Preparation method of SiOx/C surface-coated graphite cathode material

A technology of graphite anode and surface coating, which is applied in the field of preparation of SiOx/C surface-coated graphite anode materials, can solve the problems of unfavorable uniformity materials, difficult large-scale application, and high equipment requirements, and achieves improved cycle stability and ease of use. The effect of mass production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

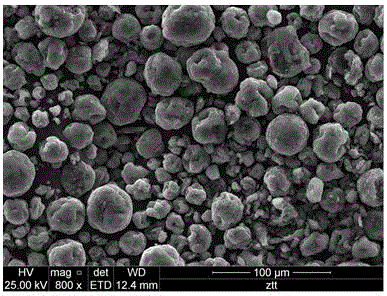

Image

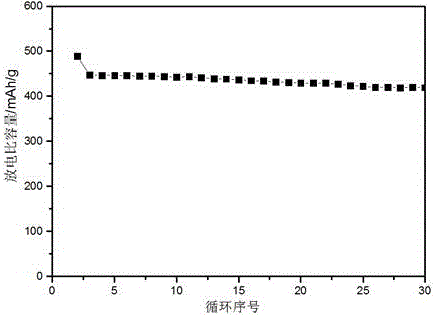

Examples

preparation example Construction

[0017] A preparation method of SiOx / C surface-coated graphite negative electrode material, the specific steps are as follows:

[0018] (1) Add SiOx, asphalt, organic acid, and dispersant to the ball mill tank to prepare a uniformly mixed slurry, and then prepare SiOx / C materials by spray granulation and pyrolysis. The content of organic acid accounts for the total 5-10% of the mass, and the dispersant accounts for 40-50% of the total mass; the ball milling time is 3-5 hours, and the rotation speed is 300-500r / min.

[0019] (2) Add SiOx / C material, graphite, additives, resin and curing agent into the reaction kettle, mix well, and then prepare SiOx / C surface-coated graphite negative electrode material through spray granulation, high-temperature pyrolysis, and classification screening process , the mass ratio of the SiOx / C material to graphite, additives, and resin is 1:1.5~2:1~1.5:1~2.5, the particle size of graphite is 2~10um, and the curing agent accounts for 3~5 of the total...

Embodiment 1

[0024] A preparation method of SiOx / C surface-coated graphite negative electrode material, the specific steps are as follows:

[0025] (1) According to the mass ratio of SiOx to asphalt, acetic acid, and deionized water as 1:1:0.2:2, add it to the ball mill tank, then seal it, and ball mill it. The time of ball milling is 3 hours, and the speed is 300 r / min. The mixture was taken out, and then granulated by a spray granulation dryer, wherein the temperature of the air inlet was 200°C, and the temperature of the air outlet was 120°C. The temperature for pyrolysis was firstly kept at 300°C for 3h, then at 700°C for 2h, the heating rate was 5°C / min, and nitrogen atmosphere.

[0026] (2) In the reactor, mix the prepared SiOx / C material with graphite, pitch, and epoxy resin in an ethanol solution at a mass ratio of 1:2:1:1, and then heat it to 150°C. And add trimethylhexamethylenediamine curing agent accounting for 5% of the total mass, continue to stir until the mixture is unifor...

Embodiment 2

[0028] A preparation method of SiOx / C surface-coated graphite negative electrode material, the specific steps are as follows:

[0029] (1) Except that the organic acid used was citric acid solution, the ball milling time was 5 hours, and the pyrolysis temperature was firstly kept at 300°C for 3h, and then kept at 800°C for 2h, the proportions of other parameters were the same as in Example 1.

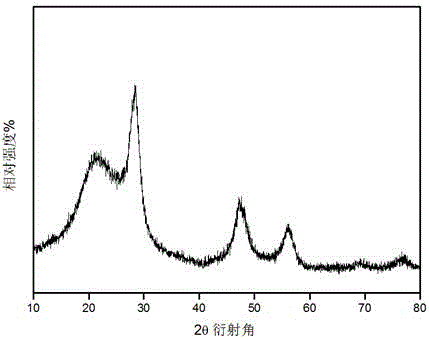

[0030] (2) Except that the resin used is phenolic resin, the heating temperature is 200°C, the curing agent is hexamethylenetetramine, the inlet and outlet temperatures of the spray granulation are 200°C and 150°C, and the pyrolysis temperature is 900°C, etc. Parameters are consistent with Example 1. Such as figure 2 Shown is the X-ray diffraction pattern of the sample prepared in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com