Patents

Literature

238 results about "Lattice girder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lattice girder is a truss girder where the load is carried by a web of latticed metal.

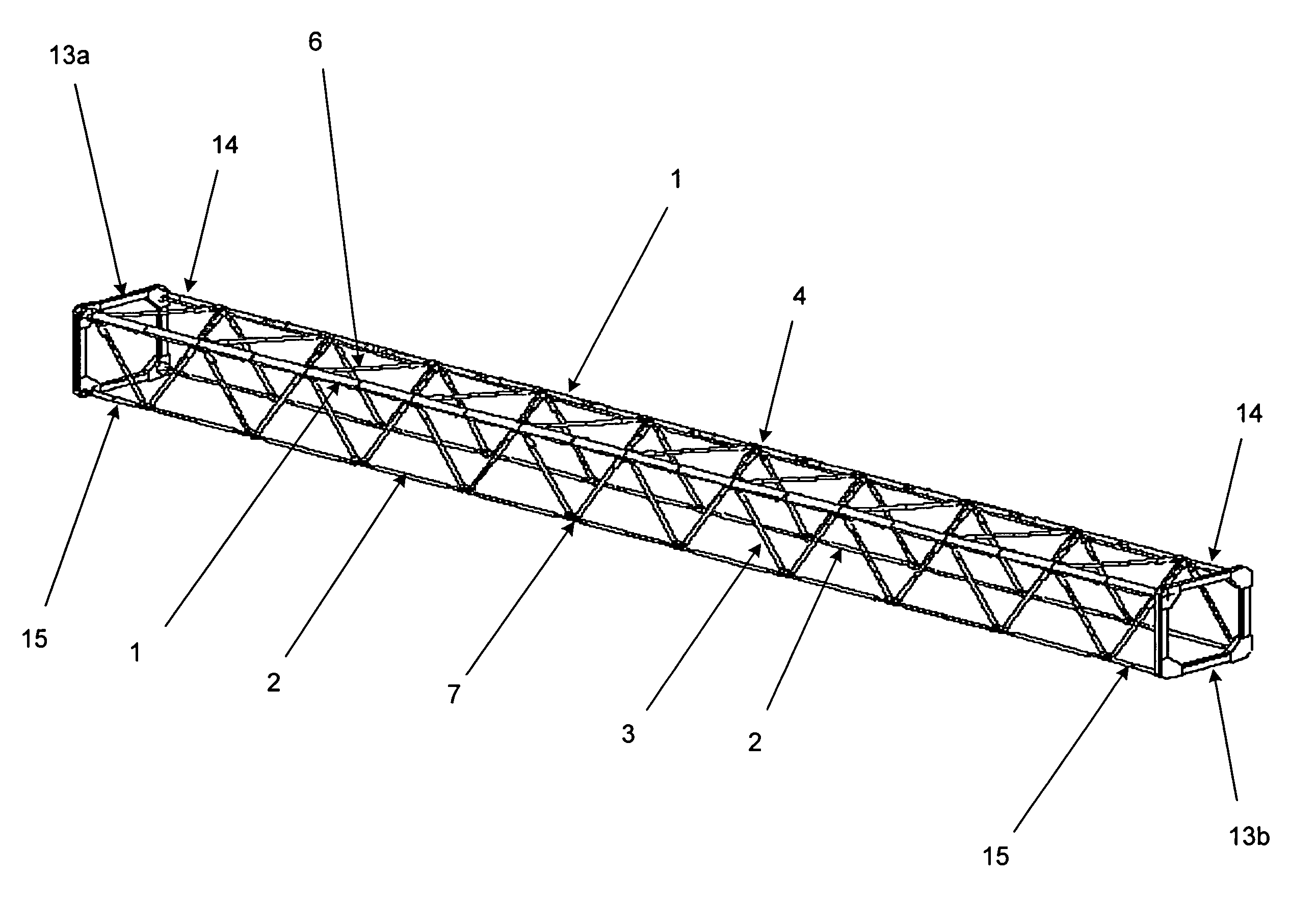

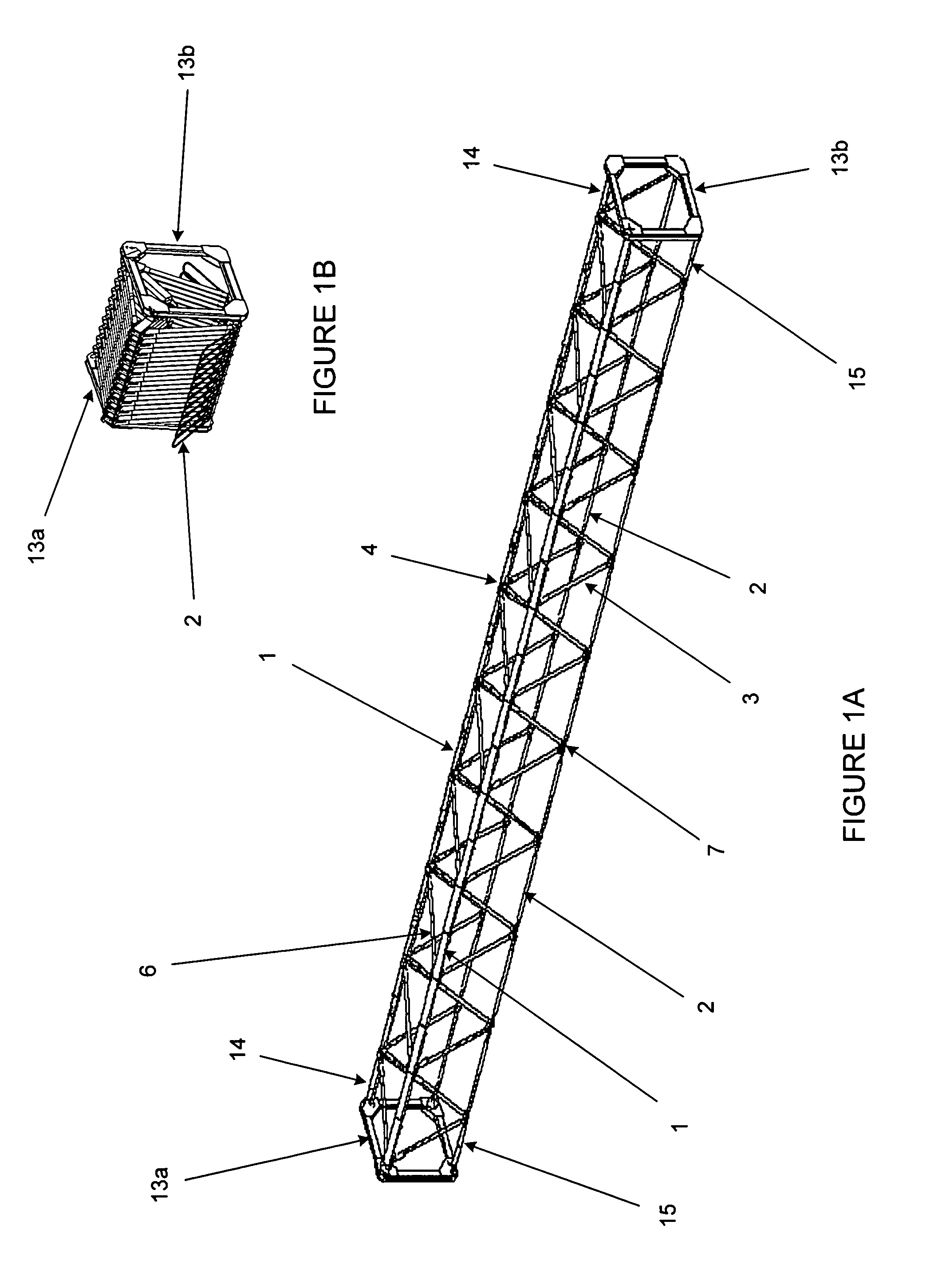

Deployable truss beam with orthogonally-hinged folding diagonals

InactiveUS7028442B2Improve stabilityHigh strengthCosmonautic vehiclesCosmonautic partsDiagonalSecondary chords

A deployable single truss with folding or removable chordal members and diagonals and orthogonal hinge joints for continuous and synchronous retraction and extension, in straight and curved configurations. One or more endframes may be used to close off or mount one of more ends of the deployable trusses. A primary orthogonal hinge joint is used to connect the chordal members and diagonals of the deployable trusses along each primary chord. A secondary orthogonal hinge joint to connect the chordal members and diagonals of the deployable trusses along each secondary chord.

Owner:CPI TECH

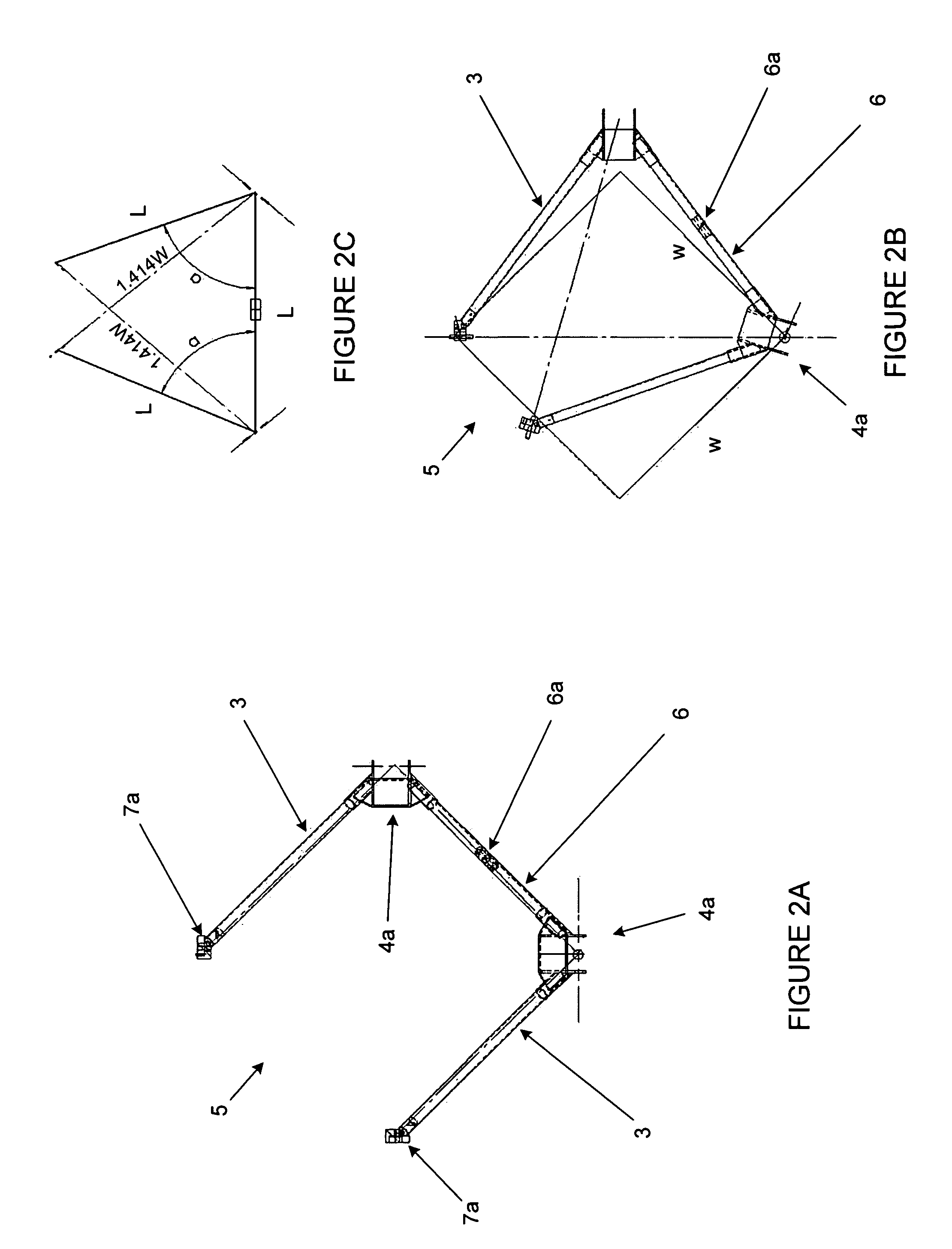

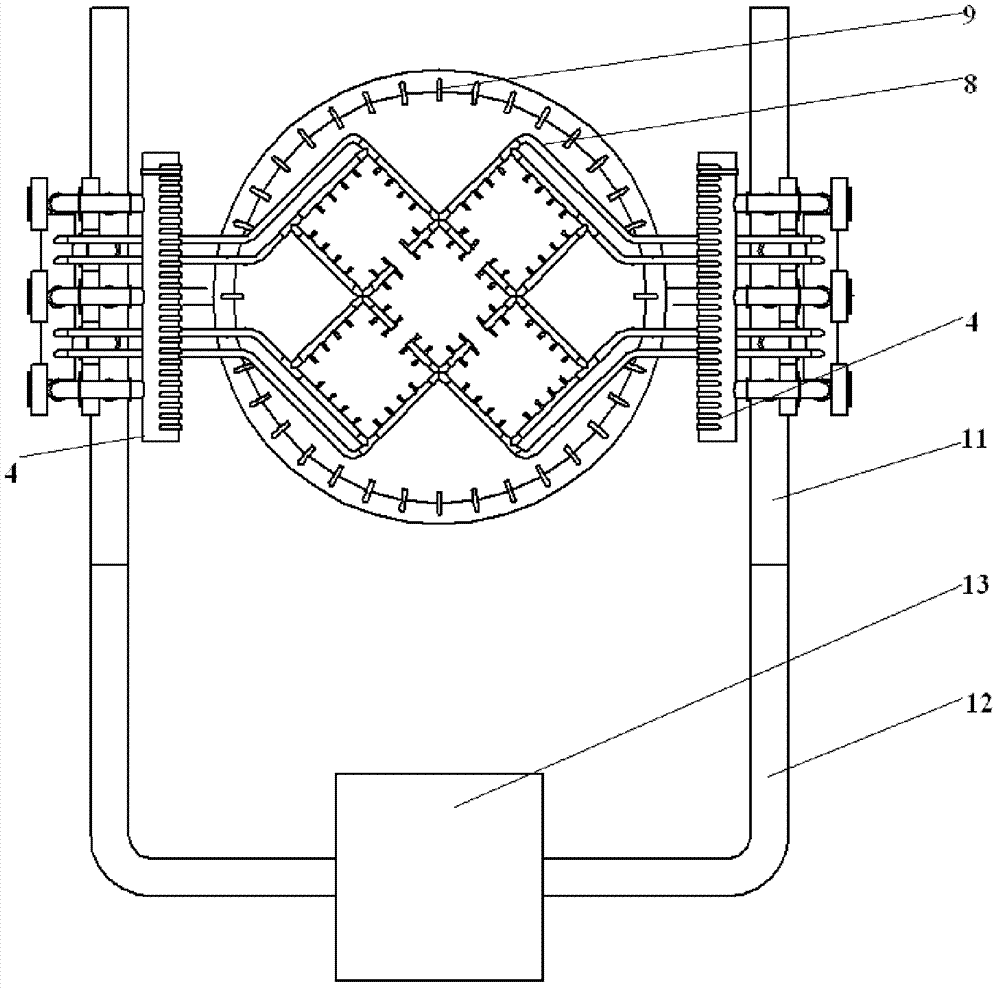

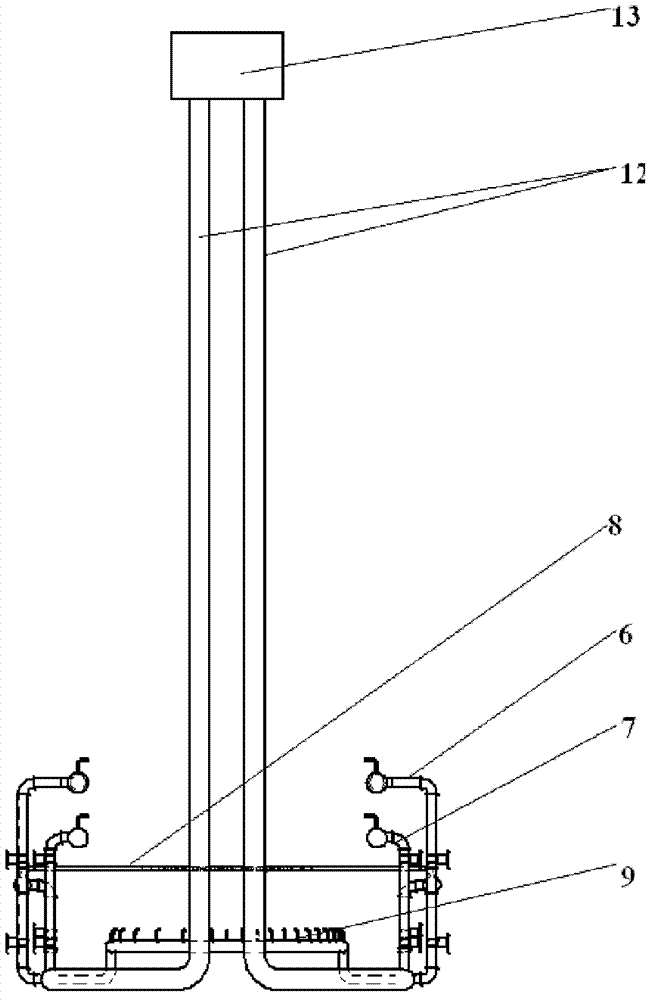

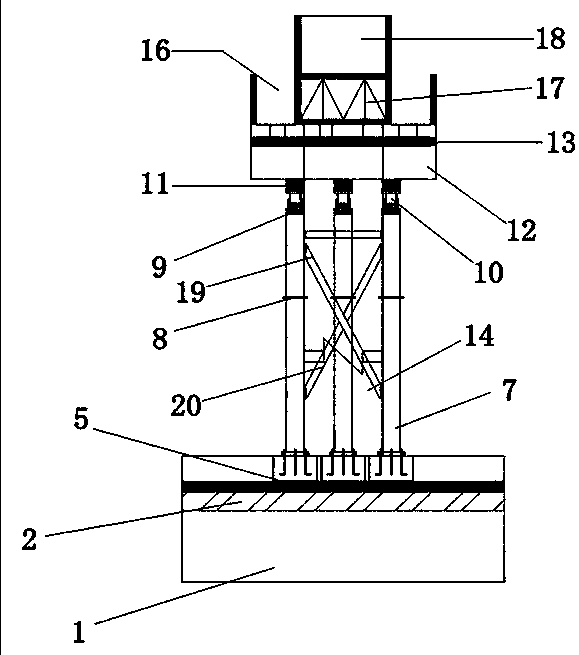

Water injection, cooling and denoising system for rocket launching

ActiveCN103090723AReduce the temperatureReduce noise intensityRocket launchersWater storageThermionic emission

The invention belongs to the technical field of rocket launching, and particularly relates to a water injection, cooling and denoising system for rocket launching. The system comprises outer water injectors, inner water injectors, a lattice girder, a lower water storage device, two water injection main lead pipes and a head water tank, a launching site is provided with the head water tank, the two water injection main lead pipes are led out from the head water tank and are both connected with the lower water storage device, the outer water injectors and the inner water injectors are arranged on the lower water storage device, the outer water injectors are positioned on two sides of a travel portion of a launching platform and parallel to the travel direction of the launching platform, top ends of the outer water injectors are higher than a platform top of the launching platform, tops ends of the inner water injectors are lower than the platform top of the launching platform, and the lattice girder is used fro supporting the outer water injectors and the inner water injectors. The system is developed aiming at bundled rocket launching technical conditions, and is applicable to occasions such as single-nozzle rocket launching test and simulation test adopting similar heat launching technical conditions.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Horizontal rotating construction method for steel truss beam bridge

ActiveCN104652290AReasonable structureClear forceTruss-type bridgeBridge erection/assemblyReinforced concreteConstruction engineering

The invention discloses a horizontal rotating construction method for a steel truss beam bridge. The horizontal rotating construction method comprises the following steps: constructing a reinforced concrete pile foundation, a cushion cap, a slideway, a main pier and a cap beam in a rotating system by using a conventional construction technology, and mounting a rotating spherical hinge as a core part for rotating; mounting an upper rotating plate on the slideway for construction; constructing the main pier and the cap beam; mounting a permanent support saddle of the main pier; preparing safety measures before rotating; determining a weight scheme before rotating; preparing a jack; rechecking before rotating; performing rotating construction operation. Compared with other processes, the horizontal rotating construction method for the steel truss beam bridge, provided by the invention, has the advantages of high construction speed and low construction cost. The construction of a lower structure can be synchronously finished in the manufacturing process of a steel beam in a factory; the hoisting operation of symmetrical cantilevers can be performed when a spliced site is hardened to reach the traveling strength of cranes like crawler crane; main expenses are rental expenses of the cranes, so the cost is reduced.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD +1

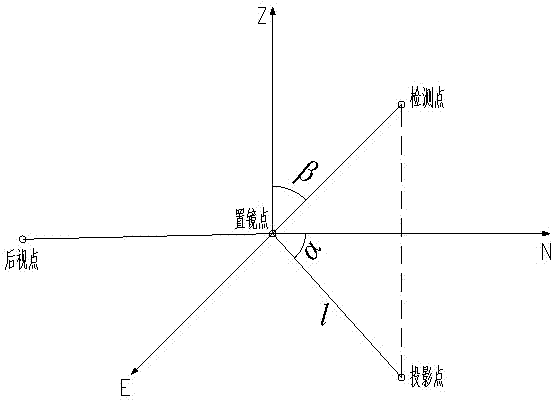

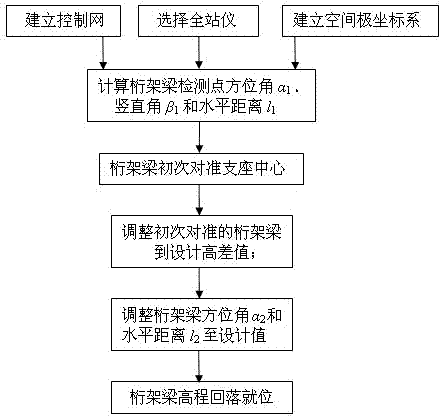

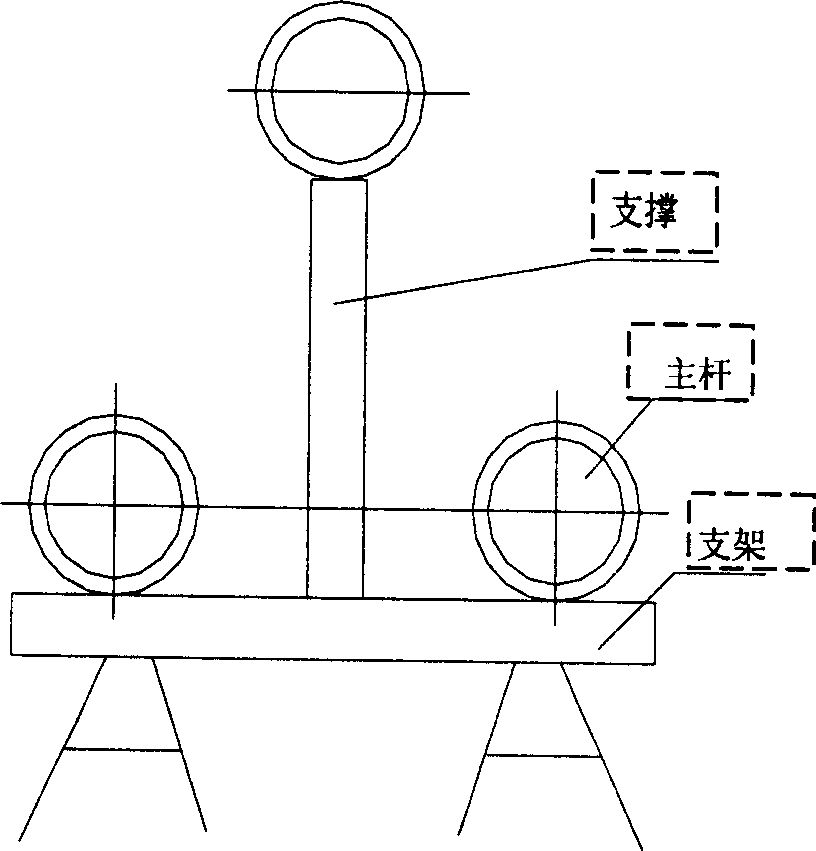

Precise locating detecting method for truss girder

ActiveCN102778893AHigh precisionAdaptableHeight/levelling measurementPosition/direction controlMeasuring instrumentStructural engineering

The invention relates to a precise locating detecting method for a truss girder. The method includes the steps: building a controlling net meeting requirements of truss girder design and measurement standard; selecting a measurement instrument as a total station; building a space polar coordinate system; calculating truss girder detecting point design value: an azimuth alpha 1, a vertical angle beta 1 and a horizontal distance l1; a truss girder detecting point is first aligned to a support center; height difference between the support center and a corresponding top face of a lower chord is measured and adjusted to design height difference value; whether the truss girder is located horizontally and correctly is judged according to deviation between the design value and actual value of azimuth and between the design value and the actual value of the horizontal distance of a setting point of the truss girder detecting point, and the truss girder detecting point is adjusted to a design position; and a jack is adjusted so as to enable the truss girder to fall back to design elevation and be located. The precise locating detecting method for the truss girder is high in detecting efficiency and precision, reliable in result, especially suitable for locating detection of truss girders which are small in bent radius and various in linear structures.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

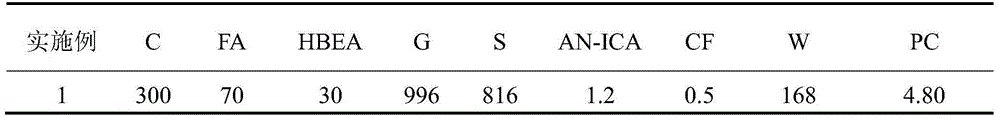

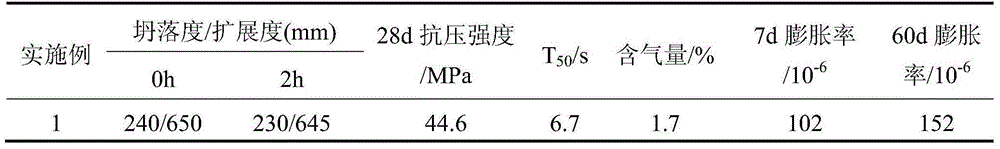

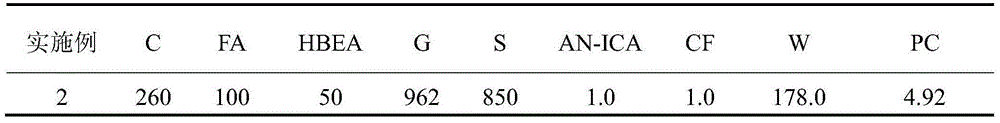

C30 self-compaction microexpanded concrete-filled steel tube and preparation method thereof

ActiveCN105084836ASolve the "out of the air" problemImprove cementing performanceSolid waste managementCelluloseCoal

The invention discloses a C30 self-compaction microexpanded concrete-filled steel tube and belongs to the field of building materials. The C30 self-compaction microexpanded concrete-filled steel tube is prepared by taking cement, coal ash, composite expansion agents, gravel, river sand, tackifying plasticity-maintaining ultra-dispersed additive, internal maintaining materials, micro-grade modified degreasing cotton cellulose and water as raw materials. The number of binding materials adopted in the C30 self-compaction microexpanded concrete-filled steel tube is small, and the C30 self-compaction microexpanded concrete-filled steel tube has the advantages of being good in self-compaction performance, low in gas content and high in durability, being slightly expanded and the like, is suitable for compact pouring of intensely reinforced large-pipe-diameter thin-wall steel tube concrete-filled steel tube underwater piles with complex shapes and a small section size, string tube pumping pouring of upper and lower concrete-filled steel tubes of concrete-filled steel tube truss bridges and high-throwing vibration-free pouring of concrete-filled steel tube pier studs. The problem of disengaging of the concrete-filled steel tube can be effectively solved, and wide application prospects are achieved.

Owner:WUHAN UNIV OF TECH

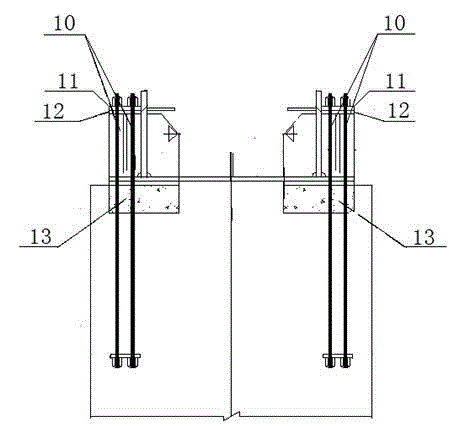

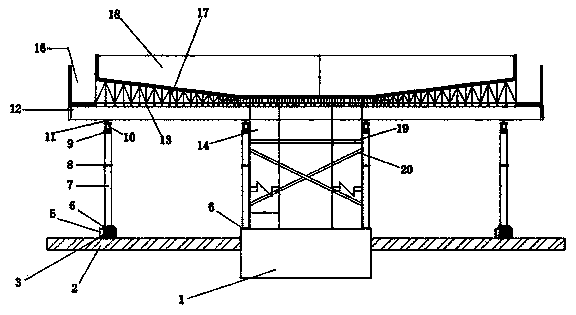

Large-cantilever prestressed-cover-beam support device and construction method

InactiveCN110820561ASolve traffic problemsSolving the Contradictions of Cantilever Cover Beam Cast-in-situ ConstructionBridge erection/assemblySupporting systemReinforced concrete

The invention provides a large-cantilever prestressed-cover-beam support device and a construction method, and relates to a road-bridge cover-beam construction device. The problem that in the prior art, a large-cantilever cover-beam supporting system influences the road traffic under a bridge is solved. The large-cantilever prestressed-cover-beam support device comprises middle supporting columnssupported at the root of a cover-beam cantilever, the middle supporting columns are symmetrically arranged on the two sides of a cover-beam pier, and the bottoms of the middle supporting columns are supported on a bearing platform where the cover-beam pier is located. The large-cantilever prestressed-cover-beam support device further comprises end supporting columns supported at the end of the cover-beam cantilever, the bottoms of the end supporting columns are supported on the ground through reinforced concrete, a bearing beam is supported at the upper ends of the middle supporting columns and the upper ends of the end supporting columns, a slope-adjusting truss beam is supported on the bearing beam, and a cover-beam bottom die is supported on the slope-adjusting truss beam. By designinga gate pier type assembly type steel pipe supporting column support system, the contradiction between normal passing on a ground road and cast-in-place construction of the cantilever cover beam is well solved, and the steel consumption of a temporary structure is small.

Owner:ZHEJIANG UNIV CITY COLLEGE +1

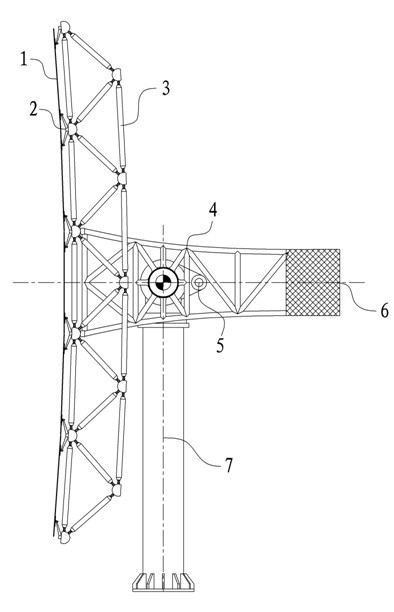

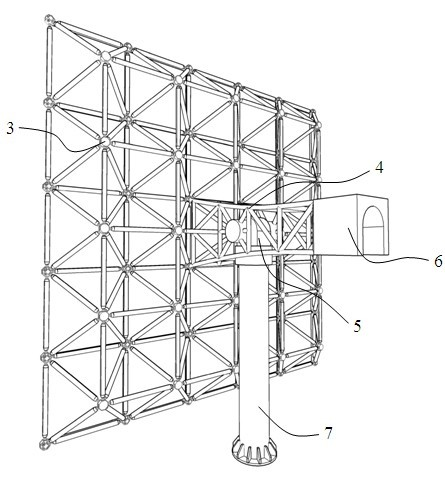

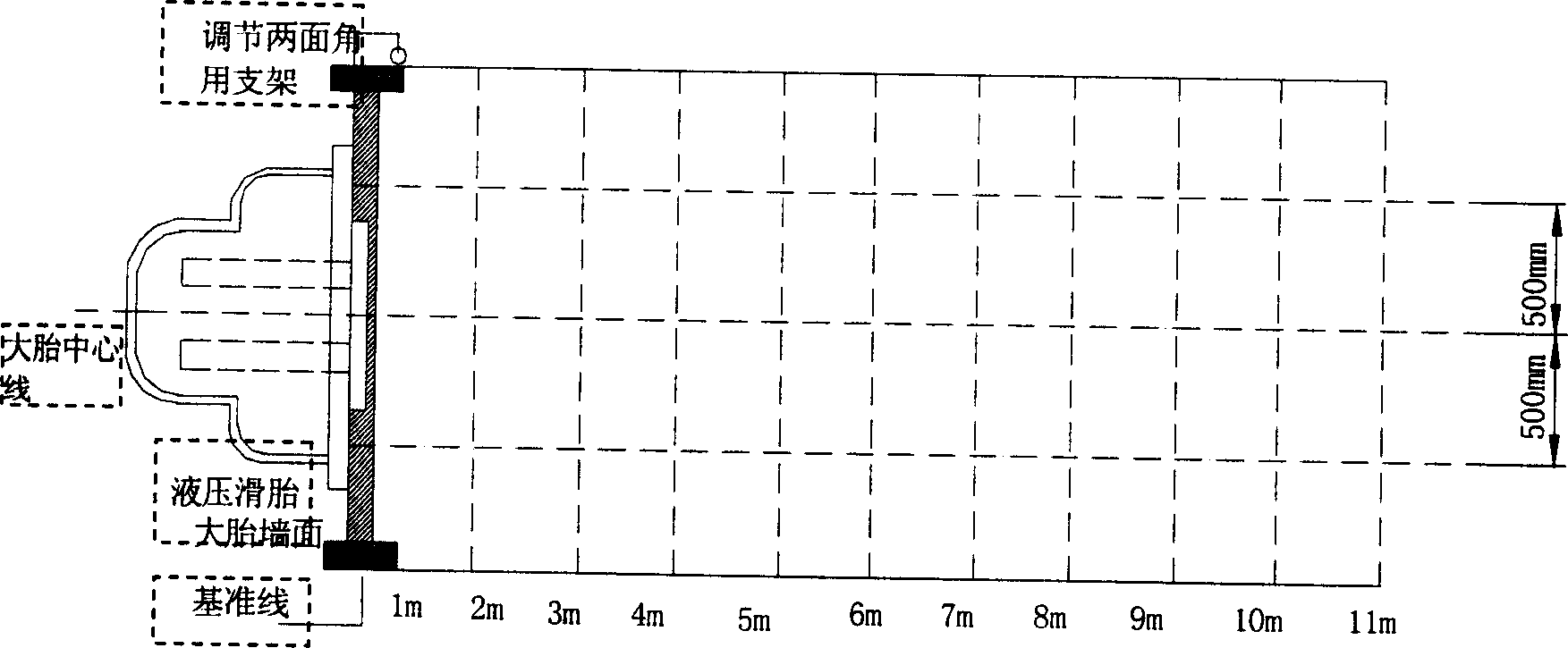

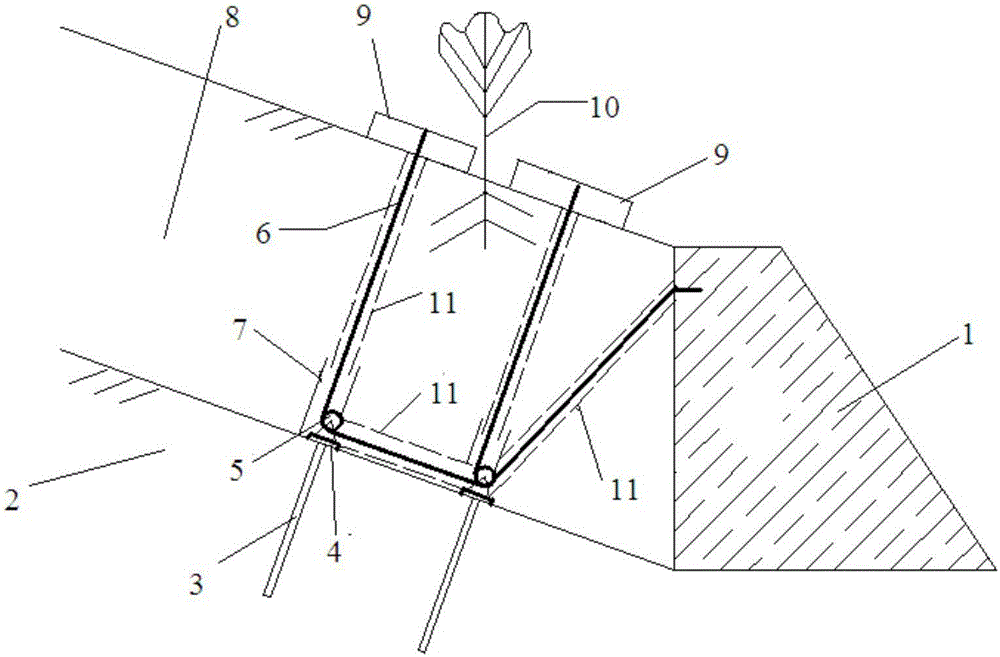

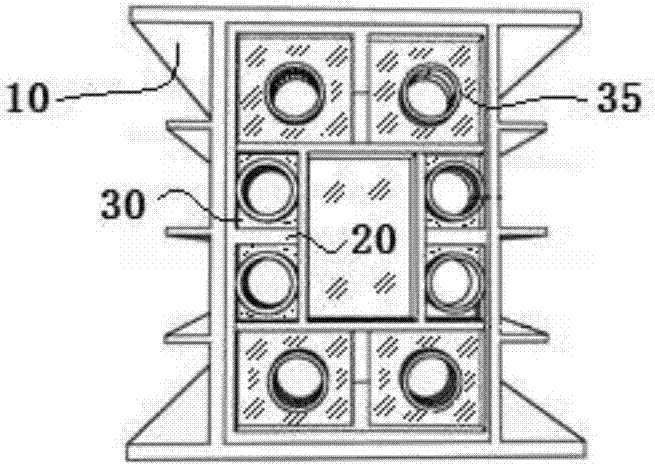

Heliostat

The invention discloses a heliostat. The heliostat comprises a reflecting surface composed of a plurality of reflector units which are spliced together, a supporting device for fixing reflectors and a transmission mechanism; the supporting device comprises an upright, a supporting net rack and a truss girder. The truss girder is connected with the upright through the transmission mechanism, the supporting net rack is mounted at one end of the truss girder and is of a quadrangular pyramid net rack structure; and the reflector units are mounted at net rack nodes of the quadrangular pyramid structure of the supporting net rack. The heliostat provided by the invention is convenient for operation, easy to process and high in structure rigidity, and the surface precision of a reflecting condensing curve can be ensured.

Owner:NANJING SCIYON AUTOMATION GRP

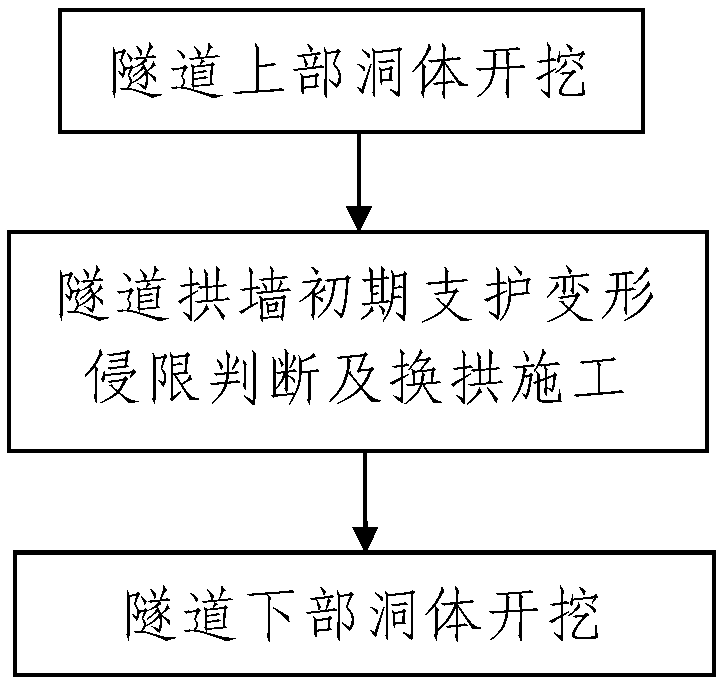

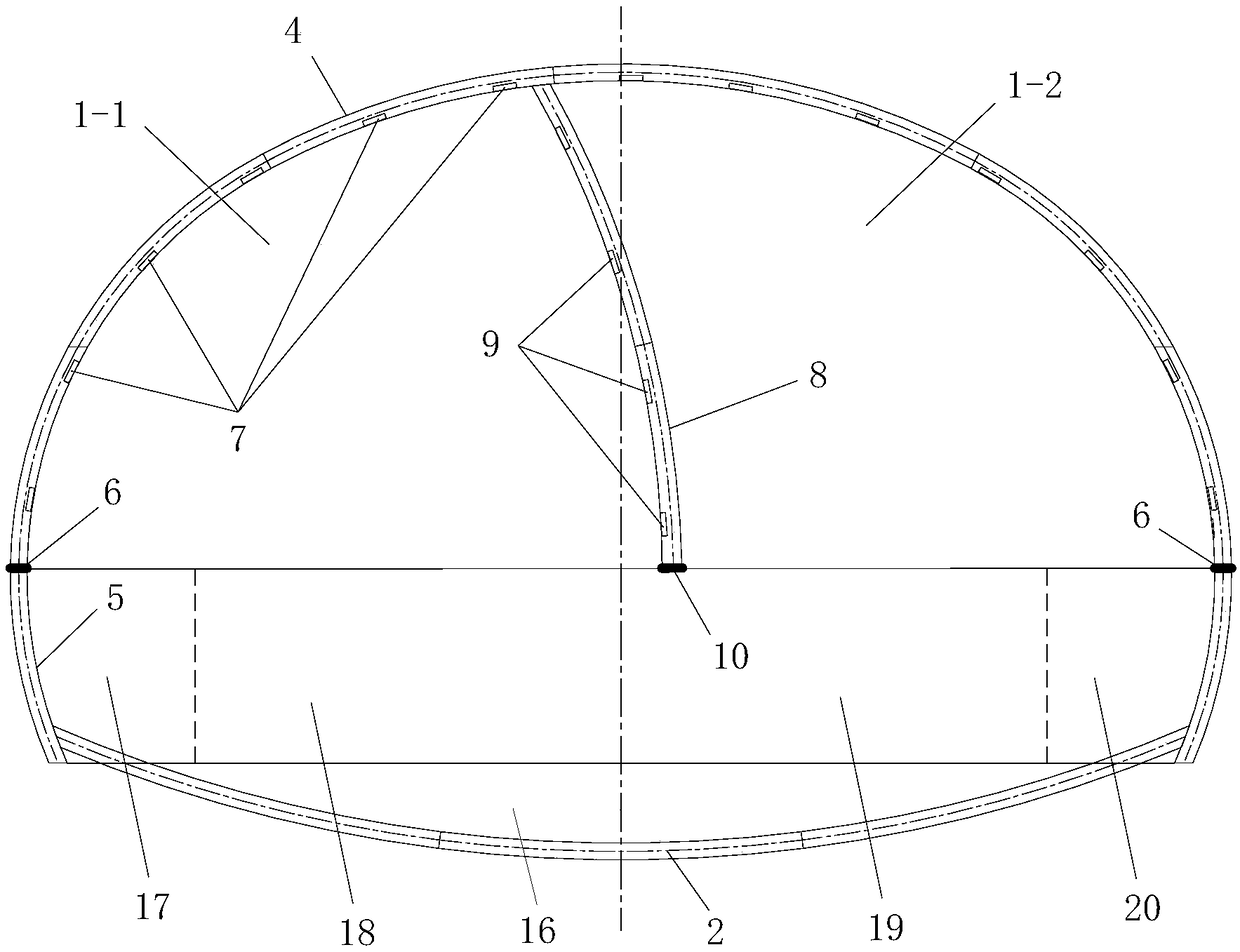

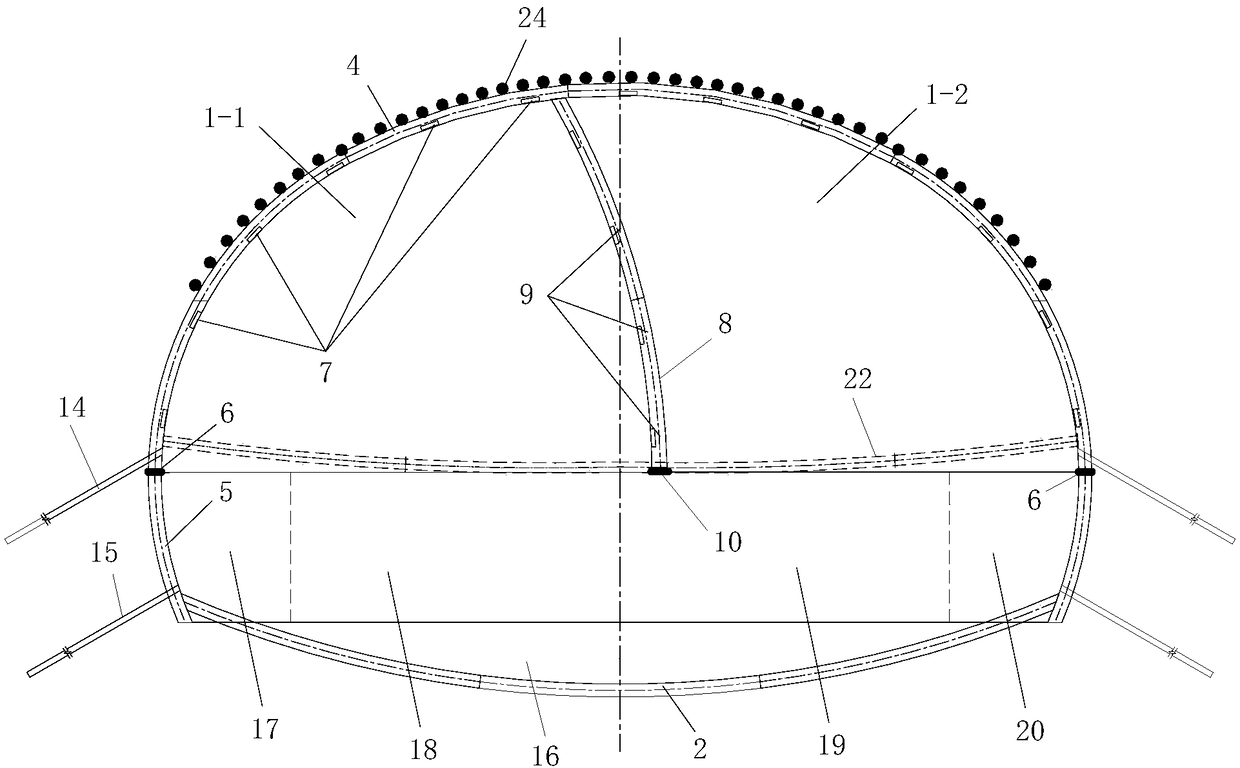

Excavation and support method of large cross-section tunnel through fault fracture zone

ActiveCN108843332AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

The invention discloses an excavation and support method of large cross-section tunnel through fault fracture zone. The initial support structure of tunnel comprises a whole cross-section support system and the lattice girder and shotcrete support structure of the tunnel. A temporary support structure of middle-partition wall is arranged between a left pilot tunnel and a right pilot tunnel. The actual construction includes the steps: 1, excavation of the upper tunnel body; 2, the judgment of the initial support deformation of the tunnel arch wall and the construction of the replacement arch; 3, excavation of the lower tunnel body. The excavation and support method of large cross-section tunnel through the fault fracture zone has reasonable design, simple construction, and good use effect.Only the upper half section of the tunnel is excavated by the center diaphragm method, and the excavation cross-section is reduced so that the stability of the arch roof is ensured. The whole cross-section support system and the temporary support structure of middle-partition wall are supported by the underpass beam and joined together to form a stable monolithic support system, which can avoid the sinking of the supporting arch and ensure the stability of the initial support effectively. Besides, the construction of replacement arch is conducted on only half cross-section of the tunnel and the cost can be saved, and the construction safety can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

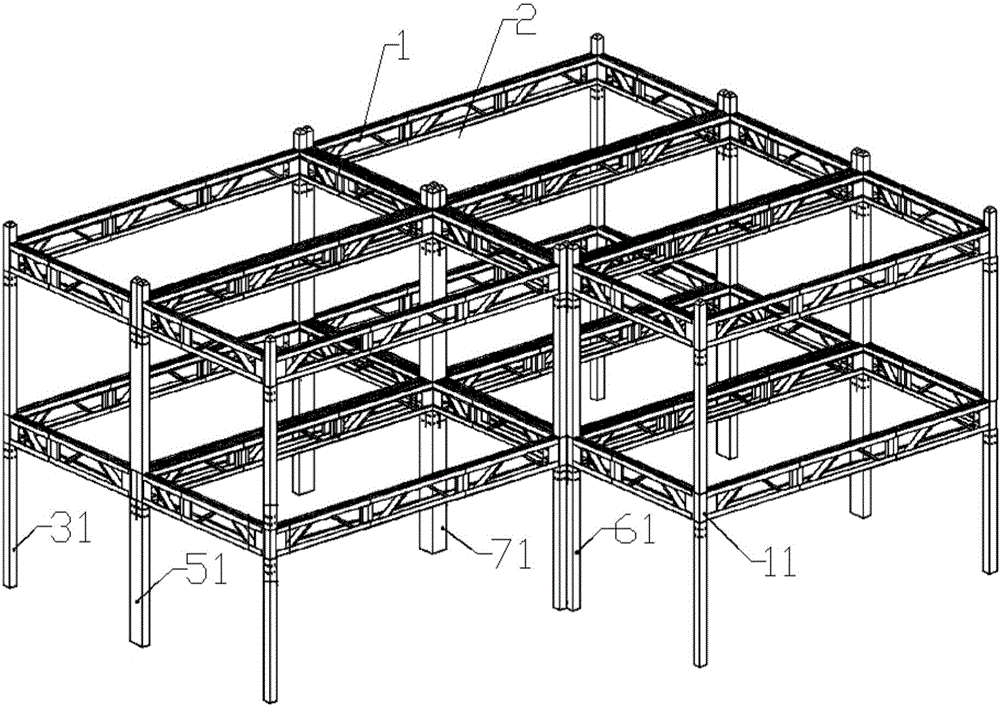

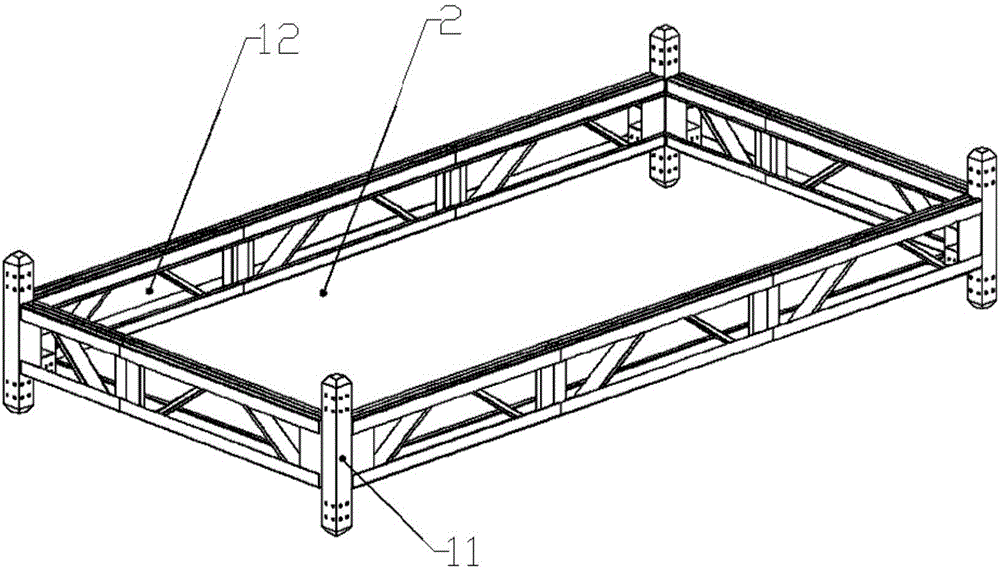

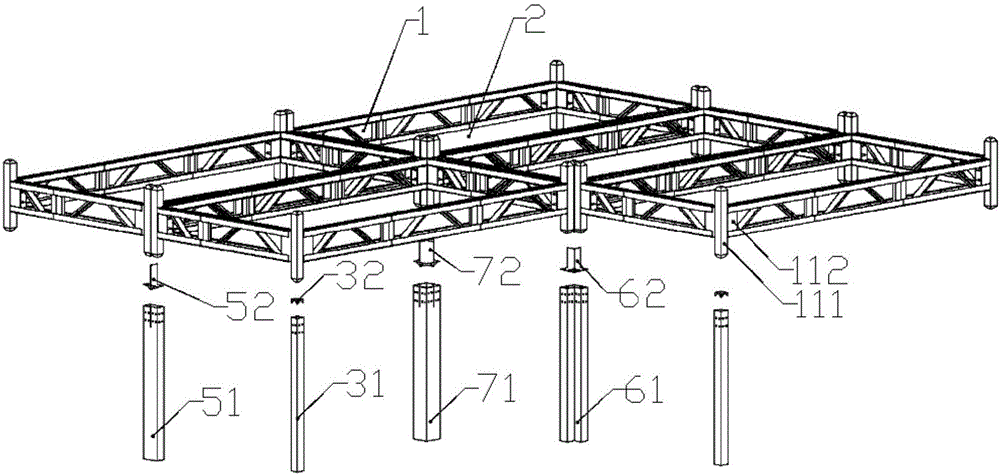

Assembled light steel frame mortise-tenon inserted-connected structure and mounting method

The invention discloses an assembled light steel frame mortise-tenon inserted-connected structure and a mounting method. The assembled light steel frame mortise-tenon inserted-connected structure comprises a light steel truss beam frame, floor slabs and support columns, the light steel truss beam frame comprises tenons and light steel truss beams, a plurality of first riveting holes are formed in two ends of each tenon, the support columns comprise vertical columns and column end plates, each column end plate is spaced from the end of the corresponding vertical column to form a tenon mounting space, a plurality of second riveting holes are formed in the vertical columns, ends of the tenons are inserted into the tenon mounting spaces of the support columns, and the first riveting holes in the tenons are fixedly connected with the second riveting holes in the support columns through pulling rivets. According to the assembled light steel frame mortise-tenon inserted-connected structure and the mounting method, stress reasonableness of an assembled building can be enhanced, construction period is shortened, and cost is reduced.

Owner:北京善筑科技股份有限公司

Industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system

The invention provides an industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system, and relates to the technical field of structural engineering. The industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system comprises assembled truss plates, assembled special-shaped columns and eccentric supporting components, wherein the assembled truss plates comprise structural truss beams and floor slabs, and the structural truss beams are provided with channel steel web members; the assembled truss plates are prefabricated in a factory, the assembled truss plates are mutually spliced with flange plates of the assembled special-shaped columns through beam-end blanking plates of the assembled truss plates at the construction site, and the assembled special-shaped columns are spliced on site through bolts in an interlayer to form a multi-layer truss plate steel frame structure; on the basis of the steel frame structure, the eccentric supporting components are connected to the truss beams in a beam plate layer of the frame structure or the bottoms of the columns to serve as lateral load resistance components; the assembled truss plates, the assembled special-shaped columns and the eccentric supporting components are all fabricated in the factory and assembled through the bolts on the construction site.

Owner:BEIJING UNIV OF TECH

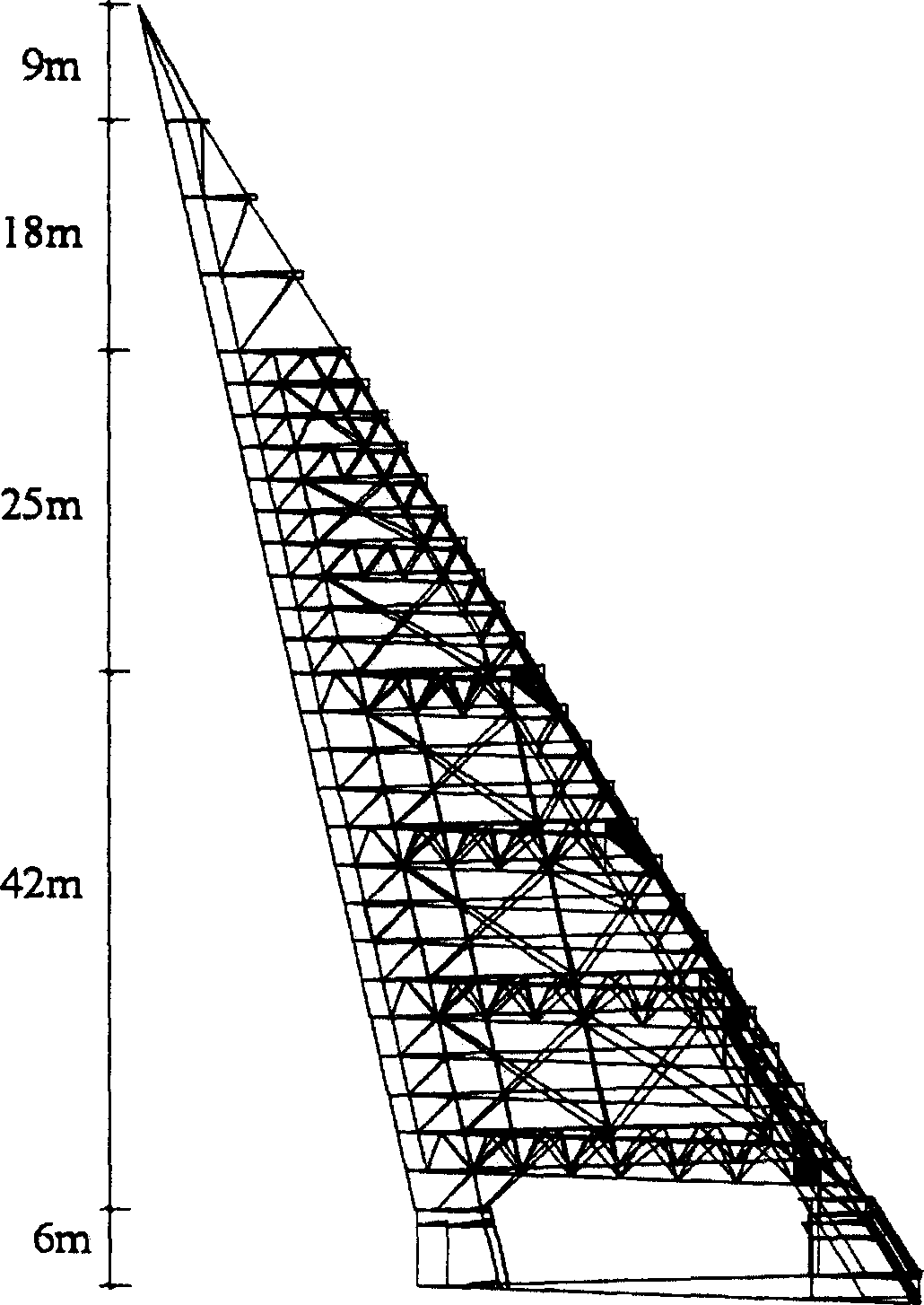

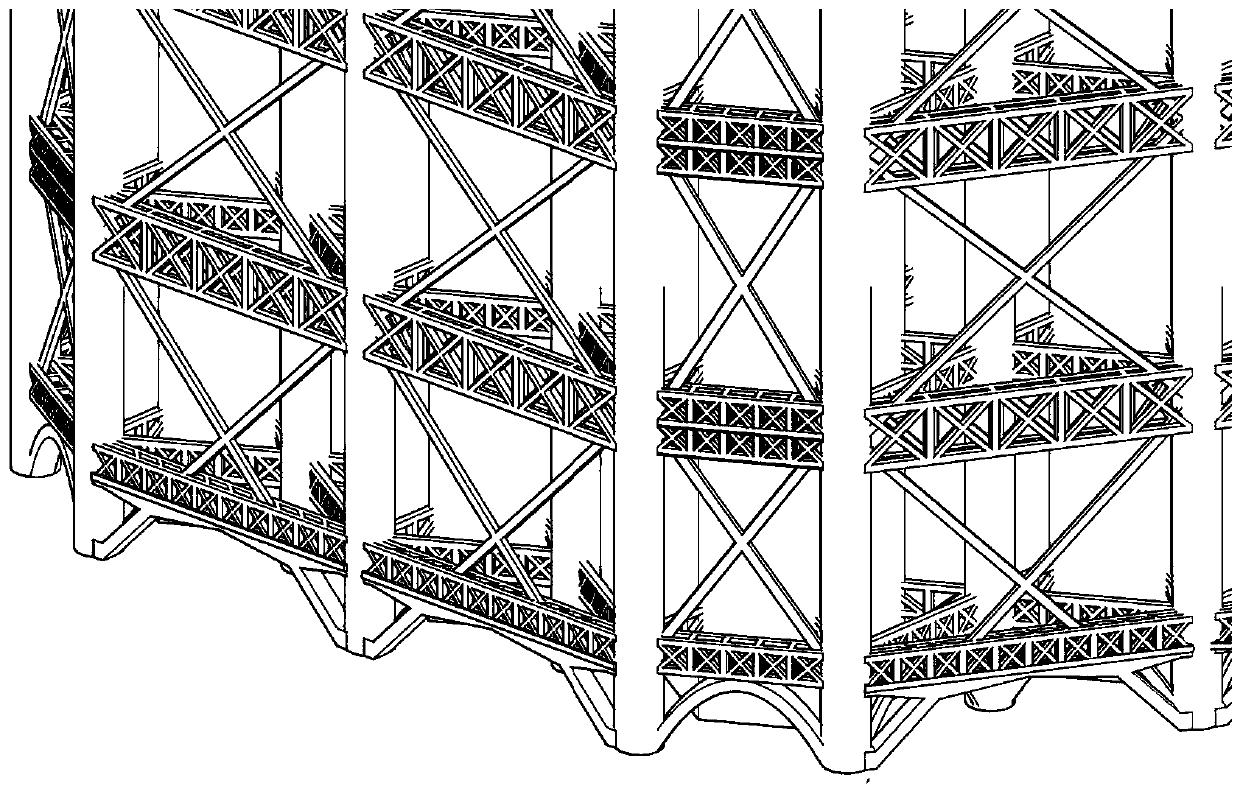

Inclined triangular pyramid truss type frame construction and method for making, mounting and measuring the same

InactiveCN1737313ASolve processing and production problemsSolving Quality Control ChallengesBuilding constructionsTowersArchitectural engineeringSteel tube

This invention discloses an inclined triangular pyramid trussed-beam frame, in addition to a manufacturing, installing and measuring method, characterized in that the frame comprises the bench and top center, and three ridge lines of the bench are the girders connected by several lattice pillars through flange; the pillar pin of the trussed-beam is fixed in one base station as the bottom, wherein one girders pillar is the forced pillar and has a included angle with the bottom from 90 to 110 Deg, while other two pillars are tension pillars and have the included angle with the bottom from 50 to 65 Deg; the bench also comprises several girders beam welded by lattice unit, separating to several parallel layer horizontal to the bottom between the girders pillars and connected by the flange; the lattice pillar unit is welded by several steel pipe and flange, and the lattice pillar units are connected each other through flange; the top center is an integrated structure welded by the steel pipe, and three ridge lines of the top center are the extended steel pipe along the girders pillar of the bench.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD +3

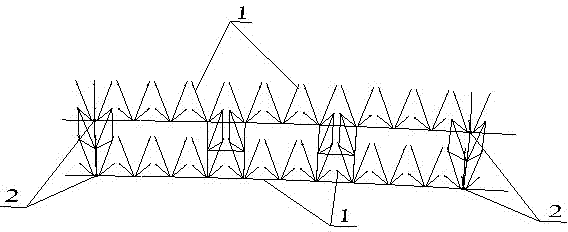

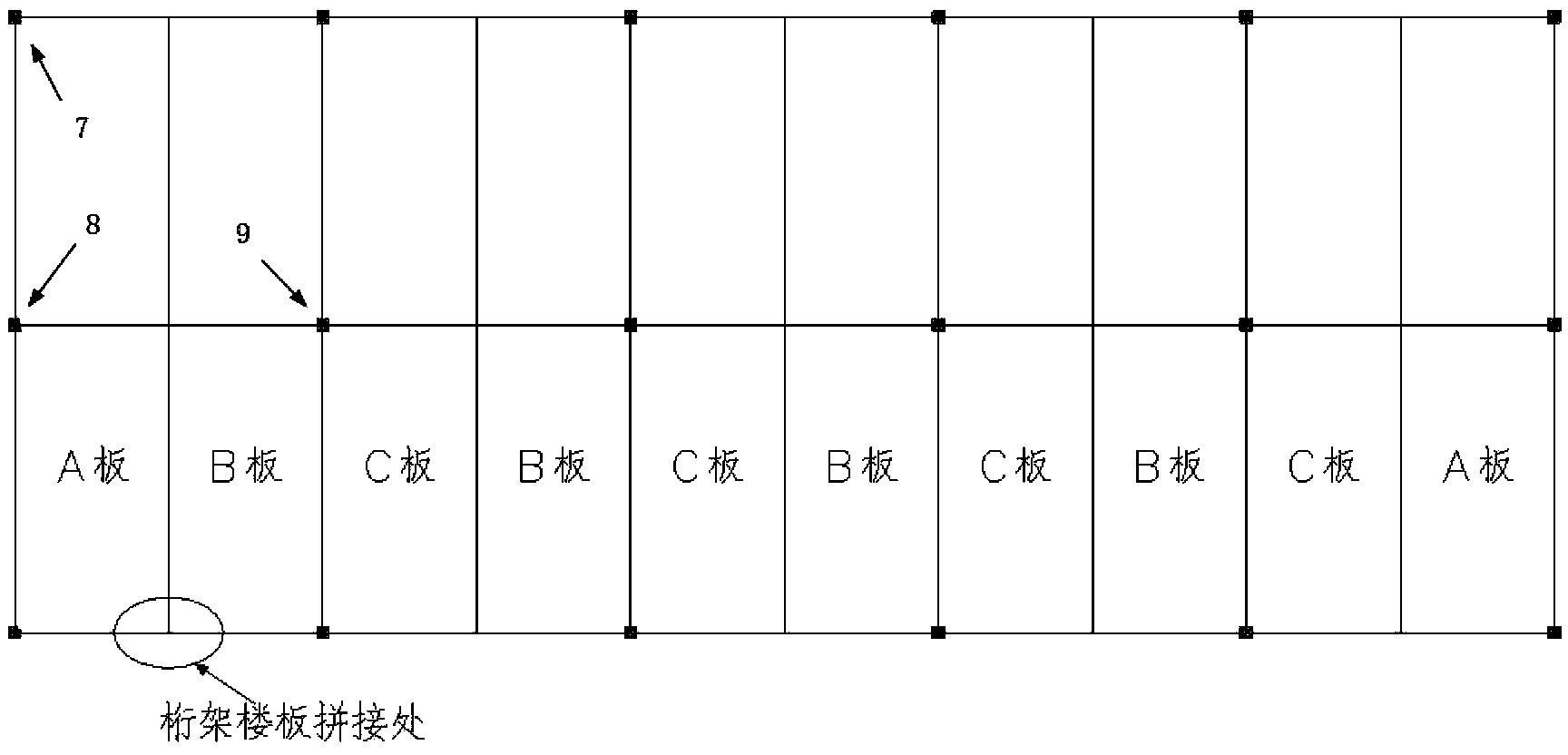

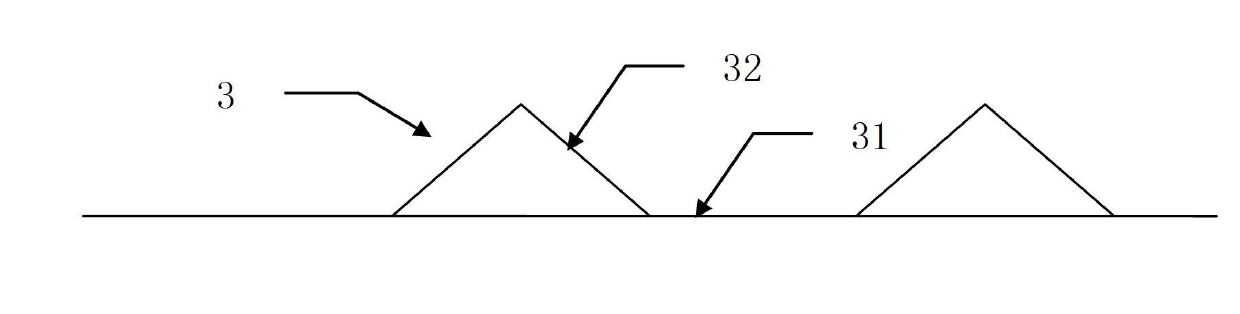

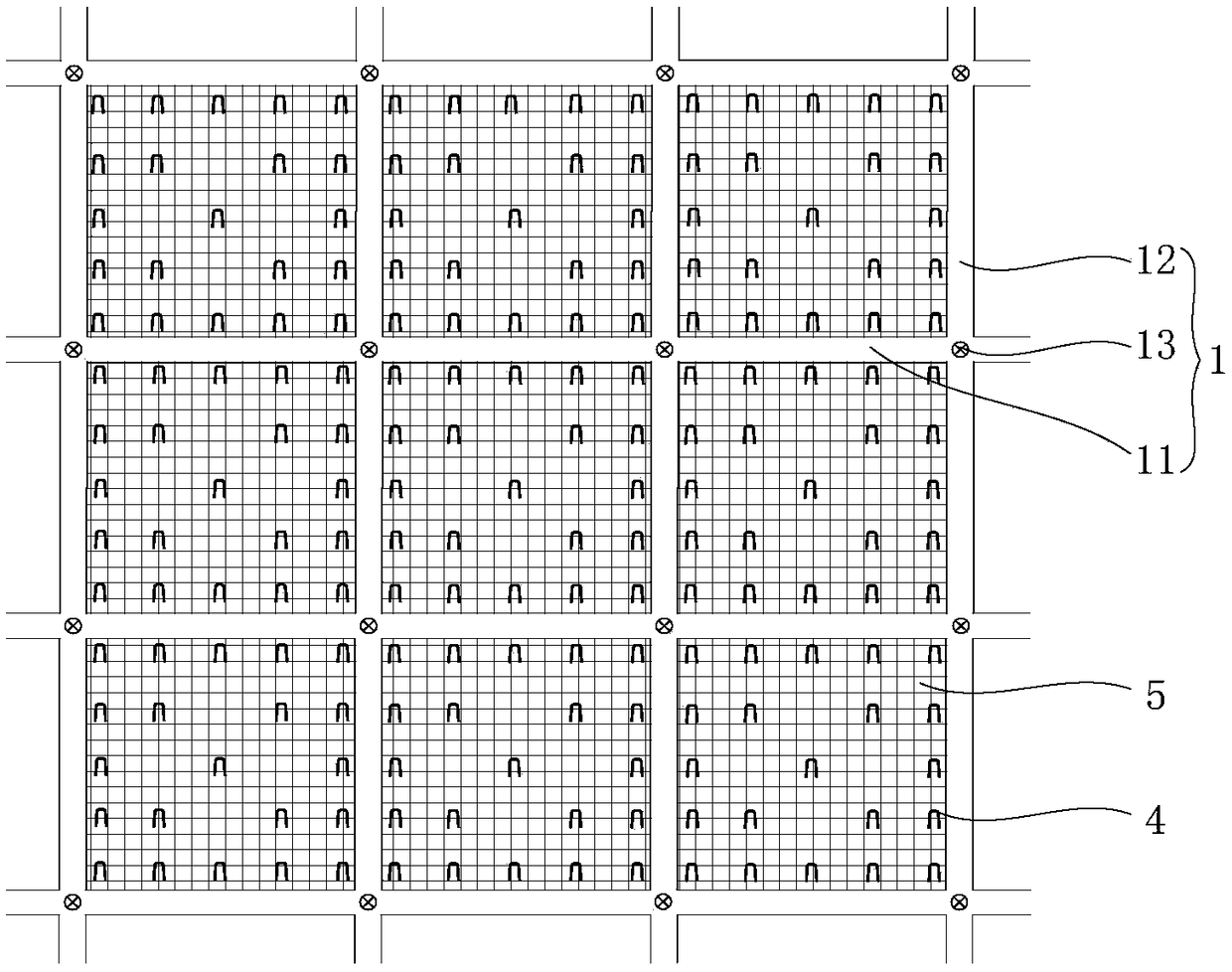

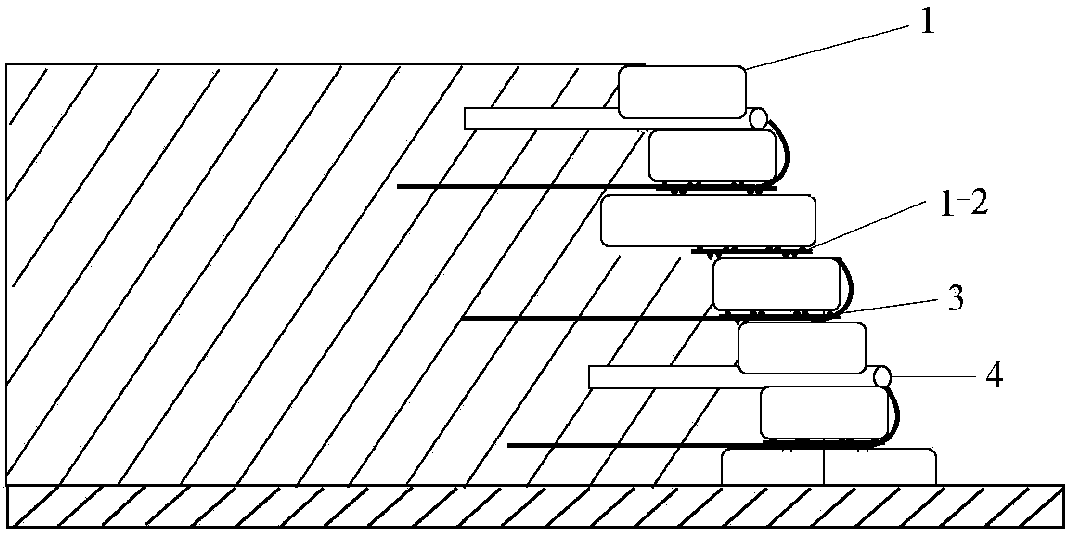

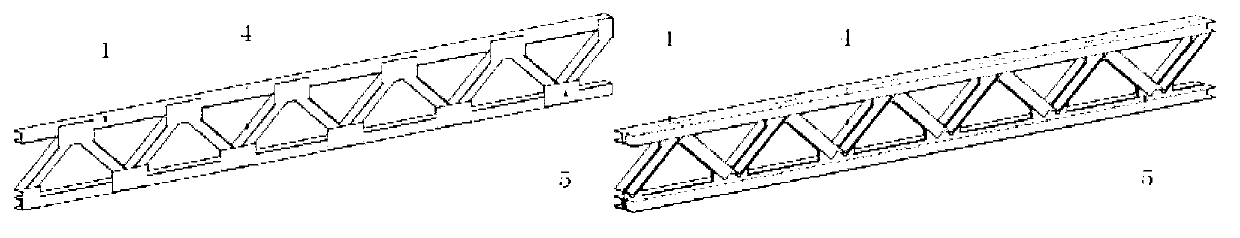

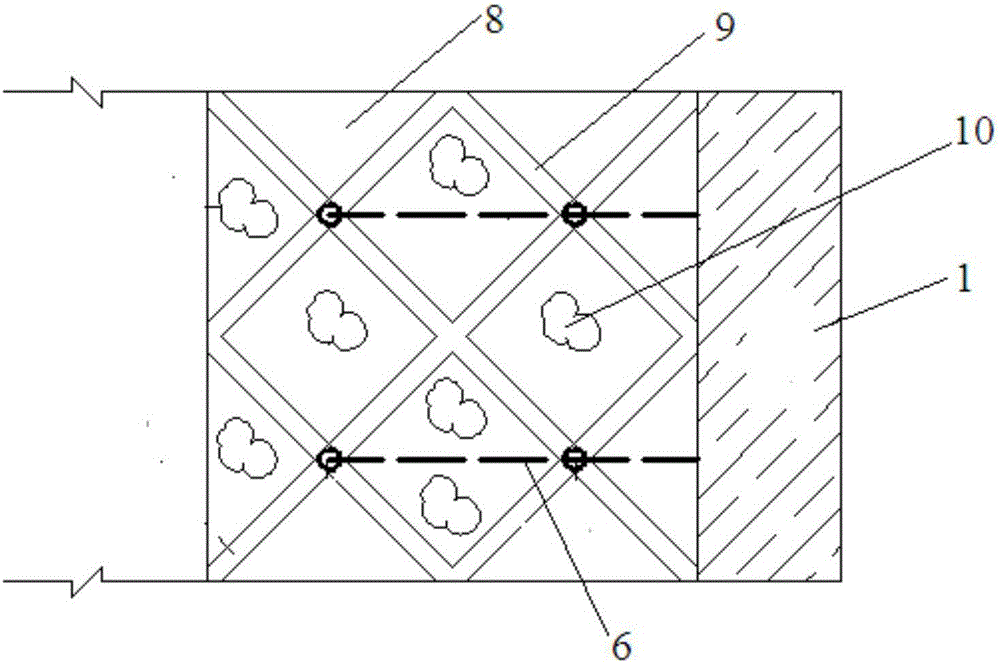

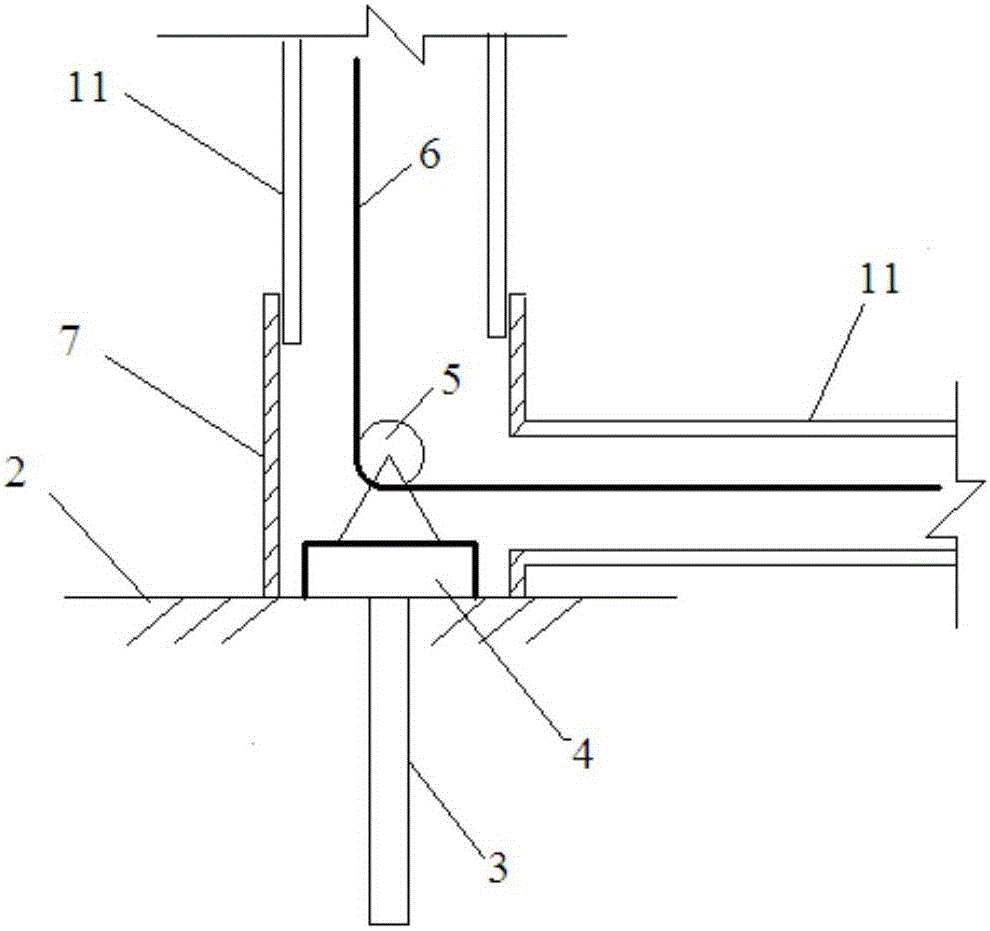

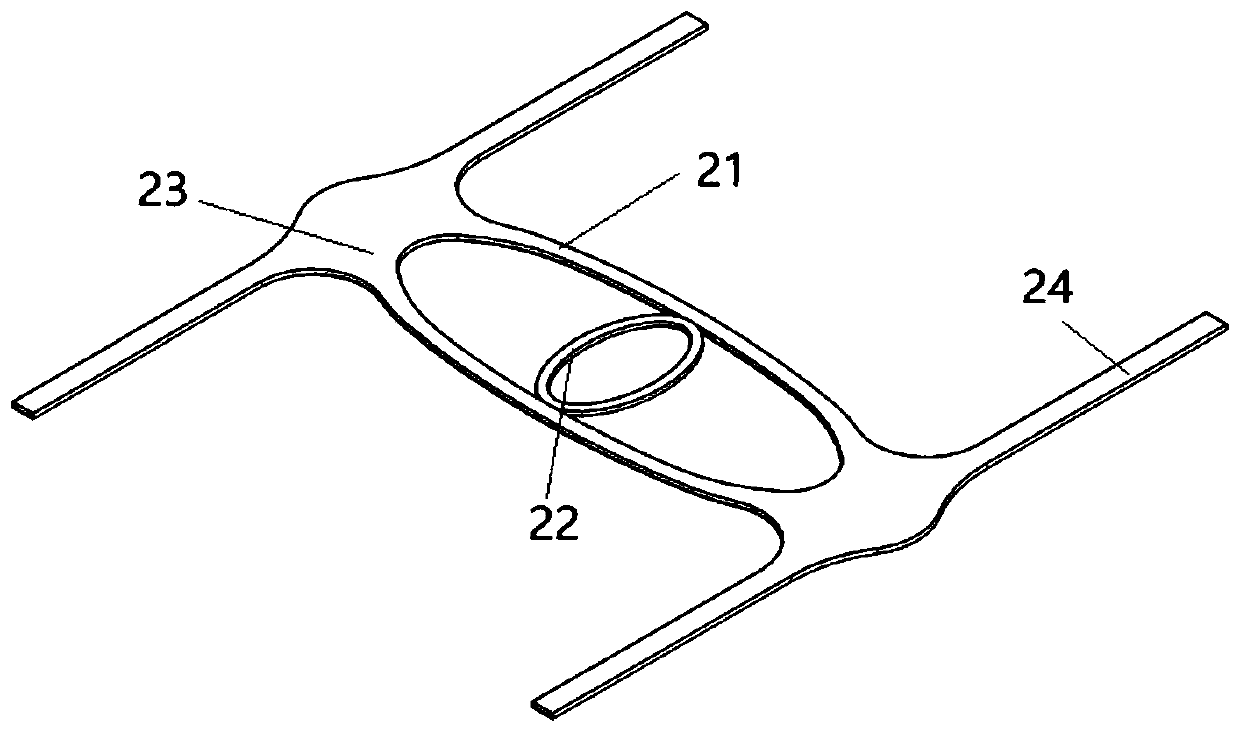

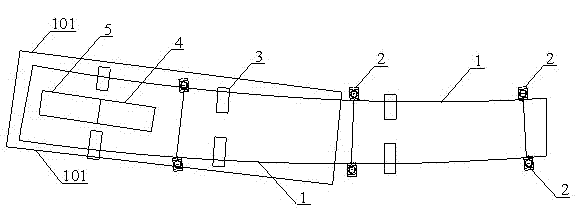

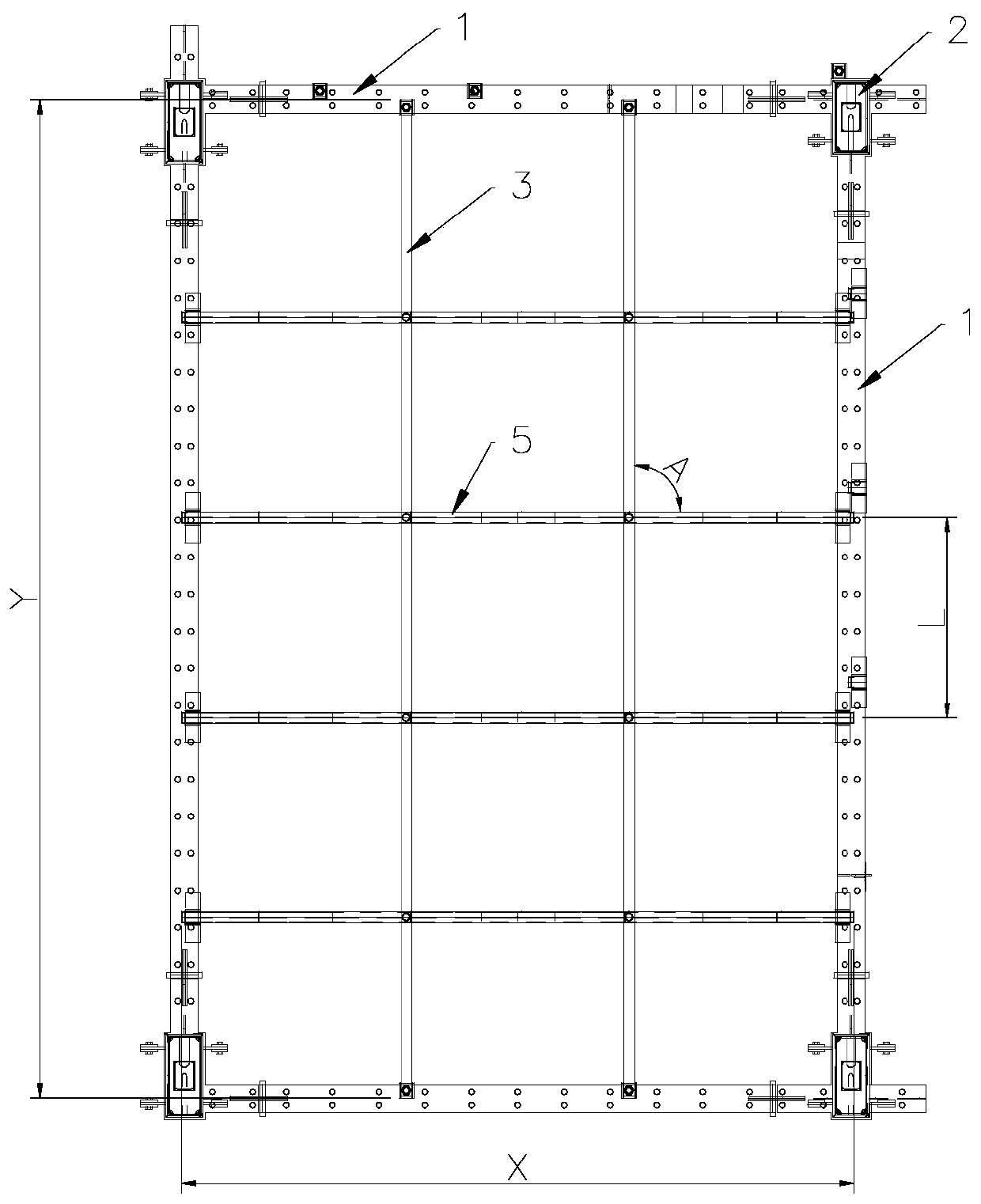

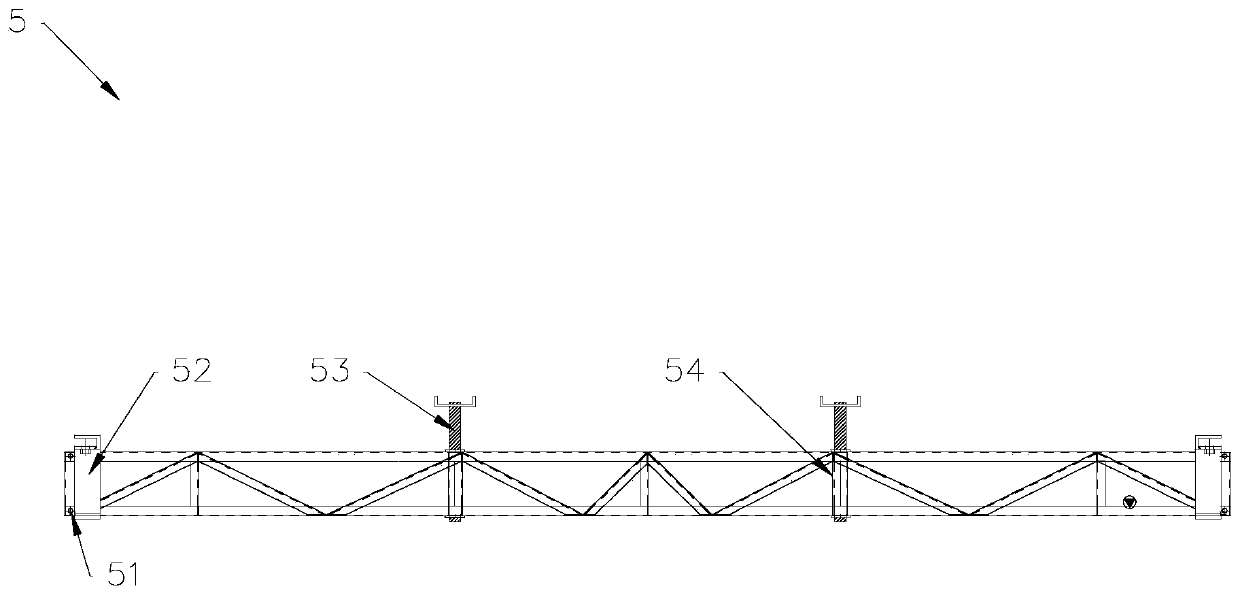

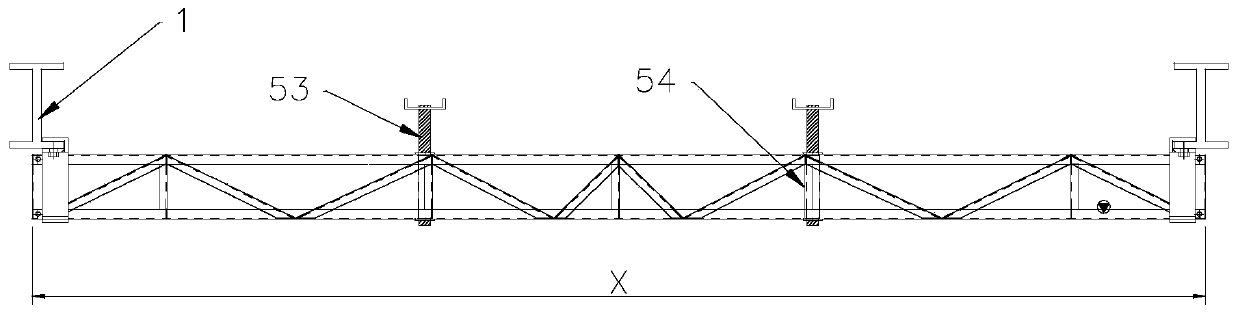

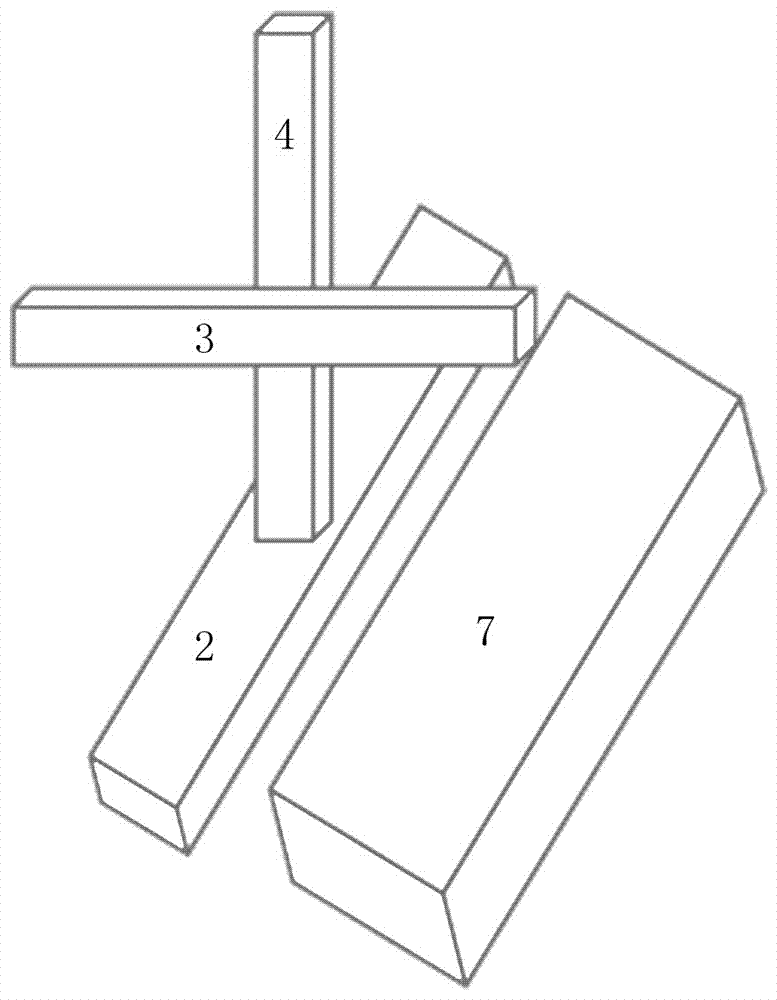

Method for cast-in-place of ferrocement panel by spliced net frame suspension template

The invention relates to a construction process for a building ferrocement panel, in particular to a method for cast-in-place of a ferrocement panel by a spliced net frame suspension template. The method comprises the concrete steps as follows: step 1, machining a horizontal plane truss beam (1), a longitudinal plane incomplete truss beam (2) and a longitudinal plane incomplete truss (3) in a factory; step 2, making a bottom die; step 3, carrying out splicing construction on field on trusses shaped like a Chinese character ''Jing'' (meaning well in English) (4); step 4, suspending the bottom die; step 5, mounting reinforced net sheets; and step 6, carrying out cast-in-place process. According to the method for cast-in-place of the ferrocement panel by the spliced net frame suspension template, a spatial net frame is changed into a spliced net frame and the spliced net frame is applied to a cast-in-place floorslab, the ferrocement panel is directly changed to be manufactured by cast-in-place and is integrated with a beam column by cast-in-place, and the application range of the ferrocement panel can be expanded to various building floorslabs.

Owner:ABO BUILDING MATERIAL KUNSHAN CO LTD

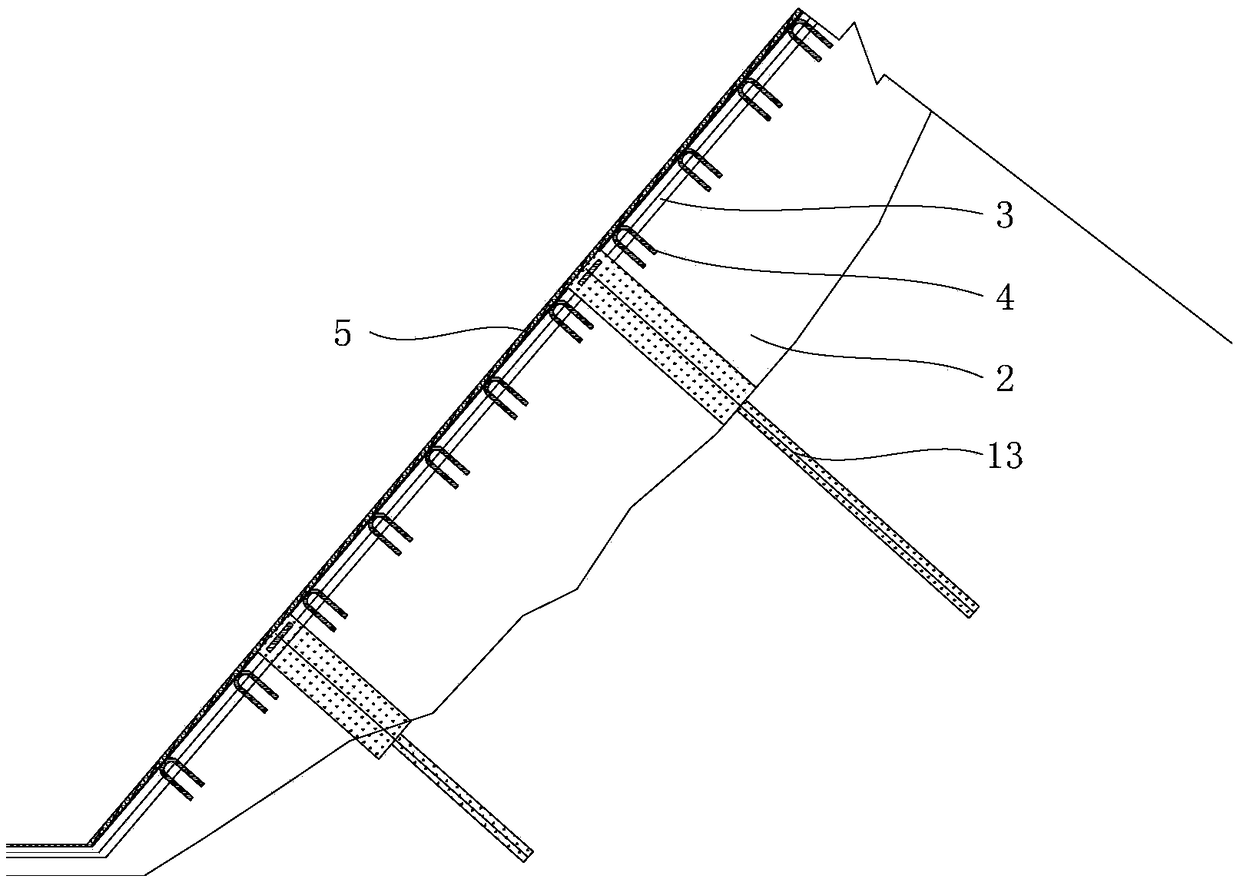

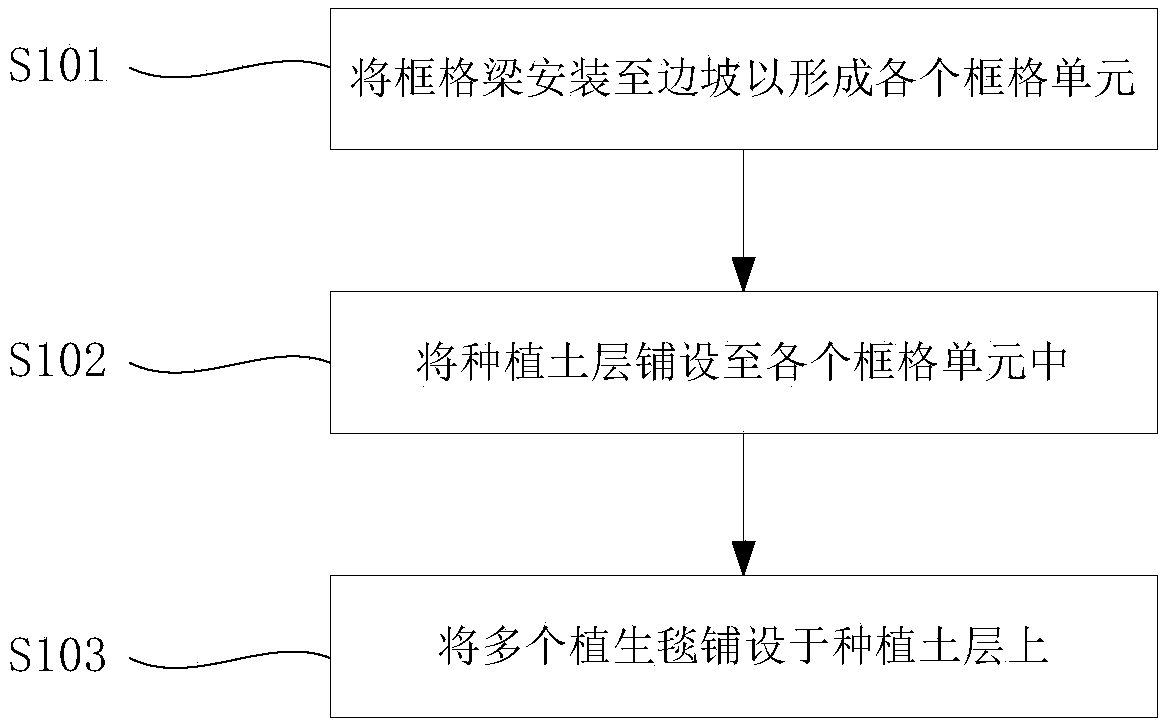

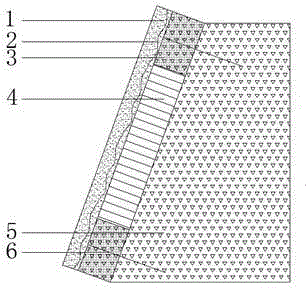

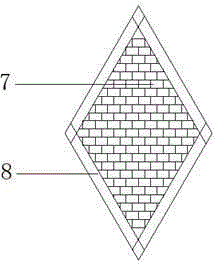

Slope ecological protective structure and construction method thereof

PendingCN108716219AEnsure safety and stabilityComprehensive governanceGrowth substratesCulture mediaGrowth plantRevegetation

The invention provides a slope ecological protective structure and a construction method thereof and relates to the technical field of slope protection. The slope ecological protective structure provided by the invention comprises a lattice girder, planting soil layers and a plurality of plant growth blanket blocks. The lattice girder comprises a plurality of lattice units, and the lattice girderis used for being arranged on a slope. The lattice units are filled with the planting soil layers, and the multiple plant growth blanket blocks are laid on the planting soil layers. According to the slope ecological protective structure provided by the invention, the slope ecology can be comprehensively managed, on the one hand, safe stability of the slope is ensured, and on the other hand, the problem that slope surface layer soil is eroded by rainwater is solved; and the good growing environment is provided for seed germination and seedling growth, and the restoration effect of slope vegetation is effectively improved.

Owner:MEILIGUOTU BEIJING ECOLOGICAL ENVIRONMENT ENG TECH RES INST CO LTD

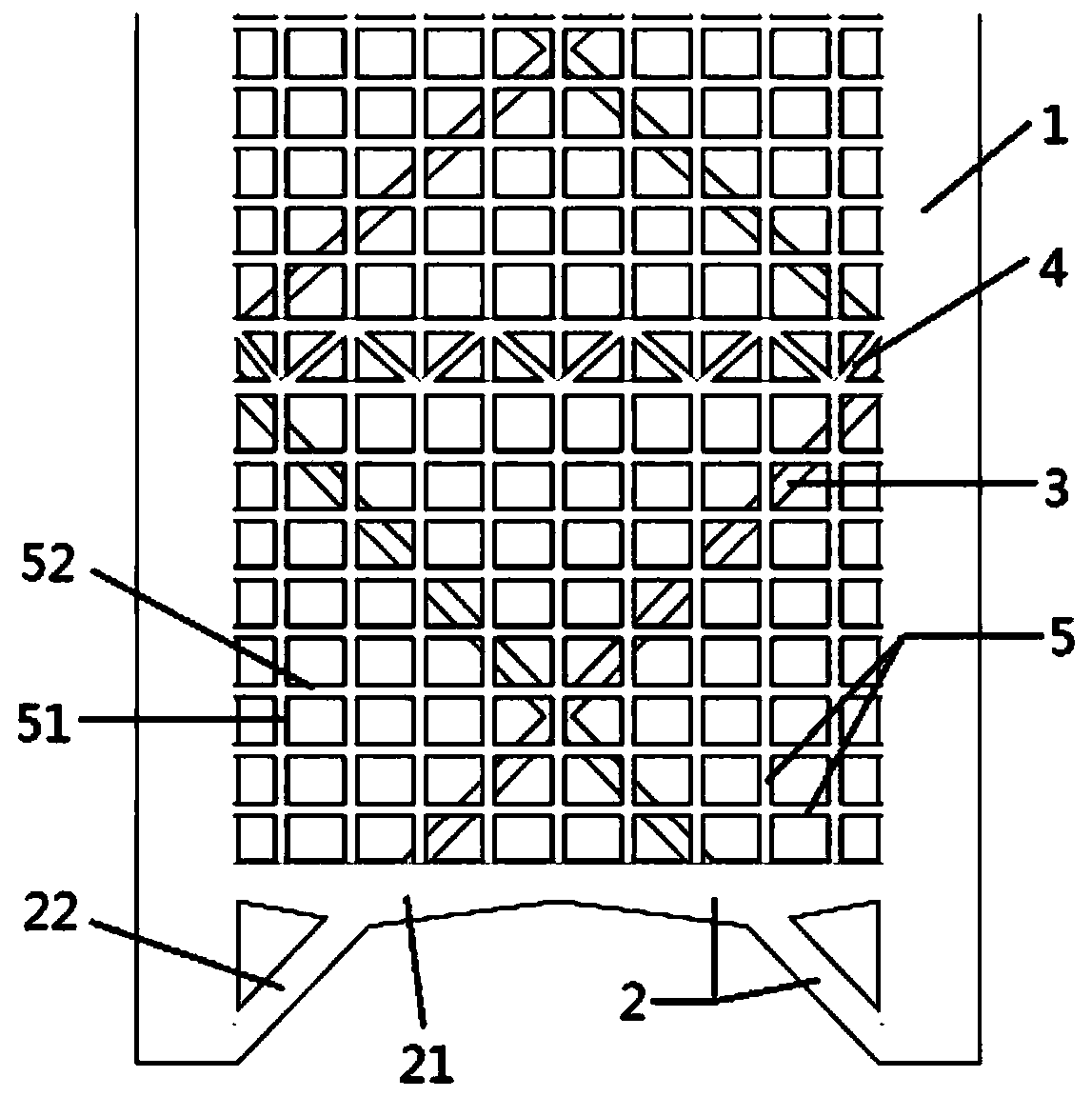

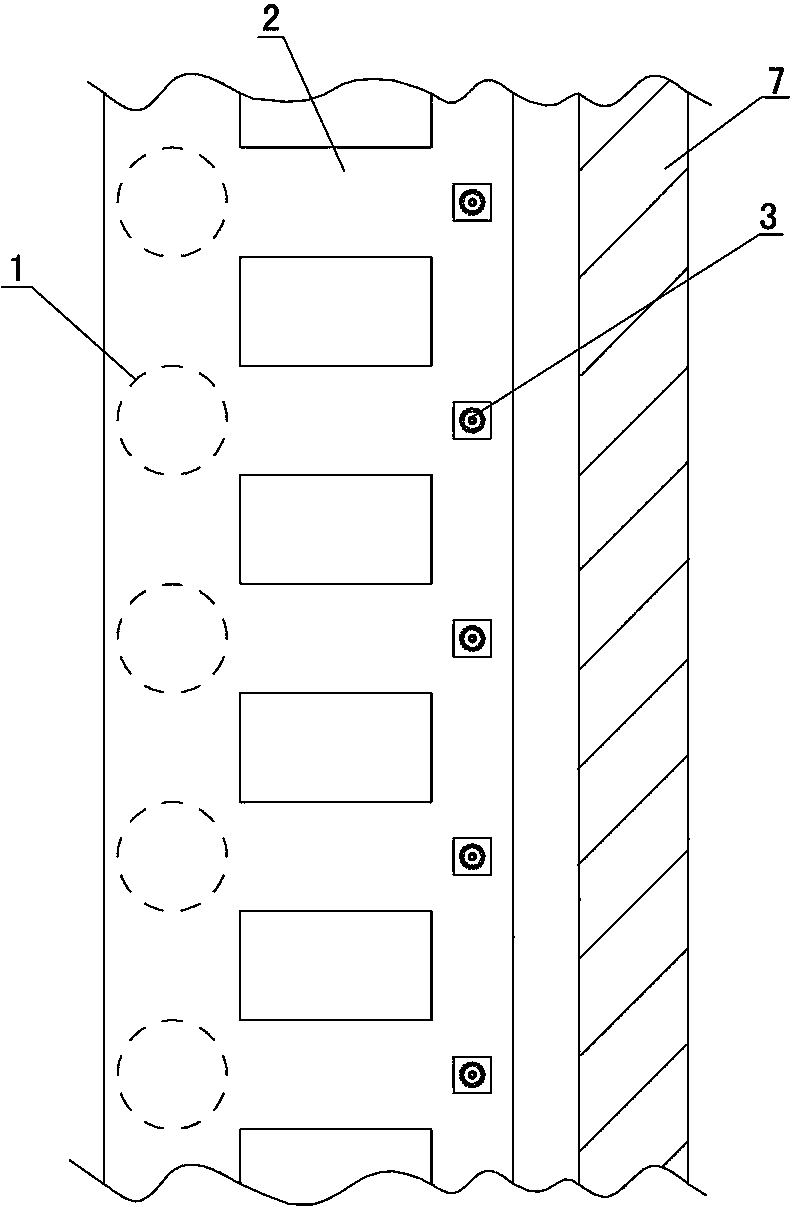

A latticed girder and vegetation bag greening structure system

InactiveCN104686239AGuaranteed Rooted SpaceGuaranteed to be rootedGrowth substratesCulture mediaSupporting systemPlanting seed

The present invention discloses a latticed girder and vegetation bag greening structure system. The system has a latticed girder, vegetation bags are stacked in lattices of the latticed girder, the vegetation bags are made of sealed woven bags filled with vegetation planting soil, the soil consists of mixed and sifted borrowed soil and peat soil sandwiched with wood fibers and plant seeds. Preferably, the latticed girder is equipped with anchor arms inserted into a side slope. The latticed girder is paved with a silk net; and the vegetation planting soil is arranged in the screen meshes of the silk net, above and below the silk net. A lattice girder with vegetation bags or a silk net connected vegetation planting soil greening structure system can be formed on the side slope, which can quickly create ecological vegetation, and make the formed greening vegetation grow and root quickly. The formed latticed girder and anchor arm support system on the side slope ensures that landslides of the slope are avoided; and the greening vegetation can be more stable and firmer since the vegetation planting soil and the growing vegetation are fixed by the combined woven bags and the silk net, and the growing root system is combined with the woven bags.

Owner:DALIAN REGREEN ECOLOGICAL TECH

Ecological bag and rock slope re-greening device

InactiveCN107815744AHigh shear forceHigh tensile strengthAnimal corpse fertilisersClimate change adaptationCardingEcological environment

The invention relates to the field of environmental protection and discloses an ecological bag and a rock slope re-greening device. A preparation method of the ecological bag comprises the following steps: (1) mixing polypropylene fiber colloidal particles and anti-aging polypropylene master batches, so as to obtain a mixture; (2) heating and fusing the mixture of the step (1), carrying out extrusion to form filaments, and carrying out oiling, traction, crimpy cutting and drying formation, so as to obtain an anti-aging polypropylene short fiber; and (3) carrying out loosening, carding, lapping, needling, heat setting and winding on the anti-aging polypropylene short fiber, so as to obtain the ecological bag. According to the ecological bag and the rock slope re-greening device, the technical defects that an unaesthetic structure is formed, the ecological environment is easily damaged, and the covered structure is unsteady after a rock slope is covered by virtue of existing lattice girder method, slurry stone-laying method and guniting method are effectively solved.

Owner:JOFO GREEN CO LTD

Slant-leg rigid-frame-type supporting structure of super-high-rise building mega-frame bottom layer and construction method

PendingCN111364616AIncrease lateral stiffnessImprove seismic performanceExtraordinary structuresBuilding material handlingEarthquake resistanceControl theory

The invention discloses a slant-leg rigid-frame-type supporting structure of a super-high-rise building mega-frame bottom layer. The slant-leg rigid-frame-type supporting structure of the super-high-rise building mega-frame bottom layer comprises mega-frame columns, a slant-leg rigid-frame-type supporting structure body, cross-supporting structures, annular belt truss beams and a sub-frame structure. The slant-leg rigid-frame-type supporting structure body is arranged between the two mega-frame columns, and the slant-leg rigid-frame-type supporting structure body is composed of two rigid-frameslant-leg columns and a rigid-frame horizontal beam. The lower ends of the rigid-frame slant-leg columns are separately connected with the two mega-frame columns, and the upper ends of the rigid-frame slant-leg columns are connected with the rigid-frame horizontal beam. The upper ends of the rigid-frame slant-leg columns extend upward and are connected with the cross-supporting structures, the upper ends of the cross-supporting structures are connected with the two mega-frame columns, the annular belt truss beams are arranged at the upper ends of the cross-supporting structures, the other cross-supporting structures are connected to the upper parts of the annular belt truss beams, and the annular belt truss beams and the cross-supporting structures are repeatedly arranged alternately upwards. The slant-leg rigid-frame-type supporting structure of the super-high-rise building mega-frame bottom layer has the advantages of large lateral rigidity, good seismic performance and the like.

Owner:CHINA CONSTR SEVENTH ENG DIV SHANGHAI CORP

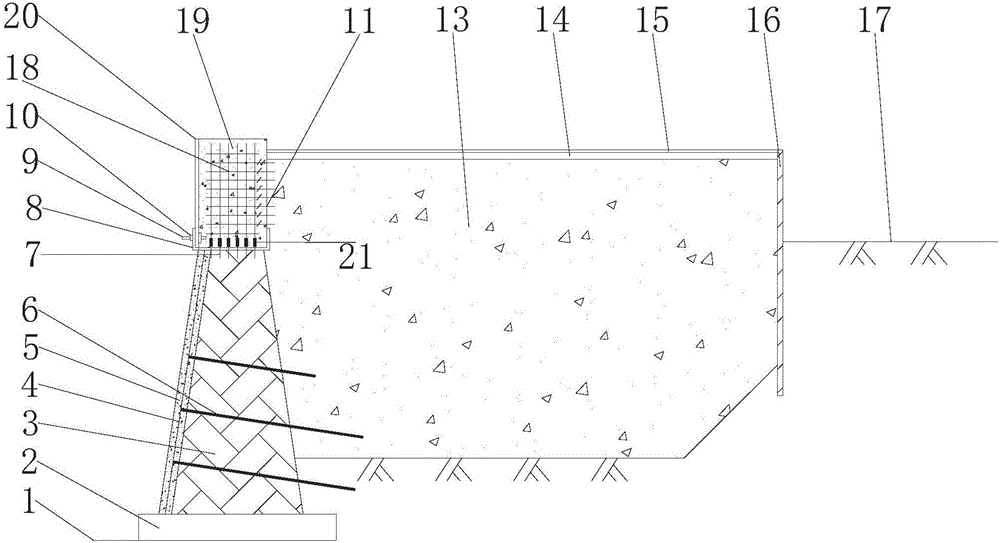

Heightened construction method for active service stone building bank protecting wall

The invention relates to a heightened construction method for an active service stone building bank protecting wall. The heightened construction method includes the following steps that (1) an original bank protecting slope is cleaned and repaired; (2) anchor rod construction is carried out; (3) lattice girder construction is carried out; (4) foam concrete construction is carried out; (5) pavement construction is carried out; (6) newly-increased protection bank construction is carried out; and (7) concrete curing is carried out. A structure related in the heightened construction method comprises angle iron arranged at the top of an original protection bank according to a certain distance, the angle iron and embedded steel bars at the top of the original protection bank are connected in a welded manner, and a foam concrete sea side formwork and a newly-increased protection bank side mold are connected with the angle iron in a fastened manner through screws; prefabricated slabs are evenly inserted and piled on the foam concrete bank side, a foam concrete bank side formwork is arranged to be in a separated manner and is connected with the prefabricated slabs in a fastened manner through box iron, the screws and nuts; and newly-increased protection bank framework reinforcing steel bars and original protection bank embedded steel bars are connected through a direct threaded sleeve. The heightened construction method for the active service stone building bank protecting wall has the beneficial effects of being reliable in structure, convenient to construct, short in time limit for a project, environment-friendly and good in concrete appearance quality.

Owner:ZHEJIANG UNIV CITY COLLEGE

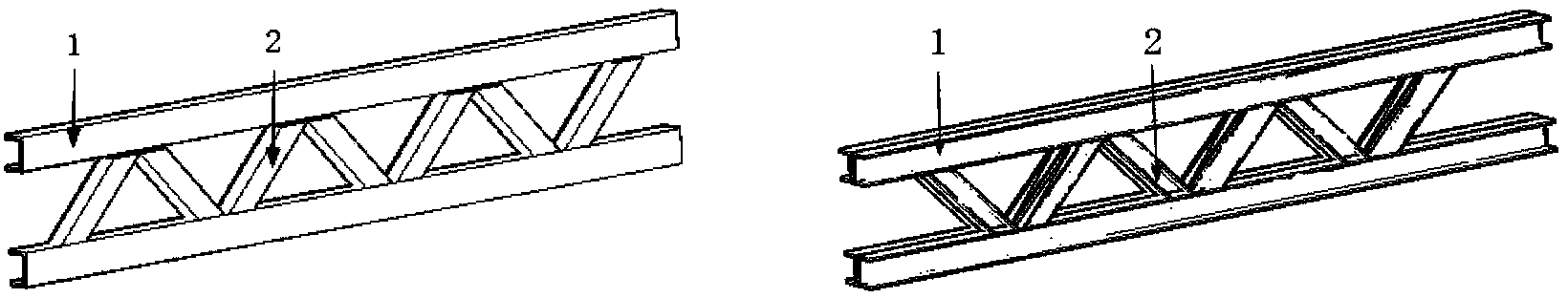

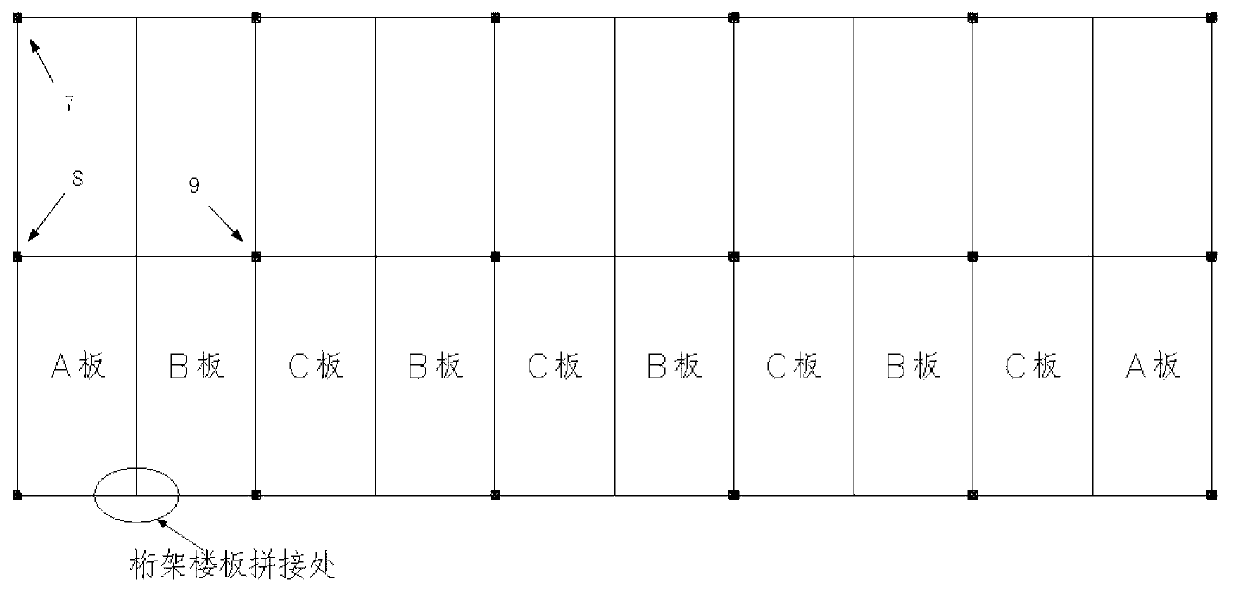

Industrialized assembly type multi-high-rise steel specially shaped column frame structure system

InactiveCN103276802AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

The invention provides an industrialized assembly type multi-high-rise steel specially shaped column frame structure system and relates to the technical field of structure engineering. The industrialized assembly type multi-high-rise steel specially shaped column frame structure system comprises assembly type truss plates and assembly type specially shaped columns. Each assembly type truss plate comprises a lattice type truss girder provided with a channel steel web member and a floor plate. Each assembly type truss plate is prefabricated in a factory and is mutually spliced with a flange plate of one assembly type specially shaped column through a girder end sealing plate of the assembly type truss plate at a construction site. The assembly type specially shaped columns are spliced among floors in site through bolts so that a multi-layer truss plate steel frame structure can be formed. The assembly type truss plates and the assembly type specially shaped columns are all prefabricated in the factory and assembled through bolts at the construction site.

Owner:BEIJING UNIV OF TECH

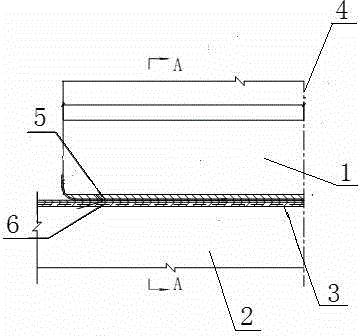

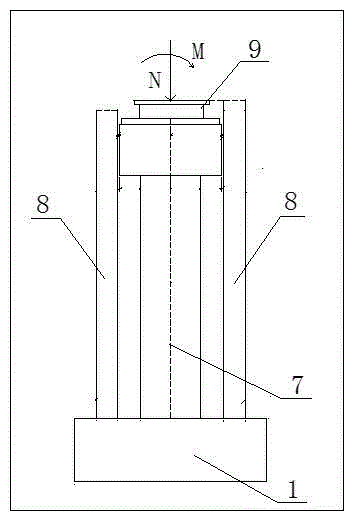

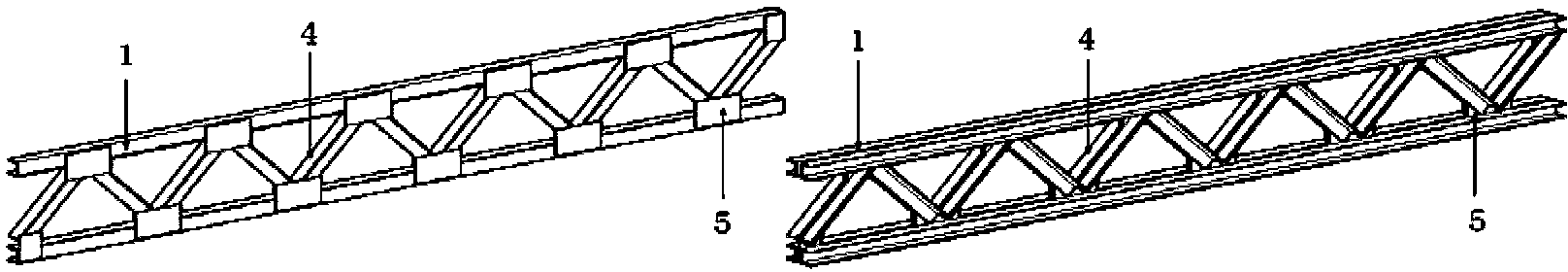

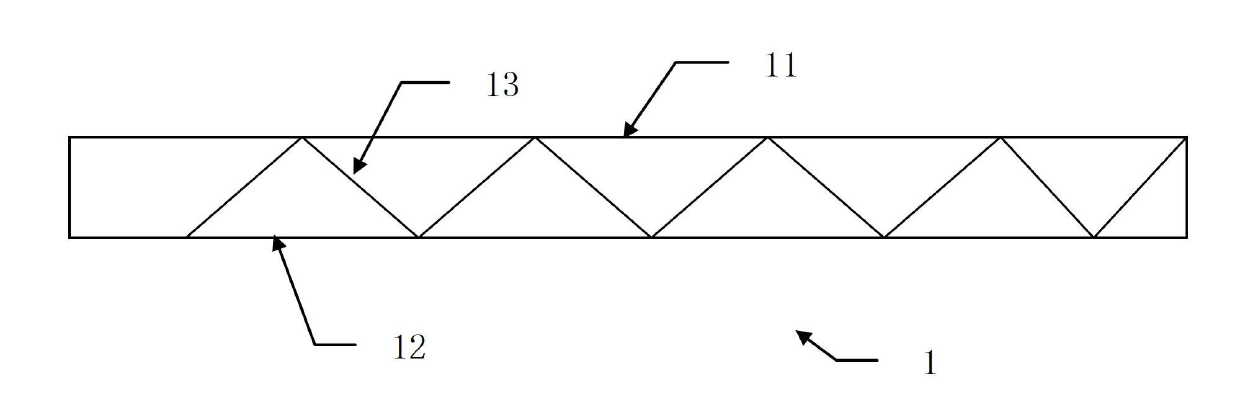

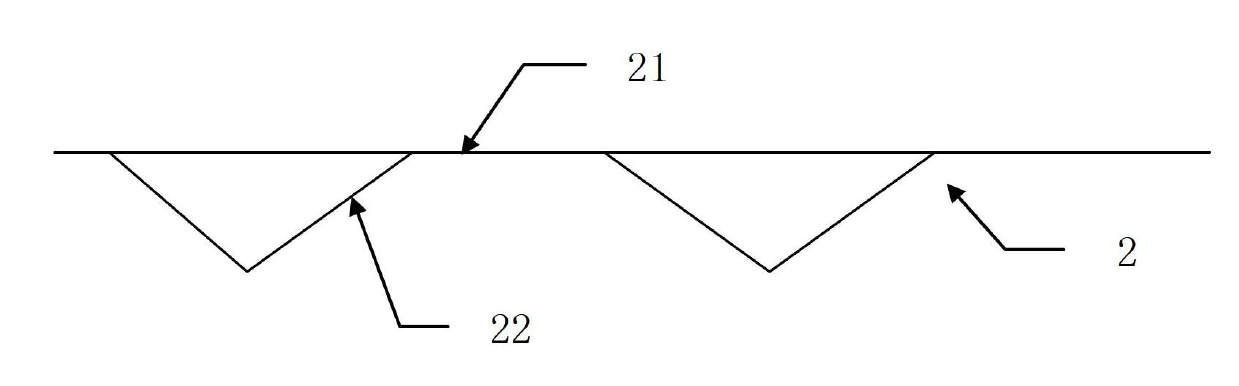

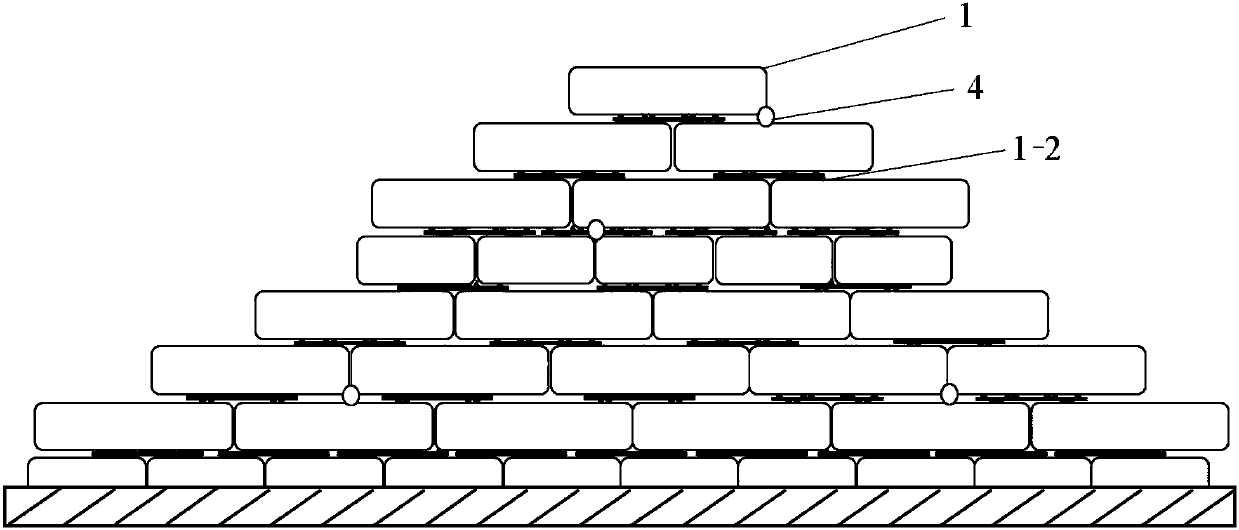

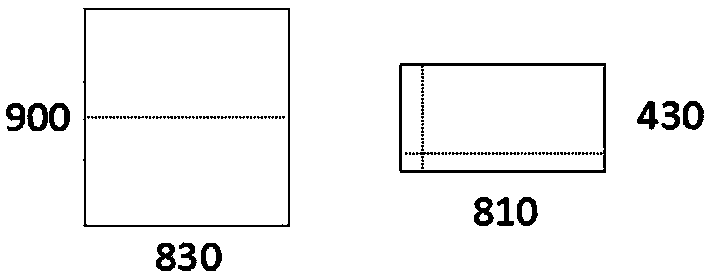

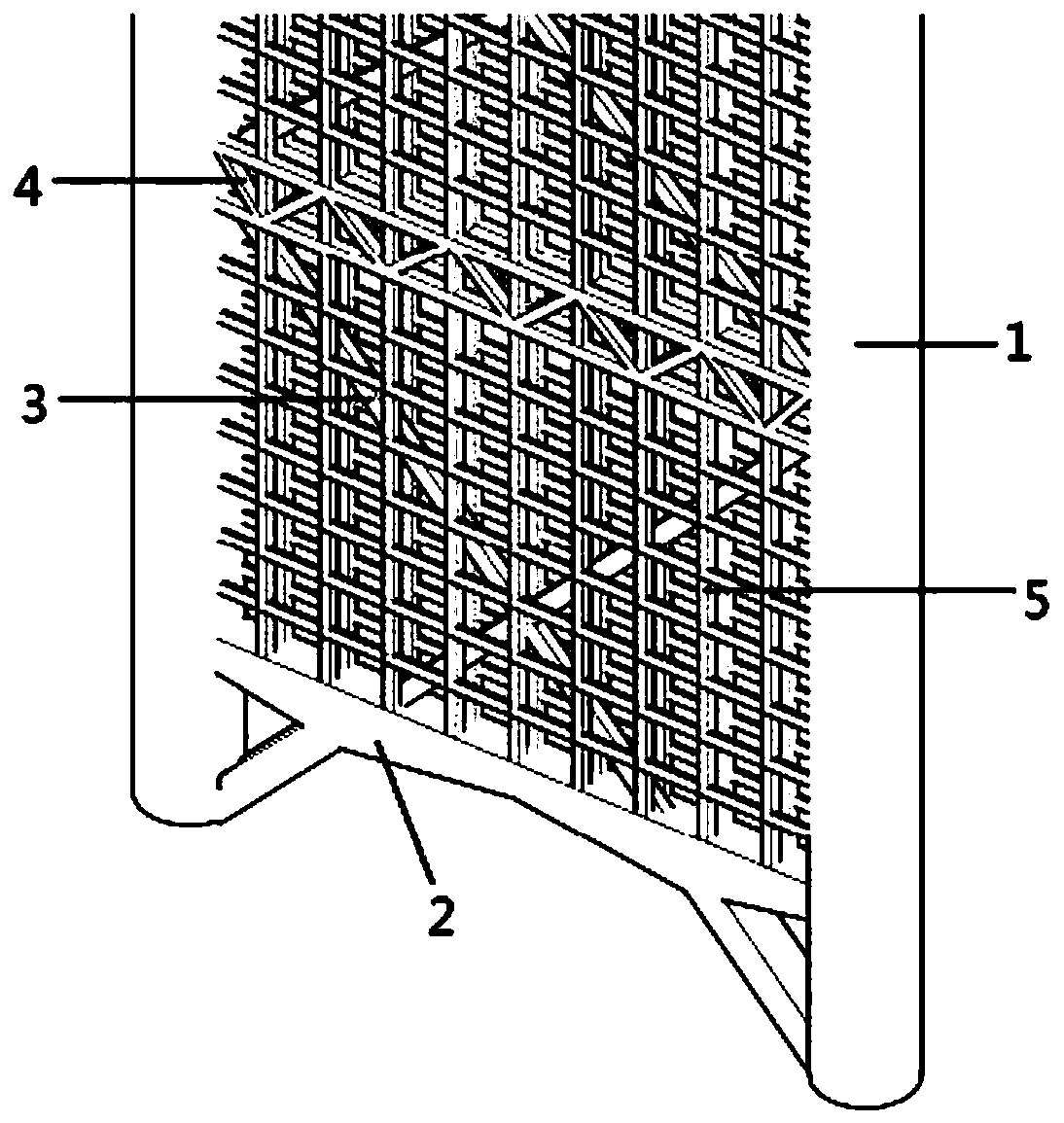

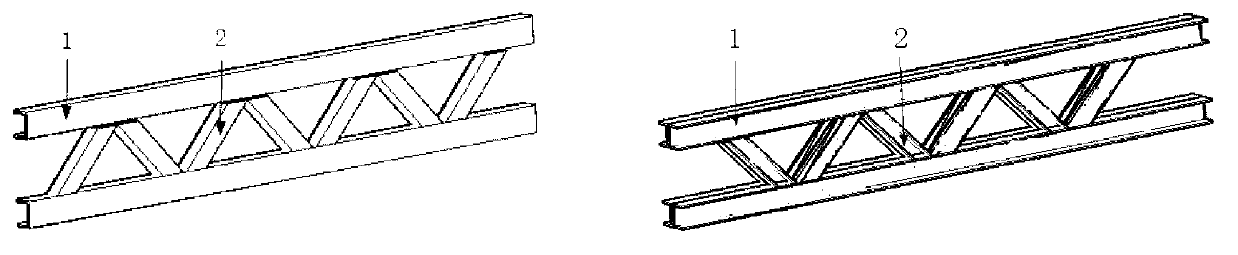

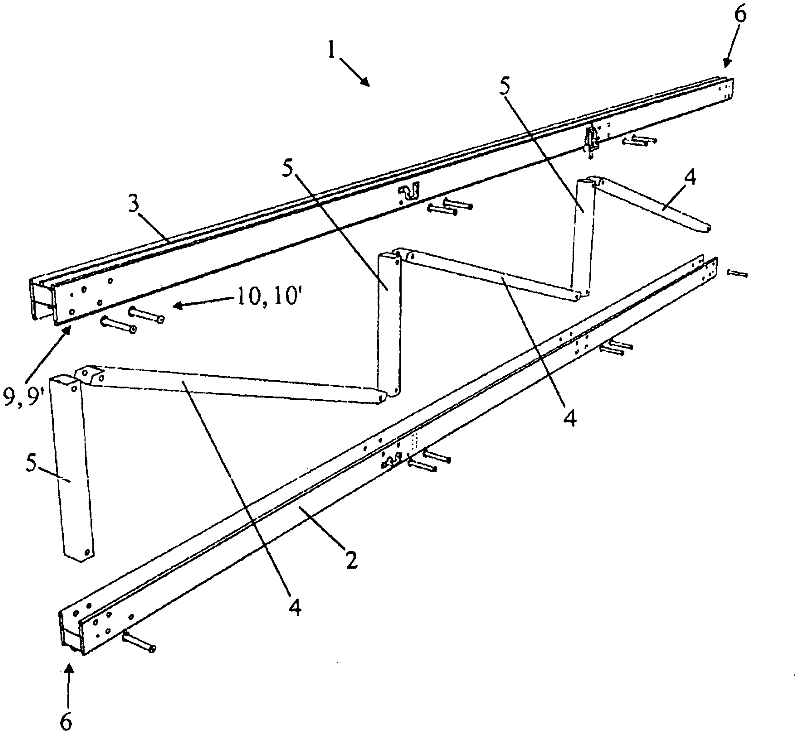

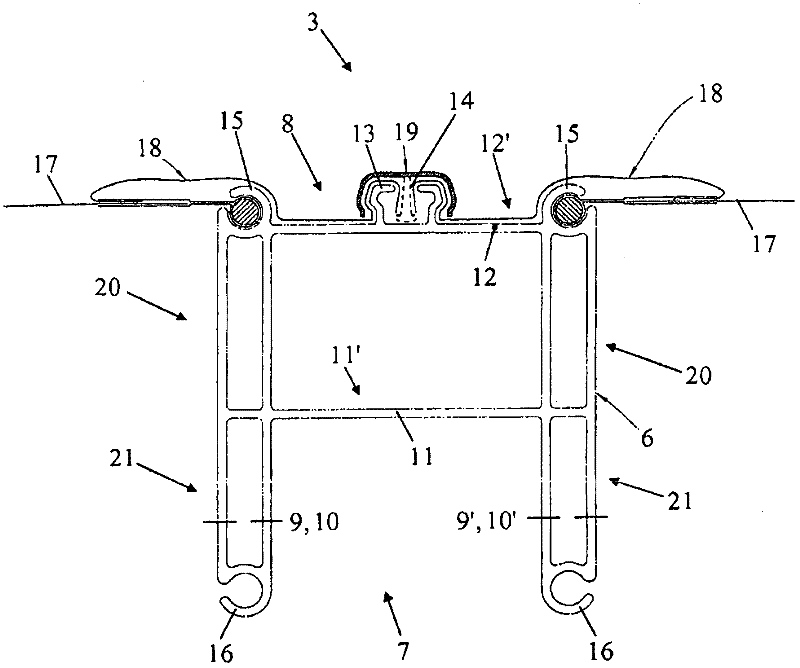

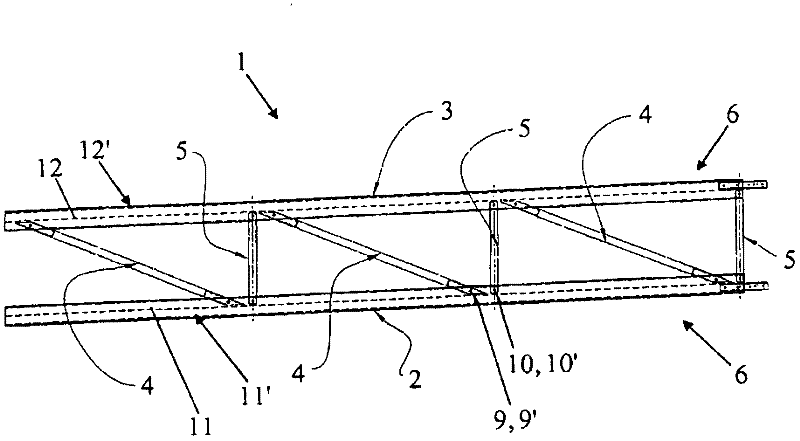

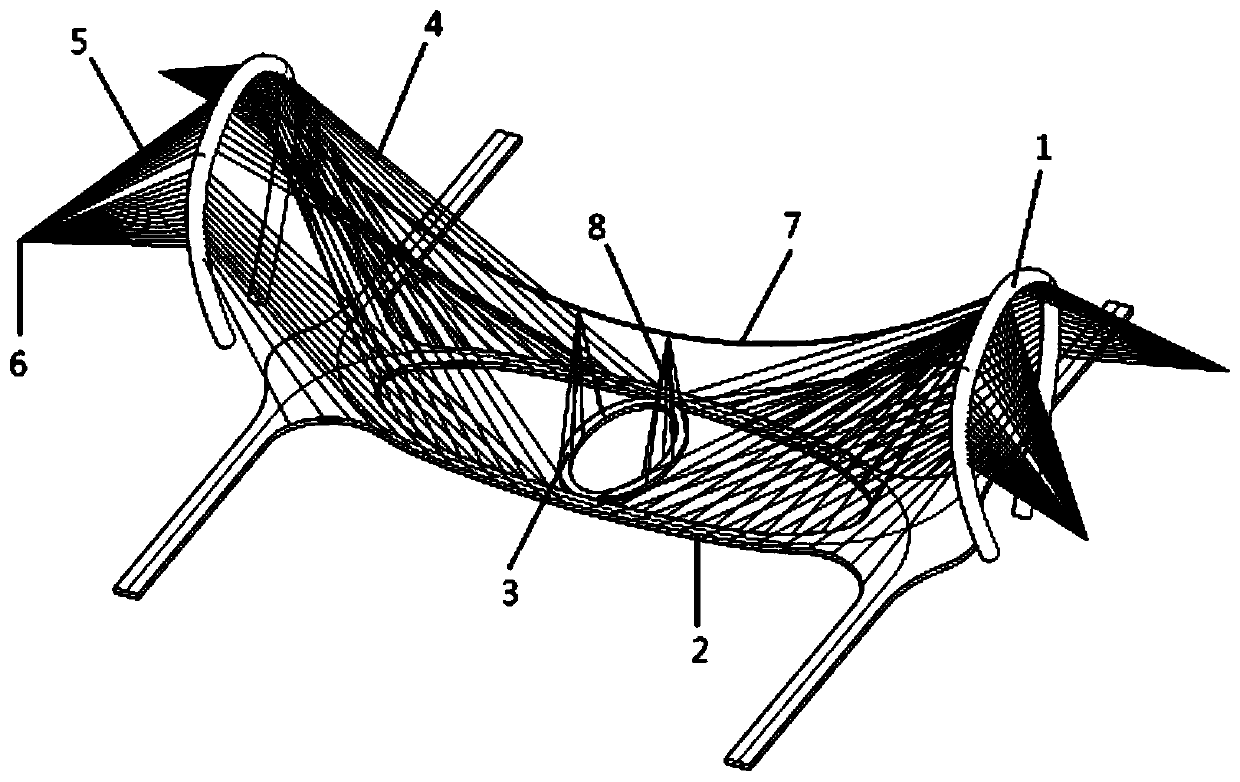

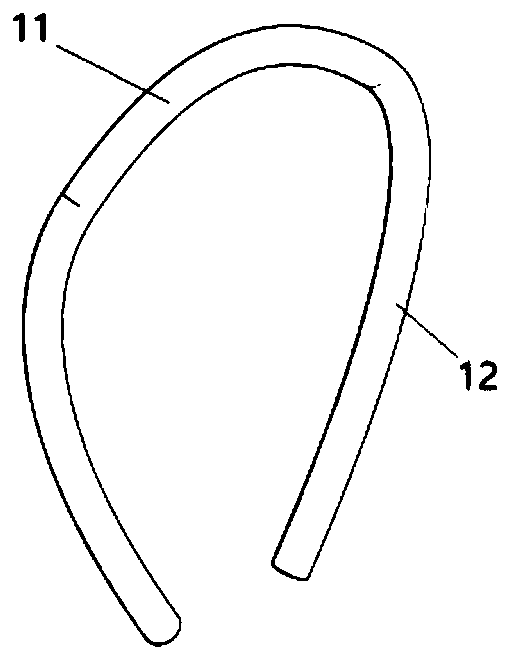

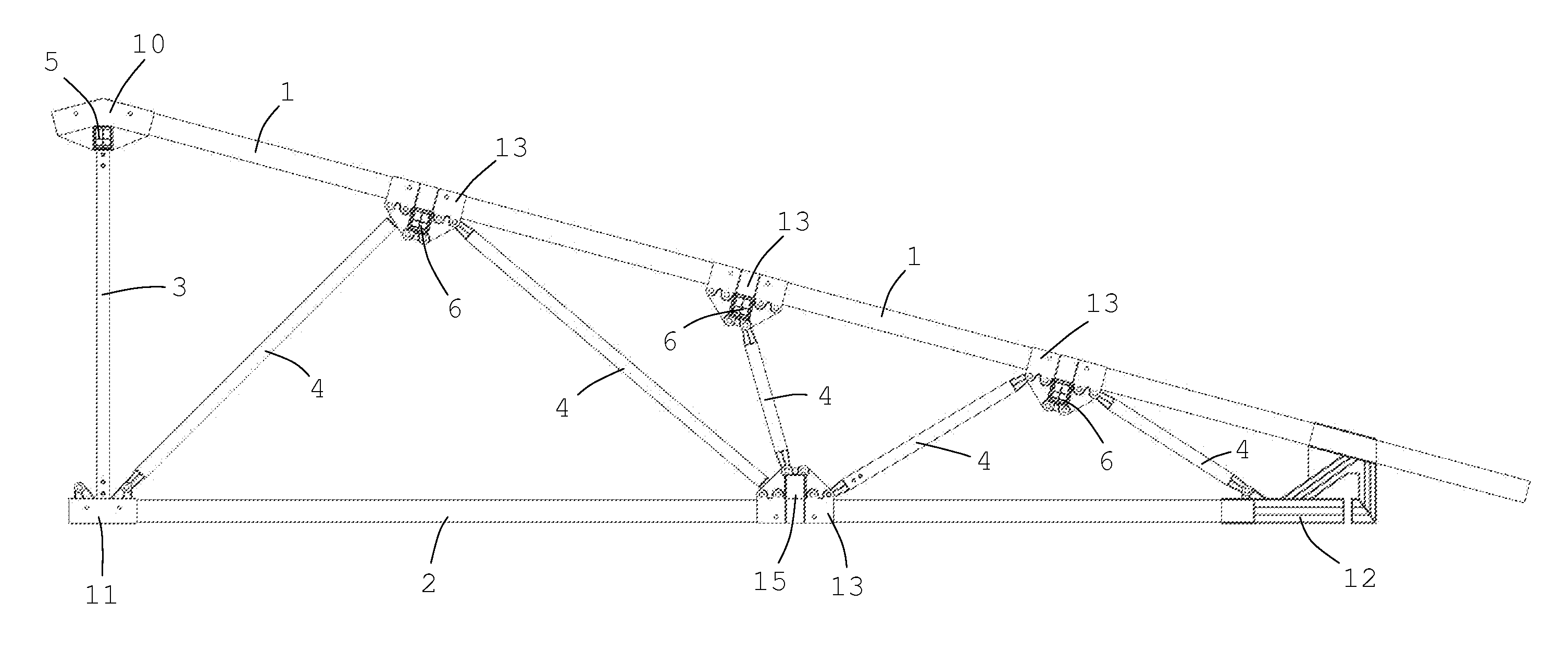

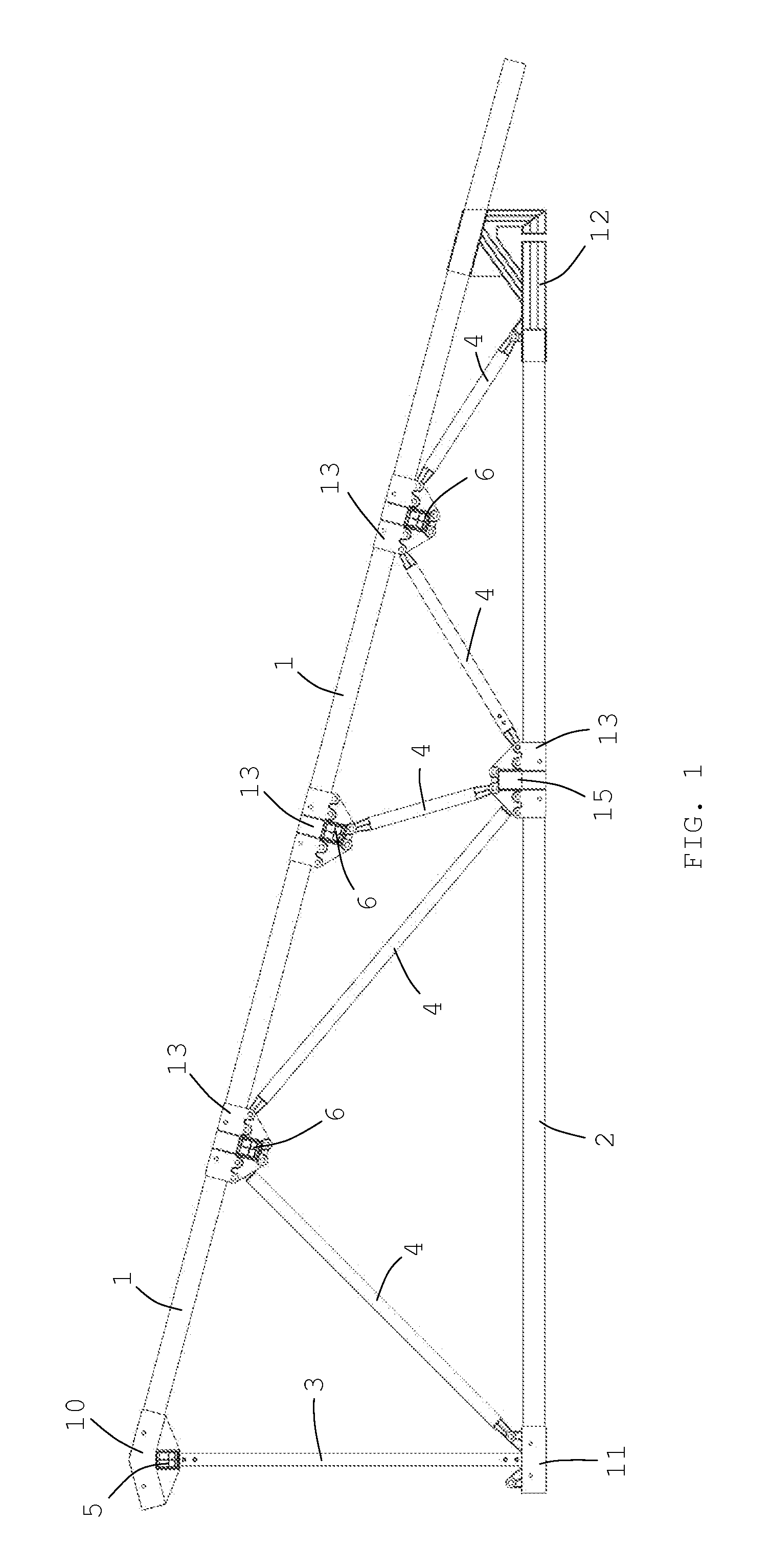

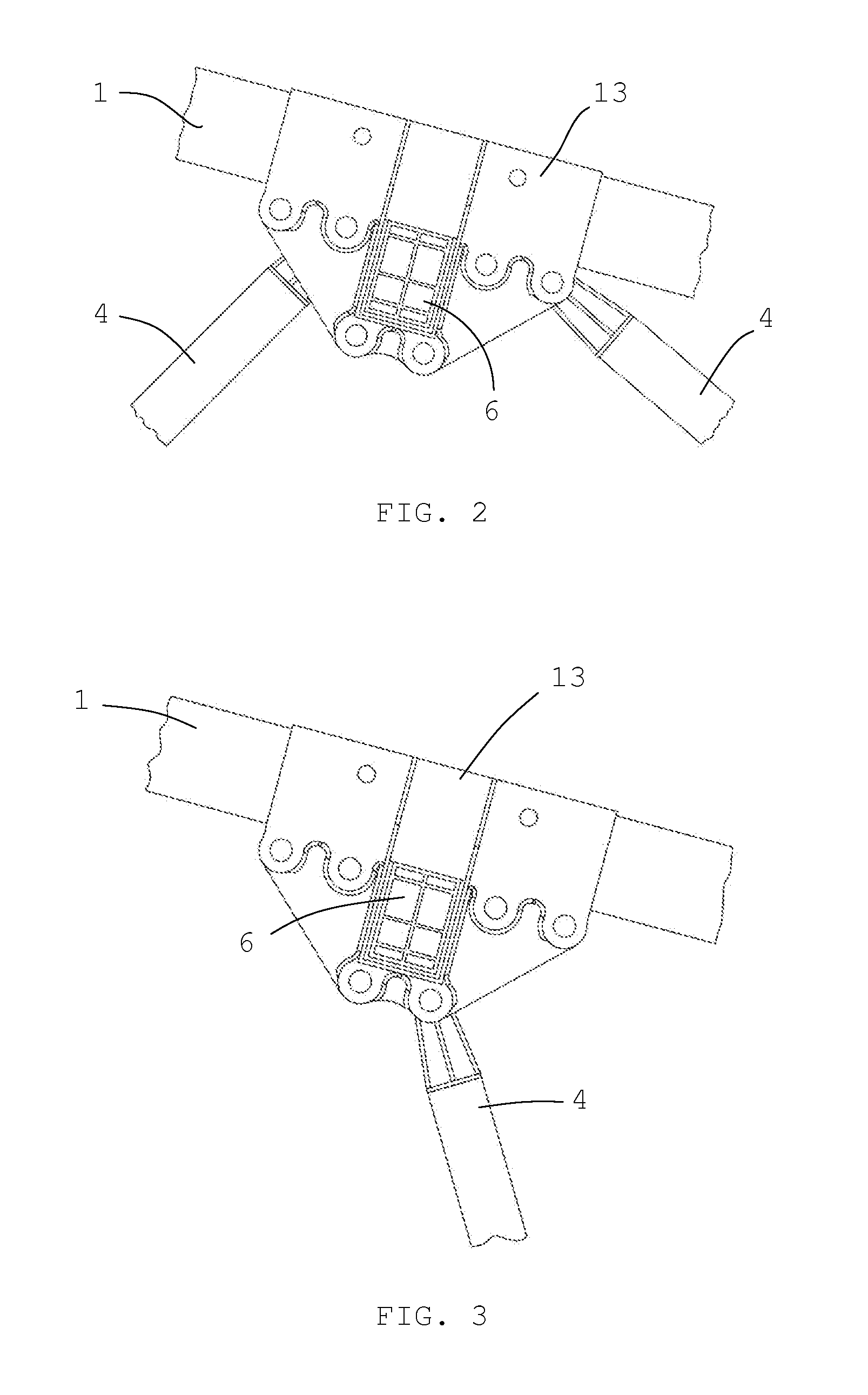

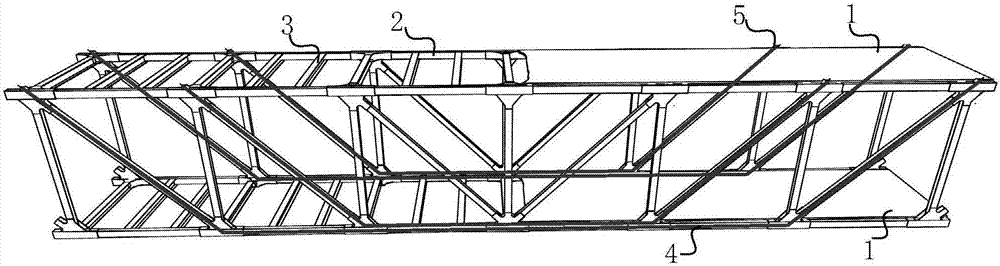

Collapsible lattice beam, truss and construction including such a beam

A preassembled lattice beam (1) formed by a lower rib (2) and an upper rib (3) interconnected by at least one diagonal (4) attached such as to be able to pivot between a transport position and a mounting position, said beam having at least one stationary upright (5) connecting the lower (2) and upper ribs (3) at a right angle in said mounting position.

Owner:SPANTECH INT SA

Root-anchor system reinforcing ecological slope protection method for fill slope

The invention provides a root-anchor system reinforcing ecological slope protection method for a fill slope. Firstly, multiple lines of reinforcing steel bar anchor rods are embedded in the surface of an existing hard side slope in the slope direction, concrete slab anchor heads are poured at the positions of the tops, exposed out of the surface of the hard side slope, of the anchor rods, and a fixed pulley with the rotation direction in the downhill direction is installed on each concrete slab anchor head; meanwhile, a banket retaining wall is constructed at the position of the toe of the hard side slope; and a pull rope is wound around each fixed pulley, one end of each pull rope is perpendicularly stretched to the designed slope surface height of the fill, and the other end of each pull rope is then wound around the other fixed pulleys, in the same line with the corresponding fixed pulley and located below the corresponding fixed pulley in the slope direction, so as to be embedded in and fixed to the back face of the retaining wall, the end, corresponding to the last anchor rod in each line of anchor rods in the slope direction, of the corresponding pull rope is directly embedded in and fixed to the back face of the retaining wall, filling is conducted till the designed slope surface height, concrete lattice girders are constructed, and the tip, perpendicularly stretched to the fill slope height, of each pull rope is anchored after being pulled and tensioned. By means of the method, deep reinforcing and ecological protection of the fill slope can be achieved.

Owner:SICHUAN UNIV +1

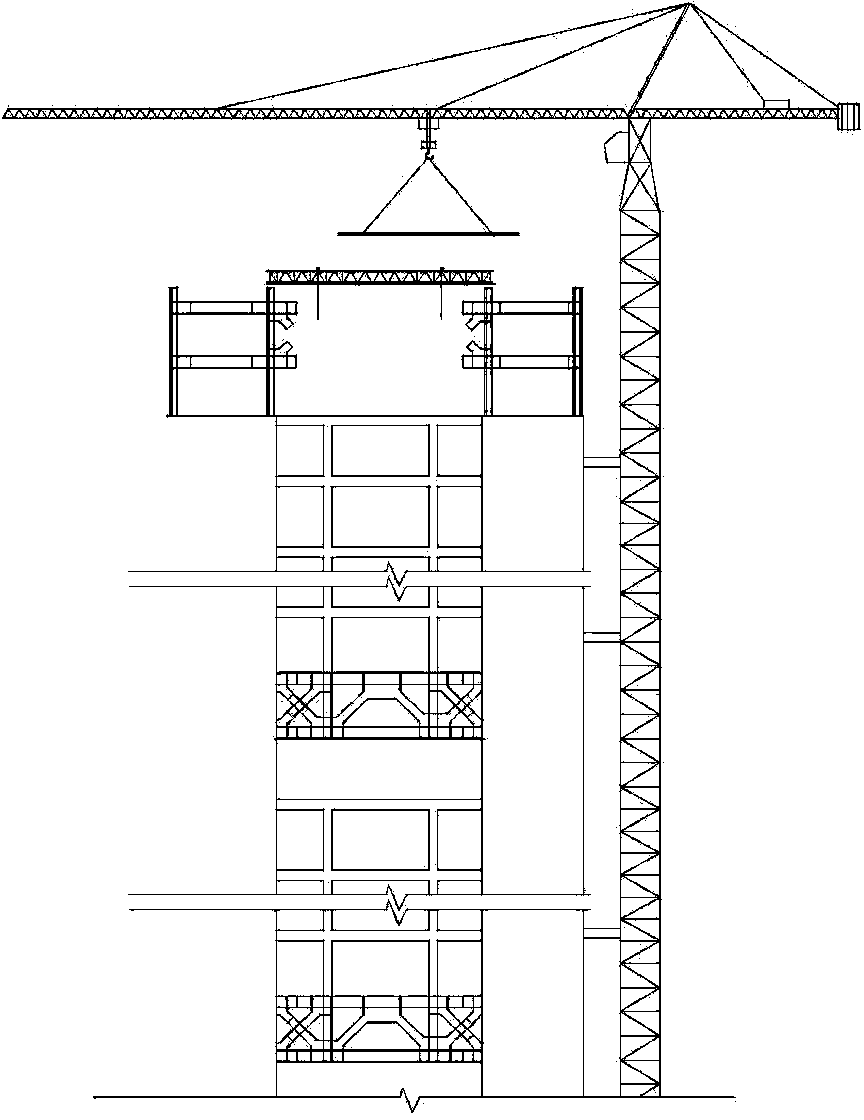

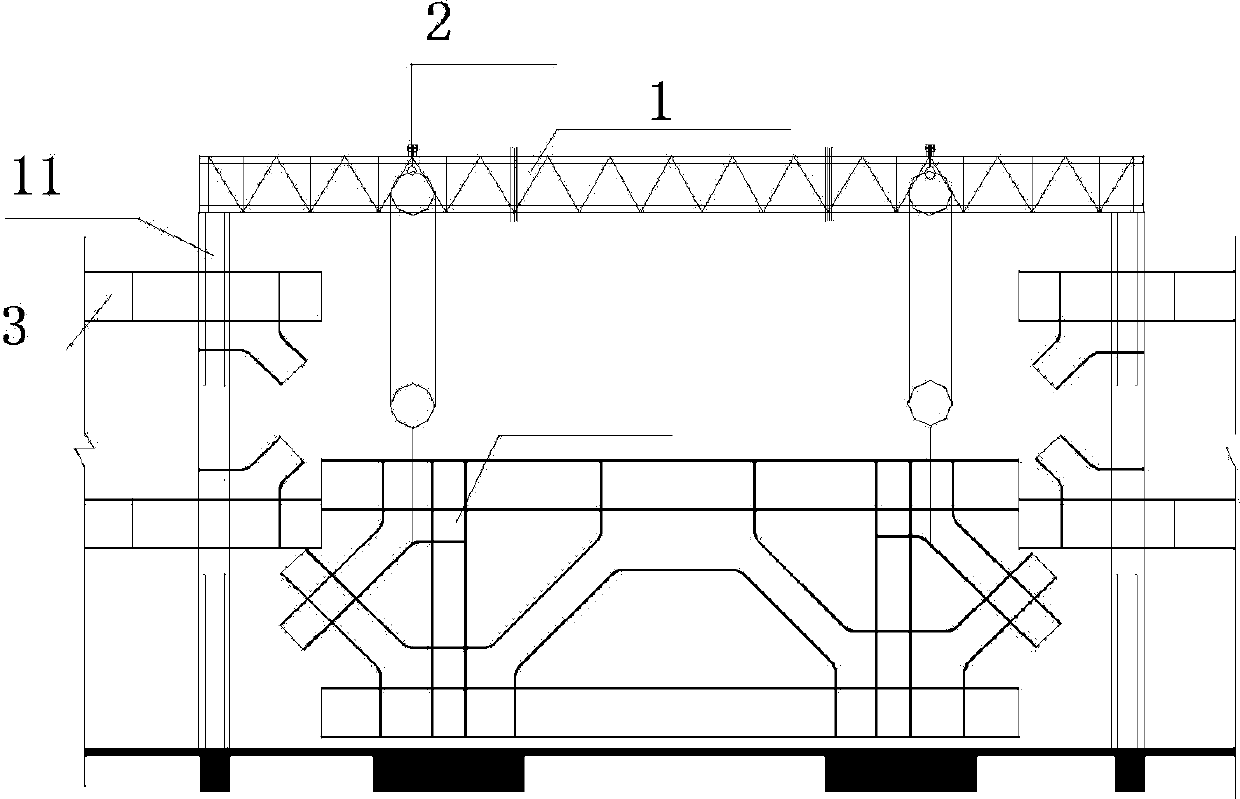

Step-by-step hoisting construction method of mega-frame steel truss beam

InactiveCN103899093AFlexible and convenient fine-tuningSimple and fast operationBuilding material handlingEconomic benefitsEngineering

The invention relates to hoisting of a mega-frame steel truss beam, in particular to a hoisting method of a mega-frame steel truss beam on a high-rise building with a steering layer. According to the technical aim, when a transfer layer is additionally arranged on the high-rise building, the steel truss beam of the transfer layer can be installed without high-altitude hoisting of a large structural member. The high-altitude hoisting of the large structural member can be decomposed to be two-step combined hoisting, only a small-tonnage tower crane and a simple gantry crane are required, supporting columns of the gantry crane utilize structural steel columns ingeniously, steel cross beams of the gantry crane are elaborately designed to be in a three-section assembled type, and therefore the investment of mechanical equipment is reduced, construction cost is lowered, social resources are saved, and remarkable economic benefits are achieved.

Owner:JIANGSU NANTONG NO 6 CONSTR GRP

Space four-cable-surface double-amplitude curve-shaped cable-stayed bridge of canyon river terrain and construction method

ActiveCN110820526AImprove integrityForce safe and reliableCable-stayed bridgeSuspension bridgeArchitectural engineeringCable net

The invention provides a space four-cable-surface double-amplitude curve-shaped cable-stayed bridge of canyon river terrain and a construction method. An arch bridge tower is built on hills on the twosides of a river valley, a four-cable-surface spatial inclined cable net tightly drags an elliptical annular double-amplitude curve-shaped main beam, inner cable nets are anchored at a top section ofa parabolic section of a duck egg arch bridge tower, outer side cable nets are anchored at a top section of an elliptical arc section tower column of the duck egg arch bridge tower, wherein the innerside cable nets are arranged in a cross anchoring mode, the center of the elliptical annular double-amplitude curve-shaped main beam is provided with the elliptical annular beam supporting member, the elliptical annular beam also serves as a sightseeing platform, a single main cable suspension cable is used for hoisting a temporary truss girder connecting beam structure, the cable hoisting methodassist the double bending cable-stayed bridge cantilever assembling construction, and after the bridge is formed, radial slings are arranged on the single main cable suspension cable, so that the elliptical annular beams are hung. The double-bending cable-stayed bridge has the advantages of being simple in structure, rich in facade, attractive in appearance, ecological, environment-friendly, smooth in traffic organization, convenient to construct, good in economical efficiency and the like, and has good application prospect.

Owner:SOUTHEAST UNIV

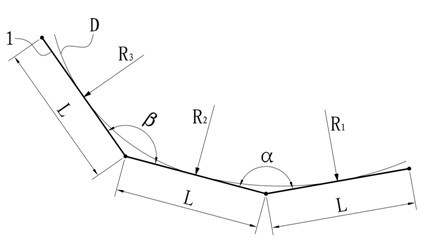

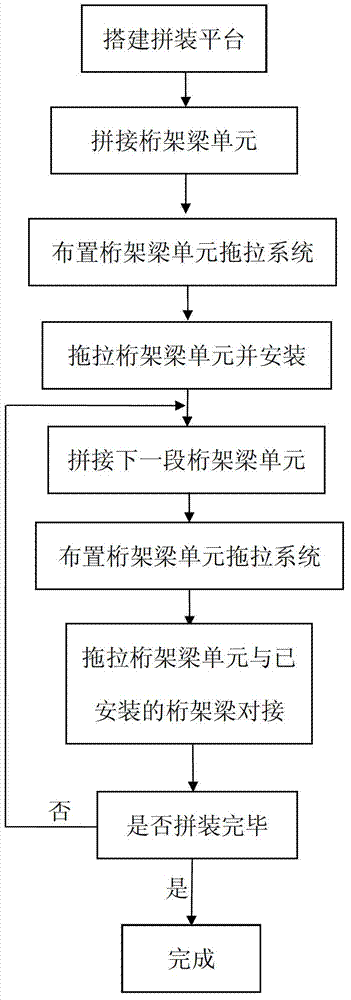

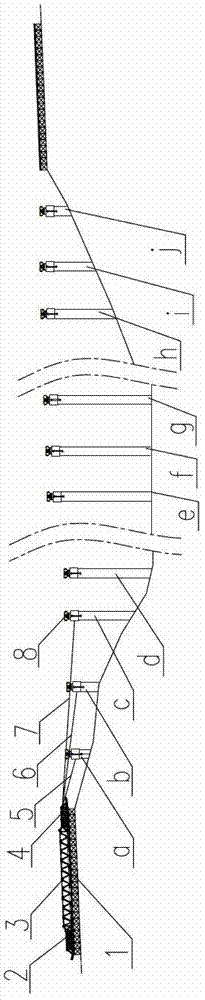

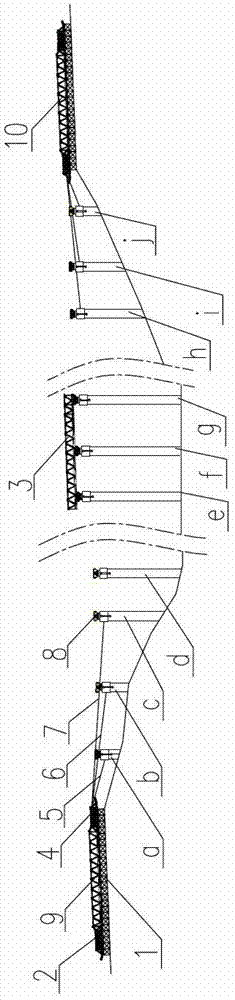

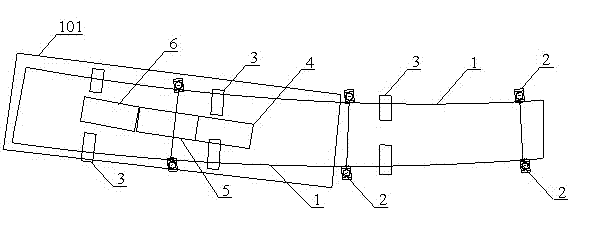

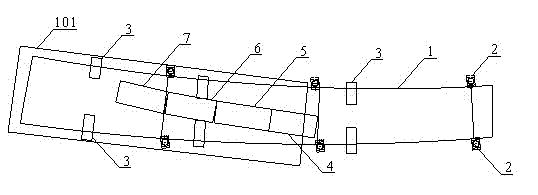

Pulling and erecting method of truss girder

ActiveCN102888813AMeet the erectionShorten the construction periodBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a pulling and erecting method of a truss girder. According to the shape of a bridge in an actual project, a truss girder is separated into several sections, then every truss girder unit is pulled and dragged in order and abutted one by one; at last, the whole truss girder is obtained. For the integrative truss girder obtained by a segmental pulling and abutting manner, the erection of a flat upright truss girder can be satisfied while the erection of the truss girder with a small curve radius also can be satisfied; meanwhile, for the truss girder can be assembled on a bracket on a shore, the truss girder can be assembled and welded, thereby the time limit is effectively shortened; by assembling a steel truss girder on the bracket on the shore, the overhead work and the water work are reduced, thus being beneficial to safe construction; and furthermore, the construction of both ends of the truss girder is realized at the same time, the work limit is effectively shortened.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

Mal-position assembly in-position method of truss bridge

ActiveCN102776840AImprove assembly efficiencyAccurateBridge erection/assemblyArchitectural engineeringAbutment

The invention relates a mal-position assembly in-position method of a truss bridge. The method comprises the steps of building an assembly platform: excavating a roadway at a bridge abutment to form a work platform or erecting a steel tube bracket platform in the middle of a bridge, and arranging a girder assembling platform in the middle of a work platform or a bracket platform; firstly assembling the truss bridge: firstly assembling the truss bridge on an assembly platform, longitudinally moving the truss bridge to empty the space of the assembly platform part; assembling the truss bridge for the second time, the longitudinally moving the truss bridge to empty the space of the assembly platform part; repeating the steps to assemble the truss bride for the third time, the fourth time and the like and putting the truss bridge in position, taking width of the assembly platform as the limit, rotating the whole truss bridge by an angle to be in position, or longitudinally positioning or horizontally positioning. According to the mal-position method of the truss bridge, the technical difficulty that the truss bridge is difficult to be in position by one step when a high-pier truss bridge is erected at a complex terrain area, the operation is simple and convenient, the truss bridge assembling efficiency is high, and the alignment is accurate.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

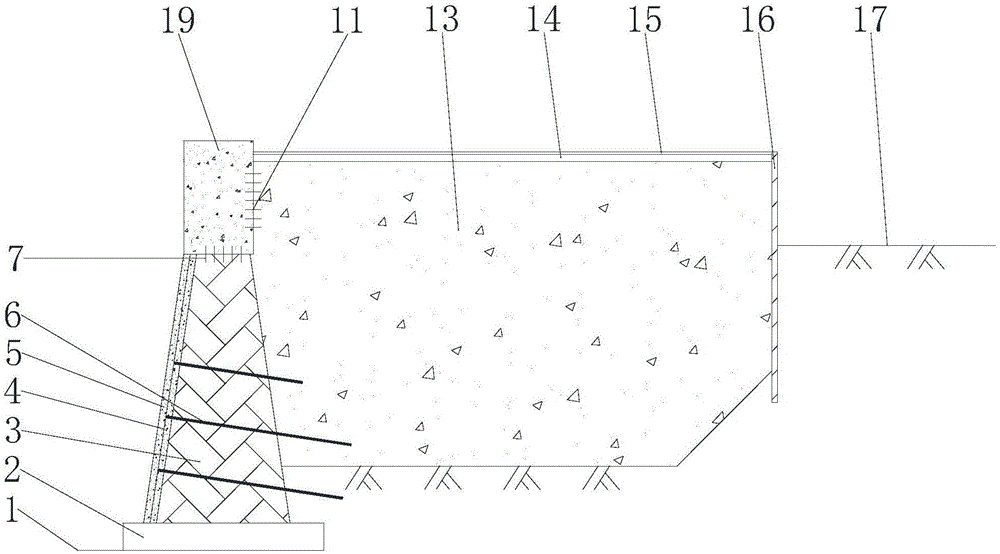

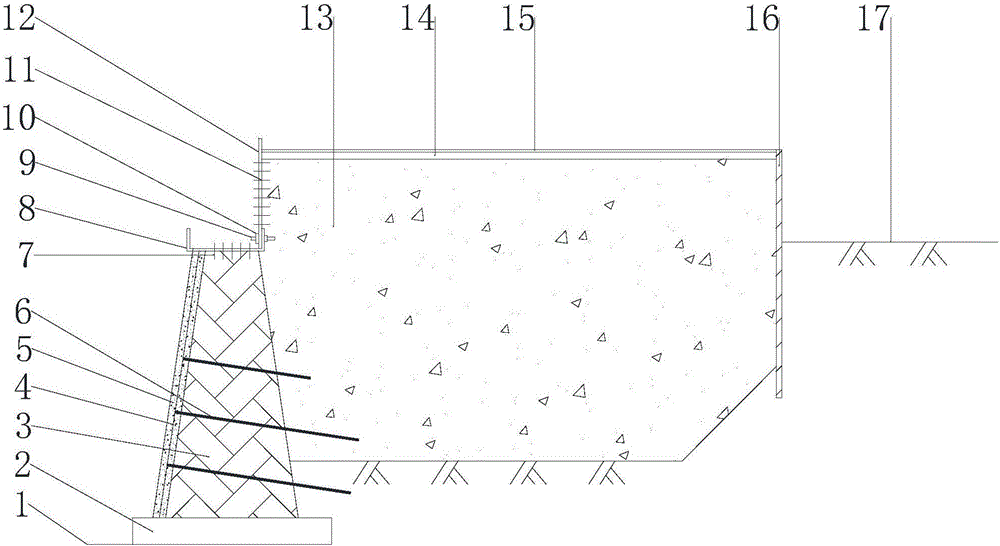

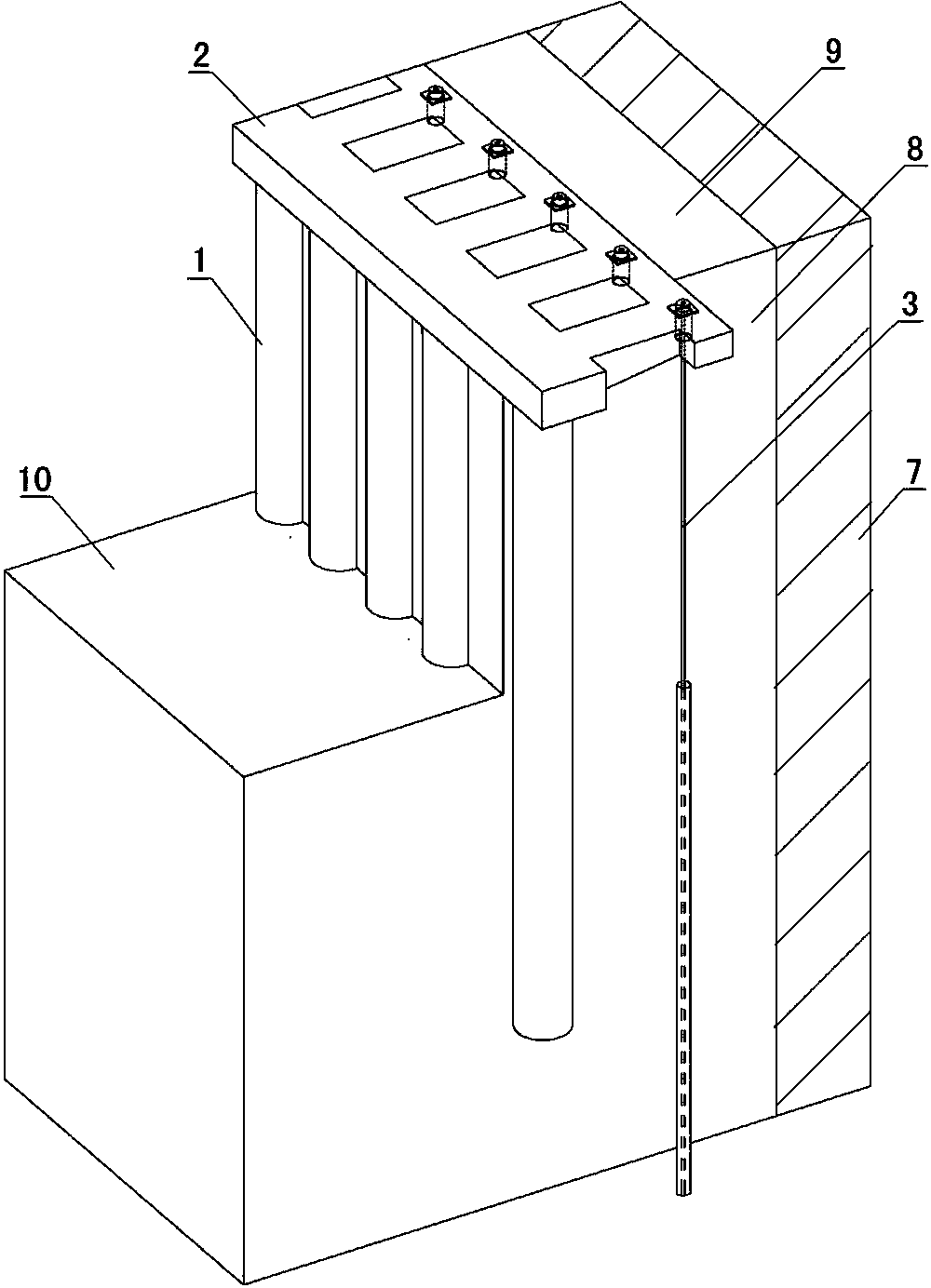

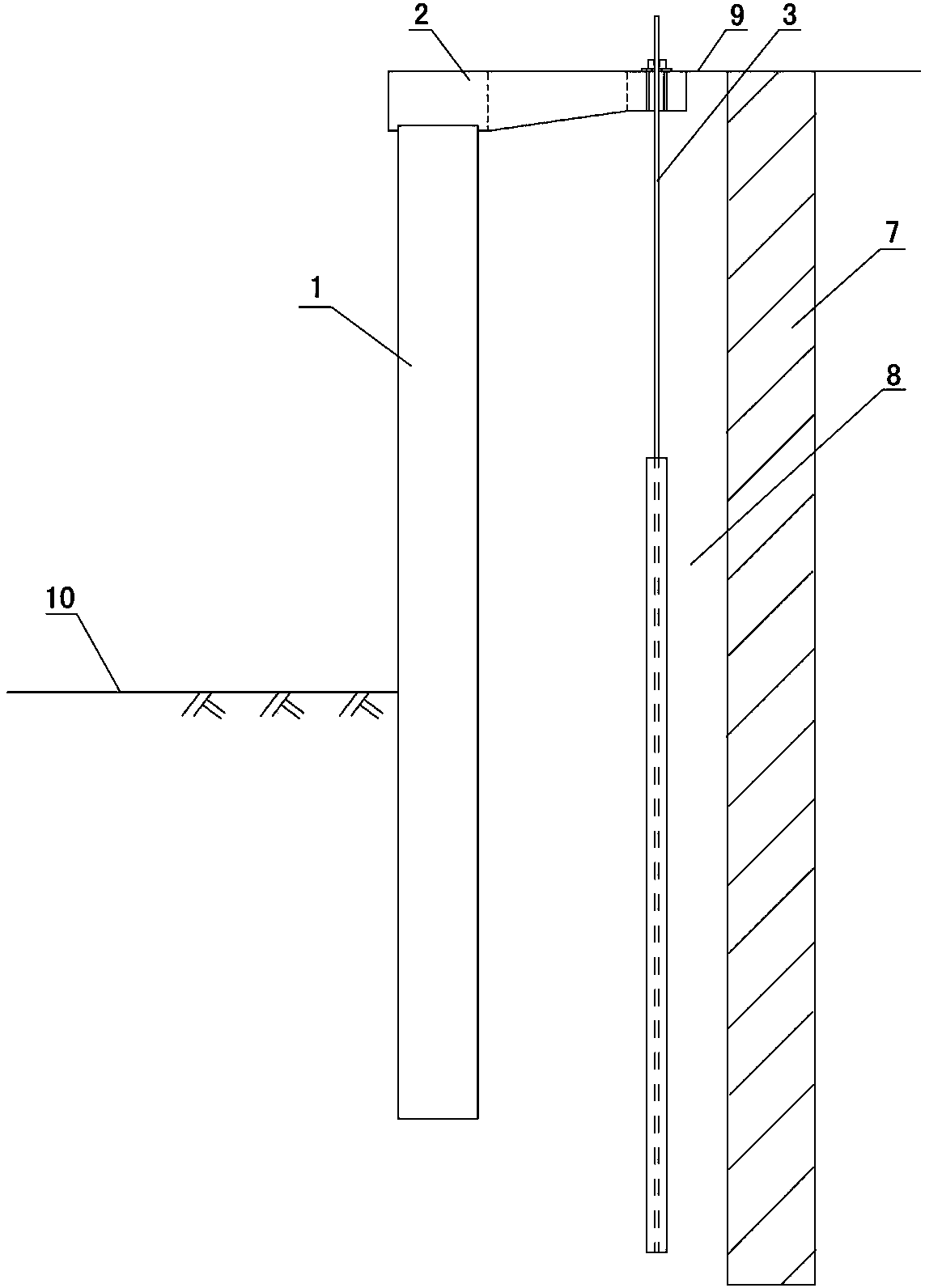

Pile beam vertical anchor support system used for supporting foundation pit and construction method of pile beam vertical anchor support system

InactiveCN103469803AOptimize the support structureImprove the support effectExcavationsSupporting systemPre stress

The invention discloses a pile beam vertical anchor support system used for supporting a foundation pit and a construction method of the pile beam vertical anchor support system. The support structure comprises slope shield piles, pile top crown beams and anchor rods, wherein a row of slope shield piles are arranged on the edge of the foundation pit; the bottoms of the slope shield piles stretch into a soil layer under a substrate; the anchor rods comprise vertical prestress anchor rods which are formed into a row at standing ground of the outer sides of the slope shield piles, are inserted from the ground at the outer sides of the slope shield piles and are anchored in the standing ground at the outer sides of the slope shield piles; the pile top crown beams are lattice girders; one sides, close to the foundation pit, of the lattice girders are in rigid connection with the tops of the slope shield piles; one sides, far away from the foundation pit, of the lattice girders are in soft connection with the upper parts of the vertical prestress anchor rods. The support system and the construction method thereof are particularly suitable for a foundation pit which is limited in underground space and is adjacent to existing buildings, have obvious advantages in the support for the foundation pit adjacent to the existing buildings, not only are good in support effect, but also have the advantages that the construction is convenient, the working procedure is simple and the cost is lower.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Lattice Girder Structure Using Innovative Multiple Joints For Roof Covering Purposes

ActiveUS20140373481A1Quick installationMinimize the bending momentArched girdersBuilding roofsPlastic materialsSacroiliac joint

Roof truss system comprising tie rods, struts, knee rafters, and innovative connection joints to cover buildings, especially suitable for being implemented by plastic materials.

Owner:SERAFINI MONICA +2

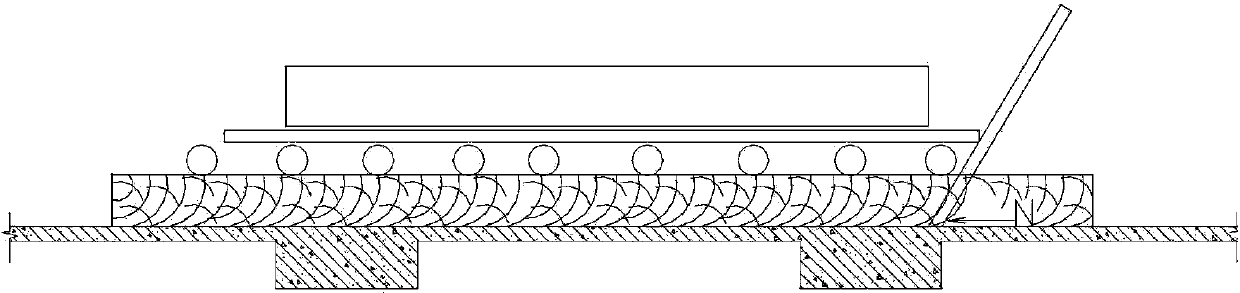

Upside-down type supporting system of floor support plate

PendingCN111441572AEasy to makeLight weightFloorsForms/shuttering/falseworksSupporting systemArchitectural engineering

The invention relates to the field of supporting of residential floor pouring, in particular to an upside-down type supporting system of a floor support plate. The system comprises multiple truss girders and multiple wood keels used for supporting the floor support plate, two ends of the truss girders are provided with clamping opening upside-down parts used for being mounted on a lower flange, clamping opening parts of the clamping opening upside-down parts are provided with ejecting bolts used for ejecting the lower flange from bottom to top, multiple fastening pin holes are formed in two ends of the truss girders, fastening pins used for preventing lateral moving of the clamping opening upside-down parts are mounted in fastening pin holes, multiple vertical embedded pipes are mounted onthe truss girders, and are provided with inner threads, first U-shaped mounting brackets upwards extending out of the embedded pipes and heights capable of being adjusted in a thread manner are mounted in the embedded pipes, and are used for supporting the wood keels, mounting is rapid and convenient, the self weight is small, two persons can finish mounting, multi-layer simultaneous constructionis carries out, a large amount of cost can be saved, a plate bottom is flat and attractive, and the whole assembling efficiency can be improved.

Owner:唐山冀东发展燕东建设有限公司

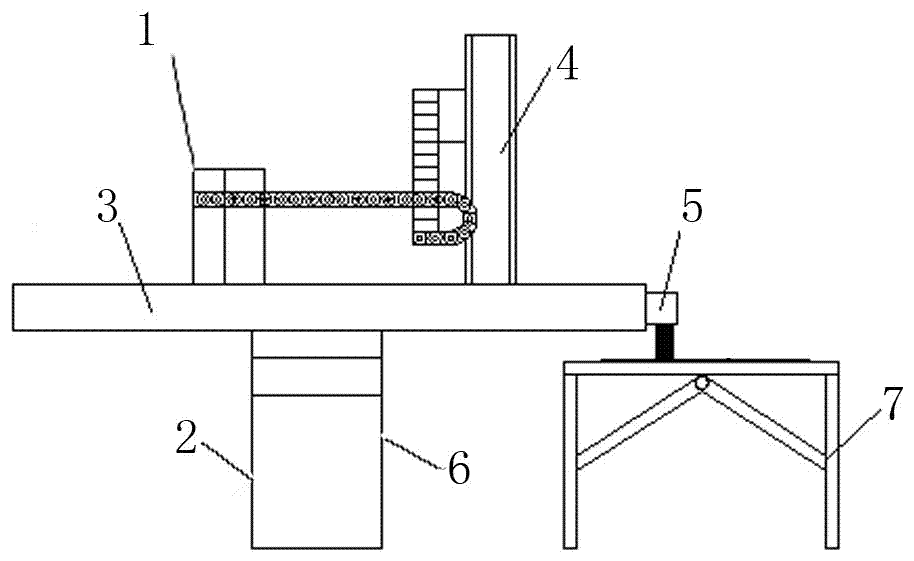

Aluminum alloy part surface paint removing treatment device and method

InactiveCN107030387ATake off accuratelyTake off efficientlyLaser beam welding apparatusLaser technologyLacquer

The invention relates to a method and a device for performing paint stripping treatment on the surface of an aluminum alloy part by using laser technology. The surface paint removal treatment device for aluminum alloy parts of the present invention includes a workbench, a three-dimensional truss, a laser, a laser scanning device and a control system, wherein the three-dimensional truss includes an X-axis truss, a Y-axis truss, and a Z-axis truss; the workbench is parallel to the Horizontal plane setting, the X-axis truss is set parallel to the workbench on the same level, wherein the X-axis truss is located at the bottom of the entire three-dimensional truss, and its top is provided with a chute extending along the X-axis direction; the Z-axis truss is movable on the X-axis truss In the chute on the top; the Y-axis truss is movably arranged on the Z-axis truss, which can slide along the Z-axis and the Y-axis respectively. The surface paint removal treatment device for aluminum alloy parts of the present invention, the control system can adjust the laser parameters in the laser and the movement track and running speed of the three-dimensional truss according to different paint layer combinations, so that the paint layer can be removed accurately and efficiently without damaging the substrate .

Owner:陕西汇智达清光电科技有限公司

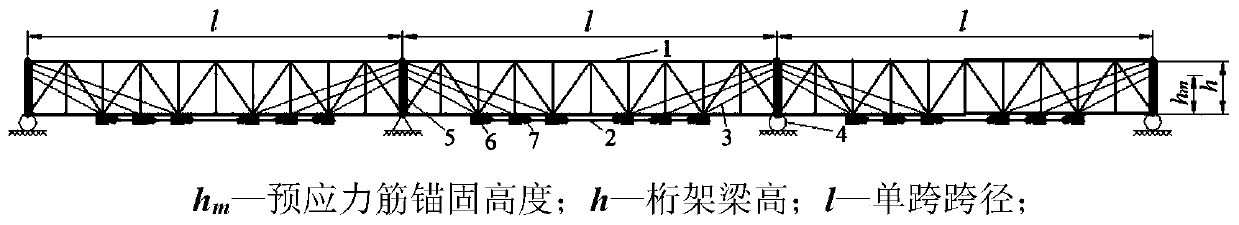

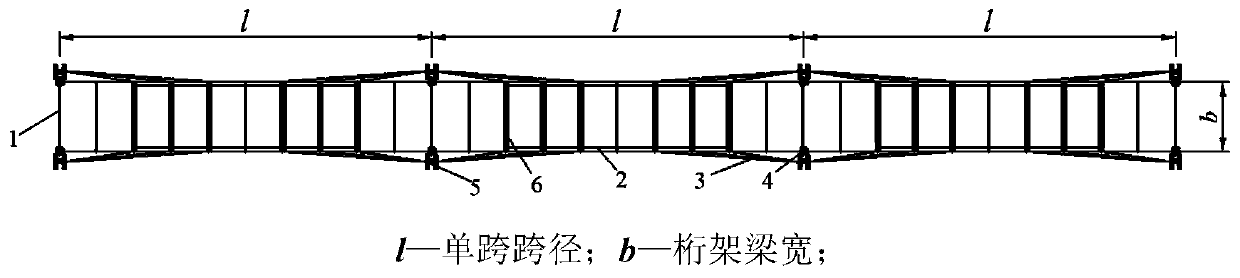

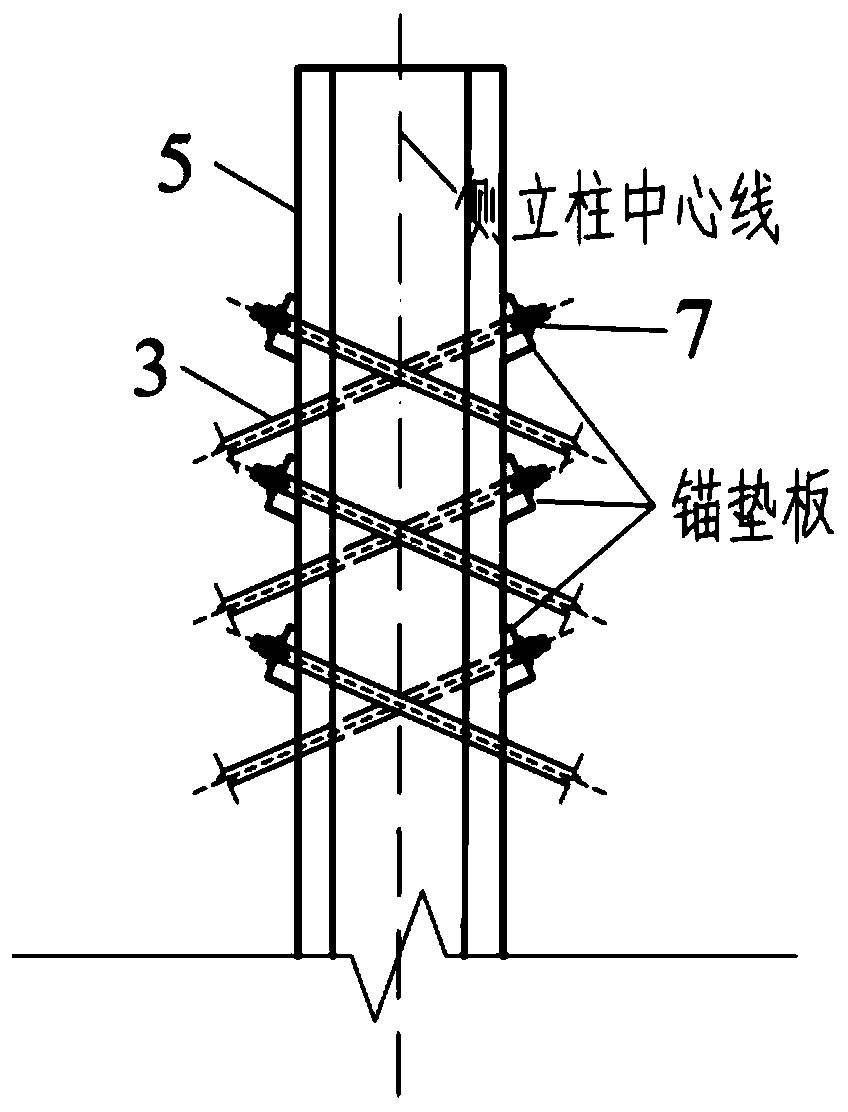

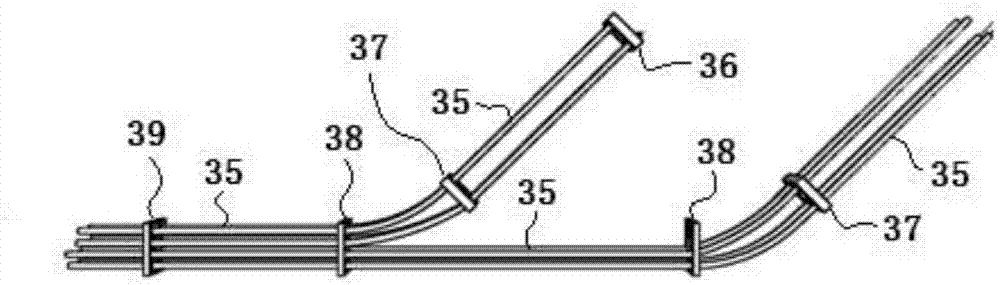

Method for improving bearing capacity of truss girder bridge through external prestressed tendons

ActiveCN111395210AIncrease stiffnessLarge spanBridge erection/assemblyBridge strengtheningGusset plateVertical plane

The invention discloses a method for improving the bearing capacity of a truss girder bridge through external prestressed tendons. In the implementation process, a truss main beam, longitudinal prestressed tendons, oblique prestressed tendons, supports, side stand columns, supporting cross beams and anchoring devices need to be used. The side stand columns are arranged at vertical web members close to the two sides of truss pier supports and used for anchoring the oblique prestressed tendons and transmitting vertical loads of anchoring forces to the piers. The supporting cross beams are arranged along the span, one side of each of the oblique prestressed tendons is anchored to one supporting cross beam, and the other sides of the oblique prestressed tendons are anchored to the side stand columns; and opposite pulling and anchoring are conducted between each pair of supporting cross beams parallel to the lower chord of the truss main beam through longitudinal prestressed tendons, so that the truss main beam is reinforced and tensioned in the vertical plane. The bending moment of the midspan area of the truss girder can be effectively reduced, the load bending moment is relatively balanced and reasonable in the span direction, the girder height of the truss is reduced, the sectional dimension of a truss rod piece is uniformized, and industrial manufacturing and design and connection of gusset plates are facilitated.

Owner:ZHEJIANG UNIV

Prestress aluminum-concrete combined truss beam and construction method thereof

A prestress aluminum-concrete combined truss beam is characterized in that at least one truss beam body of the prestress aluminum-concrete combined truss beam adopts a prestress aluminum alloy-concrete combined truss beam body; preferably, concrete is poured in a pressed upper main truss of the prestress aluminum-concrete combined truss beam, prestress ribs are arranged in the inner spaces of a lower main truss and oblique rods, and prestress anchorage points are arranged at the nodes of the upper main truss; and preferably, the prestress aluminum-concrete combined truss beam comprises a force bearing panel system, the longitudinal prestress aluminum alloy-concrete combined truss beam bodies, transverse supports and a prestress rib anchoring system, and the upper main truss and the lower main truss are arranged to be double-layer or single-layer panel structure systems. According to the prestress aluminum-concrete combined truss beam, under the condition that the prestress aluminum-concrete combined truss beam is the same as a traditional truss beam in bearing work condition, the self-weight of the prestress aluminum-concrete combined truss beam is decreased obviously, the service life is prolonged obviously, the manufacturing cost of the prestress aluminum-concrete combined truss beam is reduced, the mounting period is shortened, and the maintenance cost is reduced greatly.

Owner:BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com