Patents

Literature

34results about How to "Improve section properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

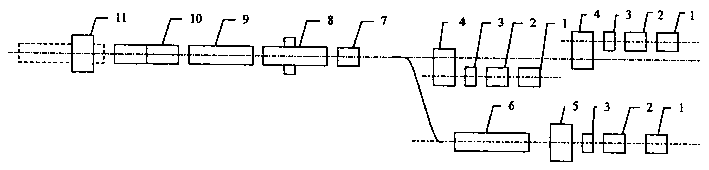

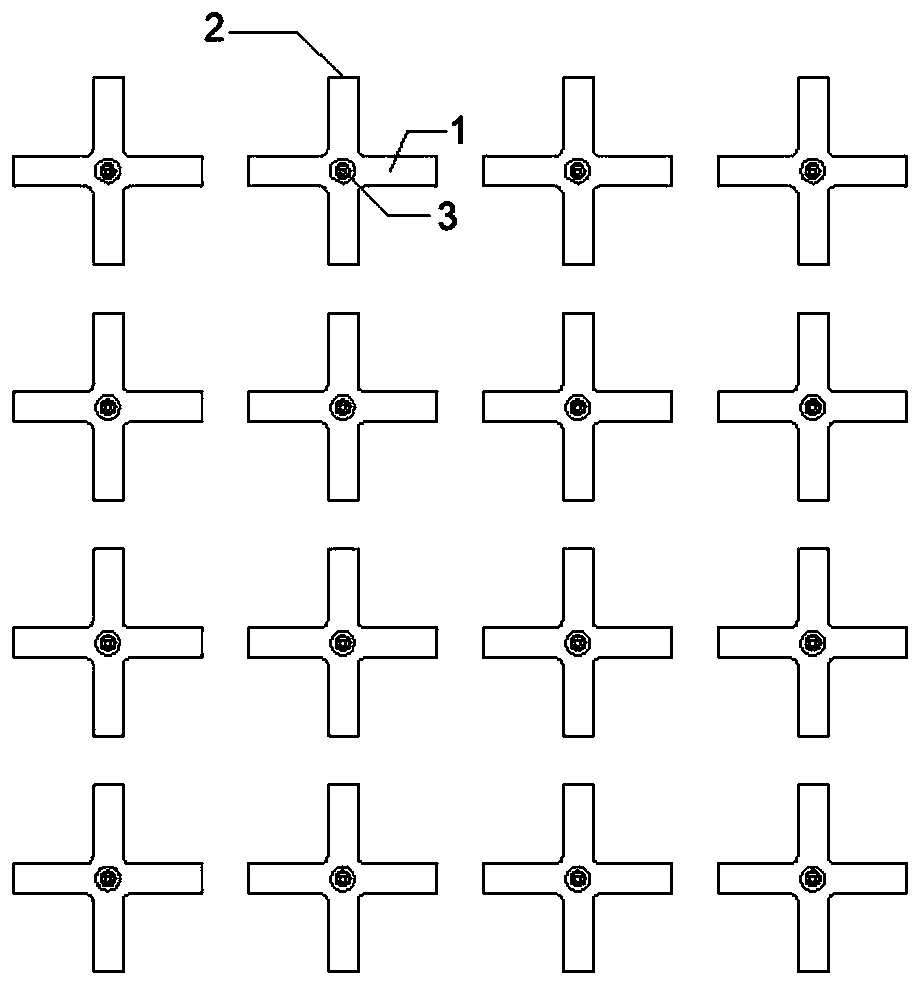

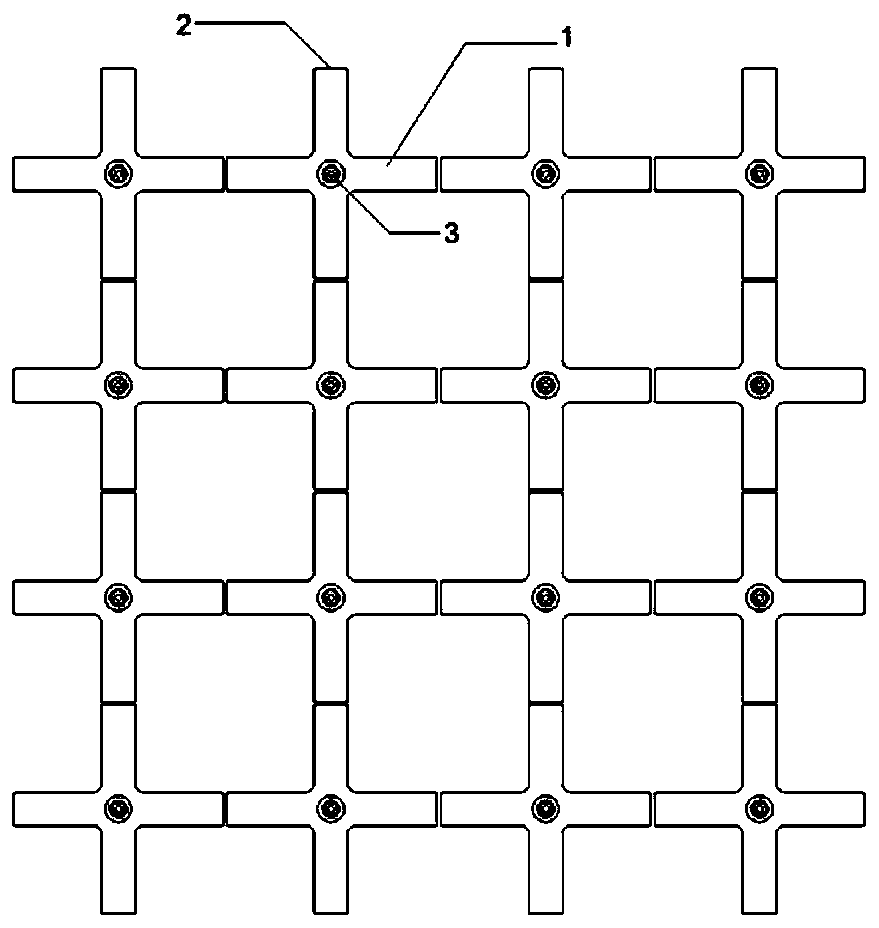

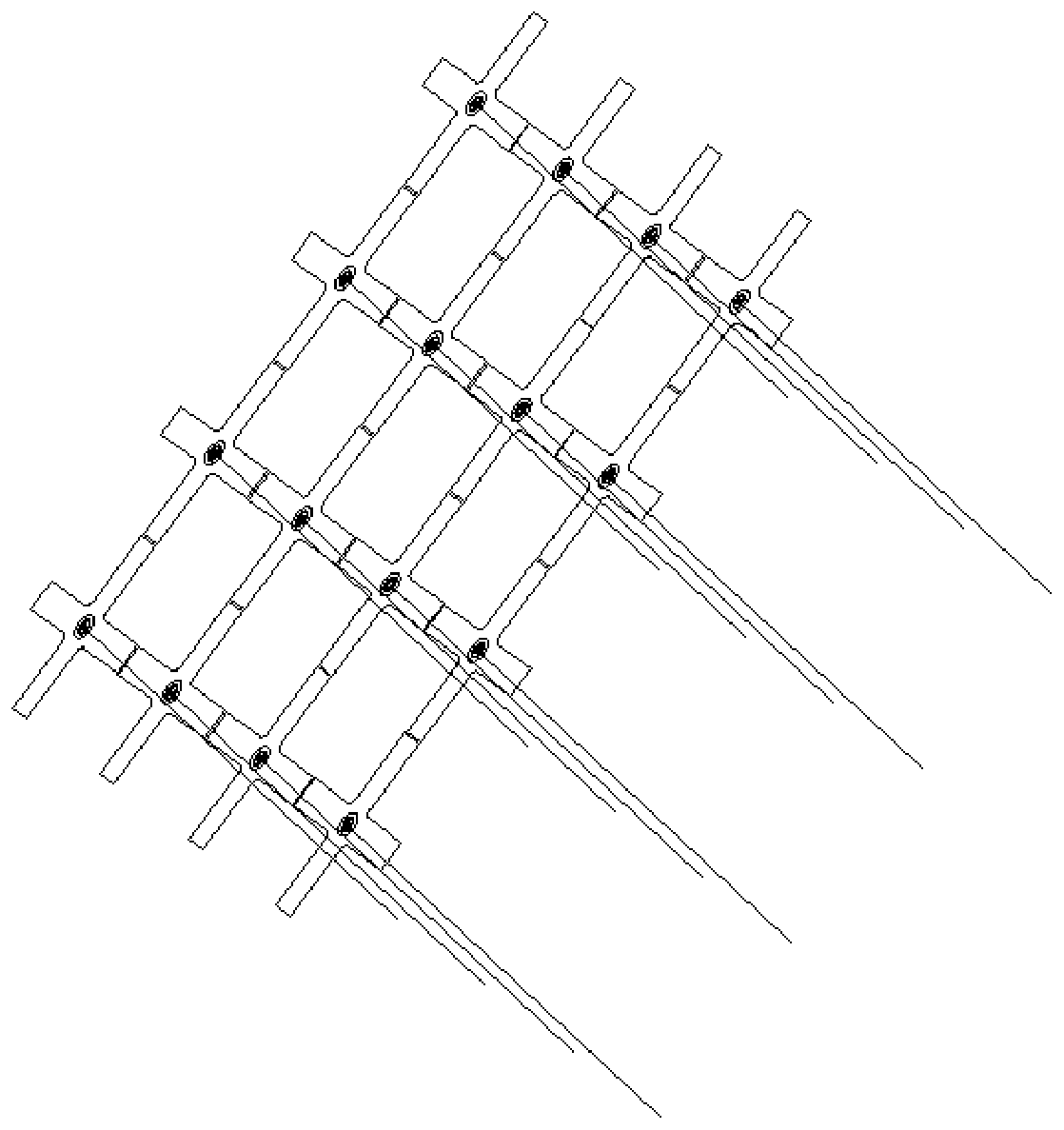

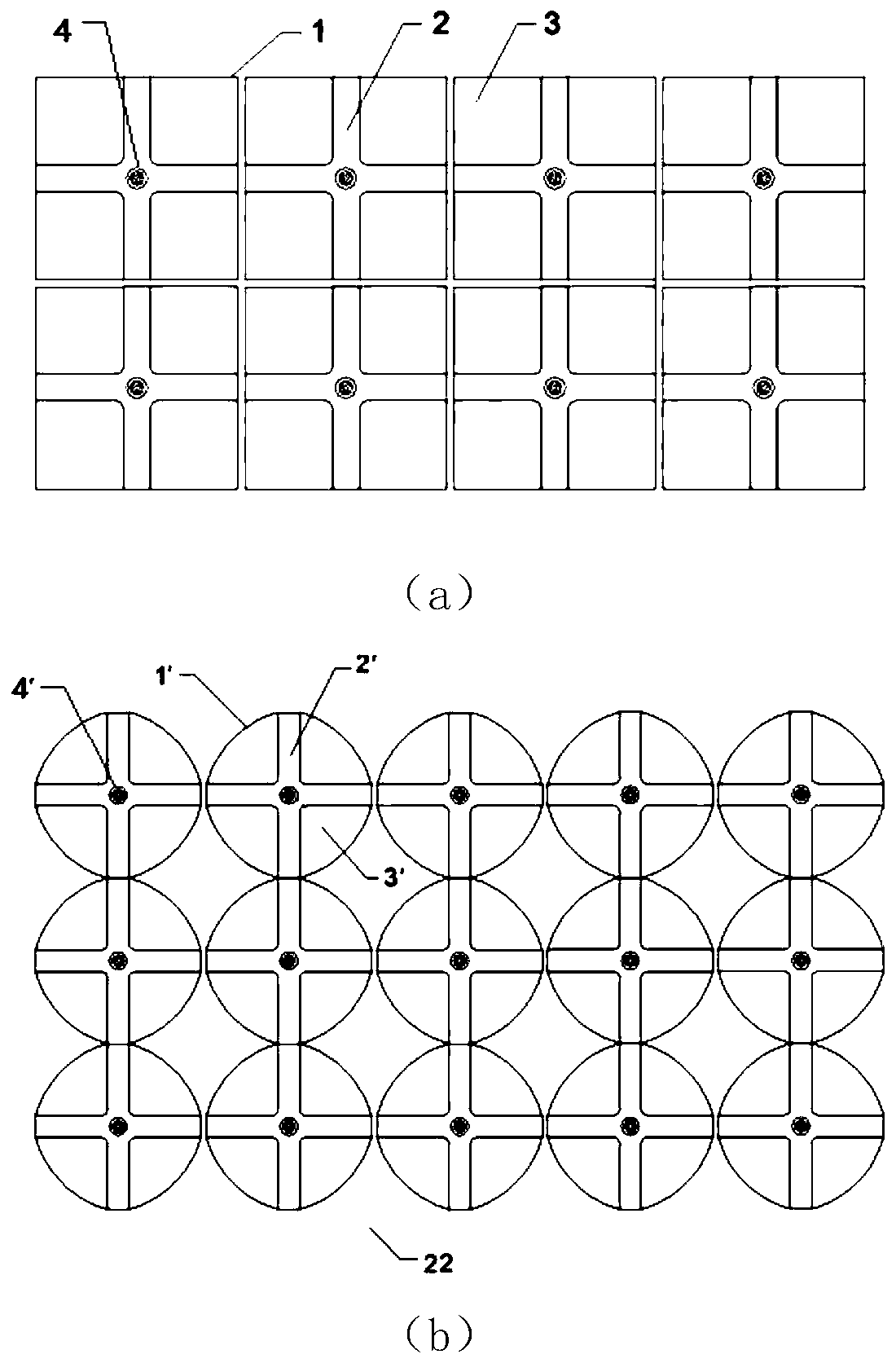

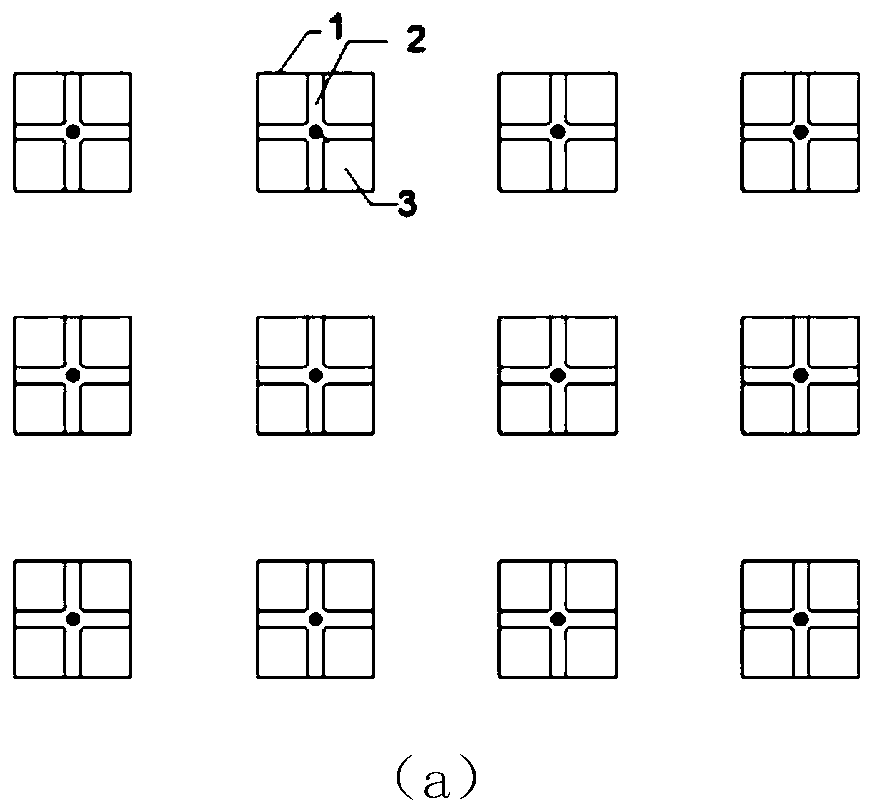

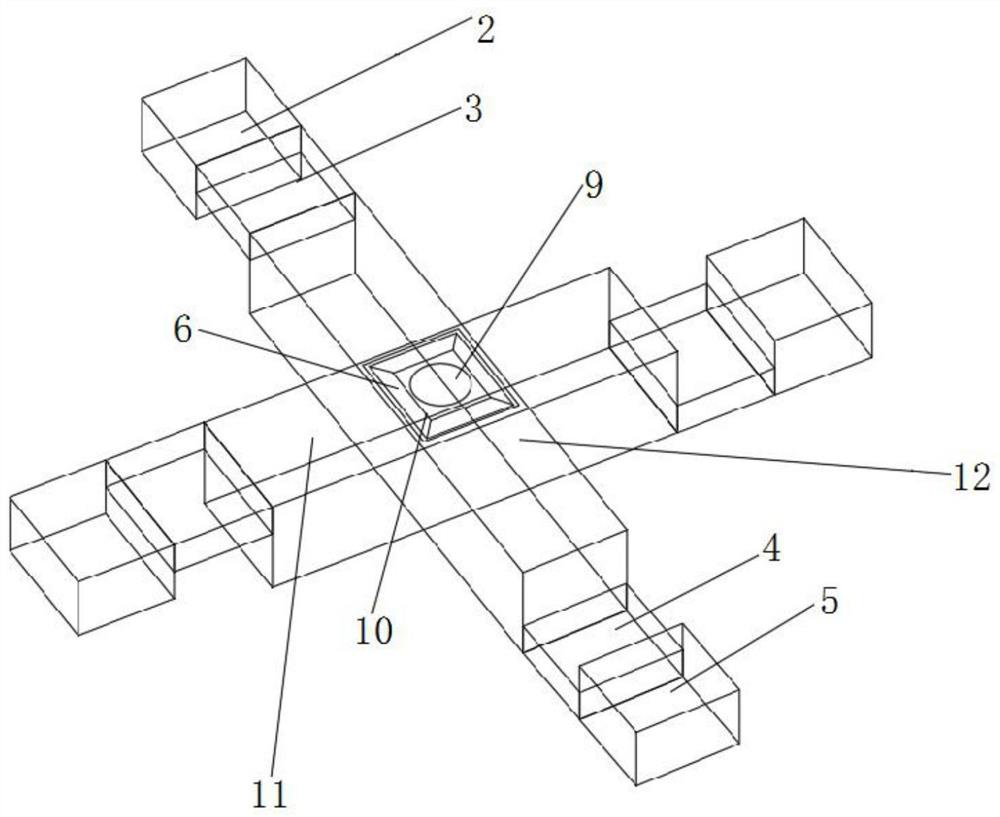

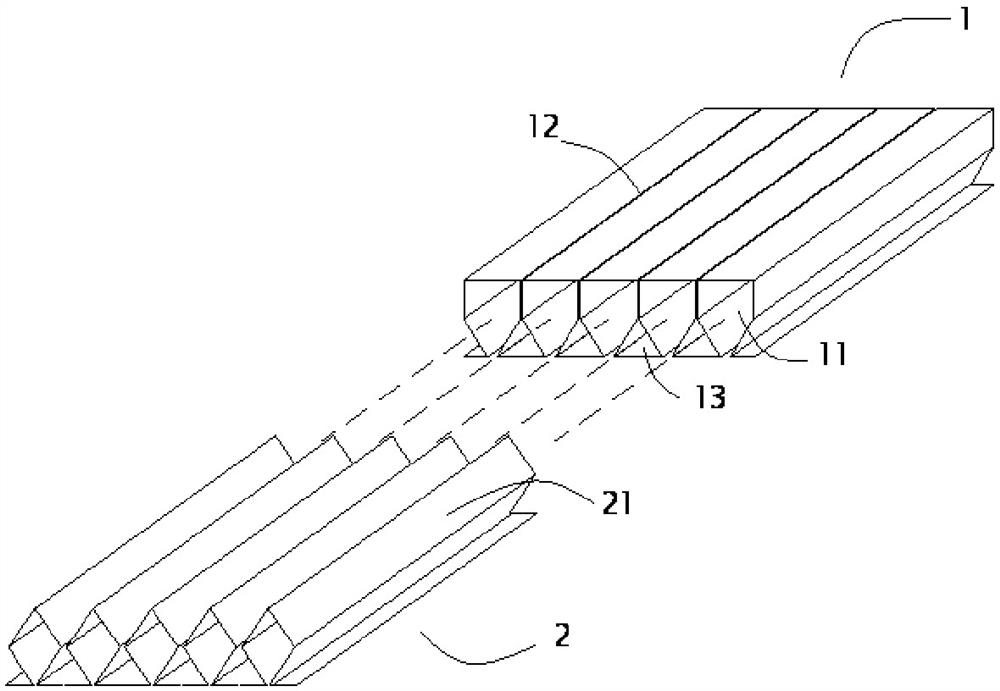

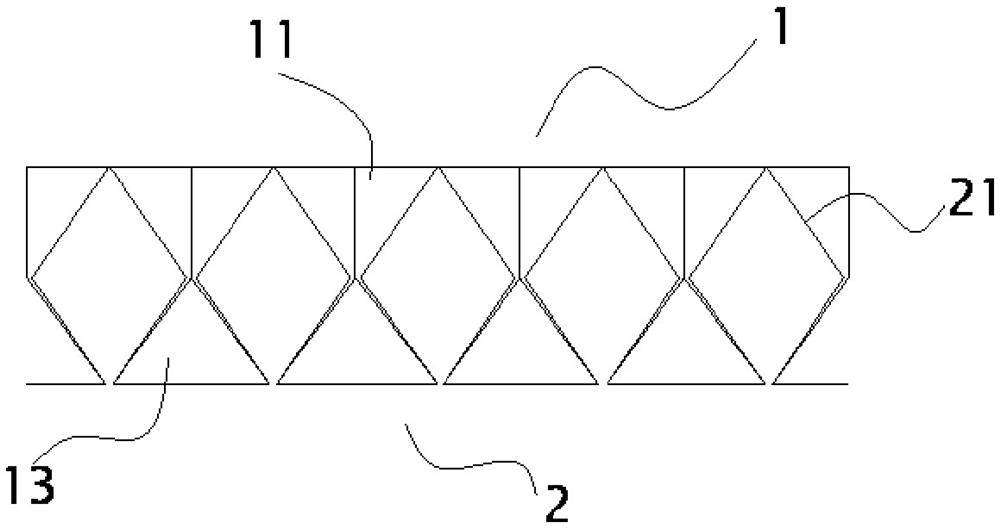

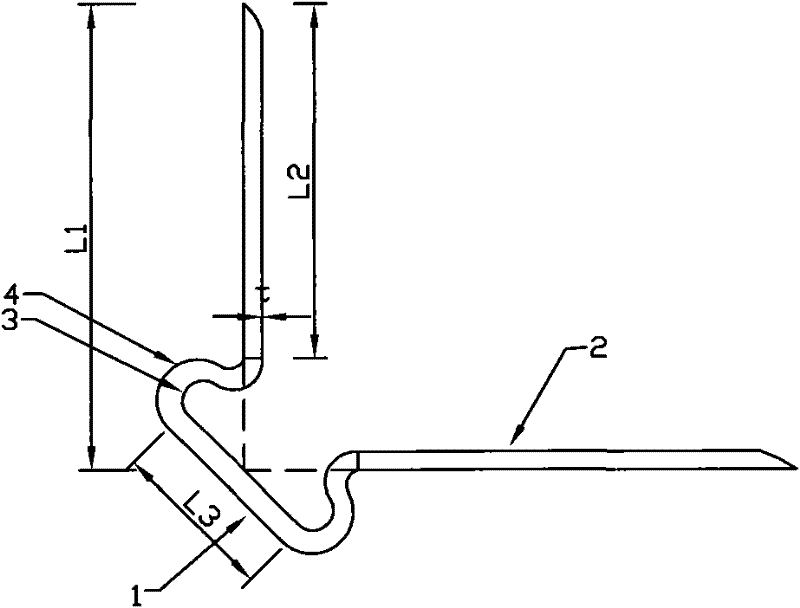

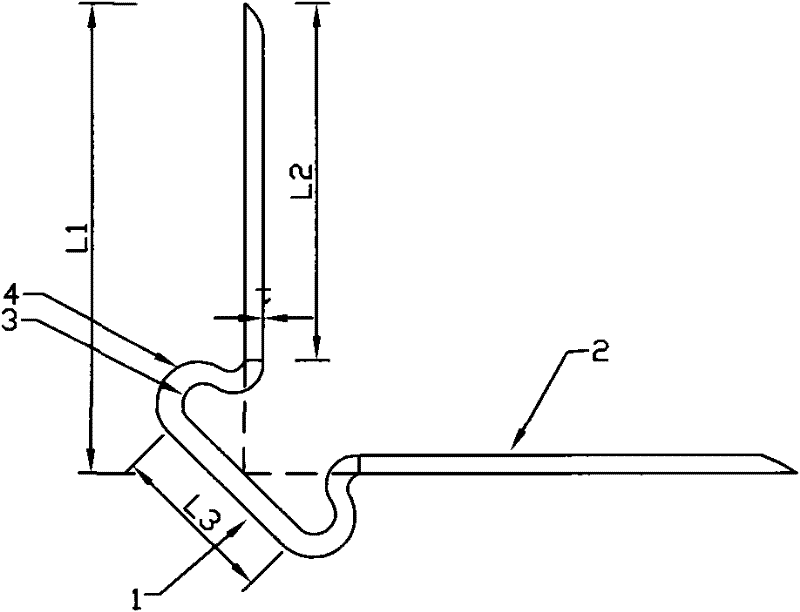

Precast lattice beam used for slope reinforcement, manufacturing method thereof and construction method for slope reinforcement adopting precast lattice beam

PendingCN107030874AEasy to manufactureEasy to installCeramic shaping apparatusExcavationsShaped beamChinese characters

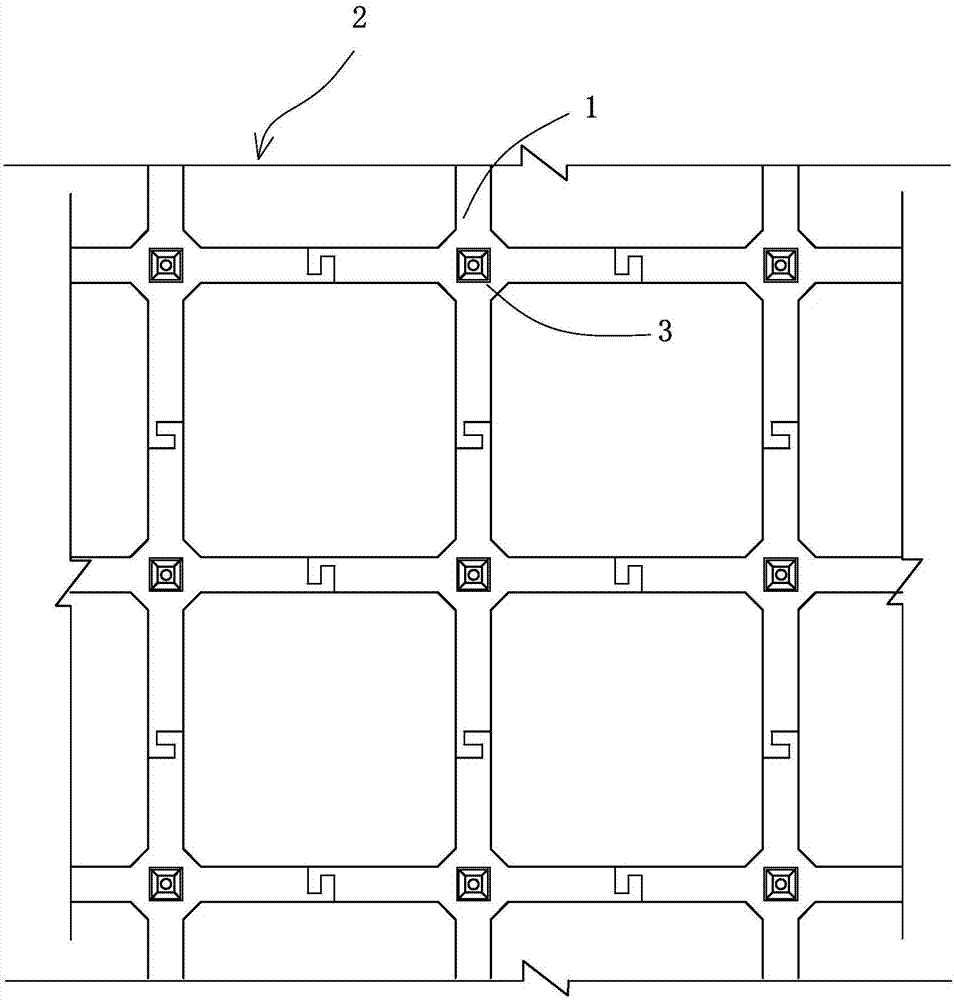

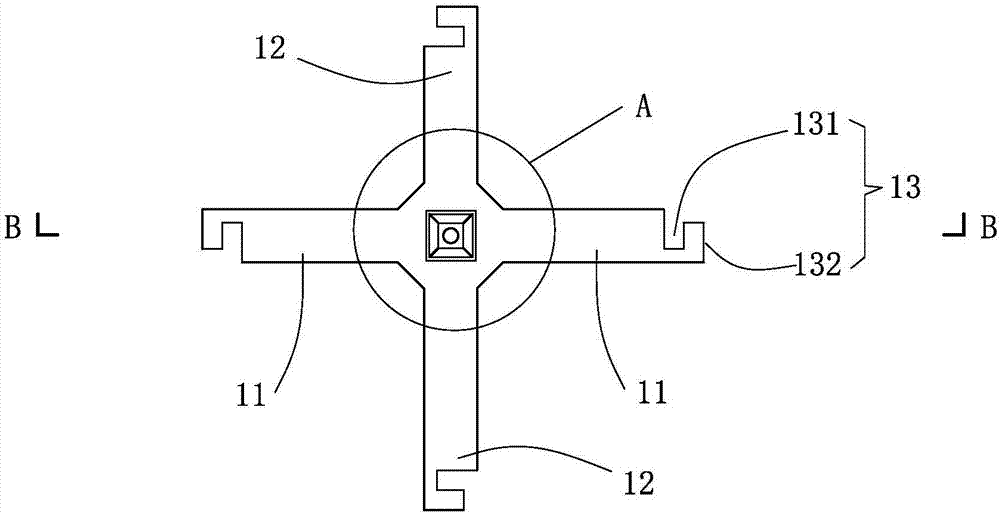

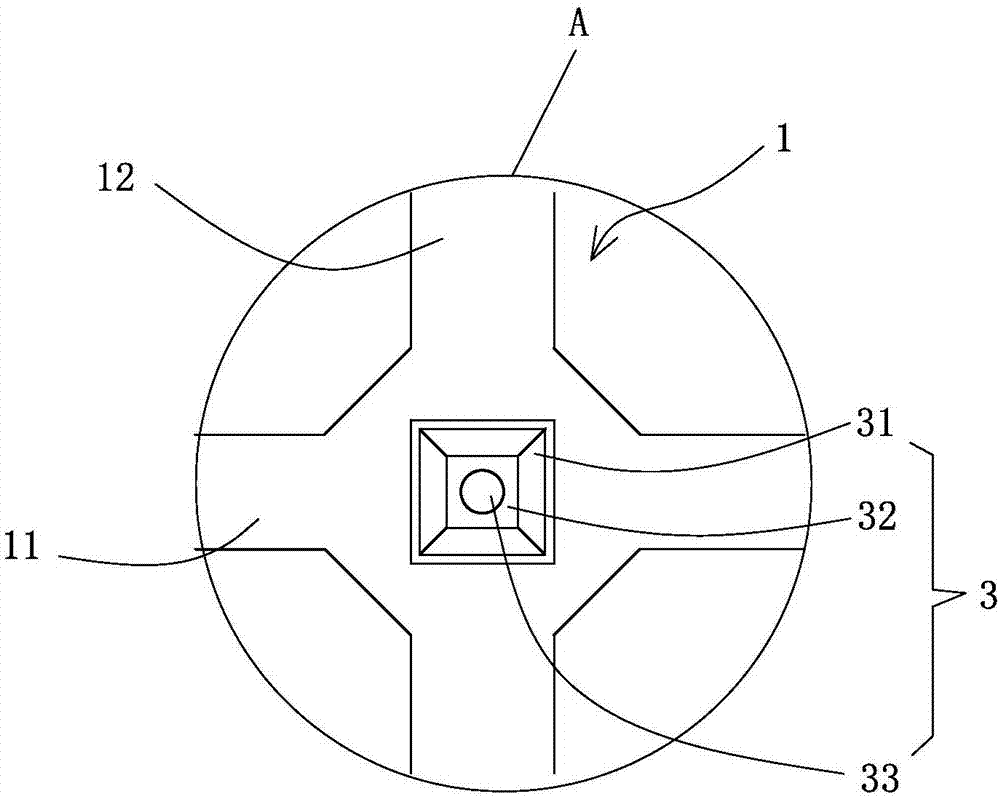

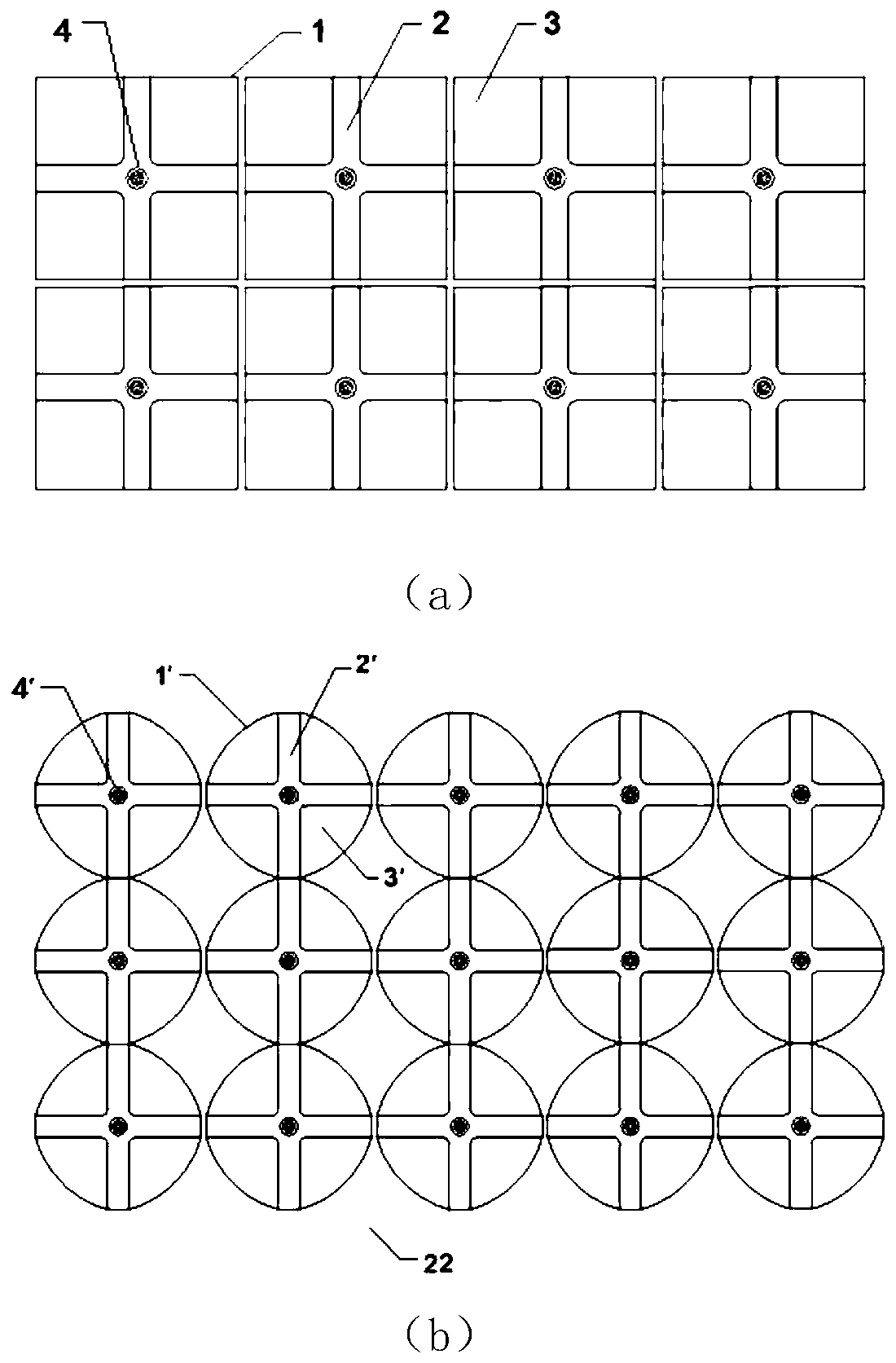

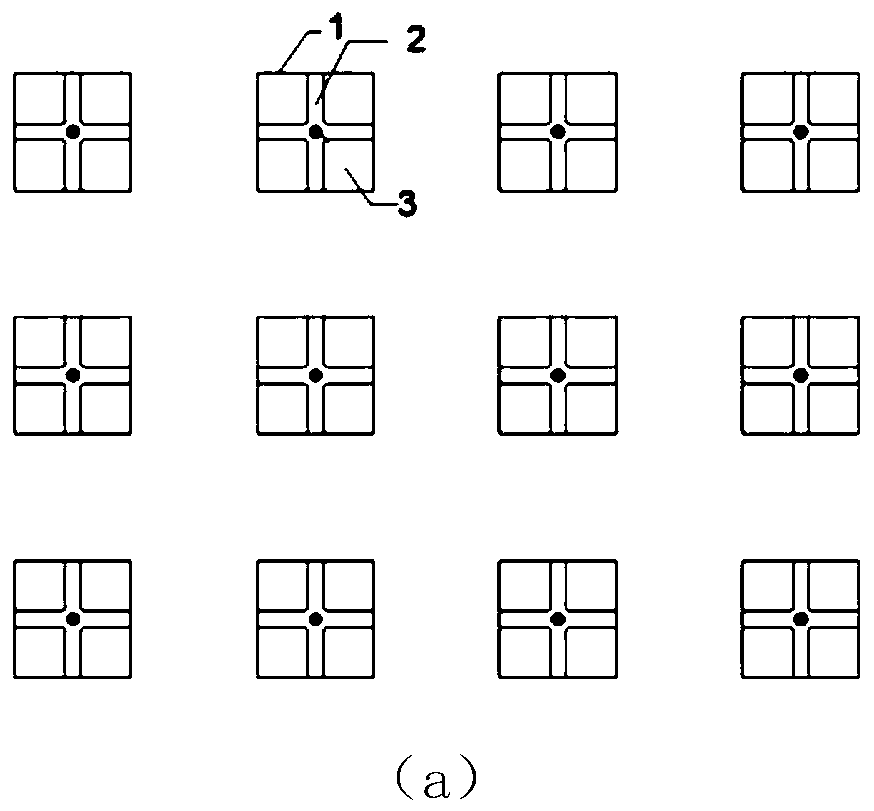

The invention provides a precast lattice beam used for slope reinforcement and a construction method for slope reinforcement adopting the precast lattice beam, as well as a slope structure reinforced by the precast lattice beam and a construction method thereof. The precast lattice beam comprises a plurality of precast cross-shaped beam units which are arranged and connected in a matrix manner; each of the cross-shaped beam units comprises a transverse beam and a longitudinal beam in intersection; an anchor head part is formed in the central interacting part of each of the cross-shaped beam units; each of the anchor head parts comprises a concrete groove and a backing plate placed on the concrete groove; an anchor hole is formed in each of the concrete grooves and the backing plates; the two end parts of the transverse beam and the two end parts of the longitudinal beam of each of the cross-shaped beam units extend respectively to form L-shaped hook parts reversed in directions; the transverse beam of each of the cross-shaped beam units is connected with that of the adjacent cross-shaped beam unit in a hooking manner through the corresponding L-shaped hook parts; the longitudinal beam of each of the cross-shaped beam units is connected with that of the adjacent cross-shaped beam unit in a hooking manner through the corresponding L-shaped hook parts; therefore the precast lattice beam is formed by splicing a plurality of structures taking the shapes of the Chinese character jing. According to the precast lattice beam used for slope reinforcement, the manufacturing method thereof and the construction method for slope reinforcement adopting the precast lattice beam, the following characteristics are achieved: on-the-spot construction steps are reduced, the construction period is shortened, the standardized management production is realized, the quality is ensured, and high efficiency and environment protection are realized.

Owner:SHENZHEN ROAD & BRIDGE CONSTR GRP

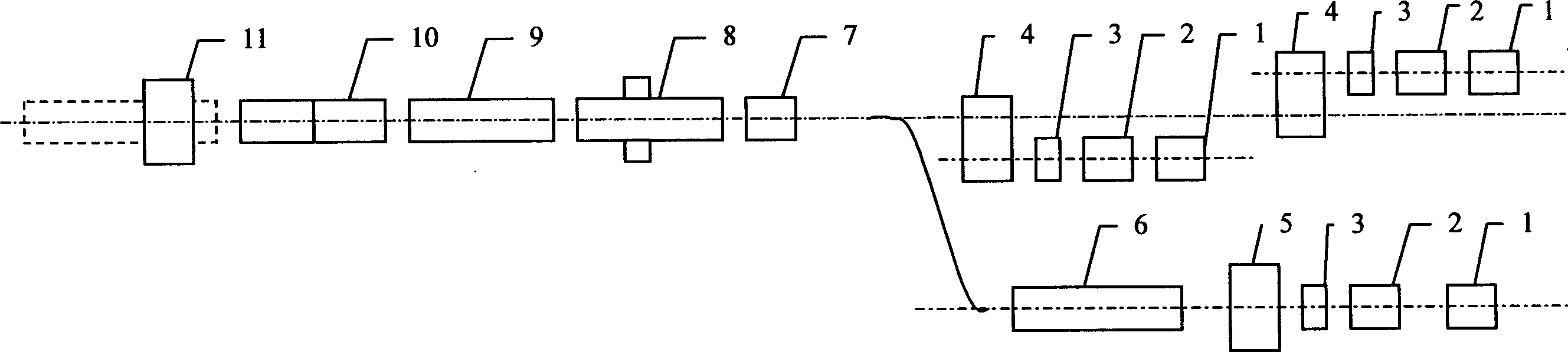

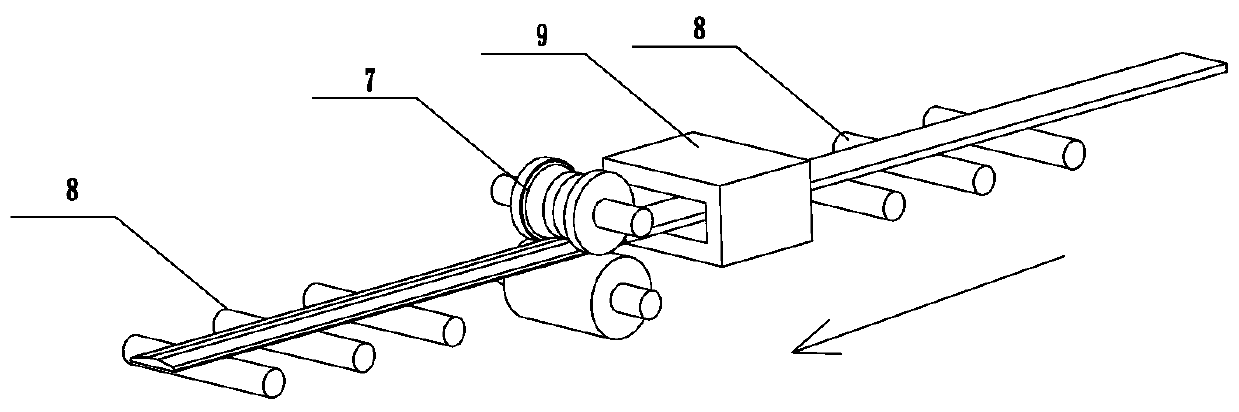

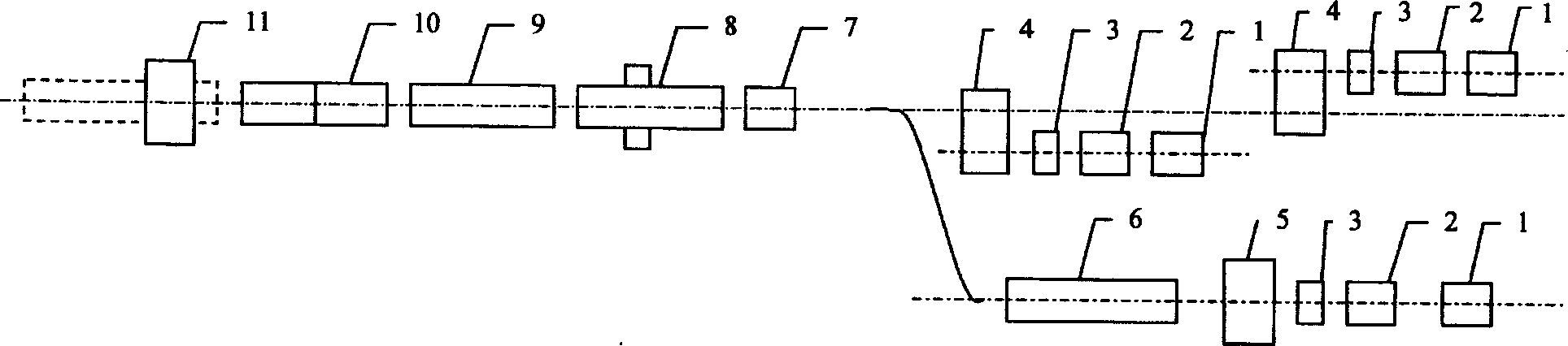

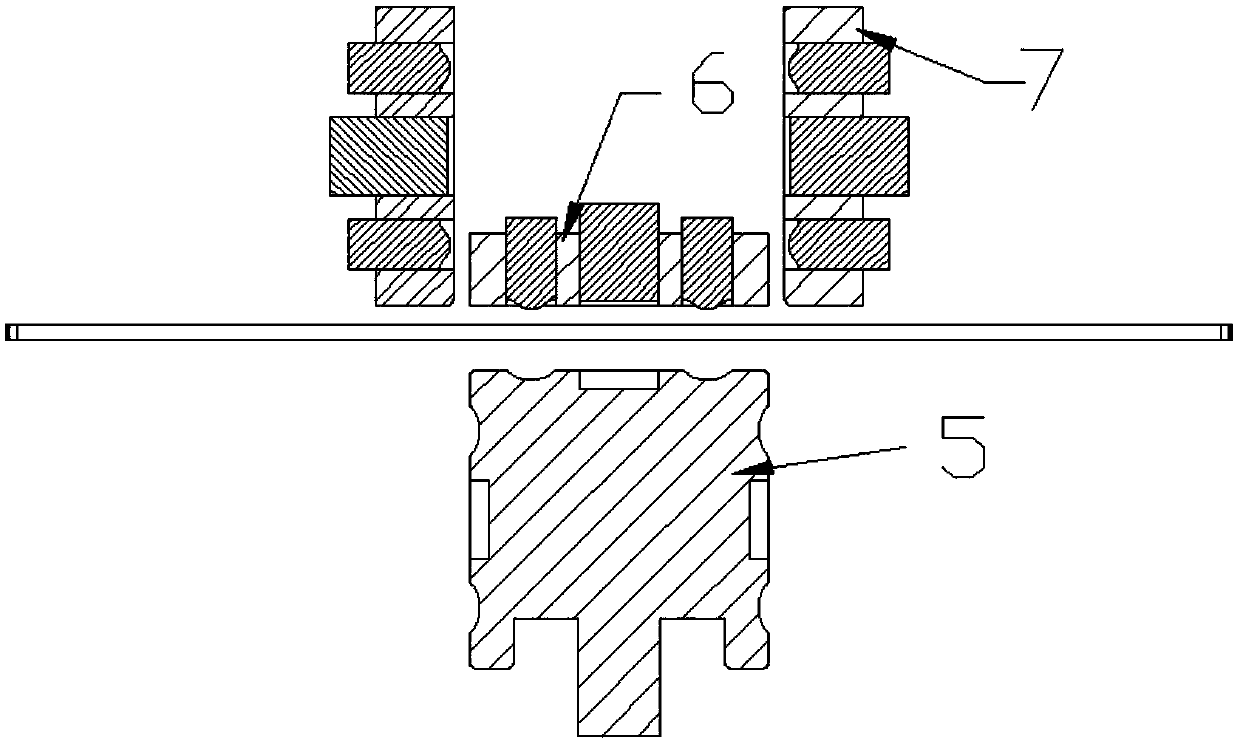

Continuous welding production method of light H-type steel

InactiveCN1411940AIncrease productivityRealize continuous productionWelding/cutting auxillary devicesAuxillary welding devicesStrip steelEngineering

The continuous welding production method of light H-type steel includes the following processes: decoiling band steel, flatening, shearing but-welding, loop stoage, web edge-upsetting, preassembling,high-frequency welding, quick-cooling, flatening drawing, length shearing. The parameters of every process are: edge-upsetting pressure is 500-8000 kgf, microtension of band steel before welding is 50-1000 Kgf, welding speed is 10-50 m / min., welding power is 100-1000 KW, and cooling speed is 1-30 deg.C / s.

Owner:CENT IRON & STEEL RES INST

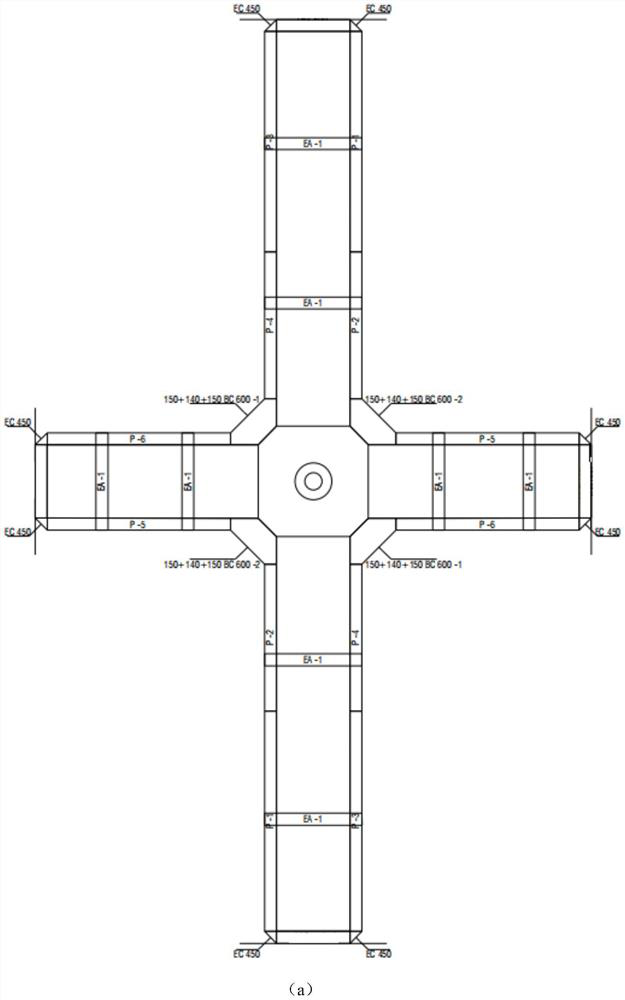

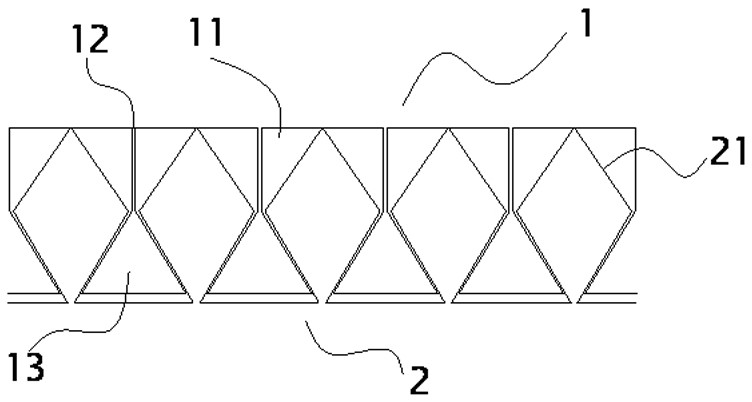

Prefabricated lattice beam for slope reinforcement, and manufacturing and construction method thereof

InactiveCN110130367AEasy to manufactureEasy to installCeramic shaping apparatusExcavationsEmergency rescueLap joint

The invention provides a prefabricated lattice beam for slope reinforcement, and a manufacturing and construction method thereof. The prefabricated lattice beam is formed by a plurality of prefabricated cross beam body units in matrix arrangement, flat laying and lap joint modes; the prefabricated cross beam body units are formed by transverse beams and longitudinal beams in an intersecting mode;anchoring head parts are arranged at the cross positions of the transverse beams and the longitudinal beams; the corners of cross connectors at the junctions of the transverse beams and the longitudinal beams are each in a circular arc shape; the anchoring head parts comprise grooves and base plates placed at the grooves; and anchor holes for allowing anchor rods or anchor cables to penetrate in are formed in the grooves and the base plates correspondingly. The prefabricated lattice beam for slope reinforcement, and the manufacturing and construction method thereof have the characteristics ofsimplifying the construction steps, shortening the construction period, lowering the construction risk, realizing standardized production management, ensuring the product quality, and being economic,environment friendly and practical. The prefabricated lattice beam can replace an existing cast-in-place anchor rod (cable) lattice beam for slope reinforcement, has outstanding advantages in slope emergency rescue reinforcement, and is also suitable for quick slope reinforcement construction in a rebuilt and expanded highway.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +3

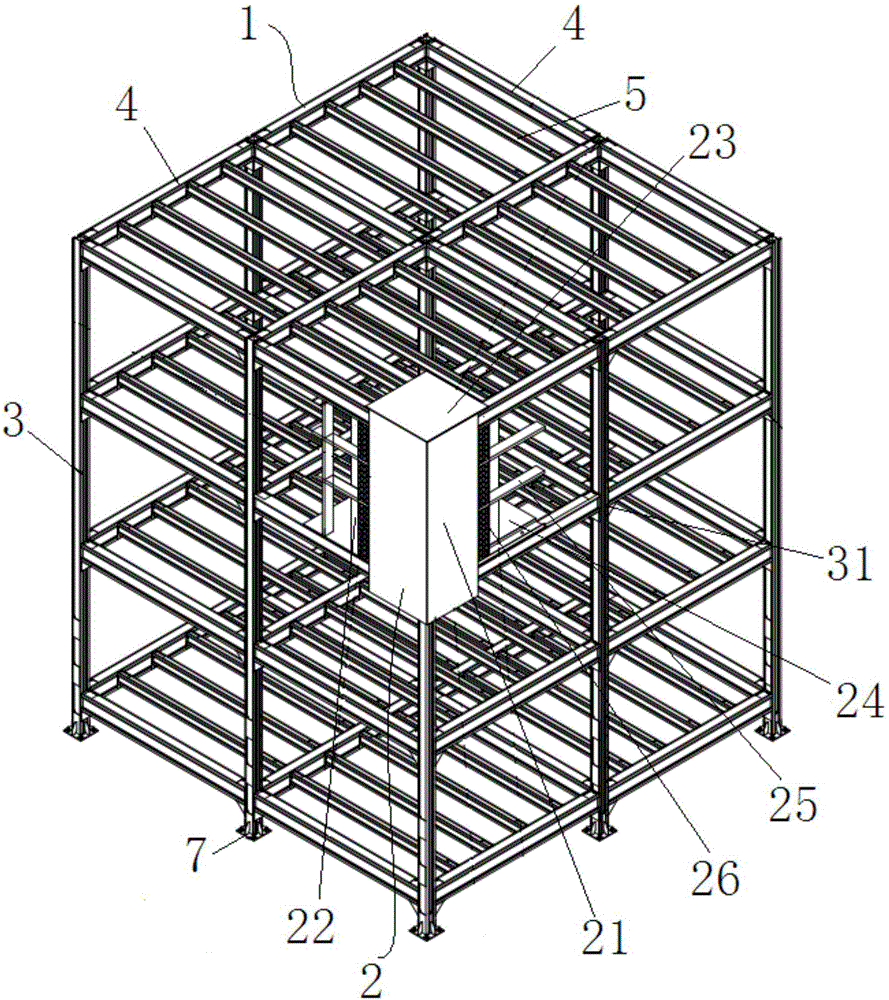

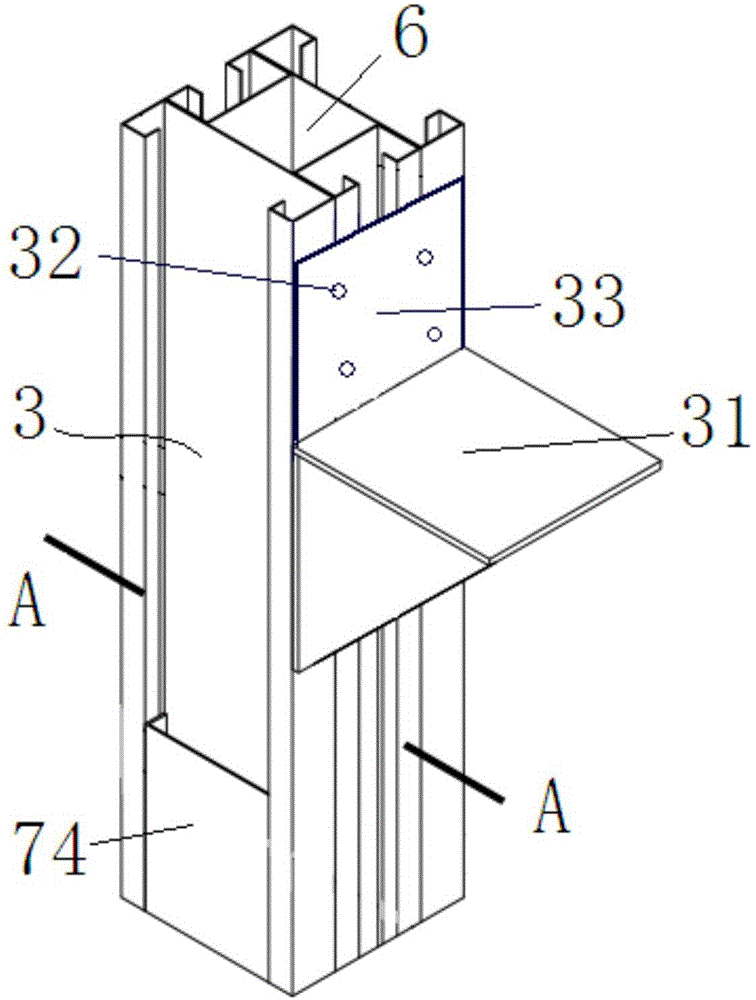

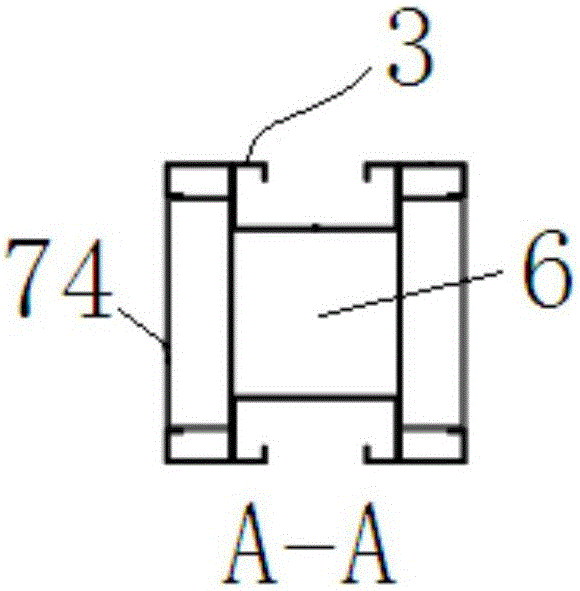

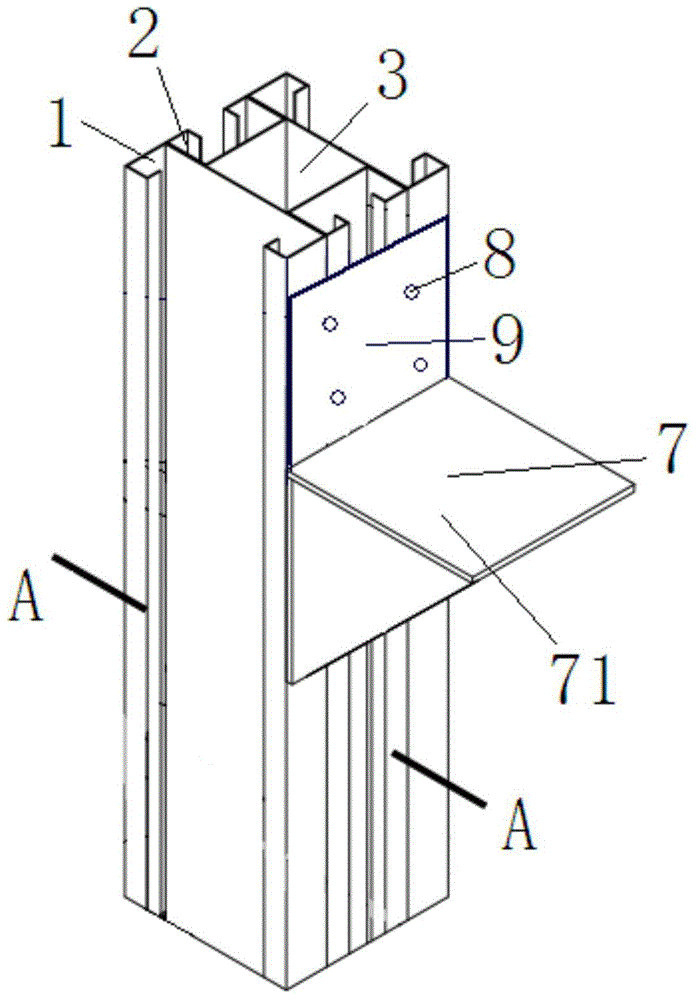

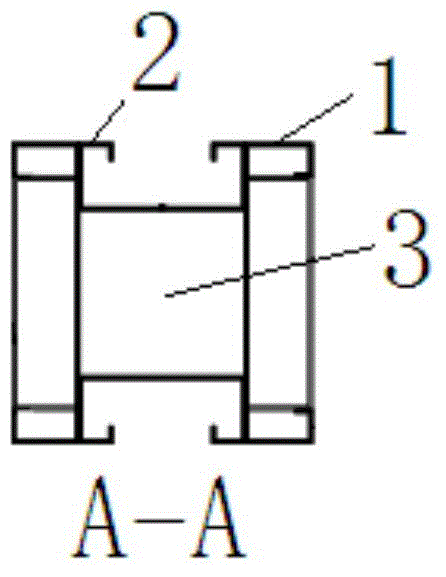

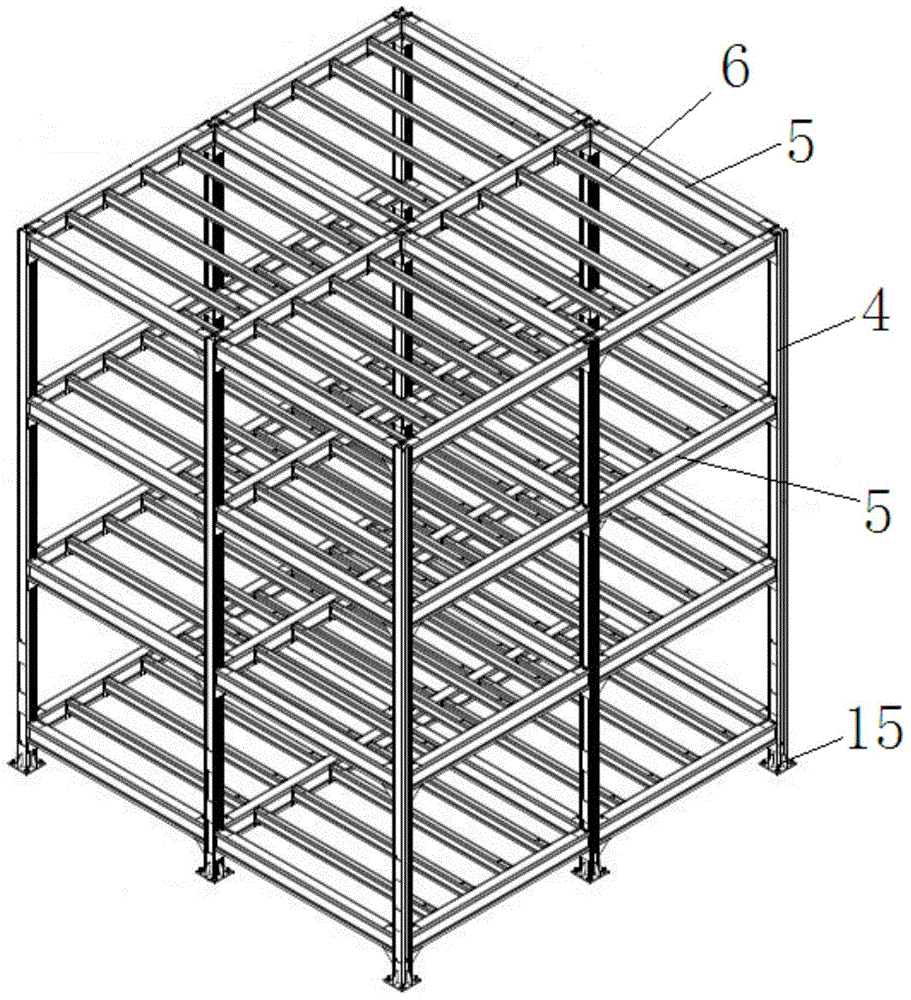

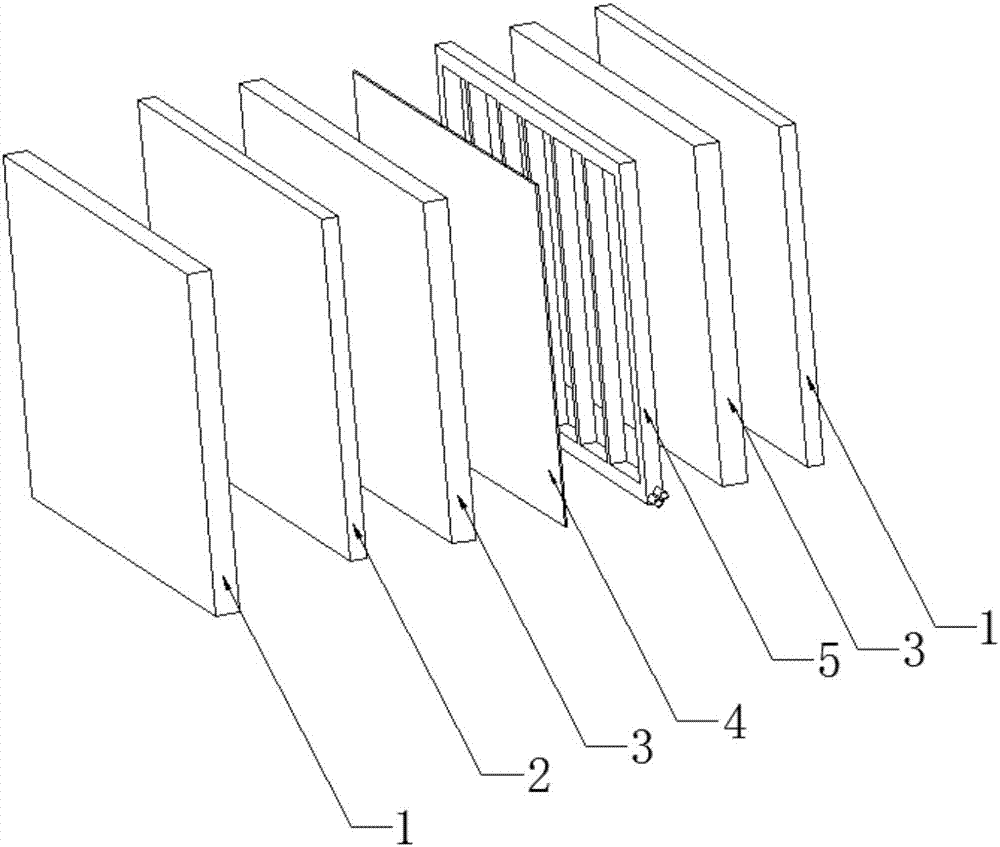

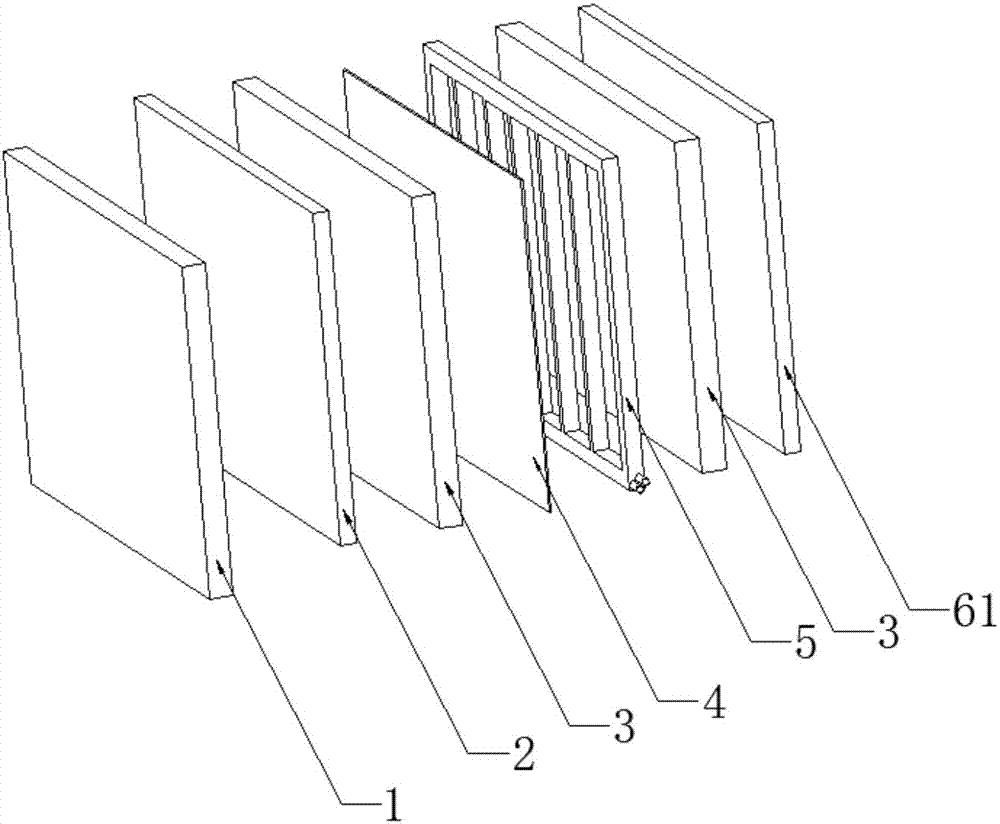

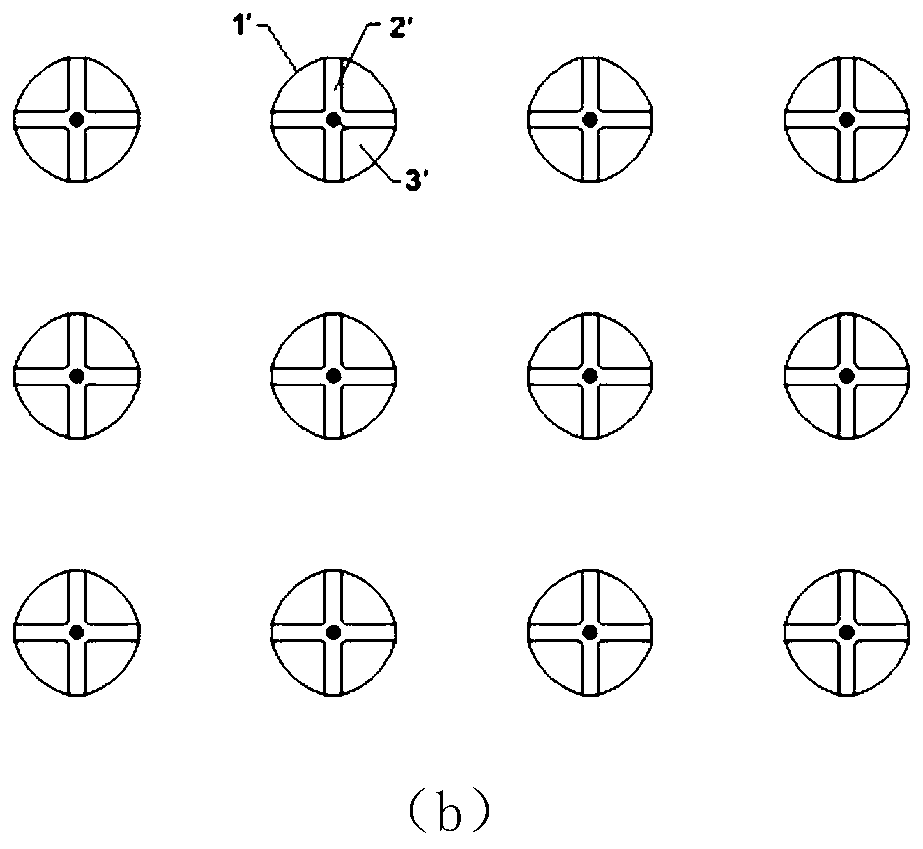

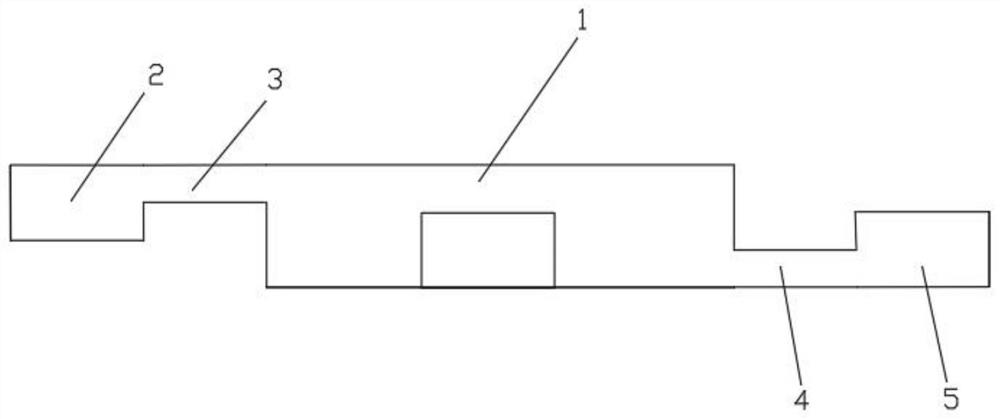

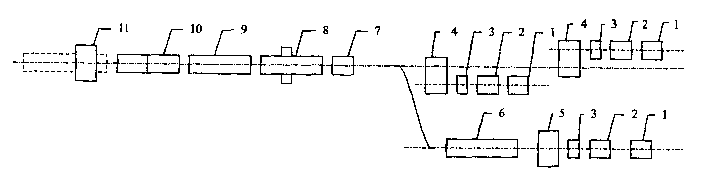

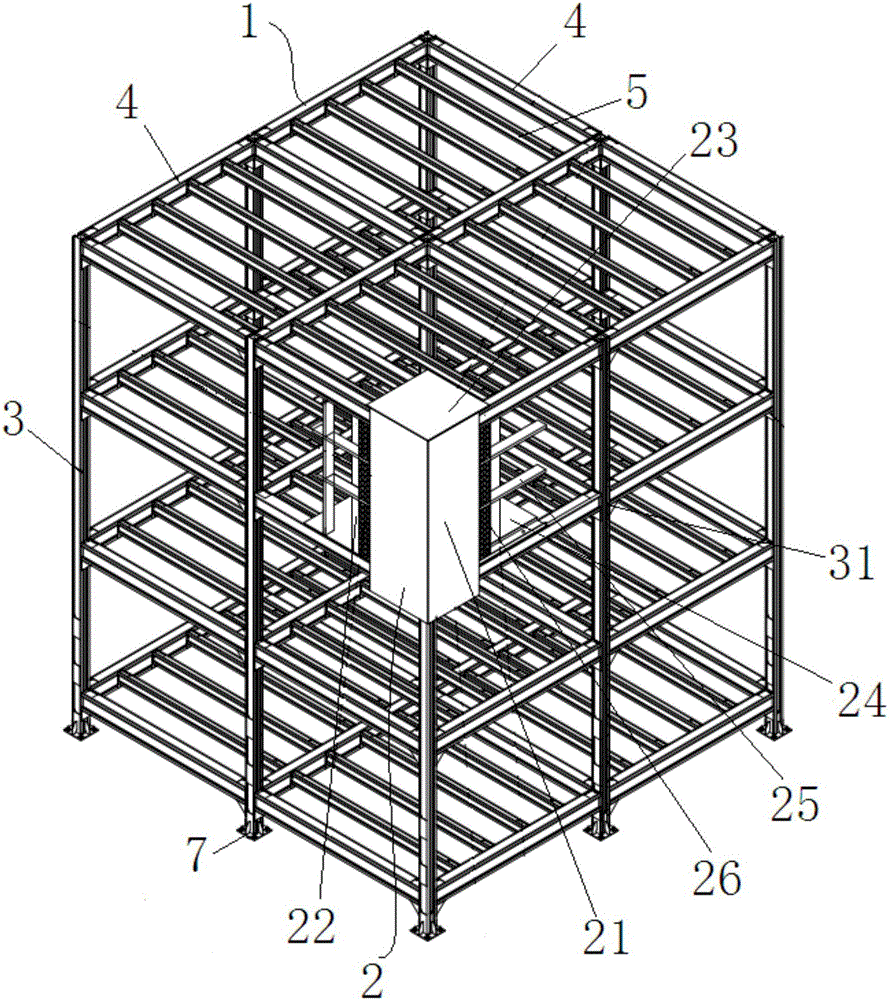

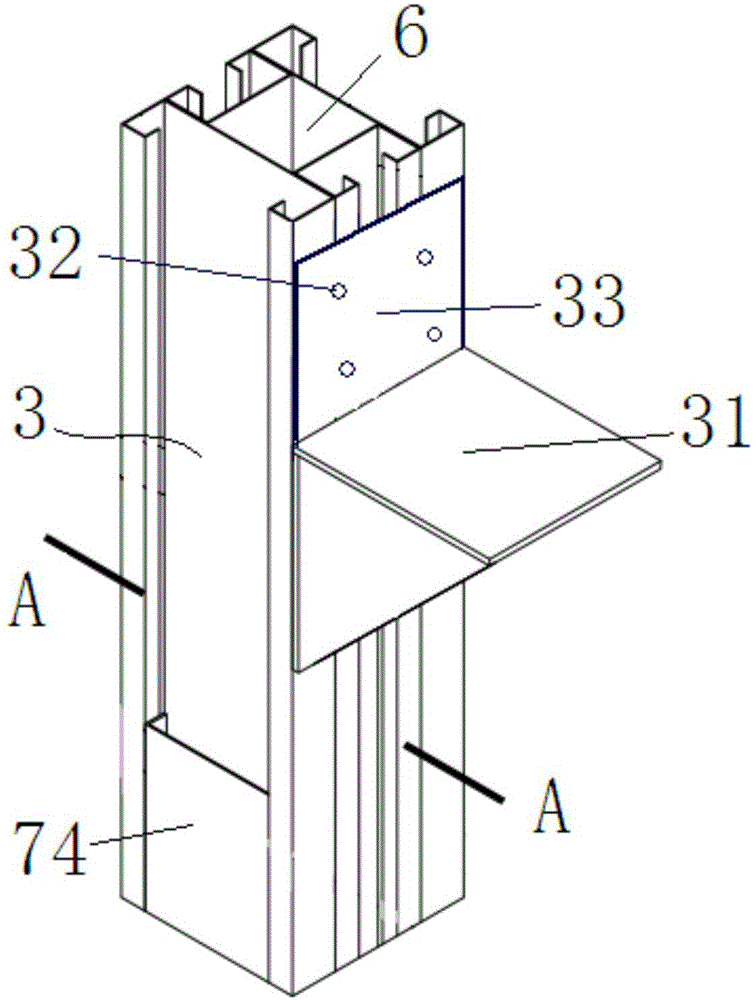

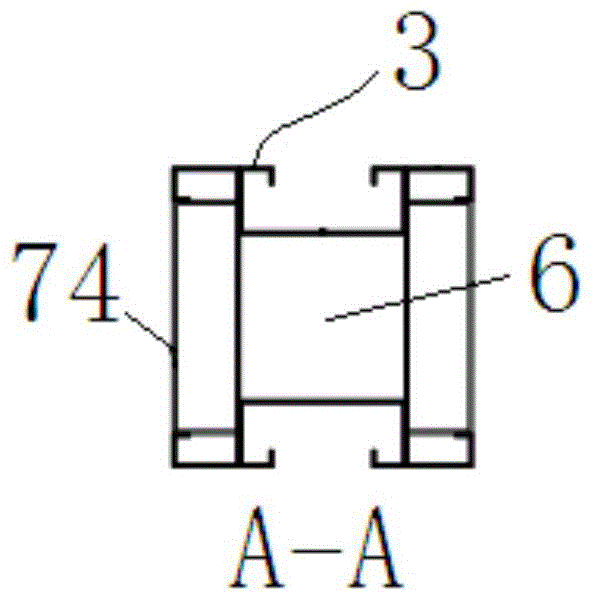

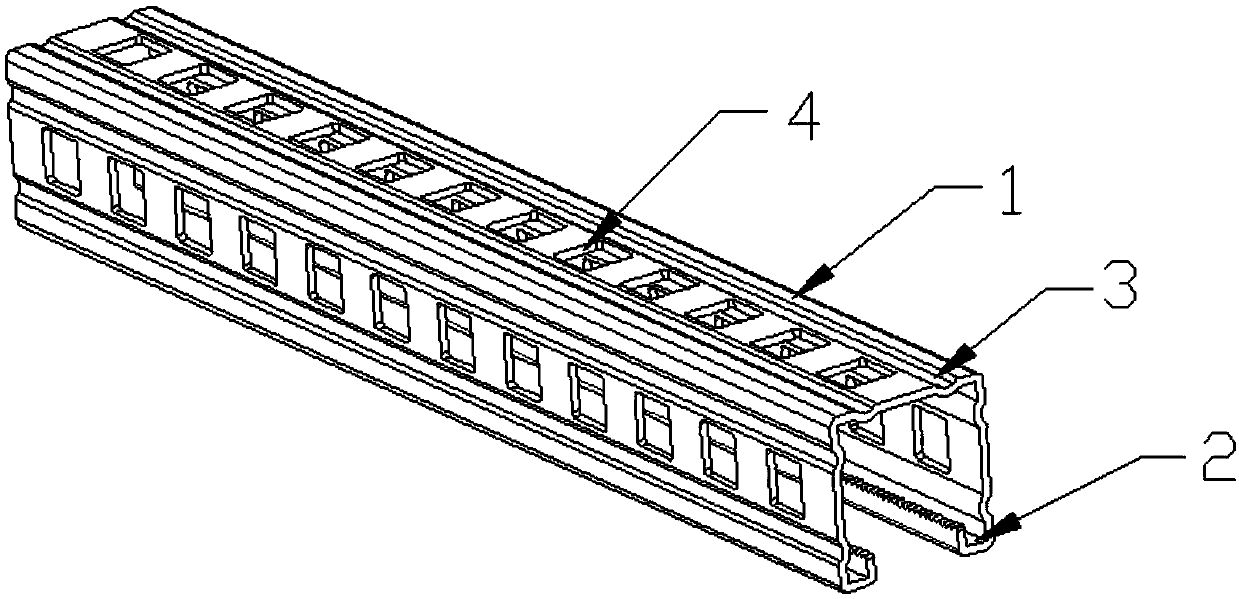

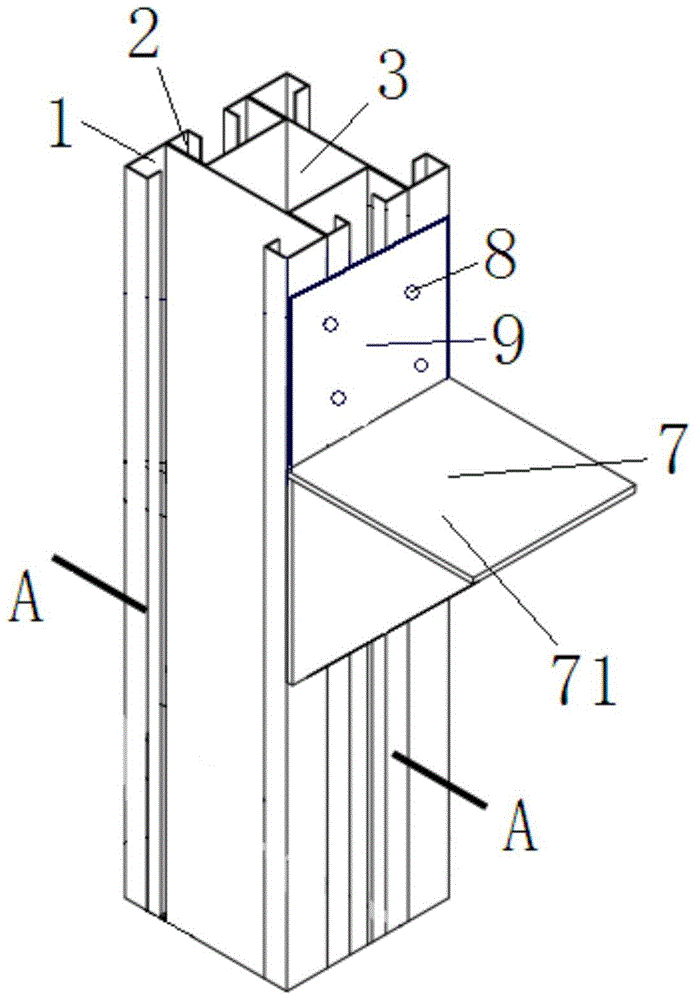

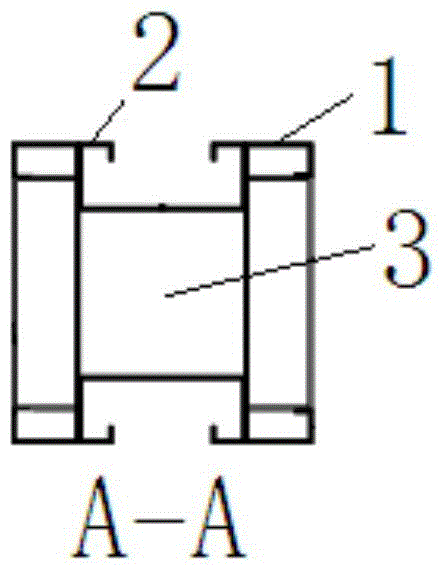

Movable building structure and making method thereof

The invention relates to a movable building structure and a making method thereof. The movable building structure is characterized in that the movable building structure comprises a bearing frame and a building enclosure fixedly connected to the bearing frame through bolts, and a doorway for mounting a door or a window opening for mounting a window is formed in the building enclosure according to the position of the door or the window; the bearing frame comprises stand columns, main girders connected between the stand columns and secondary girders connected between the main girders; the stand columns, main girders and secondary girders are each provided with two pairs of box iron arranged at intervals and with inwards-turned edges, the cold-formed thin walls of the box iron are in a C shape, two wings of one pair of box iron are welded to the backs of two webs of the other pair of box iron, the inner surfaces of the stand columns, or the main girders or the secondary girders are enclosed to form a through strip-shaped cavity, and the section of the cavity is square or rectangular; the stand columns and the main girders are each provided with a plurality of brackets and connection plates with mounting holes at intervals in a welded mode, and the bottom of each stand column is fixedly connected with a column foot; the two ends of each main girder and the secondary girder are each provided with a head plate with mounting holes in a welded mode. The multi-layer movable building structure can be used temporarily as well as permanently.

Owner:北京海东蓝涛洁净工程技术有限公司

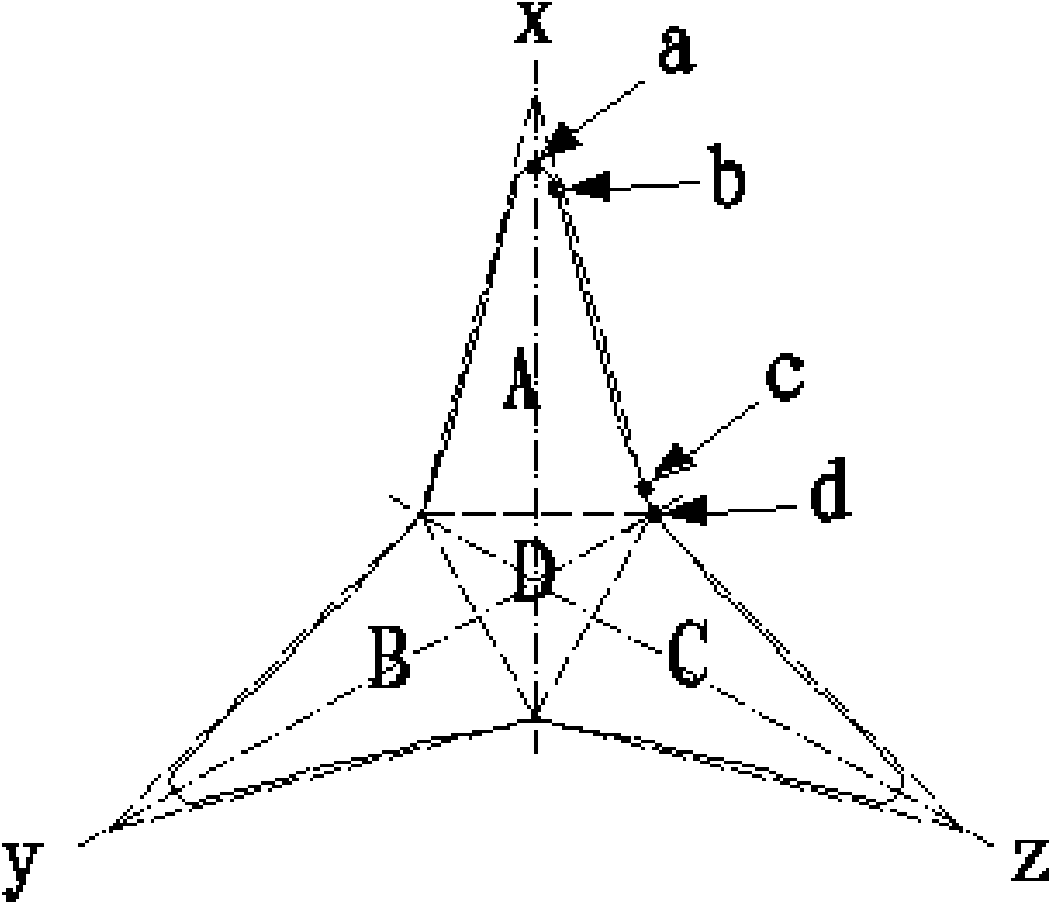

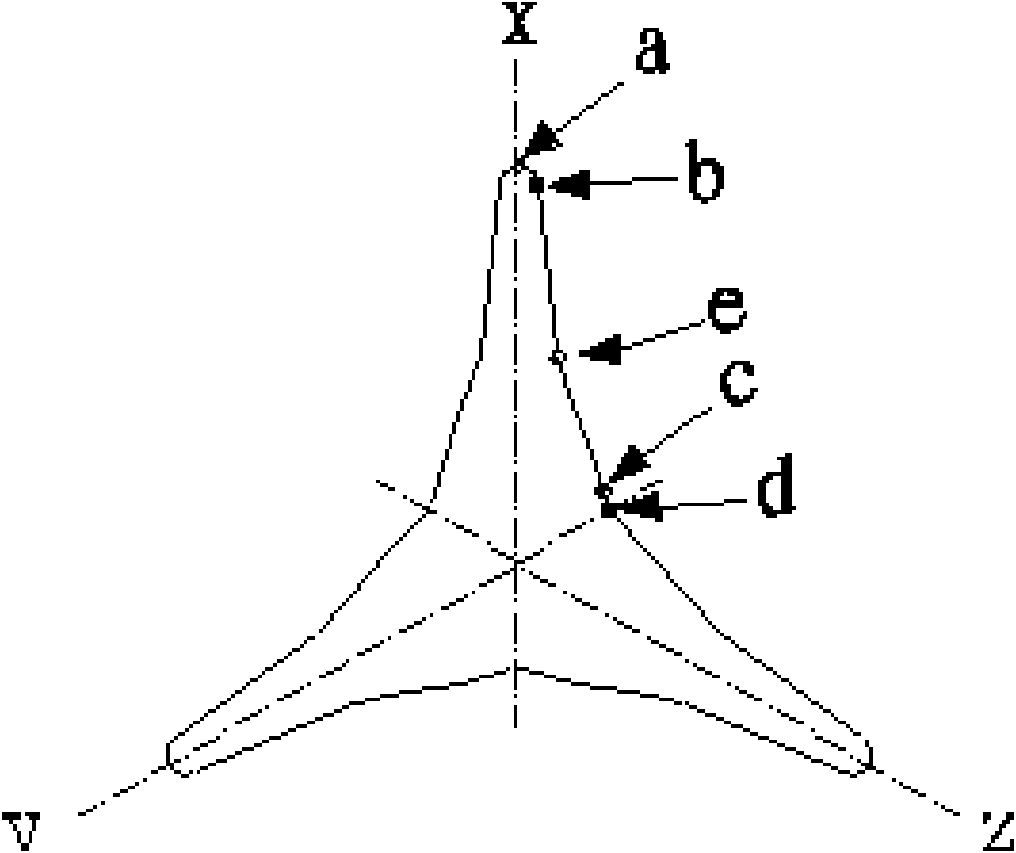

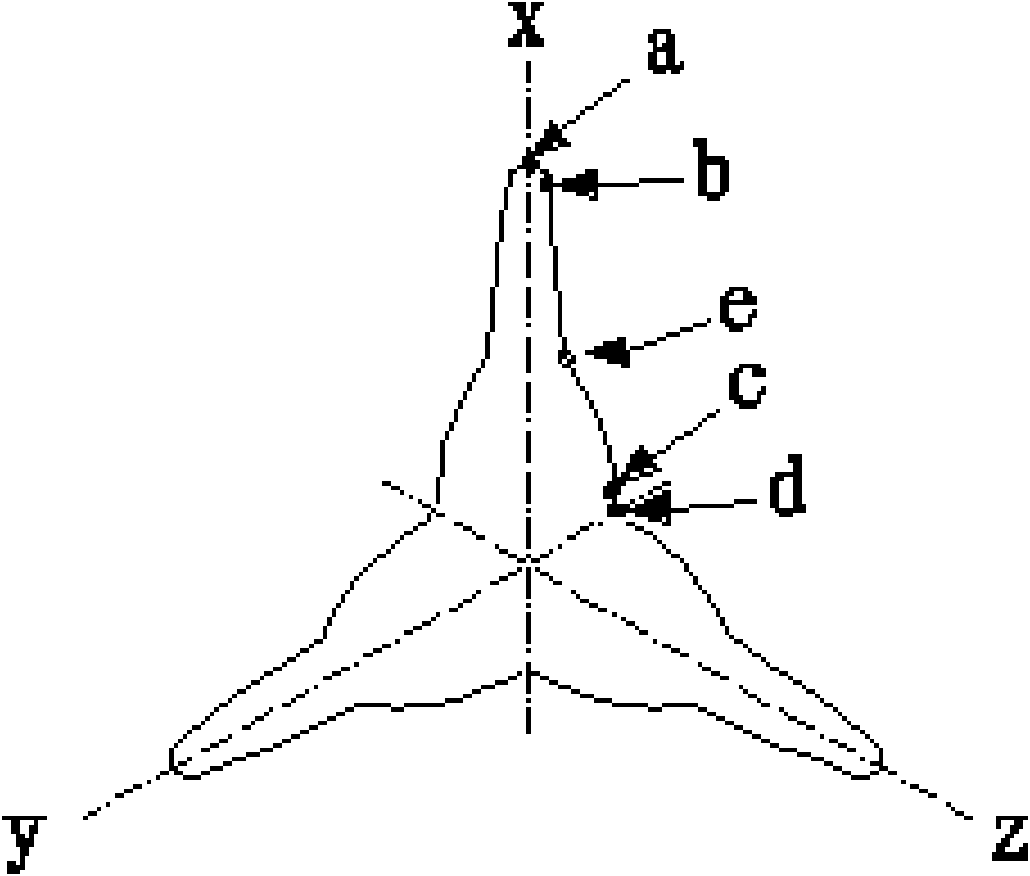

Spinneret plate, profiled filament processed by utilizing same and preparation method thereof

ActiveCN101798712ANovel shapeNovel section featuresMelt spinning methodsStretch-spinning methodsFiberMirror reflection

The invention relates to a spinneret plate, a profiled filament processed by utilizing the same and a preparation method thereof. The spinneret orifices of the spinneret plate are trilobal, are symmetrical around the x,y and z shafts which mutually form the included angle of 120 degrees and are connected by the bottom edges of the minimum circumscribed isosceles triangles A, B and C of trefoil to form an equilateral triangle D; the included angle of the side and the height of A, B or C is 5-25 degrees; the contour line bc line of the trilobal is selected from two or a plurality of and two sections of or a plurality of sections of straight lines and quadratic curves and is formed by connecting in the minimum circumscribed isosceles triangle; and the contour lines ab line and the cd line of the trilobal are smoothly transiting curves. The spinneret plate can be used on a fusant direct spinning device with an on-line adding function, and fiber has the characteristic of high gloss by utilizing the phenomenon that the spinneret plate and the profiled filament prepared by the corresponding spinning process have better mirror reflection effect.

Owner:CHINESE TEXTILE ACAD

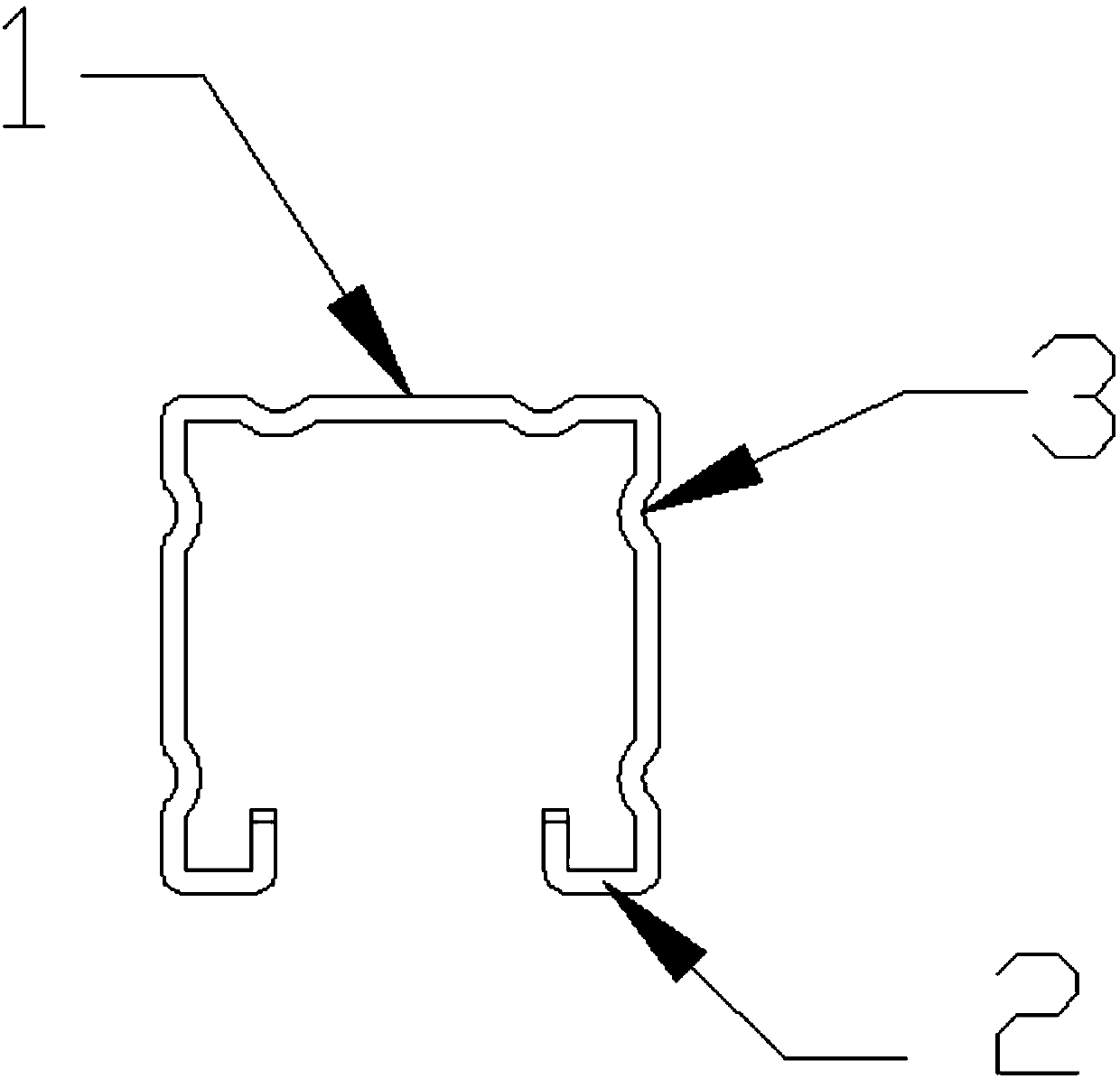

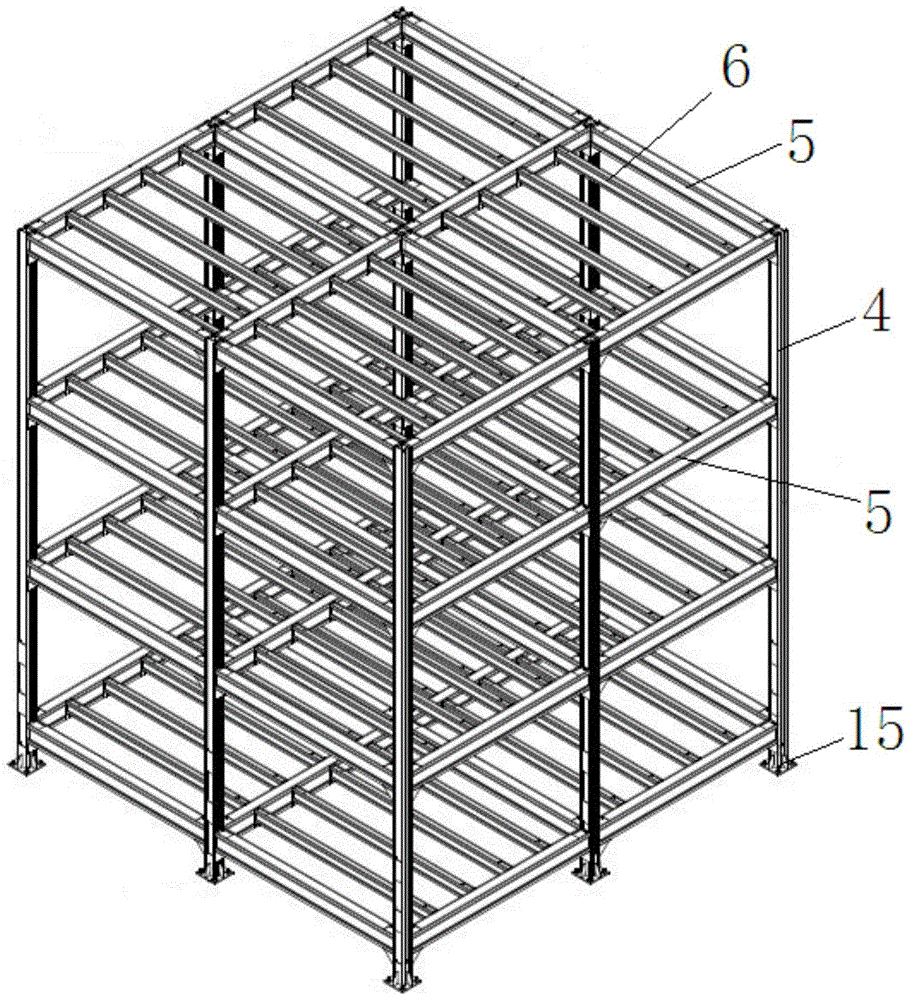

Combined component

ActiveCN104988994AImprove stabilityImprove section propertiesBuilding constructionsCold formedEngineering

Owner:北京海东蓝涛洁净工程技术有限公司

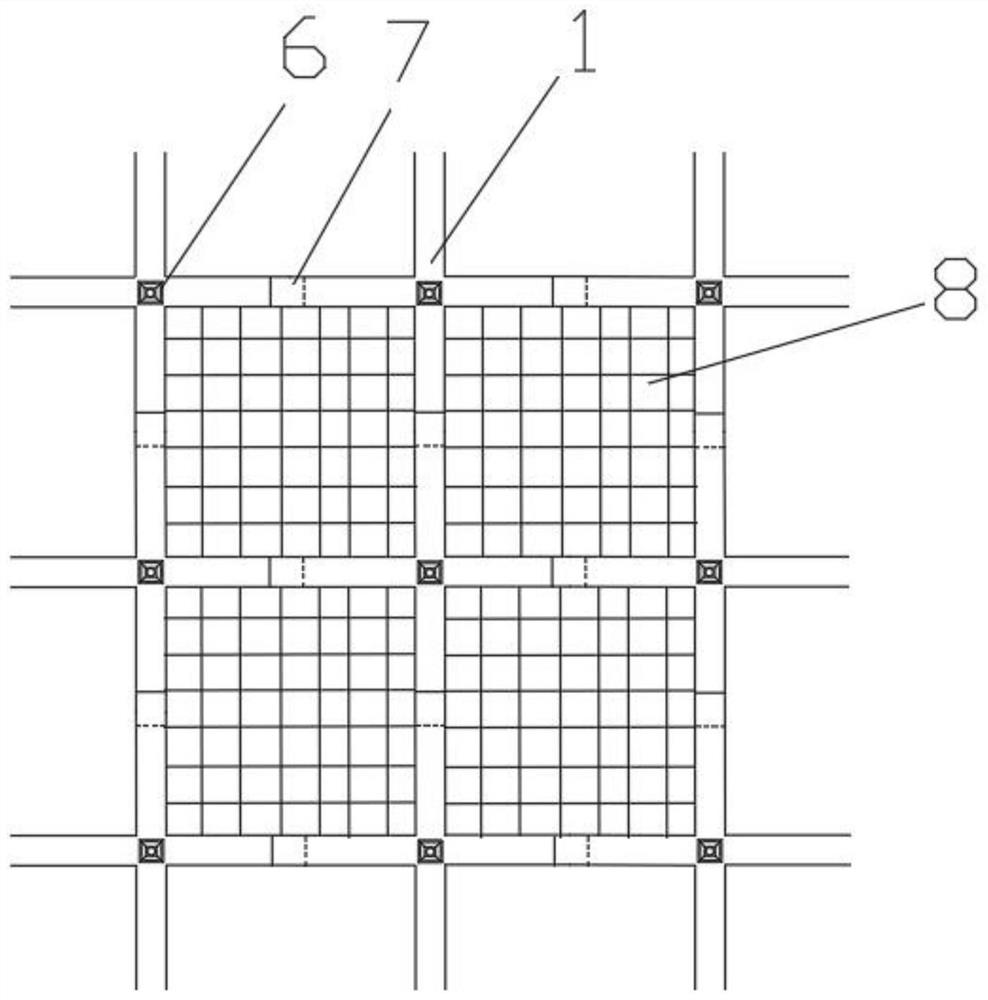

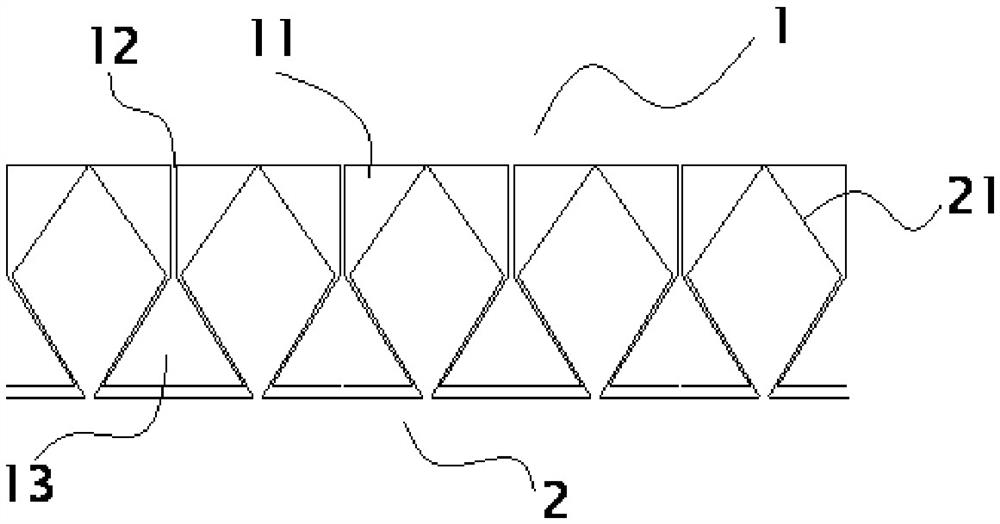

Prefabricated prestressed concrete anchorage pier for slope strengthening and manufacturing and construction methods thereof

InactiveCN110055979AEasy to manufactureEasy to installMouldsMould auxillary partsReinforced concretePre stress

The invention provides a prefabricated prestressed concrete anchorage pier for slope strengthening and manufacturing and construction methods thereof. The prefabricated prestressed concrete anchoragepier comprises a prestressed concrete anchorage pier unit provided with a cross beam and a longitudinal beam which are crossed into a cross shape, concrete ribs located on the periphery of the prestressed concrete anchorage pier unit, and an anchorage head part located at the crossed position of the cross beam and the longitudinal beam; and prestressed reinforcements are arranged in the cross beamand the longitudinal beam. The prefabricated prestressed concrete anchorage pier adopts prestressed concrete lattice beams, the section property of the beams can be improved, larger anchorage force is borne, and the defect that when traditional cast-in-place reinforced concrete lattice beams are under large anchor cable anchorage force, the midspan positions of the reinforced concrete lattice beams can be pulled cracked possibly, and consequently the rigidity of components is lowered is overcome; and according to the prefabricated prestressed concrete anchorage pier, a manufacturing process can further be simplified, mounting is convenient, adjusting is easy during mounting, the construction period is shortened, and the construction cost is saved.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +3

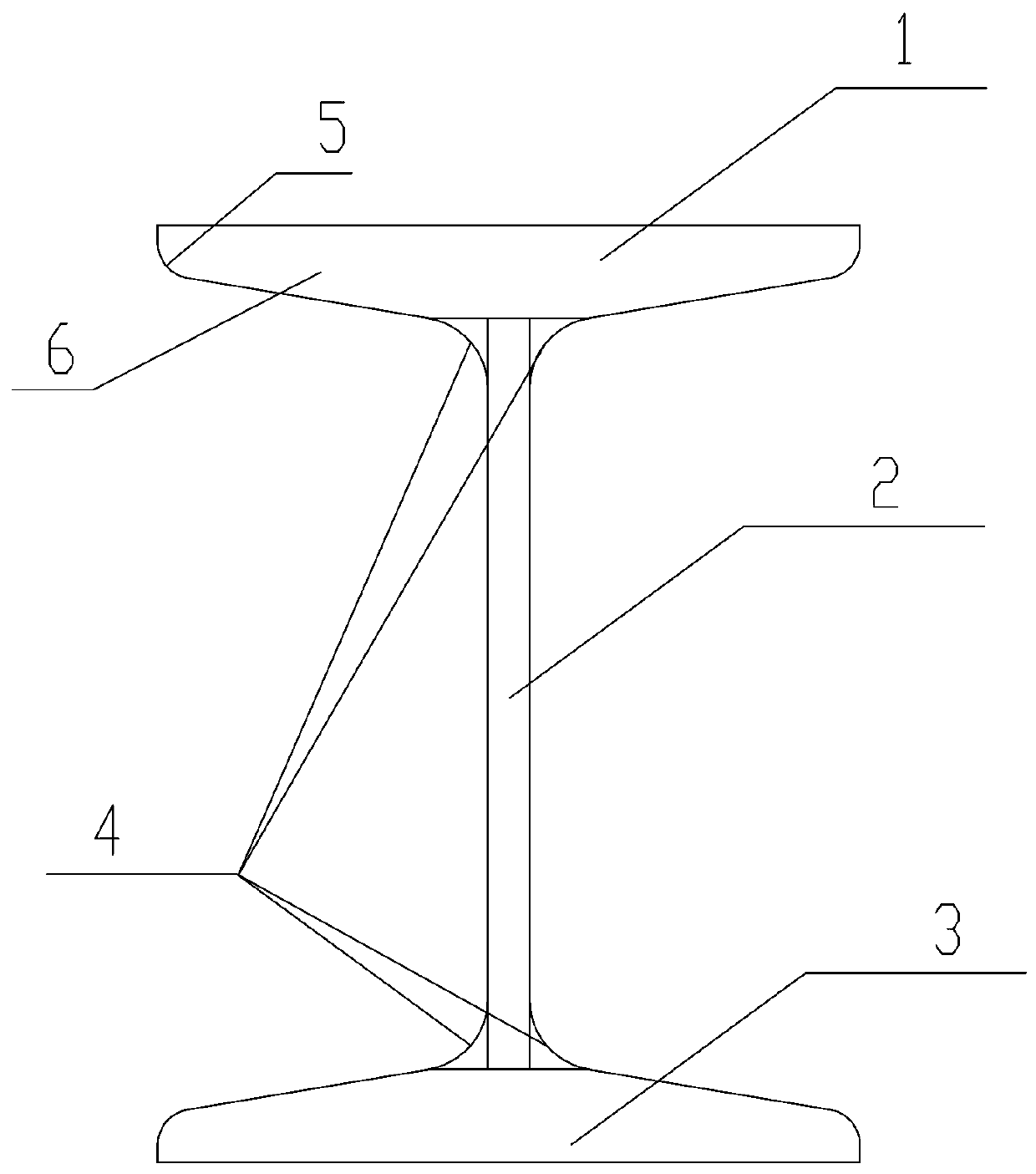

Manufacturing process of welding I-shaped steel for steel structure

InactiveCN111438497ASolve the shortcomings of not being able to process large cross-section (above 700mm) structural profilesImprove section propertiesManufacturing technologyInternal stress

The invention belongs to the technical field of steel structure buildings, and particularly relates to a manufacturing process of welding I-shaped steel for a steel structure. The manufacturing process is characterized by comprising the following steps: (1) blanking of an upper flange plate, a lower flange plate and a web plate; (2) forming and correcting of the upper flange plate or the lower flange plate; (3) web plate forming; (4) assembly of the upper flange plate, the lower flange plate and the web plate; (5) welding of the upper flange plate, the lower flange plate and the web plate; (6)correcting; and (7) relief of internal stress. The steel-structure welded I-shaped steel flange plates with the inclined surfaces manufactured with the manufacturing process not only reserve the excellent section characteristics of the traditional I-shaped steel, but also overcome the defect that the traditional I-shaped steel cannot be used for processing a section material for a large-section structure.

Owner:辽宁福瑞达建筑科技有限公司

Assembled low-energy consumption integrated wall

PendingCN107100316ASimple production processReduce dust pollutionWallsThermal insulationAcoustic board

The invention discloses an assembled low-energy consumption integrated wall. The assembled low-energy consumption integrated wall comprises a mortar board, a thermal insulation plate moisture-proof film, a structural board, a sound insulation board, an aerogel plate and an interior board. The mortar board comprises a reinforcing mesh and filling mortar. The bonded reinforcing mesh is put into a casting basin and the filling mortar is added into the casting basin so that a mortar plate is obtained. The aerogel plate is tightly close to the mortar board. The sound insulation board comprises a keel and glass fibers. Gaps formed by the keel are filled with the glass fibers. The keel is a skeleton prepared from C-shaped section steel connected through bolts and nuts according to a wall structure. The structural interior board is arranged at the innermost layer of the wall. The mortar board, the structural board, the moisture-proof film, the sound insulation board, the aerogel plate and the interior board of the wall are fastened to form an integral body through elf-drilling screws. The wall has the advantages of low energy consumption, low pollution, short construction period and excellent heat insulation performances.

Owner:广东多筑科技有限公司

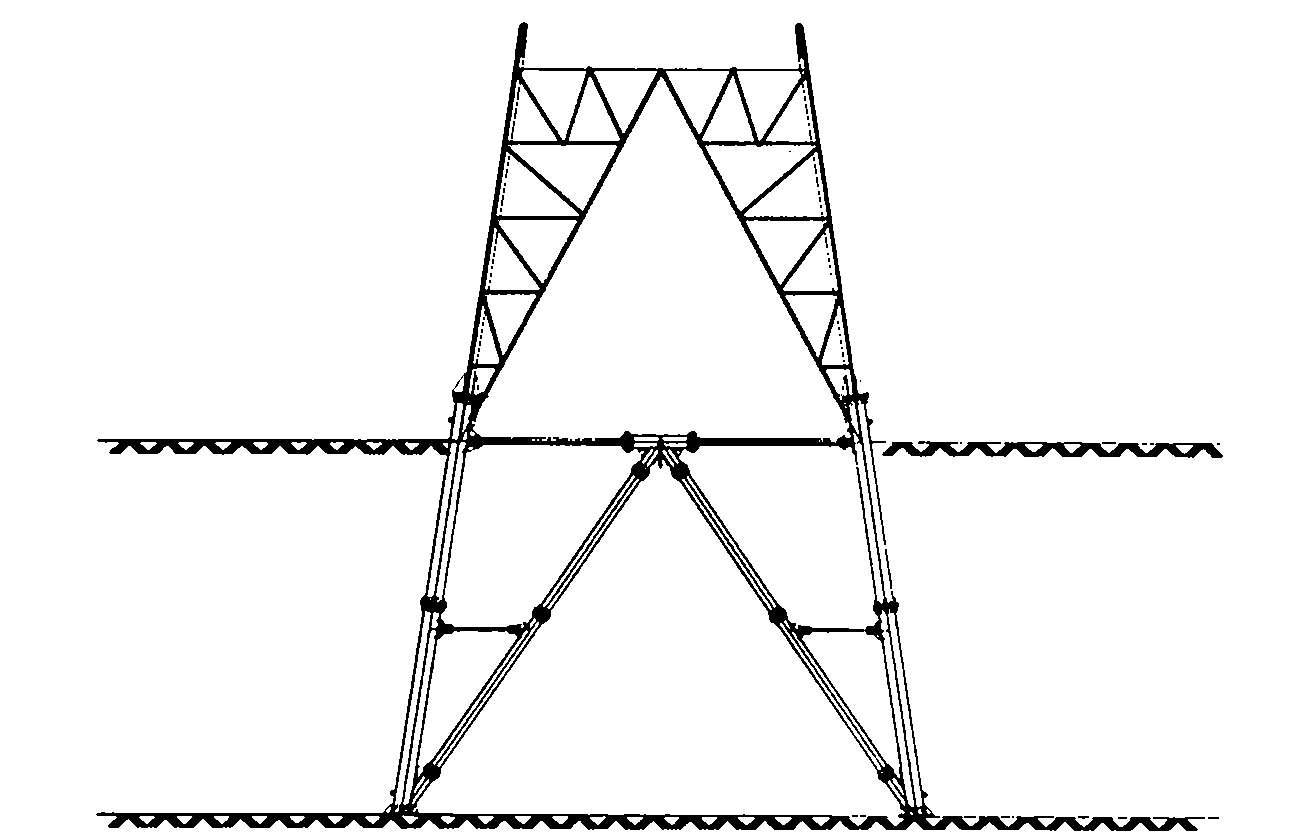

Method for lifting base plane of power transmission line tower by adopting steel pipe connecting leg

The invention discloses a method for lifting the base plane of a power transmission line tower by adopting a steel pipe connecting leg, and relates to the technical field of high-voltage power transmission lines. The method comprises the following steps of lifting an angle steel tower; connecting a steel pipe main member with an angle steel tower main member by using a flange; connecting the main members with a diagonal member by using a plug board; embedding steel pipe pins. According to the method, the problems of higher earth filling time consumption and strict construction quality requirements of an earth filling scheme can be effectively solved, the condition that a body work amount is increased by the great horizontal displacement of the ground when a pile foundation scheme is adopted is avoided, and the shortcomings of long concrete curing time and larger using amounts of reinforcements and concrete of a reinforced concrete frame structure scheme are overcome.

Owner:ANHUI HUADIAN ENG CONSULTATING & DESIGN

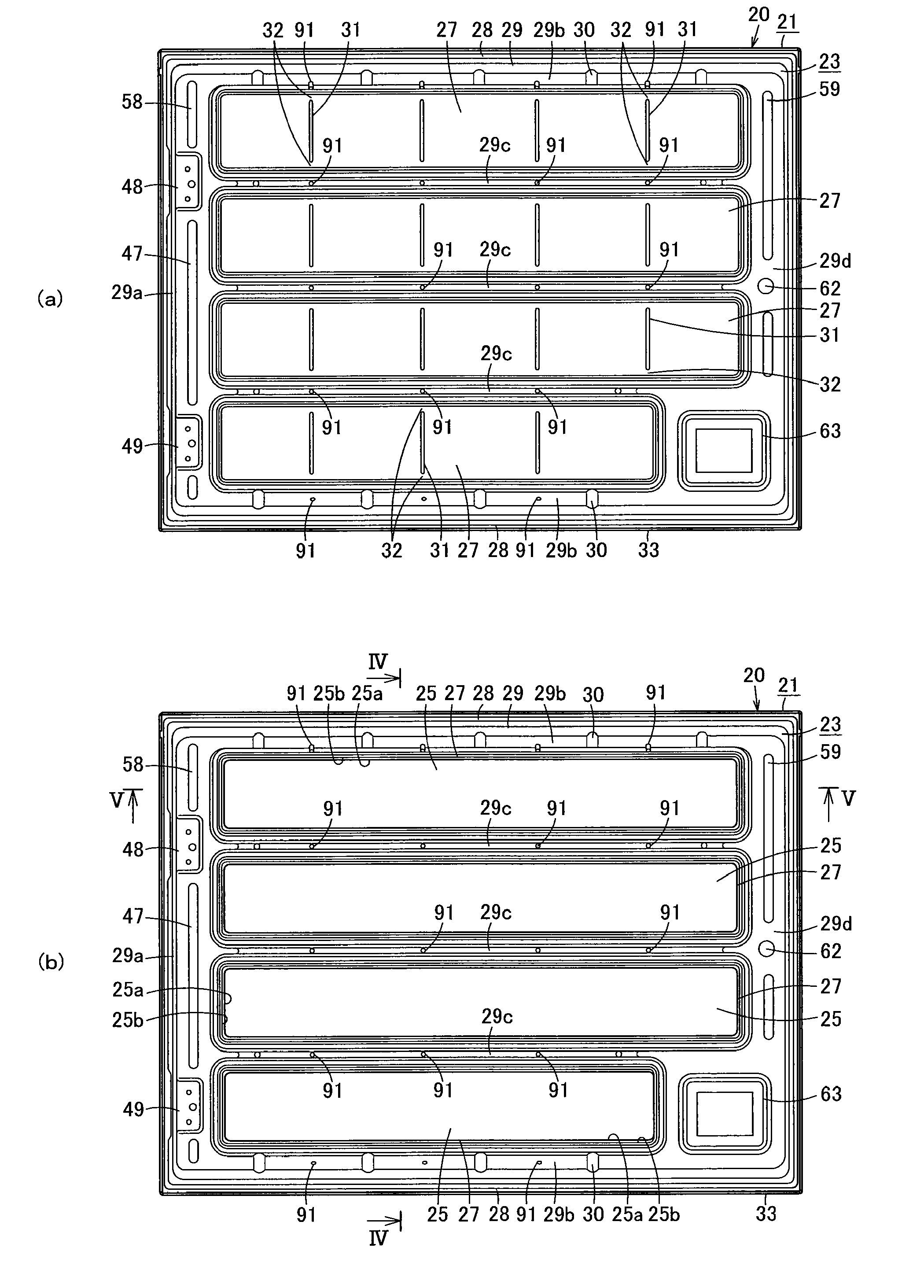

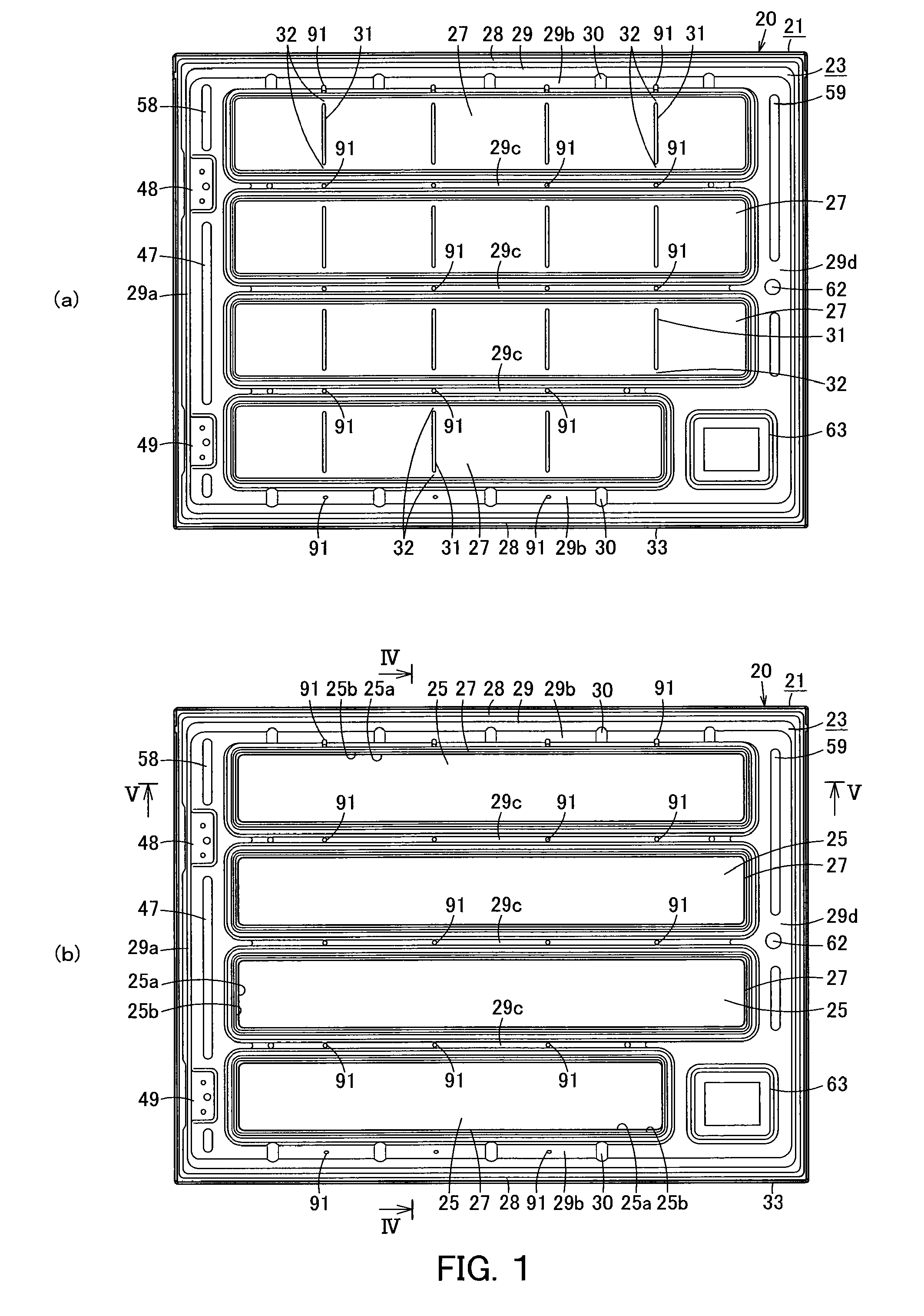

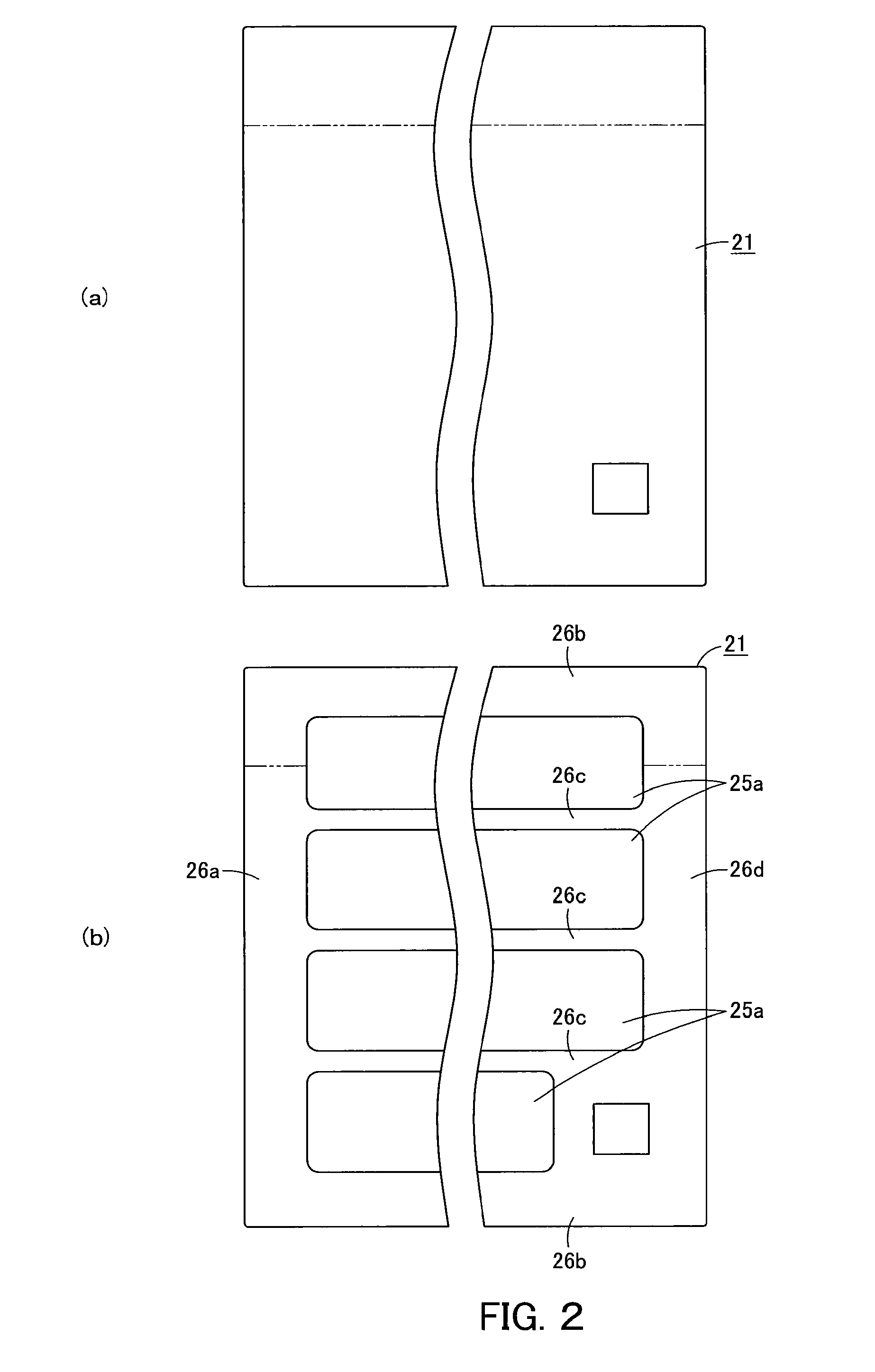

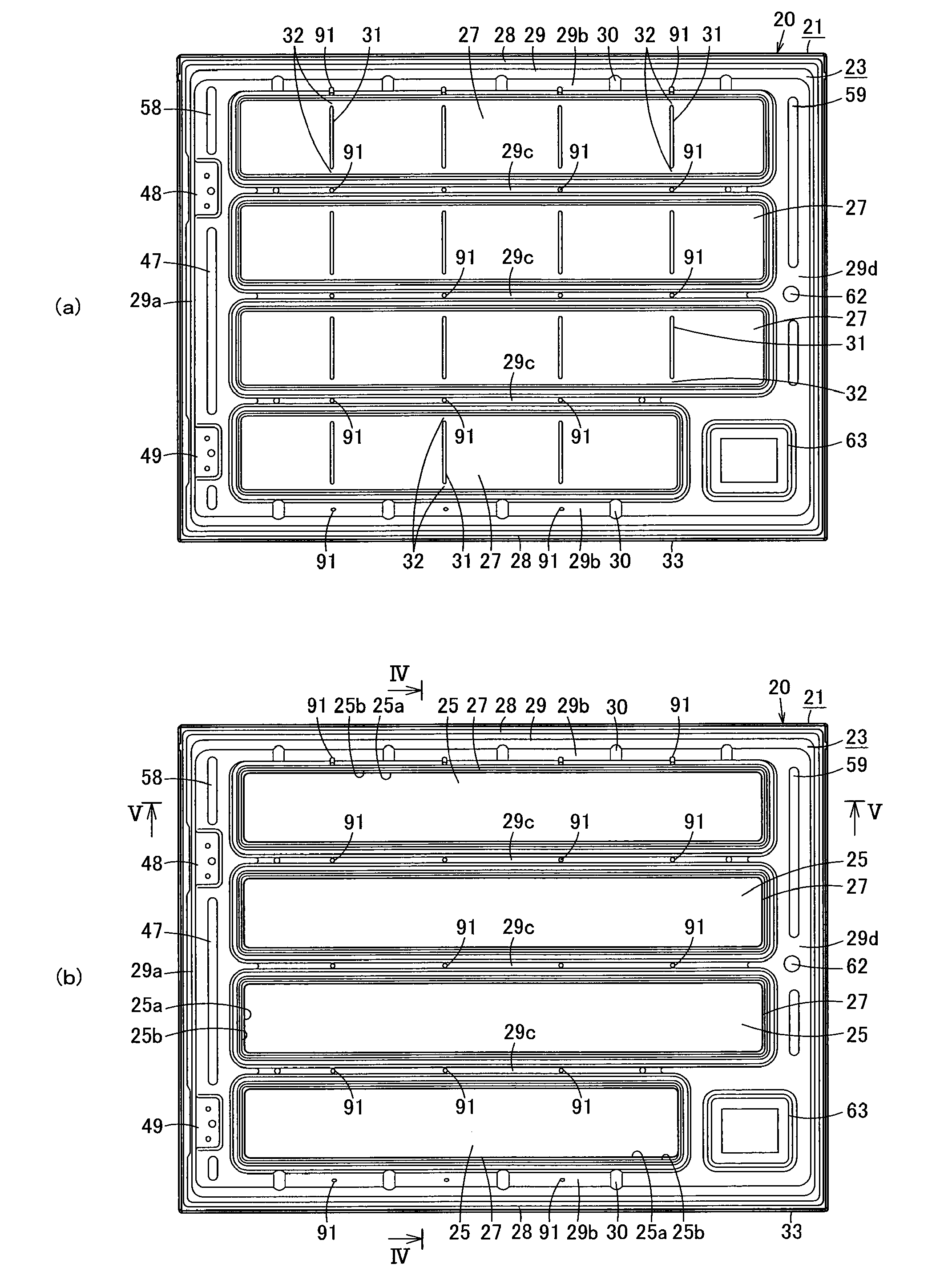

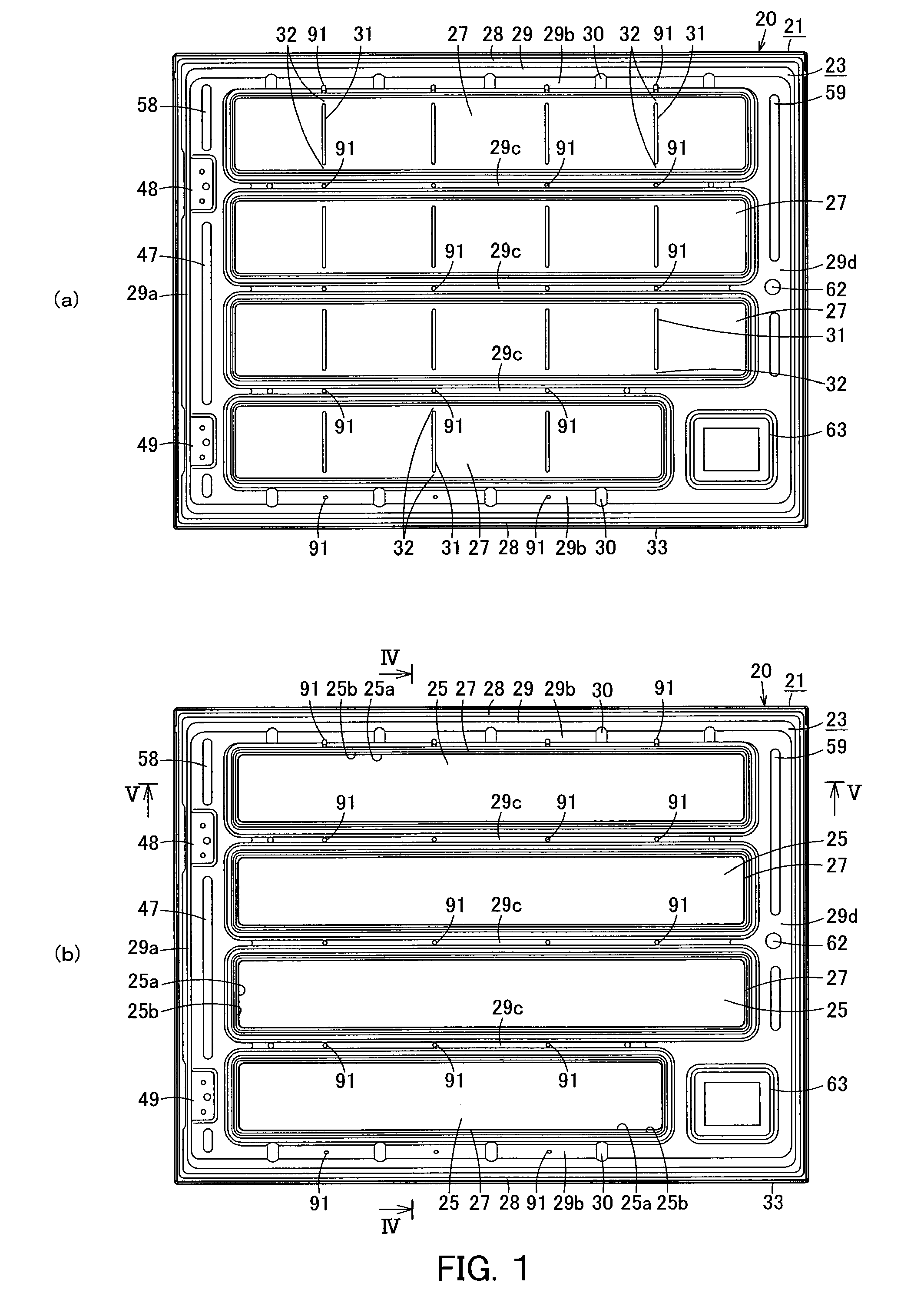

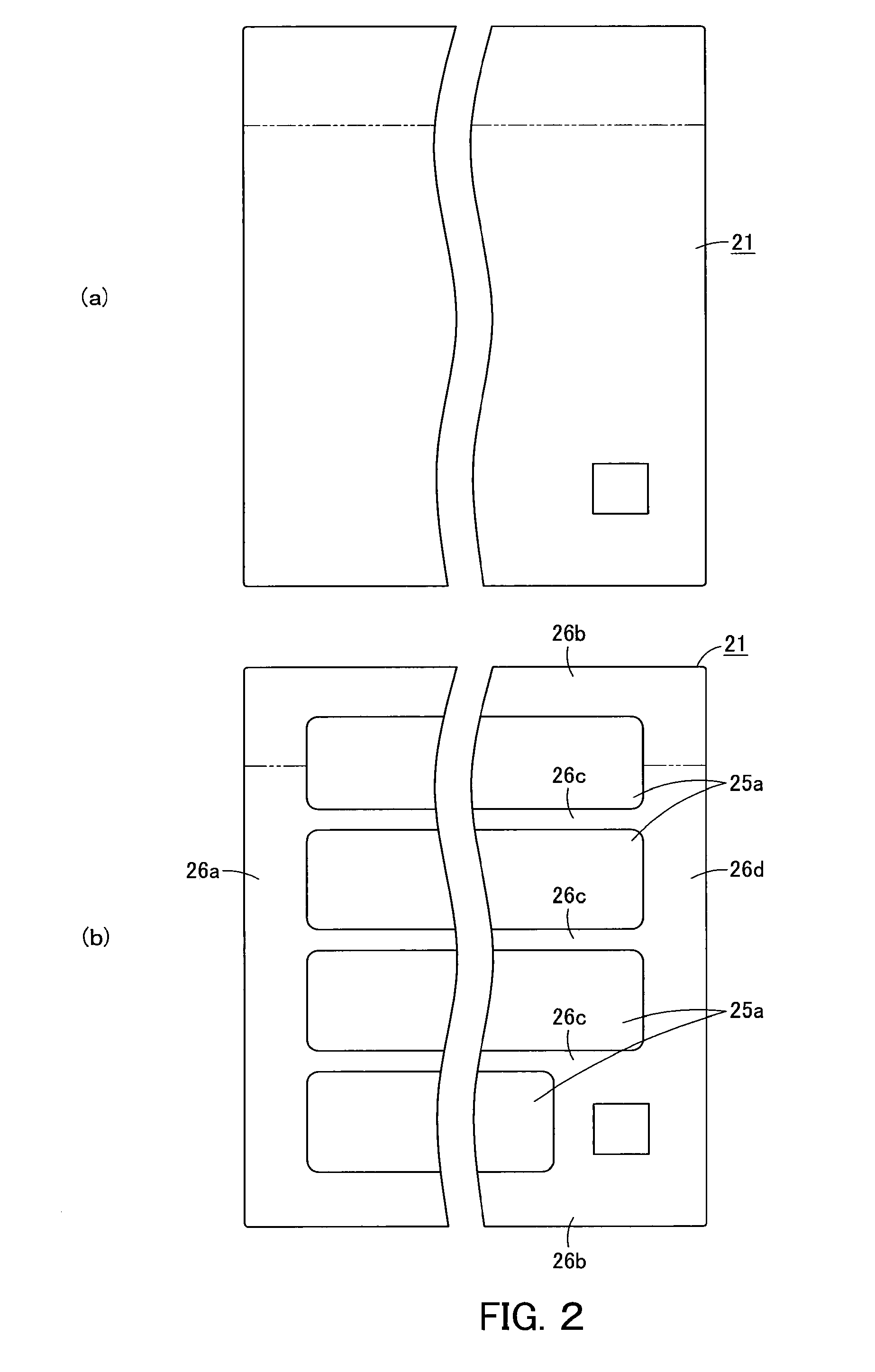

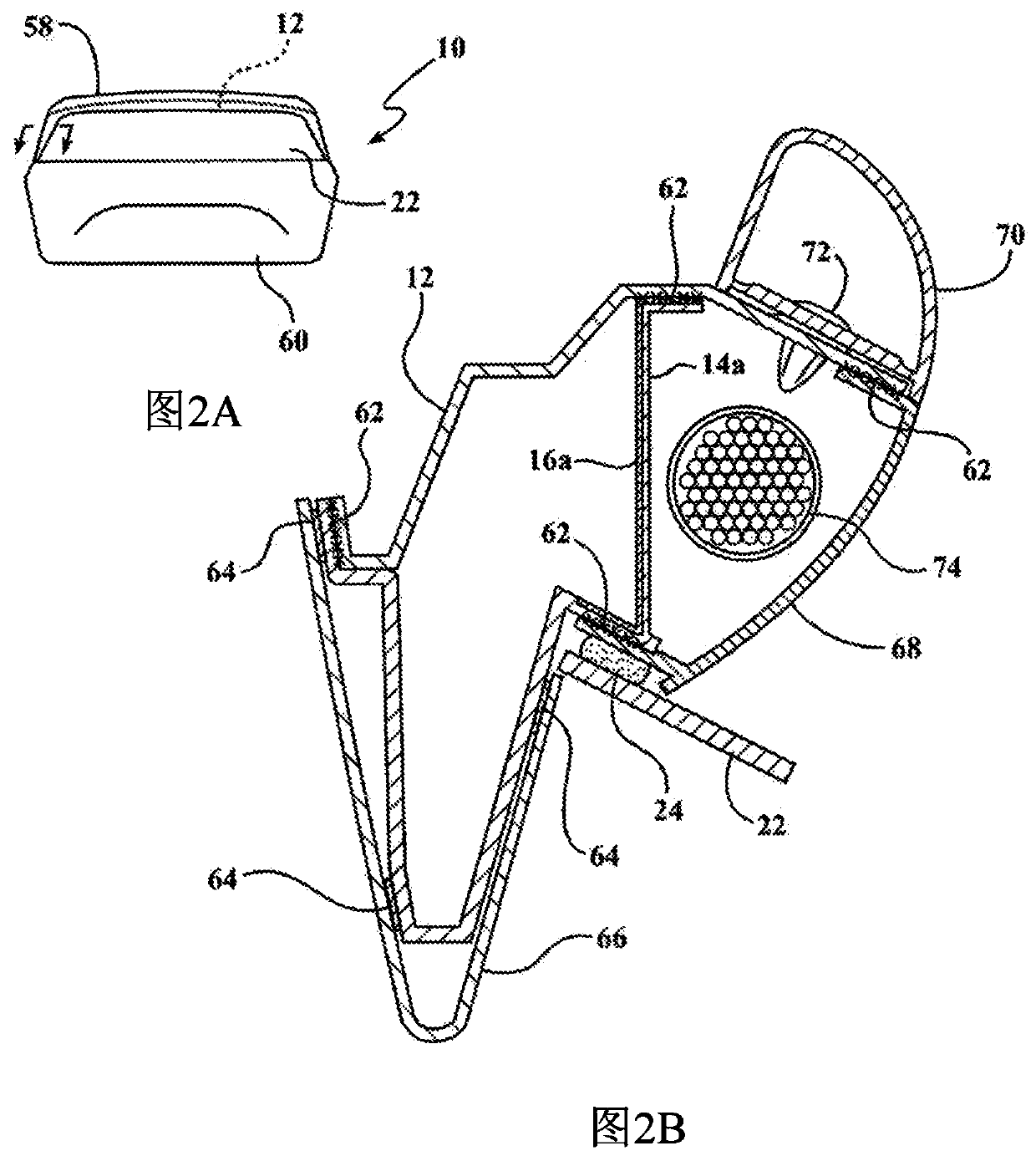

Door panel

ActiveUS8186131B2Avoid deformationImprove rigiditySoil-shifting machines/dredgersSuperstructure subunitsEngineeringUltimate tensile strength

Owner:SHIN CATERPILLAR MITSUBISHI LTD CORP

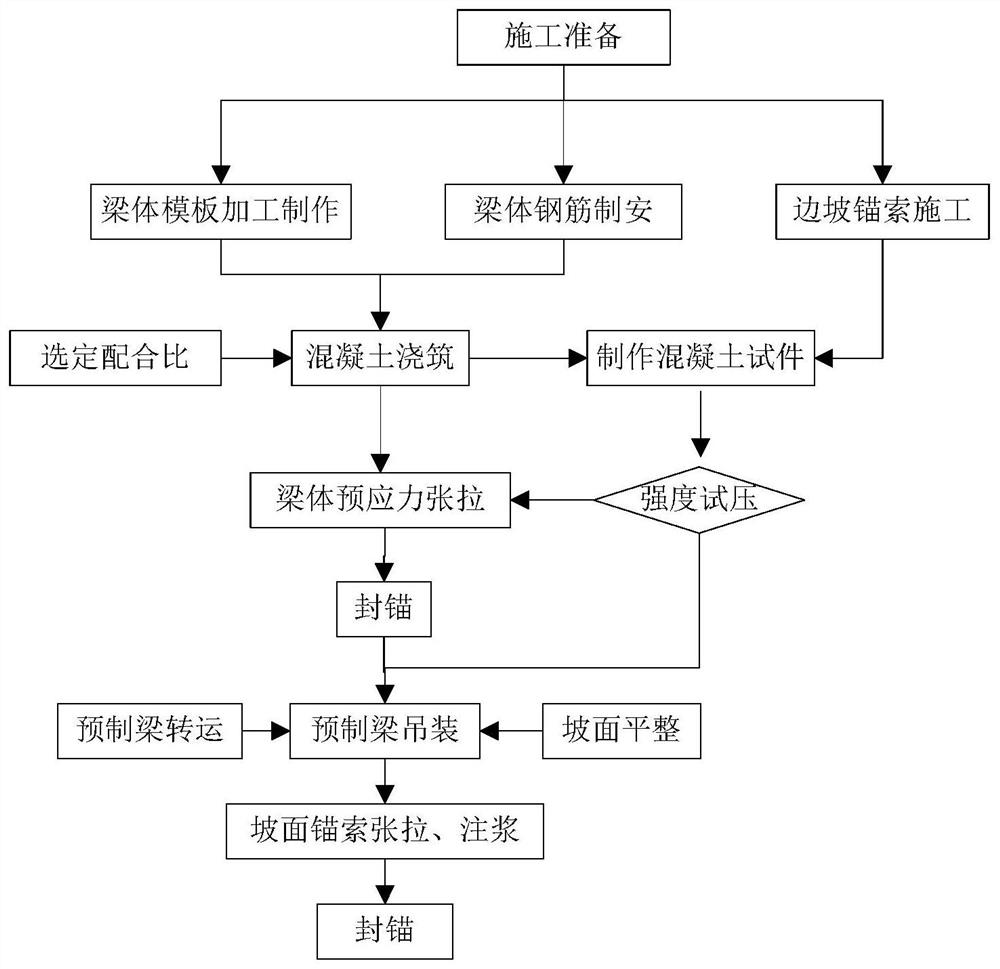

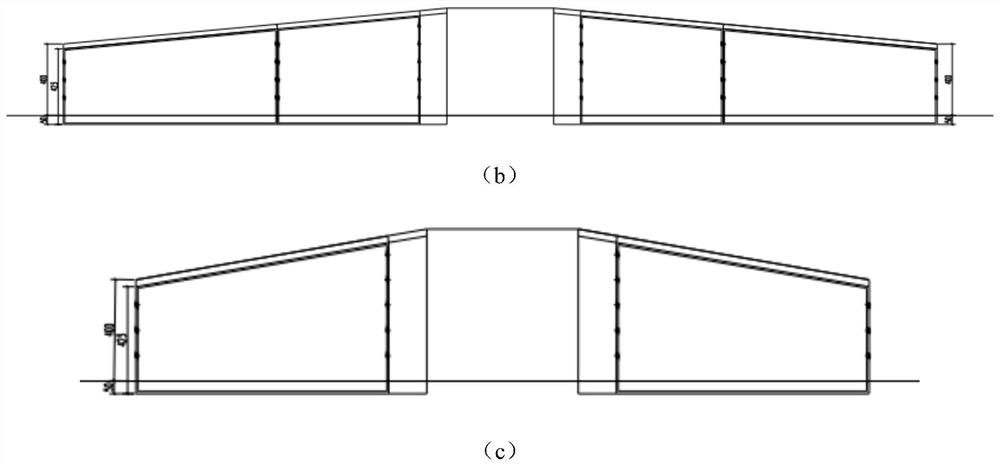

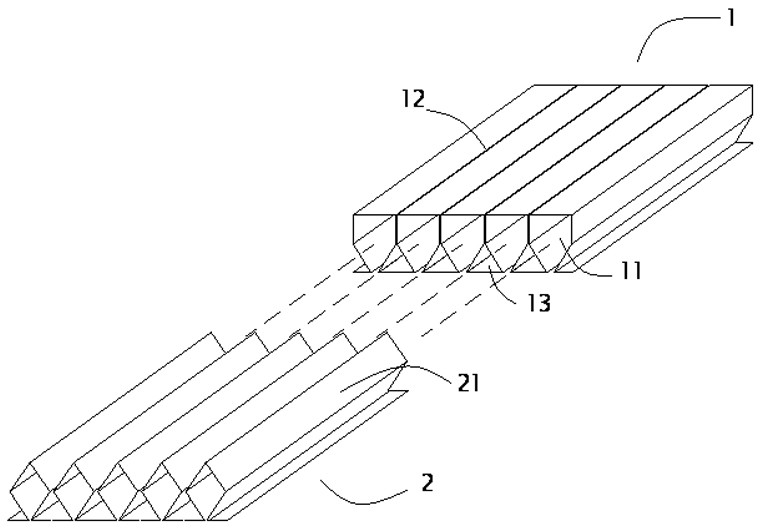

Manufacturing and construction method for slope reinforcing assembled pre-stressed anchor cable frame beam

InactiveCN111997066AImprove section propertiesSolve the defects of easy corrosion and decreased stiffnessCeramic shaping apparatusExcavationsReinforced concretePre stress

The invention relates to a manufacturing and construction method for a slope reinforcing assembled pre-stressed anchor cable frame beam. The slope reinforcing assembled pre-stressed anchor cable framebeam can improve the section performance of the beam and bear a larger anchoring force, and overcomes the defect that the rigidity is reduced as reinforcing steel bars of members in precipitation frequent areas because a conventional cast-in-situ reinforced concrete lattice girder is subjected to a relatively large anchoring force of an anchor cable. The mechanical property is improved greatly. The thickness of the beam body or the stressed reinforcing steel bars can be further reduced, and the utilization of materials is improved, so that the beam is more economical. The pre-stressed anchorcable frame beam is formed by splicing a plurality of prefabricated beam body units which are manufactured more easily, mounted more lightly and adjusted more easily when being mounted, so that the construction period is shortened greatly.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +2

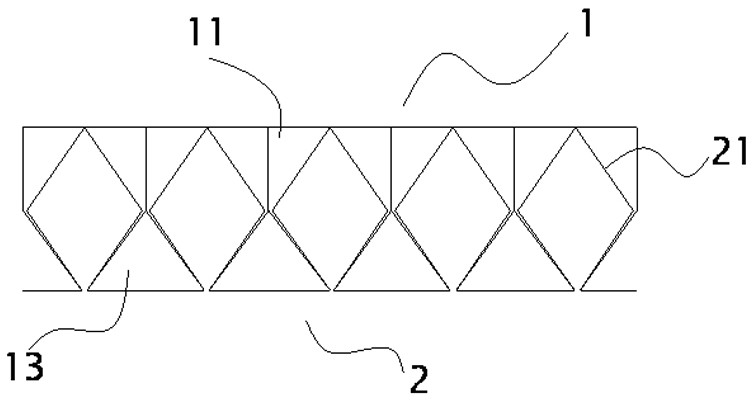

Prefabricated reinforced concrete anchorage pier for slope reinforcing and manufacturing and construction methods thereof

InactiveCN110067251AEasy to manufactureEasy to installExcavationsBulkheads/pilesReinforced concreteRebar

The invention provides a prefabricated reinforced concrete anchorage pier for slope reinforcing and manufacturing and construction methods thereof. The prefabricated reinforced concrete anchorage pieris a non-prestressed component and comprises a steel bar concrete anchorage pier unit provided with a cross beam and a longitudinal beam which are crossed into a cross shape, concrete ribs located onthe periphery of the steel bar concrete anchorage pier unit, and an anchorage head part located at the crossed position of the cross beam and the longitudinal beam; and steel bars are arranged in thecross beam and the longitudinal beam. The prefabricated reinforced concrete anchorage pier adopts reinforced concrete lattice beams of a specific structure, the section property of the beams can be improved, larger anchorage force is borne, and the defect that when traditional cast-in-place reinforced concrete lattice beams are under large anchor cable anchorage force, the midspan positions of the reinforced concrete lattice beams can be pulled cracked possibly, and consequently the rigidity of components is lowered is overcome; and according to the prefabricated reinforced concrete anchoragepier, a manufacturing process can further be simplified, mounting is convenient, adjusting is easy during mounting, the construction period is shortened, and the construction cost is saved.

Owner:红河州蒙屏高速公路投资建设开发有限公司 +3

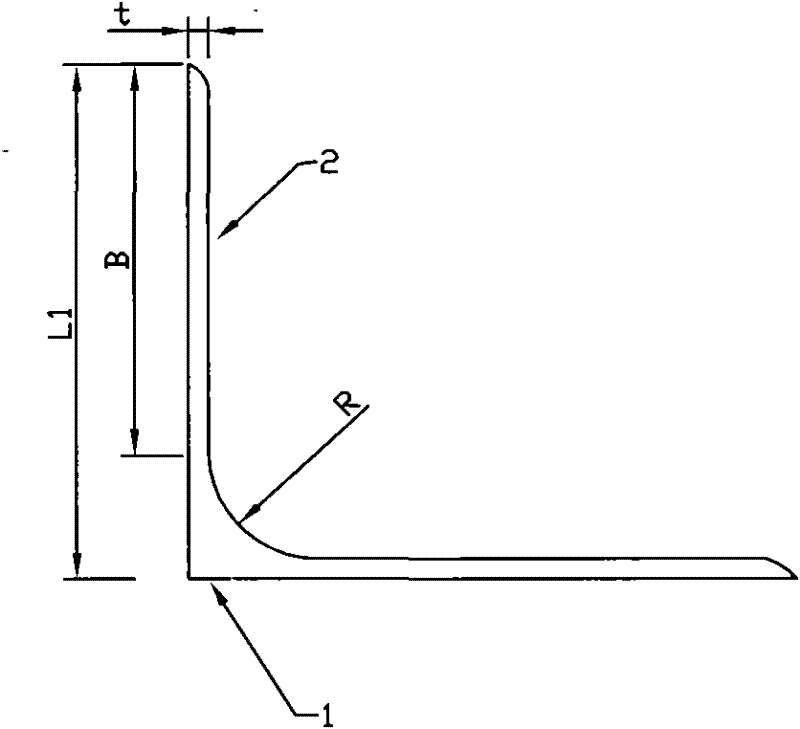

C type steel structure

InactiveCN106555458AImprove section propertiesHigh strengthLoad-supporting elementsFire proofingArchitectural engineeringSteel structures

Owner:TAIZHOU DONGSHENG STEEL STRUCTURE ENG

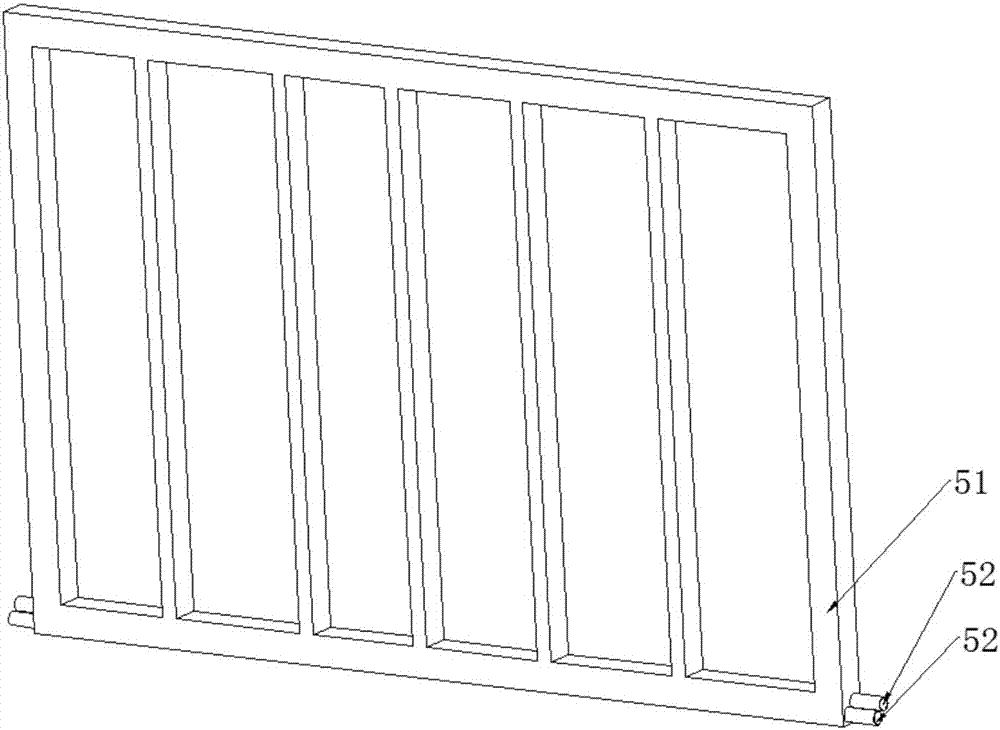

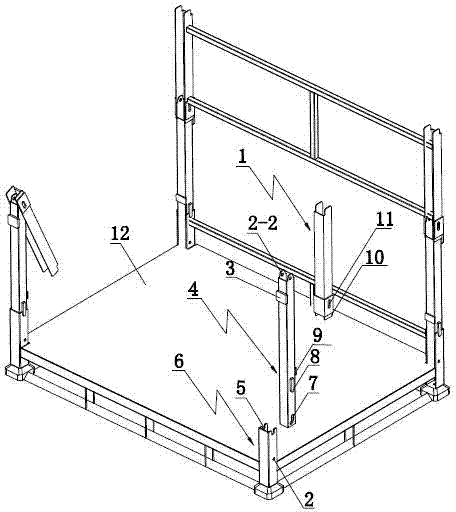

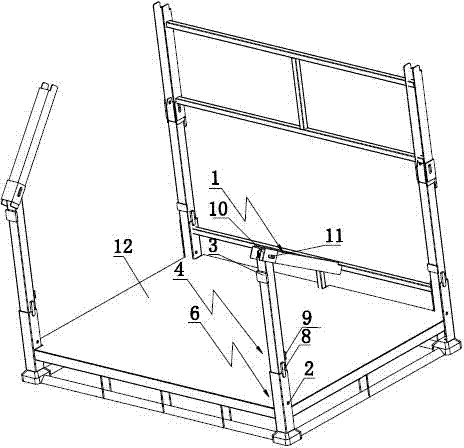

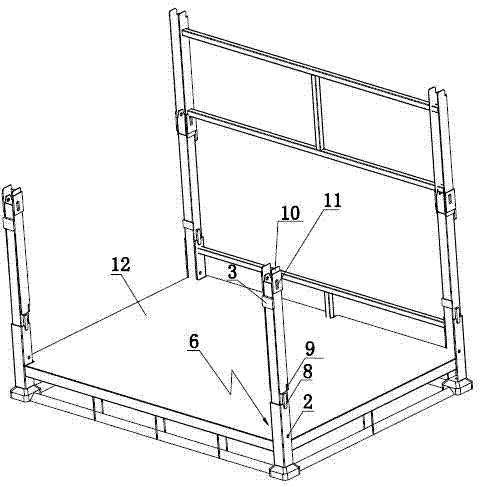

Upright post collecting and releasing type pallet structure

InactiveCN102233965AThin wall and light weightImprove section propertiesRigid containersEngineeringPallet

The invention relates to an upright post collecting and releasing type pallet structure. Fixed upright posts which are parallel to one another and are vertical are arranged at the four corners of a pallet surface; a round hole is formed in each fixed upright post; a U-shaped clamping groove is formed on the top of each fixed upright post; a special-shaped long hole is formed at the bottom of a second movable upright post; a fixed block is arranged above the special-shaped long hole; the special-shaped long hole of the second movable upright post is pivoted with the round hole of each fixed upright post; a round hole is formed on the top of the second movable upright post; a limit block is arranged on the lower part of the round hole; a baffle plate is arranged between the limit block and the fixed block; an L-shaped end part is arranged at the bottom of a first movable upright post 1; a long hole is formed above the L-shaped end part; and the long hole of the first movable upright post is pivoted with the round hole of the second movable upright post. By freely collecting and releasing the movable upright posts, the problems that the accumulation area is large, the storage space is overlarge, transportation cost is increased and the like because the conventional fixed upright post cannot be freely collected and released are solved.

Owner:WUXI JIESI LOGISTICS EQUIP

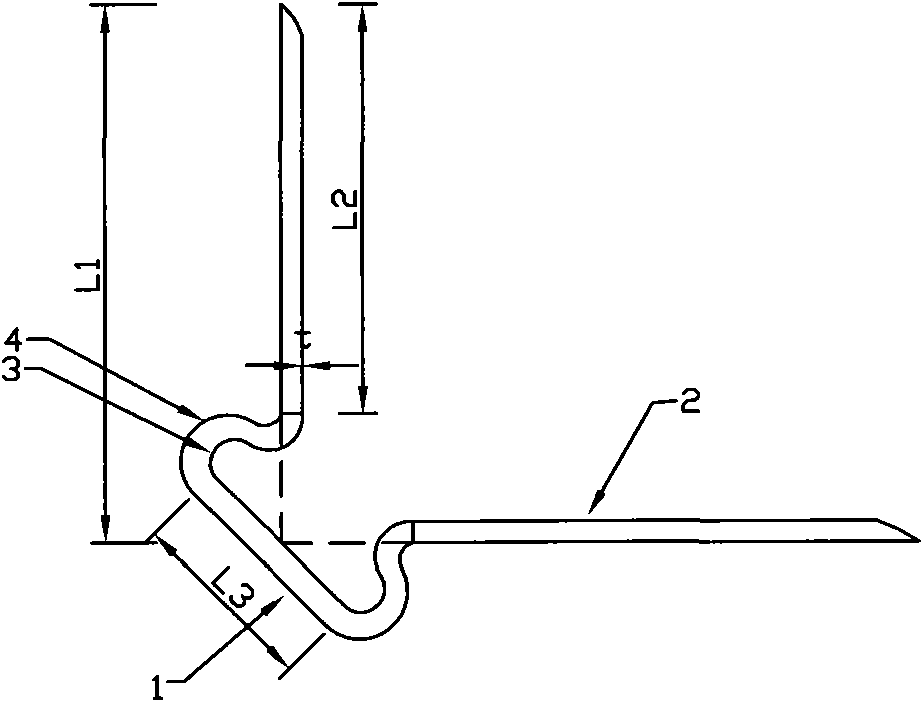

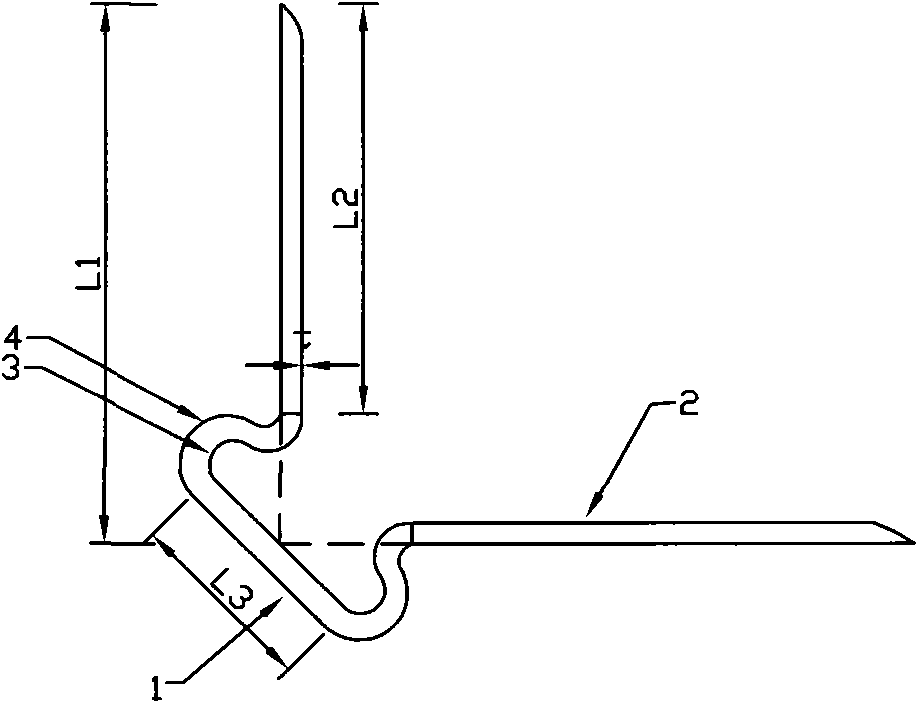

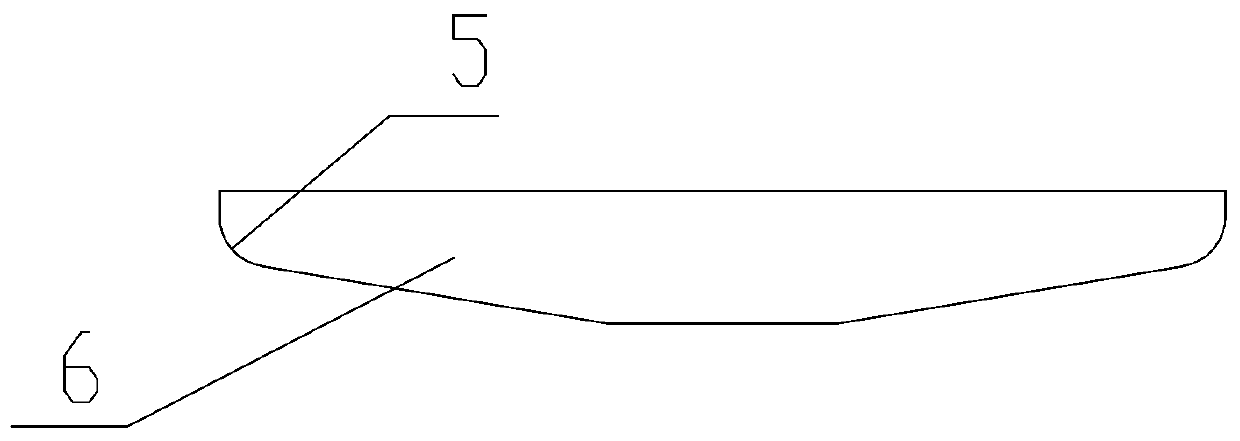

Dual-arc steel section structure design method

ActiveCN101852034AShorten the protruding lengthImprove strength utilizationTowersElectric power transmissionTransmission tower

The invention relates to a dual-arc steel section structure design method, in particular to a structure design method for a transmission tower material in the electric power transmission process. The dual-arc steel section structure of the scheme comprises a vertex angle and a limb plate, wherein the vertex angle is a flat reinforcing plate, and the connecting part of the limb plate and the reinforcing plate is in a relative S-shaped arc section. By adopting the cold-bending technology, a reasonable section shape in the optimized material distribution can be produced according to the need; and with the help of the advantages of the traditional hot-rolled angle steel and by combining the cold-bending technology, the dual-arc steel section structure of the scheme adopts a double S-shaped radian design, the ratio of the free extension length to the thickness of a flange plate can be optimized according to the need, the steel strength reduction due to stable strength is reduced, and the strength utilization ratio of member materials is improved. Compared with the traditional hot-rolled angle steel, the structure has better section characteristics through the arc design of the connecting points and the angle-strengthened protruding cold-bending processing, and the section bearing capacity is greatly improved.

Owner:CHINA ELECTRIC POWER RES INST +1

Door panel

ActiveUS20110036047A1Prevent deformationImprove rigiditySoil-shifting machines/dredgersDoor/window applicationsEngineeringElectrical and Electronics engineering

Owner:SHIN CATERPILLAR MITSUBISHI LTD CORP

Environment-friendly prefabricated fast-assembly lattice beam and construction method

InactiveCN111945748AThere will be no more problems such as vibrating, not compacting and running moldsQuality improvementExcavationsCultivating equipmentsReinforced concreteShaped beam

The invention discloses an environment-friendly prefabricated fast-assembly lattice beam and a construction method. The lattice beam comprises a lattice beam body; the lattice beam body is in a grid shape and is formed by arranging and connecting a plurality of cross-shaped beam bodies; each cross-shaped beam body is of a reinforced concrete structure; a concrete groove for containing an anchor head is formed in the center intersection of a cross beam and a vertical beam of each cross-shaped beam body; a base plate is arranged in each concrete groove; the base plates and the concrete grooves are provided with corresponding anchor holes; and ecological geotextile bags are placed in grids of the lattice beam body. The lattice beam has the advantages of short construction period, manpower andmaterial resource saving, environmental protection and the like, can be disassembled and assembled, and can realize industrialization.

Owner:DALIAN UNIV

Continuous welding production method of light H-type steel

InactiveCN1168568CIncrease productivityRealize continuous productionWelding/cutting auxillary devicesHigh frequency current welding apparatusEngineeringStrip steel

The continuous welding production method of light H-type steel includes the following processes: decoiling band steel, flatening, shearing but-welding, loop stoage, web edge-upsetting, preassembling, high-frequency welding, quick-cooling, flatening drawing, length shearing. The parameters of every process are: edge-upsetting pressure is 500-8000 kgf, microtension of band steel before welding is 50-1000 Kgf, welding speed is 10-50 m / min., welding power is 100-1000 KW, and cooling speed is 1-30 deg.C / s.

Owner:CENT IRON & STEEL RES INST

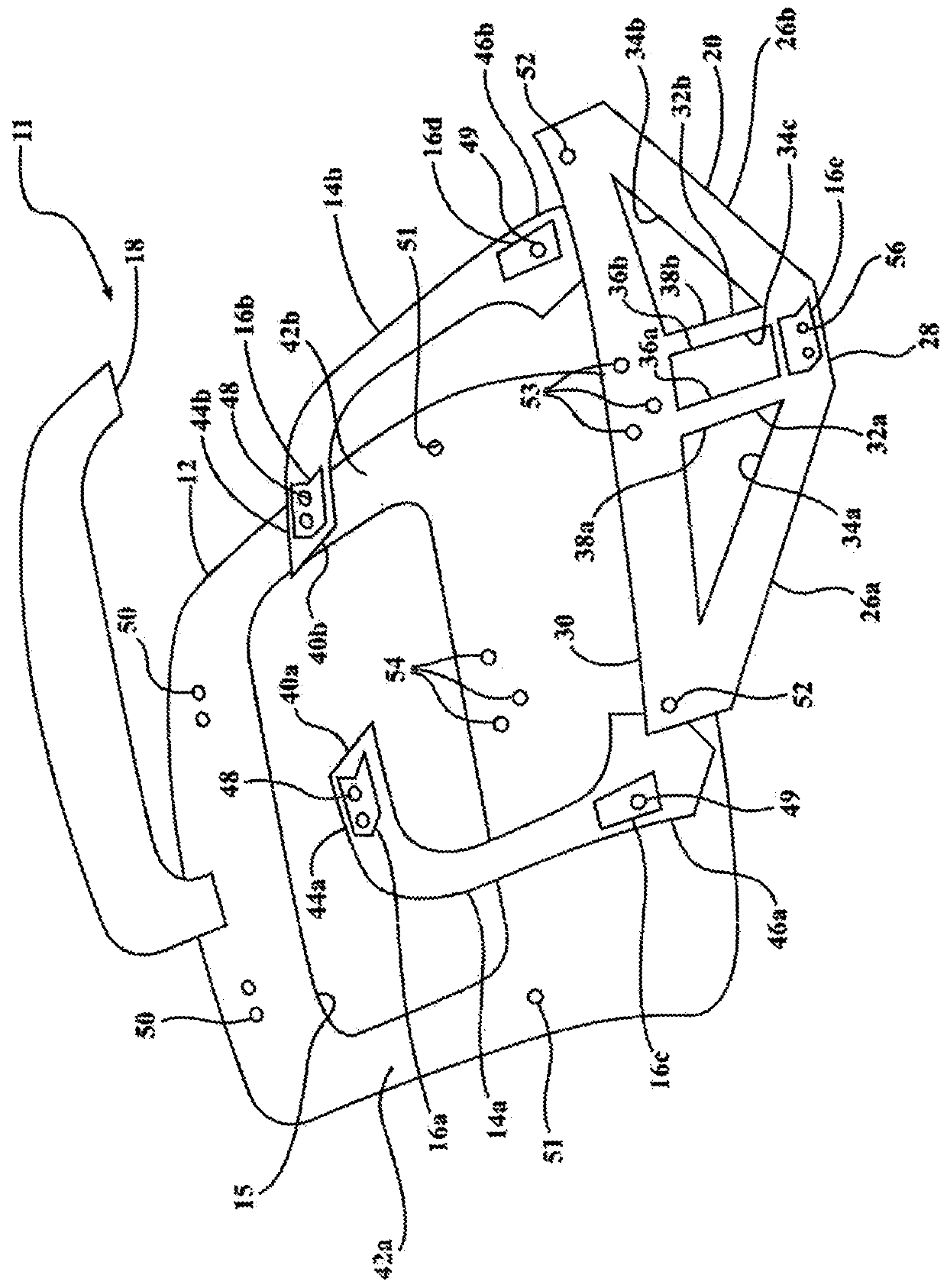

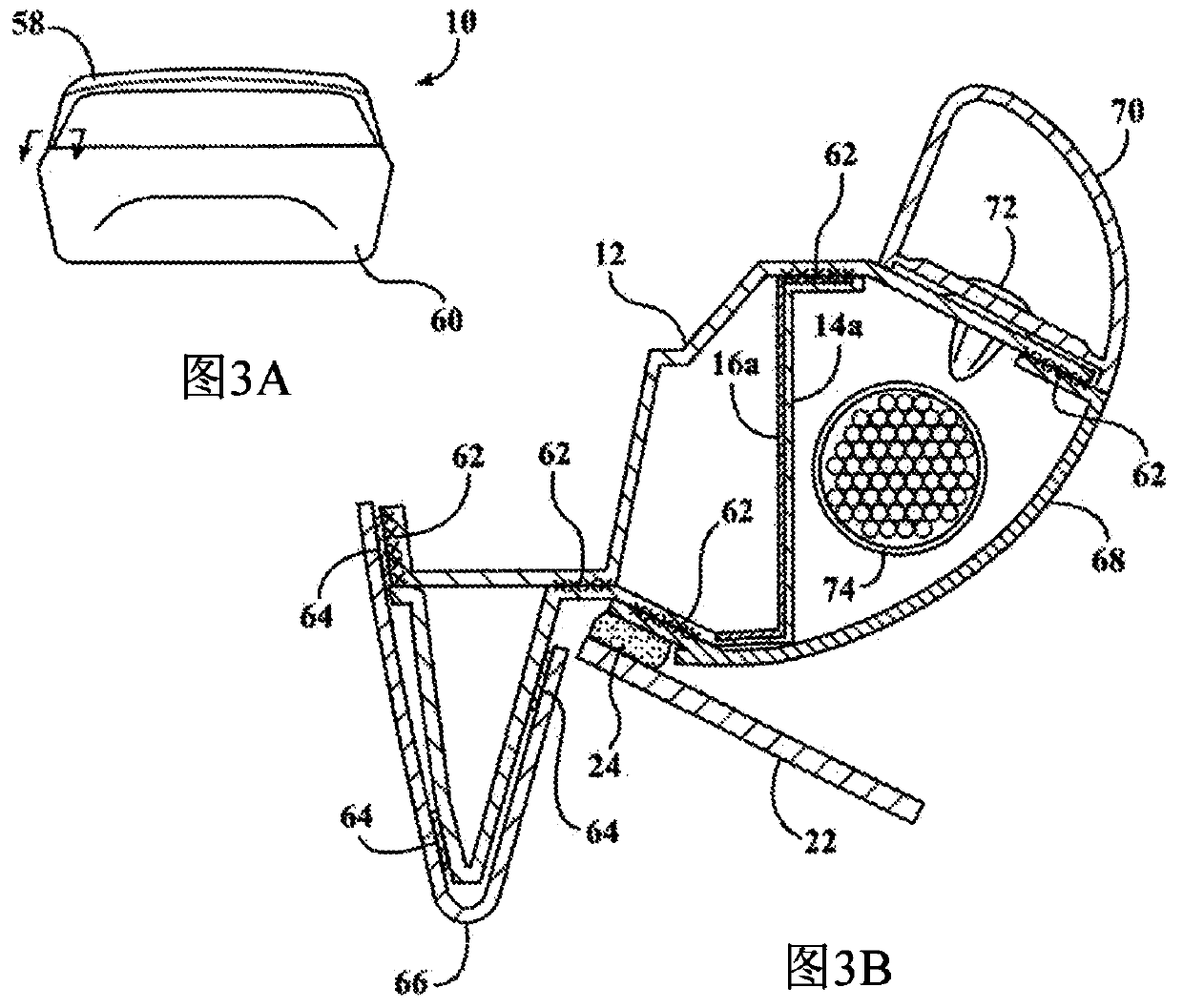

Infrared welded liftgate assembly and process of making same

A liftgate assembly having finished show surfaces, and process of manufacturing same are disclosed. The liftgate assembly includes local reinforcements that are overmolded to first reinforcements, andthe first reinforcements are infrared welding to a first panel. Second and third reinforcements are also infrared welded to the first panel. To infrared weld the respective reinforcements to the first panel in predetermined locations with respect to the first panel, nesting structures are provided to hold the respective reinforcements and first panel. At least one infrared heating fixture heats various predetermined surfaces on the reinforcements and first panel, and the parts are then pressed together for joining the predetermined surfaces of the respective parts together. The process is repeated, if needed, until all of the reinforcements are infrared welded to the first panel. Outer panels are bonded to the second and third reinforcements.

Owner:MAGNA EXTERIORS INC

A movable building structure and its manufacturing method

The invention relates to a movable building structure and a making method thereof. The movable building structure is characterized in that the movable building structure comprises a bearing frame and a building enclosure fixedly connected to the bearing frame through bolts, and a doorway for mounting a door or a window opening for mounting a window is formed in the building enclosure according to the position of the door or the window; the bearing frame comprises stand columns, main girders connected between the stand columns and secondary girders connected between the main girders; the stand columns, main girders and secondary girders are each provided with two pairs of box iron arranged at intervals and with inwards-turned edges, the cold-formed thin walls of the box iron are in a C shape, two wings of one pair of box iron are welded to the backs of two webs of the other pair of box iron, the inner surfaces of the stand columns, or the main girders or the secondary girders are enclosed to form a through strip-shaped cavity, and the section of the cavity is square or rectangular; the stand columns and the main girders are each provided with a plurality of brackets and connection plates with mounting holes at intervals in a welded mode, and the bottom of each stand column is fixedly connected with a column foot; the two ends of each main girder and the secondary girder are each provided with a head plate with mounting holes in a welded mode. The multi-layer movable building structure can be used temporarily as well as permanently.

Owner:北京海东蓝涛洁净工程技术有限公司

Fold line type profiled hollow steel plate

PendingCN113026937AImprove carrying capacityReduce dead loadHeat proofingSound proofingConstant loadFloor slab

The invention discloses a fold line type profiled hollow steel plate. The fold line type profiled hollow steel plate comprises locking plates, wherein a plurality of cavities I are formed in the locking plates in the horizontal direction; each locking plate is formed by bending a steel plate; the profiled steel plate is arranged as a buckling bone plate; a plurality of supporting bodies are arranged on the buckling bone plate in the horizontal direction; each supporting body is a fold line type supporting body formed by bending a steel plate; a cavity is formed in each supporting body; and when the locking plates are connected with the buckling bone plate, the supporting bodies are nested in the cavities I. According to the profiled hollow steel plate disclosed by the invention, through the profiled hollow steel plate and the unique space design, excellent section characteristics are obtained, the bearing capacity of a component is improved, and the constant load of a building plate is reduced; hollow lattices are formed among profiled plate layers, so that air convection is obstructed, and the requirements of sound insulation, heat insulation and fire prevention are met; and the profiled hollow steel plate can replace a concrete floor, a concrete wall plate and a roof plate, and is more green and environment-friendly.

Owner:广东江南金工科技股份有限公司

Profiled hollow steel plate

PendingCN113026936AImprove carrying capacityReduce dead loadHeat proofingSound proofingConstant loadFloor slab

The invention discloses a profiled hollow steel plate. The steel plate comprises a hollow structure formed by combining and fixing at least two layers of profiled steel plates, and the at least two layers of profiled steel plates are mutually nested and matched. According to the profiled hollow steel plate, through the unique space design of the profiled hollow steel plate, the excellent section characteristic is obtained, the bearing capacity of a component is improved, and the constant load of a building plate is reduced. Hollow lattices are formed between profiled plate layers, air convection is blocked, and the requirements for sound insulation, heat insulation and fire prevention are met. The profiled hollow steel plate can replace a concrete floor, a concrete wallboard and a roof panel, and is more environment-friendly.

Owner:广东江南金工科技股份有限公司

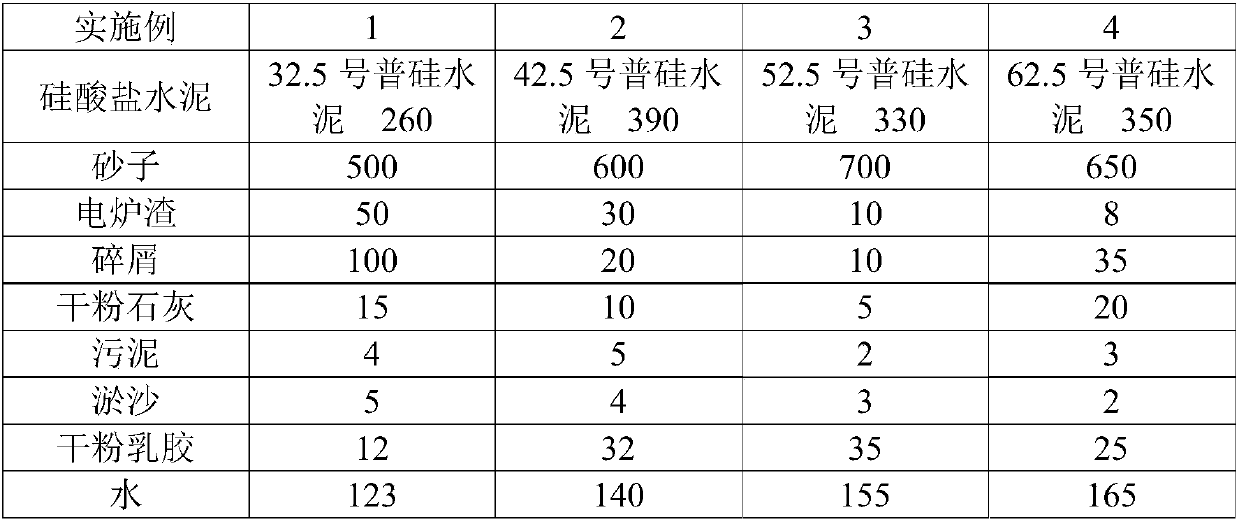

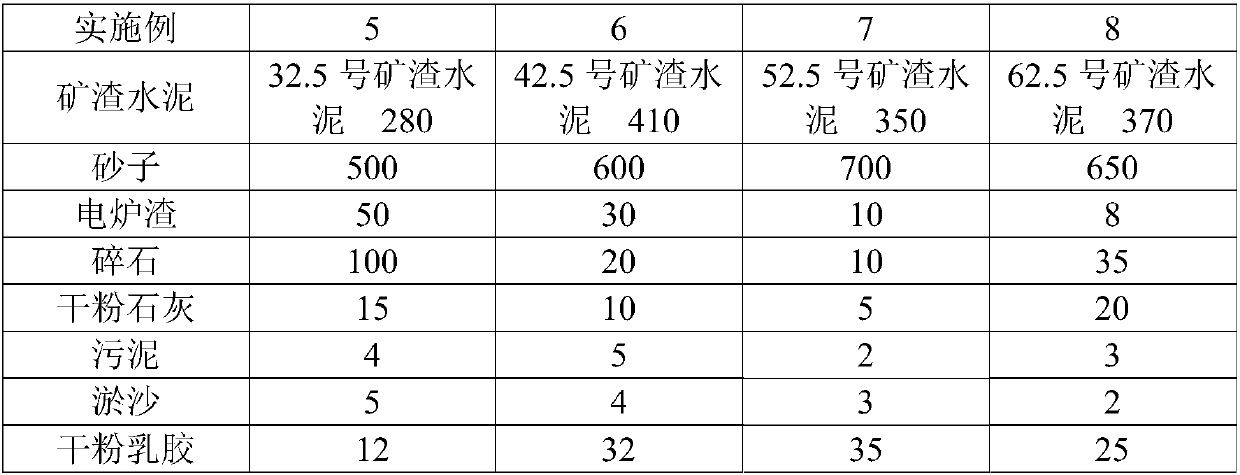

Energy-saving dry and wet dual-use composite building mortar

The invention belongs to the technical field of building materials, and particularly relates to an energy-saving dry and wet dual-use composite building mortar. The composite building mortar comprises, by mass, 260-410 parts of cement, 500-700 parts of sands, 8-50 parts of electric furnace slag, 10-100 parts of crushed aggregates, 5-20 parts of dry powdered lime, 2-5 parts of sludge, 2-5 parts of silt and 12-35 parts of dry powder latex; and the crushed aggregates adopt chippings or rubbles. The dry powder latex is used as a polymer material to effectively improve the cross-section performance, and the flexibility of the dry powder latex is combined to easily carry out accurate measurement and improve the construction convenience, so the construction quality can be effectively improved.

Owner:高国清

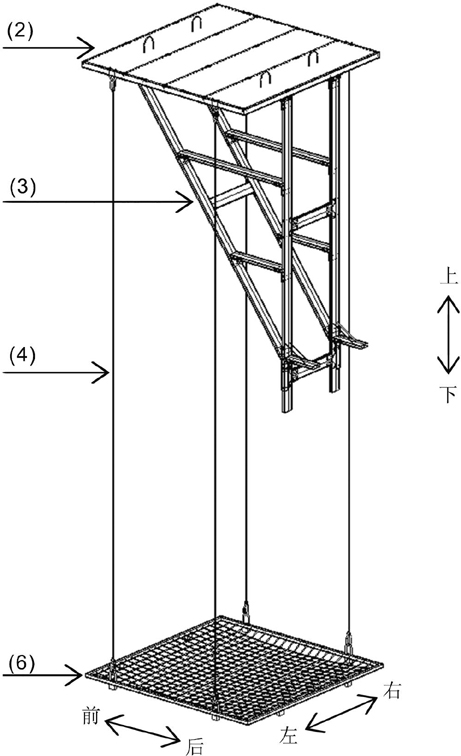

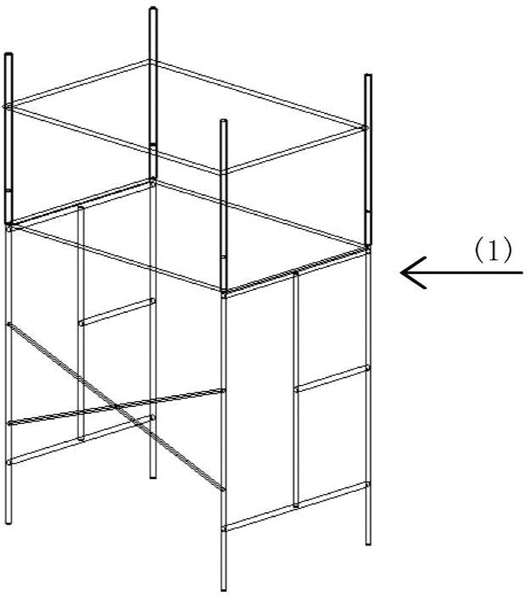

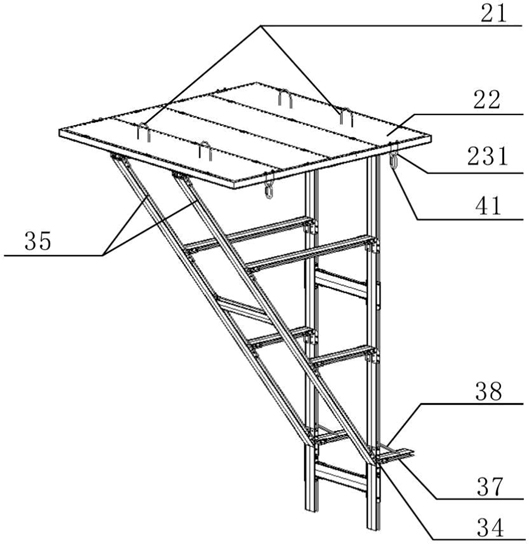

Integrated platform for construction in C-shaped steel core tube

PendingCN114165035AEnsure construction safetyImprove securityScaffold accessoriesBuilding support scaffoldsSteel frameMechanical engineering

The invention relates to an integrated platform for construction in a C-shaped steel core tube. The integrated platform comprises a scaffold operation frame body, an upper steel platform, a triangular supporting frame, a connecting device, a movable fastening device and a lower steel frame protection body. A scaffold operation frame body is fixed to the working face of an operation platform formed by connecting the two rows of triangular supporting frames and the upper steel platform, and the triangular supporting frames and the lower steel frame protection body are connected into a whole through connecting devices. And a fixing piece at the lower part of the lower steel frame protection body is clamped in a movable fastening device in a shaft wall body so as to provide protection for the interior of the core tube shaft. The platform is high in safety, and safe construction of constructors in the core tube can be effectively guaranteed. Operation is easy and convenient, installation and use are convenient, off-site pre-assembly can be achieved through the platform, and the labor cost is reduced. And the C-shaped steel frameworks of the operating platform are connected through the connecting steel sheets and the T-shaped bolts, so that the C-shaped steel frameworks are convenient to disassemble and transfer and can be repeatedly used.

Owner:SHANGHAI BAOYE GRP CORP

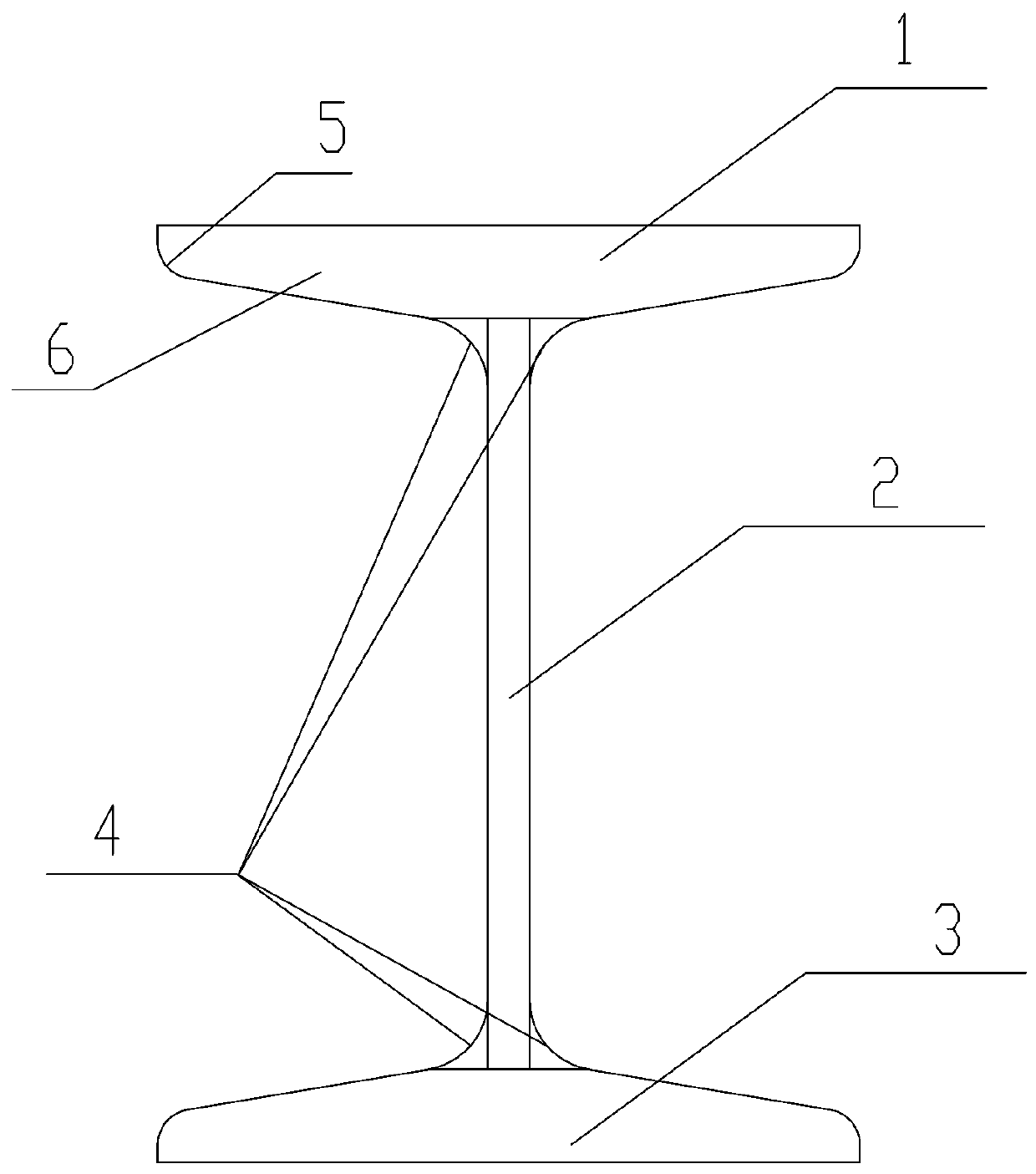

Steel structure welded I-steel

PendingCN111350305AImprove section propertiesSolve the shortcomings of not being able to process large cross-section (above 700mm) structural profilesStrutsGirdersMetallurgyEngineering

The invention belongs to the technical field of steel structure construction, and particularly relates to steel structure welded I-steel. The steel structure welded I-steel is characterized by comprising a horizontal upper flange plate and a lower flange plate connected with the upper flange plate through a vertical web; the upper flange plate is composed of a flange inclination steel plate and rounded corners arranged at the ends of the flange inclination steel plate, and the lower flange plate is composed of a flange inclination steel plate and rounded corners arranged at the ends of the flange inclination steel plate; and the upper flange plate and the lower flange plate are symmetrical about a horizontal central axis. The steel structure welded I-steel is formed by welding the flange plates with inclined planes, the excellent cross-section characteristics of traditional I-steel are retained, and the defect that large-cross-section structural profiles cannot be processed with the traditional I-steel is overcome.

Owner:辽宁福瑞达建筑科技有限公司

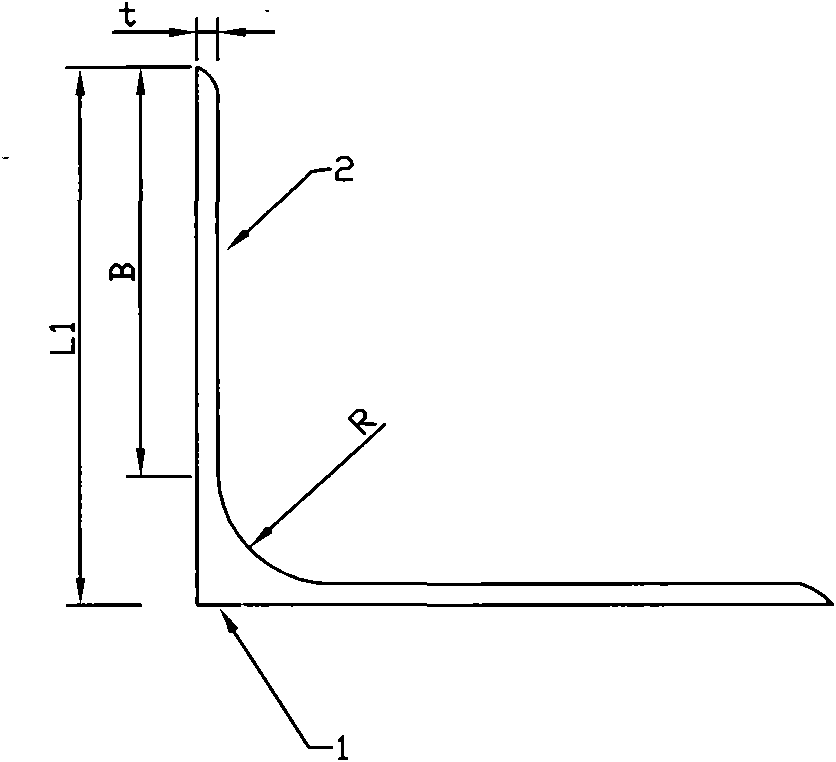

Dual-arc steel section structure design method

ActiveCN101852034BShorten the protruding lengthImprove strength utilizationTowersElectric power transmissionTransmission tower

The invention relates to a dual-arc steel section structure design method, in particular to a structure design method for a transmission tower material in the electric power transmission process. The dual-arc steel section structure of the scheme comprises a vertex angle and a limb plate, wherein the vertex angle is a flat reinforcing plate, and the connecting part of the limb plate and the reinforcing plate is in a relative S-shaped arc section. By adopting the cold-bending technology, a reasonable section shape in the optimized material distribution can be produced according to the need; and with the help of the advantages of the traditional hot-rolled angle steel and by combining the cold-bending technology, the dual-arc steel section structure of the scheme adopts a double S-shaped radian design, the ratio of the free extension length to the thickness of a flange plate can be optimized according to the need, the steel strength reduction due to stable strength is reduced, and the strength utilization ratio of member materials is improved. Compared with the traditional hot-rolled angle steel, the structure has better section characteristics through the arc design of the connecting points and the angle-strengthened protruding cold-bending processing, and the section bearing capacity is greatly improved.

Owner:CHINA ELECTRIC POWER RES INST +1

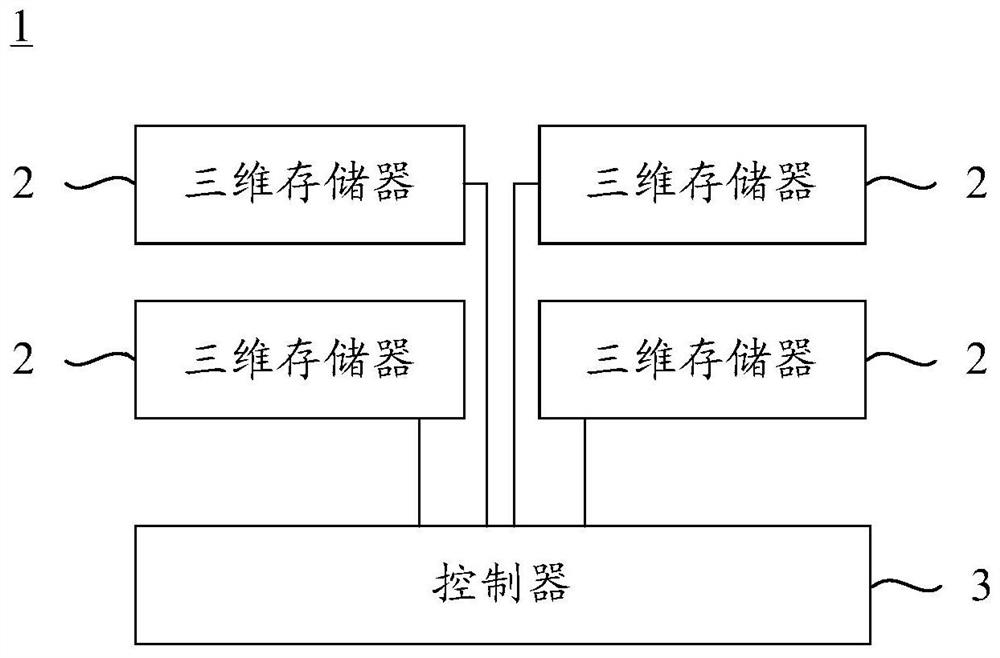

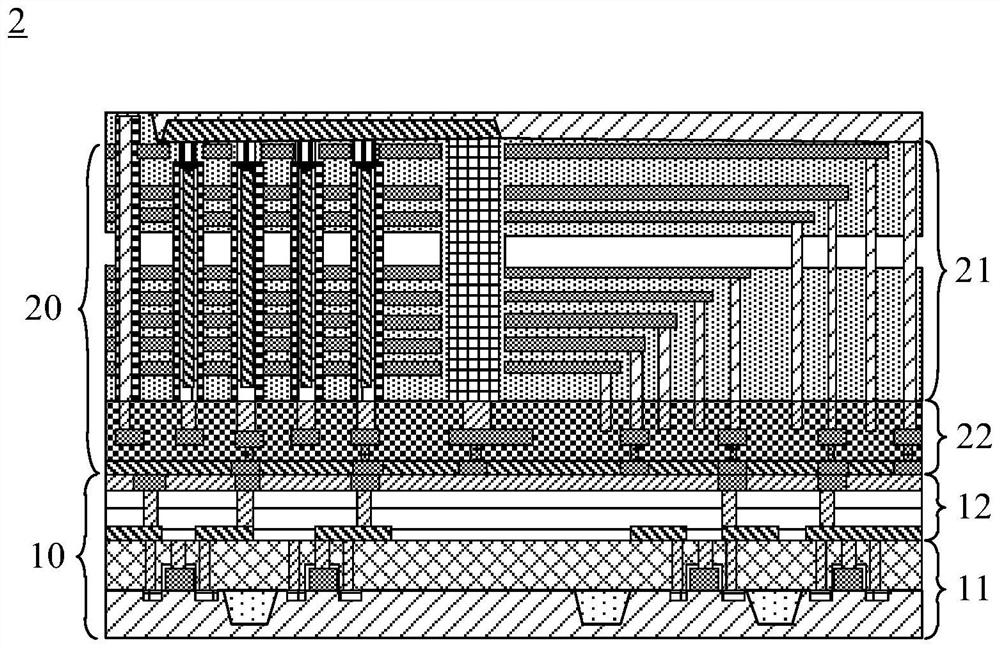

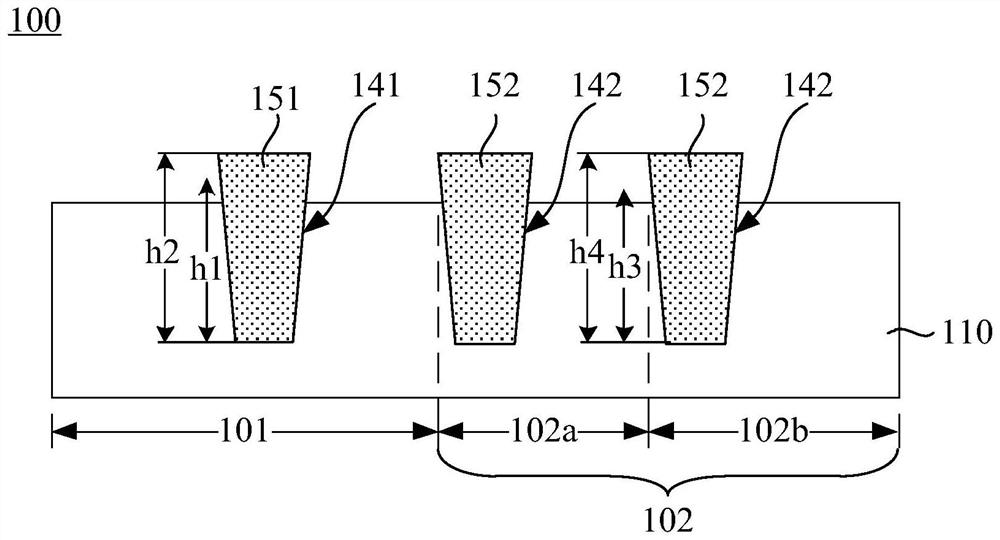

Semiconductor structure and preparation method thereof, three-dimensional memory and storage device

PendingCN114284283AHighly integratedEffective protectionSolid-state devicesSemiconductor devicesSemiconductor structureSemiconductor chip

The invention provides a semiconductor structure and a preparation method thereof, a three-dimensional memory and a storage device, relates to the technical field of semiconductor chips, and aims to solve the problem of low integration level of a peripheral circuit of the three-dimensional memory. The semiconductor structure can be divided into a high-voltage well region and a low-voltage well region; the semiconductor structure comprises a substrate which comprises a first groove and at least one second groove, the first groove is located in a high-voltage well region, and the second groove is located in a low-voltage well region; the first isolation structure is arranged in the first groove; the thickness of the first isolation structure is greater than the depth of the first groove; the second isolation structure is arranged in the second groove; the thickness of the second isolation structure is smaller than the depth of the second groove; the first gate oxide layer is located in the high-voltage well region; the first gate oxide layer is disposed on the surface of the substrate and exposes the first isolation structure. The semiconductor structure is applied to the three-dimensional memory so as to realize data reading and writing operation.

Owner:YANGTZE MEMORY TECH CO LTD

Three-sided punched C-shaped steel channel provided with six reinforcing ribs

InactiveCN109594714AHigh strengthThin wall and light weightGirdersJoistsEngineeringUltimate tensile strength

The invention provides a three-sided punched C-shaped steel channel provided with six reinforcing ribs. The section form of the steel channel is of a C-shaped structure, end parts of two sides of thesteel channel are bent inwards continuously, secondary L-shaped structures are formed, sawtooth structures are arranged at the end parts of the sides, the steel channel is provided with three sides, two parallel reinforcing ribs are arranged on each side, and a plurality of through holes are formed between the two reinforcing ribs. With the adoption of the six reinforcing ribs, strength of the C-shaped steel channel is further improved, and the C-shaped steel channel is prepared by cold bending machining, has the advantages of thin wall, light dead weight, excellent section performance and high strength, and can save materials under the same strength when compared with the traditional steel channel.

Owner:佛山凡鼎建筑科技有限公司

a composite component

ActiveCN104988994BImprove stabilityImprove section propertiesBuilding constructionsCold formedEngineering

Owner:北京海东蓝涛洁净工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com