Patents

Literature

55results about How to "Assembled precisely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

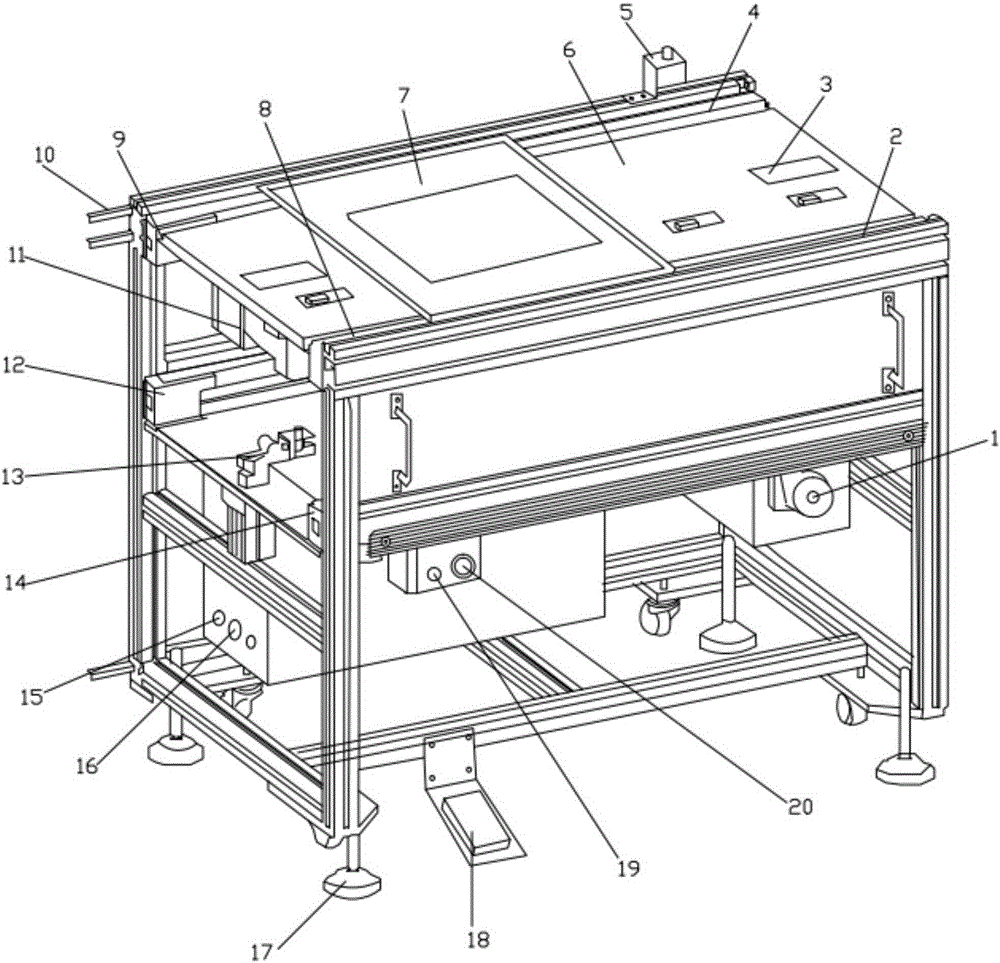

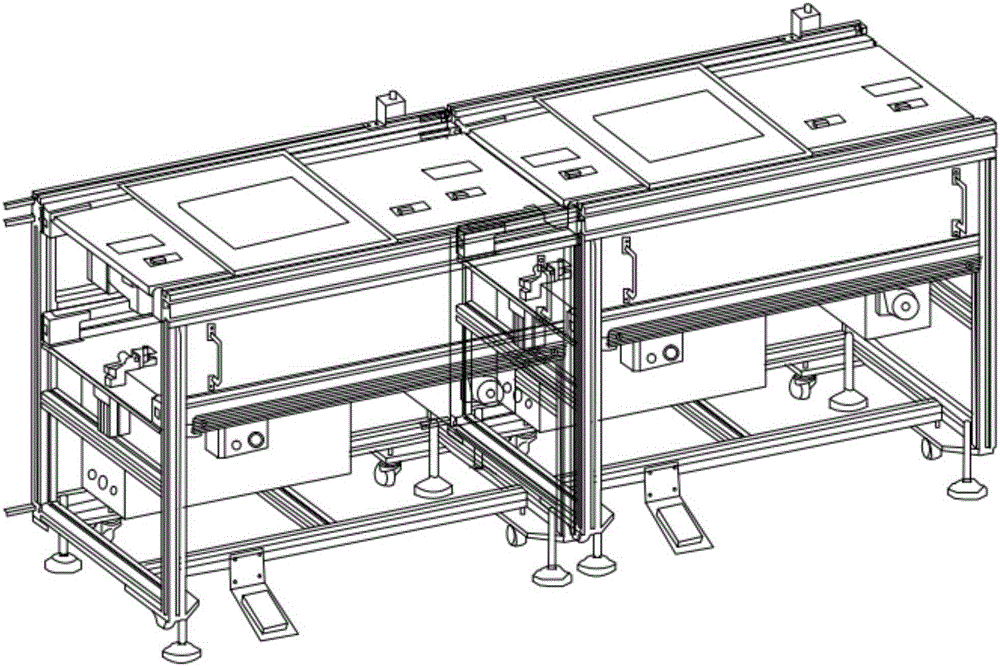

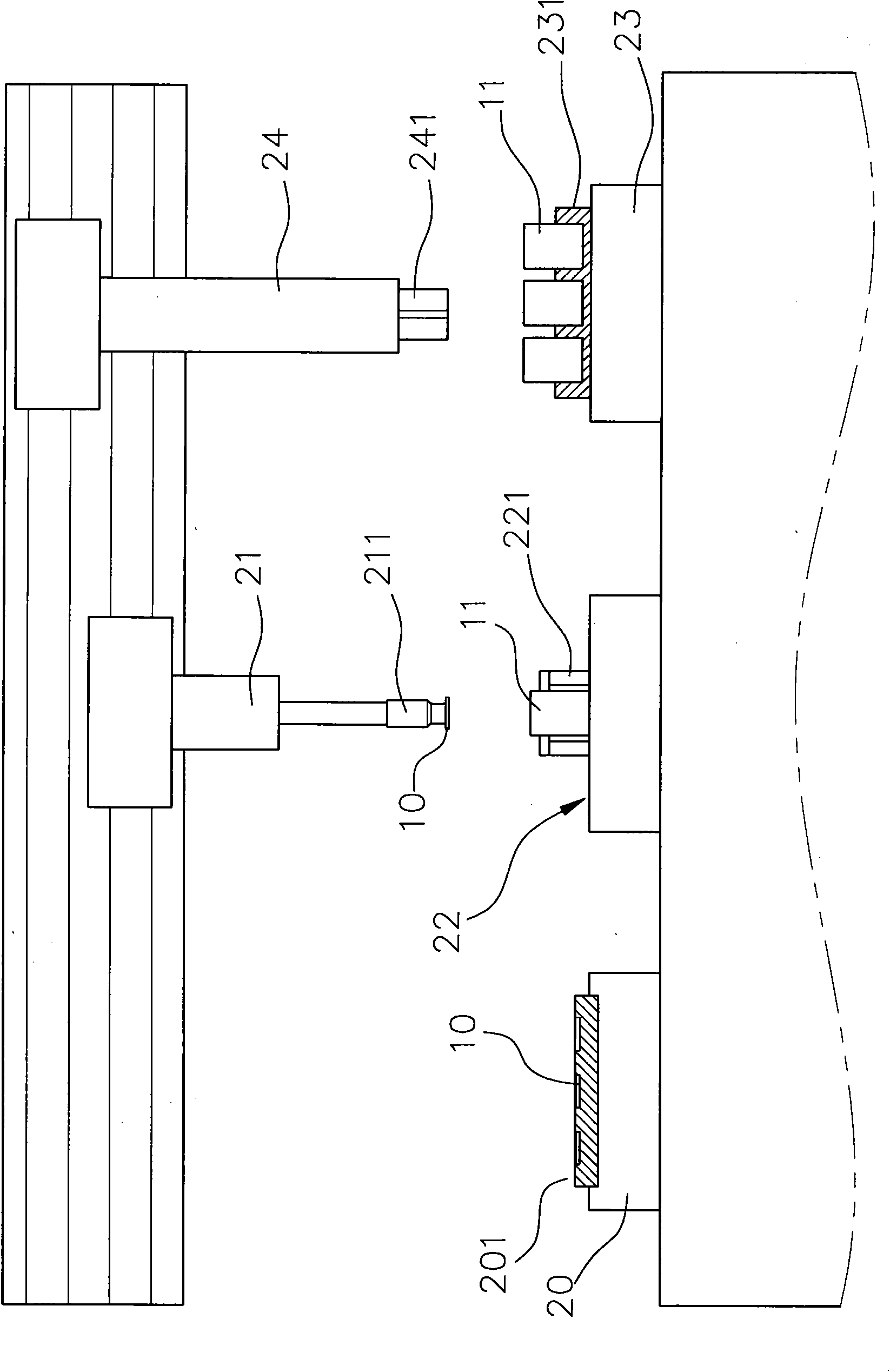

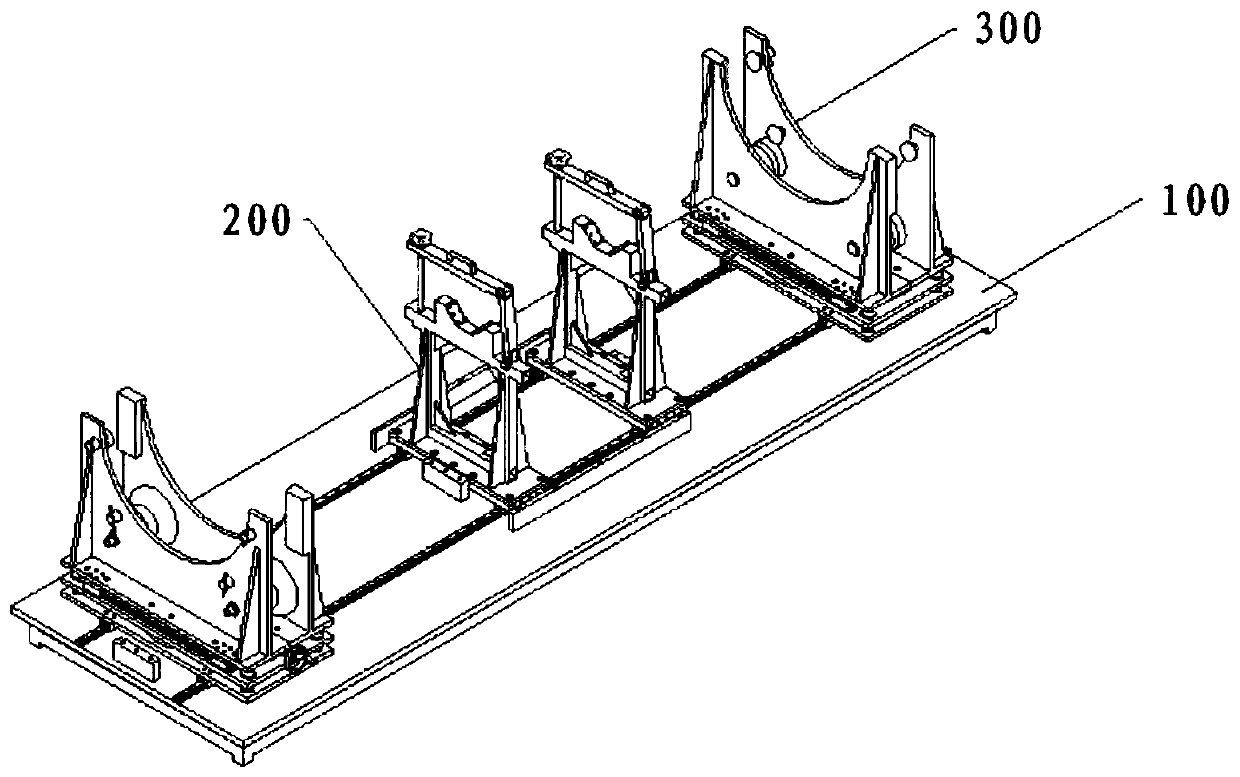

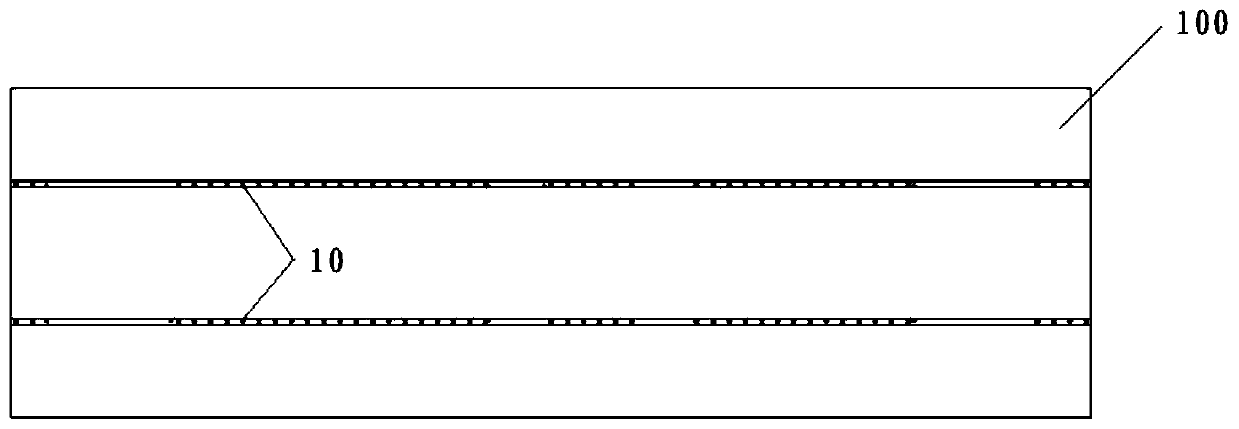

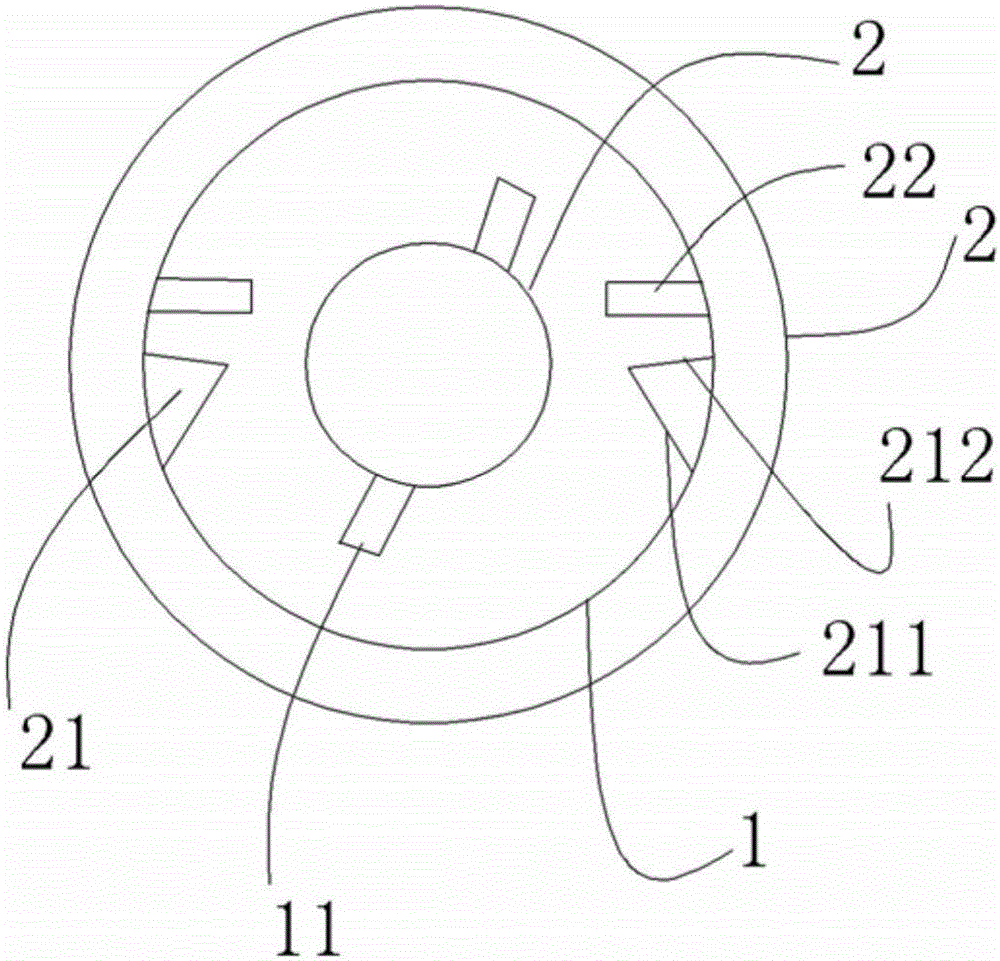

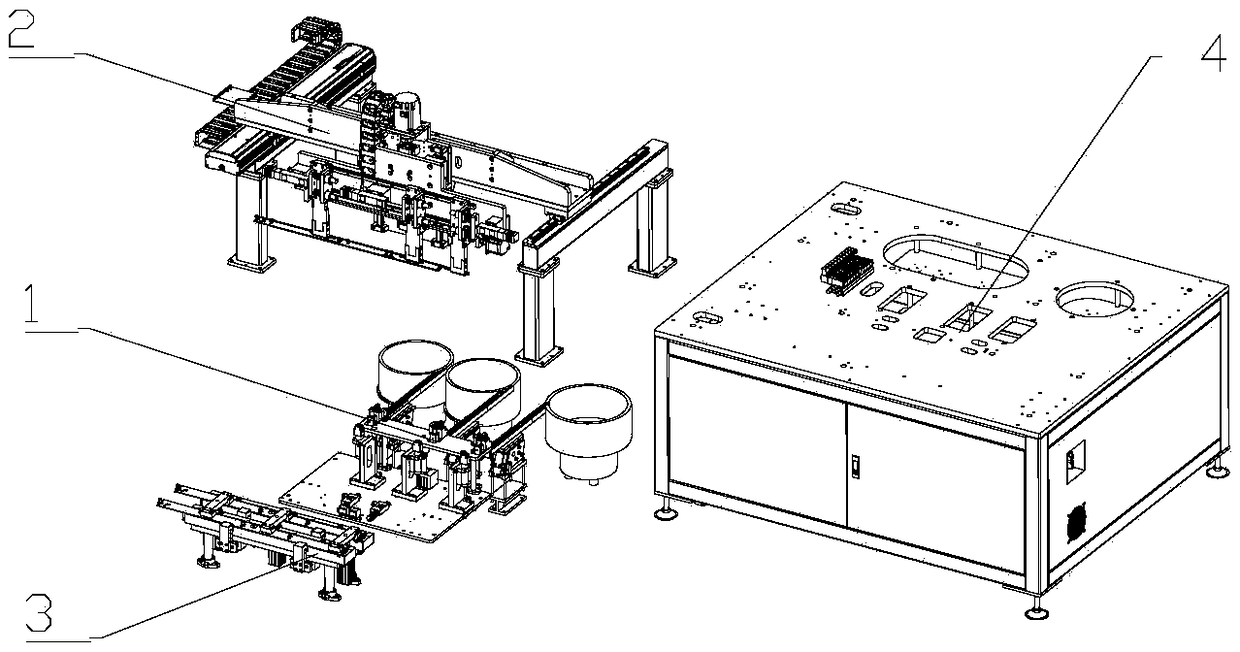

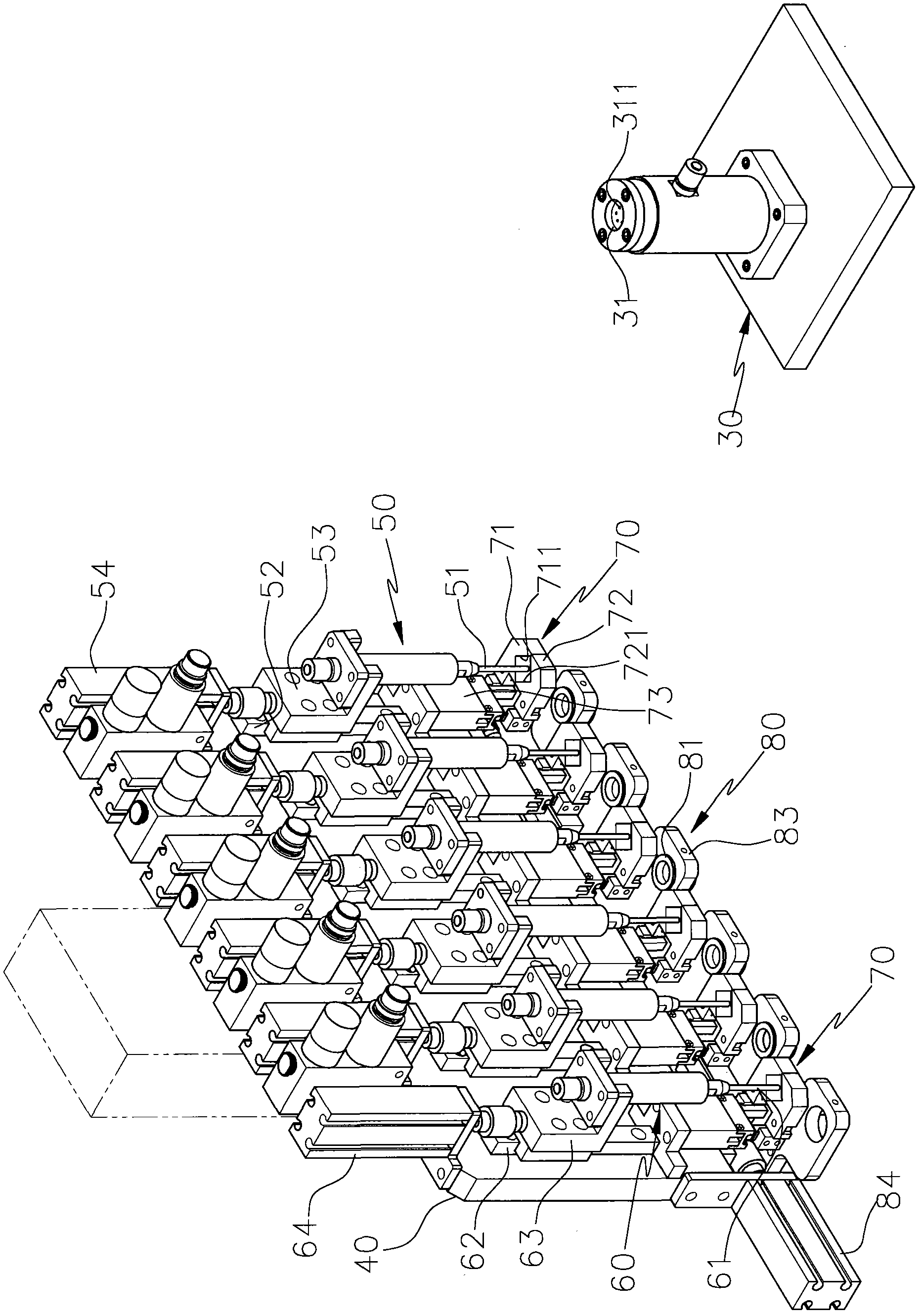

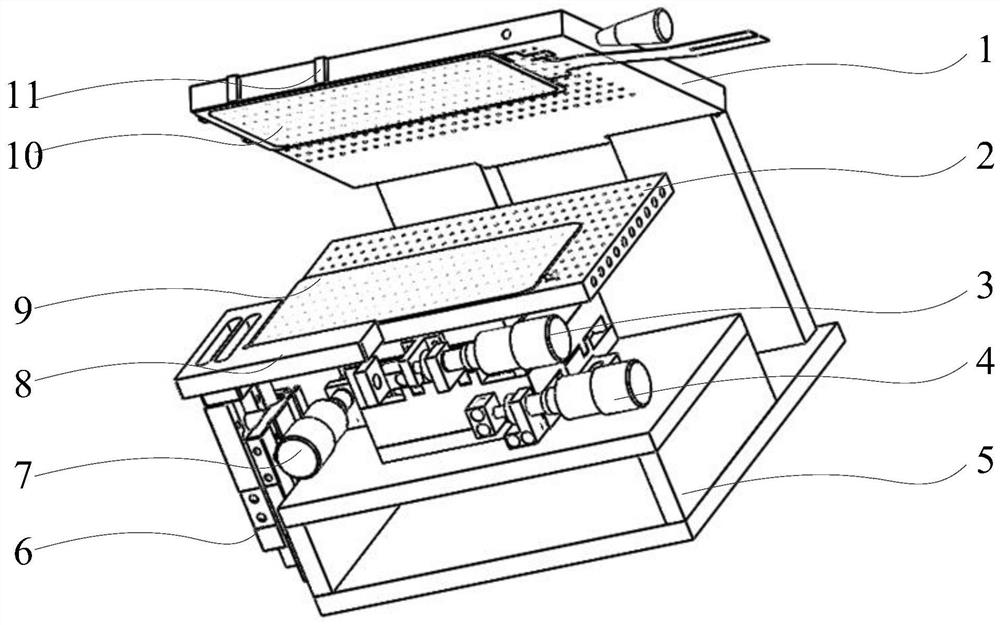

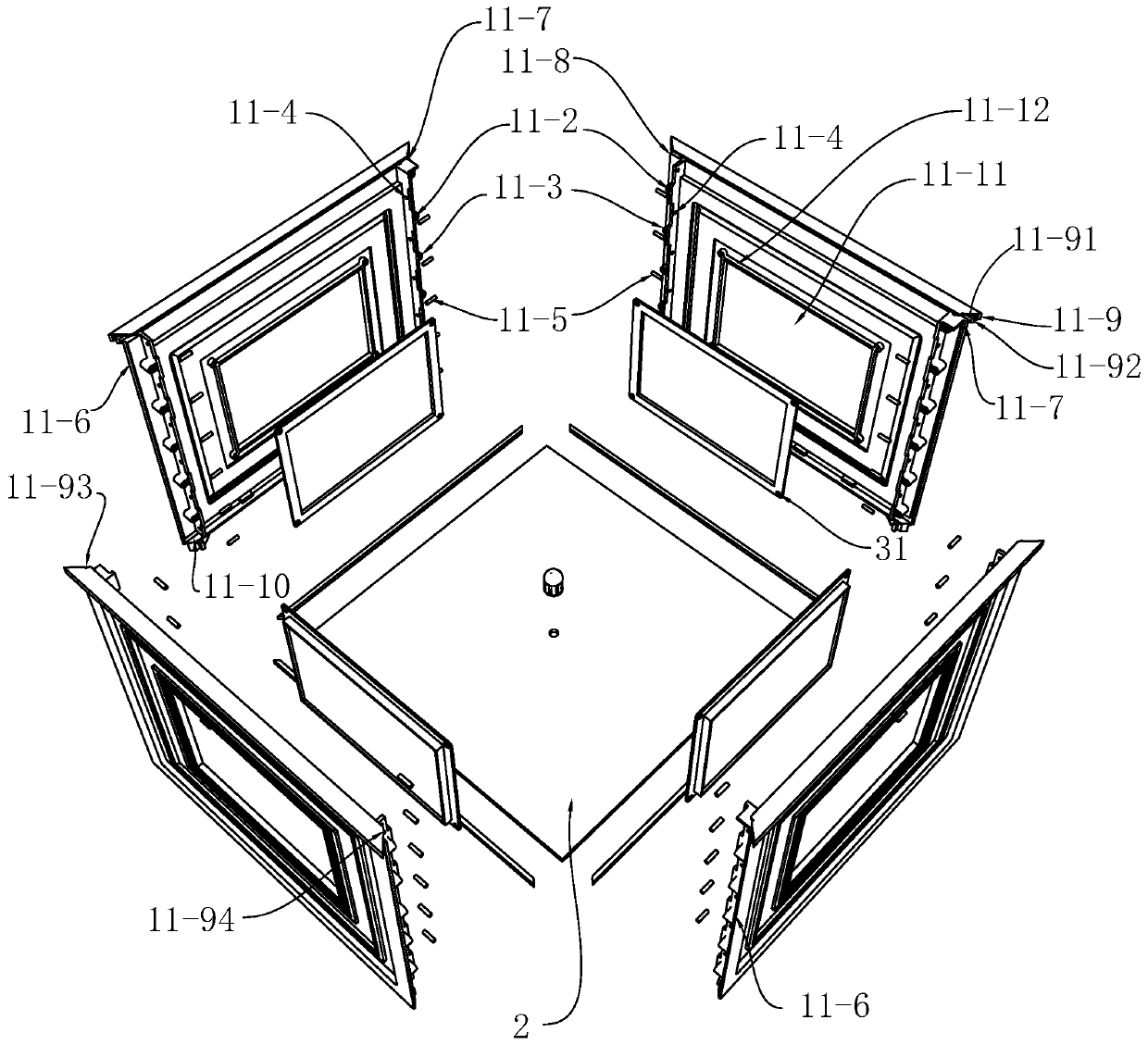

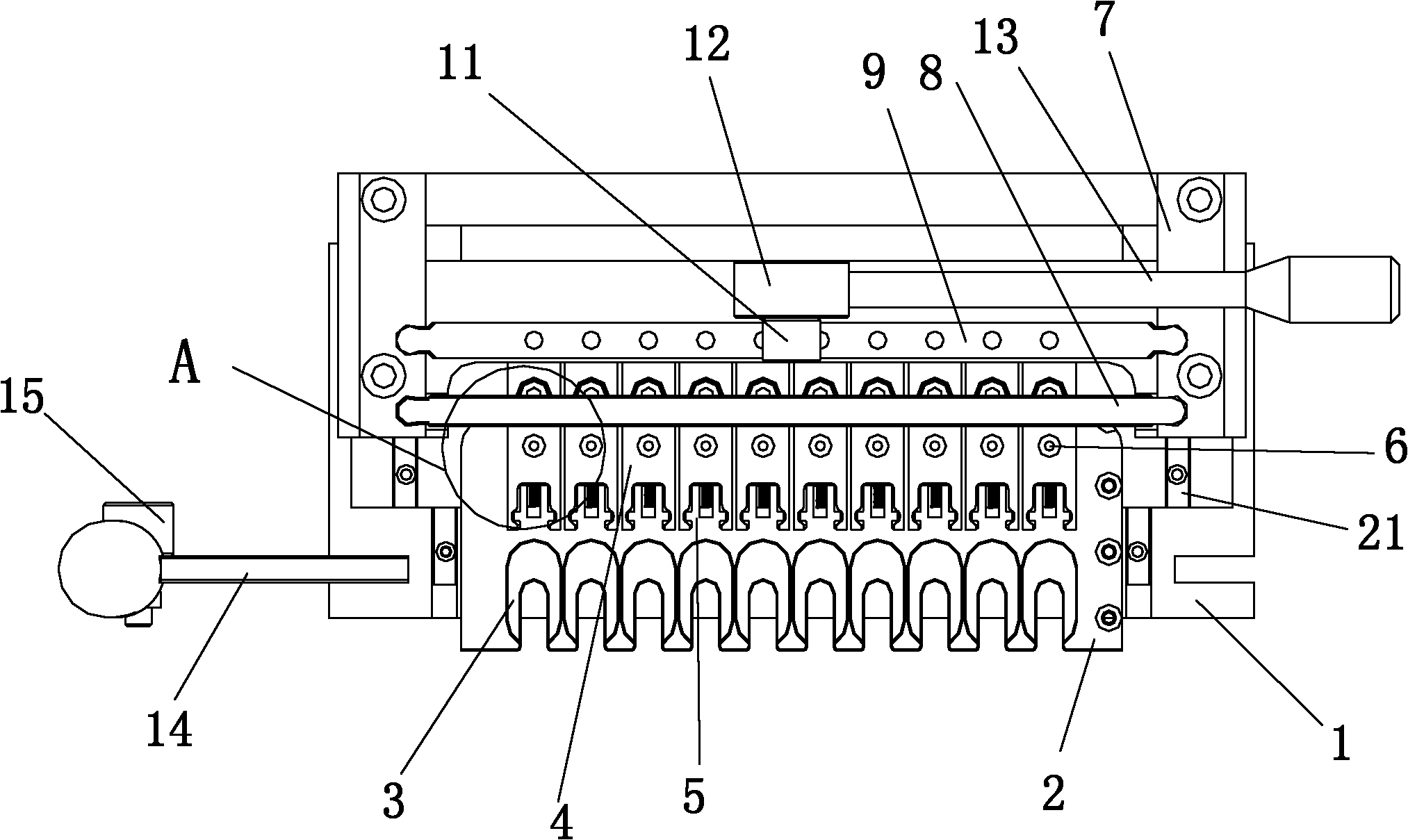

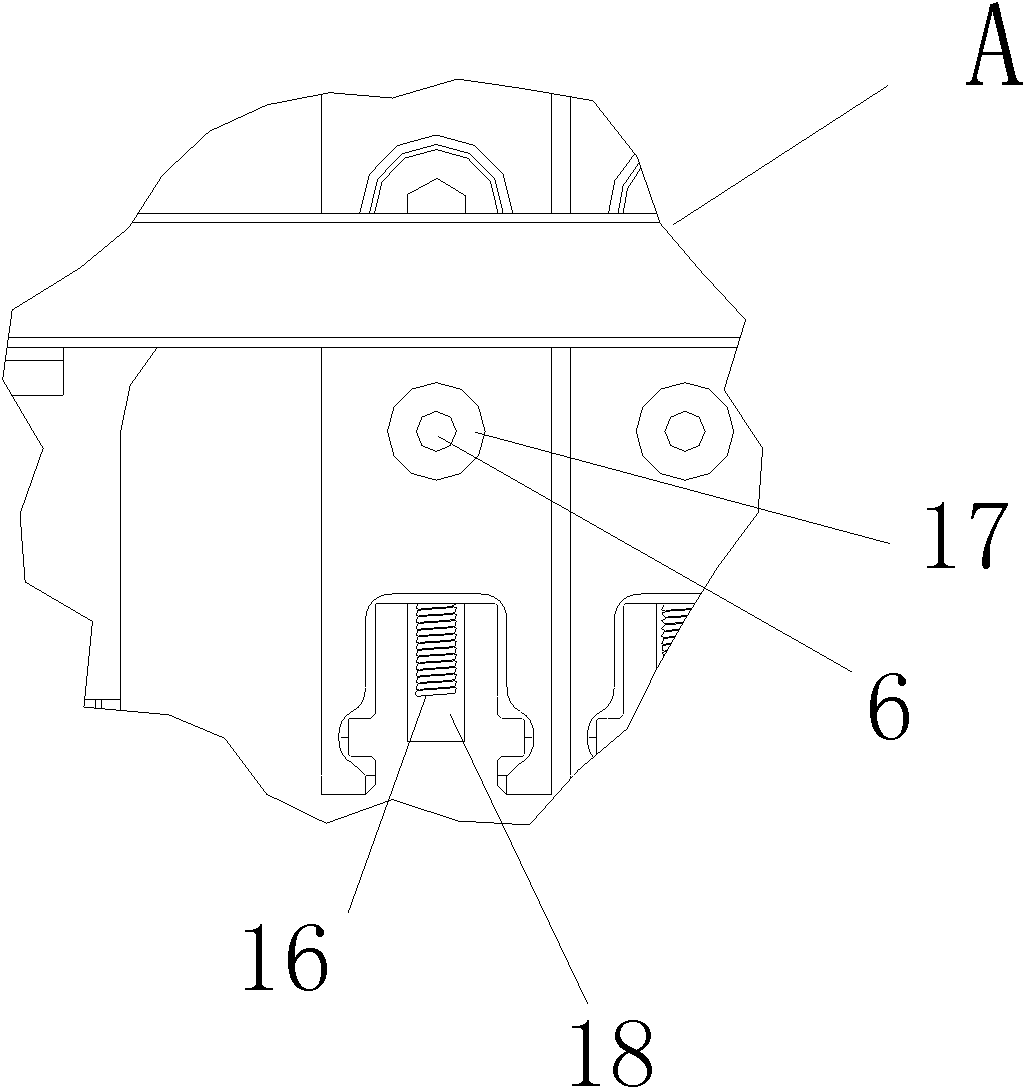

Unit line body structure of modularized intelligent assembly line

InactiveCN105173596ASave human effortImprove work efficiencyMechanical conveyorsCommunication interfaceButt joint

The invention discloses a unit line body structure of a modularized intelligent assembly line, wherein additional carrying is not needed through an assembly line design with backflow of empty trays, thus labour is saved, and working efficiency can be increased. An inductor is arranged on a cover plate of the unit line body of the assembly line, a stopper is arranged aside the inductor, and when the next procedure is not finished, the inductor at a front end in the procedure controls the stopper to stop the trays, thus avoiding damages to products due to congestion of the trays on the assembly line; the assembly line adopts a modularized design, the length of the assembly line is automatically set in a company in a splicing manner according to procedures for products, and the manner is capable of occupying a space in a workshop as less as possible; the unit line bodies are spliced by butt-joint location pins, and the assembly line is rapidly and accurately assembled; and two communication interfaces are formed in a control box, one is an upstream control interface, the other one is a downstream control interface, the two interfaces are connected with corresponding interfaces of an upstream assembly line and a downstream assembly line, and the whole assembly line is capable of running through the set parameters of a control centre.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

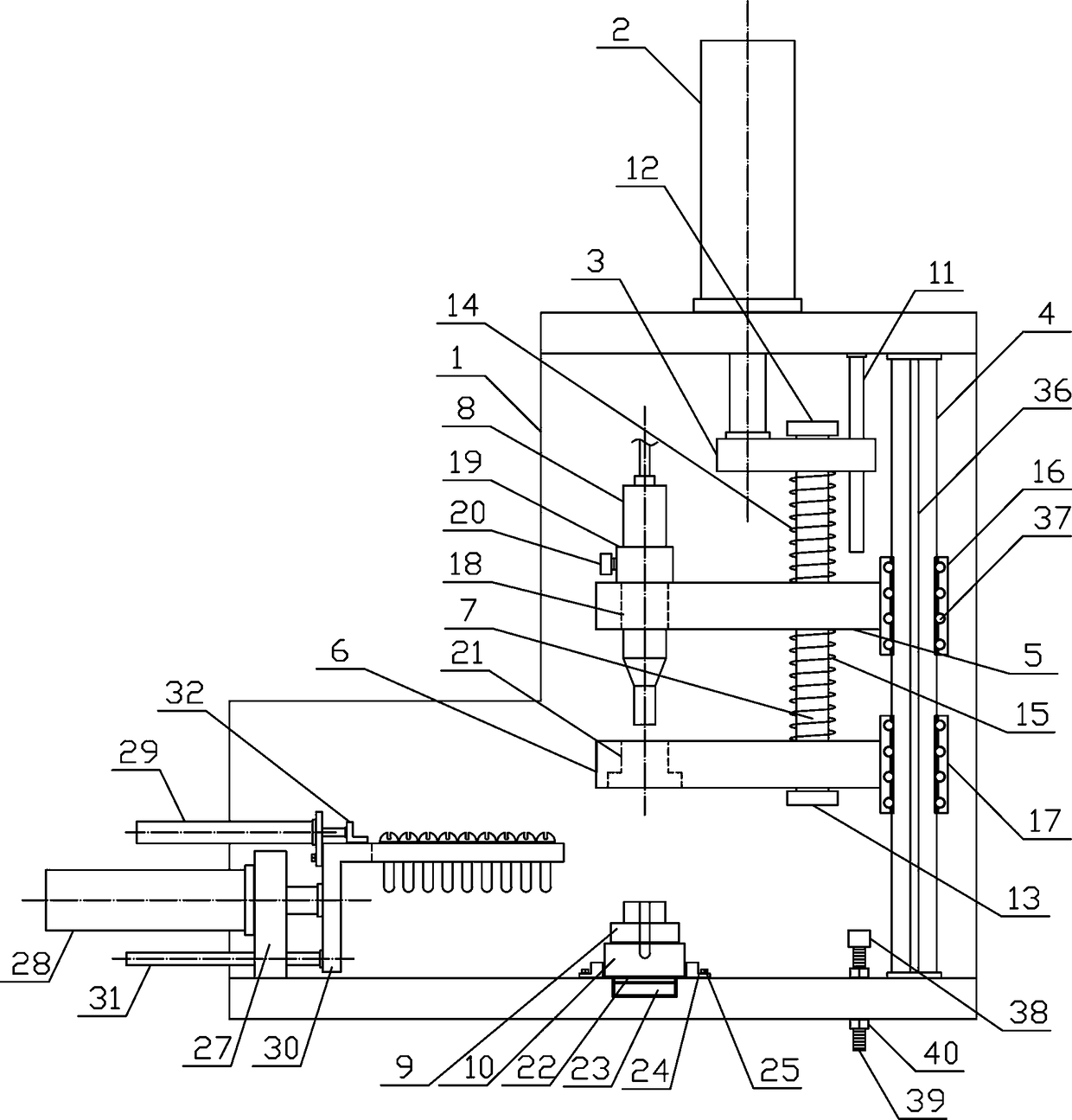

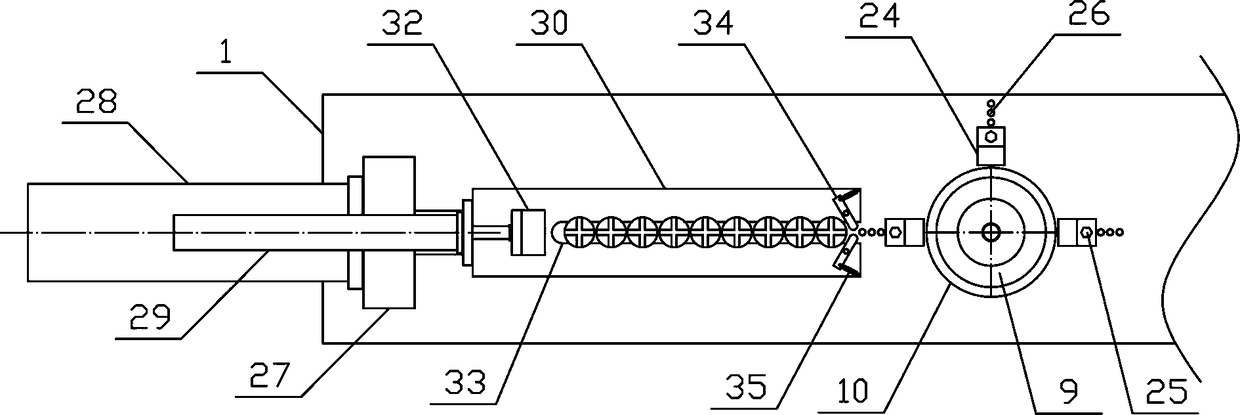

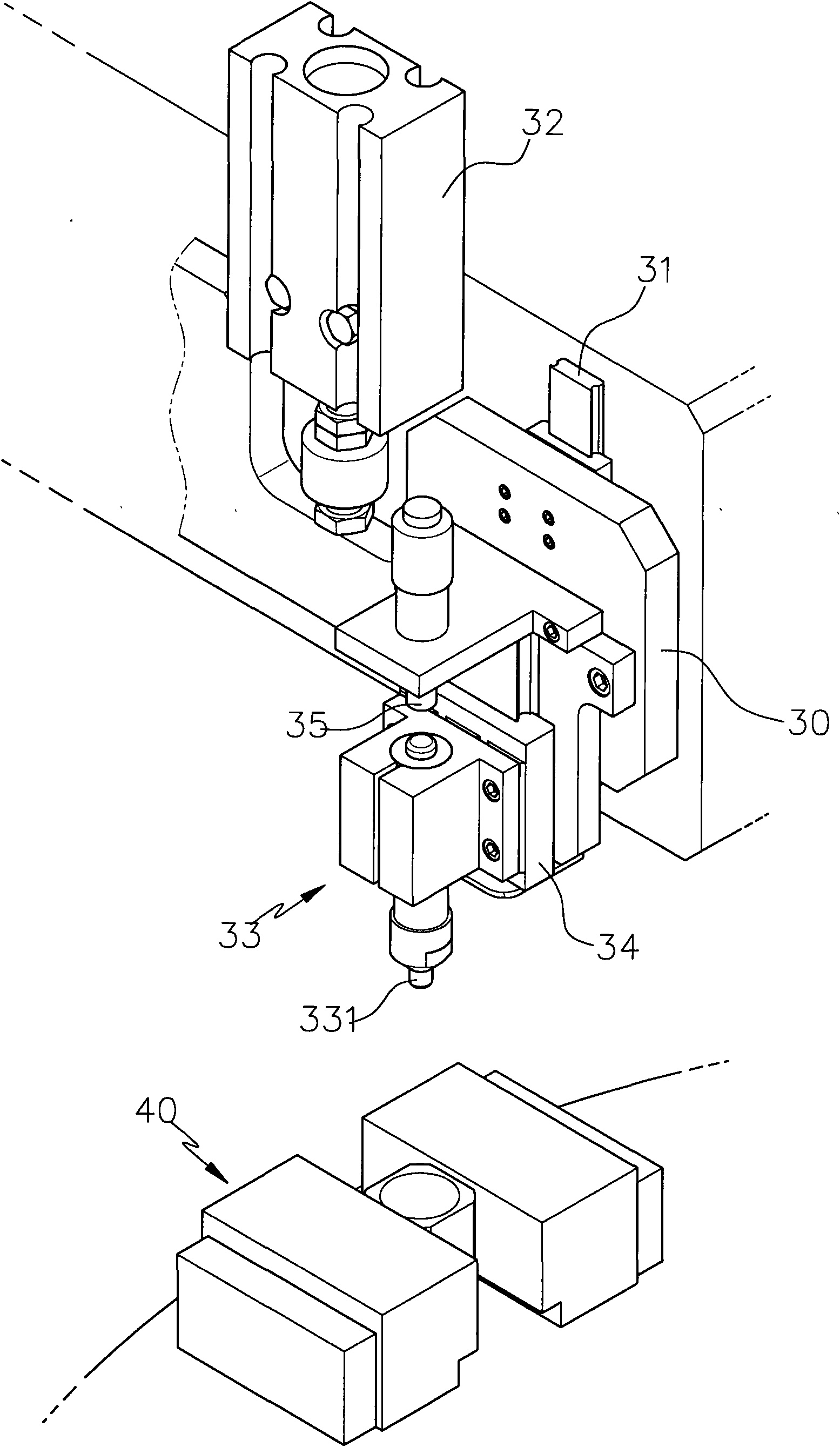

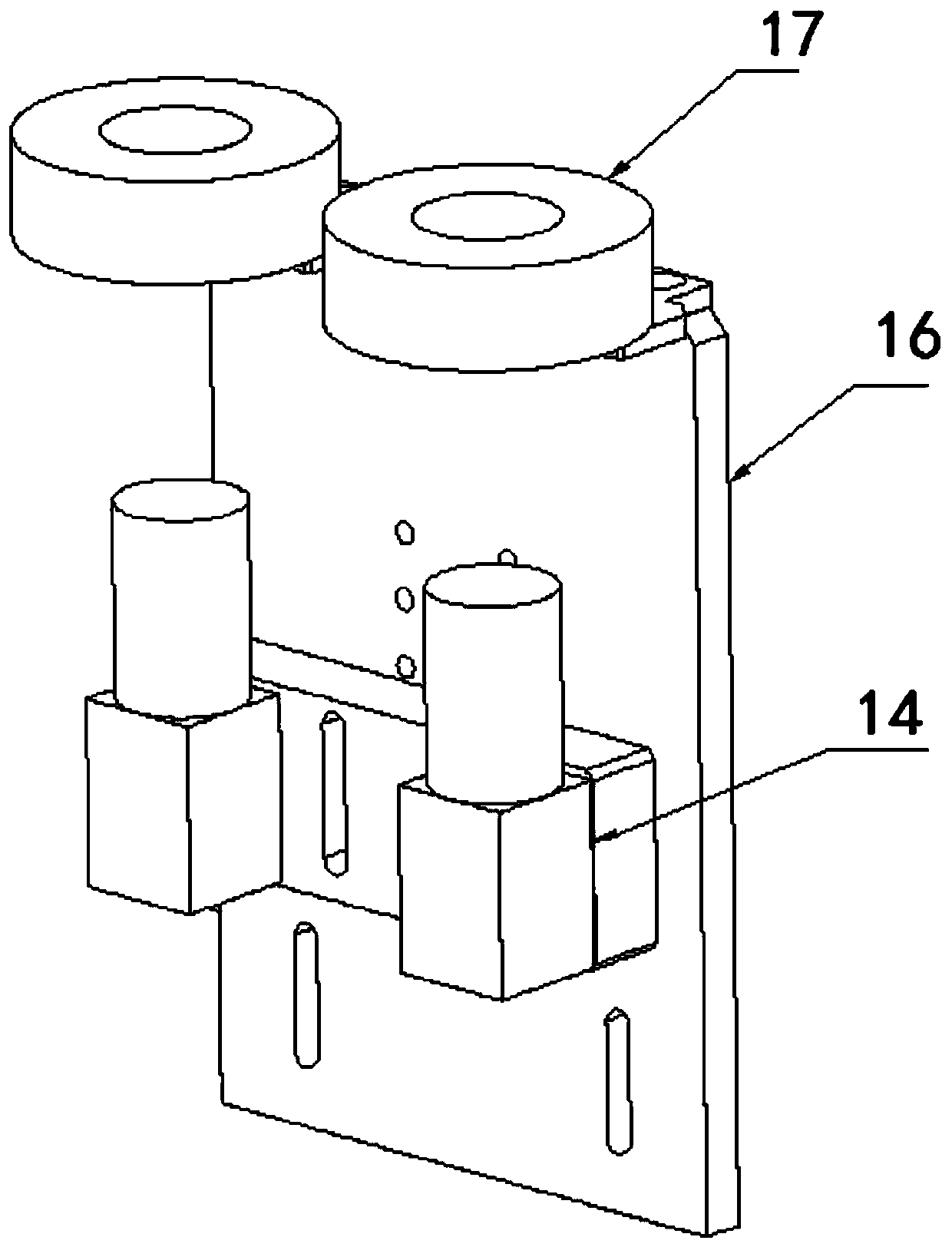

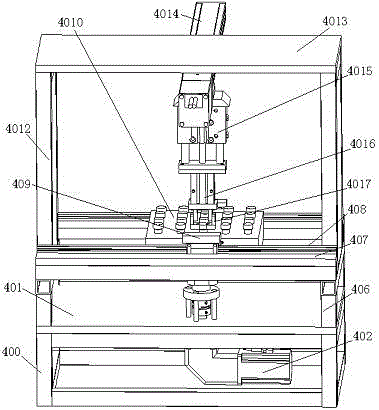

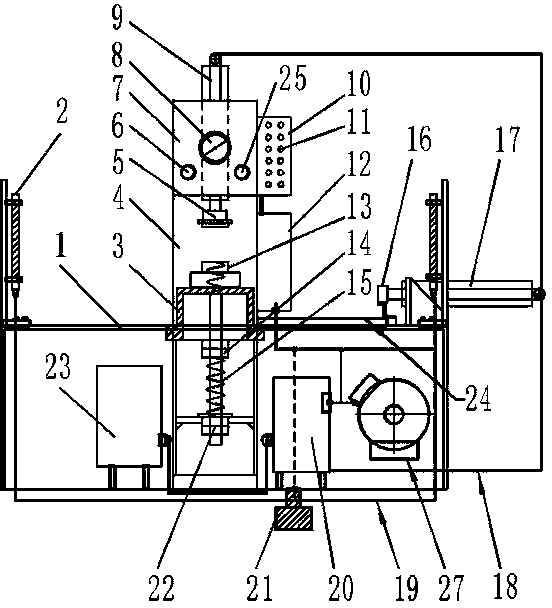

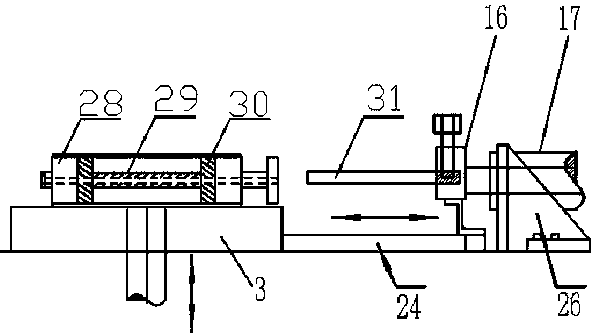

Workpiece assembling mechanism

InactiveCN108161383AAssembled preciselyEasy to take outMetal working apparatusEngineeringMechanical equipment

The invention discloses a workpiece assembling mechanism, and belongs to the field of assembly machining mechanical equipment. A screw feeding mechanism is horizontally arranged on one side below a fixed support, a driving guide plate is horizontally arranged on the lower side of an assembling air cylinder, an assembling guide rod is vertically and slidably provided with an assembling support anda pressing support from top to bottom, the lifting guide rod is provided with an assembling sleeve and a pressing sleeve in a sliding mode from top to bottom in the vertical direction, a pressing through hole is vertically formed in one side of the pressing support, an anti-skid rubber layer and a material attracting magnet are horizontally arranged on a fixed support in the middle of the lower side of a lower assembly tool from top to bottom in sequence, limiting clamping plates are symmetrically arranged on the fixed support on the outer side of the lower assembly tool; and the screw feedingmechanism comprises a feeding support, a feeding air cylinder, a nail pushing air cylinder and a screw clamping plate. The mechanism is reasonable in structural design, so that the workpiece can be stably held and fixed efficiently, and the workpiece can be assembled accurately, the automatic feeding of screws can be realized, the automation degree is high, and the requirements of assembly and use are met.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

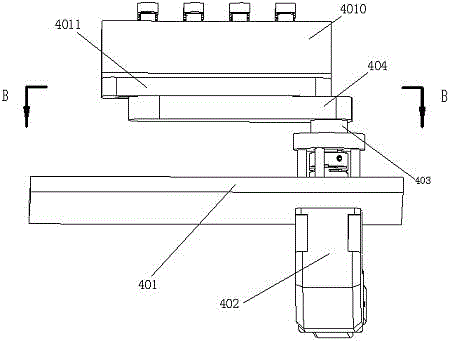

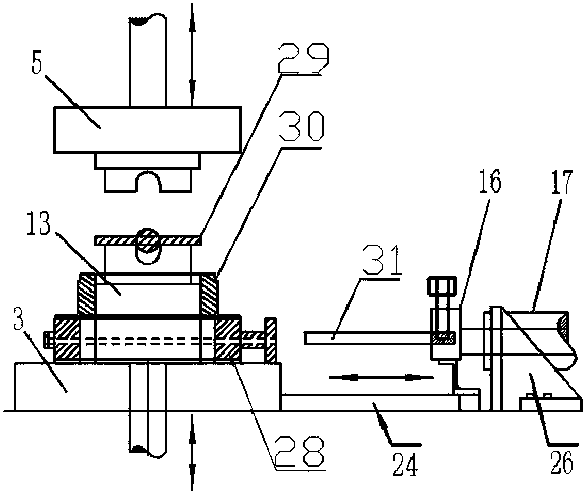

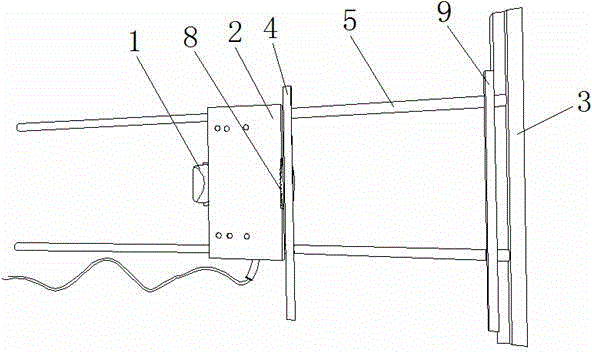

Screwdriver assembling device

InactiveCN108436435AInsert without errorConvenient for centralized processingMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of screwdriver production, in particular to a screwdriver assembling device. The screwdriver assembling device comprises a working table, a rotating motor, a supporting mechanism, a pushing mechanism and a feeding mechanism; the supporting mechanism comprises a handle supporting frame and a cutter rod supporting frame which are both of cylinder structures, the handle supporting frame and the cutter rod supporting frame are both fixedly arranged on one rotating shaft in a sleeving manner, a plurality of cutter rod containing notches are formed in the edge of the cutter rod supporting frame at intervals in the peripheral direction, a plurality of handle containing notches are formed in the edge of the handle supporting frame at intervals in the peripheral direction, all handle containing notches correspond to all cutter rod containing notches in a one-to-one manner, an arc-shaped limiting plate is arranged on the outer side of the cutter rod supportingframe, and a discharging hole is formed in the working table. By means of the screwdriver assembling device, a handle and a cutter rod can be inserted, connected and assembled accurately, manpower cost is reduced, and meanwhile, the screwdriver assembling efficiency is effectively improved.

Owner:岑佰庆

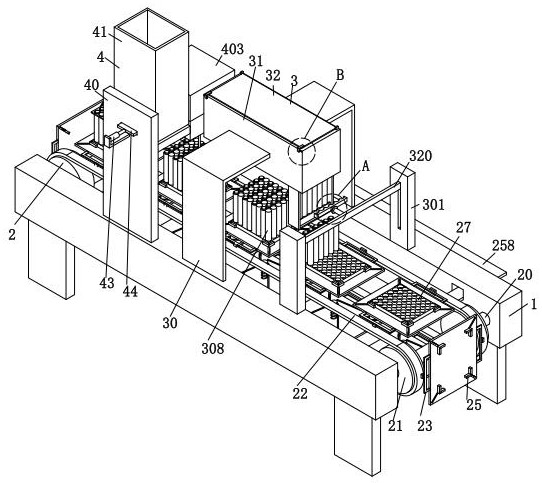

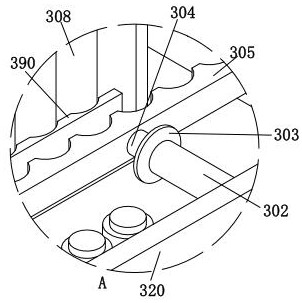

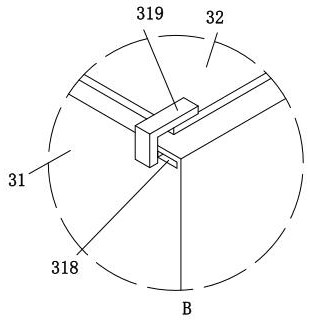

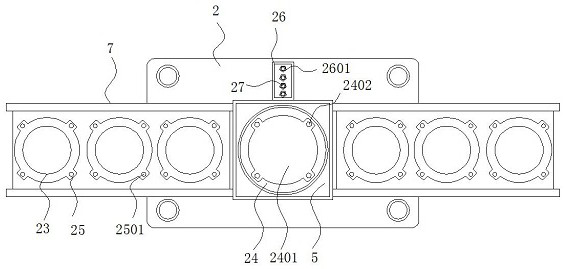

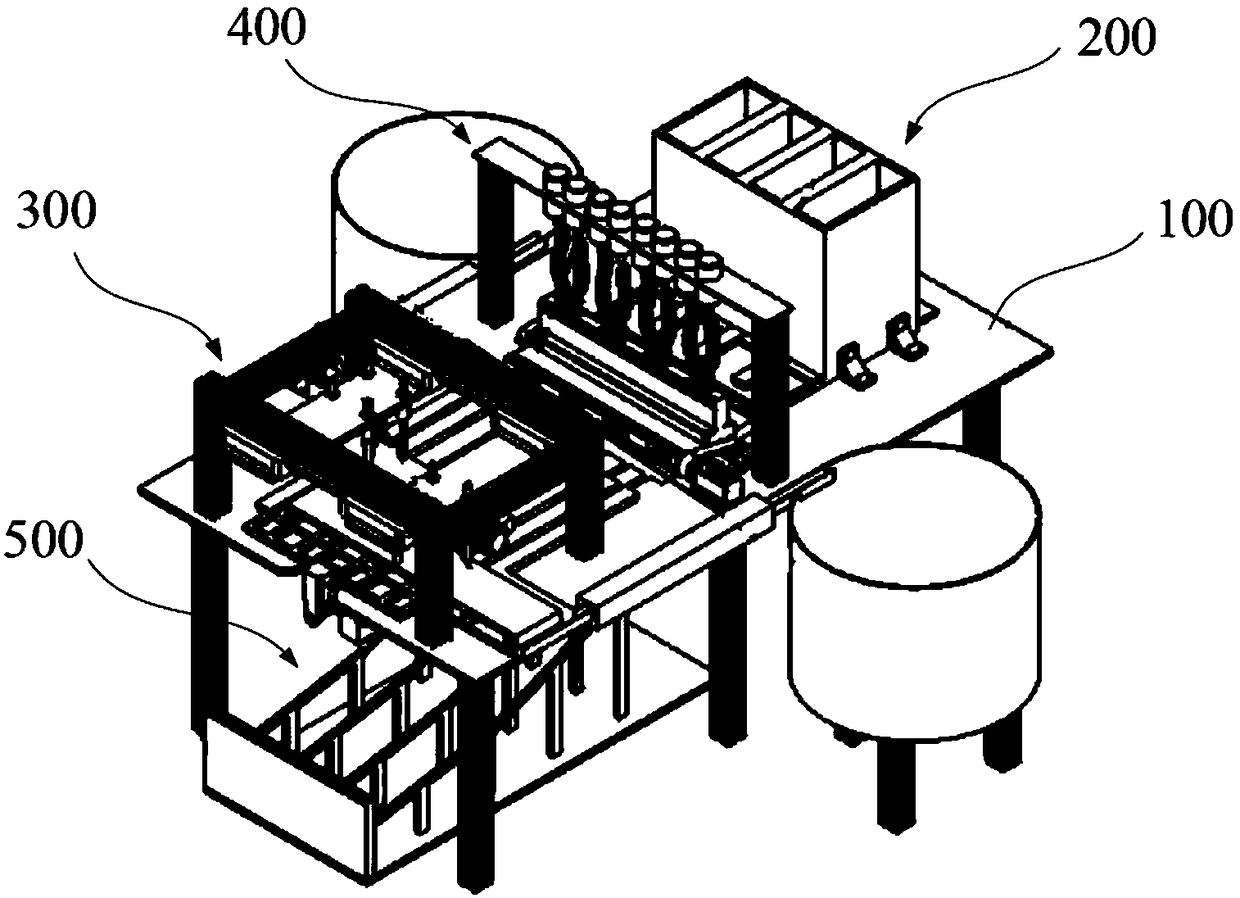

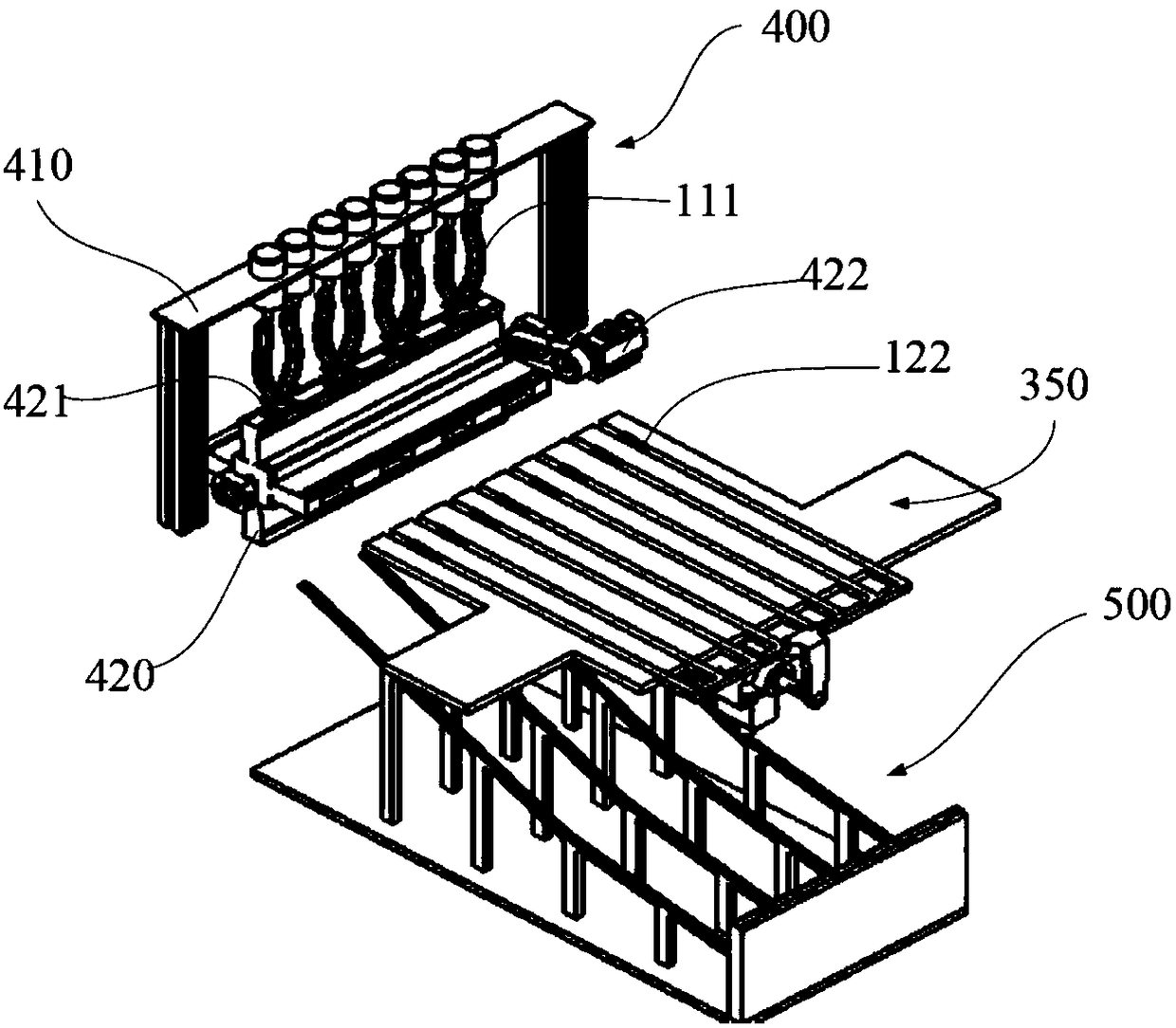

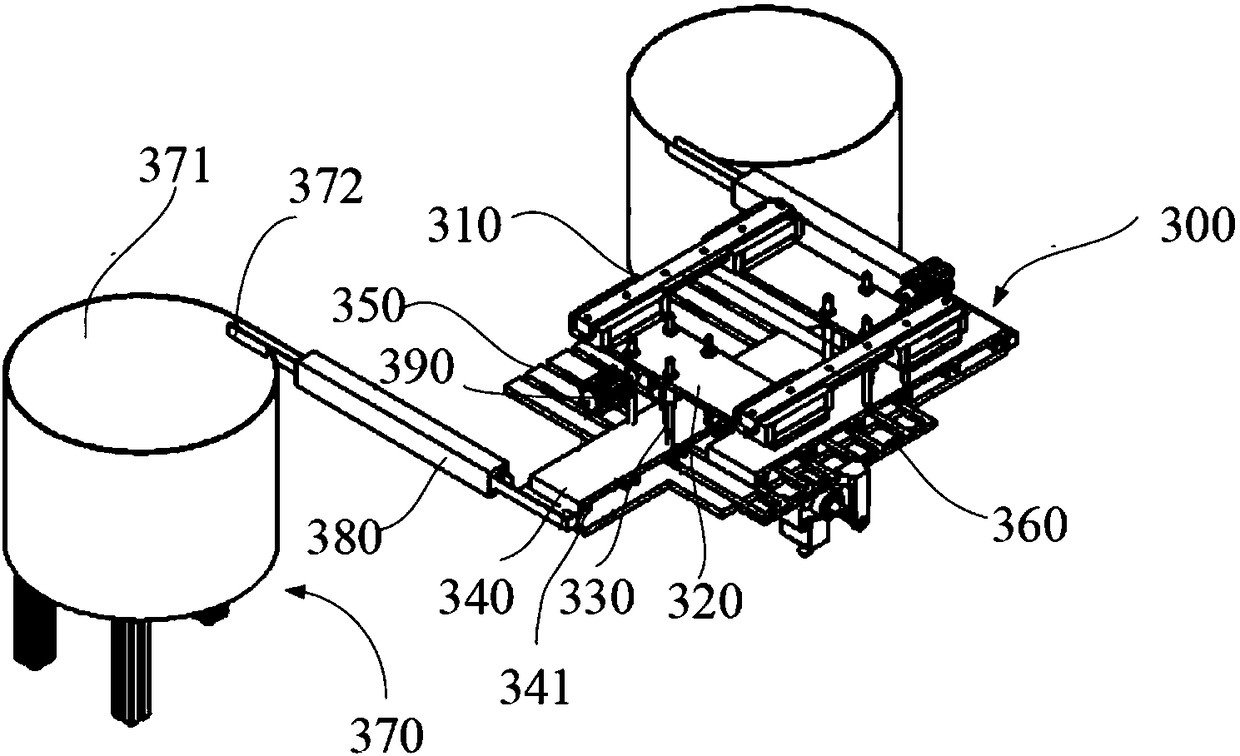

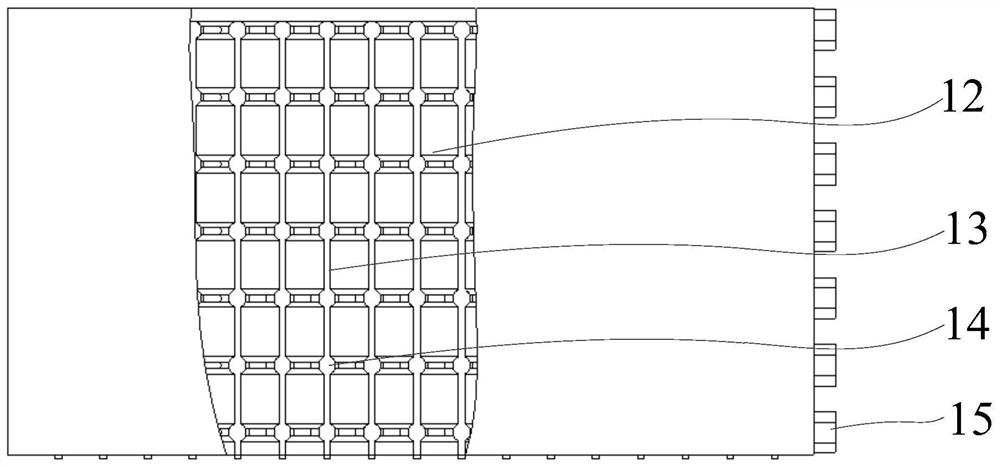

Automatic lithium battery assembling equipment and assembling method

ActiveCN113611915AAvoid the problem of hard to get stuck on the battery cellNo slipping problemPrimary cell manufactureConveyorsStructural engineeringMechanical engineering

The invention relates to the technical field of lithium battery assembly and particularly relates to automatic lithium battery assembly equipment and an assembly method. The automatic lithium battery assembly equipment comprises a support frame, a conveying mechanism and an arranging and conveying mechanism. By adopting a cover clamping mechanism, an end cover at an upper end of a battery core can continuously cover the corresponding assembled battery core, and meanwhile, an inserting rod is matched with an inserting hole before the cover is pressed, so the positioning effect is realized, the end cover can be accurately clamped on the battery core, a problem that the end cover is difficult to clamp on the battery cell due to inaccurate alignment of the end cover and the battery cell is avoided, and meanwhile, each fixed group plate on the transmission belt can be fixed by adopting the clamping and fixing group in the conveying process of the conveying mechanism, so the fixed group plates cannot move due to conveying in the whole conveying process; accuracy of subsequent insertion of the battery cell is ensured, and a problem that it is difficult to ensure that the battery cell and the battery cell fixing plate are accurately aligned and inserted into the insertion hole is solved.

Owner:深圳市冠力达电子有限公司

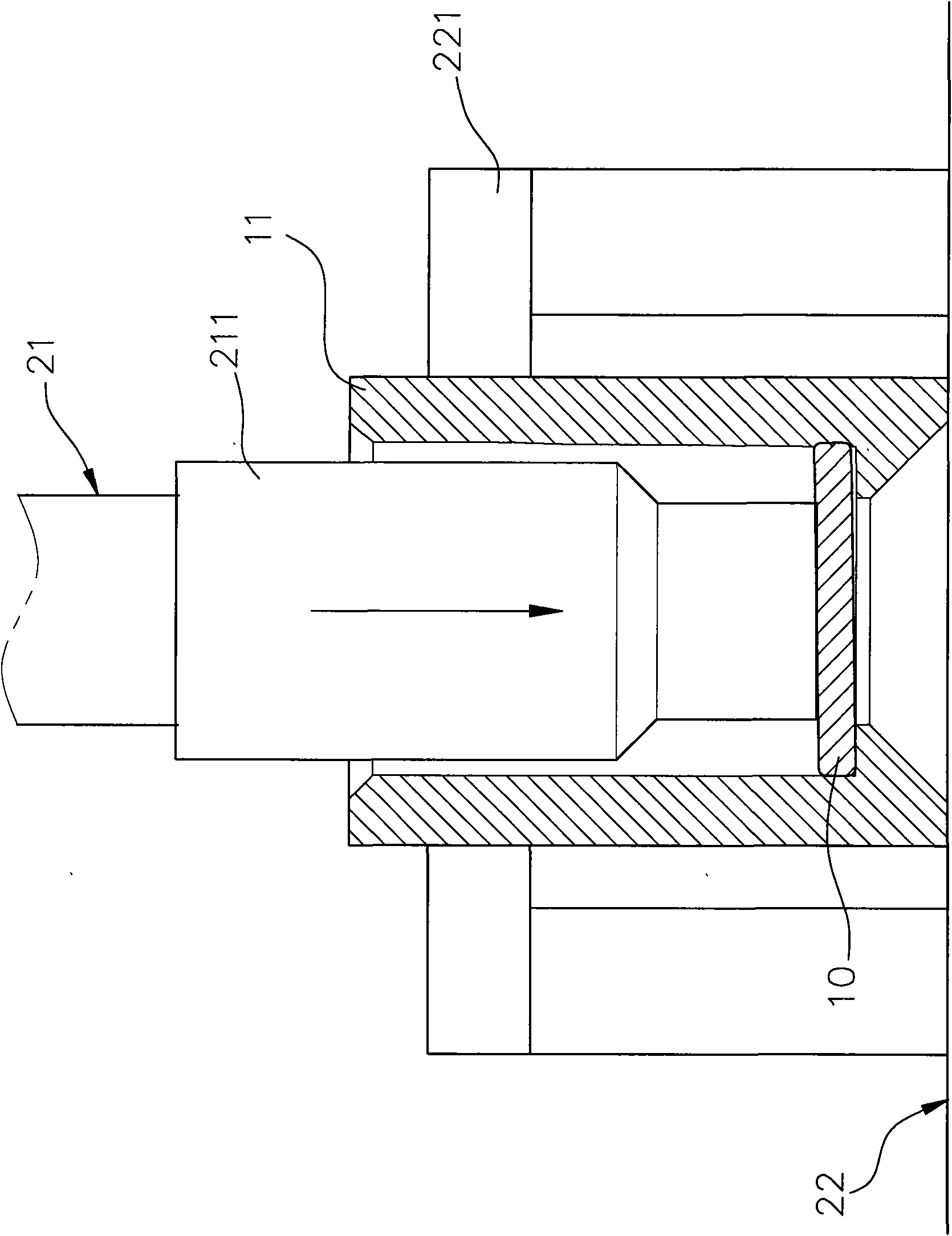

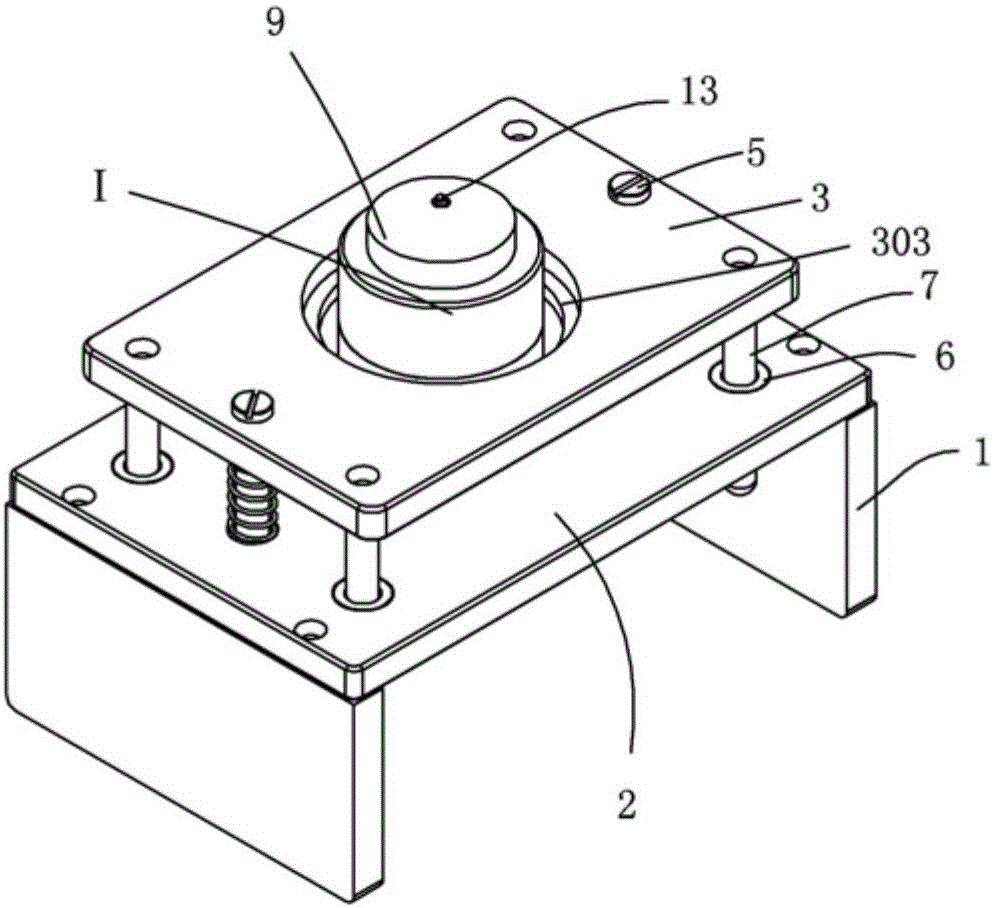

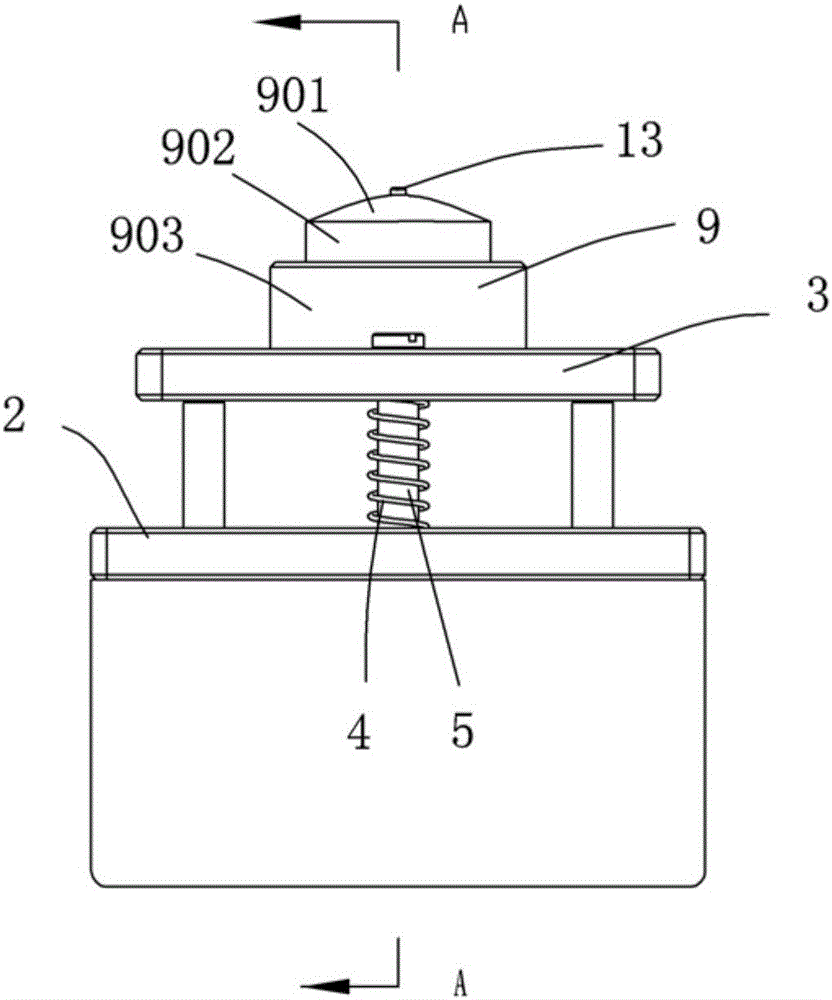

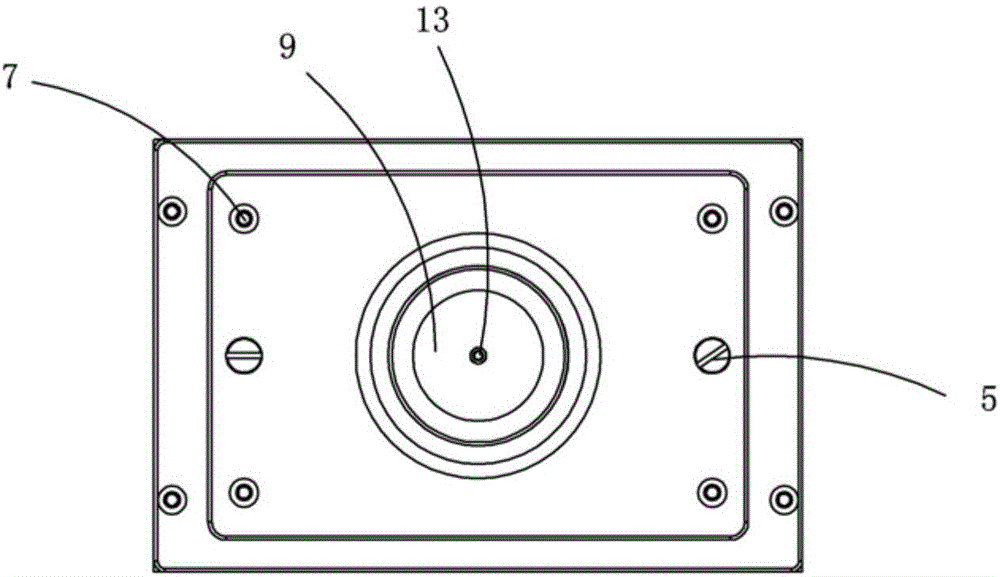

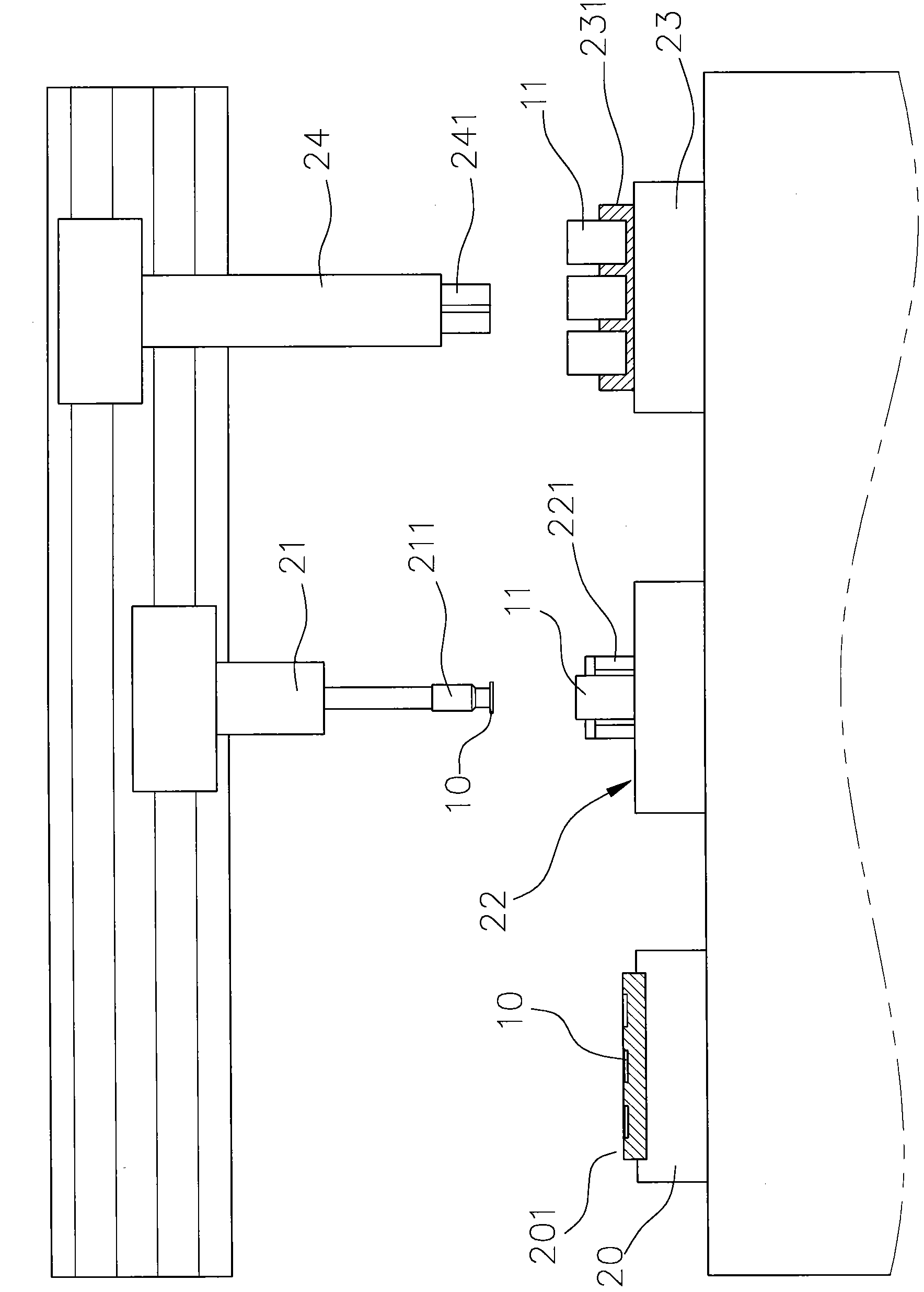

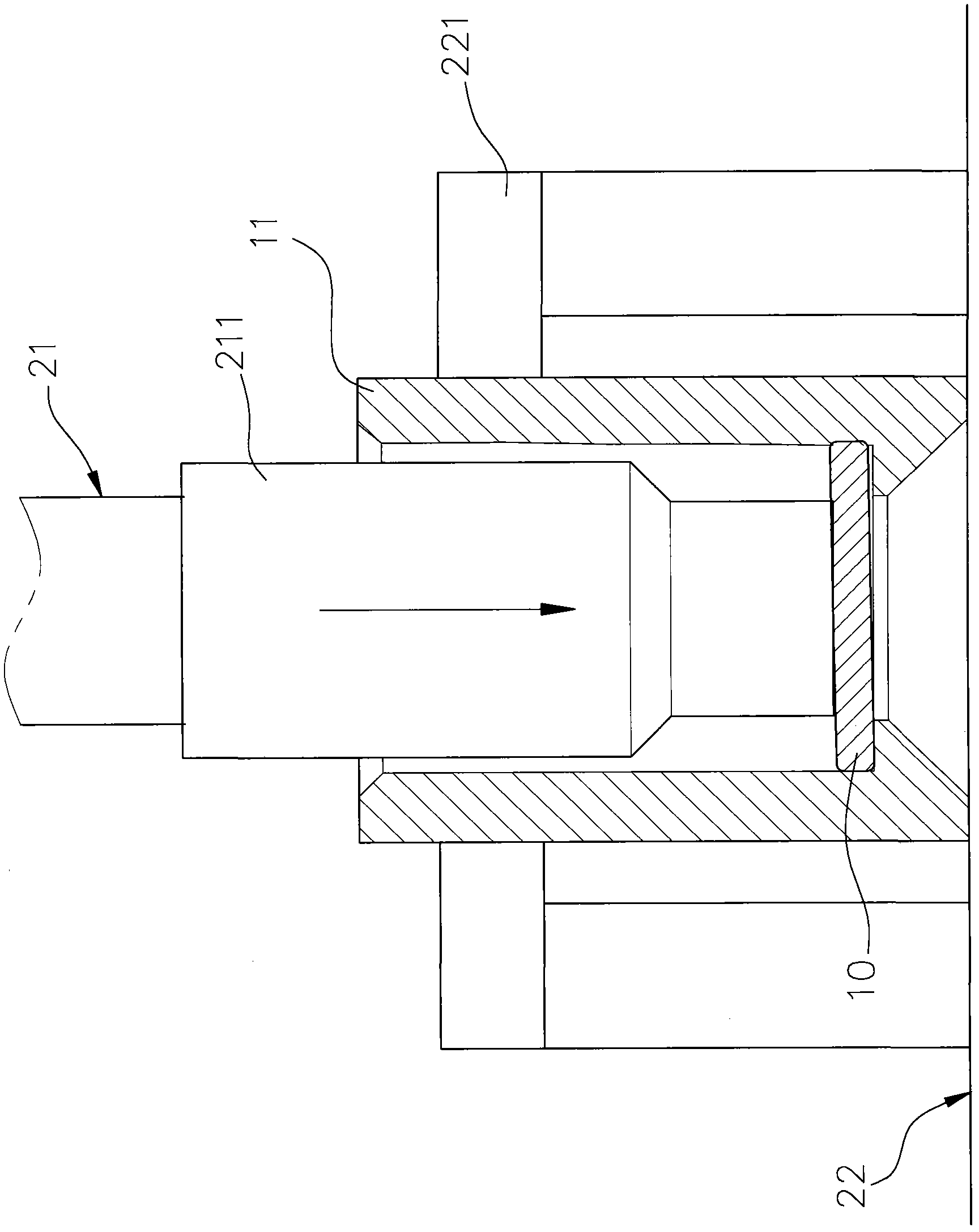

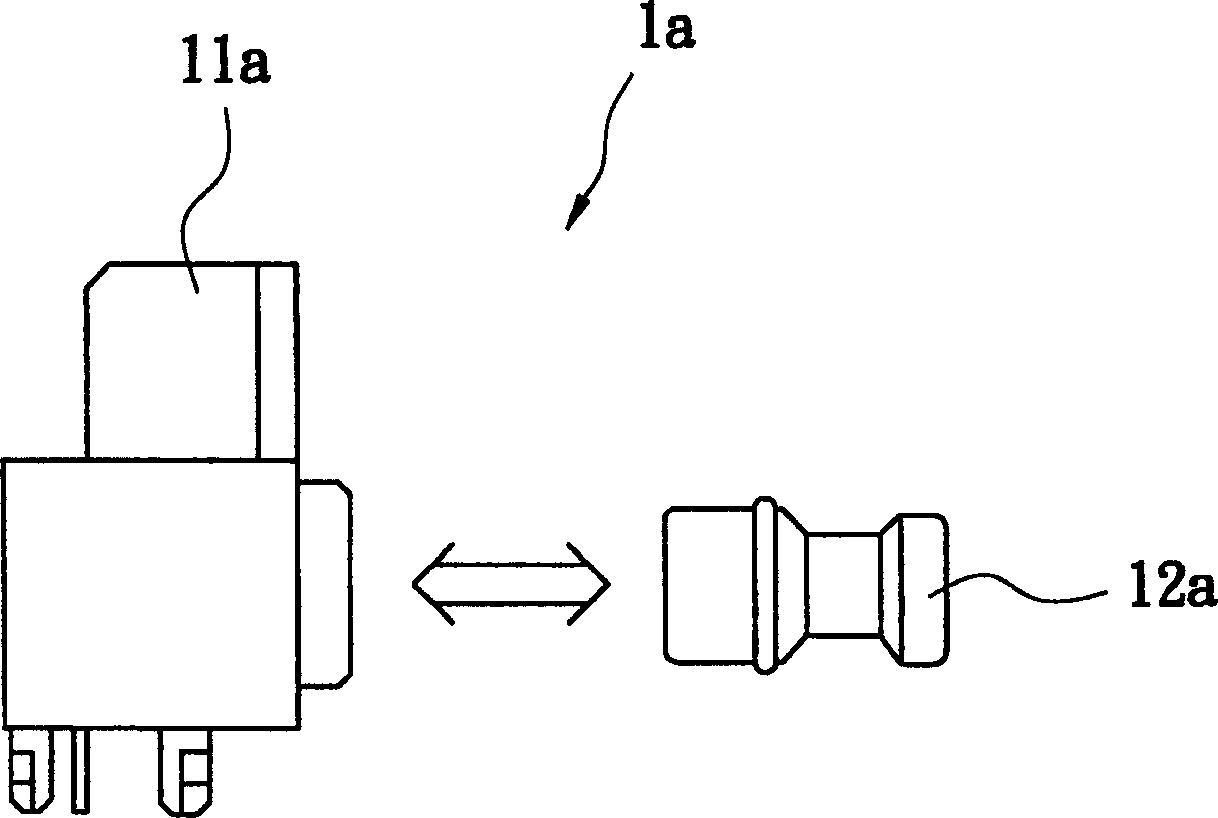

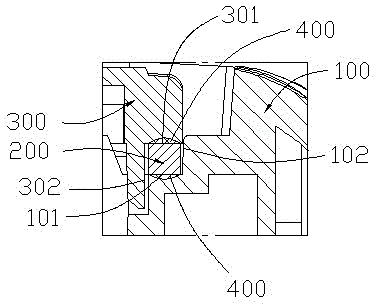

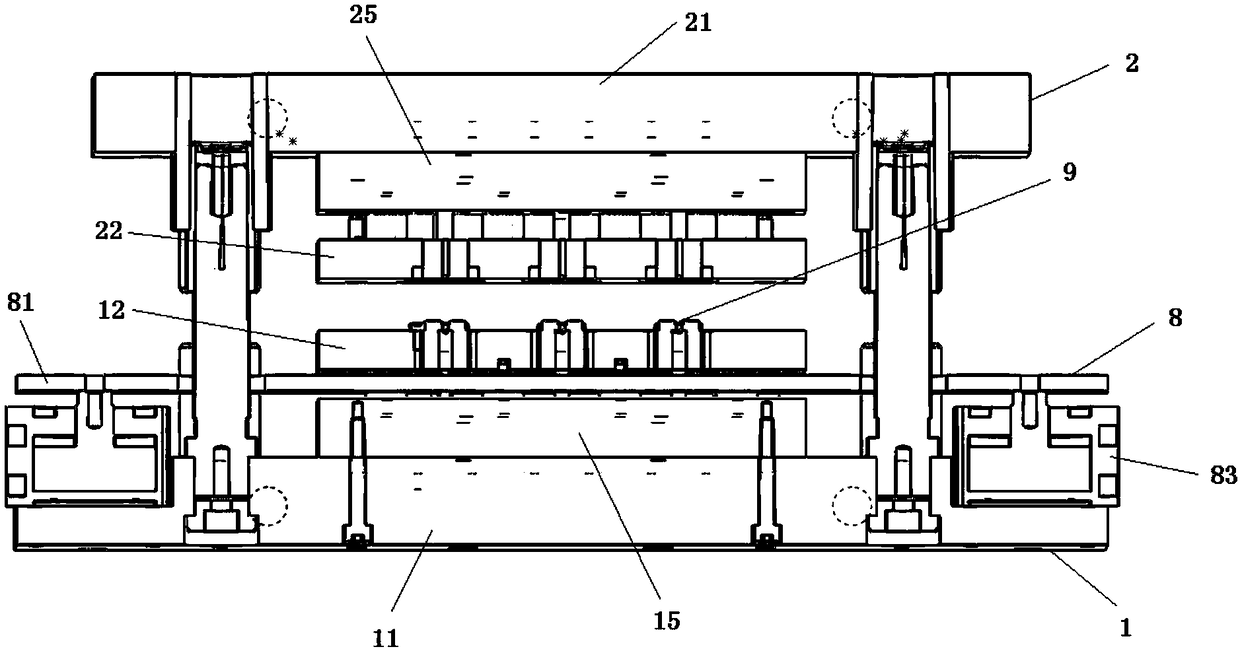

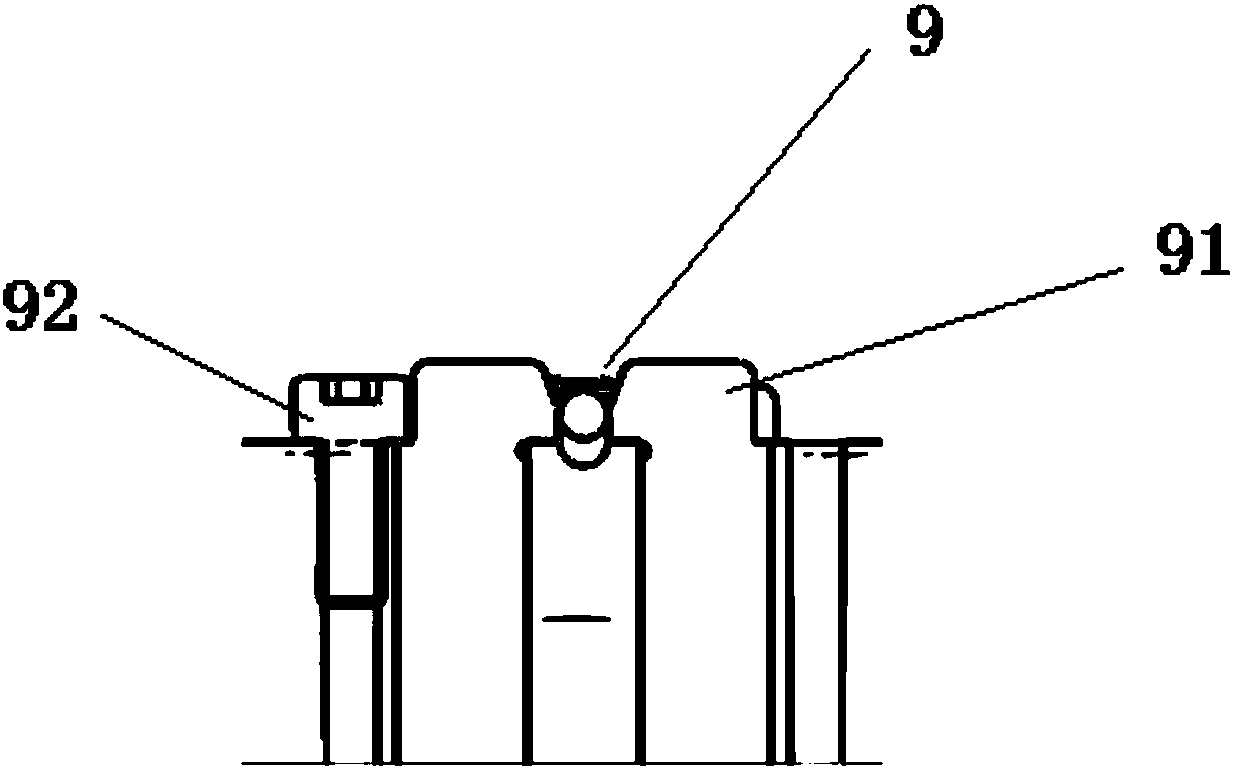

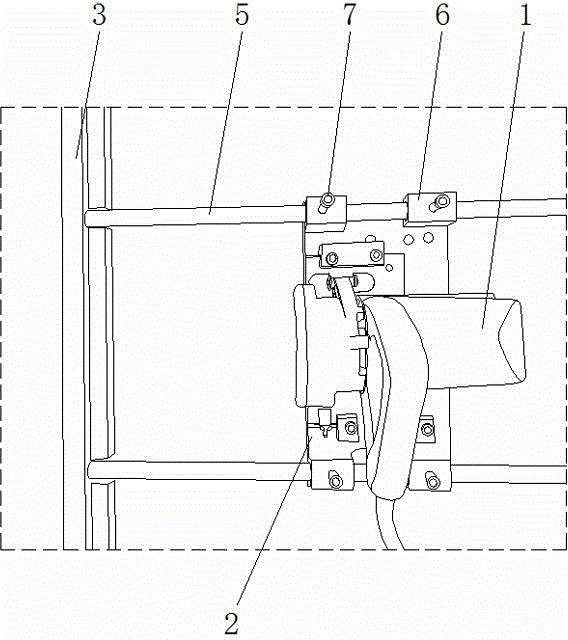

Pressing device capable of aligning lens with lens barrel and pressing method thereof

The invention discloses a pressing device capable of aligning a lens with a lens barrel and a pressing method thereof. A pressing group is assembled on a sliding seat which can be driven to lift, andis provided with a pressure head on which the lens can be placed and from which the lens can be taken; a floating mechanism is arranged between the pressure head and the sliding seat so as to make thepressure head and the sliding seat relatively lift and slide; and a bearer bears the lens barrel with a guiding part and the lens barrel is transferred to a position below the pressing group so as toperform segmented pressing operation on the lens and the lens barrel; and the pressing way is that: the sliding seat and the pressing group are driven to descend first, the pressure head of the pressing group can stop descending by means of the floating mechanism immediately when the lens is contacted with the guiding part of the lens barrel so as to enable the pressure head to slightly press thelens, and at the same time, the pressure head is driven to perform repressing after the guiding part of the lens barrel is aligned with the lens so as to press and position the lens into the lens barrel, so the practicable effects of precise assembly and great improvement on assembly qualification rate can be achieved by utilizing the floating mechanism of the pressure head.

Owner:ART CONTROL SYST LNC

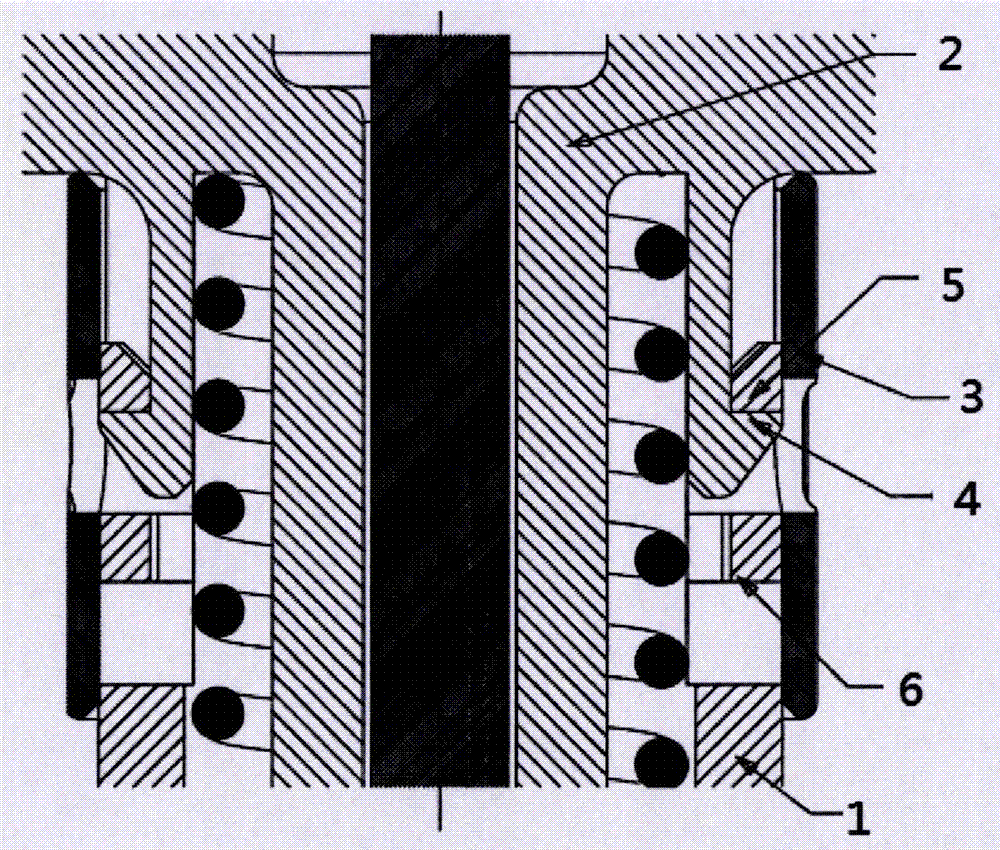

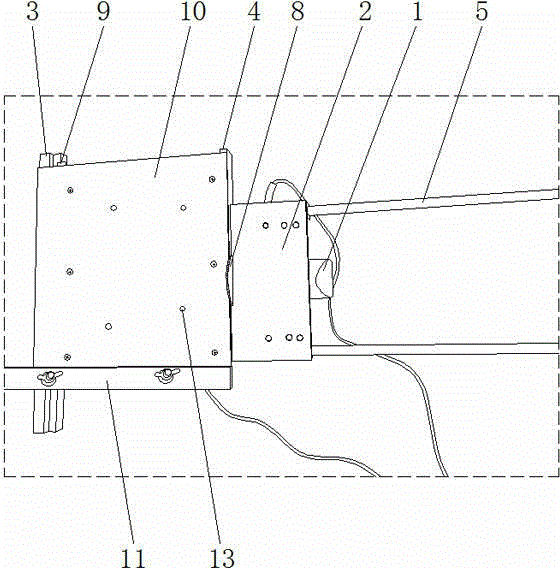

Gauge changeable wheelset assembling device and assembling method

ActiveCN111069875AQuick assemblyAssembled preciselyMetal working apparatusStructural engineeringControl theory

The invention relates to the field of rail vehicle gauge changing, and provides a gauge changeable wheelset assembling device and assembling method. The device comprises a base, wherein the base is provided with a first sliding rail or a first sliding groove, a pair of axle supporting clamping devices are arranged on the base at intervals and each comprises a support, an axle positioning part, a pressing part and a locking part, the bottoms of the supports are provided with second sliding grooves or second sliding rails matched with the first sliding rail or the first sliding groove, the axlepositioning parts are fixed on the supports, and the pressing parts are in locking connection with the supports through the locking parts; a pair of wheel adjusting devices are arranged on the base atintervals, and both wheel adjusting devices comprise supporting seats and wheel positioning parts fixed on the supporting seats; and the bottoms of the supporting seats are provided with third sliding grooves or third sliding rails matched with the first sliding rail or the first sliding groove, and each wheel positioning part comprises a pair of baffles arranged on the corresponding supporting seat at intervals and a pair of supporting rolling wheels arranged between the corresponding pair of baffles. The device can realize quick and accurate assembly of a gauge changeable wheelset, and improves the assembly efficiency and the assembly precision.

Owner:CRRC QINGDAO SIFANG CO LTD

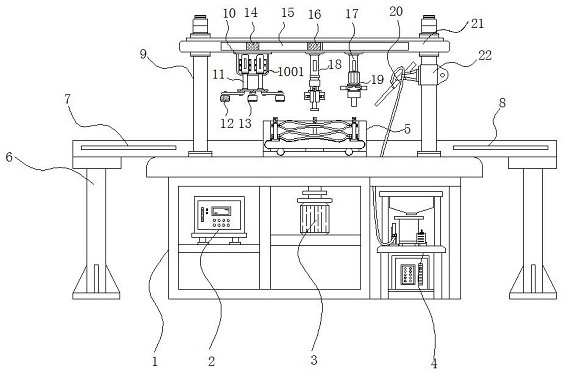

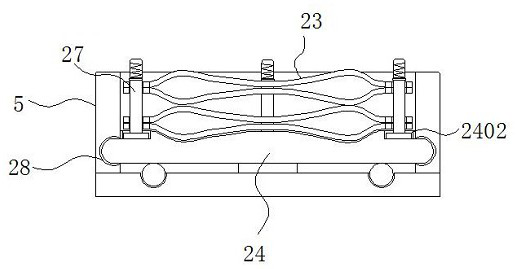

Wave spring assembling device with limiting structure

InactiveCN111958216AImprove assembly efficiencyEase of mass productionMetal working apparatusWorkbenchIndustrial engineering

The invention discloses a wave spring assembling device with a limiting structure. The wave spring assembling device with the limiting structure particularly comprises a workbench, an assembling bench, a suction mechanism and a tightening mechanism. Support frames are installed on two sides of the workbench, vertical columns are fixed at four corners of the top end of the workbench, a first conveying mechanism is installed on the support frame on one side of the workbench, a second conveying mechanism is fixed on the support frame on the other side of the workbench, a control panel is installed on one side, close to the first conveying mechanism, of the interior of the workbench, and a nut conveyor is fixed on one side, close to the second conveying mechanism, of the inner part of the workbench. According to the wave spring assembling device with the limiting structure, by arranging the suction mechanism, the tightening mechanism and the nut conveyor, the suction mechanism can suck wave springs through an electromagnet, automatic feeding and unloading are achieved, the tightening mechanism and the nut conveyor can automatically perform bolt fastening and assembling on overlapped wave springs, and batch production is facilitated.

Owner:东莞市史雷帝三维数控科技有限公司

Product movable attachment and assembly mechanism

The invention relates to a product movable attachment assembly mechanism, which comprises a fixed mounting plate installed on a support plate, a carrier floating plate is installed on the fixed mounting plate through a guide assembly, and a sleeve is passed between the carrier floating plate and the fixed mounting plate. There are equal-height screw connections of the elastic part a, the product to be attached and assembled is placed on the floating plate of the carrier, and the positioning mechanism capable of positioning the product is installed on the upper part of the fixed mounting plate. There is a sleeve fixing block between the floating plates and a positioning sleeve installed on the sleeve fixing block. There is a limit hole inside the positioning sleeve, and a jacking wire is installed in the middle of the upper part of the sleeve fixing block; The b top holds the elastic positioning pin, and the top wire, the elastic part b and the elastic positioning pin are all located in the limiting hole, and the upper end of the elastic positioning pin is exposed above the positioning sleeve. When working, press down the floating plate of the carrier, and the floating plate of the carrier presses the elastic part a and moves along the guide column to bring the product to the required position for assembly.

Owner:BOZHON PRECISION IND TECH CO LTD

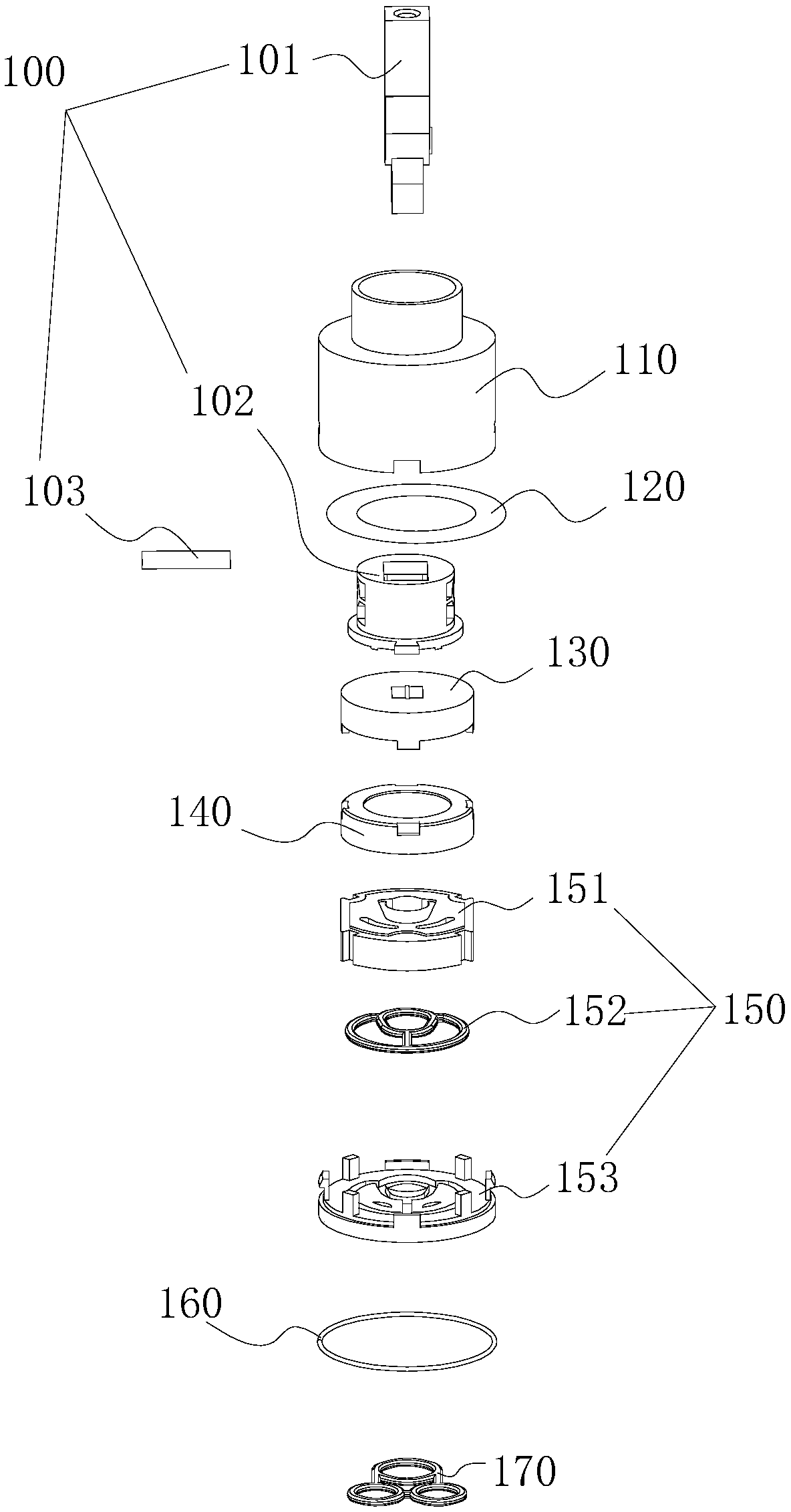

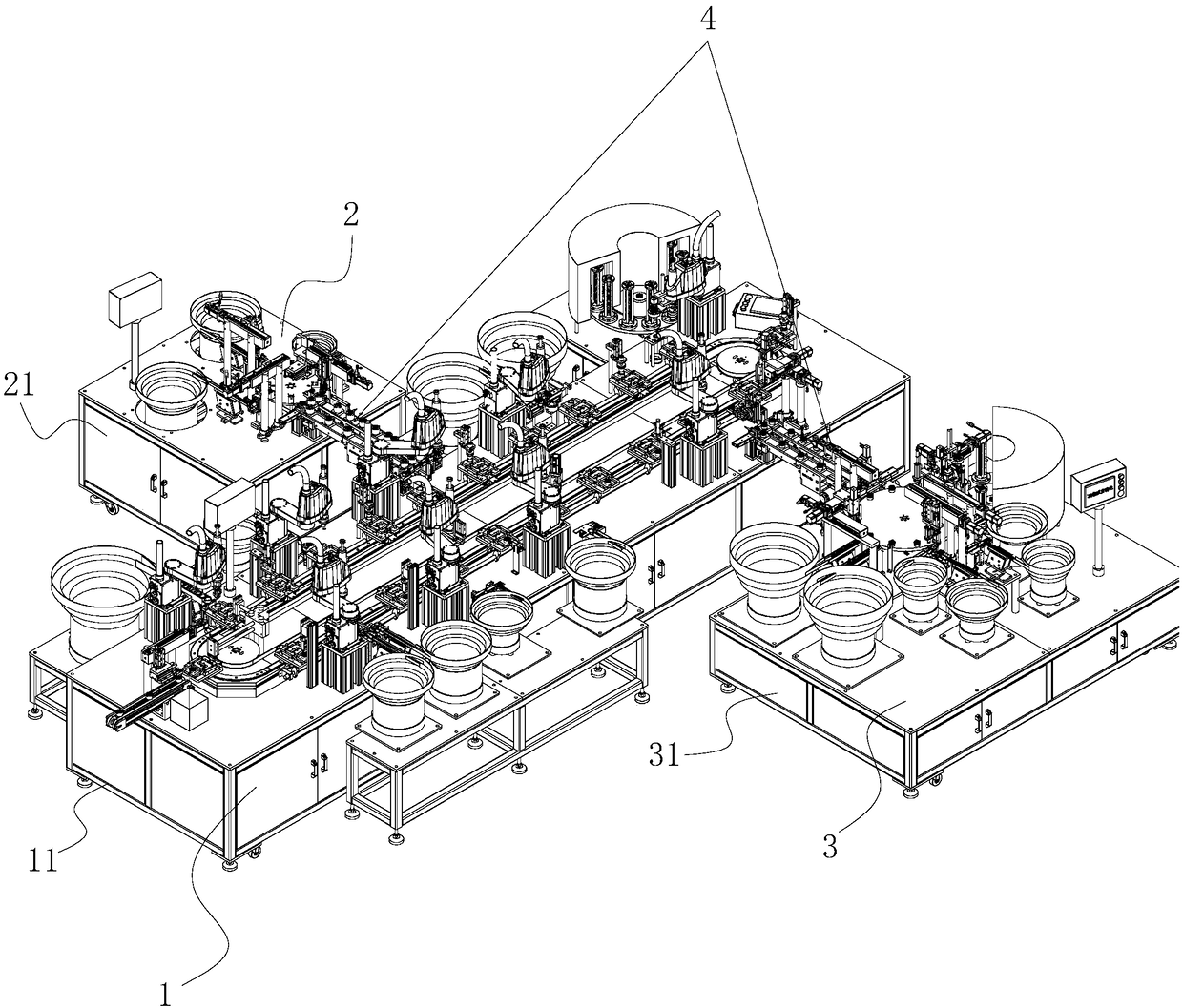

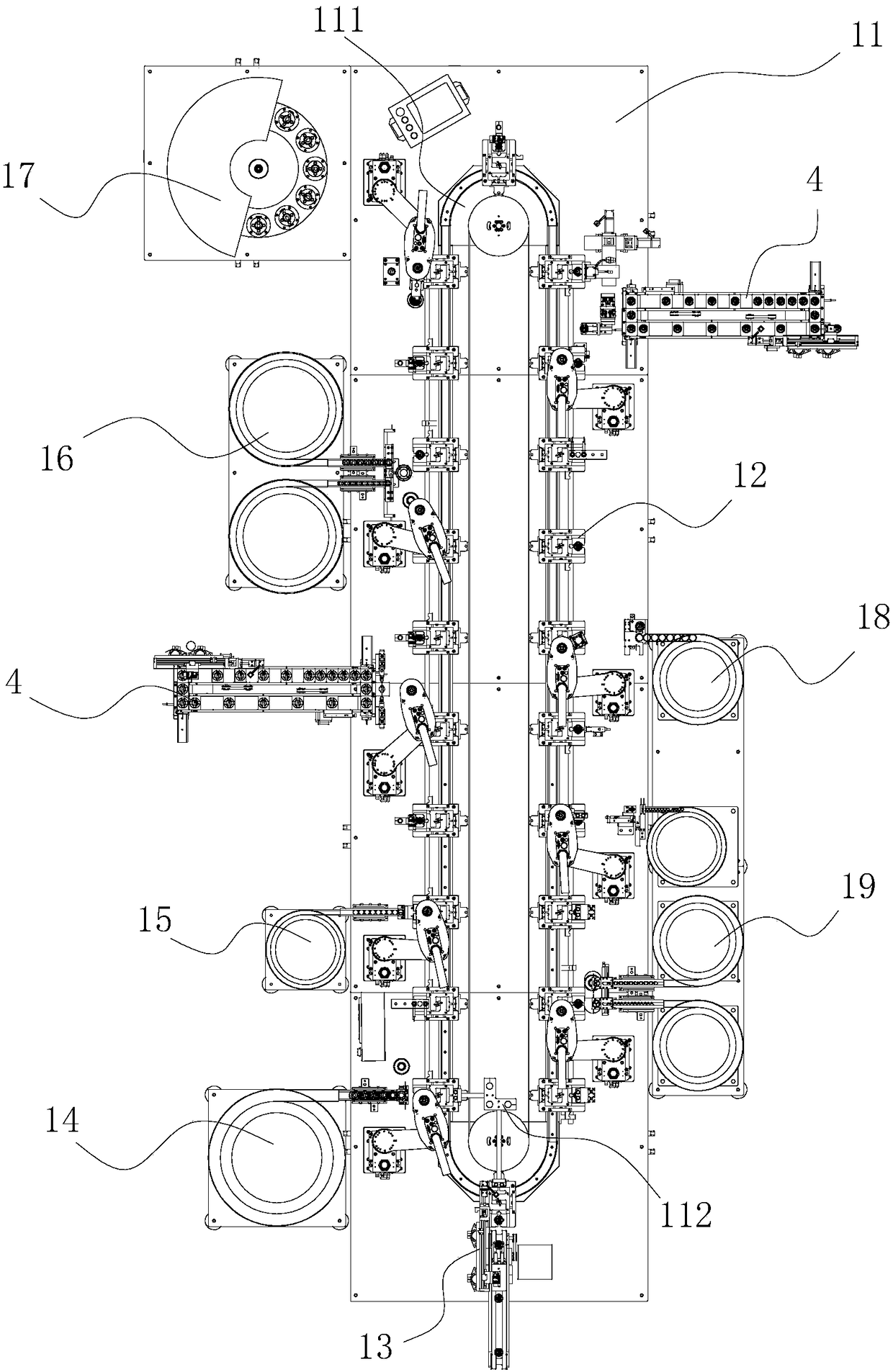

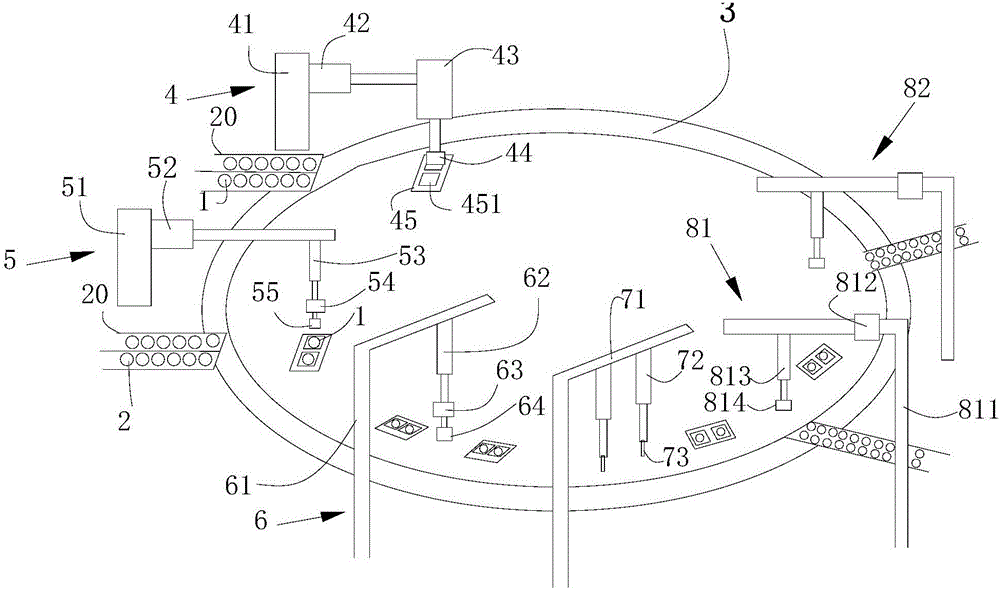

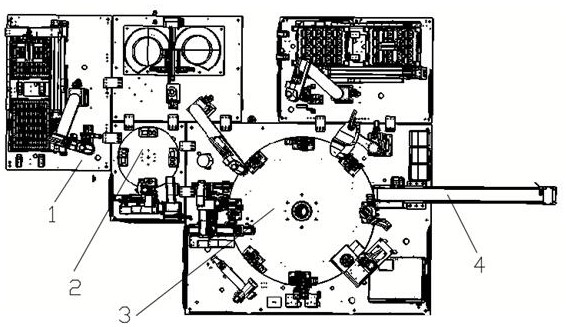

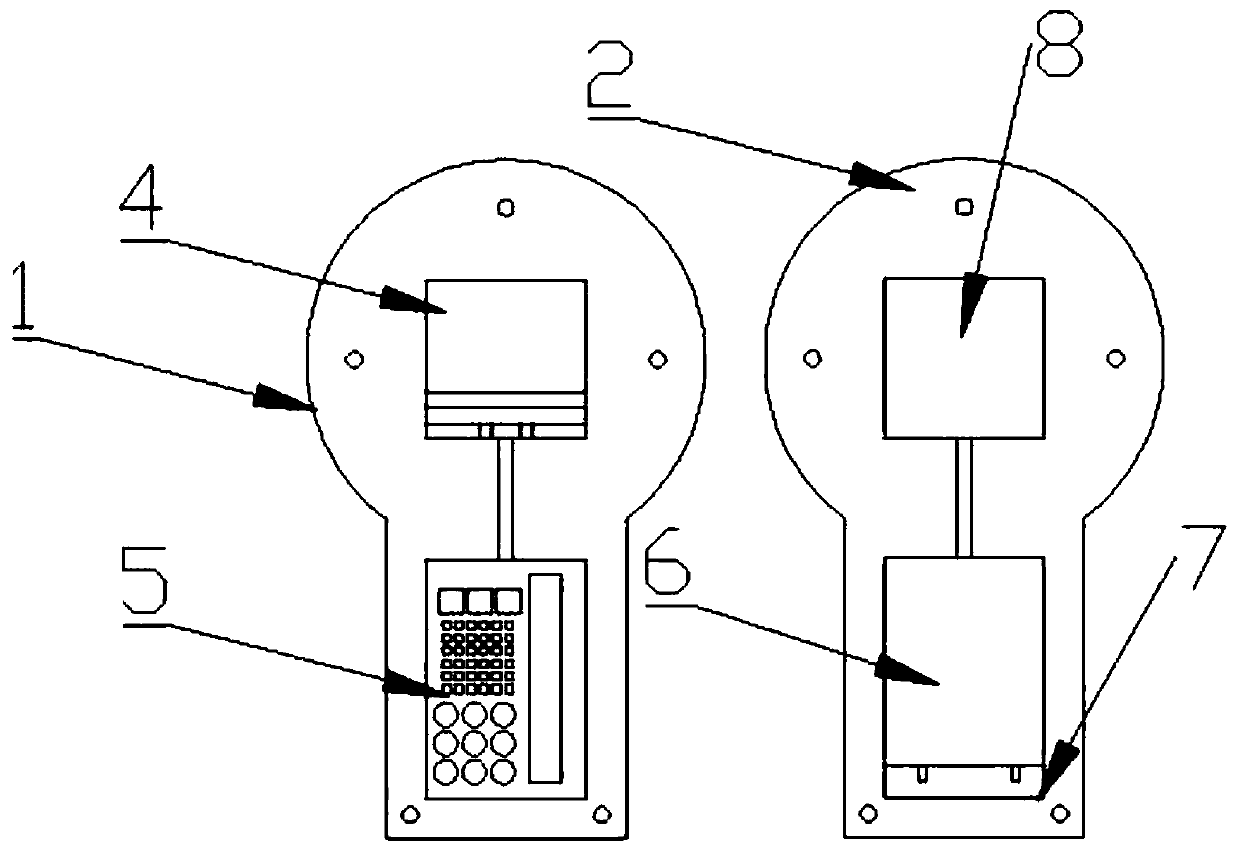

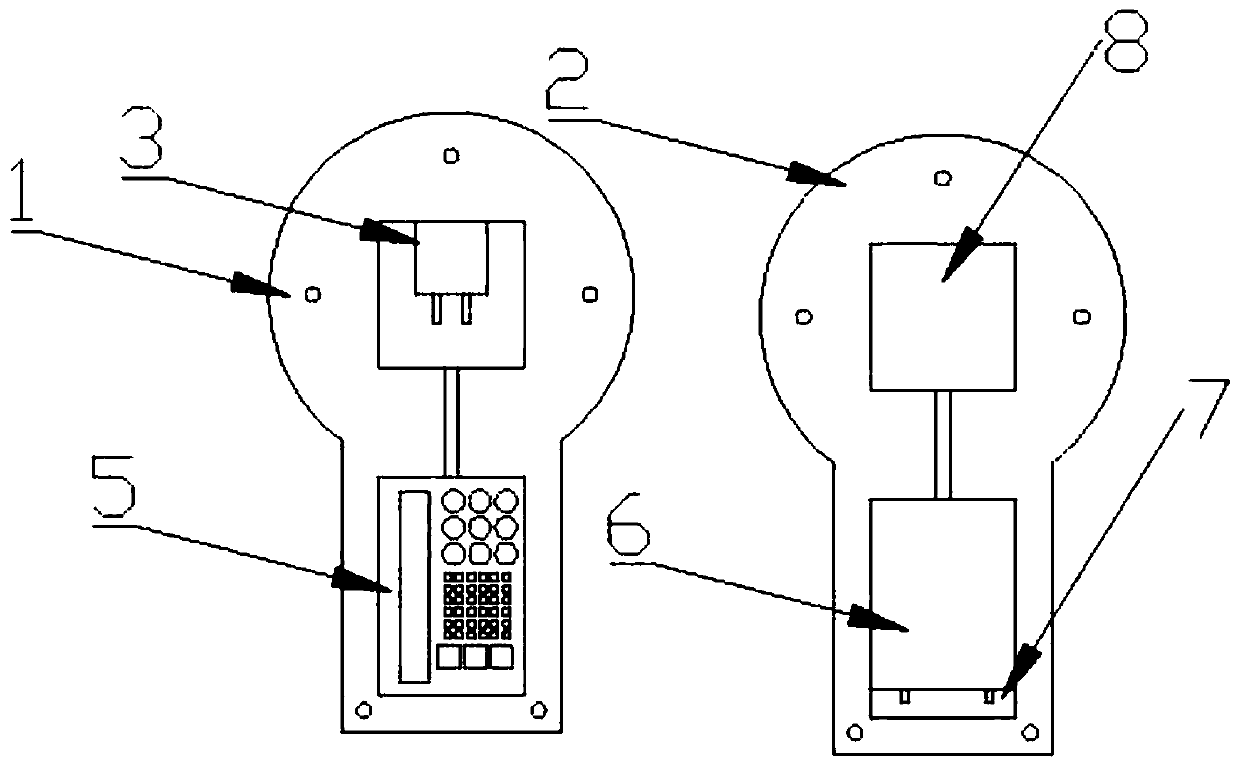

Mixing valve element automatic assembly line

The invention discloses a mixing valve element automatic assembly line, and relates to an automatic production system of a valve element. The assembly line comprises a first auxiliary assembling lineused for sequentially assembling a stirring rod, a support and a rotating shaft to combine a valve rod assembly, a second auxiliary assembling line used for sequentially assembling a base, an inner Oring and a fixed ceramic piece to combine an end cover assembly, a final assembly line used for sequentially assembling a valve body, a gasket, a valve rod assembly, a stirring disc, a movable ceramicpiece, an end cover assembly, a large O ring and an outer O ring to combine a complete mixing valve element and two assembly conveying lines arranged between the first auxiliary assembling line and the final assembly line and between the second auxiliary assembling line and the final assembly line and used for conveying a valve rod assembly and an end cover assembly to the final assembly line. The beneficial effects of being high in automation degree and free of artificial participation are achieved.

Owner:福建瑞德成自动化科技有限公司

Self-protection type bottle cap assembly machine

InactiveCN106736457AAssembled preciselyQuality improvementMetal working apparatusEngineeringBottle cap

The invention discloses a self-protection type bottle cap assembly machine. The self-protection type bottle cap assembly machine mainly comprises a working table, a feeding mechanism, an assembling mechanism and a collecting mechanism. The feeding mechanism, the assembling mechanism and the collecting mechanism are arranged on the working table or near the working table in sequence. The self-protection type bottle cap assembly machine further comprises a pre-detecting mechanism and a detecting mechanism. The pre-detecting mechanism unscrews bottle caps which are not screwed tightly through counter rotating, so that sensors on the detecting mechanism distinguish qualified products and unqualified products by detecting the heights of the bottle caps and then send signals to the collecting mechanism, and therefore the qualified products and the unqualified products are distinguished effectively. According to the self-protection type bottle cap assembly machine, the qualified products and the unqualified products can be distinguished effectively, pre-detecting is improved, full-automatic bottle cap assembly is achieved, assembling is accurate, the qualities of the bottle caps are improved, and efficiency is high.

Owner:GUANGZHOU MENSHEN PACKAGING

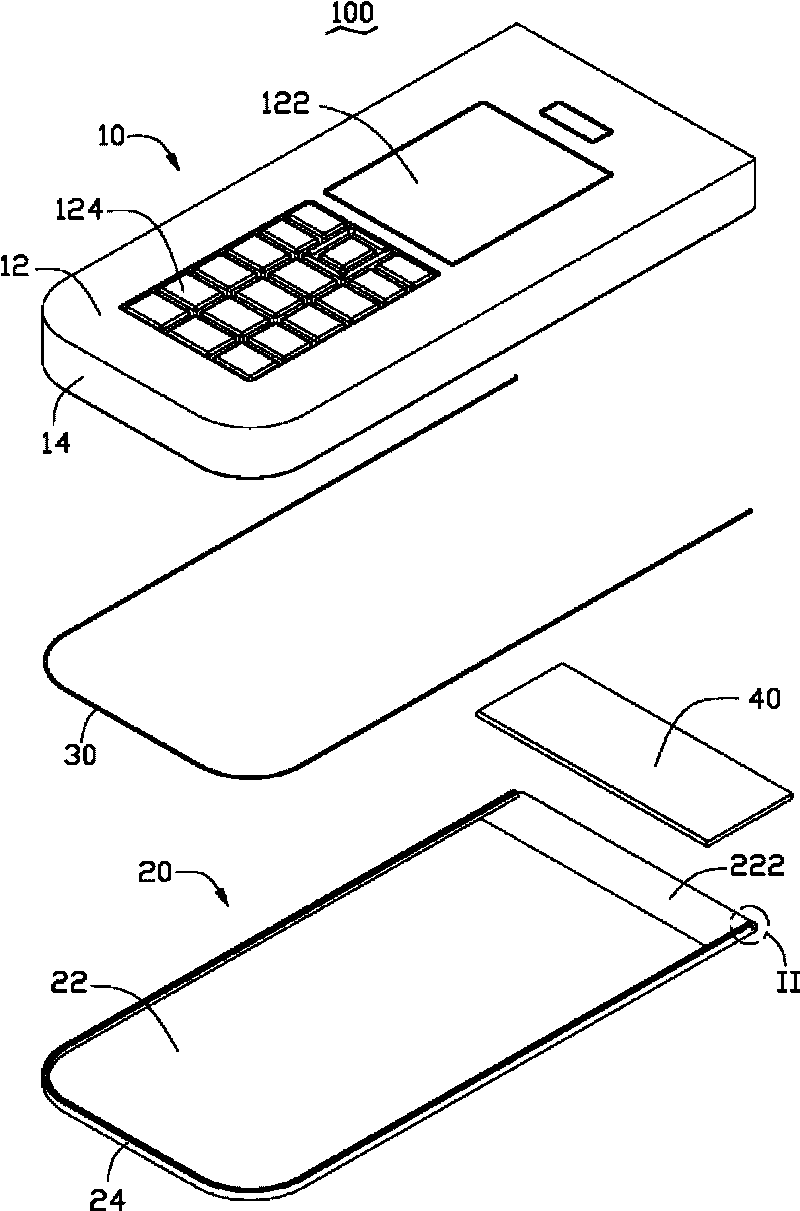

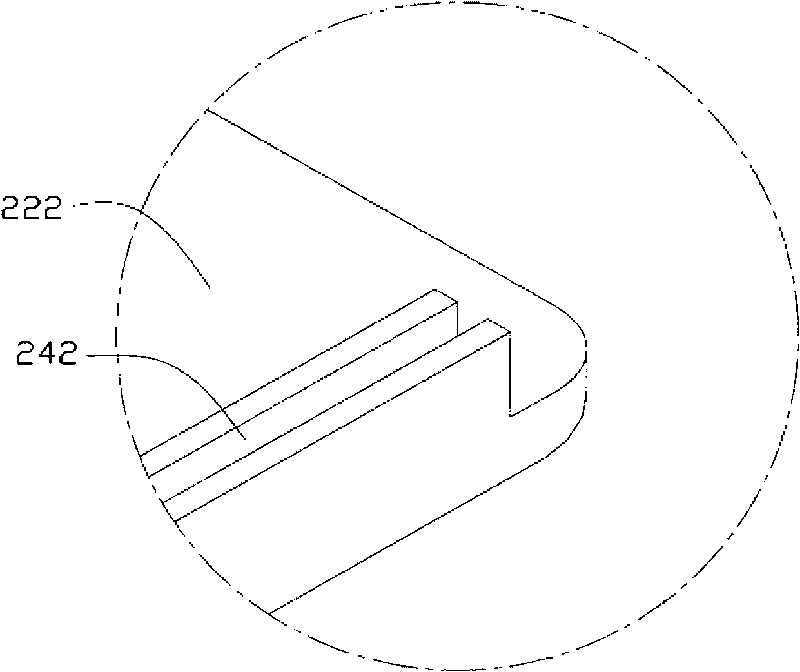

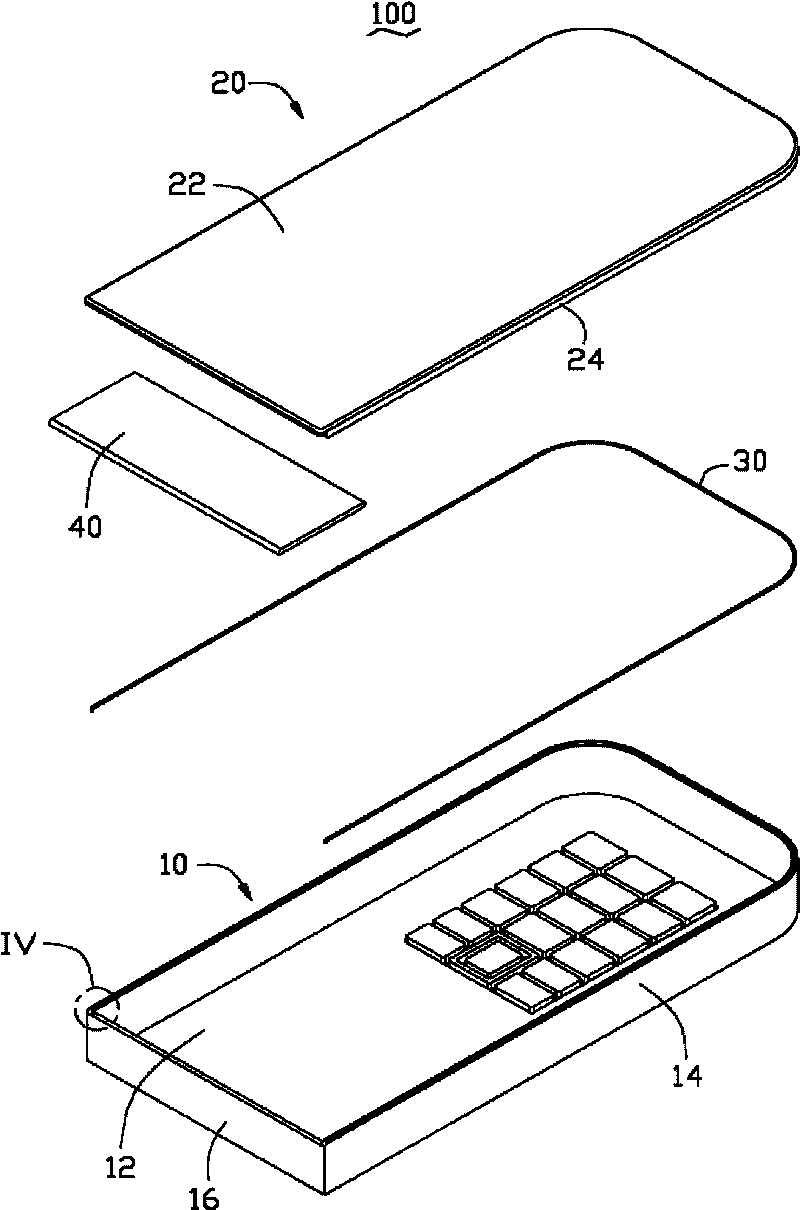

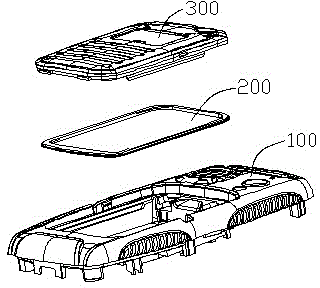

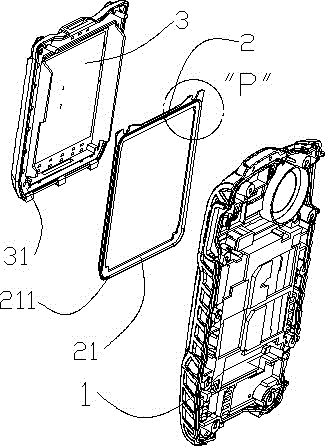

Waterproof electronic device and manufacturing method thereof

InactiveCN101754627AAssembled preciselyEasy to assembleHermetically-sealed casingsTelephone set constructionsAgricultural engineeringEngineering

The invention discloses a waterproof electronic device which comprises an upper housing, a lower housing, a waterproof strip and a waterproof soft plate, wherein a convex strip is formed on the peripheral wall of the upper housing, a groove is formed on the peripheral wall of the lower housing which corresponds to the upper housing, the upper housing is matched with the lower housing, the waterproof strip is accommodated in the groove, the convex strip is clamped in the groove and presses the waterproof strip, one end of the waterproof soft plate which is bent is connected with the upper housing, and the other end is connected with the lower housing. The waterproof electronic device has simple structure and convenient production, and can realize the effective waterproof effect.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

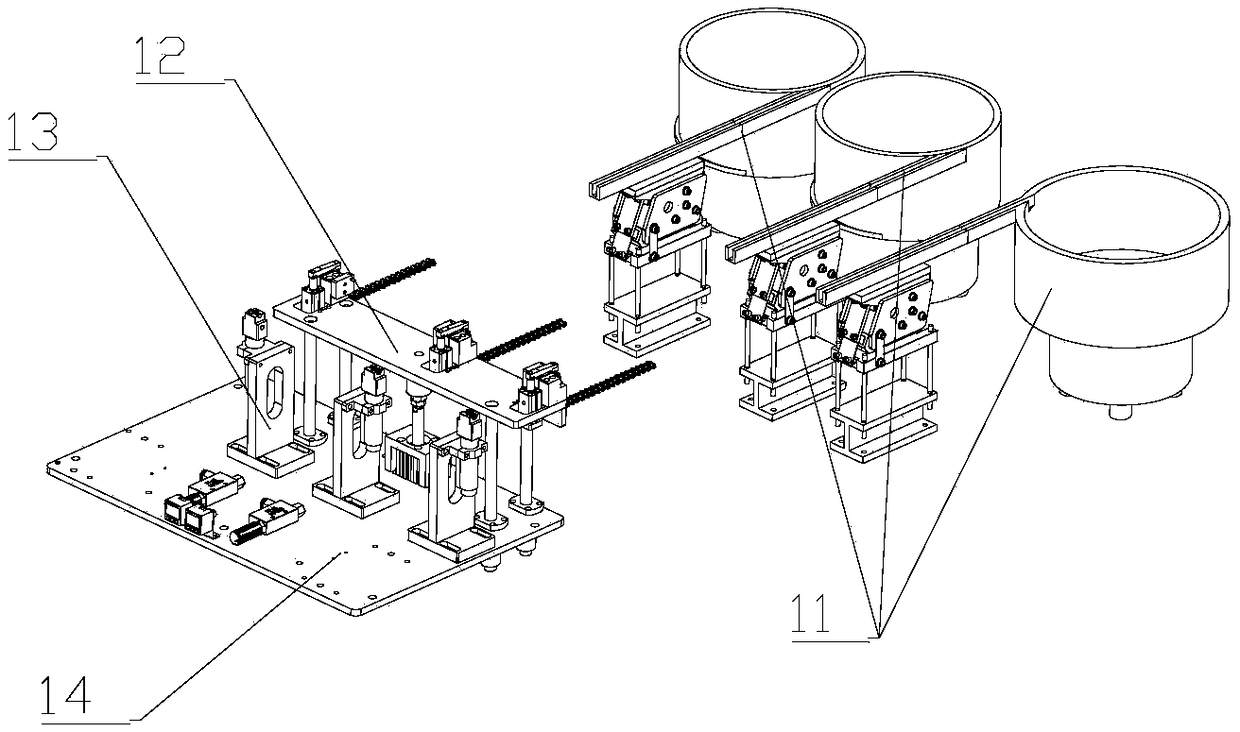

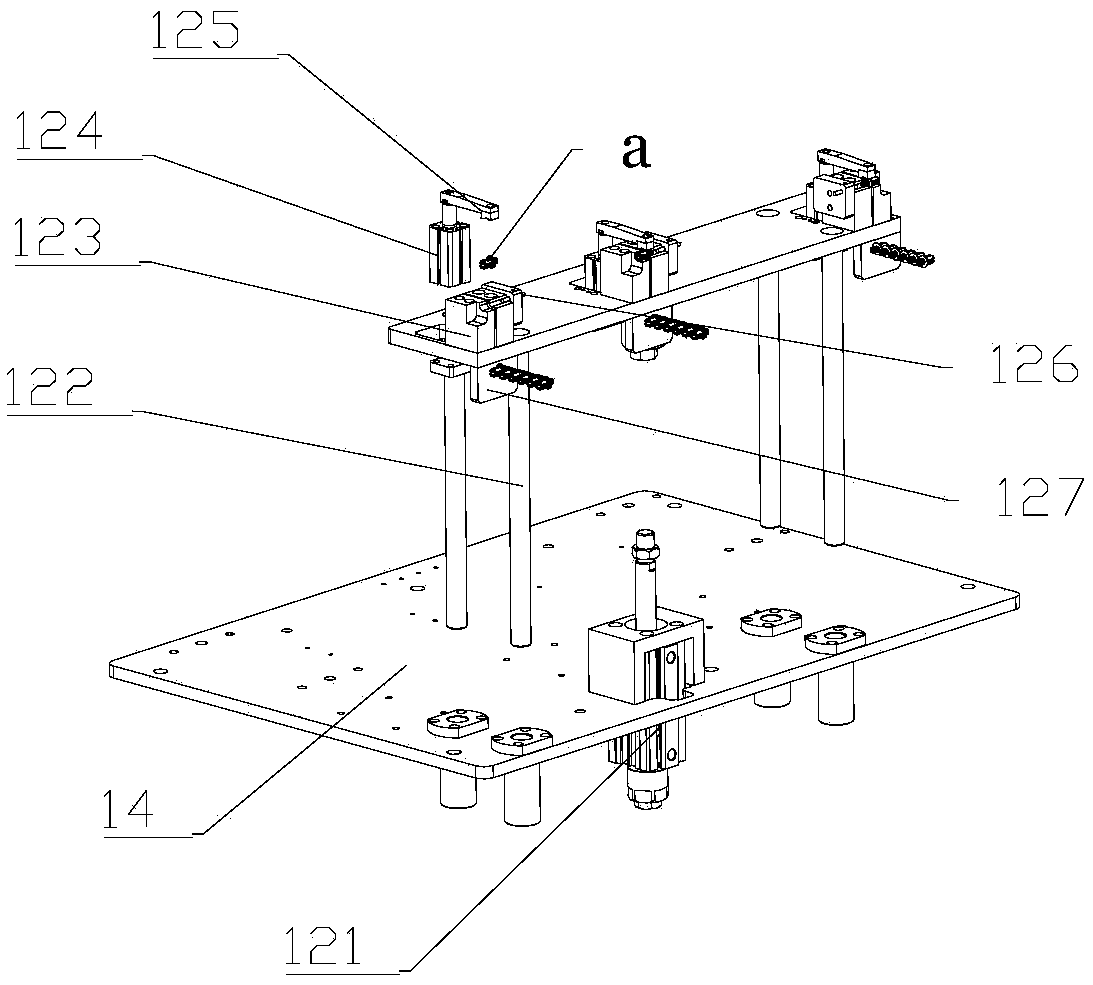

Assembling machine for shaft sleeve of air deflector of air conditioner

InactiveCN108857334AImprove yield rateEasy to removeMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of automated processing of air conditioner accessories, and provides an assembling machine for a shaft sleeve of an air deflector of an air conditioner comprises a rack, a loading device, a shaft sleeve carrying and pressing-in device and an air deflector positioning device, and the shaft sleeve loading device, the shaft sleeve carrying and pressing-in device andthe air deflector positioning device are arranged on the rack. The assembling machine for the shaft sleeve of the air deflector of the air conditioner has the advantages that shaft sleeves and air deflectors are loaded automatically, the shaft sleeves are pressed in the air deflectors, and the processing efficiency is high.

Owner:陈荣乾

Pressing mechanism capable of accurately assembling lens

The invention relates to a pressing mechanism capable of accurately assembling lens. A lens barrel is supported on an assembly table seat for pressing and assembling operation of the lens; a lens picking and placing device is mounted on a plate seat capable of being driven to move in three axial directions, and the lens can be moved onto the assembly table seat; the lens picking and placing device is connected with a lifting structure for driving lifting action of pressing the lens; the plate seat is also installed with a clamp set capable of clamping the centers of a calibrating lens and the lens barrel, and a pressing jig with a guide part; the pressing jig is connected with a displacement structure for driving the pressing jig to move to the position between the lens barrel and the lens; in pressing operation, the lens barrel and the lens are calibrated by the guide part of the pressing jig to ensure accurate calibration thereof; and, in this way, the centers of the lens barrel and the lens are corrected by calibration through the clamp set and the pressing jig, and the lens are pressed in the lens barrel after accurate calibration of the lens barrel and the lens, thereby fulfilling the aim of accurately assembling and greatly improving assembling efficiency.

Owner:SYNERGY AUTOMATION CORP

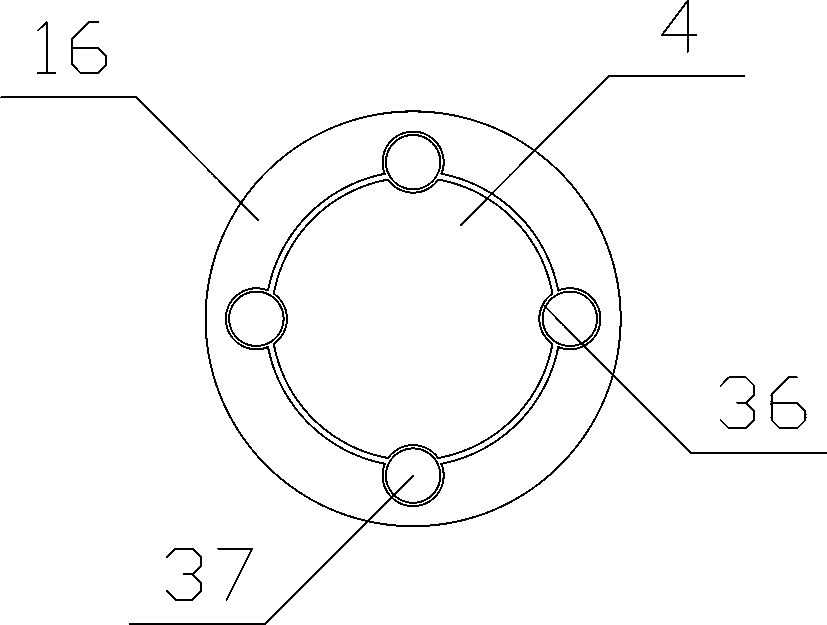

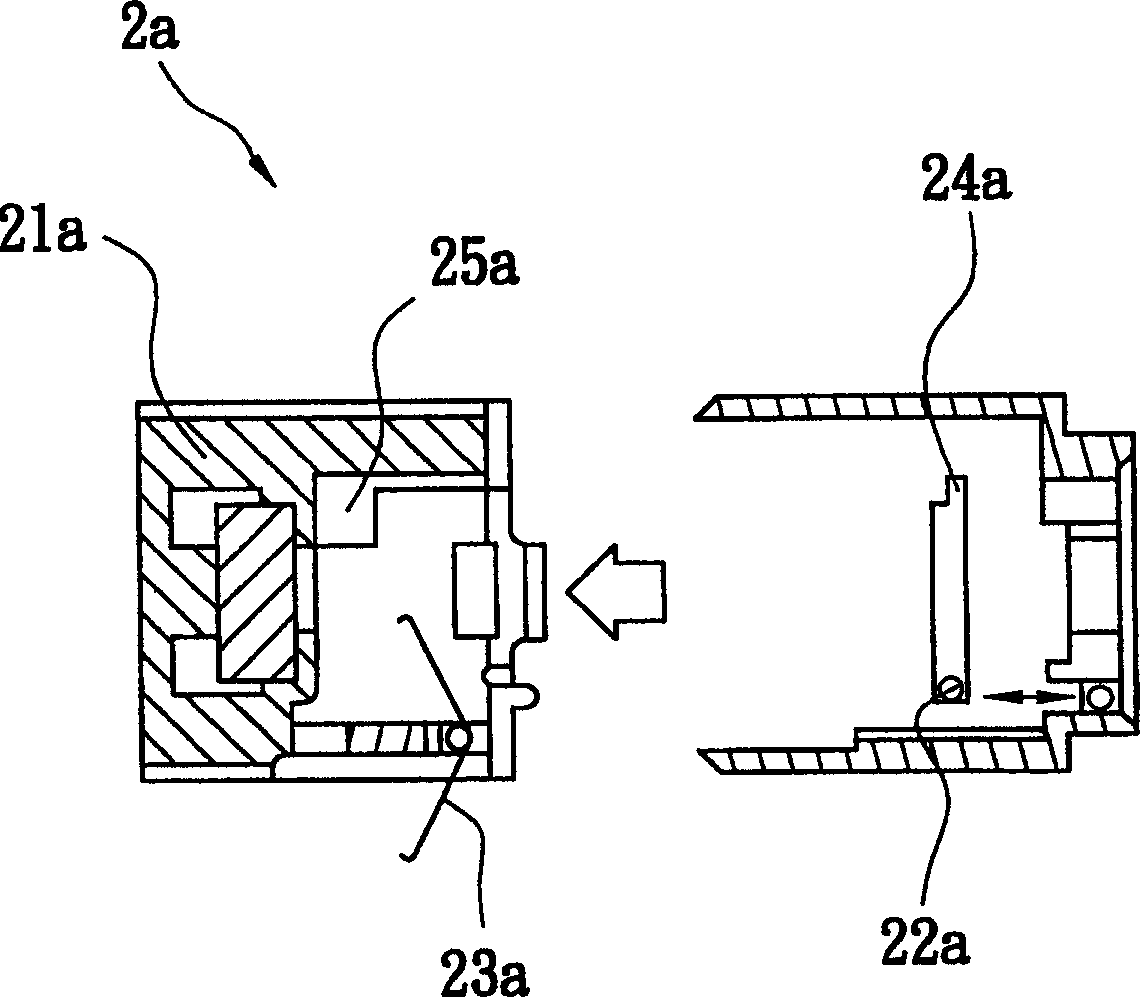

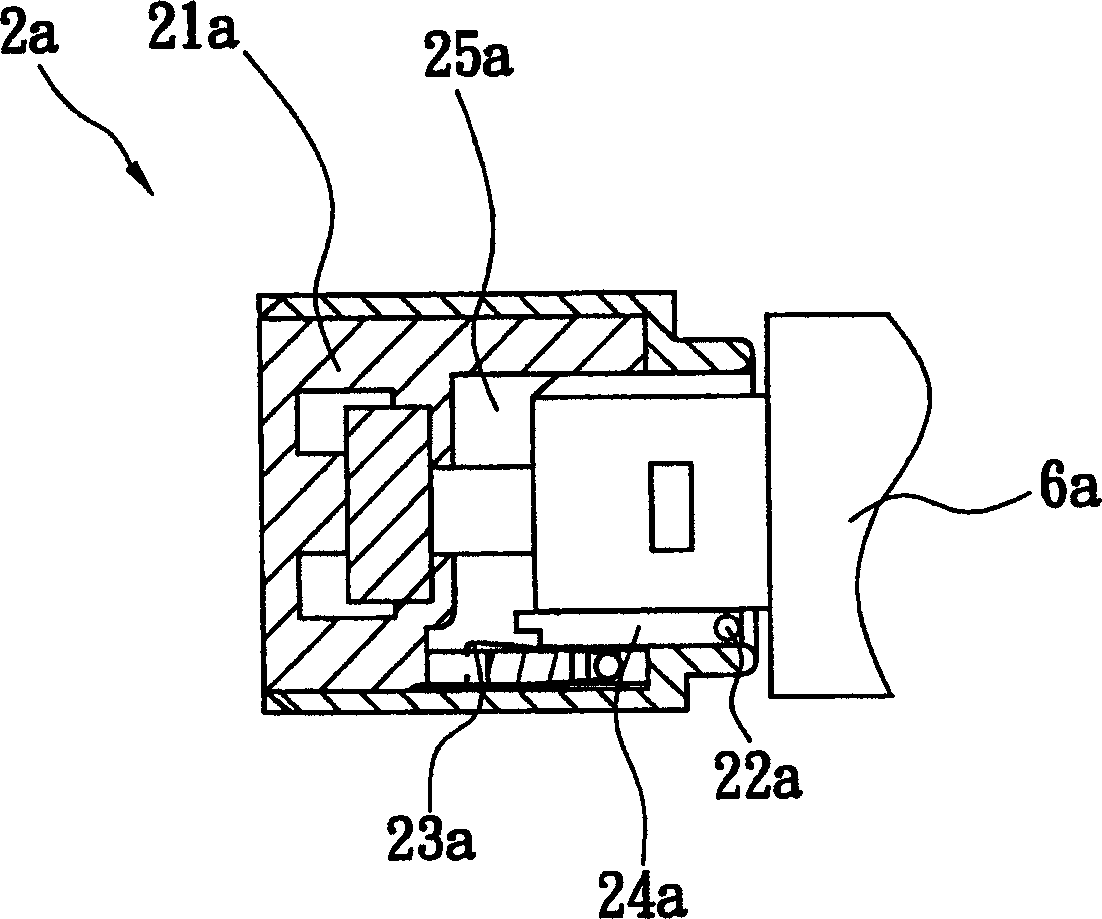

Optical fiber connector

InactiveCN1611972ASimple structureStructural stabilityCoupling light guidesForeign matterTest efficiency

This invention is a kind of optical fiber connector that used on optical fiber splice. It comprises main body and the U style mantle that cover the body. Slots are set on the bottom and top ora terminalis. The U style mantle comprises jack section and the left and right two sides plate that used to connect the section. The jack section has a dust cap from its top to the bottom, and the two sides plate has contact surface that close fit the slot along the top and bottom ora terminalis. The optical fiber connector is rotary open, and the structure is simple and firm. It can raise the assembling and testing efficiency, reduce the cost, and reach to the function of preventing the dust and foreign matter. It can restrict the insert depth of the optical fiber splice, and enhance the collimation between optical fiber splice and luminous module or module that receives the light.

Owner:LITE ON OPTO TECH (CHANGZHOU) CO LTD +1

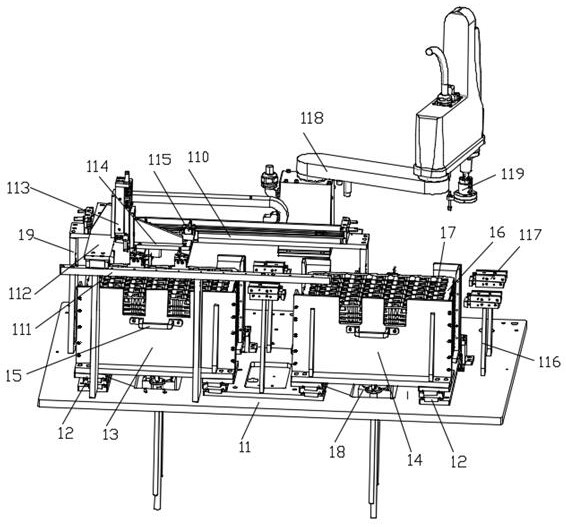

Automatic sleeving device of plier handle sleeves

PendingCN108177125AAssembled preciselyAvoid automationMaterial gluingMetal-working hand toolsEngineeringAutomation

The invention discloses an automatic sleeving device of plier handle sleeves. The automatic sleeving device comprises a frame and also comprises a plier preparing mechanism, a handle sleeve preparingmechanism and a plier assembling mechanism which are arranged on the frame, wherein the plier assembling mechanism comprises a handle glue dripping mechanism and a plier fixing device which is rotatably arranged on the frame; the plier fixing device comprises a plier fixing part and is capable of rotating between a first position and a second position; the plier fixing part faces to the plier preparing mechanism in the first position so as to receive and fix pliers conveyed by the plier preparing mechanism; the plier fixing part faces to the handle sleeve preparing mechanism in the second position so as to enable handles of pliers to receive handle sleeves conveyed by the handle sleeve preparing mechanism. The automatic sleeving device of plier handle sleeves aims to solve the technical problems of low mounting automation degree, high consumption of working time and low quality of plier rubber sleeves in the prior art.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Electronic device waterproof structure and waterproof mobile phone provided with same

ActiveCN104093290AEasy to assembleAssembled preciselyHermetically-sealed casingsTelephone set constructionsEngineeringMechanical engineering

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

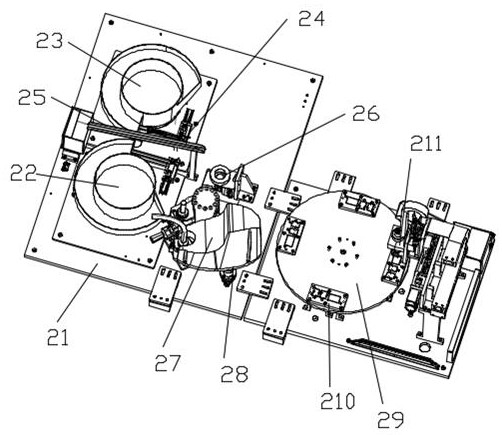

Visual aligning and blocking device for blocking slots in wine covers

PendingCN110722346APrecise Alignment AssemblyImprove pass rateMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of wine cover production equipment, and discloses a visual aligning and blocking device for blocking slots in wine covers. The visual aligning and blockingdevice comprises a rack, wherein a rotary tool disc is arranged on the top center of the rack; the edge of the upper surface of the rotary tool disc is fixedly equipped with a plurality of wine covertools which are distributed uniformly in a surrounding mode; the position, at one side of the rotary tool disc, of the top of the rack is fixedly equipped with a stand column; the top of the stand column is fixedly equipped with a fixed plate; the upper surface of the fixed plate is symmetrically fixed with two fixed blocks; a lead screw is arranged between the two fixed blocks; and the two endsof the lead screw are rotatably connected to the side walls of the two fixed blocks through rolling bearings. According to the visual aligning and blocking device for the blocking slots in the wine covers disclosed by the invention, aligning and assembly can be precisely performed through visual aligning and detecting, so that a qualification rate is increased, and universality is relatively high;moreover, the device can simultaneously accomplish assembly of two groups of wine covers once, so that production efficiency is improved; and the assembled covers are detected for non-defective products such as products with broken teeth and products with fewer teeth while aligning and assembly are performed, so that manual detection trouble is reduced.

Owner:深圳圣鑫自动化设备有限公司

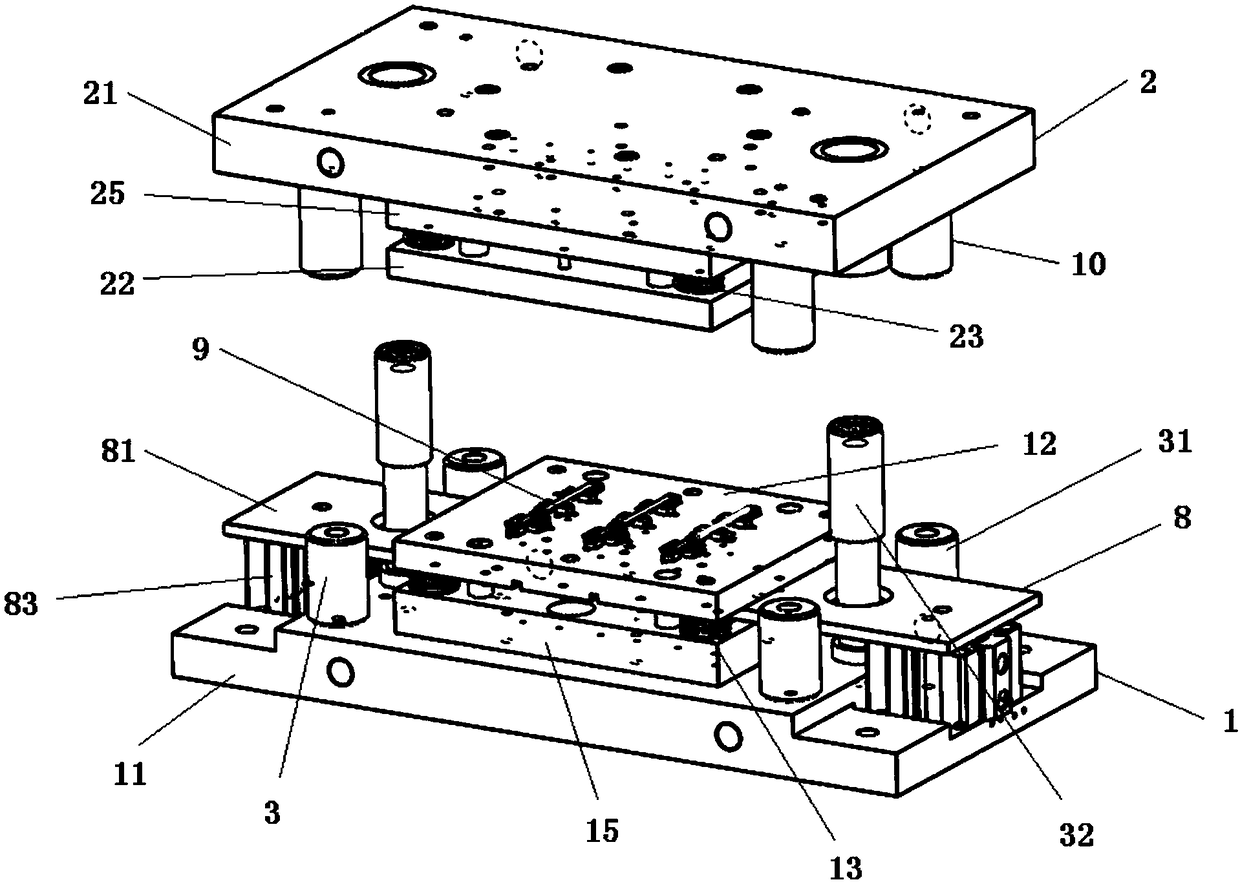

Liquid crystal module assembling jig

InactiveCN112230457ARealize the assemblyThe assembly fixture is realized by setting the positioningNon-linear opticsEngineeringMechanical engineering

The invention belongs to the technical field of production and manufacturing, and particularly relates to a liquid crystal module assembling jig which comprises a rack, a positioning platform and a positioning cover plate, wherein the positioning platform and the positioning cover plate are arranged on the rack. The positioning platform is connected with the rack through an adjusting mechanism, the adjusting mechanism is used for adjusting the position and angle of the positioning platform, the positioning platform is used for positioning a backlight assembly, and a vacuum adsorption hole is formed in the positioning platform; the positioning cover plate is rotatably connected with the rack, a first positioning block is arranged on the positioning cover plate, and the first positioning block is used for positioning an LCD assembly; a vacuum adsorption hole is formed in the working face of the positioning cover plate, and the positioning cover plate is used for adsorbing the LCD assembly and driving the LCD assembly to be attached to the backlight assembly placed on the positioning platform. The liquid crystal module assembling jig provided by the embodiment of the invention can achieve sharing of liquid crystal components of different specifications, and is good in practicability.

Owner:珠海晨新科技有限公司

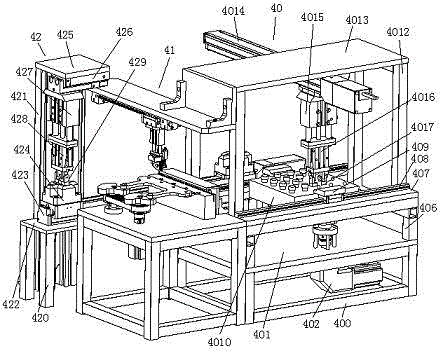

License plate small lamp assembling machine

PendingCN112643337ACompact structureSmall footprintWelding/cutting auxillary devicesAssembly machinesComputer hardwareEngineering

The invention discloses a license plate small lamp assembling machine. The machine comprises a small lamp feeding device, a small lamp welding device, a small lamp shell assembling detection device and a small lamp automatic output line, wherein the right side of the small lamp feeding device is connected with the small lamp welding device, the right side of the small lamp welding device is connected with the small lamp shell assembling detection device, and the right side of the small lamp shell assembling detection device is connected with the small lamp automatic output line. The license plate small lamp assembling machine has the beneficial effects that the small lamp device automatically feeds small lamp circuit boards, the small lamp welding device performs spot welding on small lamps and the small lamp circuit boards, the spot welding efficiency is high, and a lamp body feeding mechanical arm on the small lamp shell assembling detection device feeds two kinds of small lamp shells on a small lamp shell feeding device; and a small lamp shell assembling mechanism is used for assembling the small lamps, the small lamps are recycled through a discharging mechanical arm, qualified products are automatically discharged through the small lamp automatic output line, small lamp assembling is accurate, and the assembling efficiency is high.

Owner:昆山卓勇工业设备有限公司

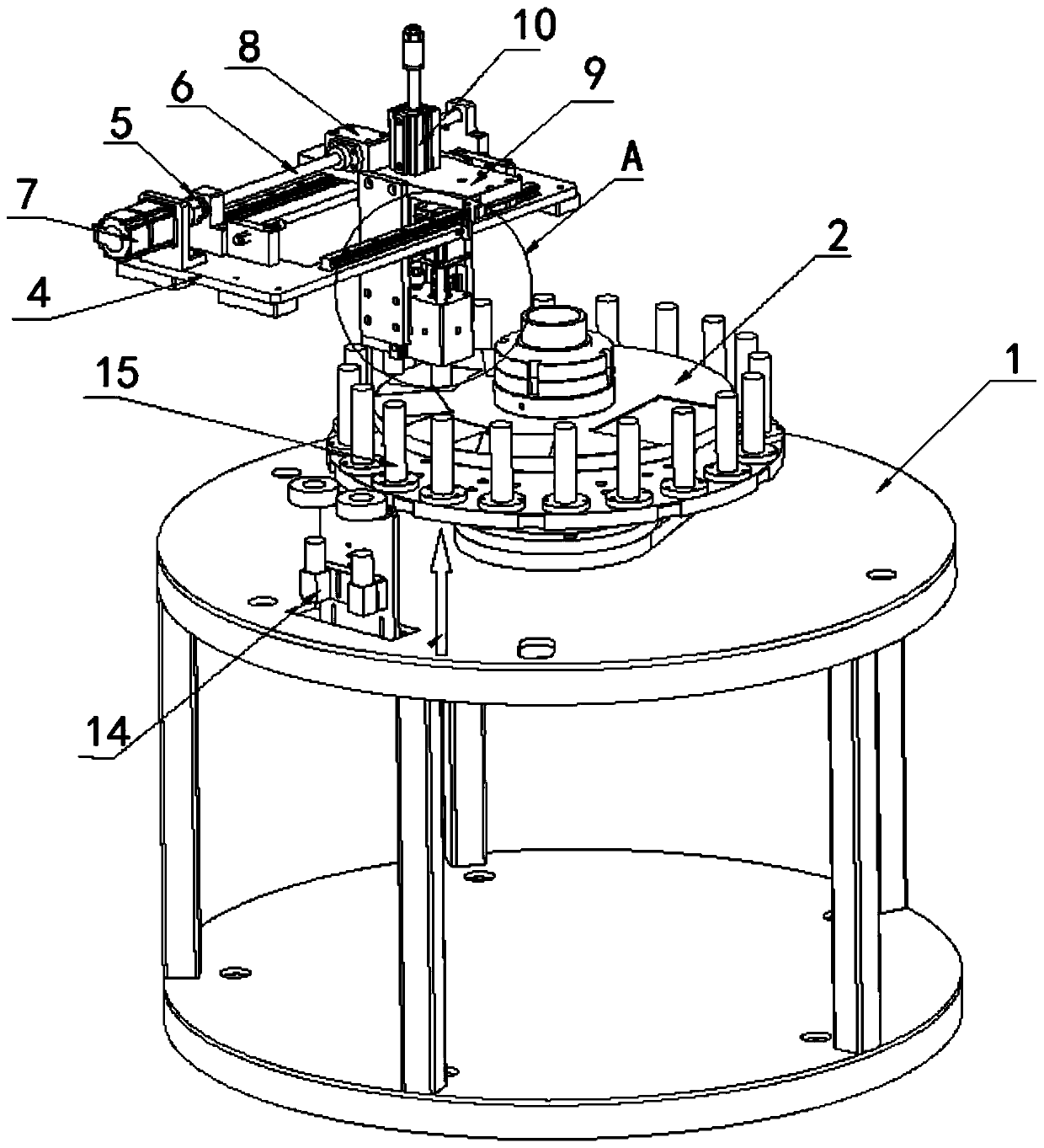

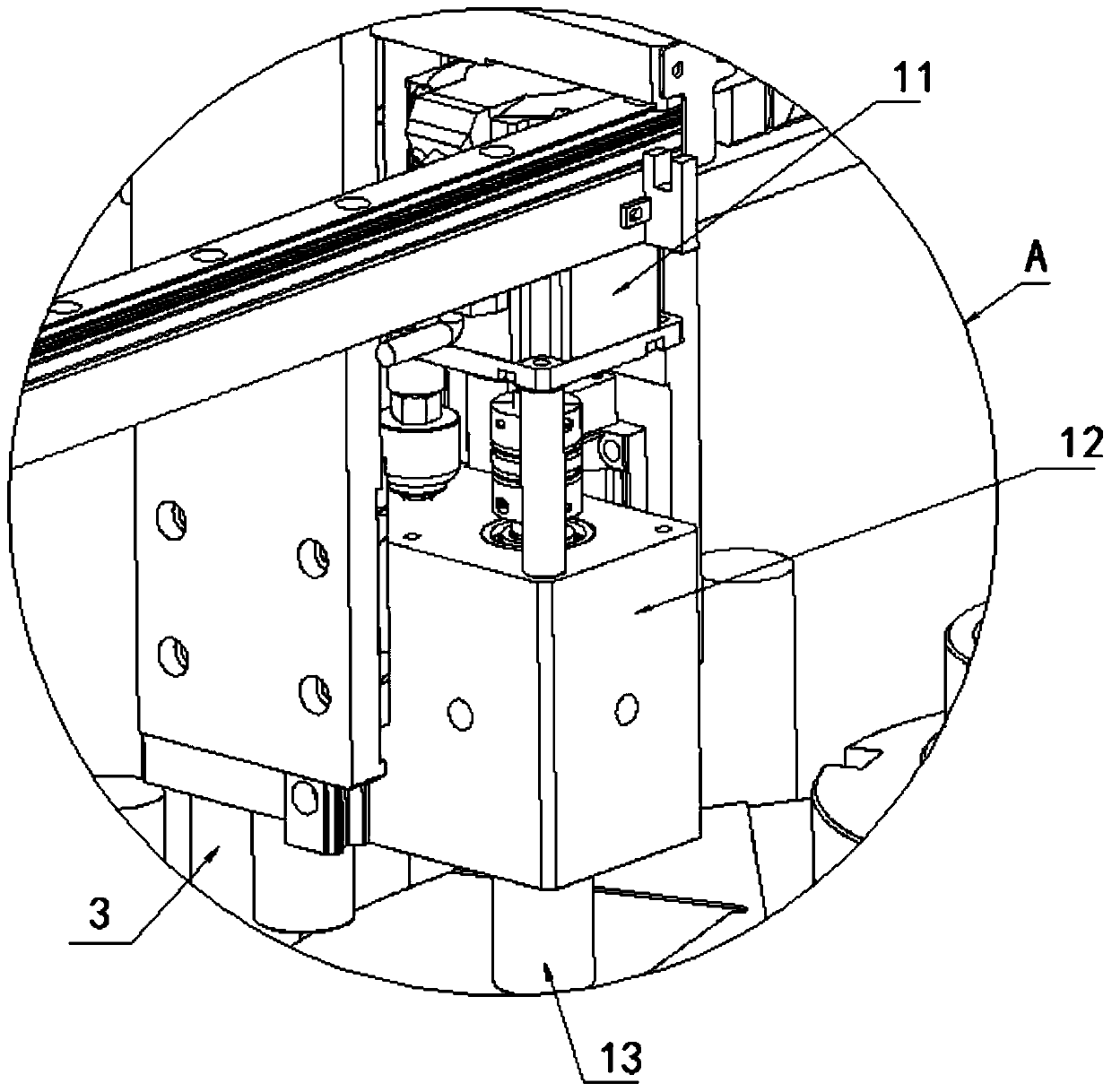

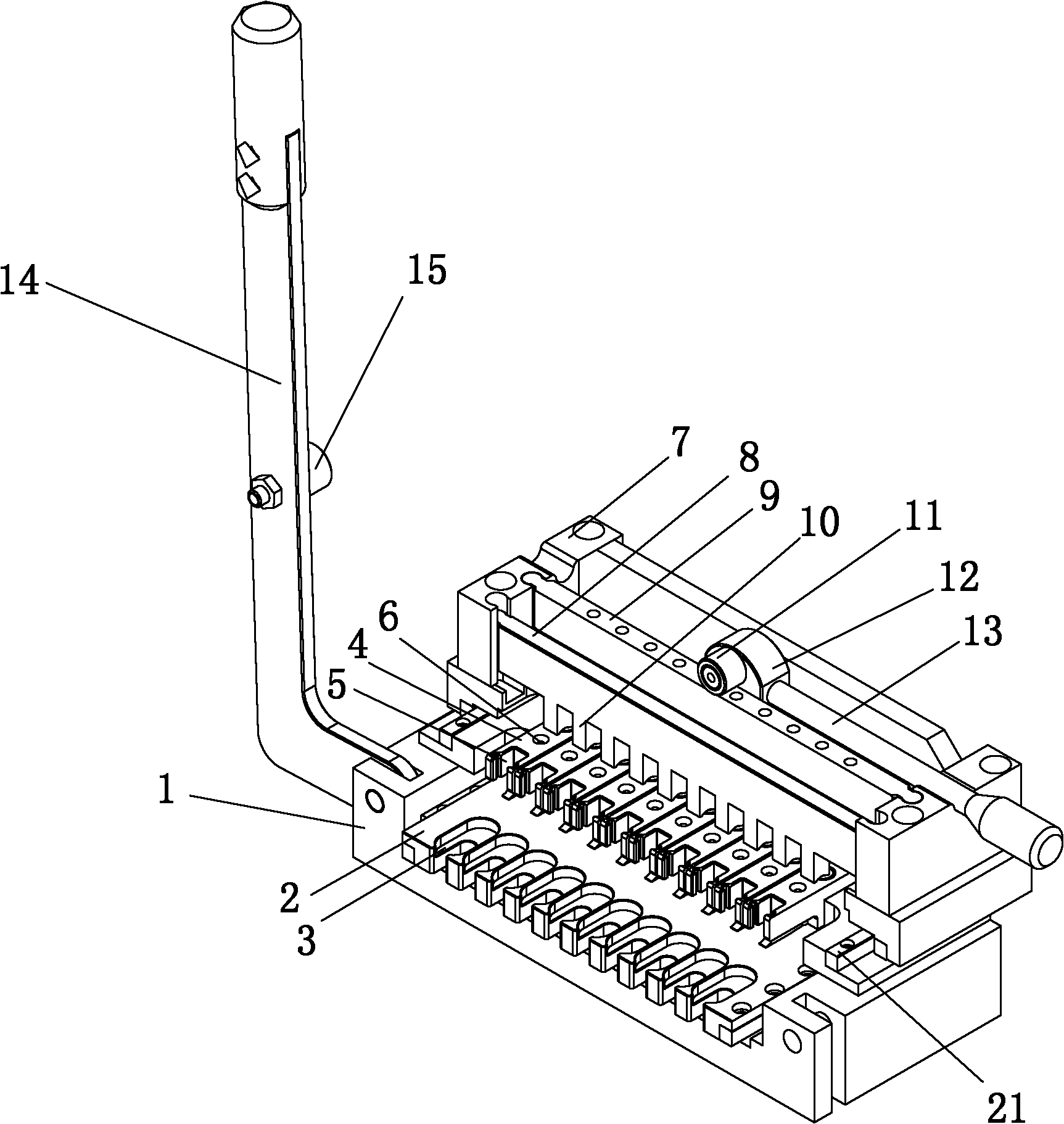

Sound attenuation sleeve head assembly mechanism for compressor crankshaft and sound attenuation sleeve head assembly machine

ActiveCN106181306AAssembled preciselySimple structureMetal working apparatusUltrasound attenuationEngineering

The invention discloses a sound attenuation sleeve head assembly mechanism for a compressor crankshaft and a sound attenuation sleeve head assembly machine. The sound attenuation sleeve head assembly mechanism for the compressor crankshaft and the sound attenuation sleeve head assembly machine comprises a sound attenuation head loading unit; a sound attenuation sheet loading unit and a sound attenuation sleeve head assembly unit are arranged at the outer side of the sound attenuation head loading unit; the sound attenuation head loading unit and the sound attenuation sheet loading unit are separately used for feeding a sound attenuation head and a sound attenuation sheet to the sound attenuation sleeve head assembly unit; and the sound attenuation sleeve head assembly unit is used for assembling the sound attenuation head and the sound attenuation sheet. In this way, the sound attenuation sleeve head assembly can be used for precisely assembling the sound attenuation sheet and the sound attenuation head.

Owner:南通硕兴机电有限公司

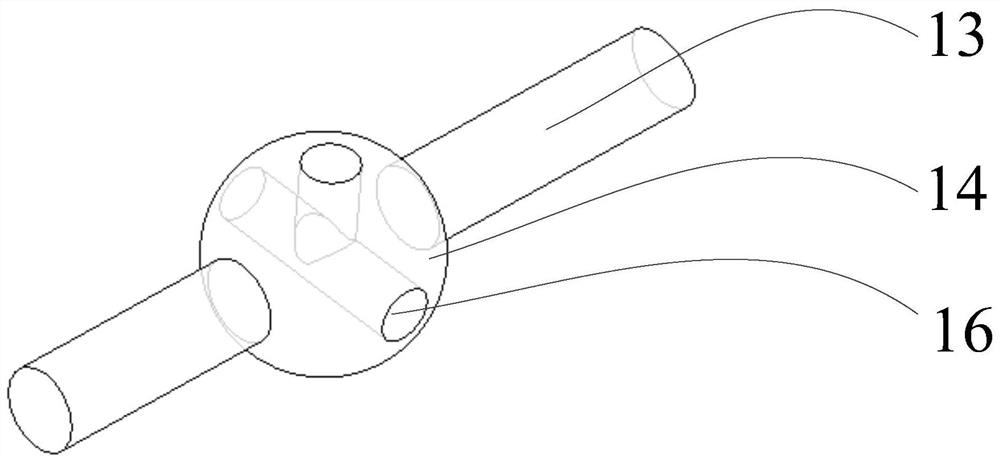

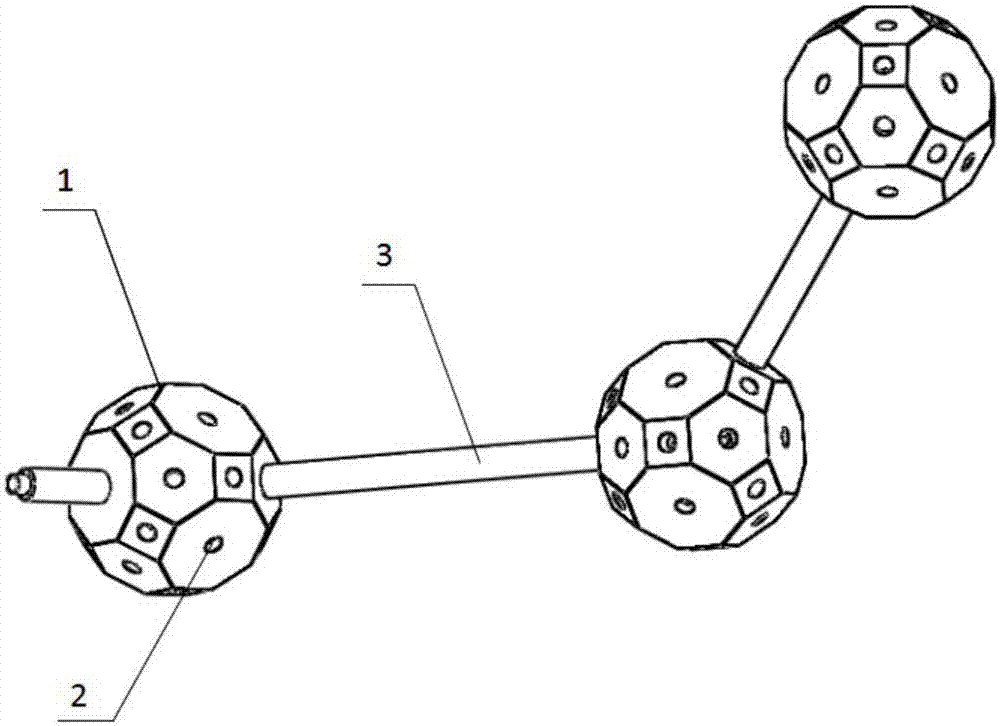

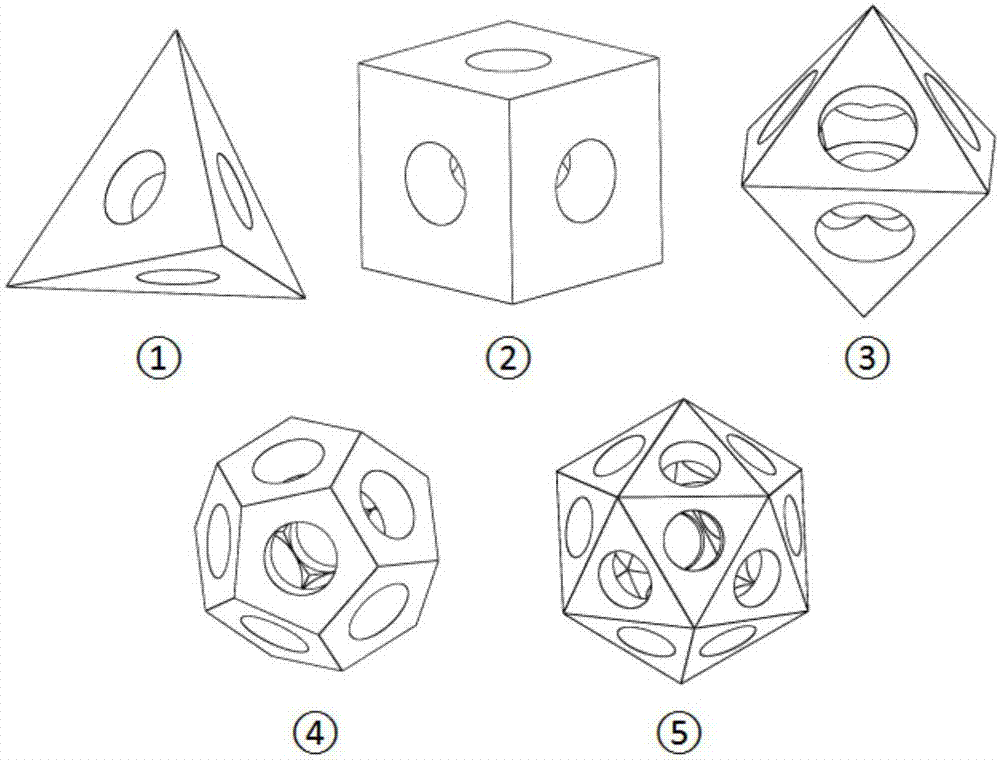

Polyhedron ball-and-stick model

InactiveCN107221242ASolve complex angle problemsSolve positioning difficultiesEducational modelsSpace-filling modelEngineering

A polyhedron ball-and-stick model comprises a plurality of geometric model polyhedrons representing atoms and cylindrical connecting rods with different lengths representing connecting keys and being connected with the atoms in a space-filling model, wherein the geometric model polyhedrons comprise regular polyhedrons formed by congruent regular polygons, semi-regular polyhedrons formed by two or more than two regular polygons and polyhedrons formed by other polygons, the center position of each surface of each polyhedron is provided with a circular hole groove having the same diameter and the same depth, and the diameter of each circular hole groove is identical with the diameter of the end portion of each cylindrical connecting rod to allow the end portions of the connecting rods can be inserted into the circular hole grooves on each surface of the polyhedrons. The problem is solved that the spherical circular hole groove is difficult to locate in a traditional ball-and-stick model, and the polyhedron ball-and-stick model can be more rapidly and accurately assemble a desired space-filling model.

Owner:YANSHAN UNIV

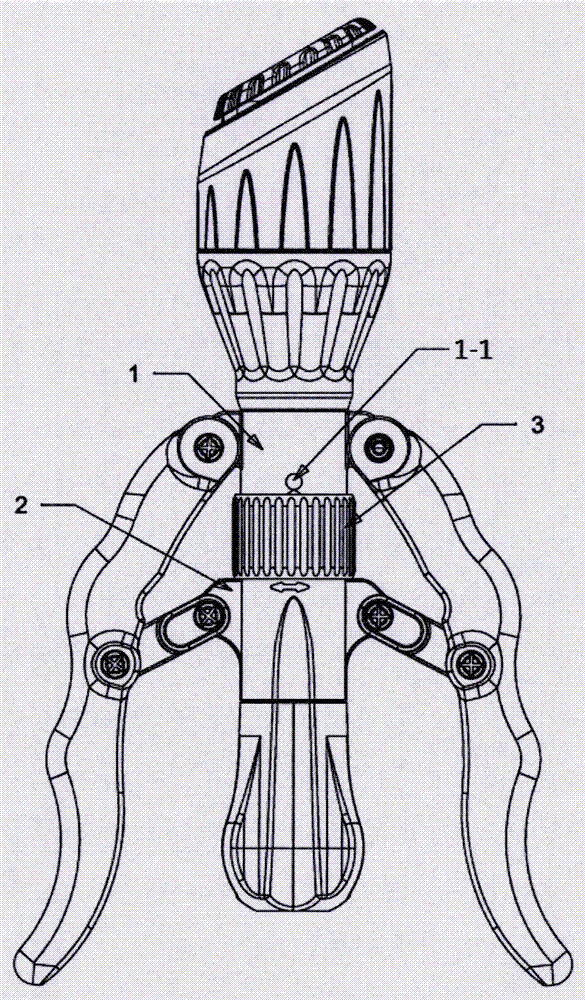

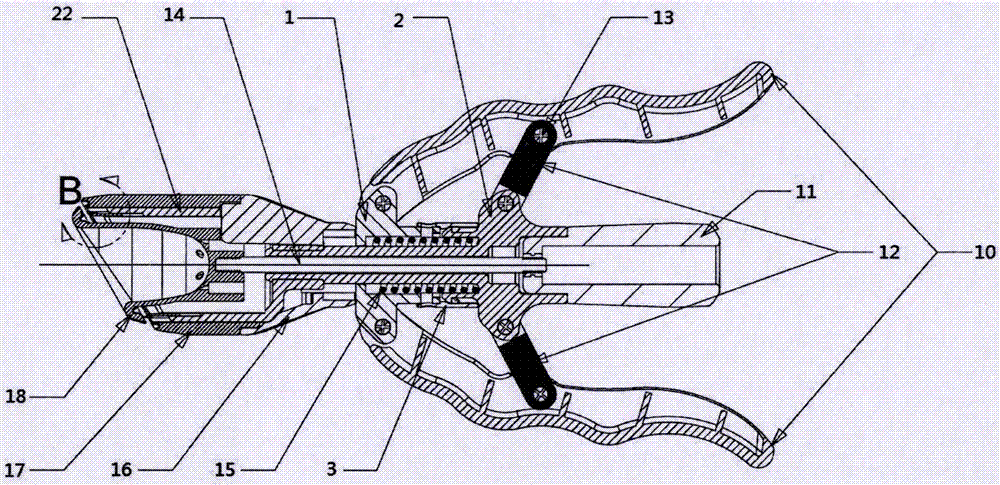

Propulsion self-locking device and circumcision device, assembling method and application method thereof

ActiveCN107041776AImplementation statusImplementation locationSurgical staplesStructural engineeringMechanical engineering

The invention relates to a propulsion self-locking device and a circumcision device, an assembling method and an application method thereof; the propulsion self-locking device comprises a hook and a platform; the platform is arranged on the inner wall of a sleeve handle; the hook is arranged on a sleeve core; the sleeve core is arranged in the sleeve handle; the hook and the platform are matched so as to allow the sleeve core to only axially unidirectionally move in the sleeve handle. The circumcise device with the self-locking device is simple in structure, clear in indications, reliable in locking, and easy to control, thus effectively preventing cross infection risks caused by repeatedly usage among patients.

Owner:WUHU SHANGRING TECH CO LTD

Riveting tooling and method for assembling connector hardware

PendingCN108526378AReduce positioning stepsMeet processing needsElectrical and Electronics engineering

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

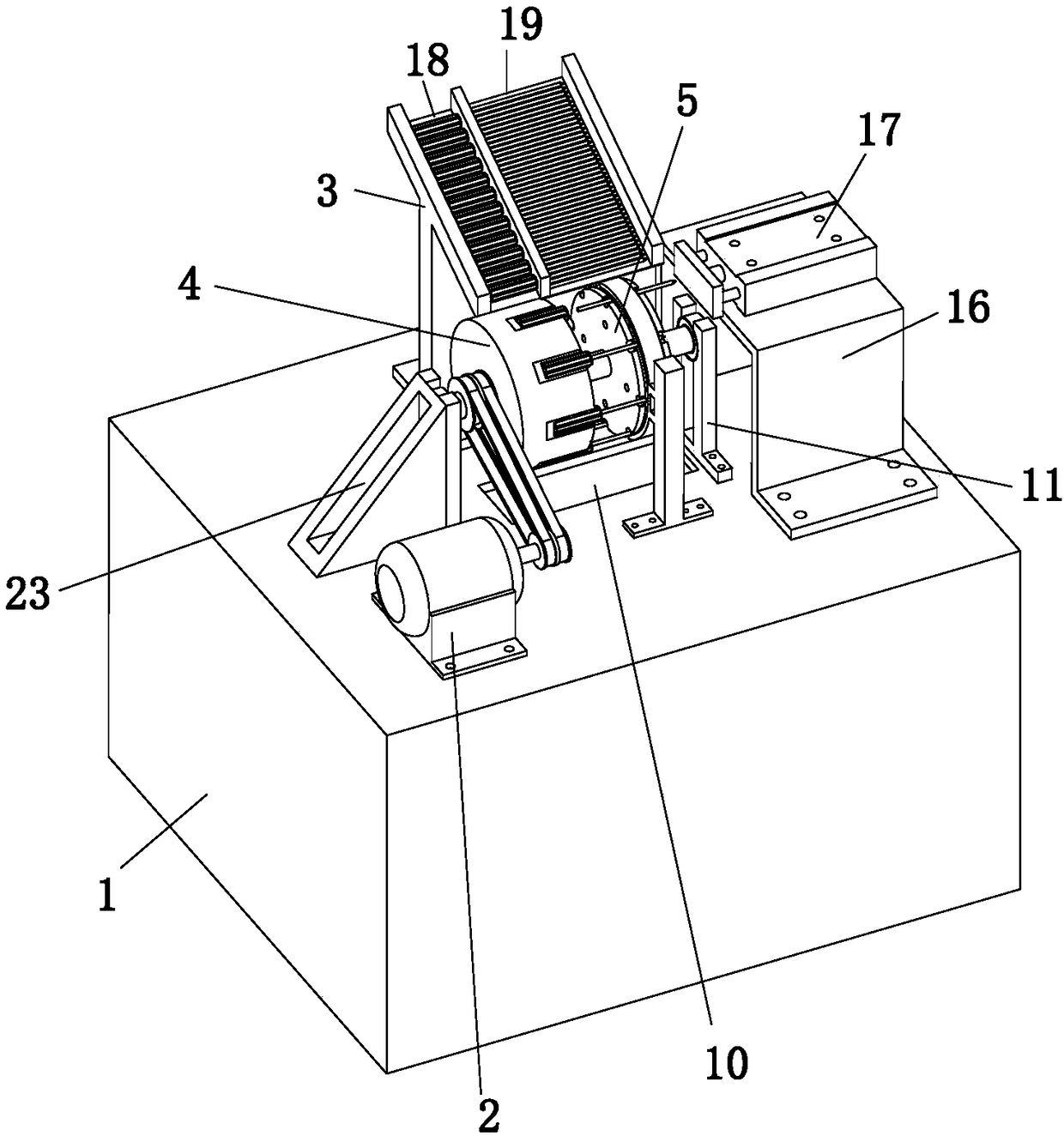

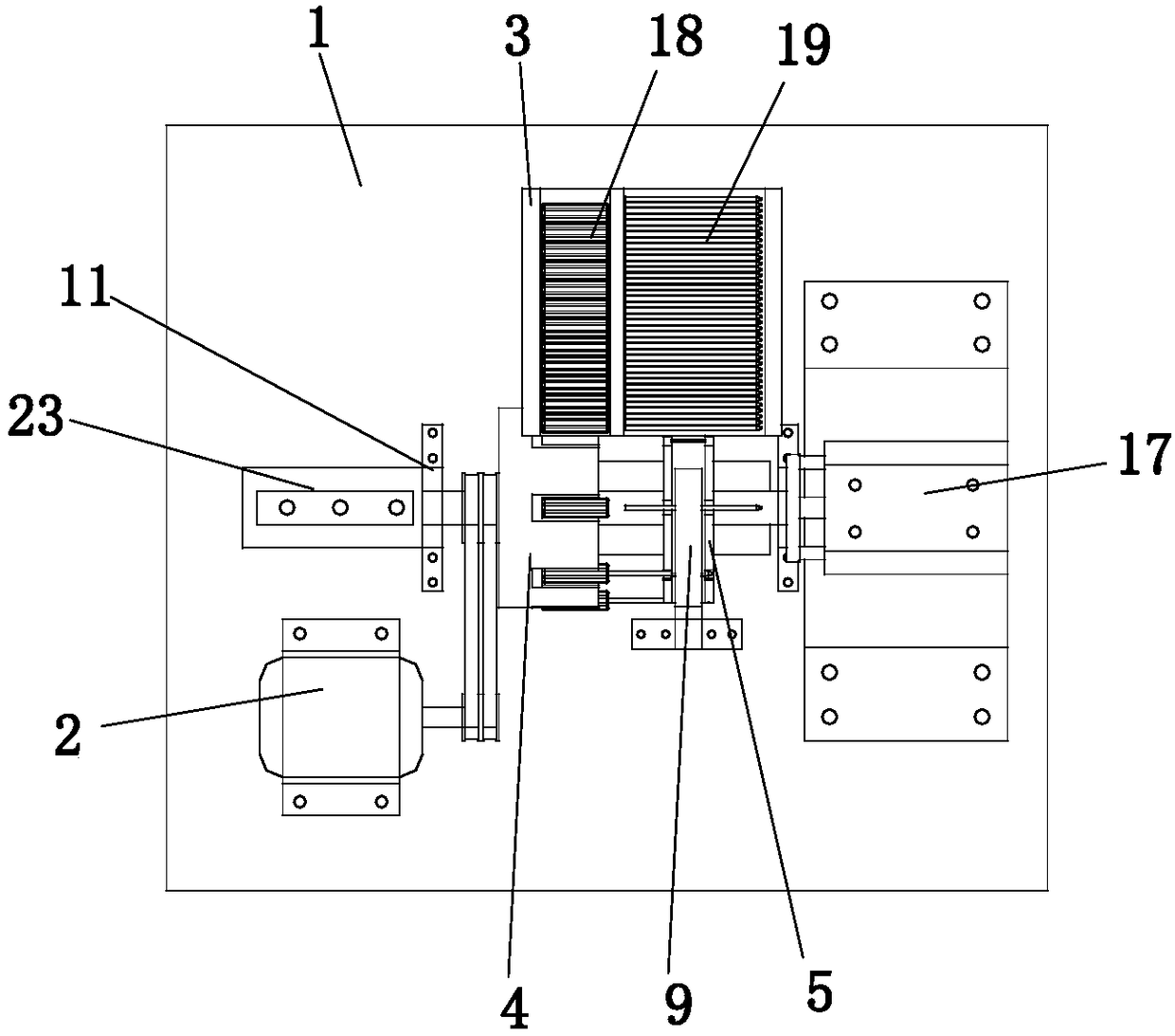

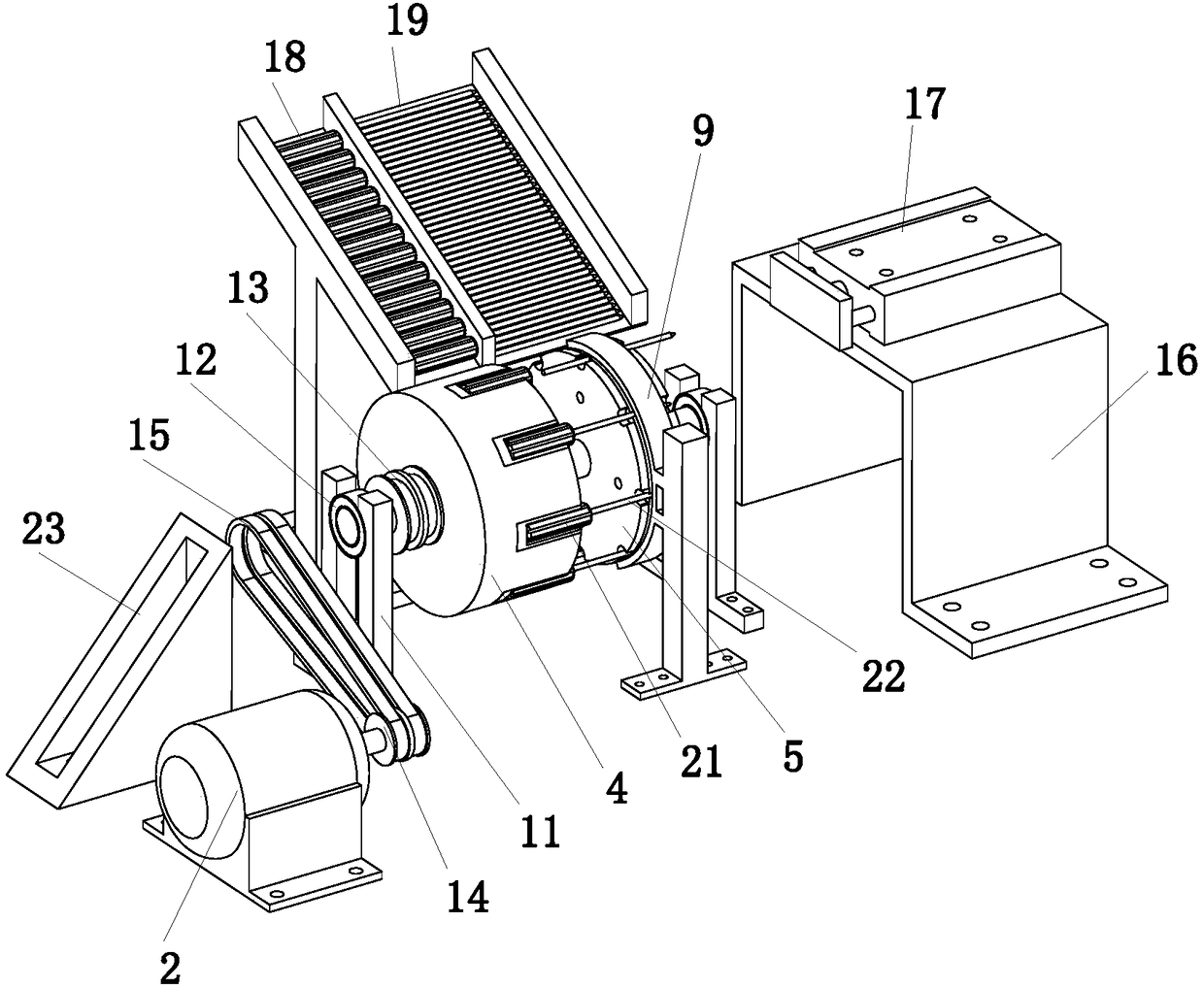

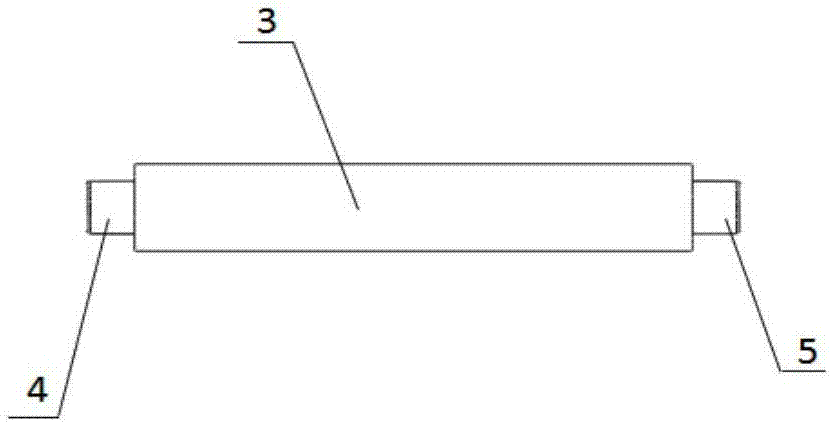

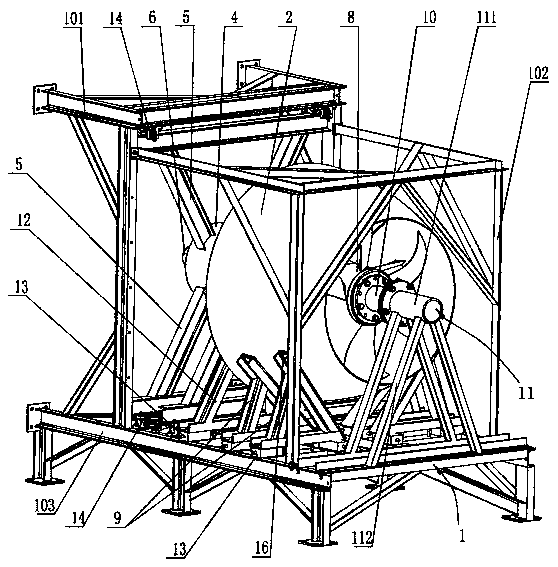

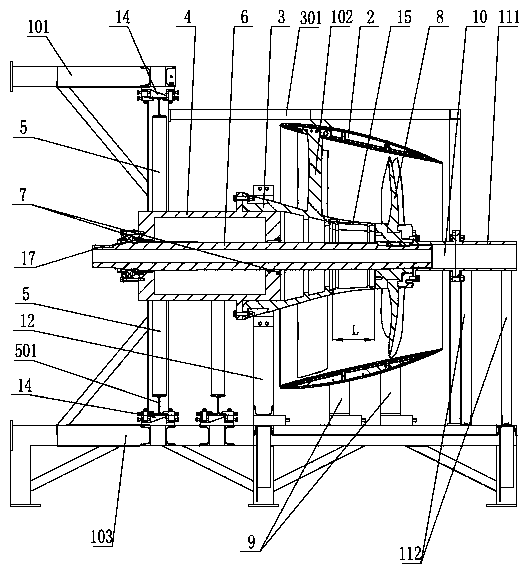

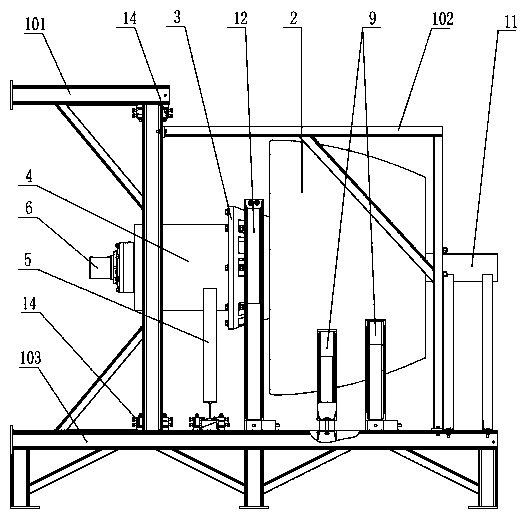

Rack for ducted propeller assembly

ActiveCN105563391AQuick assemblyAssembled preciselyWork holdersWork benchesEngineeringDucted propeller

The invention discloses a rack for ducted propeller assembly. The rack comprises a mounting frame; in a ducted propeller, the outer periphery of a duct is fixedly supported on the mounting frame through support bases 1; the outer periphery of a guide blade mounting base is fixedly supported on the mounting frame through a support base 2; one end of the guide blade mounting base is fixedly connected with a sleeve; the sleeve is arranged on one side of an inlet near the duct, is fixedly supported on the mounting frame through a bracket, and sheaths a paddle shaft in a penetrating way; the paddle shaft is slidingly supported in the sleeve through slide bearings; a paddle hub of the propeller in the duct is fixedly mounted on the paddle shaft; an axial gap is left between the propeller and the guide blade mounting base; the shaft section of the paddle shaft positioned in the axial gap is coated with a transition section; one end of the transition section is detachably and fixedly connected with the guide blade mounting base; and a rotating gap is left between the other end of the transition section and the paddle hub of the propeller. The rack can quickly and accurately finish assembly of the ducted propeller.

Owner:中国船舶重工集团公司第七〇二研究所

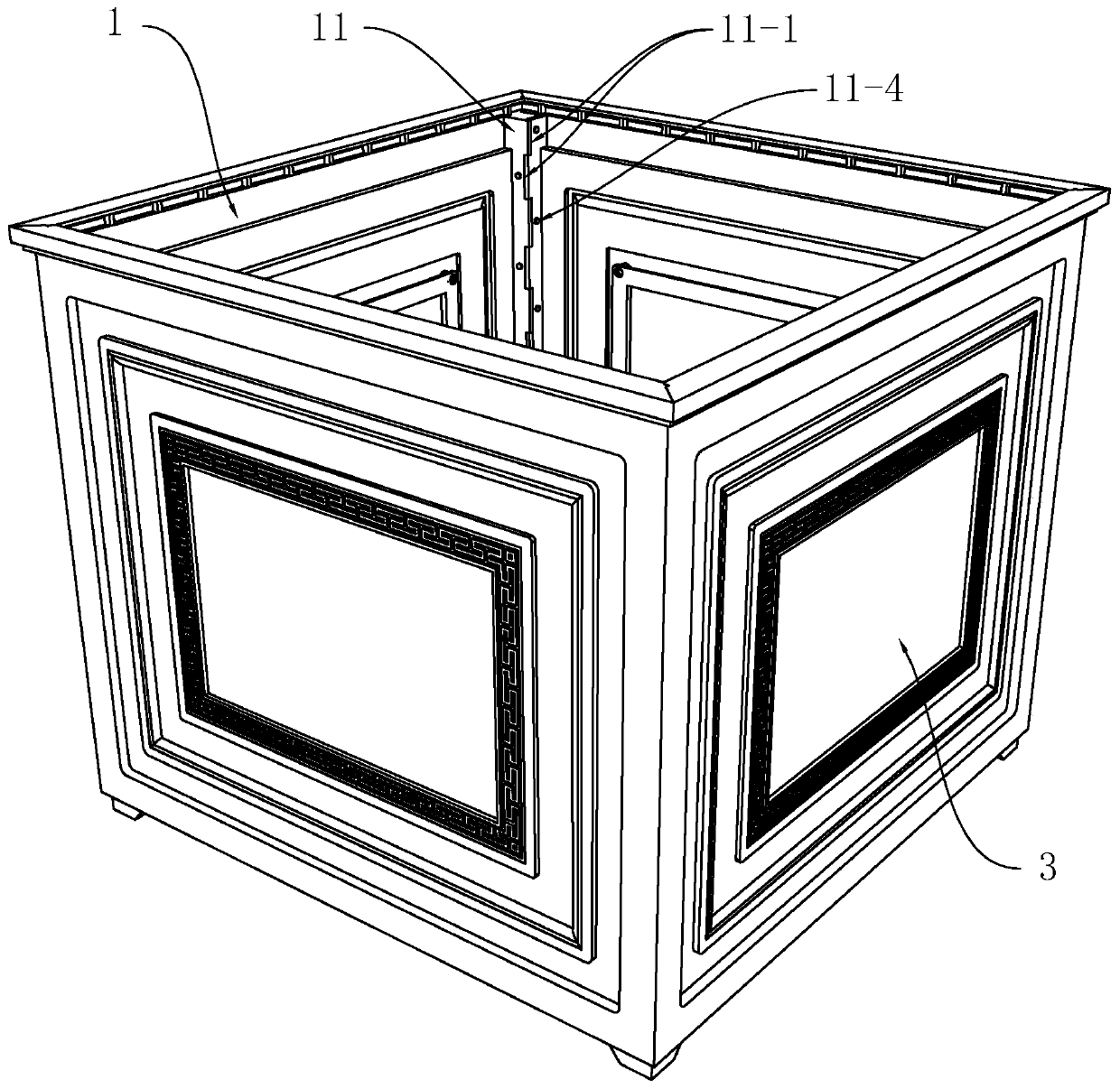

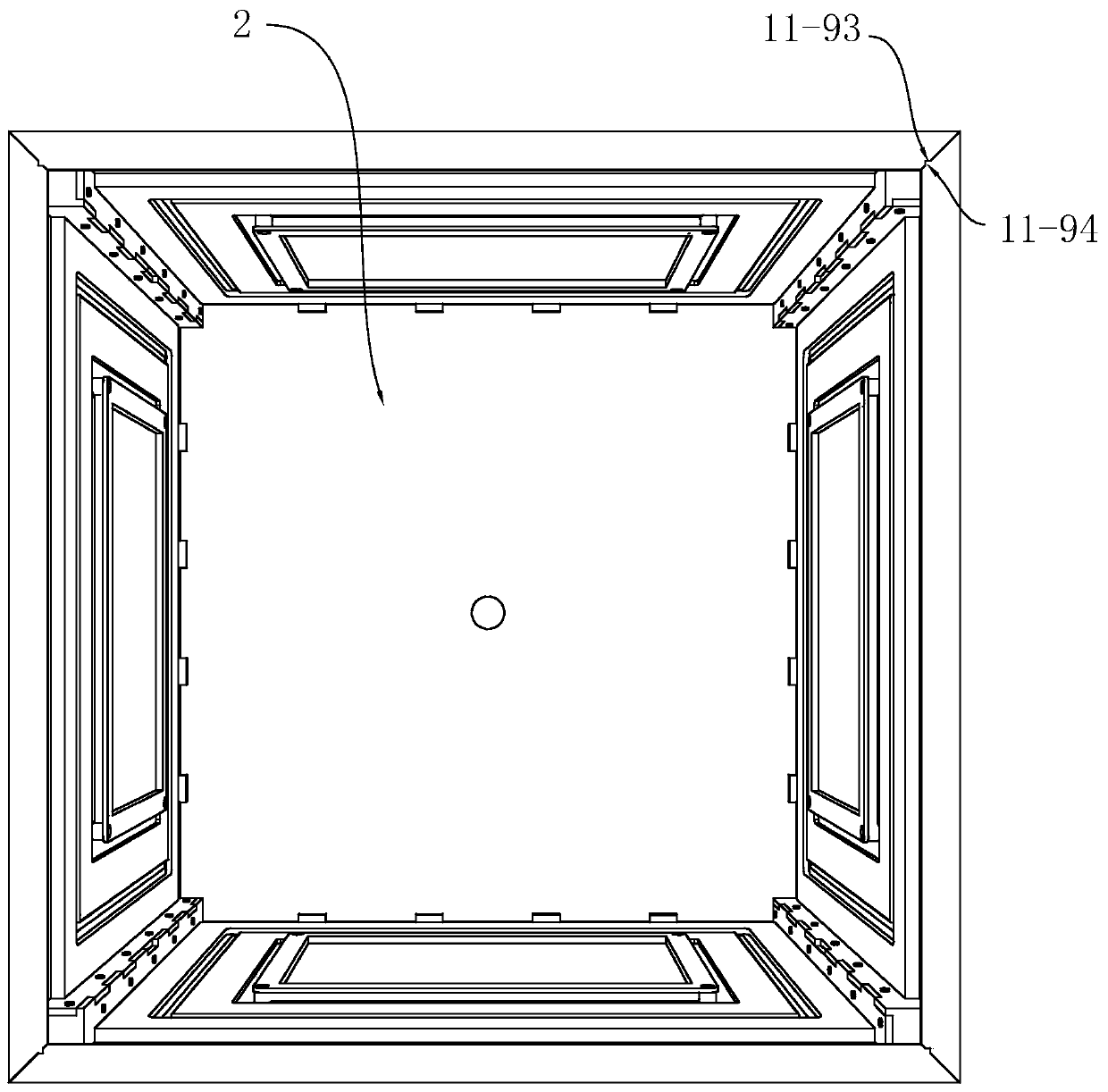

Spliced flower box

PendingCN110278802ASolve the problem of difficult splicingReduce up and downReceptacle cultivationEngineeringFading

The invention relates to a spliced flower box to solve the problems existing in adoption of independent connecting columns (strips) by side plates in the prior art and the problems, such as short service life and fading, of the flower box in the prior art. According to the technical scheme, the flower box includes side plates and a bottom plate formed by high polymer dies. The flower box is characterized in that the outer side walls of the side plates are flower box decorative faces, the two ends of the inner wall face of each side plate are provided with vertical connection parts integrally formed with the side plate, each vertical connection part includes a splicing edge with a bayonet arranged at intervals, and pore columns with pin holes are arranged on the outer sides of the splicing edges at intervals; when the adjacent side plates are spliced, the bayonets of the splicing edges are dislocated and connected mutually by inserting, and plug pins pass through through holes of the splicing edges and inserted into the pin holes of the adjacent side plates. The flower box has the advantages that the side plates and bottom plate made from high polymer materials are adopted, the splicing edges with the bayonets are dislocated and connected mutually by inserting, connection sides integrally formed on the side plates are spliced mutually, and the splicing flower box solves the problems that splicing is difficult, the service life is short, the box is easy to damage and fading easily occurs after pattern printing and coloring.

Owner:长兴肖达科技有限公司

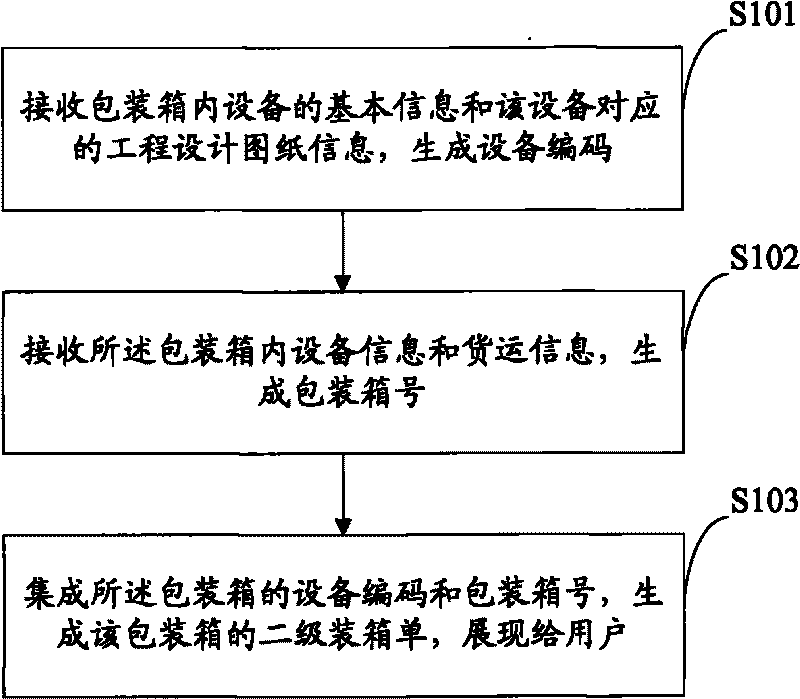

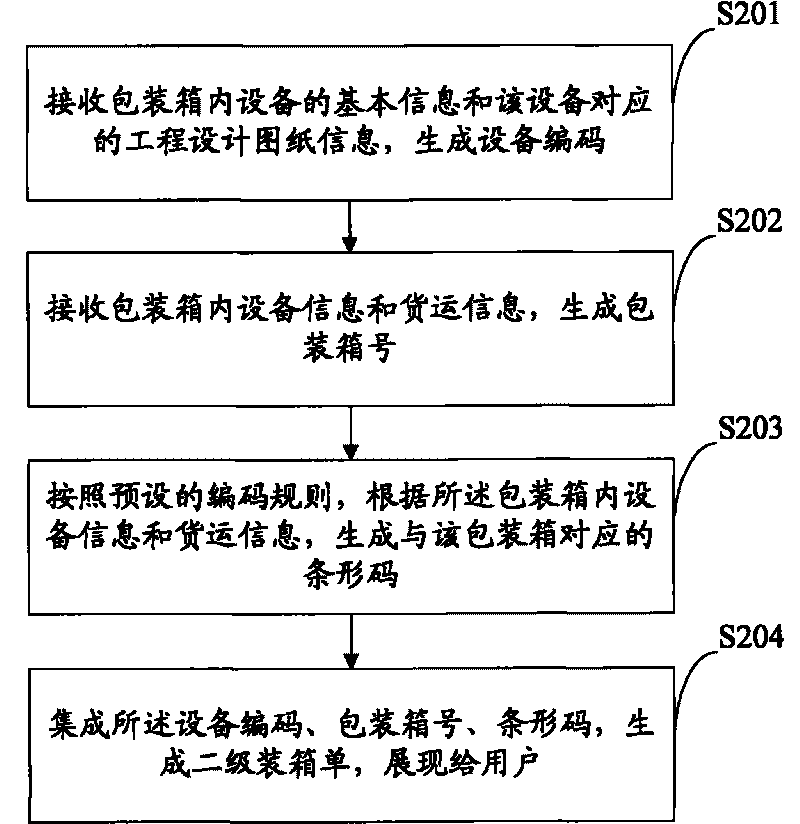

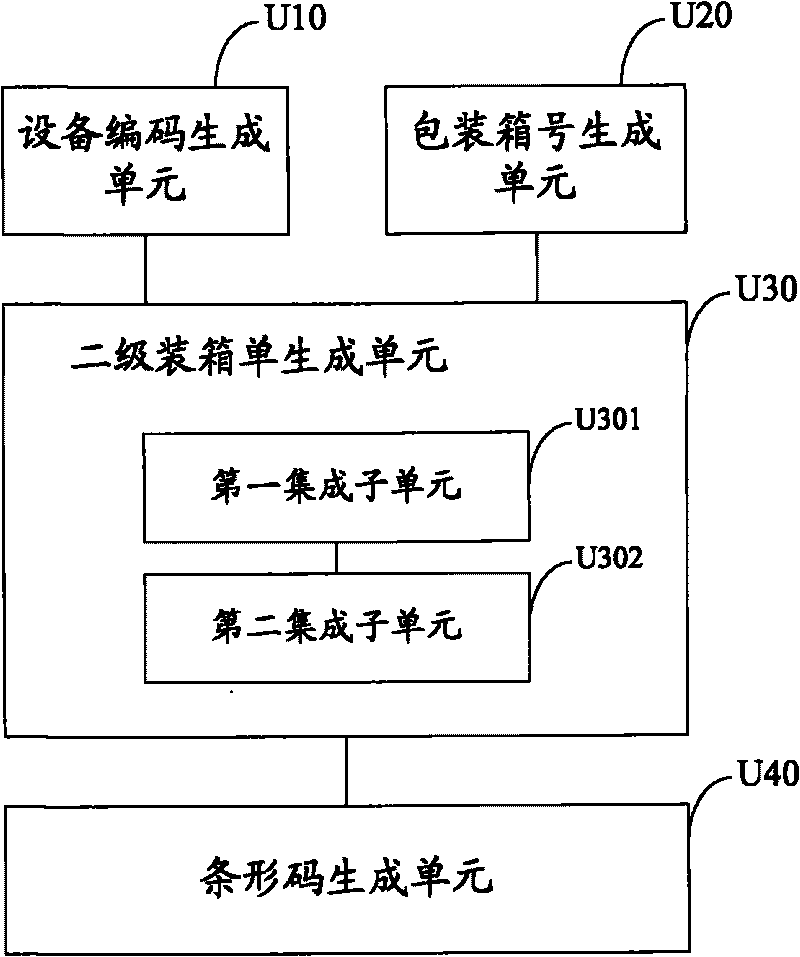

Logistics management method and device for engineer procure construct project

InactiveCN101699484AAssembled preciselyImprove construction efficiencyLogisticsLogistic managementLogistics management

The invention discloses a logistics management method for engineer procure construct project, comprising the following steps: receiving the basic information of a device in a packing box and the engineering design paper information corresponding to the device so as to generate a device code; receiving the device information and the freight information of the device in the packing box so as to generate a packing box number; and integrating the device code and the packing box number of the packing box so as to generate a two-stage packaging bill of the packing box to be presented to the user. The invention further provides a logistics management device for engineer procure construct project. The embodiment of the invention is used so that the worker can quickly and accurately recover the assembly of the engineering device so as to improve the working efficiency, the construction efficiency and the accuracy; and moreover, the computer informatization of logistics management becomes more scientific and efficient.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

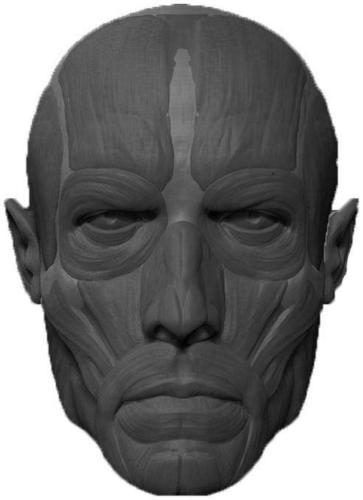

Facial anatomy teaching method using feedback type facial anatomy teaching model

ActiveCN111326056AAvoid Missing InstructionsSync progressEducational modelsPhysical medicine and rehabilitationFacial anatomy

The invention relates to a facial anatomy teaching method using a feedback type facial anatomy teaching model. The method is different from conventional abstract theory teaching of models or planar graphs. Teacher-student interaction and interaction between students and models are carried out by utilizing a feedback type facial anatomy model, the anatomy module of the feedback type facial anatomymodel can be disassembled and assembled, and a sensor is arranged in the feedback type facial anatomy model, so that wrong assembly and correct assembly can be fed back to the students, and the students can autonomously judge whether learning is correct or not; during teaching, the model in the hands of the teacher can reflect the explanation part of the teacher on the practice model of the students, so that the interactive teaching between the teacher and the students is richer.

Owner:JILIN UNIV

Lighter grinding wheel assembling machine

ActiveCN101954587AReduce manufacturing costImprove assembly success rateAssembly machinesEngineeringBlock match

The invention relates to a lighter grinding wheel assembling machine. The existing grinding wheel assembling machine can not rapidly and accurately assemble grinding wheels, has low assembling efficiency and higher production cost. In the invention, a machine head fixture used for sliding back and forth is arranged in a base; a plurality of machine head clamping parts are formed on the external end of the machine head fixture; the upper part of the machine head fixture is provided with a plurality of positioning blocks matched with the machine head clamping parts; a grinding wheel clamping opening is formed at the external end of the positioning block; the middle part of the positioning block is provided with a vertical hole for accommodating a spring and a lighting stone; the two sides of the base are respectively provided with a sliding seat; the two sliding seats are respectively provided with a sliding mount which can move back and forth and is positioned above the positioning block; the sliding mount is provided with a grinding wheel press-in plate and a grinding wheel ejector retainer plate which are arranged in parallel back and forth and can go up and down. When in the grinding wheel assembling, each part of the invention has stable and reliable operation; the grinding wheel rapid and accurate assembling is realized, and the operation is simple; one grinding wheel assembling machine can assemble multiple lighter grinding wheels at one time with high working efficiency.

Owner:XINHAI TECH GRP CO LTD

Automatic electrohydraulic-control butterfly valve assembling machine and assembling method thereof

ActiveCN106141632AImprove performanceEasy to useMetal working apparatusHydraulic cylinderAutomatic control

The invention provides an automatic electrohydraulic-control butterfly valve assembling machine and an assembling method thereof. According to the automatic electrohydraulic-control butterfly valve assembling machine and the assembling method thereof, using is convenient and safe, machining operation is convenient and fast, and the pressure of a main unit can be adjusted in time according to butterfly valves of different types and specifications; the working efficiency and quality are greatly improved, and the economic benefits are good; and since automatic control is adopted, the man-machine safety coefficient is high, time and energy resources are greatly saved, repair and maintenance cost caused by abrasion is reduced, the performance of the whole machine is improved, the service life of the whole machine is prolonged, and the production cost is reduced. The automatic electrohydraulic-control butterfly valve assembling machine is composed of a butterfly valve assembling workbench, infrared induction safety devices, a tool base, an assembling machine stand column, a pressing head tool, a pressure regulation valve, an upper oil cylinder supporting frame, a pressure gauge, an upper hydraulic cylinder device, a PLC control cabinet device, a control button, an electrical cabinet device, a butterfly valve tool, a locking nut mechanism, a pressing lead screw assembly, a valve shaft pressing head device, a lateral hydraulic cylinder device, a hydraulic pipeline and the like.

Owner:HENAN TUOFU VALVE CO LTD

Miniature multifunctional cutting machine

ActiveCN104802320AHigh precisionAssembled preciselyProfiling/shaping machinesWorking accessoriesEngineeringMultiple function

The invention provides a miniature multifunctional cutting machine. A cutting machine rack comprises a base plate, a positioning base, an adjustment positioning plate and two guide rails, wherein the two guide rails are parallel to each other; guide sliding sleeves are arranged on two sides of a plate surface of the base plate respectively; the guide sliding sleeves on two sides of the base plate sleeve the guide rails on the corresponding sides respectively and are matched with the guide rails in a sliding manner; the adjustment positioning plate is arranged on the two guide rails, is propped against one side of the base plate and corresponds to the positioning base; a cutting machine body is fixedly connected onto one plate surface of the base plate; a cutting blade on the cutting machine body extends out of the other plate surface of the base plate and is perpendicular to the other plate surface of the base plate. The miniature multifunctional cutting machine can be used for cutting stones and woods of different sizes through adjusting the adjustment positioning plate on the two guide rails, cutting right-angle edges, bevel edges and chamfers of the stones and woods, so that an effect of one machine with a plurality of functions is achieved, the processing precision is higher, and the assembly of processed stones and woods is more precise.

Owner:张盛华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com