Patents

Literature

1192results about How to "Achieve production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

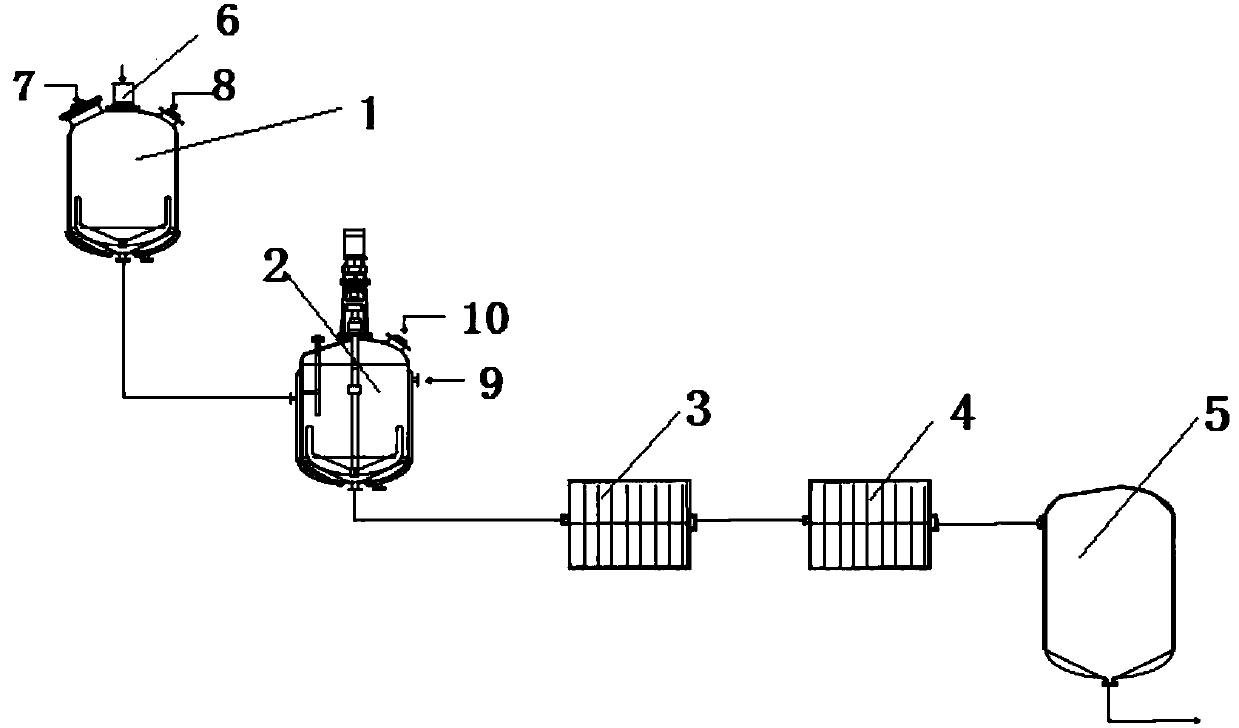

Method for preparing environmentally-friendly adhesive for lignin-based timber

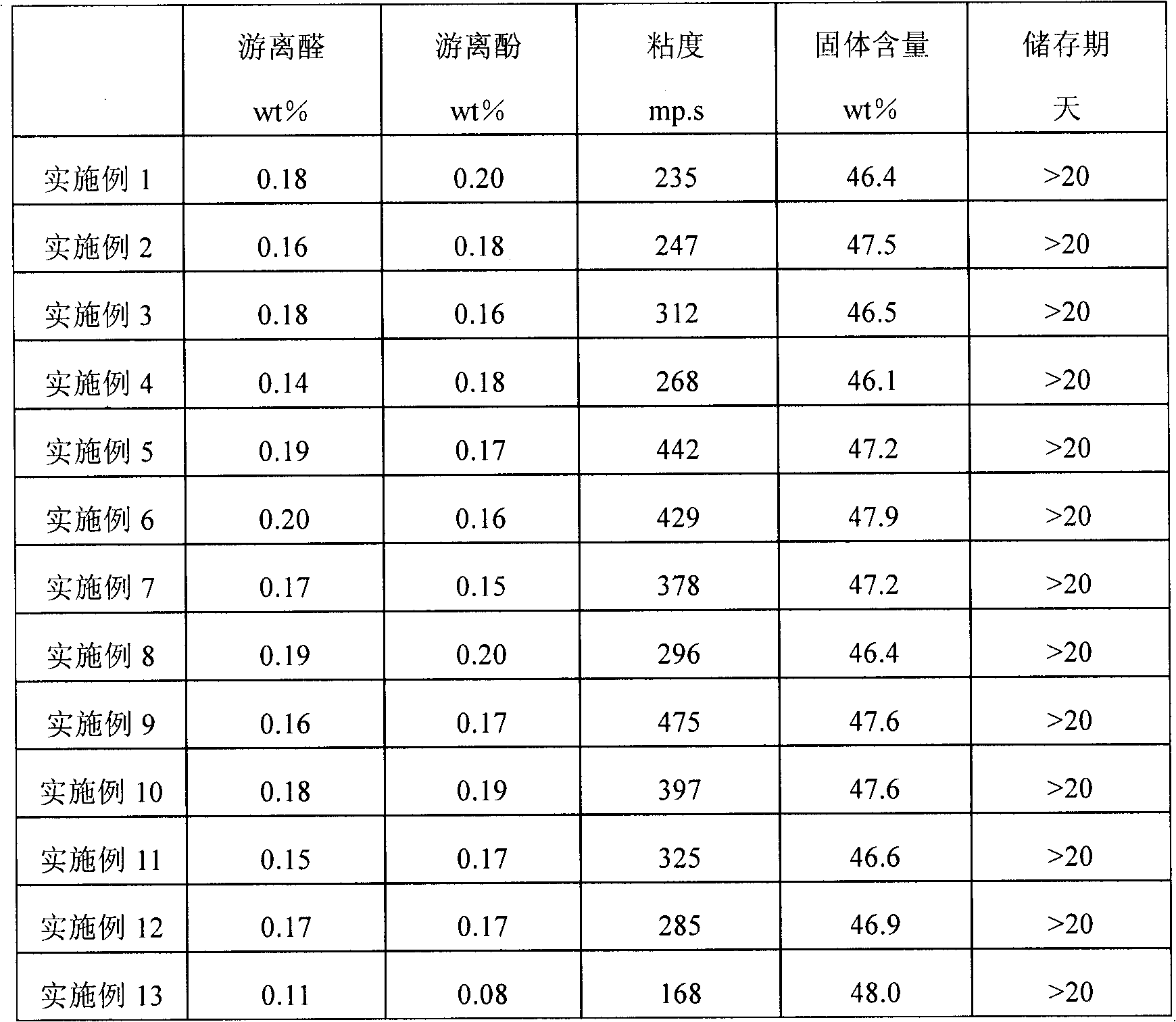

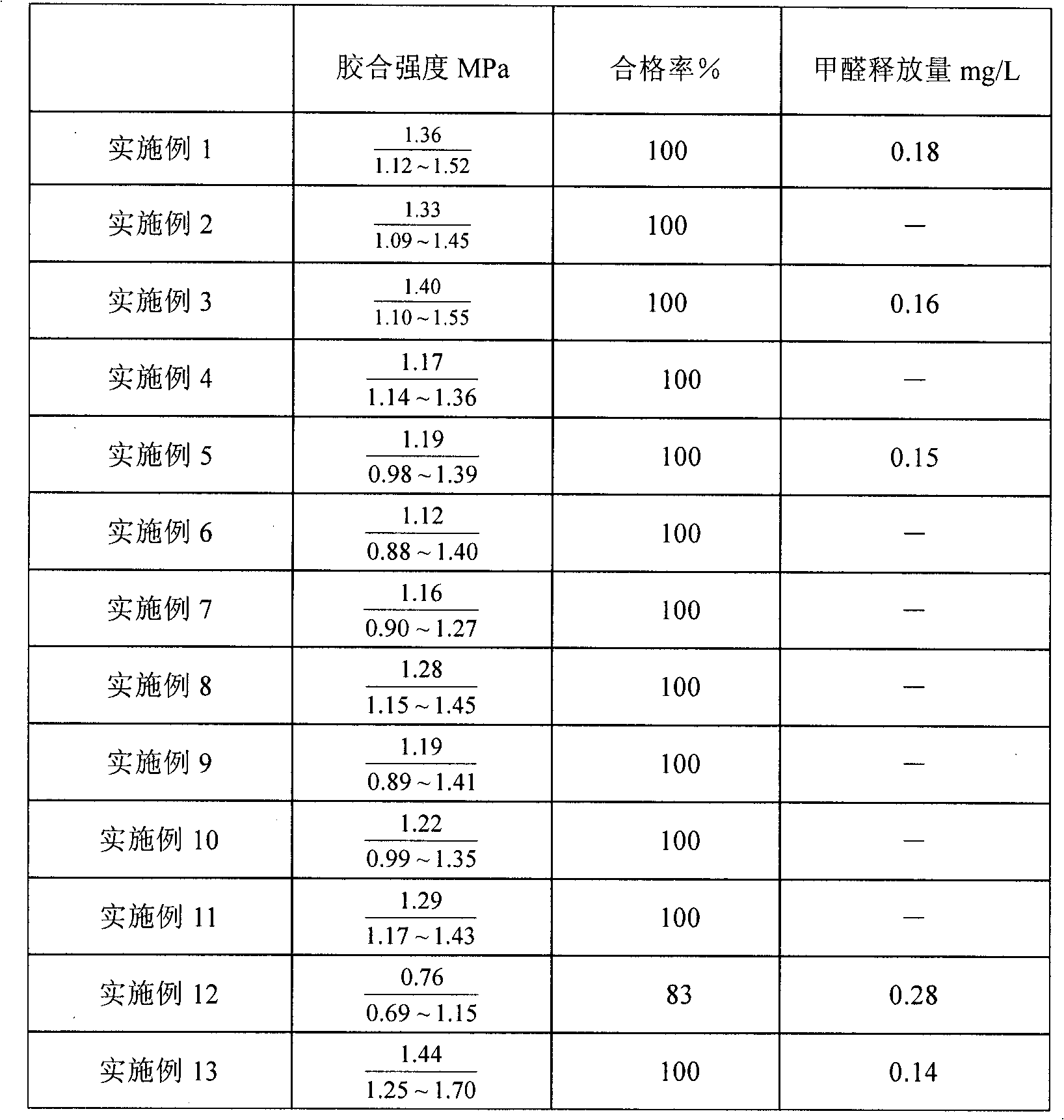

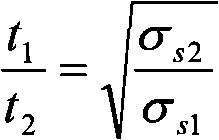

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

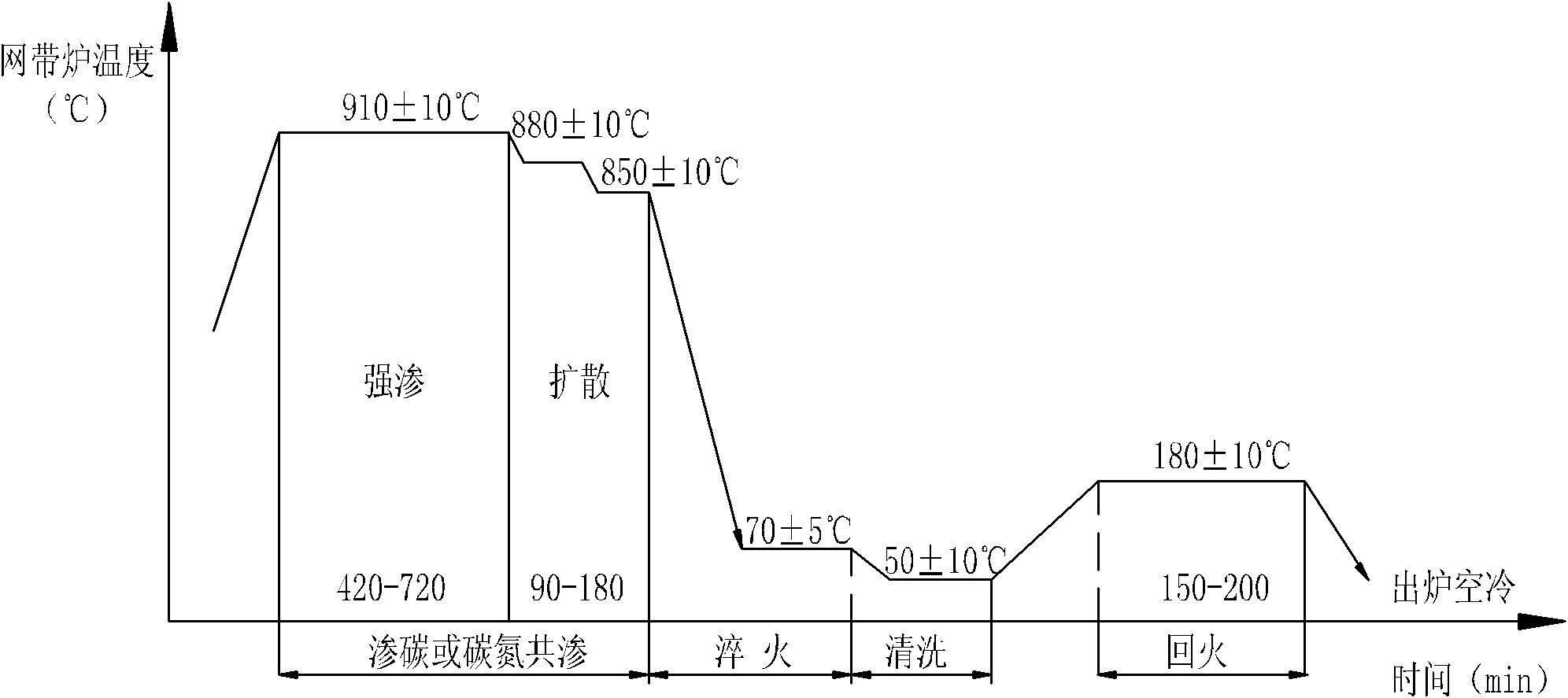

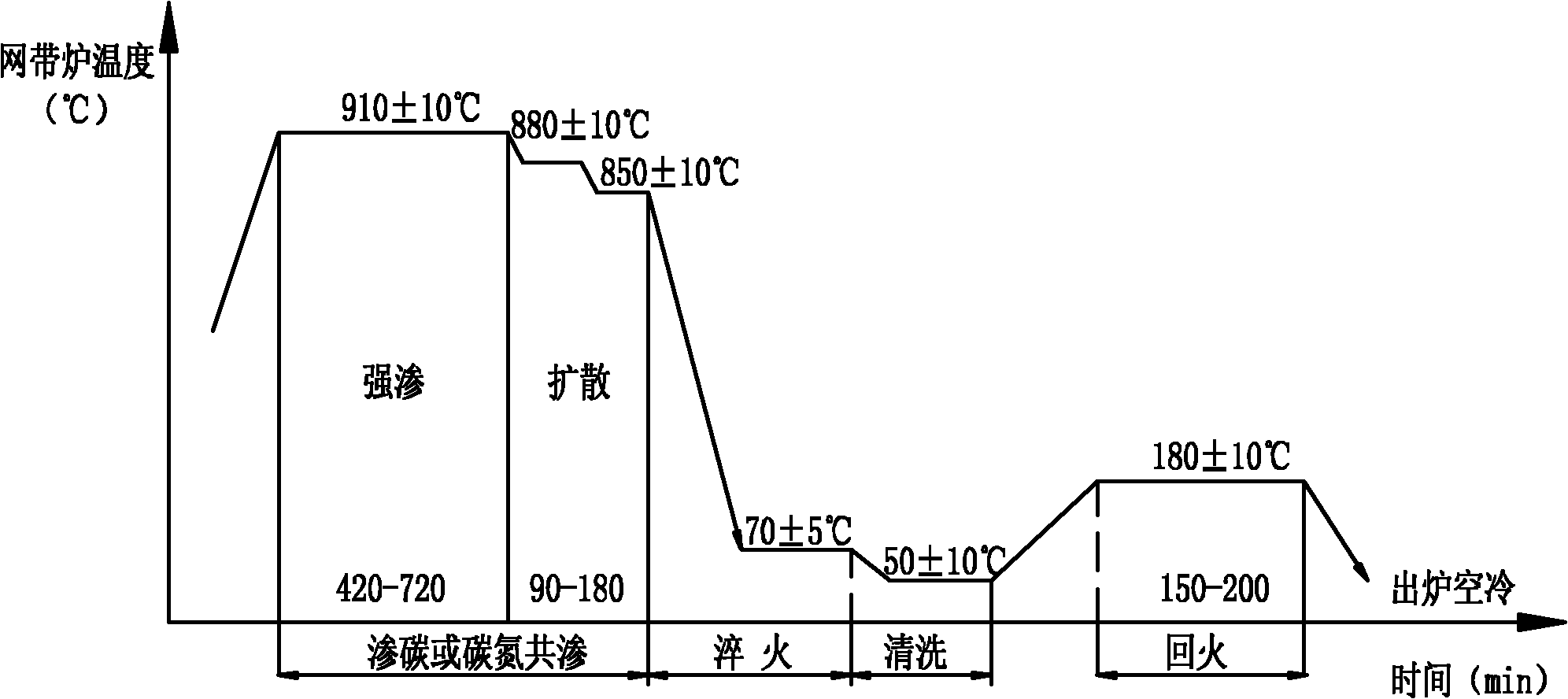

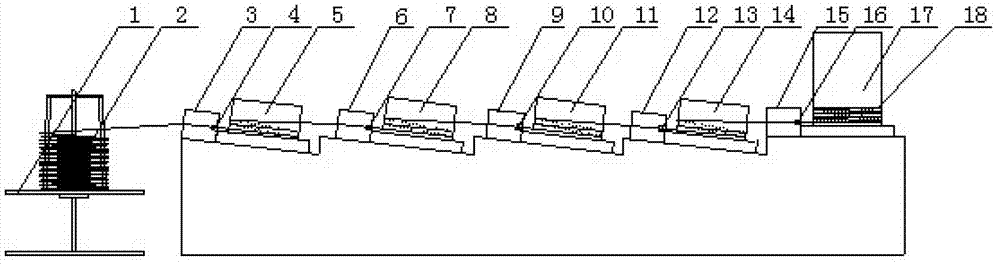

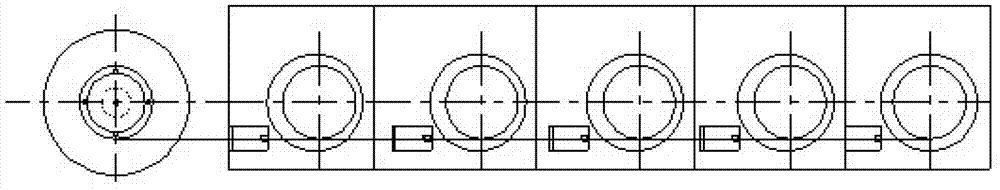

Medium-deep-layer carburization or carbonitriding thermal processing technology for bearings or clutch parts

ActiveCN102154652ALess often openLess closing actionSolid state diffusion coatingFurnace typesProduction lineCarbon potential

The invention relates to a medium-deep-layer carburization or carbonitriding thermal processing technology for bearings or clutch parts. In the invention, the carburization or carbonitriding is carried on parts by utilizing a continuous production line of a carrier roller type mesh belt furnace with a controllable atmosphere, and the technology comprises the following steps in sequence: strong permeation, diffusion, quenching, cleaning, low-temperature tempering, discharging and air cooling. In the invention, the continuous production line of the carrier roller type mesh belt furnace with the controllable atmosphere is used for carrying out the medium-deep-layer carburization or carbonitriding, thus continuous production is realized, the production efficiency is improved, the productivity is increased, frequent opening and closing actions of a gap furnace can be reduced, non-oxidization treatment is realized, and the labor intensity is reduced; and in addition, carbon potentials in all areas of the mesh belt furnace are respectively controlled so as to guarantee the quality stability.

Owner:JIANG SU NAN FANG BEARING CO LTD

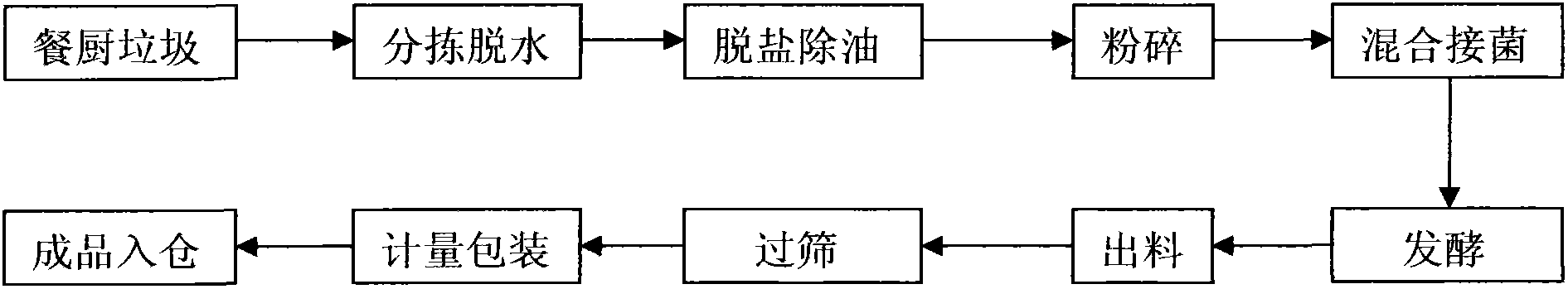

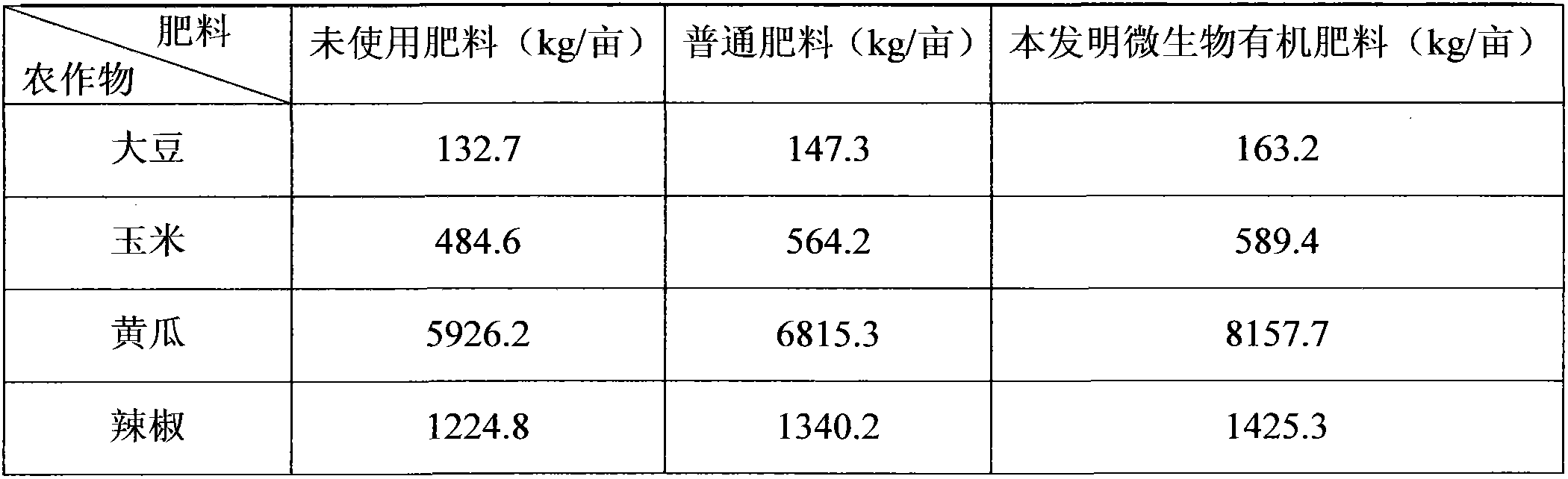

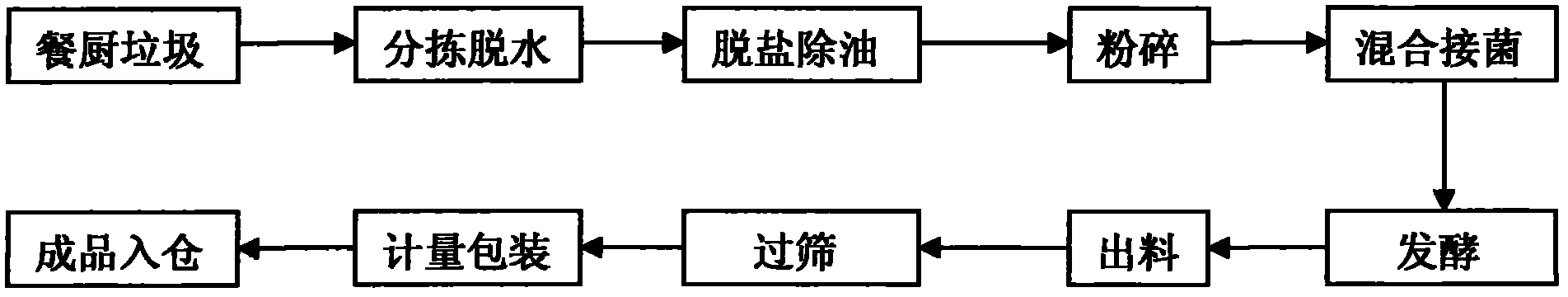

Microbial organic fertilizer prepared from restaurant-kitchen garbage and preparation method thereof

InactiveCN102320871ABig pollutionIncrease available nutrientsBio-organic fraction processingOrganic fertiliser preparationChemical structureOrganic manure

The invention relates to a microbial organic fertilizer prepared from restaurant-kitchen garbage, and relates to a soil improvement technique. The microbial organic fertilizer is prepared by taking the restaurant-kitchen garbage as the main raw material supplemented with additives, wherein the additives include subsidiary agricultural product waste, inorganic material and microbial composite bacteria groups, and the microbial organic fertilizer comprises the following components in percentage by weight: 60-75% of restaurant-kitchen garbage, 10-30% of subsidiary agricultural product waste, 1-10% of inorganic material and 1-5% of microbial composite bacteria groups. In the microbial organic fertilizer, the restaurant-kitchen garbage is adopted as the main raw material, so nutrition constituents in the restaurant-kitchen garbage can be effectively recycled, the problems of environment pollution and resource waste of the restaurant-kitchen garbage are solved, the physical and chemical structures of soil can be conditioned, the quality of agricultural products is improved, and the integrated fertility level of the soil is improved.

Owner:焦社杰

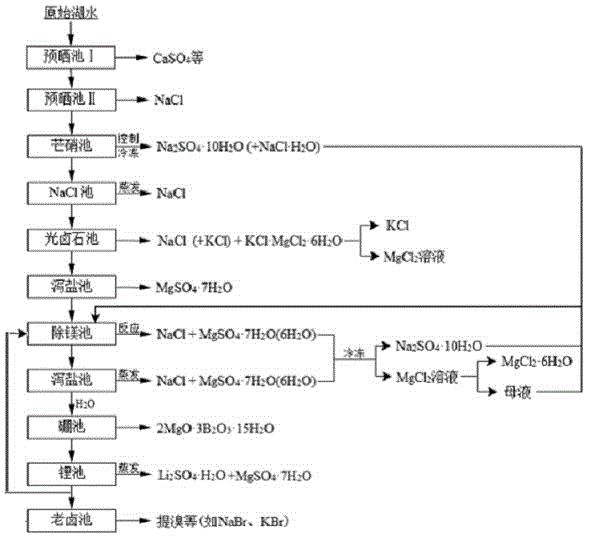

Clean production process of plateau sulfate type boron-lithium salt lake brine

InactiveCN102910652AHigh purityReduce the ratio of magnesium to lithiumChemical industryAlkali metal halide purificationHydration reactionSylvinite

The invention relates to a clean production process of plateau sulfate type boron-lithium salt lake brine. The process comprises the following steps of: (1) arranging a pre-airing pond, a mirabilite pond, a NaCl pond, a carnallite pond, an epsom salt pond I, a magnesium removing pond, an epsom salt pond II, a boron pond, a lithium pond and an old brine pond; (2) controlling the sodium ion concentration in plateau sulfate type boron-lithium salt lake brine, precipitating mirabilite out in winter to obtain brine A, naturally evaporating the brine A, and salting out to obtain brine B; (3) naturally evaporating the brine B, and precipitating sylvine and carnallite out in sequence to obtain brine C; (4) naturally evaporating the brine C, precipitating an epsom salt out, and performing solid-liquid separation to obtain brine D and a solid A; (5) blending the brine D with mirabilite, removing magnesium to obtain brine E, and naturally evaporating brine E to obtain brine F and a solid B; (6) performing a hydration reaction on brine F, naturally evaporating, and precipitating reservoir water / inderite and brine G out; and (7) evaporating brine G or refrigerating for precipitating lithium sulfate, and processing the lithium sulfate into a corresponding product. The process has the advantages of comprehensive utilization of natural energy, saving in energy and environment friendliness.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

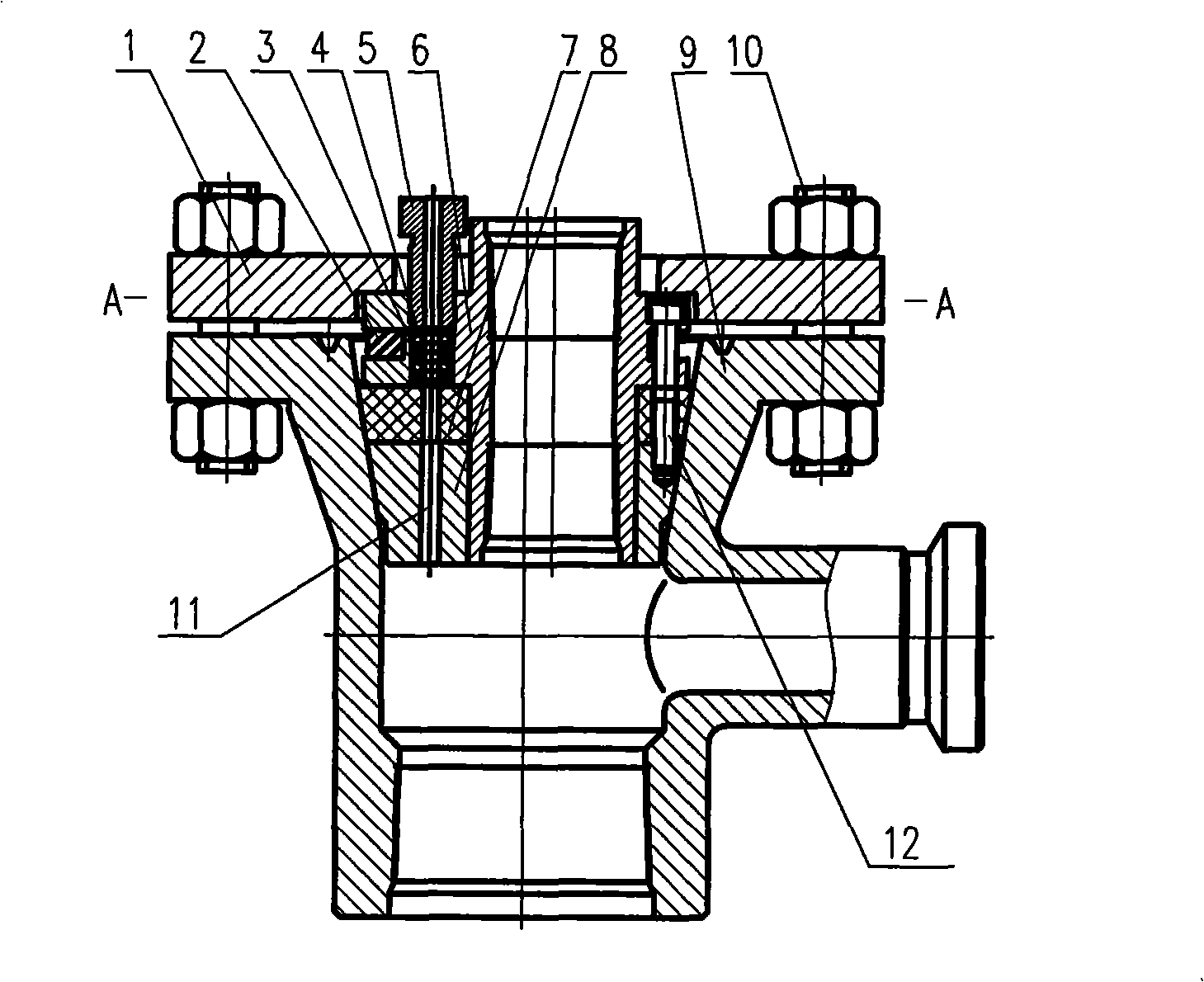

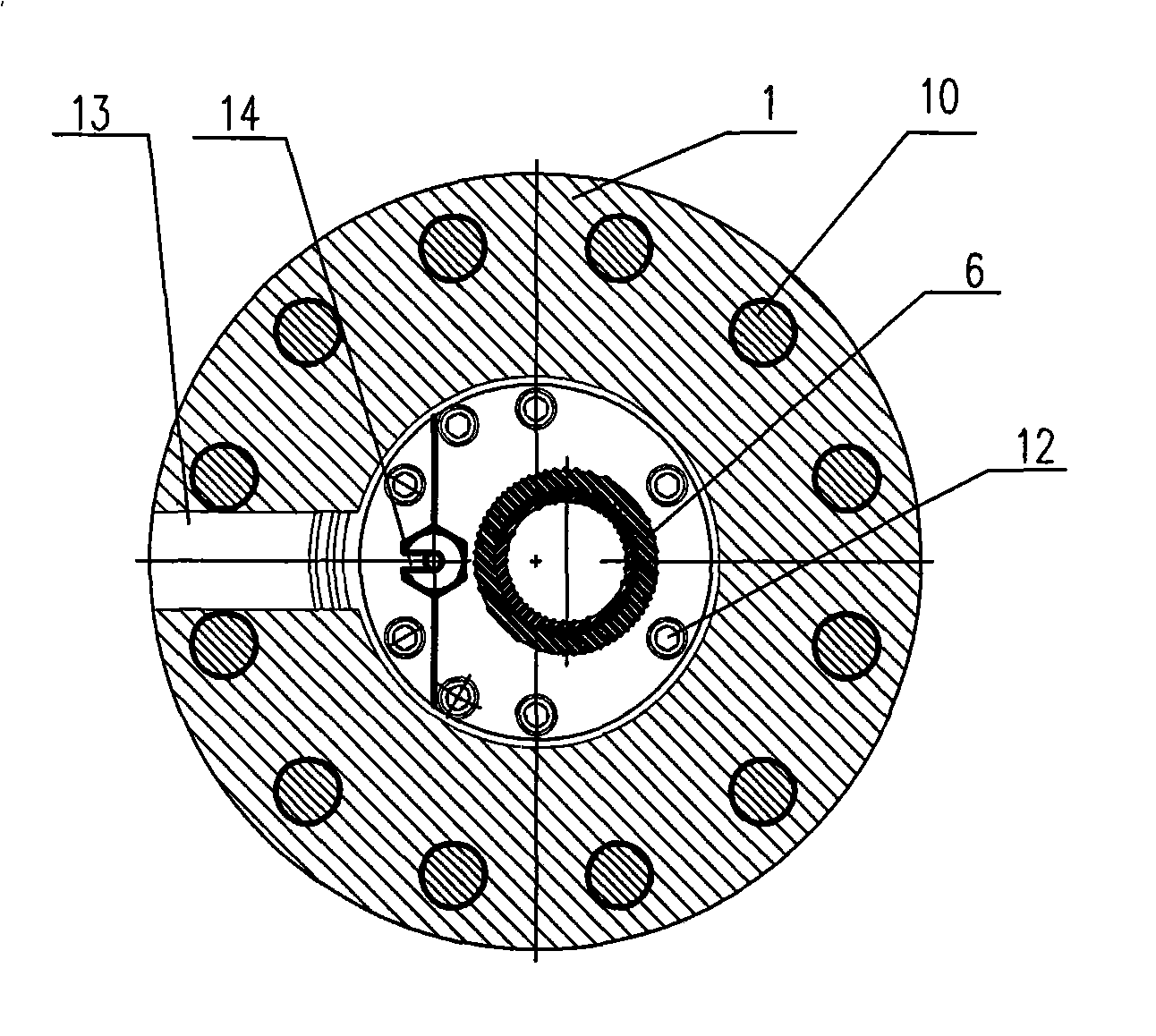

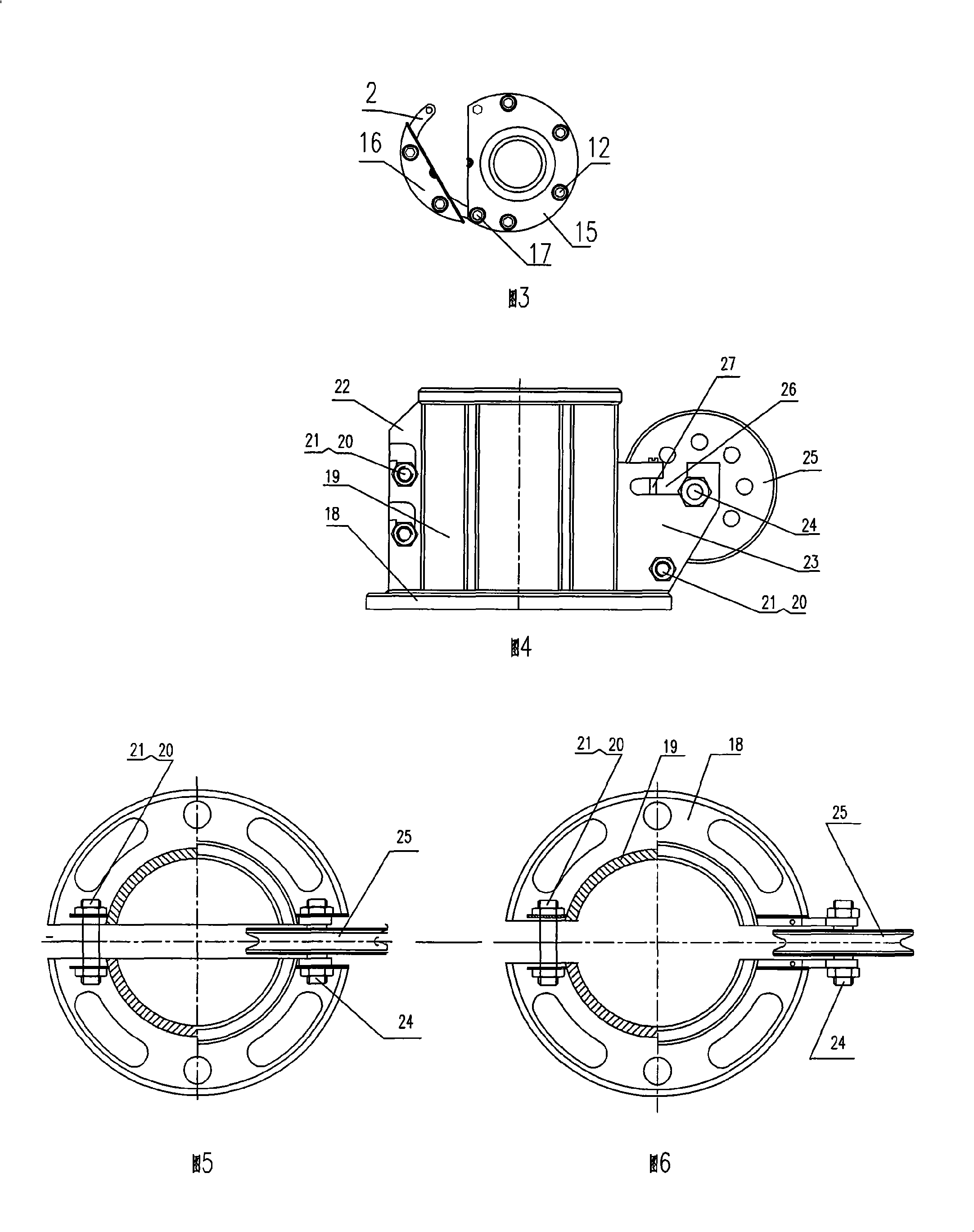

Preset production fluid section plane test method of mechanical mining horizontal well and special shaft mouth test apparatus

ActiveCN101403291AEasy to get up and downSo as not to damageSurveySealing/packingSection planeTubing hanger

The invention relates to a mechanical recovery horizontal well preset produced fluid profile testing method and a special wellhead testing device thereof, mainly aiming at solving the problem of the downhole testing of a mechanical recovery horizontal well. The invention is characterized in that: the special wellhead testing device comprises an eccentric type tubing hanger body connected with a tubing string, wherein, the side wall of the tubing hanger body is divided into a body and splits which are completely matched with each other, and the splits are fixed on a locking arm which is fixed on the body though bolts; and a corresponding matched cable penetrating a channel is arranged at the splitting seam of the body and the splits, the channel is internally provided with a cable gasket, a spacer and a pressing cap. By being matched with a special wellhead support, under the condition that a testing cable and a tester are pre-arranged in the horizontal well to test a target layer, an oil pipe does not touch the cable during the up and down process of the oil pipe. The method and the special wellhead testing device can realize the produced fluid profile testing of the mechanical recovery horizontal well, and ensure the accuracy of normal testing and data of the mechanical recovery horizontal well with simple and reliable operation method.

Owner:DAQING OILFIELD CO LTD +1

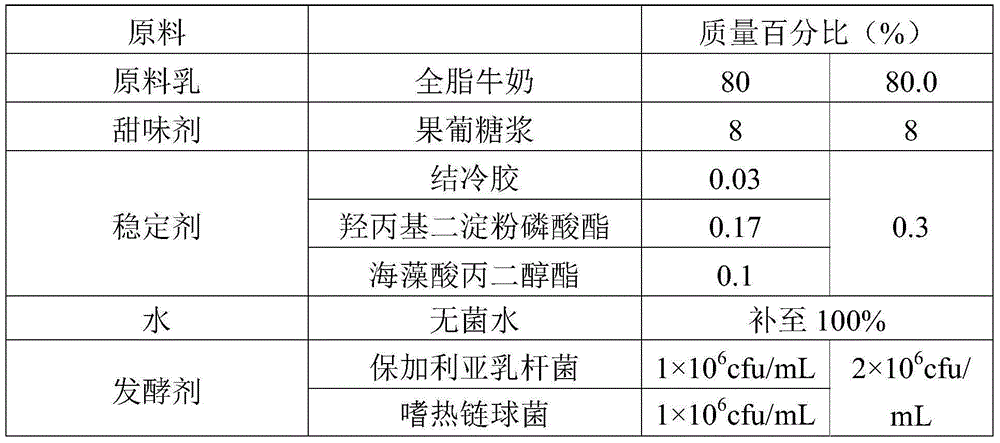

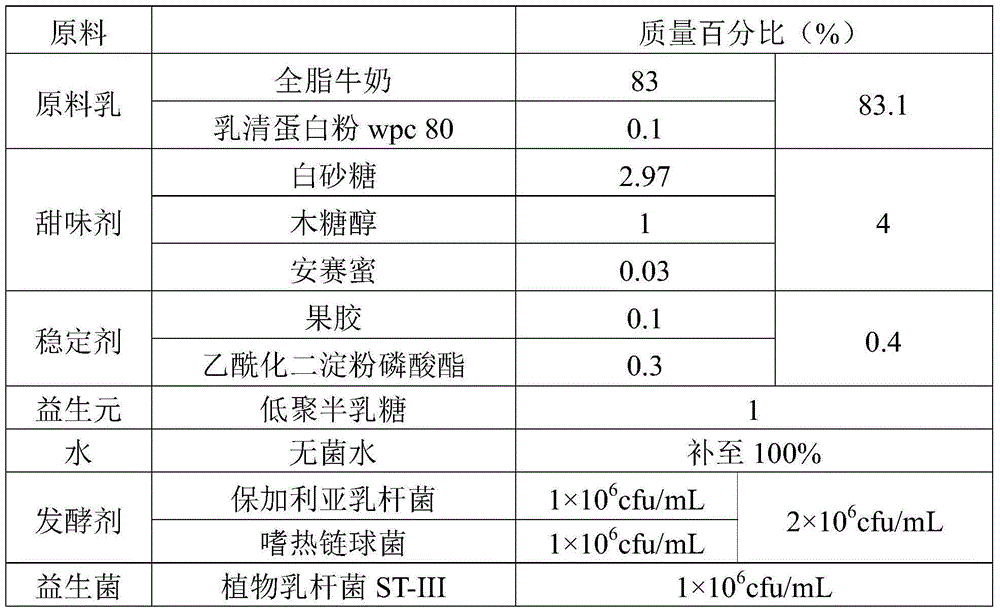

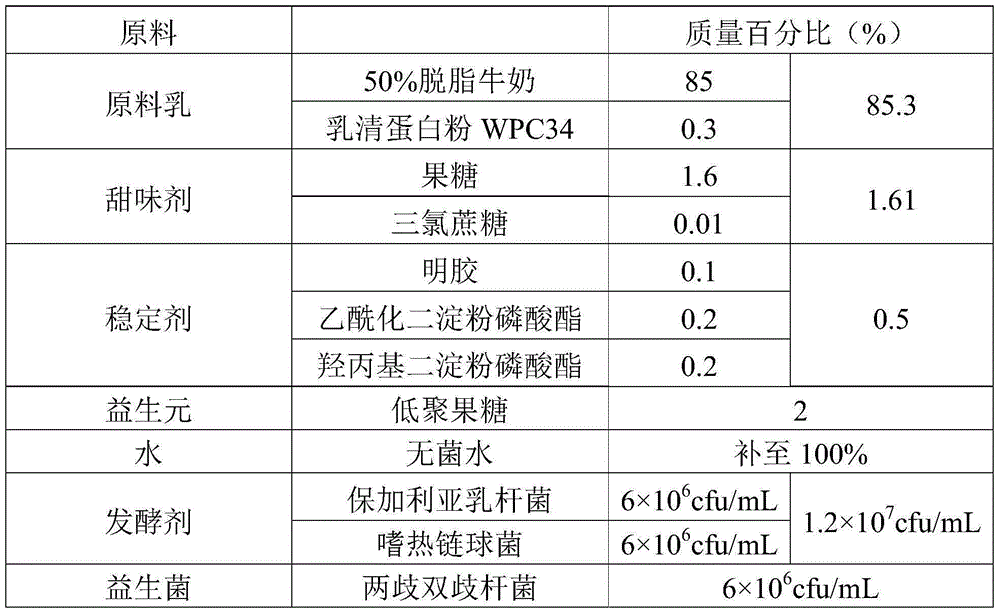

Normal-temperature set yogurt and preparation method thereof

The invention provides normal-temperature set yogurt and a preparation method thereof. Raw materials used in the preparation method comprise raw milk, a stabilizer, a sweetening agent and a leavening agent. The preparation method comprises steps as follows: (1), the raw milk, the stabilizer and the sweetening agent are uniformly mixed, homogenized, sterilized and cooled, and a mixed solution is obtained; (2), the leveling agent is inoculated to the mixed solution obtained in the step (1), and filling is performed; (3), the filling mixed solution obtained in the step (2) is fermented, cooled and processed under ultrahigh pressure of 300-600 MPa, and a finished product is obtained. After filling fermentation, a pasteurization heating processing technology commonly adopted in a normal-temperature yogurt production process is avoided, the normal-temperature set yogurt is produced and can be stored at the normal temperature, and the guarantee period is substantially prolonged.

Owner:BRIGHT DAIRY & FOOD CO LTD

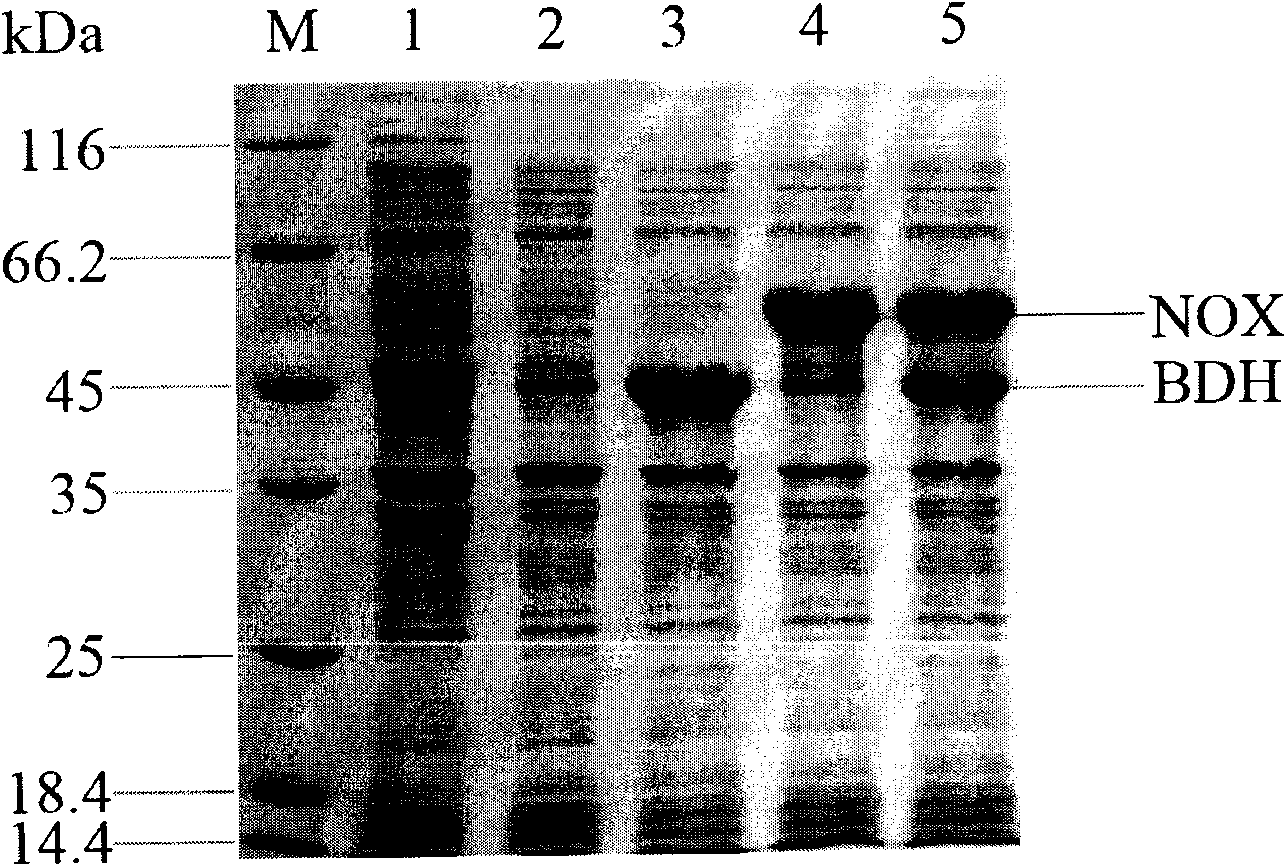

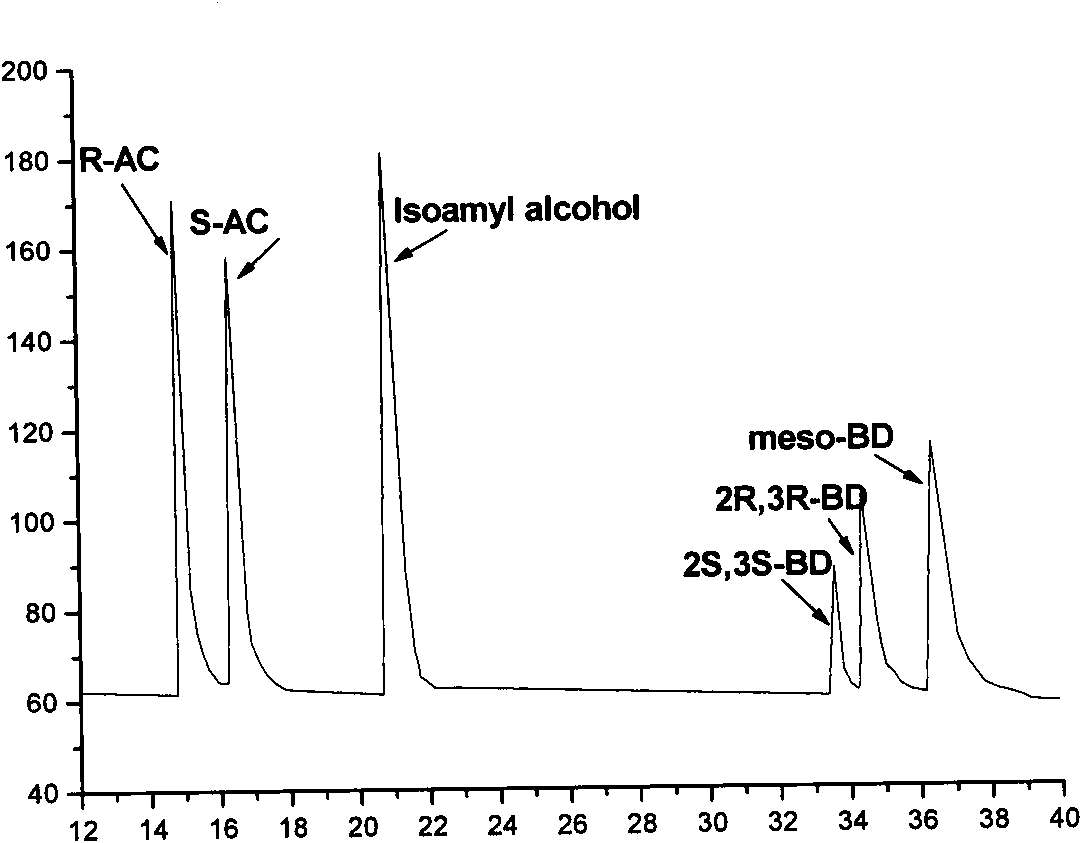

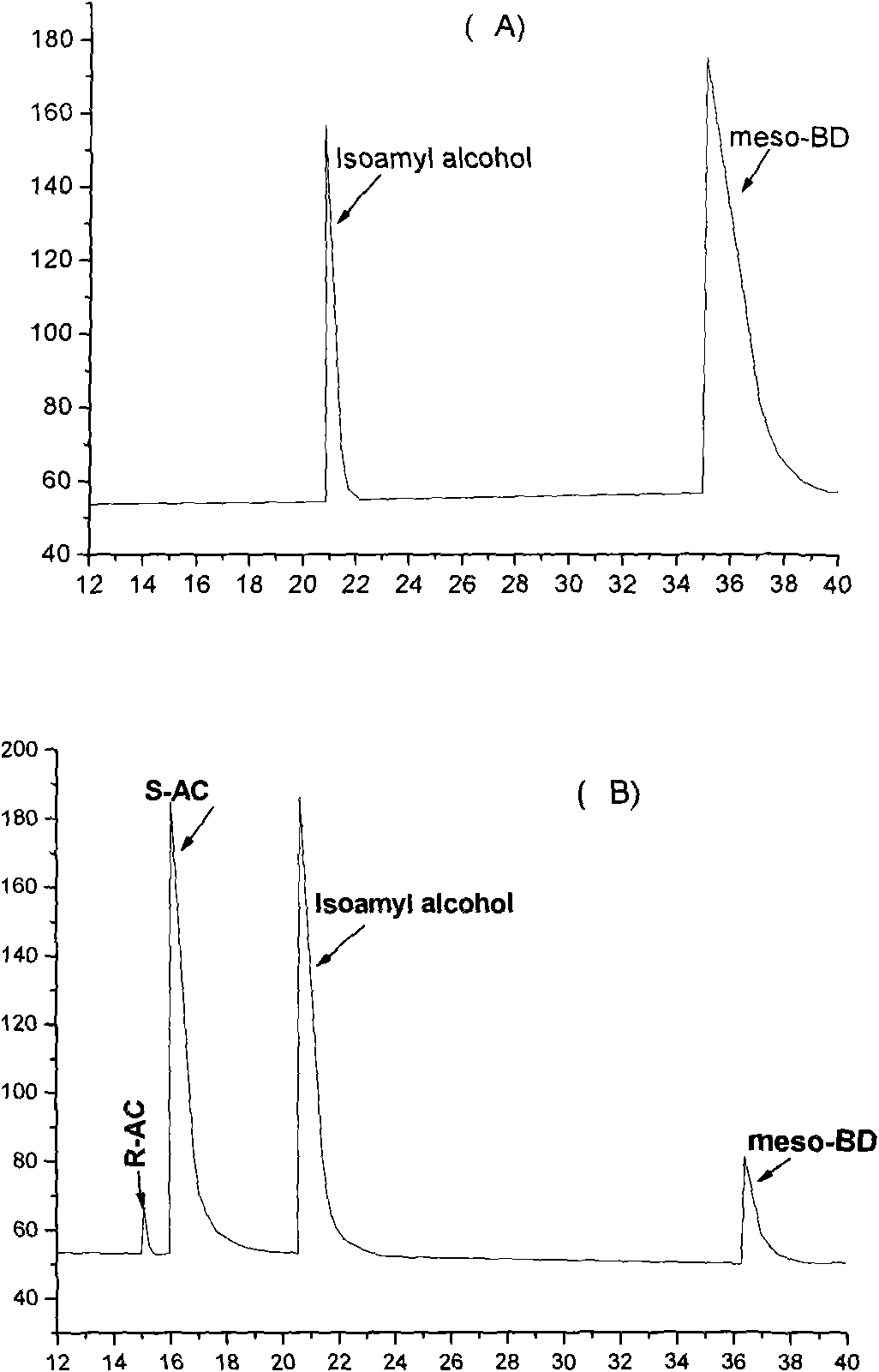

Gene recombination bacterium and application thereof in preparing chiral pure acetoin and 2,3-butanediol

InactiveCN101565685AEasy to operateAchieve productionBacteriaMicroorganism based processesEscherichia coliGram

The invention discloses an E. coli BL21(pETDuet-ydjLnox) containing a 2R,3R-butanediol dehydrogenase gene ydjL and an NADH oxidase gene nox, wherein the strain is preserved in the 'China Center for Type Culture Collection' on December 23 in 2008, and the preservation number is CCTCC NO: M 208259. The invention also discloses application of a gene recombination bacterium in producing chiral S-AC by catalyzing meso-BD, producing chiral R-AC by catalyzing 2R,3R-BD and producing chiral pure 2S,3S-BD by splitting a 2,3-BD mixture. The concentration of a chiral AC prepared from the recombinant E. coli can reach over 6 grams per liter (the ee value is more than or equal to 96 percent); and the ee value of the chiral pure 2S,3S-BD is more than or equal to 98 percent, and the regeneration of a cofactor is achieved, thus the gene recombination bacterium has great industrial application prospect.

Owner:SHANDONG UNIV

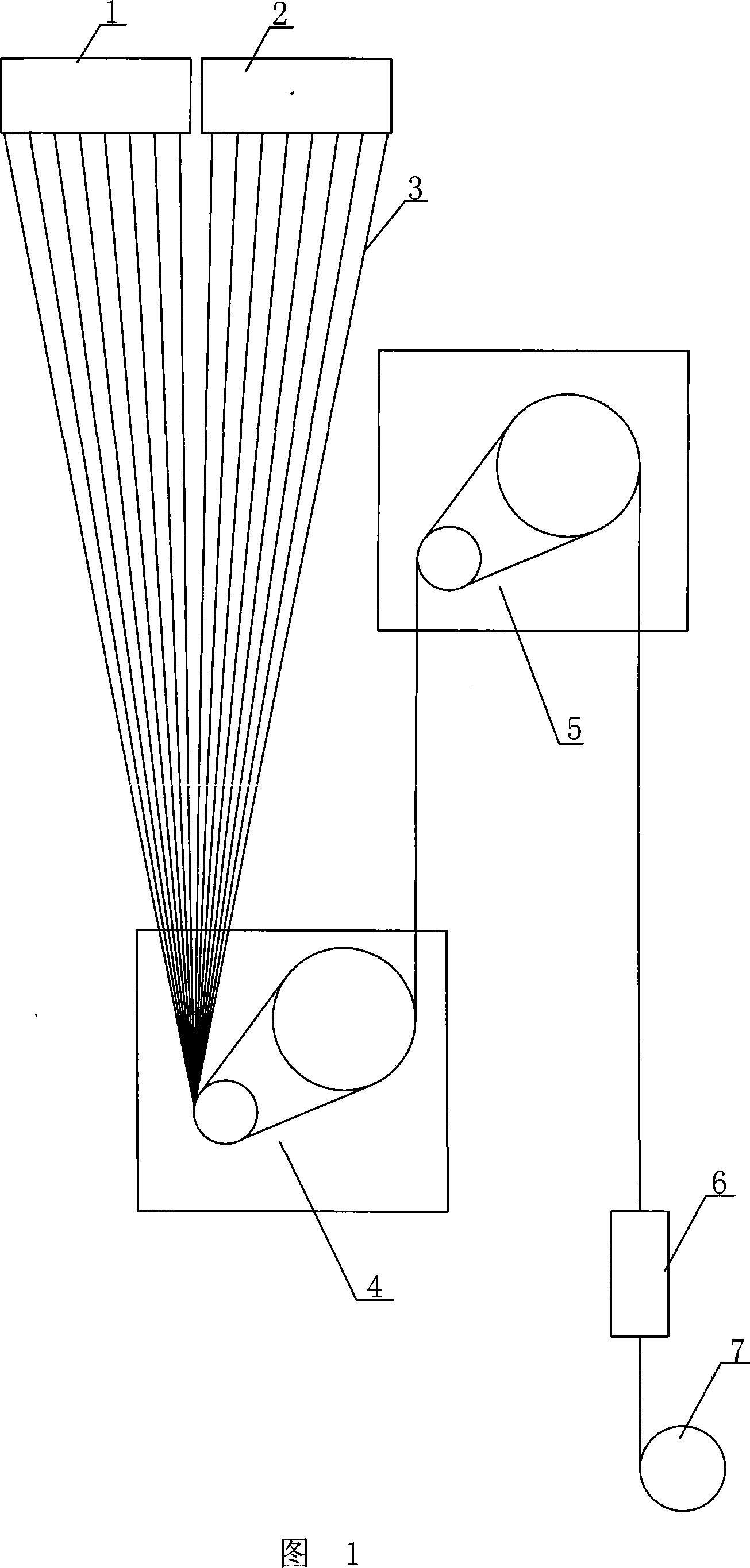

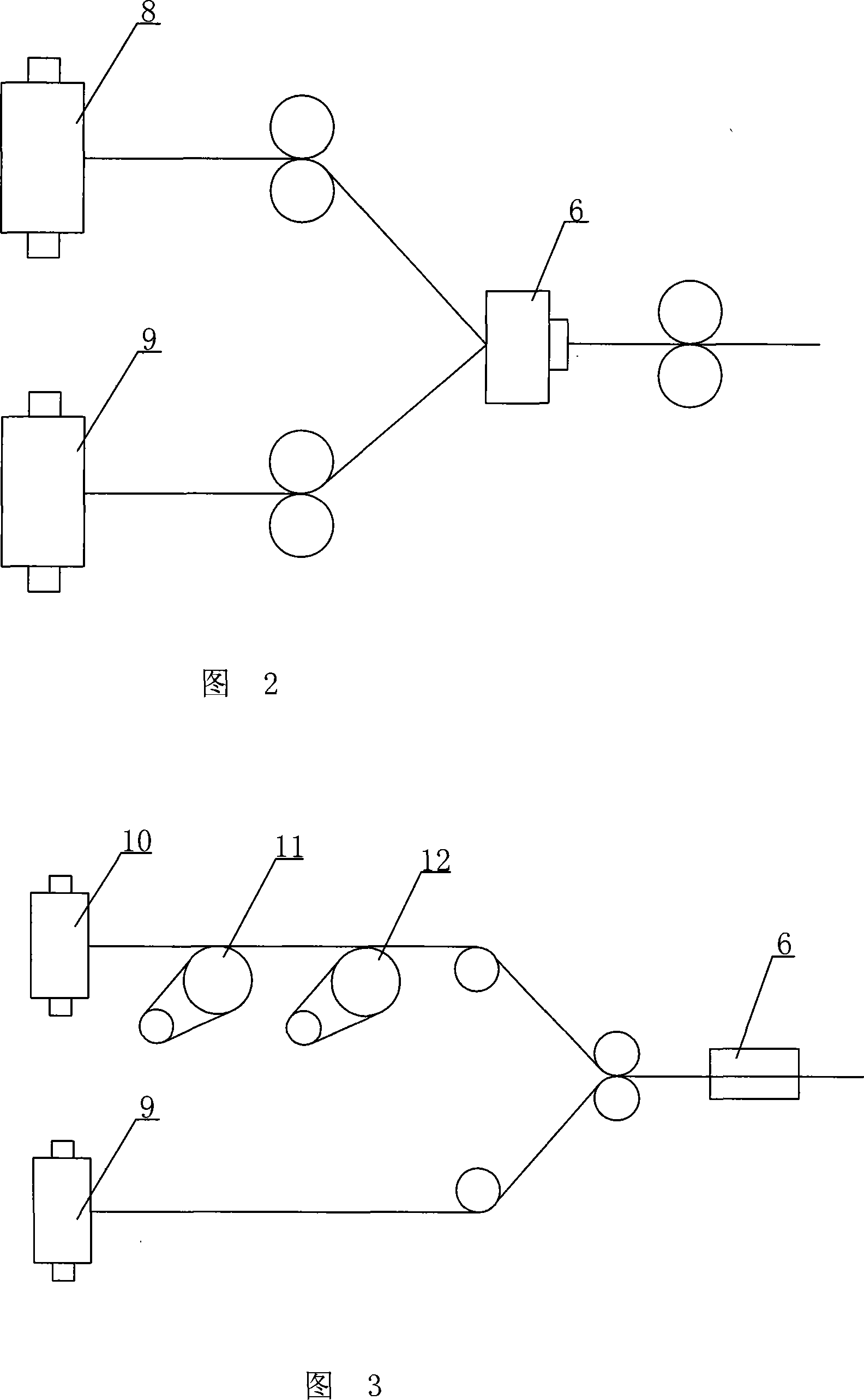

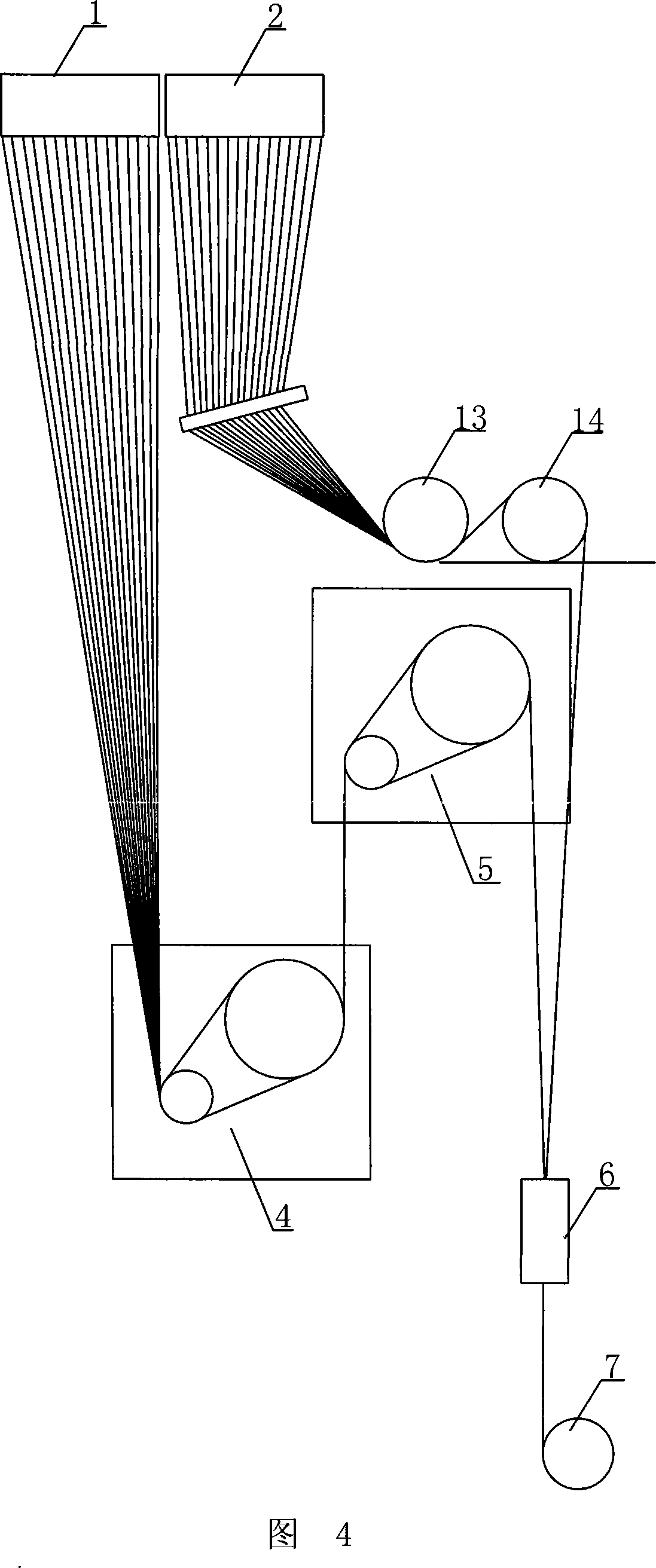

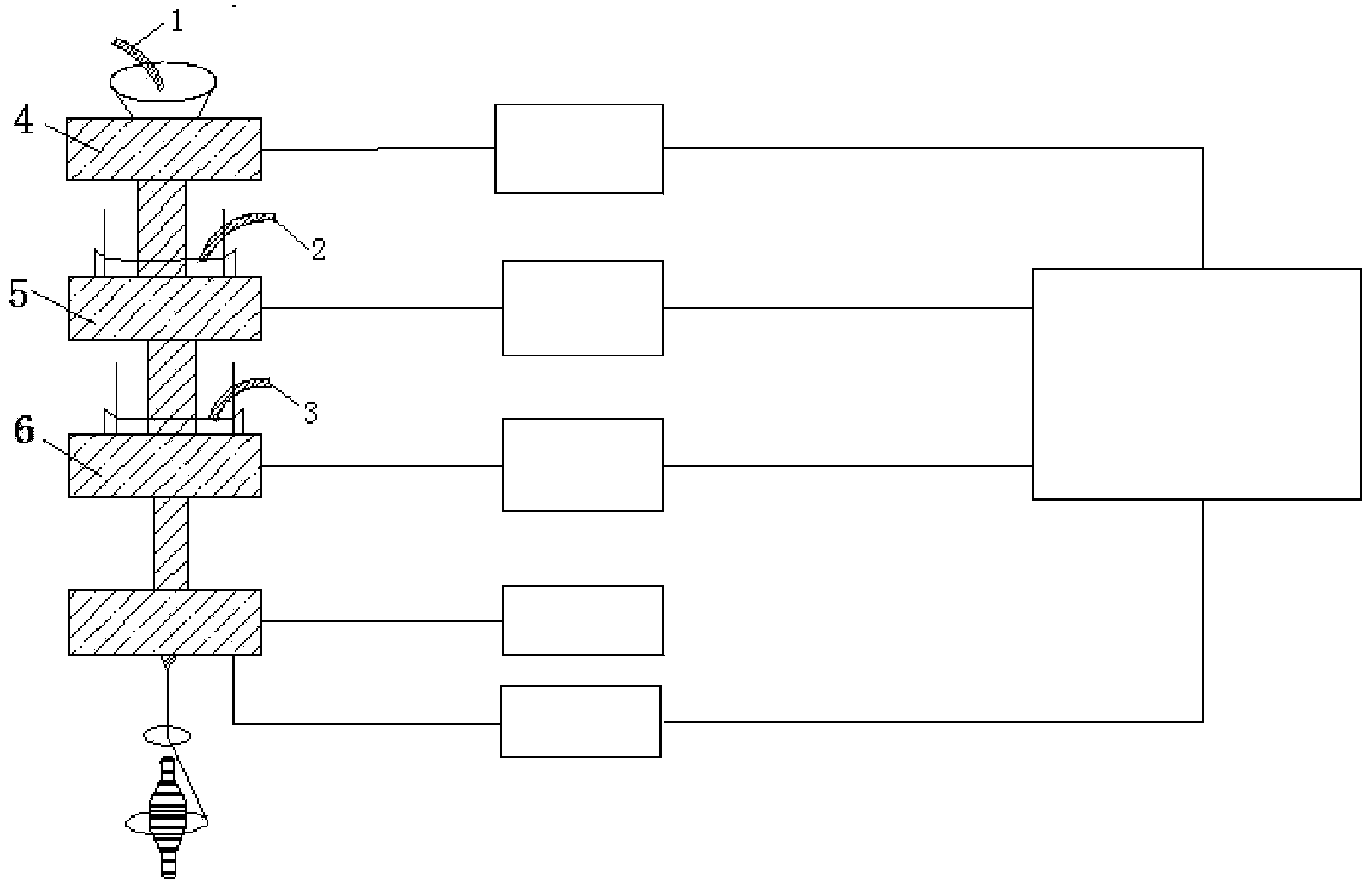

Method and device for manufacturing fully drawn yarn/pre-oriented yarn stranding composite yarn by one-step process

ActiveCN101200826AReduce consumptionSolve technical problemsSpinnerette packsFilament manufactureEngineeringRaw material

The invention discloses a one-step preparation method of stranding composite yarn of fully drawn yarn / pre-oriented yarn and a device thereof. The method includes that an FDY filament device is adopted to haul part tow on the back of a spinning box to two clod godet rollers to obtain POY yarn. The left tow is hauled to two hot godet rollers to obtain FDY yarn. The two tows are winded with a speed of 2800-3200m / min after being networked through a network device to obtain multi-strands of stranding composite yarn of fully drawn yarn / pre-oriented yarn. The device is to add two cold godet rollers on the filament device. The network device and a winding device are arranged to the back of the cold godet rollers and two hot godet rollers. The invention shortens the production process, reduces theequipment occupying space, lowers the consumption of the production cost, raw materials and energies and effectively solves the technical problem of finishing the spinning and the stranding in one step. The whole process is stable. The product quality is reliable. The quality defect that monofilament in yarn is easy to appear in a composite yarn product can be completely eliminated. The yield is three times of that of the prior art. And the production efficiency can be improved greatly.

Owner:WUJIANG FUDONG TEXTILE GROUP

Method for manufacturing blank of pipe clamp

InactiveCN105728648AAchieve productionSave materialFoundry mouldsFoundry coresMolding machineCasting defect

The invention discloses a method for manufacturing a blank of a pipe clamp and belongs to the field of construction. The method comprises the following steps that 1, a pipe clamp precoated sand mold is designed and manufactured according to a design drawing of the pipe clamp; 2, the precoated sand mold of the pipe clamp is placed on an automatic molding machine, and a precoated sand pouring sand shell model and a sand core model are manufactured; 3, pouring is carried out; and 4, a casting is taken out and cleaned. The method has the beneficial effects that production of the blank of the pipe clamp can be efficiently achieved, materials and manpower can be saved, and the mechanical machining amount can be reduced; and casting defects can be reduced, the yield is increased, and automatic production can be easily achieved.

Owner:YUZHOU KUNLUN MOLD CO LTD

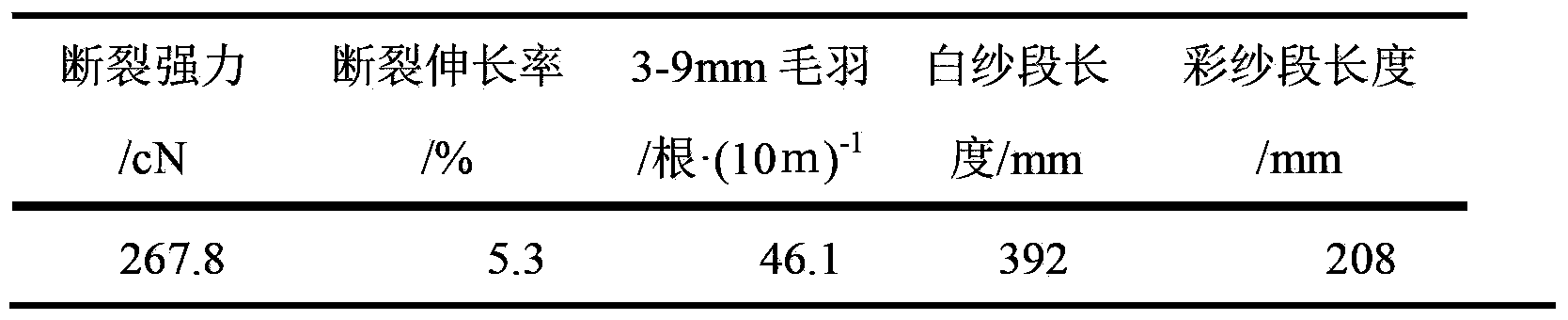

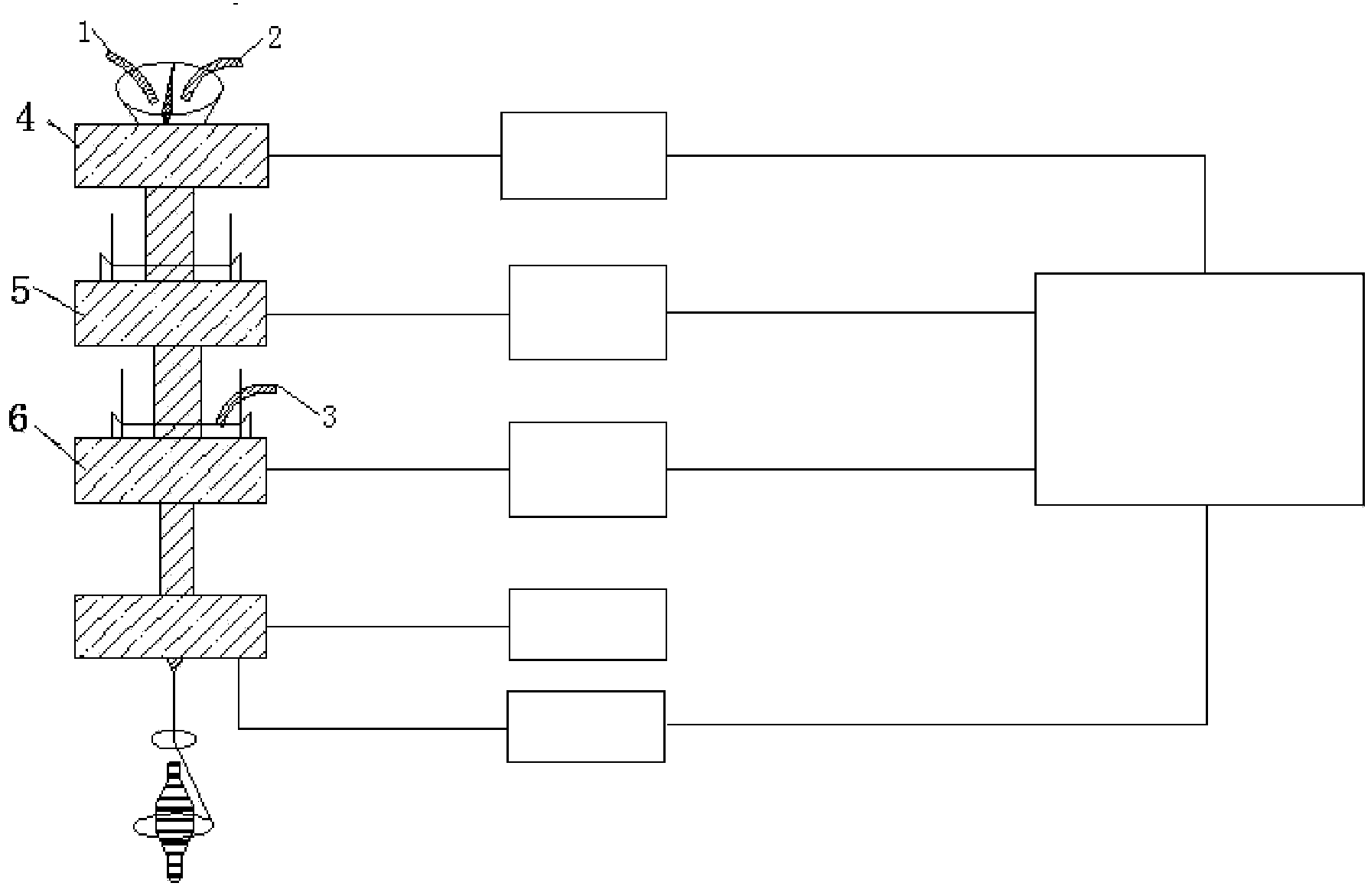

Method for spinning color segment bamboo joint color yarns

ActiveCN103397420AIncrease the added value of yarnImproving Spinnability and Yarn QualityDrafting machinesYarnYarnEngineering

The invention discloses a method for spinning color segment bamboo joint color yarns. In the spun yarn process, four rovings with at least one color are simultaneously fed into a huge drafting spinning frame which is of a four-roller, four-leather-collar and three-area type. In the four rovings, two of the four rovings are fed in from rear rollers through double-horn openings, one roving is fed in from a middle-rear roller through a yarn guiding groove, and one roving is fed in from a middle-front roller through a yarn guiding groove. According to the method, the four-roving feeding scheme is adopted, the segment color effect with four different colors at most can be achieved, and the production of segment color yarns of different styles is achieved. In the part of the spun yarn process, the four-roller, four-leather-collar and three-area type is used so that huge drafting of 30-300 times can be achieved, a foundation is laid for simultaneous feeding of the four rovings, and spinning efficiency is improved. Meanwhile, the rear rollers, the middle-rear roller and the middle-front roller in the four rollers are controlled respectively through an independent servo motor, the draft multiple in the three-area drafting can be adjusted at will, so that the segment color bamboo joint effect of various styles is achieved, and the spinning adaptability and the spinning quality of segment color yarns are improved.

Owner:SUZHOU XINDONGNAN TEXTILE TECH CO LTD

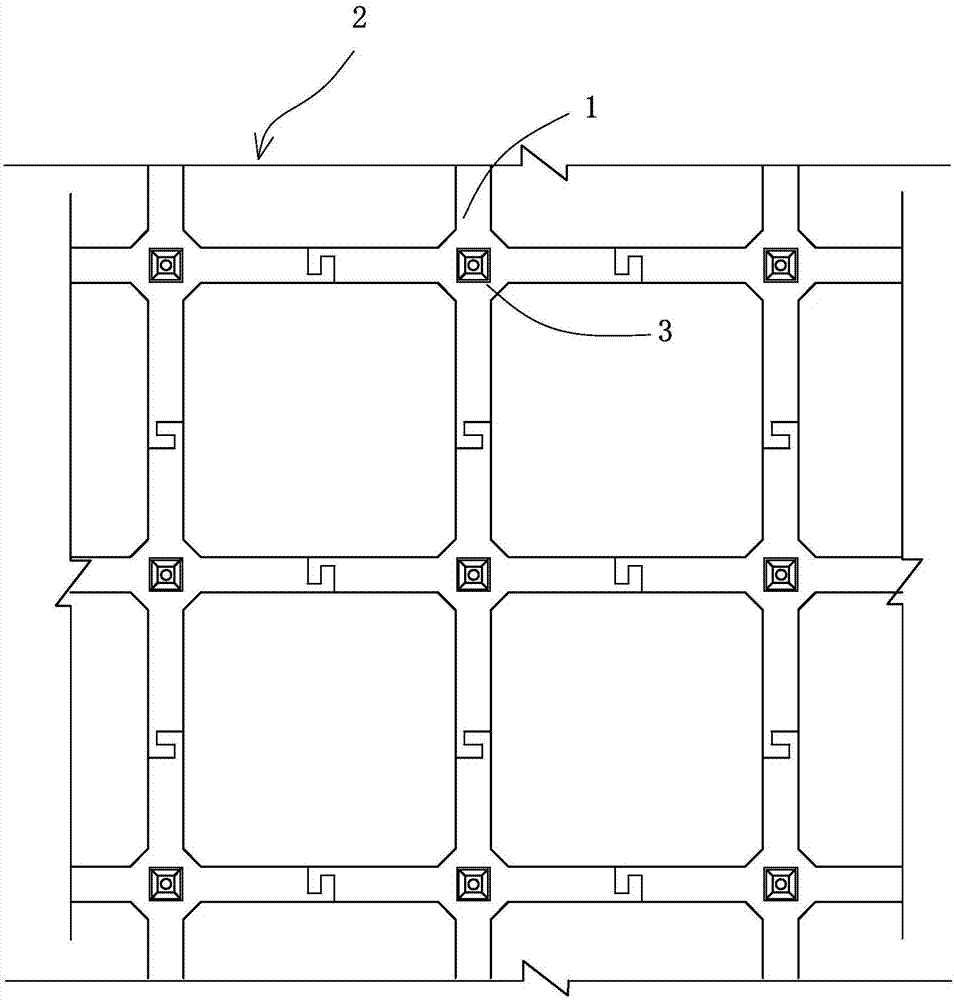

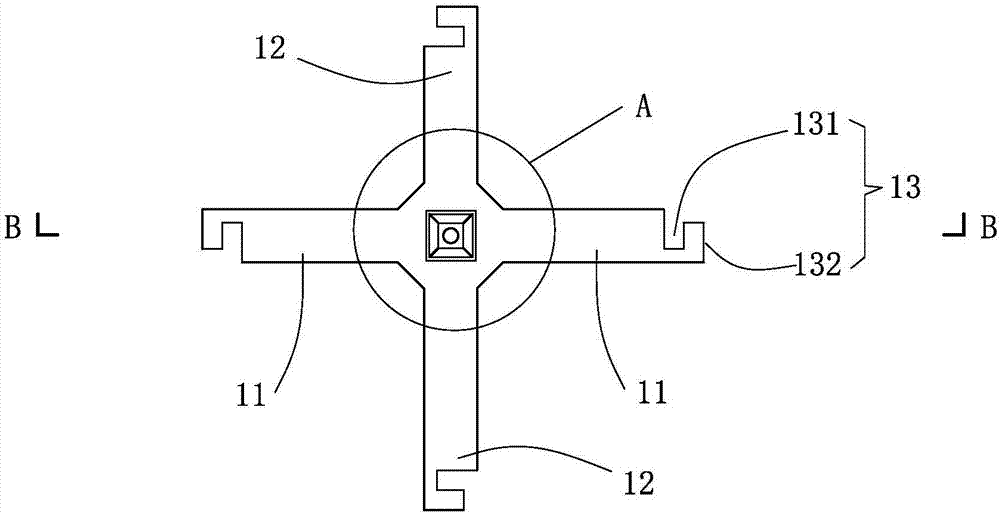

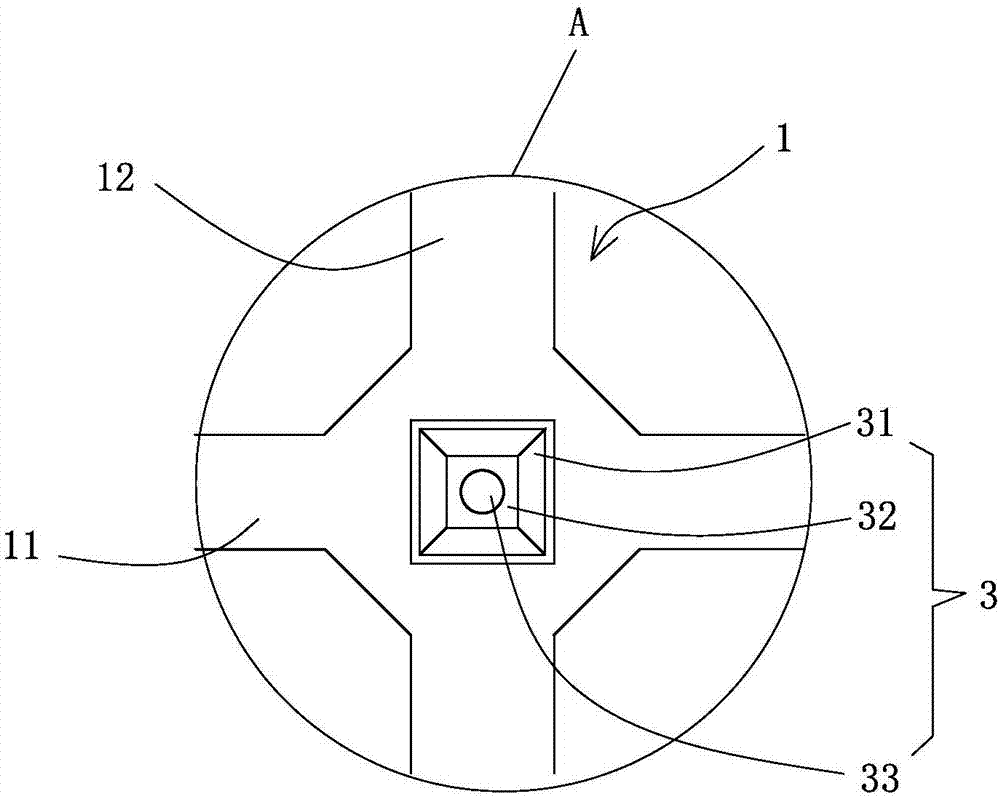

Precast lattice beam used for slope reinforcement, manufacturing method thereof and construction method for slope reinforcement adopting precast lattice beam

PendingCN107030874AEasy to manufactureEasy to installCeramic shaping apparatusExcavationsShaped beamChinese characters

The invention provides a precast lattice beam used for slope reinforcement and a construction method for slope reinforcement adopting the precast lattice beam, as well as a slope structure reinforced by the precast lattice beam and a construction method thereof. The precast lattice beam comprises a plurality of precast cross-shaped beam units which are arranged and connected in a matrix manner; each of the cross-shaped beam units comprises a transverse beam and a longitudinal beam in intersection; an anchor head part is formed in the central interacting part of each of the cross-shaped beam units; each of the anchor head parts comprises a concrete groove and a backing plate placed on the concrete groove; an anchor hole is formed in each of the concrete grooves and the backing plates; the two end parts of the transverse beam and the two end parts of the longitudinal beam of each of the cross-shaped beam units extend respectively to form L-shaped hook parts reversed in directions; the transverse beam of each of the cross-shaped beam units is connected with that of the adjacent cross-shaped beam unit in a hooking manner through the corresponding L-shaped hook parts; the longitudinal beam of each of the cross-shaped beam units is connected with that of the adjacent cross-shaped beam unit in a hooking manner through the corresponding L-shaped hook parts; therefore the precast lattice beam is formed by splicing a plurality of structures taking the shapes of the Chinese character jing. According to the precast lattice beam used for slope reinforcement, the manufacturing method thereof and the construction method for slope reinforcement adopting the precast lattice beam, the following characteristics are achieved: on-the-spot construction steps are reduced, the construction period is shortened, the standardized management production is realized, the quality is ensured, and high efficiency and environment protection are realized.

Owner:SHENZHEN ROAD & BRIDGE CONSTR GRP

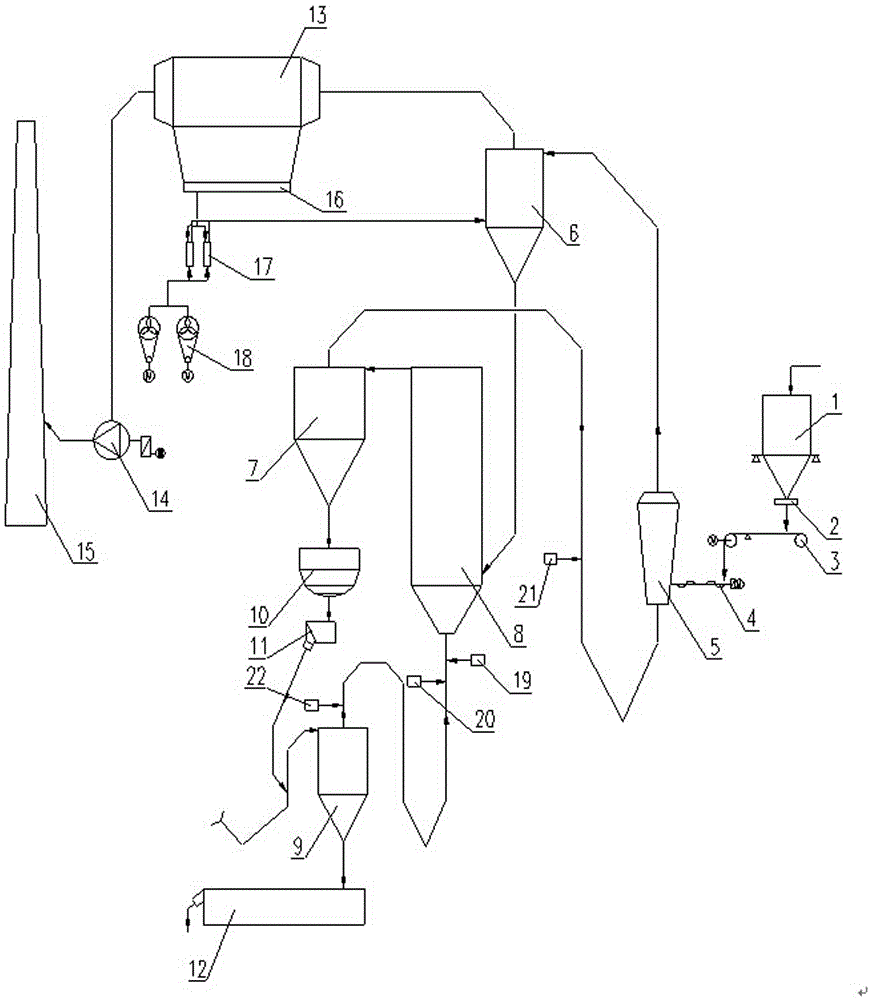

Suspension roasting device and technology for producing multiform aluminum oxide

InactiveCN104692435AReduce production linksSave construction investmentAluminium oxide/hydroxide preparationAluminium hydroxideEngineering

The invention belongs to the technical field of metallurgy, and particularly relates to a suspension roasting device and technology for producing multiform aluminum oxide. The device is composed of a feeding system, a roasting system, a crystal separation system and a cyclone dust removal system, wherein the feeding system comprises a quantitative feeder, a spiral feeder and a drier, the roasting system comprises a cyclone preheater, a roasting furnace and a burning station, the crystal separation system comprises a cyclone separator, a crystallizer, a controllable material level valve, a cyclone cooler and a drying cooler, and the cyclone dust removal system comprises a dust remover, an induced draught fan and a chimney. During working, an aluminum hydroxide filter cake serves as the raw material, the roasting temperature of the roasting furnace and the time for materials staying in the crystallizer are adjusted according to different requirements of multiform aluminum oxide products, and finally obtained different aluminum oxide products are discharged out of the drying cooler. According to the device and technology, metallurgical aluminum oxide and high-temperature aluminum oxide are produced at the same time with one set of device and the same kind of material by adjusting operating parameters.

Owner:SHENYANG XINBO IND TECH

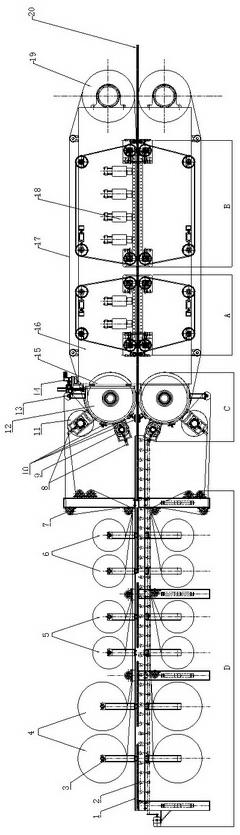

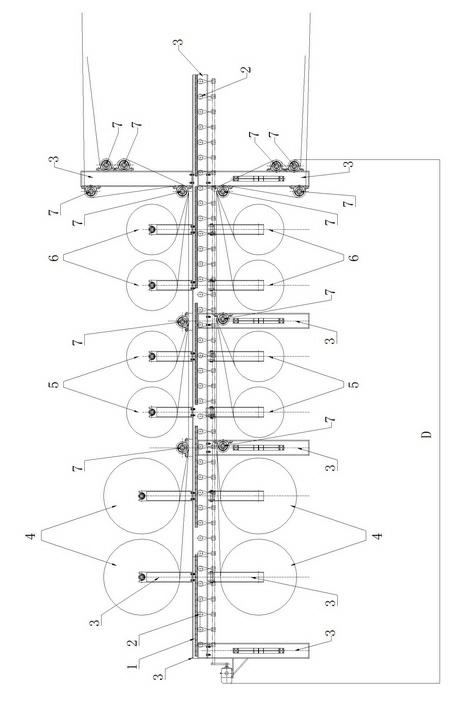

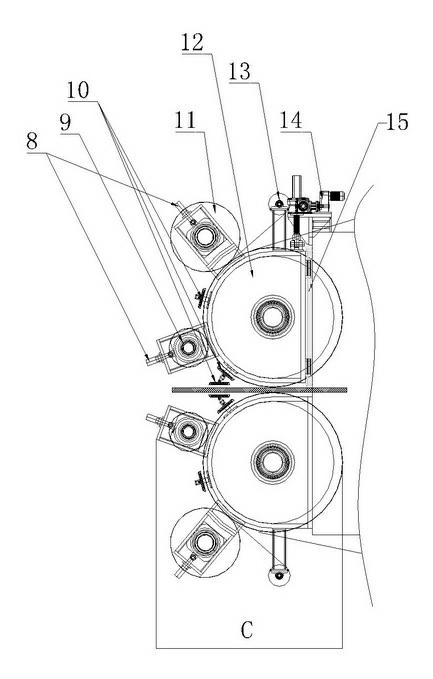

Method for producing thermoplastic composite material and double steel-belt continuous press

ActiveCN102615917AReduce area requirementsIncrease profitLaminationLamination apparatusComposite plateThermoplastic composites

The invention provides a method for producing a thermoplastic composite material and a double steel-belt continuous press. The double steel-belt continuous press mainly comprises a set of paper and board feed system D, a set of preheating and prepressurizing system C which is arranged on driven rollers at an inlet of the press, a group of driving rollers, a group of driven rollers, and steel belts which are wound on the driving rollers and the driven rollers, wherein the inner part of the press is divided into a heating section A and a cooling section B. Raw materials (core boards and paper) of a product enter the preheating and prepressurizing system C through the paper and board feed system and are combined between the two driven rollers through heating and pressurization, enter the heating section for constant-temperature setting along with the traction of the steel belts, and are cooled and molded through the cooling section to produce finished sheets and strips. The defects of the conventional production machinery for composite boards are overcome; the press has a simple structure and reliable performance, and is relatively low in cost; the finished sheets and strips are pressed by a production process that the internal gluing is not required and the raw materials are combined after being molten; and products in corresponding sizes are processed according to requirements.

Owner:DUNHUA YALIAN MACHINEY

Smelting process for producing low-carbon ultralow-phosphorus steel in converter

InactiveCN102634629ALess investmentAchieve productionManufacturing convertersSmelting processFerrosilicon

The invention discloses a smelting process for producing low-carbon ultralow-phosphorus steel in a converter. The smelting process comprises the following steps of: dephosphorizing molten iron desulfurized once by utilizing two times of slagging blowing process, namely, an early stage and a later, or three times of slagging blowing process, namely, an early stage, a middle stage and the later stage, or multiple times of slagging blowing process, wherein the content of phosphorus of the molten iron is 0.11-0.13%; utilizing silicon iron slag regulation, pouring the slag into a slag basin until the slag basin is full each time and controlling process temperature; pouring slag when oxygen blowing is carried out by 40-45%, wherein the target temperature of an early stage is 1,350-1,400 DEG C; and controlling the temperature between 1530 DEG C and 1550 DEG C when a sublance is used for blowing oxygen for 80%, and pouring the slag, so that the low-carbon ultralow-phosphorus steel with terminal phosphorus content being within 0.005% is obtained, wherein the terminal target temperature is 1560-1580 DEG C. The smelting process for producing the low-carbon ultralow-phosphorus steel in the converter, disclosed by the invention, can carry out multiple times of slagging on the molten iron desulfurized once in the converter and has the advantages of being small in molten iron physical heat loss, high in yield and efficiency, low in alloy consumption and cost, and energy-saving.

Owner:NANJING IRON & STEEL CO LTD

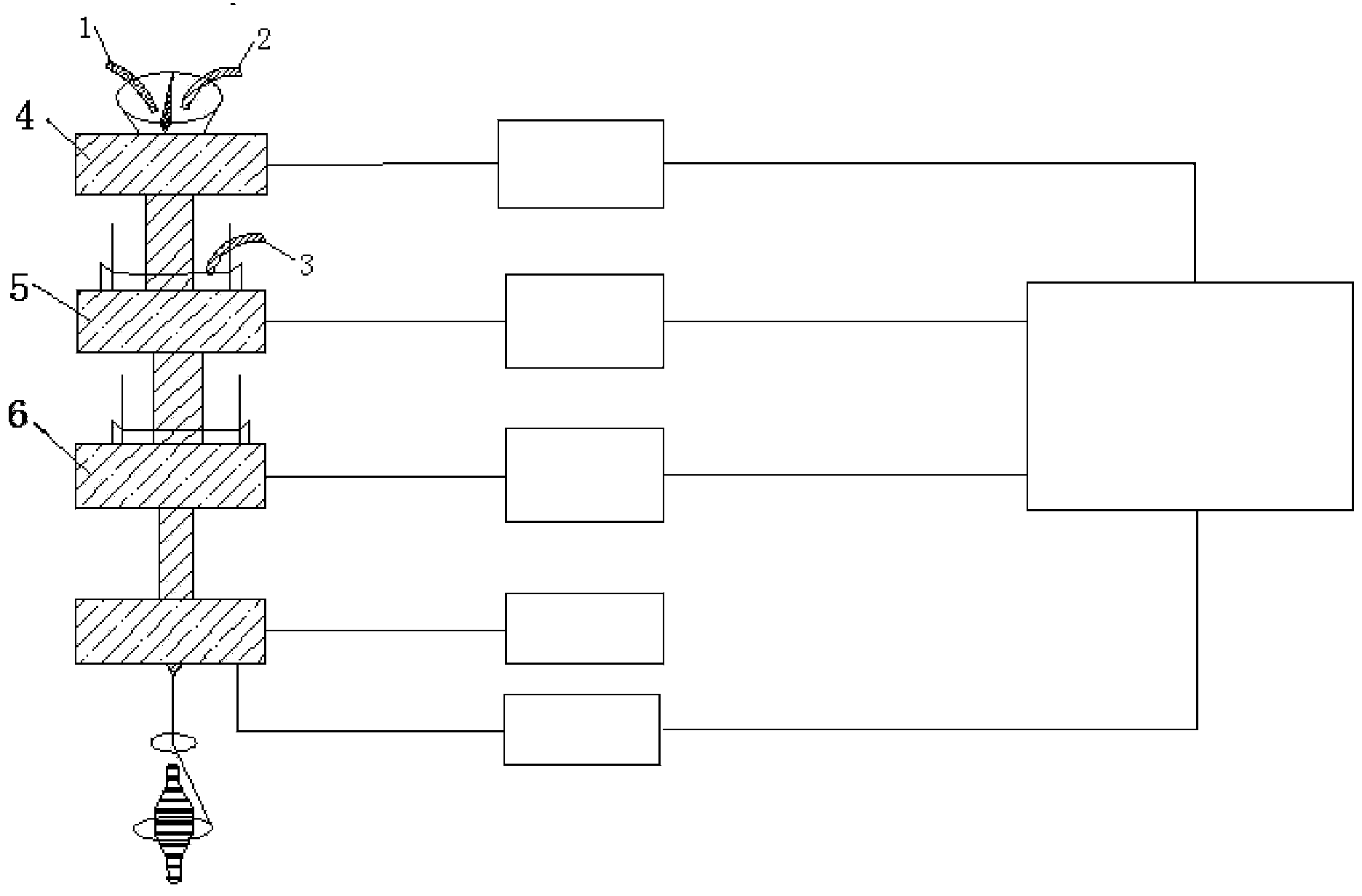

Spinning method of multi-component multi-segment color yarns

The invention discloses a spinning method of multi-component multi-segment color yarns. In the spinning procedure, three roves at least in one color and one material are simultaneously fed into a super-large drafting spinning machine which is formed by four rollers and four aprons and which operates in a three-region drafting mode. The spinning method has the advantages that according to the feeding mode of the three roves, the multi-component segmental color yarns with three different colors can be produced, the color yarns in different styles can be produced, and yarn added value is increased; in the spinning procedure, 30 to 300 times of super-large drafting can be realized through the four rollers and the four aprons in the three-region drafting mode, foundation for simultaneously feeding three roves is established, spinning efficiency is improved effectively, and meanwhile, spinning-compatibility and yarn quality of the color yarns are improved.

Owner:江苏泗水纺织有限公司

Method for producing compound fertilizer by high tower granulating

ActiveCN1935748ALower melting temperatureAchieve low temperature meltingFertiliser formsUrea compound fertilisersMelting tankPhosphate

The invention discloses a method for producing urea-base grain compound fertilizer by high-tower prilling, comprising pulping and prilling, where the pulping adopts three-step series continuous gradual cooling pulping method, comprising the steps of: adding fluxing agent and urea in a melting tank, melting the urea at low temperature and making the urea melt flow into the first stage mixing tank; in the first stage mixing tank, adding unreactable raw materials into the urea melt, and making the mixed melt flow into the second stage mixing tank; in the second stage mixing tank, adding in ammium phosphate and mixing for less than 4 min, and obtaining mixed melted pulp; spraying the mixed melted pulp through the double-speed rotating prilling nozzle of the high tower into a prilling tower to complete prilling. And it has advantages of low temperature operation, low energy consumption, low loss, good pulp fluidity, good operating environment. And the produced compound fertilizer grains are round, less broken and uniform.

Owner:拉多美科技集团股份有限公司

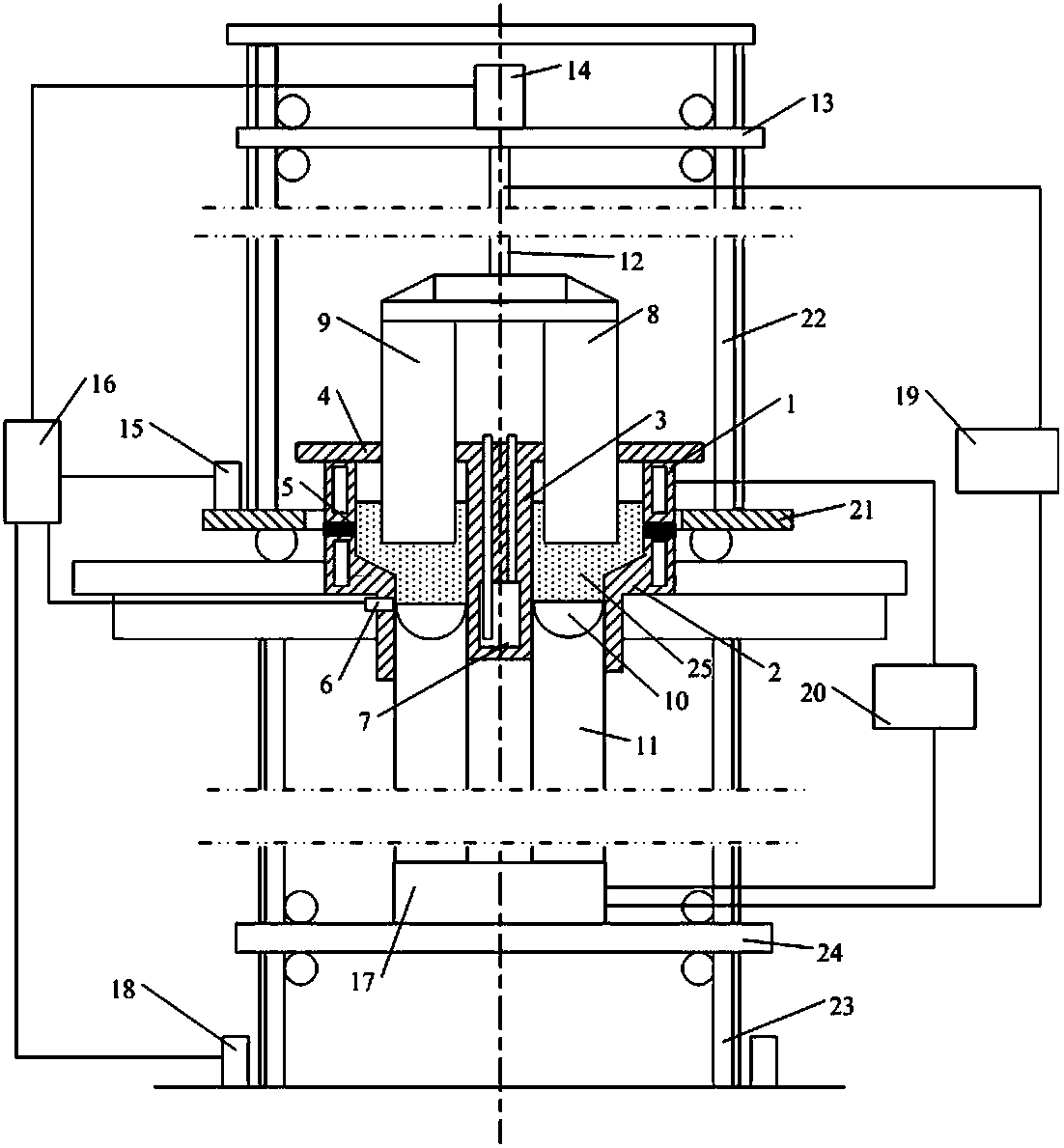

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

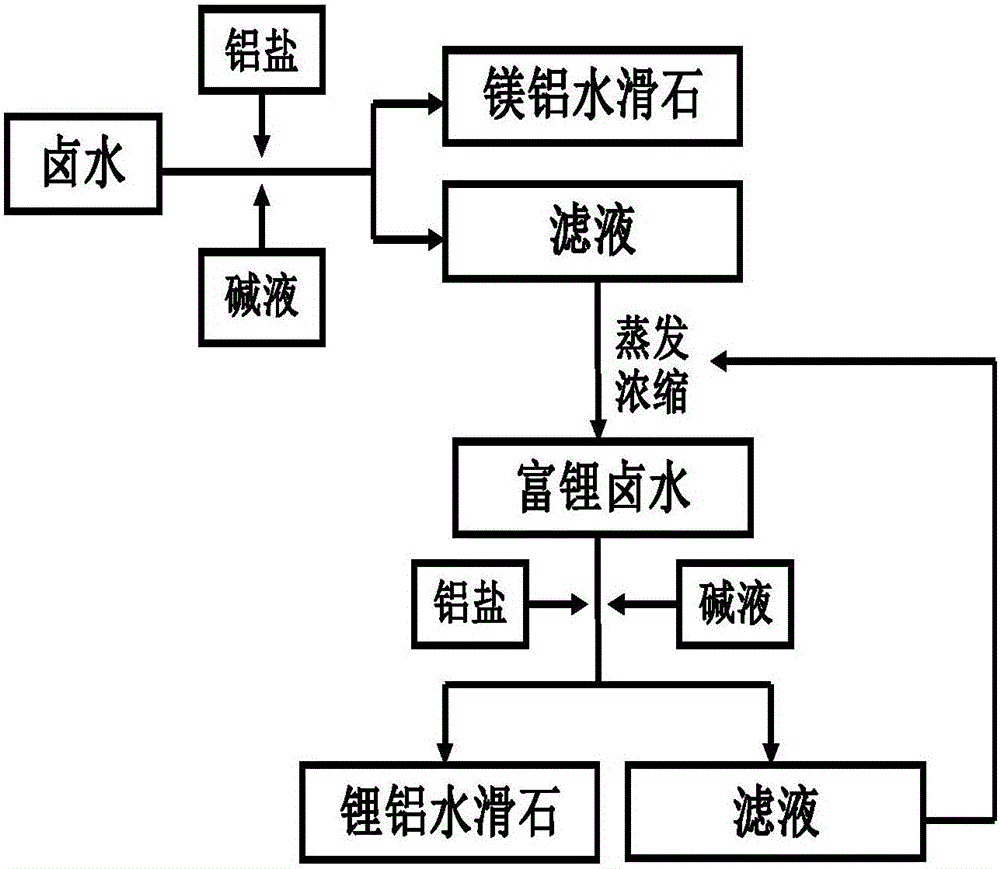

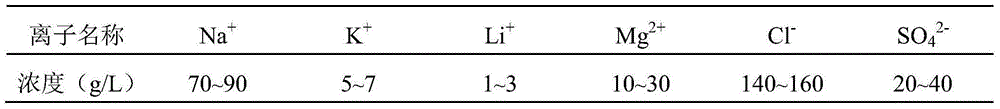

Process method for extracting Mg and Li from bittern and simultaneously producing hydrotalcite

ActiveCN105152193ARealize resource separationAchieve productionSemi-permeable membranesHydrotalciteLithiumEvaporation

The invention provides a process method for separating Mg and Li from salt lake bittern and simultaneously producing magnesium-aluminum layered double hydroxide (MgAl-LDH) and lithium-aluminum layered double hydroxide (LiAl-LDH) by a reaction-separation combined technology. The process method comprises adding an Al salt in bittern, carrying out coprecipitation and crystallization on the bittern and alkali lye for coprecipitation to obtain an MgAl-LDH solid product and a filtrate, carrying out evaporation concentration on the filtrate to obtain Li-rich bittern, adding an Al salt into the Li-rich bittern, carrying out coprecipitation on the mixed Li-rich bittern and alkali lye, carrying out separation to obtain a LiAl-LDH solid product and a filtrate, carrying out evaporation concentration on the filtrate and recycling the concentrate. Mg in bittern can form MgAl-LDH and the MgAl-LDH is separated at first so that the traditional method for separating Mg and Li from a high Mg / Li ratio solution has high difficulty. Through the reaction-separation combined technology, Mg and Li resources in salt lake bittern are separated and simultaneously, MgAl-LDH and LiAl-LDH functional material production is realized. The process method realizes salt lake resource separation and produces a high added value functional material.

Owner:QINGHAI WESTERN MAGNESIUM NEW MATERIAL CO LTD

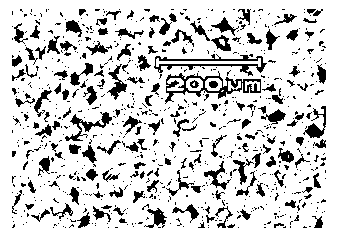

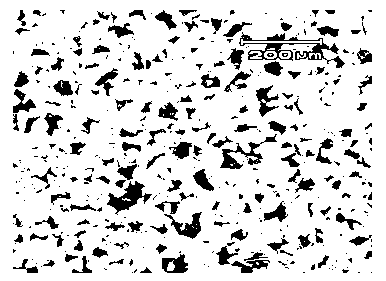

700MPa grade composite strengthening bainite steel and method for preparing same

InactiveCN101285156AEasy to useReduce alloy costMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 700MPa compound strengthening bainitic steel and a method for making the same. The compound strengthening bainitic steel is manufactured by adopting thin slab continuous casting and rolling process, wherein, the main chemical compositions in percentage by weight of the refined molten steel are: 0.03 to 0.07 percent of C , 1.51 to 2.10 percent of Mn, 0.50 to 0.80 percent of Cr, 0.10 to 0.15 percent of Ti, less than or equal to 0.30 percent of Si, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, the balance being Fe and inevitable residual elements. The invention realizes that the yield strength of the prior 345MPa hot-rolled sheet doubles and opens a new way to produce 700MPa high-strength steel by saving expensive alloying elements like Mo, Ni and so on. At the same time, the steel structure mainly comprises fine bainites, which improves the work hardening capacity of the high-strength steel and has a good forming property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

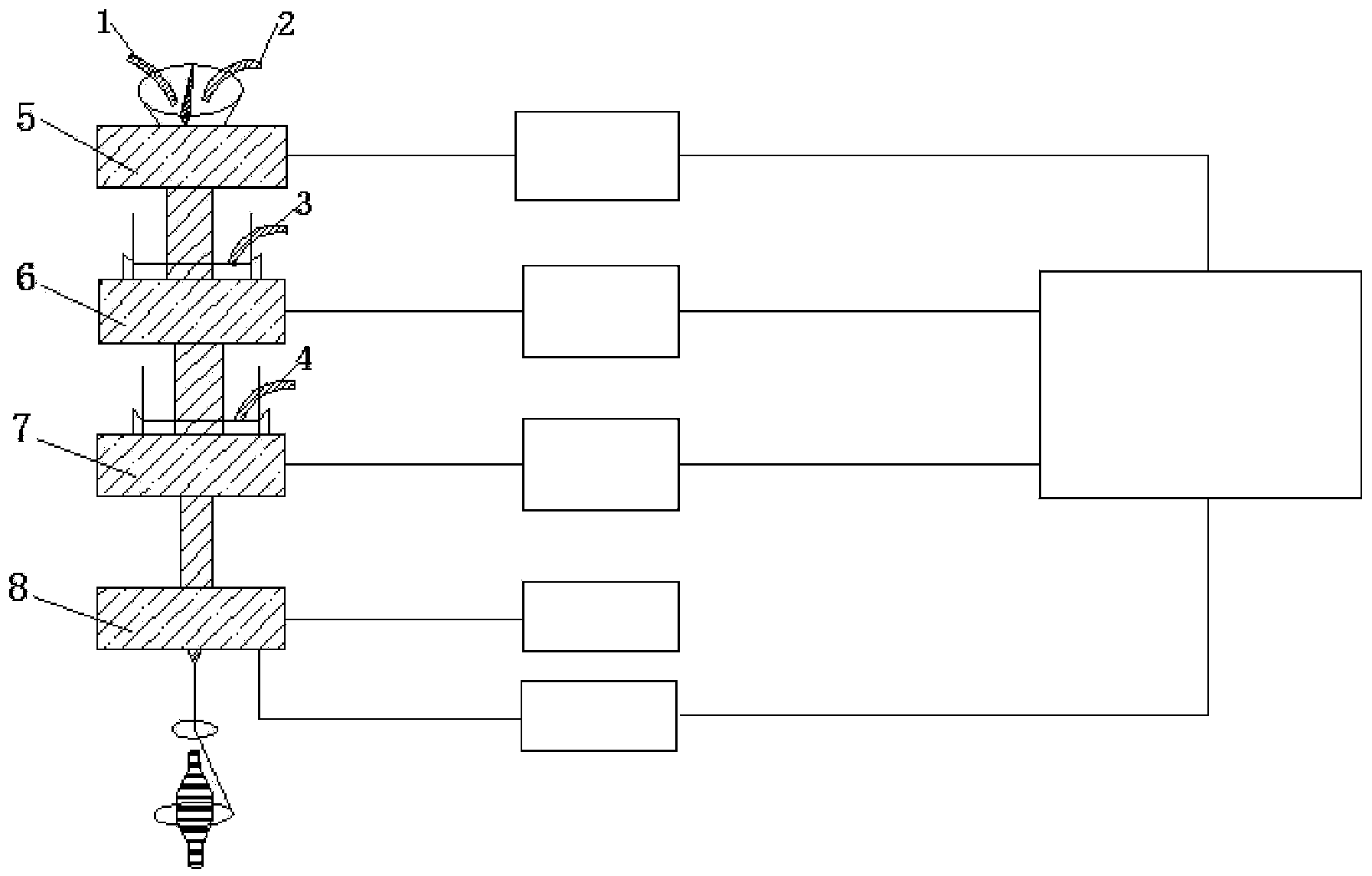

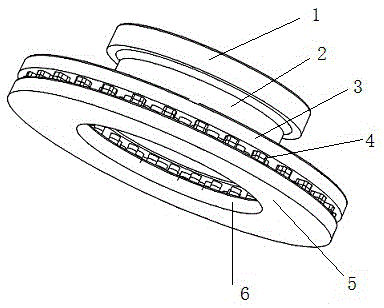

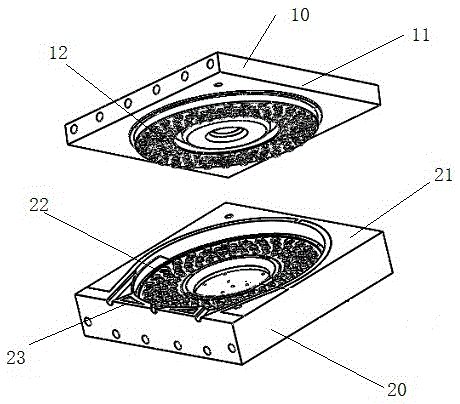

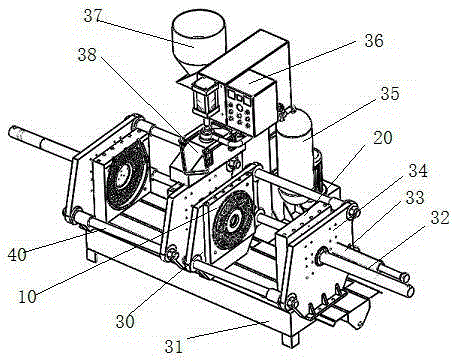

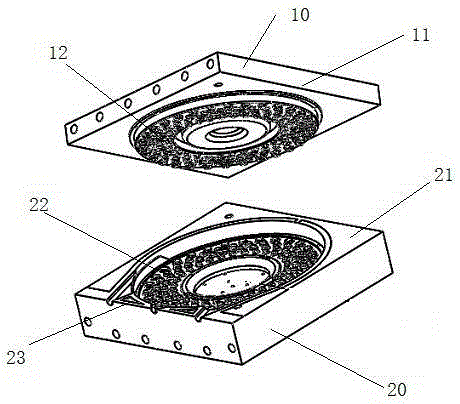

Workblank manufacturing method of automobile brake disc

InactiveCN105458184AAchieve productionSave materialFoundry mouldsMoulding machinesSand castingCasting defect

The invention discloses a workblank manufacturing method of an automobile brake disc, and belongs to the field of automobile accessory manufacturing. The method comprises the following steps that firstly, according to design paper of the brake disc, and a precoated sand shell mold and a sand core mold are designed and manufactured; secondly, the sand shell mold or sand core mold is placed on a sand shell or sand core automatic forming machine to manufacture a precoated sand casting sand shell model and a sand core model; thirdly, pouring is carried out; and fourthly, a casting is taken out and cleaned. The beneficial effects that production of the brake disc workblank can be efficiently achieved, materials and manpower are saved, mechanical allowance is reduced, casting defects are reduced, the yield is improved, and automation production is easily achieved are achieved.

Owner:YUZHOU KUNLUN MOLD CO LTD

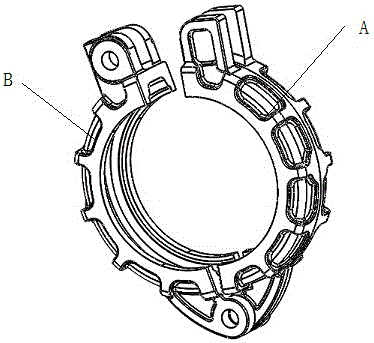

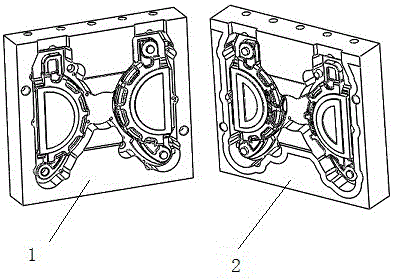

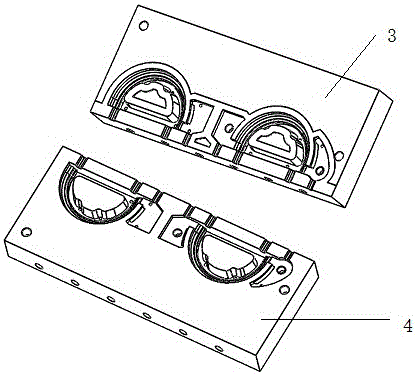

Sand shell mold for manufacturing blank of vehicle braking disc

InactiveCN105397024ASave labor and materialsReduce the amount of machiningFoundry mouldsFoundry coresVehicle brakeMaterials science

A sand shell mold for manufacturing the blank of a vehicle braking disc belongs to the field of manufacturing of car accessories, and comprises an upper mold and a lower mold; the junction surface between the upper mold and the lower mold is a poured parting surface of the braking disc; the upper mold comprises an upper mold plate and an upper cavity; the lower mold comprises a lower mold plate and a lower cavity; the lower mold plate is positioned at the periphery of the lower cavity; the lower cavity is formed inside the lower mold plate; the lower cavity is the same as a part below the parting surface of the braking disc in shape; and the size of the lower cavity is equal to the size of the part below the parting surface of the braking disc and the thickness of a sand shell. The sand shell mold has the characteristics that the production of the blank of the braking disc can be realized efficiently, materials and labors are saved, the mechanical processing capacity is reduced, casting flaws are reduced, the yield is improved, and the automatic production is easy to realize.

Owner:YUZHOU KUNLUN MOLD CO LTD

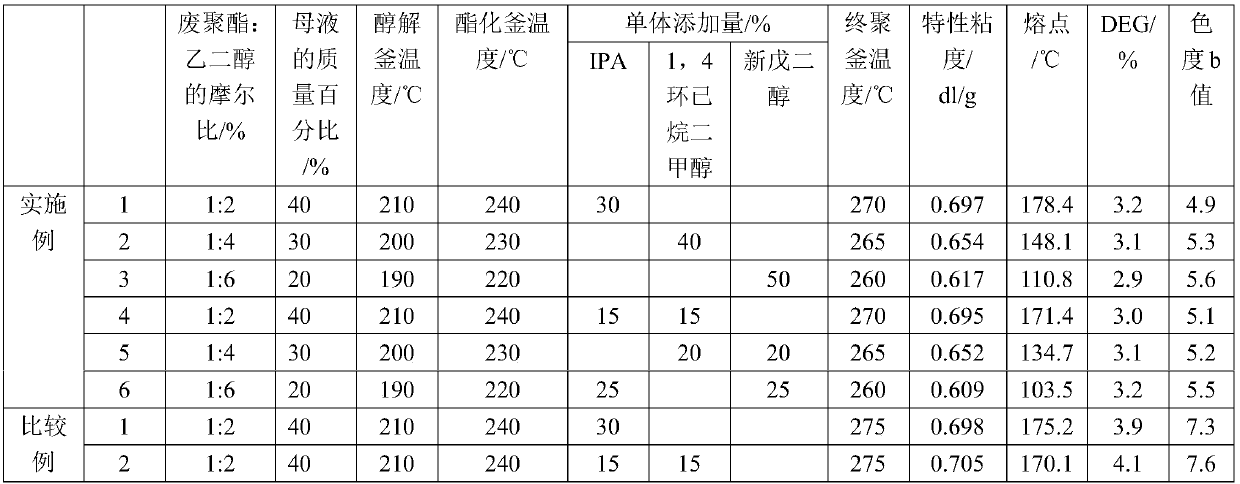

Method for preparing regenerative low-melting-point polyester with waste-polyester alcoholysis method

ActiveCN107652423AImprove alcoholysis efficiencyStabilize the quality of alcoholysis productsPlastic recyclingMonocomponent polyesters artificial filamentIonChemistry

The invention discloses a method for preparing regenerative low-melting-point polyester with a waste-polyester alcoholysis method. The method includes the steps of 1), pretreatment of waste polyester;2), alcoholysis of the waste polyester; 3), quality regulation of esters and adding of one or multiple copolymers of isophthalic acid, 1-4 cyclohexane dimethyl alcohol and neopentyl glycol; 4), polycondensation and slicing preparation, wherein the low-melting-point polyester finally obtained is 0.60-0.70dl / g in intrinsic viscosity, 100-180DEG C in melting point, 3.0+ / -0.3% in content of diglycoland smaller than 6 in chroma value of b. The obtained regenerative low-melting-point polyester is applicable to preparation of cationic-ion dyeable poester filaments and short fiber, and high-value recycling of the waste polyester is realized.

Owner:ZHEJIANG SCI-TECH UNIV

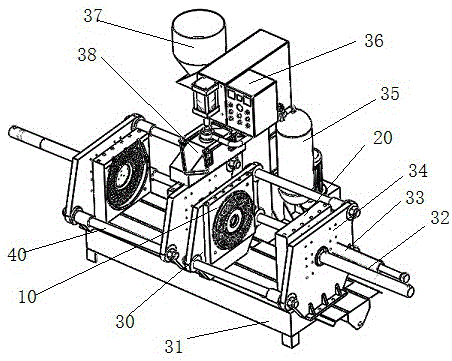

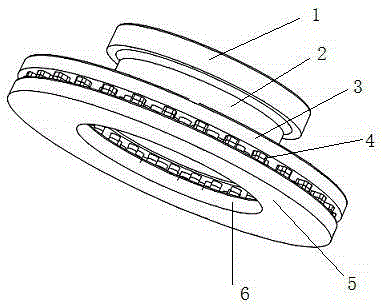

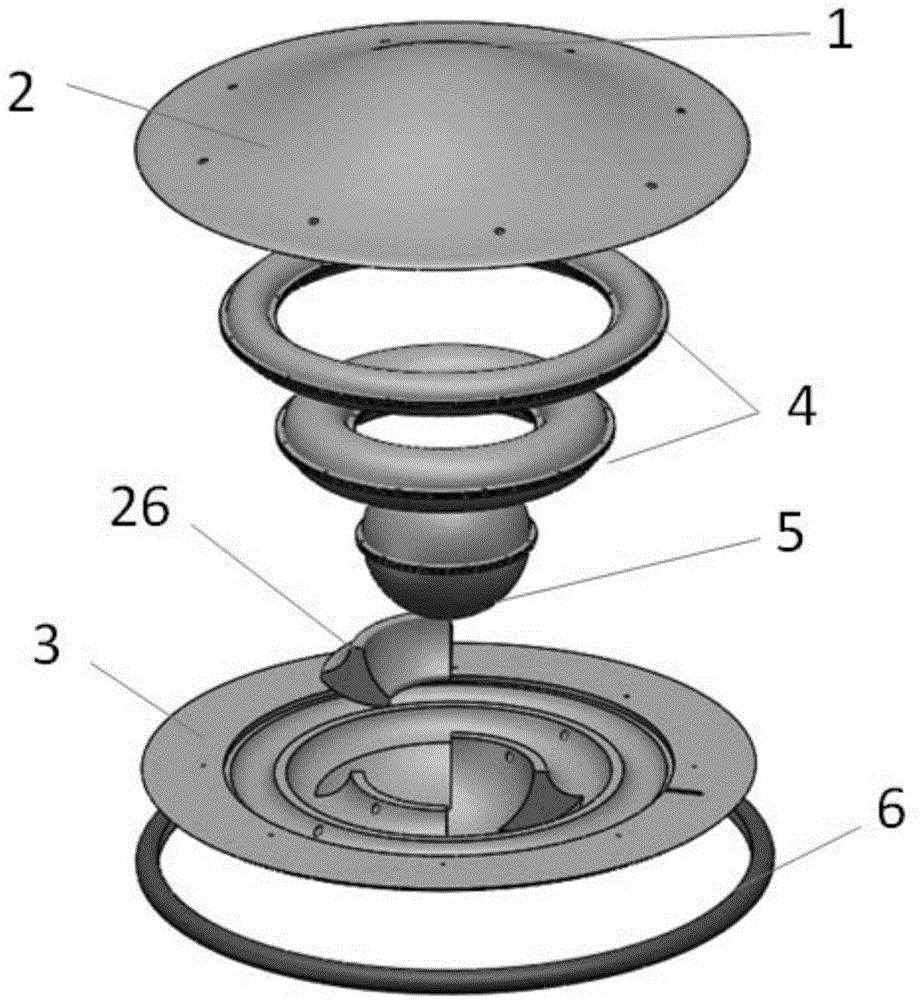

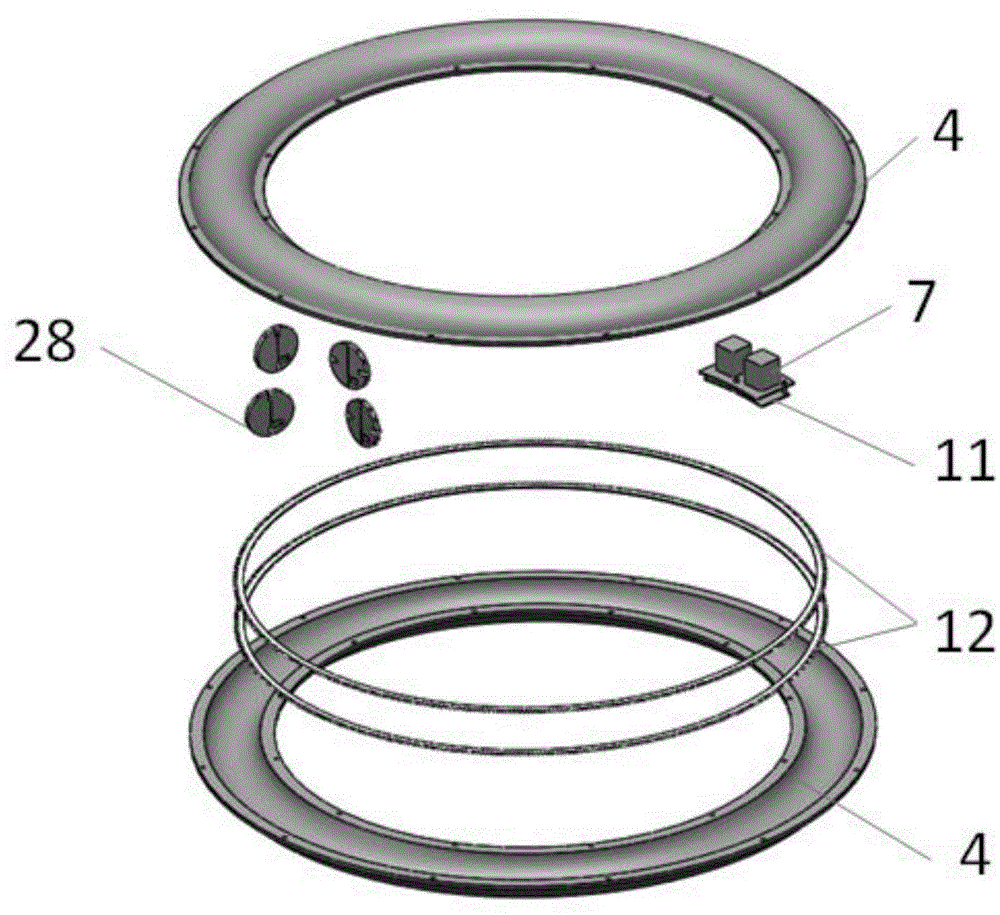

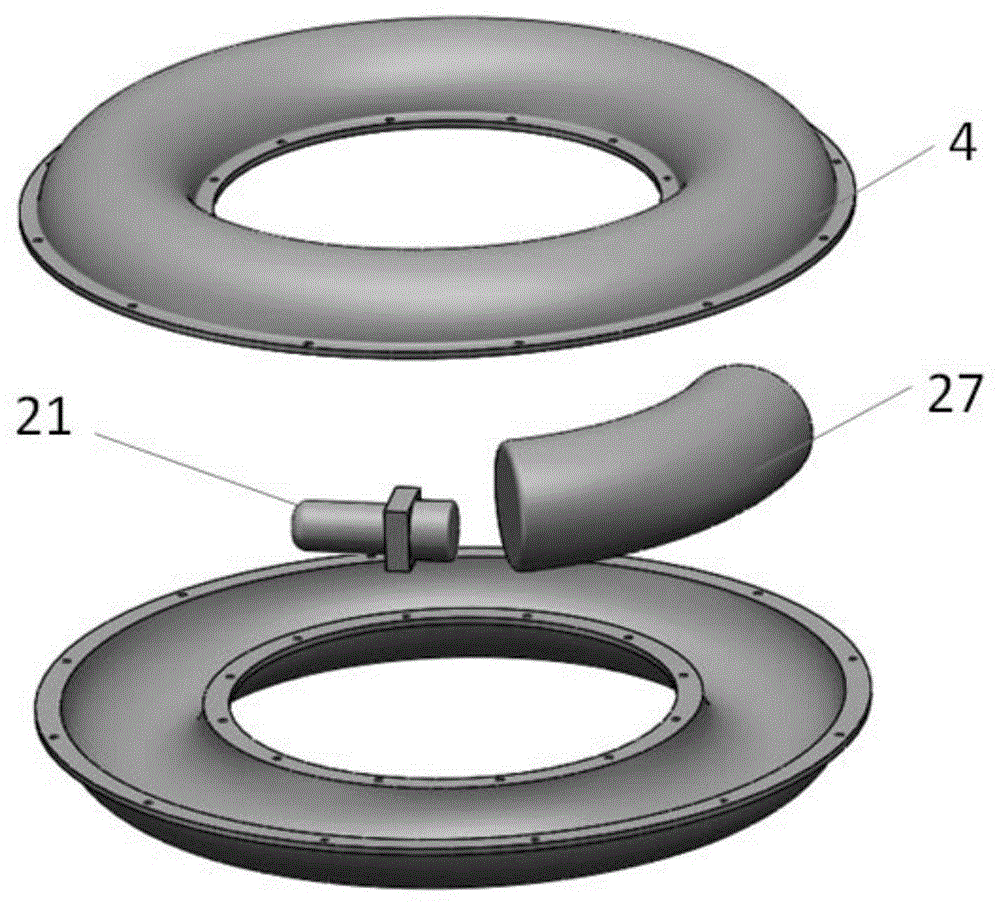

Circular-disc-shaped underwater glider and working method thereof

InactiveCN104527953AIncrease buoyancyIncrease payloadUnderwater vesselsUnderwater equipmentCircular discAttitude control

The invention discloses a circular-disc-shaped underwater glider and a working method thereof. The glider comprises a circular-disc-shaped shell, a pressure-resisting shell, a control system, a communication navigation system, a driving system, a sensor system, an energy source system and an external port. The circular-disc-shaped shell made of a buoyancy material covers the pressure-resisting shell and greater buoyancy is provided for the circular-disc-shaped underwater glider, so that effective load is improved. The pressure-resisting shell structure design scheme combining the pressure-resisting shell and a pressure-resisting hollow ring is adopted so that the utilization rate of the inner space of the circular-disc-shaped underwater glider is improved; meanwhile, the quantity of sealing nodes of internal equipment is greatly reduced, more equipment is prevented from being exposed in a deep sea complicated underwater environment, and thus the whole reliability is improved. A gravity center adjusting system is arranged in the pressure-resisting hollow ring, and a force arm and a moment, generated by a slide block, are relatively great; and the posture control efficiency is improved and the inner space of the circular-disc-shaped underwater glider is sufficiently utilized.

Owner:DALIAN MARITIME UNIVERSITY

Titanium alloy wire production method

The invention discloses a titanium alloy wire production method. A titanium alloy wire is prepared by carrying out multi-die continuous cold-drawing on a titanium alloy wire blank by using a polycrystalline wire drawing die or high-crystalline wire drawing die, wherein calcium-based wire drawing powder or sodium-based wire drawing powder is used as a lubricating agent. By using the titanium alloy wire production method, the size precision and the surface quality of a finished product of the titanium alloy wire are ensured, the production efficiency is increased, and the environment of a working site is improved.

Owner:BAOJI TITANIUM IND CO LTD

Method for rolling thick specification low-alloy structure steel plate by using middle and thin plate blank

InactiveCN101148735AIncreasing the thicknessIncrease reduction rateRoll mill control devicesMetal rolling arrangementsChemical compositionMaterials science

The present invention relates to production of structural low alloy steel plate, and is especially process of producing high strength hot rolled coiled sheet of 16-20 mm thickness with continuous cast billet of 150-170 mm thickness. The steel has chemical composition comprising C 0.15-0.20 wt%, Si 0.20-0.40 wt%, Mn 1.40-1.60 wt%, S not more than 0.030 wt%, P not more than 0.030 wt%, and Fe and impurity for the rest. The production process includes the steps of controlled heating, rough rolling, finish rolling, cooling, etc. and the produced hot rolled coiled sheet has simple composition, low cost, high tensile strength, high yield strength, high elongation, high impact toughness, high cold bending performance, good welding performance and other features.

Owner:LAIWU IRON & STEEL GRP

High-purify upper oxygen-free copper rod production method

The invention discloses a method for producing high-purity upward oxygen-free copper rods, which comprises the following steps: uniformly adding copper plates into a melting furnace in batches during melting of copper materials; adopting a Cu-RE intermediate alloy rod to continuously add single rare earth element or mischmetal element, realizing electromagnetic stirring in the melting furnace through induction heating coils, and making the rare earth element uniformly distributed in molten copper; and arranging a ceramic filtration baffle plate on the front of a sluice between the melting furnace and a heat-insulating furnace, making the ceramic filtration baffle plate completely cover the sluice, preventing rare earth oxide from being rolled into upward oxygen-free copper rods, and obtaining the high-purity upward oxygen-free copper rods. The method has the advantages of simple production technique, stable production process, less residual oxide inclusion formed by the rare earth element, good purification effect of the copper materials, and good product quality.

Owner:JIANGSU UNIV +1

Rubber composition for producing color tyre

InactiveCN102492192AAchieve productionGuaranteed wear resistanceSpecial tyresMasterbatchPolymer science

The invention provides a rubber composition for producing a color tyre. The color tyre comprises a rubber composition of tyre surface, a rubber composition of tyre sidewall, an outer protective rubber composition and sealing layer rubber composition. In a primary color glue of the rubber composition of tyre surface, the rubber composition of tyre sidewall and the outer protective rubber composition, black carbon black is substituted by white carbon black; 1574 color masterbatch, 2507 color masterbatch and titanium dioxide in a certain proportion are added to realize coloration of the rubber composition of tyre surface, the rubber composition of tyre sidewall and the outer protective rubber composition; in the sealing layer rubber composition, black carbon black is substituted by white carbon black; and black masterbatch and titanium dioxide in a certain proportion are added to avoid blackening tendency of the sealing layer, so as to realize production of the color tyre as well as guarantee wear resistance of the color tyre. The produced color tyre can satisfy national test standard.

Owner:双星东风轮胎有限公司

Aroma camellia oil and preparation method thereof

ActiveCN103725417AAvoid the effects of oil qualityAvoid influenceFatty-oils/fats refiningMaillard reactionCamellia oleifera

The invention discloses an aroma camellia oil which is prepared by adopting the following steps: (1), preparing foots slurry; (2), performing enzymolysis and Maillard reaction; (3), obtaining fragrant digestion grease; and (4), dewatering. According to the fragrant camellia oil, camellia oil foots is adopted as a raw material for preparation, and aroma substances are mainly from a protein denaturation aroma and a aroma formed by reducing sugar in camellia seeds and amino acid in a low-temperature enzymatic process through the Maillard reaction. According to the fragrant camellia oil, the problems of influence of high temperature on quality of the camellia oil in a conventional cooking aroma enhancing procedure, inactivation of active substances in nutritional ingredients in the camellia oil due to the high-temperature long-term Maillard aroma enhancement reaction of and aroma reduction of the camellia seed oil are avoided, and thus the camellia oil which is not damaged in nutrient substances and is thick in aroma is obtained. The camellia oil has the advantages of recycling waste materials, and being simple in process, low in operation cost and stable in product quality. The aroma camellia oil prepared by using the preparation method disclosed by the invention is capable of generating higher economic benefit.

Owner:ANHUI ZHONGSHENG EDIBLE OIL TECH

Smelting process for producing ultra-low phosphorous steel by converter

InactiveCN101906504AReduce alloy consumptionIncrease productionManufacturing convertersFerrosiliconSmelting process

The invention discloses a smelting process for producing ultra-low phosphorous steel by a converter. In the process, molten iron subjected to primary desulfurization is subjected to a multiple slagging smelting process through the converter to produce the ultra-low phosphorous steel. The process comprises the following steps of: removing phosphorus from the molten iron subjected to primary desulfurization by adopting a deslagging and blowing method at the early stage and the later stage twice, adjusting slag by using silicon iron, pouring into a slag pot to make the slat pot full each time, and well controlling the process temperature: the target temperature at the early stage is between 1,350 and 1,400 DEG C, the highest temperature is less than or equal to 1,450 DEG C, the temperature measured when a sublance blows 80 percent of the steel is between 1,530 and 1,550 DEG C and the target terminal temperature is between 1,610 and 1,630 DEG C to obtain the ultra-low phosphorous steel with less than or equal to 0.005 mass percent of phosphorous. The molten iron subjected to primary desulfurization is subjected to multiple deslagging through the converter to produce the ultra-low phosphorous steel, and the process has the advantages of small physical heat loss of the molten iron, high yield, high efficiency, low alloy consumption, low cost and energy conservation.

Owner:NANJING IRON & STEEL CO LTD

Low-alloy heat-resistant steel plate and manufacturing method thereof

InactiveCN103320696AGood tensile properties at room temperatureOrganization performance is stableManufacturing convertersManganeseWorking temperature

The invention belongs to the technical field of alloy material manufacturing, and especially relates to a manufacturing method of a low-alloy heat-resistant steel plate and a manufacturing method thereof. According to the low-alloy heat-resistant steel plate and the manufacturing method thereof, the steel plate comprises the following components, by weight, 0.08-0.16% of carbon, 0.15-0.40% of silicon, 0.40-0.70% of manganese, no more than 0.015% phosphorus, no more than 0.010% of sulfur, 0.90-1.20% of chromium, 0.20-0.35% of molybdenum, 0.15-0.30% of vanadium, and balance of iron and unavoidable impurities. The steel plate is produced through the processes of converter smelting, LF+VD or RH out-furnace refining, slab continuous casting, slab stacking and slow cooling, re-heating, high pressure water phosphorus removing, slab rolling, steel plate stacking and slow cooling, normalizing+ tempering, and the like. The steel plate provided by the invention has good normal temperature and high-temperature properties, and the like, such that steel plate application safety under high-temperature environment is ensured. The steel plate is mainly used for manufacturing steel structural parts with a working temperature of 540-640 DEG C in a power plant boiler, such as end cap, lug, header, gas-saving device beam, steam pipe, superheater, reheater tube, and the like.

Owner:JIGANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com