Patents

Literature

1768results about How to "Assembly precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

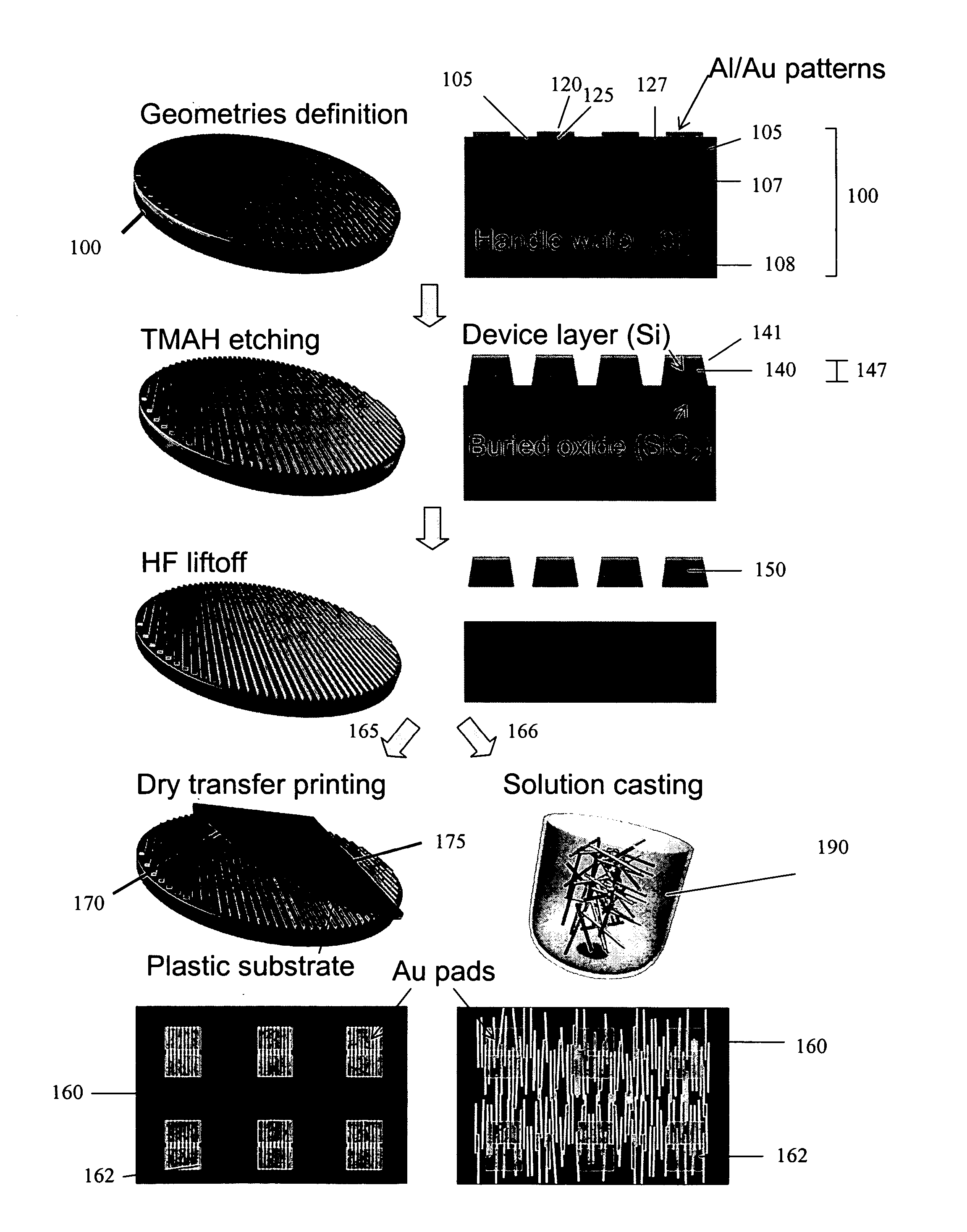

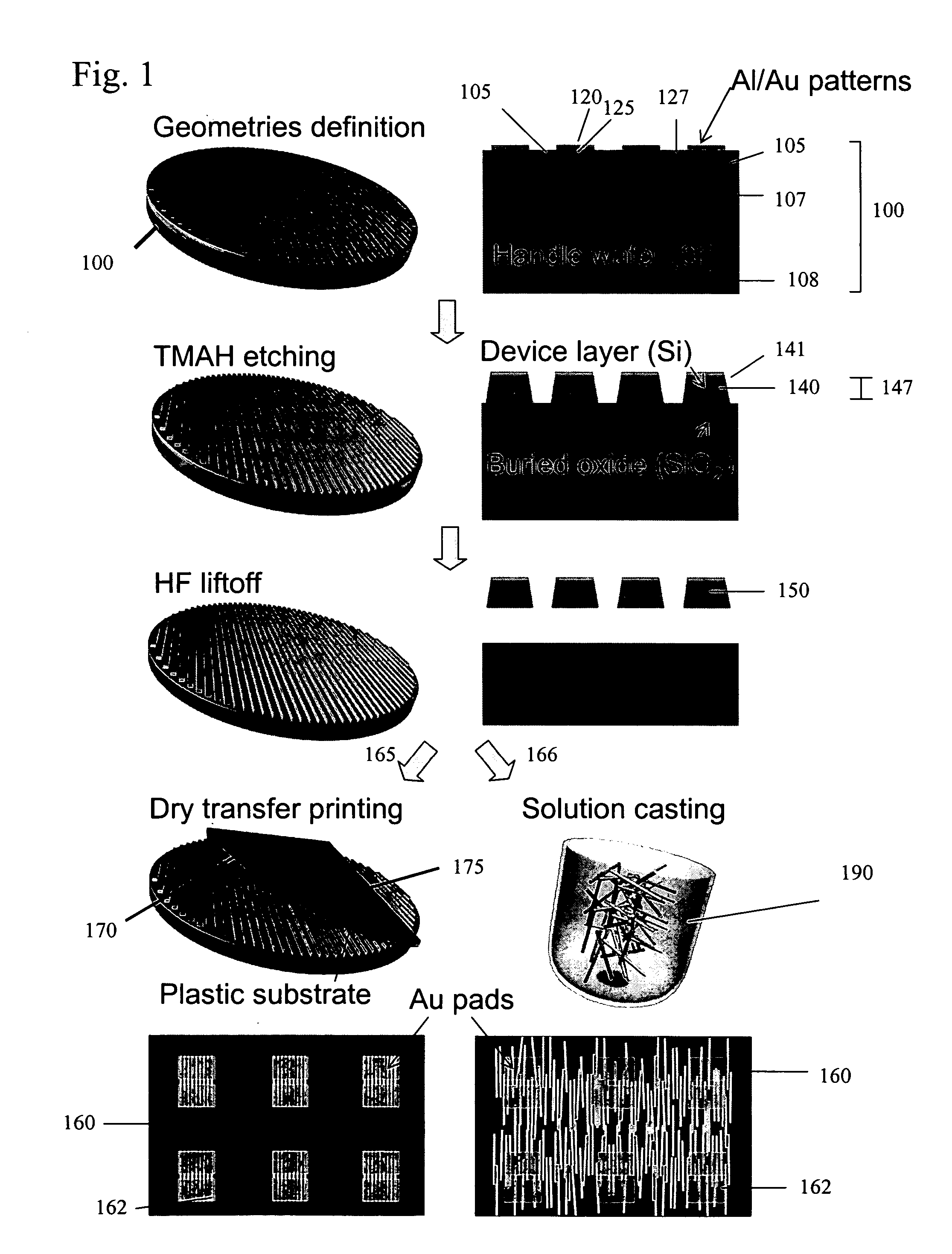

Stretchable semiconductor elements and stretchable electrical circuits

ActiveUS20060038182A1Complete release is preventedLow costTransistorDecorative surface effectsStretchable electronicsSemiconductor structure

The invention provides methods and devices for fabricating printable semiconductor elements and assembling printable semiconductor elements onto substrate surfaces. Methods, devices and device components of the present invention are capable of generating a wide range of flexible electronic and optoelectronic devices and arrays of devices on substrates comprising polymeric materials. The present invention also provides stretchable semiconductor structures and stretchable electronic devices capable of good performance in stretched configurations.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

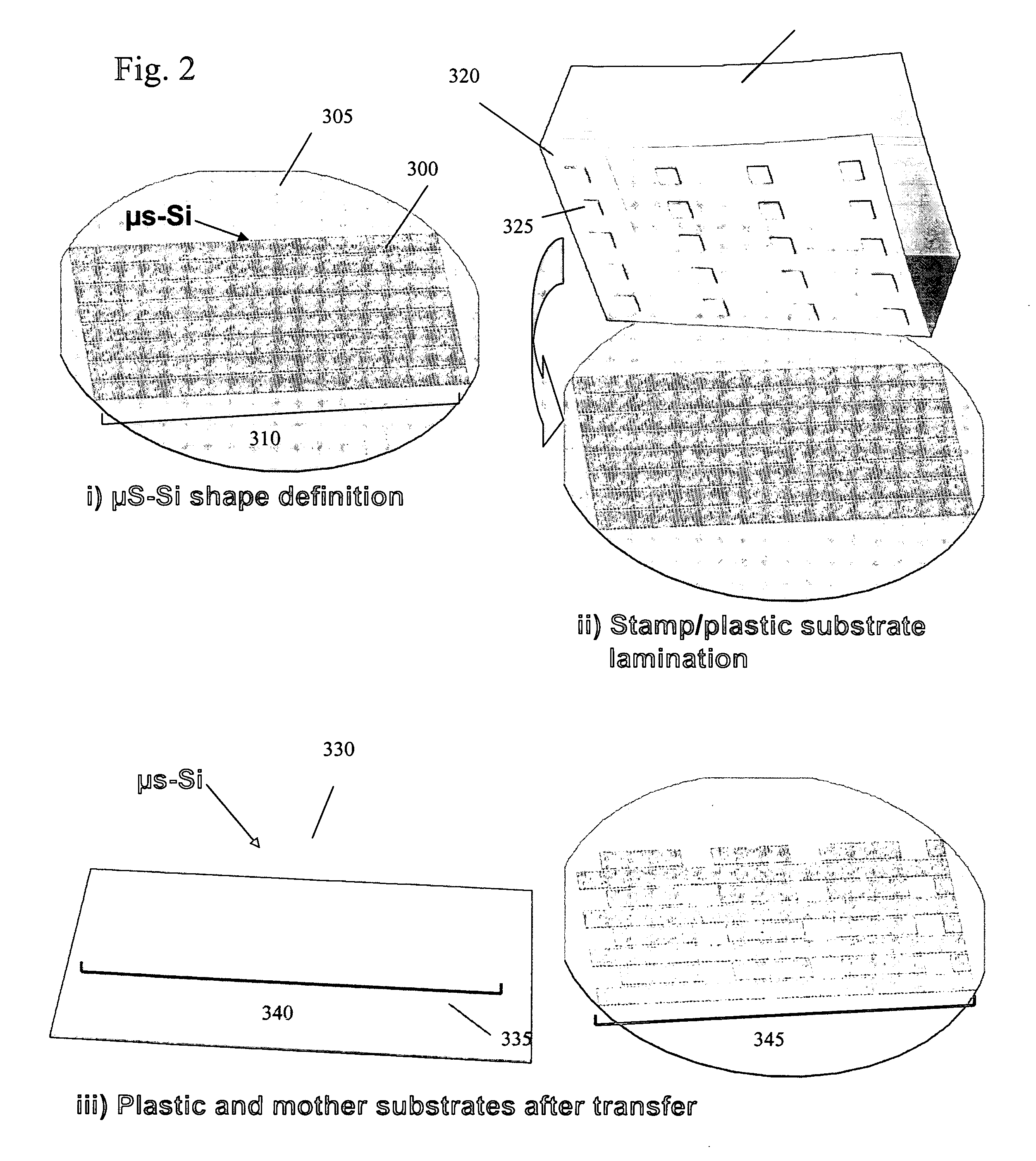

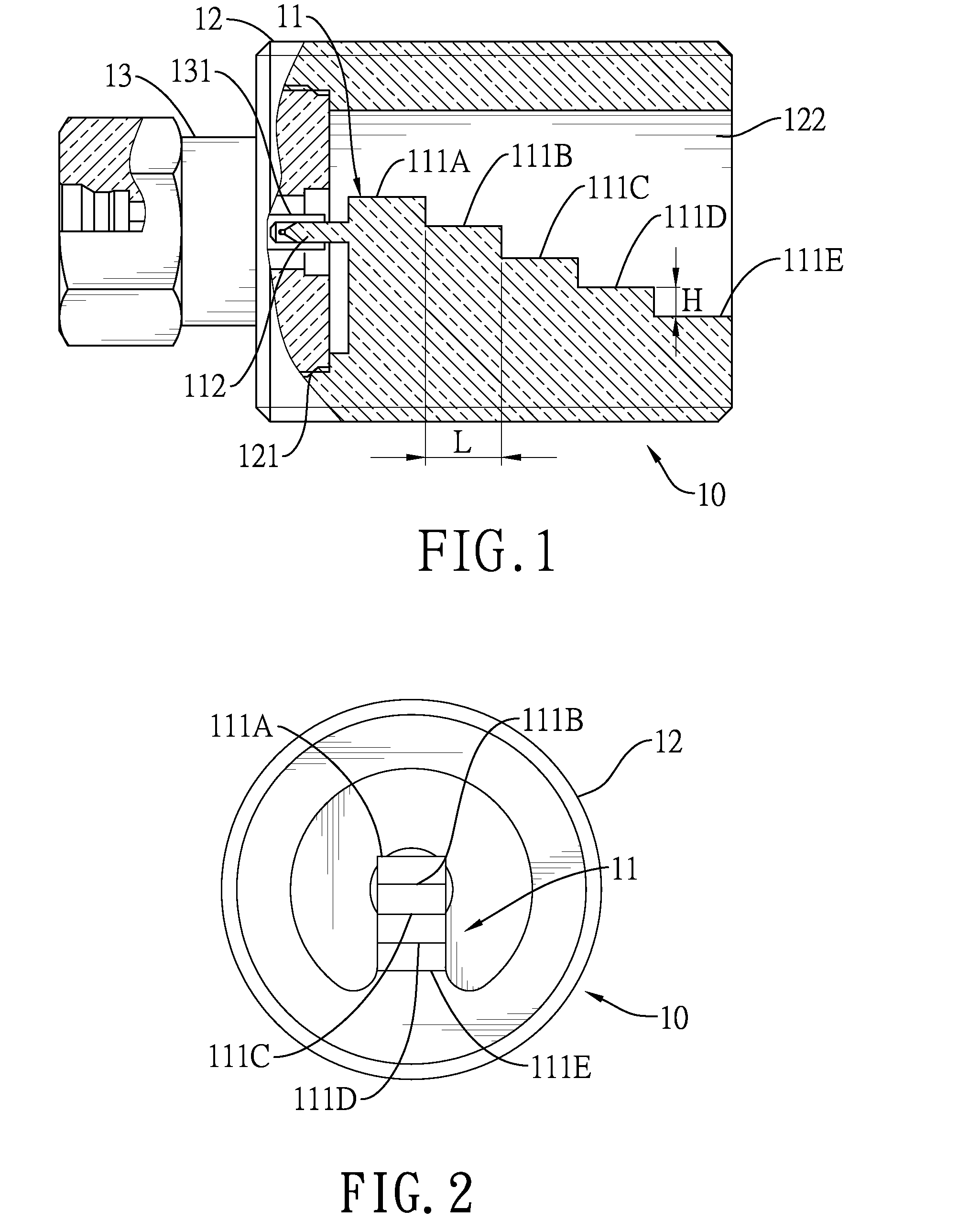

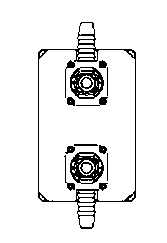

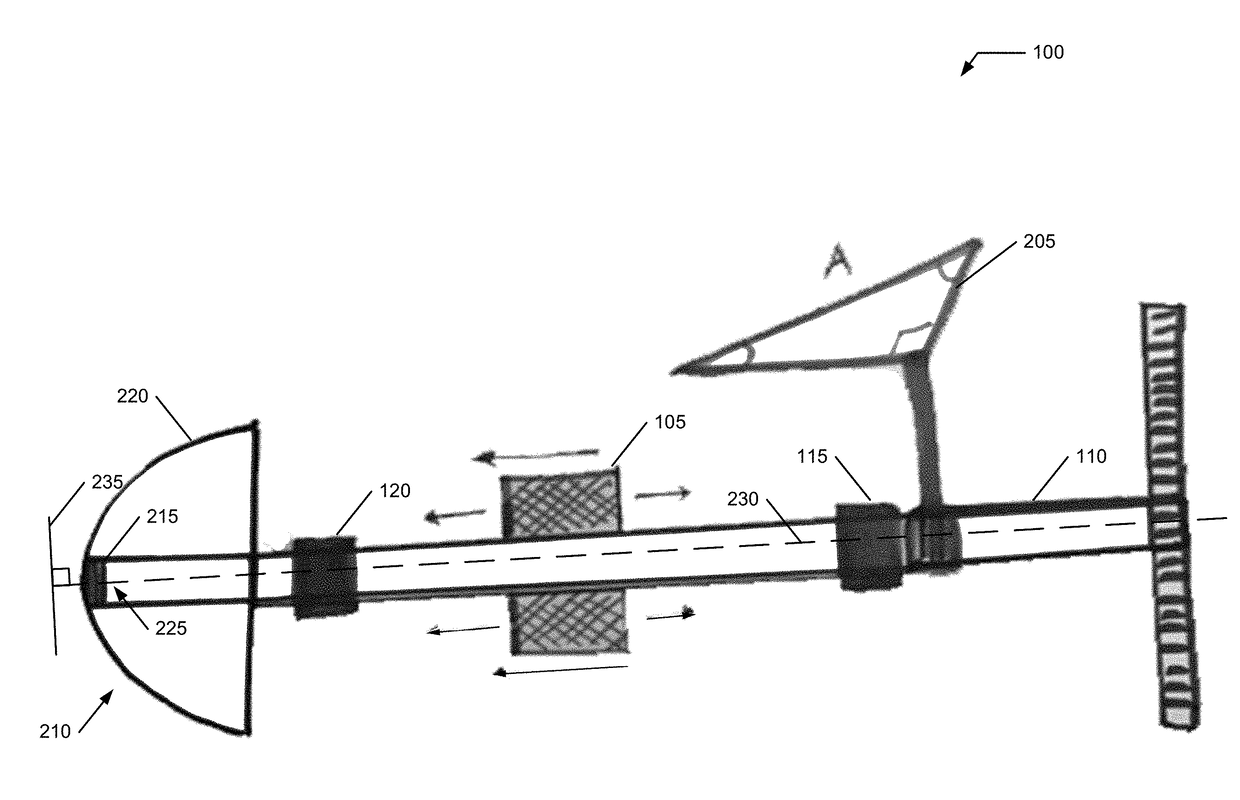

Horn antenna device and step-shaped signal feed-in apparatus thereof

ActiveUS20150029065A1Sure easyAssembly precisionWaveguide hornsAntennas earthing switches associationSignal-to-noise ratio (imaging)Noise rate

The present invention relates to a horn antenna device. The horn antenna device has a step-shaped signal feed-in apparatus and a conical horn antenna. The step-shaped signal feed-in apparatus has a stepped body having multiple stairs and a connecting pin. The stepped body is adapted to radiate electromagnetic waves and receive a reflection of the electromagnetic waves. According to the structure of the step-shaped signal feed-in apparatus of the invention, the resonating modes are easy to be determined. The directivity and the signal-to-noise rate are improved. In addition, the connecting pin is directly connected to the stairs for improving the signal stability of the horn antenna device.

Owner:FINETEK CO LTD

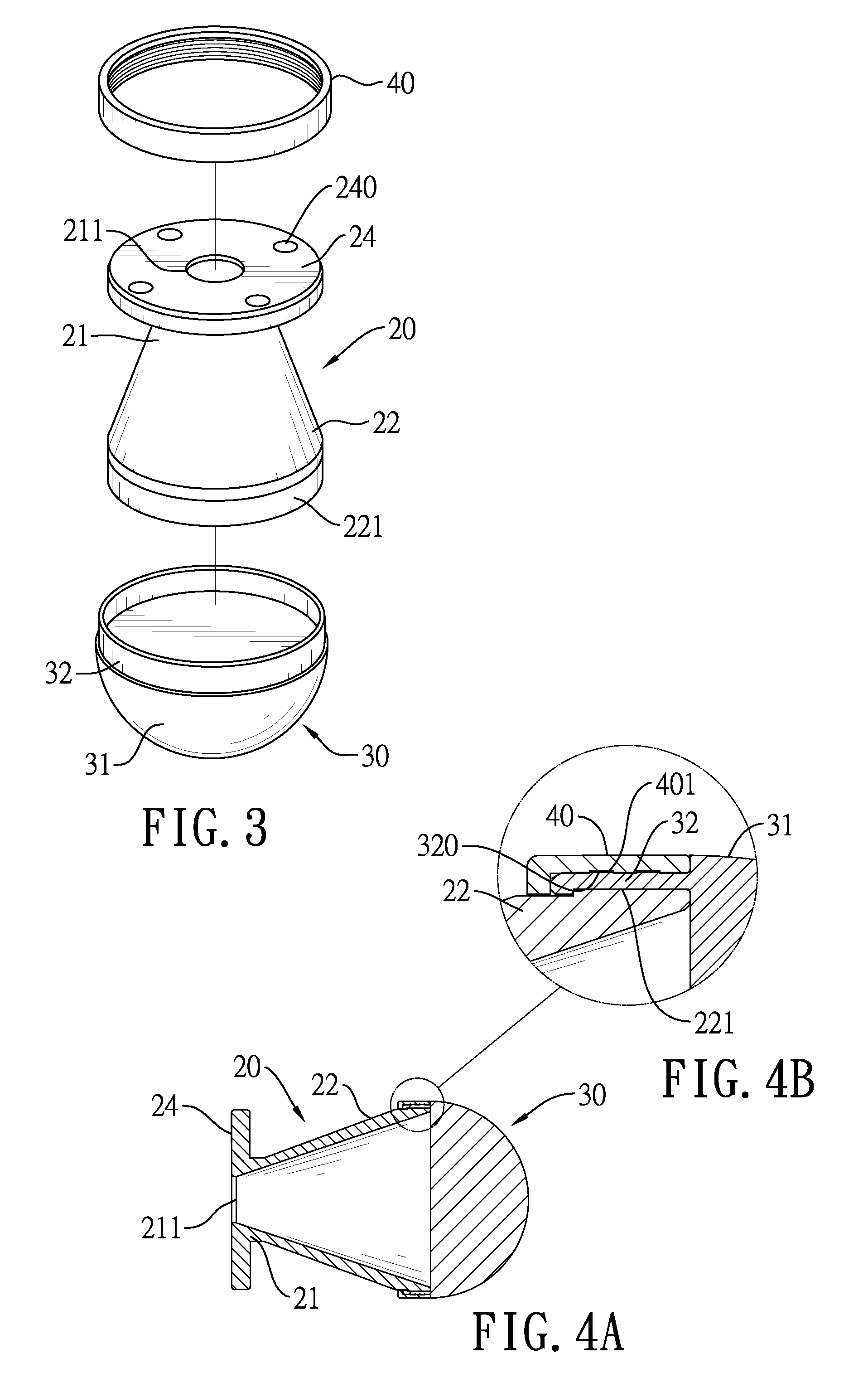

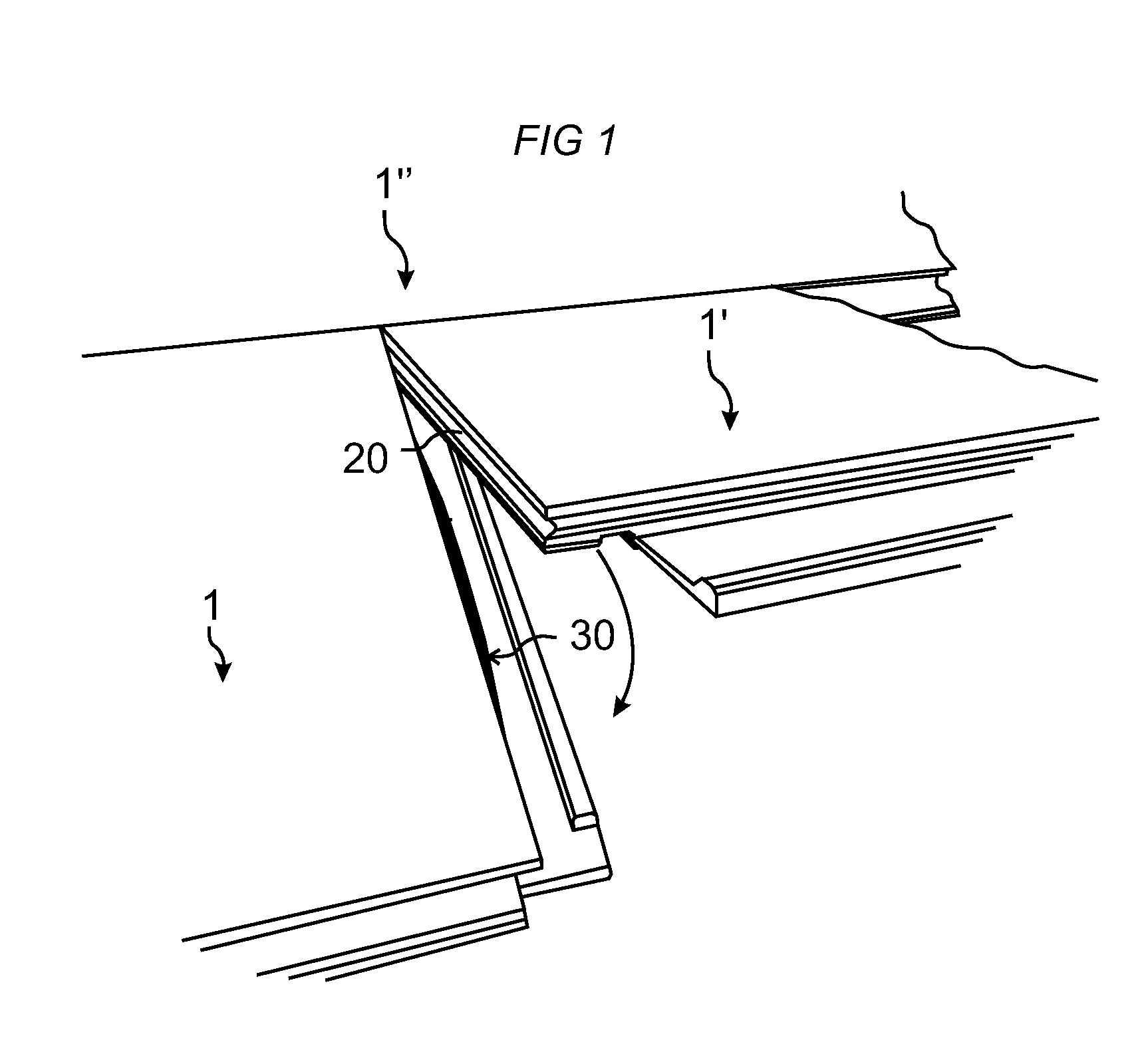

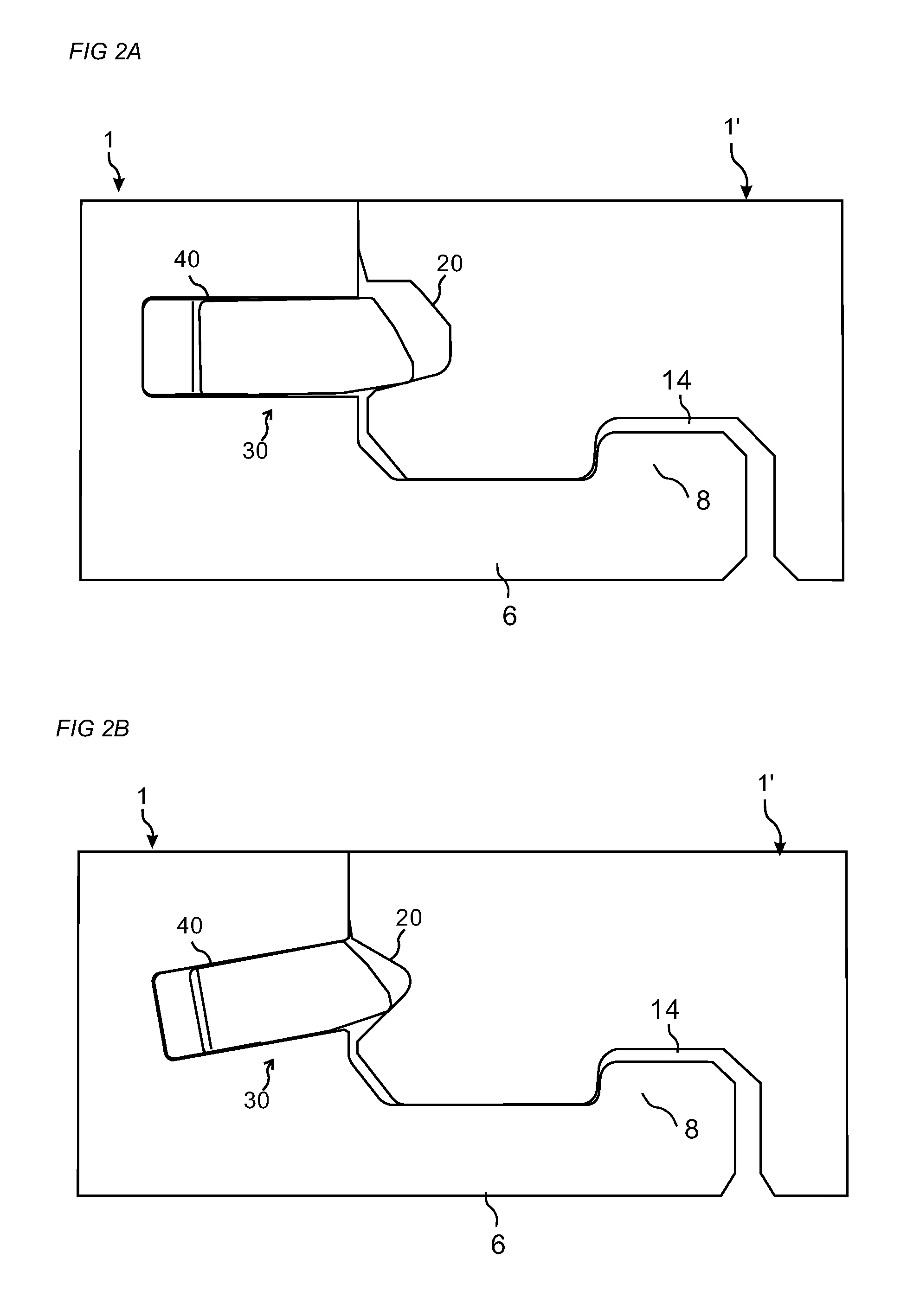

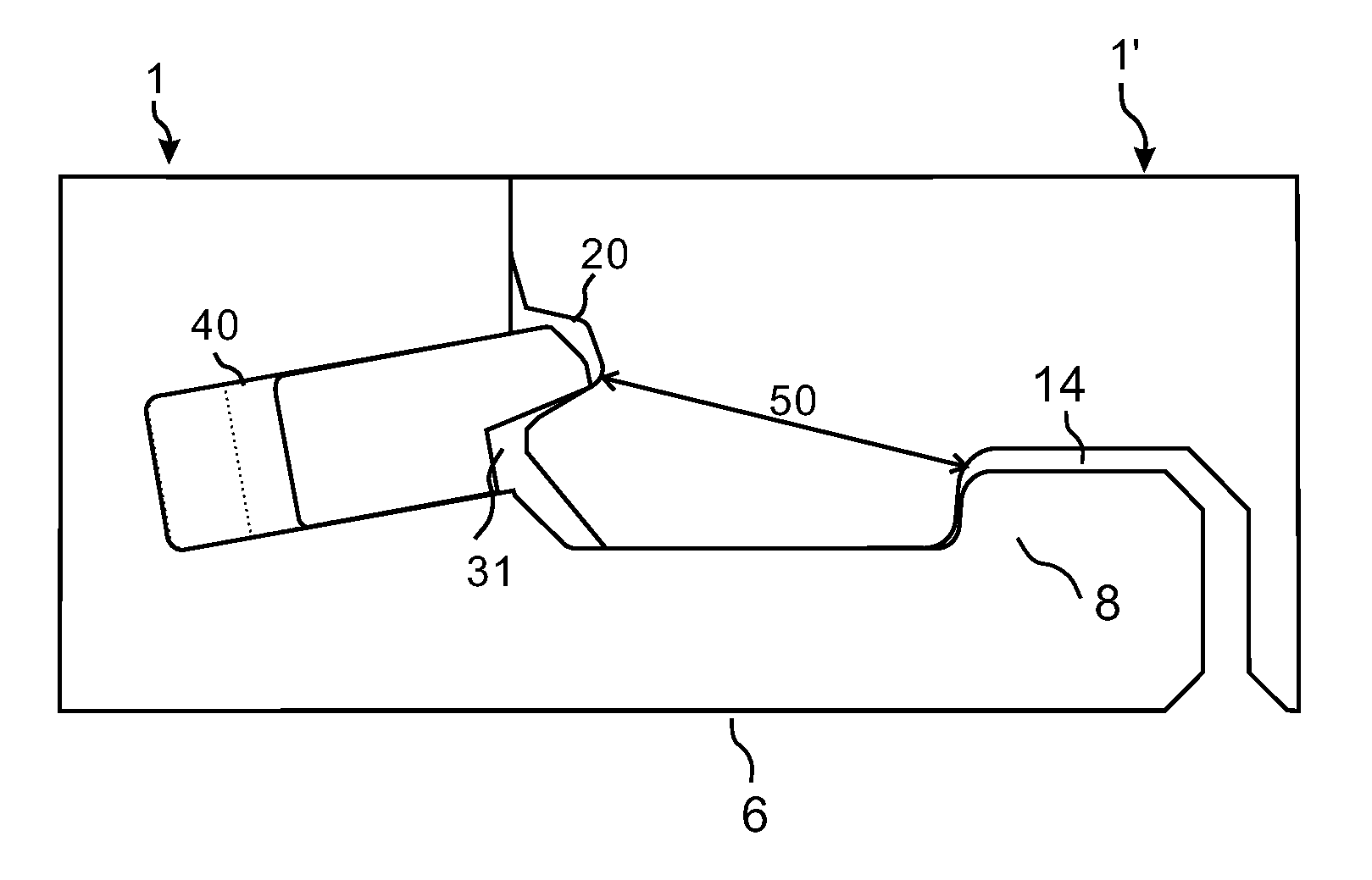

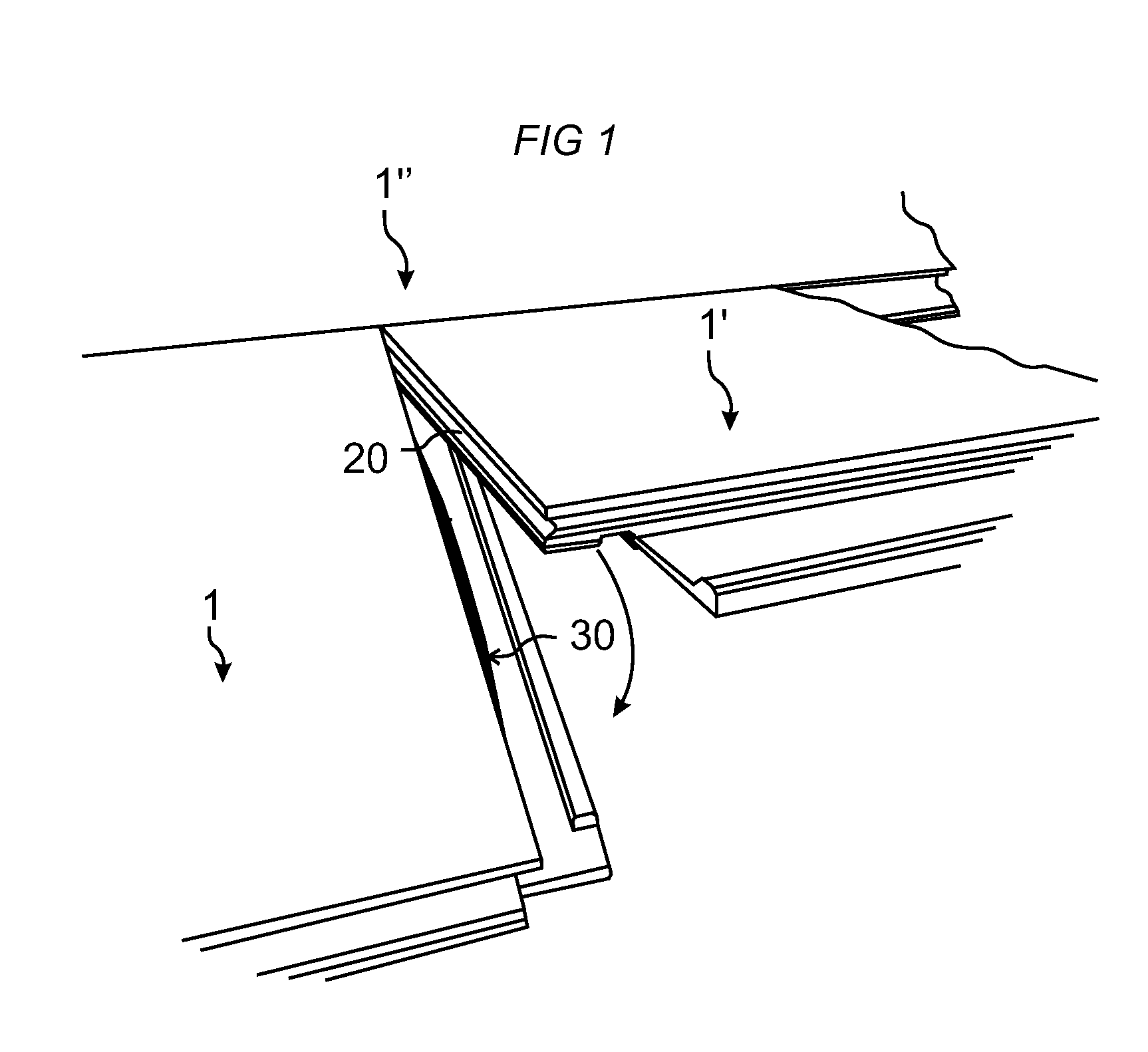

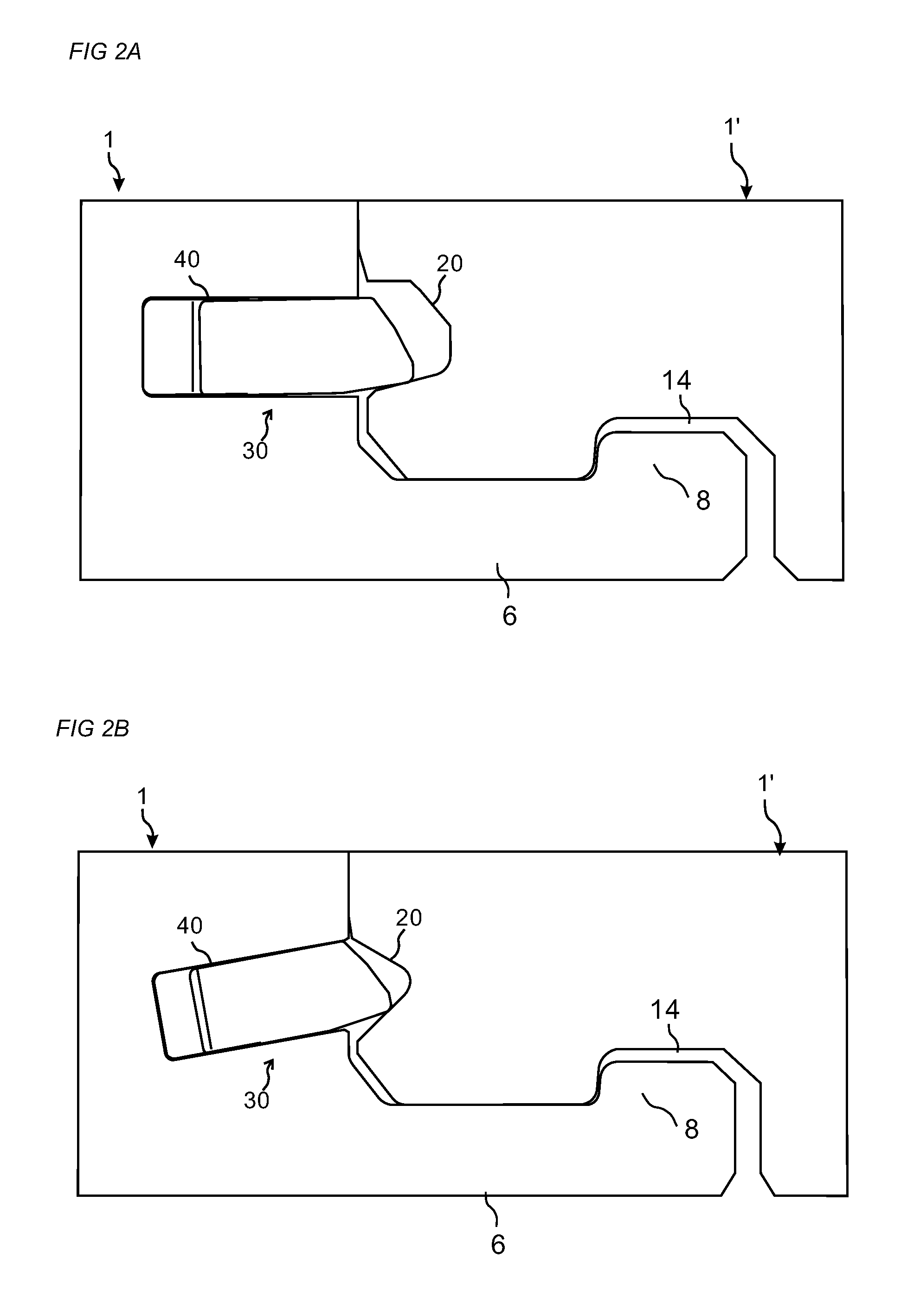

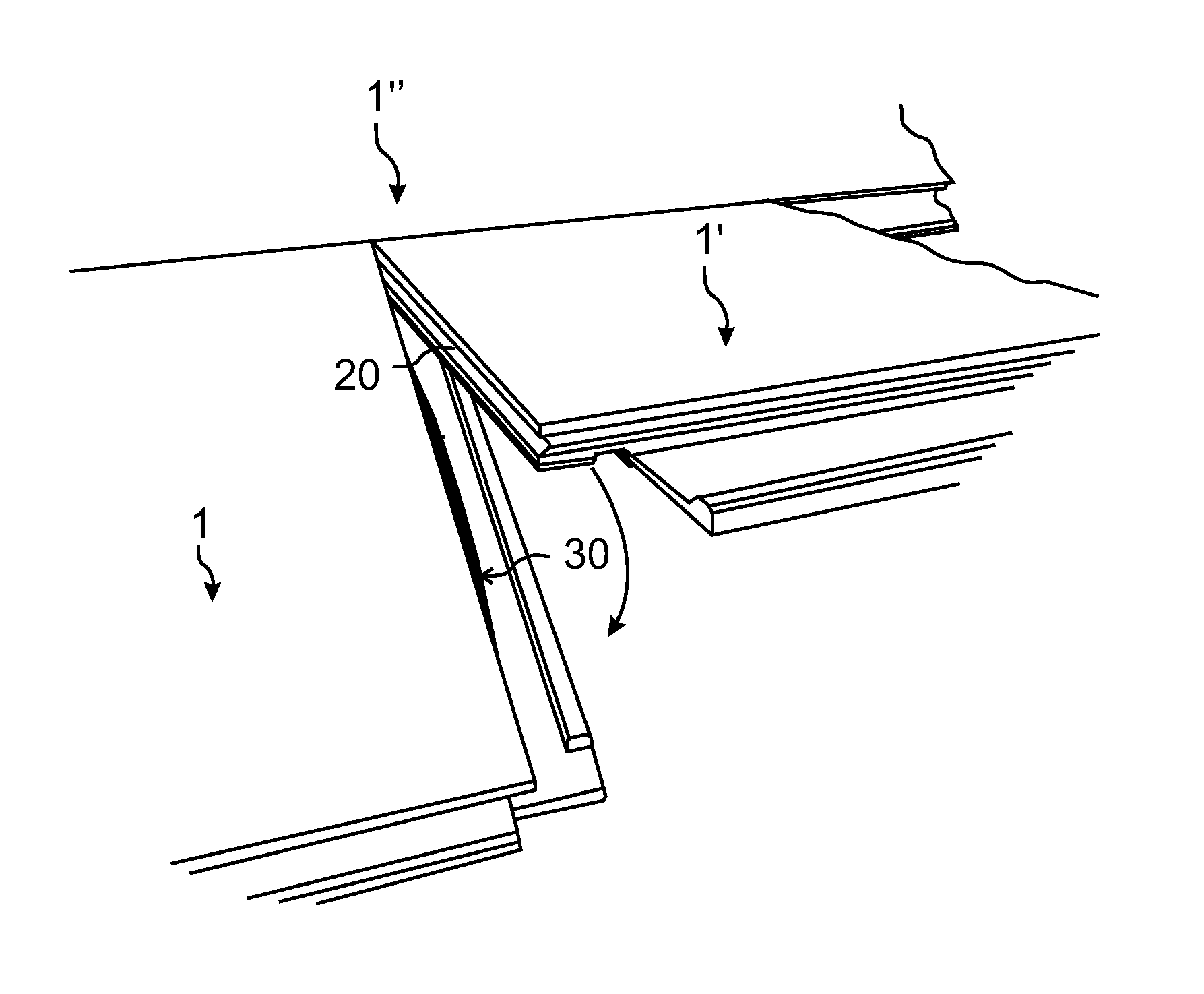

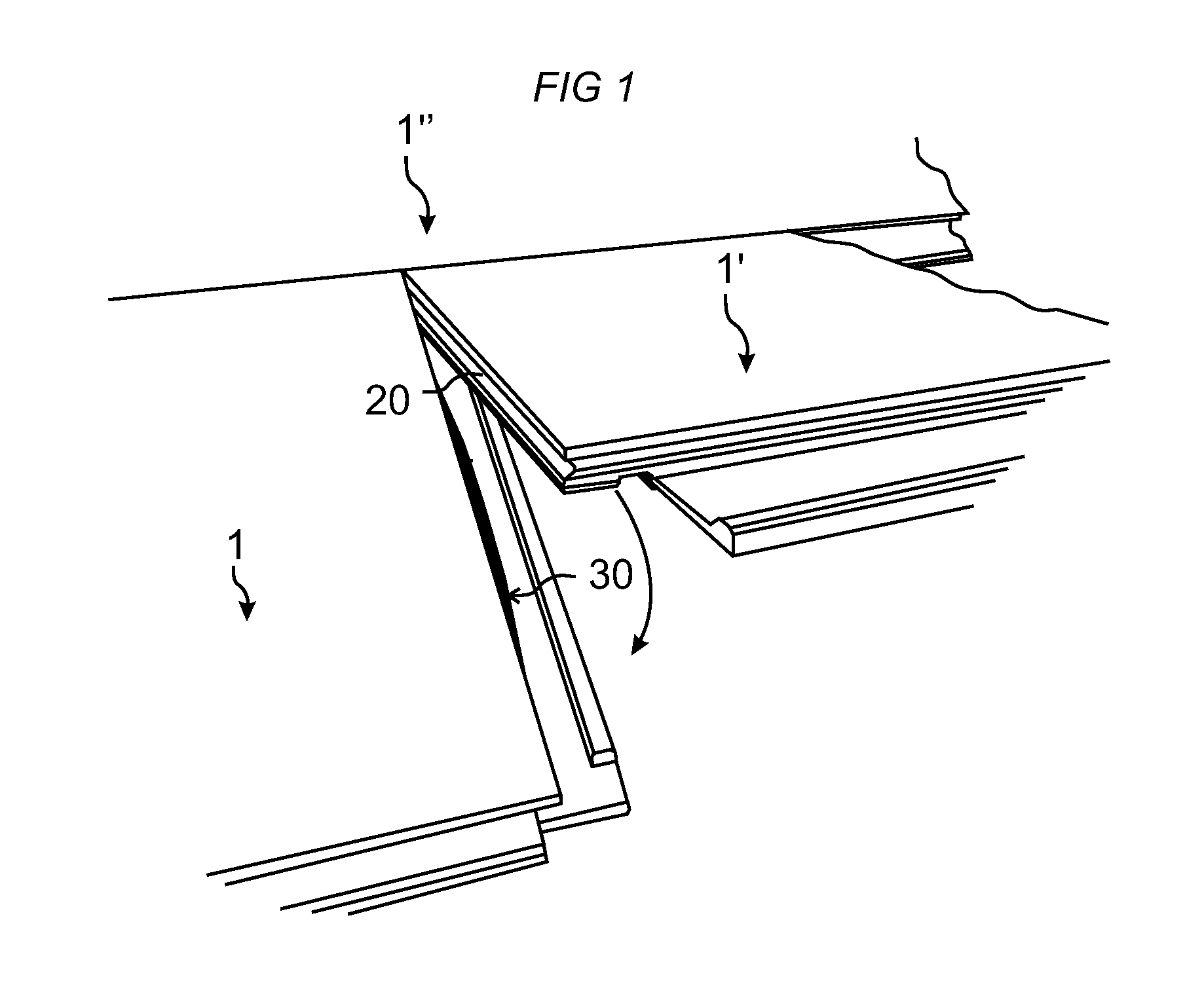

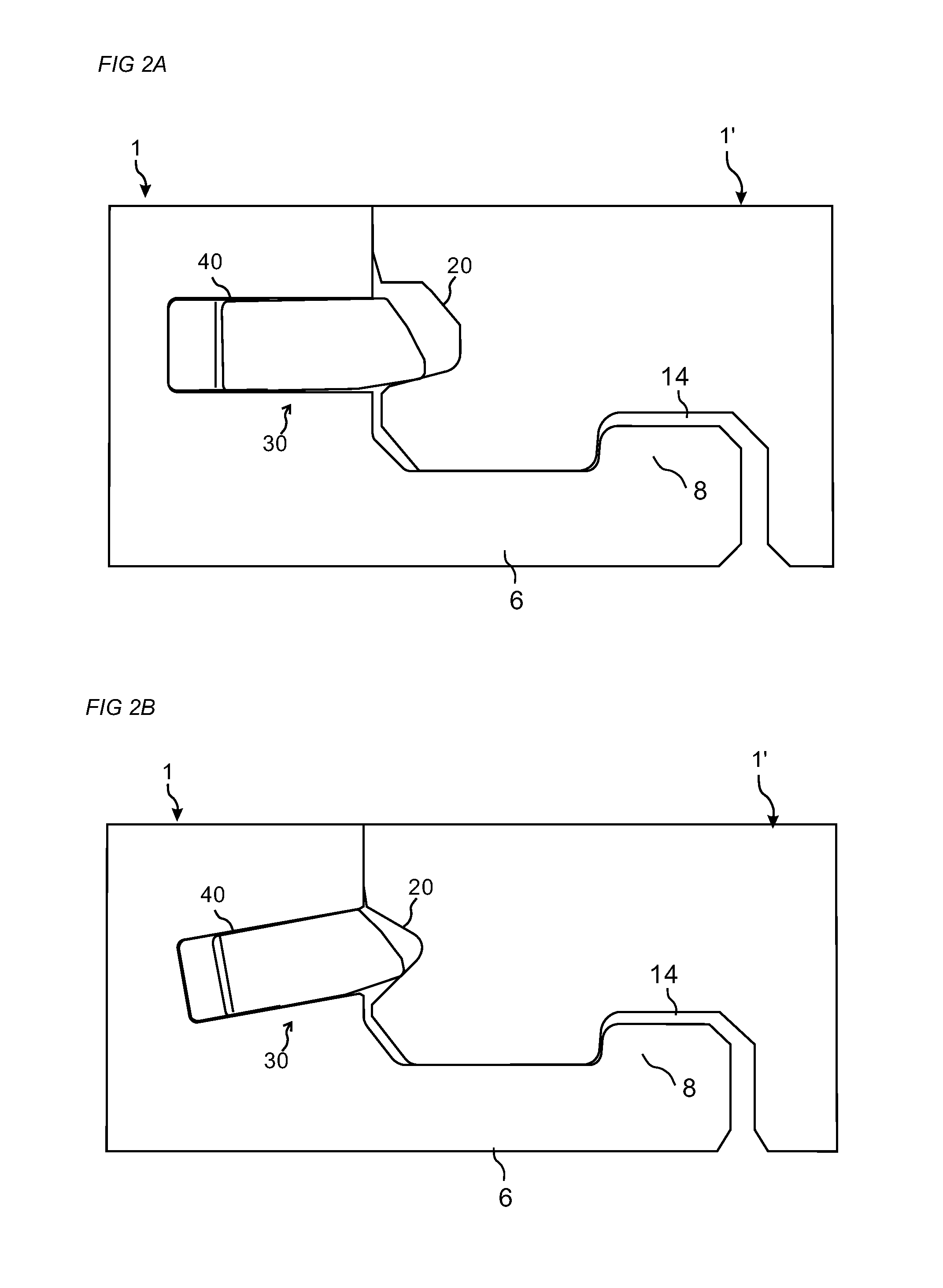

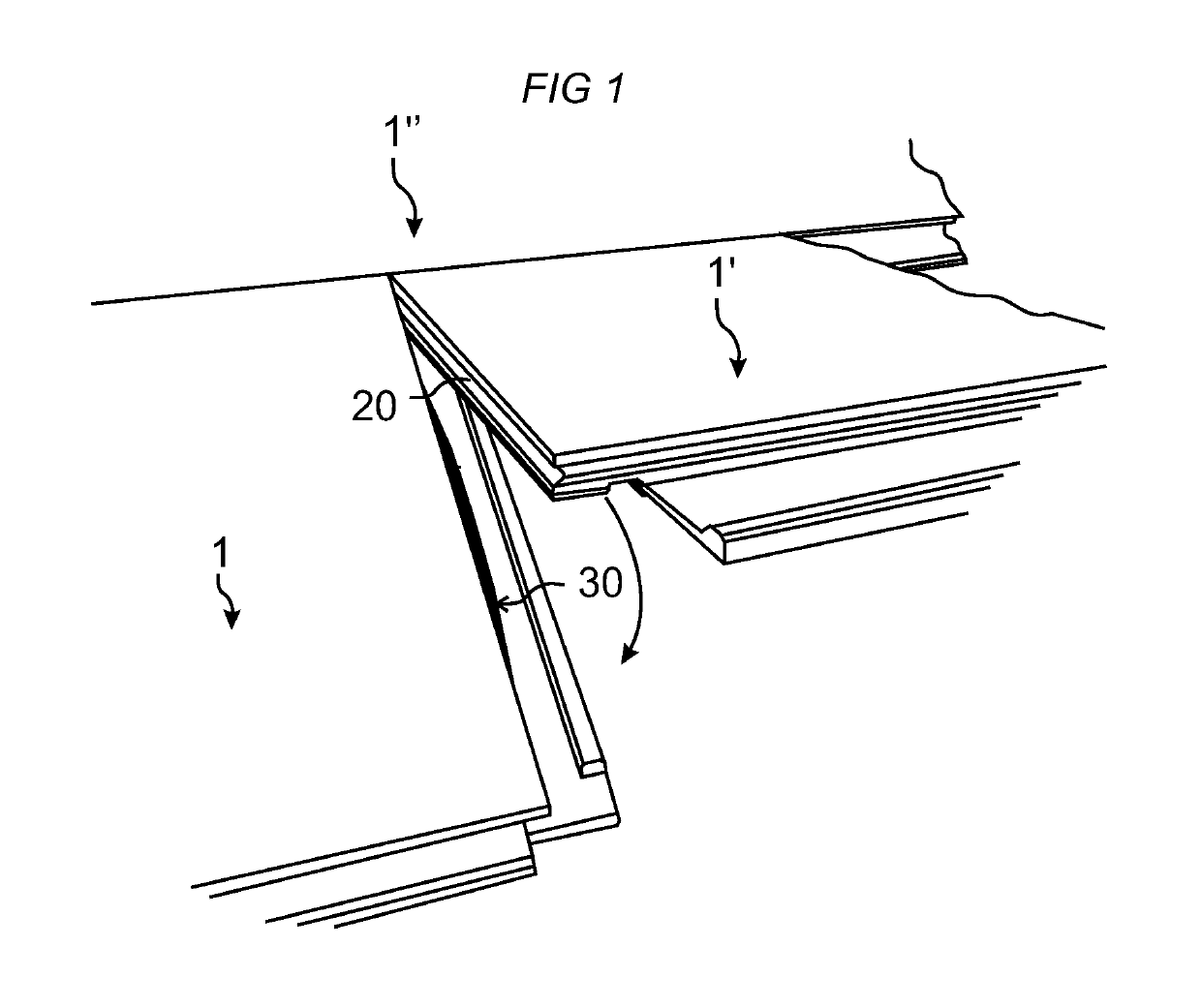

Building panel with a mechanical locking system

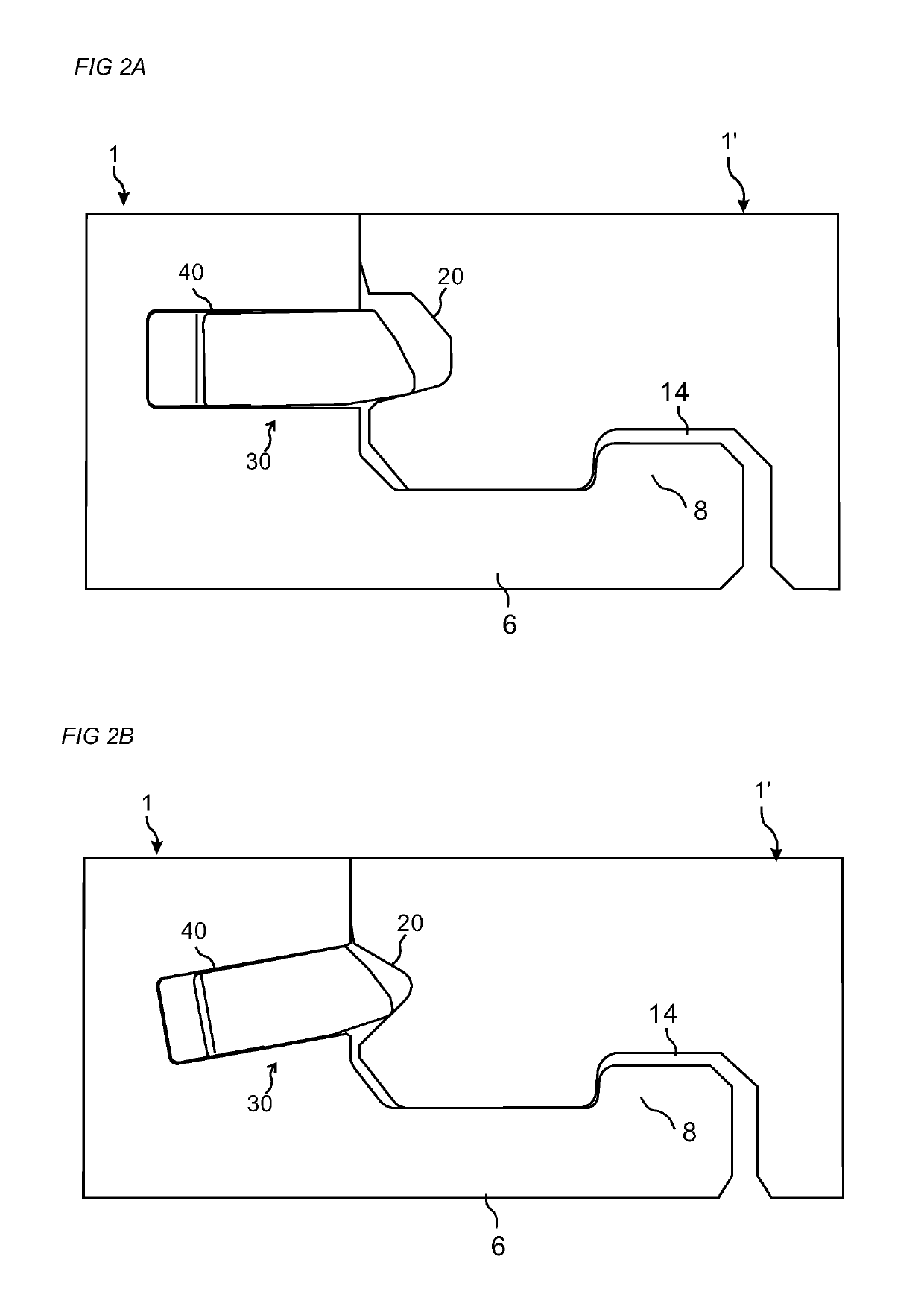

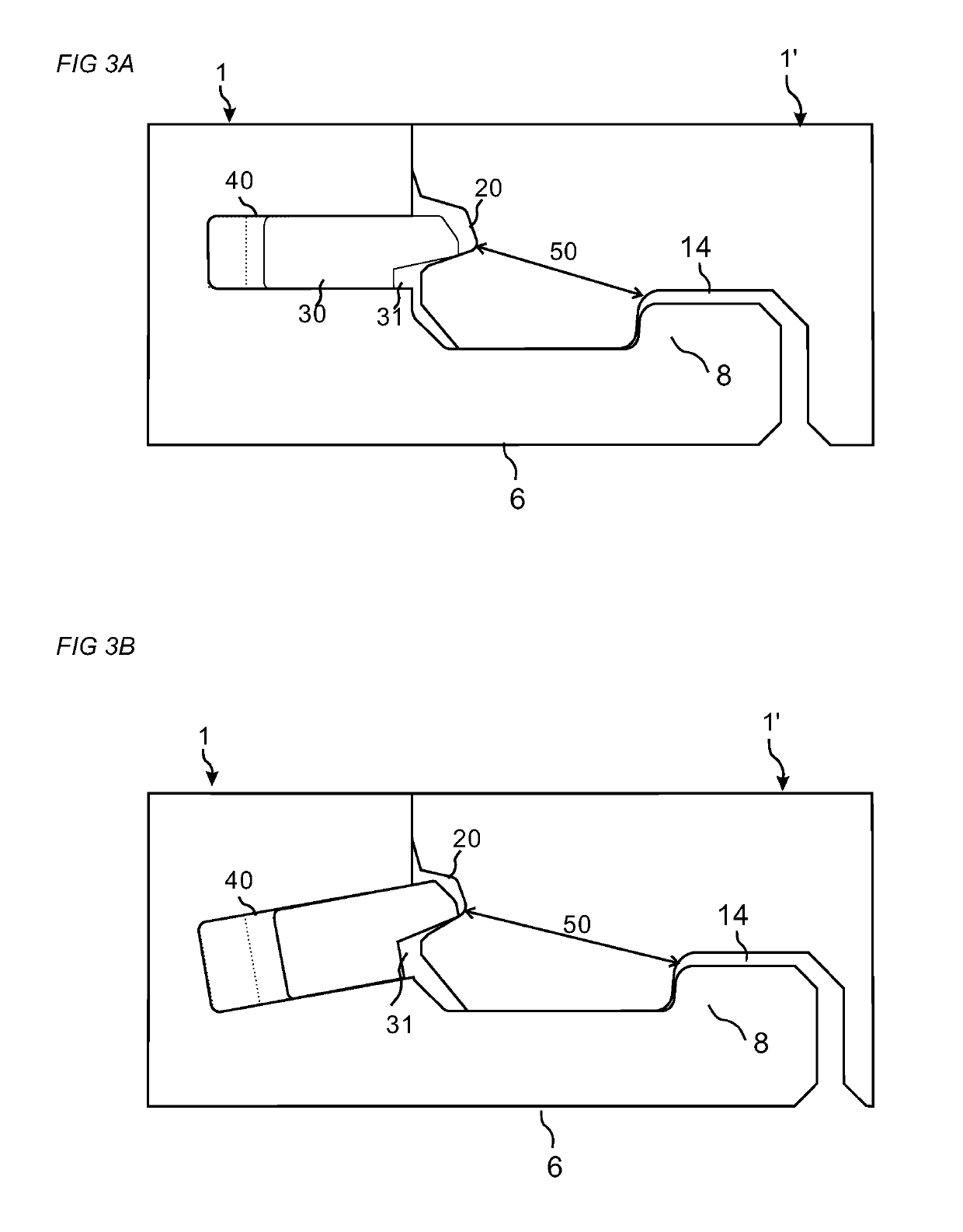

A set of essentially identical panels (1, 1′), such as building panels, provided with a mechanical locking system including a displaceable tongue (30), which is arranged in a displacement groove at a first edge of a first panel (1). A second panel is provided with a tongue groove at a second edge. The displaceable tongue is configured to cooperate with the tongue groove (20) for locking together the first and the second edge. The displaceable tongue has a spring constant that varies along the length of the tongue.

Owner:VÄLINGE INNOVATION AB

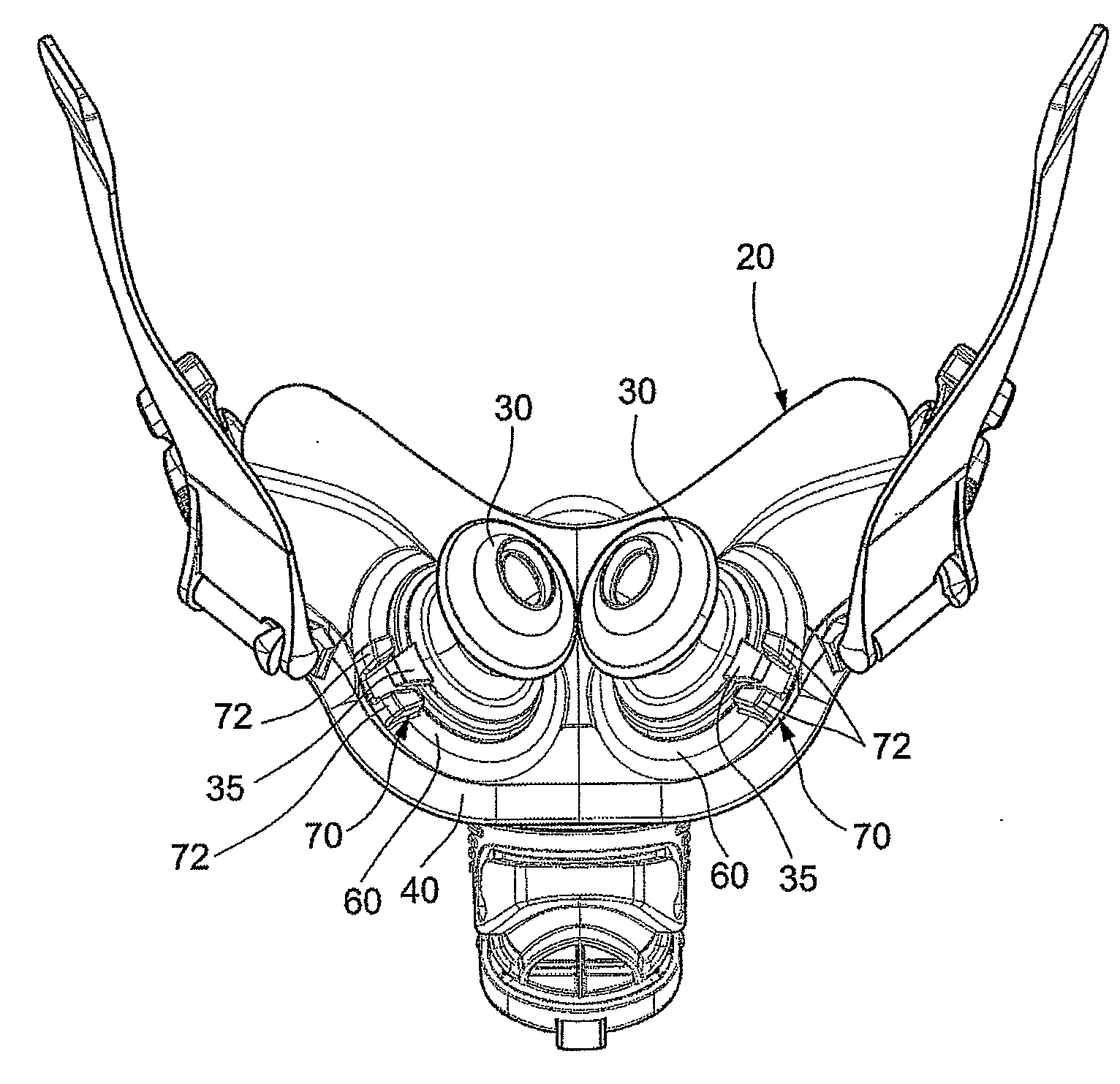

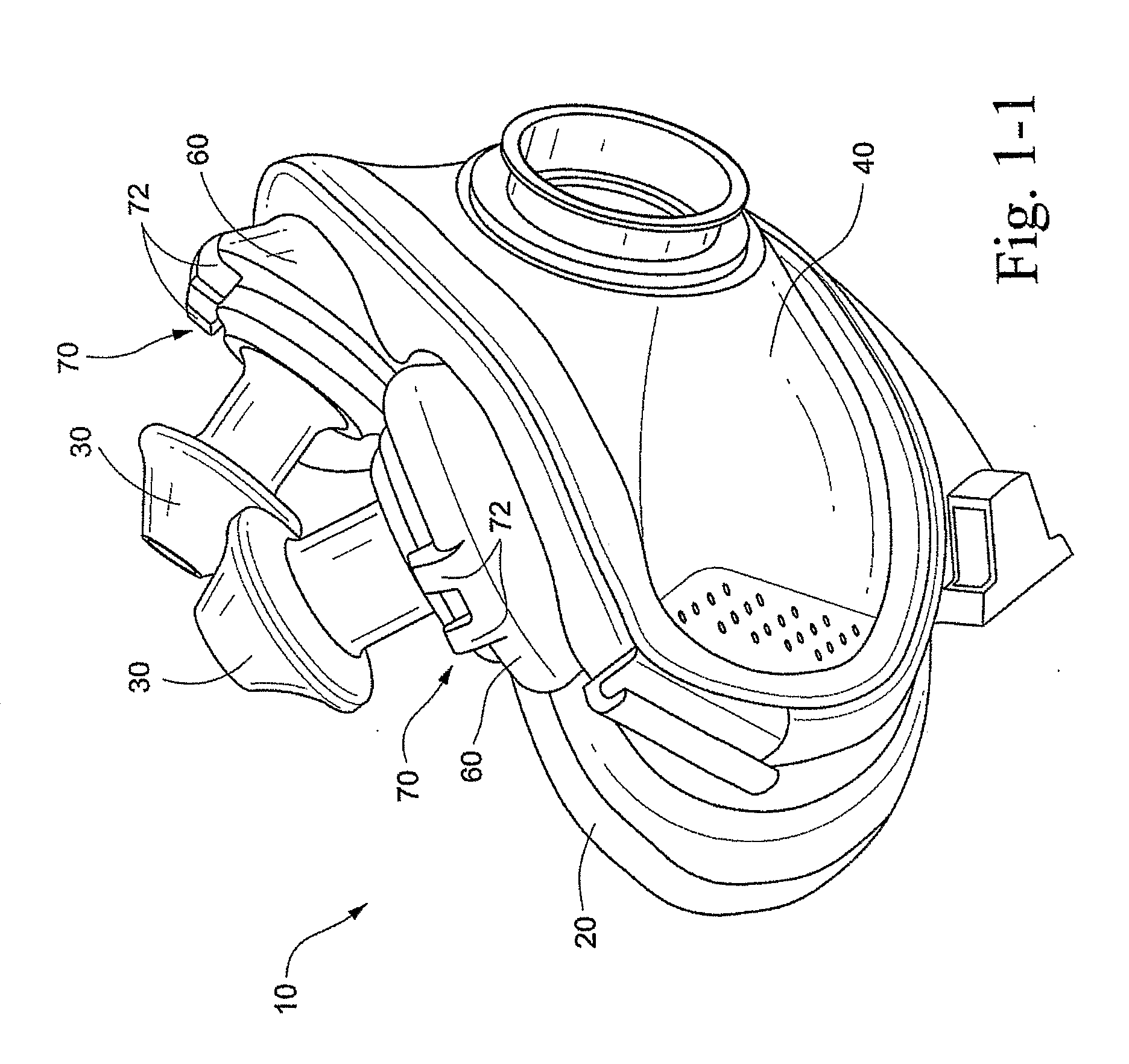

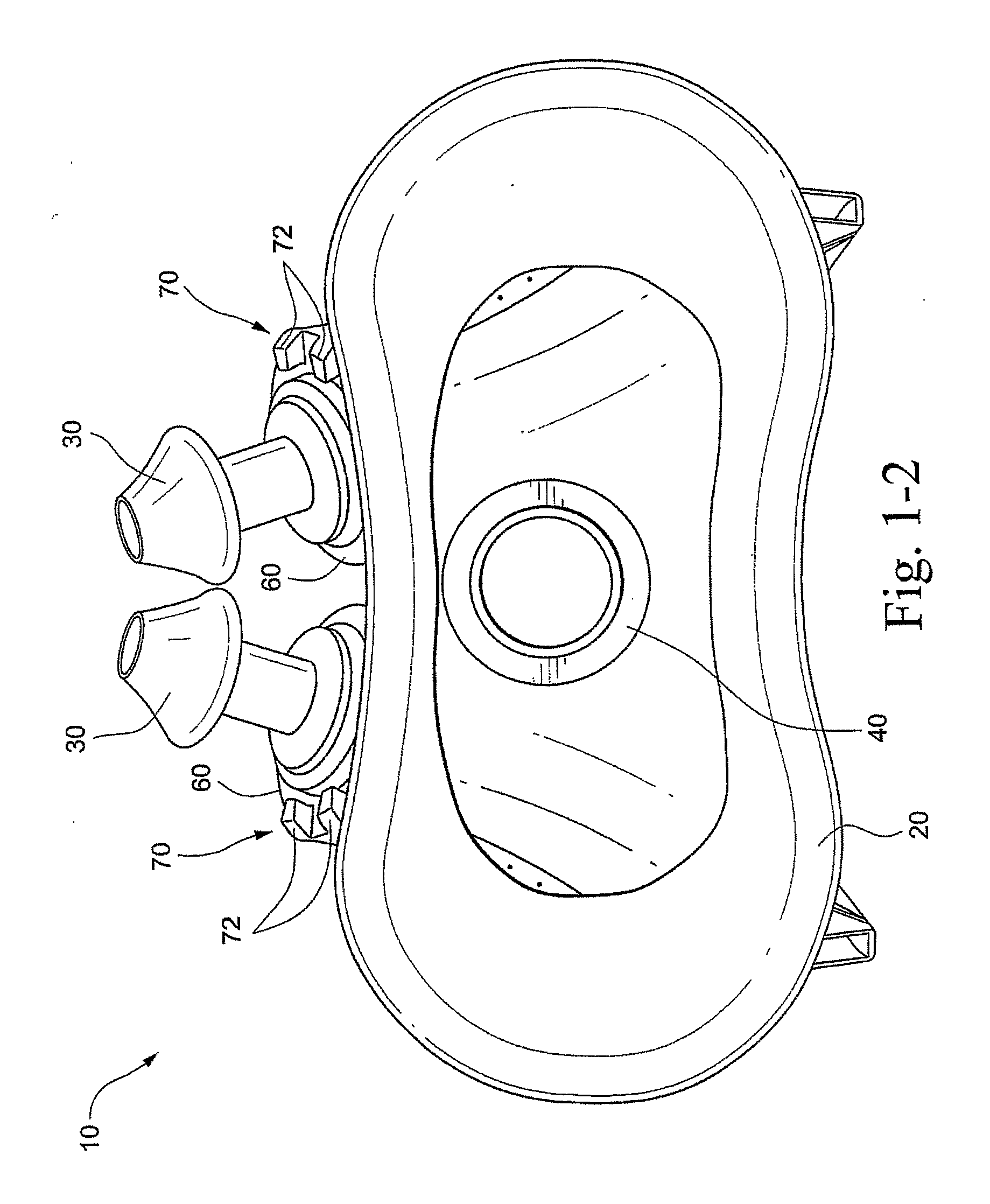

Cushion for mask system

A mouth cushion for a mask system includes a side wall, an undercushion extending away from the side wall, and a membrane provided to substantially surround the undercushion and adapted to form a continuous seal around an exterior of a patient's mouth in use. The side wall includes spaced-apart prong support structures that provide annular recesses adapted to support respective nasal prongs, and at least a portion of the undercushion includes a question-mark or sickle-shape configuration when in cross-section.

Owner:RESMED LTD

Building panel with a mechanical locking system

Owner:VÄLINGE INNOVATION AB

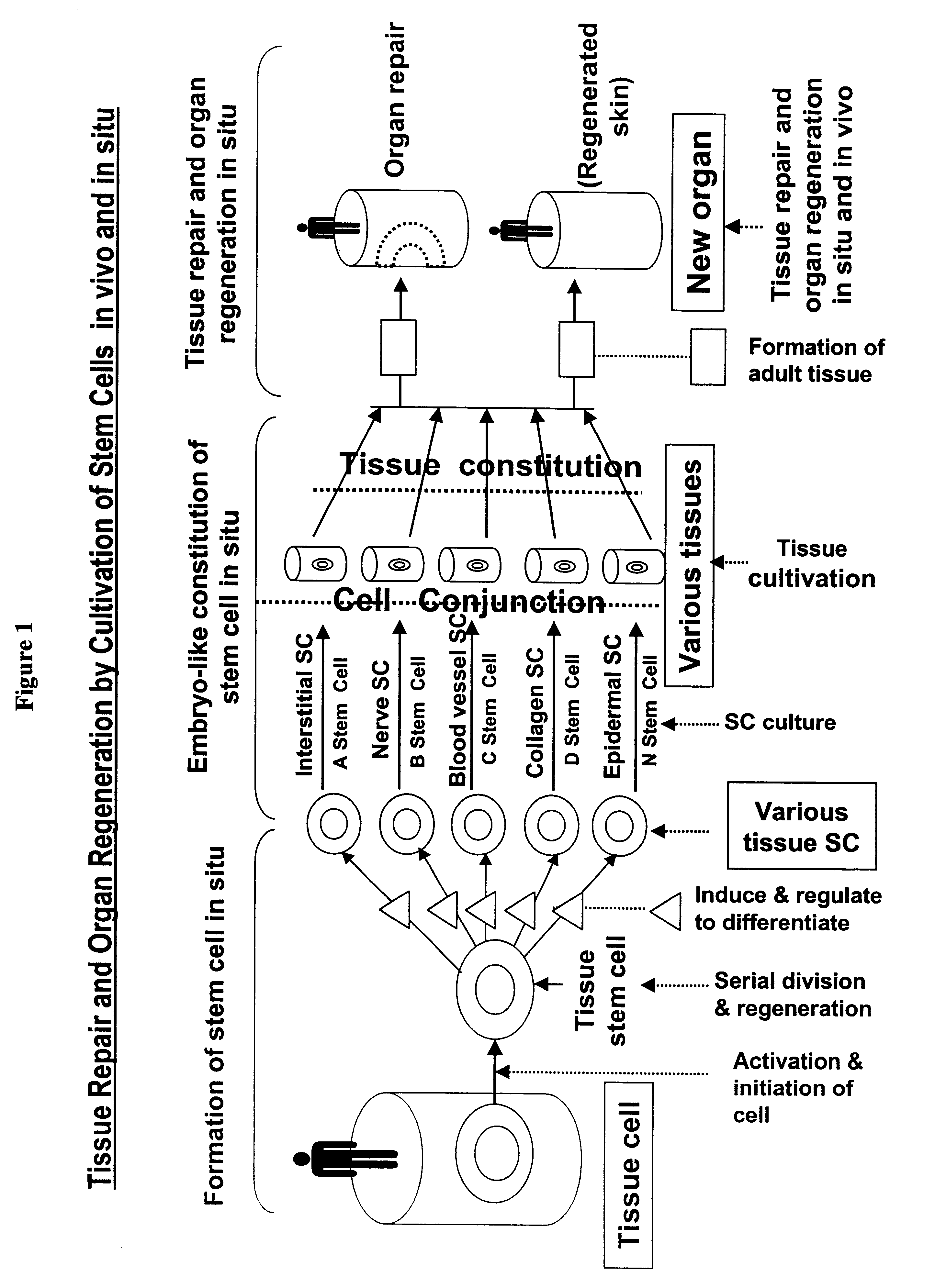

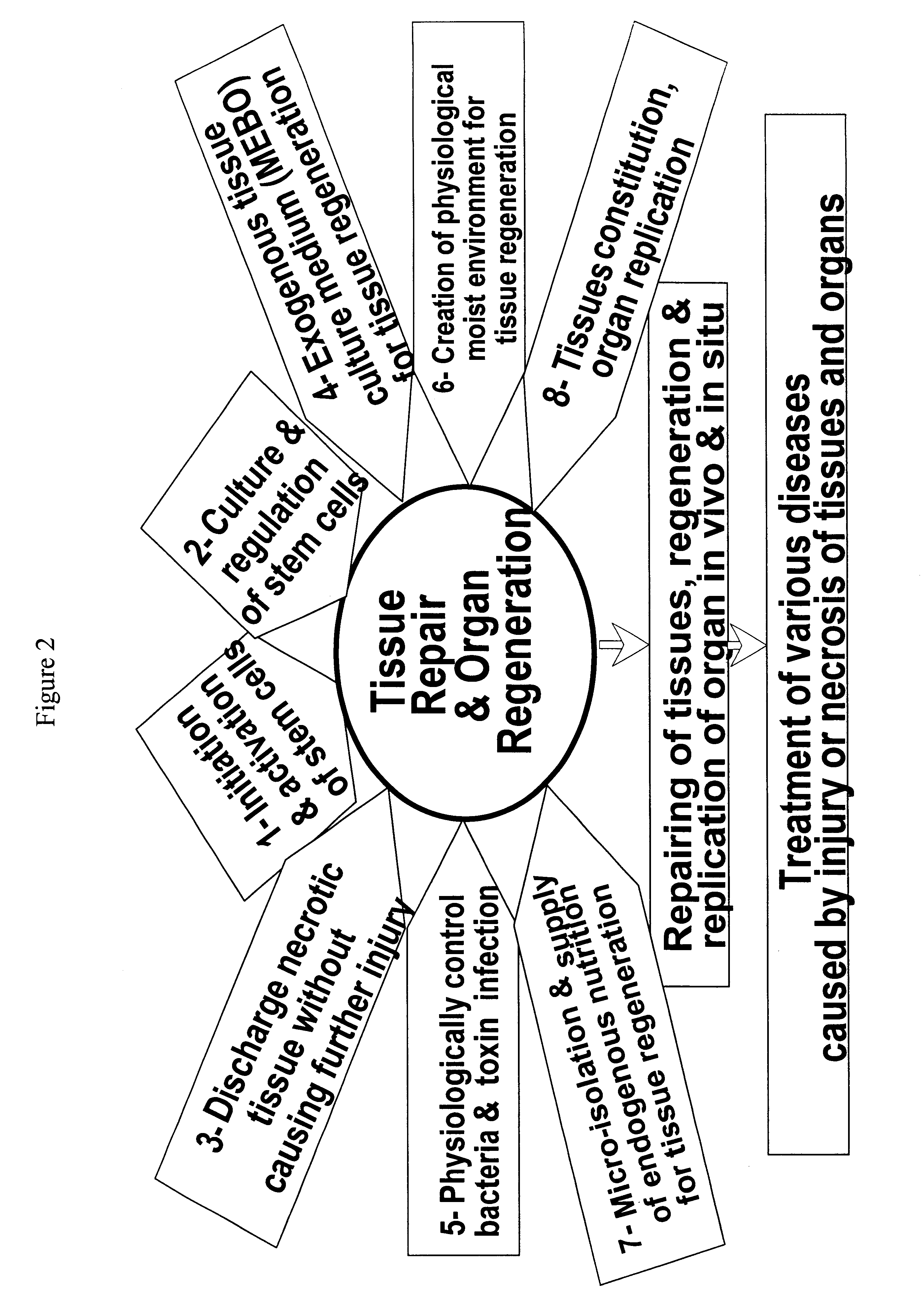

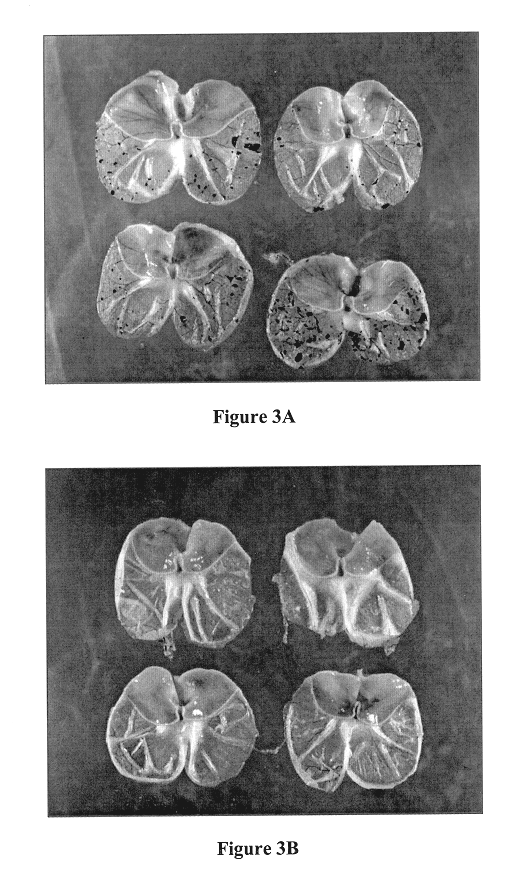

Method and composition for repairing and promoting regeneration of mucosal tissue in the gastrointestinal tract

InactiveUS6685971B2Restore physiological structure and functionPromote general health of whole bodyBiocideAerosol deliveryDiseaseAdditive ingredient

The present invention provides novel compositions and methods for protecting and promoting cell growth and restoring physiological structure and function to mucosal tissue of the body, especially mucosa in the gastrointestinal tract. The composition can be used as a pharmaceutical or nutraceutical to treat a gastrointestinal disorder or to promote general health of an animal, preferably a human. The composition is in an oral dosage form and comprises edible oil homogenized with a sterol compound at a concentration of at least 0.5% by weight and edible wax at a concentration ranging from 3% to 30% by weight. The composition can also be used to deliver other active ingredients to the gastrointestinal tract for treating various diseases.

Owner:XU RONGXIANG

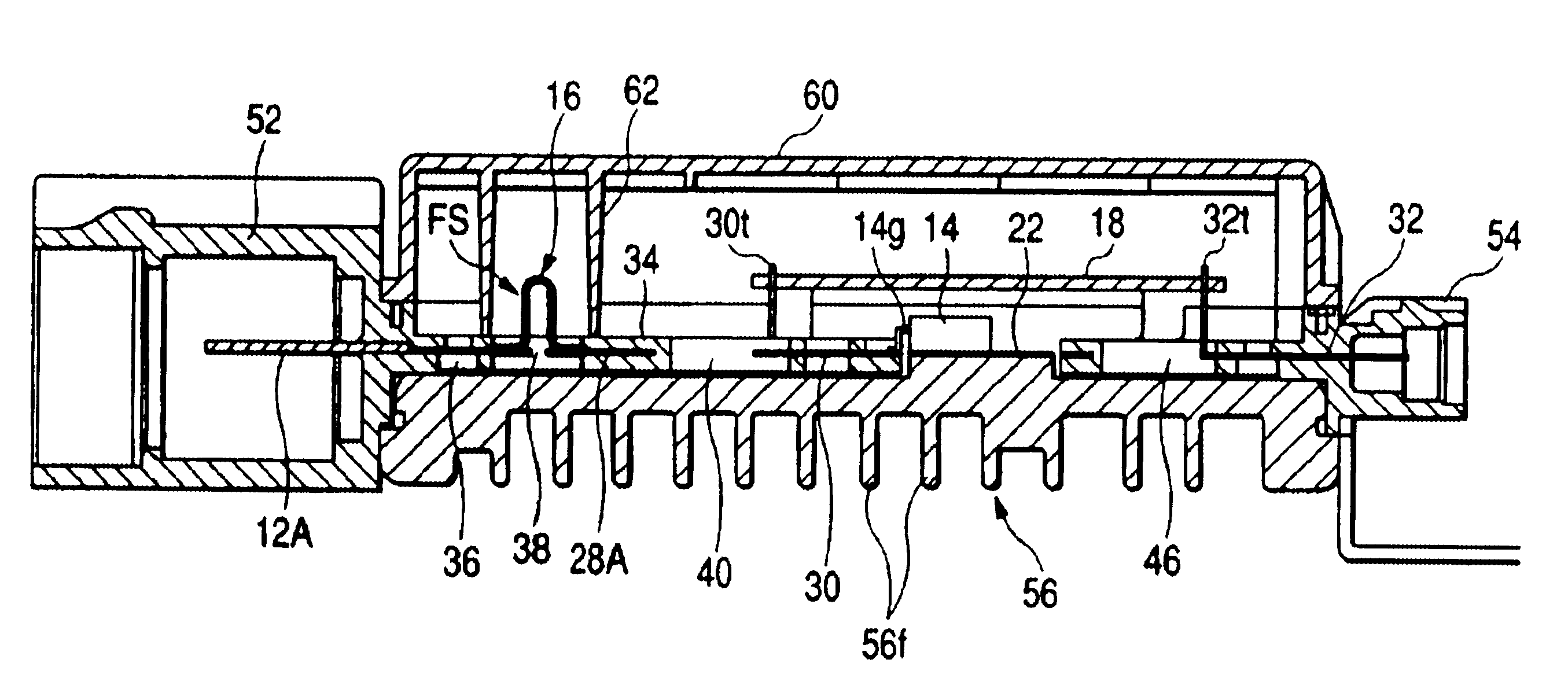

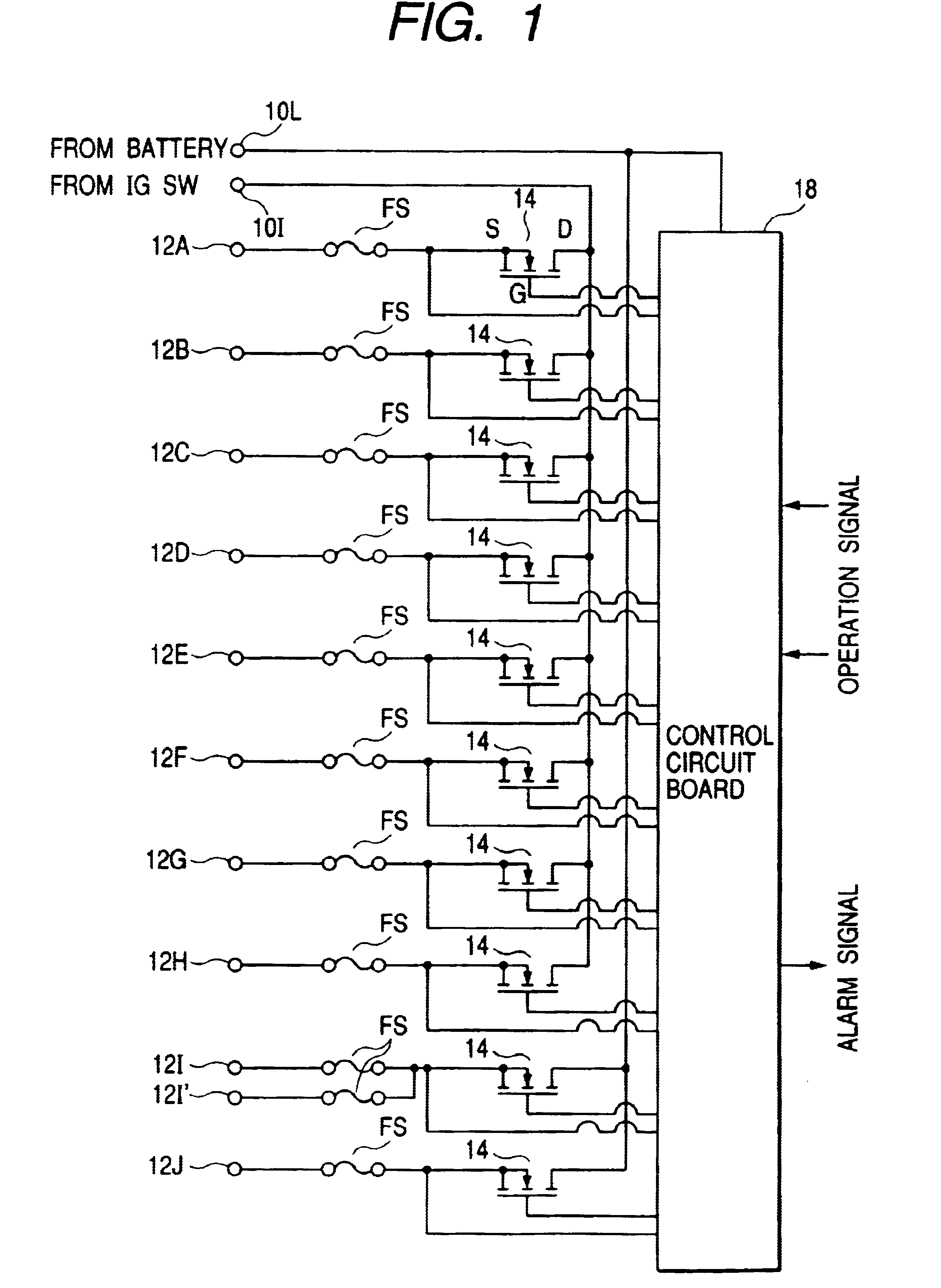

Power distributor for a vehicle and production method thereof

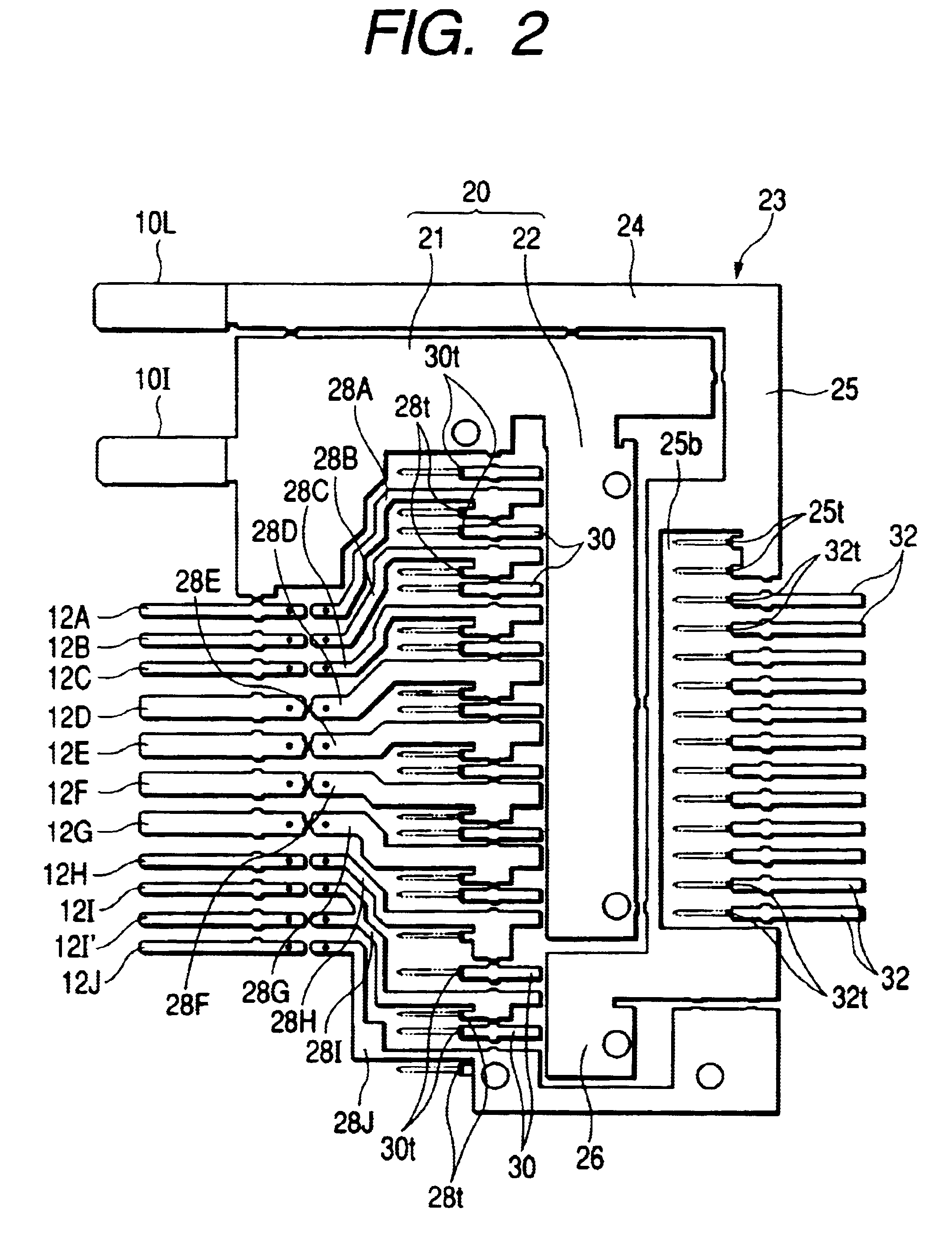

InactiveUS6724627B2Simple structureAssembly precisionSemiconductor/solid-state device detailsSolid-state devicesPunchingDistributor

In the power distributor using a semiconductor switching element, input terminals 10I and 10L, output terminals 12A-12J, connected to the element, and more preferably, the board terminals 30 and 32, are structured by a metallic plate, and arranged on the same plane perpendicular to the plate thickness. The metallic plate can be integrated by the resin mold, thereby the structure can be greatly simplified. The metallic plate can be produced by a greatly simple method by which, after the punching out of the metallic plate and the molding of the resin mold, a predetermined portion of the metallic plate is cut and the semiconductor switching element is mounted, and it can contribute to also the reduction of the cost.

Owner:AUTONETWORKS TECH LTD +2

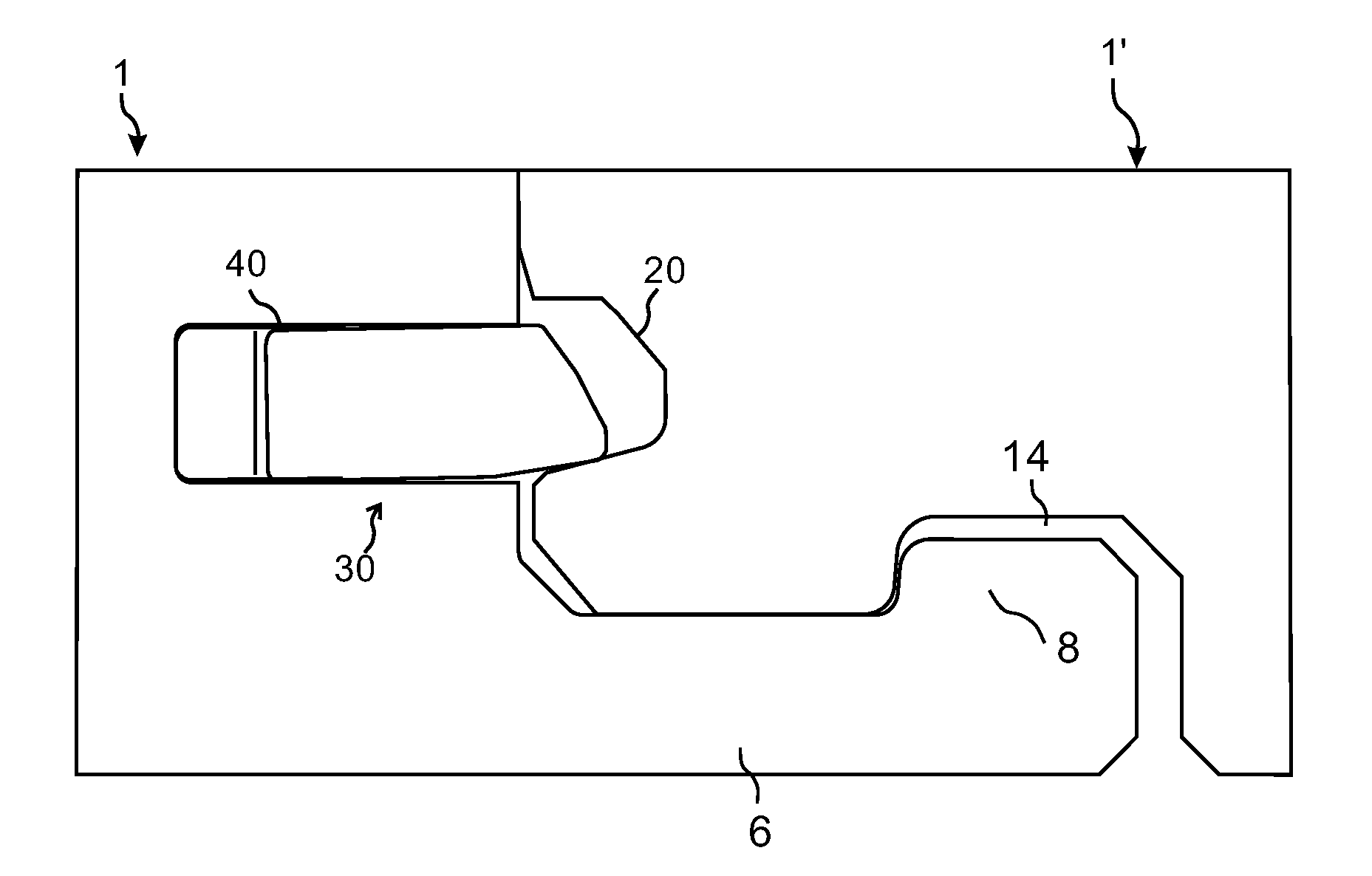

Inspection of a substrate using multiple cameras

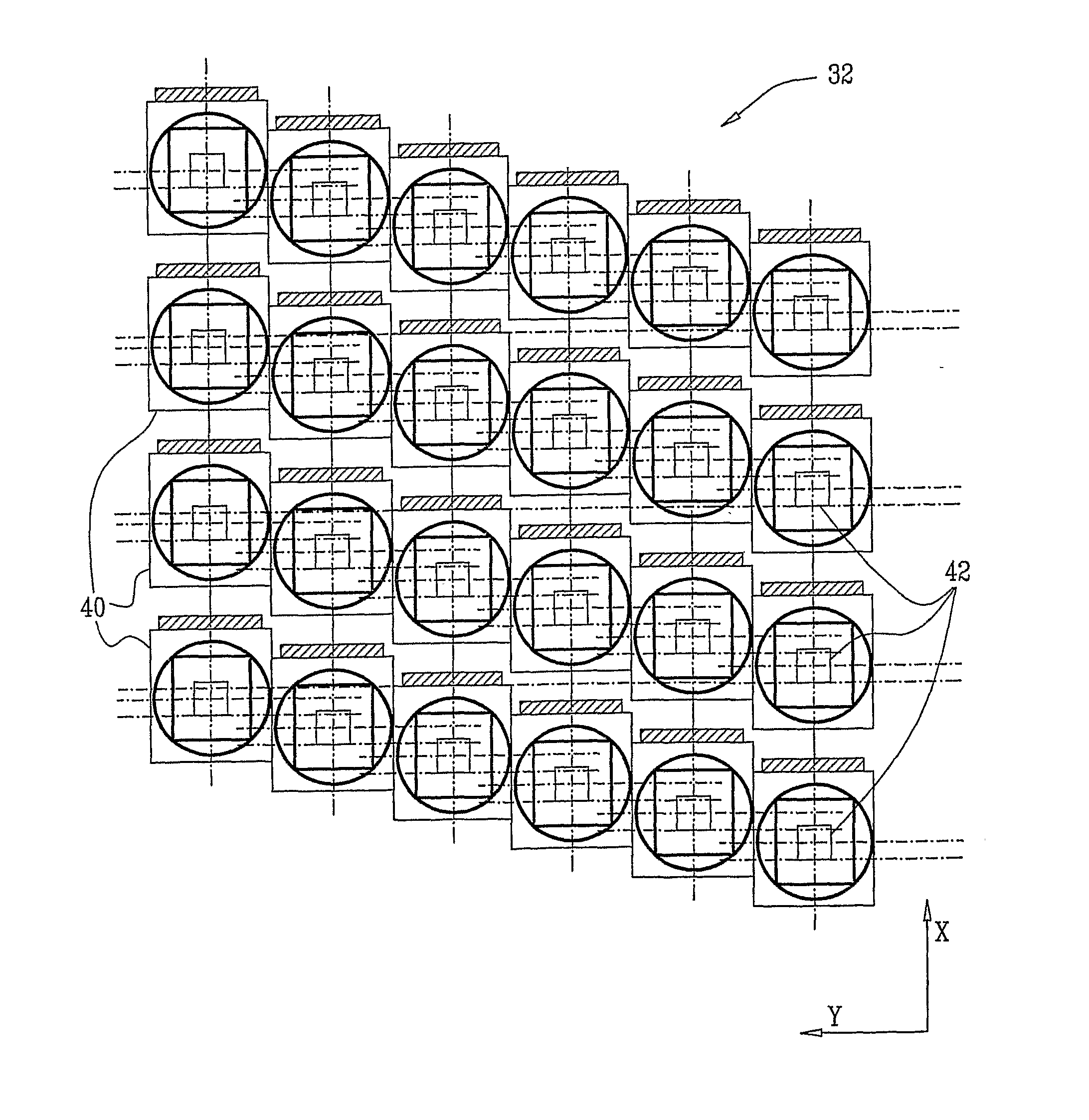

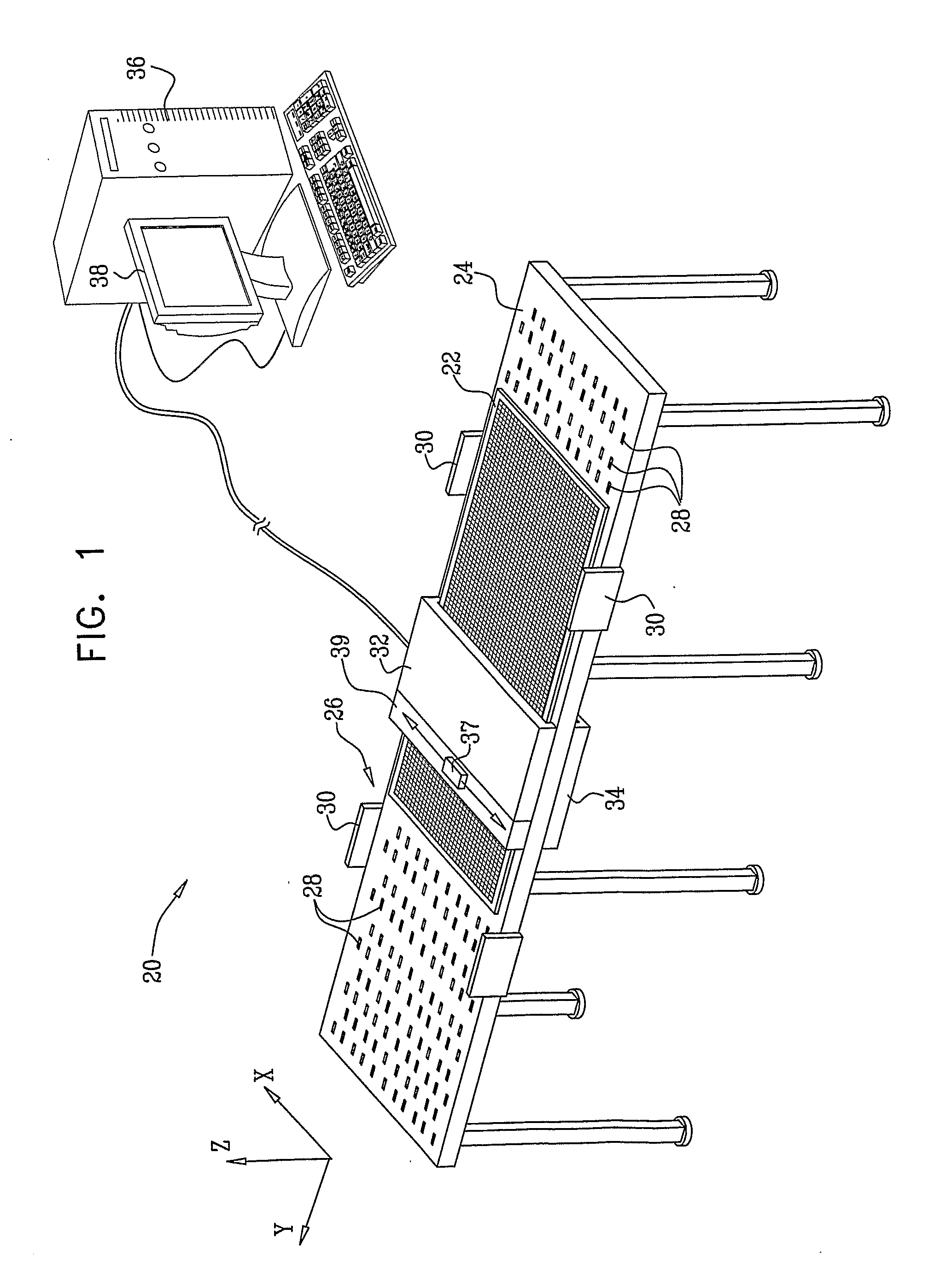

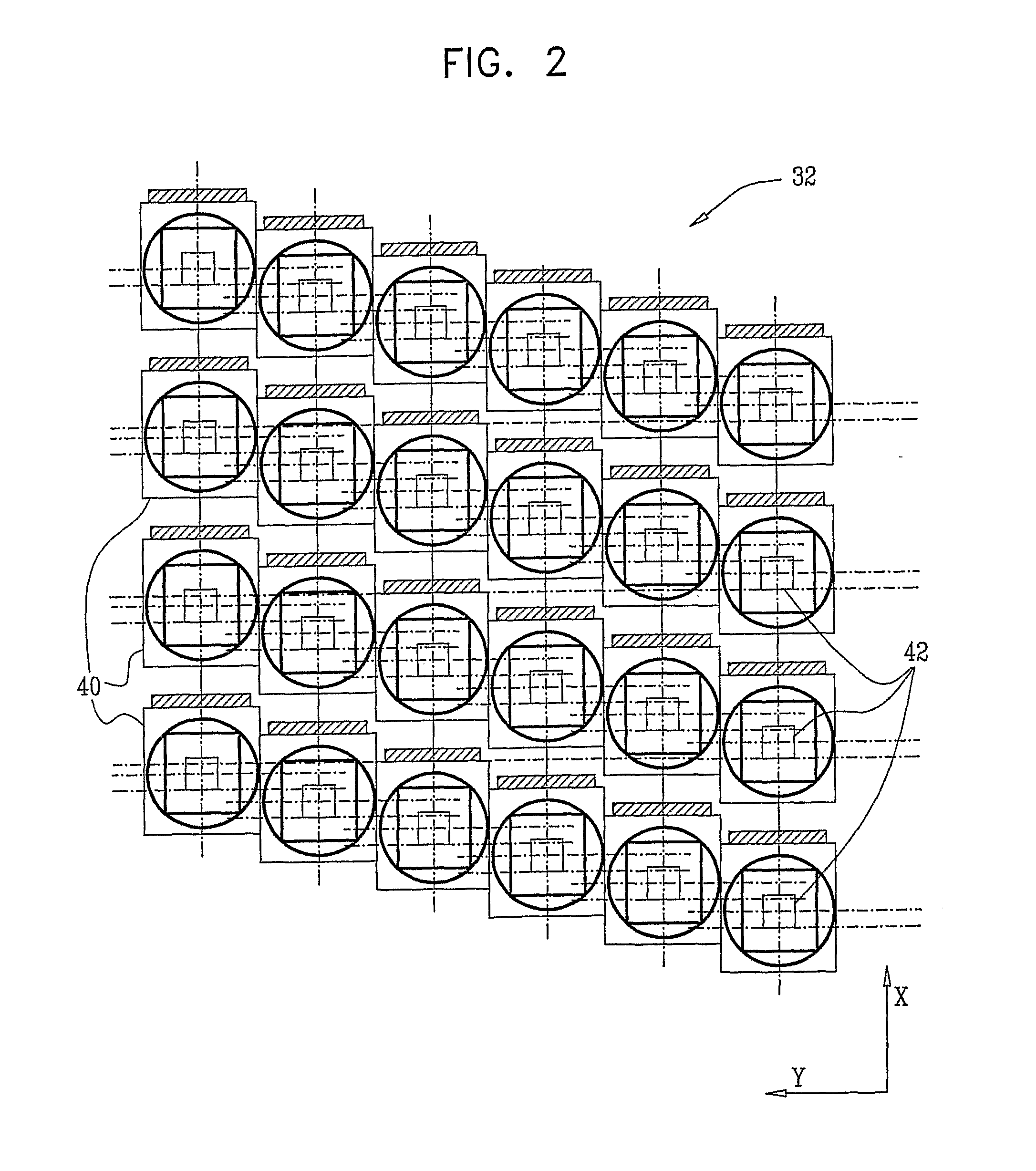

ActiveUS20100309308A1Assembly precisionReduce system costImage enhancementImage analysisPosition toleranceImage capture

Apparatus for inspection includes an imaging assembly, including a plurality of cameras, which are mounted in different, respective locations in the imaging assembly and are configured to capture respective images of a sample. A motion assembly is configured to move at least one of the imaging assembly and the sample so as to cause the imaging assembly to scan the sample with a scan accuracy that is limited by a predetermined position tolerance. An image processor is coupled to receive and process the images captured by the cameras so as to locate a defect in the sample with a position accuracy that is finer than the position tolerance.

Owner:ORBOTECH LTD

Building panel with a mechanical locking system

A set of essentially identical panels, such as building panels, provided with a mechanical locking system including a displaceable tongue, which is arranged in a displacement groove at a first edge of a first panel. A second panel is provided with a tongue groove at a second edge. The displaceable tongue is configured to cooperate with the tongue groove for locking together the first and the second edge. The displaceable tongue has a spring constant that varies along the length of the tongue.

Owner:VÄLINGE INNOVATION AB

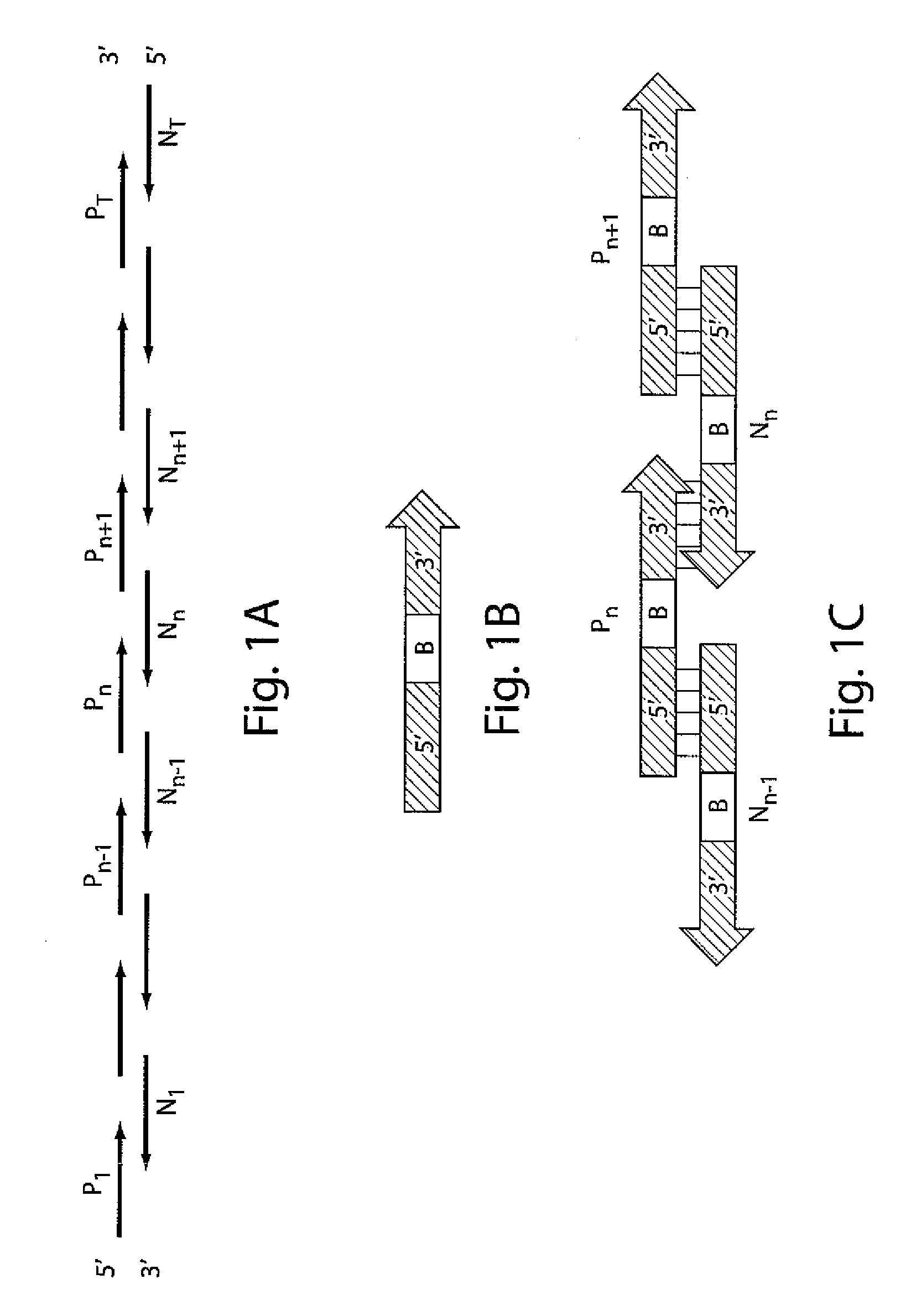

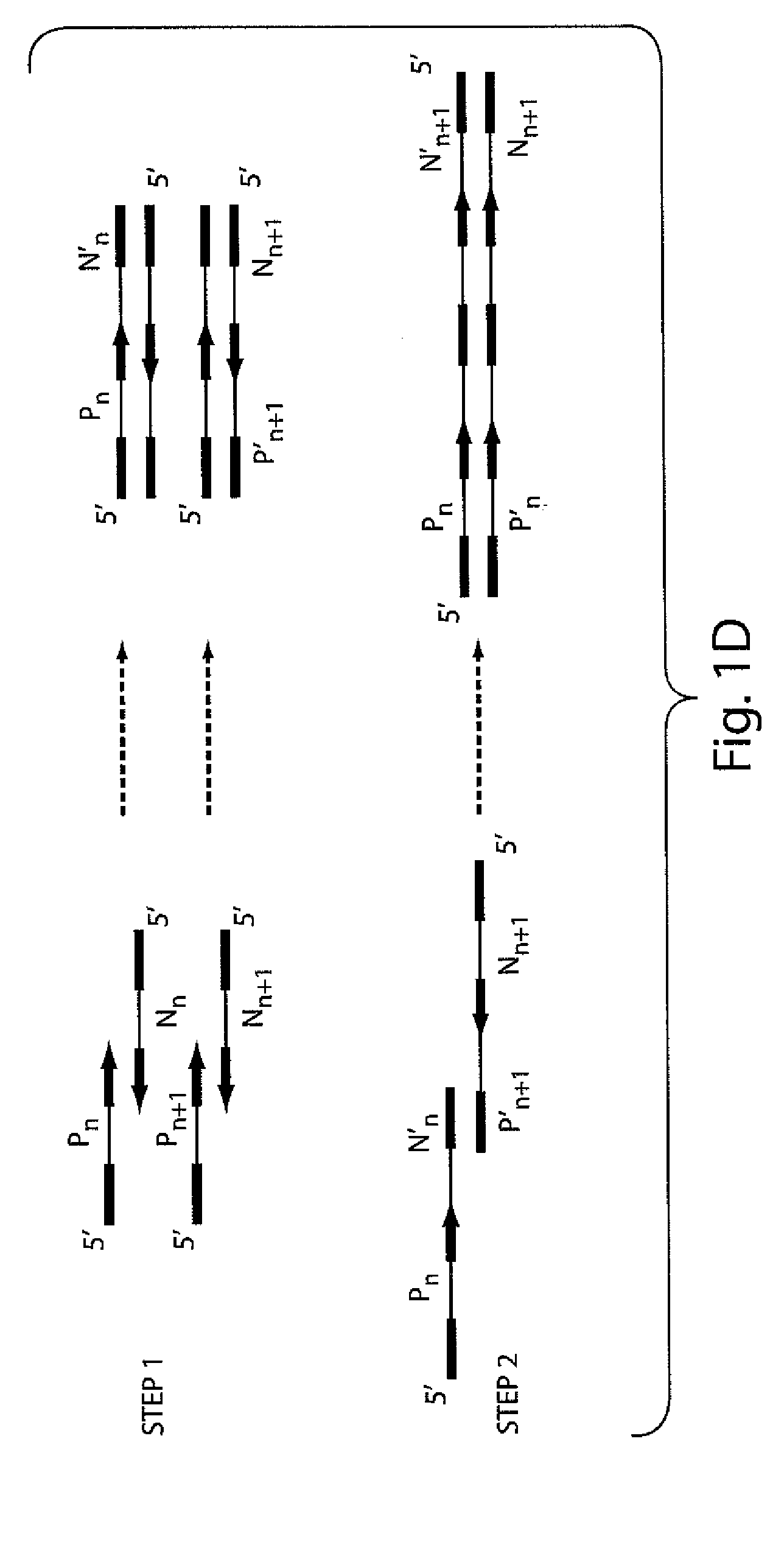

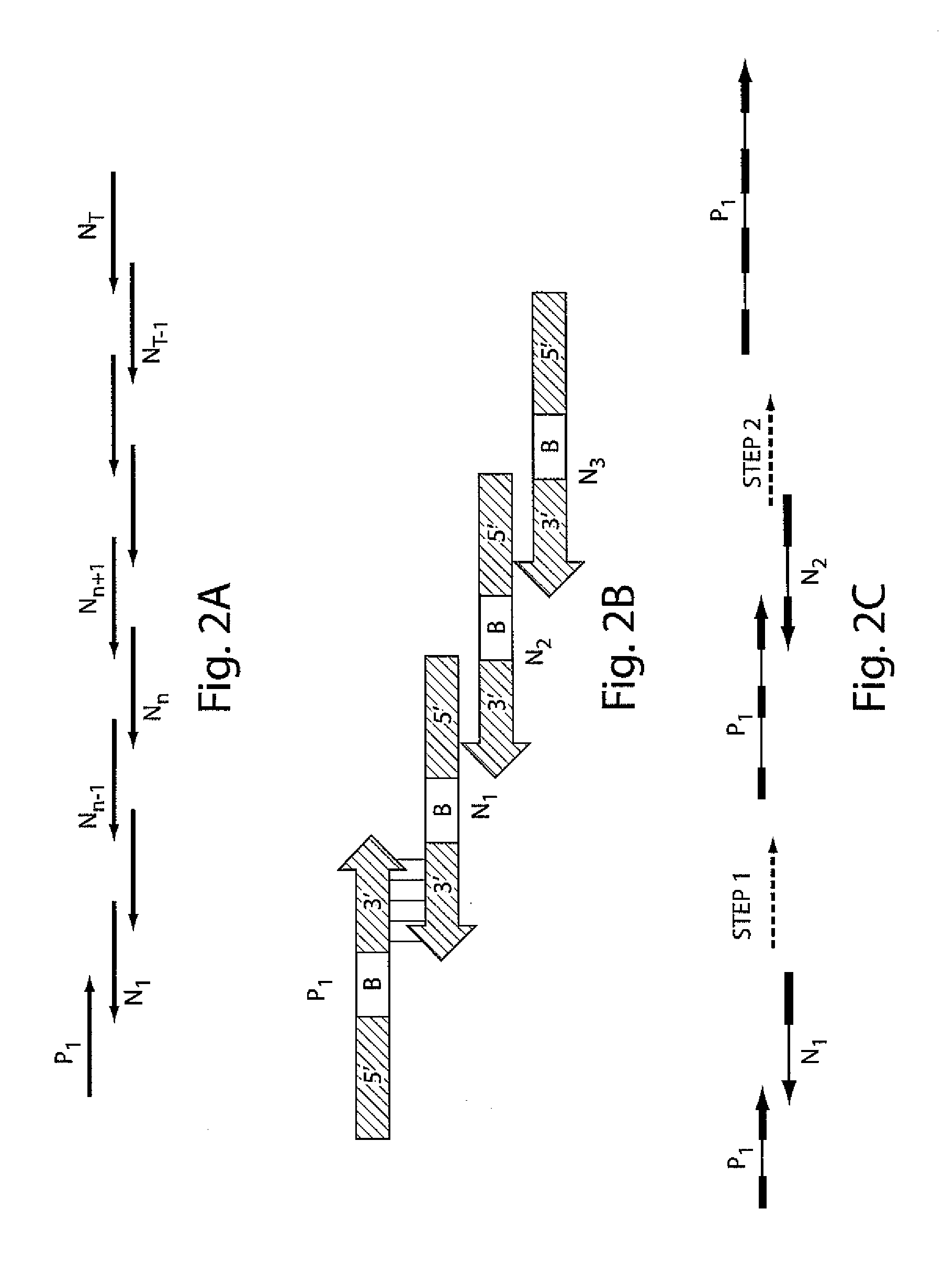

Iterative nucleic acid assembly using activation of vector-encoded traits

ActiveUS8053191B2Shorten the timeAssembly precisionSugar derivativesMicrobiological testing/measurementBiological activationSynthetic nucleic acid

Certain aspects of the present invention provide methods for assembling nucleic acid molecules using iterative activation of one or more vector-encoded traits to progressively assemble a longer nucleic acid insert. Aspects of the invention also provide kits, compositions, devices, and systems for assembling synthetic nucleic acids using iterative activation of one or more vector-encoded traits.

Owner:GEN9

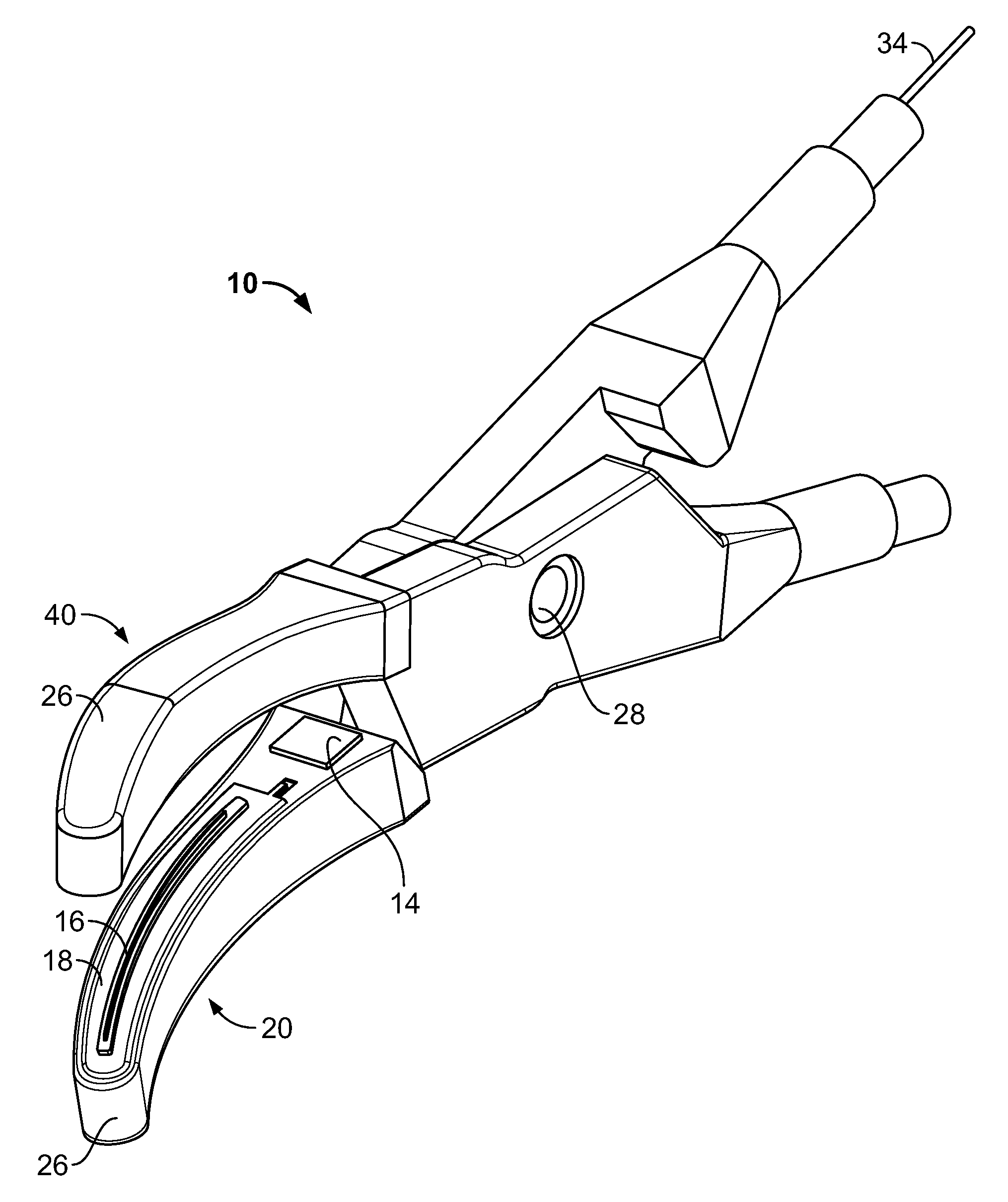

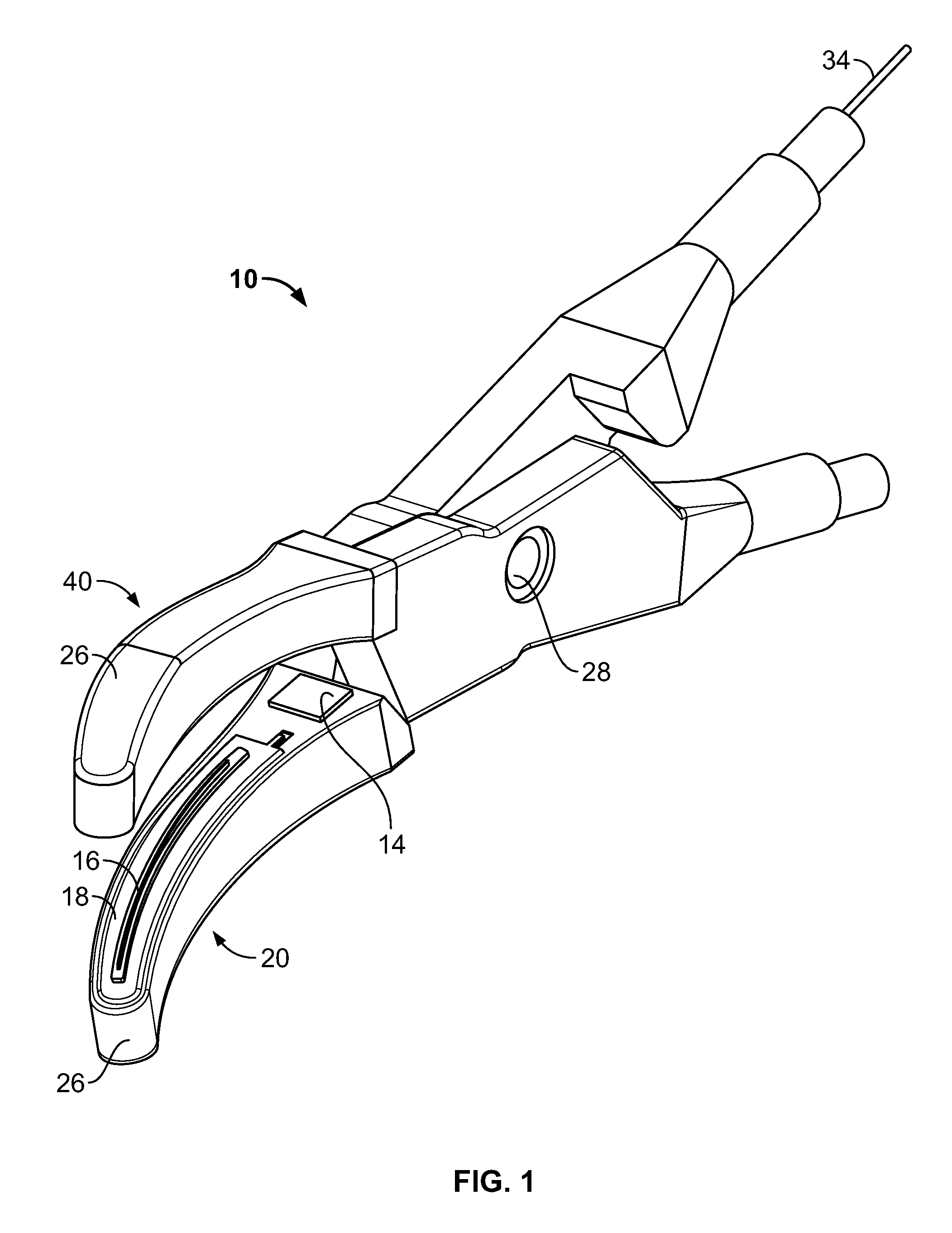

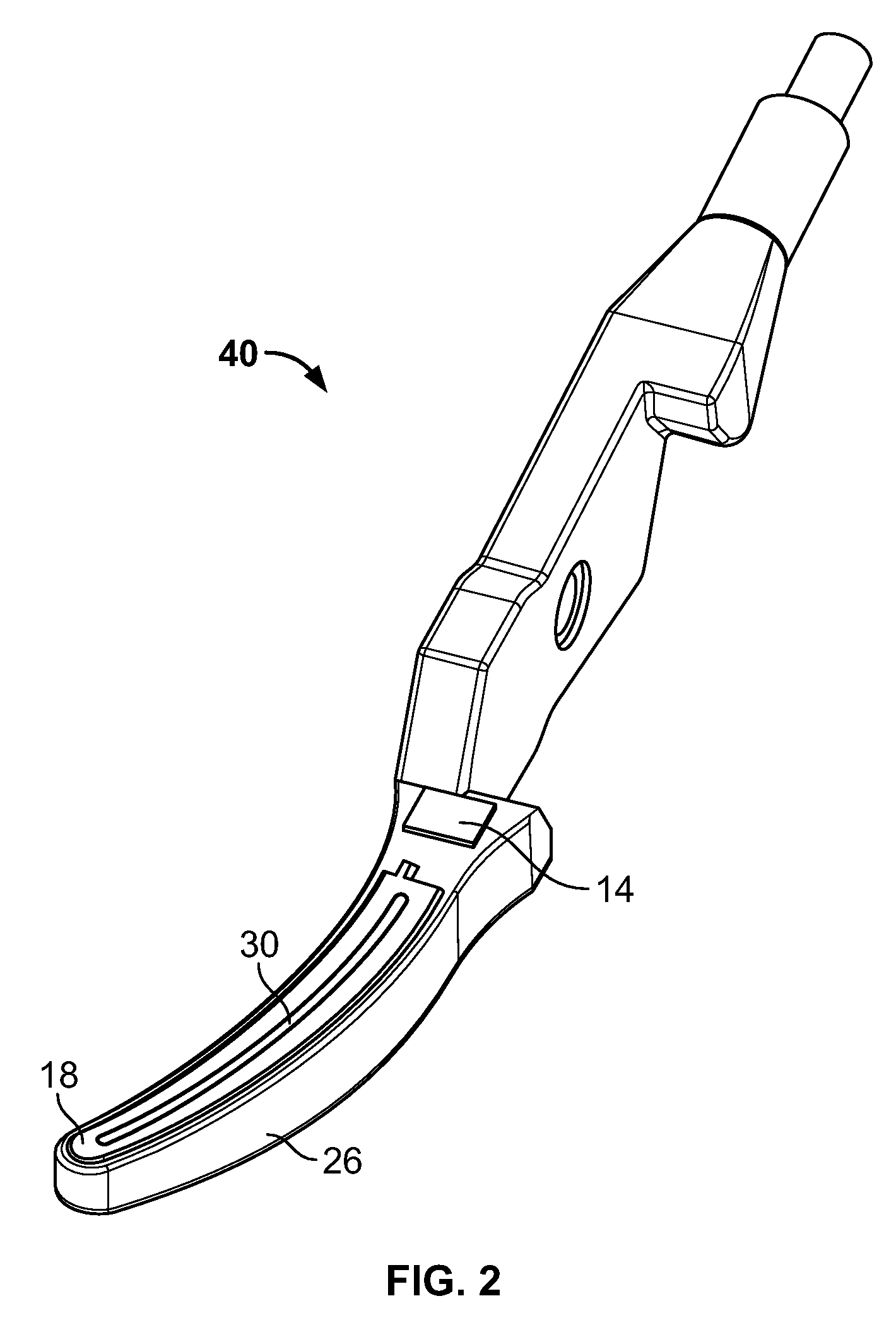

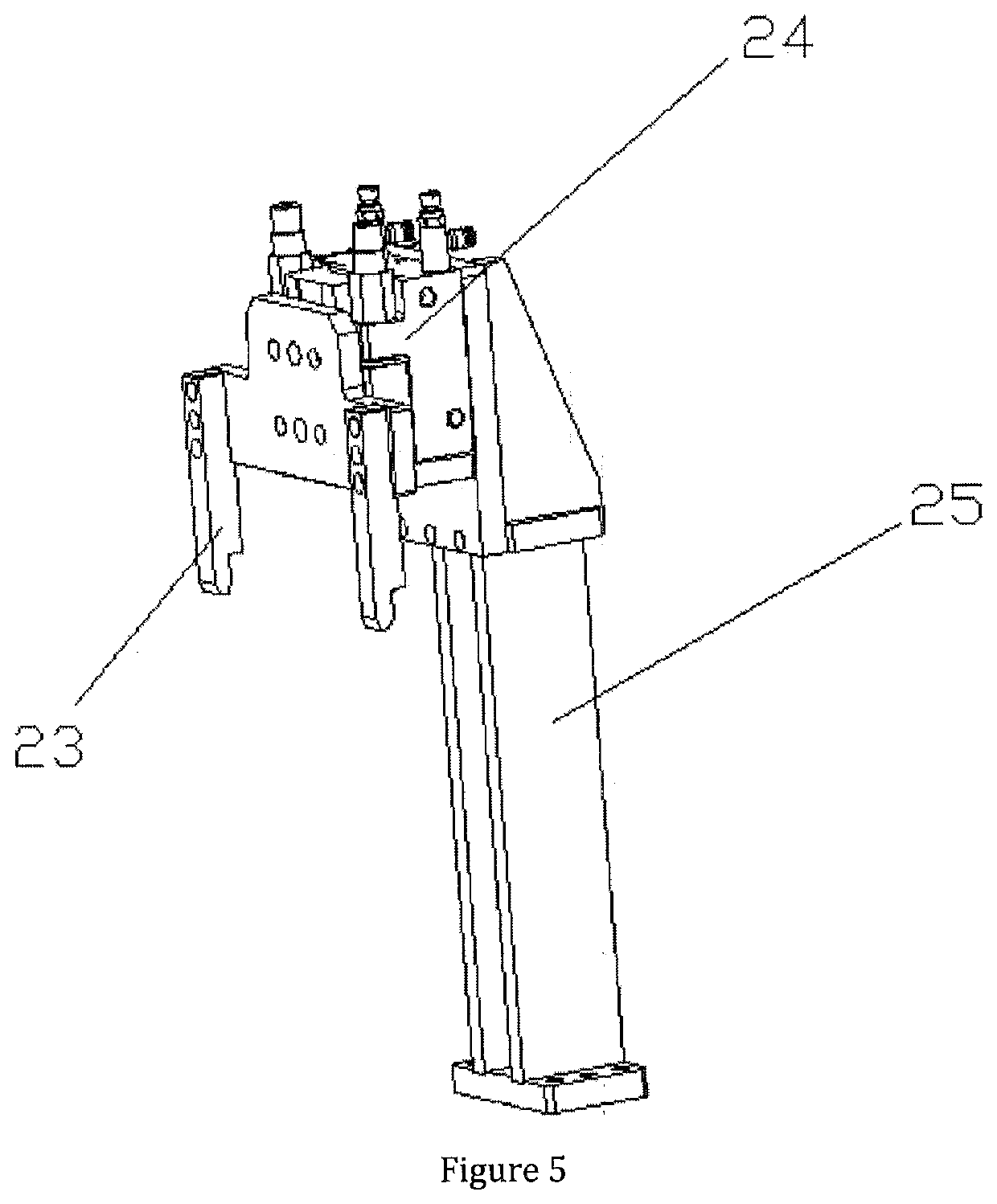

System and method for surgical jaw assembly

InactiveUS20090254081A1Assembly precisionExcessively uniformDiagnosticsAssembly machinesMechanical engineeringEngineering

A surgical jaw assembly having a top portion and a bottom portion hingedly attached. The top and bottom portion having a base, a seal plate and a cover, the seal plate and base being in direct contact and being electrically common. The bottom portion having a blade that is stationary relative to the base and the top portion having an insert configured to receive the blade when the top portion and bottom portion are in a predetermined position. The cover is overmolded onto the base, securing the seal plate to the base on both the top portion and bottom portion.

Owner:CREGANNA UNLTD

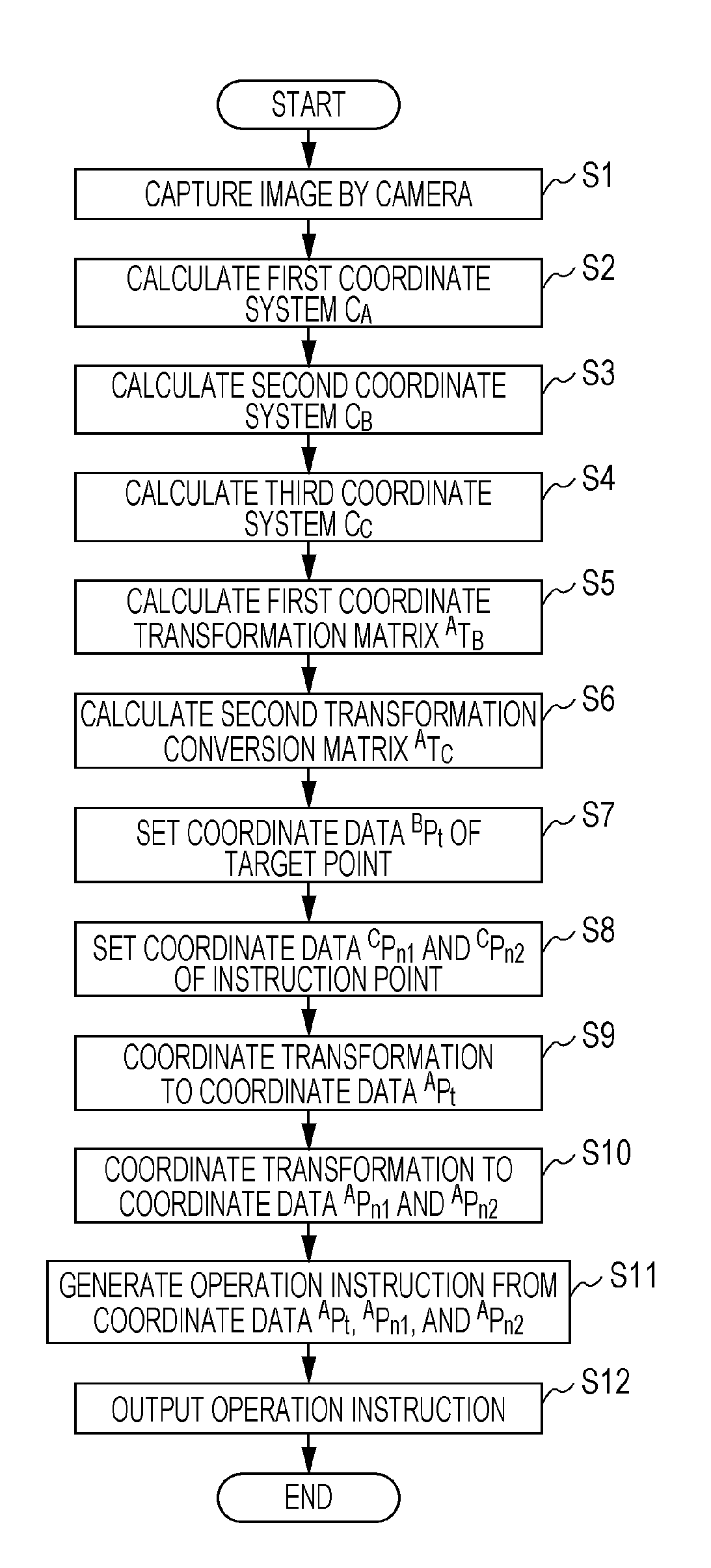

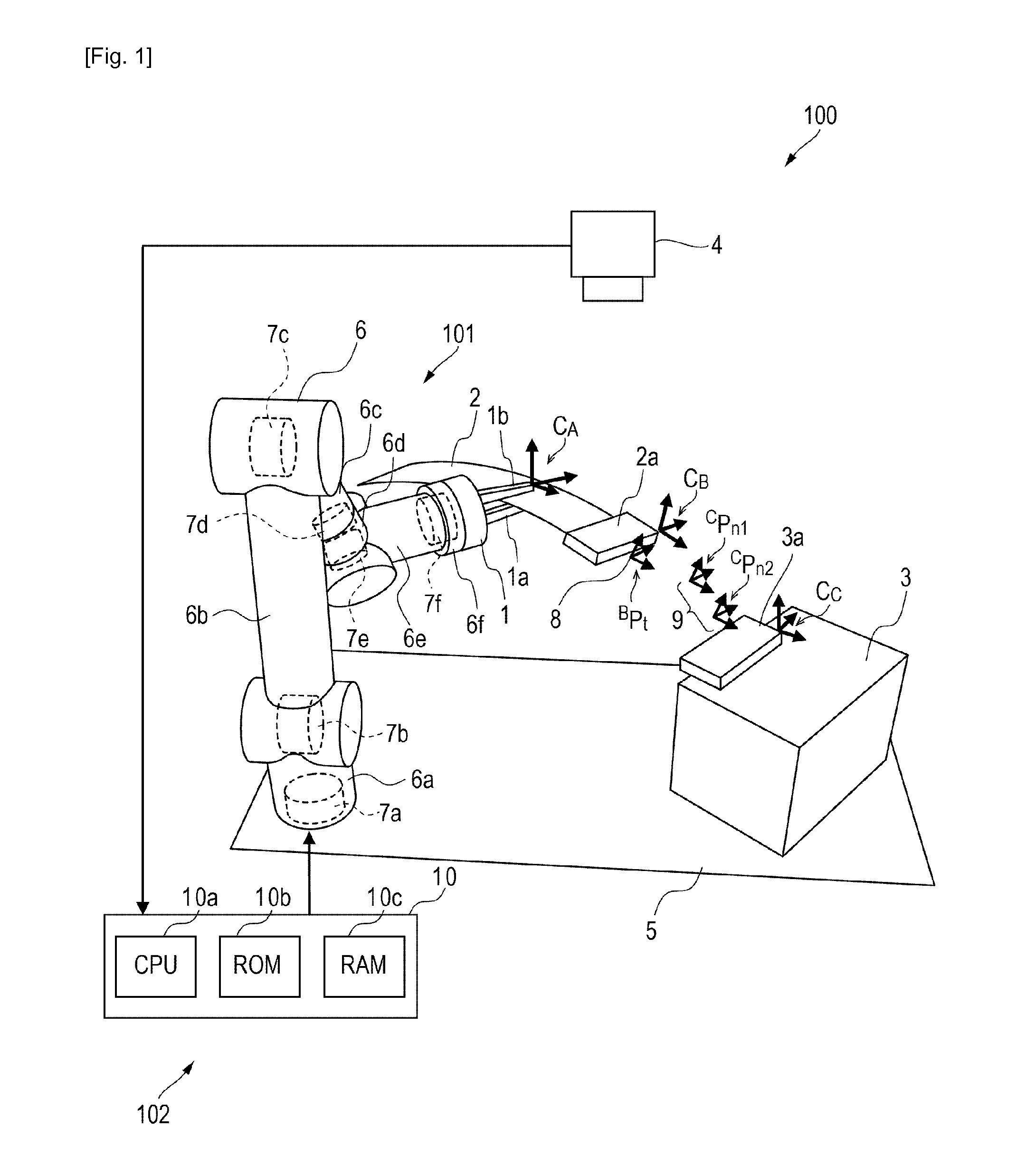

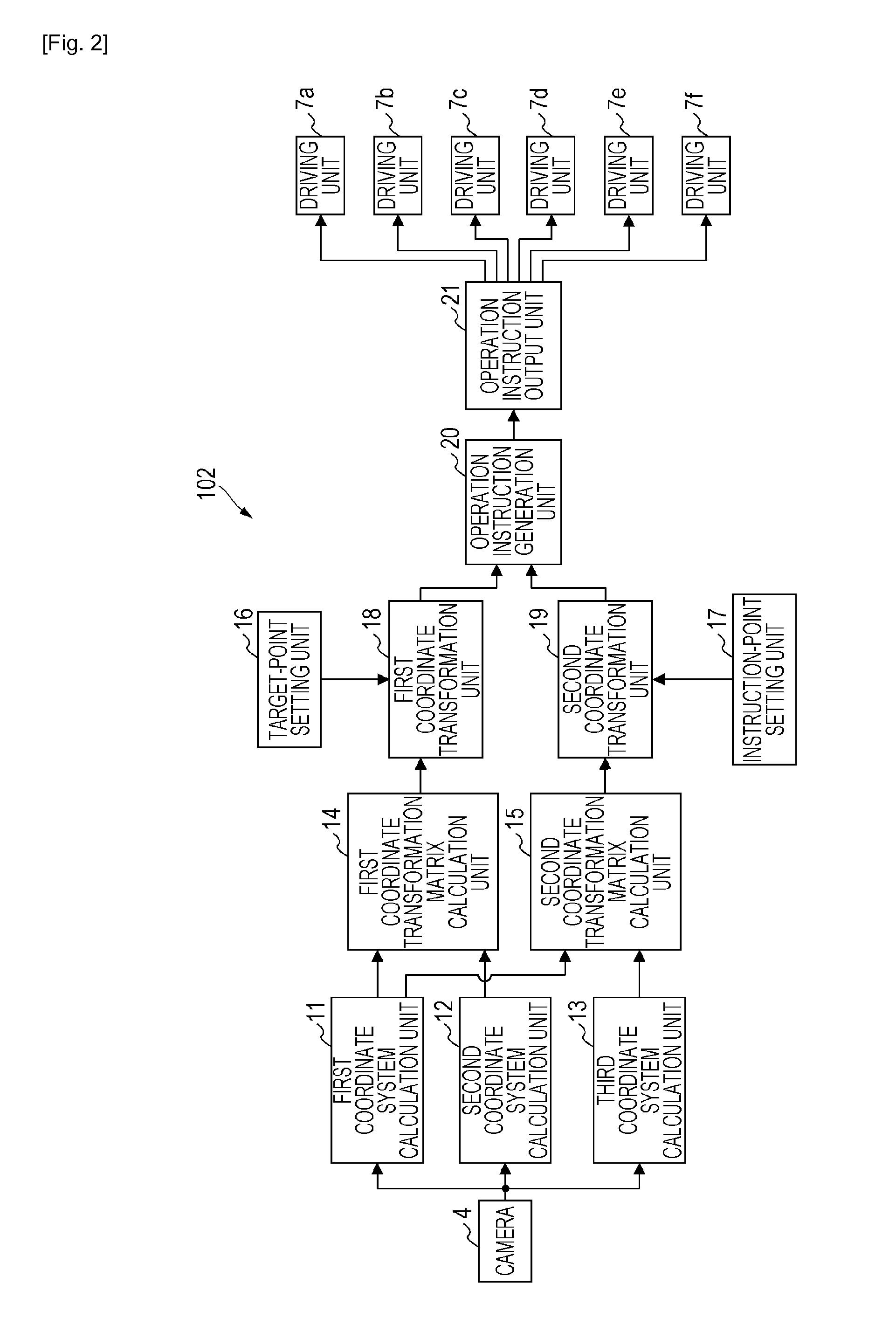

Robot control apparatus, robot control method, program, and recording medium

InactiveUS20140012416A1Assembly precisionProgramme-controlled manipulatorComputer controlComputer graphics (images)Robot control

A first coordinate system CA of the hand unit, a second coordinate system CB of the first workpiece, and a third coordinate system CC of a second workpiece in a camera coordinate system are calculated (S2, S3, and S4). First and second coordinate transformation matrices ATB and ATC are calculated (S5 and S6). Coordinate data of a target point is set in the coordinate system of the first workpiece (S7). Coordinate data of an instruction point is set in the coordinate system of the second workpiece (S8). The coordinate data of the target point is subjected to coordinate transformation using the first coordinate transformation matrix ATB (S9). The coordinate data of the instruction point is subjected to coordinate transformation using the second coordinate transformation matrix ATC (S10). Operation instructions are generated using the converted coordinate data (S11).

Owner:CANON KK

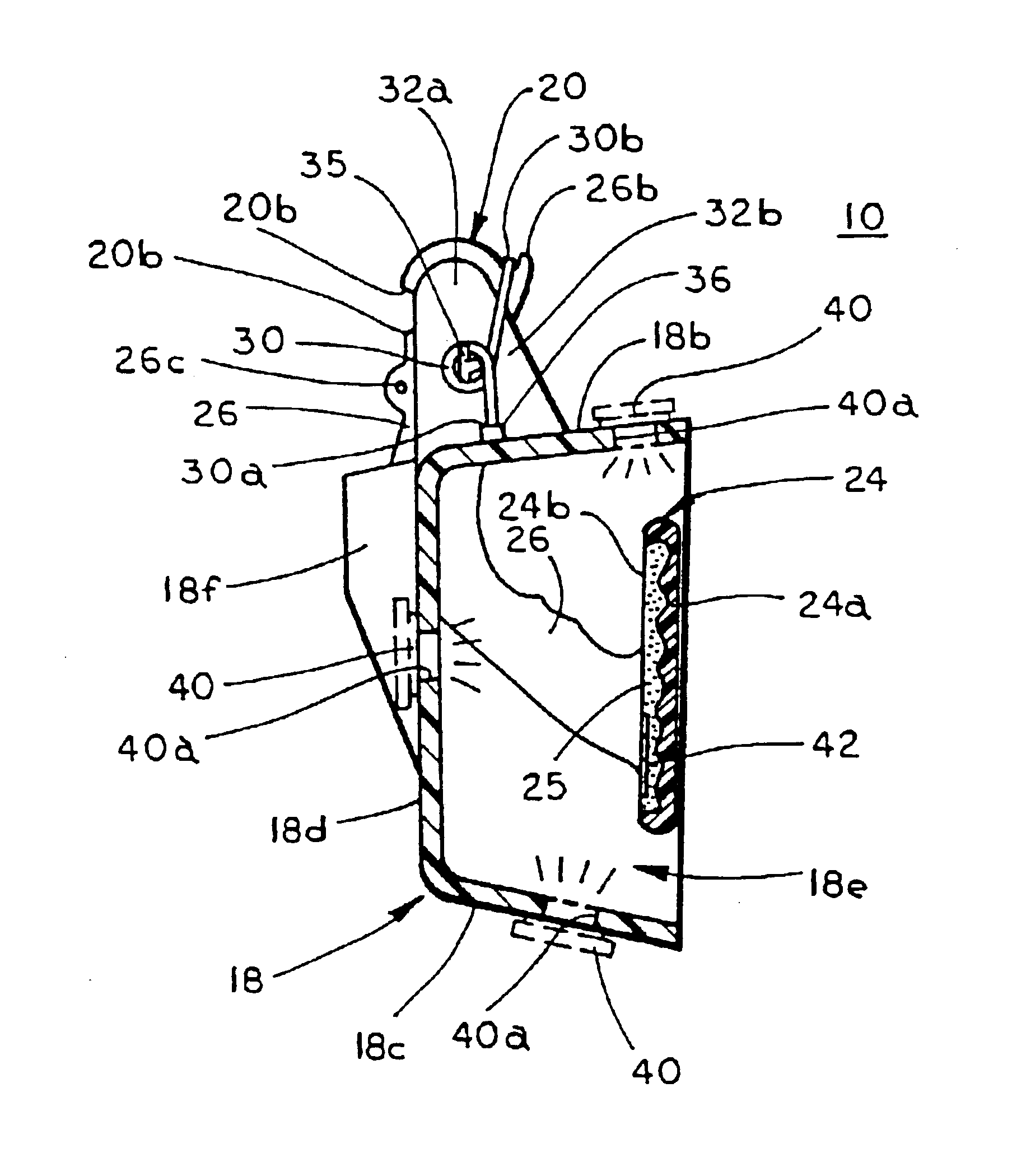

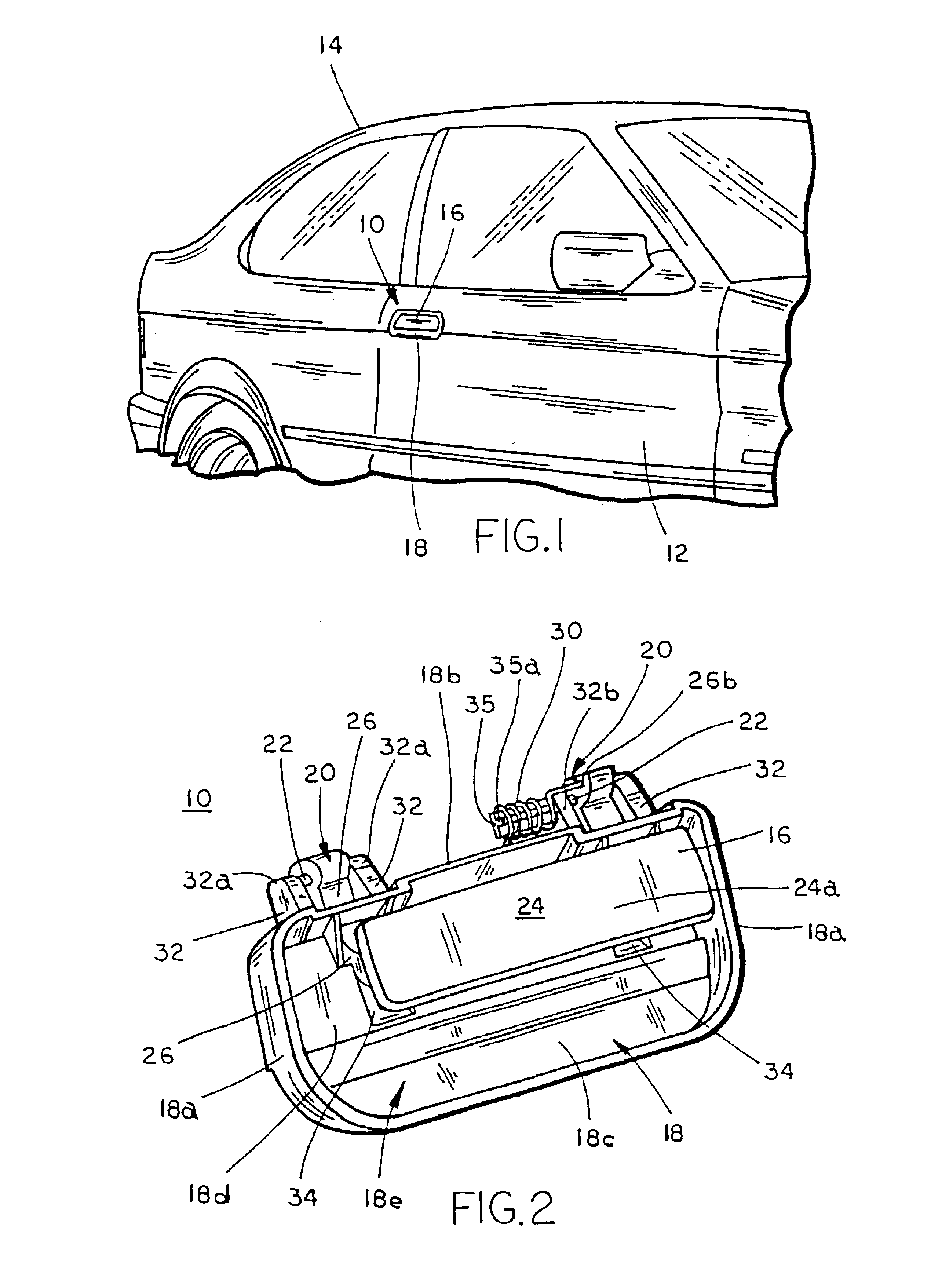

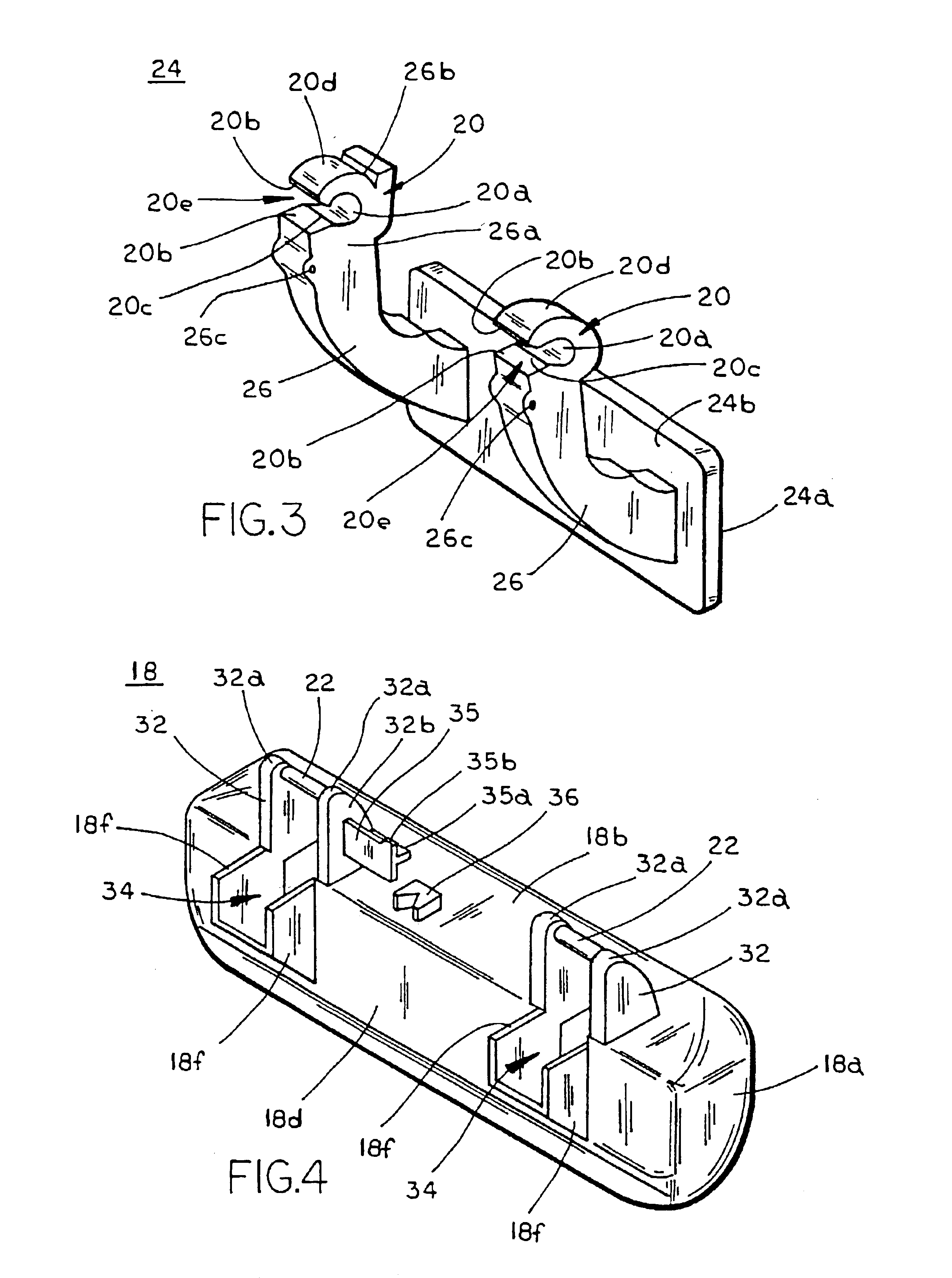

Vehicle door handle

A vehicle door handle assembly for opening a door of a vehicle includes a base which is mountable at the door of the vehicle and a handle portion which is operable to open the door via movement of the handle portion relative to the base. The handle portion includes a first portion having a first material hardness and a second portion having a second material hardness. The first material hardness is greater than the second material hardness, such that the second portion provides a softer feel to a user of the door handle assembly when opening the door of the vehicle. The door handle assembly may further include an illumination source for illuminating the handle portion and / or a heating element for heating the handle portion.

Owner:DONNELLY CORP

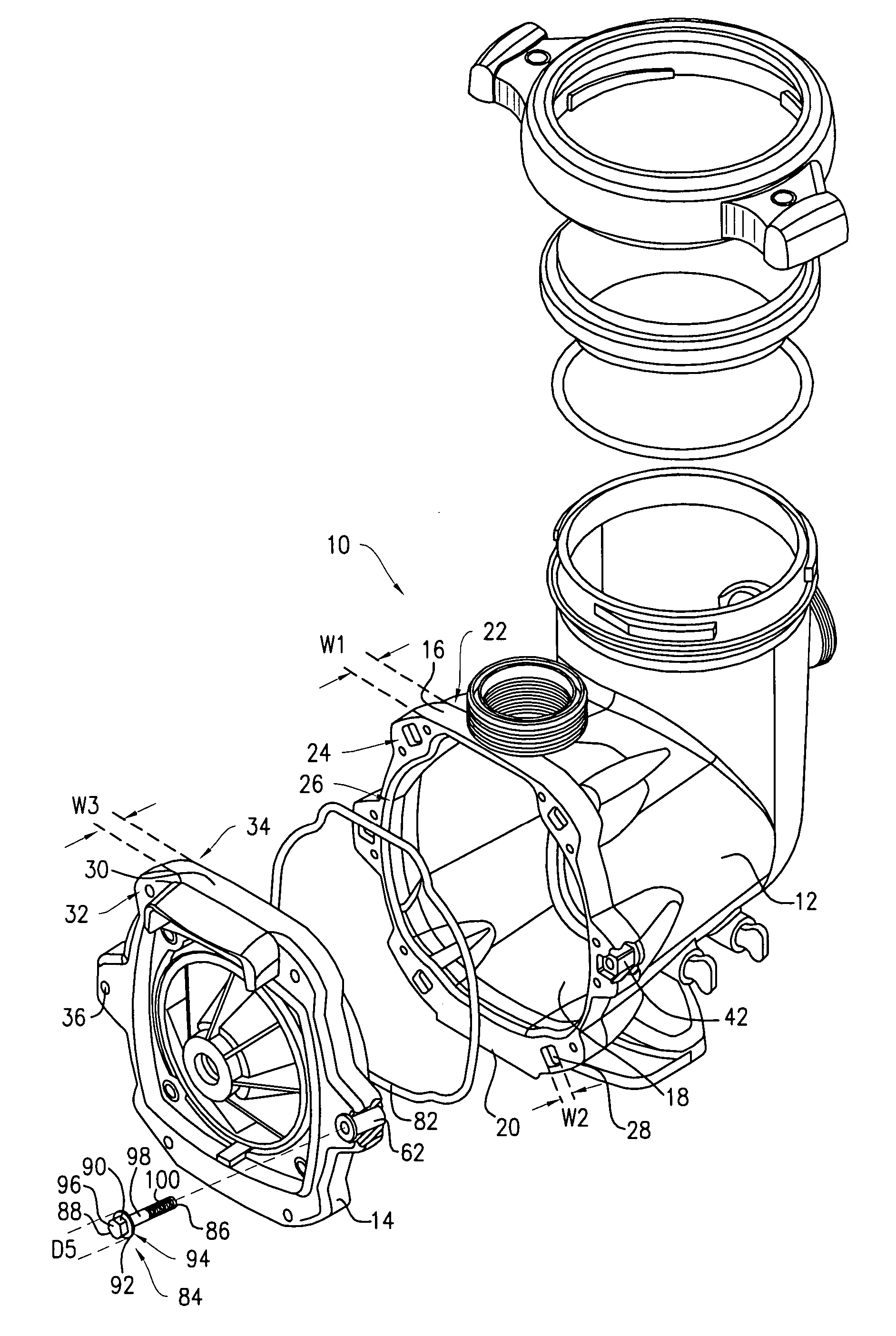

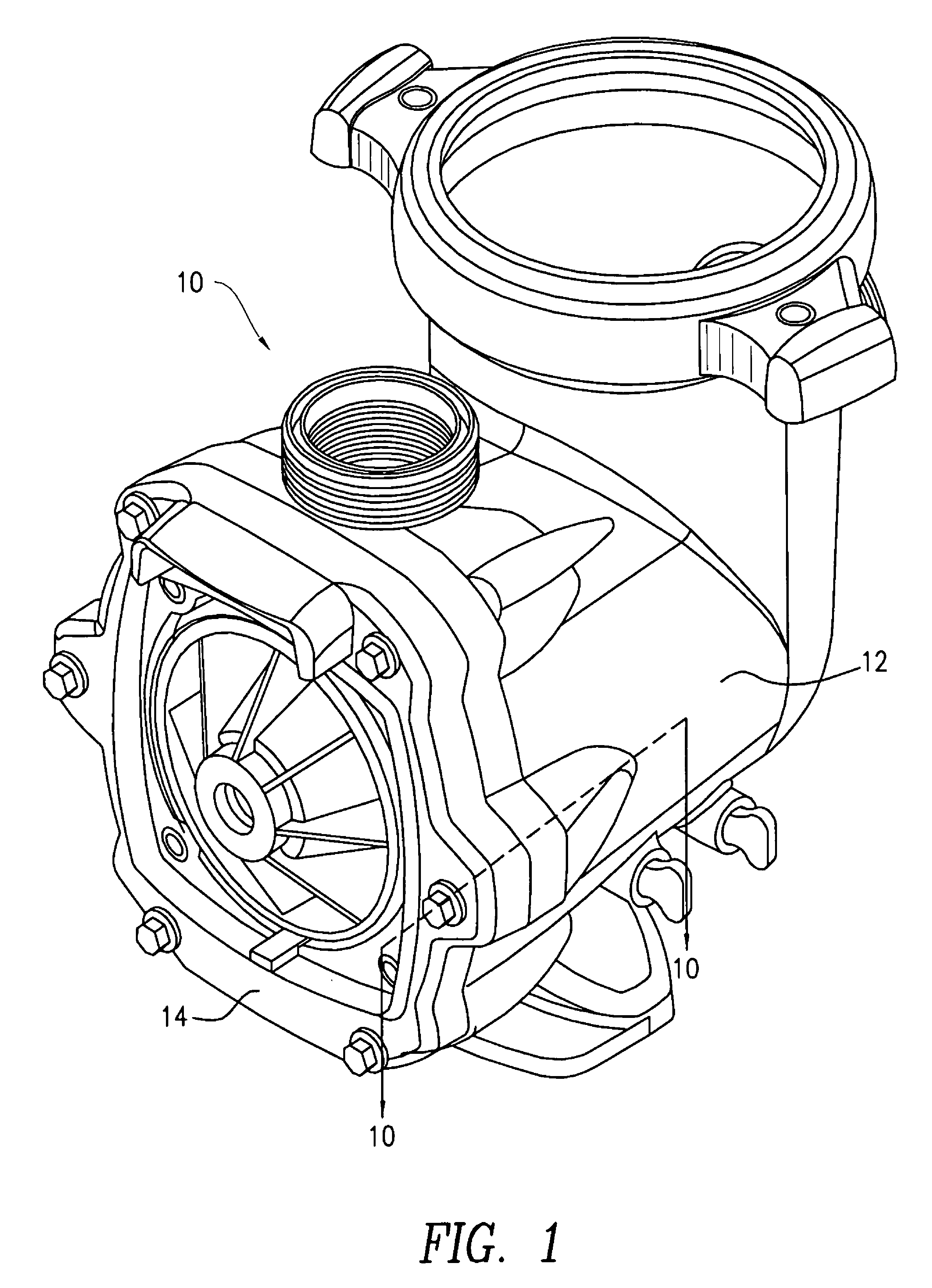

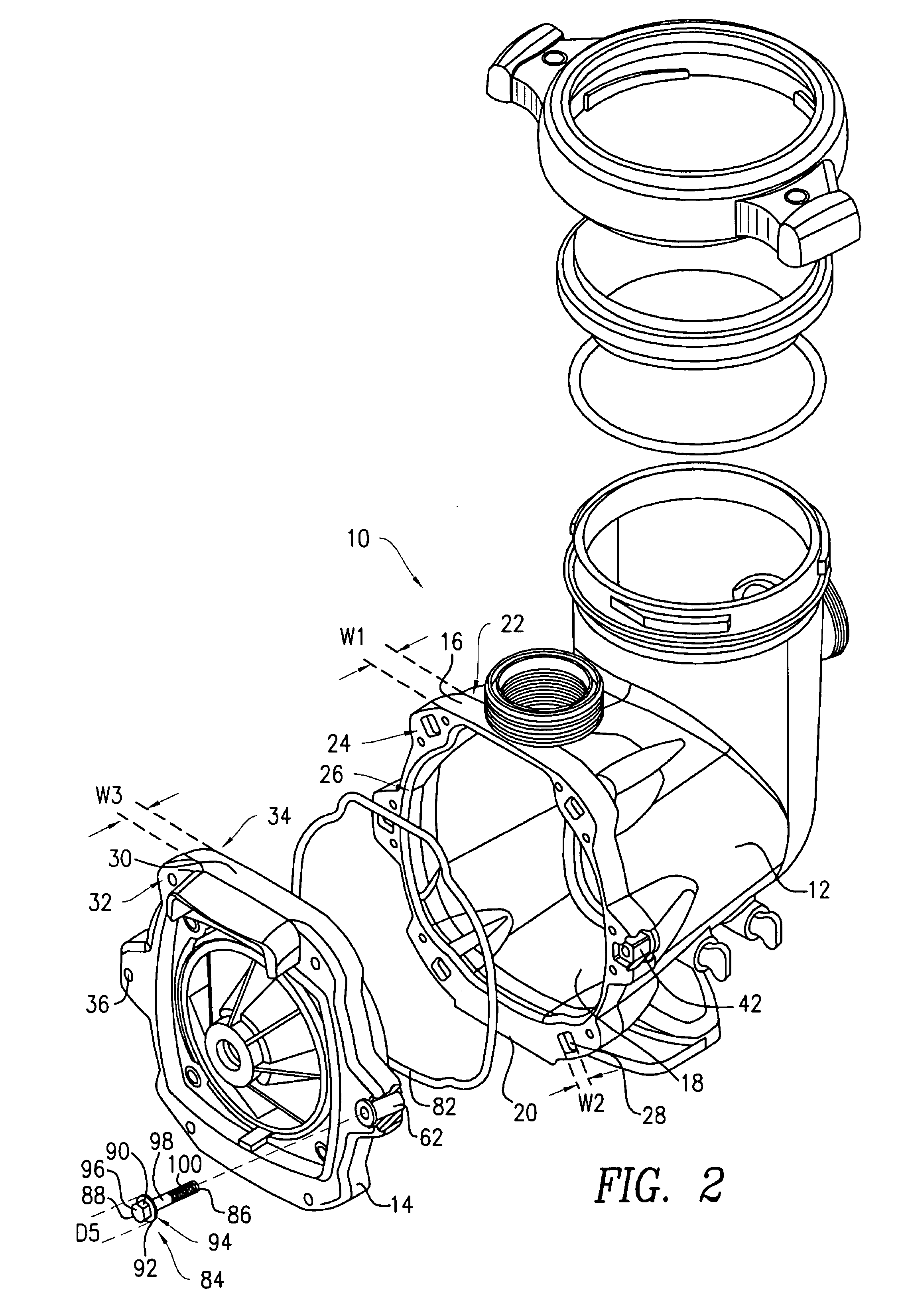

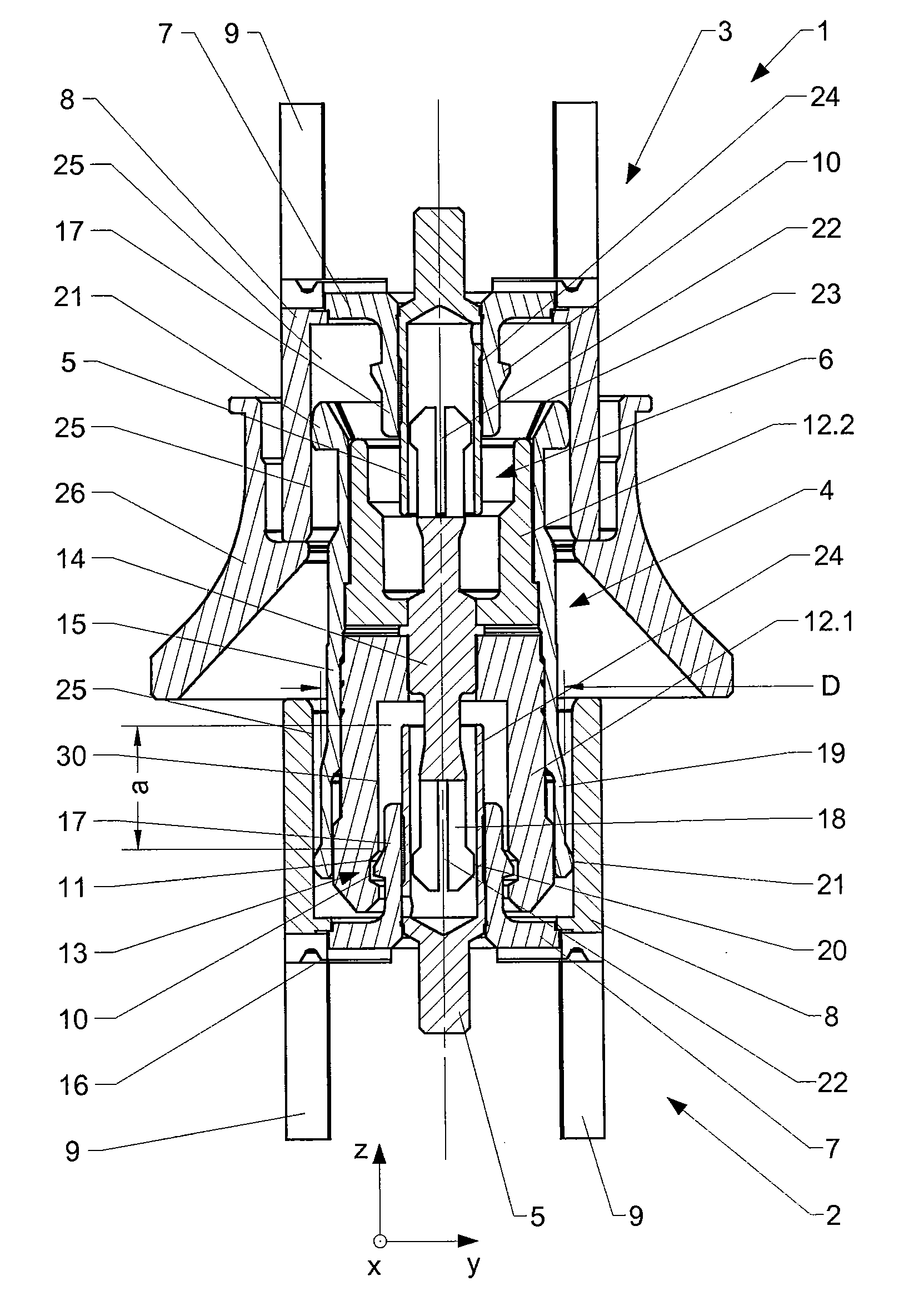

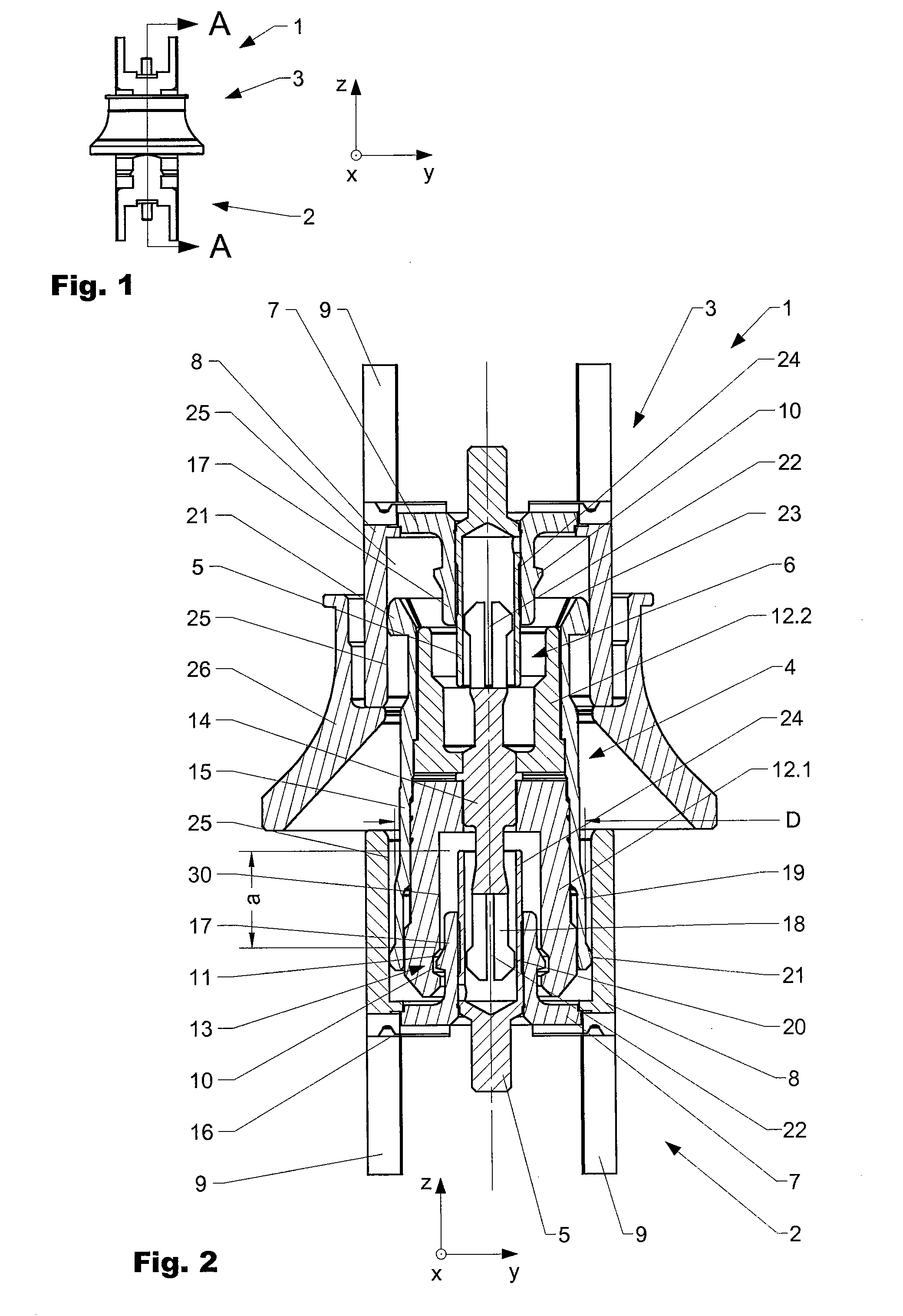

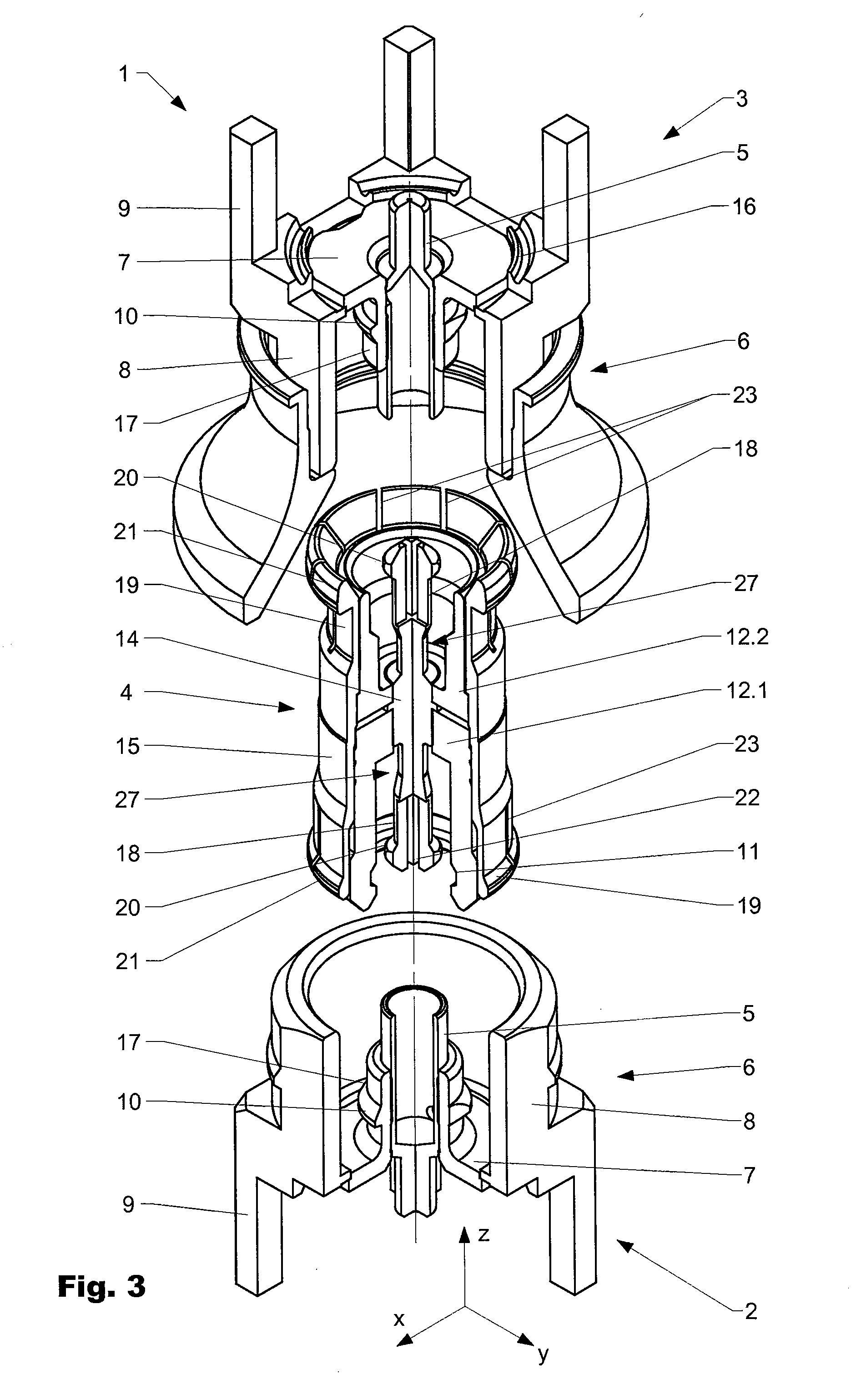

Pump housing coupling

ActiveUS8182212B2Readily and reliably in alignmentDissembled and subsequently completely reassembledReaction enginesPumpsCouplingEngineering

An assembly is disclosed for forming a fluid-tight seal between a pump housing and a seal plate. The housing includes a first flange with a first plurality of apertures formed therein, and the seal plate includes a second flange with a second plurality of apertures formed therein. A gasket is provided between the pump housing and the seal plate. A plurality of inserts extend through the first plurality of apertures, and a plurality of spacers extend through the second plurality of apertures. A plurality of threaded connectors are used to couple the seal plate to the pump housing to form a fluid-tight seal. The dimensions of the inserts and spacers are selected so as to inhibit crushing of the gasket and the flanges when the connectors are fully tightened.

Owner:HAYWARD IND INC

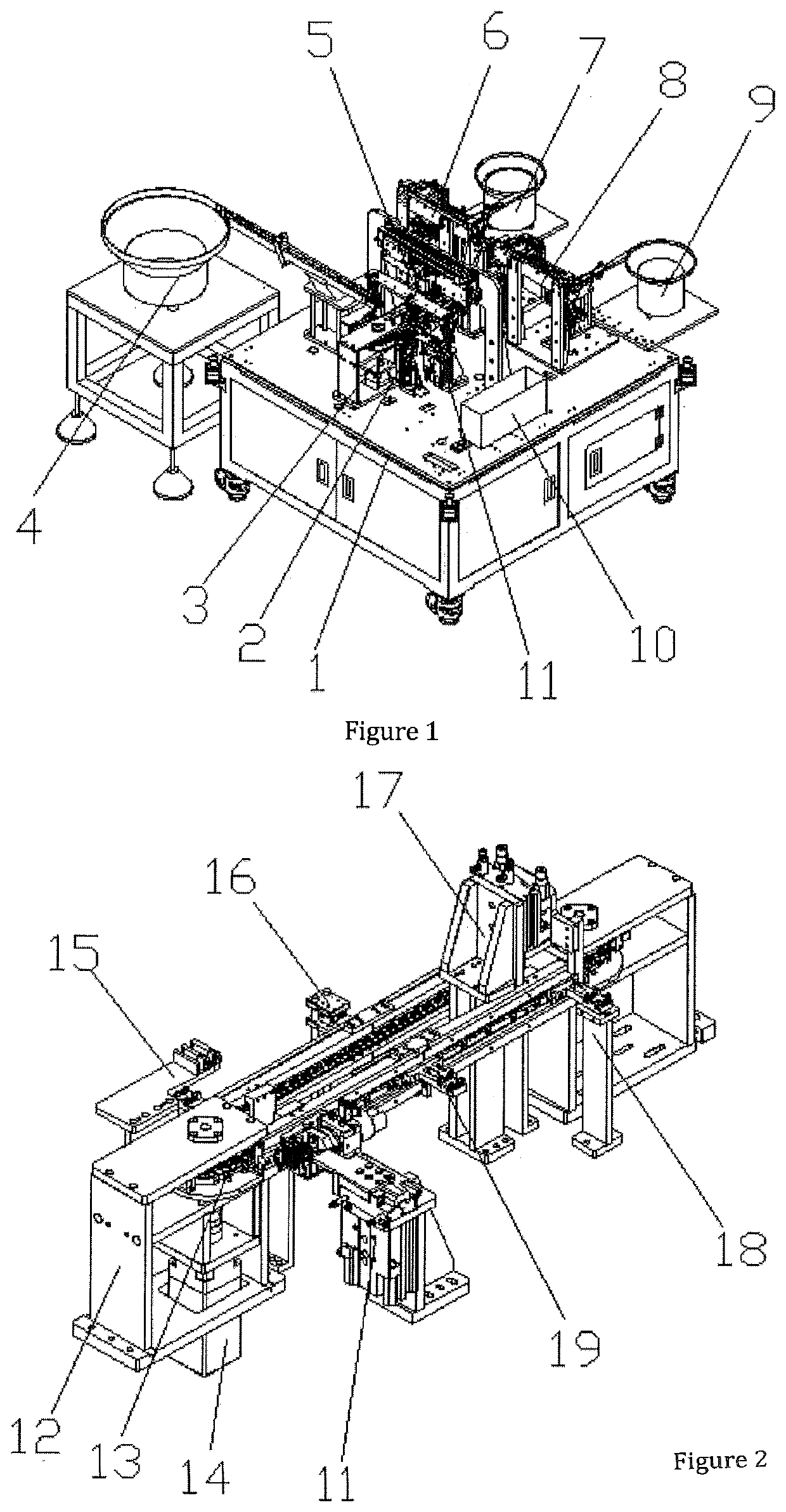

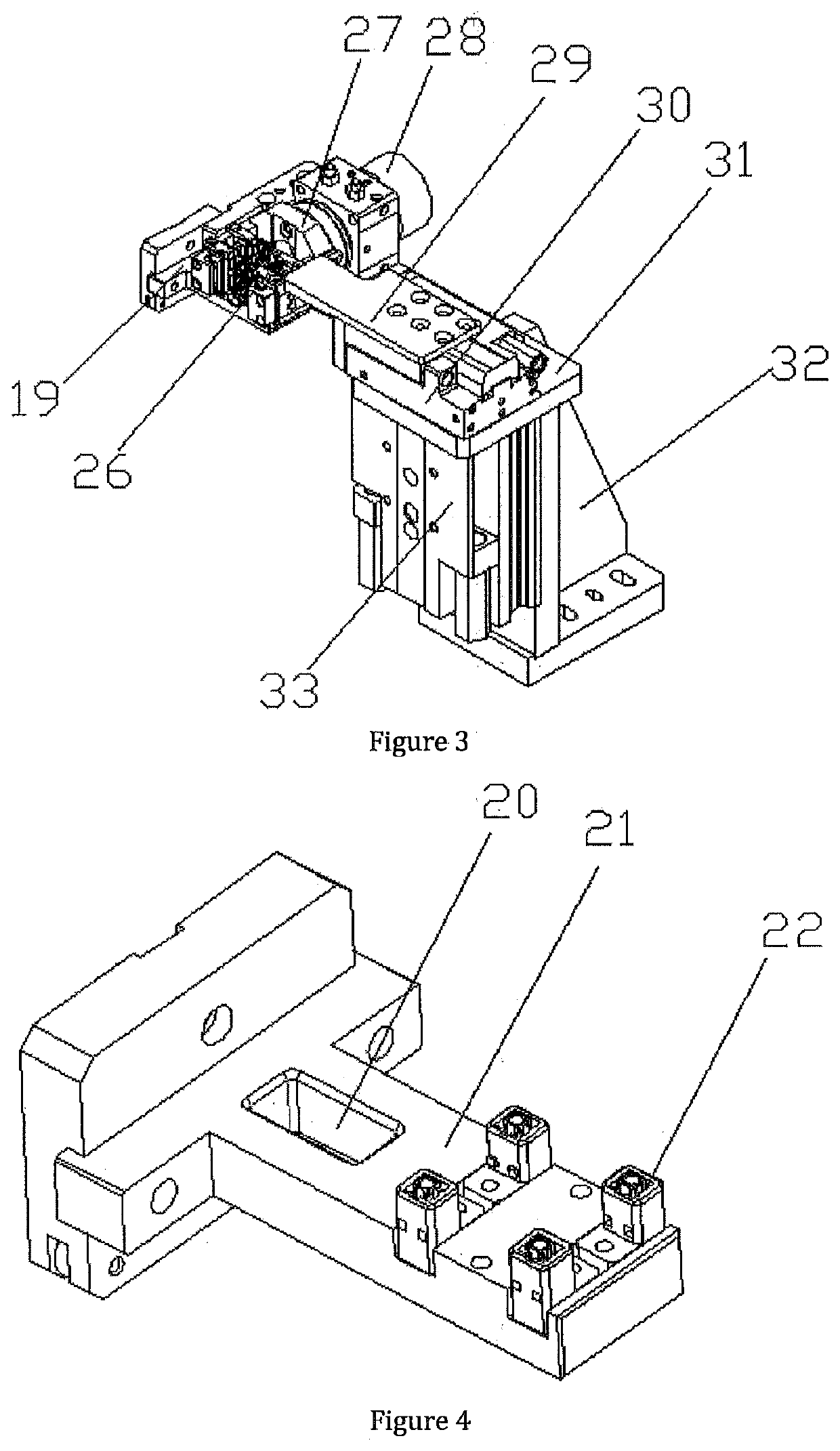

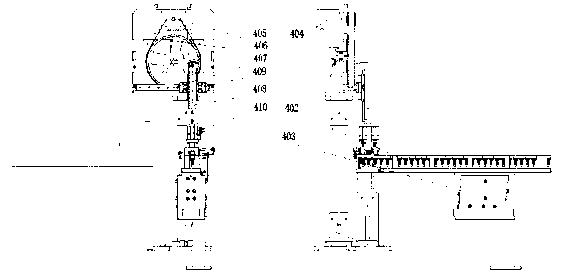

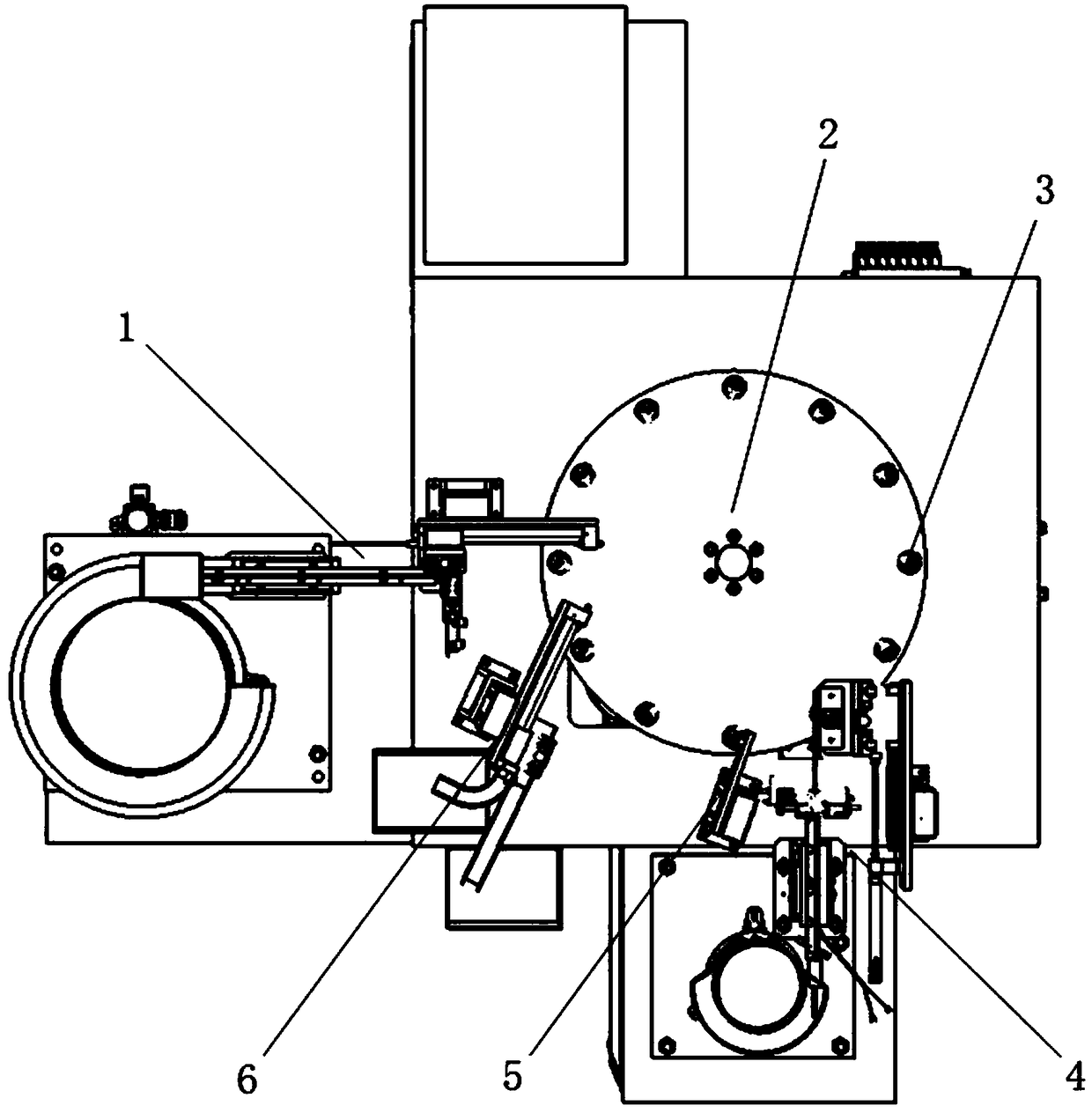

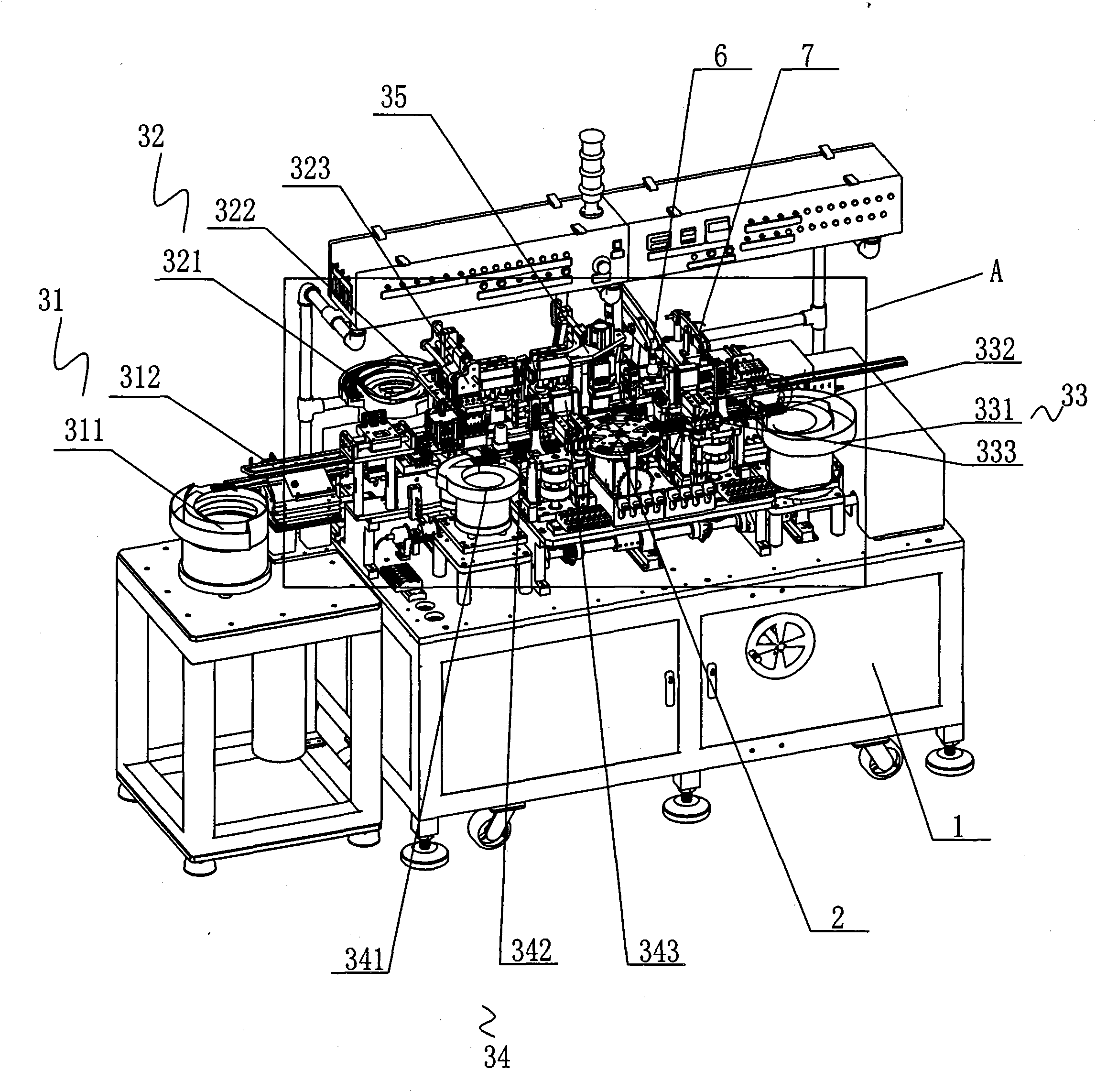

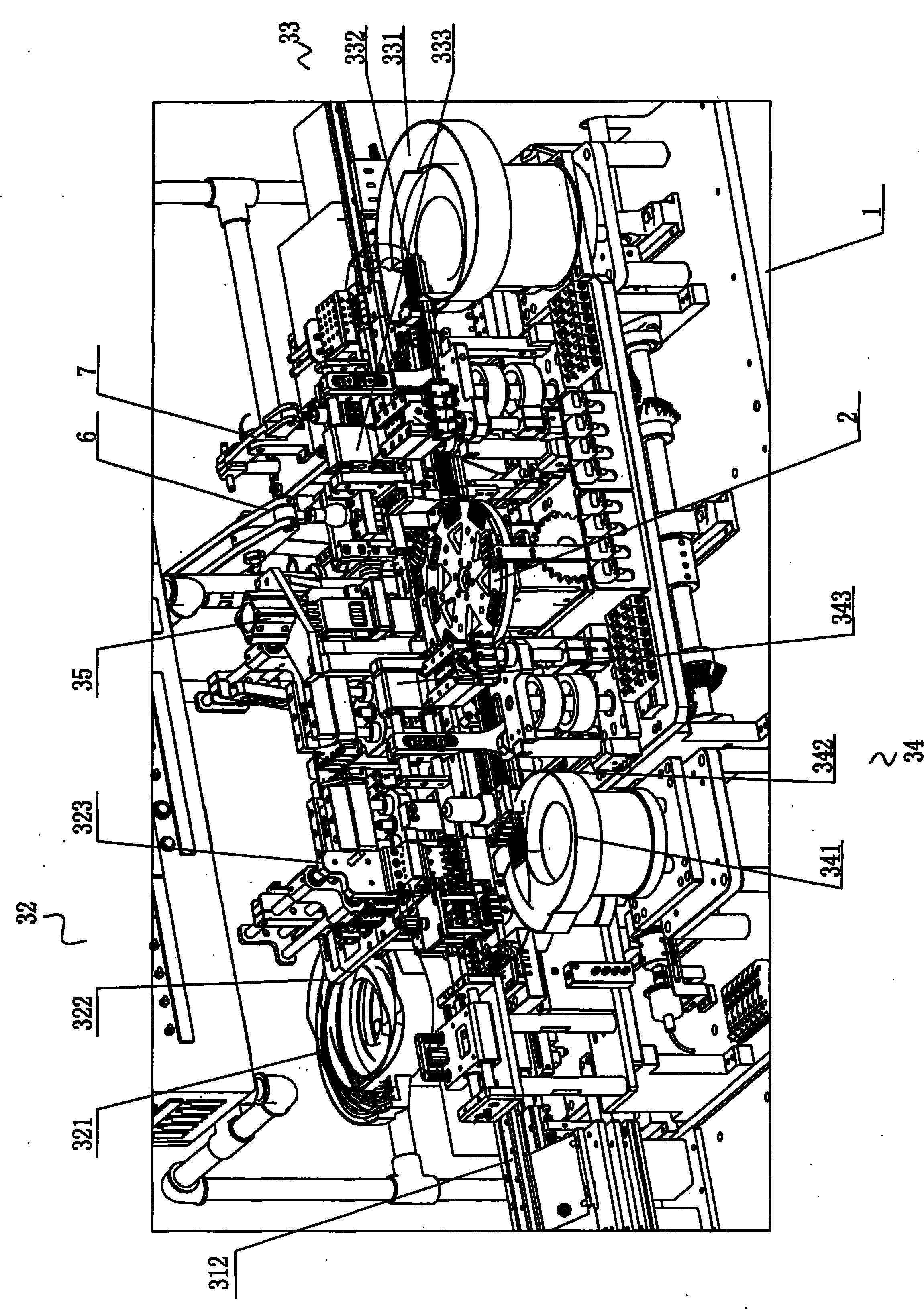

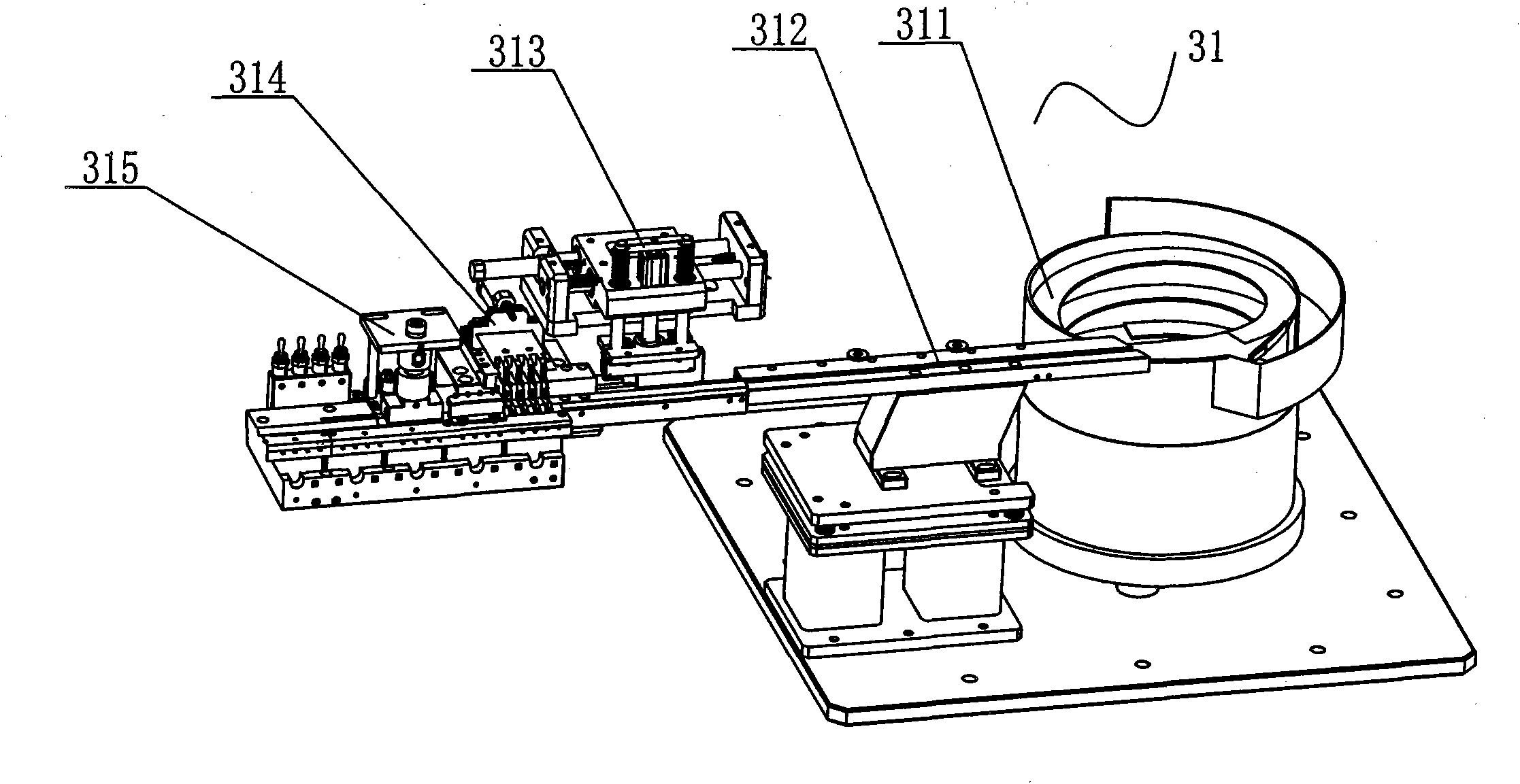

Automatic spring fastener assembly machine

ActiveUS20190337105A1Completed efficientlyCompleted fastContact member assembly/disassemblyAssembly machinesRobot handEngineering

The present invention relates to an automatic spring fastener assembly machine, including a rack and a power control box, and the rack is provided with a circulating conveying device, and a rubber casing feeding device, a fastener feeding device and a spring loading device which are in turn arranged around the circulating conveying device. The rubber casing feeding device includes a rubber casing vibration tray disposed to the left front side of the circulating conveying device, and the rubber casing feeding vibration tray is connected with a rubber casing distributing block through the rubber casing conveying track. The upper side of the circulating conveying device is provided with a rubber casing transportation manipulator, and the right front side thereof is provided with a rubber casing clamping device located below the rubber casing transportation manipulator, and a fastener pushing in device fitting the circulating conveying device is disposed under the rubber casing clamping device. In the present invention, material feeding and conveying is done by the circulating conveying device, and fasteners are fitted into corresponding holes on the rubber casings from a higher position with the fastener pushing in device, which can be completed fast and efficiently, is easy to operate, realize quick assembly of spring fasteners and improve working efficiency.

Owner:DONGGUAN UNIV OF TECH

Automatic assembly machine of quick connectors

InactiveCN103273312AAssembly precisionIncrease productivityAssembly machinesForeign matterEngineering

An automatic assembly machine of quick connectors comprises a machine frame, wherein a large turntable and a small turntable are installed on the machine frame. A main-body feeding mechanism, a main-body inner cavity foreign-matter sucking mechanism, a main-body inside foreign-matter detecting machine, a green sealing ring pressing-in mechanism, a green sealing ring detecting machine, a spacer ring assembling mechanism, a spacer ring assembling detecting machine, a blue sealing ring assembling mechanism, a blue sealing ring assembling detecting machine, a safety ring pre-assembling mechanism and a safety ring pressing-in mechanism are installed on the large turntable in sequence. A safety ring detecting machine, a locking spring assembling mechanism, a locking spring assembling detecting machine and an output mechanism are installed on the small turntable in sequence, wherein the output mechanism outputs good products and NG products of the assembled quick connectors after detection. A transition mechanism used for transferring the quick connectors in a rotating mode is installed between the safety ring pressing-in mechanism and the safety ring detecting machine. The automatic assembly machine achieves automatic assembly and detection of the quick connectors, is convenient to operate, accurate in assembly and high in production efficiency, reduces dependence on manpower resources, and saves production cost.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

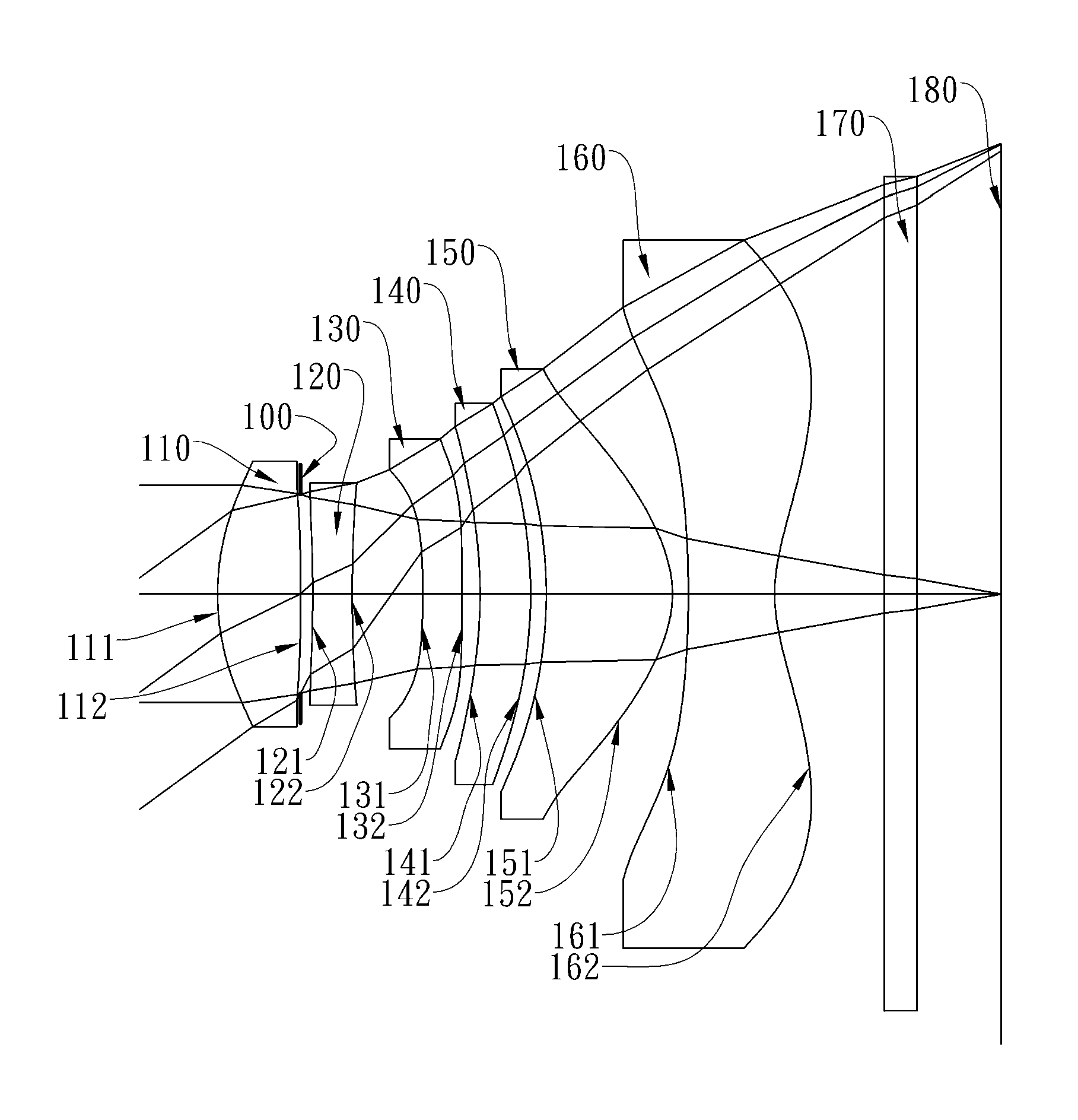

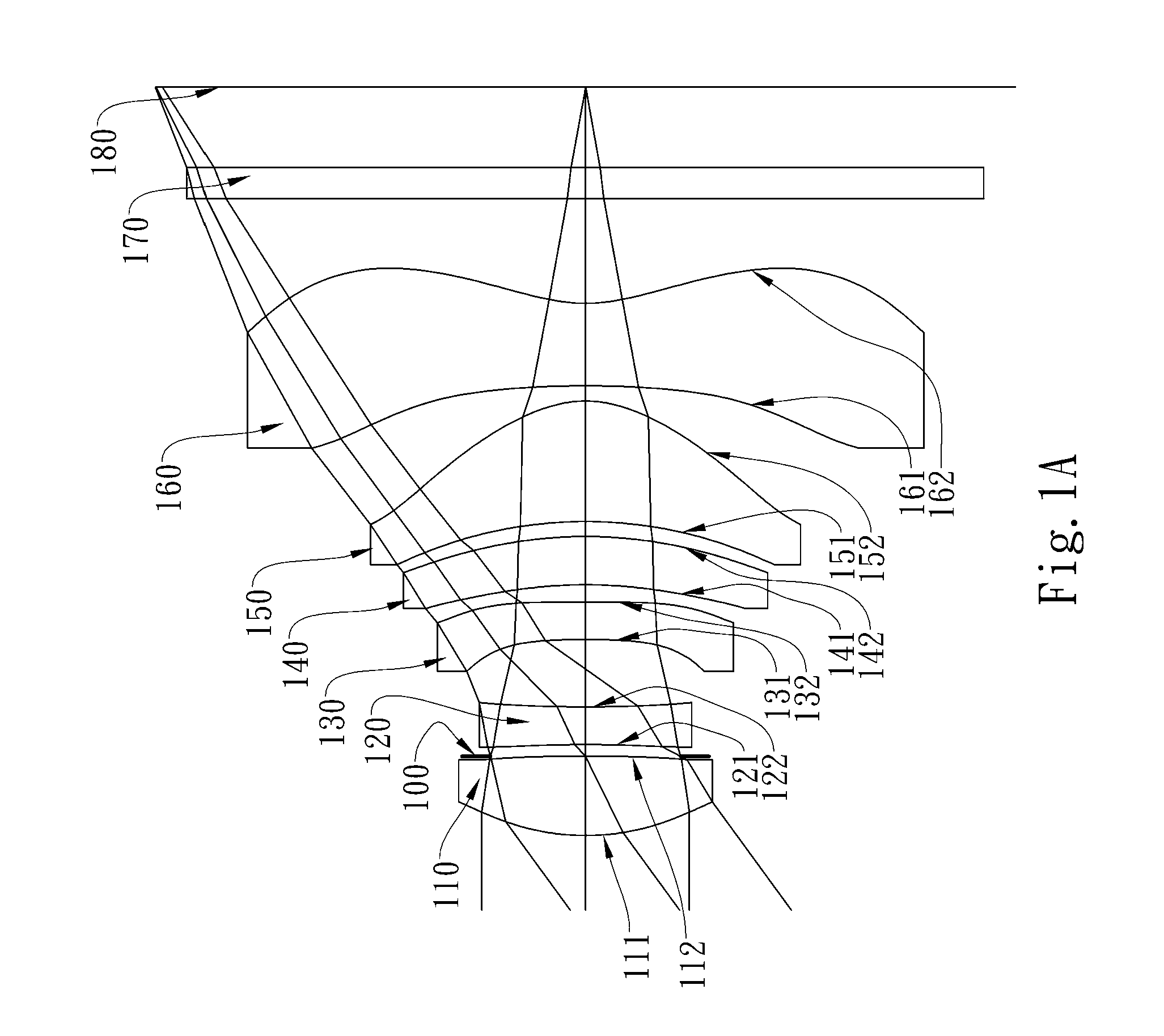

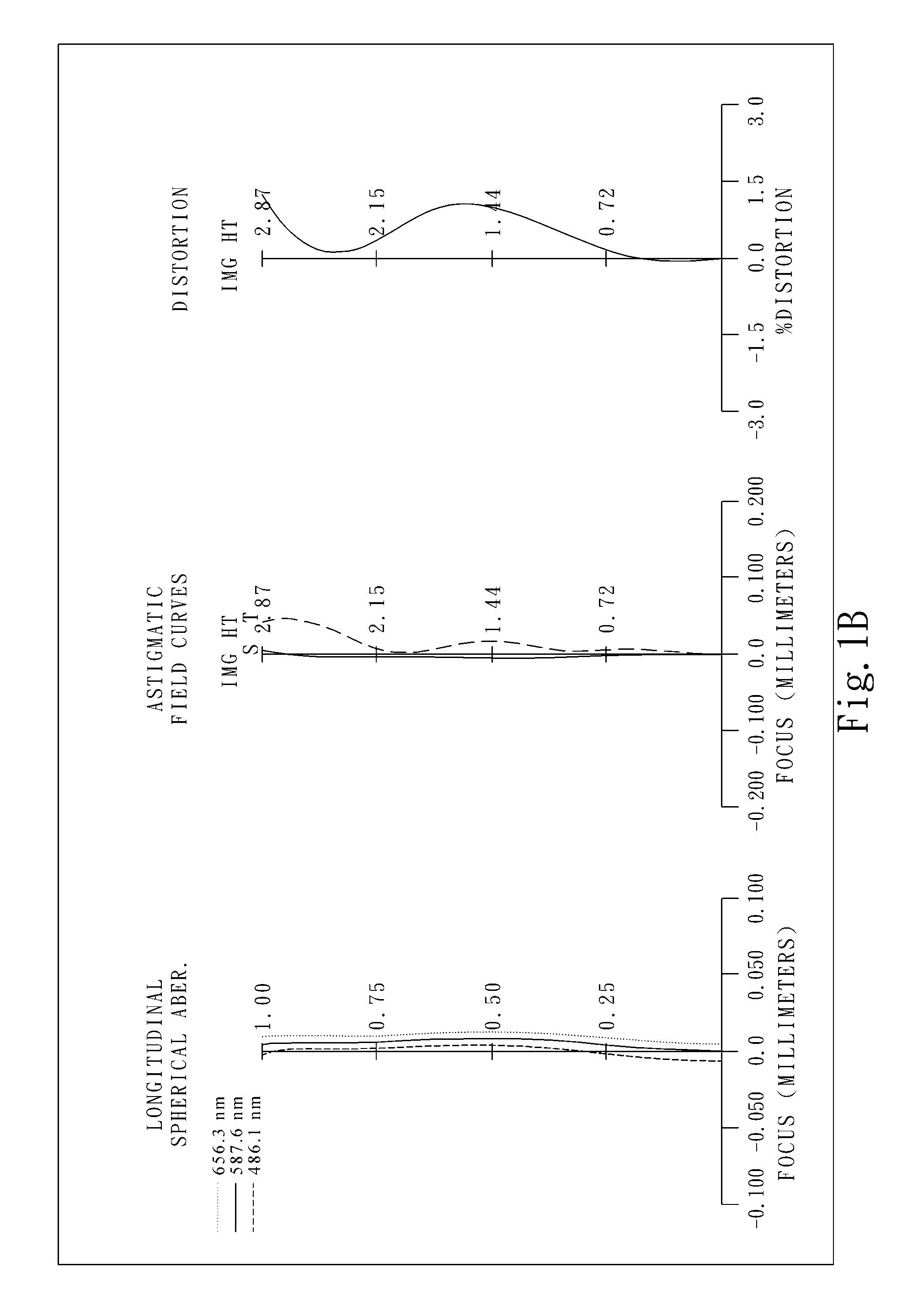

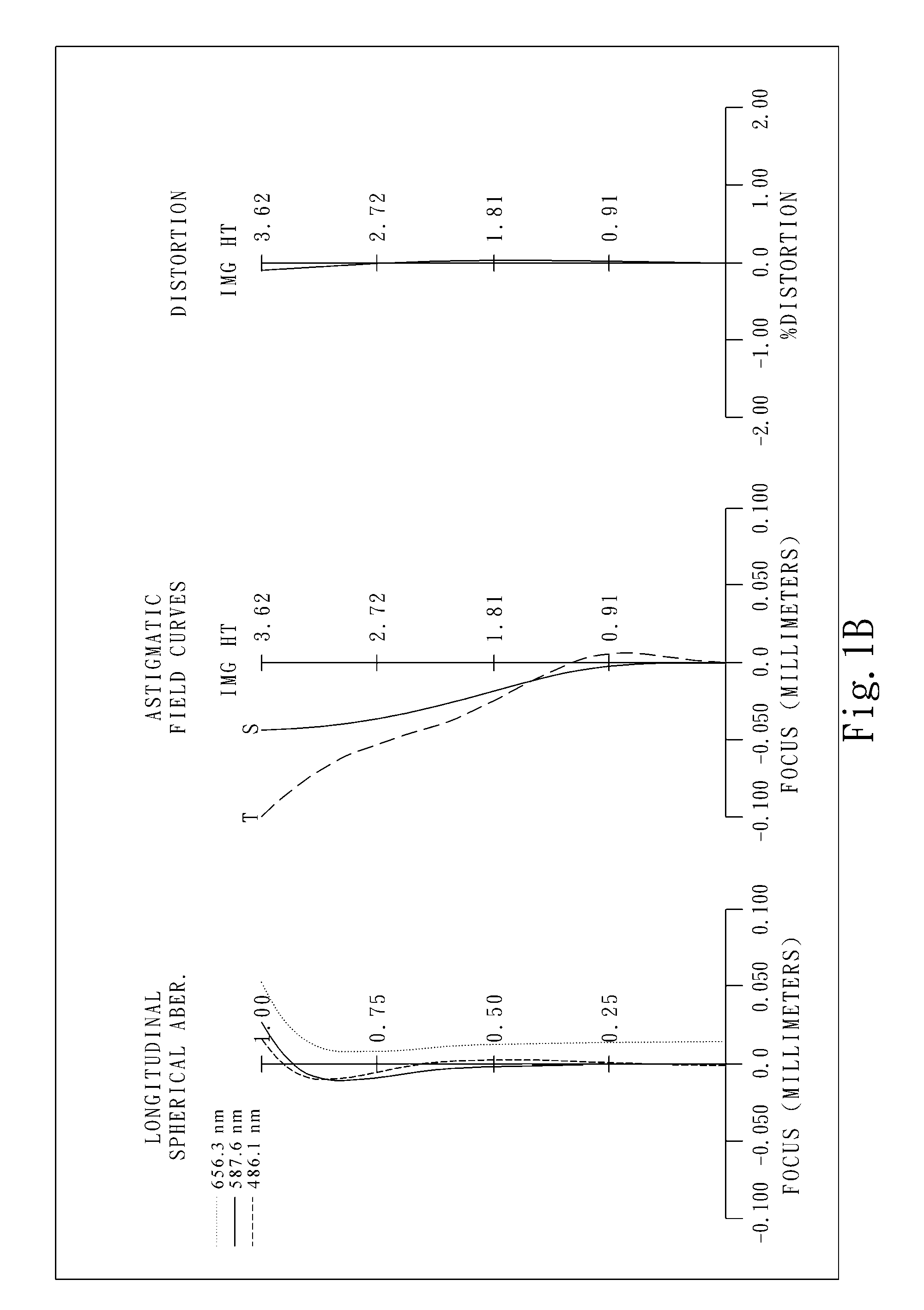

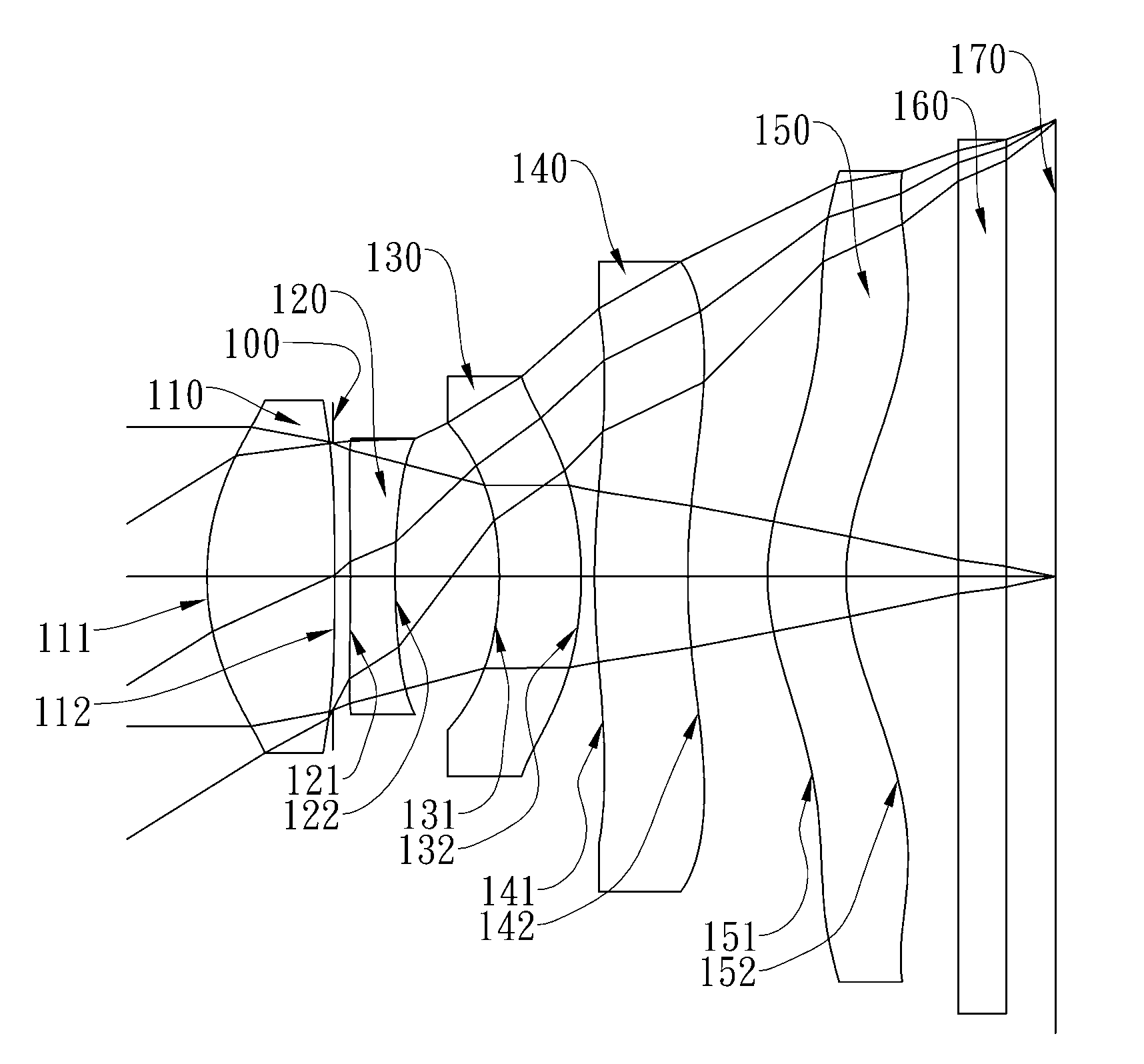

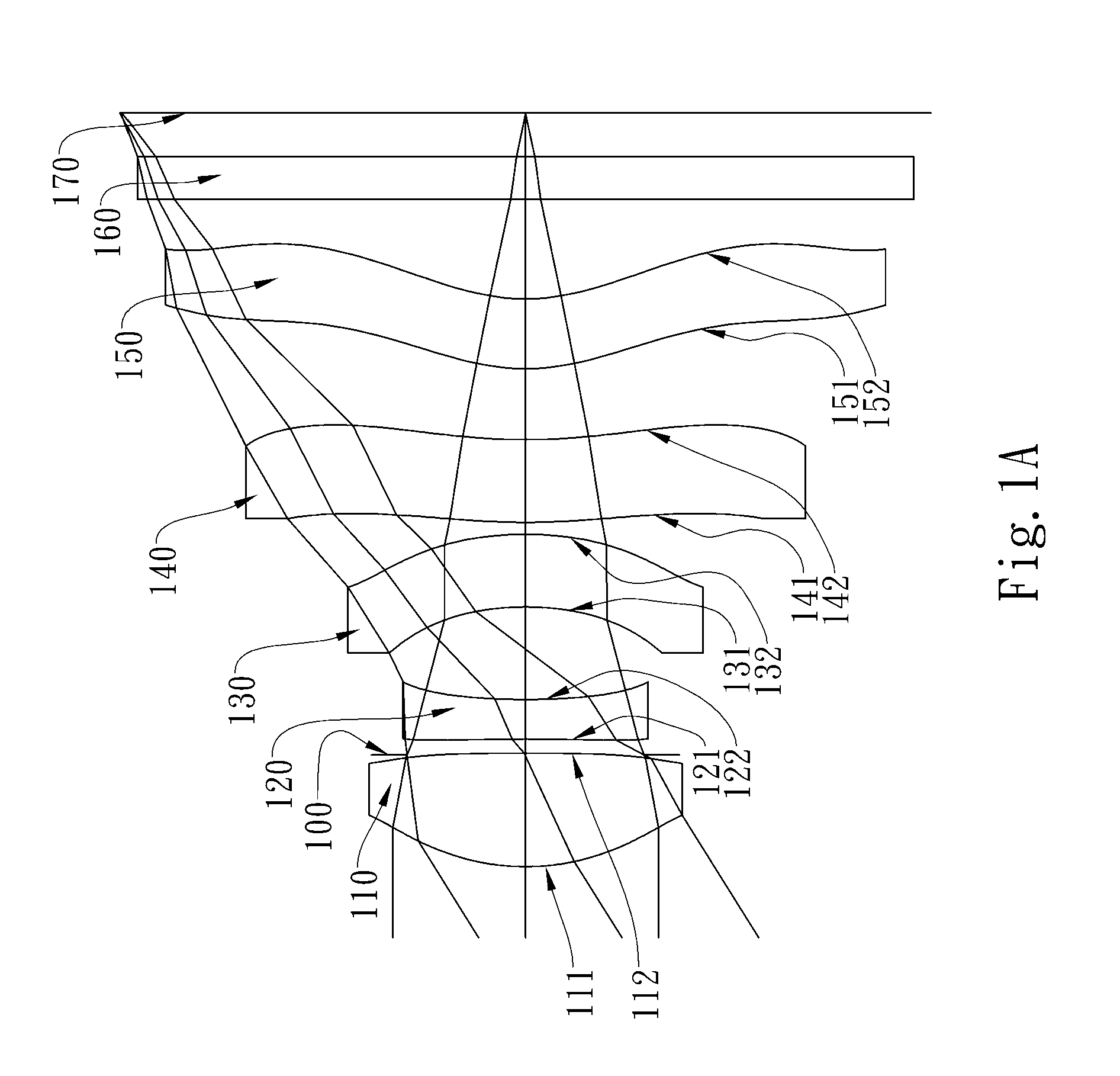

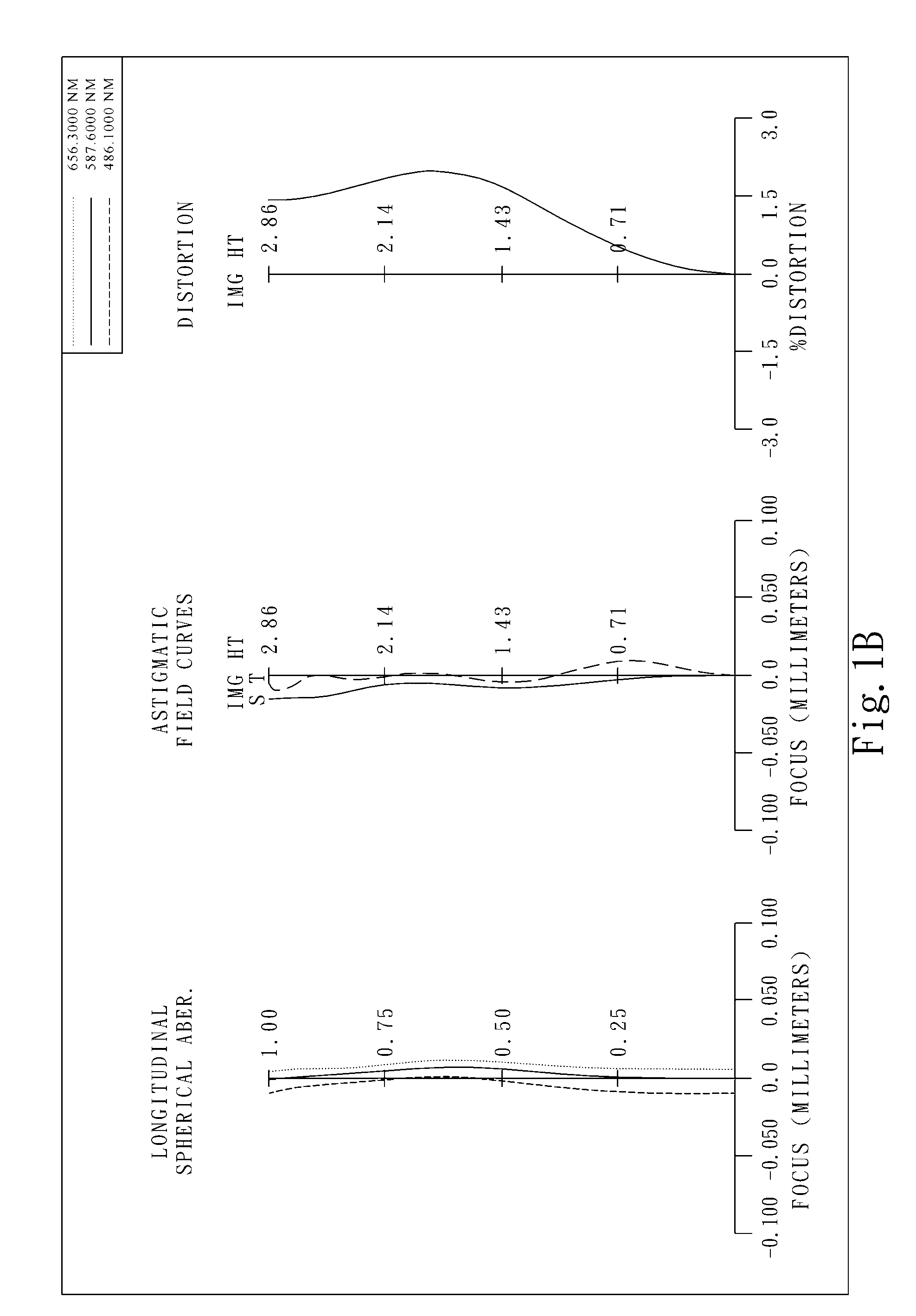

Image capturing lens assembly

This invention provides an image capturing lens assembly, in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element; a third lens element; a fourth lens element having at least one of an object-side surface and an image-side surface thereof being aspheric; a fifth lens element with positive refractive power having a convex image-side surface, at least one of an object-side surface and the image-side surface thereof being aspheric, and the fifth lens element is made of plastic; and a sixth lens element with negative refractive power having a concave image-side surface, at least one of an object-side surface and the image-side surface thereof being aspheric, and the sixth lens element is made of plastic. By such arrangement, the photo-sensitivity and the total track length of the image capturing lens assembly can be reduced. Furthermore, the aberration and astigmatism of the assembly can be effectively corrected for obtaining higher image resolution.

Owner:LARGAN PRECISION

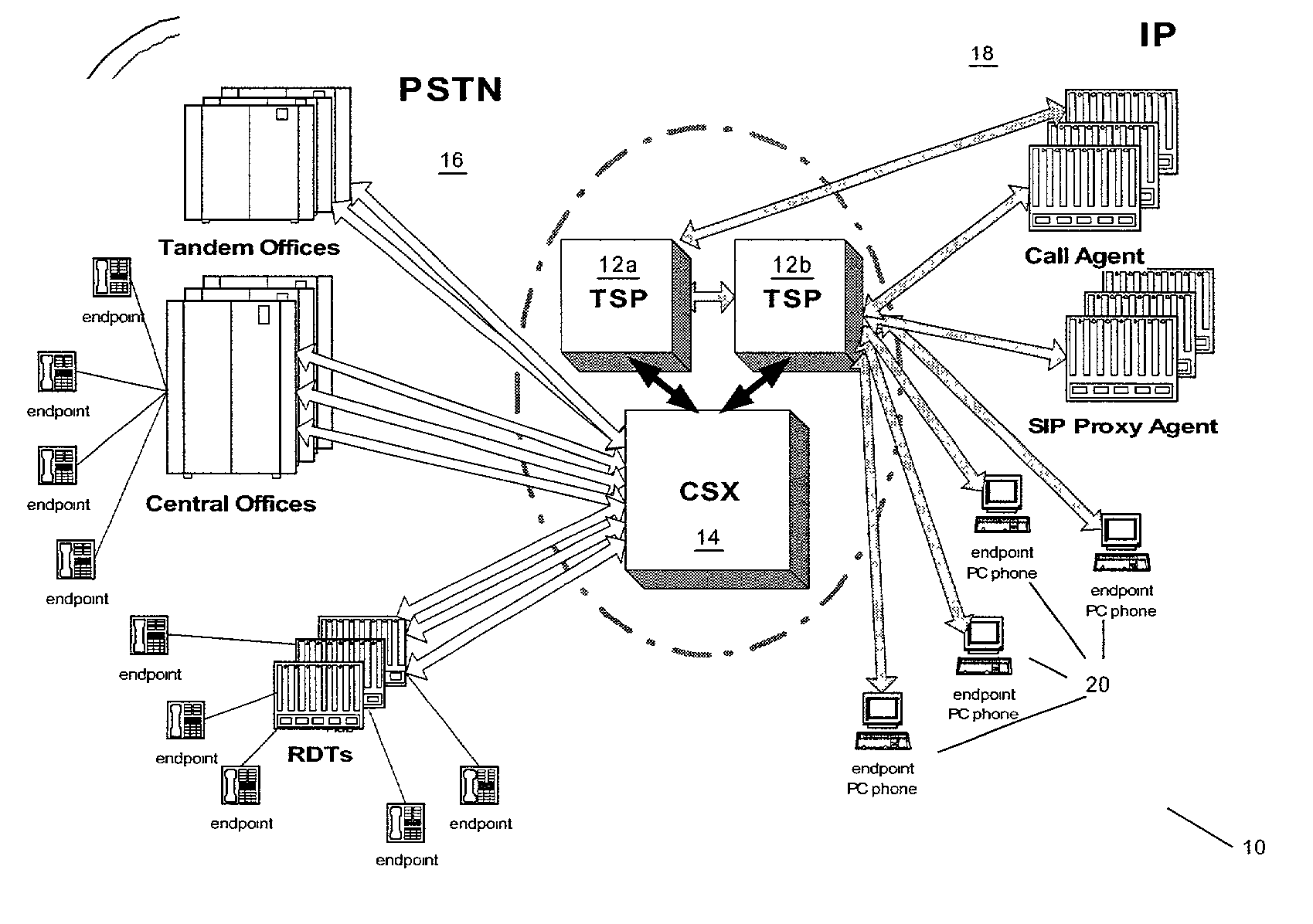

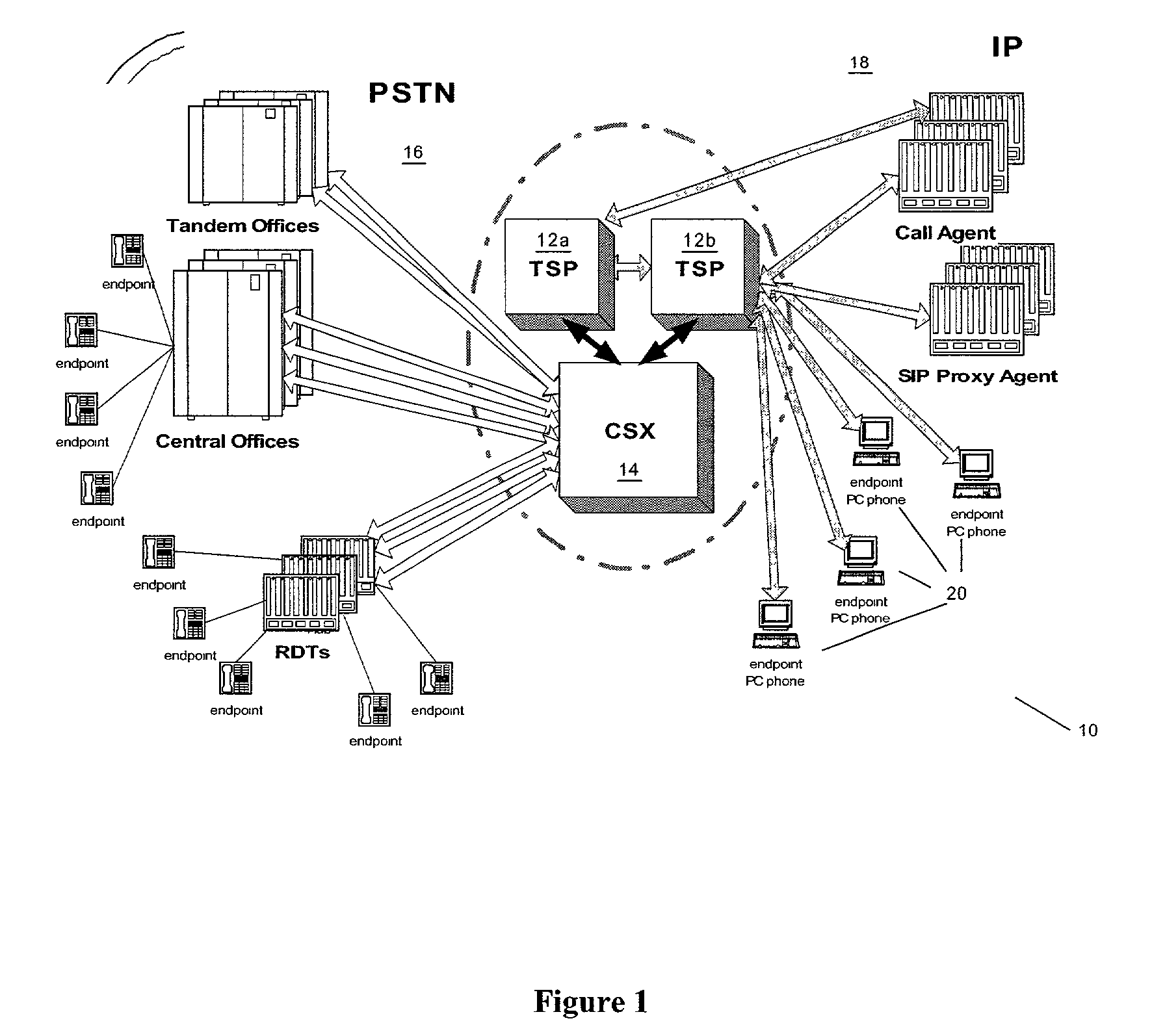

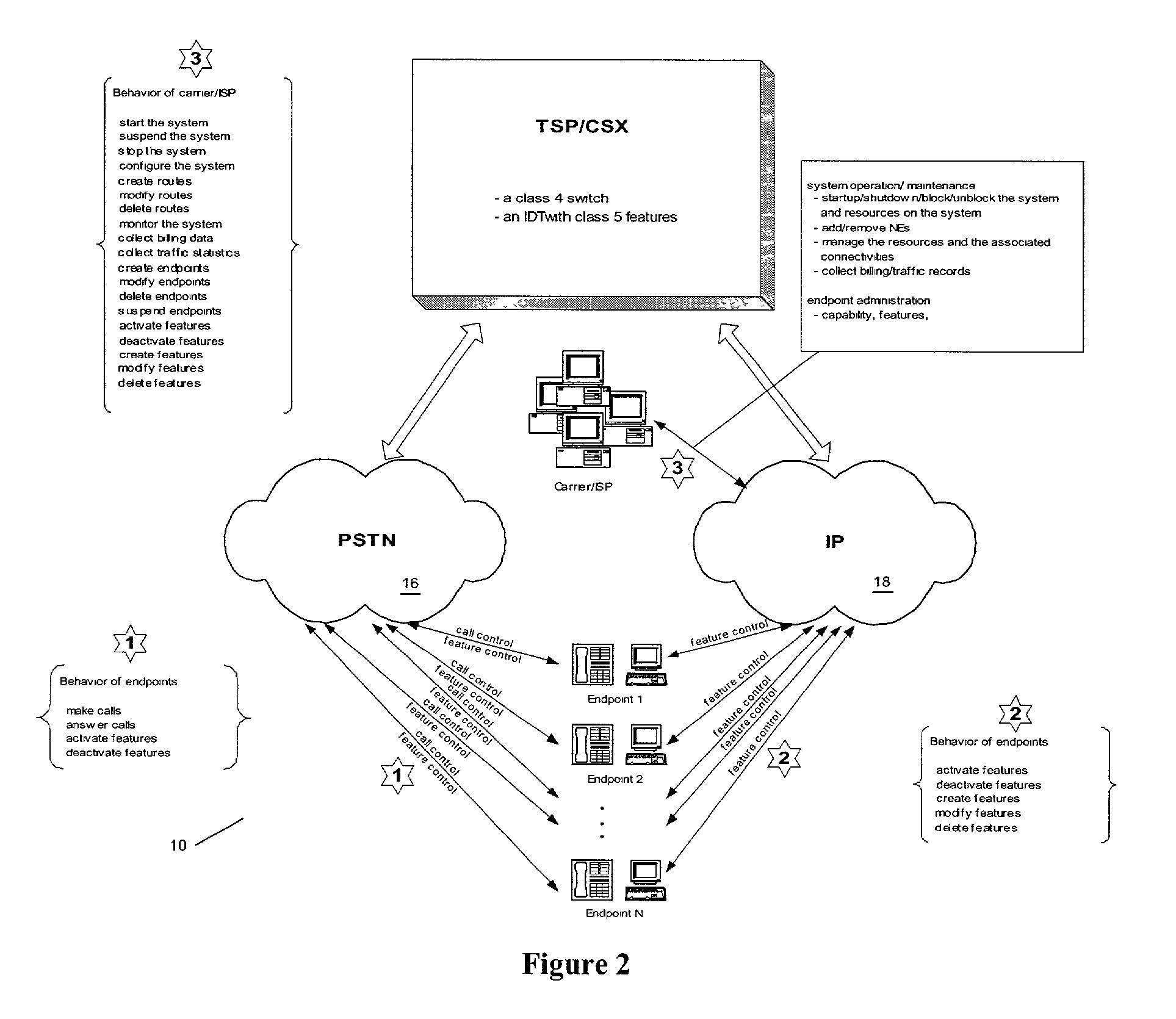

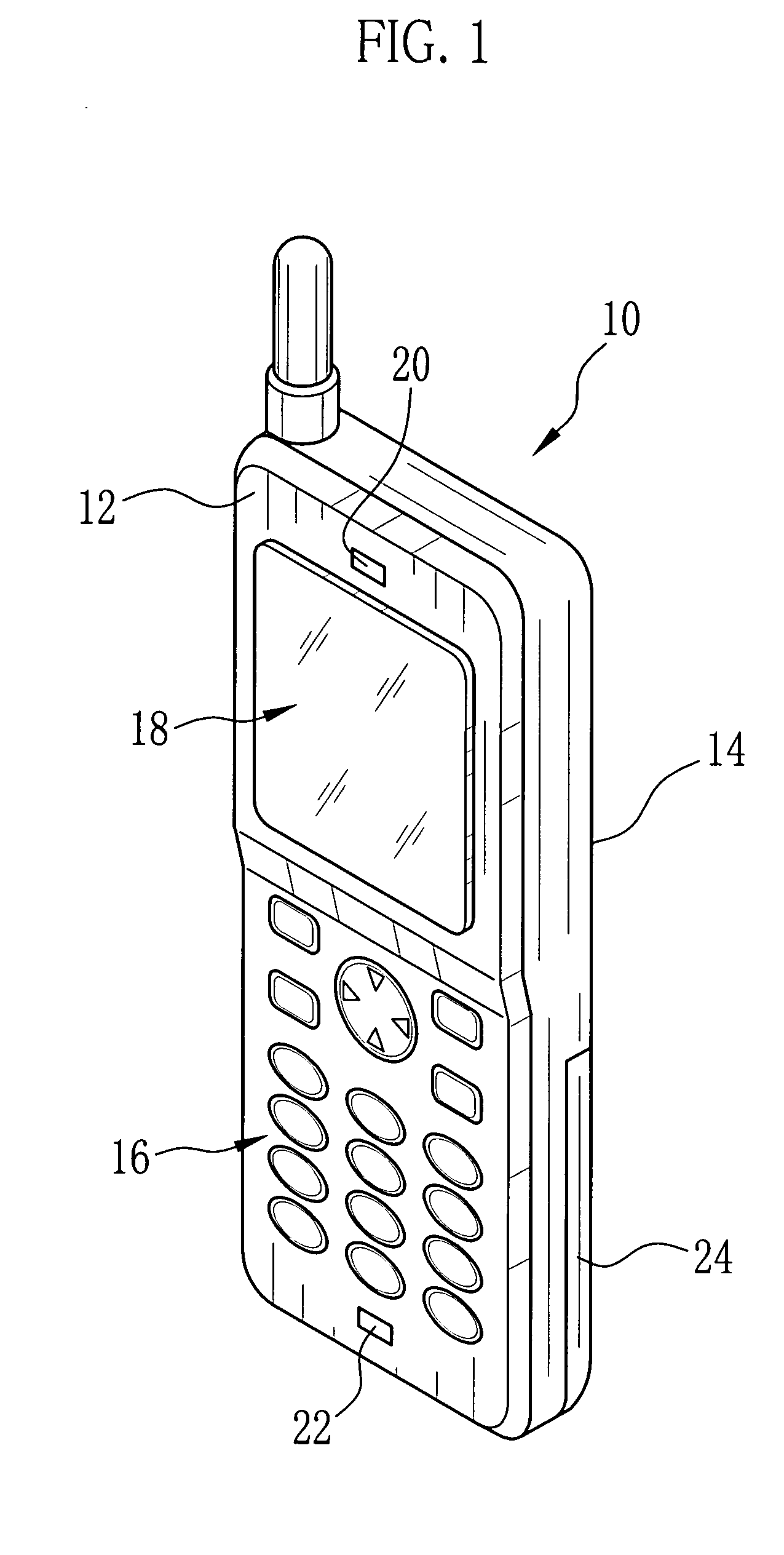

Telecommunications portal capable of interpreting messages from an external device

InactiveUS7046778B2Assembly precisionMultiplex system selection arrangementsTelephone data network interconnectionsProgramming languageXML

The present invention relates to methods and system for providing telecommunications services, such as call waiting, three-way call, and automatic recall, utilizing a plurality of state machines. Logic specifications define a set of states for each state machine. Each state in turn defines at least one action to be performed in response to a signal received by the state machine. The logic specification for each state machine can be stored, for example, in a textual format in a mark up language, such as HTML, XML, or or other markup language. A compiled representation of the logic specification is generated. Further, a context object tracks a current state of the telecommunication service. The context object accesses the compiled representation in response to an event, e.g., a call progress event, in order to effect a state transition and / or perform an action with respect to the telecommunication service.

Owner:COPPERCOM

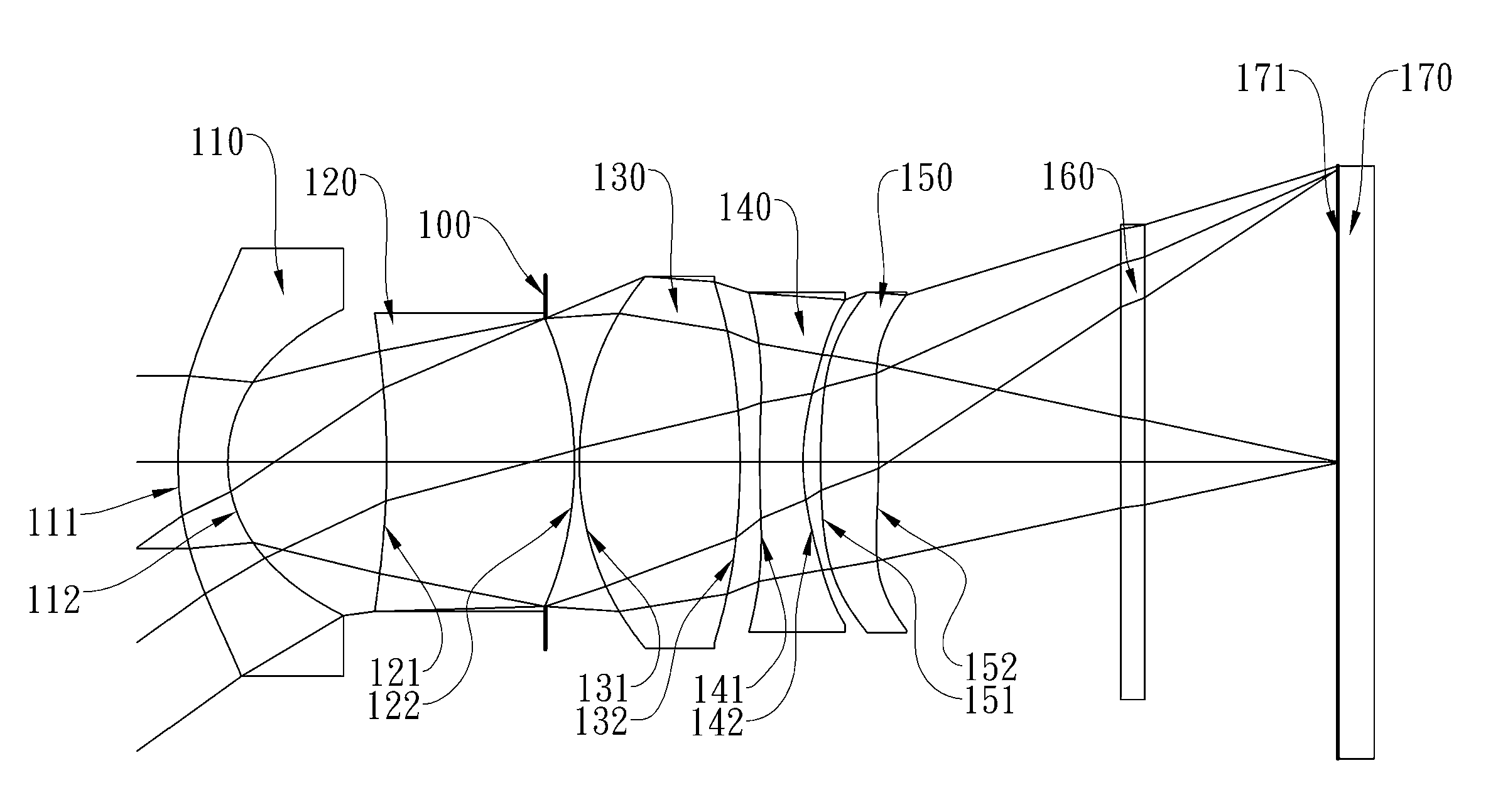

Image capturing lens assembly

ActiveUS8576497B2Favorable for enlarging field of viewEffective distributionLensCamera lensImage resolution

This invention provides an image capturing lens assembly in order from an object side to an image side comprising five lens elements with refractive power: a first lens element with negative refractive power having a convex object-side surface and a concave image-side surface, a second lens element with positive refractive power having a convex image-side surface, a third lens element with positive refractive power having a convex object-side surface, a fourth lens element with negative refractive power having a convex object-side surface and a concave image-side surface; and a fifth lens element with positive refractive power. By such arrangement, sufficient field of view is provided, and the aberration of the lens assembly is corrected for obtaining higher image resolution.

Owner:LARGAN PRECISION

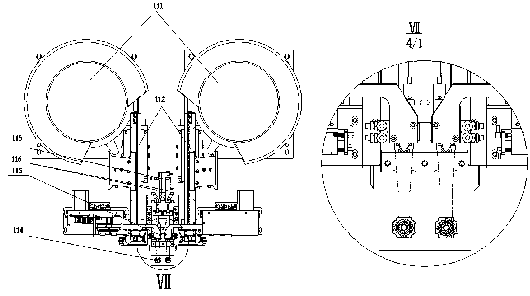

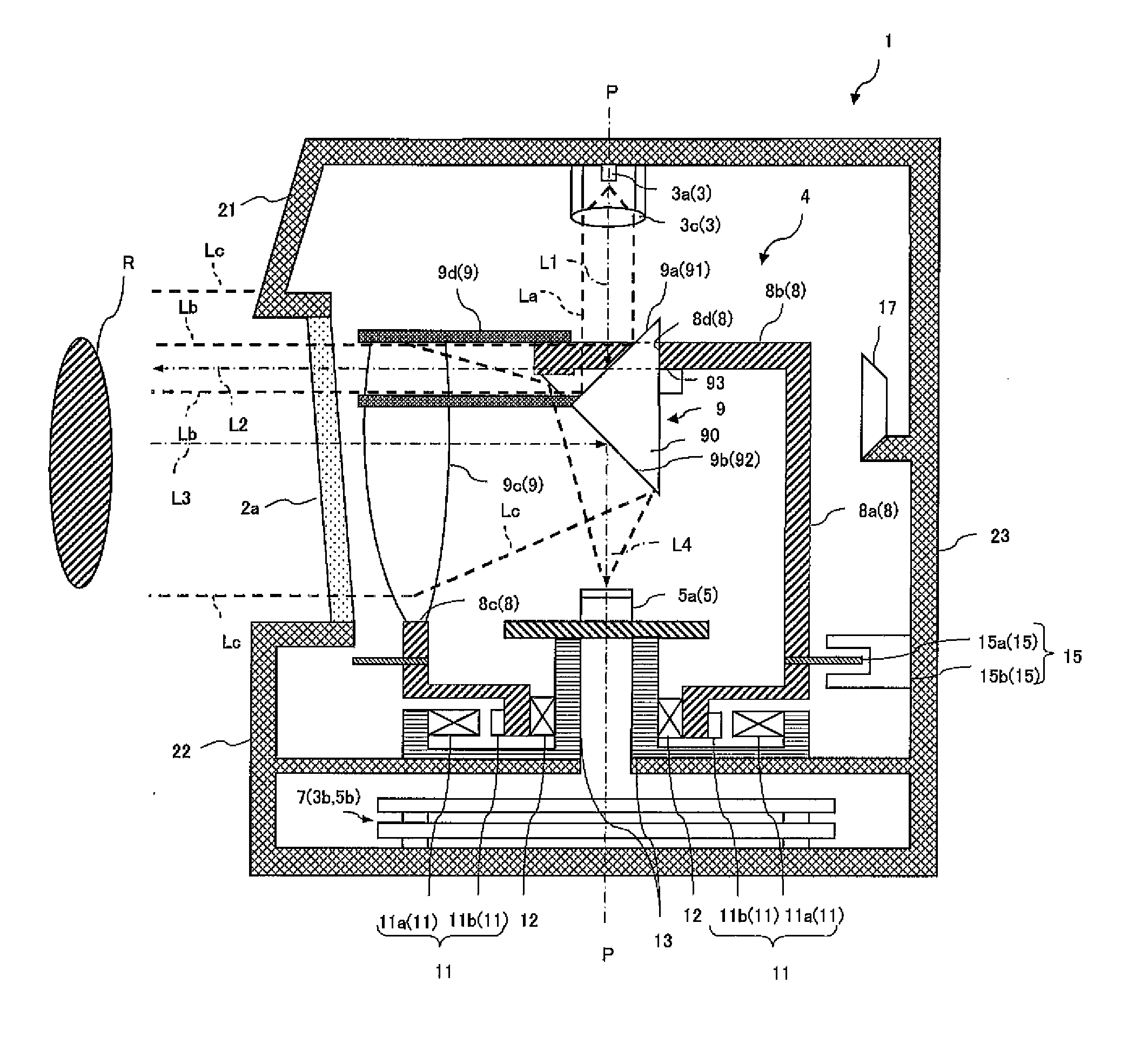

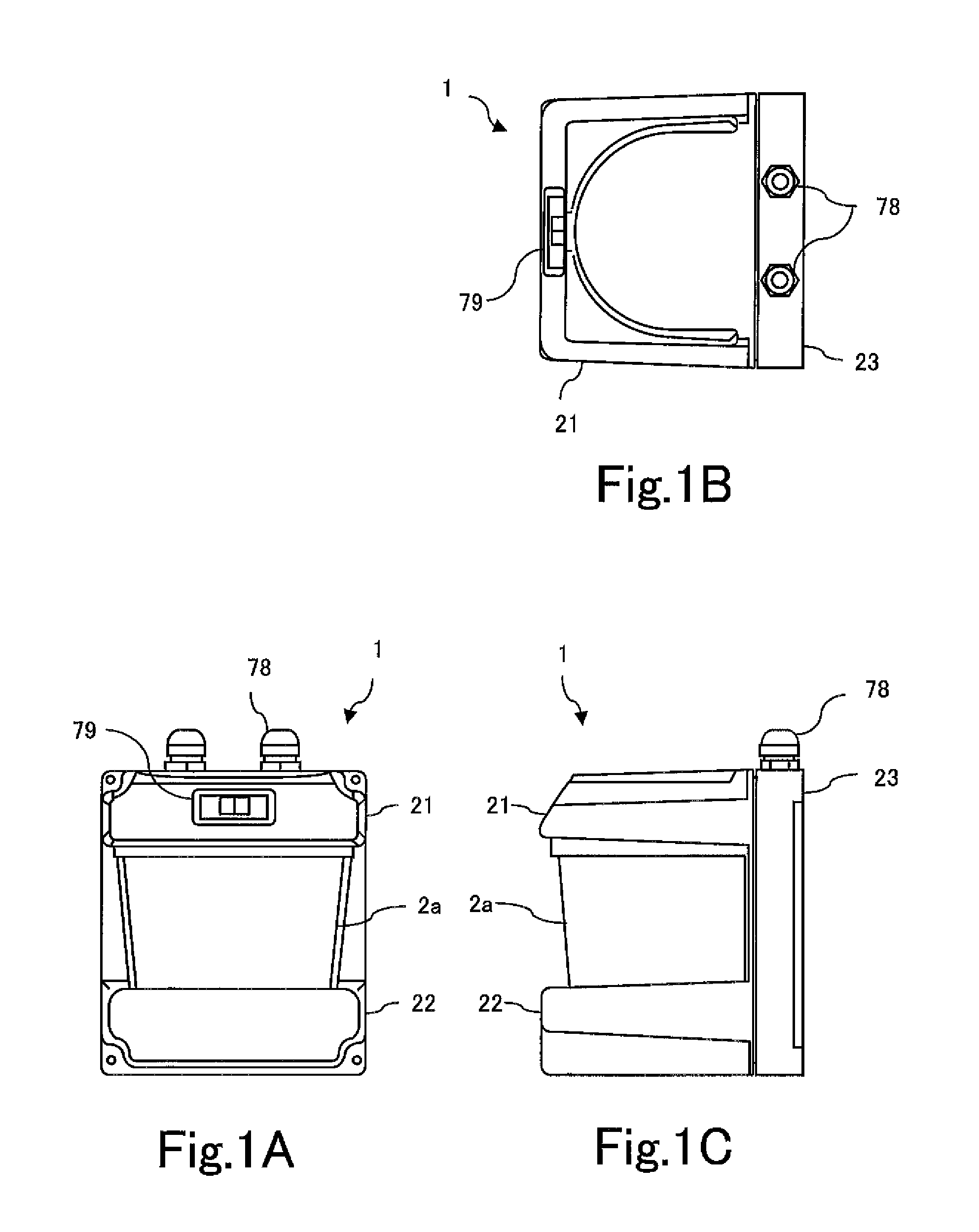

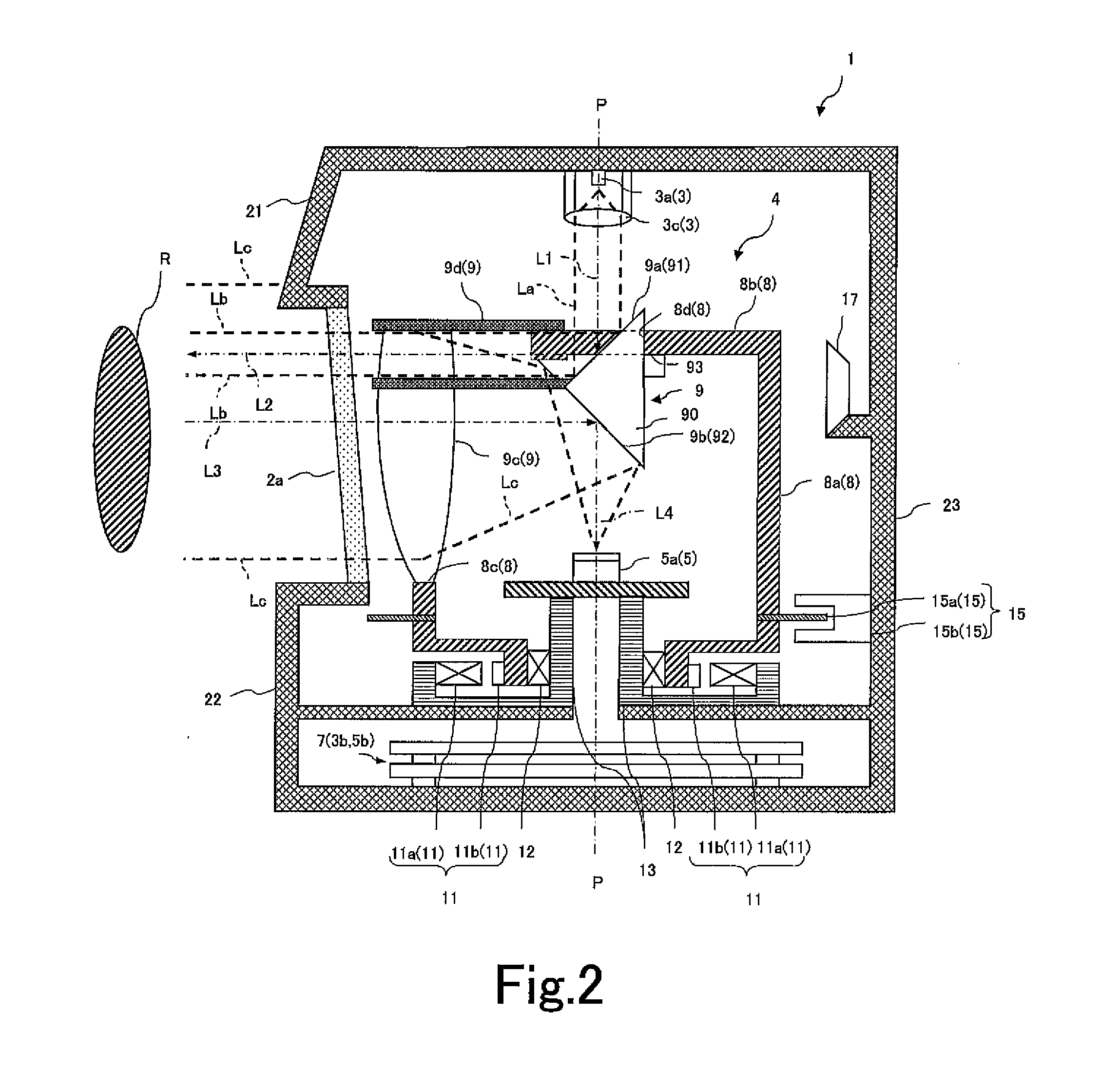

Scanning-type distance measuring apparatus

ActiveUS20110235018A1Easy to detectReliable detectionOptical rangefindersDevices using optical meansOptoelectronicsOptical path

A scanning-type distance measuring apparatus includes: an optical system 9 having a first deflecting member 9a that deflects measurement light output from a light transmitting unit 3 toward a space to be measured via an optical window, a light receiving lens 9c that condenses reflection light from an object R to be measured existing in the space to be measured, and a second deflecting member 9b that deflects the reflection light passed through the light receiving lens toward a light receiving unit 5 disposed to oppose the light transmitting unit 3; a scanning mechanism 4 that rotates the optical system 9 about a predetermined axis P; and an optical member 90 that outputs the measurement light deflected by the first deflecting member 9a from an incident light path Lc of the reflection light to the second deflecting member 9b.

Owner:HOKUYO AUTOMATIC CO

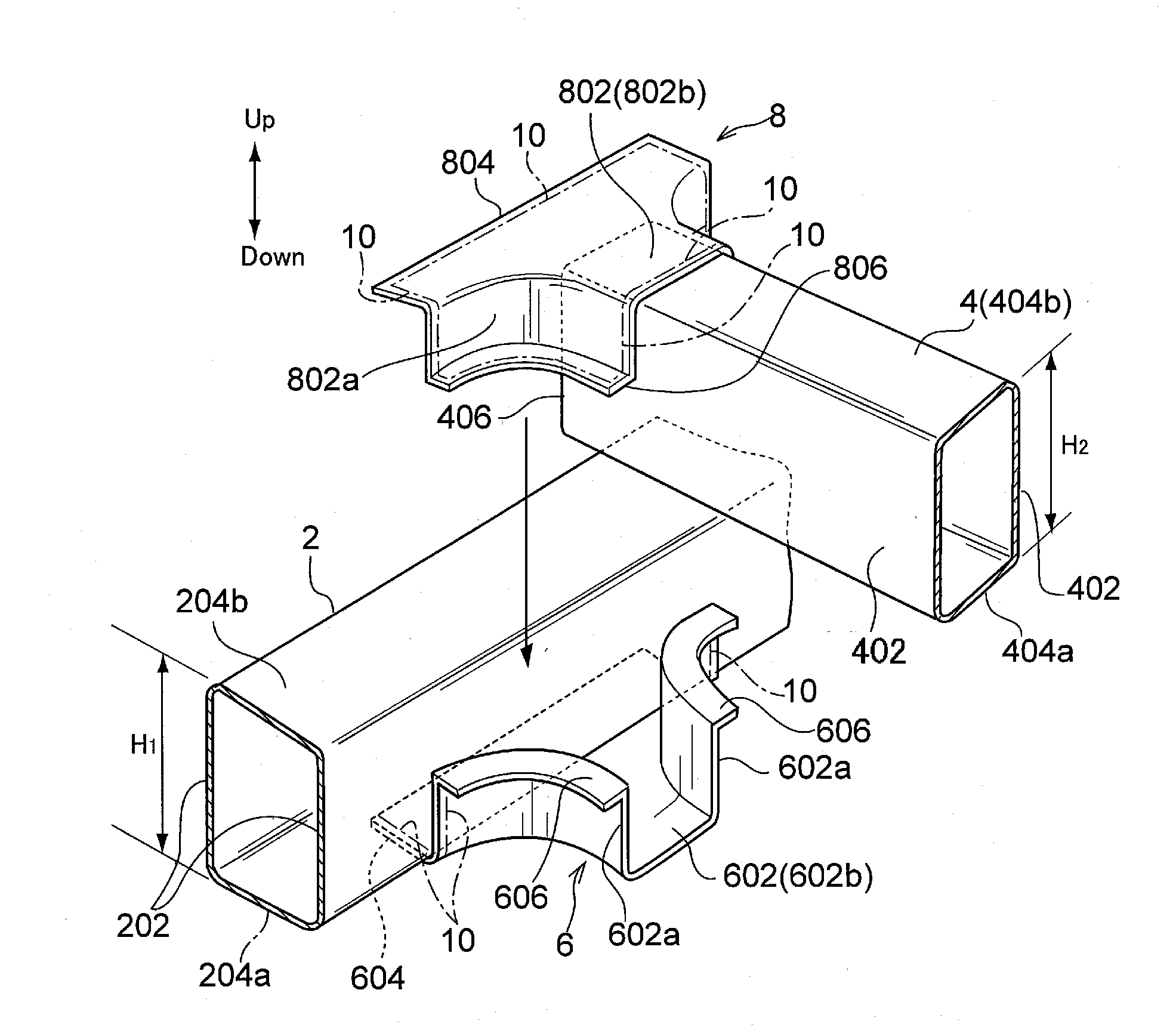

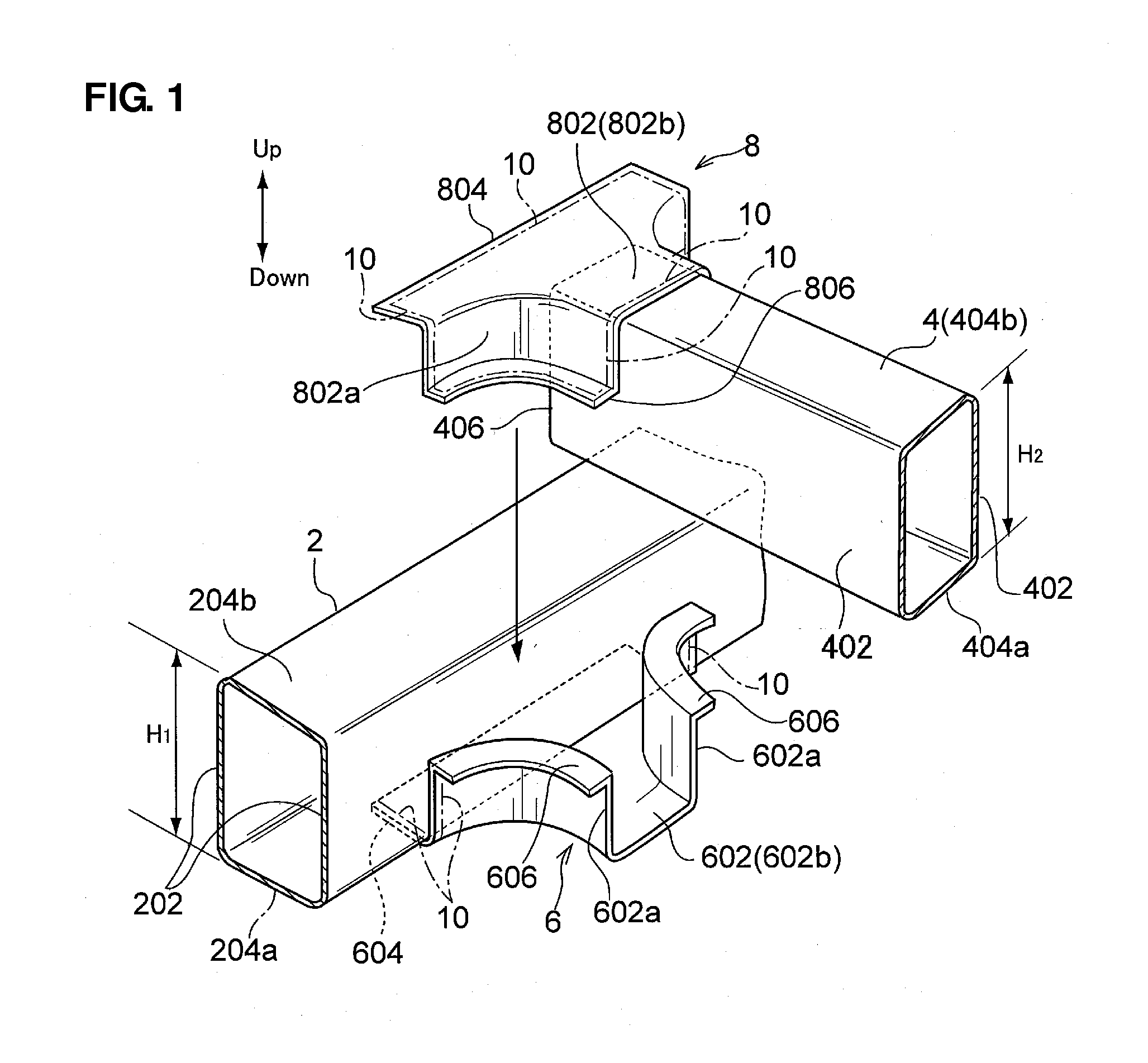

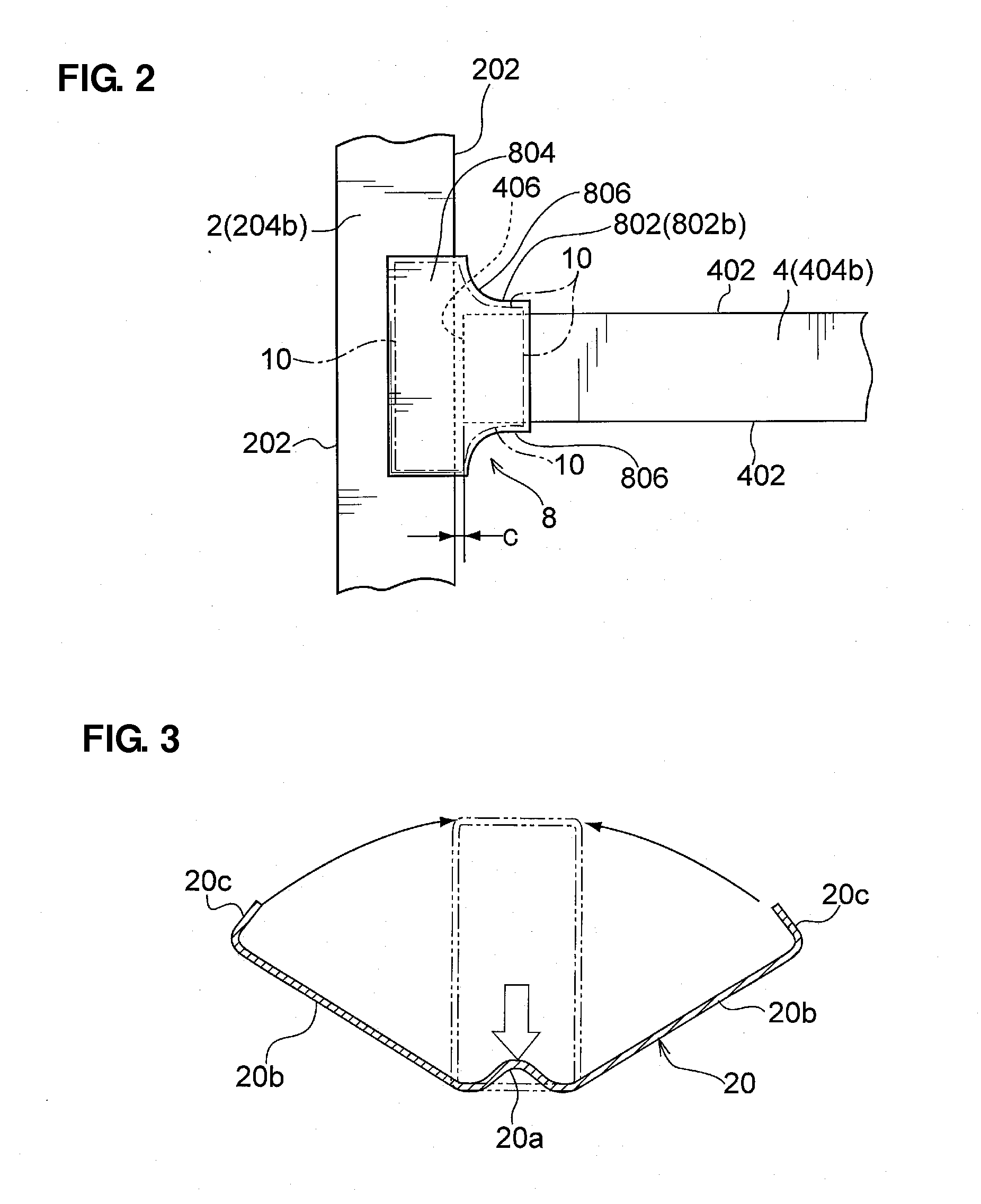

Connection structure and assembly method of tube-shaped frames

InactiveUS20100244497A1Accurate connectionEnsures rigiditySuspensionsVehicle seatsEngineeringSpot welding

A first split-bracket is joined to a first tube-shaped frame by lazar welding. A second split-bracket is joined to an end portion of a second tube-shaped frame by the lazar wielding. The second tube-shaped frame equipped with the second split-bracket is assembled to the first tube-shaped frame equipped with the first split-bracket. A second flange of the first split-bracket and a second flange of the second split-bracket are joined temporarily by spot welding. The second flange of the first split-bracket and the second flange of the second split-bracket are joined by continuous welding with lazar welding. Accordingly, the tube-shaped frames can be connected properly without forming any hole at a wall of the tube-shaped frame, ensuring the rigidity of the connection portion of the tube-shaped frames.

Owner:MAZDA MOTOR CORP

Building panel with a mechanical locking system

ActiveUS10246883B2High strengthDifficult to assembleCovering/liningsDismountable cabinetsEngineering

A set of essentially identical panels, such as building panels, provided with a mechanical locking system including a displaceable tongue, which is arranged in a displacement groove at a first edge of a first panel. A second panel is provided with a tongue groove at a second edge. The displaceable tongue is configured to cooperate with the tongue groove for locking together the first and the second edge. The displaceable tongue has a spring constant that varies along the length of the tongue.

Owner:VÄLINGE INNOVATION AB

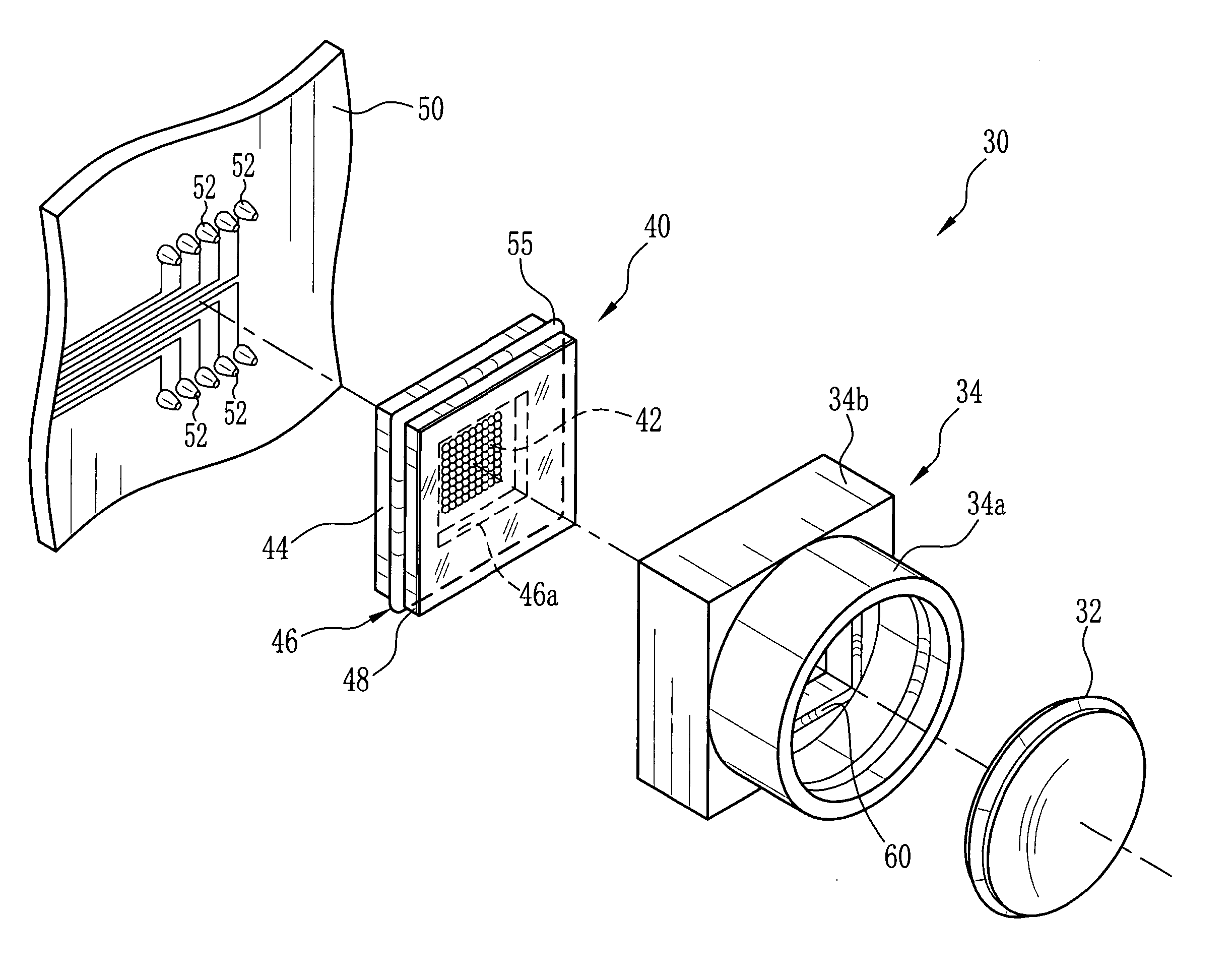

Image capture apparatus

InactiveUS20050212947A1Assembly precisionEasy to assembleTelevision system detailsSolid-state devicesOptoelectronicsCover glass

A solid state imaging device is consisted of an image sensor chip having a light receiving portion, a frame-like spacer attached on the image sensor chip so as to surround the light receiving portion, and a transparent cover glass attached on the spacer so as to close the light receiving portion. An outer periphery of the spacer is projected from that of the solid state imaging device to form a projection. Along an inner periphery of a lens holding frame, a groove is formed. When the lens holding frame is attached to the solid state imaging device to cover it, the groove of the lens holding frame is engaged to the projection of the solid state imaging device.

Owner:FUJIFILM CORP

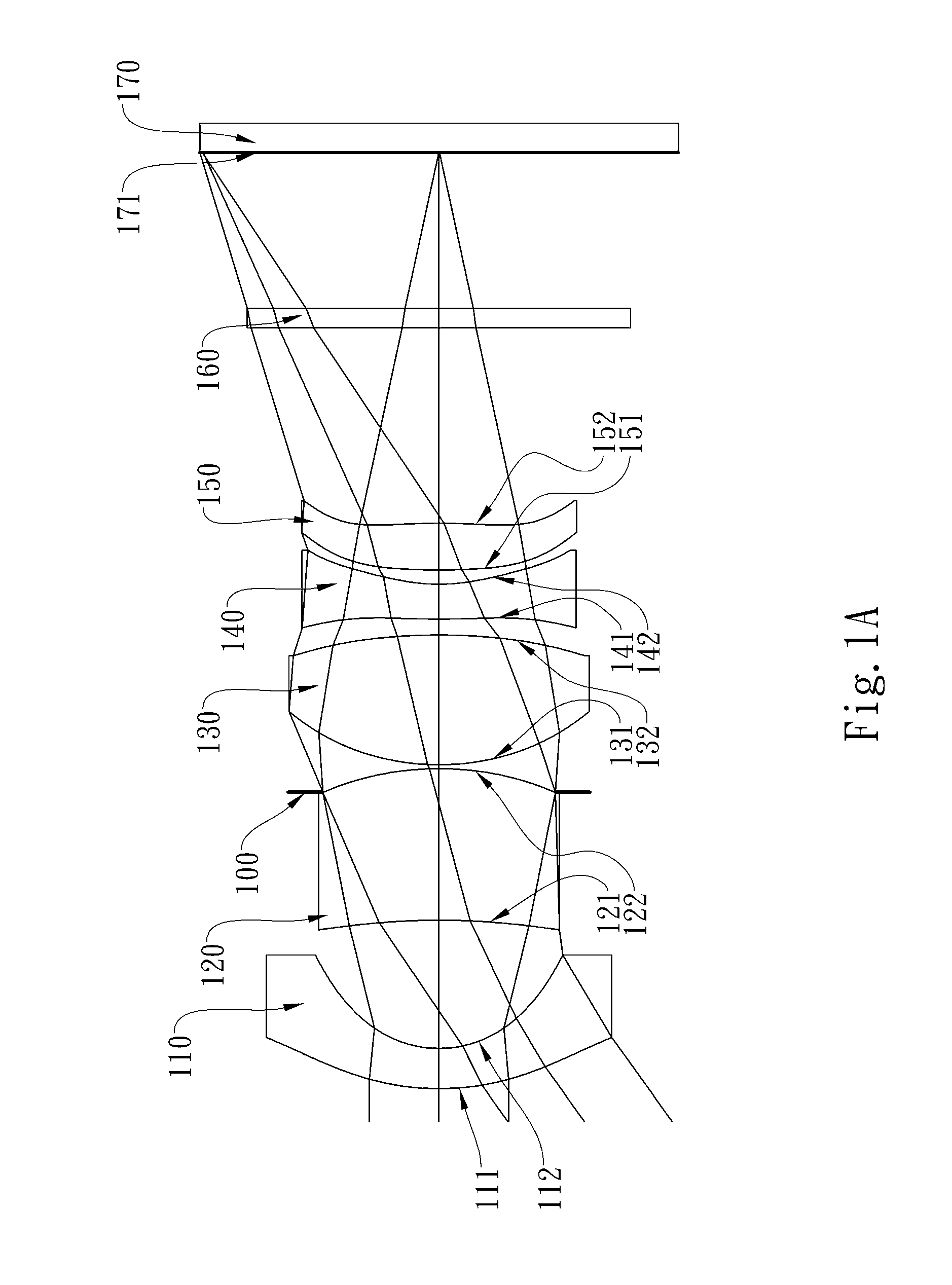

Optical imaging lens assembly

This invention provides an optical imaging lens assembly comprising five lens elements with refractive power, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with negative refractive power; a fourth lens element with negative refractive power having at least one of the object-side and image-side surfaces thereof being aspheric; and a fifth lens element having a concave image-side surface, at least one of the object-side and image-side surfaces thereof being aspheric, and made of plastic. By such arrangement, photosensitivity and total track length of the optical imaging lens assembly can be reduced, and the aberration and astigmatism of the assembly can be effectively corrected. Moreover, high image resolution can be obtained.

Owner:LARGAN PRECISION

Circuit board coaxial connector

ActiveUS20120295478A1Simplify the scaleImprove thermal conductivityElectrically conductive connectionsCoupling device detailsElectrical conductorMechanical engineering

Owner:HUBERSUHNER AG

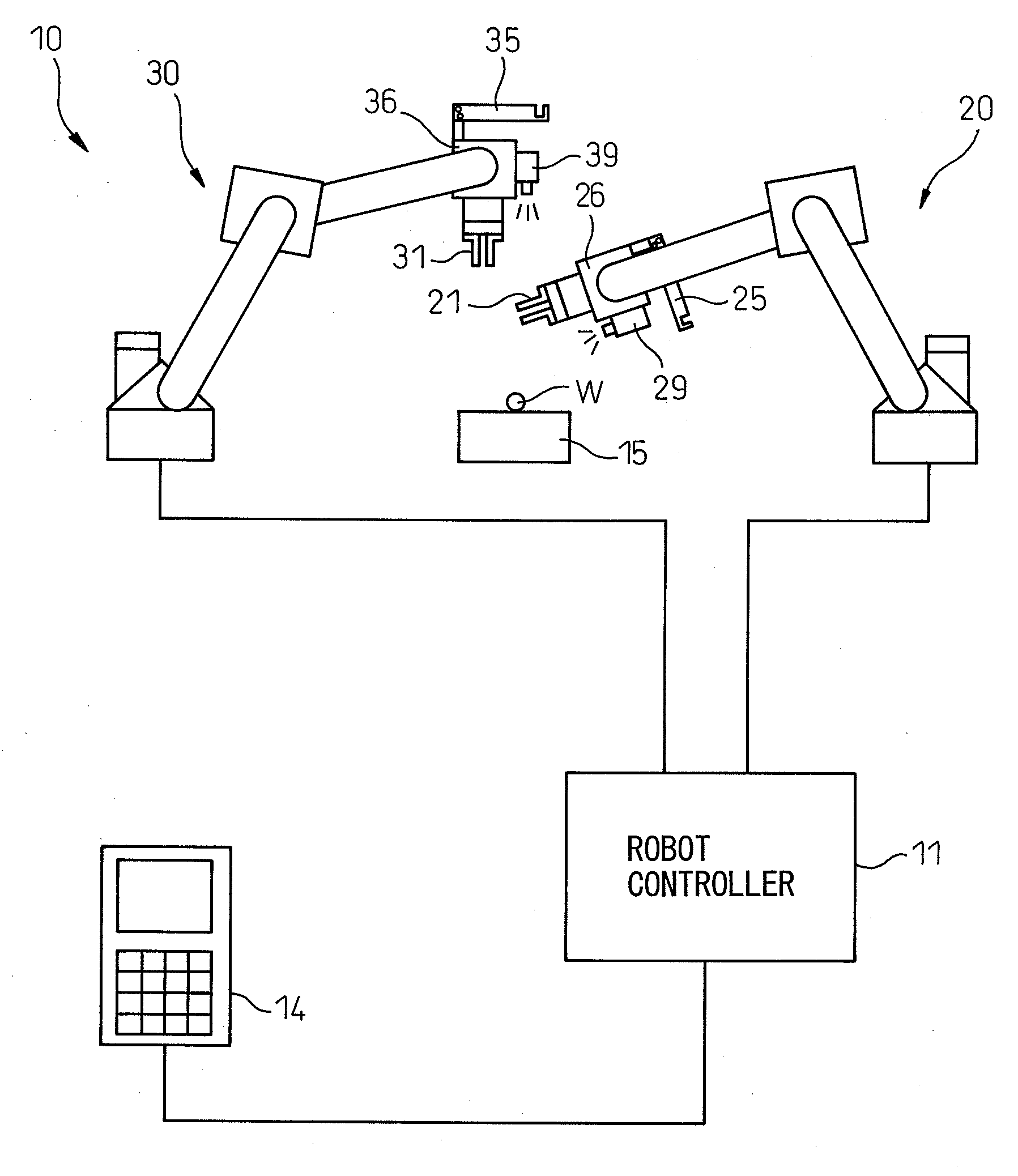

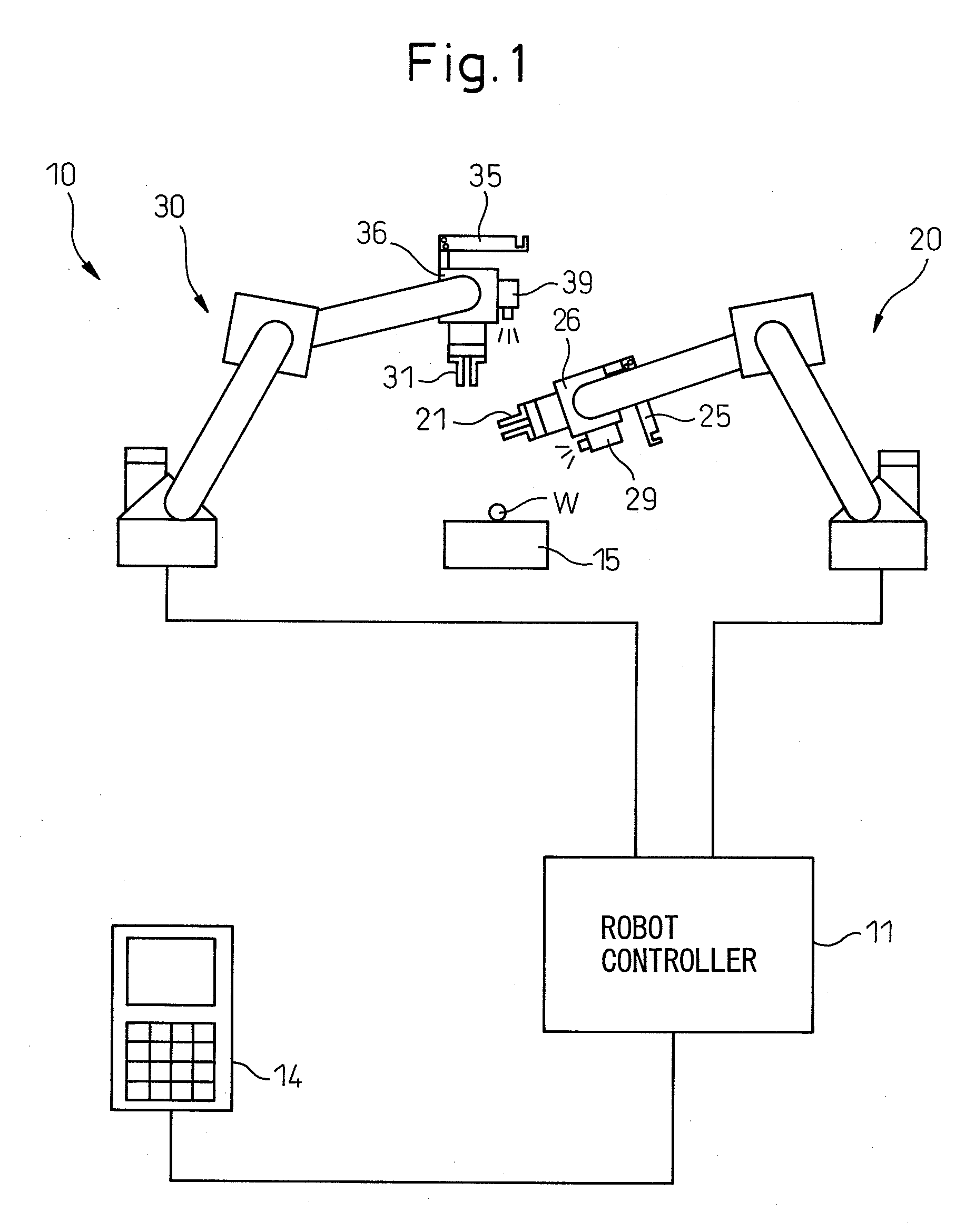

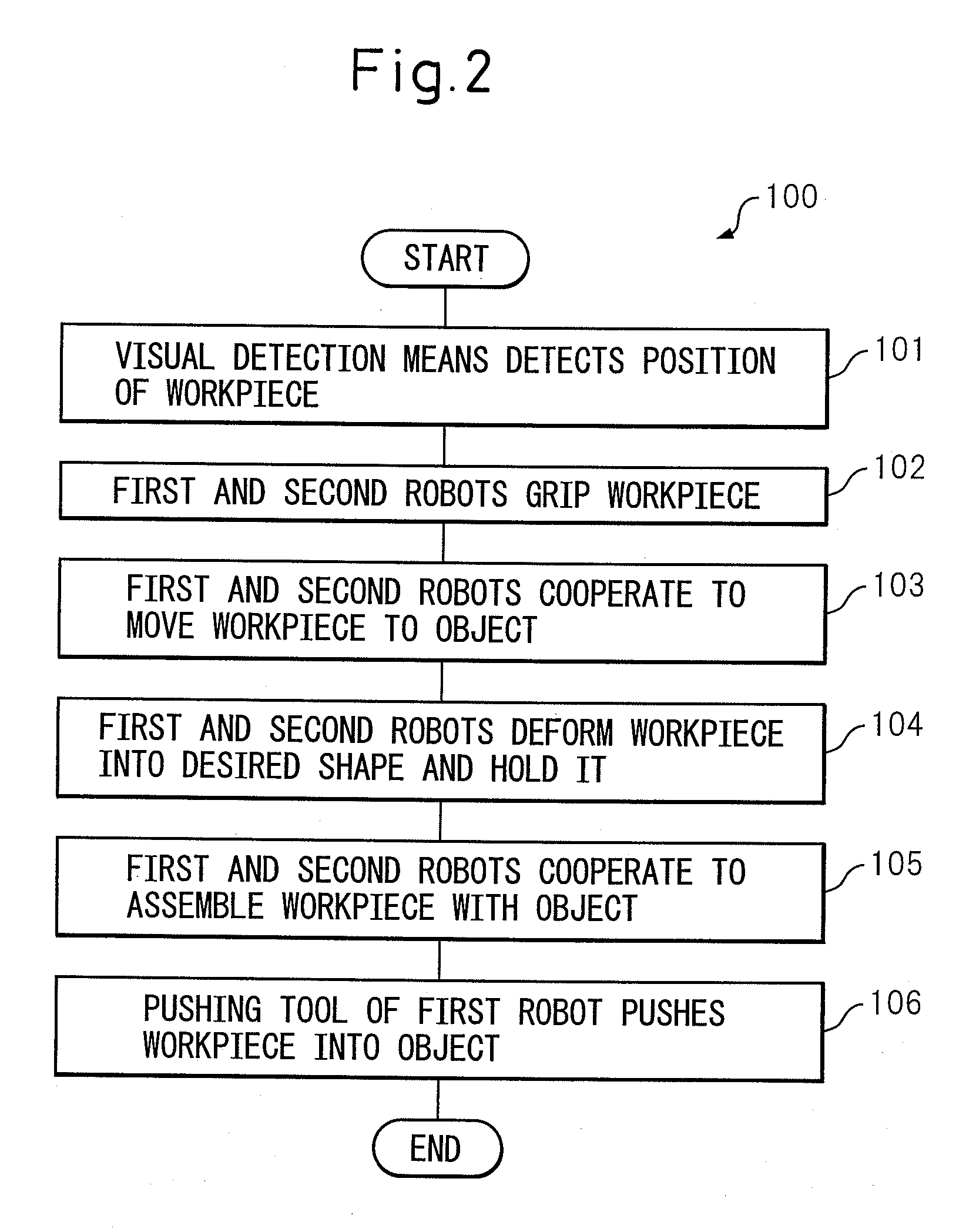

Flexible workpiece assembling method

InactiveUS20090025199A1Eliminate manual operationAssembly precisionProgramme controlProgramme-controlled manipulatorMechanical engineeringRobot

A flexible workpiece assembling method for assembling a flexible workpiece (W) with an object by using a first robot comprising a first hand and a second robot comprising a second hand includes the steps of: gripping a first portion of the flexible workpiece by the first hand and gripping a second portion of the flexible workpiece different from the first portion by the second hand; moving the flexible workpiece to the object through a cooperating operation of the first and second robots; deforming the flexible workpiece into a shape corresponding to the nonflexible object by the first and second robots; and assembling the flexible workpiece onto the nonflexible object by the first and second robots. As a result, the flexible workpiece can be accurately assembled onto the nonflexible object without breaking or tearing. The first and second robots may comprise a pushing means for pushing the flexible workpiece into the object.

Owner:FANUC LTD

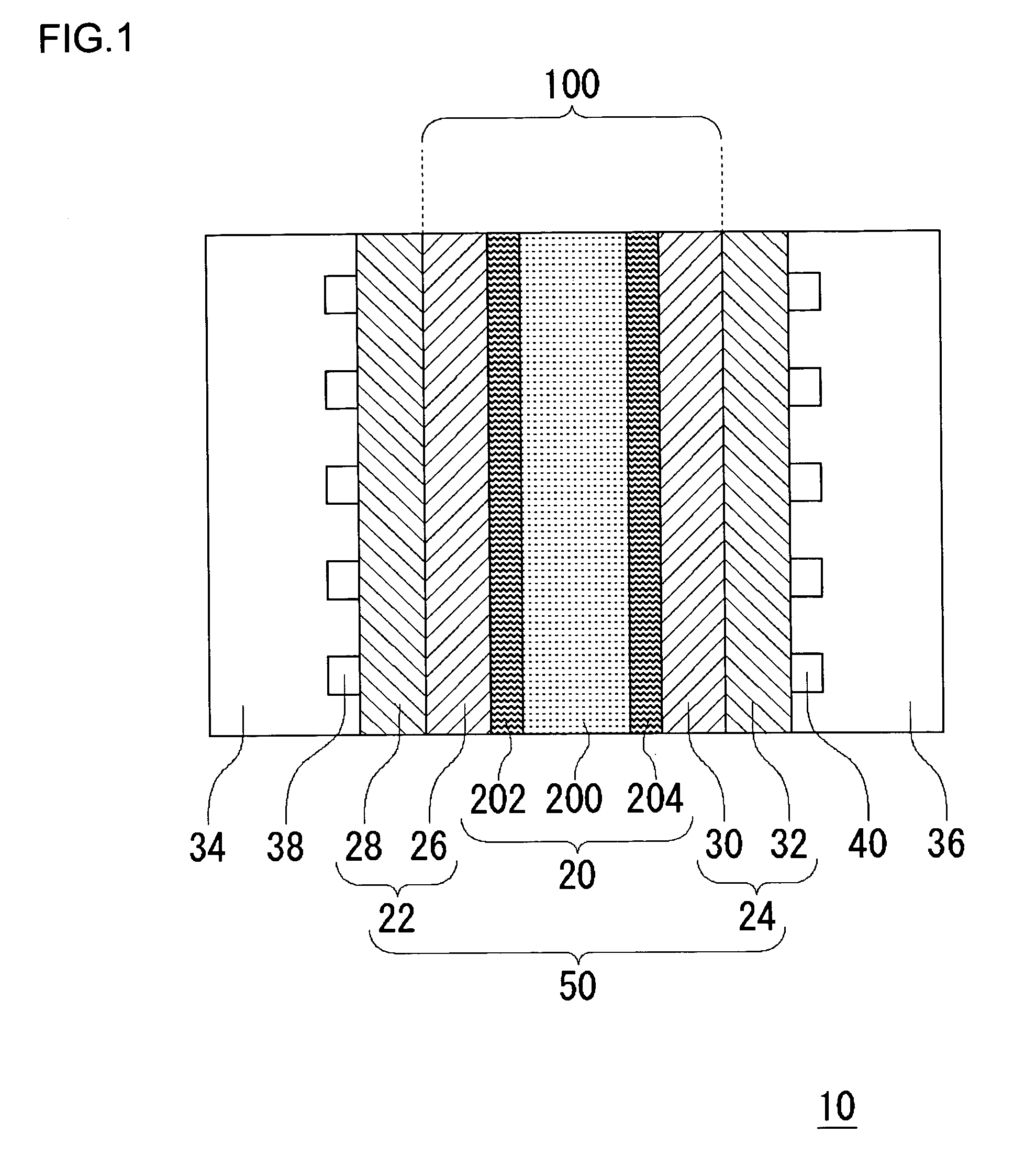

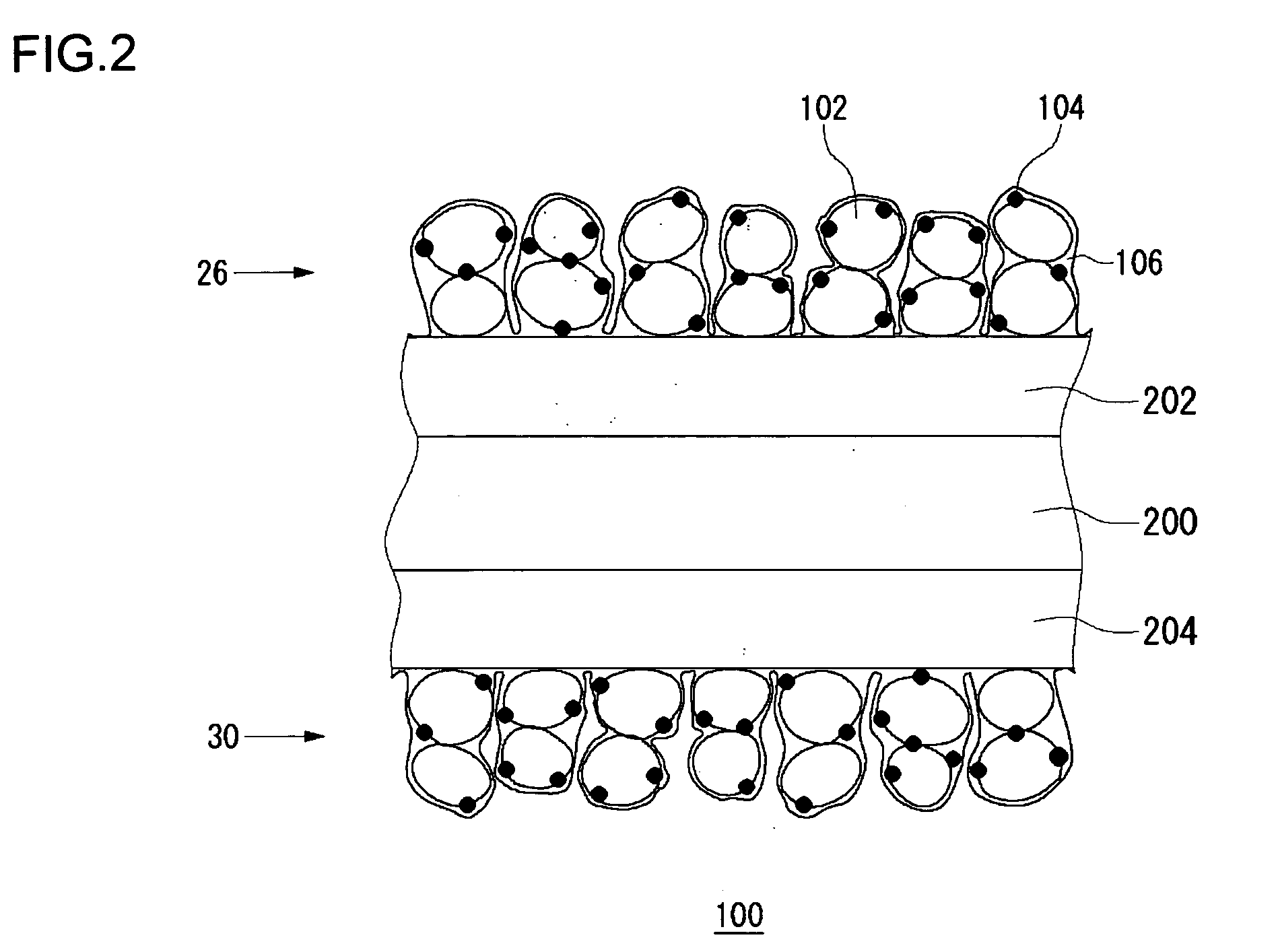

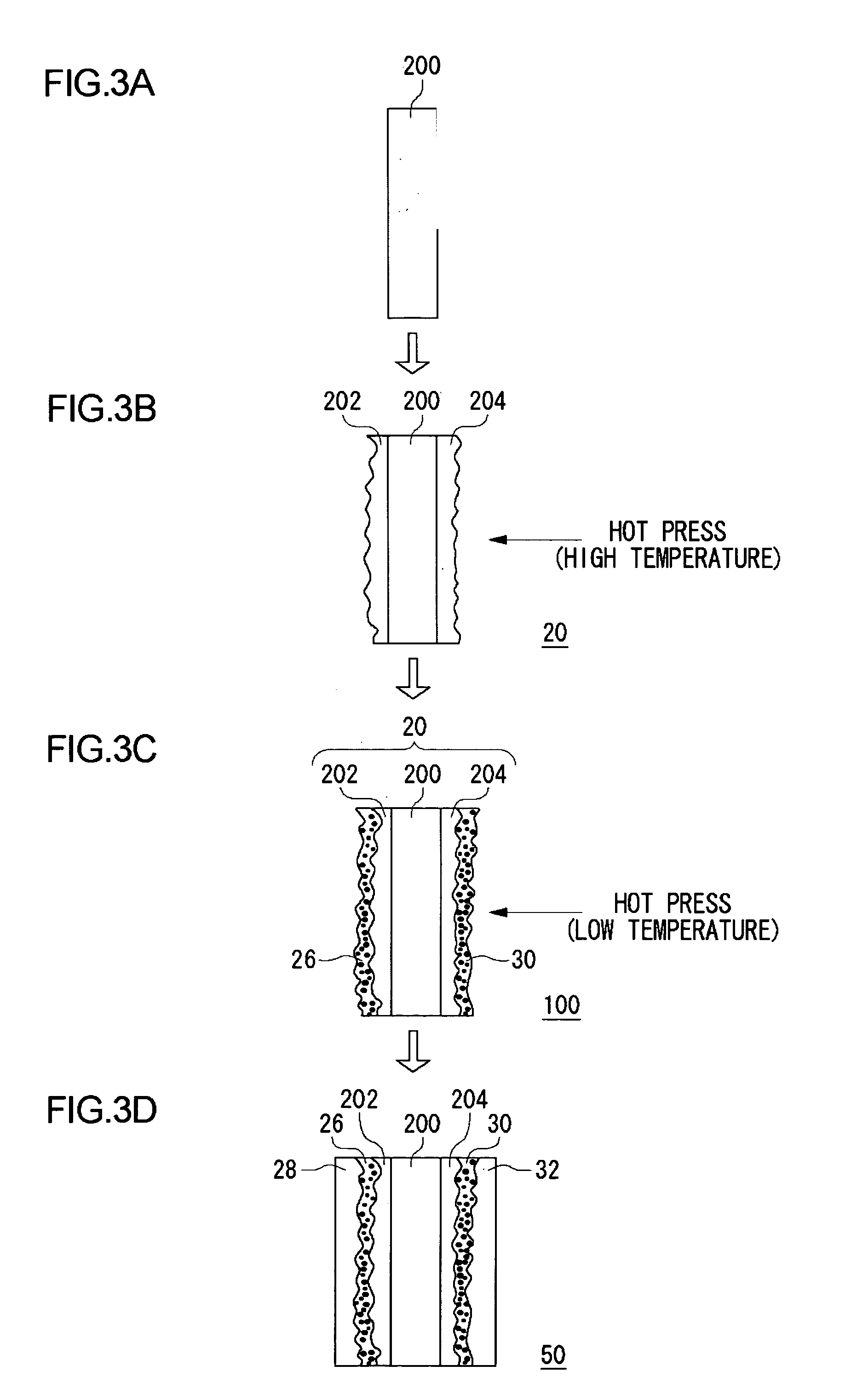

Solid polymer electrolyte membrane, solid polymer electrolyte fuel cell using the membrane and method of fabricating the same

InactiveUS20050181285A1Easy to operateAdjustable viscosityIon-exchanger regenerationElectrode carriers/collectorsPolymer electrolytesFuel cells

A solid polymer electrolyte membrane and a catalytic layer are properly assembled even when the solid polymer electrolyte membrane and an ion exchange resin in the catalytic layer are formed of different materials. In a fuel cell, a solid polymer electrolyte membrane 20 is provided with a first solid polymer electrolyte membrane 200, and second solid polymer electrolyte membranes 202 and 204 provided at respective sides thereof. The second solid polymer electrolyte membranes 202 and 204 are formed of the same material as the ion exchange resin (not shown) included in a catalytic layer 26 and a catalytic layer 30.

Owner:SANYO ELECTRIC CO LTD

O-shaped sealing ring automatic assembly device and method

InactiveCN108655689AAssembly precisionAccurate assembly tasksMetal working apparatusEngineeringMechanical engineering

The invention discloses an O-shaped sealing ring automatic assembly device and method. The device comprises a sleeve automatic loading module, an O-shaped sealing ring automatic loading module, an automatic detecting module, a finished product sorting module, all of which are arranged on the outer side of a revolving worktable module in the peripheral direction in sequence; the sleeve automatic loading module and the O-shaped sealing ring automatic loading module are in supply connection with the revolving worktable module; the automatic detecting module detects the assembly effect of O-shapedrings on the revolving worktable module in real time; and the finished product sorting module is used for realizing sorting of qualified and unqualified products through chutes according to the detecting result of the automatic detecting module. The device is simple in structure and convenient to use; and through motions of three arc plates on clamping jaws of a three-jaw cylinder and pressing plates with the same apertures as the diameters of sleeves, the clamping and assembly of the O-shaped sealing rings are achieved, the automatic assembly task of the O-shaped sealing rings can be finished with high quality, a lot of manpower and costs are saved, the assembly efficiency is quickly accelerated, and the production demands are met.

Owner:NANJING KANGNI NEW ENERGY AUTO PARTS CO LTD +1

Automatic assembly machine for touch switch

InactiveCN101777448AAssembled preciselyRealize automatic assemblyElectric switchesEngineeringTransfer mechanism

The invention discloses an automatic assembly machine for a touch switch, which comprises a machine body. The machine body is provided with an assembly rotary disc and a feeding mechanism which feeds a body, an elastic sheet, a button and a cover plate assembly of the touch switch into assembly stations respectively. The automatic assembly machine also comprises a main conveying track for bearing the body, wherein a transferring mechanism which clamps the body and does regular vertical or horizontal feed movement is arranged below the main conveying track; a body feeding mechanism is arranged at the input end of the main conveying track; an elastic sheet feeding mechanism, a button feeding mechanism and a cover plate feeding mechanism are orderly arranged along the main conveying track; the assembly rotary disc is arranged between the button feeding mechanism and the cover plate feeding mechanism for assembling the button and the cover plate integrally; a third assembling mechanism is arranged on one side of the assembly rotary disc for assembling the touch switch assembly; and the mechanisms are connected with a main control circuit and is controlled by the main control circuit. The automatic assembly machine accurately and efficiently assemblies the touch switch through automatic assembling so as to save the production cost.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

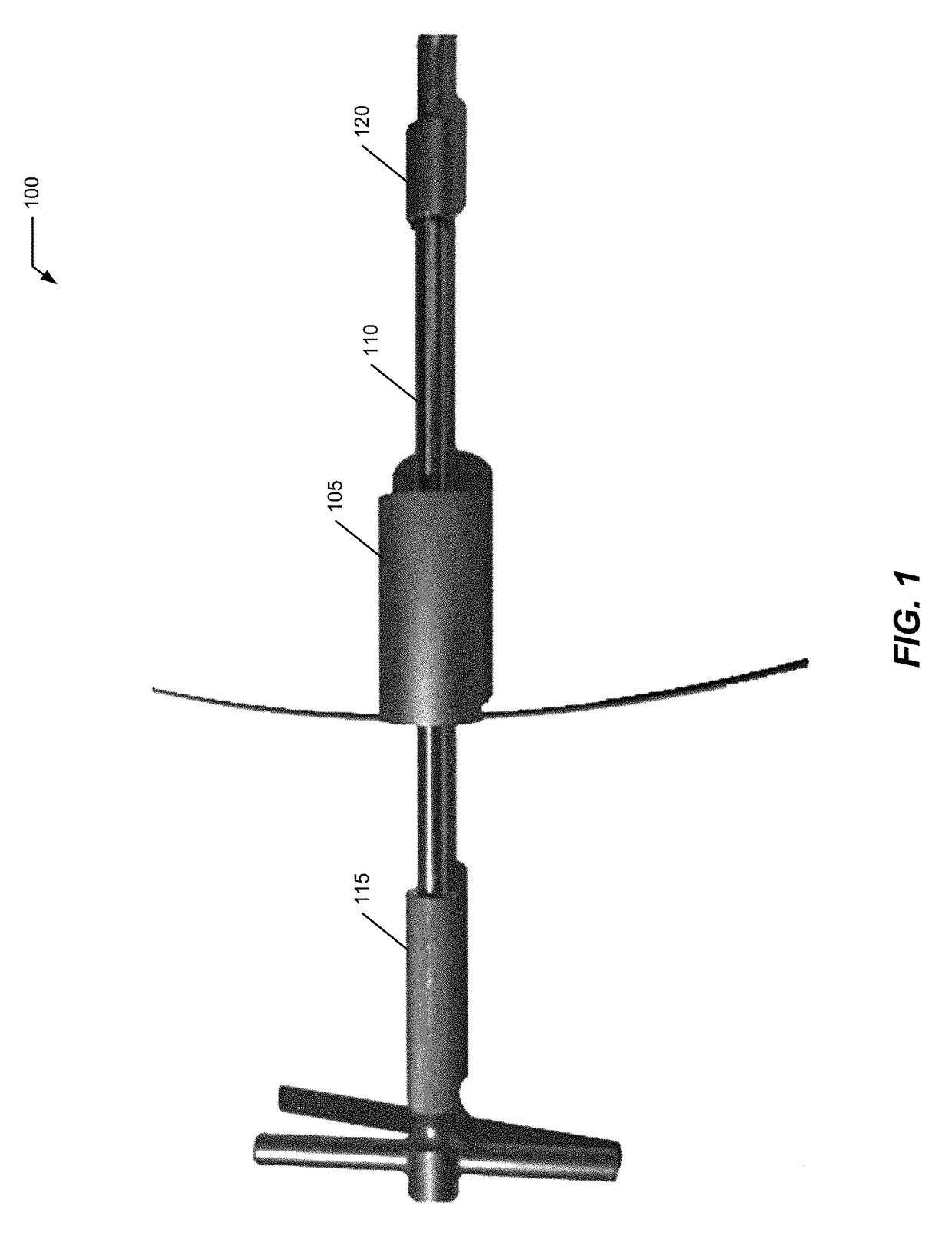

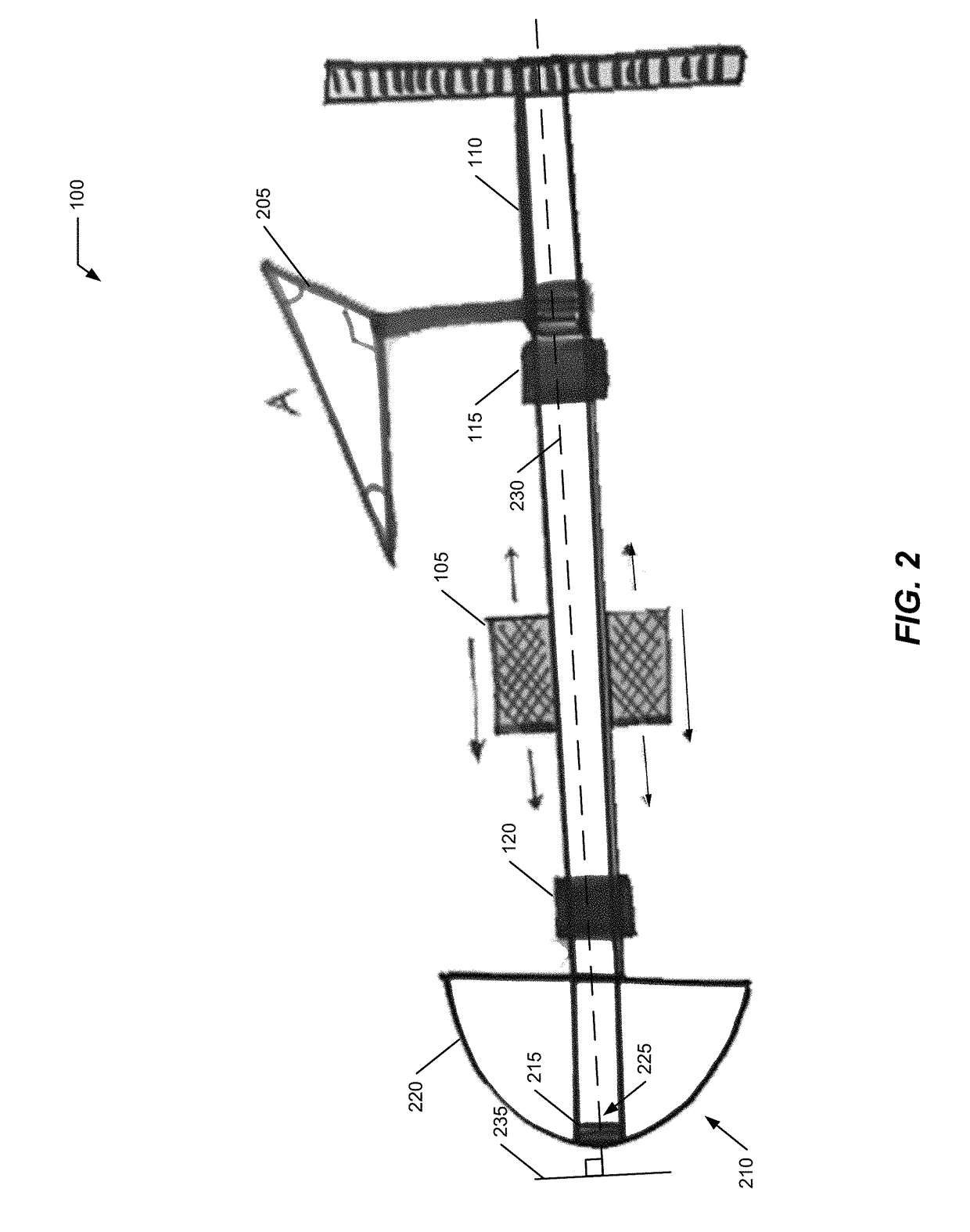

Bone preparation apparatus and method

ActiveUS20170196705A1Assembly precisionImprove site preparationJoint implantsFemoral headsProsthesisPower tool

A system and method for improving installation of a prosthesis. Devices include prosthesis installation tools, prosthesis assembly tools, site preparation systems, and improved power tools used in implant site preparation.

Owner:BEHZADI KAMBIZ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com