Mal-position assembly in-position method of truss bridge

A truss girder, out-of-position technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems that truss girders are difficult to assemble in one step, difficult to transport on site, difficult to assemble truss girders, etc., to achieve assembly High efficiency, easy operation, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

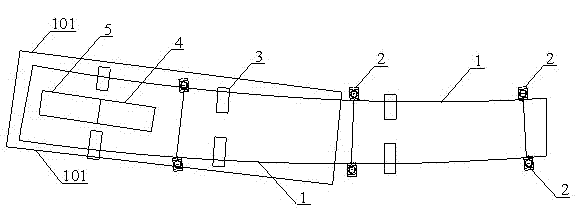

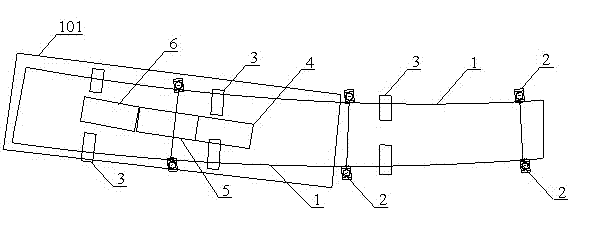

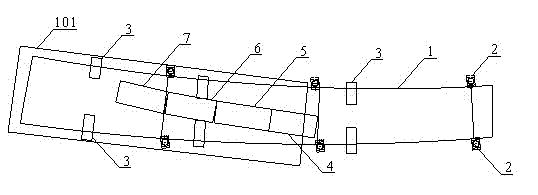

[0028] Such as Figure 1-5 As shown, the truss girder assembling in place method is characterized in that it includes the following steps:

[0029] Step 1. Build the assembly platform 101, excavate the subgrade at the abutment to form a working platform or set up a steel pipe support platform in the middle of the bridge, the working platform or support platform is the same height as the pier 2, and a truss beam is arranged in the middle of the working platform or support platform Assembled platform 101; In order to be more conducive to the assembling of truss girders, the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com