Full water-soluble urea-based composite fertilizer and preparation method thereof

A urea-based compound fertilizer, water-soluble technology, applied in fertilization equipment, fertilizer mixture, application, etc., to improve pulping conditions and realize the effect of high-phosphorus water-soluble fertilizer production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

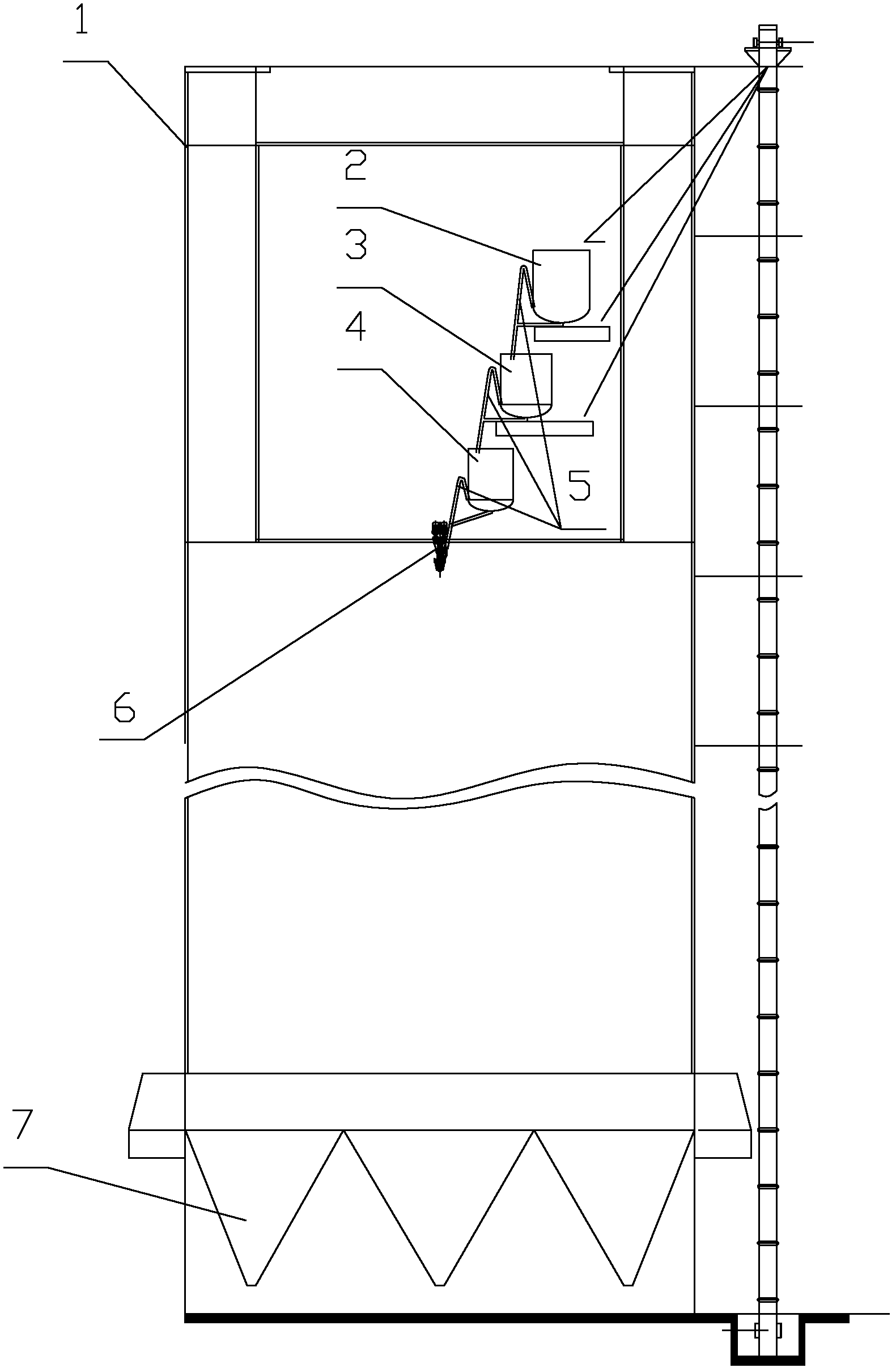

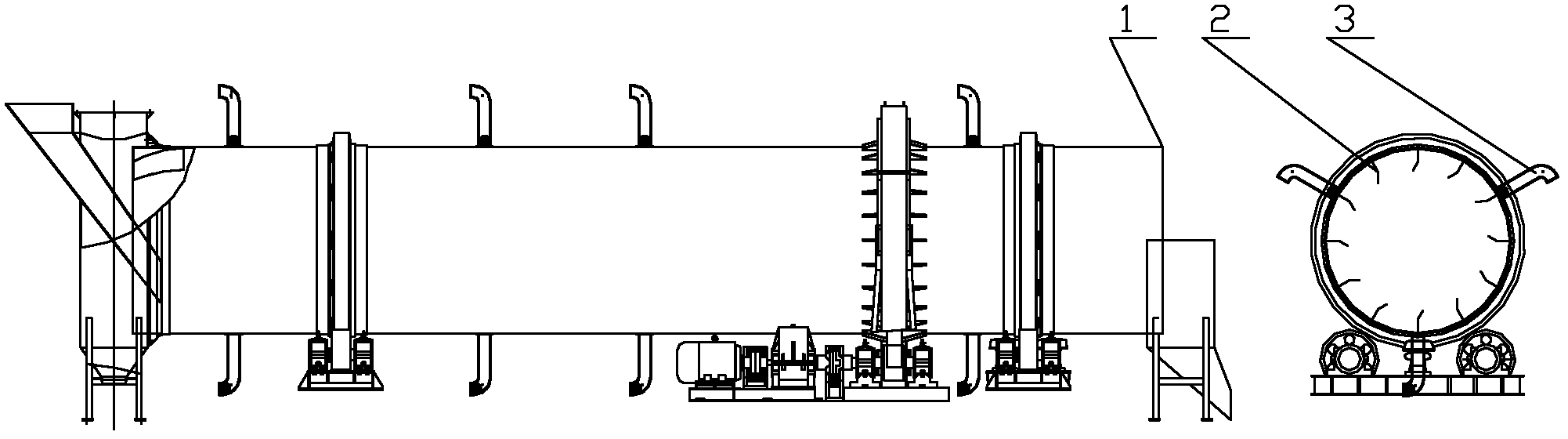

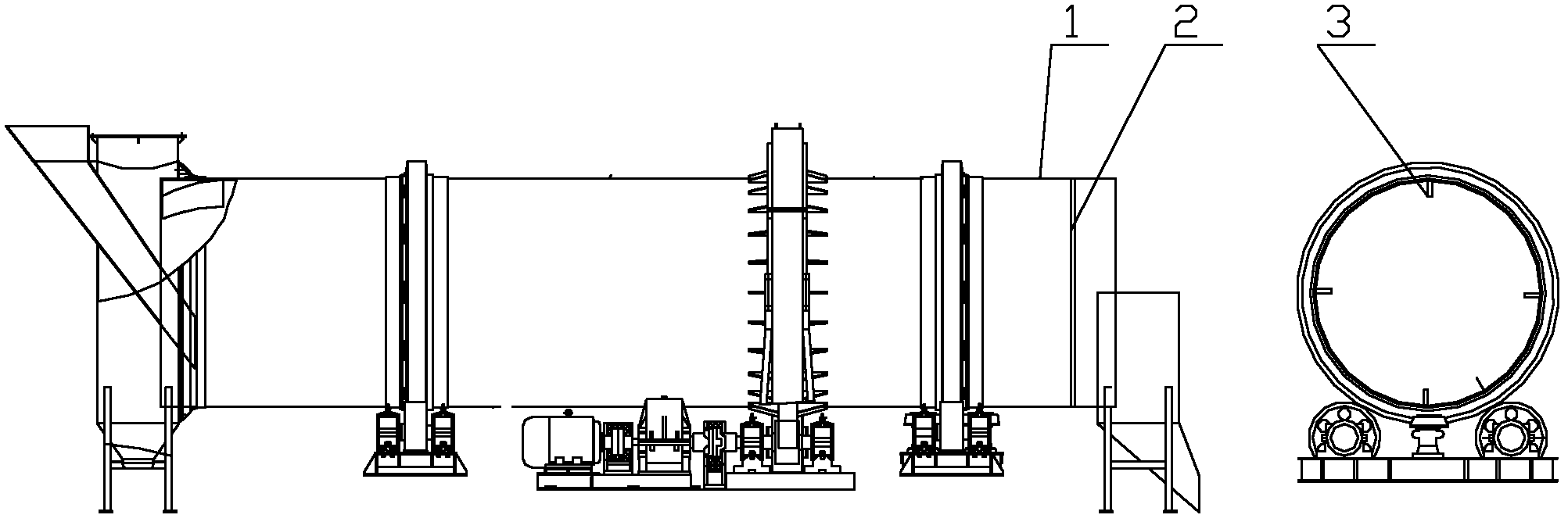

Image

Examples

Embodiment 1

[0033] The fully water-soluble urea-based compound fertilizer of this embodiment mainly includes the following materials in parts by weight: urea: industrial monoammonium phosphorus: potassium chloride: EDTA-Zn: borax=1.0:0.25:1.1:0.02:0.1.

[0034] The preparation method of the fully water-soluble urea-based compound fertilizer described in the present embodiment is as follows:

[0035] (1) Add 1.0 part of urea and 0.1 part of borax to the melting pot, control the temperature at 123°C, heat and melt indirectly with steam under constant stirring, and when the pot is full, it will naturally overflow into the primary mixing pot through the material pipe;

[0036] (2) In the primary mixing pot, add 1.1 parts of potassium chloride to the molten urea, heat and stir, and control the temperature to 105°C, and the mixed melt will naturally overflow to the secondary mixing pot;

[0037] (3) Add 0.25 parts of industrial monoammonium phosphate and 0.02 parts of EDTA-Zn into the secondary...

Embodiment 2

[0042] The fully water-soluble urea-based compound fertilizer of this embodiment mainly includes the following materials in parts by weight: urea: industrial monoammonium phosphorus: potassium chloride: EDTA-Ca: borax = 1.0: 0.9: 0.3: 0.3: 0.02.

[0043] The preparation method of the fully water-soluble urea-based compound fertilizer described in the present embodiment is as follows:

[0044] (1) In the melting pot, add 1.0 parts of urea and 0.02 parts of borax, control the temperature at 128°C, heat and melt indirectly with steam under constant stirring, and when the pot is full, it will naturally overflow into the primary mixing pot through the material pipe;

[0045] (2) In the primary mixing pot, add 0.3 parts of potassium chloride to the molten urea, heat and stir, control the temperature to 115°C, and the mixed melt naturally overflows to the secondary mixing pot;

[0046] (3) Add 0.9 parts of industrial monoammonium phosphate and 0.3 parts of EDTA-Ca into the secondary ...

Embodiment 3

[0051] The fully water-soluble urea-based compound fertilizer of this embodiment mainly includes the following materials in parts by weight: urea: industrial monoammonium phosphate: potassium chloride: EDTA-Cu: borax = 1.0: 0.6: 0.75: 0.15: 0.045.

[0052] The preparation method of the fully water-soluble urea-based compound fertilizer described in the present embodiment is as follows:

[0053] (1) In the melting pot, add 1.0 parts of urea and 0.045 parts of borax, control the temperature at 125°C, heat and melt indirectly with steam under constant stirring, and when the pot is full, it will naturally overflow into the primary mixing pot through the material pipe;

[0054] (2) In the primary mixing pot, add 0.75 parts of potassium chloride to the molten urea, heat and stir, and control the temperature to 110° C., and the mixed melt naturally overflows to the secondary mixing pot;

[0055] (3) Add 0.6 parts of industrial monoammonium phosphate and 0.15 parts of EDTA-Cu into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com