Assembling process of medical plastic needle assembly

An assembly process and plastic needle technology, which is applied in the field of assembly process of medical plastic needle components, can solve the problems of automatic assembly of medical plastic needle components and inability to apply medical plastic needle components, etc., and achieves reduction of human pollution, reasonable arrangement and process Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

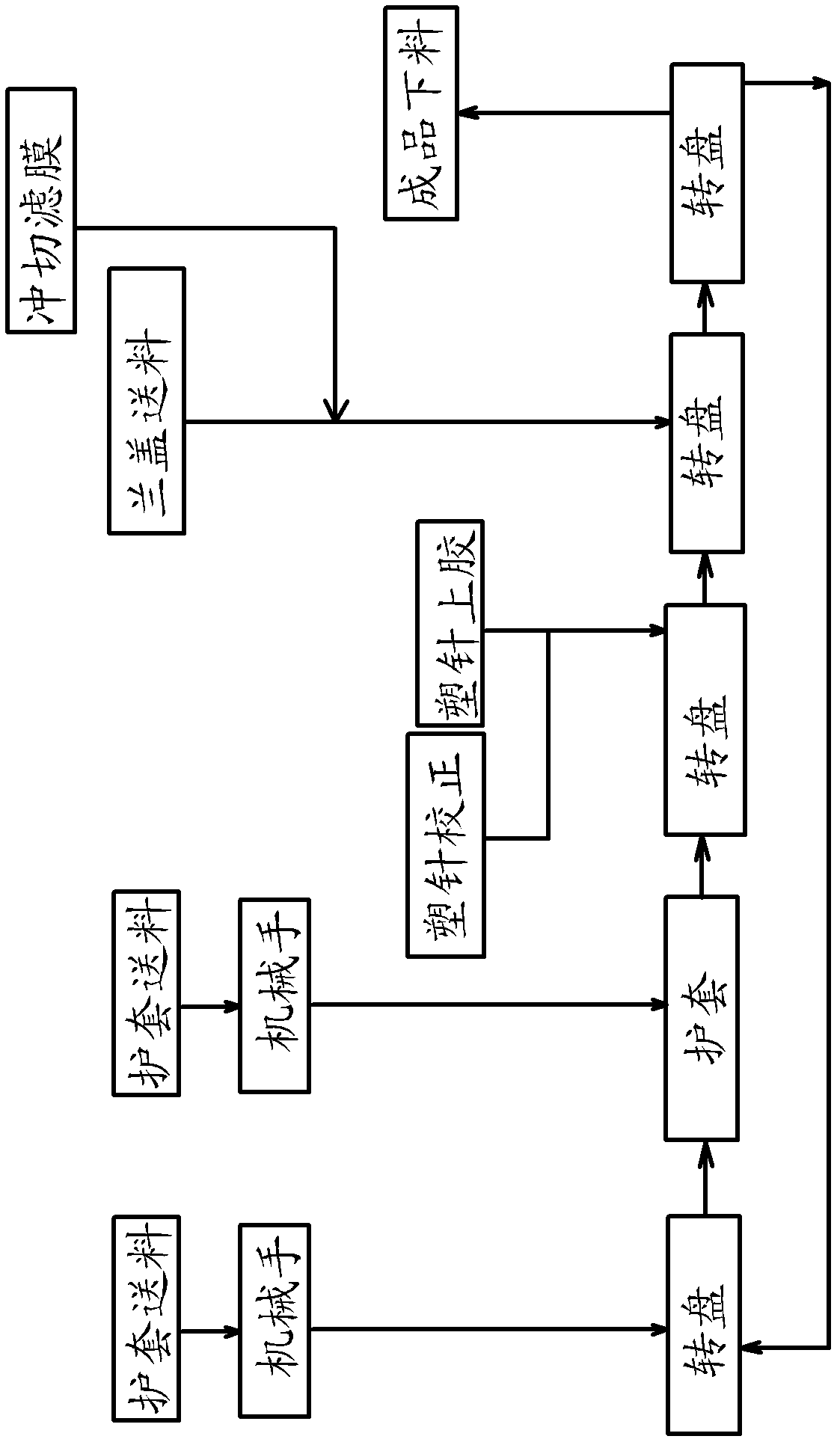

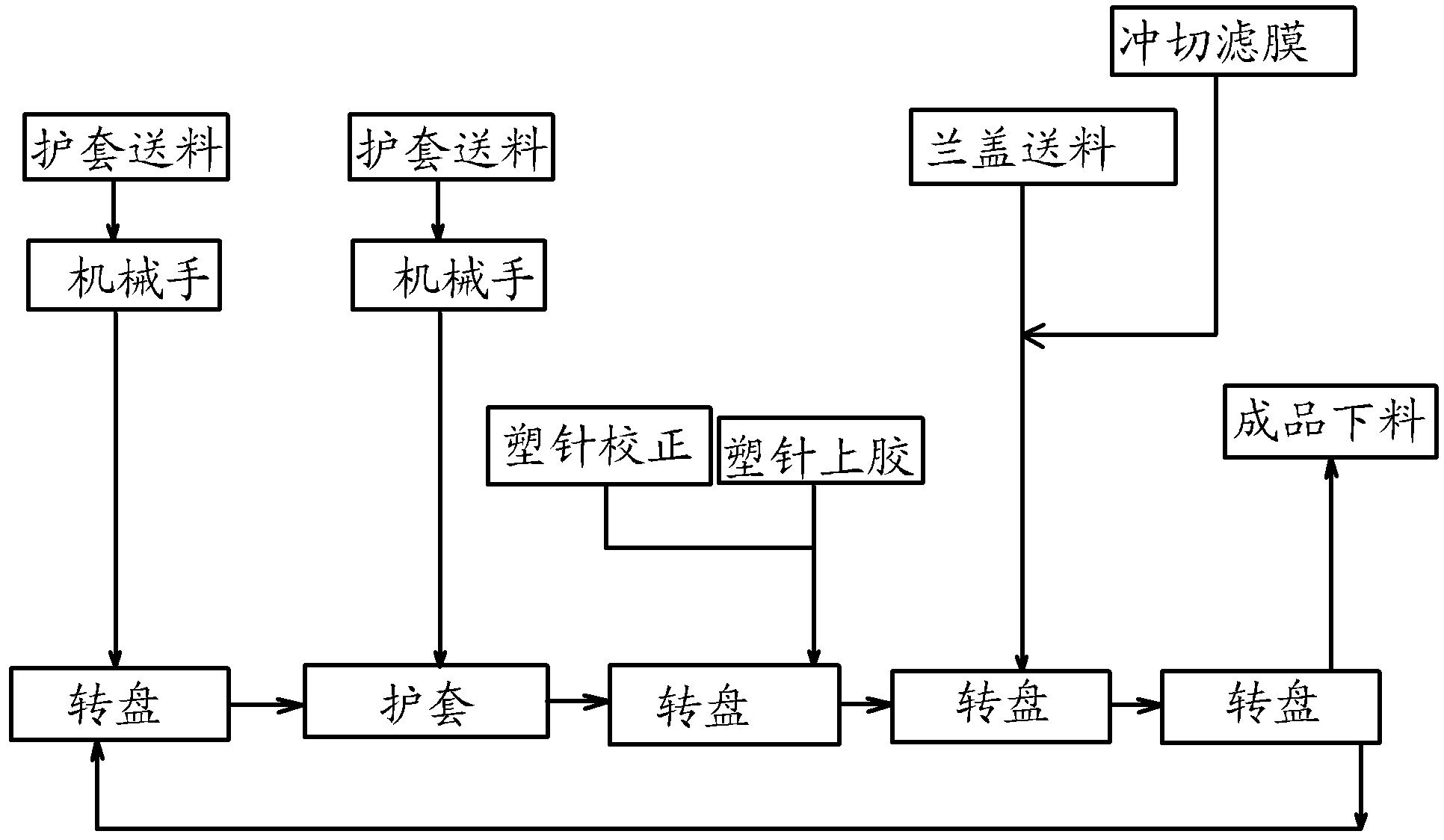

[0033] The plastic needle includes a tubular needle body, one end of the needle body is a puncture part for piercing the medicine bottle and the puncture part has a liquid inlet, and the side part of the plastic needle has an exhaust pipe communicating with the liquid inlet. The opposite end of the needle piercing part has a liquid outlet. Such as figure 1 As shown, the assembly process of the medical plastic needle assembly includes the following steps:

[0034] A. Conveying the sheath: place the sheath in the corresponding feeding device, and the feeding device will transport the sheath to the assembly turntable in an orderly manner, and position the sheath on the turntable. In this step, a manipulator is used to grab the sheath in the feeding device, and then the manipulator partially embeds the sheath into the turntable. Two sheaths are clamped on the turntable at a time.

[0035] B. Connection between the sheath and the plastic needle: place the plastic needle in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com