Precast lattice beam used for slope reinforcement, manufacturing method thereof and construction method for slope reinforcement adopting precast lattice beam

A technology of prefabricated lattice and lattice beams is applied in the fields of ecological restoration projects and slope reinforcement. The effect of utilization rate, reduction of stressed steel bars, and light installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

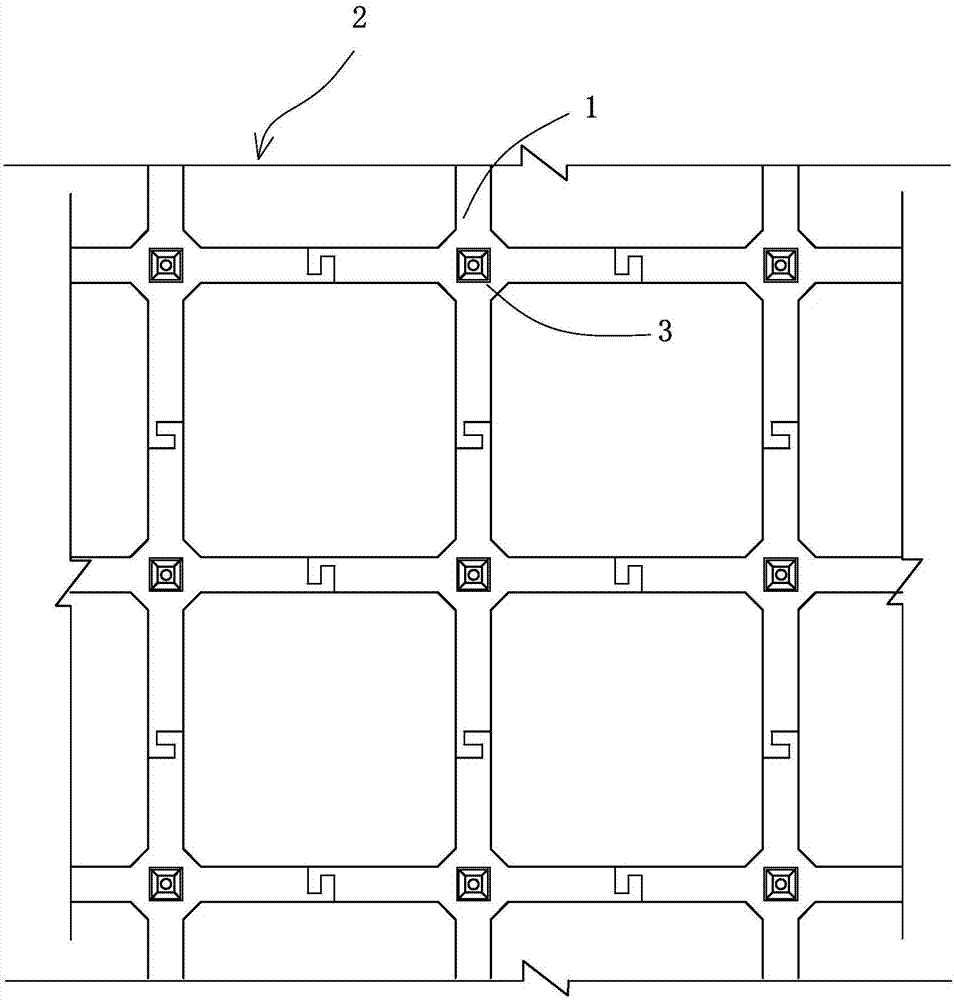

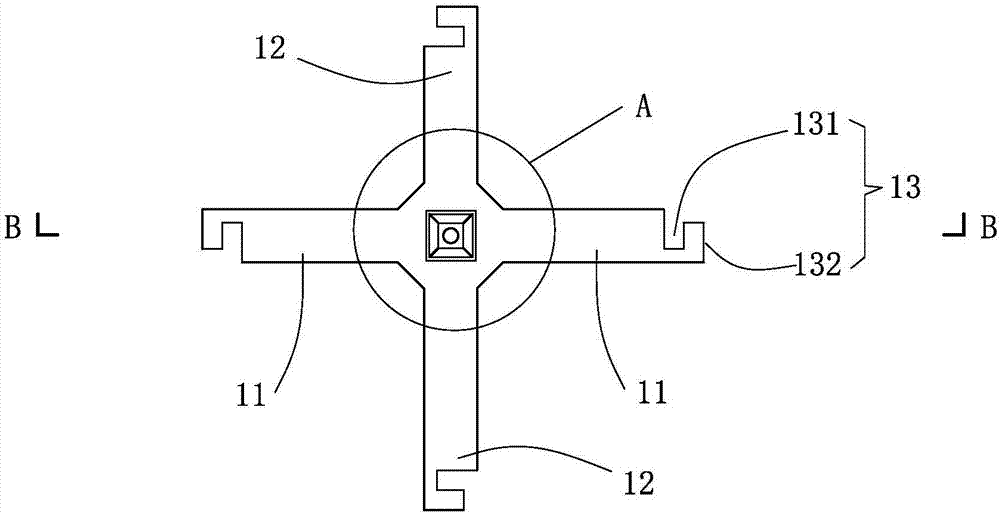

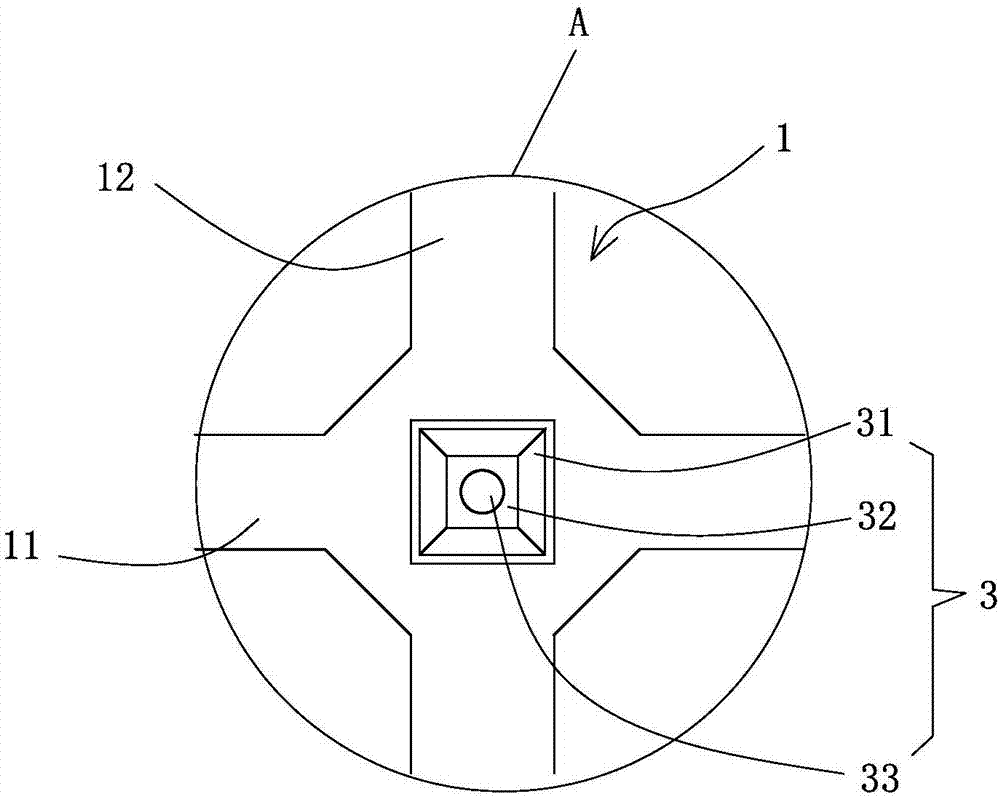

[0061] Such as Figure 1-6 As shown, the present invention relates to a prefabricated lattice beam for slope reinforcement, including a plurality of prefabricated cross-shaped beam units 1 of reinforced concrete structure formed by cross beams 11 and longitudinal beams 12 intersecting, the cross The concrete strength of the beam body unit 1 is not less than C25; the size of the internal reinforcement of the longitudinal beam 12 is not less than Ф14; the size of the internal reinforcement of the crossbeam 11 is not less than Ф6. Such as figure 2 As shown, the center intersection of the cross-shaped beam unit 1 is provided with an anchor head 3; the anchor head 3 includes a concrete groove 31 and a backing plate 32 placed on the surface of the groove, between the groove 31 and the pad Anchor holes 33 are provided on the plates 32 for the anchor rods 34 to penetrate during installation. The two ends of the crossbeam 11 and the two ends of the longitudinal beam 12 of the cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com