Dry powder extinguishing agent and method for preparing dry powder extinguishing agent from ammonium dihydrogen phosphate

A dry powder fire extinguishing agent, ammonium dihydrogen phosphate technology, applied in fire protection equipment and other directions, can solve the problems of high energy consumption, low procurement cost, dry powder agent agglomeration, etc., to reduce labor costs and energy consumption, and achieve excellent fire extinguishing effect. , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described by the following examples. It should be understood that these examples are only for the purpose of illustration and in no way limit the scope of the present invention.

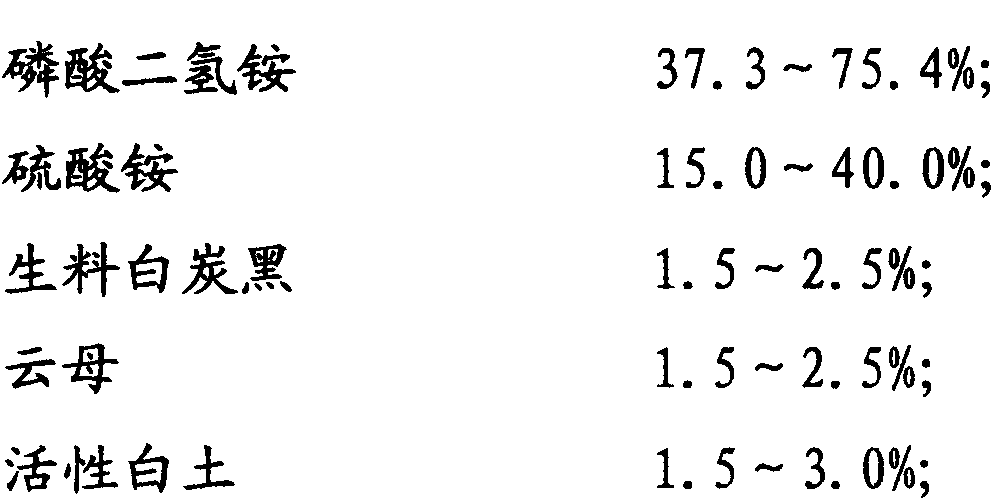

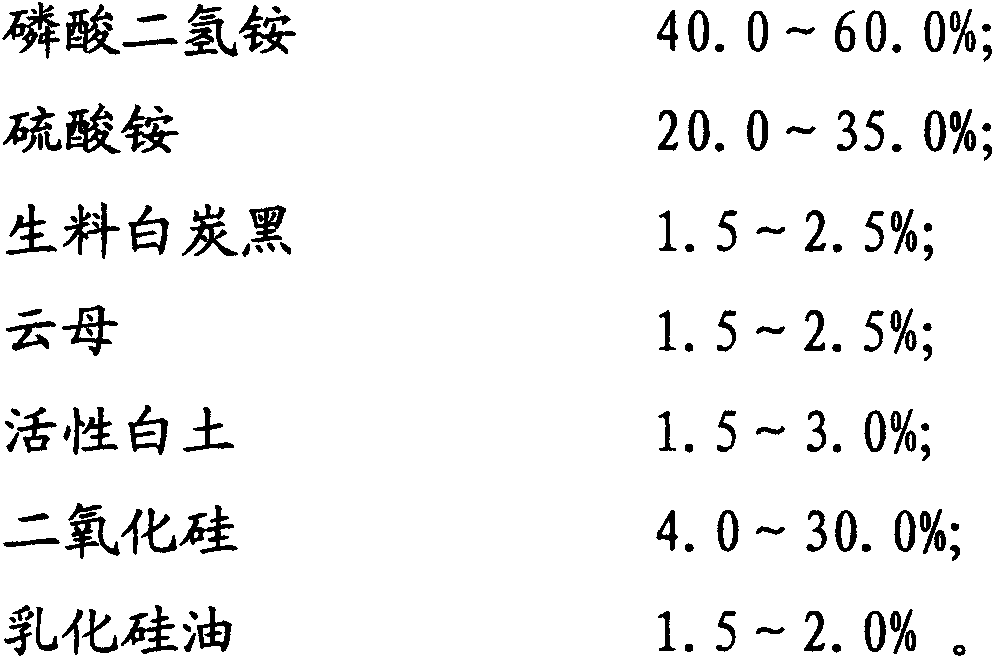

[0027] The invention provides a dry powder fire extinguishing agent, which is composed of the following ingredients according to the mass ratio:

[0028]

[0029] Compared with the prior art, the dry powder fire extinguishing agent provided by the present invention has achieved the following beneficial effects: the cost of the dry powder fire extinguishing agent can be reduced by replacing the hydrophobic white carbon black in the prior art with cheaper raw white carbon black; Raw white carbon black does not need to be silicified separately, which simplifies the process flow, reduces labor costs and energy consumption, and further reduces the cost of dry powder fire extinguishing agent; uses silicon dioxide instead of calcium carbonate or talcum powder in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com