Patents

Literature

5522results about How to "Improve construction quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

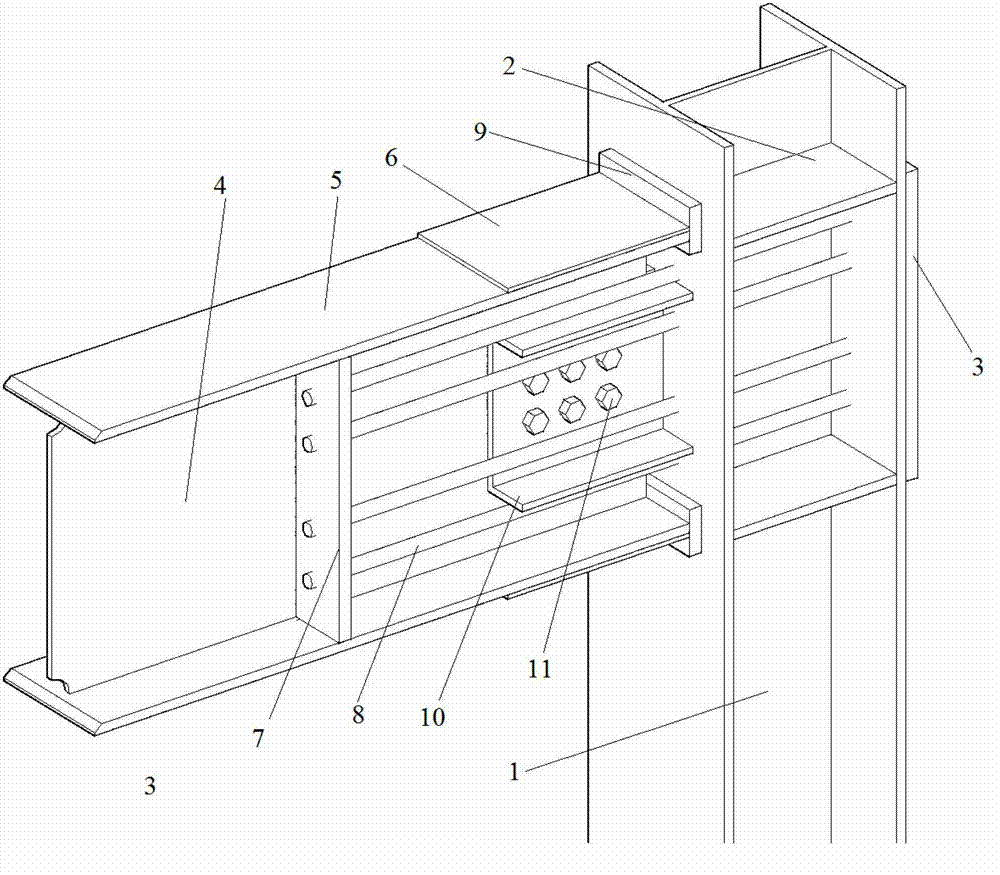

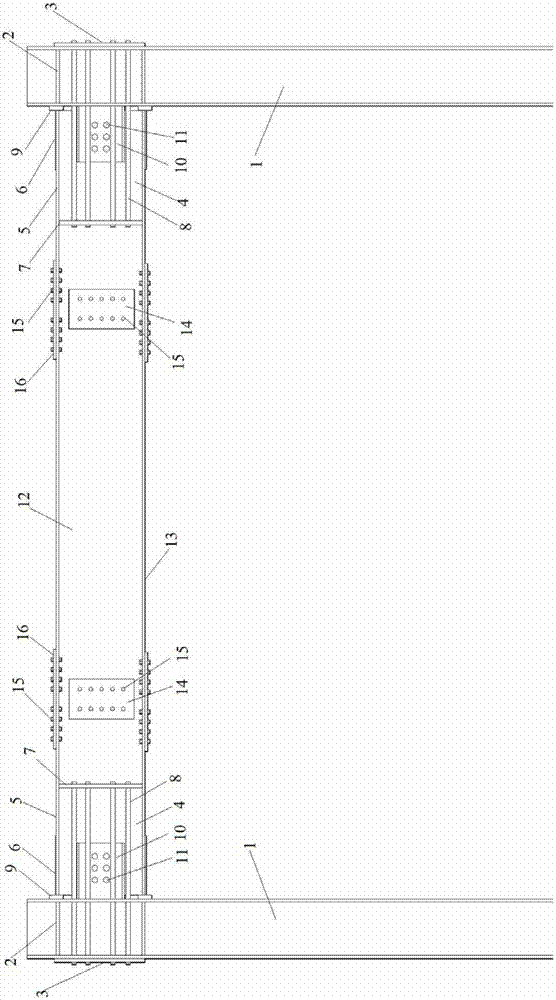

Steel frame precast prestressed beam column joint with post-earthquake recovering function

InactiveCN102817413AEasy constructionImprove construction qualityBuilding material handlingShock proofingPre stressSteel frame

The invention relates to a steel frame precast prestressed beam column joint with a post-earthquake recovering function. The joint comprises a steel frame column, a short beam section, a beam column connection device and an energy consumption device, wherein the steel frame column comprises a steel column, a column reinforced rib and a column reinforced plate; the short beam section comprises a short beam section web, a short beam section flange and a short beam section flange reinforced plate; the beam column connection device comprises a short beam section web reinforced rib, a prestressed cable and a beam end top plate; the energy consumption device comprises two channel steels and a high-strength bolt; and the two short beams are integrally connected with the column in a factory through a tension prestressed cable and two short beam section web reinforced ribs. When the earthquake action achieves a certain degree, the contact surface of the beam and the column is opened; the high-strength bolt is in friction energy dissipation so as to avoid destroying main components, such as beams and columns After the earthquake, the beams can be recovered to the former vertical position under the action of the prestress.

Owner:BEIJING UNIV OF TECH +1

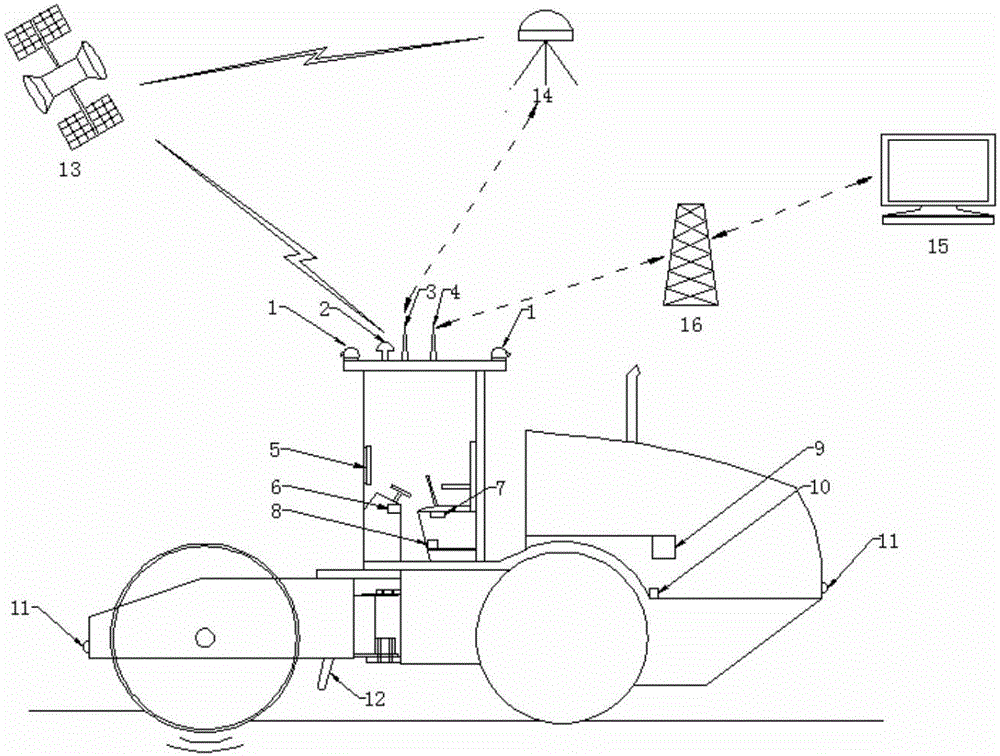

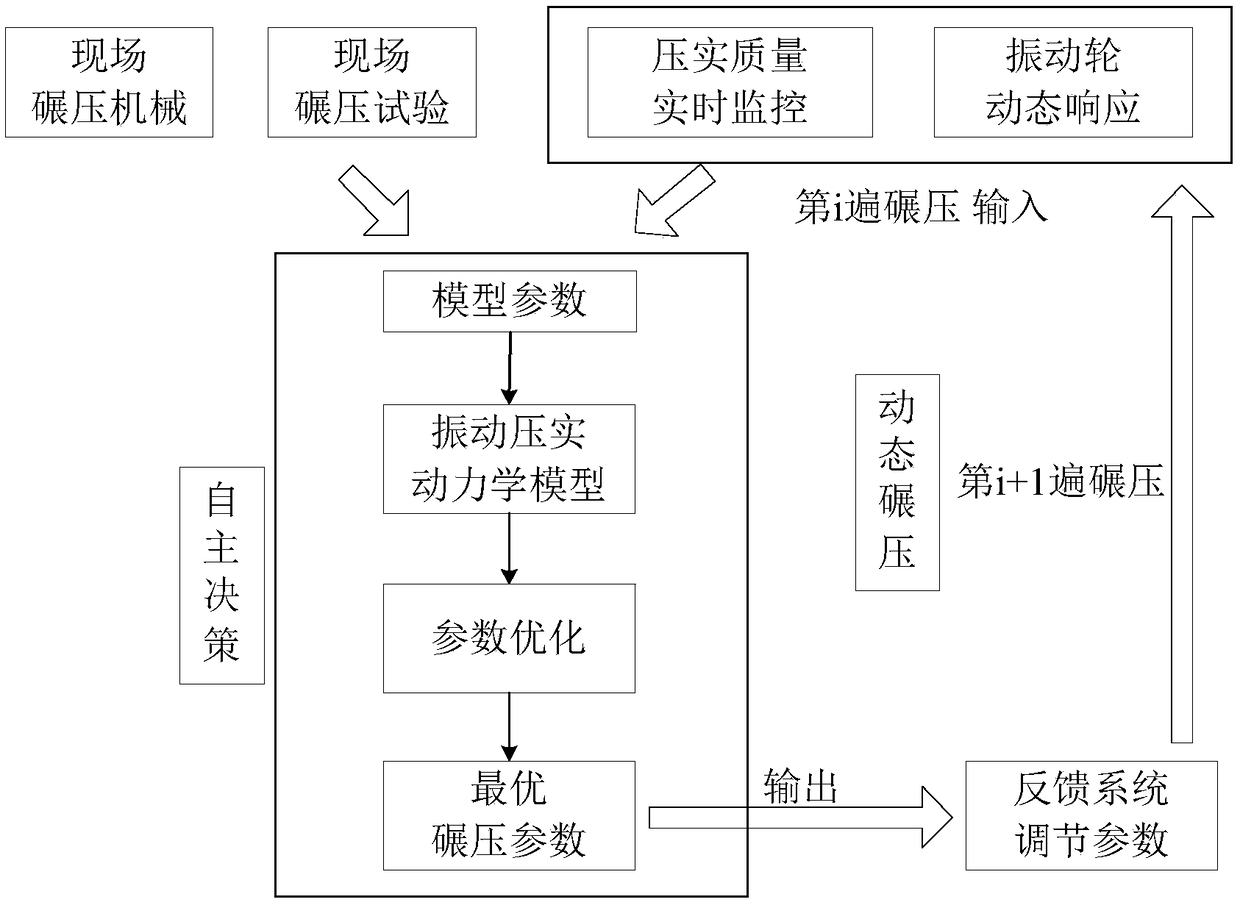

Automatic driving system and method of water conservancy construction vibration roller

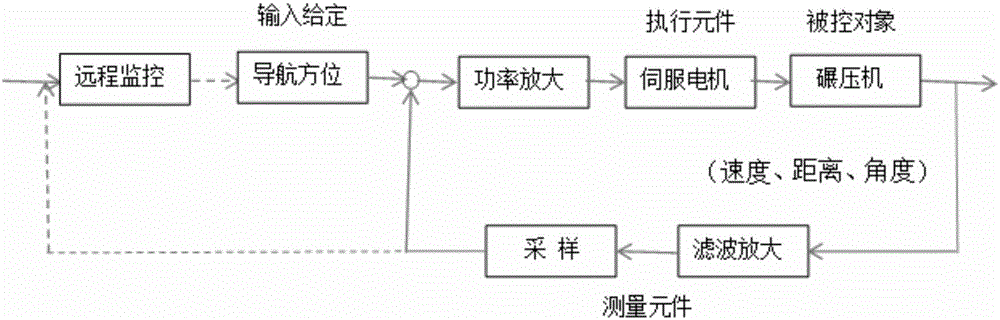

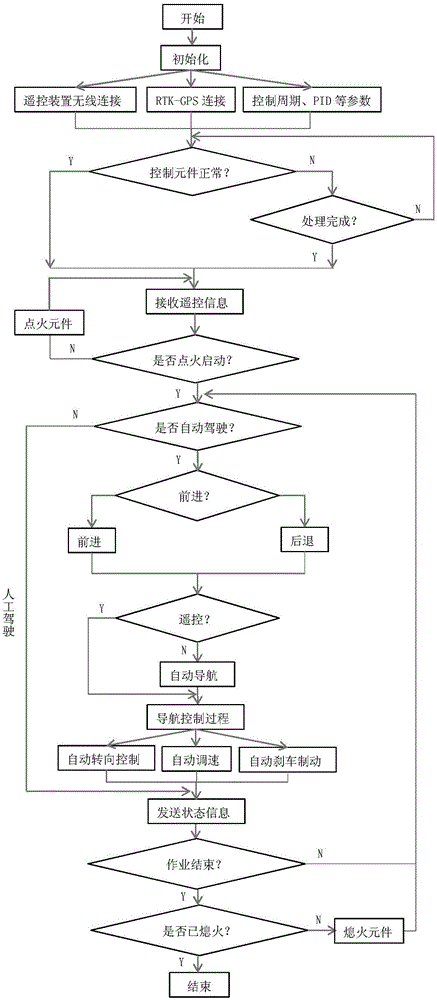

ActiveCN105137997AImprove construction qualityPrecise AutopilotPosition/course control in two dimensionsSoil preservationSteering wheelAutomatic control

The invention provides an automatic driving system and method of a water conservancy construction vibration roller. The system comprises a remote monitoring device and an onboard automatic control device. The remote monitoring device plans working areas and navigation routes according to 3D digital model man-machine interaction of construction projects, receives data like position, speed and rotation direction of the roller and working environment video information in a wireless communication manner and sends automatic navigation data and instructions to the onboard automatic control device. The remote monitoring device can also remotely control the roller based on received emergent processing requests in a man-machine interaction manner. The onboard automatic control device receives the automatic navigation instruction and remote control driving information sent by the remote monitoring device in real time, and compares the information sent by the onboard automatic control device with the information like position, speed and rotation angle detected by an onboard RTK-GPS and a sensor. After being adjusted via the PID algorithm, deviation is sent to execution elements like an electric steering wheel, an electric throttle and an electric brake to control the vibration roller to finish respected rolling work. According to the invention, the automatic driving system is compatible with a manual driving system.

Owner:TSINGHUA UNIV

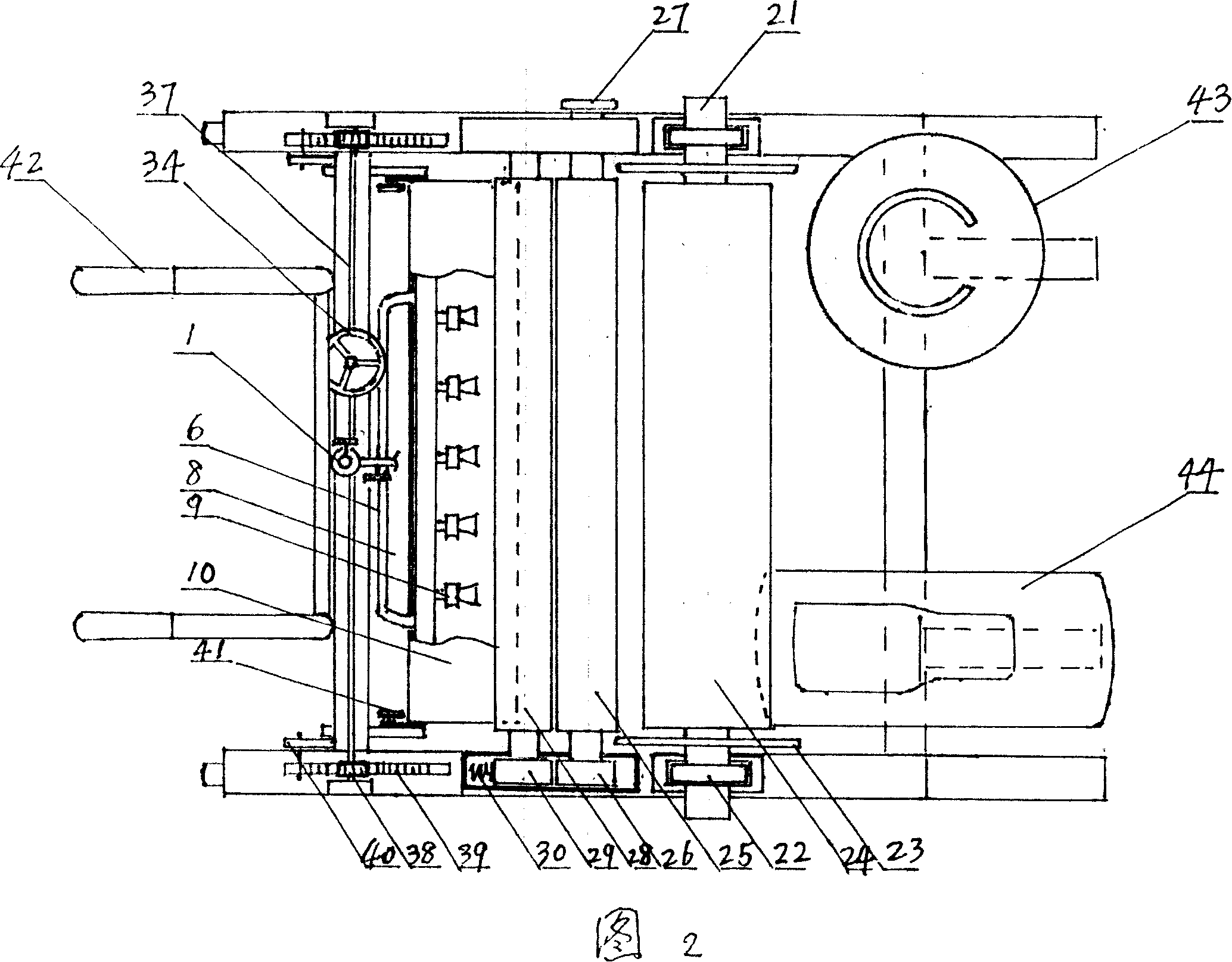

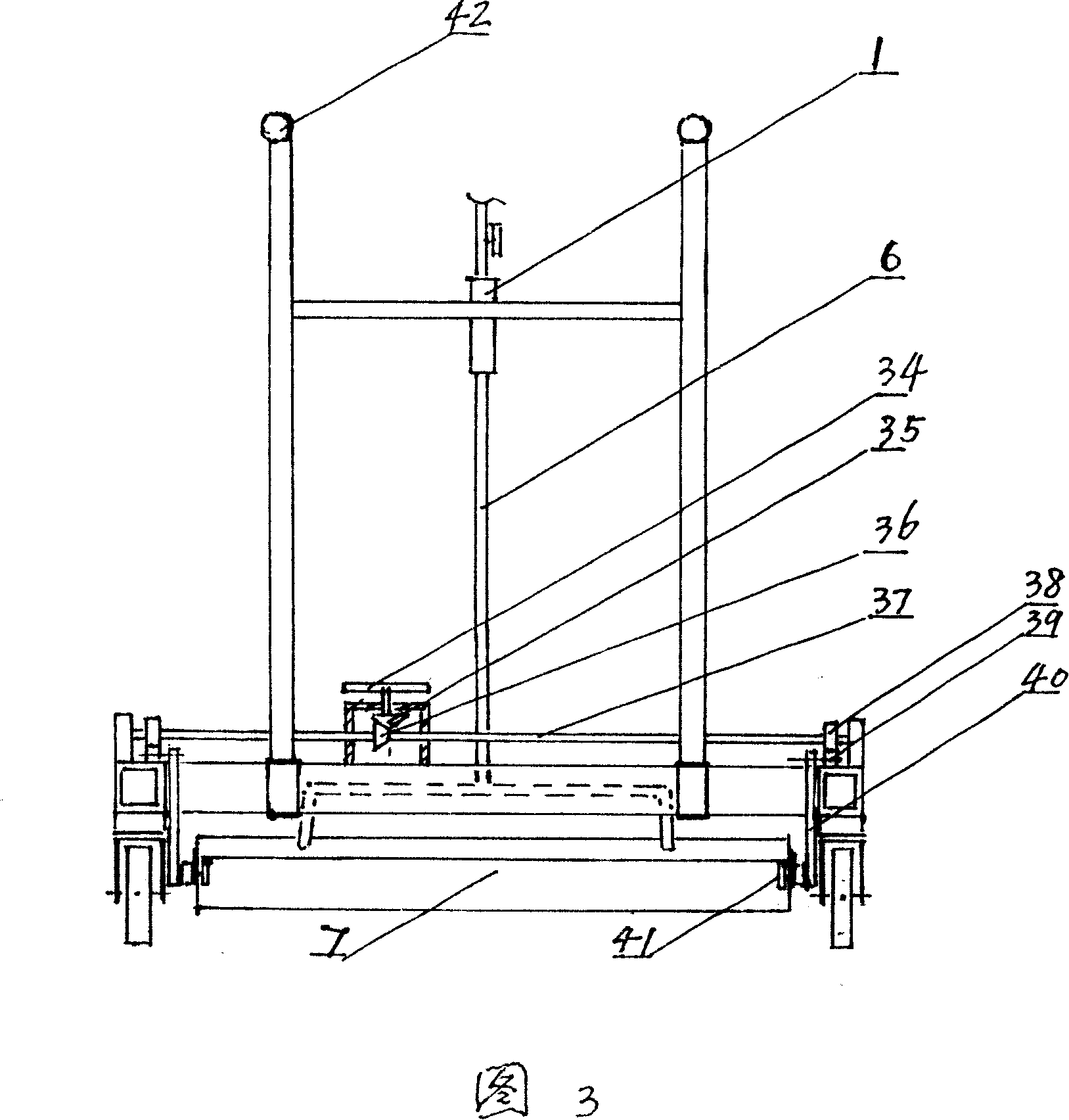

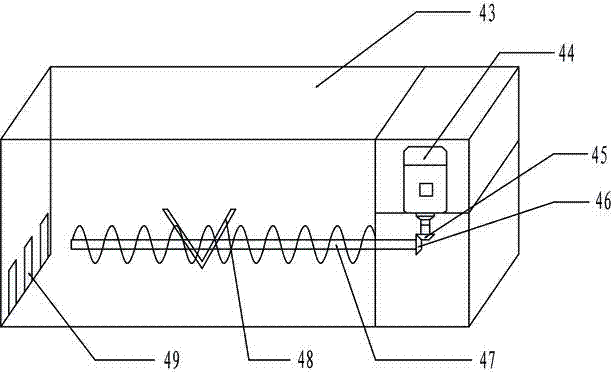

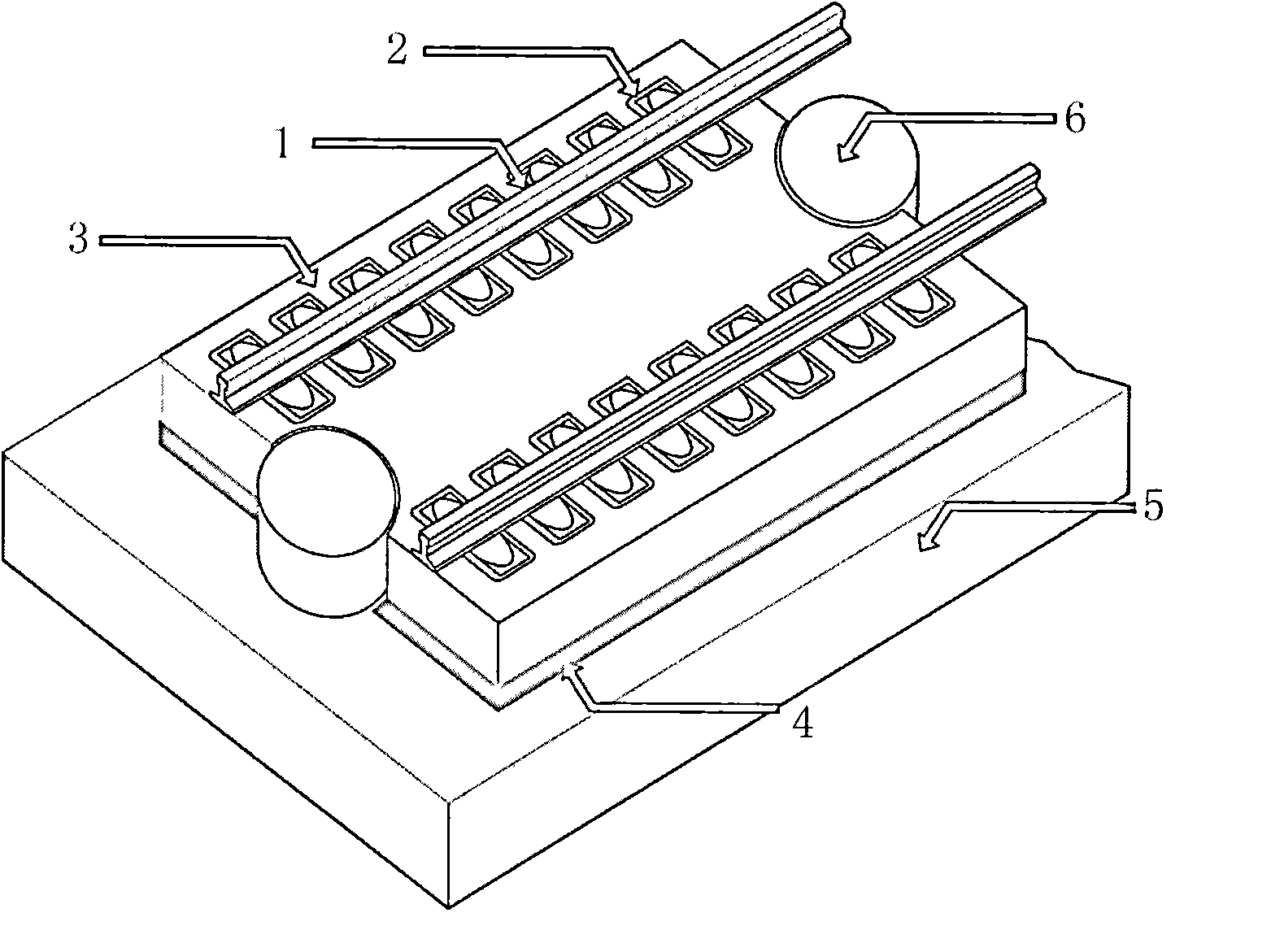

Water-proof coiled material layer

InactiveCN101109210AImprove construction efficiencyReduce labor intensityRoof toolsEngineeringGasoline

A waterproof coil laying machine is provided, which pertains to the laying equipment for waterproof coil for waterproof tech in roofs of buildings, and comprises a frame, a laying mechanism and a heater. The laying mechanism comprises a coil shaft 21, guide roll 25 and 28, a tension roll 32, and a pressing roll 33; the heater comprises a mixture gas distribution valve 1, a mixed air conveying pipe 6, and a burner 7. The mixture gas distribution valve 1 is in form of 3 pipe sets. The burner comprises a burner gas pipe 8, a row of flame nozzles 9 mounted on the gas pipe and flame covers 10. The invention realizes mechanization in laying of waterproof coil, is of high construction efficiency, lightens greatly labor intensity; the invention employs LPG, especially compressed air for supporting combustion, the fire is strong, the temperature is high, can enable the surface of the waterproof coil to melt rapidly; and in addition, as the inner course has a low temperature rise, the structure and waterproof property of the whole material will not be damaged, the construction quality is good; as using LPG, the cost is reduced comparing with using gasoline.

Owner:王新格

Self-propelled inverted arch template construction method

The invention discloses a self-propelled inverted arch template construction method for a tunnel, which comprises the following construction steps of: setting out a control line for an inverted arch digging section and a longitudinal construction joint according to the design requirement; performing smooth-wall blasting digging on an inverted arch of the tunnel; moving an inverted arch trestle in place; conveying inverted arch stone slag out of the tunnel by using an excavator and a conveying device and abandoning the stone slag in a slag field, and cleaning an inverted arch base; assembling an inverted arch end template; laying steel rails, and moving the inverted arch template to longitudinally move in place per se; starting a hydraulic device to lower the inverted arch template, and supporting the template firmly by using a screw jack; pouring inverted arch concrete; and curing the concrete with equal strength, folding the screw jack, withdrawing a hydraulic cylinder, and releasing a die. The construction method has low cost, is convenient to operate, and improves the construction efficiency; and the longitudinal construction joint is vibrated densely compared with common template construction, and has positive effect of improving the construction quality of tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

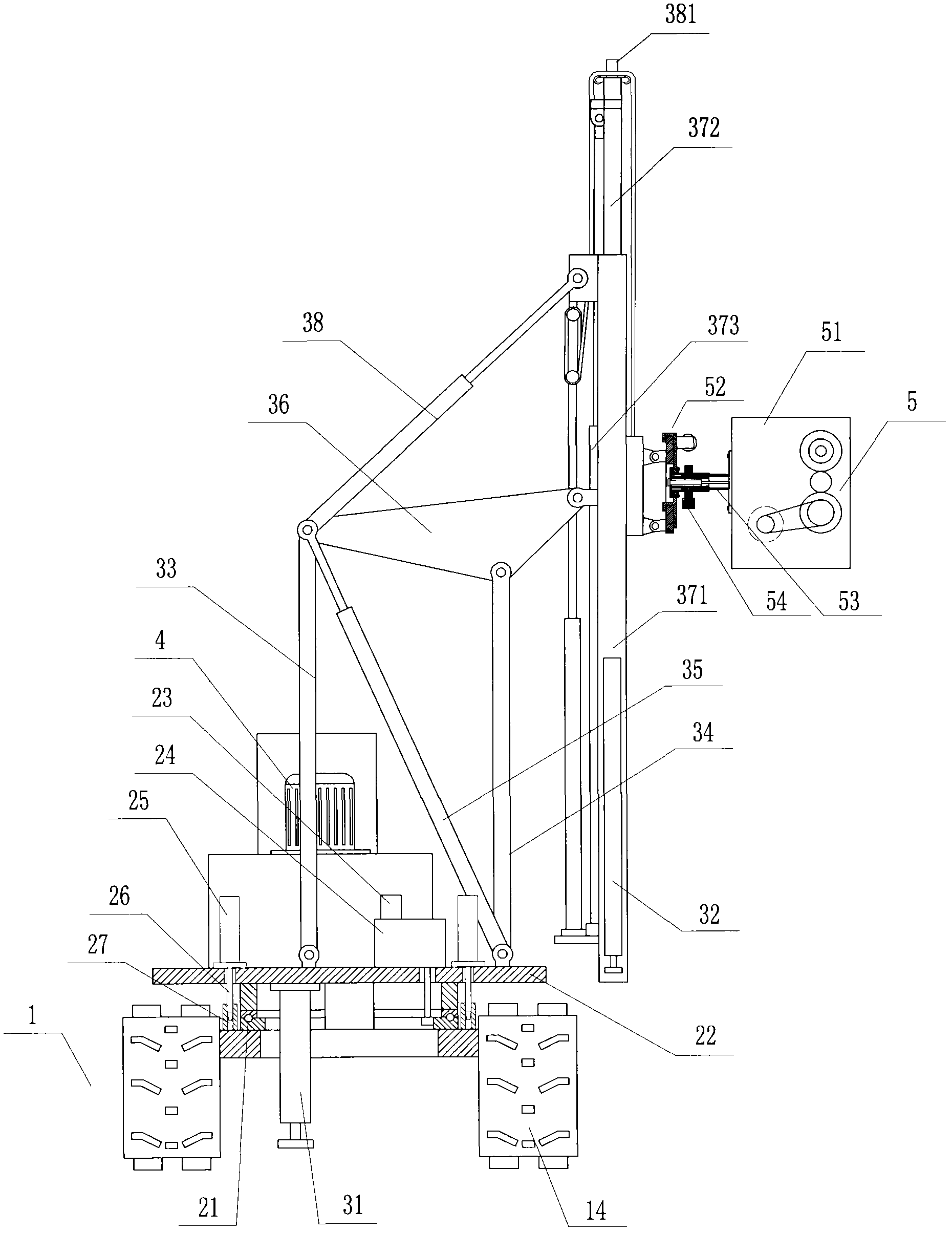

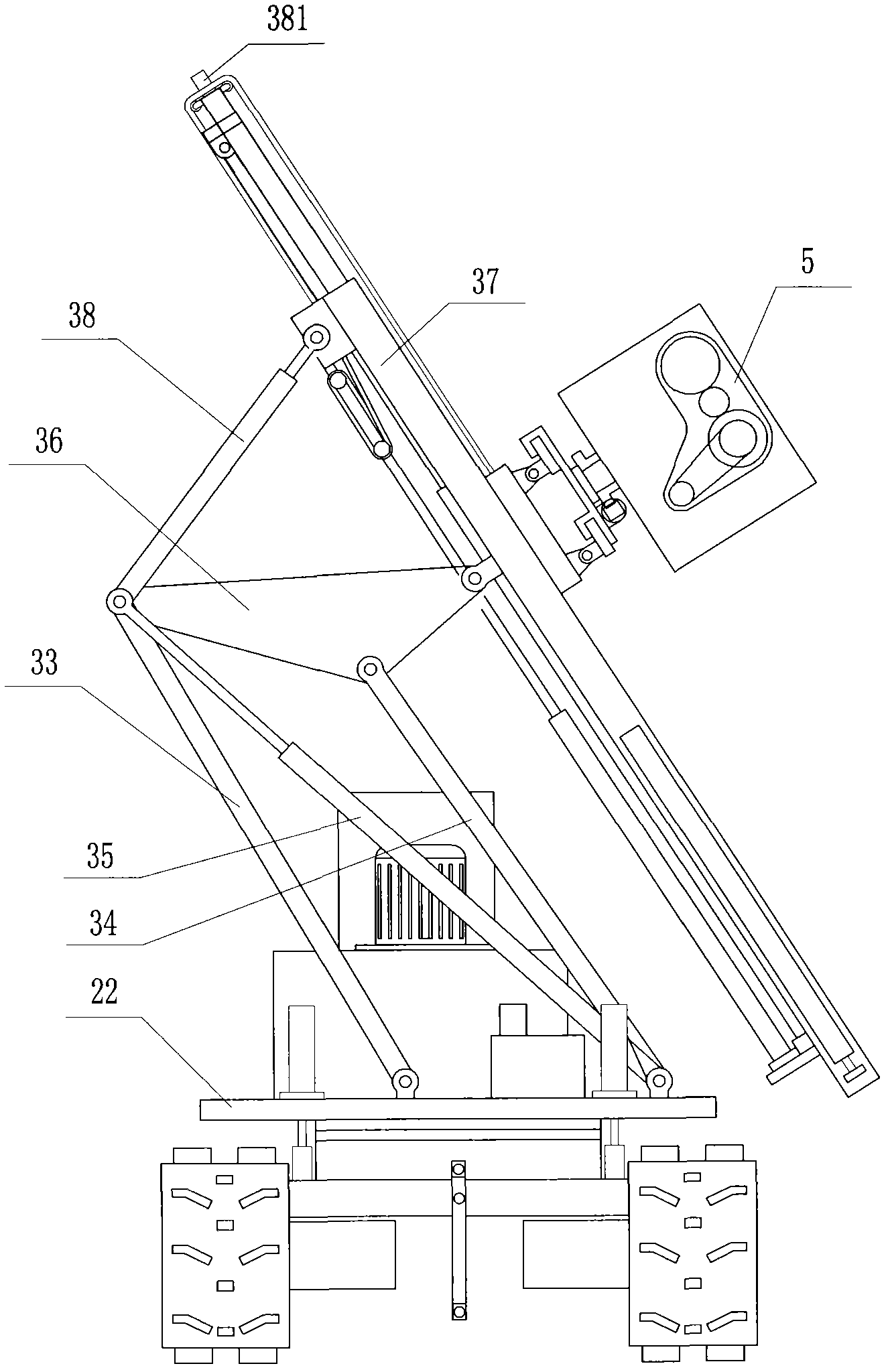

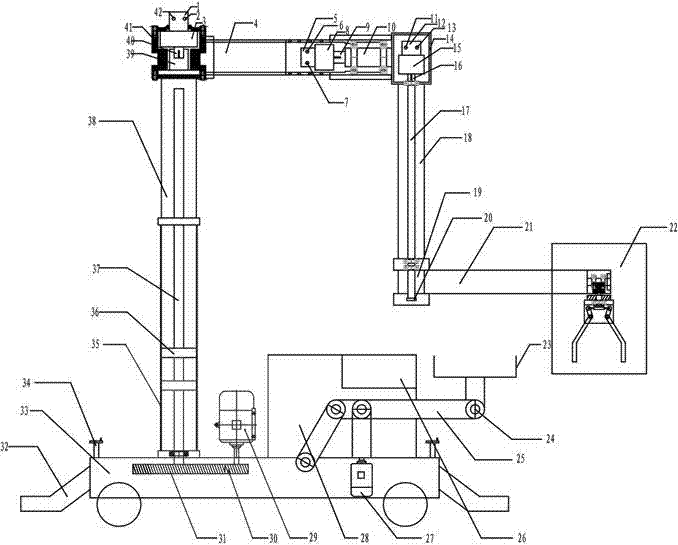

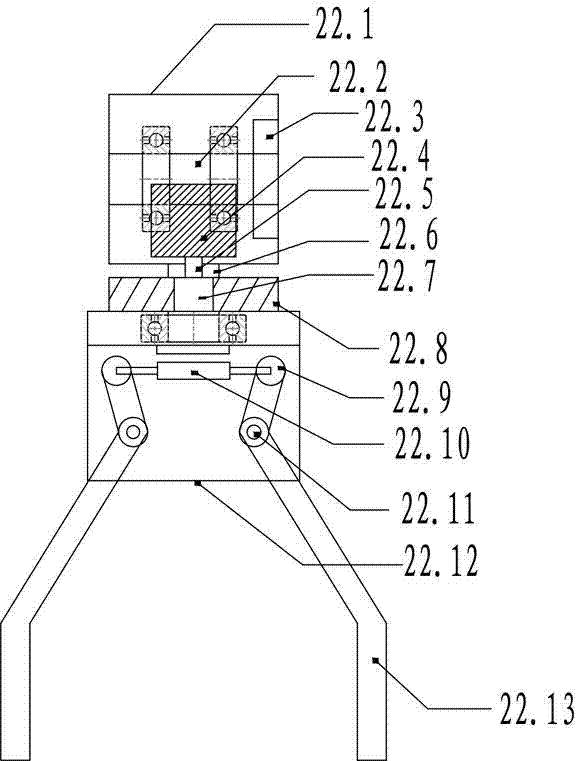

Building wall construction robot

ActiveCN102383585AWalking smoothlyImprove efficiencyBuilding constructionsEngineeringArchitectural engineering

The invention discloses a building wall construction robot, which comprises a crawler unit, a rotary turntable device, a retraction regulating mechanical arm, a construction tool lifting device, a plaster hopper device, a construction position locking device, a trackless guide device and a power device. The building wall construction robot is compact in structure, stable in walking, flexible in movement, and accurate in direction change; the construction tool has large lift; the construction tool lifting device is full automatic; and the construction process completely simulates a manual plastering mode, trackless guide is adopted, the trouble of laying a guide rail is avoided, and the construction quality and construction efficiency are greatly improved.

Owner:蒋京德

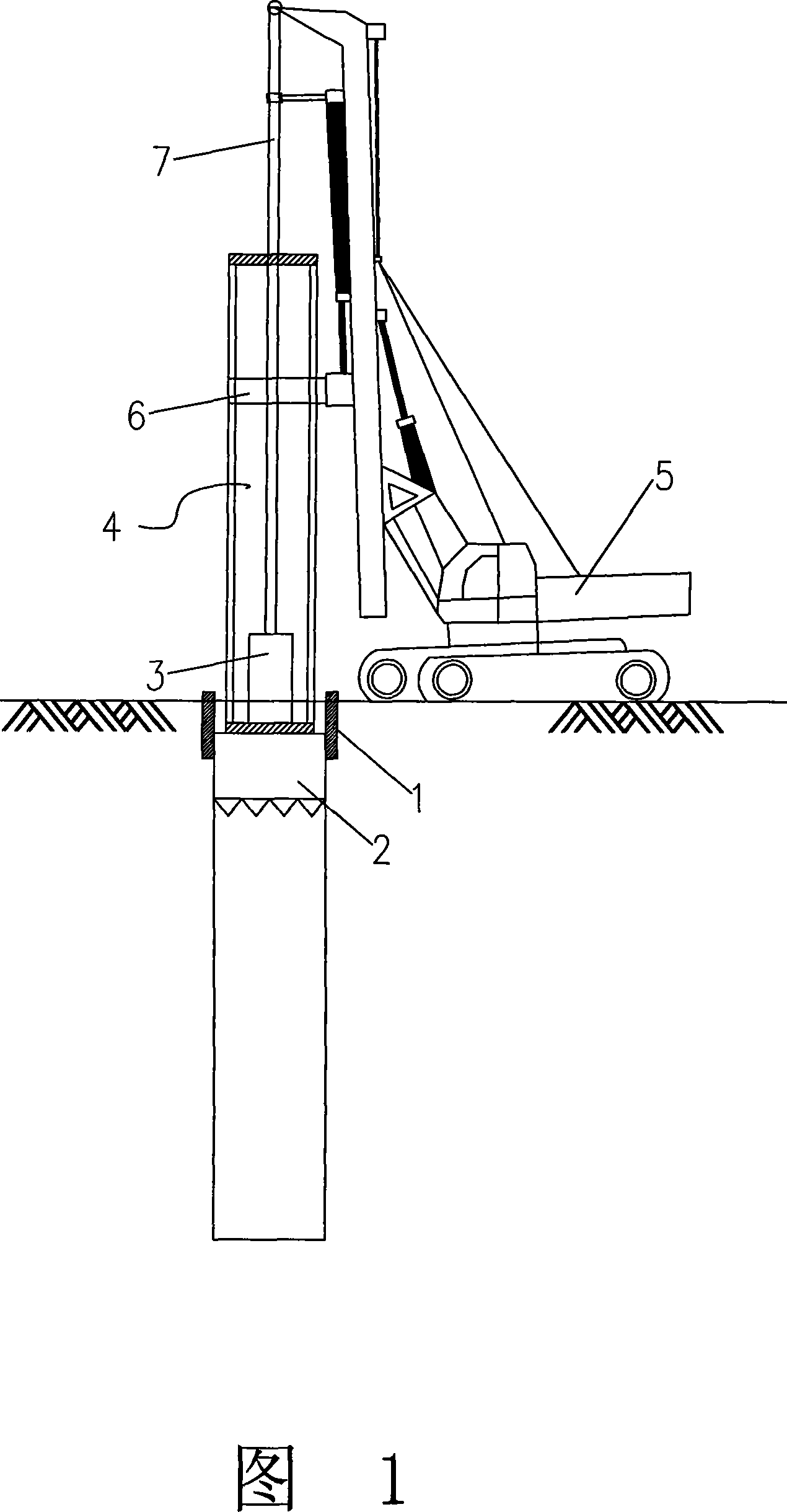

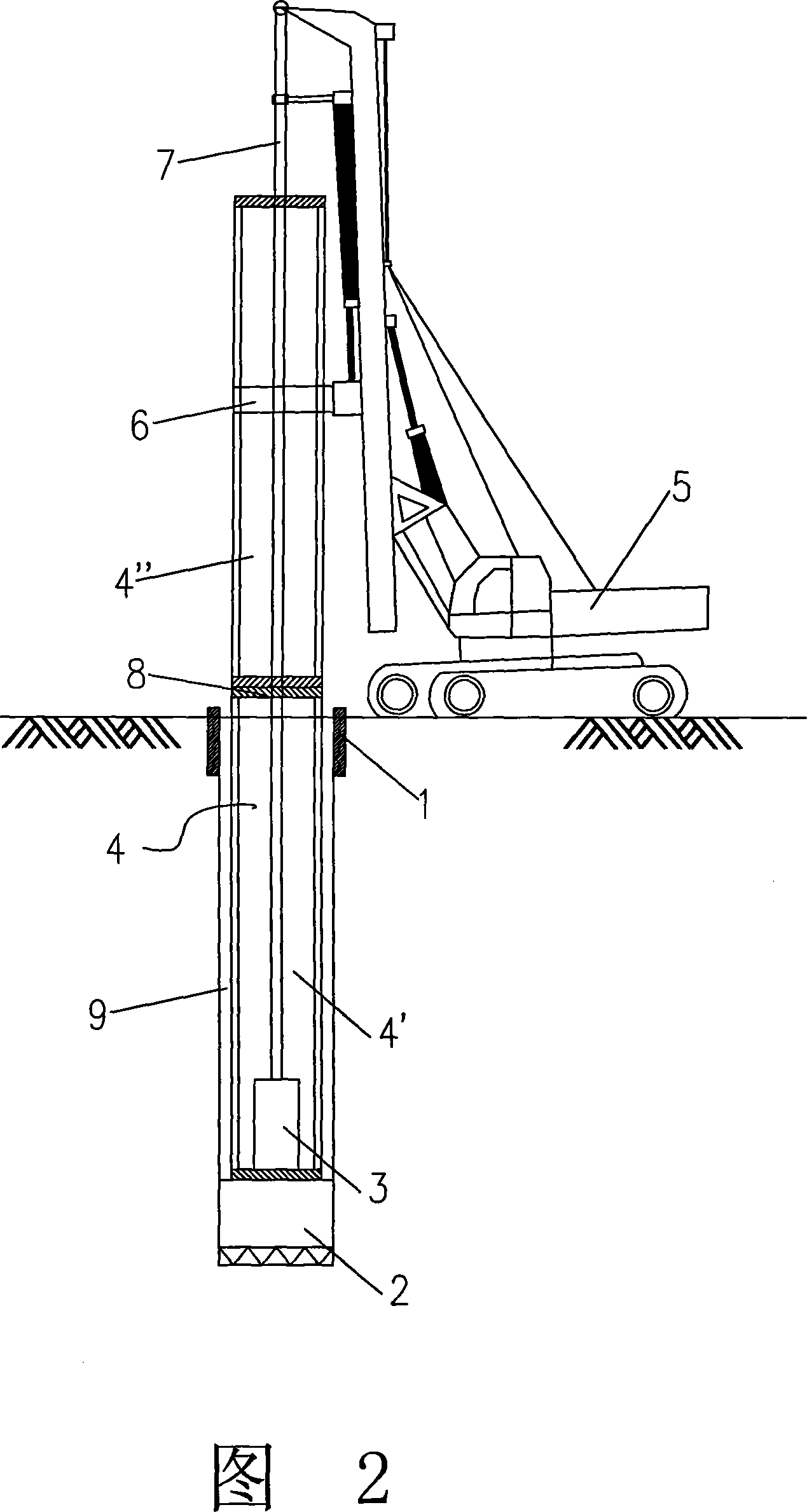

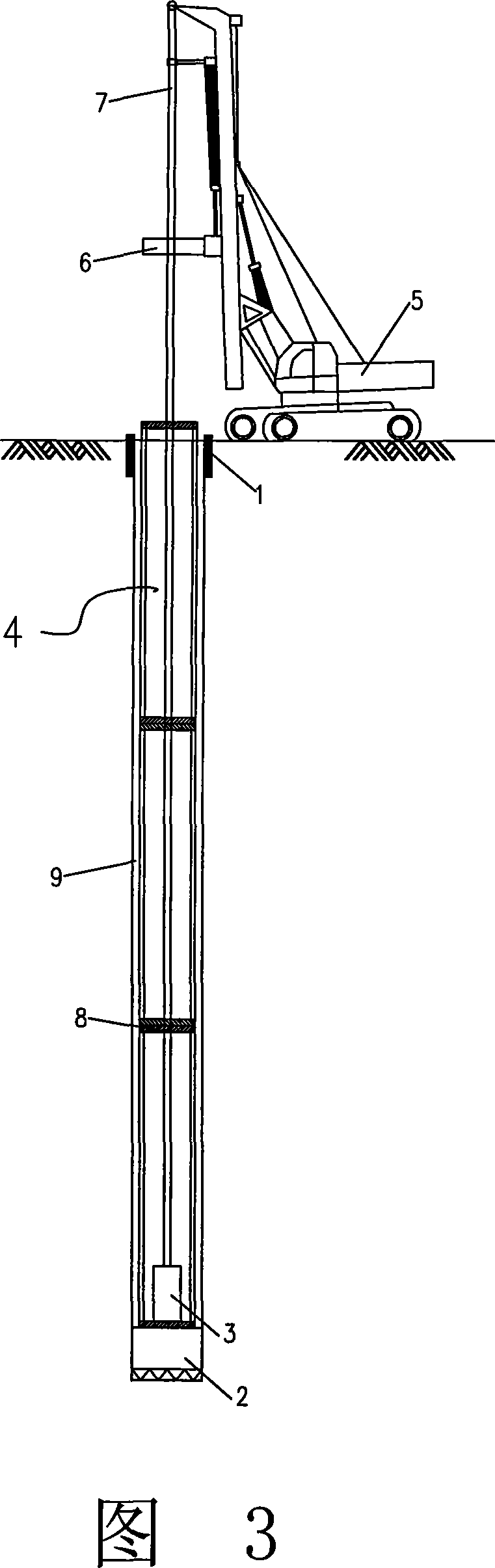

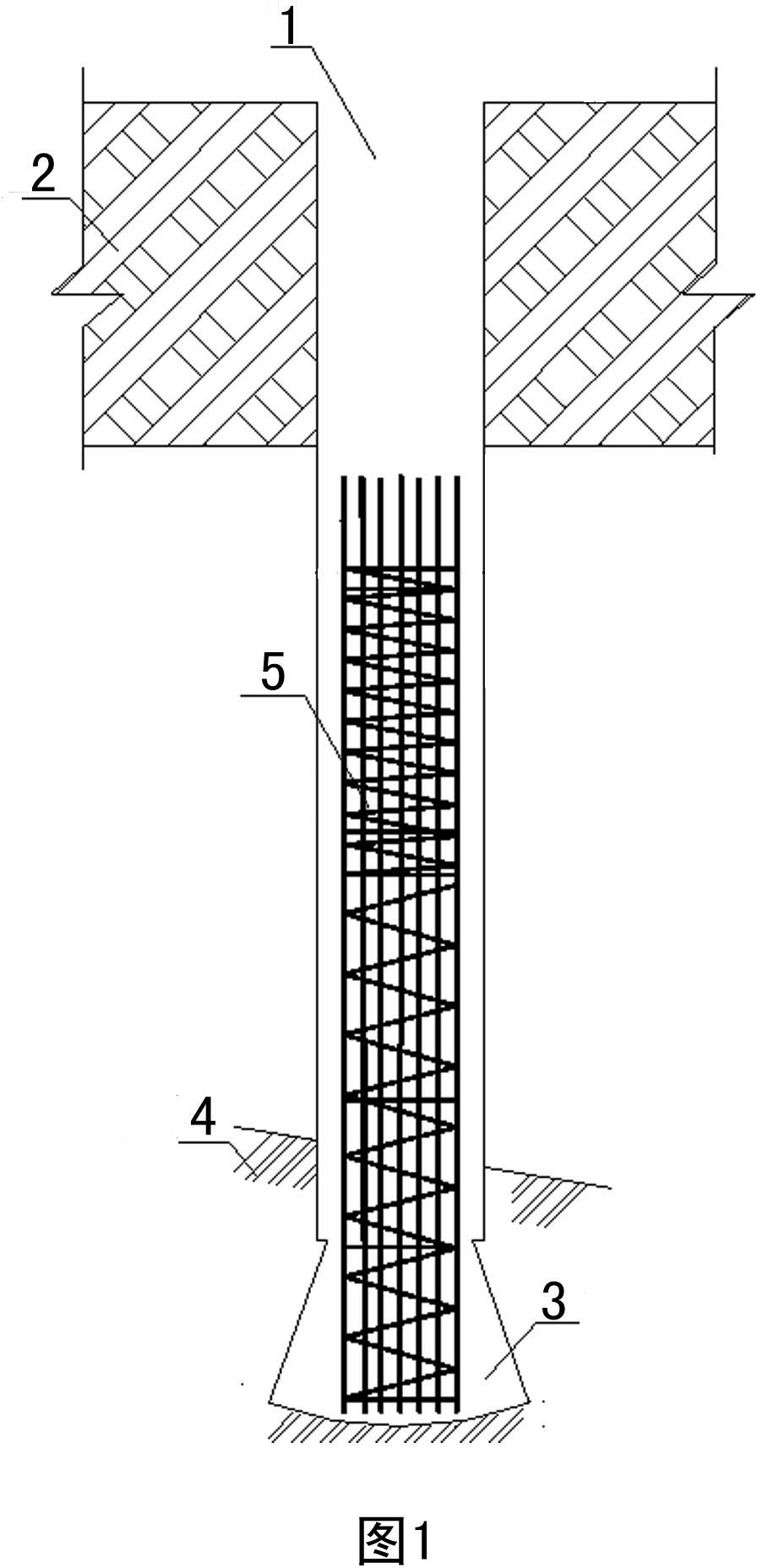

Construction method of drilling follow casting pile used for building or bridge foundation

A method for constructing pipe piles while drilling for building or bridge foundations. The construction steps are to cover high-strength prestressed concrete pipes or steel pipes with drill pipes on the ground first, and install impactors and reaming retractable drill bits at the front ends of the drill pipes. , Follow the pipe while drilling, follow the pipe retaining wall, drill to the design elevation, stop drilling, withdraw from the reaming to shrink the drill bit, use the mud pump to clean the mud and sediment, pour concrete into the pipe, and simultaneously inject pressure grout to the outside of the pipe wall , stop when concrete and grout reach the ground; the object of the invention is to propose a construction method with fast construction speed, reliable quality, less material consumption, high bearing capacity of piles, mechanized operation, and environmental protection. In the construction method of bored cast-in-place piles, the use of mud retaining walls pollutes the environment, the hole is easy to collapse during the drilling process, the quality of concrete pouring is unstable, and the prestressed pipe piles are easy to cause the soil to rise. The strength of the pile body constructed by the invention is high. , There is no sediment at the bottom of the pile, and the pile end is completely rock-socketed, which can reach more than 2 times the bearing capacity of the same diameter bored pile.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

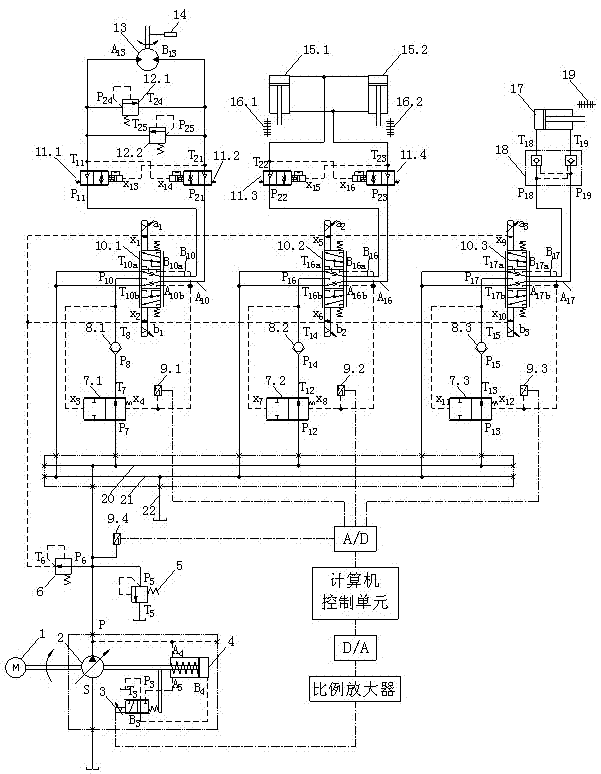

Energy-saving shield segment assembling and positioning electro-hydraulic control system adopting load-sensitive technology

InactiveCN103032396APrecise control of assembly positioningImprove construction qualityUnderground chambersServomotorsControl signalSystem pressure

The invention discloses an energy-saving shield segment assembling and positioning electro-hydraulic control system adopting a load-sensitive technology. The system comprises a motor, a variable pump, a two-position three-way proportional reversing valve, a variable cylinder, an overflow valve, a pressure reducing valve, a pressure compensating valve, a one-way valve, a multi-way valve, a balancing valve, a hydraulic lock, a hydraulic motor, a hydraulic cylinder, a moment rotation speed sensor, a displacement sensor and a pressure sensor. The multi-way valve with the pressure compensating valve in a segment assembling system is used for controlling the rotation speed of the hydraulic motor for driving the segment assembling machine to rotate and the moving speed of each hydraulic cylinder. The pressure sensor is used for detecting the pressure of a main oil passage of the system and the working pressure of each executer in real time; and a computer control unit is used for determining a variable pump control signal according to a system pressure signal, so that the displacement of the variable pump is changed with the load change so as to achieve load sensitive control. According to the invention, energy waste caused by continuous oil supply at the highest working pressure of the traditional system is avoided, the throttling loss and overflow loss are greatly reduced, and an obvious energy saving effect is obtained.

Owner:ZHEJIANG UNIV

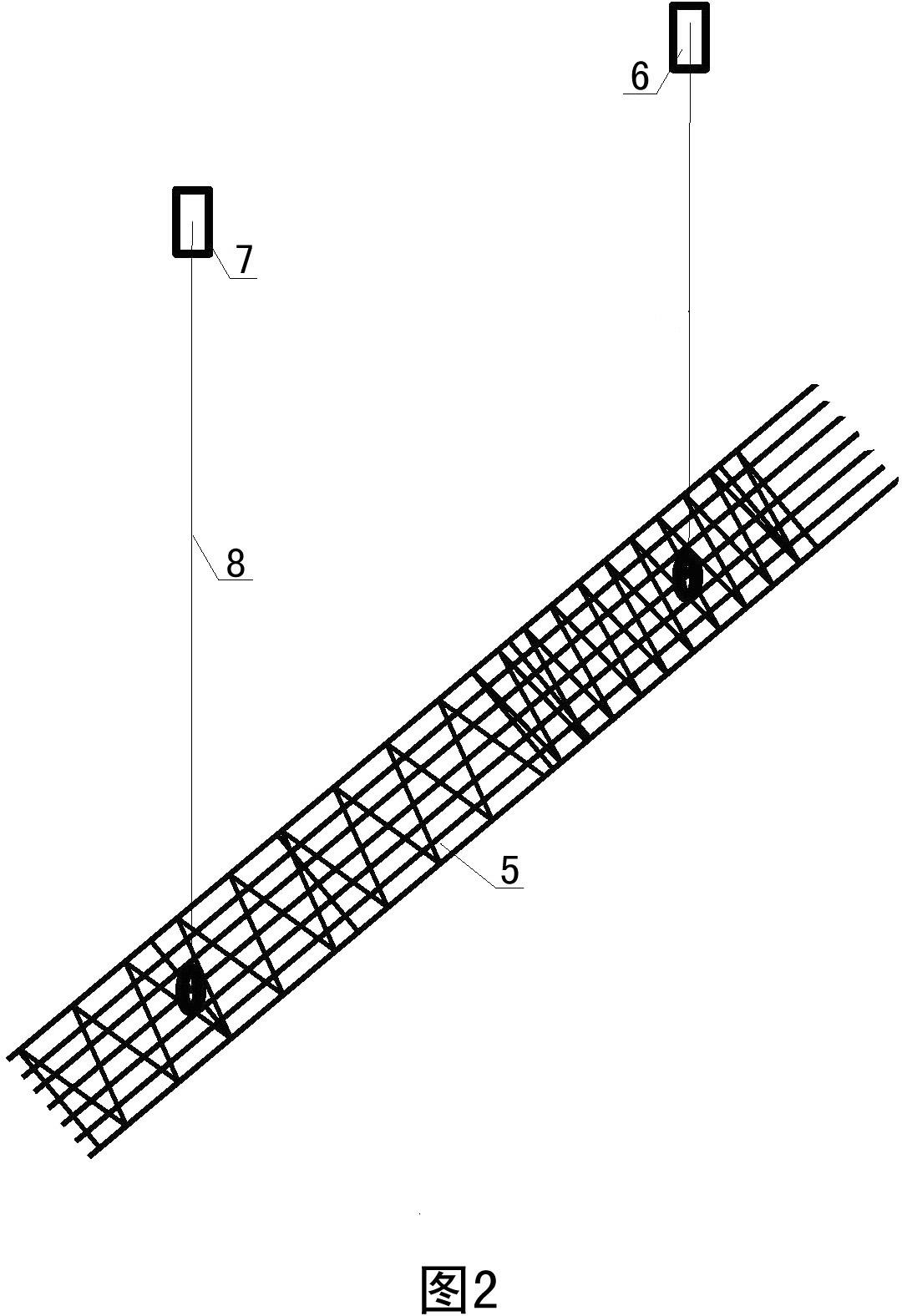

Method for constructing engineering pile by combining rotary drilling rig with manual pile base chambering

InactiveCN102425160AGuarantee the construction qualityImprove construction qualityBulkheads/pilesRebarDrill

The invention relates to a method for constructing an engineering pile by combining a rotary drilling rig with manual pile base chambering, which comprises the following steps: (1) preparation work before construction, including field leveling; (2) pile lofting; (3) pile casing embedding; (4) rig installation and rotary drilling; (5) manual pile base chambering; (6) rotary drilling drill quality detection; (7) reinforcement cage manufacturing; (8) reinforcement cage installation; (9) preparation before casting, mainly including hole cleaning, final hole acceptance check, and pump concrete casting quality safeguard measure; and (10) concrete casting, mainly including guide pipe installation, concrete casting and sampling for test and pile forming. In the method for constructing the engineering pile by combining the rotary drilling rig with the manual pile base chambering, the high efficiency of the rotary drilling rig is fully utilized, and the manual pile base chambering is utilized, the advantages of the rotary drilling rig and the manual pile base chambering are combined to make up the defects of the rotary drilling rig and the manual pile base chambering. The construction steps are detailed; the process flow is clear and definite; the construction quality of the engineering pile is ensured through an effective detail measure; the construction process of the rotary drilling rig and the process step of the manual pile base chambering are combined as a whole to realize the effective allocation of a construction field, a construction machine and construction time; and when the construction quality is ensured, the construction efficiency of a digging pile is greatly increased, thereby, the construction time of the engineering pile can be greatly saved, and the construction period requirement of the project is met.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

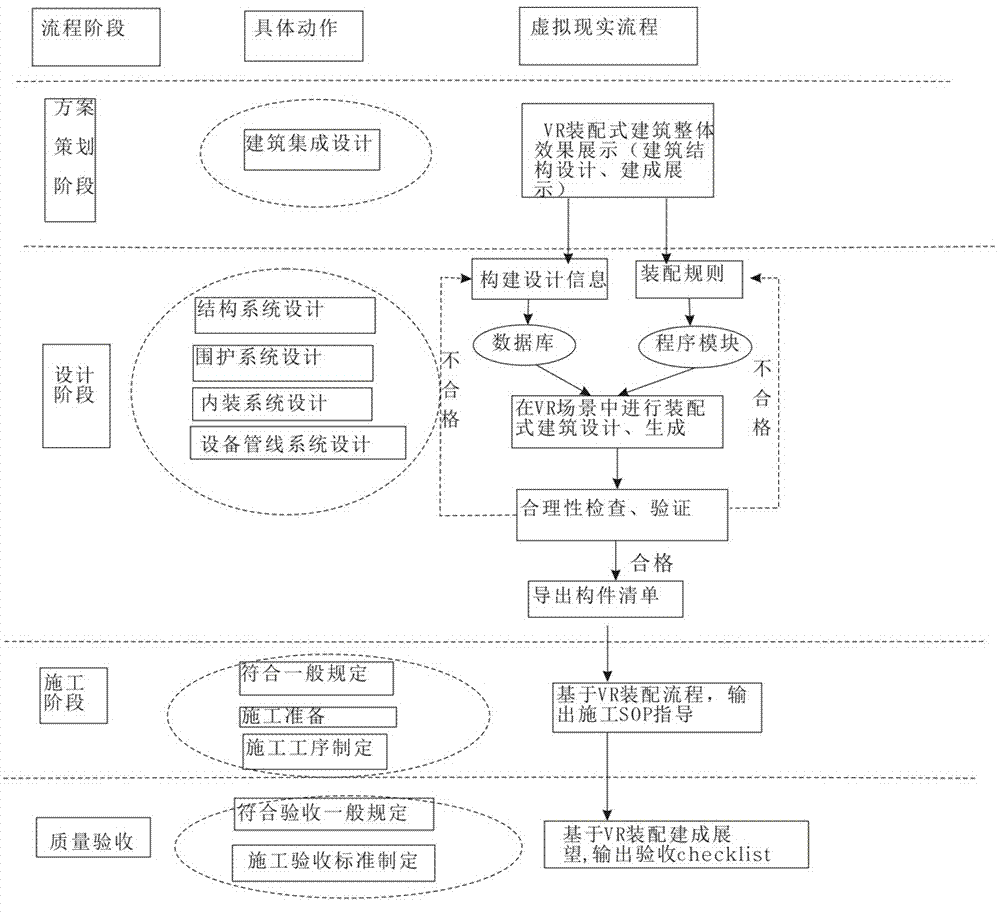

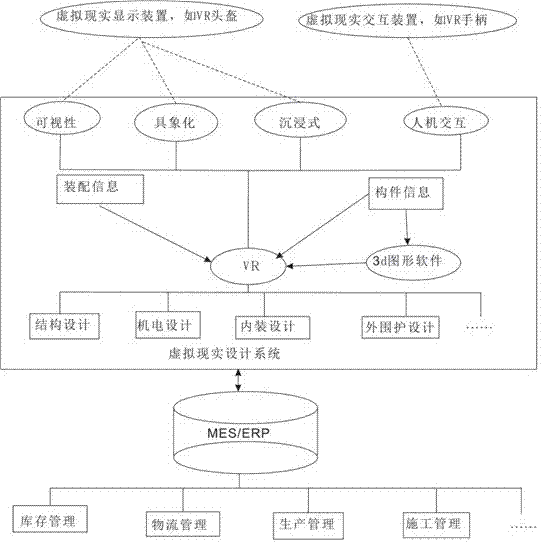

Method for applying virtual reality technology to fabricated building industry

ActiveCN106971028AImprove presentationReduce communication costsGeometric CADData processing applicationsBuilding designCommunication effects

The invention relates to a method for applying a virtual reality technology to a fabricated building industry. The method comprises the steps of firstly, building 3D models of fabricated building members, and endowing the fabricated building members with attribute information; secondly, establishing fabrication rules of the fabricated building members through a virtual reality system; thirdly, performing splicing construction of the fabricated building members based on the fabrication rules of the fabricated building members in a VR scene by a designer through wearing a VR device to generate a fabricated building; and finally, performing rationality verification on the generated fabricated building, and if the verification succeeds, exporting a fabricated building member list and calculating total mass of the fabricated building based on member list information. According to the method, the immersive experience of a fabricated building design process is realized based on the VR technology; a design concept of the fabricated building is accurately passed on; the communication cost is reduced; and the communication effect is improved.

Owner:福州众衡时代信息科技有限公司

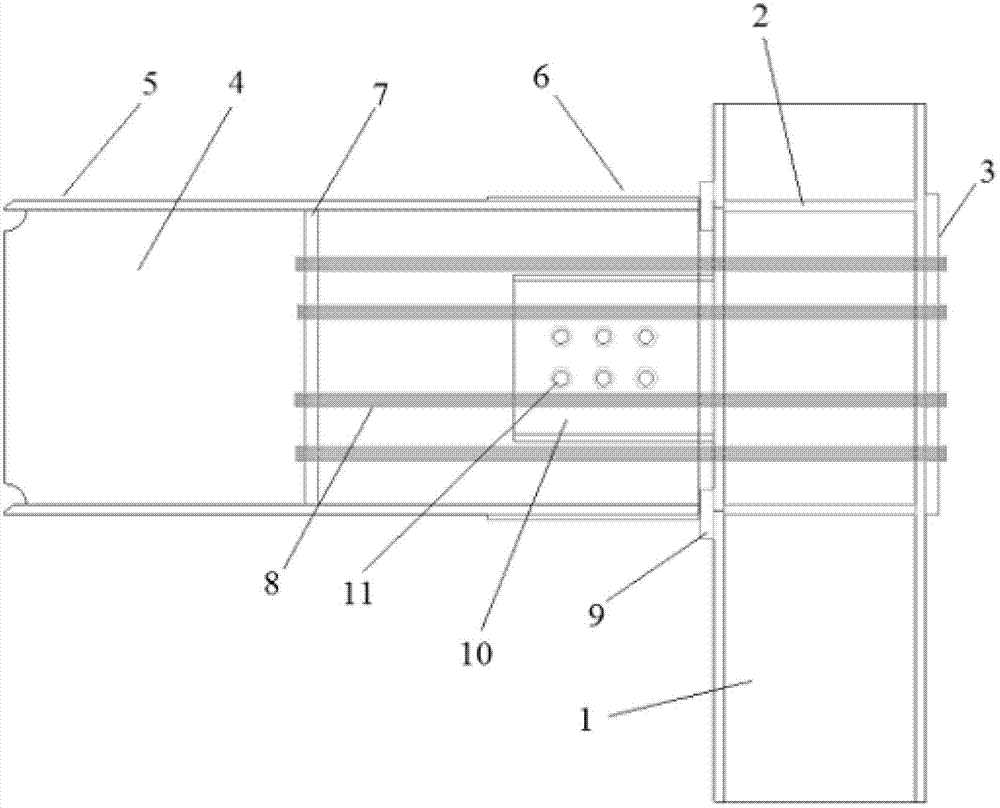

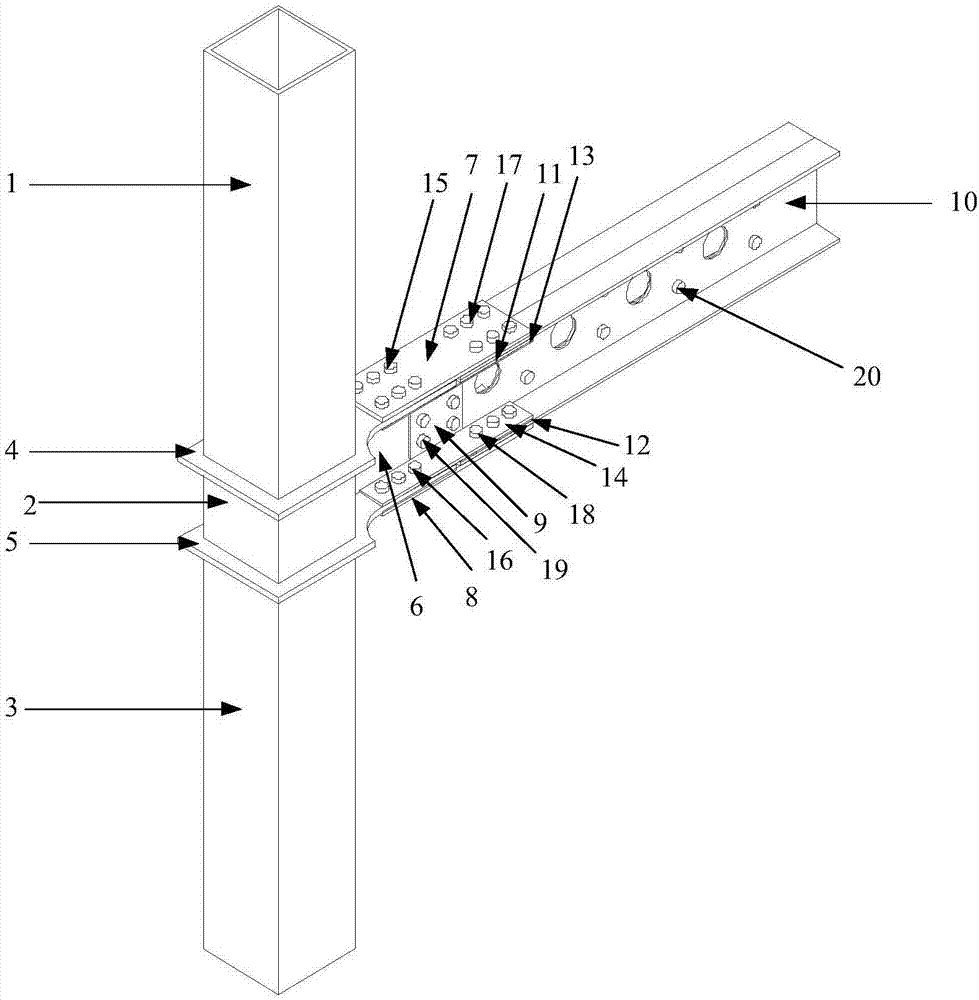

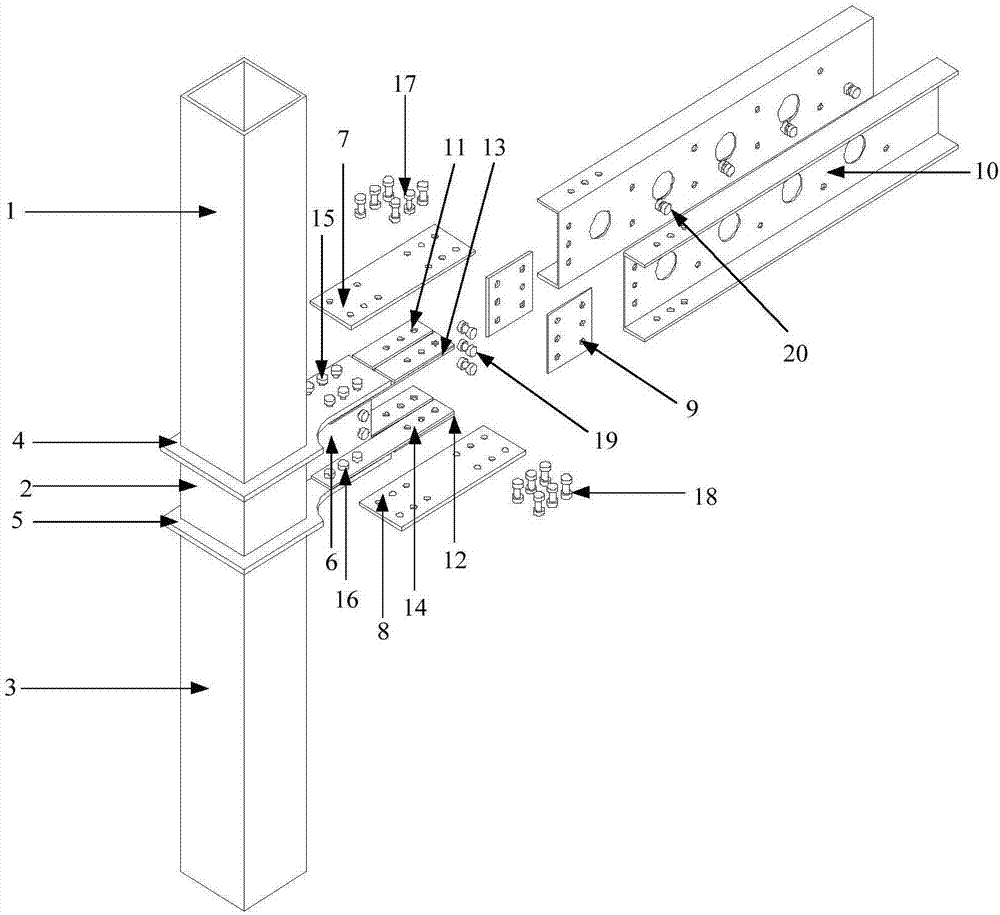

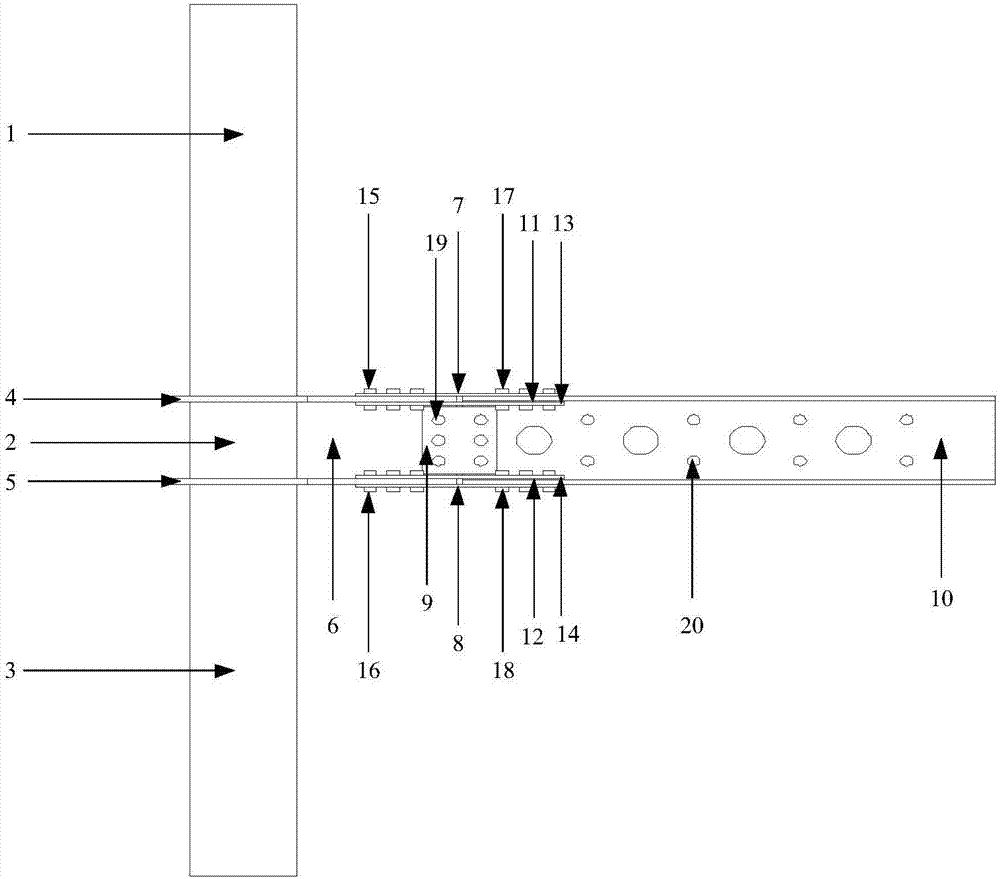

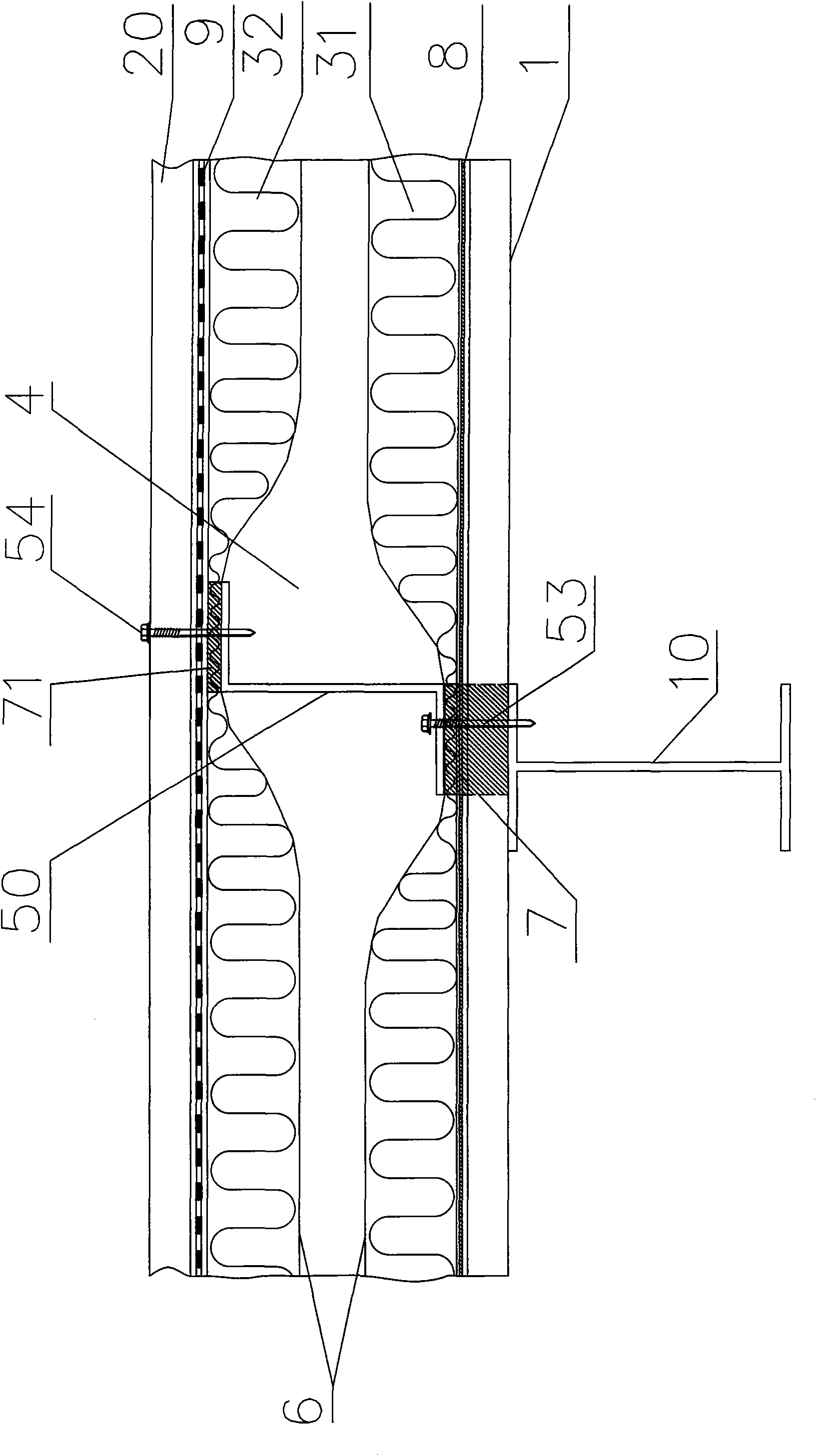

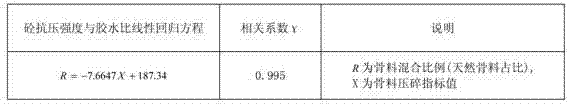

Assembly channel steel punching beam column joint connecting device capable of achieving function recovery

InactiveCN106869325AAvoid complex stress fieldsReduce construction difficultyFloorsFloor slabPunching

The invention relates to an assembly channel steel punching beam column joint connecting device capable of achieving function recovery and belongs to the field of structural engineering. The assembly channel steel punching beam column joint connecting device capable of achieving function recovery is composed of a square steel pipe column with a cantilever beam section, a channel steel punching beam section and a connecting device of the cantilever beam section and the channel punch beam section. All welding parts of the joint connection device are all finished in a factory, so that precision and quality of welds are easier to control. Construction speed is greatly increased and construction quality is greatly improved, and a spatial structure of the channel punch beam section of the channel is conducive to pipeline penetration; the channel steel punching beam and a floor can be assembled and molded in the factory to form modular assembly units. Then all the modular assembly unit and the square steel pipe column with the cantilever beam section achieve assembly connection through the channel steel punching beam. Joints of the connection device can be used for both of beam end reinforcing and cover plate connection weakening. A multi-energy dissipation mechanism can be realized, a plastic hinge is transferred to a cover plate and a connecting plate. The function of structures can be recovered only by replacing the connecting plate after an earthquake.

Owner:BEIJING UNIV OF TECH

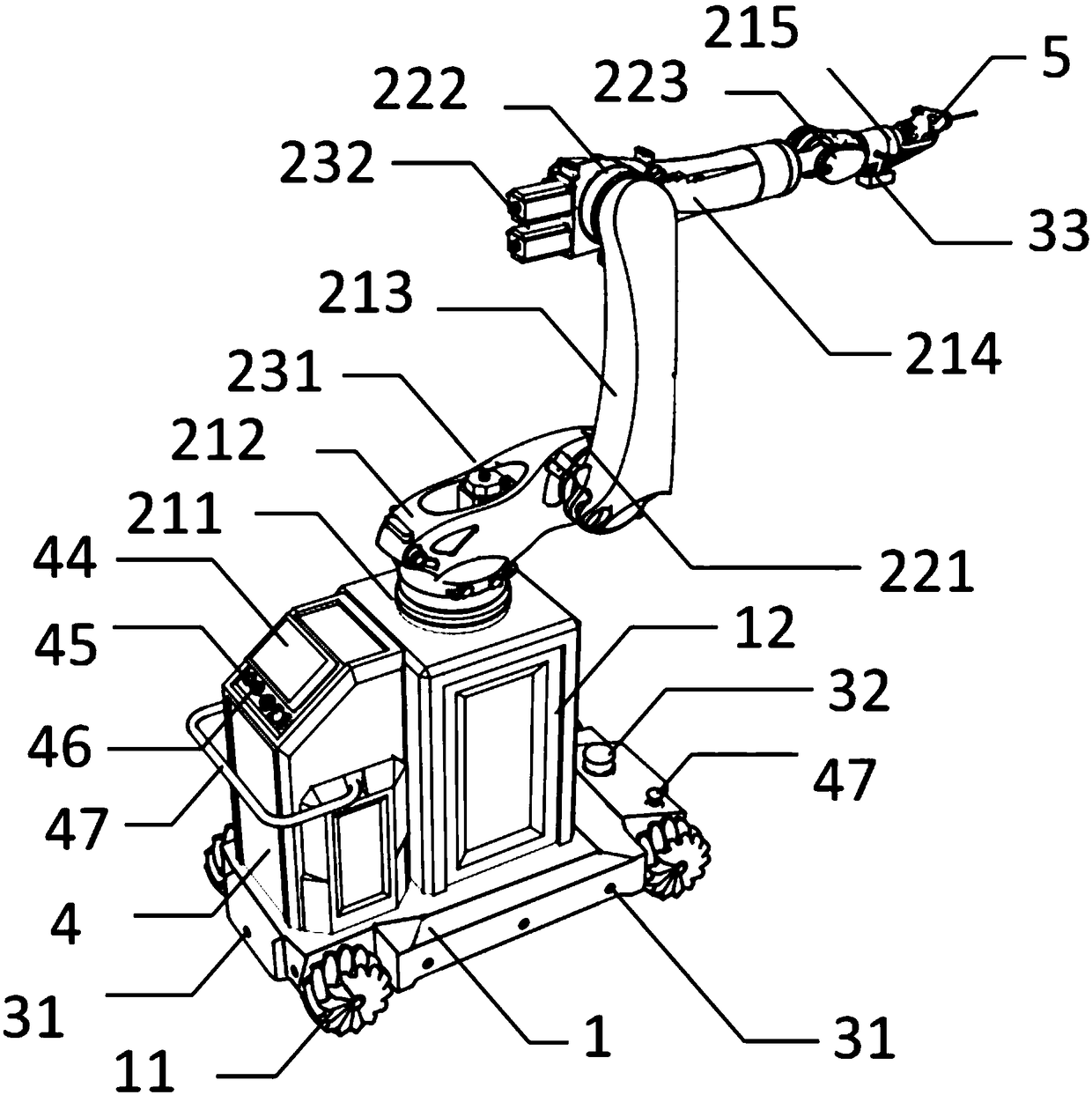

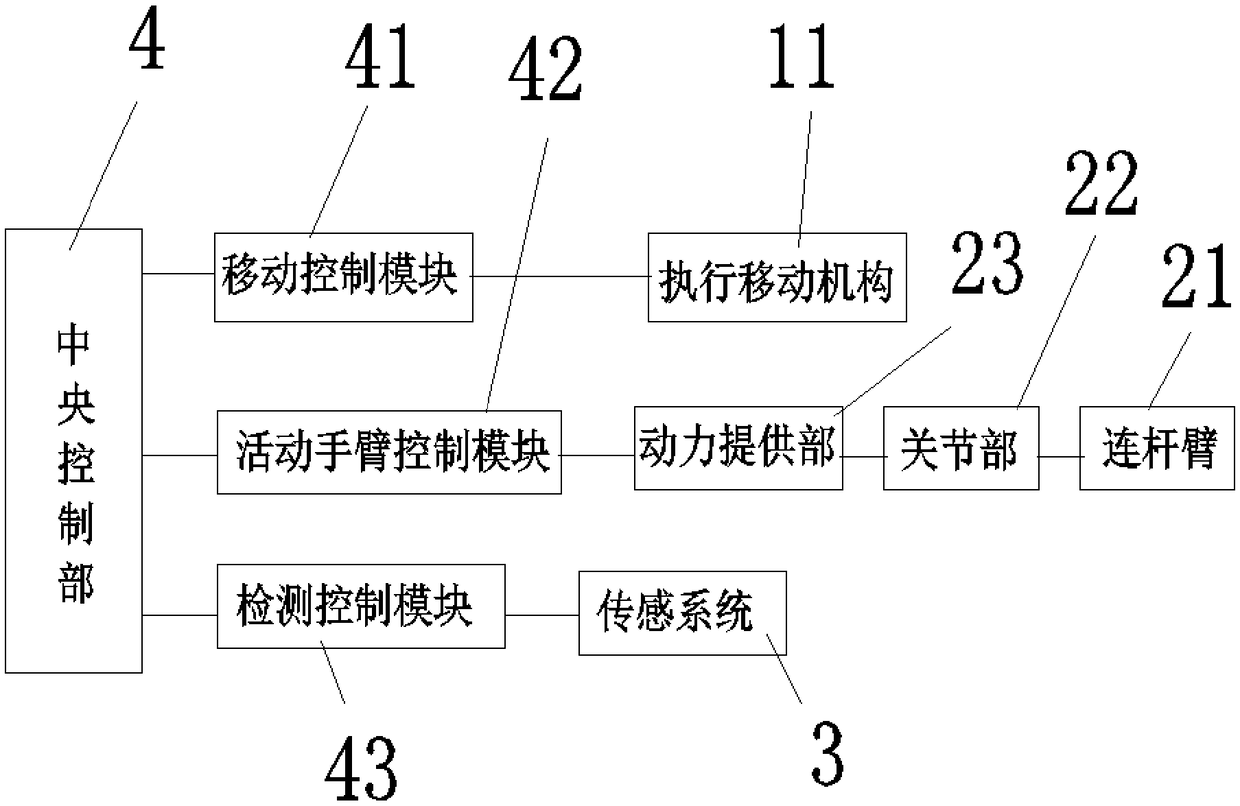

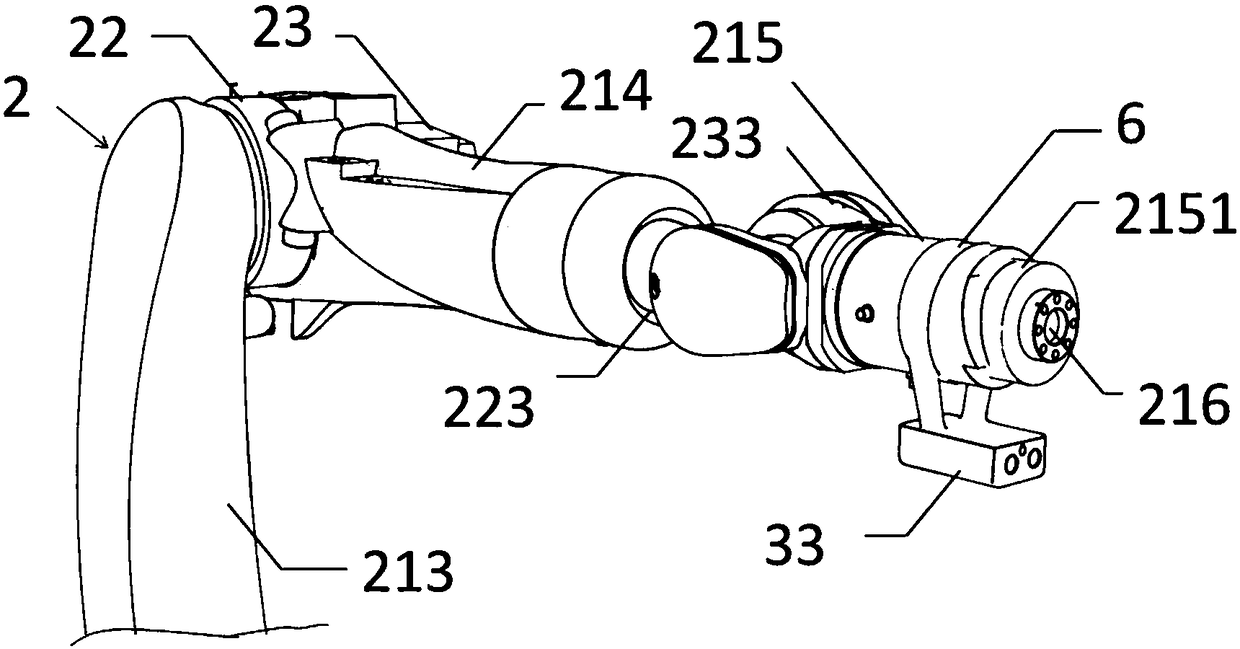

General building indoor engineering intelligent robot

PendingCN108942873AImprove health and hygieneReduce labor intensityManipulatorControl engineeringEngineering

The invention discloses a general building indoor engineering intelligent robot. The general building indoor engineering intelligent robot is characterized by comprising a movable base part, a robot movable arm, sensing systems, and a central control part, wherein the robot movable arm is provided with at least two connecting rod arms and power supply parts for driving all joint parts; the adjacent connecting rod arms move by dint of the joint parts; the sensing systems are arranged on the movable base part and the robot movable arm; the sensing systems comprise detecting modules for realizingobstacle avoidance and distances and detecting relative coordinates of space of the movable base part; the central control part is connected with the movable base part, the robot movable arm and thesensing systems; and the central control part comprises a movable control module, a movable arm control module and a detecting control module. The general building indoor engineering intelligent robotis simple in structure and easy to realize large-scale production, and effectively improves the construction quality and the working efficiency through automatic work of the movable base part, the control part, a power distribution management system and multi-axis mechanical arms.

Owner:珠海心怡科技有限公司

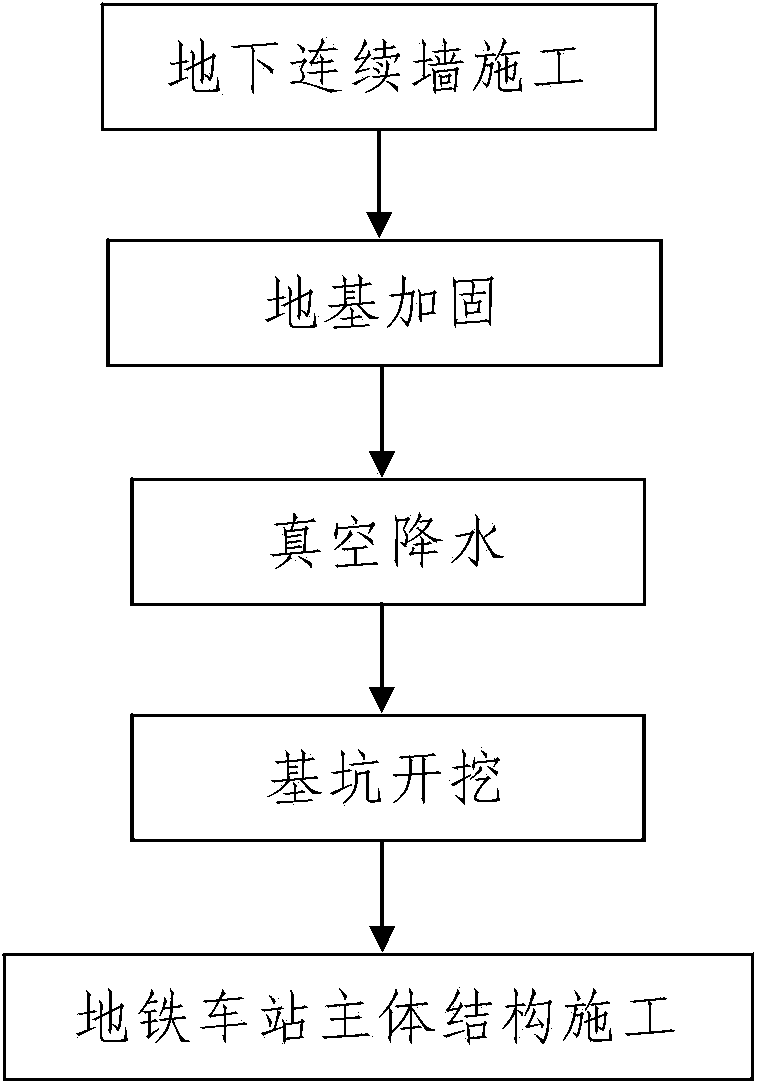

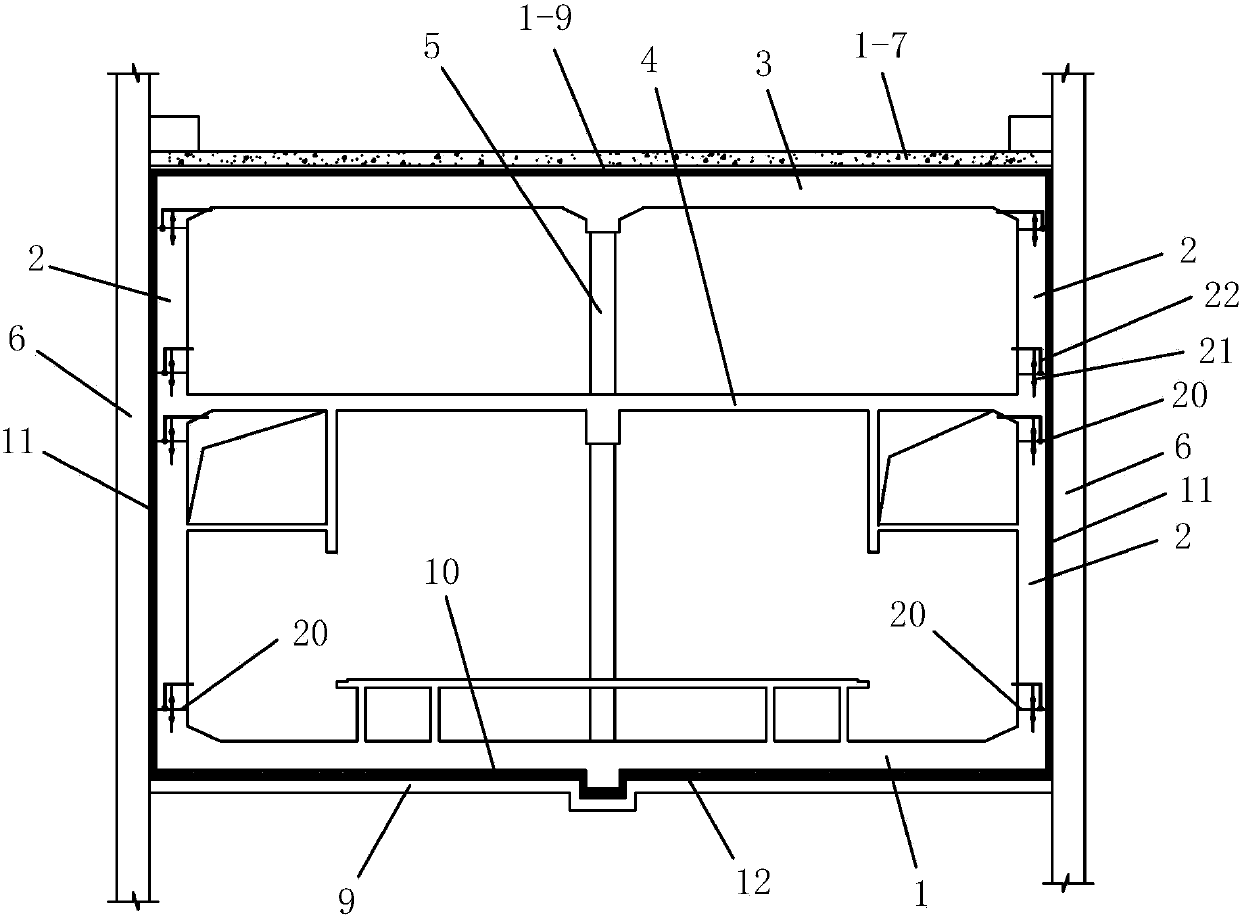

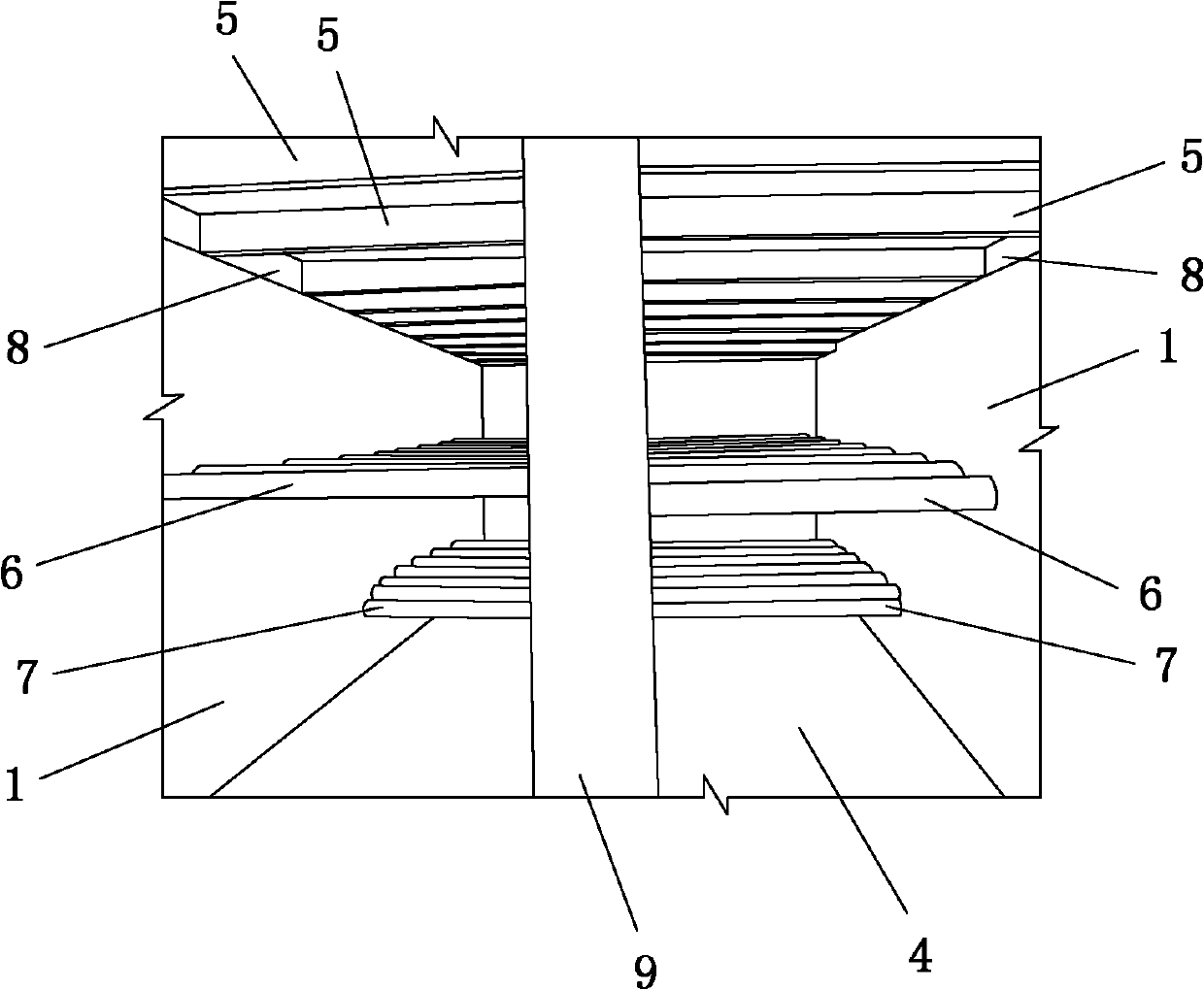

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

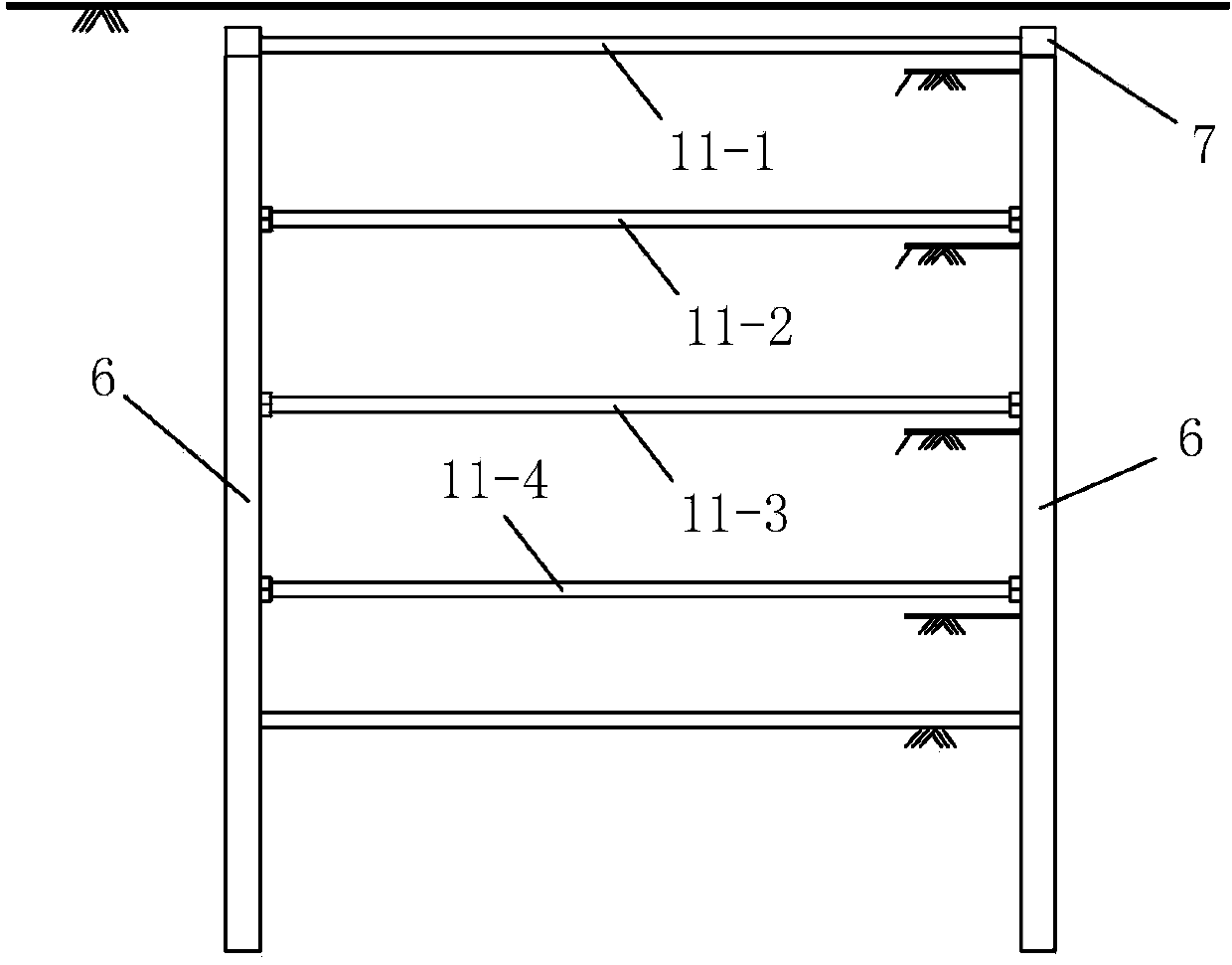

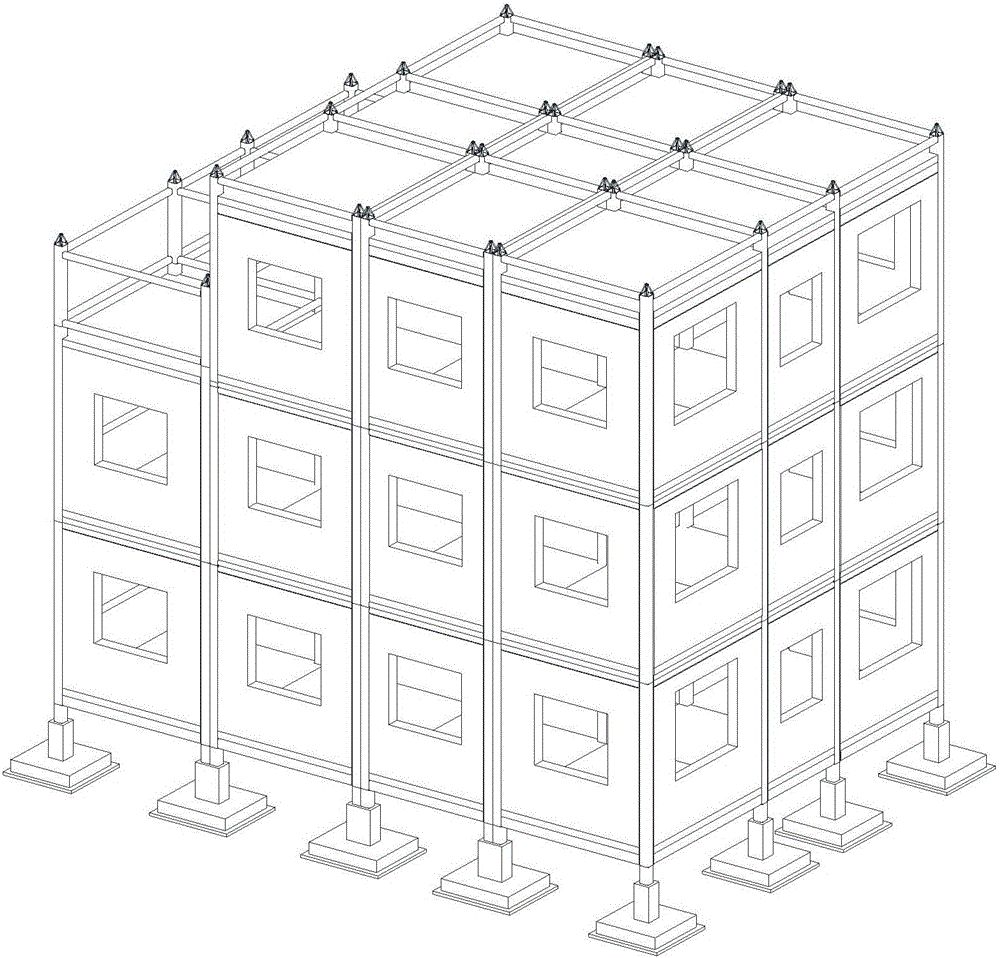

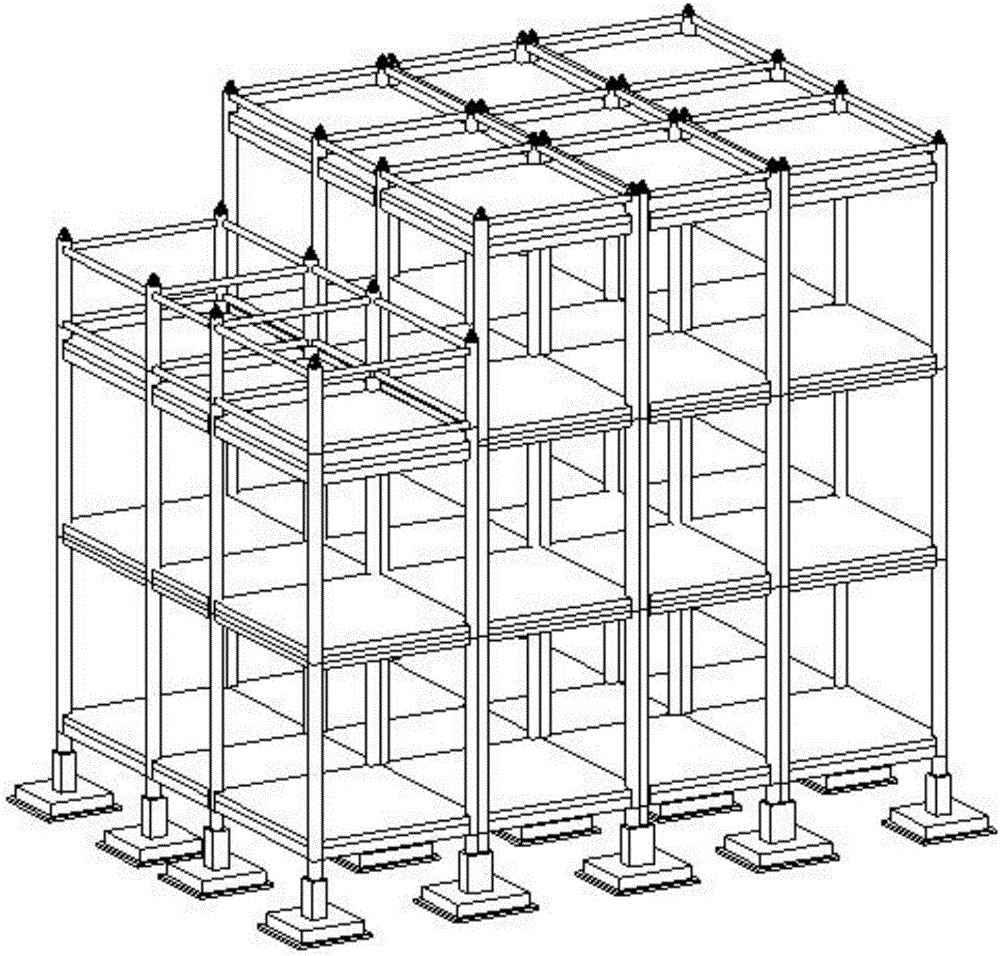

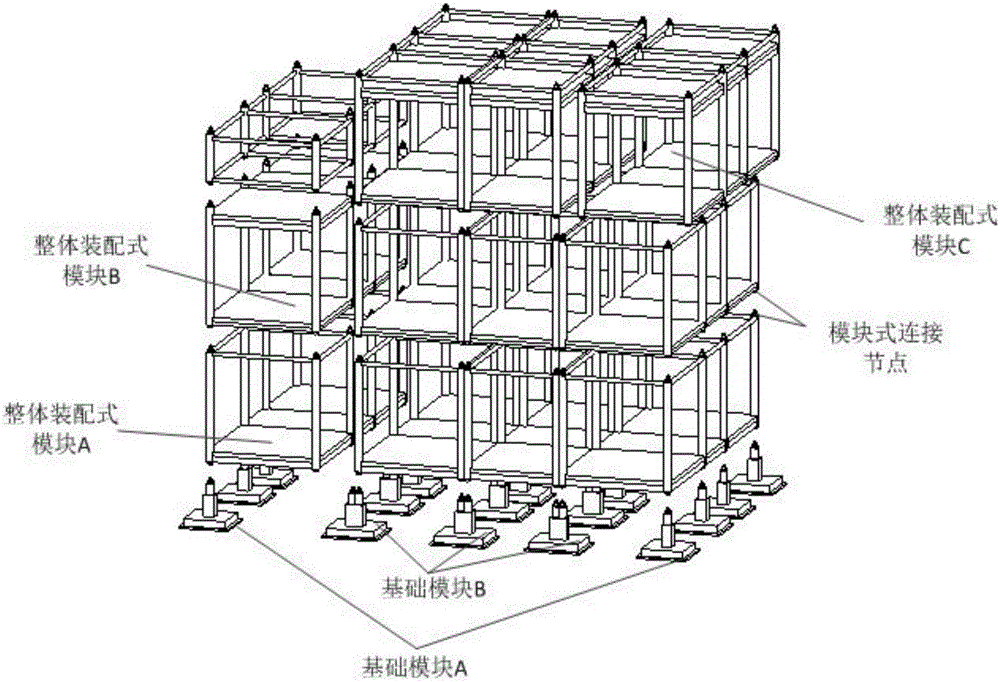

Modular multi-storeyed overall assembly type steel structural house structure system

The invention discloses a modular multi-storeyed overall assembly type steel structural house structure system, and belongs to the technical field of structural engineering. The steel structural house structure system comprises an assembling house module, a foundation module, a hanging hook between modules and a bend plate connector; various modules of the assembling house module are processed and manufactured in a factory, and every module is plugged on construction site through the hanging hook and the bending plate, and then the column is internally poured with concrete or welded, thus the structure building is completed; the hanging plate and the bending plate can plug and guide the module to the place, and anchor with concrete, and enhance the node connection; a dual-column structure is formed between the overall house modules, thus the overall structure performance of the house is strengthened. The house modules can complete the installation of inside and outside wall bodies, floor slabs, doors and windows in the factory, thus all or a part of inside decoration and outside decoration can be completed; thereby significantly reducing the work load on site and improving the construction speed.

Owner:BEIJING UNIV OF TECH

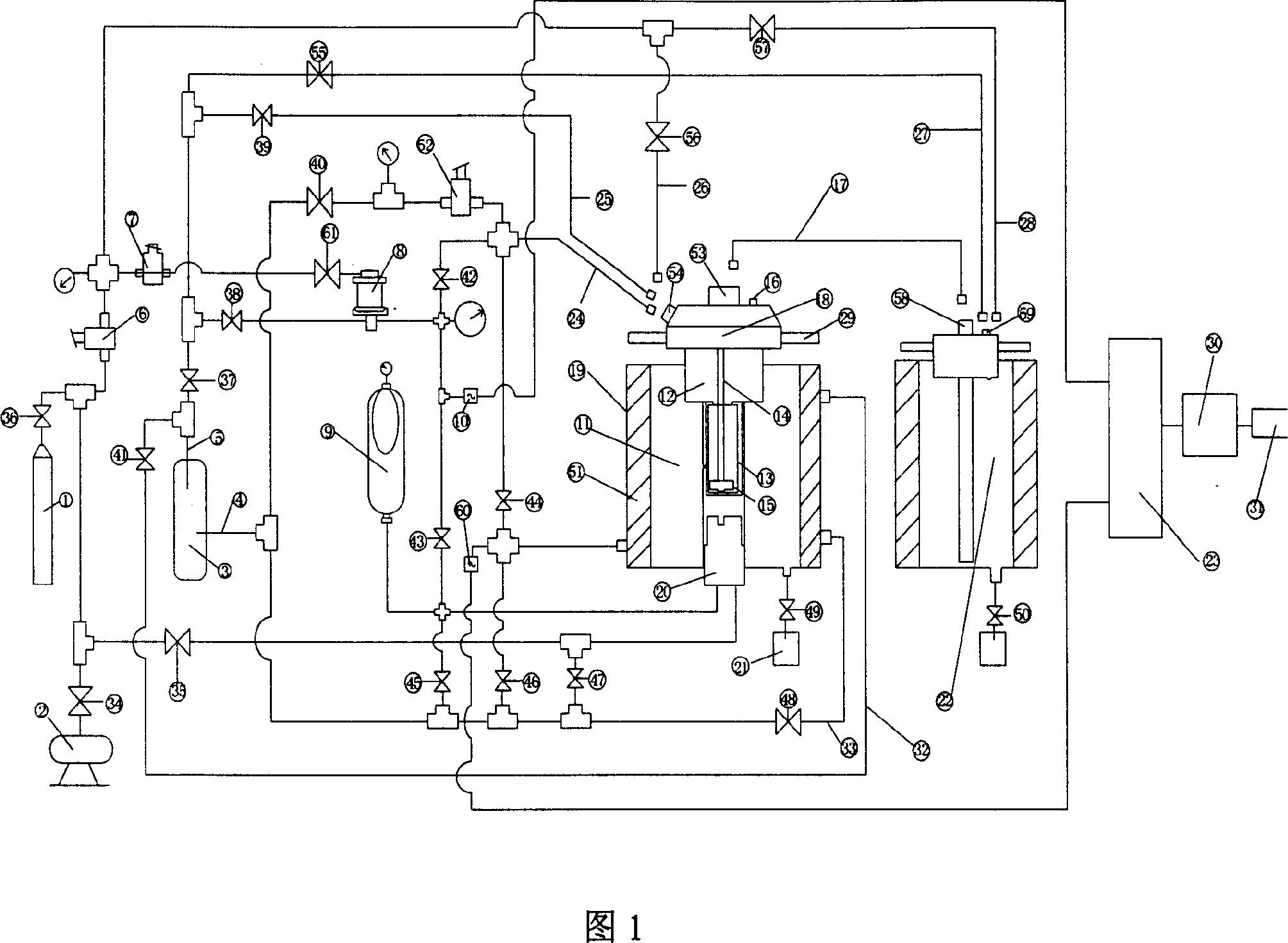

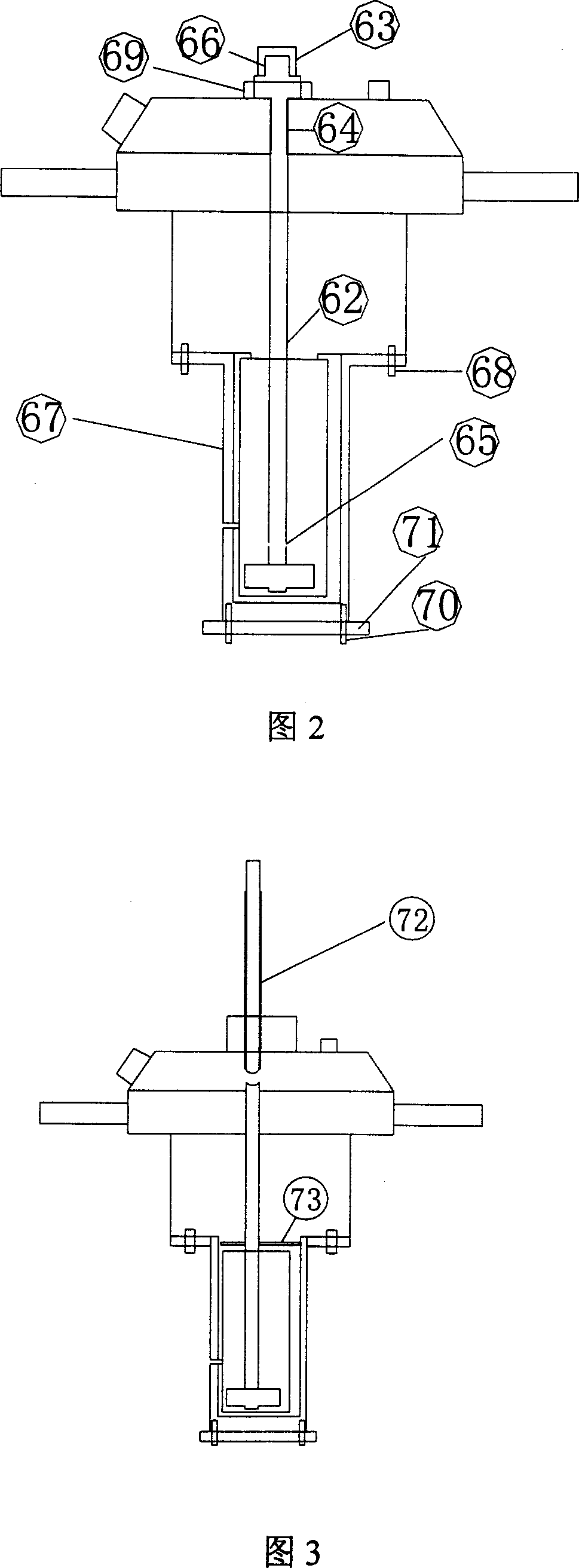

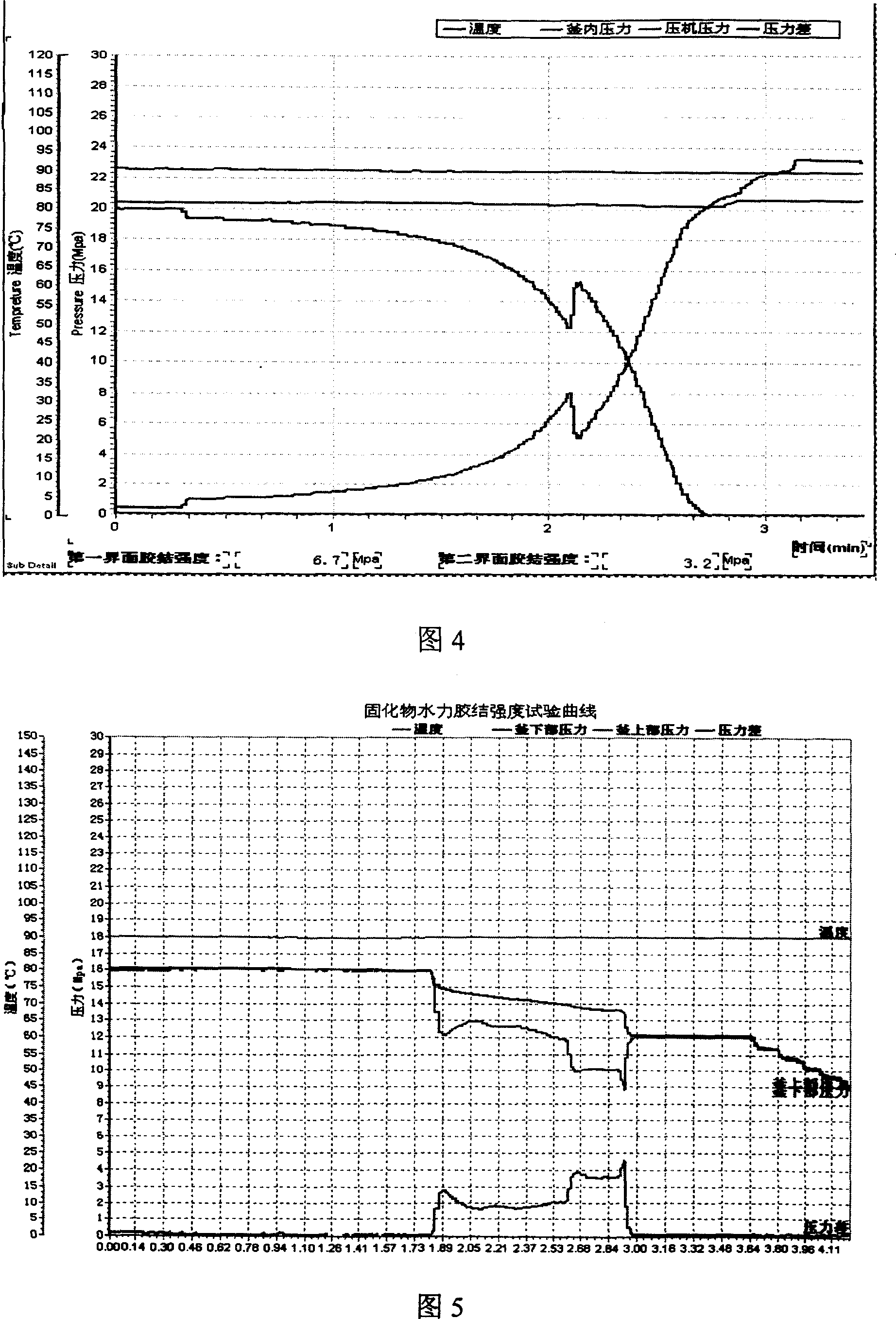

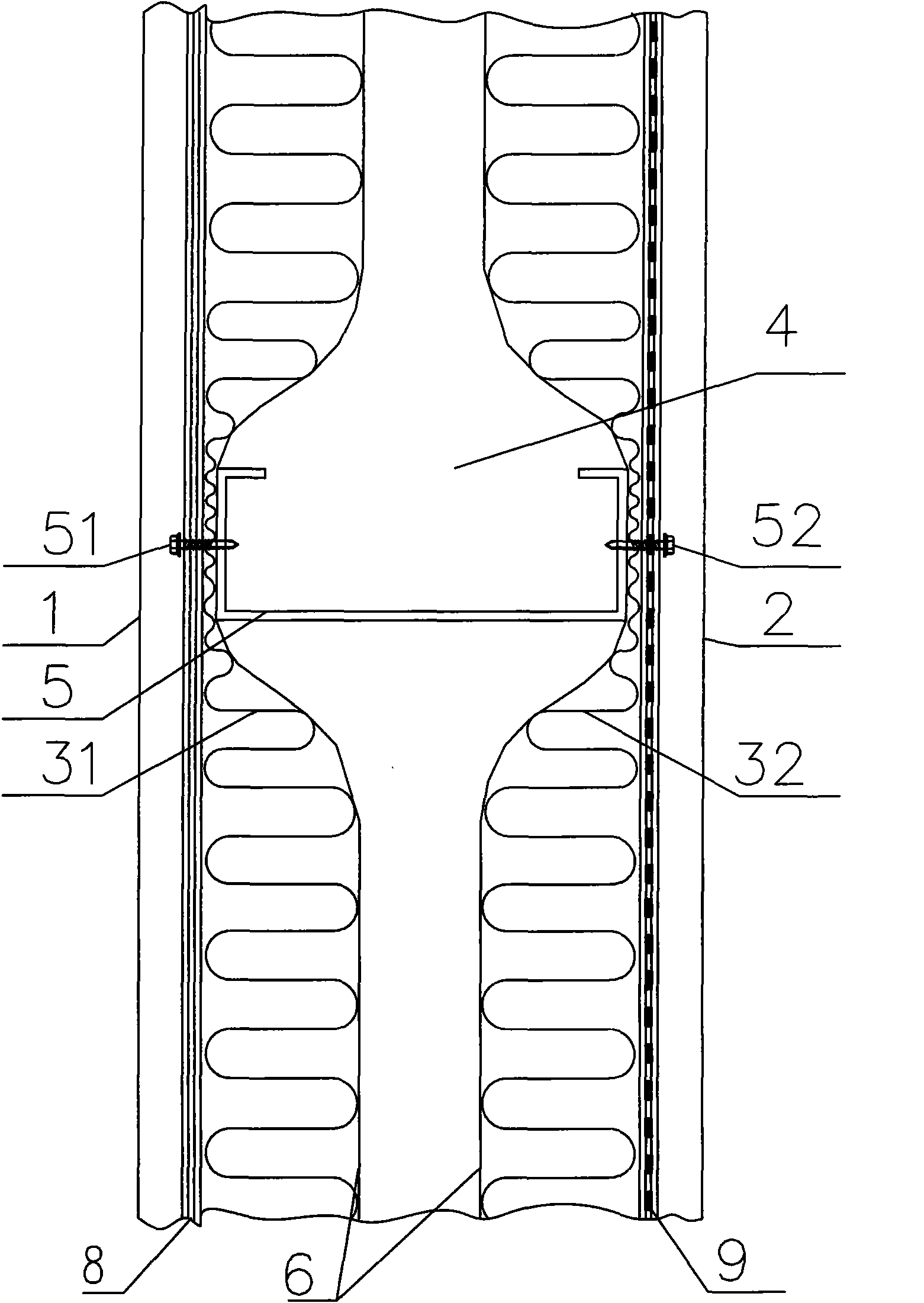

High-temperature high-pressure clay cake interface agglutination simulating-estimating device

ActiveCN101109281AOptimize formulation designImprove construction qualitySealing/packingPressure systemWell drilling

The invention provides a lab device for evaluating the hi-pressure and hi-temperature cementing quality of mud cakes, which essentially comprises a hi-temp and hi-pressure vessel 19, a simulated wellhole 13, an intermediate container 22, a heating and a cooling system, a pressure source and a pressure system, a data acquisition controller 23, a computer 30 and an output equipment 31. The function of the invention is to simulate the in-well pressure and temperature condition, realize such continuous experimental operations as well-hole type filtering of drilling fluid, rinsing and replacing of drilling fluid, injecting of well-solidifying fluid and curing of well-solidifying fluid, etc., simulate and evaluate the impact of in-well drilling fluid and the existing of mud cake on the cementing quality of the interface of the well-solidifying fluid, evaluate the flushing effects of different flushing fluids on circular space, measure the shearing and cementing strength of the interface between the flushing fluid and the circular space, measure the hydraulic cementing strength of the interface between the flushing fluid and the circular space, and provide experimental data for the optimal selection and engineering design for the drilling fluid and well-solidifying fluid in well drilling in oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

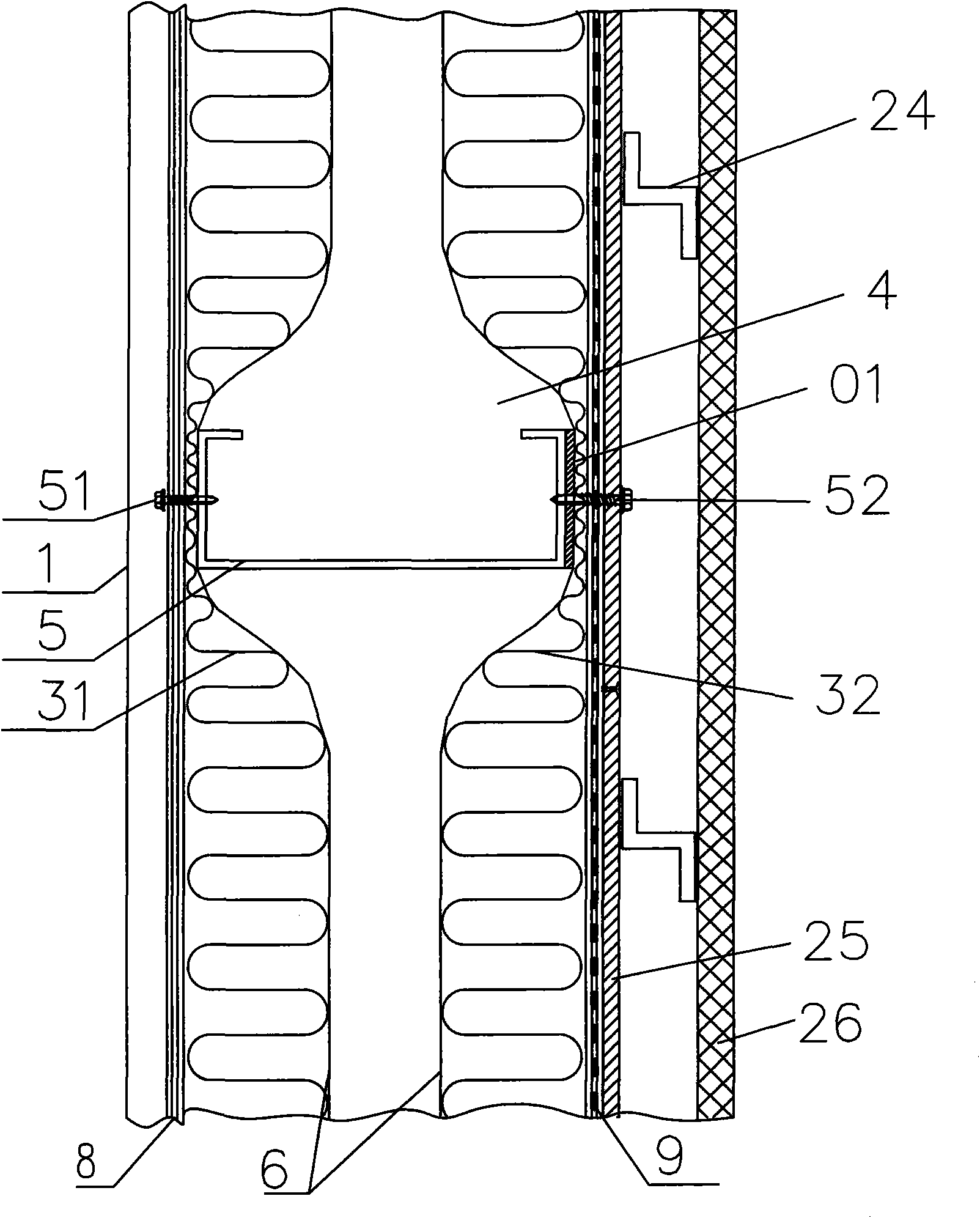

Composite heat-insulating containment system and construction method thereof

InactiveCN102094465AImprove insulation effectReduce installation stepsHeat proofingBuilding material handlingEngineeringMetal

The invention discloses a composite heat-insulating containment system and a construction method thereof, and aims to solve the problems of an unsmooth installation surface and the like in the prior art. The system consists of an inner side pressure metal plate, an outer side plate, and a heat-insulating layer arranged between the inner side pressure metal plate and the outer side plate, wherein a cavity which divides the heat-insulating layer into an inner layer and an outer layer is formed in the heat-insulating layer. In the structure, the cavity divides the heat-insulating layer into the inner layer and the outer layer, so that installation thickness is smaller, and the system is easy to install; meanwhile, an air layer is formed in the cavity, so that compared with a single-layer heat-insulating layer, the heat-insulating layer effectively improves the heat insulating property and installation quality of the whole wall and a roof under the condition of using heat-insulating materials with the same quality and quantity.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

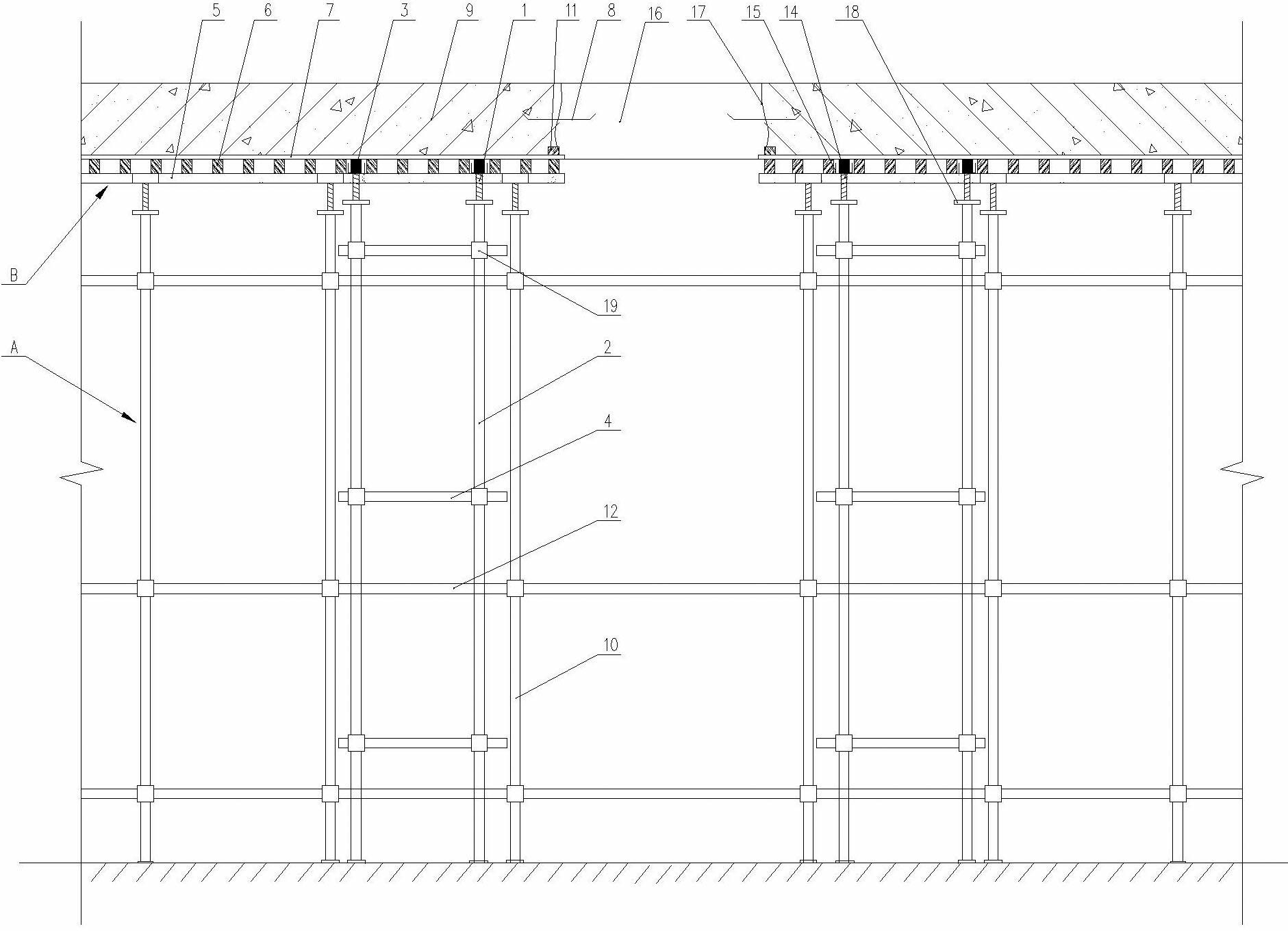

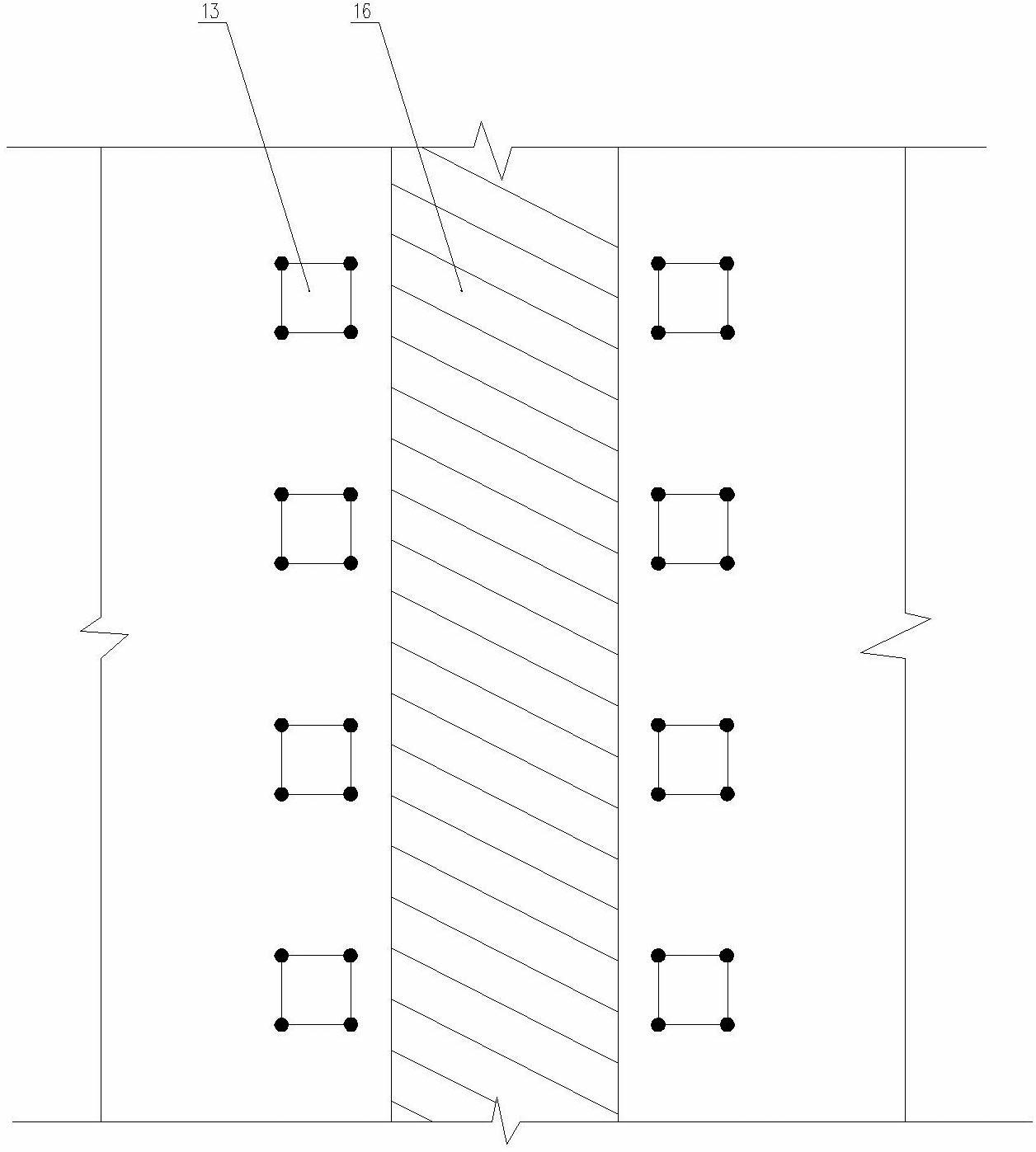

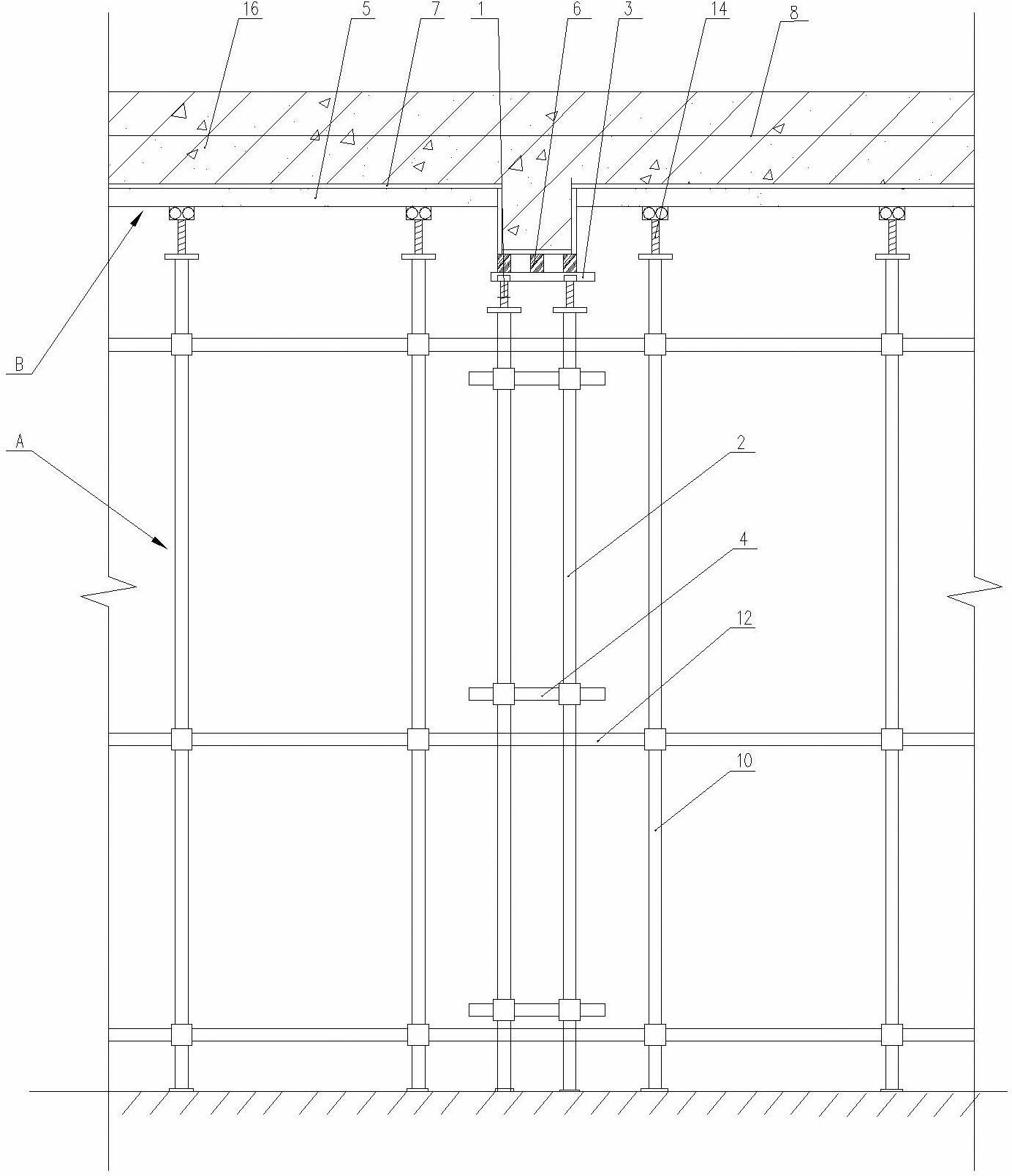

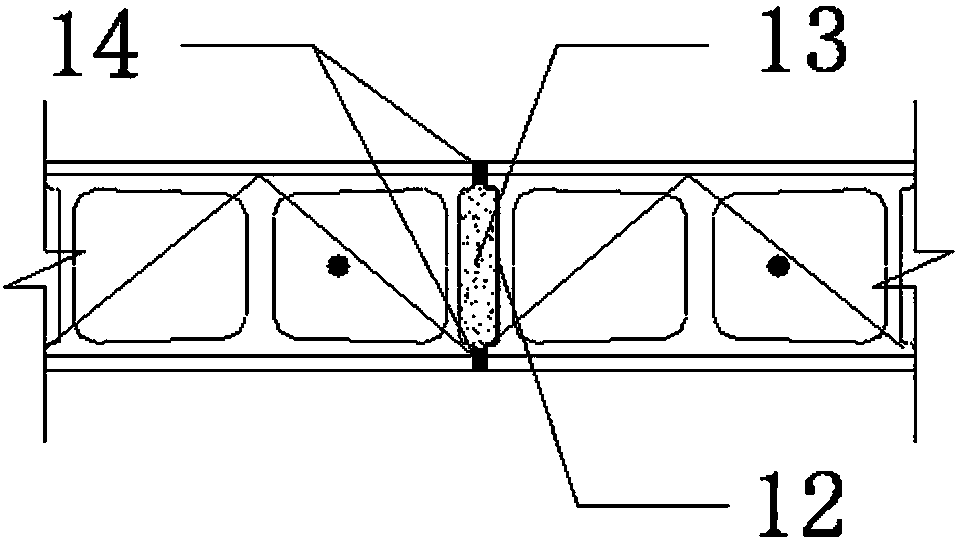

Beam plate post-cast strip template support system and construction method thereof

InactiveCN102691411AImprove construction qualityFast constructionForms/shuttering/falseworksBuilding material handlingArchitectural engineeringSupport system

The invention discloses a beam plate post-cast strip template support system and a construction method, wherein a main template support body supports all beam plates arranged at two sides of a post-cast strip, and support latticed columns are independently supported at two sides of the post-cast strip. After the main template support body is built, and when bottom templates of the beam plates are paved, the post-cast strip is unavailable without installation. When the main template support body is built, the bottom templates can be wholly paved, or the support latticed columns can be independently paved, so that the construction speed can be accelerated; the independent latticed column is convenient to uniformly set and wholly distribute; the whole template of a main template support system can be disassembled, and only the latticed columns can be remained to support, so that the mass of revolving materials can be saved, and the inconvenient material transportation traffic caused by the isolation and division of a post-cast strip-supported mould base in a basement can not be avoided; and before the concrete arranged at two sides of the post-cast strip is cast, the region is convenient and thorough to clean, and the construction quality of the post-cast strip can be preferably guaranteed.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

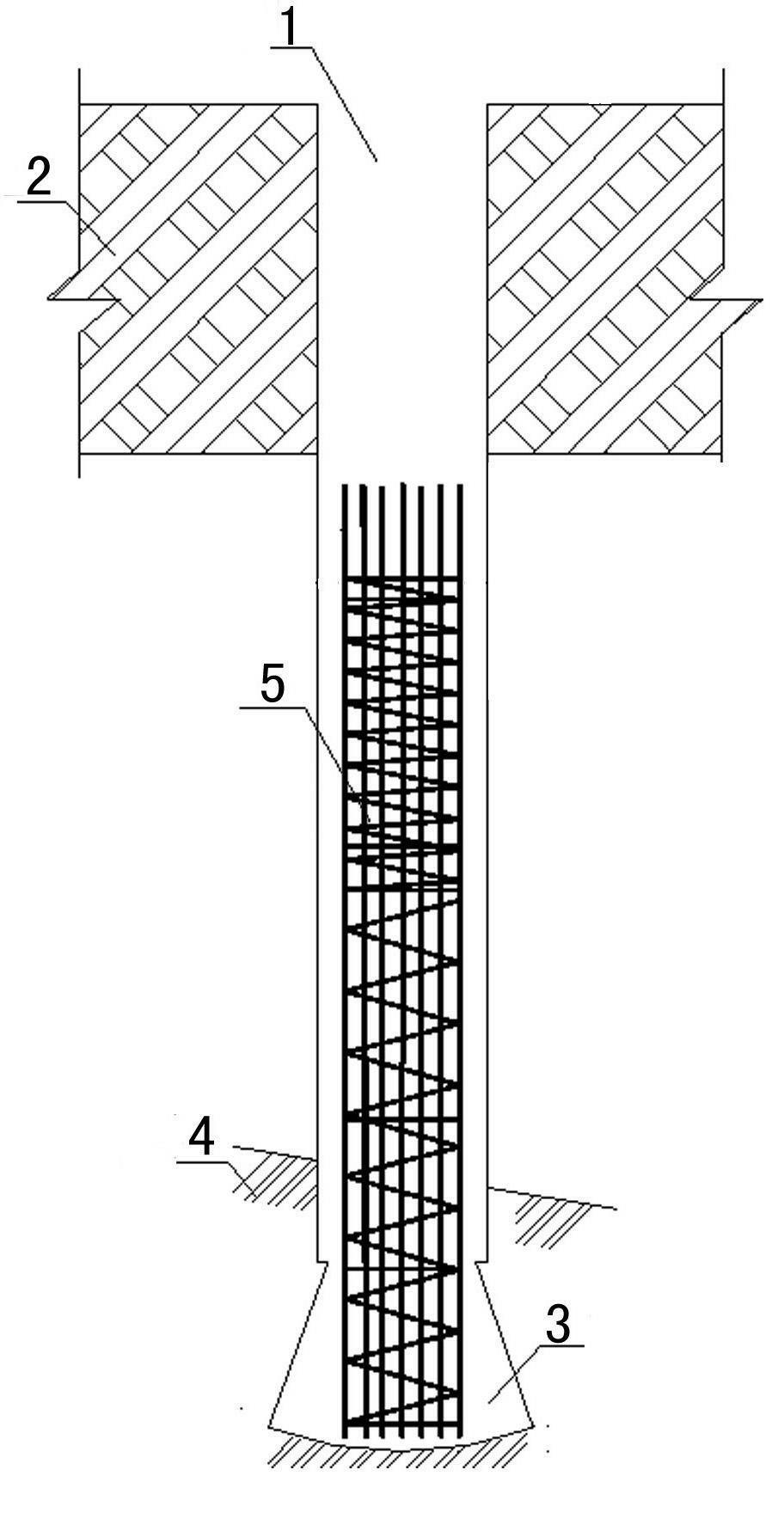

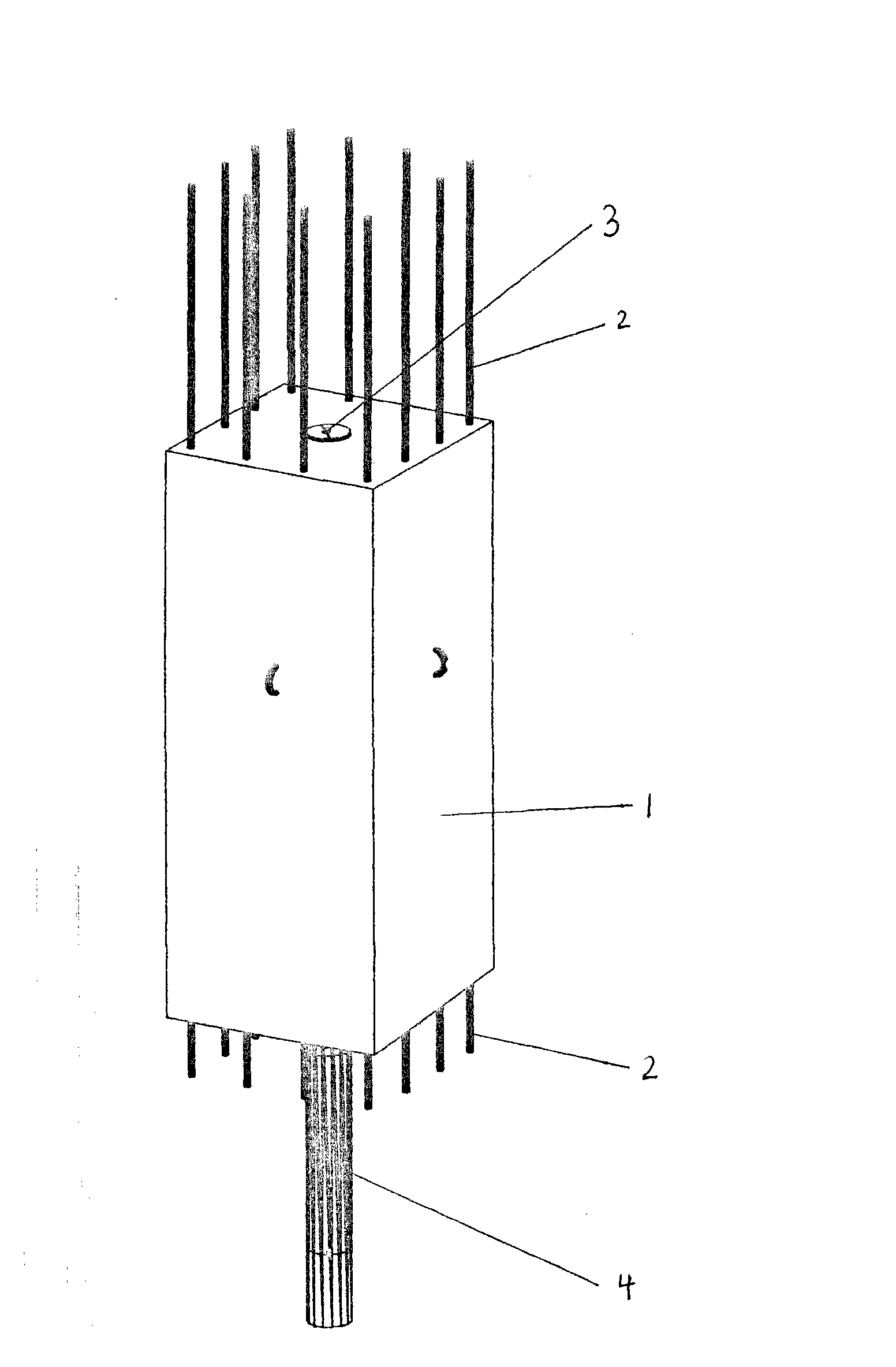

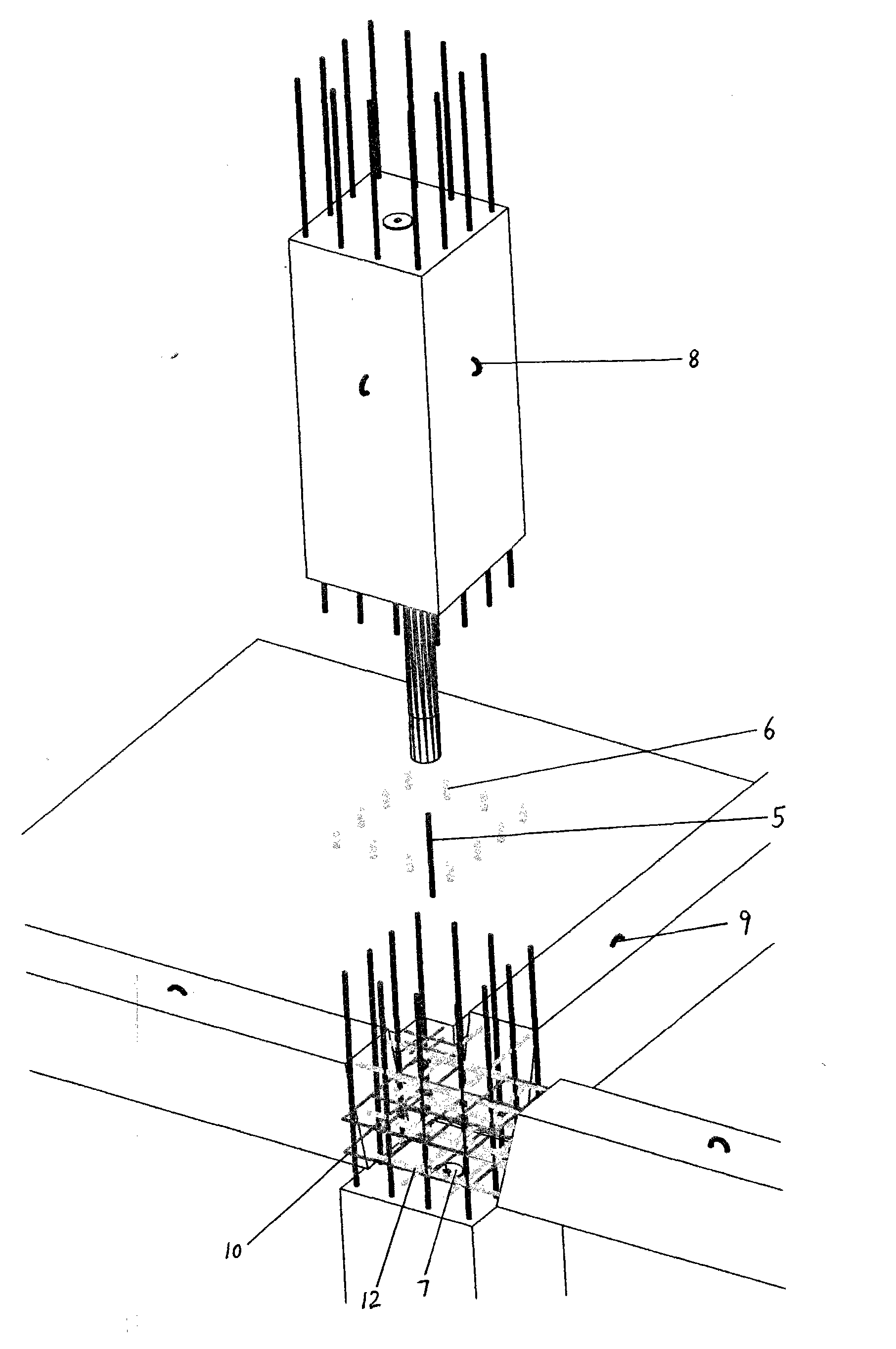

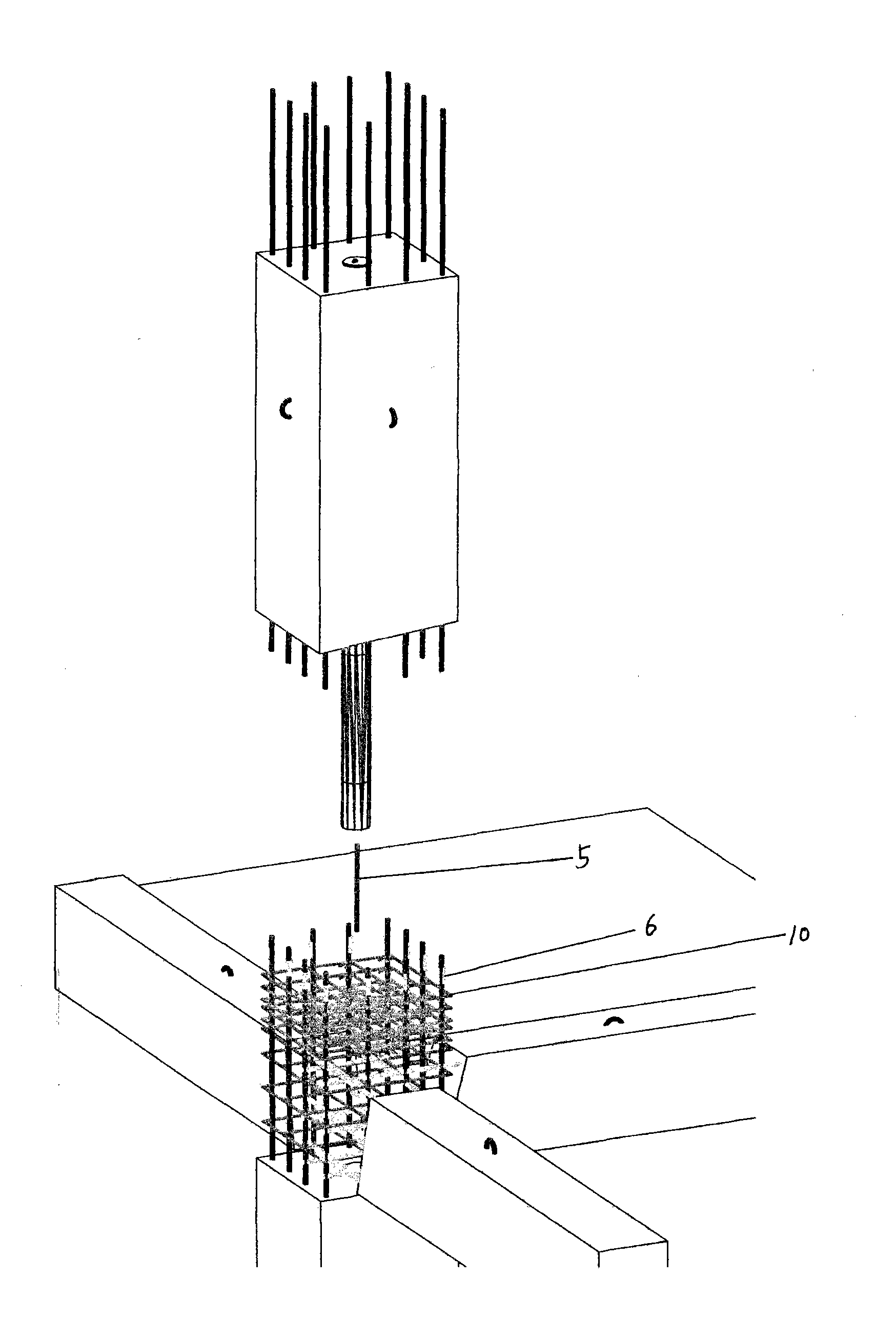

Prefabricated vertical member

The invention provides a prefabricated vertical member (including a pillar and a wall), which mainly comprises a member body and a prefabricated reinforcing bar (the reinforcing bar is the joint name of a principle bar longitudinally arranged along the member body, a vertically-distributed reinforcing bar, a hooping and a tie bar), and the principle bar or the principle bar and the vertically-distributed reinforcing bar stretch out of the upper end surface and the lower end surface of the member body. The prefabricated vertical member is characterized in that a core column is arranged in the middle of the lower end surface of the member body. The invention has the advantages that the installation of the prefabricated vertical member has no conflict with the anchoring of beam steel at a support, so as to meet the code requirement of the structure of cast-in-situ reinforced concrete; the core column is adopted for bearing load, the upper-layer construction operation can be carried out when in the joint concreting; no special design is needed; the connection of the reinforcing bar and the binding of a template are carried out at a floor slab, thereby not only ensuring the safety of workers, but also obviously improving the construction efficiency and the construction quality; the quantity of overhead work can be greatly decreased; the quantity of cast-in-situ concrete can be greatly decreased; and the operation is carried out at the floor slab, therefore, the construction speed is greatly improved.

Owner:管乃彦

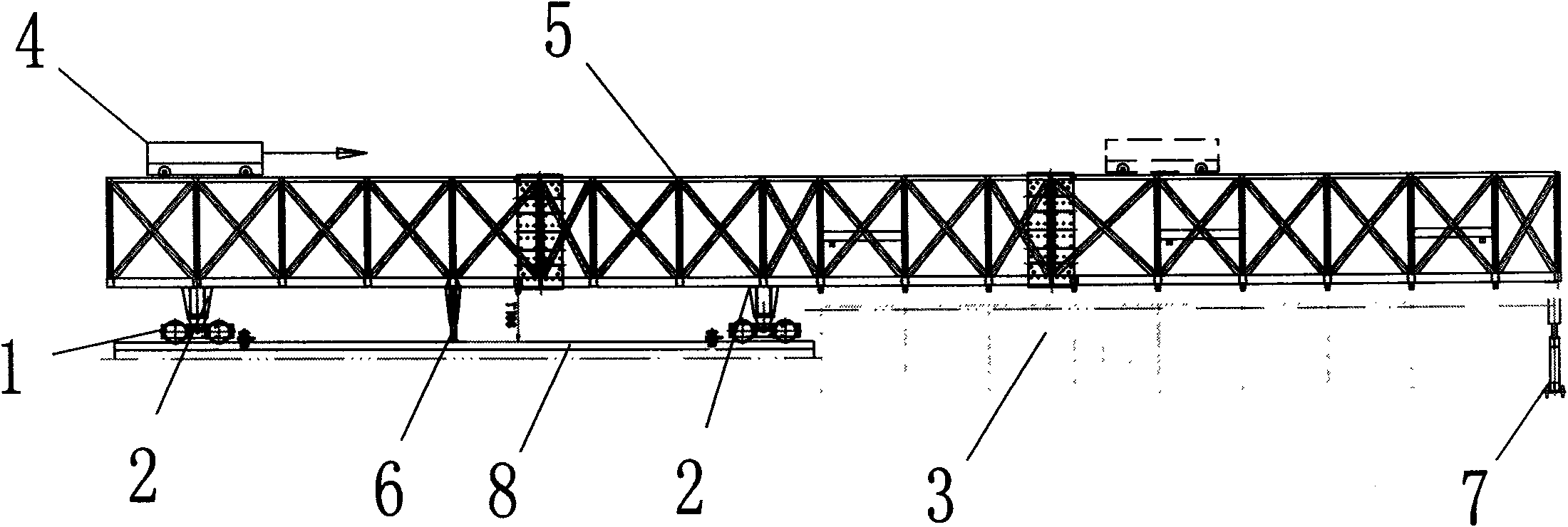

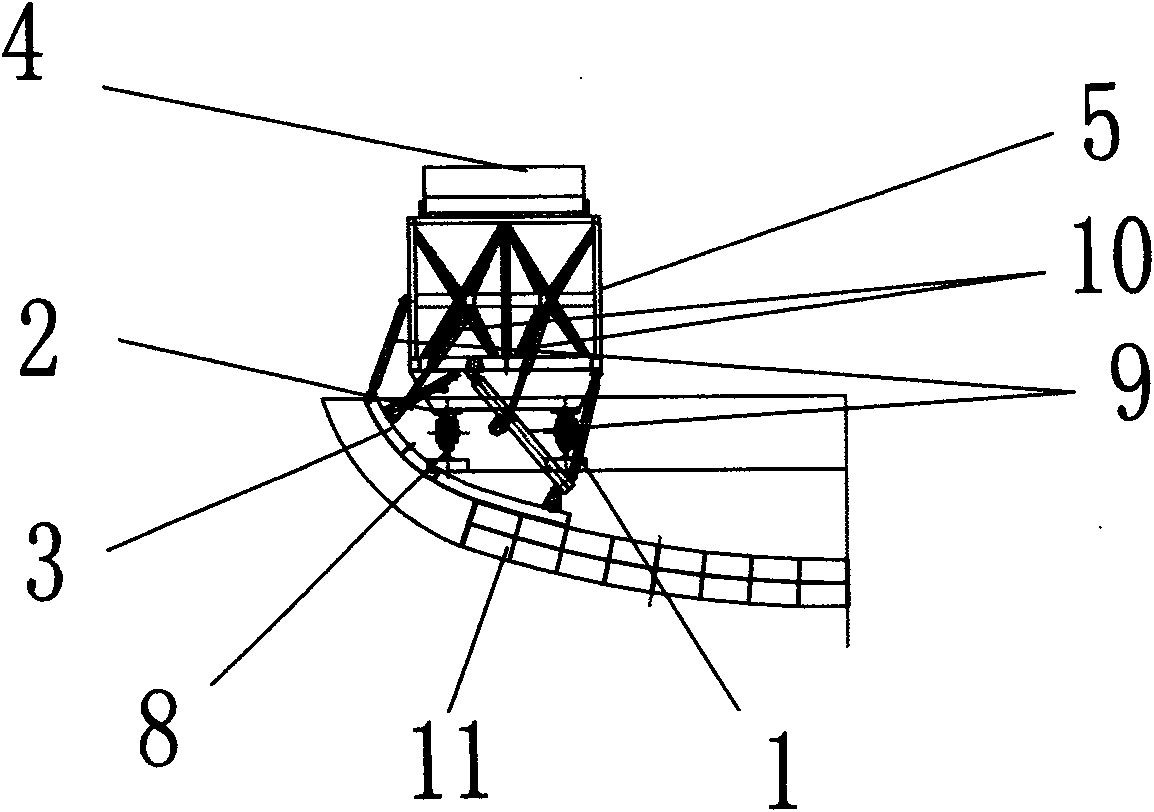

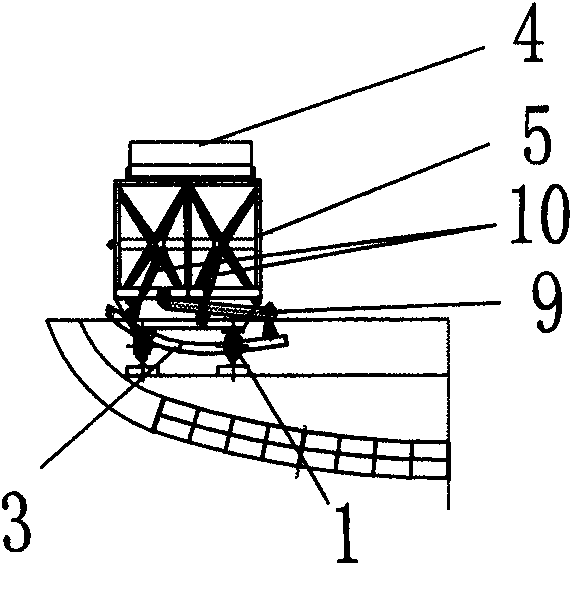

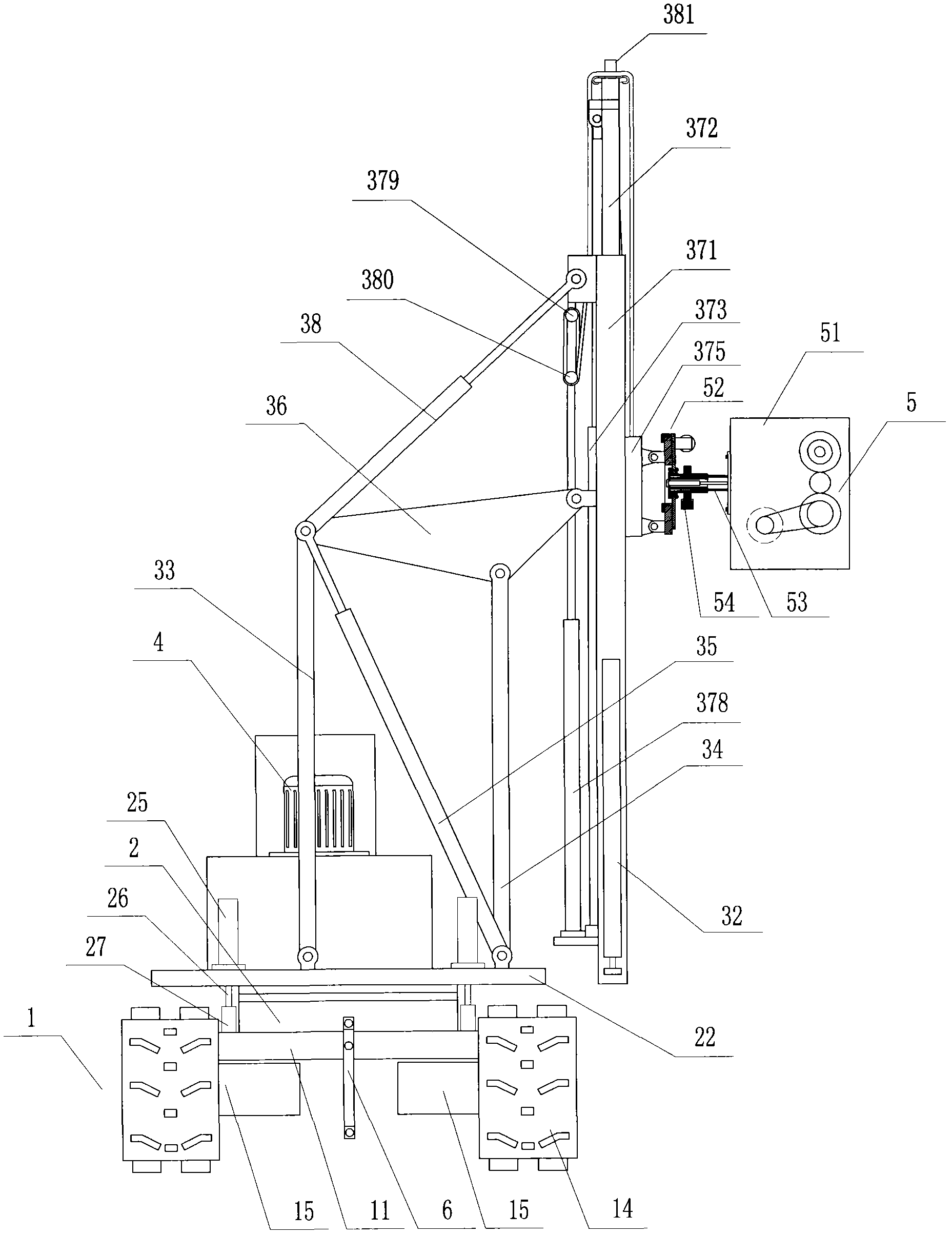

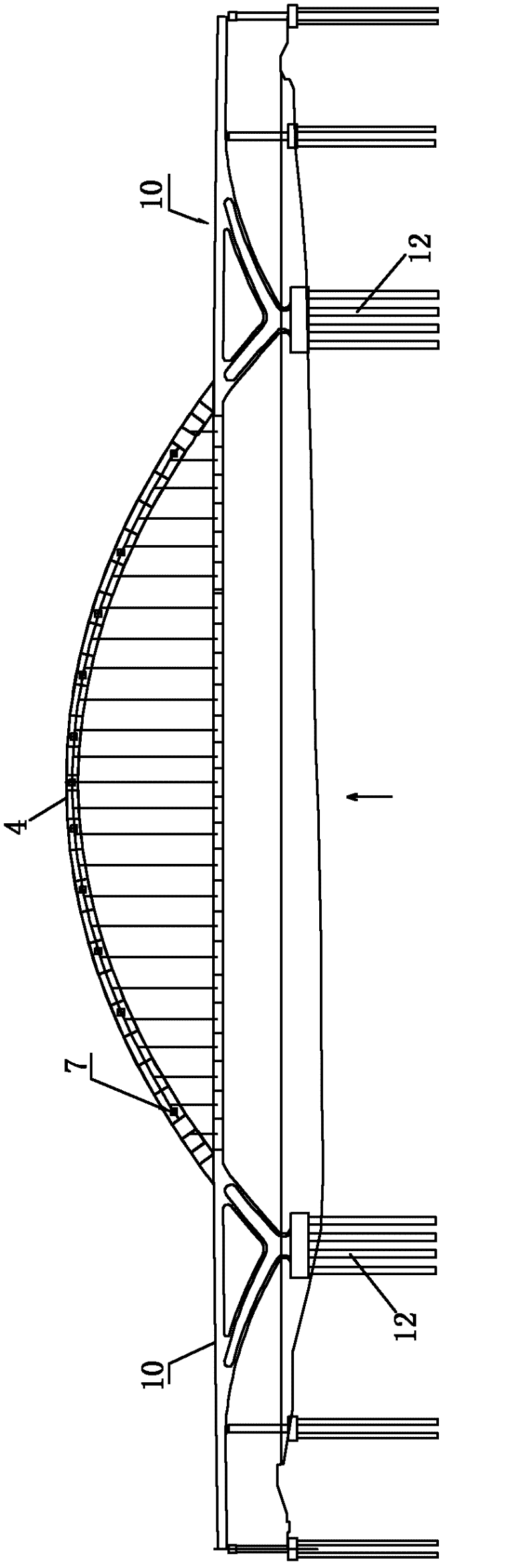

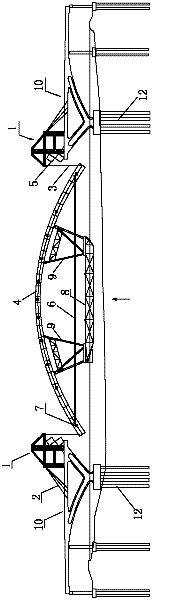

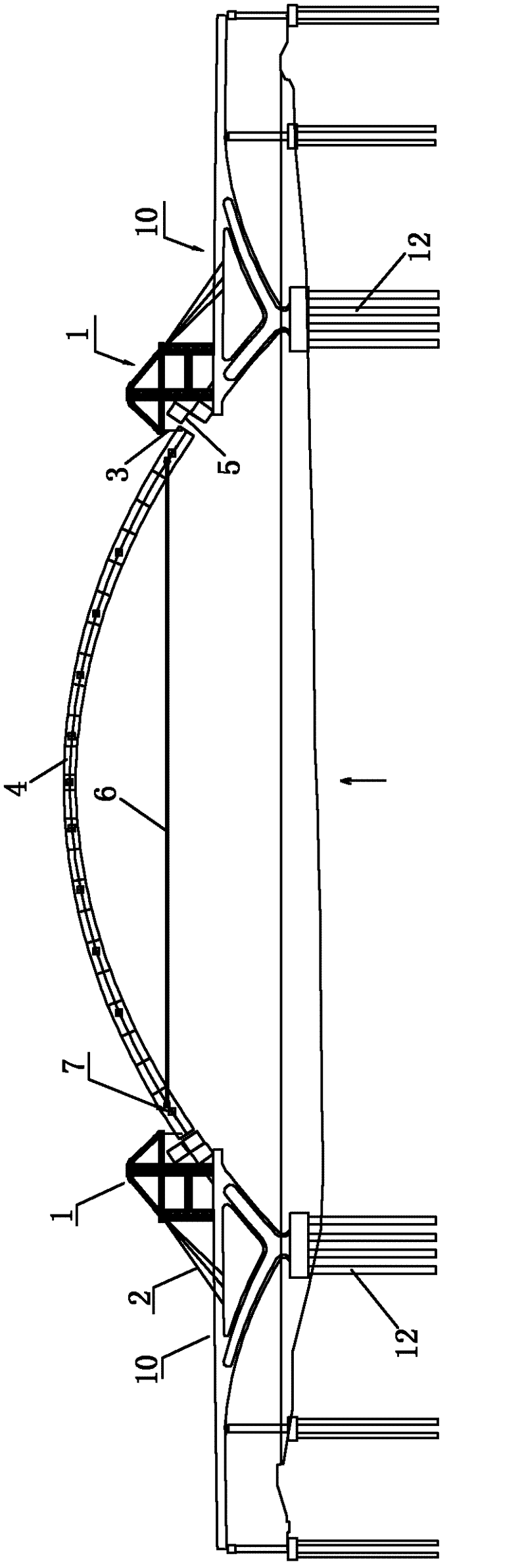

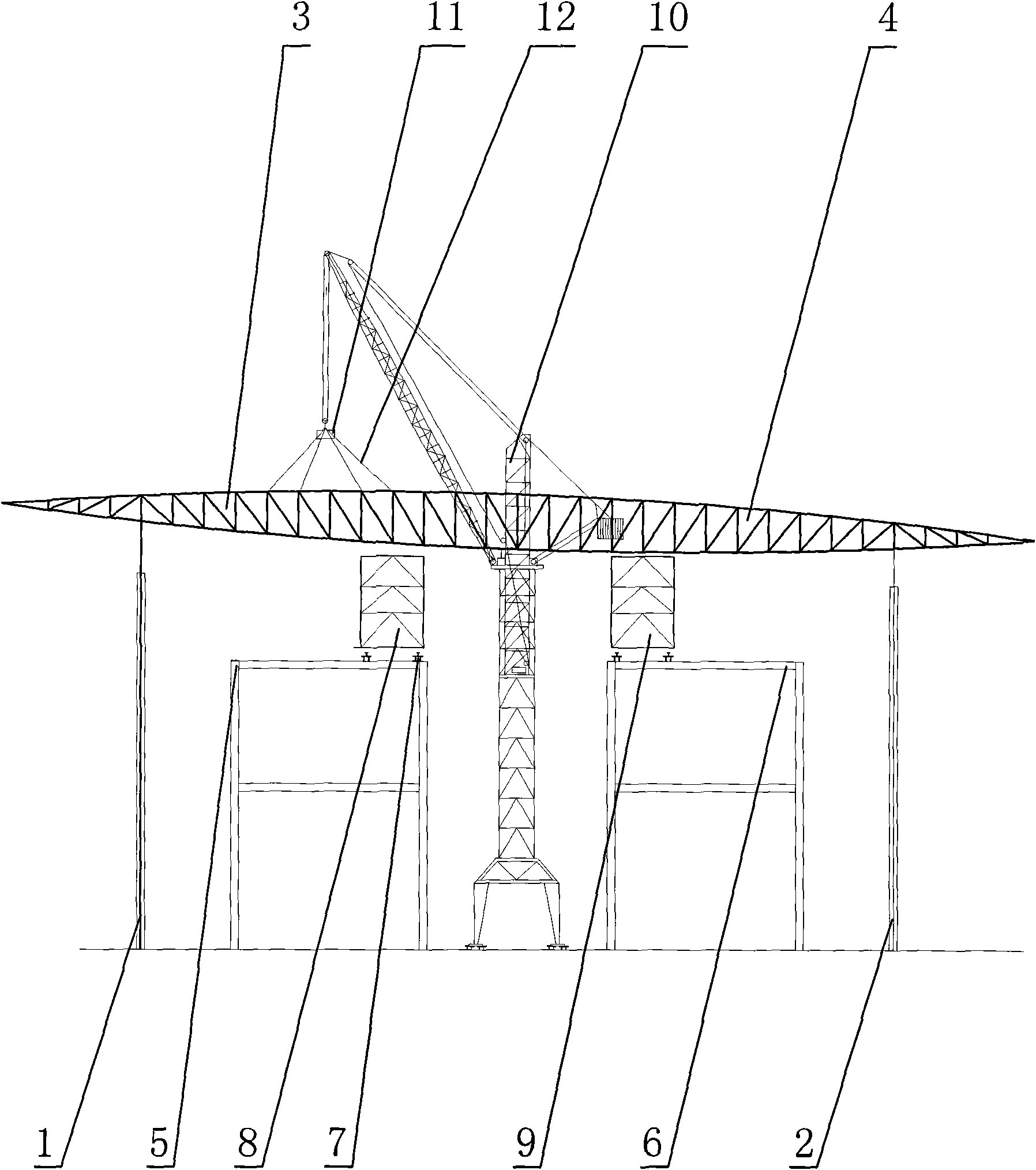

Integral lifting system and construction method for arch bridge ribs

InactiveCN102561191AReduce difficultyReduce working at heightsBridge erection/assemblySteel frameArch bridge

The invention discloses an integral lifting system and a construction method for arch bridge ribs. The integral lifting system comprises a pair of triangular steel frames, two lifting stations, arch rib brackets and an integral arch rib of an arch bridge, and a barge for conveying the integral arch rib. The triangular steel frames are fixedly rested on bridge piers and symmetrically disposed on two sides of main span of the arch bridge, an arch rib closure section in closure with the integral arch rib is disposed on the inner side of the arch bridge main span and close to the corresponding triangular steel frame, the lifting stations are disposed on the triangular frames respectively, the arch rib brackets are rested on the barge and support the integral arch rib, the lifting stations are connected with the integral arch rib through lifting steel stranded wires, the integral arch rib which is lifted up is in fixed closure with the arch rib closure sections, and accordingly the integral arch bridge is formed. The integral lifting system is adaptable to severe construction environments, and accordingly construction progress is quickened. The invention further provides the construction method for integral lifting of the arch bridge rib.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

Robot

ActiveCN104493810AAutomate operationsWorkability is goodProgramme-controlled manipulatorBuilding material handlingHydraulic motorArchitectural engineering

The invention discloses a robot. A hollow vertical rod is mounted in a vertical rod sleeve, a lead screw and nuts are mounted in the hollow vertical rod, a gear power motor and a gear mechanism connected with the lower end of the lead screw are mounted in a machine base, a first hydraulic motor inside a big-arm end is connected with a fixed shaft, the lower end of the fixed shaft is fixed on the hollow vertical rod, a second hydraulic motor is arranged inside a transverse swing arm connected with the big-arm end, a rotating arm end is further connected to a first rotating shaft connected with the second hydraulic motor, a longitudinal swing arm is connected to the rotating arm end, a second rotating shaft is connected to a third hydraulic motor inside the rotating arm end, a small-arm end is fixedly connected to the second rotating shaft, and a manipulator device is connected to the small-arm end. The robot has the advantages that the robot meets the requirements on multi-direction and multi-angle composite actions and can complete complex physical labor; when used for building construction, the robot is capable of building a wall, plastering and sticking bricks automatically, so that construction efficiency and quality of bricklaying projects are improved, labor intensity is reduced and construction cost is lowered.

Owner:苗健

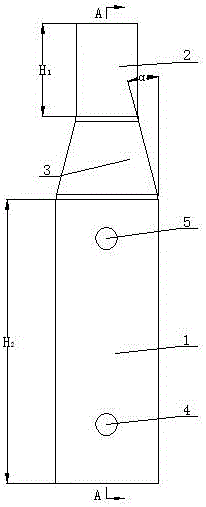

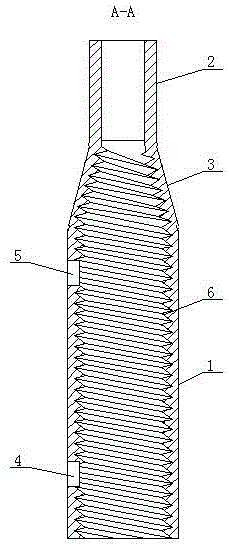

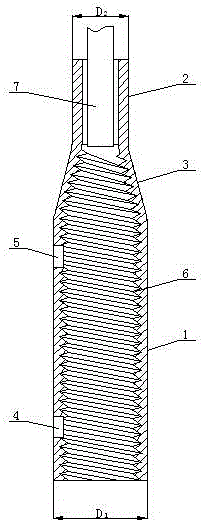

Variable-diameter half grouting sleeve and construction method thereof

InactiveCN105133795AControllable lengthShorten the lengthBuilding reinforcementsArchitectural engineeringRebar

The invention provides a variable-diameter half grouting sleeve and a construction method thereof. A seamless steel pipe is adopted as a body pipe, the inner wall of the body pipe is a concave-convex surface, the upper end of the body pipe is connected with the large-diameter end of a conical pipe, and the small-diameter end of the conical pipe is connected with one end of a cylindrical pipe. The construction method includes the steps that 1, the variable-diameter half grouting sleeve is manufactured; 2, a machining die is manufactured; 3, the upper portion of the short pipe in the step1 is heated; 4, the heated part of the short pipe is placed into a groove in a lower die, and an upper die is placed on the heated short pipe; 5, a grout injecting hole and a grout discharging hole are formed in the body pipe; 6, a connecting steel bar is inserted into the cylindrical pipe of the variable-diameter half grouting sleeve; 7, the variable-diameter half grouting sleeve, which is connected with the steel bar, in the step6 is placed into the die of a prefabricated component, and after concrete is poured for curing, and the steel bar connected with a building or the prefabricated component is placed into the body pipe to be connected after pouring. The variable-diameter half grouting sleeve makes tight contact with the connecting steel bar through extrusion to overcome the defects in the prior art.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

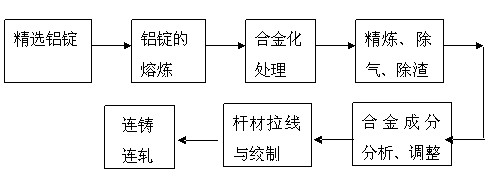

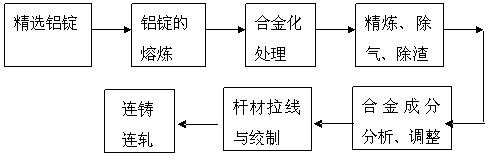

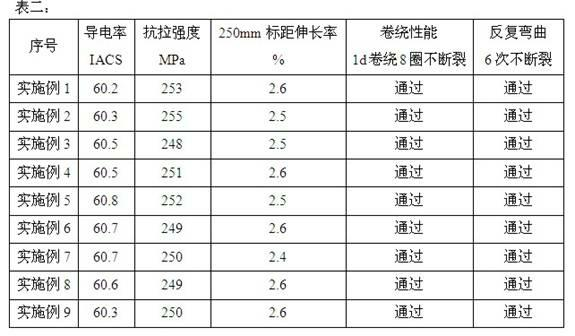

High-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and production method thereof

InactiveCN102634695ASave construction investmentImproved resistance to overloadIngotUltimate tensile strength

The invention discloses a high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and a production method of the high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire. The high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire is produced by finely selecting ingredients and contents of aluminum alloy and conducting process control. The specific steps are as follows: selecting Fe, Si, Mg, Cu and Re with different weight percents, melting aluminum ingot with the content not more than 0.03% in a vertical melting furnace, adding alloying elements in a heat insulation furnace, stirring, refining, conducting on-the-spot contents rapid analysis, carrying out content adjustment, and standing, enabling the aluminum ingot and the alloying element into a continuous casting machine for casting, rolling to be a circular aluminum alloy rod on a continuous rolling machine, pulling the circular aluminum alloy rod to be a circular aluminum alloy wire and twisting the circular aluminum alloy wire to be a conductor for aerial power transmission and distribution. According to the application of the aluminum alloy wire and the production method of the aluminum alloy wire, the aluminum alloy wire directly replaces the generally used aluminum conductor steel reinforced and is an energy-saving, environment-friendly and novel wire.

Owner:FAR EAST CABLE

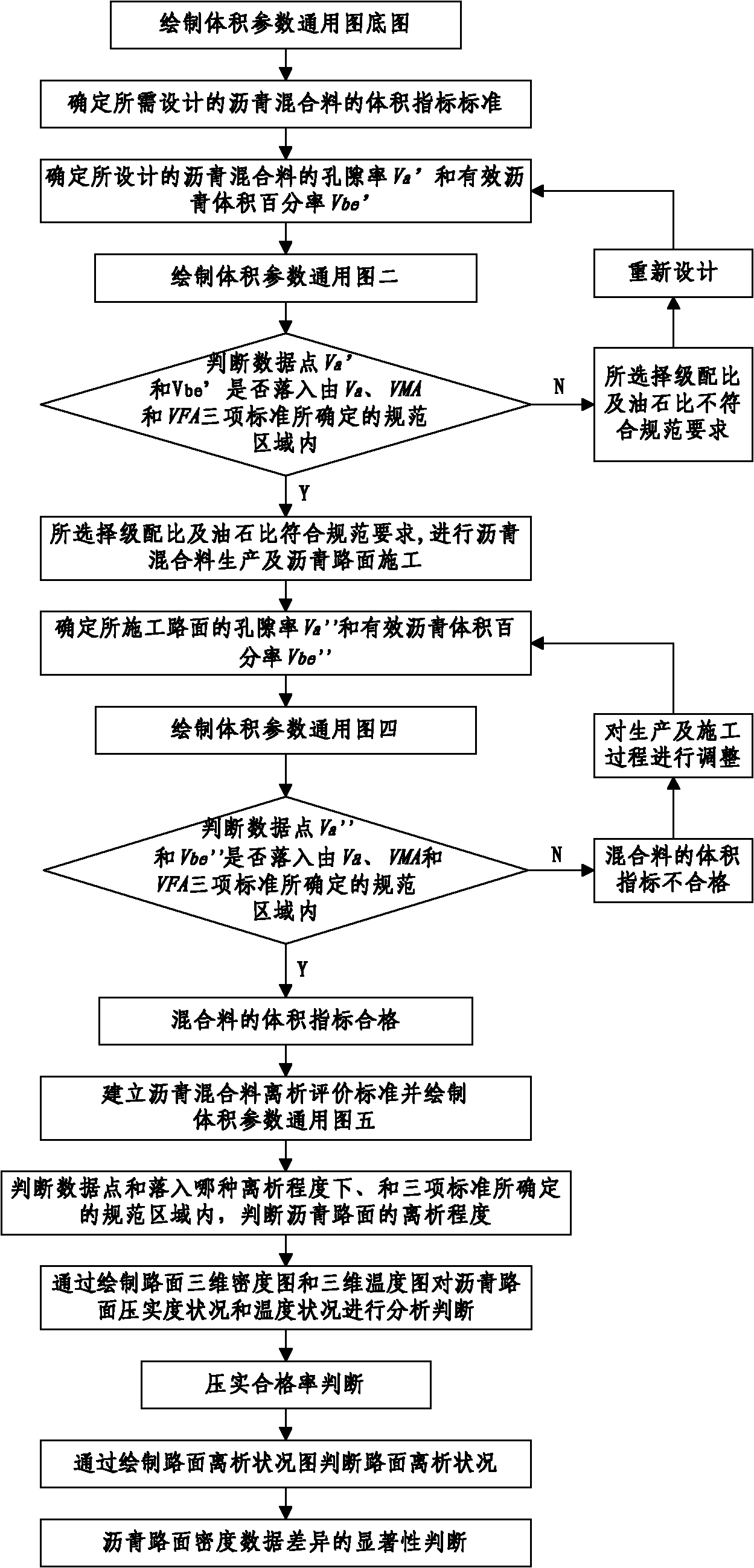

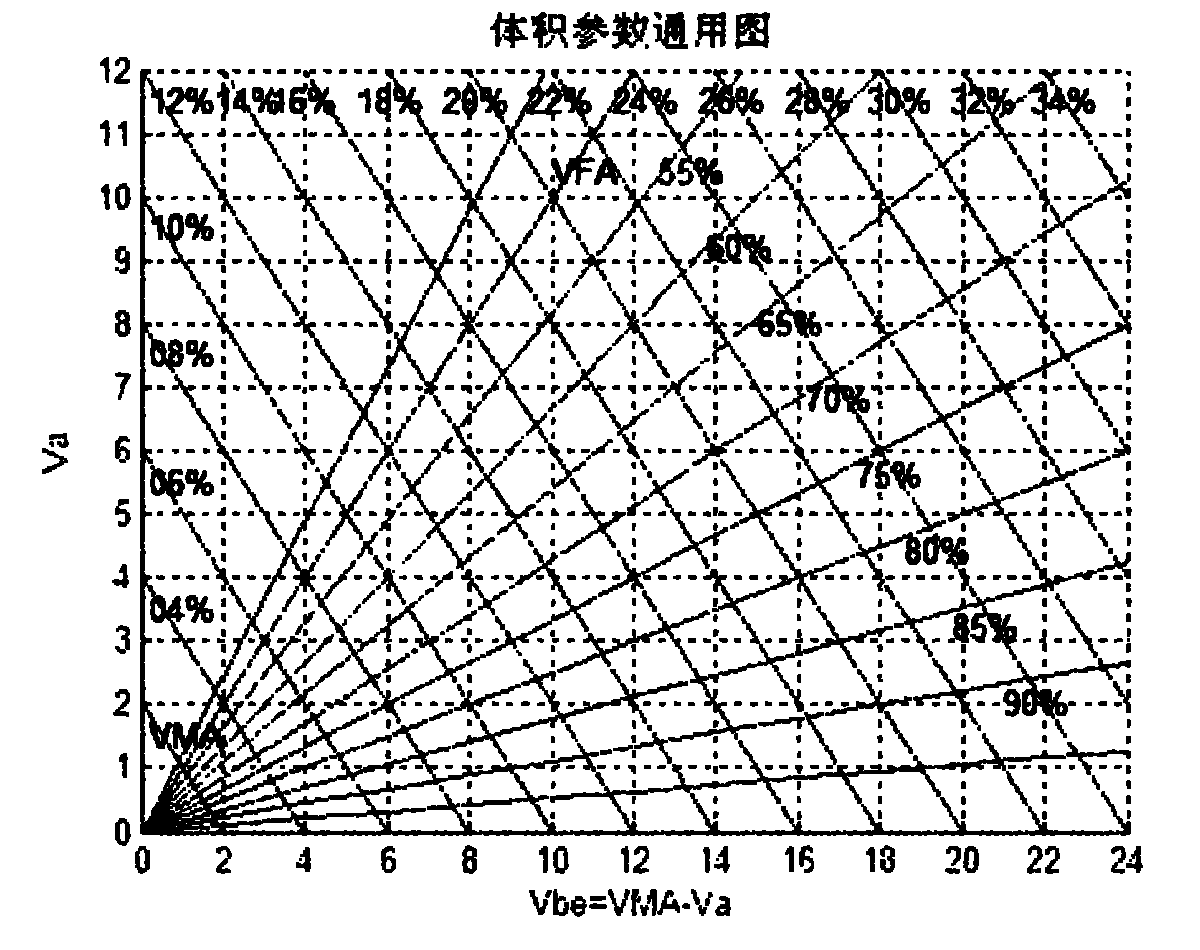

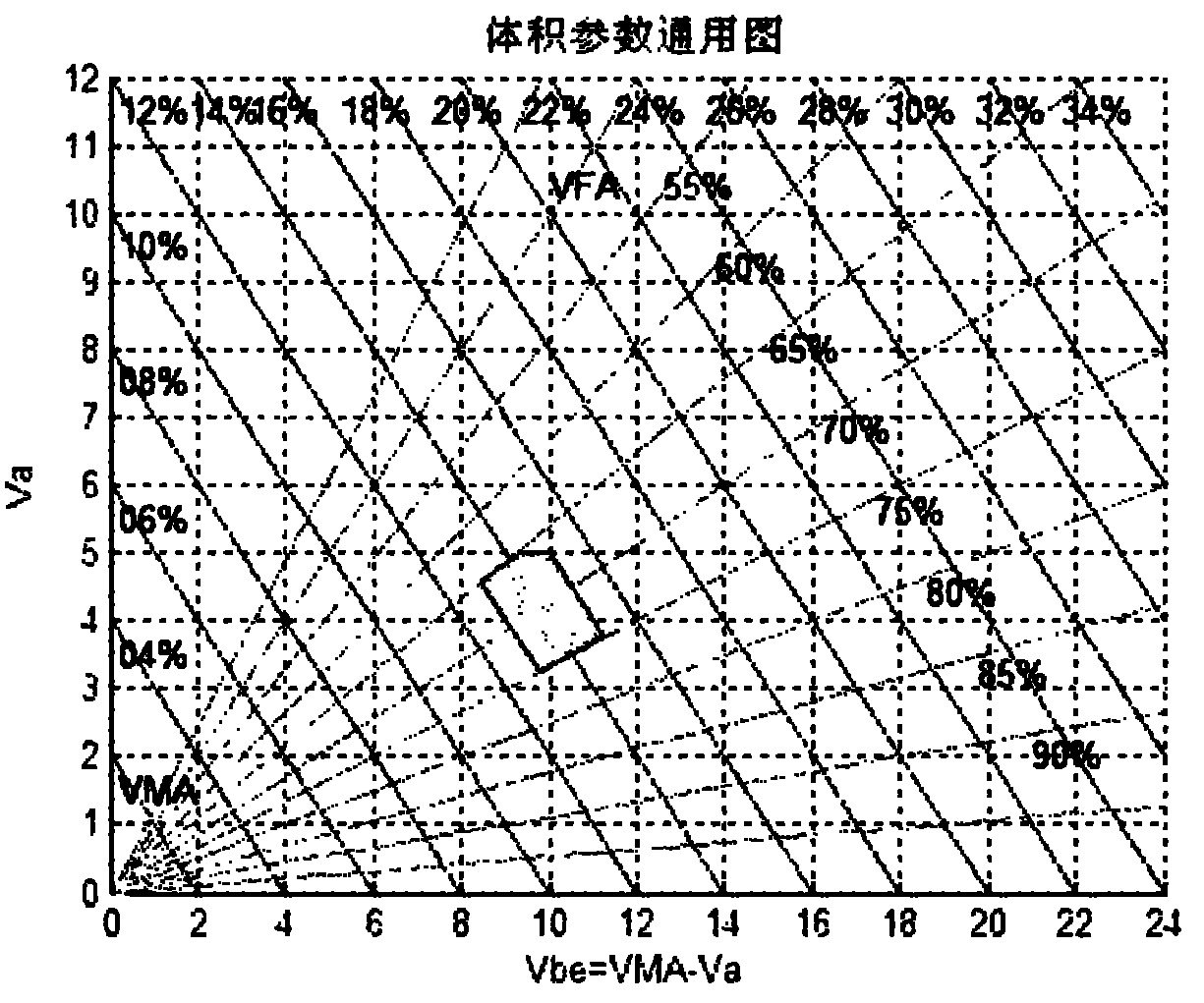

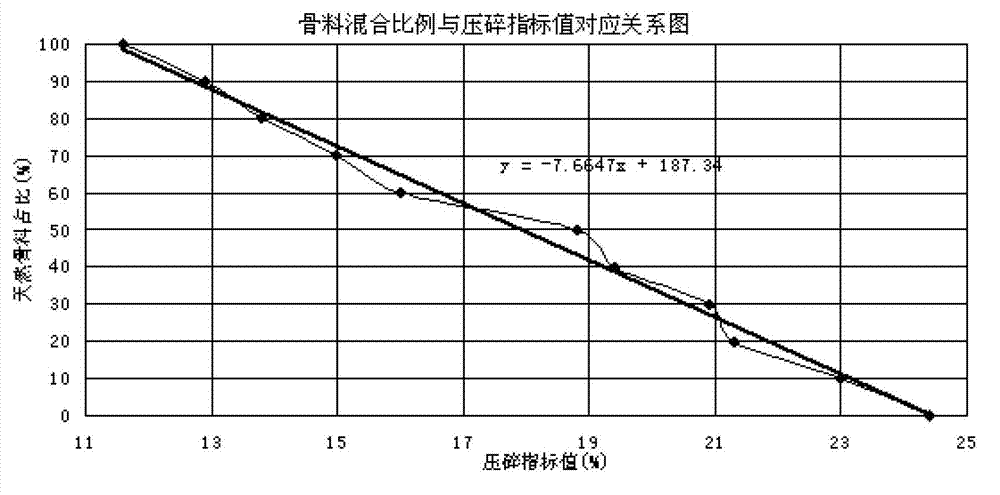

Method for controlling construction quality of asphalt pavement in real time

The invention discloses a method for controlling construction quality of an asphalt pavement in real time, which comprises the following steps of: 1, drawing a universal volumetric chart to evaluate volumetric parameter characteristics of various asphalt mixtures, and selecting a proportion of an asphalt mixture, which is suitable for the local environment and is difficult to segregate; 2, checking that whether volumetric parameter information of the asphalt mixture produced in the day meets requirements of design and construction specifications so as to quickly regulate the production process; 3, evaluating the aggregation condition of the asphalt pavement by using the universal volumetric chart; and 4, analyzing and judging the compaction degree condition and temperature condition of the asphalt pavement, judging the compaction qualified rate, judging the significance of the density data difference of the asphalt pavement, checking the construction quality of the asphalt pavement and providing quantitative basis for later period payment adjustment. The method has the advantages of reasonable design, high reliability, high operability, high real-time property, high efficiency of evaluating the construction quality of the asphalt pavement, and high practicability, and contributes to improving construction quality and saving economic cost.

Owner:XINJIANG BEIXIN ROAD & BRIDGE GRP +1

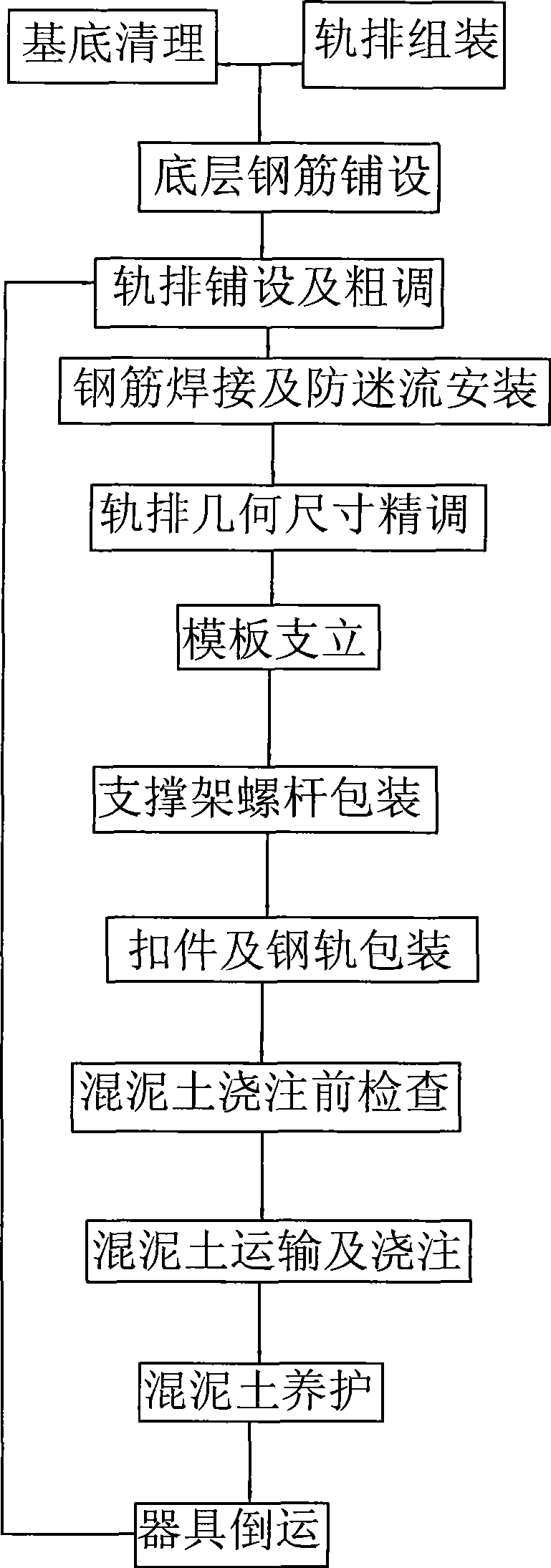

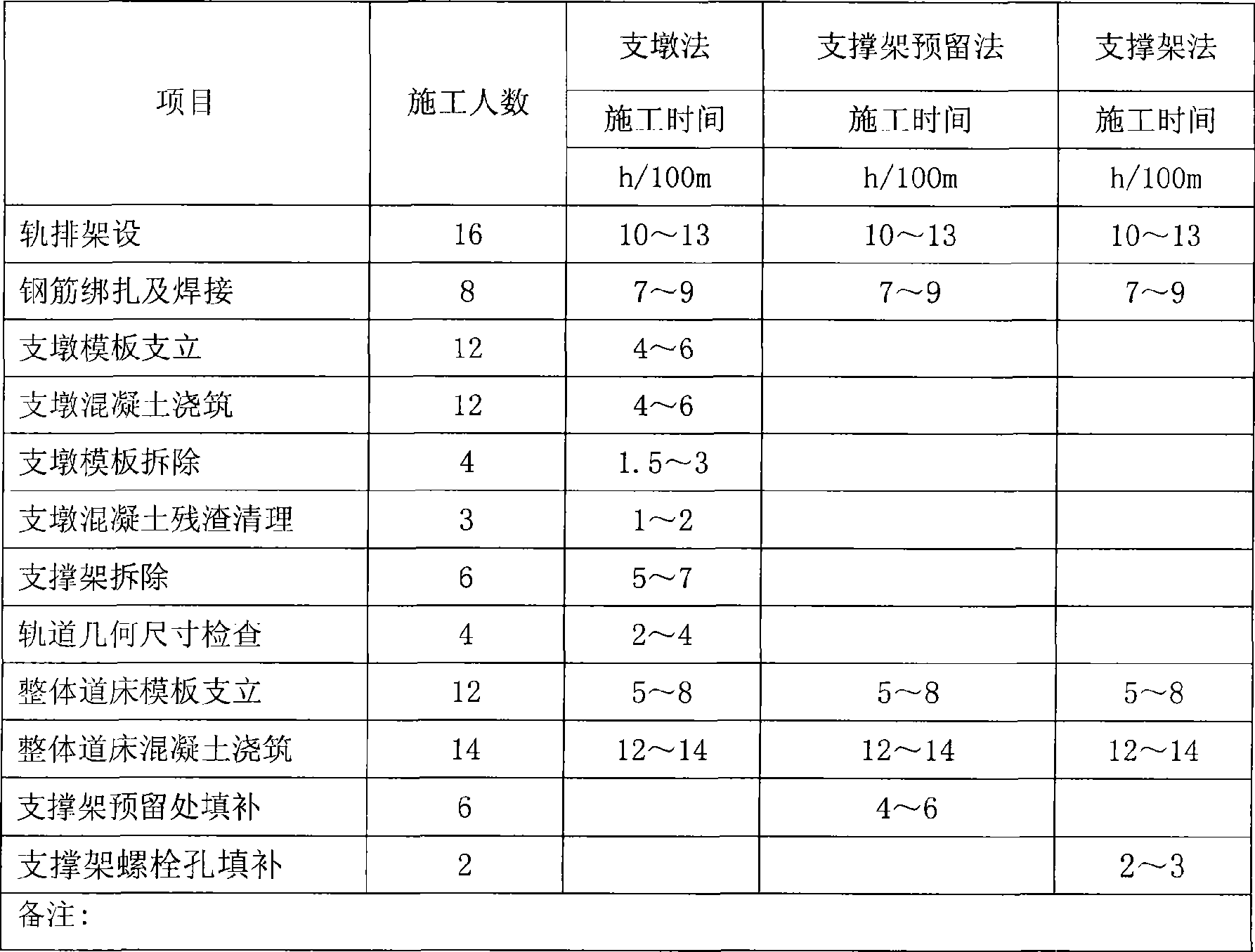

Construction method of monolithic road-bed in rail tunnel

ActiveCN101418535AReduce construction proceduresLow costRailway track constructionEngineeringLight rail

The invention discloses a method for constructing an integrated road bed of a track traffic tunnel, which is a supporting frame method for short. Firstly, a finished track panel assembled on a base is hoisted to the constructed tunnel; and the track panel of sleepers with different forms is born through adopting a supporting frame of a lower bearing type track panel; secondly, the track panel in the construction working face is hoisted to the designed elevation; the supporting frame of the track panel is mounted to support the track panel; a transverse supporting lever is utilized to approximately fix the direction of the track panel; and finally, according to fiducial mark, the elevation of track surface, the direction of the track, level and height are adjusted to the designed positions; after the binding and welding of concrete reinforcing bars and the erection of a template of the road bed are sequentially completed, and the integrated road bed is finally subjected to concrete pouring to obtain the integrated road bed; and the steps are sequentially advanced to complete the whole construction. The method reduces control links and material waste, improves construction schedule, ensures construction quality and is mainly used for the structural construction of undergrounds, light rails, tunnels, bridges, large-scale vehicle fields and other integrated road beds.

Owner:3TH ENG CO LTD OF CHINA RAILWAY CONSTR 11TH BUREAU GRP +1

High-altitude long-span roofing pipe truss installation method

InactiveCN101666163AImprove construction qualityGuarantee the construction progressBuilding material handlingRebarReinforced concrete

The invention discloses a high-altitude long-span roofing pipe truss installation method which comprises the following steps: firstly, assembling pipe trusses on the ground, then arranging a construction platform beam at the high-altitude assembling pipe truss; adopting a movable tower crane to hoist the pipe trusses, and hoisting two sections of pipe trusses on an assembling bracket and a reinforced concrete stand column; finally, conducting high-altitude joint, assembly and welding on the pipe trusses; and after passing welding inspection, moving the assembling bracket to the next axis and conducting installation of the next pipe trusses. The high-altitude long-span roofing pipe truss installation method adopts ground segment assembly, movable tower crane hoisting and the high-altitude joint welding method, not only improves construction quality, guarantees construction process and safety, and simultaneously reduces construction cost.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

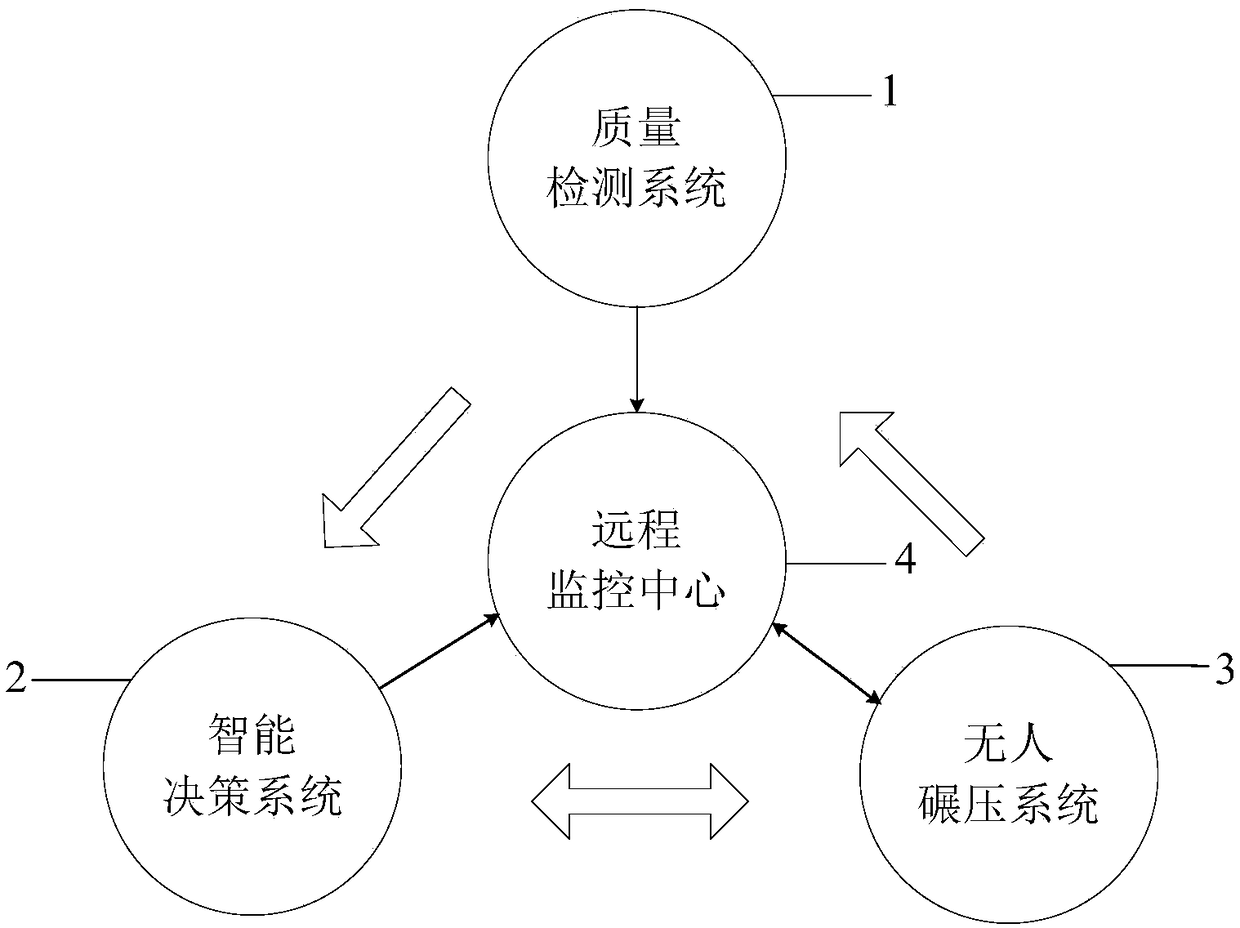

Intelligent roadbed and pavement roller compaction system

ActiveCN109356003AImprove construction qualityControlling Rolling Construction ParametersRoads maintainenceGroup schedulingClosed loop

The invention discloses an intelligent roadbed and pavement roller compaction system which comprises a quality detection system, an intelligent decision making system, an unmanned roller compaction system and a remote monitoring center. The quality detection system is used for detecting the compaction quality of various filled layers of roadbeds and pavements; compaction quality data can be analyzed by the intelligent decision making system, and roller compaction construction parameters of next procedures or new roller compaction construction regions can be obtained by the intelligent decisionmaking system; the unmanned roller compaction system can be combined with a single unmanned roller compaction machine or a group of unmanned roller compaction machines according to the roller compaction construction parameters, so that construction operation can be synergistically accomplished; real-time communication service, operation region planning, navigation routes and group scheduling service can be provided by the remote monitoring center, field operation conditions can be displayed by the remote monitoring center, and operation data can be stored by the remote monitoring center. Theintelligent roadbed and pavement roller compaction system has the advantages that the compaction quality of the different filled layers and different filling materials of the roadbed and the pavementscan be detected by the intelligent roadbed and pavement roller compaction system in an online manner, roller compaction construction operation can be controlled by means of machine decision making, accordingly, influence of human factors can be prevented, detection, analysis, decision making and control cycle can be implemented in a closed-loop manner, and the intelligent roadbed and pavement roller compaction system is particularly applicable to all-weather roadbed and pavement roller compaction construction operation scenes in hazardous regions or under extreme conditions.

Owner:北京龙马智行科技有限公司

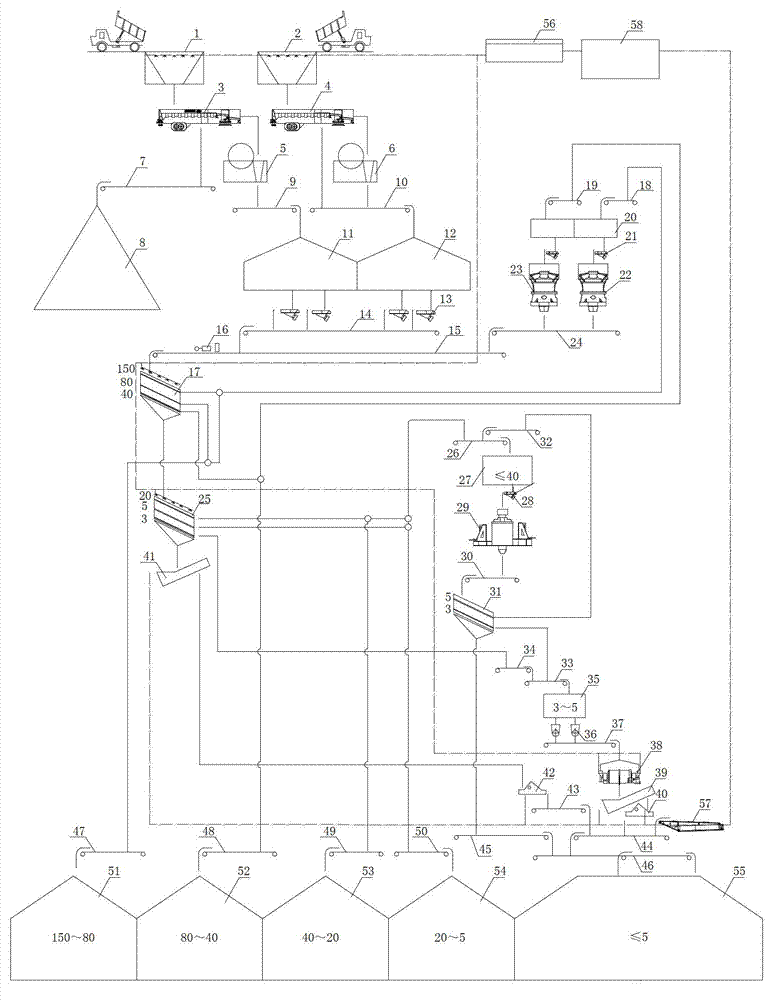

Processing system of concrete combined aggregate and construction method

InactiveCN102814862AFacilitate adjustment of gradingIncrease productivityMixing operation control apparatusControl apparatusEngineeringMachining system

The invention provides a concrete combined aggregate processing system, which comprises a first receiver bin. A first bar type feeder is disposed below the first receiver bin, the undersize part of the first bar type feeder is connected to a rejected material storage yard through a first adhesive tape machine, and the oversize part of the first bar type feeder is connected to a first jaw crusher. The discharge port of the first jaw crusher is connected to an artificial break stone storage yard through a second adhesive tape machine. A second bar type feeder is disposed below a second receiver bin. The oversize part of the second bar type feeder is connected to a second jaw crusher, and the undersize part of the second bar type feeder as well as the discharge port of the second jaw crusher is connected to a natural gravel storage yard through a third adhesive tape machine. The system provided in the invention can adopt two material sources at the same time to conduct production and processing, and the processed combined aggregate can satisfy the quality requirements of concrete aggregates, so that the work efficiency of the aggregate processing system can be enhanced. Moreover, the system is in favor of the sufficient use of project excavation ballast materials so as to reduce resource investment and project investment, and is also beneficial to environmental protection.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

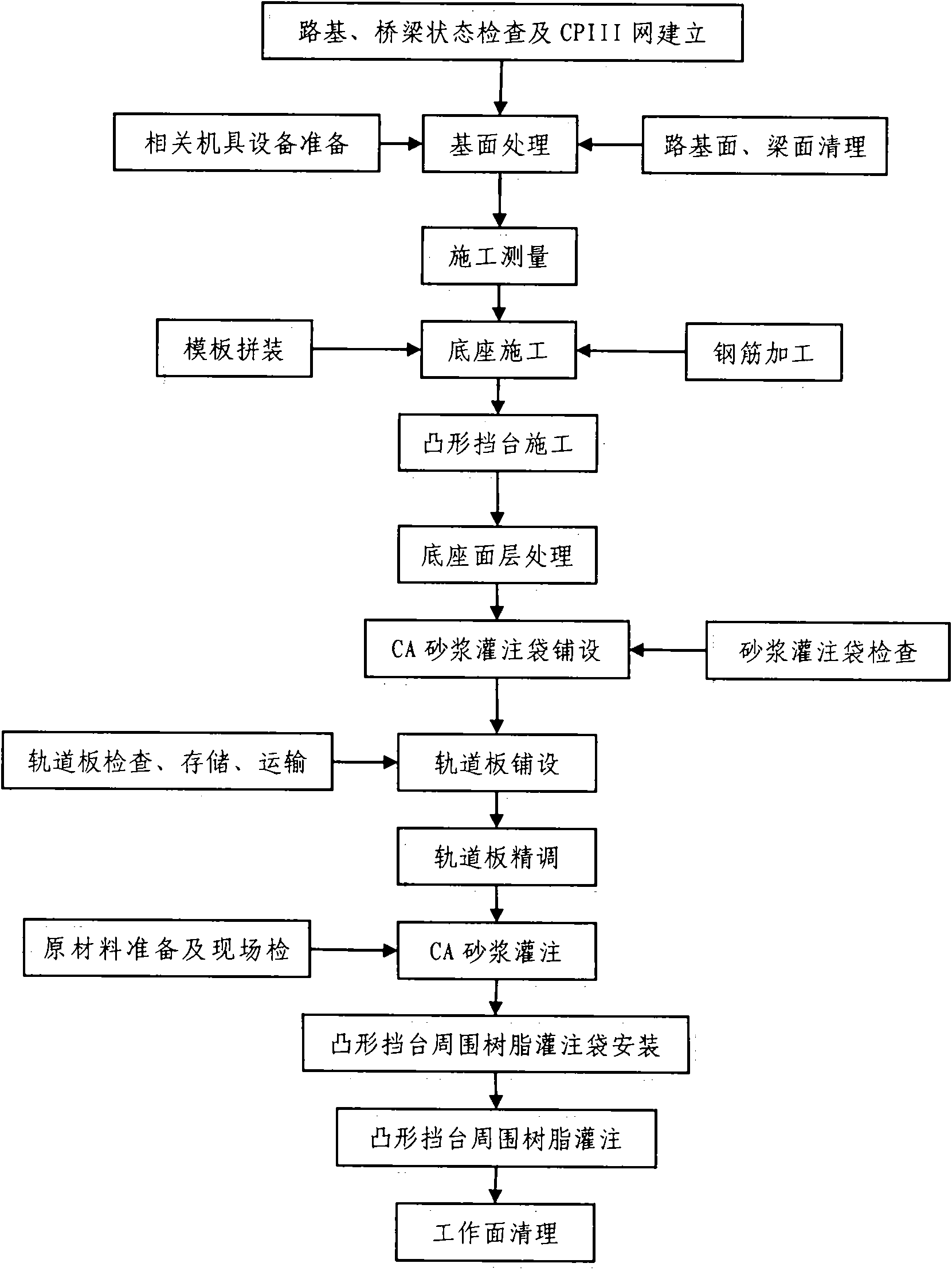

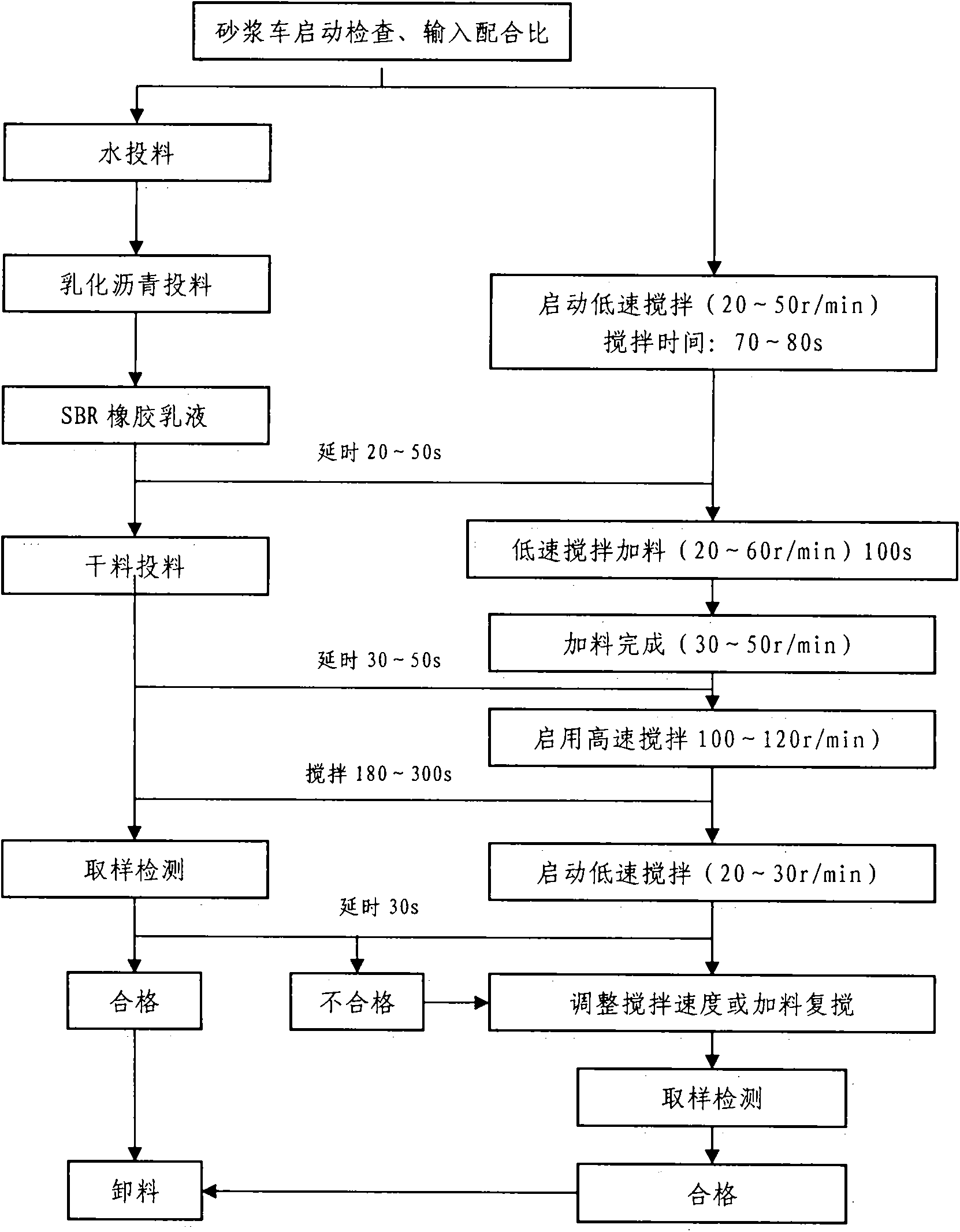

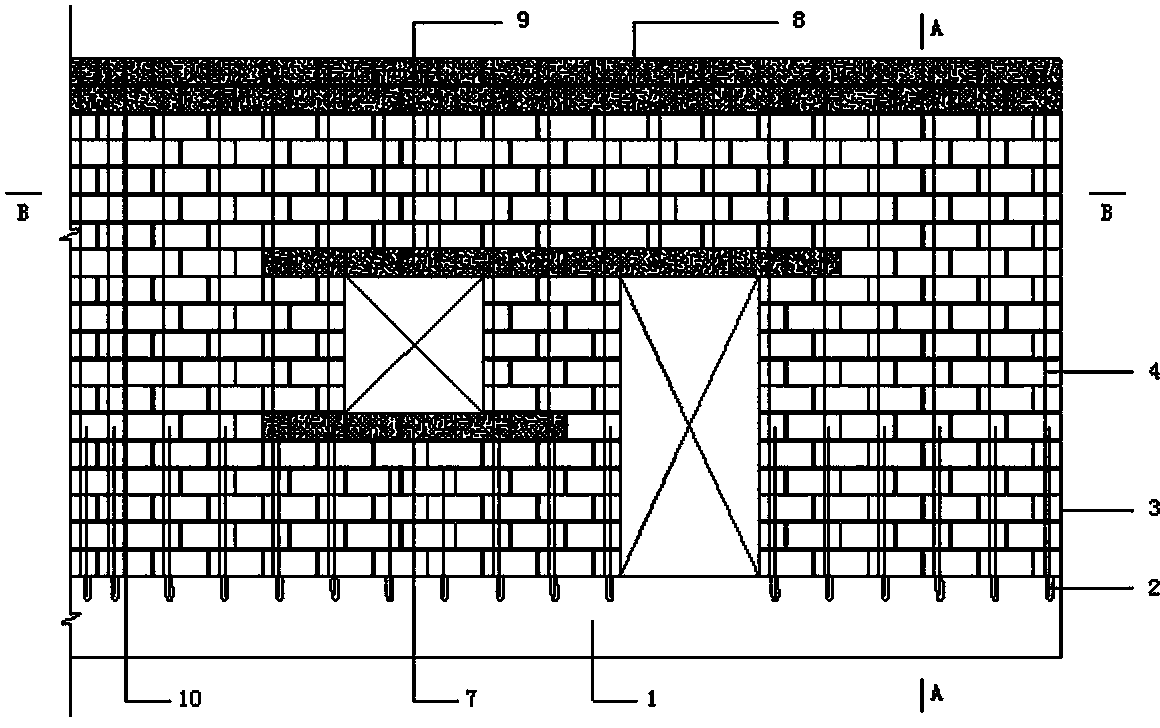

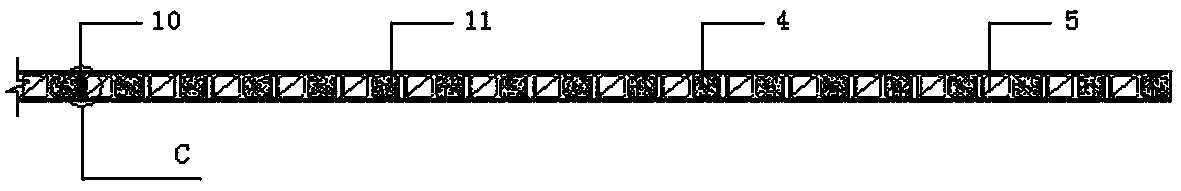

Paving method of CRTS I type plate type ballastless track slab in severe cold region

InactiveCN101851884AAdapt to climate characteristics with large annual temperature differenceHigh precisionRailway track constructionMeasuring apparatusSurface layerPrism

The invention provides a paving method of a CRTS I type plate type ballastless track slab in a severe cold region, which sequentially comprises the following steps of: building a roadbed and a CPIII control network, processing the surface of the roadbed, measuring during construction, constructing a base, constructing a convex baffling table, processing the surface layer of the base, paving a CA mortar pouring bag, paving a track slab, precisely adjusting the track slab, pouring CA mortar, arranging a resin pouring bag around the convex baffling table, pouring resin around the convex baffling table, and cleaning a work surface. The step of precisely adjusting a track slab adopts a prism frame method. The prism frame method comprises the following steps of: arranging two measuring frames at positions of screw bolt holes at the two ends of each track slab after building a CPIII control point; measuring a spherical prism on the frame after freely stationing a total station, wherein measured data represents a practical three dimensional coordinate of the track slab; counting the difference value between a theoretic three dimensional coordinate value and a practically-measured three dimensional coordinate value; precisely adjusting the track slab with a bidirectional adjustor untill that the difference value meets the criterion requirement. The CRTS I type plate type ballastless track slab which is paved with the method can meet the characteristic of the climate in the severe cold region.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Concrete hollow block reinforced wall construction technology

ActiveCN103410332AStable structureImprove performanceBuilding material handlingArchitectural engineeringRebar

A concrete hollow block reinforced wall construction technology includes the specific process of positioning and setting out, reinforcement steel implanting, wall construction, wall hole grouting, ring beam and lintel construction, and block wall and other wallboard connection. The concrete hollow block reinforced wall construction technology is firm in wall structure, good in overall performance, low in engineering cost, simple, good in construction quality, high in construction speed and safe and controllable in construction.

Owner:CHINA NUCLEAR IND 22ND CONSTR

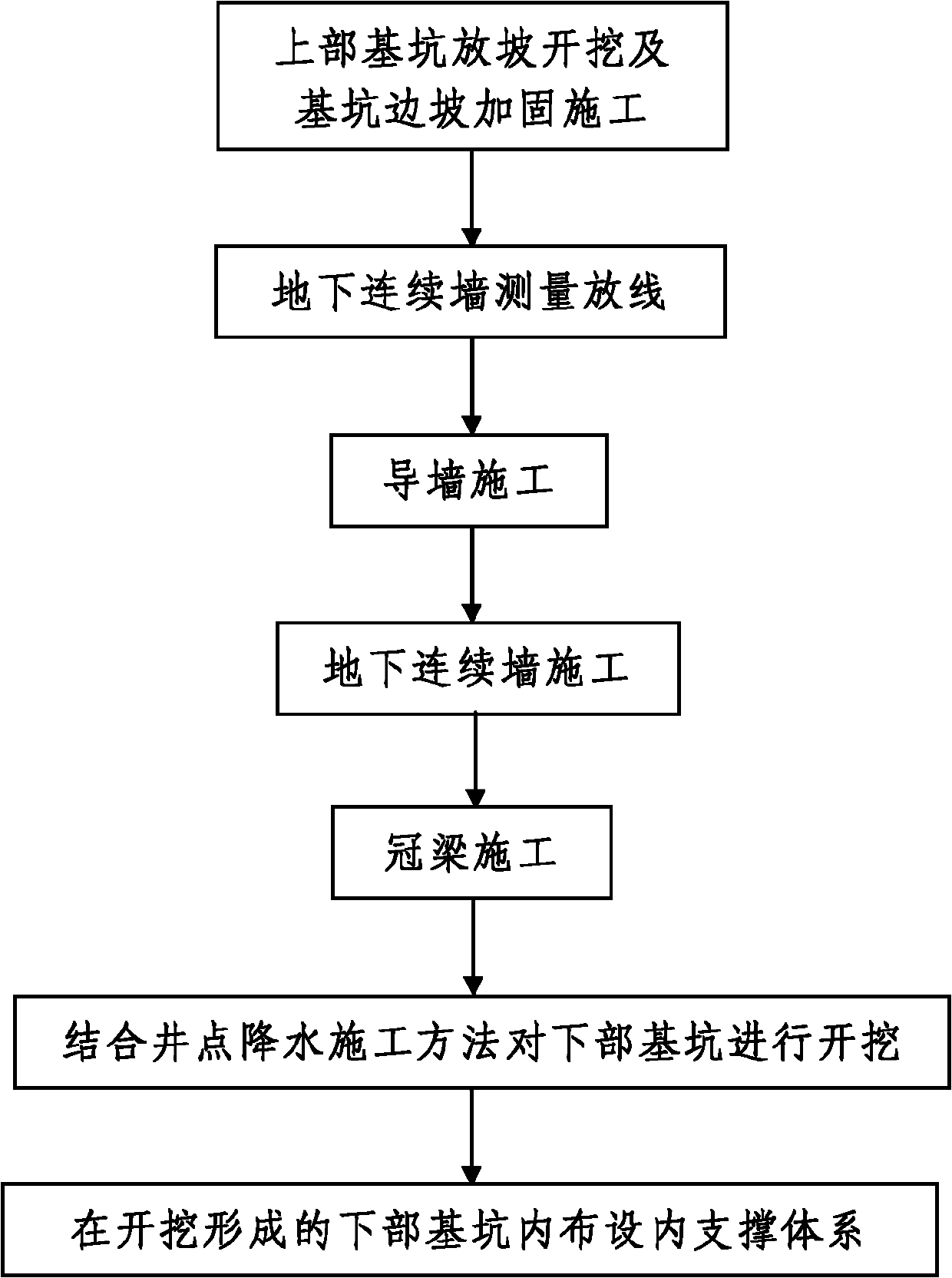

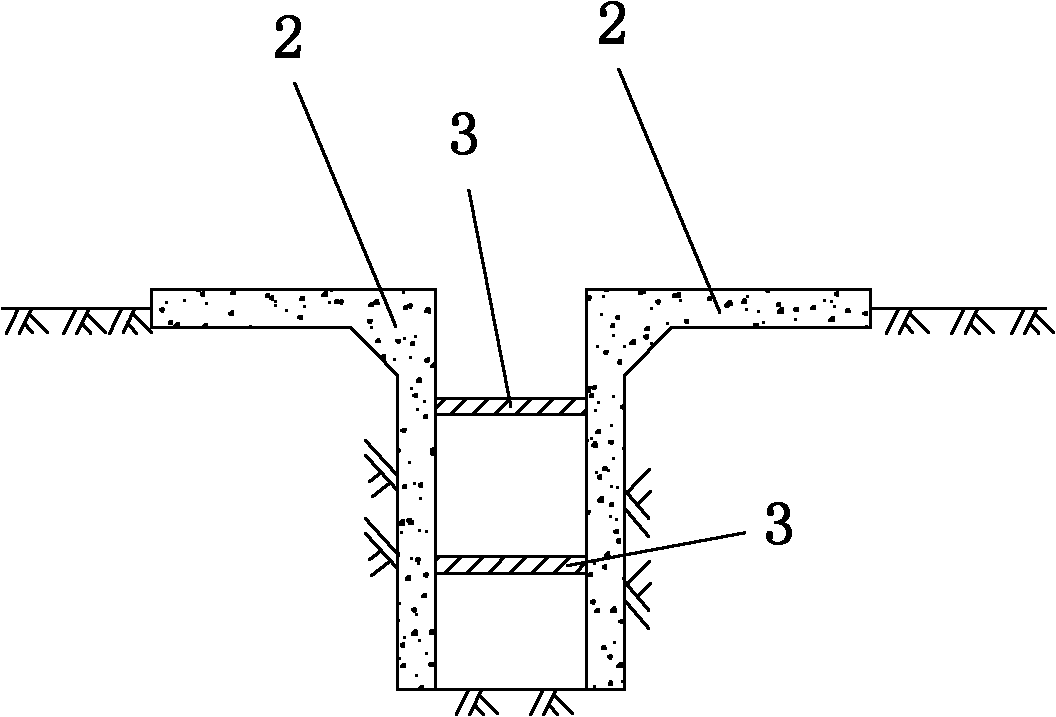

Construction method for underground diaphragm wall of deep foundation pit for subway station in collapsible loess areas

InactiveCN102322064AReasonable designSimplify construction stepsArtificial islandsExcavationsSlurry wallSubway station

The invention discloses a construction method for an underground diaphragm wall of a deep foundation pit for a subway station in collapsible loess areas. The constructed station deep foundation pit for the subway station is divided into an upper-part foundation pit and a lower-part foundation pit from top to bottom; the building enclosure of the lower-part foundation pit is the underground diaphragm wall; and the upper-part foundation pit is a foundation pit formed by slope excavation. The construction method disclosed by the invention has the following steps of: (1) construction for upper-part foundation pit slope excavation and foundation pit slope reinforcement; (2) construction for lower-part foundation pit building enclosure: surveying and paying off, guide wall construction and underground diaphragm wall construction; and (3) construction for cap beam, and then carrying out excavation on the lower-part foundation pit through combining a well-point dewatering construction method and arranging a bracing system in the excavated lower-part foundation pit. The construction method disclosed by the invention has the advantages of reasonable design, simplicity and convenience for construction, safety and reliability for construction and good construction effect, high construction quality and capability of effectively solving the practical problems, such as high difficulty for construction, complicated construction procedure, difficulty for ensuring the construction quality of deep foundation pits and the like, in a process of constructing the deep foundation pits for subway stations in the collapsible loess areas.

Owner:CHINA RAILWAY 20 BUREAU GRP

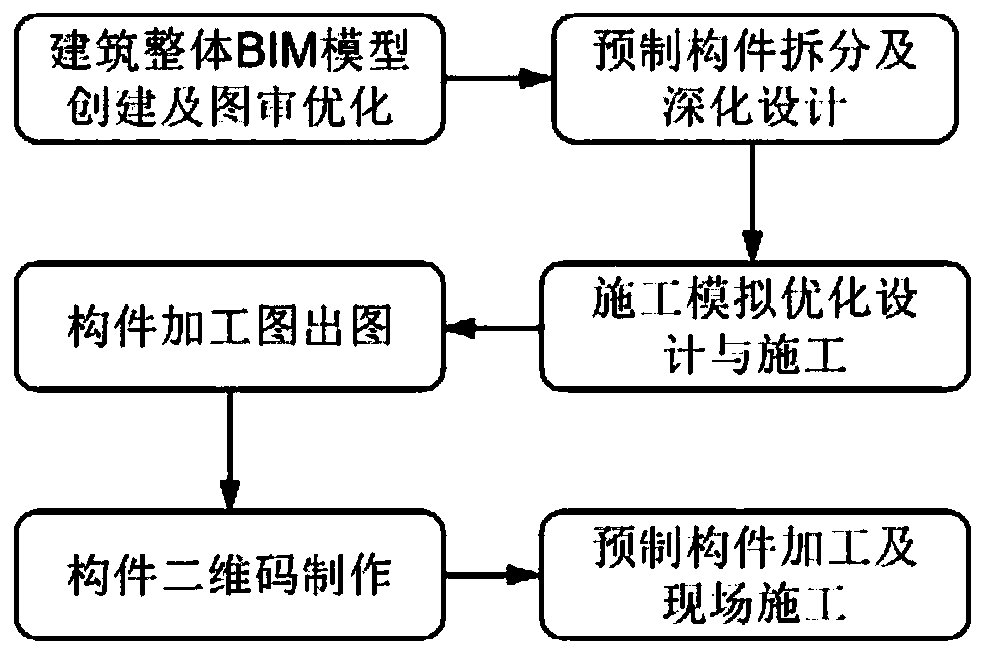

BIM-based concrete fabricated building construction method

PendingCN110929328AGuaranteed design qualityGuaranteed constructabilityGeometric CADDesign optimisation/simulationConstruction engineeringCollaborative design

The invention discloses a BIM-based concrete fabricated building construction method, comprising the following steps: creating a building full-professional integral BIM model, optimizing integral design, splitting prefabricated parts, deepening prefabricated part nodes, performing construction simulation optimization design, performing engineering quantity statistics, drawing a prefabricated partprocessing drawing, and manufacturing a prefabricated part two-dimensional code. By creating the visual informationized BIM model, the BIM-based concrete fabricated building construction method improves the collaborative design of information of the building, the structure and the electromechanical specialty, avoids the problems of mistakes, omissions, collisions and lacks of the design specialties, and improves the design quality. Meanwhile, the assembly type construction process is visually simulated through BIM, and the problem optimization design in construction is found in time, and the design and construction barrier is broken through. Besides, the BIM technology can perform rapid drawing according to the model, and the design quality is improved through automatic statistics of the engineering quantity, and visual construction simulation can further guide field construction, and the generated two-dimensional code can be used for information tracing of the prefabricated part, andthe overall construction quality of the prefabricated building is improved.

Owner:中国电建集团江西省水电工程局有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com