Patents

Literature

177results about How to "Improve assembly pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

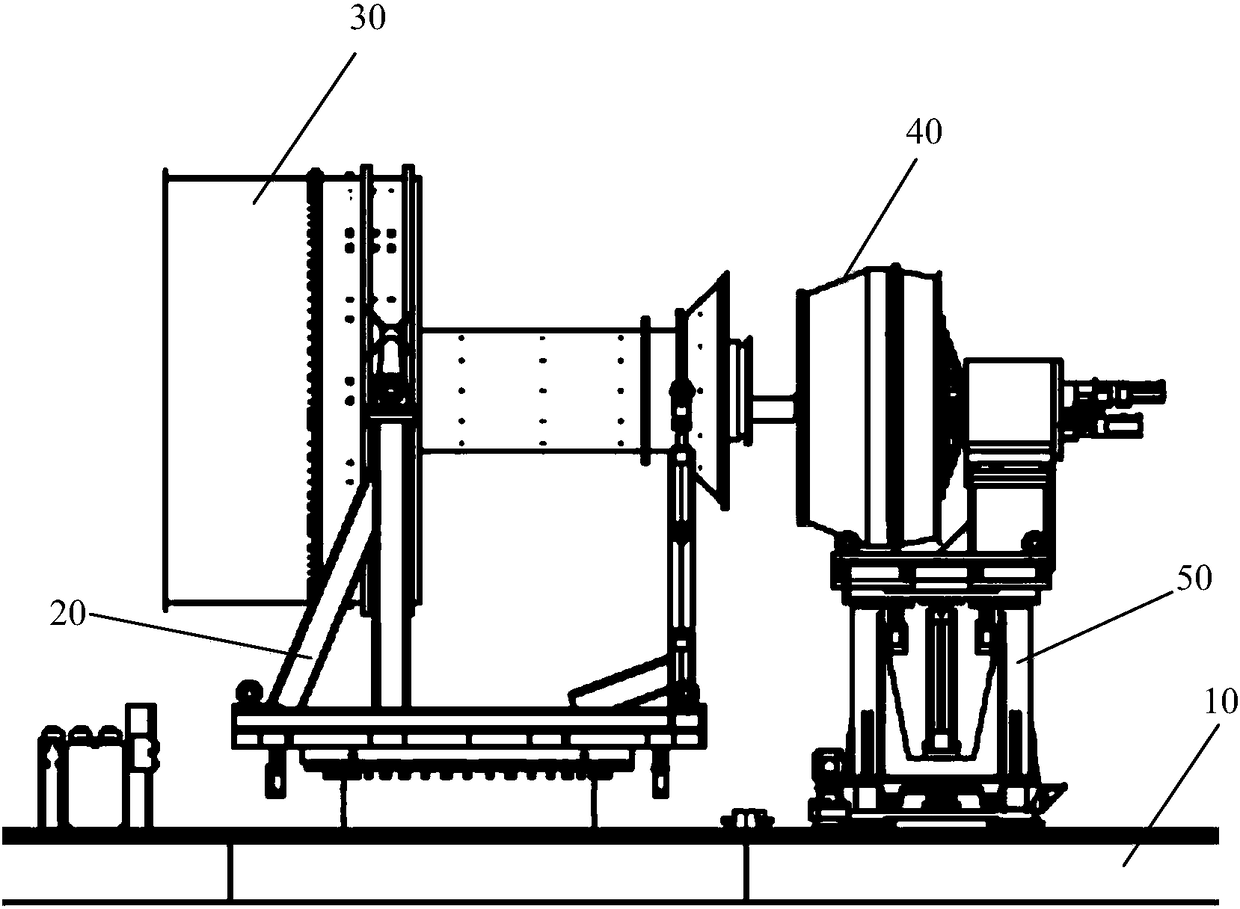

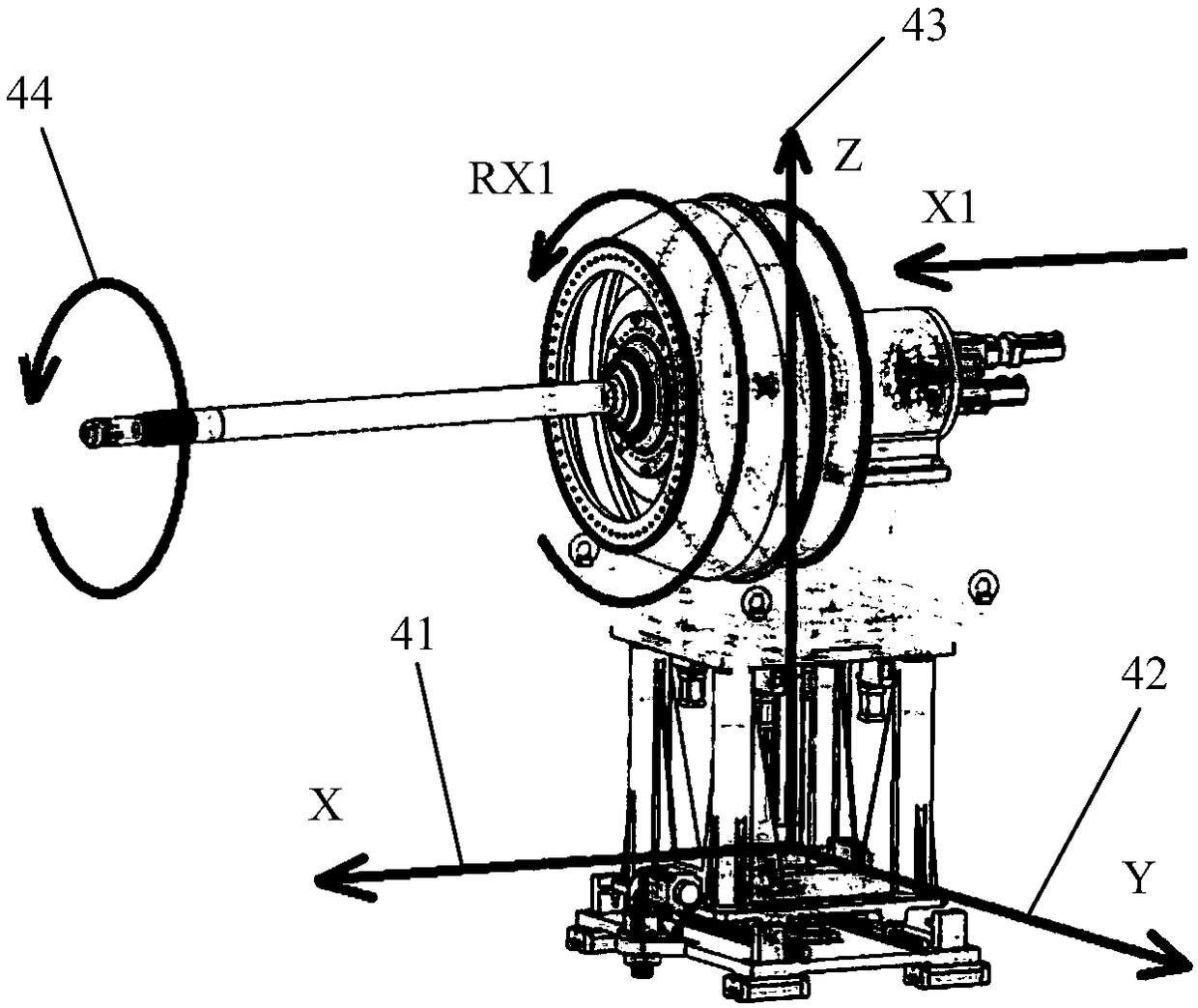

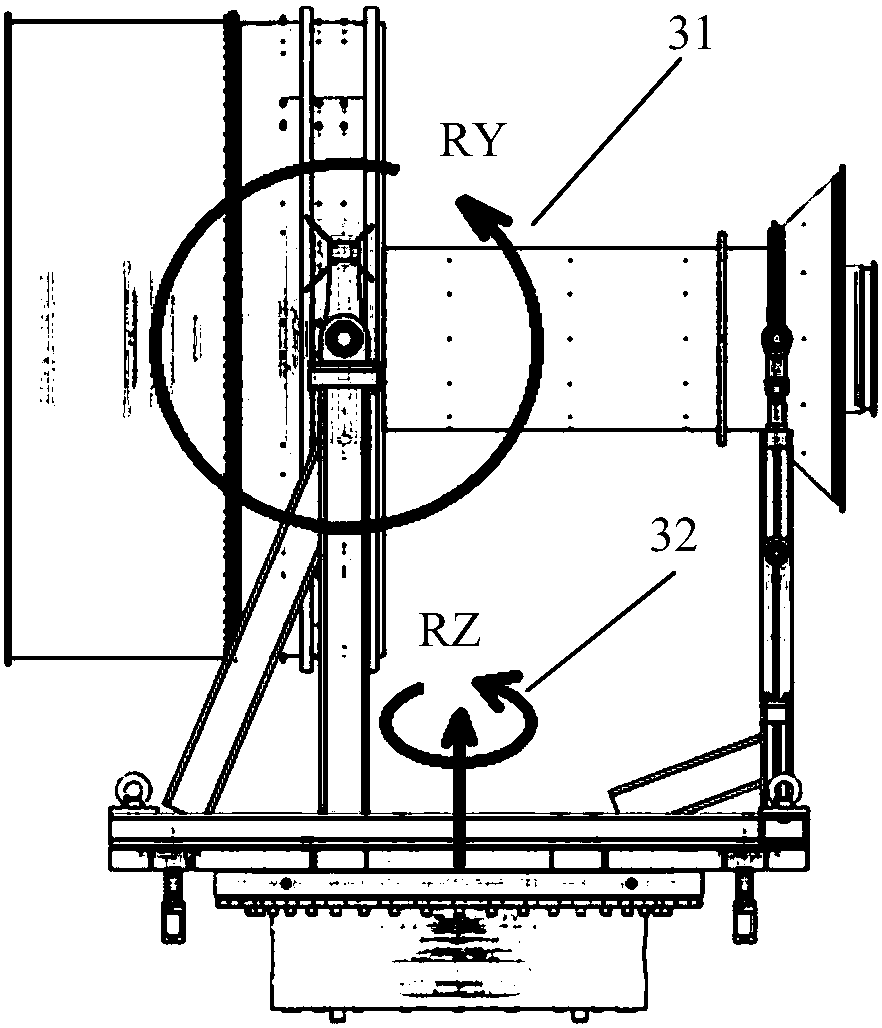

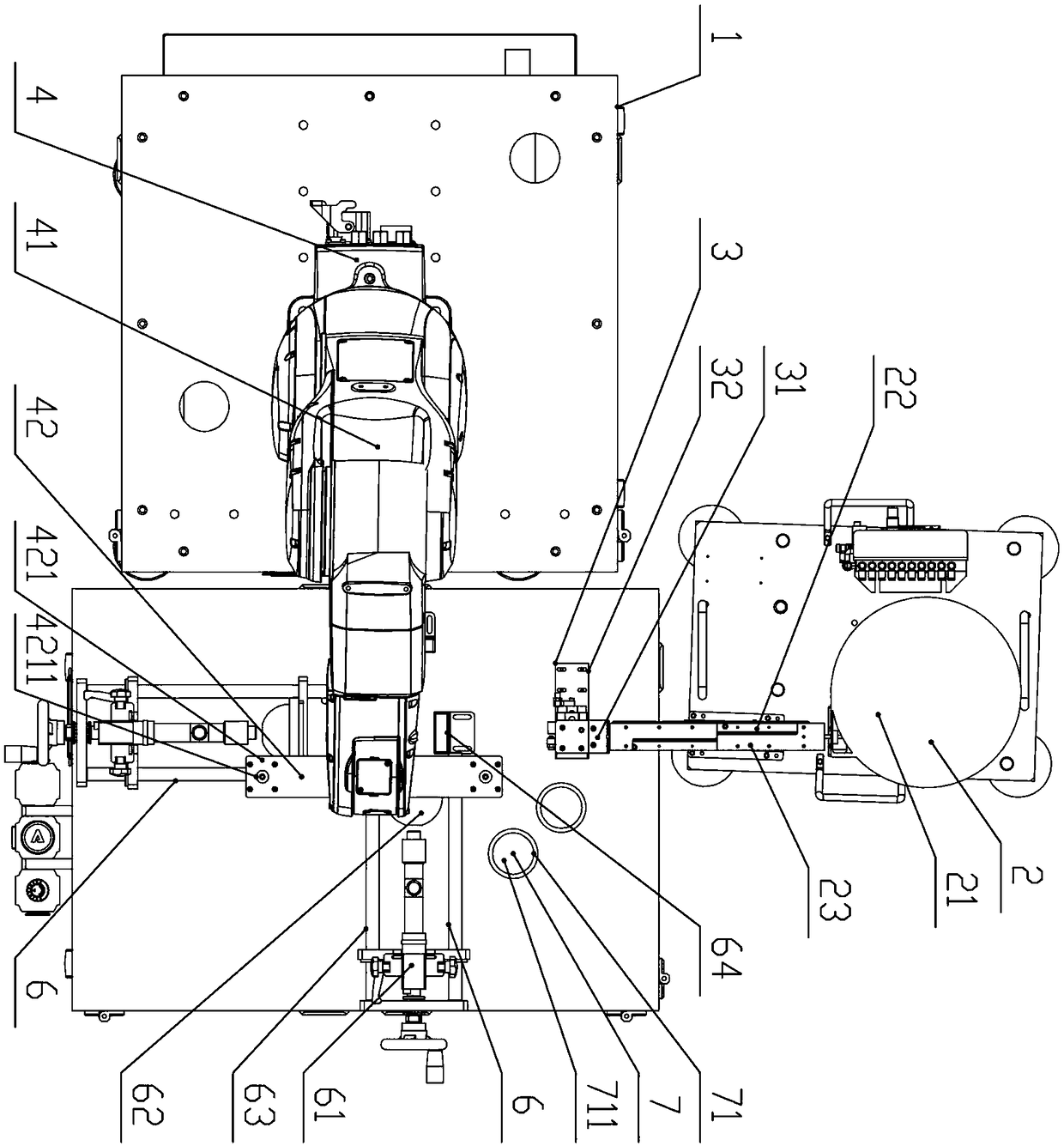

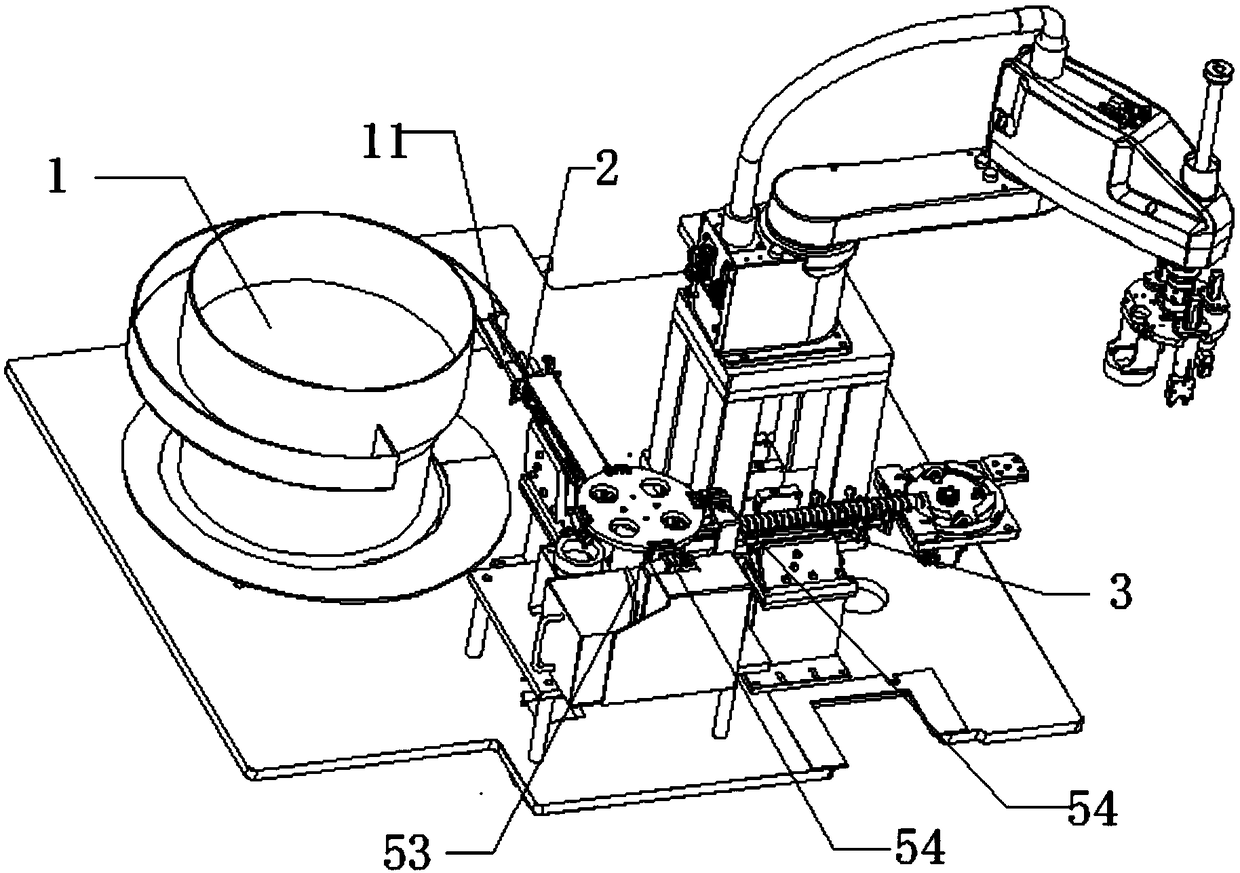

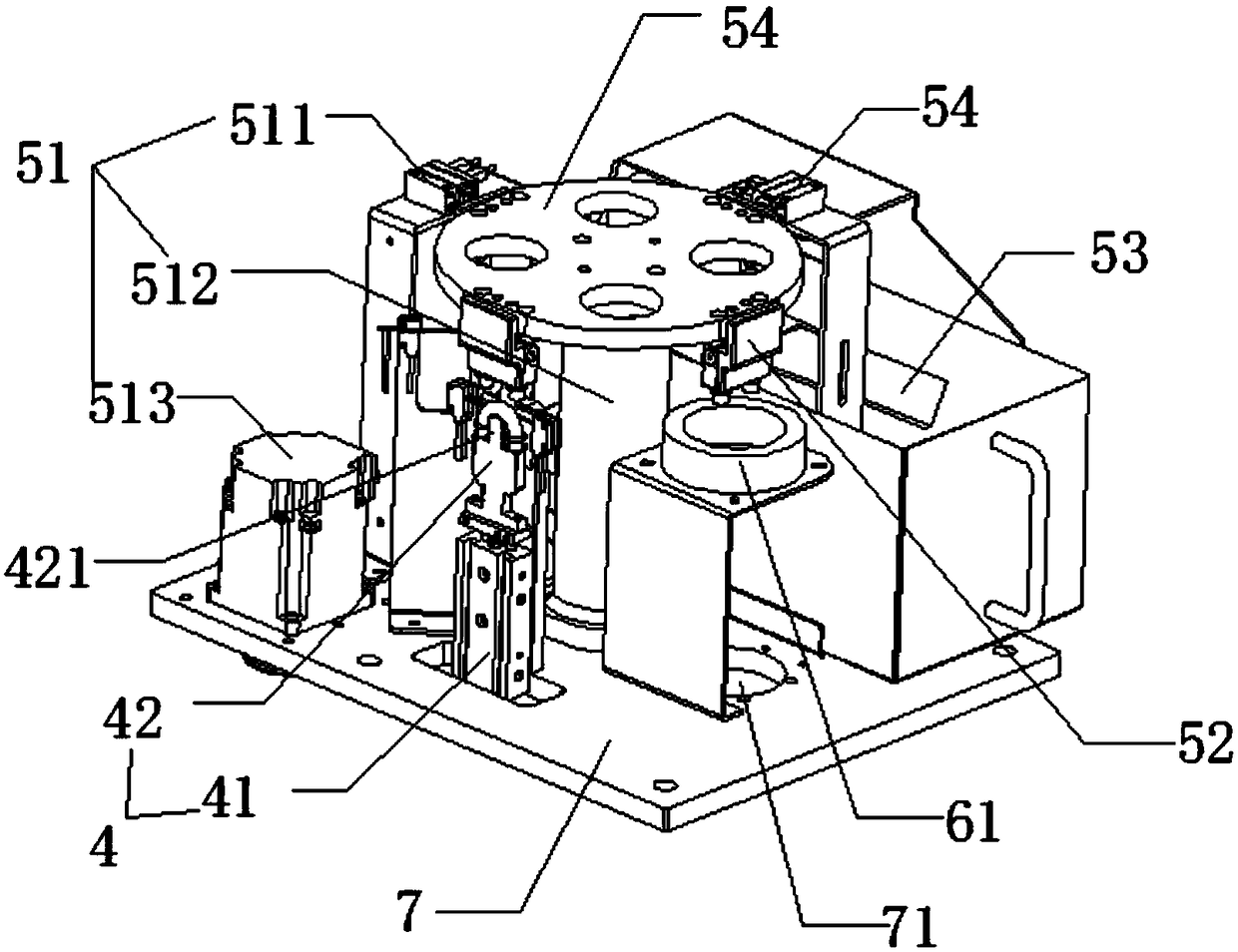

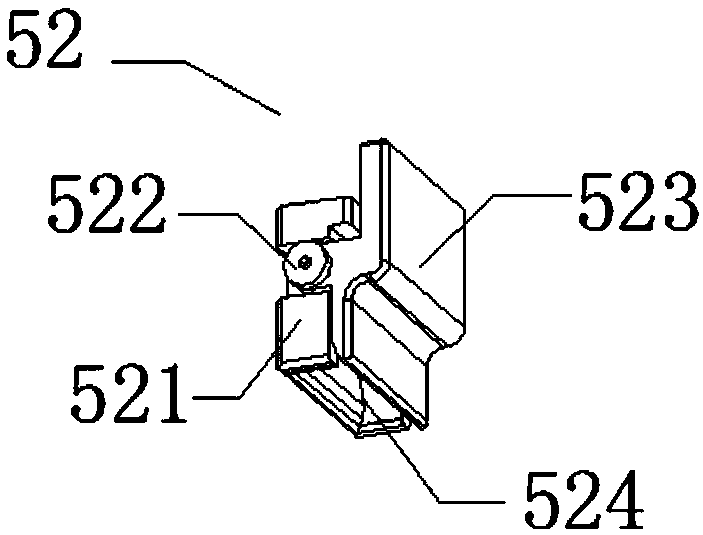

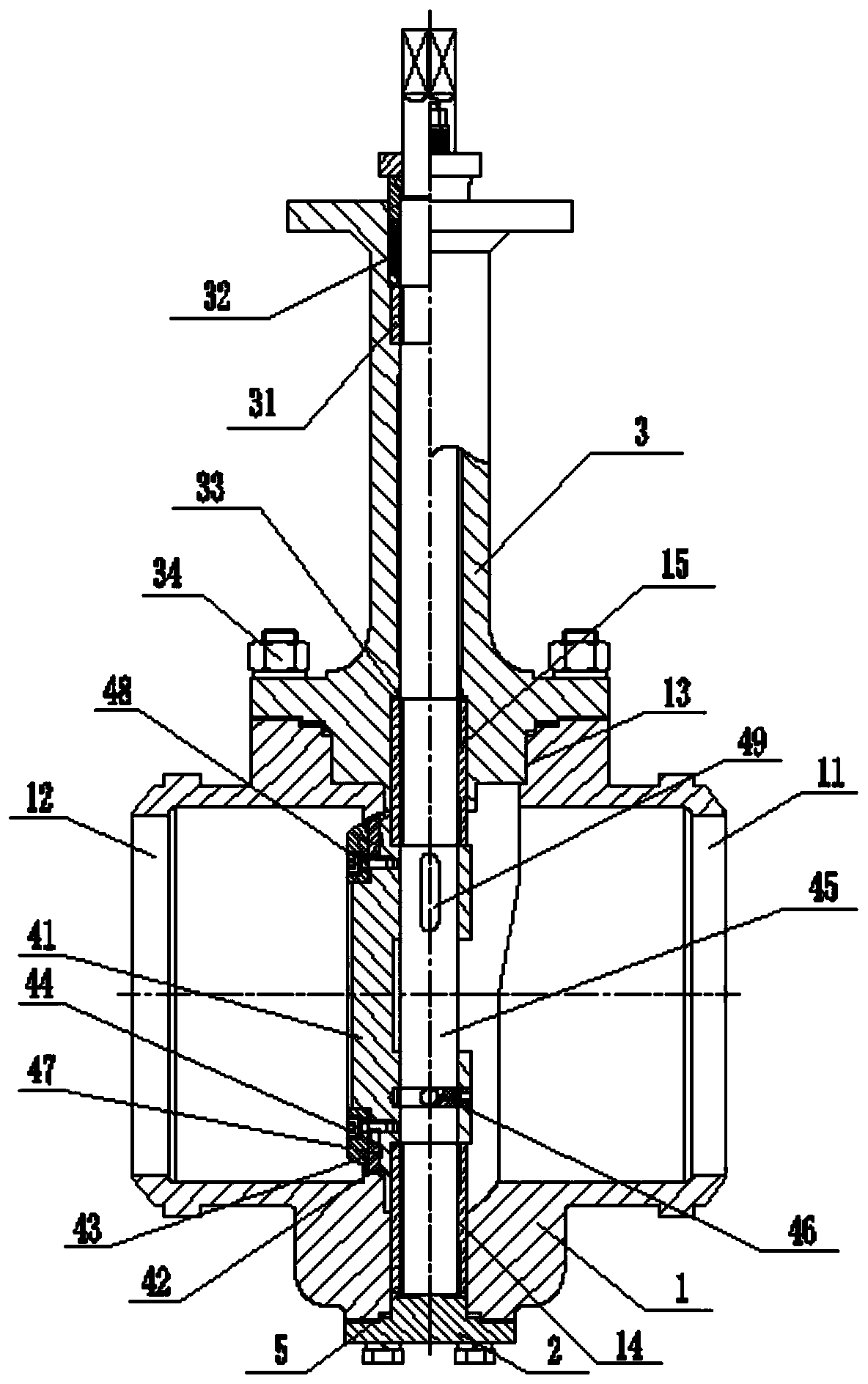

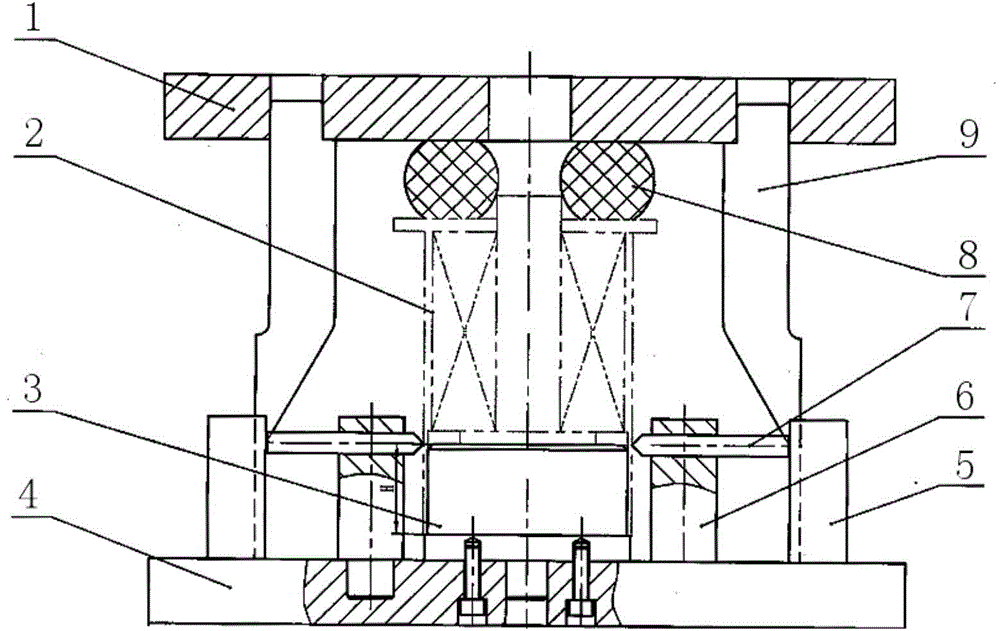

Intelligent assembly platform for low-pressure turbine module

ActiveCN109093379AImprove assembly accuracyAchieve high-precision assemblyAircraft componentsAssembly machinesDegrees of freedomTurbine

The invention provides an intelligent assembly platform for a low-pressure turbine module, and is used for the assembly of the whole aeroengine. The platform comprises a base, a fan core machine attitude adjustment system and a low-pressure turbine module position adjustment system. The fan core machine attitude adjustment system is fixed on one end of the base, and a fan core machine is installedon the fan core machine attitude adjustment system. The low-pressure turbine module position adjustment system is fixed on the other end of the base, and a low-pressure turbine module is installed onthe low-pressure turbine module position adjustment system; and the low-pressure turbine module is connected with the fan core machine, the low-pressure turbine module has four degrees of freedom ofmovement, and the fan core machine has two degrees of freedom of movement. The intelligent assembly platform for the low-pressure turbine module can improve the assembly precision, reduce the damage to parts, improve the assembly efficiency and reduce the amount of assembly labor.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

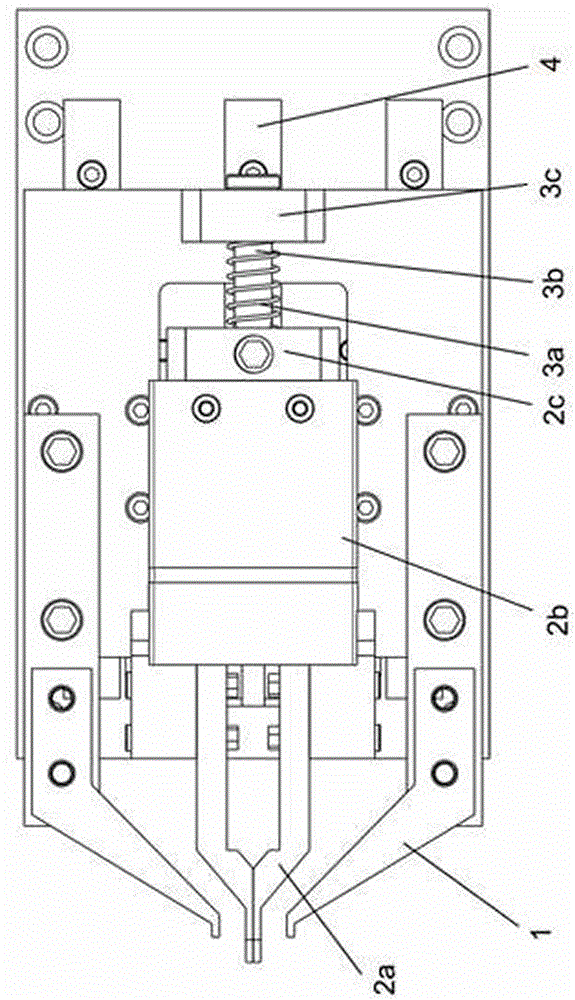

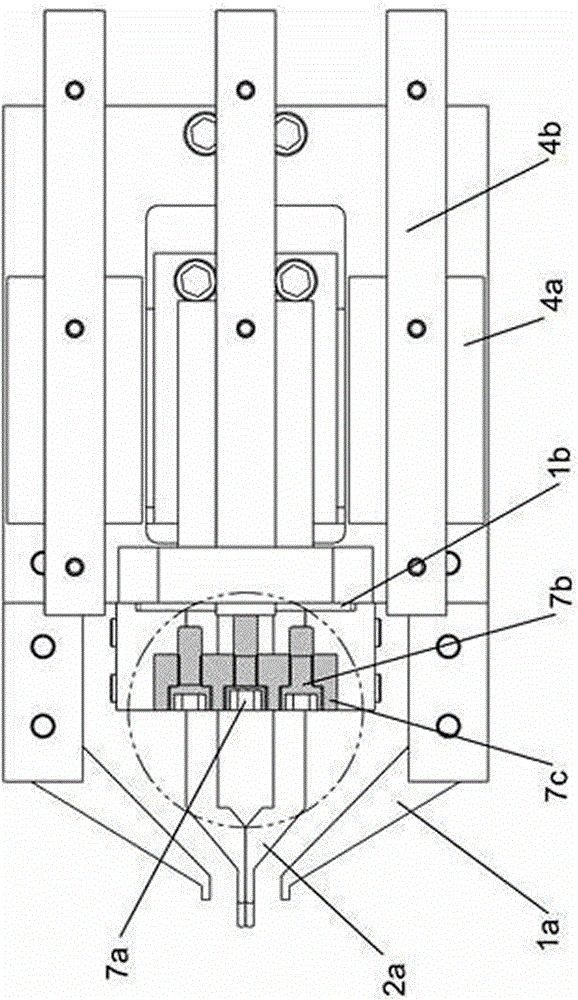

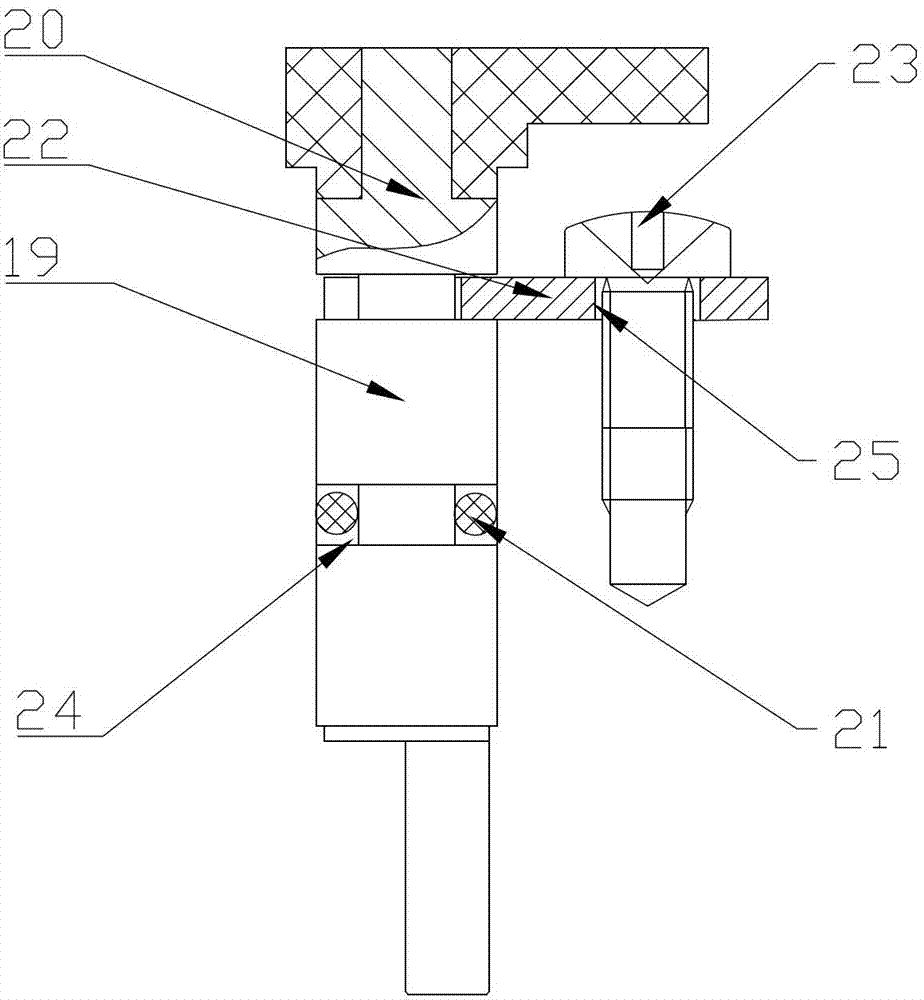

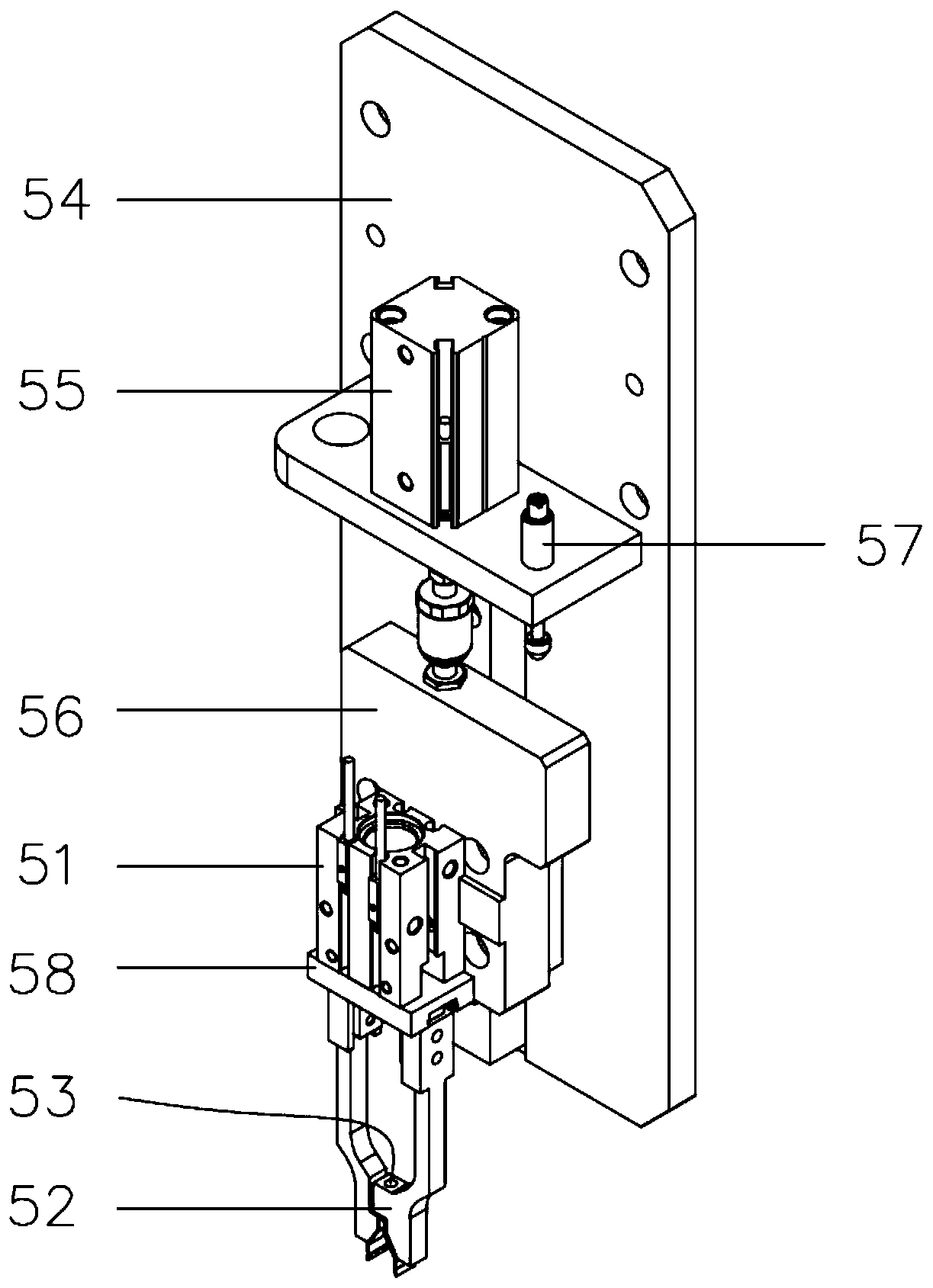

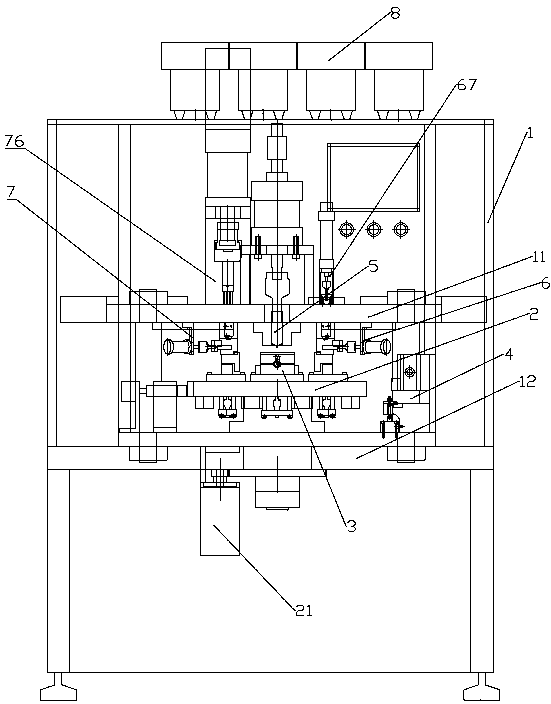

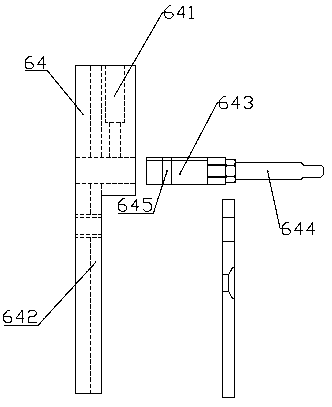

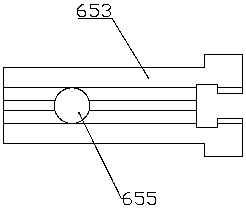

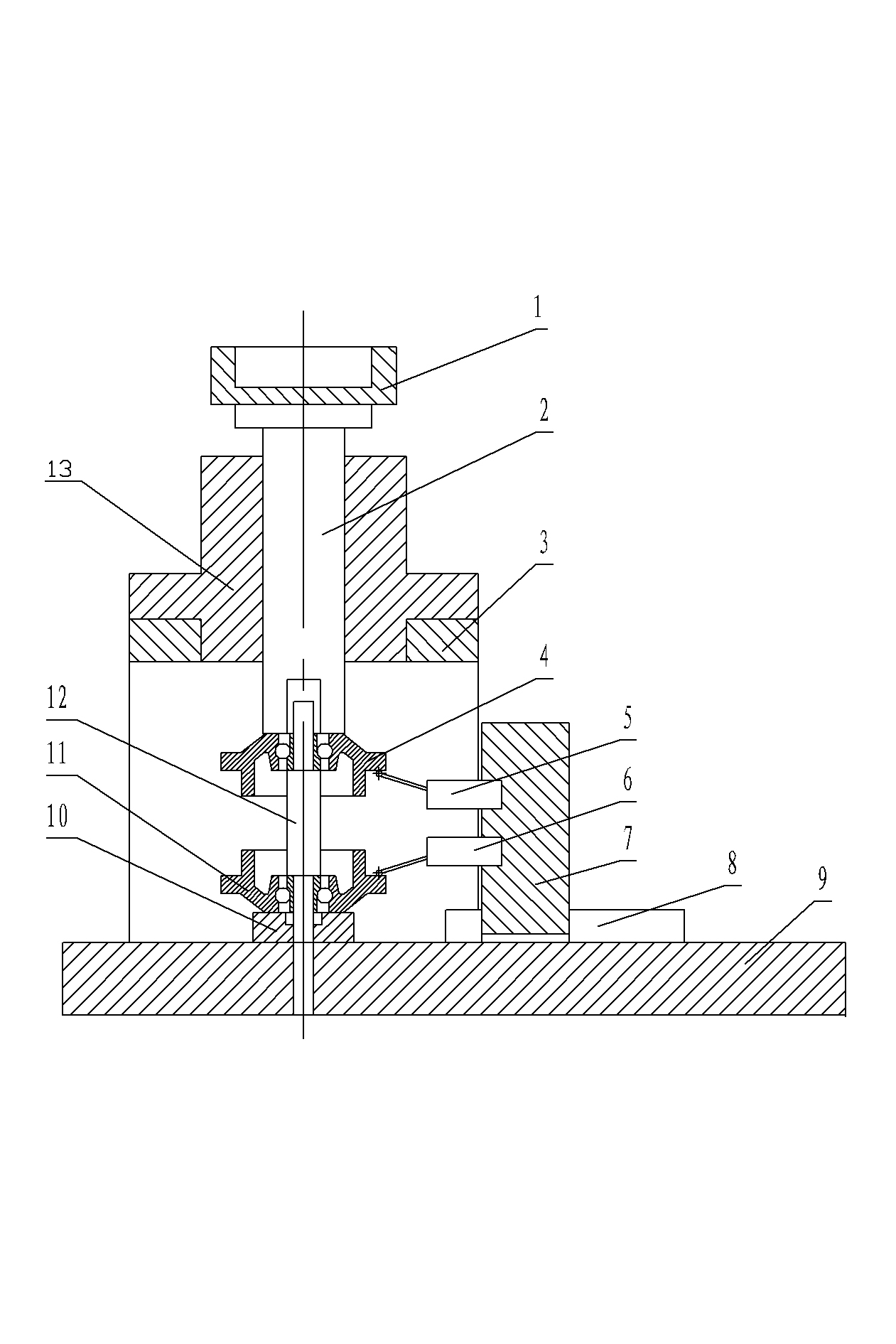

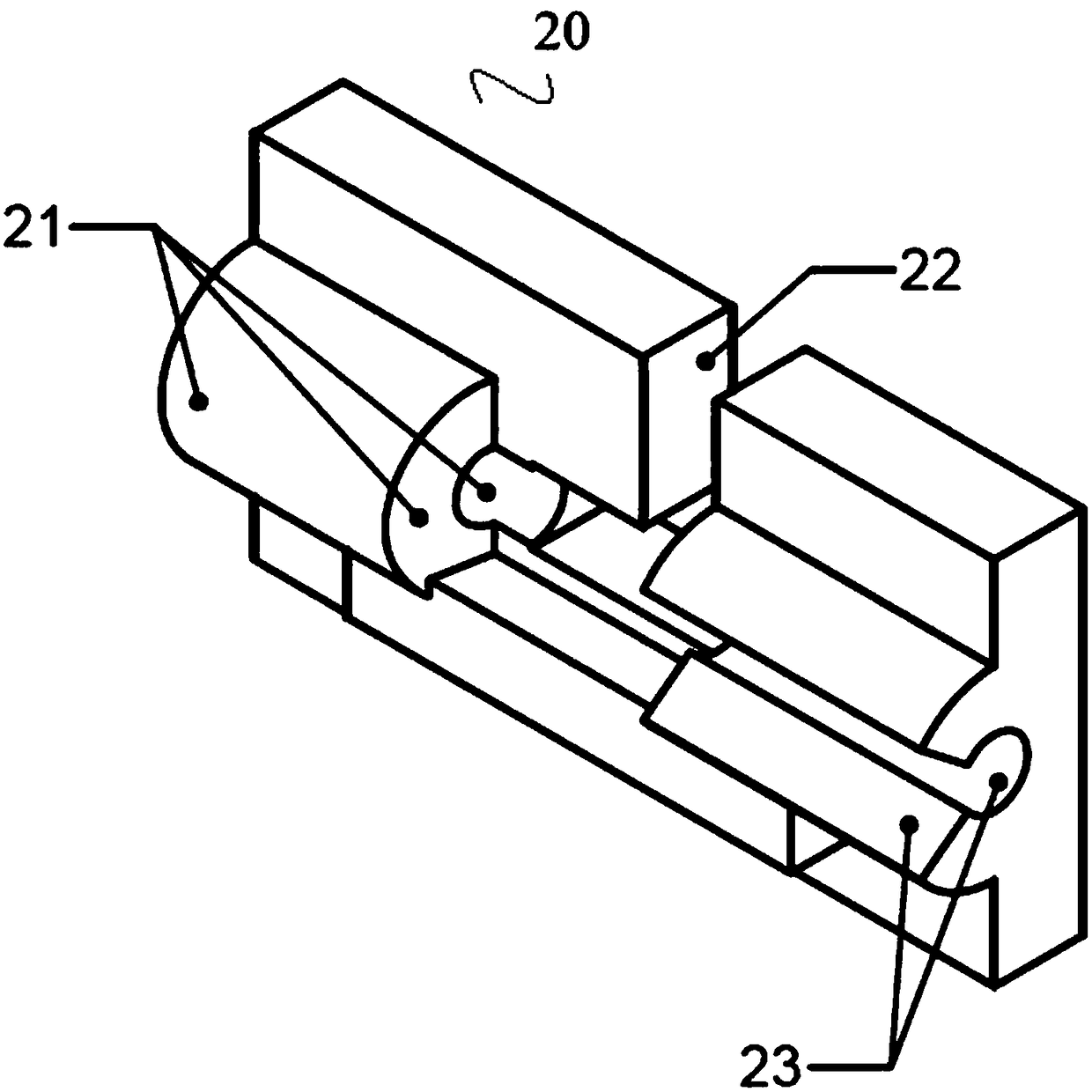

Automatic assembly device for gear shifter O-shaped ring

ActiveCN104907799AAssembly precisionImprove assembly pass rateMetal working apparatusEngineeringMechanical engineering

The invention provides an automatic assembly device for a gear shifter O-shaped ring, belongs to the technical field of automatic assembly, and particularly relates to the automatic assembly device of the gear shifter O-shaped ring. The automatic assembly device is high in assembly efficiency and compact in structure. The automatic assembly device comprises a supporting base and is structurally characterized in that a cylinder is horizontally arranged on the rear portion of the lower end of the supporting base, two side guide rails and a middle guide rail are arranged on the two sides and in the middle of the supporting base in the front and back length direction of the supporting base, two side slide blocks are arranged on the two side guide rails, the upper ends of the two side slide blocks are fixed to the lower ends of the two sides of a push jaw fixing plate, push jaws are arranged on the two sides of the front end of the push jaw fixing plate, a pneumatic jaw is arranged at an opening in the middle of the push jaw fixing plate, the lower end of the pneumatic jaw is arranged on the middle guide rail through the middle slide block, the drive end of the front end of the pneumatic jaw is connected with a clamping jaw, the rear end of the pneumatic jaw is connected with the rear end of the push jaw fixing plate through a horizontal elastic thrust mechanism, and a vertical lifting plate is arranged at the front end of the supporting base.

Owner:SHENYANG POLYTECHNIC UNIV

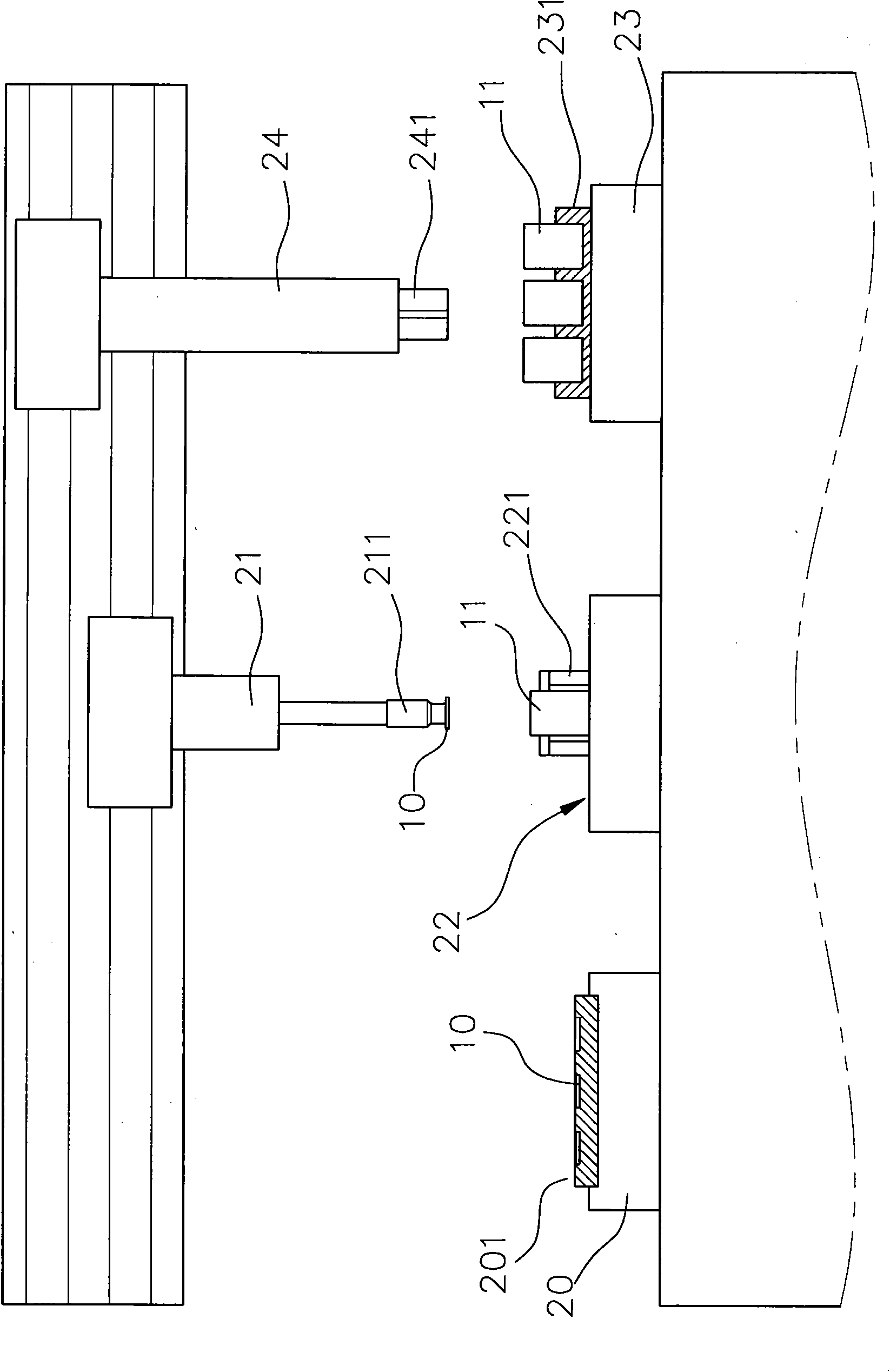

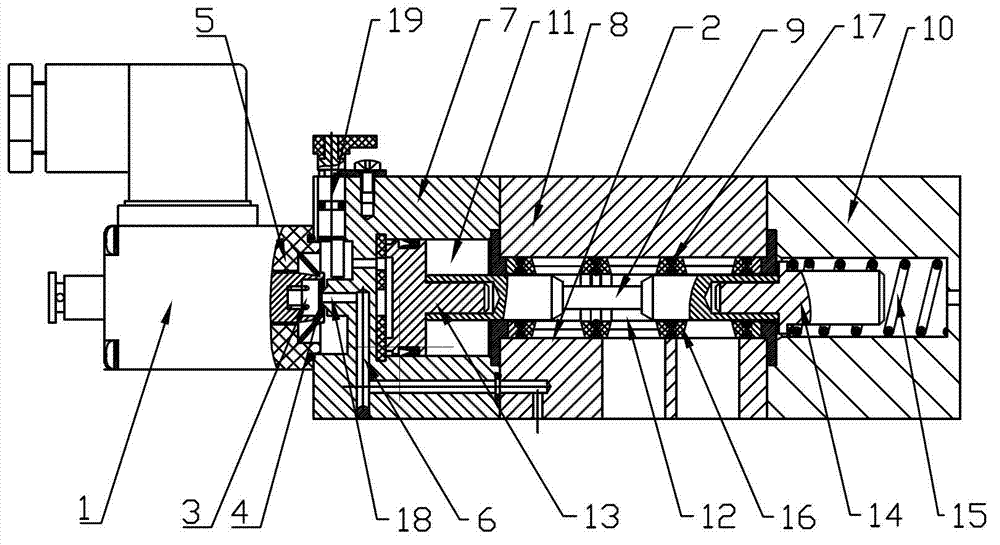

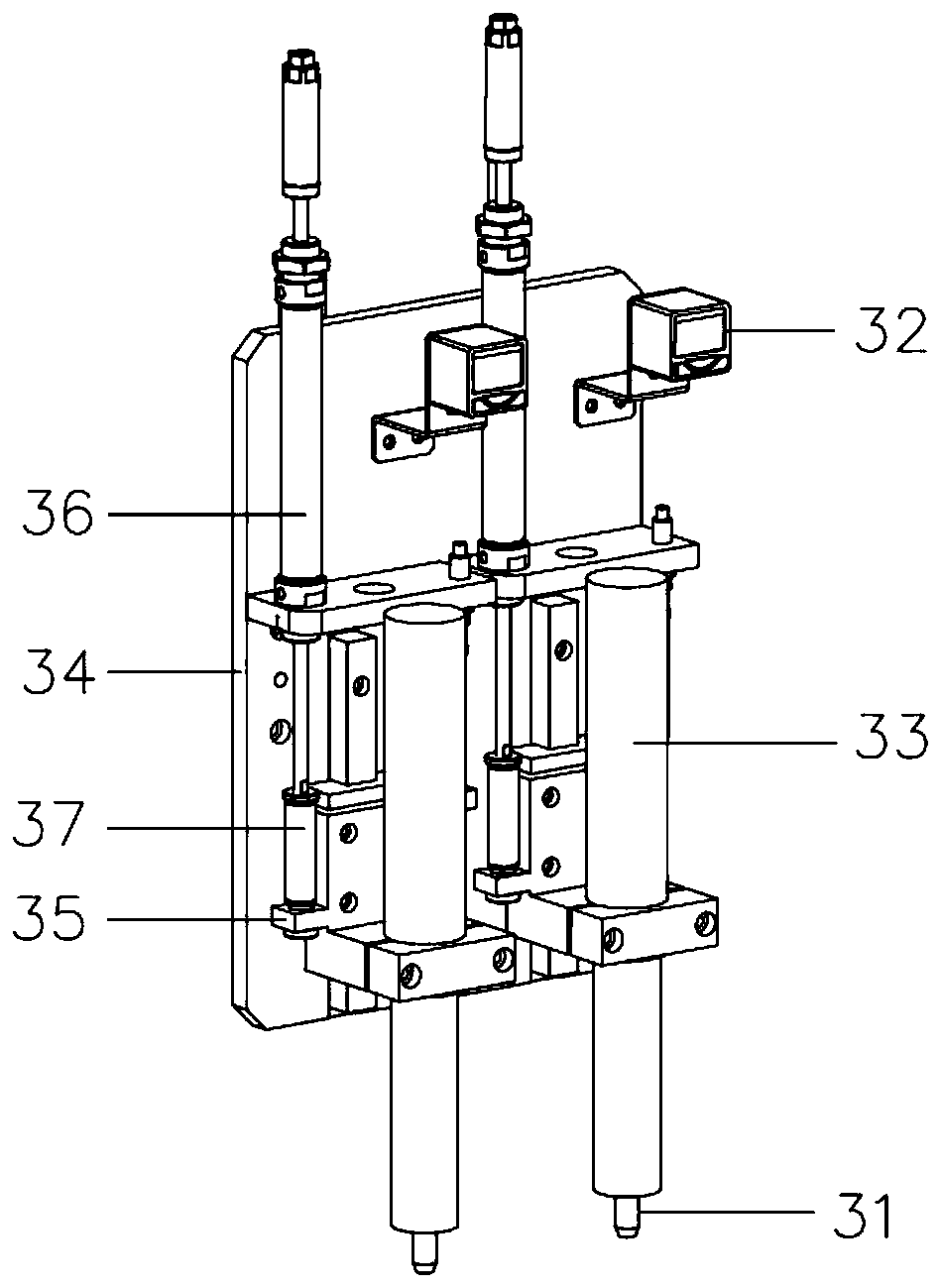

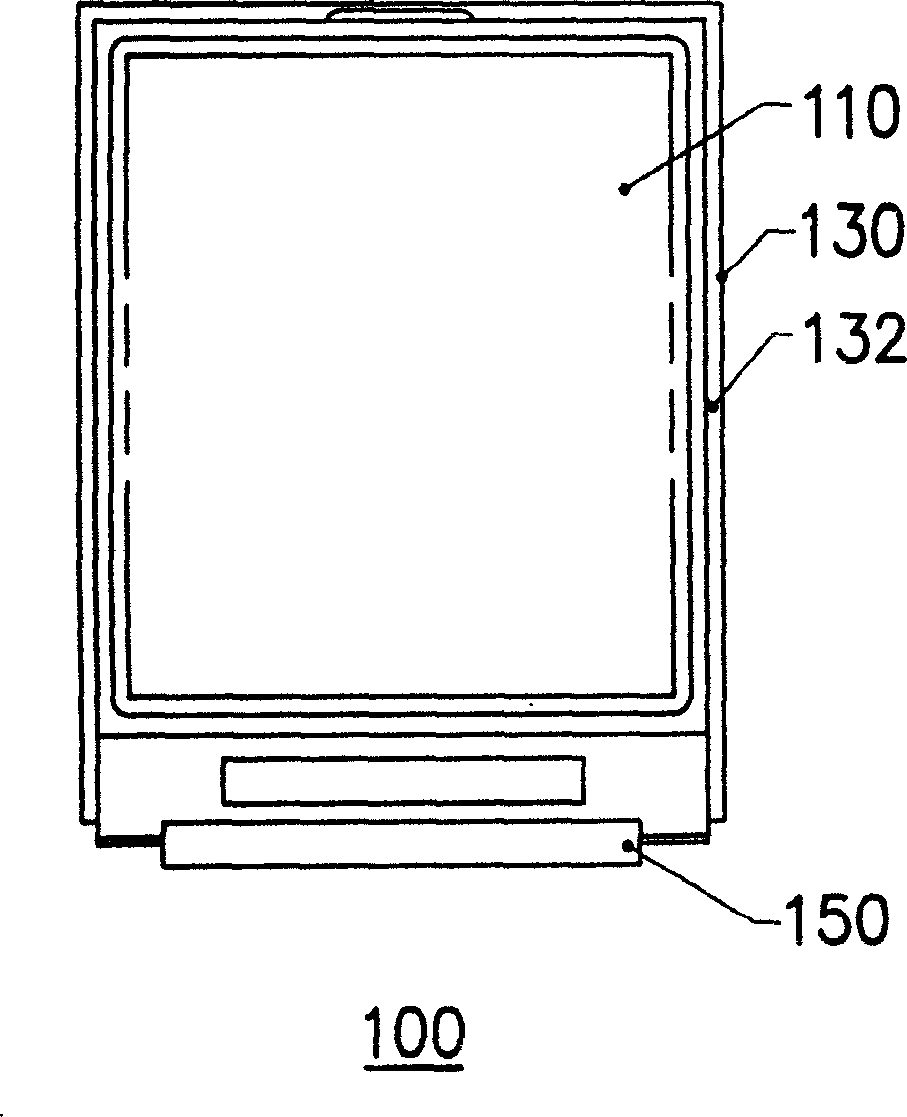

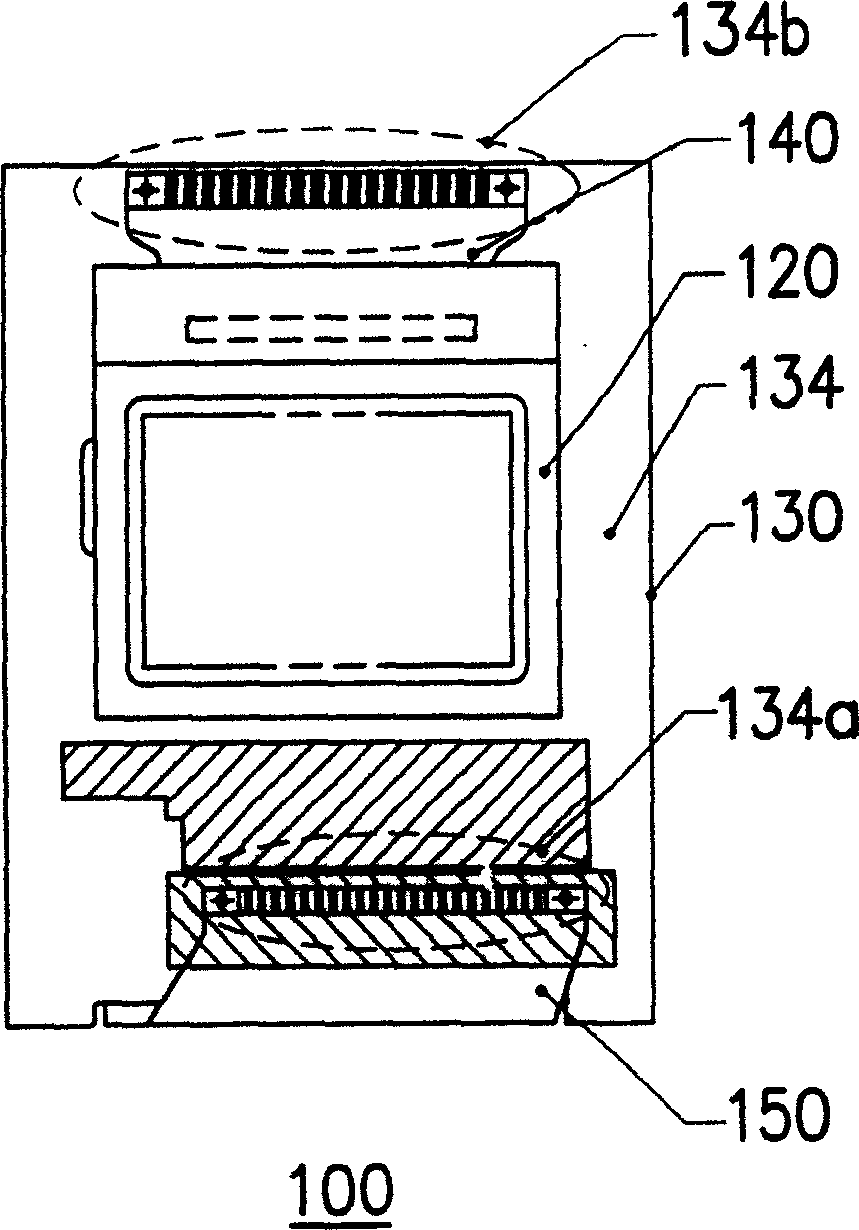

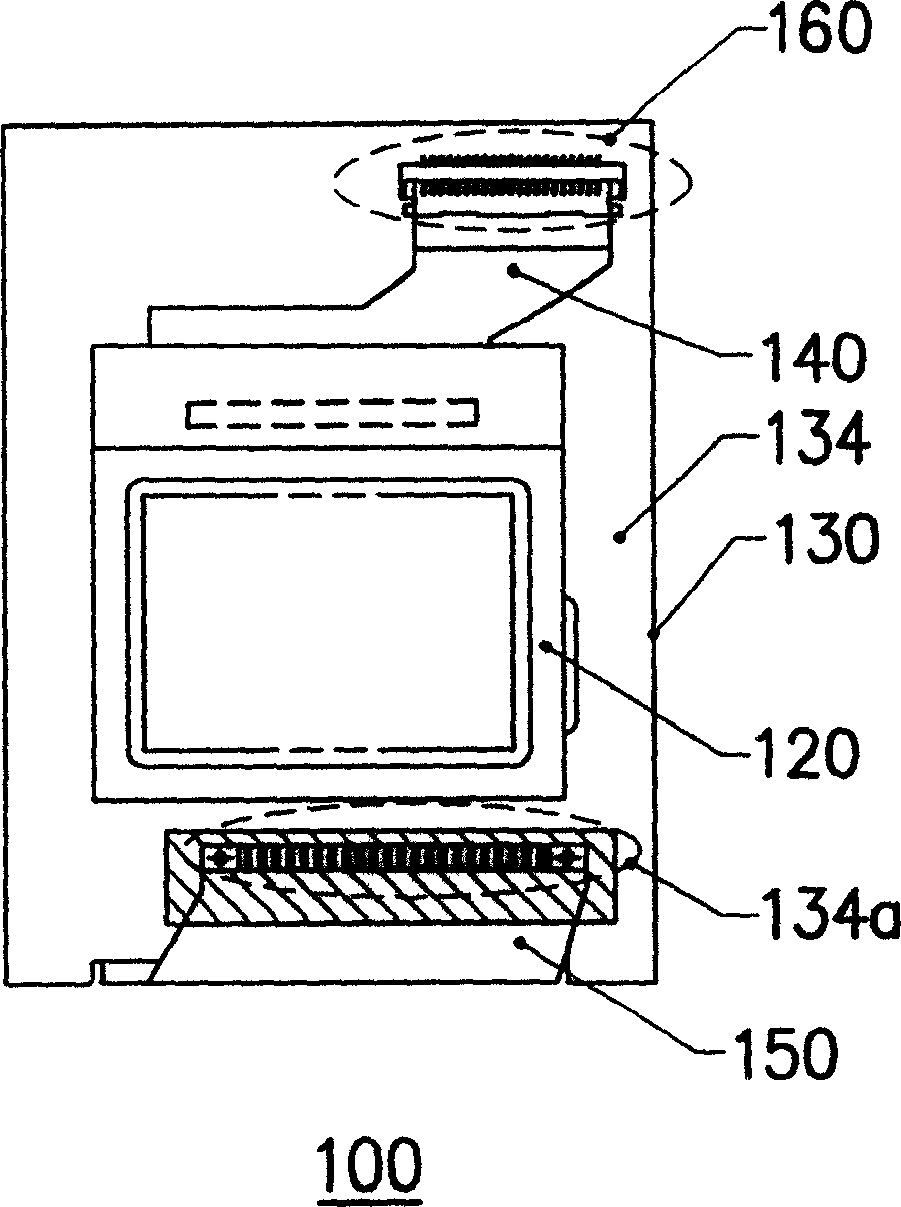

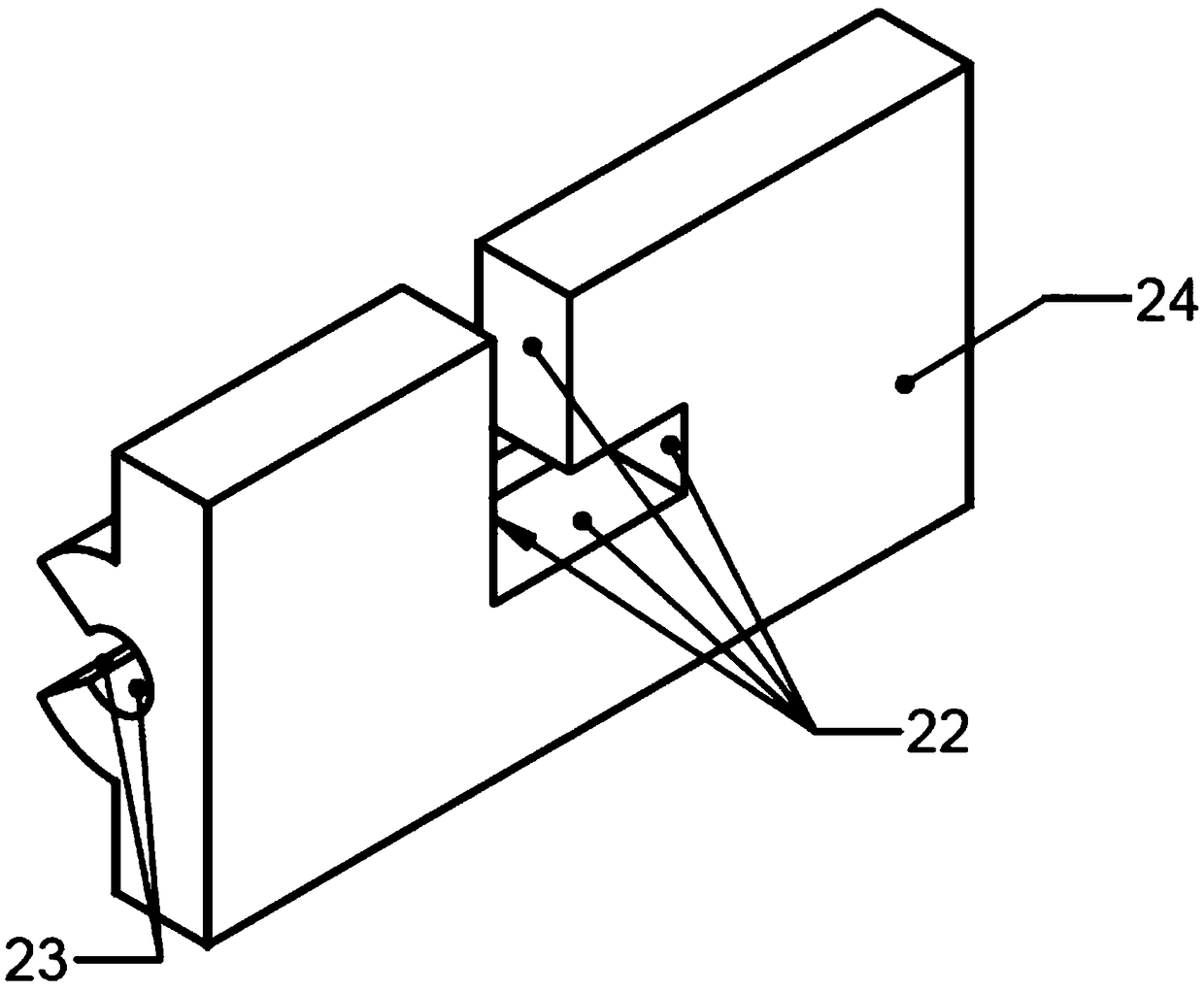

Pressing device capable of aligning lens with lens barrel and pressing method thereof

The invention discloses a pressing device capable of aligning a lens with a lens barrel and a pressing method thereof. A pressing group is assembled on a sliding seat which can be driven to lift, andis provided with a pressure head on which the lens can be placed and from which the lens can be taken; a floating mechanism is arranged between the pressure head and the sliding seat so as to make thepressure head and the sliding seat relatively lift and slide; and a bearer bears the lens barrel with a guiding part and the lens barrel is transferred to a position below the pressing group so as toperform segmented pressing operation on the lens and the lens barrel; and the pressing way is that: the sliding seat and the pressing group are driven to descend first, the pressure head of the pressing group can stop descending by means of the floating mechanism immediately when the lens is contacted with the guiding part of the lens barrel so as to enable the pressure head to slightly press thelens, and at the same time, the pressure head is driven to perform repressing after the guiding part of the lens barrel is aligned with the lens so as to press and position the lens into the lens barrel, so the practicable effects of precise assembly and great improvement on assembly qualification rate can be achieved by utilizing the floating mechanism of the pressure head.

Owner:ART CONTROL SYST LNC

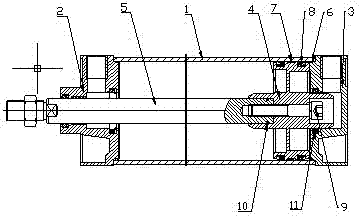

Pilot-operated electromagnetic directional valve

InactiveCN102878326AOvercome the problem of easy to scratch the "O" ring and cause air leakageImproves sealing reliabilityOperating means/releasing devices for valvesMultiple way valvesEngineeringValve stem

The invention discloses a pilot-operated electromagnetic directional valve which comprises electromagnetic pilot-operated valve, a gas circuit control master-valve and a manual regulating rod component. The gas circuit control master-valve comprises a control end cover, a valve body and a return end cover. The manual regulating rod component is disposed on the control end cover and comprises a manual regulating rod, an 'O'-shaped ring, a positioning plate and a positioning screw. An extension of the manual regulating rod, inside the control end cover, is provided with a circular groove, and the 'O'-shaped ring is disposed in the circular groove. Another extension of the manual regulating rod, outside the control end cover, is also provided with a circular groove, and one end of the positioning plate is clamped to the circular groove at the end of the manual regulating rod. One end of the positioning plate, extending out of the circular groove, is provided with a screw hole, and the positioning screw penetrates through the screw hole on the positioning plate to fasten the positioning plate onto the control end cover. A seal combined ring is disposed on a valve stem inside the valve body and is a bidirectional seal combined ring resistant to low temperature. The problem that the existing design is poor in airtightness is solved, sealing reliability is enhanced, and gas leakage is reduced effectively.

Owner:JINAN FUCHI TECH CO LTD

Tubing coupling buckle installation auxiliary device

ActiveCN104723061ANot easy to jumpNot easy to moveWork holdersMetal working apparatusMechanical engineeringExtrusion

The invention relates to a tubing coupling buckle installation auxiliary device. The tubing coupling buckle installation auxiliary device mainly comprises a base, a handle and a push rod. The handle is connected with the push rod through a connection rod. The push rod is located in a limiting sleeve which is connected with the base through a fixing plate. The handle is connected with the fixing plate through a hinge. The push rod is fixedly connected with a movable block. An extrusion block is arranged in the movable block. A buckle containing table and a fixing column are fixed to the left side of the base. The tubing coupling buckle installation auxiliary device has the advantages that positioning is conducted through a fixture, the problem that the pure manual assembly is low in efficiency is solved, and the assembly percent of pass is increased.

Owner:ANHUI ZHONGDING KEUMAH AUTO HOSE & PIPE ASSEMBLY

Shading ceramic and preparation method thereof

The invention discloses a light-shielding ceramic and a preparation method thereof. The light-shielding ceramic is composed of a ceramic layer, at least one high-refractive-index film reflection layer and at least one low-refraction-index film reflection layer. Its preparation method is to mix ceramic powder, binder, dispersant and solvent, form it by ball milling, sintering and polishing to obtain a ceramic layer; plate the corresponding high and low refractive index thin film reflection layers on the surface of the above ceramic layer according to requirements, and then . The light-shielding ceramic of the present invention includes a specific ceramic layer and a thin-film reflective layer. The light leaked by the ceramic layer can be totally reflected by the thin-film reflective layer of the present invention, so that the light-shielding ceramic achieves a complete light-shielding effect, and the thin-film reflective layer does not Conductive, overcomes the interference and weakening of fingerprint signal transmission caused by ink shading. The light-shielding ceramic of the present invention is composed of a specific ceramic layer and a specific film reflection layer, the combination of the two is firm, and the surface hardness is high, which can significantly improve the assembly qualification rate of the fingerprint recognition module.

Owner:CHAOZHOU THREE CIRCLE GRP

Rotary type 360-degree product burr detecting device

ActiveCN108982509ARealize directional deliveryTransport stableOptically investigating flaws/contaminationPulp and paper industryManipulator

The invention discloses a rotary type 360-degree product burr detecting device. The device comprises a worktable, wherein a discharging port at the left side of a vibrating tray is connected with a vibrating guide rail, a splitting part comprises a splitting block, the front end of the splitting block is connected with the end of the vibrating guide rail, the rear end of the splitting block is connected with a splitting cylinder, a stock moving part comprises a manipulator, the lower side of the manipulator is connected with a product moving fixture, the lower end of a rotary fixture is fixedto an output shaft end of a servomotor, a first observation hole, which is downwards concave inwardly, is formed in the center of the surface of the rotary fixture, the two sides of the first observation hole serve as locating tables, second observation holes penetrate through interior of centers of the locating tables and are vertical to the first observation hole, each product comprises a substrate, and two parts to be detected are symmetrically fixed to the lower surface of each substrate. The device has the effects that the splitting block accurately separates the products, two optical cameras detect burrs in a 360-degree dead-corner-free manner, and the efficiency of detection is high.

Owner:DONGGUAN SHENGXIANG PRECISION METAL

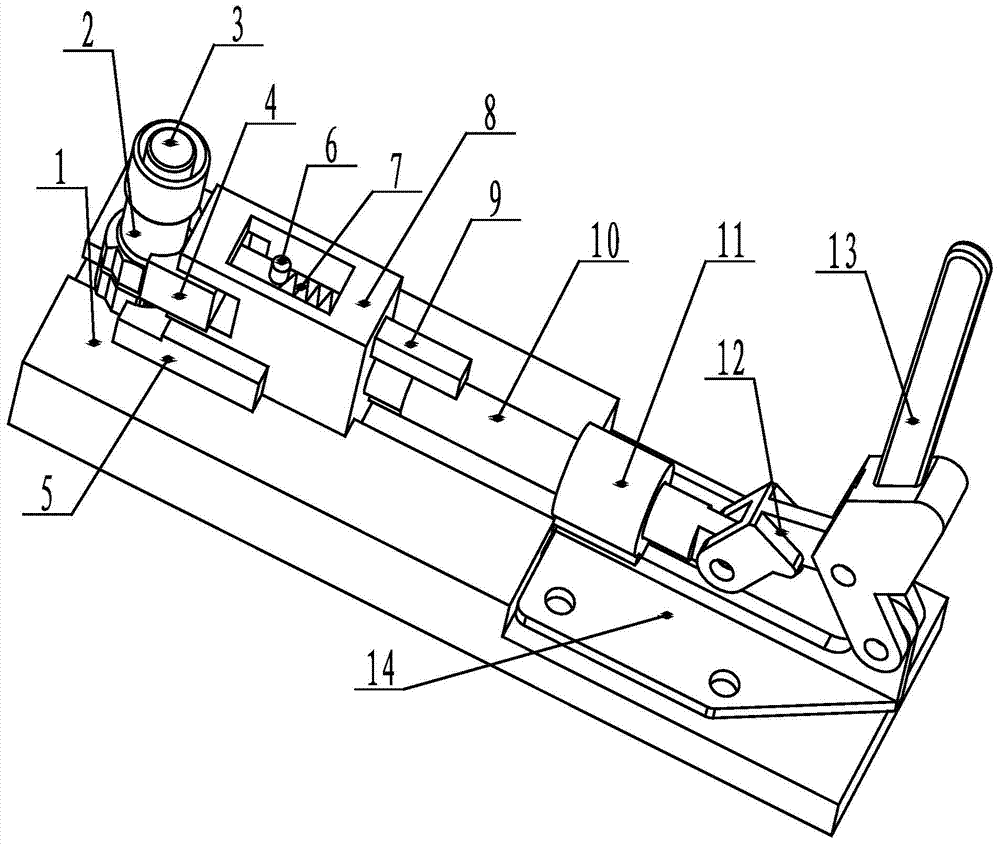

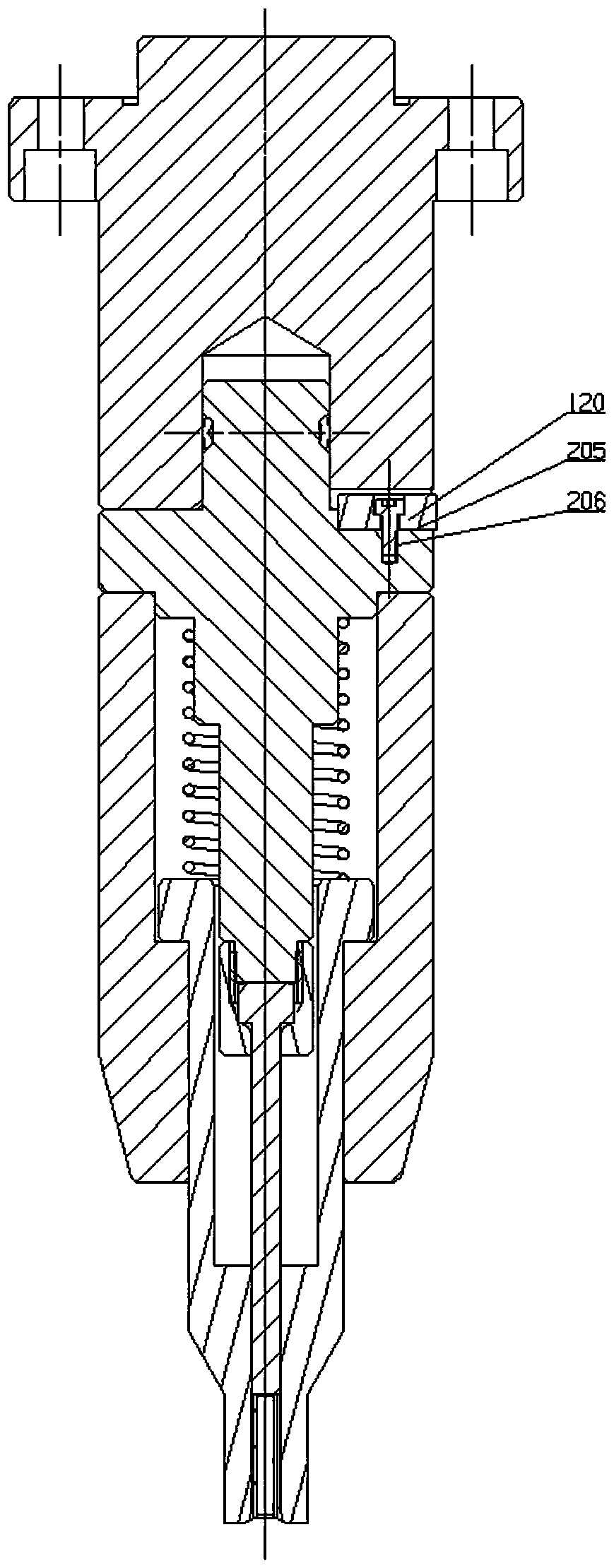

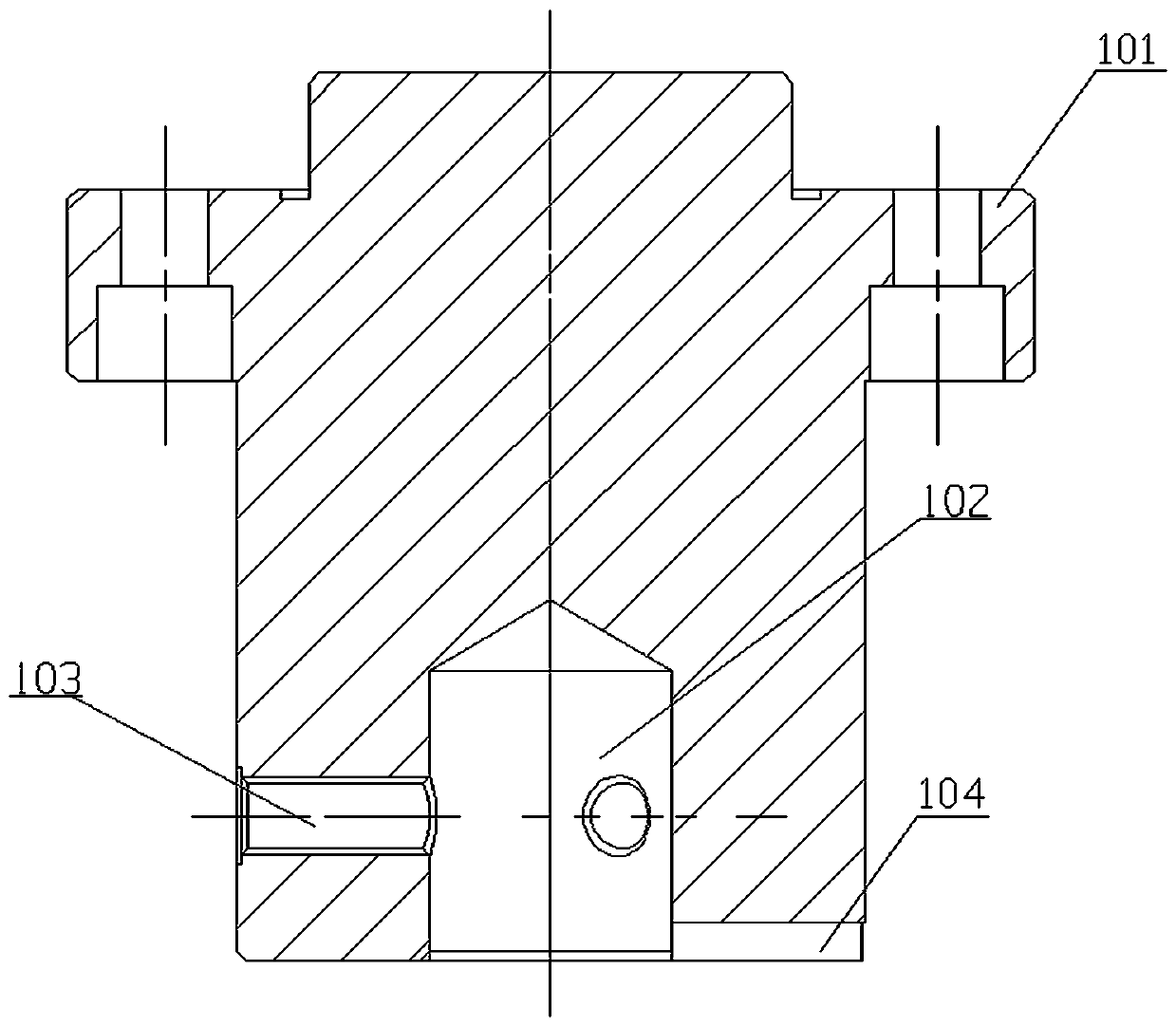

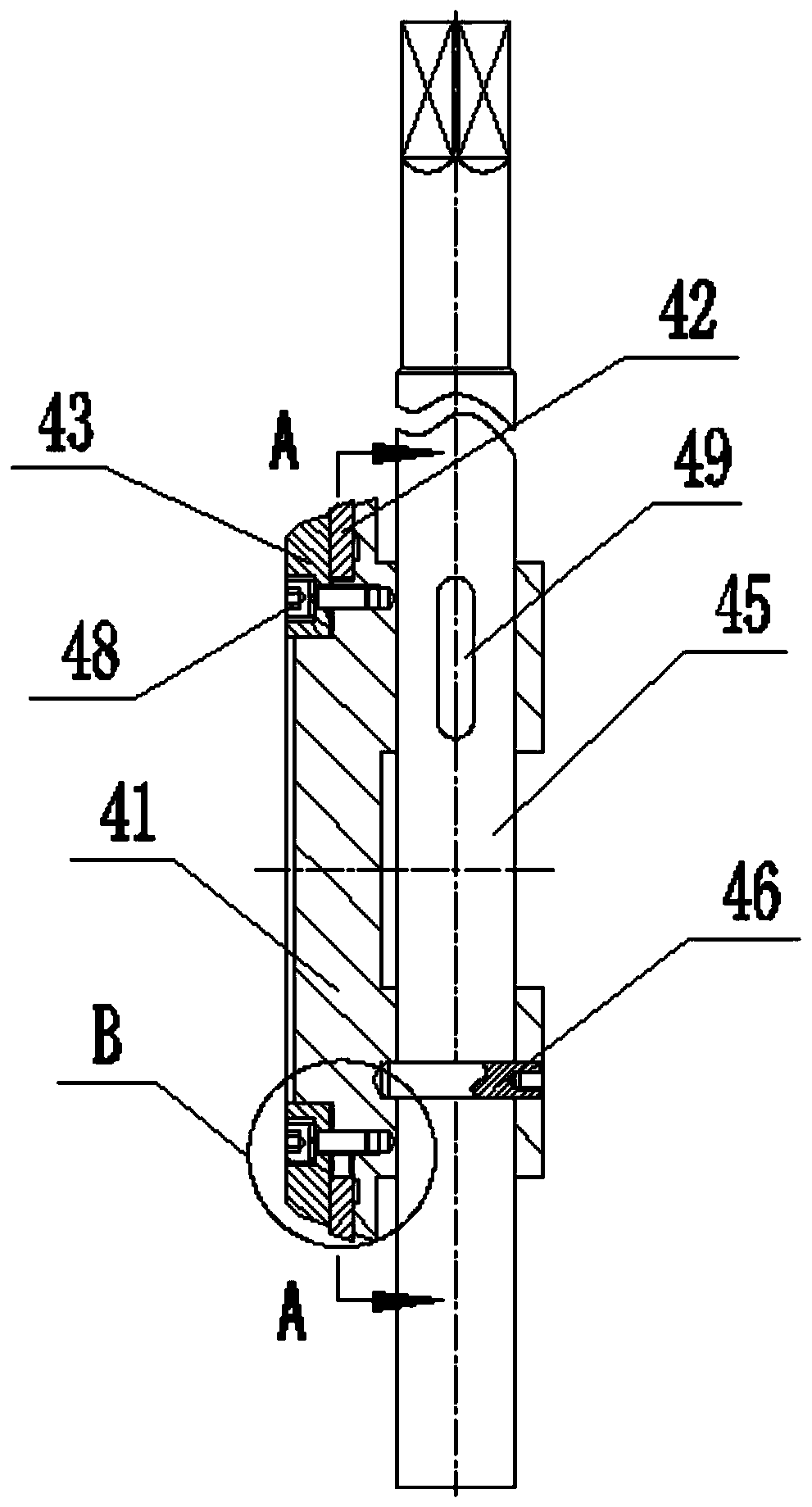

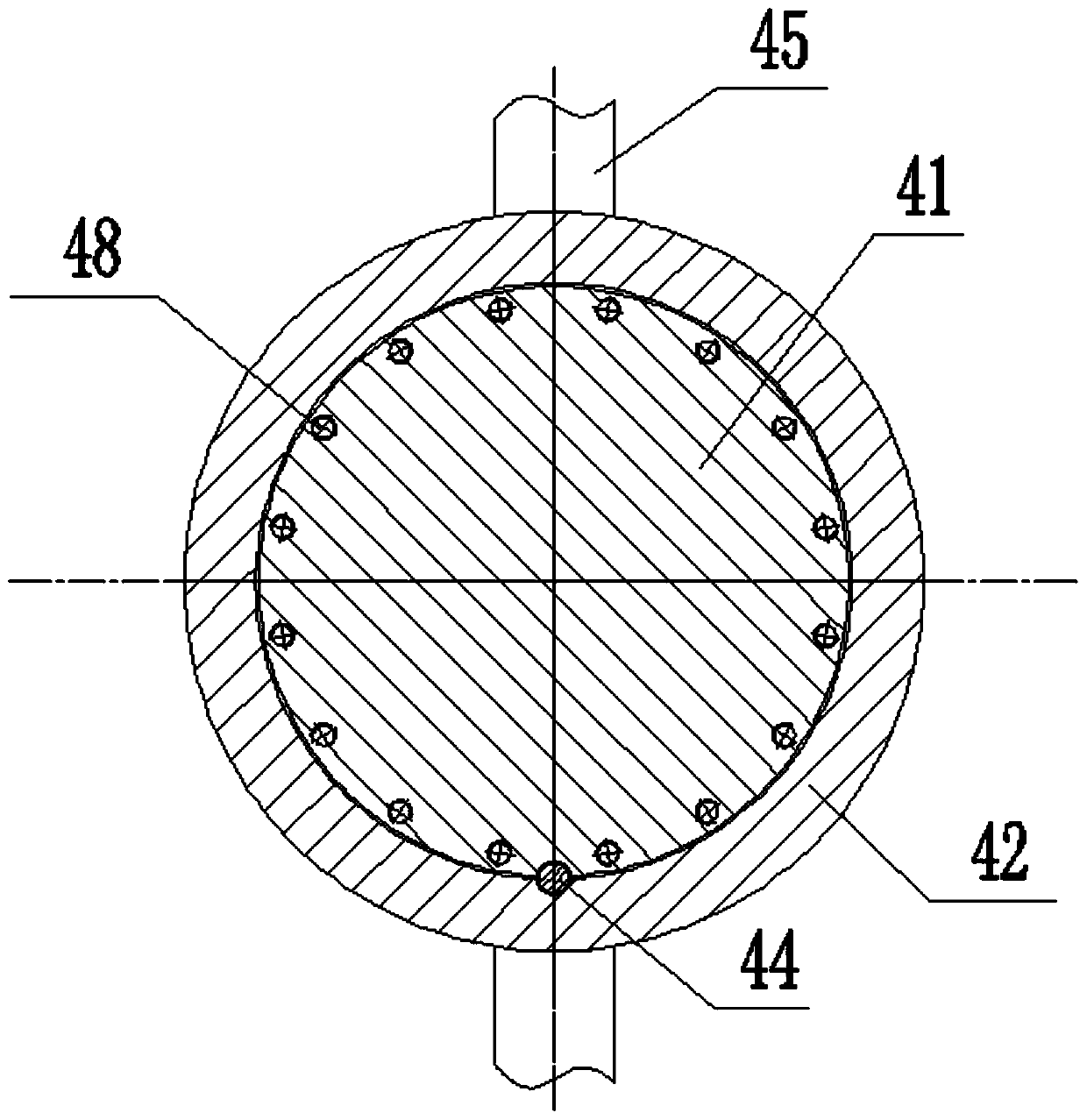

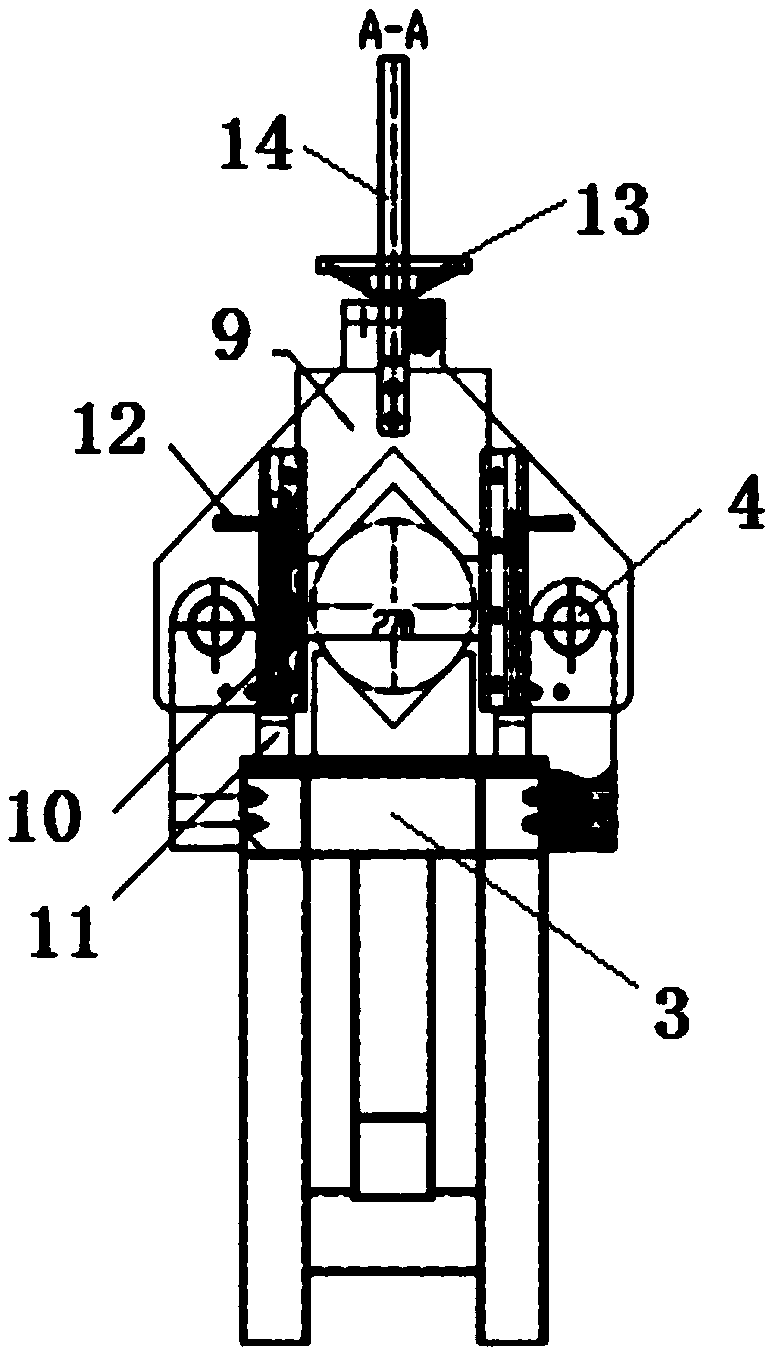

Press fitting tool for assembling elastic cylindrical pin

PendingCN109866004AReduce labor intensityEliminate the risk of injuryMetal working apparatusEngineeringScrew thread

The invention discloses a press fitting tool for assembling an elastic cylindrical pin. A pressing head seat is provided with an assembling blind hole, a threaded through hole is formed in the side wall of the blind hole, a mounting flange is arranged on the side wall of the upper end of the pressing head seat, and a circumferential positioning groove is formed in the lower end surface of the pressing head seat; a pushing head is provided with a connecting part, a mounting flange, a spring limiting step and an extending shaft section from top to bottom in sequence, and the connecting part is in clearance fit with the interior of an assembling hole of the pressing head seat; a guiding outer sleeve is provided with a stepped inner hole, a threaded hole is formed in the upper end surface of the guiding outer sleeve, and the mounting flange is fixedly connected with the guiding outer sleeve; a guiding inner sleeve is provided with a stepped shaft hole, and elastic locking devices are arranged on the side wall of the lower end of the guiding inner sleeve symmetrically; a push rod and a small diameter section of the stepped shaft hole of the guiding inner sleeve are slidably matched, a positioning flange is arranged at the upper end of the push rod, and the positioning flange is arranged in a nut sleeve in a sleeved mode and matched with an external thread of the extension shaft section of a push head through the nut sleeve to form connection and fixing between the push rod and the push head; and a first compression spring is arranged on the extension shaft section in a sleevingmode, the upper end of the first compression spring is limited by the spring limiting step, and the lower end of the first compression spring is limited by a limiting flange.

Owner:CHONGQING TSINGSHAN IND

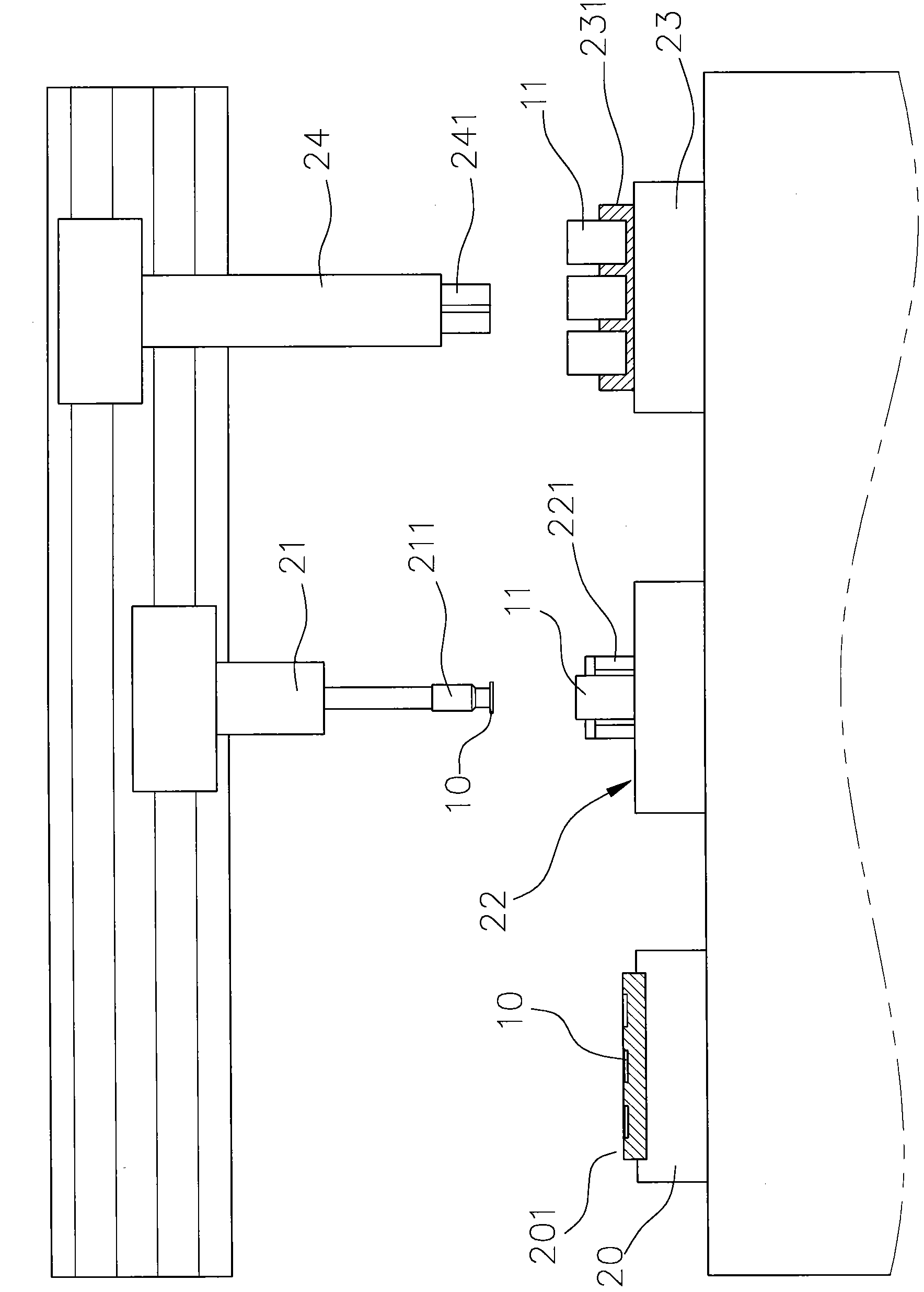

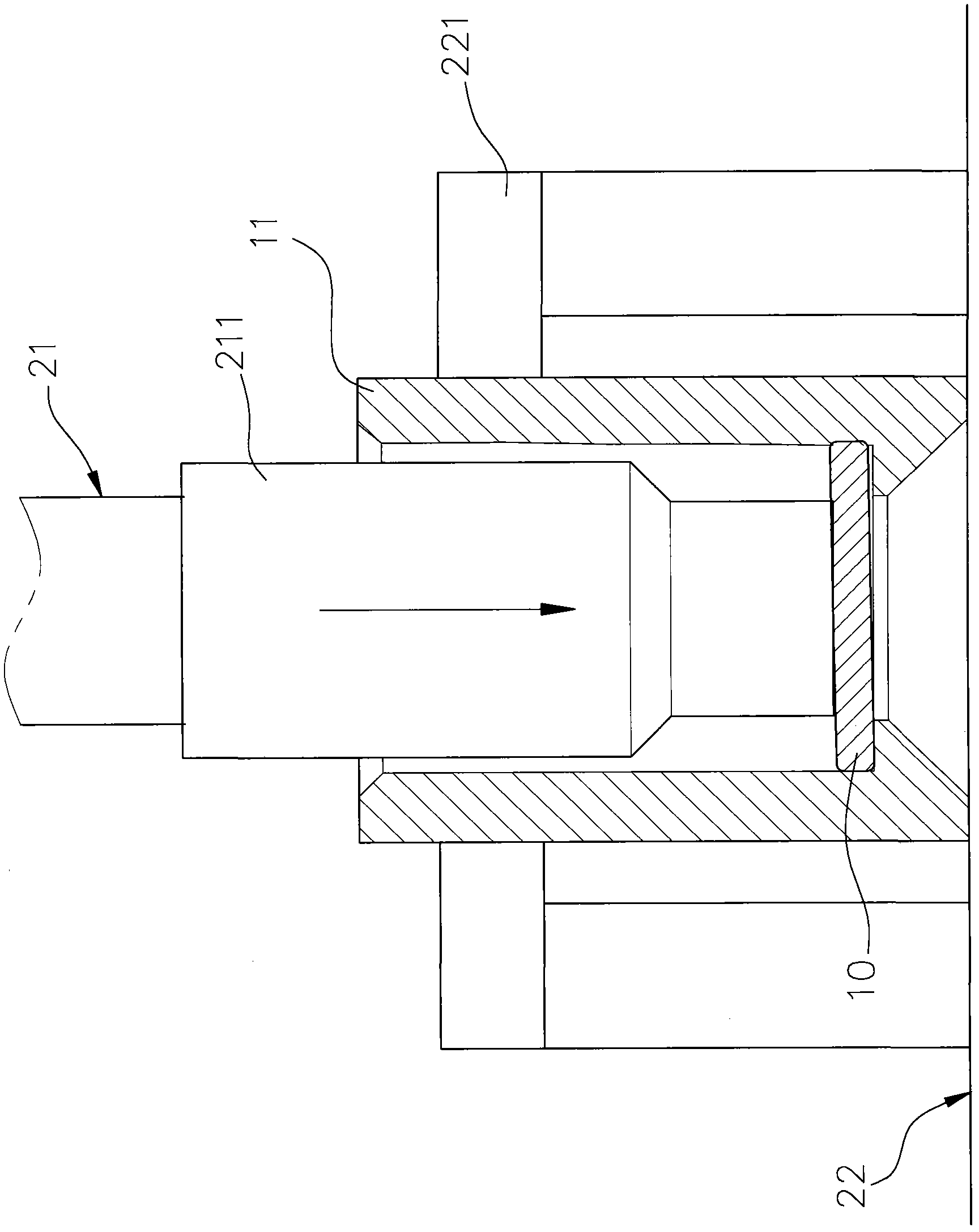

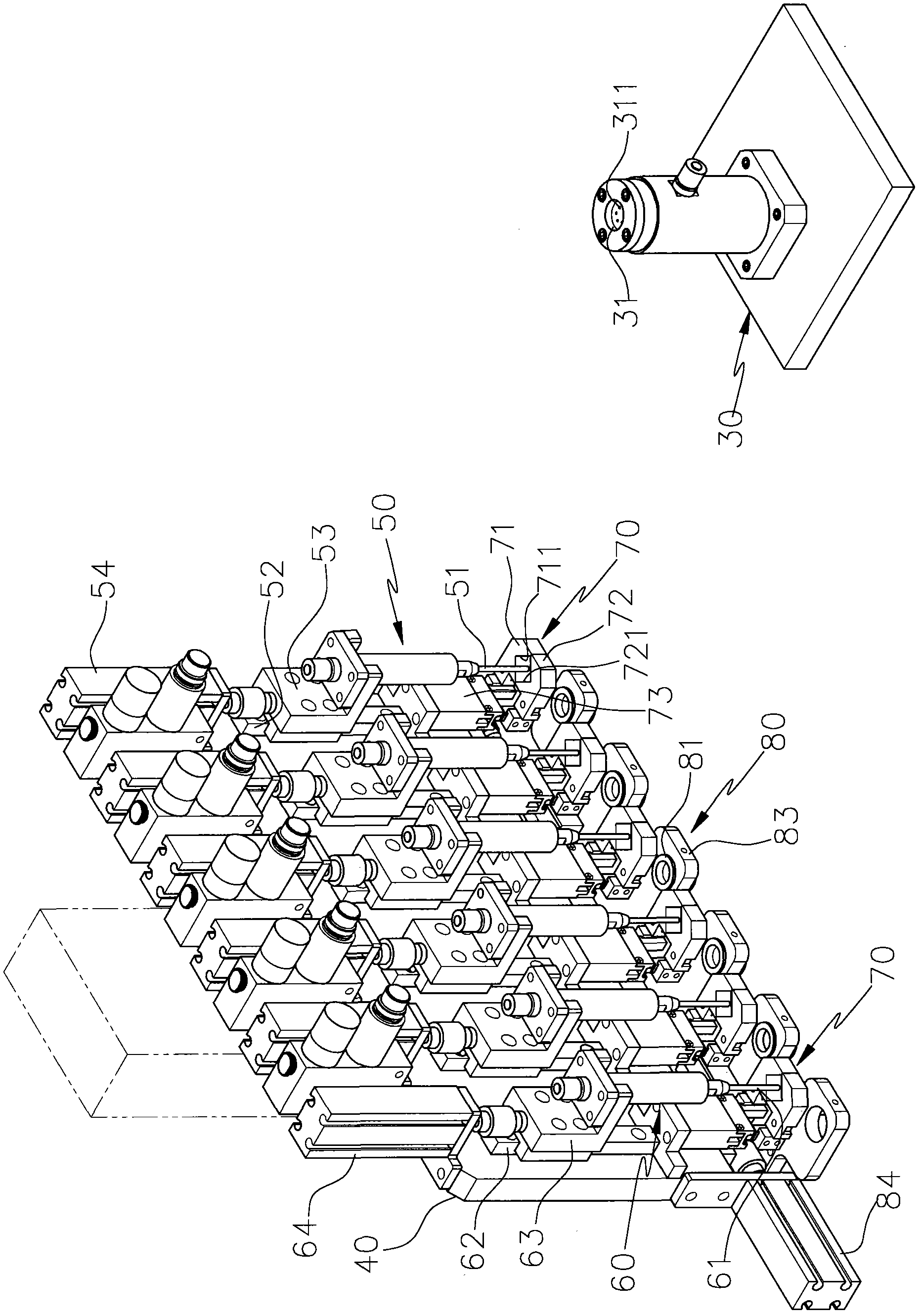

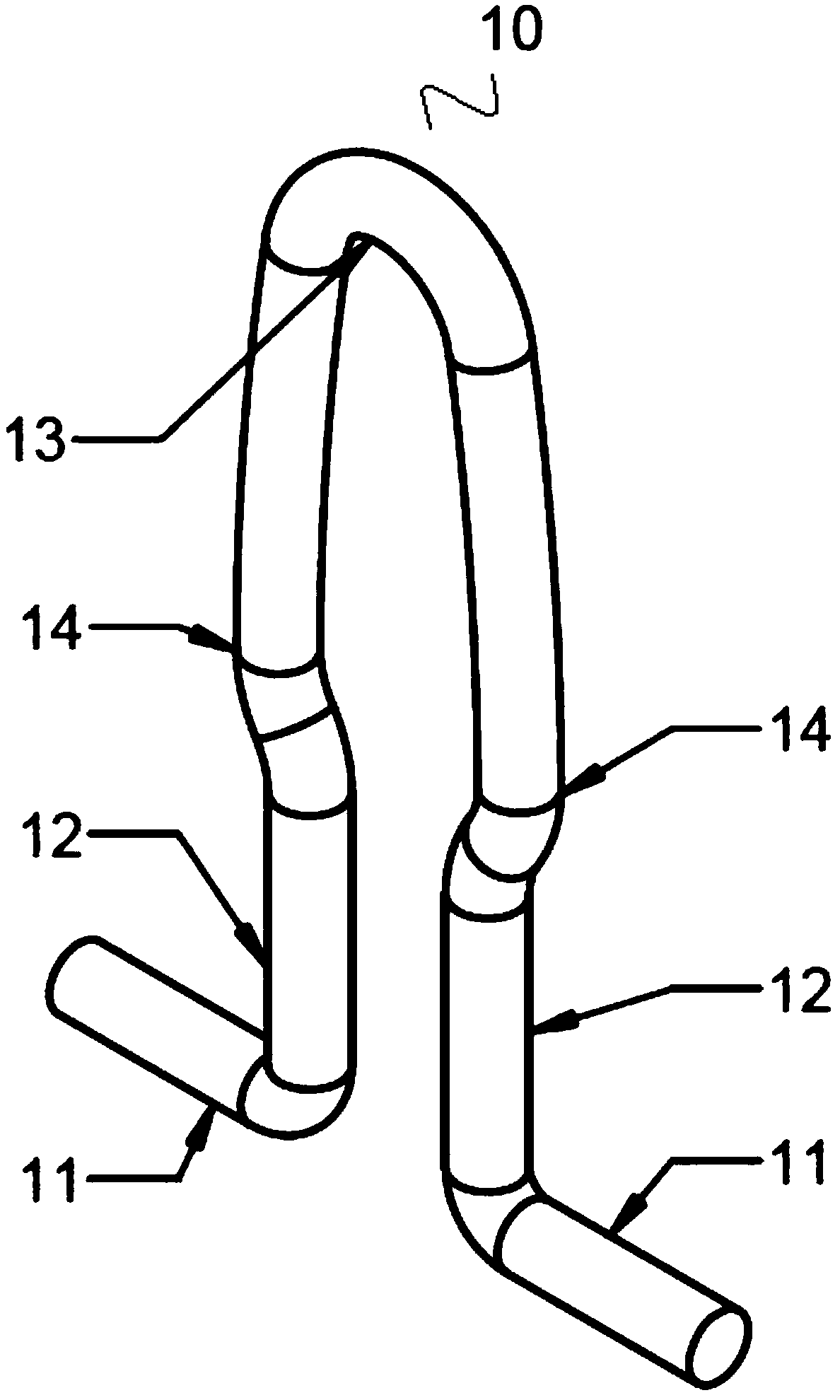

Automatic inserting equipment for U-shaped tubes

PendingCN108687502AReduce the possibilityImprove assembly pass rateMetal working apparatusEngineeringAutomatic test equipment

Automatic inserting equipment for U-shaped tubes comprises a vibrating plate, a first vibrating transfer plate, a detection component, a third vibrating transfer plate, a distribution component and agrabbing component. The automatic inserting equipment replaces manual inserting, so that the labor intensity is reduced, and the inserting efficiency of the U-shaped tubes is improved; the detection component greatly improves the accuracy of a detection result, reduces the detection error rate, and guarantees the effectiveness in follow-up distribution and insertion of the U-shaped tubes; the distribution component allows the plurality of U-shaped tubes to be arranged and distributed on a first turntable in a circumferential direction; the plurality of U-shaped tube adsorption components and alocating detection camera on a sucker of the grabbing component realize grabbing of the plurality of U-shaped tubes at a time on the basis of simultaneously performing detection and locating, so thatthe grabbing efficiency, namely the inserting efficiency, is greatly improved; and a detection role pf the locating detection camera is performed during secondary detection before insertion of the U-shaped tubes, so that the inserting effectiveness is further improved, a locating role guarantees the accuracy of inserting positions of the U-shaped tubes, and the inserting quality of the U-shaped tubes is greatly improved.

Owner:华普电子(常熟)有限公司

Butterfly valve and online fast changing type assembling method for valve plate of butterfly valve

ActiveCN109826965AQuick assemblyEasy to assembleLift valveMetal working apparatusEngineeringButterfly valve

The invention relates to the technical field of valves, in particular to a butterfly valve and an online fast changing type assembling method for a valve plate of the butterfly valve. The butterfly valve comprises a valve body and a valve plate assembly. A medium inlet and a medium outlet are formed in the opposite two sides of the valve body correspondingly. The top of the valve body is providedwith an overhaul window, and a lower end cover is arranged at the bottom of the valve body. The valve plate assembly is installed in the valve body through the overflow window, and the lower end of the valve plate assembly ejects the lower end cover. The upper end cover is connected with the upper end of the valve plate assembly and presses the valve plate assembly so that vertical moving of the valve plate assembly in the valve body can be limited. The assembling method includes the following steps that all parts of the to-be-assembled valve are prepared, and the parts are cleaned; the new valve plate assembly is assembled; the old valve plate assembly is demounted; and the new valve plate assembly is installed in the valve body from the top of the valve body. The butterfly valve and theonline fast changing type assembling method for the valve plate of the butterfly valve have the beneficial effects that modular fast assembling of the valve plate assembly is facilitated, and the assembling quality and efficiency are improved.

Owner:CHONGQING CHUANYI CONTROL VALVE

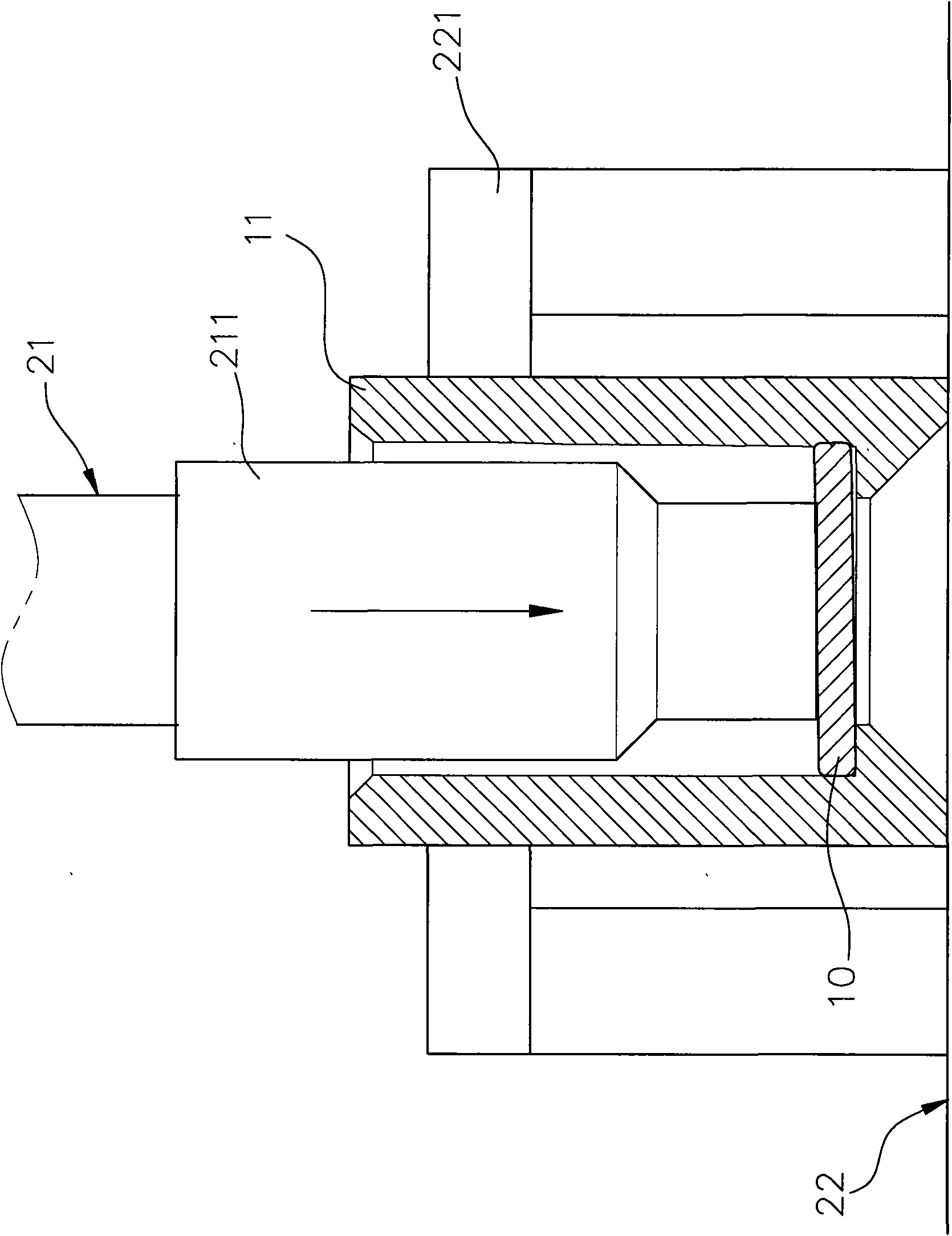

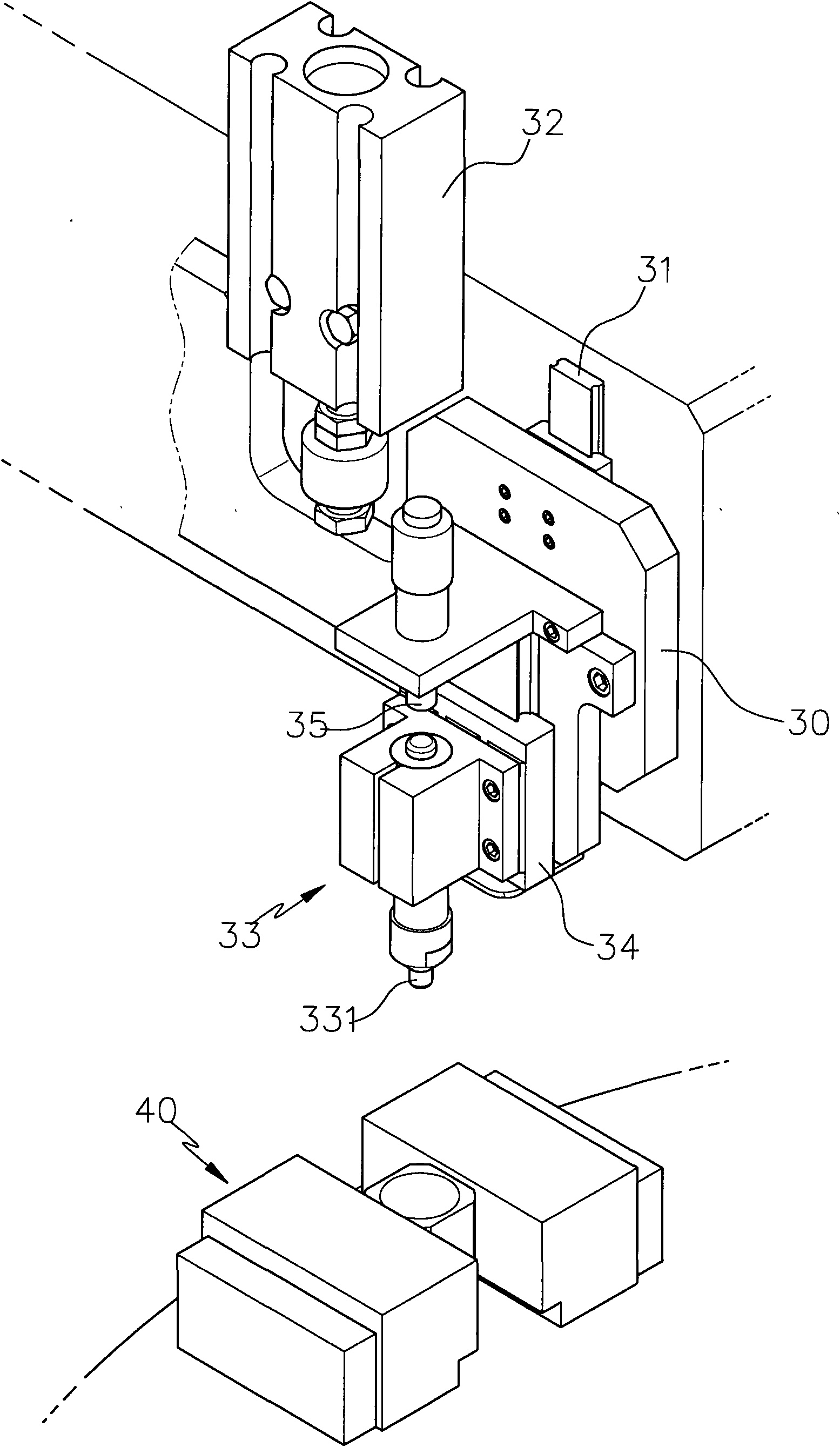

Pressing mechanism capable of accurately assembling lens

The invention relates to a pressing mechanism capable of accurately assembling lens. A lens barrel is supported on an assembly table seat for pressing and assembling operation of the lens; a lens picking and placing device is mounted on a plate seat capable of being driven to move in three axial directions, and the lens can be moved onto the assembly table seat; the lens picking and placing device is connected with a lifting structure for driving lifting action of pressing the lens; the plate seat is also installed with a clamp set capable of clamping the centers of a calibrating lens and the lens barrel, and a pressing jig with a guide part; the pressing jig is connected with a displacement structure for driving the pressing jig to move to the position between the lens barrel and the lens; in pressing operation, the lens barrel and the lens are calibrated by the guide part of the pressing jig to ensure accurate calibration thereof; and, in this way, the centers of the lens barrel and the lens are corrected by calibration through the clamp set and the pressing jig, and the lens are pressed in the lens barrel after accurate calibration of the lens barrel and the lens, thereby fulfilling the aim of accurately assembling and greatly improving assembling efficiency.

Owner:SYNERGY AUTOMATION CORP

Mechanical arm mounting device used for gear frame

PendingCN110303470AImprove assembly pass rateGuaranteed installation accuracyGripping headsInductorEngineering

The invention relates to the technical field of car accessory producing and machining, in particular to a mechanical arm mounting device used for a gear frame. The device comprises a cross beam, a first sliding rail, a first mechanical arm assembly used for picking exterior screws and mounting the screws on the gear frame, a second sliding rail and a second mechanical arm assembly used for pickingexterior buckles and mounting the exterior buckles on the gear frame, the first mechanical arm assembly is in sliding connection to the first sliding rail, the second mechanical arm assembly is in sliding connection to the second sliding rail, the first mechanical arm assembly comprises an electric screwdriver, a pressure gage and a vacuum generator, the pressure gage, the vacuum generator and the electric screwdriver are in communication, the second mechanical arm assembly comprises a clamping jaw air cylinder, a clamping jaw and an inductor, the inductor is used for inducing whether the clamping jaw clamps the clamping buckles or not, the first mechanical arm assembly and the second mechanical arm assembly are arranged on the cross beam, two procedures of screw locking and buckle arranging can be finished on the same station, the mounting precision is ensured, and through the pressure gage and the inductor, production quality and the workpiece assembling yield can be improved.

Owner:DONGGUAN HIROSAWA AUTOMOTIVE TRIM

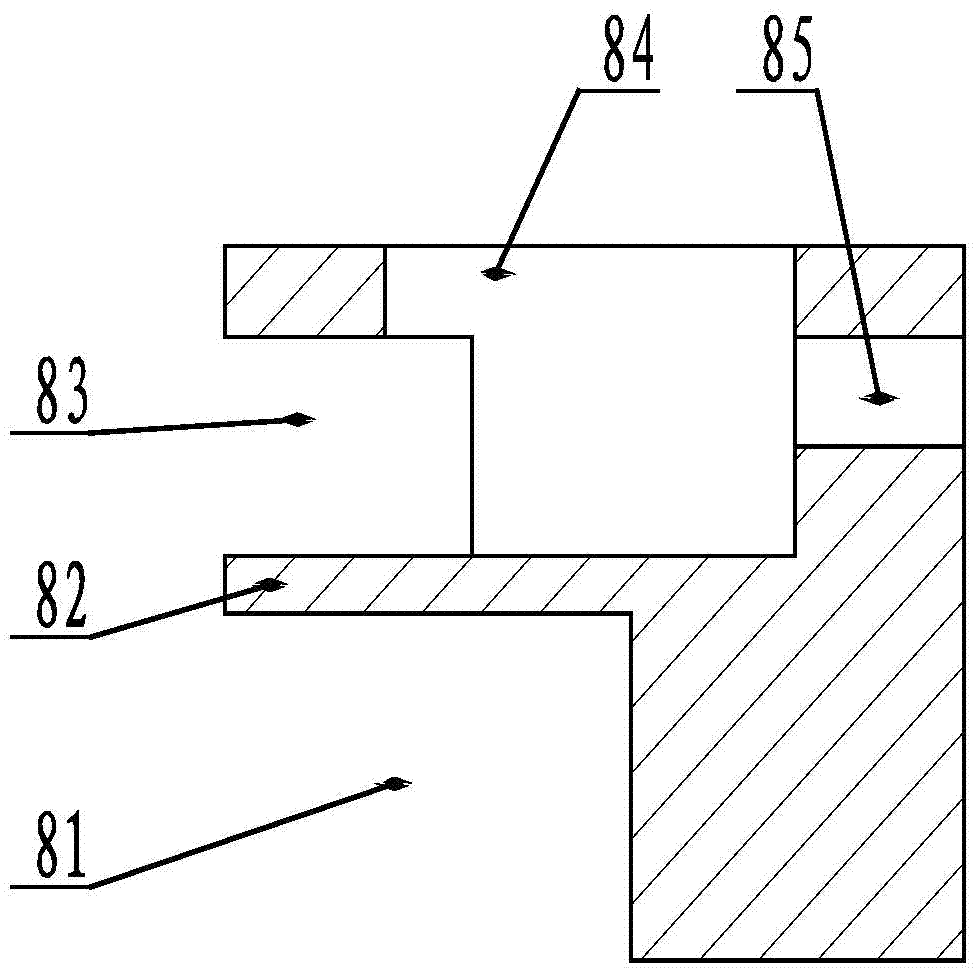

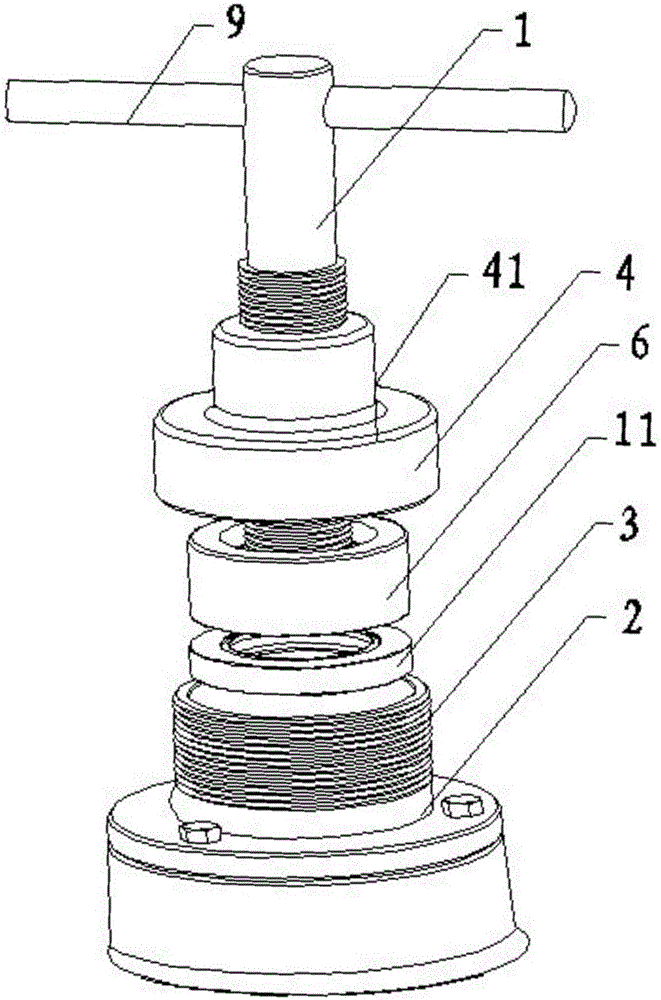

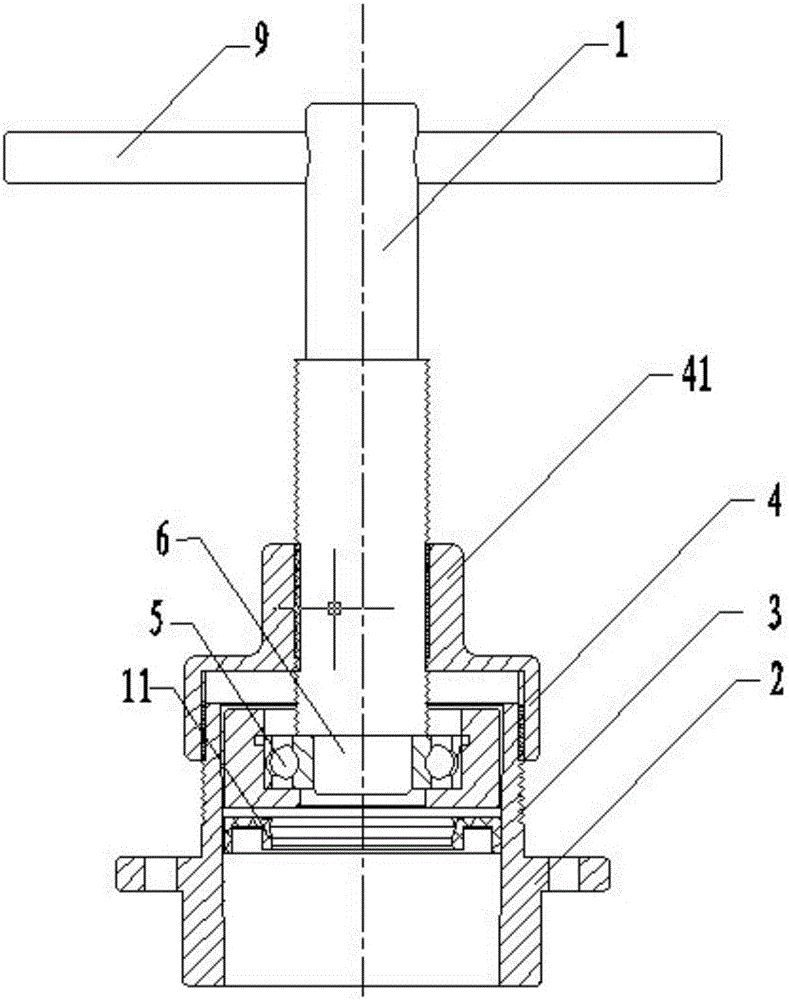

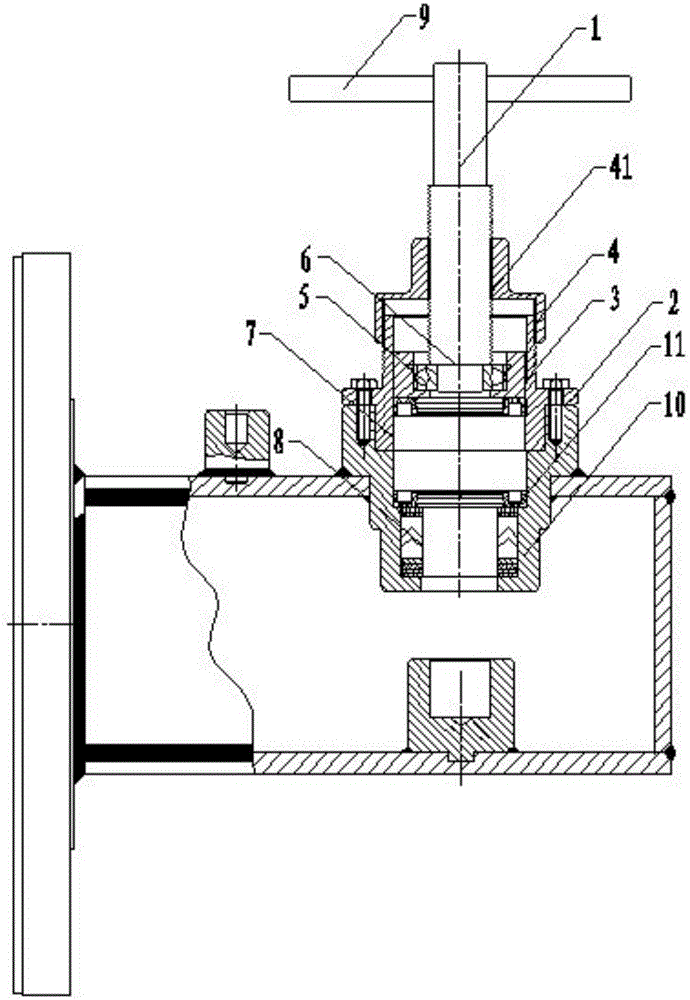

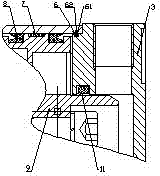

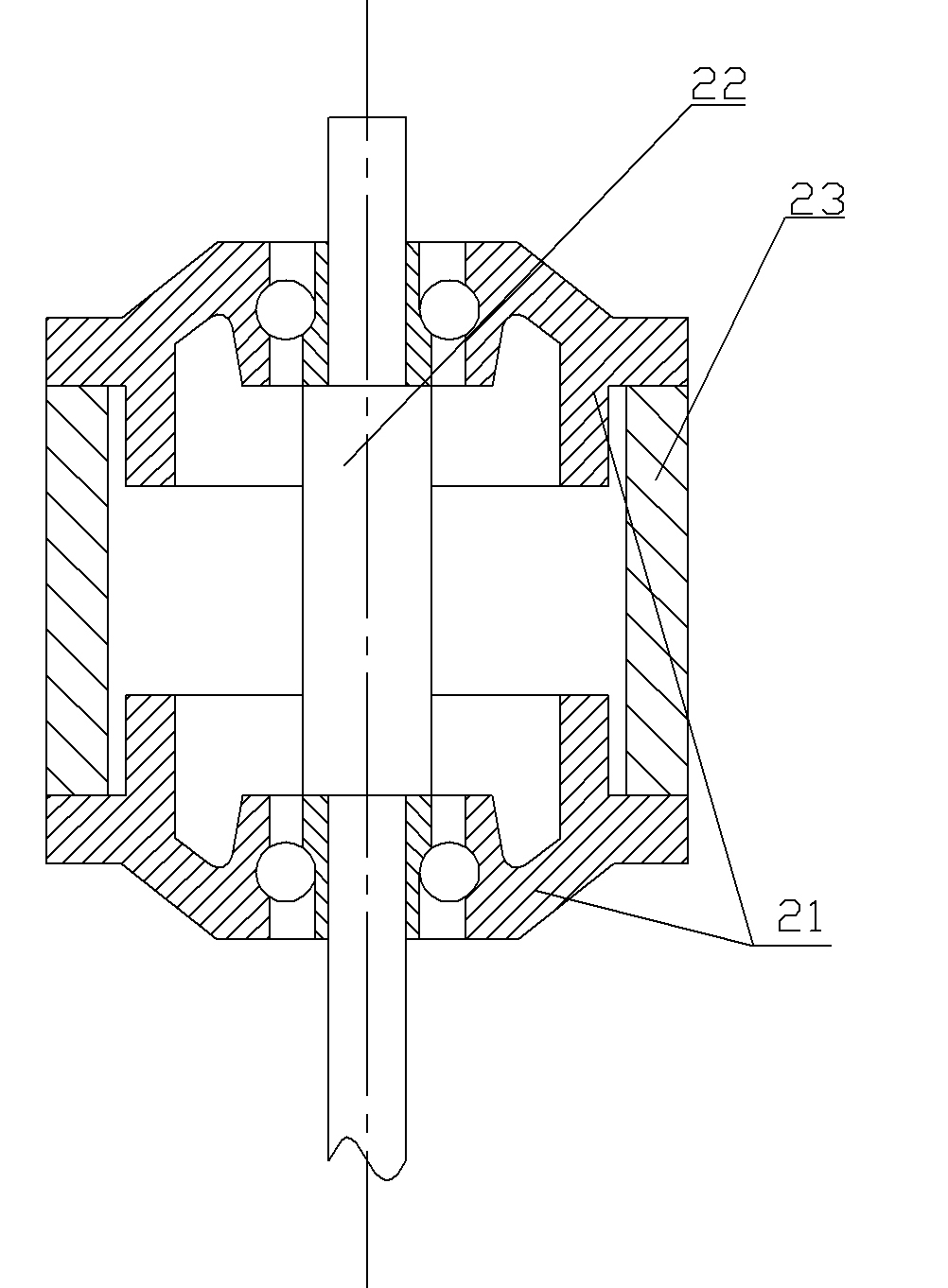

Crank arm box seal ring assembly clamp

The invention relates to a crank arm box seal ring assembly clamp which comprises a screw rod and a flange plate; the flange plate is arranged in the middle of a connecting sleeve; an external thread is arranged on the outer surface of the upper part of the connecting sleeve; a tapered through hole is formed in the connecting sleeve; the diameter of the tapered through hole is larger in upper part and smaller in lower part; a thread bushing is connected with the external thread at the upper part of the connecting sleeve; a screw rod connecting sleeve is arranged at the upper end of the thread bushing; an inner thread through hole in threaded connection with the screw rod is formed in the screw rod connecting sleeve; the screw rod is in threaded connection to the interior of the screw rod connecting sleeve; the lower end of the screw rod passes through the thread bushing; the lower end of the screw rod is connected with a pressing plate capable of passing through the least diameter end of the tapered through hole through a bearing. The invention aims to provide the crank arm box seal ring assembly clamp which has a simple structure, is convenient to assemble, can prevent abrasion or deflection of a framework seal ring in the assembly process, and ensures the assembly accuracy of the framework seal ring; besides, the assembly qualified rate is improved effectively, and the dynamic seal requirement is met.

Owner:STATE GRID CORP OF CHINA +1

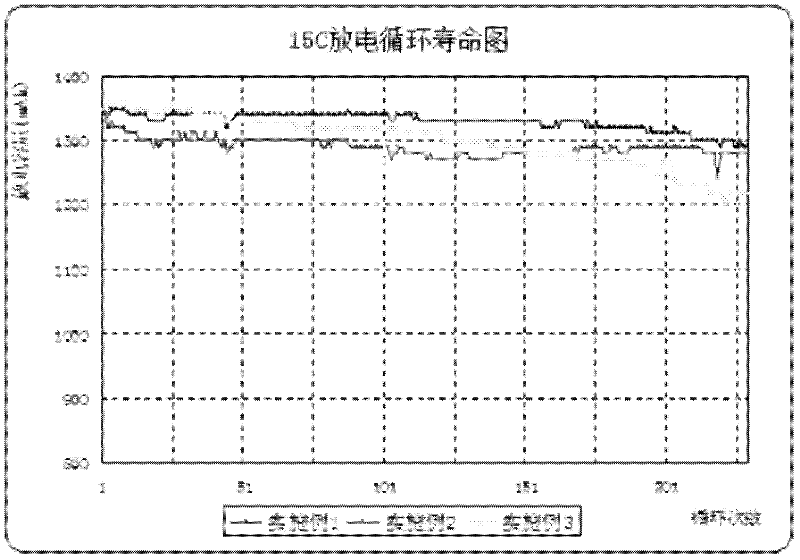

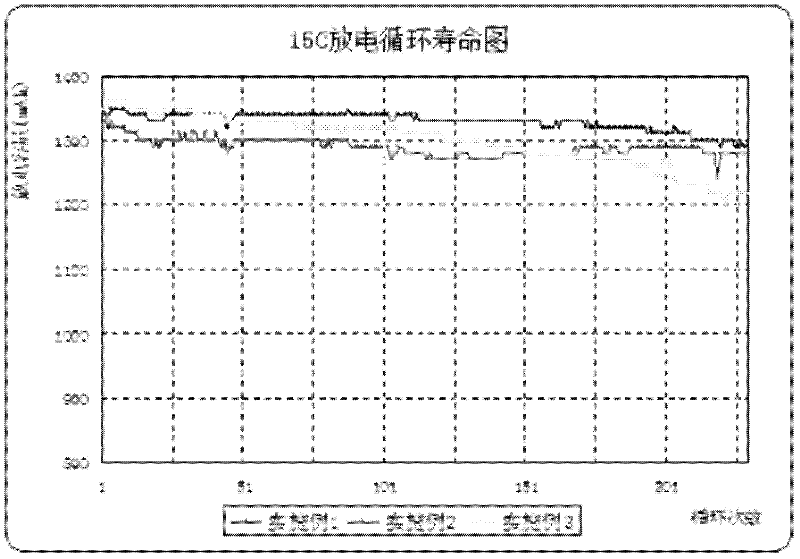

A kind of manufacturing method of high-rate type lithium-ion battery negative pole piece

The present invention discloses a manufacturing method of a high-rate type lithium-ion battery negative electrode sheet, comprising the following steps: taking artificial graphite, carbon black, carboxymethyl cellulose, and styrene-butadiene rubber emulsion, drying and cooling under vacuum conditions, and Carboxymethyl cellulose is poured into deionized water and stirred to dissolve, and then carbon black, artificial graphite and styrene-butadiene rubber emulsion are poured into the dissolved solution to make a slurry; the slurry is coated on the surface of aluminum foil, and the deionized Dry the ionized water after volatilization; add polyvinylpyrrolidone to anhydrous ethanol and stir and dissolve to make a solution; coat the solution on the pole piece coated with slurry, bake and cool the pole piece under vacuum condition, and roll the pole piece Pressed into a negative electrode sheet. The pole piece prepared by the method of the invention has the characteristics of less floating powder, smooth and burr-free surface of the pole piece, good high-rate discharge performance and high reliability, and the operation method is simple and easy, and the qualified rate of battery assembly is high. Lithium-ion batteries are suitable for power tools and electric bicycles.

Owner:无锡市明杨新能源股份有限公司

Air cylinder with end cover sealing structure

InactiveCN103498833ASolve the problem of tightening force to ensure sealing effectImproves sealing reliabilityEngine sealsPiston ringsEngineeringCylinder block

The invention discloses an air cylinder with an end cover sealing structure. The air cylinder with the end cover sealing structure comprises a cylinder body, a front end cover, a rear end cover, a piston and a piston rod. The front end cover and the rear end cover are connected with the cylinder body through a pull rod. The piston and the piston rod are both arranged inside the cylinder body. One end of the piston rod is connected to the piston, and the other end of the piston rod stretches out of the front end cover. The convex portion where the front end cover and the cylinder body are combined and the convex portion where the rear end cover and the cylinder body are combined are respectively provided with a sealing groove, sealing rings are arranged in the sealing grooves, and the sealing rings which are arranged in the sealing grooves are O-shaped sealing rings. The sealing rings are in close fit with the sealing grooves and the inner wall of the cylinder body to form a cylinder body sealing structure. The air cylinder with the end cover sealing structure effectively solves the problem that an existing air cylinder depends on screwing force of the pull rod to guarantee the sealing effect, and has the advantages of being strong in sealing reliability, easy to assemble, high in percent of pass, low in repair rate and the like.

Owner:JINAN FUCHI TECH CO LTD

Double screen display module

ActiveCN1591558ALow costHigh speedCathode-ray tube indicatorsRadio/inductive link selection arrangementsComputer moduleComputer science

Owner:AU OPTRONICS CORP

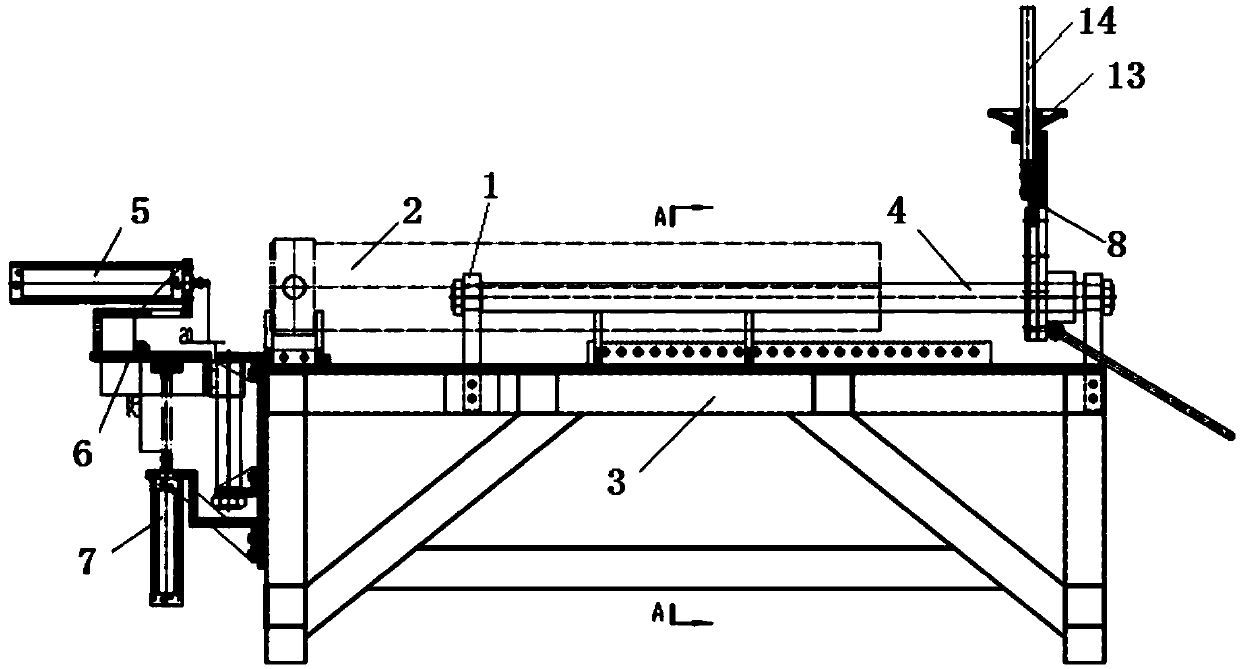

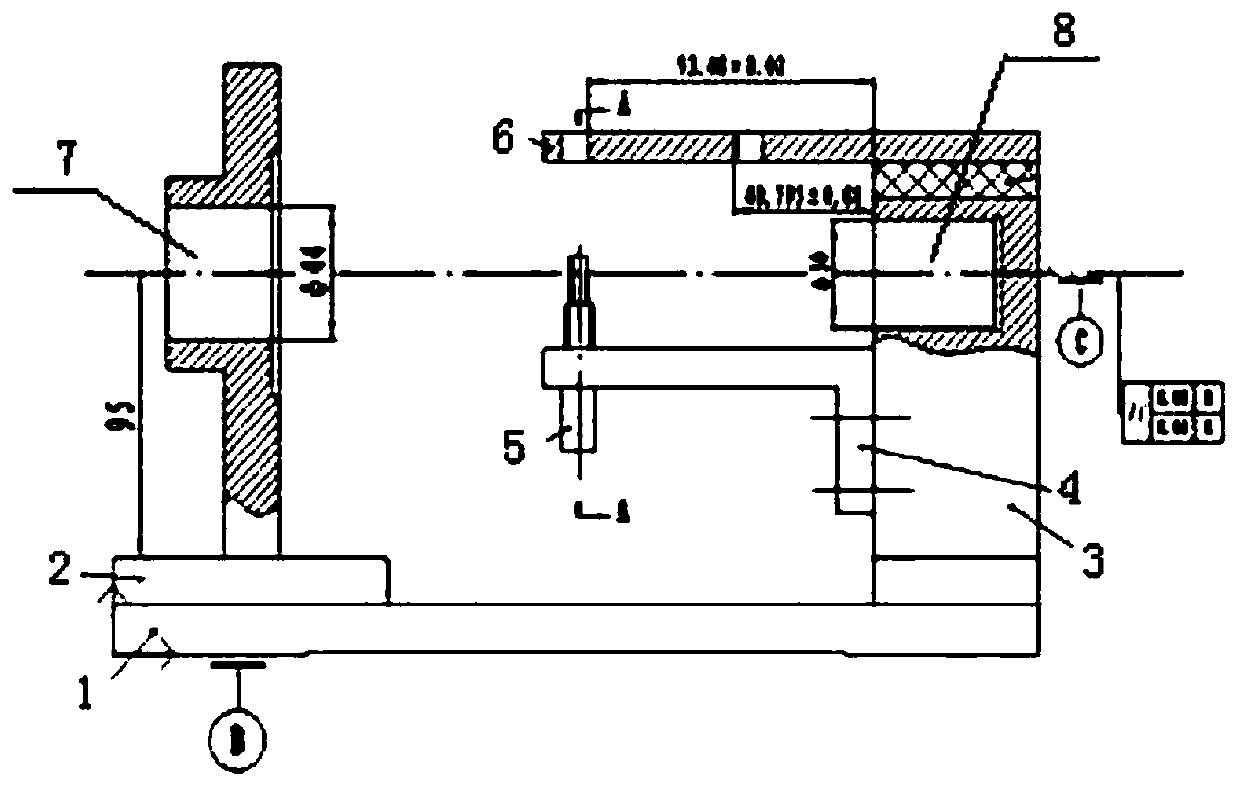

Sleeve-type oil cylinder assembly table

InactiveCN107791198AReduce labor intensityReduce manufacturing costWork benchesMetal-working hand toolsEngineeringUltimate tensile strength

The invention discloses a sleeve-type oil cylinder assembly platform, which includes a platform assembly, a lifting mechanism is installed on the left side of the platform assembly, and a lifting cylinder for longitudinally moving the lifting mechanism is arranged on the lower side of the lifting mechanism. The lifting mechanism is also provided with a thrust cylinder, and the top of the platform assembly is equipped with a guide rail through a guide rail bracket, and a positioning mechanism is installed on the guide rail, and the positioning mechanism includes a positioning V-shaped iron, a positioning inclined iron and a positioning rack. The invention realizes the lifting and advancing assembly work of the sleeve-type oil cylinder steel cylinder through the cylinder, which can reduce labor intensity, reduce the number of workers, improve work efficiency, reduce manufacturing costs, improve the pass rate of product assembly, and meet the needs of mass production .

Owner:湖北浩顶液压科技股份有限公司

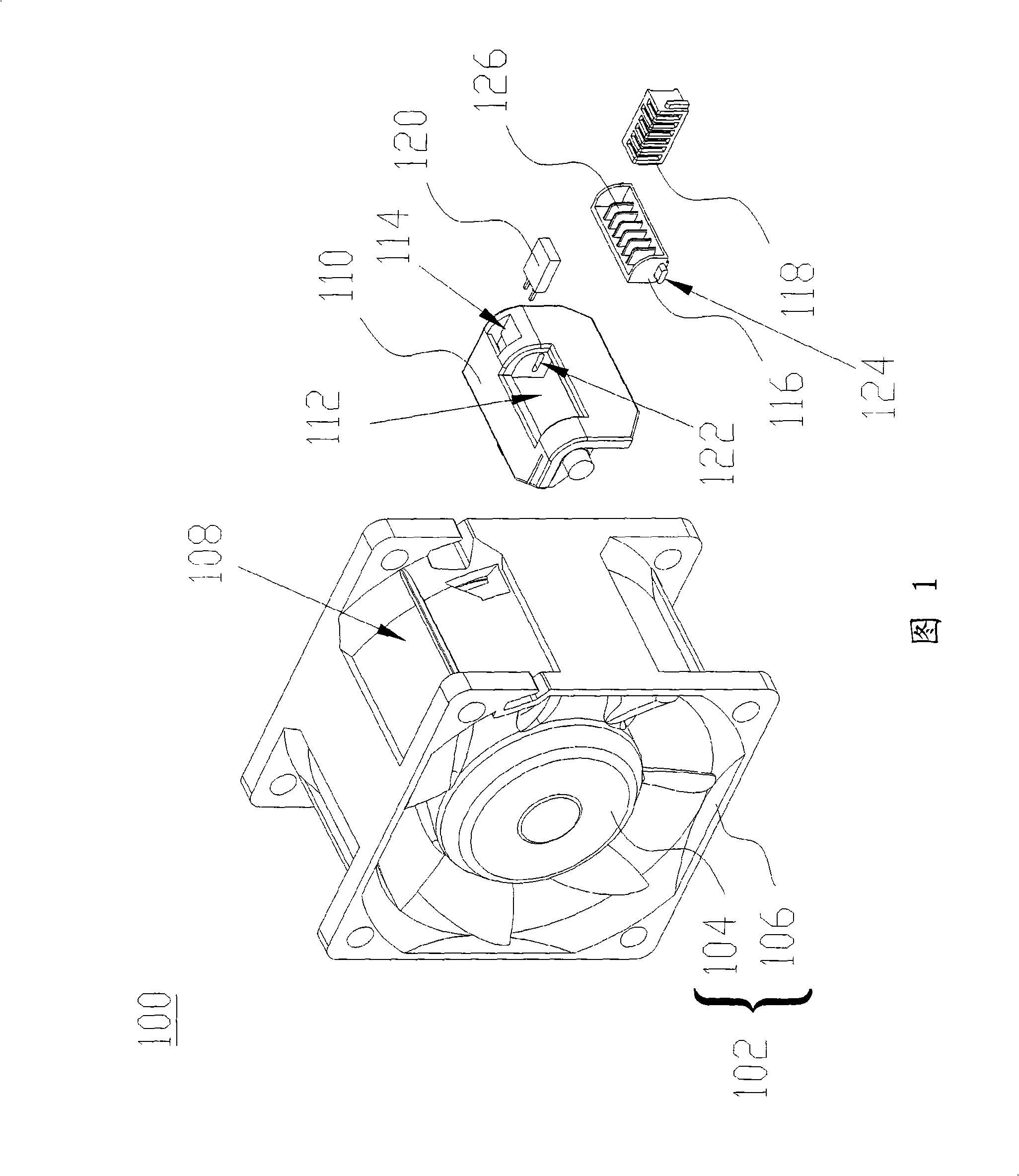

Hot-plug fan and its terminal base

InactiveCN101319680AFirmly connectedExtend your lifeElectrically conductive connectionsPump installationsImpellerEngineering

The invention discloses a hot-swap fan which comprises a fan, at lest a first terminal block and at least a second terminal block. The fan is provided with at least an impeller and at least a fan frame. The impeller is arranged in the fan frame, and the circumference of the fan frame is provided with at least a first containing groove. The first terminal block is arranged and fixed in the first containing groove, and is provided with at least a second containing groove. The second terminal block is arranged in the second containing groove, and can float in the second containing groove.

Owner:DELTA ELECTRONICS INC

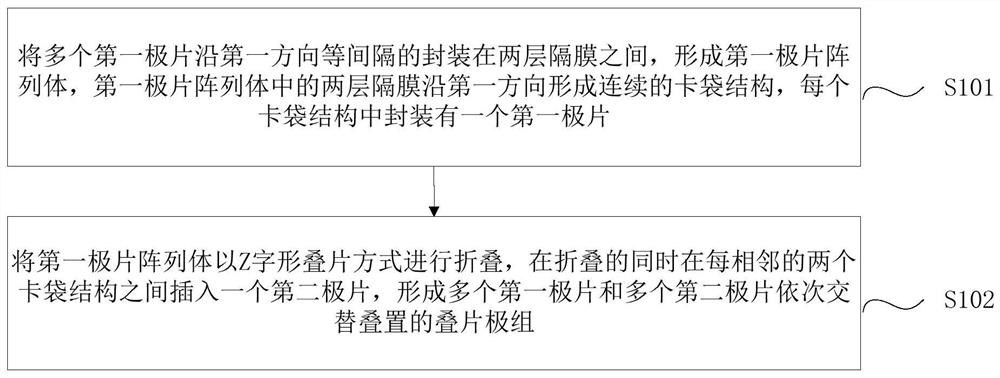

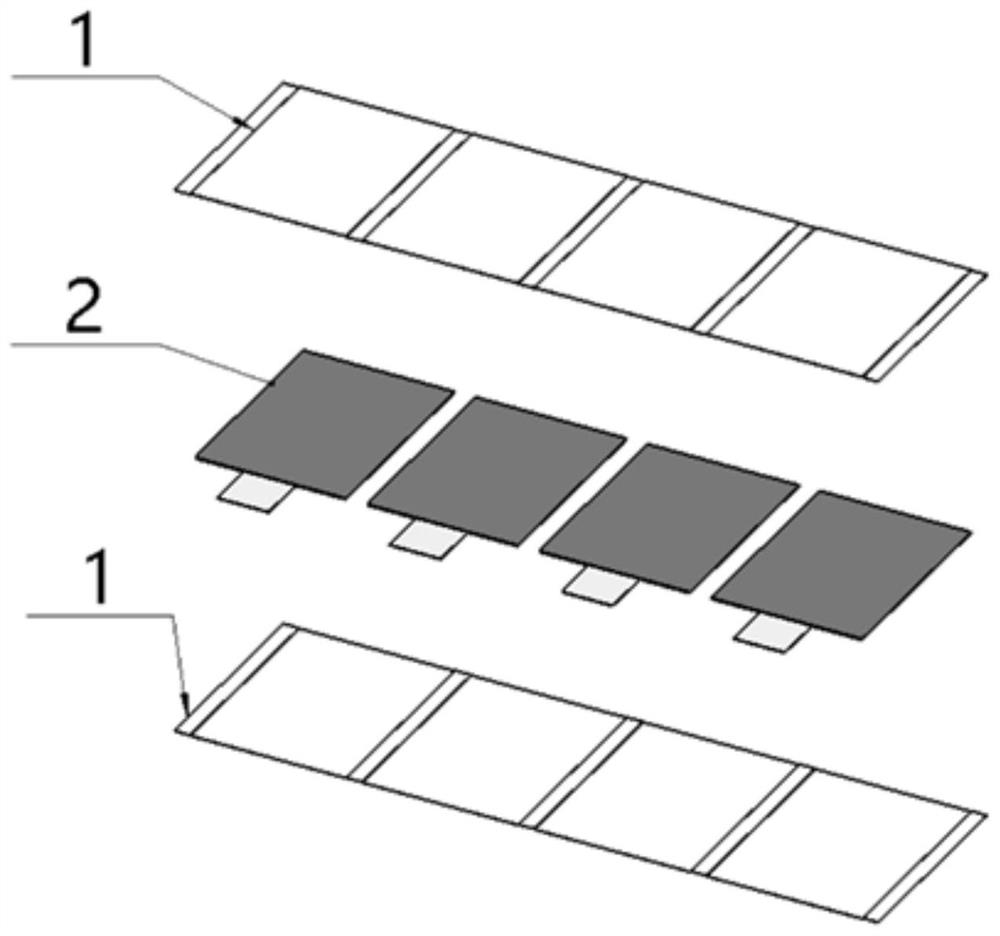

Manufacturing method of laminated pole group, laminated pole group and battery

InactiveCN113224391AImprove performanceReduce the difficulty of assemblyFinal product manufactureSecondary cellsElectrical batteryStructural engineering

The invention discloses a manufacturing method of a laminated pole group, a laminated pole group and a battery. The method comprises the following steps that: a plurality of first pole pieces are packaged between two layers of diaphragms at equal intervals along a first direction to form a first pole piece array body, and a continuous clamping bag structure is formed by the two layers of diaphragms in the first pole piece array body along the first direction, a first pole piece is packaged in each clamping bag structure; and the first pole piece array body is folded in a Z-shaped lamination mode, and a second pole piece is inserted between every two adjacent clamping bag structures while the first pole piece array body is folded, so that the lamination pole group formed by sequentially and alternately laminating the plurality of first pole pieces and the plurality of second pole pieces can be formed. The assembly difficulty is reduced, and the lamination speed, the yield and the safety of the battery are improved.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

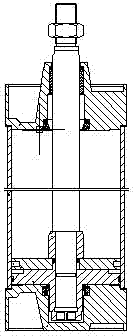

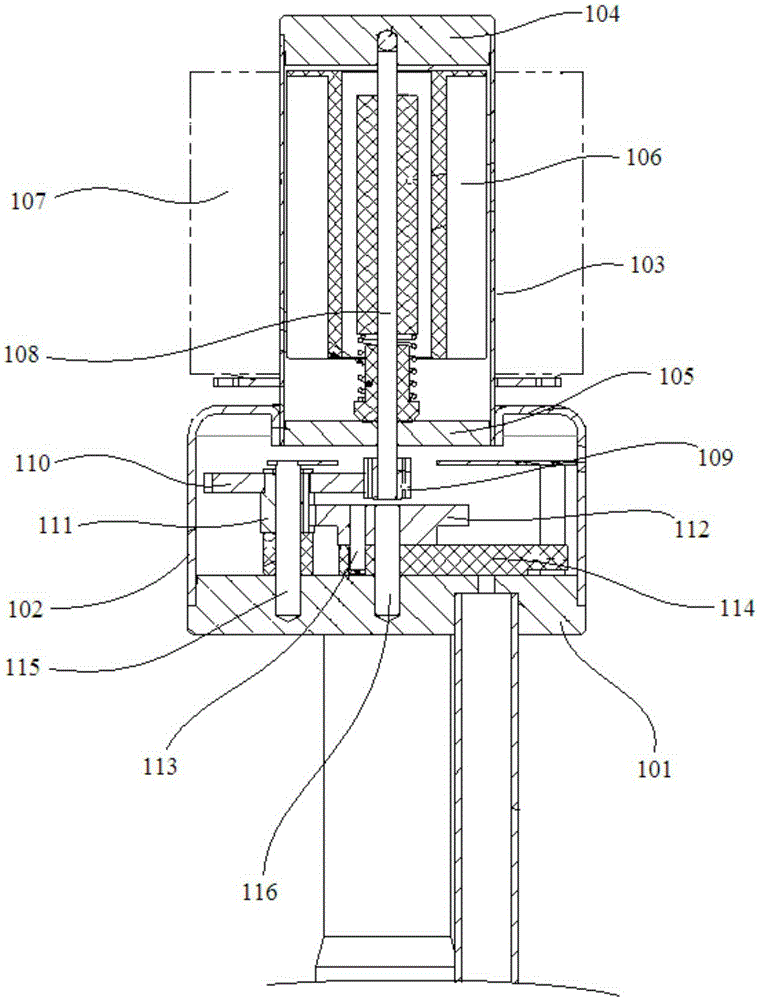

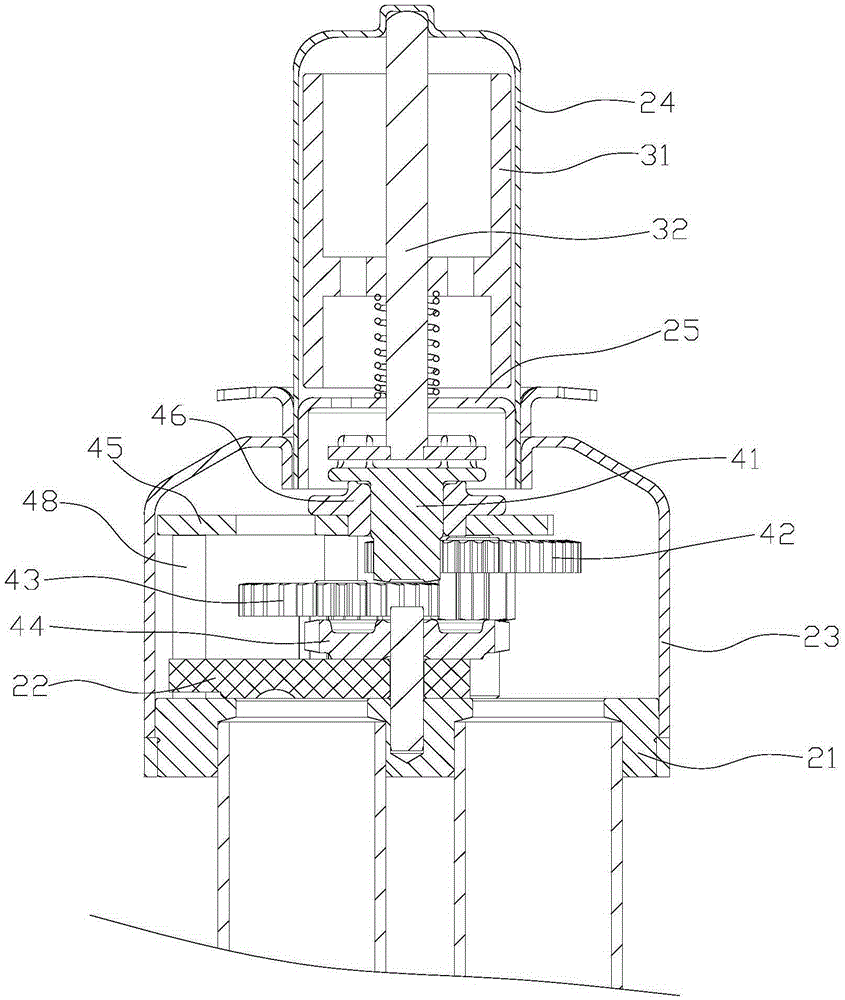

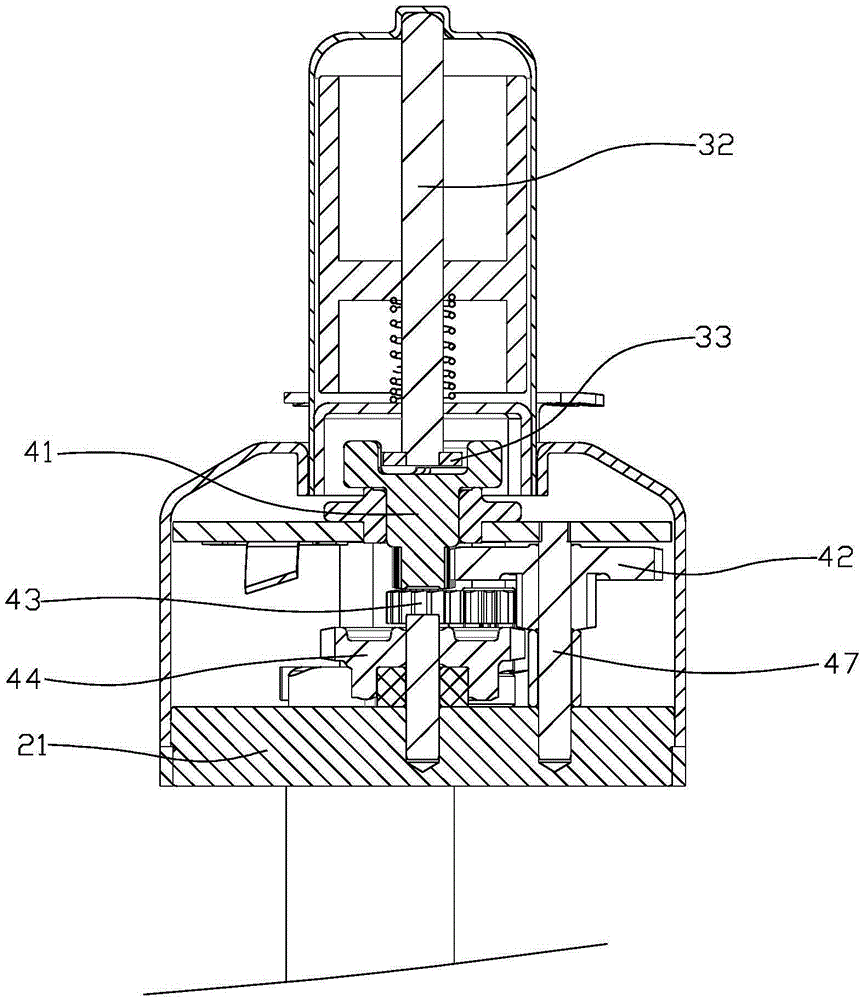

Electric switching valve

ActiveCN106838379AAvoid bad meshingAvoid stickingOperating means/releasing devices for valvesMultiple way valvesManufacturing cost reductionEngineering

The invention discloses an electric switching valve. The electric switching valve comprises a motor, a gear assembly, a slide block and a valve seat; and the slide block can be driven by the gear assembly to rotate on the valve seat under driving of the motor so as to open or close one of a plurality of output ports in the valve seat, and a rotor shaft of the motor is in flexible connection with a first gear of the gear assembly. Through structural design of the electric switching valve, assembled relevant spare parts of the gear assembly can be reduced, and the machining precision of the relevant spare parts and the control precision of assembly are lowered, so that the assembling yield of a product is improved while manufacturing cost is reduced.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

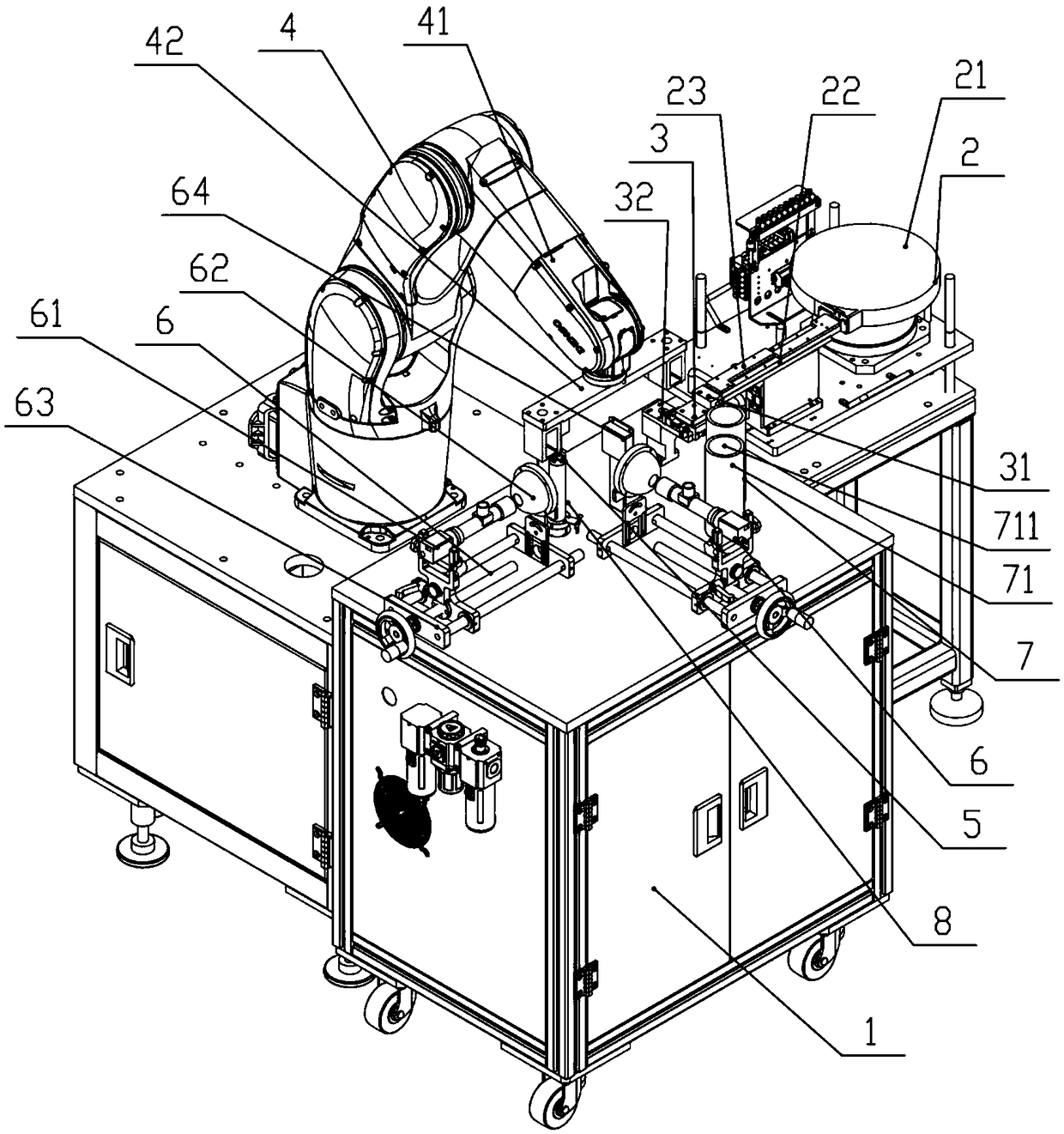

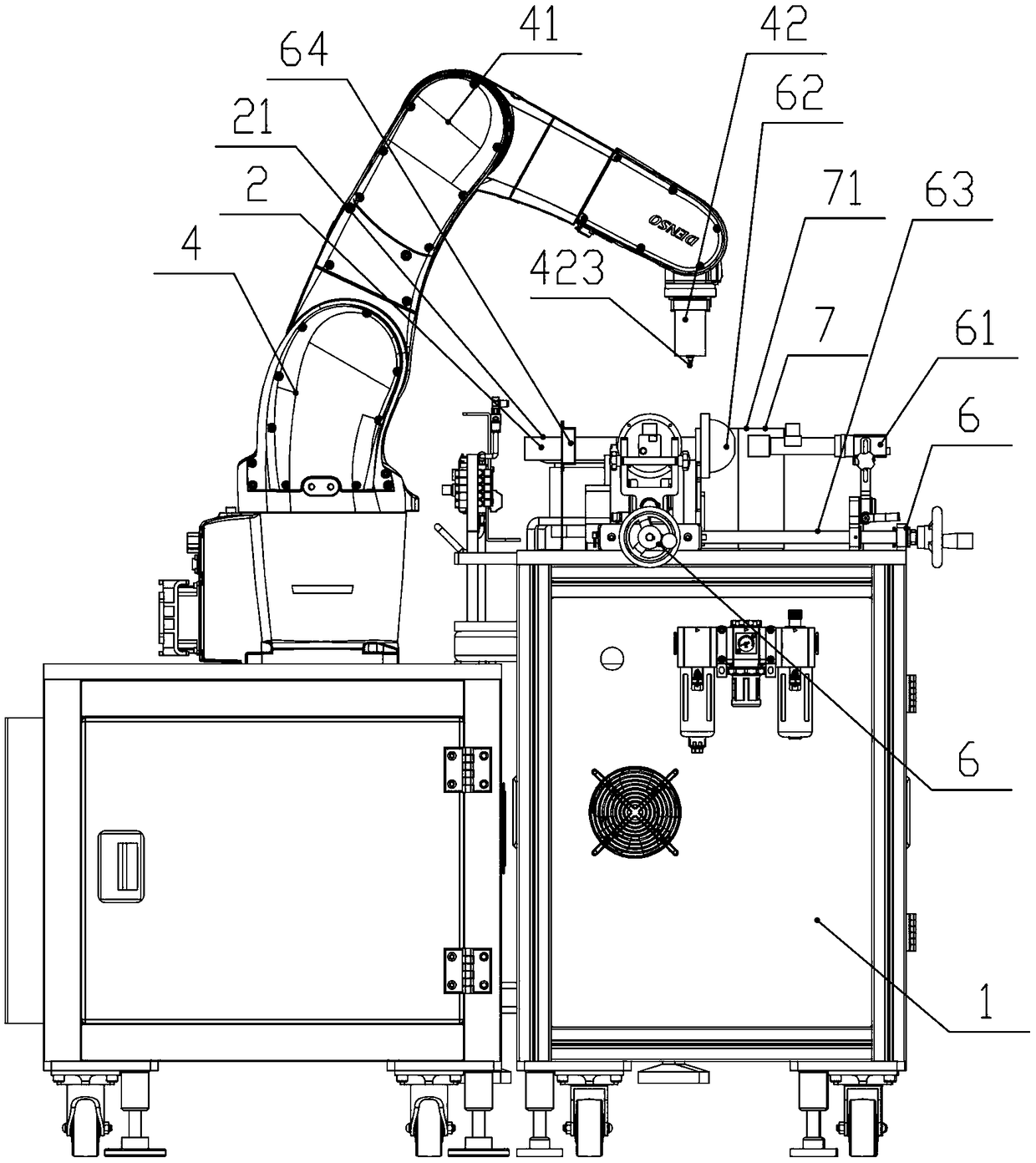

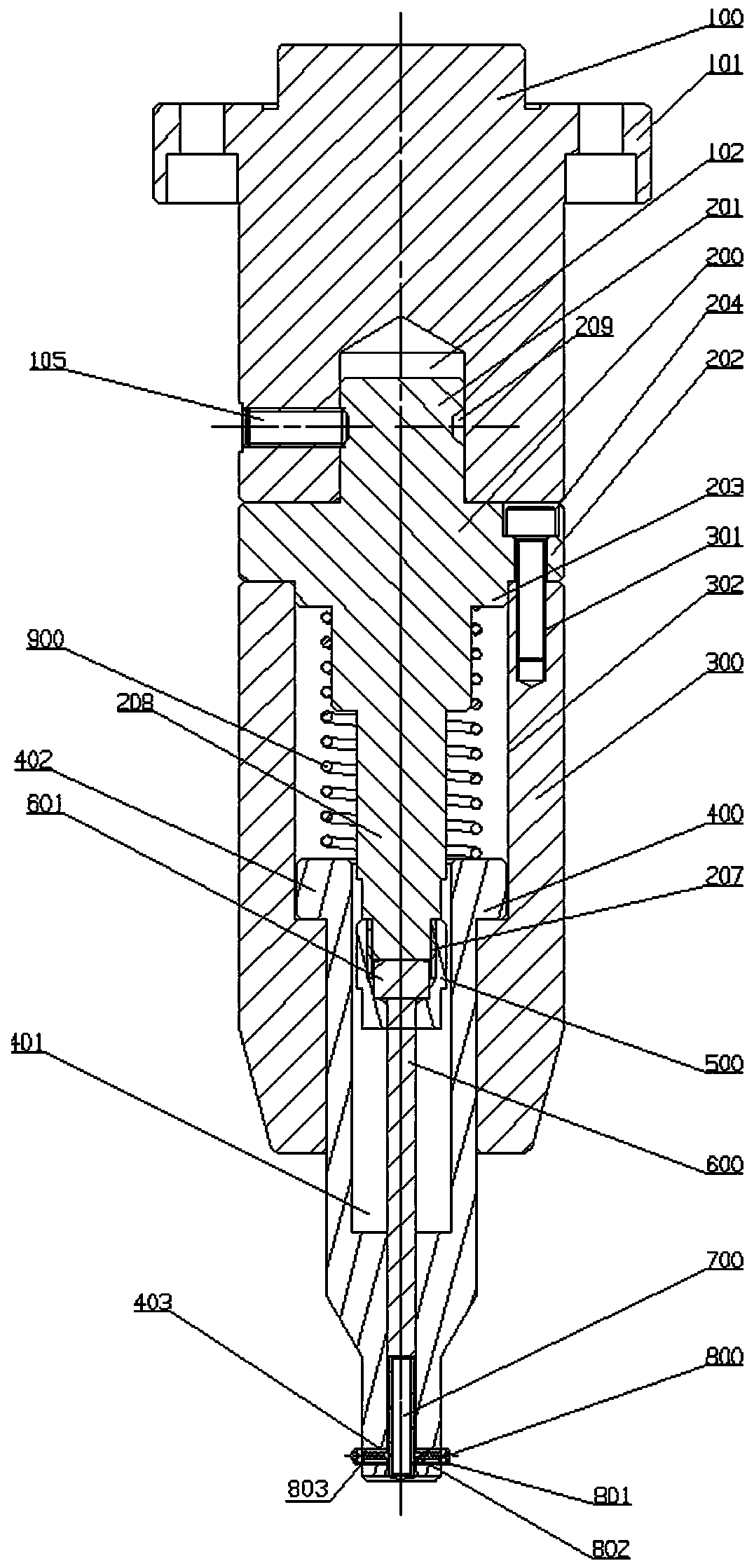

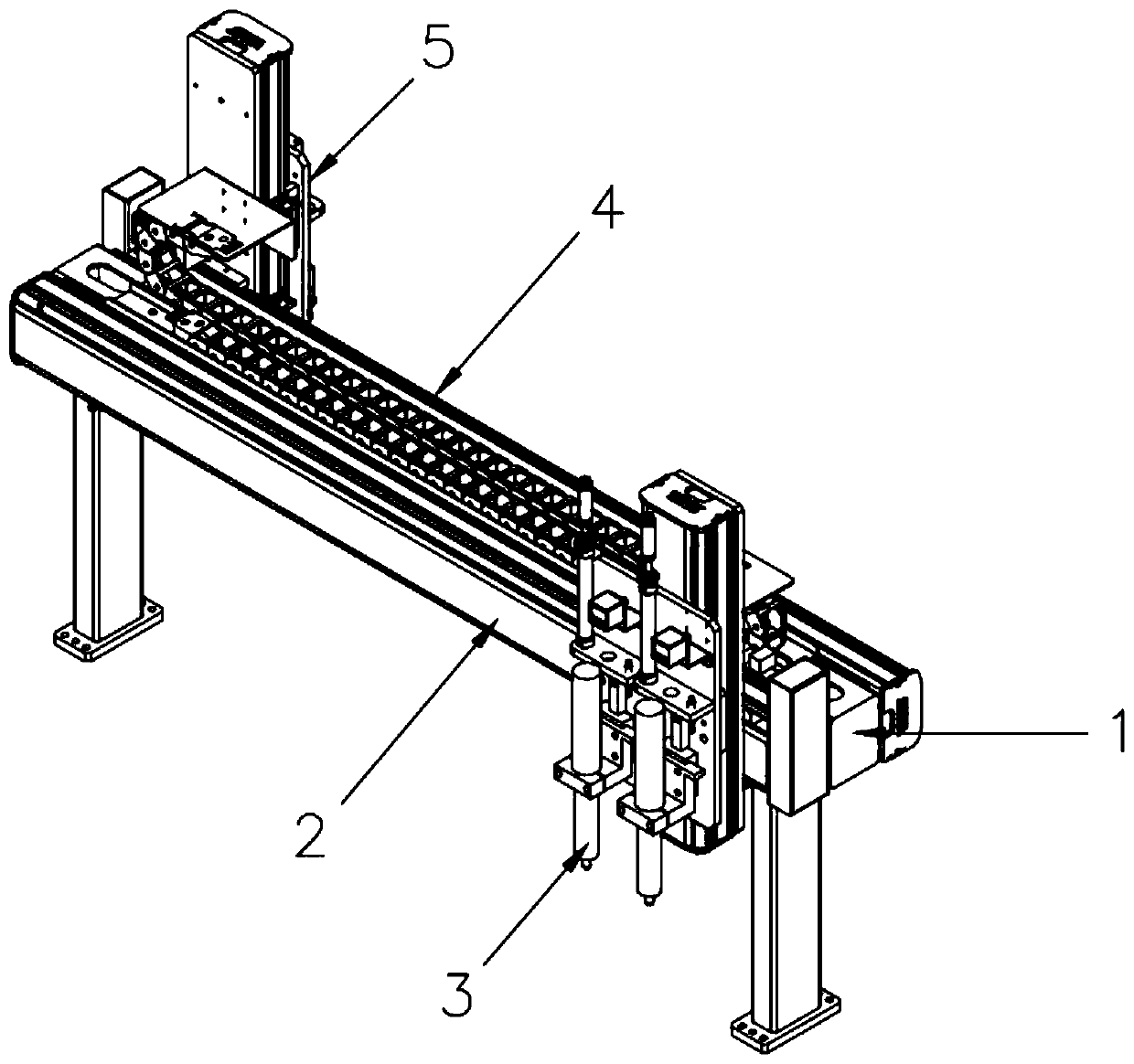

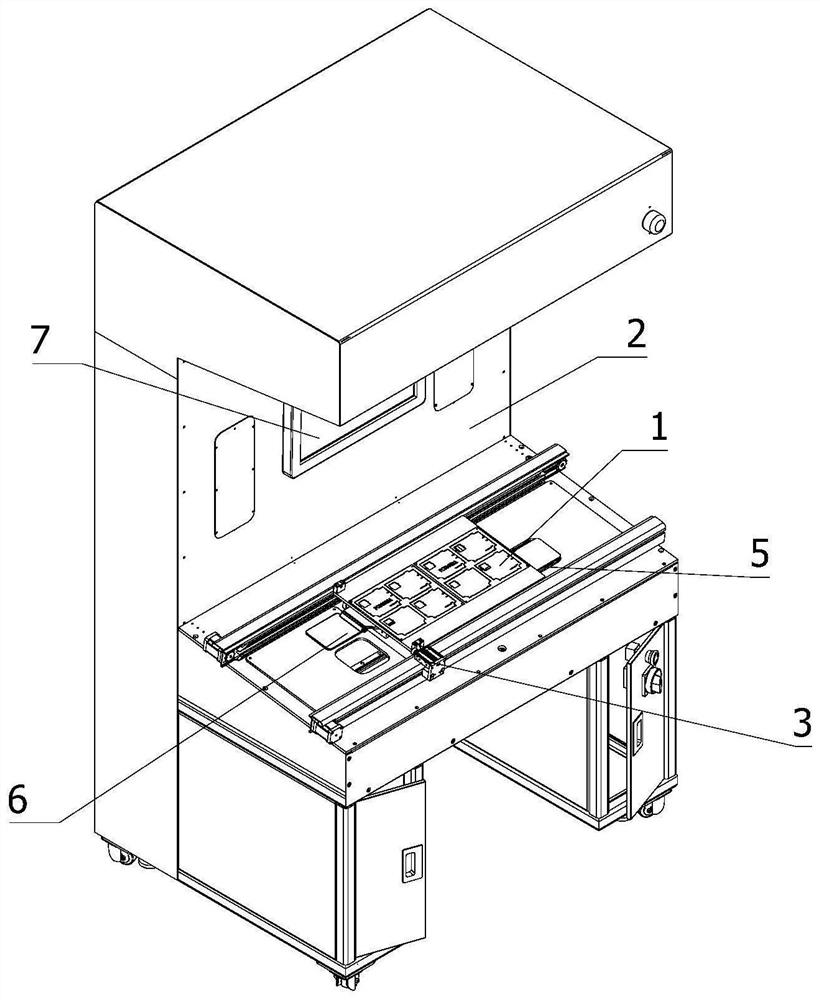

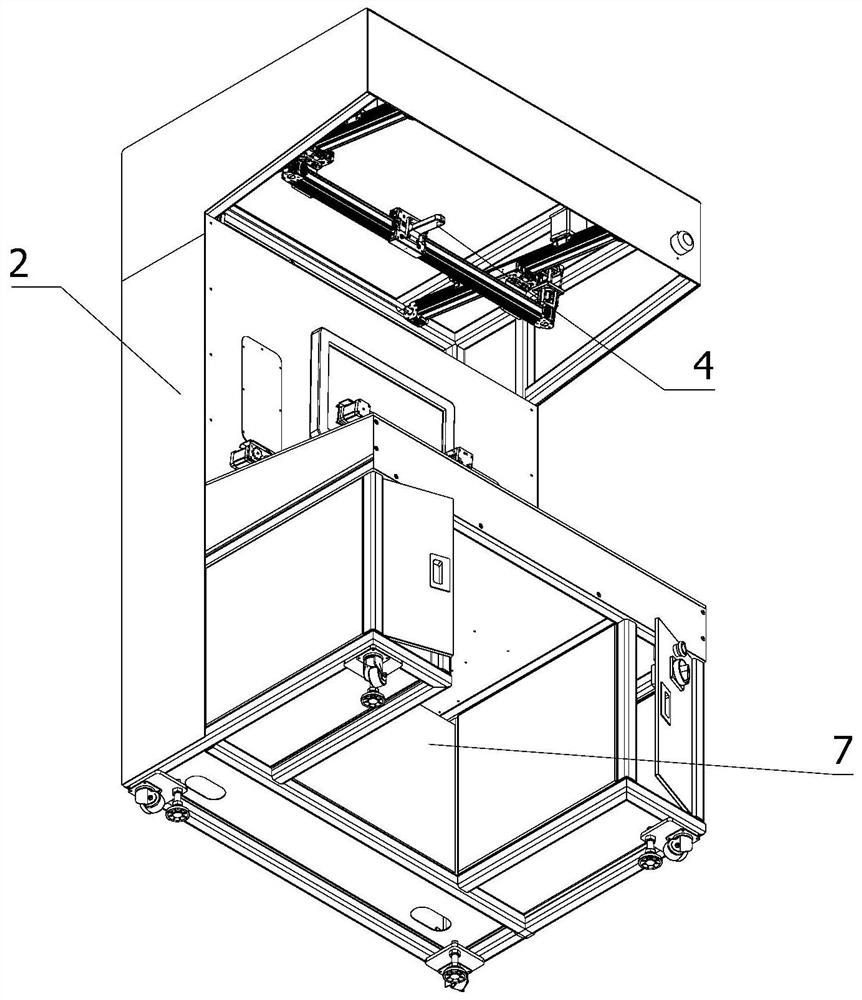

Lock cylinder installing machine

ActiveCN109605029AGood precisionImprove assembly pass rateBuilding locksAssembly machinesIngotProcessing accuracy

The invention discloses a lock cylinder installing machine, and relates to a lock assembly device. The lock cylinder installing machine comprises a rack, a rotary work table, a positioning mechanism,a marble and flat head loading-in device and a spring and sealing bead loading-in device; the rack is internally provided with a shoe-shaped gold ingot support and a table support; the rotary work table is mounted on the table support and is provided with a driving device capable of driving the rotary work table and a plurality of clamping devices arranged in the circumferential direction; the positioning mechanism, the marble and flat head loading-in device and the spring and sealing bead loading-in device are fixedly mounted on the shoe-shaped gold ingot support in sequence to correspond theclamping devices below; and each clamping device has a first state in which a lock cylinder is fixed after positioning by the positioning mechanism, a second state in which a marble and a flat head are loaded into the lock cylinder through the marble flat head loading device and a third state in which a spring and a sealing bead are installed in the lock cylinder through the spring bead sealing loading-in device. The lock cylinder installing machine has the advantages of the high automation degree, the high processing efficiency and the good processing precision.

Owner:永嘉县信达智能设备制造有限公司

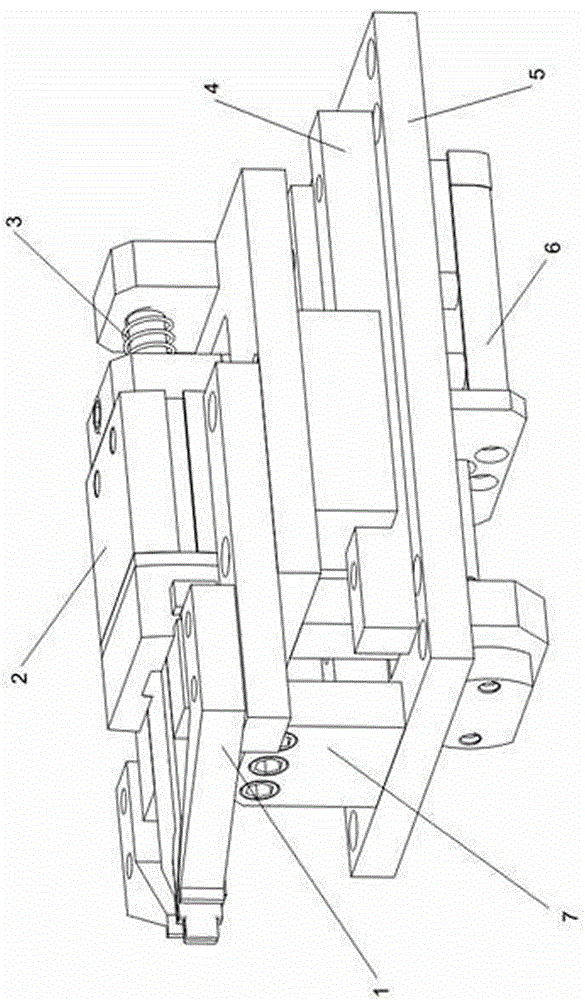

Assembly process of blind hole tool with high precision requirement

ActiveCN111168326AReduce dependency on skill levelGuaranteed accuracy requirementsStructural engineeringMachine

The invention belongs to the field of machining, and relates to an assembly process of a blind hole tool with a high precision requirement. The assembly process comprises the following steps of 1) processing a base, and ensuring the parallelism of two surfaces of the thickness of the base and the perpendicularity with an alignment reference surface; 2) processing a support plate, and ensuring theparallelism of the two surfaces of the thickness of the support plate and the perpendicularity with the bottom surface; 3) processing a support, and ensuring the parallelism of the two of the thickness of the support and the perpendicularity with the bottom surface; 4) processing a positioning plate; 5) processing a guide plate; 6) assembling the base, the support and the positioning plate into anintegral structure, fixing the integral structure on a workbench of the coordinate boring machine, machining a blind hole in the support by adopting a boring cutter, axially lifting the boring cutter, assembling the support plate on the base, replacing the boring cutter, and machining a through hole in the support plate on the support plate; and 7) assembling the guide plate on the support by anadjusting assembly method. According to the assembly process of the blind hole tool with the high precision requirement, the requirement for the assembly form and location tolerance is met, dependenceon the skill level of workers is reduced, and the assembly qualification rate can be greatly increased.

Owner:XIAN AERO ENGINE CONTROLS

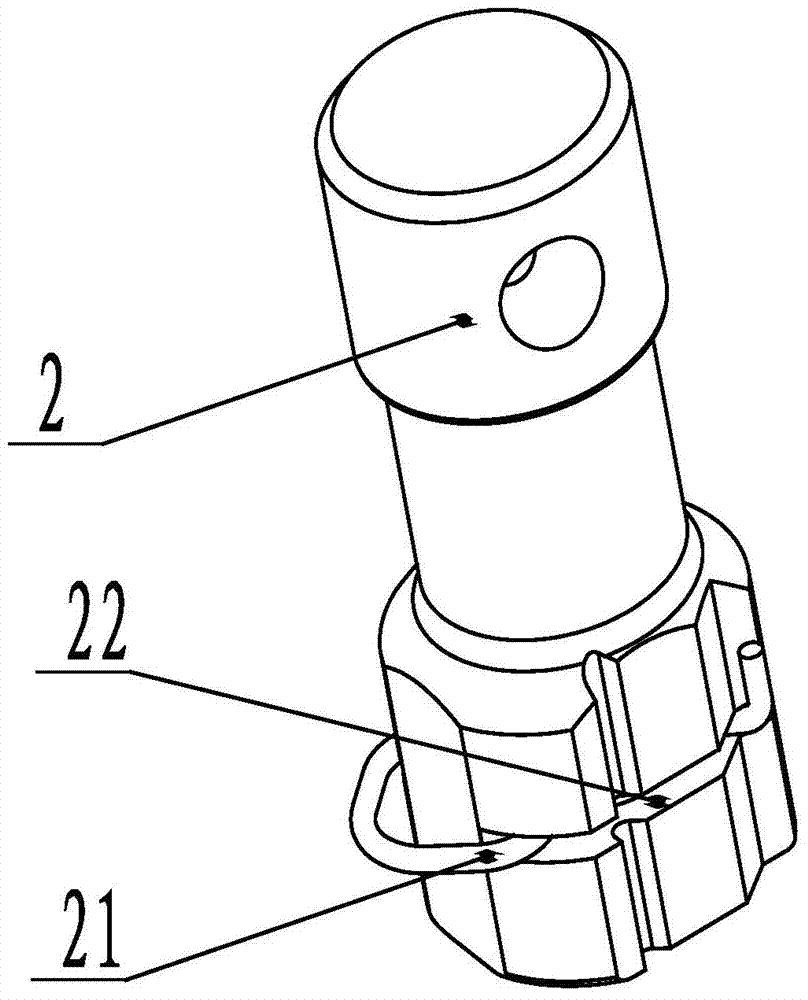

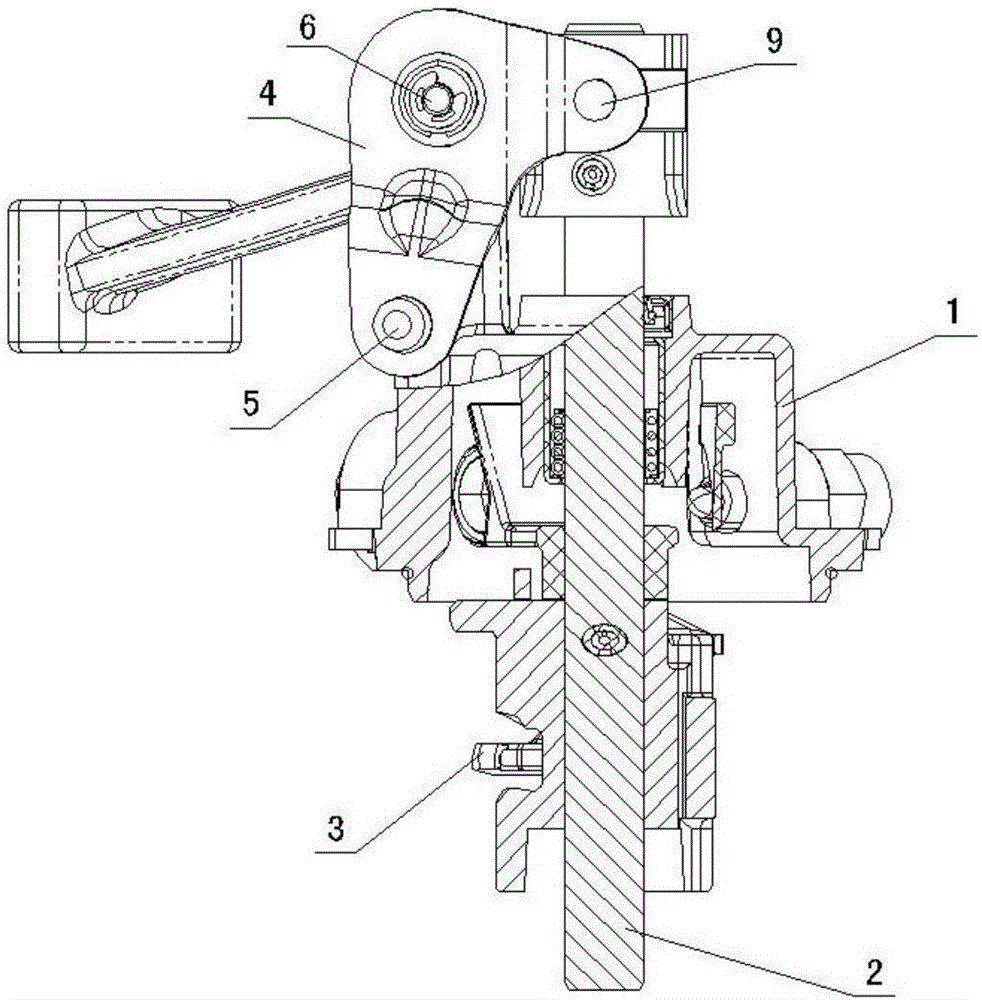

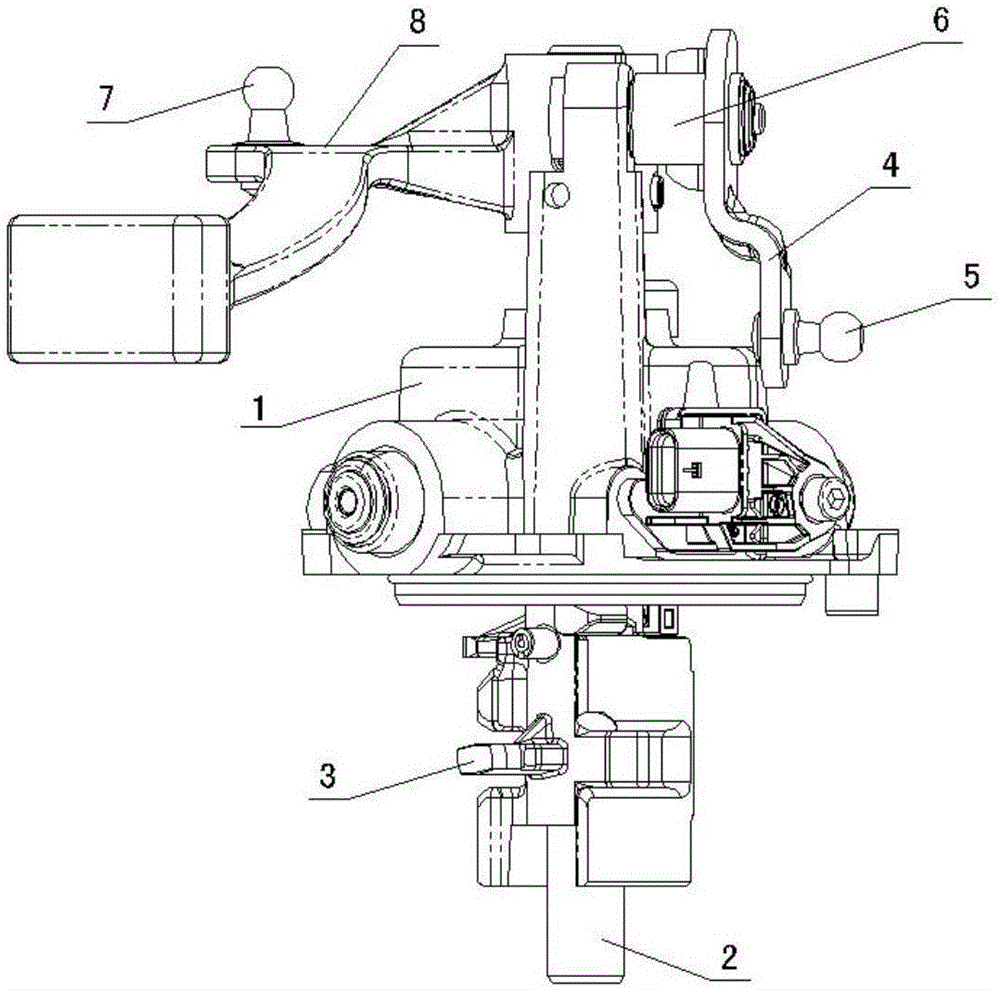

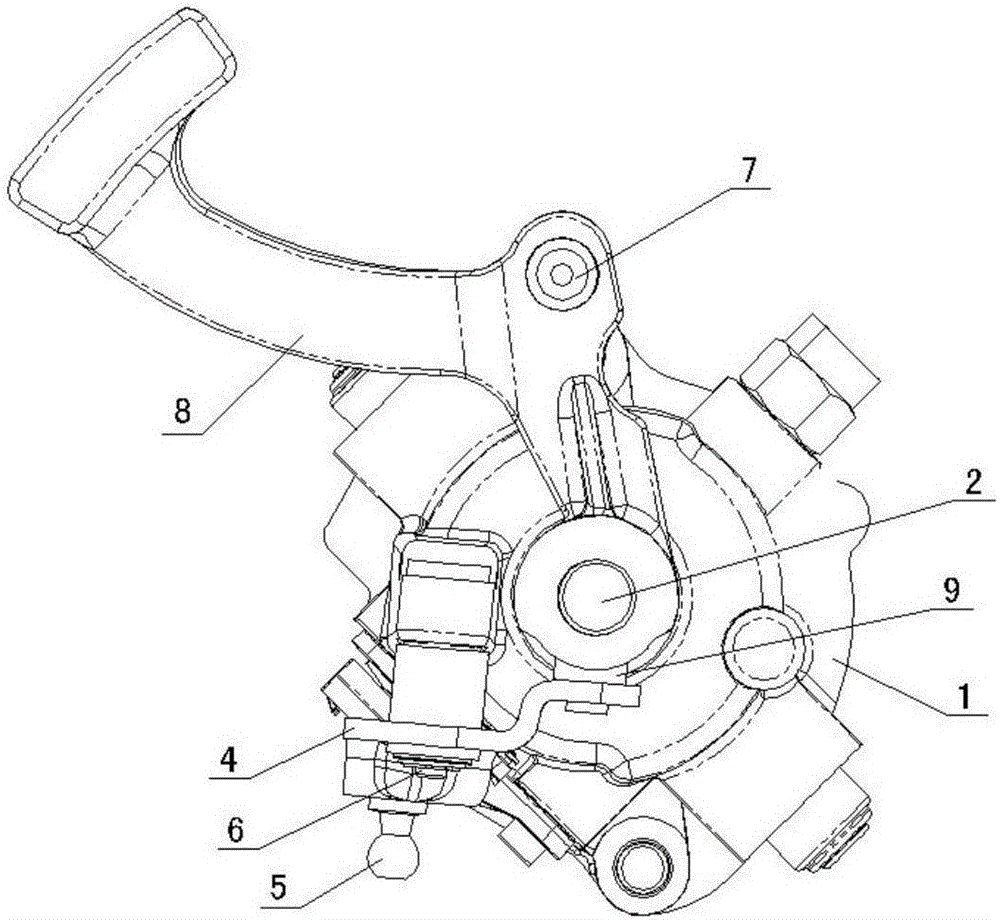

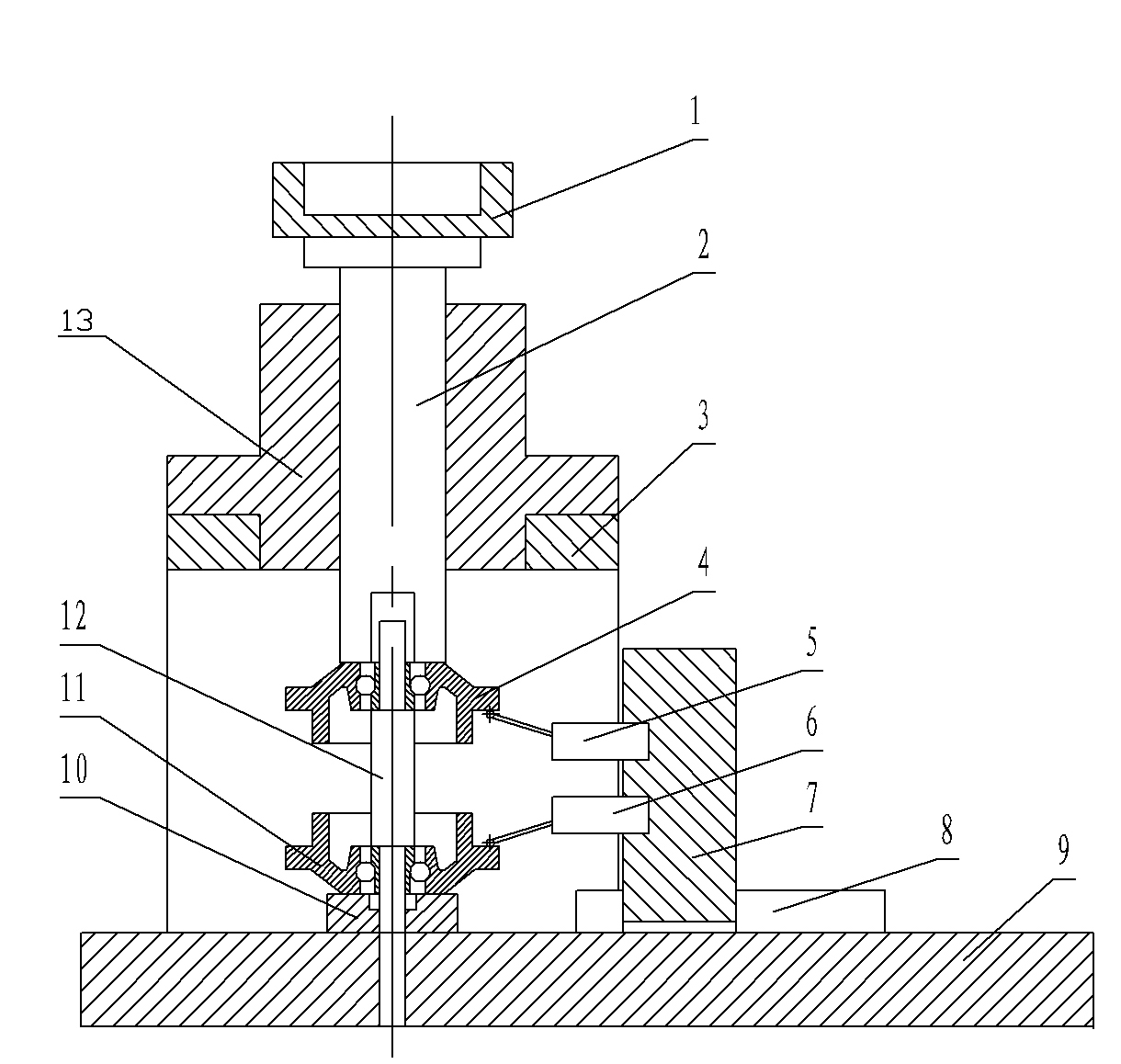

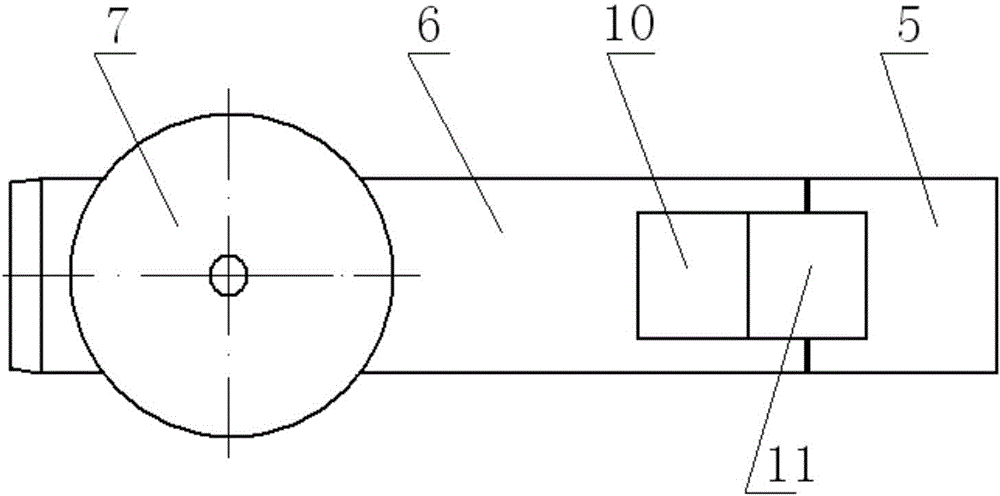

Gear selecting and shifting switching mechanism of manual transmission and application of gear selecting and shifting switching mechanism in gear selecting and shifting detection

InactiveCN106286819AImprove assembly pass rateGuarantee normal production cycleMachine gearing/transmission testingGearing controlEngineeringCantilever

The invention discloses a gear selecting and shifting switching mechanism of a manual transmission and application of the gear selecting and shifting switching mechanism in gear selecting and shifting detection. The gear selecting and shifting switching mechanism is characterized in that a gear selecting and shifting shaft capable of rotating and axially moving relative to a cylindrical shell is arranged in the cylindrical shell in a sleeved mode, and a puller for gear selecting and shifting is fixedly connected to the shaft end of the gear selecting and shifting shaft; one end of a gear selecting rotary arm is a gear selecting driving end, and the other end of the gear selecting rotary arm is connected with the gear selecting and shifting shaft through a pushing block; the gear selecting rotary arm can drive the gear selecting and shifting shaft to move axially in the cylindrical shell through the pushing block; one end of a gear shifting cantilever is fixedly connected with the gear selecting and shifting shaft, the other end of the gear shifting cantilever is an overhanging gear shifting driving end, and the gear selecting and shifting shaft can rotate in the cylindrical shell under driving of the gear shifting cantilever. The gear selecting and shifting switching mechanism is used in cooperation with gear selecting and shifting driving equipment and is correspondingly provided with a force sensor and a displacement sensor; the characteristic quantities of gear selecting and shifting mechanisms are obtained through detection in the gear selecting or shifting process, then the qualified ear selecting and shifting mechanism is screened out, the product assembly percent of pass can be effectively increased, the production takt can be guaranteed, and the production efficiency can be improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

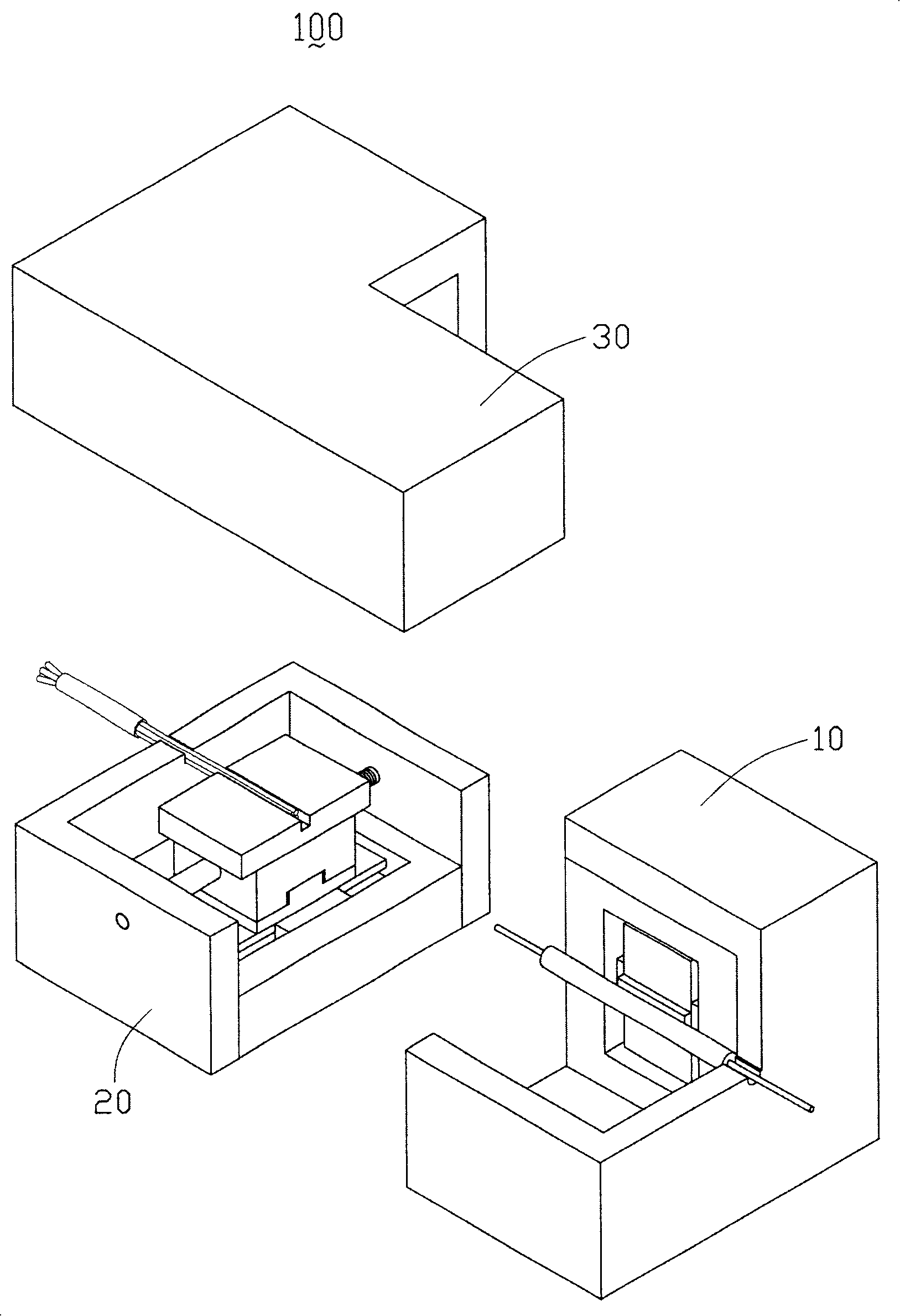

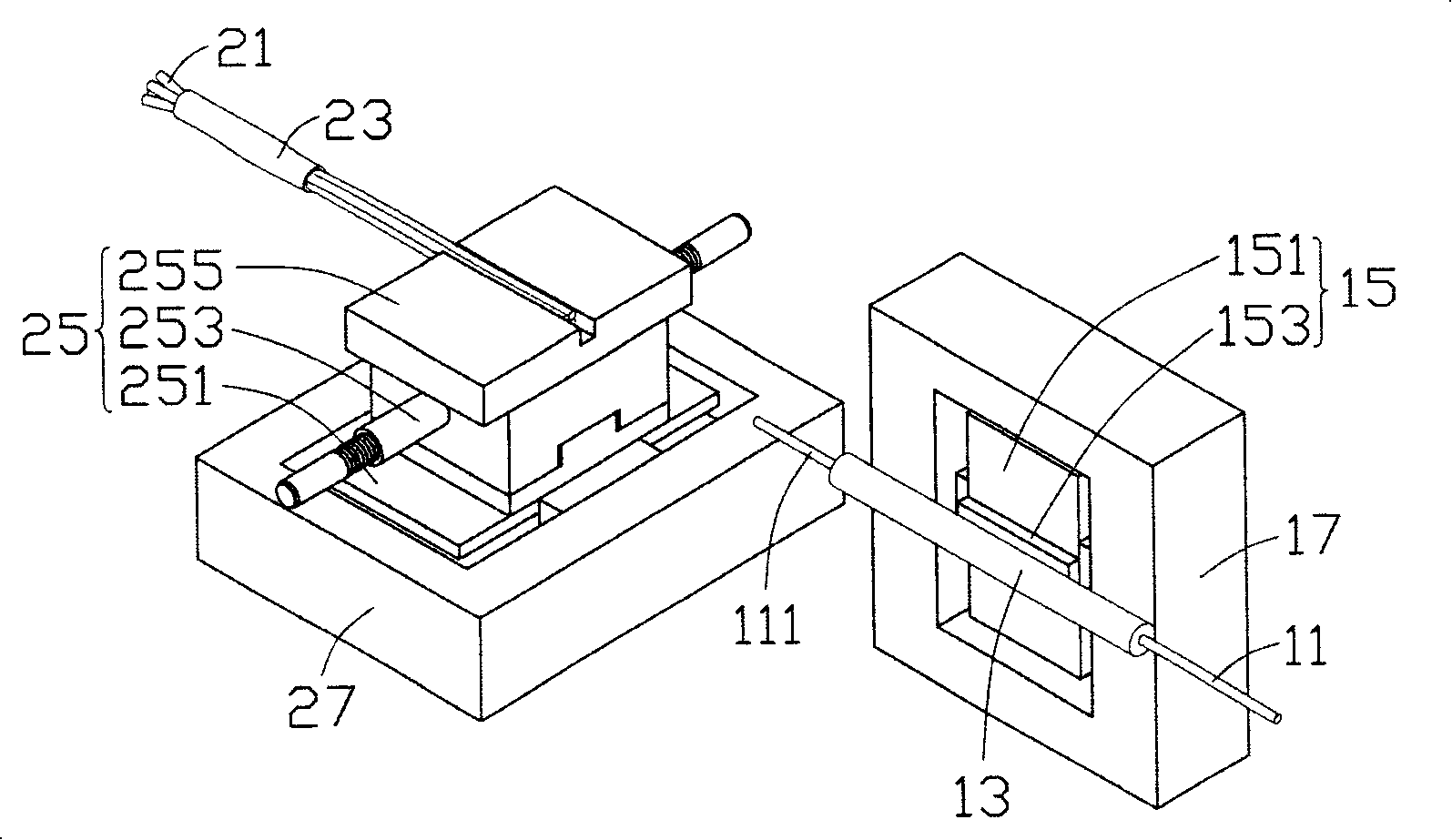

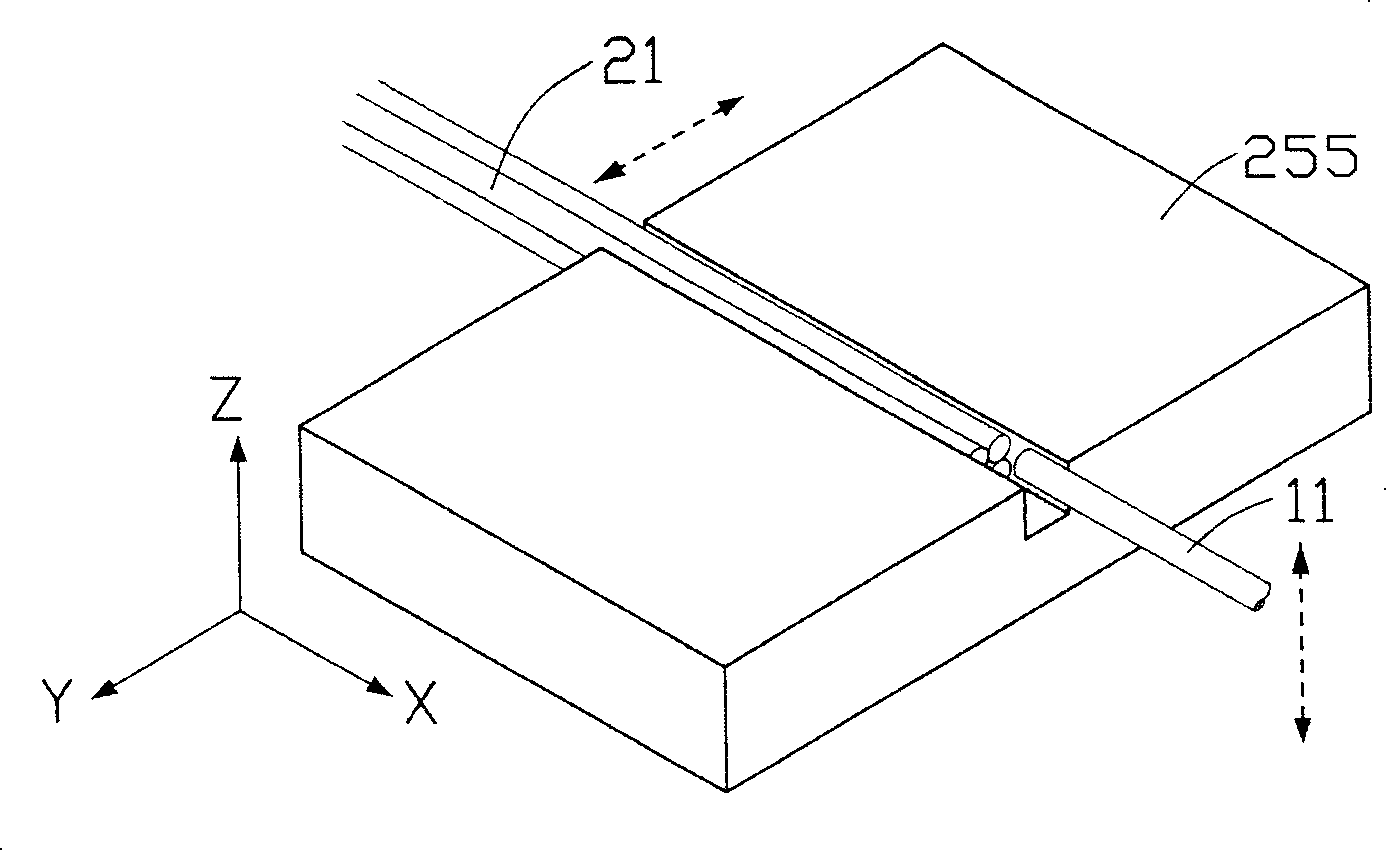

Mechanical photo switch

InactiveCN101174004AImprove assembly pass rateEasy to control and maintain alignment accuracyCoupling light guidesOptical switchOptical Module

The invention discloses a mechanical light switch, comprising a first optical fiber module and a second optical fiber module arranged in the corresponding position of the first optical fiber module, wherein the first optical fiber module comprises a first optical fiber and a first optical fiber switching device, the second optical fiber module comprises at least two second optical fibers and a second optical fiber switching device. The tip of the first optical fiber switching device which controls the first optical fiber is shifted in horizontal or vertical direction, and the tip of the second optical fiber switching device which controls the second optical fiber is shifted in the vertical direction of the moving direction of the tip of the first optical fiber to enable the first optical fiber to be on the contraposition of the second optical fiber.

Owner:范光照

PCB plug-in feeding system for guiding installation through utilizing laser

ActiveCN113939179AReduce assembly error rateLower operating thresholdElectrical componentsConveyor partsLaser transmitterElectric control

The invention relates to the field of PCB plug-in assembly, in particular to a PCB plug-in feeding system for guiding installation through utilizing laser. The PCB plug-in feeding system comprises a PCB, and further comprises a rack, a positioning and installing mechanism, a laser guiding mechanism, a feeding mechanism, a material taking mechanism and an electric control system, wherein an inclined operation platform is arranged in the middle of the rack, the positioning and installing mechanism comprises a PCB carrier platform, the laser guiding mechanism is arranged at the top end of the rack, the laser guide mechanism is provided with a laser emitter capable of freely moving in the X-axis direction and the Y-axis direction, the feeding mechanism comprises a plurality of material supply boxes capable of freely moving in the X-axis direction and the Y-axis direction, and the positioning and installing mechanism, the laser guiding mechanism, the feeding mechanism and the material taking mechanism are all electrically connected with the electric control system. According to the PCB plug-in feeding system, a laser designator, a linkage mechanical conveying device and an intelligent material supplementing system are utilized, materials needed by laser indication are automatically supplied, the probability of wrong insertion is completely eradicated, the production efficiency is improved, the pre-warning material supplementing function is achieved, and lean production is achieved.

Owner:GUANGZHOU PANYU TRIO MICROTRONIC

Method for selecting outer rotor matched with gyro motor bearings and selection device

InactiveCN101867261AFast assemblyRealize mass productionManufacturing dynamo-electric machinesAir bearingEngineering

The invention discloses a method for selecting an outer rotor matched with gyro motor bearings and a selection device. The method comprises the following steps: firstly, sheathing and installing paired gyro motor bearings onto gyro motor shafts; then, exerting a set axial load on two outer rings of the paired gyro motor bearings; at this time, measuring the shaft shoulder space value of the two outer rings after the load application; and finally, selecting the outer rotor of the gyro motor with the height corresponding to the shaft shoulder space value. The measuring device comprises an air bearing, a poise loading disc, a centering positioning seat, a first displacement sensor and a second displacement sensor. Through the method for selecting the outer rotor matched with the gyro motor bearings and the selection device, the assembling speed of the gyro motor is greatly improved, and the mass production of the gyro motor is realized.

Owner:LUOYANG BEARING RES INST CO LTD

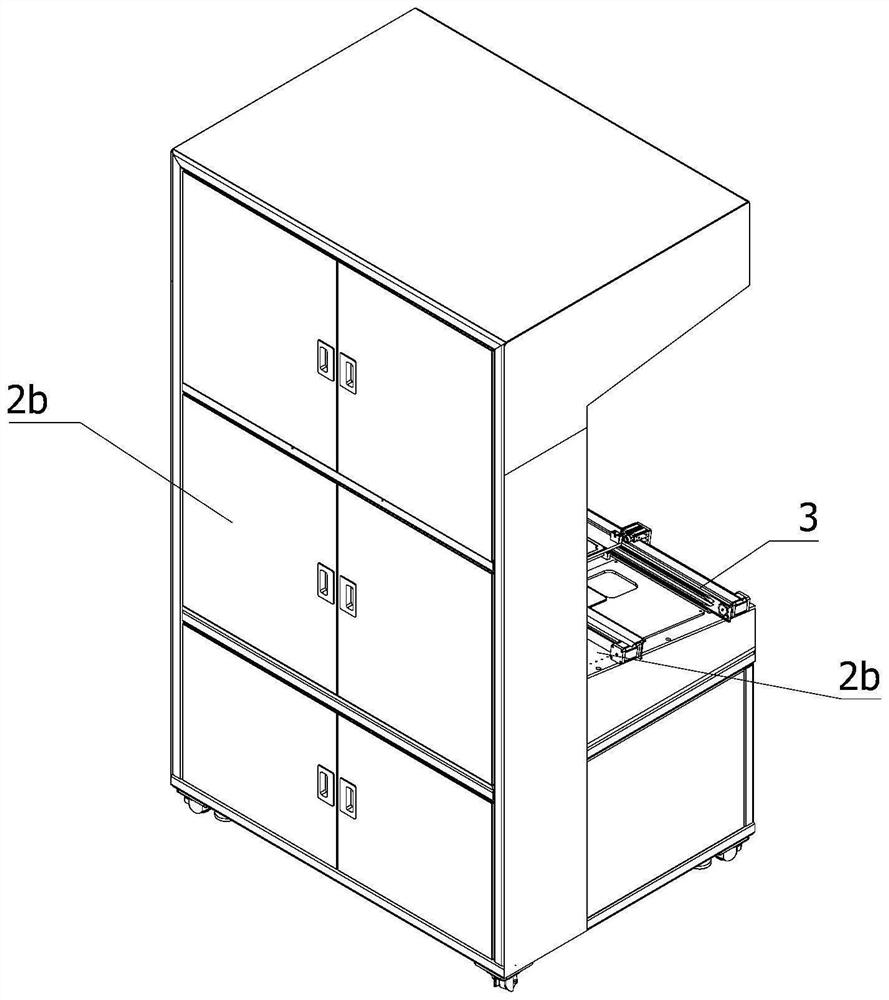

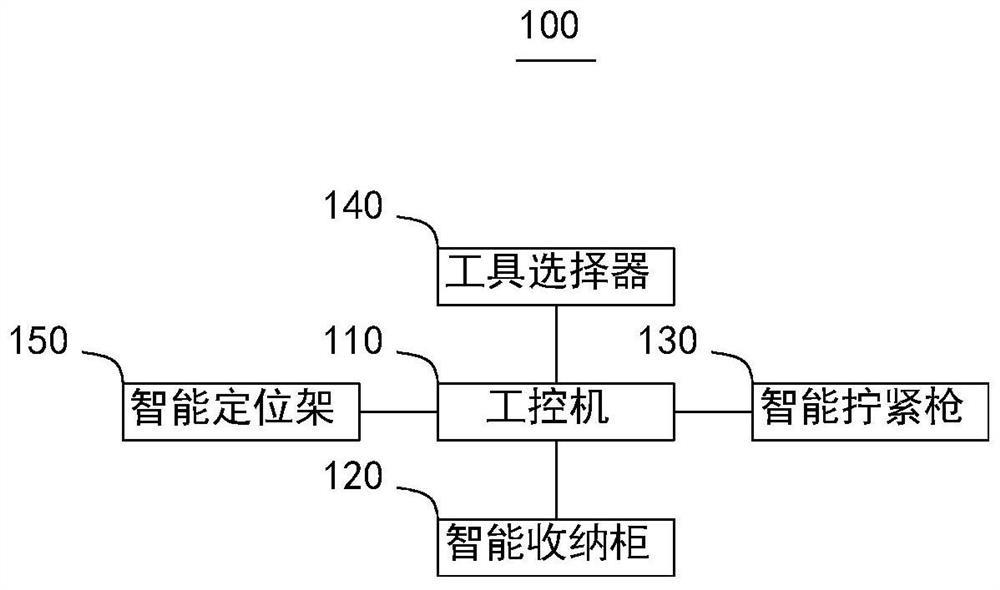

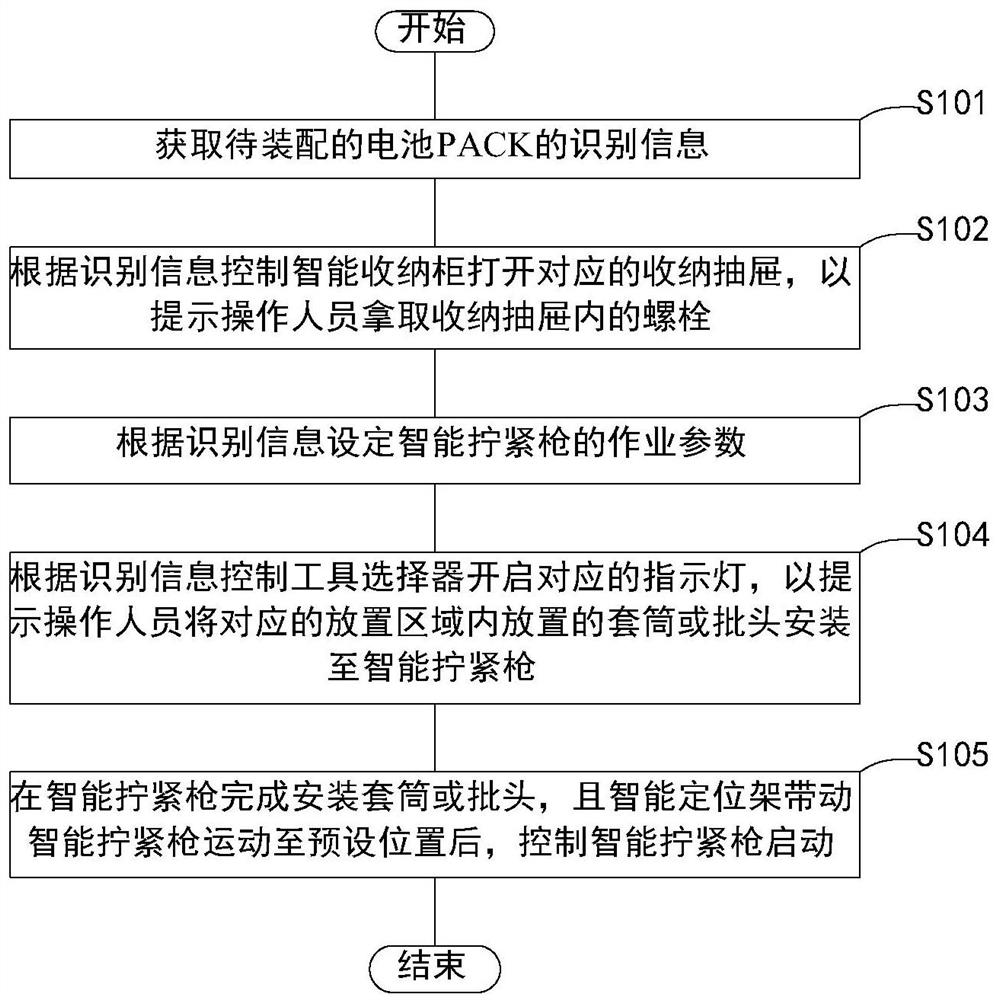

Mistake-proofing assembly system and battery PACK assembly mistake-proofing control method and device

PendingCN113523780ACorrect selectionImprove assembly pass rateAssembling battery machinesFinal product manufactureElectrical batteryPersonal computer

The invention discloses a mistake-proofing assembly system and a battery PACK assembly mistake-proofing control method and device, and relates to the technical field of battery PACKs. The mistake-proofing assembly system comprises an industrial personal computer and an intelligent storage cabinet, wherein the industrial personal computer is electrically connected with the intelligent storage cabinet, the intelligent storage cabinet is provided with a plurality of storage drawers used for storing bolts of different types, and the industrial personal computer is used for controlling the intelligent storage cabinet to open the corresponding storage drawers according to obtained identification information of a battery PACK to be assembled, so that an operator is prompted to take the bolts in the storage drawers. According to the mistake-proofing assembly system provided by the invention, the operator can be prompted to select the bolts of corresponding models according to different battery PACKs, correct bolt model selection is ensured, and the assembly qualification rate is improved.

Owner:BATTERO TECH CORP LTD

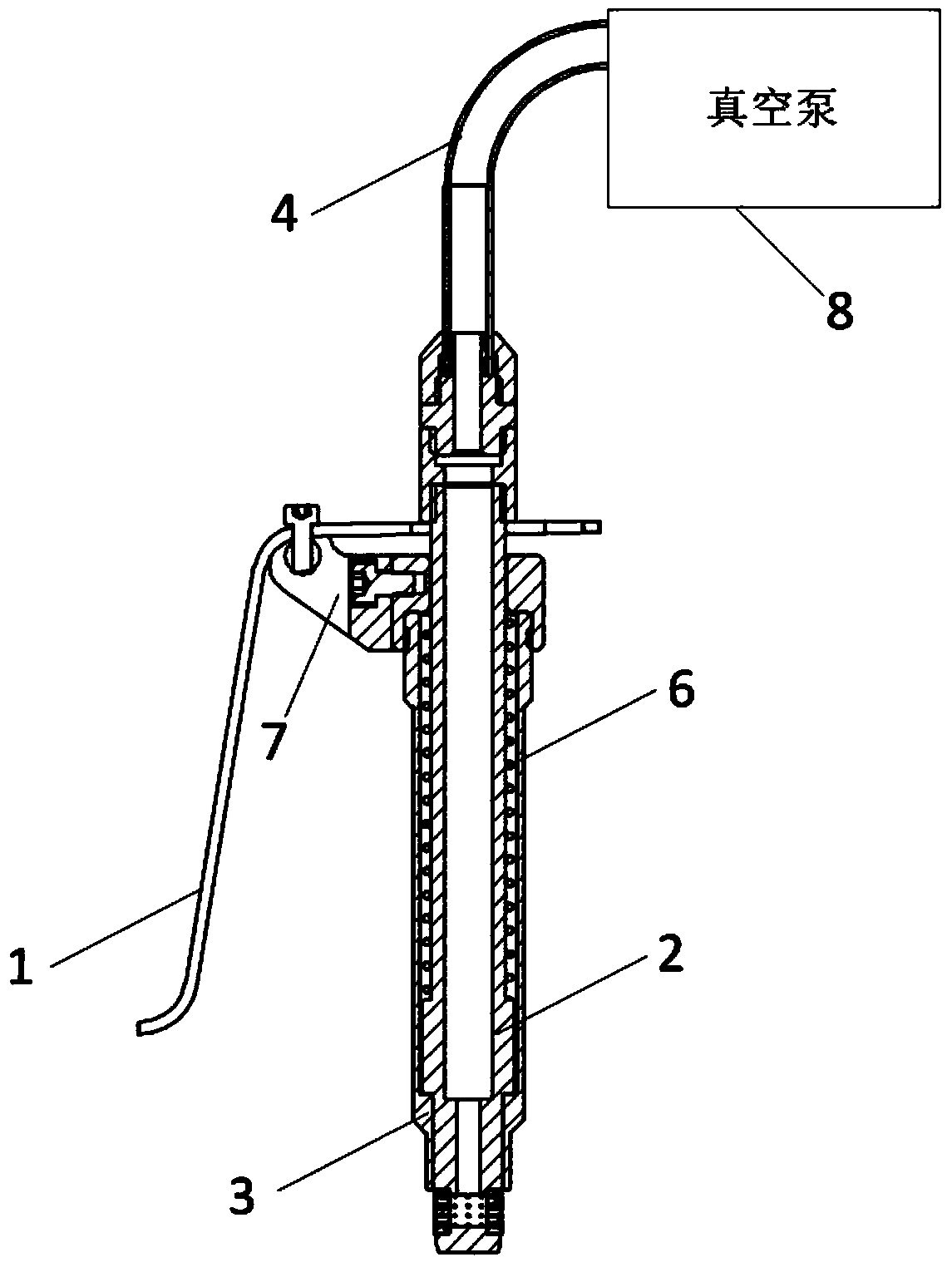

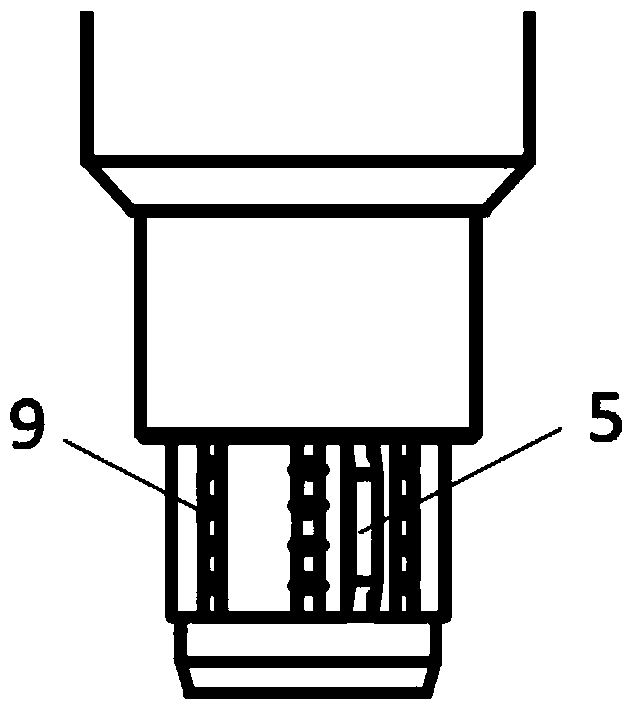

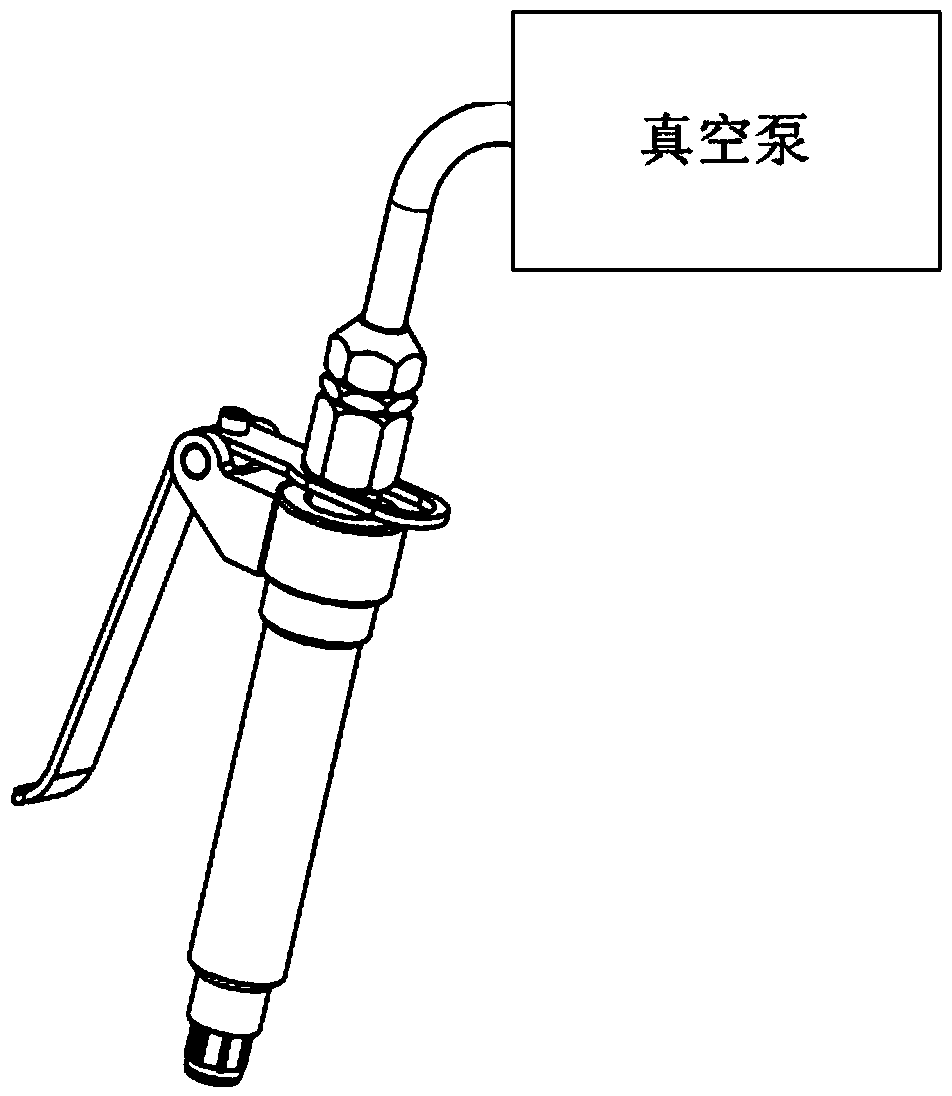

Linear bearing assembly device

ActiveCN104373468ASolving Assembly ChallengesQuality improvementBearing componentsSteel ballEngineering

The invention provides a linear bearing assembly device which comprises an outer shell, an inner shell, a handle, a vacuum sucker and a vacuum pump, wherein the outer shell is arranged outside the inner shell and can move along the surface of the inner shell; the inner shell is of a hollow structure; the front end of the inner shell is connected with the vacuum pump through the vacuum sucker; an elastic head positioning piece is arranged at the tail end of the inner shell; a plurality of through vacuum suction holes are distributed in the side wall of the tail end of the inner shell; the handle is arranged on the inner shell and is positioned between the outer shell and the vacuum sucker. According to the linear bearing assembly device, the difficulty in assembly of balls and a retainer of a linear bearing is smartly solved, when the linear bearing is assembled, only the retainer needs to be sleeved, the handle is pressed to suck the balls, then the balls are sleeved by the outer ring, and the whole assembly process of the linear bearing can be finished, so that the production efficiency is improved, the problems that the steel balls are missed, the positions of the steel balls are mistaken and the like are solved, and the quality of the bearing is improved.

Owner:SUZHOU XINHAO BEARING

Heat radiator perforation anchor fixing device

InactiveCN108419360AFirmly assembledReduce manufacturing costPrinted circuit aspectsCircuit thermal arrangementsTransverse grooveLocking mechanism

The invention discloses a heat radiator perforation anchor fixing device, which comprises a heat radiator, a PCB board and a heat radiator locking mechanism. The heat radiator comprises a plurality ofheat radiating fins, an upper surface and a lower bottom surface, the heat radiating fins are all fixed to the upper surface, and at least one U-shaped groove and a plurality of transverse grooves are formed between adjacent heat radiating fins. The PCB board comprises a board upper surface, board slot holes and a board lower bottom surface, and each board slot hole comprises a board slot hole short side and a board slot hole long side. The locking mechanism comprises claw anchors, anchor brackets and a Z-shaped spring, each anchor bracket comprises an anchor bracket hole, an anchor bracket opening, an anchor bracket V groove and an anchor bracket top surface, the Z-shaped spring comprises a spring middle portion, spring shoulder portions and spring hooks, the claw anchors penetrate the board slot holes upwards from the board lower bottom surface, the spring hooks fasten tops of the claw anchors, and the Z-shaped spring fix the heat radiator to a heat source. The fixing device has advantages that difficulty in 'mounting leg' assembly is greatly lowered, and reliability in assembly, low part machining requirement and low cost are realized.

Owner:AAVID SHANGHAI SYST

Assembly process of electromagnetic switch of automobile starter

ActiveCN104392863APrevent deviationImprove assembly pass rateRelaysEngineeringMechanical engineering

The invention discloses an assembly process of an electromagnetic switch of an automobile starter. The assembly process comprises the steps of 1) integrally riveting a coil block and a switch housing, 2) mounting a movable core mechanism assembly and a fixed core mechanism assembly, 3) mounting a bakelite end cover, and 4) welding an inner-layer starting end and an outer-layer starting end, welding an inner-layer tail end, wherein in the step 1), the coil block is integrally riveted with the switch housing on a riveting device which is composed of an upper mold and a lower mold; the upper mold comprises an upper plate, a hold-down part and four inclined-wedge knives; the lower mold comprises a lower plate, a lower mold positioning block, and four equally distributed transverse stamping knife components; the upper plate is connected with a hydraulic machine; the upper mold is lowered down, and the four transverse stamping knives are capable of completing the stamping of riveting points simultaneously. The assembly process of the electromagnetic switch of the automobile starter is capable of guaranteeing that the accuracy and the dimension of assembly conform to the technical requirements, improving the percent of pass of assembly, improving the production efficiency and reducing the manufacturing cost.

Owner:ZHEJIANG DEWEI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com