from about 6.5 to about 12.

Owner:AKZO NOBEL CHEM INT BV

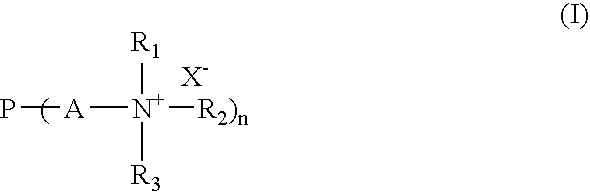

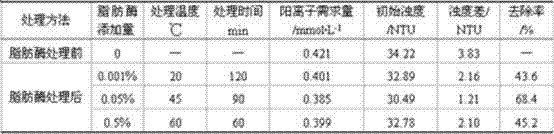

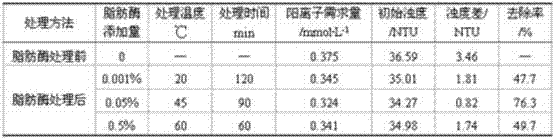

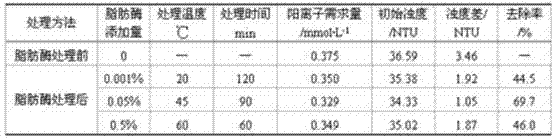

Method for controlling secondary stickies through lipase

ActiveCN103074795AEliminate hazardsQuality improvementFats/resins/pitch/waxes removal in pulpTransesterificationPulp treatment

The invention discloses a method for controlling secondary stickies in paper pulp and white water during waste paper papermaking process through lipase. According to the invention, the pH (potential of hydrogen) value of lipase ranges from 7.5 to 9.0, the enzyme activity is larger than 100 U / mL, the hydrolysis rate for triglyceride is not lower than 95%, and transesterification and lipid synthesis rate of alkaline lipase is lower than 3%; a paper pulp processing method comprises the steps that lipase which is 0.001-0.5% of paper pulp dry weight is added into paper pulp with the pulp concentration which is adjusted in a range from 2% to 5%, and then the processed pulp is filtered, centrifuged and detected; and a white water processing method comprises the steps that lipase which is 0.001-0.5% of white water weight is added into papermaking white water for processing, and then the processed white water is filtered, centrifuged and detected. The method utilizes lipase to degrade the stickies thoroughly and reduce the deposition trend of the stickies, so that the removal purpose is achieved, and the problem of secondary sticky pollution is thoroughly solved; and the operation is simple, the removing effect is remarkable, the waste paper papermaking quality is improved, and the production cost is reduced.

Owner:TAIXING YIMING BIOLOGICAL PRODS

Full water-soluble urea-based composite fertilizer and preparation method thereof

The present invention discloses a full water-soluble urea-based composite fertilizer and a preparation method thereof. The full water-soluble urea-based composite fertilizer is prepared by mixing the following raw materials, wherein the raw materials comprise: urea, a fluxing agent, industrial ammonium dihydrogen phosphate (or potassium dihydrogen phosphate), potassium sulfate, a medium and traceelement additive, the weight ratio of the urea to the industrial ammonium dihydrogen phosphate to the potasium fertilizer to the EDTA complex to the borax is 1.0:0.25-0.90:0.3-1.1:0.02-0.3:0.02-0.10,or the weight ratio of the urea to the potassium dihydrogen phosphate to the potasium fertilizer to the EDTA complex to the fluxing agent is 1.0:0.2-1.1:0.1-1.1:0.02-0.60:0.02-0.10. The preparation method mainly comprises pulping, pelletizing, cooling and film wrapping, wherein the pulping treatment adopts the step-by-step melting and mixing method to carry out pulping, the pelletizing treatment adopts the differential rotations of the two shafts to carry out pelletizing, the cooling treatment comprises high tower primary natural air cooling and secondary rotating drum air cooling, finally the film wrapping treatment is performed to obtain the product, the isolation film is wrapped on the surfaces of the fertilizer particles so as to prevent the fertilizer particles from conglutination and agglomeration. The composite fertilizer of the present invention can be used for spraying application and drip irrigation application.

Owner:拉多美科技集团股份有限公司

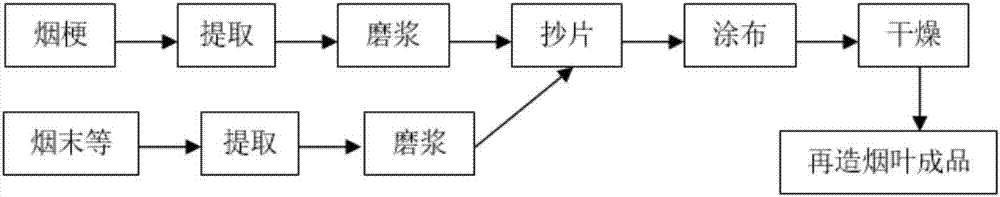

Method for preparing tobacco sheets through tobacco waste materials by papermaking method

InactiveCN102318895AReduce cut-offGood physical propertiesTobacco preparationPapermakingPulp treatment

The invention provides a method for preparing tobacco sheets through tobacco waste materials by a papermaking method, which comprises the following steps of: respectively soaking tobacco powder and mixtures of washed tobacco stems and crumbled tobacco leaves into water, carrying out extraction, respectively obtaining solid tobacco stems, tobacco leaf mixtures, solid smoke powder and two kinds of extraction liquid through solid and liquid separation, and combining two kinds of extraction liquid; regulating the tobacco stem and tobacco leaf mixtures obtained through extraction into the materialconcentration being 15 to 30 percent, and then carrying out defibering; regulating the defibered materials into the concentration being 6 to 12 percent and carrying out pulping treatment; diluting the solid smoke powder and the pulped pulp materials to the required concentration after mixing, and making the materials into substrates by a papermaking method after sieving; and concentrating the combined extraction liquid, using the concentrated extraction liquid as coating liquid to be coated on the substrates, and drying and cutting the substrates into tobacco sheet products. The preparation method provided by the invention has the advantages that the damage to material tissue structures in the preparation process is effectively reduced, the physical performance of the tobacco sheets is improved, the yield is high, and the energy consumption is low.

Owner:SOUTH CHINA UNIV OF TECH +2

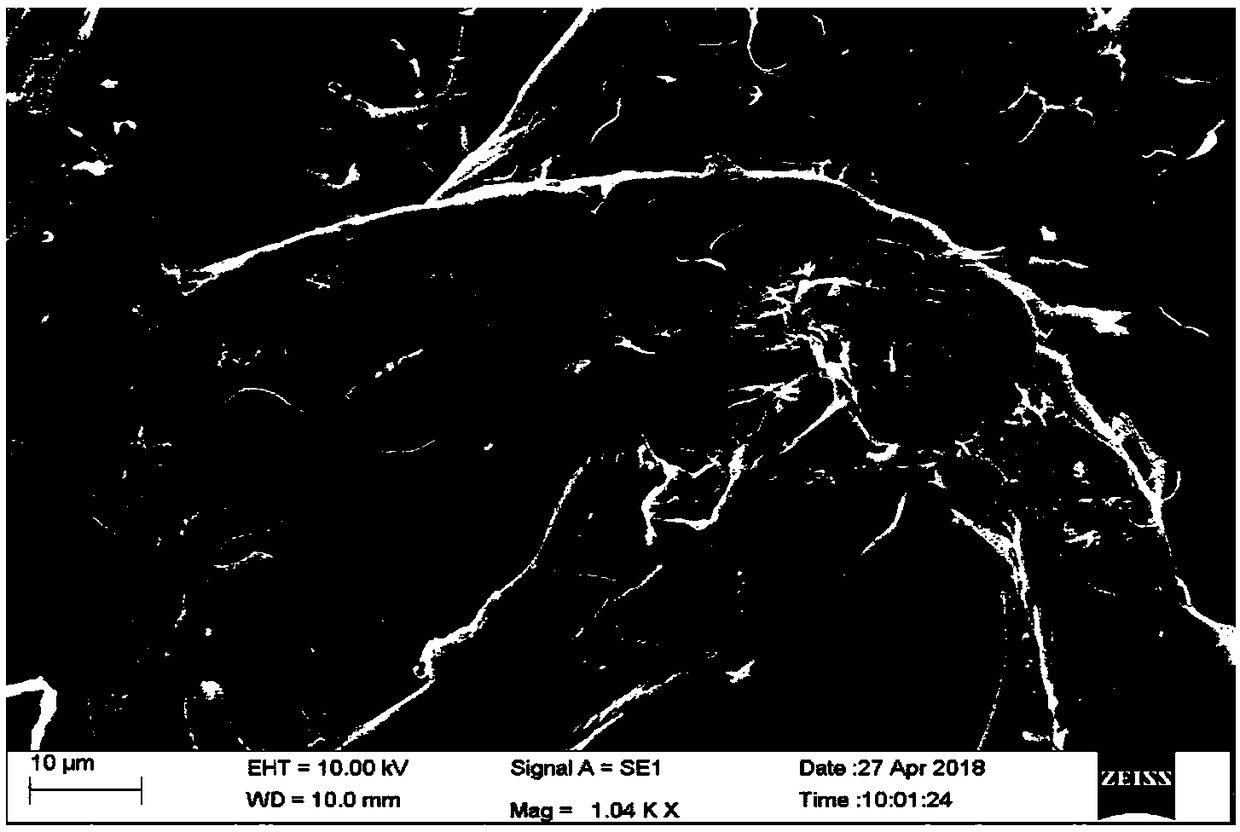

Method for preparing chitosan fiber paper-based material based on wet paper-making technology

InactiveCN109235105AImprove physical strengthTensile strength can be adjustedPulp properties modificationOrganic non-cellulose fibresChemical industryFiber

The invention discloses a method for preparing a chitosan fiber paper-based material based on a wet paper-making technology. The method comprises the following steps: adding a chitosan fiber materialinto deionized water and an acid or alkali solution of alkene, performing pretreatment, cleaning the pretreated fiber and performing pulping treatment; and diluting the fiber pulp obtained through pulping to obtain fiber suspension, and performing dehydrating and drying treatment by a paper-making former to prepare a chitosan fiber paper base material; or according to the requirements, performingdipping or surface coating treatment on the prepared chitosan fiber paper base material and drying again to obtain a material needing special application. The method is simple and convenient to operate, low in cost and convenient in industrialized product; the production cost of the chitosan material can be greatly reduced; and wide application prospect in the aspects of medical treatment, daily-use chemical industry and special materials is achieved.

Owner:SOUTH CHINA UNIV OF TECH

High-silicon composite molecular sieve adsorbent for removing VOCs and preparation method of high-silicon composite molecular sieve adsorbent

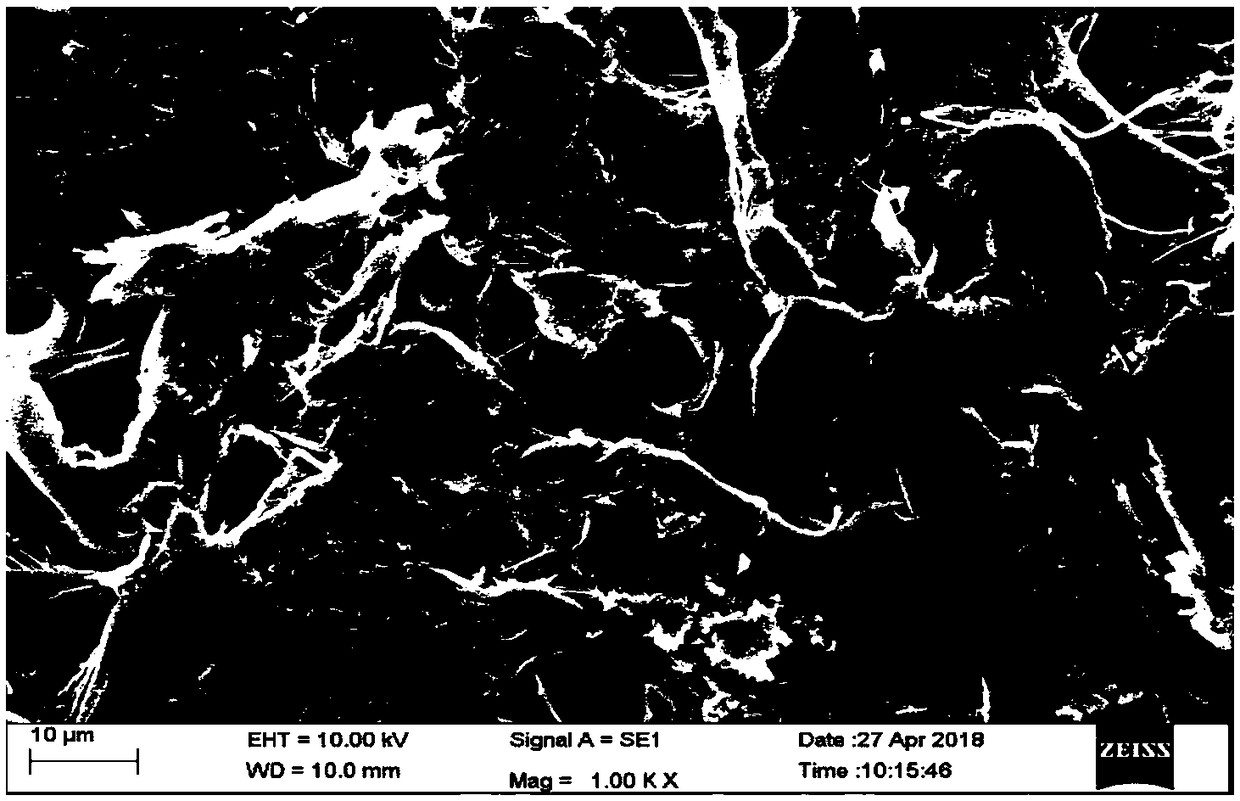

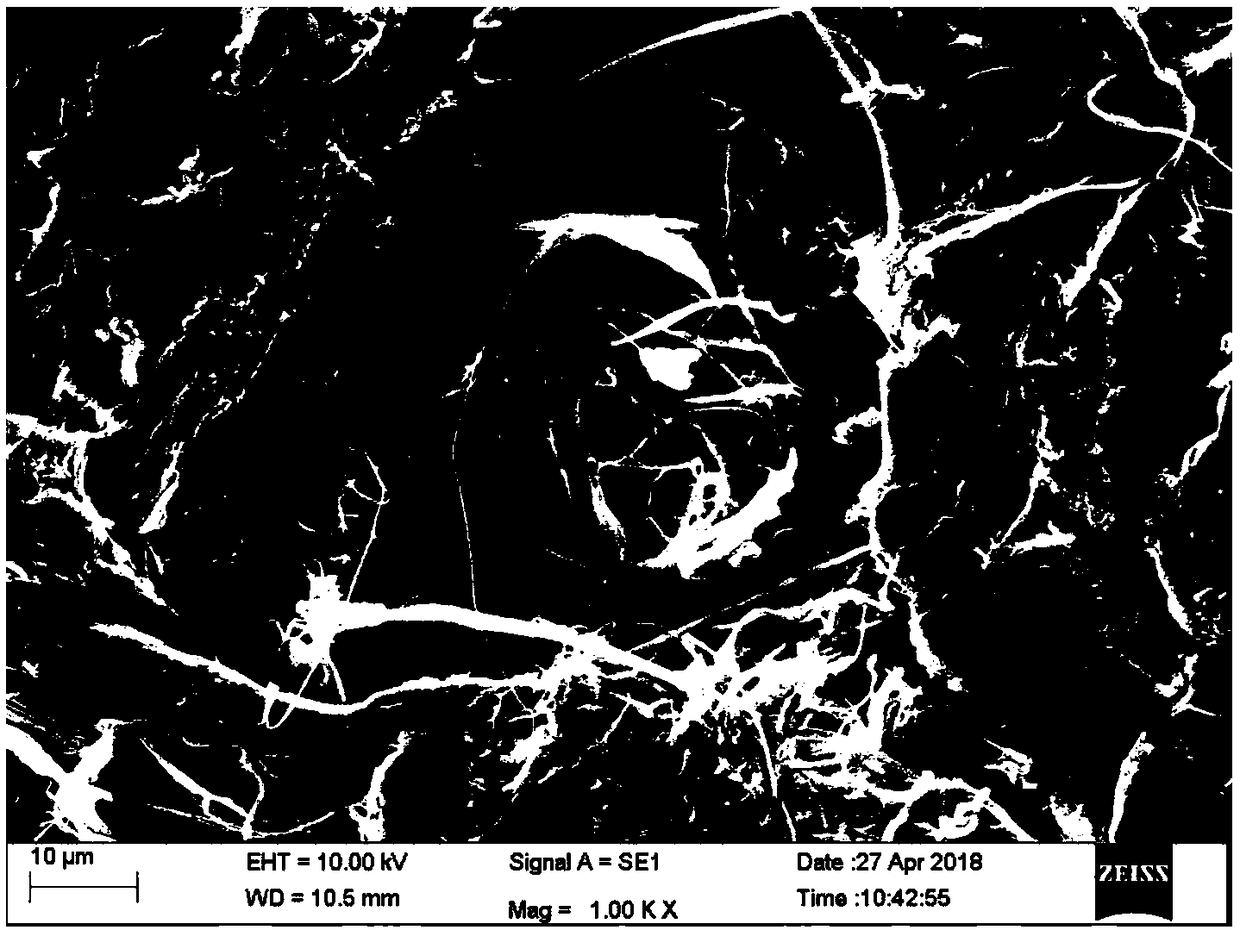

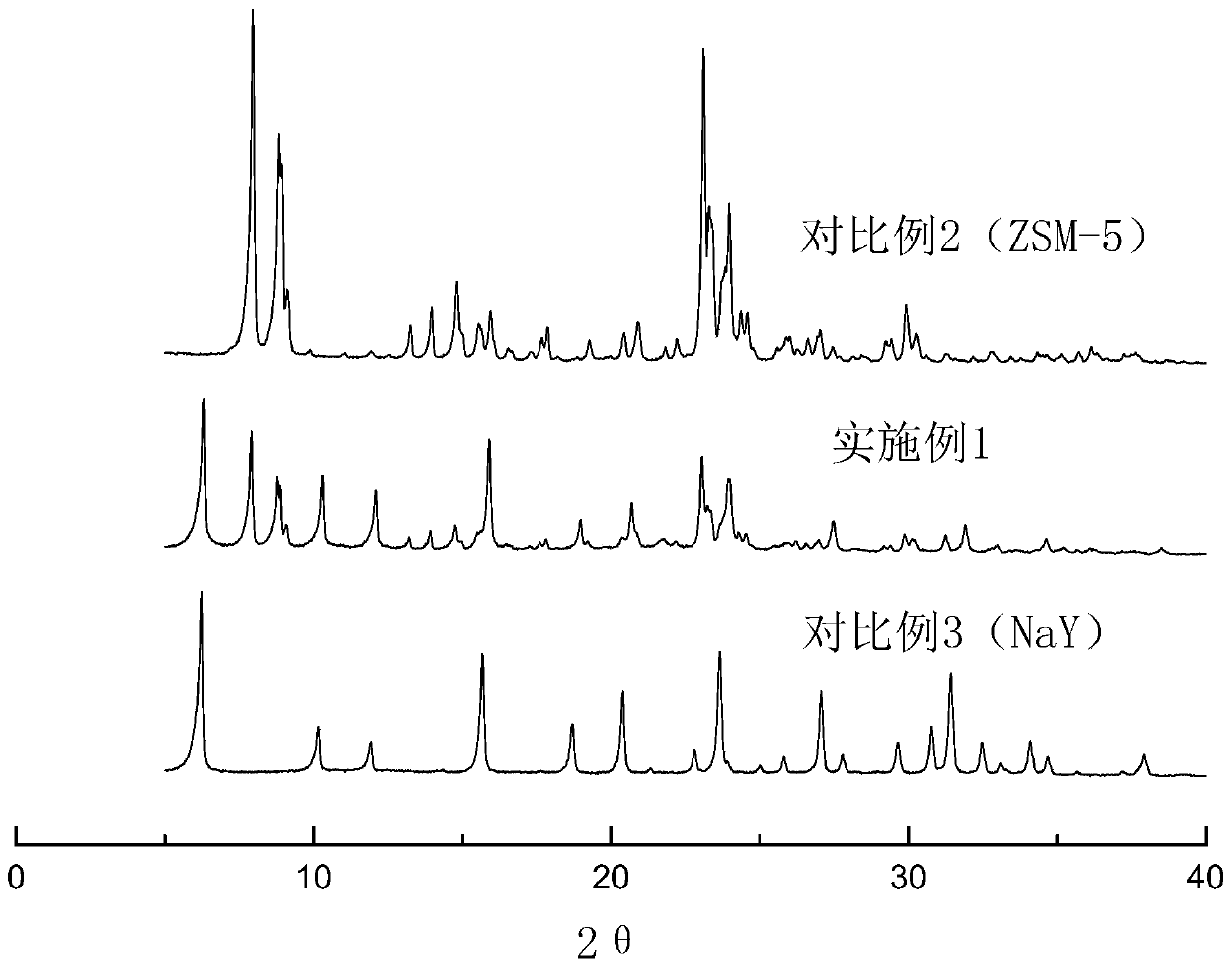

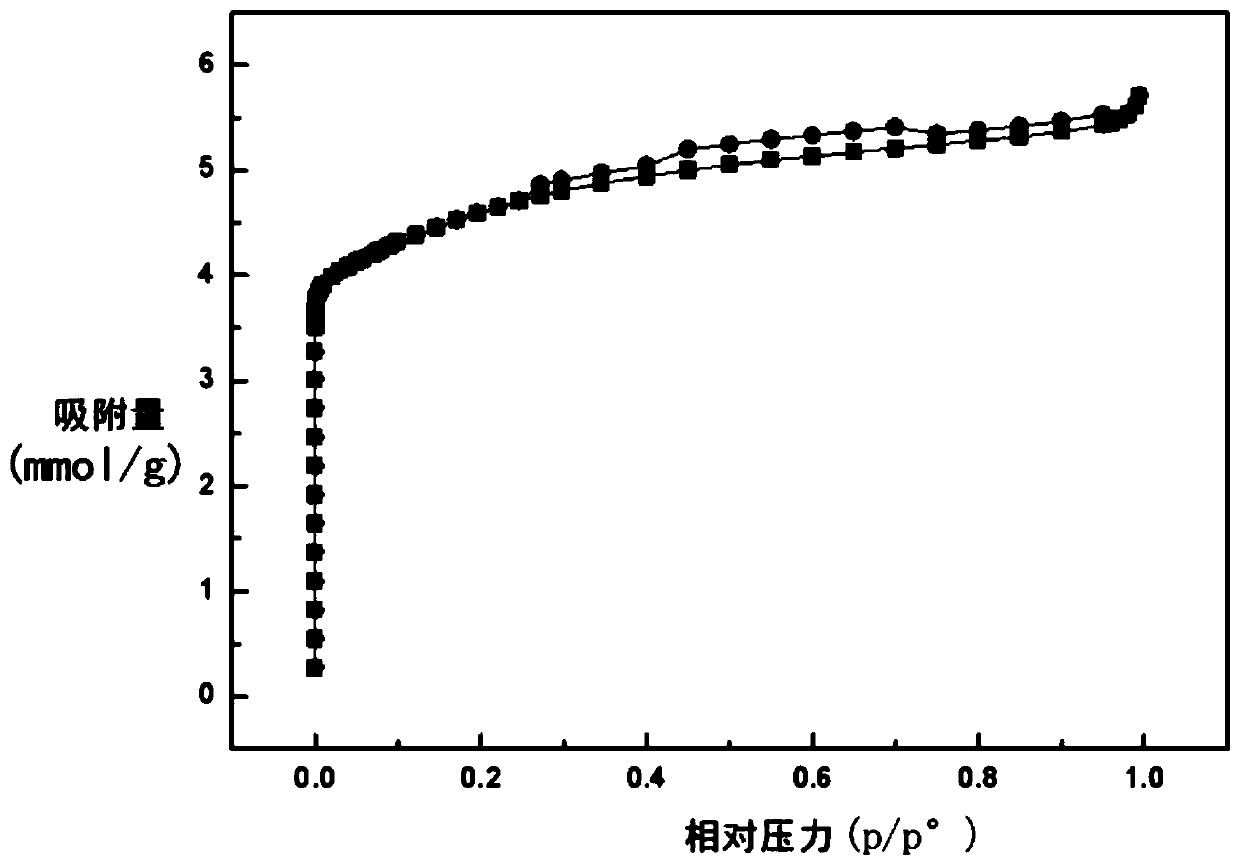

ActiveCN111408342AGood for desorption stabilityImprove adsorption capacityGas treatmentOther chemical processesMolecular sieveGlass fiber

The embodiment of the invention discloses a high-silicon composite molecular sieve adsorbent for removing VOCs and a preparation method thereof. The preparation method comprises the following steps: mixing an aluminum source I, an alkali source I and H2O, adding the mixture into a silicon source I, and carrying out ultrasonic aging treatment to obtain a Y-type molecular sieve guiding agent; mixingH2O, an alkali source II and an aluminum source II, adding n-butylamine and a silicon source II, carrying out a crystallization reaction under the microwave condition to obtain ZSM-5 crystallizationturbid liquid; adding a Y-type molecular sieve guiding agent, an aluminum source III and H2O into the ZSM-5 crystallization turbid liquid, adjusting the pH value to 12-12.5, performing hydrothermal crystallization treatment under a microwave condition, performing filtration and water washing after crystallization is completed to obtain a filter cake, and performing pulping treatment on the filtercake to obtain an emulsion; carrying out acid pickling on the emulsion, and then sequentially carrying out filtering, washing, drying and hydrothermal roasting treatment to obtain high-silicon composite molecular sieve powder; stirring the prepared powder with glass fibers, silica sol and H2O at a high speed to obtain mixed slurry, performing vacuum degassing, and performing spray molding to obtain the high-silicon composite molecular sieve adsorbent.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

Production method of high-bulk myopia-prevention paper

InactiveCN107447587AIncrease bulkHigh opacitySpecial paperWater-repelling agents additionPulp treatmentPaper production

The invention relates to the technical field of paper production, in particular to a production method of high-bulk myopia-prevention paper. The method comprises the following steps of S1, pulp treatment: respectively treating bleaching needlebush pulp, bleaching chemical reed pulp and poplar chemithermomechanical pulp through a double-disc mill so that the process requirements are met, wherein the bulk of the poplar chemithermomechanical pulp is greater than 3.5cm<3> / g; S2, dyeing: feeding the treated pulp into a pulp mixing pool; firstly, adding the poplar chemithermomechanical pulp; then, adding dyeing agents for direct yellowing; then, adding chemical reed pulp; finally adding needlebush pulp; uniformly mixing all pulp through stirring; S3, paper making by a paper making machine; S4 paper forming through dewatering and drying. The production method of the high-bulk myopia-prevention exercise book paper provided by the invention has the advantages that the paper obtained through production has high bulk; the color of the paper is maize-yellow, the nontransparency is high; the two-side printing and writing can be performed; the paper is used as the paper for exercise books for primary and secondary school students; the obvious myopia-prevention effect can be achieved.

Owner:MCC MEILI CLOUD COMPUTING IND INVESTMENT CO LTD

Breathable medical adhesive tape base material and manufacturing method thereof

ActiveCN106012658AIntertwinedSoft and bulky textureOrganic non-cellulose fibresWater-repelling agents additionPolyesterFiber

The invention relates to the field of base materials of medical supplies, in particular to a breathable medical adhesive tape base material and a manufacturing method thereof. The manufacturing method of the breathable medical adhesive tape base material comprises the following steps: (1) carrying out mild pulping treatment on wood pulp fibers, increasing degree of beating by 2-8 degrees of SR, mixing the wood pulp fibers with polyester fibers and water-soluble fibers, and adding a wet strength agent in mixed fibers; (2) manufacturing paper by using the mixed fibers through a cylinder paper machine or an inclined wire machine, carrying out enhancement through surface sizing, and drying and reeling to obtain finished products, wherein the mass percents of the wood pulp fibers, the polyester fibers and the water-soluble fibers respectively account for 50-75%, 20-45% and 1-5% of the mass percent of fibers in breathable medical adhesive tape paper, and the sum of the mass percents of the various components is 100%. A manufacturing process of the method is simple, and the prepared medical adhesive tape base material has the characteristics of high strength, good flexibility, high bulk, high breathability, good evenness and easiness in tearing.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

Method for making corrugated paper

InactiveCN104452411AImprove moisture resistanceHigh strengthWater-repelling agents additionReinforcing agents additionFiberPolyvinyl alcohol

The invention provides a method for making corrugated paper. The method includes the following steps that first, wax-bearing waste paper is selected to be used as a raw material for making the corrugated paper; second, the wax-bearing waste paper is pulped, pulp is subjected to screening, purifying and pulping treatment, the ash content of the pulp is made to be smaller than 8%, and the beating degree of fibers is 35-40 degrees SR; third, cation rosin size, aluminum sulfate and wet strength agents are added into the pulp to be evenly mixed; fourth, forming, dehydrating, squeezing and drying are conducted to obtain semi-finished corrugated paper; fifth, the semi-finished paper is subjected to surface sizing treatment, wherein the glue solution contains polyvinyl alcohol; sixth, drying is carried out, so that the finished corrugated paper is obtained. The corrugated paper produced through the manufacturing method is good in moisture resistance and high in strength and has a good application prospect.

Owner:NINE DRAGONS PAPER TAICANG LTD

Toona sinensis tea paste processing method

InactiveCN104799210ARich new varietiesRich in nutrientsTea extractionFood ingredient functionsAdditive ingredientEconomic benefits

The invention discloses a toona sinensis tea paste processing method. In a toona sinensis tea paste, toona sinensis serves as a main raw material, and the toona sinensis tea paste is prepared by the steps of toona sinensis pretreatment, pulping treatment, enzyme treatment, tea powder extracting solution preparation, blending, crushing, tea paste preparation and the like. According to the tea paste processed by the method, the toona sinensis which is environment-friendly, healthy, rich in nutrition and wide in source serves as the raw material, so that the production cost is reduced; the new varieties and the nutritional ingredients of the tea paste are increased; the tea paste is portable, stable in color and luster, and pure in mouthfeel; the economic benefit is improved; the tea paste has the effects of diminishing inflammation and detoxicating, enhancing immunologic function, and lubricating the skin.

Owner:张俊辉

Preparation method for anti-virus bacteria cellulose protective material and product thereof

InactiveCN102321261AEasy to see throughImprove mechanical propertiesProtective garmentAnti virusFiber

The invention belongs to the field of medical materials, and relates to a preparation method for an anti-virus bacteria cellulose protective material and a product thereof, in particular to a preparation method for a medical protective material which takes bacteria cellulose as a substrate and a product thereof. In the invention, pulping treatment is performed and polyvinyl alcohol (PVA) is added, so that the air permeability of the protective material can be effectively improved, the effective pore diameter is appropriately increased, random, interlayer and intersected arrangement of fiber is increased to construct a multi-bent fiber filtering layer, and bacteria, viruses and the like are prevented from permeating the compound film easily. The concentration of the adopted PVA is lower and the using amount is smaller, and the effective pore diameter of the compound film is increased and the mechanical performance of the compound film is improved by taking the three-dimensional netlike structure of bacteria cellulose as a main body and adding the PVA serving as a bonding agent. Moreover, the bacteria cellulose-base protective material with an anti-virus function is prepared by compounding chitosan which has broad spectrum antibiotic property, is non-toxic and is free from side effect.

Owner:DONGHUA UNIV

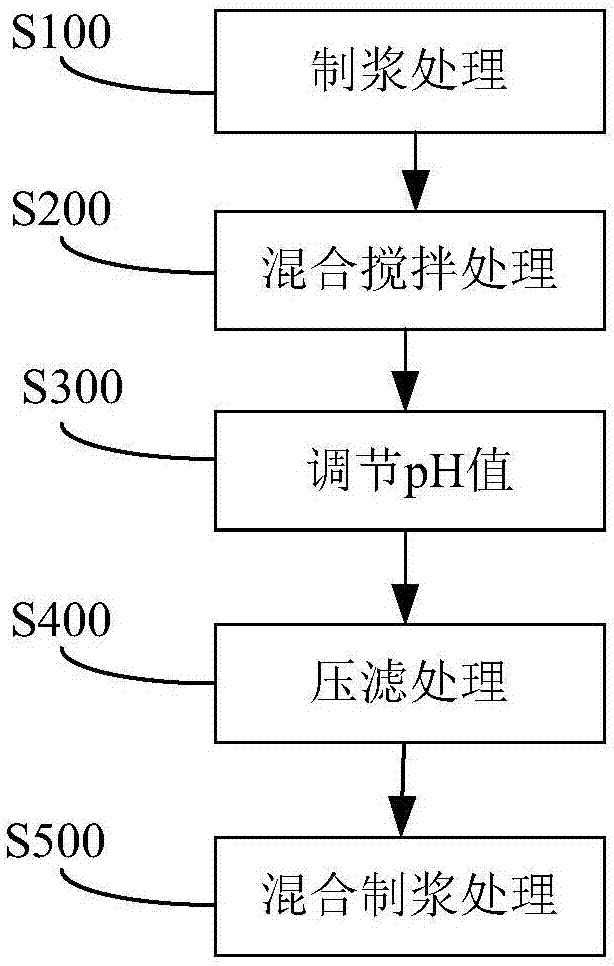

Method for preparing titanium dioxide slurry

InactiveCN106947295AReduce viscosityReduce or shield hydrogen bondsInorganic pigment treatmentHydrogenPulp treatment

The invention discloses a method for preparing a titanium dioxide slurry. The method comprises the following steps: pulping a titanium dioxide base material to obtain a titanium dioxide protoplasm; mixing and stirring the titanium dioxide protoplasm and an aluminum-containing compound to make the surfaces of titanium dioxide base material particles of the titanium dioxide protoplasm coated with an aluminum film in order to obtain aluminum coated titanium dioxide particles; adjusting the pH value of the slurry for coating the aluminum film to be less than 7 in order to obtain a pH value adjusted slurry; carrying out press filtration treatment on the pH value adjusted slurry to obtain a filter cake; and carrying out mixing and pulping treatment on the filter cake and a dispersant to obtain the titanium dioxide slurry. The method reduces or shields hydrogen bonds on the surfaces of the titanium dioxide base material particles through coating the surfaces of the titanium dioxide base material particles, so the titanium dioxide base material particles easily undergo solid-liquid separation to form the filter cake, sodium chloride is effectively removed, and the viscosity of the titanium dioxide slurry is reduced.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

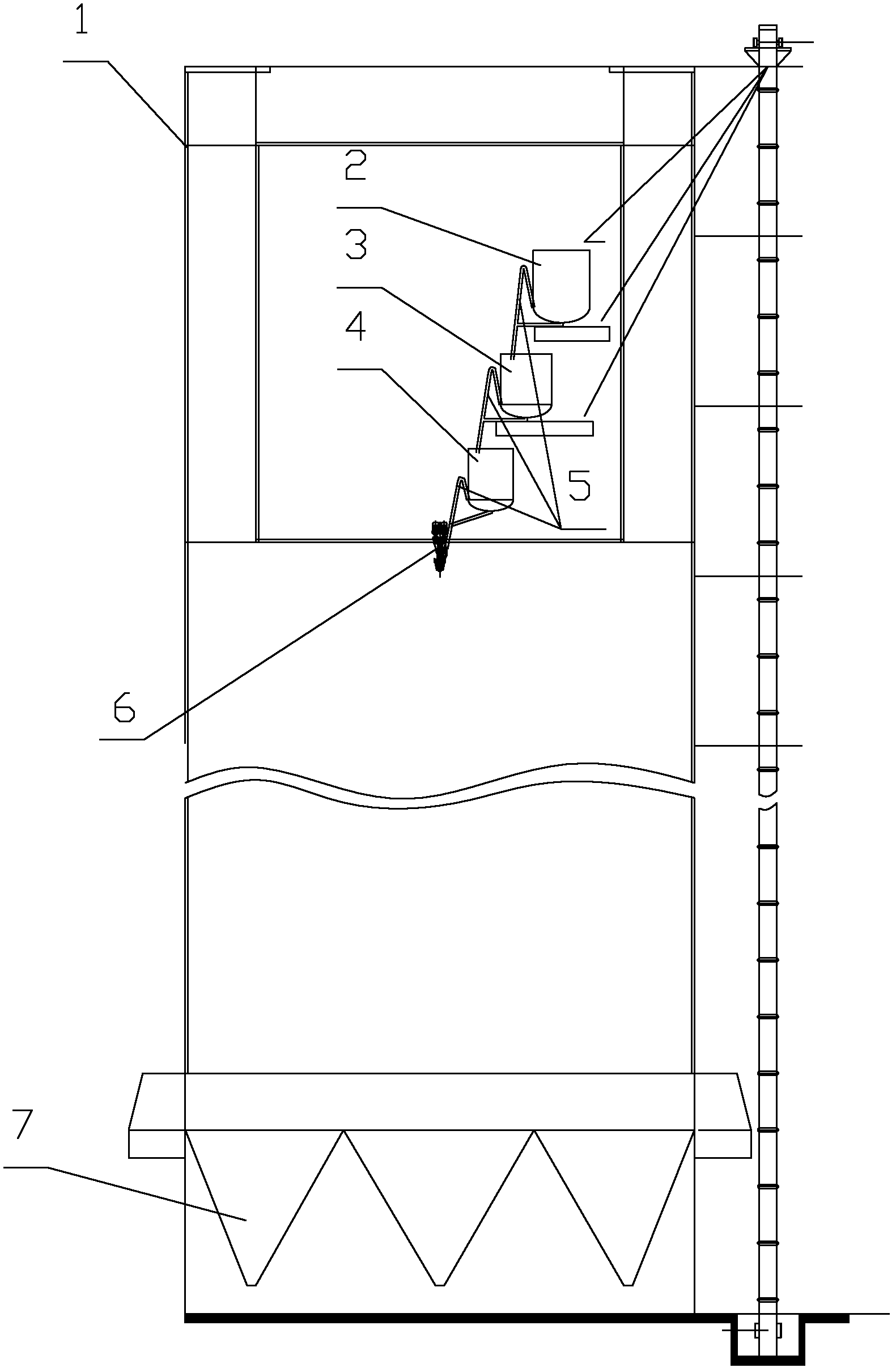

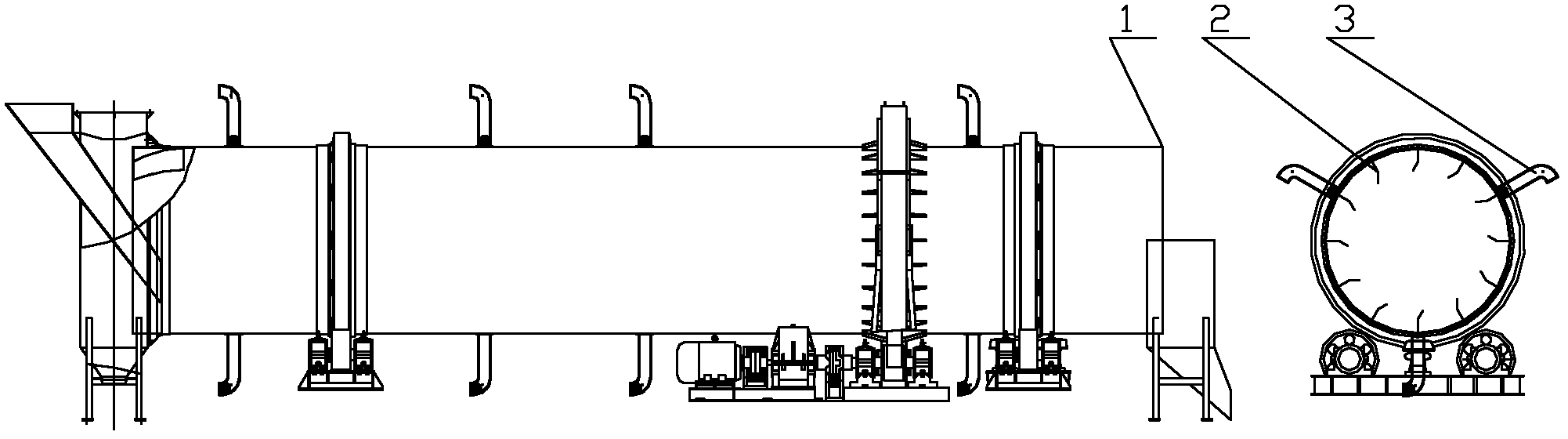

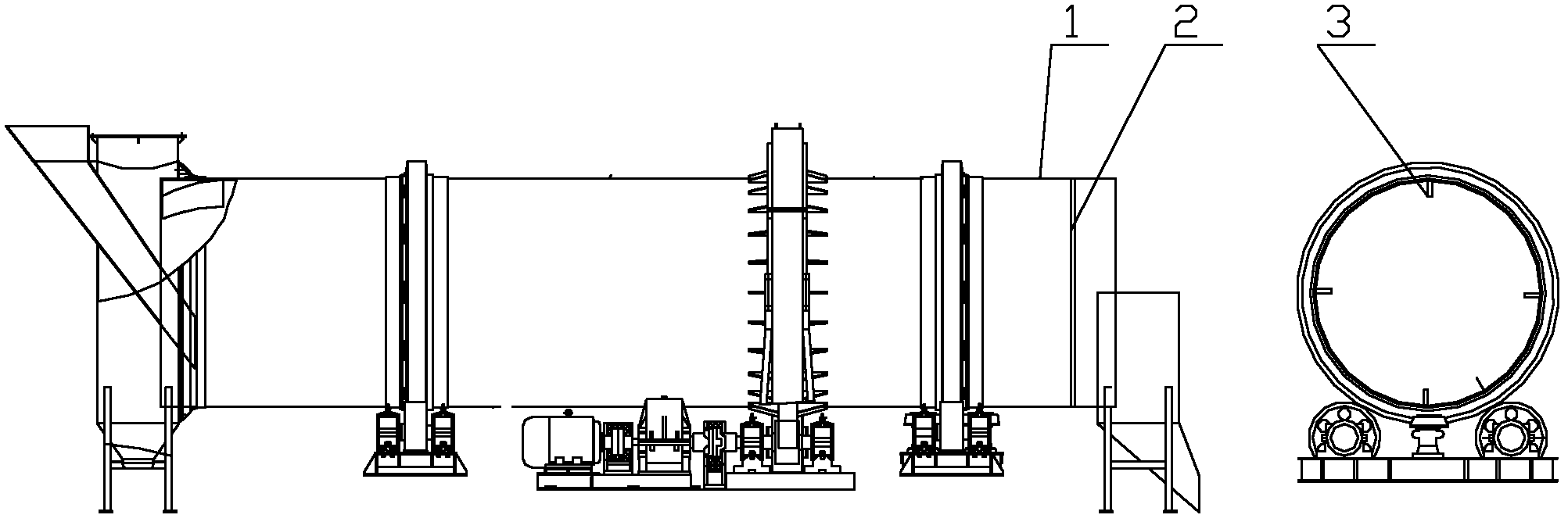

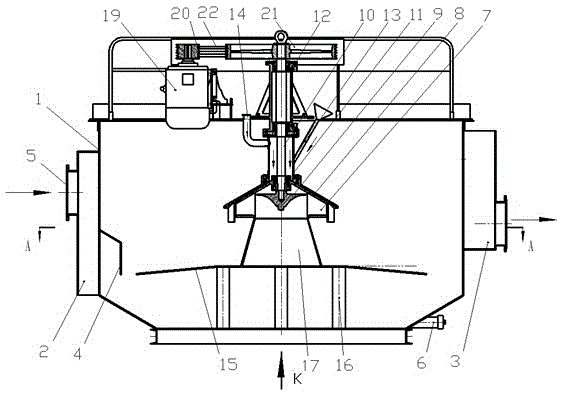

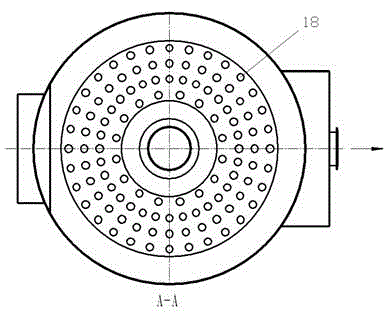

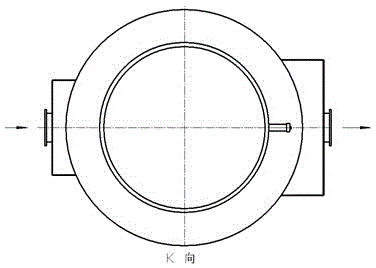

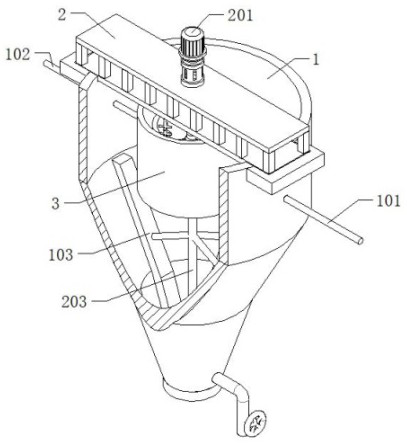

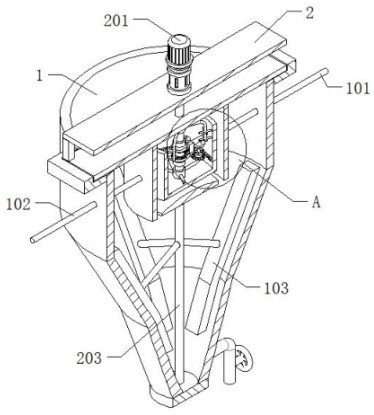

Pretreatment equipment for coal slime before floatation feed

The invention relates to pretreatment equipment for coal slime before floatation feed, belongs to the technical field of flotation equipment for the coal slime, and is used for pretreatment of the coal slime before entering flotation equipment for sorting. The pretreatment equipment adopts the technical scheme that a feeding box and a discharging box are respectively arranged on two sides of a cylinder body of a casing; a motor is fixed at the upper part of the casing, and is connected with the upper end of a stirring shaft through a leather belt; a vane wheel is mounted at the lower end of the stirring shaft, a sleeve sleeves the stirring shaft, the upper end of the sleeve is fixedly connected with the casing, and the lower end of the sleeve is connected with a stator; the lower end of a chemical dosing pipe is connected to the wall of the sleeve; the lower end surface of the stator and the upper end surface of the vane wheel are in clearance fit; a false bottom plate is a flat plate, a gap is reserved between the false bottom plate and the bottom plate of the casing, and a plurality of circular holes are uniformly distributed in the plate surface of the false bottom plate. The equipment disclosed by the invention is low in electricity consumption, the service life of the vane wheel is long, the flow state of ore pulp is reasonable, and medicament and the ore pulp are sufficiently mixed during operation; the equipment has the characteristics of high volume utilization rate, large ore pulp treatment quantity, wide particle size treatment ranges and high adaptability to coal properties.

Owner:TIANDI TANGSHAN MINING TECH

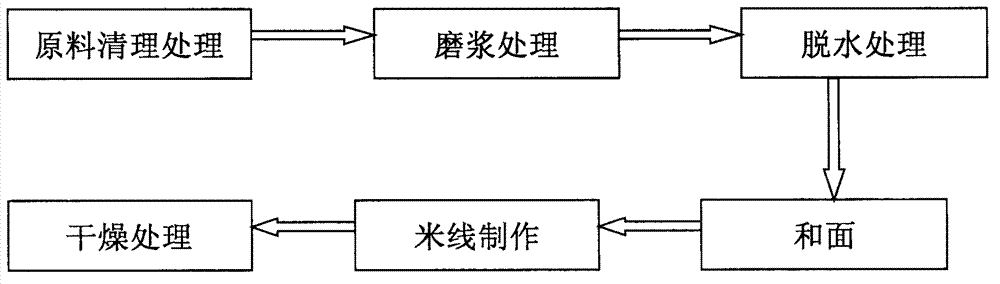

Formula of tartary buckwheat rice noodle and processing process

InactiveCN103039853AGreat tasteHigh nutritional valueFood preparationNutritive valuesSecondary hyperlipidemia

The invention provides a formula of a tartary buckwheat rice noodle and a processing process. The processing process comprises the following steps of cleaning of raw materials, pulping treatment, dewatering treatment, dough mixing and drying treatment. The tartary buckwheat rice noodle processed by the invention has the advantages of good taste, high nutritive value and no pollution, does not use any additive, and has a certain supportive therapeutic effect on diabetes mellitus, hypertension, hyperlipidemia, coronary heart disease, apoplexy and the like. Furthermore, the tartary buckwheat rice noodle is the favorite food for the old and the young, is convenient to eat, and is pure-natural green food.

Owner:蒋先富

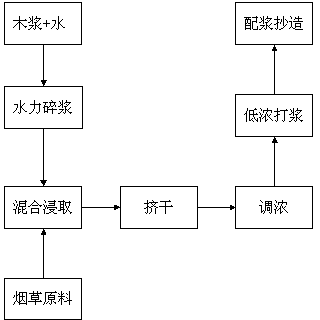

New tobacco pulp treatment method

The invention belongs to the technical field of paper-making method reconstituted tobacco, and particularly discloses a new tobacco pulp treatment method. A tobacco raw material and wood pulp slurry are mixed and leached, and the wood pulp slurry is formed by mixing wood pulp with water then hydraulically repulping. The additive amount of the wood pulp slurry is 10-30 percent of the weight of the tobacco raw material, and the concentration of the wood pulp in the wood pulp slurry is 3-5 percent. According to the method, the tobacco raw material and the wood pulp slurry are mixed and leached, so that the wiping effect is obviously increased, the soluble matter extraction yield of tobacco and the product yield are increased, and the obtained slurry is cleaner. A high consistency beating process is removed, the low consistency cascade beating is adopted, the slurry evenness is improved, and the method is more suitable for manufacturing paper with pulp.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

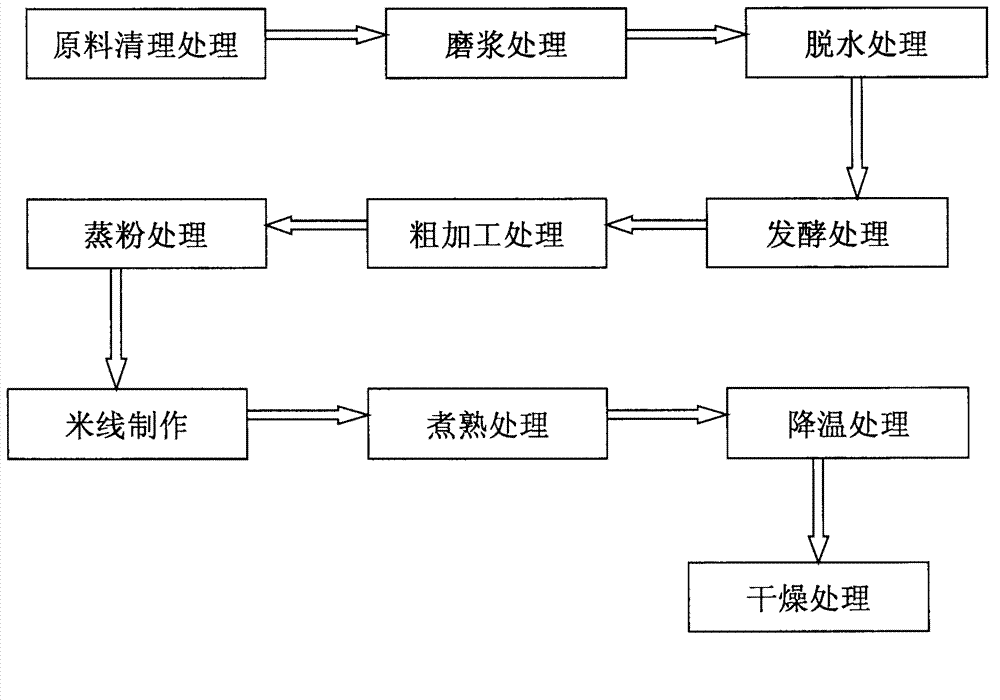

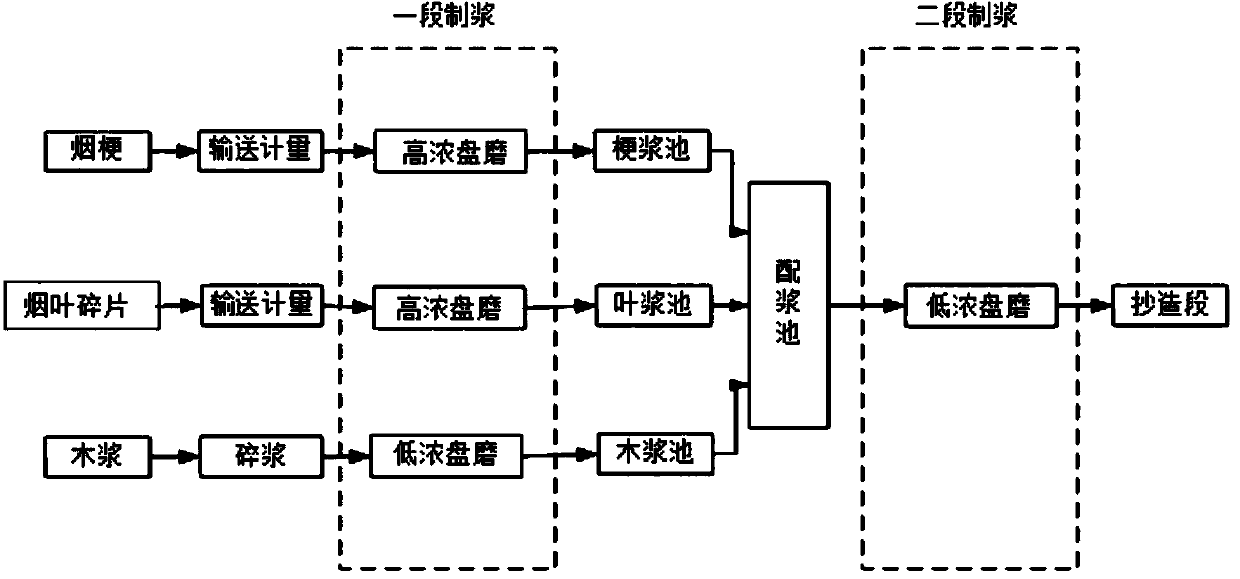

Flexibility pulping process of reconstituted tobaccos

ActiveCN103734894AFlexible adjustmentImprove quality stabilityTobacco preparationPulp treatmentPulp and paper industry

Disclosed is a flexibility pulping process of reconstituted tobaccos. The process includes the steps that extracted tobacco fragment solid materials are pulped through a high consistency disc refiner, the flow is 300-2000kg / h on the basis of oven dry stock, the pulping concentration is 8-20 percent, the pulping degree is 12-20 degrees SR, and the slurry density of leaf slurry is adjusted to be 3.0-4.5 percent; extracted tobacco stem solid materials are pulped through a high consistency disc refiner, the flow is 300-3000kg / h on the basis of oven dry stock, the pulping concentration is 8-20 percent, the pulping degree is 15-30 degrees SR, and the slurry density of stem slurry is adjusted to be 3.0-4.5 percent; mixed slurry after two-stage pulping treatment is conveyed to a reconstituted tobacco production technology for manufacturing paper with pulp and for producing. The flexibility pulping process is applied to the production process of the reconstituted tobaccos in the paper-making method, and the practical problems in the production process can be effectively solved.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Transparent paper and production method thereof

ActiveCN109137598ATightly boundImprove uniformityPulp properties modificationPaper-making machinesPulp treatmentPapermaking

The invention discloses transparent paper and a production method thereof and relates to the technical field of papermaking. The production method of the transparent paper comprises the following steps of 1, pulp treatment; 2, paper page manufacturing; 3, drying and formation. According to the transparent paper, the pulp is treated, the treated pulp is sufficiently swelled up in water and evenly hydrated, the diameter of a fiber is increased, the pulp becomes transparent, the drainability of the pulp is good, and the manufacturing condition of conventional papermaking methods is met. The highest transparency of the prepared transparent paper can reach 90%, and the transparent paper is high in tensile strength and good in insulation performance.

Owner:浙江曼特材料科技有限公司

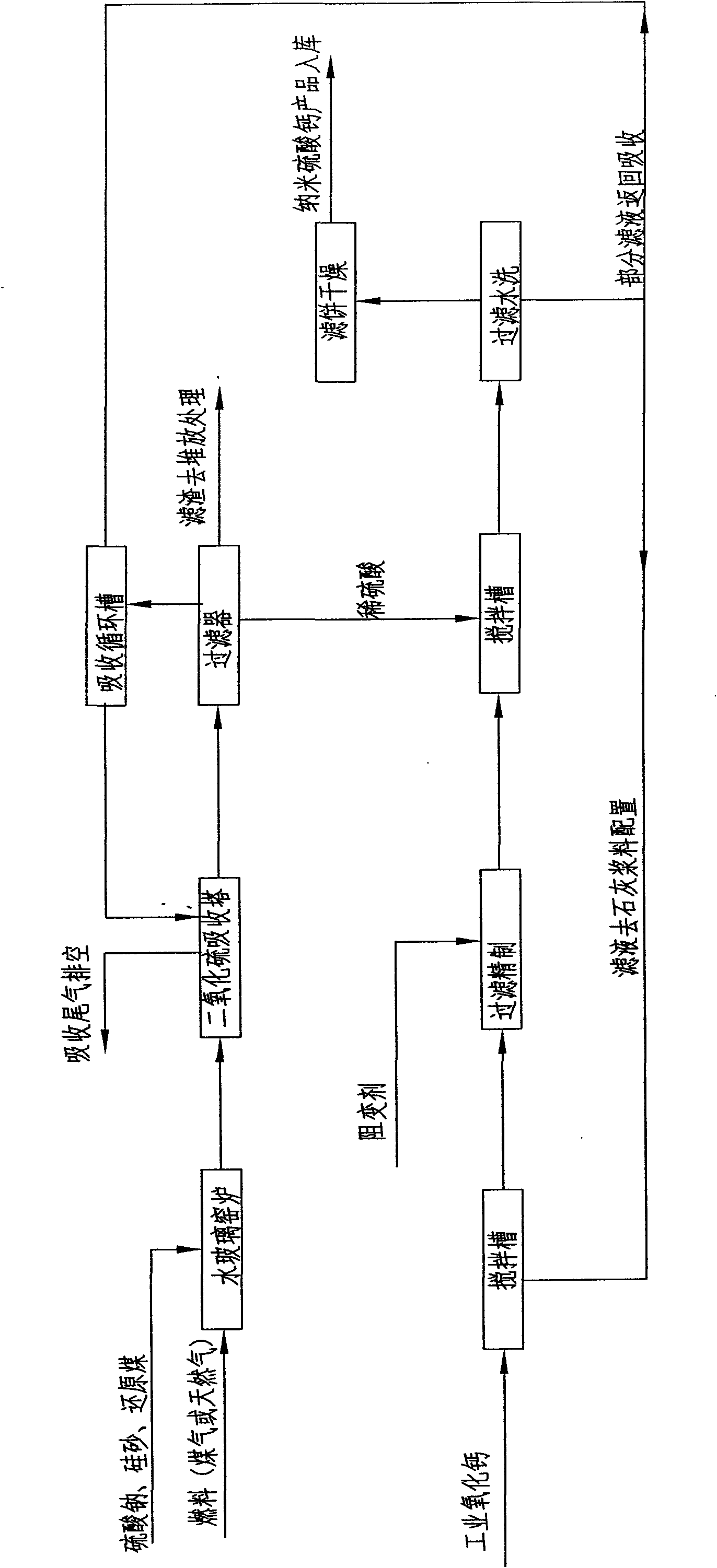

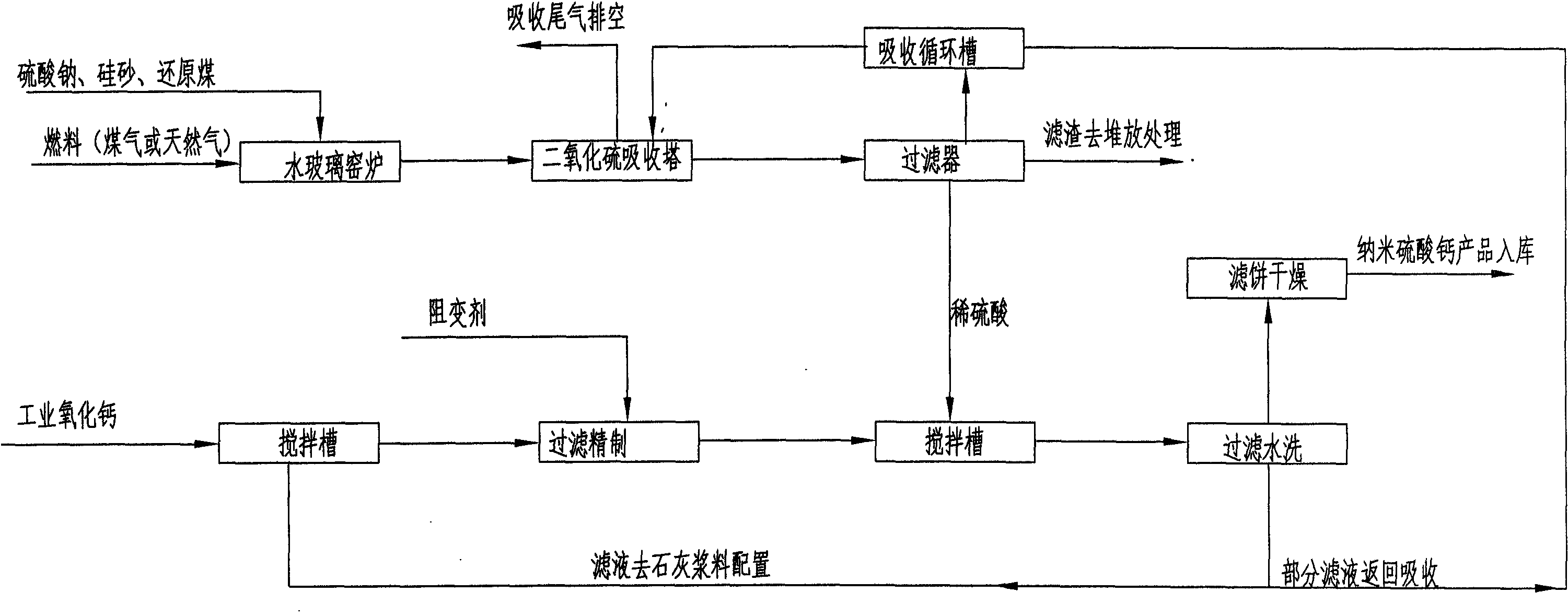

Process for preparing super-fine calcium sulfate from recycled sulfur dioxide waste gas

InactiveCN101856584ASolving Recycling ProblemsSolve the technical problem of not being able to prepare nanometer calcium sulfateCalcium/strontium/barium sulfatesDispersed particle separationSulfatePulp treatment

The invention discloses a process for preparing super-fine calcium sulfate from recycled sulfur dioxide waste gas, in particular to a process for producing high-value-added super-fine calcium sulfate from sulfur dioxide waste gas discharged from the dry-process water-glass production based on anhydrous sodium sulfate and low-cost industrial lime, which is used for achieving the effective recycling of sulfur dioxide. The process mainly comprises the following procedures: the absorption of sulfur dioxide; the catalytic oxidation of sulfur dioxide to form dilute sulfuric acid; the pulping treatment of calcium oxide; the addition of calcium sulfate growth inhibitor; the formation of super-fine calcium sulfate slurry; filter pressing and drying to obtain the product of super-fine calcium sulfate. By handling the problem of pollution caused by sulfur dioxide waste gas and producing the high-value-added super-fine calcium sulfate product at the same time, the process of the invention achieves the co-production of water-glass and super-fine calcium sulfate and obviously reduces the production cost. Therefore, the process is suitable for industrialized production.

Owner:HUNAN HENGGUANG TECH

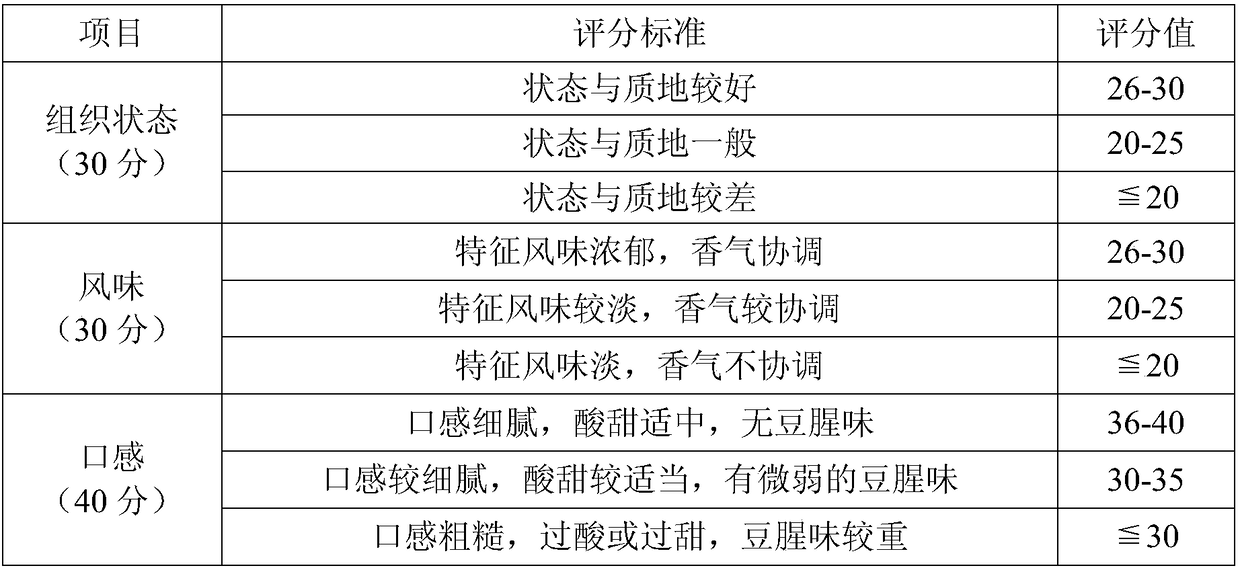

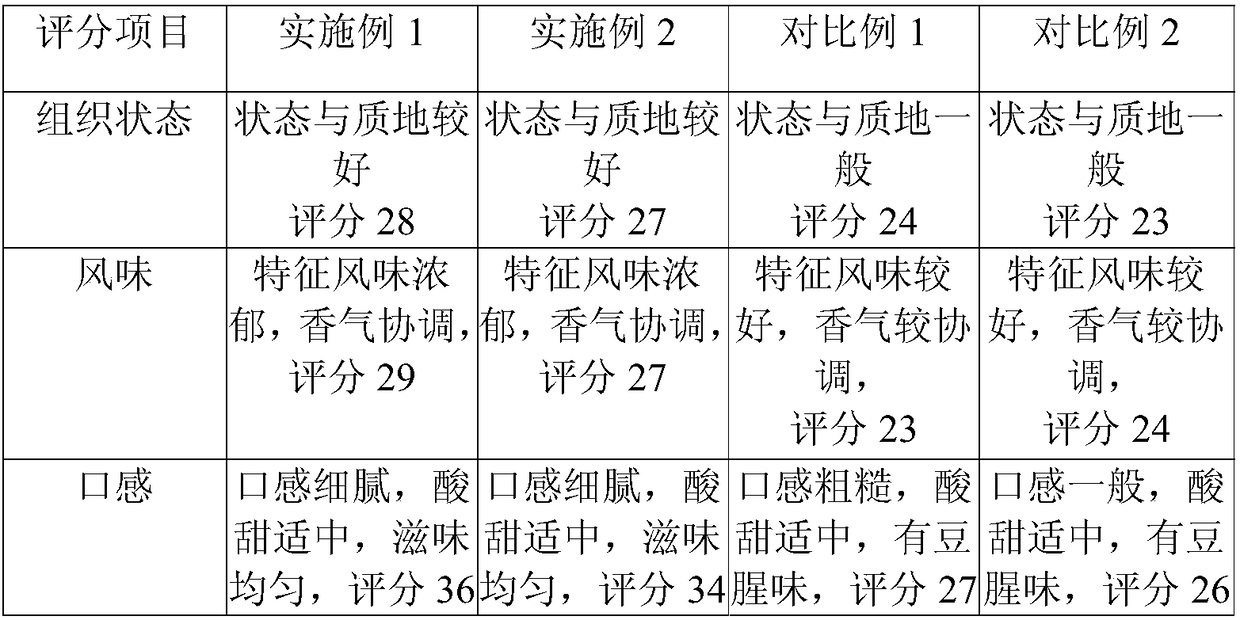

Functional active probiotic soybean milk and preparation method thereof

InactiveCN108064964ANatural aromaSoft aromaMilk substitutesFood sciencePulp treatmentVitamin B6 synthesis

The invention provides functional active probiotic soybean milk and a preparation method thereof. The soybean milk is prepared from the following steps: placing selected soybeans which are suitable for preparing soy milk in an aqueous solution containing sodium glutamate and vitamin B6, conducting soaking, then subjecting the soaked soybeans to pulping treatment, and conducting sieving to form thesoy milk; mixing the prepared soy milk with auxiliary materials; and fermenting the obtained mixed solution with a starter culture to obtain the functional active probiotic soybean milk. The fermented soybean milk of the invention has a natural and soft fragrance, a lasting fragrance and no soybean odor. Compared with fermented soybean milk in the prior art, the fermented soybean milk of the invention contains multiplied functional substances of gamma-aminobutyric acids; the auxiliary materials are decomposed into small molecules which are easier for human body to absorb; the intrinsic stability of the product is obviously improved and enhanced; and the product is endowed with better texture and flavor.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preparation method of functional cherry component

InactiveCN107296280AHigh extraction rateWith extraction rateFood thermal treatmentFood membrane processWater bathsNon toxicity

The invention discloses a preparation method of a functional cherry component. The preparation method is characterized by comprising the following steps: (1) pretreating: decoring cherries, adding deionized water, and pulping twice; (2) performing pulp treatment: respectively adding mixed enzyme and a mixed inoculum into cherry pulp for enzymolyzing and fermenting; (3) extracting: adding absolute ethanol and a cherry leaf extract into a cherry fermentation solution, heating in a water bath and performing ultrasonic oscillation; (4) performing centrifugal filtration: washing filter residues, and performing membrane filtration on a filtrate by using a vacuum membrane; (5) performing freeze drying: performing low-temperature drying and freeze drying on the cherry membrane filtrate to obtain cherry extract powder. The extraction method of the functional cherry component has the characteristics of high extraction rate, high purity, high activity of the active component and the like; the functional pharmacological effect is significant; in addition, the preparation method is simple in operation and has the characteristics of safety, non-toxicity and high efficiency.

Owner:HEFEI RUNYU AGRI TECH CO LTD

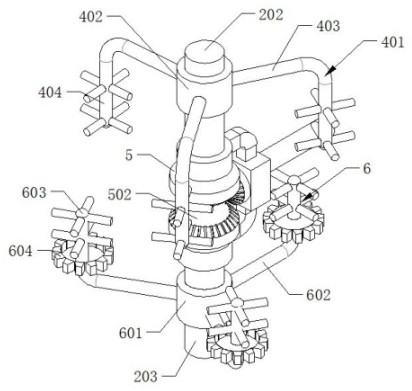

Dehydration device of efficient deep cone thickener

InactiveCN111620421AEasy to handleIncrease the degree of agitation and mixingSedimentation separationWater/sewage treatment by flocculation/precipitationPulp treatmentEngineering

The invention provides a dehydration device of an efficient deep cone thickener. The dehydration device comprises a tank body and a driving mechanism; the top wall of the tank body is connected with abridge frame; the driving mechanism is connected to the top wall of the bridge frame; the bottom wall of the bridge frame is connected with a flow stabilizing barrel; a barrel body is connected intothe flow stabilizing barrel; a stirring device is connected inside the barrel body; the stirring device comprises a first stirring mechanism and a second stirring mechanism; the first stirring mechanism is connected to the outer wall of the output end of the driving mechanism through a first connecting sleeve; the outer wall of the output end of the driving mechanism is also connected with a reverse transmission mechanism; the output end of the reverse transmission mechanism is connected with a second rotating shaft, the second stirring mechanism is connected to the outer wall of the second rotating shaft through a second connecting sleeve, an ore pulp feeding pipe and a flocculating agent feeding pipe are arranged on the outer wall of the tank body, and the ore pulp feeding pipe and the flocculating agent feeding pipe penetrate through the tank body and the flow stabilizing barrel and are communicated with the barrel body. The dehydration device is simple in structure and convenient to use, the mixing degree of ore pulp and a flocculating agent can be effectively increased, and the ore pulp treatment effect is improved.

Owner:HUAIBEI KUANGHUAN WASHES EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com