Method for selecting outer rotor matched with gyro motor bearings and selection device

An external rotor and gyro technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of reduced production efficiency, large assembly errors of gyro motor bearings, and preloads that cannot reach the rigidity and rotation accuracy. Improve assembly efficiency and installed pass rate, solve the demand for mass production, and improve the effect of assembly pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

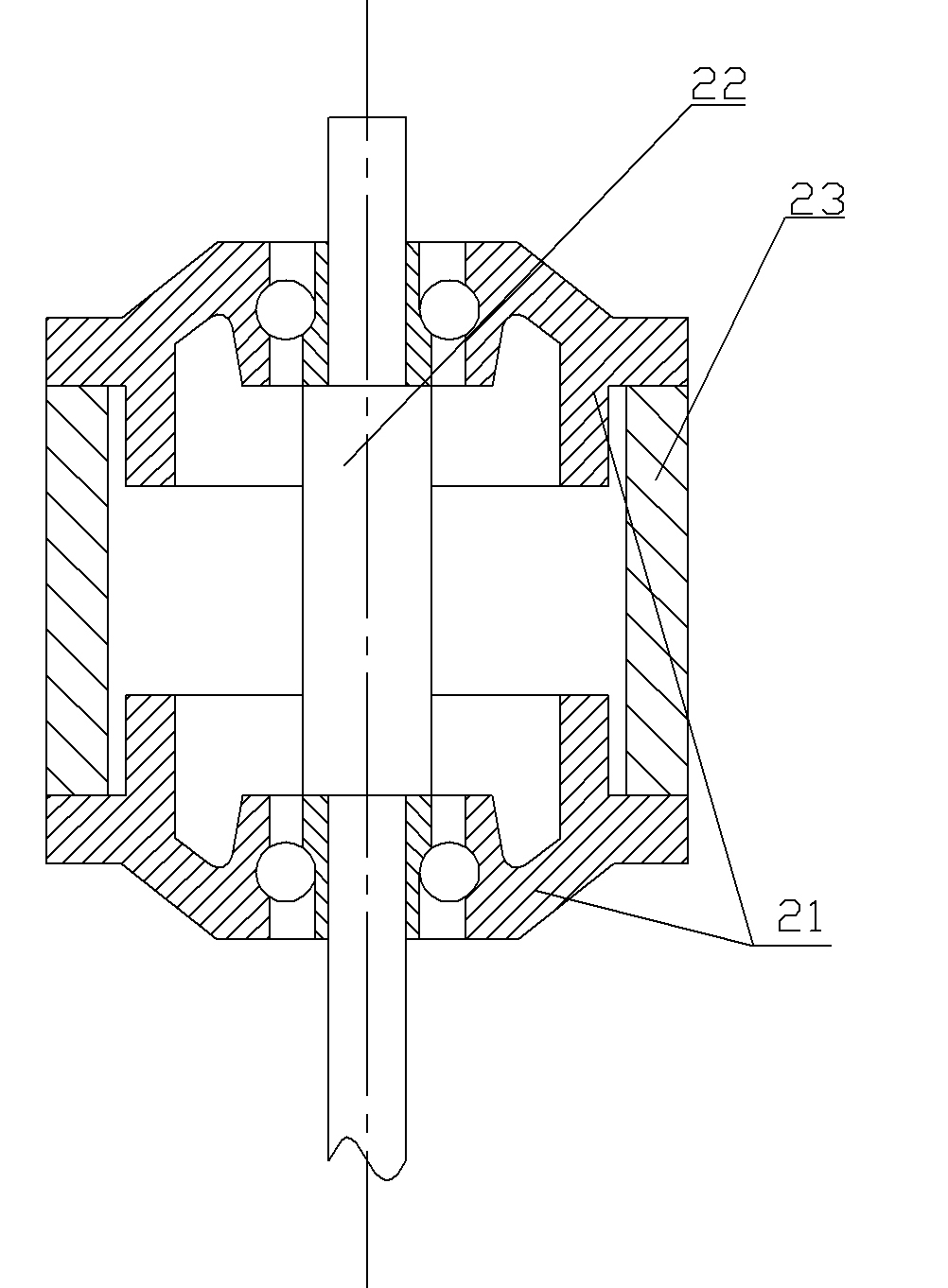

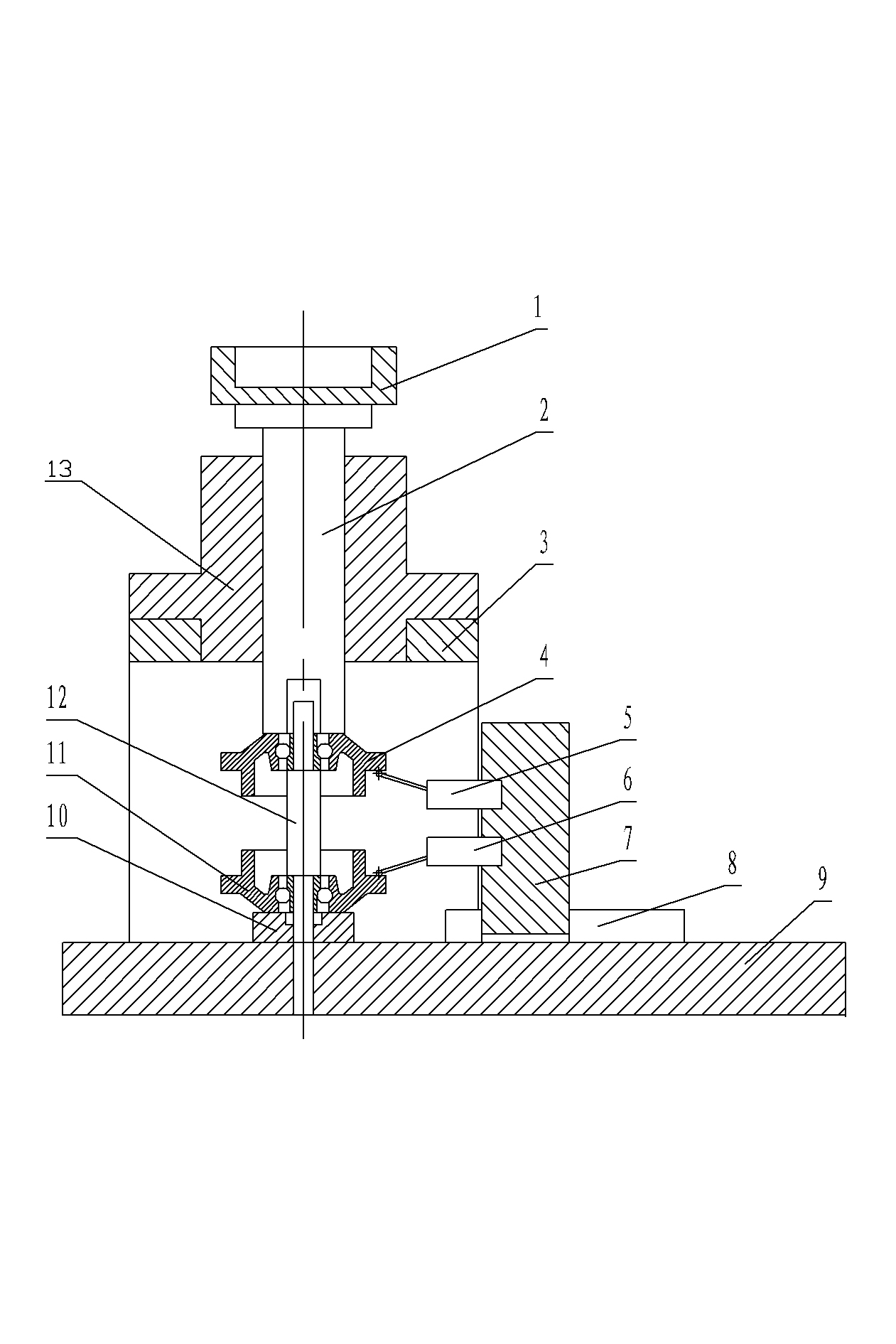

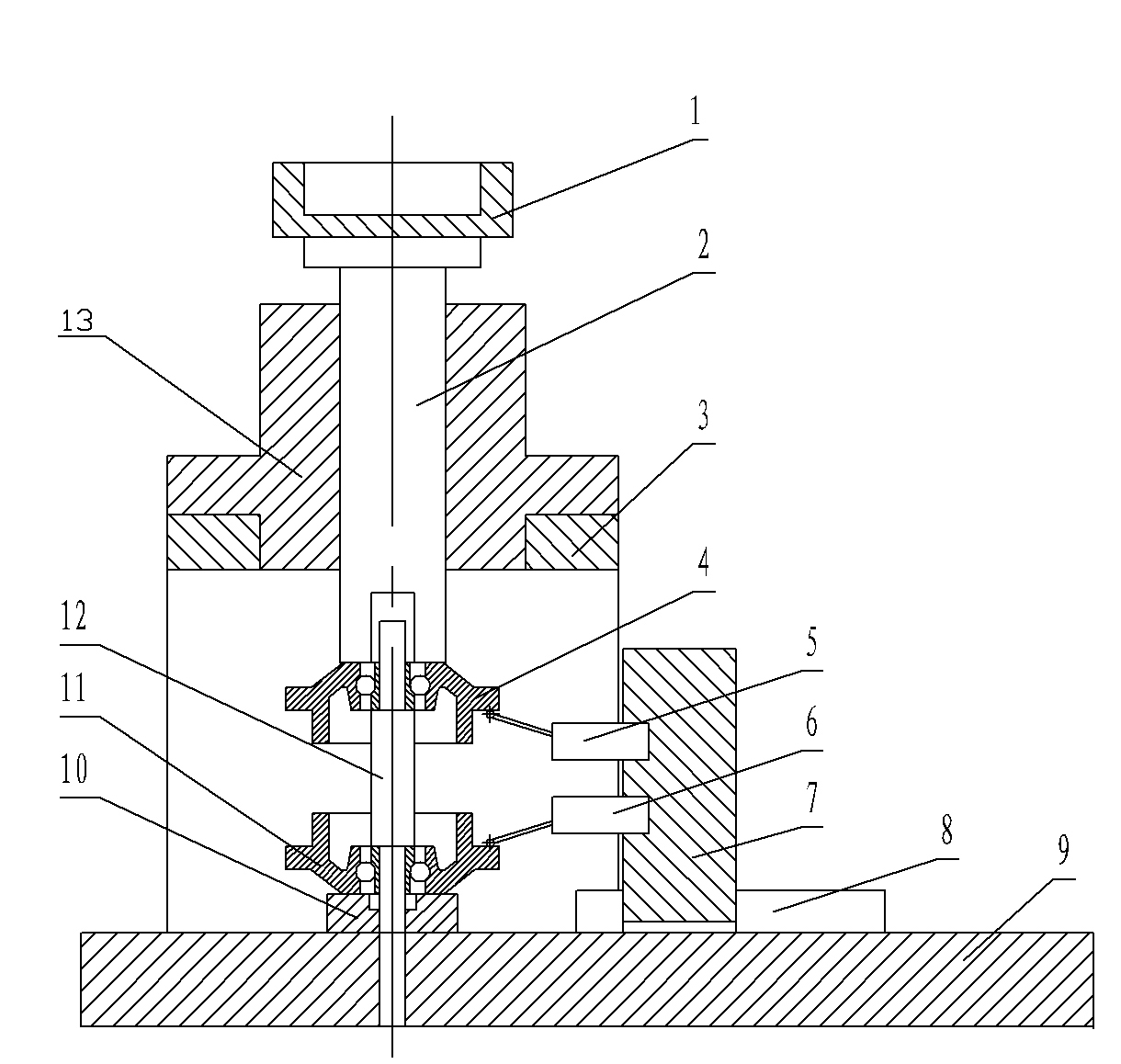

[0019] Such as figure 2 As shown, in the present invention, the method of matching the outer rotor matched with the gyro motor bearing, first, the assembled gyro motor upper bearing 4 and the gyro motor lower bearing 11 are positioned on the centering positioning seat 10 through the gyro motor shaft 12 , put a standard weight on the loading weight plate 1 and apply a set axial load to the outer ring of the upper bearing 4 of the gyro motor through the air spindle 2, and measure the gyroscope through the calibrated first displacement sensor 5 and the second displacement sensor 6 The distance value between the inner end surface of the outer ring shoulder of the motor upper bearing 4 and the inner end surface of the corresponding outer ring shoulder of the gyro motor lower bearing 11, and then select and match the gyro motor outer surface with a height equal to the distance value obtained by the measurement. rotor. The data acquisition and signal processing of the displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com