License plate small lamp assembling machine

A lamp group and license plate technology, applied in the direction of assembly machines, auxiliary devices, resistance welding equipment, etc., can solve the problems of low assembly accuracy, low assembly efficiency of small lamps, low assembly and detection automation, and achieve high assembly efficiency and compact structure , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

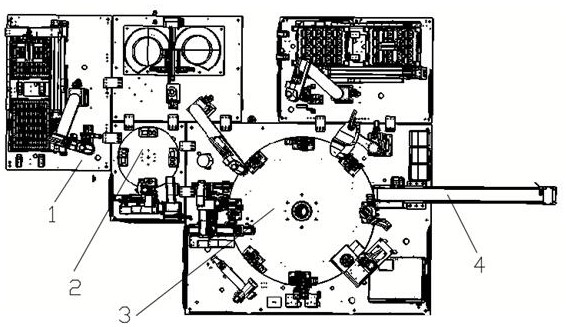

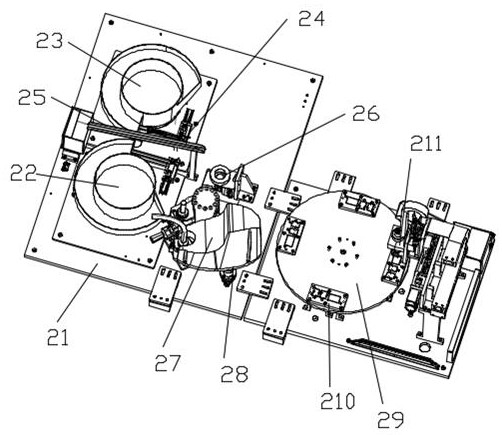

[0020] like Figure 1-6 As shown, a license plate small light assembly machine includes: small light feeding device (1), small light welding device (2), small light shell assembly detection device (3), small light automatic output line (4), The right side of the small lamp feeding device (1) is connected with the small lamp welding device (2), and the right side of the small lamp welding device (2) is assembled with the small lamp housing detection device (3), the A small lamp automatic output line (4) is connected to the right side of the small lamp housing assembly detection device (3).

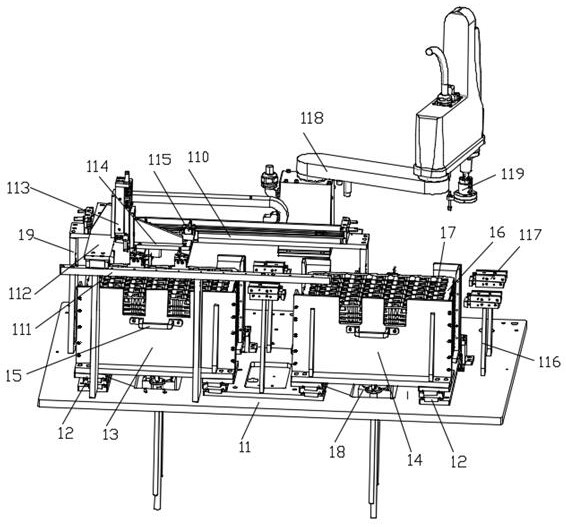

[0021] Further, the small lamp feeding device (1) includes a first frame (11), and the upper left side of the first frame (11) is slidably installed with an unloading rack (13) through a slide structure (12) , the upper right side of the first frame (11) is slidably installed with a loading rack (14) through the slide structure (12), and the outer sides of the lowering rack (13) and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com